Page 1

OPERATION AND PARTS MANUAL

SERIES

MODEL MVH150VD2

REVERSIBLE PLATE COMPACTOR

(YANMAR L48V6AF3R4AAW4 DIESEL ENGINE)

Revision #0 (10/10/08)

To fi nd the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

Diesel engine exhaust and some of

PAGE 2 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 3

NOTES

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 3

Page 4

TABLE OF CONTENTS

MVH150VD2

PLATE COMPACTOR

Proposition 65 Warning ........................................... 2

Table of Contents ..................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Information ................................................6-9

Specifi cations ........................................................ 11

Dimensions ............................................................ 12

General Information ............................................... 13

Components .......................................................... 14

Basic Engine .......................................................... 15

Inspection ......................................................... 16-17

Operation .......................................................... 18-19

Maintenance ..................................................... 20-22

Troubleshooting ................................................ 23-24

Explanation of Code in Remarks Column.............. 26

Suggested Spare Parts ......................................... 27

COMPONENT DRAWINGS

YANMAR L48V6AF3R4AAW4

Drawings

Cylinder Block Assy .......................................... 42-45

Air Cleaner Assy ............................................... 46-47

Muffl er Assy ..................................................... 48-49

Crankshaft and Camshaft Assy ....................... 50-51

Piston Assy ...................................................... 52-53

Lub OIl Pump and Governor Assy ................... 54-55

Cooling/Starting Device Assy .......................... 56-57

Fuel Tank/Fuel Line Assy ................................. 58-59

Tools, Labels, Gasket Assy ............................... 60-61

Terms and Conditions of Sale — Parts ................. 62

Nameplate and Decals ..................................... 28-29

Vibrating Plate Assy .........................................30-31

Body Assy ......................................................... 32-33

Vibrator Assy .................................................... 34-35

Control Assy ..................................................... 36-39

Hand Pump Assy .............................................. 40-41

PAGE 4 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 5

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

Effective:

January 1

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■

View Parts Diagrams

■

Order Parts

■

Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

If you have an MQ Account, to obtain a

Username and Password, E-mail us at:

parts@multiquip.com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Use the

internet

and qualify for a 5% Discount

on

Standard orders

for all orders which include

complete part numbers.*

Fax

your order in and qualify for a 2% Discount

on

Standard orders

for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

should contact

When ordering parts, please supply:

❒❒

❒

❒❒

❒

Dealer Account Number

❒❒

❒❒

❒

Dealer Name and Address

❒❒

❒❒

❒

Shipping Address (if different than billing address)

❒❒

❒❒

❒

Return Fax Number

❒❒

❒❒

❒

Applicable Model Number

❒❒

❒❒

❒

Quantity, Part Number and Description of Each Part

❒❒

All orders are treated as

Standard Orders

and will ship the same day if received prior

to 3PM PST.

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 5

Specify Preferred Method of Shipment:

❒❒

✓

UPS/Fed Ex

■

Priority One

■

Ground

■ Next Day

■

Second/Third Day

✓ DHL

✓

Tr u ck

Page 6

SAFETY INFORMATION

Do not operate or service the equipment before reading

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Potential hazards associated with the operation of this

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 7

SAFETY INFORMATION

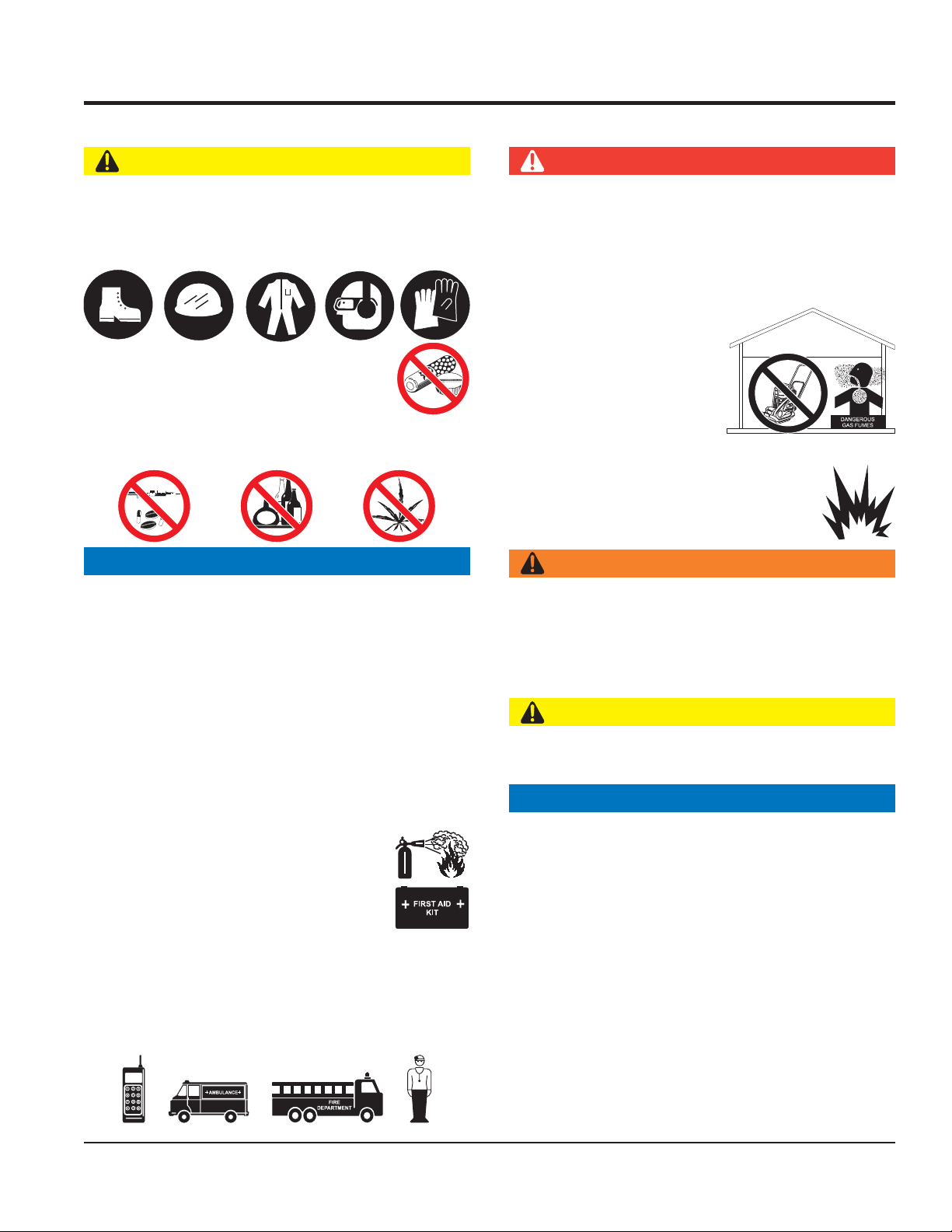

GENERAL SAFETY

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

NOTICE

COMPACTOR SAFETY

DANGER

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment requires an adequate free

fl ow of cooling air. NEVER operate this equipment in any

enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury

to people and property and

serious damage to the

equipment or engine.

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

This equipment should only be operated by trained and

qualifi ed personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

equipment modifi cation will void all warranties.

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest phone or keep

a phone on the job site. Also, know the phone numbers

of the nearest ambulance, doctor and fi re department.

This information will be invaluable in the case of an

emergency.

NEVER disconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

devices will void all warranties.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

NOTICE

ALWAYS keep the machine in proper running condition.

Fix damage to machine and replace any broken parts

immediately.

ALWAYS store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 7

Page 8

SAFETY INFORMATION

k

ENGINE SAFETY

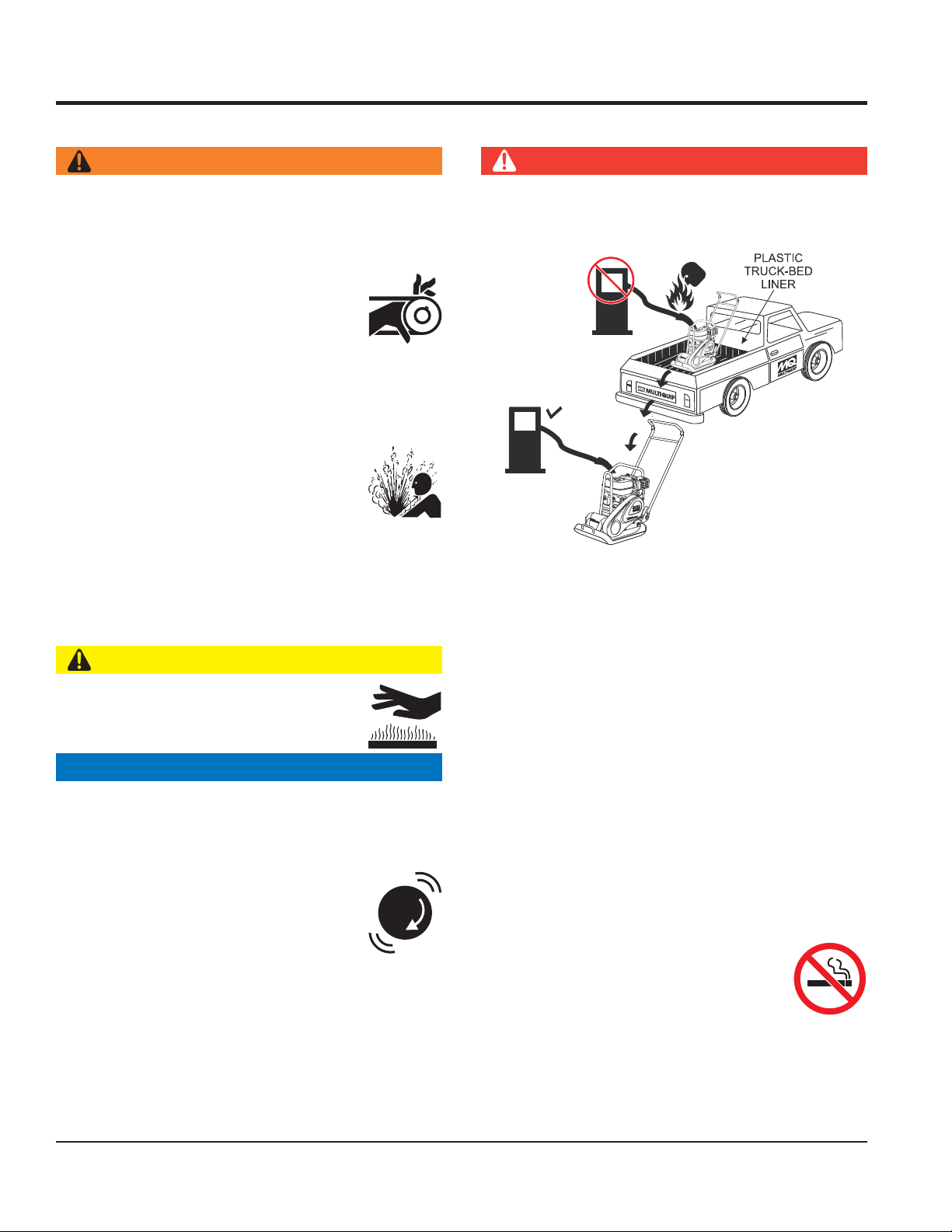

WARNING

DO NOT place hands or fingers inside engine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

DO NOT remove the radiator cap while the

engine is hot. High pressure boiling water will gush out

of the radiator and severely scald any persons in the

general area of the compactor.

DO NOT remove the coolant drain plug

while the engine is hot. Hot coolant will

gush out of the coolant tank and severely

scald any persons in the general area of

the compactor.

DO NOT remove the engine oil drain plug while the

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

compactor.

CAUTION

FUEL SAFETY

DANGER

DO NOT add fuel to equipment if it is placed inside truc

bed with plastic liner. Possibility exists of explosion or

fi re due to static electricity.

FUEL

FUEL

DO NOT start the engine near spilled fuel or combustible

fl uids. Diesel fuel is extremely fl ammable and its vapors

can cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

NOTICE

NEVER run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

PAGE 8 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 9

SAFETY INFORMATION

k

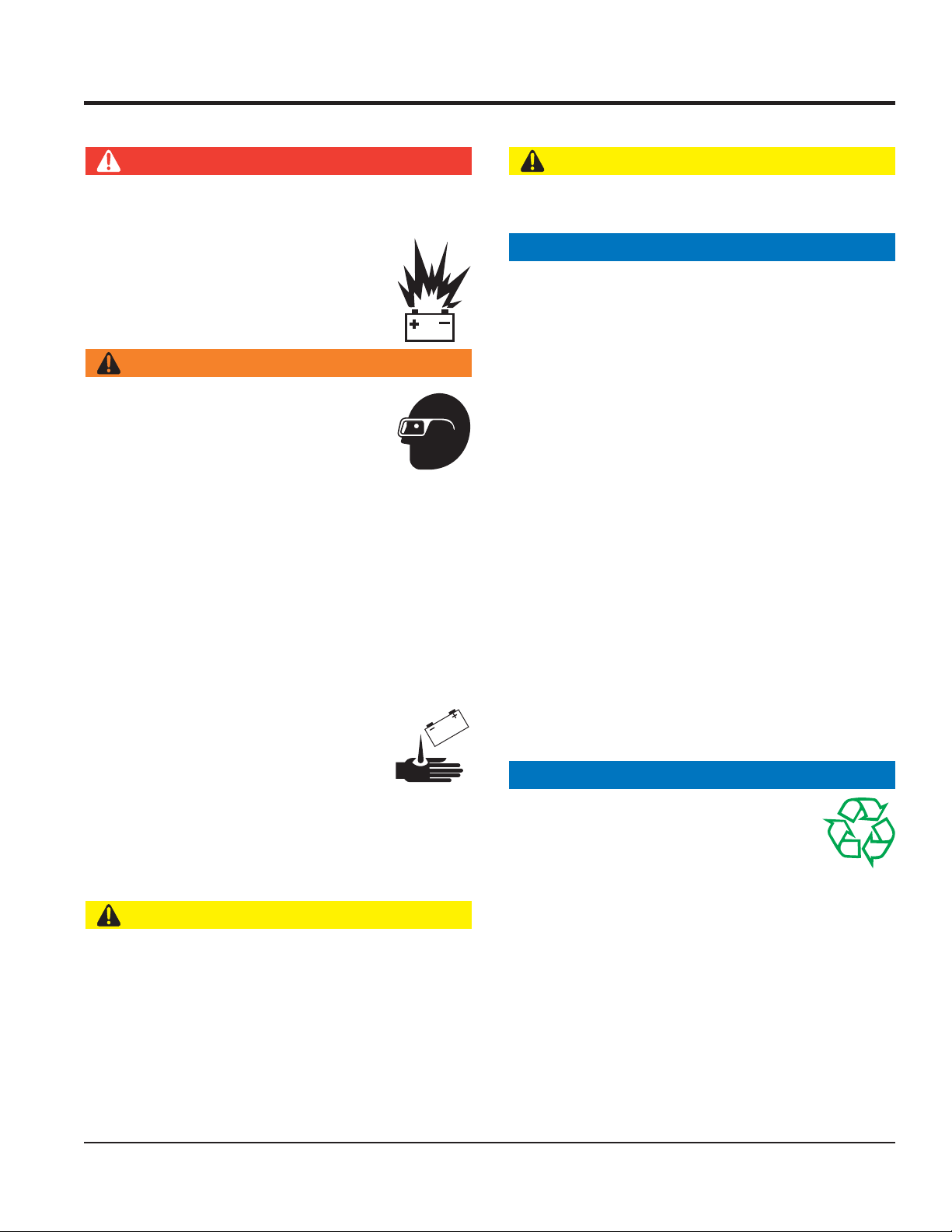

BATTERY SAFETY (ELECTRIC START ONLY)

DANGER

DO NOT drop the battery. There is a possibility that the

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

ALWAYS wear safety glasses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

Use well-insulated gloves when picking up

the battery.

ALWAYS keep the battery charged. If the battery is not

charged, combustible gas will build up.

TRANSPORTING SAFETY

CAUTION

NEVER allow any person or animal to stand underneath

the equipment while lifting.

NOTICE

Before lifting, make sure that the equipment parts (hoo

and vibration insulator) are not damaged and screws are

not loose or missing.

Always make sure crane or lifi tng device has been

properly secured to the lifting bail (hook) of the

equipment.

ALWAYS shutdown engine before transporting.

NEVER lift the equipment while the engine is running.

Tighten fuel tank cap securely and close fuel cock to

prevent fuel from spilling.

Use adequate lifting cable (wire or rope) of suffi cient

strength.

DO NOT charge battery if frozen. Battery can explode.

When frozen, warm the battery to at least 61°F (16°C).

ALWAYS recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

of combustible gases.

If the battery liquid (dilute sulfuric acid)

comes into contact with clothing or skin,

rinse skin or clothing immediately with

plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the equipment.

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

Use one point suspension hook and lift straight

upwards.

DO NOT lift machine to unnecessary heights.

ALWAYS tie down equipment during transport by

securing the equipment with rope.

ENVIRONMENTAL SAFETY

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 9

Page 10

NOTES

PAGE 10 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 11

SPECIFICATIONS

MVH150VD2 Specifi cationsTable 1.

Centrifugal Force 6,070 lbf (27 kN)

Vibration Frequency 5400 vpm (90 Hz)

Traveling Speed 0 to 82 ft/min (0 to 25 m/min)

Plate Size (L x W) 27.6 x 16.9 in (700 x 430 mm)

Max. Area of Compaction 6,942 sq. ft./h (645 sq. meters/h)

Operating Weight 331 lbs. ( 150 kg)

Vibrating Oil Capacity 0.37 quart (0.35 liter)

Engine Specifi cationsTable 2.

Model YANMAR L48V6AF3R4AAW4

Type

Bore X Stroke

Displacement 13.4 cu. in. (219 cc)

Max Power Output 4.4 HP (3.3 KW) @ 4,000 R.P.M.

Fuel Tank Capacity 2.5 quarts (2.4 liters

Fuel Diesel

Operating Speed 3,600 rpm

Lube Oil Capacity 0.85 quarts (0.8 liters)

Starting Method Recoil Start

Air-cooled, 4-cycle

Diesel Engine

2.76 in. X 2.24 in.

(70 mm x 57 mm.)

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 11

Page 12

B

DIMENSIONS

A

C

E

D

MVH150VD2Figure 1.

DimensionsTable 3.

Reference Description Measurement

A Height (Handle in Vertical Position) 46.9 in (1,190 mm)

B Height of Main Body 30.4 in (771 mm)

C Lenght of Plate 27.6 in (700 mm)

D Length (Handle in Vertical Position) 30.3 in (770 mm)

E Width of Plate 16.9 in (430 mm)

PAGE 12 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 13

GENERAL INFORMATION

PRODUCT DESCRIPTION

The Mikasa MVH150VD2 is a walk-behind, reversible

plate compactor designed for the compaction of sand and

clay. This plate compactor is a powerful compacting tool

capable of applying a tremendous force in consecutive

high frequency vibrations to a soil surface. Its applications

include soil compacting for road, embankments and

reservoirs as well as backfi lling for gas pipelines, water

pipelines and cable installation work.

ECCENTRIC WEIGHTS

A set of rotating eccentric weights within the vibrator

case produces low amplitude high frequency vibrations,

designed to compact granular soil. The rotation of the

weights are controlled hydraulically through a lever on the

control handle. Changing the position of the lever allows

smooth transition between forward and reverse travel.

The resulting vibrations cause forward motion. The engine

and handle are vibration-isolated from the vibrating plate.

The heavier the plate, the more compaction force it

generates.

ANTI-VIBRATION HANDLE SYSTEM (AVT)

This compactor is equipped with advanced anti-vibration

handle design that reduces vibration to the operator by up

to 50% compared to other plate compactors.

FREQUENCY/SPEED

The compactor's vibrating plate has a frequency of 5,400

vpm (vibrations per minute). The forward and reverse travel

speed of the compactor is approximately 82 feet/minute

(25 meters/minute).

ENGINE

The plate compactor is equipped with a Yanmar

L48V6AF3R4AAW4 air-cooled, 4-cycle, diesel engine.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 13

Page 14

10

REVERSE

NEUTRAL

11

FORWARD

6

COMPONENTS

1

2

7

8

9

Compactor ComponentsFigure 2.

Figure 2 shows the location of the controls, indicators and

general maintenance parts. The function of each control

is described below:

Breather Cap 1. — Remove this cap to bleed (remove

air) the hydraulic system. When replacing hydraulic

oil, use "Shell Tellus #46" or equivalent.

Hand Grip 2. — When operating the compactor use this

hand grip to maneuver the compactor.

Handle Lock 3. — Pull handle bar downward (working

position), then pull handle lock to lock handle bar in

place.

Vibration Case Oil Level Check Plug 4. — Remove this

plug to check the vibration case oil. Oil level should be

all the way up to the fi ller port. When replacing vibration

case oil, use 10W-30 engine oil.

Handle Bar (working position) 5. — When operating

the compactor, this handle is to be in the downward

position.

5

4

Diesel Engine 7. — This plate compactor uses a

YANMAR L48V6AF3R4AAW4 engine. Refer to the

YANMAR owner's manual for engine information.

Belt Cover 8. — Remove this cover to gain access to the

V-belts. NEVER run the compactor without the V-belt

cover. If the V-belt cover is not installed, your hand may

get caught between the V-belt and clutch, thus causing

serious injury and bodily harm.

Vibration Case 9. — Encloses the eccentric gears and

counter weights.

Forward & Reverse Lever 10. — Push the lever forward,

the compactor will move in a forward direction. Pull the

lever backwards, the compactor will move in backwards

direction. Placing the lever in the middle (midway) will

cause the compactor not to move (neutral).

Throttle Control 11. — Move the throttle lever to the rabbit

position for full throttle (max RPMs). For engine idle,

move the throttle lever to the turtle position.

3

Handle Bar (stored position) 6. — When the compactor

is to be stored, move the handle bar to the upright

position.

PAGE 14 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 15

BASIC ENGINE

9

1

2

10

11

7

8

Compactor ComponentsFigure 3.

Figure 3 shows the basic Yanmar engine. The engine must

be checked for proper lubrication and fi lled with fuel prior to

operation. Refer to the manufacturer’s engine manual for

instructions and details of operation and servicing. Each

component is described below:

Fuel Filler Cap 1. — Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fi ll.

Fuel Tank 2. — Capacity is 2.5 quarts (2.4 liters) of diesel

fuel.

DANGER

Adding fuel to the tank should be done

only when the engine is stopped and has

had an opportunity to cool down. In the

event of a fuel spill, DO NOT attempt to

start the engine until the fuel residue has

been completely wiped up and the area

surrounding the engine is dry.

Air Cleaner 3. — Prevents dirt and other debris from

entering the fuel system. Remove wing-nut on top of

air fi lter canister to gain access to fi lter element.

NOTICE

Operating the engine without an air filter, with a

damaged air fi lter, or a fi lter in need of replacement

will allow dirt to enter the engine, causing rapid engine

wear.

3

5

6

4

Muffl er4. — Used to reduce noise and emissions.

WARNING

Engine components can generate extreme

heat. To prevent burns, DO NOT touch

these areas while the engine is running

or immediately after operating. NEVER

operate the engine with the muffler

removed.

Recoil Starting Handle (pull rope) 5. — Type of engine

starting method.

Recoil Starter 6. — Manual-starting method. Pull the

starter grip until resistance is felt, then pull briskly and

smoothly.

Oil Filler Cap / Dipstick 7. — Remove this cap to add oil

to the engine crankcase. Read dipstick to determine if

oil level is low. DO NOT over fi ll.

Oil Drain Plug 8. — Unscrew plug to drain oil from engine

crankcase. Dispose of oil in a safe manner.

Decompression Lever9. — Press down before starting

engine. To prevent damage to engine, DO NOT use for

any other purpose.

Fuel Cock 10. — Controls the fl ow of diesel fuel to the

carburetor. Must be in the ON position when starting

and running the engine.

Speed Control Lever 11. — Regulates engine speed.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 15

Page 16

INSPECTION

BEFORE STARTING

Read safety instructions at the beginning of manual.1.

Clean the compactor, removing dirt and dust. 2.

Particularly, the bottom of the plate, engine cooling air

inlet, carburetor and air cleaner.

Check the air fi lter for dirt and dust. If the air fi lter is 3.

dirty, blow through the air fi lter cartridge from the inside,

moving a jet of dry compressed air up and down until

all dust is removed. Otherwise replace air fi lter with a

new one.

Check carburetor for external dirt and dust. Clean with 4.

dry compressed air.

Check fastening nuts and bolts for tightness. Loosened 5.

screws or bolts due to vibration, could lead to

unexpected accident.

ENGINE OIL CHECK

To check the engine oil level, place the plate compactor 1.

on secure level ground with the engine stopped.

Remove the fi ller cap/dipstick from the engine oil fi ller 2.

hole (Figure 4) and wipe it clean.

ENGINE OIL

DIPSTICK

Oil TypeTable 4.

Season Temperature Oil Type

Summer 25° C or higher SAE 10W-30

Spring/Fall 25° C - 10° C SAE 10W-30/20

Winter 0° C SAE 10W-10

FUEL CHECK

Remove the fuel cap located on top of fuel tank.1.

Visually inspect to see if fuel level is low. If fuel is low, 2.

replenish with diesel fuel.

When refueling, be sure to use a strainer for fi ltration. 3.

DO NOT top-off fuel. Wipe up any spilled fuel.

VIBRATOR OIL CHECK

Place the compactor horizontally on a fl at surface.1.

Check vibrator oil level by removing bolt (vibrator oil 2.

gauge) as shown in Figure 6. Use a 14-mm wrench to

remove bolt. The vibrator oil level should be maintained

between the two markings as shown in Figure 6. If oil

is required, replace using SAE 10W-30.

ENGINE OIL

FILLER HOLE

OIL GAUGE

Engine Oil DipstickFigure 4.

Insert and remove the dipstick without screwing it 3.

MAINTAIN OIL

LEVEL BETWEEN

LINES

OIL

into the fi ller neck. Check the oil level shown on the

dipstick.

Vibrator Oil GaugeFigure 6.

If the oil level is low (Figure 5), fi ll to the edge of the oil 4.

fi ller hole with the recommended oil type (Table 4).

Maximum oil capacity is 0.85 quart.

UPPER LIMIT

LOWER LIMIT

Engine Oil LevelFigure 5.

PAGE 16 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 17

INSPECTION

HYDRAULIC OIL CHECK

With handle bar positioned vertically (storage position), 1.

remove the breather cap (Figure 7) from the breather

plug.

CAP

BREATHER

PLUG

OIL LEVEL

HAND PUMP

Hydraulic Oil CheckFigure 7.

Use a 24 mm wrench and remove breather plug (Figure 2.

7). Visually check to see if hydraulic oil comes up to

the oil level line that is etched on the back side of the

handle.

If the hydraulic oil level is low, replace with "Shell Tellus" 3.

oil #46 or equivalent.

To check the V-belt tension (Figure 9), remove upper 1.

belt cover.

V-Belt LocationFigure 9.

The V-belt tension is proper if the V-belt bends 10 to 2.

15 mm (Figure 10) when depressed with fi nger at

midway between the clutch and vibration pulley shaft.

V-BELT CHECK

CAUTION

Never attempt to check the V-belt with the engine

running. Severe injury can occur if your hand (Figure 8)

gets caught between the V-belt and clutch. Always use

safety gloves.

CLUTCH

PULLEY

VIBRATOR

PULLEY

V-belt HazardFigure 8.

V-Belt TensionFigure 10.

A loose belt will decrease the power transmission 3.

output, causing reduced compaction and premature

wear of the belt. V-belt in use is RPF-3320 (A-32 can

also be used).

If the V-belt becomes worn or loose, replace it by using 4.

V-belt part number RPF-3320 or A-32.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 17

Page 18

OPERATION

CAUTION

Never attempt to check the V-belt with the engine

running. Severe injury can occur if your hand (Figure 8)

gets caught between the V-belt and clutch. Always use

safety gloves.

INITIAL STARTUP

Open the fuel cock (Figure 11). 1.

Fuel CockFigure 11.

Move the engine speed control lever (Figure 12) to the 2.

IDLE position.

Grasp the starter grip (Figure 14) and slowly pull it out. 4.

The resistance becomes the hardest at a certain

position, corresponding to the compression point. Pull

the starter grip briskly and smoothly for starting.

Starter GripFigure 14.

If the engine does not start, repeat steps 1 thru 4.5.

OPERATION

Once the engine has started, move the engine speed 1.

lever quickly to the FAST (Figure 15) position.

Push down the decompression lever (Figure 13) and 3.

release.

ENGINE SPEED

CONTROL

LEVER

Engine Speed Control Lever (Idle Figure 12.

Position)

Decompression LeverFigure 13.

IDLE

NOTICE

Always move the speed control lever quickly without

hesitation because increasing the engine speed slowly

causes the clutch to slip.

ENGINE SPEED

CONTROL

LEVER

FAST

Speed Control (Fast Position)Figure 15.

With the engine speed control lever placed in the FAST 2.

position, the engine speed should be between 2,300

~2,600 RPM’s, therefore engaging the centrifugal

clutch.

PAGE 18 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 19

OPERATION

To make the compactor move in the forward direction 3.

push the travel lever ( Figure 16) forward. To make the

compactor move in the reverse direction pull the travel

lever backwards.

Direction LeverFigure 16.

Firmly grasp the compactor's handle bar with both 4.

hands, the compactor will begin moving forward.

Slowly walk behind the compactor and be on the lookout 5.

for any large objects or foreign matter that might cause

damage to the compactor or bodily injury.

Compactor traveling speed may drop on soils which 6.

contain clay, however there may be cases where

traveling speed drops because the compaction plate

does not leave the ground surface easily due to the

composition of the soil. To rectify this problem do the

following:

Check the bottom plate to see if clay or equivalent •

material has been lodged in the plate mechanism. If

so, wash with water and remove.

NORMAL SHUTDOWN PROCEDURE

Place the speed control lever in the IDLE position. Allow 1.

the engine to cool down for 2 to 3 minutes.

Next, place the speed control lever in the STOP position 2.

(Figure 17) to stop the engine.

SPEED

CONTROL

LEVER

Speed Control Lever (Stop Position)Figure 17.

STOP

Close the fuel cock (Figure 11).3.

EMERGENCY SHUTDOWN PROCEDURE

Move the speed control lever quickly to the STOP 1.

position (Figure 17).

Close the fuel cock.2.

Remember the compactor does not work as effi ciently •

on clay or soils that have a high moisture content

level.

If the soil has a high moisture level, dry soil to •

appropriate moisture content level or carry out

compaction twice.

NOTICE

Whenever the compactor's vibration becomes weak or

lost during normal operation, regardless of operation

hours, check the V-belt and clutch immediately.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 19

Page 20

MAINTENANCE

CAUTION

Inspection and other services should always be carried

out on hard and level ground with the engine shut

down.

INSPECTION AND MAINTENANCE TABLES

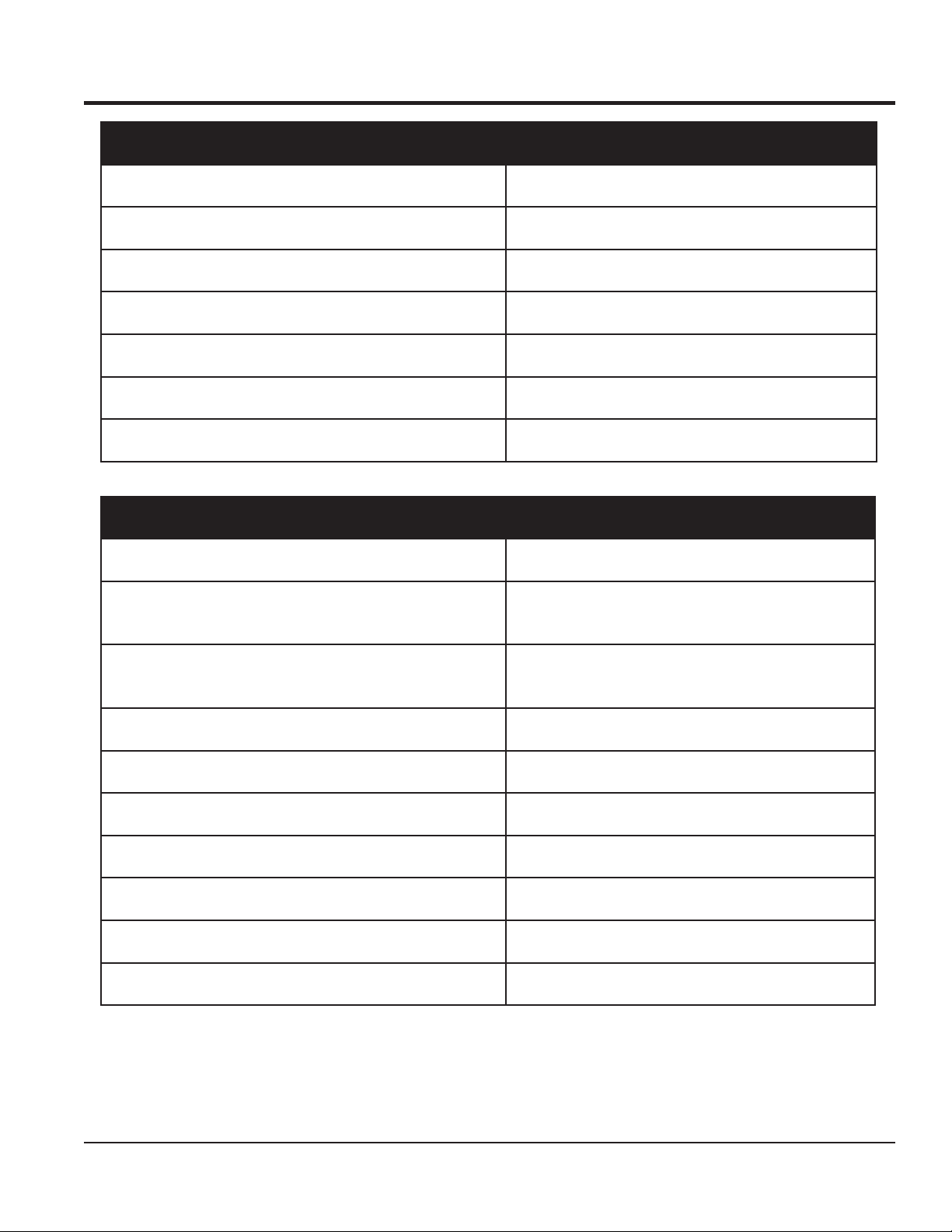

To make sure your plate compactor is always in good

working condition before using, carry out the maintenance

inspection in accordance with Tables 5 and 6.

Machine InspectionTable 5.

Item Frequency of Inspection

Loose or Missing Screws Every 8 hours (daily)

Damaged Parts Every 8 hours (daily)

Function of Controlling

System Part

Every 100 hours

Engine CheckTable 6.

Item Frequency of Inspection

Oil or Fuel Leak Every 8 hours (daily)

Tightness of Fastening

Threads

Engine Oil Check and

Replenishment

Engine Oil Replacement

Valve Clearance

(Check/Adjust)

Every 8 hours (daily)

Every 8 hours (daily)

(Replenish to specifi ed

maximum level)

After fi rst 25 hours then

every 50 to 100 hours

After fi rst 25 hours then

every 200 hours or every

year.

Air Filter Cleaning Every 100 hours

Vibrator Oil Check Every 100 hours

Vibrator Oil Replacement Every 300 hours

Hydraulic Oil Check Every 100 hours

Hydraulic Oil

Replacement

After fi rst 200 hours, then

every 1,000 hours

V-belt (clutch) Check Every 200 hours

NOTICE

These inspection intervals are for operation under

normal conditions. Adjust your inspection intervals

based on the number of hours the plate compactor

has been in use, and the type of working conditions it

is being used.

NOTICE

Fuel piping and connections should be replaced every

2 years.

See separate engine manual for details on engine check.

DAILY SERVICE

Check for leakage of fuel or oil.1.

Check for loose screws including tightness. See Table 7 2.

(Tightening Torque) for retightening.

Tightening Torque (kg cm)Table 7.

Diameter

Material

6mm 8mm 10mm 12mm 14mm 16mm 18mm 20mm

4T 70 150 300 500 750 1,100 1,400 2,000

6-8T 100 250 500 800 1,300 2,000 2,700 3,800

11T 150 400 800 1,200 2,000 2,900 4,200 5,600

300-

350

650-

700

100

*

* (for aluminum counterpart)

(Threads in use with this machine are all right-handed)

Material and quality of material is marked on each bolt and screw.

PAGE 20 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 21

MAINTENANCE

Remove soil and clean the bottom of compaction 3.

plate.

Check hydraulic pump, piping and hose for any leakage. 4.

A loosened hydraulic hose can be a cause for leakage.

Check hydraulic hose connections with wrench applied

for tightness.

Check engine oil.5.

ENGINE OIL REPLACEMENT

Replace engine oil, in fi rst 20 hours of operation and 1.

every 100 hours afterwards.

Oil may be drained more easily when it is warm after 2.

operation (For more details, see separate engine

Owner's Manual).

AIR FILTER

Remove the air cleaner cover and foam fi lter element 1.

as shown in Figure 18.

Replacing the V-belt

Remove the upper and lower belt covers. Engage an

offset wrench (13 mm) or the like to vibrator pulley (lower)

fastening bolt. Engage waste cloth or the like at midway

of V-belt on the left side and while pulling it back strongly,

rotate the offset wrench clockwise so that the V-belt will

come off.

Reinstalling the V-belt

Engage V-belt to lower vibrator pulley and push the V-belt

to left side of upper clutch. In the same manner as in

removal, rotate offset wrench clockwise so that the V-belt

goes back on.

Checking Clutch

Check the clutch simultaneously with V-belt checking. With

belt removed, visually check outer drum of the clutch for

seizure and "V" groove for wear or damage. Clean the "V"

groove as necessary. Regularly check the lining or shoe

for wear. If the shoe is worn, power transmission becomes

defi cient and slipping will result.

Air FilterFigure 18.

Tap the paper fi lter element (Figure 18) several times on 2.

a hard surface to remove dirt, or blow compressed air

[not exceeding 30 psi (207 kPa, 2.1 kgf/cm2)] through

the fi lter element from the air cleaner case side.

Clean foam element in warm, soapy water or 3.

nonfl ammable solvent. Rinse and dry thoroughly. Dip

the element in clean engine oil and completely squeeze

out the excess oil from the element before installing.

CHECKING AND REPLACING V-BELT AND CLUTCH

After 200 hours of operation, remove the upper belt 1.

cover to check the V-belt tension. Tension is proper if

the belt bends about 10 mm when depressed strongly

with fi nger between shafts. Loose or worn V-belts

reduce power transmission effi ciency, causing weak

compaction and reducing the life of the belt itself.

NOTICE

Whenever the compactor's vibration becomes weak or

lost during normal operation, regardless of operation

hours, check the V-belt and clutch immediately.

VIBRATOR OIL LEVEL CHECK

In every 300 hours of operation, with the machine 1.

positioned horizontally, remove vibrator oil level check

plug (Figure 6) off vibrator (14 mm wrench) and see

if oil is up to fi ller port. Be sure to clean area around

check hole to prevent dirt and dust from entering.

In every 300 hours of operation, replace oil (capacity 2.

400 cc). For draining oil through level check hole, have

the machine inclined with a sleeper or the like placed

under the compaction plate on opposite side.

* Use engine oil 10W-30 for this lubrication.

NOTICE

Always clean the area around the vibrator oil level check

hole before removing oil check plug. This will prevent

dirt and debris from entering the system.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 21

Page 22

MAINTENANCE

CAUTION

Make sure hydraulic oil in hand pump is at normal safe

operating level. Do not overfi ll. Overfi lling (excessive oil)

will cause excess oil to blow out of the breather plug.

HYDRAULIC OIL

Check hydraulic oil in every 100 hours of operation. 1.

With handle bar positioned vertically (storage position),

remove breather plug (Figure 1) off the top of hydraulic

pump and check for proper oil level.

Replace hydraulic oil after fi rst 200 hours and in every 2.

1,000 hours of operation.

Replacing Hydraulic Oil

After removing plug cap of hand pump (Figure 7), 1.

remove plug of breather (24 mm wrench) and

disconnect vibrator side of hydraulic hose (Figure 19)

at vibrator cylinder. With travel lever placed in the

FORWARD position, drain hydraulic oil in the pump.

STORAGE

For storage of the equipment for over 30 days, the following

is required:

Drain the fuel tank completely. 1.

Run the engine until the fuel in the injection system is 2.

completely consumed.

Completely drain the oil from the engine crankcase and 3.

follow procedures described in the engine's Owner's

Manual for engine storage.

Completely drain hydraulic oil from the vibrating 4.

case.

Clean entire plate compactor, especially the bottom 5.

plate, removing all dirt and foreign matter.

Cover plate compactor and engine with plastic covering 6.

or equivalent and store in a clean, dry place.

Hydraulic HoseFigure 19.

After draining, reconnect the hydraulic hose to 2.

vibrator.

Fill oil through breather hole of hand pump. (capacity: 3.

about 300 cc). Use Shell Tellus Oil #46 or equivalent.

Removing breather plug at vibrator cylinder causes oil 4.

to fl ow out of breather hole in a while. When aeration

disappears, replace the plug and tighten securely.

Replace breather plug of hand pump and fi t the plug 5.

cap. After making sure that oil in pump is at proper

level, replace the breather plug.

PAGE 22 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 23

TROUBLESHOOTING

Engine TroubleshootingTable 8.

Symptom Possible Problem Solution

Engine will not start

or start is delayed,

although engine can be

turned over.

At low temperatures,

engine will not start.

Speed control lever is in ""STOP"" position?

No fuel reaching injection pump? Add fuel. Check entire fuel system.

Defective fuel pump? Replace fuel pump.

Fuel fi lter clogged? Replace fuel fi lter and clean tank.

Faulty fuel supply line? Replace or repair fuel line.

Compression too low?

Fuel injector not working correctly?

Oil pressure too low? Check engine oil pressure.

Low starting temperature limit exceeded?

Fuel separates has inadequate resistance to

low temperatures?

Set speed control lever to ""START""

position.

Check piston, cylinder and valves. Adjust or

repair per engine repair manual.

Repair or replace injector in accordance

with engine repair manual.

Comply with cold starting instructions and

proper oil viscosity.

Check whether clear (not turbid) fuel

emerges from the fuel line (detach from

injection pump). If the fuel is turbid or

separated, warm up the engine or drain the

complete fuel supply system. Refuel with

winter grade diesel fuel.

Engine fi res but stops

as soon as starter is

switched off.

Engine stops by itself

during normal operation.

Low engine power,

output and speed.

Low engine power

output and low speed,

black exhaust smoke.

Engine oil too thick?

Throttle lever in STOP position? Reposition throttle lever to RUN position.

Fuel fi lter blocked? Replace fuel fi lter.

Fuel supply blocked? Check the entire fuel system.

Fuel tank empty? Add fuel.

Fuel fi lter blocked? Replace fuel fi lter.

Fuel tank empty? Fill with No.2 diesel fuel.

Fuel fi lter clogged? Replace fuel fi lter.

Fuel tank venting is inadequate? Ensure that tank is adequately vented.

Speed control lever does not remain in

selected position?

Engine oil level too full? Correct engine oil level.

Air fi lter blocked? Clean or replace air fi lter.

Incorrect valve clearances? Adjust valves per engine specifi cation.

Malfunction at injector? See engine manual.

Refi ll engine crankcase with correct type of

oil for winter environment.

See engine manual for corrective action.

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 23

Page 24

Symptom Possible Problem Solution

Engine will not start

or start is delayed,

although engine can be

turned over.

Travels forward or

reverse, but impossible

to switch direction.

TROUBLESHOOTING

Plate Compactor TroubleshootingTable 9.

Engine speed too low? Set engine speed to correct RPM.

Clutch slips? Check or replace clutch.

V-belt slips? Adjust or replace V-belt.

Excessive oil in vibrator? Drain excess oil and fi ll to proper level.

Malfunction in vibrator housing? Check eccentric, gears and counter weights.

Directional components defective? Check all directional components

Reversing lever adjustment? Adjust or repair reversing lever.

Hydraulic oil hose broken? Repair or replace hydraulic oil hose.

Aeration in hydraulic oil for reversing

system?

Check valve in hand pump clogged with

dust?

Bleed hydraulic oil system.

Clean or replace hand pump check valve.

Does not travel either

forward or reverse.

Travel lever operating

resistance is high.

Piston or bearing in cylinder (vibrator assy.)

is defective?

V-belt slips? Replace V-belt.

Clutch slips? Check clutch springs and shoes.

Vibrator locked?

Piston or bearing in cylinder defective? If worn, replace cylinder piston or bearing.

Air in hydraulic line? Bleed hrdraulic oil system.

Piston or bearing in cylinder defective? If worn, replace cylinder piston or bearing.

If worn, replace cylinder piston or bearing.

Check vibrator housing (eccentric, gears

and counterweights)

PAGE 24 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 25

NOTES

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 25

Page 26

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the help

numbers found on the back page of the manual if there are any

questions.

The contents and part numbers listed in the parts section are

subject to change

guarantee the availability of the parts listed.

Sample Parts List:

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ...................... 1 ......INCLUDES ITEMS W/

2

*

2*12347 WASHER, 3/8 IN. ... 1 ......

3 12348 HOSE ................... A/R .... MAKE LOCALLY

4 12349 BEARING ............... 1 ......S/N 2345B AND ABOVE

NO. Column

Unique Symbols - All items with same unique symbol

(*, #, +, %, or >) in the number column belong to the same

assembly or kit, which is indicated by a note in the “Remarks”

column.

Duplicate Item Numbers - Duplicate numbers indicate

multiple part numbers are in effect for the same general

item, such as different size saw blade guards in use or a

part that has been updated on newer versions of the same

machine.

When ordering a part that has more than one

item number listed, check the remarks column

for help in determining the proper part to order.

without notice

WASHER, 1/4 IN. .............

. Multiquip does not

NOT SOLD SEPARATELY

MQ-45T ONLY

*

QTY. Column

Numbers Used - Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other parts

that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed to

describe the item can also be shown.

Assembly/Kit

unique symbol will be included when this item is purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

used only with the specific model number or model number

variant listed. It can also be used to show a part is NOT

used on a specific model or model number variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

- All items on the parts list with the same

- Used to list an effective serial

- Indicates that the part is

PART NO. Column

Numbers Used - Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a part

that has not been assigned a formal part number at time of

publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will be

clarified in the “Remarks” Column.

“Make/Obtain Locally”

purchased at any hardware shop or made out of available

items. Examples include battery cables, shims, and certain

washers and nuts.

“Not Sold Separately”

purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available for

sale through Multiquip.

- Indicates that the part can be

- Indicates that an item cannot be

PAGE 26 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 27

MVH150VD2 PLATE COMPACTOR WITH YANMAR

L48V6F3R4AAW4 ENGINE

1 to 3 units

QTY. P/N DESCRIPTION

3............070100352 ............V-BELT

2............956100047 ............THROTTLE WIRE

3............11465012590 ........ELEMENT, AIR CLEANER

1............11429955040 ........CAP. FUEL TANK

1............11429976630 ........ROPE, RECOIL STARTER

2............11429935110 ........LUB OIL FILTER

2............11425055121 ........FILTER, FUEL STRAINER

1............11429955100 ........FILTER , FUEL OIL

4............939010130 ............SHOCK ABSORBER

SUGGESTED SPARE PARTS

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 27

Page 28

NAMEPLATE AND DECALS

10

9

MVH-150

8

Serial No.

Model No.

1

SHELL TELLUS OIL

46

3

?

-

?

/

?

?

?

NPA-748

J

OPERATIONAL CAUTION

Prior to OPERATION:

Check engine oil and fuel level

if not enough, add to proper level

To START engine:

1. Warm up engine at low speed for 3

to 5 minutes.

2. Operate machine always at full speed

to avoid incorrect clutch engagement.

3. Use travel lever for forward and reverse

motion. Do not push or pull lever strongly.

To STOPengine:

Move stop switch to “OFF” position.

To LIFT machine by using lifting hook in center

To STORE machine covered with plastic

sheet in a moisture.

Do not move travel lever

CAUTION

ATTENZIONE

ATENÇAÕ

* Read operator’s manual carefully before use.

* Libre le manual attentivement avant utillsation.

* Bitte lesen Sie vor inbetriebnahme der Maschine de

Bedienungsanleitung sogfältig durch.

* Prima dell’ uso leggere attentamente il manuale.

* Lee com atenÇão o manual de instruÇões antes de

usar.

* Leer detenidamente el mamual de instrucciones

antes de usar la maquina.

PRECAUCION

4

2

if engine stops

NPA-769 J

NPA-743

J

CONTACT

PARTS DEPT.

V BELT RPF-3350

NPA-335

J

7

PAGE 28 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

SAE 10W-30

MOTOR OIL

NPA-195

J

6

5

Page 29

NAMEPLATE AND DECALS

NO PART NO PART NAME QTY. REMARKS

1 920207480 DECAL,SHELL TELLUS OIL 46 ..................1 ................NPA-748

2 920207430 DECAL, CAUTION ......................................1 ................NPA-743

3 920203330 EAR PROTECTION LABEL ........................1 ................DCL333

4 920207690 DECAL, CAUTION (MANUAL) ....................1 ................NPA-769

5 920207670 DECAL, V-BELT RPF-3350 .........................1 ................NPA-335

6 920201580 DECAL,MQ MARK 71X55 1

7 920201950 DECAL,OIL SAE 10W-30 ............................1 ................NPA-195

8 PLATE, SERIAL NO ....................................1 ................CONTACT MQ PARTS DEPT.

9 920207660 DECAL, MODEL MVH-150 1

10 920207400 DECAL, DANGER-CAUTION 1

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 29

Page 30

VIBRATING PLATE ASSY

55

54

56

57

58

52

54

53

51

54

52

56

54

55

PAGE 30 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 31

VIBRATING PLATE ASSY

NO PART NO PART NAME QTY. REMARKS

51 459115390 VIBRATING PLATE 1

52 939010130 SHOCK ABSORBER MED70S 4

53 020312100 NUT M12 4

54 030212300 WASHER, LOCK M12 8

55 001221230 BOLT 12X30 T 4

56 952405600 WASHER 12.5X35X4.5 4

57 460449160 OIL GAUGE 1

58 953405260 PACKING 1/4 (CU) 1

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 31

Page 32

BODY ASSY

37

39

36

35

52

52

53

64

38

40

63

62

63

61

60

6

12

11

13

12-1

12-2

12-3

12-4

12-5

12-6

12-7

20

14

51

8

7

15

21

16

22

2

19

18

3-1

4

5

3

4

5

57

58

56

45

47

48

44

17

46

44

41

43

42

59

1

PAGE 32 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

49

43

Page 33

BODY ASSY

NO PART NO PART NAME QTY. REMARKS

1 459116670 BASE 1

2 914410024 ENGINE ASSY, L48V6AF3R4AAW4 1

3 001221040 BOLT 10X40 T 3

3-1 001221035 BOLT 10X35 T 1

4 030210250 WASHER, LOCK M10 4

5 031110160 WASHER, FLAT M10 4

6 459216380 BELT COVER PLATE 1

7 001220820 BOLT 8X20 T 4

8 030208200 WASHER, LOCK M8 4

11 458451370 SPACER 202512 1

12 458337770 CLUTCH ASSY A1-124-20 ................................1.................. INCLUDES ITEMS W/

12-1* 941040510 CLUTCH SHAFT S20D-45 1

941010390 CLUTCH PULLEY A1-124 1

12-2

*

941020030 CLUTCH SHOE T90T 3

12-3

*

941030230 CLUTCH SPRING 2

12-4

*

080200300 STOP RING S-30 1

12-5

*

080600550 STOP RING AR-55 1

12-6

*

046006006 BEARING 6006DDU 1

12-7

*

13 951406780 KEY 5X5X30 RR 1

14 458451380 CLUTCH WASHER 1

15 001520825 SOCKET HEAD BOLT 8X25 T 1

16 070100352 V-BELT A-35 BLUE/RPF3350 1

17 459214530 DUST COVER 1

18 092006010 FLAT HEAD SCREW 6X10 2

19 459338190 SPONGE, DUST COVER 1

20 459115420 BELT COVER (UPPER) 1

21 001520852 SOCKET HEAD BOLT 8X60 T 3

22 001520820 SOCKET HEAD BOLT 8X20 T 1

35 458450830 RUBBER COVER 1

36 458450810 PLATE, RUBBER COVER 1

37 001220825 BOLT 8X25 T 2

38 030208200 WASHER, LOCK M8 2

39 031108160 WASHER, FLAT M8 2

40 022710809 NYLON NUT M8 2

41 2556390111 UNION 1

42 2556380103 DRAIN HOSE 1

43 0091720000 HOSE CLAMP 2

44 0211140020 GASKET 2

45 0401140030 PLUG 1

46 459454460 JOINT 1

47 001220820 BOLT 8X20 T 1

48 030208200 WASHER, LOCK M8 1

49 221901600002 SEAL WASHER 16S 1

51 459119660 GUARD FRAME 1

52 001221225 BOLT 12X25 T 4

53 030212300 WASHER, LOCK M12 4

56 16080278260 CLAMP 1

57 001220610 BOLT 6X10 T 1

58 030206150 WASHER, LOCK M6 1

59 459455560 UNION, OIL DRAIN 1

60 930103521 SHOCK ABSORBER ME35 15X15 1

61 458347660 LOCK LEVER 1

62 030208200 WASHER, LOCK M8 1

63 020408050 NUT M8, H=5 2

64 001520830 SOCKET HEAD BOLT 8X30 T 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 33

Page 34

22

23

24

9

21

2

19

31

530

18

9

19

5

12

A

18

VIBRATOR ASSY

6

3

2

41

42

43

36

4

19

32

33

27

18

28

34

29

26

48

19

16

18

15

14

40

13

42

43

17

5

2

35

37

39

38

20

1

25

11

2

5

45

46

PAGE 34 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 35

VIBRATOR ASSY

NO PART NO PART NAME QTY. REMARKS

A 459910013 VIBRATOR ASSY ........................................1 ................INCLUDES ITEMS W/

1* 458115150 VIBRATING CASE 1

2* 047920090 ROLLER BEARING NJ307MC4 4

3* 458337700 ROTARY SHAFT, DRIVE 1

4* 458342580 ROTARY SHAFT, DRIVEN/NEW 1

5* 080200350 STOP RING S35 8

6* 951405460 KEY 10X8X19 RR 1

9* 040306907 BEARING 6907C3 2

11* 458337730 PISTON ROD 1

12* 025508050 PIN 8X50 1

13* 042506000 BEARING 6000ZZSG 2

14* 080200100 STOP RING S10 1

15* 455435051 PISTON, 22.4D 1

16* 455010070 PACKING USH22.4X30X5 1

17* 080100260 STOP RING R26 1

18* 459451850 ECCENTRIC ROTATOR 4

19* 009120306 SOCKET HEAD BOLT 10X30T 4

20* 060202040 OIL SEAL SC28458 1

21* 458337740 BEARING COVER 1

22* 031108160 WASHER, FLAT M8 4

23* 030208200 WASHER, LOCK M8 4

24* 031108160 WASHER, FLAT M8 4

25* 953405580 SEAL CAP SC458 1

26* 458214370 CYLINDER 1

27* 001220820 BOLT 8X20 T 4

28* 030208200 WASHER, LOCK M8 4

29* 031108160 WASHER, FLAT M8 4

30* 460347340 GEAR (DRIVE) 1

31* 458342590 GEAR (DRIVEN) 1

32* 001200812 BOLT 8X12 1

33* 953404600 COPPER PACKING 8X16X2 1

34* 954010020 CONNECTOR PT, PF1/4 1

35 459341310 PULLEY 90D W/ FAN 1

36* 951400990 KEY 7X7X20 1

37 459452100 WASHER 9X(2430)X17 1

38 001220835 BOLT 8X35 T 1

39 030208200 WASHER, LOCK M8 1

40* 001221240 BOLT 12X40 T 2

41 001221264 BOLT 12X120 T 6

42 030212300 WASHER, LOCK M12 8

43 031112230 WASHER, FLAT M12 8

45 459214510 BELT COVER (LOWER) 1

46 001520645 SOCKET HEAD BOLT 6X45 T 5

48* 952406180 SHIM 70800.2T 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 35

Page 36

CONTROL ASSY

64

68

63

60

56

69

70

81

62

60

61

A

57

65

66

59

60

54

55

13

58

53

12

52

11

15

51

28

19

15

49

50

18

14

13

17

45

84

82

83

92

91

95

40

94

42

30

35

36

22

41

23

90

24

32

93

20

31

91

9

10

7

93

8

90

29

92

21

35

36

94

95

91

92

PAGE 36 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 37

CONTROL ASSY

NO PART NO PART NAME QTY. REMARKS

7 031110160 WASHER, FLAT M10 1

8 939010320 STOPPER RUBBER 45X36H 1

9 020410060 NUT M10, H=6 1

10 030210250 WASHER, LOCK M10 1

11 458338001 PUMP ASSY 1

12 459337960 TRAVEL LEVER 1

13 001520820 SOCKET HEAD BOLT 8X20 T 2

14 458451420 COLLAR 1

15 033910030 WAVE WASHER 15.5X20X0.3 4

17 022710809 NYLON NUT M8 2

18 030208200 WASHER, LOCK M8 2

19 954002860 OIL HOSE 1040L 1

20 954404230 CLAMP SA12018 1

21 001220625 BOLT 6X25 T 1

22 020306050 NUT M6 1

23 030206150 WASHER, LOCK M6 1

24 031106100 WASHER, FLAT M6 1

28 458451630 BREATHER CAP 1

29 458347640 HANDLE BRACKET, L 1

30 458347650 HANDLE BRACKET, R 1

31 458461430 LOCK CATCH 1

32 009120408 SUNK HEAD BOLT 8X20 T 3

35 001221230 BOLT 12X30 T 4

36 030212300 WASHER, LOCK M12 4

40 458217830 HANDLE GRIP 1

41 001220825 BOLT 8X25 T 2

42 030208200 WASHER, LOCK M8 2

45 953406280 GROMMET NG790 1

49 458461450 MOUNT NUT, HANDLE 1

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 37

Page 38

CONTROL ASSY

64

68

63

60

56

69

70

81

62

60

61

A

57

65

66

59

60

54

55

13

58

53

12

52

11

15

51

28

19

15

49

50

18

14

13

17

45

84

82

83

92

91

95

40

94

42

30

36

22

41

35

23

90

24

32

93

20

31

91

9

10

7

93

8

90

29

92

21

35

36

94

95

91

92

PAGE 38 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 39

CONTROL ASSY

CONTINUED

NO PART NO PART NAME QTY. REMARKS

A 362910060 THROTTLE LEVER ASSY ..........................1 ................INCLUDES ITEMS W/

50 001520610 SOCKET HEAD BOLT 6X10 T 1

51 458461440 MOUNT NUT, THROTTLE 1

52 001520510 SOCKET HEAD BOLT 5X10 T 1

53 463455950 SPACER, THROTTLE 1

54* 362341550 THROTTLE BODY 1

55* 362910090 THROTTLE,GEAR CP,W/ BOLT 1

56* 362455630 THROTTLE LEVER 1

57* 362455620 SLIDER 1

58* 050100450 O-RING G45 1

59* 050200100 O-RING P10 1

60* 031110160 WASHER, FLAT M10 3

61* 032110180 CONICAL SPRING WASHER M10 2

62* 096206006 SOCKET HEAD SCREW 6X6 1

63* 020410060 NUT M10, H=6 1

64* 022131008 CAP NUT M10 1

65* 096208020 SOCKET HEAD SCREW 8X20 1

66* 020408050 NUT M8, H=5 1

68 001220625 BOLT 6X25 T 2

69 030206150 WASHER, LOCK M6 2

70 031106100 WASHER, FLAT M6 2

81 956100047 THROTTLE WIRE 845-925 1

82 16067066350 WASHER, THROTTLE 1

83 26756060002 LOCK NUT M6 PLATED 1

84 26366060002 NUT M6 1

90 930106511 SHOCK ABSORBER ME65 M12 2

91 030212300 WASHER, LOCK M12 4

92 020312100 NUT M12 4

93 939010310 STOPPER RUBBER 45X33H 2

94 030210250 WASHER, LOCK M10 2

95 020410060 NUT M10, H=6 2

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 39

Page 40

22

HAND PUMP ASSY

27

A

28

4

25

21

2

31

20

13

B

11

10

11

12

8

26

7

16

17

14

30

19

29

18

26

8

27

PAGE 40 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 41

HAND PUMP ASSY

NO PART NO PART NAME QTY. REMARKS

A 458338001 PUMP ASSY ...............................................1 ................INCLUDES ITEMS W/

B* 458010150 CAM COMP .................................................1 ................INCLUDES ITEMS W/ #

2* 458010100 COVER (HAND PUMP) 1

4* 458010170 PISTON CP (PUMP) 1

7* 458010110 CONTROL SHAFT (PUMP) 1

8* 458010120 BUSH 2

10*# 042500607 BEARING 607ZZSG 2

11*# 458010190 SPACER 2

12*# 458010090 PIN 7X30 1

13* 025406025 SPRING PIN 6X25 1

14* 458010200 SPRING (PUMP) 1

16* 458010210 STOPPER (PUMP) 1

17* 458010220 PLUG 1

18* 458010131 STOP PLUG 1

19* 458010140 HOSE JOINT 1

20* 001540635 SOCKET HEAD BOLT 6X35 S 4

21* 458010080 BREATHER (PUMP) ...................................1 ................INCLUDES ITEM W/ $

22* 458451630 BREATHER CAP 1

25* 050100250 O-RING G-25 1

26* 050200200 O-RING P-20 2

27* 050200150 O-RING P-15 2

28* 050300670 O-RING S-67 1

29* 050300080 O-RING S-8 1

30* 050200220 O-RING P-22 1

31*$ 050200180 O-RING P-18 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 41

Page 42

YANMAR L48V6AF3R4AAW4 — CYLINDER BLOCK ASSY

PAGE 42 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 43

YANMAR L48V6AF3R4AAW4 — CYLINDER BLOCK ASSY

NO PART NO PART NAME QTY. REMARKS

1 11429501050 CYLINDER BLOCK ASSY. 1

5 11439901700 STARTER COVER 1

6 26106100122 BOLT M10X 12 PLATED 2

7 24162152112 NEEDLE BEARING 1

8 26106080122 BOLT M 8X 12 PLATED 1

9 11429901200 CYLINDER HEAD BOLT A 2

10 11429901210 CYLINDER HEAD BOLT B 2

11 11429901220 CYLINDER HEAD NUT A 2

12 11429901230 CYLINDER HEAD NUT B 2

13 12495001250 WASHER 4

14 11429501330 CYLINDER HEAD GASKET ASSY. 1

20 11429901380 O- RING 1

21 11429901600 PIN 8X12 2

22 11429901800 SHIM SET 1

33 11429901830 COVER, (FO PUMP) 1

34 11425001841 GASKET 1

35 22312040080 PIN 4X8 STRAIGHT 2

36 26226060182 STUD M 6X 18 PLATED 1

37 26226060222 STUD M 6X 22 PLATED 2

38 26366060002 NUT M 6 3

39 11429901410 CRANK CASE GASKET 1

40 11428401452 CRANK CASE COVER ...............................1 ................INCLUDES ITEMS W/

45* 11425002100 MAIN BEARING US=STD. 1

45 11425002200 BEARING US=0.25, MAIN 1

45 11425002210 BEARING US=0.50, MAIN 1

48 11429935150 L.O. INLET PIPE 1

49 26106060252 BOLT M 6X 25 PLATED 14

50 26106080352 BOLT M 8X 35 PLATED 1

53 11429901690 PLUG M16 2

54 11429901760 CAP, W/LUBE OIL GAUGE .........................1 ................INCLUDES ITEMS W/#

56# 11429901950 O- RING 1

57 22190160002 SEAL WASHER 16S 2

58 11429902030 RETAINER 1

59 11425002113 BALL BEARING 1

60 11429902220 OIL SEAL 1

61 16021002220 OIL SEAL 1

62 23876010000 PLUG PT 1/8, SCREW 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 43

Page 44

YANMAR L48V6AF3R4AAW4 — CYLINDER HEAD ASSY

PAGE 44 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 45

YANMAR L48V6AF3R4AAW4 — CYLINDER HEAD ASSY

NO PART NO PART NAME QTY. REMARKS

1 11477111020 CYLINDER HEAD 1

6 11477111100 SUCTION VALVE 1

7 11477111110 EXHAUST VALVE 1

8 11429911120 VALVE SPRING 2

9 1142511180 SPRING RETAINER 2

10 27310055001 COTTER 2

11 22351040008 SPRING PIN 4X8 1

12 11477111250 ARM SUPPORT CAM .................................1 ................INCLUDES ITEMS W/

13* 11477111260 ROCKER ARM SUPPORT 1

14* 11477111650 INTAKE ARM ASSY. ....................................1 ................INCLUDES ITEMS W/ %

16*% 11425011240 VALVE ADJUST. SCREW 1

17*% 26856060002 LOCK NUT 6 1

18* 11477111660 EXHAUST ARM ASSY. ................................1 ................INCLUDES ITEMS W/ $

20*$ 11425011240 VALVE ADJUST. SCREW 1

21*$ 26856060002 LOCK NUT 6 1

22* 22242000120 CIR CLIP 12 2

23 11425011340 VALVE STEM SEAR 2

24 11926011370 VALVE CAP 2

25 11477111461 NOZZLE GASKET 1

26 11429511470 NOZZLE SPACER 1

27 11429911600 VALVE SPRING WASHER 2

28 11429911901 NOZZLE RETAINER 1

29 26106060452 BOLT M 6X45 PLATED 2

30 11471811910 STUD BOLT M6X65 2

31 26366060002 NUT M 6 2

32 11477111310 BONNET GASKET 1

33 11429511951 BONNET COMPLETE .................................1 ................INCLUDES ITEMS W/ #

35# 11425003591 SHAFT ASSY. DECOMP. 1

38# 11429903640 SPRING, DECOMP. 1

39# 22312030160 PARALLEL PIN 3X16 1

55 26106060552 BOLT M 6X 55 PLATED 3

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 45

Page 46

YANMAR L48V6AF3R4AAW4 — AIR CLEANER ASSY

PAGE 46 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 47

YANMAR L48V6AF3R4AAW4 — AIR CLEANER ASSY

NO PART NO PART NAME QTY. REMARKS

1 11429912210 GASKET, AIR CLEANER 1

2 11429912300 U- NUT 3

3 11428812511 CLEANER, AIR ASSY. ................................1 ................INCLUDES ITEMS W/

4* 11465007450 LABEL, AIR CLEANER 1

5* 11428812520 COVER COMPL. 1

6* 11428812532 CASE, AIR CLEANER 1

7* 11425212560 SEAL WASHER M8 1

8* 11465012590 ELEMENT W/ PRE- FILTER........................1 ................INCLUDES ITEMS W/ $

10*$ 11465012550 PRE- FILTER 1

11 11425212550 WING NUT M8

13 11477112010 INTAKE MANIFOLD 1

14 11477112200 AIR INTAKE GASKET 1

15 26106060252 BOLT M 6X 25 PLATED 2

16 26226060142 STUD M 6X14 PLATED 1

17 26226060552 STUD M 6X 55 2

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 47

Page 48

YANMAR L48V6AF3R4AAW4 — MUFFLER ASSY

PAGE 48 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 49

YANMAR L48V6AF3R4AAW4 — MUFFLER ASSY

NO PART NO PART NAME QTY. REMARKS

18 11429913200 MUFFLER GASKET 1

24 11428813500 MUFFLER ASSY. 1

27 26106060142 BOLT M6X14 PLATED 2

28 26216080182 STUD M 8X 18 PLATED 2

29 26366080002 NUT M 8 2

30 11429913800 EXHAUST DEFLECTOR 1

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 49

Page 50

YANMAR L48V6AF3R4AAW4 — CRANKSHAFT AND CAMSHAFT ASSY

PAGE 50 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 51

YANMAR L48V6AF3R4AAW4 — CRANKSHAFT AND CAMSHAFT ASSY

NO PART NO PART NAME QTY. REMARKS

1 71429514580 CAMSHAFT (D) ASSY. 1

6 11429914200 TAPPET 2

7 11477114260 TAPPET, F.O. 1

8 11425014451 PUSH ROD 2

10 71477221701 CRANKSHAFT ASSY. 1

19 11429921220 NUT 1

20 11429921550 FLYWHEEL WASHER 1

21 22512040120 KEY 4X 12 1

24 11429921590 FLYWHEEL ASSY. .......................................1 ................INCLUDES ITEMS W/

27* 11426221600 RING GEAR 1

61 71477028531 SHAFT ASSY. BEARING 1

66 24101062020 BEARING 6202 2

67 16031014550 WASHER 1

68 22512050300 KEY 5X30 1

69 26106080202 BOLT M8 X20 PLATED 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 51

Page 52

YANMAR L48V6AF3R4AAW4 — PISTON ASSY

PAGE 52 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 53

YANMAR L48V6AF3R4AAW4 — PISTON ASSY

NO PART NO PART NAME QTY. REMARKS

28 71429522720 PISTON W/RINGS (D) STD. ........................1 ................INCLUDES ITEMS W/#

28 71429522620 PISTON W/RING OS=0.25 ..........................1 ................INCLUDES ITEMS W/#

28 71429522580 PISTON W/RING OS=0.50 ..........................1 ................INCLUDES ITEMS W/#

30# 71429522500 PISTON RING SET STD. 1

30# 71429522540 PISTON RING SET OS=0.25 1

30# 71429522550 PISTON RING SET OS=0.50 1

36 11429922300 PISTON PIN 1

37 22252000190 CIRCLIP 19 2

38 71429923700 CONNECTING ROD ASSY. ........................1 ................INCLUDES ITEMS W/

41* 11926523200 ROD BOLT 2

42* 71477023600 CRANKPIN BEARING U.S=STD. 1

42 71477023610 CRANKPIN BEARING U.S=0.25 1

42 71477023620 CRANKPIN BEARING U.S=0.50 1

44* 11477023100 PISTON PIN BUSH 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 53

Page 54

YANMAR L48V6AF3R4AAW4 — LUB OIL PUMP AND GOVERNOR ASSY

PAGE 54 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 55

YANMAR L48V6AF3R4AAW4 — LUB OIL PUMP AND GOVERNOR ASSY

NO PART NO PART NAME QTY. REMARKS

1 11425032010 LUB. OIL PUMP ASSY. 1

7 11429932070 LUB. OIL PUMP COVER 1

9 11429932570 O- RING COVER 1

10 22312030160 PARALLEL PIN 3X16 1

11 26106060122 BOLT M 6X 12 PLATED 3

12 11429935110 LUB. OIL FILTER COMPLETE ....................1 ................INCLUDES ITEM W/ #

14# 24341000224 0- RING 1A S- 22.4 1

15 26106060162 BOLT M 6X 16 PLATED 1

16 11429561190 GOVERNOR LEVER ASSY. 1

22 22322030200 TAPER PIN 3X20 1

23 71477061100 GOVERNOR ASSY. .....................................1 ................INCLUDES ITEM W/

25* 11477061220 GOVERNOR WEIGHT ASSY. 1

29 11477061520 NEEDLE BEARING 2

30 11429961600 OIL SEAL 1

31 11477061610 THRUST WASHER 1

32 11429961190 GOVERNOR WASHER 1

40 11425266051 REGULATOR HANDLE 1

42 18336060202 REGULATOR BRACKET 1

43 10522566990 SCREW 1

44 26106060142 BOLT M 6X 14 PLATED 1

45 26106060202 BOLT M6X20 PLATED 1

46 11429966440 RETURN SPRING 1

47 11429966440 ADJUSTING BOLT 1

48 26757060002 LOCK NUT M 6 PLATED 2

49 11477161810 PLAIN WASHER 14 1

50 11477161830 PLATE 1

51 11429561940 NUT 1

52 11429966010 REGULATOR SPRING 1

53 11429966200 RETURN SPRING 1

54 11477166690 NUT M14 1

55 11481866600 FUEL LIMITER ASSY. 1

57 13521061090 LEAD 1

58 11477161890 PROTECTOR CMP .....................................1 ................INCLUDES ITEMS W/ +

60+ 11477161960 SPACER 1

61+ 24311000180 O- RING 1A P-18.0 1

62 22451060000 WIRE 0.6 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 55

Page 56

YANMAR L48V6AF3R4AAW4 — COOLING/STARTING DEVICE ASSY

PAGE 56 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 57

YANMAR L48V6AF3R4AAW4 — COOLING/STARTING DEVICE ASSY

NO PART NO PART NAME QTY. REMARKS

1 11429945210 CYLINDER COVER 1

2 26106060122 BOLT M 6X12 PLATED 1

4 11429545100 COOLING FAN CASE 1

5 11429945300 CUSHION RUBBER 4

6 11429945310 FAN CASE COLLAR 4

7 11429945330 FAN CASE SEAL 1

8 11429945350 FAN CASE BOLT 4

10 11429976250 RECOIL STARTER (D) ASSY. .....................1 ................INCLUDES ITEMS W/

11* 11429976500 STARTER CASE 1

13* 11429976520 REEL 1

15* 11439976530 RATCHET 1

17* 11439976540 SPIRAL SPRING 1

19* 11439975550 RATCHET COVER 1

20* 11439976560 SPRING 1

21* 11439976570 RETURN SPRING 1

22* 11439976580 SCREW 1

23* 11439976620 STARTER KNOB 1

24* 11429976630 STARTER ROPE 1

25 11429976590 STARTER PULLEY 1

26 26106060082 BOLT M 6X8 PLATED 4

27 26106060122 BOLT M 6X12 PLATED 3

29 11429976600 PLUNGER 1

30 11429976610 PLUNGER HOLDER 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 57

Page 58

YANMAR L48V6AF3R4AAW4 — FUEL TANK/FUEL LINE ASSY

PAGE 58 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 59

YANMAR L48V6AF3R4AAW4 — FUEL TANK/FUEL LINE ASSY

NO PART NO PART NAME QTY. REMARKS

1 71429955720 FUEL TANK, BLACK ...................................1 ................INCLUDES ITEMS W/ #

3# 10530055080 DRAIN PLUG 1

4# 23414080000 ROUND GASKET 8 1

5# 11429955100 FILTER, FUEL OIL 1

6# 11429955040 FUEL TANK CAP ASSY. 1

7# 11429955201 FUEL TANK DAMPER 4

8 11425055121 FILTER, FUEL STRAINER ..........................1 ................INCLUDES ITEM W/ %

9% 11425055130 GASKET 1

10# 11429955210 STAY 1

11 11429955230 STAY (B) 1

12 11425055301 COCK ..........................................................1 ................INCLUDES ITEM W/ +

13+ 24341000150 O- RING 1A S- 15.0 1

14 11429955810 LIFTING BOLT 1

15 22117080000 WASHER 8 1

16 26106080452 BOLT M 8X 45 PLATED 1

17 26368060002 NUT M6 2

18 26106060162 BOLT M6X 16 PLATED 2

19 11477059030 FUEL OIL PIPE ASSY. ................................1 ................INCLUDES ITEMS W/

20* 11427059010 HOSE CLIP 2

21* 11426859061 FUEL OIL PIPE 1

22 12472259050 CLAMP 9 2

23 11425059060 FUEL RETURN PIPE 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 59

Page 60

YANMAR L48V6AF3R4AAW4 — TOOLS, LABELS, GASKET ASSY

PAGE 60 — MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08)

Page 61

YANMAR L48V6AF3R4AAW4 — TOOLS, LABELS, GASKET ASSY

NO PART NO PART NAME QTY. REMARKS

3 11429907100 AIR COOLED LABEL 1

4 11429907110 YANMAR LABEL 1

5 11421007120 CAUTION LABEL 1

6 11421007130 HOW TO START - E LABEL 1

7 11429907160 DIESEL LABEL 1

10 11429992590 TOOL ASSY. ................................................1 ................INCLUDES ITEMS W/

11* 11429992600 TOOL BAG 1

12* 11429992710 SPANNER 1

13* 11429992720 SPANNER 1

14* 11429992730 DRIVER 1

15* 11429992740 FUEL FITTING 1

16 71411092600 GASKET SET ..............................................1 ................INCLUDES ITEMS W/ #

17# 11429501330 CYLINDER HEAD GASKET ASSY. 1

23# 11429901280 O- RING 1

24# 11429901410 CRANKCASE GASKET 1

25# 11429901950 O- RING 2

26# 11425001841 GASKET 1

27# 22190160002 WASHER SEAL 16S 2

28# 11425011340 VALVE STEM SEAL 2

29# 11477111461 NOZZLE GASKET 1

30# 11477111310 BONNET GASKET 1

31# 11429912210 AIR CLEANER GASKET 1

32# 11477112200 AIR INTAKE GASKET 1

33# 11429913200 MUFFLER GASKET 1

34# 11429932570 O- RING, COVER 1

35# 24341000100 O- RING 1A S-10.0 1

36# 23414080000 PACKING 8 1

37# 24341000224 O- RING 1A S- 22.4 1

38# 24341000150 O- RING 1A S- 15.0 1

*

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 61

Page 62

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or