Page 1

OPERATION AND PARTS MANUAL

SERIES

MODEL MTR40SF

TAMPING RAMMER

(ROBIN EH092F GASOLINE ENGINE)

Revision #0 (11/28/12)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

PAGE 2 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 3

NOTES

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 3

Page 4

TABLE OF CONTENTS

MTR40SF Rammer

Proposition 65 Warning ........................................... 2

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Information ................................................6-9

Specifications ........................................................ 10

General Information ............................................... 11

Components .......................................................... 12

Basic Engine .......................................................... 13

Inspection ......................................................... 14-15

Operation .......................................................... 16-17

Maintenance ..................................................... 18-20

Troubleshooting ................................................21-23

Explanation Of Code In Remarks Column............. 24

Suggested Spare Parts ......................................... 25

Component Drawings

Nameplates And Decals ................................... 26-27

Crankcase And Engine Assy ............................ 28-31

Guide Cylinder Assy ......................................... 32-33

Fuel Tank And Handle Assy .............................. 34-35

Foot Assy .......................................................... 36-37

Narrow Foot Assy. (Option) ............................... 38-39

Trench Shoe Assy ............................................. 40-41

Robin EH09-2F Engine

Crankcase Assy. ............................................... 42-43

Crankshaft, Piston Assy. .............................................44-45

Intake, Exhaust Assy. ........................................ 46-47

Carburetor Assy. ............................................... 48-49

Air Cleaner Assy. .............................................. 50-51

Governor, Operation Assy. ..................................... 52-53

Blower Housing Assy. ....................................... 54-55

Recoil Starter Assy. .......................................... 56-57

Electric Device Assy. ......................................... 58-59

Accessories ...................................................... 60-61

Terms And Conditions Of Sale — Parts ................ 62

NOTICE

Specifications and part numbers are subject to change

without notice.

PAGE 4 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 5

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

Choose from three easy options:

January 1st, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at: parts@multiquip.

com.

To ob tain an MQ Ac cou nt , co nta ct yo ur

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 5

Page 6

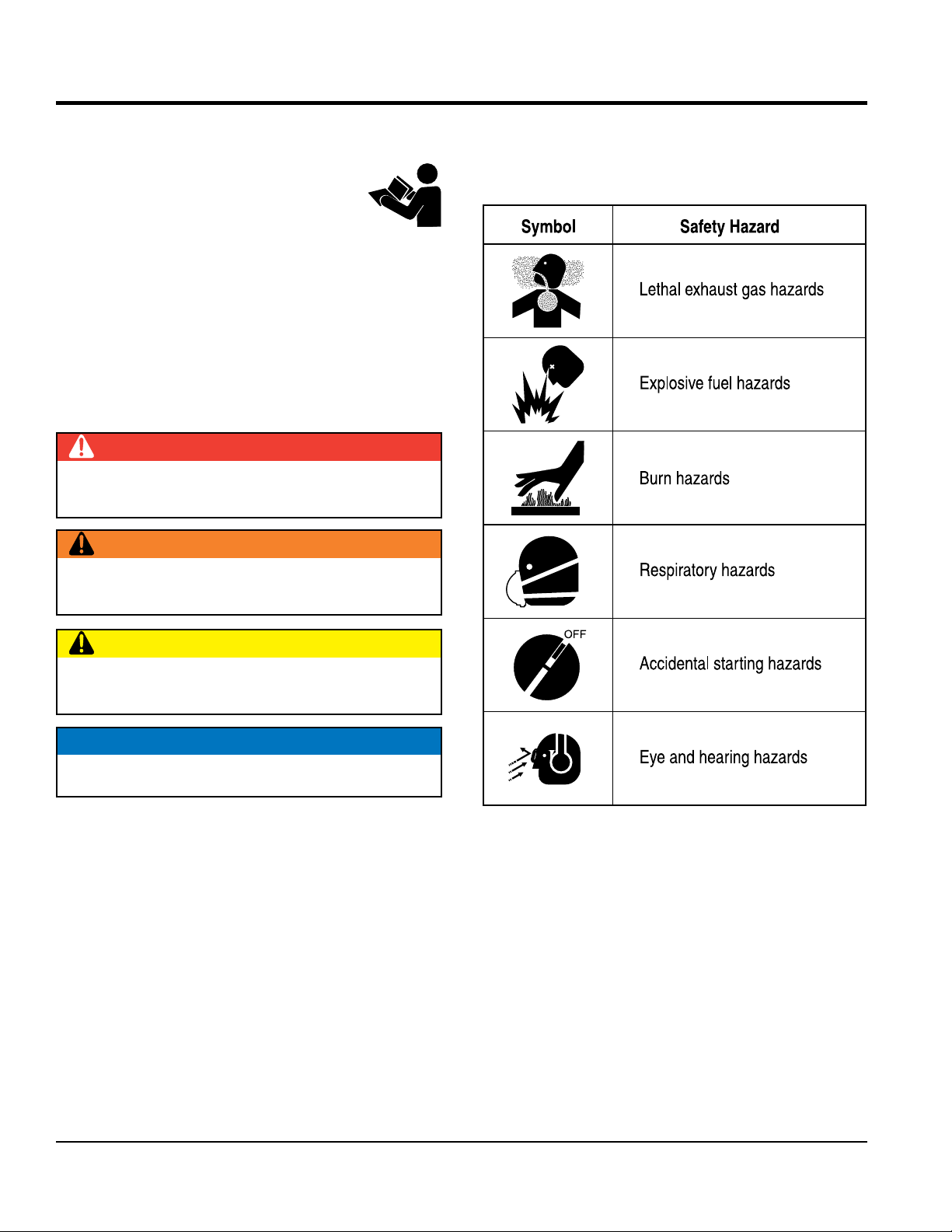

SAFETY INFORMATION

Do not operate or service the equipment before reading

Potential hazards associated with the operation of this

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 7

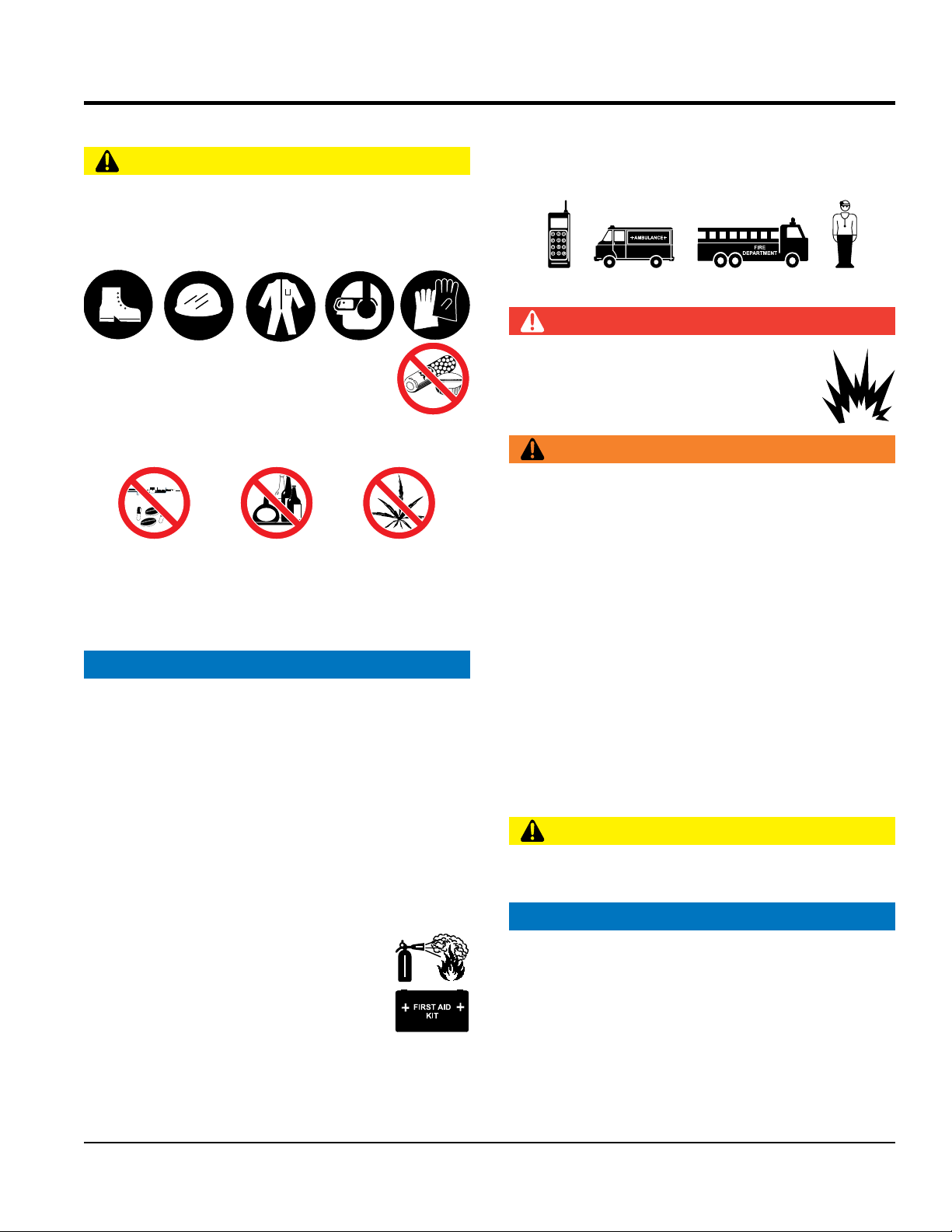

GENERAL SAFETY

CAUTION

ALWAYS know the location of the nearest phone or keep a

Also, know the phone numbers of

This

information will be invaluable in the case of an emergency.

emergency or safety devices.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

use this machine on ground that is harder than

the machine can handle, or for driving pilings or tamping

rock beds. Furthermore, use of the machine on sloping

ground, such as the side of an embankment, may make

the machine unstable and can cause an accident. It can

Use the machine with confi dence for tamping earth and

use the machine

keep the machine in proper running condition.

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

SAFETY INFORMATION

phone on the job site.

the nearest ambulance, doctor and fi re department.

RAMMER SAFETY

DANGER

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

ALWAYS check the equipment for loosened threads or

bolts before starting.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

NOTICE

This equipment should only be operated by trained and

qualifi ed personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

equipment modifi cation will void all warranties.

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

NEVER disconnect any

These devices are intended for operator safety.

devices will void all warranties.

DO NOT

also result in premature machine wear due to uneven

loads on the machine.

sand, soil, gravel, and asphalt. DO NOT

for other types of jobs.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

NOTICE

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 7

ALWAYS

Fix damage to machine and replace any broken parts

immediately.

ALWAYS

Page 8

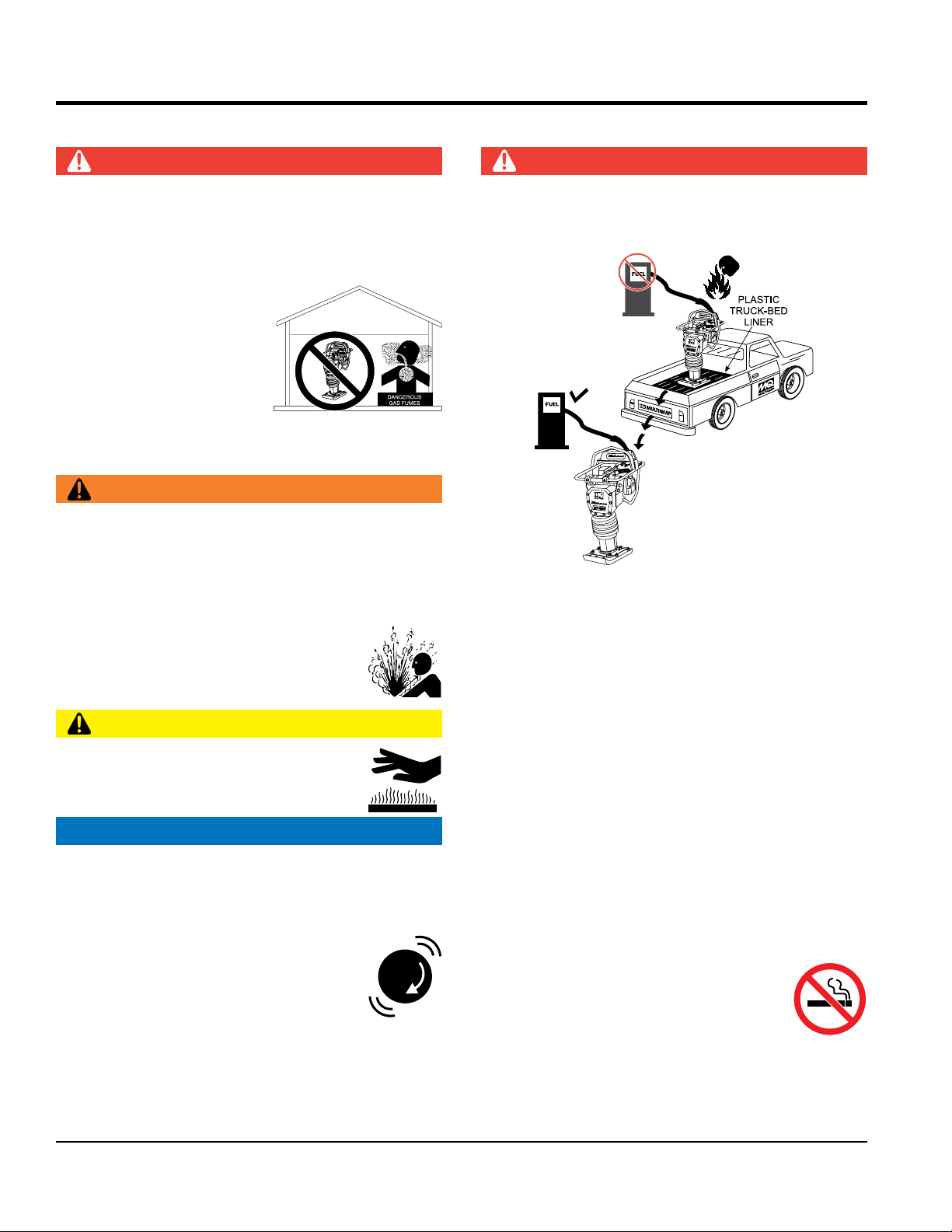

SAFETY INFORMATION

ENGINE SAFETY

FUEL SAFETY

DO NOT add fuel to equipment if it is placed inside truck

start the engine near spilled fuel or combustible

fl uids. Fuel is extremely fl ammable and its vapors can

overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

DANGER

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment

requires an adequate free fl ow

of cooling air. NEVER operate

this equipment in any enclosed

or narrow area where free fl ow

of the air is restricted. If the air

fl ow is restricted it will cause

injury to people and property

and serious damage to the

equipment or engine.

WARNING

D O NOT pl ace h ands or fingers inside engine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

DANGER

bed with plastic liner. Possibility exists of explosion or

fi re due to static electricity.

DO NOT

DO NOT remove the engine oil drain plug

while the engine is hot. Hot oil will gush

out of the oil tank and severely scald any

persons in the general area of the rammer.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

NOTICE

NEVER run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke ar ound or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

PAGE 8 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 9

TRANSPORTING SAFETY

CAUTION

NEVER allow any person or animal to stand underneath

the equipment while lifting.

NOTICE

Before lifting, make sure that the equipment parts (hook

and vibration insulator) are not damaged and screws are

not loose or missing.

Always make sure crane or lifting device has been

properly secured to the lifting bail (hook) of the

equipment.

ALWAYS shutdown engine before transporting.

NEVER lift the equipment while the engine is running.

Tighten fuel tank cap securely and close fuel cock to

prevent fuel from spilling.

SAFETY INFORMATION

Use adequate lifting cable (wire or rope) of suffi cient

strength.

Use one point suspension hook and lift straight

upwards.

DO NOT lift machine to unnecessary heights.

ALWAYS tie down equipment during transpor t by

securing the equipment with rope.

Never allow any person or animal to stand underneath the

equipment while lifting.

ENVIRONMENTAL SAFETY

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 9

Page 10

SPECIFICATIONS

Table 1. Rammer Specifications

Overall Height 43.7 in. (1,110 mm))

Overall Width 13.8 in. (351 mm)

Over Length 24.5 in. (622 mm)

Shoe Size (W x L) 5.9 x 10.6 in. (150 x 270 mm)

No. of Impacts Per Minute 650 ~ 699

Tamping Area 1,453 sq. ft. per hr (135 sq.m per hr)

Impact Force 1,215 lbs./blow ( 550 kg/blow)

Clutch Automatic Centrifugal

Travel Speed 30 fpm (9 mpm))

Stroke (Jump Height) 2.2 in. (55 mm)

Operating Weight 101 lbs. (46 kg)

Table 2. Engine Specifications

Model Robin EH092F45010 Engine

Type

Bore x Stroke

Piston Displacement 5.24 cu. in (86 cm3)

Max. Output 3.3 H.P./4100 R.P.M. (2.5 kW))

Fuel Unleaded gasoline

Fuel Tank Capacity 2.1 quarts (2.0 liters)

Lube Oil Capacity 0.79 gal. (0.3 liters)

Speed Control Method Centrifugal Fly-weight Type

Spark Plug NKG BMR4A

Air Cleaner Dual Element Type

Ignition System Flywheel Magneto (Soild State)

Starting Method Recoil Start

Dimension (L x W x H)

Air-cooled 4-stroke, single cylinder, OHV,

horizontal shaft gasoline engine

2.01 in. X 1.65 in.

(51 mm x 42 mm)

9.1 x 11.6 X 13.0 in.

(232 X 295 X 330 mm.)

Dry Net Weight Dry Net Weight 20.7 lbs. (9.4 Kg.)

PAGE 10 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 11

GENERAL INFORMATION

The Multiquip MTR40SF tamping rammer is a powerful

compacting tool capable of applying a tremendous force

in consecutive impacts to a soil surface. Its applications

include soil compacting for r backfilling for gas pipelines,

water pipelines and cable installation work.

The impact force of the MTR40SF levels and uniformly

compacts voids between soil particles to increase dry

density.

Circular motion is converted to create impact force.

The MTR40SF tamping rammer develops a powerful

compacting force at the foot of the rammer. To maintain

optimum performance, proper operation and service are

essential.

The MTR40SF is equipped with an air cooled, four- cycle

gasoline engine. Transmission of the power takes place

by increasing the engine speed to engage the centrifugal

clutch.

The Mikasa MTR40SF uses zerk grease fittings to lubricate

the spring cylinder and crankcase bearings. Lubricate these

grease fittings as indicated in the maintenance section of

this manual.

CAUTION

Before starting operation check the lifting

handle to:

1. Make sure that there is no damage on the bolts.

2. Make sure that there is no crack or breakage on

handle.

3. Make sure that there is no fissure on the surface.

If there is any abnormality or damage, replace

with new one.

For operation:

This handle is to be used to lift up the shoe part of

the machine with the body laid down on the ground

or truck bed.

1. Use proper lifting techniques to avoid back injury.

This handle is for manual lifting only.

2. Do not use this handle as a rammer lift point. Use

the lifting point on the top of the machine.

Before starting the MTR40SF Tamping Rammer identify

and understand the function of the controls.

3. Do not move the rammer with the lifting handle

and the front rollers more than 16 feet (5 meters).

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 11

Page 12

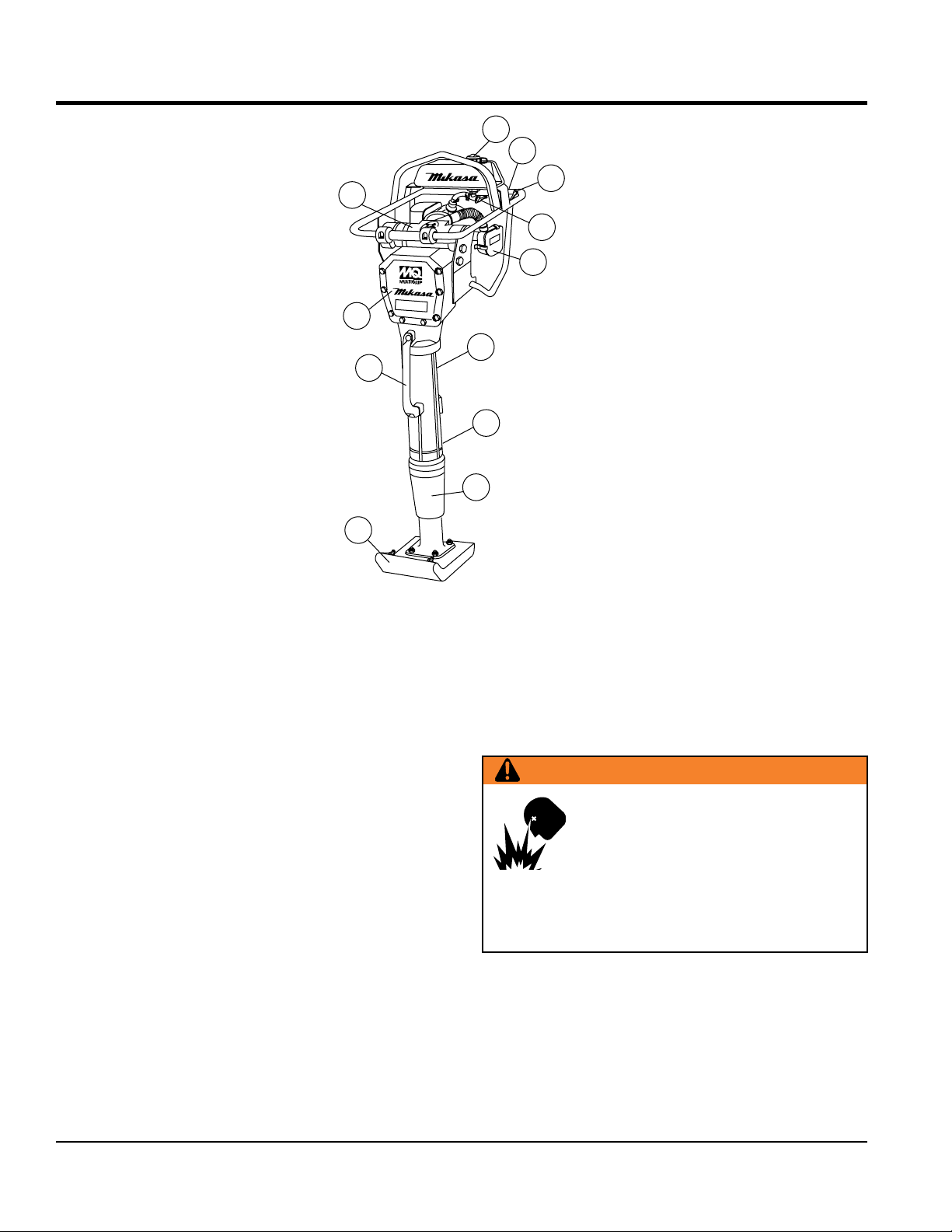

COMPONENTS

8

7

1

3

2

9

6

11

5

11

10

4

Figure 1. MTR40SF Rammer

Figure 1 shows the location of the controls and components

for the MTR40SF Tamping Rammer. The functions of each

control is described below:

1. Throttle Lever — Used to adjust engine speed (rpm).

Move lever forward (SLOW) to reduce engine speed,

move lever back toward operator (FAST) to increase

speed.

2. Fuel Shut-Off Valve — Supplies fuel from the fuel tank

to the engine. To begin fuel flow, move the fuel shut-off

valve downward.

3. Primary Air Cleaner — Pre-cleans (first stage) dirt

and other debris from entering the engine.

4. Foot — Laminated wood with tempered steel plate for

superior shock absorption.

5. Grip — When transporting the rammer, carry it by

griping the handle.

6. Nameplate — Displays information regarding the

rammer.

7. Handle — To operate rammer GRIP handle assembly

firmly on both sides.

8. Fuel Tank/Cap — Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

WARNING

Adding fuel to the ta nk sho uld be

accomplished only when the engine is

stopped and has had an opportunity to

cool down. In the event of a fuel spill, DO

NOT attempt to start the engine until the

fuel residue has been completely wiped up, and the

area surrounding the engine is dry.

9. Engine Air Cleaner — Prevents dirt (second stage)

and other debris from entering the engine.

10. Dust Sleeve — Prevents dust and debris from entering

into the spring cylinder.

11. Zerk Fittings — Lubr icates main springs and

crankcase bearings.

PAGE 12 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 13

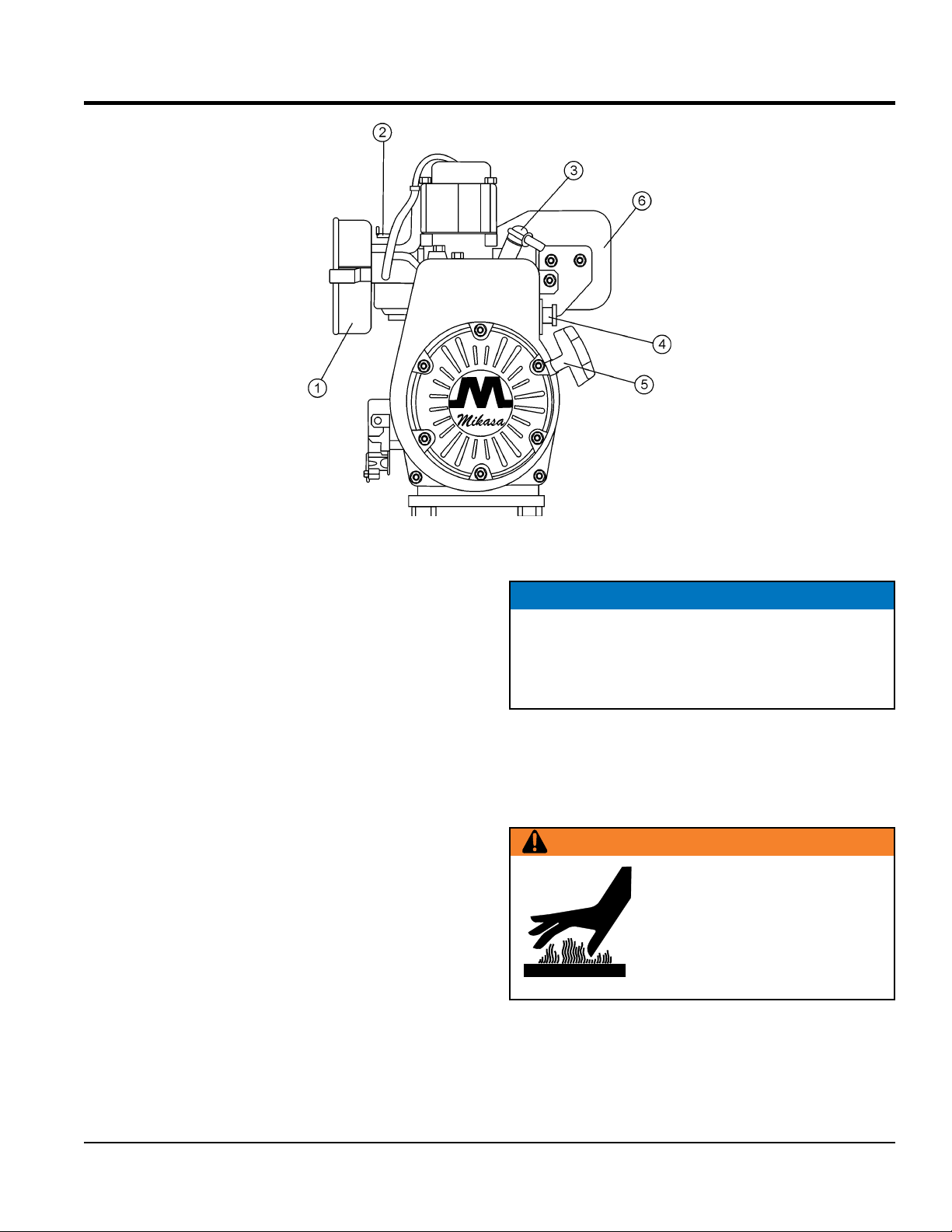

BASIC ENGINE

Figure 2. Robin Engine

The engine (Figure 2) must be checked for proper

lubrication and filled with fuel prior to operation. Refer

to the manufacturer's engine manual for instructions and

details of operation and servicing.

1. Secondary Air Cleaner — Prevents dirt and other

debris from entering the fuel system. Remove wingnut on top of air filter cannister to gain access to filter

element.

2. Choke Lever — Used when starting the engine.

Normally used in cold weather conditions. In cold

weather turn the choke lever to the fully closed

position, in warm weather set choke lever half way or

completely open.

3. Spark Plug — Provides spark to the ignition system.

Set spark plug gap to 0.02 - 0.03 inch (0.6 - 0.7 mm).

Clean spark plug once a week.

4. Engine ON/OFF Switch — Controls the starting and

stopping of the engine. Switch must be in the "ON"

position when starting the engine.

NOTICE

Operating the engine without an air filter, with a

damaged air filter, or a filter in need of replacement

will allow dirt to enter the engine, causing rapid engine

wear.

5. Recoil Starter (pull rope) — Manual-starting method.

Pull the starter grip until resistance is felt, then pull

briskly and smoothly.

6. Muffler — Used to reduce noise and emissions.

WARNING

Engine components can generate

extreme heat. To prevent burns, DO

NOT touch these areas while the

engine is running or immediately

after operating. NEVER operate the

engine with the muffler removed.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 13

Page 14

INSPECTION

Use only unleaded gasoline. High test ethyl gasoline

is not

recommended.

only

unleaded

gasoline. Motor fuels are

highly flammable

and can be dangerous if mishandled. DO NOT smoke while

refueling. DO NOT attempt to refuel the rammer if the engine

is

hot!or running

.

INSPECTION

Fuel

1. This rammer is equipped with a two-cycled gasoline engine.

Use only unleaded gasoline. High test ethyl gasoline

is not

recommended.

2. If fuel is low, remove the fuel filler cap (Figure 4) and fill with

only

unleaded

gasoline. Motor fuels are

highly flammable

and can be dangerous if mishandled. DO NOT smoke while

refueling. DO NOT attempt to refuel the rammer if the engine

is

hot!or running

.

Figure 4. Fuel Tank

Engine Oil Check

1. To check the engine oil level, place the rammer on secure

level ground with the engine stopped.

2. Remove the filler cap/dipstick from the engine oil filler hole

(Figure 5) and wipe it clean.

INSPECTION

This section is intended to assist the operator with the

inspection of the rammer. It is extremely important that

this section be read carefully before attempting to operate

the rammer.

DO NOT use your rammer until this section is thoroughly

understood.

Check all nuts, bolts fasteners for tightness. Retighten

as necessary.

Clean any dirt from the recoil starter and engine cooling

fins. Wipe the entire rammer clean before operating.

Replace any missing or damaged Safety Operation

decals. It is extremely important that this section be read

carefully before attempting to operate the rammer. DO

NOT use your rammer until this section is thoroughly

understood.

Prior to Operation

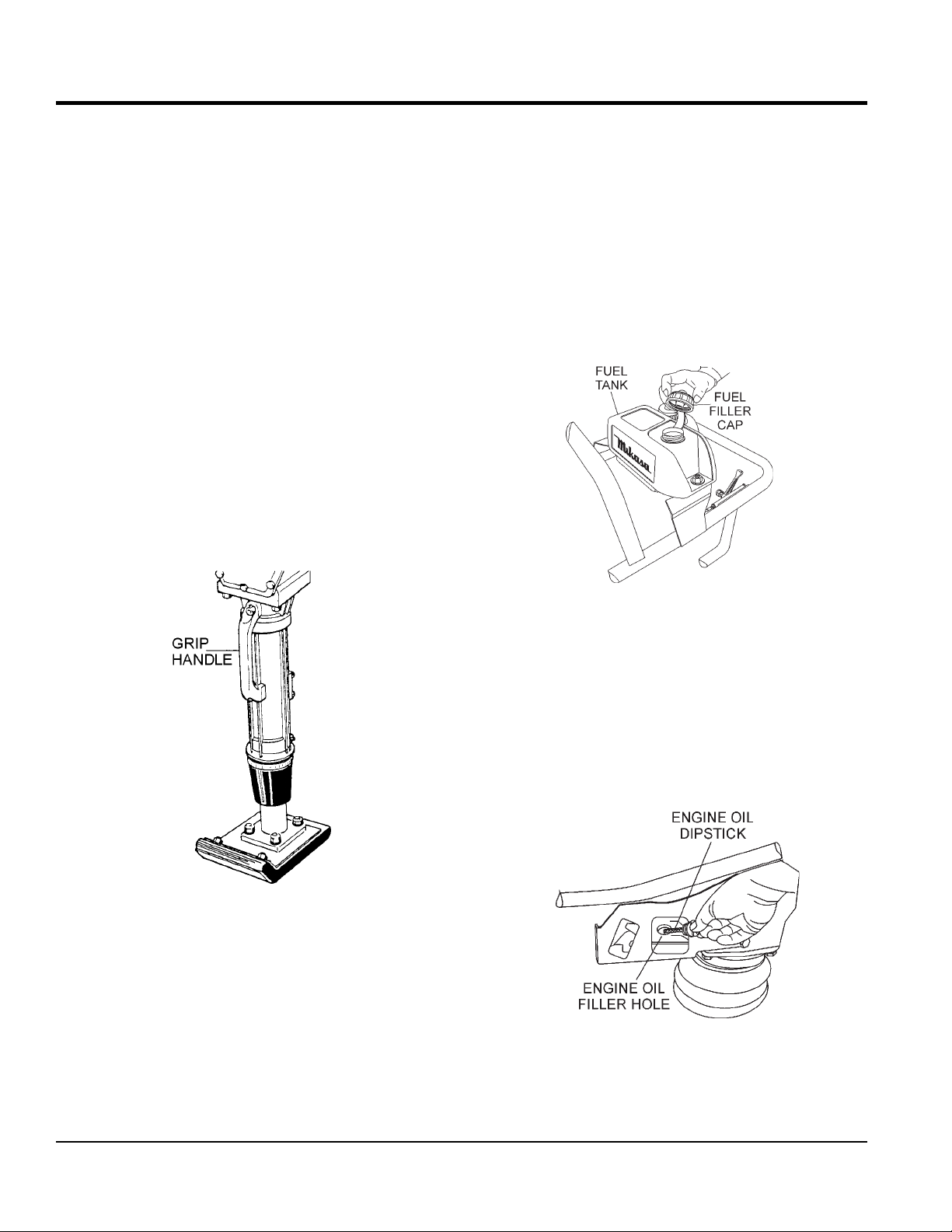

1. When transporting the rammer, carry it by the grip

handle located on the body (Figure 3).

Fuel

1. This rammer is equipped with a two-cycled gasoline

engine. Use only unleaded gasoline. High test ethyl

gasoline is not recommended.

2. If fuel is low, remove the fuel filler cap (Figure 4) and

fill with onlyunleaded gasoline. Motor fuels are highly

flammable and can be dangerous if mishandled. DO

NOT smoke while refueling. DO NOT attempt to refuel

the rammer if the engine is hot or running.

Figure 4. Fuel Tank

Main Spring and Crankcase Lubrication

1. There are 2 grease fittings (Figure 18) that require

lubrication of the main springs. Lubricate these fittings

as outlined in the maintenance section of this manual.

2. There are 2 grease fittings (Figure 19) that require

lubrication of the crankcase. Lubricate these fittings as

outlined in the maintenance section of this manual.to

replenish it often (Figure 5).

Figure 3. Grip Handle

Engine Oil Check

1. To check the engine oil level, place the rammer on

secure level ground with the engine stopped.

2. Remove the filler cap/dipstick from the engine oil filler

hole (Figure 5) and wipe it clean.

Figure 5. Engine Oil Dipstick

3. Insert and remove the dipstick without screwing it into

the filler neck. Check the oil level shown on the dipstick.

PAGE 14 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 15

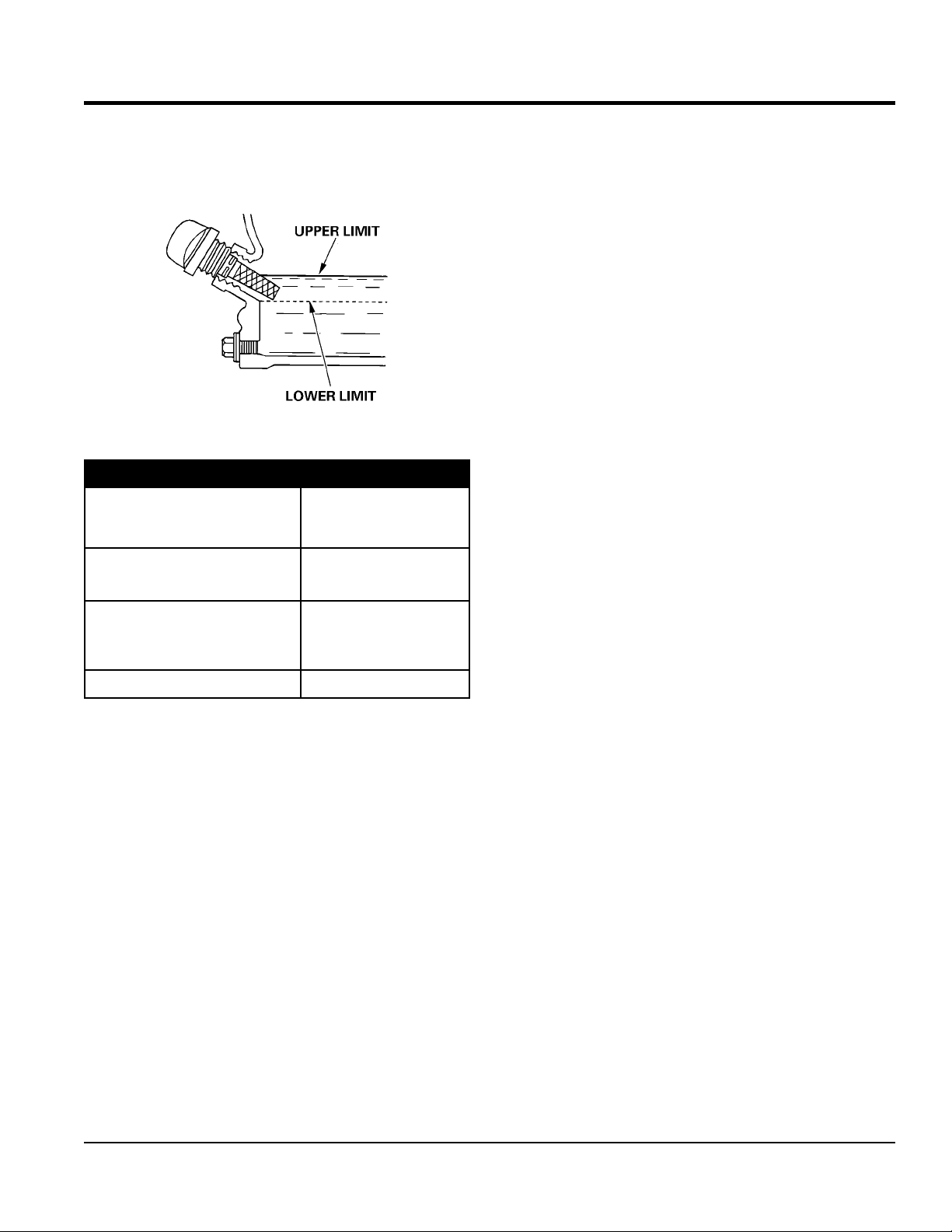

4. If the oil level is low (Figure 6), fill to the edge of the

oil fillerhole with the recommended oil type (Table 3).

Maximum oil capacity is .079 gallons (0.3 liters).

Figure 6. Oil Level

.

Table 3. Motor Oil Grade

INSPECTION

Season or Temperature

Spring, Summer or Autumn

+120° F to +15° F

Winter

+40° F to +15° F

Below +15° F SAE 10W-30

Grade of motor oil

(higher than MS class)

SAE 30

SAE 30

GENERAL INSPECTION

1. Check all nuts, bolts fasteners for tightness. Retighten

as necessary.

2. Clean any dirt from the recoil starter and foot pedestal.

Wipe the entire unit clean before operating.

3. Replace any missing or damaged Safety Operation

decals.

4. Adjust height of handle. Adjust handle by loosening

nuts and moving handle to suit operation. Retighten

nuts.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 15

Page 16

OPERATION

Open the

fuel shut- off valve

by moving the

fuel cock

lever to the

open

position (Figure 7).

5 Grip the recoil starter (Figure 11) handle and pull it until you feel

a slight resistance. Then pull sharply and quickly. Return the

Figure 10. Choke Lever (Closed)

4. In cold weather, start the unit with choke lever "Fully Closed"

(Figure 10). In warm weather or when the engine is warm,

the unit can be started with choke halfway or completely

open.

OPERATION

Figure 7. Fuel Shut-Off Valve (Open)

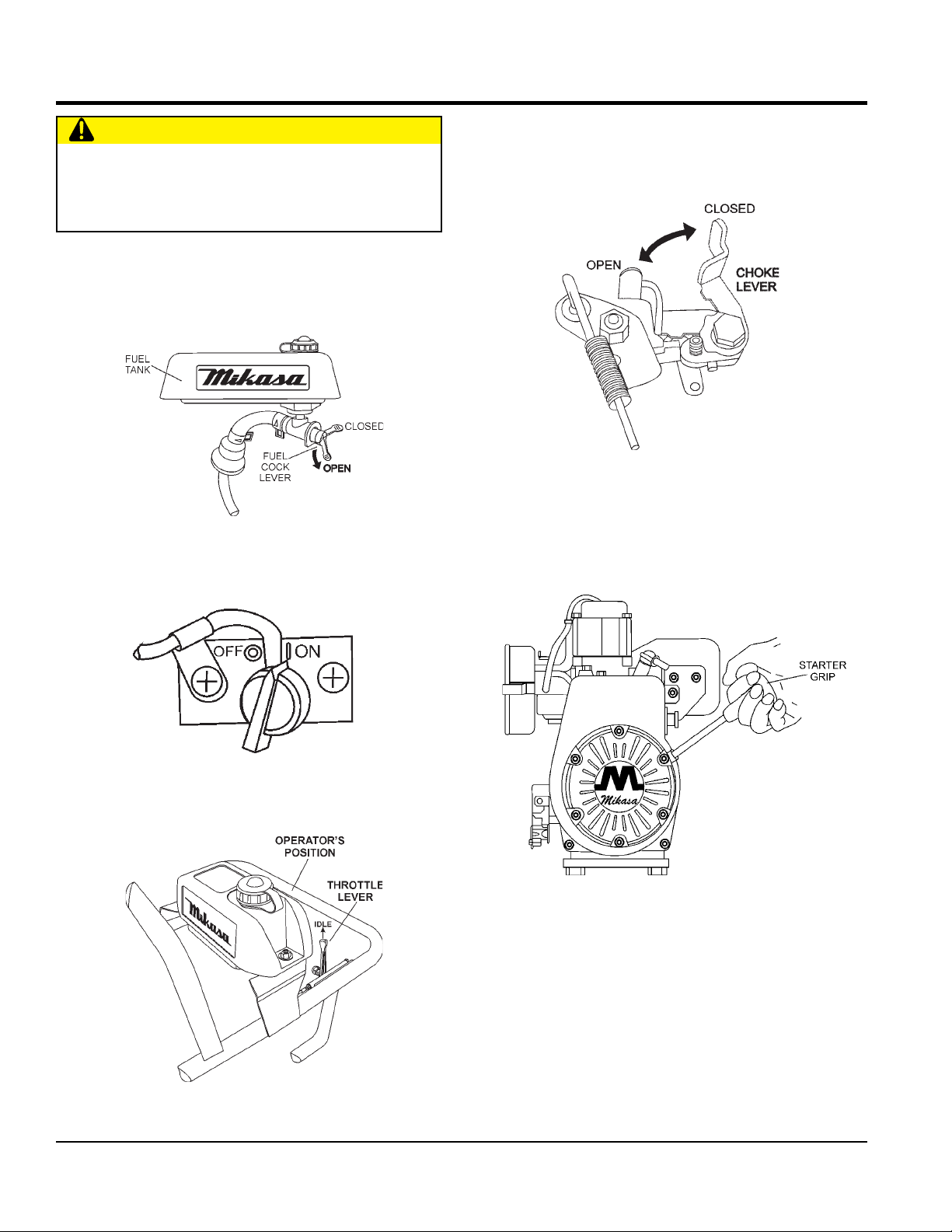

Operation

The following steps outline the procedure for starting the engine:

1. Open the

fuel shut- off valve

by moving the

fuel cock

lever to the

open

position (Figure 7).

5 Grip the recoil starter (Figure 11) handle and pull it until you feel

a slight resistance. Then pull sharply and quickly. Return the

recoil starter handle to the starter position before releasing.

Figure 10. Choke Lever (Closed)

4. In cold weather, start the unit with choke lever "Fully Closed"

(Figure 10). In warm weather or when the engine is warm,

the unit can be started with choke halfway or completely

open.

2. Set the engine ON/OFF switch (Figure 8) to the "ON"

position (start).

OPERATION

Figure 7. Fuel Shut-Off Valve (Open)

Operation

The following steps outline the procedure for starting the engine:

1.

Open the

fuel shut- off valve

by moving the

fuel cock

lever to the

open

position (Figure 7).

5 Grip the recoil starter (Figure 11) handle and pull it until you feel

a slight resistance. Then pull sharply and quickly. Return the

recoil starter handle to the starter position before releasing.

Figure 11. Recoil Starter

6. If engine fails to start, move the choke lever (Figure 10) to

the half open position to avoid flooding.

7. Repeat steps 1 through 6.

8. If the engine does not start after repeated attempts,

check the spark plug for excess fuel. Clean and replace

the spark plug as needed.

Figure 10. Choke Lever (Closed)

4. In cold weather, start the unit with choke lever "Fully Closed"

(Figure 10). In warm weather or when the engine is warm,

the unit can be started with choke halfway or completely

open.

2.

Set the engine ON/OFF switch (Figure 8) to the "ON"

position (start).

Figure 8. ON/OFF Switch (ON Position)

3. Move the throttle lever to the "IDLE" position (Figure 9).

OPERATION

OPERATION

CAUTION

Failure to understand the operation of the Tamping

Rammer could result in severe damage to the unit or

personal injury.

When starting the MTR40SF, perform the following:

1. Open the fuel shut- off valve by moving the fuel cock

lever to the open position (Figure 7).

.

Figure 7. Fuel ShutOff Valve (Open)

2. Set the engine ON/OFF switch (Figure 8) to the "ON"

position (start).

4. In cold weather, start the unit with choke lever "Fully

Closed" Figure 10). In warm weather or when the

engine is warm, the unit can be started with choke

halfway or completely open.

Figure 10. Choke Lever (Closed)

5. Grip the recoil starter (Figure 11) handle and pull it

until you feel a slight resistance. Then pull sharply and

quickly. Return the recoil starter handle to the starter

position before releasing.

Figure 8. ON/OFF Switch (ON Position)

3. Move the throttle lever to the "IDLE" position (Figure 9).

Figure 9. Throttle Lever (Idle)

PAGE 16 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

6. If engine fails to start, move the choke lever (Figure 10)

Figure 11. Recoil Starter

to the half open position to avoid flooding.

7. Repeat steps 1 thru 6.

8. If the engine does not start after repeated attempts,

check the spark plug for excess fuel. Clean and replace

the spark plug as needed.

Page 17

OPERATION

cools

, turn the engine

ON/OFF

switch to the

OPERATION

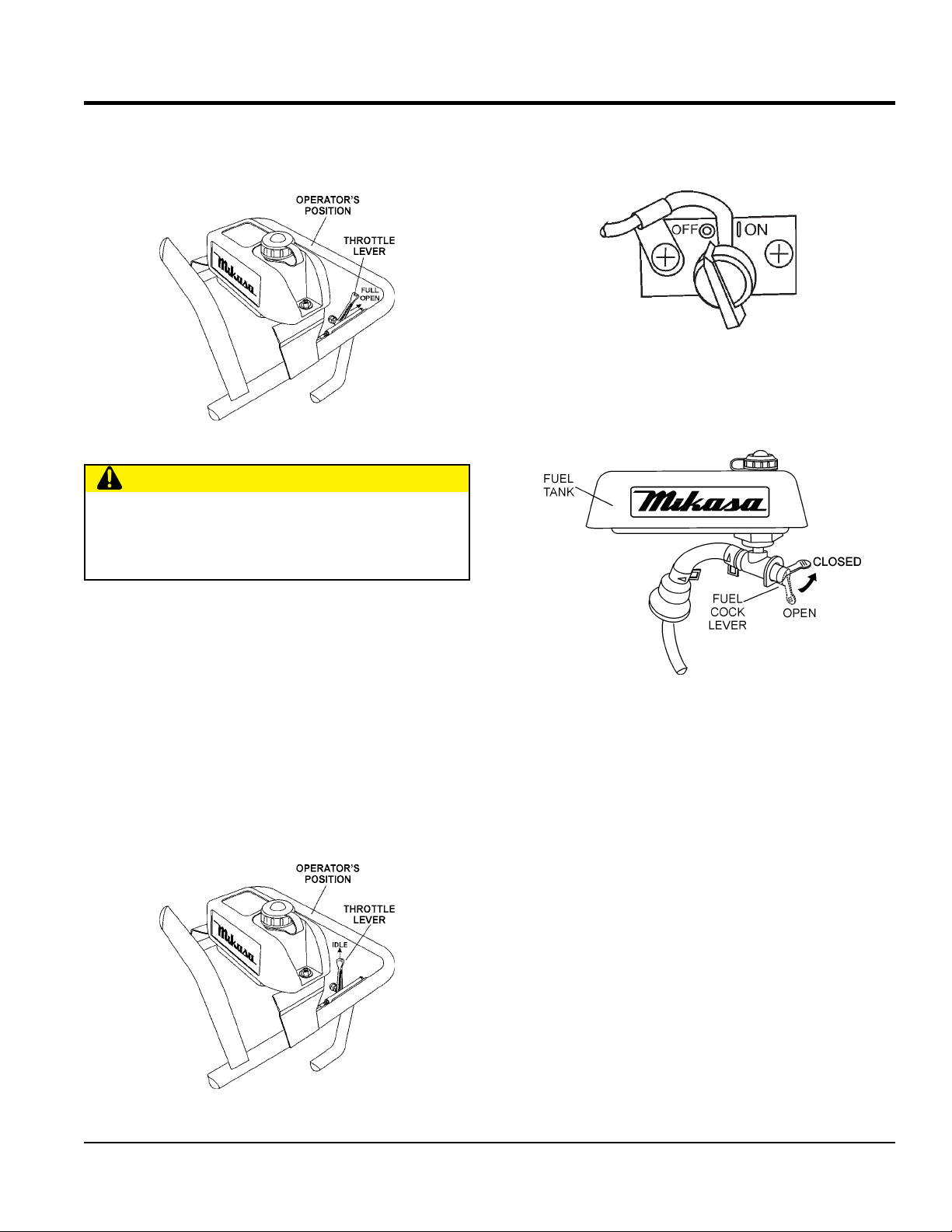

1. To start the rammer tamping action, move the throttle

lever (Figure 12) quickly from IDLE (close) to the FULL

OPEN position. DO NOT move the throttle lever slowly

as this may cause damage to the clutch or spring.

Figure 12. Throttle Lever (Full Open)

CAUTION

Make sure that the throttle lever is moved to the FULL

OPEN position. Operating the rammer at less than full

speed can result in damage to the clutch springs or foot.

3. After the engine cools, turn the engine ON/OFF switch

to the “OFF” position (Figure 14).

Figure 14. ON/OFF Switch (OFF Position)

4. Close the fuel shut- off valve (Figure 15) by moving the

fuel cock lever to the CLOSED position.

2. The MTR40SF tamping rammer is designed to run

at 3,800 to 4,100 rpm. At optimum rpm the foot hits

at the rate between 590 - 695 impacts per minute.

Increasing throttle speed past factory set rpm does

not increase impacts and may damage unit. The

MTR40SF is designed to advance while tamping. For

faster advance, pull back slightly on the handle so that

rear of foot contacts soil first.

STOPPING THE ENGINE

Move throttle lever quickly from the FULL OPEN to IDLE

position (Figure 13) and run the engine for three minutes

at low speed.

Figure 15. Fuel ShutOff Valve (Closed)

Emergency Showdown

1. Move the throttle lever quickly to the IDLE position, and

turn the engine ON/OFF switch to the OFF position.

Turn the fuel valve lever to the CLOSED position.

Figure 13. Throttle Lever (Idle)

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 17

Page 18

DAILY

Thoroughly remove dirt and oil from the engine compartment

and rammer. Clean or replace the air cleaner elements as

necessary. Check and retighten all fasteners as necessary.

Check the bellows for oil leaks. Repair or replace as needed.

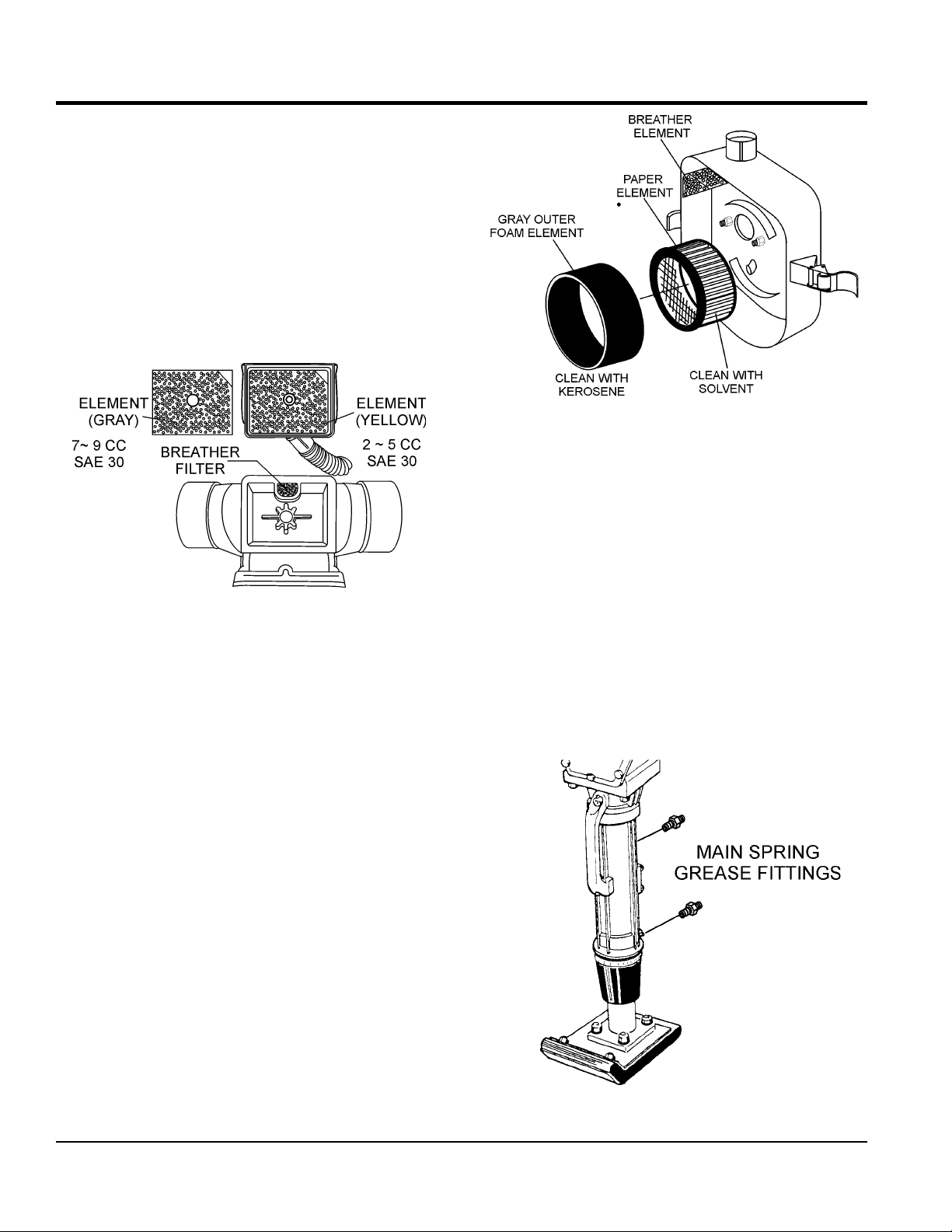

200 - 300 HOURS (PRE-CLEANER)

Remove the element from the pre-cleaner (Figure 16) at the

top of the crankcase (body side) and clean it with cleaning

oil (kerosene).

MAINTENANCE

Figure 17. Engine Air Cleaner

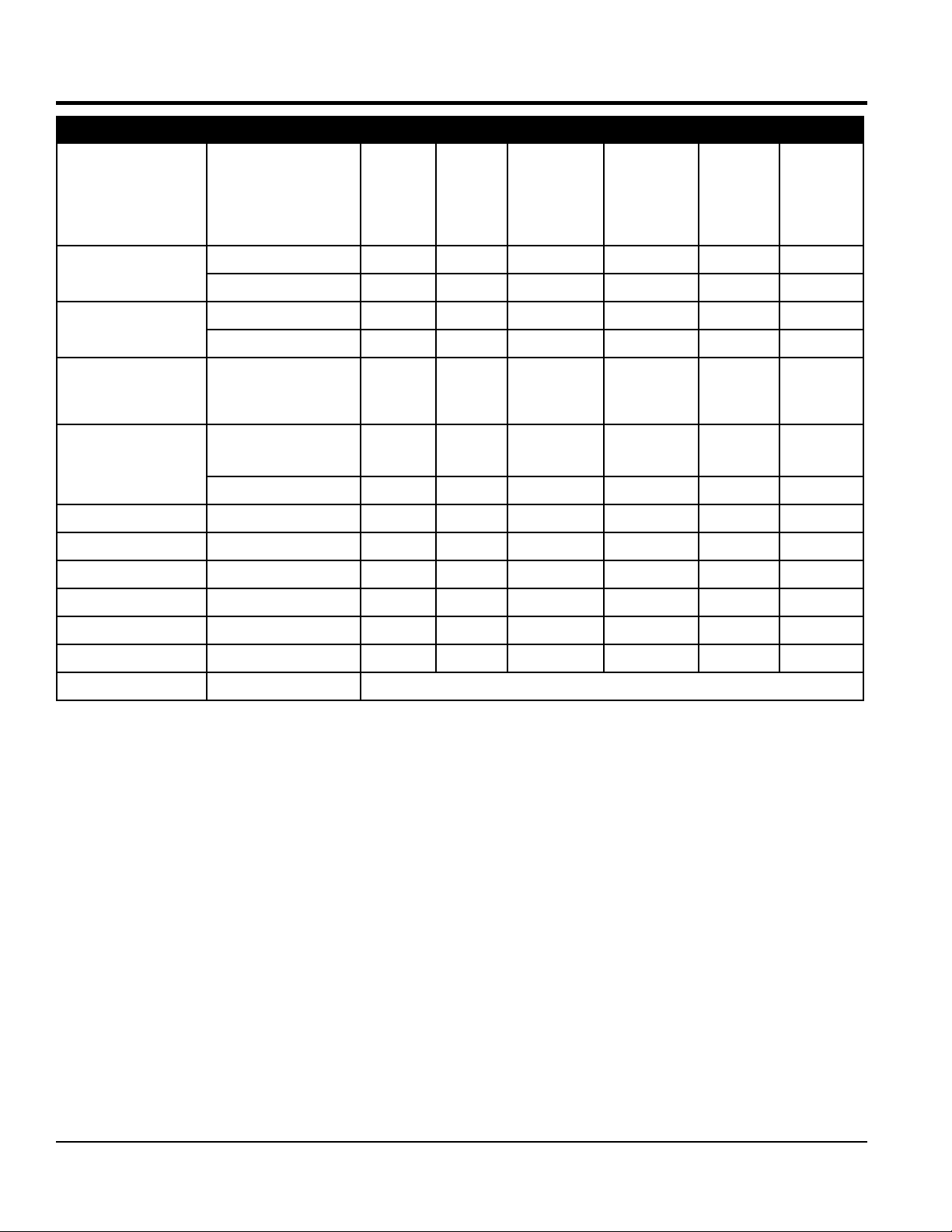

MAIN SPRINGS LUBRICATION

The rammer main springs (Figure 18) should be

lubricated with five shots of grease with a hand grease

gun after each eight (8) hours of use.

Figure 16. Primary Air Cleaner

Lubricate the top element (yellow) with 2~5 cc of engine

oil SAE-30.

Lubricate bottom element (gray) with 7~9 cc of engine

oil SAE-30 and completely squeeze out the excess oil

from the element before installing.

AIR CLEANER

The air cleaner (Figure 17) on the engine side will hardly

be contaminated, if it is, clean the outer foam gray

element with cleaning solvent. Tightly squeeze outer

foam element to remove any excess solvent before

reinstalling.

Tap the paper filter element (Figure 17) several times on

a hard surface to remove dirt, or blow compressed air

[not exceeding 30 psi (207 kPa, 2.1 kgf/cm2)] through

the filter element from the air cleaner case side. NEVER

brush off dirt. Brushing will force dirt into the fibers.

Replace the paper filter element if it is excessively dirty.

Use MQ HIGH TEMPERATURE GREASE, P/N GRS2

or its equivalent.

Equivalent greases include Shell Darina or Texaco

Thermatex, both of which have a bentone base and

EP-2 rating.

If an inferior grease is used, it may become too thick or

too thin due to changes in temperature, and improper

lubrication could result.

Figure 18. Grease Fittings (Main Springs)

PAGE 18 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 19

MAINTENANCE

CRANKCASE LUBRICATION

The rammer crankcase bearings (Figure 19) should be

lubricated with five shots of grease with a hand grease

gun after each eight (8) hours of use.

Figure 19. Grease Fittings (Crankcase)

Use MQ HIGH TEMPERATURE GREASE, P/N GRS2

or its equivalent.

FUEL LINES

Check the fuel and oil lines regularly for damage and

ensure that there are no leaks.

Replace the fuel lines every two years to maintain the

performance and flexibility of the fuel lines.

SPARK PLUG

Remove and clean the spark plug (Figure 20), then

adjust the spark gap to 0.024 ~0.028 inch (0.6~0.7

mm). This unit has electronic ignition, which requires

no adjustments.

Figure 20. Spark PLug Gap

LONG TERM STORAGE

Drain fuel from fuel tank, fuel line and carburetor.

Remove spark plug and pour a few drops of motor oil into

cylinder. Crank engine 3 to 4 times so that oil reaches

all internal parts

Clean exterior of rammer with an oil-moistened cloth.

Store unit covered with plastic sheet in moisture free and

dust free location out of direct sunlight.

CLEANING THE RAMMER

If using a high pressure spray washer, be careful not

to splash water directly on the air cleaner, carburetor,

muffler, and fuel cap. Excessive amounts of water may

cause severe engine damage.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 19

Page 20

Table 4. Engine Maintenance Schedule

MAINTENANCE

FIRST

DESCRIPTION (3) OPERATION BEFORE

Engine Oil

Air Cleaner

All Nuts & Bolts

Spark Plug

Cooling Fins CHECK X

Spark Arrester CLEAN X

Fuel Tank CLEAN X

Fuel Filter CHECK X

CHECK X

CHANGE X

CHECK X

CHANGE X (1)

Re-tighten If

Necessary

CHECK-CLEAN X

REPLACE X

X

MONTH

OR

10 HRS.

EVERY

3 MONTHS

OR

25 HRS.

EVERY

6 MONTHS

OR

50 HRS.

EVERY

YEAR

OR

100 HRS.

EVERY

2 YEARS

OR

200 HRS..

Idle Speed CHECK-ADJUST X (2)

Valve Clearance CHECK-ADJUST X (2)

Fuel lines CHECK Every 2 years (replace if necessary) (2)

(1) Service more frequently when used in DUSTY areas.

(2) These items should be serviced by your service dealer, unless you have the proper tools and are mechanically proficient.

Refer to the ROBIN shop Manual for service procedures

(3) For commercial use, log hours of operation to determine proper maintenance intervals.

PAGE 20 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 21

Symptom Possible Problem Solution

Diffi cult to start, fuel is available, but no spark at

spark plug.

Diffi cult to start, fuel is available, and spark is

present at the spark plug.

Diffi cult to start, fuel is available, spark is

present and compression is normal.

Diffi cult to start, fuel is available, spark is

present and compression is low.

No fuel present at carburetor.

TROUBLESHOOTING

Troubleshooting (Engine)

Combo lever in incorrect position? Make sure combo lever is in start position.

Spark plug bridging? Check gap, insulation or replace spark plug.

Carbon deposit on spark plug? Clean or replace spark plug.

Short circuit due to defi cient spark plug

insulation?

Improper spark plug gap? Set to proper gap.

Fuel reaching carburetor? Check fuel line.

Water in fuel tank? Flush or replace fuel tank.

Fuel fi lter clogged? Replace fuel fi lter.

Stuck carburetor? Check fl oat mechanism.

Spark plug is red? Check transistor ignition unit.

Spark plug is bluish white?

No spark present at tip of spark plug?

No oil? Add oil as required.

ON/OFF switch is shorted? Check switch wiring, replace switch.

Ignition coil defective? Replace ignition coil.

Improper spark gap, points dirty? Set correct spark gap and clean points.

Condenser insulation worn or short circuiting? Replace condenser.

Spark plug wire broken or short circuiting? Replace defective spark plug wiring.

Wrong fuel type?

Water or dust in fuel system? Flush fuel system.

Air cleaner dirty? Clean or replace air cleaner.

Choke open? Close choke.

Suction/exhaust valve stuck or protruded? Reseat valves.

Piston ring and/or cylinder worn? Replace piston rings and/or piston.

Cylinder head and/or spark plug not tightened

properly?

Head gasket and/or spark plug gasket damaged? Replace head and spark plug gaskets.

No fuel in fuel tank? Fill with correct type of fuel.

Fuel cock does not open properly?

Fuel fi lter/lines clogged? Replace fuel fi lter.

Fuel tank cap breather hole clogged? Clean or replace fuel tank cap.

Air in fuel line? Bleed fuel line.

Check spark plug insulation, replace if worn.

If insuffi cient compression, repair or replace

engine. If injected air leaking, correct leak. If

carburetor jets clogged, clean carburetor.

Check transistor ignition unit is broken, and

replace defective unit. Check if voltage cord

cracked or broken and replace. Check if spark

plug if fouled and replace.

Flush fuel system, replace with correct type of

fuel.

Torque cylinder head bolts and spark plug.

Apply lubricant to loosen fuel cock lever,

replace if necessary.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 21

Page 22

Symptom Possible Problem Solution

Weak in power, compression is proper and

does not misfi re.

Weak in power, compression is proper but

misfi res.

Engine overheats.

Rotational speed fl uctuates.

Recoil starter malfunctions. (if applicable)

Starter malfunctions.

Burns too much fuel.

Exhaust color is continuously "white".

Exhaust color is continuously "black".

Will not start, no power with key "ON". (if

applicable)

TROUBLESHOOTING

Troubleshooting (Engine) - continued

Air cleaner dirty? Clean or replace air cleaner.

Improper level in carburetor? Check fl oat adjustment, rebuild carburetor.

Defective spark plug? Clean or replace spark plug.

Improper spark plug? Set to proper gap.

Water in fuel system?

Dirty spark plug? Clean or replace spark plug.

Ignition coil defective? Replace ignition coil.

Spark plug heat value incorrect? Replace with correct type of spark plug.

Wrong type of fuel? Replace with correct type of fuel.

Cooling fi ns dirty? Clean cooling fi ns.

Intake air restricted?

Oil level too low or too high? Adjust oil to proper level.

Governor adjusted incorrectly? Adjust governor.

Governor spring defective? Replace governor spring.

Fuel fl ow restricted? Check entire fuel system for leaks or clogs.

Recoil mechanism clogged with dust and dirt? Clean recoil assembly with soap and water.

Spiral spring loose? Replace spiral spring.

Loose, damaged wiring?

Battery insuffi ciently charged? Recharge or replace battery.

Starter damaged or internally shorted? Replace starter.

Over-accumulation of exhaust products?

Wrong spark plug?

Lubricating oil is wrong viscosity? Replace lubricating oil with correct viscosity.

Worn rings? Replace rings.

Air cleaner clogged? Clean or replace air cleaner.

Choke valve set to incorrect position? Adjust choke valve to correct position.

Carburetor defective, seal on carburetor

broken?

Poor carburetor adjustment, engine runs too

rich?

ON/OFF device not activated ON? Turn on ON/OFF device.

Battery disconnected or discharged?

Ignition switch/wiring defective? Replace ignition switch. Check wiring.

Flush fuel system and replace with correct

type of fuel.

Clear intake of dirt and debris. Replace air

cleaner elements as necessary.

Ensure tight, clean connections on battery

and starter.

Check and clean valves. Check muffl er and

replace if necessary.

Replace spark plug with manufacturer's

suggested type.

Replace carburetor or seal.

Adjust carburetor.

Check cable connections. Charge or replace

battery

PAGE 22 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 23

TROUBLESHOOTING

Troubleshooting (Rammer)

Symptom Possible Problem Solution

Engine runs but rammer jumps

erratically or not at all.

Operating speed of throttle lever is

incorrectly set?

Oil in excess? Drain excess oil. Bring to correct level.

Clutch slips? Replace or adjust clutch.

Spring Failure? Replace spiral spring.

Speed of engine improper?

Soil over-compacted? Shut down machine and test soil.

Set throttle lever to correct position.

Adjust engine speed to correct

operating RPM setting.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 23

Page 24

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

PART NO. Column

QTY. Column

— Item quantity can be indicated by a

A/R (As Required) is generally used for hoses or other

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarifi ed in the “Remarks”

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

same unique symbol will be included when this item is

— Used to list an effective serial

— Indicates that the part

part is NOT used on a specifi c model or model number

available items. Examples include battery cables, shims,

— Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

Numbers Used

number, a blank entry, or A/R.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT .....................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ..........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ..1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

parts that are sold in bulk and cut to length.

Column.

REMARKS Column

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specifi c Model Number Use

is used only with the specifi c model number or model

number variant listed. It can also be used to show a

variant.

Indicated by:

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarifi ed in the “Remarks” Column.

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

and certain washers and nuts.

“Not Sold Separately”

for sale through Multiquip.

PAGE 24 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 25

SUGGESTED SPARE PARTS

MTR40SF TAMPING RAMMER WITH ROBIN ROBIN EH09-2F ENGINE

1 to 3 units

Qty. P/N Description

1............956100040 ............ THROTTLE WIRE

3............362030030 ............ ELEMENT, AIR CLEANER

1............361910070 ............ CAP, FUEL TANK W/STRAP

3............301419750 ............ FILTER, IN-LINE FUEL

3............0650140380 .......... SPARK PLUG

1............2745011208 .......... ROPE, RECOIL STARTER

3............20F3260608 .........ELEMENT, ENGINE

NOTICE

Part numbers on this Suggested Spare Parts list may

supersede/replace the part numbers shown in the

following parts lists.

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 25

Page 26

NAMEPLATES AND DECALS

NAMEPLATE AND DECALS

1

13

12

NPA-961 E

18

&$87,21

$77(1=,21(

$7(1$

Read operator’s manual carefully before use

/LUHOHPDQXHODWWHQWLYHPHQW DYDQWXWLOLVDWLRQ

%LWWHOHVHQ 6LHYRU OQEHWULHEQDKPHGHU0DVFKLQH GLH

EHGLHQXQJVDQOHLWXQJ VRUJ¦OWLJGXUFK

3ULPDGHOXVR OHJJHUHDWWHQWDPHQWHLOPDQXDOH

/HHFRPDWHQ¥RPDQXDOGHLQVWUX· DQWHVGH

XVDU

/HHUGHWHQLGDPHQWHHOPDQXDOGHLQVWUXFFLRQHV

DQWHV GHXVDUODPDTXLQD

35(&$8&,21

NPA-769 J

17

LAY DOWN TOWARD THIS

DIRECTION ONLY

15

Oil

öl

I’ huile

SAE30

7~9 cc

11

35,0$5< $,5),/7(5

&+(&. '$,/<

16

To start, switch must be

in the “ ” position21

J019-APN

M

NPA1018

J

*$62/,1( 21/<

NPA293

T

R

-

4

0

F

2

NPA1017

J

J

%HIRUH 2SHUDWLRQ

Check all nuts and bolts for tightness

Keep machine at the upright operating position to check

1. Give each grease fitting five (5) shots of grease with

a hand grease gun.

2. Check the engine oil level and if the level is low,

it should be refilled from the filler hole.

NPA-1100 J

Gasoline Only

Bitte nur Benzine einfüllen

Essence Uniquement

Usare solo Benzina

Solo para Gasolina

23(5$7,21

7R 67$57 HQJLQH

Open fuel filter valve and close choke lever on carburetor.

Place starter switch to “ON” and pull start rope.

When engine starts, open the choke lever and warm up the

engine for 4-5 minutes before operation.

Then move throttle lever from “OFF” to “ON” to operate.

7R 6723HQJLQH

Move the throttle lever quickly from “ON” to “OFF” position.

Then move starter lever quickly to “OFF” and close the fuel filter valve.

5

NPA-896 J

4

3

3800 ~ 4100 RPM

NPA-957 J

When you stop

the engine, be

sure to close

the fuel cock

NPA-399 J

14

6(&21'$5< $,5),/7(5

CLEANTHE ELEMENT WITH KEROSENE WHEN DIRTY.AFTER THE

CLEANING,LUBRICATE IT MIXED OIL (KEROSENE 2~4: ENGINE OIL

1),SQUEEZE OUT THE OIL, AND REPLACE IT.AND CLEAN IT MORE

OFTENWHEN OPERATING IN DUSTY CONDITIONS.

9

1$0(3/$7(

NPA-831 J

READ OWNER’S SERVICE MANUAL BEFORE OPERATINGOR

SERVICING THIS MACHINE.

ALWAYS KEEP UNAUTHORIZED, INEXPERIENCED,

UNTRAINED PEOPLE AWAY FROM THIS MACHINE.

MAKE SURE ALL SAFETYDEVICES ARE OPERATIONAL

BEFORE THIS MACHINE IS STARTED.MAKE SURE ENGINE

IS TURNED OFF AND SPARKPLUG WIRE DISCONNECTED

BEFORE SERVICING THE MACHINE OR COMING IN

CONTACT WITHANY MOVING PART. IF EQUIPMENT IS

POWERED BY AN ELECTRIC MOTOR DISCONNECT

ELECTRICAL PLUG.

NEVER LEAVE MACHINE UNATTENDEDWHEN OPERATING.

ALWAYS STOP ENGINE AND ALLOW ENGINE TO COOL

BEFORE ADDING FUEL OR OIL.

6(59,&( 0217+/<

8

&/($1,1* (/(0(17 :

Remove the element from the pre-cleaner

Clean the element with solvent

Apply SAE30 motor oil with 7~9 cc, and

squeeze out excess oil before re-installing.

NPA-963 J

6

13$

7

NPA-329 J

19

NPA1016

J

GREASE

NPA-120 J

10

20

Operation of this equipment may create sparks

that can start fires around dry vegetation.

A spark arrestor may be required.

The operator should contact local fire agencies

for laws or regulations relating to fire prevention

requirements.

WARNING

PAGE 26 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

NPA-1410

Page 27

NAMEPLATES AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 920210170 DECAL: GASOLINE ONLY 1

2 920211000 DECAL: CAUTION (OPERATION) 1

3 920203990 DECAL: CAUTION (FUEL COCK) 1

4 920209570 DECAL: ENGINE RPM 1

5 920208960 DECAL: ELEMENT SET 1

6 920210160 DECAL: SECONDARY AIR FILTER 1

7 920203290 DECAL: CAUTION 1

8 920209630 DECAL: CLEANING ELEMENT 1

9 PLATE: SERIAL NO. .........................................1................CONTACT MQ PARTS DEPT

10 920100120 DECAL: GREASE .............................................3 ...............REPLACES 920101200

11 920210180 DECAL: PRIMARY AIR FILTER 1

12 920209100 DECAL: RAMMER BOOT & HEARING 1

13 920209610 DECAL: DECAL OIL 7-9 CC 1

14 920208310 DECAL: CAUTION/OIL INJECT 1

15 920100240 DECAL: (M-MARK) 1

16 920202930 DECAL: SWITCH-ON 1

17 920206910 DECAL: LAYDOWN 1

18 920207690 DECAL: CAUTION 1

19 920211690 DECAL: LEVER OPERATION 1

20 920214100 DECAL: E/G FIRE WARNING 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 27

Page 28

CRANKCASE AND ENGINE ASSY

CRANKCASE AND ENGINE ASSY.

PAGE 28 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 29

CRANKCASE AND ENGINE ASSY

NO. PART NO. PART NAME QTY. REMARKS

1 305117260 CRANK CASE 1

2 305343780 CRANK GEAR 1

3 041006305 BEARING 6305Z 1

4 041006203 BEARING 6203Z 1

5 952401450 WASHER 8.5X22X3 1

6 011208025 BOLT 8X25 T .....................................................1................REPLACES 001220825

7 030208200 WASHER, LOCK M8 1

9 362455660 BEARING COVER 1

10 011706020 BOLT 6X20 H, SW ............................................2................REPLACES 002210620

11 050100350 O-RING G-35 1

13 305333090 CONNECTING ROD 1

14 042006304 BEARING 6304ZZ 1

15 080100520 STOP RING R-52 1

16 952400130 WASHER 9304 1

17 011208025 BOLT 8X25 T .....................................................1................REPLACES 001220825

18 030208200 WASHER, LOCK M8 1

20 303010084 PINION 1

21 042006007 BEARING 6007ZZ 2

22 351437750 SPACER 1

23 080200350 STOP RING S-35 1

24 351421900 SPACER, CLUTCH DRUM 1

25 060504010 OIL SEAL VB-40525 1

26 050300900 O-RING S-90 1

27 361463840 CLUTCH ASSY. CE120P ...................................1................INCLUDES ITEMS W/

27-1* 943020020 CLUTCH SHOE C812 4

27-3* 943060100 CLUTCH GUIDE (A) 1

27-4* 943060020 CLUTCH GUIDE (B) 1

27-5* 943030021 CLUTCH SPRING 2

28 0053204201 WOODRUFF KEY 1

29* 301010210 LOCK WASHER, CLUTCH 1

30 0173120010 LOCK NUT 1

32 362341610 PACKING, FRONT COVER 1

33 011706020 BOLT 6X20 H, SW ............................................9................REPLACES 002210620

34 351010050 GREASE FITTING A-MT6X1 1

35 959010320 GREASE FITTING B-MT6X1 1

37 2741500123 ADAPTER FLANGE 1

38 0011408400 BOLT AND WASHER ASSY. 4

39 020108060 NUT ...................................................................4................REPLACES 0021808000

40 030208200 WASHER, LOCK ...............................................4................REPLACES 0032008000

*

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 29

Page 30

CRANKCASE AND ENGINE ASSY

CRANKCASE AND ENGINE ASSY.

PAGE 30 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 31

CRANKCASE AND ENGINE ASSY

NO. PART NO. PART NAME QTY. REMARKS

41 0031008000 WASHER ...........................................................4................REPLACES 0031108000

42 0310060020 DOWEL PIN 2

63 959006120 CLIP (TCP-10509B) 1

64 362341620 OIL GAUGE PROTECTOR 1

65 362341630 LINK PROTECTOR 1

66 3013820 BOLT 8X20 W/FLAT/LOCK WASHER ................4................REPLACES 002400820

67 2741600113 STIFFENER 1

68 0011408250 BOLT AND WASHER 4

69 0011408300 BOLT AND WASHER ASSY. 2

71 362116871 AIR CLEANER ASSY. ........................................1................INCLUDES ITEMS W/#

71-1# 362030011 COVER CP, AIR CLEANER 1

71-2# 362030020 PACKING, AIR CLEANER 1

71-3# 362030030 ELEMENT CP, AIR CLEANER 1

71-4# 362030040 BOLT CP, AIR CLEANER 1

72 362341210 INTAKE PIPE 1

73 507010110 CLAMP TC-200 2

74 050300070 O-RING (7) 1

75 0401450080 WASHER, FLAT M8 ...........................................1................REPLACES 031108160

81 306010020 FRONT COVER 1

86 911210918 ENGINE ASSY., EH092F 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 31

Page 32

GUIDE CYLINDER ASSY

GUIDE CYLINDER AND FOOT ASSY.

PAGE 32 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 33

GUIDE CYLINDER ASSY

NO. PART NO. PART NAME QTY. REMARKS

1 305464130 PISTON PIN 1

2 368459920 PISTON PIN PLUG 1

3 305337980 PISTON ROD, M14 1

4 305451550 PISTON END, M14 1

6 305446400 STOPPER, UPPER 1

7 305446410 CYLINDER CAP 1

8 305446420 MAIN SPRING 2

9 305212710 SPRING CYLINDER 1

11 305112730 GUIDE CYLINDER 1

12 065105010 DUST SEAL DKI-5367811 1

13 080510680 STOP RING TH-R-68 1

14 351010050 GREASE FITTING A-MT6X1 2

15 305446430 STOPPER 1

16 001220816 BOLT 8X15 H, SW .............................................4................REPLACES 002200815

18 305446440 GRIP 1

19 001520815 SOCKET HEAD BOLT 8X15 T 2

20 305446450 DUST SLEEVE 1

21 305446460 SLEEVE BAND 1

22 011208035 BOLT 8X35.........................................................1................REPLACES 001220835

23 020308060 NUT M8 ..............................................................1................REPLACES 020308060

25 050100800 O-RING G-80 1

26 012210025 BOLT 10X25 H, SW ...........................................4................REPLACES 002211025

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 33

Page 34

FUEL TANK AND HANDLE ASSY

TANK AND HANDLE ASSY.

PAGE 34 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 35

FUEL TANK AND HANDLE ASSY

NO. PART NO. PART NAME QTY. REMARKS

1 306117960 HANDLE 1

2 351319900 SHOCK ABSORBER 2

3A 009110007 SOCKET HEAD BOLT 10X20 T 4

3B 033121009 TOOTHED LOCK WASHER B M10 4

4 012210020 BOLT 10X20 H, SW ..........................................4................REPLACES 002211020

5 939010210 STOPPER RUBBER EH1002 1

6 030208200 WASHER, LOCK M8 1

7 020108060 NUT M8 .............................................................1................REPLACES 020308060

9# 361910070 TANK CAP CP (ORANGE) 1

10 305910036 FUEL TANK (EVP) ASSY. .................................1................INCLUDES ITEMS W/#

11# 362458350 SUB CAP 1

17# 351437785 HOLDER, COCK 1

18# 954406020 PACKING, FUEL TANK 1

19 954300720 FUEL COCK ASSY./CVL-08 1

20# 954406010 STRAINER (#110) 1

21 011208030 BOLT 8X30 T .....................................................2 ...............REPLACES 001220830

22 030208200 WASHER, LOCK M8 2

23 022710809 NYLON NUT M8 2

24 952401450 WASHER 8.5X22X3 2

31# 954404890 FILTER, TANK 1

32 0561080020 HOSE CLAMP 4

33 959328404 FUEL HOSE, L=150 EVP 2

34 301419750 FUEL FILTER CP 1

41# 363218260 F. TANK 2L (GRAY) EVP 1

43 362910060 THROTTLE LEVER ASSY. ...............................1................INCLUDES ITEMS W/

44* 362341550 THROTTLE BODY 1

45* 362910090 THROTTLE, GEAR CP. W/BOLT 1

47* 362455620 SLIDER 1

48* 362455630 THROTTLE LEVER 1

49* 050100450 O-RING G-45 1

50* 050200100 O-RING P-10 1

51* 031110160 WASHER, FLAT M10 3

52* 033910230 CONICAL SPRING WASHER 2

53* 096206006 SOCKET HEAD SCREW 6X6 1

54 022131008 CAP NUT M10 1

55 020310080 NUT M10, H=6 ..................................................1................REPLACES 020410060

56* 014208020 SOCKET HEAD SCREW 8X20 ........................1................REPLACES 096208020

57* 020408050 NUT M8, H=5 2

58* 956100040 THROTTLE WIRE 620-710 1

59 011206020 BOLT 6X20T .....................................................2................REPLACES 001220620

60 030206150 WASHER, LOCK 2

61 022130605 CAP NUT M6 2

*

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 35

Page 36

FOOT ASSY

FOOT ASSY. (OPTION)

PAGE 36 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 37

FOOT ASSY

NO. PART NO. PART NAME QTY. REMARKS

30 305910050 FOOT ASSY. 150B .............................................1................INCLUDES ITEMS W/

31* 306347930 FOOT 150B 1

32* 306347960 METAL SHEET 150B 1

33* 306461630 FOOT COVER 1

34* 009110033 SUNK HEAD BOLT 10X50 H 2

35* 021110120 NYLON NUT M10 ..............................................2................REPLACES 022711012

36* 030210250 WASHER, LOCK M10 2

37* 009110034 SUNK HEAD BOLT 12X65 H 4

38* 021112140 NYLON NUT M12 ..............................................4................REPLACES 022711214

39* 030212300 WASHER, LOCK M12 4

*

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 37

Page 38

NARROW FOOT ASSY. (OPTION)

NARROW FOOT ASSY. (OPTION)

PAGE 38 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 39

NARROW FOOT ASSY. (OPTION)

NO. PART NO. PART NAME QTY. REMARKS

A 305910060 FOOT ASSY. 200B .............................................1................INCLUDES ITEMS W/

A 305910070 FOOT ASSY. 100B .............................................1................INCLUDES ITEMS W/ #

1* 306347940 FOOT 200B ........................................................1................200B

1# 306347920 FOOT 100B ........................................................1................100B

2* 306347970 METAL SHEET 200B .........................................1................200B

2# 306347950 METAL SHEET 100B .........................................1................100B

3* 306461630 FOOT COVER ...................................................1................200B

3# 306461620 FOOT COVER 96B ............................................1................100B

4*# 015110050 SUNK HEAD BOLT 10X50 H .............................2................REPLACES 001611050

5*# 021110120 NYLON NUT M10 ..............................................2................REPLACES 022711012

6*# 030210250 WASHER, LOCK M10 2

7*# 015112060 SUNK HEAD BOLT 12X60 H .............................4................REPLACES 001611252

8*# 021112140 NYLON NUT M12 ..............................................4................REPLACES 022711214

9*# 030212300 WASHER, LOCK M10 4

*

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 39

Page 40

TRENCH SHOE ASSY.

TRENCH SHOE ASSY

PAGE 40 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 41

TRENCH SHOE ASSY

NO. PART NO. PART NAME QTY. REMARKS

11 305333160 TRENCH SHOE 500H-120B 1

11 305333170 TRENCH SHOE 800H-120B 1

11 305334390 TRENCH SHOE 305H-100B 1

12 012212035 BOLT 12X35 T....................................................4................REPLACES 001221235

13 020312100 NUT M12 4

14 0039312000 WASHER, LOCK M12........................................4................REPLACES 030212300

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 41

Page 42

ROBIN EH09-2F ENGINE — CRANKCASE ASSY.

ROBIN EH09-2F ENGINE —

CRANKCASE ASSY.

PAGE 42 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 43

ROBIN EH09-2F ENGINE — CRANKCASE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

10 20F1010421 CRANKCASE CP ...............................................1................INCLUDES ITEMS W/#

20& 2371420203 VALVE GUIDE 2

26& 2771601001 STEM SEAL CP 1

30# 2096244508 OIL SEAL 20X32X6 ..........................................1................REPLACES 0440200070

40# 0600200110 BALL BEARING, 60074C3 1

50# 0310060020 DOWEL PIN 2

70 0105060430 STUD 2

75# 0440060020 OIL SEAL 1

80 0401140030 PLUG 1

90 0211140020 GASKET 1

150 2741600113 STIFFENER 1

160 0011408250 BOLT & WASHER 4

161 0011408300 BOLT & WASHER ASSY. 2

205 0241090060 GROMMET 1

210 20F1110131 MAIN BEARING COVER ...................................1................INCLUDES ITEMS W/*

220* 0440200110 OIL SEAL 20X32X6 1

230* 0600200110 BALL BEARING, 6004C3 1

250 2844500301 GOVERNOR GEAR CP 1

260 2054190103 GOVERNOR SLEEVE 1

265* 0013908500 STUD 4

268* 0310060020 DOWEL PIN 2

270 2306360111 OIL GAUGE .......................................................1................INCLUDES ITEMS W/%

280% 0213160020 GASKET ...........................................................1................REPLACES X213160020

300 0130060200 BOLT & WASHER 9

430 2741500123 ADAPTER FLANGE 1

437 020108060 NUT ...................................................................4................REPLACES 0021808000

438 030208200 SPRING WASHER .............................................4................REPLACES 0032008000

439 0031008000 WASHER ..........................................................4................REPLACES 0031108000

610 2841300110 CYLINDER HEAD ASSY. ...................................1................INCLUDES ITEMS W/&

620 2841500113 GASKET HEAD 1

630 0110080210 FLANGE BOLT 1

631 0100080410 BOLT 2

680 2841550203 ROCKER COVER 1

685 2841450203 OIL SHELTER PLATE 1

690 2841600703 GASKET, ROCKER COVER 3

700 2771501103 PIPE KNOCK 2

710 0110060400 FLANGE BOLT 4

721 2841560203 BREATHER PLATE 1

722 2841600103 LEAF VALVE 1

723 2841600203 BREATHER PLATE 1

724 2841450103 OIL SHELTER PLATE 1

725 0131050020 SCREW & WASHER ASSY. 2

726 0131050020 SCREW & WASHER ASSY. 1

810 2841700103 COVER CASE 1

830 2301600613 GASKET TAPPET COVER NA 1

860 0011406160 BOLT & WASHER ASSY. 2

960 2849900407 GASKET SET 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 43

Page 44

ROBIN EH09-2F ENGINE — CRANKSHAFT, PISTON ASSY.

ROBIN EH09-2F ENGINE —

CRANKSHAFT AND PISTON ASSY.

PISTON KIT

(STD)

(O/S 0.25)

(O/S 0.50)

390

391

392

PISTON RING SET

(STD)

(O/S 0.25)

(O/S 0.50)

PISTON

(STD)

(O/S 0.25)

(O/S 0.50)

360

361

362

370

371

372

380

350

380

310

105

40

41

42

320

50

60

70

10

80

PAGE 44 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 45

ROBIN EH09-2F ENGINE — CRANKSHAFT, PISTON ASSY.

NO. PART NO. PART NAME QTY. REMARKS

10 2842030101 CRANKSHAFT CP 1

40 0230200100 SPACER T=0.8 1

41 0230200110 SPACER T=1.0 1

42 0230200120 SPACER T=1.2 1

50 0021814000 NUT 1

60 0032014000 SPRING WASHER .............................................1................REPLACES 0032012000

70 0053203101 WOODRUFF KEY 1

80 0053204201 WOODRUFF KEY 1

105 0173120010 LOCK NUT 1

310 2842250130 CONNECTING ROD ASSY ...............................1................INCLUDES ITEMS W/%

320% 2842300103 CONNECTING ROD BOLT 2

350 2302330103 PISTON PIN 1

360 28423401H3 PISTON 1

361 28423402H3 PISTON 0.25MM 1

362 28423403H3 PISTON 0.50MM 1

370 2842351107 PISTON RING SET 1

371 2842351207 PISTON RING SET 0.25MM 1

372 2842351307 PISTON RING SET 0.50MM 1

380 0565110010 CLIP 2

390 28427011H7 PISTON KIT/EH09-2/MT, STD 1

391 28427012H7 PISTON KIT/EH09-2/0.25/MT 1

392 28427013H7 PISTON KIT/EH09-2/0.50/MT 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 45

Page 46

ROBIN EH09-2F ENGINE — INTAKE, EXHAUST ASSY.

ROBIN EH09-2F ENGINE —

INTAKE AND EXHAUST ASSY.

PAGE 46 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 47

ROBIN EH09-2F ENGINE — INTAKE, EXHAUST ASSY.

NO. PART NO. PART NAME QTY. REMARKS

10 2843170121 CAMSHAFT CP .................................................1................INCLUDES ITEMS W/%

34% 2273860123 PIN (SPRING) 1

35% 2843640103 RELEASE LEVER 1

36% 0051904100 SPRING PIN 1

37% 0031517000 SNAP RING 1

38% 2743870123 RETURN SPRING 1

50 2743330103 TAPPET 2

60 2743360103 VALVE SPRING 2

70 2743370203 SPRING RETAINER 2

80 2743340103 INTAKE VALVE 1

90 2743350103 EXHAUST VALVE 1

95 13210KA031 COLLET VALVE 4

210 2743530103 PUSH ROD 2

220 2843600113 ROCKER ARM 2

230 2693580103 BOLT (PIVOT) 2

240 0170060090 NUT 2

260 2743650103 GUIDE PLATE 1

310 20F3010501 MUFFLER CP 1

340 2843520103 GASKET (EXHAUST) 1

351 0023808000 FLANGE NUT 2

357 0200080170 WASHER 1

365 0110060460 FLANGE BOLT 2

366 0011408160 BOLT & WASHER 8X16 1

370 0130080240 BOLT & WASHER ASSY. 1

540 1063292103 INSULATOR 1

550 2843590213 GASKET (INSULATOR) 1

560 1573500103 GASKET 2 (INSULATOR) 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 47

Page 48

ROBIN EH09-2F ENGINE — CARBURETOR ASSY.

ROBIN EH09-2F ENGINE —

CARBURETOR ASSY.

PAGE 48 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 49

ROBIN EH09-2F ENGINE — CARBURETOR ASSY.

NO. PART NO. PART NAME QTY. REMARKS

210 2846237200 CARBURETOR ASSY. .......................................1................INCLUDES ITEMS W/#

2# 2306253608 THROTTLE VALVE 1

3# 2776258008 SCREW 30400 1

4# 2366252808 CHOKE VALVE 1

5# 2796235608 SCREW 2

6# 2306244608 SPRING 1

9# 2466243508 ADJUST SCREW 1

10# 2796242108 PILOT JET/EH09-2F 1

11# 1066238408 O-RING 1

12# 2936235008 PLATE/EH09-2F 1

13# 2796235108 SCREW 1

14# 2936253008 TH, SHAFT/EH09-2F 1

17# 2366254008 PACKING, CHAMBER 826-42001 1

18# 2366250508 FLOAT 1

19# 2936250508 FLOAT. BAY 1

20# 2366245008 PACKING 826-08003 1

21# 2376245008 BOLT PV18/695 1

22# 2936252008 CHOKE SHAFT 1

25# 1616235208 NEEDLE 1

26# 2366244508 SPRING 1

27# 2146251508 FLOAT PIN 1

29# 2766240008 MAIN JET 30100 1

30# 2106231808 SPRING 1

31# 2246245008 SCREW 1

33# 2846236008 HOSE 1

34# 2936244018 NOZZLE 1

35# 2356242508 GUIDE HOLDER 1

36# 2844550103 BUSH, THRO 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 49

Page 50

ROBIN EH09-2F ENGINE — AIR CLEANER ASSY.

ROBIN EH09-2F ENGINE —

AIR CLEANER ASSY.

C

500

570

900

520

(40mm)

510

PAGE 50 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 51

ROBIN EH09-2F ENGINE — AIR CLEANER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

C 20F3260300 AIR CLEANER ASSY. .......................................1................INCLUDES ITEMS W/#

500# 20F3265108 PACKING, CLEANER/09-2F 1

510# 20F3264108 CLEANER COVER/EH09-2F/MT 1

520# 20F3260608 ELEMENT ASSY/09-2F/MT 1

570 0176060030 SELF LOCK NUT 2

850 2841610403 RUBBER PIPE 1

900# 0732004430 LABEL, CHOKE 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 51

Page 52

ROBIN EH09-2F ENGINE — GOVERNOR, OPERATION ASSY.

ROBIN EH09-2F ENGINE —

GOVERNOR, OPERATION ASSY.

PAGE 52 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 53

ROBIN EH09-2F ENGINE — GOVERNOR, OPERATION ASSY.

NO. PART NO. PART NAME QTY. REMARKS

10 2844230403 GOVERNOR LEVER 1

20 2304220113 GOVERNOR SHAFT .........................................1................REPLACES 2304220103

30 2844270201 GOVERNOR ROD 1

35 2844560103 LINKAGE BUSHING 1

40 2844280403 ROD SPRING 1

50 0031305000 CLIP 2

60 0011406300 BOLT & WASHER ASSY. 1

70 2844900201 WEIGHT CP 1

80 2524250323 GOVERNOR SPRING 1

200 2304330210 SPEED CONTROL ASSY. 1

201 2744510101 BASE PLATE 1

207 957010600800 FLANGE BOLT ...................................................2................REPLACES 0110060010

210 0043104140 SCREW, PAN HEAD 1

213 0230100040 SPACER 1

215 2264500313 RETURN SPRING 1

230 0043106300 SCREW 1

240 020106050 NUT ....................................................................1................REPLACES 0022706000

255 0217100020 FRICTION WASHER 1

260 0140040070 SCREW 1

265 2684500113 CONTROL SPRING 1

280 2264310301 LINK PIVOT 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 53

Page 54

ROBIN EH09-2F ENGINE — BLOWER HOUSING ASSY.

ROBIN EH09-2F ENGINE —

BLOWER HOUSING ASSY.

60

80

10

110

20

40

Separate sale

220

Separate sale

41

216

PAGE 54 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 55

ROBIN EH09-2F ENGINE — BLOWER HOUSING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

10 20F5110213 BLOWER HOUSING CP 1

20 2849510203 LABEL 1

40 0010408350 FLANGE BOLT 1

41 0010408200 FLANGE BOLT 1

60 2845260123 CYLINDER BAFFLE 1

80 957010600800 FLANGE BOLT ...................................................2................REPLACES 0110060010

110 2845410103 COOLING BLOWER 1

216 920100240 DECAL, M-MARK 1

220 957010600800 FLANGE BOLT ...................................................3................REPLACES 0110060010

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 55

Page 56

ROBIN EH09-2F ENGINE — RECOIL STARTER ASSY.

ROBIN EH09-2F ENGINE —

RECOIL STARTER ASSY.

230

Separate sale

6

8

49

11

24

1

25

4

3

2

7

5

A

PAGE 56 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 57

ROBIN EH09-2F ENGINE — RECOIL STARTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

A 2845021130 RECOIL STARTER ASSY. .................................1................INCLUDES ITEM W/

1* 2745011508 SPIRAL SPRING 1

2745012018 REEL 1

2

*

2745011208 STARTER ROPE 1

3

*

2615010008 STARTER KNOB 1

4

*

2705012508 RATCHET 2

5

*

2745013108 FRICTION SPRING 1

6

*

2275013508 RETURN SPRING 2

7

*

2705026108 RATCHET GUIDE 1

8

*

2845014508 STARTING PULLEY 1

11

*

2745015208 SLIDE PLATE, B 1

24

*

1315015008 SLIDE PLATE 1

25

*

2275015208 SET SCREW 1

49

*

0110060020 FLANGE BOLT 4

230

*

*

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 57

Page 58

ROBIN EH09-2F ENGINE — ELECTRIC DEVICE ASSY.

ROBIN EH09-2F ENGINE —

ELECTRIC DEVICE ASSY.

11

60

110

70

100

75

30

10

PAGE 58 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 59

ROBIN EH09-2F ENGINE — ELECTRIC DEVICE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

10 2847933021 FLYWHEEL CP 1

11 2847943021 IGNITION COIL CP 1

30 0011706250 BOLT & WASHER ASSY. 2

60 0660000471 SWITCH ASSY. 1

70 0043504120 SCREW & WASHER ASSY. 2

75 0566030010 CLAMP 1

100 0650140380 SPARK PLUG 1

110 2847510203 SPARK PLUG CAP 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 59

Page 60

ROBIN EH09-2F ENGINE — ACCESSORIES

ROBIN EH09-2F ENGINE —

ACCESSORIES ASSY.

PAGE 60 — MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12)

Page 61

ROBIN EH09-2F ENGINE — ACCESSORIES

NO. PART NO. PART NAME QTY. REMARKS

10 2269030710 ACCESSORY TOOL KIT 1

MTX40SF RAMMER • OPERATION AND PARTS MANUAL — REV. #0 (11/28/12) — PAGE 61

Page 62

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

5. Par ts must be in new and resalable

Multiquip reser ves the right to quote and

who use our products as integral parts of their

LIMITATIONS OF SELLER’S LIABILITY

liable for loss of profi t or good will or for any

connection with the sale of its products. Apart

statutory, which extend beyond the description

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and

the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments wil l be accepted and

credit will be allowed, subject to the following

provisions:

1. A Returned Ma terial Authoriza ti on

must be approved by Multiquip prior to

shipment.

2. To obtain a Return Material Authorization,

a list must be provided to Multiquip

Parts Sales that defi nes item numbers,

quantities, and descriptions of the items

to be returned.

a. The parts numbers and descriptions

b. The list must be typed or computer

c. The list must state the reason (s)