Page 1

OPERATION AND PARTS MANUAL

Tamping Rammer

Model MTR-35HS

© COPYRIGHT 2001, MULTIQUIP INC.

Revision #5 (11/09/04)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

Page 2

PAGE 2 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 3

Page 4

TABLE OF CONTENTS

Here's How To Get Help ........................................ 3

Table Of Contents ................................................. 4

Parts Ordering Procedures ................................... 5

Rules For safe Operation .................................. 6-7

Operation and Safety Decals ................................ 8

General Information .............................................. 9

MTR-35HS

Specification ........................................................ 10

Controls and Components .................................. 11

Operation .......................................................11-14

Maintenance .................................................. 15-16

Troubleshooting Guide ................................... 17-18

Explanation Of Codes In Remarks Column ........ 20

Suggested Spare Parts ....................................... 21

Name Plate and Decals ................................. 22-23

Crankcase and Engine Assembly ..................24-25

Guide Cylinder and Foot Assembly ...............26-27

Tank and Handle Assembly ........................... 28-29

Narrow Foot and Trench Shoe Assembly ......30-31

ROBIN EC-08HS ENGINE

Crankcase and Cylinder Assembly ................ 32-33

Crankshaft and Piston Assembly ...................34-35

Governor Assembly .......................................36-37

Muffler Assembly ........................................... 38-39

Carburetor and Oil Pump Assembly ..............40-41

Recoil Starter & Blower Housing Assembly ..42-43

Air Cleaner Assembly.................................. 44-45

Carburetor Components Assembly ............... 46-47

Recoil Starter Components Assembly ...........48-49

Magneto Assembly ........................................ 50-51

Terms and Condition of Sale

— Parts ..................... 52

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 5

PARTS ORDERING PROCEDURES

■■

■ Dealer account number

■■

■■

■ Dealer name and address

■■

■■

■ Shipping address (if different than billing address)

■■

■■

■ Return fax number

■■

■■

■ Applicable model number

■■

■■

■ Quantity, part number and description of each part

■■

■■

■ Specify preferred method of shipment:

■■

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

■■

■

UPS Ground Service at no charge for freight

■■

■■

■

PS Third Day Service at one-half of actual freight cost

■■

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

UPS

Special

For faxed orders only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 5

800/6-PARTS-7 • 800-672-7877

Page 6

RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual

may lead to serious injury or even death!

This equipment is to be operated by trained

and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used when

operating the MTR-35HS Tamping Rammer:

GENERAL SAFETY

■

DO NOT operate or service this equipment before

reading this entire manual.

■

This equipment should not be operated by persons

under 18 years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steel-toed

boots and other protective devices required by the

job.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Manufacture does not assume responsibility for any accident

due to equipment modifications.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

engine or rammer.

■

High Temperatures – Allow the engine to cool before

adding fuel or performing service and maintenance

functions. Contact with

burns.

■

The engine section of this rammer requires an adequate

free flow of cooling air. NEVER operate the rammer in any

hot

components can cause serious

enclosed or narrow area where free

flow of the air is restricted. If the air

flow is restricted it will cause serious

damage to the rammer or engine

and may cause injury to people.

Remember the rammer's engine

gives off

gas.

DEADLY

carbon monoxide

■

ALWAYS check the machine for loosened threads or bolts before

starting.

■

ALWAYS wear proper respiratory (mask),

hearing and eye protection equipment when

operating the rammer.

PAGE 6 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

■

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT

machine. Fire or explosion could result from

fuel vapors, or if fuel is spilled on a hot

engine.

■

NEVER operate the rammer in an explosive atmosphere or

near combustible materials. An explosion or fire could result

causing severe

■

Topping-off to filler port is dangerous, as it tends to spill fuel.

bodily harm or even death.

smoke around or near the

Page 7

RULES FOR SAFE OPERATION

■

NEVER Run engine without air filter. Severe engine may

occur.

■

Always service air cleaner frequently to prevent carburetor

malfunction.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using rammer.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

Transporting

■

■

■

■

Emergencies

■

the equipment and/or injury to user may result.

■

NEVER Run engine without air cleaner. Severe engine

damage may occur.

■

Always read, understand, and follow procedures in Operator’s

Manual before attempting to operate equipment.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using pump.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

Refer to the

technical questions or information

ROBIN Engine Owner's Manual

for engine

recommended by Multiquip

for this equipment. Damage to the equipment and/or injury to

Maintenance Safety

■

■

■

■

■

user may result.

■

Always shutdown engine before transporting.

Tighten fuel tank cap securly and close fuel cock to prevent

fuel from spilling.

Drain fuel when transporting rammer over long distances or

bad roads.

When placing the rammer inside a truck-bed for transport,

always tie-down the rammer.

Always know the location of the nearest

and

first aid kit

. Know the location of the nearest telephone.

Also know the phone numbers of the nearest

doctor

and

fire department

. This information will be

fire extinguisher

ambulance

,

invaluable in the case of an emergency.

NEVER lubricate components or attempt service on a running

machine.

Always allow the machine a proper amount of time to cool

before servicing.

Keep the machinery in proper running condition.

Fix damage to the machine immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

DO NOT use plastic containers to dispose of hazardous

waste.

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 7

Page 8

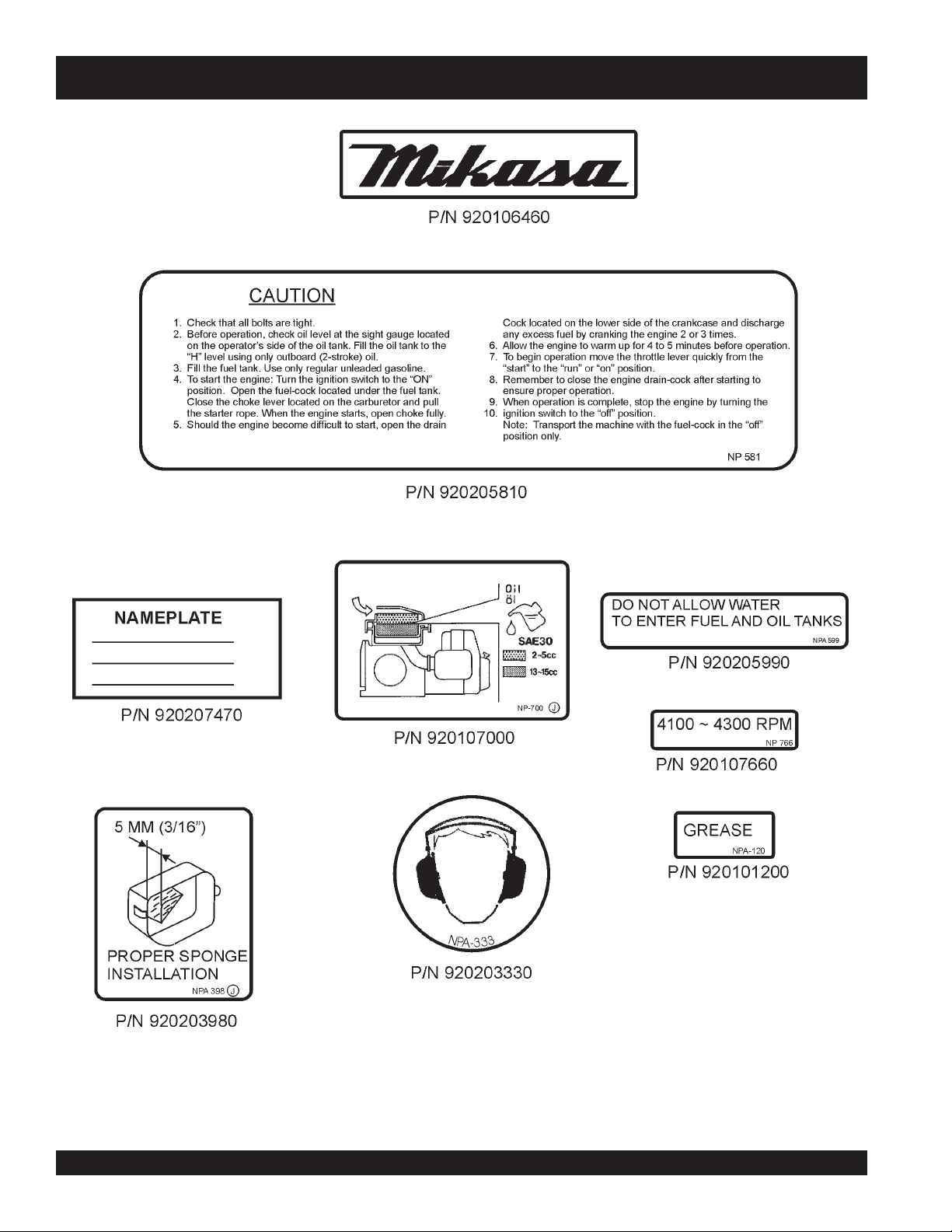

OPERATION AND SAFETY DECALS

PAGE 8 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 9

Definition of Tamping Rammer

The Mikasa MTR-35HS Tamping Rammer is a powerful

compacting tool capable of applying a tremendous force in

consecutive impacts to a soil surface. Its applications include

soil compacting for backfilling for gas pipelines, water pipelines

and cable installation work.

The impact force of the MTR-35HS levels and uniformly

compacts voids between soil particles to increase dry density.

Circular motion is converted to create impact force. The MTR35HS tamping rammer develops a powerful compacting force at

the foot of the rammer. To maintain optimum performance, proper

operation and service are essential.

Construction of Tamping Rammer

The Mikasa MTR-35HS is equipped with an Robin air cooled,

oil-injected two cycle gasoline engine. Transmission of the power

takes place by increasing the engine speed to engage the

centrifugal clutch.

Rammer Gearbox and Spring Cylinder

GENERAL INFORMATION

The Mikasa MTR-35HS uses an oil bath lubrication system.

Always check the oil level through the oil level sight glass at the

rear of the tamper foot.

Controls

Before starting the MTR-35HS Tamping Rammer identify and

understand the function of the controls, see Figure 1 on page 11.

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 9

Page 10

baT

LEDOM)cirtem(.S.USH53-RTM

thgieHllarevO)mm550,1(.ni5.14

htdiWllarevO)mm063(.ni1.41

htgneLrevO)mm545(.ni5.12

ziSeohS)mm072X051(.ni6.01X9.5

e

etunim/swolB057~027

aerAgnipmaT )rhrepm.qs531(rhrep.tf.qs354,1

SPECIFICATIONS

snoitacificepSremmaRSH53-RTM.1elbaTsnoitacificepSremmaRSH53-RTM.1elbaT

snoitacificepSremmaRSH53-RTM.1elbaTsnoitacificepSremmaRSH53-RTM.1elbaT

snoitacificepSremmaRSH53-RTM.1el

ecroFtcapmI)wol

hctulClagufirtneCcitamotuA

thgieWgnitarepO)gk14(.sbl09

-CENIBOR.2elbaT

LEDOMENIGNESH80-CENIBOR

epyTenignEenilosaGekortS2delooC-riA

ekortSXeroB mm04Xmm05(.ni23/7-1X.ni23/13-1

ecalpsiDnotsiP)cc5.87(.ni.uc21.5

tnem

oitaRnoisserpmoC1:5.6

tuptuOdetaRsuounitnoCmpr000,4/ph8.1

tuptuO.xaMmpr005,

euqroT.xaM )mpr006,3/m-gk155.0(mpr006,3bl-tf7.3

metsySgnilooCnaFyBdelooC-riA

b/gk055(wolb/.sbl2121

snoitacificepSenignESH80-CENIBOR.2elbaTsnoitacificepSenignESH80-CENIBOR.2elbaT

snoitacificepSenignESH80-CENIBOR.2elbaTsnoitacificepSenignESH80-CENIBOR.2elbaT

snoitacificepSenignESH80

5/ph3.3

metsySnoitacirbuL mets

noitpmusnoCleuF)mpr005,4/ph2.2(h/ph/bl48.0

leuFenilosaG

gulPkrapSSH6-BKGN

ySgnitratSretratSlioceR

mets

NOTE

Specifications are general and are subject to change without notice. If exact

measurements are required, equipment should be weighed and measured.

PAGE 10 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

ySgniyarpSliOnoitacirbuL-leuF

Page 11

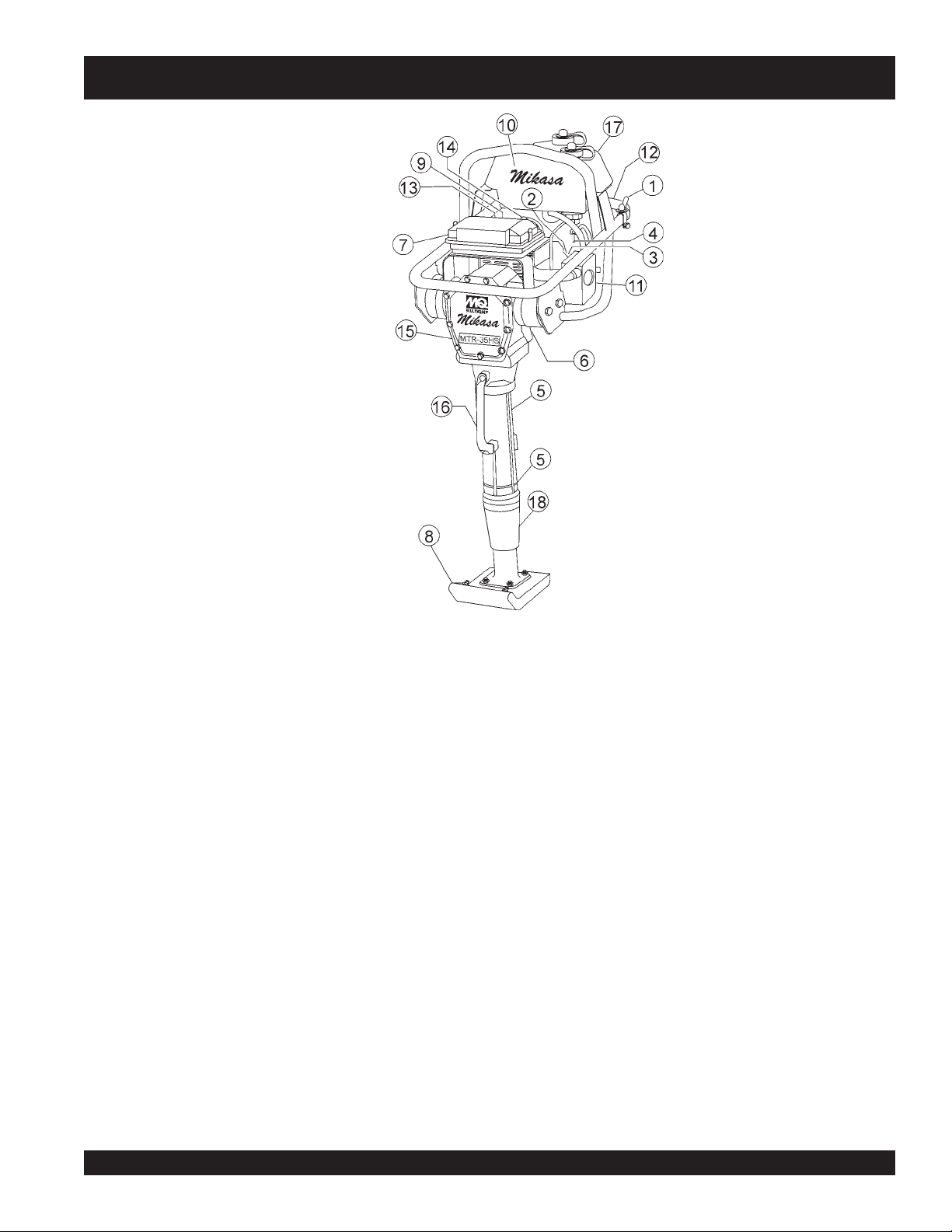

MTR-35HS — CONTROLS AND COMPONENTS

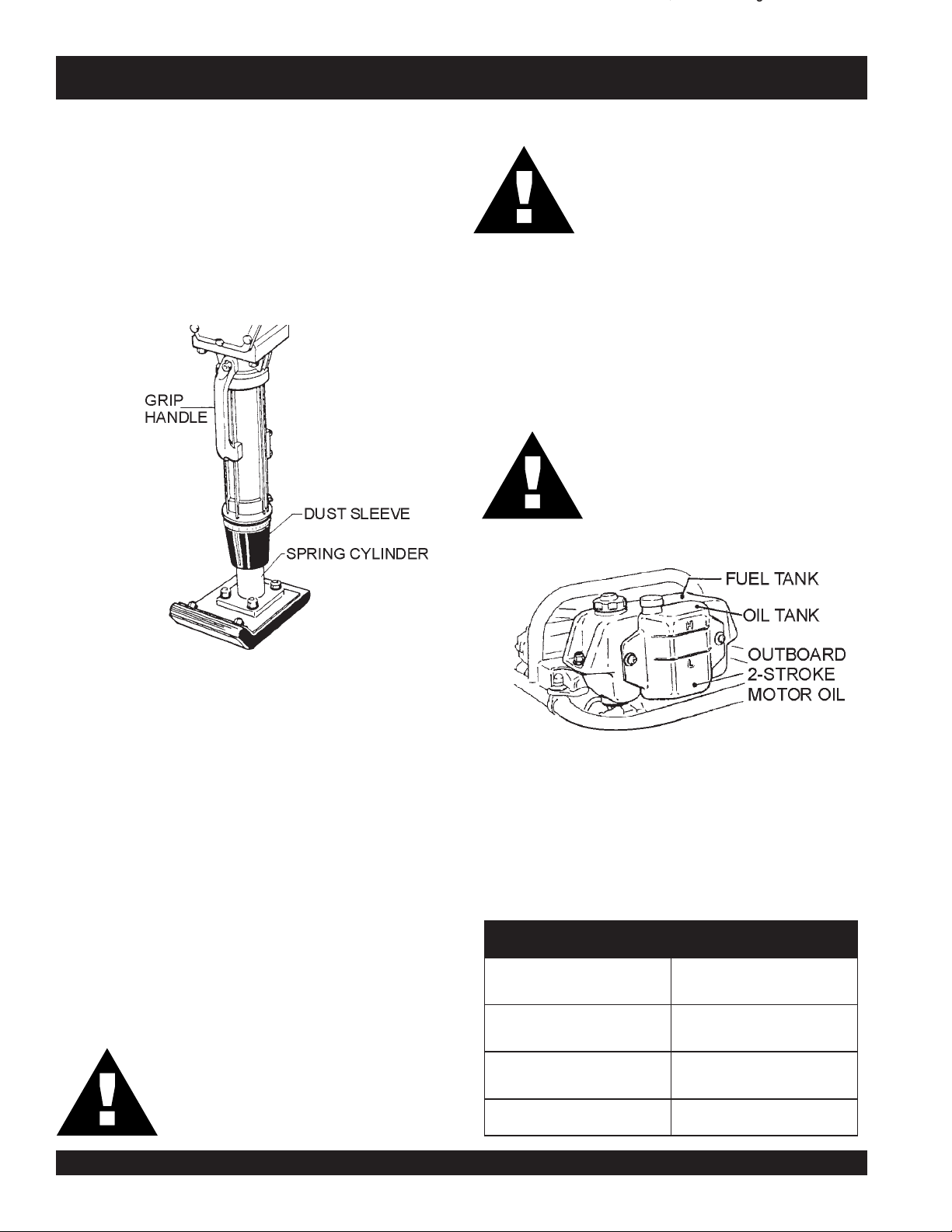

Figure 1. MTR-35HS Rammer

Figure 1 shows the location of the controls and components

for the MTR-35HS Tamping Rammer. The functions of each

control is described below:

8. Foot– Laminated wood with tempered steel plate for

superior shock absorption.

9. Recoil Starting Handle – Used when starting the engine.

Pull starter handle sharply and quickly, then return

1. Throttle Lever – Controls engine speed and the tamping

action of the rammer.

2. Engine Stop Switch – Controls the starting and stopping

of the engine. Switch must be in the "ON" position when

starting the engine.

3. Choke Lever – Used when starting the engine. Normally

used in cold weather conditions. In cold weather turn the

choke lever to the fully closed position, in warm weather

set choke lever half way or completely open.

4. Fuel Shut-Off Valve – Supplies fuel from the fuel tank to

the engine. To begin fuel flow move the fuel shut-off valve

downward.

L1. A Returned Material Authorization must be approved by Multiquip prior to shipment. A copy of the Authorization must

5. Grease Fill Plug – Open this plug to add oil to the oil bath

accompany the shipment to the designated Warehouse. A copy of the original Multiquip invoice to the customer must

reservoir.

also accompany the shipment.

6. Fuel Valve – Open this valve to remove excess fuel from

the carburetor or crankcase.

7. Pre- Cleaner – Pre-cleans (first stage) dirt and other

debris from entering the engine.

starter handle to starter case before releasing.

10. Fuel Tank/Cap – Poly fuel tank to avoid rust and

corrosion, remove this cap to add gasoline.

11. Engine Air Cleaner – Prevents dirt (second stage) and

other debris from entering the engine.

12. Handle – To operate rammer

GRIP

handle assembly

firmly on both sides.

13. Muffler– Used to reduce noise and emissions.

14. Spark Plug – Provides spark to the ignition system,

replace with engine manufactures recommended type

spark plug.

15. Nameplate – Displays information regarding the rammer.

16. Grip – When transporting the rammer, carry it by griping

the handle.

17. Oil Tank – Fill oil tank with 2-stroke outboard motor oil.

18. Dust Sleeve – Prevents dust and debris from entering

into the spring cylinder.

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 11

Page 12

it often.

MTR-35HS — OPERATION

This section is intended to assist the operator with the initial

start-up of the MTR-35HS Tamping Rammer. It is extremely

important that this section be read carefully before attempting to

operate the rammer.

DO NOT use your rammer until this section is thoroughly

understood.

Prior to starting the operation

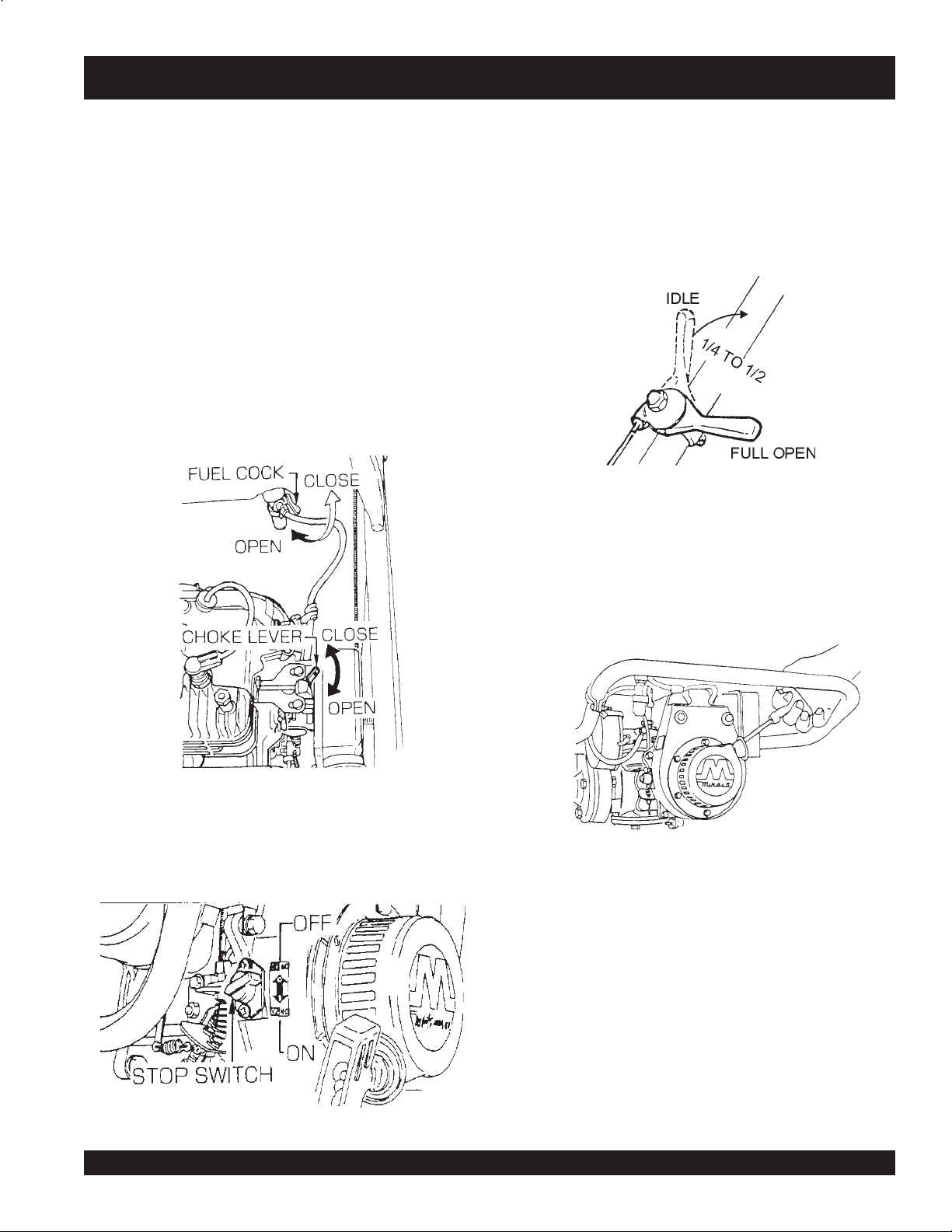

1. When transporting the machine, carry it by the grip handle

located on the body (Figure 2).

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Engine

1. Fill the fuel tank (Figure 3 ) with unleaded gasoline. At the

same time, check the engine oil level at the sight gauge

located on the operator's side of the oil tank. Fill the oil tank

to the "H" level using only outboard (2-stroke) oil. Replenish

the oil regularly before the oil level reaches the "L" level of the

oil tank.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Failure to understand the operation of the MTR35HS Tamping Rammer could result in severe

damage to the rammer or personal injury.

The oil hose is not to be depressed or

damaged. A sensor detects lack of oil and

shuts down the engine automatically.

Figure 2. Grip Handle

2. The rammer should be greased with three shots of grease

after each eight (8) hours of use.

3. Use MQ HIGH TEMPERATURE GREASE, (part #GS or its

equivalent

4. Equivalent greases include Shell Darina or Texaco

Thermatex, both of which have a bentone base and EP-2

rating.

5. If an inferior grease is used, it may become too thick or too thin

due to changes in temperature, and improper lubrication

could result.

6. The rammer is equipped with a two-cycled gasoline engine.

A regular grade gasoline should be used. High test ethyl

gasoline is not recommended. The oil should be good grade

of two- cycle or outboard motor oil.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

DO NOT USE REGULAR AUTOMOTIVETYPE MOTOR OIL.

2. Low levels of oil may result in engine seizure due to high

levels of consumption during operations.

3. Check the engine oil level and if the engine oil level is low, it

should be refilled. Use the proper motor oil as suggested in

the Table 3 below.

Figure 3. Fuel/Oil Tank

erutarepmeTronosaeS

nmutuAroremmuS,gnirpS

F°51+otF°021+

retniW

1+otF°04+

F°5

F°51+woleB03-W01EAS

edarGliOrotoM3elbaT

liorotomfoedarG

)ssalcSMnahtrehgih(

03EAS

03EAS

PAGE 12 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 13

Inspection

1. Check all nuts, bolts fasteners for tightness. Retighten as

necessary.

2. Clean any dirt from the recoil starter and foot pedestal. Wipe

the entire unit clean before operating.

3. Replace any missing or damaged Safety Operation decals.

4. Adjust height of handle. Adjust handle by loosening nuts and

moving handle to suit operation. Retighten nuts.

Initial Start-up

When starting the MTR-35HS Tamping Rammer perform the

following:

3. Close the choke lever (Figure 4) . Turning the choke lever

90 degrees clockwise closes the choke . In cold weather, start

the unit with choke fully closed. In warm weather or when the

engine is warm, the unit can be started with choke halfway

or completely open.

4. Move the throttle lever (Figure 6) between 1/4 to 1/2 from the

idle position.

MTR-35HS — OPERATION

1. Open the fuel shut- off valve by moving the

open

to the

Figure 4. Fuel Cock and Choke Lever

2. Set the engine ON/OFF switch (Figure 5) to the "ON"

posit ion (start).

position (Figure 4).

fuel cock

lever

Figure 6. Throttle Lever (1/4 to 1/2)

5. Grip the recoil starter (Figure 7) handle and pull it until you

feel a slight resistance. Then pull sharply and quickly. Return

the recoil starter handle to the starter position before releasing.

Figure 7. Recoil Starter

6. If engine fails to start, move the choke lever (Figure 4) to the

half open position to avoid flooding.

Figure 5. Engine On/Off Switch

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 13

7. Repeat steps 1 thru 5.

8. If the engine does not start after repeated attempts,

check the spark plug for excess fuel. Clean and replace

the spark plug as needed.

Page 14

MTR-35HS — OPERATION

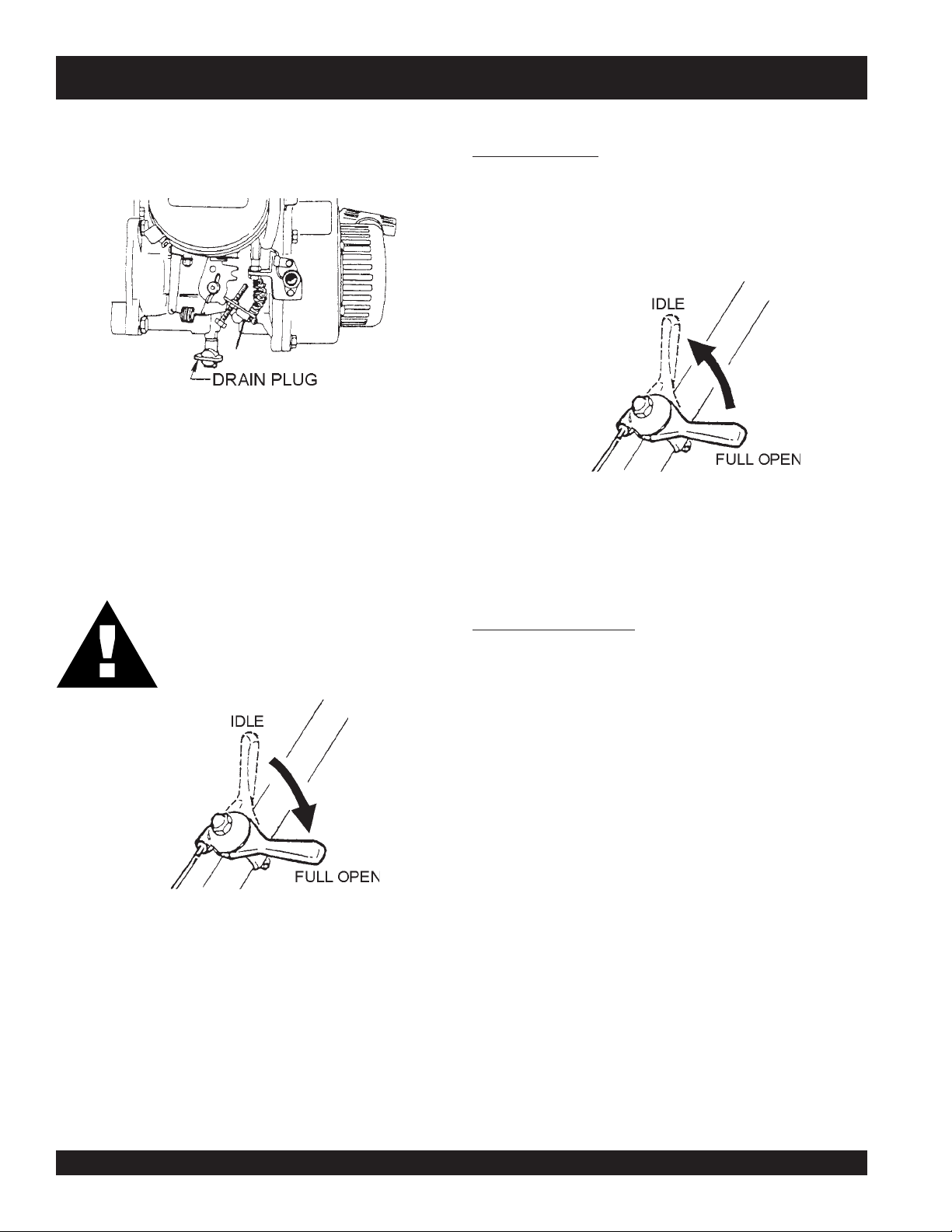

9. If the carburetor is flooded or the crankcase is loaded with

excess fuel, open the drain plug as shown in (Figure 8) and

drain out excess fuel.

Figure 8. Drain Plug

Operation

1. To start the rammer tamping action, move the throttle lever

(Figure 9) quickly from IDLE (close) to the FULL OPEN

position . DO NOT move the throttle lever slowly as this may

cause damage to the clutch or spring.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Stopping The Engine

Normal Shutdown

1. Move throttle lever quickly from the FULL OPEN to IDLE

position (Figure 10) and run the engine for three minutes at

low speed. After the engine

switch to the “OFF” position (Figure 5) until engine comes

to a complete stop.

2. Close the fuel shut- off valve by moving the fuel cock lever to

the CLOSED position. See Figure 4.

cools

, turn the engine

Figure 10. Throttle Lever (Idle)

start/stop

Make sure that the throttle lever is moved to the

FULL OPEN position. Operating the rammer at

less than full speeds can result in damage to

the clutch springs or foot

Figure 9. Throttle Lever (Full Open)

2. The MTR-35HS Tamping rammer is designed to run at 4,100

rpm. At optimum rpm the foot hits at the rate of 750 impacts

per minute. Increasing throttle speed past factory set rpm

does not increase impacts and may damage unit. The MTR35HS is designed to advance while tamping. For faster

advance, pull back slightly on the handle so that rear of foot

contacts soil first.

Emergency Showdown

1. Move the throttle lever quickly to the

the engine start/stop switch (Figure 5) to the

IDLE

position, and turn

STOP

position.

PAGE 14 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 15

■

Maintenance

Perform the scheduled maintenance procedures as indicated:

DAILY

■

Thoroughly remove dirt and oil from the engine and control

area. Clean or replace the air cleaner elements as necessary.

Check and retighten all fasteners as necessary. Check the

spring box and bellows for oil leaks. Repair or replace as

needed.

WEEKLY

■

Remove the fuel filter cap and clean the inside of the fuel

tank.

■

Remove or clean the filter at the bottom of the tank.

■

Remove and clean the spark plug, then adjust the spark gap

to 0.02~0.03 inch (0.6~0.7 mm). This unit has electronic

ignition, which requires no adjustments.

■

Clean air cleaner cover.

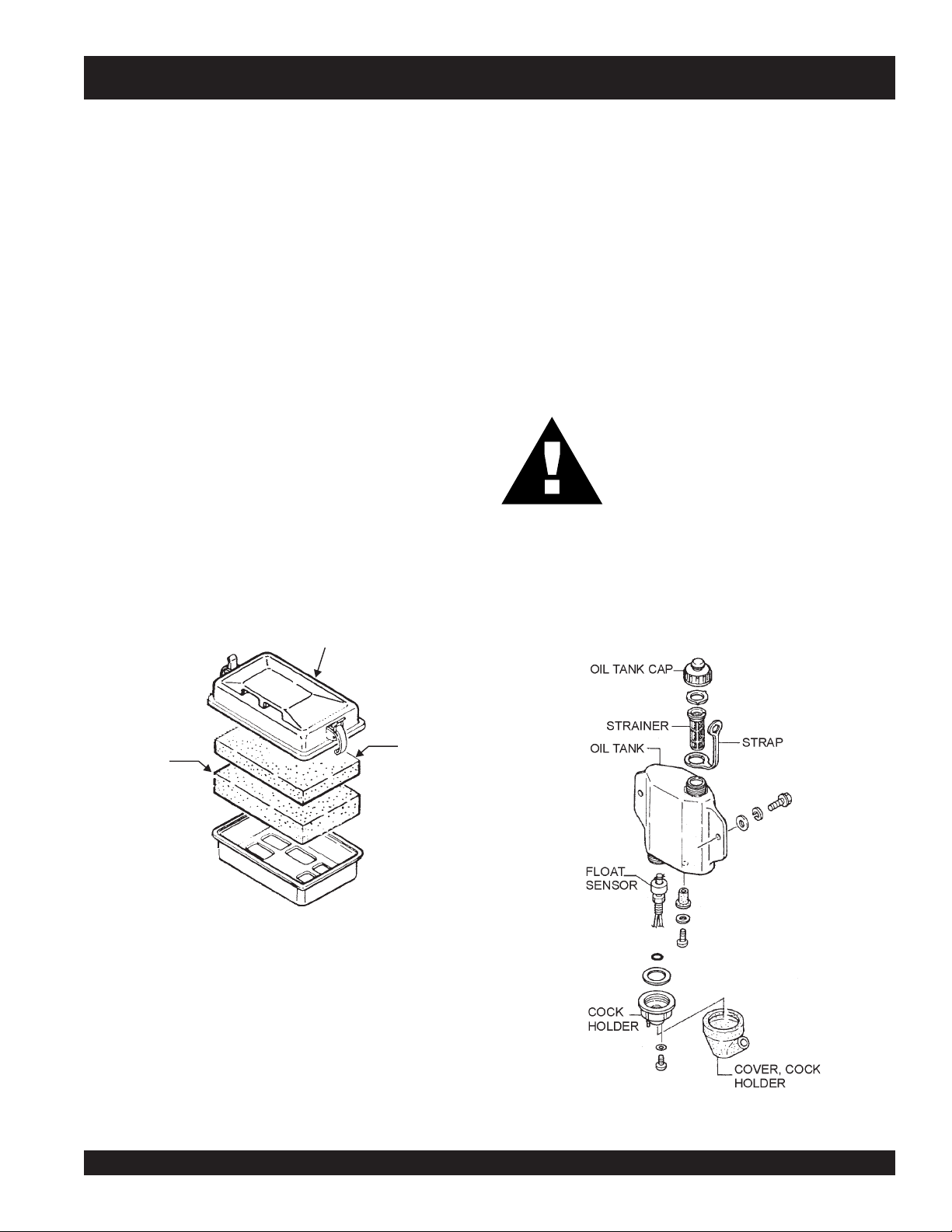

200 - 300 HOURS (Pre-Cleaner)

■

Remove the element from the pre-cleaner (Figure 11) at the

top of the crankcase (body side) and clean it with cleaning oil

(kerosene).

The air cleaner on the engine side will hardly be contaminated,

if it is, however after cleaning the element with kerosene, dip

it in mixed oil consisting of 3 parts of gasoline and 1 part of

engine oil. Then tightly squeeze outer primary element

(sponge) and shake off well the inner secondary element

before installing them.

CLEANING THE OIL TANK

■

Clean the inside of the oil tank regularly, preferably 2 or 3 times

a year.

■

In winter, be sure to clean the inside of oil tank to avoid the

freezing of water that may have accumulated inside the tank.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

■

When cleaning the oil tank (Figure 12) perform the following

procedure:

MTR-35HS — MAINTENANCE

If water accidently got inside the oil tank, the oil

may appear muddy. If this situation occurs,

simply flush the tank, removing all foreign matter

including water, and fill oil tank with fresh 2stroke outboard motor oil.

PRE-CLEANER

GRAY

13 -15 CC

SAE 30

Figure 11. Pre-Cleaner

■

Lubricate the top element (yellow) with 2~5 cc of engine oil

SAE-30.

■

Lubricate bottom element (gray) with 13 ~15 cc of engine oil

SAE-30 and completely squeeze out the excess oil from the

element before installing.

YELLOW

2-5 CC

SAE 30

1. Remove the cock holder cover, oil hose, red and black lead

wires from the float sensor.

Figure 12. Oil Tank

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 15

Page 16

MTR-35HS — MAINTENANCE

2. Remove the bolts that secure the oil tank to the fuel tank, and

drain all oil from the tank.

3. Remove cock holder, then clean strainer and cock holder in

a kerosene solution.

4. Make sure every part is clean and dry, then reassemble oil

tank. Fill oil tank with 2-stroke outboard motor oil (FB class)

to the "H" level.

FUEL AND OIL LINES

■

Check the fuel and oil lines regularly for damage and ensure

that there are no leaks.

■

Replace fuel and oil lines every 2 years to maintain

performance.

■

When replacing the oil hose perform the following procedure:

1. Replace oil hose with manufactures suggested type hose or

equivalent.

2. If necessary, fill oil tank with 2-stroke outboard motor oil.

3. Fill fuel tank with 25:1 fuel mix ratio.

4. Operate rammer with 25:1 fuel mixture until all air is bled from

oil injection line.

CLEANING THE RAMMER

■

If using a high pressure spray washer, be careful not to splash

water directly on the air cleaner, carburetor, muffler, fuel and

oil tank caps. Excessive amounts of water may cause severe

engine damage.

Yearly

■

Check the fuel line and the oil line regularly for damage and

to ensure that there are no leaks.

■

Replace the oil and fuel lines every two years to maintain the

performance and flexibility lines.

Long Term Storage

■

Drain fuel from fuel tank, fuel line and carburetor.

■

Remove spark plug and pour a few drops of motor oil into

cylinder. Crank engine 3 to 4 times so that oil reaches all

internal parts.

■

Clean exterior of rammer with an oil-moistened cloth.

■

Store unit covered with plastic sheet in moisture free and

dust free location out of direct sunlight

5. Once it is certain that all air has been purged from the oil

injection line, regular unleaded gasoline may be used.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

It is normal for a new 2-stroke engine to emit

excess smoke, until moving parts have been

seated to their normal operating specifications.

This excess smoke normally stops after one full

tank of fuel.

PAGE 16 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 17

MTR-35HS — TROUBLESHOOTING GUIDE

GNITOOHSELBUORTENIGNE.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

tratsottluciffiD

?egdirbgniebgulpnoitingI .metsysnoitingikcehC

.)elbacnoisnethgihta

rewoP(.etingitonlliw TON

noisserpmoc(setingi )lamron .

noisserpmoc(setingi wol .)

yrotcafsitastonnoitarepO

gulpkrapstubelbaliavasileuF

elbaliavarewoP(.etingitonlliw

?srotalusni

gulpkrapstubelbaliavasileuF

.)elbacnoisnethgihtaelbaliava

?stisoped

gulpkrapsdnaelbaliavasileuF

gulpkrapsdnaelbaliavasileuF

?etauqedani

?)tsud

?nrowrednilyC .rednilycecalpeR

?noitingitatisopednobraC .noitingiecalperronaelC

evitcefedoteudtiucrictrohS

?pagkrapsreporpmI .pagtcerrocehtotpaggulpkrapsteS

?hctiwspotstatiucrictrohS .evitcefedfihctiwspotsecalpeR.tiucrichctiwspotskcehC

?evitcefedliocnoitingI .liocnoitingiecalpeR

nobrachtiwdeggolcrelffuM

siytilauqleufdexiM

,retaw(etauqedaniesunileuF

?deggolcrenaelCriA .renaelcriaecalperronaelC

?teksagdaehrednilycevitcefeD .teksagdaehecalperrostlobdaehrednilycnethgiT

?esoolgulpkrapS .gulpkrapsnehgiT

.srotalusniecalpeR

.relffumecalperronaelC

.erutximliootleufkcehC

.leufhserfhtiwecalperdnametysleufhsulF

?deggolcrenaelcriA

elbaliavarewophguonetoN

-ssimon,lamronnoisserpmoc(

.)gnirif

elbaliavarewophguonetoN

-ssim,lamronnoisserpmoc(

.)gnirif

?)tsud

.staehrevoenignE

?enilleufniriA .enilleufmorf)riaevomer(deelB

?reporpmirebmahc

siytilauqleufdexiM

?etauqedani

.nobrac

taolfrotaerubracnilevelleuF

?rednilycnistisopednobraC rednilycecalperronaelC

?evitcefedliocnoitingI .leufhserfhtiwecalperdnametysleufhsulF

?strohsnetfogulpnoitingI .noitinginaelc,seriwnoitingiecalpeR

,retaw(etauqedaniesunileuF

ninoitsopednobracevissecxE

?rebmahcnoitsubmoc

htiwdeggolcrelffumrotsuahxE

?tcerrocnieulavtaehgulpkrapS .gulpkrapsepyttcerrochtiwgulpkrapsecalpeR

taolfrotaerubractsujdA

.leufhserfhtiwecalperdnametysleufhsulF

.erutximliootleufkcehC

.esacknarcecalperronaelC

.relffumecalperronaelC

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 17

Page 18

MTR-35HS — TROUBLESHOOTING GUIDE

ENGINEENGINE

ENGINE

ENGINEENGINE

MOTPMYS MELBORPELBISSOP NOITULOS

yrotcafsitastonnoitarepO

?reporpmitnemtsujdaronrevoG .reveltcerrocotronrevogtsujdA

?evitcefedgnirpsronrevoG .noitingiecalperronaelC

.setautculfdeepslanoitatoR

?enil

gnikrowtonretratslioceR

.ylreporp

?citarrewolfleuF .enilleufkcehC

noitcushguorhtninekatriA

?trapgnitatornitsuD .ylbmessaretratsliocernaelC

?eruliafgnirpsgnirpS .gnirpslairpsecalpeR

)deunitnoc(GNITOOHSELBUORTENIGNE.4ELBAT

.enilnoitcuskcehC

GNITOOHSELBUORTREMMAR.5ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?tesyltcerrocnisi

?ssecxeniliO .leveltcerrocotgnirB.liossecxeniarD

ediutilpmatubsetatorenignE

.ekirtstonseodromrofinuton

?spilshctulC .hctulctsujdaroecalpeR

?eruliaFgnirpS .gnirpslairpsecalpeR

revelelttorhtfodeepsgnitarepO

?reporpmienignefodeepS .gnittesMPRgnitarepotcerrocotdeepsenignetsujdA

.noitisoptcerrocotrevelelttorhtteS

PAGE 18 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 19

NOTE PAGE

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 19

Page 20

EXPLANATION OF CODE IN REMARKS COLUMN

How to read the marks and remarks used in this parts

book.

Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Items Found In the “Items Number” Column

All parts with same symbol in the number column,

■

, belong to the same assembly or kit

If more than one of the same reference number is

listed, the last one listed indicates newest (or latest)

part available.

, #, +, %, or

*

NOTE

NOTE

The contents of this catalog are

subject to change without notice

PAGE 20 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

.

Page 21

MTR-35HS — SUGGESTED SPARE PARTS

MTR-35HS RAMMER 1 TO 3 UNITS

Qty. P/N Description

1 ............ 956225020 ............ LEVER, THROTTLE

3 ............ 354030030 ............ ELEMENT, YELLOW

3 ............ 354030040 ............ ELEMENT, GRAY

1 ............ 361910020 ............ CAP, FUEL TANK

1 ............ 954406000 ............ COCK, FUEL

1 ............ 954404890 ............ STRAINER, FUEL TOP/BOTTOM

2 ............ 301419750 ............ FILTER, IN-LINE FUEL

3 ............ 1573620101 .......... ELEMENT, SET ENGINE

3 ............ 0650140031 .......... SPARK PLUG

1 ............ 0660000361 .......... SWITCH,STOP(

1 ............ 301010900 ............ THROTTLE ,WIRE

1 ............ 402010110 ............ SPRING, THROTTLE RETURN

ABOVE C-4154-4178)

MTR-35HS RAMMER 3 TO 5 UNITS

1 ............ 956225020 ............ LEVER, THROTTLE

1 ............ 301010900 ............ THROTTLE WIRE

1 ............ 402010110 ............ SPRING, THROTTLE RETURN

4 ............ 354030030 ............ ELEMENT, YELLOW

4 ............ 354030040 ............ ELEMENT, GRAY

1 ............ 361910020 ............ CAP, FUEL TANK

1 ............ 954406000 ............ COCK, FUEL

2 ............ 954404890 ............ STRAINER, FUEL TOP/BOTTOM

4 ............ 301419750 ............ FILTER, IN-LINE FUEL

4 ............ 1573620101 .......... ELEMENT SET ENGINE

6 ............ 0650140031 .......... SPARK PLUG

1 ............ KITCARBEC08H ... CARBURETOR KIT

2 ............ 0660000361 .......... SWITCH, STOP (ABOVE C-4154-4178)

NOTE

MTR-35HS RAMMER 5 TO 10 UNITS

2 ............ 956225020 ............ LEVER, THROTTLE

2 ............ 301010900 ............ THROTTLE WIRE

2 ............ 402010110 ............ SPRING, THROTTLE RETURN

6 ............ 354030030 ............ ELEMENT, YELLOW

6 ............ 354030040 ............ ELEMENT, GRAY

2 ............ 361910020 ............ CAP, FUEL TANK

2 ............ 954406000 ............ COCK, FUEL

4 ............ 954404890 ............ STRAINER, FUEL TOP/BOTTOM

6 ............ 301419750 ............ FILTER, IN-LINE FUEL

3 ............ 1573620101 .......... ELEMENT SET ENGINE

10 .......... 0650140031 .......... SPARK PLUG

3 ............ 0660000361 .......... SWITCH, STOP (ABOVE C-4154 & C-4207)

3 ............ 1293500403 .......... GASKET, COMPLETE EXHAUST

3 ............ 2263272008 .......... GASKET, AIR CLEANER

4 ............ 1063500103 .......... GASKET, INSULATOR, CARBURETOR

3 ............ KITCARBEC08H ... CARBURETOR KIT

1 ............ 5806111000 .......... CARBURETOR ASSEMBLY

2 ............ 050100800 ............ O-RING, UPPER GUIDE CYLINDER

MTR-35HS RAMMER 10+ UNITS

6 ............ 956225020 ............ LEVER, THROTTLE

6 ............ 301010900 ............ THROTTLE WIRE

6 ............ 402010110 ............ SPRING, THROTTLE RETURN

16 .......... 354030030 ............ ELEMENT, YELLOW

16 .......... 354030040 ............ ELEMENT, GRAY

10 .......... 361910020 ............ CLAMP, BELLOWS

4 ............ 954406000 ............ COCK, FUEL

6 ............ 954404890 ............ STRAINER, FUEL TOP/BOTTOM

12 .......... 301419750 ............ FILTER, IN-LINE FUEL

16 .......... 1573620101 .......... ELEMENT SET ENGINE

16 .......... 0650140031 .......... SPARK PLUG

4 ............ 0660000361 .......... SWITCH, STOP (ABOVE C-4154-4178)

3 ............ 1293500403 .......... GASKET, COMPLETE EXHAUST

3 ............ 2263272008 .......... GASKET, AIR CLEANER

4 ............ 1063500103 .......... GASKET, INSULATOR, CARBURETOR

1 ............ 301421363 ............ CLUTCH ASSY

1 ............ 1063273110 .......... AIR CLEANER ASSEMBLY

5 ............ KITCARBEC08H ... CARBURETOR KIT

1 ............ 5806111000 .......... CARBURETOR ASSEMBLY

1 ............ 5805001000 .......... RECOIL STARTER ASSEMBLY

4 ............ 050100800 ............ O-RING, UPPER GUIDE CYLINDER

Part number on this Suggested

Spare Parts List may super cede/

replace the P/N shown in the text

pages of this book.

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 21

Page 22

NAMEPLATE AND DECALS

MTR-35HS — NAMEPLATE AND DECALS

PAGE 22 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 23

MTR-35HS — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

NO PART NO PART NAME QTY. REMARKS

1

*

2

*

3

*

4

*

5

*

6 PLATE, SERIAL NO. ........................... 1 ..... CONTACT MQ SERVICE DEPT. W/MODEL & S/N

7

*

8

*

9

*

10 DCLMTR-35HS KIT, DECAL .......................................... 1 ..... INCLUDES ITEMS W/

FOR DECAL ILLUSTRATIONS SEE PAGE 8.

920205990 DECAL, CAUTION (WATER) 1

920106460 DECAL, MIKASA MARK (ORANGE) 1

920203980 DECAL, ELEMENT SET ...................... 1 ..... REPLACES 920106450

920107660 DECAL, ENGINE RPM 1

920101200 DECAL, GREASE 3

920107000 DECAL, PRE-CLEANER 1

920205810 DECAL, CAUTION/OIL INJECT 1

920203330 DECAL, EAR PROTECTION 1

*

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 23

Page 24

CRANKCASE AND ENGINE ASSY.

MTR-35HS — CRANKCASE AND ENGINE ASSY.

PAGE 24 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 25

MTR-35HS — CRANKCASE AND ENGINE ASSY.

CRANKCASE & ENGINE ASSY.

NO PART NO PART NAME QTY. REMARKS

CLUTCH GUIDE / A 1

1 305112711 CRANKCASE ....................................... 1 ............REPLACES 305112710

45 0053204201 WOODRUFF KEY 1

2 041006305 BEARING 6305Z 1

3 041006203 BEARING 6203Z 1

46 301010210 LOCK WASHER CLUTCH 1

4 952401450 WASHER 8.25X22X3 1

47 956300130 THROTTLE LEVER AY 25 1

5 011208025 BOLT 8X25 T ........................................ 1 ............ REPLACES 001220825

6 030208200 SW M8 1

7 050100350 O-RING G-35 1

8 305333090 CONNECTING ROD 1

9 042006304 BEARING 6304ZZ 1

10 080100520 STOP RING R-52 1

11 952400130 WASHER 9304 1

12 011208025 BOLT 8X25 T ........................................ 1 ............ REPLACES 001220825

13 030208200 SW M8 1

14 351010050 GREASE FITTING A-MT6X1 2

21 303010084 PINION 1

22 042006007 BEARING 6007ZZ 2

23 080200350 STOP RING S-35 1

24 351437750 SPACER 35.4-42.7-11 1

25 351421900 SPACER, CLUTCH DRUM 1

26 060504010 OIL SEAL VB-40525 1

27 050300900 O-RING S-90 1

28 351434563 BEARING COVER 1

29 002210620 BOLT 6X20 H,SW ................................2 ............ REPLACES 002210620

32 301421365 CLUTCH ASSY. C812E ........................ 1 ............INCLS. ITEMS W/

32-1

32-2

32-3

32-4

32-5

33 301010210 LOCK WASHER, CLUTCH 1

34 305333100 CRANK GEAR 1

35 305214430 FRONT COVER (MQ) 1

36 351319880 PACKING, FRONT COVER 1

37 002210620 BOLT 6X20 H,SW ................................9 ............ REPLACES 002210620

41 911100842 ENGINE ASSY ECO85HS(EPA) 1

42 0053204201 WOODRUFF KEY 1

43 956225020 THROTTLE LEVER ASSY. 25D 1

44 301010900 THROTTLE WIRE S335-445 1

45 959401750 WIRE STOPPER ASSY 1

47 402010110 COIL SPRING ...................................... 1 ............REPLACES 0830000010

48 959403750 RUBBER,SLIP STOP 1

49 011708030 BOLT 8ZX30 H,SW .............................. 4 ............ REPLACES 002210830

50 0173120010 LOCK NUT 1

60 353332810 CLEANER STAY 1

61 354211841 AIR CLEANER ASSY ........................... 1 ............ INCLUDES ITEMS W/#

62 002210815 BOLT 8X15 H,SW 4

63 354330590 INTAKE PIPE 1

64 507010110 CLAMP TC-200 1

65# 354030011 BODY, W-CLEANER 1

66# 354030020 BACK PLATE 1

67# 354030030 ELEMENT, YELLOW 1

68# 354030040 ELEMENT, GRAY 1

69# 354030050 ELEMENT, FRAME 1

943020020 CLUTCH SHOE C812 4

*

943050050 CLUTCH BOSS C812 1

*

943060010 CLUTCH GUIDE/A 1T 1

*

943060020 CLUTCH GUIDE/B 1

*

943030020 CLUTCH SPRING C812 2

*

REPLACES 301421363

*

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 25

Page 26

GUIDE CYLINDER AND FOOT ASSY.

MTR-35HS — GUIDE CYLINDER AND FOOT ASSY.

PAGE 26 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 27

MTR-35HS — GUIDE CYLINDER AND FOOT ASSY.

GUIDE CYLINDER & FOOT ASSY.

NO PART NO PART NAME QTY. REMARKS

A 305910010 FOOT ASSY. 150B ............................... 1 ............ INCL'S TEMS W/* 6" (WIDTH) X 11" (LENGTH)

1 305446380 PISTON PIN 1

2 080100120 STOP RING R-12 2

3 305333110 PISTON ROD (M12) 1

3 305337980 PISTON ROD (M14) 1

4 305446390 PISTON END (M12) 1

4 305451550 PISTON END (M14) 1

5 022910140 NUT M12-P1.5 (B=17) 1

6 305446400 STOPPER, UPPER 1

7 305446410 CYLINDER CAP 1

8 305446420 MAIN SPRING 2

9 305212710 SPRING CYLINDER 1

11 305112730 GUIDE CYLINDER 1

12 065105010 DUST SEAL DKI-5367811 1

13 080510680 STOP RING TH-R-68 1

14 351010050 GREASE FITTING A-MT6X1 2

15 305446430 STOPPER 1

16 002210815 BOLT 8X15 H,SW 4

17 050300320 O-RING S-32 1

18 305446440 GRIP 1

19 096208010 SOCKET HEAD BOLT 8X15 T ............2 ............ REPLACES 001520815

20 305446450 DUST SLEEVE 1

21 305446460 SLEEVE BAND 1

22 001200830 BOLT 8X30 1

23 020308060 NUT M8 1

25 050100800 O-RING G-80 1

26 002211025 BOLT 10X25 H,SW 4

31

32

33

34

35

36

37 015112060 SUB K HEAD BOLT 12X60 H .............. 4 ............ REPLACES 001611252

38 021112140 NYLON NUT M12 ................................4 ............ REPLACES 022711214

39 030212300 SW M12 4

305910010 FOOT 150B ......................................... 1 ............REPLACES 305333120

*

305333130 METAL SHEET 150B 1

*

305446470 FOOT COVER 1

*

001611050 SUNK HEAD BOLT 10X50 H 2

*

022711012 NYLON NUT M10 2

*

030210250 SW M10 2

*

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 27

Page 28

TANK & HANDLE ASSY.

MTR-35HS — TANK AND HANDLE ASSY.

PAGE 28 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 29

MTR-35HS — TANK AND HANDLE ASSY.

TANK & HANDLE ASSY.

NO PART NO PART NAME QTY. REMARKS

A 353213710CPL OIL TANK ASSY. W/CAP ...................... 1 ................ REPLACES 353910030

1 305115250 HANDLE 1

2 351319900 SHOCK ABSORBER 2

3 001521020 SOCKET HEAD BOLT 10X20T 4

4 033121009 TOOTHED LOCK WASHER B M10 4

5 002211020 BOLT 10X20 H,SW 4

11 355113610 FUEL TANK 1

12 954404890 FILTER, TANK /MR 1

13 361910020 TANK CAP ASSY, ORANGE 1

14 351437785 HOLDER, COCK 1

15 954406020 PACKING, FUEL TANK 1

16 954406010 STRAINER (110) 1

17 001220830 BOLT 8X30 T 2

18 952401450 WASHER 8.5X22X3 2

19 030208200 SW M8 2

20 022710809 NYLON NUT M8 2

21 954406000 FUEL COCK ASSY. N18L-02 1

22 351435160 FUEL HOSE B-95 1

23 954404590 HOSE BAND 9.5D 2

24 351436350 FUEL HOSE 150 1

25 954403030 HOSE BAND (8) 2

30 301419750 FUEL FILTER CP, NQ75MIC 1

31-1 353213710 OIL TANK 1

32-1 353030070 OIL TANK CAP CP, YELLOW HS 1

36-1 355448071 COVER, COCK HOLDER 1

37 009110011 SOCKET HEAD SCREW 8X20 2

38 030208200 SW M8 2

39 952401450 WASHER 8.5X22X3 2

40 001200610 BOLT 6X10 1

41 030206150 SW M6 1

42 2267510103 CLAMP 1

45 353448490 WIRE CP 1

47 5806113020 OIL HOSE L=750 1

53 353449350 PACKING, OIL TANK CAP/HS 1

54 353449001 STRAINER, OIL TANK 1

55 353449010 STRAP, OIL TANK 2

58 353030080 WELL NUT M5 1

59 091005015 SCREW 5X15 1

60 952405970 WASHER 6.4D-20D 1

62-1 353450220 GUARD, OIL HOSE 1

65 1616391608 CLIP 1

66 5806113040 PROTECTOR 1

67 353910020 OIL SENSOR ASSY. 1

68 355450600 OUTER LINER 525L 1

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 29

Page 30

MTR-35HS — NARROW FOOT AND TRENCH SHOE ASSY. (OPTION)

NARROW FOOT AND TRENCH SHOE ASSY.

PAGE 30 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 31

MTR-35HS — NARROW FOOT AND TRENCH SHOE ASSY. (OPTION)

NARROW FOOT AND TRENCH SHOE ASSY.

NO PART NO PART NAME QTY. REMARKS

A 305910020 FOOT ASSY. 200B 1

A 305910040 FOOT ASSY. 100B 1

1 305333140 FOOT 200B 1

1 305334930 FOOT 100B 1

2 305333150 METAL SHEET 200B 1

2 305334940 METAL SHEET 100B 1

3 305446470 FOOT COVER 1

3 305447810 FOOT COVER 1

4 001611050 SUNK HEAD BOLT 10X50 H 2

5 022711012 NYLON NUT M10 2

6 030210250 SW M10 2

7 001611252 SUNK HEAD BOLT 12X60 H 4

8 022711214 NYLON NUT M12 4

9 030212300 SW M12 4

11 305333160 TRENCH SHOE 500H-120B/MTR 1

11 305333170 TRENCH SHOE 800H-120B/MTR 1

11 305334390 TRENCH SHOE 305H-100B/MTR 1

12 001221235 BOLT 12X35 T 4

13 020312100 NUT M12 4

14 030212300 SW M12 4

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 31

Page 32

ROBIN EC-08HS ENGINE — CRANKCASE AND CYLINDER ASSY.

CRANKCASE AND CYLINDER ASSY.

PAGE 32 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 33

ROBIN EC-08HS ENGINE — CRANKCASE AND CYLINDER ASSY.

CRANKCASE AND CYLINDER ASSY.

NO PART NO PART NAME QTY. REMARKS

10 5801056000 CRANK CASE CP ................................ 1 ............INCLUDES ITEMS W/

30

35

36

40

41

50

95 0011406450 BOLT ASSY 4

105

115

140 0643109980 DRAIN COCK 1

145 5809011000 PROTECTOR COMP. 1

146 0011308180 BOLT AND WASHER ASSY 3

170 5801501800 GASKET,CYLINDER 1

180 0021706000 NUT ...................................................... 4 ............ REPLACES 0021806000

190 030206150 SPRING WASHER ............................... 4 ............ REPLACES 0032006000

200 0031006000 WASHER 4

510 5801501400 CYLINDER CP 1

850 1507520103 CLAMP ................................................. 1 ............ REPLACES 0566099950

0440200020 OIL SEAL 1

*

0440200020 OIL SEAL 1

*

0440060010 OIL SEAL 1

*

0600200010 BALL BEARING 6004C3 1

*

0600200020 BALL BEARING 6204C3 1

*

0052606140 DOWEL PIN 2

*

0105060050 STUD 1

*

0105064940 STUD 4

*

*

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 33

Page 34

ROBIN EC-08HS ENGINE — CRANKSHAFT AND PISTON ASSY.

CRANKSHAFT AND PISTON ASSY.

PAGE 34 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 35

ROBIN EC-08HS ENGINE — CRANKSHAFT AND PISTON ASSY.

CRANKSHAFT AND PISTON ASSY.

NO PART NO PART NAME QTY. REMARKS

10 5802028000 CRANK SHAFT 1

30 0323049950 WOODRUFF KEY 1

40 1292500103 SPACER 2

50 0039310000 NUT ...................................................... 1 ............ REPLACES 0021810000

60 030210250 SPRING WASHER ............................... 1 ............ REPLACES 0032010000

65 030206150 WASHER .............................................. 1 ............ REPLACES 0031010000

70 0053204201 WOODRUFF KEY 1 REPLACES 0323049950

130 5804010000 PLATE, GOVERNOR 1

131 0131050020 SCREW (PAN HEAD) .......................... 3 ............ REPLACES 0043105080

132 0032005000 SPRING WASHER 3

140 5514500100 GOVERNOR SLEEVE 1

160 0230230020 SPACER 1

170 0173120010 LOCK NUT 1

350 5802500700 PISTON PIN ......................................... 1 ............ REPLACES 5802500400

360 5802500600 PISTON 1

370 5802023000 PISTON RING SET .............................. 1 ............ REPLACES 5000008100

380 0565119990 CLIP 2

390 0610120010 NEEDLE BEARING 1

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 35

Page 36

GOVERNOR ASSY.

PAGE 36 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 37

ROBIN EC-08HS ENGINE — GOVERNOR ASSY.

GOVERNOR ASSY.

NO PART NO PART NAME QTY. REMARKS

10 5804005000 GOVERNOR LEVER 1

15 5804500900 BUSH 2

16 2266255008 BUSH, NYLON ..................................... 1 ............REPLACES 5806083060

20 1294220103 GOVERNOR SHAFT 1

30 1054270111 GOVERNOR ROD 1

40 1064280113 ROD SPRING ...................................... 1 ............REPLACES 1064280111

80 1294250111 GOVERNOR SPRING 1

90 1294210113 GOVERNOR YOKE 1

100 0140039980 SCREW ASSY 2

120 57028 NUT ......................................................1 ............REPLACES 0021706000

130 030206150 SPRING WASHER ............................... 1 ............ REPLACES 0032006000

305 0217060020 FRICTION WASHER 1

310 5804500800 CONTROL LEVER 1

340 5804500600 STOP PLATE 1

341 0230060090 SPACER 1

342 0105050616 BOLT ....................................................1 ............ REPLACES 6202500400

350 0200070010 WASHER 1

360 0016506400 BOLT 1

370 57028 NUT ......................................................1 ............REPLACES 0021706000

380 0170069960 U NUT 1

400 1294500103 CLIP 1

480 402010110 COIL SPRING ...................................... 1 ............REPLACES 0830000010

610 0149060040 ADJUSTING SCREW .......................... 1 ............REPLACES 0149069981

620 020106050 NUT ......................................................1 ............REPLACES 0022706000

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 37

Page 38

MUFFLER ASSY.

ROBIN EC-08HS ENGINE — MUFFLER ASSY.

PAGE 38 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 39

ROBIN EC-08HS ENGINE — MUFFLER ASSY.

MUFFLER ASSY.

NO PART NO PART NAME QTY. REMARKS

310 5803032000 MUFFLER 1

330 5803033000 MUFFLER BRACKET A 1

331 5803034000 MUFFLER BRACKET B 1

340 1293500403 GASKET (MUFFLER) 1

350 0170069960 U NUT 2

355 030206150 SPRING WASHER ............................... 6 ............ REPLACES 0032006000

356 0031006000 WASHER 4

361 0016706160 BOLT (MUFFLER) 4

362 0031006000 WASHER 2

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 39

Page 40

ROBIN EC-08HS ENGINE — CARBURETOR AND OIL PUMP ASSY.

CARBURETOR AND OIL PUMP ASSY.

PAGE 40 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 41

ROBIN EC-08HS ENGINE — CARBURETOR AND OIL PUMP ASSY.

CARBURETOR AND OIL PUMP ASSY.

NO PART NO PART NAME QTY. REMARKS

210 5806111000 CARBURETOR ASSY .........................1 ............ SEE CARBURETOR FIG. FOR COMPONENTS

250 1616235308 HOSE 1

700 5806113000 OIL PUMP ASSY 1

705 5806502300 WORM GEAR 1

706 0323039980 WOODRUFF KEY 1

710 0011306250 BOLT AND WASHER ASSY 2

716 0031520000 SNAP RING, OUTER 2

720 1616350101 COLLAR CP (OIL INJ.) 1

730 5806501900 OIL PUMP HOUSING 1

731 0119089970 SOCKET HEAD BOLT 4

732 030208200 SPRING WASHER ............................... 4 ............ REPLACES 0032008000

733 0031008000 WASHER 4

740 5806502000 GROMMET 1

745 5806502100 SEAL 1

750 5806502200 PLATE 1

760 0566059980 CLAMP 1

765 0119059610 SOCKET HEAD BOLT 1

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 41

Page 42

ROBIN EC-08HS ENGINE — RECOIL STARTER AND BLOWER ASSY.

RECOIL STARTER AND BLOWER ASSY.

PAGE 42 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 43

ROBIN EC-08HS ENGINE — RECOIL STARTER AND BLOWER ASSY.

RECOIL STARTER AND BLOWER ASSY.

NO PART NO PART NAME QTY. REMARKS

10 5805501200 FAN COVER 1

15 5515500200 GUIDE RUBBER 1

20 920100240 DECAL, (M-MARK) 1

25 5809500701 LABEL, MODEL 1

40 0011106200 BOLT ASSY 4

50 5805022000 CYLINDER COVER CP 1

51 011206020 BOLT (CYLINDER) .............................. 2 ............ REPLACES 0016706200

52 0031206000 WASHER 2

53 030206150 SPRING WASHER ............................... 2 ............ REPLACES 0032006000

210 5805001000 RECOIL STARTER ASSY ....................1 ............ SEE RECOIL STARTER FIG. FOR COMPONENTS’

REPLACES 5805011001

220 0011006100 BOLT AND WASHER ASSY 3

230 0011006140 BOLT ASSY 2

850 0566000250 CLAMP 2

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 43

Page 44

AIR CLEANER ASSY.

ROBIN EC-08HS ENGINE — AIR CLEANER ASSY.

PAGE 44 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 45

ROBIN EC-08HS ENGINE — AIR CLEANER ASSY.

AIR CLEANER ASSY.

NO PART NO PART NAME QTY. REMARKS

510 1063273110 AIR CLEANER ASSY ........................... 1 ............ INCLUDES ITEMS W/

520*1573620101 ELEMENT SET .................................... 1 ............REPLACES 1573260007

521

522

526 0736439980 LABEL 1

540 1293290103 INSULATOR 1

550 1063500103 GASKET (INSULATOR) 2

560 2363590303 GASKET 2 (INSULATOR) 1

580 0011306800 BOLT 2

600 030206150 SPRING WASHER ............................... 2 ............ REPLACES 0032006000

1613261008 ELEMENT 1

*

2263272008 GASKET (AIR CLEANER) 1

*

*

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 45

Page 46

ROBIN EC-08HS ENGINE — CARBURETOR COMPONENTS ASSY.

CARBURETOR COMPONENTS ASSY.

PAGE 46 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 47

ROBIN EC-08HS ENGINE — CARBURETOR COMPONENTS ASSY.

CARBURETOR COMPONENTS ASSY.

NO PART NO PART NAME QTY. REMARKS

A 5806111000 CARBURETOR ASSY ............................ 1 ................ INCLUDES ITEMS W/

1

*

2

*

3

*

4

*

5

*

6

*

7

*

8

*

9

*

11

12

13

14

15

16

17

18

19

20

22

28

40

41

60

62

63

82

104

106

107

108

# KITCARBEC08H KIT, CARBURETOR EC08HS ................ 1 ................ INCLUDES ITEMS W/#

1616253508 THROTTLE VALVE ................................ 1 ................ REPLACES 5806083110

5806111010 SCREW AND WASHER ASSY 2

5806083310 CHOKE VALVE 1

5806111010 SCREW AND WASHER ASSY 2

# 2076242008 PILOT JET .............................................. 1 ................ REPLACES 5606003020

# 2136239008 PILOT SCREW ....................................... 1 ................ REPLACES 5416002150

# 2096244508 SPRING .................................................. 1 ................ REPLACES 8046001230

5806083040 CHOKE LEVER 1

5806083050 RING 1

5806083030 THROTTLE SHAFT ASSY 1

*

# 5806083020 BOLT 1

*

5806083360 RING 1

*

# 1616235208 NEEDLE 1 REPLACES 5806083400

*

# 2146251508 PIN .......................................................... 1 ................ REPLACES 5416002050

*

161235008 FLOAT BODY ASSY ............................... 1 ................ REPLACES 5806083010

*

# 2366245008 PACKING ................................................ 1 ................ REPLACES 5806083330

*

# 2366254008 PACKING ................................................ 1 ................ REPLACES 5806083340

*

# 5806083350 FLOAT 1

*

5806083260 MAIN NOZZLE 1

*

# 1296240008 MAIN JET 1 REPLACES 5306011010

*

5806083150 SCREW 1

*

# 2366235008 SCREW 1 REPLACES 5416002230

*

# 2096244508 SPRING .................................................. 1 ................ REPLACES 8046001230

*

5806083230 PACKING ................................................ 1 ................ REPLACES 5806083230

*

5806083210 SEAL 1

*

5806083230 SCREW .................................................. 1 ................ REPLACES 5806083230

*

# 2366244508 SPRING .................................................. 1 ................ REPLACES 5806083240

*

2366254108 PACKING ................................................ 1 ................ REPLACES 5806083320

*

5806083140 SPRING 1

*

5806083120 RING 1

*

5806083370 FLOAT STOPPER 1

*

*

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 47

Page 48

ROBIN EC-08HS ENGINE — RECOIL STARTER COMPONENTS ASSY.

RECOIL STARTER COMPONENTS ASSY.

PAGE 48 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 49

ROBIN EC-08HS ENGINE — RECOIL STARTER COMPONENTS ASSY.

RECOIL STARTER COMPONENTS ASSY.

NO PART NO PART NAME QTY. REMARKS

A 5805001000 RECOIL STARTER ASSY. ................... 1 ............ INCLUDES ITEMS W/

1

2

3

4

5

6

7

11

13

35

49

*

*

*

*

*

*

*

5805004020 SPIRAL SPRING 1

5805004030 REEL 1

5805011040 STARTER ROPE 1

5805001030 STARTER HANDLE 1

5805004040 RATCHET 1

5805004110 FRICTION SPRING 1

5805004050 RETURN SPRING 1

5805004140 STARTER PULLEY .............................. 1 ............ REPLACES EC08A050311

*

5515005160 ROPE STOPPER 1

*

5805004120 FRICTION PLATE ................................ 1 ............ REPLACES EC08A05038

*

5805011020 CENTER SCREW 1

*

*

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 49

Page 50

MAGNETO ASSY.

ROBIN EC-08HS ENGINE — MAGNETO ASSY.

PAGE 50 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 51

ROBIN EC-08HS ENGINE — MAGNETO ASSY.

MAGNETO ASSY.

NO. PART NO. PART NAME QTY. REMARKS

10 5807005010 FLYWHEEL 1

11 5807007020 IGNITION COIL 1

18 0851029960 VINYL PIPE 1

30 0011105250 BOLT AND WASHER ASSY 2

40 1507520103 CLAMP ................................................. 1 ............ REPLACES 0566099950

60 0660000361 STOP SWITCH ASSY (ON-OFF) 1

70 0043304100 SCREW 4X10 2

81 0241069980 GROMMET 1

95 0659000010 SPARK PLUG CLIP .............................. 1 ............ REPLACES 0655000100

100 0650140031 SPARK PLUG ....................................... 1 ............REPLACES 00650149730

110 0655000140 SPARK PLUG CAP

1

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 51

Page 52

Effective: July 1, 2000

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 10 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a signed

manifest has been obtained from the carrier,

and any claim for shortage or damage must be

settled between the consignee and the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and credit

will be allowed, subject to the following

provisions:

1. A Returned Material Authorization must

be approved by Multiquip prior to shipment.

2. To obtain a Return Material Authorization,

a list must be provided to Multiquip Parts

Sales that defines item numbers,

quantities, and descriptions of the items to

be returned.

a. The parts numbers and descriptions

must match the current parts price

list.

b. The list must be typed or computer

generated.

c. The list must state the reason(s) for

the return.

d. The list must reference the sales

order(s) or invoice(s) under which

the items were originally purchased.

e. The list must include the name and

phone number of the person

requesting the RMA.

3. A copy of the Return Material

Authorization must accompany the return

shipment.

4. Freight is at the sender’s expense. All

5. Parts must be in new and resalable

6. The following items are not returnable:

7. The sender will be notified of any material

8. Such material will be held for 5 working

9. Credit on returned parts will be issued at

10. In cases where an item is accepted for

11. Credit issued will be applied to future

PRICING AND REBATES

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

condition, in the original Multiquip package

(if any), and with Muiltiquip part numbers

clearly marked.

a. Obsolete parts. (If an item is listed

in the parts price book as being

replaced by another item, it is

obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

c. Any line item with an extended dealer

net price of less than $5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

received that is not acceptable.

days from notification, pending

instructions. If a reply is not received

within 5 days, the material will be returned

to the sender at his expense.

dealer net price at time of the original

purchase, less a 15% restocking charge.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

purchases only.

Prices are subject to change without prior

notice. Price changes are effective on a specific

date and all orders received on or after that date

will be billed at the revised price. Rebates for

price declines and added charges for price

increases will not be made for stock on hand at

the time of any price change.

Multiquip reserves the right to quote and sell

direct to Government agencies, and to Original

Equipment Manufacturer accounts who use

our products as integral parts of their own

products.

SPECIAL EXPEDITING SERVICE

A $20.00 to $50.00 surcharge will be added to

the invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable here under for

damages in excess of the purchase price of the

item with respect to which damages are claimed,

and in no event shall Multiquip be liable for loss

of profit or good will or for any other special,

consequential or incidental damages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are made in

connection with the sale of parts or trade

accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes not

authorizes any person to assume for it any

other obligation or liability whatever in

connection with the sale of its products. A part

from such written statement of warranty, there

are no warranties, express, implied or statutory,

which extend beyond the description of the

products on the face hereof.

PAGE 52 — MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04)

Page 53

NOTE PAGE

MTR-35HS — OPERATION & PARTS MANUAL — REV. #5 (11/09/04) — PAGE 53

Page 54

OPERATION AND PARTS MANUAL

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

MULTIQUIP INC.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

WWW: multiquip.com

Quebec, Canada • Manchester, UK • Rio De Janiero, BR • Guadalajara, MX

Atlanta • Boise • Dallas • Houston • Newark

manufactured for Multiquip Inc.

by

MIKASA SANGYO CO., LTD. Tokyo, Japan

Loading...

Loading...