Page 1

OPERATION AND PARTS MANUAL

Vibration Roller

Model MRH-800DS

(Diesel)

© COPYRIGHT 2003, MULTIQUIP INC.

Revision #3 (02/02/05)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

Page 2

PAGE 2 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT

800-421-1244

FAX: 310- 537-4259

TECHNICAL ASSISTANCE

800-478-1244

FAX: 310- 631-5032

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 3

Page 4

TABLE OF CONTENTS

Proposition 65 Warning ............................................. 2

Here's How To Get Help ............................................ 3

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

MIKASA MRH-800DSVIBRATION ROLLER

Safety Message Alert Symbols .............................. 6-7

Rules for Safe Operation ........................................ 8-9

Operation and Safety Decals ............................. 10-11

Roller Specifications ................................................ 12

Engine Specifications .............................................. 13

Dimensions ............................................................. 14

Features .................................................................. 15

Vibration roller Components .............................. 16-17

Handle Bar/Lever Components.......................... 18-19

Engine Components ............................................... 20

Inspection ........................................................... 22-23

Initial Startup ...................................................... 24-25

Operation ........................................................... 26-27

Maintenance ...................................................... 28-33

Roller Troubleshooting ....................................... 34-35

Engine Troubleshooting ...................................... 36-37

Yanmar L100ee-DEVMK2 Engine

Cylinder Block Assembly .................................... 72-73

Cylinder Head and Cover Assembly .................. 74-75

Muffler Assembly ............................................... 76-77

Air Cleaner Assembly......................................... 78-79

Crankshaft, Piston and Camshaft Assembly ..... 80-81

Lub. Oil Pump and Governor Assembly ............. 82-83

Cooling and Starting Device Assembly .............. 84-85

Fuel Injection PumpAssembly ............................ 86-87

Fuel Tank and Fuel Line Assembly .................... 88-89

Starting Motor and Dynamo Assembly .............. 90-91

Tool Label and Gasket Set Assembly ................ 92-93

Terms and Conditions of Sale ................................. 94

PARTS ILLUSTRATIONS

Explanation Of Code In Remarks Column .............. 38

Suggested Spare Parts ........................................... 39

Decal Placement ................................................ 40-41

Axle Assembly .................................................... 42-43

Base Assembly .................................................. 44-45

Front Guard Assembly ....................................... 46-47

Side Cover Assembly ......................................... 48-49

Water Tank Assembly ......................................... 50-51

Hydraulic System Assembly ............................... 52-55

Hydraulic Oil Tank Assembly .............................. 56-57

Engine Assembly ............................................... 58-59

Electric Device Assembly ................................... 60-61

Clutch (Vibration) Assembly .............................. 62-63

Vibrator Assembly .............................................. 64-65

Upper Control Arm Assembly ............................ 66-69

Lower Control Arm Assembly ............................ 70-71

PAGE 4 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

NOTE

Specification and

part number are

subject to change

without notice.

Page 5

PARTS ORDERING PROCEDURES

When ordering parts,

please supply the following information:

❒❒

❒ Dealer account number

❒❒

❒❒

❒ Dealer name and address

❒❒

❒❒

❒ Shipping address (if different than billing address)

❒❒

❒❒

❒ Return fax number

❒❒

❒❒

❒ Applicable model number

❒❒

❒❒

❒ Quantity, part number and description of each part

❒❒

❒❒

❒ Specify preferred method of shipment:

❒❒

✓ FedEx or UPS Ground

✓ FedEx or UPS Second Day or Third Day

✓ FedEx or UPS Next Day

✓ Federal Express Priority One

✓ DHL

✓ Tr u ck

Note: Unless otherwise indicated by customer, all

orders are treated as “Standard Orders”, and will

ship within 24 hours. We will make every effort to

ship “Air Shipments” the same day that the order is

received, if prior to 2PM west coast time. “Stock

Orders” must be so noted on fax or web forms.

Here’s how to get help...

Please have the model and serial number on

hand when calling.

Parts Department

800-427-1244 Fax: 800-672-7877

310-537-3700 Fax: 310-637-3284

Mayco Parts

800-306-2926 Fax: 800-672-7877

310-537-3700 Fax: 310-637-3284

Service Department

800-478-1244 Fax: 310-537-4259

310-537-3700

MQ Power Service Department

800-835-2551 Fax: 310-638-8046

310-537-3700

Warranty Department

800-421-1244, Ext. 279 Fax: 310-537-1173

310-537-3700, Ext. 279

Multiquip’s Main Phone Numbers

800-421-1244 Fax: 310-537-3927

310-537-3700

Place Your Parts Order Via Web or Fax

For Even More Savings!

Extra Discounts!

All parts orders which include complete part numbers

and are received by our automated web parts order

system, or by fax qualify for the following extra

discounts:

Ordered Standard Stock orders

via orders ($750 list and above)

Fax 3% 10%

Web 5% 10%

Special freight allowances

when you order 10 or more

line items via Web or Fax!**

FedEx Ground Service

No other allowances on freight shipped by any other

carrier.

NOTE: DISCOUNTS ARE SUBJECT TO CHANGE

at no charge for freight

MULTIQUIP INC.

18910 WILMINGTON AVENUE

POST OFFICE BOX 6254

CARSON, CALIFORNIA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

WWW: multiquip.com

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 5

Direct TOLL-FREE access

to our Parts Department:

Toll-free nationwide — 800-427-1244

Page 6

MRH-800DS — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read and understand the

Safety Messages and Operating Instructions could result in

injury to yourself and others.

This Owner's Manual has been

developed to provide complete

NOTE

Before using this vibration roller, ensure that the operating

individual has read and understands all instructions in this

manual.

instructions for the safe and efficient

operation of the Multiquip Model

MRH-800DS Vibration Roller.

Refer to the enginemanufacturer’s

instructions for data relative to its safe

operation.

HAZARD SYMBOLS

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

GASOLINE is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you do not follow

directions.

WARNING: You CAN be KILLED or

SERIOUSLY injured if you do not follow

directions.

CAUTION: You CAN be injured if you

do not follow directions.

Potential hazards associated with this vibration roller operation

will be referenced with Hazard Symbols which appear

throughout this manual, and will be referenced in conjunction

with Safety Message Alert Symbols.

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. Never operate the engine with heat

shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep fingers, hands, hair and

clothing away from all moving parts to prevent

injury.

PAGE 6 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 7

MRH-800DS — SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the engine ON/OFF switch in

the OFF position, when the vibration roller is

not in use.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Respiratory Hazard

ALWAYS wear approved respiratory

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your vibration roller, other property,

or the surrounding environment.

NOTE

This vibration roller, other

property, or the surrounding

environment could be

damaged if you do not follow

instructions.

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 7

Page 8

CAUTION:

Failure to follow instructions in this manual

may lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is

for industrial use only.

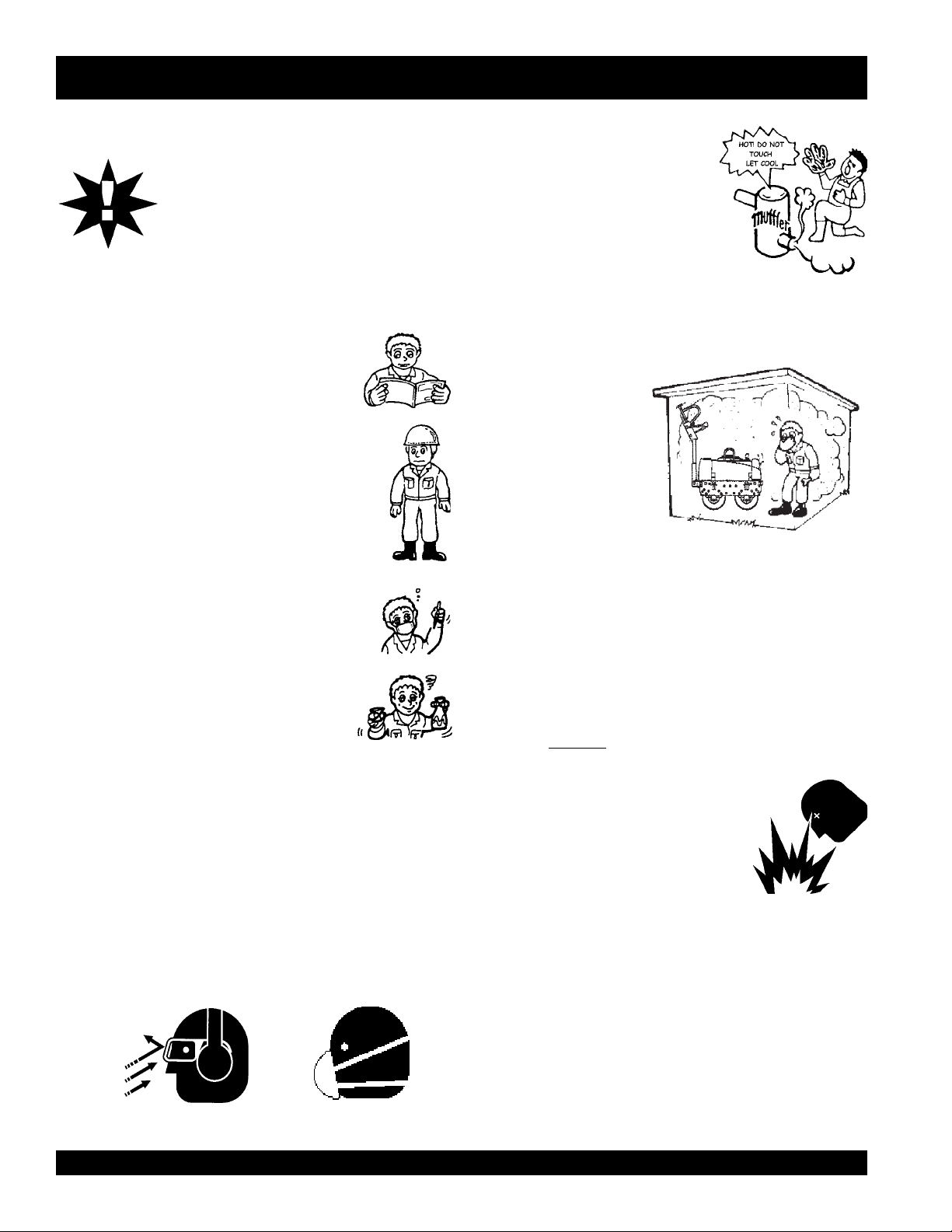

MRH-800DS — RULES FOR SAFE OPERATION

■

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to

cool before servicing engine or vibration

roller.

The following safety guidelines should always be used when

operating the MIKASA MRH-800DS Vibration Roller:

GENERAL SAFETY

■

DO NOT operate or service this equipment before

reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steeltoed boots and other protective devices required

by the job. ALWAYS wear slip resistant safety

shoes or boots.

■

NEVER operate this equipment when not feeling

well due to fatigue, illness or taking medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS wear proper respiratory (mask), hearing and eye

protection equipment when operating the vibration roller.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

■

The engine of this

vibration roller requires

an adequate free flow of

cooling air. NEVER

operate the vibration

roller in any enclosed or

narrow area where free

flow of the air is restricted.

If the air flow is restricted

it will cause serious

damage to the vibration

roller or engine and may cause injury to people and property.

Remember the vibration roller's engine gives off DEADLY

gases.

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

■

ALWAYS use extreme caution when working with flammable

liquids. When refueling, stop the engine and allow it to cool.

DO NOT

explosion could result from fuel vapors, or if fuel is spilled on

a hot engine.

■

NEVER operate the vibration roller in

an explosive atmosphere or near

combustible materials. An explosion or

fire could result causing severe

harm or even death.

■

Topping-off to filler port is dangerous, as it tends to spill fuel.

■

ALWAYS store the vibration roller in a clean, dry location out

of the reach of children.

components can cause serious burns.

smoke around or near the machine. Fire or

bodily

■

NEVER run engine without air cleaner. Severe engine

damage may occur.

■

NEVER leave the vibration roller unattended, turn off engine.

■

CAUTION must always be observed while servicing this

vibration roller. Rotating parts can cause injury if contacted.

■

DO NOT leave vibration roller with engine running. Use

chock blocks if parking

PAGE 8 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

vibration roller on a grade.

Page 9

MRH-800DS — RULES FOR SAFE OPERATION

■

ALWAYS use extreme care when operating near obstructions,

on slippery surfaces, grades and side slopes.

■

When reversing, particularly on the edges and banks of

ditches, as well as in front of obstacles, the operator must

stay in a standing position at a safe distance from the machine.

■

When operating near any house/building or pipelines, always

check the effect of machine vibration. Stop the work if

necessary.

■

Unauthorized equipment modifications will void all

warranties.

■

Refer to the

questions or information.

■

DO NOT operate the vibration roller with the front or rear

cover open.

■

Replace any worn or damaged vibration roller components

immediately.

■

ALWAYS turn the engine

maintenance.

■

ALWAYS make sure vibration roller is correctly secured to

the trailer. Check all supports attaching the vibration roller to

the trailer and make sure they are tight.

■

ALWAYS keep the machine away from workers and

obstacles. Also keep the immediate area free of bystanders.

■

ALWAYS check the machine for loosened threads or bolts

before starting.

■

ALWAYS read, understand, and follow procedures in

Operator’s Manual before attempting to operate equipment.

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operations techniques before using vibration

roller.

■

A copy of this manual shall accompany the vibration roller at

all times.

■

DO NOT use worn out hoses or couplings; inspect daily.

Engine Owner's Manual

for engine technical

OFF

before performing

■

■

Emergencies

■

Maintenance Safety

■

■

■

■

■

■

■

Lifting

■

High Temperatures – Always stop engine and allow the

engine to cool before adding fuel, oil or performing service

hot

and maintenance functions. Contact with

can cause serious burns.

NEVER disconnect any

These devices are intended for operator safety. Disconnection

of these devices can cause severe injury, bodily harm or

even death! Disconnection of any of these devices will void

all warranties.

ALWAYS know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

and

invaluable in case of an emergency.

NEVER lubricate components or attempt service on a

running machine.

ALWAYS allow the machine a proper amount of time to

cool before servicing.

Keep the machinery in proper running condition.

Fix damage to the machine immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, fuel and

fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

The vibration roller has an operating weight of approximately

1562 lbs. (709 kg). Use lifting equipment capable of lifting

this weight.

. Know the location of the nearest telephone.

fire department

"emergency or safety devices"

. This information will be

components

.

fire extinguisher

ambulance

,

■

Make sure the engine is off before lifting the machine.

■

Use reliable cable in lifting the machine.

■

Lift upright with sufficient bearing capacity to prevent

machine from tilting or slipping.

■

When lifting, keep the machine away from workers and

animals.

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 9

Page 10

MRH-800DS — OPERATION AND SAFETY DECALS

Figure 1 displays the operation and safety decals as they appear on the vibration roller. Should any of these decals become

damaged or unreadable, contact the Multiquip Parts Department for a replacement set.

Figure 1. Operation and Safety Decals

PAGE 10 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 11

MRH-800DS — OPERATION AND SAFETY DECALS

Figure 1. Operation and Safety Decals (Continued)

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 11

Page 12

MRH-800DS — ROLLER SPECIFICATIONS

snoisnemiD )mm0601x296x0762(ni7.14x2.72x501

retemaiDmurD )mm604(.ni61

htdiWmurD)mm056(.ni6.52

SNOITACIFICEPSRELLORNOITARBIVSG008-HRM.1ELBAT

ecnaraelCbruC

gnahrevOediS)mm12(.ni38.

)retawhtiw(thgieWgnitarepO )gk017(.sbl2651

ycneuqerFnoitarbiVmpv003,

ecroFlagufirtneC fgk/nk004,2/5.32

metsySevirDrotoMciluardyH

metsySnoitarbiVemarF

dohteMnoitarbiVevirDtleB

tf

ahSrotarbiVniwT

ytililbaedarGseerged02

deepSgnikroW )hpk8.4-0(hpm3-0

yticapaCknaTleuF )sretil1.7(snollag88.1

liOgnitacirbuL )sretil52(snollag6.6

yticapaCknaTretaW )sretil04(snollag75.01

3

)mm342(.ni6.9

ledoMenignE 1KMVED-EE001Lledo

metsySgnitratS tratSlioceR/cirtcelE

PAGE 12 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

MRAMNAY

Page 13

MRH-800DS — ENGINE SPECIFICATIONS

.2elbaTENIGNE)RAMNAY(SNOITACIFICEPS

ledoMenignE 1KMVED-EE001LRAMNAY

epyTenignEleseiDdelooc-riA

ekortSXeroBrednilyC )mm07x88(ni57.2x64.3

lpsiD)cc604(zolf7.31

tnemeca

tupuOmumixaMPH01

yticapaCknaTleuF)sretil5.5(strauq8.5

yticapaCliO )sretil56.1(strauq47.

thgieWteNyrD)gk35(.sbl6.611

)HxWxL(snoisnemiD )mm494x074x714(ni4.91x5.81x4.61

1

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 13

Page 14

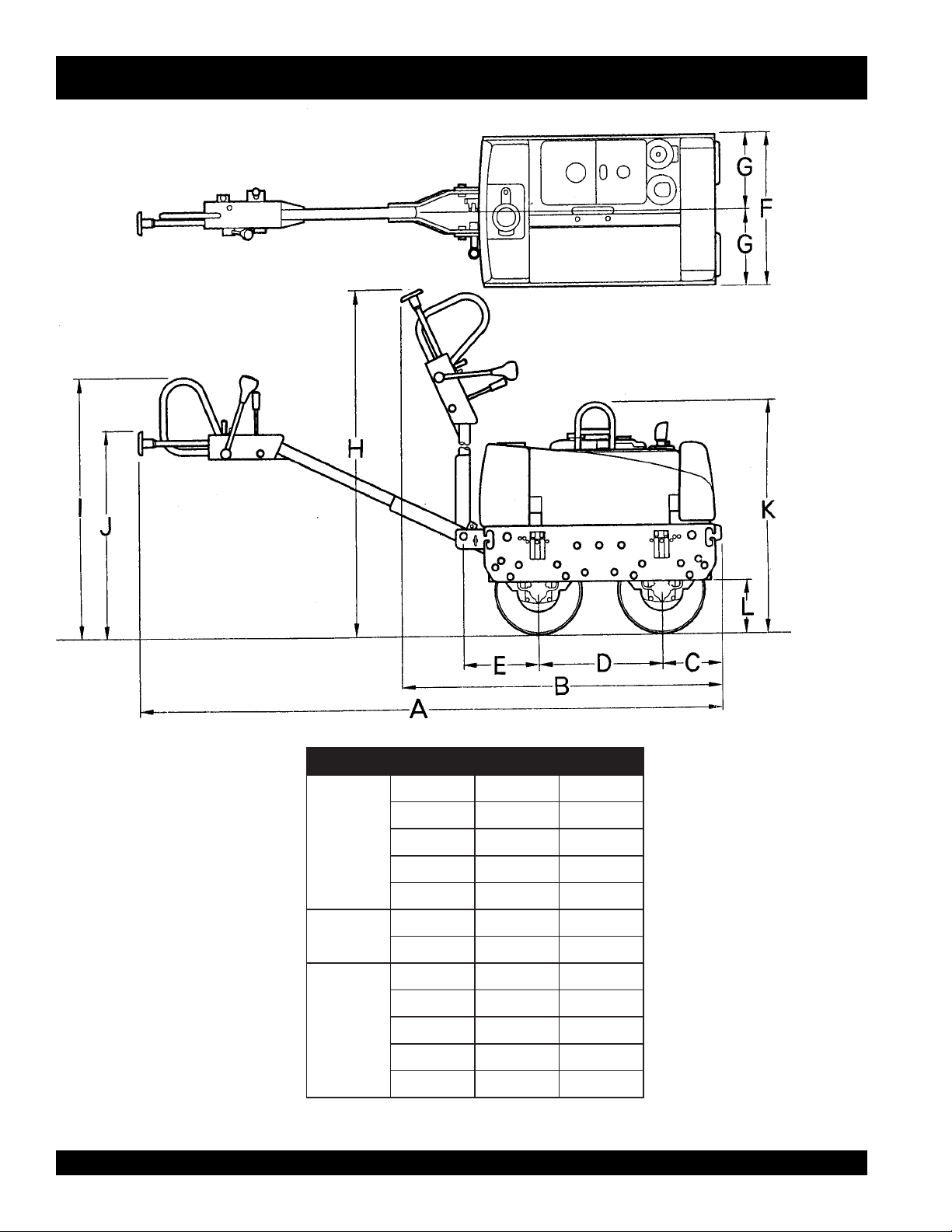

MRH-800DS— VIBRATION ROLLER DIMENSIONS

SNOISNEMID.3ELBAT

A.ni501.mm0762

B.ni75.mm5441

HTGNEL

HTDIW

THGIEH

C.ni01.mm552

D.ni8.22.mm085

E.ni8.31.mm053

F.ni2.72.mm296

G.ni6

H.ni3.87.mm0991

I.ni5.64.mm0811

J.ni4.73.mm059

K.ni7.14.mm0601

L.ni6.9.mm542

.31.mm643

Figure 2. MRH-800DS Vibration Roller Dimensions

PAGE 14 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 15

The Mikasa Model MRH-800DS is a powerful compacting

tool capable of applying a tremendous force in consecutive

impacts to a soil surface. Its applications include soil compacting

for backfilling for gas pipelines, water pipelines and cable

installation work.

The impact force of the MRH-800DS levels and uniformly

compacts voids between soil particles to increase dry density.

Features include:

Hydraulic transmission to allow speed change without

gear shifting.

Deadman device which when pressed or hit will

cause the travel lever to return to neutral position

bringing the machine to a stop.

A horn to warn of machine’s approach.

Non-corrosive water tank for the sprinkler system with a

capacity of more than 10 gallons.

Lifting hook to transport machine.

Front bumper and working light.

MRH-800DS— FEATURES

Narrow profile with less than one inch wall clearance.

Narrower width allows access to tighter areas. No

exposed hydraulic hoses.

Oil bath lubricated bearings and external vibration

for less servicing and more dependability.

Front and rear drum scrapers.

Drum sprinkler system controls located near the

operator.

Easy access to hydraulic components and hydraulic

filter.

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 15

Page 16

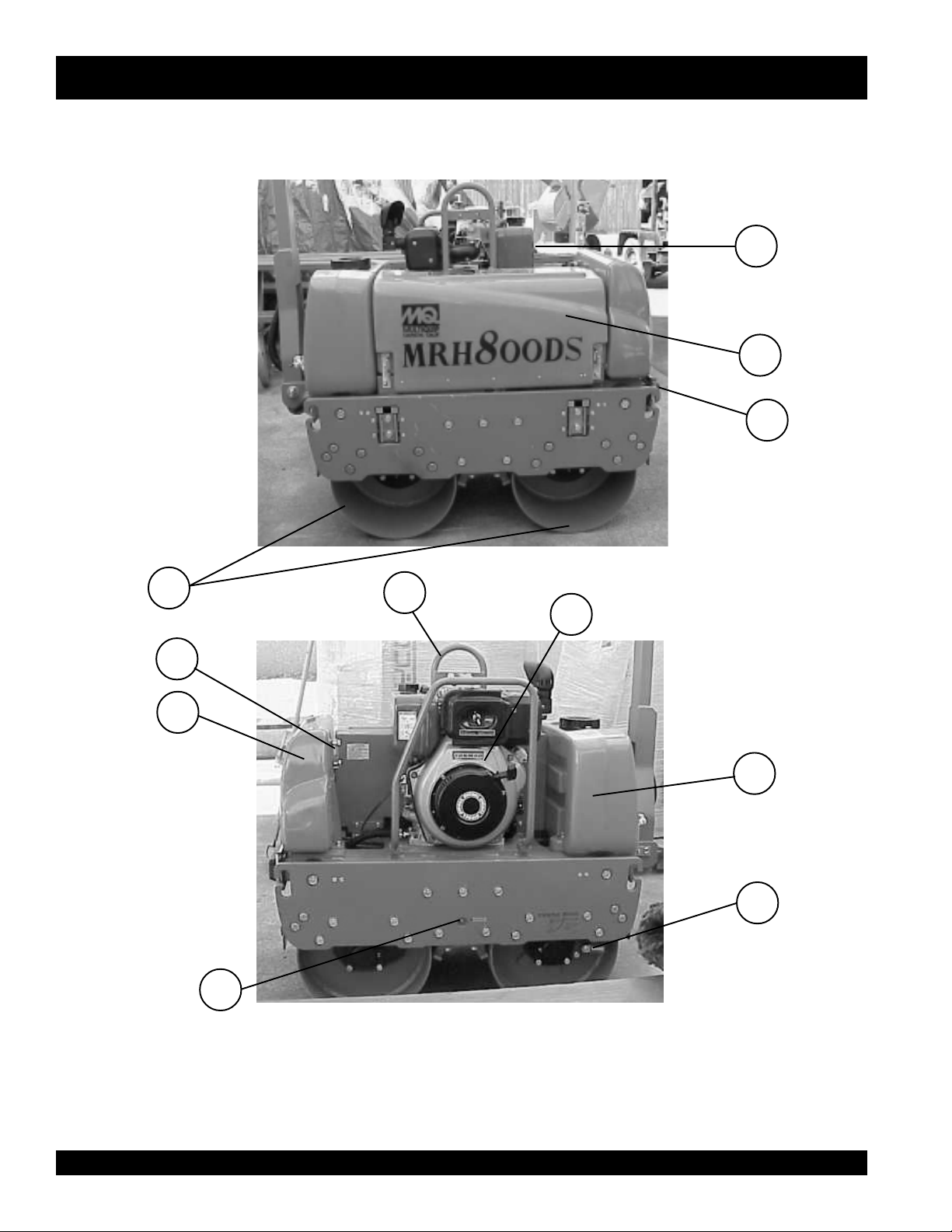

MRH-800DS— VIBRATION ROLLER COMPONENTS

1

2

4

3

8

9

5

6

10

11

7

Figure 3. MRH-800DS Vibration Roller Components

PAGE 16 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 17

MRH-800DS— VIBRATION ROLLER COMPONENTS

Figure 3 illustrates the location of the major components

for the MRH-800DS Vibration Roller. The function of each

component is described below:

1. Fuel Tank/Cap – Fill with diesel fuel. Fuel tank holds

approximately 2 gallons (7.5 liters). DO NOT top off fuel.

Wipe up any spilled fuel immediately.

2. Center Cover – When opened and supported by strut,

provides access to oil pump and filter, battery, V-belt, and

clutch box.

3. Vibration Rollers – 25-inch wide steel drums that provide

compaction force in the compaction and patching of asphalt

type surfaces.

4. Front Headlights – Activate using switch on control

handle. Use to illuminate ground durring nighttime or low

light operating conditions.

5. Hydraulic Oil Gauge – Indicates the hydraulic oil level.

6. Oil Tank – Fill with proper grade of hydraulic oil.

7. Vibrator Oil Level Plug – Remove to check vibrator oil

level.

8. Lifting Hook – Used to lift the machine with crane or other

lifting device.

9. Engine – This machine uses the Yanmar L100A engine.

Refer to the engine Owner’s Manual for more information.

10. Water Tank– Holds 10.57 gallons (40 liters) for the sprinkler

system.

11. Parking Brake – Makes sure machine will not accidentally

move when parked or not in use.

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 17

Page 18

3

4

MRH-800DS— HANDLE BAR/LEVER COMPONENTS

1

2

6

5

Figure 4. MRH-800DS Lever Components

PAGE 18 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 19

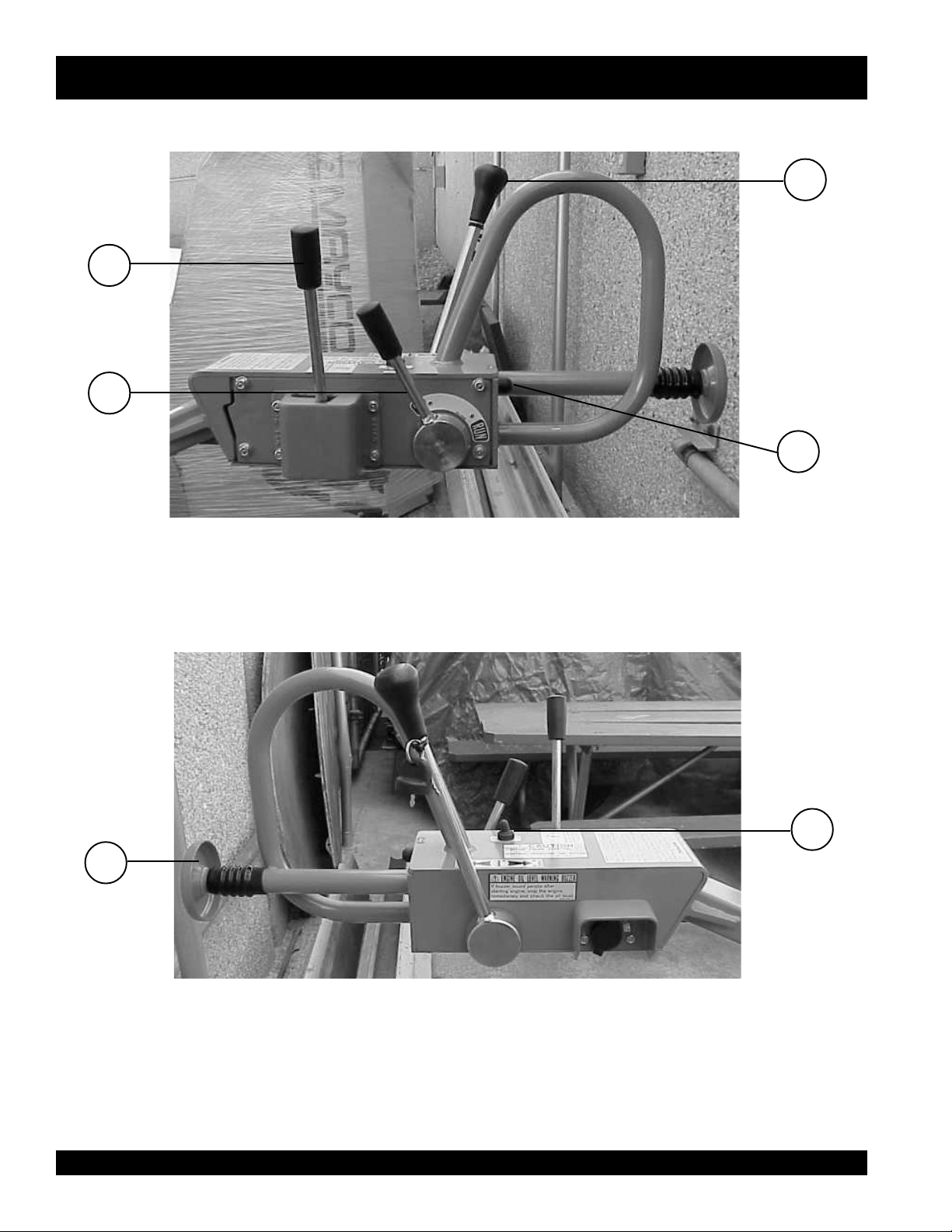

MRH-800DS — HANDLE BAR/LEVER COMPONENTS

HANDLE BAR/LEVER COMPONENTS

Figure 4 illustrates the location of the major lever

components on the handle bar of the machine. Each

component is described below:

1. Travel Lever – Controls the direction of travel of the

machine (forward and reverse).

2. Horn Button – When pressed, gives a warning sound of

the machine approaching.

3. Vibration Lever – Turns vibration on and off.

4. Throttle Lever – Controls the start up of the machine.

5. Dead-Man Device – When pressed or hit while traveling

in reverse, causes the travel lever to return to neutral

position to stop the machine.

6. Light ON/OFF Switch - Turns headlight on and off.

7. Starter Switch - Engine starts when key is turned to the

RUN position

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 19

Page 20

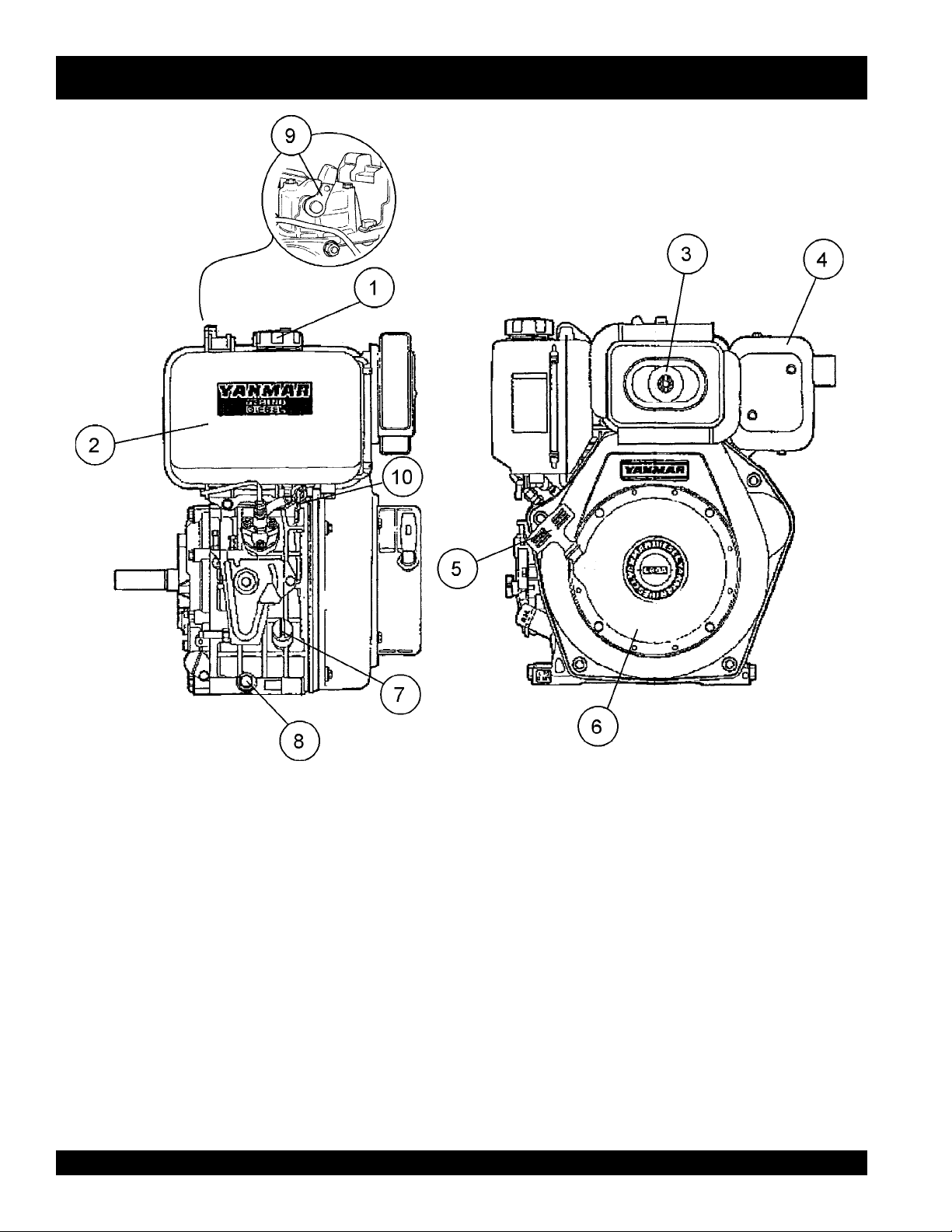

MRH-800DS— ENGINE COMPONENTS

Figure 5. MVH-402DSB Engine Components

ENGINE COMPONENTS

Figure 5 illustrates the location of the major engine

components of the machine. Each component is described

below:

1. Fuel Filler Cap – Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tighten securely.

DO NOT over fill.

2. Fuel Tank – Diesel engine holds 5.8 quarts of diesel fuel.

3. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element.

4. Muffler – Used to reduce noise and emissions.

5. Recoil Starter (pull rope) – Type of engine starting method.

Alternate type would be electric start (ignition key).

PAGE 20 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

6. Recoil Starter – Housing for pull rope and starter.

7. Oil Filler Cap/Dipstick – Remove this cap to add oil to the

oil tank. Use dipstick to check oil level.

8. Oil Drain Plug – Unscrew plug to drain oil from engine

crankcase. Dispose of oil in a safe manner.

9. Decompression Lever – Press down before starting

engine. To prevent damage to the engine, DO NOT use for

any other purpose.

10. Fuel Cock – Controls the flow of diesel fuel to the engine.

Must be in the ON position when starting and running the

engine.

Page 21

NOTE PAGE

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 21

Page 22

MRH-800DS— INSPECTION

DANGER

NEVER operate the

compactorin a confined

area or enclosed area

structure that does not

provide ample

.

of air

ALWAYS wear approved eye and hearing

protection before operating the compactor.

Before Starting

1. Read safety instructions at the

beginning of manual.

2. Remove dirt and dust, particularly

in theengine cooling air inlet,

carburetor and air cleaner.

3. Check the air filter for dirt and dust.

If air filter is dirty, replace air filter

with a new one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

free flow

3. Insert and remove the dipstick without screwing it into the

filler neck. Check the oil level shown on the dipstick.

4. If the oil level is low, fill to the edge of the oil filler hole with the

recommended oil type (Table 3). Maximum oil capacity is

1.16 quarts (1.1 liters).

Checking The Hydraulic System

1. Check the oil tank level gauge (Figure 7). Oil level

should be at the middle indication of the gauge or

higher. Fill as required

2. Check the surroundings of the oil tank, hydraulic

pump and motor for oil leakage.

Level should

be middle of

gauge or

higher

Figure 7. Hydraulic System Oil Level Gauge

5. Check fastening nuts and bolts for tightness.

6. Understand the geographical features and regulations of

the job site.

Engine Oil Check

1. To check the engine oil level, place the compactor on secure

level ground with the engine stopped.

2. Remove the filler dipstick from the engine oil filler hole

(Figure 6) and wipe clean.

Figure 6. Engine Oil Level

EPYTLIO.4ELBAT

nosaeS erutarepmeT epyTliO

DANGER

Checking The V-Belt

1. Remove the 2 bolts, one on each side of the center

cover, with a #13 socket wrench. Open the center

cover of the machine and support it with the strut by

inserting its end to the hole in the base (Figure 8).

2. Check V-belt for proper tension. Insufficient tension

causes weak vibration.

Center

Cover

Strut

V-Belt

ALWAYS keep hands and fingers away from

pinch points. DO NOT allow anyone to reach in

on dangerous sections of the machine to avoid

any accidents.

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

PAGE 22 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Figure 8. Checking V-Belt Tension

Page 23

MRH-800DS— INSPECTION

Checking The Vibrator Oil Level

1. Check vibrator casing for any oil leakage.

2. If any leakage is noticed, remove the level plug on the side

of the plate (Figure 9).

3. Check the oil level.

Vibrator Oil

Level Plug

Figure 9. Checking Vibrator Oil Level

Fuel Check

1. Remove the fuel cap located on top of the engine fuel tank.

2. Visually inspect to see if the fuel level is low. If fuel is low,

replenish with unleaded gasoline using a strainer for

filtration. DO NOT top-off fuel. Wipe up any spilled fuel

immediately!

Checking Levers and Horn

1. Check travel, vibration, and throttle levers to make sure

they are functioning properly (Figure 4).

2. With travel lever placed in reverse, push the deadman

device and verify that the travel lever returns to neutral

position. The travel lever stays in neutral position once the

deadman device is released.

3. Press the horn and verify that it functions properly.

Checking Scrapers

1. Check scrapers and make sure that they are not clogged

with mud, bent or damaged (Figure 11).

2. Adjust clearance between drums and scrapers as

necessary.

DANGERDANGER

DANGER

DANGERDANGER

Motor fuels are highly

flammable and can be

dangerous if mishandled.

DO NOT smoke while

refueling. DO NOT attempt to refuel the pump

if the engine is

Checking Water Tank

1. Check the water tank to see if filled. Add water if necessary.

The water tank has a capacity of approximately 10 gallons

(40 liters) (Figure 10).

hot! or running

Figure 10. Checking Water Tank

.

CAUTION :

Scrapers

Figure 11. Checking Scrapers

Checking Bolts, Nuts and Screws

1. Check bolts, nuts, and screws on various parts of the

machine, including the engine, for proper tightness.

Positioning the Handle Bar

1. Release the handle bar release pin (Figure 12) and position

the handle bar to the lowered position before starting

operation.

2. When machine is not in use, release the handle bar release

pin and position the handle bar to the upright position.

Handle Bar

Release Pin

Be careful not to confuse the water tank with the

oil tank.

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 23

Figure 12. Positioning the Handle Bar

Page 24

MRH-800DS— INITIAL STARTUP

CAUTION :

DO NOT attempt to operate the roller until the Safety, General

Information and Inspection sections of this manual have been

read and thoroughly understood

This section is intended to assist the operator with the

start-up

be read carefully before attempting to use the compactor in the

field.

STARTING THE ENGINE

The engine can be started by motor (electric) or manually

(recoil). Refer to Figures 3 and 4 for the location of

controls and components.

of the roller. It is extremely important that this section

.

initial

CAUTION :

Make sure to follow all safety rules referenced in

the safety section of this manual before operating

roller. Keep work area clear of debris and other

objects that could cause damage to the roller or

bodily injury.

5. Insert the starter key into the key switch and turn it to

the RUN position (Figure 14). The buzzer should

sound at this time.

6 Turn the starter key further to the right to the START

position to start the engine. Buzzer stops sounding

when the engine speed increases. With safety switch

equipped, motor runs only when the travel lever is in

the neutral position.

Figure 14. Starter Key (Run Position)

CAUTION :

When the engine is running, NEVER turn the

starter key to the START position

Electric Start

1. On the control handle:

A. Move the

B. Move the

C. Move the

4. Open the fuel cock by turning it clockwise to the down

position (Figure 13).

throttle lever

travel lever

vibration lever

to the RUN position.

to the NEUTRAL position.

to the OFF position.

Fuel Cock

(Open

Position)

7. If the engine fails to start, DO NOT continue to rotate

the starter key for more than 5 seconds. Return the

key to the RUN position and wait 20 to 30 seconds

before starting again.

8. After starting the engine, continue to warm up the

engine for about 3 to 10 seconds especially in cold

weather.

9. If the buzzer does not stop sounding after the engine

has started, shutdown engine immediately and check

engine oil level. The buzzer functions as engine oil

level warning also.

Figure 15. Starter Key (Start Position)

Figure 13. Open Fuel Cock

PAGE 24 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 25

MRH-800DS— INITIAL STARTUP

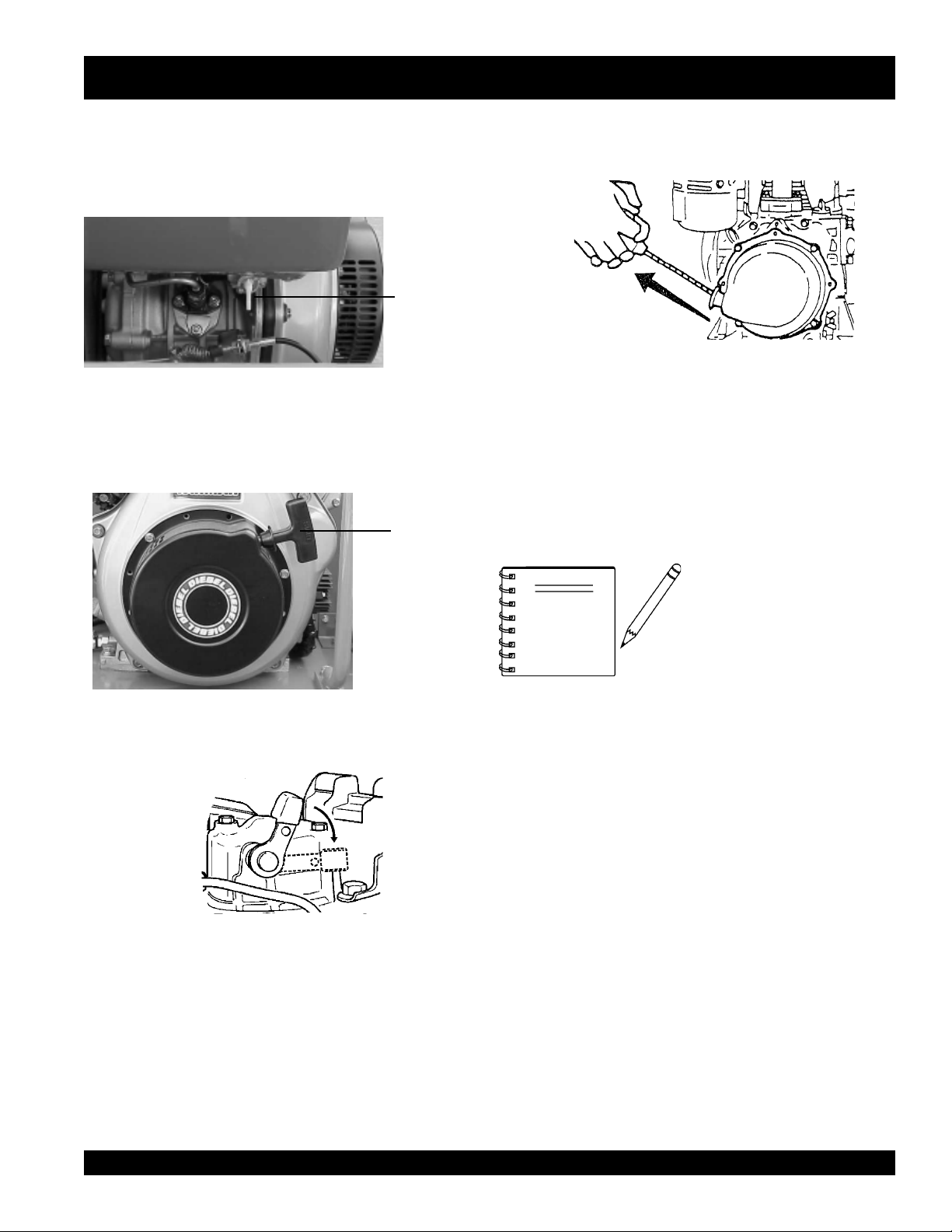

Recoil Start

1. Move the throttle lever to the RUN position.

2. Open the fuel cock by turning it clockwise to the down

position (Figure 16).

Fuel Cock

(Open

Position)

5. Pull the starting handle hard and fast to start engine

(Figure 19).

Figure 19. Engine Start Handle

Figure 16. Open Fuel Cock

3. Pull the starting handle slowly until you feel some

resistance (Figure 17). Return handle to original

position.

Pull

Handle To

Start

Figure 17. Engine Start Handle

4. Push down the decompression lever (Figure 18).

6. If the engine does not start, repeat steps

3 through 5.

NOTE

When starting with a motor

starter, a decompressor is

not normally required.

However, when ambient

temperature or battery

charger level is low, use of

a decompressor will help

make the start-up easier.

Figure 18. Decompression Lever

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 25

Page 26

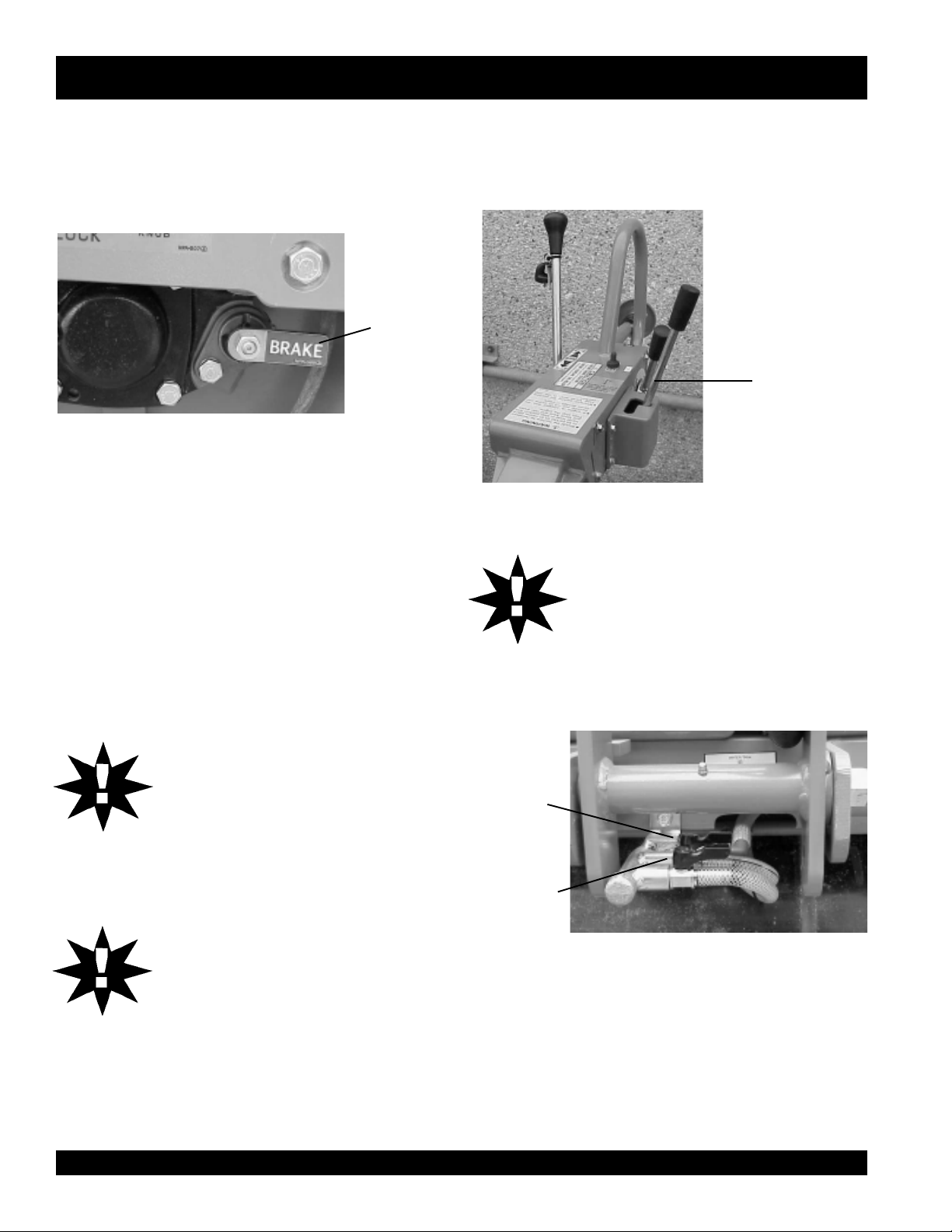

MRH-800DS—OPERATION

TRAVELING

1. Before starting to travel, make sure to release parking brake

located on the left side of the rear roller. If the parking brake

lever is tight, moving the roller back and forth will make it

easier (Figure 20).

Parking

Brake

(Released

Position)

Figure 20. Parking Brake

2. With the throttle lever in the RUN position, increase

the engine rotation.

3. Push the travel lever forward slightly. This will cause

the roller to travel forward at slow speed.

4. To increase the travel speed, push the travel lever

further.

5. Travel speed can be varied between 0 and 3 km/h

(both forward and reverse).

6. Push the travel lever backward to go in the reverse

direction.

CAUTION :

DO NOT reduce speed during work. When

shifting travel lever from forward to reverse,

be sure to stop the lever at the neutral

position first before moving the lever to the

opposite direction. DO NOT shift the lever

from forward to reverse (or reverse to

forward) in one motion.

CAUTION :

After test travel, shut down engine and

check for any problems including oil

leakage. If any trouble is found, correct the

problem before attempting to operate the

roller again.

VIBRATING

1. Shift the vibration lever AWAY from its OFF position. The

vibration lever will automatically spring forward and the

roller will start vibrating (Figure 21).

CAUTION :

WATERING

1. For watering work, turn the water cocks clockwise, at the

rear of the machine, to start sprinkling. (Figure 22).

Watercock

for Front

Drum

Watercock

for Rear

Drum

Off Position of

Vibration Lever

Figure 21. Vibration Lever

Using vibration with clutch slipping causes

the clutch to burn. Also, vibration should

NOT be used over completely compacted

area, paved road surface, or with stationary

roller.

Figure 22. Water Cocks

PAGE 26 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 27

SAFETY FEATURES

MRH-800DS—OPERATION

1. A horn is provided to warn of approach.

2. The dead man device prevents accidental traveling

in reverse. It automatically makes the travel lever

return to neutral position by stopping the machine

when an object comes in contact with the dead man

device.

STOPPING

1. With travel lever in the NEUTRAL position, and the

vibration lever in the OFF position, return the throttle

lever to the START position. Allow the machine to

cool down for 3 to 5 minutes.

2. Push the throttle lever forward to stop the engine. In

a motor start, return the key switch to the STOP

position as soon as the engine stops.

Bypass

Valve

Bolt

CAUTION :

CAUTION :

Neglecting to return the key switch to the

STOP position will cause the battery to

discharge making start up impossible the

next time.

3. After the engine stops, close the fuel cock.

4. Lock the parking brake by pulling the brake lever

and rotating it 90 degrees clockwise.

Parking brake system should

NOTE

always be kept clean to avoid

mud deposits.

LIFTING

1. Use a crane or lift to load and unload the machine. A

skilled crane operator is required to perform the job.

2. When lifting the machine, check for any damaged or

loose bolts, lifting hooks, and shock mounts.

3. Check any damaged or loose bolts in the guard frame to

avoid machine sliding off.

4. Make sure that the machine is shut off before machine is

lifted.

5. Use reliable cable for lifting.

6. ALWAYS lift the machine vertically and keep the

machine away from workers and animals.

Figure 23. Location of Bypass Valve Bolt

NEVER tow roller with any type of vehicle.

Doing so will damage the hydraulic system.

NEVER perform unloading procedure on a

slope. This may cause roller to roll down if

parking brake or blocking is deficient.

7. DO NOT lift the machine higher than the required

UNLOADING

1. If you need to move the roller by pushing it manually

once engine is stopped, loosen bolt of bypass valve

on oil pump by one rotation counterclockwise. This

will cause the hydraulic break to disengage and allow

the roller to be moved more easily (Figure 23).

2. After moving, tighten the bolt again. Tightening torque

is 55 to 70 kgf-cm.

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 27

height.

TRANSPORTING

1. Always make sure that the machine is shut off while

being transported.

2. Check that the fuel cap is properly closed and

tightened.

3. When traveling long distances or on rugged terrain,

drain the fuel of the machine before transporting.

4. Tie down the machine securely on the

transportation so that it will not move or topple over.

Page 28

MRH-800DS—MAINTENANCE

CAUTION:

Inspection and other services should ALWAYS

be carried out on hard and level ground with the

engine shutdown.

Inspection and Maintenance Service Tables.

1. To make sure your plate compactor is always in good

working condition before using, carry out the maintenance

inspection in accordance with Tables 5 through 7.

SD008-HRM.5ELBATNOITCEPSNIENIHCAM

METI

gnissiMroesooL

swercS

straPdegamaD

gnillortnoCfonoitcnuF

traPmetsyS

FOSRUOH

NOITAREPO

sruoh8yrevE

)yadyreve(

sruoh8yrevE

)yadyreve(

sruoh8yrevE

)yadyreve(

SKRAMER

CAUTION:

Fuel piping and connections should be replaced

every 2 years.

METINOITAREPOFOSRUOH

kaeLleuFroliO)yadyreve(sruoh8yrevE

sdaerhT

tnemhsinelpeR

gnE

gninaelCretliFriAsruoh001yrevE

nigneetarapeseeS

SD008-HRM.6ELBATKCEHCENIGNE

gninetsaFfossenthgiT

nakcehCliOenignE

d

)level

tnemecalpeRliOeni

sruoh001

)yadyreve(sruoh8yrevE

)yadyreve(sruoh8yrevE

mumixamdeificepsothsinelpeR(

ot05yrevenehtsruoh52tsrifretfA

.kcehcenignenosliatedroflauname

kaeLmetsySciluardyHsruoh001yrevE72egapeeS

tarbiVsruoh001yrevE72egapeeS

kcehCliOro

liOrotarbiV

tnemecalpeR

kcehCliOciluardyHsruoh001yrevE62eg

liOciluardyH

tnemecalpeR

kcehC)hctulc(tleb-Vsruoh002

kcehCyrettaBsruoh001yrevE82egapeeS

yrevE72egapeeS

CAUTION:

These inspection intervals are for operation

under normal conditions. Adjust your inspection

intervals based on the number of hours the roller

is in use, and your particular working conditions.

sruoh003yrevE62egapeeS

002retfatsriF

yreveneht,sruoh

sruoh000,1

Daily Service

z

Check for leakage of fuel or oil.

z

Check for loose screws including tightness. See Table 7

below (tightening torque ), for retightening:

apeeS

mm6 mm8 mm01 mm21 mm41 mm61 mm81 mm02

lairetaM

72egapeeS

T4 07 051 003 005 057 001,1 004,1 000,2

T8-6 001 052 005 008 003,1 000,2 007,2 008,3

T11 051 004 008 002,1 000,2 009,2 002,4 006,5

~003

* 001

z

Remove soil and clean the bottom of compaction plate.

z

Check hydraulic pump, piping and hose for any leakage.

~056

053

007

)munimulafositrap-retnuocesacnI(*

kramsilairetamfoytilauqdnalairetaM

)mc/gk.ni(EUQROTGNINETHGIT.7ELBATRETEMAID

)dednahthgirllaeraenihcamsihthtiwesunisdaerhT(

.wercsdna,tlobhcaenode

A loosened hydraulic hose can be a cause for leakage.

Check hydraulic hose connections with wrench applied for

tightness.

z

Check engine oil.

PAGE 28 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 29

CLUTCH

PULLEY

VIBRATOR

PULLEY

MRH-800DS—MAINTENANCE

Engine Oil Replacement:

1. Replace engine oil in the first 25 hours of operation and

every 50 to 100 hours afterwards.

2. Oil may be drained more easily when it is warm after

operation (For more details, see separate engine Owner's

Manual).

Air Filter

1. The air filter element should be cleaned because a clogged

air cleaner can cause poor engine starting, lack of power

and shorten engine life substantially.

CAUTION:

CAUTION :

Figure 24. Engine Air Filter and Element

2. To clean or replace air filter loosen the wing nut on the air

filter housing (Figure 24) remove the cover and take out air

filter cartridge. If only cleaning of the air filter is desired blow

through the air filter cartridge from the inside, moving a jet of

dry compressed air up and down until all dust is removed.

VIBRATION CLUTCH ADJUSTMENT

1. Move vibration lever to the OFF position.

2. Loosen the front and rear nuts at the end of vibration clutch

cable (Figure 25).

3. Turn in the nut on the front side again and at the position

that release fork starts to move, turn in the nut by one or two

threads. Lock it a this position together with the rear nut.

HYDRAULIC SYSTEM INSPECTION AND SERVICE

1. Check motor and pump for any damage.

2. Check hoses and pipes for proper tightness and make sure

there are no leaks.

3. Check nylon tubes for hydraulic oil intake and drain.

Retighten brass nut if loose and if a leak is detected. If leak

continues after retightening, replace nylon tube, nut and

sleeve.

NEVER attempt to check the V-belt with the engine running. Severe injury can occur if your hand

gets caught between the V-belt and the clutch

(Figure 26). Always use safety gloves.

Figure 26. V-Belt Hazard

Excessive turning of front nut may cause the

sliding engagement of clutch to take place or

no vibration takes place even when vibration

lever is engaged.

On the other hand, insufficient turn may cause

sliding engagement of clutch even when the

vibration lever is placed in the OFF position or

for vibration to remain engaged.

4. Check oil tank for proper oil level using the hydraulic system

oil level gauge (See Figure 7). Make sure hydraulic oil has

not whitened or emulsified. Whitish color means aeration in

Rear Nut

Fork

Front Nut

Figure 25. Vibration Clutch Adjustment

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 29

pump. Retighten pipe and correct level of oil. Emulsification

means water in the hydraulic oil. Replace the oil.

ROLLER INSPECTION AND ADJUSTMENT

1. Refer to Table 8 for oil and grease requirements.

2. Check oil tank level daily.

3. Check the machine for oil leak and proper function of lever,

cables, and links daily.

Page 30

zz

z

DO NOT close the exhaust outlet of battery. The gas pressure

MACHINE MAINTENANCE

1. At the end of each day’s operation, wash down dust and

dirt off the machine. Clean area around drums ad scrapers

making sure all mud is removed.

2. Drain water tank completely.

3. Cover the machine to prevent dust and store in dry place

away from sun exposure.

LONG TERM STORAGE

1. Conduct thorough lubrication and oil change.

2. Disconnect battery terminals and dismount battery from

machine. Store battery.

3. If there a possibility that ambient temperature will drop

below freezing point, add antifreeze agent to coolant.

4. Cover the inlet and outlet of air cleaner and muffler

securely.

5. Store machine indoors. Do not leave outdoors.

Refer to Table 7 for lubrication necessary for the machine.

BATTERY MAINTENANCE

DANGER :

Lead-acid battery contains sulfuric

acid, which may damage eyes or

skin on contact.

zz

building up in the battery may cause explosion.

zz

z

Before using a battery charger, read and understand the

zz

charger instruction manual thoroughly.

zz

Charge the battery in a non-spark, well-ventilated area. Avoid

z

zz

fire from cigarette sparks or matches.

1. If a battery has not been used for some time, reduce

the charge level initially to protect each plate inside

the battery.

2. Check the battery terminals periodically to ensure

that they are in good condition.

3. Use wire brush or sand paper to clean the battery

terminals.

4. Check battery for cracks or any other damage. If white

pattern appears inside the battery or paste has

accumulated at the bottom, replace the battery.

5. Measure the specific gravity of electrolyte:

zz

z

zz

zz

z

zz

6. If the machine will not be in operation for a long

period of time, charge the battery sufficiently, tighten

all caps, correctly, store in cool dry place and check

the battery charge level every month to maintain the

performance of the battery.

BATTERY CABLE CONNECTION

MRH-800DS—MAINTENANCE

completely charged: 1.270 - 1.290

needs charging: 1.260 or lower

1. When removing cable, disconnect the ground side (normally

negative) first (Figure 27).

FOR YOUR SAFETY:

zz

z

ALWAYS wear a face shield to avoid acid getting into the

zz

eyes. If acid gets in contact with eyes, flush immediately with

clean water and get medical advice.

zz

z

Wear rubber gloves and protective clothes to keep acid off

zz

skin. If acid gets in contact with skin, wash off immediately

with clean water.

zz

z

Use a flashlight to check battery electrolyte level. ALWAYS

zz

check the engine is stopped.

zz

z

DO NOT charge battery or jump-start engine when the

zz

battery is frozen. Warm the battery to 15 degrees F or battery

may explode.

zz

z

Replace the battery with the same or similar capacity battery

zz

or battery may explode.

PAGE 30 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Negative

Terminal

Positive

Terminal

Figure 27. Battery Connection

2. When installing cable connect the ground side (normally

negative) last.

Page 31

FORWARD AND REVERSE TRAVEL ADJUSTMENT

1. If neutral position for forward and reverse travel has been

displaced, conduct the neutral adjustment.

2. If roller travels forward with the ball of ball plunger remaining

in V slot of the guide, loosen M8 bolt and slide the slide

plate slightly toward the engine. If the roller travels

backward, slide the plate towards side plate (Figure 28).

MRH-800DS—MAINTENANCE

Plunger

M8 Bolt

Figure 28. Adjustment of Neutral Position

3. With M8 bolt tightened, start engine and check the neutral

for forward and reverse. If still displaced, repeat the

procedure.

4. If neutral position of forward/reverse lever has been

displaced, use the turn buckle located on the oil pump side

of forward/reverse cable.

Guide

Slide Plate

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 31

Page 32

MRH-800DS—MAINTENANCE

TRAHCNOITACIRBULSD008-HRM.8ELBAT

METI

arbiV

,reveL

liOrotarbiVliOecalpeR

liOenignEliOecalpeR

noit

liOciluardyHliOecalpeR

,reveLlevarT

reveLelttorhT

ECNANETNIAM

DEDEEN

noitarepO

noitarepOfo

noitacirbuLddA

gnidilSotliO

straP

noitarepO

YCNEUQERFEPYTNOITACOL

fosruoH003yrevE

02ot01retfA-yllaitinI

noitarepOfosruoH

ot05yrevE-retfaerehT

noitarepOfosruoH001

fosruoH05yrevE

AS92erugiFees

)remmuS-gnirpS(

)retniW-llaF(

03W01EAS

xE(

:ytisocsiV

noigerdloc

sruoH0051ot0001yrevE

noigermrawrof-

64sulleTllehS

)sretil52(

liOnoitacirbuL4erugiFees

)sretil5.1(03W01E

03W01EASro03#EAS

03W01EASro02#EAS

)noigeRdloCylemert

rof-tnelaviuqe23GVOSI

tnela

viuqe65ro64GVOSI

htiwyrotcafmorfdeppihS

6erugiFees

7erugiFees

s'naMdaeD

eciveD

raBeldnaH

niPesaeleR

gniraeB

revoC

xoBhctulC

eveLlevarT

r

retliFliOretliFliOecalpeR

esaerGetacirbuL

gnittiF

tacirbuL

gnittiF

gnittiF

gnittiF

straP

esaerGe

E

esaerGetacirbuL

esaerGetacirbuL

gnidilSetacirbuL

noitarepO

noitarepO

noitarepO

noitarepO

noitarepO

noitarepO

fosruoH05yrevE

fosruoH05yrevE

fosruoH05yrev

fosruoH05yrevE

fosruoH05yrevE

2retfA-yllaitinI

noitarepOfosruoH

fosruoH5

005yrevE-retfaerehT

esaerG4erugiFees

esaerG23erugiFees

esaerG13,03serugiFees

esaerG52erugiFees

esaerG4erugiFees

norcim01eniuneGasakiM

repaPretliF

62erugiFees

PAGE 32 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 33

Vibrator Oil

Level Plug

Figure 29. Vibrator Oil Maintenance

MRH-800DS—MAINTENANCE

Handle Bar Release

Pin Grease Fitting

Figure 32. Handle Bar Maintenance

Vibrator Oil

Drain Plug

Clutch Box Grease Fitting

FIgure 30. Bearing Cover Grease Fitting

Bearing Cover Grease Fitting

Figure 31. Bearing Cover Maintenance

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 33

Figure 33. Clutch Box Maintenance

Hydraulic Oil Filter

Figure 34. Hydraulic Oil Filter Location

Page 34

NOTE PAGE

PAGE 34 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 35

MRH-800DS— ROLLER TROUBLESHOOTING

GNITOOHSELBUORT.9ELBAT

MOTPMYSMELBORPELBISSOPNOITULOS

.levarttonseodtinU?degagnellitsekarbgnikraP .reveleka

?hctulclagufirtnecevitcefeD .hctulcecalperroriape

?egnalfdnagnilpuocrebburdegamaD .egnalfdnagnilpuocrebburecalpeR

?knildnaelbaclevartevitcefeD .knildnael

rolevarttonseodtinU

odegamaD.retlifecalpeR

.htoomstonsilevart

elrodegamaD .rotomciluardyhecalperroriapeR

?noitatormurddaB .murdec

?retlifliodeggolcr

?epipciluardyhgnikaelrodegamaD .strapecalperroriapeR

?liodetanimatnocrolevelliowoL

?pmupciluardyhgnikaelrodegamaD .pmupciluardyhecalperroriapeR

?rotomciluardyhgnika

?gniraebdnaraegmurddegamaD.strapriapeR

?hctulclagufirtnecevitcefeD .hctulcecalperroriapeR

R

?reparcsnidumhcumootroreparcsdegamaD .reparcsriaperroecalpeR

rbgnikrapesaeleR

alperroriapeR

baclevartecalperroriapeR

.lioecalperrohsinelpeR

leb-VgnippilsrodegamaD .noisnettsujdarotleb-VecalpeR

?t

?egaknildnaelbacnoitarbivdegamaD

roetarbivtonseodtinU

.noitarbivkaewsah

eD.tleb-VecalpeR

?hctulcnoitarbivdegamaD .hctulcecalperrotsujdA

?tleb-Vyelluprotarbivhctulcevitcef

?dnahhtiwylhtoomsnruttonseodrotarbiV

.egaknil

onsilevel

iaperroecalpeR

.hgihylevissecxet

dnaelbacnoitarbivr

liofikcehC.rotarbivriaperdnakcehC

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 35

Page 36

MRH-800DS— ENGINE TROUBLESHOOTING

GNITOOHSELBUORTENIGNE.01ELBAT

NOTPMYSMELBORPELBISSOPNOITULOS

?noitisop"POTS"nisirevellortnocdeepS .noitisop"TRATS"otrevellortnocdeepsteS

oitcejnignihcaerleufoN .metsysleuferitnekcehC.leufddA

?pmupleufevitcefeD.pmupleufecalpeR

uF .knatnaelcdnaretlifleufecalpeR

sitratsrotratstonlliwenignE

,deyaled

.revodenruteb

oltA

.tratston

nacenignehguohtla

lliwenigneserutarepmetw

?deggolcretlifle

?enilylppusleufytluaF.enilleufriaperroecalpeR

?wolootnoisserpmoC

?wolooterusserpliO.erusserplioenignekcehC

erutarepmetgnitratswoL

?serutarepmetwolot

?pmupn

A.sevlavdnarednilyc,notsipkcehC

.launamriaperenignerepriaper

?yltcerrocgnikrowtonrotcejnileuF

dedeecxetimil

ecnatsiseretauqedanisahsetarapesleuF

.launamriaperenigne

.ytisocsivlioreporp

.leufleseidedargretniw

occanirotcejniecalperroriapeR

rotsujd

htiwecnadr

dnasnoitcurtsnignitratsdlochtiwylpmoC

leuf)dibrutton(raelcrehtehwkcehC

mo

rfhcated(enilleufehtmorfsegreme

rodibrutsileufehtfI.)pmupnoitcejni

ehtniardroenigneehtpumraw,detarapes

tiwleufeR.metsysylppusleufetelpmoc

h

?kcihtootlioenignE

elttorhT .noitisopNURotrevelelttorhtnoitisopeR

sanoosspotstubserifenignE

.ffodehctiwssiretrats

gnirudflestiybspotsenignE

.noitarepolamron

F.retlifleufecalpeR

?dekcolbretlifleuF.retlifleufecalpeR

?dekcolbylppusleuF .me

?ytpmeknatleuF.leufddA

?dekcolbretlifleu

?noitisopPOTSnirevel

nignellifeR

.tnemnorivneretniwroflio

tsysleuferitneehtkcehC

foepyttcerrochtiwesacknarce

PAGE 36 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 37

MRH-800DS— ENGINE TROUBLESHOOTING

)DEUNITNOC(GNITOOHSELBUORTENIGNE.01ELBAT

NOTPMYSMELBORPELBISSOPNOITULOS

?ytpmeknatleuF.retlifleufecalpeR

?deggolcretlifleuF.retlifleufecalpeR

dnatuptuo,rewopenignewoL

.deeps

?noitisop

?llufootlevellioenignE ?levellioenignetcerroC

?

dnatuptuorewopenignewoL

tsuahxekcalb,deepswol

.ekoms

dekcolbretlifriA .retlifriaecalperronaelC

?

rotcejnitanoitcnuflaM.launamenigneeeS

?etauqedanisignitnevknatleuF .detnevyle

detcelesniniamertonseodrevellortnocdeepS

?secnaraelcevlavtcerrocnI .noitacificepsenignerepsevlavtsujdA

tauqedasiknattahterusnE

.noitcaevitcerrocroflaunamenigneeeS

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 37

Page 38

EXPLANATION OF CODE IN REMARKS COLUMN

How to read the marks and remarks used in this parts book.

Section 1: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial number

range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model number

or model number variant.

Section 3: Items Found In the “Items Number” Column

NOTE

If more than one of the same

reference number is listed, the

last one listed indicates

newest (or latest) part

available.

All parts with same symbol in the number column,

■

, belong to the same assembly or kit.

NOTE

The contents of this parts

, #, +, %, or

*

catalog are subject to

change without notice.

PAGE 38 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 39

MRH-800DS VIBRATION ROLLER 1 TO 3

UNITS WITH YANMAR L100EE-DEVMK2

DIESEL ENGINE

Qty. P/N Description

1 ............ 954401890 ...... FILTER, WATER TANK

2 ............ 954001380 ...... FILTER, HYDRAULIC OIL

2 ............ 070503000 ...... V-BELT, ENGINE

1 ............ 956100022 ...... THROTTLE WIRE

1 ............ 954300340 ...... CAP, WATER TANK

2 ............ 070100381 ...... V-BELT, VIBRATOR ASSY.

1 ............ 71487553101 .. VALVE ASSY., FUEL INJECTOR

1 ............ 71465651110 .. PUMP ASSY., FUEL INJECTOR

3 ............ 11465012590 .. ELEMENT, AIR CLEANER

1 ............ 11428855041 .. CAP ASSY., FUEL TANK

2 ............ 11425035110 .. STRAINER, LUB. OIL ASSY.

1 ............ 11425055100 .. FILTER, FUEL STRAINER

2 ............ 11425055121 .. FILTER, FUEL OIL

2 ............ 955000010 ...... KEY, STARTING

SUGGESTED SPARE PARTS

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 39

Page 40

DECAL PLACEMENT

MRH-800DS VIBRATION ROLLER — DECAL PLACEMENT

PAGE 40 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 41

MRH-800DS VIBRATION ROLLER — DECAL PLACEMENT

PLACEMENT

NO. PART NO. PART NAME QTY. REMARKS

1 920205690 DECAL, BRAKE LEVER ..................................1 ...... NPA-569

2 9202009660 DECAL, CAUTION - ENGINE SPEED .............1 ...... NPA-966

3 920206280 DECAL, DANGER - PINCH POINT ..................1 ...... NPA-628

4 920102490 DECAL, LIGHT SWITCH ..................................1 ...... NPA-249

5 920101480 DECAL, CHECK OIL LEVEL ............................1 ...... NP-148

6 DCL210 DECAL, MIKASA MOBILE DTE 25 1

7 920108070 DECAL, FORWARD/REVERSE LEVER .......... 1 ...... NPA-507

8 920100120 DECAL, GREASE POINT ................................ 1 ...... NPA-120

9 920208070 DECAL, PARKING BREAK .............................. 1 ...... NPA-907

10 920206160 DECAL, CAUTION - INCLINE PARKING ..........1 ...... NPA-616

11 920206200 DECAL, WATER TANK SPRINKLE PIPE ......... 1 ...... NPA-620

12 920203330 DECAL, HEARING PROTECTION ................... 1 ...... NPA-333

13 920201910 DECAL, MULTIQUIP - CARSON ...................... 1 ...... NPA-191

14 920101510 DECAL, MIKASA ............................................. 1 ...... NP-151

15 920200320 DECAL, WATER TANK ...................................... 1 ...... NP-32

16 920207620 DECAL, MRH-800DS........................................ 1 ...... NPA-762

17 920206290 DECAL, CAUTION - OWNERS MANUAL .........1 ...... NPA-629

18 920202810 DECAL, CAUTION - VIBRATION LEVER .........1 ...... NPA-281

19 920104280 DECAL, FREEZING PREVENTION .................1 ...... NPA-428

20 920200470 DECAL, OIL TANK ............................................1 ...... NPA-47

21 920202870 DECAL, CAUTION - INSTRUCTIONS PLATE .. 1 ...... NPA-287

22 920205640 DECAL, WARNING - INCLINE PARKING ......... 1 ...... NPA-564

23 920105170 DECAL, THROTTLE .........................................1 ...... NPA-517

24 920202860 DECAL, CAUTION - MOVING PLATE ..............1 ...... NPA-286

25 920201450 DECAL, HORN ................................................. 1 ...... NPA-145

26 920202920 DECAL, CAUTION - STARTING ENGINE ........ 1 ...... NPA-292

27 920205680 DECAL, WARNING - INCLINE PLATE ..............1 ...... NPA-292

28 920106760 DECAL, IGNITION ........................................... 1 ...... NPA-676

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 41

Page 42

AXLE ASSY.

MRH-800DS VIBRATION ROLLER — AXLE ASSY.

PAGE 42 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 43

MRH-800DS VIBRATION ROLLER — AXLE ASSY.

AXLE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 515112960 DRUM 1

2 515112970 DRUM 1

3 515333990 GEAR PLATE 2

4 515334000 GEAR (39) 2

5 509429660 COLLAR 405510 2

6 001121630 BOLT 16X30 T 16

7 515117050 DRUM BRACKET (R) 2

8 506425980 FELT (DRUM) 5X5X1200 1

9 060605020 OIL SEAL VC-55727 2

10 042006308 BEARING 6308DU 4

11 020130240 NUT M30, P2.0 4

12 031130450 WASHER M30 4

13 515334010 BEARING COVER (R) 2

14 050100850 O-RING G-85 2

15 001221025 BOLT 10X25 T 20

16 030210250 WASHER M10 28

17 505015060 GREASE FITTING A-PT1/8 4

18 351010050 GREASE FITTING A-MT6X1 2

19 515113000 DRUM BRACKET (L) 1

20 515113010 DRUM BRACKET (LB) 1

21 506425670 COLLAR 405520 2

22 060705010 OIL SEAL TB4-55729 2

23 515334040 BEARING COVER (L) 2

24 050300950 O-RING S-95 2

25 515446960 LOCK PUN, BRAKE 1

26 515446950 SPRING, BRAKE 1

27 025405025 SPRING PIN 5X25 1

28 515446970 KNOB, BRAKE 1

29 020410060 NUT M10, H=6 1

30 515117040 SIDE PLATE (R) 1

31 515114350 SIDE PLATE (L) 1

32 001221430 BOLT 14X30 T 16

33 515341930 BRACKET (A), SCRAPER 2

34 515341940 VRACKET (B), SCRAPER 2

35 515334020 SCRAPER (OUT) 2

36 515447510 MOUNT NUT, SCRAPER 4

37 001121435 BOLT 14X35 T 8

38 001221030 BOLT 10X30 T 8

39 031110160 WASHER M10 12

40 515334030 SCRAPER (IN) 2

41 959010330 GREASE FITTING B-M6FX1 1

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 43

Page 44

BASE ASSY.

MRH-800DS VIBRATION ROLLER — BASE ASSY.

PAGE 44 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 45

MRH-800DS VIBRATION ROLLER — BASE ASSY.

BASE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 515114460 BASE (YANMAR-L100) 1

2 939010010 SHOCK ABSORBER, STOPPER 45 2

3 030210250 WASHER, LOCK M10 9

4 020310080 NUT M10 3

5 930710031 SHOCK ABSORBER RV1-100 4

6 020316130 NUT M16 4

7 030216400 WASHER, LOCK M16 4

8 001221625 BOLT 16X25 T 4

10 001221440 BOLT 14X40 T 2

11 030214350 WASHER, LOCK M14 2

12 515447010 SAFETY GUARD 4

13 001520815 SOCKET HEAD BOLT 8X13 T 8

14 501402870 HANDLE STOPPER 1

15 959010413 EYE NUT M10 1

15 959010416 T- KNOB (M10) 1

16 501402880 SPRING / HANDLE (1. 4X18X44) 1

17 001221230 BOLT 12X30 T 2

18 0039312000 NUT M12 ................................................ 2 ........... REPLACES 020312100

30 5153344100 STAY, COVER (F) 1

32 012210020 BOLT 10X20 T ........................................ 5 ........... REPLACES 001221020

33 031110160 WASHER, FLAT M10 7

34 0105050616 BOLT 6X15 T .......................................... 8 ........... REPLACES 001220615

35 030206150 WASHER, LOCK M6 8

36 952404470 WASHER, FLAT M6 ................................ 8 ........... REPLACES 031106100

56 515334050 SUPPORT , WATER COCK 1

57 014208020 BOLT 8X20 T .......................................... 2 ........... REPLACES 001220820

58 030208200 SWM8 2

59 509010010 CAP 3/8 1

60 954403240 COCK PT1/4, BH-1211 (PL) 2

61 954405660 ELBOW 3/8X12 1

63 515446980 WATER HOSE (T-V) 300L 1

64 515446990 WATER HOSE (F) 1200L 1

66 515447470 WATER HOSE (R) 260L 1

67 515910030 SPRINKLING PIPE AY MRH 2 ........... INCLUDES ITEMS W/

68 506425750 CAP, SPRINKLING PIPE 4

68A

68-1+ 001220620 BOLT 6X20 T 4

68-2+ 031106100 WASHER, FLAT M6 4

69 515449900 CLAMP 00 4

72 171010120 GREASE FITTING A-M6F 1

73 954001590 SOCKET PT3/8-3/8 1

91 515213600 HOOK (L100) 1

92 515113710 GUARD (L100) 1

93 001221035 BOLT 10X35T 2

94 001221020 BOLT 10X20t 2

95 030210250 WASHER, LOCK M10 4

96 091004016 WASHER, FLAT M10 4

515910050 CAP AY, W/BOLT, WASHER ................... 4 ........... INCLUDES ITEMS W/+

*

*

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 45

Page 46

FRONT GUARD ASSY.

MRH-800DS VIBRATION ROLLER — FRONT GUARD ASSY.

PAGE 46 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 47

MRH-800DS VIBRATION ROLLER — FRONT GUARD ASSY.

FRONT GUARD ASSY.

NO. PART NO. PART NAME QTY. REMARKS

75 031110160 FLAT WASHER, M10 2

76 030210250 LOCK WASHER, M10 2

77 001221035 BOLT 10x35 mm 2

78 515336200 FRONT GUARD 1

79 515336210 BUMPER 2

80 515449720 SPACER, BUMPER 4

81 001221040 BOLT 10X40 T 4

82 031110160 WASHER, FLAT M10 4

84 953405940 PIPE INSERT PZ-7 2

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 47

Page 48

SIDE COVER ASSY.

MRH-800DS VIBRATION ROLLER — SIDE COVER ASSY.

PAGE 48 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 49

MRH-800DS VIBRATION ROLLER — SIDE COVER ASSY.

SIDE COVER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

3 030210250 WASHER, LOCK M10 9

20 515336250 SUPPORT, COVER 1

21 515449890 ROD HOLDER 1

24 515334600 RUBBER HINGE 1

25 515010090 RIVET 2

26 515010100 RIVET 14

27 092004008 SCREW 4X8 7

29 515113080 COVER, E/G 1

31 515447030 STAY, COVER (R) 1

32 012210020 BOLT 10X20 T ............................................ 5 .......... REPLACES 001221020

33 031110160 WASHER, FLAT M10 7

34 0105050616 BOLT 6X15 T .............................................. 8 .......... REPLACES 001220615

35 030206150 WASHER, LOCK M6 8

36 952404470 WASHER, FLAT M6 ................................... 8 .......... REPLACES 031106100

38 0105091025 BOLT 10X25 T ............................................ 2.......... REPLACES 001221025

39 515447380 ROD, COVER 1

40 607010080 COTTER PIN 6 1

97 091004016 SCREW 4X16 1

98 031104080 WASHER, FLAT M4 2

99 020304030 NUT M4 1

170 515114870 COVER (EXP) 1

171 515214240 STAY, COVER (EXP) 1

172 515450780 HANDLE BRACKET 2

173 515450790 HANDLE (COVER) 2

174 091004015 SCREW 4X15 4

175 031104080 WASHER, FLAT M4 4

176 030204100 WASHER, LOCK M4 4

177 001220815 BOLT 8X15 T 2

178 031108160 WASHER, FLAT M8 2

179 030208200 WASHER, LOCK M8 2

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 49

Page 50

WATER TANK ASSY.

MRH-800DS VIBRATION ROLLER — WATER TANK ASSY.

PAGE 50 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 51

MRH-800DS VIBRATION ROLLER — WATER TANK ASSY.

WATER TANK ASSY.

NO. PART NO. PART NAME QTY. REMARKS

41 515114200 WATER TANK 1

42 954300340 CAP, WATER TANK /MR 1

43 001241030 BOLT 10X30 U 1

44 033910010 WASHER 10.5X21X2 SUS 2

45 022910180 NYLON NUT M10 (SUS) 1

46 954404910 HOSE JOINT 17D 1

47 954404890 FILTER, TANK /MR 1

48 953404900 PACKING 26X36X3 2

49 959404880 NUT 3/4 2

50 506403990 CAP PS1 2

51 953404000 PACKING, CAP PS1 1

52 506434680 STOPPER, FRONT 2

53 506434690 SPACER, WATER TANK 39L 4

54 001221253 BOLT 12X65 T 4

55 030212300 WASHER, LOCK M12 4

62 954405680 CONNECTOR 1/4x10 2

65 515447000 WATER LOSE (T) 280 1

70 515449870 HOLDER, STOPPER 2

71 515448290 STOPPER 2

71 517338540 STOPPER 2

74 001220610 BOLT 6X10 T 4

75 031106100 WASHER, FLAT M6 4

76 030206150 WASHER, LOCK M6 4

86 515449880 HOLDER (R) 2

87 952405950 WASHER 13506 2

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 51

Page 52

MRH-800DS VIBRATION ROLLER — HYDRAULIC SYSTEM ASSY.

HYDRAULIC SYSTEM ASSY.

PAGE 52 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 53

MRH-800DS VIBRATION ROLLER — HYDRAULIC SYSTEM ASSY.

HYDRAULIC SYSTEM ASSY.

NO. PART NO. PART NAME QTY. REMARKS

7 954001350 OIL FILTER CPO 3-80 ..................... 1 ...... INCLUDES ITEMS W/

7-1*954001390 FILTER HEAD 1

7-2*954001380 OIL ELEMENT 1

8 954001530 ELBOW LIN-1/2-PT3/8 3

9 954001501 TUBE 9.6-12.7 - 300 1

10 959020011 SPIRAL TUBE 11D-350L 1

11 954001511 TUBE 9.6-12.7-360 1

12 955404275 SPIRAL TUBE 11D-400L 1

14 515010050 OIL PUMP PV10-610 1

14 515010110 OIL PUMP PV10 -625 1

15 515114390 BRACKET (PV10) 1

16 952404110 COLLAR 10225 2

17 012210035 BOLT 10X35 T ................................. 2 ...... REPLACES 001221035

18 030210250 WASHER, LOCK M10 22

19 515334070 COUPLING 1

20 515334080 FLANGE (PV10) 1

21 515447020 COUPLING PIN 2

22 046006009 BEARING 6009DDU 1

23 080200450 STOP RING S -45 1

24 952400450 WASHER 7X30X4.5 1

25 954001460 BUSHING CP-3/8 2

26 954001710 ELBOW PF3/8 - PF1/4X2 2

27 954001370 OIL HOSE ML90-ML90X560 1

27 954001830 OIL HOSE ML90-ML90X560 BS 1

28 959020013 SPIRAL TUBE 11D-600L 1

29 516010080 OIL HOSE ML90-1005X600 1

29 954001840 OIL HOSE ML90-1005X600 BS 1

30 955404270 SPIRAL TUBE/11D-700L 1

31 515010040 OIL MOTOR K2355(BLUE) 2

32 515446940 PINION (12) 2

33 952400130 WASHER 9304 2

34 012210035 BOLT 10X35 T ............................... 14 ...... REPLACES 001221035

35 0105050616 BOLT 6X15 T ................................... 2 ...... REPLACES 001220615

36 030206150 WASHER, LOCK M6 2

37 515447130 JOINT 1/2-3/8-31 4

38 050210180 O-RING P-18-1B 4

39 512010120 JOINT, LLM-UE-10X3/8-B 4

40 515447110 PIPE, OM-A-E 2

41 515447120 PIPE, OM-B-E 2

*

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 53

Page 54

MRH-800DS VIBRATION ROLLER — HYDRAULIC SYSTEM ASSY.

HYDRAULIC SYSTEM ASSY.

PAGE 54 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 55

MRH-800DS VIBRATION ROLLER — HYDRAULIC SYSTEM ASSY.

HYDRAULIC SYSTEM ASSY.

NO. PART NO. PART NAME QTY. REMARKS

42 515447160 HOLDER, UPPER 2

43 515447170 HOLDER, LOWER 2

44 001520820 SOCKET HEAD BOLT 8X20 T 8

45 515447140 COVER, PIPE 2

46 012210020 BOLT 10X20 T .............................. 4 ......... REPLACES 001221020

47 031110160 WASHER, FLAT M10 8

48 515447150 PIPE, OM-B--OM-A 1

49 515447300 STAY, PIPE 1

50 607010040 CLAMP CLA-3200 (7D) 1

51 952404470 WASHER, FLAT M6 ...................... 2 ......... REPLACES 031106100

52 020106050 NUT M6 ........................................ 1 ......... REPLACES 020306050

53 507010110 CLAMP TC-200 5

55 014208020 BOLT 8X20 T ................................ 4 ......... REPLACES 001220820

56 030208200 WASHER, LOCK M8 2

57 954001520 ADAPTER CIN-1/2XPT3/8 1

58 031108160 WASHER, FLAT M8 2

59 515335300 CHECK VALVE 7/16 2

60 954001090 ADAPTER CIN-3/8-PT1/4 1

61 954001010 JOINT PT3/8 1

62 954001620 FITTING, TEE STIN3/8-PT3/8 1

63 954001630 NIPPLE PT3/8 1

64 954001650 TUBE 9.5D-7D-370 1

65 954001640 TUBE 9.5D-7D-290 1

66 954001100 ELBOW LIN-3/8-PT1/4 1

67 454010020 CLAMP TC-100 12

68 959021817 SPIRAL TUBE 6D-350L 1

69 959021818 SPIRAL TUBE 6D-510L 1

70 954001040 CAP PF1/4 2

81 515335451 SPACER (PV10) 1

82 0109051045 BOLT 10X40 T .............................. 4 ......... REPLACES 001221040

83 012010030 BOLT 10X30 T .............................. 2 ......... REPLACES 001221030

84 515447020 COUPLING PIN 2

MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05) — PAGE 55

Page 56

MRH-800DS VIBRATION ROLLER — HYDRAULIC OIL TANK ASSY.

HYDRAULIC OIL TANK ASSY.

PAGE 56 — MQ-MIKASA MRH-800DS VIBRATION ROLLER — PARTS & OPERATION MANUAL — REV. #3 (02/02/05)

Page 57

MRH-800DS VIBRATION ROLLER — HYDRAULIC OIL TANK ASSY.

HYDRAULIC OIL TANK ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 515114221 OIL TANK , (GREEN) 1

1 515010140 OIL TANK , (ORANGE) 1

2 953405840 DRAIN PLUG M18 ........................... 1 ...... REPLACES 953102781

3 953402930 COPPER PACKING 19X30X1 1

4 953400270 PLUG 1/4X14 10L 1

5 953405260 PACKING 1/4 (CU) 1

13 959010120 LEVEL GAUGE/L =60 1

18 030210250 WASHER, LOCK M10 22