Page 1

APPLICA TION & INST ALLA TION MANUAL

MQ POWER

Industrial Generator Set

Application & Installation

Manual

© COPYRIGHT 2007, MQ PPOWER

Revision #4 (09/07/07)

MQPOWE R

A Division of Multiquip Inc.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 800-883-2551

F AX: 310-632-2656

E-MAIL: mqpower@multiquip.com

WWW: www .mqpower.com

PARTS DEPARTMENT:

800-427-1244

F AX: 800-637-3284

SERVICE DEPAR TMENT :

800-835-2551

F AX: 310-638-8046

Page 2

PAGE 2 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER

MUL TIQUIP’S MAIN PHONE NUMBERS

800-421-1244 FAX: 310-537-3927

310-537-3700

PARTS DEP ARTMENT

800-427-1244 FAX: 310-637-3284

310-537-3700

MQ POWER SERVICE DEP ARTMENT

800-835-2551 FAX: 310-638-8046

310-537-3700

TECHNICAL ASSIST ANCE

800-478-1244 FAX: 310-631-5032

WARRANTY DEP ARTMENT

800-421-1244, EXT. 279 FAX: 310-537-1173

310-537-3700, EXT. 279

ON-HAND

WHEN CALLING

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 3

Page 4

T ABLE OF CONTENTS

Proposition 65 California Warning............................. 2

Here's How To Get Help............................................ 3

Table Of Contents ..................................................... 4

Safety Message Alert Symbols.............................. 6-7

Important Safety Instructions............................... 8-13

Introduction ............................................................. 14

Installation Overview.......................................... 15-16

ApplicationApplication

Application

ApplicationApplication

Genset Sizing.....................................................17-21

Determining Load Characteristics ......................22-26

Environmental Consideration — dB(A)..............27-32

Mechanical InstallationMechanical Installation

Mechanical Installation

Mechanical InstallationMechanical Installation

Mounting Foundation ......................................... 33-34

Mounting Genset .................................................... 35

Mounting — Vibration Isolators ............................... 36

Fuel System .......................................................37-45

Exhaust System .................................................46-49

Battery System...................................................50-51

Installing New Battery ........................................52-53

Testing Batter y ...................................................54-55

Charging Battery ................................................ 56-59

VV

entilation and Coolingentilation and Cooling

V

entilation and Cooling

VV

entilation and Coolingentilation and Cooling

Ventilation and Cooling ...................................... 60-61

Mounted Radiator Cooling ................................. 62-63

Remote Radiator Cooling .................................. 64-65

Hot Well Cooling...................................................... 66

Heat Exchanger Cooling ......................................... 67

Coolant Treatment................................................... 68

Electrical InstallationElectrical Installation

Electrical Installation

Electrical InstallationElectrical Installation

DC Control Wiring ................................................... 69

Control Box Back Panel......................................70-72

AC Electrical Connections.................................. 73-75

System Grounding .............................................76-77

Equipment Grounding............................................. 78

Electrical Distribution System.................................. 79

Pre-Start Preparation ......................................... 80-81

AppendixAppendix

Appendix

AppendixAppendix

Installation Checklist .........................................82

Table 25, Main-Line Circuit Breakers................83-84

Table 26, Generator Specifications...................85-87

Table 27, Engine Specifications ........................88-91

Table 28, Dimension and Weights..................... 92-93

NOTE

PAGE 4 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

All specifications in this

manual are subject to change

without notice.

Page 5

NOTES PA GE

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 5

Page 6

SAFETY MESSA GE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when installing

or operating this equipment. Failure to read and understand the

Safety Messages and Installation Instructions could result in

injury to yourself and others.

This genset Installation Manual has

been developed to provide

NOTE

complete instructions for the safe

implementation of MQ Power

Gensets for field installation.

Depending on the power plant you

can be also extremly dangerous if inhaled. They are odorless

but a smell has been added to detect any leaks. IMMEDIATELY

shut off the gas source if a leak is detected. If in an enclosed

area, vacate the premises until the area is ventilated.

have selected, please refer to the

engine manufacturers instructions for data relative to its safe

operations.

Before installing any MQ Power Genset, ensure that all

authorized personnel have read and understands all

installation or operating instructions referenced in this

manual.

Diesel fuel is extremely flammable, and its vapors

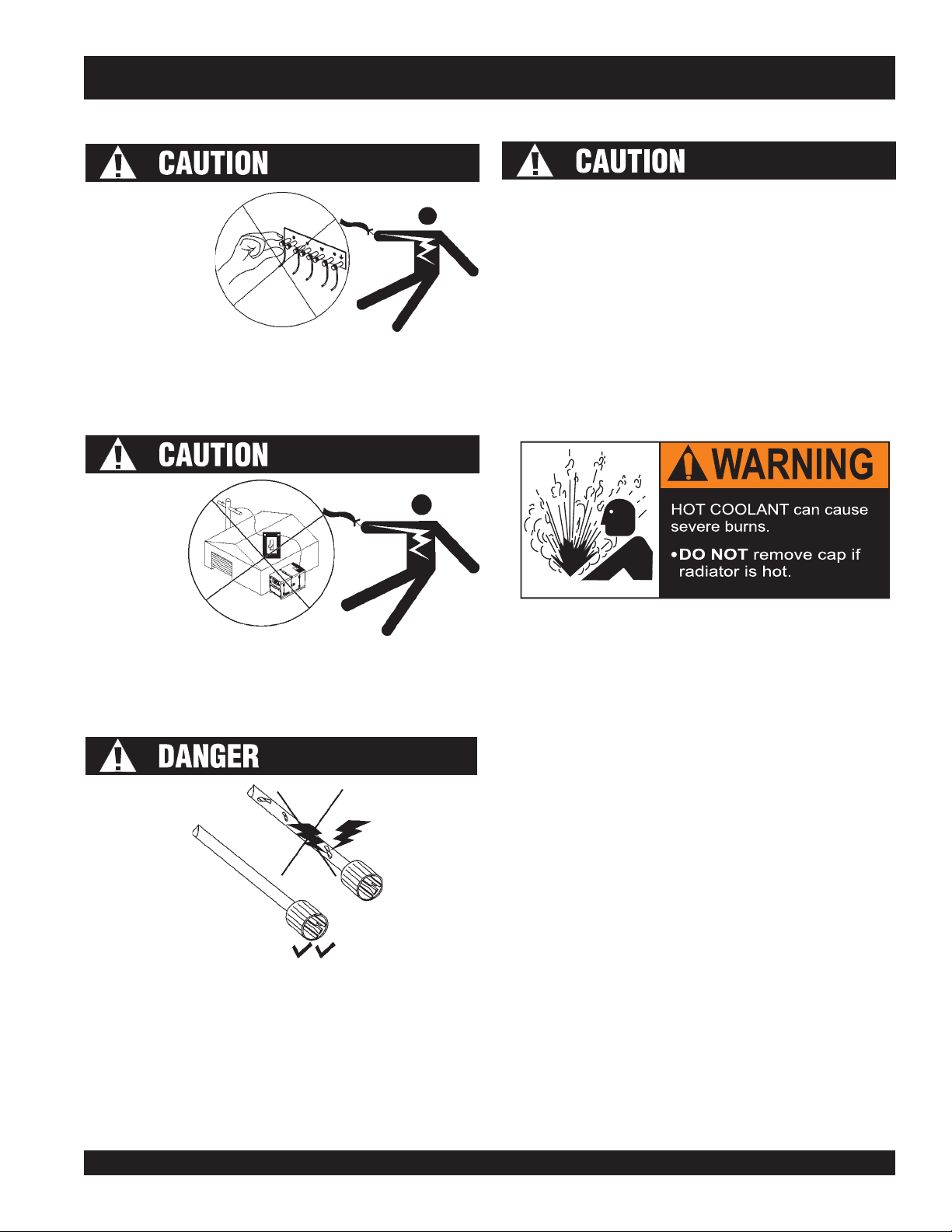

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded b y one of three words: DANGER,

WARNING, or CAUTION.

You WILL be

if you DO NOT follow these directions.

KILLED

or

SERIOUSLY INJURED

approved containers, in well-ventilated areas and away from

sparks and flames. NEVER use fuel as a cleaning agent.

Natural gas and LPG are extremely flammable and will explode

and catch fire if exposed to sparks or flame. NEVER smoke in

any area where gases are stored or supplied. IMMEDIATELY

shut off the gas source if a leak is detected. Be certain that the

area is well ventilated before exposing it to any mechanical or

electrical device that may emit heat or sparks.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a

confined area or enclosed structure that

does not provide ample free flow air.

Natural gas and liquid petroelum gas (LPG)

Explosive Fuel

can cause an explosion if ignited.

DO NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

You CAN be KILLED or

you DO NOT follow these directions.

SERIOUSLY INJURED

if

while the engine is running or immediately after

operation. NEVER operate the engine with heat

shields or heat guards removed.

Rotating Parts

You CAN be

these directions.

Potential hazards associated with MQ Power Gensets field

installation will be referenced with Hazard Symbols which appear

throughout this manual, and will be referenced in conjunction

with Safety Message Alert Symbols.

PAGE 6 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

INJURED

if you DO NOT f ollo w

NEVER operate equipment with covers or

guards removed. Keep fingers, hands, hair

and clothing away from all moving parts to

prevent injury.

Page 7

SAFETY MESSA GE ALERT SYMBOLS

Accidental Starting

ALWAYS place the ignition switch or genset

starting device in the OFF position, remove key

and/or disconnect the battery before servicing

the engine or equipment.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

Guards and Covers In Place

NEVER operate the genset without guards and

covers in place.

Respiratory Hazard

ALWAYS wear approved respiratory protection.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your genset, other property, or the

surrounding environment.

THIS MQ POWER GENSET, OTHER PROPER TY, OR THE SURROUNDING

EQUIPMENT COULD BE DAMA GED IF Y OU DO NOT FOLLOW INSTRUCTIONS

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

■

SAVE THESE INSTRUCTIONS — This manual

contains important safety instructions for MQ

Power Industrial generators that should be

followed during installation, operation, and

maintenance of the engine-generator set.

F ailure to follow instructions in this manual may lead to

serious injury or even death! This equipment is to be

operated by trained and qualified personnel only! This

equipment is for industrial use only.

GENERAL SAFETY

■

DO NOT install, operate , or service this

equipment before reading this entire

manual along with the operation

manual.

High Temperatures – Allow the engine to cool before

adding fuel or performing service and maintenance

functions. Contact with

burns.

■

The engine of this generator requires an adequate free

flow of cooling air. Never operate the generator in any

enclosed or narrow area where free flow of the air is

restricted. If the air flow is restricted it will cause serious

damage to the generator or engine and may cause injury

to people. The generator engine giv es off DEADLY carbon

monoxide gas.

NEVER operate

the genset in a

restricted air flow

environment!

hot

components can cause serious

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the

influence of drugs or alcohol.

■

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to cool

before servicing engine or generator .

■

■

■

■

■

DO ALWAYS refuel in a well-ventilated area, away from

sparks and open flames. Fire or explosion could result

from fuel vapors, causing severe bodily harm — even

death!

DO NOT smoke around or near the

machine. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a

hot engine, causing severe bodily harm

— even

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow

it to cool.

NEVER operate the generator in an

explosive atmosphere or near

combustible materials. An explosion or fire could result

causing severe

Topping-off to filler por t is dangerous, as it tends to spill

fuel.

death!

bodily harm or even death!

PAGE 8 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 9

IMPORT ANT SAFETY INSTR UCTIONS

GENERAL SAFETY

■

NEVER touch output terminals during operation. This is

extremely dangerous. Always stop the machine and

disconnect the battery when contact with the output

terminals is necessar y.

RADIAT OR

■

1. Radiator Cap - Removing the radiator cap while the

DO NOT touch or open an y of the components mentioned

below while the generator is running. Always allow

sufficient time for the engine and generator to cool before

performing maintenance.

engine is hot will result in high pressurized, boiling water

or coolant to gush out of the radiator, causing severe

scalding to any persons in the general area of the

generator .

■

NEVER connect the generator to house wiring. This is

illegal and very dangerous. Electrical shock could occur

causing damage to the generator and bodily harm — even

2. Coolant Drain Plug - Removing the coolant drain plug

death!

3. Engine Oil Drain Plug - Removing the engine oil drain

■

NEVER use damaged or worn cables when connecting

power tools or equipment to the generator. Make sure

power connecting cables are securely connected to the

generator’ s output terminals, insufficient tightening of the

terminal connections may cause arcing and damage the

generator . Touching worn or frayed electrical cables may

cause electrical shock, which could result in severe bodily

harm or even

death!

while the engine is hot will result in hot coolant to drain

out of the coolant drain plug, and could cause severe

scalding to any persons in the general area of the

generator .

plug while the engine is hot will result in hot oil to drain

out of the oil drain plug, and could cause severe scalding

to any persons in the general area of the generator .

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 9

Page 10

IMPORTANT SAFETY INSTRUCTIONS

Operation Safety

■

ALWAYS be sure the operator is familiar with proper saf ety

■

precautions and operations techniques before using

generator .

■

DO NOT allo w unauthorized people near equipment.

■

ALWAYS wear ear protection when working in

a loud environment.

■

NEVER run engine without air filter. Engine damage will

occur.

■

DO NOT leave the generator running in the MANUAL

mode unattended.

■

NEVER use accessories or attachments which are not

recommended by MQ P ower for this equipment. Damage

Maintenance Safety

When performing maintenance on MQ Po wer generator sets,

it is important to prevent automatic start-up of the unit by a

remote contact closure by disconnecting the engine battery

before servicing.

to the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any

accident due to equipment modifications.

■

ALWAYS check the machine for loosened par ts or bolts

before starting.

Always disconnect the battery cable negative (first) before

performing service on the generator. Reconnect battery cable

negative (last) after service is complete.

In emergencies

phone or

phone numbers of the nearest

fire department

case of an emergency .

always

know the location of the nearest

keep a phone on the job site

. This inf ormation will be invaluable in the

. Also know the

ambulance, doctor

and

Emergencies

Always be prepared for an emergency such as fire, personnel

injury , or other emergency situation. It is important to identify

all possible emergency situations and to provide adequate

prevention methods and response methods.

■

Install the appropriate fire extinguishers in convenient

locations. Consult the local fire department for the correct

type of extinguisher to use. DO NOT use foam on

electrical fires. Use extinguishers that are rated ABC by

the National Fire Protection Association (NFPA).

■

ALWAYS know the location of the

nearest

fire extinguisher

.

■

Keep the machinery in proper running condition.

■

NEVER lubricate components or attempt service on a

running machine.

■

Always allow the machine a proper amount of time to

cool before servicing.

■

Fix damage to the machine immediately and always

replace broken parts.

■

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, coolant,

fuel, and fuel filters.

■

DO NOT use plastic containers to dispose of hazardous

waste.

■

■

ALWAYS know the location of the nearest

first aid kit

■

ALW AYS pro vide an emergency escape route in the event

.

DO NOT pour waste , oil, coolant or fuel directly onto the

ground, down a drain, or into any water source

■

Whene ver necessary , replace nameplate, operation and

safety decals when they become difficult read.

of an emergency.

■

Never leave rags or tools on or near the generator-set.

■

Refer to the

Volvo Engine Owner's Manual

for engine

technical questions or information.

PAGE 10 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 11

IMPORT ANT SAFETY INSTR UCTIONS

Battery Safety

The battery is a major component of the engine-generator

set. The genset will not start without a properly maintained

battery . Disconnecting the battery prevents the engine from

starting. Always observe the following safety guidelines

when interaction with the battery is necessary. Servicing of

batteries should be performed by authorized personnel only .

1. Wear full eye protection and protective clothing, including

rubber gloves and boots when handling a battery.

2. Remove watches, rings or other metal objects when

handling a battery .

3. Use tools with insulated handles.

4. In case the battery liquid (dilute sulfuric acid) comes in

contact with

with plenty of water and discard clothing.

5. In case the battery liquid (dilute sulfuric acid) comes in

contact with your eyes, rinse eyes immediately with

plenty of water for fifteen minutes, then contact the

nearest doctor or hospital, and seek medical attention.

6. Spilled electrolyte is to be washed down with an acid

neutralizing agent. A common practice is to use a

solution of one pound (500 grams) bicarbonate of soda

to one gallon (4 liters) of water . The bicarbonate of soda

solution is to be added until the evidence of reaction

(foaming) has ceased. The resulting liquid is to be

flushed with water and the area dried.

7. DO NOT expose the battery to open flames, sparks,

cigarettes etc. The battery contains

combustible gases and liquids. If these

gases and liquids come in contact with a

flame or spark, an explosion could occur .

8. DO NOT lay tools or metal parts on top of batter ies.

9. DO NOT drop the battery; there is the risk the battery

may explode.

10. ALWAYS discharge static electricity from the body

before touching batteries by first touching a grounded

metal surface.

clothing or skin

, rinse skin immediately

14. Only use a battery that is in proper working condition.

Replace battery as recommended by manufacturer .

The battery contains electrolyte which is a dilute sulfuric

acid that is harmful to the skin and eyes. Electrolyte is

electrically conductive and very corrosive.

The installation of the engine-generator set must provide

enough ventilation to ensure that gases generated by vented

batteries during charging, or caused by equipment

malfunction are removed.

risk of fire because they generate hydrogen gas.

If using a serviceable battery, ne v er ov er fill the battery with

water above the upper limit.

Always disconnect a battery charger from its AC source

before disconnecting the battery cables. Failure to do so

can result in voltage spikes high enough to damage the genset

DC control circuits and charger .

Make certain the battery is well-ventilated before servicing.

Arcing can ignite explosive hydrogen gas given off by batteries,

causing severe personal injury. Arcing can occur when the

cable is removed or reattached, or when negative (-) battery

cable is connected and a tool used to connect or disconnect

positive (+) battery cable touches the frame or other grounded

metal that is part of the set. Alwa ys remo ve negative (-) cable

first, and reconnect it last. Make certain hydrogen gas from the

battery, engine fuel, and other explosive fumes are fully

dissipated. This is especially important if the battery has been

connected to a battery charger.

Lead-acid batteries present a

11. ALWAYS keep the battery charged. If the battery is not

charged a buildup of combustib le gas will occur.

12. ALWAYS keep battery charging and booster cables in

good working condition. Repair or replace all worn cables.

13. ALWAYS recharge the battery in an open air environment,

to avoid risk of a dangerous concentration of combustible

gases.

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 11

On generators not having a grounded supply circuit,

determine if the battery is inadver tently grounded. When

inadvertently grounded, remove source of ground. Contact

with any part of a grounded battery is capable of resulting in

electrical shock. The risk of such shock is reduced when

such grounds are removed during installation and

maintenance.

Page 12

IMPORT ANT SAFETY INSTR UCTIONS

Fire Protection

■

The design, selection, and installation of fire protection

systems is beyond the scope of this manual because of the

wide range of factors to consider . In general, ev ery possible

measure should be taken to prevent fire hazards and to

protect property and people. Consider the follo wing:

■

A protection system must comply with the requirements

of the authority having jurisdiction. This could include

the building inspector , fire marshal, or insurance carrier.

■

In general, the generator room will be required to have a

one hour fire resistance rating. If the generator set will

be in a Level 1 (life safety) application, as defined by

NFPA 110, the generator room construction will have a

two hour resistance rating.

■

The generator room should not be used for storage

purposes.

■

Generator rooms should be classified as hazardous

locations (as defined by the NEC) solely by reason of

the engine fuel.

■

The authority having jurisdiction will usually classify the

engine as a low heat appliance when use is only brief,

infrequent periods.

■

The authority having jurisdiction may specify the quantity ,

type, and sizes of approved portable fire extinguishers

required for the generator room.

The authority having jurisdiction may have more stringent

restrictions on the amount of fuel that can be stored inside

the building than published in national standards.

■

Fuel tanks located inside buildings and above the lowest

story or basement should be diked in accordance with

NFPA standards.

■

The genset should be exercised periodically under at least

30% load until it reaches stable operating temperatures

and run under nearly full load at least once a year to

prevent fuel from accumulating in the exhaust system.

■

Properly store fuel, batteries, and other fire hazardous

material.

■

The genset should be inspected regularly for fire hazards.

■

When open bottom generator is used, it is recommended

the assembly be installed over noncombustible materials

and located in such a manner such that it prevents a

combustible materials from accumulating under the

generator set.

■

Installation should provide a safe easy method to clean

up spilled engine fluids.

■

Post NO SMOKING signs near generator set, battery

storage, and fuel storage areas.

■

Install the appropriate fire extinguishers in convenient

locations. Consult the local fire department for the correct

type of extinguisher to use. DO NOT use foam on

electrical fires. Use extinguishers that are rated ABC

by the NFPA.

■

Use dry chemical, foam, or carbon dioxide (CO

extinguishers on battery fires.

■

A manual EMERGENCY STOP station outside the

generator room or remote from a generator set in an

outside enclosure is recommended for shutting down the

generator set in the event of a fire or other type of

emergency.

PAGE 12 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

) fire

2

Page 13

IMPORT ANT SAFETY INSTR UCTIONS

Lifting the Generator Set

■

Before lifting, make sure the generator's lifting devices

are secure and that there is no apparent damage to the

generator itself (loose screws, nuts and bolts). If any

part is loose or damaged, please take corrective action

before lifting.

■

Always drain fuel prior to lifting.

■

Always make sure crane or lifting device has been

properly secured to the hook of guard frame on generator .

■

NEVER lift the machine while the engine is running.

■

Use adequate lifting cable (wire or rope) of sufficient

strength.

■

When lifting the generator, always use the balanced

center-point suspension hook and lift straight upwards.

■

NEVER allow any person or animal to stand underneath

the machine while lifting. Make sure the lifting path of

the generator set is clear before moving.

■

When loading the generator on a truck, be sure to use

the front and back frame bars as a means to secure the

generator during transport.

■

Do not lift the generator set by the lifting eyes attached

to the engine and/or alternator. These lifting eyes are

used only during generator assembly and are not capable

of supporting the entire weight of the genset.

■

A four-point lifting method is necessary to lift the genset.

To maintain generator balance during lifting, the lifting

apparatus must utilize the four skid lifting holes. One

method of lifting the genset uses an apparatus of hooks

and cables joined at a single rigging point. The use of

spreader bars is necessary with this method to avoid

damage to the set during the lifting procedure. The

spreader bars should be slightly wider than the genset

skid so the set is not damaged by lifting cables and only

vertical force is applied to the skid while lifting. The

genset may also be lifted by placing bares through the

skid lifting holes and attaching hooks to the end of the

bars. Be sure all lifting equipment is properly sized for

the weight of the genset.

Transporting

■

Always shutdown engine before transporting.

■

Nev er transport generator with air intake doors open.

■

Tighten fuel tank cap securely.

■

Drain fuel when transporting generator over long distances

or bad roads.

■

Always tie-down the generator during transportation by

securing the generator.

■

If the generator is mounted on a trailer, make sure the

trailer complies with all local and state safety

transportation laws. See the operation manual for towing

procedures.

■

The transporting vehicle/trailer must be sized for the

dimension and weight of the genset. Consult the set

dimensional drawing or contact the factory for information

(weight, dimensions) pertinent to planning transport. The

overall height of a generator set in transit (including

vehicle/trailer) must not exceed 13.5 ft (4.1 m) unless

special hauling permits are obtained (check Federal,

State, and local laws prior to transporting). Larger units

(above 1000 kW) should be tr ansported on low-boy-type

trailers with a deck height of 25 in. (635 mm) or less to

meet clearance requirements. Large (unboxed) generators

with radiators should be loaded with the radiator facing

the rear to reduce wind resistance while in transit.

Radiators with free-wheel fans must have the fan secured

to prevent rotation that might introduce flying objects to

the radiator core or fan blades.

■

Even the heaviest of units is capable of movement

during shipment unless properly secured. Fasten the

set to the vehicle/trailer bed with properly sized chain

routed through the mounting holes of the skid. Use chain

tighteners to remove slack from the mounting chain.

Cover the entire unit with a heavy-duty tarpaulin and

secure tarpaulin to the genset or trailer as circumstances

dictate.

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 13

Page 14

INTRODUCTION

Introduction

Engine-Generator sets provide emergency power in the event

of utility power failure, provide power where utility power is

not available and can provide an alternative power means in

areas where utility power may be more expensive.

Part of the reason for the growing emphasis on emergency/

standby power systems is the proliferation of electronic

computers in data processing, process control and life

support systems, and any other system that requires a

continuous, uninterrupted flow of electrical energy . Gener ator

sets must be applied in such a way as to provide reliable,

electrical power of the

About This Manual

This manual provides specific recommendations for

installation of MQ Power's Industrial generator sets

(gensets). This manual will contain the f ollowing information:

1. Application — This section provides information on

sizing the correct generator set, determining load

characteristics, and environmental considerations.

2. Mounting Recommendations — This section pro vides

mounting recommendations such as typical fastening,

footing, foundations, proper space requirements, and

vibration isolation.

3. Mechanical Connections — This section provides

typical information regarding the fuel system, battery

system, exhaust system, proper ventilation, and proper

cooling.

4. Ventilation and Cooling — This section shows diff erent

installation methods for ventilating and cooling the

genset.

quality

and

capacity

required.

Safety Considerations

MQ Po wer's gensets have been carefully designed to provide

safe and efficient service when properly installed, maintained,

and operated. However, the overall safety and reliability of

the complete system is dependent on many factors outside

the control of the generator set manufacturer. This manual

is provided to illustrate recommended electrical and

mechanical guidelines for a safe and efficient installation.

All systems external to the generator (fuel, exhaust,

electrical, etc.) must comply with all applicable codes. Make

certain all required inspections and test have been

completed and all code requirements have been satisfied

before certifying the installation is complete and ready for

service.

Always remember: SAFETY FIRST!!! Safety involves two

aspects: safe operation of the generator set itself (and its

accessories) and reliable operation of the system. Reliable

operation of the system is related to safety because

equipment affecting life and health, such as life-support

equipment in hospitals, emergency lighting, building

ventilators, elevators, and fire pumps may depend upon the

generator set.

In North Amer ica, many safety (and environmental) issues

related to generator set applications are addressed by the

following standards of the National Fire Protection

Association (NFPA):

z

Flammable and Combustib le Liquids Code — NFPA 30

z

National Fuel Gas Code — NFPA 54

z

National Electrical Code — NFPA 70

z

Health Care Facilities Code — NFPA 99

z

Life Safety Code — NFPA 110

z

Emergency and Standby P ower Systems — NFPA 110

z

Storage and Handling of Liquified Natural Gas —

NFPA 59A

Many national, state, and local codes incorporate the above

5. Electrical Connections — This section provides the

location of electrical connection points for DC Controls,

AC electrical connections, and system & equipment

grounding.

6. Pre-Start Preparation — Checklist of items or

procedures needed to prepare the generator set for

operation.

PAGE 14 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

standards (and others) by reference. Each of these

standards and the codes that reference them are periodically

updated, requiring continual review. Compliance with all

applicable codes is the responsibility of the facility design

engineer. For example, some areas may have certificateof-need, zoning permit, building permit, or other site specific

requirements. Be sure to check with all local governmental

authorities before designing the generator set installation.

Page 15

INST ALLA TION O VERVIEW

Overview

These installation recommendations apply to typical

installations with standard model gensets. Whenever

possible, these recommendations also cover factory

designed options or modifications. However, because of

the large amount of variables involved with any installation,

it is not possible to provide specific recommendations for

every possible situation.

This manual

information for selecting a genset or designing the complete

installation.

are any questions not answered by this manual, contact

your nearest MQ P o wer dealer or distributor f or assistance .

Application and Installation

A standby power system must be carefully planned and

correctly installed for proper operation. This involves two

essential elements of application and installation.

Application

Application as it applies to genset installations refers to the

design of the complete standby power system. Such an

effort usually considers power distribution equipment, transf er

switches, ventilation equipment, and mounting pads.

Consideration is also given to cooling, exhaust, and fuel

systems.

Each subsystem must be correctly designed so the

complete system will function as intended. Application and

design is an engineering function generally done by specifying

engineers or other trained specialists. Specifying consulting

engineers are responsible for the designing the complete

standby system and for selecting the materials and products

to be used.

Installation

Installation refers to the actual setup and assembly of the

standby power system. The installers, usually licensed

contractors, set up and connect the various components of

the system as specified in the system design plan. The

complexity of the standby system normally requires the

special skills of qualified electricians, plumbers, sheet metal

workers, construction workers, etc. to complete the various

segments of the installation. This is necessary so all

components are assembled using standard methods and

practices.

does not

This manual is a reference tool only

provide complete application

. If there

Selection and Application

Generator set size and site location should be considered

in the preliminary design and budget estimate. The

generator size should be selected according to the required

load. Choosing a mounting site located inside the building

or outside in a shelter or housing will help determine how

the genset will be installed and what specific issues need to

be addressed.

Sizing

It is important to assemble a reasonably accurate load

schedule as soon as possible for budgeting project costs.

If all the load equipment information needed for sizing is not

available early in the design planning, estimates and

assumptions will have to be made during the preliminary

calculation in order to account for all needed pow er . When

all the information becomes available, it is important to

recalculate the sizing requirements to ensure reliable

operation.

Large motor loads, uninterrupted power supplies (UPS),

variable frequency drives, and medical diagnostic imaging

equipment have a considerable effect on the generator set

sizing and should be considered closely. Too, the required

power to start a motor can be considerably larger than the

power required to maintain the load.

Fuel Requirements

Diesel engine generator sets are recommended for

emergency/standby applications. Premium No. 2-D Grade

diesel fuel is recommended for performance and engine life.

On-site fuel storage must be provided. The storage life for

diesel fuel is up to two years when stored properly. Proper

supply tank sizing should allow fuel turnover based on

scheduled ex ercise and test periods. To avoid condensation

mixing with the fuel, do not provide a fuel tank that is too

large. A microbicide may be required if fuel turnover is low

or conditions promote the growth of microbes in the fuel.

Always consider emissions requirements when designing

the fuel and exhaust system. Refer to the Fuel System

section for more information.

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 15

Page 16

INST ALLA TION O VER VIEW

Cold Climates and Derating Factors

Extreme temperature and high elevation effect the efficiency

of the engine-generator set. Always take into account

derating factors of climate and elevation when sizing a

generator set.

Use Premium No.1-D Grade diesel fuel when the ambient

temperature is below freezing. Fuel heating may be required

to prevent fuel filters from clogging when temperatures fall

below the cloud point of the fuel at approximately 20°F

(-6°C) for No . 2-D and -15°F (-26°C) f or No . 1-D .

Location

Location of the generator set will determine the cost

effectiveness of an installation. The generator set can be

located inside a building or outside the building with a shelter

or weather-protective housing. The location will help

determine the layout of the fuel tanks, louvers, ventilation

ducts, accessories, etc. Consider the following when

deciding where to locate the generator set:

Safety considerations

Noise. See pages 27 thru 32 for environmental

considerations.

Ambient temperature

Mounting

Fuel, exhaust, ventilation, and cooling systems

Location of the distribution switchboard and transfer

switch

Branch circuits for coolant heaters , battery charger, etc.

Security from flooding, fire, icing, and vandalism

Containment of accidentally spilled or leaked fuel or

engine fluids

Mounting - Ensure generator is located (mounted) over

non-combustible materials and is situated in such a

manner as to prevent combustible materials from

accumulating under the generator .

Indoor Locations

Dedication of room for the generator sets only. For

emergency power systems, codes may require the

generator room be dedicated for that purpose only . Also

consider the effect of the large ventilation air flows would

have on other equipment in the same room.

Fire rating of the room construction. Most codes specify

a 1 or 2 hour rating. Check with the local fire authority

for code guidelines.

Working space. Working space around electrical

equipment is usually specified by code. There should

be at least four feet (1200 mm) of clearance around

each generator set. The generator should be accessib le

for service without removing the set or any accessories.

Type of cooling system. A factory-mounted radiator is

recommended.

V entilation. Large volumes of air flow are inv olved. Room

ventilation fans might be required for a heat exchanger

or remote radiator configurations.

Engine exhaust. The engine exhaust outlet should be

as high as practical on the downwind side of the building

and away from vents and building openings.

Fuel storage and piping. Codes may restrict fuel storage

inside buildings. It is important to consider a safe method

for refueling the fuel tank. Check with the local fire

authority for code guidelines.

Outdoor Locations

Airborne noise. Locate and/or route engine exhaust

piping away from nearby windows & doorways.

Outdoor enclosures. Give consideration to type of

outdoor housing, including weather-protective and/or

sound attenuated types.

Security. Consider use of security fences and site

barriers.

Property line distances. Ensure before proceeding with

final installation plans you are aware of your property

lines.

Engine exhaust. Engine exhaust must be routed away

from building intake vents, windows, doorways and other

openings.

PAGE 16 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 17

GENSET SIZING

Generator Set Sizing Calculations

The generator set must be sized to supply the maximum

starting (power surge) demands and the steady-state running

loads of the connected equipment.

It is important to have the correct generator to meet the

demands of the starting kVA (SkVA), star ting kW (SkW),

running kVA (RkVA) and running kW (RkW). A value for

generator kW (GkW) is also obtained when nonlinear loads

are included in the sizing calculation.

Once the starting and running loads have been determined,

it is typical to add a margin factor of up to 25% for future

expansion or to select a generator set of the next largest

The use of closed-transition autotransformer starters for

reduced voltage starting of large motor loads will reduce the

size of the generator set required relative to across-the-line

starting. Resistor-type reduced-voltage motor starting may

actually increase the size of the generator set required due

to high starting power factors. Wound rotor motors are the

easiest type of motor for a generator set to start.

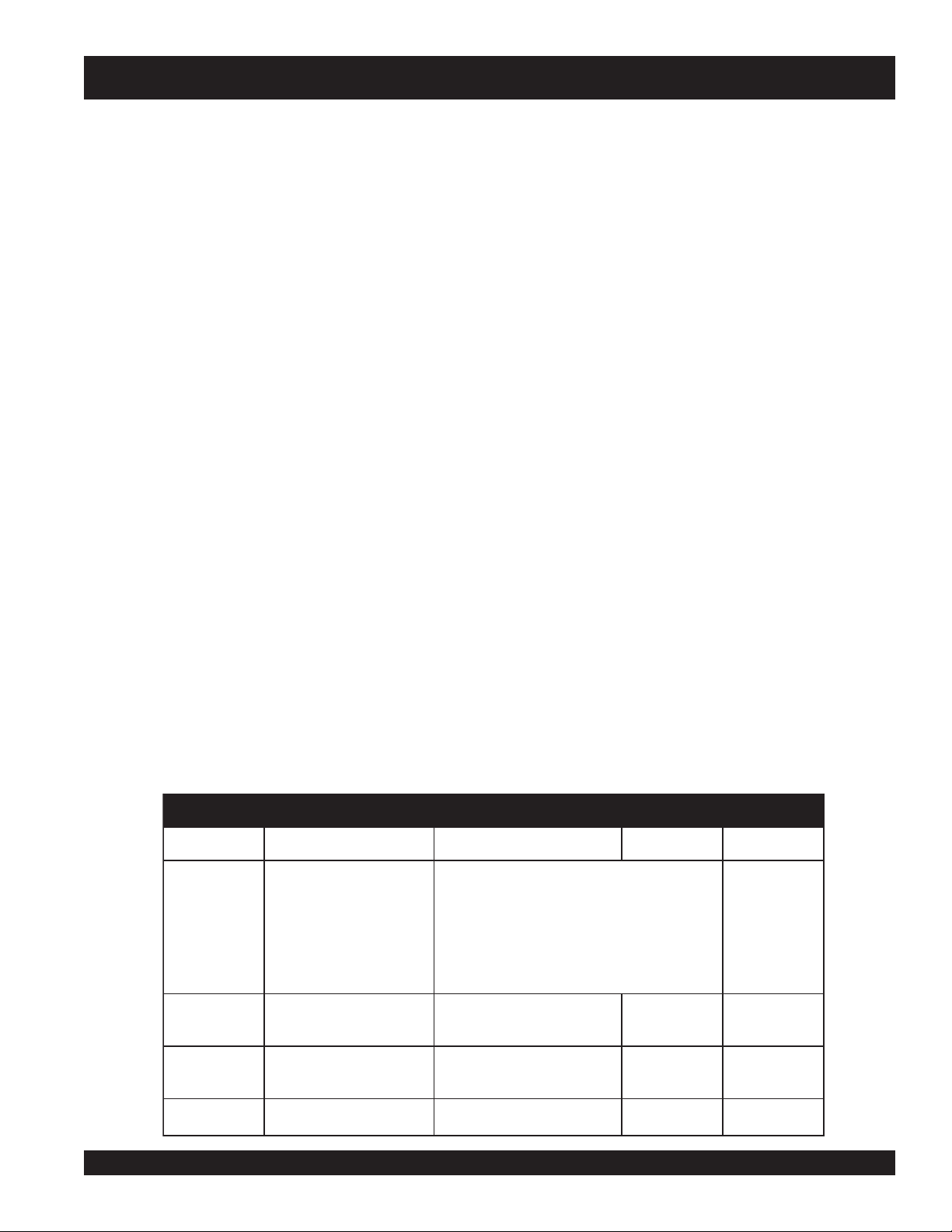

The first step is to create a reasonably accurate schedule

of connected loads as early in the preliminary design as

possible. A sample load schedule sheet can be found below

on T able 1.

Genset Sizing Procedure

standard rating. A large connected load that does not run

during usual power outages, such as a fire pump, can serve

as part of a margin factor. For a fuel efficiency standpoint,

the running load should stay within approximately 50 to 80%

of the generator kW rating. To avoid "wet stacking", the

running load should not be less than 30% of the generator

set rating.

When calculating the generator size needed for the

application, consider the following procedure:

Step 1. Prepare a load schedule

Step 2. Enter loads in step sequence on the worksheet

Step 3. Enter individual load characteristics on the

It may be necessary to oversize a generator set in

applications where the voltage and frequency dip

performance specifications are more stringent than usual,

particular ly when large motors are started across-the-line

or UPS equipment is involved. Applications that involve

any of the following nonlinear loads may also make it

necessary to oversize the generator set or the generator:

Static Uninterrupted Power Supplies (UPS)

Battery Charging Rectifiers (T elecommunications)

V ariable Frequency Driv es (VFD)

Medical Diagnostic Imaging Equipment

Step 4. Find the load step totals

Step 5. Select a generator set

Step 1. Prepare a Load Schedule

All the loads that will be connected to the generator set

should be recorded on the load schedule. Identify each

load as to type, power rating, and quantity. See Table 1

below for the loads listed (in

calculation.

worksheet

italics

) for an example

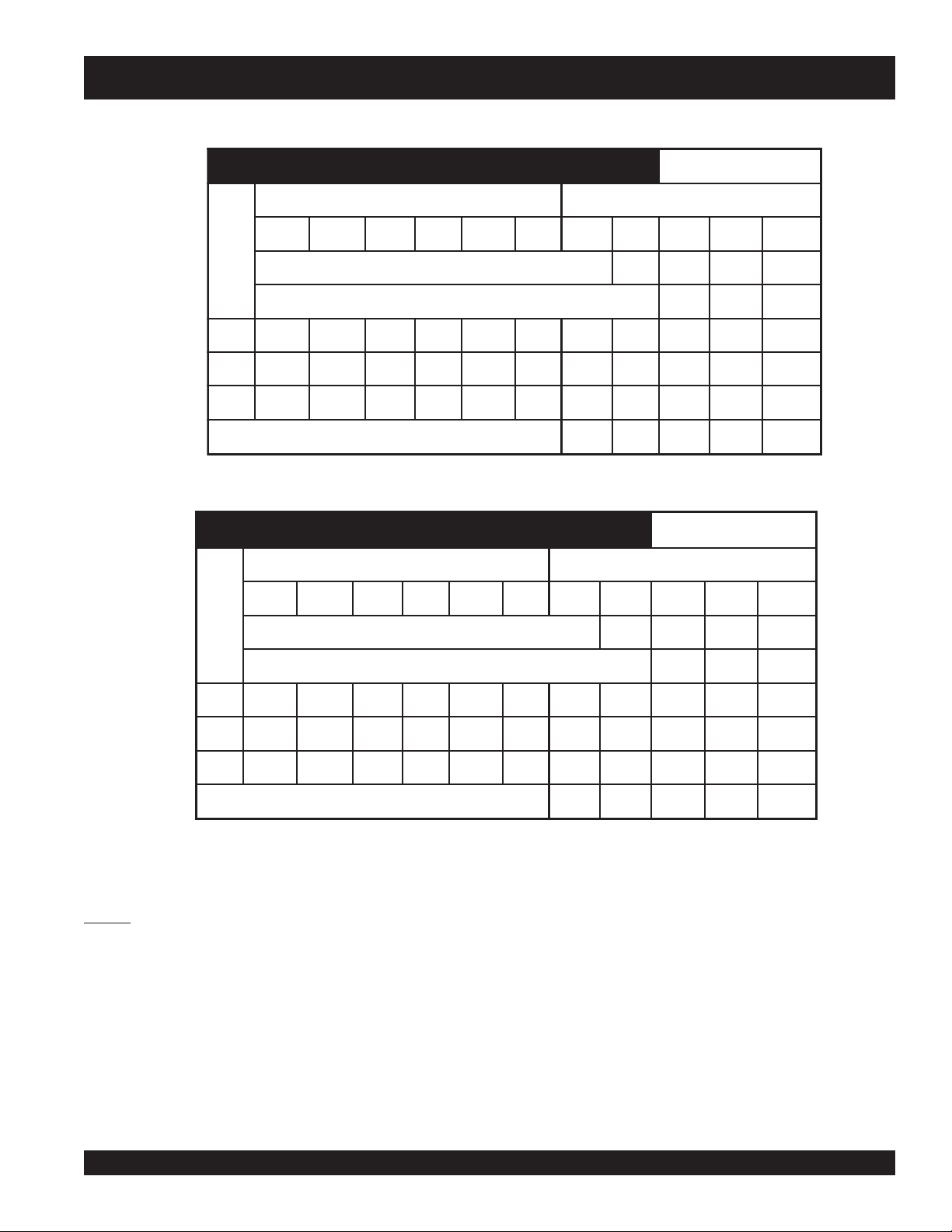

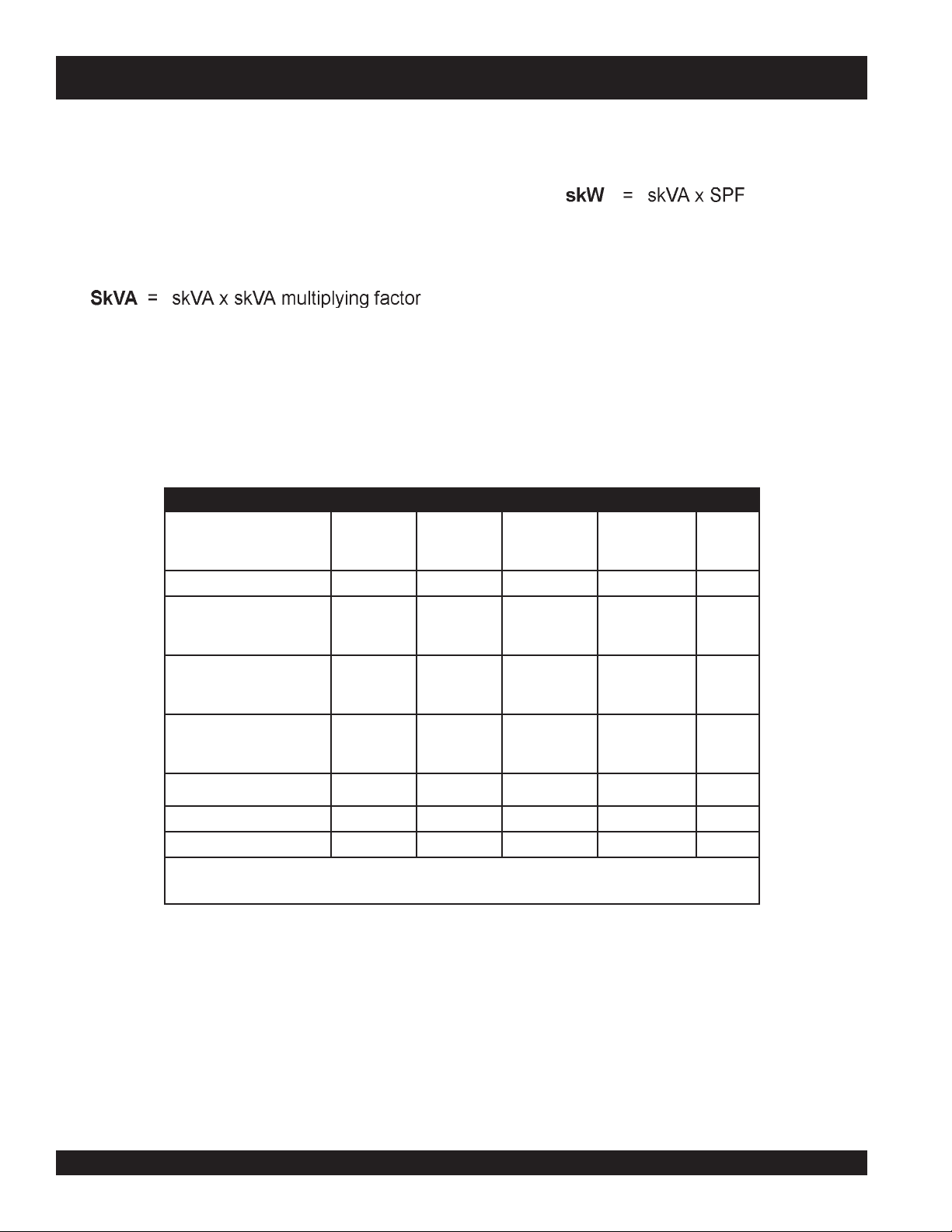

eludehcSdaoL.1elbaT

#daoLnoitpircseDdaoLdaoLfoepyTgnitaRrewoP.YTQdaoL

:selpmaxE

Wk...................................gnithgiL

AVk..............................SPUcitatS

PH............sevirDdeepSelbairaV

AVk.............srefitceRCDmoceleT

PH.....................................srotoM

1

2

3

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 17

2#&1#spmuPretaW,GretteledoCameN,rotoM

)paT%08(retratsremrof

3#spmuPretaW,GretteledoCameN,rotoM

)paT%08(retratsremrof

gnithgiLtnecsroulFgnithgiLPH01

PH001

PH001

2

1

1

Page 18

GENSET SIZING

Generator Set Sizing Calculations (Continued)

Step 2. Create a Generator Set Worksheet

a. When creating a worksheet, number a worksheet for each

sequenced load step. The n umber block is in the upper

right hand corner of the wor ksheet. Worksheet #1 will

coincide with Load Step #1, Worksheet #2 will coincide

with Load Step #2, and etc.. The

will provide additional information to be followed here.

The worksheets need not have load step numbers unless

starting is sequential.

b. Enter the individually assigned load numbers (load

schedule) onto the appropriate generator set sizing

worksheet. That is, all the load n umbers for load step #1

should be entered on worksheet #1, for load step #2 on

worksheet #2, and etc.

c. For each load, enter the

schedule in the column labeled

Figure 1 on page 19 is an example load calculation for an

application involving a two-step load starting sequence.

Because the application is a two-step load starting

sequence, it requires two worksheets as shown. The entries

are in

italics

.

step sequence guidelines

Load QTY

marked on the load

QTY

on the worksheet.

Step Sequence Guidelines

Single Step, Simultaneous Starting — One commonly

used approach is to assume that all connected loads

will be started simultaneously in a single step, regardless

of the number of transf er switches used. This approach

assures that the genset is properly sized to meet the

entire load demand and is the most conservative

method.

Single Step, with Diversity F actor — This is similar to

simultaneous starting in a single step, except that an

estimated diversity factor, of perhaps 80 percent, is

applied to reduce the starting kVA (SkVA) and starting

kW (SkW) totals to account for whatever automatic

starting controls may be provided with the load

equipment.

Multiple Step Sequence — Sequenced starting of

loads (where possible) will often permit the most precise

load demand for selecting a generator .

A step sequenced start may be approximated, for e xample,

by dividing the loads into blocks each served by a separate

transfer switch and then using the standard time delay on

transfer to stagger connection of each block onto the

generator set. However, once all of the loads have been

brought up on line with the genset, the load equipment may

be frequently started and stopped by automatic controls. In

such cases, the genset will have to be sized to start the

largest motor last, with all other connected loads on line.

Consider the following when controls or delays are provided

to step sequence the loads onto the generator set:

Start the largest motor first. Use only when on a manual

starting system.

Load the UPS last. UPS equipment is typically frequency sensitive, especially to the rate of change of

frequency. A pre-loaded genset will be more stable in

accepting the UPS load.

PAGE 18 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 19

GENSET SIZING

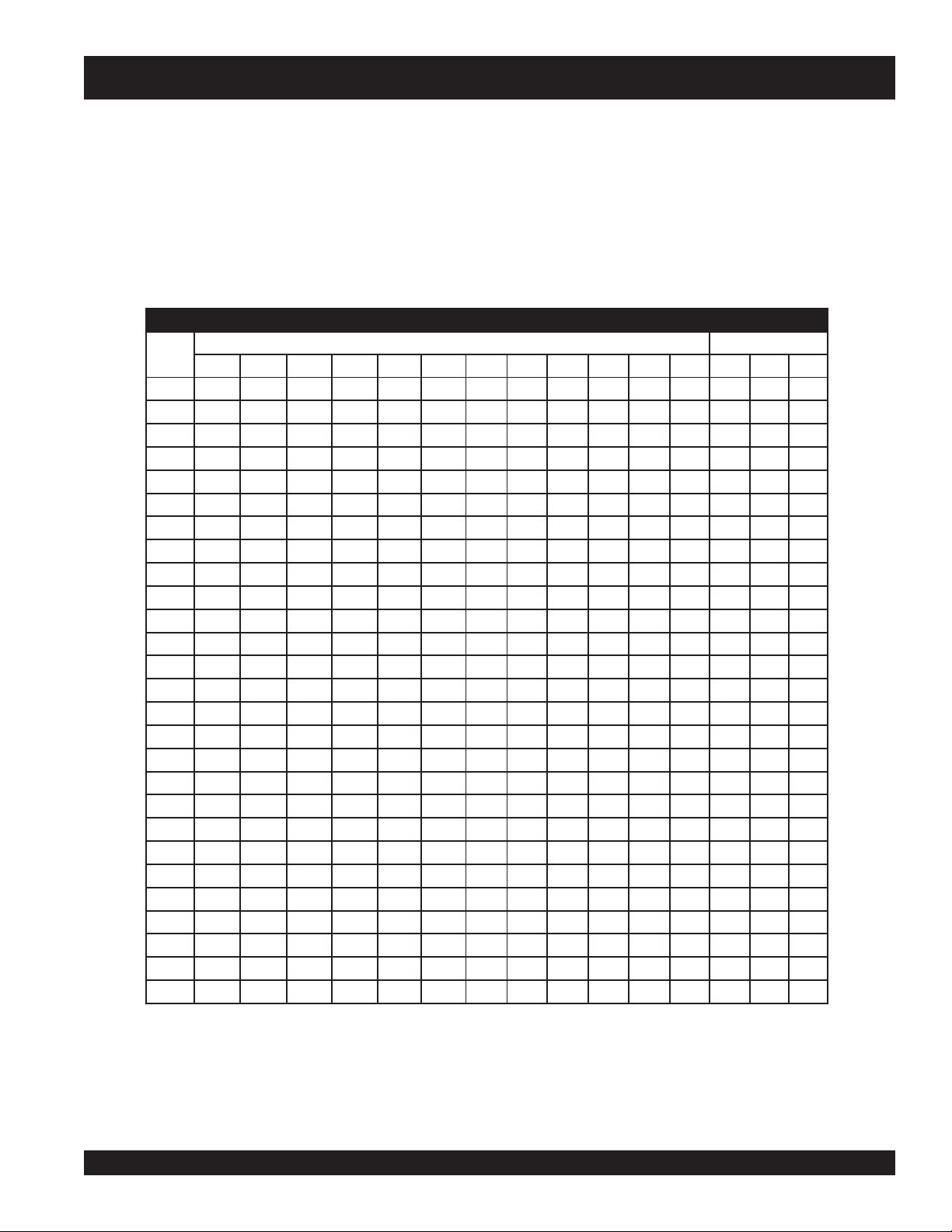

teehskroWgniziSteSrotareneG 1#petSdaoL

scitsiretcarahCdaoLlaudividnIslatoTpetSdaoL

AVkSWkSAVkRWkRWkGYTQAVksWksAVkRwkRwkG

>---petsdaolsuoiverpmorflatotWkRretnE—

daoL

#

.16.773

a

b

3.311

d

98

c

9.18

e

9.18

2

.3—————1 5.01

-.557

f

2

g

—— ————————— —

--petsdaolsuoiverpmorfslatotWkGdna,WkR,AVkRretnE

—— —

>-

f

822

g

01

f

871

g

5.01

8.361

g

01

-e

f

8.361

f,

e

01

>--------------------------slatoTpetSdaoL

8325.8818.3718.371

7.567

teehskroWgniziSteSrotareneG 2#petSdaoL

scitsiretcarahCdaoLlaudividnI

AVkSWkSAVkRWkRWkGYTQAVksWksAVkRwkRwkG

8.371

---petsdaolsuoiverpmorfslatotWkGdna,WkR,AVkRretnE

>

h

9.18

5.8818.3718.371

h

98

h

9.18

h

8.361

daoL

#

.2—————198

—— —————

———— —

>---petsdaolsuoiverpmorflatotWkRretnE

h

—— ———————— — —

>--------------------------slatoTpetSdaoL

98

7.5525.7727.5526.733

Figure 1. Genset Sizing Worksheets

(Example Two-Step Loading Application)

NOTES:

a. For the two 100 HP motors, SkVA = HP x NEMA Code Letter Multiplier (Tab le 6) = 100 x 5.9 x 0.64 = 377.6

b. SkW = SkV A x SPF = 377.6 x 0.3 =113.3

c. RkW = HP x 0.746 / 0.91 = 81.9

d. RkV A = RkW / RPF = 81.9 / 0.92 = 89

e. A GkW total will need to be found because Load #2 is a nonlinear load. Therefore , enter values f or GkW f or the linear loads. GkW= RkW for

linear loads.

f. These values are twice the values in the

individual load characteristics

columns because QTY is 2 for Load #1.

g. For the fluorescent lighting, RkW = SkW . SPF and RPF both = 0.95

h. For the 100 HP VFD motor: GkW = RkW x generator sizing f actor = 81.9 x 2.0 = 163.8; SkW = RkW; and SkVA = RkVA.

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 19

Page 20

GENSET SIZING

Generator Set Sizing Calculations (Continued)

Step 3. Enter Individual Load Characteristics

a. Calculate the values for SkVA, SkW, RkVA, and RkW

and then enter the values on the worksheets. See

determining load characteristics

instructions on how to calculate the values for various

types of loads.

b. If the load quantity (QTY) is one, enter the values for

SkVA, SkW, RkVA, and RkW directly onto the columns

under the

c. If the load quantity is greater than one, enter the values

for SkVA, SkW, RkVA, and RkW in the columns under

the

each load entry by the number under QTY and enter the

products under the

SkW, RkVA, and RkW.

d. If nonlinear loads are included, calculate a GkW value

for each nonlinear load and enter it under the GkW

column. Follow the guidelines in part C above for m ultiple

nonlinear loads.

load step totals

heading.

individual load characteristics

load step totals

on page 22 for

heading. Then multiply

heading for SkVA,

Step 4. Enter Individual Load Characteristics

Now all the loads on the

the

generator set sizing worksheets

characteristics should be calculated and entered on the

worksheets, and the worksheets numbered in load step

sequence.

Referring back to Figure 1, find the load step totals as

follows:

a. Starting with worksheet #1 (Load Step #1), add the

entries in each column under the

and enter the sums on the

b. On worksheet #2 enter the

worksheet #1 as instructed on the worksheet.

c. Repeat steps a and b as necessary through all the

worksheets.

d. Go back through all the worksheets and highlight or circle

the highest load step total of SkVA, SkW, RkVA, RkW,

and GkW. Generator set selection will be based on

these values.

load schedule

should be listed on

load step totals

load step totals

load step totals

, all the load

heading

line.

from

e. In order to obtain a total GkW in applications that include

linear as well as nonlinear loads, enter the values for

RkW for all the linear loads under GkW as well (RkW =

GkW for linear loads only).

PAGE 20 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 21

Generator Set Sizing Calculations (Continued)

Step 5. Select a Generator Set

a. Establish the minimum size required

i. At this point the addition of future loads should be

considered. The RkW and RkVA values that were

highlighted or circled in Step 4 (previous page)

should be multiplied by a factor representing your

best judgement.

ii. Referring to the genset specification sheets, pick

the generator set model having a kW/kVA rating

that meets the highest RkW and RkVA totals

highlighted or circled in Step 4. Use the values

calculated for RkW and RkVA in sub-step i above if

the future addition of load was factored in.

iii. In addition to the specification sheet, the motor

starting curve should be referenced. Make sure to

take into account any derating factors such as high

altitudes or ambient temperature.

b. In applications where it is necessary to limit transient

voltage dip to approximately 10 to 20 percent of nominal

voltage, multiply the SkVA highlighted or circled in Step

4 by at least 1.25. Repeat the selection steps above.

A transient voltage dip of approximately 20 to 40% can

c. In applications where GkW has been determined (Step

4) and where GkW is greater than the kW rating of the

generator set that has been selected, an alternator (AC

generator) must be picked for the set which has a kW

rating equal to or greater than GkW.

i. See the alternator data sheet for the alternator

ii. If GkW is too high for the alternator selected to meet

iii. If none of the alternators available for the generator

be expected when the genset selected is only slightly

greater than the maximum SkVA. The actual transient

voltage dip is a function of several factors and is difficult

to determine accurately .

GENSET SIZING

temperature rise. Compare GkW to the alternator

kW rating at the appropriate voltage. The greater

the voltage, the greater the kW rating.

the temperature rise specifications (if any), find the

alternator data sheet for the alternator specified for

the next lower temperature rise. Compare GkW to

the alternator kW rating at the appropriate voltage.

Repeat the procedure with any other models. If there

are no generator temperature rise specifications that

have to be met, consider comparing GkW to the

kW rating at the higher temperature rise rating of

125°C.

set has a kW rating sufficient to meet GkW, refer to

the specification sheet for the next larger size

generator set and repeat the selection process.

NOTE

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 21

The running load should not be

less then 30 percent of the

generator set rating.

Page 22

GENSET SIZING — DETERMINING LO AD CHARACTERISTICS

Determining Load Characteristics

Lighting

For all types of lighting loads:

RkW = The sum of the r ated watts of all lamps and ballasts.

Single-Phase Induction Motor

For 1Ø motors, use the SkVA, SkW, RkVA, and RkW values

in Table 4 below that correspond to the motor nameplate

horsepower and type.

Typical ballast wattages are defined by Table 2 below:

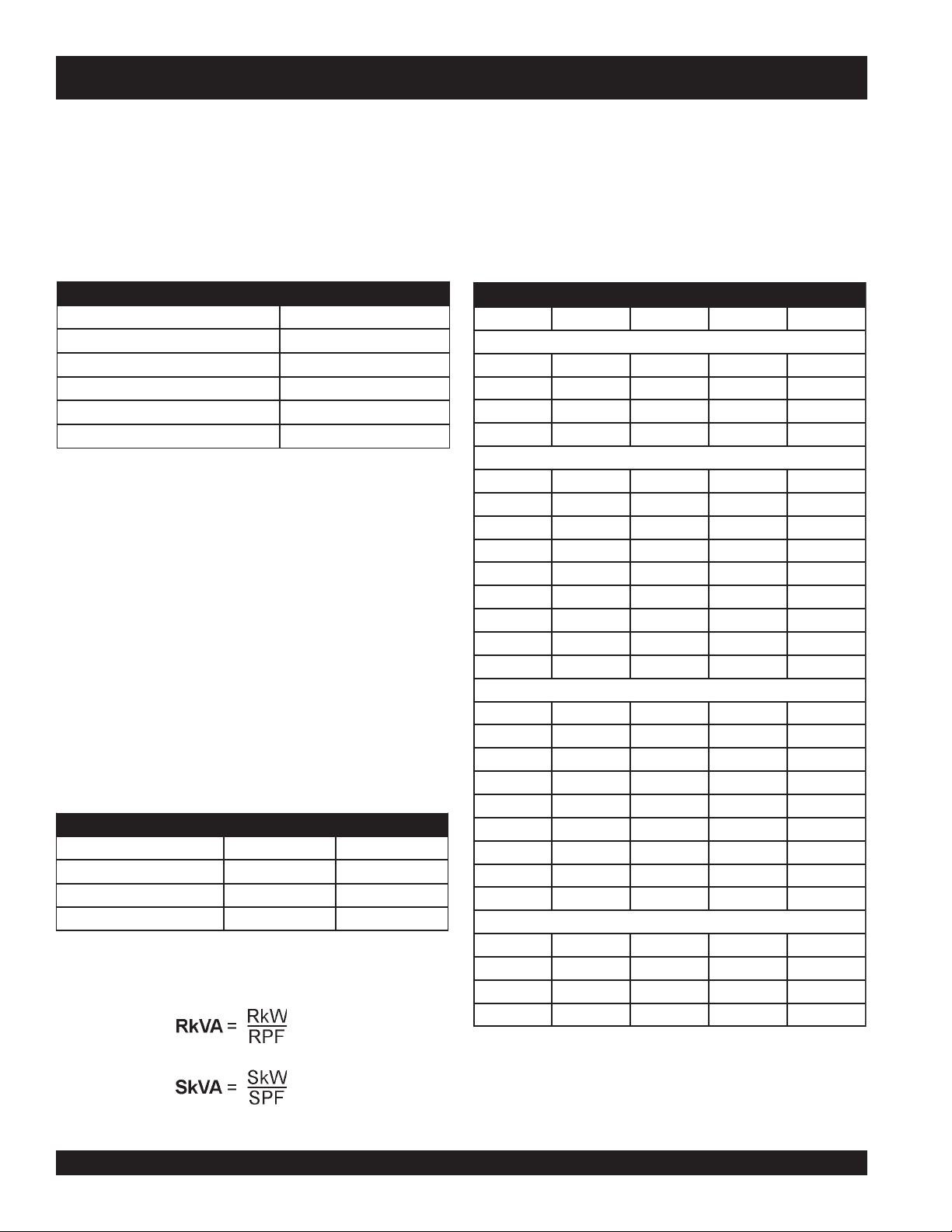

segattaWtsallaB.2elbaT

PMALTSALLAB

taeherP,W04,21-Thcni84W01

tratSdipaR,W04,21-Thcni84W41

tnecseroulFW04tuptuOhgiHW52

W001,yrucreMW53-81

W004,yrucreMW56-52

For all types of lighting loads, except for high intensity

discharge (HID), use the following:

SkW = RkW

Due to the starting characteristics of HID lighting, assume

that

PHWkRAVkRAVkSWkS

6/13.05.05.38.2

4/14.06.08.48.3

3/15.07.06.55.4

2/17.09.07.71.6

6/13.05.06.20.2

4/14.06.03.36.2

3/15.07.09.31.3

2/17.09.03.552.4

4/30.152.11.77.5

12.16.15.96.7

2/1-16.10.252.414.11

22.27.2912.51

33.31.45.828.22

SkW = 0.75 x RkW

6/13.05.08.23.2

Unless otherwise known, assume the follo wing starting and

running power factors (SPF and RPF, respectively , see Table

3 below) for the following types of lighting:

rotcaFrewoPgninnuR&gnitratS.3elbaT

gnithgiLfoepyTFPSFPR

tnecseroulF59.059.0

tnecsednacnI00.100.1

egrahcsiDytisnetnIhgiH58.009.0

Then the following can be calculated:

4/14.06.08.30.3

3/15.07.06.39.2

2/17.09.09.57.4

4/30.152.10.84.6

12.16.16.017.21

2/1-16.10.20.617.21

22.27.22.120.71

33.31.48.135.52

6/13.05.00.18.0

4/14.06.05.12.1

3/15.07.00.26.1

2/17.09.00.34.2

scitsiretcarahCrotoMesahPelgniS.4elbaT

esahPtilpS

nuRnoitcudnI/tratSroticapaC

nuRroticapaC/tratSroticapaC

)CSP(roticapaCtilpStnenamreP

PAGE 22 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 23

GENSET SIZING — DETERMINING LO AD CHARACTERISTICS

Three-Phase Induction Motors

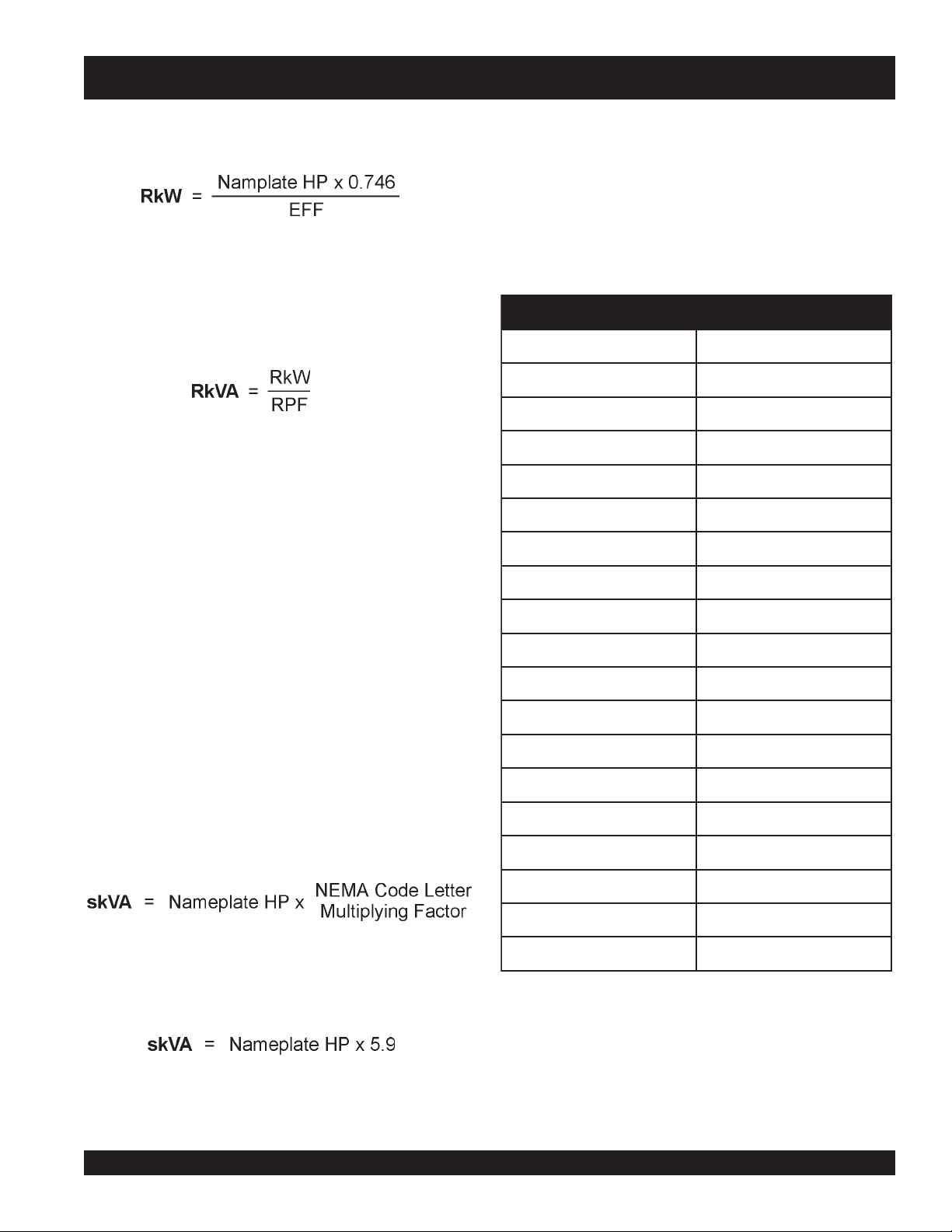

Calculate RkW as follows:

NEMA Code Letter Multiplying Factor

Use Table 5 below to calculate the starting kVA. DO NOT

confuse the NEMA (National Electrical Manufacturers

Association)

The code letter refers to the ratio of loc ked rotor kVA to HP,

whereas the design letter refers to the ratio of torque to speed.

If EFF (motor running efficiency) of the motor is not known,

refer to T ab le 5 and use the value corresponding to the motor

horsepower .

Calculate RkVA as follows:

If RPF (running power factor) is unknown, ref er to T a b le 5

and use the value corresponding to the motor horsepower .

Calculate SkVA as follows:

1. If the NEMA motor code letter is unknown, refer to

Table 4 on previous page and select the SkVA value

corresponding to the code letter and the horsepower.

The factors used to generate these values are shown

in T ab le 5.

motor code

A0.2

B3.3

C8.3

D2.4

E7.4

F3.5

G9.5

H7.6

J5.7

and

design letters

.

rotcaFgniylpitluMretteLedoCAMEN.5elbaT

2. If the NEMA motor code letter is unknown, refer to

Table 7 on page 25 and select the SkVA value in bold

letters that corresponds to the motor horsepower . The

bold letters show the values for the NEMA code letters

that are typical for standard motors.

3. If the motor is rated greater than 500 HP and the NEMA

motor code is known, calculate SkVA as follows:

4. If the motor is rated more than 500 HP and the NEMA

motor code is not known, assume a NEMA code letter

of G and calculate SkVA as follows:

where 5.9 is the multiplying factor corresponding to NEMA

code letter G in Table 5.

K5.8

L5.9

M6.01

N8.11

P2.31

R0.51

S0.61

T0.91

U2.12

V0.32

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 23

Page 24

GENSET SIZING — DETERMINING LO AD CHARACTERISTICS

Determining Load Characteristics (continued)

5. If reduced voltage motor starting is used, determine

SkVA as in Steps 1, 2, 3, or 4 on previous page, and

then multiply the value by the appropriate multiplying

factor in Table 5. Use the following formula:

lluF%

dohteMgnitratS

egatloVlluF0010010010.1—

egatloVdecudeR

remrofsnartotuA

rotcaeRseireS

rotsiseRseireS

egatloV

deilppA

08

56

05

08

56

05

08

56

05

46

24

52

08

56

05

08

56

05

Calculate SkW as follows:

1. If SPF (Starting Power F actor) is unknown, ref er to Table

4 on page 22 and use the value corresponding to the

motor horsepower.

motor starting is used, use the value for SPF

below .

2. Multiply SkW by 0.5 for motors with low inertia loads

(i.e., centrifugal fans, compressors and pumps) where

starting torque requirements are low.

lluF%

AVkegatloV

lluF%

egatloV

euqroT

46

24

52

46

24

52

46

24

52

If a resistor-type reduced voltage

in Table 6

scitsiretcarahCdnasdohteMgnitratSegatloVdecudeR.6elbaT

AVkS

gniylpitluM

rotcaF

46.0

24.0

52.0

08.0

56.0

05.0

08.0

56.0

05.0

FPS

—

—

—

—

—

—

06.0

07.0

08.0

atleDratS001333333.0—

)lacipyT(gnidniWtraP00106846.0—

rotoMrotoRdnuoW001*061*001*6.1—

ehtfoeulavehtnodnepedhcihw,tnerrucgninnurfosrotcafrostnecreperaesehT—*

.sgnidniwrotorehtotdeddasecnatsiserseires

PAGE 24 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 25

GENSET SIZING — DETERMINING LO AD CHARACTERISTICS

Three Phase NEMA Motor Code Table

Table 7 lists the 3Ø motor star ting kVA, starting power factor, and motor factors. Do not confuse the NEMA (National

Electrical Manufacturers Association) motor Code and design letters. The code letter refers to the ratio of loc ked rotor kVA

to HP, whereas the design letter refers to the ratio of torque to speed.

FPRdna,FFE,FPS,AVkSrotoMesahPeerhT.7elbaT

PH

ABCDEFGHJKLNFPSFFEFPR

4/15.08.09.00.12.13.15.17.19.11.24.2

2/10.17.19.11.24.26.20.33.38.32.47.4

4/35.15.28.22.36.30.45.40.57.54.61.7

1 2 3 4 4 55678892167.00.3707.0

2/1-13566789011131

2478891121315171

36 0111314161810232

50151911242620333

2/1-751528223630454

0102338324743595

51030575461797

020476575859601

52054849601911231

0306001311721241951

0408431151071091212

05001761981212732562

06021102622552582813

57051152382813653793

001002533773524574035

521052814174135395266

051003205665736217497

0020049664579489499501

052005638349160168114231

00300640011311472142419851

05300717110231684116613581

00400883318051896189818112

005000137615881321237328462

sretteLedoCrotoMAMENsrotcaFrotoM

9.2

9.5

9.8

8127.09.6767.0

41

4207.01.9797.0

91

825366.05.2828.0

52

24749516.08.3858.0

83

7546179865.01.5878.0

05

57585981135.09.5878.0

76

00131172124177194.09.6888.0

98

43115107109163264.06.7898.0

911

76198121273259244.00.8898.0

941

10262255258245324.04.8898.0

871

86220304308357493.09.8809.0

832

53377352457409563.06.9809.0

792

20435401507580763.06.9809.0

753

20566573621758843.00.0909.0

644

076557948949081113.05.0919.0

595

73834926017811574192.09.0919.0

347

4001231147214241077182.02.1919.0

298

9331905199619981063252.07.1919.0

9811

4761688142124732059242.00.2919.0

6841

9002462294529482045322.03.2929.0

4871

3432146237923233031491.01.3929.0

1802

8762810389338973027491.01.3929.0

8732

8433377384248474009571.08.3929.0

3792

28.08.2655.0

28.08.2655.0

87.03.9646.0

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 25

Page 26

GENSET SIZING — DETERMINING LO AD CHARACTERISTICS

Synchronous Motors

Although starting requirements for synchronous motors are

lower , it is recommended to determine starting requirements

in the same manner as induction motors previously covered.

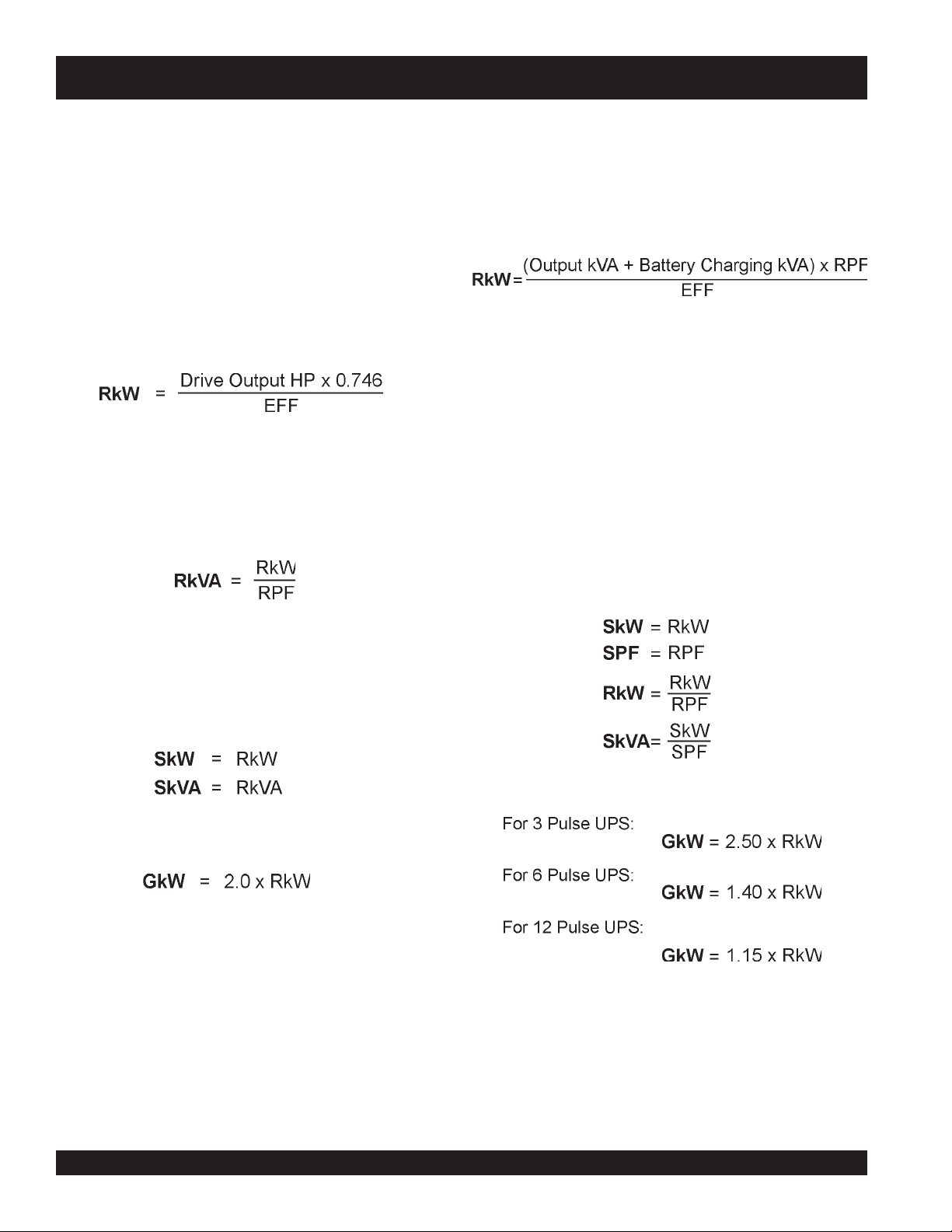

V ariable Frequency Drives

Variable Frequency Drives are nonlinear loads for which a

calculation of GkW is made, in addition to RkW , RkV A, SkW ,

and SkVA.

Calculate RkW as follows:

Assume 0.9 for EFF (drive running efficiency) unless

otherwise known.

Calculate RkVA as follows:

Static UPS

Uninterrupted power supplies are nonlinear loads for which

a calculation of GkW will be made, in addition to RkW , RkV A,

SkW, and SkVA.

Calculate RkW as follows:

In the equation above:

1. Output kVA is the nameplate kVA capacity of the

UPS

2. Battery charging kVA is that required for battery

charging, and can range from zero to fifty (0-50%)

percent of the UPS kVA rating.

3. If the RPF (Running Power Factor) for the UPS is

unknown, assume 0.9 RPF.

4. If the EFF (Running Efficiency) for the UPS is

unknown, assume 0.85 EFF.

Unless otherwise known:

Assume 0.9 for RPF (running power factor) unless

otherwise known.

Since these drives are all current limiting:

Calculate GkW as follows:

Calculate GkW using the following formula, assuming a

generator

When sizing for a pulse width modulated (PWM) drive,

consult the drive manufacturer to verify that the drive limits

harmonic current is less than 10 percent THD on a high

impedance source (e.g. a generator set), assume a sizing

factor of 1.4.

Using these factors for GkW results in selecting a generator

reactance low enough to limit voltage distortion caused by

nonlinear loads to approximately 10 to 15%.

sizing factor of 2

unless otherwise known.

T elecom DC Rectifiers and Battery Charging Equipment

Telecom DC Rectifiers and battery charging equipment are

nonlinear loads and similar to static UPS and should be

sized using the same method.

PAGE 26 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 27

ENVIRONMENT AL CONSIDERATIONS — dB(A)

Noise Consideration

Because noise effects the surrounding environment, it is

important to consider noise factors when installing a genset.

The following is a brief approach to evaluating noise sources

and noise level reduction.

Noise requires a source, a path, and a receive r. In a standby

system, the genset is the source, the path is air or air and a

structure which transmits the noise vibrations, and the

receiver is a person in the vicinity (including the operator).

Since little prevention can be done with the source or the

receiver , the treatment method is to manipulate the pathwa y

of noise.

The three main components of noise from an enginegenerator set are:

1. Engine exhaust (low frequency sound)

2. Engine moving parts (low and high frequency sound)

3. Radiator discharge air (high frequency sound).

Noise Laws and Regulations

There are many state and local codes establishing maximum

noise levels. Most noise regulations specify the maximum

allowable noise level at the property line. Table 8 is an

example of typical maximum allowable noise levels. OSHA

has specific noise regulations where persons working in a

generator room will be required to wear ear protection.

Noise Level Measurement and Decibel / dB(A) Units

T o measure noise properly , the subjective response of human

hearing is substituted by an objective measurement of sound

measured by a meter. The unit of measurement for sound

is the decibel (dB). The decibel is a convenient number on

a logarithmic scale expressing the ratio of two sound

pressures, comparing the actual pressure to a reference

pressure.

Noise regulations are written in terms of "decibels 'A' scale"

or dB(A). This term means the sound pressure level has

been adjusted to duplicate how the imperfect human ear

hears noise. The human ear can only hear within a r ange of

frequencies. The dB(A) weighted scale tries to simulate

human loudness perception. Loudness is dependent on

sound pressure lev el (amplitude) and frequency . See Figure

2 on page 28 for a dB(A) comparison.

Decibel tests are conducted in a "free field". A free field is

a sound field in which the effects of obstacles or boundaries

on sound propagated in the field are negligible. A "reverberant

field" is a sound field in which the effects of obstacles or

boundaries on sound propagated in the field are not negligible.

Accurate noise measurements require the microphone to

be placed outside the "near field". The near field is defined

as the region within one wavelength or two times the largest

dimension of the noise source, whichev er is g reater. Noise

cannot be measure accurately for compliance with

specifications calling for measurements within the near field.

Noise measurements should be made using a sound level

meter and octave band analyz er. The microphones should

be placed in a circle of 23 feet (7 meters) radius centered on

the generator set.

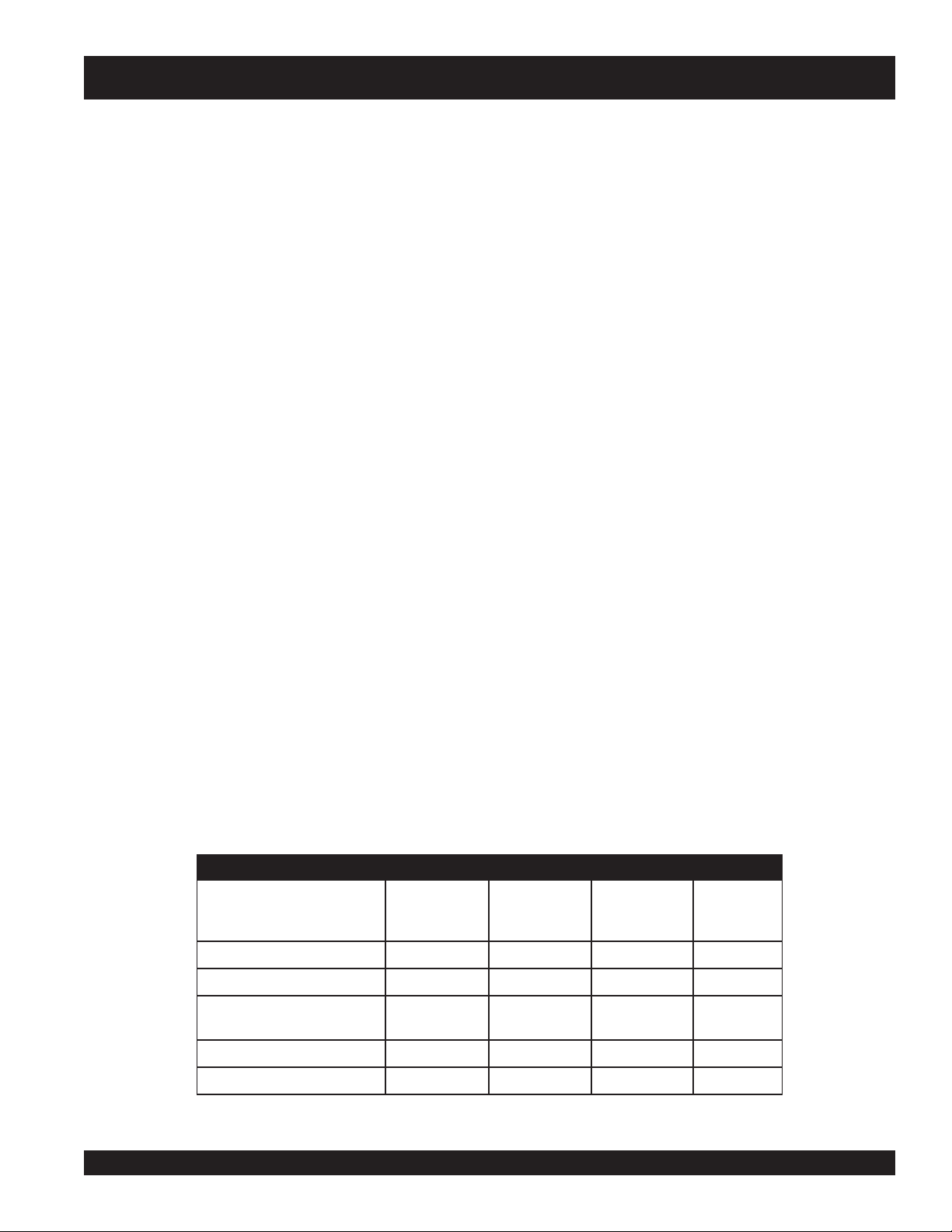

sleveLesioNedistuOrofairetirClacipyT.8elbaT

senoZesioN

laitnediseR—nabrU26257574

laitnediseR—nabrubuS75742524

ronabrubuSetiuQyreV

laitnediseRlaruR

yrtsudnIybraeN—nabrU76752625

yrtsudnIyvaeH27267675

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 27

yaDkaeP

)A(Bd

25247473

thgiNkaeP

)A(Bd

suounitnoC

yaD

)A(Bd

suounitnoC

thgiN

)A(Bd

Page 28

ENVIRONMENT AL CONSIDERATIONS — dB(A)

Comparison Chart dB(A)

Figure 2 below provides a comparison of dB(A) levels for

daily noises and the typical range of generator sets. Open

generator sets are unhoused units where the path of noise

is unobstructed. An acoustic housing encloses the genset

to impede and absorb the path of noise.

For applications that require even quieter operation, see the

WhisperWatt™ product line f or dB(A) lev els as low as 62. If

quieter levels are required, please contact an MQ Power

dealer.

Figure 2. dB(A) Comparison Chart

PAGE 28 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 29

ENVIRONMENT AL CONSIDERATIONS — dB(A)

Adding Additional Sound Sources

The noise level at a given location is the sum of the noise

levels from all sources, including reflecting sources. For

example, the noise level in a free field along side of two

identical generator sets would be double the noise level of

either set when both sets are running. A doubling of the

noise level is represented as an increase of approximately

3 dB(A). In this case, if the noise level from either set is

measured as 70 dB(A), the expected result of the combined

generators would be 73 dB(A) when both units are running.

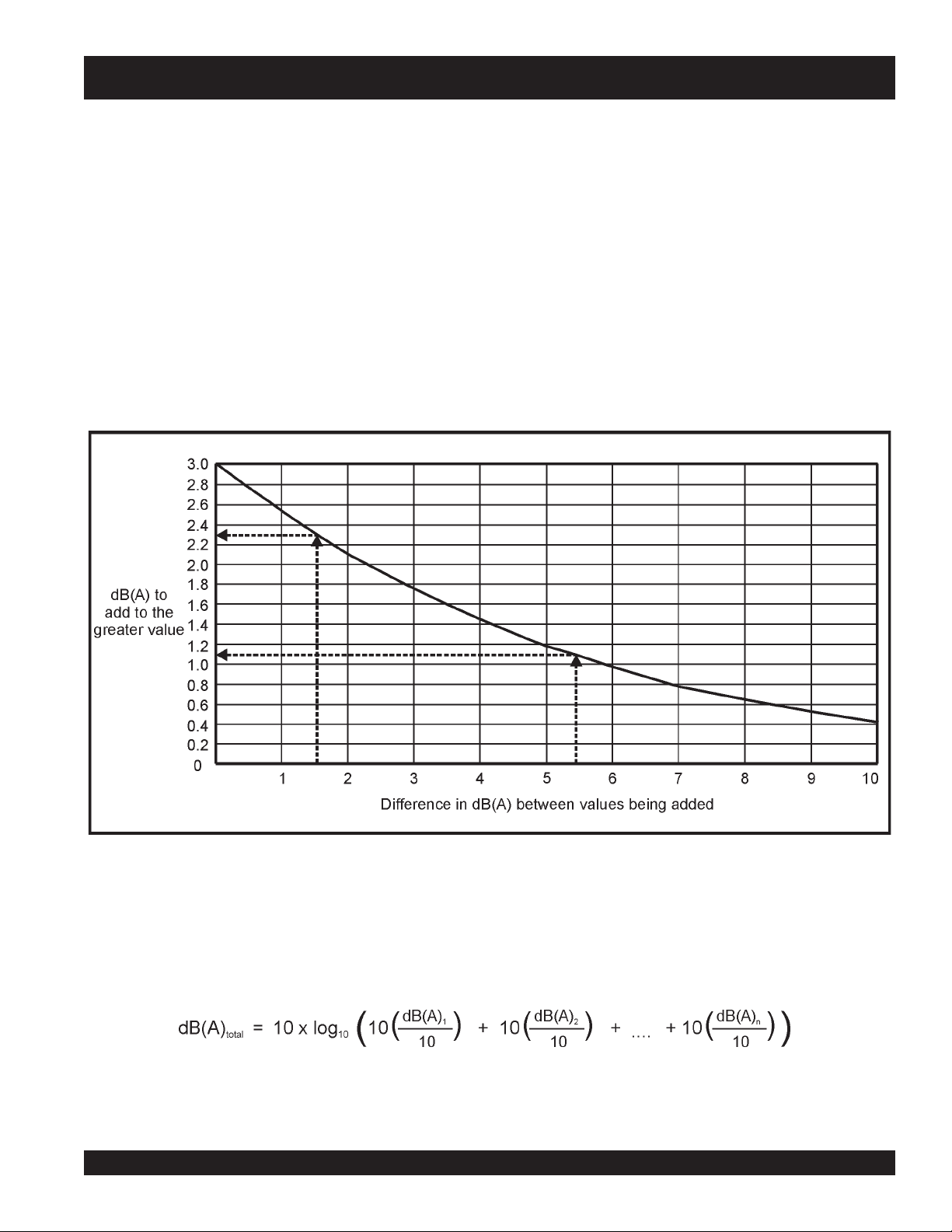

Figure 3 below estimates the noise level from multiple

noise sources:

1. To find the difference in dB(A) between two of the

sources (any pair), locate the dB(A) difference value

on the horizontal scale as shown by the horizontal arrow .

Add this value to the larger dB(A) value of the pair.

2. Repeat Step 1 between the value just determined and

the next value. Keep repeating the process until all

noise sources have been accounted for.

Figure 3. dB(A) Comparison Chart

Alternatively, the following formula can be used to add

sound pressure levels measured in dB(A):

INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07) — PAGE 29

Page 30

ENVIRONMENT AL CONSIDERATIONS — dB(A)

Effects of Distance

As the distance between a noise source and receiver

increases, the sound level decreases. If a second sound

measurement is taken twice as far from the source, the

second reading will be approximately 6 dB(A) less than the

first reading. If the sound pressure level (SPL

at distance d

distance d

is known, the sound pressure level (SPL

1

can be found as follows:

2

) of a source

1

2

It should be noted the background noise level must be at

least 10 dB(A) below the noise level of the generator set,

the installation must approximate a free field environment

and the generator set must be equipped with a critical grade

muffler.

) at

Figure 4. below can be used as an alternative to the formula

for estimating the sound level at various distances (such as

to the property line). For instance , as shown by the dashed

arrows, if the noise rating of the generator set is 95 dB(A) at

7 meters, the noise level 100 meters away will be

If the sound pressure level (SPL

dB(A), then at 7 meters (d

) the sound pressure level (SPL

2

) at 21 meters (d1) is 100

1

will be:

approximately 72 dB(A).

)

When using Figure 4, draw a line parallel to the slanted lines

2

from the known dB(A) value on the vertical scale line to the

vertical line for the specified distance. Then dra w a horizontal

line back to the ver tical scale line and read the new dB(A)

value.

Figure 4. Distance Effects on dB(A)

PAGE 30 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

Page 31

ENVIRONMENT AL CONSIDERATIONS — dB(A)

Reducing Noise

Structure-Borne Noise

Structure-borne noise is transmitted or generated as

vibrations in structures. Vibrating structures create sound

pressure wav es (noise) in the surrounding air . Connections

to a genset can cause vibrations in the building structure,

creating noise. Typically, these include the skid anchors,

radiator discharge air duct, exhaust piping, coolant piping,

fuel lines, and wiring conduit. Also, the walls of a genset

housing can vibrate and cause noise.

Reducing Noise

Airborne Noise

Airborne noise is usually the most dominant type of noise.

Airborne noise has a directional characteristic, particularly

at the high end of the frequency range. Table 9 below shows

ways of minimizing airborne noise.

The following will help reduce airborne noise:

1. Redirect noise away from receiv ers. V ertical radiator or

exhaust outlets point the noise away from people at

grade level and keep them out of the path of noise.

2. Line-of-sight barriers are effective in reducing noise. A

The following will help reduce structure-borne noise:

1. Mounting a genset on spring-type vibration isolators