Page 1

OPERATION AND PARTS MANUAL

MODEL MQP20P

20KW STANDBY GENERATOR

(PERKINS 404D-22 DIESEL ENGINE)

Revision #1 (11/28/11)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

Diesel engine exhaust and some of

PAGE 2 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 3

NOTES

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 3

Page 4

TABLE OF CONTENTS

MQP20P Standby Generator

Proposition 65 Warning ........................................... 2

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Information ..............................................6-11

Specifications ........................................................ 12

Dimensions ............................................................ 13

Installation ........................................................14-15

General Information .......................................... 16-17

Major Components ................................................ 18

Basic Engine Components .................................... 19

Digital Controller Panel .......................................... 20

Connector Outlet Box And Main Circuit Breaker ... 21

Load Application/Generator Output ....................... 22

Inspection/Setup ............................................... 23-26

Startup .............................................................. 27-29

Protective Devices ................................................. 30

Transporting ........................................................... 31

Maintenance ..................................................... 32-35

Troubleshooting (Generator) .................................. 36

Troubleshooting (Engine) ....................................... 37

Troubleshooting (Controller) ............................. 38-39

Troubleshooting (Voltage Regulator) ..................... 40

Maintenance Parts Locator .................................... 41

Generator Wiring Diagram (Single Phase) ....... 42-43

Generator Wiring Diagram (Three Phase) ........ 44-45

Explanation Of Code In Remarks Column............. 46

Suggested Spare Parts ......................................... 47

Component Drawings

Housing Assy. ................................................... 48-49

Engine And Generator Mounting Assy. ............. 50-51

Fuel Assy. ......................................................... 52-53

Electrical Assy. .................................................. 54-55

Jacket Water Heater Assy. ................................ 56-57

Solenoid Assy. .................................................... 5-59

Radiator Assy. ................................................... 60-61

Air Filter Assy. ................................................... 62-63

Engine Exhaust Assy. ....................................... 64-65

Engine Oil Assy. ................................................ 66-67

Control Panel Assy. ........................................... 68-69

Controller Assy. ................................................. 70-71

Saddlebox Assy. ...............................................72-73

Circuit Breaker Assy. ........................................... 74-5

Camlok Assy. .................................................... 76-77

Terms And Conditions Of Sale — Parts ................ 78

NOTICE

Specifications and part numbers are subject to change

without notice.

PAGE 4 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 5

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

Choose from three easy options:

January 1st, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at: parts@multiquip.

com.

To ob tain an MQ Ac cou nt , co nta ct yo ur

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 5

Page 6

SAFETY INFORMATION

Do not operate or service the equipment before reading the

Potential hazards associated with the operation of this

entire manual. Safety precautions should be followed at all

times when operating this equipment. Failure to read and

understand the safety messages and operating instructions

could result in injury to yourself and others.

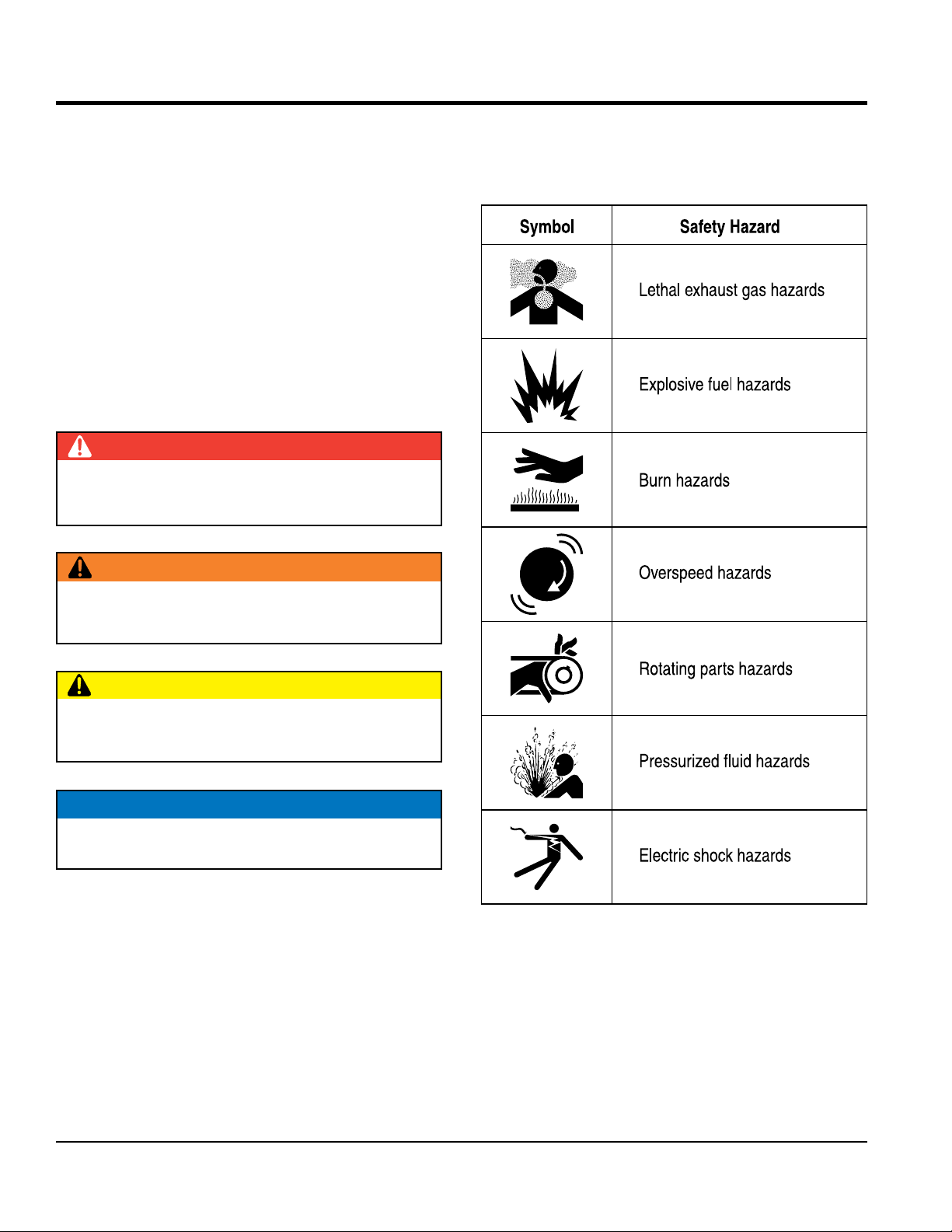

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 7

SAFETY INFORMATION

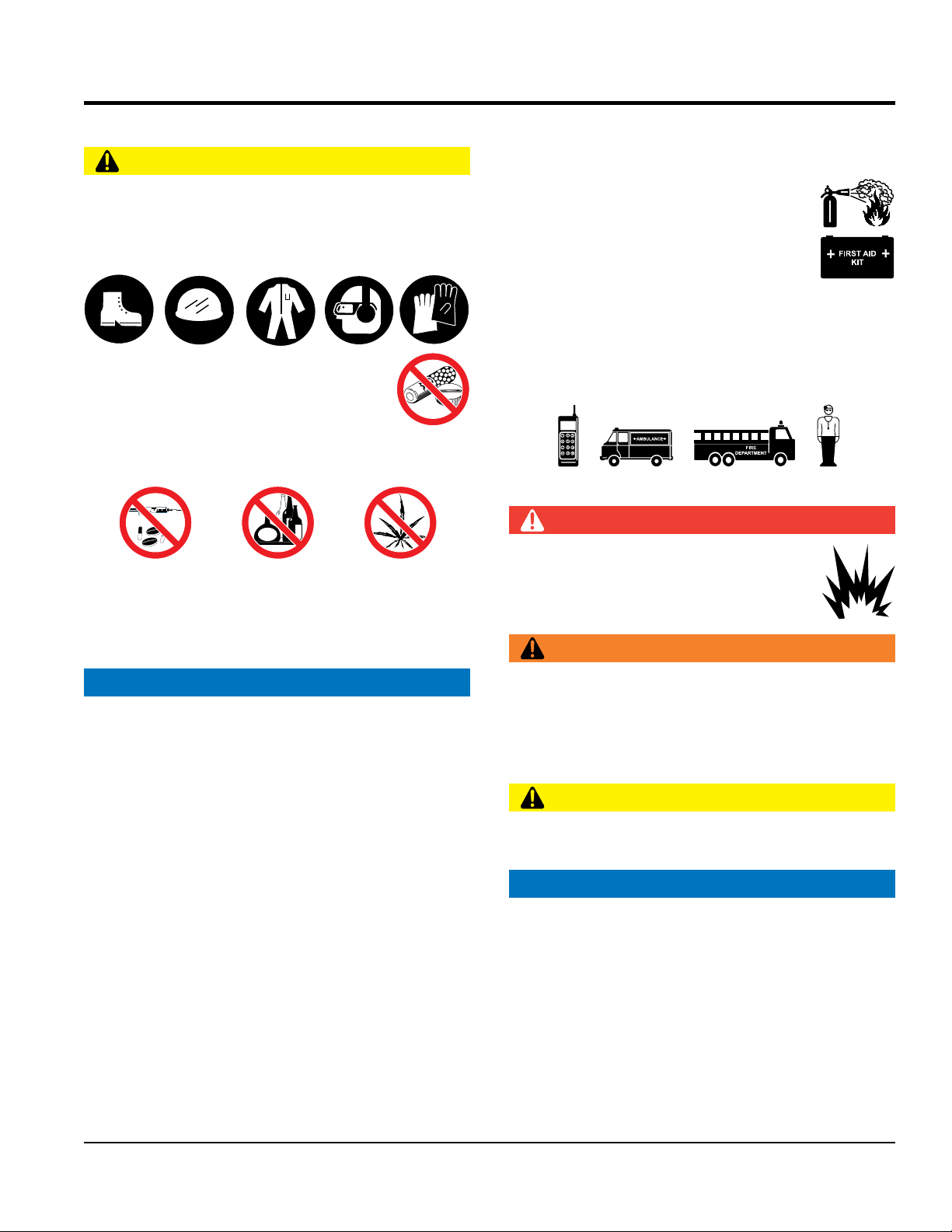

GENERAL SAFETY

NEVER use accessories or attachments that are not

recommended by MQ Power for this equipment. Damage

Also, know the

and

This information will be invaluable in

emergency or safety devices.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

ensure generator is on level ground before use.

keep the machine in proper running condition.

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

ALWAYS check the equipment for loosened threads or

bolts before starting.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest

phone or keep a phone on the job site.

phone numbers of the nearest ambulance, doctor

fi re department.

the case of an emergency.

GENERATOR SAFETY

DANGER

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

NOTICE

This equipment should only be operated by trained and

qualifi ed personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

equipment modifi cation will void all warranties.

NEVER disconnect any

These devices are intended for operator safety.

devices will void all warranties.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

NOTICE

ALWAYS

ALWAYS

Fix damage to machine and replace any broken parts

immediately.

ALWAYS

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 7

Page 8

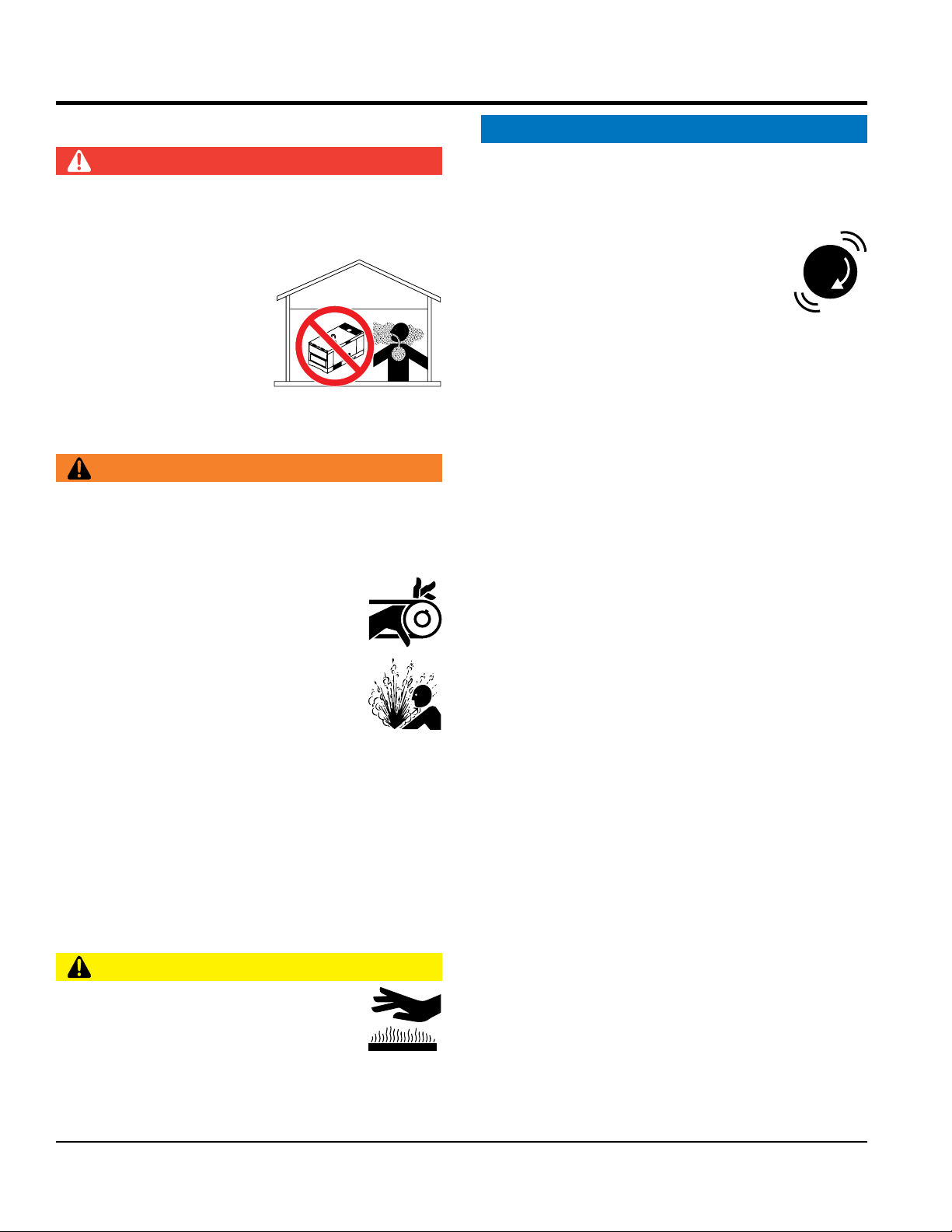

ENGINE SAFETY

NOTICE

run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

Wet stacking is a common problem with diesel engines

no load applied. When a diesel engine operates without

suffi cient load (less than 40% of the rated output), it will

not operate at its optimum temperature. This will allow

In order for a diesel engine to operate at peak effi ciency,

it must be able to provide fuel and air in the proper ratio

and at a high enough engine temperature for the engine

applied to relieve the condition. It can reduce the system

Codes specify that in certain locations, spark arresters

must be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed

from the engine exhaust. Spark arresters are qualifi ed

SAFETY INFORMATION

DANGER

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment

requires an adequate free

fl ow of cooling air. NEVER

operate this equipment in

any enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury to people and property and

serious damage to the equipment or engine.

WARNING

D O NOT pl ace h ands or fing ers inside e ngine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

DO NOT remove the radiator cap while the

engine is hot. High pressure boiling water

will gush out of the radiator and severely

scald any persons in the general area of

the generator.

DO NOT remove the coolant drain plug while the engine

is hot. Hot coolant will gush out of the coolant tank and

severely scald any persons in the general area of the

generator.

NEVER

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

which are operated for extended periods with light or

unburned fuel to accumulate in the exhaust system,

which can foul the fuel injectors, engine valves and

exhaust system, including turbochargers, and reduce

the operating performance.

to completely burn all of the fuel.

Wet stacking does not usually cause any permanent

damage and can be alleviated if additional load is

performance and increase maintenance. Applying an

increasing load over a period of time until the excess

fuel is burned off and the system capacity is reached

usually can repair the condition. This can take several

hours to burn off the accumulated unburned fuel.

State Health Safety Codes and Public Resources

DO NOT remove the engine oil drain plug while the

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

generator.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

PAGE 8 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

to prevent accidental discharge of sparks or fl ames

and rated by the United States Forest Service for this

purpose. In order to comply with local laws regarding

spark arresters, consult the engine distributor or the

local Health and Safety Administrator.

Page 9

FUEL SAFETY

DANGER

Make sure the hitch and coupling of the towing vehicle

NEVER

tow a trailer with defective hitches, couplings, chains, etc.

Trailer tires should be infl ated to 50 psi cold.

safety

attach trailer’s safety chains to towing

make sure the vehicle and trailer directional,

unless

posted otherwise. Recommended off-road towing is not to

Avoid sudden stops and starts. This can cause skidding,

Trailer should be adjusted to a level position at all times

rolling

underneath the trailer’s bumper

Use the trailer’s swivel jack to adjust the trailer height to

SAFETY INFORMATION

are rated equal to, or greater than the trailer “gross

vehicle weight rating.”

DO NOT start the engine near spilled fuel or combustible

fl uids. Diesel fuel is extremely fl ammable and its vapors

can cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke ar ound or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

TOWING SAFETY

Check with your local county or state safety

towing regulations, in addition to meeting

Department of Transpor tation (DOT)

Safety Towing Regulations, before towing

your generator.

Refer to MQ Power trailer manual for additional safety

information.

In order to reduce the possibility of an accident while

transporting the generator on public roads, ALWAYS

make sure the trailer that supports the generator and

the towing vehicle are mechanically sound and in good

operating condition.

ALWAYS shutdown engine before transporting

CAUTION

ALWAYS inspect the hitch and coupling for wear.

Check the tire air pressure on both towing vehicle and

trailer.

Also check the tire tread wear on both vehicles.

ALWAYS make sure the trailer is equipped with a

chain.

ALWAYS properly

vehicle.

ALWAYS

backup, brake and trailer lights are connected and

working properly.

DOT Requirements include the following:

• Connect and test electric brake operation.

• Secure portable power cables in cable tray with tie

wraps.

The maximum speed for highway towing is 55 MPH

exceed 15 MPH or less depending on type of terrain.

or jack-knifi ng. Smooth, gradual starts and stops will

improve towing.

Avoid sharp turns to prevent rolling.

when towing.

Raise and lock trailer wheel stand in up position when

towing.

Place chock blocks underneath wheel to prevent

while parked.

Place support blocks

to prevent tipping while parked.

a level position while parked.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 9

Page 10

ELECTRICAL SAFETY

DANGER

Make sure power cables are securely connected to the

make certain that proper power or extension

cord has been selected for the job. See Cable Selection

make sure that electrical circuits are properly

Severe injury or death by

can result from operating an ungrounded

DO NOT touch output terminals during

operation. Contact with output terminals

during operation can cause electrocution,

electrical shock or burn.

SAFETY INFORMATION

generator’s output receptacles. Incorrect connections

may cause electrical shock and damage to the

generator.

NOTICE

ALWAYS

The electrical voltage required to

operate the generator can cause severe

injury or even death through physical contact with live

circuits. Turn generator and all circuit breakers OFF

before performing maintenance on the generator or

making contact with output terminals.

NEVER insert any objects into the output

receptacles during operation. This is

extremely dangerous. The possibility exists

of electrical shock, electrocution or

death.

Backfeed to a utility system can cause

electrocution and/or property damage.

NEVER connect the generator to a

building’s electrical system without

a transfer switch or other approved

device. All installations should be

performed by a licensed electrician in accordance with

all applicable laws and electrical codes. Failure to do so

could result in electrical shock or burn, causing serious

injury or even death.

Chart in this manual.

Grounding Safety

DANGER

ALWAYS

grounded to a suitable earth ground (ground rod) per

the National Electrical Code (NEC) and local codes

before operating generator.

electrocution

generator.

NEVER use gas piping as an electrical ground.

Power Cord/Cable Safety

DANGER

NEVER let power cords or cables lay in water.

NEVER stand in water while AC power from the

generator is being transferred to a load.

NEVER use damaged or worn cables or cords when

connecting equipment to generator. Inspect for cuts in

the insulation.

NEVER grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

PAGE 10 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 11

BATTERY SAFETY

ENVIRONMENTAL SAFETY

pour waste, oil or fuel directly onto the ground,

SAFETY INFORMATION

DANGER

DO NOT drop the battery. There is a possibility that the

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

ALWAYS wear safety glasses when handling

the battery to avoid eye irritation. The battery

contains acids that can cause injury to the

eyes and skin.

Use well-insulated gloves when picking up the battery.

ALWAYS keep the battery charged. If the battery is not

charged, combustible gas will build up.

ALWAYS recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

of combustible gasses.

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to

dispose of hazardous waste.

DO NOT

down a drain or into any water source.

If the battery liquid (dilute sulfuric acid) comes into

contact with clothing or skin, rinse skin or clothing

immediately with plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the generator.

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 11

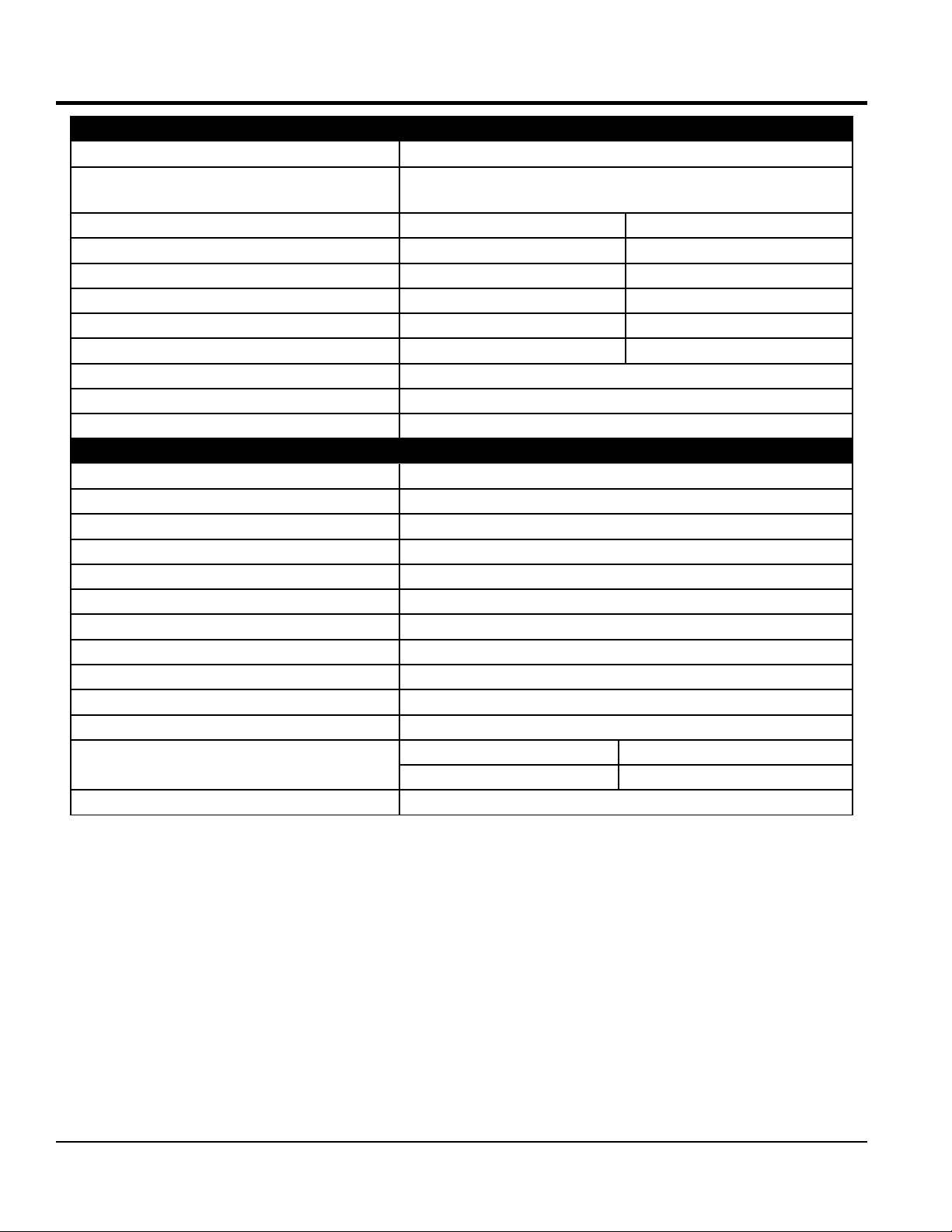

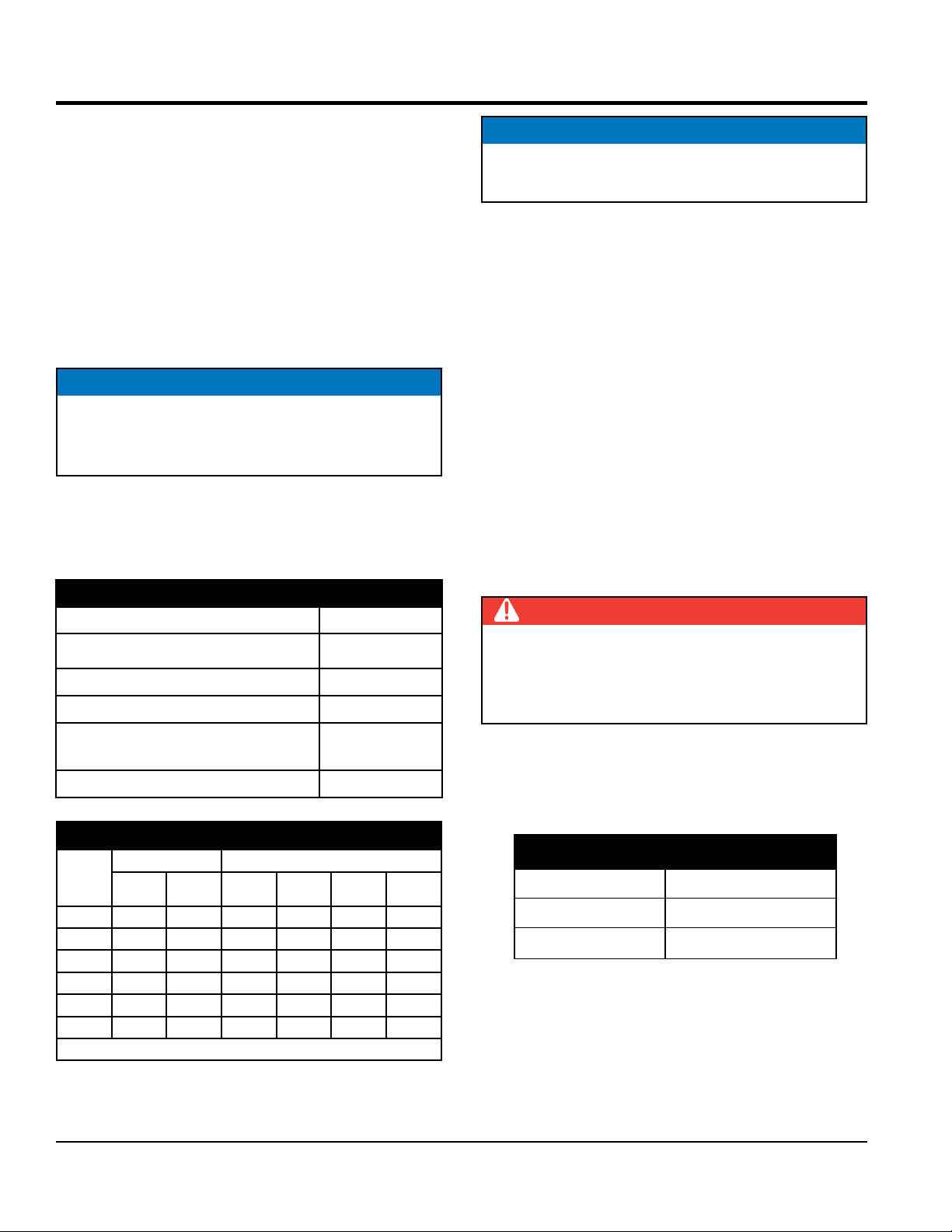

Page 12

Model

Type

Armature Connection

Phase

Standby Output

Prime Output

Voltage

Power Factor

Frequency

Speed

Aux. AC Power

Model

Type

No. of Cylinders

Bore x Stroke

Displacement

Rated Output

Starting

Coolant Capacity

Lube Oil Capacity

Fuel Type

Fuel Tank Capacity

Fuel Consumption

Battery

SPECIFICATIONS

Table 1. Generator Specifications

MQP20P

Rotating field, 4-pole,

brushless, shunt excitation design

High Voltage Series High Voltage Series (WYE)

Single Three

20 kW (25 kVA) 20 kW (25 kVA)

17 kW (21.25 kVA) 17 kW (21.25 kVA)

240 V 277Y/480V

1.0 0.8

60 Hz

1800 rpm

Single Phase, 60 Hz

Table 2. Engine Specifications

Perkins 404D-22 Tier 4

4 cycle, indirect injection

4 cylinders In -Line

3.30 in. x 3.93 in. (84 mm x 100 mm)

135 cu. in. (2.2 liters)

32.6 HP at 1800 rpm

Electric

0.9 gal. (3.6 liters)

2.8 gal. (10.6 liters)

#2 Diesel Fuel

126 gal. (475 liters)

1.5 gal. (5.7 L)/hr at full load 1.2 gal. (4.5 L)/hr at 3/4 load

0.8 gal. (3.0 L)/hr at 1/2 load 0.7 gal. (2.6 L)/hr at 1/4 load

12 VDC

PAGE 12 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 13

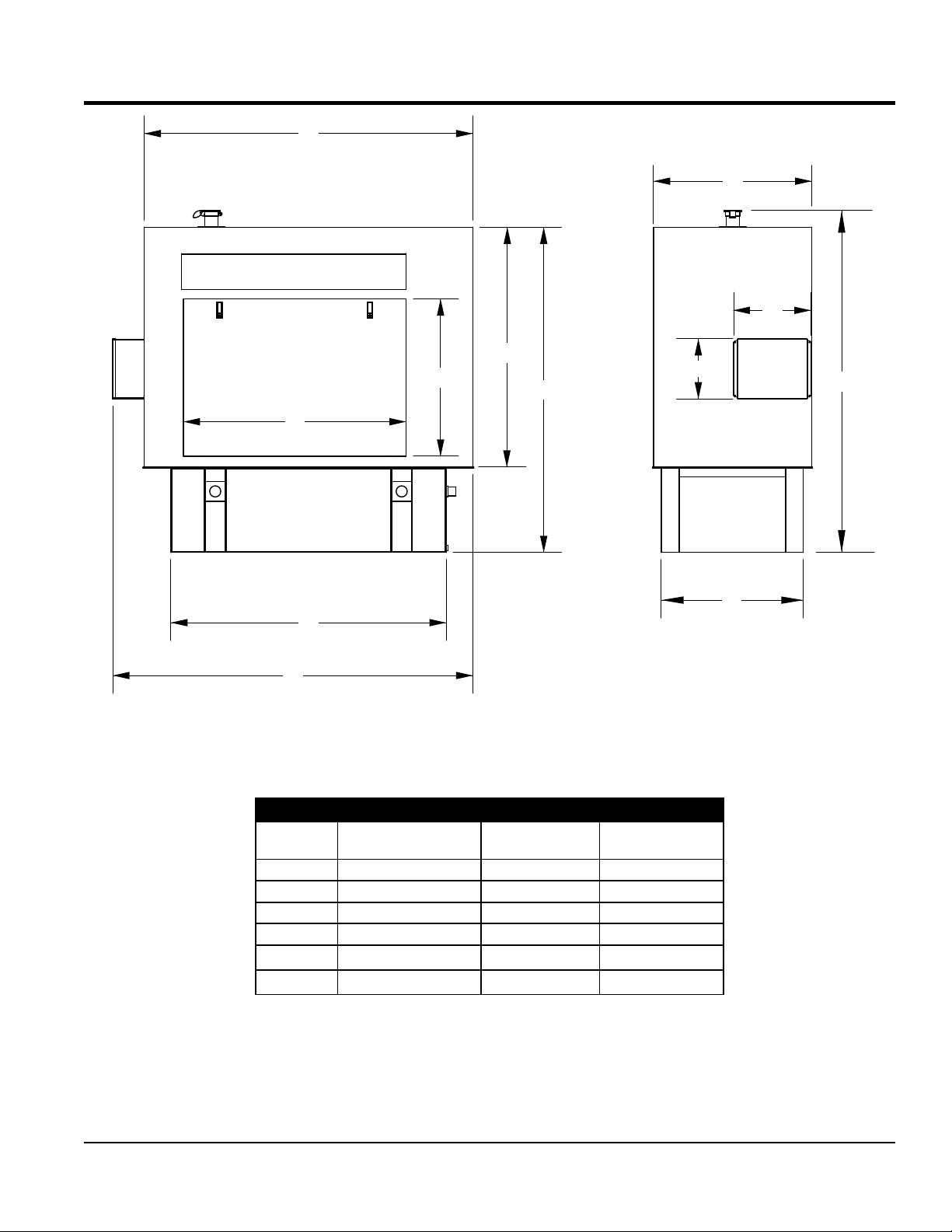

G

DIMENSIONS

A

M

J

L

H

D

K

C

E

F

Figure 1. Dimensions

Table 3. Dimensions

Reference

Letter

A 74 in. (1879.6 mm.) G 50.19 in. (1274.8 mm.)

B 32 in. (812.8 mm.) H 35.31 in. (896.9 mm.)

C 77 in. (1955.8 mm.) J 17.5 in. (444.5 mm.)

D 73.06 in. (1855.7 mm.) K 15 in. (381 mm.)

E 62 in. (1574.8 mm.) L 54.06 in. (1373.1 mm.)

F 82.5 in. (2095.5 mm.) M 35.5 in. (901.7 mm.)

Dimension in. (mm) Reference Letter Dimension in. (mm)

B

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 13

Page 14

INSTALLATION

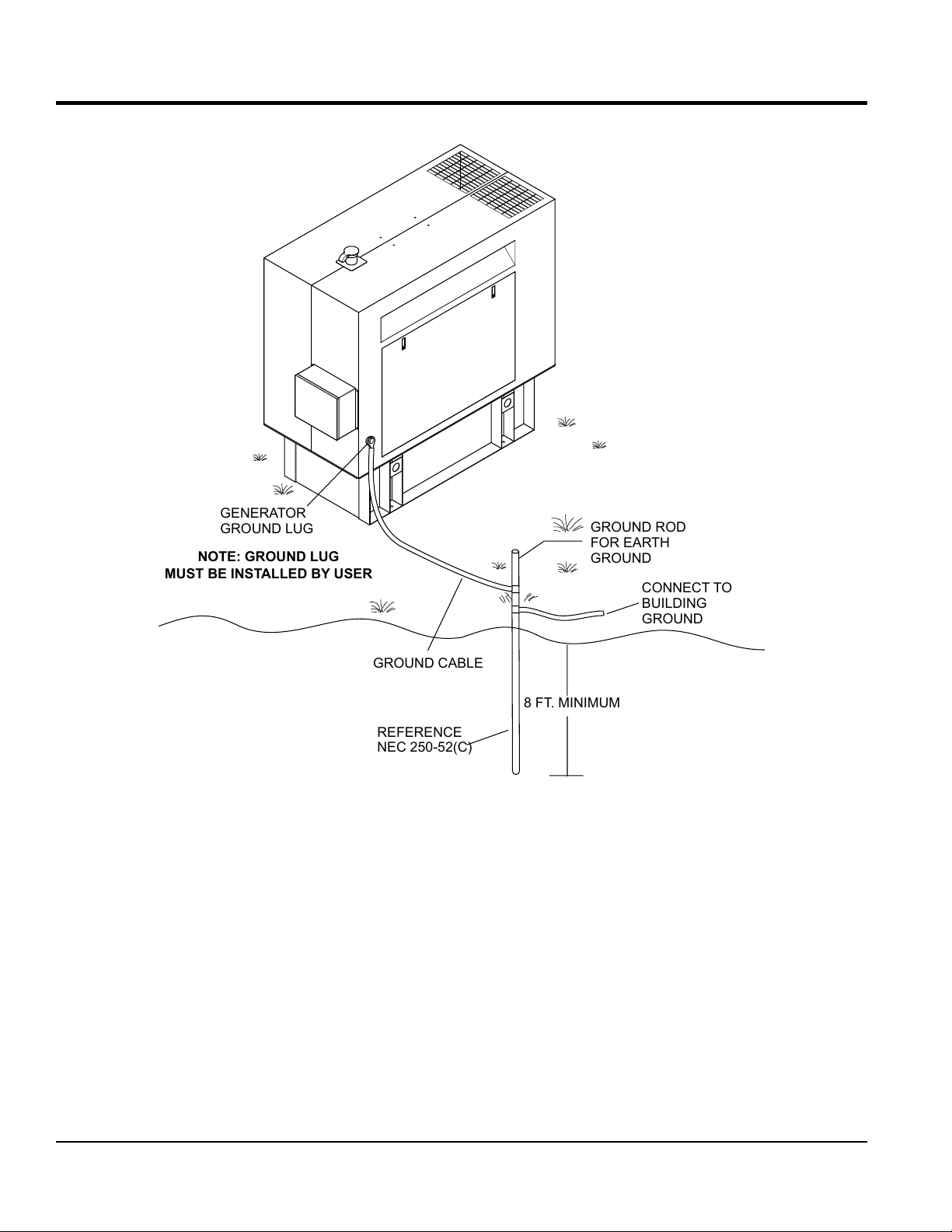

GROUND ROD

FOR EARTH

GROUND

GROUND CABLE

GENERATOR

GROUND LUG

CONNECT TO

BUILDING

GROUND

8 FT. MINIMUM

REFERENCE

NEC 250-52(C)

NOTE: GROUND LUG

MUST BE INSTALLED BY USER

PAGE 14 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Figure 2. Typical Generator Grounding Application

Page 15

INSTALLATION

OUTDOOR INSTALLATION

Install the generator in a area that is free of debris,

bystanders, and overhead obstructions. Make sure the

generator is on secure level ground so that it cannot slide

or shift around. Also install the generator in a manner so

that the exhaust will not be discharged in the direction of

nearby homes.

The installation site must be relatively free from moisture

and dust. All electrical equipment should be protected

from excessive moisture. Failure to do so will result in

deterioration of the insulation and will result in short circuits

and grounding.

Foreign materials such as dust, sand, lint and abrasive

materials have a tendency to cause excessive wear to

engine and alternator parts.

CAUTION

Pay close attention to ventilation when operating the

generator inside tunnels and caves. The engine exhaust

contains noxious elements. Engine exhaust must be

routed to a ventilated area.

INDOOR INSTALLATION

GENERATOR GROUNDING

To guard against electrical shock and possible damage to

the equipment, it is important to provide a good EARTH

ground.

Article 250 (Grounding) of the National Electrical Code

(NEC) provides guidelines for proper grounding and

specifies that the cable ground shall be connected to the

grounding system of the building as close to the point of

cable entry as practical.

NEC articles 250-64(b) and 250-66 set the following

grounding requirements:

1. Use one of the following wire types to connect the

generator to earth ground.

a. Copper — 8 AWG (5.3 mm2)

b. Aluminum — 6 AWG (8.4 mm2)

2. When grounding the generator (Figure 2) connect the

ground cable between the lock washer and the nut on

the generator and tighten the nut fully. Connect the

other end of the ground cable to earth ground.

3. NEC article 250-52(c) specifies that the earth ground rod

should be buried a minimum of 8 ft. into the ground.

Exhaust gases from diesel engines are extremely

poisonous. Whenever an engine is installed indoors the

exhaust fumes must be vented to the outside. The engine

should be installed at least two feet from any outside wall.

Using an exhaust pipe which is too long or too small can

cause excessive back pressure which will cause the engine

to heat excessively and possibly burn the valves.

MOUNTING

The generator must be mounted on a solid foundation (such

as concrete) and set firmly on the foundation to isolate

vibration of the generator when it is running. The generator

must sit at least 6 inches above the floor or grade level (in

accordance to NFPA 110, Chapter 5-4.1).

NOTICE

When connecting the generator to any building electrical

system, ALWAYS consult a licensed electrician.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 15

Page 16

GENERAL INFORMATION

GENERATOR

This generator (Figure 3) is a high-quality, reliable, backup

power source used by telecommunications companies to

keep their networks connected.

CONTROL PANEL (MEC 20™ Digital Controller)

AC Metering Display

• Voltage/Amperage / Frequency

• Generator Phase Voltage / Current

• Generator Frequency

Engine Information Display

• Engine Temperature / Oil Pressure (psi)

• Battery Voltage (DC) / Tachometer

• Hourmeter

Minor Fault Warning Display

• Switch Not In Auto

• Low Fuel Level

• Low Oil Pressure Alarm

• Low Engine Temperature

• High Engine Temperature Alarm

• Low Battery Voltage

• High Battery Voltage

• Weak Battery Condition

• Battery Charger Input Fail

• Undervoltage

• Over / Underfrequency

• Overcurrent

Major Fault Shutdown Display

• Overvoltage

• Emergency Stop

• Loss Of Speed

• Overcrank

• Overspeed

• Low Oil Pressure

• High Engine Temperature

• Low Coolant Level

• Spare Programmable Digital Faults

Switches And Operating Controls

• Run / Off / Auto / Load Test Buttons

• Decrement / Increment / Previous

(Exit) /Next (Enter) Program Buttons

• Emergency Stop Button

• Audible Alarm Horn – 80 dB(A) at 2 ft.

• Alarm Horn Silence Button

• Lamp Test Button

• Fault Reset Function

• RJ45 Remote Communications,

External Expansion Module Ports

Timer Countdown Display

• Engine Start Delay

• Oil Bypass

• Overcrank

• Cycle Crank

• Starter Re-engage Delay

• Bypass Delay

Control LED Indicators

• Switch Position (Run,Off,Auto,Test)

• Common Alarm (Minor Fault)

• Common Shutdown (Major Fault)

• Generator Ready (When in Auto)

• Speed Signal

• Emergency Stop

Diagnostic LED Indicators:

• Run Output Energized

• Crank Output Energized

• Remote Start Signal Initiated

• Common Fail Output Energized

• Watchdog - CPU Running

• Programmable Output Contacts

CAMLOK OUTLET BOX PANEL

The “Camlok Panel” is provided with the following receptacles:

Ground (GRND.) - Green

Neutral (NEUT.) - White

LEG 1 - Black

LEG 2 - Red

LEG 3 - Blue

PAGE 16 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 17

GENERAL INFORMATION

PRINCIPLE OF OPERATION

This generator is a brushless, self-excited, externally

voltage regulated, synchronous AC generator. The

generator is made up of six major components: main stator

(armature), main rotor (field), exciter stator (field), exciter

rotor (armature), rectifier assembly, and voltage regulator.

The generator's exciter consists of a stationary field and

a rotating armature. The stationary field (exciter stator)

is designed to be the primary source of the generator's

residual magnetism. This residual magnetism allows the

exciter rotor (armature) to produce AC voltage even when

the exciter stator (field) is not powered. This AC voltage

is rectified to DC by the rotating rectifier assembly and

fed directly to the main rotor (field). As the generator

shaft continues to rotate, the main rotor (field) induces a

voltage into the generator's main stator (armature). At rated

speed, the main stator's voltage produced by the residual

magnetism of the exciter allows the automatic voltage

regulator to function.

The regulator provides voltage to the exciter resulting in

a build-up of generator terminal voltage. This system of

using residual magnetism eliminates the need for a special

field flashing circuit in the regulator. After the generator

has established the initial residual voltage, the regulator

provides a controlled DC field voltage to the exciter stator

resulting in a controlled generator terminal voltage.

VOLTAGE REGULATION

In the standard configuration (shunt excited), the automatic

voltage regulator receives both its input power and voltage

sensing from the generator's output terminals. The regulator

automatically monitors the generator's output voltage

against an internal reference set point and provides the

necessary DC output voltage to the exciter field required

to maintain constant generator terminal voltage. The

generator's terminal voltage is changed by adjusting the

regulator's reference set point.

ENGINE

This standby generator incorporates a Perkins 404D-22

Tier 4 diesel engine. This engine is designed to meet every

performance requirement for the generator. Refer to Table 2

for engine specifications.

In keeping with Multiquip’s policy of constantly improving

its products, the specifications quoted herein are subject

to change without prior notice.

ELECTRONIC GOVERNOR SYSTEM

The electronic governor system controls the RPMs of the

engine. When the engine demand increases or decreases,

the governor system regulates the frequency variation to

± 0.25%.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 17

Page 18

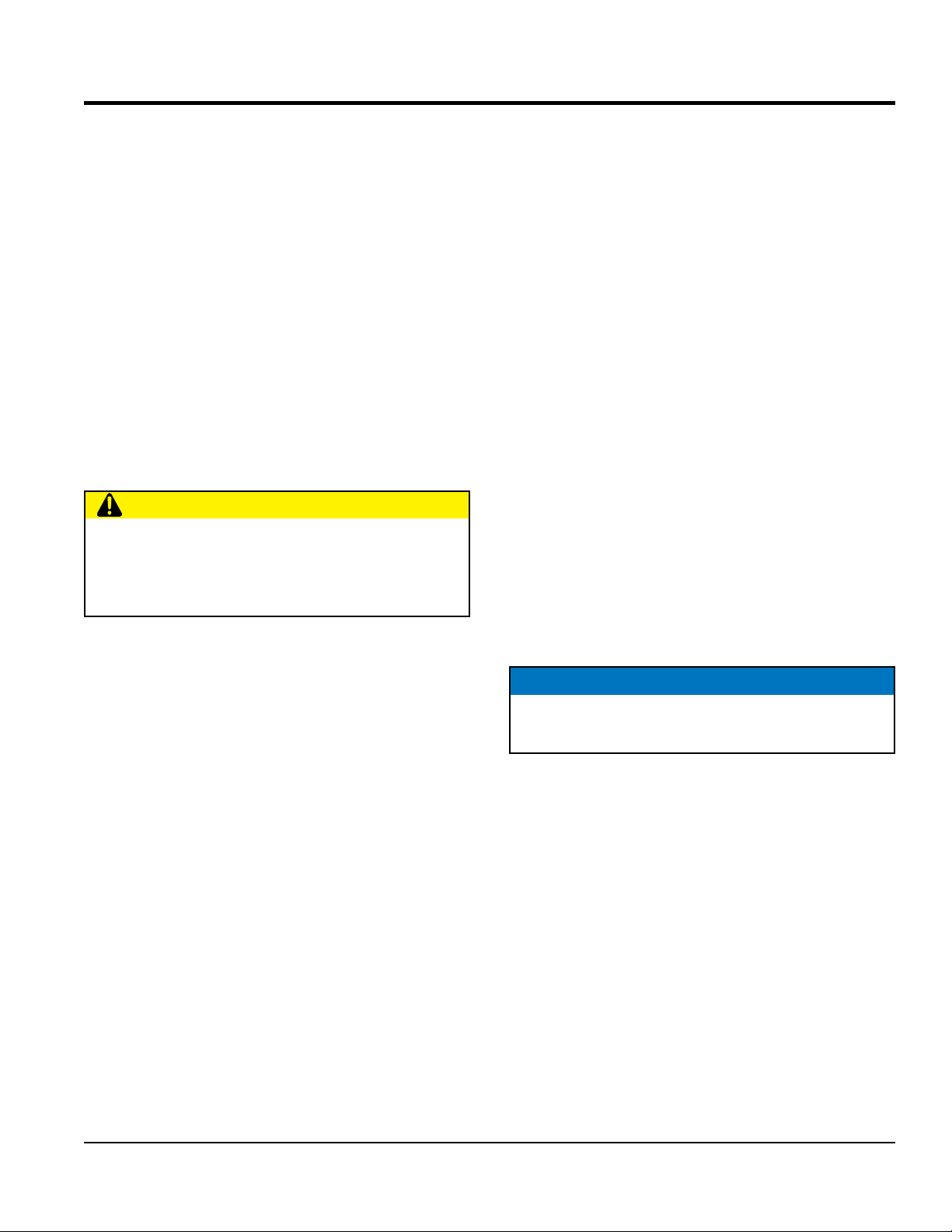

MAJOR COMPONENTS

2

1

3

4

5

6

7

13

14

9

8

10

11

12

Figure 3. Major Components

Table 4. Generator Major Components

ITEM NO. DESCRIPTION

1 Housing Assembly

PAGE 18 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

2 Exhaust Rain Cap

3 Camlok Connector Box Assembly

4 Fuel System Sub Base Assembly

5 Door Assembly

6 Generator Assembly

7 Circuit Breaker Assembly

8 Battery Assembly

9 Jacket Water Heater Assembly

10 Battery Charger Assembly

11 Starter Solenoid

12 Engine Assembly

13 Controller Assembly

14 Glow Plug Relay

Page 19

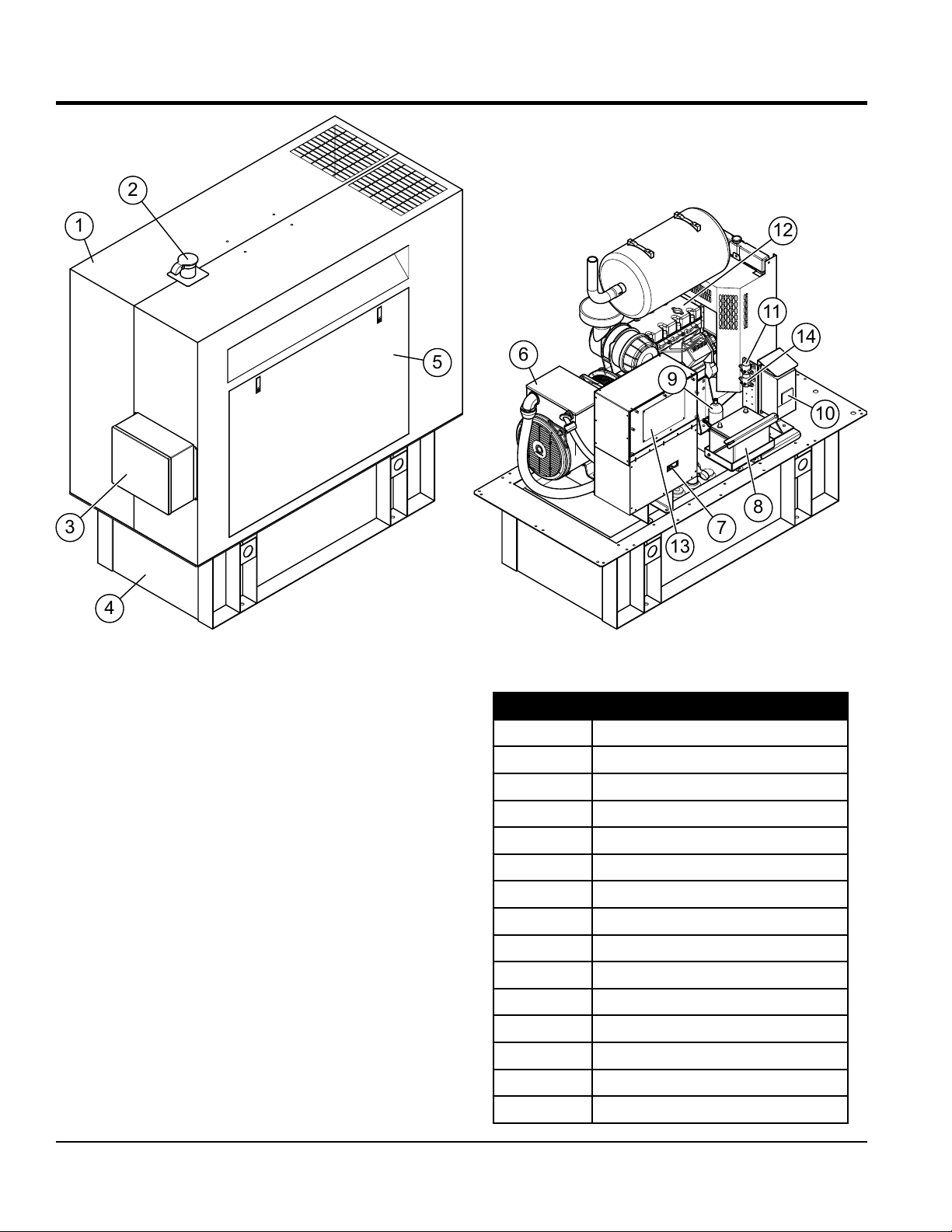

BASIC ENGINE COMPONENTS

6

1

5

4

12

2

11

7

3

8

Figure 4. Basic Engine Components

Table 5. Basic Engine Components

ITEM NO. DESCRIPTION

1 Radiator

2 Alternator

3 Starter

4 Air Filter

5 Oil Filler Cap

6 Muffler

7 Fuel Filter

8 Oil Drain Plug

9 Oil Filter

9

10

10 Oil Dipstick

11 Governor Actuator

12 Fuel Injection Pump

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 19

Page 20

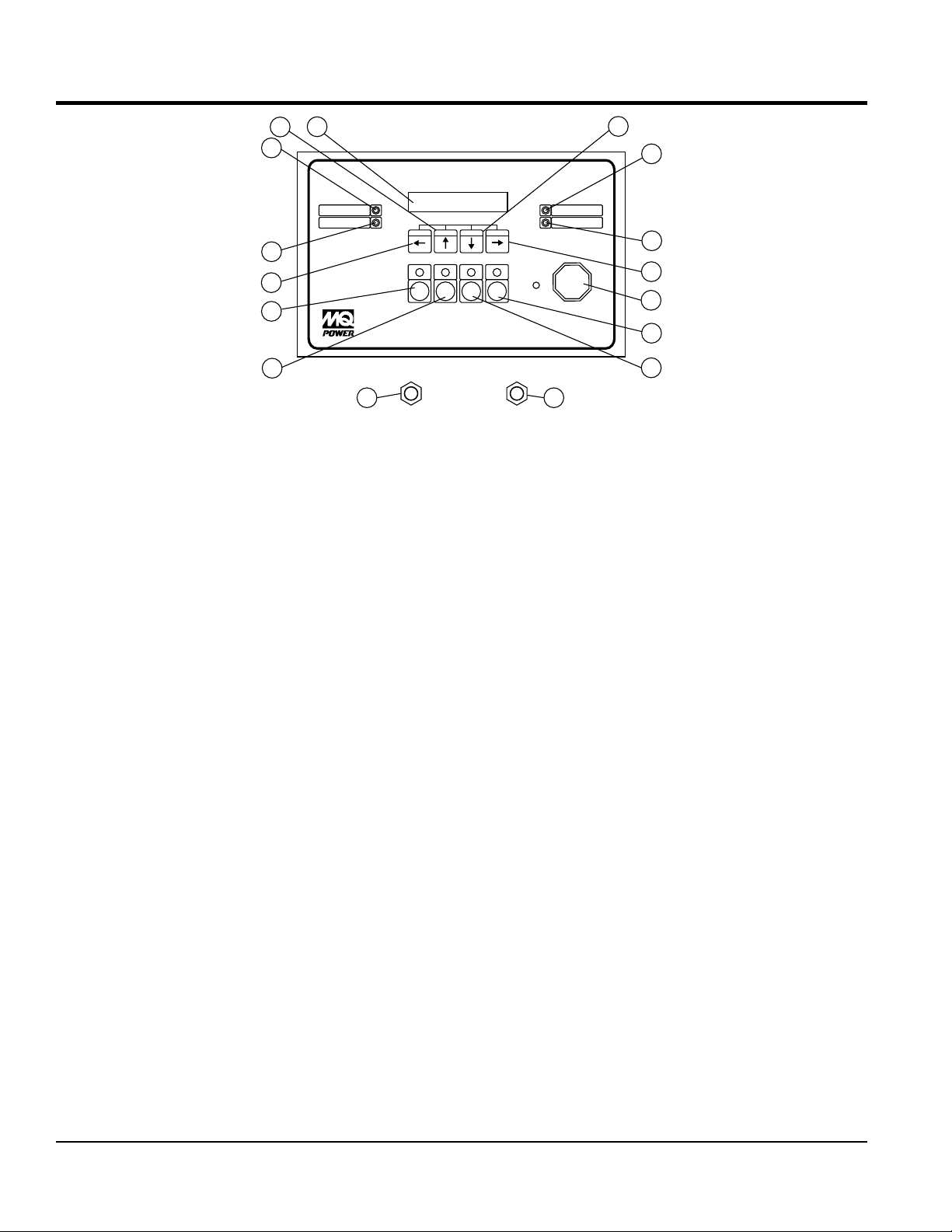

DIGITAL CONTROLLER PANEL

1

3

13

Microprocessor Engine Controller

Vavg

EXIT

RUN OFF

FREQUENCY

ADJUST

600

SILENCE

14

ALARM

SHUTDOWN

2

6

7

15 16

Figure 5. Digital Controller Components

1. Liquid Crystal Display — Displays voltage, amperage,

frequency,engine information, fault warnings, and other

generator and engine information.

2. EXIT Pushbutton — Press button to scroll backwards

through the status menus or programming prompts.

Press and hold for approximately 2 seconds to exit

programming menu when in the programming mode.

3. DECREMENT Pushbutton — Press button to change

a programming value while in the programming

mode. Press and hold this button to decrease value

continuously and release when desired value is

displayed. NOTE: The longer the button is held down,

the faster the value will decrease.

4. INCREMENT Pushbutton — Press button to change

a programming value while in the programming mode

or to select a desired programming menu loop. Press

and hold this button to increase value continuously and

release when desired value is displayed. NOTE: The

longer the button is held down, the faster the value

will increase.

5. ENTER Pushbutton — Press button to scroll through

the status menus or programming prompts. This

button is used to enter a programming mode as well

as accepting changed programming values. NOTE:

The longer the button is held down, the faster the next

menu prompt will appear.

6. RUN Pushbutton and LED — Press button to initiate

a manual start signal to the generator. The LED will

light when in RUN mode.

4

11

MEC 20

Aavg

Freq

508

LAMP TEST

DECREMENT INCREMENT

AUTO

RESET

60.0

ENTER

LOAD

TEST

VOLTAGE

ADJUST

READY

SPEED SIGNAL

EMERGENCY

STOP

12

5

10

9

8

7. OFF Pushbutton and LED — Press button to initiate

a stop signal to the generator. The LED will light when

in OFF mode.

8. AUTO Pushbutton and LED — Press button to initiate

automatic operation of the generator. The LED will light

when in AUTO mode.

9. LOAD TEST Pushbutton and LED — Press button to

initiate load test of the generator when connected to

an associated transfer switch. The LED will light when

in LOAD TEST mode.

10. EMERGENCY STOP Pushbutton and LED — Press

button to initiate an emergency stop signal to the

generator.

11. READY LED — Lights when the generator is set for

automatic operation and no shutdown or alarm faults

have been activated.

12. SPEED SIGNAL LED — Lights when the engine speed

signal is detected.

13. ALARM LED — Lights when any pre-programmed

alarm fault has been activated.

14. SHU TDOWN LE D — Flas hes when any preprogrammed shutdown fault has been activated.

15. FREQUENCY ADJUST — This screwdriver adjustable

potentiometer is used to fine tune the roll-off frequency

from 54 to 61 Hz.

16. VOLTAGE ADJUST — This screwdriver adjustable

potentiometer is used to fine tune the generator output

voltage.

PAGE 20 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 21

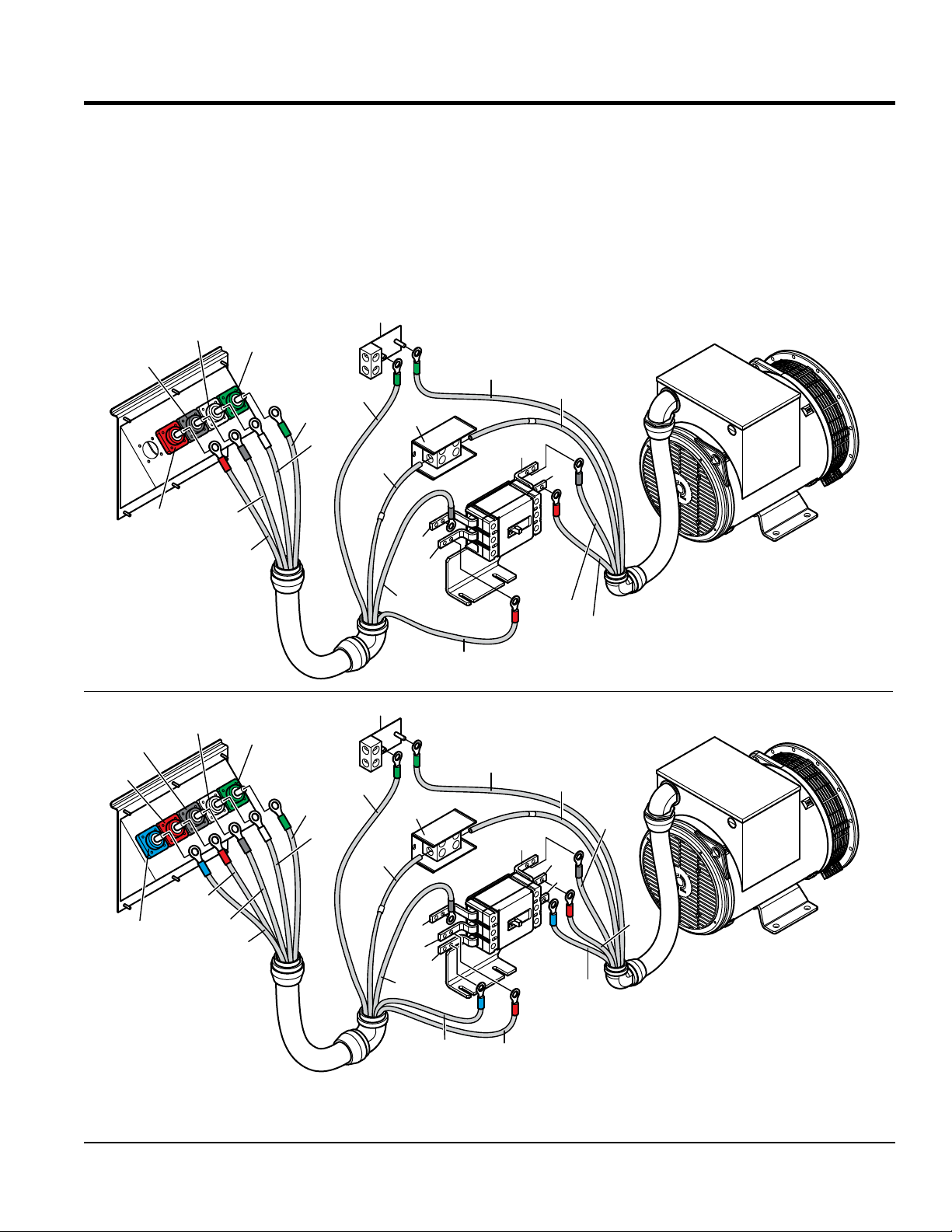

CONNECTOR OUTLET BOX AND MAIN CIRCUIT BREAKER

Ground

Neutral

OUTLET CONNECTORS

The Camlok outlet box has the following connectors

Ground (GRND.)

Neutral (NEUT.)

LEG 1, LEG 2, LEG 3 (3-phase only)

Black

Red

Ground

(Green)

Camlok

Panel

Green

White

Green

Neutral

White

L1

L2

Black

Leg 1

(Black)

(White)

Leg 2

(Red)

Red

MAIN CIRCUIT BREAKER

The generator is equipped with a three-pole, 100 or 30

amp, (single/three phase) circuit breaker to protect the

generator from overload.

See Figure 6 for connections.

Green

White

L1

L2

Circuit

Breaker

100A

Black

Red

Generator

Single Phase

Leg 2

(Red)

Leg 1

(Black)

Leg 3

(Blue)

Neutral

(White)

Red

Black

Ground

Ground

(Green)

Camlok

Panel

Green

White

Green

Neutral

White

Green

White

Black

L1

L2

L3

L1

Blue

L2

Black

L3

Blue

Red

Circuit

Breaker

30A

Blue

Figure 6. Camlok Box and Circuit Breaker Connections

Generator

Red

Three Phase

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 21

Page 22

LOAD APPLICATION/GENERATOR OUTPUT

SINGLE PHASE LOAD

Always be sure to check the nameplate on the generator

and equipment to insure the wattage, amperage, frequency,

and voltage requirements are satisfactorily supplied by the

generator for operating the equipment.

Generally, the wattage listed on the nameplate of the

equipment is its rated output. Equipment may require

130—150% more wattage than the rating on the nameplate,

as the wattage is influenced by the efficiency, power factor

and starting system of the equipment.

.

NOTICE

If wattage is not given on the equipment’s name plate,

approximate wattage may be determined by multiplying

nameplate voltage by the nameplate amperage.

WATTS = VOLTAGE x AMPERAGE

The power factor of this generator is 1.0. See Table 6 below

when connecting loads.

Table 6. Power Factor By Load

Type of Load Power Factor

Single-phase induction motors 0.4-0.75

Electric heaters, incandescent lamps 1.0

Fluorescent lamps, mercury lamps 0.4-0.9

NOTICE

Motors and motor-driven equipment draw much greater

current for starting than during operation.

An inadequate size connecting cable which cannot carry

the required load can cause a voltage drop which can burn

out the appliance or tool and overheat the cable. Refer to

Table 7 to select the correct cable size.

When connecting a resistance load such as an

incandescent lamp or electric heater, a capacity of up to

the generator’s rated output (kW) can be used.

When connecting a fluorescent or mercury lamp, a

capacity of up to the generator's rated output (kW)

multiplied by 0.6 can be used.

When connecting an electric drill or other power tools,

pay close attention to the required starting current

capacity.

When connecting ordinary power tools, a capacity of up to

the generator’s rated output (kW) multiplied by 0.8 can be

used.

DANGER

Before connecting this generator to any building’s

electrical system, a licensed electrician must install

a transfer switch. Serious damage to the building’s

electrical system may occur without this transfer switch.

Electronic devices, communication

equipment

Common power tools 0.8

1.0

Generator Amperage

Table 8 shows the maximum amps the generator can

provide. DO NOT exceed the maximum amps as listed.

Table 7. Cable Selection (60 Hz, Single Phase Operation)

Current

in

Amperes

2.5 300 600 1000 ft. 600 ft. 375 ft. 250 ft.

5 600 1200 500 ft. 300 ft. 200 ft. 125 ft.

7.5 900 1800 350 ft. 200 ft. 125 ft. 100 ft.

10 1200 2400 250 ft. 150 ft. 100 ft.

15 1800 3600 150 ft. 100 ft. 65 ft.

20 2400 4800 125 ft. 75 ft. 50 ft.

Load in Watts Maximum Allowable Cable Length

At 100

Volts

CAUTION: Equipment damage can result from low voltage

At 200

Volts

#10 Wire #12 Wire #14 Wire #16 Wire

Table 8. Generator Maximum Amps

Rated Voltage Maximum Amps

1Ø 120 Volt 83 X 2 amps (4 wire)

1Ø 240 Volt 83 amps (4 wire)

PAGE 22 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 23

INSPECTION/SETUP

MAIN CIRCUIT BREAKER

The generator is equipped with a 3-pole, 100-amp circuit

breaker to protect it from overload. Make sure that the circuit

breaker is in the OFF position prior to starting the engine.

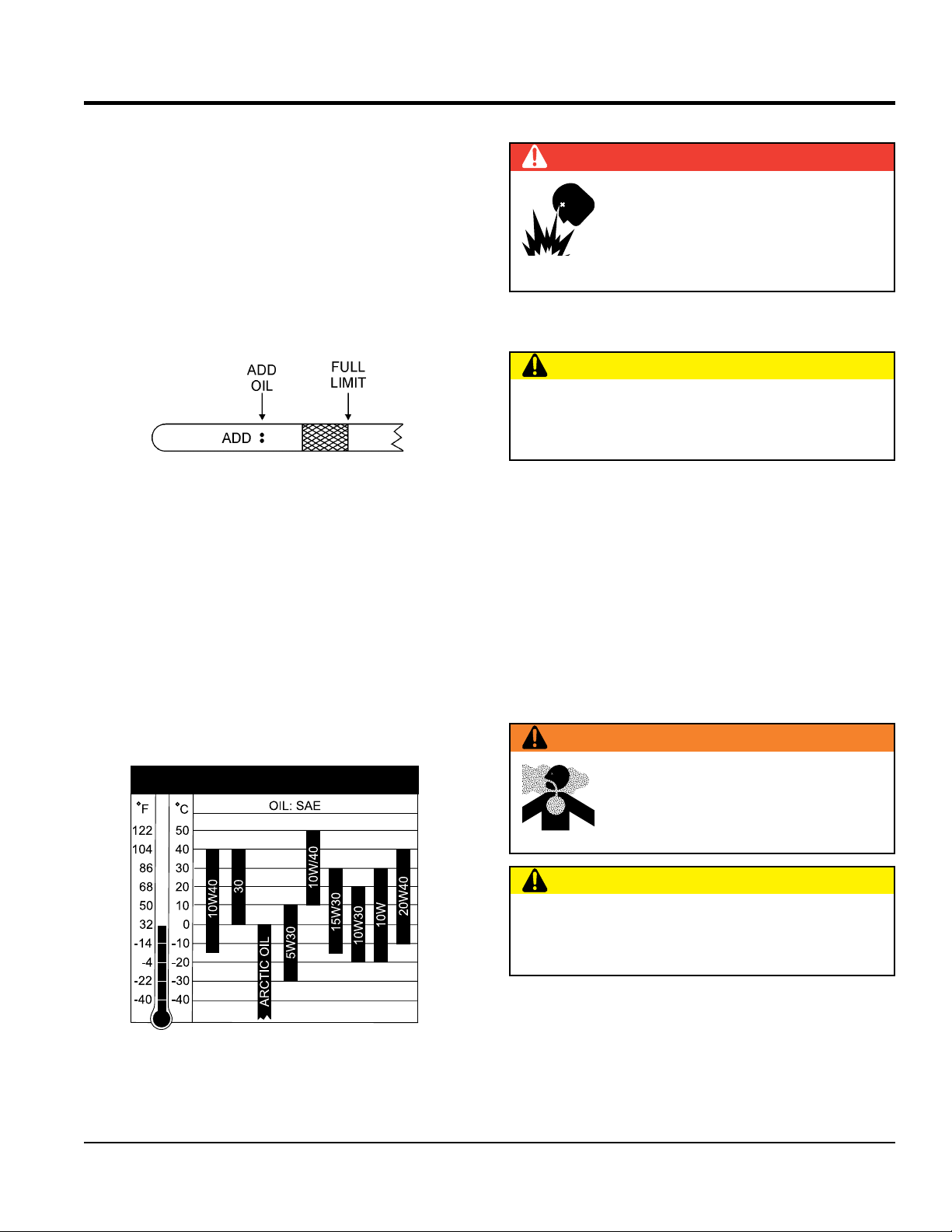

LUBRICATION OIL

Fill the engine crankcase with lubricating oil through the

filler hole, but DO NOT overfill. Make sure the generator

is level and verify that the oil level is maintained between

the two notches (Figure 7) on the dipstick. See Table 9 for

proper selection of engine oil.

Figure 7. Engine Oil Dipstick

When checking the engine oil, be sure to check if the oil is

clean. If the oil is not clean, drain the oil by removing the

oil drain plug, and refill with the specified amount of oil as

outlined in the Perkins Engine Owner’s Manual. Oil should

be warm before draining.

Other types of motor oils may be substituted if they meet

the following requirements:

API Service Classification CC/SC

API Service Classification CC/SD

API Service Classification CC/SE

API Service Classification CC/SF

FUEL CHECK

DANGER

Fuel spillage on a hot engine can cause

a fire or explosion. If fuel spillage occurs,

wipe up the spilled fuel completely to

prevent fire hazards. NEVER smoke

around or near the generator.

Refilling the Fuel System

CAUTION

ONLY properly trained personnel who have read

and understood this section should refill the fuel tank

system.

This generator has a fuel tank located in the sub base

assembly frame (Figure 3). ALWAYS fill the fuel tank with

clean fresh #2 diesel fuel. DO NOT fill the fuel tank beyond

its capacity.

Pay attention to the fuel tank capacity when replenishing

fuel. The fuel tank cap must be closed tightly after filling.

Handle fuel in a safe container. If the container does

not have a spout, use a funnel. Wipe up any spilled fuel

immediately.

Refueling Procedure:

WARNING

Table 9. Recommended Motor Oil

CAUTION

ALWAYS make sure generator is on firm level ground

before refueling to prevent spilling and maximize the

amount of fuel that can be pumped into the tank.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 23

Diesel fuel and its vapors are dangerous

to your heal th and the surrounding

environment. Avoid skin contact and/or

inhaling fumes.

Page 24

INSPECTION/SETUP

DO NOT fill on

1. Place the generator level with the ground. Failure to do

so will cause fuel to spill from the tank before reaching

full capacity (Figure 8).

70

unlevel ground

!

!

NOTICE

=

Unlevel Ground

Level Ground

Figure 8. Only Fill on Level Ground

Unlevel Ground

Level Ground

ONLY use #2 diesel fuel when refueling.

2. Unlatch and remove the cabinet door of the generator.

Remove fuel cap and fill tank (Figure 9).

3. Monitor the fuel gauge while filling fuel tank. Stop filling

when the fuel gauge indicates full (Figure 10). DO NOT

wait for fuel to rise in filler neck.

1/2

E F

Figure 10. Full Fuel Tank

CAUTION

DO NOT OVERFILL fuel system. Leave room for fuel

expansion. Fuel expands when heated (Figure 11).

DIESEL

Figure 9. Fueling the Generator

FUEL

Heat Source

Fuel EXPANDS

when heated

1/2

!

!

Figure 11. Fuel Expansion

E F

PAGE 24 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 25

INSPECTION/SETUP

COOLANT (ANTIFREEZE/SUMMER COOLANT)

Perkins recommends antifreeze/summer coolant, for use in

their engines, which can be purchased in concentrate (and

mixed with 50% demineralized water) or pre-diluted. See the

Perkins Engine Owner’s Manual for further details.

WARNING

If adding coolant/antifreeze mix to the

radiator, do not remove the radiator cap

until the unit has completely cooled. The

possibility of hot coolant exists which can

cause severe burns.

The engine coolant capacity is 3.8 quarts (3.6 liters).

OPERATION IN FREEZING WEATHER

When operating in freezing weather, be certain the proper

amount of antifreeze (Table 10) has been added.

FAN BELT TENSION

A slack fan belt may contribute to overheating, or to

insufficient charging of the battery. Inspect the fan belt for

damage and wear and adjust it in accordance with the

Perkins Engine Owner’s Manual.

The fan belt tension is proper if the fan belt bends 10 to

15 mm (Figure 12) when depressed with the thumb as

shown below.

Figure 12. Fan Belt Tension

CAUTION

Table 10. Anti-Freeze Operating Temperatures

Vol %

Anti-

Freeze

50 -37 -34 108 226

NOTICE

When the antifreeze is mixed with water, the antifreeze

mixing ratio must be less than 50%.

Freezing Point Boiling Point

°C °F °C °F

CLEANING THE RADIATOR

The engine may overheat if the radiator fins become

overloaded with dust or debris. Periodically clean the

radiator fins with compressed air. Cleaning inside the

machine is dangerous, so clean only with the engine turned

off and the negative battery terminal disconnected.

AIR CLEANER

Periodic cleaning/replacement is necessary. Inspect it in

accordance with the Perkins Engine Owner’s Manual.

NEVER place hands near the belts or fan

while the generator is running.

BATTERY

This unit is of negative ground. DO NOT connect in reverse.

Always maintain battery fluid level between the specified

marks. DO NOT over fill. Battery life will be shortened if

the fluid level is not properly maintained. Add only distilled

water when replenishment is necessary.

Check to see whether the battery cables are loose. Poor

contact may result in poor starting or malfunction. Always

keep the terminals firmly tightened. Coat the terminals with

an approved battery terminal treatment compound. Replace

battery with only recommended type battery.

The battery is sufficiently charged if the specific gravity

of the battery fluid is 1.28 (at 68° F). If the specific gravity

should fall to 1.245 or lower, the battery is dead and needs

to be recharged or replaced.

Before charging the battery with an external electric source,

be sure to disconnect the battery cables.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 25

Page 26

INSPECTION/SETUP

Battery Cable Installation

ALWAYS make sure that the battery cables (Figure 13) are

properly connected to the battery terminals as shown below.

CAUTION

ALWAYS disconnect the negative terminal FIRST and

reconnect negative terminal LAST.

Figure 13. Battery Connections

When connecting the battery do the following:

ALTERNATOR

The polarity of the alternator is negative grounding type.

When an inverted circuit connection takes place, the circuit

will short instantaneously resulting in alternator failure.

DO NOT put water directly on the alternator. Water in the

alternator can cause corrosion and damage.

WIRING

Inspect the generator for bad, worn electrical wiring or

connections. If any wiring or connections are exposed

(insulation missing), replace wiring immediately.

PIPING AND HOSE CONNECTION

Inspect all piping, oil hose, and fuel hose connections for

wear and tightness. Tighten all hose clamps and check

hoses for leaks.

If any hose (fuel or oil) lines are defective, replace them

immediately.

1. Place a small amount of battery terminal treatment

compound around both battery terminals. This will

ensure a good connection and will help prevent

corrosion around the battery terminals.

2. Connect the red cable to the positive terminal of the

battery and the black cable to the negative terminal

of the battery.

.

NOTICE

If the battery cable is connected incorrectly, electrical

damage to the generator will occur. Pay close attention

to the polarity when connecting the battery.

CAUTION

Inadequate battery connections may cause poor

starting of the generator, and create other malfunctions.

PAGE 26 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 27

STARTUP

BEFORE STARTING

CAUTION

The engine’s exhaust contains harmful emissions.

ALWAYS have adequate ventilation when operating.

Direct exhaust away from nearby personnel.

WARNING

NEVER manually start the engine with the main circuit

breaker in the ON position.

1. Place the main circuit breaker (Figure 14) in the OFF

position prior to starting the engine.

3. Listen for any abnormal noises. If any abnormalities

exist, shut down the engine and correct the problem.

4. Using the controller display, verify that the no-load

frequency and speed is approximately 62.5 Hz

(1875 rpm).

5. Place the main circuit breaker (Figure 16) to the ON

position. Voltage is now available at the receptacles.

Figure 16. Main Circuit Breaker (ON)

STARTING (AUTO MODE)

DANGER

Figure 14. Main Circuit Breaker (OFF)

2. Connect the load to the receptacles on the Camlok

outlet box. See Figure 6.

3. Tighten terminal nuts securely to prevent load wires

from slipping out.

STARTING (MANUAL)

1. Press the RUN button (Figure 15) on the controller to

start the engine.

Figure 15. Run Button

2. Once the engine starts, let the engine run for 1-2

minutes. At temperatures below freezing, this time

period must be extended to 2-4 minutes.

Before connecting the generator to a

building’s electrical system, a licensed

el ec tr ician must install a t ransfer

switch. Serious damage to the building’s

electrical system may occur without a

transfer switch.

CAUTION

When connecting the generator to an automatic transfer

switch, ALWAYS have power applied to the generator’s

internal battery charger. This will ensure that the engine

will not fail due to a dead battery.

WARNING

When running the generator in the AUTO mode, the

generator can start up at any time without warning.

NEVER attempt to perform any maintenance when the

generator is in the AUTO mode.

NOTICE

When the generator is placed in the AUTO mode, the

engine glow plugs will be warmed and the engine will

start automatically.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 27

Page 28

STARTUP

1. Press the AUTO button (Figure 17) on the digital

controller to place the generator in the auto mode. This

mode allows the controller to monitor the remote-start

contacts.

Closure of the remote-start contacts will begin engine

cranking. When the contacts are opened, cranking will

stop or if the engine is running, engine will stop.

Figure 17. Auto Button

NOTICE

If the generator is to be connected to a building's

AC power source via an automatic transfer switch

(ATS), press the AUTO button (Figure 17) to place the

generator in auto mode.

NORMAL SHUTDOWN PROCEDURE

To shutdown the generator, use the following procedure:

WARNING

NEVER stop the engine suddenly except in an

emergency.

1. Place the main circuit breaker (Figure 19) in the OFF

position.

Figure 19. Main Circuit Breaker (OFF)

In this position, should an outage occur, the automatic

transfer switch (ATS) will start the generator automatically

through the generator remote-start contacts connected

to the automatic transfer switch start contacts.

Refer to your ATS installation manual on how to connect

the ATS to the generator remote-start contacts.

CLOSING THE ENCLOSURE DOOR

1. Close the engine enclosure door once the generator

has started or set to auto start (Figure 18).

CORRECT INCORRECT

Figure 18. Engine Enclosure Door

2. Let the engine cool by running it at low speed for 3-5

minutes with no load applied.

3. Press the OFF button (Figure 20) on the digital

controller to shutdown the engine.

Figure 20. OFF Button

EMERGENCY SHUTDOWN PROCEDURE

1. Place the main circuit breaker (Figure 19) in the OFF

position.

2. Press the OFF button (Figure 20) on the digital

controller to shutdown the engine.

2. If access to the controls or other components is

necessary while the engine is running, make sure the

door is not left open for an extended period of time.

PAGE 28 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 29

JACKET WATER HEATER AND INTERNAL BATTERY

CHARGER

This generator is equipped with a jacket water heater and

an internal battery charger. They are provided with electric

cords to connect to a commercial power source.

These units will ONLY function when commercial power has

been supplied to them (Figure 21). When using extension

cords, refer to Table 7 for the correct size and length.

The battery charger should always be connected to a

commercial power source to ensure that the battery does

not get discharged.

When using the generator in hot climates there is no

need to apply power to jacket water heater. However, if the

generator will be used in cold climates, it is best to apply

power to the jacket water heater at all times.

STARTUP

Jacket

Water

Heater

Battery

Charger

Connect to external

120 VAC power source

Figure 21. Battery Charger and Jacket Water

Heater Power Connections

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 29

Page 30

PROTECTIVE DEVICES

PROTECTIVE DEVICES

Protection devices and emergency stop devices are

provided for protection of the generator against trouble

during operation. The alarm LED on the digital controller

lights or flashes when a fault is detected.

When a major fault is detected, such as low oil pressure,

high water temperature, and overspeed, the engine

automatically shuts down. Check the display for the fault

and correct the problem.

For minor faults, the engine will continue working. Stop the

engine and remedy the cause of the problem.

Before inspecting or troubleshooting the generator, press

the OFF button on the Digital Controller. Place all circuit

breakers in the OFF position and allow sufficient time for

adequate cooling.

After automatic shutdown, always inspect the generator

and eliminate any problems that might have caused the

shutdown before attempting to restart the generator.

When ready to restart the generator, make sure all circuit

breakers are OFF. Also check and make sure that the OFF

button on the Digital Controller has been pressed to clear

the system and that the OFF LED on the Digital Controller

is RED. Restart the generator as outlined in the Startup

section of this manual.

Refer to the MEC20 Microprocessor Engine/Generator

Controller Manual for detailed information of faults and

display information.

PAGE 30 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 31

TRANSPORTING

TRANSPORTING

When transporting the generator in a flatbed truck:

1. Make sure that the fuel tank is empty.

2. Secure the generator with chains through the lifting eyes on the fuel tank. See Figure 22.

LIFTING

EYE

TYPICAL TIE-DOWN APPLICATION

CHAIN

Figure 22. Transporting On A Flatbed Truck

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 31

Page 32

MAINTENANCE

Engine

Generator

Table 11. Inspection/Maintenance

10 Hrs

DAILY

250 Hrs 500 Hrs

1000

Hrs

Check Engine Fluid Levels X

Check Air Cleaner X

Check Battery Acid Level X

Check Fan Belt Condition X

Check for Leaks X

Check for Loose Parts X

Replace Engine Oil and Filter *

1

X

Clean Air Filter X

Check Fuel Filter/Water Separator Bowl X

Clean Unit, Inside and Outside X

Change Fuel Filter X

Clean Radiator and Check Coolant Level*

Replace Air Filter Element *

Check all Hoses and Clamps *

3

4

2

X

X

Clean Inside of Fuel Tank X

Measure Insulation Resistance Over 3M ohms X

Check Rotor Rear Support Bearing X

*1 Replace engine oil and filter at 100 hours, first time only.

*2 Add “Supplemental Coolant Additives (SCA’s)” to recharge the engine coolant.

3

Replace primary air filter element when restriction indicator shows a vacuum of 625 mm (25 in. H20).

*

4

*

If blowby hose needs to be replaced, ensure that the slope of the blowby hose is at least a 1/2 inch per

foot, with no sags or dips that could collect moisture and/or oil.

X

GENERAL INSPECTION

When the air filter element is clogged, air intake restriction

becomes greater and the air filter indicator signal shows

Prior to each use, the generator should be cleaned and

inspected for deficiencies. Check for loose, missing or

damaged nuts, bolts, and other fasteners. Also check for

RED. When indicator is red, replace filter immediately. After

changing the air filter, press the air filter indicator button

to reset.

fuel, oil, and coolant leaks. Use Table 11 as a general

maintenance guideline. For engine maintenance, refer to

the engine instruction manual.

AIR FILTER

Every 250 hours: Remove air filter element (Figure 23) and

clean the filter element with low pressure compressed air.

Air pressure must not exceed 30 psi (207 kPa). The filter

can be cleaned and reused for up to six times if properly

cleaned. Replace air filter if rips or tears are detected while

cleaning.

Air Filter

Element

Air Filter Dust Indicator

The air filter indicator (Figure 23) is attached to the air filter.

PAGE 32 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Figure 23. Air Filter/Indicator

Air Filter

Indicator

Page 33

MAINTENANCE

NOTICE

The air filter should be changed more frequently in

dusty operating conditions.

If the engine is operating in very dusty or dry grass

conditions, a clogged air cleaner will result. This can lead to

a loss of power, excessive carbon buildup in the combustion

chamber and high fuel consumption. Change air cleaner

more frequently if these conditions exist.

FUEL ADDITION

Add diesel fuel (the grade may vary according to season

and locations).

Removing Water from the Fuel Tank

After prolonged use, water and other impurities accumulate

in the bottom of the tank. Occasionally inspect the fuel tank

for water contamination and drain the contents if necessary.

During cold weather, the more empty volume inside the

tank, the easier it is for water to condense. This can be

reduced by keeping the tank full with diesel fuel.

Cleaning Inside the Fuel Tank

If necessary, drain the fuel inside the fuel tank completely.

Using a spray washer (Figure 24) wash out any deposits

or debris that have accumulated inside the fuel tank.

FUEL TANK INSPECTION

In addition to cleaning the fuel tank, the following

components should be inspected for wear:

Rubber Suspension — look for signs of wear or

deformity due to contact with oil. Replace the rubber

suspension if necessary.

Fuel Hoses — inspect nylon and rubber hoses for signs

of wear, deterioration, and hardening.

Fuel Tank Lining — inspect the fuel tank lining for signs

of excessive amounts of oil and other foreign matter.

Replacing Fuel Filter

Replace the fuel filter cartridge with a new one every

500 hours.

Loosen the drain plug at the lower top of the fuel filter.

Drain the fuel in the fuel body together with the mixed

water. DO NOT spill the fuel during disassembly.

Vent any air.

AIR REMOVAL

If air enters the fuel injection system of a diesel engine,

starting becomes impossible. After running out of fuel, or

after disassembling the fuel system, bleed the system.

Refer to the Perkins engine manual for details.

CHECK OIL LEVEL

Check the crankcase oil level prior to each use, or when the

fuel tank is filled. Insufficient oil may cause severe damage

to the engine. The oil level must be between the two notches

on the dipstick as shown in Figure 7.

Replacing Oil Filter

1. Remove the old oil filter.

2. Apply a film of oil to the gasket on the new oil filter.

3. Install the new oil filter.

4. After the oil filter has been replaced, the engine oil will

drop slightly. Run the engine for a while and check for

leaks before adding more oil if needed. Clean excessive

Figure 24. Fuel Tank Cleaning

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 33

oil from engine.

Page 34

MAINTENANCE

Remove

FLUSHING OUT RADIATOR AND REPLACING

COOLANT

1. Remove radiator cap. Remove the coolant drain plug.

Move the lever to the open position to start draining

out coolant. See Figure 25.

Radiator Cap

Battery

Charger

Turn to

Open

Radiator

Drain

Remove

Drain Plug

Figure 25. Draining Coolant

2. Flush the radiator by running clean tap water through

radiator until signs of rust and dirt are removed. Do

not clean radiator core with any objects, such as a

screwdriver.

Radiator

RADIATOR CLEANING

The radiator (Figure 26) should be cleaned with a highpressure washer when excessive amounts of dirt and debris

have accumulated on the cooling fins or tube. When using

a high pressure washer, stand at least 5 feet (1.5 meters)

away from the radiator to prevent damage to the fins and

tube.

Figure 26. Radiator Cleaning

VOLTAGE REGULATOR ADJUSTMENTS

When the voltage regulator is defective or broken and is

replaced, the following adjustment procedure needs to be

performed on the newly installed voltage regulator.

Potentiometers

3. Check hoses for softening and kinks. Check clamps

for signs of leakage.

4. Move lever to the closed position and reinstall coolant

drain plug.

5. Replace with coolant as recommended by the engine

manufacturer.

6. Close radiator cap tightly.

WARNING

Allow engine to cool before flushing out

radiator. Flushing the radiator while hot

could cause serious burns from water or

steam.

Figure 27 shows the screwdriver adjustable potentiometers

on the front of the voltage regulator.

VOLTAGE REGULATOR

VOLT

STAB

U/F

1

3

2

Figure 27. Voltage Regulator Potentiometers

1. Coarse Voltage Adjust — A screwdriver adjustable

potentiometer on the front of the voltage regulator

PAGE 34 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 35

MAINTENANCE

used to adjust the generator output voltage. Clockwise

adjustment increases the generator output voltage.

2. Stability Adjust — System stability is the ability of the

generator to respond to load transients. Decreasing the

stability makes the generator less sluggish and faster

to respond to load transients.

If the stability of the regulator is decreased too much,

the generator will tend to hunt under steady state

conditions. Increasing stability increases the response

time of the generator while decreasing stability

decreases response time.

The screwdriver adjustable potentiometer is used

to adjust the system stability. Clockwise adjustment

increases stability.

3. Roll-Off Frequency Selection — The roll-off point is

the frequency where the generator voltage starts to

decrease. This reduces the kilowatt load to the engine,

which allows the engine to recover in speed under any

load transient condition.

The voltage regulator has the roll-off point preset to

58 Hz in the 60 Hz mode. To change the roll off point,

perform the following:

a. Adjust the engine to the desired rated speed

(60 Hz).

b. Set the voltage to the desired setting at rated

speed.

c. Adjust the engine speed to the desired roll-off point.

d. Turn the potentiometer counterclockwise until the

voltage returns to rated.

e. Readjust the engine speed to rated speed.

Adjustment Procedure

F1 and the negative lead to F2 or use an appropriate

AC voltmeter on the generator output leads.

6. Start and run the generator at no load and rated speed.

The generator voltage should build up to a minimum

level. If it does not build up, refer to the generator

manual for field flashing information.

7. Slowly adjust the Voltage Adjust potentiometer until

the generator voltage reaches the nominal value. Also

adjust the remote Voltage adjust to set the generator

voltage to the exact value desired.

8. Turn the Stability Adjust potentiometer counterclockwise

until instability is shown on the voltmeter. With the

system operating in an unstable condition, slowly

adjust the Stability Adjust potentiometer clockwise until

generator stability is reached.

9. Interrupt the regulator power for a short period of time

(1 to 2 seconds).

10. If the generator remains stable, no further adjustment

is necessary.

11. If generator does not remain stable, increase the

stability slightly and interrupt the regular power again.

12. Repeat step 11 until system stability is reached and

maintained.

GENERATOR STORAGE

For long term storage of the generator the following is

recommended:

1. Drain the fuel tank completely. Treat with a fuel stabilizer

if necessary.

2. Completely drain the oil from the crankcase and refill,

if necessary, with fresh oil.

3. Clean the entire generator, inside and outside.

1. Make sure that the voltage regulator is connected

correctly to the generator. Refer to the generator wiring

diagram.

2. Turn t he Volta ge A djus t po tent iom eter ful ly

counterclockwise.

3. Turn Stability Adjust potentiometer fully clockwise.

4. Set the remote Voltage Adjust to the center position.

5. Connect the positive lead of a 100 VDC voltmeter to

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 35

4. Disconnect the battery.

5. Make sure engine coolant is at proper level.

6. Cover the generator and store in a clean, and dry place.

Page 36

TROUBLESHOOTING (GENERATOR)

Troubleshooting (Generator)

Symptom Possible Problem Solution

AC Voltmeter defective? Check output voltage using a voltmeter.

Is wiring connection loose? Check wiring and repair.

No Voltage Output

Low Voltage Output

High Voltage Output

Circuit Breaker Tripped

Is voltage regulator defective? Replace if necessary.

Defective Rotating Rectifier? Check and replace.

Defective Exciter Field? Check and replace.

Is engine speed correct? Turn engine throttle lever to “High”.

Is wiring connections loose? Check wiring and repair.

Defective AVR? Replace if necessary.

Is wiring connections loose? Check wiring and repair.

Defective AVR? Replace if necessary.

Short Circuit in load? Check load and repair.

Over current? Confirm load requirements and reduce.

Defective circuit breaker? Check and replace.

Over current Relay actuated? Confirm load requirement and replace.

PAGE 36 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 37

Symptom Possible Problem Solution

Engine will not start or start is delayed,

although engine can be turned over.

At low temperatures engine will not start.

Engine fires but stops soon as starter is

switched off.

Engine stops by itself during normal

operation.

Low engine power, output and speed.

TROUBLESHOOTING (ENGINE)

Troubleshooting (Engine)

No Fuel reaching injection pump? Add fuel. Check entire fuel system.

Defective fuel pump? Replace fuel pump.

Fuel filter clogged? Replace fuel filter and clean tank.

Faulty fuel supply line? Replace or repair fuel line.

Compression too low?

Fuel pump not working correctly? Repair or replace fuel pump.

Oil pressure too low? Check engine oil pressure.

Low starting temperature limit exceeded?

Defective battery? Charge or replace battery.

Air or water mixed in fuel system?

Engine oil too thick?

Defective battery? Replace battery.

Fuel filter blocked? Replace fuel filter.

Fuel supply blocked? Check the entire fuel system.

Defective fuel pump? Replace fuel pump.

Fuel tank empty? Add fuel.

Fuel filter blocked? Replace fuel filter.

Defective fuel pump? Replace fuel pump.

Mechanical oil pressure shutdown sensor

stops the engine due to low oil?

Fuel tank empty? Replace fuel filter.

Fuel filter clogged? Replace fuel filter.

Fuel tank venting is inadequate? Ensure that tank is adequately vented.

Leaks at pipe unions?

Speed control lever does not remain in

selected position?

Engine oil level too full? Correct engine oil level.

Injection pump wear?

Check piston, cylinder and valves. Adjust or

repair per engine repair manual.

Comply with cold starting instructions and

proper oil viscosity.

Check carefully for loosened fuel line

coupling, loose cap nut, etc.

Refill engine crankcase with correct type of

oil for winter environment.

Add oil. Replace low oil shutdown sensor if

necessary.

Check threaded pipe unions tape and tighten

unions a required.

See engine manual for corrective action.

Use No. 2-D diesel fuel only. Check the fuel

injection pump element and delivery valve

assembly and replace as necessary.

MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11) — PAGE 37

Page 38

TROUBLESHOOTING (CONTROLLER)

CAUTION

Before opening the enclosure to perform troubleshooting

or any service task, isolate the controller from any

possible source of power. Failure to do so may result in

serious personal injury or death due to electrical shock.

Troubleshooting (MEC20 Controller)

Symptom Possible Problem Solution

Does not power up even

with correct DC power

applied

LCD is not operational

Controller cannot be

"reset"

No "RUN" output signal

Overspeed shutdown occurs

at normal speed

Voltage or current metering

is reading incorrectly

Wiring errors or short circuit?

Microprocessor defective?

Insufficient DC supply voltage? Check voltage at input terminals B+ and B- (10-30 VDC).

Bad LCD resolution?

Controller not in OFF mode?

Engine is running?

Shutdown circuits reset?

No engine speed signal?

RUN output LED off?

Controller not correctly programmed?

Controller not correctly programmed?

Battery not properly grounded?

Analog input not properly calibrated?

Incorrect wiring?

Check wiring and repair. NOTE: The MEC 20 electronic

fuse triggers when there is an overload condition and does

not reset until the supply voltage is removed and overload

condition is corrected.

Check that the "watchdog" LED on the rear of the PCB is

flashing red meaning that the microprocessor is working. If

not, repair or replace microprocessor.

Adjust LCD contrast potentiometer (R115) on the rear of

PCB for good pixel resolution for the operating temperature

of the unit.

Check that the controller is set to the OFF mode before

resetting.

Check that the engine has come to a complete stop before

resetting.

Check that all shutdown circuits are reset (red shutdown

LED must be off).

Engine speed signal must be detected (speed signal green

LED on) during cranking if the "run-output fail safe" feature

is enabled. Verify correct magnetic pick-up signal at cranking

(2.0 VAC min.)

Check that the RUN output LED (on the rear of the PCB) is

on. If yes, verify relay contact operation on terminals #18 and

#19.

Verify that the controller has been programmed with the correct

values for the number of flywheel teeth, nominal RPM, and

overspeed setpoint percentage.

Verify that the controller has been programmed with the correct

values for voltage sensing PT ratio and/or current sensing CT

ratio.

Verify that the battery supply DC negative conductor is properly

grounded to the engine block (i.e. to a common ground point.)

Verify that the controller's analog input has been properly

calibrated.

Verify that the voltage sensing wiring connection to the

controller matches power distribution type (Note: standard

direct voltage connection requires that the generator's neutral

is solidly grounded).

PAGE 38 —MQP20P STANDBY GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (11/28/11)

Page 39

Symptom Possible Problem Solution

Engine temperature or oil

pressure display is reading

incorrectly

Engine temperature or oil

displays "9999"

Engine alarms on high

engine temperature or low

oil pressure when engine

is operating within normal

limits

Keys on faceplate do not

operate.

TROUBLESHOOTING (CONTROLLER)

Troubleshooting (MEC20 Controller) - continued

Improper calibration?

Incorrect engine sensor wiring?

Battery not properly grounded?

Incorrect wiring?