Page 1

OPERATION AND PARTS MANUAL

MP1 SERIES

MODELS

MP1H (5.5 HP GASOLINE)

MP115E (1.5 HP ELECTRIC)

MP120E (2.0 HP ELECTRIC)

MASONRY SAWS

Revision #1 (03/29/10)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 38261

Page 2

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 3

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 3

Page 4

TABLE OF CONTENTS

MP1 SERIES MASONRY SAW

Proposition 65 Warning ............................................. 2

Silicosis/Respiratory Warnings .................................. 3

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

Safety Message Alert Symbols .............................. 6-7

Rules For Safe Operation .................................... 8-10

Operation and Safety Decals .................................. 11

Specifications .......................................................... 12

Dimensions ............................................................. 13

General Information ................................................ 14

Controls and Components ................................. 16-17

Electric Motor Components .................................... 18

Engine Components ............................................... 19

Pre-Setup (Electric) ............................................ 20-23

Pre-Setup (Gasoline) ......................................... 24-25

Operation (Electric) ............................................ 26-27

Operation (Electric) ............................................ 28-29

Maintenance ...................................................... 30-33

Electric Motor Wiring Diagram ................................ 34

Troubleshooting (Blade) .......................................... 36

Troubleshooting (Electric Motor) ............................. 37

Troubleshooting (Gasoline Engine) ................... 38-39

Explanation of Code In Remarks Column............... 40

Suggested Spare Parts ........................................... 41

HONDA GX160K1QXC9

GASOLINE ENGINE

COMPONENT DRAWINGS

NOTE

PAGE 4 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 5

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

N View Parts Diagrams

N Order Parts

N Print Specification Information

Goto www.multiquip.com and click on

Order Parts

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

to log in and save!

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

When ordering parts, please supply:

R Dealer Account Number

R Dealer Name and Address

R Shipping Address (if different than billing address)

R Return Fax Number

R Applicable Model Number

R Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

R Specify Preferred Method of Shipment:

UPS/Fed Ex DHL

N Priority One Tr uck

N Ground

N Next Day

N Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 5

Page 6

SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when operating

this equipment. Failure to read and understand the Safety

Messages and Operating Instructions could result in injury to

yourself and others.

This Owner's Manual has been

developed to provide complete

instructions for the safe and

NOTE

Before using this MASONRY SAW, ensure that the operating

individual has read and understands all instructions in this

manual.

efficient operation of the

MULTIQUIP MP1. For engine

maintenance information, please

refer to the engine manufacturers

instructions for data relative to its

safe operation.

HAZARD SYMBOLS

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

Guards and Covers In Place

NEVER operate the saw without blade guards

and covers in place. Adhere to safety

guidelines ANSI American National

Standards Institute, OSHA or other applicable

local regulations.

Rotating Blade

Rotating blade can cut and crush. Keep

hands and feet clear.

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

Rotating Parts

WARNING: You CAN be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

NEVER operate equipment with covers, or

guards removed. Keep fingers,

and

clothing

prevent injury.

away from all moving parts to

CAUTION: You CAN be injured if you

DO NOT follow directions.

Accidental Starting

Potential hazards associated with masonry saw operation will

be referenced with "

this manual, and will be referenced in conjunction with Safety

"

Message Alert Symbols

Hazard Symbols

".

" which appear throughout

PAGE 6 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

ALWAYS place the engine ON/OFF

switch in the OFF position, when the saw

is not in use.

hands, hair

Page 7

SAFETY MESSAGE ALERT SYMBOLS

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

Respiratory Hazard

ALWAYS wear approved respiratory protection

that complies with ANSI-Z87.1.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection that complies with ANSI-Z87.1

HAZARD SYMBOLS - Gasoline Powered Models

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Gasoline is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

Equipment Damage Messages

NOTE

Other important messages are provided throughout this manual

to help prevent damage to your concrete saw, other property, or

the surrounding environment.

This

saw

, other property, or the

surrounding environment could be

damaged if you do not follow

instructions.

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 7

Page 8

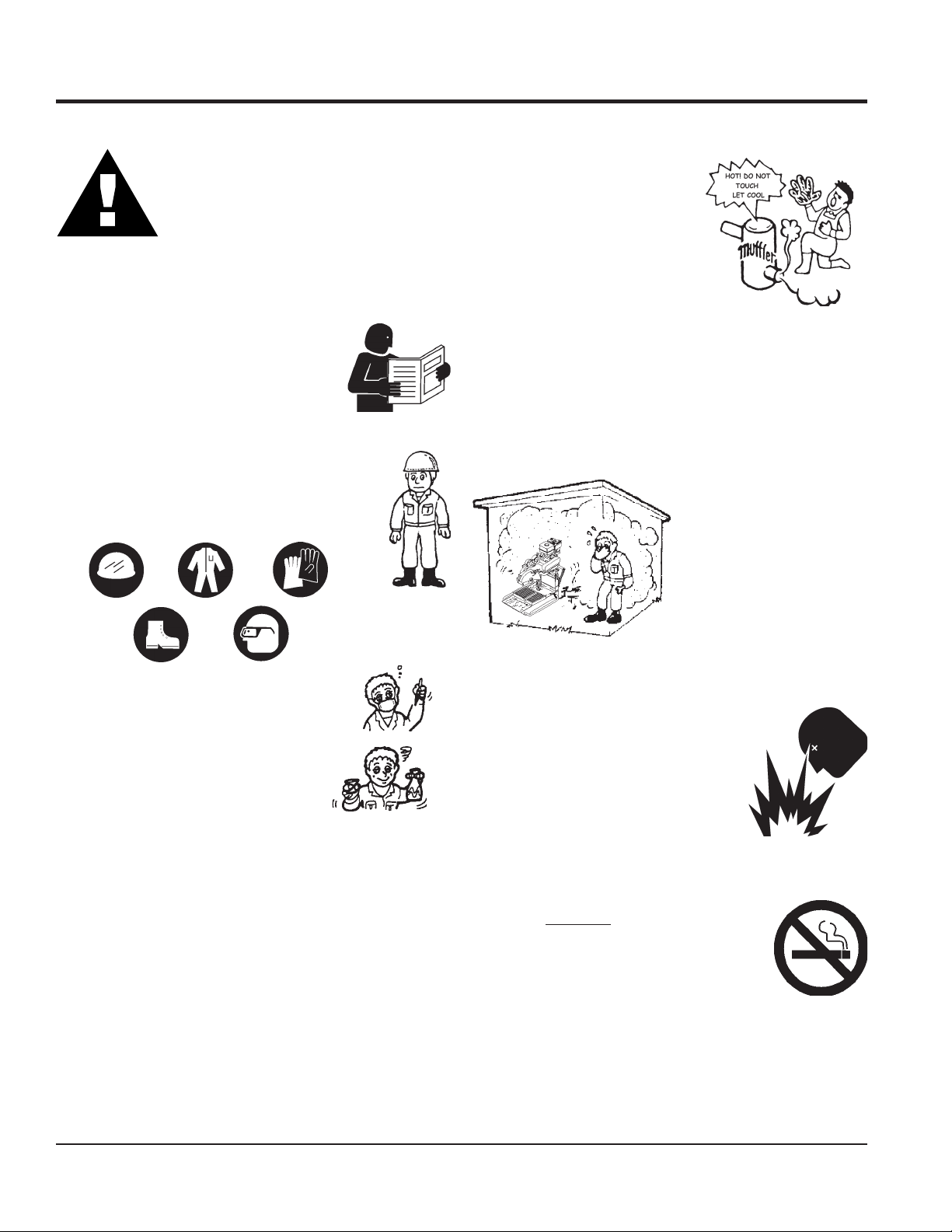

RULES FOR SAFE OPERATION

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is

for industrial use only.

The following safety guidelines should always be used when

operating the MP1 SAW. Unless otherwise noted, these

guidelines refer to saws with gasoline powered engines.

SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate the saw without proper protective

clothing, shatterproof glasses, steel-toed boots

and other protective devices required by the job.

SAFETY - GASOLINE POWERED ENGINES

■

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

the saw.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot!

with

■

The engine of this saw (

adequate free flow of cooling air. NEVER operate the saw in

components can cause serious burns.

gasoline model only

any enclosed or narrow area

where free flow of the air is

restricted. If the air flow is

restricted it will cause serious

damage to the saw's engine

and may cause injury to

people. Remember the

saw's engine gives off

DEADLY

gas.

) requires an

carbon monoxide

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate the saw under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments,

which are not recommended by Multiquip

for this equipment. Damage to the equipment and/or injury to

user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications. Unauthorized equipment

modification will void all warranties.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS check the saw for loosened threads or bolts before

starting.

■

NEVER operate the saw in an explosive atmosphere where

fumes are present or near combustible materials. An explosion

or fire could result causing severe

bodily harm or even

death.

■

NEVER use fuel as a cleaning agent.

■

■

■

■

■

■

■

ALWAYS stop the engine before servicing, adding fuel and

oil.

ALWAYS refuel in a well-ventilated

area, away from sparks and open

flames.

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to cool.

NEVER

machine. Fire or explosion could result from

fuel vapors

engine.

Topping-off to filler port is dangerous, as it tends to spill fuel.

ALWAYS service air cleaner frequently to prevent carburetor

malfunction.

NEVER run the engine without the air filter. Severe engine

damage could occur. (Gasoline powered engines)

smoke

around or near the

, or if fuel is spilled on a

hot!

PAGE 8 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 9

RULES FOR SAFE OPERATION

SAFETY - ELECTRIC POWERED MODELS

■

ALWAYS connect the motor to a power source in compliance

with all local electrical codes. This must be performed by a

qualified electrician.

■

ALWAYS use only outdoor approved GROUNDED extension

cords.

■

MAKE CERTAIN the power cord/extension cord is free from

damage and that the grounding circuit is operational.

■

MAKE CERTAIN the extension cord used is intended to be

used in the environment you will be using it in. If an extension

is used, NEVER submerge the connection in water. To reduce

the risk of electrical shock, always make water-tight

connections.

■

MAKE CERTAIN the "ON/OFF" switch is in the "OFF" position

before plugging in the power cord/extension cord to avoid

accidental starting.

■

ALWAYS stop the motor before servicing. MAKE CERTAIN

the motor is stopped and turned "OFF" at the switch, and the

power cord is disconnected from the power source.

■

Use only the guage wire and length of cord recommended

for the motor size.

■

When cutting, ALWAYS be aware of the location of the cord.

BLADE SAFETY

■

■

■

■

WARNING

■

ALWAYS check to make sure that the

operating area is clear before starting the

engine.

Use appropriate blades manufactured for use on masonry

saws.

WARNING

Always inspect blades before each

use. The blade should exhibit no

cracks, dings, or flaws in the steel

centered core and/or rim. Center

(arbor) hole must be undamaged and

true.

Examine blade flanges for damage, excessive wear and

cleanliness before mounting blade. Blade should fit snugly

on the shaft and against the inside/outside blade flanges.

Ensure the blade is marked with an operating speed greater

than the blade shaft speed of the saw.

GENERAL SAFETY

■

ALWAYS read, understand, and follow procedures in

Operator's Manual before attempting to operate equipment.

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operating techniques before using the saw.

■

NEVER leave the machine

■

Block the unit when leaving or when using on a slope.

■

ALWAYS check to make sure that the operating area is clear

before starting the engine.

■

Maintain this equipment in a safe operating condition at all

times.

■

AVOID wearing jewelry or loose fitting clothing that may snag

on the controls or moving parts, this can cause a serious

injury.

■

ALWAYS keep clear of

operating or the saw.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of

the reach of children.

■

NEVER use accessories or attachments which are not

recommended by the manufacturer for this equipment.

Damage to the equipment and/or injury to user may result.

unattended

rotating

or

while running.

moving parts

while

■

■

■

■

■

■

■

■

Only cut the material that is specified by the blade. Read the

specifications of the blade to ensure the proper tool has been

matched to the material being cut.

Always keep blade guards in place.

Exposure of the blade must not

exceed 180 degrees.

NEVER touch or try to stop a moving

blade with your hands. ALWAYS

keep hands clear of the blade.

Ensure that the blade does not come

into contact with the ground or surface

during transportation. DO NOT drop the blade on ground or

surface.

The engine governor is designed to permit maximum engine

speed in a no-load condition. Speeds that exceed this limit

may cause the blade to exceed the maximum safe allowable

speed.

Ensure that the blade is mounted for proper operating

direction.

Keep all inexperienced and unauthorized people away from

the equipment at all times.

ALWAYS use or operate the saw on a level surface to prevent

the saw from tipping.

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 9

Page 10

RULES FOR SAFE OPERATION

SAW MAINTENANCE (CLEANING)

■

ALWAYS clean the saw before maintenance or repair.

■

DO NOT use aggressive cleaners (i.e. containing solvents).

DO NOT use high pressure water jets, aggressive detergents

or solutions and liquids with a temperature exceeding 86 F.

Use a fluff-free cloth only.

■

Use a cloth which may be lightly moistened only for removing

dust and dirt. Hard packed dirt can be removed with a

brush.

■

NEVER let water, cleaning liquid or vapor penetrate into the

electric motor, connectors, plugs, and switches. When

cleaning cover all apertures or openings on all electrical

components.

■

ALWAYS use a soft, low-pressure water jet and a brush to

rinse dirt and incrustations away. Be particularly careful not

to spray water on sensitive parts of of the saw (e.g. electric

motor, ON/OFF switch). Clean the motor and ON/OFF switch

moist

by wiping with a

■

DO NOT rinse the bearings of the drive elements (gasoline

model only).

cloth.

soft

SAW TRANSPORTATION SAFETY

■

■

■

■

EMERGENCIES

■

■

Use an appropriate lifting equipment to ensure the safe

movement of the saw.

DO NOT use the handles as lifting points.

Safeguard against extreme saw attitudes relative to level.

An engine tipped to extreme angles may cause oil to gravitate

into the cylinder head making the engine start difficult.

(Gasoline powered engines)

NEVER transport the saw with the blade mounted.

ALWAYS know the

location of the nearest

fire extinguisher

ALWAYS know the location of the

nearest and

.

first aid kit

.

■

In emergencies

nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in the case of an

emergency.

always

know the location of the

keep a phone on the job site

and

fire department

.

. This

PAGE 10 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 11

NOTES

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 11

Page 12

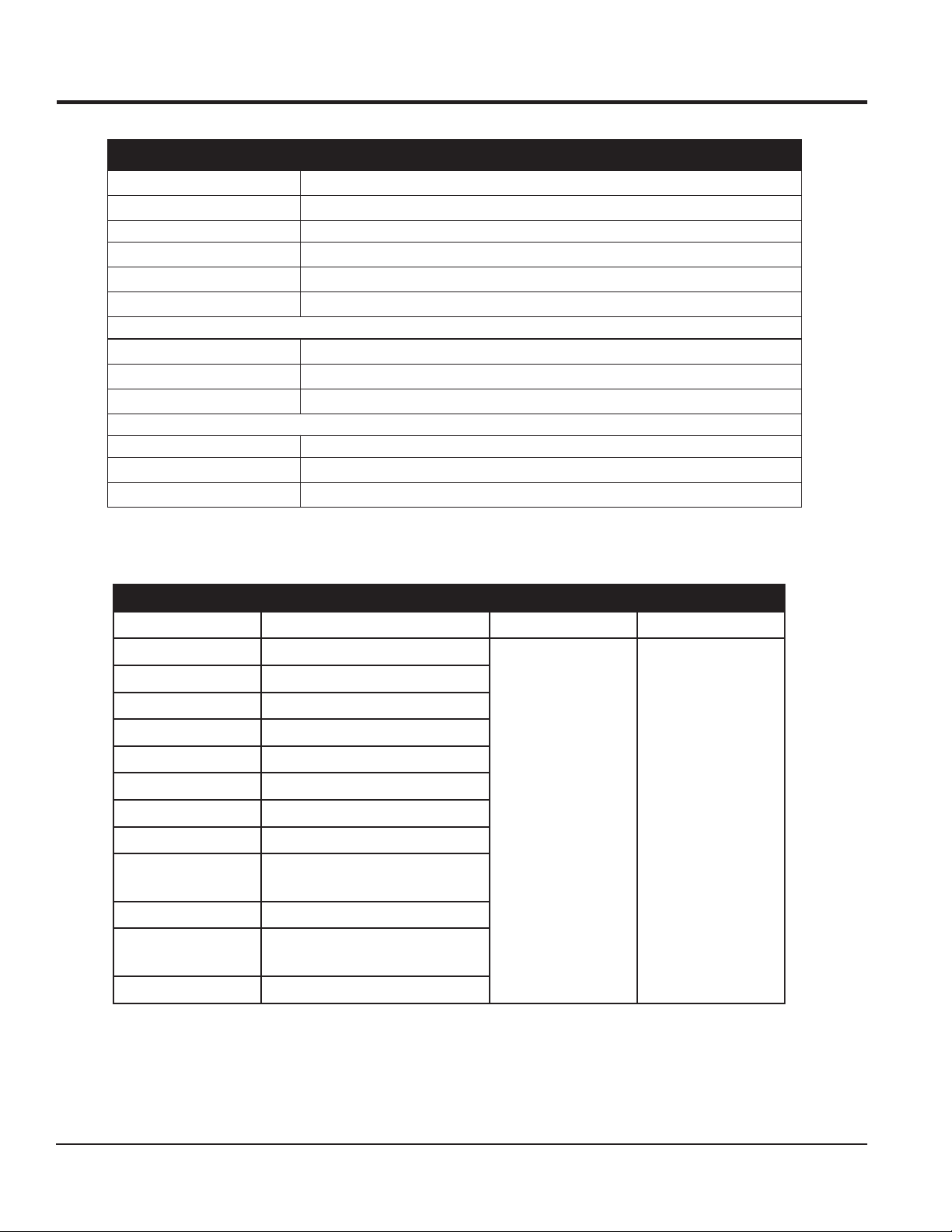

SPECIFICATIONS (SAW/ENGINE)

ELBATWAS1PM.1SNOITACIFICEPS

snoisnemiD

thgieWetamixorppA

).gK57(.sbl561

)mc85.86xmc28.38xmc521.111("72x"33x"57.34

deepSrotoMcirtcelE

deepSedalB

MPR8852

pmuPretaW

)2elbaTeeS(MPR0543

detcetorpyllamrehT,zH06/V511

)enilosaG(enignE

deepSedalB

pmuPretaW

LARENEG

yticapaCedalB

htpeDgnittuC

Table 2. MP1 Electric Motor/Engine Specifications

Saw Model MP1H MP115E MP120E

Engine/Motor Honda GX160K1QXC9

Type 4-Stroke OHV Single Cylinder

MPR0082

205-70852tiKlanoitpO

mumixamedalb.ni41

edalb.ni41htiw.ni5

)2elbaTeeS(adnoH,delooCriA,rednilyCelgniS,elcyc4PH5.5

Bore xStroke 2.7 x 1.8in. (68 x 45mm)

Displacement 9.9 cu. in. (163 cc)

Max Output 5.4 bhp (4.0 KW) @ 3600 rpm

Fuel Tank Cap. 0.95 US Gal. (3.6 liters)

Fuel Unleaded Gasoline

Lube Oil Cap. 0.63 US Qt. (0.60 liters)

Speed Control

Method

Starting Method Recoil Start

Dimension

Dry Net Weight 33.1 lbs. (15.0 kg)

Centrifugal Fly-Weight type

12.0 x 14.3 x 13.2 in

(304 x 362 x 335mm)

1.5 HP

Heavy Duty Electric

115/230V

Single Phase

60Hz

Dual Voltage

Amps F.L

17.2/8.6

2.0 HP

Heavy Duty Electric

115/230V

Single Phase

60Hz

Dual Voltage

Amps F.L

16.8/8.4

DANGER

PAGE 12 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 13

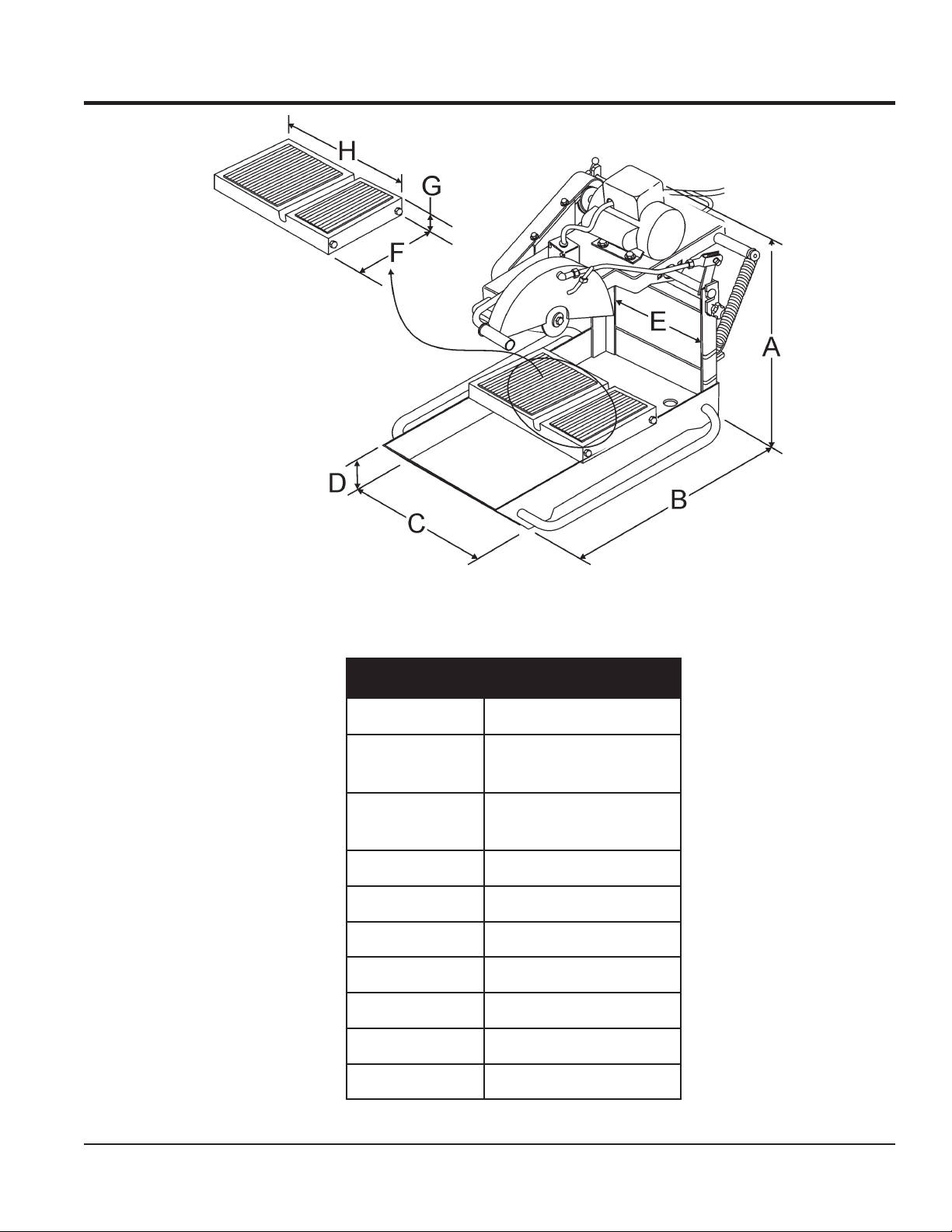

DIMENSIONS

Figure 1. Dimensions

.FERSNOISNEMID

A

)rotomcirtcele(

A

)enigneenilosag(

B)mc601(.ni0.24

C)mc6.85(.ni0.72

D)mc79.31(.ni5.5

E)mc8.63(.ni5.41

F)mc2.92(.ni5.11

G)sretem53.6(.ni5.2

SNOISNEMID.3ELBAT

)mc47(.ni0.92

)mc47(.ni0.92

H)sretem2.84(.ni0.91

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 13

Page 14

GENERAL INFORMATION

MP1 MASONRY SAW

The MP1 masonry saw is designed for vigorous wet-cutting

masonry applications. The heavy-duty aluminum conveyor cart

and ball bearing roller wheels ensure material stability and

smooth travel. In addition a reinforced jig-welded steel frame

provides rigidity for cutting accuracy and long service life.

This saw is available with either an

engine

1.5 HP or 2.0 HP with overload protection. Each motor can

operate at either 115 VAC or 230 VAC. The electric motor input

voltage is selectable by means of a toggle switch. Always make

sure that the input voltage being supplied to the motor matches

the position of the voltage selector toggle switch located on top

of the motor.

If desired, the MP1 saw can be configured with a 5.5 HP Honda

GX160 gasoline engine.

All MP1 models include a high flow water pump, cutting jig, water

hoses and associated plumbing to enable the operator to begin

wet cutting.

DRY CUTTING APPLICATIONS

The MP1 masonry saw is shipped from the factory for wet-cutting

saw applications, however it can be used for dry-cutting saw

applications (see dry-cutting saw applications in this manual).

The most import thing to remember is to

pump

failure to disconnect the pump (when running dry) will cause

pump failure. NEVER! have the water pump engaged when dry

cutting applications are involved.

BLADE APPLICATIONS

. The heavy duty electric motors are available in either

. The water pump is cooled by the flow of water, and

electric motor

disconnect the water

or a

gasoline

ACCESSORIES/REPLACEMENT PARTS

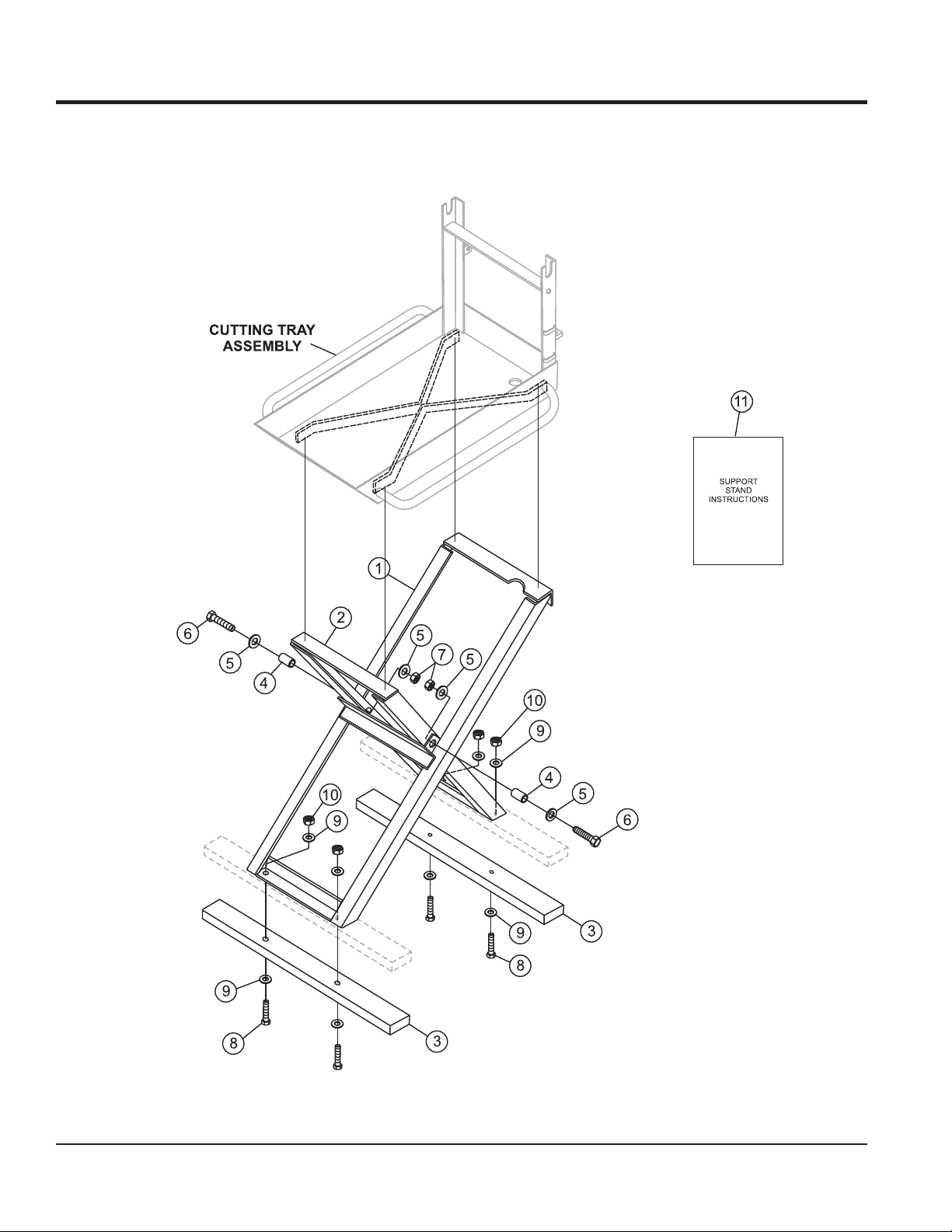

If desired the MP1 masonry saw can be equipped with a scissors

type support stand P/N TRAK14SS, this stand is ideal when the

saw needs to be transported and placed on a secure reliable

platform.

OVERVIEW OF FEATURES

■

1.5 or 2.0 HP, 115/230 VAC , 60 Hz heavy duty electric motors

with overload protection.

■

5.5 HP Honda GX160 gasoline engine.

■

14-inch blade capacity provides 5-inch depth of cut.

■

Rugged aluminum conveyor cart for optimum stability.

■

Open back design permits capability of cutting large

materials.

■

Ergonomically designed cutting head provides operator

relief in high tempo operations.

■

Mounted carrying handles for easy transportation.

■

Rubber-matted cutting table helps hold the material being

cut in place while resisting vibrations for smoother cuts with

less chipping.

■

Cutting table marked in inches and centimeters (ruler) for

precision cuts.

■

Stay-level blade guard for operator safety.

■

Rigid steel frame minimizes vibrations and assures accurate

cutting.

■

Mechanical Water Pump Kit (Gasoline Model Only)

■

Electric Submersible Water Pump Kit (Electric Models Only).

This saw has been designed to incorporate the use of diamond

blades as the cutting tool. The optimum performance of this saw

is best evidenced by using 14-inch (356 mm) diamond blades

that match the material being cut. Ask your dealer, or call

MULTIQUIP about your specific cutting application.

PAGE 14 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 15

NOTES

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 15

Page 16

CONTROLS AND COMPONENTS

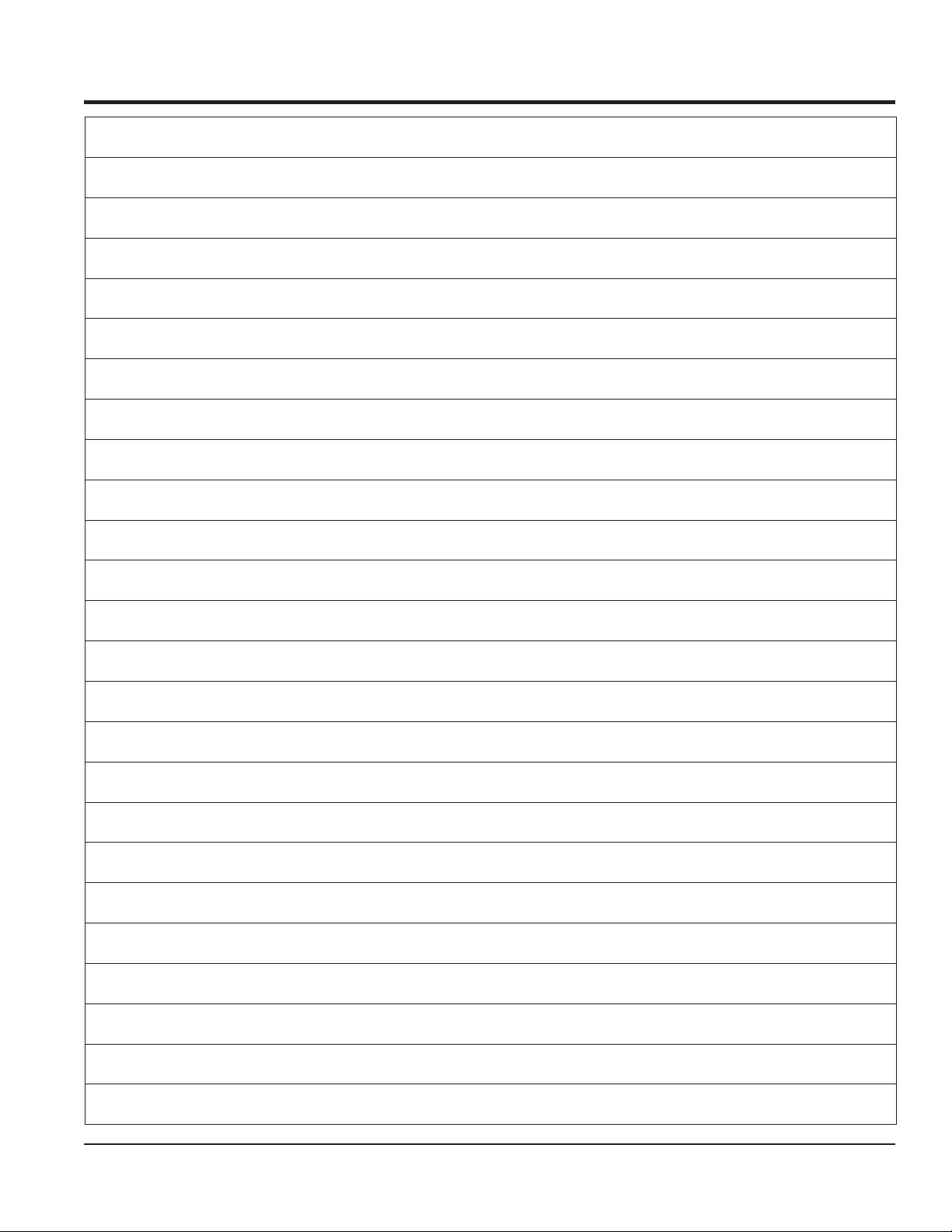

Figure 2. MP1 Saw (Electric/Gasoline)

PAGE 16 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 17

CONTROLS AND COMPONENTS

Figure 2 shows the location of the basic controls or components

for the MP1 saw. Listed below is a brief explanation of each

control or component.

1. Ruler Backstop – When cutting, place material against

backstop. Use measurement rail (ruler) to determine where

material is to be cut.

16. Carrying Handle (Tray) – Grip this handle (right-side) to

trasport the saw.

17. Electric Water Pump – For best results place the pump

between the splash shield and the rear of the water tray.

This is for electric models only. Plug water pump power

cord into AC receptacle on electric motor conduit box.

NEVER

2. Water Tray – When wet cutting is required, fill with clean

fresh water. Make sure submersible is totally immersed in

water.

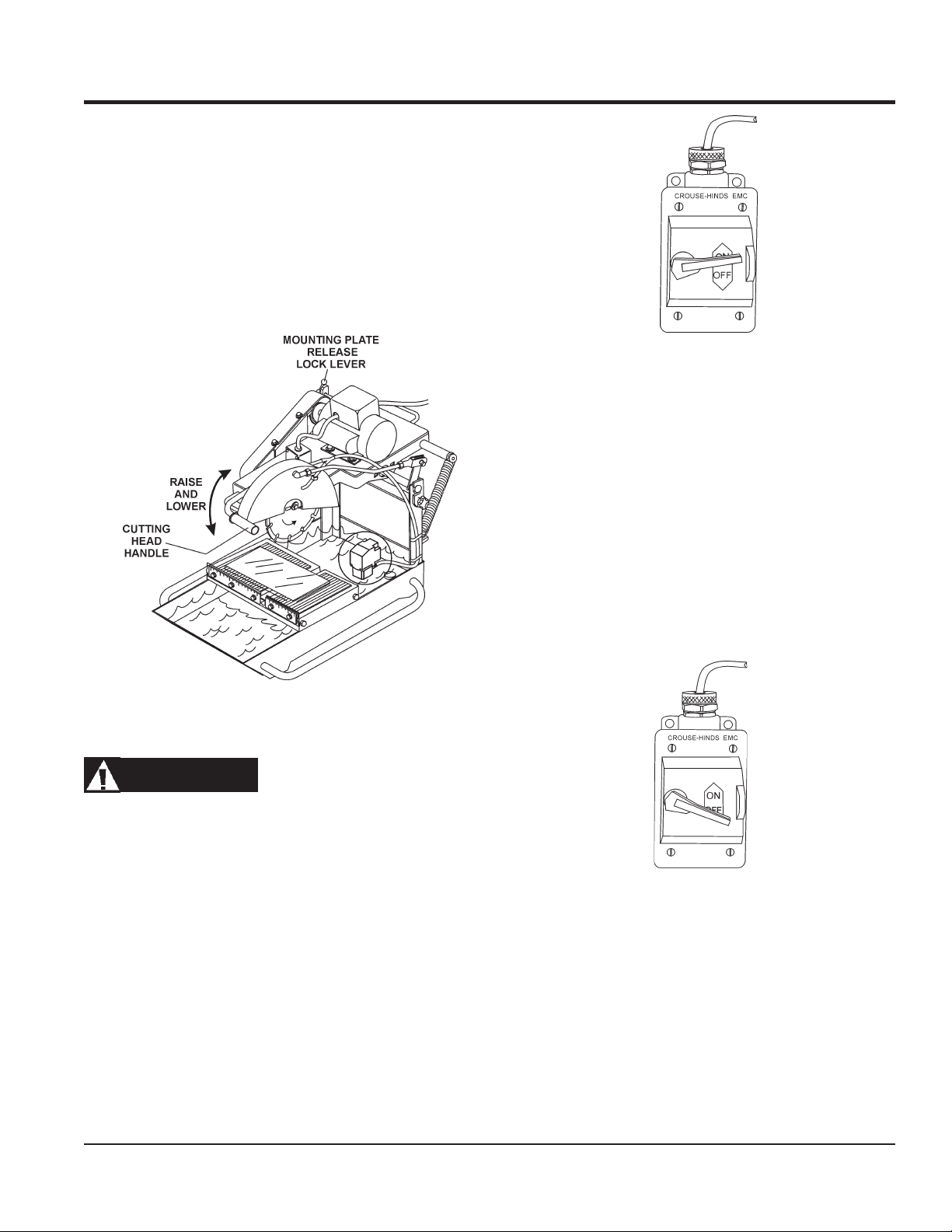

3. Cutting Head Handle – Grab hold of this handle to move

up

the cutting blade head either

cutting head, release the mounting plate release/lock lever.

4. Carrying Handle (Head) – Grip this handle (front) to lift

the mounting plate.

5. Blade Guard – Protects the user from the cutting blade.

NEVER

6. Power ON/OFF Box – This box is used on

models

position. Place in the OFF position to shut-down the saw.

7. V-belt Cover – Remove this cover to access the drive Vbelt.

8. Mounting Plate Release/Lock Lever – Push this lever

backwards to release

the cutting head to move either up or down. Push the lever

forward to lock

9. Electric Motor/Conduit Box– This unit uses 2 different

types of electric motors and voltages (see Table 2). Always

make sure the voltage selector switch has been set to the

correct position for the voltage being supplied to the motor.

Plug the water pump (electric models only) power cord

into the AC receptacle located on the conduit box.

10. Mounting Plate – Supports the electric motor/gasoline

engine. Plate has slotted holes for horizontal (right-side)

and vertical (left-side) adjustment of cutting head.

11. Carrying Handle (Head) – Grip this handle (rear) to lift

the mounting plate.

12 . Tie Rod – The tie rod length has been set at the factory for

best blade guard position for the majority of the cutting that

will be done.

13. Spring Tensioner – Allows for an easy up and down

movement of the mounting plate.

operate the saw with the blade guard removed.

saws only

NEVER

. To turn on the saw place in the ON

operate the saw with the V-belt cover removed.

the mounting plate. This will allow

the mounting plate in place.

or down. To move the

electric

18. Spindle Bolt/Outside Blade Flange – When mounting

of the cutting blade is required, remove the spindle bolt

and outside blade flange. Align cutting blade with inside

flange arbor and reassemble spindle and outside blade

flange.

19. Splash Guard – Keeps water and debris from leaving the

water tray.

20. Carrying Handle (Tray) – Grip this handle (left-side) to

trasport the saw.

21. Mechanical Water Pump – This pump is used on gasoline

models only. Saw is shipped from the factor for wet cutting

applications (pump handle down). Place pump handle

upwards to disengage pump.

22. Engine – The gasoline model saws uses a 5.5 HP Honda

GX160, 4-stroke, OHV, single cylinder, air cooled gasoline

engine.

23. V-belt Cover (Gasoline Only) – Remove this cover to

access the engine shaft-side V-belt.

saw with the V-belt cover removed.

24. Water Lines – Replace the clear vinyl tubing water lines

when they become brittle, worn or clogged. Water kits are

available through your dealer.

25. Priming Bulb – Squeeze this bulb to prime the mechanical

water pump (gasoline models only).

26. Blade Wrench – Use this tool to mount and remove cutting

blade.

27. Strainer – For best results place the strainer between the

splash shield and the rear of the water tray. This is for

gasoline models only.

be immersed in water.

28. Miter Box – For angled cuts, place the lip of the miter box

on the measurement rail with the threaded thumb knob

facing you and tighten.

run pump dry. Pump must be immersed in water.

NEVER

NEVER

run pump dry. Strainer must

run pump dry.

NEVER

operate the

14. Mounting Plate Lock/Release Knobs – Turn knob (2)

clockwise to release the mounting plate. Turn counterclockwise to tighten.

15. Stopper – Place stopper in tray when filling with water.

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 17

Page 18

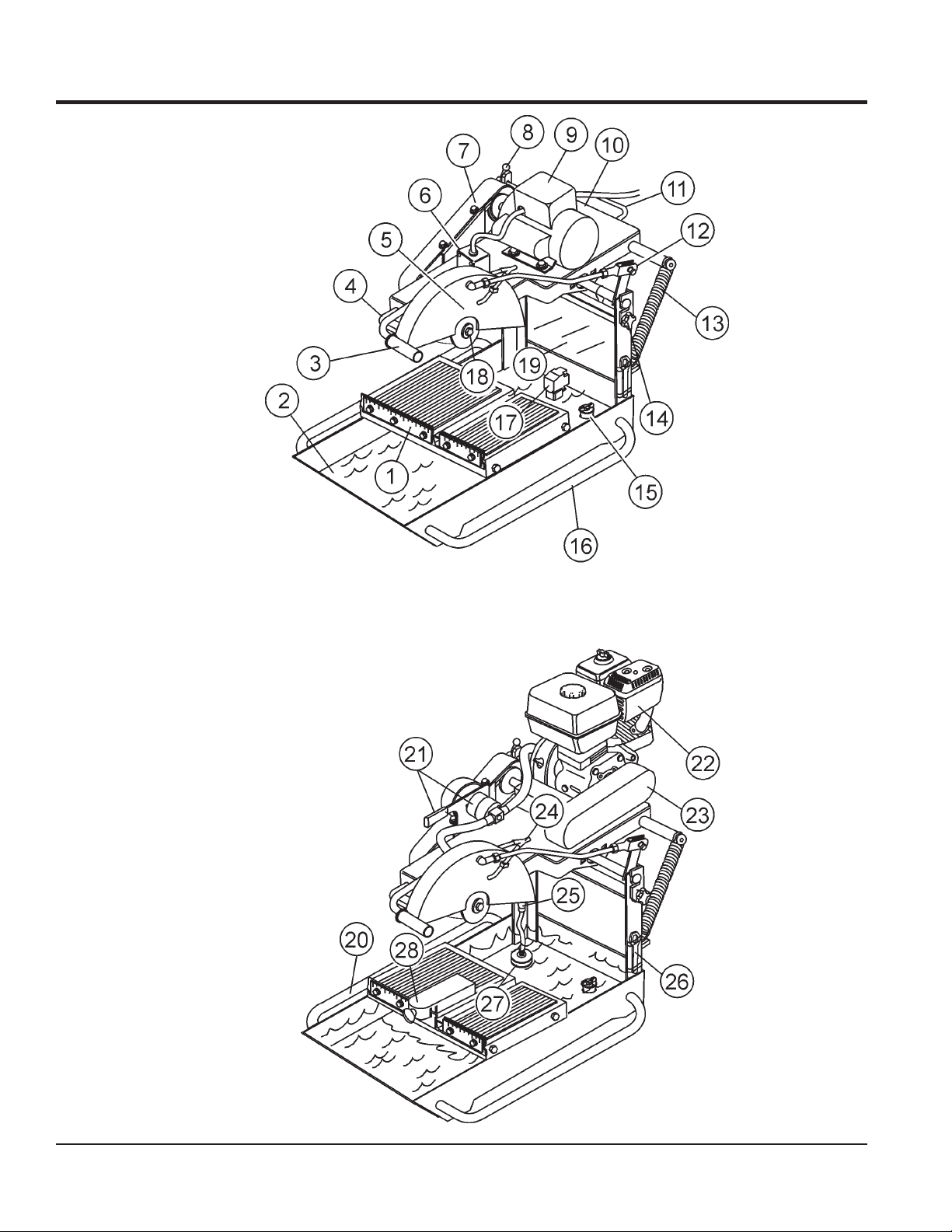

MP1 — ELECTRIC MOTOR COMPONENTS

Figure 3. Electric Motor Components

PAGE 18 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 19

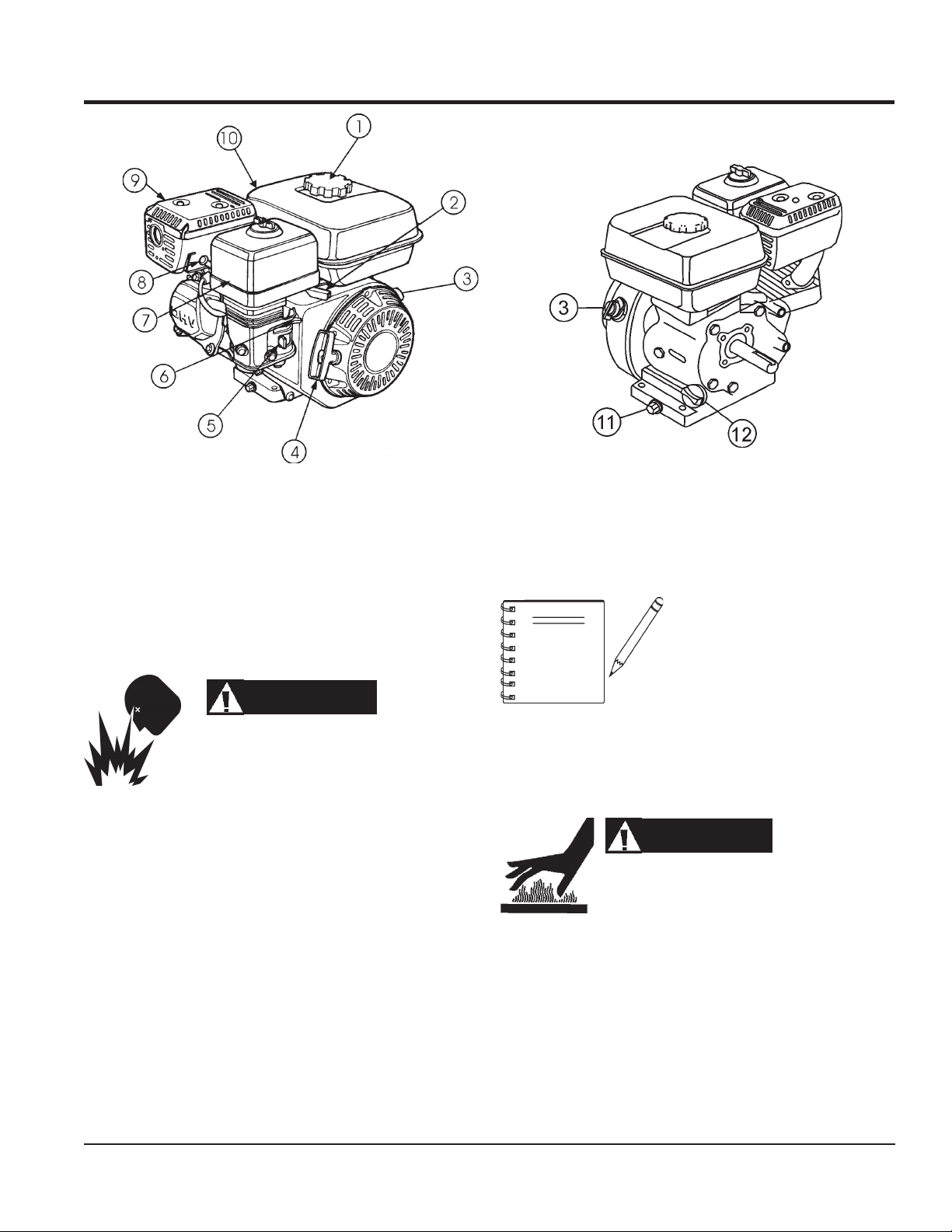

MP1 — ENGINE COMPONENTS

Figure 4. Engine Controls and Components

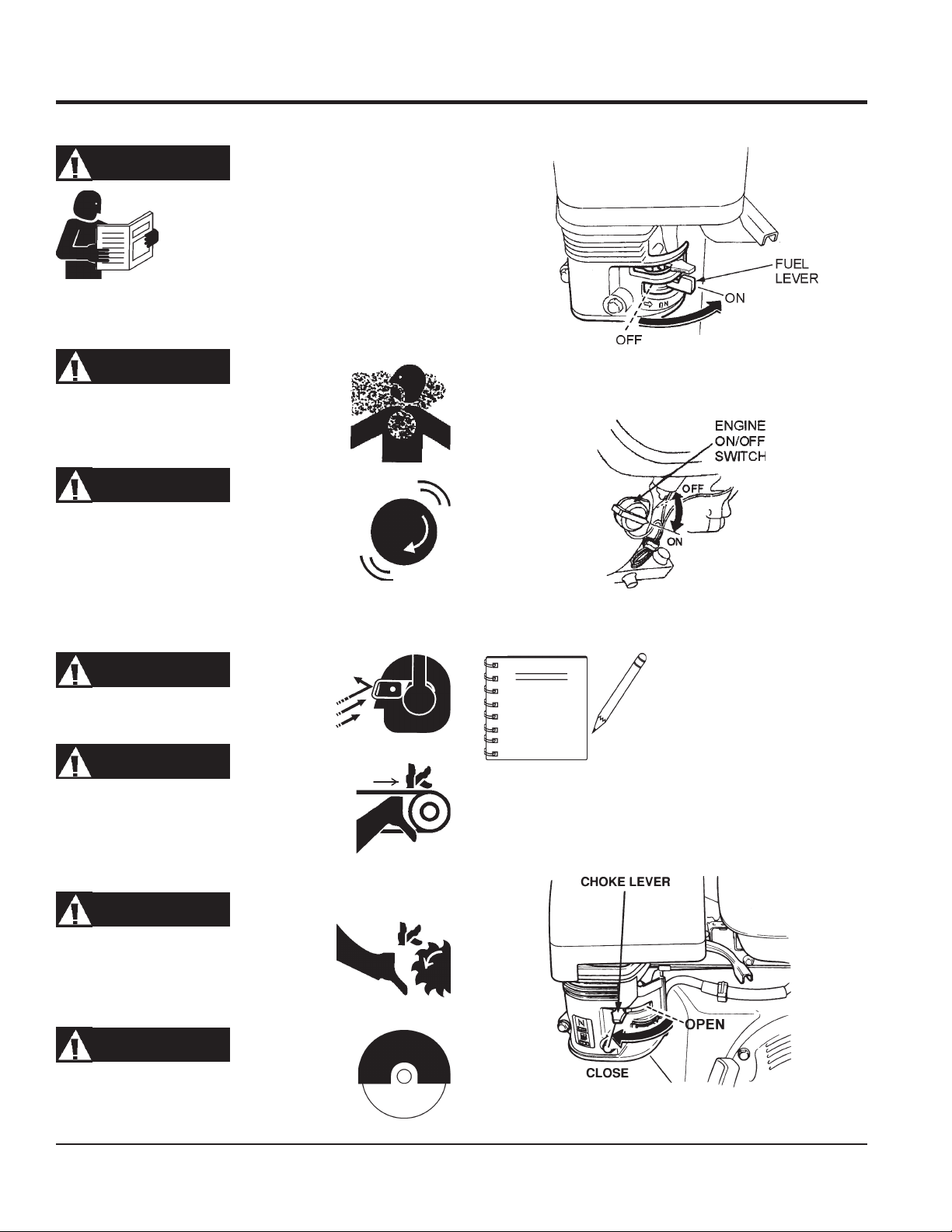

INITIAL SERVICING-GASOLINE ENGINE

The engine (Figure 4) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturers engine

manual for instructions & details of operation and servicing.

1. Fuel Filler Cap – Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

7. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element.

NOTE

DANGER

Adding fuel to the tank should be done only when

the engine is stopped and has had an opportunity

to cool down. In the event of a fuel spill, DO NOT

attempt to start the engine until the fuel residue has been completely

wiped up, and the area surrounding the engine is dry.

2. Throttle Lever – Used to adjust engine RPM speed (lever

SLOW

advanced forward

FAST

).

3. Engine ON/OFF Switch – ON position permits engine

starting, OFF position stops engine operations.

4. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

5. Fuel Valve Lever – OPEN to let fuel flow, CLOSE to stop

the flow of fuel.

6. Choke Lever – Used in the starting of a cold engine, or in

cold weather conditions. The choke enriches the fuel

mixture.

, lever back toward operator

8. Spark Plug – Provides spark to the ignition system. Set

spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch) Clean

spark plug once a month.

9. Muffler – Used to reduce noise and emissions

operating. NEVER operate the engine with the muffler removed.

10. Fuel Tank – Holds unleaded gasoline. For additional

information refer to engine owner's manual.

11. Oil Drain Bolt – Drain used oil while the engine is warm.

12. Oil Level Cap and Dipstick – Check engine oil with

engine stopped and in a level position.

Operating the engine without an

air filter, with a damaged air filter,

.

or a filter in need of replacement

will allow dirt to enter the engine,

causing rapid engine wear.

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 19

Page 20

PRE-SETUP (ELECTRIC)

PRE-SETUP

6. Insert the water pump

on the electric motor conduit box as shown in Figure 6.

WARNING

Whenever cleaning, adjusting or lubricating any part of the saw,

MAKE CERTAIN to place the power ON/OFF switch in the OFF

position and disconnect the plug from the power source.

Assembly (Electric Powered Saws Only)

1. Open the shipping container carefully, lift the saw by its carrying

handles and place it on a suitable table or platform. Make sure

the table or platform can support the weight of the saw. The

saw platform should be rigid and stationary so that it will not

move, sag, or sway due to the vibrations and movements of

the saw.

2. If using the MP1 series

attach stand to the under-side of the water tray. Follow the

instructions supplied with the support stand kit when attaching

it to the water tray.

3. Attach the clear plastic water hose (Figure 5) coming from the

blade guard to the water pump.

support stand kit

(P/N TRAK14SS),

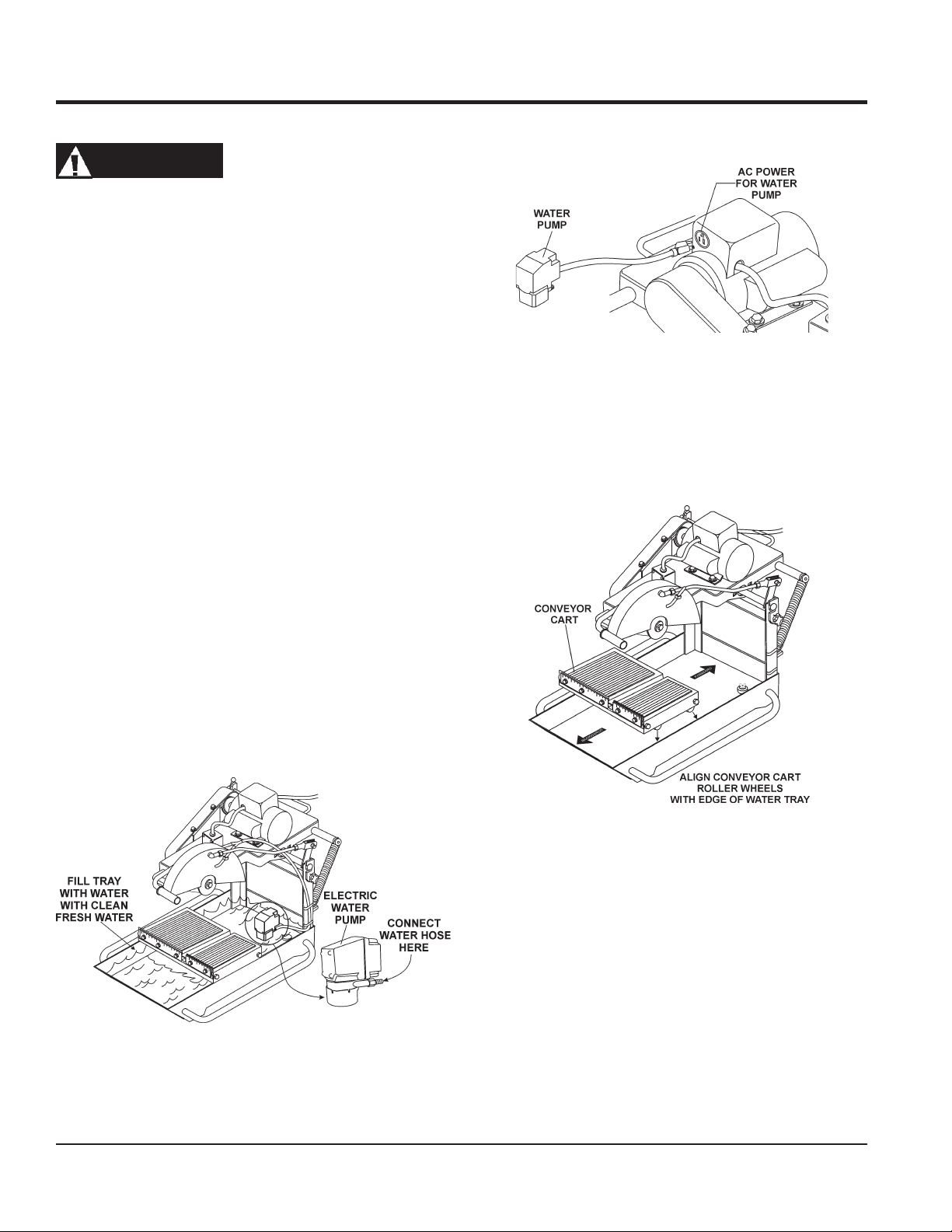

CONVEYOR CART PLACEMENT

1. Place the conveyor cart across the water tray as shown in

Figure 7. Align the wheels of the cart with the outer edge of the

water tray. Push the cart back and forth, it should move freely in

both directions.

power plug

Figure 6. Water Pump Power Connection

into the outlet receptacle

4. Fill the water tray with

clean fresh water

intake must always be fully covered by water

keep the pump intake free of sludge, debris and other

materials that may accumulate in the tray.

5. Make certain that the water hose will not come in contact

with the blade or interfere with any moving parts. The best

location for the water pump/strainer is between the splash

shield and the rear of the water tray. This will prevent some

of the abrasive particles from flowing through the pump.

. The

water pump

. Also,

Figure 7. Conveyor Cart Placement

Figure 5. Water Tray/Water Pump

PAGE 20 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 21

PRE-SETUP (ELECTRIC)

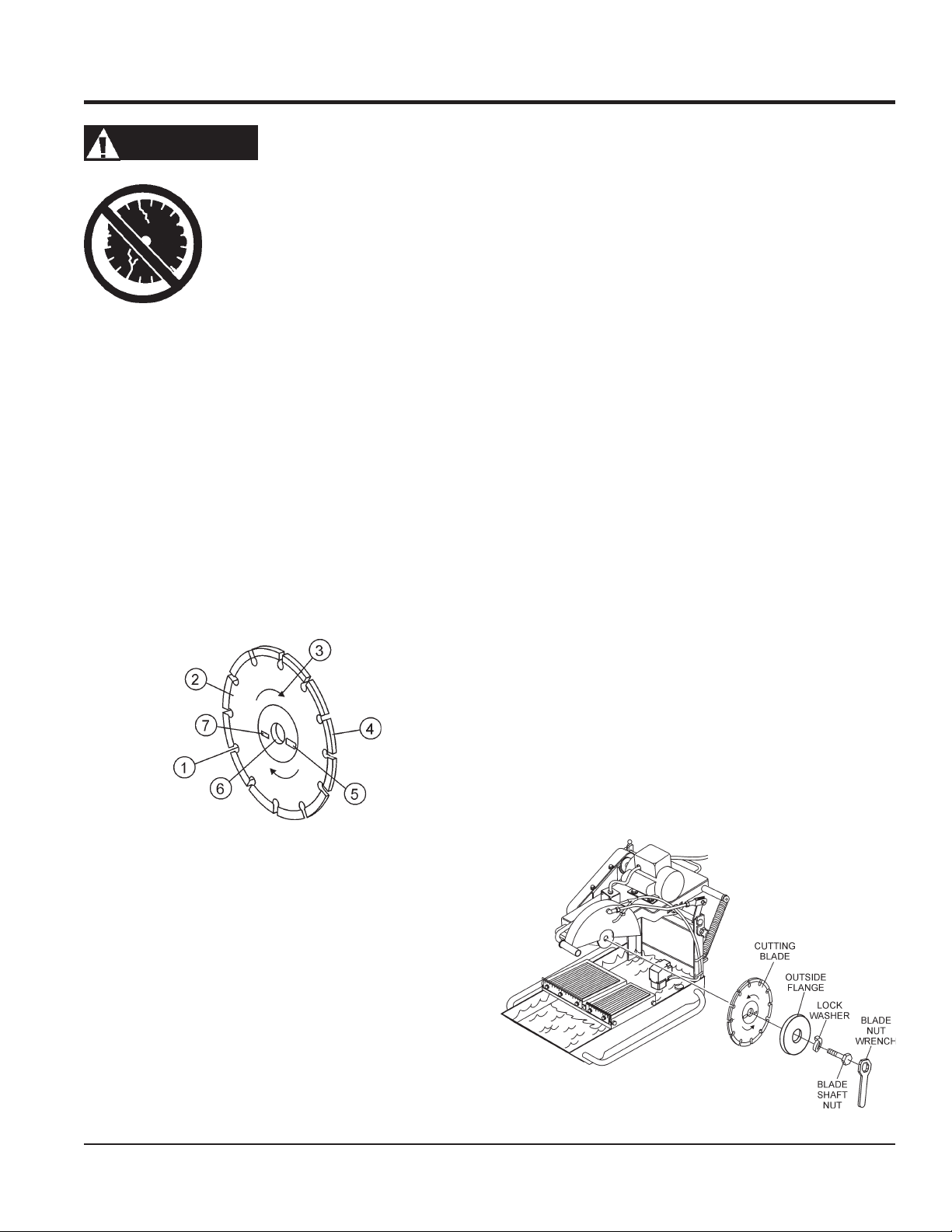

WARNING

4. Diamond Segment or Rim - Ensure there are no cracks,

Failure to thoroughly inspect the blade for

operational safety could result in damage

to the blades or the saw and may cause

serious injury to the user or others in the

operating area. Inspect the blade flanges

and shaft for damage before installing the

blade.

SAW BLADES

Diamond blades are recommended for you saw. Ask your

MULTIQUIP dealer about your specific cutting application.

SAW BLADE DEFINITIONS (FIGURE 8)

1. Stress Relief Holes (Gullets) - Check the steel core for

cracks that may have propagated from the slots and/or

gullets. Cracks indicate extreme fatigue failure and if sawing

continues, catastrophic failure will occur.

5. Specifications - Ensure that the blade specifications, size,

6. Arbor Hole - It is essential that the arbor hole diameter

7. MAX RPM - This RPM reference is the maximum safe

BLADE INSTALLATION

dings, or missing portions of the diamond segment/rim. DO

use a blade that is missing a segment or a portion

NOT

of the rim.

cause damage to your saw or injury to the user or others in

the operating area.

and diameter properly match up to sawing operations.

Utilizing a blade not matched properly to the task may result

in poor performance and/or blade damage.

properly matches the blade, and that it is free from distortion.

Correct blade flanges (collars) must be used. The inside

face of the flanges must be clean and free of debris. An outof-round arbor condition will cause damage to the blade

and the saw.

operating speed for the blade selected. NEVER exceed the

max RPM on the diamond blade. Exceeding the maximum

RPM is dangerous and may cause poor performance and

may damage the blade.

Damaged and /or missing segments/rims may

1. Use the

2. Ensure the capacity of the blade guard matches the diameter

3. Using the blade nut wrench, remove the

Figure 8. Diamond Blade

2. Edge of the Steel Core - Check the diameter edge for

discoloration (blue oxidation) indicating an overheating

condition caused by insufficient cooling water/air.

Overheating of blades may lead to loss of core tension and/

or increase the possibility for blade failure. Make sure the

steel core's width is uniform about the rim of the blade, and

not succumbing to an "under-cutting" condition brought

about by highly abrasive material or improper under-cutting

core protection.

3. Directional Arrow - Ensure that the blade is oriented

properly on the blade shaft for sawing. Reference the

directional arrow on the blade and place it so the direction

of rotation "downcuts" with the turn of the shaft.

blade nut wrench

to install the cutting blade.

of your cutting blade.

(Figure 9) supplied with the saw

blade shaft nut

outside blade flange

blade flange arbor

blade shaft nut. Tighten securely. DO NOT over tighten.

Figure 9. Blade Placement

. Install the cutting blade onto the

. Re-install the outside blade flange and

inside

and

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 21

Page 22

PRE-SETUP (ELECTRIC)

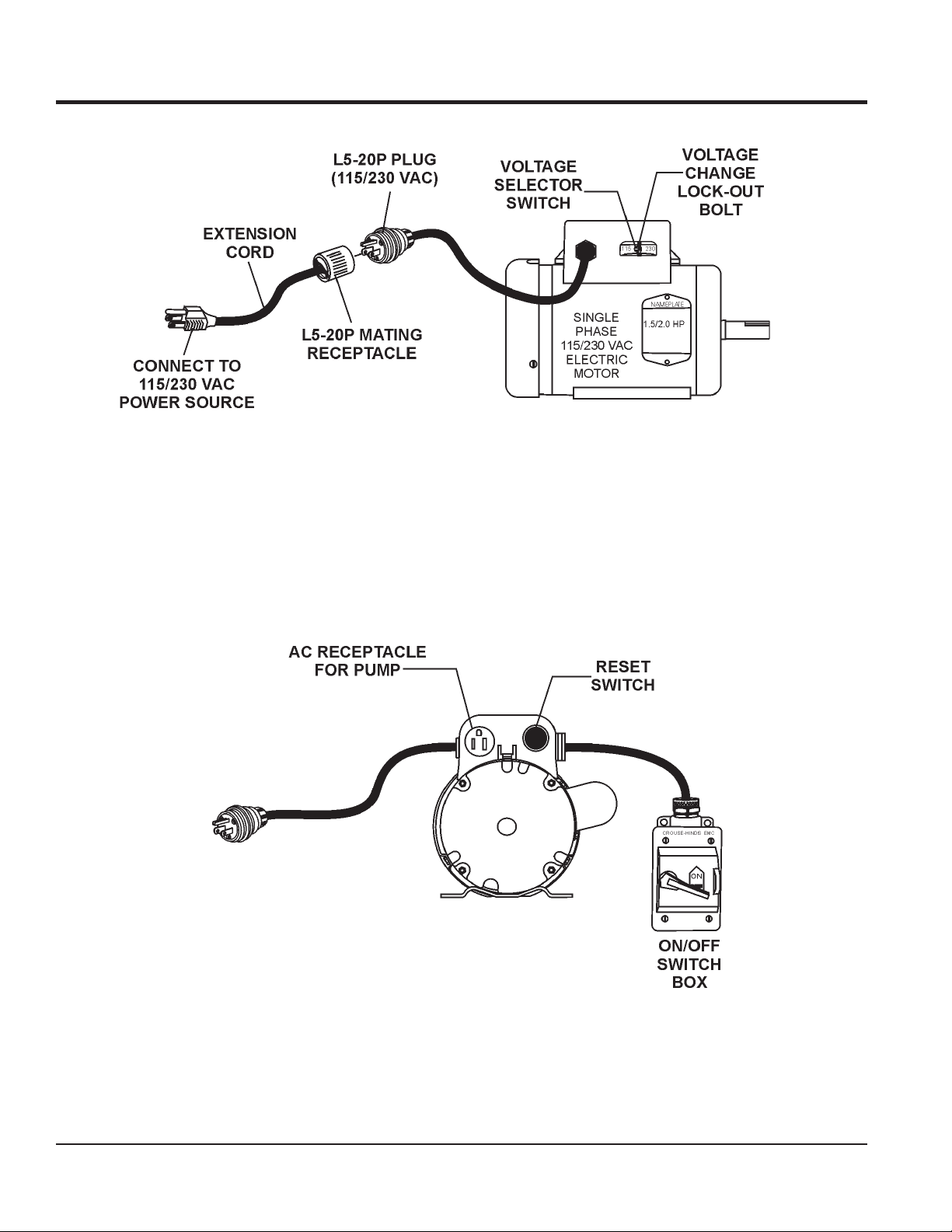

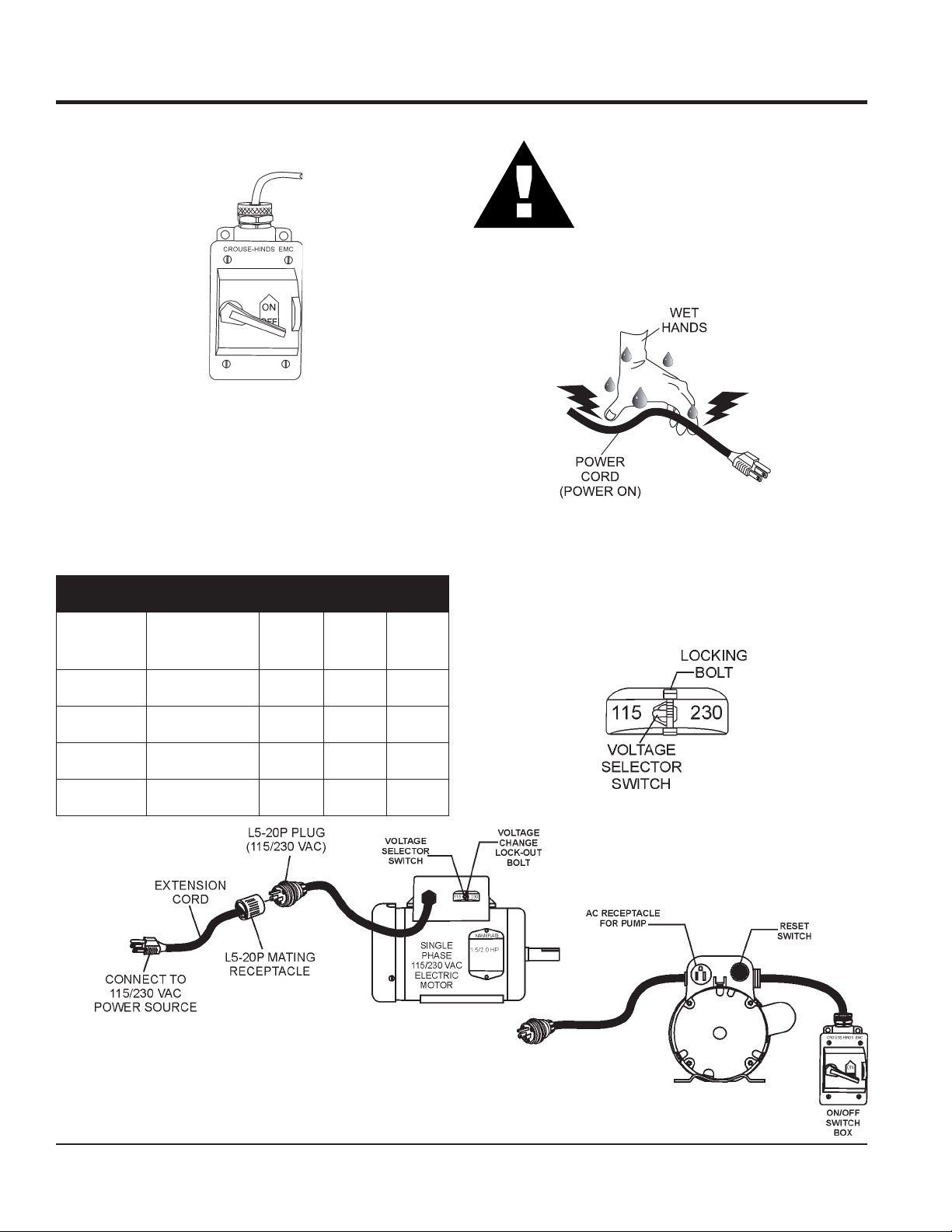

CONNECTING THE POWER (FIGURE 10)

1. Place the power ON/OFF switch (Figure 10) in the OFF

position (down).

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

NEVER use

connecting to a power source. Defective cables may cause

damage to the saw's electric motor or electrical shock.

Figure 10. Power ON/OFF Switch (OFF)

2. Connect an extension cord (Figure 13) of adequate current

carrying capacity to the power plug on the electric motor.

3. MAKE CERTAIN that the correct size extension cord is used.

Undersize wires will burn out motors. Use Table 4 to determine

the correct extension cord size.

ROTOM

EGATLOV

CAV

'05

GNOL

seziSdroCnoisnetxE.4ELBAT

'57

GNOL

4. This unit is shipped from the factory with the

switch

position of the switch from 115 VAC to 230 VAC, remove the

locking bolt and place the switch in the 230 VAC position. Re-

'001

GNOL

install the locking bolt to prevent accidently flipping the switch.

NEVER grab or touch a live power cord

(Figure 11) with wet hands , the possibility

exists of electrical shock, electrocution, and

even

death!

a damaged

Figure 11. Voltage Selector Switch

(Figure 12) in the 115 VAC position. To change the

or

worn

extension cable when

voltage selector

PH5.1 511

PH5.1

PH0.2 511

PH0.2

01.ON .ON

032 1.ON

032 21.ON .ON

4

1.ON

0

01

.ON

41

.ON

8

21

.ON

8

.ON

41

6.ON

21.ON

Figure 13. Extension Cord Connection

Figure 12. Voltage Selector Switch

PAGE 22 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 23

PRE-SETUP (ELECTRIC)

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

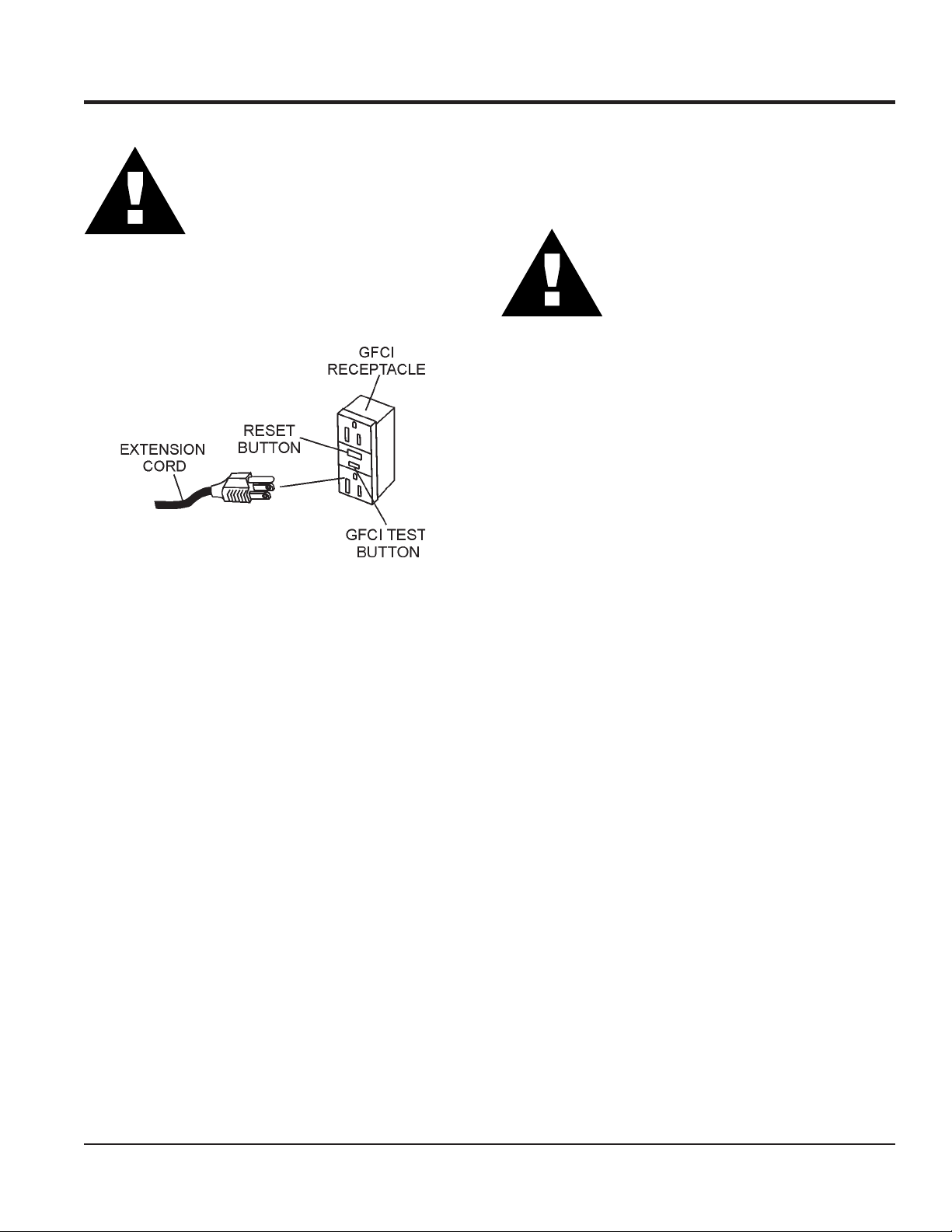

5. Plug the free end of the extension cord into an AC power

receptacle. Whenever possible use a GFCI receptacle

(Figure 14) to reduce the risk of electrical shock.

ALWAYS use a

extension cord and MAKE CERTAIN that the

motor is connected to a properly grounded

electric circuit. If possible use a ground fault

circuit interrupter to protect the operator from

possible

electric shock

grounded (3-wire

.

DRY CUTTING (ELECTRIC SAWS ONLY)

)

1. Un-plug the water pump power cord from the outlet

receptacle on the electric motor conduit box.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

2. The MP1 masonry saw is now ready for

setup procedures for

complete.

NEVER

to a AC power source. Running the pump

dry

disconnect the pump's power cord when

dry cutting.

dry cut

will

electric models saws only

with the pump connected

damage

the pump. Always

dry cutting

. The pre-

is now

Figure 14. GFCI Receptacle

6. The MP1 masonry saw is now ready for

setup procedures for

complete.

electric models saws only

wet cutting

. The pre-

is now

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 23

Page 24

PRE-SETUP (GASOLINE)

PRE-SETUP

WARNING

Whenever cleaning, adjusting or lubricating any part of the saw,

MAKE CERTAIN to stop the engine and disconnect the spark

plug wire from the spark plug.

Assembly (Gasoline Powered Saws Only)

1. Remove the MP1 saw from its container and place it on a

suitable table or platform. Make sure the table or platform can

support the weight of the saw. The saw platform should be

rigid and stationary so that it will not move, sag, or sway due to

the vibrations and movements of the saw.

2. If using the MP1 series

attach stand to the under-side of the water tray. Follow the

instructions supplied with the support stand kit when attaching

it to the water tray.

3. The

gasoline powered

This pump operates by drawing power from the drive V-belts,

and has been adjusted and locked for wet cutting operation

when shipped from the factory.

support stand kit

saw uses a

(P/N TRAK14SS),

mechanical water

pump.

The MP1 gasoline model utilizes some of the same procedures

that are used for the MP1 electric models. Please reference pages

20 and 21 for the below referenced procedures:

■

Conveyor Cart Placement

■

Blade Selection and Inspection

■

Saw Blades

■

Blade Installation

DRY CUTTING (GASOLINE ONLY)

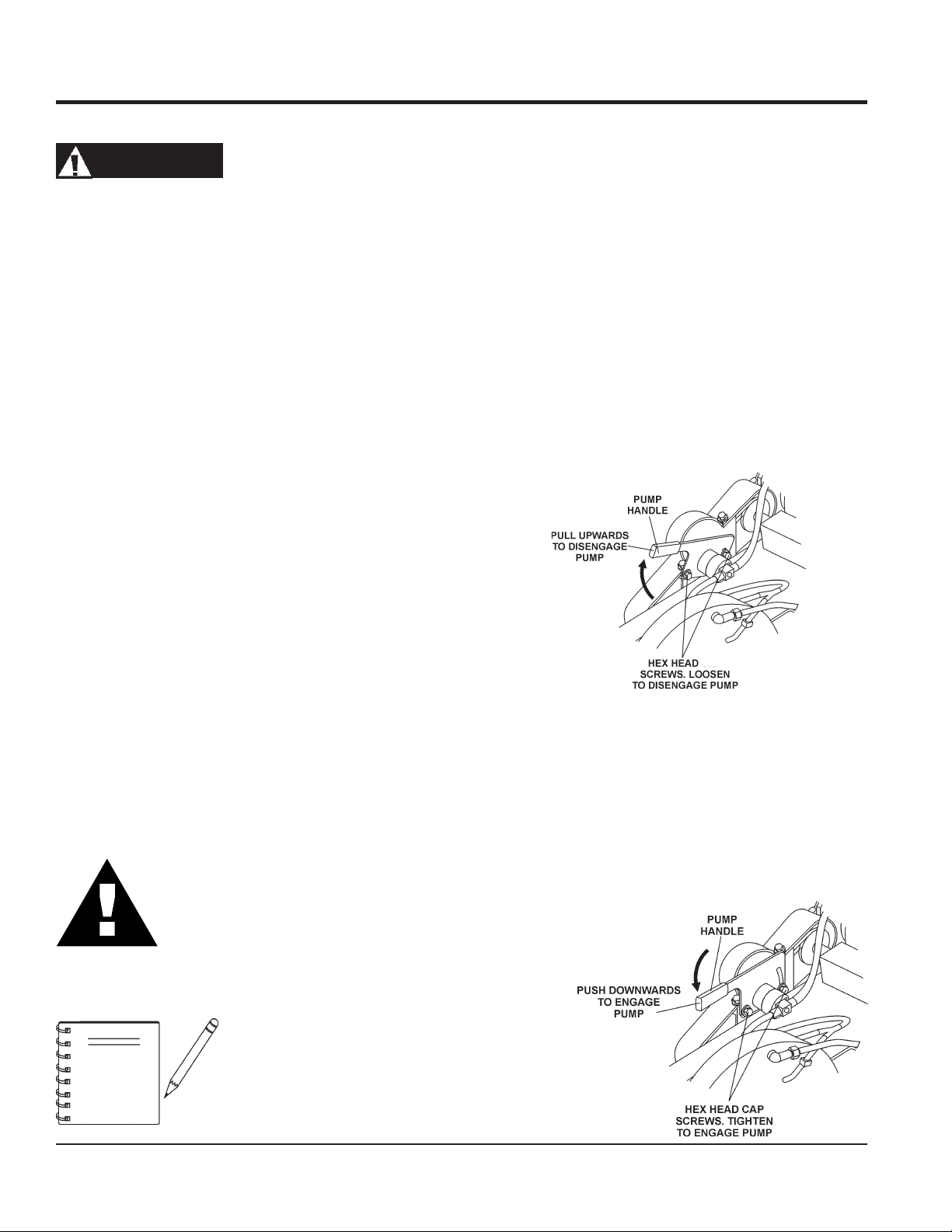

To disconnect the

belts perform the following:

1. Loosen the 2 hex head cap screws (Figure 15) that secure

the pump mount bracket.

2.

Pull

3. Tighten the 2 hex head cap screws that secure the pump

mount bracket.

mechanical water pump

the pump handle

upward

from the drive V-

to disengage the pump.

4. Fill the water tray with clean fresh water. The

intake (strainer) must always be fully covered by water

to operate effectively

sludge, debris and other materials that may accumulate in

the tray.

5. Make certain that the water hose will not come in contact

with the blade or interfere with any moving parts. The best

location for the water pump/strainer is between the splash

shield and the rear of the water tray. This will prevent some

of the abrasive particles from flowing through the pump.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ALWAYS

tray in a manner that will allow the free

movement of the conveyor cart, and clearance

from the cutting blade and cutting action.

NOTE

. Also, keep the pump intake free of

position the

The mechanical water pump is

shipped from the factory for

cutting

strainer

applications.

water pump

in the water

wet

WET CUTTING (GASOLINE ONLY)

To connect the

perform the following:

1. Loosen the 2 hex head cap screws (Figure 16) that secure

the pump mount bracket.

2.

Push

3. Tighten the 2 hex head cap screws that secure the pump

mount bracket.

Figure 15. Pump Disengage

mechanical water pump

the pump handle

downward

to the drive V-belts

to engage the pump.

Figure 16. Pump Engage

PAGE 24 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 25

BEFORE STARTING

1. Read safety instructions at the

beginning of manual.

2. Clean the saw, removing dirt and

dust, particularly the engine

cooling air inlet, carburetor and air

cleaner.

PRE-SETUP (GASOLINE)

3. Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

5. Check fastening nuts and bolts for tightness.

ENGINE OIL CHECK

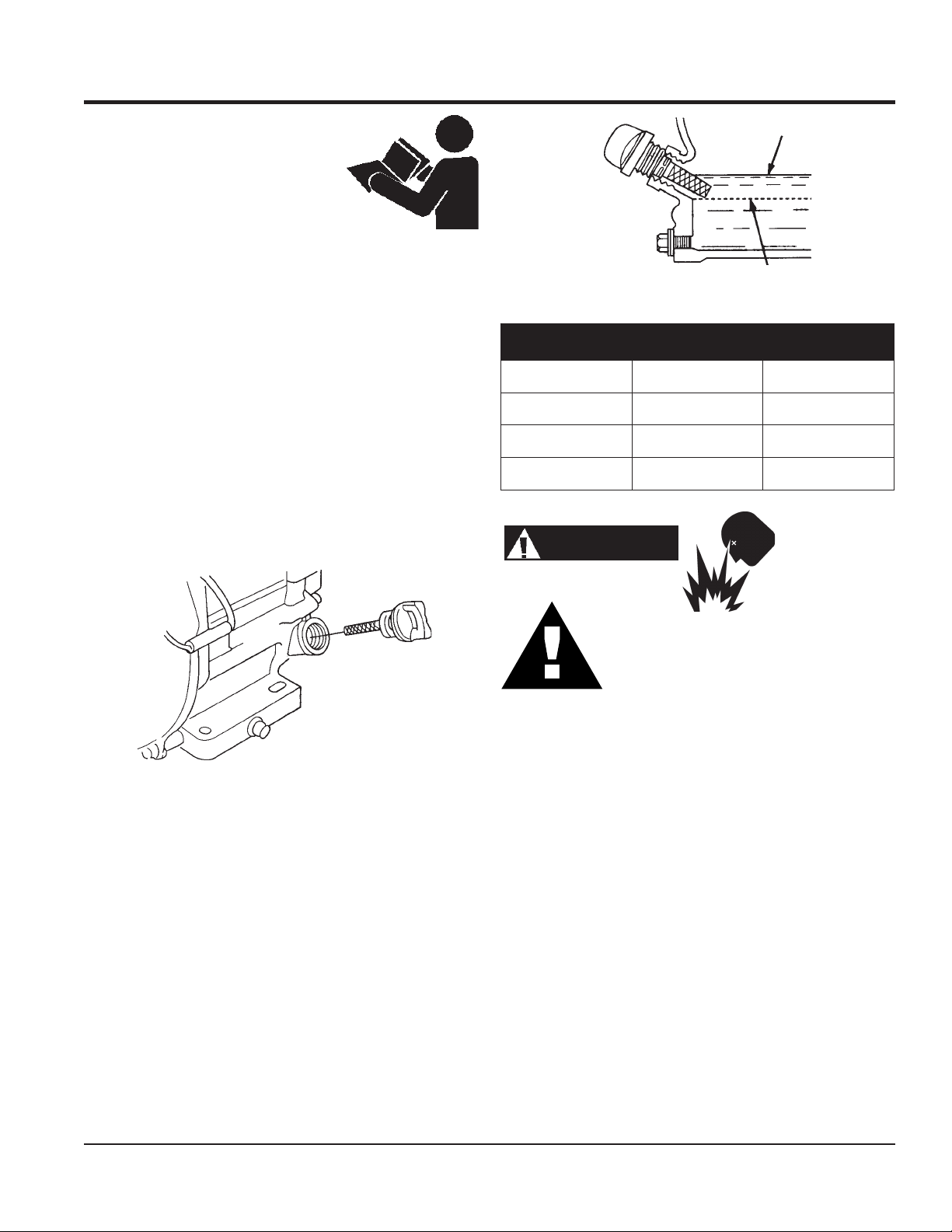

1. To check the engine oil level, place the saw on a secure

level surface with the engine stopped.

2. Remove the filler dipstick from the engine oil filler hole

(Figure 17) and wipe clean.

DANGERDANGER

DANGER

DANGERDANGER

FUEL CHECK

Figure 18. Engine Oil Dipstick (Oil Level)

epyTliO.5elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

Explosive Fuel

Motor fuels are highly flammable and can be

dangerous if mishandled. DO NOT smoke

while refueling. DO NOT attempt to refuel the

pump if the engine is

hot! or running

.

1. Remove the gasoline cap located on top of fuel tank.

Figure 17. Engine Oil Dipstick (Removal)

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 18), fill to the edge of the oil filler

hole with the recommended oil type (Table 5). Maximum oil

capacity is 0.63 quarts (0.60 liters)

2. Visually inspect to see if the fuel level is low. If fuel is low,

replenish with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel

immediately!

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 25

Page 26

OPERATION (ELECTRIC)

START-UP ELECTRIC MOTOR

CAUTION

Read and fully understand this manual before

starting or attempting to operate the saw

Before starting the saw's electric motor make

sure that the

Inspection

been completed and understood. DO NOT

proceed until the above mentioned sections have been

completed.

ALWAYS use the

blades are being used. If dry cutting is required

water pump.

water feed system

Safety, General Information

and

Pre-setup

unless special

sections have

dry cut

disconnect

NEVER lift the blade guard while the blade

is rotating. The possibility exists of

bodily harm

.

contact with the rotating saw blade. Wait for

the blade to

,

blade guard.

WARNING

ALWAYS wear approved eye and hearing

protection before operating the saw.

WARNING

NEVER place hands or feet inside the belt

guard or blade guard while the engine is

running. ALWAYS shut the engine down before

performing any kind of maintenance

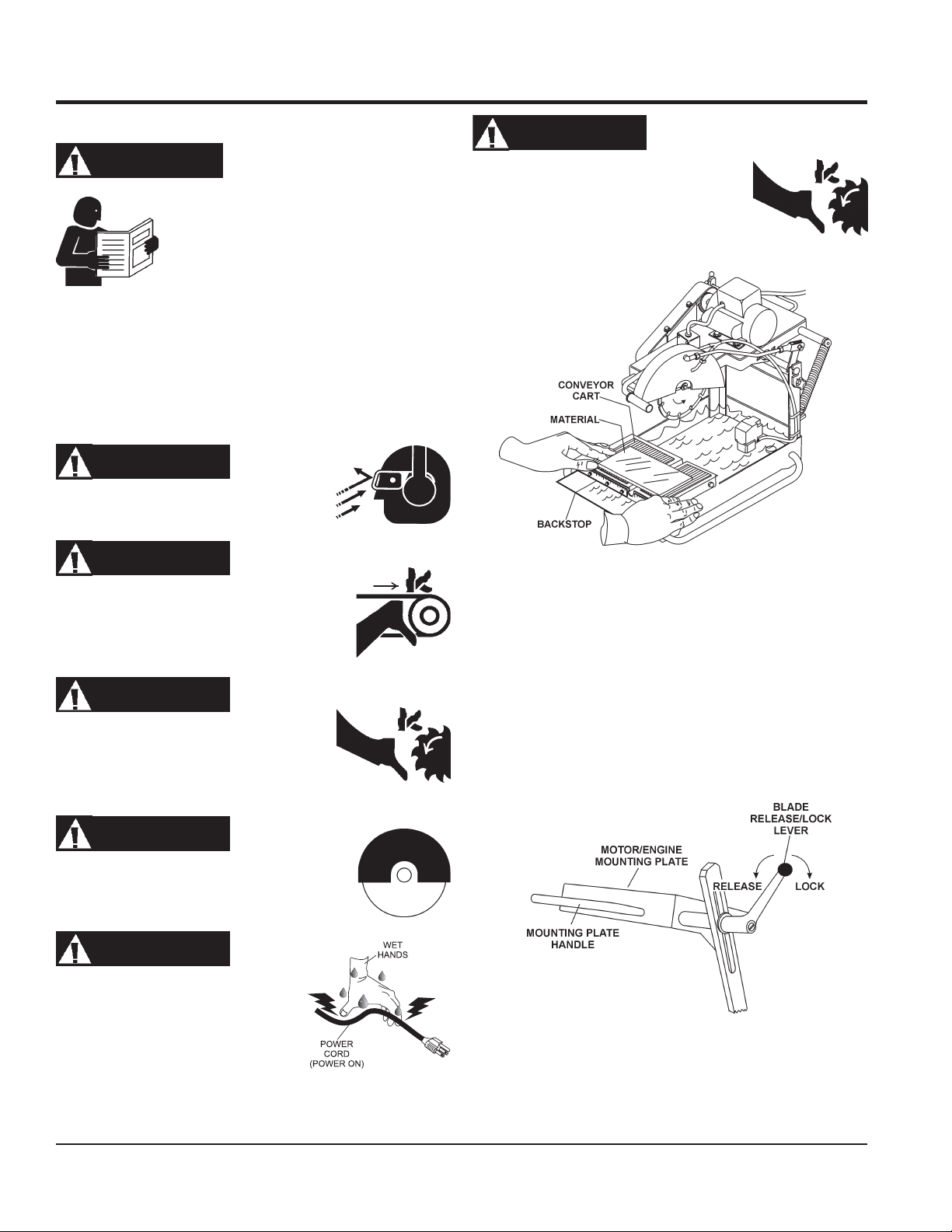

1. Place the material to be cut (Figure 19) on the conveyor

cart against the backstop.

WARNING

severe

if fingers or hands come in

stop rotating

Figure 19. Material Placement

before lifting the

WARNING

NEVER place hands and fingers near the

cutting blade. The possibility exist of severe

bodily harm if hands and fingers come in

contact with rotating saw blade.

WARNING

ALWAYS ensure that the cutting blade has

been mounted correctly and that it is raised

above the surface you are about to cut.

DANGER

NEVER touch a live power cord with

wet hands. The possibility exists of

electrical shock, electrocution which

could cause severe bodily harm even

death.

2. Place the

in the release position (pull back to release). When

releasing the lock, hold on to the mounting plate handle to

prevent the plate from rising rapidly, possibly causing the

saw to become unstable. Let the plate raise slowly.

Figure 20. Mounting Plate Release/Lock Lever

mounting plate release/lock lever

(Figure 20)

PAGE 26 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 27

3. Adjust the cutting depth by pulling up or down on the

Cutting Head Handle

and is best utilized as a "

plate release/lock lever is released, the optimum cutting

action is attained by using the

rotate down onto the material to be cut. Simultaneously the

conveyor cart is moved slowly forward

material and cutting action.

A heavy-duty spring supports ergonomic return0t0-height

action of the cutting head assembly.

(Figure 21). This saw is designed,

Chop-Saw

". Once the mounting

Raise/Lower Handle

to advance the

to

OPERATION (ELECTRIC)

Figure 22. Power ON/OFF Switch (ON)

5. Push the

until the cut is complete. Move the cart back and remove

the cut pieces.

6. Avoid overloading the motor when cutting. However, the electric

motors are protected with a manual-reset thermal overload

switch that will turn the saw off if the motor is overheated. In the

event that the switch is tripped, turn the "ON/OFF" switch to

the "OFF" position and allow the motor to cool before

attempting to restart.

SHUTDOWN PROCEDURE

1. Place the power ON/OFF switch (Figure 23) in the OFF

position (down).

Figure 21. Cutting Head Handle

DANGER

ALWAYS

saw and be extremely aware of your body position - especially

your hands in relationship to the rotating blade. The possibility

exists of

in contact with the rotating saw blade.

be alert to the fact that there is a rotating blade on the

severe bodily harm even death

if your body comes

conveyor cart

Figure 23. Power ON/OFF Switch (OFF)

with the material, slowly and evenly

4. Turn the power ON/OFF switch (Figure 22) to the ON

position with the blade away from the material to be cut, the

cutting blade should begin to rotate. Before cutting

remember to follow all safety rules referenced in this

manual.

2. Wait for the cutting blade to stop rotating.

3. Disconnect the saw's AC power cord from the power source.

NEVER

unattended. This will prevent accidental starting.

4. Using a soft cloth, clean any excess debris or residue that

may have accumulated on the saw.

5. Store saw in a clean dry location where it will be out of the

reach of children.

leave the saw connected to a power source when

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 27

Page 28

OPERATION (GASOLINE)

START-UP GASOLINE ENGINE

WARNING

Read and fully understand this manual before

starting or attempting to operate the saw

Before starting the saw's electric motor make

sure that the

Inspection

been completed and understood. DO NOT proceed until the

above mentioned sections has been completed.

Safety, General Information

and

Pre-setup

sections have

.

,

WARNING

NEVER operate the saw in a confined area or

enclosed area structure that does not provide

free flow of air

ample

.

WARNING

The engine speed has been set at the factory.

Changing the governor speed could damage the

blade and/or the saw.

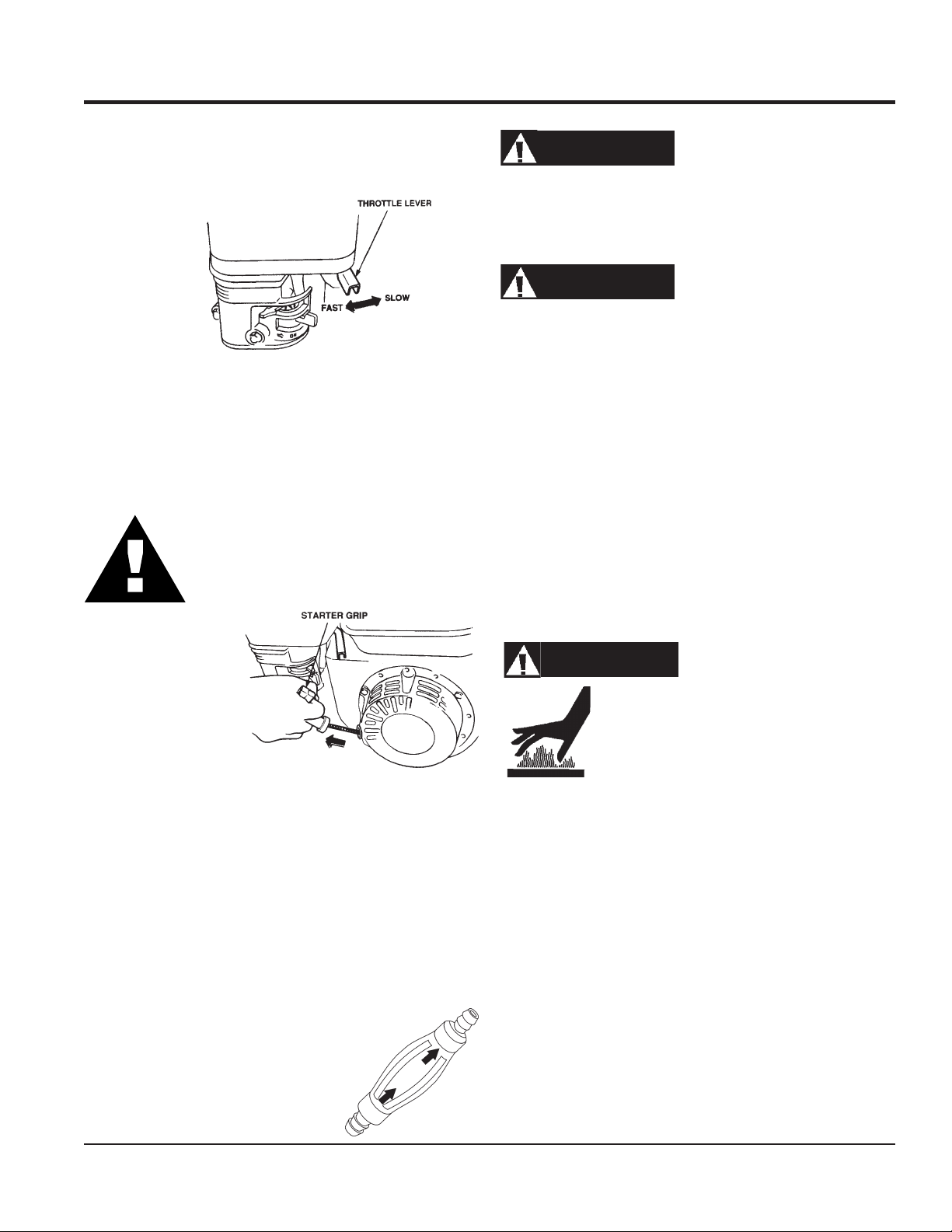

1. Place the

2. Place the

position.

fuel valve lever

Figure 24. Engine Fuel Valve Lever

Engine ON/OFF switch

(Figure 24) to the "ON" position.

(Figure 25) in the "ON"

ALWAYS use the

blades are being used. If dry cutting is required disconnect water

pump.

water feed system

unless special

dry cut

WARNING

ALWAYS wear approved eye and hearing

protection before operating the saw.

WARNING

NEVER place hands or feet inside the belt

guard or blade guard while the engine is

running. ALWAYS shut the engine down

before performing any kind of maintenance

service on the saw.

3. Place the

position.

WARNING

NEVER place hands and fingers near the

cutting blade. The possibility exist of severe

bodily harm if hands and fingers come in

contact with rotating saw blade.

Figure 25. Engine ON/OFF Switch

The CLOSED position of the

choke lever enriches the fuel

NOTE

Choke Lever

mixture for starting a COLD engine.

The OPEN position provides the

correct fuel mixture for normal

operation after starting, and for

restarting a warm engine.

(Figure 26) in the "

CLOSED

"

WARNING

ALWAYS ensure that the cutting blade has

been mounted correctly and that it is raised

above the surface you are about to saw.

Figure 26. Choke Lever

PAGE 28 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 29

OPERATION (GASOLINE)

4. Rotate the

and

engine governor speed is factory set to ensure optimum

blade operating speeds.

5. Grasp the starter grip (Figure 28) and slowly pull it out. The

resistance becomes the hardest at a certain position, corresponding to the compression point. Pull the starter grip briskly

and smoothly for starting.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

throttle lever

slow

for starting. All cutting is done at

Figure 27. Throttle Lever

DO NOT pull the starter rope all the way to

the end. DO NOT release the starter rope

after pulling. Allow it to rewind as soon as

possible.

(Figure 27) halfway between

full throttle

fast

. The

WARNING

ALWAYS

cut with the saw at less than full throttle could cause the blade to

bind or stop abruptly in the slab resulting in serious injury to the

operator or others in the area.

cut with the saw at FULL THROTTLE. Attempting to

DANGER

ALWAYS

saw and be extremely aware of your body position - especially

your hands in relationship to the rotating blade. The possibility

exists of

contact with the rotating saw blade.

10. Push the

11. Avoid overloading the engine when cutting. In the event that

STOPPING

be alert to the fact that there is a rotating blade on the

severe bodily harm even death

conveyor cart

until the cut is complete. Move the cart back and remove

the cut pieces.

the engine becomes overloaded, turn the engine ON/OFF

switch to the OFF position and allow the engine to

attempting to restart.

with the material, slowly and evenly

if your body comes in

cool

before

Figure 28. Starter Grip

6. If the engine has started, slowly return the choke lever

(Figure 26) to the

started repeat steps 1 through 5.

7. Before the saw is placed into operation, run the engine for

several minutes. Check for fuel leaks, and noises that would

associate with a loose guards and/or covers.

8. Gradually move the engine throttle lever toward the

position. (

9. Squeeze the water pump

water begins to flow through the

water lines. If the pump is working

correctly, the cutting blade should be

covered with a steady water mist.

This will keep the blade cool.

"OPEN"

All cutting should be done at full

position. If the engine has not

fast

throttle

priming bulb

(Figure 29)until

1. Set the engine throttle lever to

2. Turn the engine ON/OFF switch to the "OFF" position.

3. Place the fuel valve lever in the

4. Let the engine cool.

5. Using a soft cloth, clean any excess debris or residue that

).

6. Store saw in a clean dry location where it will be out of the

idle for 3-5 minutes.

may have accumulated on the saw.

reach of children.

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

slow

speed and let the engine

closed

position.

Figure 29. Priming Bulb

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 29

Page 30

MAINTENANCE (SAW)

MAINTENANCE

A good preventive maintenance program of regular inspection

and care will increase life and improve the performance of the

saw and cutting blades.

B. Gasoline Powered Saws - To adjust belt tension, loosen the

four (4) jackshaft mounting bolts and remove the belt guard.

Screw the adjusting bolt back to increase the tension. Proper

belt tension is 4-5 lbs. of force with approximately 1/8" of belt

deflection measured at a point halfway between the pulleys.

WARNING

Whenever cleaning, adjusting, or lubricating any part of the saw,

MAKE CERTAIN to do the following:

Electric Powered Saws

■

Place power ON/OFF switch to the OFF position.

■

Disconnect power cord from AC source.

■

NEVER attempt to check the V-belt with the engine running.

Severe bodily injury can occur.

Gasoline Powered Saws

■

Turn the engine switch to the "OFF" position, disconnect the

spark plug wire and secure it away from the spark plug.

■

NEVER attempt to check the V-belt with the engine running.

Severe bodily injury can occur.

BASIC MAINTENANCE

1. Tighten loose nuts or screws and replace any cracked or

broken parts.

2. Clean the machine frequently. Remove the belt guard and

clean the pulleys. The belts and pulleys will wear rapidly if

excessive dust builds up.

3. Clean the sludge that accumulates on the bottom of the water

tray at least once a day and refill with clean water. It may be

necessary to clean the tray out twice a day in heavy cutting.

The sludge is abrasive and will shorten the life of the water

pump and blades.

4. After each day's use, clean the sludge from the bottom of the

tray and run clean water through the water pump and water

hoses. This extends pump and blade life.

5. Lubricate the blade adjustment rod after every eight (8) hours

of use.

6. Check the spindle bolt for tightness periodically.

7. Keep the drive belts tight. It is very important to replace worn

belts as soon as possible.

A. Electric Powered Saws - To adjust belt tension, loosen

the four (4) motor mounting bolts and remove the belt

guard. Tighten the two (2) adjusting nuts on the back of

the motor plate to increase the tension. Proper belt

tension is 4-5 lbs. of force with approximately 3/16" of

belt deflection measured at a point midway between

the pulleys. Tighten the motor mounting bolts and reattach the belt guard.

NOTE

Tighten the jackshaft bearing mounting bolts (4) that are located

under the weldment. Next, loosen the (4) engine mounting

bolts and remove the belt guard. Tighten the (2) nuts on the

engine tensioning bolts that are at the rear of the weldment.

Proper belt tension is 4-5 lbs. of force with approximately 1/8"

of belt deflection measured at a point halfway between the

pulleys. Tighten the engine mounting bolts.

Pull on the recoil to make certain everything moves smoothly

and freely. If the recoil pulls hard, the belts are probably adjusted

a little

continuing. Attach the belt guards to the saw. Make certain

that the guards do not come in contact with the belts or each

other. There are slots in the guard mounting plates so

adjustments can be made if necessary. Tighten all bolts on the

guards and their mounts.

8. MAKE CERTAIN that the cutting head is aligned properly.

Misalignment can adversely affect blade life.

9. The blade flanges must have a diameter of 4". Undersize

flanges will reduce blade life and cause breakage. Therefore,

they should be replace at once.

10. Cutting blades must fit the arbor snugly. This is very important

with diamond blades as pounding will occur and serious blade

damage can result. If the arbor shoulder of the inner blade

flange is grooved from blade slippage, the flange must be

replaced.

11. Inspect the conveyor cart periodically. Replace the wood insert

and wheels when necessary.

12. Lubricate spindle bearings after each day's operation. When

dry cutting, grease bearings several times during the day's

operation to protect them from the dust.

too tight

. Belt tensions should be readjusted before

It is very important that the jackshaft

and blade arbor

to each other. This can be

accomplished by using the

adjusting bolt located on the

engine mounting plate to help keep

the jackshaft from cocking.

remain parallel

PAGE 30 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 31

MAINTENANCE (SAW)

13. Replace the spindle bearings as soon as they begin to make

any strange noises. Worn bearings can destroy blades very

quickly.

14. Grease pivot bearings periodically.

CUTTING HEAD ALIGNMENT (BLADE)

Make certain the

can adversely affect blade life. The motor/engine plate is slotted

so adjustment to the blade can be made as needed. The left side

has vertical slots, and the right side has horizontal slots. To adjust

the cutting head either vertical or horizontally perform the

following:

VERTICAL ADJUSTMENT

Remove the motor or engine from the mounting plate. Loosen

the pivot bearing bolts (2) on the left side of the mounting plate.

Move the pivot bearing to the extreme top of the slots in the

mounting plate. Thread a 3/8-16 bolt (adjusting bolt) down

through the hole in the top of the mounting plate. Tighten the bolt

against the bearing.

This will raise the mounting plate. Continue to tighten the bolt

until the blade is perpendicular to the conveyor cart. Tighten the

pivot bearing bolts. Remove the adjusting bolt and reassemble.

cutting head

is aligned properly. Misalignment

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

from the pivot shaft, MAKE CERTAIN the motor/engine plate is

supported to prevent the cutting head from dropping.

CUTTING HEAD REMOVAL

To remove the cutting head (Figure 31) perform the following:

1. Loosen the knobs (2) located on each side of uprights.

2. Slide the hooks (2) up and away from the pivot shaft.

3. Remove the handle lock that fastens the blade height adjusting

arm to the motor/engine plate. This is accomplished by simply

removing the cotter pin.

4. Disconnect the spring from the pivot shaft by raising the cutting

head until the tension is relieved from the spring.

5. To reassemble the cutting head, reverse these steps.

When loosening the handle lock, hold onto

the front of the motor/engine plate handle to

prevent the plate from raising rapidly, possible

causing the saw to become unstable. Let the

plate raise slowly. When removing the spring

HORIZONTAL ADJUSTMENT

Loosen the pivot bearings (2) on the right-side of the mounting

plate. Slide the pivot bearing forward or backwards as needed,

until the blade is parallel with the conveyor cart. Tighten the pivot

bearing bolts.

BEARING LUBRICATION CARE

There are two (2) grease points (Figure 30) for the MP1

model saw. Use only Premium Lithium 12 based Grease,

conforming to NLG1 Grade #2 consistency. Grease

gasoline

daily

.

Figure 31. Cutting Head Removal

Figure 30. Zerk Fittings (Lubrication)

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 31

Page 32

MP1 — MAINTENANCE (ENGINE)

ENGINE MAINTENANCE

Perform engine maintenance procedures as referenced by

Table 6 below:

eludehcSecnanetniaMenignE.6elbaT

TSRIF

)3(NOITPIRCSEDNOITAREPOEROFEB

KCEHCX

liOenignE

EGNAHCX

KCEHCX

renaelCriA

EGNAHC)1(X

stloB&stuNllA

gulPkrapS

sniFgnilooCKCEHCX

retserrAkrapSNAELC X

knaTleuFNAELC X

fInethgit-eR

yrasseceN

NAELC-KCEHCX

ECALPER X

X

HTNOM

RO

.SRH01

YREVE

SHTNOM3

RO

.SRH52

YREVE

SHTNOM6

RO

.SRH05

YREVE

RAEY

RO

01

.SRH0

YREVE

SRAEY2

RO

.SRH002

retliFleuFKCEHC X

DA-KCEHC )2(X

nidesunehwylt

resebdluohssmetiesehT)2(

serudecorpecivresroflaunaMpohsADNOHehtotrefeR.tneiciforp

reporpenimretedotnoitarepofosruohgol,esulaicremmocroF)3(

.slavretniecnanetniam

yllacinahcemeradnaslootreporpehtevahuoysselnu,relaedcivresruoyybdeciv

NOTE

deepSeldITSUJ

ecnaraelCevlaVTSUJDA-KCEHC )2(X

senilleuFKCEHC )2()yrassecenfiecalper(sraey2yrevE

neuqerferomecivreS)1( YTSUD .saera

Reference manufacturer engine

manual for specific servicing

instructions.

PAGE 32 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 33

MP1 — MAINTENANCE (ENGINE)

MAINTENANCE

Perform the engine maintenance procedures as indicated below:

DAILY

■

Thoroughly remove dirt and oil from the engine and control

area. Clean or replace the air cleaner elements as necessary.

Check and retighten all fasteners as necessary. Check the

spring box and bellows for oil leaks. Repair or replace as

needed.

WEEKLY

■

Remove the fuel filter cap and clean the inside of the fuel

tank.

■

Remove or clean the filter at the bottom of the tank.

■

Remove and clean the spark plug (Figure 32), then adjust

the spark gap to 0.028 ~0.031 inch (0.6~0.7 mm). This unit

has electronic ignition, which requires no adjustments.

DANGER:DANGER:

DANGER:

DANGER:DANGER:

ENGINE AIR CLEANER

1. Remove the air cleaner cover and foam filter element as

2. Tap the paper filter element (Figure 34) several times on a

3. Clean foam element in warm, soapy water or nonflammable

DO NOT use gasoline as a cleaning solvent,

because that would create a risk of fire or

explosion.

shown in Figure 34.

hard surface to remove dirt, or blow compressed air [not

exceeding 30 psi (207 kPa, 2.1 kgf/cm

element from the air cleaner case side.

Brushing will force dirt into the fibers. Replace the paper filter

element if it is excessively dirty.

solvent. Rinse and dry thoroughly. Dip the element in clean

engine oil and completely squeeze out the excess oil from the

element before installing.

2

)] through the filter

NEVER

brush off dirt.

Figure 32. Spark Plug Gap

ENGINE OIL

warm

1. Drain the engine oil when the oil is

Figure 33.

2. Remove the oil drain bolt and sealing washer and allow

the oil to drain into a suitable container.

3. Replace engine oil with recommended type oil as listed

in Table 5. Engine oil capacityis 0.63 quarts (0.60 liters).

DO NOT overfill.

4. Install drain bolt with sealing washer and tighten securely.

as shown in

Figure 34. Engine Air Cleaner

Figure 33. Engine Oil (Draining)

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 33

Page 34

WIRING DIAGRAM - ELECTRIC MOTOR

Figure 34. Electric Motor Wiring Diagram

PAGE 34 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 35

NOTES

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 35

Page 36

Symptom Possible Problem Solution

Blade slows or stops cutting, still

remains on blade

Blade does not cut straight and/

or true.

Blade discoloring, crackling and/or

wearing excessively.

TROUBLESHOOTING - BLADE

Table 7. Blade Troubleshooting

Consult dealer or Multiquip for correct blade. Try cutting

Blade too hard for the material being cut?

Engine torque diminished because of loose

V-belt?

Insufficient engine power? Check throttle setting. Check engine horsepower.

Improper direction of rotation?

Blade is slipping onto the blade shaft?

Blade being used on misaligned saw? Check blade shaft bearings and alignment integrity.

Blade is excessively hard for the material

being cut?

Blade improperly mounted on arbor

shoulders and flanges?

Excessive force applied to blade while

cutting?

Blade is too hard for material being cut?

Blade improperly mounted on arbor

shoulders and flanges?

Blade not receiving enough cooling water or

air?

Arbor hole out of round? Ensure blade is properly affixed on the blade shaft.

Incorrect blade chosen for material being

cut?

Excessive force applied to blade while

cutting?

very soft material (sandstone, silica brick, cinder block)

to “redress” the blade.

Tighten and/or replace V-belt.

Check that the blade is properly oriented and rotational

arrow points in a “down-cutting” direction.

Check that the blade and flange pin are properly

installed on the blade shaft.

Check specification of the blade with the material being

cut. Consult dealer or Multiquip for information.

Ensure blade is properly affixed on the blade shaft.

DO NOT force the blade in the cut. Apply a slow and

steady pace when sawing.

Consult dealer or Multiquip for correct blade. Try cutting

very soft material (sandstone, silica brick, cinder block)

to “redress” the blade.

Ensure blade is properly affixed on the blade shaft.

Ensure proper flow and volume of water is provided

for wet cutting blades. Ensure sufficient cooling air is

circulated about a dry cutting blade.

Check specification of the blade with the material being

cut. Consult dealer or Multiquip for information.

DO NOT force the blade in the cut. Apply a slow and

steady pace when sawing.

PAGE 36 — MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10)

Page 37

TROUBLESHOOTING - ELECTRIC MOTOR

)ROTOMCIRTCELE(GNITOOHSELBUORT.8ELBAT

NOTPMYSMELBORPELBISSOPNOITULOS

?nideggulpdrocrewoP detcennocylreporpsiwa

?drocrewopevitcefeD.drocrewopecalpeR

nehwnurtonseodwaS

.nohctiwssirewop

?snoitcennoclacirtceleesooL aybdekcehcmetsyslacirtceleevaH

?rotomevitcefeD .yrassecenfiecalperdnarotomkcehC

netxe/drocrewoP foelbacnoisnetxe/drocrewopaesU

elttilecnamrofrepwasrooP

.rewop

astcerrocnI otsdnopserrochcihwedalbwasaesU

)tuostucrewop(spotsrotoM

?edalbw

?tneiciffusnisiecruosrewoP ebtsumti

?evitcefedwasnohctiwsrewopniaM .yrassecenf

?gnolootelbacnois

?deepsdetartanurrotomseoD .yrassecenfiecalpe

?gnittucelihwdetrexehcumooT .gnittucnehwerusserpsseltrexE

stahtkcehC

.ecruosrewopaot

ihctiwsecalperdnakcehC

ifilauq

rdnarotomkcehC

.naicirtceledesnecilde

.4elbaTeeS.htgneldetar

ucriC.tiucriclacirtcelekcehC

.muminimspma02gniylppusfoelbac

.tucgnieblairetameht

?metsyslacirtceleevitcefeD aybdekcehcmets

MP1 SERIES MASONRY SAWS — OPERATION AND PARTS MANUAL — REV. #1 (03/29/10) — PAGE 37

yslacirtceleevaH

.naicirtceledesnecildeifilauq

Page 38

TROUBLESHOOTING - GASOLINE ENGINE

MOTPMYS MELBORPELBISSOP NOITULOS

tratsottluciffiD

?egdirbgniebgulpnoitingI .metsysnoitingikcehC

GNITOOHSELBUORTENIGNE.9ELBAT

.)elbacnoisnethgihta

rewoP(.etingitonlliw TON

noisserpmoc(setingi )lamron .

noisserpmoc(setingi wol .)

yrotcafsitastonnoitarepO

gulpkrapstubelbaliavasileuF

elbaliavarewoP(.etingitonlliw

?srotalusni

gulpkrapstubelbaliavasileuF

.)elbacnoisnethgihtaelbaliava

?stisoped

gulpkrapsdnaelbaliavasileuF

gulpkrapsdnaelbaliavasileuF

?etauqedani

?)tsud

?nrowrednilyC .rednilycecalpeR

?noitingitatisopednobraC .noitingiecalperronaelC

evitcefedoteudtiucrictrohS

?pagkrapsreporpmI .pagtcerrocehtotpaggulpkrapsteS

?hctiwspotstatiucrictrohS .evitcefedfihctiwspotsecalpeR.tiucrichctiwspotskcehC

?evitcefedliocnoitingI .liocnoitingiecalpeR

nobrachtiwdeggolcrelffuM

siytilauqleufdexiM

,retaw(etauqedaniesunileuF