OPERATION & PARTS MANUAL

SERIES

MODEL MVC-88VGH/VGHW

ONE-WAY PLATE COMPACTOR

(HONDA GASOLINE ENGINE)

Revision #1 (05/08/06)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

MVC-88VGH/VGHW PLATE COMPACTOR — PROPOSITION 65 WARNING

l

PAGE 2 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

NOTE PAGE

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 3

MVC-88VGH/VGHW PLATE COMPACTOR — TABLE OF CONTENTS

Multiquip —MVC88VGH/VGHW

Plate Compactor

Proposition 65 Warning ............................................. 2

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

Safety Message Alert Symbols .............................. 6-7

Rules For Safe Operation ...................................... 8-9

Operation and Safety Decals .................................. 10

Specifications (Compactor/Engine) ........................ 11

General Information ................................................ 12

Components (Plate Compactor) ............................. 13

Components (Engine) ............................................. 14

Inspection ........................................................... 15-16

Initial Start-Up .................................................... 17-18

Operation ................................................................ 18

Maintenance ...................................................... 19-21

Preparation For Long Term Storage ....................... 22

Troubleshooting (Engine) ................................... 23-24

Troubleshooting (Plate Compactor) ........................ 24

Explanation Of Codes In Remarks Column ............ 26

Suggested Spare Parts ........................................... 27

Honda GX160U1QMX2 Engine

Cylinder Head Assembly ....................................38-39

Cylinder Barrel (Recoil) Assembly ..................... 40-41

Crankcase Cover Assembly ...............................42-43

Crankshaft Assembly .........................................44-45

Piston/Rings Assembly....................................... 46-47

Camshaft Assembly ........................................... 48-49

Recoil Starter .....................................................50-51

Fan Cover Assembly ..........................................52-53

Carburetor Assembly .........................................54-55

Air Cleaner Assembly......................................... 56-57

Muffler Assembly ...............................................58-59

Fuel Tank Assembly ...........................................60-61

Cooling Fan & Flywheel Assembly ..................... 62-63

Ignition Coil Assembly ........................................ 64-65

Control Assembly ...............................................66-67

Terms and Conditions Of Sale — Parts .................. 68

Component Drawings

Nameplate and Decals....................................... 28-29

Body Assembly .................................................. 30-31

Vibrator Assembly .............................................. 32-33

Sprinkler Assembly (Option) .............................. 34-35

Transport Wheel Assembly (Option) .................. 36-37

l

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

Effective: June 1st, 2005

Ordering parts has never been easier!

PARTS ORDERING PROCEDURES

Choose from three easy options:

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■

View Parts Diagrams

■

Order Parts

■

Print Specification Information

Go to www.multiquip.com and click on

Order Par ts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

If you have an MQ Account, to obtain a

Username and Password, E-mail us at:

parts@multiquip.com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Use the

internet

and qualify for a 5% Discount

on

Standard orders

complete part numbers.*

Fax

your order in and qualify for a 3% Discount

on

Standard orders

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

for all orders which include

for all orders which include

International Customers

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

should contact

When ordering parts, please supply:

❒❒

❒

Dealer Account Number

❒❒

❒❒

❒

Dealer Name and Address

❒❒

❒❒

❒

Shipping Address (if different than billing address)

❒❒

❒❒

❒

Return Fax Number

❒❒

❒❒

❒

Applicable Model Number

❒❒

❒❒

❒

Quantity, Part Number and Description of Each Part

❒❒

NOTE

www.multiquip.com

Unless otherwise indicated by customer, all orders are treated as

within 24 hours. We will make every effort to ship

if received prior to 2PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 5

❒❒

❒

Specify Preferred Method of Shipment:

❒❒

✓

Fed Ex/UPS

■

■

■ Next Day

■

Stock Orders

✓ DHL

Priority One

Ground

Second/Third Day

✓

Truck

Standard Orders

Air Shipments

must be noted on fax or web order form.

the same day the order is received,

and will ship

MVC-88VGH/VGHW PLATE COMPACTOR — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed

at all times when operating this

equipment. Failure to read and

understand the Safety Messages and

Operating Instructions could result in

injury to yourself and others.

This manual has been developed to

provide complete instructions for the

safe and efficient operation of the

NOTE

Before using this plate compactor, ensure that the

operating individual has read and understood all

instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

Mikasa

Compactor

manufacturer's instructions for data

relative to its safe operation.

MVC-88VGH/VGHW

. Refer to the engine

MQ

Plate

HAZARD SYMBOLS

Potential hazards associated with the operation of an

MVC-88VGH/VGHW Plate Compactor

with Hazard Symbols which appear throughout this manual,

and will be referenced in conjunction with Safety Message

Alert Symbols.

Engine exhaust gases contain

poisonous carbon monoxide. This gas

is colorless and odorless, and can

cause death if inhaled. NEVER operate

this equipment in a confined area or

enclosed structure that does not provide

ample free flow air.

Gasoline is extremely flammable, and

its vapors can cause an explosion if

ignited. DO NOT start the engine near

spilled fuel or combustible fluids.

Lethal Exhaust Gases

WARNINGWARNING

WARNING

WARNINGWARNING

WARNINGWARNING

WARNING

WARNINGWARNING

Lethal Exhaust Gas Hazards

Explosive Fuel Hazards

will be referenced

DANGERDANGER

DANGER

DANGERDANGER

You WILL be

if you DO NOT follow these directions.

WARNINGWARNING

WARNING

WARNINGWARNING

You CAN be KILLED or

you DO NOT follow these directions.

CAUTICAUTI

CAUTION

CAUTICAUTI

You CAN be

these directions.

KILLED

INJURED

if you DO NOT follow

or

SERIOUSLY INJURED

l

SERIOUSLY INJURED

if

DO NOT fill the fuel tank while the engine is running or

hot. DO NOT overfill tank, since spilled fuel could ignite if

it comes into contact with hot engine parts or sparks from

the ignition system. Store fuel in approved containers, in

well-ventilated areas and away from sparks and flames.

WARNINGWARNING

WARNING

WARNINGWARNING

Engine components can generate extreme

heat. To prevent burns, DO NOT touch

these areas while the engine is running or

immediately after operation. Never operate

the engine with heat shields or heat guards

removed.

WARNINGWARNING

WARNING

WARNINGWARNING

ALWAYS wear approved

protection when required.

Burn Hazards

Respiratory Hazards

respiratory

PAGE 6 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

MVC-88VGH/VGHW PLATE COMPACTOR — SAFETY MESSAGE ALERT SYMBOLS

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

NEVER operate equipment with covers,

or guards removed. Keep fingers, hands,

hair and clothing away from all moving

parts to prevent injury.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ALWAYS place the engine ON/OFF switch

in the OFF position, when the plate

compactor is not in use.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ALWAYS wear approved eye and hearing

protection.

Rotating Parts Hazards

Accidental Starting Hazards

Eye and Hearing Hazards

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Other important messages are provided throughout this

manual to help prevent damage to your equipment, other

property, or the surrounding environment.

Equipment Damage

Hazards

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 7

MVC-88VGH/VGHW PLATE COMPACTOR — RULES FOR SAFE OPERATION

■

WARNING - Read This Manual

Failure to follow instructions in this manual may lead to

Serious Injury

operated by trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used

when operating the Mikasa MVC-88VGH/VGHW Plate

Compactor.

Safety:

■

DO NOT operate or service this

equipment before reading this entire

manual.

■

This equipment should not be

operated by persons under 18 years of age.

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

or even

Death

. This equipment is to be

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to

cool before servicing engine or

generator.

■

High Temperatures – Allow the engine

to cool before adding fuel or performing

service and maintenance functions.

hot!

Contact with

■

The engine of this plate compactor requires an adequate

free flow of cooling air. NEVER operate the plate

compactor in any enclosed or narrow area where free

flow of the air is restricted. If the air flow is restricted it

will cause serious damage to

the plate compactor or engine

and may cause injury to people

and property. Remember the

compactor's engine gives off

DEADLY gases.

■

ALWAYS refuel in a well-ventilated area, away from

sparks and open flames.

components can cause serious burns.

■

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate the plate compactor under the influence

or drugs or alcohol.

■

■

NEVER disconnect any

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death! Disconnection of any of these

devices will void all warranties.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any

accident due to equipment modifications. Unauthorized

equipment modification will void all warranties.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS check all the bolts on the plate compactor for

tightness.

"emergency or safety devices"

.

l

■

■

■

■

■

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT smoke around or near the

machine. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a

hot engine.

NEVER operate the plate compactor in

an explosive atmosphere or near

combustible materials. An explosion or

fire could result causing severe

bodily

harm or even death.

Topping-off to filler port is dangerous, as it tends to spill

fuel.

ALWAYS store the plate compactor in a clean, dry

location out of the reach of children.

NEVER run engine without air cleaner. Severe engine

damage may occur.

NEVER leave the plate compactor unattended, turn off

engine.

CAUTION must always be observed while servicing this

plate compactor. Rotating parts can cause injury if

contacted.

PAGE 8 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

MVC-88VGH/VGHW PLATE COMPACTOR — RULES FOR SAFE OPERATION

Loading and Unloading (Crane):

■

Before lifting, make sure that machine parts (hook and

vibration insulator) are not damaged and screws are not

loosened or lost.

■

ALWAYS make sure crane or lifting device has been

properly secured to the hook of guard frame on compactor.

■

NEVER lift the machine while the engine is running.

■

Use adequate lifting cable (wire or rope) of sufficient

strength.

■

Use one point suspension hook and lift straight upwards.

■

NEVER allow any person or animal to stand underneath

the machine while lifting.

■

Try not to lift machine to unnecessary heights.

Transporting

■

ALWAYS shutdown engine before transporting.

■

Tighten fuel tank cap securely and close fuel cock to

prevent fuel from spilling.

■

Drain fuel when transporting compactor over long

distances or bad roads.

■

ALWAYS tie down the compactor during transportation

by securing the compactor's guard frame with rope.

Maintenance Safety:

■

■

■

■

■

■

■

Emergencies:

■

■

■

NEVER lubricate components or attempt service on a

running machine.

ALWAYS allow the machine a proper amount of time to

cool before servicing.

Keep the machinery in proper running condition.

Fix damage to the machine immediately and always

replace broken parts.

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, fuel and

fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

ALWAYS know the location of the

nearest

ALWAYS know the location of the

nearest

In emergencies

of the nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in the case of an

emergency.

fire extinguisher

first aid kit

always

.

.

know the location

keep a phone on the job site

and

fire department

.

. This

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 9

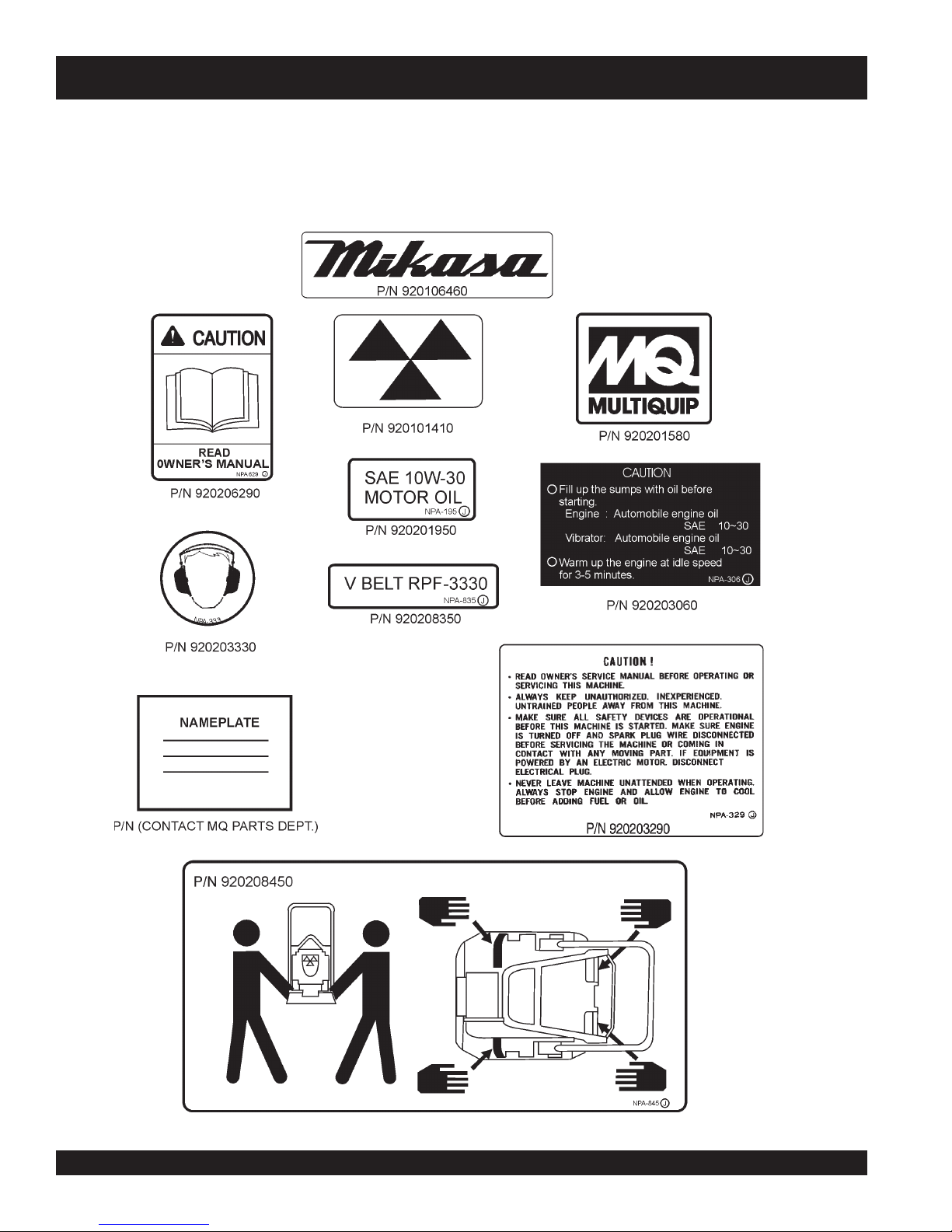

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION AND SAFETY DECALS

Machine Safety Decals

The MVC-88VGH/VGHW Plate Compactor is equipped with a number of safety decals. These decals are provided for operator

safety and maintenance information. The illustration below shows these decals as they appear on the machine. Should any of these

decals become unreadable, replacements can be obtained from your dealer.

l

PAGE 10 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

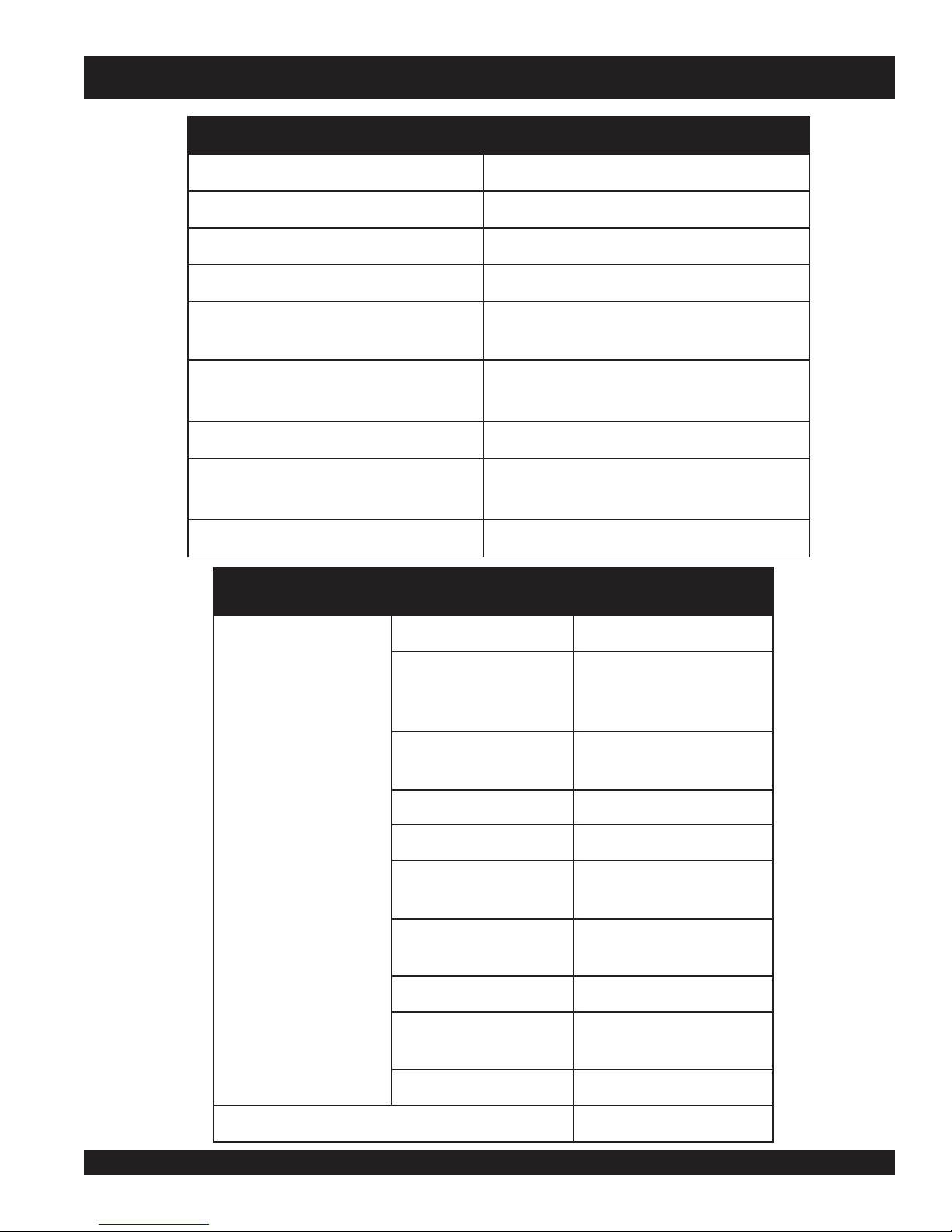

MVC-88VGH/VGHW PLATE COMPACTOR — SPECIFICATIONS

)rotcapmoC(snoitacificepS.1ELBAT

sledoMWHGV88-CVM/HGV88-CVM

ecroFlagufirtneC)gk9.465,1(.sbl054,3

VforebmuNnim/snoitarbiv008,5

snoitarbi

deepSgnilevarT)nim/sretem71(nim/.tf65

)WxL(eziSetalP

)

HGV(thgieWgnitarepO

)WHGV(thgieWgnitarepO

yticapaCknaTleuF)sretil6.3(.tq

yticapaCknaTretaW

ylnOledoMWHGV

noitcapmoCfOaerA.xaM.rh/.tf.qs0085

ledoM2XMQ1U061XGADNOH

epyT

.ni7.02x7.91

mm525.x005.

).gk0.98(.sbl691

).gk5.89(.sbl712

8.3

)sretil0.31(.tq7.31

)enignE(snoitacificepS.2elbaT

elgniS,ekorts4delooc-riA

latnoziroH,VHO,rednilyC

enignEenilosaGtfahS

SXeroB

ekort

tnemecalpsiD)ni-uc9.9(cc361

tuptuOxaM.M.P.R0063/.P.H5.5

enignE

yticapaCknaTleuF

leuF

yticapaCliOebuL)stq36.0(sretil06.

tnoCdeepS

thgieWteNyrD

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 11

dohteMlor

dohteMgnitratStratSlioceR

.ni8.1x.ni7.2

)mm54xmm86(

llag.S.U59.0.xorppA

sno

)sretil6.3(

elibomotuAdedaelnU

enilosaG

thgiew-ylFlagufirtneC

epyT

).gK51(sbl33

MVC-88VGH/VGHW PLATE COMPACTOR — GENERAL INFORMATION

Definition of Plate Compactor

The Mikasa MVC-88VGH/VGHW is a walk behind, plate

compactor designed for the compaction of sand, mixed soils

and asphalt. This plate compactor is a powerful compacting tool

capable of applying a tremendous force in consecutive high

frequency vibrations to a soil surface. Its applications include

compacting for road, embankments and reservoirs as well as

backfilling for gas pipelines, water pipelines and cable installation

work.

Vibratory Plates

The vibratory plates of the MVC-88GH/GHW produce low

amplitude high frequency vibrations, designed to compact

granular soils and asphalt.

The resulting vibrations cause forward motion. The engine and

handle are vibration isolated from the vibrating plate.

Frequency/Speed

The compactor's vibrating plate has a frequency range between

5800 vpm (vibrations per minute). The travel speed of the

compactor is approximately 17 meters/minute (56 ft./minute).

Engine

The Mikasa MVC-88VGH/VGHW Plate Compactor is equipped

with a Honda GX160U1QMX2 air cooled, 4-cycle gasoline

engine. The engine drives an eccentric weight at a high speed

to develop a compaction force. In addition this engine is equipped

Oil Alert

with an

before the engine falls below safe engine oil operating limits.

Always be sure to check the engine oil level prior to starting

the engine.

Controls

Before starting the MVC-88VGH/VGHW Plate Compactor identify

and understand the function of the controls and components.

system that will automatically stop the engine

l

PAGE 12 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

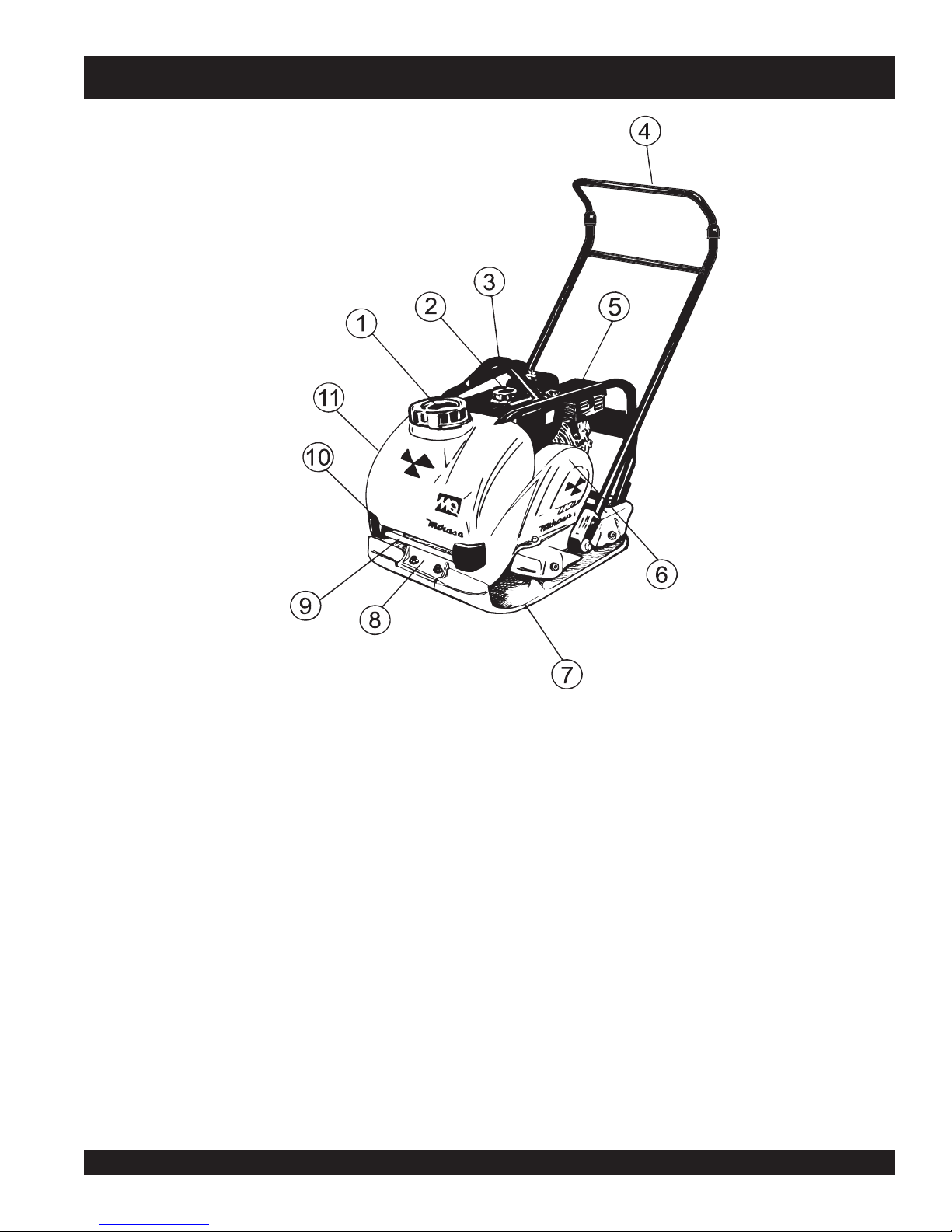

MVC-88VGH/VGHW PLATE COMPACTOR — COMPONENTS (COMPACTOR)

Figure 1. Plate Compactor Controls

Figure 1 shows the location of the basic controls and components

of the MVC-88VGH/VGHW Plate Compactor. The function of

each control is described below:

1. Water Tank Cap (VGHW Only) – Remove this cap to add

water to the water tank.

2. Fuel Tank Cap – Remove this cap to add fuel.

3. Lifting Bale – When lifting of the compactor is required

either by forklift, crane etc., tie rope or chain around this

lifting point.

4. Handle Bar – When operating the compactor use this

handle bar to manuever the compactor.

5. Gasoline Engine – This plate compactor uses a HONDA

GX160U1QMX2 engine. Refer to the HONDA owner's

manual for engine information and related topics.

6. Belt Cover – Remove this cover to gain acess to the V-belts.

NEVER run the compactor without the V-belt cover. If the Vbelt cover is not installed, the possibility exists that your

hand may get caught between the V-belt and clutch, causing

serious injury and bodily harm.

7. Vibrating Plate – A flat, open plate made of durable cast

iron construction used in the compacting of soil.

8. Vibration Case – Encloses the eccentric, gears and

counter weights.

9. Water Tube (Sprinkler) – Supplies water to the soil via a

splash plate.

10. Water Shut-Off Valve – Turn this valve downward to let

water flow from the water tank to the water tube.

11. Water Tank (VGHW only) – Holds 13.7 quarts of water

(removable, no tools required).

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 13

MVC-88VGH/VGHW PLATE COMPACTOR — COMPONENTS ( ENGINE)

Figure 2. Engine Controls & Components

ENGINE COMPONENTS

The engine (Figure 2) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturers Engine

manual for instructions & details of operation and servicing.

1. Fuel Filler Cap – Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

DANGERDANGER

DANGER

DANGERDANGER

Adding fuel to the tank should be done only when

the engine is stopped and has had an opportunity

to cool down. In the event of a fuel spill, DO NOT

attempt to start the engine until the fuel residue

has been completely wiped up, and the area surrounding the

engine is dry.

2. Throttle Lever – Used to adjust engine RPM speed (lever

advanced forward -

FAST

).

3. Engine ON/OFF Switch – ON position permits engine

starting, OFF position stops engine operations.

4. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

SLOW

Explosive

Fuel Hazard

l

, lever back toward operator -

5. Fuel Valve Lever – OPEN to let fuel flow, CLOSE to stop

the flow of fuel.

6. Choke Lever – Used in the starting of a cold engine, or in

cold weather conditions. The choke enriches the fuel

mixture.

7. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element.

NOTE

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operating. NEVER operate the engine with the

muffler removed.

8. Spark Plug – Provides spark to the ignition system. Set

spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch) Clean

spark plug once a week.

9. Muffler – Used to reduce noise and emissions.

10. Fuel Tank – Holds unleaded gasoline. For additional

information refer to engine owner's manual.

WARNINGWARNING

WARNING

WARNINGWARNING

Operating the engine without an air

filter, with a damaged air filter, or a filter

in need of replacement will allow dirt

to enter the engine, causing rapid

engine wear.

Burn Hazard

PAGE 14 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

MVC-88VGH/VGHW PLATE COMPACTOR — INSPECTION

Before Starting

1. Read safety instructions at the

beginning of manual.

2. Clean the compactor, removing

dirt and dust, particularly the

engine cooling air inlet, carburetor

and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

5. Check fastening nuts and bolts for tightness. Loosened

screws or bolts due to vibration, could lead to unexpected

accident.

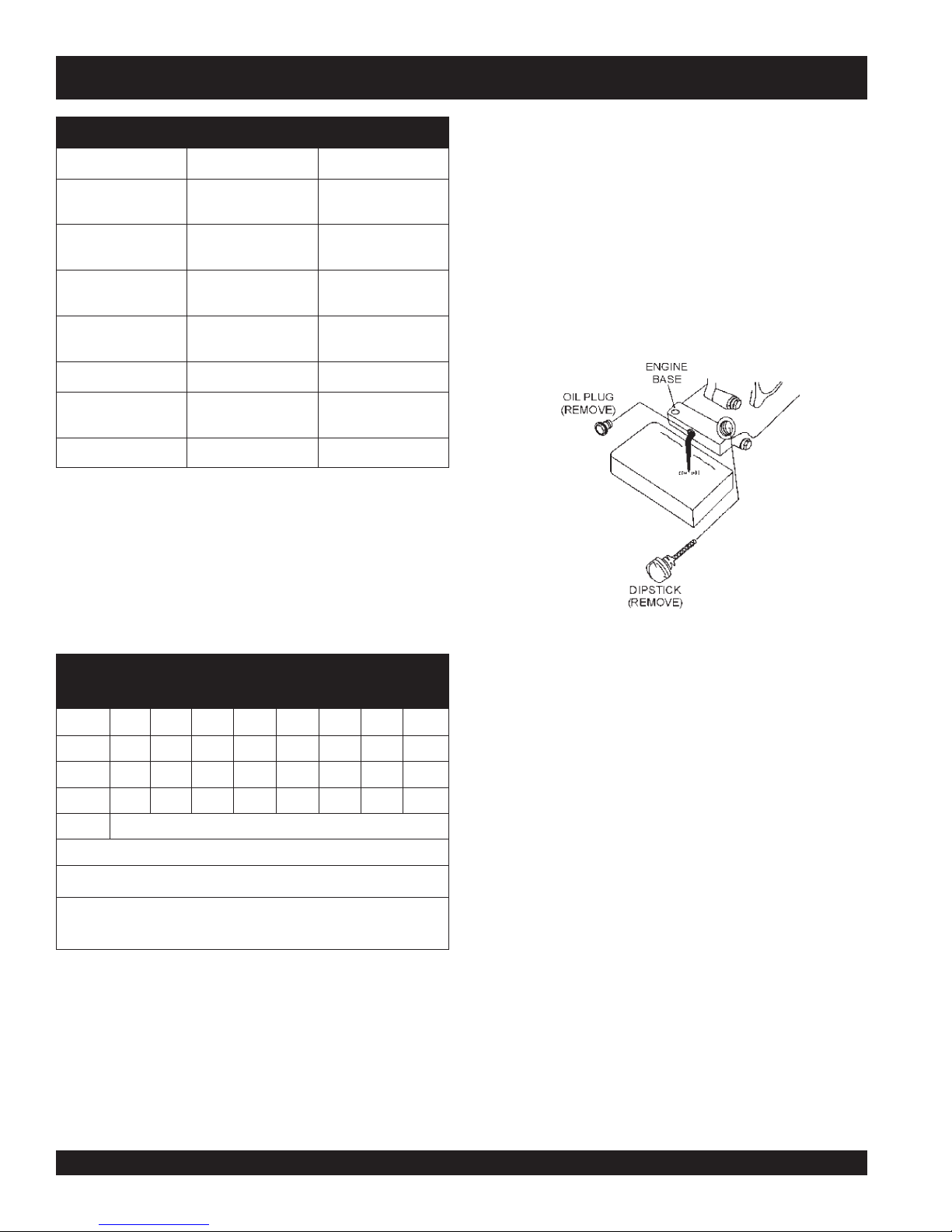

Engine Oil Check

1. To check the engine oil level, place the pump on secure

level ground with the engine stopped.

2. Remove the filler dipstick from the engine oil filler hole

(Figure 3) and wipe clean.

NOTE

Adding fuel to the fuel tank should be done only

when the engine is stopped and has had an

opportunity to cool down. In the event of a fuel

spill, DO NOT attempt to start the engine until the

fuel residue has been completely wiped up, and the area

surrounding the engine is dry. DO NOT attempt to refuel the

compactor if the engine is

The Oil Alert System will automatically

stop the engine before the engine falls

below safe limits. Always be sure to

check the engine oil level prior to

starting the engine.

epyTliO.3elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

DANGERDANGER

DANGER

DANGERDANGER

Explosive

Fuel Hazard

hot! or running

.

Fuel Check

Figure 3. Engine Oil Dipstick (Removal)

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 4), fill to the edge of the oil filler

hole with the recommended oil type (Table 3). Maximum oil

capacity is 0.63 quarts (0.60 liters)

Figure 4. Engine Oil Dipstick (Oil Level)

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 15

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if the fuel level is low. If fuel is low,

replenish with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel

immediately!

MVC-88VGH/VGHW— INSPECTION

V-Belt Check

CAUTICAUTI

CAUTION

CAUTICAUTI

NEVER attempt to check the V-belt with the engine running.

Severe injury can occur of your hand (Figure 5) gets caught

between the V-belt and the clutch. Always use safety gloves.

CLUTCH

PULLEY

VIBRATOR

PULLEY

Figure 5. V-Belt Hazard

2. The V-belt tension is proper if the V-belt bends 10 to 15 mm

3. A loose V-belt will decrease the power transmission output,

4. If the V-belt becomes worn or loose, replace it.

(Figure 7) when depressed with finger at midway between

the clutch and vibration pulley shafts.

Figure 7. V-Belt Tension

causing reduced compaction and premature wear of the

belt.

1. To check the V-belt tension, remove the three bolts that

secure the belt cover to the frame as shown in Figure 6.

l

Vibrator Oil Check

1. Place the MVC-88VGH/VGHW plate compactor horizontally

on a flat surface. Make sure the compactor is level when

checking the oil in the vibrator assembly.

2. Check vibrator oil level by removing the plug (vibrator oil gauge)

as shown in Figure 8. The oil level should be up to the oil plug.

The vibrator holds 140 cc (approximately 1 pint). IMPORTANT,

if oil is required, replace using only SAE10W-30 motor oil.

Figure 8. Vibrator Oil Plug

Figure 6. V-Belt Cover Removal

PAGE 16 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

MVC-88VGH/VGHW— INITIAL START-UP

CAUTICAUTI

CAUTION

CAUTICAUTI

DO NOT attempt to run the compactor until

the Safety and Initial Start-upsectionshave

been read and understood.

1. Place the

2. Place the

position.

fuel valve lever

Figure 9. Fuel Valve Lever

Engine ON/OFF switch

(Figure 9) in the "ON" position.

D

(Figure 10) in the "ON"

NOTE

4. Place the

and

throttle lever

slow

.

The CLOSED position of the

choke lever enriches the fuel

mixture for starting a COLD

engine. The OPEN position

provides the correct fuel

mixture for normal operation

after starting, and for restarting

a warm engine.

(Figure 12) halfway between

fast

Figure 10. Engine ON/Off Switch

3. Place the

Choke Lever

(Figure 11) in the "OPEN" position.

Nnnn

Figure 12. Throttle Lever

5. Grasp the starter grip (Figure 13) and slowly pull it out. The

resistance becomes the hardest at a certain position, corresponding the compression point. Rewind the rope a little from

that point and pull out sharply.

CAUTICAUTI

CAUTION

CAUTICAUTI

DO NOT pull the starter rope all the way to the end

DO NOT release the starter rope after pulling. Allow it to

rewind as soon as possible.

D

Figure 11. Choke Lever

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 17

Figure 13. Starter Grip

MVC-88VGH/VGHW— INITIAL START-UP/OPERATION

6. If the engine has started, slowly return the choke lever

(Figure 11) to the

started repeat steps 1 through 5.

7. Before the compactor is put into operation run the engine for

3-5 minutes.

8. Check for abnormal engine noises or fuel leaks.

Operation

CAUTICAUTI

CAUTION

CAUTICAUTI

Make sure to follow all safety rules referenced in the safety

section of this manual before operating compactor. Keep work

area clear of debris and other objects that could cause

damage to the compactor or bodily injury.

1. Once the engine has started, move the engine throttle lever

quickly to the

2. With the throttle lever in the fast position, the engine speed

should be around 2,300 RPM, therefore engaging the centrifugal clutch.

CLOSED

fast

position.

position. If the engine has not

Stopping the Engine

NEVER stop the engine suddenly while working at high

speeds.

1. Place the

listen for the engine speed to decrease.

2. Place the

" position.

3. Place the

CAUTICAUTI

CAUTION

CAUTICAUTI

throttle lever

Engine ON/OFF switch

fuel valve lever

(Figure 12) in

(Figure 9) in the "OFF" position.

D

slow

position, and

(Figure 10) in the "

OFF

ALWAYS

NOTE

5. Firmly gasp the compactor's handle bar with both hands , the

compactor will begin moving forward.

6. Slowly walk behind the compactor and be on the lookout for

any large objects or foreign matter that might cause damage

to the compactor or bodily injury.

7. Compactor traveling speed may drop on soils which contain

clay, however there may be cases where traveling speed

drops because the compaction plate does not leave the

ground surface easily due to the composition of the soil. To

rectify this problem do the following:

■

Check the bottom plate to see if clay or equivalent material

has been lodge in the plate mechanism. If so, wash with

water and remove.

■

Remember the compactor does not work as efficiently on

clay or soils that have a high moisture content level.

quickly without hesitation,

because increasing the engine

speed slowly causes the clutch

to slip.

move the throttle lever

l

■

If the soil has a high moisture level, dry soil to appropriate

moisture content level or carry out compaction twice.

PAGE 18 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

MVC-88VGH/VGHW— MAINTENANCE

CAUTICAUTI

CAUTION

CAUTICAUTI

Inspection and other services should

always

be carried out

on hard and level ground with the engine shutdown.

Inspection and Maintenance Service Tables.

1. To make sure your plate compactor is always in good

working condition before using, carry out the maintenance

inspection in accordance with Tables 4 through 6.

TSRIF

)3(NOITPIRCSEDNOITAREPOEROFEB

KCEHCX

liOenignE

EGNAHCX

HTNOM

RO

CAUTICAUTI

CAUTION

CAUTICAUTI

These inspection intervals are for operation under normal

conditions. Adjust your inspection intervals based on the

number hours plate compactor is in use, and particular

working conditions.

CAUTICAUTI

CAUTION

CAUTICAUTI

Fuel piping and connections should be replaced every 2

years.

eludehcSecnanetniaMenignE.4elbaT

YREVE

SHTNOM3

RO

.SRH01

.SRH52

YREVE

SHTNOM6

RO

.SRH05

YREVE

RAEY

RO

.SRH0

01

YREVE

SRAEY2

RO

.SRH002

KCEHCX

renaelCriA

EGNAHC)1(X

stloB&stuNllA

gulPkrapS

sniFgnilooCKCEHCX

retserrAkrapSNAELC X

knaTleuFNAELC X

retliFleuFKCEHC X

deepSeldITSUJ

ecnaraelCevlaVTSUJDA-KCEHC )2(X

senilleuFKCEHC )2()yrassecenfiecalper(sraey2yrevE

neuqerferomecivreS)1( YTSUD .saera

fInethgit-eR

yrasseceN

NAELC-KCEHCX

ECALPER X

DA-KCEHC )2(X

vresebdluohssmetiesehT)2(

X

nidesunehwylt

yllacinahcemeradnaslootreporpehtevahuoysselnu,relaedecivresruoyybdeci

.serudecorpecivresroflaunaMpohSADNOHehtotrefeR.tneiciforp

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 19

amreporpenimretedotnoitarepofosruohgol,esulaicremmocroF)3(

.slavretniecnanetni

MVC-88VGH/VGHW — MAINTENANCE

metI noitarepOfosruoH skrameR

)kcehcgnitratS(

tsolrodenesooL

swercs

trapynafoegamaD

trapmetsys

kcehcliorotarbiV sruoh001yrevE .91egapeeS

liorotarbiV

tnemecalper

kcehc)hctulc(tleb-V ruoh002yrevE .91egapeeS

)yad

)yad

)yad

gnillortnocfonoitcnuF

)yad

Daily Service

■

Check for leakage of fuel or oil.

■

Check engine oil.

yreve(sruoh8yrevE

yreve(sruoh8yrevE

yreve(sruoh8yrevE

yreve(sruoh8yrevE

sruoh002yrevE .91egapeeS

NOITCEPSNIENIHCAM.5ELBAT

ENGINE OIL

1. Drain the engine oil when the oil is

warm

as shown in

Figure 14.

2. Remove the dipstick and then unscrew the oil plug and

allow the oil to drain into a suitable container.

3. Replace engine oil with recommended type oil as listed

in Table 3. For engine oil capacity, see Table 2 (engine

specifications). DO NOT overfill.

4. Install drain bolt with sealing washer and tighten securely.

■

Check for loose screws including tightness. See Table 6

below (tightening torque ), for retightening.

.6ELBAT

mm6 mm8 mm01 mm21 mm41 mm61 mm81 mm02

lairetaM

T4 07 051 003 005 057 001,1 004,1 000,2

T8-6 001 052 005 008 003,1 000,2 007,2 008,3

T11 051 004 008 002,1 000,2 009,2 002,4 006,5

* )mm01(007~056)mm8(053~003)mm6(001

l

)munimulafositrap-retnuocesacnI(*

.wercsdna

Figure 14. Engine Oil (Draining)

ENGINE AIR CLEANER

retemaiD)mc/gk.ni(EUQROTGNINETHGIT

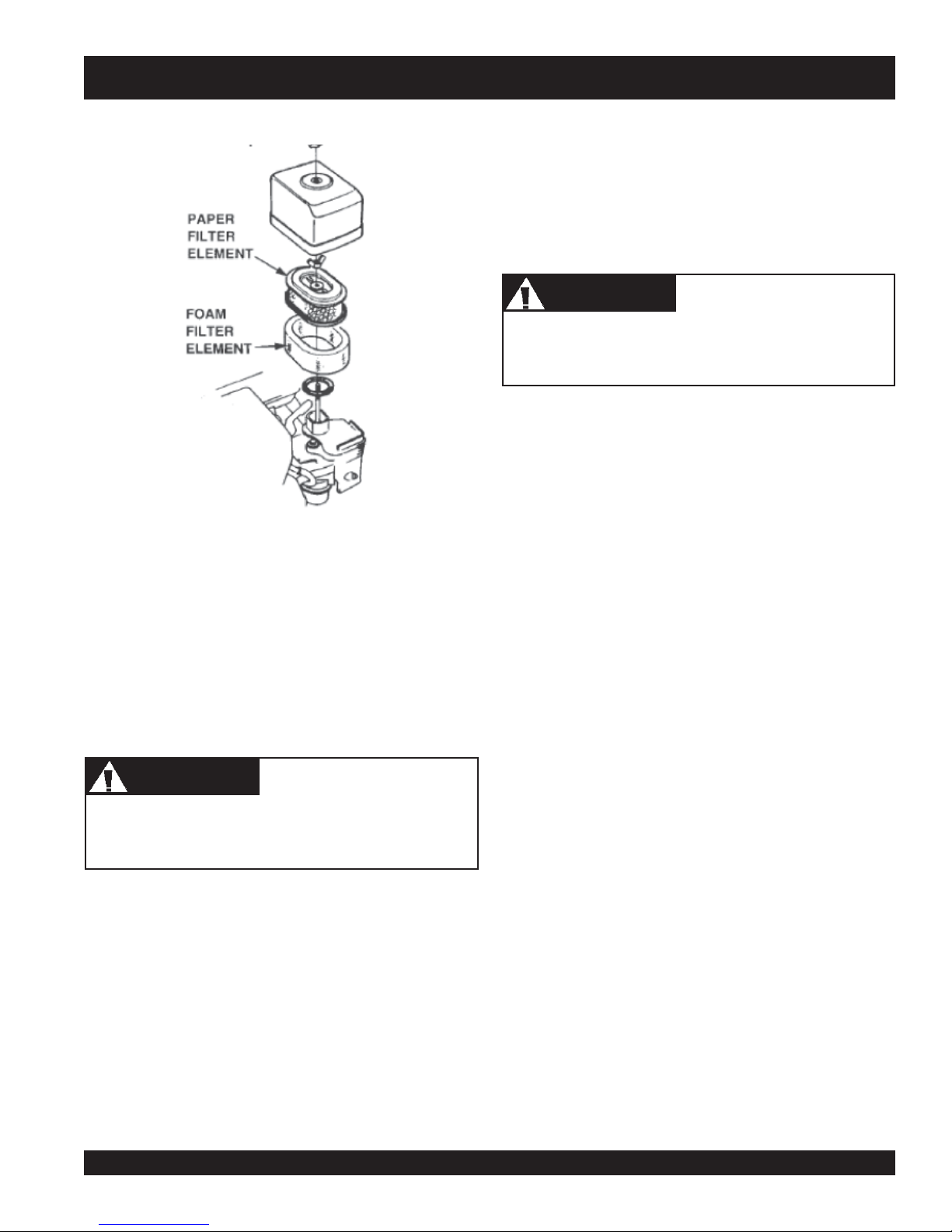

1. Remove the air cleaner cover and foam filter element as

shown in Figure 15.

2. Tap the paper filter element (Figure 15) several times on a

hard surface to remove dirt, or blow compressed air [not

2

exceeding 30 psi (207 kPa, 2.1 kgf/cm

element from the air cleaner case side.

)] through the filter

NEVER

brush off dirt.

Brushing will force dirt into the fibers. Replace the paper filter

element if it is excessively dirty.

)dednahthgirllaeraenihcamsihthtiwesunisdaerhT(

,tlobhcaenodekramsilairetamfoytilauqdnalairetaM

3. Clean foam element in warm, soapy water or nonflammable

solvent. Rinse and dry thoroughly. Dip the element in clean

engine oil and completely squeeze out the excess oil from the

element before installing.

PAGE 20 — MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06)

MVC-88VGH/VGHW— MAINTENANCE

Checking and Replacing the V-Belt and Clutch

1. After 200 hours of operation, remove the upper belt cover to

check the V-belt tension. Tension is proper if the belt bends

about 10 mm when depressed strongly with finger between

shafts. Loose or worn V-belts reduces power transmission

efficiency, causing weak compaction and reduces the life of

the belt itself.

CAUTICAUTI

CAUTION

CAUTICAUTI

Whenever the compactor's vibration becomes weak or lost

during normal operation regardless of operation hours, check

the V-belt and clutch immediately.

■

Replacing the V-belt

Remove the upper and lower belt covers. Engage an offset

wrench (13 mm) or the like to vibrator pulley (lower) fastening

bolt. Engage waste cloth or the like at midway of V-belt on the left

side and while pulling it back strongly, rotate the offset wrench

clockwise so that the V-belt will come off.

Figure 15. Air Cleaner

CHANGING VIBRATOR OIL

1. When changing the vibrator oil, remove the drain plug

located at the bottom- right of the vibrator (Figure 5), and

simply tip the compactor to drain the oil. Note that the oil will

drain more easily while it is hot. Remember to use only

10W-30 motor oil when replacing vibrator oil.

CAUTICAUTI

CAUTION

CAUTICAUTI

NEVER attempt to check the V-belt with the engine running.

Severe injury can occur if your hand (Figure 6) gets caught

between the V-belt and the clutch. Always use safety gloves.

■

Reinstalling the V-belt

Engage V-belt to lower vibrator pulley and push the V-belt to left

side of upper clutch and, in the same manner as in removal,

rotate offset wrench clockwise so that the V-belt goes back on.

■

Checking Clutch

Check the clutch simultaneously with V-belt checking. With belt

removed, check outer drum of the clutch for seizure and "V"

groove for wear or damage with your eyes. Clean the "V" groove

as necessary. Wear of lining or shoe should be checked with

running check. If the shoe is worn, power transmission becomes

deficient and slipping will result.

MVC-88VGH/VGHW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (05/08/06) — PAGE 21

Loading...

Loading...