Page 1

OPERATION AND PARTS MANUAL

SERIES

MODEL MG30T2D

MODEL MG30M2D

PLASTER MORTAR PUMPS

MODEL MG30T3D

MODEL MG30M3D

FIREPROOFING PUMPS

Revision #3 (09/15/11)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

Diesel engine exhaust and some of

PAGE 2 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 3

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 3

Page 4

TABLE OF CONTENTS

Table of Contents .................................................... 4

Parts Ordering Procedures ..................................... 5

Safety Message Slert Dymbols ............................... 6

Rules for Safe Operation .................................... 8-10

Operation and Safety Decals ........................... 12-13

Specifications ........................................................ 14

Dimensions (MG30-M2D Mobile unit) .................. 16

Dimensions (MG30-T2D Tag unit) ....................... 17

General Information ......................................... 18-22

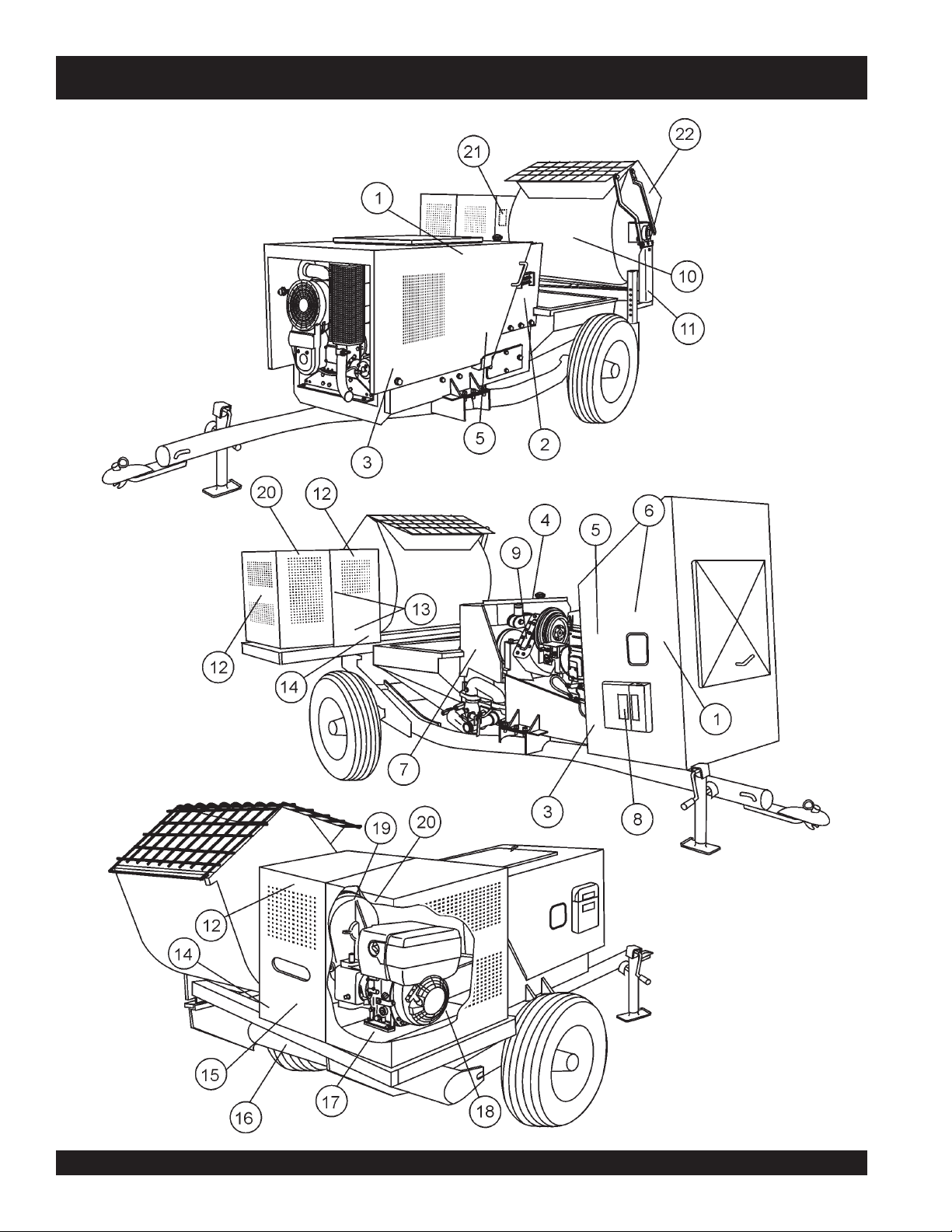

MQ MAYCO MG-30 Mobile/Tag Units

Plaster/Fireproofing Pump

Application........................................................ 23-26

Mixer Major Components ................................. 26-27

MG30 M2D Major Components ....................... 28-29

Hatz 8.5 HP Engine Components .................... 30-31

Pre-Inspection (Mixer) ...................................... 32-34

Initial Start-Up (Mixer Mobile only) ........................ 35

Pre-Inspection (Pump) ..................................... 36-39

Initial Start-Up (Pump) .......................................... 40

Initial Start-Up/Operation ...................................... 41

Remote Operation ................................................. 42

Towing Guidelines ............................................ 43-45

Trailer Safety Guidelines................................... 46-47

Maintenance (Mixer) ........................................ 48-49

Maintenance (Pump) ........................................ 50-53

Troubleshooting (Engine) ...................................... 54

Troubleshooting (Engine/Mixer) ............................ 55

Troubleshooting (Pump) ........................................ 56

Wiring Diagram ................................................ 57-58

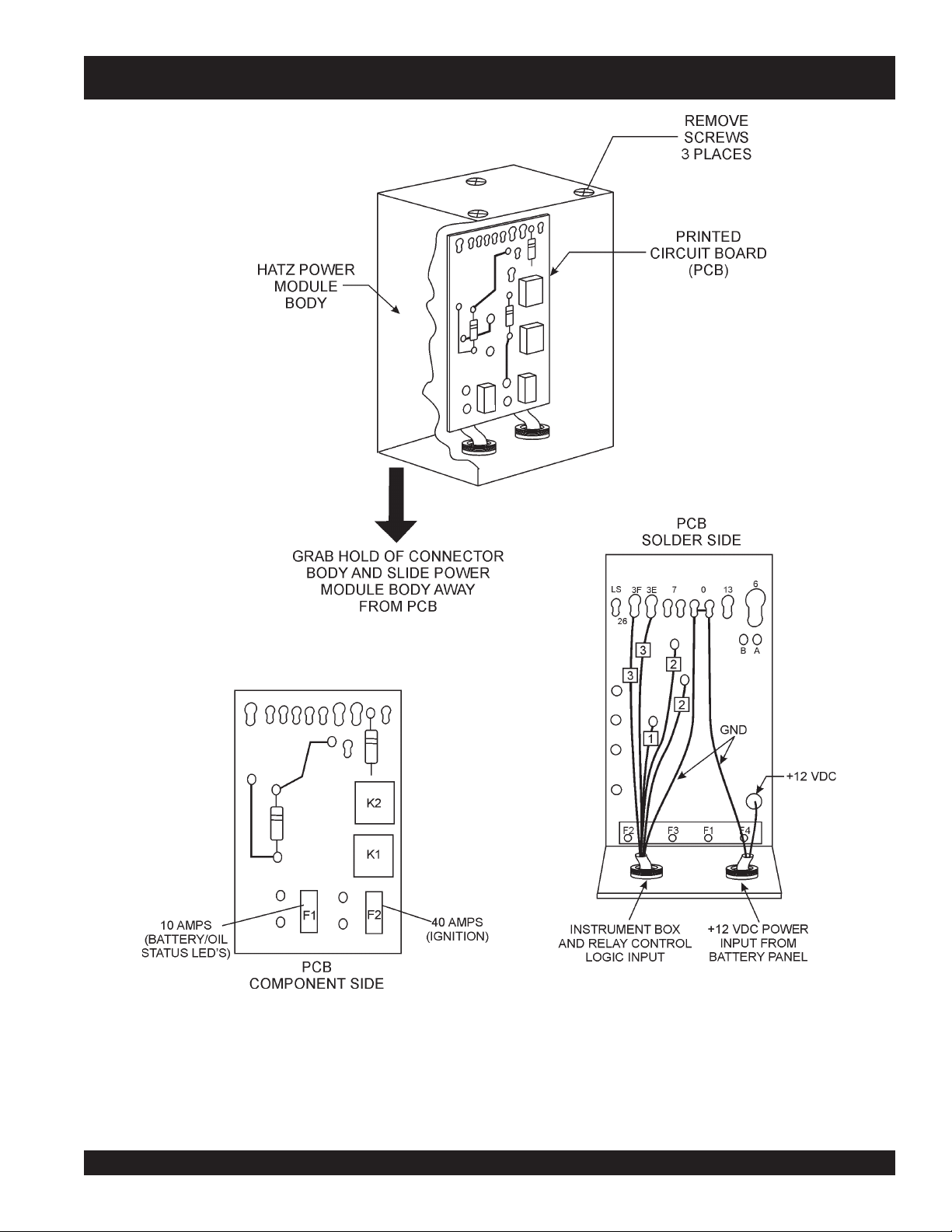

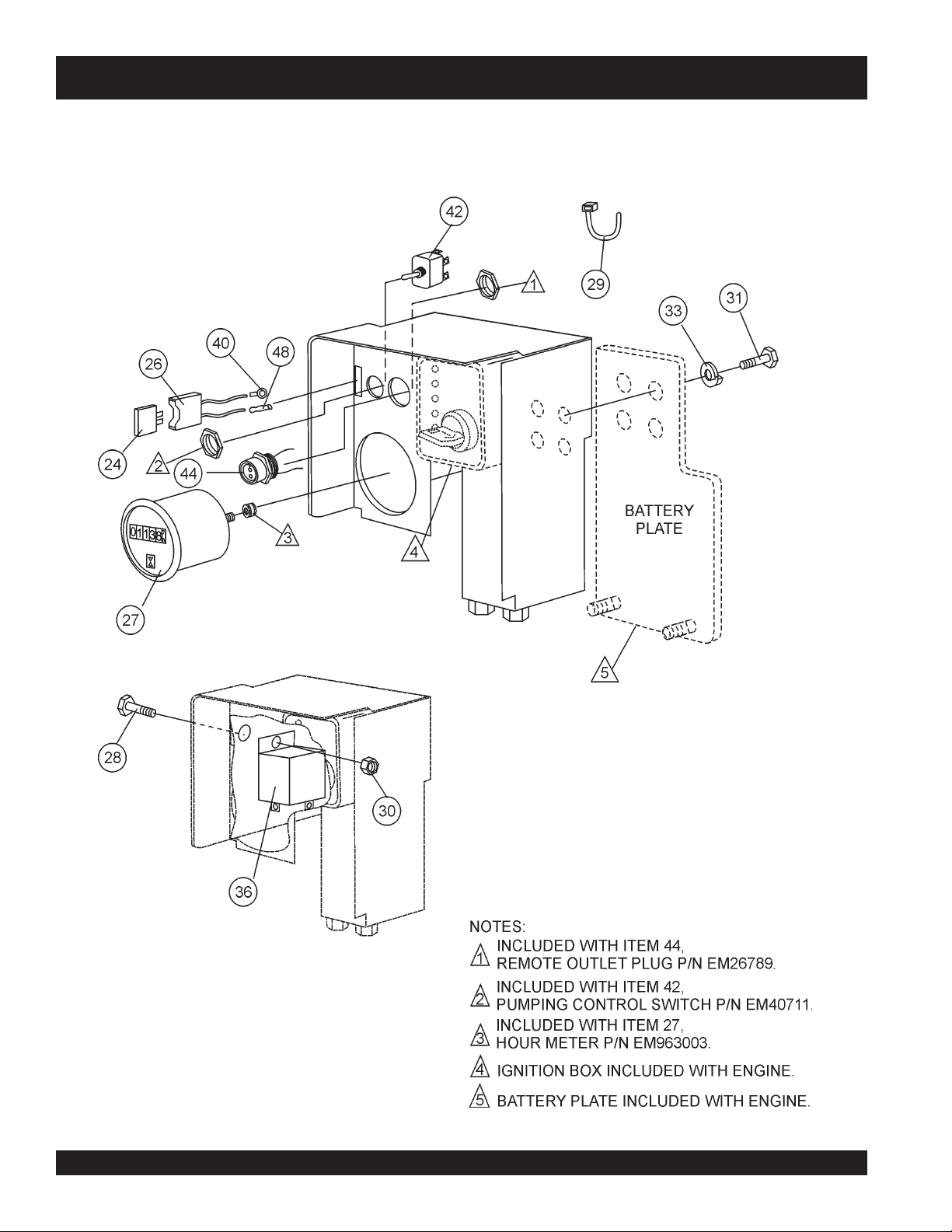

Power Module Layout ............................................ 59

PARTS ILLUSTRATIONS

Explanation of Code in Remarks Column ............. 60

Suggested Spare Parts ......................................... 61

Decal Placement .............................................. 62-63

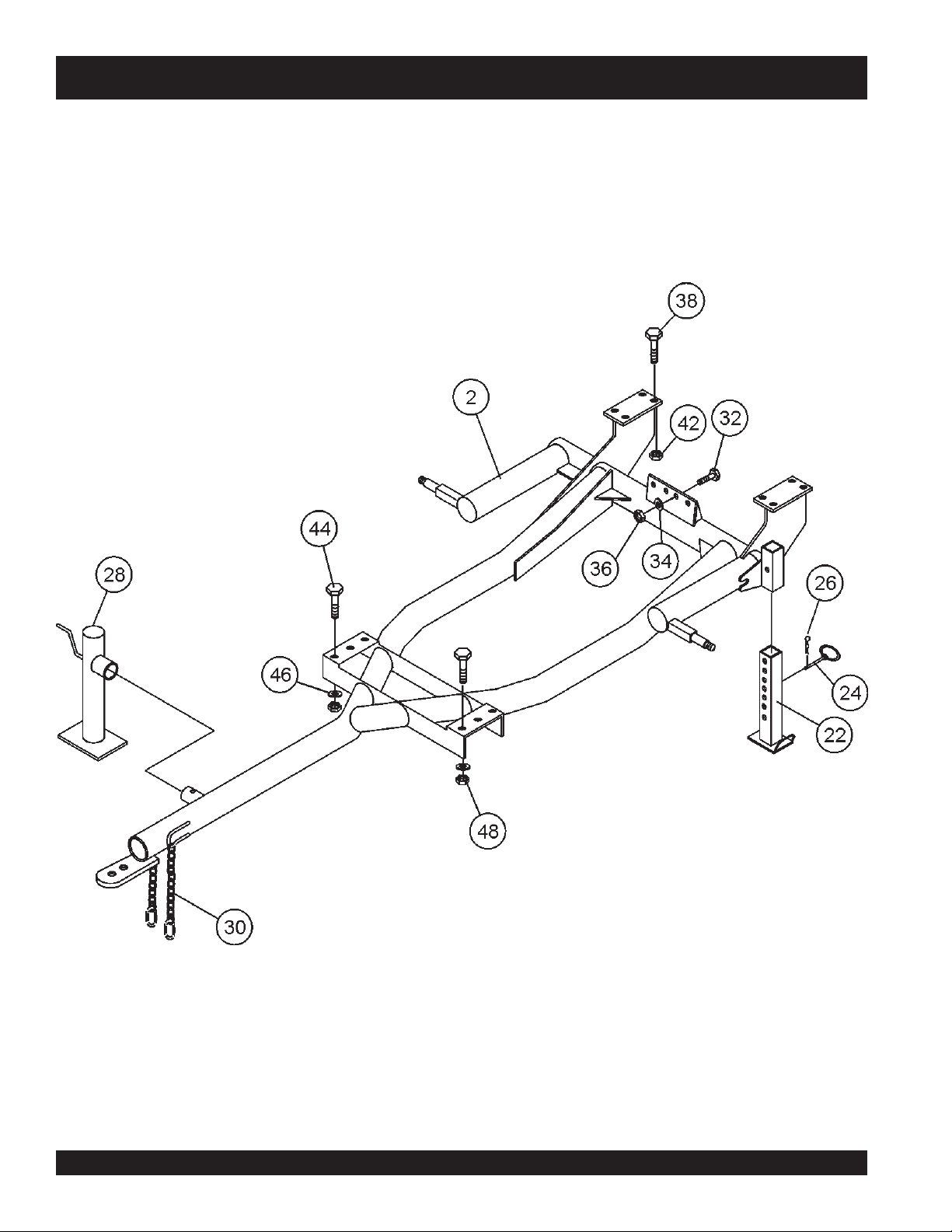

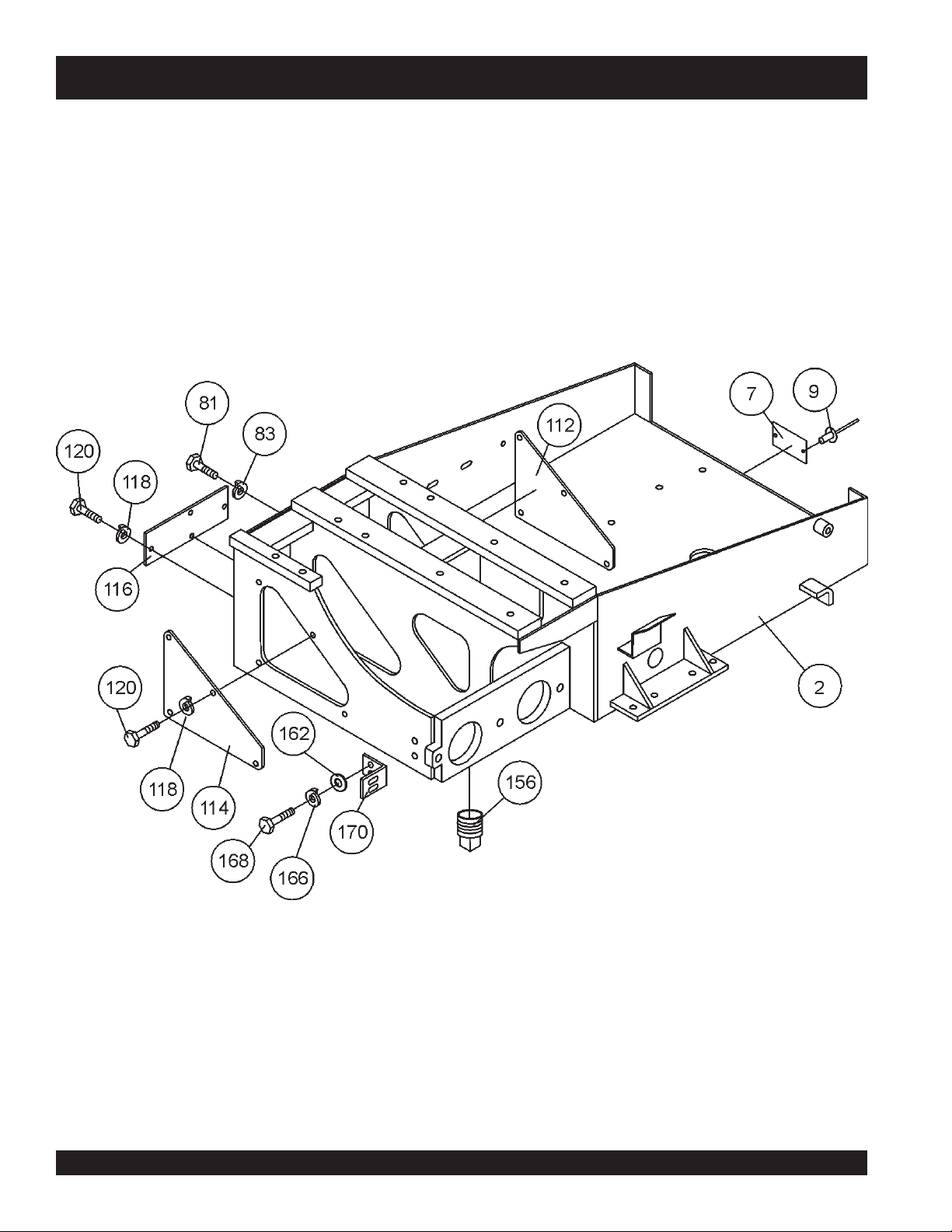

Frame Assembly .............................................. 64-65

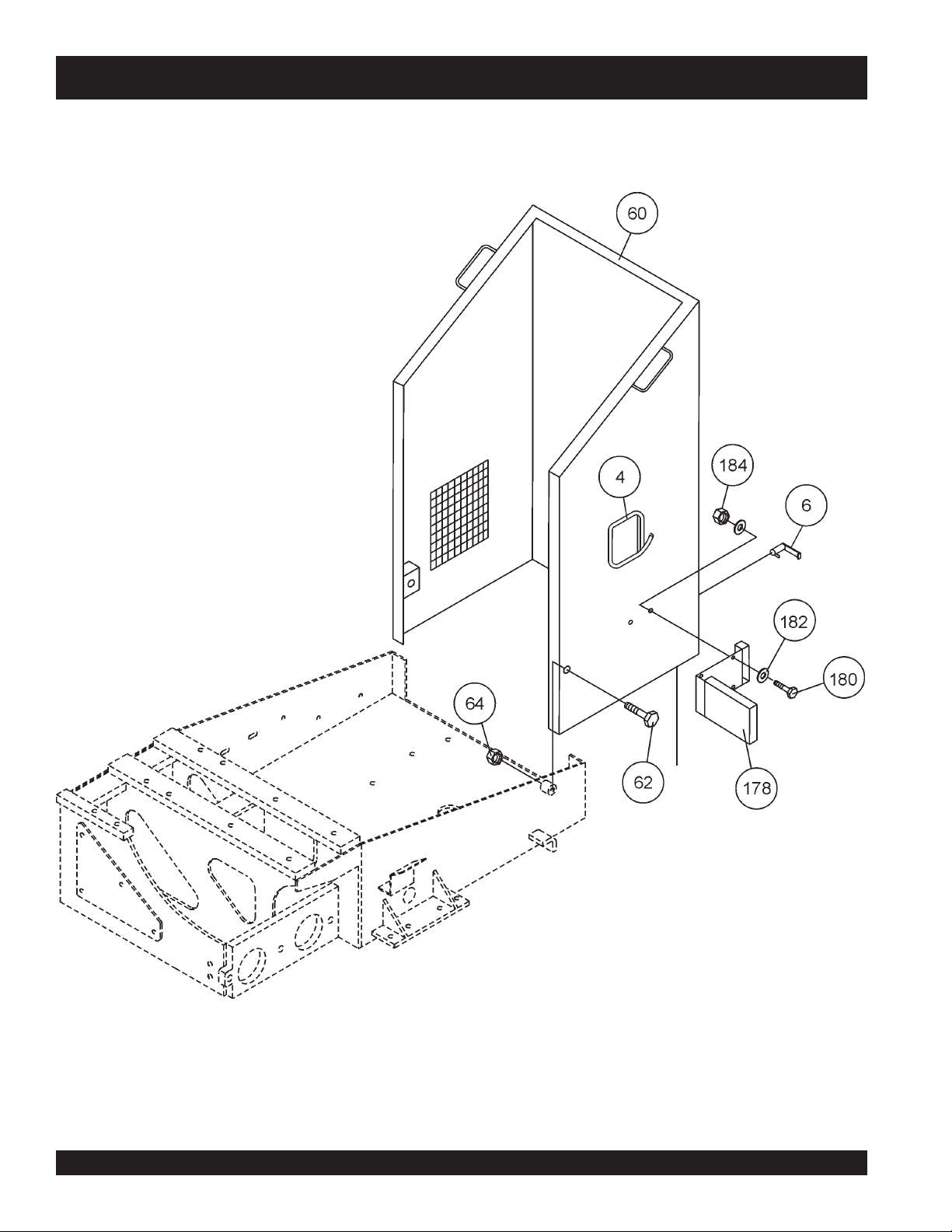

Hood Assembly ................................................ 66-67

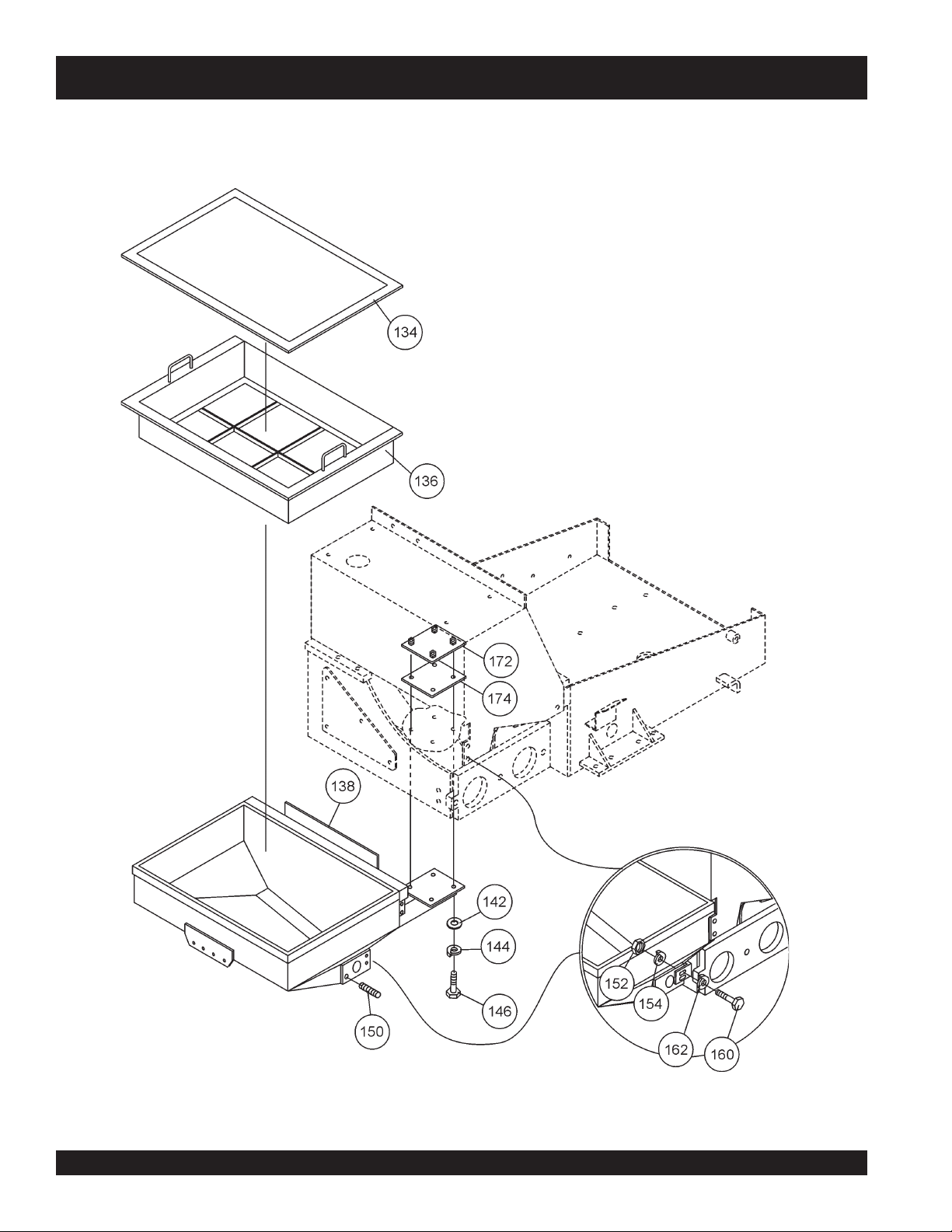

Hopper Assembly ............................................. 68-69

Chassis Assembly ............................................ 70-71

Compressor Assembly ..................................... 72-43

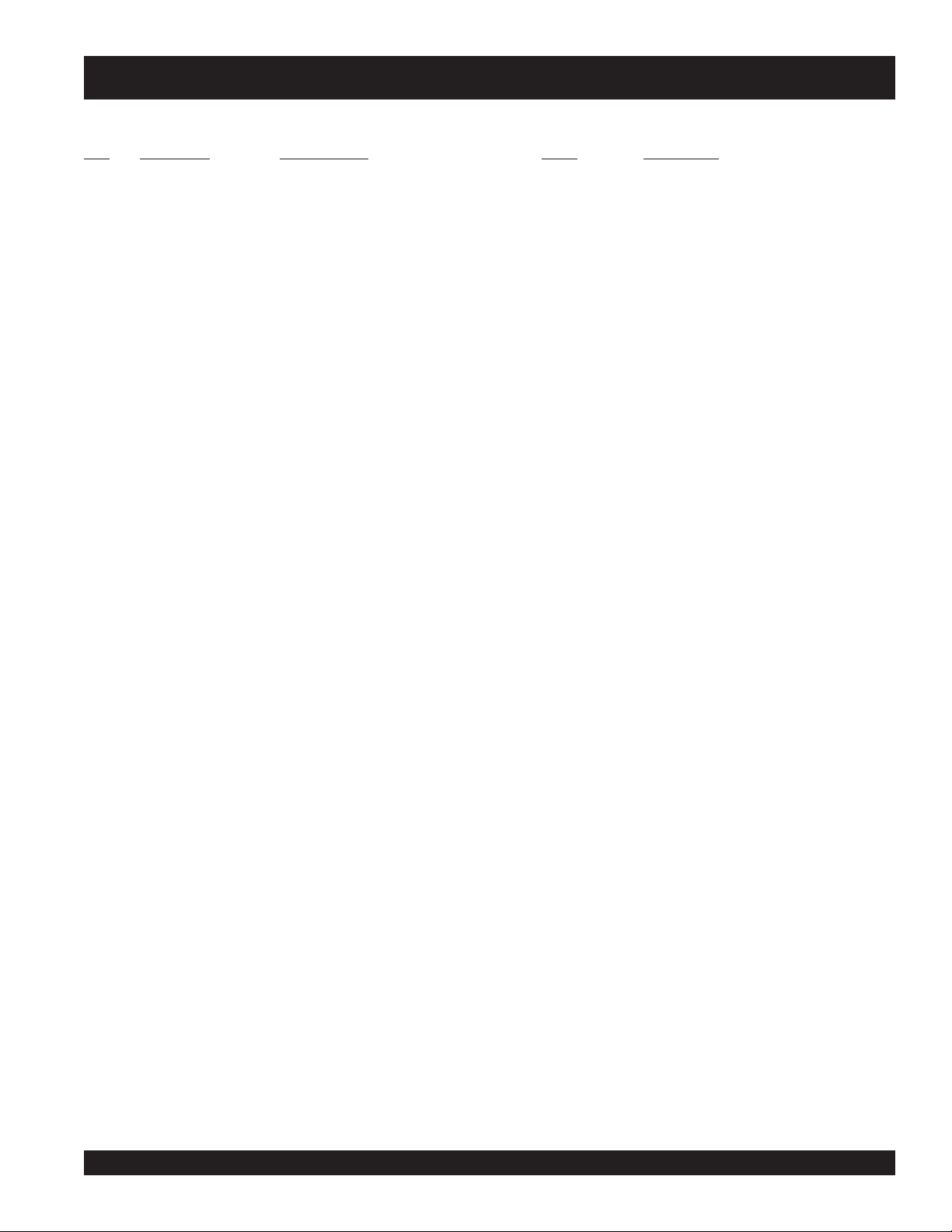

Fuel Tank Assembly ......................................... 74-75

Piston Oiler Tank Assembly .............................. 76-77

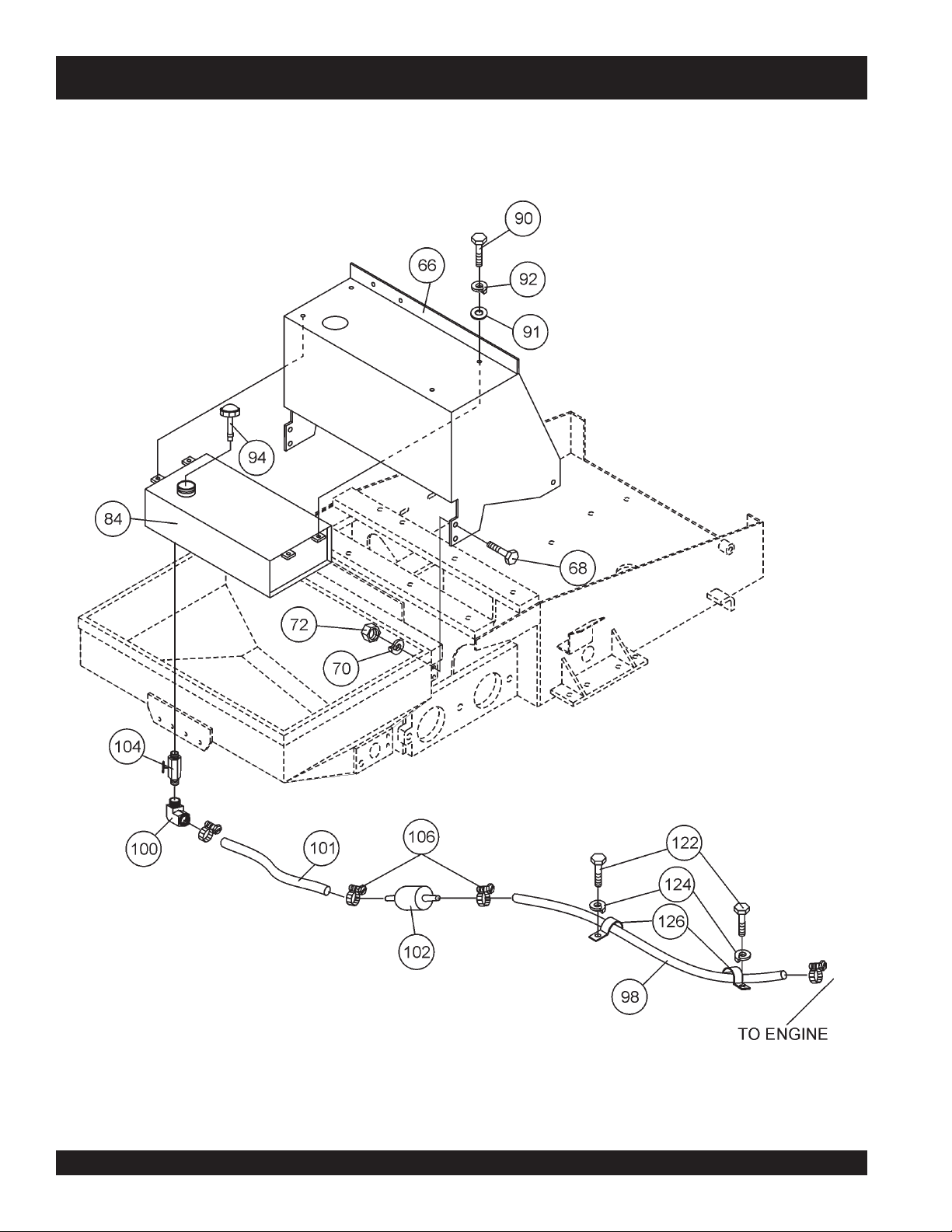

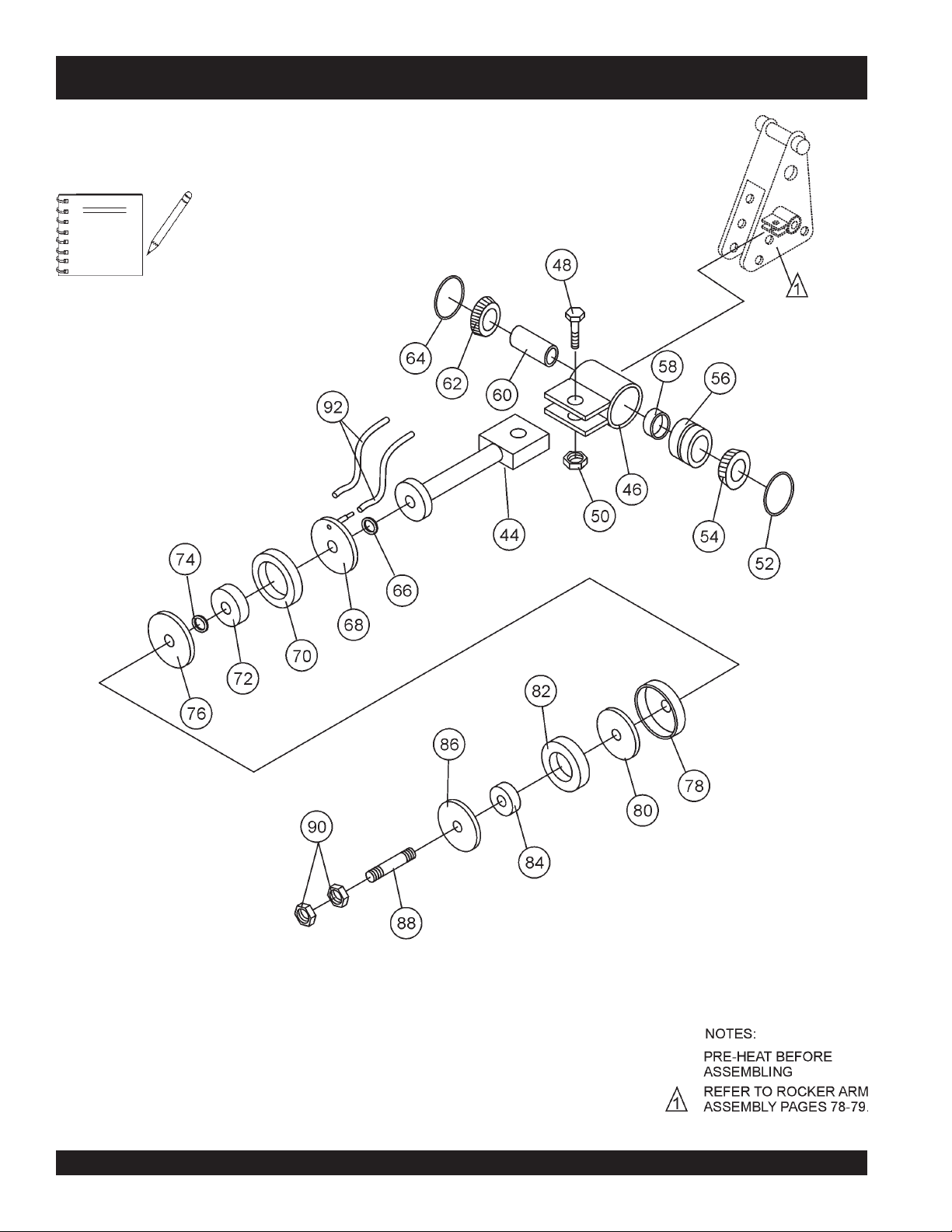

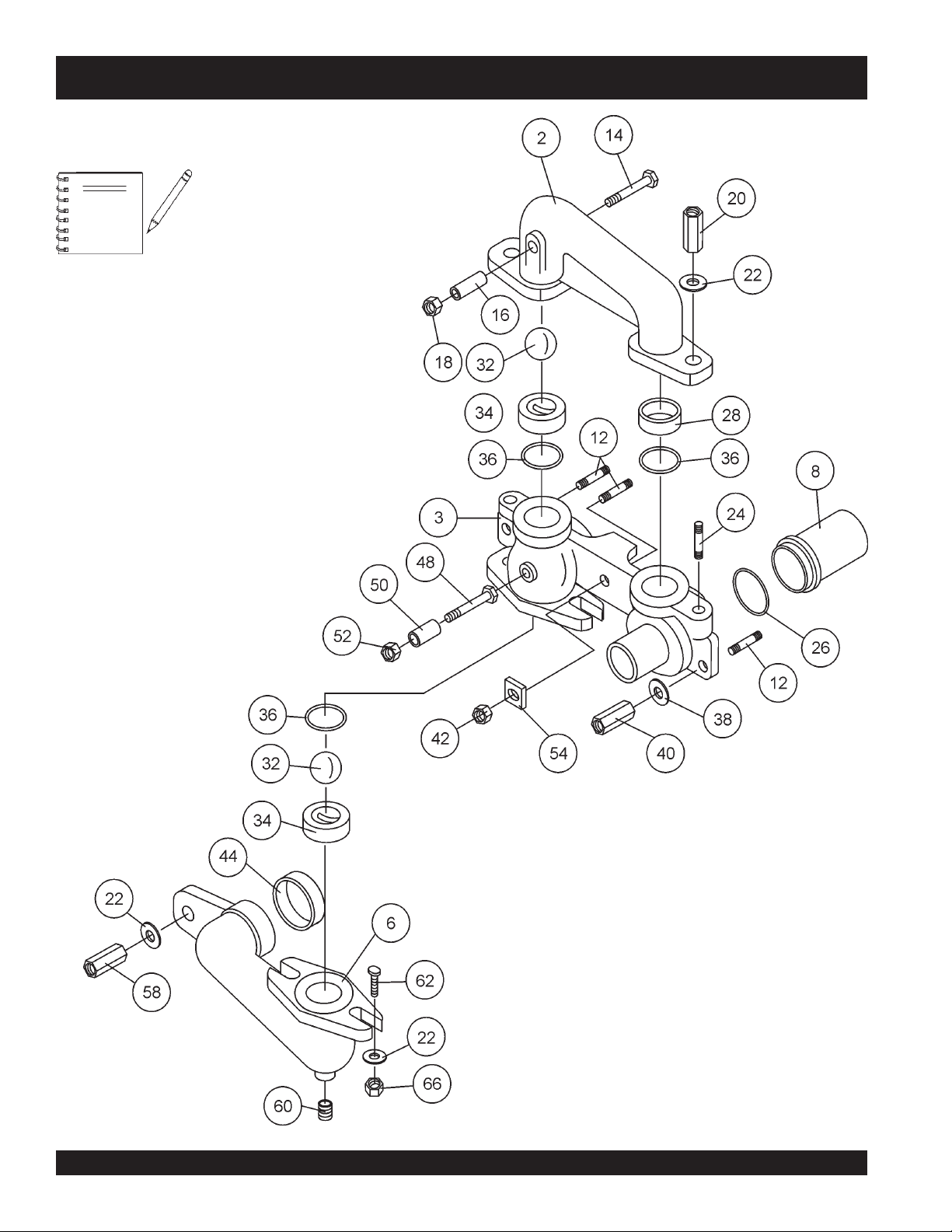

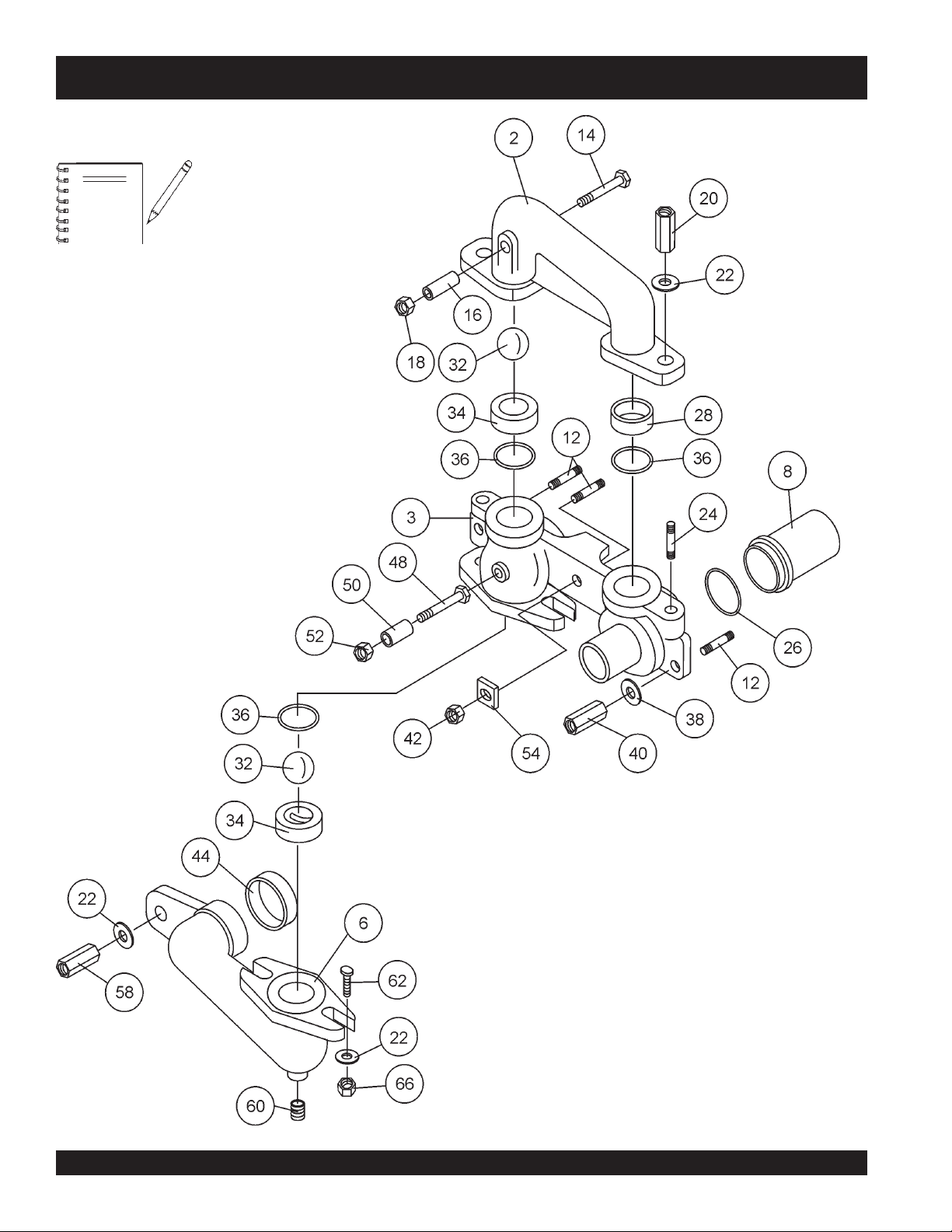

Rocker Arm Assembly ...................................... 78-79

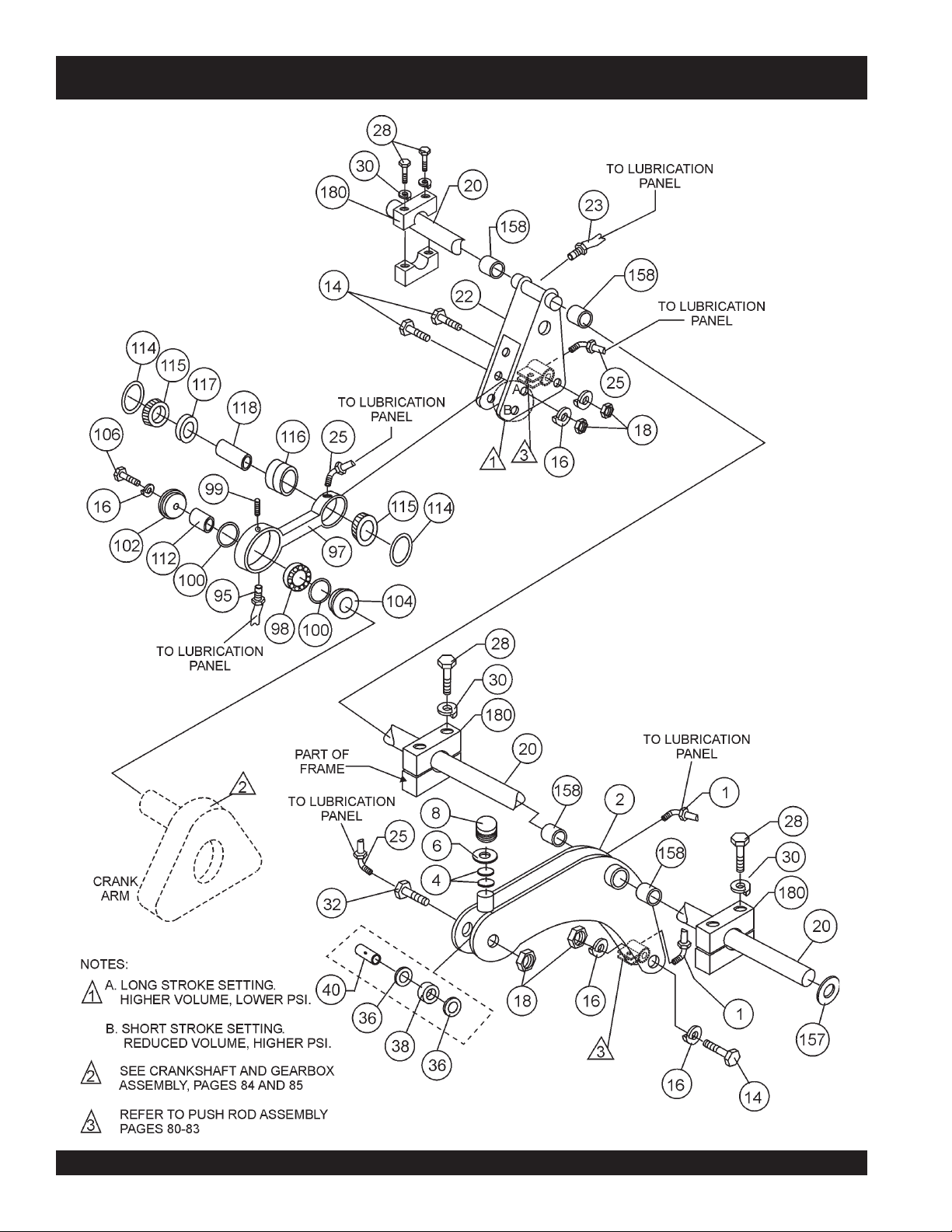

Push Rod (3.5-Inch) Assembly ........................ 80-81

Push Rod (3.75-Inch) Assembly ...................... 82-83

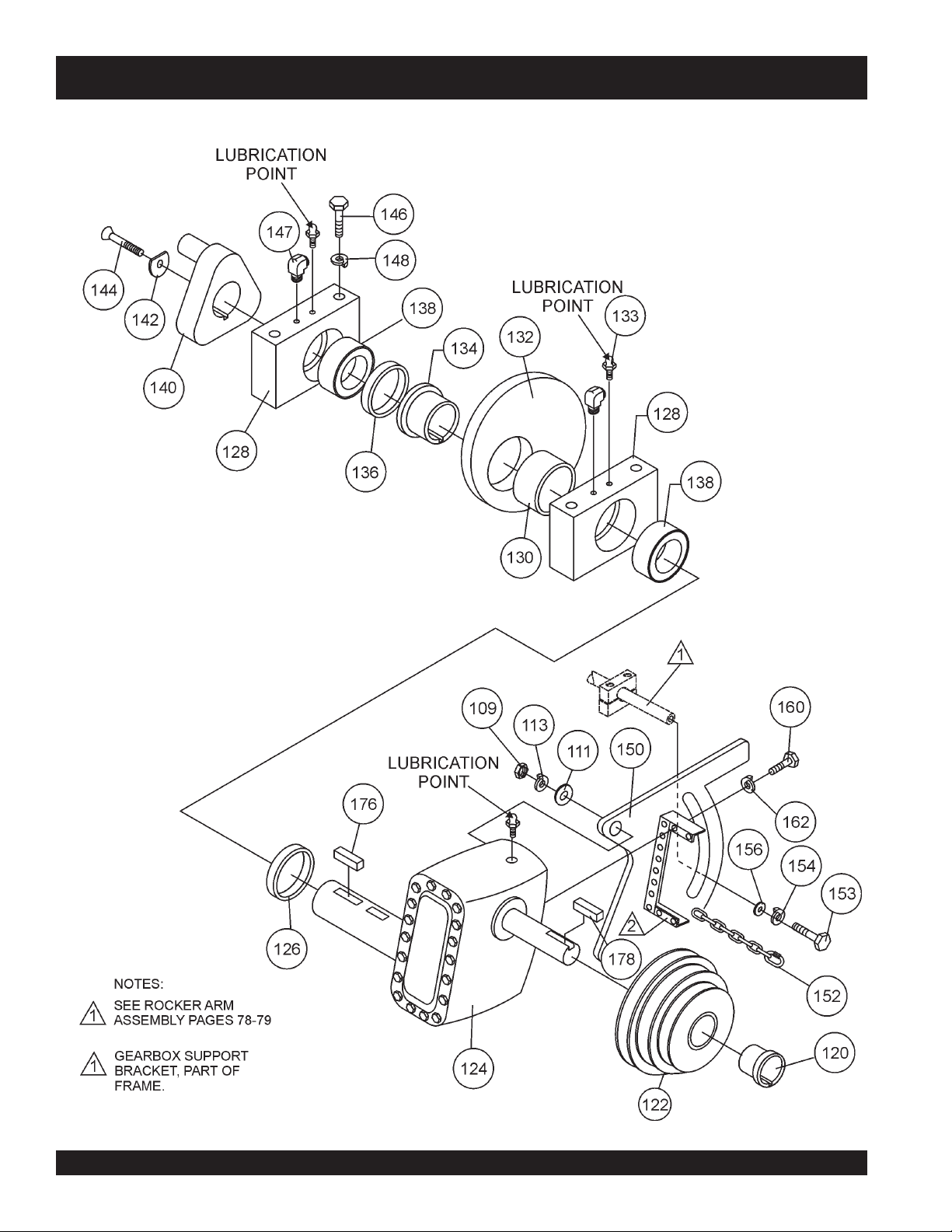

Crankshaft and Gear Box Assembly ................ 84-85

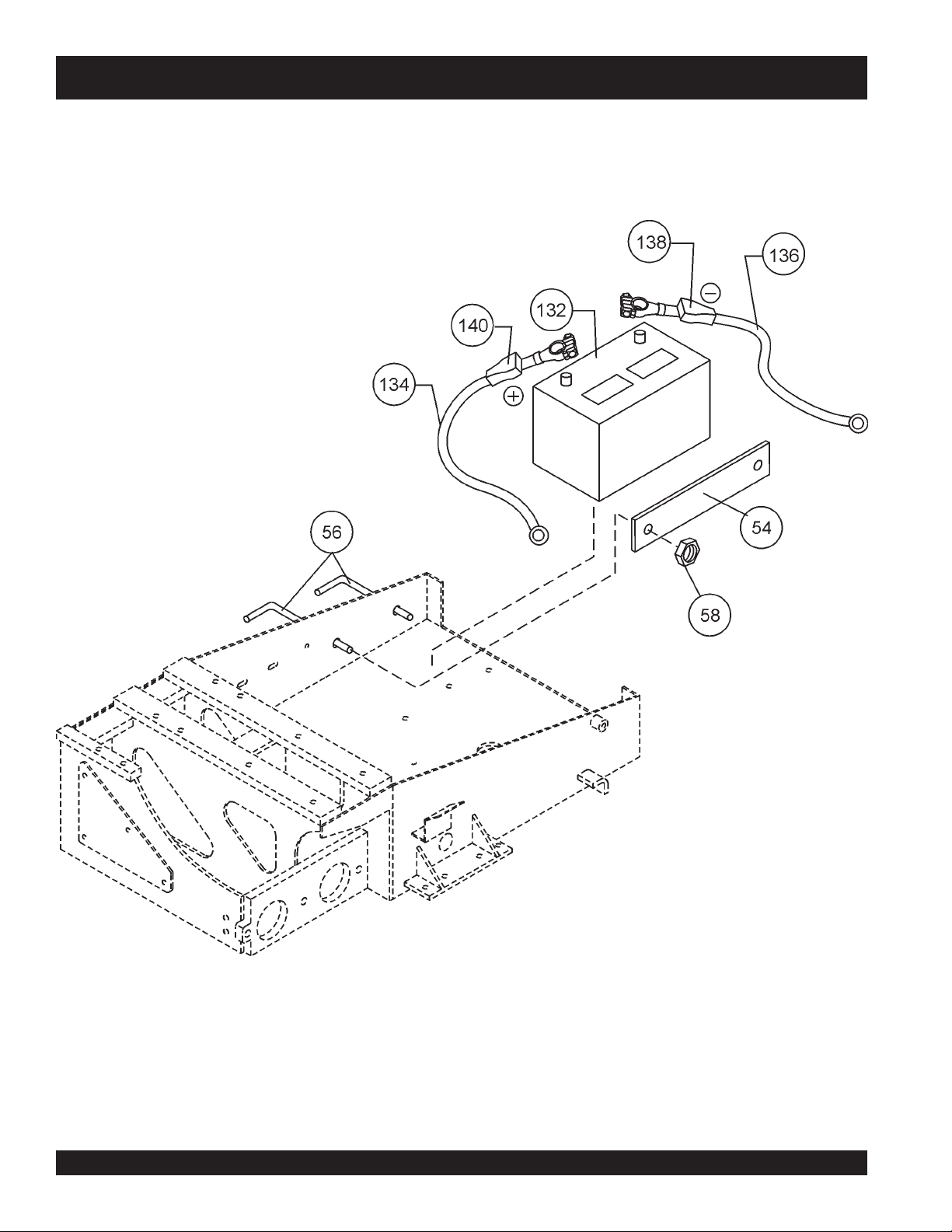

Battery Assembly ............................................. 86-87

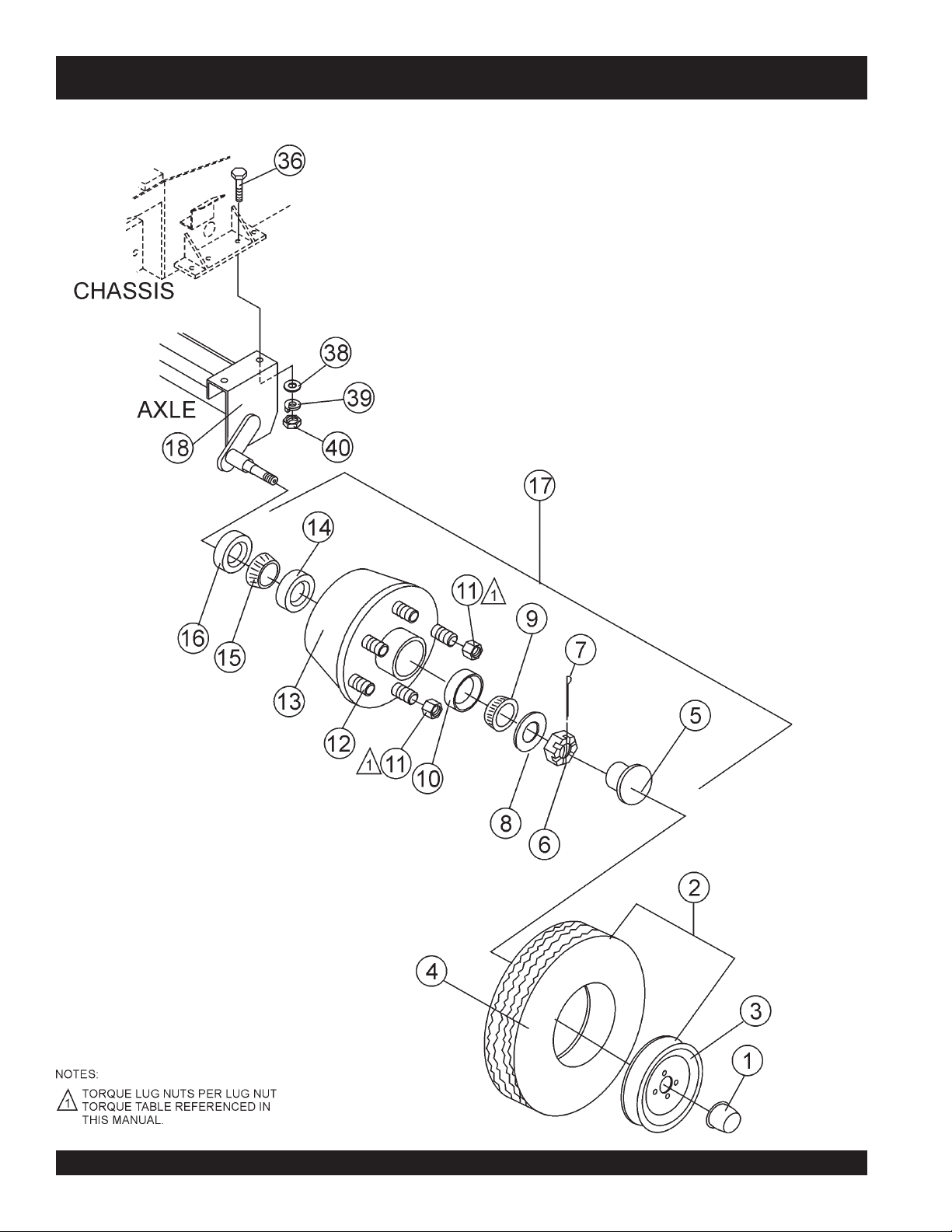

Tag Unit Axle Assembly .................................... 88-89

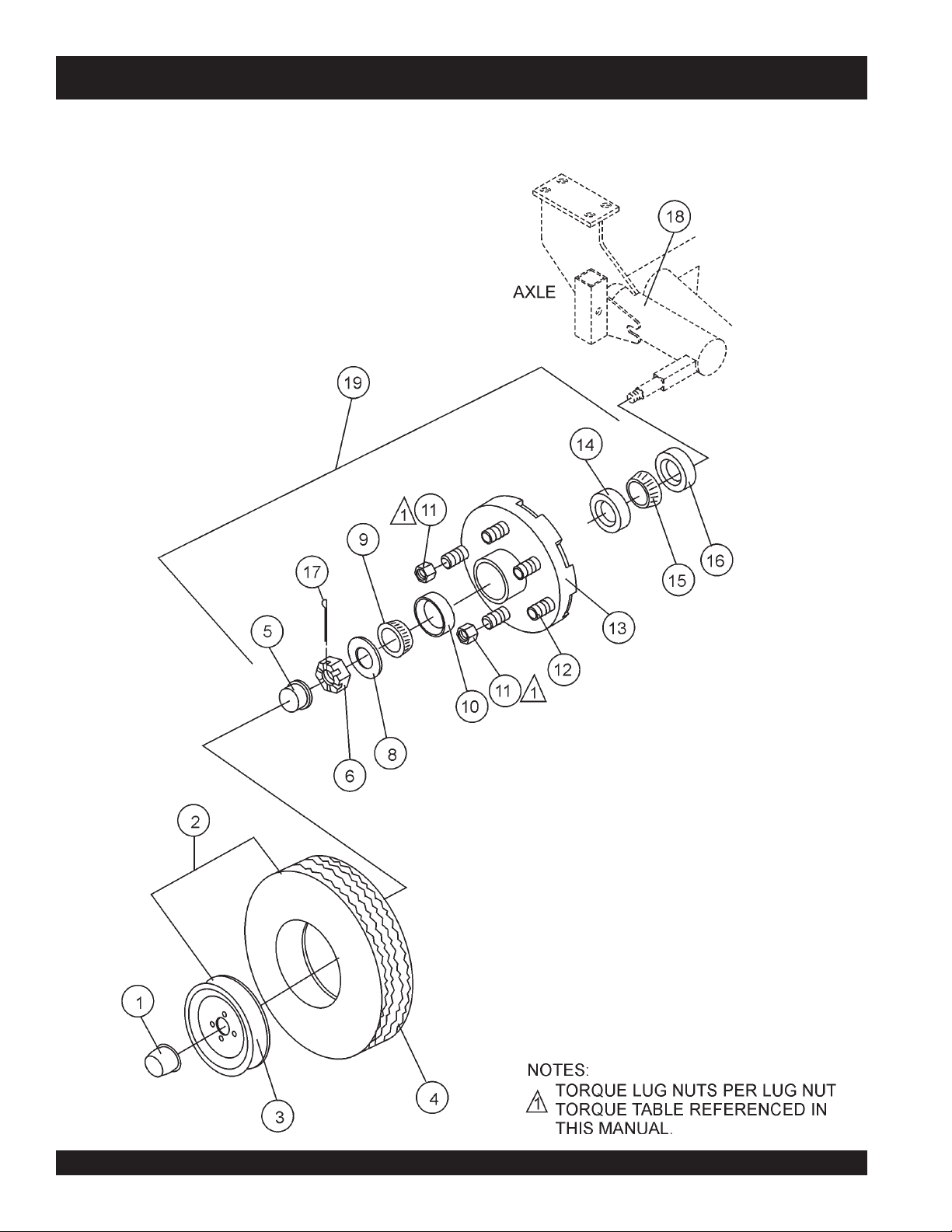

Mobile Unit Axle Assembly ............................... 90-91

Control Box Assembly ...................................... 92-93

Manifold (2-inch Outlet) Assembly ................... 94-95

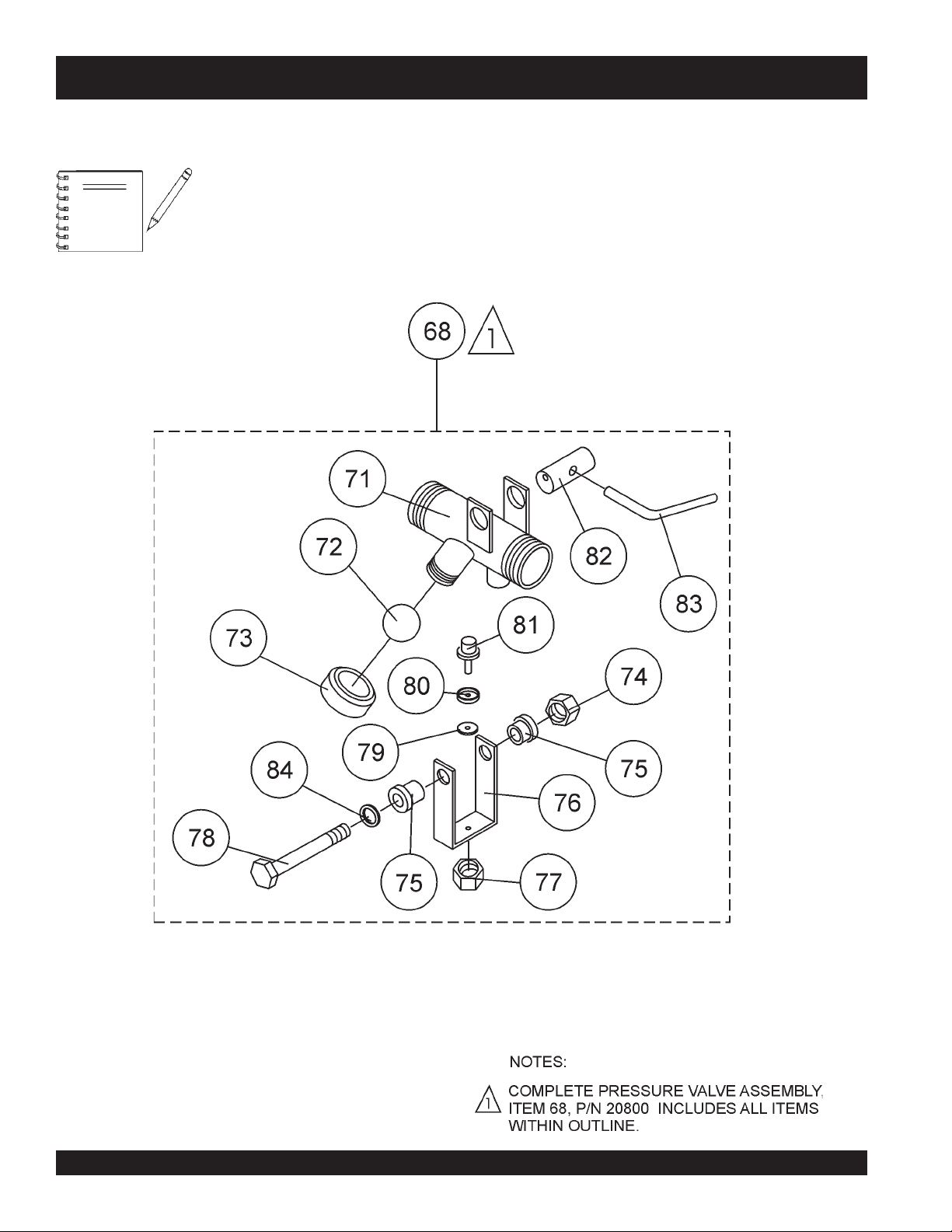

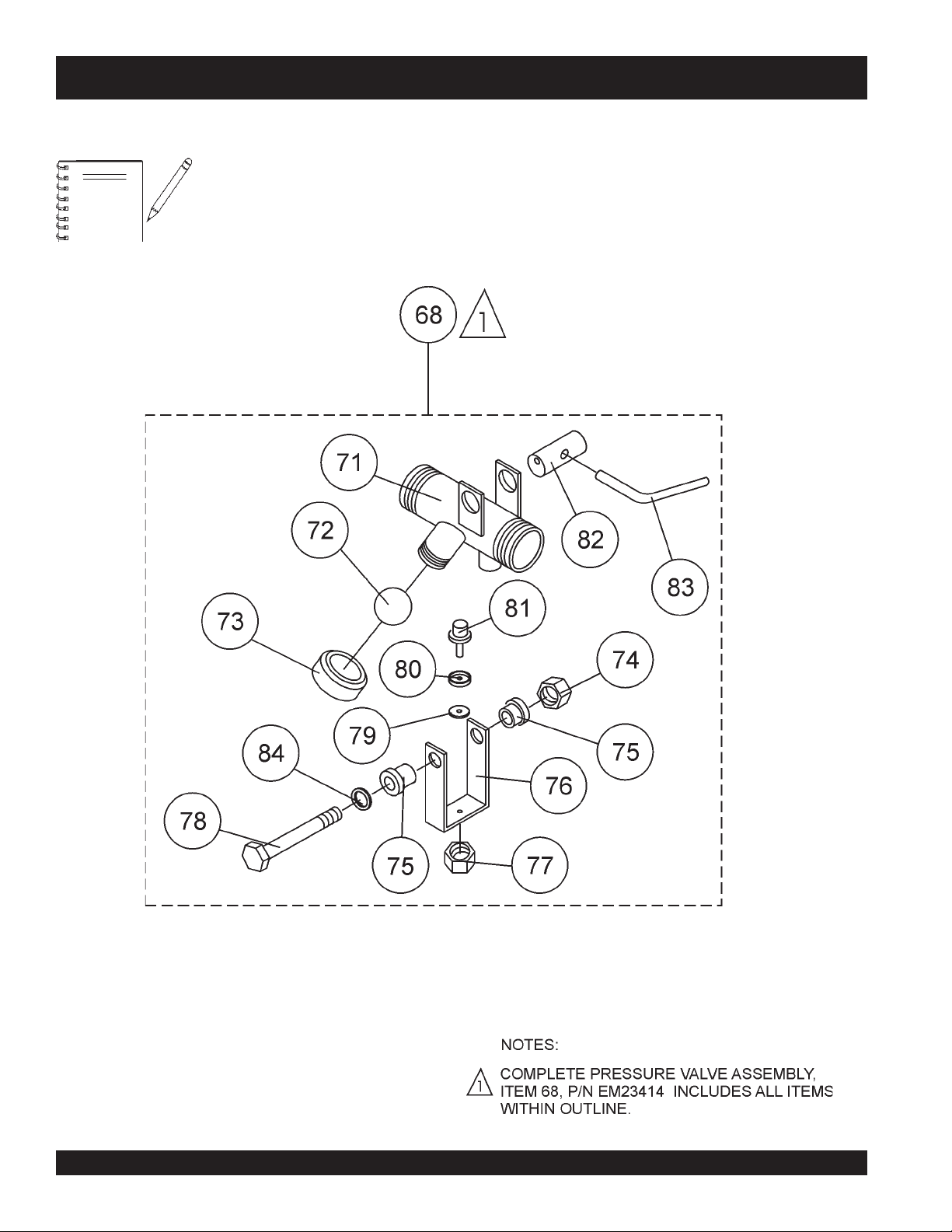

Pressure Relief Valve (2-Inch Outlet) Assembly .. 96-97

Manifold (3-Inch Outlet) Assembly ................... 98-99

Pressure Relief Valve (3-inch Outlet) Assembly ..... 100-101

Lubrication Panel Assembly ........................ 102-103

Remote Control Cable Assembly .................104-105

Tag Unit Trailer Assembly ............................. 106-107

Hatz 2M41LZ Engine Assembly ................... 108-109

Hatz 1B30 Engine (Clutch) Assembly .......... 110-111

Mixing Drum Assembly................................. 112-113

Paddle Shaft Assembly................................ 114-115

Frame Assembly .......................................... 116-117

Cab Assembly .............................................. 118-119

Transmission Assembly ................................ 120-121

HATZ 1B30 DIESEL ENGINE

Spare Parts Kit Assembly ............................. 122-123

Accessories Assembly.................................. 124-125

Crankcase and Engine Mount Assembly ..... 126-127

Crankshaft Assembly ................................... 128-129

Camshaft Assembly ..................................... 130-131

Piston Assembly ........................................... 132-133

Cylinder Head Assembly ..............................134-135

Oil Pump/Governor Assembly ...................... 136-139

Timing Cover Assembly ............................... 140-141

Flywheel Assembly ....................................... 142-143

Fuel Injection Assembly ............................... 144-147

Recoil Starter Assembly ............................... 148-149

Air Duct Assembly ........................................ 150-153

Crankcase Breather Assembly..................... 154-155

Fuel Tank Assembly ..................................... 156-157

Air Filter Assembly ....................................... 158-159

Muffler Assembly .......................................... 160-161

Starter/Alternator Assembly ......................... 162-163

Electronic Components Assembly................ 164-165

Speed Control Assembly .............................. 166-167

Terms and Conditions of Sale— Parts ................ 168

NOTE

Specification and part number are

subject to change without notice.

PAGE 4 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 5

r

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

to log in and save!

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact you

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Tr uck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 5

Page 6

MG-30 PUMP — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when operating

this equipment. Failure to read and understand the Safety

Messages and Operating Instructions could result in injury to

yourself and others.

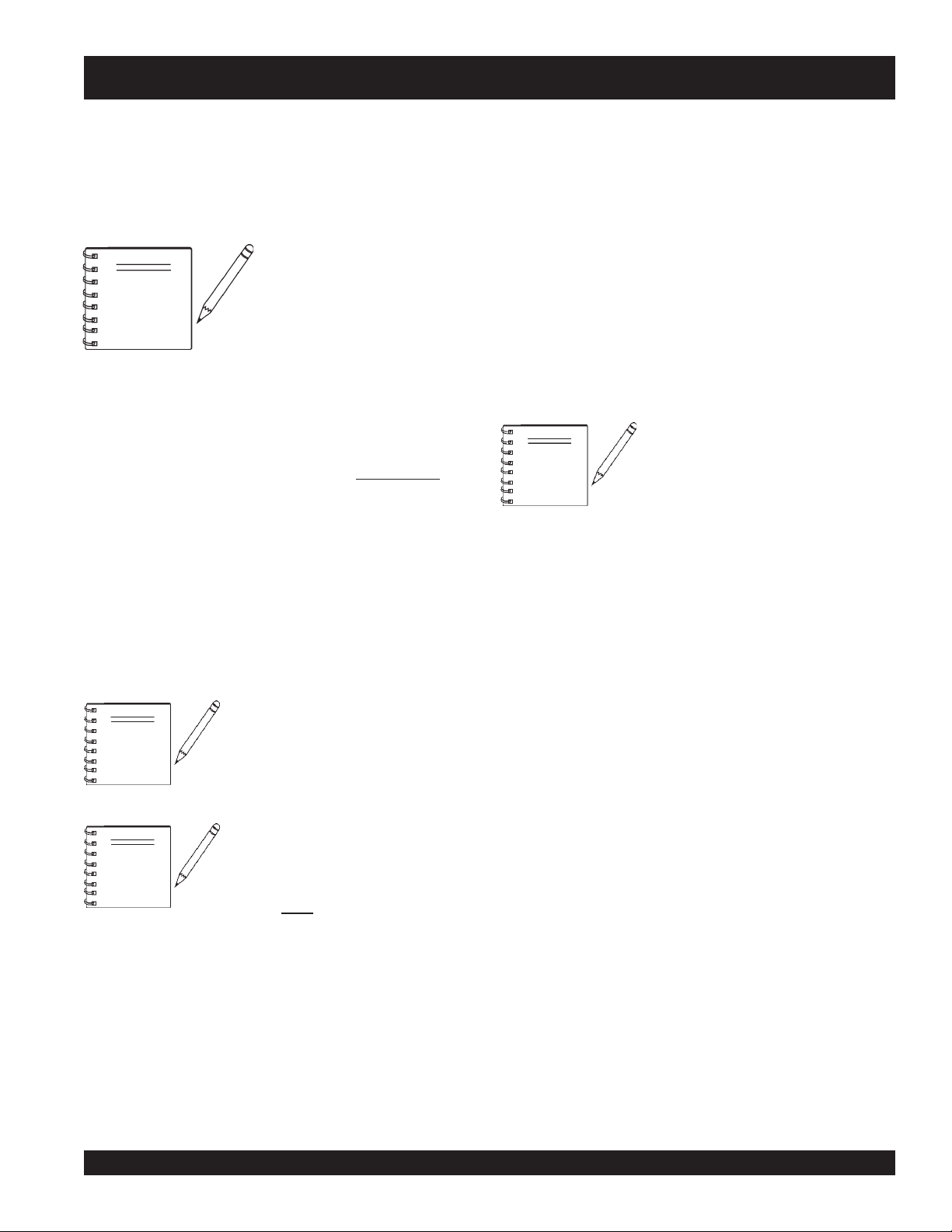

This Owner's Manual has been

developed to provide complete

NOTE

Before using this pump, ensure that the operating

individual has read and understands all instructions in this

manual.

instructions for the safe and efficient

operation of the Multiquip MAYCO

MG30-M (Mobile Unit) and

MG30-T (Tag Unit) plaster

fireproofing

engine manufacturers instructions for

data relative to its safe operation.

pump. Refer to the

and

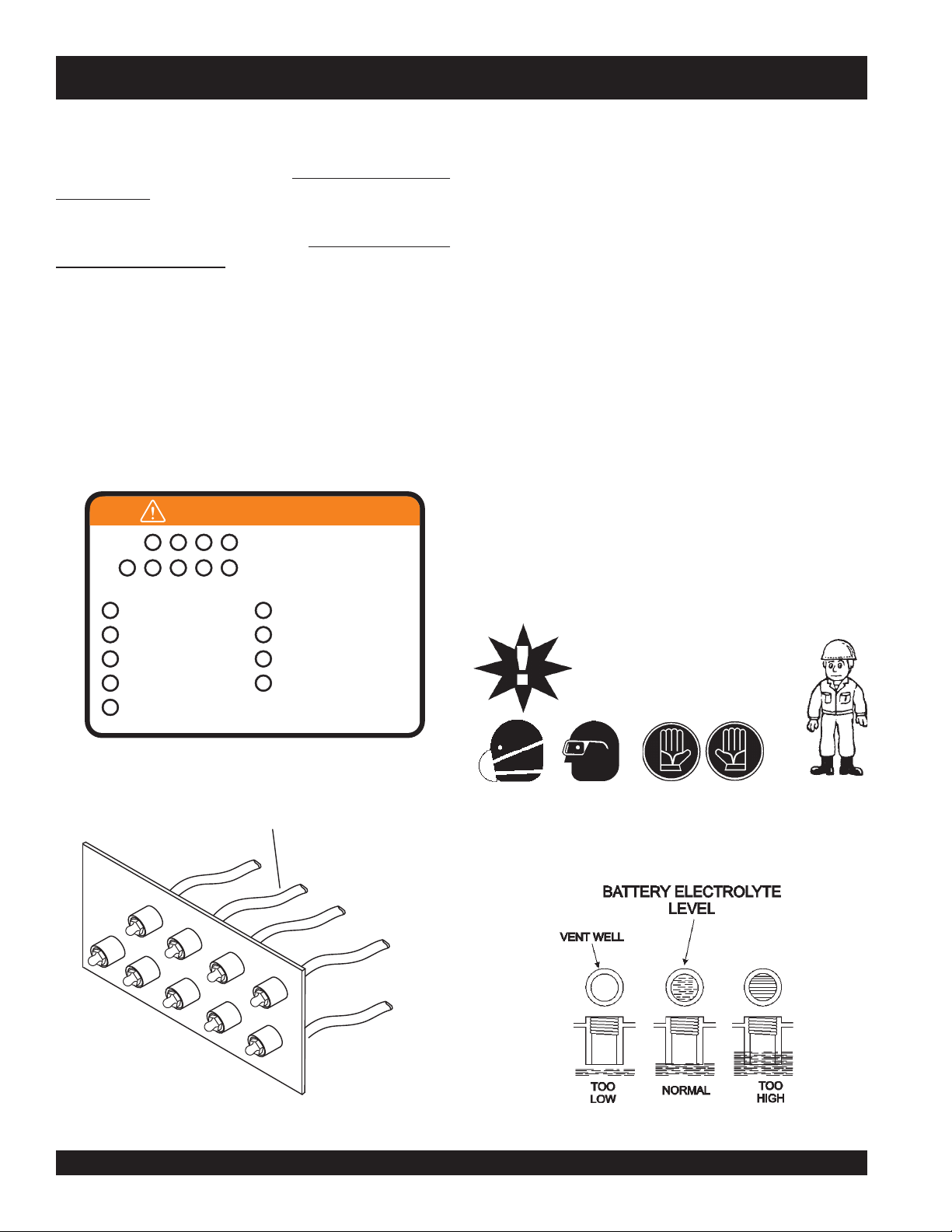

HAZARD SYMBOLS

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

Lethal Exhaust Gases

Diesel engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Diesel fuel

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

is extremely flammable, and its

DANGER: You WILL be KILLED or

SERIOUSLY injured if you do not follow

directions.

WARNING: You CAN be KILLED or

SERIOUSLY injured if you do not follow

directions.

CAUTION: You CAN be injured if you

do not follow directions.

Potential hazards associated with operation of the pump will be

referenced with Hazard Symbols which appear throughout this

manual, and will be referenced in conjunction with Safety

Message Alert Symbols.

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep

and clothing away from all moving parts to

prevent injury.

fingers, hands, hair

PAGE 6 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 7

MG-30 PUMP — SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the ON/OFF switch in the OFF

position. NEVER perform maintenance on the

unit with the ignition key in the ON position.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

This

pump

surrounding environment could

NOTE

be damaged if you do not follow

instructions.

, other property, or the

Respiratory Hazard

ALWAYS wear approved

protection.

respiratory

Sight and Hearing hazard

ALWAYS wear approved

protection.

eye

and

hearing

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your plaster and fireproofing pump,

other property, or the surrounding environment.

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 7

Page 8

MG-30 PUMP — RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual

may lead to serious injury or even

This equipment is to be operated by

trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used when

operating the MG30-M2D (Mobile Unit) and MG30-T2D (Tag

Unit) plaster and fireproofing pump:

GENERAL SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by persons under 18

years of age.

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

■

NEVER operate this equipment when not feeling

well due to fatigue, illness or taking medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

ALWAYS check the machine for loosened threads or bolts

before starting.

■

ALWAYS wear proper respiratory (mask),

protection equipment when operating the pump .

hearing

death!

and

eye

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Manufacture does not assume responsibility for any accident

due to equipment modifications.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to

cool before servicing engine or pump .

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

with

■

The engine section of this pump requires an adequate free

flow of cooling air.

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

■

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool.

■

NEVER

Fire or explosion could result from

vapors

hot!

components can cause serious burns.

smoke

NEVER

around or near the machine.

operate the pump in any enclosed

or narrow area where free

flow of the air is restricted. If

the air flow is restricted it

will cause serious damage

to the pump or engine and

may cause injury to

people. Remember the

pump's engine gives off

DEADLY

gas.

carbon monoxide

fuel

, or if fuel is spilled on a

hot!

engine.

■

NEVER operate the pump in an explosive

atmosphere or near combustible materials. An explosion or

fire could result causing severe

■

Topping-off to filler port is dangerous, as it tends to spill fuel.

PAGE 8 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

bodily harm or even death.

Page 9

MG-30 PUMP — RULES FOR SAFE OPERATION

■

ALWAYS remove the

unattended.

■

ALWAYS block the

ignition key

wheels

on the unit when using on a

when leaving the pump

Transporting

■

■

slope.

■

ALWAYS maintain this equipment in a safe operating

■

condition at all times.

■

ALWAYS stop the engine before servicing, adding fuel or oil.

■

NEVER run engine without air filter. Severe engine damage

may occur.

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operation techniques before using pump.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of

the reach of children.

■

DO NOT operate this equipment unless all guards and safety

Towing

■

■

■

■

devices are attached and in place.

■

CAUTION must be exercised while servicing this equipment.

■

Rotating and moving parts can cause injury if contacted.

■

Keep all

from the equipment at all times.

■

Before start-up, check the hopper and remove all foreign

matter and debris.

inexperienced

and

unauthorized

people away

■

■

■

ALWAYS shutdown engine before transporting the pump.

Tighten fuel tank cap securely and close fuel valve to prevent

fuel from spilling.

Drain fuel when transporting pump over long distances or

bad roads.

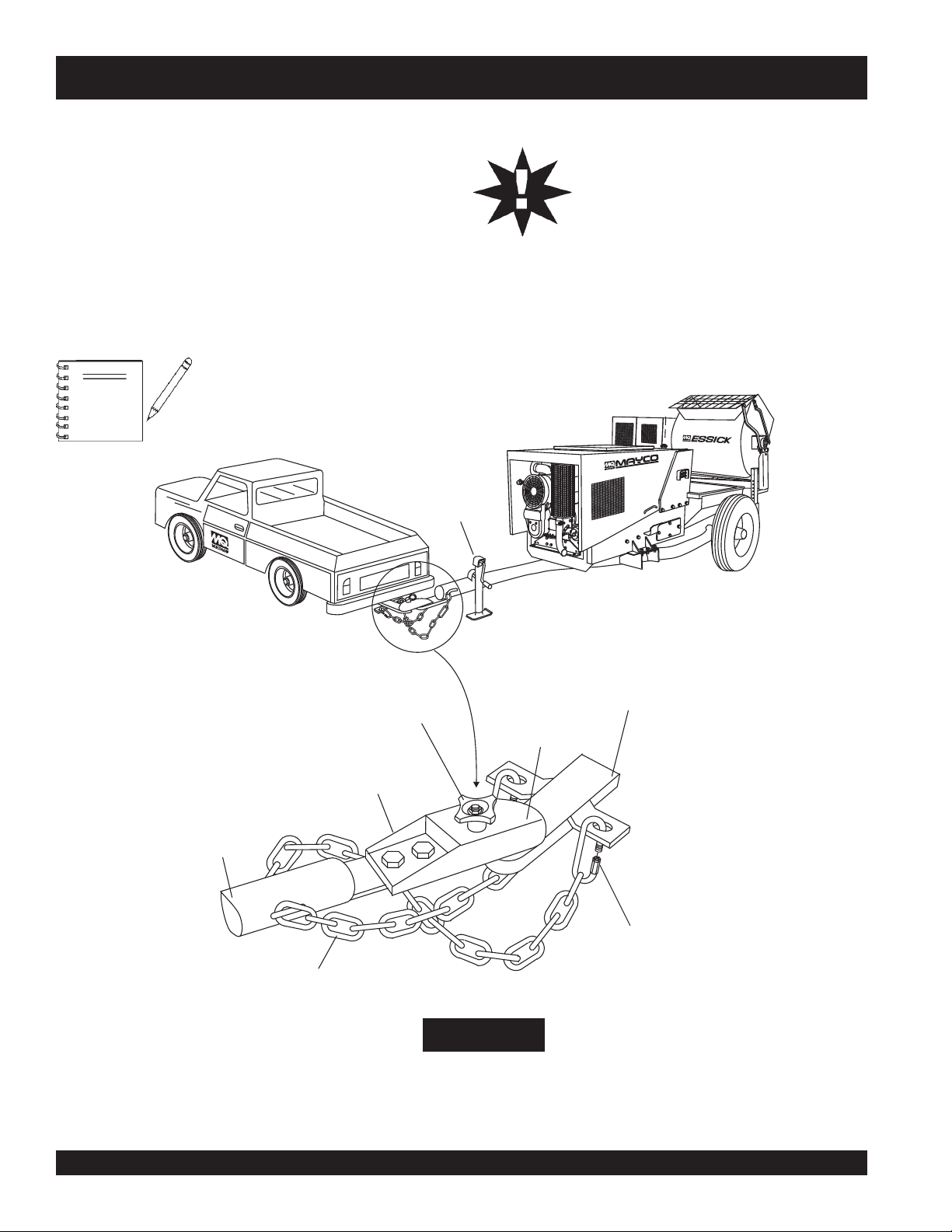

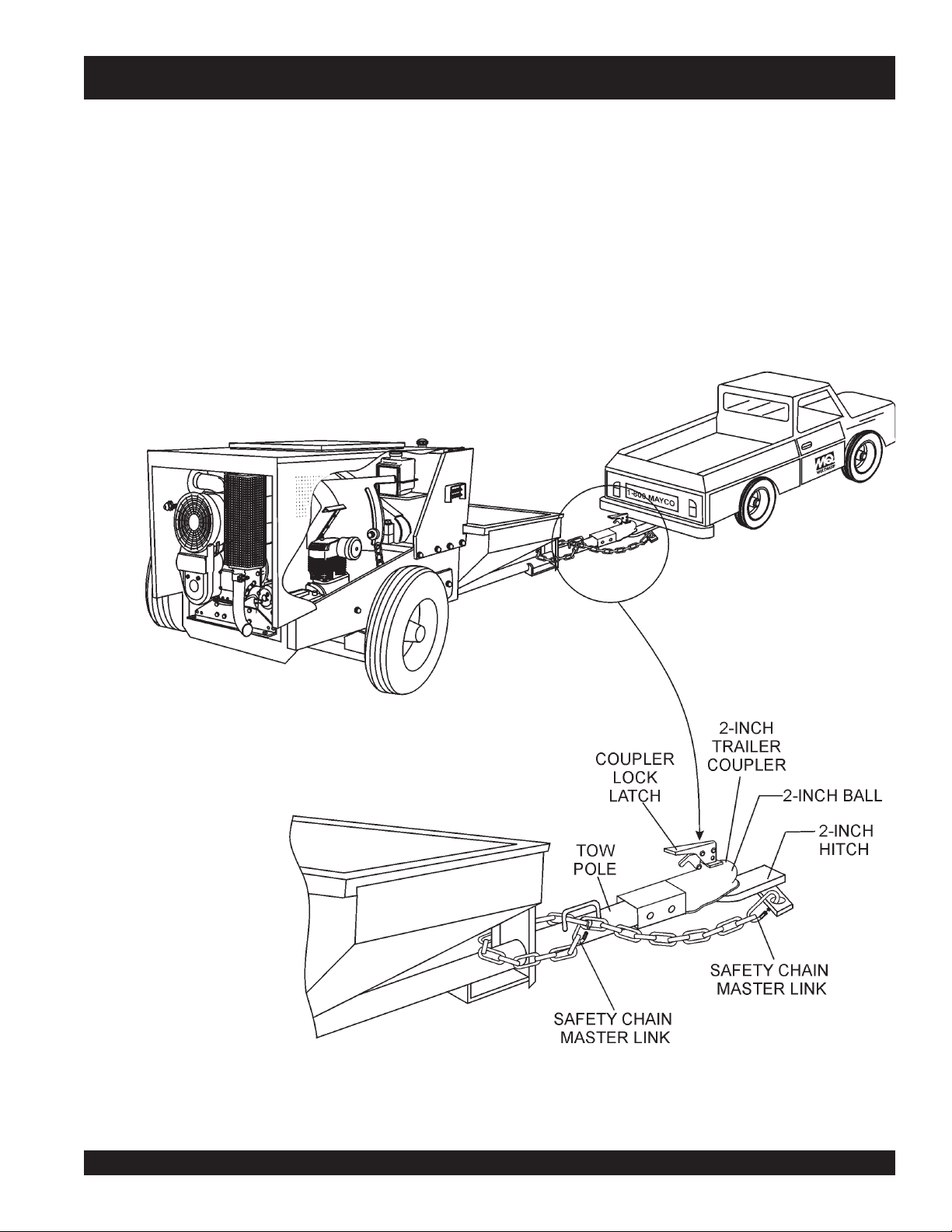

Before towing, check the hitch and secure the safety chain to

the towing vehicle.

When towing, an adequate safety chain must be fastened to

the frame, refer to pages 44 and 45.

Tow only with a vehicle and hitch rated to pull a 5,000 lbs.

load.

If unit is equipped with ball hitch coupler, use only 2" all steel

ball rated for minimum of 5,000 lbs. Use 1" hardened steel

pull pin, if not equipped with ball hitch.

This equipment shall not be towed or operated by individuals

who cannot read understand the signs, decals or operating

instructions.

When towing at night,

always

have rear tail lights ON.

DO NOT tow unit with hopper full of material.

DO NOT tow unit with hoses attached.

■

DO NOT use worn or damaged hose couplings, inspect all

■

hoses and couplings for wear. Replace any worn or defective

hose or couplings immediately.

■

Keep hands out of the hopper when the engine is running.

■

DO NOT operate unit with the

■

DO NOT disconnect hose couplings or nozzle while under

hood open

.

Maintenance Safety

■

■

pressure. Relieve pressure by manually activating pressure

relief valve at manifold.

■

Unauthorized equipment modifications will void all

■

■

warranties.

■

Check all fasteners periodically for tightness. Also check

■

towing tongue bolt, lock nut and wheel lug nuts for wear.

■

Test the

pump's ON/OFF

switch. The purpose of this test is

■

to shut down the engine.

■

Refer to the

questions or information

Engine Owner's Manual

for engine technical

recommended by Multiquip for this

equipment. Damage to the equipment and or injury to user

may result.

DO NOT tow unit in excess of 45 MPH on highways..

NEVER lubricate components or attempt service on a running

pump .

ALWAYS allow the pump a proper amount of time to cool

before servicing.

Keep the pump in proper running condition.

Fix damage to the pump immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

DO NOT use plastic containers to dispose of hazardous

waste.

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 9

Page 10

MG-30 PUMP — RULES FOR SAFE OPERATION

Emergencies

■

ALWAYS know the location of the nearest

■

ALWAYS know the location of the nearest and

fire extinguisher

first aid kit

.

.

■

In emergencies

nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in the case of an

emergency.

always

know the location of the

keep a phone on the job site

and

fire department

.

. This

PAGE 10 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 11

NOTE PAGE

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 11

Page 12

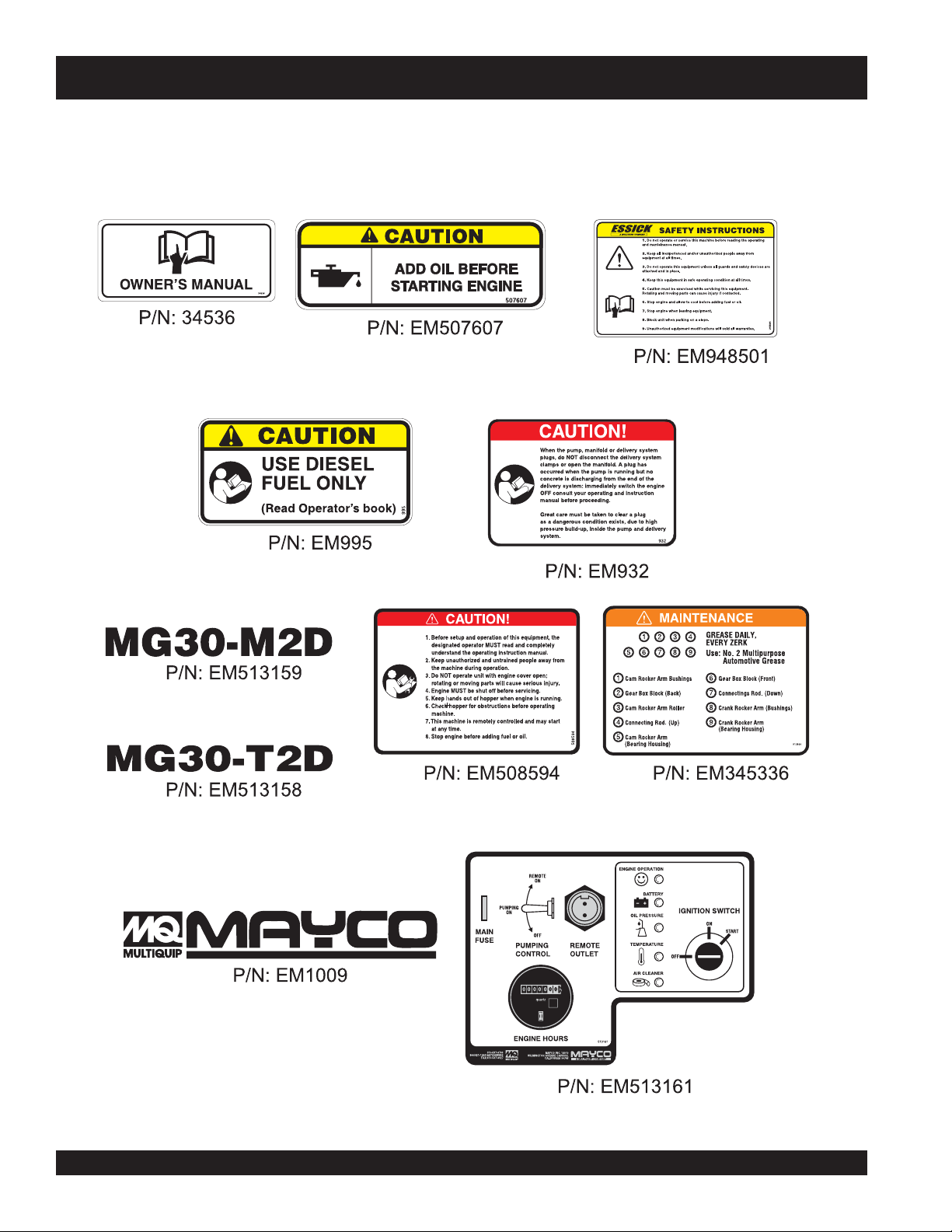

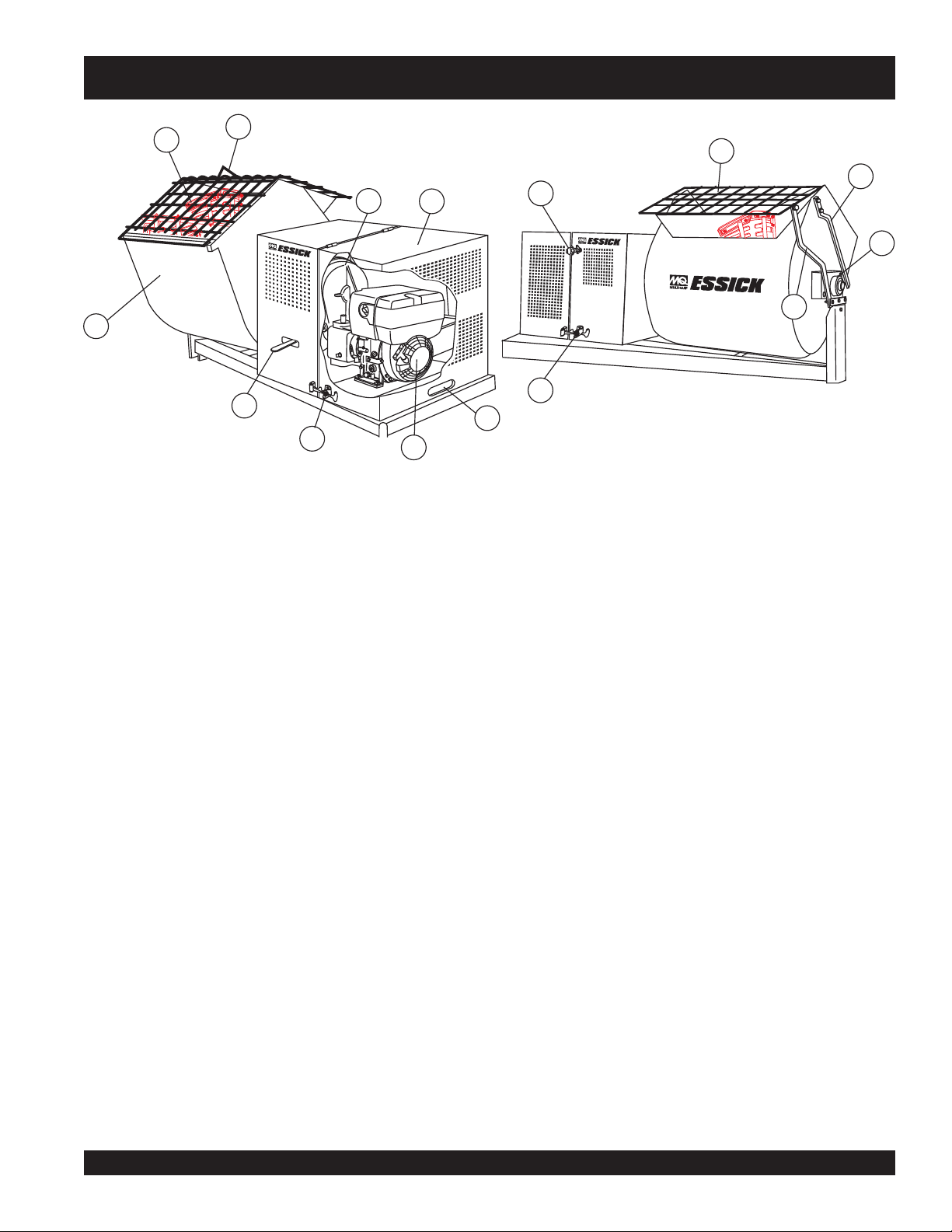

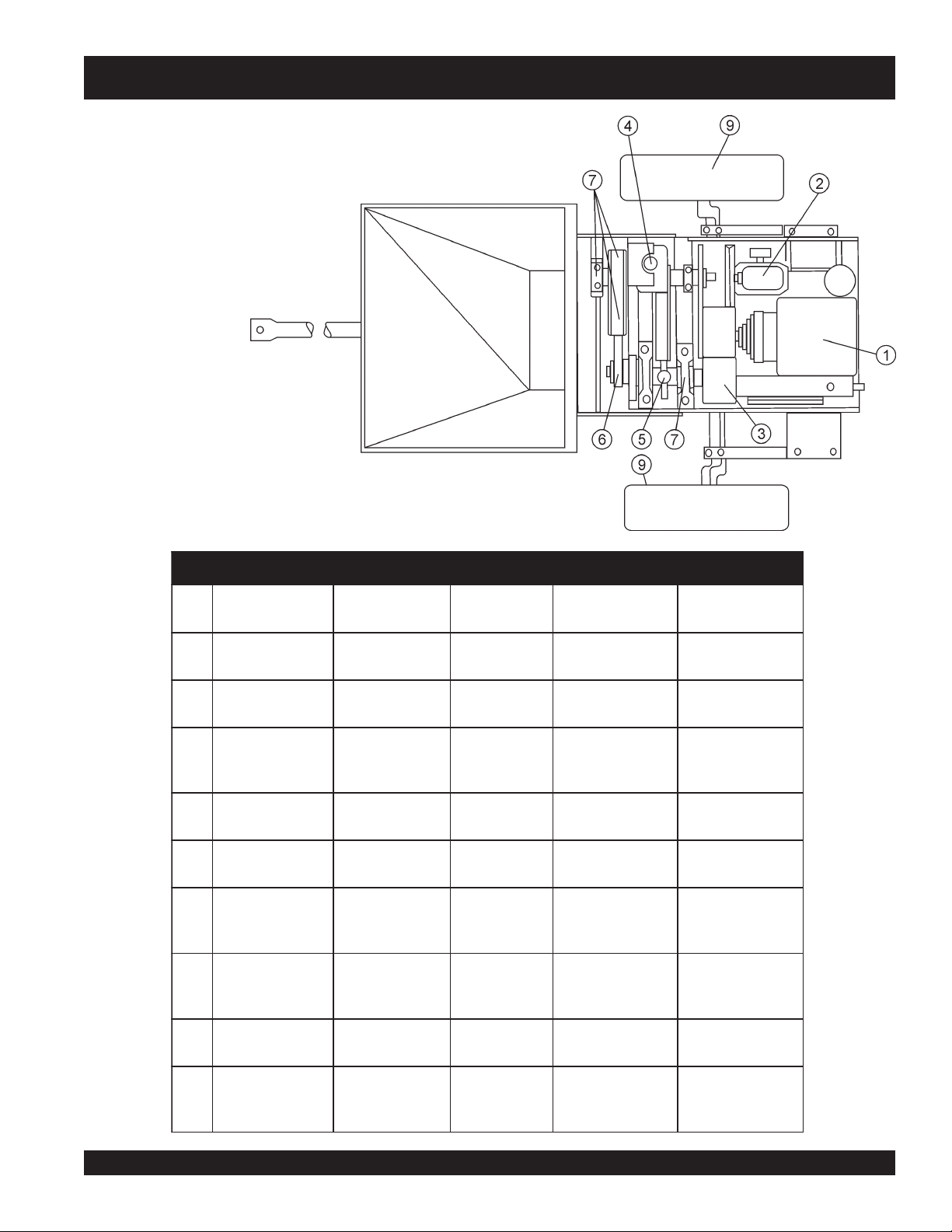

MG-30 PUMP — OPERATION AND SAFETY DECALS

Machine Safety Decals

The MG-30 mortar and plaster pump is equipped with a number of safety decals. These decals are provided for operator safety and

maintenance information. Figure 1 below illustrates these decals as they appear on the machine. Should any of these decals

become unreadable, replacements can be obtained from your dealer.

Figure 1. MG-30 Operation and Safety Decals (Pump Only)

PAGE 12 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 13

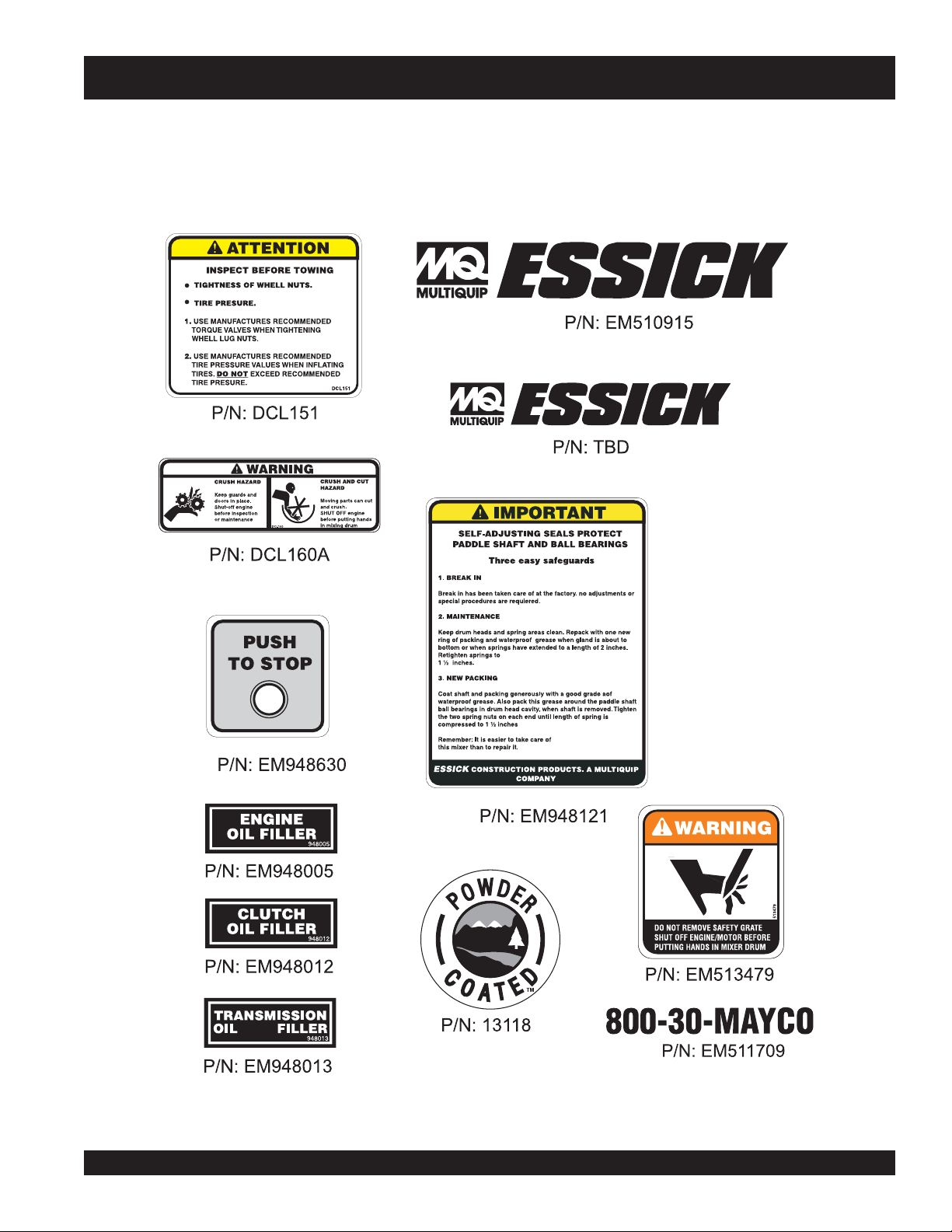

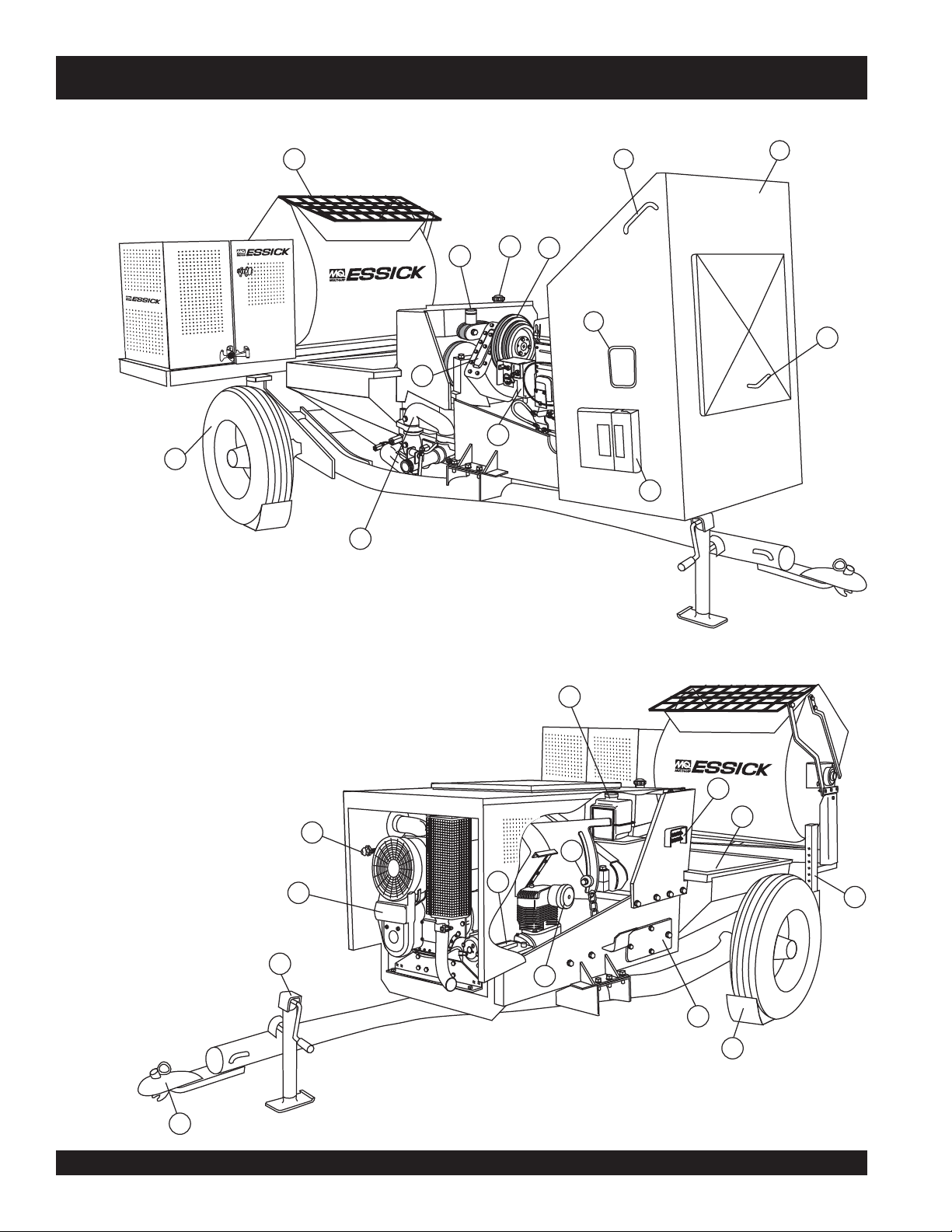

MG-30 PUMP — OPERATION AND SAFETY DECALS

Machine Safety Decals

The Essick EM 120SM mortar and plaster mixer is equipped with a number of safety decals. These decals are provided for operator

safety and maintenance information. Figure 2 below illustrates these decals as they appear on the mixer. Should any of these decals

become unreadable, replacements can be obtained from your dealer.

Figure 2. MG-30 Operation and Safety Decals (Mixer Only)

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 13

Page 14

MG-30 PUMP — SPECIFICATIONS

)pmuP(snoitacificepS.1elbaT

03-GM-ledoMgnipmuP

retsalP.uc5.6

gnifoorperiF.uc9

S021ME

)kcissE(

etaR

.sdy.rh/

.rh/.sdy

gaB

yticapaC

0.4-5.3.tf.uc

lairetaM

rednilyC

)ekortSxretemaiD(

.ni6x05.3

).mc42.51x98.8(

.ni8x57.3

(

).mc23.02x25.9

pmuP

erusserP

ISP0001.ni2

ISP0001.ni3

dlofinaM

.aiDteltuO

.mc80.5(

)

).mc26.7(

rosserpmoC

rednilyC-2

notsiP

@MFC01

ISP001

@MFC01

ISP001

reppoH

yticapaC

.tf.uc9

)sretil(552

.tf.uc9

)sretil(552

leuF

yticapaC

)leseiD2.oN(

.lag3.5

)sretil02(

.lag3.5

)sretil02(

)rexiM(snoitacificepS.2elbaT

murD

yticapaC

21

)sretil043(

enignEevirDpmuD

leseiDztaH

lacinahceMlaunaM.ni57

03B1ledoM

egrahcsiD

noitcA

thgieH

thgieW

)sleehwssel(

.sbl090,1

).mc191(

).gk494(

)enignEZL14M2ZTAH(snoitacificepS.3elbaT

.oN

leseiDZTAH

srednilyC

ledoM

ekortSxeroBtnemecalpsiDeldI

liOebuL

deepS

yticapaC

yrettaB

W

thgie

epyT

niM/xaM

ZL14M2

2.ni31.4x20.4

).mm501x201(

.ni.uc7.401

)sretil617.1(

008

s'MPR

.stq2.3/8.5

)sretil0.3/5.5(

V21

hA341/88

.sbl294

).gk322(

)enignE03B1ZTAH(snoitacificepS.4elbaT

leseiDZTAH

03B1ledoM

delooC-riA

liOenignE

epyT

leuFepyT

.oN

srednilyC

1.mc.uc743

tnemecalpsiDeldI

)sretil743.(

liOebuL

deepS

008

s'MPR

yticapaC

.stq50.1

)sretil1(

riAepyT

renaelC

yrD

tnemelE

gnitratS

thgieW

dohteM

lioceR

tratS

.sbl77.38

).gk83(

-DC-IPAro@DP-5D-4D-CMCC

DPHSroGC-FC-EC

-2A/1A9682SB10615NID-095NE

D2/D1-579DMTSA

PAGE 14 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 15

NOTE PAGE

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 15

Page 16

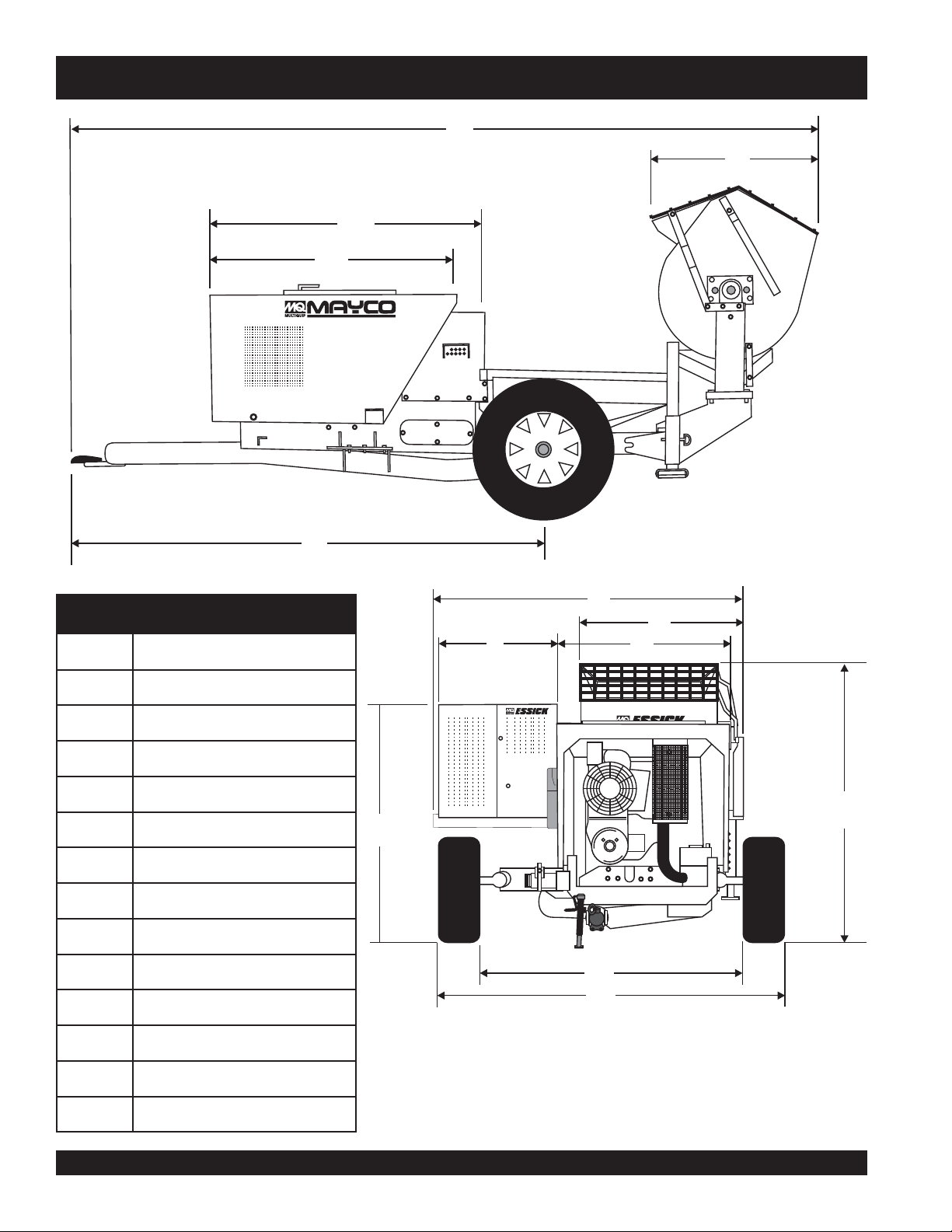

MG-30 PUMP — DIMENSIONS (MG30-M2D MOBILE UNIT)

I

M

L

K

MG30-M2D

.FERSNOISNEMID

A)sretem27.1(.ni0.86

B)sretem82.2(.ni0.09

C)sretem10.1(.ni0.04

D)sretem60.1(.ni0.24

E)sretem218.(

F)sretem00.2(.ni0.97

G)sretem74.1(.ni0.85

H)sretem27.1(.ni0.86

I)sretem43.4(.ni171

J)sretem18.2(.ni111

.ni0.23

J

F

tinUliboMsnoisnemiD.5elbaT

E

G

A

B

D

C

H

K)

L)sretem35.1(.ni5.06

M)sretem569.(.ni83

PAGE 16 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

sretem73.1(.ni0.45

Figure 3. MG-30 (Mobil Unit Dimensions)

Page 17

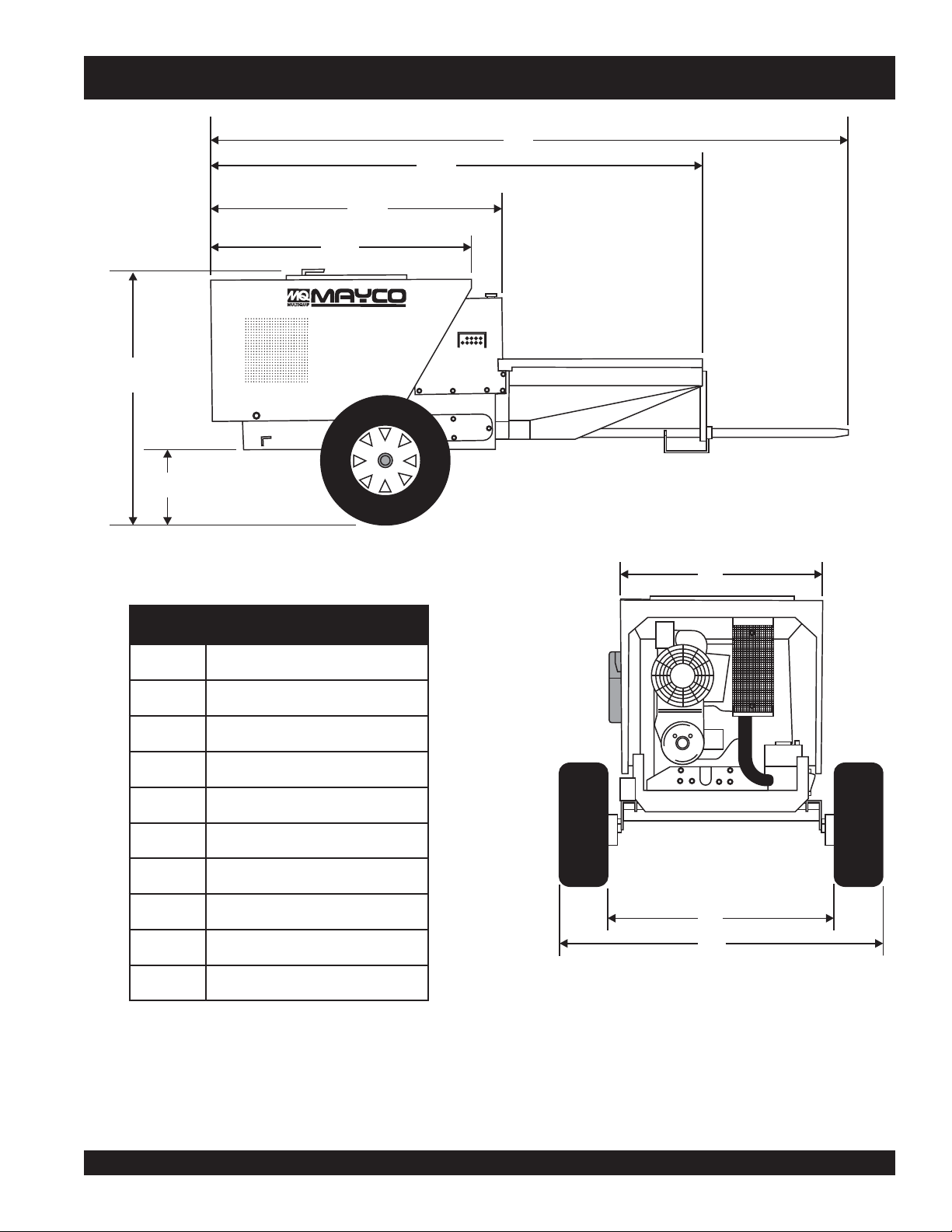

MG30-2

A

B

C

D

I

E

F

G

H

MG-30 PUMP — DIMENSIONS (MG30-TD2 TAG UNIT)

tinUgaTsnoisnemiD.6elbaT

.FERSNOISNEMID

A)sretem90.1(.ni0.34

B)sretem25.1(.ni0.06

C)sretem678.(.ni5.43

D)sretem81.1(.ni5.64

E)sretem73.1(

F)sretem35.1(.ni5.06

G)sretem34.2(.ni0.69

H)sretem40.3(.ni021

I)sretem292.(.ni5.11

.ni0.45

Figure 4. MG-30 (Tag Unit Dimensions)

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 17

Page 18

MG-30 PUMP — GENERAL INFORMATION

General

The MAYCO Model MG30-M and MG30T plaster-mortar,

fireproofing pumps are designed to pump material at a steady

rate of flow. This is accomplished with two pistons. One piston

does all the pumping; the other is a

piston is a

which causes the pulsating material from the pumping piston to

be pumped at a steady rate of flow.

Your MAYCO pump has been serviced and test-run at the

factory. Upon delivery and inspection the machine is ready for

operation on the job.

This pump uses a 3-1/2 inch pumping piston and therefore

develops a higher pressure than most concrete pumps. It is

extremely critical that the pump drive components, pumping lines

and components are of the finest quality and maintained in a

manner to prevent accidents. Use only

hoses and couplings.

The MG-30 has been assembled with a

installed at the discharge port on the manifold. NEVER pump

materials unless this (pressure relief valve) mechanism is

installed.

Normally, the 750 psi rated brass cap is used in plaster

applications, whereas the 1,000 psi rated unit is used for higher

pressure applications and fireproofing. The brass cap and ball

should be removed and

to prevent material setting up around the ball.

If material hardens around the ball, it will not be effective as a

relief valve when high pressure develops. Install ball discharge

in downward position. Use the manual relief part of this valve to

relieve line pressure before disconnecting material lines or hoses

Power for the operation of this pump is supplied by a Hatz Model

2M41LZ, 35 H.P. diesel air-cooled engine. This engine transfers

power through a V-belt to a totally enclosed speed reducer and

also operates a twin-cylinder piston type air compressor.

The MG-30 is equipped with an

solenoid

electrically controlled solenoid allows the operator to

stop

When the solenoid valve is energized (i.e. electric current is

applied to the solenoid) the engine speed will increase to the

pre-set governed speed, engaging the

pump. When the solenoid is de-energized, the engine speed

will decrease, returning to idle, disengaging the centrifugal clutch

and pump.

compensation piston

cleaned daily

valve

and

gravity-feed piston oiler system

the pump remotely from the nozzle.

slave piston

and operates in a manner

high pressure

pressure relief valve

, or more often if necessary,

electrically controlled

centrifugal clutch

. The slave

rated

. The

start

and

Located at the rear of the pump is the mixing unit. The drum

batch capacity of this mixing unit is between 3.5 and 4.0 bags.

The mixer section of the pump can be powered by a either a XX

HP Honda gasoline engine, 8.0 HP Hatz diesel or 2.0 HP electric

motor.

Due to the abrasive nature of the materials being pumped, some

parts of the machine are likely to be worn from use more rapidly

than others. It is therefore suggested that spare parts be kept in

ready reserve at the job site to prevent downtime.

CAUTION :

to

whip

or move in a manner that could cause injury to personnel.

When moving hoses from one job site application to another it is

important to walk the entire system and

kinks or sharp bends in the hose, before starting or resumong

.

the pumping operation.

The following definitions will help assist you in understanding

common pump terminology.

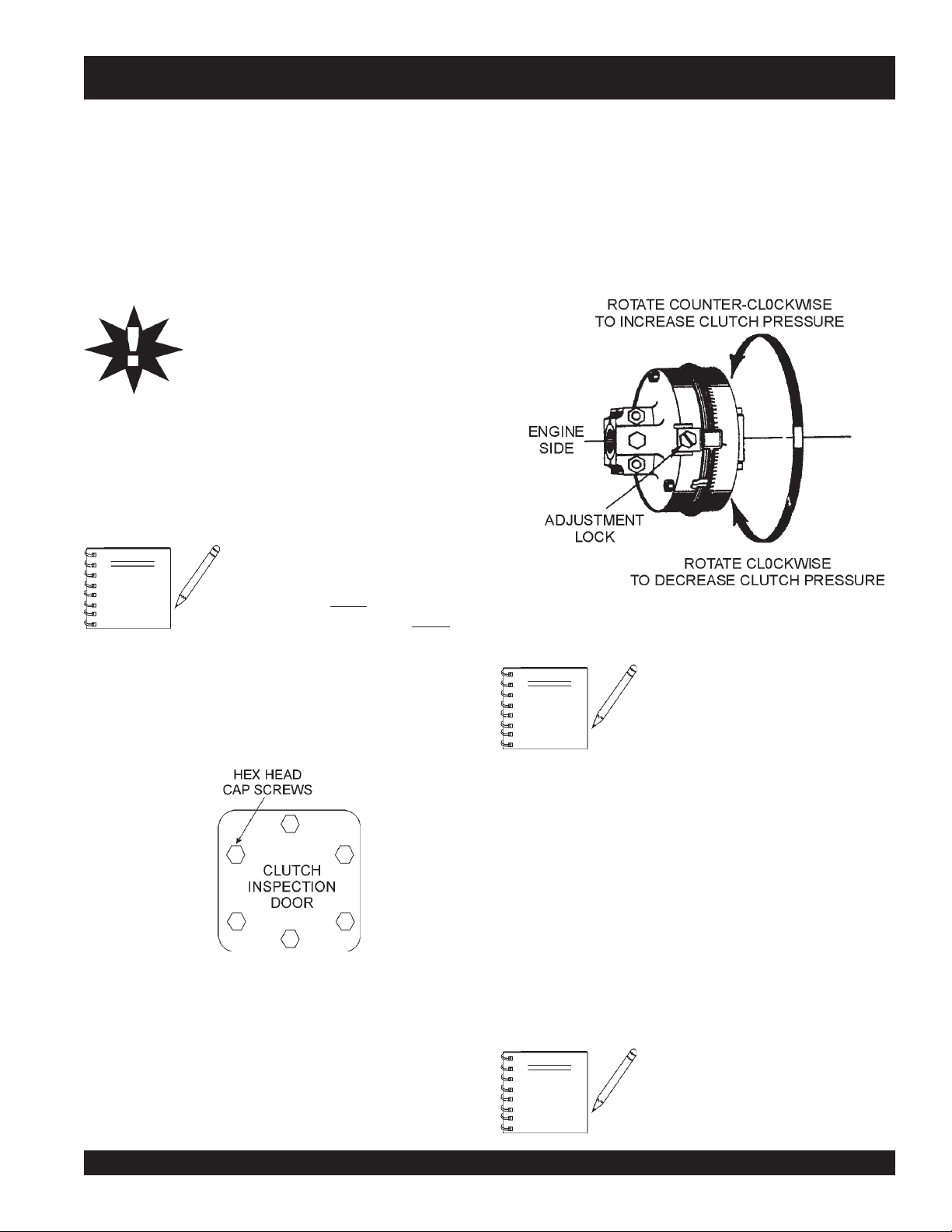

Centrifugal Clutch

The centrifugal clutch is designed to slip when the engine speed

drops due to overloading of the pump. This is a safety device to

protect other parts of the machine from damage and to prevent a

buildup of pressure in the material hose. Continued operation of

the machine when the clutch is slipping will cause damage to

the clutch. The clutch needs no adjustment or lubrication.

Pump Head Unit

The pump head unit consists of two pistons--one being the

pumping piston and the other a compensating piston, driven by

the cam and rocker arm principle.

The pump housing is equipped with inlet and outlet valve seats

and two special hard rubber or steel balls. When the piston is

and

retracted, the inlet valve seat opens for intake of material into the

piston chamber; when the piston is extended, the inlet valve

closes and the outlet valve opens, allowing material to be

pumped. There are three sections to the pump head unit.

ALWAYS ASSEMBLE THESE SECTIONS PRIOR TO

MOUNTING PUMP HEAD UNIT ON FRAME, MAKING SURE

THE SEAL RINGS FIT UP AIRTIGHT.

If hoses or lines are

if lines are

pumping cycle, the pump pressure could

straighten out the kink or force out the blockage.

The rapid surge of material could cause the lines

kinked

blocked

when starting up or during

for any reason, or

visually inspect

for any

PAGE 18 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 19

MG-30 PUMP — GENERAL INFORMATION

Main Bearings

The two main crankshaft bearings are sealed bearings. These

bearings should be greased about every two days of pump

operation. Any good lithium base grease is acceptable. Too much

grease cause the bearings to overheat.

Rocker Arm Shaft

The two rocker arms have bronze bearings. These bearings

should be greased

Rod Ends

Each piston rod and connecting rod from the crankshaft has a

roller bearing. Lubricate these four roller bearing daily with lithium

base grease.

NOTE

Cylinders

The cylinder walls do not wear to any degree. Care should be

taken not to damage the surface on the ends of the cylinders as

this will cause an air leak between the end of the cylinders and

the pump housing.

NOTE

every day

of operation.

Daily lubrication of the roller bearings

(except main bearing) will prevent any

dirt and foreign matter from entering the

bearings.

NEVER!

pump. The cylinder bore is

plated

chrome.

use

muriatic acid

to clean the

chrome

. Muriatic acid will dissolve the

The rubber check balls are components of the pump that will

wear quite

high pressure

balls. The rubber check balls can last anywhere from a week to

2 or 3 days depending on the pumping pressure. Jamming the

pump or running the pump at a very high pressure may split the

rubber check balls.

NOTE

Steel Check Ball

Steel check balls are used in

they form a water tight seal at the valve seat. This prevents the

check valve from packing due to separation at the valve.

Leather Piston Cup

The piston, which is held to the push rod by a nut, consists of

several parts made of various materials with close tolerances,

having as the center a

cup is in constant contact with the cylinder and the material and

it wipes clean the cylinder on each stroke, thereby preventing

damage to the cylinder. When the machine is shut down, the

piston cups should be periodically inspected and replaced if

frayed or damaged.

The leather piston cups will outwear the rubber balls. The leather

piston cups as well as the rubber balls can be damaged

prematurely if exposed to

jamming of the pump.

rapidly

and must be replace frequently.

is the main cause of wear to the rubber check

When replacing either rubber check ball,

always

of wear. Make sure the o-rings and

associated parts are clean and free of

dirt when the rubber check valve is

reassembled.

inspect the other ball for signs

fireproofing

applications, because

pre-lubricated leather piston cup

excessive pump pressure

Excessive

. This

or

Leather Piston Lubrication

Pump Housing

There are 3 sections to the pump housing,

housing

are held together with "T" slot bolts and are aligned to each

other with guide rings on the flange surface.

Always assemble these 3 sections into a complete unit before

placing it on the pump. It is important that when the pump housing

unit is placed on the pump that all of the gaskets and o-rings are

aligned properly with an air tight fit.

Rubber Check Ball

Rubber check balls (not steel) are used in

applications, because they form a water tight seal at the valve

seat. This prevents the check valve from packing due to

separation at the valve.

(center), and

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 19

crossover housing

hopper elbow, main

. These 3 housings

plaster

and

stucco

Due to the close tolerance of the piston to the cylinder, the piston

is equipped with a felt ring to keep the cylinder constantly

lubricated for increased life. The felt ring is lubricated through

the oiler fitting and tubing installed at rear of piston.

The oiler tank is mounted adjacent to the fuel tank. The

should be checked regularly

if necessary, with a good grade of S.A.E. 20W or 30W motor oil.

Oiler tank capacity is 1.5 quarts (.709 liters).

With the engine running, open needle valve (located below oil

tank) very slightly. Oil should flow for approximately 5 minutes

before pumping material. This will allow oil to reach and penetrate

the felt ring. Opening the valve too far will cause oil to flow

excessively. Close the valve when the machine is not in use to

prevent all the oil draining from the tank.

oil level

during operation and tank filled,

Page 20

MG-30 PUMP — GENERAL INFORMATION

O-Rings

O-Rings have been installed at sealing points throughout the

pump head unit. These O-rings act as seals and are very

important for the efficiency of the machine. Great care should be

taken when assembling or disassembling those parts where “O”

rings have been installed. Always clean O-ring groove thoroughly

grease O-ring before installing.

Inspection of O-rings should be made regularly. It should be

done each time a part containing an O-ring has been

disassembled. Carefully remove and check O-ring to see it is

not chipped, broken, peeled or has any other signs of deformity.

If any of these conditions exists, the O-ring should be replaced.

Pump Overloading

If at any time the pump is jammed from separation or a sand

pack in the hose, the clutch on the engine will slip. This will

protect the moving mechanical parts of the pump from being

overloaded and damaged. The capability allows the pump to

shut itself down in the event an operator is not near pump if a

sand pack or jam-up occurs.

When the drive belt is moved from the largest pulley on the

clutch to the smallest, the output power of the pump is increased

by a factor of three. So, when operating the pump at the lower

speed, the RPM of the engine should also be reduced. This will

allow the clutch to slip in the event of a separation or sand pack,

and therefore will safeguard the hoses and the mechanical

working parts of the pump from damage.

USE ONLY "O-RINGS" OBTAINED

NOTE

Valve Seats

The valve seats are a loose fit in the pump housing. There are no

set screws holding them in place. When the valve seat has been

worn to a point where a

the valve seat (keeping the ball from seating properly), the valve

seat should be replaced.

Sand Packs

Washed sand left in the material hose can cause a sand pack

(clog) in the hose. When the material hose is washed out, make

sure all of the loose sand is washed out of the hose. If loose sand

is allowed to remain in the hose, the new material coming through

the hose will push the sand ahead until it forms a clog in the

hose.

Separation

Separation in the pump or the material hose is caused by water

being forced out of the material through a loose connection.

Make sure that none of the gaskets or o-rings in the pumping

system leak. Loose hose connections are one of the most

common causes of separation.

Whenever water leaks out through a hose connection, the

material will build up slowly. In an hour or so, depending on how

bad the leak, a restriction will form at the connection causing the

pump to work much harder to force the material through the

restriction. This also slows down the output production of the

pump. If this condition is not corrected, the pump will jam and

stop.

FROM THE FACTORY

manufactured of a special hardened

rubber to meet this specific application.

new

rubber check ball strikes the bar in

, as they are

NOTE

hoses when the pumping of stiff materials is required. Make sure

that all hoses are in good condition and that all connections are

air tight. When using the lower pumping speeds, run the engine

at a lower speed.

Leaks

Water can become separated from the material being pumped.

This is usually caused by loose connections or damaged seals.

When separation occurs, a restriction caused by a buildup of

material around the leak forces the pump to work harder. As a

result, pump output is lowered and eventually the pump will

stop.

Hose and Fittings

Due to the high pressure which the machine is capable of

producing we recommend the use of specially constructed

MAYCO hose. This hose has been designed to withstand the

pressures required to pump the material.

MAYCO hoses are available in 25 ft. and 50 ft. lengths. Each size

is equipped with a male insert on each end.

It is suggested to use all 2-inch (5.08 cm.) hose with the exception

of the last 25 or 50 ft. This should be 1.5 inch (3.81 cm.) hose, to

be used as a whipline.

Wheels

The machine is equipped with

rotating on tapered roller bearings. These bearings have been

packed at the factory and need not be repacked for approximately

6 months, at which time they should be removed, cleaned and

repacked with a good grade of wheel bearing grease.

Operating the pump at lower speeds

(placing the drive belt in either of the two

pulley groves next to the engine) will

develop high pressure in the material

pneumatic (air) type wheels

,

PAGE 20 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 21

MG-30 PUMP — GENERAL INFORMATION

Reducers

sizes of hose.

Air Compressor

Your plaster and mortar pump is equipped with a piston type

Quincy Air Compressor

This air compressor supplies air to the nozzle for spraying of

material.

Factors Affecting Hose Pressure

Stiffness of the mix is the most important factor affecting hose

pressure. There are others, however, that can be equally

important.

1. Hose Length – Pressure varies directly with the length of

2. Hose Size – The pressure required to pump material

3. Gypsum – In using gypsum plaster a rich mix (such as

4. Binders – Some binders for plaster take more pressure

5. Aggregates – The most familiar types of aggregate are

and

unions

NOTE

the hose. The pump must develop twice as much pressure

with a 100-ft. length of hose as it does with a 50-ft. length.

through a hose varies with the area of the hose. Thus, if the

pressure required for a length of 2-inch diameter (5.08 cm.)

hose is 300 pounds (136 Kg.), the pressure required for

the same length of 1.5-inch diameter (3.81 cm.) hose would

be over 500 pounds (227 Kg.) using the same pumping

rate.

2:1) will take more pressure to pump than a leaner mix. In

a 2:1 mix you will probably have to make your mix

somewhat softer than a 3:1 mix.

than others. A plaster using gypsum will require the most

pressure. Portland Cement pumps quite easily with a

minimum of pressure, as does clay or lime.

sand, vermiculite, perlite

has its own characteristics. As most sand absorbs very

little water, it is the easiest with which to control the

consistency of materials.

other hand, absorb considerably

under pressure, as do most perlites. Therefore, in the latter

cases, whether the binder is gypsum or

your mix must be somewhat softer.

NOTE

are available for connecting the various

Connecting material hoses by means of

any type of quick coupling device is

recommended because they generally

do not have an adequate pressure rating

and are hazardous.

, driven by V-belts from the engine.

and

zonolite

vermiculite or zonolite, on the

. Each one of these

more water

when pumped

Portland Cement

All materials being pumped become

stiffer, when applied under pressure.

Therefore, the mix at the machine must

be softer than if it were taken from the

mixer for hand application.

Effect of Hose Pressure On Height

When elevating a plaster containing gypsum and light weight

aggregate add about one-half pound per square inch to the

not

required horizontal pump pressure for every foot you elevate the

nozzle above the Mayco Model MG-30 plastering unit. This

additional pressure is generally not serious because you will

probably be running between 1 and 2 lbs. per square inch per

foot to overcome friction in the hose.

.

As an example, if you were using a 40 ft. (12 meters) hose with a

pressure of 1-1/2 psi per foot or a total of 60 psi when plastering

a wall, and you sprayed a 20 ft. (6 meters) ceiling, you would only

increase the pressure 10 lbs. (4.53 Kg.) or have a total of 70 lbs. (32

Kg.) pump pressure. If you wanted to spray a 40 ft. (12 meters)

ceiling and needed another 40 ft. (12 meters) of hose, your pump

pressure would be:

NOTE

Nozzle

The MAYCO spray nozzle is constructed of a lightweight material.

It has been designed with a removable cap for changing to various

size orifices and is also equipped with an atomizer for variance

in spray patterns.

The output from the spray nozzle can be controlled to supply a

volume from zero to 4.5 cu. ft. per minute. Because of this

considerable range in volume, the orifice in the nozzle must be

changed to fit the desired volume in order to obtain a good pattern.

In most cases a 5/8-inch (1.58 cm.) orifice will give a good pattern

in most browning or scratching applied to paperback wire. On

metal lath you should use as large an orifice as possible and

lower the air pressure. In most cases the air jet should be set

,

back from the orifice 1/2 to 5/8 inch (1.27 to 1.58 cm.). You will

find an air valve at the nozzle to control the air pressure.

First 40 feet @ 1-1/2 psi/ft. .............60 psi

Second 40 feet@ 1-1/2 psi/ft. ......... 60 psi

Elevation pressure 40 psi/2 ........... 20 psi

Total pump pressure .......140 psi

Material hose, steel delivery line and

couplings are available in various

pressure ratings when

and

tear

wear

calculated pressure rating.

will reduce the above

new. Age

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 21

Page 22

MG-30 PUMP — GENERAL INFORMATION

To change from a fine texture to a heavy browning pattern, follow

these steps:

1. Lower the air pressure.

2. Change to a larger size orifice.

3. Set the air jet farther back from the orifice.

4. Increase the volume of material.

To increase nozzle frequency and obtain small plaster globules,

reverse the above procedure.

How the Nozzle Operates

With the machine running at a rate to brown 80 square yards 1/2"

thick, you should use a 1/2-inch (1.27cm.) orifice and the distance

from the air stem to the orifice would be 3/8-inch (.952 cm.). To

scratch metal lath at the same pumping speed, you would set the air

stem from 1/2 to 5/8-inch (1.27 to 1.58 cm.) from the orifice, and you

would probably use a 5/8-inch (1.58 cm) orifice.

When adjusting the air pressure, it is desirable to get a good

even pattern in the spray. If the air pressure is too high, the plaster

will rebound from the wall. If the air pressure is too low, the spray

pattern will be very narrow and plaster cannot be sprayed on

‘evenly. Adjust air pressure at nozzle to obtain the desired pattern.

Since the operator feels little or no pulsation when running the

Mayco Model MG30 plastering unit, it would appear that plaster

comes from the nozzle in a steady stream. Actually, in operation,

a globule of plaster comes from the nozzle and is then followed

by a globule of compressed air.

ESSICK MIXER

The Essick Model EM120SM

shipped completely assembled and has been factory tested.

The drum batch capacity of these mixers is between 3.5 and

4.0 bags. With proper care, they will give continuous service

year-after-year.

This mixer is powered by a

engine. The power from the engine is transmitted via a clutch/

reduction assembly that is coupled directly to the paddle shaft.

Therefore providing high mixer torque and eliminating V-belts .

BEFORE STARTING

Before starting the engine, read the engine

owners manual and thoroughly understand the

safety information.

OIL LEVELS

Be sure to check the oil levels in the engine and transmission

before starting the mixer.

DIESEL ENGINE CARE

For care and operation of either

engine manufacturer’s operating instructions furnished with the

engine. We recommend draining and refilling the engine

crankcase at least every thirty hours of operation. Check the

engine oil level daily.

plaster

HATZ

HATZ

and mortar mixer is

Model 1B30, 8.0 HP

diesel engine, refer to the

diesel

The Mayco nozzle can be operated with as few as 50 plaster

globules per second, or a frequency of 50 cycles per second,

and as high as 1,000 cycles per second with the pump operating

at a constant volume.

When the nozzle is emitting 50 plaster globules per second,

each globule is 20 times the size of the plaster globules emitted

when the nozzle is set for 1000 plaster globules per second.

Here lies the basis for the various applications of the Mayco

Model MG30.

For example, when a fine texture is desired, the nozzle should

operate at a high frequency to break the plaster up into small

particles. In scratching metal lath, it is desirable to produce large

plaster globules that will adhere to the metal lath. Difference in

frequency can be detected by the sound of the nozzle in

operation. When the sound at the nozzle is high, almost at a

scream like pitch, the frequency is high and the globule size is

small.

PAGE 22 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 23

How It Works

MG-30 PUMP — APPLICATION

Mayco Plaster Pump,

The

materials at a steady rate of flow. This is done by using two

cylinders. The crank powered pumping cylinder does all of the

pumping. The cam powered slave cylinder is a compensating

cylinder and operates in a manner which causes the pulsating

material from the pumping cylinder to be pumped at a steady

rate of flow. The slave cylinder will not move until enough pressure

is developed to produce this steady rate of flow.

Model MG-30 designed to pump

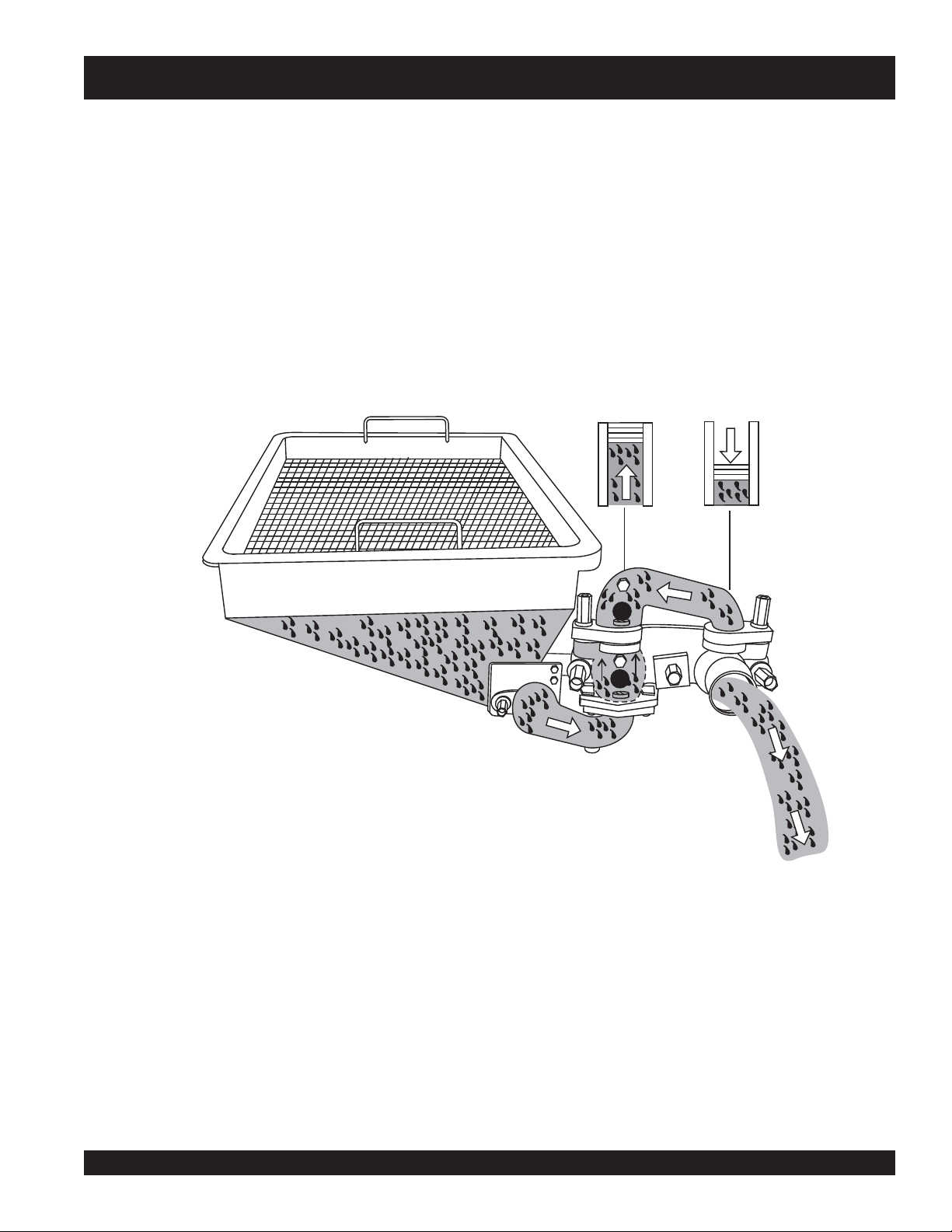

As shown in Figure 5, the pumping cylinder retracts drawing

the material past the ball A and filling the cylinder. The slave

cylinder is pumping the material out to the nozzle and

causing ball

to the pumping cylinder intake.

HOPPER

B

to seat

PUMPING

CYLINDER

INTAKE

preventing the material from returning

B

SLAVE

CYLINDER

INTAKE

A

DISCHARGE

Figure 5. Pumping Cylinder (Discharge)

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 23

Page 24

MG-30 PUMP — APPLICATION

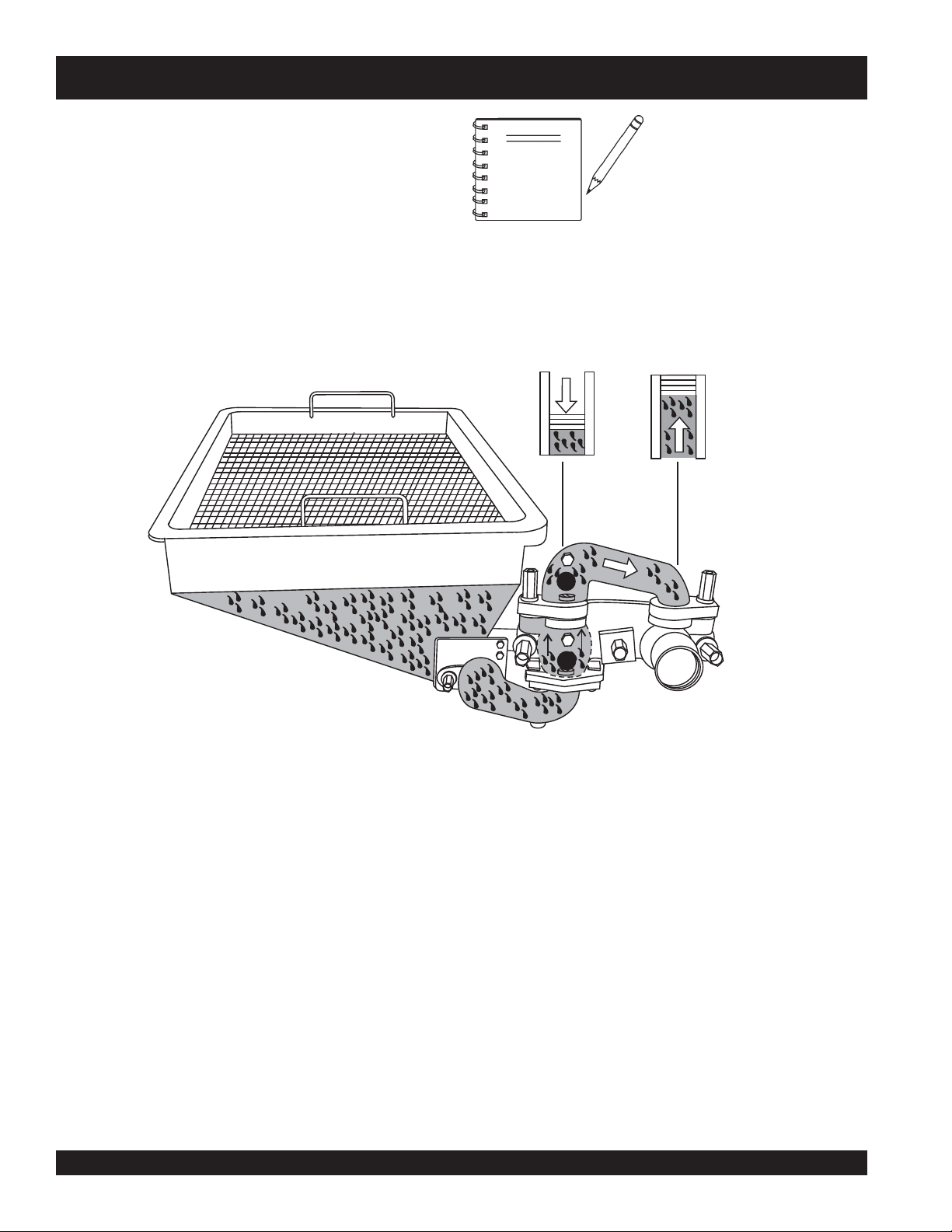

The pumping cylinder (Figure 6) is forcing the material past

ball B and out to the nozzle, also

material will not flow back to the hopper. This action also

fills the slave cylinder for the next stroke.

seating ball

A so that the

NOTE

HOPPER

PUMPING

CYLINDER

PUMPING

B

The slave piston will not move until

enough pressure is developed to

produce a steady rate of flow.

SLAVE

CYLINDER

INTAKE

A

N0

DISCHARGE

Figure 6. Pumping Cylinder (No Discharge)

PAGE 24 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 25

MG-30 PUMP — APPLICATION

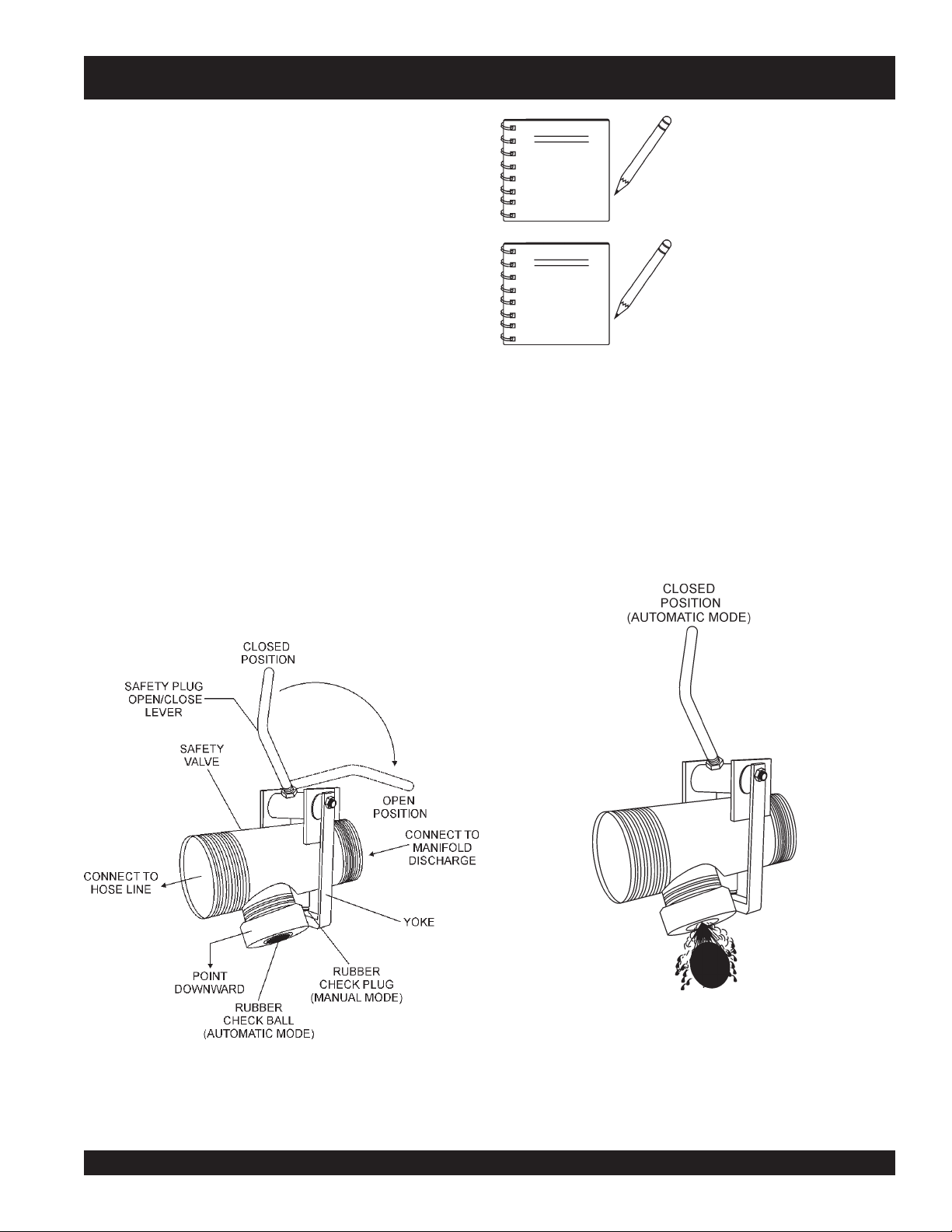

Pressure Relief Valve (Automatic)

Purpose

To provide the capability that will

pressure in a material hose or line whenever the flow of material

is restricted for any reason, causing unsafe pressure to build up

in the hose or line.

Safety Valve Placement (Automatic)

Place the automatic safety valve at the outlet side of the plaster

pump, ahead of the hose connection. This automatic safety valve

is to be used in conjunction with the manual release mechanism

(

safety relief pressure plug

Theory of Operation

Located on the

(Figure 7), is a pipe nipple with an opening which is sealed off

with a rubber ball that is held against the opening with a

cap

.

It is the responsibility of the pump operator to ensure that the

delivery hose and line system with all clamps and accessories

have a higher pressure rating than the safety cap being used.

bottom

of the

automatically

).

release the

safety relief pressure valve

brass

NOTE

NOTE

Suggestion:

DO NOT use a 1000 psi cap if your pumping requirement is less

than 750 psi.

system pressure.

The rubber ball will stay in place until an excessive amount of

pressure occurs that will cause the ball to

opening (Figure 8) in the brass cap and release the pressure in

the hose or line.

Always

NEVER place the MG-30 into

operation without a safety relief

pressure valve with a manual

release control installed on the

pump discharge.

ALWAYS

safety valve

prevent the ball from striking

someone and possibly causing

injury.

use a cap that is rated less than the total

point the brass cap on the

downward

blow

. This will

out through the

Figure 8. Safety Relief Pressure Valve

(Rubber Check Ball Release)

Figure 7. Safety Relief Pressure Valve

(Automatic Mode)

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 25

Page 26

MG-30 PUMP — APPLICATION

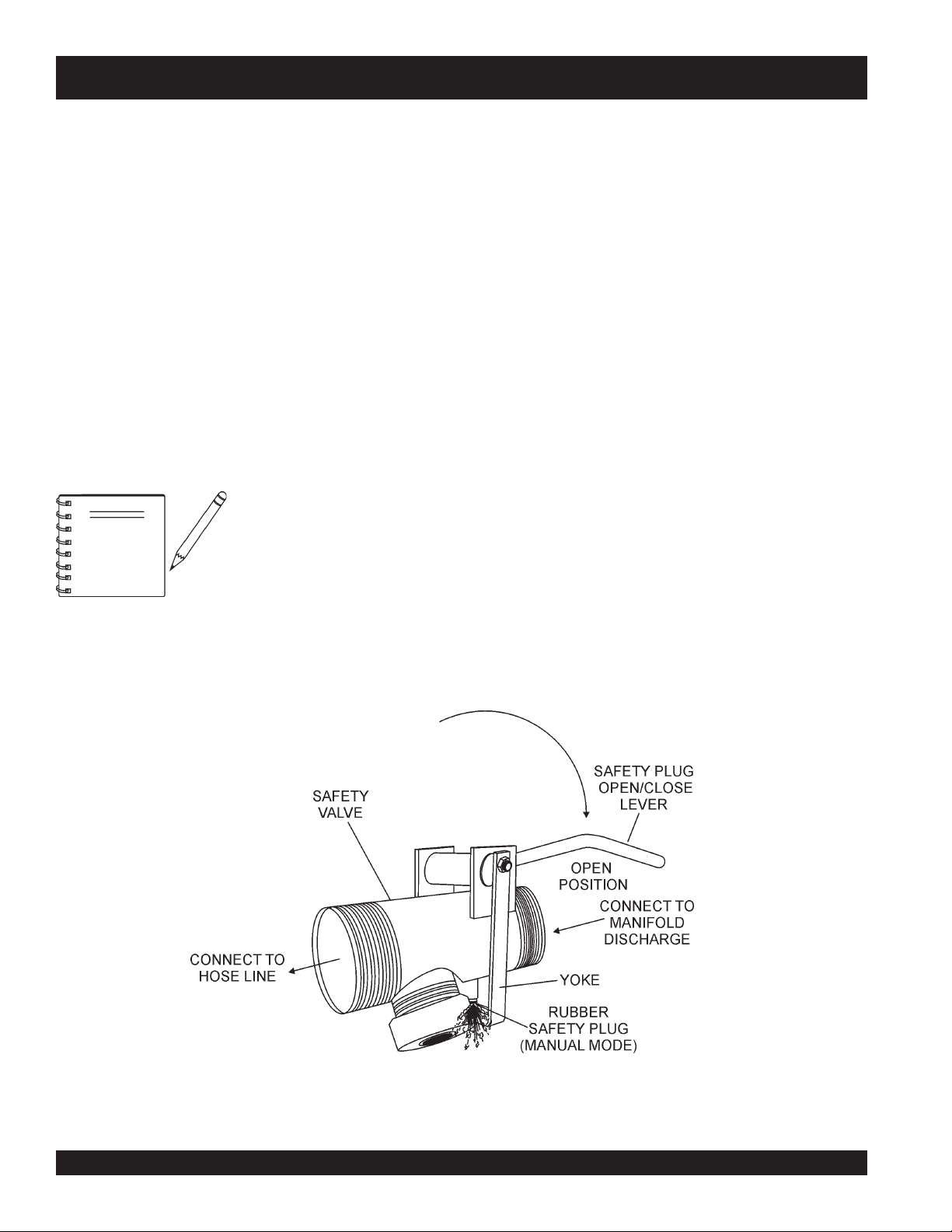

Pressure Relief Plug (Manual Operation)

Purpose

To provide the capability that will

in a material hose or line whenever the flow of material is restricted

for any reason, causing unsafe pressure to build up in the hose

or line.

Safety Valve Placement (Manual)

Place the

discharge side of the plaster pump, ahead of the hose connection.

Located on the pressure relief valve is a

release plug

a steel clamp (

downward

This manual pressure release plug is to be used in conjunction

with the automatic release mechanism (

safety relief pressure valve

(manual activation), the plug is held in position by

yoke) and is

to release the pressure in the system.

manually

activated by pulling the lever

ALWAYS

NOTE

release plug before disconnecting

any part of the delivery hose, line or

clamp system.

release the pressure

(Figure 9) at the

rubber pressure

rubber check ball

open the manual pressure

Before activating the manual pressure release

must

do the following:

1. Stop the engine.

2. Warn all workers and bystanders to stand at least 20 feet

away from the pump and turn their heads away from the

pressure relief safety valve.

3. The operator shall position himself/herself beside the

pressure relief safety valve with his/hers back to the

pump.

4. Wearing safety glasses, reach down with one hand, grasp

the release lever on top of the safety valve.

5. Turn head away from the pressure release plug and lift lever

upwards (open)

6. Remain facing away from the pressure relief valve until

).

counting up to 20, slowly. By that time, the material ejecting

under pressure will be slowly discharging. Work can resume

only after the material has been discharged for a minimum

of 20 seconds.

7. After correcting the problem that caused the excess pressure

in the system line, close the safety plug by pushing the plug

open/close lever

ing.

.

downward (

closed), and resume pump-

plug

the operator

Anytime it is necessary to uncouple or remove any part of

the delivery system, the manual pressure release plug must

be opened to relieve pressure in the system.

Figure 9. Rubber Safety Relief Pressure Plug

PAGE 26 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 27

MG-30 PUMP — MIXER MAJOR COMPONENTS

2

1

3

4

8

7

5

5

6

12

7

Figure 10 illustrates the major components and controls of

the mixer.

13

9

10

11

Figure 10. Mixer Major Components

1. Mixing Drum — Made of

steel

. Mixing materials such as

8. Clutch Lever — Push the clutch lever

concrete, mortar, plaster are to be placed into this drum for

mixing. Always clean the drum after each use. Drum

capacity is 12 cu. ft.

2. Mixing Paddles — Used in the mixing of material. This

9. Dump Handle — Pull this handle downward to dump the

unit uses four different types of paddles to provide a fast

uniform mix.

3. Bag Cutter— This feature allows compound mixing bags

10. Pivot Point/Zerk Fitting — There is, on each end of the

to be opened easily, therefore allowing the contents of the

bag to fall directly into the mixing drum. Bag capacity is 3.5

to 4 bags.

4. Transmission — Totally inclosed oil bath transmission.

12. Safety Grill Lock Handle — To prevent injury to hands

5. Engine Cover — Lift this cover to gain access to the engine

and transmission compartments.

6. Engine — The mixer unit is powered by a Hatz Model

IB30, 8.5 HP

diesel

engine. See page 30 for engine

component definitions.

13. Safety Grill — Provided for operator safety. This safety grill

7. Engine Cover Grip — Place hand inside grip then lift

upwards to raise cover. When lifting of the cover is required

make sure both rubber bunjee latches have been released.

8. Rubber Latch — Use this latch to secure the engine

compartment cover.

forward

, toward

the tow (tongue) end of the mixer to engage clutch. Once

clutch is engaged paddle shaft will rotate. To disengage

clutch pull the clutch

backwards

towards the engine.

contents of the drum. Push the handle upward to return the

drum to its vertical position.

mixing drum a zerk grease fitting. These fittings lubricate

the dumping mechanism. Lubricate both fittings at least

twice a week.

and arms, the safety grill should ALWAYS be locked when

the mixing of plaster or mortar is required. Also when

transporting the mixer the safety grill should be locked. The

safety grill should only be un-locked when cleaning of the

blades and drum is required.

is designed to keep hands and solid objects out of the

mixing drum when in use. This grill should be closed at all

times when pump is in use. DO NOT remove the grill or

grill opening bar. Keep the grill clean by washing it down

daily.

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 27

Page 28

MG-30 PUMP — MG30 M2D MAJOR COMPONENTS

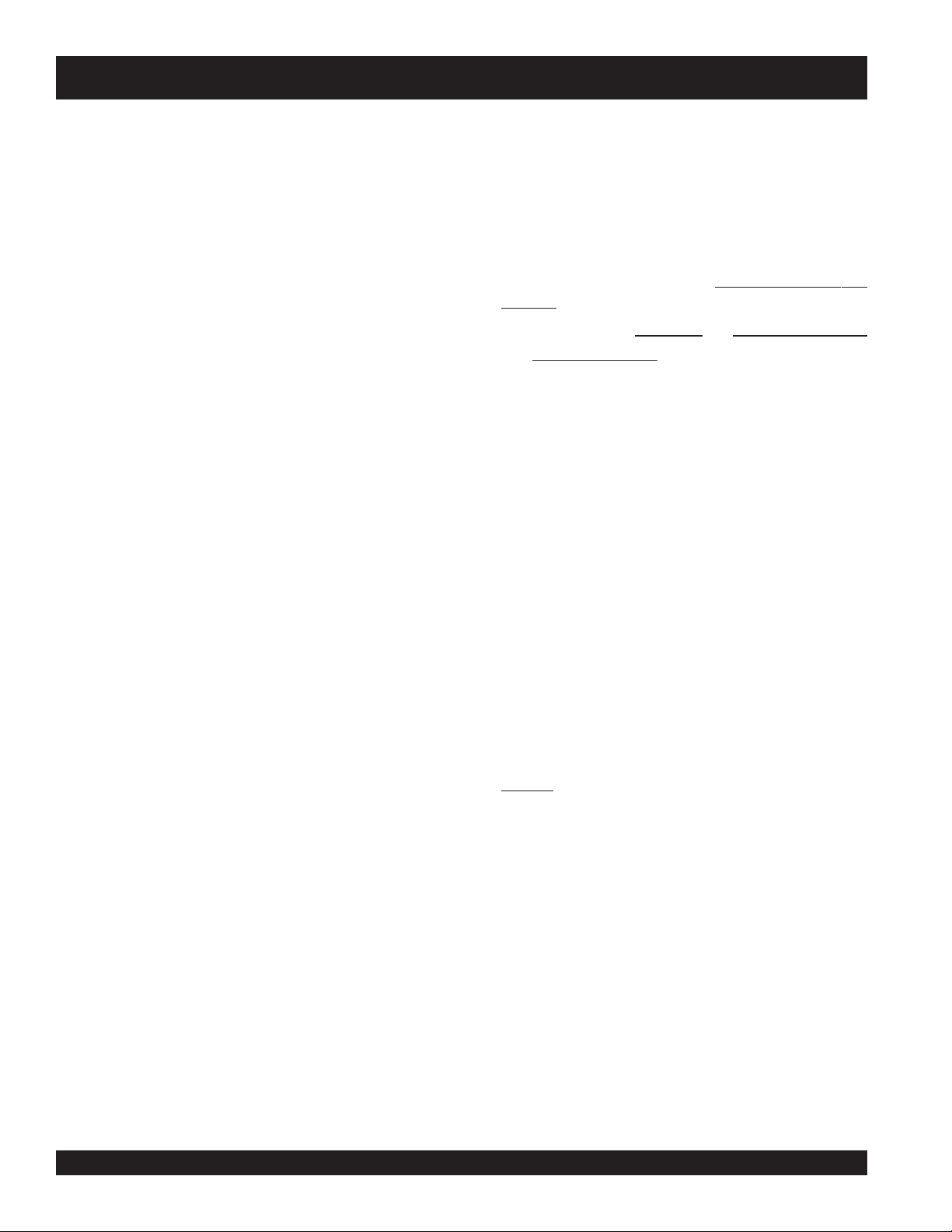

Figure 11 illustrates the major components and controls of

the MG-30 (Mobil Unit).

2

3

4

12

5

13

6

MG30-M2D

7

9

11

8

10

1

Figure 11. MG-30 Major Components

22

23

24

14

15

16

19

20

17

21

18

26

25

PAGE 28 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 29

MG-30 PUMP — MG30-M2D MAJOR COMPOUNDS

1. Manifold — Cast steel manifold, 2 in. (5.08 cm.) for plaster,

3 inch (7.62 cm.) for fireproofing. This manifold is designed

with a

manual pressure relief valve

safety pressure relief valve

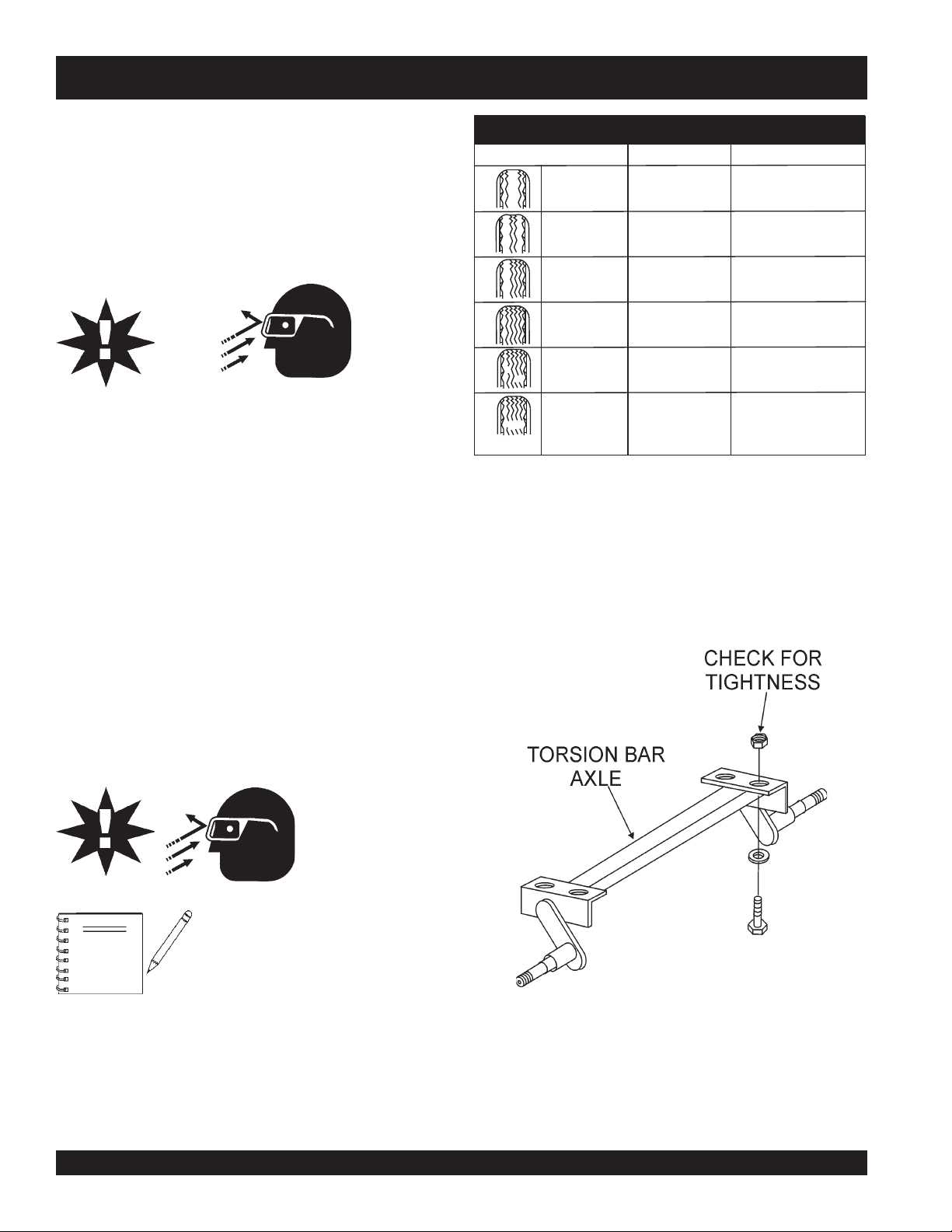

2. Tires — This trailer uses two ST205-750 x14C type tires.

Tire inflation pressure is the most important factor in tire

life. Pressure should be checked to

operation. DO NOT bleed air from tires when they are hot.

Check inflation pressure weekly during use to insure the

maximum tire life and tread wear.

3. Mixer — This unit uses a "

and

plaster mixer

definitions.

4. Oiler — Cam bearing oiler. Fill with SAE 20 or 30 wt. motor

oil. Lubricates cam surface.

5. Fuel Gauge/Fuel Cap — Read the top of this cap to

determine if the fuel level is low. If fuel level is low, remove

cap to add #2 diesel fuel.

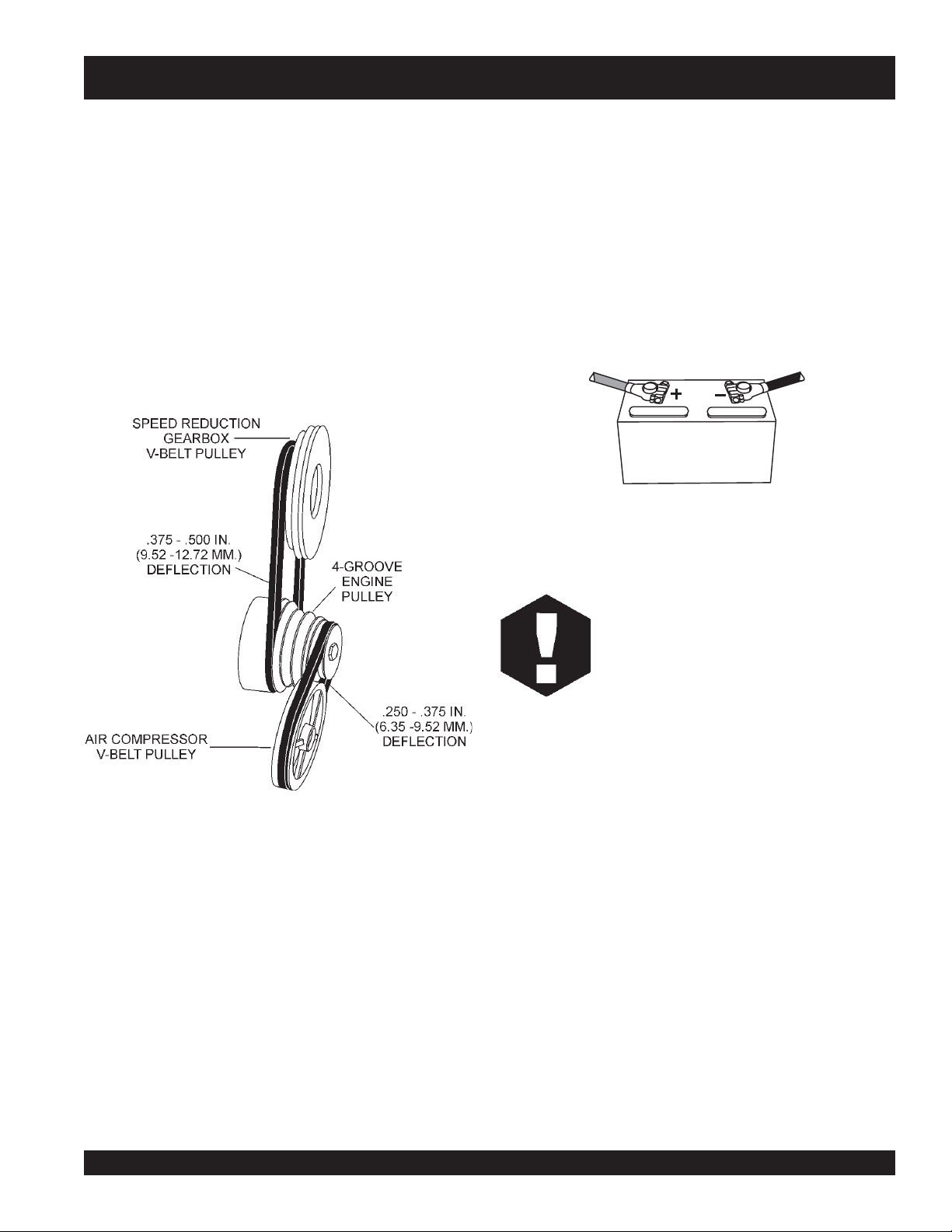

6. Gear Reduction Pulley — This is an adjustable 4-groove

pulley. Select the pulley speed that fits your pumping

requirement.

. See page 27 for mixer component

rated between 700-1000 PSI.

Essick

and an

automatic

50 psi cold

" mechanical 12 ft3

before

mortar

14. Piston Oiler Tank— Fill this tank to the "

15. Lubrication Port Panel — Central grease panel. All

16. Hopper — This unit uses a galvanized hopper which can

17. Mixer End Jack Stand – Use this jack stand to level

18. Lubrication Box Access Cover – There are four access

19. Gear Reduction Adjustment Bolt – Loosen this bolt to

20. Battery – This unit uses a +12 VDC type battery.

FULL

" level for

normal operating conditions. Check regularly. Fill with SAE

30 wt. type motor oil. Oiler tank capacity is 1-1/2 quarts (1.14

liters).

lubrication points can be accessed via this panel. Allows

lubrication of all bearings without lifting the hood.

hold up to 12.0 cu. ft. (340 liters) of mix. NEVER put hands

or any other parts of you body into the hopper.

and support the pump.

covers on the pump. Remove these doors to gain access to

drive and piston assemblies when maintenance is required.

pivot the gearbox assembly upwards or downwards. This

will allow for the placement of the V-belt on one of the four

pulley grooves.

ALWAYS

use gloves and eye protection when handling the battery.

7. Compartment Hood Lift Handles — There are two

compartment hood lift handles located on each side of the

hood. Grip handle and pull upwards to lift hood.

8. Compartment Hood — This hood encloses the engine,

compressor, gear reduction pulley, reduction gearbox,

battery, control box and other associated components

required to operate the pump.

with the hood in the up position.

9. View Access Window — This opening allows the user to

start the unit and have access to the control box without

lifting the compartment hood.

10. Access Cover/Handle — Turn this handle clockwise to

release latch, then lift upwards. When this cover is in the

open position it will provide a more free flow of air to help

keep the engine and associated components cool.

11. Documentation Box — Contains information regarding

the pump and mixer.

12. Speed Reduction Gearbox — A constant-mesh type and

total enclosed gearbox with all gears immersed in oil. Fill

with SAE 90 wt. motor oil.

proper operating level.

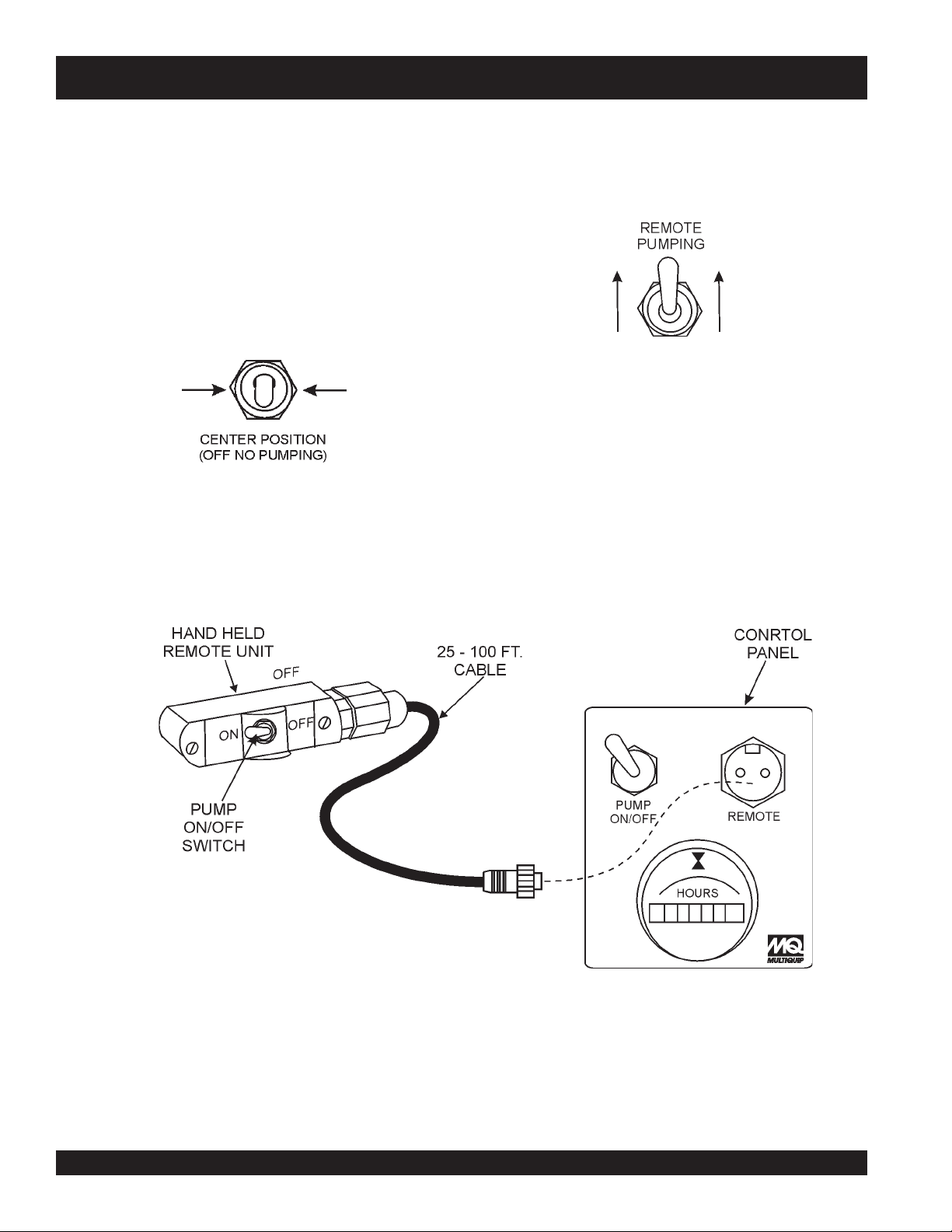

13. Engine Control Box — Contains the engine ignition

switch, operation switch, engine status LED's (5), hour meter,

remote control connector and 25 amp fuse.

NEVER!

ALWAYS

operate the pump

keep gearbox oil at

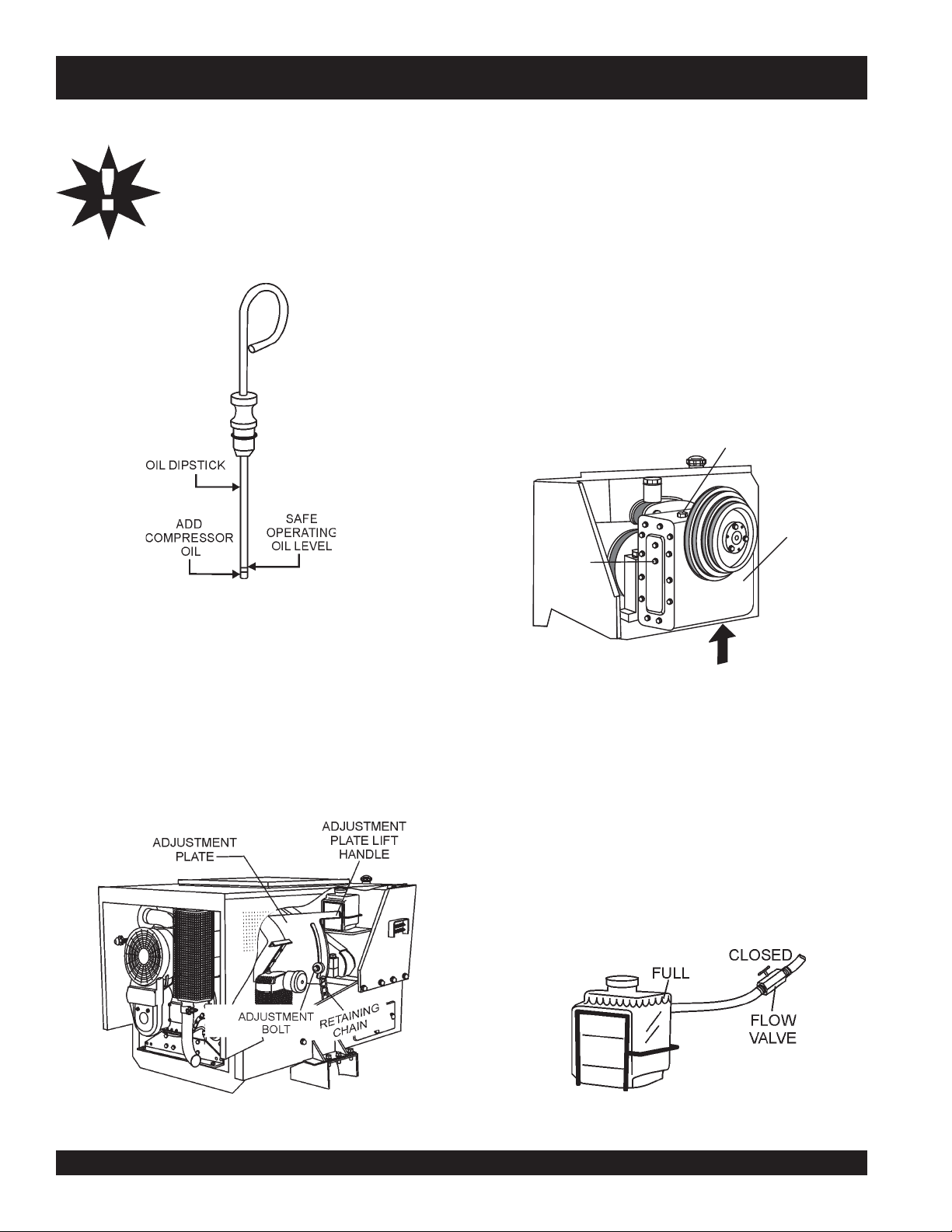

21. Air Compressor – This unit uses a piston type

22. Throttle Control Knob – This is a variable speed type

23. Engine – This unit uses a

24. Tow End Jack Stand – Use this jack stand to level and

25. Tow Hitch Coupler – Requires a 2-inch ball hitch or a

26. Chock Blocks – Place these blocks (not included as

Quincy

Air Compressor

air compressor supplies air to the nozzle for spraying of

material. The compressor has an output of 10 CFM @ 100

psi. A weekly check should be made of the crankcase oil

level to make sure it is at the

the two marks on the dipstick.

control. Turning the throttle lock (CCW) left unlocks the

throttle allowing the throttle control cable to be pulled out to

the desired position. Once the desired throttle position

(speed) has been achieved, turning the throttle lock to the

(CW) right locks it in place. Use the fine tune adjustment

knob to fine tune the engine rpm's.

To place the engine in idle, press the top button inward all

the way.

cooled diesel engine. See page 31 for engine component

definitions.

support the pump.

pin. Capable of towing 5,000 lbs.

part of your concrete pump package) under each wheel

to prevent rolling or when parked on a slope.

, driven by V-belts from the engine. This

full mark

HATZ

, or at least between

Model 2M4LZ, 35 HP air

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 29

Page 30

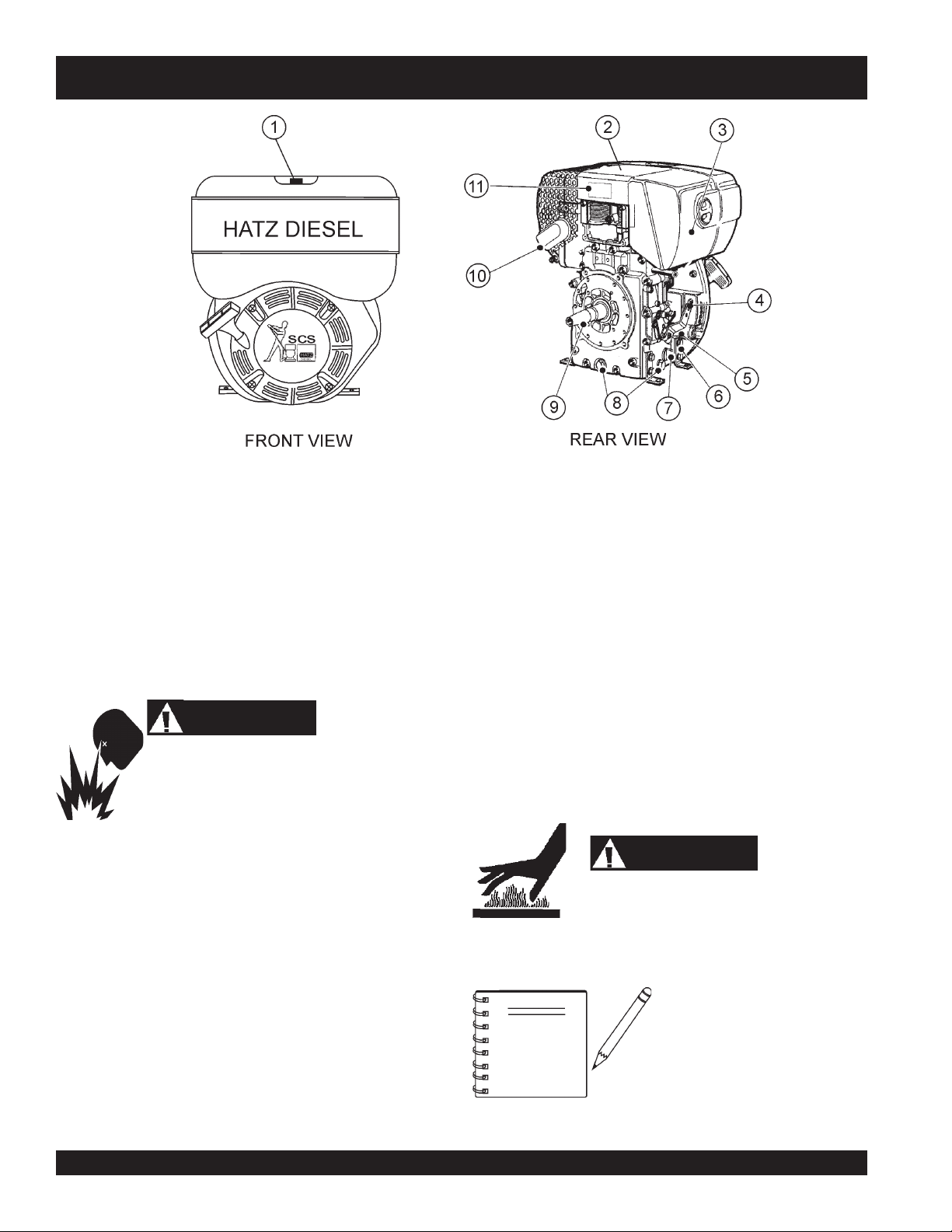

MG-30 PUMP — HATZ 8.5 HP ENGINE COMPONENTS

Figure 12. Hatz Model 1B30 8.5 HP Diesel Engine

INITIAL SERVICING

The

mixer's

lubrication and filled with fuel prior to operation. Refer to the

manufacturers Engine manual for instructions & details of operation

and servicing.

1. Fuel Filler Cap/Fuel Tank – Pull this latch to add

fuel to the tank. After refueling, always make sure the fuel

cap is latched properly. DO NOT over fill. For additional

information refer to engine owner's manual.

engine (Figure 12) must be checked for proper

diesel

WARNING

Adding fuel to the tank should be accomplished only

when the engine is stopped and has had an

opportunity to cool down. In the event of a fuel spill,

DO NOT attempt to start the engine until the fuel residue has been

completely wiped up, and the area surrounding the engine is dry.

2. Engine Lifting Straps/Cover – Remove the air cleaner

cover, then lift this cover (the one with decals on it) to gain

access to the engine lifting straps.

3. Air Cleaner/Cover – Prevents dirt and other debris from

entering the fuel system. Remove wing-nut on side of air

filter cover to gain access to filter element.

4. Speed Control Lever – This lever is connected to the

throttle control which is located on the side of the engine

compartment cover. Use this lever to control engine speed.

5. Dip Stick – Remove dipstick to determine if the engine oil

level is low. If low add oil as specified in Table 4, page 14.

6. Engine Motor Mounts – Attach these engine mounts to

the mixer frame. Tighten securely.

7. Oil Filter – Remove this bolt to gain access (internal) to the

engine oil filter. Service the oil filter as recommended in the

maintenance section of this manual.

8. Oil Drain Plugs – There are two oil drain plugs, one is

underneath the flywheel, the other on the side of the engine.

Remove these plugs to drain engine oil from the engine

crankcase.

9. Crankshaft – Connect this shaft to the input of the

transmission.

10. Muffler – Used to reduce noise and emissions.

11. Nameplate – Contains information about the engine.

while the engine is running or immediately after operating. NEVER

operate the engine with the muffler removed.

NOTE

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

Operating the engine without an

air filter, with a damaged air filter,

or a filter in need of replacement

will allow dirt to enter the engine,

causing rapid engine wear.

PAGE 30 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 31

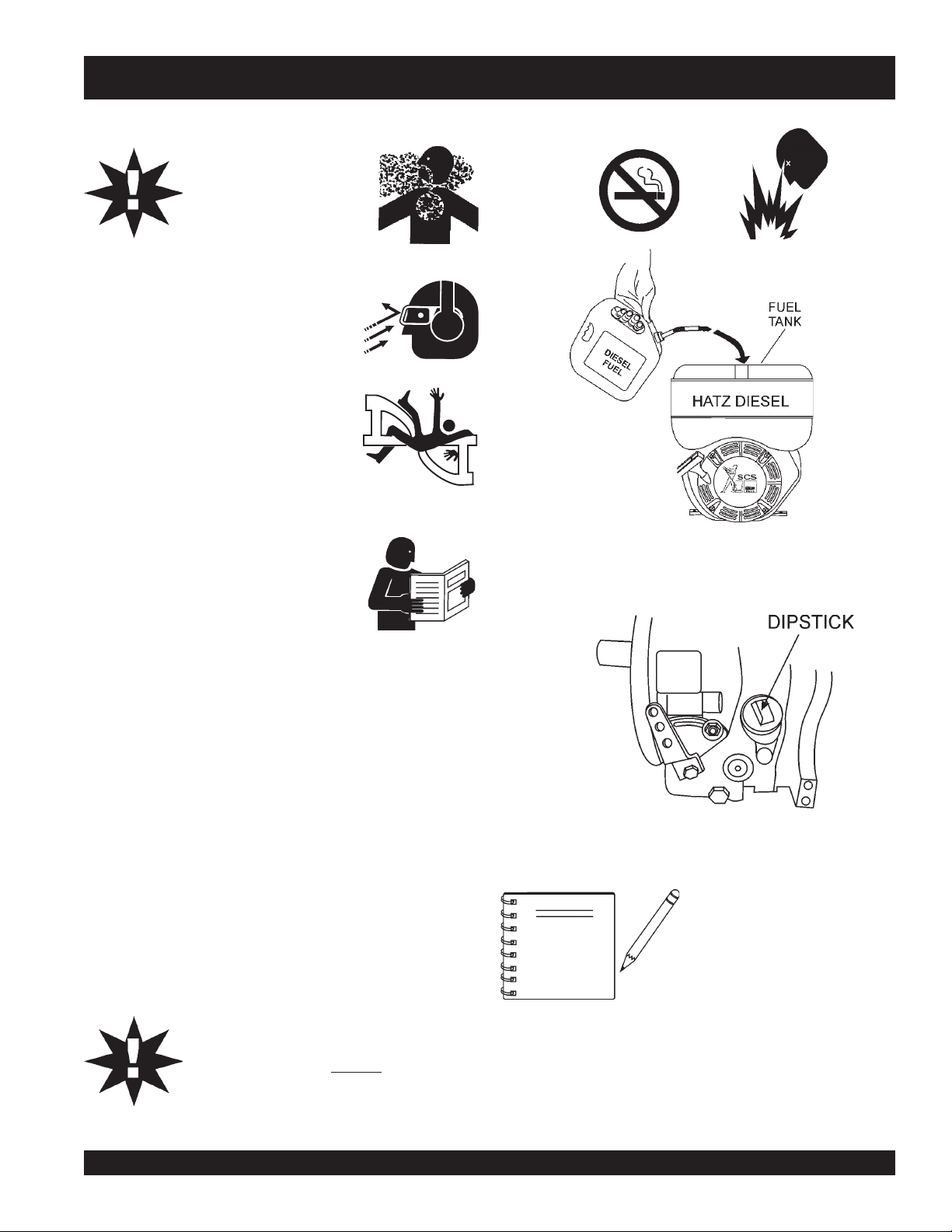

MG-30 PUMP — HATZ 35 HP ENGINE COMPONENTS

Figure 13. Hatz Model 2M41LZ 35 HP Diesel Engine

INITIAL SERVICING

The

pump's

lubrication and filled with fuel prior to operation. Refer to the

manufacturers Engine manual for instructions & details of operation

and servicing.

1. Muffler – Used to reduce noise and emissions.

touch the muffler while it is hot! Serious burns can result.

NEVER

2. Dip Stick – Remove dipstick to determine if the engine oil

level is low. If low add oil as specified in Table 8, page 37.

3. Speed Control Lever – This lever is connected to the

throttle control which is located on the side of the engine

compartment cover. Use this lever to control engine speed.

4. Oil Filter – Prevents dirt and other debris from entering the

engine. Service the oil filter as recommended in the

maintenance section of this manual.

engine (Figure 13) must be checked for proper

NEVER

operate the engine with the muffler removed.

5. Side Oil Drain Plug – Remove this plug to drain engine

oil from the engine crankcase. For best results drain engine

oil when oil is warm.

6. Air Filter/Cover – Prevents dirt and other debris from

entering the fuel system. Release the latches on the side of

the air filter cover to gain access to filter element.

7. Starter/Solenoid – This engine uses a 12 VDC , 2.7kW

(3.7 HP) starter motor with solenoid.

8. Front Oil Drain Plug – Remove this plug to drain engine

oil from the engine crankcase. For best results drain engine

oil when oil is warm.

9. V-Belt Cover – Remove this cover to gain access to the Vbelt. When replacing V-belt , use only recommended type

V-belt.

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 31

Page 32

MG-30 PUMP — PRE-INSPECTION (MIXER )

Blade Check

Adjust paddles as shown in Figure 14. Make sure paddle blades

are adjusted correctly before using mixer. Replace all

or

damaged

blades immediately.

defective

Figure 14. Paddle Blade Adjustment, Steel Drum

PAGE 32 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 33

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

NEVER operate the mixer in

a confined area or enclosed

area structure that does not

provide ample

free flow of air

.

MG-30 PUMP — PRE-INSPECTION (MIXER)

ALWAYS wear approved

protection before operating the mixer.

NEVER place hands or feet inside the mixing

ALWAYS

drum.

on the mixer is locked while the engine is

running. ALWAYS shut-down the engine

before performing any kind of maintenance

service on the mixer.

Before Starting

1. Read safety instructions at the beginning

of manual.

2. Clean the

ticularly the engine cooling air inlet, and air filter.

3. Check the

replace air filter with a new one as required.

make sure the

entire mixer

air filter

eye

and

hearing

safety grill

, removing dirt and dust, par-

for dirt and dust. If air filter is dirty,

Figure 15. Adding Diesel Fuel

ENGINE OIL

1. Remove the engine oil dipstick from its holder (Figure 16).

4. Check fastening nuts and bolts for tightness.

See Figure 12, page 30 for the location of any control or

component referenced in this section.

FUEL

1. Lift the fuel cap latch located on top of the fuel tank then look

inside the tank and determine if the mixer's engine fuel is

low . If fuel is low, fill with

Table 4 for other types of recommended fuel.

#2 diesel fuel

(Figure 15). See

NOTE

CAUTION:

Handle fuel safely. Motor fuels are highly

flammable

mishandled. DO NOT

DO NOT attempt to refuel mixer if the engine is

hot or running.

before refueling.

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 33

and can be dangerous if

smoke

ALWAYS

while refueling.

allow engine to

cool

Figure 16. Oil Filler Port/Dipstick

Reference manufacturer engine

manual for specific servicing

instructions.

Page 34

MG-30 PUMP — PRE-INSPECTION (MIXER)

2. Determine if the mixer engine oil is low (Figure 17), add

correct amount of engine oil to bring oil level to a normal

safe level. See Table 7 for recommended oil type.

LUBRICANTS

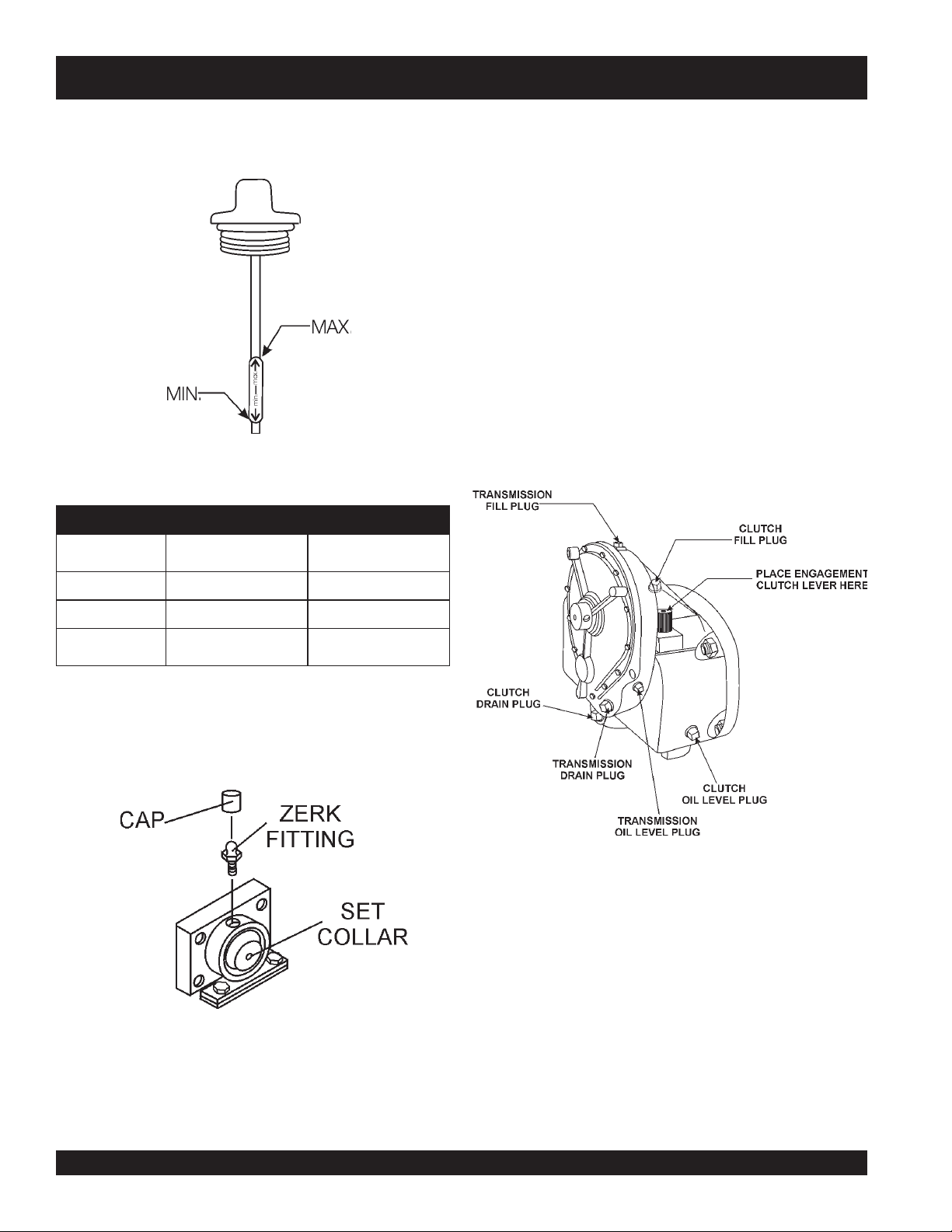

CLUTCH OIL

1. Remove the clutch oil level plug (Figure 19). If oil begins

to seep out as the plug is being removed, then it can be

assumed that the clutch oil is at the proper operating level.

2. If oil does not seep out as the oil level plug is being removed,

then remove the clutch oil fill plug and fill with SAE 30

engine oil to the proper operating level.

GEAR REDUCTION OIL (TRANSMISSION)

1. Remove the transmission oil level plug (Figure 19). If

oil begins to seep out as the plug is being removed, then it

can be assumed that the transmission oil is at the proper

operating level.

2. If oil does not seep out as the oil level plug is being removed,

then remove the transmission oil fill plug and fill with

Figure 17. Dipstick (Mixer Engine)

edarGliOrotoM.7elbaT

nosaeSerutarepmeT

remmuSrehgiHro)F°77(C°5203-W01EAS

liOrotoMfoedarG

)ssalcSMnahtrehgih(

SAE 90 transmission oil to the proper operating level.

llaFgnirpS)F°05(C°01~

retniW

)F°77(C°5202/03-W01EAS

)F°23(C°0

rewoLrO

01-W01EAS

W5EAS

ZERK GREASE FITTINGS

1. Check the zerk grease fittings at each end of the mixing

drum (Figure 18). These grease fittings lubricate the

dumping mechanism. If the dumping handle is stiff or hard

to move lubricate these fittings.

Figure 18. Zerk Fittings (Bearings)

Figure 19. Transmission/Clutch Lubrication

PAGE 34 — MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11)

Page 35

MG-30 PUMP — INITIAL START-UP (MIXER MOBIL ONLY)

WARNING!!

STAND

CLEAR

OF DUMP

HANDLE

Push

This section is intended to assist the operator with the initial

start-up of the

ESSICK

Model EM120SM mixer. It is extremely

important that this section be read carefully before attempting to

use the mixer in the field. The mixer unit is

not available

on the

TAG unit.

4.

toward the

throttle lever so that paddle shaft inside mixer rotates

between 30 - 40 RPM's. The number of RPM's will vary

depending on the load.

DO NOT use your mixer until this section has

been read and thoroughly understood.

CAUTION:

the clutch engagement lever forward (Figure 22),

tow end

of the mixer. When engine starts adjust

Failure to understand the operation of the

ESSICK

Model EM120SM mixer could result

in severe damage to the mixer or personal

injury.

STARTING THE ENGINE

The following steps outline the procedure for starting the

.

engine

1. Make sure the

clutch engagement lever

(Figure 22) is in

mixer's

the dis-engage position (lever is pointing towards the

engine end

2

PUSH

).

the "RED" button (Figure 20) on the throttle control

and pull the round black knob about halfway out. Make

sure that the throttle lock knob has been dis-engaged.

PUSH-IN, THEN PULL

TO SET THROTTLE

(RPM’s)

THROTTLE LOCK

KNOB, TURN CLOCKWISE

TO LOCK THROTTLE CABLE.

CLUTCH

LEVER

ENGAGE

DIS-ENGAGE

Figure 22. Clutch Engagement Lever

MIXING

1. The paddle shaft inside the drum should be rotating at this

time.

2. Lift the mixing bag compound onto the steel grate over the

bag cutter and let the contents fall into the drum.

3. Add water, and mix compound to desired consistency,

WARNING:

Be sure to stand clear of the

when the mixer is operational. Any binding of

material between the mixer blades and the

drum will cause the drum and dump handle to

suddenly move upwards, thus causing bodily

harm.

dump handle

THROTTLE RELEASE

AND STOP BUTTON

PUSH ALL THE DOWN

TO STOP ENGINE

Figure 20. Throttle Control Knob (Mixer)

Pull

the

3.

starter grip

(Figure 21) lightly until you feel

resistance, then pull briskly. Return the starter grip gently.

Figure 21. Starter Grip

MAYCO MG-30 PUMP — OPERATION AND PARTS MANUAL — REV. #3 (09/15/11) — PAGE 35

Figure 23. Mixer Dump Handle

STOPPING THE ENGINE

1. Place the clutch engagement lever in the dis-engage

position (lever is pointing towards the

2.

PUSH

the "RED" throttle button halfway in (idle speed).

engine end

).

Allow the engine to cool for 3-5 minutes.

PUSH

3.

the "RED" throttle button all the way in, this will stop

the engine.

Page 36

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

NEVER operate the pump in

a confined area or enclosed

area structure that does not

provide ample

free flow of air

.

MG-30 PUMP — PRE-INSPECTION (PUMP)

CAUTION:

Handle fuel safely. Diesel fuel is highly

flammable

mishandled. DO NOT

DO NOT attempt to refuel mixer if the engine is

hot or running.

before refueling.

and can be dangerous if

smoke

ALWAYS

while refueling.

allow engine to

cool

ALWAYS wear approved

protection before operating the pump .