Page 1

OPERATION AND PARTS MANUAL

JTO

RIDE-ON TROWEL

RIDE-ON POWER TROWEL

MODEL #

SERIAL #

Revision #5 (11/08/07)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

P/N 11280

Page 2

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT

800-421-1244

FAX: 310- 537-4259

TECHNICAL ASSISTANCE

800-478-1244

FAX: 310- 631-5032

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 3

Page 4

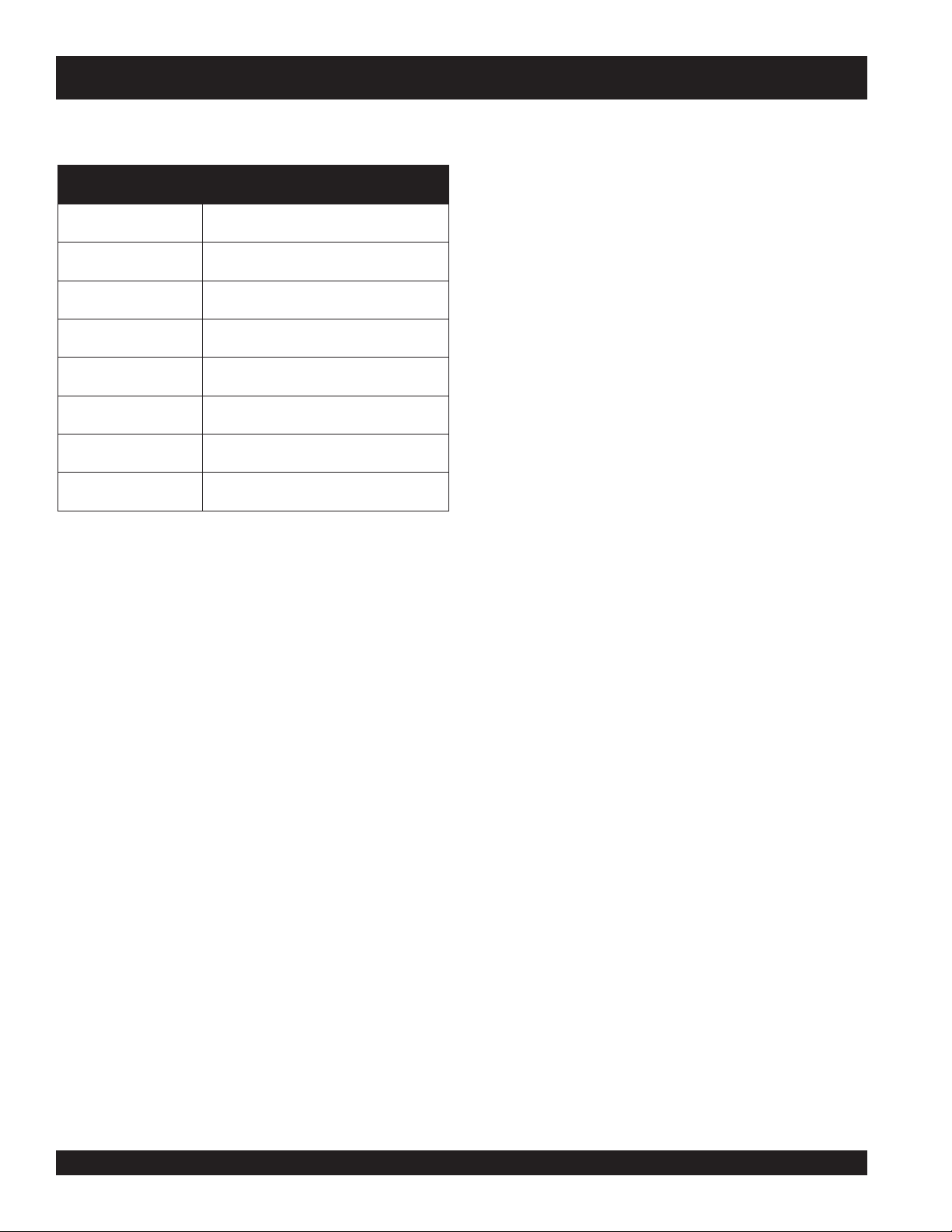

JTO RIDE-ON POWER TROWEL— TABLE OF CONTENTS

MQ WHITEMAN JTO RIDE-ON

POWER TROWEL

Here's How to Get Help ............................................ 3

Table of Contents ...................................................... 4

Training Checklist ...................................................... 5

Daily Pre-Operation Checklist ................................... 6

Parts Ordering Procedures ....................................... 7

Safety Message Alert Symbols ................................. 8

Rules For Safe Operation .................................... 9-12

Operation and Safety Decals .................................. 13

Specifications (Trowel) ............................................ 14

Specifications (Engine) ........................................... 15

Engine Components (Honda) ................................. 16

Engine Components (Vanguard) ............................ 17

General Information ................................................ 18

Controls and Indicators (Front) ............................... 20

Controls and Indicators (Rear) ............................... 21

New Machine Set-up Instructions ........................... 22

Initial Start-up ..................................................... 23-25

Maintenance ...................................................... 26-32

Troubleshooting (Trowel) ................................... 33-34

Troubleshooting (Engine) ................................... 35-36

Explanation od Code In Remarks Column.............. 37

Suggested Spare Parts ........................................... 38

4-Blade Spider Assembly (Left-Side) ................. 72-73

4-Blade Spider Assembly (Right-Side) .............. 74-75

Blades and Adjustment Fixture Assembly ......... 76-77

Twin Pitch Handle Assembly (RT/LT) .................78-79

Twin Pitch Tower Assembly (RT/LT) ...................80-81

Twin Pitch Miter Box Assembly .......................... 82-83

Main Frame Assembly ....................................... 84-85

Seat Frame Assembly ........................................ 86-87

Retardant Spray Tank Assy.

Retardant Spray Tank Assy.

S/N 30058 & Below . 88-89

S/N 30059 & Above 90-91

Foot Pedal Assembly ......................................... 92-93

Throttle/Foot Pedal ............................................ 94-95

Battery Assembly ............................................... 96-97

Lights Assembly .................................................98-99

Front Panel Assembly (Vanguard) .................100-101

Front Panel Assembly (Honda)) ..................... 102-103

E-Z Mover & Lift Handle Assembly ................ 104-105

Wiring Diagram, Vanguard .............................106-107

Wiring Diagram, Honda.................................. 108-109

Terms and Conditions of Sale ............................... 110

COMPONENT DRAWINGS

Nameplate and Decals.......................................40-41

Vanguard Engine and Clutch Assembly............. 42-43

Honda Engine and Clutch Assembly ................. 44-45

Drive Assembly .................................................. 46-47

Steering Assy. (LS) S/N 43489 & Below............. 48-49

Steering Assy. (RS) S/N 43489 & Above ............50-51

Steering Assy. (LS) S/N 43490-46645 ...............52-53

Steering Assy. (RS) S/N 43490-46645...............54-55

Steering Assy. (LS) S/N 46645-61579 ...............56-57

Steering Assy. (RS) S/N 46645-61579...............58-59

Gearbox Pivot Assembly .................................... 60-61

Gearbox Assembly (Right-Side) ........................ 62-65

Gearbox Assembly (Left-Side) ........................... 66-69

Thrust Bearing Kit .............................................. 70-71

PAGE 4 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

NOTE

Specifications and

part numbers are

subject to change

without notice.

Page 5

JT0 RIDE ON TROWEL — TRAINING CHECKLIST

TRAINING CHECKLIST

This checklist will lists some of the minimum requirements for machine maintenance and operation. Please feel free to detach it and

make copies. Use this checklist whenever a new operator is to be trained or it can be used as a review for more experienced

operators.

TSILKCEHCGNINIART

.ON NOITPIRCSED ?KO ETAD

1 .yletelpmoclaunaMs’rotarepOdaeR

2

3 .erudecorpgnileufer,metsysleuF

4 .)deppiuqefi(sthgildnayarpsfonoitarepO

5 .)gninnurtonenihcam(slortnocfonoitarepO

6 .noitarepo"hctiwsllik"taes,slortnocytefaS

7 .serudecorppotsycnegremE

8 .enihcamfoputratS

9 .revohagniniatniaM

01 .gnirevuenaM

11 .gnihctiP

21

dnaenignefognikcehc,stnenopmocfonoitacol,tuoyalenihcaM

.slevelliociluardyh

ehtgnigagnesid,™hctiPniwTsrewotneewtebhctipedalbgnihctaM

.egaknil

31 .seuqinhcetgnihsinifetercnoC

41 .enihcamfonwodtuhS

51 .)spooltfil(enihcamfognitfiL

61 .egarotsdnatropsnartenihcaM

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 5

Page 6

JTO RIDE ON TROWEL — DAILY PRE-OPERATION CHECKLIST

DAILY PRE-OPERATION CHECKLIST

1 .levellioenignE

2 .levellioxobraeG

3 .leveltnaloocrotaidaR

4 .sedalbfonoitidnoC

5 .noitarepohctipedalB

6 .noitarepo)taes("hctiwslliK"

7 .noitarepolortnocgnireetS

8 .stlebfonoitidnoC

TSILKCEHCNOITAREPO-ERPYLIAD

COMMENTS:

PAGE 6 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 7

JTO RIDE-ON POWER TROWEL— PARTS ORDERING PROCEDURES

When ordering parts,

please supply the following information:

❒❒

❒ Dealer account number

❒❒

❒❒

❒ Dealer name and address

❒❒

❒❒

❒ Shipping address (if different than billing address)

❒❒

❒❒

❒ Return fax number

❒❒

❒❒

❒ Applicable model number

❒❒

❒❒

❒ Quantity, part number and description of each part

❒❒

❒❒

❒ Specify preferred method of shipment:

❒❒

✓ FedEx or UPS Ground

✓ FedEx or UPS Second Day or Third Day

✓ FedEx or UPS Next Day

✓ Federal Express Priority One

✓ DHL

✓ Tr u c k

Note: Unless otherwise indicated by customer, all

orders are treated as “Standard Orders”, and will

ship within 24 hours. We will make every effort to

ship “Air Shipments” the same day that the order is

received, if prior to 2PM west coast time. “Stock

Orders” must be so noted on fax or web forms.

Here’s how to get help...

Please have the model and serial number on

hand when calling.

Parts Department

800-427-1244 Fax: 800-672-7877

310-537-3700 Fax: 310-637-3284

Mayco Parts

800-306-2926 Fax: 800-672-7877

310-537-3700 Fax: 310-637-3284

Service Department

800-478-1244 Fax: 310-537-4259

310-537-3700

MQ Power Service Department

800-835-2551 Fax: 310-638-8046

310-537-3700

Warranty Department

800-421-1244, Ext. 279 Fax: 310-537-1173

310-537-3700, Ext. 279

Multiquip’s Main Phone Numbers

800-421-1244 Fax: 310-537-3927

310-537-3700

Place Your Parts Order Via Web or Fax

For Even More Savings!

Extra Discounts!

All parts orders which include complete part numbers

and are received by our automated web parts order

system, or by fax qualify for the following extra

discounts:

Ordered Standard Stock orders

via orders ($750 list and above)

Fax 3% 10%

Web 5% 10%

Special freight allowances

when you order 10 or more

line items via Web or Fax!**

FedEx Ground Service

No other allowances on freight shipped by any other

carrier.

NOTE: DISCOUNTS ARE SUBJECT TO CHANGE

at no charge for freight

MULTIQUIP INC.

18910 WILMINGTON AVENUE

POST OFFICE BOX 6254

CARSON, CALIFORNIA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

WWW: multiquip.com

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 7

Direct TOLL-FREE access

to our Parts Department:

Toll-free nationwide — 800-427-1244

Page 8

JTO RIDE ON TROWEL — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at

all times when operating this equipment.

Failure to read and understand the Safety

Messages and Operating Instructions

could result in injury to yourself and others.

This Owner's Manual has been

developed to provide complete

instructions for the safe and efficient

operation of the MQ Whiteman

NOTE

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Ride-On Trowel

trowel, ensure that the operating

individual has read and understands

all instructions in this manual.

Before using this

JTO

HAZARD SYMBOLS

Rotating Parts

NEVER operate equipment with covers,

or guards removed. Keep fingers, hands,

hair and clothing away from all moving

parts to prevent injury.

Accidental Starting

ALWAYS place the engine ON/OFF

switch in the OFF position, when the

trowel is not in use.

Over-Speed Conditions

NEVER tamper with the factory settings of

the engine governor settings. Personal

injury and damage to the engine or

equipment can result if operating speed

ranges above maximum allowable.

DANGER:DANGER:

DANGER:

DANGER:DANGER:

SERIOUSLY injured if you DO NOT follow

directions.

WW

ARNING:ARNING:

W

ARNING:

WW

ARNING:ARNING:

SERIOUSLY injured if you DO NOT follow

directions.

CAUTION: CAUTION:

CAUTION:

CAUTION: CAUTION:

DO NOT follow directions.

Potential hazards associated with the JTO ride-on trowel

operation will be referenced with Hazard Symbols which appear

throughout this manual, and will be referenced in conjunction

with Safety Message Alert Symbols.

You WILL be KILLED or

You CAN be KILLED or

You CAN be injured if you

Other important messages are provided throughout this manual

to help prevent damage to your trowel, other property, or the

surrounding environment.

NOTE

Sight and Hearing Hazard

ALWAYS wear approved

hearing

Respiratory Hazard

ALWAYS wear approved

protection when required.

Equipment Damage Messages

protection when required.

This trowel, other property, or the

surrounding environment could be

damaged if you DO NOT follow

instructions.

eye

and

respiratory

PAGE 8 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 9

JTO RIDE ON TROWEL— RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is

for industrial use only.

The following safety guidelines should always be used when

operating the

SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate the trowel without proper protective clothing,

shatterproof glasses, steel-toed boots and other protective

devices required by the job.

JTO Ride-On Trowel

.

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

the trowel.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot!

with

■

The engine of this trowel requires an adequate free flow of

cooling air. NEVER operate the trowel (except electric models)

components can cause serious burns.

in any enclosed or narrow

area where free flow of the

air is restricted. If the air flow

is restricted it will cause

serious damage to the

trowel's engine and may

cause injury to people.

Remember the trowel's

engine gives off

carbon monoxide gas.

DEADLY

■

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate the trowel under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS check the trowel for loosened threads or bolts

before starting.

■

■

■

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it

to cool.

NEVER

machine. Fire or explosion could result from

fuel vapors

engine.

NEVER operate the trowel in an explosive atmosphere or

near combustible materials. An explosion or fire could result

causing severe

Topping-off to filler port is dangerous, as it tends to spill fuel.

smoke

around or near the

, or if fuel is spilled on a

bodily harm or even death.

hot!

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 9

Page 10

JTO RIDE-ON TROWEL — RULES FOR SAFE OPERATION

The following safety guidelines should always be used when

operating the JTO ride-on trowel:

General Safety

■

DO NOT operate or service this equipment before reading

this entire manual.

■

This equipment should not be operated by persons under 18

years of age.

■

DO NOT operate this trowel unless all guards and safety

devices are attached and in place.

■

ALWAYS check to make sure that the operating area is clear

before starting the engine.

■

ALWAYS test the

■

NEVER place your feet inside the guard rings while starting

or operating this trowel.

■

ALWAYS keep clear of rotating or moving parts while

operating this trowel.

■

NEVER leave the trowel unattended while running.

■

NEVER modify the safety kill switch. It is design for operator

safety.

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

■

ALWAYS use extreme caution when working with flammable

liquids. When refueling, stop the engine and allow it to cool.

DO NOT

explosion could result from flames or sparks, or if fuel is spilled

on a hot engine.

safety kill switch

smoke

before operating the trowel .

around or near the machine. Fire or

■

NEVER run engine without air filter. Severe engine damage

may occur.

■

ALWAYS service air filter frequently to prevent engine

malfunction.

■

ALWAYS be sure the operator is familiar with proper safety

precautions when operating the trowel.

■

ALWAYS store trowel properly when not in use.

■

DO NOT leave the trowel running unattended.

■

DO NOT allow unauthorized people to operate this trowel.

■

ALWAYS read, understand, and follow procedures in

Operator’s Manual before attempting to operate equipment.

■

Refer to the

Owner's Manual

information.

Transporting

■

ALWAYS shutdown engine before transporting.

■

Tighten fuel tank cap securely.

■

If the trowel is being transported via a trailer, make sure

trailer complies with all local and state safety

transportation laws. See “

for basic towing techniques in this manual.

Briggs and Stratton or Honda Engine

for engine technical questions or

Towing Safety Precautions

”

■

Moving Parts - Shut down the engine and disconnect battery

before performing service or maintenance functions. Contact

with moving parts can cause serious injury.

■

When lifting of the trowel is required, a chain can be attached

to the lift loops, allowing a forklift or crane to lift the ride-on

trowel up onto a slab of concrete. The strap or chain should

have a minimum 2,000 pounds (1000-kg) lifting capacity and

the lifting gear must be capable of lifting at least this amount.

■

NEVER stand underneath the trowel when it is being lifted.

■

This ride-on trowel is very

Use proper heavy lifting procedures and DO NOT attempt to

lift the ride-on trowel by the

PAGE 10 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

heavy

and awkward to move around.

guard rings

.

Page 11

JTO RIDE-ON TROWEL— RULES FOR SAFE OPERATION

Maintenance Safety

■

Disconnect the battery and spark plug wires before attempting

any type of service.

■

Securely support any trowel components that must be raised.

■

NEVER lubricate components or attempt service on a running

machine.

■

ALWAYS allow the trowel a proper amount of time to cool

before servicing.

■

Keep the trowel in proper running condition.

■

Make sure that there is no buildup of concrete, grease, oil or

debris on the trowel.

■

Fix damage to the trowel immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

■

DO NOT use plastic food containers to dispose of hazardous

waste.

■

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

■

NEVER store trowel with fuel in the tank for any extended

period of time. Always clean up spilled fuel immediately.

Battery

The battery contains acids that can cause injury to the eyes

and skin. To avoid eye irritation,

Use well insulated gloves when picking up the battery. Use

the following guidelines when handling the battery:

■

■

■

■

always

DO NOT drop the battery. There is the possibility of risk

that the battery may explode.

DO NOT expose the battery to

open flames, sparks, cigarettes

etc. The battery contains

combustible gases and liquids. If

these gases and liquids come in

contact with a flame or spark, an

explosion could occur.

ALWAYS keep the battery charged. If the battery is not

charged a buildup of combustible gas will occur.

ALWAYS keep battery charging and cables in good working

condition. Repair or replace all worn cables.

wear safety glasses.

DANGER:DANGER:

DANGER:

DANGER:DANGER:

Pay close attention to

ventilation when operating

the trowel inside tunnels

and caves. The engine

exhaust contains noxious elements.

Engine exhaust must be routed to a

ventilated area.

■

ALWAYS disconnect the

performing service on the trowel.

■

ALWAYS recharge the battery in an vented air

environment, to avoid risk of a dangerous concentration

of combustible gases.

■

In case the battery liquid (dilute sulfuric acid) comes in

contact with

immediately with plenty of water.

■

In case the battery liquid (dilute sulfuric acid) comes in

contact with your eyes, rinse eyes immediately with plenty

of water, then contact the nearest doctor or hospital, and

seek medical attention.

clothing or skin

negative battery terminal

, rinse skin or clothing

before

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 11

Page 12

JTO RIDE-ON TROWEL — RULES FOR SAFE OPERATION

Towing Safety Precautions

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Conform to

(DOT)

towing generator.

To reduce the possibility of an accident while transporting

the trowel on public roads, always make sure the trailer that

supports the trowel and the towing vehicle are in good

operating condition and both units are mechanically sound.

The following list of suggestions should be used when towing

your generator:

■

Make sure the hitch and coupling of the towing vehicle

are rated equal to, or greater than the trailer "gross vehicle

weight rating" (GVWR) of 6,000 lbs.

■

ALWAYS inspect the hitch and coupling for wear. NEVER

tow a trailer with defective hitches, couplings, chains

etc.

Department of Transportation

Safety Towing Regulations

before

■

Avoid sharp turns.

■

Trailer should be adjusted to a level position at all times

when towing.

■

Raise and lock trailer wheel stand in up position when

transporting.

■

DOT Requirements include the following:

z

z

Emergencies

■

ALWAYS know the location of the nearest

■

ALWAYS know the location of the nearest and

Connect and test electric brake operation.

Secure portable power cables in cable tray with

tie wraps.

fire extinguisher

first aid kit

.

.

■

Check the tire air pressure on both towing vehicle and

trailer.

Also check the tire tread wear on both vehicles.

■

ALWAYS make sure the trailer is equipped with a "Safety

Chain".

■

ALWAYS attach trailer’s safety chains to towing vehicle

properly.

■

ALWAYS make sure the vehicle and trailer directional,

backup, brake, and trailer lights are connected and

working properly.

■

The maximum speed for highway towing is 45 MPH

unless posted otherwise. Recommended off-road towing

is not to exceed 10 MPH or less depending on type of

terrain.

■

Place

rolling, while parked.

■

Use the trailer’s swivel jack to adjust the trailer height to

a level position while parked.

■

Avoid sudden stops and starts. This can cause skidding,

or jack-knifing. Smooth, gradual starts and stops will

improve towing.

Trailer tires should be inflated to 50 psi cold.

chock blocks

underneath each wheel to prevent

■

In emergencies

nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in the case of an

emergency.

always

know the location of the

keep a phone on the job site

and

fire department

.

. This

PAGE 12 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 13

JTO RIDE-ON TROWEL— RULES FOR SAFE OPERATION

Machine Safety Decals

The JTO-Series Ride-On Trowel is equipped with a number of safety decals. These decals are provided for operator safety and

maintenance information. Figure 1 below illustrates these decals as they appear on the machine. Should any of these decals

become unreadable, replacements can be obtained from your dealer.

Figure 1. Operation and Safety Decals

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 13

Page 14

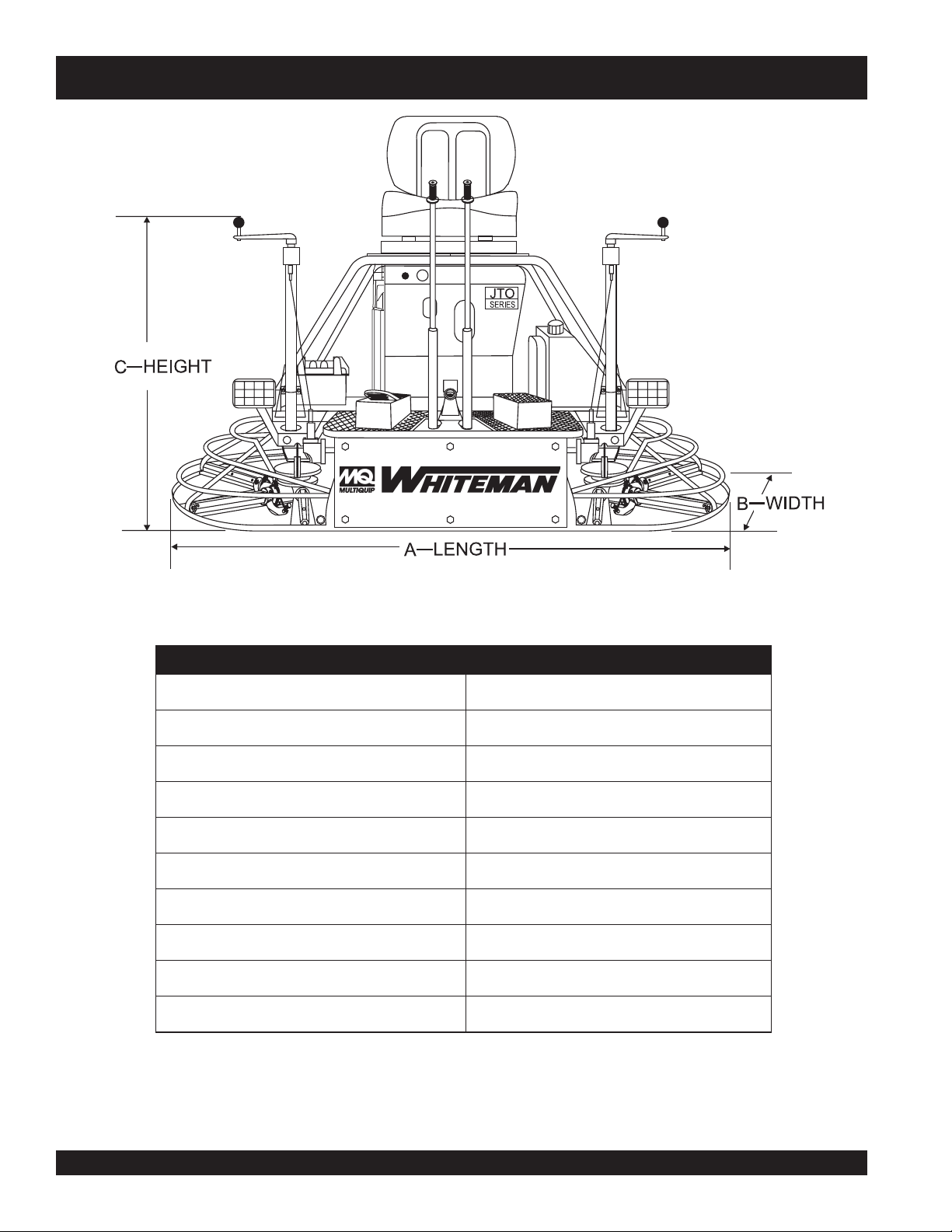

JTO RIDE-ON TROWEL — SPECIFICATIONS (TROWEL)

Figure 2. Trowel Dimensions

htgneL–A ).mc081(.ni0.17

htdiW–B ).mc99(.ni0.93

1

thgieH–C

gnitarepO).sgk(.sbl–thgieW ).sgk002(.sbl044

yticapaCknaTleuF )sretil8(.lag2.2

emiTnuR .rh/.lag95.1

deepSrotoR MPR831

rotoR/sedalB 4

htdiWhtaP ).mc571(.ni96

yticapaCliOnoitacirbuLxobraeG )sretil897.(.zo72

)leworT(snoitacificepS.1elbaT

).mc711(.ni0.64

NOTE:

1. This value does not include seat height. To obtain total

height (seat ) add 4 inches (10.2 cm.).

PAGE 14 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 15

JTO RIDE-ON TROWEL — SPECIFICATIONS (ENGINE)

)enignE(snoitacificepS.2elbaT

erutcafunaMenignE)nottartS&sggirB(draugnaVadnoH

epyT/noitacificepSenignE

ekortSXeroB

tnemcalpsiDcc075cc416

rewoPmumixaM)mpr006,3(ph0.81)mpr006,3(ph0.02

TmumixaM

euqro

deepSeldImpr

MPRdaoLoNmumixaMmpr001±0063mpr001±0063

noitpmusnoCleuFcificepS

yticapaCknaTleuF

apaCliOesacknarC

ytic

metsySgnitratScirtcelE/lioceRcirtcelE/lioceR

p

aGgulPkrapS

renaelCriAtnemelElauDtnemelElauD

thgi

eWyrD

HXWXLsnoisnemiD

50.6(

ia,evlavdaehrevo

96x88.17(

±004,1mpr051±004,1

.rh/.slag46.1

snollag02.2

)sretil23.8(

stnip25.3

)sretil66.1(

.sbl0.47

).gk65.33(

,rednilycniwT106800744053

deloocr

.ni57.2x28.2

).mm58.

)mpr008,2(.sbl-tf07.13

)mpr008,2(m-fgk73.41

).rh/sretil/

.ni030.0-820.0

).mm67.0-07.0(

.ni41.81x06.01x04.71

.mm164x962x244

.ni06.2x30.3

).mm0.66x0.77(

.rh/.slag45.1

).rh/sretil/28.5(

snollag02.2

)sretil23.8(

stnip81.3

)sretil05.1(

.ni130.0-820.0

).mm87.0-07.0(

.sbl6.29

).gk0.24(

x03.51

daehrevo,ekorts-41BXQ1K026XG

)niwT-V°09(srednilyc2,evlav

)mpr005,2(.sbl-tf5.23

)mpr005,2(m-fgk05.4

.ni8.71x0.81

.mm254x754x883

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 15

Page 16

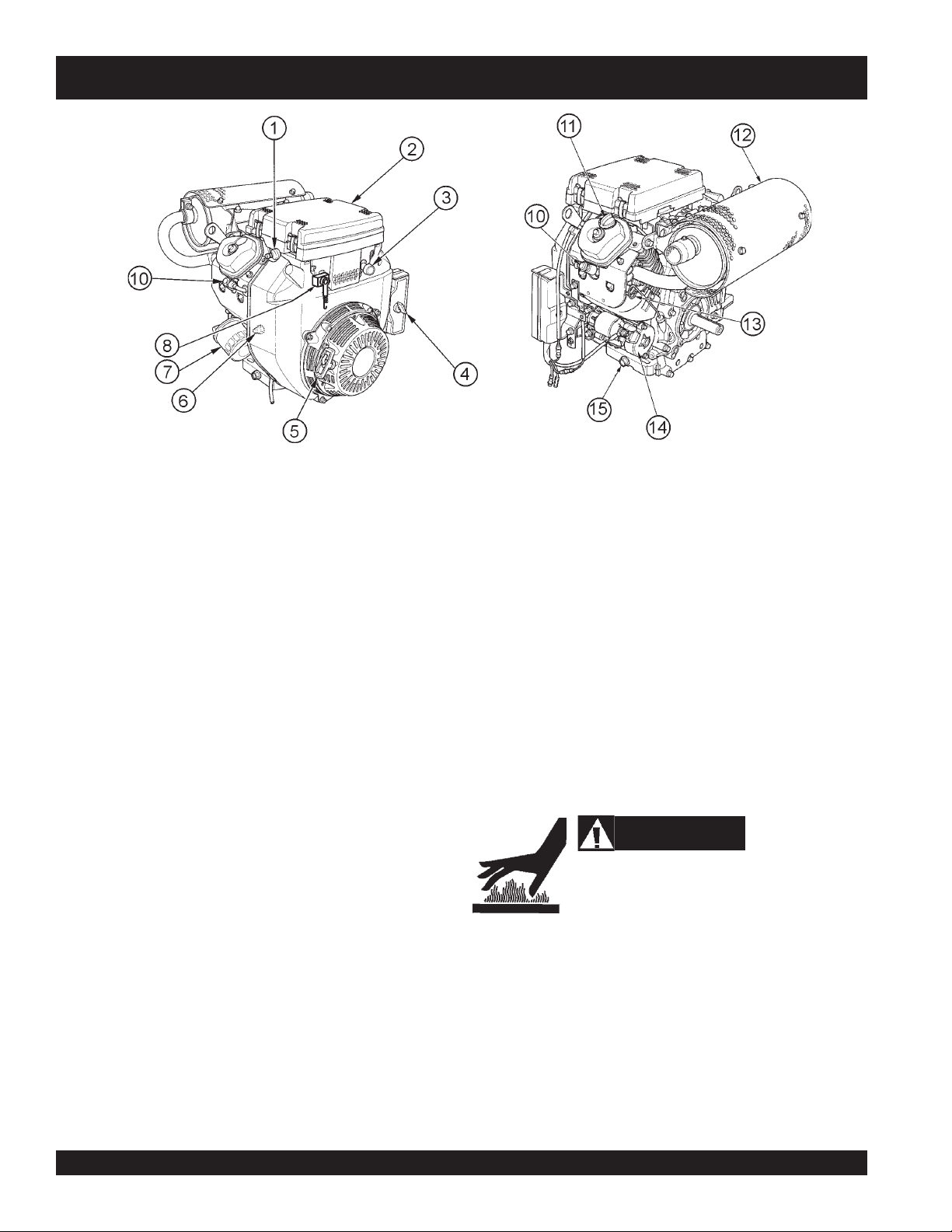

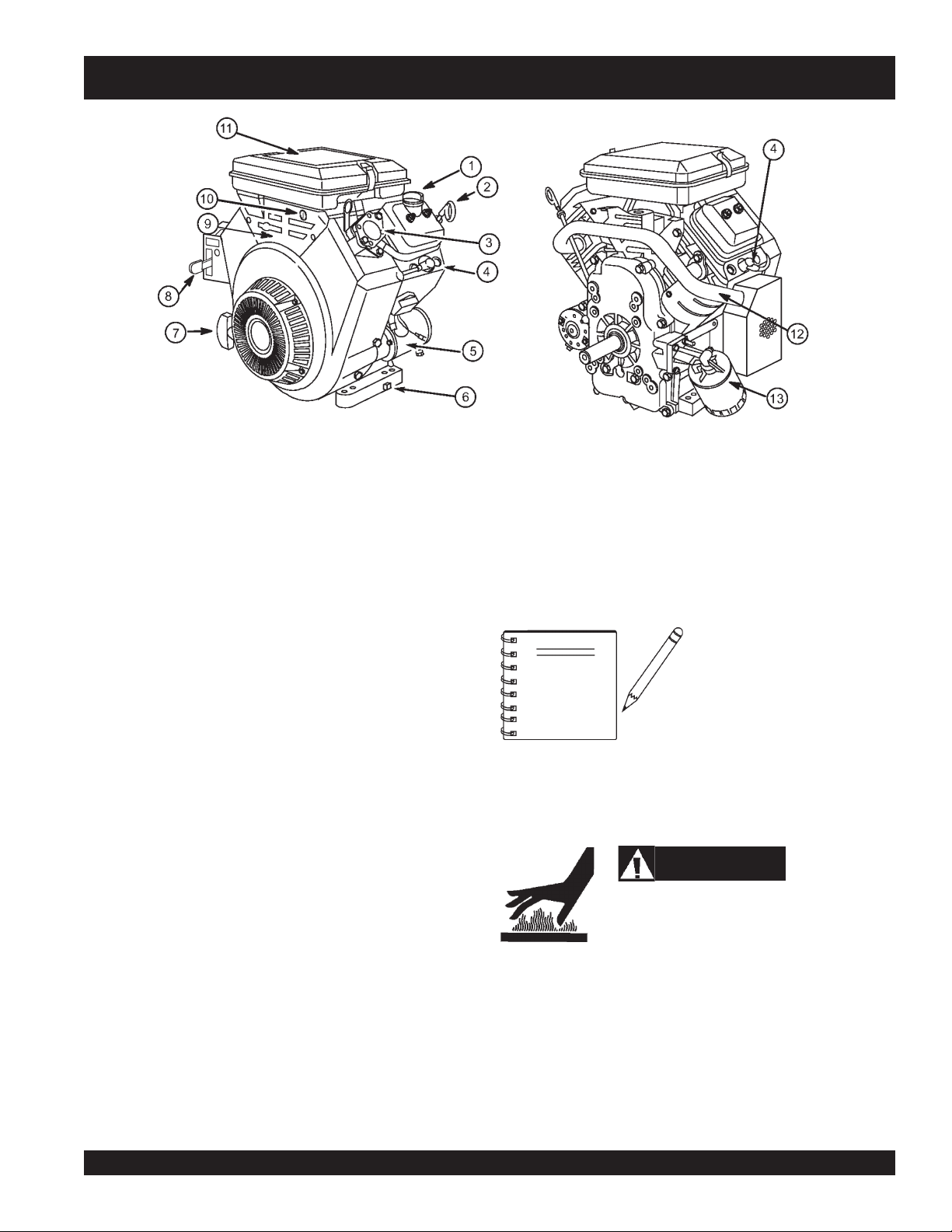

JTO RIDE-ON TROWEL— ENGINE COMPONENTS (HONDA)

Figure 3. Engine Controls and Components (Honda)

INITIAL SERVICING

The engine (Figure 3) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturer's engine

manual for instructions & details of operation and servicing. The

engine shown above is a HONDA engine. Operation for other

types of engines may vary somewhat.

1. Fuel Filter – Filters fuel for contaminants.

2. Air Filter – Prevents dirt and other debris from entering the

fuel system. Unsnap air filter cover to gain access to filter

element.

3. Choke Knob – Used in the starting of a cold engine or in

cold weather conditions. The choke enriches the fuel

mixture.

4. Engine ON/OFF Switch – "ON" position permits engine

starting, "OFF" position stops engine operations.

5. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

6. Oil Sensor Switch – This switch monitors the oil level in

the engine crankcase. In the event of low oil, the engine

will be shut down.

7. Oil Filter – Spin-on type, filters oil for contaminants.

8. Throttle Lever – Controlled by accelerator pedal,

increases or decreases engine RPM.

10. Spark Plug – Provides spark to the ignition system. Set

spark plug gap to 0.71 - 0.78 mm (0.028 - 0.031 inch) Clean

spark plug once a week.

11. Oil Filler Cap – Remove cap to refill or replace oil with

recommended type as listed in Table 3. Make sure cap is

tightened securely. DO NOT over fill.

12. Muffler –Used to reduce noise and emissions.

touch the muffler while it is hot! Serious burns can result.

NEVER

operating. NEVER operate the engine with the muffler removed.

13. Oil Dip Stick – Remove to check amount and condition of

oil in crankcase.

14. Starter – Starts engine when ignition key is rotated to the

"ON" position.

NEVER

operate the engine with the muffler removed.

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

15. Oil Drain Plug – Remove to drain crankcase oil.

PAGE 16 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 17

JTO RIDE-ON TROWEL — ENGINE COMPONENTS (VANGUARD)

INITIAL SERVICING

Figure 4. Engine Controls and Components (Vanguard)

The engine (Figure 4) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturers Engine

manual for instructions & details of operation and servicing.

1. Oil Fill Cap – Remove cap to refill or replace oil with

recommended type as listed in Table 3. Make sure cap is

tightened securely. DO NOT over fill.

2. Oil Dipstick – Remove to check amount and condition of

oil in crankcase.

3. Fuel Pump – Pumps fuel from the fuel tank into the

carburetor.

4. Spark Plugs – Provides spark to the ignition system. Set

spark plug gap to 0.71 - 0.76 mm (0.028 - 0.030 inch) Clean

spark plug once a week.

5. Electric Starter – Starts engine when ignition key is rotated

to the “ON” position.

6. Oil Drain Plug – Remove to drain crankcase oil.

7. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

8. Throttle Lever – Used to adjust engine RPM speed (lever

SLOW

advanced forward

FAST

).

9. Choke Lever – Used in the starting of a cold engine, or in

cold weather conditions. The choke enriches the fuel

mixture.

, lever back toward operator

10. Ignition Switch – Insert the ignition key here to start the

engine. Turn the key clockwise to the

continue turning clockwise to the

release. To stop the engine turn the key fully counterclockwise to the

NOTE

11. Air Filter – Prevents dirt and other debris from entering

the fuel system. Release the latches on the sides of the air

filter cover to gain access to filter element.

12. Muffler – Used to reduce noise and emissions.

touch the muffler while it is hot! Serious burns can result.

NEVER

13. Oil Filter – Prevents dirt and other debris from entering the

engine. Service the oil filter as recommended in the

maintenance section of this manual.

ON

position, then

STOP

START

position.

Operating the engine without

an air filter, with a damaged air

filter, or a filter in need of

replacement will allow dirt to

enter the engine, causing rapid

engine wear.

position and

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operating. NEVER operate the engine with the

muffler removed.

NEVER

operate the engine with the muffler removed.

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 17

Page 18

JTO RIDE-ON TROWEL — GENERAL INFORMATION

JTO RIDE-ON TROWEL FAMILIARIZATION

The JTO ride-on trowel is designed for the floating and finishing

of concrete slabs. This ride-on trowel is a overlapping trowel.

Take a walk around the trowel. Take notice of all the major

components (see Figures 5 and 6) like the engine, blades, air

cleaner, fuel system, fuel shut-off valve, ignition switch etc. Check

that there is always oil in the engine, and gear oil in the gear box

assembly.

Read all the safety instructions carefully. Safety instructions will

be found throughout this manual and on the machine. Keep all

safety information in good, readable condition. Operators should

be well trained on the operation and maintenance of the trowel.

Look at the operator control levers. Grab the control levers and

move them around a bit. Look to see how moving the control

levers causes the gearboxes and frame to move.

Notice the foot pedal which controls the engine speed. Also take

a look at the main driveline of the trowel. Take note and reference

how the belts look, this is the way the belts should look when

adjusted properly.

Before using your ride-on trowel, test it on a flat watered down

section of finished concrete. This trial test run will increase your

confidence in using the trowel and at the same time it will

familiarize you with the trowel’s controls and indicators. In addition

you will understand how the trowel will handle under actual

conditions.

Engine

This trowel is equipped with either a air-cooled 18 HP Vanguard

(Briggs and Stratton) gasoline engine or a 20 HP air-cooled

Honda gasoline engine (GX620). Refer to the engine owner’s

manual for specific instructions regarding engine operation. This

manual is included with the ride-on trowel at the time of shipping

from Whiteman. Please contact your nearest Multiquip Dealer

for a replacement should the original manual disappear.

Gearboxes

The JTO ride-on trowel consist of two separate gearbox

assemblies that are enclosed in rugged cast aluminum gear

cases. The main gear is a high quality bronze and steel

composite. The worm gear is composed of hardened steel.

Cooling fins and fans are integrated into the gearbox to provide

maximum cooling for the gearbox oil. The gearbox casing holds

50% more oil capacity than competitors, which allows more

lubrication to be provided to critical points.

Steering Assist

Dual control levers located in front of the operator's seat are

provided for steering the trowel. The control levers are linked to

two spring loaded cylinders. Push the left control lever forward

and pull the right control lever backward and the trowel will rotate

clockwise on approximately a center axis. Pull the left control

lever backward and push the right control lever forward and the

trowel will rotate counterclockwise. See Table 4 for a complete

description on the control levers directional positioning.

Constant Velocity Joints (CV-Joints)

Constant velocity joints insure the efficient transfer of power to

the drive shaft and maintains the timing of the gearboxes without

any chance of slippage.

Training

For proper training, please use the “TRAINING CHECKLIST”

located in the front of this manual. This checklist will provide an

outline for an experienced operator to provide training to a new

operator.

Blades

The blades of the trowel finish the concrete as they are rotated

around the surface. Blades are classified as

(8 inches wide),

inches wide). This trowel comes equipped with four blades

per rotor equally spaced in a radial pattern and attached to

vertical rotating shaft by means of a

float

(10 or 8 inches wide), and finish (6

spider assembly.

PAGE 18 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

combination

Page 19

NOTE PAGE

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 19

Page 20

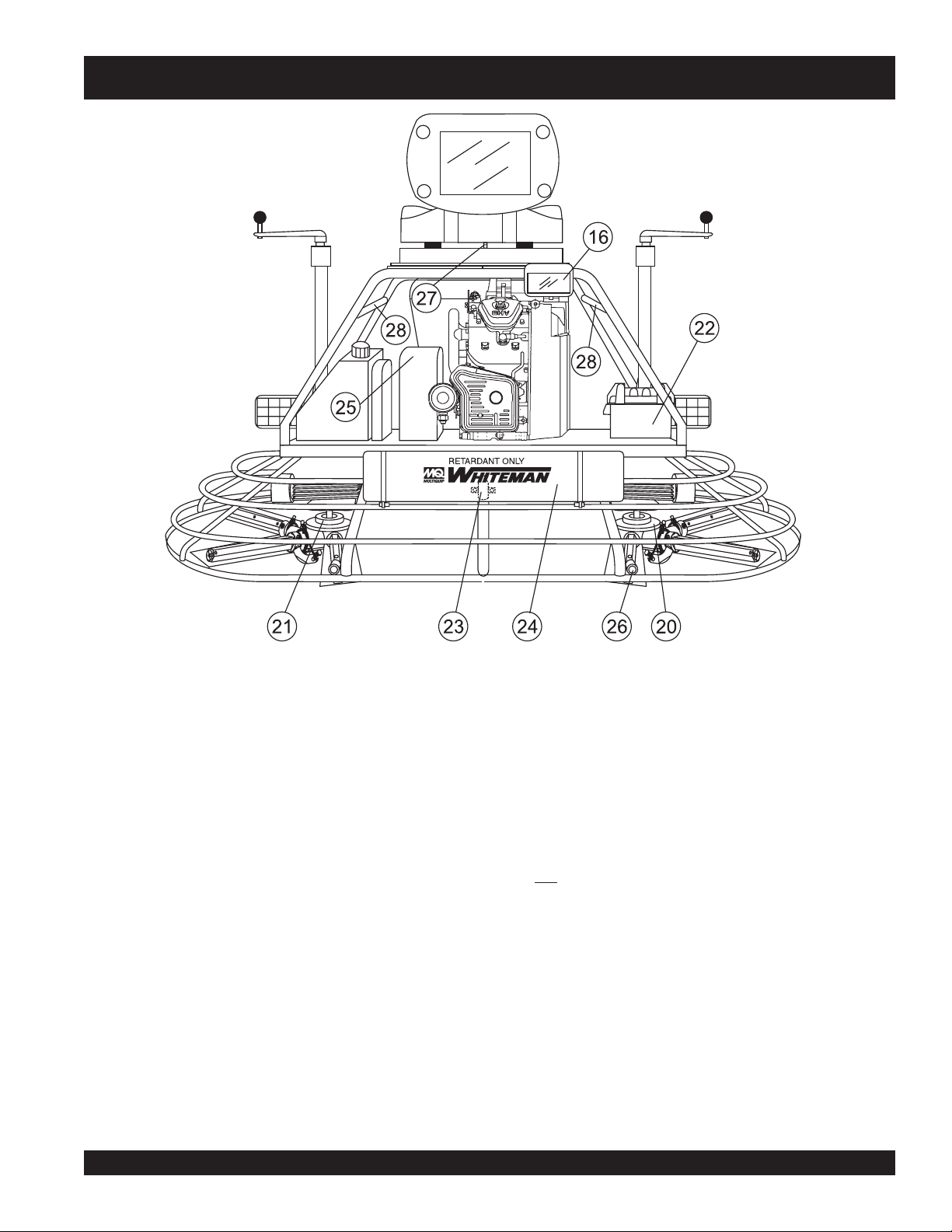

JTO RIDE-ON TROWEL — CONTROLS AND INDICATORS

Figure 5. JTO Controls and Indicators (Front)

1. Seat – Place for operator to sit. Engine will not start unless

operator is seated. Seat is adjustable, fore and aft for

operator comfort.

2. Steering Control Lever (right-side) -Allows the unit to

move in either a forward, reverse left or right direction.

3. Retardant Spray Control Button – When pressed allows

retardant spray to flow through the spray nozzle located at

the front of the machine.

4. Twin Pitch Control – Adjusts the blade pitch for right side

of the trowel. Turn the crank as marked on its top surface to

increase or decrease blade pitch.

5. Twin Pitch Control – Adjusts the blade pitch for left side

of the trowel. Turn the crank as marked on its top surface to

increase or decrease blade pitch.

6. Steering Control Lever (left-side) -Allows the unit to

move in either a forward, reverse left or right direction.

7. Light Switch – When activated, turns on four halogen

lights. Lights offer better visibility when working indoors.

8. Ignition Switch – With key inserted turn clockwise to start

engine.

9. Fuel Gauge/Filler Cap - Indicates the amount of fuel in

the fuel tank. Remove this cap to add fuel.

10. Fuel Tank - Holds 2.2 gallons of unleaded gasoline.

11. Spare Belt Carrier - Contains 2 spare belts. Belts are used

on the drive pulley.

12. Left Foot Riser – Operator foot rest pedal.

13. Spray Nozzle – Spray nozzle for retardant.

14. Right Foot Pedal – Controls blade speed. Slow blade

speed is accomplished by slightly depressing the foot pedal.

Maximum blade speed is accomplished by fully depressing

the foot pedal.

15. EZ- Mover Boss – Front -side insertion point for EZ Mover.

Used when the transporting of the trowel is required.

16. Lights – Four 12 volt halogen lights are provided with this

unit.

17. Hour Meter - Indicates number of hours machine has been

in use or hours engine was run.

18. Dip Stick- Access hole provided to check engine oil

through this cutout.

19. Spark Plug- Access the spark plug through this cutout.

PAGE 20 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 21

JTO RIDE-ON TROWEL — CONTROLS AND INDICATORS

HTN/HTO-31V — CONTROLS AND INDICATORS

Figure 6. JTO Controls and Indicators (Rear)

20. Right-Side Spider – Consists (basic) of trowel arms,

blades, wear plate, and thrust collar etc.

21. Left-Side Spider – Consists (basic) of trowel arms, blades,

wear plate, and thrust collar etc.

22. Battery – Provides +12V DC power to the electrical system

23. Retardant Spray Motor – Used in conjunction with the

left spray control button.

24. Retardant Spray Tank – Holds 5 gallons of retardant.

25. Belt Guard – Encloses V-belts used in conjunction with

26. EZ- Mover Boss – Back- side insertion point for EZ Mover.

27. Safety Kill Switch – Shuts down engine when operator is

28. Lift Loops – Located on both the left and right sides of the

clutch.

Used when the transporting of the trowel is required.

not sitting in seat.

main frame. Used when the trowel must be lifted onto a

concrete slab.

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 21

Page 22

JTO RIDE-ON TROWEL— NEW MACHINE SETUP INSTRUCTIONS

Trowel Pre-Set-Up Instructions

The purpose of this section is to assist the user in the setting up

NEW

of a

handles, knobs and battery, then this section can be skipped.

Before packaging and shipping this Whiteman Ride-On Power

Trowel was run and tested at the factory. If there are problems,

please let us know.

Control Handle Setup

1. Remove the bolts from the plastic bag tied to the control

2 Remove all protective wrapping and straps from the control

3. Slip the top (loose) piece into the base of the corresponding

4. Install the bolt through the lined up holes and tighten the

trowel. If your trowel is already assembled (seats,

The new ride-on trowel cannot be

put into service until the pre-setup

NOTE

towers.

handles.

handle, making sure to line up the holes.

installation instructions are

completed. These pre-setup

instructions only need to be

performed at the time of unpacking

NEW

a

trowel.

Seat Assembly

The seat is not installed on the trowel for shipping purposes. To

attach the seat perform the following:

1. Remove the seat from the protective wrapping.

2. Remove the bolts on the bottom of the seat, and place seat

on the seat mounting plate, then insert the bolts through

the holes or slots on the seat mounting plate and tighten.

NOTE

on tracks, similar to an automobile seat. This seat can be adjusted

fore and aft via the control lever under the front of the seat.

Battery Setup

This trowel was shipped with a wet charged battery. This battery

may need to be charged for a brief period of time as per the

manufacturer instructions.

When charging the battery, always wear

rubber gloves. Use the following rules when charging the

battery:

There are two types of seats,

depending on what type of trowel

you have. J and H series trowels

have slots on the seat mounting

plate that allow fore and aft

adjustment of the seat. H-series

trowels have a seat that is mounted

eye

protection and

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Some models are equipped with

adjustable height handles. Adjust

NOTE

the height by placing the bolt

through the set of holes that

corresponds to the most comfortable

height.

■

DO NOT expose the battery to

open flames, sparks, cigarettes

etc. The battery contains

5. Pay close attention to any wires that may be inside the

control handles. DO NOT pinch or cut any wires during

installation.

6. Inside the plastic bag of parts are two knobs for the pitch

control tower cranks. Install these two knobs onto the tower

crank levers.

combustible gases and liquids. If these gases and liquids

come in contact with a flame or spark, an explosion could

occur.

■

ALWAYS keep the battery charged. If the battery is not

charged a buildup of combustible gas will occur.

To install the battery on the trowel, make sure that the

■

ALWAYS keep battery charging and cables in good working

battery is well seated in the battery box and the

condition. Repair or replace all worn cables.

terminals are properly connected. Close the plastic

battery box cover and secure the battery box.

■

ALWAYS recharge the battery in an vented air

environment, to avoid risk of a dangerous concentration

of combustible gases.

PAGE 22 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 23

JTO RIDE-ON TROWEL — INITIAL START-UP

This section is intended to assist the operator

with the initial start-up of the JTO ride-on trowel.

It is extremely important that this section be read

carefully before attempting to use the trowel in

the field.

DO NOT use your ride-on power trowel until this section is

thoroughly understood.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Failure to understand the operation of the JTO

Ride-On Trowel could result in severe damage

to the trowels or personal injury.

See Figures 5 and 6 for the location of any control or indicator

referenced in this manual.

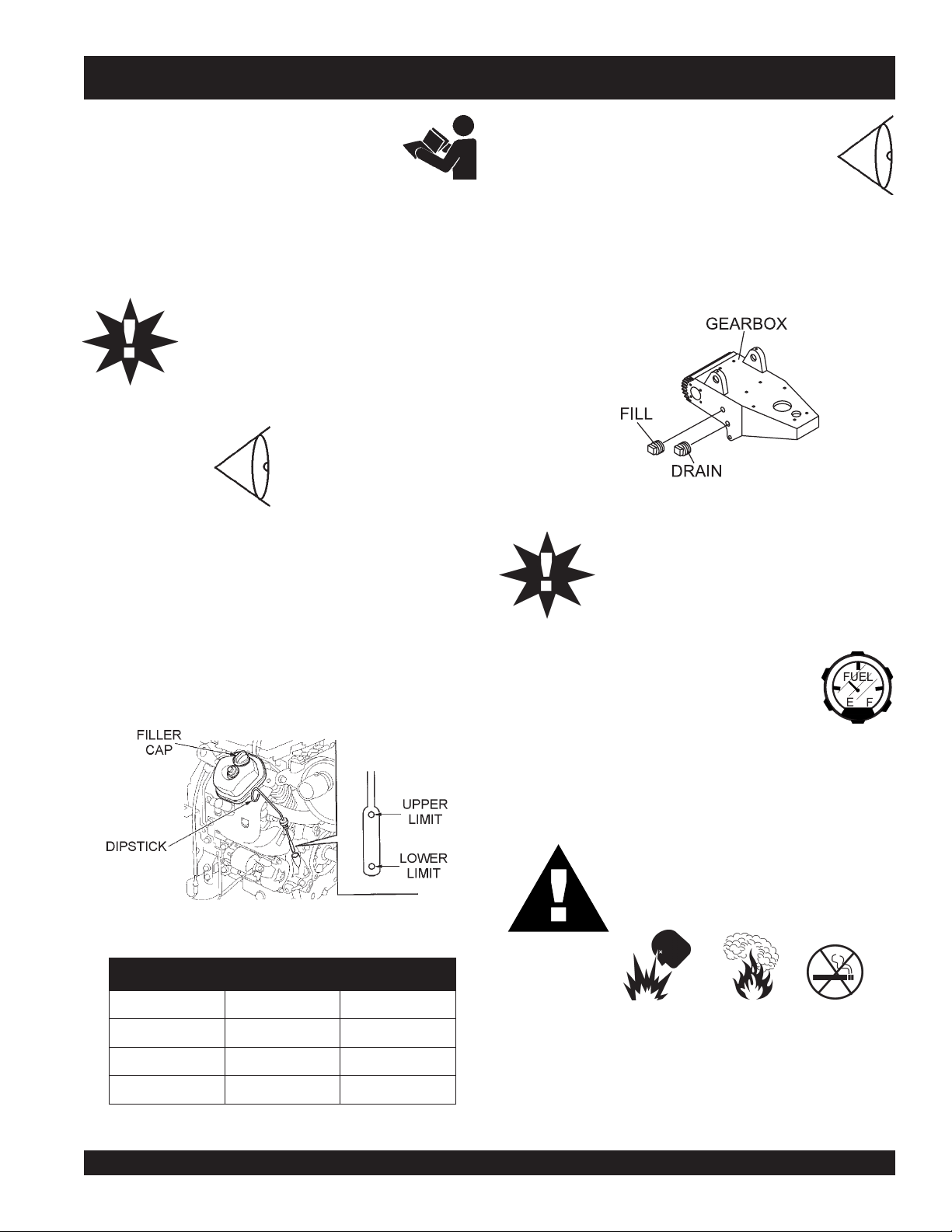

Engine Oil Level

1. To check the engine oil level, place the trowel on secure

level ground with the engine stopped.

2. Remove the dipstick from its holder as shown in Figure 7

and wipe clean.

3. Insert and remove the dipstick into the holder. Check the oil

level shown on the dipstick.

4. If the oil level is low (Figure 7), fill to the correct operating

level with the recommended oil type as listed in Table 3.

See Table 2 for engine oil capacity.

Gearbox Oil Level

1. Check the gearbox oil level in both gearboxes

by removing the plug located on the side of the

gearbox. See Figure 8.

2. The level of oil in the gearbox should just reach the bottom

of the fill plug hole. The fill hole plug is located

approximately half way up the side of the gearbox. If needed,

refill with specially formulated Whiteman gearbox lubricant

P/N 10139 or ISO 680 oil. Gearbox oil capacity is 27 oz.

(.798 liters).

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Fuel

1. Determine if the engine fuel is low. If fuel level

is low, remove the fuel filler cap and fill with

unleaded gasoline. Handle fuel safely. Motor

fuels are highly flammable and can be

dangerous if mishandled. DO NOT smoke while refueling.

DO NOT attempt to refuel the ride-on trowel if the engine is

hot or running.

Figure 8. Gearbox Oil Plugs

Use caution when removing plugs on the

gearbox, there are two of them. Removal of the

bottom most plug (

in the gearbox.

drain plug

) will drain the oil

DANGER:DANGER:

DANGER:

DANGER:DANGER:

Figure 7. Engine Oil Dipstick

epyTliO.3elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 23

ALWAYS

gasoline.

expansion.

The fuel tank cap must be closed tightly after filling. Handle

fuel in a safety container. If the container does not have a

spout, use a funnel. Wipe up any spilled fuel immediately.

fill the fuel tank with clean and fresh unleaded

DO NOT over fill fuel tank. Leave room for

Fuel spillage on a

a

fire

or

explosion

wipe up the spilled fuel completely to

prevent fire hazards.

around or near the generator.

hot!

engine can cause

. If fuel spillage occurs,

NEVER!

smoke

Page 24

JTO RIDE-ON TROWEL — INITIAL START-UP

Starting the Engine (Honda)

1. With one foot on the ground and the other foot placed on

the trowel’s platform, grab hold of any part of the frame and

lift yourself onto the trowel. Then sit down in the operator’s

seat.

2. The MQ Whiteman JTO ride-on trowel is equipped with a

kill switch

safety

assembly. Remember the engine will not start unless an

operator is sitting in the operator’s seat. The weight of an

operator depresses an electrical switch, which will allow

the engine to start.

3. It is recommended that the

engine after every use. Doing this will verify that the switch

is working properly and presents no danger to the operator.

Remember to turn the key to the “OFF” position after

stopping the trowel. Not doing so may drain your units’

battery.

4. The right foot pedal (Figure 9) controls blade and engine

speed. The position of the foot pedal determines the blade

speed. Slow blade speed is obtained by slightly depressing

the pedal. Maximum blade speed is obtained by fully

depressing the pedal.

. This switch is located beneath the seat

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

NEVER disable or disconnect the kill switch. It is

provided for the operator's safety and injury

may result if it is disabled, disconnected or

improperly maintained.

kill switch

be used to stop the

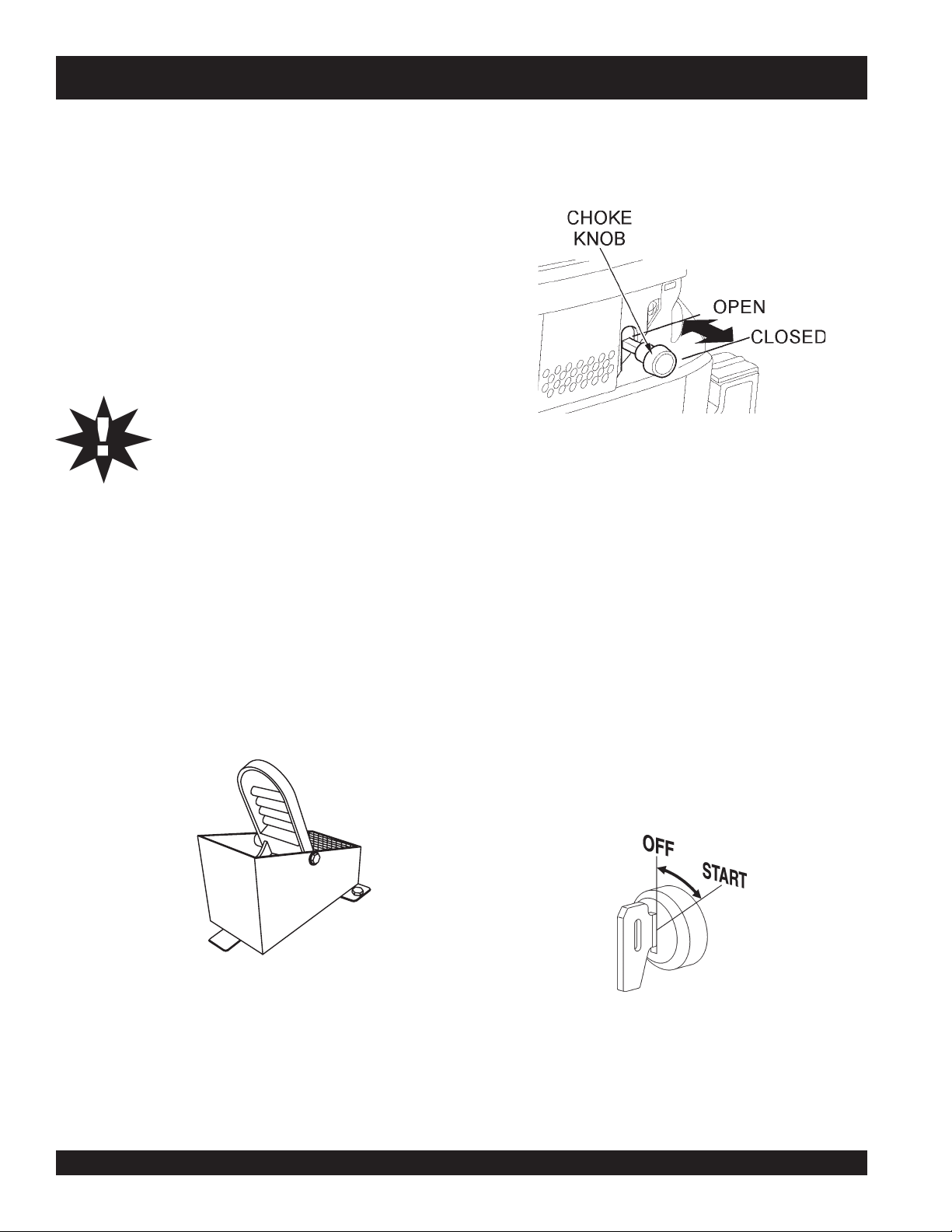

5. When starting a cold engine, pull the choke knob (Figure 10)

out to the

engine is warm, the unit can be started with choke halfway

or completely

6. Keep your foot OFF the gas pedal (right foot pedal). If the

engine is cold, adjust the choke but in all circumstances,

start the engine at idle (without touching the gas pedal).

7. Insert the

8. Turn the ignition key (Figure 11) clockwise and listen for

the engine to start. Once the engine starts release ignition

key.

9. If the engine fails to start in this manner, consult the engine

owner's manual supplied with the trowel.

10. Test the safety "kill switch" by standing up briefly. The switch

under the seat should cause the engine to stop. If the "kill

switch" fails to shut down the engine. Turn off the engine

with the key switch and fix the safety "kill switch". See Table 6

(Troubleshooting ) for possible problems.

close

position. In warm weather or when the

open

.

Figure 10. Choke Knob

ignition key

into the ignition switch.

11. Repeat this section a few times to get fully acquainted with

the engine starting procedure.

Figure 9. Blade Speed Control Foot Pedal

Figure 11. Ignition Switch/Key

PAGE 24 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 25

JTO RIDE-ON TROWEL — INITIAL START-UP

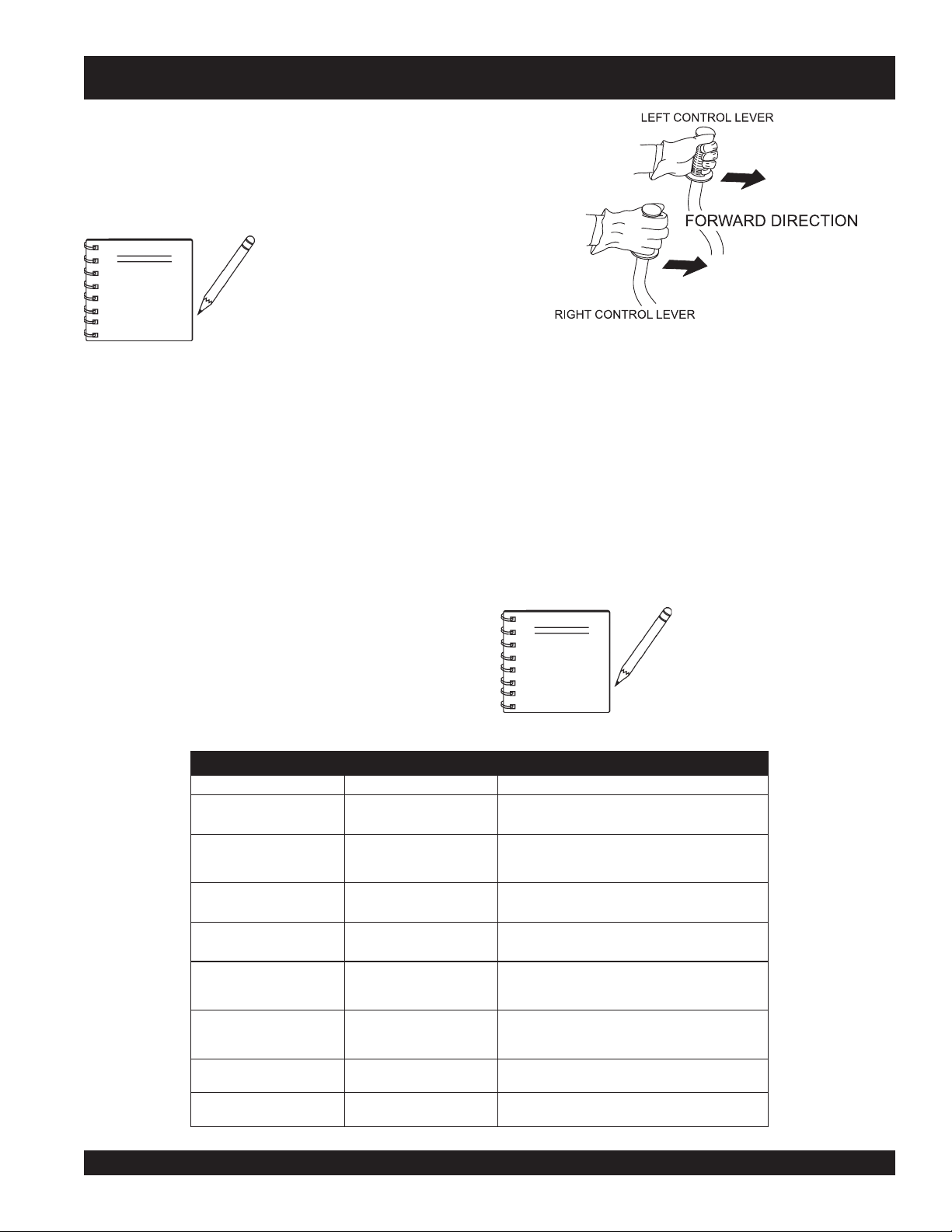

Steering

Two control levers located in front of the operator’s seat provide

directional control for the trowel. Table 4 below illustrates the

various directional positions of the control levers and their effect

on the ride-on trowel.

All directional references with

NOTE

respect to the steering control

levers are from the

operator’s

seat

position.

Figure 12. Left and Right Control Levers

1. Push both the left and right control levers forward. See

Figure 12.

2. With your right foot quickly depress the right foot pedal

halfway. Notice that the ride-on power trowel begins to move

in a forward direction. Return both joystick controls to their

neutral position to stop forward movement, then remove

your right foot from the right foot pedal.

3. Practice holding the machine in one place as you increase

blade speed. When about 75% of maximum blade speed

has been reached, the blade will be moving at proper

finishing speed. The machine may be difficult to keep in

4. Practice maneuvering the ride-on trowel using the

information listed in Table 4. Try to practice controlled

motions as if you were finishing a slab of concrete. Practice

edging and covering a large area.

5. Try adjusting the pitch of the blades. This can be done with

the ride-on trowel stopped or while the trowel is moving,

whatever feels comfortable. Test the operation of optional

equipment like retardant spray and lights if equipped.

6. Push both the left and right joysticks backward and repeat

steps 3 through 6 while substituting the word reverse for

forward.

one place. Trying to keep the ride-on trowel stationary is a

good practice for operation.

NOTE

REVELLORTNOC NOITCERID STLUSER

tfeL

reveLlortnoCevoM

drawroF

It is strongly suggested that all

operators (experienced and novice)

Slabs on Grade

read “

” published

by the American Concrete Institute,

Detroit Michigan.

gninoitisoPlanoitceriDreveLlortnoC.4elbaT

otlewortno-edirehtsesuaC

.thgirehtotdnadrawrofevom

tfeL

thgiR

thgiR

thgiRdnatfeL

thgiRdnatfeL

thgiRdnatfeL

thgiRdnatfeL

reveLlortnoCevoM

drawkcaB

reveLlortnoCevoM

drawroF

reveLlortnoCevoM

drawkcaB

htoBevoM

drawroFsreveLlortnoC

htoBevoM

drawkcaBsreveLlortnoC

htoBevoM

thgiRehtotsreveLlortnoC

htoBevoM

tfeLehtotsreveLlortnoC

otlewortno-edirehtsesuaC

.tfelehtotdnadrawkcabevom

otlewortno-edirehtsesuaC

.tfelehtotdnadrawrofevom

otlewortno-edirehtsesuaC

.thgirehtotdnadrawkcabevom

lewortno-edirehtsesuaC

nidrawrofevomot

.enilthgiartsa

lewortno-edirehtsesuaC

drawkcabevomot

.enilthgiartsani

lewortno-edirehtsesuaC

.thgirehtotevomot

lewortno-edirehtsesuaC

tfelehtotevomot

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 25

Page 26

JTO RIDE-ON TROWEL— MAINTENANCE

Use Table 5 as a general guideline when servicing of the engine is

required.

TSRIF

)3(NOITPIRCSEDNOITAREPOEROFEB

liOenignE

renaelCriA

stloB&stuNllA

gulPkrapS

sniFgnilooCKCEHCX

retserrAkrapSNAELC X

knaTleuFNAELC X

retliFleuFKCEHC X

deepSeldITSUJ

ecnaraelCevlaVTSUJDA-KCEHC )2(X

seniLliO/leuFKCEHC )2()yrassecenfiecalper(sraey2yrevE

KCEHCX

EGNAHCX

KCEHCX

EGNAHC)1(X

fInethgit-eR

yrasseceN

ECALPER X

DA-KCEHC )2(X

wyltneuqerferomecivreS)1( YTSUD .saera

ecivresebdluohssmetiesehT)2(

X

NAELC-KCEHCX

nidesuneh

HTNOM

RO

eludehcSecnanetniaMenignE.5elbaT

YREVE

SHTNOM3

RO

.SRH01

.SRH52

YREVE

SHTNOM6

RO

.SRH05

.slavretniecnanetniamreporpenimretedotnoitarepofosruohgol,esulaicremmocroF)3(

YREVE

RAEY

RO

01

.SRH0

serudecorpecivresroflaunaMpohsnottartSdnasggirBroADNOHehtotrefeR.tneiciforp

YREVE

SRAEY2

RO

.SRH002

yllacinahcemeradnaslootreporpehtevahuoysselnu,relaedcivresruoyybd

Spark Plug (100 Hours)

1. Inspect the spark plug every 100 hours, replace plug if the

electrodes are worn, or if the insulator is cracked or chipped.

Clean the spark plug with a wire brush, if plug is to be

reused.

Engine Maintenance Schedule (Daily)

Daily (8-10 Hours)

■

Check the oil level in the engine crankcase and gear box, fill

as necessary.

■

Check V-belt.

Long Term Storage

■

Drain fuel from fuel tank, fuel line and carburetor.

■

Remove spark plug and pour a few drops of motor oil into

cylinder. Crank engine 3 to 4 times so that oil reaches all

internal parts.

■

Clean exterior with a cloth soaked in clean oil.

■

Store unit covered with plastic sheet in moisture free and

Figure 13. Spark Plug

2. For Honda engines adjust the spark gap (Figure 13) to

dust free location out of direct sunlight.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

0.028~0.031 inch (0.70~0.78 mm). For Vanguard engines

adjust spark gap to 0.030 inch (76 mm). Both engines have

electronic ignition, which requires no adjustments. Replace

spark plug every 300 hours.

PAGE 26 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

NEVER store the ride-on trowel with fuel in the

tank for any extended period of time. ALWAYS

clean up spilled fuel immediately.

Page 27

JTO RIDE-ON TROWEL— MAINTENANCE

Maintenance

Perform the scheduled maintenance procedures as indicated:

DAILY

■

Thoroughly remove dirt and oil from the engine and control

area. Clean or replace the air cleaner elements as necessary.

Check and retighten all fasteners as necessary.

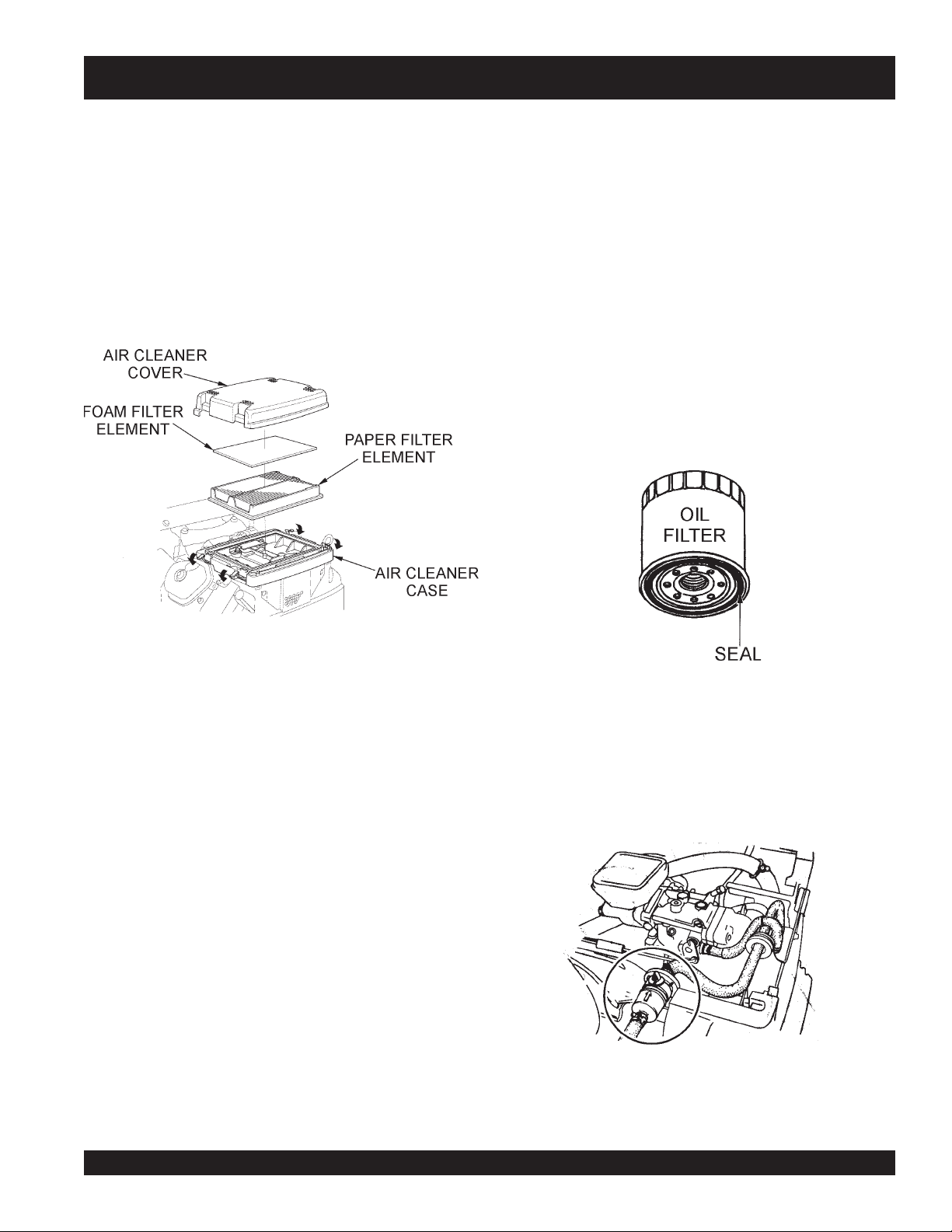

Air Cleaner (Daily)

1. Release the four latch tabs (Figure 14) from the air cleaner

cover, and remove the cover.

9. Reinstall the foam air filter element to the air cleaner cover,

then reinstall the paper air filter element and cover to the

air cleaner case. Securely latch the four hook tabs on the

air cleaner cover

Changing Engine Oil (100 Hours)

1. Change the engine oil after the first 20 hours of use, then

change every 6 months or 100 hours.

2. Remove the oil filler cap and fill engine crankcase with

recommended type oil as listed in Table 3. Fill to the upper

limit of dipstick.

3. Fill crankcase with oil. Reference Table 2 for crankcase oil

capacity.

Oil Filter (200 Hours)

1. Replace the engine oil filter (Figure 15) every 200 hours.

Figure 14. Air Cleaner

2. Remove the foam filter from the cover.

3. Remove the paper filter from the air cleaner case.

4. Inspect both air filter elements, replace them if necessary.

5. To clean the paper air filter, tap the filter element several

times on a hard surface to remove dirt, or blow compressed

air (not to exceed 30 psi (207 kPa, 2.1 kgf/cm

filter element from the air cleaner case side.

NEVER!

6.

fibers. If the paper element is excessively dirt, replace

element.

7. Clean the

rinse and allow to dry thoroughly. Or clean with a

nonflammable solvent and allow to dry. DO NOT pour any

type of oil into the foam element.

8. Wipe dirt from the inside of the air cleaner body and cover,

using a moist cloth. Be careful not to let any dirt or debris to

enter the air chamber that leads to the carburetor.

try to brush off dirt; brushing will force dirt into the

foam air filter element

in warm soapy water,

2

) through the

Figure 15. Oil Filter

2. Be sure to coat the

engine oil.

Fuel Filter (200 Hours)

1. Replace the engine fuel filter (Figure 16) every 200 hours.

Figure 16. Fuel Filter

seal

of the new oil filter with clean

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 27

Page 28

JTO RIDE-ON TROWEL— MAINTENANCE

Belt Changing Procedure

The belts need to be changed as soon as they show signs of

wear. Remember that all belts should be changed at the same

time. Do not reuse a belt under any circumstances. Indications of

excessive belt wear are fraying, squealing when in use, belts

that emit smoke or a burning rubber smell when in use.

Under normal operating conditions, a set of belts may last

approximately six months. If you trowel is not reaching this kind

of life span for belts, there are some things to check when you

replace a set of belts.

Check to ensure that the belts are tensioned correctly. Next, check

to make sure that the lower drive pulley (Figure 17) is aligned

properly.

Your machine is equipped with a spare belt carrier (Figure 17). It

is located opposite the clutch, mounted on the fuel tank. Make

sure that there are belts in the carrier before the trowel is placed

on a slab to finish concrete.

To install new belts from the spare belt carrier, first cut off the old

belts. Next, remove the spare belt carrier by unscrewing the two

bolts that attach it to the fuel tank.

NOTE

Make sure that there are belts in

the belt carrier before the trowel is

placed on a slab to finish concrete.

The next step is to loosen the four engine mounting bolts and

slide the engine toward the rear of the trowel. Slide the first belt

over the clutch and place it on the upper drive pulley, then pull it

down and place it on the lower drive pulley. Repeat this procedure

for the second belt.

Realign the engine as described in the Belt Tension

Adjustment Procedure, and replace the belts in the spare belt

carrier.

Replacing Spare Belts

.

After the spare set of belts has been installed on the clutch pulley,

it will be necessary to replace the spare set of belts that were in

the spare belt carrier.

To replace a spare set of belts, be prepared to disassemble the

driveline

The driveline is located directly under the spare belt carrier.

There are three bolts that need to be removed that will disconnect

the CV-joint from the gearbox coupler. See Figure 17.

Once the CV-joint has been separated from the gearbox coupler,

.

push the CV-joint inward so that a gap exist between the coupler

and the CV-joint. Slide the replacement belts between this gap,

and place them onto the spare belt carrier. Secure the spare belt

carrier to the fuel tank.

.

Figure 17. Belt Changing Diagram

PAGE 28 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 29

JTO RIDE-ON TROWEL — MAINTENANCE

See the engine manual supplied

with your trowel for appropriate

NOTE

engine maintenance schedule and

troubleshooting guide for problems.

At the front of this manual there is a “

Checklist

basis.

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

Trowel Maintenance Schedules

Weekly (50-60 Hours)

■

■

”. Make copies of this checklist and use it on a daily

ALWAYS allow the engine to

cool before servicing. NEVER

attempt any maintenance work

hot!

on a

Relube arms, thrust collar and clutch.

Replace blades if necessary.

engine.

Daily Pre-Operation

Trowel Arm Adjustment Procedure

The following procedure should be

followed to adjust trowel arms when

NOTE

level

, clean area to test the trowel prior to and after is essential.

A

spots

Any uneven

will give an incorrect perception of adjustment. Ideally, a 5 x 5"

three-quarter inch thick

To determine which blades need adjustment, place the trowel in

the test area (three-quarter inch thick plate) and look for the

following conditions:

■

Pitch the blades as flat as possible and look at the

adjustment bolts

with the

that one of them is not making contact, some adjustment

will be necessary.

■

Is the machine wearing out blades unevenly (i.e. one

blade is completely worn out while the others look new)?

in the floor or debris under the trowel blades

lower wear plate

it becomes apparent that the trowel

is finishing poorly or in need of

routine maintenance.

flat

steel plate should be used for testing.

. They should all barely make contact

on the spider. If you can see

Figure 18 below illustrates a "

Monthly (200-300 Hours)

■

Remove, clean, reinstall and relube the arms and thrust collar.

Adjust the blade arms.

■

Remove, clean, reinstall clutch.

Yearly (2000-2500 Hours)

■

Check and replace if necessary the arm bushings, thrust

collar bushings and shaft seals.

■

Check pitch control cables for wear.

■

Adjust blade speed.

trowel arms

touching (0.10" max. clearance) lower wear plate. All alignment

bolts should be spaced the same distance from the lower wear

plate.

Figure 19 below illustrates the "

plate (as shipped from the factory).

worn spider bushings or bent

". Check to see that adjustment bolt is barely

Figure 18. Worn Spider Plate

correct alignment

" for a spider

Figure 19. Correct Spider Plate Alignment

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 29

Page 30

JTO RIDE-ON TROWEL — MAINTENANCE

2. Start engine, and bring trowel blades up to full speed and look

b. Loosen the jam nut and cone point square head set

for the following conditions:

■

Does the trowel have a perceived rolling or bouncing

motion when in use?

■

Look at the trowel while it is running, does the guard

ring “rock up and down” relative to the ground?

Spider Removal

c. If the trowel is equipped with an outer stabilizer ring

1. Once it is determined that an adjustment is required, remove

the spider assembly from the gearbox shaft as follows:

a. Locate the cone point square head set screw (Figure 20)

and attached jam nut found on the side of the spider

assembly.

REMOVE

TO FREE

SPIDER

ASSEMBLY

screw, and carefully lift the

upper trowel assembly

off

of the spider assembly. A slight tap with a rubber mallet

may be necessary to dislodge the spider from the main

shaft of the gearbox.

(Figure 21), remove the four bolts at the end of each

spider arm.

STABILIZER

RING

Figure 20. Stabilizer Ring

d. Examine stabilizer ring for out of round or bends. If ring

is damaged, replace ring. If ring is found to be correct with

no damage, set aside.

Trowel Arm Removal

1. Each trowel arm is held in place at the spider plate by a hex

head bolt (zerk grease fitting) and a roll pin. Remove both the

hex head bolt and the roll pin (Figure 22) from the spider

plate.

2. Remove the trowel arm from the spider plate.

Figure 20. Spider/Gearbox Removal

Figure 22. Removing Roll Pin

and Zerk Grease Fitting

PAGE 30 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 31

JTO RIDE-ON TROWEL — MAINTENANCE

3. Should the trowel arm inserts (bronze bushing ) come out

with the trowel arm, remove the bushing from the trowel arm

and set aside in a safe place. If the bushing is retained inside

the spider plate, carefully remove the bushing.

4. Examine the bronze trowel arm bushing insert (Figure 23),

clean if necessary. Replace bushing if out-of-round or worn.

Figure 23. Bronze Bushings

Trowel Blade Removal

1. Remove the trowel blades from the trowel arm by removing

the three hex head bolts (Figure 24) from the trowel arm. Set

blades aside.

Trowel Arm Flatness Test

1. Using a piece of 3/4 inch thick steel plate or any surface which

true

is

flatness.

2. Check each of the six sides of the trowel arm (hex section

only) using a ten thousands of an inch (max.) feeler gauge

(Figure 25) between the flat of the trowel arm and an

tremely flat

and

flat

, check all

test surface.

six sides

of each trowel arm for

ex

-

Figure 24. Trowel Blades

Wire brush

2.

trowel arm. Repeat this for the remaining three arms.

any build-up of concrete from all six sides of the

Figure 25. Trowel Arm Flatness Test

3. If the trowel arm is found to be

trowel arm. A bent trowel will not allow the trowel to operate

in a smooth fluid rotation.

4. Next, check each of the six sides of the round machined shaft

section of the trowel arm. Each section should have the

clearance

test surface.

between the round of the trowel arm shaft and the

uneven

or

bent

, replace the

same

Trowel arms can be damaged by

NOTE

rough handling or by striking

exposed plumbing or forms while in

operation.

ALWAYS

look-out for

objects which might cause damage

to the trowel arms.

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 31

Page 32

JTO RIDE-ON TROWEL — MAINTENANCE

Trowel Arm Adjustment

Shown in Figure 26 is the adjustment fixture with a trowel arm

inserted. As each trowel arm is locked into the fixture, the arm bolt

is adjusted to where it contacts a stop on the fixture. This will

consistently adjust all of the trowel arms, keeping the finisher as

flat and evenly pitched as possible.

1. Locate the trowel arm adjustment tool P/N 9177. Set the

adjustment tool for a clock-wise blade rotation, meaning the

fixture arm is in the "UP" position.

3. Un-screw the locking bolts on the adjustment tool, and place

the trowel arm into the adjustment fixture channel as shown

in Figure 34. A

holes on the trowel arm. Make sure to align the trowel

adjustment bolt with the fixture adjustment bolt.

4. Using an allen wrench, tighten the locking bolts on the

adjustment tool and securely lock the trowel arm in place.

5. Loosen the locking nut on the trowel arm lever, then turn the

trowel arm adjusting bolt until it barely touches (.010") the

adjusting bolt on the fixture.

6. After the correct adjustment has been made, tighten lock nut

on trowel arm lever to lock in place.

7. Loosen locking bolts on adjustment fixture, and remove

trowel arm from fixture.

8. Repeat steps 2-7 for the remaining trowel arms.

Re-Assembly

1. Clean and examine the upper/lower wear plates and thrust

collar. Examine the entire spider assembly. Wire brush any

concrete or rust build-up. If any of the spider components are

found to be damaged or out of round, replace them.

thin shim

may be required to cover the blade

2. Make sure that the bronze trowel arm bushing is not damage

3. Reinstall bronze bushing onto trowel arm.

4. Repeat steps 2 -3 for each trowel arm.

5. Make sure that the spring tensioner is in the correct position

6. Insert all trowel arms with levers into spider plate (with bronze

7. Lock trowel arms in place by tightening the hex head zerk

Figure 26. Trowel Arm Adjustment Tool

2. Trowels manufactured prior to June of 1982 require that the

distance from the end of the adjusting bolt and the fixture arm

must be 7/8" (Figure 26). Conversely, trowels manufactured

after June of 1982 require that the distance from the end of

the adjusting bolt and the fixture arm must be 1/2".

8. Re-install the blades back onto the trowel arms

8. Install stabilizer ring onto spider assembly.

9. Reinstall lower wear plate,

or out of round. Clean the bushing if necessary. If the bronze

bushing is damage or worn, replace it.

to exert tension on the trowel arm.

bushing already installed) using care to align grease hole on

bronze bushing with grease hole fitting on spider plate.

grease fitting and jam nut.

thrust collar

in the

ring

the spider shaft. Make sure that there is little or no lateral

movement between the thrust collar and the spider shaft.

reverse order

that they were dis-assembled onto

and

upper wear

PAGE 32 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 33

JTO RIDE-ON TROWEL — TROUBLESHOOTING (TROWEL)

)LEWORT(GNITOOHSELBUORT.6ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?noitcnuflamhctiwslliK

.lla

tatonrohguorgninnurenignE

?leuF

?noitingI

?smelborprehtO .launams’rerutcafunamenignetlusnoC

.gninoitcnuftonhctiwsllikytefaS

?stcatnocdaB .hctiwsecalpeR

?sedalB

?redipS

?snoitcennoceriwesooL .yrassecensaecalpeR.gniriwkcehC

?smraleworttneB

.yltcerrocgninoitcnuf

.yrassecenfihctiwsecalper;detaes

.rabedalbehtotlellarapdna

.yletaidemmitiecalper,tnebylthgilsnevesismra

sirotarepoehtnehwgninoitcnufsihctiwsllikehttahterusekaM

otdeilppusgniebleufsierehterusekaM.metsysleufehttakooL

.deggolctonsiretlifleufehttahterusneotkcehC.enigneeht

sidnarewopsahhctiwsnoitingiehttahterusneotkcehC

.nrowylevissecxeton,noitidnocdoognierasedalbniatrecekaM

ehtmorf)mm05("2nahtsselonerusaemdluohssedalbhsiniF

onerusaemdluohssedalbobmoc,egdegniliartehtotrabedalb

thgiartsebdluohsedalbfoegdegniliarT.)mm98("5.3tahtssel

saelgnahctipemasehttateserasedalbllatahtkcehC

rofelbaliavasiloottnemtsujdadleifA.redipsehttaderusaem

.)tnempiuqElanoitpOees(smralewortehtfotnemtsujdathgieh

ehtfoenofI.smraleworttnebrofylbmessaredipsehtkcehC

sllor,secnuob“lewortfI

nevenusekamro,etercnoc

.”etercnocnislriws

?ralloctsurhT

?hctipedalB

?tfahsniaM

elbitpecrepasahenihcaM

.gninnurelihwnoitomgnillor

?ekoY

?sgnihsubmraleworT

?gnihsubralloctsurhT

?nrowgniraebtsurhT

om

.ralloctsurhtehtnignihsubehtecalper

.eerfgninnipssititahteesotgniraebtsurhtehtkcehC

.yrassecenfiecalpeR

.yrassecenfisnoitcurtsni

.tnioptnemhcatta

.yrassecensaekoyecalpeR.pacraeweht

ybenodebnacsihT.ssenthgitrofsgnihsubmralewortehtkcehC

"8/1nahteromsierehtfI.nwoddnapusmralewortehtgniv

ebdluohssgnihsubeht,mraehtfopitehttalevartfo)mm2.3(

.emitemasehttadecalperebdluohssgnihsubllA.decalper

.redipsehtnotignitatorybralloctsurhtehtfossentalfehtkcehC

.ralloctsurhtehtecalper)mm5.0("20.0nahteromybseiravtifI

tlitnactifI.redipsehtnotignikcorybralloctsurhtehtkcehC

,].D.Oralloctsurhtehttaderusaemsa[)mm6.1("61/1nahterom

noitcesecnanetniaMreptsujdA.hctiptnetsisnocrofsedalbkcehC

ebdluohsylbmessaxobraegehtfotfahstuptuoniamehT

dnathgiartsnurtsumtfahsniamehT.ssenthgiartsrofdekcehc

redipsehttadnuorfotuo)mm80.0("300.0nahteromebtonnac

noylnevesserpekoyehtfosregnifhtobtahterusekamotkcehC

JTO RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (11/08/07) — PAGE 33

Page 34

JTO RIDE-ON TROWEL — TROUBLESHOOTING (TROWEL)

)LEWORTDEUNITNOC(GNITOOHSELBUORT.6ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?gniriW

.gnikrowton)lanoitpo(sthgiL

?sthgiL .nekorbfiecalpeR.doogllitserasblubthgilfieesotkcehC

?tnadrateR

?gniriW

ton)lanoitpo(yarpstnadrateR

.gnikrow

?hctiwsdaB

?pmupyarpsdaB

?tnemtsujdafotuodeepsedalB

?stnenopmocnroW

otkcehcdna

.yrassecensaecalpeR

.yrassecen

.pmupehtecalper,doog

.tnemtsujdadeepsedalbnonoitceseeS

.yrassecenfiecalper

hctiwsffo/noretsamehtgnidulcni,snoitcennoclacirtcelellakcehC

.strohsonhtiwnoitidnocdoognisigniriwfiees

saknatlliF.tneserpsitnadratererusekamotknatehtkcehC

hctiwsffo/noretsamgnidulcni,snoitcennoclacirtcelellakcehC

.yrassecensagniriwdnastnenopmocecalpeR.snoitcennoc

.nekorbfiecalpeR.hctiwsffo/noretsamfoytiunitnocehtkcehC

tub,nodenrutsihctiwsehtnehwtneserpegatlovasahpmupfI

erapmupehtotsnoitcennoclacirtcelednaetarepotonseod

stnenopmocegaknildnasgniraebgnireetsforaewrofkcehC

.evisnopsernusignireetS

?stoviP

?erusserpciluardyH

sinoitisopgnitarepO

.elbatrofmocnu

hctiPcirtcelEnodaehrewoP

.gnikrowton)lanoitpo(

)lanoitpo(hctiPniwTnoegakniL

.gnikrowton

?gniriW

?hctiwS

?seldnahknarC

?trapnekorB

?rotareporoftsujdataeS

?strapesoolronekorB

wop

.ecivresrof

.yletaidemmiecalper

.erusserpciluardyhgnikcehcno

.yletaidemmistrapnekorbllaecalpeR

.srotomevirdciluardyhfotnemevomeerferusneotkcehC

noitceseeS.etauqedasierusserpciluardyhtahterusneotkcehC

.taesehtfotnorfehtnodetacolrevelhtiwtaestsujdA

ehtedisnistrap,detceffatonsihctipehtdnasnurrotomehtfI

relaedotdaehrewopnruteR.nekorbroesoolebyamdaehre

ytiunitnocehtkcehC.gniriwdnasnoitcennoclacirtcelellakcehC

ehttatneserpegatlovsierehttahtyfireV.tinudaehrewopehtta

.noitisop”no“ehtnihctiwsyekehthtiwhctiwsdaehrewop

,gninoitcnuflamsihctiwsfI.hctiwsehtfoytiunitnocehtkcehC

sarafsanwoddehsuperaseldnahknarchtobtahterusekaM

.degagnesiegaknilehttahtserusnesihtgnioD.elbissop

PAGE 34 — JTO RIDE-ON POWER TROWEL— OPERATION & PARTS MANUAL — REV. #5 (11/08/07)

Page 35

JTO RIDE-ON TROWEL — TROUBLESHOOTING (ENGINE)

MOTPMYS MELBORPELBISSOP NOITULOS

tratsottluciffiD

?egdirbgniebgulpnoitingI .metsysnoitingikcehC

GNITOOHSELBUORTENIGNE.7ELBAT

.)elbacnoisnethgihta

rewoP(.etingitonlliw TON

noisserpmoc(setingi )lamron .

noisserpmoc(setingi wol .)

yrotcafsitastonnoitarepO