Page 1

OPERATION AND PARTS MANUAL

JIMMY SERIES

MODELS:

JB5135, JB7135, JB5090, JB7090,

JB8090, JB9180, JB11090

HYDRAULIC REBAR BENDERS

MODEL JPU1

ELECTRIC-HYDRAULIC PUMP

Revision #9 (01/04/08)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

JIMMY SERIES HYDRAULIC REBAR BENDERS — SILICOSIS WARNING

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 2

Page 3

JIMMY SERIES HYDRAULIC REBAR BENDERS — TABLE OF CONTENTS

Multiquip Jimmy Series

Hydraulic Rebar Benders

Silicosis Warning ....................................................... 2

Table Of Contents ..................................................... 3

Parts Ordering Procedures ....................................... 4

Safety Message Alert Symbols ................................. 5

Rules For Safe Operation ...................................... 6-8

Specifications (Rebar Unit) ....................................... 9

Specifications (Pump) ............................................. 10

General Information ........................................... 11-12

Components............................................................ 13

Inspection ................................................................ 14

Applying Power ....................................................... 15

Operation ........................................................... 16-19

Shut-Down .............................................................. 19

Maintenance ........................................................... 20

Explanation Of Code In Remarks Column .............. 22

Suggested Spare Parts ........................................... 23

Nameplate and Decals....................................... 24-25

JB5135 Assembly ............................................. 26-27

JB7135 Assembly ............................................. 28-29

JB5090 Assembly ............................................. 30-31

JB7090 Assembly ............................................. 32-33

JB8090 Assembly ............................................. 34-35

JB9180 Assembly ............................................. 36-37

JB11090 Assembly ........................................... 38-39

Electric Pump Assembly..................................... 40-41

Control Valve Assembly...................................... 42-43

NOTE

NOTE

As a continuing effort to

update our parts book,

contact the MULTIQUIP

literature department for the

latest revision of your

"Operation and Parts

Manual"

Specification and part number

are subject to change without

notice.

Terms and Conditions of Sale ................................. 44

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 3

Page 4

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

Effective:

January 1

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■

View Parts Diagrams

■

Order Parts

■

Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

Order via Phone:

If you have an MQ Account, to obtain a

Username and Password, E-mail us at:

parts@multiquip.com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

internet

Use the

on

Standard orders

and qualify for a 5% Discount

for all orders which include

complete part numbers.*

Fax

your order in and qualify for a 2% Discount

on

Standard orders

for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

should contact

When ordering parts, please supply:

❒❒

❒

❒❒

Dealer Account Number

❒

❒❒

❒❒

❒

Dealer Name and Address

❒❒

❒❒

Shipping Address (if different than billing address)

❒

❒❒

❒❒

❒

Return Fax Number

❒❒

❒❒

❒

Applicable Model Number

❒❒

❒❒

❒

Quantity, Part Number and Description of Each Part

❒❒

All orders are treated as

Standard Orders

and will ship the same day if received prior

to 3PM PST.

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 4

Specify Preferred Method of Shipment:

❒❒

✓

UPS/Fed Ex

■

Priority One

■

Ground

■ Next Day

■

Second/Third Day

✓ DHL

✓

Tr u ck

Page 5

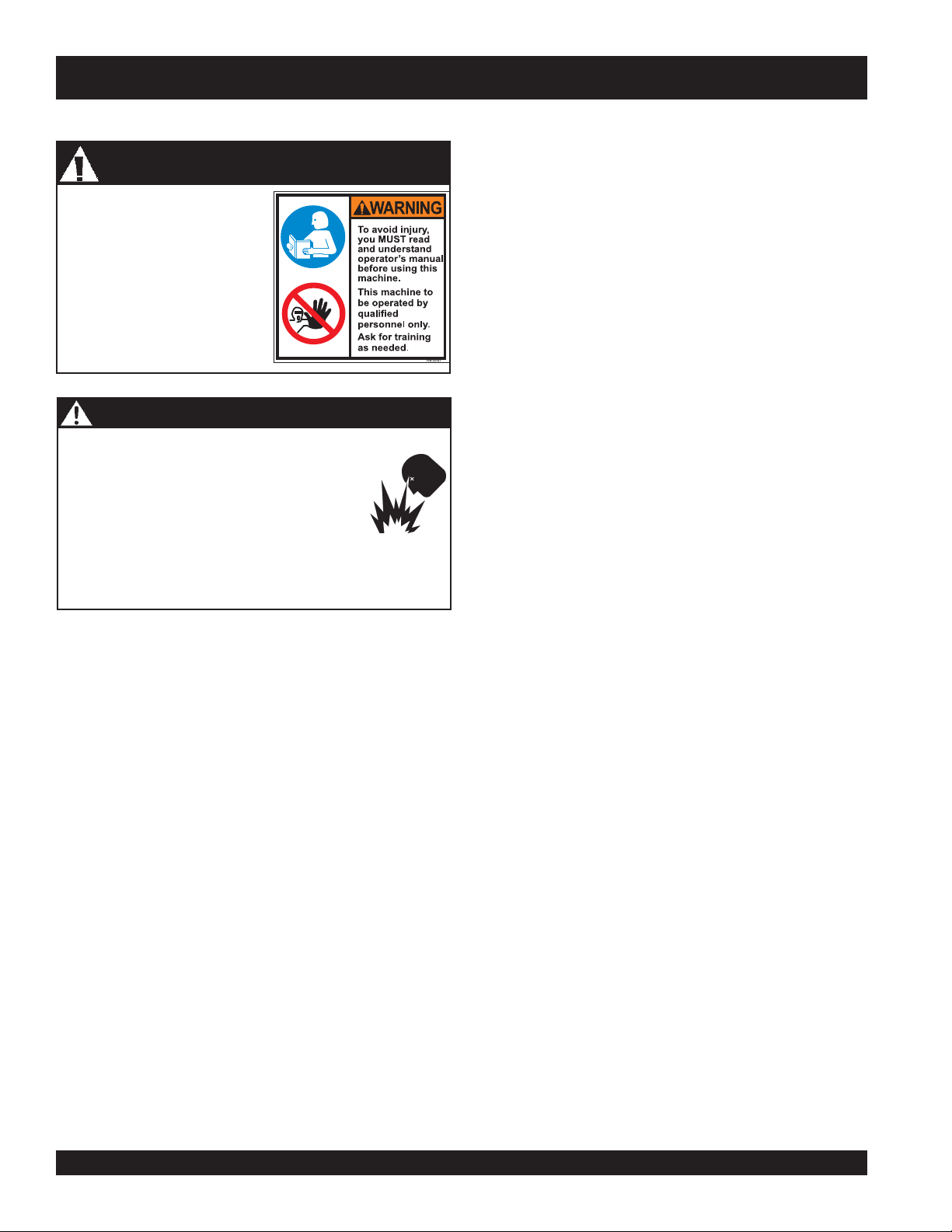

JIMMY SERIES HYD. REBAR BENDERS— SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when operating

this equipment. Failure to read and understand the Safety

Messages and Operating Instructions could result in injury to

yourself and others.

This Operation and Parts Manual

NOTE

Before using this hydraulic rebar bender and pump, ensure

that the operating individual has read and understands all

instructions in this manual.

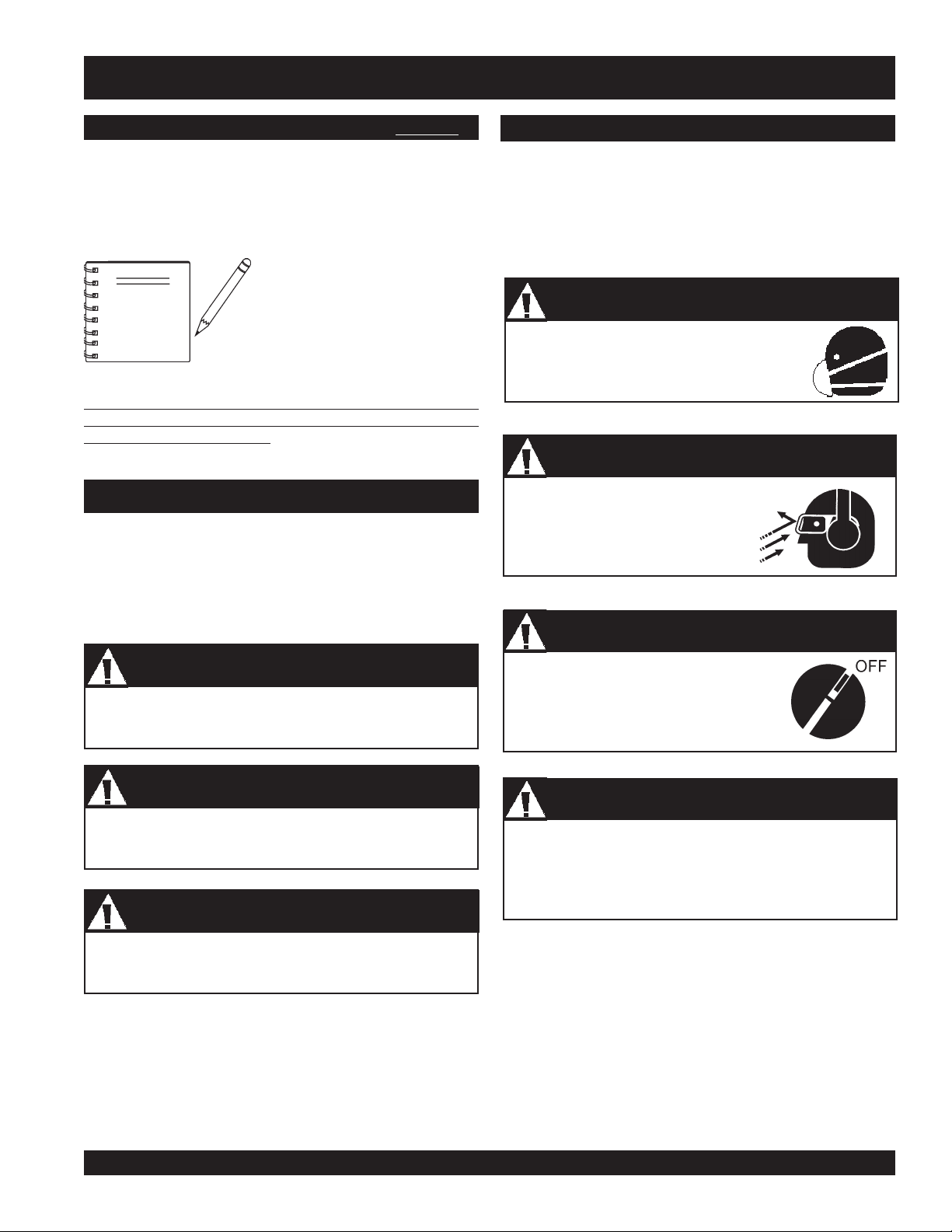

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure

to the operator, and are preceded by one of three words:

DANGER, WARNING, or CAUTION.

has been developed to provide

complete instructions for the safe

and efficient operation of the

Series Hydraulic Rebar Bender

and Electric-Hydraulic Pump.

Jimmy

HAZARD SYMBOLS

Potential hazards associated with the operation of the

Series Hydraulic Rebar Benders and Electric Hydraulic

Pump

will be referenced with Hazard Symbols which appear

throughout this manual, and will be referenced in conjunction

with Safety Message Alert Symbols.

ALWAYS wear approved

protection when required.

ALWAYS wear approved eye and

hearing protection.

Jimmy

WARNING - Respiratory Hazards

respiratory

CAUTION - Eye and Hearing Hazards

CAUTION - Accidental Starting Hazards

DANGERDANGER

DANGER

DANGERDANGER

You WILL be

NOT follow directions.

You CAN be

NOT follow directions.

CAUTION

You CAN be

KILLED

WARNINGWARNING

WARNING

WARNINGWARNING

KILLED

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

INJURED

or

SERIOUSLY

or

SERIOUSLY

if you DO NOT follow directions.

injured if you DO

injured if you DO

ALWAYS place the power control unit's

ON/OFF switch in the OFF position when

the rebar bender is not in use.

CAUTION - Equipment Damage Hazards

Other important messages are provided throughout this

manual to help prevent damage to your rebar bender, other

property, or the surrounding environment.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 5

Page 6

JIMMY SERIES HYDRAULIC REBAR BENDERS — RULES FOR SAFE OPERATION

■

DANGERDANGER

DANGER

DANGERDANGER

Failure to follow instructions in this manual may lead to

serious injury or even death! This equipment is to be

operated by trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used when

operating the

Electric-Hydraulic Pump.

GENERAL SAFETY

■

DO NOT operate or service this

equipment before reading this entire

manual.

■

This equipment should not be operated by persons under

18 years of age.

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots, hard hat

and other protective devices required by the job.

Jimmy Series Hydraulic Rebar Bender and

Read this manual!

NEVER operate the rebar bender in an

explosive atmosphere or near

combustible materials. The possibility

exists of the rebar bender emitting a spark

during operation. A explosion or fire could

result causing severe

bodily harm or

even death if the sparks make contact with combustible

or explosive materials.

■

Maintain this equipment in a safe operating condition at

all times.

■

Keep bystanders, children and visitors away while

operating the rebar bender. Distractions can cause you

to lose control.

■

DO NOT wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away from moving

parts.

■

ALWAYS store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children.

■

ALWAYS be sure the operator is familiar with proper

safety precautions and operation techniques before using

rebar bender.

■

■

NEVER operate this equipment when not feeling

well due to fatigue, illness or taking medicine.

■

NEVER operate this equipment under the influence of

drugs

or

alcohol

■

ALWAYS wear proper respiratory (mask),

hearing and eye protection equipment when

operating the rebar bender.

■

ALWAYS replace any worn or damaged warning decals.

■

Manufacturer does not assume responsibility for any

accident due to equipment modifications.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

.

■

■

■

■

■

■

■

ALWAYS keep work area clean and free of foreign matter

and debris. Also keep work area well lit.

NEVER leave the rebar bender unattended. When not in

use always unplug the rebar bender from power source.

Keep all

from the equipment at all times.

Become familiar with the components of the rebar bender

before operating.

Use this rebar bender only for its intended purpose. DO

NOT use this rebar bender for applications not

recommended.

Inspect the rebar bender after each use. Replace any

damaged or worn parts immediately. DO NOT use a

defective rebar bender.

If a malfunction occurs, immediately unplug the rebar

bender from the power source and correct the problem. If

the problem can not be corrected, contact your nearest

MQ service center.

All WARNING statements must be carefully observed to

help prevent personal injury.

inexperienced

and

unauthorized

people away

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 6

Page 7

JIMMY SERIES HYDRAULIC REBAR BENDERS — RULES FOR SAFE OPERATION

UNIT SAFETY INSTRUCTIONS

■

All hose connections must be tightened with the proper

tools before operating hydraulic power unit. DO NOT over

tighten. Connections should only be tightened securely

and leak-free. Over tightening can cause premature thread

failure or high-pressure fittings to split at pressures lower

than their rated capacities.

■

Should a hydraulic hose ever rupture, burst, or need to

be disconnected, immediately shut off the pump and

release all pressure. NEVER attempt to grasp a leaking

pressurized hose with your hands. The force of escaping

hydraulic fluid could cause serious injury.

■

NEVER subject the hose to potential hazard such as

fire, sharp surfaces, extreme heat or cold, or heavy

impact. DO NOT allow the hose to kink, twist curl, crush,

cut, or bend so tightly that the fluid flow within the hose

is blocked or reduced. Periodically inspect the hose for

wear, because any of these conditions can damage the

hose and possibly result in personal injury.

■

NEVER use the hose to move attached equipment. Stress

can damage the hose and possibly cause personal injury.

■

Hose material and coupler seals must be compatible with

the hydraulic fluid used. Hoses also must not come in

contact with corrosive materials such as creosoteimpregnated objects and some paints. Hose deterioration

due to corrosive materials can result in personal injury.

Consult the manufacturer before painting a hose. NEVER

paint a coupler.

■

Use only approved accessories and approved hydraulic

fluid. Hoses, seals and all components used in a system

must be compatible with the hydraulic fluid used.

■

DO NOT exceed the rated capacities of the cylinders.

Excess pressure can result in personal injury.

■

Inspect each cylinder and coupler before each shift or

usage to prevent unsafe conditions from developing.

■

DO NOT use cylinders if they are damaged, altered or in

poor condition.

■

DO NOT use cylinders with bent or damaged couplers or

damaged port threads.

■

DANGER - High Pressure Hazard

When extending a cylinder or ram

under load, always insure that the

couplers or port threads have not

been damaged or do not come in

contact with any rigid obstruction.

If this condition does occur, the

coupler’s attaching threads may

become stripped or pulled from the cylinder or ram

resulting in the instantaneous release of high pressure

hydraulic fluid, flying objects, and loss of the load. All of

these possible results could cause serious injury or even

death.

CAUTION - System Evaluation

Cylinder hoses, couplings and hydraulic pump must all be

rated for the same operating pressure, correctly connected

and compatible with the hydraulic fluid used. An improperly

matched system could cause the system to fail and

possibly cause serious injury. Always maintain the correct

operating for optimal performance. If you have any

questions, please contact your nearest MQ service center.

Avoid pinch points or crush points that can be created

by the load or parts of the cylinder. Do not wear loose

jewelry when operating the rebar bender.

WARNING

Moving parts can

crush and cut.

ALWAYS

clear of rollers while

rebar bender is

operating.

keep hands

■

NEVER use extreme heat to disassemble a hydraulic

cylinder or ram. Metal fatigue and/or seal damage will

result and can lead to unsafe operating conditions.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 7

Page 8

JIMMY SERIES HYDRAULIC REBAR BENDERS — RULES FOR SAFE OPERATION

ELECTRICAL SAFETY

■

ALWAYS test the

unit before operating. The purpose of this switch is to shut

down the rebar bender.

■

NEVER use a extension cord that is frayed or damaged

where the insulation has been cut.

■

NEVER carry the hydraulic power unit by its power cord

or disconnect it by yanking the cord from the power outlet.

■

ALWAYS make certain that the proper extension cord

has been selected for the job. See Table 5.

■

NEVER allow power cord to

■

NEVER

■

When connecting the hydraulic power unit to a power

receptacle, make sure the receptacle circuit is connected

to either a GFCI receptacle or a receptacle protected by

a 20 amp circuit breaker.

■

When plugging the hydraulic power unit into a power

receptacle, check the nameplate for the correct operating

voltage. Operating the rebar bender at the wrong voltage

will damage the electrical components. ALWAYS read

the nameplate before applying power.

■

This hydraulic power unit is equipped with a 3-prong male

power plug. DO NOT use a 2-prong adapter when plugging

into a wall outlet. This will defeat the purpose of the ground

circuit. If the plug does not fit into the receptacle, contact

a qualified electrician to install a 3-conductor wall

receptacle (outlet).

■

Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased

risk of electrical shock if your body is grounded.

■

DO NOT expose the hydraulic power unit to rain or wet

conditions. Water entering the power unit will increase

the risk of electrical shock.

stand in water

ON/OFF

switch on the hydraulic power

lay in wate

while operating the rebar bender.

r.

POWER UNIT TRANSPORTING (Electric-Hydraulic Pump)

■

■

MAINTENANCE

■

■

■

EMERGENCIES

■

■

When transporting of the power unit (pump) is required,

ALWAYS carry unit by its handle.

ALWAYS wrap power and remote cable cords neatly to

avoid tripping and damage when transporting.

NEVER lubricate components or attempt service on a

operational rebar bender.

ALWAYS maintain rebar bender in correct operating

condition.

ALWAYS fix damage to the rebar bender immediately

and always replace broken parts. Replace with only MQ

recommended parts.

ALWAYS know the location of the nearest

extinguisher

In emergencies

nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in the case of an

emergency.

and first aid kit.

always

know the location of the

keep a phone on the job site

and

fire department

. This

fire

.

■

When operating the hydraulic power unit outside, be sure

to use the appropriate outdoor extension cord. This type

of extension cord reduces the risk of electrical shock.

■

ALWAYS remove the AC power cord from the power

source before performing any service or maintenance on

the rebar bender. This preventative safety measure

reduces the possibility of accidental starting.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 8

Page 9

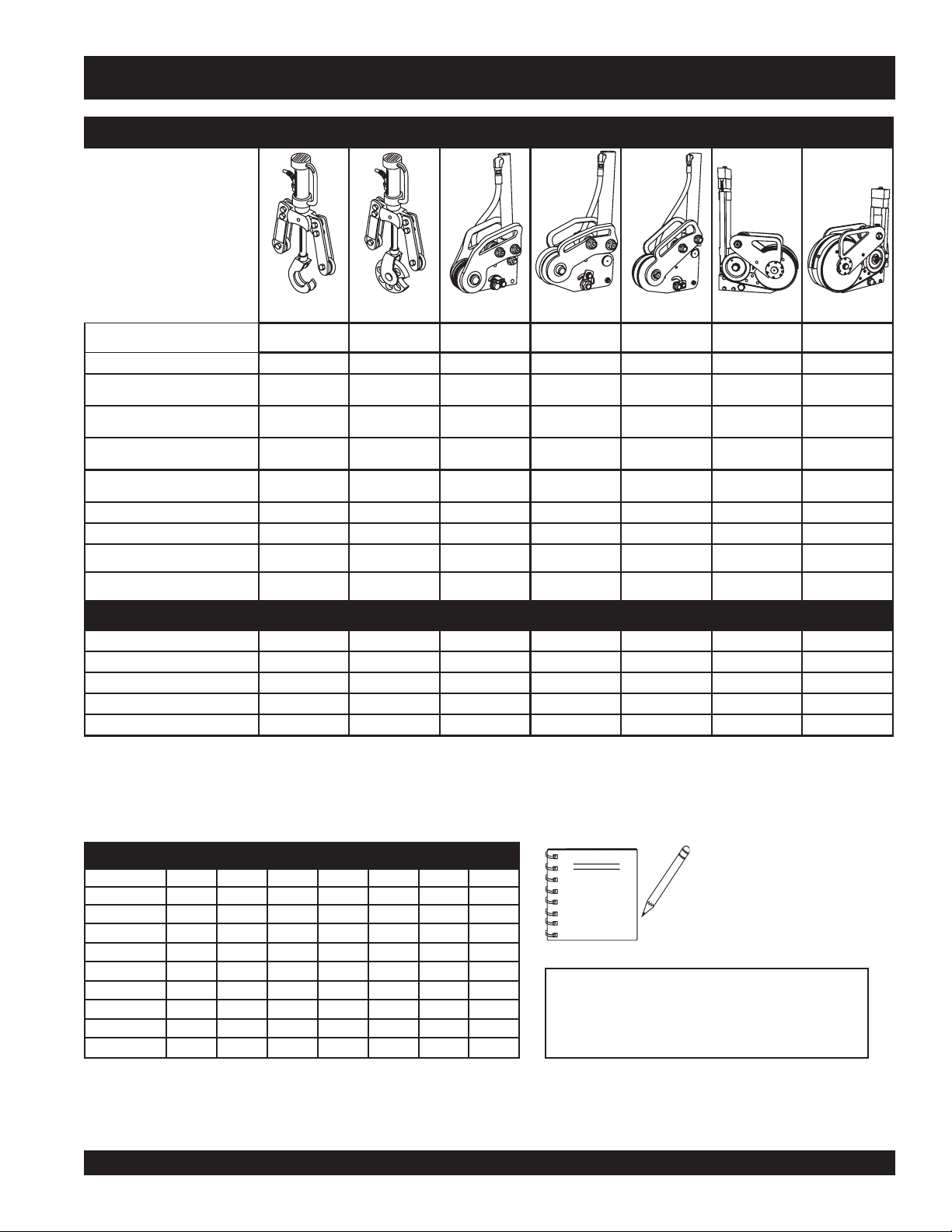

JIMMY SERIES HYDRAULIC REBAR BENDERS — SPECIFICATIONS (REBAR UNIT)

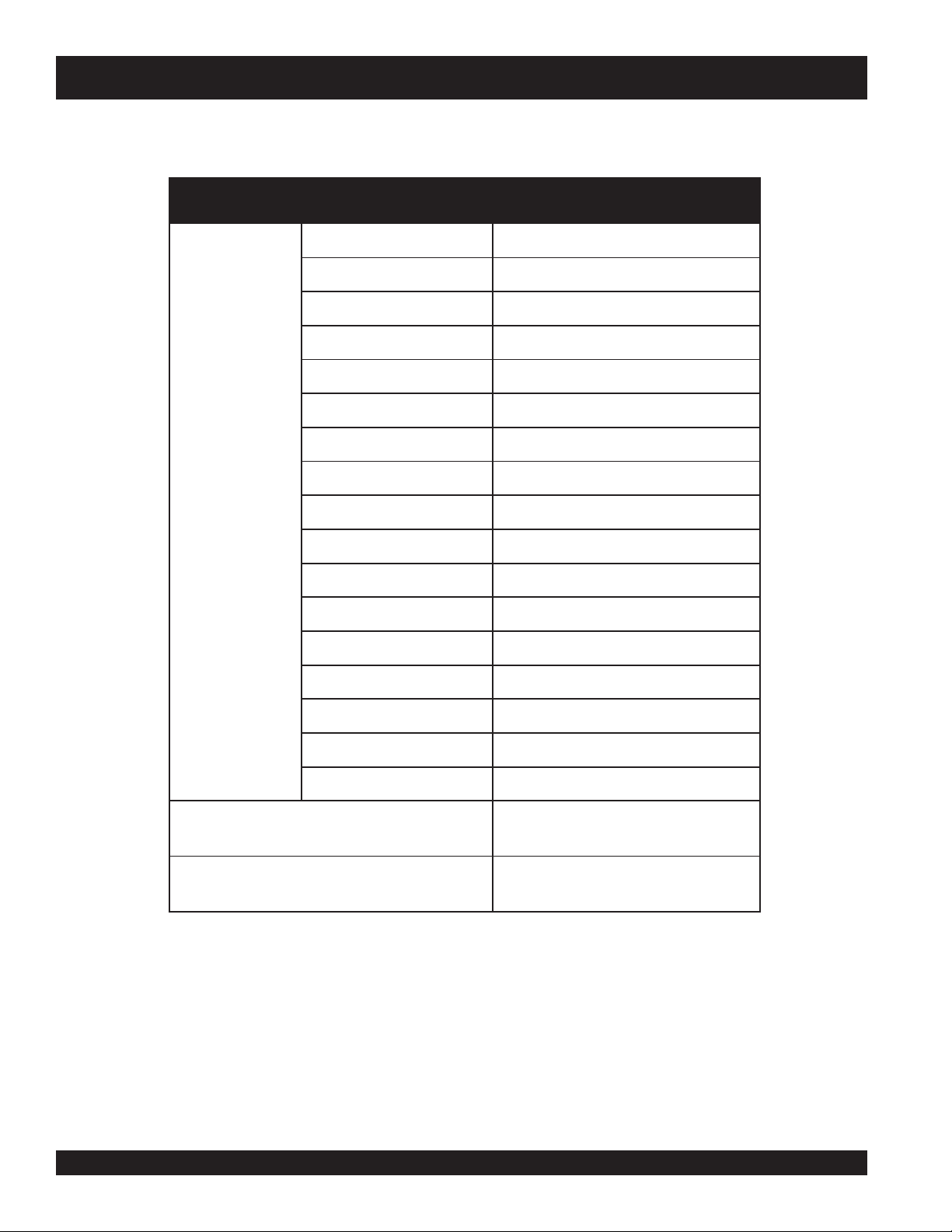

snoitacificepSredneBrabeR.1elbaT

ledoM5315BJ5317BJ0905BJ0907BJ0908BJ0819BJ09011BJ

elgnAgnidneB

yticapaCrabeR

)eziSraB(

dneBmuminiM

*)mc(.ni

nosehcnignicapSraBmuminiM

retnec

dneB;rebmuNraBdevorppA-ICA

**suidaR

)gk(.blthgieW

)gk(.blthgieWgnippihS

)mc(.nisnoisnemiDllarevO

)mc(.nisnoisnemiDgnippihS

dneBdradnatS°09

kooHenaC°081

sdneBtesffO

gninethgiartS

kooHeiTdnapurritScimsieS

* Minimum bend measured from bottom of machine to top of angle.

** American Concrete Institute (ACI) has approved the wheel used in this device as the proper radius for bending the bar size indicated; Concrete Reinforcing Steel

Institute(CRSI) requirements are met for the bar size indicated.

°531°531°09°09°09°081°09

5#,4#7#,6#6#,5#,4#8#,7#,6#9#,8#,7#,6#01#,9#,8#,7#11#,01#,9#,8#

)7.21(5)7.21(5)7.21(5)3.02(8)3.02(8)9.72(11)6.53(41

22333 5.35.3

°531;5#°531;7#°09;5#°09;7#°09;8#°081;9#°09;11#

)01(22)21(62)21(62)62(85)92(26)54(001)05(011

)51(43)12(74)81(93)33(47)04(98)45(911)26(631

5.3x11x32

)9.8x9.72x4.85(

42x31x03

)16x33x67(

3x9x91

)6.7x9.22x3.84(

42x31x03

)16x33x67(

5.4x9x71

)4.11x9.22x2.34(

42x31x03

)16x33x67(

5.5x5.21x5.12

)41x8.13x6.45(

51x31x42

)83x33x16(

5.5x41x72

)41x6.53x6.86(

51x31x42

)83x33x16(

6x71x91

)2.51x2.34x3.84(

51x31x42

)83x33x16(

6x91x72

)2.51x3.84x6.86(

51x31x42

)83x33x16(

snoitacilppA

✓✓✓✓✓✓✓

✓

✓✓✓✓✓✓✓

✓✓✓✓✓✓✓

✓✓

trahCeziSrabeR.2elbaT

ledoM5315BJ5317BJ0905BJ0907BJ0908BJ0819BJ09011BJ

°531°531°09°09°09°081°081

suidaRgnidneB

)31#/M01(4#

★★★★

)61#/M51(5#

)91#/M02(6#

)22#/AN(7#

)52#/M52(8#

)92#/M03(9#

)23#/AN(01#

★★★★★★★★

★★★★★★★★★★★

★★★★★★★★★★★★★

★★★★★★★★★

★★★ ★★

)63#/M53(11#

NOTE

Standard 1/8 inch increments

★★★

ACI/CRSI Approved for this size

★★

Acceptable bend radius for ACI/CRSI requirements

★

★★

★★★

Capable of bending rebar but does not meet ACICRSI requirements

Not capable of bending this size rebar

Rebar Size:

(Metric Hard/Soft

Conversion)

Example:

#8 Rebar ÷ 8 = 1-inch

#4 Rebar ÷ 8 = 4/8 = 1/2-inch

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 9

Page 10

JIMMY SERIES HYDRAULIC REBAR BENDERS — SPECIFICATIONS (PUMP)

snoitacificepSpmuPciluardyHcirtcelE.3elbaT

ledoM1UPJ

noitacificepSrotoMT1051WEP

epyTpmuPcirtcelE

rotoM)wk11.1(PH5.1

deepSMPR5271

egatloVtupnIzH06@511

tnerruCspmA2.61

leveLdnuoSABd08

pmuP

yticapaCliO)sretill87.3(lag1

gnitaRerusserP)aPk159,86(isp000,01

erusserPegatStsriF)aPk628,4(

daoLoN@etaRwolFni514

isp000,01@etaRwolFni16

isp007

3

3

3

mc008,6(nim/

mc000,1(nim/

)nim/

3

)nim/

elbaClortnoCetomeR)sretem75.4(.tf51

evlaVlortnoCnoitisoP-3yaW-3launaM

thgieWteN).gk7.23(.sbl2.97

WssorG).gk1.74(.sbl401

thgie

)HxWxL(noisnemiDnotraC

)HxWxL(noisnemiDetarC

.ni8/1-12x8/1-11x8/5-61

).mc56.35x52.82x22.24(

.ni8/7-22x8/5-11x2/1-71

).mc01.85x25.92x54.44(

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 10

Page 11

JIMMY SERIES HYDRAULIC REBAR BENDERS — GENERAL INFORMATION

GENERAL INFORMATION

The

MQ Jimmy Series Hydraulic Rebar Benders

to be used as

in-place rebar to approved American Concrete Institute (ACI) radius.

Labor time and injuries are greatly reduced from manually bending

rebar. Bends of 90°, 135° or 180° can now be completed in seconds

at the correct elevation after forms are stripped away.

With seven models to choose from, the Jimmy Series rebar benders

can accommodate a wide variety of rebar angles and sizes. Please

reference Tables 1 and 2 in this manual for the rebar bender that

best fits your application.

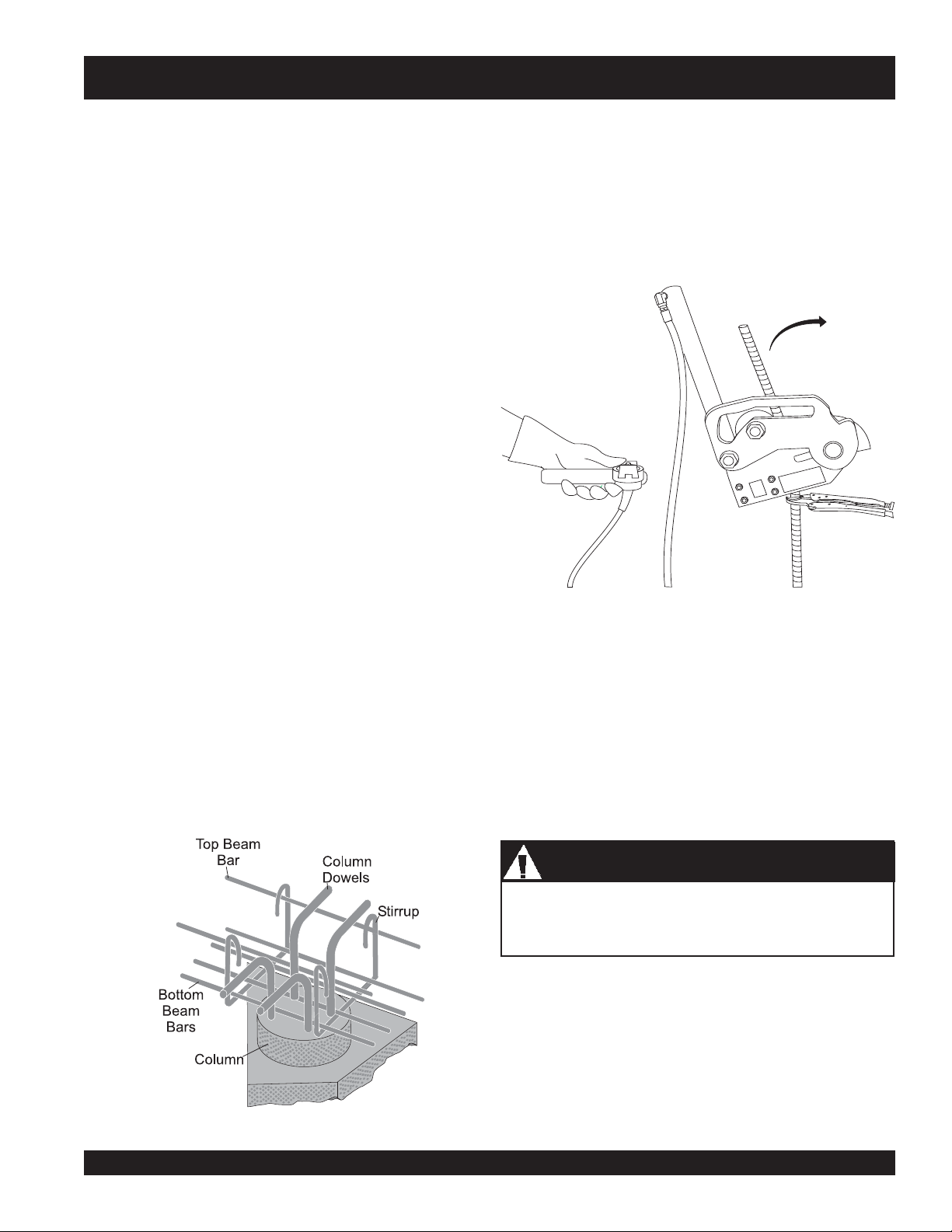

REBAR BENDING APPLICATIONS (Figures 1 thru 4)

■

Pilings

■

Caissons

■

Bridge and Decking

■

Retrofits

■

Columns

■

Straightening

■

Walls

portable

on-site rebar benders, capable of bending

are designed

Rebar Straightening

■

Rebar can be straightened using JB5090, JB7090, JB8090,

JB9180 and JB11090.

■

NEVER straighten rebar that is bent greater than 30°. Check

with building codes before straightening rebar

Figure 2. Rebar Straightening

Rebar Columns

■

■

90° rebar (Figure 1) at top of column can be bent after forms

have been removed

■

Bending after concrete is poured allows you to stock bottom

beam bars, eliminating the need to thread bottom beam bars.

■

Rebar at top of column can be bent at exactly the correct

elevation allowing top beam bars to placed on top of 90°

bend.

Before the rebar can be straightened by the JB5090, JB7090

or JB8090, it will be necessary to replace the main roller with

the straightening roller. The straightening roller is included

with each of the above models from the factory. To accomplish

this task remove the main shaft as outlined in Figure 14.

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Some agencies may not permit the straightening of rebar

for existing bends of more than 30°. DO NOT attempt to

straighten rebar bends greater than 30°.

Figure 1. Columns

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 11

Page 12

JIMMY SERIES HYDRAULIC REBAR BENDERS — GENERAL INFORMATION

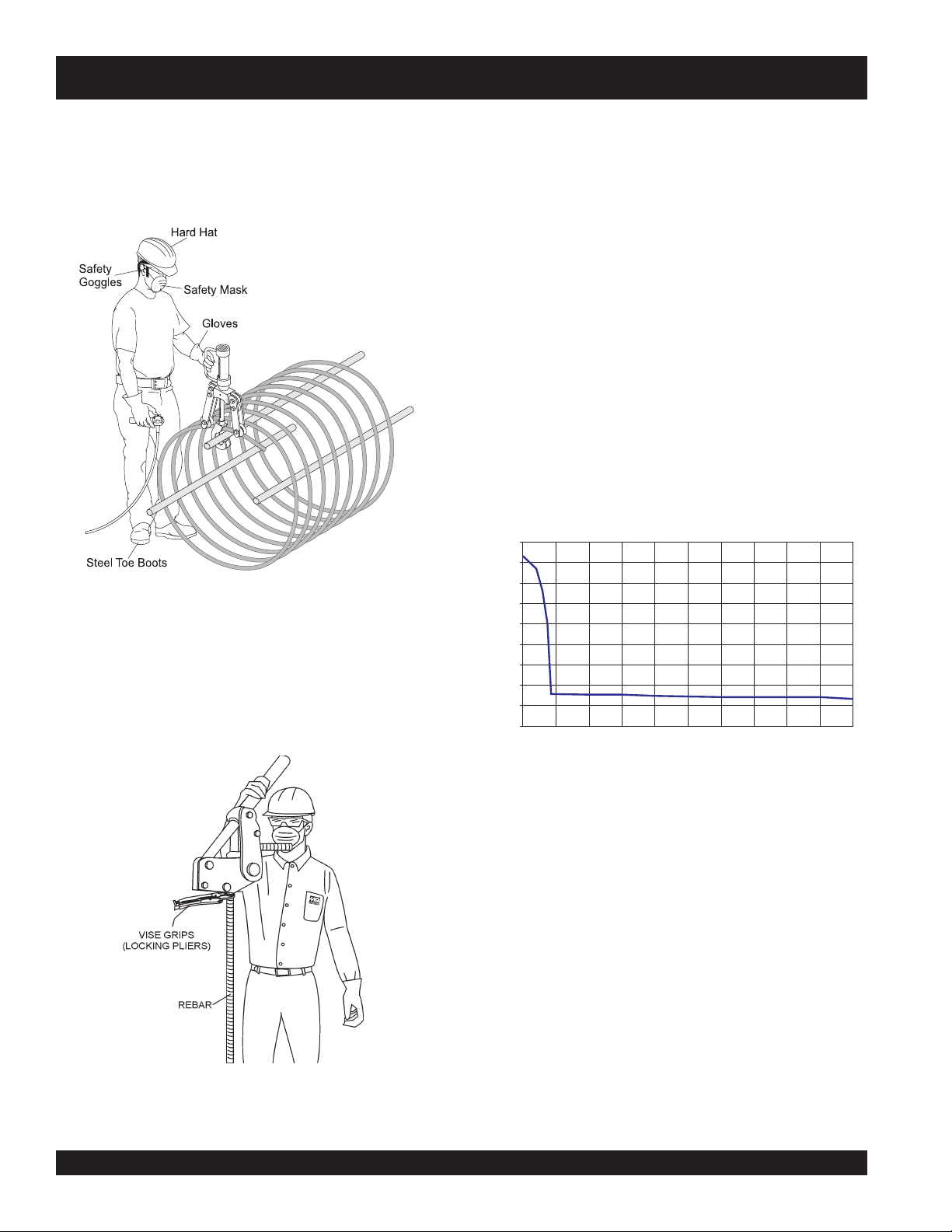

Rebar Spirals and Cages

■

Can bend rebar up to 135° (Figure 3) and fits between spirals

as close as 2 in. (5 cm. ) on center.

■

No welding required.

Electric-Hydraulic Pump

All Jimmy Series Hydraulic Rebar Benders require an electricpowered hydraulic pump to supply the necessary pressure to actuate

the hydraulic cylinder. This hydraulic pump consists of a drive

cylinder, oil reservoir and electronics for either remote or manual

operation.

The electric motor for this pump is a 1.5 HP motor. Each electric

motor requires 115 VAC, 60 Hz input for normal operation. Amperage

draw for the electric motor at 10,0000 psi (68,951 kpa) is

approximately 13 amps. Reference Figure 5 for oil volume versus

pressure.

The hydraulic pump is equipped with a 3-way, 3- position manual

operated valve. This valve allows the operator to remotely control

the

(4.57 meters) remote control cable allows the operator to control the

pump remotely.

Figure 3. Rebar Spirals and Cages

Rebar Walls

■

No welding required

■

Bends hooks in rebar after forms have been removed.

■

Bends graduated bars to precise elevations.

■

Reduces size and number of holes and splices required in

forms.

advance, hold

450

400

350

300

250

200

150

Oil Volume (cu.in/min)

100

50

0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

and

return

functions of the rebar bender. A 15 ft.

Pre ssure (psi)

Figure 5. Oil Volume vs Pressure

Model PEW1501T Electric/Hydraulic Pump

Figure 4. Rebar Walls

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 12

Page 13

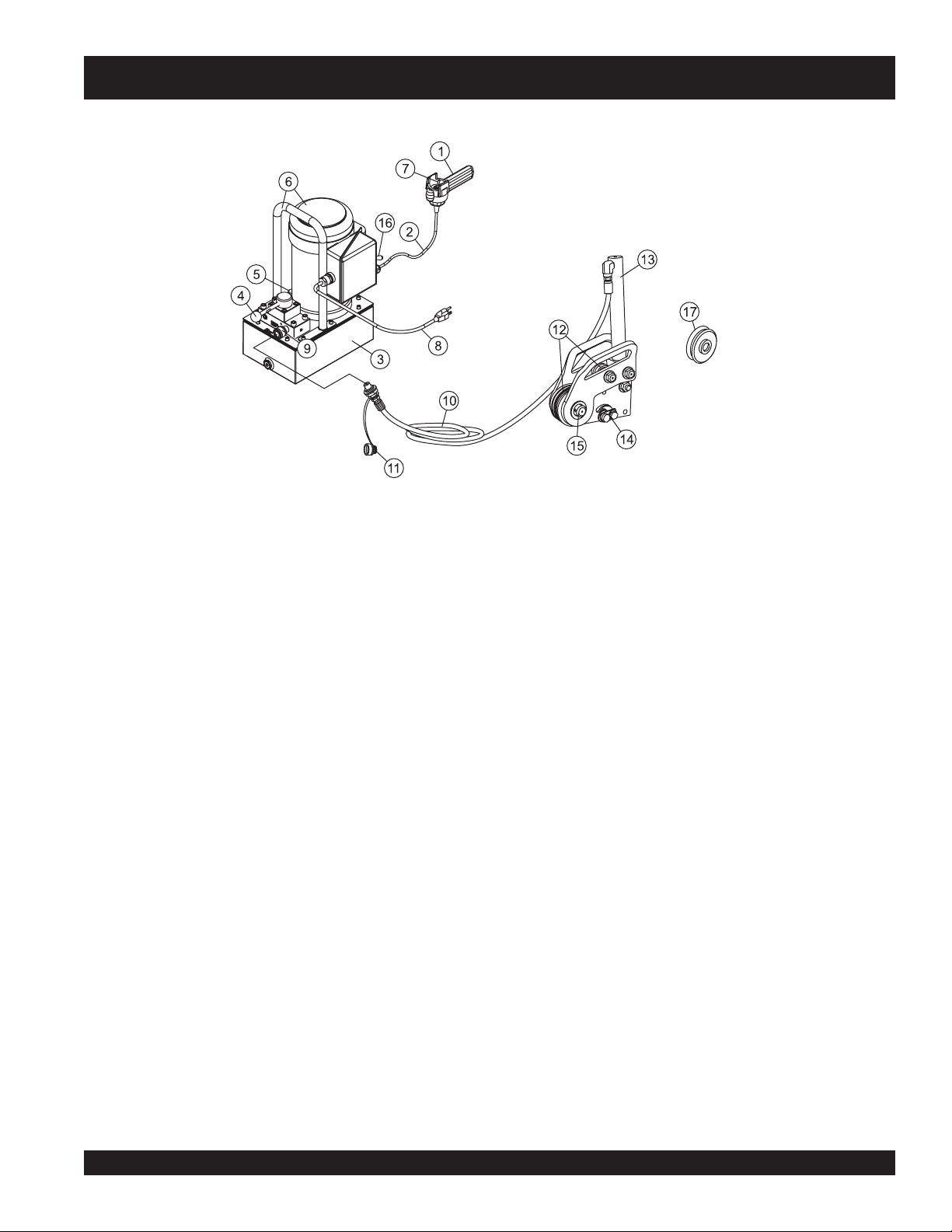

JIMMY SERIES HYDRAULIC REBAR BENDERS — COMPONENTS

Figure 6. Jimmy Hydraulic Rebar Bender Components

1. Remote Control Unit – Allows the hydraulic cylinder

on the rebar unit to be

2. Remote Control Cable – Allows the Electric-Hydraulic

Pump to be operated remotely.

3. Hydraulic Reservoir– Holds 1.00 gallon (3.78 liters)

of hydraulic oil. Fill only with recommended type

hydraulic oil.

4. Pump Control Lever – Move this lever to actuate the

hydraulic cylinder on the rebar bender. The lever allows

the cylinder to be

5. Hydraulic Oil Fill Cap – Remove this cap to add

hydraulic fluid to the reservoir. Fill with commercial

hydraulic oil.

6. Electric-Hydraulic Pump/Carrying Handle – When

transporting of the pump is required, always use the

carrying handle or lifting bale to lift the unit.

7. Electric-Hydraulic Pump ON/OFF Switch – Move the

toggle switch to the forward position to activate the

electric motor. The electric motor will stay on as long

as the switch is held. Release the switch to turn off the

electric motor.

8. AC Power Cord – Plug this 10 ft. (3.0 meters) power

cord into a 115 VAC grounded type receptacle. NEVER

remove the ground pin from the plug. This will defeat

the ground circuit and greatly increase the possibility

of electrical shock.

9. Female Quick Disconnect Fitting – Connects to the

hydraulic hose and allows for easy removal.

advanced

or

advanced, held

held

or

returned.

.

10. Hydraulic Hose (Rebar Bender) – Connect one end

11. Hose Cap – When the rebar bender is not in use,

12. Main and Upper Arm Rollers – Always keep large

13. Hydraulic Cylinder – When actuated can apply a force

14. Rebar Adjustment Bolt – There is an adjustment bolt

15. Main Roller Shaft – To remove the large roller (main)

16. Electric Motor On/Off Switch – When placed in the

17. Straightening Roller – Accessory roller for

of this hose to the female quick disconnect fitting on

the electric-hydraulic pump, connect the other end (90°

fitting) to the hydraulic input port on the rebar bender

cylinder.

ALWAYS cover the hose’s male fitting with this cap.

This will prevent dirt and foreign matter from entering

the cylinder cavity.

and small rollers clean and lubricated to insure smooth

rolling. Remove any dirt or debris that may have

accumulated on the rollers during operation.

between 2~10 tons (2,032 ~10,160 kg.)

on the side plate of the rebar bender. Adjust these bolts

to accommodate different size rebar.

or stuck rebar from the unit, push the roller shaft inward

to release. Some units have a pin-clip mechanism for

the removal of the main roller. See Figure 14.

ON position, supplies 115VAC, 60Hz power to the

electric motor.

straightening rebar. For use with JB5090, JB7090,

JB8090 only.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 13

Page 14

JIMMY SERIES HYDRAULIC REBAR BENDERS — INSPECTION

BEFORE STARTING

CAUTION - Read Manual

Before attempting to operate

this rebar bender, and to avoid

serious injury to personnel,

always read and understand

operation manual. Failure to

read and understand operation

manual could result in serious

harm or even death!

DANGER - Flammable/Combustible Materials

NEVER operate the rebar bender or

hydraulic pump in or around flammable

materials. The possibility exists of the rebar

bender emitting a spark during operation. If

contact is made between the sparks and the

flammable material, the result could be fire

or explosion causing damage to the equipment and severe

bodily harm even death!

INSPECTION

Before each use, visually inspect the items listed below.

Regular maintenance and visual checks of the rebar bender

and power unit prior to operation will minimize repairs and

help ensure normal operation of the bender and electrichydraulic pump.

■

Check for wear and damage to rollers, pin, nuts and bolts,

clip, side plates and hydraulic arm. Clean, lubricate and

replace as required.

■

Rebar bender can

hydraulic pump rated at 10,000 PSI. Refer to the pump’s

manual for operation and maintenance instructions.

■

Check the hydraulic pump fluid level.

■

Check that all hydraulic connections are clean.

■

Check all hydraulic hoses for cuts, holes, or excessive

wear.

■

Inspect all fittings and couplers, make sure they are clean

and fitted with dust caps.

■

Check that couplings to pump and bender are tightened

securely.

ONLY

be used with a standard

■

Check for a cracked or damaged cylinder or rebar bender

■

Check for excessive wear, bending, damage, or

insufficient thread engagement.

■

Check for leaking hydraulic fluid

■

Check for a scored or damaged piston rod.

■

Improperly functioning or damaged components

■

Check for loose bolts.

■

Check for damaged or improperly assembled accessory

equipment.

■

Check for modified, welded, or altered equipment.

■

Check for bent or damaged couplers or port threads.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 14

Page 15

JIMMY SERIES HYDRAULIC REBAR BENDERS — APPLYING POWER

CONNECTING THE POWER

1. The electric-hydraulic pump requires 115 VAC, 60 Hz

NOTE

power. Applying power to the pump that is not specified will cause severe damage to the pump's electric

motor. Always read the

electrical data plate

before

applying power to the pump.

4. Connect the hand-held remote control cable to the power

2. The power plug on the pump is a 3-prong grounded type

input receptacle on the power unit

plug. ALWAYS connect this plug to a 3-prong grounded

receptacle. NEVER plug this device into a 2-prong type

receptacle. This will defeat the ground circuit. The use of

5. To apply power to the electric-hydraulic pump, place the

ON/OFF toggle switch (Figure 7) to the ON position (up).

a 3-prong to 2-prong adapter is strictly prohibited.

3. Connect the pump's AC power cord to a 115 VAC wall

receptacle or portable generator (Figure 7) that is protected by a 20 amp circuit breaker. For best results

connect the power cord to a GFCI receptacle.

Since

distance

drop

when using an extension cord,

can affect

voltage

ALWAYS make certain that the

proper extension cord has been selected for the job. See Table 4.

Figure 7. Connecting The Power

DANGER - ELECTROCUTION HAZARDS

During operation of this rebar bender, there

exists the possibility of

electrical shock or burn,

severe bodily harm

To avoid these hazards:

NEVER use damaged or worn cables when plugging the

rebar bender into an AC power receptacle.

NEVER grab or touch a live power

cord with wet hands.

NEVER stand in water and touch a

live power cord.

electrocution,

which can cause

or even

DEATH!

POWER

CORD

(POWER ON)

WET

HANDS

nitnerruC

serepmA

5.2003.tf0001.tf006.tf573.tf052

5006.tf005.tf003.tf002.tf521

5.7009.tf053.tf002.tf521.tf001

010021.tf052.tf051.tf001

510081.tf

020042.tf521.tf57.tf05

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 15

nIdaoL

sttaW

021tA

stloV

eriW01#eriW21#eriW41#eriW61#

051.tf001.tf56

.egatlovwolmorftlusernacegamadtnempiuqE:NOITUAC

)noitarepOesahPelgniS,zH06(noitceleSelbaC.4elbaT

htgneLelbaCelbawollAmumixaM

Page 16

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION

OPERATION

Control Valve Lever

1. This hydraulic pump has a 3-way, 3-position valve that

is activated by a control valve lever (Figure 8). In the

neutral

is no flow of pressurized fluid.

2. In the

meaning the flow of pressurized fluid is allowed (Figure

9) and the hydraulic cylinder will extend once the remote

control toggle switch is pressed.

position, “PORT A” is CLOSED, meaning there

Figure 8. Control Valve Lever (Neutral Position)

forward (extend)

position, “PORT A” is OPEN,

Remote Control Unit

1. On the remote control unit there is a toggle switch.

When pressed, this toggle switch (Figure 11) will

activate (extend) the hydraulic cylinder. Releasing

the toggle switch will hold the cylinder in place.

Figure 11. Remote Control Unit

Figure 9. Control Valve Lever (Forward Position)

3. In the

hydraulic fluid back into tank (Figure 10) and the hydraulic cylinder retracts.

Figure 10. Control Valve Lever (Reverse Position)

NOTE

reverse (retract)

The cylinder on the JB5135 and

JB7135 models retract when the

control valve lever is in the forward

position and extend when the lever is

in the reverse position. See Figure 15.

position, “PORT A” returns

The Remote Control Unit does not

NOTE

Positioning the Rebar Bender (Method 1)

For Models JB5090, JB7090, JB8090, JB9180, JB11090

1. Place the pump control valve lever

neutral

2. Place the rebar bender over the rebar between the main

roller and upper roller arm at the desired elevation of the

bend as shown in Figure 12. Use vise-grips to hold the

rebar bender base in place.

3. Rotate the rebar bender until the hydraulic cylinder is in

the opposite direction of the desired bend.

Make certain the area is clear of bystanders before starting

the bending process.

position.

CAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

retract the hydraulic cylinder. The

retraction of the cylinder must be

done manually (Power Unit).

(Figure 8) in the

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 16

Page 17

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION

Figure 12. Rebar Placement

4. Place the pump control valve lever in the

position (Figure 9).

5. Place and hold the toggle switch on the remote control

unit in the ON position. The rebar bending process should

begin.

6. When the desired rebar bend angle (Figure 13) has been

achieved, release the toggle switch on the remote

control unit. This will stop the forward motion of the

cylinder.

7. To retract the cylinder, place the pump control valve

lever in the

retract with or without the pump running.

8. To remove the rebar bender, place the pump control

valve lever in the

bender over the end of the rebar or remove the main roller

and shaft (Figure 14) and slide the rebar bender off the

rebar.

reverse

/retract position. The cylinder will

neutral position

and either lift the

forward

Positioning the Rebar Bender (Method 2)

For Models JB5090, JB7090, JB8090, JB9180, JB11090

1. Place the pump control valve lever

neutral

2. Remove the Main Roller Shaft as shown in Figure 14.

Apply a suitable amount of pressure to the shaft to

either insert or remove it. It is held in place by a detent

ball plunger

Figure 13. 90° Rebar Bend

(Figure 8) in the

position.

Figure 14. Removing the Main Roller Shaft

The JB5090, JB7090 and JB8090

NOTE

bender may require adjustment in

order to obtain a 90° bend. See

Rebar Adjustment Bolt section.

WARNING

Use ONLY graded rebar. Ungraded rebar may break and

cause serious injury!

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 17

3. Next, remove the

over the rebar. Use vise-grips to hold the rebar bender

base in place.

3a. When bending rebar with models JB5090, JB7090,

JB8090 only: exchange the main roller for the straightening roller supplied from the factory.

4. Reinsert the main roller, making sure the rebar is positioned

between the main roller and the upper roller arm.

5. Operate rebar bender as outlined in Method 1, steps 3 thru 8.

main roller

and place the rebar bender

Page 18

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION

Figure 15. JB5135 Rebar Placement — Rebar Bending

Positioning the Rebar Bender (Method 3)

For Model JB5135

1. Place the pump control valve lever

neutral

2. Send the end of the spiral rebar through the gap in the puller

hook. Secure the puller hook around the straight rebar and

align the puller rollers on the spiral rebar (Figure 15).

3. Place the pump control valve lever in the

position.

4. Place and hold the toggle switch on the remote control

unit (ON position). The rebar bending process should

begin.

5. Activating the rebar bender will then cause the puller

hook and cylinder to retract and curl the end of the spiral

rebar up to 135° around the straight rebar.

6. When the desired angle has been achieved, release the

toggle switch on the remote control unit. This will stop the

retraction of the puller hook and cylinder.

7. To extend the puller hook and cylinder, place the pump

control valve lever in the

8. To remove the rebar bender, place the pump control

lever in the

end of the rebar.

position.

neutral

reverse

position and lift the bender over the

(Figure 8) in the

forward

/retract position.

valve

Figure 16. JB7135 Rebar Placement — Rebar Bending

Positioning the Rebar Bender (Method 4)

For Model JB7135

1. Place the pump control valve lever

neutral

2. Send the end of the spiral rebar through the gap between

the puller hook and main roller. Rotate the main roller so

that the main roller groove is in the 1 o’clock position.

Secure the straight rebar in the main roller groove. Align

the puller rollers on the spiral rebar (Figure 16).

3. Operate rebar bender as outlined in Method 3, steps 3 thru 8.

position.

(Figure 8) in the

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 18

Page 19

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION/SHUT-DOWN

Rebar Adjustment Bolt

For Model JB5090, JB7090, JB8090

The rebar bender may require adjustment in order to obtain a

90° bend. Adjustment is necessary due to inconsistencies in the

rebar produced by steel mills and because each bender is

capable of handling multiple diameters of rebar.

1. Use a 19 MM socket to loosen the bolt and a 24 MM

socket to loosen the locknut (Figure 17) until the adjustable block can be slid easily in the crescent groove on

the side of the rebar. Note: there is no need to remove the

hardware.

2. Insert a piece of the rebar to be used into the machine

Shutting Down the Rebar Bender and Power Unit

1. Remove Rebar Bender from the rebar.

2. Place ON/OFF toggle switch in the OFF position.

3. Unplug AC Power cord from receptacle.

4. Disconnect hydraulic hose from Power Unit.

5. Place protective hose cap on the male coupler end of

the hose.

6. Roll up hydraulic hose. Store Rebar Bender in a safe

place.

7. On the Power Unit, wrap the power and remote cords

neatly. Store Power Unit in safe place.

to assist in positioning the adjustable stop.

3. Slide the adjustable stop towards the rebar (away from

the hydraulic ram) until it makes contact with the rod.

4. Back the adjustable stop off the rebar slightly so the rod

can pass easily through the machine without binding.

5. Tighten the hardware securely , connect the bender to

the pump and make a test bend. You should now be able

to attain the desired bending angle. If the desired bend is

not attained, repeat the process until the desired result

is achieved.

Figure 17. Rebar Adjustment Bolt

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 19

Page 20

JIMMY SERIES HYDRAULIC REBAR BENDERS — MAINTENANCE

PREVENTIVE MAINTENANCE

Preventive maintenance should be performed on a daily or

CHANGING HYDRAULIC OIL

1. Change hydraulic oil

weekly basis depending on the amount and working use. A

higher than normal operating pressure could indicate a need

for immediate maintenance.

A clean well lubricated rebar bender will operate faster and

smoother and will allow for more accurate readings from

2. Remove drain plug, tilt the pump, then pour used fluid

into a sealable container.

3. Dispose the hydraulic fluid in accordance with local

regulations.

pump pressure gauges.

4. Install drain cap.

PUMP MAINTENANCE (Cleaning and Lubrication)

5. Remove vent cap and fill with recommended type

hydraulic oil.

1. Remove the side plates on the rebar bender to expose

moving parts. Clean all moving parts with a clean rag

and solvent.

NOTE

2. Check the cylinder on all models for leaks.

3. Lubricate all moving parts with

high pressure grease

.

4. For rebar bender models with cables (Models JB11090

and JB9180), lubricate the five grease fittings daily or

after approximately 50 rebar bend operations. Check

hydraulic cables daily for fraying.

NOTE

4. For rebar models JB135 and JB7135, visually check for

dents or cracks in the side plates. Replace plates

immediately if damaged. Clean and lubricate both rollers

to insure smooth rotation.

5. Check hydraulic oil every 40 hours of operation. Add

recommended hydraulic oil will void warranty and damage the

pump and hydraulic hose used in the rebar bending application.

hydraulic oil if necessary. Oil can be added by removing

the vent cap. Use a funnel.

STORAGE

When the rebar bender and electric hydraulic pump are not

used, please store in a clean dry location out of the reach of

ADDING HYDRAULIC OIL

children and away from unauthorized personnel.

once a year

Completely change hydraulic oil

every

300 hours

Change the oil more frequently when

pump is used in an extremely dusty

environment or when the oil has

been overheated.

Use only good quality hydraulic oil.

Multiquip recommends Mobil DTE

15M or equivalent. NEVER use

brake fluid, transmission fluid,

turbine oil, motor oil alcohol glycerin

etc. Use of other than the

.

of operation.

1. Make sure electric motor is OFF.

Be sure that all dust caps are attached to their respective

hoses and the hand-held remote control cable and pump

2. Depressurize system by placing pump control lever in

the

neutral

position. Disconnect hydraulic hose from

power cord are neatly wrapped.

port A of system.

3. Remove

vent cap

on top plate of reservoir. Visually

inspect to see if oil level is low. Oil level should be about

2 inches (50 mm) from top of reservoir plate.

4. Using a funnel, add oil to about 2 inches (50 mm) from

top of reservoir plate.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 20

Page 21

NOTE PAGE

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 21

Page 22

JIMMY SERIES HYD. REBAR BENDERS — EXPLANATION OF CODE IN REMARKS

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the help

numbers found on the back page of the manual if there are any

questions.

The contents and part numbers listed in the parts section are

subject to change

guarantee the availibility of the parts listed.

Sample Parts List:

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ...................... 1 ...... INCLUDES ITEMS W/

2

*

2*12347 WASHER, 3/8 IN. ... 1 ......

3 12348 HOSE ................... A/R ....MAKE LOCALLY

4 12349 BEARING ............... 1 ......S/N 2345B AND ABOVE

NO. Column

Unique Symbols - All items with same unique symbol

(*, #, +, %, or >) in the number column belong to the same

assembly or kit, which is indicated by a note in the “Remarks”

column.

Duplicate Item Numbers - Duplicate numbers indicate

multiple part numbers are in effect for the same general

item, such as different size saw blade guards in use or a

part that has been updated on newer versions of the same

machine.

When ordering a part that has more than one

item number listed, check the remarks column

for help in determining the proper part to order.

without notice

WASHER, 1/4 IN. .............

. Multiquip does not

NOT SOLD SEPARATELY

MQ-45T ONLY

*

QTY. Column

Numbers Used - Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other parts

that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed to

describe the item can also be shown.

Assembly/Kit

unique symbol will be included when this item is purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

used only with the specific model number or model number

variant listed. It can also be used to show a part is NOT

used on a specific model or model number variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

- All items on the parts list with the same

- Used to list an effective serial

- Indicates that the part is

“Make/Obtain Locally”

PART NO. Column

Numbers Used - Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a part

that has not been assigned a formal part number at time of

publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will be

clarified in the “Remarks” Column.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 22

purchased at any hardware shop or made out of available

items. Examples include battery cables, shims, and certain

washers and nuts.

“Not Sold Separately”

purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available for

sale through Multiquip.

- Indicates that the part can be

- Indicates that an item cannot be

Page 23

JIMMY SERIES HYD. REBAR BENDERS — SUGGESTED SPARE PARTS

JIMMY SERIES HYDRAULIC REBAR BENDER

1 to 3 Units (JB5135)

Qty. ..... P/N ...................... Description

1 ......... RB252698 ........... PULLER HOOK

1 ......... RB252818 ........... CAP SCREW, 5/8-18 X 2-1/2 LG

1 ......... RB252703 ........... ROLLER PIN

1 ......... RB252828 ........... BALL PLUNGER, 3/8-16

1 ......... RB252701 ........... WHEEL PULLER HOUSING

1 ......... RB252699 ........... PULLER ROLLER

2 ......... RB252852 ........... SET SCREW, 5/16 X 24 X 1/4

1 ......... RB9681 ............... STREET ELBOW FITTING

1 ......... CH38F ................ QUICK DISCONNECT COUPLER

1 ......... RB9777 ............... RUBBER HOSE, 10 FT

1 ......... RBHOSECAP ...... HOSE CAP

1 ......... CH38M ............... MALE HALF COUPLER, 3/8-18NPTF

JIMMY SERIES HYDRAULIC REBAR BENDER

1 to 3 Units (JB7135)

Qty. ..... P/N ...................... Description

1 ......... RB252710 ........... ROLLER PIN

1 ......... RB252828 ........... BALL PLUNGER, 3/8-16

1 ......... RB252707 ........... MAIN ROLLER

1 ......... RB252706 ........... PULLER HOOK

1 ......... RB10621 ............. 90 DEGREE FITTING, 3/8 NPTF

1 ......... CH38F ................ QUICK DISCONNECT COUPLER

1 ......... RB9777 ............... RUBBER HOSE, 10 FT

1 ......... RBHOSECAP ...... HOSE CAP

1 ......... CH38M ............... MALE HALF COUPLER, 3/8-18NPTF

JIMMY SERIES HYDRAULIC REBAR BENDER

1 to 3 Units (JB5090)

Qty. ..... P/N ...................... Description

1 ......... RB252671 ........... MAIN ROLLER SHAFT

1 ......... RB252828 ........... BALL PLUNGER, 3/8-16

1 ......... RB252665 ........... MAIN ROLLER

1 ......... RB9681 ............... STREET ELBOW FITTING

1 ......... CH38F ................ QUICK DISCONNECT COUPLER

1 ......... RB9777 ............... RUBBER HOSE, 10 FT

1 ......... RB HOSECAP ..... HOSE CAP

1 ......... RB001WHL ......... STRAIGHTENING WHEEL

1 ......... CH38M ............... MALE HALF COUPLER, 3/8-18NPTF

JIMMY SERIES HYDRAULIC REBAR BENDER

1 to 3 Units (JB7090)

Qty. ..... P/N ...................... Description

1 ......... RB252685 ........... MAIN ROLLER SHAFT

1 ......... RB252829 ........... BALL PLUNGER, 1/2-13

1 ......... RB252679 ........... MAIN ROLLER

1 ......... RB9681 ............... STREET ELBOW FITTING

1 ......... CH38F ................ QUICK DISCONNECT COUPLER

1 ......... RB9777 ............... RUBBER HOSE, 10 FT

1 ......... RBHOSECAP ...... HOSE CAP

1 ......... RB001WHL ......... STRAIGHTENING WHEEL

1 ......... CH38M ............... MALE HALF COUPLER, 3/8-18NPTF

JIMMY SERIES HYDRAULIC REBAR BENDER

1 to 3 Units (JB8090)

Qty. ..... P/N ...................... Description

1 ......... RB252685 ........... MAIN ROLLER SHAFT

1 ......... RB252829 ........... BALL PLUNGER, 1/2-13

1 ......... RB252694 ........... MAIN ROLLER

1 ......... RB9681 ............... STREET ELBOW FITTING

1 ......... CH38F ................ QUICK DISCONNECT COUPLER

1 ......... RB9777 ............... RUBBER HOSE, 10 FT

1 ......... RBHOSECAP ...... HOSE CAP

1 ......... RB001WHL ......... STRAIGHTENING WHEEL

1 ......... CH38M ............... MALE HALF COUPLER, 3/8-18NPTF

JIMMY SERIES HYDRAULIC REBAR BENDER

1 to 3 Units (JB9180)

Qty. ..... P/N ...................... Description

1 ......... RB252720 ........... MAIN WHEEL PIN

1 ......... RB252829 ........... BALL PLUNGER, 1/2-13

1 ......... RB252717 ........... FRONT PULLEY

1 ......... RB9681 ............... STREET ELBOW FITTING

1 ......... CH38F ................ QUICK DISCONNECT COUPLER

1 ......... RB9777 ............... RUBBER HOSE, 10 FT

1 ......... RBHOSECAP ...... HOSE CAP

1 ......... CH38M ............... MALE HALF COUPLER, 3/8-18NPTF

2 ......... RB252731 ........... CABLE, 44-1/2" LG.

JIMMY SERIES HYDRAULIC REBAR BENDER

1 to 3 Units (JB11090)

Qty. ..... P/N ...................... Description

1 ......... RB252720 ........... MAIN WHEEL PIN

1 ......... RB252829 ........... BALL PLUNGER, 1/2-13

1 ......... RB252717 ........... FRONT PULLEY

1 ......... RB9681 ............... STREET ELBOW FITTING

1 ......... CH38F ................ QUICK DISCONNECT COUPLER

1 ......... RB9777 ............... RUBBER HOSE, 10 FT

1 ......... RBHOSECAP ...... HOSE CAP

1 ......... CH38M ............... MALE HALF COUPLER, 3/8-18NPTF

1 ......... RB252738 ........... CABLE, 45-1/2" LG.

ELECTRIC-HYDRAULIC PUMP

1 to 3 Units (JPU1)

Qty. ..... P/N ...................... Description

1 ......... PEW01 ................ PENDANT SWITCH

1 ......... E0539940101 ...... REPAIR KIT FOR PISTON BLOCK

1 ......... E0539980105 ...... REPAIR KIT FOR MANIFOLD

1 ......... E0539960109 ...... REPAIR KIT FOR GEAR PUMP

1 ......... 64110100104 ...... SOCKET HEAD SCREW, M10X1.5X10

1 ......... E0561009101 ...... HANDLE, D10 X 98.5

1 ......... E0561008109 ...... KNOB, D30MM

1 ......... E0539910104 ...... BOLT KIT

1 ......... E0539911106 ...... REPAIR KIT

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 23

Page 24

JIMMY SERIES HYDRAULIC REBAR BENDERS — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

1

WARNING

Read, understand and follow any

and all printed materials provided

with and on this device. Do not

overload beyond rated capacity.

Never work under a load

supported by a hydraulic cylinder.

Immediately support liftef load

with suitable mechanical means.

Failure to heed these markings

may result in personal injury

and/ or property damage.

Engineered in U.S.A. Made in Taiwan

SFA Companies © 2003

BY MULTIQUIP

SERIAL NO. 59- 9 0 0 2

2

MODEL

JBXXXX

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 24

Page 25

JIMMY SERIES HYDRAULIC REBAR BENDERS — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

NO PART NO PART NAME QTY. REMARK

1 TBD WARNING, READ MANUAL DECAL 1

2 NAMEPLATE, JB5135 ................................................. 1 ............CONTACT MQ PARTS DEPT.

2 NAMEPLATE, JB7135 ................................................. 1 ............CONTACT MQ PARTS DEPT.

2 NAMEPLATE, JB5090 ................................................. 1 ............CONTACT MQ PARTS DEPT.

2 NAMEPLATE, JB7090 ................................................. 1 ............CONTACT MQ PARTS DEPT.

2 NAMEPLATE, JB8090 ................................................. 1 ............CONTACT MQ PARTS DEPT.

2 NAMEPLATE, JB9180 ................................................. 1 ............CONTACT MQ PARTS DEPT.

2 NAMEPLATE, JB11090 ............................................... 1 ............CONTACT MQ PARTS DEPT.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 25

Page 26

JB5135 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB5135 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 26

Page 27

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB5135 ASSY.

JB5135 ASSY.

NO PART NO PART NAME QTY. REMARK

1 RB252698 PULLER HOOK 1

2 RB252818 CAP SCREW(5/8- 18 X 2- 1/2LG.) 4

3 RB252839 LOCK NUT(5/8- 18) 4

4 RB252745 DECAL 1

5 RB9681 STREET ELBOW FITTING (3/8 NPTF) 1

6 CH38M MALE HALF COUPLER (3/8-18NPTF) 1

7 RB9777 RUBBER HOSE (10FT.) 1

8 HP0205PB CYLINDER (2 TON; 5IN. STROKE, ADAPTER INCLUDED) ........ 1 ............... REPLACES RP25PAC

9 RB252702 HANDLE ASSY. 1

10 RB252696 CYLINDER MOUNT 1

11 RB252697 PULLER ARM (LEFT & RIGHT) 1

12 RB252700 PULLER ROLLER 2

13 RB252703 ROLLER PIN 1

14 RB252828 BALL PLUNGER (3/8-16) 1

15 RB252701 WHEEL PULLER HOUSING 1

16 RB252699 PULLER ROLLER 1

17 RB252852 SET SCREW (5/16- 24 X 1/4 LG. NYLON

LOCKING TIP INCLUDED) 2

18 RB253081 CAP SCREW (3/4- 16 X 2- 1/2 LG.: LONG SHANK) 2

19 RB252835 JAM NUT (3/4- 16) 2

20 RBHOSECAP HOSE CAP 1

21 CH38F QUICK DISCONNECT COUPLER 1

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 27

Page 28

JB7135 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB7135 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 28

Page 29

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB7135 ASSY.

JB7135 ASSY.

NO PART NO PART NAME QTY. REMARK

1 RB252710 ROLLER PIN 1

2 RB252828 BALL PLUNGER 1

3 RB252707 MAIN ROLLER 1

4 RB252706 PULLER HOOK 1

5 RB252841 LOCK NUT 4

6 RB252820 CAP SCREW (3/4-16X 2-12) 4

7 RB252746 DECAL 1

8 CH38M MALE HALF COUPLER (3/8-18NPTF) 1

9 RB10621 90° ELBOW FITTING (3/8 NPTF) 1

10 RB9777 RUBBER HOSE (10FT) 1

11 HP0505PB CYLINDER(5 TON; 5-1/2 IN. STROKE) ............................... 1 ........... REPLACES RP55PAC

12 RB252709 HANDLE ASSEMBLY 1

13 RB252704 CYLINDER MOUNT 1

14 RB252705 PULLER ARM (LEFT & RIGHT) 4

15 RB252708 PULLER ARM ROLLER 1

16 RB252852 SET SCREW (5/16- 24 X 1/4 LG. NYLON

LOCKING TIP INCLUDED) 1

17 RB253081 CAP SCREW (3/4- 16 X 2- 1/2 LG.: LONG SHANK) 2

18 RB252835 JAM NUT (3/4- 16) 2

19 RBHOSECAP HOSE CAP 1

20 CH38F QUICK DISCONNECT COUPLER 1

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 29

Page 30

JB5090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB5090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 30

Page 31

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB5090 ASSY.

JB5090 ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 RB252839 LOCKNUT (5/8-18) 6

2 RB252844 WASHER (5/8) 6

3 RB252662 OUTSIDE PLATE (LEFT AND RIGHT) 1

4 RB252672 CENTRAL SHAFT 1

5 RB9681 STREET ELBOW FITTING (3/8 NPTF) 1

6 RB9777 RUBBER HOSE (10') 1

7 H0509PB CYLINDER (5 TON; 9-1/8" STROKE) ..................... 1 ................... REPLACES C59C-PAC

8 RB252675 PLUNGER CLEVIS 1

9 RB252852 SET SCREW (5/16-24 X 1/4 LG.) 1

10 RB252669 CYLINDER TRUNION 1

11 RB252667 UPPER ARM ROLLER 1

12 RB252663 INSIDE SIDE PLATE RIGHT HAND 1

13 RB252815 CAP SCREW (1/2-20 X 1-1/4 LG.) 1

14 RB252843 WASHER (1/2") 1

15 RB252674 STOP BOLT ASSEMBLY 1

16 RB252668 ADJUSTABLE STOP 1

17 RB252665 MAIN ROLLER 1

18 RB252673 INSIDE PLATE SPACER 2

19 RB252664 INSIDE SIDE PLATE LEFT HAND 1

20 RB252817 CAP SCREW (8-5/8-18 X 2-1/2 LG.) 1

21 RB252671 MAIN ROLLER SHAFT 1

22 RB252828 BALL PLUNGER (3/8-16) 1

23 RB252831 EXTERNAL LOCKWASHER (5/8") 1

24 RB252830 EXTERNAL LOCKWASHER (1/2") 1

25 CH38M MALE HALF COUPLER (3/8-18NPTF) 1

26 RBHOSECAP HOSE CAP 1

27 RB001WHL STRAIGHTENING WHEEL 1

28 CH38F QUICK DISCONNECT COUPLER 1

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 31

Page 32

JB7090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB7090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 32

Page 33

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB7090 ASSY.

JB7090 ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 RB252840 LOCKNUT (7/8-14) 5

2 RB252845 WASHER (7/8) 5

3 RB252676 OUTSIDE PLATE (LEFT AND RIGHT) 1

4 RB252686 CENTRAL SHAFT 1

5 RB9681 STREET ELBOW FITTING (3/8 NPTF) 1

6 RB9777 RUBBER HOSE (10') 1

7 H1012PB CYLINDER (10 TON; 12" STROKE) .......................... 1 ............ REPLACES C1012C-PAC

8 RB252689 PLUNGER CLEVIS 1

9 RB252852 SET SCREW (5/16-24 X 1/4 LG.) 1

10 RB252683 CYLINDER TRUNION 1

11 RB252681 UPPER ARM ROLLER 1

12 RB252684 SPACER 1

13 RB252678 INSIDE SIDE PLATE LEFT HAND 1

14 RB252843 WASHER (1/2") 1

15 RB252815 HEX CAP SCREW (1/2-20 X 1-1/4 LG.) 1

16 RB252688 STOP BOLT WASHER 1

17 RBRB253046 EXTERNAL LOCKWASHER (7/8") 1

18 RB252830 EXTERNAL LOCKWASHER (1/2") 1

19 RBRB252682 ADJUSTABLE STOP 1

20 RB252679 MAIN ROLLER 1

21 RB252687 INSIDE PLATE SPACER 1

22 RB252677 INSIDE SIDE PLATE RIGHT HAND 1

23 RB252821 HEX CAP SCREW (7/8-14 X 3-1/4 LG.) 1

24 RB252816 HEX CAP SCREW (1/2-20 X 2-3/4 LG.) 1

25 RB252685 MAIN ROLLER SHAFT 1

26 RB252829 BALL PLUNGER (1/2-13) 1

27 RB252838 LOCKNUT (1/2-20) 1

28 RB252690 DOWEL PIN (7/8" DIA X 2") 1

29 RB252854 GREASE FITTING (1/4-20) 5

30 CH38M MALE HALF COUPLER (3/8-18NPTF) 1

31 RBHOSECAP HOSE CAP 1

32 RB001WHL STRAIGHTENING WHEEL 1

33 CH38F QUICK DISCONNECT COUPLER 1

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 33

Page 34

JB8090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB8090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 34

Page 35

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB8090 ASSY.

JB8090 ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 RB252840 LOCKNUT (7/8-14) 5

2 RB252845 WASHER (7/8) 5

3 RB252691 OUTSIDE PLATE (LEFT AND RIGHT) 1

4 RB252686 CENTRAL SHAFT 1

5 RB9681 STREET ELBOW FITTING (3/8 NPTF) 1

6 RB9777 RUBBER HOSE (10') 1

7 H1014PB CYLINDER (10 TON; 14" STROKE) ......................... 1 ............ REPLACES C1014C-PAC

8 RB252689 PLUNGER CLEVIS 1

9 RB252852 SET SCREW (5/16-24 X 1/4 LG.) 1

10 RB252683 CYLINDER TRUNION 1

11 RB252681 UPPER ARM ROLLER 1

12 RB252684 SPACER 1

13 RB252693 INSIDE SIDE PLATE LEFT HAND 1

14 RB252843 WASHER (1/2") 1

15 RB252815 HEX CAP SCREW (1/2-20 X 1-1/4 LG.) 1

16 RB252688 STOP BOLT WASHER 1

17 RB253046 EXTERNAL LOCKWASHER (7/8") 1

18 RB252830 EXTERNAL LOCKWASHER (1/2") 1

19 RB252682 ADJUSTABLE STOP 1

20 RB252694 MAIN ROLLER 1

21 RB252687 INSIDE PLATE SPACER 1

22 RB252692 INSIDE SIDE PLATE RIGHT HAND 1

23 RB252821 HEX CAP SCREW (7/8-14 X 3-1/4 LG.) 1

24 RB252816 HEX CAP SCREW (1/2-20 X 2-3/4 LG.) 1

25 RB252685 MAIN ROLLER SHAFT 1

26 RB252829 BALL PLUNGER (1/2-13) 1

27 RB252838 LOCKNUT (1/2-20) 1

28 RB252690 DOWEL PIN (7/8" DIA X 2") 1

29 RB252047 GREASE FITTING (1/4-20) 5

30 CH38M MALE HALF COUPLER (3/8-18NPTF) 1

31 RBHOSECAP HOSE CAP 1

32 RB001WHL STRAIGHTENING WHEEL 1

33 CH38F QUICK DISCONNECT COUPLER 1

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 35

Page 36

JB9180 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB9180 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 36

Page 37

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB9180 ASSY.

JB9180 ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 RB252716 TOP ROLLER 1

2 RB252807 HEX CAP SCREW (1/4-20 X 1" LG.) 2

3 RB252711 OUTSIDE SIDE PLATES (RIGHT AND LEFT) 2

4 RB252854 GREASE FITTING (1/4-20) 5

5 RB252741 COIL SPRING 2

6 RB252811 HEX CAP SCREW (3/8-24 X 2-1/2" LG.) 1

7 RB252713 INSIDE SIDE GUIDE PLATE (RIGHT AND LEFT) 2

8 RB252715 HALF MAIN WHEEL (DOWEL PINS INCLUDED) 1

9 RB252719 RAM SUPPORT AND CENTER SPACER (DOWEL PINS INCLUDED) 1

10 RB252723 INSIDE MAIN PLATE PULLEY BUSHING (RIGHT AND LEFT) 2

11 RB252742 SPACER 6

12 RB252712 SIDE GUARD (RIGHT AND LEFT) 2

13 RB252725 MAIN PULLEY BUSHING (RIGHT AND LEFT) 2

14 RB252829 BALL PLUNGER (1/2-13) 1

15 RB252720 MAIN WHEEL PIN 1

16 RB253074 HEX CAP SCREW (5/16-24 X 1" LG.) 2

17 RB252840 LOCKNUT (7/8-14) 4

18 RB252845 WASHER (7/8") 6

19 RB252717 FRONT PULLEY 2

20 RB252731 CABLE (44-1/2" LG.) 2

21 RB253067 HEX CAP SCREW (1/4-20 X 1-1/4 LG.) 6

22 RB252813 HEX CAP SCREW (3/8-24 X 2-3/4 LG.) 3

23 RB252842 WASHER (3/8”) 6

24 RB252726 BAR STOP BUSHING 1

25 RB252824 SOC. HD. CAP SCREW (5/16-18 X 3-1/2 LG.) 2

26 RB252718 RAM PAD AND CENTER SUPPORT (DOWEL PIN INCLUDED) 1

27 RB252721 FRONT PULLEY SHAFT 1

28 RB252837 LOCKNUT (3/8-24) 3

29 RB252814 HEX CAP SCREW (1/2-20 X 1" LG.) 1

30 RB252843 WASHER (1/2") 2

31 RB9681 STREET ELBOW FITTING (3/8 NPTF) 1

32 RB9777 RUBBER HOSE (10') 1

33 H1014PB CYLINDER (10 TON; 14" STROKE) ........................................................... 1 ....... REPLACES C1014C-PAC

34 RB252714 RAM TOWER 1

35 RB252727 CABLE GUIDE BLOCK 1

36 RB252728 CABLE STOP BLOCK 1

37 RB252816 HEX CAP SCREW (1/2-20 X 2-3/4 LG.) 1

38 RB252821 HEX CAP SCREW (7/8-14 X 3-1/4 LG.) 1

39 RB252823 HEX CAP SCREW (7/8-14 X 5" LG.) 1

40 RB252722 TOP ROLLER PIN 1

41 RB252826 FLAT HD. SOC. SCREW (1/4-28 X 3/4 LG.) 12

42 RB252833 JAM NUT (3/8-24) 1

43 RB252827 FLAT HD. SOC. SCREW (1/4-20 X 3/4 LG.) 12

44 RB25200A SET SCREW (5/16-24 X 3/4 LG.) 1

45 CH38M MALE HALF COUPLER (3/8-18NPTF) 1

46 RBHOSECAP HOSE CAP 1

47 CH38F QUICK DISCONNECT COUPLER 1

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 37

Page 38

JB11090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB11090 ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 38

Page 39

JIMMY SERIES HYDRAULIC REBAR BENDERS — JB11090 ASSY.

JB11090 ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 RB252737 TOP ROLLER 1

2 RB252807 HEX CAP SCREW (1/4-20 X 1" LG.) 2

3 RB252732 OUTSIDE SIDE PLATES (RIGHT AND LEFT) 2

4 RB252854 GREASE FITTING (1/4-20) 5

5 RB252741 COIL SPRING 2

6 RB252811 HEX CAP SCREW (3/8-24 X 2-1/2" LG.) 1

7 RB252734 INSIDE SIDE GUIDE PLATE (RIGHT AND LEFT) 2

8 RB252736 HALF MAIN WHEEL (DOWEL PINS INCLUDED) 1

9 RB252719 RAM SUPPORT AND CENTER SPACER (DOWEL PINS INCLUDED) 1

10 RB252723 INSIDE MAIN PLATE PULLEY BUSHING (RIGHT AND LEFT) 2

11 RB252742 SPACER 6

12 RB252729 SIDE GUARD (RIGHT AND LEFT) 2

13 RB252725 MAIN PULLEY BUSHING (RIGHT AND LEFT) 2

14 RB252829 BALL PLUNGER (1/2-13) 1

15 RB252720 MAIN WHEEL PIN 1

16 RB253074 HEX CAP SCREW (5/16-24 X 1" LG.) 2

17 RB252840 LOCKNUT (7/8-14) 4

18 RB252845 WASHER (7/8") 6

19 RB252717 FRONT PULLEY 2

20 RB252738 CABLE (45-1/2" LG.) 2

21 RB253067 HEX CAP SCREW (1/4-20 X 1-1/4 LG.) 6

22 RB252813 HEX CAP SCREW (3/8-24 X 2-3/4 LG.) 3

23 RB252842 WASHER (3/8") 6

24 RB252726 BAR STOP BUSHING 1

25 RB252824 SOC. HD. CAP SCREW (5/16-18 X 3-1/2 LG.) 2

26 RB252718 RAM PAD AND CENTER SUPPORT (DOWEL PIN INCLUDED) 1

27 RB252721 FRONT PULLEY SHAFT 1

28 RB252837 LOCKNUT (3/8-24) 3

29 RB252814 HEX CAP SCREW (1/2-20 X 1" LG.) 1

30 RB252843 WASHER (1/2") 2

31 RB9681 STREET ELBOW FITTING (3/8 NPTF) 1

32 RB9777 RUBBER HOSE (10') 1

33 H1010PB CYLINDER (10 TON; 10" STROKE) ......................................................... 1 ...... REPLACES C1010C-PAC

34 RB252730 RAM TOWER 1

35 RB252727 CABLE GUIDE BLOCK 1

36 RB252728 CABLE STOP BLOCK 1

37 RB252816 HEX CAP SCREW (1/2-20 X 2-3/4 LG.) 1

38 RB252821 HEX CAP SCREW (7/8-14 X 3-1/4 LG.) 1

39 RB252823 HEX CAP SCREW (7/8-14 X 5" LG.) 1

40 RB252722 TOP ROLLER PIN 1

41 RB252826 FLAT HD. SOC. SCREW (1/4-28 X 3/4 LG.) 12

42 RB252833 JAM NUT (3/8-24) 1

43 RB252827 FLAT HD. SOC. SCREW (1/4-20 X 3/4 LG.) 12

44 RB25200A SET SCREW (5/16-24 X 3/4 LG.) 1

45 CH38M MALE HALF COUPLER (3/8-18NPTF) 1

46 RBHOSECAP HOSE CAP 1

47 CH38F QUICK DISCONNECT COUPLER 1

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 39

Page 40

JIMMY SERIES HYDRAULIC REBAR BENDERS — ELECTRIC PUMP ASSY.

PUMP ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 40

Page 41

JIMMY SERIES HYDRAULIC REBAR BENDERS — ELECTRIC PUMP ASSY.

PUMP ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 E1649001108 MOTOR, 1.5 HP 1

2 E0569002107 GASKET, MOTOR 1

3 E0569003109 RESERVOIR COVER PLATE 1

4 E0569004101 RESERVOIR GASKET 1

5 E1643000106 UPPER PLATE ASSEMBLY 1

6 E0569006105 ECCENTRIC 5/8" SHAFT 1

7 62260318100 BEARING 1

8 E0569007107 SLEEVE ECCENTRIC BEARING 1

9 E1544000104 PISTON BLOCK 4

10 51170064109 O-RING D6.4 X 1.8 2

11 E1645002100 LOWER PLATE ASSEMBLY 1

12 E0542000106 OIL FILLER (VENT) CAP 1

13 64910060407 BOLT M6X1X25 10

14 60130064106 WASHER 10

15 D0901002100 CONTROL VALVE, 3 WAY-3 POSITION 1

16 64910095204 SOCKET HEAD SCREW (3/8"-16UNC) 4

17 E0548000106 MANIFOLD, SAFETY VALVE 1

18 65810064305 HEX. HEAD BOLT (1/4"-20UNC) 8

19 E0546003102 GEAR PUMP ASSY. 1

20 H2361000102 MAGNET 1

21 E0539005105 RESERVOIR 1

22 53230160104 SPECIAL WASHER 1

23 E0568008104 DRAIN PLUG 1

24 E0537000105 CARRY HANDLE 1

25 PEW01 PENDANT SWITCH 1

26 E0539901103 DRAIN PLUG ASSEMBLY 1

27 E0539902105 BOLT KIT FOR RESERVOIR 1

30 E0539940101 REPAIR KIT FOR PISTON BLOCK (ITEM #9) ...... 1 ............ USE FOR ITEM 9

31 E0539980105 REPAIR KIT FOR MANIFOLD (ITEM #17) ............ 1 ............ USE FOR ITEM 17

32 E0539960109 REPAIR KIT FOR GEAR PUMP (ITEM #19) ......... 1 ............ USE FOR ITEM 19

37 HYDRAULIC OIL, 1 GAL ....................................... 1 ............ OPTION, MOBIL DTE 15M

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 41

Page 42

JIMMY SERIES HYDRAULIC REBAR BENDERS — CONTROL VALVE ASSY.

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 42

Page 43

JIMMY SERIES HYDRAULIC REBAR BENDERS — CONTROL VALVE ASSY.

CONTROL VALVE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 E0561002107 CAP VALVE 1

2# SOCKET HEAD SCREW (3/8-16UNC X 1-1/2") 4

3+ SPRING DETENT 1

4+ STEEL BALL, 1/4" 1

5 E0561003109 VALVE BONNET 1

6+ O-RING, 3.5 X 44.45 1

7+ O-RING, 1.8 X 15.8 1

8 61130190109 THRUST-WASHER 1

9 62260190102 THRUST-BEARING 1

10 E0531005105 ROTOR ASSEMBLY 1

11 E0541001103 SHEAR SEAL ASSEMBLY ...................................... 2 ................ INCLUDES ITEMS W/

12

13*+ BACK-UP RING, 8.1 X 11.15 1

14*+ O-RING, 8 X 1.8 1

15*+ SPRING WASHER 3

16 D0961009100 VALVE BLOCK 1

17# SOCKET HEAD SCREW (3/8-16UNC X 2") 4

18 60910075105 HEX SOCKET PLUG, 1/16NPT 2

19+ GASKET, VALVE 1

20 64110100104 SOCKET HEAD SCREW (M10 X 1.5 X 10) 1

21 E0561009101 HANDLE, D10 X 98.5 1

22 E0561008109 KNOB, D30MM 1

23 60140060101 ROLL PIN, D6 X 12 1

24 D0561001106 HEX SOCKET PLUG, H19 X 23 1

25 E0541004105 ADAPTER ASSEMBLY ............................................ 1 ................ INCLUDES ITEMS W/%

26% E0561004101 ADAPTER 1

27%+ BACK-UP RING, D9.7 X 1.45 2

28%+ 0-RING, D1.8 X 9.5 2

29 H1868104106 HEX SOCKET PLUG 1

30 E0539910104 BOLT KIT ................................................................. 1 ................ INCLUDES ITEMS W/#

31 E0539911106 REPAIR KIT .............................................................. 1 ................ INCLUDES ITEMS W/+