Page 1

OPERATION AND PARTS MANUAL

GloBug 4-Spot

MODEL GB43SC

LIGHTING SYSTEM

(FOR USE WITH MQ SERIES GENERATORS)

Revision #3 (12/15/08)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

PAGE 2 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 3

NOTE PAGE

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 3

Page 4

TABLE OF CONTENTS

MQ GLOBUG 4-SPOT LIGHTINGMQ GLOBUG 4-SPOT LIGHTING

MQ GLOBUG 4-SPOT LIGHTING

MQ GLOBUG 4-SPOT LIGHTINGMQ GLOBUG 4-SPOT LIGHTING

SYSTEMSYSTEM

SYSTEM

SYSTEMSYSTEM

Proposition 65 Warning ............................................. 3

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

Safety Message Alert Symbols .............................. 6-7

Rules For Safe Operation .................................... 8-11

Specifications .......................................................... 12

Dimensions ............................................................. 13

General Information ................................................ 14

Components....................................................... 16-17

Setup .................................................................. 18-20

Operation ................................................................ 21

Storage .............................................................. 22-23

Maintenance ...................................................... 24-27

Troubleshooting (Lamps) ........................................ 28

Troubleshooting (Mast) ........................................... 29

Explanation Of Codes In Remarks Column ............ 30

Suggested Spare Parts ........................................... 31

COMPONENT DRACOMPONENT DRA

COMPONENT DRA

COMPONENT DRACOMPONENT DRA

Nameplate and Decals....................................... 32-33

Baseplate Assy. .................................................. 34-35

Electrical Assy. ...................................................36-37

Ballast Assy. ....................................................... 38-39

Main Mast Assy. ................................................. 40-41

T-Handle Assy. ...................................................42-43

Steering Assy. .................................................... 44-45

Outrigger Assy. .................................................. 46-47

Mast Adapter Assy. ............................................48-49

Mast Section Assy. ............................................. 50-51

Terms and Conditions Of Sale — Parts .................. 52

WINGSWINGS

WINGS

WINGSWINGS

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 5

Effective: January 1st, 2006

Ordering parts has never been easier!

PARTS ORDERING PROCEDURES

Choose from three easy options:

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■

View Parts Diagrams

■

Order Parts

■

Print Specification Information

Goto www.multiquip.com and click on

Order Par ts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

If you have an MQ Account, to obtain a

Username and Password, E-mail us at:

parts@multiquip.com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

internet

Use the

on

Standard orders

complete part numbers.*

Fax

your order in and qualify for a 2% Discount

on

Standard orders

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

and qualify for a 5% Discount

for all orders which include

for all orders which include

International Customers

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

should contact

❒❒

❒

❒❒

❒❒

❒

❒❒

❒❒

❒

❒❒

❒❒

❒

❒❒

❒❒

❒

❒❒

❒❒

❒

❒❒

www.multiquip.com

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 5

When ordering parts, please supply:

Dealer Account Number

Dealer Name and Address

Shipping Address (if different than billing address)

Return Fax Number

Applicable Model Number

Quantity, Part Number and Description of Each Part

NOTE

All orders are treated as

and will ship the same day if received prior

to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

❒❒

❒

❒❒

Standard Orders

Specify Preferred Method of Shipment:

✓

UPS/Fed Ex

■

Priority One

■

Ground

■ Next Day

■

Second/Third Day

✓ DHL

✓

Tr uck

Page 6

GLOBUG 4-SPOT — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed

at all times when operating this

equipment. Failure to read and

understand the Safety Messages and

Operating Instructions could result in

injury to yourself and others.

This Owner's Manual has been

NOTE

developed to provide complete

instructions for the safe and

efficient operation of the

MQ

GLOBUG 4-SPOT.

Before using this Lighting System, ensure that the operating

individual has read and understands all instructions in this

manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure

to the operator, and are preceded by one of three words:

DANGER, WARNING, or CAUTION.

DANGER

Potential hazards associated with the

operation will be referenced with Hazard Symbols which

appear throughout this manual, and will be referenced in

conjunction with Safety Message Alert Symbols.

HAZARD SYMBOLS

WARNING - Lethan Exhaust Gasses

Engine exhaust gases contain

poisonous carbon monoxide. This gas

is colorless and odorless, and can

cause death if inhaled. NEVER operate

this equipment in a confined area or

enclosed structure that does not provide

ample free flow air.

WARNING - Explosive Fuel

Gasoline fuel is extremely flammable,

and its vapors can cause an explosion if

ignited. DO NOT start the engine near

spilled fuel or combustible fluids.

DO NOT fill the fuel tank while the engine is running or

hot. DO NOT overfill tank, since spilled fuel could ignite if

it comes into contact with hot engine parts or sparks from

the ignition system. Store fuel in approved containers, in

well-ventilated areas and away from sparks and flames.

GLOBUG 4-SPOT

You WILL be

NOT follow directions.

WARNING

You CAN be

NOT follow directions.

CAUTION

You CAN be

KILLED

KILLED

INJURED

PAGE 6 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

or

SERIOUSLY

or

SERIOUSLY

if you DO NOT follow directions.

injured if you DO

injured if you DO

WARNING - Burn Hazards

Engine components can generate extreme

heat. To prevent burns, DO NOT touch

these areas while the engine is running or

immediately after operations. Never

operate the engine with heat shields or heat

guards removed.

CAUTION - Respiratory Hazard

ALWAYS wear approved

protection when required.

respiratory

Page 7

GLOBUG 4-SPOT — SAFETY MESSAGE ALERT SYMBOLS

CAUTION - Rotating Parts

NEVER operate equipment with covers,

or guards removed. Keep fingers, hands,

hair and clothing away from all moving

parts to prevent injury.

CAUTION - Accidental Starting

ALWAYS place the power source, circuit

breakers or ON/OFF switch in the OFF

position, when the generator is not in use,

unless connected to transfer switch.

CAUTION - Sight and Hearing Hazards

ALWAYS wear approved eye and

hearing protection.

CAUTION - Equipment Damage Messages

Other important messages are provided throughout this

manual to help prevent damage to your lighting system,

other property, or the surrounding environment.

This lighting system, other

NOTE

property, or the surrounding

environment could be

damaged if you

instructions.

do not

follow

CAUTION - Over-Speed Conditions

NEVER tamper with the factory settings of

the engine governor settings. Personal injury

and damage to the engine or equipment can

result if operating speed ranges above

maximum allowable.

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 7

Page 8

GLOBUG 4-SPOT — RULES FOR SAFE OPERATION

WARNING - READ THIS MANUAL

Failure to follow instructions in this manual may lead to

Serious Injury

operated by trained and qualified personnel only! This

equipment is for industrial use only.

or even

Death

. This equipment is to be

■

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to

cool before servicing engine or mixer.

The following safety guidelines should always be used

when operating the GLOBUG 4-SPOT.

The following safety guidelines should always be used when

operating the GLOBUG 4-SPOT:

GENERAL SAFETY

■

DO NOT operate or service this

equipment before reading this entire

manual.

■

This equipment should not be operated by persons under

18 years of age.

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

■

NEVER operate this equipment when not feeling

■

High Temperatures – Allow the engine to cool before

adding fuel or performing service and maintenance

functions. Contact with

burns.

■

The engine of this lighting system/generator requires an

adequate free flow of cooling air. NEVER operate the

generator in any enclosed or narrow area where free flow of

the air is restricted. If

the air flow is restricted

it will cause serious

damage to the

generator engine and

may cause injury to

people. Remember the

engine of the lighting

system/generator

gives off DEADLY

carbon monoxide gas.

well due to fatigue, illness or taking medicine.

hot!

components can cause serious

■

NEVER operate this equipment under the influence of

drugs

■

Whenever necessary, replace nameplate, operation and

or

alcohol

.

safety decals when they become difficult read.

■

Manufacturer does not assume responsibility for any

■

■

■

accident due to equipment modifications.

■

NEVER use accessories or attachments, which are not

■

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

PAGE 8 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

ALWAYS use extreme caution when working with

flammable liquids. When refueling, stop the

engine and allow it to cool. DO NOT

around or near the machine. Fire or explosion

could result from fuel vapors, or if fuel is spilled

on a hot engine.

NEVER operate the GloBug in an explosive

atmosphere or near combustible materials. An

explosion or fire could result causing severe

bodily harm or even death.

Topping-off to filler port is dangerous, as it tends to spill fuel.

Wipe up any spilled fuel immediately.

smoke

Page 9

GLOBUG 4-SPOT — RULES FOR SAFE OPERATION

■

ALWAYS make sure that the GloBug is secure on firm level

ground so that it cannot slide or shift around, endangering

workers. Also keep the immediate area free of bystanders.

■

ALWAYS keep area behind GloBug clear of people while

raising and lowering mast.

■

To prevent the GloBug from overturning, NEVER use in winds

that exceed 22 mph(10m/s).

■

To prevent the GloBug from rolling, ALWAYS place the

GloBug on a firm flat surface. Surface slant should not exceed

5 degrees.

■

To prevent the GloBug from rolling, ALWAYS apply the

parking brake. For additional safety place chock blocks

behind the wheels.

■

The GloBug must use a generator that is at least 220

lbs. (100 kg) minimum. This will prevent the GloBug from

tipping over.

■

The GloBug should only be used in temperatures between

23-104 degrees Fahrenheit (-5 to 40 degrees Celsius).

Failure to comply with these operating parameters could

cause the lamp to malfunction and shorten the ballast

life.

■

NEVER use the GloBug in

rain, snow

or areas of high

humidity that could generate electrical storms.

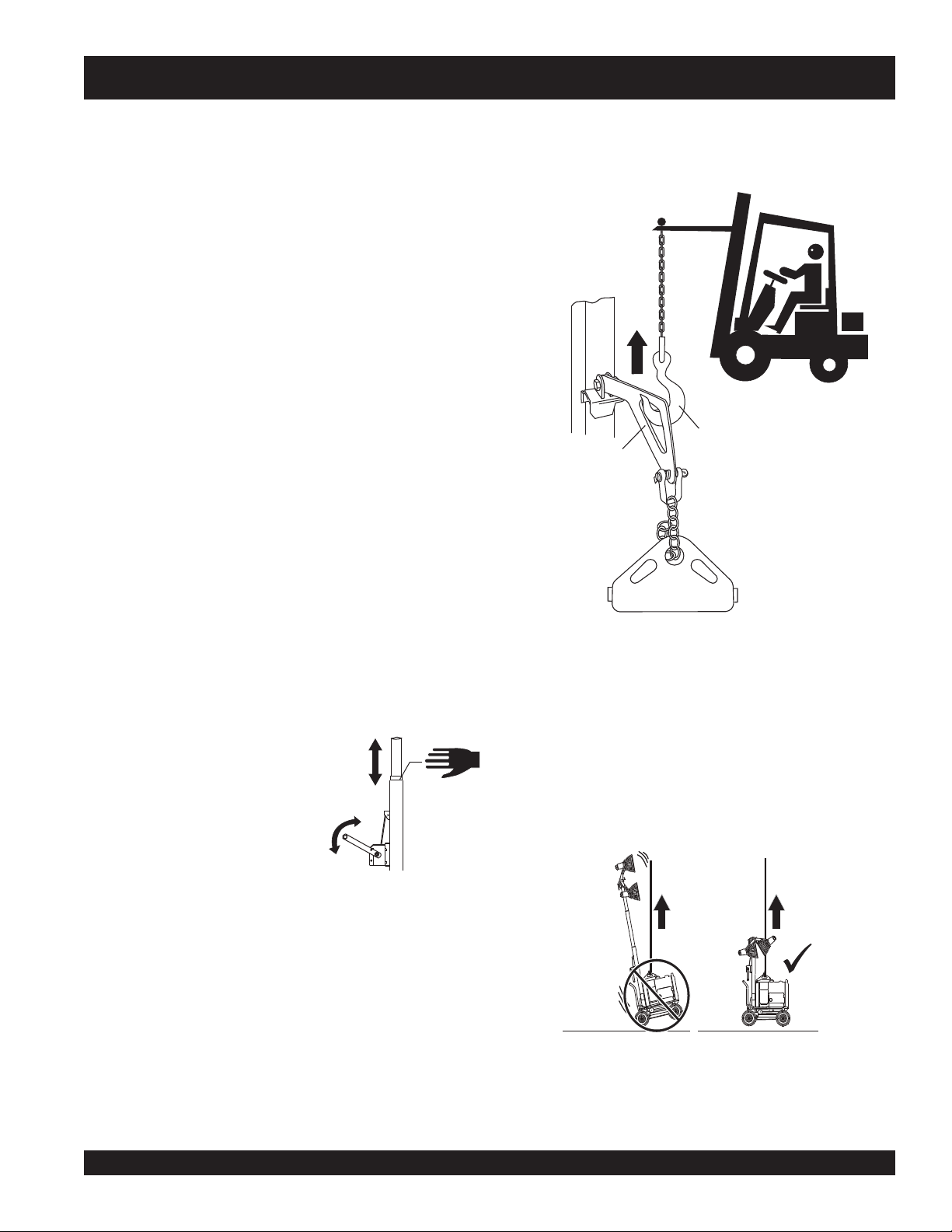

LIFTING/TRANSPORTING THE GLOBUG

■

ALWAYS use the lifting hanger, when lifting of the GloBug

is required.

LIFTING

HOOK

LIFTING

HANGER

GENERATOR

LIFTING BALE

LIFTING

SCHACKLE

■

Set the GloBug's tire air pressure to 35.5 psi (245kPa).

Check daily. Low tire pressure could adversely affect the

parking brake.

MAST SAFETY

■

When raising or lowering the mast,

keep hands and fingers clear of

the various mast sections, this will

PINCH

POINT

prevent hands and fingers from

getting pinched.

■

When raising the mast and to prevent tipping, ALWAYS

deploy outriggers

.

■CHECK the mast and winch cables for wear. If any problem

occurs when lower or raising the mast STOP immediately!

Contact a trained MQ technician for assistance.

■

NEVER pivot or retract mast while unit is operating.

■

NEVER use the lighting system mast as a crane. DO

NOT lift anything with the mast.

■

NEVER attach anything to the lighting system mast.

■

Use a crane, forklift or suitable lifting device of adequate

lifting capability when the lifting of the GloBug is required.

■

Make sure the mast is completely lowered before lifting

the GloBug.

■

When the GloBug is lifted from its correct lifting point, it

should lift straight up (not tilted). DO NOT attempt to lift

the GloBug if its position is tilted while lifting.

INCORRECT

CORRECT

■

ALWAYS lower the tower when not in use, or if high winds

or electrical storms are expected in the area.

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 9

Page 10

GLOBUG 4-SPOT — RULES FOR SAFE OPERATION

■

When transporting the GloBug 4-Spot, lower the mast

.

Tighten the lamp adjustment lever and make sure

fully

that the lighting unit assembly is fixed to the mast before

transporting. This will prevent the light assembly from

falling down or being damaged during transport.

LAMP SAFETY AND CARE

■

NEVER leave any grease or oil residue on lamp surface

when replacing or removing lamp. This can create hot

spots, reducing the service life of the lamp.

■

ALWAYS make sure the lamp surface is clean and dry.

■

ALWAYS replace with MQ recommended type lamp. See

parts section of this manual.

■

NEVER use force when installing a lamp. Excessive force

could cause the lamp to break causing bodily harm.

■

NEVER attempt to replace lamp with the power on. Always

unplug the power cord from the generator when changing

the lamp.

■

ALWAYS allow a sufficient amount of time for the lamp to

cool

before changing. The possibility exists of severe

burns.

DANGER - GloBug High Danger Areas

The

DANGER

considered

to. Failing to understand these areas could result in

Harm, Electrical

Please pay close attention when operating the lighting

system.

items listed below and on the next page are

High DANGER

Shock, Electrocution

areas and should be adhered

Bodily

, and even

Death!

DANGER - Grounding the GloBug for Operation

The GLOBUG 4-SPOT is equipped

with a

ground terminal

protection. ALWAYS complete the

grounding path

system to an external grounding source.

ALWAYS make certain the GloBug is well grounded and

securely fastened to a good earth ground (ground rod). The

possibility exists of

even Death

if the GloBug is not grounded.

for your

from the lighting

Electrical Shock, Electrocution, and

■

ALWAYS have a

trained technician

to install and remove

lamp, or replace any damaged fixture wiring.

PAGE 10 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 11

GLOBUG 4-SPOT — RULES FOR SAFE OPERATION

DANGER - GloBug Electric Shock Hazards

ALWAYS keep electrical cords in good condition. Worn,

bare or frayed wiring can cause electrical

shock, thus causing

even Death

.

Bodily Harm or

WET

HANDS

NEVER grab or touch a live power

cord with wet hands, the possibility

exists of

Electrical Shock,

Electrocution, and even Death!

POWER

CORD

(POWER ON)

DANGER - GloBug Electric Shock Hazards

NEVER operate the

GloBug or handle any

electrical equipment

while standing in water,

while bare foot, while

hands are wet, or in the

rain. A dangerous

electrical shock

occur causing

could

Severe

Bodily Harm or even

Death.

Maintenance Safety

■

NEVER lubricate components or attempt service on a running

GloBug.

■

ALWAYS allow the GloBug a proper amount of time to cool

before servicing.

■

Keep the GloBug in proper running condition.

■

Fix damage to the GloBug immediately and always replace

broken parts.

■

ALWAYS use the required tool for the job application.

Using damaged or worn tools or using tools inappropriate

for the required application is very dangerous, and may

cause damage to

the machine and

service personnel.

Make sure to use

the appropriate tool

for the specific job.

Emergencies

■

ALWAYS know the location of the

nearest

fire extinguisher

.

DANGER - GloBug Overhead Obstructions

ALWAYS make sure the

area above GloBug is

open and clear of

overhead power lines

and other obstructions.

The tower extends in

excess of 16.5 ft. (5

meters). Contact with

overhead powerlines or

other obstructions could

result in equipment

damage,

Serious Injury or Death

!

■

ALWAYS know the location of the nearest

first aid kit

■

In emergencies

or

keep a phone on the job site

numbers of the nearest

department

.

always

know the location of the nearest phone

. Also know the phone

ambulance, doctor

. This information will be invaluable in the case

of an emergency.

and

fire

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 11

Page 12

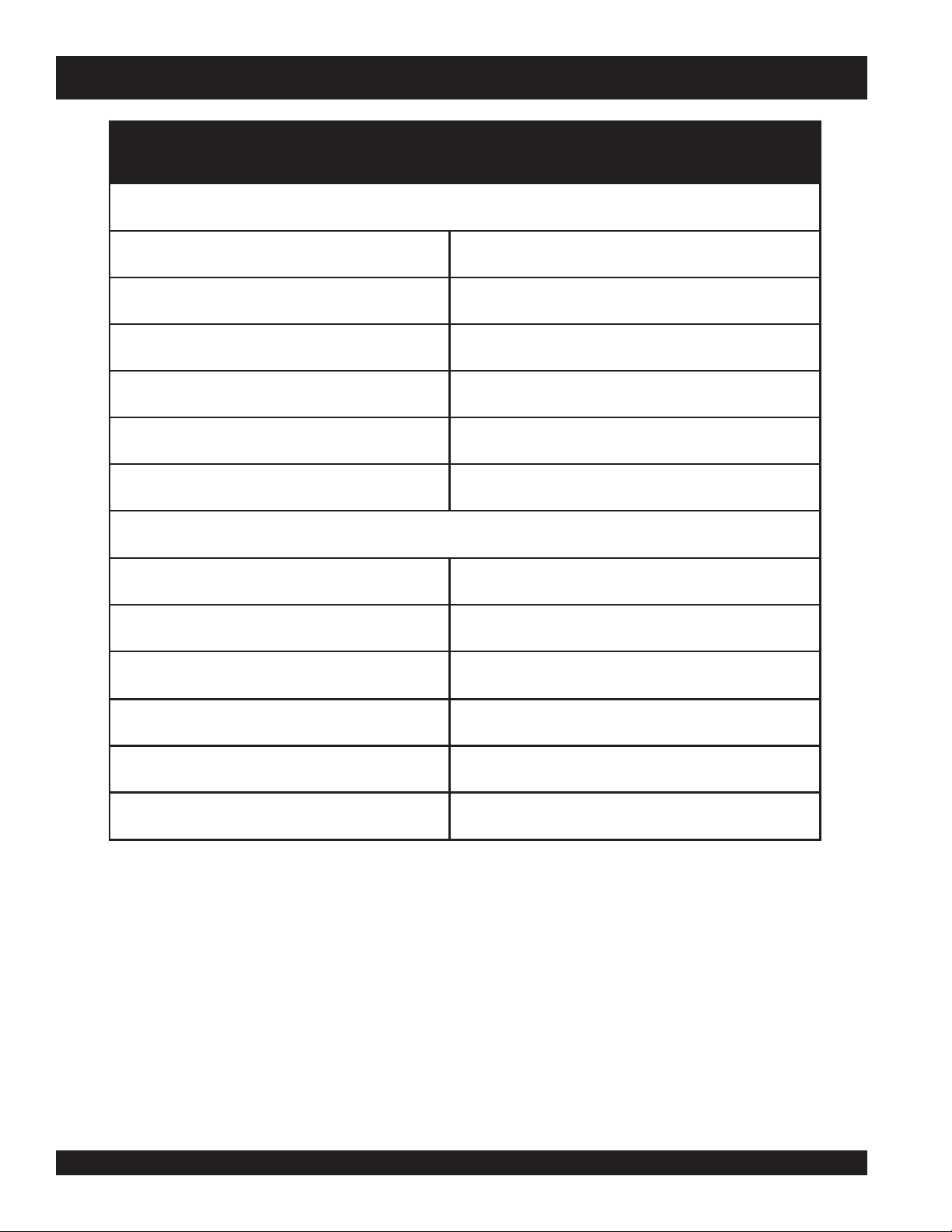

GLOBUG 4-SPOT — SPECIFICATIONS

topS-4guBolG

ledoMCS34BG

egatloVtupnICAV021

ycneuqerFesahP-elgniSzH06

tnerruC.xaMspmA81

snoitacificepS.1elbaT

dniW)hpk64.08(hpm56

)rotarenegssel(thgieW)gk561(.sbl463

pmaL

epyTpmaLedilaHlateMttaW004)4(

snemuL000,631

tsaM

egatSforebmuN3

s

thgieHmumixaM)sretem2.4(.tf8.31

rotareneG

rotareneGhtiwytilibatS

launaMrotareneGdeificepSeeS

PAGE 12 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 13

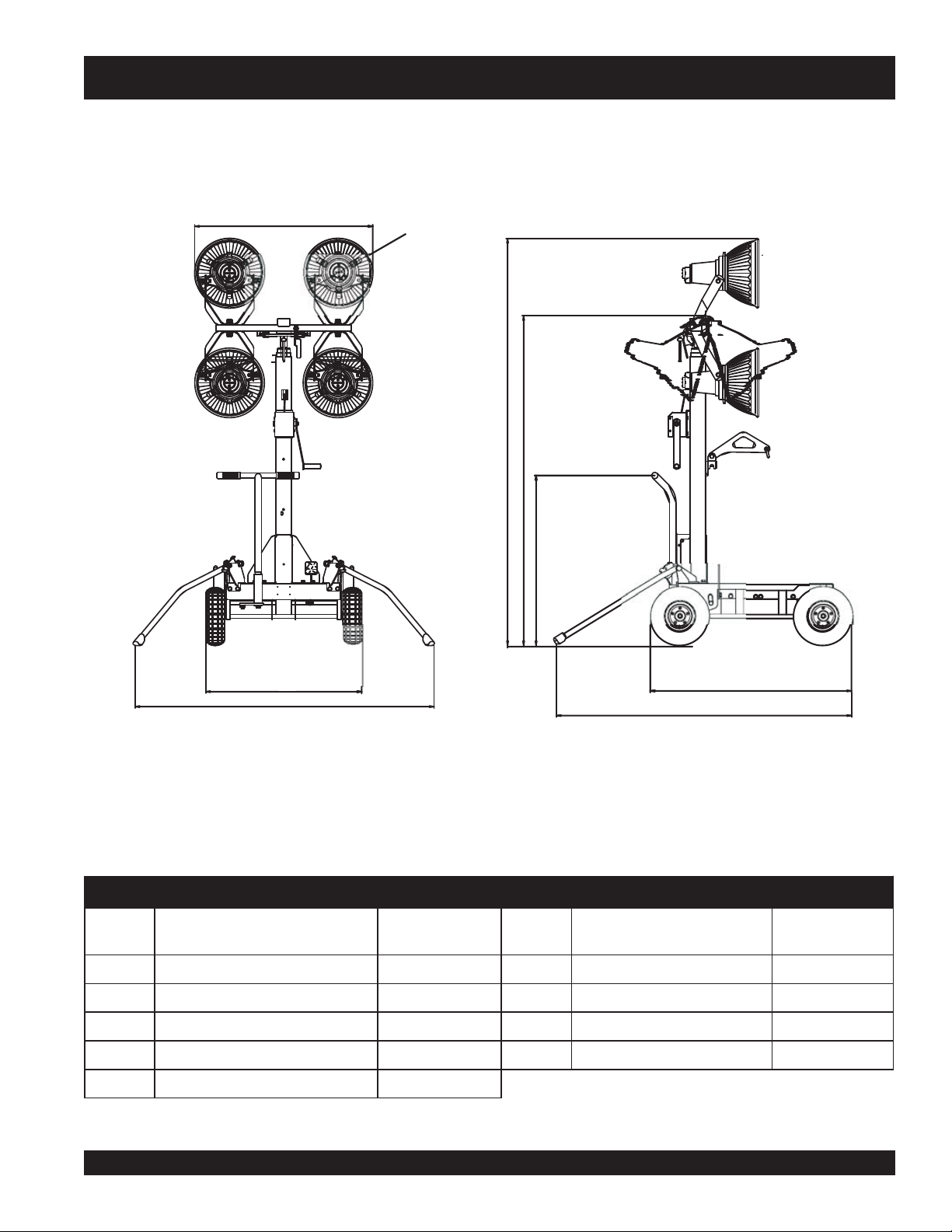

C

GLOBUG 4-SPOT — DIMENSIONS

D

E

F

G

A

B

Figure 2. Dimensions

SNOISNEMID.2ELBAT

ecnerefeR

retteL

AesaBleehW).mm008

B)deyolpeDsreggirtuO(htdiW).mm006,1(.tf52.5G )eldnaHgnire

noitpircseD

.tfnoisnemiD

).mm(

(.tf26.2F )noitisoPdewotStsaM(thgieH).mm007,1(.tf85.5

ecnerefeR

retteL

etS(thgieH).mm878(.tf88.2

H

I

noitpircseD

.tfnoisnemiD

).mm(

C)stinUgnithgiL(htdiW).mm029(.tf20.3H )leehWraeRottnorF(thgneL).mm040,1(.tf14.3

D)tin

E)noitisoPdeyolpeDtsaM(thg

ieH.xaM).mm0024(.tf87.31

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 13

UgnithgiL(retemaiD).mm063(.tf81.1I )reggirtuOotleehWtnorF(htgneL).mm055,1(.tf90.5

Page 14

GLOBUG 4-SPOT — GENERAL INFORMATION

The Multiquip GLOBUG 4-SPOT is a general purpose

floodlight tower intended for emergency and remote lighting

conditions. The GloBug can be powered by a variety of

Multiquip's series generators. Power requirements for running

the GloBug are 120 VAC, 60 Hz @ 18 amps.

Please read carefully the specified

generator manual that will accompany your

GLOBUG 4-SPOT. This manual will explain

how to operate and maintain the generator.

All information related to the

generator will be referenced in a

NOTE

separate (supplied) "Operation

and Parts Manual". Operation

and maintenance of the generator

will not

manual.

be referenced in this

DANGER - GloBug Overhead Obstructions

ALWAYS make sure the

area above GloBug is

open and clear of

overhead power lines

and other obstructions.

The tower extends in

excess of 14 ft. (4.3

meters). Contact with

overhead powerlines or

other obstructions could

result in equipment

damage,

The lighting system of Multiquip's GLOBUG 4-SPOT is

comprised of four "Metal Halide" 400 watt lamp with an output

of 136,000 lumens.

Serious Injury or Death

!

The GloBug 4-Spot has the following features:

Stainless steel mast which prevents rust.

Mast stopper prevents sudden drop of mast.

Steering wheel for easy cart movement.

Large-sized pneumatic tires for easy travel even in

rough and uneven roads.

Secure lock-type foot brake.

Tire bumper for protection.

Easy to disassemble and service parts.

Safety winch prevents reverse winding.

PAGE 14 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 15

NOTE PAGE

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 15

Page 16

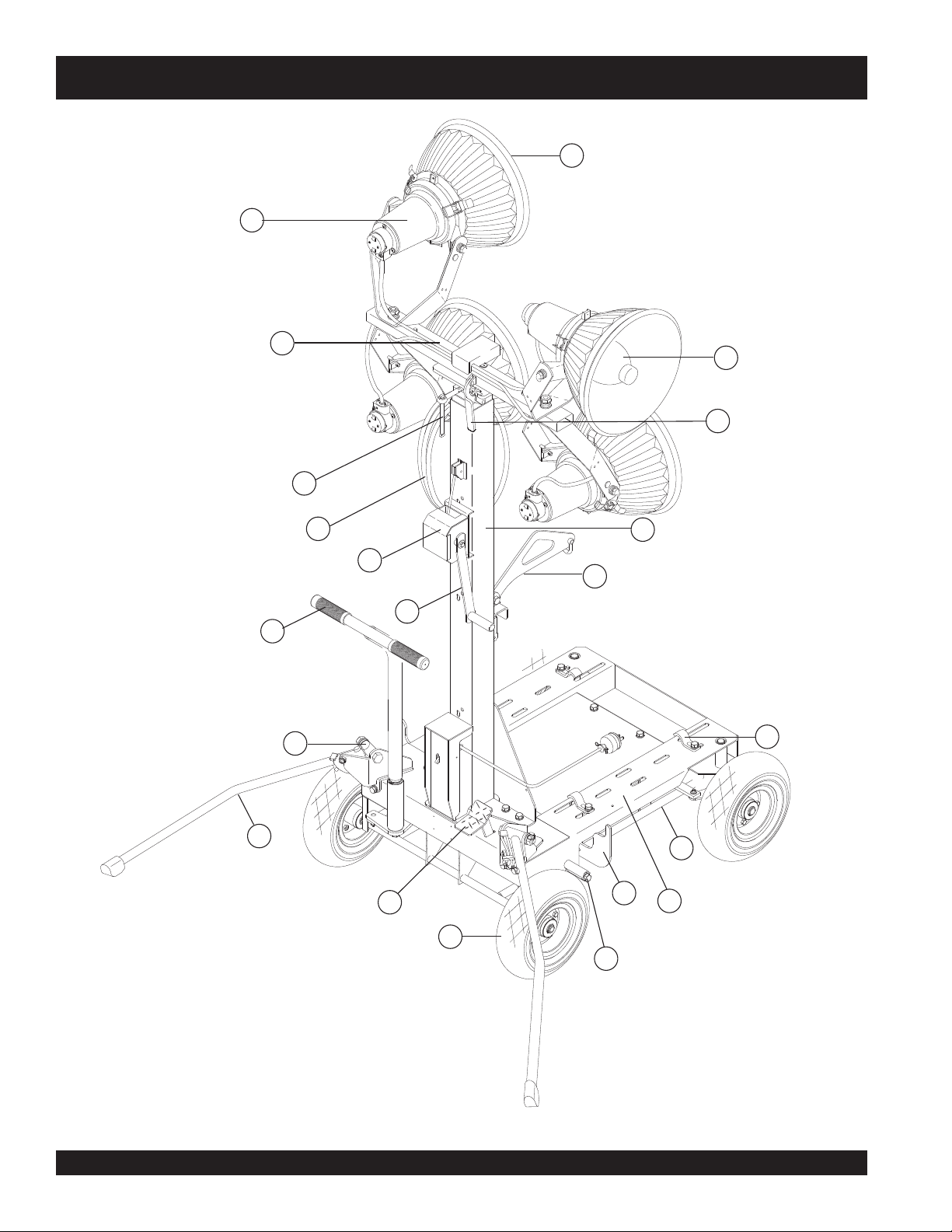

GLOBUG 4-SPOT — COMPONENTS

1

2

12

3

5

7

9

11

10

13

8

4

6

14

15

17

20

19

21

16

18

Figure 6. Major Components

PAGE 16 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 17

GLOBUG 4-SPOT — COMPONENTS

Figure 6 shows the location of the controls and components

for the GLOBUG 4-SPOT. The functions of each control is

described below:

1. Reflex Mirror – Enhances lighting from the bulbs.

2. Lighting Unit – Consists of 4 lamps in their sockets.

3. Lamp Stand – holds the four lamps of the lighting unit

together.

4 Lamp – 400 watt metal-halide type lamp. Replace with

only MQ recommended type lamp. Always allow a

sufficient amount of time for the lamp to

before changing.

5. Adjust Lever – This lever allows the lamp to be

positioned up or down. Turn counterclockwise to release

lamp and position. Turn clockwise to tighten.

6. Fold Lever – Holds the lamp stand in place after

adjusting its height.

7. Lamp Power Cable – Connects the lamps to the power

(generator).

8. Mast – This mast is comprised of three separate stages.

The mast can be raised in excess of 13.78 feet. (4.2

meters). Again when raising the mast, always be on the

lookout for overhead obstructions.

cool down

14. Locking Clamps – To secure the generator to the

GloBug cart platform, place clamps (4) around the pipe

frame of the generator. Tighten securely to prevent

movement.

15. Outriggers – ALWAYS deploy the outriggers when

raising the mast.

16. Guide Square Pipe - frames the generator.

17. Brake Pedal – Step on this pedal to apply the brakes. To

release the brakes, press down on brake pedal again.

18. Cart – Holds the generator that supplies power to the

lighting unit.

19. Tires – The GloBug 4-Spot uses 4 pneumatic type tires.

Replace with only recommended type tire . NEVER allow

the rear tires to go flat. This could adversely affect the

braking system. Inflate tires to 35.5 psi (245kPa).

20. Catcher – Holds the outrigger in place in the stow

position.

21. Brake Pad – When the brake pedal is pressed, this pad

will strike and hold the rear tires in place. Make sure rear

tires are inflated to the correct air pressure.

9. Mast Winch – Use this winch to raise and lower the mast.

Always be on the lookout for overhead obstructions.

Keep immediate area free of bystanders and debris when

raising the mast.

10. Winch Handle– Use this handle to adjust the mast

height.

11. Lift Hanger – When lifting of theGloBug is required

always use a suitable lifting device of adequate lifting

capability. NEVER stand underneath the GloBug while it

is being lifted.

12. Steering Handle – The GloBug can be moved in either

a forward or reverse direction by pulling back or pushing

forward on the T-handle. In addition the front wheels are

designed to turn in the opposite direction of the T-handle

placement thus allowing the GloBug to turn either left or

right.

13. Counterweight Lever – Holds the outriggers in place

when deployed.

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 17

Page 18

GLOBUG 4-SPOT — SETUP

AC

CIRCUIT

BREAKER

120/240V

30A

V

OFF

21A

SOCKET

LAMP

CAUTION - Read Manual

backwards and place it in the deployed position, as shown

in Figure 9. The outriggers will automatically lock in place

3. Lift up on each outrigger (2) from its stow position, rotate

Please read this entire manual carefully

once they touch the ground,

before attempting to operate the GloBug.

Failure to read this manual could cause

damage to the GloBug and serious injury

to the operator.

GloBug Setup

1. Using the T-handle (Figure 7) place the GloBug on a

firm level surface

so that it will not slide or turn over.

STOW

POSITION

ON

0N

FF

O

F

OF

E

L

L

N

D

O

O

I

I

R

T

A

T

H

R

N

C

E

T

P

I

O

O

W

C

S

V

0

2

A

1

0

0

2

2

1

V

0

4

2

/

R

V

E

0

W

2

O

P

1

H

L

C

L

T

I

F

U

W

F

F

S

O

A

0

2

V

0

A

2

1

1

2

T

I

A

U

0

C

3

R

I

R

E

C

K

C

A

A

E

R

B

V

0

4

2

/

A

0

0

2

3

1

6000

H

-6

A

G

OUTRIGGERS

DEPLOYED

Figure 9. Outriggers (Deployed Position)

Figure 7. T-Handle (Directional Control)

2. To apply the parking brake (Figure 8), step on the brake

pedal and pull back on the T-handle. This will lock the

rear wheels. For additional safety use chock blocks to

prevent rolling.

STEP DOWN

ON BRAKE PEDAL

Lamp Assembly

1. Screw the lamp into the socket (use 400 watt metalhalide type lamp). Always allow a sufficient amount of

time for the lamp to cool down before changing. See

Figure 10.

Figure 10. Installing the Lamp

PARKING

BRAKE SET

Figure 8. Parking Brake (Set Position)

PAGE 18 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 19

GLOBUG 4-SPOT — SETUP

2. Adjust the reflex mirror and the socket together so that

the cables of the two upper light ing units are positioned

downward sand the cables of the two lower lighting units

Raising the Lamp Stand

1. Support the lighting units with one hand and pull up the

fold lever with the other hand. The lever wil spring up.

are positioned upwards. See Figure 11.

SOCKET

CABLE

REFLEX

MIRROR

Figure 11. Positioning the Socket

2. Push up the lighting unit and push down the fold lever

to lock the lamp stand (Figure 14).

3. Tighten all three latches to secure reflex mirror to the

socket. See Figure 12.

FOLD LEVER

Figure 13. Raising Lamp Stand

LATCH

FOLD LEVER

Figure 12. Securing Latch

Figure 14. Locking Lamp Stand

CAUTION - FOLD LEVER PINCH POINT

When operating the fold lever, keep hands and fingers

clear of the pinch points to prevent injury.

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 19

Page 20

GLOBUG 4-SPOT — SETUP

Turning All Lights In One Direction

1. Loosen the adjust lever. Turn the lighting units in the

desired direction (Figure 15).

CAUTION - MAST PINCH POINT

When raising or lowering the mast, keep hands and fingers

clear of the various mast sections, this will prevent hands

and fingers from getting pinched.

ADJUST LEVER

Adjusting Height of the Lights

Figure 15. Adjusting Direction of Lighting Units

1. Turn the handle of the mast winch clockwise to raise

the lighting unit and turn the handle of the mast winch

Turning Lights Individually

counterclockwise to lower the lighting unit (Figure 18).

1. Hold the arm of the lamp and turn it to the desired

direction (Figure 16.

ARM

Figure 16. Adjusting Direction of Individual Lamp

Adjusting Angle of the Lights

1. Hold the socket of the lamp and tilt it to the desired

direction (Figure 17).

SOCKET

DANGER - HIGH VOLTAGE POWER LINES

When raising mast, ALWAYS be on

the lookout for overhead obstructions

such as high voltage power lines. The

possibility exists of electrocution,

even death! if the GloBug comes in

Figure 17. Adjusting Angle of Light

PAGE 20 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

contact with

UP

DOWN

WINCH

HANDLE

Figure 18. Adjusting Height of Light

high voltage power lines

.

Page 21

GLOBUG 4-SPOT — OPERATION

DANGER - HIGH VOLTAGE POWER LINES

When raising mast, ALWAYS be on

the lookout for overhead obstructions

such as high voltage power lines. The

possibility exists of electrocution,

even death, if the GloBug comes in

contact with

high voltage power lines

.

Section" of the supplied generator manual.

4. Leave the engine idling for about 3 minutes to warm it

up.

5. Place the generator lamp switch (Figure 19) to the ON

position.

6. The lamp should light up and give a fully bright light in

3. Start the generator as referenced in the "Start-up

Applying Power

about 5 minutes. If the lamp is not on, check all

connections and repeat steps 1 through 5. If the lamp

1. Make sure the generator lamp switch (Figure 19) is in

the OFF position.

still does not come on contact the MQ service

department.

Shutdown

STARTER KEY

1. Place the generator lamp switch (Figure 19) to the OFF

position.

GENERATOR

LAMP SWITCH

2. Disconnect the GloBug 4-Spot AC power cable from the

generator.

3. Shutdown generator as referenced in the "Shutdown

Section" of the supplied generator manual.

Figure 19. GeneratorLamp Switch

CAUTION - READ GENERATOR MANUAL

Before attempting to operate the

generator, READ the entire operation

section of the manual. Failure to read

manual could cause severe damage to

the equipment and bodily harm to the

operator.

2. The GloBug has a power requirement of 120 VAC, 60 Hz

@ 18 amps. Connect the GloBug 4-Spot AC power cord

to the 120 VAC twist-lock receptacle (Figure 20) on the

the supplied generator.

120 VAC

TWIST-LOCK

RECEPTACLE

GLOBUG 4-SPOT

POWER CABLE

20A

120V

TYPICAL

GENERATOR

FRONT PANEL

CAUTION - LAMP COOL DOWN

Allow a sufficient amount of time (15-20 minutes) for the

lamp to

cool down

before turning on lighting unit again.

Do not touch lamp before cooling down. Lamp surface is

very hot and can cause burns (Figure 21).

CAUTION - GENERATOR DAMAGE

DON NOT shut down generator engine with the lamp

switch on. This could cause damage or break the

generator.

Figure 21. Hot Lamp Surface

Figure 20. 120 VAC Receptacle

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 21

Page 22

GLOBUG 4-SPOT — STORAGE

PUSH DOWN

LIGHTING UNIT

Preparation of Lighting Unit For Storage

1. Using the mast winch (Figure 18),

lower the mast fully

.

Turn winch handle counterclockwise to lower mast.

2. Set the lighting units facing the front (Figure 22).

LIGHTING UNIT

FACING FRONT

Figure 22. Lighting Unit Facing Front

4. Push down the lighting unit (Figure 24). Some force is

required when pushing down because of the installed

springs.

Figure 23. Pushing Down Lighting Unit

5. After lighting unit has been completely pushed down,

push down fold lever (Figure 24) to lock the lamp stand

in place.

3. Holding the lighting unit with one hand, pull up the fold

lever with the other hand (Figure 23).

FOLD LEVER

Figure 23. Fold Lever

PUSH DOWN

LOCK LEVER

Figure 24. Locking Lamp Stand

PAGE 22 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 23

GLOBUG 4-SPOT — STORAGE

7. To unlock outriggers, push downward on the counter-

weight lever indicated by arrow (Figure 25). Grab hold of

outrigger, pull upward, push down and place in stow

position (Figure 26..

Figure 25. Outriggers (Released)

Storage

1. Wipe dirt or foreign matter that may have accumulated

on the GloBug 4-Spot during operation. Use a mild

detergent to clean the unit. DO NOT spray the engine

with water.

2. Avoid storing the GloBug 4-Spot in areas that can be

exposed to rain, harsh elements, and high humidity.

3. Place the GloBug 4-Spot in a clean dry location away

from dirt and debris.

CAUTION - READ SAFETY GUIDELINES

Before performing any maintenance

procedures, be sure to READ the lamp,

balloon, and general safety guidelines in

this manual. Failure to

understand

could cause severe equipment damage

and bodily harm.

these safety guidelines

read

and

Figure 26. Outriggers (Stow Position)

8. Press down on the top of the brake pedal (Figure 22)

and hold, then release. This action will dis-engage the

brake mechanism and allow the GloBug to be moved.

Figure 22. Parking Brake (Release Position)

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 23

Page 24

LIGHTING UNIT 1

LIGHTING UNIT 3

9

LIGHTING UNIT 2

17

16

LIGHTING UNIT 4

BALLAST

GLOBUG 4-SPOT — MAINTENANCE (WIRING DIAGRAM)

15

BALLAST

RED

1

CAPACIT R

AC120V

YEL

YEL/BLK

YEL

13

14

2

WHT

BLK

BLK

WHT

11

10

6

BLK

4

2

RED

GRAY

BRUE

WHT

BROWN

ORANGE

YEL

BLK

ORANGE

WHT

RED

BRUE

GRAY

BROWN

BLK

YEL

3

8

LIGHTING UNIT

WHT

5

7

YEL

2

YEL

YEL/BLK

12

BALLAST

①

RED

O

RED

RED

CAPACITOR

④

YEL/BLK

YEL/BLK

YEL

RED

CAPACIT R

BALLAST

RED

YEL

YEL

YEL

RED

BALLAST

CAPACITOR

RED

③

O

11

10

BROWN

BROWN

GRAY

GRAY

RED

RED

ORANGE

ORANGE

BLK

WHT

WHT

BLK

BUEL

BUEL

YEL

YEL

②

1311001002 LIGHTING UN AY

17

16

15

E000069800

14

1367020430 TERMINAL R2-4

13

E000034400 TERMINAL TMEV2-4S

12

E000047600 TERMINAL TMEV1.25-3S

E000044800

11

E000044900

10

1407021030

9

1407020930

8

E000031600 TERMINAL

7

A400082000

6

5

A400081900

A300069900

4

3

A300069501

2

A300069601

1

A300069700

REF.

DESC

BALLAST A (400 W)

RECEPTACLE HOUSING 2

RECEPTACLE HOUSING 12

PLUG HOUSING 12

CABLE (JUMPER-BLACK) CP

CABLE (JUMPER-WHITE) CP

CABLE (JOINT-43SC-USA) CP

CABLE (LAMP-43SC-USA) CP

CABLE (BALLAST-43SC-USA) CP

CABLE (LAMP-43SC-USA) CP

LAMPE000031700

PLUG HOUSING 2

DESCRIPTIONPART NUMBER

PAGE 24 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 25

NOTE PAGE

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 25

Page 26

L1

M3

M4

L3

E1

M2

L5

L2

M5

M6

GLOBUG 4-SPOT — MAINTENANCE

L4

M1

L6

L7

L8

C6

C1

C7

C9

C2

C3

C4

PAGE 26 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

C5

C10

C8

Page 27

GLOBUG 4-SPOT — MAINTENANCE

For a prolonged life cycle an extended quality follow the

recommended GloBug 4-Spot service guidelines as

referenced in Table 3.

ERUGIFTRAPMETIKCEHCNOITULOS

ECNANETNIAMDNAKCEHCCIDOIREP.3ELBAT

1LesaBpmaL?esoolesabpmaL.ylerucesniwercS

2LtcatnoCniP?detcennocsidroesooltcatnocniP .ylerucestcennocronethgiT

3LtuN?thgitoottonroesooloottontuN.yltcerrocnethgiT

4LdnatSpmaLrofegniH?ylhtoomsevomtonseodegniH.esaergylppA

pmaL

5LdnatSpmaLroftoviP?ylhtoomsnruttonseodtoviP.esaergylppA

6LpmaL?nekorbrodenrubpmaL.ecalpeR

7LssalGtnorF?ytridssalgtnorF.tridffoepiW

8LrorriMxelfeR?nekorbroytridrorrimxelfeR .ecalperrotridffoepiW

1MreveLdloF?ylreporpkcolnudnakcolseodreveldloF.riapeR

2MecafruSgnidilStsaM?ylhtoomsedilstonseodecafrusgnidilstsaM.esaergylppA

3MepoReriW?degamaD .ecalperroesaergylppA

tsaM

4MdnEepoReriW?)gnikluac(degamaddneeriwsI.ecalpeR

5MhcniW?ekarbhcniwevitcefeD.ecalperroriapeR

6MpotSytefaS?evitcefedhctalytefaS.ecalperroriapeR

1CthgieW-retnuoC?ylhtoomslevomtonseoD.esaergyarpS

❖

■

❖

●

●

❖

❖

❖

●

❖

❖

❖

❖

▲

●

2CsreggirtuO?ylhtoomsevomtonseoD.esaergyarpS

3CsleehWdnaeldnah-T?sknilesooL.ylerucesnethgiT

4CeldnaHroftloB?tlobesooL.ylerucesnethgiT

5CladePekarB?ylhtoomsgnikrowtonegakniLesaergyarps,kcehC

traC

cirtcelE

5CladePekarB?tuo-nrowhctoN.ecalpeR

6CregnaH?noitallatsniesooL.ylerucesnetsaF

7CtoviPleehWtnorF?ylhtoomsnruttonseoD.esaergylppa,kcehC

8CseriT?)aPk492(isp5.53tonerusserperiT.tsujdA

9CtfahStnorFrofkniL?ylhtoomsevomtpnseodegakniL.esaergyarpS

01CekarB?ylreporpkrowtonseoD.tsujdA

1EelbaCrewoP?elbacnrowroevitcefeD.ecalpeR

2EegatloVdaol-noN?CAV521tontuptuorotarenegsI .rotarenegecalperrotsujdA

kcehCyliaD-

❖

■

sruoH02yrevE-

●

sruoh001yrevE-

▲

sruoh005yrevE-

●

■

■

❖

❖

■

●

❖

●

❖

❖

●

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 27

Page 28

GLOBUG 4-SPOT — TROUBLESHOOTING (LAMPS)

Practically all breakdowns can be prevented by proper

handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the

diagnosis based on the Lamp Troubleshooting (Table 4)

information shown below.

MOTPMYSMELBORPELBISSOPNOITULOS

?esoolpmalsI .tekcosotniylerucespmalwercS

.thgiltonseodpmaL

?ecruos

sI

?)CAV021-egatlov

If the problem cannot be remedied, please leave the unit

just as it is and consult or company's service department.

?detcennocylerucestonsrelpuocerA.yltcerrocrelpuoctcennoC

?ffodenruthctiwspmalrotarenegsI.hctiwsnonruT

?detcennocylreporptonsrotcennocerA .rotcatnocdetcennocsidtcennoC

rehto(secnailppacirtcelerehtoynaerA

rewopotnideggulp)rewotthgilnaht

daol-non(lamrontonegatlovrotareneg

GNITOOHSELBUORTPMAL.4ELBAT

.secnailpparehtollagulpnU

.rotarenegecalperroriapeR

?elbitapmoctonpmalfoledomsI.pmalQMeniunegesU

?niagathgilothguonelooctonpmalsI

deriuqersisetunim03ot02folavretnI(

)niagapmalnogninruterofeb

daol-non(lamrontonegatlovrotarenegsI

arofsthgilylnopmaL

.emittrohs

?)V021-egatlov

nahterom(hgihooterutarepmettneibmasI

?)C°04(F°401

.noitalitnev

.nwodloocotpmalroftiaW

.rotarenegecalperroriapeR

reporpsierehterehwpmalevoM

PAGE 28 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 29

GLOBUG 4-SPOT — TROUBLESHOOTING (MAST)

Practically all breakdowns can be prevented by proper

handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the

diagnosis based on the Mast Troubleshooting (Table 5)

information shown below.

MOTPMYSMELBORPELBISSOPNOITULOS

?tsamnithguacelbacsI.eerfelbacteS

ebtonnactsaM

.desiar

gnimocspeektsaM

.nwod

?hcniw

?noitcerid

?evitcefedhctalhcniwsI .ylreporpgninoitcnuftonfitrapecalpeR

?esooltfahsmardsI .noitarepostikcehcdnatfahsmardnethgiT

If the problem cannot be remedied, please leave the unit

just as it is and consult or company's service department.

morfdetcennocsideporeriwfodnesI

?ylhtoomsedilstontsamfoecafrusseoD .ts

gnorwehtnidenrutgniebeldnahhcniwsI

GNITOOHSELBUORTTSAM.5ELBAT

.hcniwoteporeriwtcennoC

amfoecafrusgnidilsotesaergylppA

.yltcerrocetarepO

?ylhtoomsedilstontsamfoecafrusseoD .tsamfoecafrusgnidilsotesaergylppA

ebtonnactsamehT

.derewol

?thgitdlehhcniwfoksidekarbsI

?yltcerrocgnikrowtonreppotsytefassI

.)riapeR(tinodaolagnittup

ehtevomer,yleruceseldnahhcniwgnidloH

.)riapeR(ylwolstsamrewoldnahctal

ybtsamrewoldnaelttilatsampuhcniW

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 29

Page 30

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and remarks

used in the Parts section of this manual. Use the help numbers

found on the back page of the manual if there are any questions.

The contents and part numbers listed in the parts section are

subject to change

guarantee the availibility of the parts listed.

Sample Parts List:

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ....................... 1 .... INCLUDES ITEMS W/

2

*

2*12347 WASHER, 3/8 IN. .... 1 ....

3 12348 HOSE .................... A/R .. MAKE LOCALLY

4 12349 BEARING ................ 1 .... S/N 2345B AND ABOVE

NO. Column

Unique Symbols - All items with same unique symbol

, #, +, %, or >) in the number column belong to the same

(

*

assembly or kit, which is indicated by a note in the “Remarks”

column.

Duplicate Item Numbers - Duplicate numbers indicate

multiple part numbers are in effect for the same general item,

such as different size saw blade guards in use or a part that

has been updated on newer versions of the same machine.

NOTE

without notice

WASHER, 1/4 IN. ...........

When ordering a part that has more

than one item number listed, check

the remarks column for help in

determining the proper part to order.

. Multiquip does not

NOT SOLD SEPARATELY

MQ-45T ONLY

QTY. Column

Numbers Used - Item quantity can be indicated by a number,

a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other parts

that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

*

Column are listed below. Other additional notes needed to

describe the item can also be shown.

Assembly/Kit

symbol will be included when this item is purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

only with the specific model number or model number variant

listed. It can also be used to show a part is NOT used on a

specific model or model number variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

- All items on the parts list with the same unique

- Used to list an effective serial number

- Indicates that the part is used

PART NO. Column

Numbers Used - Part numbers can be indicated by a number,

a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a part that

has not been assigned a formal part number at time of

publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will be

clarified in the “Remarks” Column.

PAGE 30 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

“Make/Obtain Locally”

purchased at any hardware shop or made out of available

items. Examples include battery cables, shims, and certain

washers and nuts.

“Not Sold Separately”

purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available for

sale through Multiquip.

- Indicates that the part can be

- Indicates that an item cannot be

Page 31

GLOBUG 4-SPOT

1 TO 3 UNITS

Qty. P/N Description

3 ......... E000031700 .... BULB

1 ......... A300069800 .... BALLAST ASSY

1 ......... E000032000 ....

1 ......... 1311100161 ..... MIRROR/LENS

CAPACITOR

GLOBUG 4-SPOT — SPARE PARTS

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 31

Page 32

GLOBUG 4-SPOT — NAMEPLATE AND DECALS

A

C

C

IR

C

U

IT

B

R

E

A

KER

1

2

0

/

2

40V

30

A

V

O

F

F

2

1A

NAMEPLATE AND DECALS

NEVER touch a live power cord

or active electrical components

with wet hands or while standing

21

in water.The possibility of electrical

shock or even death! exists.

DCL410

CAUTION

LAMP INFORMATION

ALWAYS OFFturnlamp

first, before shutting down

11

generator.

Once lamp is turned

Allow lamp to cool down

before turning back on.

t will take about 20 minutes

I

before lamp can be turned

back on.

CAUTION

When the GloBug is used for

non-lighting applications,

6

un-plug GloBug AC power cord

from the generator.

DANGER

ELECTRICAL

SHOCK HAZARD

ALWAYS

4

DANGER

ELECTRICAL

SHOCK HAZARD

When replacing lamp and to prevent electrical

shock, shutdown the generator beforeALWAYS

replacing lamp. Remember to let lamp cool before

removing. Use only recommended type lamp as

listed in parts manual.

OFF,

DCL409

DCL402

7

DCL416

WARNING

BURN HAZARD

Toprevent burns, NEVER

touch lamp while lamp is on.

Lamp surface gets extremely

hot! ALWAYS allow sufficient

time for lamp to cool down

before touching.

5

DCL417

12

WARNING

3

WARNING

When lifting of the GloBug is

required, attach a rope

ALWAYS

DANGER

or chain to the lift hanger.

use any other lifting points to

lift the GloBug.

HANGER

DO NOT

LIFT

DCL412

13

8

DCL401

DANGER

GlowBug

INFORMATION

NEVER

Toprevent tipping, use

inwinds that exceed 22 mph

(10m/sec).

NEVERuse on an incline of 5

degreesor more. The possibility

oftipping exists.

NEVERuse in rain or wet

conditions.The possibility of

electrocutionexists.

ALWAYSapply parking brake

toprevent moving.

Whenmoving is required, lower

mastfully.

W

ALWAYShen raising mast,

deployoutriggers to prevent

tipping.

ALWAYS OFFturn generator

beforeperforming maintenance.

14

DCL411

20

WARNING

BURN HAZARD

To prevent burns,

NEVER

ballast or cover while

touch

lamp is on. These surfaces are

extremely hot! allow

ALWAYS

sufficient time for both surfaces

to before touching.

cool down

BALLAST

DCL415

BOX

10

DANGER

ELECTRICAL

SHOCK HAZARD

NEVERplace the GloBug

wheelsin standing water. The

possibilityof electrical shock,

evendeath! Exists.

15

DANGER

ELECTRICAL

SHOCK HAZARD

GROUND

Toprevent electrical shock or

electrocution, the generator

be connected to an

MUST

(SeeNEC Article 250)

DCL400

18

WARNING

Toavoid injury,

you MUST read

and understand

operator’s manual

before using this

machine.

This machine to

be operated by

qualified

personnel only.

Ask for training

as needed.

CAUTION

TIRE PRESSURE

ALWAYSkeep tires inflated

to correct pressure. Low or

incorrect tire pressure could

result in brake malfunction.

Recommendedtire pressure:

P/N35137

MODEL

SERIAL NO.

35.5 PSI

(225 kPa)

DCL407

9

19

WARNING

OUTRIGGER

DEPLOYMENT

SETTING:

Pull outrigger upward at the tip end

and rotate backwards until it locks in

place.

RELEASE:

To unlock outrigger, push downward

on the counter-weight lever indicated

by arrow. Grab hold of outrigger, pull

upward, push down and place in stow

position.

OUTRIGGERS

DEPLOYED

STOW

POSITION

N

O

N

0

F

F

O

F

F

O

E

L

L

N

D

O

O

I

I

T

R

A

T

H

R

N

C

E

T

P

I

O

O

W

C

S

V

0

2

A

1

0

0

2

2

1

V

0

4

2

/

R

V

E

0

W

2

O

P

1

H

L

C

L

T

I

F

U

F

W

F

S

O

A

0

2

V

0

A

2

1

1

2

T

I

A

U

0

C

3

R

I

R

E

C

K

C

A

A

E

R

B

V

0

4

2

/

A

0

0

2

3

1

0

00

6

-6H

GA

DCL414

earth ground.

DCL405

16

17

HIGH VOLTAGE

DANGER

DCL418

PAGE 32 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 33

GLOBUG 4-SPOT — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

3 DCL412 DECAL; WARNING, LIFT HANGER 1

4 DCL416 DECAL; DANGER, ELECTRICAL SHOCK HAZ. 1

5 DCL417 DECAL; WARNING, BURN HAZARD (LAMP) 1

6 DCL402 DECAL; CAUTION, REMOVE POWER CORD 1

7 DCL428A DECAL; MQ LOGO 1

8 DCL401 DECAL; WINCH UP/DOWN 1

9 DCL407 DECAL; CAUTION, TIRE PRESSURE 1

10 DCL400 DECAL; DANGER, ELECTRICAL SHOCK (TIRES) 1

11 DCL409 DECAL; CAUTION, LAMP INFORMATION 1

12 DCL406A DECAL; WARNING, ADJ. LEVER HAZARD 1

13 DCL403A DECAL; DANGER ELECTRIC SHOCK (GLOBUG) 1

14 DCL411 DECAL; DANGER, GLOBUG INFORMATION 1

15 DCL405 DECAL; DANGER, ELECTRICAL SHOCK (GND) 1

16 DCL414 DECAL; WARNING, OUTRIGGER DEPLOYMENT 1

17 DCL418 DECAL; DANGER, HIGH VOLTAGE 1

18 35137 DECAL; WARNING, READ MANUAL 1

19 NAMEPLATE .................................................................. 1........... CONTACT MQ PARTS DEPT.

20 DCL415 DECAL; BURN HAZARD (BALLAST) 1

21 DCL410 DECAL; DANGER, ELECTRICAL SHOCK (CORDS) 1

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 33

Page 34

BASE PLATE ASSY.

GLOBUG 4-SPOT — BASE PLATE ASSY.

3

2

1

8

5

4

5

4

7

6

7

6

PAGE 34 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 35

GLOBUG 4-SPOT — BASE PLATE ASSY.

BASE PLATE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 A100030203 BOX (BALLAST) CP ....................................................... 1........... REPLACES P/N A100030201

2 A100030101 COVER (BALLAST) ........................................................ 1........... REPLACES P/N A100030100

3 0010510025 BOLT AND WASHER (M10 X 25) 4

4 A400041101 STOPPER ....................................................................... 4 ........... REPLACES P/N A400041100

5 0010512025 BOLT AND WASHER (M12 X 25) 4

6 0040112000 WASHER (M12) 4

7 0030112000 NUT (M12) 4

8 E000032100 FREE BRUSH 1

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 35

Page 36

ELECTRICAL ASSY

GLOBUG 4-SPOT — ELECTRICAL ASSY.

4

6

7

8

9

9

15

10

11

5

2

3

1

12

13

14

PAGE 36 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 37

GLOBUG 4-SPOT — ELECTRICAL ASSY.

ELECTRICAL ASSY

NO. PART NO. PART NAME QTY. REMARKS

1 E000031700 LAMP 4

2 E000048100 LIGHTING UNIT ASSY ................................................... 4........... INCLUDES ITEMS W/ #

3# 1311100161 MIRROR/LENS 4

4# 1311300161 LIGHT SOURCE TUBE 4

5# 1311200162 ARM (LIGHTING UNIT) 4

6 0031116000 NUT (M16) 4

7 0040116000 WASHER (M16) 4

8 1042000230 SPRING 4

9 1502180110 WASHER 8

10 1407021030 RECEPTACLE HOUSING 1

11 A300069501 CABLE (LAMP) CP ......................................................... 1........... REPLACES P/N A300069500

12 A300069601 CABLE (BALLAST) CP ................................................... 1........... REPLACES P/N A300069600

13 A300069700 CABLE (MAIN) CP 1

14 A300069900 CABLE (JOINT) CP 1

15# E000012300 BOLT SET, CHR-50 8

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 37

Page 38

BALLAST ASSY

GLOBUG 4-SPOT — BALLAST ASSY.

1

2

3

15

14

16

9

16

10

8

6

7

5

12

11

13

12

PAGE 38 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 39

GLOBUG 4-SPOT — BALLAST ASSY.

BALLAST ASSY

NO. PART NO. PART NAME QTY. REMARKS

1 A300069800 BALLAST ASSY 4

2 0013505015 BOLT AND WASHER (M5X 15) ...................................... 8........... REPLACES P/N 0010506025

3 A300060801 HOLDER (BALLAST) ...................................................... 4........... REPLACES P/N A300060800

5 0030105000 NUT (M5) 8

6 0020305065 SCREW AND WASHER (M5 X 65) 8

7 0020304012 SCREW AND WASHER (M4 X 12) 4

8 A400078900 HOLDER (CAPACITOR) 2

9 E000032000 CAPACITOR 4

10 E000031800 CLAMP 4

11 0010505015 NUT (M5) ........................................................................ 8........... REPLACES P/N 0030106000

12 0030104000 NUT (M4) 6

13 E000031600 TERMINAL 1

14 A400081900 CABLE (JUMPER-W) 1

15 A400082000 CABLE (JUMPER-B) 1

16 0020304020 SCREW AND WASHER (M4 X 20) 2

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 39

Page 40

MAIN MAST ASSY.

GLOBUG 4-SPOT — MAIN MAST ASSY.

4

10

12

11

13

5

14

2

3

6

7

7

8

7

2

1

6

9

7

1

7

7

SERIAL NOS. G5000029 AND ABOVE

PAGE 40 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 41

GLOBUG 4-SPOT — MAIN MAST ASSY.

MAIN MAST ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 A100028102 FIRST MAST .......................................... 1 ..........S/N G5000028 AND BELOW

1 A100028105 FIRST MAST .......................................... 1 ..........S/N G5000029 AND ABOVE

2 0010510025 BOLT AND WASHER (M10x25) 9

3 1011000701 WINCH HM-G103 1

4 1642001430 GROMMET 1

5 0040112041 WASHER (12dx40Dx3.2t) 1

6 A200029800 SWITCH COVER .................................... 1 ..........S/N G5000028 AND BELOW

6 A200036500 SWITCH COVER .................................... 1 ..........S/N G5000029 AND ABOVE

7 0020304012 SCREW & WASHER (M4x12) ................. 3 .......... S/N G5000028 AND BELOW

7 0020304012 SCREW & WASHER (M4x12) ................. 5 ..........S/N G5000029 AND ABOVE

8 2002500430 BOLT (SUPPORT) (MK-440) 1

9 0010112040 BOLT (M12x40) 1

10 0030112000 NUT (M12) 1

11 1052001710 HANGER 1

12 0040212000 SPRING WASHER (M12) 1

13 0040112000 WASHER (M12) 1

14 1711080130 SHACKLE 2

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 41

Page 42

T-HANDLE ASSY.

1

GLOBUG 4-SPOT — T-HANDLE ASSY.

2

1

3

4

6

4

5

7

PAGE 42 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 43

GLOBUG 4-SPOT — T-HANDLE ASSY.

T-HANDLE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 1102700130 HANDLE GRIP 2

2 A200023001 HANDLE 1

3 0040730000 SNAP RING (30) 1

4 1503300130 SLEEVE BEARING (30Dx34Dx20) 2

5 A100018905 BASE PLATE .................................................1 ........... REPLACES P/N A100018903

6 A300087403 SIDE GUARD ..................................................2 ........... S/N G5000029 AND ABOVE

7 0010508015 BOLT AND WASHER .......................................4 ........... S/N G5000029 AND ABOVE

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 43

Page 44

GLOBUG 4-SPOT — STEERING ASSY.

STEERING ASSY.

13

2

12

9

3

1

25

3

4

15

14

7

26

6

8

11

10

2

10

3

1

27

13

6

9

5

9

4

21

10

20

9

22

12

11

24

3

23

19

3

18

17

4

3

16

18

19

4

3

3

PAGE 44 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 45

GLOBUG 4-SPOT — STEERING ASSY.

STEERING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0010510025 BOLT AND WASHER (M10X25) 10

2 A400033402 CATCHER (OUTRIGGER) 2

3 0040720000 SNAP RING (20) 8

4 E000014500 TIRE ASSY (4.10/3.50-5) 4

5 A200022803 FRONT SHAFT (R) 1

6 E000031200 WASHER (20dx36Dx1.5) 2

7 A200022903 FRONT SHAFT (L) 1

8 A400055101 SPACER 1

9 1504120130 WASHER (12.5dx18Dx0.5t) 8

10 0040108000 WASHER (M8) 5

11 0030208000 SELF-LOCK NUT (M8) 3

12 A300090600 LINK (HANDLE).............................................. 1 ........... REPLACES P/N A300046003

13 0040112000 WASHER (M12)

14 0010512025 BOLT AND WASHER (M12x25) 1

15 0040112041 WASHER (12dx40Dx3.2t) 1

16 1521120130 BOLT (M12x75) LEFT SCREW 1

17 0010112075 BOLT (M12x75) 1

18 2071214010 BRAKE 2

19 1503180130 SLEEVE BEARING (18dx20Dx20) 2

20 2071213211 BRAKE SHAFT 1

21 2001200312 BRAKE PEDAL 1

22 0030108000 NUT (M8) 2

23 1041000131 SPRING (BRAKE) 1

24 0010308030 BOLT (M8x30) SUS 1

25 A400055501 LINK (FRONT SHAFT) 1

26 A400055401 LINK (STEERING) 1

27 0030808000 PUSH NUT (8) 3

1

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 45

Page 46

OUTRIGGER ASSY.

GLOBUG 4-SPOT — OUTRIGGER ASSY.

PAGE 46 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 47

GLOBUG 4-SPOT — OUTRIGGER ASSY.

OUTRIGGER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0010116090 BOLT (M16x90) 2

2 A100011600 BRACKET (OUT,R) R 1

3 0010510025 BOLT & WASHER (M10x25) 10

4 1501160111 SPACER (OUT,R) 2

5 A200015302 OUTRIGGER R ............................................ 1 ............. INCLUDES ITEM W/

6 A200015202 OUTRIGGER L ............................................. 1 ............. INCLUDES ITEM W/

7

*

8 0040110000 WASHER (M10) 4

9 1501100430 SPACER (10.2dx13.8Dx6.5L) 2

10 0030210000 SELF LOCK NUT (M10) 2

11 0040116000 WASHER (M16) 2

12 0040216000 SPRING WASHER (M16) 2

13 0030116000 NUT (M16) 2

14 2031321113 WEIGHT (OUT,R) R 1

15 A100011500 BRACKET (OUT,R) L 1

16 2031320213 WEIGHT (OUT,R) L 1

1641000330 RUBBER FOOT 2

*

*

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 47

Page 48

MAST ADAPTER ASSY.

GLOBUG 4-SPOT — MAST ADAPTER ASSY.

PAGE 48 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 49

GLOBUG 4-SPOT — MAST ADAPTER ASSY.

MAST ADAPTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0020304012 SCREW & WASHER (M4 X 12) 4

2 2202350110 LAMP STAND CP 1

3 1643000110 FREE BUSH 2

4 1045000130 SPRING (LEVER) 1

5 1652000130 CAP 2

6 1043001230 SPRING (LAMP STAND) L 1

7 1043001330 SPRING (LAMP STAND) R 1

8 0010308020 BOLT (M8 X 20) 1

9 0030108000 NUT (M8) 4

10 2072310112 ADJUST LEVER (LAMP STAND) 1

11 1603000130 CLAMP 1

12 2072400510 CONNECTOR COVER 1

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 49

Page 50

MAST SECTION ASSY.

GLOBUG 4-SPOT — MAST SECTION ASSY.

PAGE 50 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 51

GLOBUG 4-SPOT — MAST SECTION ASSY.

MAST SECTION ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 A200027200 SECOND MAST 1

2 2002262010 BRACKET (PULLEY) ................................1 ........... MAST SECTION 2

3 A200027301 THIRD MAST ............................................ 1 ........... REPLACES P/N A200027300

4 0020204006 SCREW (M4x6) 6

5 0020204010 SCREW (M4x10) 6

6 1031040211 WIRE ROPE (4Dx6300L) 1

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 51

Page 52

Effective: February 22, 2006

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a signed

manifest has been obtained from the carrier,

and any claim for shortage or damage must be

settled between the consignee and the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip is $15.00 net. Customers will be asked

for instructions regarding handling of orders

not meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and credit

will be allowed, subject to the following provisions:

1. A Returned Material Authorization must

be approved by Multiquip prior to shipment.

2. To obtain a Return Material Authorization,

a list must be provided to Multiquip Parts

Sales that defines item numbers, quantities, and descriptions of the items to be

returned.

a. The parts numbers and descriptions

must match the current parts price

list.

b. The list must be typed or computer

generated.

c. The list must state the reason(s) for

the return.

d. The list must reference the sales

order(s) or invoice(s) under which the

items were originally purchased.

e. The list must include the name and

phone number of the person requesting the RMA.

3. A copy of the Return Material Authorization must accompany the return shipment.

4. Freight is at the sender’s expense. All

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

5. Parts must be in new and resalable con-

6. The following items are not returnable:

7. The sender will be notified of any material

8. Such material will be held for five working

9. Credit on returned parts will be issued at

10. In cases where an item is accepted, for

11. Credit issued will be applied to future

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a specific date and all orders received on or after that

date will be billed at the revised price. Rebates

for price declines and added charges for price

increases will not be made for stock on hand

at the time of any price change.

Multiquip reserves the right to quote and sell

dition, in the original Multiquip package (if

any), and with Multiquip part numbers

clearly marked.

a. Obsolete parts. (If an item is in the

price book and shows as being replaced by another item, it is obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were purchased more than six months prior to

the return date.

c. Any line item with an extended dealer

net price of less than $5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

received that is not acceptable.

days from notification, pending instructions. If a reply is not received within five

days, the material will be returned to the

sender at his expense.

dealer net price at time of the original

purchase, less a 15% restocking charge.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

purchases only.

direct to Government agencies, and to Original

Equipment Manufacturer accounts who use

our products as integral parts of their own

products.

SPECIAL EXPEDITING SERVICE

A $35.00 surcharge will be added to the invoice

for special handling including bus shipments,

insured parcel post or in cases where Multiquip

must personally deliver the parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of the

item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental dam-

ages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are made

in connection with the sale of parts or trade

accessories nor as to any engine not manufac-

tured by Multiquip. Such warranties made in

connection with the sale of new, complete units

are made exclusively by a statement of war-

ranty packaged with such units, and Multiquip

neither assumes nor authorizes any person to

assume for it any other obligation or liability

whatever in connection with the sale of its

products. Apart from such written statement of

warranty, there are no warranties, express,

implied or statutory, which extend beyond the

description of the products on the face hereof.

PAGE 52 — GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08)

Page 53

NOTE PAGE

GLOBUG 4-SPOT — OPERATION AND PARTS MANUAL — REV. #3 (12/15/08) — PAGE 53

Page 54

OPERATION AND PARTS MANUAL

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER

UNITED STATES

Multiquip Corporate Office MQ Parts Department

18910 Wilmington Ave. Tel. (800) 421-1244 800-427-1244 Fax: 800-672-7877

Carson, CA 90746 Fax (800) 537-3927 310-537-3700 Fax: 310-637-3284

Contact: mq@multiquip.com

Mayco Parts Warranty Department

800-306-2926 Fax: 800-672-7877 800-421-1244, Ext. 279 Fax: 310-537-1173

310-537-3700 Fax: 310-637-3284 310-537-3700, Ext. 279

Service Department Technical Assistance

800-421-1244 Fax: 310-537-4259 800-478-1244 Fax: 310-631-5032

310-537-3700

MEXICO UNITED KINGDOM

MQ Cipsa Multiquip (UK) Limited Head Office

Carr. Fed. Mexico-Puebla KM 126.5 Tel: (52) 222-225-9900 Hanover Mill, Fitzroy Street, Tel: 0161 339 2223

Momoxpan, Cholula, Puebla 72760 Mexico Fax: (52) 222-285-0420 Ashton-under-Lyne, Fax: 0161 339 3226

Contact: pmastretta@cipsa.com.mx Lancashire OL7 0TL

CANADA BRAZIL

Multiquip Multiquip

4110 Industriel Boul. Tel: (450) 625-2244 Av. Evandro Lins e Silva, 840 - grupo 505 Tel: 011-55-21-3433-9055

Laval, Quebec, Canada H7L 6V3 Fax: (450) 625-8664 Barra de Tijuca - Rio de Janeiro Fax: 011-55-21-3433-9055

Contact: jmartin@multiquip.com Contact: cnavarro@multiquip.com.br, srentes@multiquip.com.br

ON-HAND

WHEN CALLING

Contact: sales@multiquip.co.uk

© COPYRIGHT 2008, MULTIQUIP INC.

Multiquip Inc. and the MQ logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are

the property of their respective owners and used with permission.

This manual MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations are based on the

Illustrations, descriptions, references and technical data contained in this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the

right to discontinue or change specifications, design or the information published in this publication at any time without notice and without incurring any obligations.

GloBug 4-Spot Lighting System.

Your Local Dealer is:

Loading...

Loading...