OPERATION AND PARTS MANUAL

GLOBUG

MODEL GB2000

LIGHT TOWER MOUNT TYPE

BALLOON LIGHT

SERIAL NO. G3000021 AND ABOVE

Revision #1 (02/25/14)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

NOTES

PAGE 2 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 3

TABLE OF CONTENTS

GB2000 BALLOON LIGHT

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Information .............................................. 6-13

Specifications ........................................................ 14

Dimensions ............................................................ 15

Footcandle Plot ...................................................... 16

General Information ............................................... 17

Components .......................................................... 18

Setup ................................................................ 19-23

Lamp Lighting Options ...................................... 24-29

Operation .......................................................... 30-31

Maintenance ..................................................... 32-34

Wiring Diagram ...................................................... 35

Explanation Of Code In Remarks Column............. 36

Suggested Spare Parts ......................................... 37

Component Drawings

Nameplate And Decals ..................................... 38-39

Electrical Assy. ................................................... 4043

Bracket And J-Box Assy. .................................. 44-45

Terms And Conditions Of Sale — Parts ................ 46

NOTICE

Specifications and part numbers are subject to change

without notice.

PAGE 4 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

PARTS ORDERING PROCEDURES

www.multiquip.com

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

parts@multiquip.

To obtain an MQ Account, contact your

Effective:

, 2006

Choose from three easy options:

January 1

st

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at:

com.

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 5

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Tr uc k

■ Ground

■ Next Day

■ Second/Third Day

SAFETY INFORMATION

Do not operate or service the equipment before reading the

entire manual. Safety precautions should be followed at all

times when operating this equipment. Failure to read and

understand the safety messages and operating instructions

could result in injury to yourself and others.

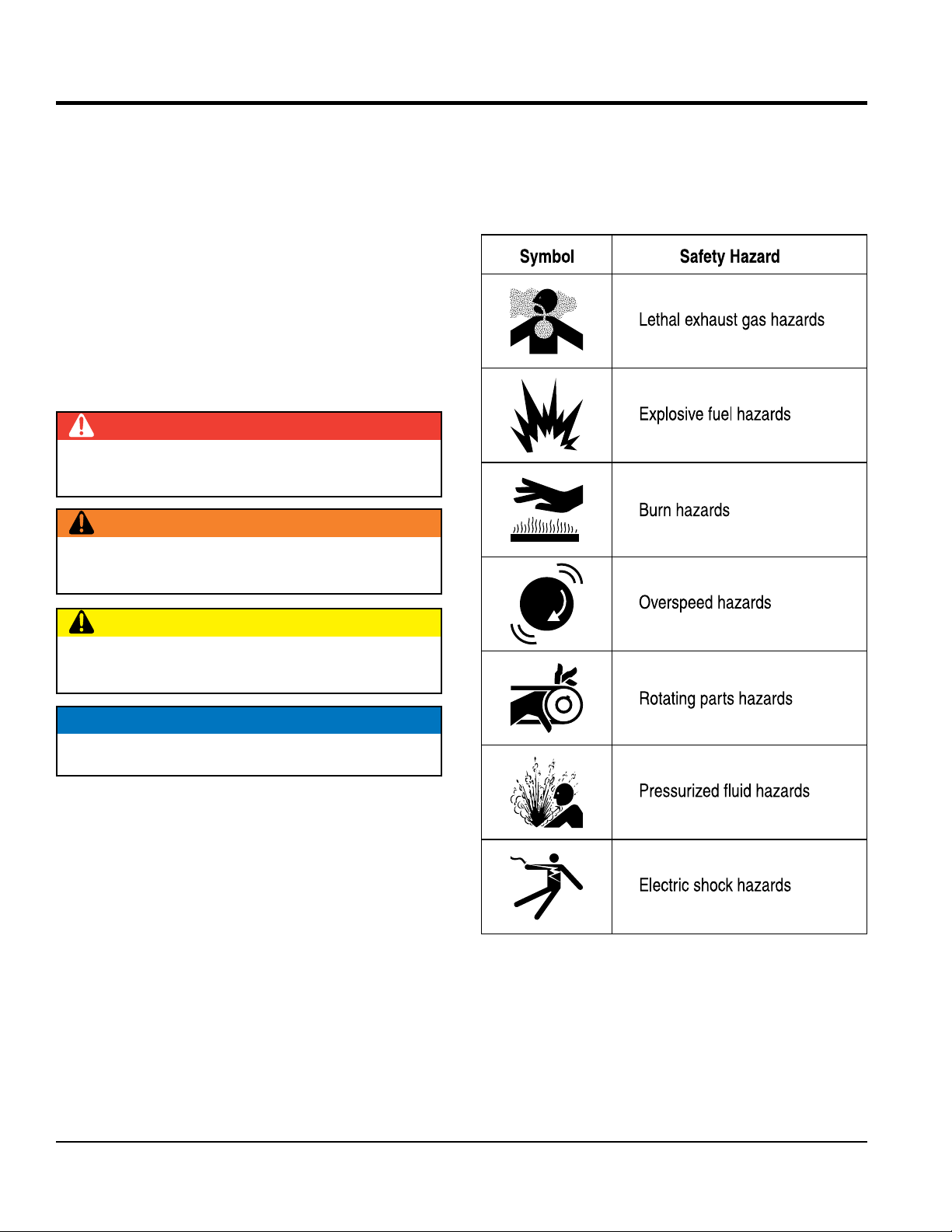

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION

SAFETY SYMBOLS

SAFETY SYMBOLS

Potential hazards associated with the operation of this

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

or NOTICE.

safety messages.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

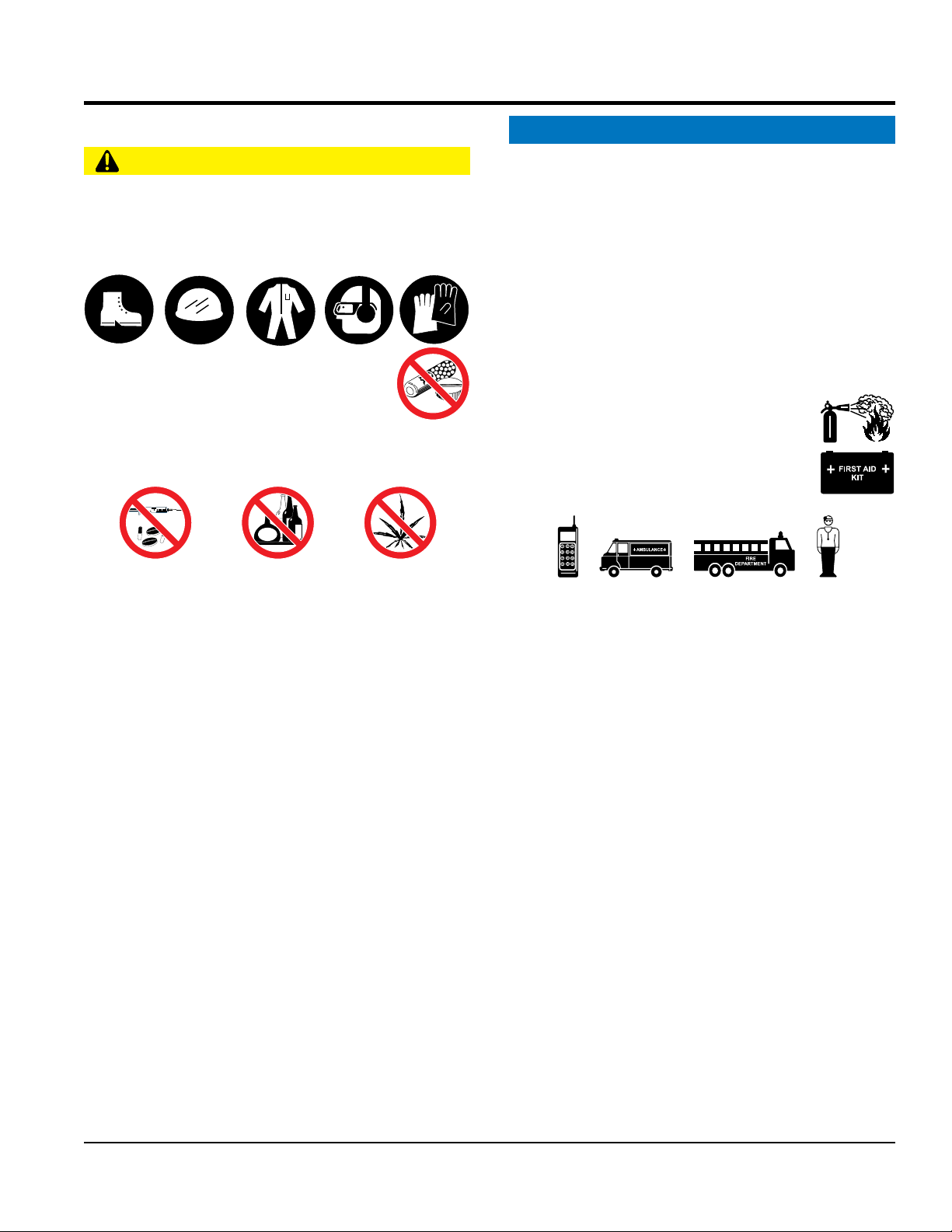

GENERAL SAFETY

NOTICE

This equipment should only be operated by trained and

Whenever necessary, replace nameplate, operation and

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

know the location of the nearest phone or

Also, know the phone

fi re

This information will be invaluable in the

SAFETY INFORMATION

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

ALWAYS check the equipment for loosened threads or

bolts before starting.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

qualifi ed personnel 18 years of age and older.

safety decals when they become diffi cult read.

equipment modifi cation will void all warranties.

NEVER

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS

keep a phone on the job site.

numbers of the nearest ambulance, doctor and

department.

case of an emergency.

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 7

LIGHT TOWER SAFETY

NOTICE

keep the immediate area surrounding the light

Fix damage to machine and replace any broken parts

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

use

attempt to replace lamp with the power on.

Always shut down the engine and turn off circuit breakers

allow a suffi cient amount of time for the lamp to

before touching or changing. The possibility exists of

use force when installing the lamp. Excessive force

leave any grease or oil residue on lamp surface

when replacing or removing lamp. This can create hot

install and remove

SAFETY INFORMATION

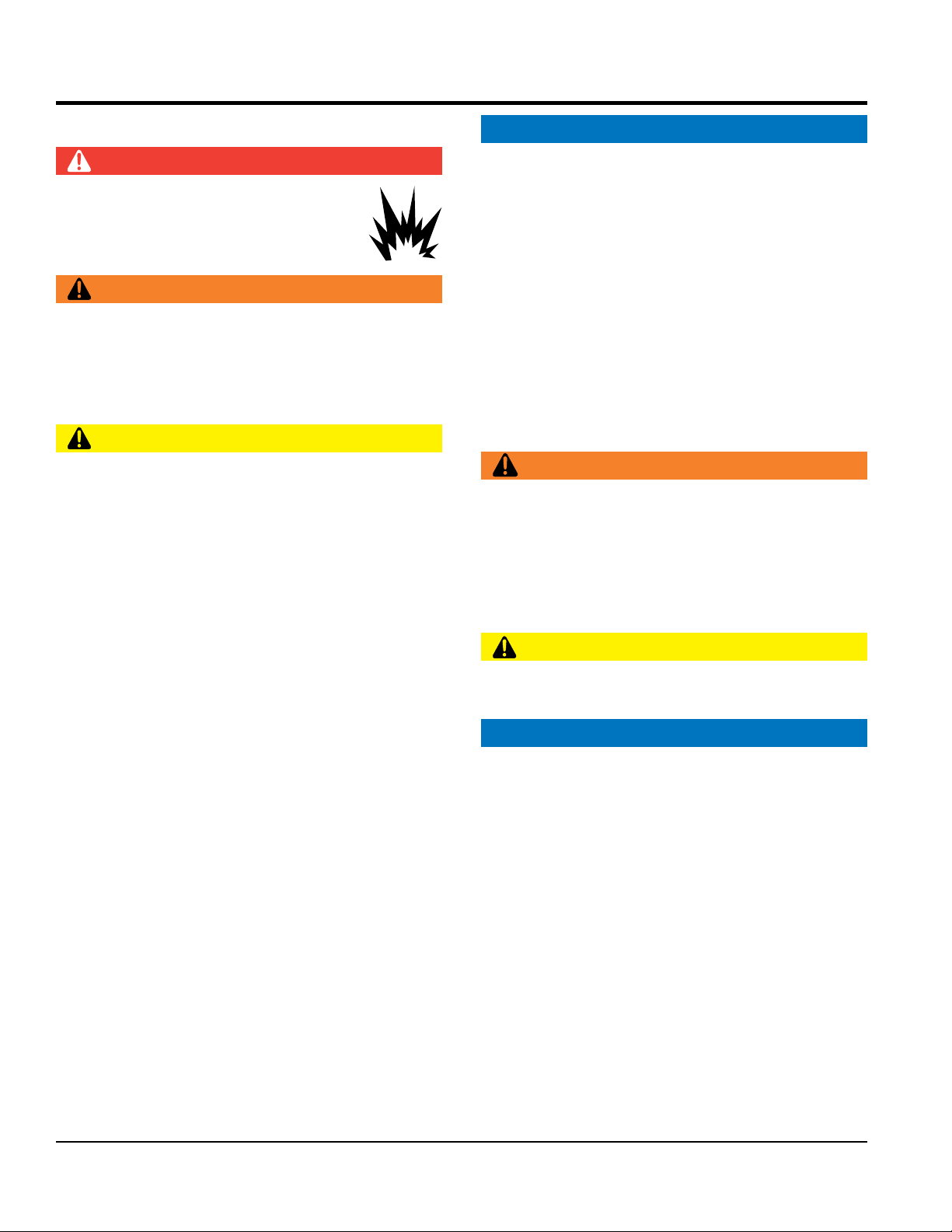

DANGER

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

NEVER disconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

devices will void all warranties.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

ALWAYS ensure light tower is on level ground before use

so that it cannot slide or shift around, endangering workers.

Always keep immediate area free of bystanders.

ALWAYS make sure trailer is leveled with all outriggers

extended before raising tower. Outriggers must remain

extended while tower is up.

ALWAYS keep area behind trailer clear of people while

raising and lowering mast.

NEVER remove safety pin or pull mast locking pin while

tower is in a raised position!

CHECK the mast and winch cables for wear. If any

problem occurs when lowering or raising the tower, STOP

immediately! Contact a trained technician for assistance.

NEVER pivot or retract mast while unit is operating.

NEVER use the light tower mast as a crane. DO NOT

lift anything with the mast.

ALWAYS lower the light tower when not in use, or if high

winds or electrical storms are expected.

ALWAYS

tower clean, neat, and free of debris.

ALWAYS keep the machine in proper running condition.

immediately.

ALWAYS

To prevent the light tower from overturning, NEVER

in winds that exceed 65 MPH (105 km/h).

LAMP SAFETY

WARNING

NEVER

when changing the lamp.

ALWAYS

cool

severe burns.

CAUTION

NEVER

could cause the lamp to break, causing bodily harm.

NOTICE

NEVER

spots, reducing the service life of the lamp.

ALWAYS make sure lamp surface is clean and dry.

ALWAYS replace with MQ recommended type lamp.

ALWAYS have a trained technician

a fl oodlight, or replace any damaged fi xture wiring.

PAGE 8 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

ENGINE SAFETY

DANGEROUS

GASFUMES

NOTICE

run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

tip the engine to extreme angles during lifting as

it may cause oil to gravitate into the cylinder head, making

Wet stacking is a common problem with diesel engines

which are operated for extended periods with light or

no load applied. When a diesel engine operates without

suffi cient load (less than 40% of the rated output), it will

not operate at its optimum temperature. This will allow

unburned fuel to accumulate in the exhaust system,

which can foul the fuel injectors, engine valves and

exhaust system, including turbochargers, and reduce

it must be able to provide fuel and air in the proper ratio

and at a high enough engine temperature for the engine

damage and can be alleviated if additional load is

applied to relieve the condition. It can reduce the system

performance and increase maintenance. Applying an

increasing load over a period of time until the excess

fuel is burned off and the system capacity is reached

usually can repair the condition. This can take several

State Health Safety Codes and Public Resources

Codes specify that in certain locations, spark arresters

must be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed

to prevent accidental discharge of sparks or fl ames

from the engine exhaust. Spark arresters are qualifi ed

and rated by the United States Forest Service for this

purpose. In order to comply with local laws regarding

spark arresters, consult the engine distributor or the

SAFETY INFORMATION

DANGER

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment

requires an adequate free

fl ow of cooling air. NEVER

operate this equipment in

any enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury to people and property and

serious damage to the equipment or engine.

WARNING

DO NOT place hands or fingers inside engine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

DO NOT remove the radiator cap while the engine is hot.

High pressure boiling water will gush out of the radiator

and severely scald any persons in the general area of

the generator.

NEVER

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

NEVER

the engine start diffi cult.

the operating performance.

In order for a diesel engine to operate at peak effi ciency,

to completely burn all of the fuel.

Wet stacking does not usually cause any permanent

DO NOT remove the coolant drain plug

while the engine is hot. Hot coolant will

gush out of the coolant tank and severely

scald any persons in the general area of

the generator.

DO NOT remove the engine oil drain plug while the

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

generator.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

hours to burn off the accumulated unburned fuel.

local Health and Safety Administrator.

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 9

FUEL SAFETY

DANGER

TOWING SAFETY — LIGHT TOWER

ALWAYS inspect the hitch and coupling for wear. NEVER

Check the tire air pressure on both towing vehicle and

Trailer tires should be infl ated to 50 psi cold.

safety

attach trailer’s safety chains to towing

make sure the vehicle and trailer directional,

backup, brake and trailer lights are connected and

55 MPH

) unless posted otherwise. Recommended off-

)or less

Avoid sudden stops and starts. This can cause skidding,

or jack-knifi ng. Smooth, gradual starts and stops will

Trailer should be adjusted to a level position at all times

Raise and lock trailer jack stands in up position when

DO NOT start the engine near spilled fuel or combustible

fl uids. Diesel fuel is extremely fl ammable and its vapors

can cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

SAFETY INFORMATION

tow a trailer with defective hitches, couplings, chains, etc.

trailer.

Also check the tire tread wear on both vehicles.

ALWAYS make sure the trailer is equipped with a

chain.

ALWAYS properly

vehicle.

ALWAYS

working properly.

DOT Requirements include the following:

• Connect and test electric brake operation.

• Secure portable power cables in cable tray with tie

wraps.

NEVER use fuel as a cleaning agent.

DO NOT smoke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

CAUTION

Check with your local county or state safety

towing regulations, in addition to meeting

Department of Transportation (DOT)

Safety Towing Regulations, before towing

your light tower.

In order to reduce the possibility of an accident while

transporting the light tower on public roads, ALWAYS

make sure the trailer that supports the light tower and

the towing vehicle are mechanically sound and in good

operating condition.

ALWAYS shutdown engine before transporting.

The maximum speed for highway towing is

(86 km/h

road towing is not to exceed 15 MPH (24 km/h

depending on type of terrain.

improve towing.

Avoid sharp turns to prevent rolling.

when towing.

towing.

NOTICE

ALWAYS remove and stow the GB2000 lamp fi xture

prior to towing the light tower.

Make sure the hitch and coupling of the towing vehicle

are rated equal to, or greater than the trailer “gross

vehicle weight rating.”

PAGE 10 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

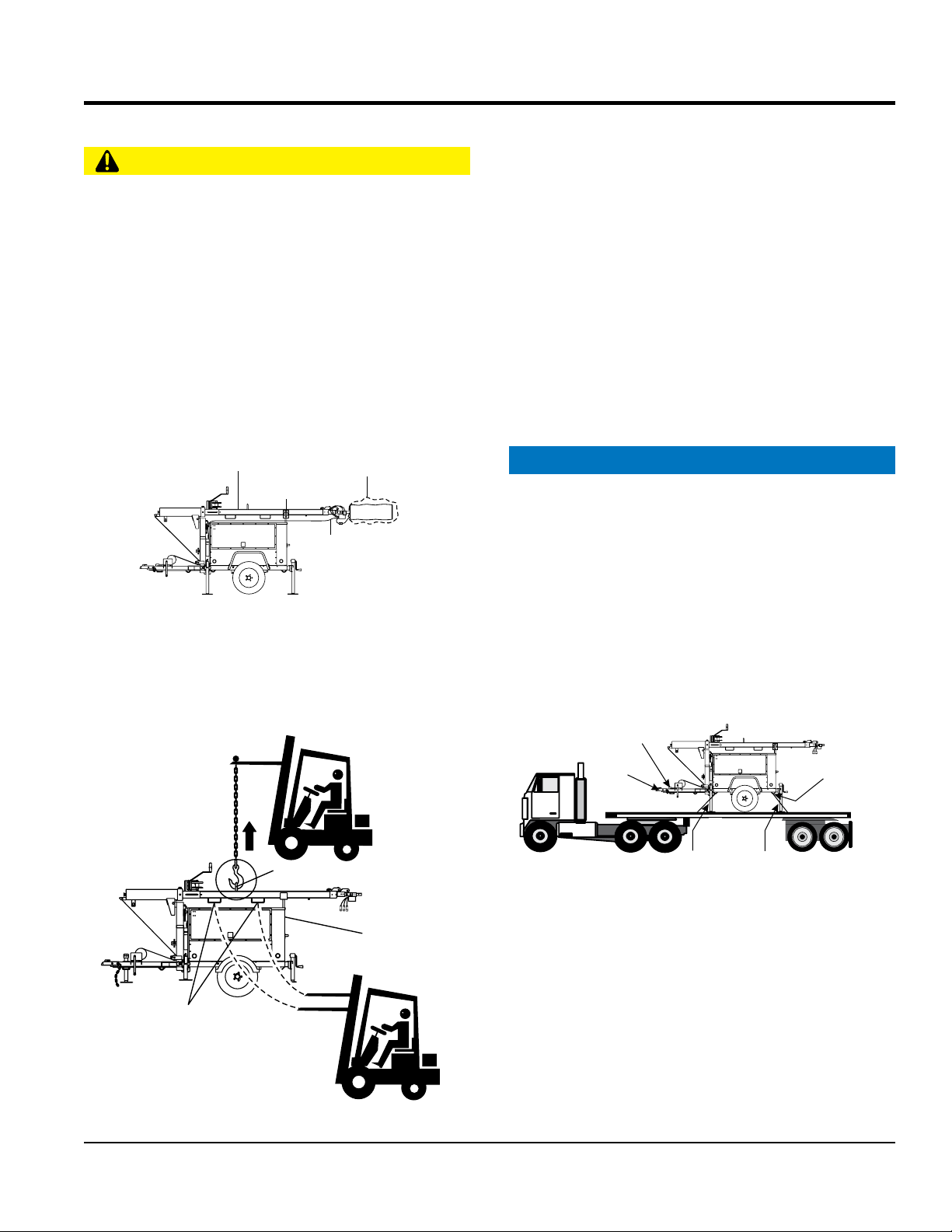

TRANSPORTING SAFETY

CAUTION

TING

If lifting through pockets, make sure forks of forklift are

rolling

underneath the trailer’s bumper

Use the trailer’s swivel jack to adjust the trailer height to

allow any person or animal to stand underneath

Before loading light tower to fl atbed truck, disconnect all

connectors and tie-wrap the cables against the T-bar to

Remove and stow the GB2000 in a safe place where it

will not get damaged before loading the light tower onto

When loading onto fl atbed truck, make sure that front

jackstand of light tower is retracted and in the horizontal

position so that the foot does not make contact with the

Make sure that the two side (left and right) and two rear

jackstands are in the vertical postion, slightly extended,

Straps and chains should be routed through the transport

tie-down points located beneath each corner of the

cabinet to allow even application of force to the front

secure the unit by running a strap or chain over

the tongue of the light tower. This may cause severe

TRANSPORT

TIE-DOWN

POINT (4)

FRONT JACKSTAND

RETRACTED

TONGUE

SIDE

JACK

STAND (2)

REAR

JACK

STAND (2)

Before lifting, make sure that light tower parts are not

damaged and screws are not loosened or lost.

ALWAYS make sure crane or lifting device has been

properly secured to lifting hook of the equipment.

NEVER lift the equipment while engine is running.

Remove fan power cord from junction box before towing.

Make sure tower (mast) is in the stowed position and the

GB2000 is removed from the mast before lifting.

SAFETY INFORMATION

inserted in pockets as far as possible before lifting.

Place chock blocks underneath wheel to prevent

while parked.

Place support blocks

to prevent tipping while parked.

a level position while parked.

NEVER

the equipment while lifting.

DO NOT lift equipment to unnecessary heights.

REMOVE

STOWED

POSITION

MAST

LOCK

GB2000

BEFORE

TRANSPOR

REMOVE

FAN

POWER

CORD

ALWAYS Make sure rear mast lock is secure before

lifting.

Use adequate lifting cable (wire or rope) of suffi cient

strength.

Use one point suspension hook and lift straight upwards.

LIFTING BALE

Loading and Tie-Down on Flatbed Truck

NOTICE

prevent damage to the cables and connectors.

a fl atbed truck, towing, or shipping via a container.

deck fl oor.

FORKLIFT

POCKETS

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 11

LIGHT TOWER

so that each foot makes contact with the deck fl oor.

and rear of the machine.

DO NOT

damage to the unit.

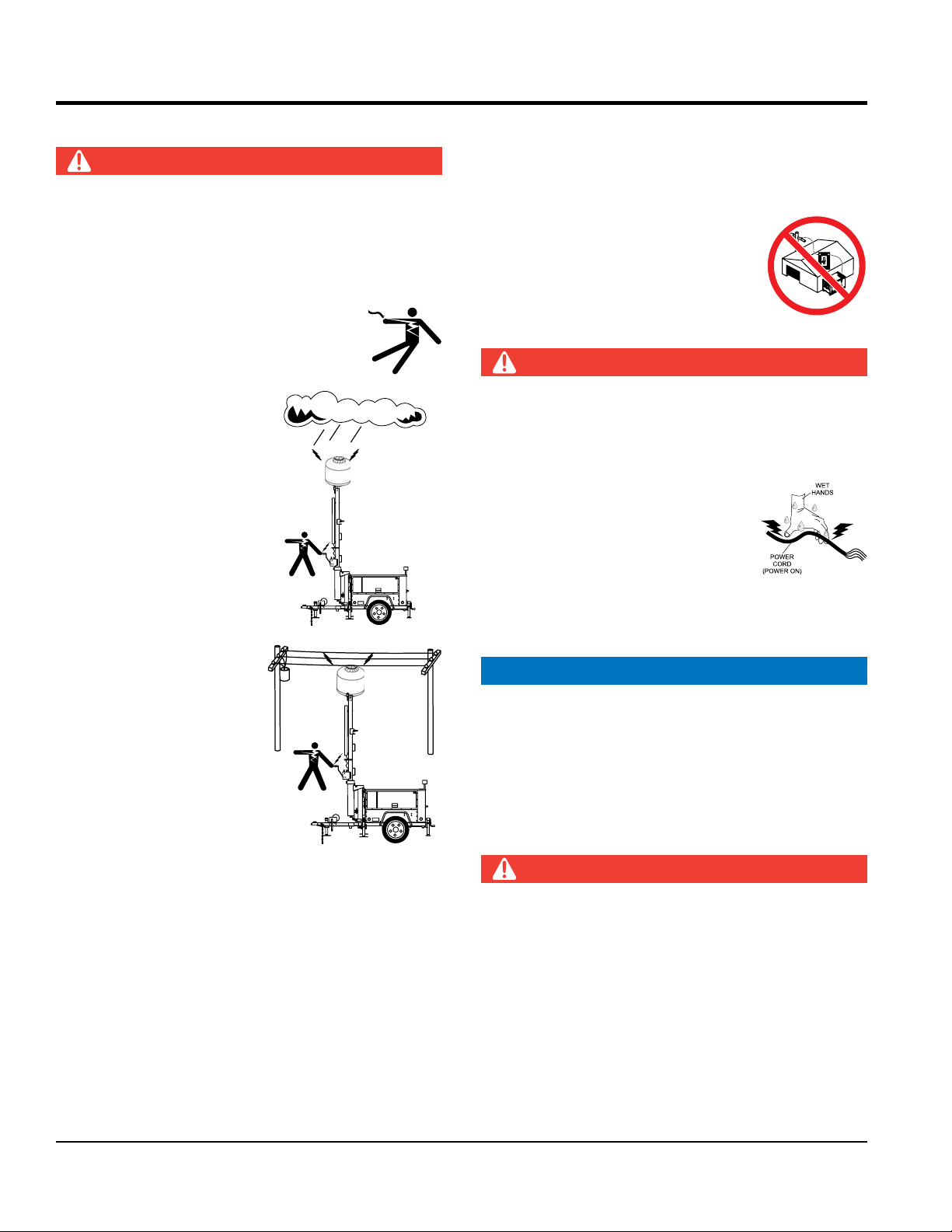

ELECTRICAL SAFETY

DANGER

Backfeed to a utility system can cause electrocution

connect the generator

to a building’s electrical system without a transfer switch

or other approved device. All installations should be

cables or cords when

connecting equipment to generator. Inspect for cuts in

Make sure power cables are securely connected.

Incorrect connections may cause electrical shock and

make certain that proper power or extension

Ensure fan power cable is safely routed and secured

as it travels from the junction box down the mast to the

The light tower is equipped with a ground terminal for

complete the grounding path

make sure that electrical circuits are properly

grounded to a suitable earth ground (ground rod) per

the National Electrical Code (NEC) and local codes

Severe injury or death by

can result from operating an ungrounded

The electrical voltage required to operate the generator

can cause severe injury or even death through physical

contact with live circuits. Turn generator and all circuit

breakers OFF before performing maintenance on the

generator.

NEVER insert any objects into the output

receptacles during operation. This is

extremely dangerous. The possibility exists

of electrical shock, electrocution or

death.

NEVER operate light tower

or handle any electrical

equipment while standing in

water, while barefoot, while

hands are wet or in the rain.

A dangerous electrical

shock could occur, causing

severe bodily harm or

even death.

SAFETY INFORMATION

and/or property damage. NEVER

performed by a licensed electrician in

accordance with all applicable laws and

electrical codes. Failure to do so could

result in electrical shock or burn,

causing serious injury or even death.

Power Cord/Cable Safety

DANGER

NEVER let power cords or cables lay in water.

NEVER use damaged or worn

the insulation.

NEVER grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

ALWAYS make sure the

area above the light tower is

open and clear of overhead

power lines and other

obstructions. The tower

extends in excess of 30

feet (9 meters). Contact

with overhead power

lines or other obstructions

could result in equipment

damage, electrical shock,

electrocution and even

death.

Similar to boom equipment, light tower may become

energized with high voltage. DO NOT operate the light

tower within a radial distance of 17 feet (5.1 meters)

from high voltage power lines. If light tower becomes

energized with high voltage, contact with the equipment

could result in electrocution.

NEVER operate GB2000 in winds in excess of 40 MPH

(64 km/h).

PAGE 12 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

damage to the light tower.

NOTICE

ALWAYS

cord has been selected for the job.

GFCI receptacle.

Grounding Safety

DANGER

your protection. ALWAYS

from the light tower to an extrnal grounding source.

ALWAYS

before operating generator.

electrocution

generator.

NEVER use gas piping as an electrical ground.

SAFETY INFORMATION

BATTERY SAFETY

ENVIRONMENTAL SAFETY

use food or plastic containers to dispose of

pour waste, oil or fuel directly onto the ground,

DANGER

DO NOT drop the battery. There is a possibility that the

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

ALWAYS wear safety glasses when handling

the battery to avoid eye irritation. The battery

contains acids that can cause injury to the

eyes and skin.

Use well-insulated gloves when picking up the battery.

ALWAYS keep the battery charged. If the battery is not

charged, combustible gas will build up.

ALWAYS recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

of combustible gasses.

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT

hazardous waste.

DO NOT

down a drain or into any water source.

If the battery liquid (dilute sulfuric acid) comes into

contact with clothing or skin, rinse skin or clothing

immediately with plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the generator.

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 13

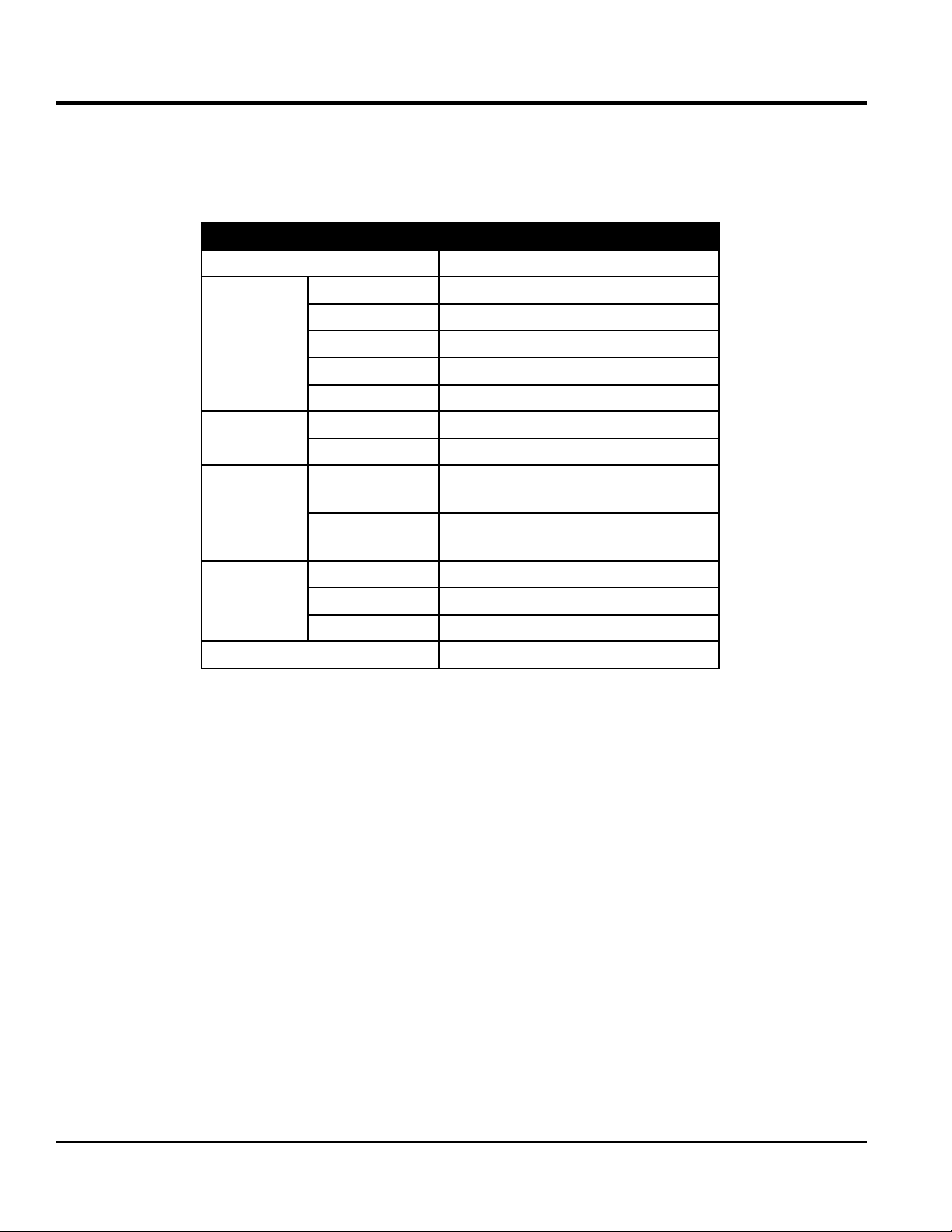

Table 1. Specifications

Model GB2000

Type 1000 W Metal Halide (X2)

Number of Bulbs 2

SPECIFICATIONS

Lamp

Fan

Dimensions

Weight

Appropriate Generator 3.2 kW and above

Current 18.6 A (9.3 A x 2)

Voltage 120 V

Lumens 214,000 (107,000 x 2) lm

Current 1.2 A

Voltage 24 VDC

Storage

Working

Balloon 33 lb (15 kg)

Bracket & J-Box 19.2 lb (8.7 kg)

Total 52.2 lb (23.7 kg)

13.7 x 13.7 x 39.5 in

(350 x 350 x 1005 mm)

35.4 x 35.4 x 40.5 in

(900 x 900 x 1030 mm)

PAGE 14 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

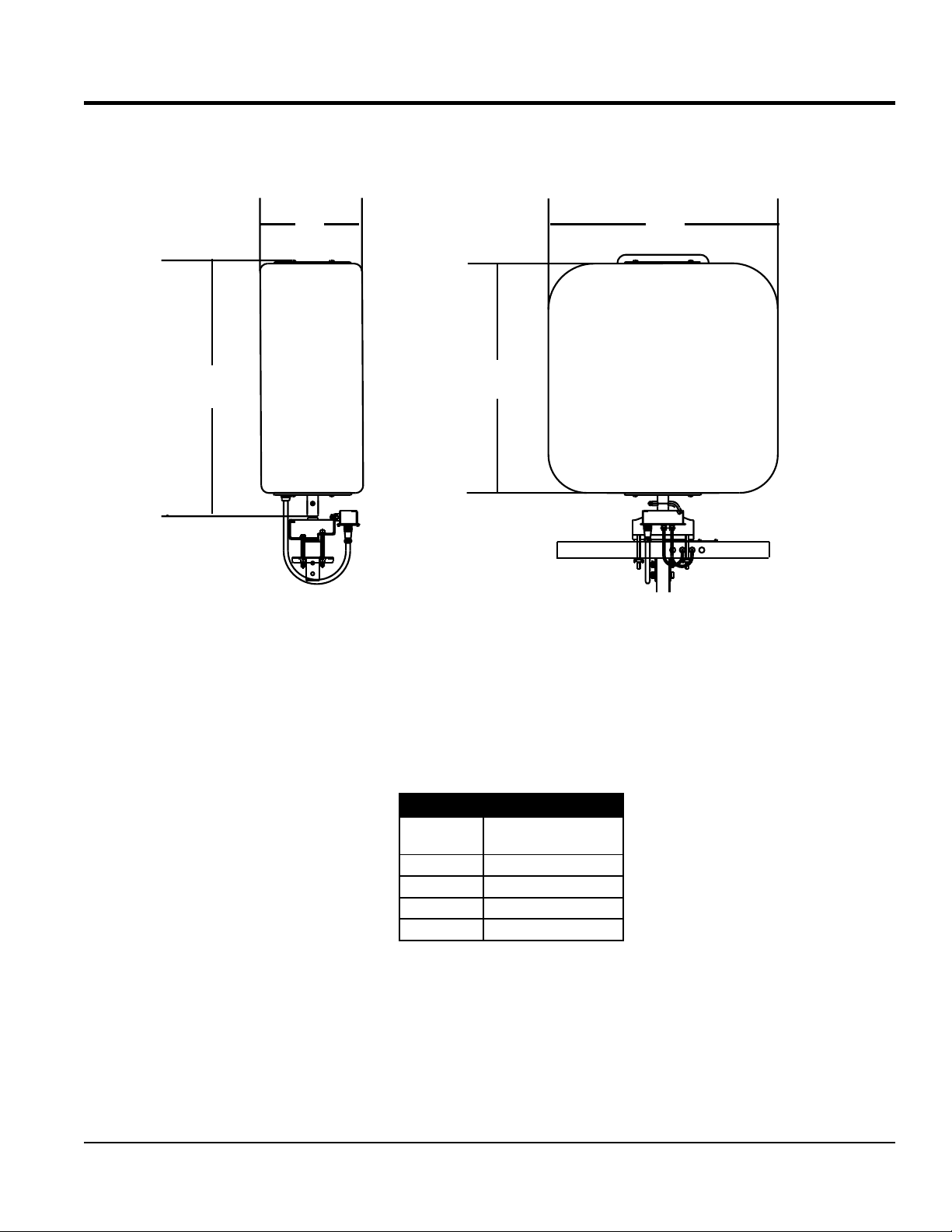

DIMENSIONS

A

B

D

CLOSED OPENED

C

Figure 1. Dimensions

Table 2. Dimensions

Reference

Letter

A 13.7 (350)

B 39.5 (1,005)

C 35.4 (900)

D 35.4 (900)

Dimension

in. (mm)

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 15

30

FOOTCANDLE PLOT

20

10

5

Illuminance (Footcandle)

Diameter (Feet)

3010203210

5658221211160

2

1

0.5

0.25

1 grid = 40 ft.

0.5

216

0.25

262

0.1

360

Figure 2. Footcandle Plot

PAGE 16 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

The GB2000 lamp fixture is a difused balloon light that is

designed to be mounted and operated on most conventional

mobile light tower masts. Its design and features permit

clean, difused light to be cast uniformly over 232 feet (70.7

meters).

The shadow-less lighting dramatically reduces glare in

the work area. This type of lighting improves safety and

enhances the illuminated area. The GB2000 is ideal for

highway work, construction job sites, security support, and

special events.

The balloon light assembly is supported by two 1000 watt

metal halide lamps, self-inflating durable polyester balloon

bag, protective lamp guard, quick disconnect communal

mast bracket, and self-contained electrical junction box.

Once attached to the mast, the GB2000 utilizes the ballast

assembly, electrical conduits, and receptacle connections

of conventional mobile light towers to permit operation.

The GB2000 requires 2000 watts of power and the host

light tower electrical ballast system for operation. Total lamp

operation will be limited to the design and capacity of the

host light tower.

GENERAL INFORMATION

The unit easily disconnects from the light tower mast and

can be easily stored in its protective canvas cover case.

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 17

COMPONENTS

5

3

2

1

4

6

7

1. Lamp Fixture — Made of heat resistant polyester

balloon, with a diameter of 35.5 inches (902 mm) and

two 1000 watt metal halide lamps.

2. Locking Pin — Locks the lamp fixture in place when

attached to the pole on the bracket.

3. Balloon Power Cable — Provides AC power to the

lamps, fan and balloon inflation circuit.

4. Adapter Plate — Attaches to the T-Bar and mast

interface of the light tower to allow the GB2000 to be

installed.

NOTICE

This adapter plate (item 4) fits most conventional light

tower masts.

5. Junction Box — Holds the electrical connection and

cables to connect the lamp fixture to the T-Bar and to

the power cable.

6. Support Bracket — Attaches to T-Bar to support

adapter plate (hardware not shown).

7. Connector Caps — Provides protection to the

receptacles on the junction box when not in use.

Figure 3. GB2000 Components

PAGE 18 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

STOWED

POSITION

MAST

LOCK

SETUP

TMENT

4-PIN POWER

CABLE

PREPARATION

1. Place the light tower in an area free of dirt and debris

with enough clearance as not to interfere with any

overhead obstructions. Make sure it is on secure level

ground with chock blocks underneath each wheel to

prevent the light tower from rolling.

DANGER

ALWAYS make sure the area above

light tower is open and clear of

overhead power lines and other

obstructions. The tower extends in

excess of 30 ft. (9 meters). Contact

with overhead power lines or other

obstructions could result in equipment

damage, serious injury or death!

2. If the light tower is in the deployed position, place the

tower mast into the cradle support (stowed position).

See Figure 4. Make sure cradle lock/release pin has

been inserted and the mast is locked.

POWER DISCONNECTION

1. For LT12D light towers, disconnect the negative cable

(black) from battery. See Figure 5.

DISCONNECT

NEGATIVE

BATTERY CABLE

Figure 5. Disconnecting Battery

2. For MLT series light towers disconnect the 4-pin power

cable (Figure 6) from the 120 VAC twist-lock receptacle

on the front panel of the generator.

MLT

LIGHT TOWER

Figure 4. Light Tower in Stowed Position

NOTICE

The new lamp adapter plate requires no existing lamp

removal for installation. All lamps can remain in place

during installation of the adapter plate.

NOTICE

Only mount the GB2000 on Light Towers that are

equipped with one of the following ballasts:

• UNIVERSAL LIGHTING TECHNOLOGIES INC:

M1000120AC5M

• PHILIPS LIGHTING ELECTRONICNA : 71A-6592.

WHISPERWATT

7KW AC

Model DA-7000SS

AC CIRCUIT

BREAKER

7000 WATT

DIESELPOWERED AC GENERA

20A

25A

120V

ON

RUN

STOP

HEA

T

OFF

IDLE CONTROL

AC VOL

TMETER

0 0

0

HOURS

HOUR METER

TOR

25A

120/240V

START

0

0

STARTER SWITCH

25A

DISCONNECT

TO BALLAST

COMPAR

Figure 6. MLT Power Cable Removal

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 19

SETUP

LAMP ADAPTER PLATE MOUNTING INSTALLATION

1. Remove the adapter plate kit hardware from its

container.

2. Before proceeding make sure the light tower mast is

in the stow position (down) and the cradle lock/release

pin has been inserted and the mast is locked.

3. Attach the lamp adapter plate to the T-Bar as shown

in Figure 7. Align adapter plate so that adapter spacer

notch fits over screw on T-Bar. Please pay close

attention to the orientation of the 2 support brackets.

4. Mount the flat end of both support brackets flush

against the T-Bar with the low end of each bracket

facing inward toward the mast. The raised end of each

bracket should be facing outward.

NOTICE

Please pay close attention to the orientation of the 2

support brackets. Each bracket has a high and low side.

The low side of the bracket should be facing inwards

towards the mast.

5. Next, insert a bolt (4) and flat washer (4) thru the

mounting holes on the adapter plate as shown in Figure

7. Again, pay close attention on which set of holes to

insert the bolt thru. Bolt number 2 must be oriented

so that it passes between receptacles J1 and J2 on

the T-Bar.

6. Secure the adapter plate to the T-Bar using the supplied

flat washer (4), lock washer (4) and nut (4). Make sure

the adapter plate is level (use a bubble level) and both

brackets are straight (vertical), not slanted before

tightening

PAGE 20 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

SETUP

VIEW FROM BACK SIDE

BOLT (4)

FLAT WASHER (8)

LOCK WASHER (4)

HEX NUT (4)

SUPPORT

BRACKET (2)

T-BAR

LAMP ADAPTER

PLATE

BUBBLE LEVEL

SPACER

LOW END

BOLT

1

NOTES:

It is important for the adapter SPACER to seat

against the T-Bar as shown above.

2

For proper alignment of the adapter plate,

use of a bubble level is required.

FLUSH W/

T-BAR BOTT

OM

1

2

BACK SIDE

UNDERNEATH

1

2

3

4

1

2

3

4

T-BAR

J1

J2

BOLT

SUPPORT

BRACKET

2

LAMP ADAPTER

PLATE

Figure 7. Adapter Plate Mounting Installation

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 21

SETUP

JUNCTION BOX MOUNTING

1. Secure the junction box (Figure 8) to the adapter plate

using the supplied bolts (2), lock washer (2), and flat

washer (2). Tighten mounting bolts securely.

T-BAR

LAMP

ADAPTER

PLATE

BOLT

(2)

POLE

LOCK

WASHER (2)

FLAT

WASHER

(2)

LAMP MOUNTING

1. Place the GB2000 lamp fixture onto the lamp adapter

plate pole as shown in Figure 9.

2. Insert locking pin into hole opening on pole, then insert

cotter pin to lock pin in place.

BALLOON POWER CABLE

1. Connect the balloon power cable (Figure 9) to the 10pin receptacle on the junction box.

JUNCTION BOX

Figure 8. Junction Box Mounting

LAMP 3

(BOTTOM)

LAMP 4

(TOP)

J3

J4

LAMP 1

(BOTTOM)

J1

J2

LOCKING

PIN

COTTER

PIN

JUNCTION

BOX

BALLOON FIXTURE

LAMP 2

(TOP)

PLATE

ADAPTER

POLE

2 FT. (10 PIN)

BALLOON

POWER CABLE

Figure 9. Balloon Power Cable Connection

PAGE 22 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

SETUP

Use Figure 10 as a reference when determining orientation of lamps and receptacles on T-Bar. Figure 10 is looking at the

light tower from the rear to the front.

LAMP 4

GB2000 BALLOON

LAMP 2

LAMP 2

(TOP)

LAMP 4

(TOP)

LAMP 1

J2

J1

J4

J3

LAMP 3

LAMP 1

(BOTTOM)

REAR

LAMP 3

(BOTTOM)

FRONT

Figure 10. Light Tower Orientation View

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 23

LAMP LIGHTING OPTIONS

LAMP CABLE CONNECTIONS

On the T-Bar (Figure 11) there are four power receptacles J1, J2, J3 and J4. These receptacles provide AC power to the

existing rectangular lamps. When the GB2000 lamp assembly is employed only two of the existing rectangular lamps (bottom

lamps recommended) will be available for use. Please reference Figure 11 thru Figure 16 for the various lighting options.

GB2000

T-BAR

LT12 LAMP

CIRCUIT BREAKERS

OFF OFF ON ON

CB1 CB2 CB3 CB4

All Lamps Removed

GB2000 Operational

JUNCTION BOX

1 2 3

4

MLT LAMP

CIRCUIT BREAKERS

CB1 CB2

ON

OFF

Figure 11. Option 1 Lighting Configuration

PAGE 24 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

Table 3.

GB2000

LAMP LIGHTING OPTIONS

NOT USED

LAMP 2

TOP

LAMP 1

BOTTOM

LT12 LAMP

CIRCUIT BREAKERS

OFF OFF ON ON

2

1

3 4

MLT LAMP

CIRCUIT BREAKERS

CB1 CB2

ON

LAMP 4

TOP

NOT USED

LAMP 3

BOTTOM

OFF

CB1 CB2 CB3 CB4

4 Lamps Installed on T-Bar

Only GB2000 Operational

Figure 12. Option 2 Lighting Configuration

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 25

GB2000

LAMP LIGHTING OPTIONS

LAMP 1

BOTTOM

LT12 LAMP

CIRCUIT BREAKERS

ON ONON ON

CB1 CB2 CB3 CB4

2 Top Lamps Removed

GB2000 Operational

2 Bottom Lamps Operational

Figure 13. Option 3 Lighting Configuration

2

31 4

LAMP 3

BOTTOM

MLT LAMP

CIRCUIT BREAKERS

CB1 CB2

ON ON

PAGE 26 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

2 Bottom Lamps Operational

GB2000

LAMP LIGHTING OPTIONS

NOT USED

LAMP 2

TOP

LAMP 1

BOTTOM

LT12 LAMP

CIRCUIT BREAKERS

ON ON ON ON

2

1

3 4

MLT LAMP

CIRCUIT BREAKERS

CB1 CB2

ON ON

LAMP 4

TOP

NOT USED

LAMP 3

BOTTOM

CB1 CB2 CB3 CB4

4 Lamps Installed on T-Bar

GB2000 Operational

Figure 14. Option 4 Lighting Configuration

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 27

GB2000

2 Top Lamps Operational

LAMP LIGHTING OPTIONS

NOT USED

LAMP 2

TOP

LAMP 1

BOTTOM

LT12 LAMP

CIRCUIT BREAKERS

ON ONON ON

2

1

3 4

MLT LAMP

CIRCUIT BREAKERS

CB1 CB2

ON ON

LAMP 4

TOP

LAMP 3

BOTTOM

NOT USED

CB1 CB2 CB3 CB4

4 Lamps Installed on T-Bar

GB2000 Operational

Figure 15. Option 5 Lighting Configuration

PAGE 28 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

GB2000

2 Top Lamps Operational

LAMP LIGHTING OPTIONS

LAMP 2

TOP

LT12 LAMP

CIRCUIT BREAKERS

ON ONON ON

CB1 CB2 CB3 CB4

2

1

3 4

MLT LAMP

CIRCUIT BREAKERS

CB1 CB2

ON ON

LAMP 4

TOP

2 Bottom Lamps Removed

GB2000 Operational

Figure 16. Option 6 Lighting Configuration

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 29

OPERATION

REMOVING BALLOON PROTECTIVE COVER

CAUTION

DO NOT use excessive force when

zipping or unzipping the balloon. The

possibility exists of the zipper tearing,

which would make the balloon unusable.

1. Expose the balloon by unsnapping the buttons and

unzipping the protective cover as shown in Figure 17.

SNAPS

UNZIP

PROTECTIVE

COVER

BALLOON

FULLY

EXPOSED

FOLD PROTECTIVE

COVER INTO ITSELF

4. Once, the engine has started, place the main circuit

breaker switch (Figure 18) on the LT12 control panel

in the ON position.

LT12

LIGHT TOWER

240 VAC/30A

120 VAC/15A

MAIN

GFCI

BREAKER

BREAKER

MAIN

CIRCUIT

BREAKER

ON

CB4

CB1

CB3CB2

LIGHT CONTROL/BREAKER

Figure 18. Main Breaker ON (LT12)

5. Next, turn on lamp circuit breakers as indicated in

the lamp lighting options section of this manual. The

balloon should begin to inflate and the selected lamps

will light.

Figure 17. Removing Protective Cover

2. Next, fold the protective cover into itself and zip. See

Figure 17.

INFLATING BALLOON AND TURNING ON LAMPS

(LT12 ONLY)

1. On LT12 series light towers, reconnect negative battery

cable (black).

2. Slightly raise the light tower mast to allow clearance

for the balloon to inflate.

3. Start the light tower engine as referenced in the LT12

light tower operation manual.

6. Secure any unused lamp cables.

7. Raise the light tower mast (Figure 19) to the desired

upright height.

LAMP 2

LAMP 2

FACING

OUTWARD

LAMP 1

NOT USED

NOT USED

BALLOON

LAMP 4

LAMP 4

FACING OUTWARD

LAMP 3

Figure 19. Balloon Deployed

(Typical Application)

PAGE 30 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

OPERATION

CABLE

INFLATING BALLOON AND TURNING ON LAMPS

(MLT ONLY)

1. On MLT series light towers, reconnect the 4-pin power

cable (Figure 20) to the 120 VAC twist-lock receptacle

on the front panel of the generator.

MLT LIGHT TOWER

WHISPERWATT

7KWAC

Model DA-7000SS

AC CIRCUIT

BREAKER

7000 WATT

DIESELPOWERED AC GENERA

20A

25A

120V

4-PIN POWER

CABLE

Figure 20. MLT Ballast 4-pin

Power Cable

2. Slightly raise the light tower mast to allow clearance

for the balloon to inflate.

3. Start the light tower engine as referenced in the MLT

operation manual.

ON

RUN

STOP

HEA

T

OFF

IDLE CONTROL

AC VOL

TMETER

TOR

25A

0 0

0

0

0

HOURS

HOUR METER

120/240V

STARTER SWITCH

25A

START

TO BALLAST

COMPARTMENT

5. Next, turn on lamp circuit breakers as indicated in

the lamp lighting options section of this manual. The

balloon should begin to inflate.

6. Secure any unused lamp cables.

7. Raise the light tower mast (Figure 19) to the desired

upright height.

DEFLATING AND STORING BALLOON

1. Turn lamps OFF and allow to cool for at least five

minutes.

2. Once the lamps have cooled, place the main breaker

switch in the OFF position.

NOTICE

ALWAYS make sure lamps are turned off and allowed

to cool before deflating balloon to avoid any damage

to the balloon. NEVER transport GB2000 lamp fixture

while attached to mast.

3. When the balloon is completely deflated, unzip the

protective cover and fold the balloon inside the cover.

4. Carefully zip up the cover and snap the buttons to fully

close the protective cover.

5. Remove all cables from T-Bar, and remove balloon

power cable from junction box.

4. Once, the engine has started, place the main circuit

breaker switch (Figure 21) on the MLT front control

panel in the ON position.

MLT LIGHT TOWER

WHISPERWATT

MAIN CIRCUIT

BREAKER

()ON

7KWAC

Model DA-7000SS

AC CIRCUIT

BREAKER

7000 WATT

DIESELPOWERED AC GENERA

20A

25A

120V

ON

RUN

STOP

HEA

T

OFF

IDLE CONTROL

AC VOL

TMETER

TOR

25A

120/240V

HOUR METER

START

0 0

0

0

0

HOURS

STARTER SWITCH

25A

TO BALLAST

4-PIN POWER

COMPARTMENT

Figure 21. Main, GFCI Circuit Breakers (ON/MLT)

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 31

6. Pull cotter pin from locking pin and remove lamp

assembly from light tower mast.

7. Store lamp assembly in a safe place where it will not

get damaged.

MAINTENANCE

LOCK HOOK

REPLACING LAMP

DANGER

Never attempt to replace lamp in a wet place. The

possibility exists of electric shock.

WARNING

Always allow sufficient time for the lamp to

cool down before replacing. The possibility

exists of severe burns if hot lamp is

touched.

\

CAUTION

Always shutdown power source and remove balloon

assembly from mast when replacing a broken lamp.

Utmost care should be taken in handling broken lamp.

The possibility exists of serious injury from handling a

broken lamp.

1. Unzip the zipper at the bottom of the balloon and roll

the balloon up to expose the lamp. See Figure 22.

3. Press the tabs on the lamp holder and push up lamp

holder to release it from lamp. Do the same to the lower

lamp if necessary. See Figure 24.

LAMP HOLDER

Figure 24. Lamp Holder

4. Remove lamp from the lamp socket by turning lamp

counterclockwise. See Figure 25.

LAMP

BALLOON

ZIPPER

Figure 22. Exposing Balloon

2. Release the lamp guard hooks from the poles and

remove the two lamp guards. See Figure 23.

LAMP GUARD

P

LAM

SOCKET

Figure 25. Removing Lamp

5. Install new lamp into socket and turn lamp in a

clockwise direction until tight. See Figure 26.

LAMP

P

LAM

SOCKET

Figure 26. Installing New Lamp

Figure 23. Removing Lamp Guard

PAGE 32 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

MAINTENANCE

ZIPPERS

BALLOON

NOTICE

Do not use excessive force when screwing the lamp to

prevent lamp from breaking.

6. Secure lamp holder on top of the lamp.

7. Reinstall lamp guard.

8. Pull down balloon and zip the bottom zipper to cover

lamp.

REPLACING BALLOON

1. Unzip the top and bottom of the balloon. See Figure 27.

UNZIP TOP AND

BOTTOM

3. Slide in the new replacement balloon over the top of

the lamp guard assembly. See Figure 29.

INSTALL NEW

BALLOON

Figure 29. Replacing Balloon

4. Zip up the top and bottom of the new balloon. See

Figure 30.

ZIP UP

NEW BALLOON

Figure 27. Unzipping Balloon

2. Slide out the old or worn balloon over the top of the

lamp guard assembly. See Figure 28.

Figure 30. Zipping Up New Balloon

REMOVE OLD

BALLOON

Figure 28. Removing Old Balloon

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 33

MAINTENANCE

FAN MOTOR

Table 4. Troubleshooting

SYMPTOM POSSIBLE PROBLEM SOLUTION

Is plug disconnected? Plug in correctly.

Is generator power switched off? Turn on switch.

Lamp does not light.

Is lamp loose? Screw lamp securely into socket.

Is power connector disconnected or

loose?

Connect disconnected connector.

Is model of lamp incompatible? Use genuine MQ lamp.

Lamp only lights for a short time.

Is ambient temperature too high more than 104° F (40° C)?

Move lamp where there is proper

ventilation.

Is fan motor not working properly? Check and repair fan motor.

Balloon does not inflate.

Is balloon cloth defective? Repair or replace balloon cloth.

Is Lamp 1 on but fan is not working? Check and repair fan motor.

Only Fan is working. Is Lamp 1 not turning on? Check Lamps and cable wiring.

Shuts down after 30 seconds. Is Microswitch being pressed?

Check Microswitch or repair fan

motor.

LAMP 1

LAMP 1

MICRO SWITCH

Figure 31. Location of Maintenance Parts

PAGE 34 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

LAMP

BOTTOM

LAMP

TOP

WIRING DIAGRAM

WHITE

WHITE

M

BLUE

M M

F

F

F

3

D E AB G

4

2

SOCKET

M

F

3

F

1

SOCKET

WHITE

M

F

WHITE

M

M

F

M

F

RED

DC FAN MOTOR

1

RELAY

3

1

M

F

BLACK

F

WHITE

BLACK

F

M

F

M

WHITE

BLACK

DC CONVERTER

C

RED

M

M

F

F

RED

MICRO SWITCH

BALLOON

F

D E AB G

C

Connectors

Connector Number Color

M

M

MM

GREEN

A 1 Black

B 2 White

D 3 Red

E 4 Orange

G Green/Yellow Green

WHITE

F F

BLACK

3P 3P

2

F F

WHITE

BOX RELAY

1

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 35

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

SAMPLE PARTS LIST

NO.

1 12345 BOLT

2% WASHER, 1/4 IN.

2% 12347 WASHER, 3/8 IN.

3 12348 HOSE

4 12349 BEARING

NO. Column

PART NO. Column

QTY. Column

— Item quantity can be indicated by a

A/R (As Required) is generally used for hoses or other

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarifi ed in the “Remarks”

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

— All items on the parts list with the

same unique symbol will be included when this item is

— Used to list an effective serial

— Indicates that the part

is used only with the specifi c model number or model

number variant listed. It can also be used to show a

part is NOT used on a specifi c model or model number

— Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

— Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

Numbers Used

number, a blank entry, or A/R.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

PART NO. PART NAME QTY. REMARKS

.....................1 .....INCLUDES ITEMS W/%

..........NOT SOLD SEPARATELY

..1 .....MQ-45T ONLY

..................A/R ...MAKE LOCALLY

..............1 .....S/N 2345B AND ABOVE

Unique Symbols — All items with same unique symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

parts that are sold in bulk and cut to length.

Column.

REMARKS Column

to describe the item can also be shown.

Assembly/Kit

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarifi ed in the “Remarks” Column.

PAGE 36 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

Specifi c Model Number Use

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally”

and certain washers and nuts.

“Not Sold Separately”

for sale through Multiquip.

GB2000 BALLOON LIGHT

1 to 3 units

Qty. P/N Description

2............E000127300 ......... LAMP

2............A100079601 ......... BALLOON COVER CP

3............A400038301 ......... FILTER

NOTICE

Part numbers on this Suggested Spare Parts list may

supersede/replace the part numbers shown in the

following parts lists.

SUGGESTED SPARE PARTS

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 37

2

3

B UR N HAZ AR D

To pre vent burns, NE V E R

touch la mp while la mp is on.

La mp sur fa ce gets e xtremely

hot! A LWA YS a llow sufficient

time for lamp to c ool down

before touching.

AV E R TIS S E ME NT

R IS QUE DE B R ÛL UR E

P our éviter les brulures, NE

J AMA IS touche r la lampe, le

ballas t ou le couver cle tant que la

lampe est allumée. C es surfac es

sont trè s c haudes ! TOU J OUR S

permettre a ux de ux s urfaces de se

ref roid ir a vant d’y toucher.

E LE C TR ICAL

S HOC K HAZA RD

When replacing lamp and to prevent electrical

shock, ALWAYS shutdown the generator before

replacing lamp. Remember to let lamp cool before

removing. Use only recommended type lamp as

listed in parts manual.

A-400 2526-0 0

A-400 3369-0 0

A-400 2525-0 0

NAMEPLATE AND DECALS

G B 2000

120V 60Hz 2000 W

4

Metal halide lam p 1000W× 2 T YP E M47

G X XX X X X

R IS QUE DE C HOC É LE C TR IQU E

Lors du remplacement de la lampe et pour

prévenir le risque de choc électrique, TOUJOURS

éteindre le générateur avant de remplacer la lampe.

Ne pas oublier de laisser la lampe se refroidir avant

de l’enlever. Utiliser uniquement le type de lampe

recommandé dans le manuel des pièces.

1

ATTE NT ION

IN F OR MA T IO N S S U R L A L AM P E

NE JAMAIS laisser la lampe se cogner

une surface dure. Tout impact excessif

pourrait causer des dommages et

r duire la dur e de vie utile de la lampe

IN F OR M AT IO N S S U R L E B A LL O N

NE JAMAIS laisser le ballon toucher la

surface de lampe lorsque celle-ci est

chaude. from dust, dirt and adverse weather

conditions.Avant de ranger globug, TOUJOURS

couvrir enti rement ballon pour viter tout

dommage.

A-4003242-00

A-400 3368-0 0

7

6

NE V ER disconnect the connector when

power is applied. The possibility exists of

Electrical shock or equipment damage.

NE V ER grab or touch a live power cord with

wet hands, the possibility exists of Electrical

shock, Electrocution and even Death!

YO U MUS T TU RN T HE 1s t L A MP

ON , W HE N Y OU AR E

OP E R ATI NG TH IS L IGH TIN G

FI XT UR E .

A-4003 366-0 0

5

ALWAYS remove the ba llon/lamp

as sembly from the mas t to

prevent damage to ba lloon/light

as sembly when trans portating the

light towe r.

A-4002 528-0 0

8

NE J A MAI S débrancher le connecteur lorsqull’

est sous tension. ll existe une possibilité de choc

électrique ou de dommages matériels.

NE J A MAI S saisir ou toucher un cordon

d’alimentation sous tension avec les mains

mouillées,il existe une possibilité de choc

électrique, d'électrocution et même la mort !

P RÉ V E NIR : VO US de vez

AL L UME R L A 1ère LA MP E ,

QU AND V OUS O P ÉR E Z CE T

AP PA R E IL de l 'É CL AI R AG E .

A-4003 370-0 0

TO UJ OU RS e nle ver l’ens emble

ballon/la mpe du mât pour prévenir

les dommages à l’ens emble

ballon/la mpe lors du transport de

la tour d’éclaira ge.

A-400 3367-0 0

PAGE 38 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 A400290900 DECAL; CAUTION, LAMP INFORMATION (ENGLISH) 1

1 A400324200 DECAL; CAUTION, LAMP INFORMATION (FRENCH) 1

2 A400252500 DECAL; DANGER, ELECTRICAL SHOCK HAZARD (ENGLISH) 1

2 A400336800 DECAL; DANGER, ELECTRICAL SHOCK HAZARD (FRENCH) 1

3 A400252600 DECAL; WARNING, BURN HAZARD (ENGLISH) 1

3 A400336900 DECAL; WARNING, BURN HAZARD (FRENCH) 1

4 DECAL; SERIAL PLATE .........................................................1 ........ CONTACT MQ PARTS DEPT.

5 A400252800 DECAL; DANGER, BALLOON/LAMP REMOVAL (ENGLISH) 1

5 A400336700 DECAL; DANGER, BALLOON/LAMP REMOVAL (FRENCH) 1

6 A40033660 0 DECAL; DANGER, ELECTRICAL SHOCK CONNECTOR (ENGLISH) 1

6 A40033700 0 DECAL; DANGER, ELECTRICAL SHOCK CONNECTOR (FRENCH) 1

7 A400326400 DECAL; CAUTION, LAMP TYPE 1

8 A400325000 DECAL; CAUTION, AC ONLY 1

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 39

ELECTRICAL ASSY.

33

42

30

26

41

58

27

53

55

57

45

47

49

12

40

51

11

5

59

36

25

36

56

34

35

46

54

22

7

21

1

34

39

38

23

16

37

32

33

37

62

63

3

7

8

9

4

5

18

36

6

15

14

47

43

47

44

20

17

19

12

13

2

17

19

18

17

23

16

11

12

10

2

17

17

48

25

20

23

22

27

26

28

29

60

9

8

50

27

52

61

17

20

16

21

1

24

31

24

PAGE 40 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

ELECTRICAL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 E000127300 LAMP 2

2 A100100002 LAMP GUARD 2

3 A100085103 BALLOON 1

4 A100079601 BALLOON COVER CP 1

5 2204500230 SEAL (PACKING) 2

6 2204220130 PLATE (CAP) 1

7 0014710035 BUTTON BOLT (M10x35) 8

8 0043210000 SPRING WASHER (M10) 8

9 0043110000 WASHER (M10) 8

10 1800001000 SHEET (TOP) 1

11 2204500131 SEAL (NORMAL) 2

12 0023204010 COUNTERSUNK SCREW (M4x10) 12

13 A200097900 PLATE (HEAD) 1

14 E000128900 SPACER ASB-460E 4

15 A300276802 PLATE 1

16 0021704005 SET SCREW (M4x5) 26

17 0013806012 FLANGE BOLT (M6x12) 16

18 0023304015 SCREW WASHER (M4x15) 4

19 A400327202 HOLDER (GUARD) 4

20 0033206000 SELF LOCK NUT (M6) 8

21 A300285400 SOCKET ASSY 2

22 E000038200 CAP (RUBBER) 2

23 A400321501 STOPPER 13

24 A300285000 LAMP HOLDER 2

25 A200097703 PLATE (LAMP) 1 2

26 0043104000 WASHER (M4) 8

27 0033104000 NUT(M4) 12

28 A400199500 PACKING (LAMP) 6

29 0023304012 SCREW & WASHER (M4x12) 6

30 0043204000 SPRING WASHER (M4) 2

31 A400306301 SPRING (LAMP) 2

32 A400240701 POLE JOINT 2 4

33 A300286100 MAIN POLE 2 2

34 A300286000 MAIN POLE 1 2

35 0023404030 SCREW TRUSS (M4x30) 2

36 0024304008 SCREW TRUSS (M4x8) 14

37 0023405008 SCREW TRUSS (M5x8) 16

38 0023404035 SCREW TRUSS (M4x35) 4

39 0033204000 SELF LOCK NUT (M4) 4

40 1400150210 MICRO SWITCH 1

41 1400150300 MICRO SWITCH COVER 1

42 1400150410 MICRO SWITCH CAP 1

43 A300168800 FAN MOTOR ASSY 1

44 A200100702 PLATE (FAN) 1

45 A200075900 VESSEL 1

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 41

ELECTRICAL ASSY. (CONTINUED)

7

33

42

30

26

41

58

27

53

57

45

47

49

12

55

40

36

51

11

5

59

36

25

56

34

35

46

54

22

21

1

34

39

38

23

16

37

32

33

37

62

63

3

7

8

9

4

5

18

36

6

15

14

47

43

47

44

20

17

19

12

13

2

17

19

18

17

23

16

11

12

10

2

17

17

48

25

20

23

22

27

26

28

29

60

9

8

50

27

52

61

17

20

16

21

1

24

31

24

PAGE 42 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

ELECTRICAL ASSY. (CONTINUED)

NO. PART NO. PART NAME QTY. REMARKS

46 A400240602 POLE JOINT 1 1

47 A400243501 POLE JOINT 3 3

48 A300287300 RELAY ASSY 1

49 A300286700 FAN POWER SOURCE 1

50 0013112030 BOLT (M12x30) 1

51 A200100502 FLANGE 1

52 E000099000 PIN 1

53 1800001100 SHEET (BOTTOM) 1

54 A300283300 PLATE (GUARD) 1

55 A200076103 PLATE (BOTTOM) 1

56 A400038301 FILTER (200) 1

57 E000119300 WAVE WASHER 3

58 A400030700 STOPPER (FILTER) 3

59 E000010301 SPACER (M4x4) 3

60 A200018000 PLATE (AIR) 1

61 A300287200 CABLE (BALLOON) 1 CP 1

62 A400334400 CABLE (POLE) W CP 1

63 A400334500 CABLE (POLE) R CP 1

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 43

BRACKET AND J-BOX ASSY.

PAGE 44 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

BRACKET AND J-BOX ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 A200102501 BOX (RELAY) 1

2 A300282800 RUBBER CAP 1

3 A300284400 PLATE CAP 1

4 0033304000 CAP NUT (M4) 8

5 0024304008 SCREW TRUSS (M4x8) 2

6 0023305015 SCREW & WASHER (M4x12) ...........................8................REPLACES 0023304012

7 0033104000 NUT(M4) 2

8 A100088602 ADAPTER CP 1

9 E000122700 WASHER 2

10 A400288001 RETAINER 2

11 A300215302 CABLE (LAMP) 3 CP 2

12 A300288400 CABLE (LAMP) 2 CP 1

13 0013112130 BOLT M12x130 4

14 0013510025 BOLT & WASHER (M10x25) 2

15 0023303012 SCREW & WASHER (M3x12) 4

16 E000128500 CAP 1

17 0043112000 WASHER (M12) 8

18 0043212000 SPRING WASHER (M12) 4

19 A400287902 SPACER 1 1

20 0023205015 SCREW (M5x15) 4

21 0033112000 NUT (M12) 4

22 A400287801 SPACER 2 2

23 0033103000 NUT(M3) 1

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 45

PAYMENT TERMS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and

the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and

credit will be allowed, subject to the following

provisions:

1.

2.

3.

4.

5. Parts must be in new and resalable

Multiquip reserves the right to quote and

sell direct to Government agencies, and to

Original Equipment Manufacturer accounts

who use our products as integral parts of their

A $35.00 surcharge will be added to the

invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of

the item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profi t or good will or for any

other special, consequential or incidental

No warranties, express or implied, are

made in connection with the sale of parts or

trade accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes nor

authorizes any person to assume for it

any other obligation or liability whatever in

connection with the sale of its products. Apart

from such written statement of warranty,

there are no warranties, express, implied or

statutory, which extend beyond the description

A Returned Material Authorization

must be approved by Multiquip prior to

shipment.

To obtain a Return Material Authorization,

a list must be provided to Multiquip

Parts Sales that defi nes item numbers,

quantities, and descriptions of the items

to be returned.

a. The parts numbers and descriptions

must match the current parts price

list.

b. The list must be typed or computer

generated.

c. The list must state the reason(s)

for the return.

d. The list must reference the sales

order(s) or invoice(s) under

which the items were originally

purchased.

e. The list must include the name

and phone number of the person

requesting the RMA.

A copy of the Return Material Authorization

must accompany the return shipment.

Freight is at the sender’s expense. All

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

TERMS AND CONDITIONS OF SALE — PARTS

condition, in the original Multiquip

package (if any), and with Multiquip part

numbers clearly marked.

6. The following items are not returnable:

a. Obsolete parts. (If an item is in the

7. The sender will be notifi ed of any material

8. Such material will be held for five

9. Credit on returned parts will be issued

10. In cases where an item is accepted, for

11. Credit issued will be applied to future

price book and shows as being

replaced by another item, it is

obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

c. Any line item with an extended

dealer net price of less than

$5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

received that is not acceptable.

working days from notifi cation, pending

instructions. If a reply is not received

within five days, the material will be

returned to the sender at his expense.

at dealer net price at time of the original

purchase, less a 15% restocking

charge.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

purchases only.

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a

specifi c date and all orders received on or

after that date will be billed at the revised price.

Rebates for price declines and added charges

for price increases will not be made for stock

on hand at the time of any price change.

own products.

SPECIAL EXPEDITING SERVICE

parts to the carrier.

damages.

LIMITATION OF WARRANTIES

of the products on the face hereof.

Effective: February 22, 2006

PAGE 46 —GB2000 BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)

NOTES

GB2000 CSA BALLOON LIGHT• OPERATION AND PARTS MANUAL — REV. #1 (02/25/14)— PAGE 47

OPERATION AND PARTS MANUAL

HERE’S HOW TO GET HELP

© COPYRIGHT 2014, MULTIQUIP INC.

Multiquip Inc

the MQ logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property

of their respective owners and used with permission.

This manual

The information and specifi cations included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifi cations, design or the information published

in this publication at any time without notice and without incurring any obligations.

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

UNITED STATES

Multiquip Corporate Offi ce MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact : mq@multiquip.com

Service Department Warranty Department

800-421-1244

310-537-3700

Technical Assistance

800-478-1244 Fax: 310-943-2238

CANADA

Multiquip Multiquip (UK) Limited Head Offi ce

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact : jmartin@multiquip.com

Tel. (800) 421-1244

Fax (310) 537-3927

Fax: 310-537-4259 800-421-1244

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

800-427-1244

310-537-3700

310-537-3700

UNITED KINGDOM

Unit 2, Northpoint Industrial Estate,

Globe Lane,

Dukinfi eld, Cheshire SK16 4UJ

Contact : sales@multiquip.co.uk

Fax: 800-672-7877

Fax: 310-637-3284

Fax: 310-943-2249

Tel: 0161 339 2223

Fax: 0161 339 3226

,

MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

Your Local Dealer is:

Loading...

Loading...