Page 1

PARTS AND OPERATION MANUAL

CONCRETE SAW

MODEL FS2

MODEL #

SERIAL #

© COPYRIGHT 2001, MULTIQUIP INC.

Revision #2 (11/08/01)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

P/N 15700

Page 2

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 3

Page 4

TABLE OF CONTENTS

Here's How To Get Help ........................................... 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Message Alert Symbols ............................. 6-7

Decals ...................................................................... 8

Rules for Safe Operation ....................................9-11

Dimensions ............................................................ 12

Weights .................................................................. 13

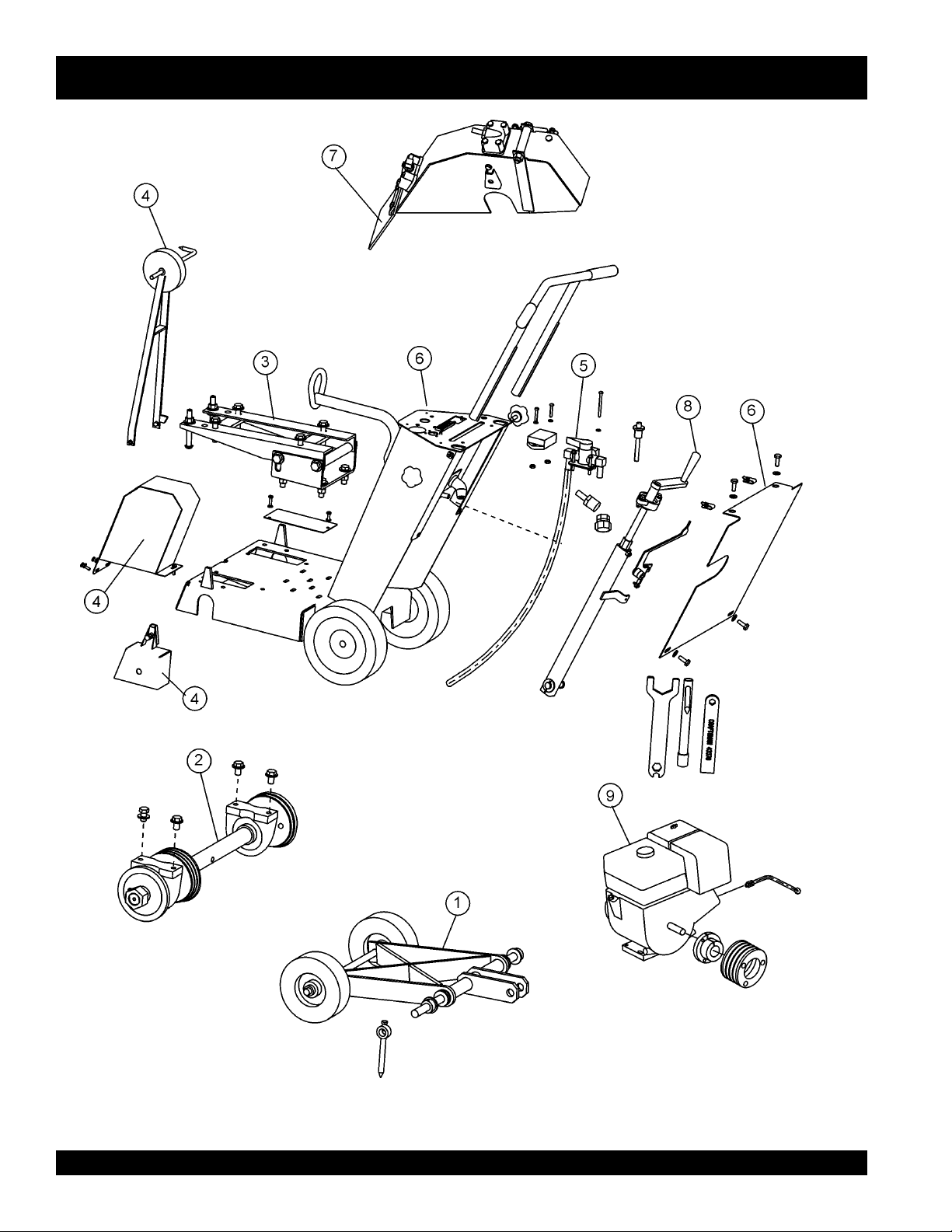

Basic Components ................................................. 14

Basic Engine Components ..................................... 16

General Information ..........................................17-19

MQ-Whiteman — FS2 Concrete

Saw

Inspection Engine .................................................. 20

Inspection Blade .................................................... 21

Inspection Blade Placement .................................. 22

Inspection-Guards, Covers, and V-Belts ...........23-24

Initial Start-Up ...................................................25-26

Operation ..........................................................27-28

Maintenance ..................................................... 29-31

Explanation Of Codes In Remarks Column ........... 32

Suggested Spare Parts .......................................... 33

Troubleshooting (Engine) .................................. 34-35

Under Carriage Assembly ................................. 36-37

Blade Shaft Assembly .......................................38-39

Engine Mount Assembly ...................................40-41

Pointers and Covers Assembly ......................... 42-43

Water System Assembly ...................................44-45

Basic Platform Assembly .................................. 46-47

Blade Mist 14-Inch Assembly............................48-49

Blade Mist 19-Inch Assembly............................50-51

Manual Raise and Lower Assembly ................. 52-53

Engines

Engine Assemblies............................................54-55

Terms and Conditions Of Sale — Parts ................. 56

22

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 5

PARTS ORDERING PROCEDURES

n

Dealer account number

n

Dealer name and address

n

Shipping address (if different than billing address)

n

Return fax number

n

Applicable model number

n

Quantity, part number and description of each part

n

Specify preferred method of shipment:

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

n

UPS Ground Service at no charge for freight

n

PS Third Day Service at one-half of actual freight cost

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 5

800/6-PARTS-7 • 800-672-7877

Page 6

FS2 CONCRETE SAW — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read and understand the

Safety Messages and Operating Instructions could result in

injury to yourself and others.

HAZARD SYMBOLS

NOTE

This Owner's Manual has been developed to provide

complete instructions for the safe and efficient operations

of the MQWhiteman FS2 Concrete Saw. Depending on

the power plant you have selected, please refer to the

engine manufacturers instructions for data relative to its

safe operations.

Before using this Concrete Saw, ensure that the

operating individual has read and understands all

instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Gasoline is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you do not follow

directions.

WARNING: Yo u CAN be KILLED or

SERIOUSLY injured if you do not follow

directions.

CAUTION: You CAN be injured if you

do not follow directions.

Potential hazards associated with Concrete Saw operations

will be referenced with Hazard Symbols which appear

throughout this manual, and will be referenced in conjunction

with Safety Message Alert Symbols.

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. Never operate the engine with heat

shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep fingers, hands, hair and

clothing away from all moving parts to prevent

injury.

PAGE 6 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 7

FS2 CONCRETE SAW — SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place ON/OFF switch to OFF,

remove key and/or disconnect the spark

plug lead before servicing the engine or

equipment. Ground the lead to prevent

sparks that could ignite a fire.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

Guards and Covers In Place

NEVER operate the saw without blade guards

and covers in place. Adhere to safety guidelines

ANSI American National Standards Institute,

OSHA or other applicable local regulations.

Respiratory Hazard

ALWAYS wear approved respiratory

protection.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your concrete saw, other property, or

the surrounding environment.

NOTE

This concrete saw, other property, or the

surrounding environment could be damaged

if you do not follow instructions.

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 7

Page 8

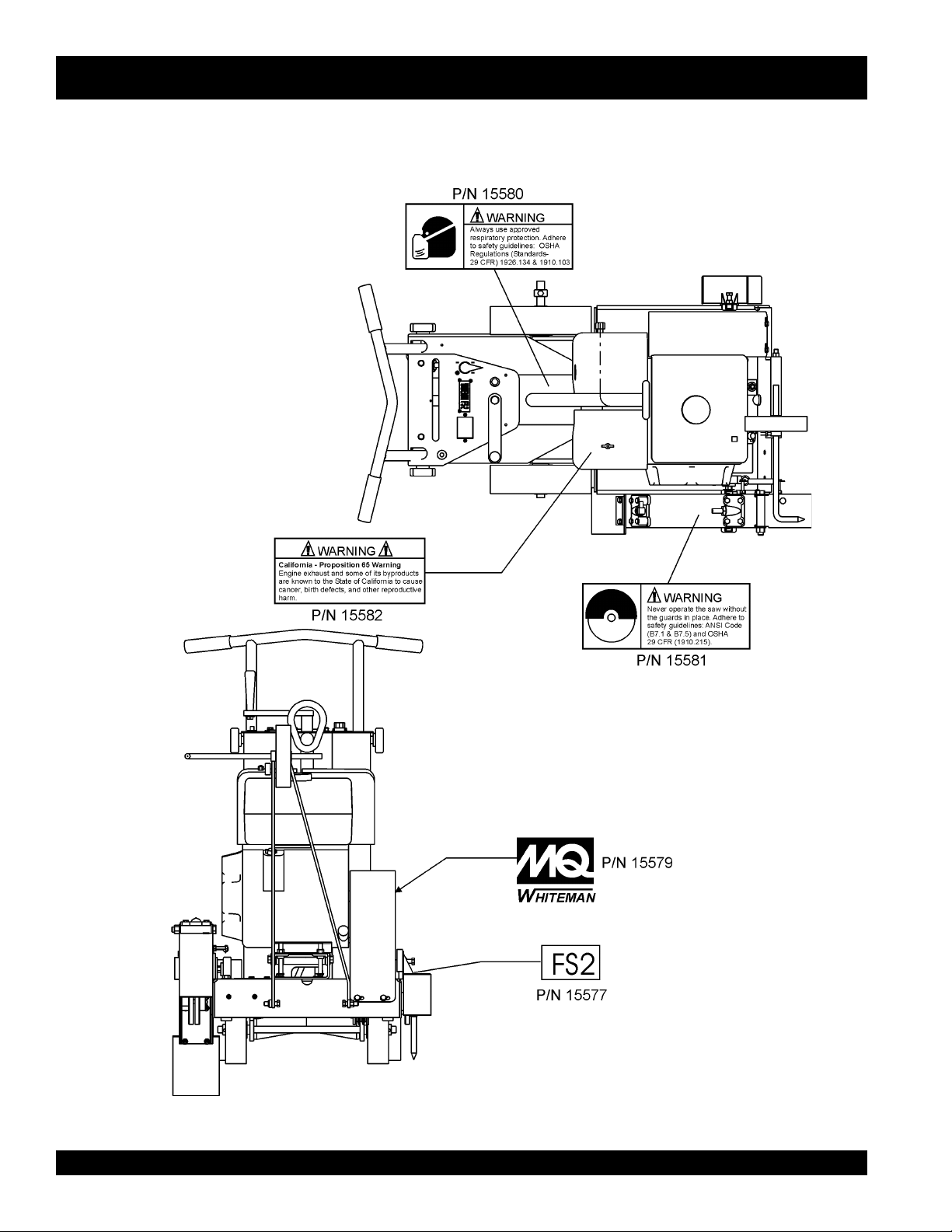

FS2 CONCRETE SAW — DECALS

Machine Safety Decals

The FS2 Concrete Saw is equipped with a number of safety decals (Figure 1). These decals are provided for operator safety and

maintenance information. The illustration shows these decals as they appear on the concrete saw. Should any of these decals become

unreadable, replacements can be obtained from you dealer.

Figure 1. FS2 Concrete Saw Decal Placement

PAGE 8 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 9

FS2 CONCRETE SAW — RULES FOR SAFE OPERATION

■

WARNING:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the MQ Whiteman FS2 Concrete Saw:

GENERAL SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by persons under 18

years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steeltoed boots and other protective devices required

by the job.

NEVER touch the hot exhaust manifold, muffler or cylinder. Allow

these parts to cool before

servicing engine or saw.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

■

The engine section of this saw requires an adequate free flow

of cooling air. Never operate the saw in any enclosed or

components can cause serious burns.

narrow area where free flow of

the air is restricted. If the air flow

is restricted it will cause serious

damage to the saw or engine

and may cause injury to

people. Remember the saw's

engine gives off DEADLY

carbon monoxide gas.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

The manufacturer does not assume responsibility for any

accident due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult to read.

■

Always check the machine for loosened threads or bolts before

starting.

■

■

■

■

■

Always refuel in a well-ventilated area, away from sparks and

open flames.

Always use extreme caution when working

with flammable liquids. When refueling,

stop the engine and allow it to cool. DO

smoke around or near the machine.

NOT

Fire or explosion could result from fuel

vapors, or if fuel is spilled on a hot engine.

NEVER operate the saw in an explosive atmosphere or near

combustible materials. An explosion or fire could result

causing severe

Topping-off to the filler port is dangerous, as it tends to spill

fuel.

NEVER use fuel as a cleaning agent.

bodily harm or even death.

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 9

Page 10

FS2 CONCRETE SAW — RULES FOR SAFE OPERATION

GENERAL SAFETY

■

Always read, understand, and follow procedures in Operator’s

Manual before attempting to operate equipment.

■

Always be sure the operator is familiar with proper safety

precautions and operating techniques before using the saw.

■

Stop the engine when leaving the saw unattended.

■

Block the unit when leaving or when using on a slope.

■

Maintain this equipment in a safe operating condition at all

times.

■

Always stop the engine before servicing, adding fuel and oil.

■

NEVER Run engine without air filter. Severe engine damage

may occur.

■

Always service air cleaner frequently to prevent carburetor

malfunction.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

NEVER operate this saw in areas that contain combustible material

or fumes. Fire and/or explosions may result from errant sparks

from the equipment.

DIAMOND BLADE SAFETY

■

■

■

■

■

■

■

■

Use appropriate steel centered diamond blades manufactured

for use on concrete saws.

Always inspect diamond blades before each use. The blade

should exhibit no cracks, dings, or flaws in the steel centered

core and/or rim. Center (arbor) hole must be undamaged and

true.

Examine blade flanges for damage, excessive wear and

cleanliness before mounting blade. Blade should fit snugly on

the shaft and against the inside/outside blade flanges.

Ensure that blade is marked with an operating speed greater

than the blade shaft speed of the saw.

Only cut the material that is specified by the diamond blade.

Read the specifications of the diamond blade to ensure the proper

tool has been matched to the material being cut.

Always keep blade guards in place. Exposure of the diamond

blade must not exceed 180 degrees.

Ensure that the diamond blade does not come into contact with

the ground or surface during transportation. DO NOT drop the

diamond blade on ground or surface.

The engine governor is designed to permit maximum engine

speed in a no-load condition. Speeds that exceed this limit may

cause the diamond blade to exceed the maximum safe allowable

speed.

■

WARNING:

SAW TRANSPORTATION SAFETY

■

DO NOT operate this equipment unless all

guards and safety devices are attached and in

place.

■

Caution must be exercised while servicing this equipment.

Rotating and moving parts can cause injury if contacted.

■

Keep all inexperienced and unauthorized people away from

the equipment at all times.

■

Unauthorized equipment modifications will void all warranties.

■

Test the

switch is to shut down the engine.

ON/OFF

switch before operating. The purpose of the

■

■

■

■

■

■

Ensure that the blade is mounted for proper operating direction.

Use the lifting bail and appropriate lifting equipment to ensure

the safe movement of the saw.

DO NOT use the handle bars and/or front pointer as lifting points.

NEVER tow the saw behind a vehicle.

Ensure that both pointer bars are positioned appropriately to

minimize their exposure during transportation.

Safeguard against extreme saw attitudes relative to level. Engines

tipped to extreme angles may cause oil to gravitate into the cylinder

head making the engine difficult to start.

NEVER transport the saw with the blade mounted.

PAGE 10 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 11

FS2 CONCRETE SAW — RULES FOR SAFE OPERATION

Emergencies

■

Always know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

invaluable in the case of an emergency.

Maintenance Safety

■

■

■

■

■

■

and

NEVER lubricate components or attempt service on a running

machine.

Always allow the machine a proper amount of time to cool

before servicing.

Keep the machinery in proper running condition.

Fix damage to the machine immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

. Know the location of the nearest telephone.

fire department

. This information will be

fire extinguisher

ambulance

,

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 11

Page 12

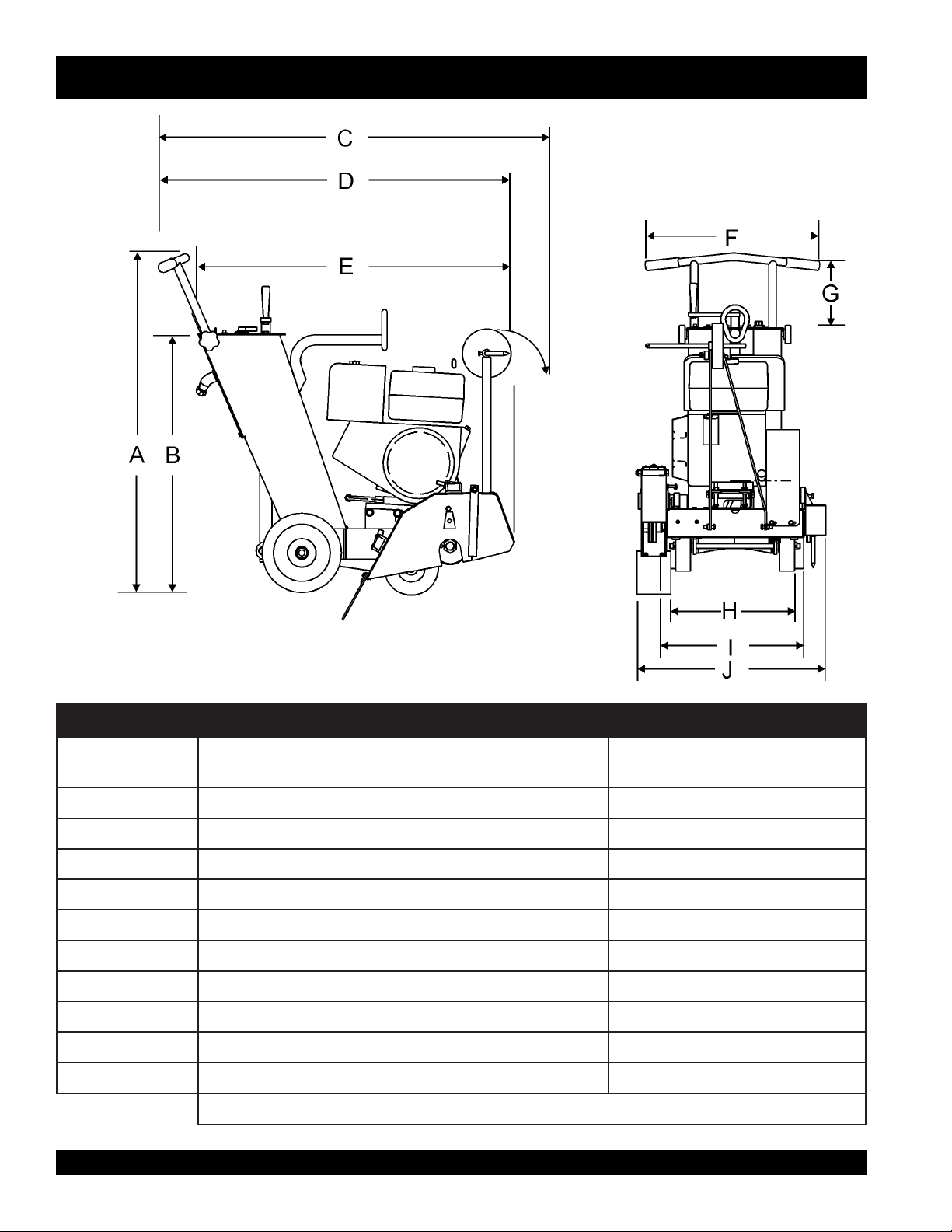

FS2 CONCRETE SAW — DIMENSIONS

Figure 2. FS2 Concrete Saw Dimensions

SNOISNEMID.1ELBAT

ECNEREFER

RETTEL

A

B

C

D

E

F

G

H

I

J

htdiWxaM )066("0.62

htdiWraBeldnaHxaM )795("5.32

noitcelfeDraBeldnaHxaM )604("0.61

esaBleehWtnorF )493("5.51

esaBleehWraeR )754("0.81

NOITPIRCSED )MM(NOISNEMID

)desiaRylluFsraBeldnaH(thgieHxaM )7021("5.74

)derewoLylluFsraBeldnaH(thgieHxaM )199("0.93

)derewoLretnioPtnorF&desiaRylluFsraBeldnaH(htgneLxaM )6761("0.66

)desiaRretnioPtnorF&desiaRylluFsraBeldnaH(htgneLxaM )4911("0.74

)desiaRretnioPtnorF&derewoLylluFsraBeldnaH(htgneLxaM )2901("0.34

)8111("44x)267("03x)4911("74)HxWxL(noisnemiDdetarC

PAGE 12 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 13

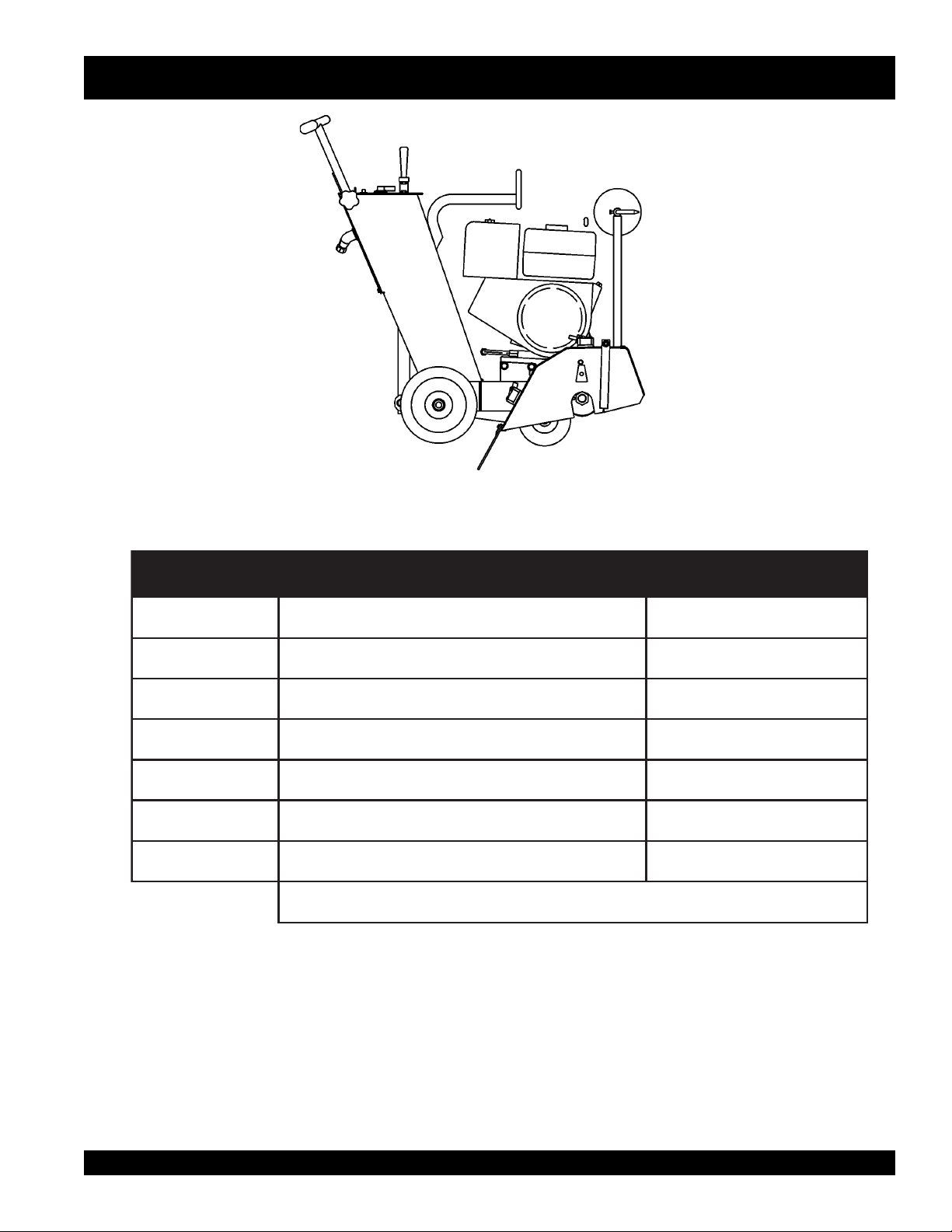

FS2 CONCRETE SAW — WEIGHTS

Figure 3. FS2 Concrete Saw Weights

STHGIEW.2ELBAT

WAS NOITPIRCSED )sgk(THGIEW

41EL-2SF ENIGNESSEL,HSUP,"41,2SF,WAS )19(002

41K8-2SF RELHOKPH5.8,HSUP,"41,2SF,WAS )521(572

41H9-2SF ADNOHPH9,HSUP,"41,2SF,WAS )521(572

41H11-2SF ADNOHPH11,HSUP,"41,2SF,WAS )721(082

41K21-2SF RELHOKPH21,HSUP,"41,2SF,WAS )721(082

41H31-2SF ADNOHPH31,HSUP,"41,2SF,WAS )721(082

).sgk(thgieWdetarC)361(sbl063

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 13

Page 14

BASIC COMPONENTS

FS2 CONCRETE SAW — BASIC COMPONENTS

Figure 4. FS2 Concrete Saw Basic Components

PAGE 14 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 15

FS2 CONCRETE SAW — BASIC COMPONENTS

BASIC COMPONENTS

NO DESCRIPTION PAGE

1 UNDER CARRIAGE ASSEMBLY SEE PAGE 36

2 BLADE SHAFT ASSEMBLY SEE PAGE 38

3 ENGINE MOUNT ASSEMBLY SEE PAGE 40

4 POINTERS AND COVERS ASSEMBLIES SEE PAGE 42

5 WATER SYSTEM ASSEMBLY SEE PAGE 44

6 FS2 BASIC PLATFORM ASSEMBLY SEE PAGE 46

7 14-INCH BLADE GUARD ASSEMBLY SEE PAGE 48

7 18-INCH BLADE GUARD ASSEMBLY SEE PAGE 50

8 RAISE/LOWER ASSEMBLY SEE PAGE 52

9 GASOLINE ENGINE ASSEMBLIES SEE PAGE 54

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 15

Page 16

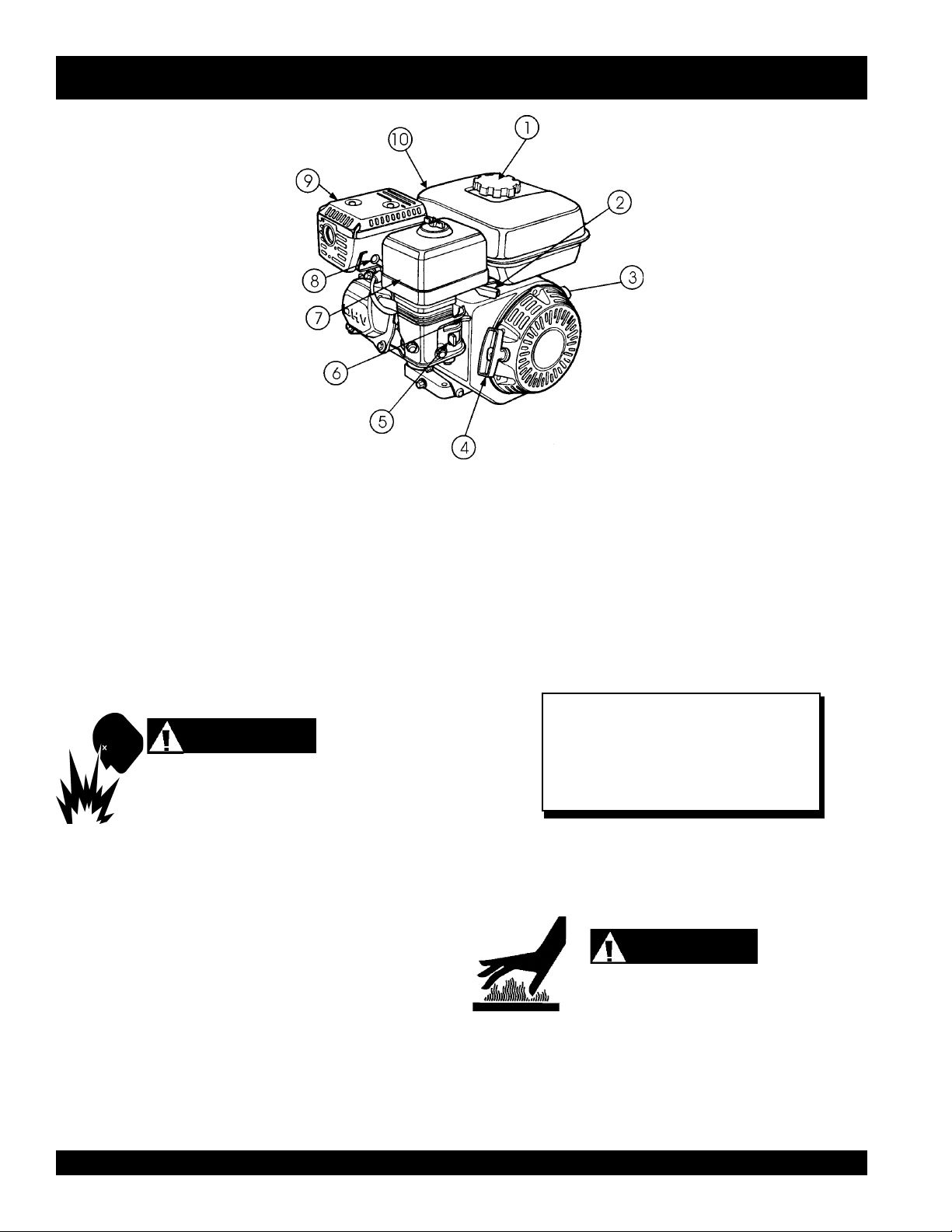

FS2 CONCRETE SAW — BASIC ENGINE COMPONENTS

Figure 5. Engine Controls and Components

INITIAL SERVICING

The engine (Figure 5) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturers Engine

manual for instructions & details of operation and servicing.

1. Fuel Filler Cap – Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

5. Fuel Valve Lever – OPEN to let fuel flow, CLOSE to stop

the flow of fuel.

6. Choke Lever – Used in the starting of a cold engine, or in

cold weather conditions. The choke enriches the fuel

mixture.

7. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element.

WARNING

WARNING

Adding fuel to the tank should be accomplished only

when the engine is stopped and has had an

opportunity to cool down. In the event of a fuel spill,

DO NOT attempt to start the engine until the fuel residue has been

completely wiped up, and the area surrounding the engine is dry.

2. Throttle Lever – Used to adjust engine RPM speed (lever

advanced forward

FAST

).

3. Engine ON/OFF Switch – ON position permits engine

starting, OFF position stops engine operations.

4. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

SLOW

, lever back toward operator

8. Spark Plug – Provides spark to the ignition system. Set

spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch) Clean

spark plug once a week.

9. Muffler – Used to reduce noise and emissions.

while the engine is running or immediately after operating. NEVER

operate the engine with the muffler removed.

10. Fuel Tank – Holds unleaded gasoline. For additional

information refer to engine owner's manual.

NOTE

Operating the engine without an air filter,

with a damaged air filter, or a filter in need of

replacement will allow dirt to enter the

engine, causing rapid engine wear.

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

PAGE 16 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 17

FS2 CONCRETE SAW — GENERAL INFORMATION

FAMILIARIZATION

The MQ Whiteman FS2 Series Concrete Saws are designed for

wet or dry cutting utilizing diamond blades. They have been

engineered for general, industrial and high production flat sawing

applications. The exceptional performance of these saws centers

around innovative features, top quality components, and committed

attention to state-of-the-art manufacturing.

The reinforced heavy gauge steel frame and chassis assembly has

been precisely jig welded to eliminate operational bending and/or

flex that would lead to diminished blade performance. Additionally,

the general weight-to-strength ratio design of the frame and chassis

assembly provides for optimum weight distribution to keep the blade

running true in the cut.

An innovative outboard blade shaft bearing assembly ensures

minimal flutter and shaft harmonics providing the most advantageous

condition for a diamond blade at operating speeds. Heavy duty

front and rear axles, oversized reinforced wheels supported by roller

wheel bearings and locking collars, and industrial under carriage

assembly ensure accurate tracking and years of reliable use.

The positive locking Raise/Lower screw feed system with accurate

depth gauge easily orients blade elevation, and will not permit blade

creep during cutting operations.

A unique water plumbing system allows for independent orientation

of either fluted floodwater to the blade for wet cutting applications or

cones of aerosol mist to diminish material dust when dry cutting.

Operator control of the saw is safely accomplished with adjustable

ergonomic handle bars, and a combination of conveniently oriented

items on the console such as: Raise/Lower Handle, Tachometer/

Hourmeter, 3-way water valve, depth feed gauge, and engine ON/

OFF switch.

All FS2 saws are designed, engineered and manufactured

with strict adherence to American National Standards Institute,

Inc. (ANSI) guidelines B7.1 and B7.5.

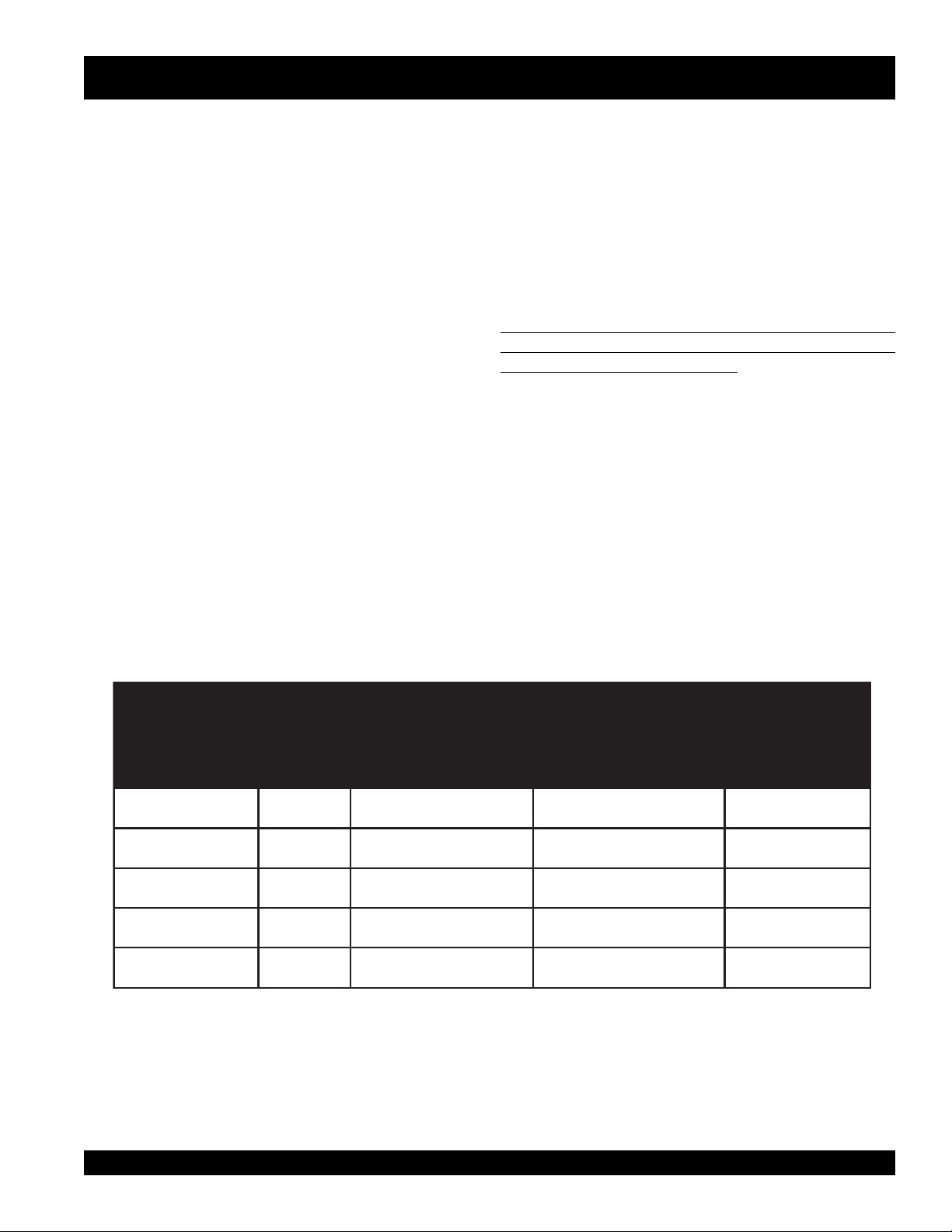

POWER PLANTS

The FS2 Saw Series provides a variety of gasoline engine choices

(Table 3). Selection of a specific engine, and its capacity measured

in horsepower/torque, directly affects the performance of the diamond

blade.

The FS2 series is generally classified in the industry as a "

MEDIUM

when selecting the proper diamond blade for an application. Refer

to the engine Owner's Manual for specific instructions regarding

engine operation and maintenance practices.

LOW

to

" horsepower saw. This classification is particularly useful

STNALPREWOP.3ELBAT

.RFMENIGNE PH METSYSGNITRATS RENAELCRIA

ADNOH 9 launaM noitartliFriAenolcyC )1.6(6.1

ADNOH 11 launaM noitartliFriAenolcyC )4.6(7.1

ADNOH 31 launaM noitartliFriAenolcyC )4.6(7.1

RELHOK 5.8 launaM noitartliFriAenolcyC )1.6(6.1

RELHOK 21 launaM noitartliFriAenolcyC )8.6(8.1

KNATLEUF

)sretiL(.LAG

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 17

Page 18

FS2 CONCRETE SAW — GENERAL INFORMATION

UNDER CARRIAGE SYSTEM

A jig welded heavy steel gauge under carriage assembly supports

the saw in tracking, pivoting and stabilization. A 3/4" diameter rear

axle supports two solid rubber (10" x 2.75" x 3/4") cast hub wheels

with roller bearings, grease fittings and locking collars. A 5/8" diameter

front axle supports two solid rubber (5" x 2" x 5/8") cast hub wheels

with roller bearings, grease fittings and locking collars. The assembly

pivots about the rear axle and is lubricated through a 90-degree

grease fitting in the rear axle tube. See page 36.

WATER SYSTEM

The FS2 Series employs an independent water system that provides

either floodwater or aerosol misting water to the blade. For floodwater,

two 6" fluted tubes are connected via a manifold, and are oriented

inside the blade guard to provide optimum water volume and

dispersal to both sides of the blade.

A separate water misting system (14" blade guard) utilizes

specifically positioned spray nozzles that project a special cone of

aerosol water to the blade when dry cutting and/or cutting operations

that require minimal usage of water. This misting spray

BLADE DRIVE SYSTEM

An innovative blade shaft assembly has been specifically designed

to support the optimum distribution of torque from the engine shaft to

the blade shaft, and to ensure minimal vibratory conditions on the

tips of the shaft.

Balanced engine & blade shaft pulleys are connected to their respect

shafts via taper lock bushings, and three 3VX V-belts connect the

engine pulley to the blade shaft pulley. The 1- 1/4" diameter blade

shaft is supported by two self-aligning pillow block bearings that are

uniquely positioned on the most outboard portion of the reinforced

frame.

The combination of pulley and blade shaft bearing positioning

ensures minimal vibration & flutter to the ends of the blade shaft.

The blade drive system has been designed for left and right hand

cutting. See page 38.

(approximately 5 gallons/hour), along with the geometry of the blade

guard considerably diminish the dust signature generated by dry

cutting. The water misting system requires approximately 40 psi of

pressure for effective results.

A standard "garden hose" hookup valve connects the water source

to the saw, and a 3-way water lever (OFF/MIST/FLOOD) is

conveniently located on the console. See page 44.

CONSOLE

An ergonomically designed control console allows the operator to

easily understand and/or operate the depth feed gauge, positive 3way water valve, raise/lower control handle, digital engine

tachometer/hourmeter, engine ON/OFF switch, handle bar

assembly, and standard "garden hose" water hook up. A rear panel

cover assembly is easily removed to permit access inside the console

of the saw. See page 44.

MECHANICAL RAISE/LOWER SYSTEM

CCC

BLADE GUARD ASSEMBLY

The two-piece heavy gauge blade guard, available in 14" or 18".

The 14" blade guard (standard) is designed with two fully

independent water systems to meet the challenges of dry or wet

cutting operations. First, a fluted floodwater manifold assembly

supplies optimum volume and dispersal of water to both sides of the

diamond blade for wet cutting applications.

The sizable (6") fluted tubes that direct the floodwater resist clogging

and are easily removed for maintenance. Second, a true water

misting manifold assembly provides specifically oriented cones of

aerosol spray to the blade via two water jet nozzles.

A positive locking mechanical raise and lower screw feed assembly

supports elevation cycling operations. A crank raise/lower handle

is located on the console with "clockwise" rotation providing lowering

action, and "counter-clockwise" rotation providing raising action.

An ACME precision screw and thread assembly provide accurate

travel; while a spring loaded plunge ball system ensures positive

height position locking.

A steel pointer assembly is synchronized with raise/lower handle

rotations to accurately depict depth feed. See Table 4 for blade

selection with respect to depth of cut. Blade orientation is referenced

on the console's horizontal depth feed gauge (see page 52), and is

calibrated for 12", 14", 16" and 18" diamond blades.

The spray pattern and orientation, in conjunction with the design of

the blade guard, provides exceptional dust suppression when cutting

dry, and may also be desired when the job site requires minimal use

of water.

The blade guard is removable for quick blade changes, and easily

seats itself on the chassis bayonet fitting. The blade guard may be

oriented for left or right hand cutting. See pages 48 and 50.

edalBdnomaiD

).nI(retemaiD

"21 "8/53

"41 "8/54

"61 "8/55

"81 "8/56

NOITCELESEDALB.4ELBAT

tuCfohtpeD

PAGE 18 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 19

FS2 CONCRETE SAW — GENERAL INFORMATION

TACHOMETER/ HOURMETER

A self-powered digital Tachometer/Hourmeter keeps true

running RPM and time. The operation is triggered by an external

lead wrapped around the spark plug of the engine. When the

engine is running, the display will read the RPM of the engine.

When the engine is off, the display will switch to run time (initially

in minutes), and then switching to hours after the first hour of

operation. This instrument provides quartz crystal solid-state

technology, and is built with a custom chip and die bonding

construction for maximum durability.

Figure 6 shows the location of the components of the FS2

Console. The function of each component is described below:

1. Horizontal Depth Feed Gauge – Indicates the blade

cutting depth in inches. The scale allows for orientation of

12, 14, 16 and 18 inch diamond blades.

Depending on the blade diameter selected, the steel

pointer head will indicate zero inches when the blade is

just touching the surface, positive numbers when below

the surface, and negative numbers when above the surface.

The "Depth Feed Gauge" is calibrated in inches and is set

at the factory

2. 3-Way Water Valve – 3 position selector valve, OFF, Mist

or Flood.

3. Raise Lower Crank Handle – Raises or lowers the cutting

blade. This handle is used in conjunction with the horizontal

depth gauge.

4. Digital Tachometer/Hourmeter – Indicates engine RPM's

and operational hours saw has been in use.

5. Engine ON/OFF Switch – Pull this switch to permit the

engine to be started by pull rope. Push the switch inward to

stop the engine.

Figure 6. FS2 Concrete Saw Console

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 19

Page 20

FS2 CONCRETE SAW — INSPECTION -ENGINE

Before Starting

1. Read safety instructions at the beginning of manual.

2. Clean the SAW, removing dirt and dust, particularly the

engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

5. Check fastening nuts and bolts for tightness.

Engine Oil Check

1. To check the engine oil level, place the saw on secure level

ground with the engine stopped, and the diamond blade

removed.

2. Remove the filler cap/dipstick from the engine oil filler hole

(Figure 7) and wipe it clean.

Figure 8. Engine Oil Dipstick (Oil Level)

NOTE

Some engines used with the FS2

Concrete Saw have an oil Alert System.

This system will automatically stop the in

the event of low oil level. ALWAYS be sure

to check the engine oil level prior to

starting the engine.

Figure 7. Engine Oil Dipstick (Removal)

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 8), fill to the edge of the oil filler

hole with the recommended oil type (Table 5). Maximum oil

capacity is 400 cc.

NOTE

Reference manufacturer engine manual for

specific servicing instructions.

Gasoline Check

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if fuel level is low. If fuel is low, replenish

with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel.

epyTliO.5elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

Explosive Fuel

PAGE 20 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 21

FS2 CONCRETE SAW — INSPECTION -BLADE

WARNING

Failure to thoroughly inspect the diamond blade (Figure 9) for

operational safety could result in damage to the blade, the saw,

and may cause injury to the user or others in the operating area.

4. Directional Arrow – Check to ensure that the blade is

oriented properly on the blade shaft for sawing. Reference

the directional arrow in the blade and place it so the direction

of rotation “downcuts” with the turn of the shaft.

5. Diamond Segment or Rim – Ensure there are no cracks,

dings, or missing portions of the diamond segment/rim. DO

NOT

of

cause damage to your saw, and injury to the user or others

in the operating area.

6. Specifications – Ensure that the blade specifications, size,

and diameter properly match up to the sawing operation.

Wet blades must have water to act as a coolant. Utilizing a

diamond blade not matched properly to the task may result

in poor performance and/or blade damage.

7. Arbor Hole – It is essential that the arbor hole diameter

properly matches the blade, and that it is free from

distortions. Correct blade flanges (collars) must be used.

The inside face of the flanges must be clean & free of debris.

An out of round arbor condition will cause damage to the

blade and the saw.

use a blade that is missing a segment or a portion

the rim

. Damaged and/or missing segments/rims may

8. MAX RPM – This RPM reference is the maximum safe

Figure 9. Diamond Blade

1. Drive Pin Hole – A commonly located hole located on the

diamond blade core that prevents operational blade

slippage between the inner & outer blade flanges (collars).

Inspect the diameter of the hole to ensure there is no

distortion, and that a snug fit develops between the hole

and drive pin.

2. Stress Relief Holes (Gullets) –

cracks that may have propagated from the slots and/or

gullets. Cracks indicate extreme fatigue failure and if sawing

continues, catastrophic failure will occur.

Check the steel core for

3. Edge Of The Steel Core – Check the diameter edge for

discoloration (blue oxidation) indicating an overheating

condition caused by insufficient cooling water/air.

Overheating of blades may lead to loss of core tension

and/or increase the possibility for blade failure. Check to

make sure the steel core’s width is uniform about the rim of

the blade, and not succumbing to an “under cutting”

condition brought about by highly abrasive material or

improper under cutting core protection.

operating speed for the blade selected. NEVER exceed

the max RPM on the diamond blade. Exceeding the MAX

RPM is dangerous, and may cause poor performance and

may damage the blade.

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 21

Page 22

FS2 CONCRETE SAW — INSPECTION -BLADE PLACEMENT

WARNING

Failure to thoroughly inspect the diamond blade (Figure 9) for

operational safety could result in damage to the blade, the saw,

and may cause injury to the user or others in the operating area.

NOTE

The following steps should be accomplished

before placing the diamond blade on the

blade shaft.

4. Diamond Blade – Ensure that the proper diamond blade

has been selected for the job. Pay close attention to the

directional arrows on the blade, clockwise for right-hand

cutting and counter-clockwise for left-hand cutting, then

place the blade onto the blade shaft, and ensure the arbor

hole of the blade matches the diameter of the shaft.

5. Blade Drive Pin – Line up the blade drive pin with the

inner flange (collar) pin hole. The blade’s operating

directional arrows must point in a “down-cutting” direction

(whether cutting on right side or left) to perform correctly.

6. Inner Flange (Collar) – This flange is fixed upon the blade

shaft, and is manufactured with a drive pin hole. The inside

■

Set the engine ON/OFF switch to the OFF

position.

surface of the flange must be free of debris and permit a

tight closure on the surface of the blade.

7. Blade Shaft Torque Hole – A conveniently placed opening

■

Place the console ON/OFF button in the

OFF position.

■

Raise the saw to a high position by cranking the Raise/Lower

handle in a counterclockwise direction.

■

Use the Blade Nut Wrench & Blade Shaft Locking Wrench

stored in the lower section of the console to install the diamond

blade.

on the frame permits the use of the shaft lock wrench to

assist in blade changes. The pointed end of the locking

wrench fits into the saw frame hole and a machined hole in

the blade shaft. Once in place, the blade shaft can not

rotate making it easier to remove the blade nut.

■

Reference Figure 10 (Diamond Blade Placement) when

removing or installing the diamond blade.

1. Belt Guard – Unscrew the guard security knob and remove

the blade guard from its bayonet fitting and set it beside the

saw.

2. Blade Hex Nut – Unscrew the [blade shaft nut “right hand”

side loosens clockwise, and tightens counter clockwise],

[blade shaft nut “left side” loosens counter clockwise and

tightens clockwise]. Utilize the blade nut wrench and shaft

lock wrench located on the lower inside console cavity. Do

not overtighten the nut (approximately 45-50 ft.-lb/ 61-68

N/m) when finalizing the assembly.

3. Outside Blade Flange (Collar) – Ensure that the outside

blade flange is placed flush against the diamond blade,

and that the flange drive pin goes through the blade pin

hole and seats properly into the inner flange drive pin hole.

The inside surface of the flange must be free of debris and

permit a tight closure on the surface of the blade core.

Figure 10. Diamond Blade Placement

PAGE 22 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 23

FS2 CONCRETE SAW — INSPECTION -GUARDS, COVERS AND V-BELTS

Guards and Covers Check

V-belts and Cover

CAUTION:

WARNING

NEVER operate the saw without blade guards and covers

(Figures 11 and 12) in place. DO NOT operate with the front of

the blade guard raised. The blade exposure cannot exceed 180

degrees during operations. Adhere to the safety guidelines of

the American National Standards Institute (ANSI) B7.1 and

B7.5.

Figure 11. Blade Guard

NEVER attempt to check the V-belt with the engine running

because severe injury can occur. Keep fingers, hands, hair and

clothing away from all moving parts.

V-belts Alignment and Tensioning

This concrete saw is equipped with three premium V-belts that

have been aligned and tensioned by factory personnel. All three

V-belts MUST be installed for proper operation of the saw. Failure

to run the saw with less than three belts may damage the saw or

equipment.

Use the following procedure to check the alignment of V-belts:

1. Remove the 3 bolts that secure the V-belt cover (Figure 13)

to the saw frame.

CHECK the following on the "blade guard":

■

Check to ensure the capacity of the blade guard matches the

diameter of your diamond blade.

■

Check that the guard seats firmly upon the bayonet fitting of

the saw frame.

■

Check that the spring tensioned front cover of the guard is

firmly seated with the rear section of the guard, and there are

no gaps.

■

Check the fit of the water hoses about the two water manifolds

(14" guard). NEVER lift the blade guard while cutting.

■

Check that the flood water tubes and water jets are clear and

open. Test the water supply for pressure and flow (to both

sides of the blade) before sawing operations.

CHECK the following on the "blade flange cover":

■

Check that the flange cover seats firmly upon the bayonet

fitting of the saw frame prior to operation.

■

This flange cover is to be in place when cutting from either the

right or left side of the saw.

2. Check uniform parallelism (Figure 14) of V-belts and pulley

Figure 13. V-Belt Cover

(sheaves). Use a straight edge or machinists's square

against both pulleys and adjust both pulleys until equally

aligned.

Figure 12. Blade Flange Cover

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 23

Figure 14. V-Belt Parallelism

Page 24

FS2 CONCRETE SAW — INSPECTION -GUARDS, COVERS AND V-BELTS

3. Check V-belt tension (Figure 15) by using a tensionmeter

(6.0 - 9.0 lbs) against the inside belt at a mid point between

the two pulleys, or by deflecting the center belt at a mid point

3/8” (10mm) - 1/2” (13mm).

Figure 15. V-Belt Tension

4.

DO NOT over or under tension the V-belts. Severe damage

can occur to the saw and engine crank shaft if the belts are

over tensioned. A decrease of power to the blade and poor

performance will result if the belts are under tensioned (loose

on pulleys).

5. If the V-belts becomes worn or loose, replace them by using

V-belt part number 15082.

PAGE 24 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 25

FS2 CONCRETE SAW— INITIAL START-UP

CAUTION:

DO NOT attempt to operate the saw until the

Safety, General Information and Inspection

sections have been read and understood.

Depending on engine manufacturer, operating

steps may vary. See engine manufactures

operating manual. The following start-up procedure makes

reference to a HONDA engine.

Ensure the diamond blade has been mounted correctly and

1.

that it raised above the surface you about to saw.

2. Connect to water source (as applicable) see item 14 on page

44 (Water System Assembly), and test for adequate flood

water [ 4 to 5 gallons per minute (15 to 19 LT/min)], and/or

misting water [steady geometric aerosol spray at 40 psi].

3. Place the

fuel valve lever

(Figure 16) to the "ON" position.

D

The CLOSED position of the choke lever enriches

the fuel mixture for starting a COLD engine. The

OPEN position provides the correct fuel mixture

for normal operation after starting, and for

restarting a warm engine.

6. Place the

NOTE

Choke Lever

Figure 19. Choke Lever

(Figure 19) in the "OPEN" position

Figure 16. Fuel Valve Lever

4. Place the

position.

5. PULL the Console

the "PULL-ON" position.

Engine ON/OFF switch

Figure 17. Engine ON/Off Switch

Engine ON/OFF switch

(Figure 17) in the "ON"

(Figure 18) to

CAUTION:

The engine governor speed has been set at the factory. Changing

the governor speed could damage the blade and/or the saw.

7. Place the

and

engine governor speed is factory set to ensure optimum

blade operating speeds.

throttle lever

slow

for starting. All sawing is done at full throttle. The

(Figure 20) halfway between

fast

Figure 20. Throttle Lever

Figure 18. Console Engine ON/Off Switch

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 25

Page 26

FS2 CONCRETE SAW — INITIAL START-UP

8. Grasp the starter grip (Figure 21) and slowly pull it out. The

resistance becomes the hardest at a certain position, corresponding to the compression point. Pull the starter grip briskly

and smoothly for starting.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

l

DO NOT pull the starter rope all the way

to the end.

l

DO NOT release the starter rope after

pulling. Allow it to rewind as soon as

possible.

Stopping the Engine

NEVER stop the engine while the blade is in the cut, except

for extreme emergencies. A sudden stoppage of the engine

at high speed while in a cut could damage the blade and/or

saw, and may cause injury to the user or other in the

operating area.

1. Place the throttle lever (Figure 20) in the slow position, and

listen for the engine speed to decrease.

2. Push the console engine ON/OFF switch (Figure 18) to the

“OFF” position.

3. Place the engine ON/OFF switch (Figure 17) to the “OFF”

position.

4. Place the fuel valve lever (Figure 16) to the “OFF” position.

Maneuvering The Saw

WARNING

The blade is spinning whenever the engine is running.

Figure 21. Starter Grip

9. If the engine has started, slowly return the choke lever

(Figure 19) to the

started repeat steps 1 through 5.

Before the saw is placed into operation, run the engine for

10.

several minutes. Check for fuel leaks, and noises that would

associate with a loose guard and/or covers.

11. All sawing is done at full throttle. Your engine governor has

been set at the factory to ensure an optimum speed setting.

CLOSED

position. If the engine has not

Raise the blade high above the surface when maneuvering

the saw. Damage to the blade and/or saw may occur if the

blade strike the pavement.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

l

NEVER stop the engine in the cut while

working at high speeds, except for

extreme emergencies.

PAGE 26 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 27

FS2 CONCRETE SAW — OPERATION

Saw Alignment

1.

The FS2 employs a front and rear pointer (Figure 22) that has

been precisely aligned with the diamond blade at the factory.

Referencing the figure below, accurate tracking is accomplished by referencing the front and rear pointer tips over the

cut line. Precise saw direction is accomplished by slight

operator pressure against the handle bars.

Figure 22. Saw Pointers (Front/Rear)

2.

To reorient a pointer position, loosen the hex screw that

secures the pointer bar to the shaft, adjust as necessary, and

retighten the hex screw.

5. Set the depth and saw only as the job conditions and

specifications require. Unnecessary deep sawing is wasteful

to the life of your blade.

6. The preferred method of sawing is to step cut in increments

of 2” (51mm). “Step-cutting” provides the optimum opportunity for the blade to cut fast and last its longest.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

ALWAYS saw in a straight line only. Serious

damage to the blade may occur if the saw is

twisted or forced to cut radius shapes.

7. The rotation of the blade creates a tendency for the saw to pull

in a particular direction (to the right if the blade is mounted on

the right, to the left if the blade is mounted on the left).

8. To ensure a straight line of sawing, apply pressure to the

appropriate handle as you slowly advance the saw forward.

DO NOT force the blade to the cut any faster than its natural

tendency.

3. For operator comfort, an ergonomically designed handle bar

adjusts by loosening two clamping knobs (page 46, item 8),

and adjusts to the desired height. Tighten the knobs back

down when the desired height is met.

Wet Saw Operation

WARNING

The operator must wear the appropriate protective equipment

and clothing while engaged in sawing.

1. Connect hose from water source to the hose fitting connec-

tion (see item 14, page 44 "Water System Assembly") on the

saw. The source pressure should be approximately 40 psi.

If the engine stalls for any reason during

sawing, raise the blade out of the cut

before restarting.

9. The operator must recognize and adhere to the optimum

speed that the saw advances while sawing. DO NOT

the saw in the cut

to time to get the feel for a smooth sawing pace relative to

RPM.

10. Factors for sawing economy:

l

l

l

2. Select the “flood” position on the console (Figure 6), and

ensure the proper flow and rate 4-5 gallons/ minute (15-19

Lt/min) is equally directed to both side of the blade.

3. Advance engine throttle to full (FAST) position.

4. Slowly lower the blade onto your cut line by cranking the

Raise/Lower handle clockwise: while observing the depth of

the cut desired by referencing the depth feed gauge (Figure

IF the water supply to your blade is interrupted, stop

6).

sawing immediately.

l

WARNING

force

. Observe the engine tachometer from time

Type of Blade

Depth of Cut

Sawing Speed

Characteristics of the Material Being Cut

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 27

Page 28

FS2 CONCRETE SAW — OPERATION

Dry Saw Operation

WARNING

Engine components can

generate extreme heat.

Diamond Blades and Blade Speed

The operator must wear the appropriate protective equipment

and clothing while engaged in sawing.

1. Ensure the proper DRY Cutting blade is selected for the job.

2. With the 14" blade guard, select the “MIST” position (misting

water) or the “OFF” position on the console (Figure 6). If

misting water is desired, the water source must be able to

deliver 40 psi of pressure to ensure an optimum spray

pattern.

3. The Water Misting system is designed to suppress the dust

signature caused by dry sawing. The aerosol spray pattern

and blade guard design greatly diminish the amount of dust

that is created. The misting water also acts as an added

coolant for the blade.

4. The preferred method of sawing is to step cut in increments

of 2” (51mm). “ Step-cutting” provides the optimum opportunity for the blade to cut fast and last its longest. Airflow acts

as a blade coolant during sawing. Cutting too deep with one

pass, or exerting excessive forward/sideward pressure may

damage the blade.

Finishing a Cut

1.

Diamond Sawing consists of cutting WET or DRY.

2. Matching the correct blade for the specific job and material

being cut optimizes performance and value.

3. Selection of the proper diamond blade consists of:

4. Selecting the “grade” of diamond blade often defines the

performance factors that can be achieved. Multiquip offers a

variety of diamond blade grades to provide the desired level

of valve and performance.

Blade Speed

WARNING

l

Determining WET or DRY cutting

l

Material to be Cut

l

Type of Saw Being Used

l

Horsepower of Saw

l

Hardness Characteristics of the Material

l

Performance Expectations

1.

Raise the blade out of the cut by cranking the Raise/Lower

handle counter-clockwise (Figure 6). Raise the blade high

enough out of the cut to clear the surface and allow the saw

to be maneuvered.

2. Move the engine throttle lever to the idle (SLOW) position

(Figure 20).

3. Push the console engine ON/OFF button to the “OFF”

position (Figure 6).

4. Set the engine ON/OFF switch to the “OFF” position

(Figure 6).

5. Place the three-way water valve (Figure 17) in the “OFF”

position (as required).

PAGE 28 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

1. A diamond blade’s performance is directly connected to

specific peripheral (rim) speeds.

2. The following shaft rotational speeds have been factory set

to ensure optimum blade performance.

l

FS2 14” Capacity-3,200 RPM.

l

FS2 18” Capacity-2,700 RPM.

WARNING

Operating saw blades at rotational speeds

greater than those specified by the manufacture can cause blade damage, and may injure the user or others in the operating area.

Page 29

FS2 CONCRETE SAW — MAINTENANCE

ENGINE AIR FILTER

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

General maintenance practices are crucial

to the performance and longevity of your saw.

The extreme environments of sawing operations require routine cleaning, lubrication, belt

tensioning, and inspection for wear and damage

WARNING

The following procedures devoted to maintenance can prevent serious saw damage or

malfunctioning. Before servicing or inspection,

ALWAYS park the saw on a level surface with

the blade removed, and the Console Engine ON/OFF switch &

Engine ON/OFF switch in “OFF” position.

4.

when DRY cutting. See Engine Owner’s Manual for detailed

information.

ENGINE TANK & STRAINER

5.

hours.

FUEL LINE:

6.

7.

SPARK PLUG:

Replace every year/ or 300 hours.

Bearing Lubrication Care

There are nine (9) grease points (zerk fittings, Figure 23) on the

FS2 Concrete Saw. Use only Premium Lithium 12 based Grease,

conforming to NLG1 Grade #2 consistency.

WARNING

1. FRONT & REAR WHEELS: Grease daily, see page 36,

Some maintenance operations may require

the engine to be run. Ensure that the maintenance area is well ventilated. Exhaust contains poisonous carbon monoxide gas that can cause of unconsciousness and may

result in DEATH

Under Carriage Assembly.

2. BLADE SHAFT BEARINGS: Grease daily, see page 38,

Blade Shaft Assembly.

: Clean air filter 2 TO 3 times daily

: Clean every year/ or 300

Replace every two years/ or as necessary.

Clean/adjust every 6 months/or 100 hours.

Figure 23. Zerk Fitting

General Engine Care

1.

ENGINE CHECK

thread nut & bolt tightness, and overall cleanliness.

ENGINE OIL

2.

saw frame level on a level surface. Keep the oil clean, and

at the proper servicing level (Figure8). DO NOT OVERFILL!

SAE 10W30 of SG is recommended for general use.

ENGINE OIL CHANGE

3.

or 20 hours of operation. Then every 3 months/ or 50 HOURS

ALWAYS dispose of used oil in a responsible

manner. Ensure that the disposition of all hazardous

waste is handled properly. Call your Recycling

Center for information about recycling engine oil.

: Check daily for any oil and/or fuel leakage,

: Check daily. Inspect with blade removed and

: Change engine oil the first month

NOTE

NOTE

When cutting DRY, lubricate blade shaft bearings 2

to 3 times daliy. The grease can provide an added

protective seal for the bearings.

3. RAISE/LOWER DEPTH CONTROL BEARING:Grease

daily, see page 52, Manual Raise Lower Assembly

4. ADJUST TUBE: Grease daily, see page 52, Manual Raise

Lower Assembly.

5. AXLE ASSEMBLY: Grease weekly/or 25 hours, see page

36, Under Carriage Assembly.

General Cleanliness

Clean the machine daily. Remove all dust and slurry build up.

If the saw is steam cleaned, ensure that lubrication is accomplished AFTER steam cleaning operations.

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 29

Page 30

FS2 CONCRETE SAW — MAINTENANCE

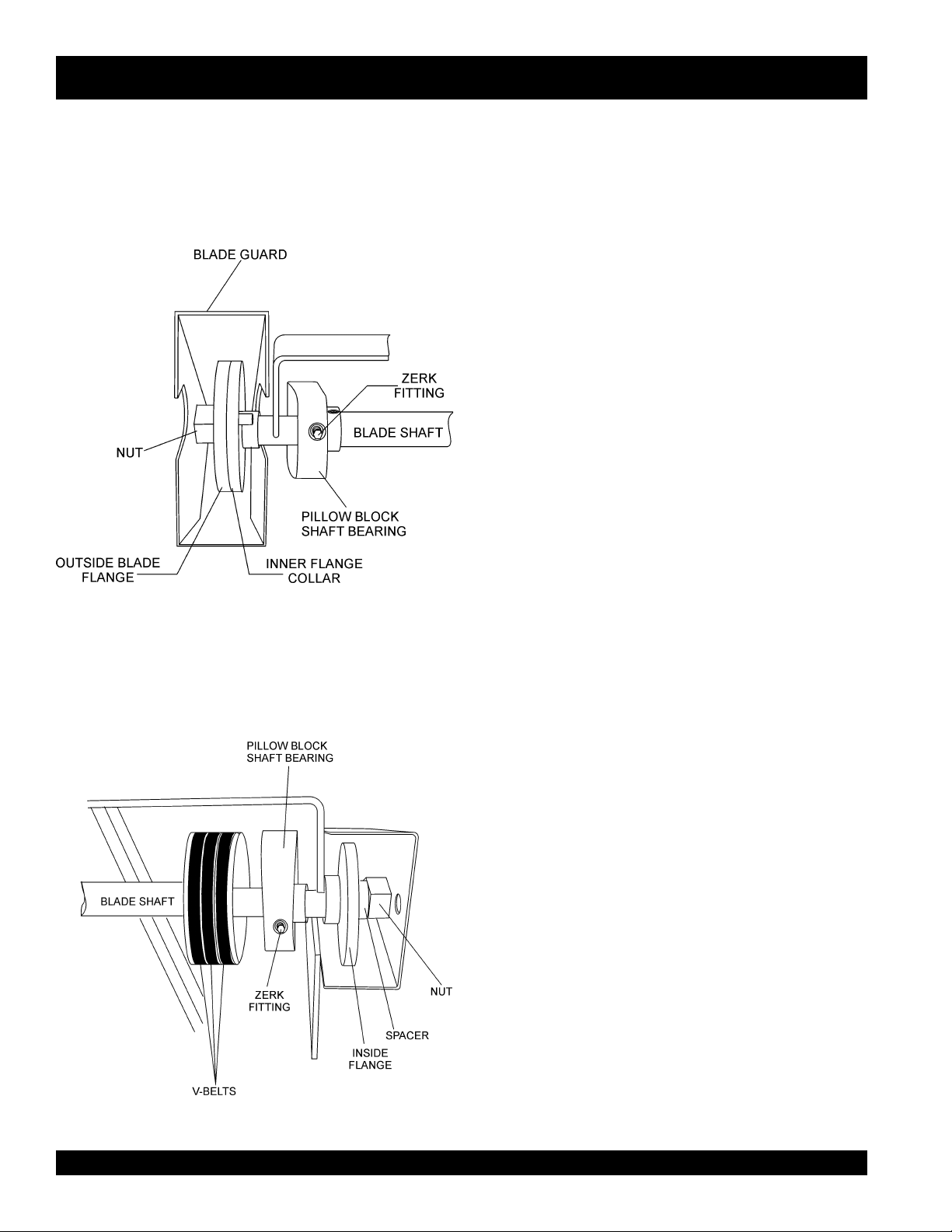

Blade Shaft Bearing Replacement

The FS2 is supported by “tapped base lock collar (w/set screw)’

self-aligning blade shaft bearings. These heavy duty bearings

support the 1-1/4 blade shaft, and have grease (zerk) points

(Figures 24 and 25) conveniently located for service.

3.

To loosen the tension on the three V-Belts perform the

following:

l

Remove the Belt Cover, item 4, page 42. (Pointers and

Covers Assembly)

l

Loosen the Carriage Bolts, item 11, page 40 (Engine

Mount Assembly).

l

Loosen the Hex Head Cap Screws, item 12, page 40

(Engine Mount Assembly).

l

Rotate the engine down to provide slack in the V-Belts

Replacement of the Blade Shaft Bearings

Perform the following to replace the blade shaft bearings:

4.

l

Remove Blade Flanges (items 7 and 8, page 38, Blade

Shaft Assembly) as required to permit the Shaft Bearing(s)

to slide off the Blade Shaft.

l

Loosen/remove Shaft Bearing(s) Hex Head Cap Screws,

item 11, page 38.

l

Loosen Set Screw on the Blade Shaft Bearing collar.

l

Figure 24. Left-Side Shaft Bearing

Reference pages 38 ( Blade Shaft Assembly) and 40( Engine

1.

Mount Assembly).

2. Its recommended to replace both left & right hand bearings

collectively.

Slide “old” Bearing(s) off the Blade Shaft and replace with

“new” Bearing(s)- grease (zerk) fitting pointing forward, and

the lock collar oriented to the “right" as you face the saw.

5. Loosely bolt the bearing(s) into place on the saw frame, then

ensure the alignment by referencing past bearing positioning.

6. Tighten the hex head cap screw, item 11, page 38 to secure

the Shaft Bearing (s) to the frame.

7. To complete the re-installation process , reverse the order of

the above mentioned steps. For V-belt adjustment, see V-belt

tension section on page 23 (Figure 14).

Figure 25. Right-Side Shaft Bearing

PAGE 30 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 31

FS2 CONCRETE SAW — MAINTENANCE

Raise/Lower Height Adjustment

The FS2 is equipped with an Raise/ Lower assembly that is

supported by the following:

l

ACME Screw

l

Precision Thread

l

Depth Gauge Bearing

l

Depth Gauge Pointer

l

Tube Height Adjustment

The height adjustment of the FS2 has been factory set utilizing

precision standards.

Reference Manual Raise and Lower Assembly on page 52

unless otherwise noted.

The saw must be operated with

justed collectively and properly to be effective

The V-Belt adjustment of the FS2 has been factory set utilizing

precision standards. For V-Belt adjustments only, see page 23,

V-belts Alignment Tensioning.

V-Belt Replacement

To replace the entire set of V-belts (3) perform the following

procedure:

Setting The Height Of The Depth Gauge Pointer

Perform the following to set the height of the Depth Gauge Pointer:

1. Place the saw on a level working surface.

2. Remove the rear panel cover, see page 46, item 9.

3. Install an appropriate new diamond blade on the saw and

take reference to the diameter.

4. Lower the blade until flush contact is made with the level

surface.

5. Loosen the two hex nuts, item 18, that tighten against the

upper and lower rod ends, item 19.

6. Loosen the hex nut, item 13, that secures the plunge ball, item

12, depth lock against the adjustment tube.

7. Loosen (counter-clockwise) the plunge ball with an allen

wrench. This will unlock the plunge ball from the ACME

screw, item 9.

8. Set the blade height indicator to "0" (relative to the diameter

of the blade and depth scale). See Figure 6, "Concrete Saw

Console".

10. Remove the upper pan-head screw, item 20, to enable the

rod end adjustments.

11. Adjust the rod ends as required to ensure that the throw of

both rod ends and threaded rod, item 14, support the "0"

position of the depth gauge located on the console.

12. Tighten the plunge ball, item 12, to the full depth against the

ACME screw, item 9.

13. Unscrew the plunge ball, item 12, 1 FULL TURN (counterclockwise).

14. Tighten the hex nuts, item 13, against the "Adjustment Tube",

item 10, to lock the plunge ball in place.

V-Belt Tension Check

Check tension after first day of operations, then weekly/or 25

hours. Replace as required (see Figure 14). NEVER operate

with less than 3 belts.

The FS2 is equipped with (3) premium 3VX V-belts (Figure 14)

that provide optimum torque transfer.

Reference pages 38 (Blade Shaft Assembly), 40 (Engine

1.

Mount Assembly) and 42 ) Pointers and Covers Assembly).

2. Loosen the tension on the V-Belts.

3. Remove the Belt Cover, item 4, page 42.

4. Loosen the Carriage Bolts, item 11, page 40.

5 Loosen the Hex Head Cap Screws, item 12, page 40.

6. Rotate the engine down to provide slack in the V-Belts.

7. Loosen shaft bearing(s), hex head cap (shaft bearing) screws

item 11, page 38.

8. Remove the (2) hex head cap screws, item 11, page 38, that

support the ‘pulley-side’ blade shaft bearing.

9. Orient the blade shaft so the belt(s) to be replaced can slide

off the blade shaft pulley and engine pulley.

10. Orient the replacement belt(s) around the blade shaft pulley

and engine pulley.

11 Replace and tighten the (2) hex head cap shaft bearing

screws, item 11, page 38.

V-Belt Tension

1.

Adjust carriage bolts, item 11, page 40, until the proper belt

tension is achieved.

2. Tighten the (2) hex head cap screws, item 12, page 40.

3. Replace the belt cover, item 4, page 42.

all (3) V-belts, and must be ad-

Figure 26. V-Belts

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 31

Page 32

FS2 CONCRETE SAW — EXPLANATION OF CODE IN REMARKS COLUMN

How to read the marks and remarks used in this parts book.

Section 1: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial number

range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model number

or model number variant.

Section 3: Items Found In the “Items Number” Column

All parts with same symbol in the number column,

■

, belong to the same assembly or kit.

Note: If more than one of the same reference number is listed,

the last one listed indicates newest (or latest) part available.

NOTE

The contents of this parts catalog are subject to

change without notice.

, #, +, %, or

*

PAGE 32 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 33

FS2 CONCRETE SAW — SUGGESTED SPARE PARTS

FS2 CONCRETE SAW 1 TO 3 UNITS

1 to 3 Units

Qty. P/N Description

1 ............ 15172 ............... BLADE SHAFT ASSY. 14" W/FLANGES KIT

1 ............ 15065 ............... SHAFT, BLADE

2 ............ 15063 ............... FLANGE, BLADE INSIDE

1 ............ 15064 ............... FLANGE, BLADE OUTSIDE

2 ............ 15119 ............... KEY, WOODRUFF

2 ............ 15066 ............... BEARING, PILLOW BLOCK

1 ............ 15092 ............... NUT, BLADE, RIGHT-HAND

1 ............ 15093 ............... NUT, BLADE, LEFT-HAND

1 ............ 6059B ............... KEY, 1/4" SQ. X 2"

3 ............ 15082 ............... V-BELT, 3VXV355

2 ............ 15091 ............... WHEELS, REAR

2 ............ 15090 ............... WHEELS, FRONT

1 ............ 15097 ............... WRENCH, ALL PURPOSE

1 ............ 15098 ............... TOOL, SHAFT LOCK

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 33

Page 34

FS2 CONCRETE SAW — TROUBLESHOOTING (ENGINE)

GNITOOHSELBUORTENIGNE.6ELBAT

NOTPMYSESUACELBISSOPNOITULOS

?gnigdirbgulpkrapS

ontub,elbaliavasileuf",tratsottluciffiD

."gulpkrapstaKRAPS

?noitalusni

?detrohs

?evitcefedliocnoitingI.liocnoitingiecalpeR

dna,elbaliavasileuf",tratsottluciffiD

."gulpkrapsehttatneserpsiKRAPS

?gnitiucric

?epytleufgnorW

kraps,elbaliavasileuf",tratsottluciffiD

"lamronsinoisserpmocdnatneserpsi

?gulpkrapsnotisopednobraC .gulpkrapsecalperronaelC

gulpkrapstneicifedoteudtiucrictrohS

?paggulpkrapsreporpmI.pagreporpotteS

sihctiwsFFO/NOenigneroelosnoC

?yrtridstniop,pagkrapsreporpmI

trohsronrownoitalusniresnednoC

?gnitiucrictrohsronekorberiwgulpkrapS

?metsysleufnitsudroretaW.metsysleufhsulF

.nrowfiecalper

.hctiws

.stniopnaelc

.gniriw

ronoitalusni,pagkcehC

.gulpkrapsecalper

,noitalusnigulpkrapskcehC

ecalper,gniriwhctiwskcehC

dnapagkrapstcerrocteS

.resnednocecalpeR

gulpkrapsevitcefedecalpeR

ecalperdna,metsysleufhsulF

.leuffoepyttcerrochtiw

?ytridrenaelcriA .renaelcriaecalperronaelC

?dedurtorprokcutsevlavtsuahxe/noitcuS.sevlavtaes-eR

?nrowrednilycro/dnagnirnotsiP

kraps,elbaliavasileuf",tratsottluciffiD

"wolsinoisserpmocdnatneserpsi

?ylreporpdenethgit

?degamad

.roterubractatneserpleufoN

?deggolcretlifleuF.retlifleufecalpeR

?enilleufniriA.enilleufdeelB

tongulpkrapsro/dnadaehrednilyC

teksaggulpkrapsro/dnateksagdaeH

?knatleufnielbaliavatonleuF .leuffoepyttcerrochtiwlliF

?ylreporpnepotonseodkcocleuF

?deggolcelohrehtaerbpacknatleuF .packnatleufecalperronaelC

.notsip

.gulpkraps

.steksag

rodnasgnirnotsipecalpeR

dnastlobdaehrednilyceuqroT

gulpkrapsdnadaehecalpeR

leufnesoolottnacirbulylppA

.yrassecenfiecalper,revelkcoc

PAGE 34 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 35

FS2 CONCRETE SAW — TROUBLESHOOTING (ENGINE)

)DEUNITNOC(GNITOOHSELBUORTENIGNE.6ELBAT

NOTPMYSESUACELBISSOPNOITULOS

?naelctonrenaelcriA renaelcriaecalperronaelC

sinoisserpmoc"rewopnikaeW"

.erifsimtonseoddnareporp

sinoisserpmoc"rewopnikaeW"

.serifsimtubreporp

.staehrevoenignE

.setautculfdeepslanoitatoR

?gulpkrapsytriD .gulpkrapsecalperronaelC

?ytridsnifgnilooC.snifgniloocnaelC

?detcirtserwolfleuF

?roterubracnilevelreporpmI

?gulpkrapSevitcefeD .gulpkrapsecalperronaelC

?gulpkrapSevitcefeD

?metsysleufniretaW

?evitcefedliocnoitingI.liocnoitingiecalpeR

?reporpmieulavtaehgulpkrapS

?leuffoepyttcerroC leuffoepyttcerrochtiwecalpeR

?yltcerrocdetsujdaronrevoG.ronrevogtsujdA

?evitcefedgnirpsronrevoG.gnirpsronrevogecalpeR

.rotaerubrac

.gulpkraps

.sgolcroskael

dliub-er,tnemtsujdataolfkcehC

ecalperdna,metsysleufhsulF

.leuffoepyttcerrochtiw

foepyttcerrochtiwecalpeR

rofmetsysleuferitnekcehC

dnatsudhtiwdeggolcmsinahcemlioceR

.noitcnuflamretratslioceR

?trid

?esoolgnirpslairpS.gnirpslairpsecalpeR

.retawdna

paoshtiwylbmessaliocernaelC

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 35

Page 36

UNDER CARRIAGE ASSY.

FS2 CONCRETE SAW — UNDER CARRIAGE ASSY.

PAGE 36 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 37

FS2 CONCRETE SAW — UNDER CARRIAGE ASSY.

UNDER CARRIAGE ASSY.

NO PART NO PART NAME QTY. REMARKS

1 15028 SET COLLAR 5/8 DIA ............................... 2 ..................... INCLUDES ITEM W/

2 1162A CAP, ZERK FITTING 4

3 2621 ZERK FITTING 4

4 15090 WHEEL 5.0 X 2W X .625 ID400 CAP 2

5 15515 FRONT AXLE ASSY. 1

6 16749 ZERK, GREASE 1/4-28 90 DEGREE 1

7 15106 REAR, POINTER 1

8 0655 SCREW, HHC 5/16-18 X 3/4 1

9 15013 AXLE,REAR 1

10 8151 WASHER, FLAT 3/4 SAE 6

11

*

12 15091 WHEEL, R 9.75 OD X 2.75W X75BB 2

13 3615 COLLAR, SET 3/4 SAE............................. 2 ..................... INCLUDES ITEM W/

SET SCREW 1

*

*

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 37

Page 38

BLADE SHAFT ASSY.

FS2 CONCRETE SAW — BLADE SHAFT ASSY.

PAGE 38 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 39

FS2 CONCRETE SAW — BLADE SHAFT ASSY.

BLADE SHAFT ASSY.

NO PART NO PART NAME QTY. REMARKS

1 2621 ZERK FITTING 2

2 1162A ZERK FITTING CAP 2

3 15119 KEY, WOODRUFF 2

4 6059B KEY, 1/4 SQ X 2” 1

5 15065 SHAFT, BLADE 1

6 15066 BEARING, PILLOW BLOCK 11/4 BORE 2

7 15063 FLANGE, BLADE INSIDE 2

8 15012 FLANGE, DRIVEN ASSY. 1

9 15093 NUT, 1-14-28-LH 1

10 0448 WASHER, FLAT 7/16 SAE 4

11 15563 SCREW, HHC 7/16-14 X 3/4 4

12 15082 BELT, V BLADE 3X V335 3

13 15061 PULLEY, TL 3V 4.50 0D 1

14 15060 BUSHING, TL 1 1/4 BORE 1

15 15148 SPACER, BLADE SHAFT 1

16 15092 NUT, 1-14-28 1

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 39

Page 40

ENGINE MOUNT ASSY.

FS2 CONCRETE SAW — ENGINE MOUNT ASSY.

PAGE 40 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 41

FS2 CONCRETE SAW — ENGINE MOUNT ASSY.

ENGINE MOUNT ASSY.

NO PART NO PART NAME QTY. REMARKS

1 15156 MOUNT,ENGINE, RIGHT, W/A 1

2 15033 BAR THREATED 2

3 15032 SPACER, PIPE 2

4 15157 MOUNT,ENGINE, LEFT, W/A 1

5 0448 WASHER, FLAT 7/16 SAE 4

6 1023 SCREW, HHC 3/8-16 X 1-1/4 4

7 15030 MOUNT, ENGINE BASE 1

8 10136 WASHER, FLAT3/8 SAE 10

9 9154 SCREW, HHC 3/8-16 X 1-3/4 4

10 1456 NUT, HEX FINISH 3/8-16 6

11 15174 BOLT, CARRIAGE 3/8-16 X 3 2

12 15564 SCREW, HHC 3/8-16 X 1-3/4 2

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 41

Page 42

FS2 CONCRETE SAW — POINTERS AND COVERS ASSY.

POINTERS AND COVERS ASSY.

PAGE 42 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 43

FS2 CONCRETE SAW — POINTERS AND COVERS ASSY.

POINTERS AND COVERS ASSY.

NO PART NO PART NAME QTY. REMARKS

1 15053 WHEEL, POINTER ARM 1

2 15070 POINTER, FRONT W/A 1

3 0730 SCREW, HHC 1/4-20 X 1 3

4 15011 BELT COVER 1

5 1023 SCREW, HHC 3/8-16 X 1-1/4 2

6 10133 NUT, NYLOC 3/8-16 2

7 15088 COVER, BLADE FLANGE 1

8 0131A SCREW, HHC 1/4-20 X 3/4 1

9 15052 ROD, POINTER 1

10 0948 WASHER, FLAT 1/4 SAE 3

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 43

Page 44

WATER SYSTEM ASSY.

FS2 CONCRETE SAW — WATER SYSTEM ASSY.

PAGE 44 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 45

FS2 CONCRETE SAW — WATER SYSTEM ASSY.

WATER SYSTEM ASSY.

NO PART NO PART NAME QTY. REMARKS

1 15135 SUPPORT 3 WAY VALVE 1

2 15181 HOSE, 3/8 BLACK WATER 200 PSI 8

3 15538 CLAMP, WORM HOSE, 7/16-11/16 6

4 15137 POINTER,3 WAY VALVE 1

5 15183 PIN, ROLL 195X1 1

6 15532 SCREW, PAN HEAD 8-32X2.0 1

7 15176 SCREW, PAN HEAD 8-32X 1-1/2 3

8 15502 SWITCH, ENG ON/OFF 1

9 15533 HARNESS WIRE BUNDLE 1

10 15062 VALVE 3 WAY 4 POSITION 1

11 15669 FITTING,1/4 MPT90 3/8 HOSE BARB PL 3

12 15180 FITTING, 1/2 NPT 3/8 BARB 1

13 2190 SPACER, 0.25 00 X 0.25L .035W 1

14 15544 FITTING,FNPTX 3/4 GARDEN HS BRASS 1

15 15546 GASKET,3/4 HOSE GASKET/SCREEN 1

16 15173 WASHER, FLAT #8 10

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 45

Page 46

BASIC PLATFORM ASSY.

FS2 CONCRETE SAW — BASIC PLATFORM ASSY.

PAGE 46 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 47

FS2 CONCRETE SAW — BASIC PLATFORM ASSY.

BASIC PLATFORM ASSY.

NO PART NO PART NAME QTY. REMARKS

1 15001 CHASSIS 1

2 15105 PLATE, UPCUT SLOT COVER 1

3 0948 WASHER, FLAT 1/4 SAE 6

4 0730 SCREW, HHC 1/4-20 X1 2

5 15664 DECAL, FS2 CONSOLE 1

6 15018 HANDLEBAR 1

7 15081 HANDLE, GRIPS 1” DIA 2

8 15072 HANDLE, CLAMPING 2

9 15084 PANEL, REAR COVER 1

10 0131A SCREW, HHC 1/4-20 X 3/4 4

11 11534 NUT U TYPE 1/4-20 4

12 15138 WRENCH, 6” POCKET SOCKET 1

13 15098 TOOL, SHAFT LOCK SOCKET 1

14 15097 WRENCH, ALL PURPOSE 1

MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01) — PAGE 47

Page 48

BLADE MIST 14-INCH ASSY.

FS2 CONCRETE SAW — BLADE MIST 14-INCH ASSY.

PAGE 48 — MQ-WHITEMAN FS2 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #2 (11/08/01)

Page 49

FS2 CONCRETE SAW — BLADE MIST 14-INCH ASSY.