Page 1

OPERATION AND PARTS MANUAL

CUTTER 1

MODEL CD613H18

(HONDA GX390 GASOLINE ENGINE)

MODEL CD605E16

(5 HP ELECTRIC MOTOR)

CONCRETE/ASPHALT SAW

Revision #6 (06/06/08)

To find the latest revision of this

publication, visit our website at:

www.stowmfg.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 25498

Page 2

STOW CUTTER 1 SAW — PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 3

NOTES

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 3

Page 4

STOW CUTTER 1 SAW — TABLE OF CONTENTS

Proposition 65 Warning ............................................. 2

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

Safety Message Alert Symbols .............................. 6-7

Rules For Safe Operation .................................... 8-10

Specifications (Saw) ................................................ 11

Specifications (Engine) ........................................... 12

STOW — CUTTER 1 SAW

Controls & Components .......................................... 13

Basic Engine ........................................................... 14

Preparation/Pre-Inspection ................................ 15-17

Blades ..................................................................... 18

Blade Placement ..................................................... 19

Initial Start-Up ....................................................20-21

Operation ................................................................ 21

Maintenance ...................................................... 22-23

Troubleshooting (Saw) ............................................ 24

Troubleshooting (Engine) ................................... 25-26

Explanation of Codes in Remarks Column ............. 28

Suggested Spare Parts ........................................... 29

Nameplate and Decals....................................... 30-31

Engine, Belts And Pulleys Assembly .................. 32-33

Electric Motor Assembly..................................... 34-35

Undercarriage Assembly ................................... 36-37

Blade Assembly & Water System Assembly....... 38-39

Pointer Assembly ............................................... 40-41

HONDA GX390K1QWT2/

GX390U1QWT2 ENGINES

Air Cleaner Assembly......................................... 42-43

Camshaft Assembly ...........................................44-45

Carburetor Assembly ......................................... 46-47

Control Assembly ............................................... 48-49

Crankcase Cover Assembly ............................... 50-51

Crankshaft Assembly .........................................52-53

Cylinder Barrel Assembly ................................... 54-55

Cylinder Head Assembly .................................... 56-57

Fan Cover Assembly .......................................... 58-59

Flywheel Assembly ............................................ 60-61

Fuel Tank Assembly ........................................... 62-63

Ignition Coil Assembly ........................................ 64-65

Muffler Assembly ............................................... 66-67

Piston Assembly ................................................. 68-69

Recoil Starter Assembly..................................... 70-71

Labels ................................................................ 72-73

Terms and Conditions of Sale — Parts ................... 74

NOTE

Specifications and

part numbers are

subject to change

without notice.

PAGE 4 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 5

STOW CUTTER 1 SAW — PARTS ORDERING PROCEDURES

When ordering parts,

please supply the following information:

❒❒

❒ Dealer account number

❒❒

❒❒

❒ Dealer name and address

❒❒

❒❒

❒ Shipping address (if different than billing address)

❒❒

❒❒

❒ Return fax number

❒❒

❒❒

❒ Applicable model number

❒❒

❒❒

❒ Quantity, part number and description of each part

❒❒

❒❒

❒ Specify preferred method of shipment:

❒❒

✓ FedEx or UPS Ground

✓ FedEx or UPS Second Day or Third Day

✓ FedEx or UPS Next Day

✓ Federal Express Priority One

✓ DHL

✓ Truck

Note: Unless otherwise indicated by customer, all

orders are treated as “Standard Orders”, and will

ship within 24 hours. We will make every effort to

ship “Air Shipments” the same day that the order

is received, if prior to 2PM west coast time. “Stock

Orders” must be so noted on fax or web forms.

Here’s how to get help...

Please have the model and serial number

on hand when calling.

STOW MAIN OFFICE

18910 Wilmington Ave. 800-421-1244

FAX:

Carson, CA 90746

Email: stow@stowmfg.com

Internet: www.stowmfg.com

SALES DEPARTMENT

310-661-4242 Fax: 310-604-9237

877-289-7869 (877-BUY-STOW)

PARTS DEPARTMENT

800-427-1244

310-537-3700

SERVICE DEPARTMENT

800-478-1244

310-537-3700

TECHNICAL ASSISTANCE

800-478-1244

WARRANTY DEPARTMENT

800-421-1244,

310-537-3700,

EXT.

EXT.

279

279

310-537-3927

FAX:

800-672-7877

FAX:

310-637-3284

FAX:

310-537-4259

FAX:

310-631-5032

FAX:

310-537-1173

Place Your Parts Order Via Web or Fax

For Even More Savings!

(Domestic USA Dealers Only)

Extra Discounts!

All parts orders which include complete part numbers and

are received by our automated web parts order system, or

by fax qualify for the following extra discounts:

Ordered Standard Stock orders

via orders ($750 list and above)

Fax 3% 10%

Web 5% 10%

Special freight allowances

when you order 10 or more

line items via Web or Fax!**

FedEx Ground Service

No other allowances on freight shipped by any other

carrier.

**Common nuts, bolts and washers (all items under $1.00

list price) do not count towards the 10+ line items.

NOTE: DISCOUNTS ARE SUBJECT TO CHANGE

at no charge for freight

STOW CONSTRUCTION EQUIPMENTSTOW CONSTRUCTION EQUIPMENT

STOW CONSTRUCTION EQUIPMENT

STOW CONSTRUCTION EQUIPMENTSTOW CONSTRUCTION EQUIPMENT

A DIVISION OF MULTIQUIP INC.

POST OFFICE BOX 6254 CARSON, CA 90749

888-252-STOW [888-252-7869] 310-537-3700

FAX: 310-537-1986 FAX: 800-556-1986

E-MAIL: stow@multiquip.com INTERNET: www.stowmfg.com

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 5

Direct TOLL-FREE access

to our Parts Department:

Toll-free nationwide — 800-427-1244

Toll-free FAX — 800-6-PARTS-7

(800/672-7877)

Page 6

STOW CUTTER 1 SAW — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when operating

this equipment. Failure to read and understand the Safety

Messages and Operating Instructions could result in injury to

yourself and others.

HAZARD SYMBOLS

NOTE

This Owner's Manual has been developed to provide

complete instructions for the safe and efficient operation

STOW CUTTER 1 SAW

of the

information, please refer to the engine manufacturers

instructions for data relative to its safe operation.

Before using this CONCRETE/ASPHALT SAW,

ensure that the operating individual has read and

understands all instructions in this manual.

. For engine maintenance

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Gasoline is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

WARNING: You CAN be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

CAUTION: You CAN be injured if you

DO NOT follow directions.

Potential hazards associated with STOW CUTTER 1 SAW

operation will be referenced with "

appear throughout this manual, and will be referenced in

conjunction with Safety "

Message Alert Symbols

Hazard Symbols

" which

".

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep

and

clothing

prevent injury.

fingers, hands, hair

away from all moving parts to

PAGE 6 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 7

STOW CUTTER 1 SAW — SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the engine ON/OFF

switch in the OFF position, when the saw

is not in use.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

Guards and Covers In Place

NEVER operate the saw without blade guards

and covers in place. Adhere to safety

guidelines ANSI, OSHA, or other applicable

local regulations.

Respiratory Hazard

ALWAYS wear approved respiratory protection.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your concrete saw, other property, or

the surrounding environment.

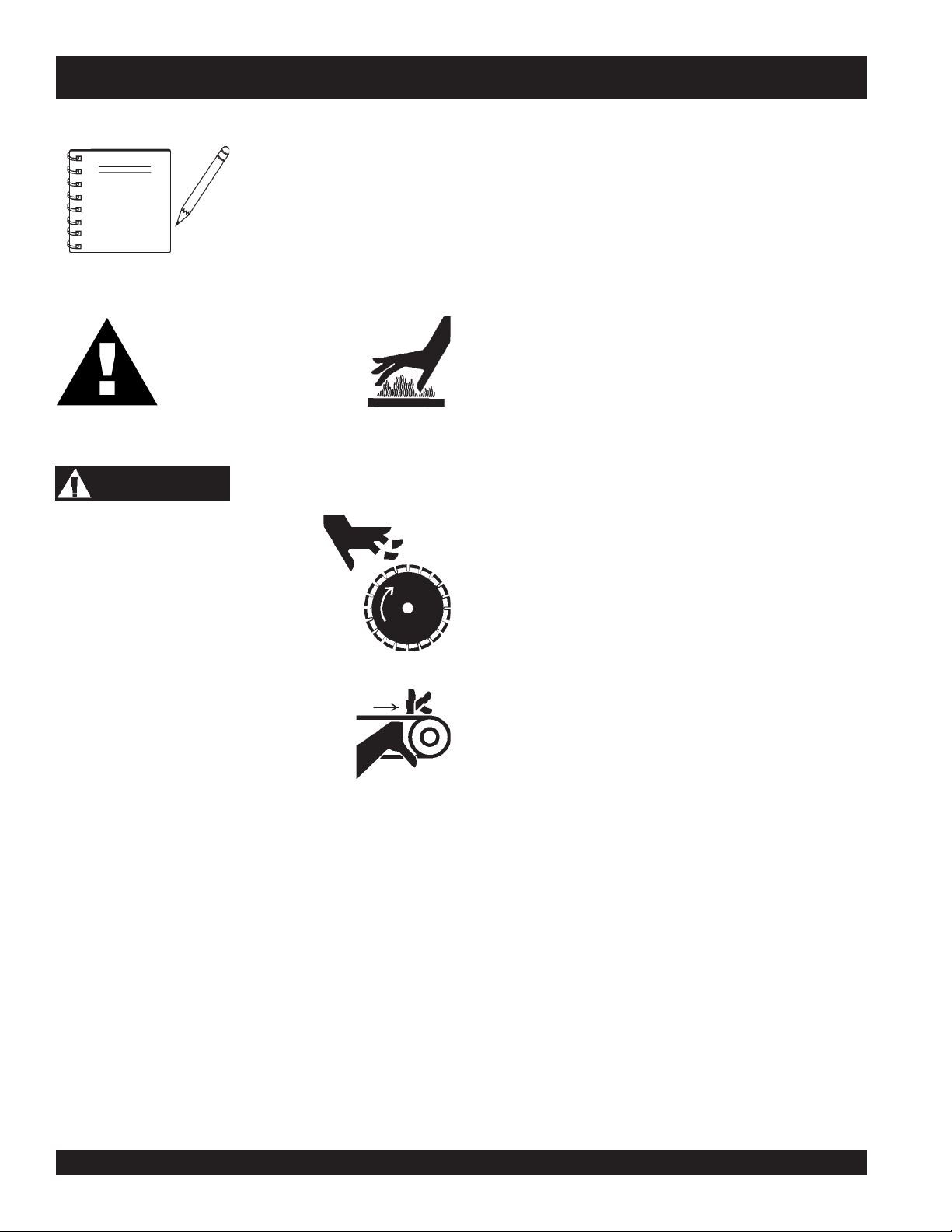

Rotating Blade

NOTE

Rotating blade can cut and crush. Keep

hands and feet clear.

This

concrete/asphalt saw

, other

property, or the surrounding

environment could be damaged if

you do not follow instructions.

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 7

Page 8

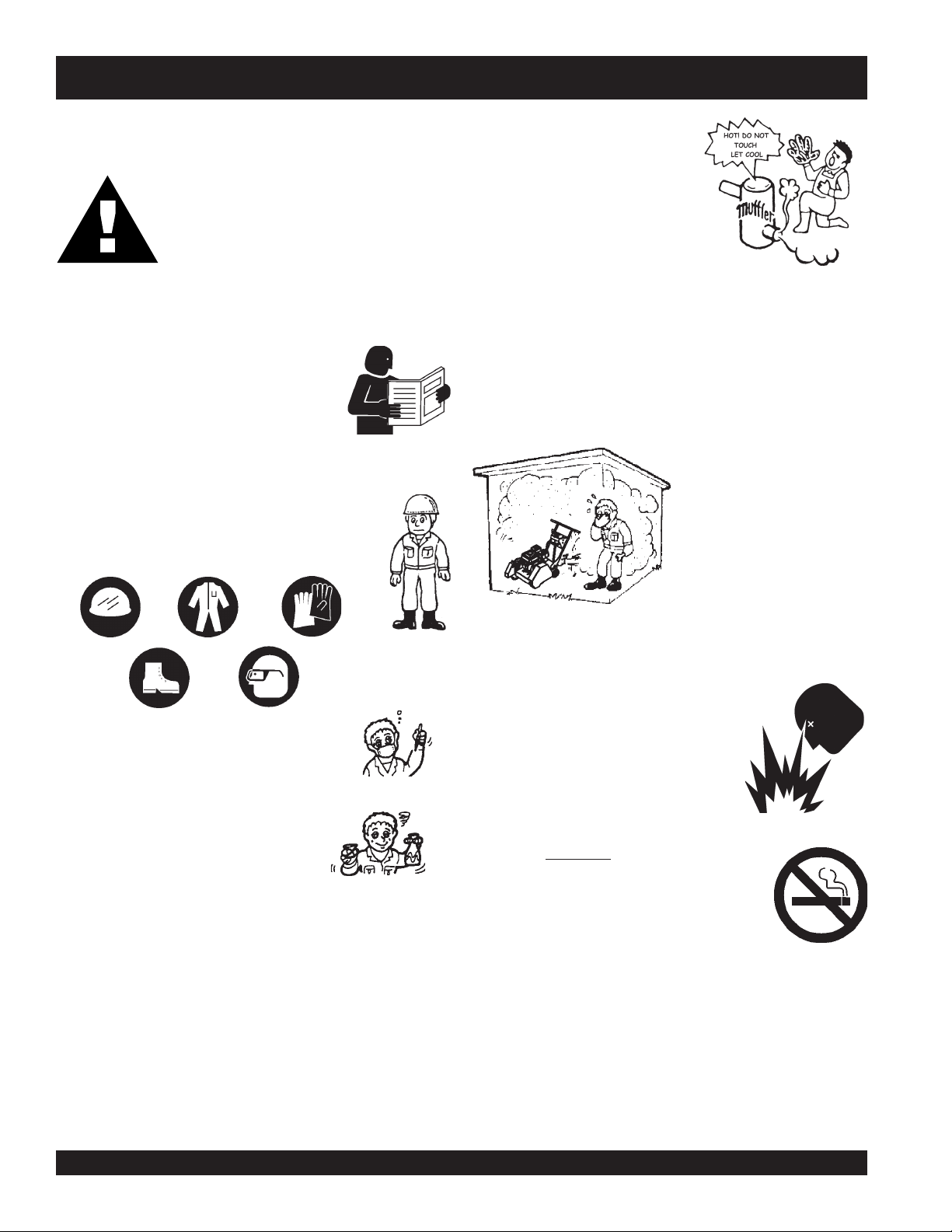

STOW CUTTER 1 SAW — RULES FOR SAFE OPERATION

RULES FOR SAFE OPERATION

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is

for industrial use only.

The following safety guidelines should always be used when

operating the STOW CUTTER 1 SAW . Unless otherwise noted,

these guidelines refer to saws with gasoline powered engines.

SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by persons under 18

years of age.

■

NEVER operate the saw without proper protective

clothing, shatterproof glasses, steel-toed boots

and other protective devices required by the job.

■

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

the saw.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot!

with

■

The engine of this saw requires an adequate free flow of

cooling air. NEVER operate the saw in any enclosed or narrow

components can cause serious burns.

area where free flow of the

air is restricted. If the air flow

is restricted it will cause

serious damage to the saw's

engine and may cause injury

to people. Remember the

saw's engine gives off

DEADLY

gas.

carbon monoxide

■

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate the saw under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by STOW or Multiquip for this equipment.

Damage to the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications. Unauthorized equipment

modification will void all warranties.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS check the saw for loosened hardware such as nuts

and bolts before starting.

■

■

■

■

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, STOP the engine and allow

it to cool.

NEVER

machine. Fire or explosion could result from

fuel vapors

engine.

NEVER operate the saw in an explosive atmosphere where

fumes are present or near combustible materials. An explosion

or fire could result causing severe

smoke

around or near the

, or if fuel is spilled on a

hot!

bodily harm or even

death.

Topping-off to filler port is dangerous, as it tends to spill fuel.

NEVER use fuel as a cleaning agent.

PAGE 8 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 9

STOW CUTTER 1 SAW — RULES FOR SAFE OPERATION

General Safety

■

ALWAYS read, understand, and follow procedures in

Operator's Manual before attempting to operate equipment.

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operating techniques before using the saw.

■

NEVER leave the machine

■

Block the unit when leaving or when using on a slope.

■

ALWAYS check to make sure that the operating area is clear

before starting the engine.

■

Maintain this equipment in a safe operating condition at all

times.

■

ALWAYS stop the engine before servicing, adding fuel and

oil.

■

NEVER run the engine without the air filter. Severe engine

damage could occur.

■

ALWAYS service air cleaner frequently to prevent carburetor

malfunction.

■

AVOID wearing jewelry or loose fitting clothing that may snag

on the controls or moving parts, this can cause a serious

injury.

■

ALWAYS keep clear of

saw is in operation.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of

the reach of children.

■

NEVER use accessories or attachments which are not

recommended by the manufacturer for this equipment.

Damage to the equipment and/or injury to user may result.

unattended

rotating

or

while running.

moving parts

while the

■

■

■

■

■

■

Diamond Blade Safety

■

■

■

■

WARNING

MAKE CERTAIN the power cord/extension cord is free from

damage and that the grounding circuit is operational.

MAKE CERTAIN the extension cord that you are using is

intended to be used in the environment you are using it in. If

an extension is used, NEVER submerge the connection in

water. To reduce the risk of electric shock, always make watertight connections.

MAKE CERTAIN the "ON/OFF" switch is in the "OFF" position

before plugging in the power cord/extension cord to avoid

accidental starting.

Use only the gauge wire and length of cord recommended for

the motor size. Refer to Table 3 in this manual.

When cutting, ALWAYS be aware of the location of the cord.

NEVER use a

Use appropriate steel centered diamond blades

manufactured for use on concrete saws.

worn, frayed

or

damaged

extension cord.

WARNING

ALWAYS inspect diamond blades

before each use. The blade should

exhibit no cracks, dings, or flaws in

the steel centered core and/or rim.

Center (arbor) hole must be

undamaged and true.

Examine blade flanges for damage, excessive wear and

cleanliness before mounting blade. Blade should fit snugly

on the shaft and against the inside/outside blade flanges.

Ensure the blade is marked with an operating speed greater

than the blade shaft speed of the saw.

■

ALWAYS check to make sure that the

operating area is clear before starting the

engine.

■

Keep all inexperienced and unauthorized people away from

the equipment at all times.

Electric Saws

■

ALWAYS connect electric motor of the saw to a power source

in compliance with all local and state electrical codes. This

must be performed by a qualified electrician. After this

connection is made, it will be necessary to check the rotation

of the motor shaft. The shaft rotation should be

clockwise

end. If the rotation of the shaft is incorrect make necessary

changes for the correct shaft rotation.

when viewing the motor from the shaft extension

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 9

counter-

■

■

■

■

■

Only cut the material that is specified by the diamond blade.

Read the specifications of the diamond blade to ensure the

proper tool has been matched to the material being cut.

ALWAYS keep blade guards in place. Exposure of the

diamond blade must not exceed 180 degrees.

Ensure that the diamond blade does not come into contact

with the ground or surface during transportation. DO NOT

drop the diamond blade on ground or surface.

The engine governor is designed to permit maximum engine

speed in a no-load condition. Speeds that exceed this limit

may cause the diamond blade to exceed the maximum safe

allowable speed.

Ensure that the blade is mounted for proper operating

direction.

Page 10

STOW CUTTER 1 SAW — RULES FOR SAFE OPERATION

Saw Transportation Safety

■

Use appropriate lifting equipment to ensure the safe

movement of the saw.

■

DO NOT use the handle bars and/or front pointer as lifting

points.

■

When trasporting of the saw is required, place saw directly

inside towing vehicle truck-bed and tie-down securely.

NEVER tow saw directly behind towing vehicle.

■

DO NOT use the saw on slopes or on extremely un-level

surfaces. An engine tipped to extreme angles may cause oil

to gravitate into the cylinder head making the engine start

difficult.

■

NEVER transport the saw with the blade

EMERGENCIES

mounted.

■

ALWAYS know the location of

the nearest

fire extinguisher

.

Machine Operation And Safety Decals

The STOW CUTTER 1 SAW is equipped with a number of

operation and safety decals. Should any of these decals become

unreadable, replacements can be obtained from your dealer.

■

ALWAYS know the location of the

nearest

■

In emergencies

nearest phone or

Also know the phone numbers of the nearest

first aid kit

ambulance, doctor,

information will be invaluable in the case of an

emergency.

.

always

know the location of the

keep a phone on the job site

and

fire department

.

. This

Figure 1. STOW CUTTER 1 SAW Decals

PAGE 10 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 11

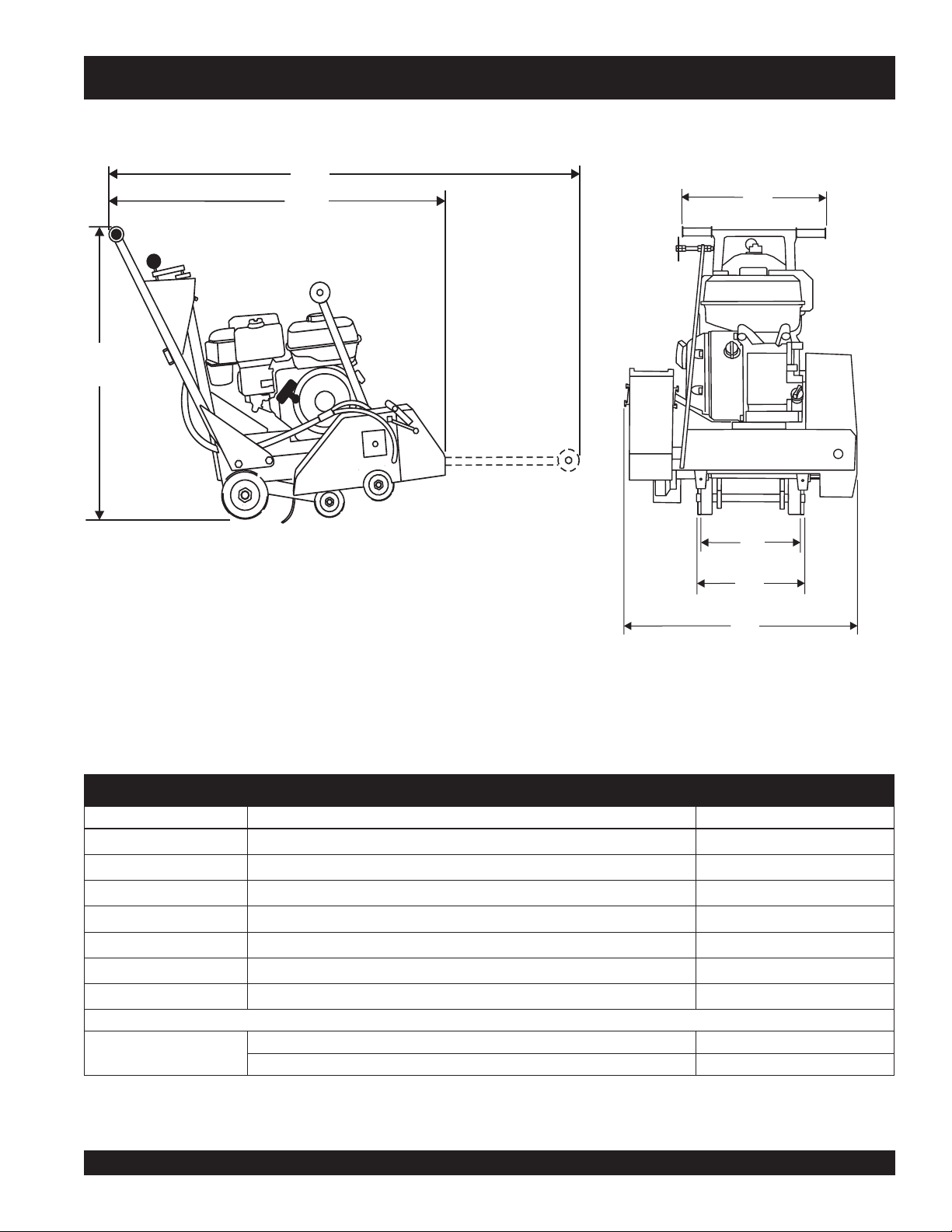

A

STOW CUTTER 1 SAW — SPECIFICATIONS (SAW)

C

B

G

A

B

C

D

E

F

G

Side View

Front View

Figure 2. STOW CUTTER 1 SAW Dimensions

snoitacificepS1rettuC.1elbaT

RETTELECNEREFER NOITPIRCSED )mc(NOISNEMID

thgieHxaM

)desiaRretnioPtnorF(htgneLxaM

)derewoLretnioPtnorF(htgneLxaM

htdiWxaM )mc55(.nI5.12

esaBleehWraeR )mc04(.nI0.71

esaBleehWtnorF )mc4.52(.nI0.01

htdiWraBeldnaH )mc55(.nI5.12

F

E

D

)mc49(.nI0.73

)mc08(.nI0.23

)mc831(.nI5.45

ENIGNE

EPYT

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 11

NOITPIRCSED )GK(THGIEW

ENIGNEADNOHPH31,1RETTUC )g.K79(.sbl412

Page 12

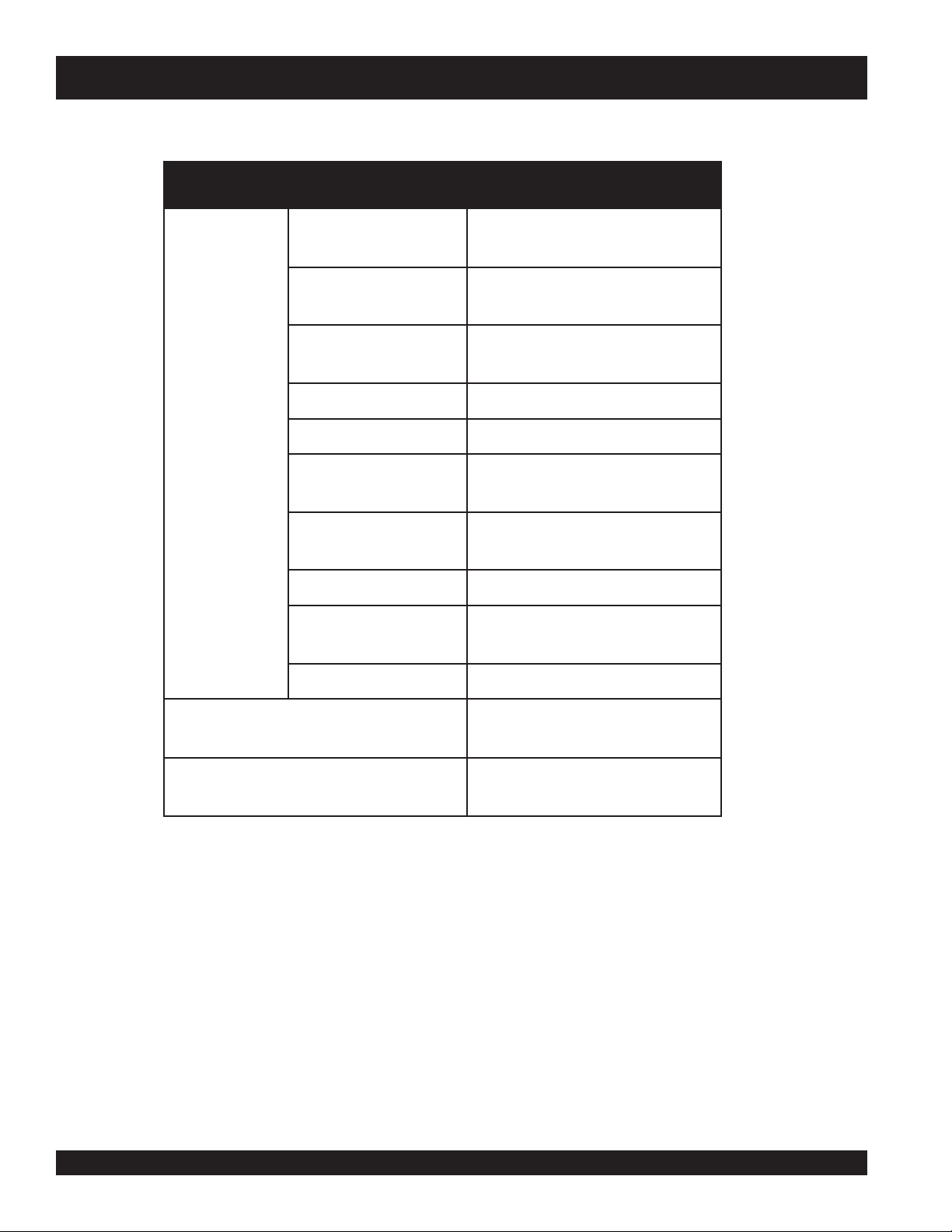

STOW CUTTER 1 SAW — SPECIFICATIONS (ENGINE)

)enignE(snoitacificepS.2elbaT

ledoM

epyT

eroB

enignE

leuF

ekortSX

tnemecalpsiD)cc983(.ni-uc7.32

tuptuOxaM.M.P.R0063/.P.H0.31

yticapaCknaTleuF

yticapaCliOebuL)retil1.1(tqSU61.1

lortnoCdeepS

dohteM

ADNOH

2TWQ1U093XG/2TWQ1K093XG

elgniS,ekorts4delooc-riA

enignEenilosaG,VHO,rednilyC

.ni5.2X.ni5.3

)mm46xmm88(

snollaG.S.U27.1.xorppA

)sretiL5.6(

enilosaGelibomotuAdedaelnU

rehgihroenatcO68

epyTthgiew-ylFlagufirtneC

dohteMgnitratStratSlioceR

noisnemiD

)HxWxL(

yrD

thgieWteN

.ni4.71X7.71x0.51

)mm344X054X083(

).gK13(sbl4.86

PAGE 12 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 13

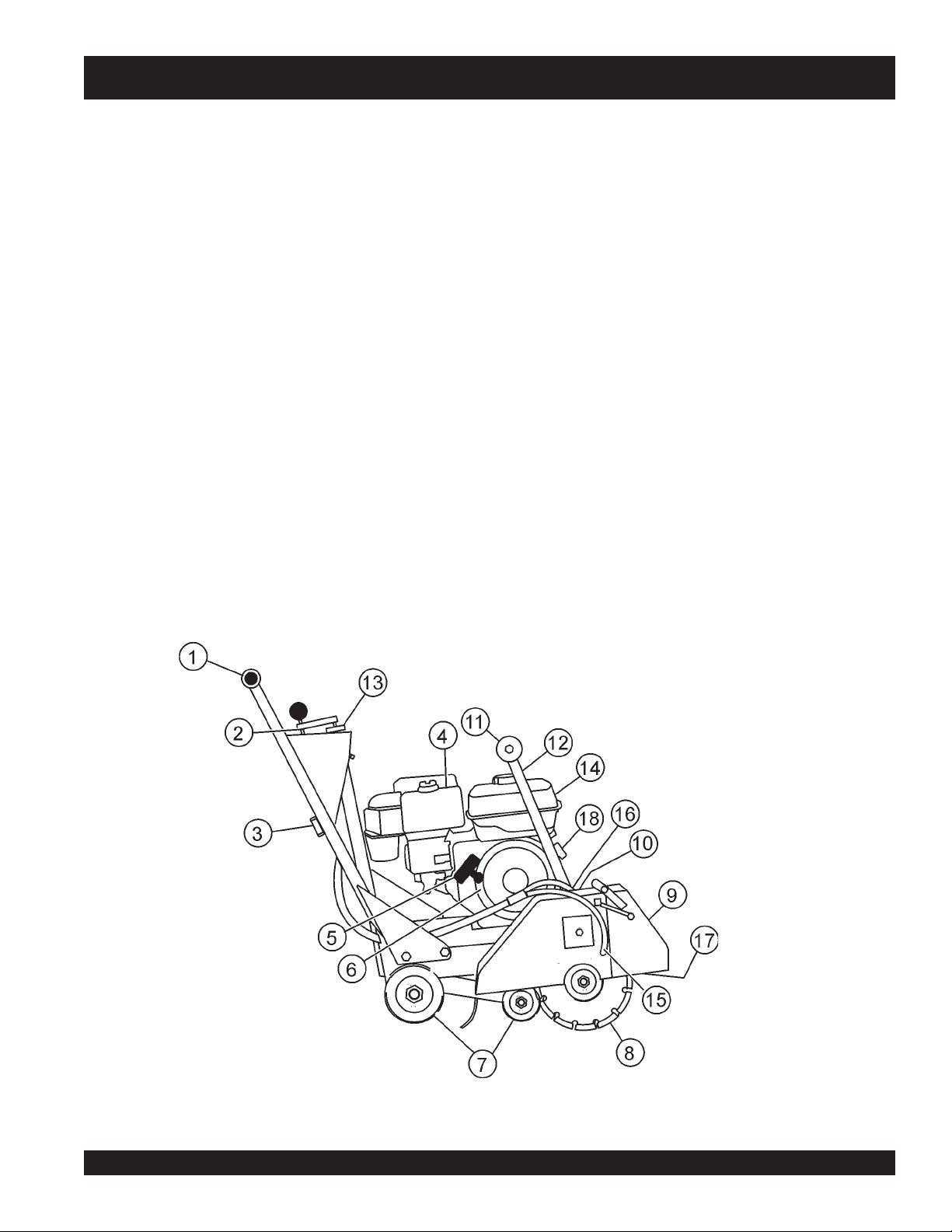

STOW CUTTER 1 SAW — CONTROLS & COMPONENTS

CONTROLS & COMPONENTS

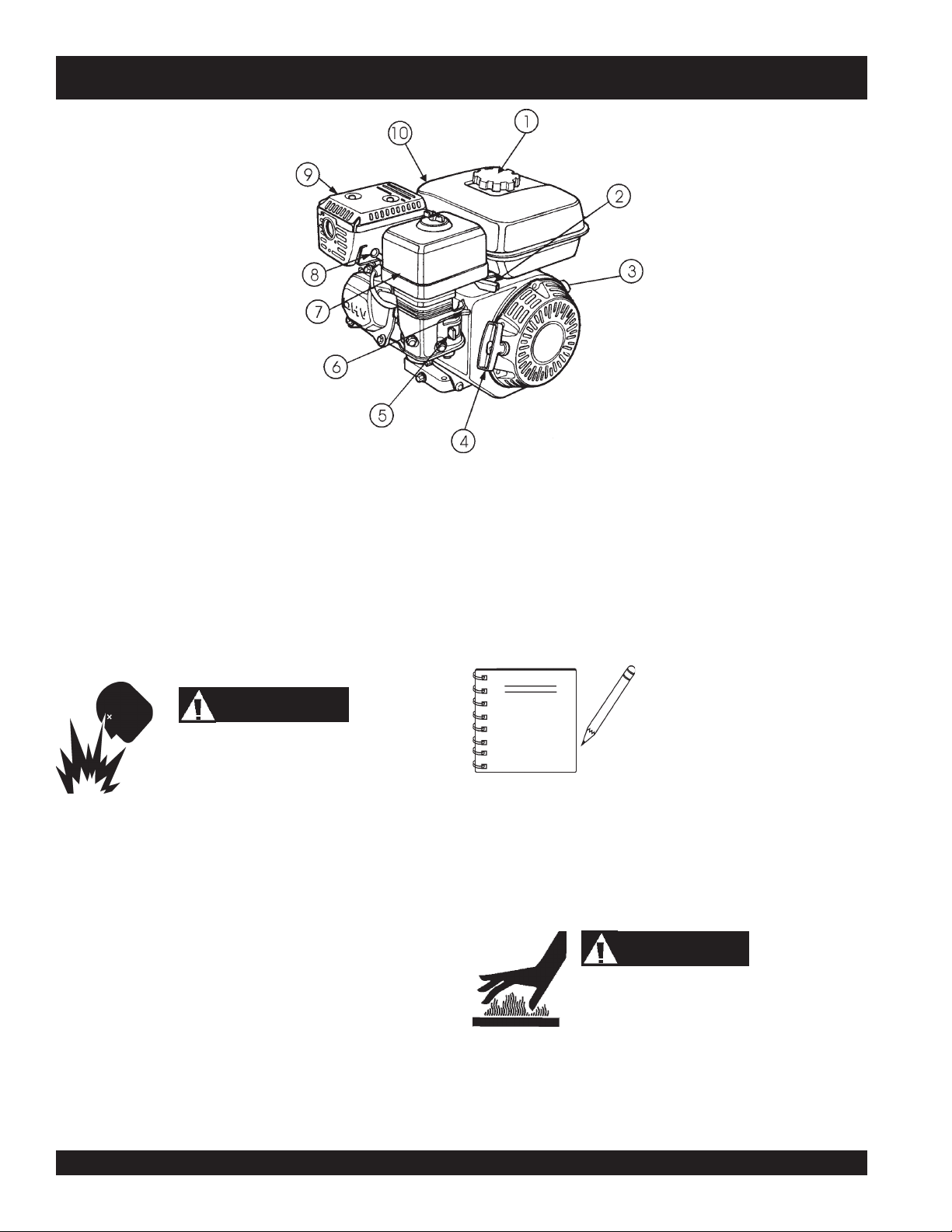

Figure 3 shows the location of the basic controls or components

for the STOW CUTTER 1 SAW. Listed below is a brief

explanation of each control or component. (Gasoline-powered

unit shown)

1. Hand Grips/Handlebar – When operating the saw, place

both hands on each grip to maneuver the saw. Replace

hand grips when they become worn or damaged.

2. Handle Lock – Lock blade depth to desired position.

3. Garden Hose Connecter – Connect to water source to

provide blade cooling while cutting concrete or asphalt.

4. Air Filter – Prevents dirt and debris from entering the engine

air intake. Check filter periodically and keep cleaned or

replace when necessary.

5. Recoil Starter Handle – Pull to engage and start the

engine.

6. Recoil Starter Assembly – Engages the engine when

the handle is pulled and rewinds the starter rope when the

handle is released.

7. Wheels/Carriage Assembly – Heavy-duty polyurethane

wheels with permanently sealed ball bearings.

8. Cutting Blade – Use appropriate type blades for cutting

concrete or asphalt.

9. Blade Guard – Covers saw blade and flips up to allow

blade to be changed.

10. Belt Tension Adjuster – Adjusts belt tension.

11. Front Pointer – Front pointer wheel assists in straight

tracking.

12. Front Pointer Arm – Stows up for storage and pivots down

for use.

13. Cutting Depth Adjuster – turn operating crank clockwise

or counter-clockwise to adjust the cutting depth up or down.

14. Fuel Tank – Use unleaded gasoline. Do not overfill.

15. Blade Coolant System – Provides cooling water to blade

during cutting operations.

16. V-Belt Cover – Remove this cover to gain access to the Vbelt. NEVER operate the saw with this cover removed.

17. Arbor Shaft Grease Zerks – Conveniently located for

lubrication.

18. On/Off Switch – Turn to the "ON" position to allow engine

to be started and turn to the "OFF" position to shut the

engine off.

Figure 3. Cutter 1

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 13

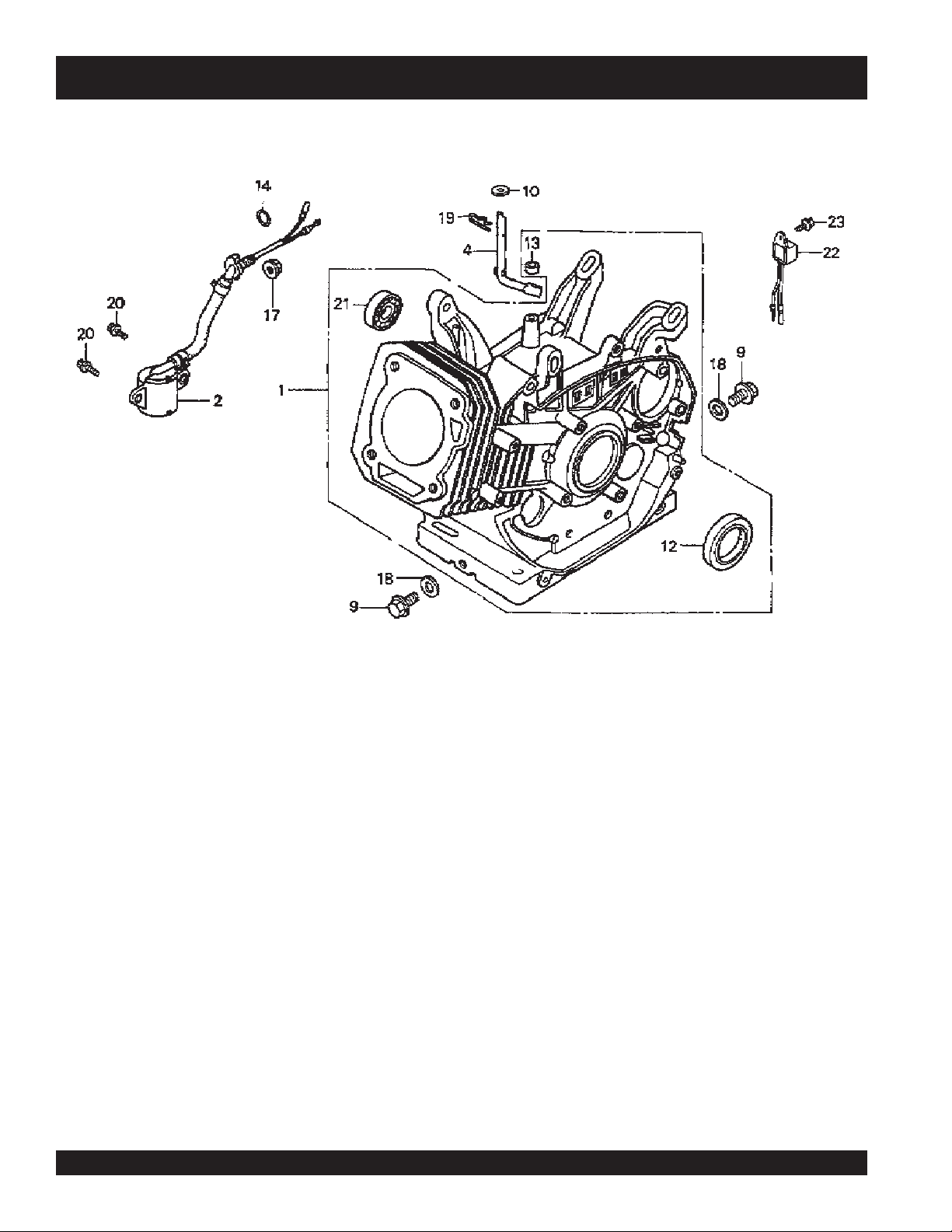

Page 14

BASIC ENGINE

STOW CUTTER 1 SAW — BASIC ENGINE

Figure 4. Engine Controls and Components

Initial Servicing

The engine (Figure 4) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturers engine

manual for instructions & details of operation and servicing.

1. Fuel Filler Cap – Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

DANGER

Adding fuel to the tank should be done only when

the engine is stopped and has had an opportunity

to cool down. In the event of a fuel spill, DO NOT attempt to start the

engine until the fuel residue has been completely wiped up, and the

area surrounding the engine is dry.

2. Throttle Lever – Used to adjust engine RPM speed (lever

SLOW

advanced forward

FAST

).

3. Engine ON/OFF Switch – ON position permits engine

starting, OFF position stops engine operations.

4. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

5. Fuel Valve Lever – OPEN to let fuel flow, CLOSE to stop

the flow of fuel.

, lever back toward operator

6. Choke Lever – Used in the starting of a cold engine, or in

cold weather conditions. The choke enriches the fuel

mixture.

7. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element.

NOTE

8. Spark Plug – Provides spark to the ignition system. Set

spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch) Clean

spark plug once a month.

9. Muffler – Used to reduce noise and emissions.

operating. NEVER operate the engine with the muffler removed.

10. Fuel Tank – Holds unleaded gasoline. For additional

information refer to engine owner's manual.

Operating the engine without an air

filter, with a damaged air filter, or a

filter in need of replacement will

allow dirt to enter the engine, causing

rapid engine wear.

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

PAGE 14 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 15

STOW CUTTER 1 SAW — PREPARATION/PRE-INSPECTION

PREPARATION / PRE-INSPECTION

1. Read and fully understand this manual,

the safety instructions in particular, and

the engine manufacturer's manual

supplied with the saw.

ALWAYS use a grounded (3-wire) extension cord and MAKE

CERTAIN that the motor is connected to a properly grounded

electric circuit to protect the operator from possible electric shock.

2. Select the correct blade for each application. If abrasive

blades are used, MAKE CERTAIN they are designed for

use on a concrete floor saw. They must be reinforced and

have a hole for the driving pin. When wet cutting with an

abrasive blade, MAKE CERTAIN the blade is intended for

wet cutting. Water will destroy a dry cut abrasive blade.

Some diamond blades require water cooling and failure to

do so will destroy them almost immediately. Other diamond

blades can be used with or without water. Refer to the Blades

and Blade Placement sections on pages 18 and 19 for further

information.

3. Handle all blades with care and NEVER use a damaged

blade. NEVER use an abrasive blade that has been

dropped.

Electric Powered Saws (50 or 60 HZ)

1. The electric motor of this saw requires 230 VAC input

voltage (50/60 Hz, single-phase). Always make certain that

the rated operating line voltage of the motor is correct when

cutting. Electric motors can burn out when the line voltage

Gasoline Powered Saws

falls 10% below the voltage rating of the motor.

2. After the correct input voltage has been applied to the saw,

turn the saw on, and check the rotation of the motor shaft.

The shaft rotation MUST be counter-clockwise when

viewing the motor from the shaft extension end. If the rotation

of the shaft is incorrect make the necessary changes for

the correct shaft rotation.

3. MAKE CERTAIN the correct size extension cord is used.

Undersize extension cords can burn out an electric motor.

Use Table 3 to determine the correct extension cord size.

4.

NEVER!

use a

worn

or

frayed

extension cord.

5. Record the model and serial number of the saw on the

front of the Operating and Parts Manual for future reference.

1. Clean the

engine cooling air inlet, carburetor and air cleaner.

2. Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

3. Check carburetor for external dirt and dust. Clean with dry

compressed air.

4. Check fastening nuts and bolts for tightness.

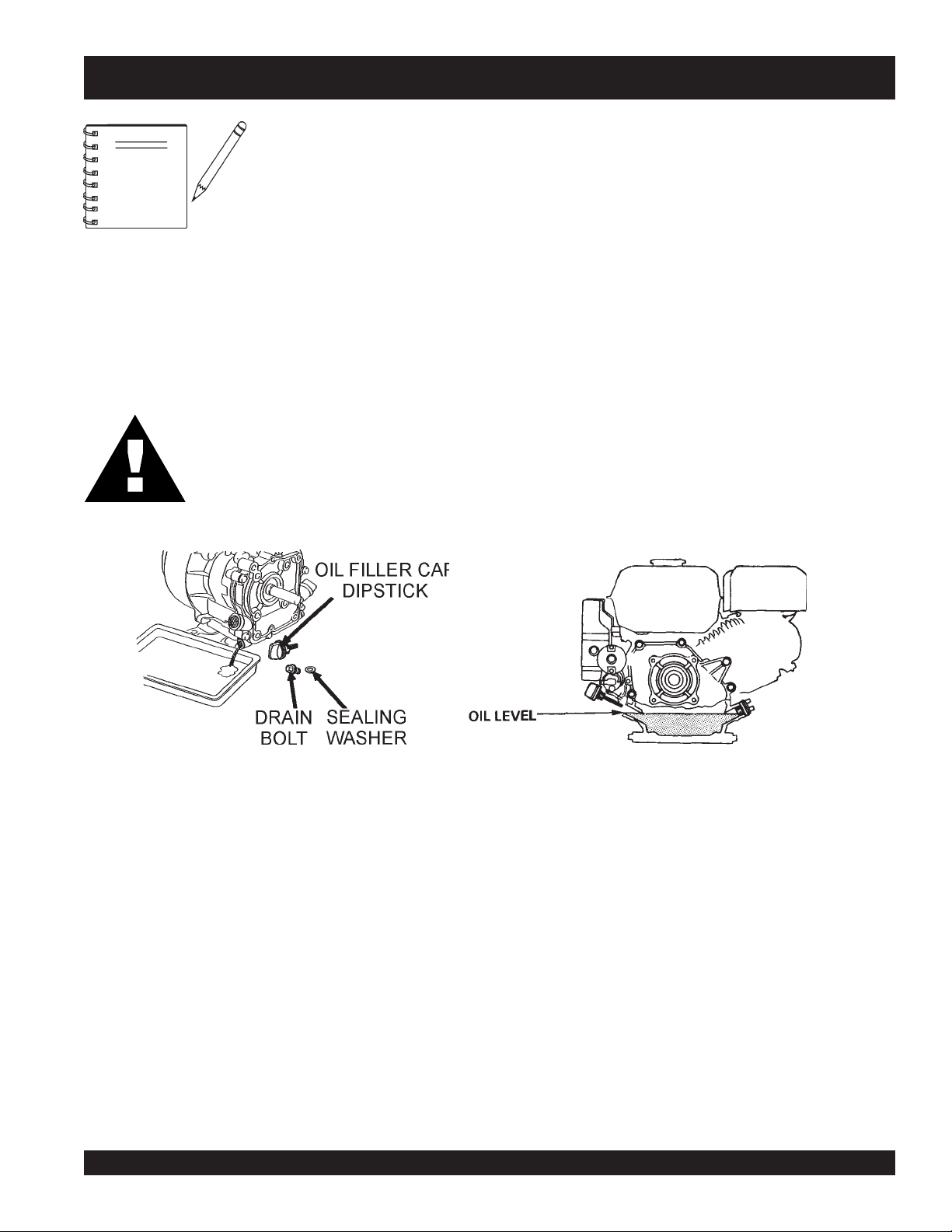

Engine Oil Check

1. To check the engine oil level, place the saw on secure level

ground with the engine stopped. The frame platform

be level

2. Remove the filler dipstick from the engine oil filler hole

(Figure 6) and wipe it clean.

eziSdroCnoisnetxE.3elbaT

WARNING

NEVER!

wet hands

touch the power cord (Figure 5) with

or while

standing in water

when it is connected to a power source. The

possibly exists of electrical shock (electrocution)

even death.

NEVER!

spray water directly on

the electric motor.

WET

HANDS

POWER

CORD

(POWER ON)

Figure 5. Extension Cord (Wet Hands)

saw,

removing dirt and dust, particularly the

must

to accurately check the engine oil.

eriW21.oNeriW01.oNeriW8.oNeriW6.oN

)teef(05

)sretem42.51(

)teef(57

sretem68.22(

2

)teef(001

sretem84.03(

)teef(00

sretem69.06(

Figure 6. Engine Oil Dipstick (Removal)

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 15

Page 16

STOW CUTTER 1 SAW — PREPARATION/PRE-INSPECTION

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 7), fill to the edge of the oil filler

hole with the recommended oil type (Table 4).

Guards And Covers

Reference manufacturer engine

NOTE

manual for specific servicing

instructions.

Figure 6. Engine Oil Dipstick (Oil Level)

WARNING

NEVER operate the saw without blade guards

and covers in place. DO NOT operate with

the front of the blade guard raised. The blade

exposure cannot exceed 180 degrees during

operation. Adhere to the safety guidelines of

the American National Standards Institute

(ANSI) B7.1 and B7.5.

epyTliO.4elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

Explosive Fuel

Fuel Check

Motor fuels are highly flammable and can be

dangerous if mishandled. DO NOT smoke

while refueling. DO NOT attempt to refuel the

trowel if the engine is

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if fuel level is low. If fuel is low, replenish

with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel.

hot! or running

.

CHECK the following on the blade guard (Figure 8):

■

■

■

ENSURE the V-belt Cover is in place and securely fastened

during operation of the saw (Figure 8).

V-Belt Check

A worn or damaged V-belt can adversely affect the performance

of the saw. If a V-belt is defective or worn, replace ALL the Vbelts. V-belts should always be replaced in sets.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Figure 7. Blade Guard

Ensure the capacity of the blade guard matches the diameter

of your diamond blade.

Check that the guard is bolted firmly upon the saw frame.

Check that the spring tensioned front cover of the guard is

firmly seated with the rear section of the guard and there are

no gaps. NEVER lift the blade guard while cutting.

NEVER attempt to check

the V-belt with the engine

running. Severe injury can

occur. Keep fingers, hands,

hair, and clothing away

from all moving parts.

PAGE 16 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 17

STOW CUTTER 1 SAW — PREPARATION/PRE-INSPECTION

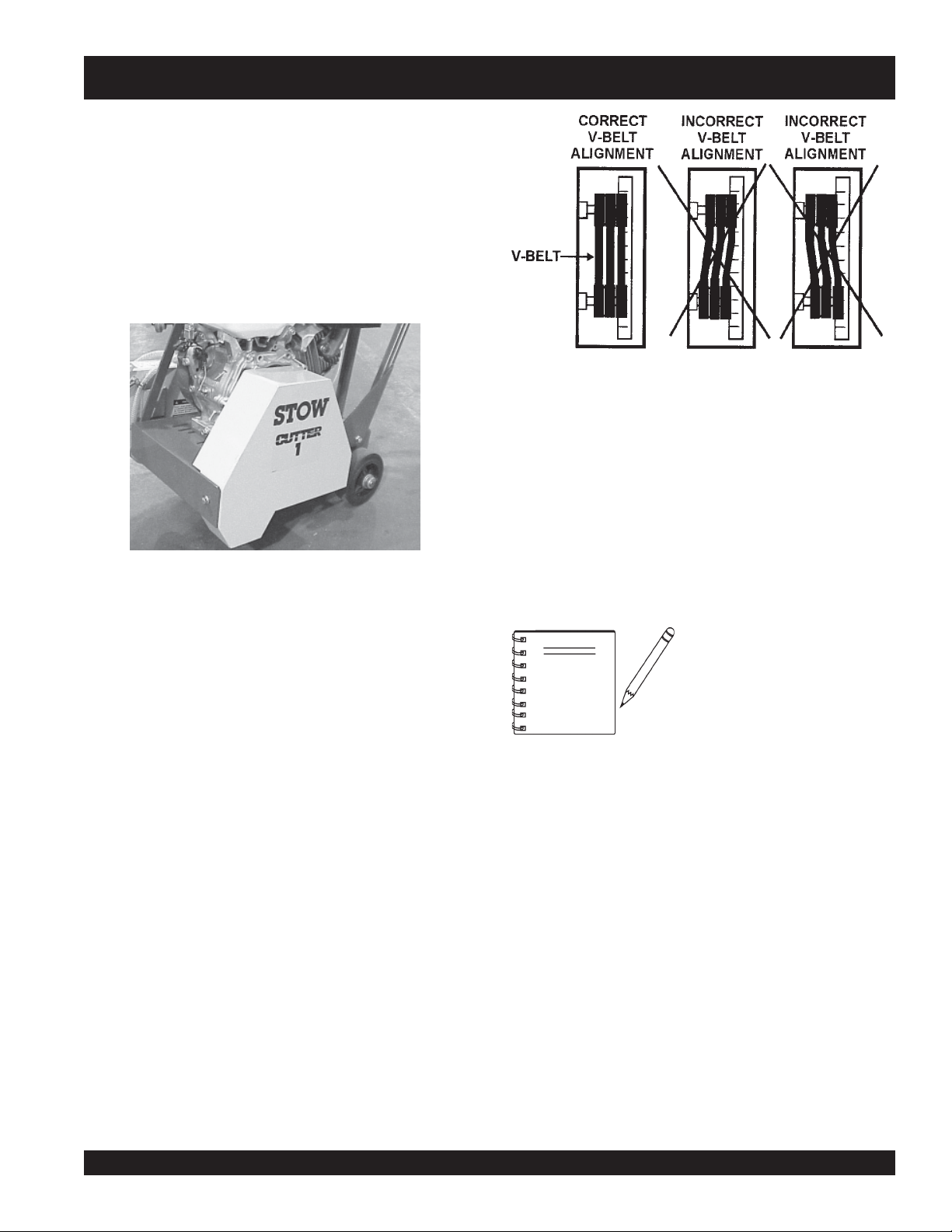

V-belt Alignment and Tensioning

This saw is equipped with a premium V-belt that has been aligned

and tensioned by factory personnel. The V-belt must be aligned

and tensioned for proper operation of the saw.

Use the following procedure to check the alignment of V-belt:

1. Remove the bolts that secure the V-belt cover (Figure 9) to

the saw frame.

Figure 9. V-Belt Cover

2. Check uniform parallelism (Figure 10) of V-belt and pulley

(sheaves). Use a straight-edge or machinist's square against

both pulleys and adjust both pulleys until equally aligned.

Figure 10. Pulley Alignment

3. Check V-belt tension by using a tension meter (3.0 lbs.)

against the inside belt at a mid point between the two pulleys,

or by deflecting the center belt at a mid point 3/16" (5 mm).

4. DO NOT over or under tighten the V-belt. Severe damage

can occur to the saw and engine crankshaft if the belt is

over-tensioned. A decrease of power to the blade and poor

performance will result if the belt is under-tensioned (loose

on pulleys).

V-belt alignment must be

NOTE

rechecked after adjusting belt

tension.

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 17

Page 18

STOW CUTTER 1 SAW — BLADES

BLADES

Saw blades, or cutting disks, are available in either an abrasive

design or as diamond blades. Either blade will work on the

STOW CUTTER 1 SAW , however, diamond blades are

recommended. Ask your dealer about your specific cutting

application.

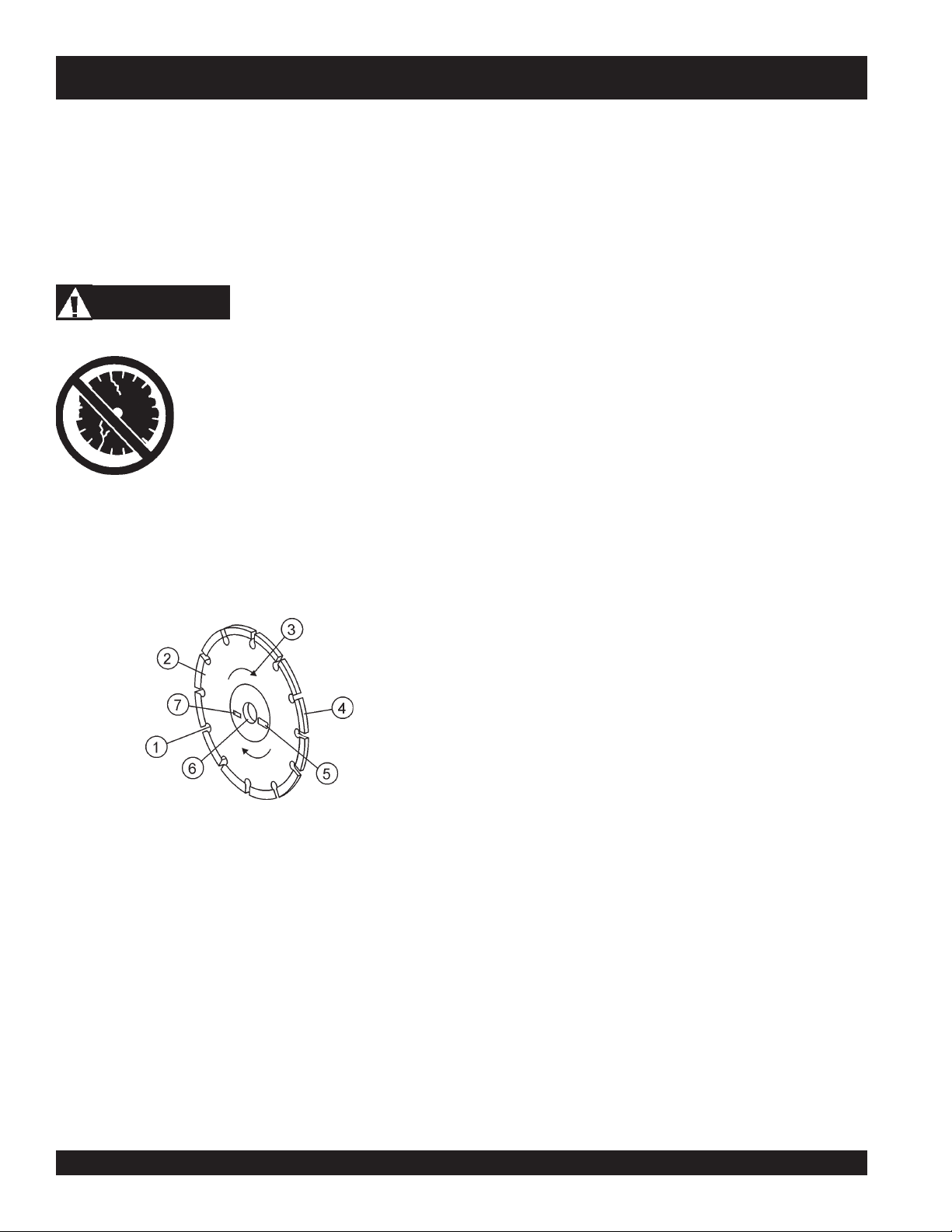

SAW BLADE INSPECTION

WARNING

Failure to thoroughly inspect the diamond

blade (Figure 11) for operational safety

could result in damage to the blades or

the saw and may cause injury to the user

or others in the operating area.

2. Edge of the Steel Core - Check the diameter edge for

discoloration (blue oxidation) indicating an overheating

condition caused by insufficient cooling water/air.

Overheating of blades may lead to loss of core tension and/

or increase the possibility for blade failure. Make sure the

steel core's width is uniform about the rim of the blade, and

not succumbing to an "under-cutting" condition brought

about by highly abrasive material or improper under-cutting

core protection.

3. Directional Arrow - Ensure that the blade is oriented

properly on the blade shaft for sawing. Reference the

directional arrow on the blade and place it so the direction

of rotation "downcuts" with the turn of the shaft.

4. Diamond Segment or Rim - Ensure there are no cracks,

dings, or missing portions of the diamond segment/rim. DO

NOT

of the rim.

cause damage to your saw or injury to the user or others in

1. Stress Relief Holes (Gullets) - Check the steel core for

cracks that may have propagated from the slots and/or

gullets. Cracks indicate extreme fatigue failure and if sawing

continues, catastrophic failure will occur.

the operating area.

5. Specifications - Ensure that the blade specifications, size,

and diameter properly match up to sawing operations.

Utilizing a blade not matched properly to the task may result

in poor performance and/or blade damage.

use a blade that is missing a segment or a portion

Damaged and /or missing segments/rims may

Figure 11. Diamond Blade

6. Arbor Hole - It is essential that the arbor hole diameter

properly matches the blade, and that it is free from distortion.

Correct blade flanges (collars) must be used. The inside

face of the flanges must be clean and free of debris. An outof-round arbor condition will cause damage to the blade

and the saw.

7. MAX RPM - This RPM reference is the maximum safe

operating speed for the blade selected. NEVER exceed the

max RPM on the diamond blade. Exceeding the maximum

RPM is dangerous and may cause poor performance and

may damage the blade.

PAGE 18 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 19

STOW CUTTER 1 SAW — BLADE PLACEMENT

BLADE PLACEMENT

WARNING

Failure to thoroughly inspect the diamond

blade for operational safety could result in

damage to the blades or the saw and may

cause injury to the user or others in the

operating area.

1. Blade Guard - Pivot the blade guard

front cover all the way back. The guard

tension spring will keep the front cover in position.

2. Blade Hex Nut - Unscrew the blade shaft nut (right side

loosens clockwise and tightens counter-clockwise while the

left side loosens counter-clockwise and tightens clockwise.

DO NOT overtighten the nut (approximately 45-50 ft. lb/6168 N/m) when finalizing the assembly.

3. Outside Blade Flange (Collar) - Ensure that the outside

blade flange is placed flush against the diamond blade.

The inside surface of the flange must be free of debris and

permit a tight closure on the surface of the blade core.

4. Diamond Blade - Ensure that the proper diamond blade

has been selected for the job. Pay close attention to the

directional arrows on the blade. The blade's operating

directional arrows must point in a "down-cutting" direction

to perform correctly. When placing the blade onto the blade

shaft, ensure the arbor hole of the blade matches the

diameter of the shaft.

damage the diamond blade and may

cause serious damage to the saw and

bodily harm.

Blade Removal and Replacement

1. Set the engine ON/OFF switch to the

2. Place the saw on a stable level working

3. Ensure the blade is raised and the raise/lower crank is locked

5. Lift up the blade guard cover to gain access to the blade.

6. Use the provided blade nut and blade shaft locking

WARNING

Dropping or forcing the

blade onto the cutting

surface can severely

"OFF" position. (Unplug electric

models.)

surface.

into position.

When removing or installing a

NOTE

wrenches to remove and install the blade.

diamond blade, please note that the

blade retaining nuts are left and righthand threaded.

5. Inner Flange (Collar) - This flange is fixed upon the blade

shaft. The inside surface of the flange must be free of debris

and permit a tight closure on the surface of the blade.

Blade Speed

A diamond blade’s performance is directly connected to specific

peripheral (rim) speeds.

The following shaft rotational speeds have been factory set to

ensure optimum blade performance.

z

CUTTER 1- 18-inch (457.2 mm) Capacity - 2,836 RPM.

NOTE

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 19

The following steps should be

accomplished before using the saw

on any cutting surface.

■

■

■

Cutting Depth Adjustment

The saw is equipped with a Raise/Lower Assembly that is

supported by the following components.

■

Raise/Lower Acme Screw

■

Jack Arm

■

Blade Guard

■

Adjusting Handle Crank

While holding the blade shaft with the locking wrench,

remove the blade hex nut (clockwise direction) and outer

blade flange.

Remove the old blade and install a new blade in the

same rotational direction as marked on the old blade.

Reinstall the outer blade flange and hex nut. Tighten

the nut firmly (counter-clockwise direction). DO NOT

OVER TIGHTEN.

Page 20

STOW CUTTER 1 SAW — INITIAL START-UP

INITIAL START-UP

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ALWAYS wear approved eye and hearing

protection before operating the saw.

DO NOT attempt to operate the saw until

the Safety, General Information and

Inspection sections of this manual have

been read and thoroughly understood.

Depending on engine manufacturer,

operating steps may vary. See engine

manufactures operating manual.

NEVER operate the saw in

a confined area or

enclosed area structure

that does not provide ample

free flow of air

.

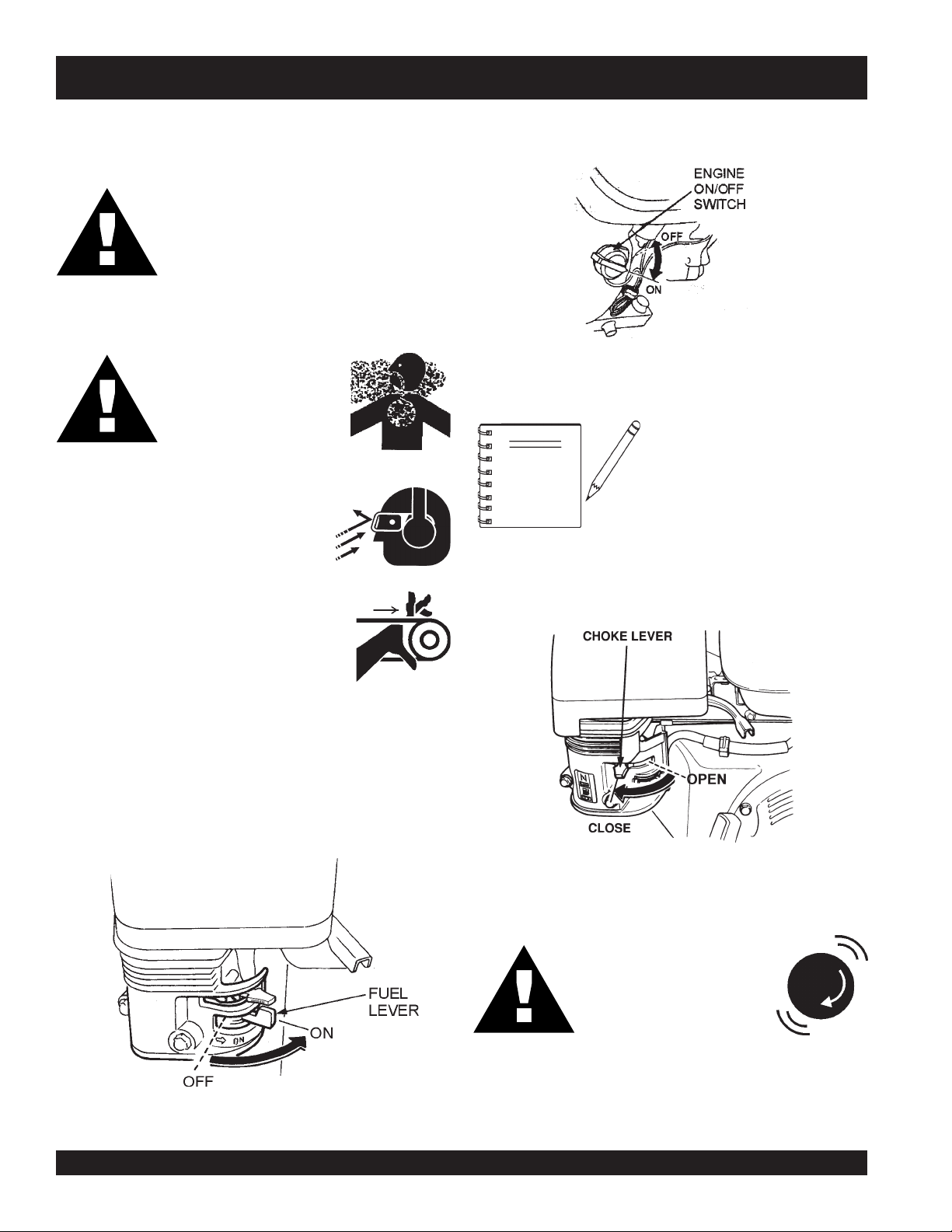

3. Place the

position.

NOTE

Engine ON/OFF switch

Figure 13. Engine ON/OFF Switch

(Figure 13) in the "ON"

The CLOSED position of the

choke lever enriches the fuel

mixture for starting a COLD engine.

The OPEN position provides the

correct fuel mixture for normal

operation after starting, and for

restarting a warm engine.

NEVER place hands or feet inside the belt

guard or blade guard while the engine is

running. ALWAYS shut the engine down

before performing any kind of maintenance

service on the saw.

1. Ensure the diamond blade has been mounted correctly and

that it is raised above the surface you are about to saw.

2. Place the

fuel valve lever

(Figure 12) to the "ON" position.

4. Place the

position.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Choke Lever

Figure 14. Choke Lever

The engine speed has

been set at the factory.

Changing the governor

speed could damage the

blade and/or the saw.

(Figure 14) in the "

CLOSED

"

Figure 12. Engine Fuel Valve Lever

PAGE 20 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 21

STOW CUTTER 1 SAW — INITIAL START-UP/OPERATION

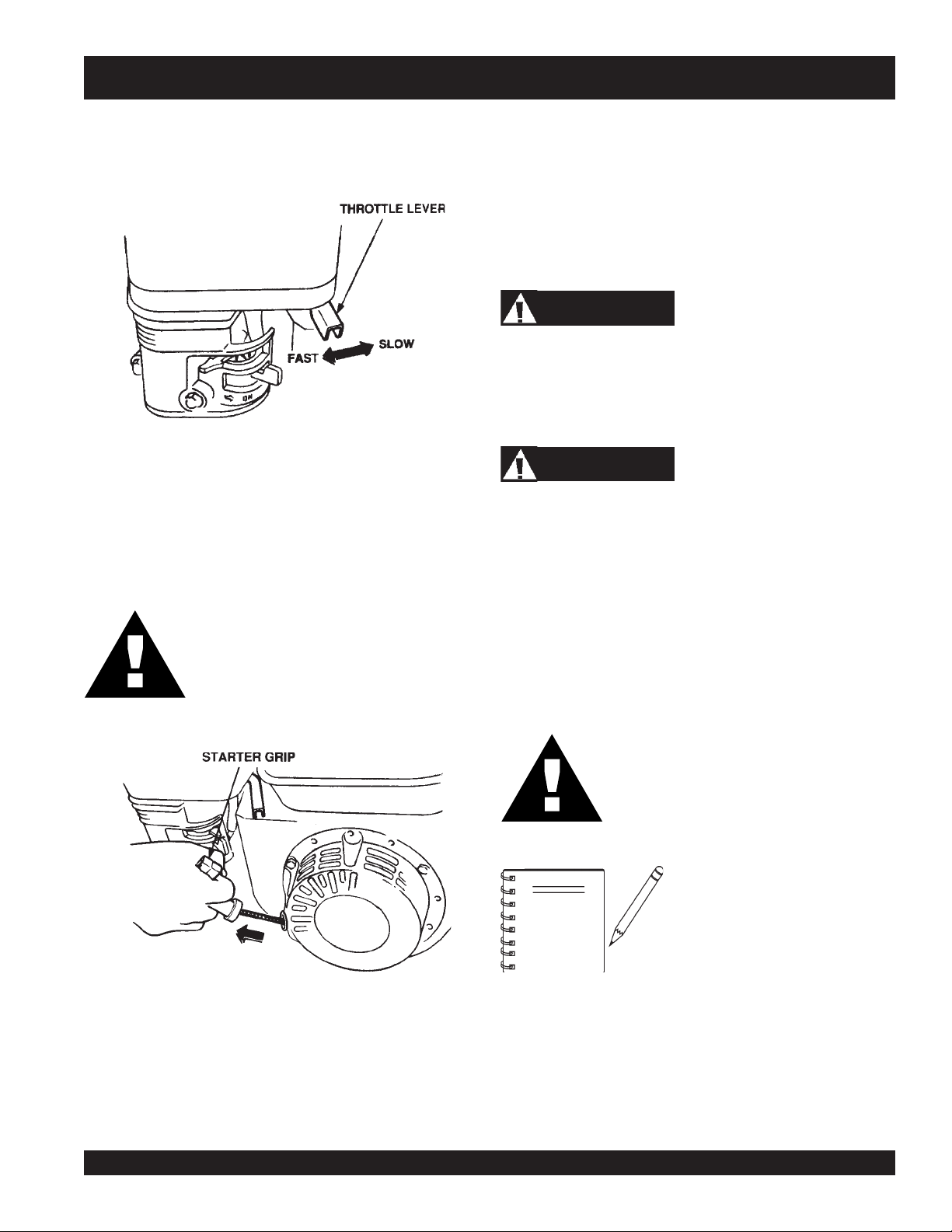

5. Rotate the

and

engine governor speed is factory set to ensure optimum

blade operating speeds.

6. Grasp the starter grip (Figure 16) and slowly pull it out. The

resistance becomes the hardest at a certain position, corresponding to the compression point. Pull the starter grip briskly

and smoothly for starting.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

throttle lever

slow

for starting. All sawing is done at

Figure 15. Throttle Lever

(Figure 15) halfway between

full throttle

fast

. The

8. Before the saw is placed into operation, run the engine for

several minutes. Check for fuel leaks, and noises that would

associate with a loose guards and/or covers.

OPERATION

1. Start the engine. Rotate the throttle lever (Figure 14) toward

full throttle.

WARNING

ALWAYS cut with the saw at FULL THROTTLE. Attempting to

cut with the saw at less than full throttle could cause the blade to

bind or stop abruptly in the slab resulting in serious injury to the

operator or others in the area.

WARNING

ALWAYS keep clear of

this equipment.

2. To begin sawing, lower the rotating blade allowing it to cut to

the preset depth.

rotating

or

moving

parts while operating

DO NOT pull the starter rope all the way to

the end. DO NOT release the starter rope

after pulling. Allow it to rewind as soon as

possible.

Figure 16. Starter Grip

7. If the engine has started, slowly return the choke lever

(Figure 14) to the

started repeat steps 1 through 6.

"OPEN"

position. If the engine has not

3. When blade has reached full cutting depth, slowly walk

behind the saw at a rate that will allow the engine to operate

without losing optimum RPM.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

NOTE

4. When the end of the cut has been reached, raise the blade

out of the cut by pulling back on the handlebars (using a

downward pressure) until the raise/lower rod drops into its

slot with the blade in the raised position.

5. If cutting is complete, turn the engine off and wait for the blade

to stop rotating.

DO NOT try to cut faster than the blade will

allow. Cutting too fast will cause the blade to

rise up out of the cut. Improper cutting rate

can decrease the life of the engine and

blades.

Mark the cutting line clearly and always

saw in a STRAIGHT LINE ONLY.

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 21

Page 22

STOW CUTTER 1 SAW — MAINTENANCE

MAINTENANCE

See the engine manual supplied

NOTE

with your machine for appropriate

engine maintenance schedule and

troubleshooting guide for problems.

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

ALWAYS allow the engine to

cool before servicing. NEVER

attempt any maintenance

hot!

work on a

engine.

WARNING

ALWAYS ensure that the engine ON/

OFF switch is in the "OFF" position,

(power cable UNPLUGGED on electric

models), and that the arbor shaft has

COMPLETELY STOPPED ROTATING

before performing any of the following

operations:

3. Adjust the front pointer wheel so it just touches the side of the

straightedge or level.

4. Remove the straightedge or level.

5. Position the front pointer and blade directly over the chalk

line.

6. Start the saw and lower the blade onto the chalk line.

7. Begin cutting and make sure the blade follows the chalk line

as closely as possible.

8. The pointer should follow the chalk line as well. If it does not,

adjust the pointer by loosening then tightening the jam nuts

on the pointer until the pointer follows the same path as the

blade.

Chassis Lubrication

■

Blade Shaft Bearings - Two zerk fittings are located at

the lower-front area of the saw. Lubricate before daily

use. Use a good quality automotive or general purpose

grease. Check and lubricate more often if unit is under

heavy use. Do not overfill bearings. Overfilling can

damage the grease seals which can result in bearing

exposure to dirt and contaminants which can then shorten

the life of the bearings. Excess grease can also drip onto

the cutting surface.

■

REMOVING

■

ADJUSTING

■

LUBRICATING

■

REMOVING

■

INSPECTING, ADJUSTING, OR REPLACING

belt, arbor shaft, arbor shaft bearings or

part

Saw Blade Removal and Installation

Saw blade removal and installation is covered on page 19.

Front Pointer Adjustment

The front pointer wheel has been set at the factory. Use these

procedures only if the pointer is suspect of being out of alignment.

1. Chalk out a straight line on the prepared slab or cutting

surface.

2. Use a 4 foot straightedge or level by placing it flat against the

blade.

or

INSTALLING

front or rear pointers

any components

engine mounting bolts

blades

ANY

drive engine

Drive Belt

Refer to pages 16 and 17 of this manual for Drive Belt adjustment

procedures and Removal and Replacement procedures.

Engine

Follow the maintenance procedures outlined in the engine

owner's manual.

Engine Oil Change

Drain the used oil while the engine is warm by the following:

Refer to Figure 17.

1. Place an oil pan or suitable container below the engine drain

plug to catch the used oil.

2. Remove the filler cap/dipstick and the drain plug.

3. Drain the oil completely and reinstall the drain plug. Ensure

the drain plug is tightened securely.

PAGE 22 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 23

STOW CUTTER 1 SAW — MAINTENANCE

Dispose of used oil properly. DO

NOT pour used oil on the ground,

NOTE

4. Make sure the engine is in a level position and fill to the outer

edge of the oil filler hole with the recommended oil. (See

Table 4.) Engine oil capacity is 1.16 US quart (1.1 liter).

5. Screw in the filler cap/dipstick securely.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Running the engine with a low oil level can

cause engine damage.

down a drain, or throw in the trash.

Used oil can generally be taken to

your local recycling center or

service station for reclamation.

Figure 17. Engine Oil Change

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 23

Page 24

STOW CUTTER 1 SAW — TROUBLESHOOTING (SAW)

GNITOOHSELBUORTEDALB.5ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

gnieblairetamehtrofdrahootedalB

?tuc

foesuacebdehsinimideuqrotenignE

?tleb-Vesool

.gnittucspotsroswolsedalB

thgiartstuctonseodedalB

.eurtro/dna

?gnittuc

?rewopenignetneiciffusnI .rewopesrohenignEkcehC.gnitteselttorhtkcehC

?tucgnieblairetam

?segnalfdnasredluohs

?noitatorfonoitceridreporpmI

?tfahsedalbehtnognippilssiedalB

?wasdengilasimnodesugniebedalB .ytirgetnitnemngiladnasgniraebtfahsedalbkcehC

ehtrofdrahylevissecxesiedalB

?MPRreporpmitadesugniebedalB

robranodetnuomylreporpmiedalB

elihwedalbotdeilppaecrofevissecxE

TONOD dnawolsaylppA.tucehtniedalbehtecrof

.edalbeht"sserdeR"

.stleB-Vecalperro/dnanethgiT

.noitcerid"gnittuC-nwoD"anistniopworra

.tfahsedalbeht

.000,6yletamixorppa

.gniwasnehwecapydaets

gnittucyrT.edalbtcerrocrofpiuqitluMrorelaeDtlusnoC

ot)kcolbrednic,kcirbacilis,enotsdnas(lairetamtfosyrev

lanoitatordnadetneiroylreporpsiedalbehttahtkcehC

nodellatsniylreporperanipegnalf&edalbehttahtkcehC

gnieblairetamehthtiwedalbehtfonoitacificepskcehC

.noitamrofnirofpiuqitluMrorelaeDtlusnoC.tuc

si)MPFS(deepsetunimrepteefecafrusedalberusnE

.tfahsedalbehtnodexiffaylreporpsiedalberusnE

gnieblairetamehtrofdrahootsedalB

?tuc

robranodetnuomylreporpmiedalB

?segnalfdnasredluohs

gniloochguonegniviecertonedalB

gnilkcarc,gnirolocsidedalB

.ylevissecxegniraewro/dna

?riaroretaw

?dnuorfotuoelohrobrA .tfahsedalbehtnodexiffaylreporpsiedalberusnE

lairetamrofnesohcedalbtcerrocnI

?tucgnieb

?gnittuc

ev

.edalbeht"sserdeR"

.edalbgnittucyrdatuoba

elihwedalbotdeilppaecrofevissecxE

TONOD dnawolsaylppA.tucehtniedalbehtecrof

.gniwasnehwecapydaets

gnittucyrT.edalbtcerrocrofpiuqitluMrorelaeDtlusnoC

ot)kcolbrednic,kcirbacilis,enotsdnas(lairetamtfosyr

.tfahsedalbehtnodexiffaylreporpsiedalberusnE

tewrofdedivorpsiretawfoemulov&wolfreporperusnE

detalucricsiriagnilooctneiciffuserusnE.sedalbgnittuc

gnieblairetamehthtiwedalbehtfonoitacificepskcehC

.noitamrofnirofpiuqitluMrorelaeDtlusnoC.tuc

PAGE 24 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 25

STOW CUTTER 1 SAW — TROUBLESHOOTING (ENGINE)

)ENIGNE(GNITOOHSELBUORT.6ELBAT

MOTPMYSESUACELBISSOPNOITULOS

?gnigdirbgulpkrapS

?gulpkrapsnotisopednobraC .gulpkrapsecalperronaelC

ontub,elbaliavasileuf",tratsottluciffiD

."gulpkrapstaKRAPS

dna,elbaliavasileuf",tratsottluciffiD

eserpsiKRAPS

."gulpkrapsehttatn

?noitalusni

?gnitiucric

ifedoteudtiucrictrohS

?paggulpkrapsreporpmI.pagreporp

?evitcefedliocnoitingI.liocnoitingiecalpeR

?detrohssihctiwsFFO/NO

ronekorberiwgulpkrapS

?epytleufgnorW

gulpkrapstneic

.nrowfiecalper

otteS

.hctiws

?ytridstniop,pagkrapsreporpmI

trohsronrownoitalusniresnednoC

?gnitiucrictrohs

.stniopnaelc

.gniriw

ronoitalusni,pagkcehC

.gulpkrapsecalper

,noitalusnigulpkrapskcehC

ecalper,gniriwhctiwskcehC

krapstcerrocteS

dnapag

.resnednocecalpeR

gulpkrapsevitcefedecalpeR

ecalperdna,metsysleufhsulF

.leuffoepyttcerrochtiw

kraps,elbaliavasileuf",tratsottluciffiD

inoisserpmocdnatneserpsi

ileuf",tratsottluciffiD

."lamrons

kraps,elbaliavas

."wolsinoisserpmocdnatneserpsi

.roterubracehttatneserpleufoN

udroretaW.metsysleufhsulF

?ytridrenaelcriA .renaelcriaecalperronaelC

?nepOekohC.ekohCesolC

denethgit

?degamad

?ylreporp

?deggolcretlifleuF.retlifleufecalpeR

enilleufniriA.enilleufdeelB

?

?metsysleufnits

eR

?dedurtorprokcutsevlavtsuahxe/noitcuS.sevlavtaes-

?nrowrednilycro/dnagnirnotsiP

tongulpkrapsro/dnadaehrednilyC

teksaggulpkrapsro/dnateksagdaeH

?deggolcelohrehtaerbpacknatleuF .packnatleufecalperronaelC

.notsip

.steksag

?)ypmeknat(knatleufnielbaliavatonleuF .leuffoepyttcerroc

htiwlliF

.gulpkraps

ro/dnasgnirnotsipecalpeR

dnastlobdaehrednilyceuqroT

gulpkrapsro/dnadaehecalpeR

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 25

Page 26

STOW CUTTER 1 SAW — TROUBLESHOOTING (ENGINE)

)DEUNITNOC,ENIGNE(GNITOOHSELBUORT.6ELBAT

MOTPMYSESUACELBISSOPNOITULOS

?naelctonrenaelcriA .renae

reporpsinoisserpmoc"rewopnikaeW"

.erifsimtonseoddna

tcefeD .gulpkrapsecalperronaelC

reporpsinoisserpmoc"rewopnikaeW"

ifsimtub

.ser

.staehrevoenignE

?gulpkrapsevi

?paggulpkrapsreporpmI.pagreporpotteS

?metsysleufniretaW

?evitcefedliocnoitingI.liocnoit

?gulpkrapsytriD .gulpkrapsecalperronaelC

?epytleufgnorW

?roterubracnilevelleufreporpmI

ingiecalpeR

hsulF

?reporpmieulavtaehgulpkrapS

.gulpkraps

lcriaecalperronaelC

.tnemtsujdataolfkcehC

.roterubracdliubeR

ecalperdnametsysleufhsulF

.leufepyttcerrochtiw

ecalperdna,metsysleuf

.leuffoepyttcerrochtiw

foepyttcerrochtiwecalpeR

looC.snifgniloocnaelC

.setautculfdeepslanoitatoR

.noitc

nuflamretratslioceR

?trid

irpslaripS.gnirpslaripsecalpeR

?ytridsnifgni

?yltcerrocdetsujdaronrevoG.ronrevogtsujdA

efedgnirpsronrevoG.gnirpsronrevogecalpeR

?detcirtserwolfleuF

?esoolgn

?gnissimroevitc

rofmetsysleuferitnekcehC

.sgolcroskael

dnatsudhtiwdeggolcmsinahcemlioceR

.retawdna

paoshtiwylbmessaliocernaelC

PAGE 26 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 27

NOTES

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 27

Page 28

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the help

numbers found on the back page of the manual if there are any

questions.

The contents and part numbers listed in the parts section are

subject to change

guarantee the availibility of the parts listed.

Sample Parts List:

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ...................... 1 ...... INCLUDES ITEMS W/

2

*

2*12347 WASHER, 3/8 IN. ... 1 ......

3 12348 HOSE ................... A/R .... MAKE LOCALLY

4 12349 BEARING ............... 1 ......S/N 2345B AND ABOVE

NO. Column

Unique Symbols - All items with same unique symbol

(*, #, +, %, or >) in the number column belong to the same

assembly or kit, which is indicated by a note in the “Remarks”

column.

Duplicate Item Numbers - Duplicate numbers indicate

multiple part numbers are in effect for the same general

item, such as different size saw blade guards in use or a

part that has been updated on newer versions of the same

machine.

When ordering a part that has more than one

item number listed, check the remarks column

for help in determining the proper part to order.

without notice

WASHER, 1/4 IN. .............

. Multiquip does not

NOT SOLD SEPARATELY

MQ-45T ONLY

QTY. Column

Numbers Used - Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other parts

that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

*

Column are listed below. Other additional notes needed to

describe the item can also be shown.

Assembly/Kit

unique symbol will be included when this item is purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

used only with the specific model number or model number

variant listed. It can also be used to show a part is NOT

used on a specific model or model number variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

- All items on the parts list with the same

- Used to list an effective serial

- Indicates that the part is

PART NO. Column

Numbers Used - Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a part

that has not been assigned a formal part number at time of

publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will be

clarified in the “Remarks” Column.

PAGE 28 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

“Make/Obtain Locally”

purchased at any hardware shop or made out of available

items. Examples include battery cables, shims, and certain

washers and nuts.

“Not Sold Separately”

purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available for

sale through Multiquip.

- Indicates that the part can be

- Indicates that an item cannot be

Page 29

STOW CUTTER 1 SAW — SUGGESTED SPARE PARTS

SUGGESTED SPARE PARTS

STOW CUTTER 1 SAW CONCRETE/ASPHALT SAW

1 TO 3 UNITS WITH HONDA 13 HP GX390K1QWT2/GX390U1QWT2 ENGINES

AND 5HP ELECTRIC MOTOR.

1 to 3 Units

Qty. ......P/N ........................... Description

3 20478 ................... HAND GRIP

4 2621 ..................... GREASE ZERK, SPINDLE BEARING

4 1162 A .................. CAP, GREASE ZERK

3 13249 ................... BELT (3VX315) 13HP HONDA

3 16779-006 ............ BELT (3VX300) 5HP ELECTRIC MOTOR

3 9807956846 ......... SPARK PLUG, BPR6ES, NKG

1

1

1

2 17210ZE3010 ...... AIR CLEANER ELEMENT

1

1

2 28086001 ............. 8" REAR WHEEL ( GAS MODEL)

2 23668001 ............. 6" REAR WHEEL ( ELECTRIC MODEL)

2 26221001 ............. 4" FRONT WHEEL

1 29013001 ............. 1-1/2" BOX WRENCH

17620ZH7023 ...... TANK CAP, BLACK, (S/N 3605677 AND BELOW)

17620Z0T305 ...... TANK CAP, CHROME PLATED, (S/N 3605678 AND ABOVE)

◊◊

◊

17620Z0T305 ...... TANK CAP, CHROME PLATED

◊◊

28462ZV7003 ...... ROPE, RECOIL STARTER

◊◊

◊

28462ZE3W01 .... ROPE, RECOIL STARTER

◊◊

NOTE

NOTE

The contents of this parts catalog

are subject to change without

notice.

GX390K1QWT2: Model S/N DECEMBER 2005 AND BELOW

◊◊

◊

GX390U1QWT2: Model S/N JANUARY 2006 AND ABOVE

◊◊

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 29

Page 30

DECALS

STOW CUTTER 1 SAW — NAMEPLATE AND DECALS

PAGE 30 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 31

STOW CUTTER 1 SAW — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 25215-001 DECAL, WARNING .......................... 1 .......... ELECTRIC MODEL ONLY

2 28997-001 DECAL, PROP 65 WARNING 1

3 13118 DECAL, POWDER COATED 1

4 22972-003 DECAL, STOW 6.00 1

5 23653-001 DECAL, STOW CUTTER 1 SAW 1

6 SERIAL NUMBER PLATE ............... 1 .......... CONTACT PARTS DEPT.

7 22122-001 DECAL, WARNING 1

8 25250-001 DECAL, WARNING FEET 1

9 22972-004 DECAL, STOW 7.00 1

10 23330-001 DECAL, CAUTION BLADE GUARD 1

11 25491 DECAL, ROTATION 1

12 25249-001 DECAL, WARNING HANDS 1

13 11246 DECAL SHEET, INTL STDS. 1

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 31

Page 32

STOW CUTTER 1 SAW — ENGINE, BELTS AND PULLEYS ASSY.

ENGINE, BELTS AND PULLEYS ASSY.

PAGE 32 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 33

STOW CUTTER 1 SAW — ENGINE, BELTS AND PULLEYS ASSY.

ENGINE, BELTS AND PULLEYS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

2 15103 ENGINE 13 HP HONDA CYCLONE 1

3 0669 A SCREW. HHCS 5/16-18 x 2-1/4" 4

4 0300 B FLAT WASHER 5/16" 10

5 5283 NUT, 5/16 - 18 LOCK 4

6 23811-352 BELT TENSIONER 2

7 6059 B SQUARE KEY, 1/4 X 2 1

8 23665-001 PULLEY, ENGINE 1

9 25354 SCREW, SHS 1/4 - 20 X 1/2 ALLOY4

10 13249 BELT, 3VX315 3

11 23665-009 PULLEY, SPINDLE 1

12 27044-001 SPACER 2

13 26105-351 BELT GUARD, 13HP 1

14 0202 SCREW, 5/16 - 12 X 1 2

15 161 C WASHER, LOCK 5/16 2

16 26112-354 FRAME 1

17 9152 KEY, 1/4 X 1-3/4 1

18 10779-011 CAP 2

19 10133 NUT, 3/8 - 16 2

20 10136 WASHER, FLAT 3/8 2

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 33

Page 34

ELECTRIC MOTOR ASSY.

2

STOW CUTTER 1 SAW — ELECTRIC MOTOR ASSY.

1

3

8

9

4

10

11

5

7

11

13

6

12

PAGE 34 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 35

STOW CUTTER 1 SAW — ELECTRIC MOTOR ASSY.

ELECTRIC MOTOR ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 26142-352 BELT GUARD 1

2 16779-006 BELT - 3VX300 3

3 23665-005 PULLEY (MOTOR) 1

4 26152-502 MOTOR, 5 HP ELECTRIC 1

5 27084-002 SPACER 2

6 23665-009 PULLEY (SPINDLE) 1

7 26145-351 FRAME 1

8 25215-001 LABEL, WARNING 1

9 23865-001 SCREW, 10 - 24 X 3/4 2

10 2623 SCREW, HHC 5/16 -18 x 1-1/4" 4

11 07030-005 FLAT WASHER 5/16 8

12 26136-004 SPINDLE 1

13 5283 NUT, 5/16 - 18 LOCK 4

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 35

Page 36

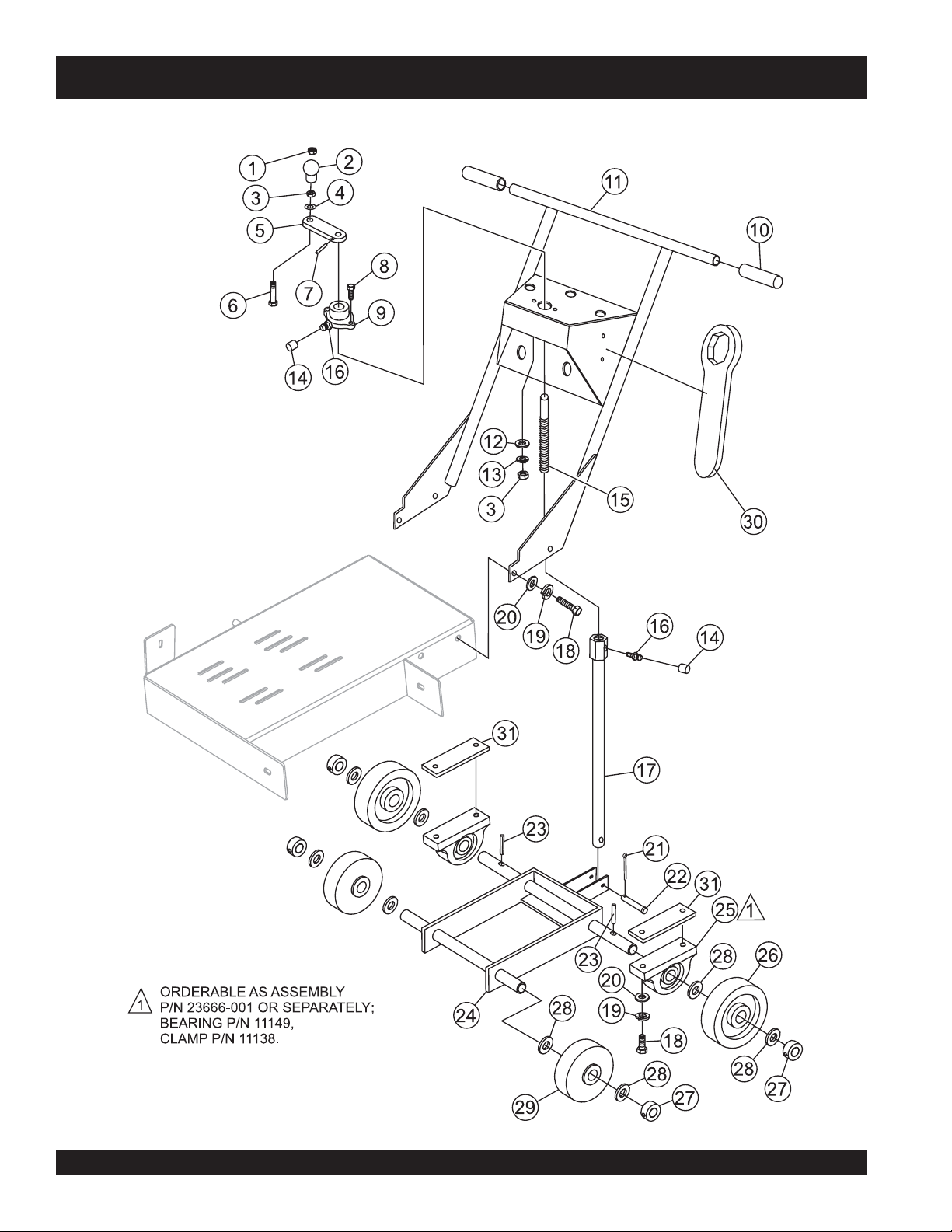

UNDERCARRIAGE ASSY

STOW CUTTER 1 SAW — UNDERCARRIAGE ASSY.

PAGE 36 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 37

STOW CUTTER 1 SAW — UNDERCARRIAGE ASSY.

UNDERCARRIAGE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 08233-005 LOCKNUT, 5/16 - 18 1

2 18637-001 KNOB 1

3 0161 D HEX NUT, 5/16 - 18 3

4 25496 BUSHING 1

5 28808-002 CRANK HANDLE 1

6 26164-001 LOCK PIN 1

7 4568 ROLL PIN 3/16 X 1 1

8 07046-011 BOLT, CARRIAGE 5/16-18 X 1-1/2 2

9 23284-001 WRAPPER-BLADE GUARD 1

10 20478 HAND GRIP 2

11 26126-352 HANDLE 1

12 0300 B FLAT WASHER 5/16 2

13 0161 C LOCK WASHER 5/16 2

14 1162 A CAP, GREASE ZERK 4

15 26137-002 ACME SCREW 1

16 2621 ZERK, GREASE STR 1/4 - 28 1

17 29408-352 JACK ARM (SUPPORT TUBE) 1

18 0205 SCREW, HHCS 3/8 - 16 X 1-1/4 8

19 0166 A LOCK WASHER, 3/8 8

20 10136 FLAT WASHER 3/8 8

21 6014 B COTTER PIN 3/32 X 1 1

22 08326-019 PIN 3/8 X 2-5/16 1

23 07402-024 ROLL PIN 1/8 X 1-1/2 2

24 26120-352 WHEEL BASE ASSEMBLY 1

25 23666-001 CLAMP & BEARING ASSEMBLY 2

25A 11138 CLAMP ASSEMBLY 2

25B 11149 BEARING 2

26 23668-001 REAR WHEEL, (6X2 ELECTRIC MODEL) 2

26 28086-001 REAR WHEEL, (8X2 GAS MODEL) 2

27 26133-001 LOCKING COLLAR 4

28 8151 FLAT WASHER, 3/4 6

29 26121-001 FRONT WHEEL 2

30 29013-001 1-1/2" BOX WRENCH 1

31 25677 SPACER, REAR AXLE BEARING 2

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 37

Page 38

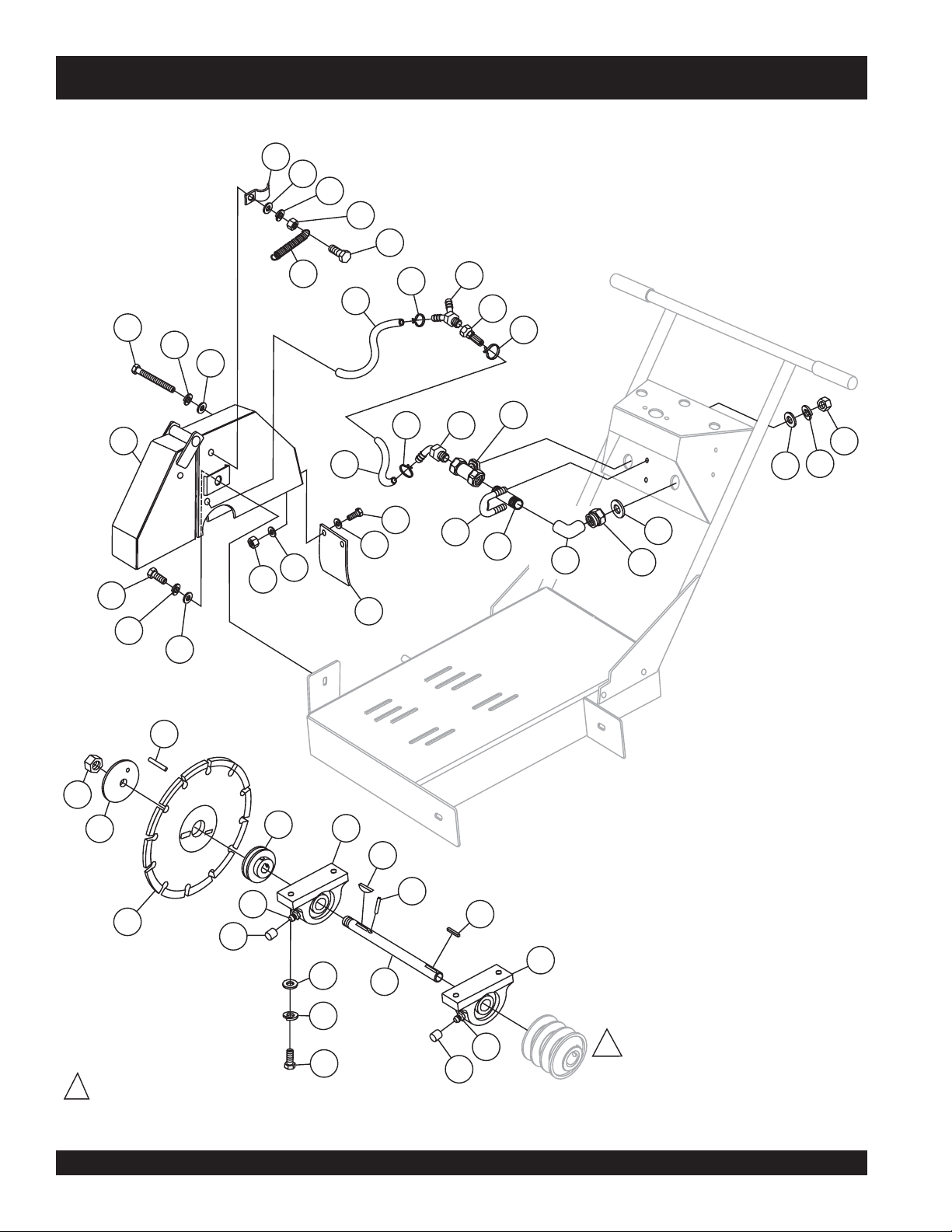

STOW CUTTER 1 SAW — WATER SYSTEM AND BLADE ASSY.

WATER SYSTEM AND BLADE ASSY.

1

2

3

4

5

28

27

6

26

26

25

25

24

23

7

19

20

18

17

16

16

10

9

4

8

21

2

12

11

13

15

14

3

2

22

30

29

31

41

PULLEY ASSEMBLY.

1

SEE PAGE 30.

PAGE 38 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

37

40

32

33

26

34

35

36

38

30

37

39

40

35

1

Page 39

STOW CUTTER 1 SAW — WATER SYSTEM AND BLADE ASSY.

WATER SYSTEM AND BLADE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 22129-001 CLAMP 2

2 0948 FLAT WASHER, 1/4 5

3 0181 B LOCK WASHER 1/4 5

4 0949 HEX NUT 1/4 - 20 5

5 0424 SCREW, HHCS 1/4 - 20 X 1 4

6 29406-352 BLADE GUARD 1

7 18626-001 SPRING 2

8 23255-011 HOSE 26" 1

9 23566-001 BARBED FITTING 90 DEG. 1

10 35122-402 VALVE 1

11 11708 NIPPLE 1/2 1

12 16378-005 U-BOLT 1/4 1

13 23252-002 ELBOW 1/2 1

14 15544 CONNECTOR, GARDEN HOSE 1

15 13336-001 WASHER, RUBBER 1

16 12694-006 HOSE CLAMP 2

17 24778-001 SWIVEL CONNECTOR 1

18 24642-001 Y-FITTING 1

19 12694-004 HOSE CLAMP 2

20 60021 .............. HOSE, 1.0 FT. ................................. 2 .......... SOLD PER FOOT

21 0131 A SCREW, HHCS 1/4 - 20 X 3/4 2

22 28729-005 CHIP GUARD 1

23 10930 FENDER WASHER 1/4 2

24 10024 LOCKNUT, 1/4 - 20 2

25 10136 FLAT WASHER 3/8 6

26 0166 A LOCK WASHER 3/8 2

27 06501-032 SCREW, HHCS 3/8 - 16 X 4 1

28 0205 SCREW, HHCS 3/8 - 16 X 1 1

29 06922-003 NUT L.H. 1 - 1/4 1

30 15046 DOWEL PIN 3/8 X 1-1/4 2

31 26928-004 FLANGE, OUTER 1

32 28811-001 FLANGE, INNER 1

33 4001 FLAT WASHER 4

34 1284 SCREW, HHCS 3/8 - 16 X 1-1/2 4

35 3200 BEARING 2

36 0125 WOODRUFF KEY 1/4 X 1 1

37 1162 A CAP, GREASE ZERK 2

38 26135-002 SPINDLE 1

39 9152 KEY 1/4 X 1-3/4 1

40 2621 GREASE ZERK 2

41 9SWG BLADE, DIAMOND BACK 1

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 39

Page 40

POINTER ASSY.

STOW CUTTER 1 SAW — POINTER ASSY.

PAGE 40 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 41

STOW CUTTER 1 SAW — POINTER ASSY.

POINTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1

2

3

4

5

6

7

8 29042-501 INDICATOR ASSEMBLY ................. 1 .......... INCLUDES ITEMS W/

21017 SCREW, POINTER ARM 1

*

29043-001 WHEEL, POINTER 1

*

1007 NUT, HEX JAM 3/8 - 16 2

*

1456 NUT, HEX FINISH 3/8 - 16 2

*

10133 NUT, NYLOC 3/8 - 16 2

*

27073-001 ARM, POINTER 1

*

10136 WASHER, FLAT 3/8 2

*

*

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 41

Page 42

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — AIR CLEANER ASSY.

AIR CLEANER ASSY.

PAGE 42 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 43

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — AIR CLEANER ASSY.

AIR CLEANER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1

16271ZE2000 GASKET, ELBOW 1

◊◊

1

2 17210ZE3010 ELEMENT, AIR CLEANER ........................ 1 ......... INCLUDES ITEMS W/

3

4# 17219ZE3840 SEAL, AIR CLEANER COVER 1

5 17230ZE3841 COVER, AIR CLEANER (CYCLONE) 1

6

7# 17238ZE2310 COLLAR, AIR CLEANER 2

8# 17239ZE3840 COLLAR B, AIR CLEANER 1

9 17410ZE3840 ELBOW, AIR CLEANER ............................ 1 ......... INCLUDES ITEMS W/#

10

10

11 17475ZE3841 CAP, PRE AIR CLEANER 1

12 17476ZE3841 GUIDE, PRE AIR CLEANER 1

13 90142MB0000 SCREW, PAN 5X16.5 5

14 90325044000 WINGNUT, TOOL BOX SETTING 2

15 90009ZE2003 BOLT- WASHER 6X22 1

16 9405006000 NUT, FLANGE 6MM 2

16271ZE2010 GASKET, ELBOW 1

◊

◊◊

17218ZE3000 FILTER, OUTER 1

*

17232891000 GROMMET, AIR CLEANER 1

*

17470ZE3841 CASE, PRE AIR CLEANER 1

◊◊

◊

17470ZE3842 CASE, PRE AIR CLEANER 1

◊◊

*

NOTE

GX390K1QWT2: Model S/N DECEMBER 2005 AND BELOW

◊◊

◊

GX390U1QWT2: Model S/N JANUARY 2006 AND ABOVE

◊◊

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 43

Page 44

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CAMSHAFT ASSY.

CAMSHAFT ASSY.

PAGE 44 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 45

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CAMSHAFT ASSY.

CAMSHAFT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 14100ZF6W01 CAMSHAFT ASSEMBLY .......................... 1 ......... INCLUDES ITEM W/

2 14410ZE3013 ROD, PUSH 2

3 14431ZE2010 ARM, VALVE ROCKER 2

4 14441ZE2000 LIFTER, VALVE 2

5 14451ZE1013 PIVOT, ROCKER ARM 2

6

7 14711ZE3000 VALVE, INTAKE 1

8 14721ZE3000 VALVE, EXHAUST 1

9 14751ZE2003 SPRING, VALVE 2

10 14771ZE2000 RETAINER,INTAKE VALVE SPRING 1

11 14773ZE2000 RETAINER, EXHAUST VALVE SPRING 1

12 14775ZE2010 SEAT, VALVE SPRING 1

13 14781ZE2000 ROTATOR, VALVE 1

14 14791ZE2010 PLATE, PUSH ROD GUIDE 1

15 90012ZE0010 BOLT, PIVOT 8MM 2

16 90206ZE1000 NUT, PIVOT ADJ. 2

17 12209ZE8003 SEAL, VALVE STEM 1

14568ZE1000 SPRING, WEIGHT RETURN 1

*

*

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 45

Page 46

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CARBURETOR ASSY.

CARBURETOR ASSY.

PAGE 46 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 47

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CARBURETOR ASSY.

CARBURETOR ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 16010ZE2812 CARBURETOR, GASKET SET 1 INCLUDES ITEMS W/+

2$ 16011ZA0931 VALVE SET, FLOAT 1

3$ 16013ZA0931 FLOAT SET 1

4$ 16015ZE8005 CHAMBER SET, FLOAT ...................... 1 ............. INCLUDES ITEM 4A

............................................................................. INCLUDES ITEM W/>

4A+ GASKET, CHAMBER SET FLOAT ...................... NOT SOLD SEPARATELY

5$ 16016ZH7W01 SCREW SET, PILOT 1

6$> 16024ZE1811 SCREW SET, DRAIN, .......................... 1 ............. INCLUDES ITEM 6A

6A+ GASKET, SCREW SET DRAIN ........................... NOT SOLD SEPARATELY

7$ 16028ZE0005 SCREW SET ....................................... 1............. INCLUDES ITEM 7A

7A+ GASKET, SCREW SET ....................................... NOT SOLD SEPARATELY

8$ 16044ZE3W20 CHOKE SET 1

9$ 16100ZF6V21 CARBURETOR ASSY. (BE85C B) ....... 1............. INCLUDES ITEMS W/$

10$ 16124ZE0005 SCREW, THROTTLE STOP 1

11$ 16166ZF6W10 NOZZLE, MAIN 1

12$+ 16173001004 GASKET, FUEL STRAINER CUP 1

13 16211ZF6000 INSULATOR, CARBURETOR 1

14 16220ZA0702 SPACER, CARBURETOR 1

15 16221ZF6800 GASKET, CARBURETOR 1

16 16223ZE3W00 GASKET, INSULATOR 1

20 16610ZE1000 LEVER, CHOKE (STD) ........................1 ............. INCLUDES ITEM W/

22$ 16953ZE1812 LEVER, VALVE 1

23$ 16954ZE1812 PLATE, LEVER SETTING 1

24$ 16956ZE1811 SPRING, VALVE LEVER 1

25$+ 16957ZE1812 GASKET, VALVE 1

26$ 16967ZE0811 CUP, FUEL STRAINER 1

28$ 93500030061H SCREW, PAN (3X6) 2

31

*

33$ 99101ZH80950 JET, MAIN (#95) (OPTIONAL) 1

33$ 99101ZH80980 JET, MAIN (#98) (OPTIONAL) 1

33$ 99101ZH81000 JET, MAIN (#100) 1

34$ 99204ZA00450 JET SET, PILOT (#45) ......................... 1............. INCLUDES ITEM 34A

34A+ GASKET, JET SET PILOT (#45) ......................... NOT SOLD SEPARATELY

35$ 16172ZE3W10 COLLAR, SET 1

9430520122 PIN, SPRING (2X12) 1

*

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 47

Page 48

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CONTROL ASSY.

CONTROL ASSY.

PAGE 48 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 49

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CONTROL ASSY.

CONTROL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

2 16551ZE3000 ARM, GOVERNOR 1

3 16555ZE3000 ROD, GOVERNOR 1

4 16561ZE3000 SPRING, GOVERNOR 1

5 16562ZE3000 SPRING, THROTTLE RETURN 1

6 16570ZE3W20 CONTROL ASSY. (REMOTE) .................... 1 ......... INCLUDES ITEMS W/

10

11

12

13

14

15

17

18

21 90013883000 BOLT, FLANGE (6X12) (CT200) 2

22 90015ZE5010 BOLT, GOVERNOR ARM 1

24

27

28

29 9405006000 NUT, FLANGE (6MM) 1

16571ZE3W00 LEVER, CONTROL 1

*

16574ZE1000 SPRING, LEVER 1

*

16575ZE2W00 WASHER, CONTROL LEVER 1

*

16576891000 HOLDER, CABLE 1

*

16578ZE1000 SPACER, CONTROL LEVER 1

*

16581ZE3W00 BASE, CONTROL 1

*

16584883300 SPRING, CONTROL ADJUSTING 1

*

16592883310 SPRING, CABLE RETURN 1

*

90114SA0000 NUT, SELF-LOCK (6MM) 1

*

93500050320A SCREW, PAN (5X32) 1

*

93500050160A SCREW, PAN (5X16) 1

*

*

STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08) — PAGE 49

Page 50

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CRANKCASE ASSY.

CRANKCASE COVER ASSY.

PAGE 50 — STOW CUTTER 1 SAW — OPERATION & PARTS MANUAL — REV. #6 (06/06/08)

Page 51

HONDA GX390K1QWT2/GX390U1QWT2 ENG. — CRANKCASE ASSY.

CRANKCASE COVER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

2

2

◊◊

2

◊

◊◊

3 11381ZE3801 GASKET, CASE COVER 1

4 15600ZG4003 CAP ASSY., OIL FILLER .................................1 ................ INCLUDES ITEM W/#