Page 1

OPERATION MANUAL

SERIES

MODEL CA4HCMODEL CA4HC

MODEL CA4HC

MODEL CA4HCMODEL CA4HC

WALK-BEHIND TROWEL

(HONDA GASOLINE ENGINE)

KOHLER 27 HP

KOHLER 28 HP EFI

Revision #0 (09/29/06)

THIS MANUAL MUST ACCOMPANY

THE EQUIPMENT AT ALL TIMES.

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

P/N 21768

Page 2

Page 3

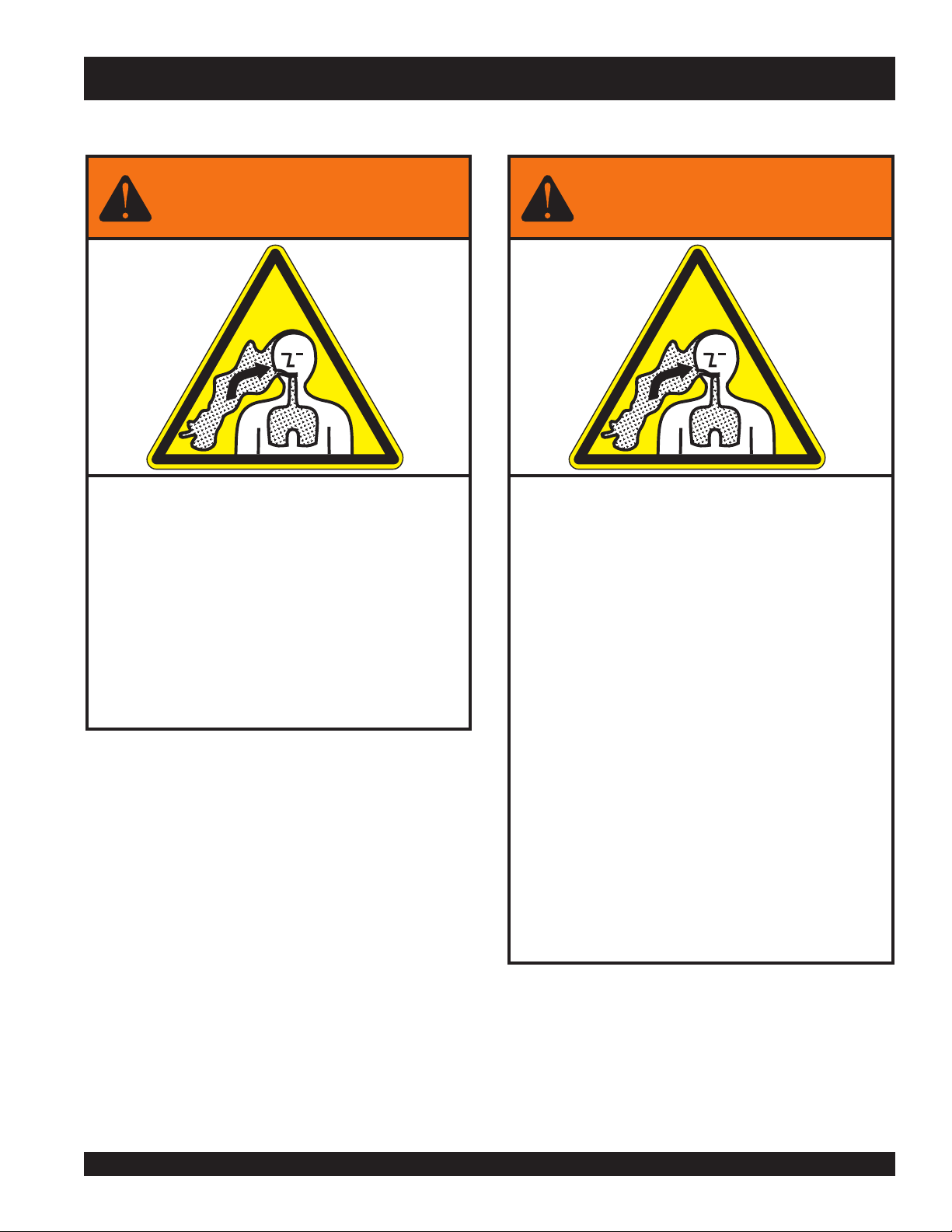

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

Page 4

CA4HC TROWEL— TABLE OF CONTENTS

MQ WHITEMAN CA4HC

WALK-BEHIND TROWEL

Table Of Contents ..................................................... 4

Dimensions ............................................................... 5

Specifications ............................................................ 6

Training Checklist ...................................................... 8

Daily Pre-Operation Checklist ................................... 9

Safety Message Alert Symbols .......................... 10-11

Rules For Safe Operation .................................. 12-13

Operation And Safety Decals .................................. 14

General Information ................................................ 15

Controls and Components ...................................... 16

Basic Engine ........................................................... 17

Handle Assemblies ............................................ 18-19

Pre-Inspection .................................................... 21-22

Initial Start-Up ....................................................23-24

Operation ........................................................... 25-26

Options .................................................................... 26

Maintenance ...................................................... 27-30

Troubleshooting (Trowel) ........................................ 31

Troubleshooting (Engine) ........................................ 32

Terms and Condition Of Sale .................................. 35

NOTE

Specifications and

part numbers are

subject to change

without notice.

PAGE 4 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 5

D

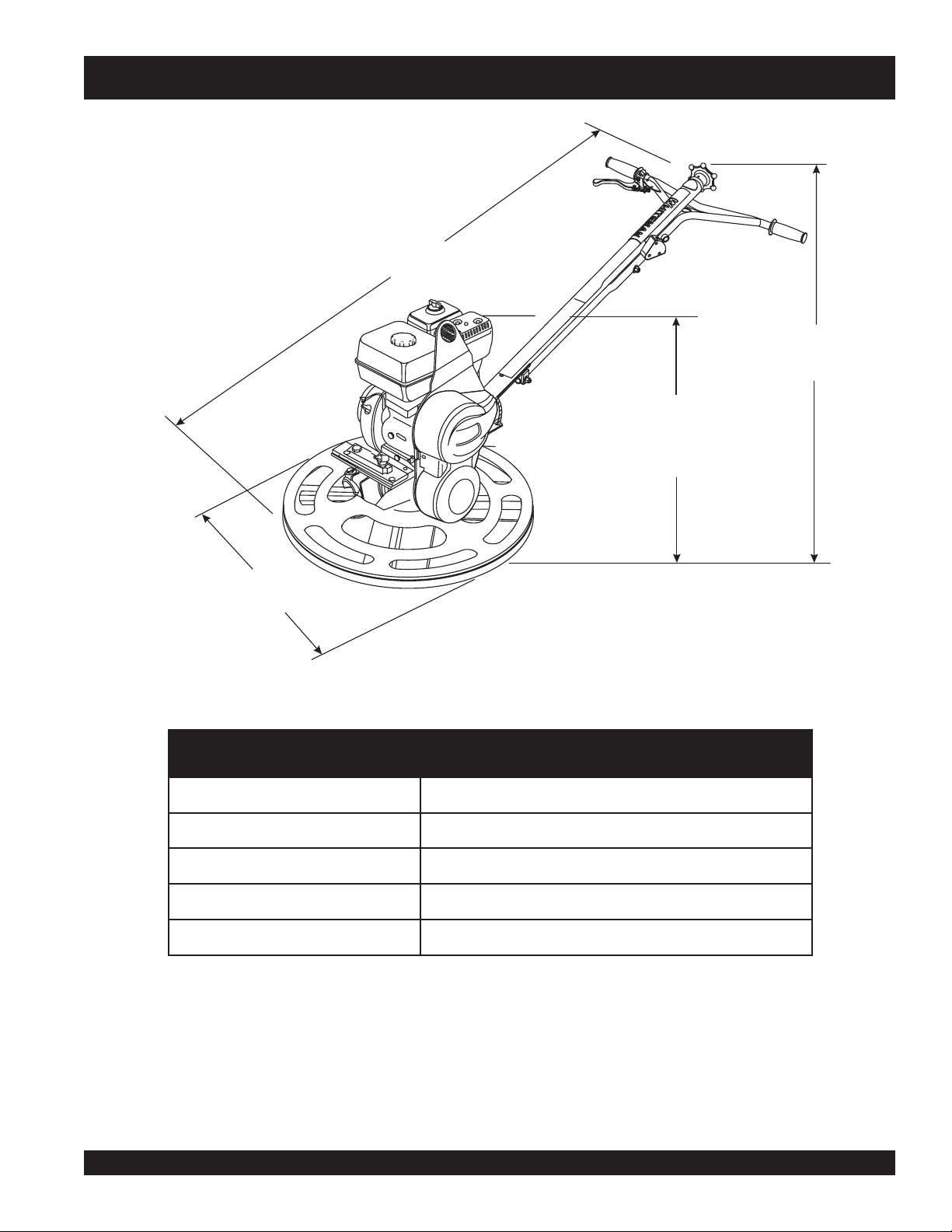

CA4HC TROWEL— DIMENSIONS

B

A

C

Figure 1. CA4HC Trowel Dimensions

)elaBgnitfiL(thgieH-A).ni0.82(mm117

)reveLtnemegagnE(thgieH-B).ni52.63(mm129

htdiW-C).ni42(mm016

htgneL-D).tf80.5(m55.1

thgieW).sbl521(gk75

thgieW&snoisnemiDleworTMH4-4AC.1elbaT

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 5

Page 6

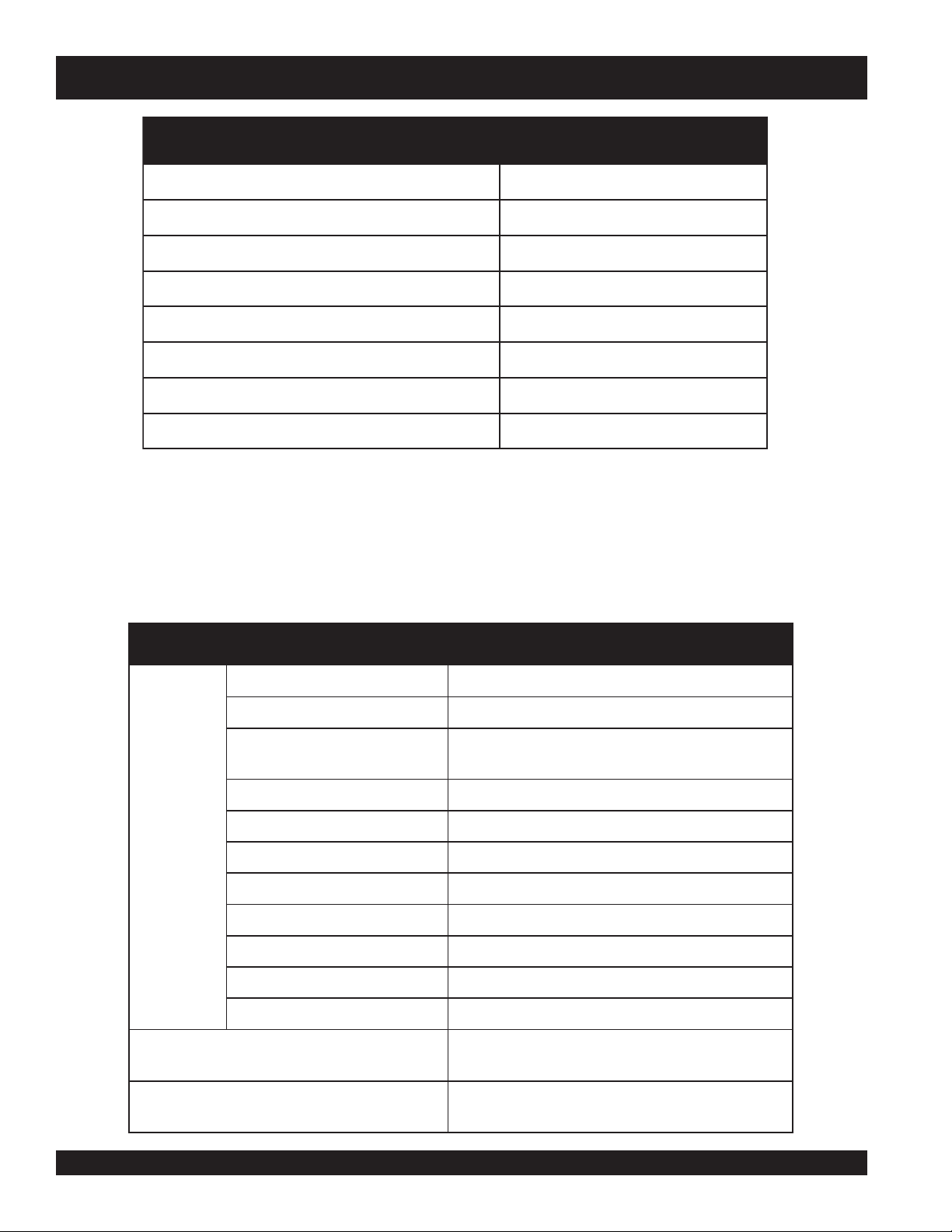

CA4HC TROWEL— SPECIFICATIONS

sedalBforebmuN4

retemaiDgniR ).mc16(.ni0.42

rotoR MPR031-07

htdiWhtaP ).mc16(.ni42

snoitacificepSleworTCH4AC.2elbaT

1

)mrA/dnaH(noitarbiV

2

)dethgieW-A(erusserPdnuoS

)dethgieW-C,kaeP(erusserPdnuoS )C(Bd5.09

)dethgieW-A(leveLrewoPdnuoS )A(Bd79

NOTE:

1. The vibration level indicated is the maximum RMS (Root

Mean Square) value obtained at the handle grip while

operating the walk-behind trowel at full throttle on steel

plate with blades partially pitched.

2. Sound pressure is a weighted measure. It is measured at

the operator's ear position while the walk-behind trowel is

operating at full throttle on concrete in a manner most often

experienced in “

may vary depending upon the condition of the concrete.

ledoM 2XQ1K021XGADNOH

epyT rednilyCelgniS,evlavdaehrevO,ekorts-4

ekortSXeroB

normal

snoitacificepSenignE.3elbaT

2

s/m9.81

)A(Bd5.38

” circumstances. Sound pressure

.ni7.1X.ni4.2

)mm24xmm06(

tnemecalpsiD)cc911(.ni.uc3.7

tuptuOxaM .M.P.R006,3ta)SP0.4,Wk9.2(.P.H9.3

enignE

leuFenilosaGdedaelnU

noisnemiD

)HxWxL(

teNyrD

thgieW

PAGE 6 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

yticapaCknaTleuF )sretiL5.2(snollaG.S.U66.0.xorppA

deepSeldIdradnatS .M.P.R051-/002+004,1

yticapaCliOebuL )sretiL06.0(strauQ.S.U36.0

dohteMlortnoCdeepS epyTthgiew-ylFlagufirtneC

dohteMgnitratStratSlioceR

.ni5.21X4.31x7.11

)mm813X143X792(

).gK0.31(.sbl7.82

Page 7

NOTE PAGE

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 7

Page 8

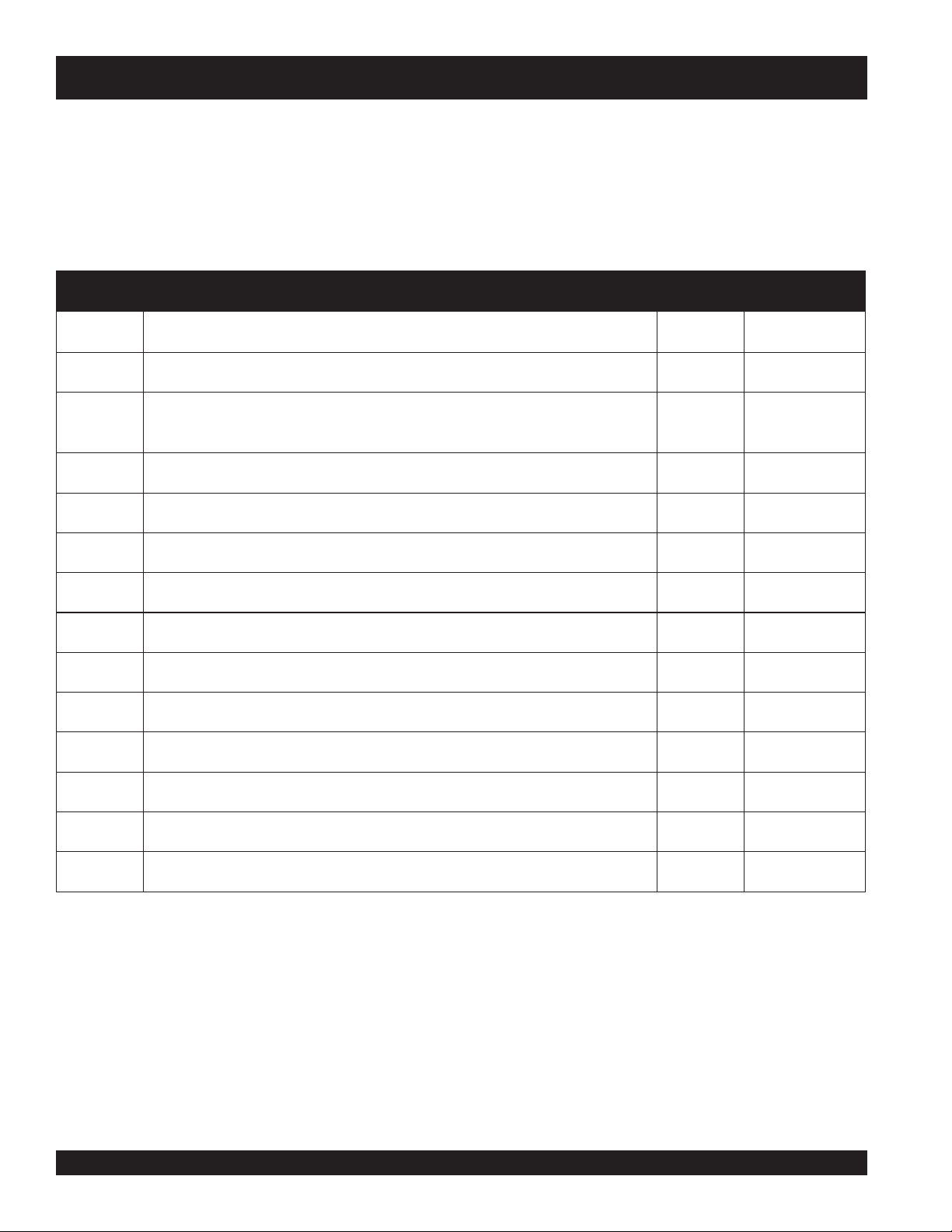

CA4HC TROWEL— TRAINING CHECKLIST

TRAINING CHECKLIST

This checklist will lists some of the minimum requirements for

machine maintenance and operation. Please feel free to detach

it and make copies. Use this checklist whenever a new operator

is to be trained or it can be used as a review for more experienced

operator’s.

.ON NOITPIRCSED ?KO ETAD

1 .yletelpmoclaunaMs’rotarepOdaeR

TSILKCEHCGNINIART

2

3 .erudecorpgnileufer,metsysleuF

4 .)gninnurtonenihcam(slortnocfonoitarepO

5 .slortnocytefaS

6 .serudecorppotsycnegremE

7 .enihcamfoputratS

8 .gnirevuenaM

9 .gnihctiP

01 .seuqinhcetgnihsinifetercnoC

11 .enihcamfonwodtuhS

21 .enihcamfognitfiL

dnaenignefognikcehc,stnenopmocfonoitacol,tuoyalenihcaM

.leveldiulfxobraeg

31 .egarotsdnatropsnartenihcaM

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

PAGE 8 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 9

CA4HC TROWEL— DAILY PRE-OPERATION CHECKLIST

DAILY PRE-OPERATION CHECKLIST

TSILKCEHCNOITAREPO-ERPYLIAD

1

2

3

4

COMMENTS:

diulFxobraeGleveL

.leveLliOenignE

.

sedalBfonoitidnoC

.

.noitarepOhctiPedalB

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 9

Page 10

CA4HC TROWEL— SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when operating

this equipment. Failure to read and understand and comply with

the Safety Messages and Operating Instructions could result in

injury to yourself and others.

This Owner's Manual has been developed to provide complete

instructions for the safe and

efficient operation of the MQ

NOTE

Before using this WALK-BEHIND TROWEL, ensure that the

operating individual has read, understands, and complies

with all instructions in this manual.

Whiteman CA4HC TROWEL.

For engine maintenance

information, please refer to the

engine manufacturer's

instructions for data relative to its

safe operation.

HAZARD SYMBOLS

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Gasoline is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

Burn Hazards

DANGERDANGER

DANGER

DANGERDANGER

You WILL be

if you DO NOT follow these directions.

WARNINGWARNING

WARNING

WARNINGWARNING

You CAN be KILLED or

you DO NOT follow these directions.

CAUTICAUTI

CAUTION

CAUTICAUTI

You CAN be

these directions.

Potential hazards associated with trowel operation will be

referenced with Hazard Symbols which appear throughout this

manual, and will be referenced in conjunction with Safety

Message Alert Symbols.

KILLED

INJURED

if you DO NOT follow

or

SERIOUSLY INJURED

SERIOUSLY INJURED

if

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

Guards and Entanglement Hazards

NEVER operate equipment with covers, or

guards removed. Keep

and

clothing

prevent injury.

away from all moving parts to

fingers, hands, hair

Rotating Blades Hazards

NEVER place hands or feet inside the guard

rings while the engine is running.

PAGE 10 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 11

CA4HC TROWEL— SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the engine ON/OFF

switch in the OFF position, when the

trowel is not in use.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

Respiratory Hazard

ALWAYS wear approved respiratory protection.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your trowel, other property, or the

surrounding environment.

CAUTICAUTI

CAUTION

CAUTICAUTI

This walk-behind trowel, other property, or the

surrounding environment could be damaged

if you do not follow instructions.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 11

Page 12

CA4HC TROWEL — RULES FOR SAFE OPERATION

RULES FOR SAFE OPERATION

WARNINGWARNING

WARNING

WARNINGWARNING

Failure to follow instructions in this manual may lead to serious

injury or even death! This equipment is to be operated by

trained and qualified personnel only! This equipment is for

industrial use only.

■

NEVER operate this equipment when not feeling well due to

fatigue, illness or taking medicine.

■

NEVER operate the trowel under the influence or drugs or

alcohol.

■

Replace nameplate, operation and safety decals when they

become difficult to read.

■

ALWAYS check the trowel for loosened hardware such as

nuts and bolts before starting.

The following safety guidelines should always be used when

operating the CA4HC.

SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual. The

manual must be kept available and accessible

to the operator.

■

This equipment should not be operated by persons under the

minimum statutory age limit.

■

NEVER use this machine for any purpose other than those

described in this manual.

■

NEVER operate the trowel without proper protective clothing,

shatterproof glasses, steel-toed boots and other protective

devices required for the job.

■

NEVER touch the hot exhaust manifold, muffler

or cylinder. Allow these parts to cool before

servicing the trowel.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot!

with

■

The engine of this trowel requires an adequate free flow of

cooling air. NEVER operate the trowel in any enclosed or

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

components can cause serious burns.

narrow area where free flow

of the air is restricted. If the

air flow is restricted it will

cause serious damage to

the engine and may cause

injury to people. Remember

the engine gives off

DEADLY

gas.

carbon monoxide

■

■

■

NEVER use accessories or attachments which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications. Unauthorized equipment

modification will void all warranties. Any modification which

could lead to a change in the original characteristics of the

machine should be made only by the manufacturer who shall

confirm that the machine is in conformity with appropriate

safety regulations.

PAGE 12 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

■

■

■

ALWAYS use extreme caution when working with flammable

liquids. When refueling, STOP the engine and allow it to cool.

NEVER operate the trowel in an

explosive atmosphere where fumes

are present, or near combustible

materials. An explosion or fire could

result in severe

death.

NEVER

Fire or explosion could result from

vapors

Topping-off to filler port is dangerous, as it tends to spill fuel.

NEVER use fuel as a cleaning agent.

smoke

, or if fuel is spilled on a

bodily harm or even

around or near the machine.

fuel

hot!

engine.

Page 13

CA4HC TROWEL — RULES FOR SAFE OPERATION

■

NEVER Run engine without air filter. Severe engine damage

may occur. Service air filter frequently to prevent carburetor

malfunction.

■

NEVER place your

while starting or operating this equipment.

■

AVOID wearing jewelry or loose fitting clothing that may snag

on the controls or moving parts as this can cause a serious

injury.

■

ALWAYS keep clear of

operating the trowel.

■

Moving Parts – Shut down the engine before performing

service or maintenance functions. Contact with moving parts

can cause serious injury.

■

ALWAYS check to make sure that the operating area is clear

before starting the engine.

■

NEVER leave the machine

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operations techniques before using trowel.

■

ALWAYS keep the work area well organized.

feet

or

rotating

hands

inside the guard rings

or

moving parts

unattended

while running.

while

■

■

Maintenance Safety

■

■

■

■

■

■

When placing the trowel inside a truck-bed for transport,

always tie-down the trowel.

ALWAYS use proper lifting techniques when moving the

trowel.

NEVER lubricate components or attempt service on a running

trowel.

ALWAYS allow the trowel a proper amount of time to cool

before servicing.

Keep the trowel in proper running condition.

Fix damage to the trowel immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

■

ALWAYS clear the work area of any debris, tools, etc. that

would constitute a hazard while the trowel is in operation.

WARNINGWARNING

WARNING

WARNINGWARNING

ALWAYS check to make sure that the operating area is

clear before starting the engine.

■

No one other than the operator is to be in the working area

when the trowel is in operation.

■

Always observe all applicable compulsory regulations

relevant to environmental protection, especially, fuel storage,

the handling of hazardous substances, and the wearing of

protective clothing and equipment. Instruct the user as

necessary, or, as the user, request this information and

training.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

Transporting

Emergencies

■

■

■

ALWAYS know the location of

the nearest

ALWAYS know the location of the

nearest

In emergencies

nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information is invaluable in the case of an

emergency and could keep a serious situation from

becoming a tragic one .

fire extinguisher

first aid kit

.

always

keep a phone on the job site

and

.

know the location of the

.

fire department

. This

■

ALWAYS shutdown engine before transporting.

■

Tighten fuel tank cap securely and close fuel cock to prevent

fuel from spilling.

■

Drain fuel when transporting trowel over long distances or

bad roads.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 13

Page 14

CA4HC TROWEL— OPERATION AND SAFETY DECALS

P/N35168

OPERATION AND SAFETY DECALS

The CA4HC walk-behind trowel is equipped with a number of operation, safety and maintenance decals. Should any of these

decals become unreadable, replacements can be obtained from your dealer.

P

O

W

E

R

R

T

P/N 1848

MODEL

SERIAL NO.

CONTACT

PART S

DEPARTMENT

P/N: 13118

O

W

P/N 2942 WHITE TEXT 13”

L

E

WARNING

To avoid injury,

you MUST read

and understand

operator’s manual

before using this

P/N 11092

machine.

This machine to

be operated by

qualified

personnel only.

Ask for training

as needed.

P/N 35137

P/N 20816

P/N 36099 (ISO Blue)

P/N35137

BELT DRIVE

GEAR DRIVE

CHECK

HOT

CLOCKWISE

GEAR DRIVE

CHECK

COUNTER

CLOCKWISE

LIFTING POINTLIFTING POINT

LUBRICATION

P/N: 1492

(STANDARD MODEL)

P/N: 21455

LUBRICATION

WARNING

P/N: 11246

Engine exhaust and some of

its constituents,and somedust created

by power sanding, sawing, grinding,

drillingand otherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Someexamples of thesechemicals are:

Leadfromlead-based paints.

Crystallinesilica frombricks.

Cementand othermasonryproducts.

ROTATING BLADE

HAZARD

Keep hands

and feet clear

of guard rings.

Stop engine

before servicing.

P/N35168

P/N 35168

PAGE 14 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Arsenicand chromiumfromchemically

treatedlumber.

Yourrisk from these exposures varies,

dependingon howoftenyou dothistype

of work.To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masksthat are specially designed

to filterout microscopic particles.

P/N 20525

P/N 21302

Figure 2. Operation and Safety Decals

LUBRICATION

LUBRICATION

P/N 20936

Page 15

CA4HC TROWEL— GENERAL INFORMATION

Intended Use

Operate the CA4HC Trowel, tools and components in accordance

with the manufacturer's instructions. Use of any other tools for

stated operation is considered contrary to designated use. The

risk of such use lies entirely with the user. The manufacturer

cannot be held liable for damages as a result of misuse.

CA4HC Trowel Familiarization

This walk-behind trowel is designed for the

finishing

Take a walk around the trowel. Take notice of all the major

components (see Figure 2) like the engine, blades, Standard or

Quick Pitch™ handle, etc.

Read

be found throughout this manual and on the trowel. Keep all

safety information in good, readable condition. Operators should

be well trained on the operation and maintenance of the trowel.

Before using your trowel, test it on a flat watered down section of

finished concrete that is free of any debris and other objects.

This trial test run will increase your confidence in using the trowel

and at the same time it will familiarize you with the trowel’s

controls. In addition you will understand how the trowel handles

under actual conditions.

of concrete slabs.

all the safety instructions carefully. Safety instructions will

floating

and

Spider

The vertical output shaft of the gearbox connects to a machined

hub called the

that are used for attachment of blades or other accessories.

Remember as the gearbox output shaft rotates so does the spider

assembly.

Guard Ring

This unit is equipped with a special rotating

designed to allow the operator to run the machine alongside

walls, pipes, and obstructions without marring the surface.

Blades

The blades of the trowel finish the concrete as they are rotated

around the surface. This trowel comes equipped with four

combination

spaced in a radial pattern and attached to vertical rotating

shaft by means of the spider assembly

Centrifugal Clutch

In the event of a trowel runaway condition (operator releases

the handle), a

bring the trowel to a halt.

spider

. The spider has 4 arms that extend outward

(8 in./203mm wide)

centrifugal clutch

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

guard ring

blades

per rotor equally

.

will stop the engine and

. It is

Engine

This trowel is available with an 4 HP

Refer to the engine owner’s manual for instructions regarding

the operation and maintenance of your engine. Please contact

your nearest Multiquip Dealer for a replacement should the

original manual disappear or otherwise become unusable.

Drive System

Power is transferred from the engine to the gearbox input shaft

via a

V-belt pulley drive system

centrifugal clutch. See Parts section of this manual.

Gearbox

gearbox

The

to the spider assembly. The gearbox controls the rotational speed

of the trowel and is equipped with two shafts (input and output).

is located beneath the engine and transfers power

HONDA gasoline engine

. The pulley engages using a

NEVER attempt to

.

the assistance of another person to help lift the trowel .

Training

For proper training, please use the “TRAINING CHECKLIST”

located in the front of this manual (Page 8). This checklist will

provide an outline for an experienced operator to provide training

to a new operator

lift

the trowel by yourself. ALWAYS get

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 15

Page 16

CA4HC TROWEL— CONTROLS AND COMPONENTS

Figure 3. Controls and Components

14

7

10

11

6

8

5

9

1

17

4

3

19

16

13

12

15

18

20

2

Figure 3 shows the location of the basic controls or components,

CA4HC TROWEL

for the

. Listed below is a brief explanation of

each control or component

1. Standard Handle – Employs a "starwheel" for manually

adjusting blade pitch.

2. Foldable Quick Pitch Handle – Employs a lever handle

to quickly adjust blade pitch. Handle folds for storage.

3. Throttle w/ "Kill" Switch – Uses an integrated "kill" switch.

4. Safety Switch – Centrifugal safety switch shuts the engine

off in a "runaway" situation. (Standard Handle)

5. Throttle Control Lever – Controls the speed of the engine.

Move the hand lever towards the operator to increase

engine speed (high), away from the operator to decrease

engine speed (low).

6. Hand Grip/Handle Bar – When operating the trowel, place

both hands on each grip to maneuver the trowel. Replace

hand grips when they become worn or damaged.

7. Engine – Honda GX120 4 H.P. gasoline engine.

8. Pitch Adjust-Standard Handle - Turn clockwise or

counterclockwise to adjust blade pitch.

9. Quick Pitch Handle – Pivots back and forth to adjust blade

pitch.

10. Guard Ring – Helps protect the rotating blades from

damage and helps protect the operator from injury. NEVER

put hands or feet inside the guard ring when engine is

running. NEVER attempt to lift the trowel by the guard ring.

11. Trowel Arm – Provides attachment points for the blades. If

the blades show uneven wear patterns or some blades

wear out faster than others, the trowel arm may need to be

replaced.

12. Blades – This trowel is equipped with special combination

blades. Designed specifically for edging.

13. V-Belt Cover – Remove cover to gain access to the V-belt.

14. Lifting Bale – Provides lifting point for safe lifting of trowel.

15. Thumbwheel Adjuster – Use to adjust throttle cable.

16. Tee Handle – Loosen to fold handle.

17. Trigger Lock – Use to lock blade pitch position.

18. "Kill" Switch – Integrated into Quick Pitch Handle.

19. Throttle Lever Idle Detent – Pressed in, the detent will

hold the lever away from the "kill" switch, allowing the

engine to run at idle.

20. Quick Pitch Latching Bolt – Provides secure positioning

of pitch handle into slotted pitch comb.

PAGE 16 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 17

CA4HC TROWEL— BASIC ENGINE

3

Figure 4. Honda GX120 Engine Controls and Components

INITIAL SERVICING

The engine (Figure 4) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturer's engine

manual for instructions & details of operation and servicing. The

engine shown above is a HONDA engine, operation for other

types of engines may vary somewhat.

1. Fuel Filler Cap – Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

DANGER

Adding fuel to the tank should be done only

when the engine is stopped and has had an

opportunity to cool down. In the event of a

fuel spill, DO NOT attempt to start the engine

until the fuel residue has been completely

wiped up, and the area surrounding the

engine is dry.

5. Fuel Valve Lever – OPEN to let fuel flow, CLOSE to stop

the flow of fuel.

6. Choke Lever – Used in the starting of a cold engine, or in

cold weather conditions. The choke enriches the fuel

mixture.

7. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element.

NOTE

8. Spark Plug – Provides spark to the ignition system. Set

spark plug gap according to engine manufacturer's

instructions. Clean spark plug once a week.

9. Muffler – Used to reduce noise and emissions.

10. Fuel Tank – Holds unleaded gasoline. For additional

information refer to engine owner's manual.

11

13

12

Operating the engine without an air

filter, with a damaged air filter, or a

filter in need of replacement will

allow dirt to enter the engine, causing

rapid engine wear.

2. Throttle Lever – Used to adjust engine RPM speed (lever

SLOW

advanced forward

FAST

).

3. Engine ON/OFF Switch –

OFF

starting,

4. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

position stops engine operation.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 17

, lever back toward operator

ON

position permits engine

11. Oil Drain Plug – Remove this plug to remove oil from the

12. Dipstick/Oil Filler Cap – Remove this cap to determine if

13. Output Shaft – Drive power is transferred from the engine

engine's crankcase.

the engine oil is low. Add oil through this filler port as

recommended in Table 4.

output shaft to the gearbox via a V-Belt pulley drive system.

Page 18

CA4HC TROWEL— HANDLE ASSEMBLIES

Assembly and Installation

Before the trowel can be put into operation there are some

components that must be installed before the trowel can be used.

This section provided general instructions on how to install those

components. Instruction sheet p/n 21766 Rev A (Standard

Handle), or Instruction sheet p/n 21849 Rev A (Folding Quick

Pitch Handle) provides further details for the handle assembly.

Handle Tube Installation (All Models)

1. Install the

The mounting hardware should be contained in the shipping

container.

handle tube

4

to the gearbox as shown in (Figure 5).

1

3

Figure 6. Throttle Idle-Run Position (Standard Handle

2

1

3

1 Throttle Cable

2 Throttle Lever

3 Run Position

4 Idle Position

shown)

4

2

1 Main Handle Tube

2 Gearbox

3 Nyloc Hex Nut

4 Hex Screw

Figure 5. Handle Tube Installation

Throttle Cable Connection (All Models)

The throttle cable length is preset

NOTE

and installed into the throttle lever

at the factory.

2. Install the throttle cable to the engine as shown in Figure 7.

6

3

1

8

5

7

2

4

9

1 Adjuster Nut

2 Cable Housing Clamp

3 Swivel Stop Screw

4 Swivel Stop Hole

5 Cable Housing Edge

6 Cable End

7 Housing Clamp Screw

8 Engine Idle Return Spring

9 Cable Ferrule

1. Set the throttle lever to the idle position (Figure 6) (lever away

from the operator).

PAGE 18 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

3. Adjust throttle cable at throttle lever on handle bar. (Figure 8)

Figure 7. Throttle Cable to Engine

Page 19

CA4HC TROWEL— HANDLE ASSEMBLIES

1

2

3

4

1

1 Throttle Lever

2 Throttle Cable

3 Idle Detent

4 Thumbwheel Adjuster

Figure 8. Throttle Cable Adjust

Pitch Cable Installation

1. Expose the pitch cable to maximum by adjusting the handle

pitch to the "no pitch", counter-clockwise position (Standard

Handle)(Figure 9). Pivot the pitch handle forward or no

pitch for the folding Quick Pitch handle, (Figure 10).

3

4

2

Figure 10. "No Pitch" Position (Quick Pitch Handle)

2. Remove any nuts from the pitch cable end. Insert the cable

through the yoke eyelet, (Figure 11). Thread the conical

nut up to the eyelet first. Tighten the conical nut by hand to

remove all the slack from the cable.

3. Thread the brass locking nut up to the conical nut. Use a

wrench to tighten the conical nut up against the yoke boss.

This will lock the cable in place. Use a wrench to tighten up

the brass nut up against the yoke boss.

Figure 9. Pitch cable (Standard Handle)

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

The Quick-Pitch™ handle is spring loaded, personal injury

or damage could result from improper handling or

installation. Be careful when installing this component.

Considerable force may be

NOTE

required when moving the QuickPitch™ handle forward or

backward.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 19

1 Yoke Eyelet

2 Yoke

3 Conical Nut

4 Locking Nut

Figure 11. Pitch Cable to Yoke Install

Page 20

CA4HC TROWEL— HANDLE ASSEMBLIES

Quick Pitch™ Handle Assembly

If your CA4HC TROWEL is equipped with a folding upper handle

(Figure 12), you will need to unfold and adjust the trowel handle

to the upright position prior to operation. It was assembled at the

factory and shipped in its folded or stowed position.

Considerable force may be

NOTE

Unfolding the Trowel for Operation

1. Make sure that the Quick Pitch™

attached to the upper handle bar and the pitch control cable

has slack. Remove the

on the top side of the upper handle bar, by rotating the

knob counter-clockwise.

required when moving the

Quick Pitch™ handle forward

or backward.

handle

T-handle knob

has been

from the swing bolt

2. Move the Quick Pitch™

position and unfold the upper handle bar away from the

engine into the

so that it fits through the slot in the hinge plate. Turn the Thandle knob counter-clockwise securely to hold upper

handle bar in place.

2. When folding the handle assembly, remember to move the

Quick Pitch™ handle forward first to avoid stretching

the throttle cable.

DO NOT operate unless T-Handle Knob is securely in place.

upright

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

6

handle

position. Re-insert the swing bolt

toward's the operator's

7

1

4

5

2

3

1 Operational Position

2 Upper Handle

3 T-Handle Knob

4 Quick Pitch Handle forward

when handle in folded position

5 Folded Position

6 Trigger Lock

7 Quick Pitch Handle

Figure 12. Trowel Folded and Operational Positions

PAGE 20 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 21

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ALWAYS wear approved eye and

hearing protection before operating the

trowel.

NEVER place hands or feet inside the

guard rings while the engine is running.

CA4HC TROWEL— PRE-INSPECTION

Figure 13. Engine Oil Dipstick (Removal)

ALWAYS shut the engine down before

performing any kind of maintenance

service on the trowel.

Before Starting

1. Read safety instructions at the beginning of manual.

2. Clean the trowel, removing dirt and dust, particularly the

engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

5. Check fastening nuts and bolts for tightness.

Engine Oil Check

1. To check the engine oil level, place the trowel on secure

level ground with the engine stopped.

2. Remove the filler dipstick from the engine oil filler hole

(Figure 13) and wipe clean.

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 14), fill to the edge of the oil filler

hole with the recommended oil type (Table 3). Maximum oil

capacity is 0.48 quarts (.45 liters).

NOTE

Reference manufacturer engine

manual for specific servicing

instructions.

Figure 14. Engine Oil Dipstick (Oil Level)

epyTliO.4elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 21

Page 22

DANGERDANGER

DANGER

DANGERDANGER

CA4HC TROWEL— PRE-INSPECTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

EXPLOSIVE FUEL!

Motor fuels are highly flammable and can

be dangerous if mishandled. DO NOT

smoke while refueling. DO NOT attempt to

hot!

refuel the trowel if the engine is

running

Fuel Check

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if fuel level is low. If fuel is low, replenish

3. When refueling, be sure to use a strainer for filtration. DO

Gearbox Oil

1. Determine if the

.

with unleaded fuel.

NOT top-off fuel. Wipe up any spilled fuel.

gearbox

plug located on the side of the gearbox. This plug will be

marked by the "

level of the lubrication oil should be to the bottom of the fill

plug.

check

oil is low by removing the oil

" decal. See Figure 15. The correct

or

V-Belt Check

A worn or damaged V-belt can adversely affect the performance

of the trowel. If a V-belt is defective or worn simply replace the Vbelt as outlined in the maintenance section of this manual.

Belt Guard Check

Check for damage, loose or missing hardware.

Blade Check

Check for worn or damaged blades. Check to see if one blade is

worn out while the others look new. If this is the case there could

be a blade pitch problem. Refer to the maintenance section of

this manual for blade pitch adjustment procedure. Replace any

worn blades.

Centrifugal Clutch

This finisher model is equipped with a

unit automatically stops rotating when the handle is released.

Disconnect the spark plug wire from the spark plug and

secure away from the engine before performing

maintenance or adjustments on the machine.

centrifugal clutch

. The

1

2

1 Gearbox

2 Oil Level Sight Glass

Figure 15. Gearbox

2. If lubrication oil begins to seep out as the drain plug is

being removed, then it can be assumed that the gearbox

has a sufficient amount of oil.

3. If lubrication oil does not seep out as the drain plug is

being removed, fill with type ISO 680 (P/N 10139) gearbox

lubricant oil until the oil filler hole overflows.

PAGE 22 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 23

CA4HC TROWEL — INITIAL START-UP

IDLE

POSITION

THROTTLE

LEVER

This section is intended to assist the operator with the initial

start-up of the walk-behind trowel. It is extremely important that

this section be read carefully before attempting to use the trowel

in the field.

DO NOT use your trowel until this section is thoroughly

understood

Lifting the Trowel Onto a Slab

Extra care should be taken when lifting the trowel off the ground.

Serious damage to the machine or personal injury could be

caused by dropping a trowel.

WARNINGWARNING

WARNING

WARNINGWARNING

NEVER attempt to lift this machine alone. NEVER lift the

trowel by the guard ring as it may rotate and cause injry.

Use only the manufacturer's approved lifting points. The

trowel may be lifted at the center lifting bale by crane or other

lifting device of adequate capacity.

3. Place the

if starting a

Figure 17. Throttle Lever (Idle Position)

choke lever

cold

(Figure 18) in the "

engine.

CLOSED

" position

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

DO NOT attempt to operate the trowel until the Safety,

General Information and Inspection sections of this manual

have been read and thoroughly understood.

Starting the Engine

1. Place the engine

position.

fuel valve lever

(Figure 16) to the "ON"

4. Place the

starting a

5. Place the

position.

choke lever

Figure 19. Engine Choke Lever (Open)

engine ON/OFF switch

Figure 18. Engine Choke Lever

(Figure 19) in the "

warm engine

or the

temperature is warm.

OPEN

" position if

(Figure 20) in the "

ON

"

Figure 16. Engine Fuel Valve Lever

2. Place the trowel's

position.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 23

throttle lever

(Figure 17) to the "IDLE"

Figure 20. Engine ON/OFF Switch

Page 24

CA4HC TROWEL — INITIAL START-UP

6. Grasp the starter grip (Figure 21) and slowly pull it out. The

resistance becomes the hardest at a certain position, corresponding to the compression point. Pull the starter grip briskly

and smoothly for starting.

Figure 21. Starter Grip

7. If the engine has started, slowly return the choke lever

OPEN

(Figure 19) to the

repeat steps 1 through 6.

8. Before the trowel is placed into operation, run the engine for

several minutes. Check for fuel leaks, and noises that would

associate with a loose V-belt cover or component.

position. If the engine has not started

Stopping The Engine

1. Move the throttle lever to the IDLE or SLOW position (Figure

22) and run the engine for three minutes at low speed.

2. After the engine

“OFF” position (Figure 23).

Figure 23. Engine ON/OFF Switch (OFF Position)

3. Close the

valve lever to the OFF position.

cools

, turn the engine start/stop switch to the

fuel shut- off valve

(Figure 24) by moving the fuel

To begin troweling, move the throttle lever (Figure 22) toward

9.

FAST

the "

" position.

Figure 22. Throttle Lever (Run Position)

Figure 24. Fuel Valve Lever (OFF Position)

PAGE 24 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 25

CA4HC TROWEL — OPERATION

The following steps are intended as a basic guide to machine

operation, and are not to be considered a complete guide to

concrete finishing. We suggest that all operators (experienced

and novice) read “

Concrete Institute, Detroit, Michigan

section of this manual for more information.

The figure illustrates a typical walk-behind trowel application.

Practice maneuvering the trowel. The trick is to let the trowel do

the work.

Slabs on Grade

” published by the

. Read the “Training”

American

Maneuvering the Trowel

1. Get into the operator’s position behind the handle. With a

secure foothold and a firm grasp on the handles slowly

increase the engine speed until the desired blade speed is

obtained.

2. To maneuver the trowel, gently lift up on or press down on

the main trowel handle. To move the machine to the operator’s

left,

down

3. The best method for finishing concrete is to slowly walk

backwards (Figure 25) with the trowel, guiding the trowel

from side to side. This will cover all footprints on wet concrete.

4. Remember that if you let go of the trowel, just step away and

let the trowel come to a complete stop before trying to recover

the trowel.

lift up

on the handle, to move machine to the right,

on the handle.

push

Figure 25. Maneuvering The Trowel

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

feet

or

hands

NEVER place your

the guard rings while starting or operating

this equipment.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 25

inside

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ALWAYS keep clear of

moving

equipment.

parts while operating this

rotating

or

Page 26

CA4HC TROWEL — OPERATION - OPTIONS

Pitching The Blades - Standard Handle

Adjust the blade pitch on the

26) by turn the Pitch Adjust Wheel clockwise or counterclockwise.

Standard handle

, (Figure

Blades are a vital part of finishing concrete. This finisher has been

designed to finish concrete and is built to stringent quality standards

out of the finest trowel steel. If you need replacement blades,

consult your parts list in this manual for part numbers and order

them from your Multiquip parts dealer or importer.

PITCH ADJUST

WHEEL

Figure 26. Standard Pitch Adjust

Pitching The Blades - Quick Pitch Handle

1. To pitch the blades upwards using the

handle

and pull the handle towards the operator. Pushing the

handle towards the engine will cause the blades to lay

flat.

, (Figure 27) simply squeeze the trigger lock

2

"Quick Pitch

1

Combo Blades

This trowel was equipped with

blades as original equipment. These blades have been designed

for optimum performance in both the floating and finishing of

concrete. These blades are versatile and should take care of most

troweling needs.

™"

combination type

Figure 28. Combination Blade

(Figure 28)

4

1 Quick Pitch Handle

2 Blade Pitch Trigger Lock

3 Increase Blade Pitch

4 Decrease Blade Pitch

(Compresses spring inside handle tube)

Figure 27. Quick Pitch™ Handle

Blades

NOTE

Optional Float Discs (Pans)

These round discs (Figure 29) attach to the spiders and allow the

machine to “

3

Blades should be changed when

they fail to finish concrete in a

satisfactory manner.

floating and easy movement from wet to dry areas. They are also

very effective in embedding large aggregates and surface

hardeners.

float

” on “

wet

” concrete. The disc design allows early

Figure 29. Float Disk (Pan)

PAGE 26 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 27

CA4HC TROWEL — MAINTENANCE

See the engine manual supplied

NOTE

with your machine for appropriate

engine maintenance schedule

and troubleshooting guide for

problems.

At the front of the book (Page 10) there is a “

Checklist

basis.

ALWAYS allow the engine to cool before

servicing. NEVER attempt any maintenance

work on a

Disconnect the spark plug wire from the spark plug and

secure away from the engine before performing

maintenance or adjustments on the machine.

MAINTENANCE SCHEDULE

Daily (8-10 Hours)

”. Make copies of this checklist and use it on a daily

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

hot!

engine.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Daily Pre-Operation

Trowel Arm Adjustment

Use the following procedure to check and adjust trowel arms,

and check for worn or damaged components when it becomes

apparent that the trowel is finishing poorly or in need of routine

maintenance.

Look for the following indications. Trowel arm alignment, worn

spider bushings or bent trowel arms may the cause.

■

■

■

1. Place the trowel in a FLAT, LEVEL area.

A

Any unlevel

will give an incorrect perception of adjustment. Ideally, a 5 x 5 Ft.

(1.5 x 1.5 Meter) three-quarter inch (19 mm) thick

plate should be used for testing.

2. Pitch the blades as flat as possible. The

Are blades wearing unevenly? Is one blade completely

worn out while the others look new?

Does the machine have a perceptible rolling or bouncing

motion when in use?

Look at the machine while it is running; do the guard rings

“rock up and down” relative to the ground?

level

, clean area to test the trowel prior to and after is essential.

spots

in the floor or debris under the trowel blades

FLAT

steel

adjustment bolts

should all barely make contact with the

the spider. If one is not making contact, adjustment will be

necessary. (Item 1, Figure 30).

lower wear plate

on

1. Check the oil level in the engine crankcase and gear box,

fill as necessary.

2. Check V-belt.

Weekly (50-60 Hours)

1. Relube arms, thrust collar and clutch

2. Replace blades if necessary.

3. Check and clean or replace the engine air filter as

necessary.

4. Replace engine oil and filter as necessary, see engine

manual.

Monthly (200-300 Hours)

1. Remove, clean, reinstall and relube the arms and thrust

collar. Adjust the blade arms.

Yearly (2000-2500 Hours)

1. Check and replace if necessary the arm bushings, thrust

collar bushings and shaft seals.

2. Check pitch control cables for wear.

3. Adjust blade speed.

Refer to pages 21 and 22 for oil and lube procedures.

Figure 30 illustrates, "

bushings or bent trowel arms

is barely touching (0.10" max. clearance) lower wear plate. All

alignment bolts should be spaced the same distance from the

lower wear plate.

4

Figure 31 illustrates the "

(as shipped from the factory).

incorrect alignment", worn spider

. Check that the adjustment bolt

1

2

3

1 Adjustment Bolt

2 Lower Wear Plate

3 Surface

4 "Dished" Effect on Finished Concrete

Figure 30. Incorrect Spider Plate Alignment

correct alignment

" for a spider plate

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 27

Page 28

CA4HC TROWEL — MAINTENANCE

1

2

6

1 Gearbox

2 Trowel Arm

3 Surface

3

4 Mounting Bar

5 Blade

6 Correct Alignment

4

5

Figure 31. Correct Spider Plate Alignment

b. Lift the upper trowel assembly off the spider assembly.

Spider Removal

1. Once it is determined that an adjustment is required, remove

the spider assembly from the gearbox shaft as follows:

a. Remove the zerk fitting and allen head screw desig-

nated by the letter "S" (Figure 32). In addition, on the

opposite side of the spider block there is another zerk

fitting and allen head screw, remove both of these

Trowel Arm Removal

1. Remove the two remaining zerk fittings and allen head

screws from the spider assembly (Figure 33).

components.

1 Gearbox

2 Gearbox Shaft

3 Thrust Collar Bearing

4 Thrust Collar

5 Lower Wear Plate

6 Spider Plate

7 Zerk Cap

8 Zerk Fitting

9 Washer

10 Allen Screw

Figure 32. Spider/Gearbox Removal

A slight tap with a rubber mallet may be necessary to

dislodge the spider from the main shaft of the gearbox.

1

2

3

2

2

1

3

4

S

4

1 Spider Plate

2 Zerk Fitting

3 Washer

5

4 Zerk Cap

Figure 33. Trowel Arms Removal

6

8

S

7

PAGE 28 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

10

9

Page 29

CA4HC TROWEL — MAINTENANCE

Trowel Blade Removal

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Disconnect the spark plug wire from the spark plug and

secure away from the engine before performing

maintenance or adjustments on the machine.

1. Remove the trowel blades from the trowel arm by removing

the two hex head bolts (Figure 34) from the trowel arm. Set

blades aside.

3

5

4

1

2

1 Blade

2 Blade Arm

3 Hex Head Bolt

4 Lock Washer

4 Remove From Arm

Figure 34. Trowel Blades

6. Insert all trowel arms with levers into spider plate (with bronze

bushing already installed) using care to align grease hole on

bronze bushing with grease hole fitting on spider plate.

7. Lock trowel arms in place by tightening the hex head bolt with

zerk grease fitting and jam nut.

8. Re-install the blades onto the trowel arms.

9. Install stabilizer ring onto spider assembly.

10. Lubricate all grease points (zerk fittings) with premium

Lithum 12"

"

consistency.

Changing Blades Only

We recommend that

. The machine may wobble or bounce if only some of the

time

blades are changed at one time.

1. Place the machine on a flat, level surface. Adjust the blade

pitch control to make the blades as flat as possible. Note the

blade orientation on the trowel arm.

NOTE

based grease, conforming to NLG1 Grade #2

all the blades be changed at the

same

Before removing the

blades, please note the

orientation of the blade on

the trowel arm.

Wire brush

2.

trowel arm. Repeat this for the remaining three arms.

Re-Assembly

1. Clean and examine the upper/lower wear plates and thrust

collar. Examine the entire spider assembly. Wire brush any

concrete or rust build-up. If any of the spider components are

found to be damaged or out of round, replace them.

2. Make sure that the bronze trowel arm bushing is not damage

or out of round. Clean the bushing if necessary. If the bronze

bushing is damaged or worn, replace it.

3. Reinstall bronze bushing onto trowel arm.

4. Repeat steps 2 -3 for each trowel arm.

5. Make sure that the spring tensioner is in the correct position

to exert tension on the trowel arm.

any build-up of concrete from all six sides of the

1. Remove the two bolts and lock washers that secure the blade

to the trowel arm. Remove the blade.

2. Using a wire brush, scrape all concrete particles and foreign

debris from the trowel arm.

3. Install the new trowel blade onto the trowel arm. Make sure

blade is installed correctly, maintaining the proper orientation for direction of rotation

4. Reinstall

blade to the trowel arm. Tighten both bolts securely.

5. Repeat steps 1 - 4 for all remaining blades.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 29

.

the two bolts and lock washers that secure the

Page 30

CA4HC TROWEL — MAINTENANCE

Installing Pans Onto Finisher Blades

WARNINGWARNING

WARNING

WARNINGWARNING

ALWAYS install pans either on the work area or on an area

that is next to and level with the work area. DO NOT lift the

trowel when the pans are attached.

Refer to Figure 35 when installing pans onto finisher blades.

1. Lift trowel just enough to slide pan under blades. Lower

finisher onto pan with blades (item #1) adjacent to Z-Clips

(item #4).

2. Rotate blades into position under Z-Clips. Ensure that the

blades are rotated in the direction of travel when the machine

is in operation or use the engine to rotate the blades into

position.

3. Attach the blade tie-downs (item #3) to the far side of the ZClip brackets (item #4) with tie-down knobs (item #2) as

shown in figure 35.

4. Check to make certain that the blade edges are secured

under the Z-Clips and the tie-downs are secured completely

over the edges of the blade bar before the machine is put back

into operation.

Decommissioning Trowel/Components

Decommissioning is a controlled process used to safely retire a

piece of equipment that is no longer serviceable. If the equipment

poses an

or damage or is no longer cost effective to maintain, (beyond lifecycle reliability) and is to be decommissioned,

dismantlement), the following procedure must take place:

unacceptable and unrepairable safety risk due to wear

(demolition and

1. Drain all fluids completely. These may include oil, gasoline,

2

3

hydraulic oil and antifreeze. Dispose of properly in accordance with local and governmental regulations. Never pour

on ground or dump down drains or

2. The remainder can be brought to a salvage yard or metal

reclamation facility for further dismantling.

sewers.

1

4

1 Blade Assembly

2 Knob, Tie-down Z-Clip Pans

3 Tie-down, Blade

4 Z-Clip, Pan

Figure 35. Pan Installation

PAGE 30 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 31

CA4HC TROWEL — TROUBLESHOOTING (TROWEL)

GNITOOHSELBUORT.5ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?smraleworttneB

nihctiwSFFO/NOenignE

?snoitcennoceriwesooL .yrassecensariaperroecalpeR.gniriwkcehC

FFO/NOnistcatnocdaB

.yrassecenfihctiws

.yltcerrocgninoitcnuf

.hctiwsFFO/NOecalpeR

.rabedalbehtotlellarapdna

.yletaidemmitiecalper,tnebylthgilsnevesismra

.decalper

ronoitisop"FFO"

?gninoitcnuflam

?leuF

.llatatonrohguorgninnurenignE

,etercnocsllor,secnuob“lewortfI

nislriwsnevenusekamro

.”etercnoc

?noitingI

?hctiws

?sedalB

?tnemtsujdahctiP

?redipS

ecalperroNOsihctiwSFFO/NOenignEehttahterusekaM

otdeilppusgniebleufsierehterusekaM.metsysleufehttakooL

.deggolctonsiretlifleufehttahterusneotkcehC.enigneeht

sidnarewopsahhctiwsnoitingiehttahterusneotkcehC

.nrowylevissecxeton,noitidnocdoognierasedalbniatrecekaM

ehtmorf)mm05("2nahtsselonerusaemdluohssedalbhsiniF

onerusaemdluohssedalbobmoc,egdegniliartehtotrabedalb

thgiartsebdluohsedalbfoegdegniliarT.)mm98("5.3tahtssel

saelgnahctipemasehttateserasedalbllatahtkcehC

rofelbaliavasiloottnemtsujdadleifA.redipsehttaderusaem

).tpeDstraPtcatnoC(.smralewortehtfotnemtsujdathgieh

ehtfoenofI.smraleworttnebrofylbmessaredipsehtkcehC

ehtgnivomybenodebnacsihT.redipsnismrafotifkcehC

fo)mm2.3("8/1nahteromsierehtfI.nwoddnapusmralewort

ebdluohssmradnaredipseht,mraehtfopitehttalevart

?ralloctsurhT

?ralloctsurhT

?nrowgniraebtsurhT

?tfahsniaM

.gninnurelihwnoitom

gnillorelbitpecrepasahenihcaM

?ekoY

?hctiPedalB

.yrassecen

.launam

.ralloctsurhtehtecalper

.tnioptnemhcatta

.yrassecensaekoyecalpeR.pacraeweht

.redipsehtnotignitatorybralloctsurhtehtfossentalfehtkcehC

.ralloctsurhtehtecalper)mm5.0("20.0nahteromybseiravtifI

tlitnactifI.redipsehtnotignikcorybralloctsurhtehtkcehC

,].D.Oralloctsurhtehttaderusaemsa[)mm4.2("23/3nahterom

fiecalpeR.eerfgninnipssititahteesotgniraebtsurhtehtkcehC

ebdluohsylbmessaxobraegehtfotfahstuptuoniamehT

dnathgiartsnurtsumtfahsniamehT.ssenthgiartsrofdekcehc

redipsehttadnuorfotuo)mm80.0("300.0nahteromebtonnac

noylnevesserpekoyehtfosregnifhtobtahterusekamotkcehC

emasehtevahotdetsujdasiedalbhcaetahterusneotkcehC

ninoitcesecnanetniamreptsujdA.sedalbrehtollasahctip

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 31

Page 32

CA4HC TROWEL — TROUBLESHOOTING (ENGINE)

)ENIGNE(GNITOOHSELBUORT.6ELBAT

MOTPMYSESUACELBISSOPNOITULOS

?gnigdirbgulpkrapS

ontub,elbaliavasileuf",tratsottluciffiD

."gulpkrapstaKRAPS

?noitalusni

?evitcefedliocnoitingI.liocnoitingiecalpeR

dna,elbaliavasileuf",tratsottluciffiD

."gulpkrapsehttatneserpsiKRAPS

?gnitiucric

?epytleufgnorW

?gulpkrapsnotisopednobraC .gulpkrapsecalperronaelC

gulpkrapstneicifedoteudtiucrictrohS

?paggulpkrapsreporpmI.pagreporpotteS

?detrohssihctiwsFFO/NO

?ytridstniop,pagkrapsreporpmI

trohsronrownoitalusniresnednoC

?gnitiucrictrohsronekorberiwgulpkrapS

.nrowfiecalper

.hctiws

.stniopnaelc

.gniriw

ronoitalusni,pagkcehC

.gulpkrapsecalper

,noitalusnigulpkrapskcehC

ecalper,gniriwhctiwskcehC

dnapagkrapstcerrocteS

.resnednocecalpeR

gulpkrapsevitcefedecalpeR

ecalperdna,metsysleufhsulF

.leuffoepyttcerrochtiw

?metsysleufnitsudroretaW.metsysleufhsulF

kraps,elbaliavasileuf",tratsottluciffiD

."lamronsinoisserpmocdnatneserpsi

kraps,elbaliavasileuf",tratsottluciffiD

."wolsinoisserpmocdnatneserpsi

.blubgnimirpedisnitneserpleufoN

?ytridrenaelcriA .renaelcriaecalperronaelC

)dlocenignE(?nepOekohC.ekohCesolC

)mrawenignE(?desolCekohC.ekohCnepO

?nrowrednilycro/dnagnirnotsiP

tongulpkrapsro/dnadaehrednilyC

?ylreporpdenethgit

?degamad

?knatleufnielbaliavatonleuF .leuffoepyttcerrochtiwlliF

?deggolcretlifleuF.retlifleufecalpeR

?enilleufniriA.enilleufdeelB

?dedurtorprokcutsevlavtsuahxe/noitcuS.sevlavtaes-eR

teksaggulpkrapsro/dnateksagdaeH

?deggolcelohrehtaerbpacknatleuF .packnatleufecalperronaelC

rodnasgnirnotsipecalpeR

.notsip

dnastlobdaehrednilyceuqroT

.gulpkraps

gulpkrapsdnadaehecalpeR

.steksag

PAGE 32 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 33

NOTE PAGE

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 33

Page 34

NOTE PAGE

PAGE 34 — CA4HC WALK-BEHIND TROWEL— OPERATION MANUAL — REV. #0 (09/29/06)

Page 35

Effective: February 22, 2006

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a signed

manifest has been obtained from the carrier,

and any claim for shortage or damage must be

settled between the consignee and the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip is $15.00 net. Customers will be asked

for instructions regarding handling of orders

not meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and credit

will be allowed, subject to the following provisions:

1. A Returned Material Authorization must

be approved by Multiquip prior to shipment.

2. To obtain a Return Mater ial Authorization,

a list must be provided to Multiquip Parts

Sales that defines item numbers, quantities, and descriptions of the items to be

returned.

a. The parts numbers and descriptions

must match the current parts price

list.

b. The list must be typed or computer

generated.

c. The list must state the reason(s) for

the return.

d. The list must reference the sales

order(s) or invoice(s) under which the

items were originally purchased.

e. The list must include the name and

phone number of the person requesting the RMA.

3. A copy of the Return Material Authorization must accompany the return shipment.

4. Freight is at the sender’s expense. All

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

5. Parts must be in new and resalable con-

6. The following items are not returnable:

7. The sender will be notified of any material

8. Such material will be held for five working

9. Credit on returned parts will be issued at

10. In cases where an item is accepted, for

11. Credit issued will be applied to future

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a specific date and all orders received on or after that

date will be billed at the revised price. Rebates

for price declines and added charges for price

increases will not be made for stock on hand

at the time of any price change.

Multiquip reserves the right to quote and sell

dition, in the original Multiquip package (if

any), and with Multiquip part numbers

clearly marked.

a. Obsolete parts. (If an item is in the

price book and shows as being replaced by another item, it is obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were purchased more than six months prior to

the return date.

c. Any line item with an extended dealer

net price of less than $5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

received that is not acceptable.

days from notification, pending instructions. If a reply is not received within five

days, the material will be returned to the

sender at his expense.

dealer net price at time of the original

purchase, less a 15% restocking charge.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

purchases only.

direct to Government agencies, and to Original

Equipment Manufacturer accounts who use

our products as integral parts of their own

products.

SPECIAL EXPEDITING SERVICE

A $35.00 surcharge will be added to the invoice

for special handling including bus shipments,

insured parcel post or in cases where Multiquip

must personally deliver the parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of the

item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental dam-

ages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are made

in connection with the sale of parts or trade

accessories nor as to any engine not manufac-

tured by Multiquip. Such warranties made in

connection with the sale of new, complete units

are made exclusively by a statement of war-

ranty packaged with such units, and Multiquip

neither assumes nor authorizes any person to

assume for it any other obligation or liability

whatever in connection with the sale of its

products. Apart from such written statement of

warranty, there are no warranties, express,

implied or statutory, which extend beyond the

description of the products on the face hereof.

CA4HC WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #0 (09/29/06) — PAGE 35

Page 36

OPERATION MANUAL

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER

ON-HAND

WHEN CALLING

UNITED STATES

Multiquip Corporate Office MQ Parts Department

18910 Wilmington Ave. Tel. (800) 421-1244 800-427-1244 Fax: 800-672-7877

Carson, CA 90746 Fax (800) 537-3927 310-537-3700 Fax: 310-637-3284

Contact: mq@multiquip.com

Mayco Parts Warranty Department

800-306-2926 Fax: 800-672-7877 800-421-1244, Ext. 279 Fax: 310-537-1173

310-537-3700 Fax: 310-637-3284 310-537-3700, Ext. 279

Service Department Technial Assistance

800-421-1244 Fax: 310-537-4259 800-478-1244 Fax: 310-631-5032

310-537-3700

MEXICO UNITED KINGDOM

MQ Cipsa Multiquip (UK) Limited Head Office

Carr. Fed. Mexico-Puebla KM 126.5 Tel. (52) 222-225-9900 Hanover Mill, Fitzroy Street, Tel. 0161 339 2223

Momoxpan, Cholula, Puebla 72760 Mexico Fax (52) 222-285-0420 Ashton-under-Lyne, Fax 0161 339 3226

Contact: pmastretta@cipsa.com.mx Lancashire OL7 0TL

Contact: sales@multiquip.co.uk

CANADA BRAZIL

Multiquip Multiquip

4110 Industriel Boul. Tel. (450) 625-2244 Av. Evandro Lins e Silva, 840 - grupo 505 Tel. 011-55-21-3433-9055

Laval, Quebec, Canada H7L 6V3 Fax (450) 625-8664 Barra de Tijuca - Rio de Janeiro Fax 011-55-21-3433-9055

Contact: jmartin@multiquip.com Contact: cnavarro@multiquip.com.br, srentes@multiquip.com.br

© COPYRIGHT 2006, MULTIQUIP INC.

Multiquip Inc, the MQ logo and the Whiteman logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All

other trademarks are the property of their respective owners and used with permission.

This manual MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations are based on the

Walk-Behind Power Trowel.

Multiquip Inc. reserves the right to discontinue or change specifications, design or the information published in this publication at any time without notice and without

incurring any obligations.

Illustrations, descriptions, references and technical data contained in this manual are for guidance only and may not be considered as binding.

Your Local Dealer is:

MULTIQUIP INC

18910 WILMINGTON AVE.

CARSON, CALIFORNIA 90746

800-421-1244 • 310-537-3700

FAX: 310-537-3927

E-mail:mq@multiquip.com

Internet:multiquip.com

MQ Whiteman CA4HC Series

..

.

..

Loading...

Loading...