Page 1

OPERATION AND PARTS MANUAL

C-4 FINISHER

WALK-BEHIND TROWEL

MODEL #

SERIAL #

© COPYRIGHT 2002, MULTIQUIP INC.

Revision #1 (07/24/02)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

P/N 10689

Page 2

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 3

Page 4

C-4 FINISHER TROWEL— TABLE OF CONTENTS

Here's How To Get Help ............................................ 3

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

Training Checklist ...................................................... 6

Daily Pre-Operation Checklist ................................... 7

Safety Message Alert Symbols .............................. 8-9

Rules For Safe Operation .................................. 10-11

Operation And Safety Decals .................................. 12

Specifications (Trowel) ............................................ 12

Specifications (Engine) ........................................... 14

General Information ................................................ 15

MQ WHITEMAN — C-4 FINISHER TROWEL

Controls and Components ...................................... 16

Basic Engine ........................................................... 17

Assembly ................................................................. 18

Pre-Inspection .................................................... 19-20

Initial Start-Up (Gasoline Engine) ......................21-22

Operation ........................................................... 23-24

Options .................................................................... 25

Maintenance ...................................................... 26-29

Troubleshooting (Trowel) ................................... 30-31

Troubleshooting (Engine) ........................................ 32

Explanation of Codes in Remarks Column ............. 34

Suggested Spare Parts ........................................... 35

Nameplate and Decals.......................................36-37

Quick Pitch™ Handle Assembly........................ 38-39

Spider and Blades Assembly ............................. 40-41

Gearbox Assembly ............................................. 42-43

Engine2.5 HP Honda Assembly ......................... 44-45

Guard Ring Assy. ............................................... 46-47

Blades and Adjustment Fixture Assembly ......... 48-49

HONDA GX240K1 ENGINE

Air Cleaner Assembly......................................... 50-51

Camshaft Assembly ........................................... 52-53

Carburetor Assembly ......................................... 54-55

Control Assembly ............................................... 56-57

Crankcase Cover Assembly ............................... 58-59

Crankshaft Assembly .........................................60-61

Cylinder Barrel Assembly ................................... 62-63

Fan Cover Assembly .......................................... 64-65

Flywheel Assembly ............................................ 66-67

Fuel Tank Assembly ........................................... 68-69

Gasket Kit Assembly ............................................... 71

Ignition Coil Assembly ........................................ 72-73

Muffler Assembly ............................................... 74-75

Piston Assembly ................................................. 76-77

Recoil Starter Assembly.....................................78-79

Labels Assembly ................................................ 80-81

Terms and Conditions of Sale — Parts ................... 82

NOTE

Specification and part

number are subject to

change without notice.

PAGE 4 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 5

C-4 FINISHER TROWEL— PARTS ORDERING PROCEDURES

■■

■ Dealer account number

■■

■■

■ Dealer name and address

■■

■■

■ Shipping address (if different than billing address)

■■

■■

■ Return fax number

■■

■■

■ Applicable model number

■■

■■

■ Quantity, part number and description of each part

■■

■■

■ Specify preferred method of shipment:

■■

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

■■

■

UPS Ground Service at no charge for freight

■■

■■

■

UPS Third Day Service at one-half of actual freight

■■

cost

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

800-421-1244

Toll-free FAX:

800/6-PARTS-7 • 800-672-7877

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 5

Page 6

C-4 FINISHER TROWEL— TRAINING CHECKLIST

TRAINING CHECKLIST

This checklist will lists some of the minimum requirements for

machine maintenance and operation. Please feel free to detach

it and make copies. Use this checklist whenever a new operator

is to be trained or it can be used as a review for more experienced

operator’s.

.ON NOITPIRCSED ?KO ETAD

1 .yletelpmoclaunaMs’rotarepOdaeR

TSILKCEHCGNINIART

2

3 erudecorpgnileufer,metsysleuF

4 .)gninnurtonenihcam(slortnocfonoitarepO

5 .noitarepohctulc,slortnocytefaS

6 .serudecorppotsycnegremE

7 .enihcamfoputratS

8 gnirevuenaM

9 gnihctiP

01 .seuqinhcetgnihsinifetercnoC

11 .enihcamfonwodtuhS

21 .)tnempiuqelanoitpo(enihcamfognitfiL

31 .egarotsdnatropsnartenihcaM

dnaenignefognikcehc,stnenopmocfonoitacol,tuoyalenihcaM

.leveldiulfxobraeg

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

PAGE 6 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 7

C-4 FINISHER TROWEL— DAILY PRE-OPERATION CHECKLIST

DAILY PRE-OPERATION CHECKLIST

1 .leveLliOenignE

2 .leveLdiulFxobraeG

3 .sedalBfonoitidnoC

4 .noitarepOhctiPedalB

5 noitarepOhctulC

COMMENTS:

TSILKCEHCNOITAREPO-ERPYLIAD

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 7

Page 8

C-4 FINISHER TROWEL— SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when operating

this equipment. Failure to read and understand the Safety

Messages and Operating Instructions could result in injury to

yourself and others.

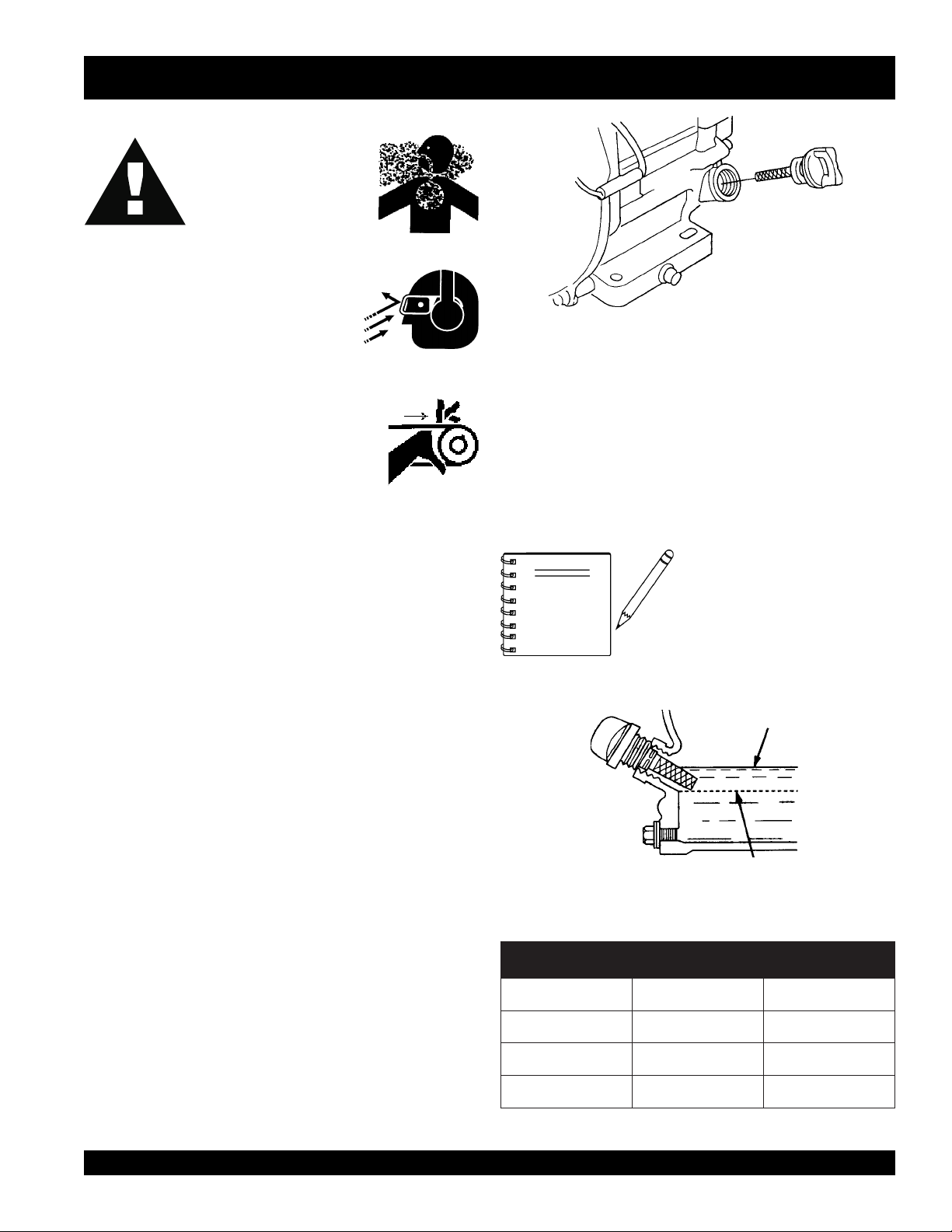

HAZARD SYMBOLS

NOTE

This Owner's Manual has been developed to provide

complete instructions for the safe and efficient operation

of the MQ Whiteman C-4 FINISHER TROWEL. For

engine maintenance information, please refer to the

engine manufacturers instructions for data relative to its

safe operation.

Before using this WALK-BEHIND TROWEL, ensure

that the operating individual has read and

understands all instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Gasoline is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

WARNING: You CAN be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

CAUTION: You CAN be injured if you

DO NOT follow directions.

Potential hazards associated with C-4 FINISHER trowel

operation will be referenced with "

appear throughout this manual, and will be referenced in

conjunction with Safety "

Message Alert Symbols

Hazard Symbols

" which

".

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep fingers,

clothing

injury.

away from all moving parts to prevent

hands, hair

and

PAGE 8 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 9

C-4 FINISHER TROWEL— SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the engine ON/OFF

switch in the OFF position, when the

trowel is not in use.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

This

property, or the surrounding

NOTE

environment could be damaged

if you do not follow instructions.

walk-behind trowel

, other

Respiratory Hazard

ALWAYS wear approved respiratory

protection.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your trowel, other property, or the

surrounding environment.

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 9

Page 10

C-4 FINISHER TROWEL — RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is

for industrial use only.

The following safety guidelines should always be used when

operating the

SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate the trowel without proper protective clothing,

shatterproof glasses, steel-toed boots and other protective

devices required by the job.

C-4 FINISHER

walk-behind power trowel.

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

the trowel.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot!

with

■

The engine of this trowel requires an adequate free flow of

cooling air. NEVER operate the trowel in any enclosed or

components can cause serious burns.

narrow area where free flow

of the air is restricted. If the

air flow is restricted it will

cause serious damage to

the trowel's engine and

may cause injury to people.

Remember the trowel's

engine gives off

carbon monoxide gas.

DEADLY

■

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate the trowel under the

influence or drugs or alcohol.

■

ALWAYS check the trowel for loosened threads or bolts before

starting.

■

ALWAYS wear proper

protection equipment when operating the trowel.

■

Manufacture does not assume responsibility for any accident

due to equipment modifications.

respiratory

(mask),

hearing

and

eye

■

■

■

■

■

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it

to cool.

NEVER

Fire or explosion could result from

vapors

NEVER operate the trowel in an explosive atmosphere or

near combustible materials. An explosion or fire could result

causing severe

Topping-off to filler port is dangerous, as it tends to spill fuel.

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

smoke

, or if fuel is spilled on a

around or near the machine.

hot!

bodily harm or even death.

fuel

engine.

PAGE 10 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 11

C-4 FINISHER TROWEL — RULES FOR SAFE OPERATION

■

NEVER Run engine without air filter. Severe engine may

occur. Service air filter frequently to prevent carburetor

malfunction.

■

NEVER place your

feet

or

hands

inside the guard rings

while starting or operating this equipment.

■

AVOID wearing jewelry or loose fitting clothing that may snag

on the controls or moving parts, this can cause a serious

injury.

■

ALWAYS keep clear of

rotating

or

moving parts

while

operating the trowel.

■

Moving Parts – Shut down the engine before performing

service or maintenance functions. Contact with moving parts

can cause serious injury.

■

ALWAYS check to make sure that the operating area is clear

before starting the engine.

■

NEVER leave the machine

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operations techniques before using trowel.

unattended

while running.

Maintenance Safety

■

■

■

■

■

■

Emergencies

■

NEVER lubricate components or attempt service on a running

trowel.

ALWAYS allow the trowel a proper amount of time to cool

before servicing.

Keep the trowel in proper running condition.

Fix damage to the trowel immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

ALWAYS know the location of the nearest

fire extinguisher

.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

ALWAYS read, understand, and follow procedures in

Operator’s Manual before attempting to operate equipment.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

Refer to the

technical questions or information

HONDA Engine Owner's Manual

for engine

recommended by Multiquip

for this equipment. Damage to the equipment and/or injury to

■

■

user may result.

Transporting

■

ALWAYS shutdown engine before transporting.

■

Tighten fuel tank cap securely and close fuel cock to prevent

fuel from spilling.

■

Drain fuel when transporting trowel over long distances or

bad roads.

■

When placing the trowel inside a truck-bed for transport,

always tie-down the trowel.

ALWAYS know the location of the nearest and

In emergencys

nearest phone or

always

know the location of the

keep a phone on the job site

first aid kit

.

.

Also know the phone numbers of the nearest

ambulance, doctor

and

fire department

. This

information will be invaluable in the case of an

emergency.

■

ALWAYS use proper lifting techniques when moving the

trowel.

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 11

Page 12

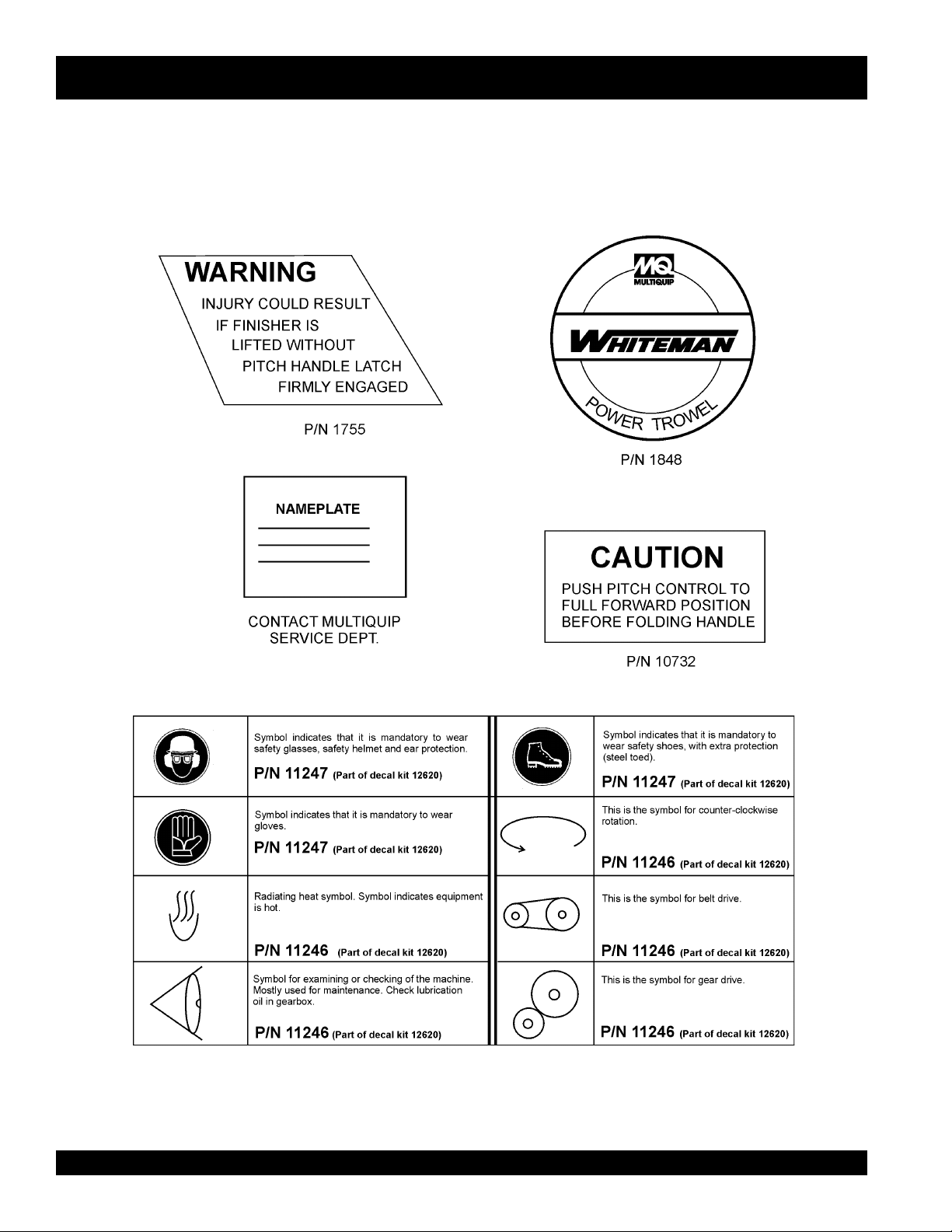

C-4 FINISHER TROWEL— OPERATION AND SAFETY DECALS

Machine Safety Decals

The

C-4 Finisher

safety and maintenance information. Figure 1 below illustrates these decals as they appear on the machine. Should any of these

decals become unreadable, replacements can be obtained from your dealer.

walk-behind trowel is equipped with a number of safety decals (Figure 1). These decals are provided for operator

Figure 1. C-4 Finisher Decals

PAGE 12 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 13

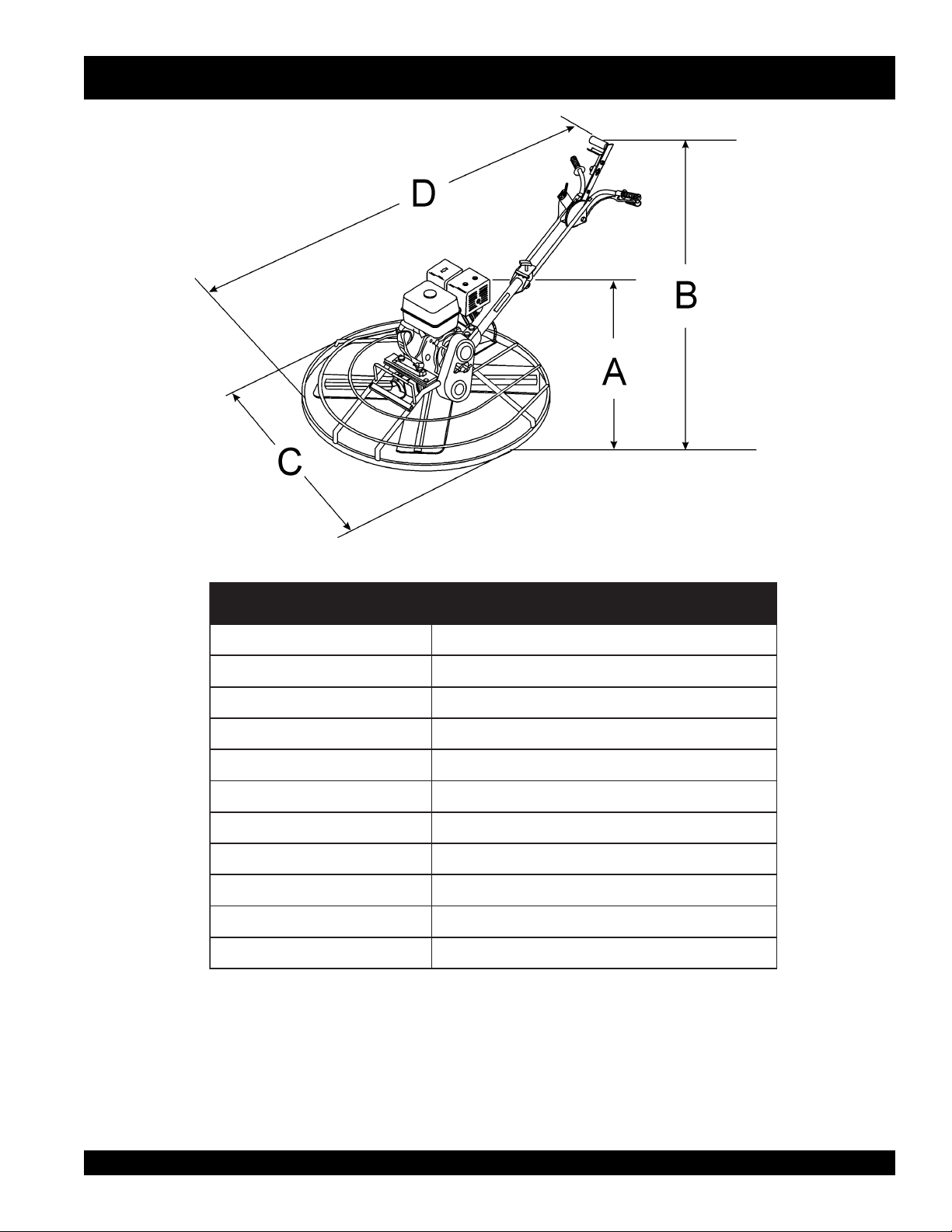

C-4 FINISHER TROWEL— SPECIFICATIONS (TROWEL)

Figure 2. C-4 Finisher Trowel Dimensions

)elaBgnitfiL(thgieH-A).mm795(.ni5.32

)reveLtnemegagnE(thgieH-B).mm129(.ni52.63

htdiW-C).mm016(.ni42

htgneL-D).mm055,1(.ni16

erusserPdnuoSbd49

noitarbiVs/m(g0.2

retemaiDgniR).mc(.ni

sedalBforebmuN4

rotoRMPR701-05

htdiWhtaP).mc16(.ni42

thgieW).gk14(.sbl09

NOTE:

1. Sound pressure is a weighted measure. Measured at the

operators ear position while the walk-behind trowel is

operating at full throttle on concrete in a manner most often

experienced in “

normal

” circumstances. Sound pressure

may vary depending upon the condition of the concrete.

Hearing protection is always recommended.

2. The vibration level indicated is the maximum RMS (Root

Mean Square) value obtained at the handle grip while

operating the walk-behind trowel on curing concrete in a

manner most often experienced in “

Values were obtained from all three axes of motion. The

values shown represent the maximum RMS value from

these measurements.

snoitacificepSleworTseireS4-C.1elbaT

2

)

normal

” circumstances.

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 13

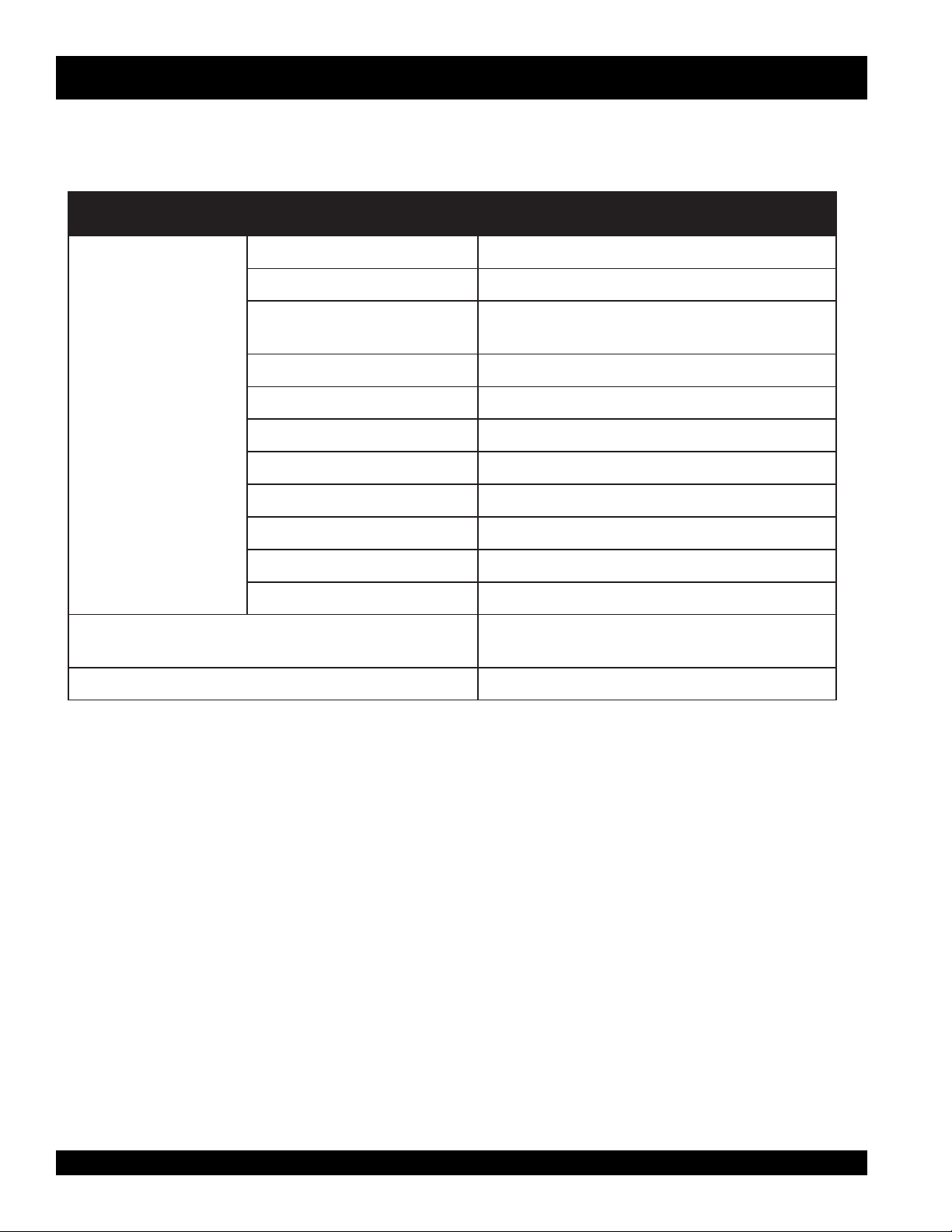

Page 14

C-4 FINISHER TROWEL— SPECIFICATIONS (ENGINE)

snoitacificepSenignE.2elbaT

ledoM 2AQ2K001GADNOH

epyT rednilyCelgniS,evlavediS,ekorts-4

ekortSXeroB

tnemecalpsiD)cc89(.ni.uc0.6

tuptuOxaM .M.P.R006,3ta.P.H5.2

rotoMcirtcelE/enignE

leuF enilosaGelibomotuAdedaelnU

)HxWxL(noisnemiD

thgieWteNyrD ).gK7.8(sbl2.91

yticapaCknaTleuF )sretiL4.1(snollaG.S.U73.0.xorppA

deepSeldIdradnatS.M.P.R001±004,1

yticapaCliOebuL )sretiL54.0(strauQ.S.U84.0

dohteMlortnoCdeepS epyTthgiew-ylFlagufirtneC

dohteMgnitratStratSlioceR

.ni1.81X.ni5.02

)mm64xmm25(

.ni6.31X6.01x8.01

)mm543X072X572(

PAGE 14 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 15

C-4 FINISHER TROWEL— GENERAL INFORMATION

C-4 Trowel Finisher Familiarization

This walk-behind finisher is designed for the

finishing

Take a walk around the trowel. Take notice of all the major

components (see Figure 3, page16) like the engine, blades,

Quick Pitch™ handle, clutch lever, etc. Check that there is always

oil in the engine.

Read

be found throughout this manual and on the trowel. Keep all

safety information in good, readable condition. Operators should

be well trained on the operation and maintenance of the trowel.

Before using your trowel, test it on a flat watered down section of

finished concrete that is free of any debris and other objects.

This trial test run will increase your confidence in using the trowel

and at the same time it will familiarize you with the trowel’s

controls. In addition you will understand how the trowel handles

under actual conditions.

Engines

This trowel is available with an 2.5 HP

Refer to the engine owner’s manual for instructions regarding

the operation and maintenance of your engine. The engine

manual is included with your trowel at the time of shipping from

Whiteman. Please contact your nearest Multiquip Dealer for a

replacement should the original manual disappear.

Drive System

Power is transferred from the engine to the gearbox input shaft

via a V-belt pulley drive system. The pulley engages using a

manual clutch. See parts section of this manual.

of concrete slabs.

all the safety instructions carefully. Safety instructions will

HONDA

floating

gasoline engine.

and

Blades

The blades of the trowel finish the concrete as they are rotated

around the surface. Blades are classified as

inches wide),

wide). This trowel comes equipped with four blades per

rotor equally spaced in a radial pattern and attached to

vertical rotating shaft by means of a

Manual Clutch

In the event of a trowel runaway condition (operator releases

the handle), a

the trowel to a halt.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Moving the Trowel

This trowel is light weight, however for safety purposes always

two people

use

Training

For proper training, please use the “TRAINING CHECKLIST”

located in the front of this manual (Page 6). This checklist will

provide an outline for an experienced operator to provide training

to a new operator

combination

float

(10 or 8 inches wide), and finish (6 inches

spider assembly.

manual clutch

NEVER attempt to

ALWAYS get the assistance of another

person to help lift the trowel .

to lift the trowel up onto a slab of concrete.

will stop the engine and bring

lift

the trowel by yourself.

(8

Gearbox

gearbox

The

spider

to the

of the trowel and is equipped with two shafts (input and output).

Spider

The vertical output shaft of the gearbox connects to a cast hub

called the

that are used for attachment of blades or other accessories.

Remember as the gearbox output shaft rotates so does the spider

assembly.

is located beneath the engine and transfers power

assembly. The gearbox controls the rotational speed

spider

. The spider has 4 arms that extend outward

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 15

Page 16

C-4 FINISHER TROWEL— CONTROLS AND COMPONENTS

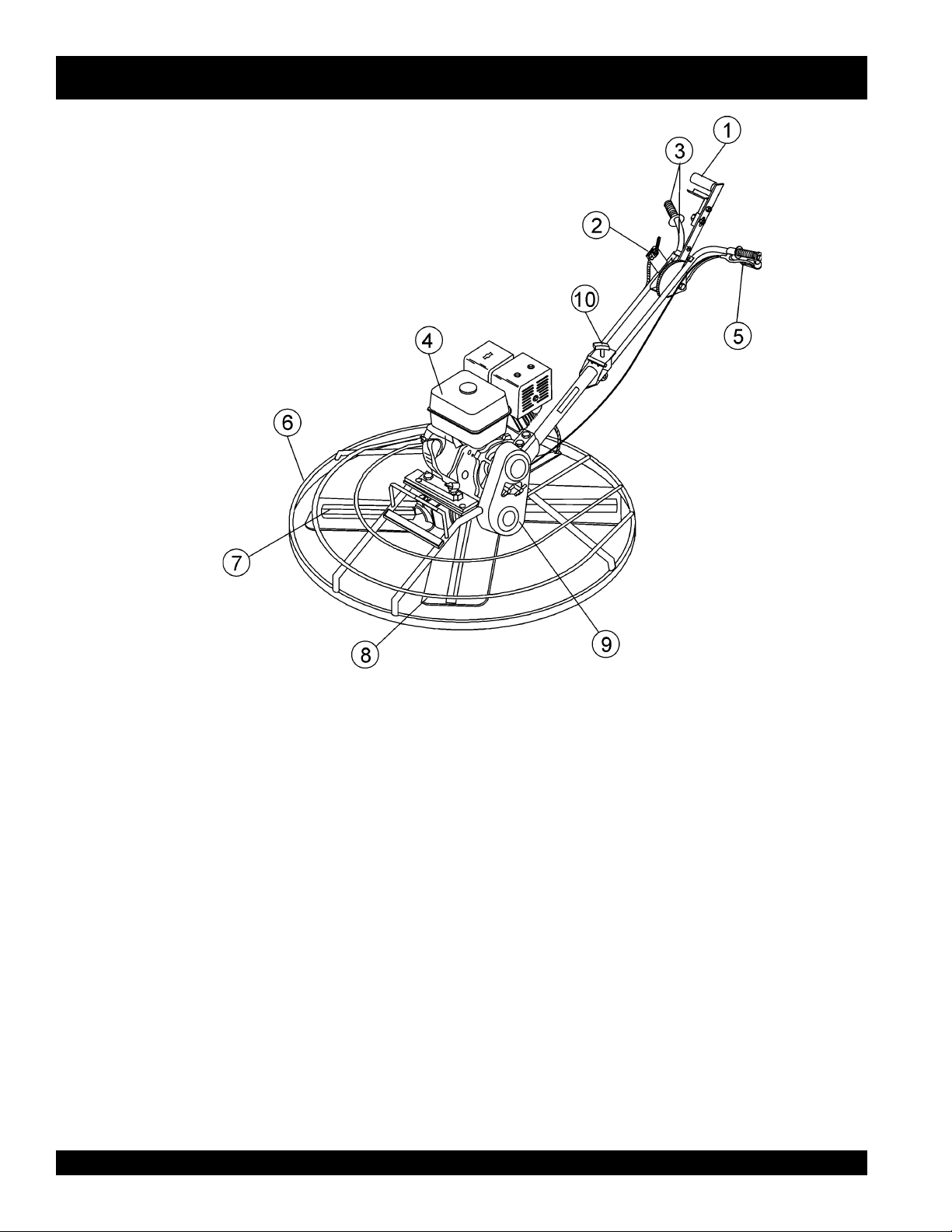

Figure 3. Controls and Components

Figures 3 shows the location of the basic controls or components,

C-4 FINISHER

for the

of each control or component

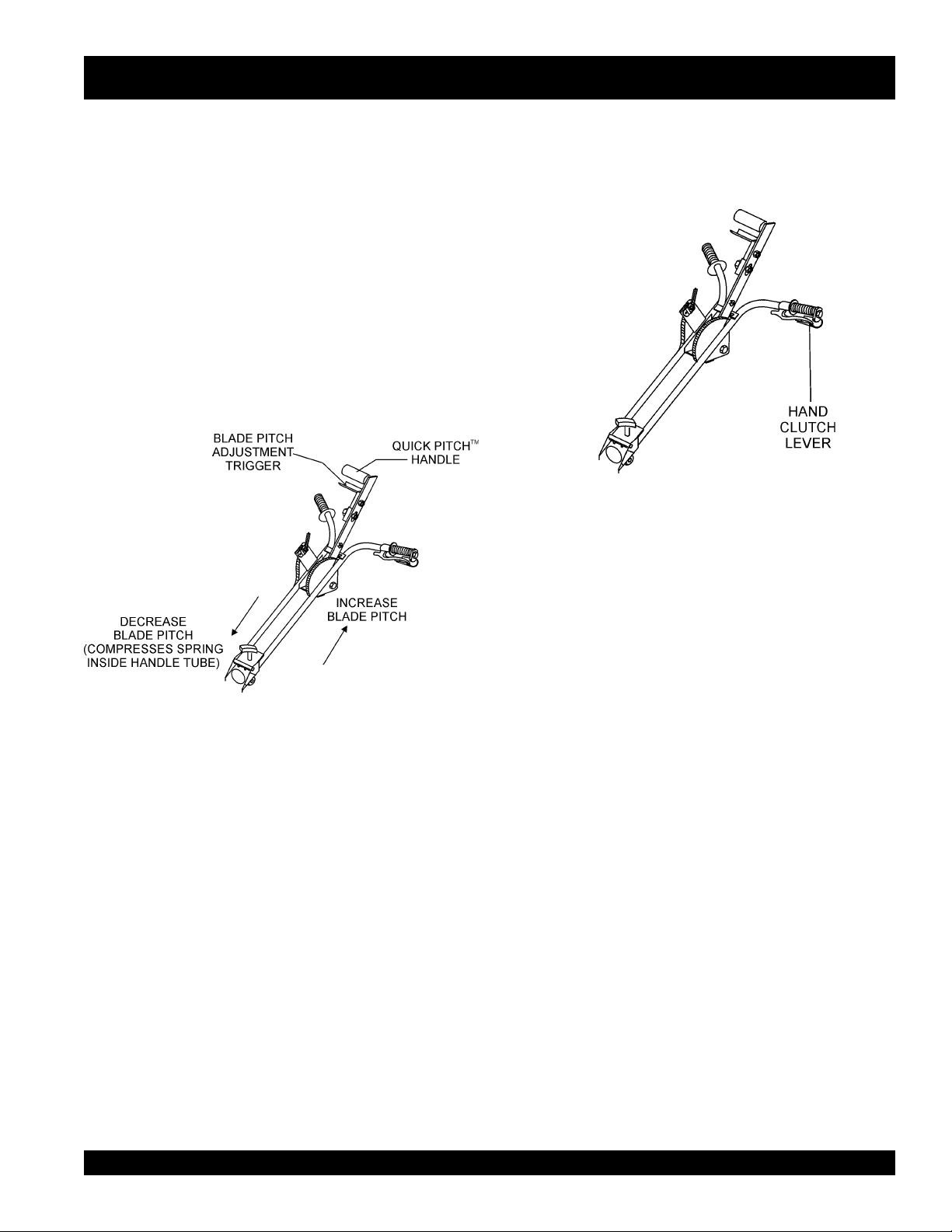

1. Quick Pitch™ Control Handle – To adjust the pitch of

the blades, grasp the handle then squeeze and either move

the handle forward or backward to achieve the desired

blade pitch.

2. Throttle Control Lever – Controls the speed of the engine.

Move the hand lever towards the operator to increase

engine speed (high), away from the operator to decrease

engine speed (low).

3. Hand Grip/Handle Bar – When operating the trowel, place

both hands on each grip to maneuver the trowel. Replace

hand grips when they become worn or damaged.

4. Engine – This trowel uses a Honda G100K2QA2 gasoline

engine.

5. Clutch Lever - Clutch engagement lever. When this lever

is engaged, the blades will begin to rotate.

trowel. Listed below is a brief explanation

6. Guard Ring- NEVER! put hands or feet inside guard ring.

7. Trowel Arm – NEVER operate the trowel with a bent, broken

or out of adjustment trowel arm. If the blades show uneven

wear patterns or some blades wear out faster than others,

the trowel arm may need to be replaced.

8. Blades – This trowel is equipped with combination blades.

These blades are versatile and should take care of most

troweling needs. In addition float discs can be attached to

the trowel arms that will allow the trowel to float on "

concrete.

9. V-Belt Cover – Remove this cover to gain access to the Vbelt. NEVER operate the trowel with this cover removed.

10. T-Handle Release Knob – Turn this handle counterclockwise to release the upper handle and place in either

down position or operate position. Turn handle clockwise

to lock upper handle in place.

wet

"

PAGE 16 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 17

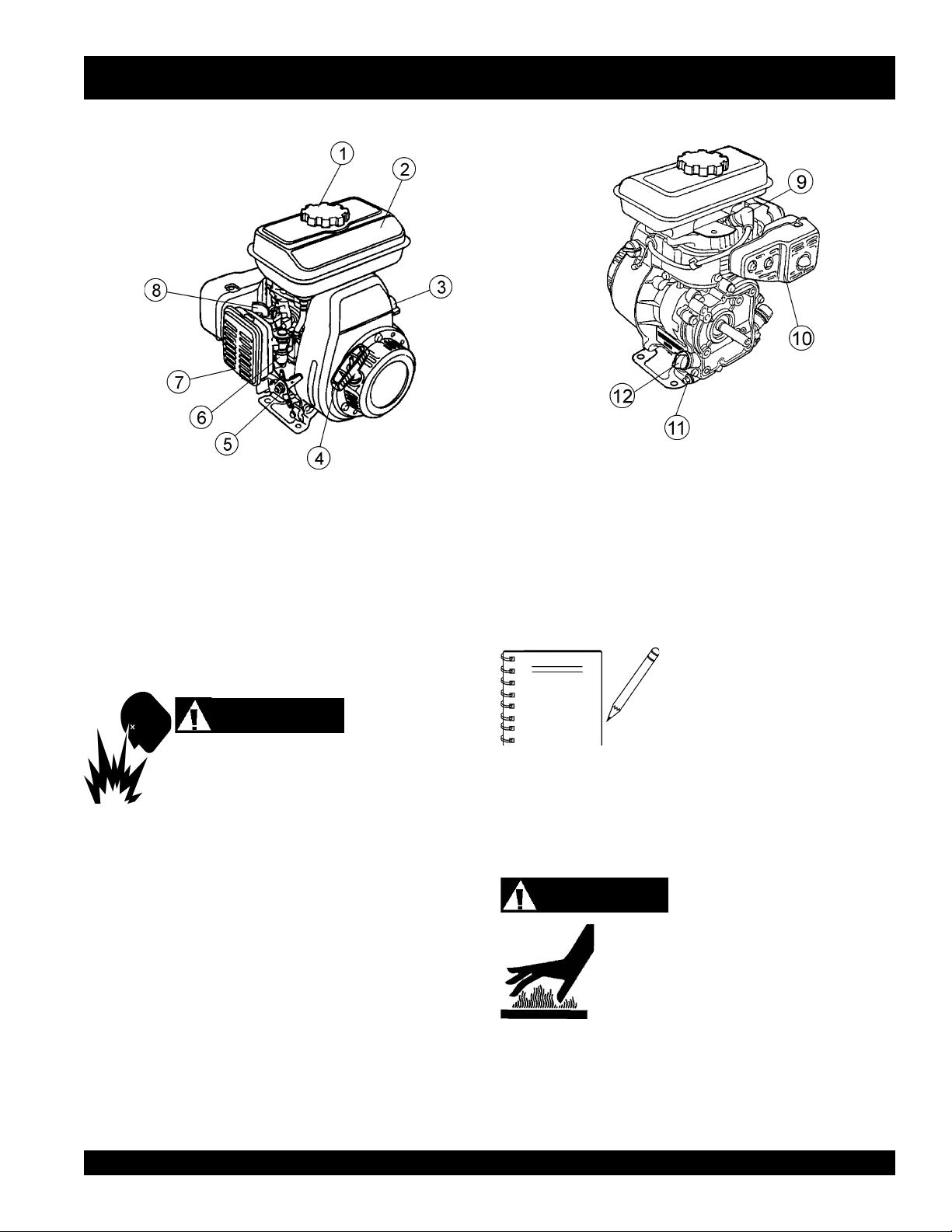

C-4 FINISHER TROWEL— BASIC ENGINE

Figure 4. Engine Controls and Components

INITIAL SERVICING

The engine (Figure 4) must be checked for proper lubrication and

filled with fuel prior to operation. Refer to the manufacturers engine

manual for instructions & details of operation and servicing. The

engine shown above is a HONDA engine, operation for other

types of engines may vary somewhat.

1. Fuel Filler Cap – Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

DANGER

Adding fuel to the tank should be done only when

the engine is stopped and has had an opportunity to

cool down. In the event of a fuel spill, DO NOT

attempt to start the engine until the fuel residue has been completely

wiped up, and the area surrounding the engine is dry.

2. Fuel Tank – Holds unleaded gasoline. For additional

information refer to engine owner's manual.

3. Engine ON/OFF Switch –

OFF

starting,

4. Recoil Starter (pull rope) – Manual-starting method. Pull

the starter grip until resistance is felt, then pull briskly and

smoothly.

5. Throttle Lever – Used to adjust engine RPM speed (lever

advanced forward

FAST

).

Fuel Valve Lever – OPEN to let fuel flow, CLOSE to stop

6.

the flow of fuel.

position stops engine operation.

SLOW

ON

position permits engine

, lever back toward operator

7. Air Cleaner – Prevents dirt and other debris from entering

the fuel system. Remove wing-nut on top of air filter

cannister to gain access to filter element.

8. Choke Lever – Used in the starting of a cold engine, or in

cold weather conditions. The choke enriches the fuel

mixture.

NOTE

9. Spark Plug – Provides spark to the ignition system. Set

spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch) Clean

spark plug once a week.

10. Muffler – Used to reduce noise and emissions.

11. Oil Drain Plug – Remove this plug to remove oil from the

engine's crankcase.

12. Dipstick/Oil Filler Cap – Remove this cap to determine if

the engine oil is low. Add oil through this filler port as

recommended in Table 3.

Operating the engine without an air

filter, with a damaged air filter, or a

filter in need of replacement will

allow dirt to enter the engine,

causing rapid engine wear.

WARNING

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operating. NEVER operate the engine with the

muffler removed.

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 17

Page 18

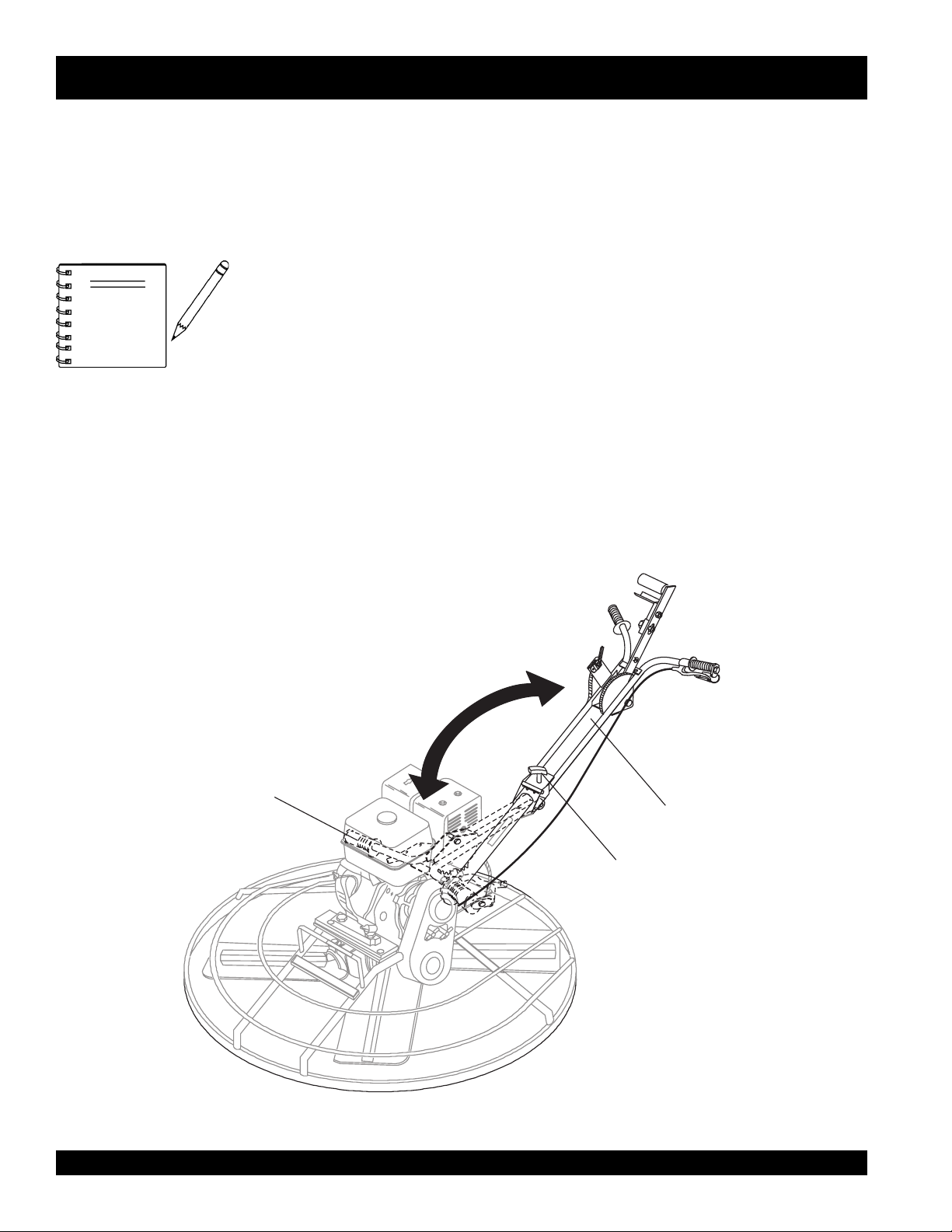

C-4 FINISHER TROWEL — ASSEMBLY

Quick Pitch™ Handle Assembly

The C-4 finisher trowel is equipped with a folding upper handle

(Figure 4). It was assembled at the factory and shipped in its

folded or stow position. You will need to unfold and adjust the

trowel handle to the upright position prior to operation.

Considerable force may be

NOTE

Unfolding the Trowel for Operation

required when moving the

Quick Pitch™ handle forward

or backward.

1. Make sure that the Quick Pitch™

attached to the upper handle bar and the pitch control cable

has slack. Remove the

on the top side of the upper handle bar, by rotating the

knob counter-clockwise. Move the Quick Pitch™

toward's the operator's position and unfold the upper

handle bar away from the engine into the

Re-insert the swing bolt so that it fits through the slot in the

hinge plate. Turn the T-handle knob counter-clockwise

securely to hold upper handle bar in place.

T-handle knob

FOLDED

POSITION

handle

has been

from the swing bolt

handle

upright

position.

OPERATIONAL

POSITION

UPPER

HANDLE

T-HANDLE

KNOB

Figure 5. Trowel Folded and Operational

Positions

PAGE 18 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 19

C-4 FINISHER TROWEL— PRE-INSPECTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

NEVER operate the trowel

in a confined area or

enclosed area structure

that does not provide ample

free flow of air

ALWAYS wear approved eye and hearing

protection before operating the trowel.

NEVER place hands or feet inside the guard

rings while the engine is running. ALWAYS shut

the engine down before performing any kind

of maintenance service on the trowel.

.

Figure 5. Engine Oil Dipstick (Removal)

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 6), fill to the edge of the oil filler

hole with the recommended oil type (Table 3). Maximum oil

capacity is 0.48 quarts (.45 liters)

Before Starting

1. Read safety instructions at the beginning of manual.

2. Clean the trowel, removing dirt and dust, particularly the

engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

5. Check fastening nuts and bolts for tightness.

Engine Oil Check

1. To check the engine oil level, place the trowel on secure

level ground with the engine stopped.

2. Remove the filler dipstick from the engine oil filler hole

(Figure 5) and wipe clean.

NOTE

Reference manufacturer engine

manual for specific servicing

instructions.

Figure 6. Engine Oil Dipstick (Oil Level)

epyTliO.3elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 19

Page 20

Explosive Fuel

C-4 FINISHER TROWEL— PRE-INSPECTION

V-Belt Check

A worn or damaged V-belt can adversely affect the performance

of the trowel. If a V-belt is defective or worn simply replace the Vbelt as outlined in the maintenance section of this manual.

Fuel Check

Motor fuels are highly flammable and can be dangerous if

mishandled. DO NOT smoke while refueling. DO NOT attempt

to refuel the trowel if the engine is

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if fuel level is low. If fuel is low, replenish

with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel.

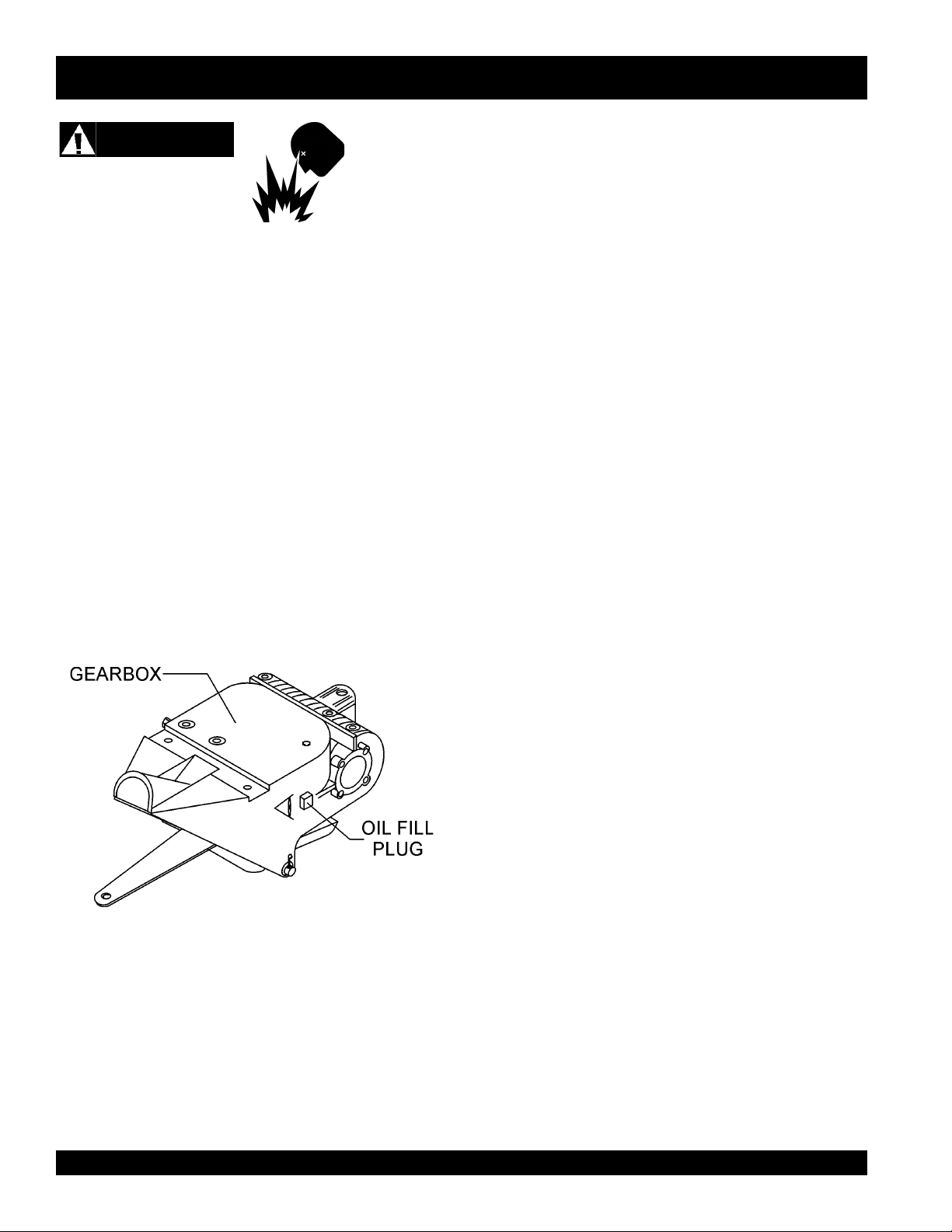

Gearbox Oil

1. Determine if the

plug located on the side of the gearbox. This plug will be

marked by the "

level of the lubrication oil should be to the bottom of the fill

plug.

gearbox

check

hot! or running

oil is low by removing the oil

" decal. See Figure 7. The correct

.

Blade Check

Check for worn or damaged blades. Check to see if one blade is

worn out while the others look new. If this is the case there could

be a blade pitch problem. Refer to the maintenance section of

this manual for blade pitch adjustment procedure. Replace any

worn blades.

CONTROLS

Hand Clutch

Some finisher models are equipped with a

. The unit automatically stops rotating when the clutch lever

clutch

is released. Clutch operation should be tested each time the

machine is started.

DO NOT let the machine sit unused with the engine at high speed

for an extended period of time. It will cause premature belt wear

or may destroy the belt. Always set the engine speed to idle when

the hand clutch is disengaged.

hand operated

Figure 7. Gearbox

2. If lubrication oil begins to seep out as the drain plug is

being removed, then it can be assumed that the gearbox

has a sufficient amount of oil.

3. If lubrication oil does not seep out as the drain plug is

being removed, fill with type ISO 680 (Whiteman P/N

10139) gearbox lubricant oil until the oil filler hole overflows.

PAGE 20 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 21

C-4 FINISHER TROWEL — INITIAL START-UP

Lifting the Trowel Onto a Slab.

Extra care should be taken when lifting the trowel off the ground.

Serious damage to the machine or personal injury could be

caused by dropping a trowel.

Even though the trowel is lightweight, always use two people

when lifting the trowel onto a slab of concrete or truck bed.

This section is intended to assist the operator with the initial

start-up of the walk-behind trowel. It is extremely important that

this section be read carefully before attempting to use the trowel

in the field.

DO NOT use your trowel until this section is thoroughly

understood

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

DO NOT attempt to operate the trowel until

the Safety, General Information and

Inspection sections of this manual have

been read and thoroughly understood.

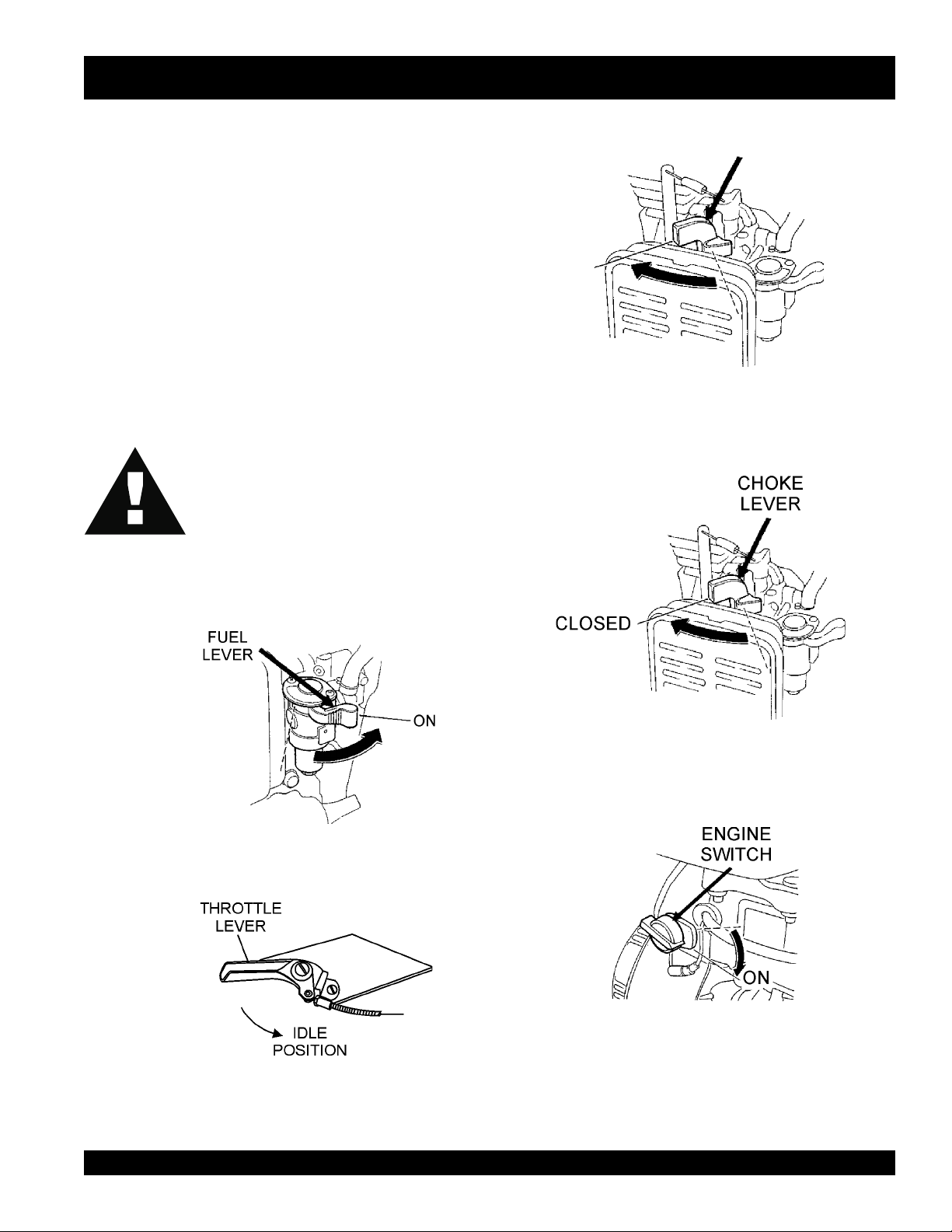

Starting the Engine (

HONDA

engine)

3. Place the

if starting a

4. Place the

if starting a

choke lever

cold

Figure 10. Engine Choke Lever (Open)

choke lever

warm engine

(Figure 10) in the "

engine.

(Figure 11) in the "

or the

OPEN

" position

CLOSED

temperature is warm.

" position

1. Place the engine

position.

Figure 8. Engine Fuel Valve Lever

2. Place the trowel's

position.

fuel valve lever

throttle lever

(Figure 8) to the "ON"

(Figure 9) to the "IDLE"

Figure 11. Engine Choke Lever (Closed)

5. Place the

Figure 12. Engine ON/OFF Switch (ON Position)

engine ON/OFF switch

(Figure 12) in the "

ON

"

Figure 9. Throttle Lever (Idle Position)

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 21

Page 22

C-4 FINISHER TROWEL — INITIAL START-UP

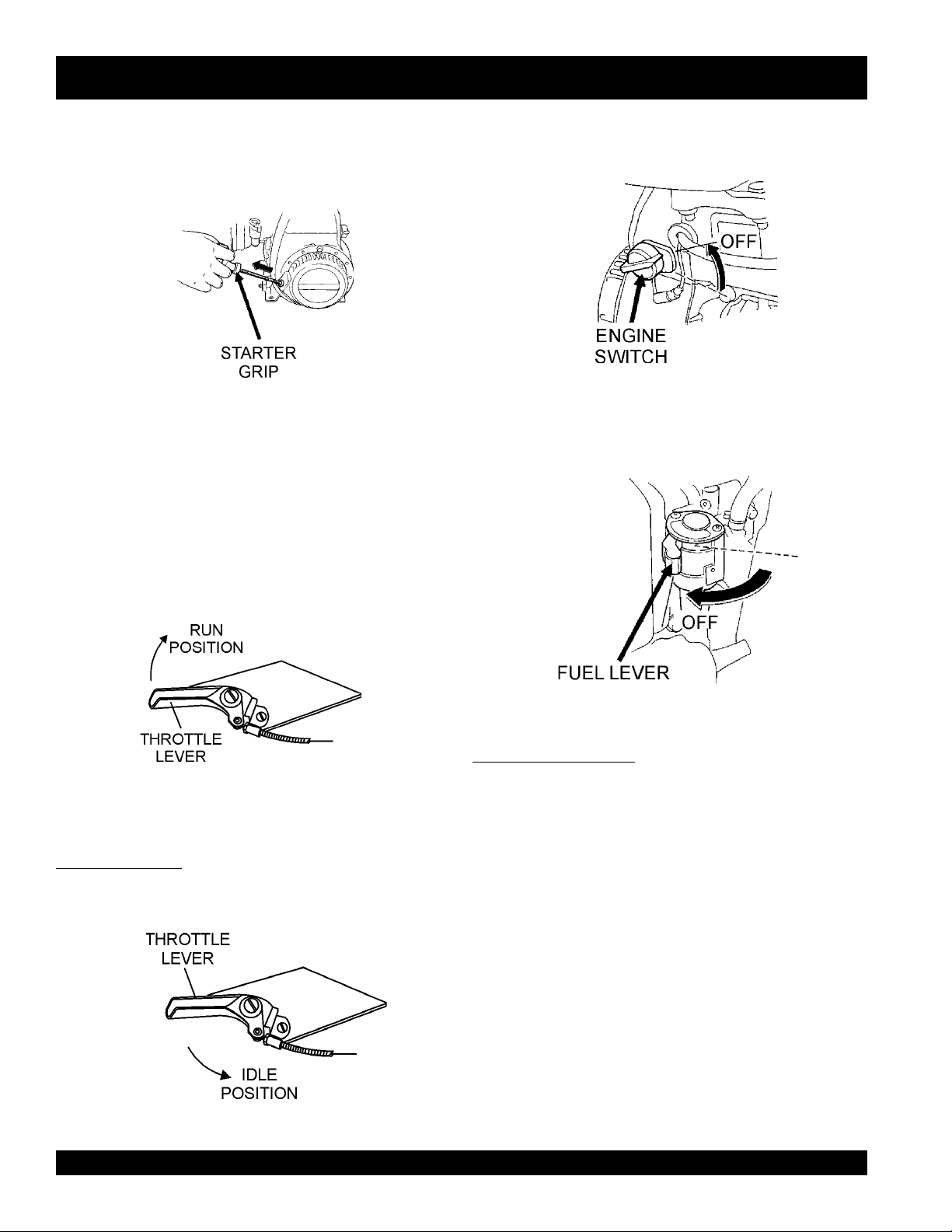

6. Grasp the starter grip (Figure 13) and slowly pull it out. The

resistance becomes the hardest at a certain position, corresponding to the compression point. Pull the starter grip briskly

and smoothly for starting.

Figure 13. Starter Grip

7. If the engine has started, slowly return the choke lever

(Figure 11 ) to the

started repeat steps 1 through 6.

Before the trowel is placed into operation, run the engine for

8.

several minutes. Check for fuel leaks, and noises that would

associate with a loose guard ring and/or covers.

CLOSED

position. If the engine has not

2. After the engine

“STOP” position (Figure 16 ).

3. Close the

valve lever to the CLOSED position.

cools

, turn the engine start/stop switch to the

Figure 16. Throttle Lever (Run Position)

fuel shut- off valve

(Figure 17) by moving the fuel

9. To begin troweling, place the throttle lever (Figure 14 ) in the

RUN

" position

"

Figure 14. Throttle Lever (Run Position)

Stopping The Engine

Normal Shutdown

1. Move the throttle lever to the IDLE position (Figure 15) and

run the engine for three minutes at low speed.

Figure 17. Throttle Lever (Run Position)

Emergency Showdown

1. Move the throttle lever quickly to the

the engine start/stop switch to the

IDLE

STOP

position.

position, and turn

Figure 15. Throttle Lever (Idle Position)

PAGE 22 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 23

C-4 FINISHER TROWEL — OPERATION

To maneuver the trowel, gently lift up on or press down on the

The following steps are intended as a basic guide to machine

operation, and are not to be considered a complete guide to

concrete finishing. We suggest that all operators (experienced

and novice) read “

Concrete Institute, Detroit, Michigan

section of this manual for more information.

Slabs on Grade

” published by the

. Read the “Training”

American

Pitching The Blades.

Quick Pitch Handle

2.

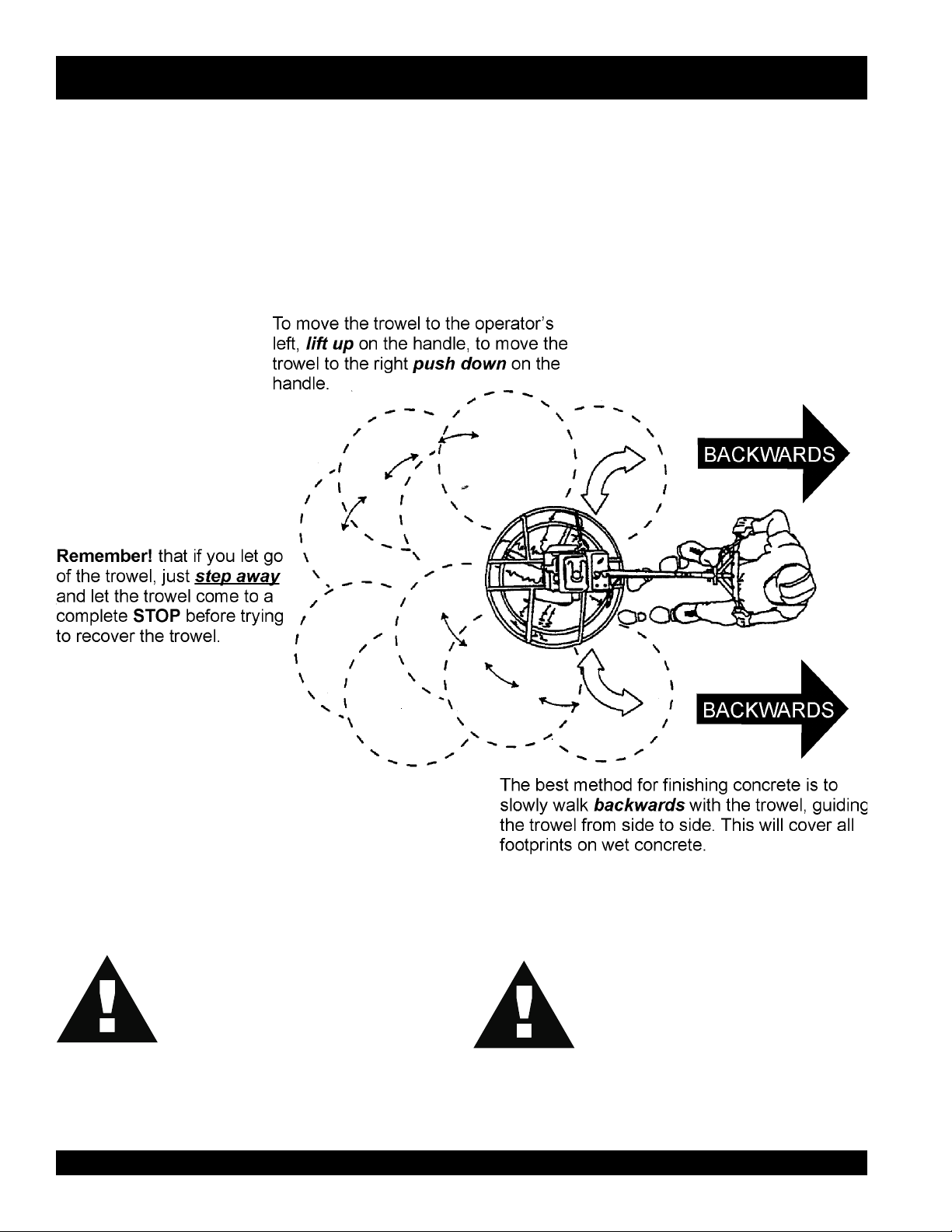

main trowel handle. To move the machine to the operator’s

left,

down

lift up

on the handle, to move machine to the right,

on the handle.

push

1. To pitch the blades upwards using the

handle

, (Figure 18) simply squeeze the trigger lock

"Quick Pitch

™"

and pull the handle towards the operator. Pushing the

handle towards the engine will cause the blades to lay

flat.

Figure 18. Quick Pitch™ Handle

Figure 19. Hand Clutch Lever

3. The best method for finishing concrete is to slowly walk

backwards (Figure 20) with the trowel, guiding the trowel

from side to side. This will cover all footprints on wet concrete.

4. Remember that if you let go of the trowel, just step away and

let the trowel come to a complete stop before trying to recover

the trowel.

Maneuvering the Trowel

Get into the operator’s position behind the handle. With a

1.

secure foothold and a firm grasp on the handles slowly

increase the engine speed until the desired blade speed is

obtained.

If your trowel has a

speed with the throttle, then pull on the hand clutch lever to

start the blades turning. Adjust the blade speed after the hand

clutch is fully engaged.

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 23

hand clutch (Figure 19)

, set your engine

Page 24

C-4 FINISHER TROWEL — OPERATION

Figure 20 below illustrates a typical walk-behind trowel

application. Practice maneuvering the trowel. The trick is to let

the trowel do the work.

Continue to practice maneuvering the trowel. Try to practice as if

you were finishing a slab of concrete. Practice edging and

covering a large area. Remember a good finishing technique is

to work backwards. Be careful when moving backwards so that

hazards can be avoided. The best way to get accustomed to the

trowel is repeated use.

Figure 20. Maneuvering The Trowel

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

NEVER place your

guard rings while starting or operating this

equipment.

PAGE 24 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

feet

or

hands

inside the

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

ALWAYS keep clear of

parts while operating this equipment.

rotating

or

moving

Page 25

C-4 FINISHER TROWEL — OPTIONS

Blades

Blades should be changed when

they fail to finish concrete in a

NOTE

Blades are a vital part of finishing concrete. This Whiteman

finisher has been designed to finish concrete and is built to

stringent quality standards out of the finest trowel steel. If you need

replacement blades, consult your parts list in this manual for part

numbers and order them from your Multiquip parts dealer or

importer.

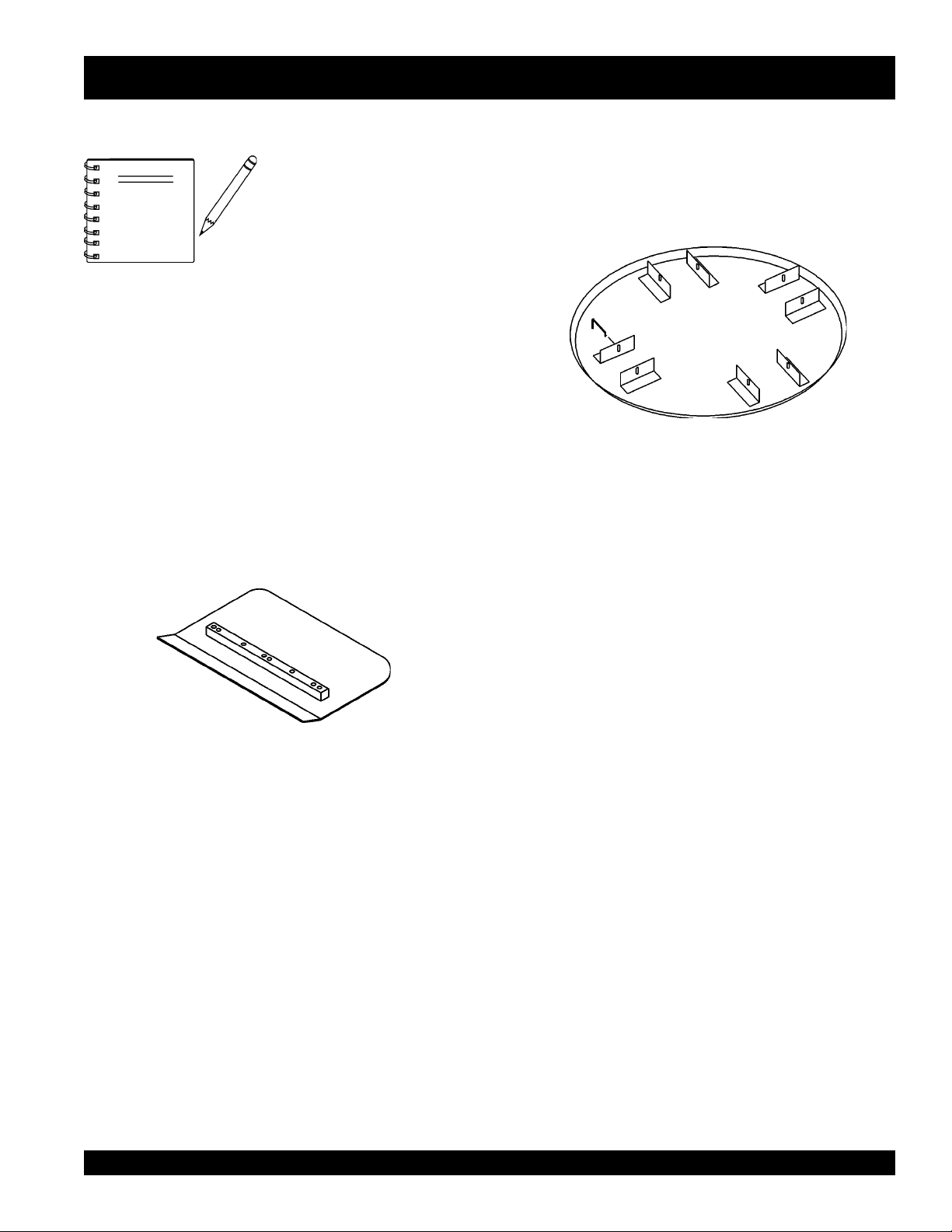

Combo Blades

This trowel was equipped with

blades as original equipment. These blades have been designed

for optimum performance in both the floating and finishing of

concrete. These blades are versatile and should take care of most

troweling needs.

satisfactory manner.

combination type

(Figure 21)

Float Discs (Optional)

These round discs (Figure 22) attach to the spiders and allow the

machine to “

floating and easy movement from wet to dry areas. They are also

very effective in embedding large aggregates and surface

hardeners.

float

” on “

wet

” concrete. The disc design allows early

Figure 22. Float Disk

Figure 21. Combination Blade

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 25

Page 26

C-4 FINISHER TROWEL — MAINTENANCE

See the engine manual supplied

Trowel Arm adjustment Procedure

NOTE

with your machine for appropriate

engine maintenance schedule

and troubleshooting guide for

problems.

At the front of the book (Page 7) there is a “

Checklist

basis.

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

ALWAYS allow the engine to cool before

servicing. NEVER attempt any maintenance work

on a

MAINTENANCE SCHEDULE

Daily (8-10 Hours)

1. Check the oil level in the engine crankcase and gear box,

2. Check V-belt.

Weekly (50-60 Hours)

1. Relube arms, thrust collar and clutch

”. Make copies of this checklist and use it on a daily

hot!

engine.

fill as necessary.

Daily Pre-Operation

NOTE

level

, clean area to test the trowel prior to and after is essential.

A

Any unlevel

will give an incorrect perception of adjustment. Ideally, a 5 x 5"

three-quarter inch thick

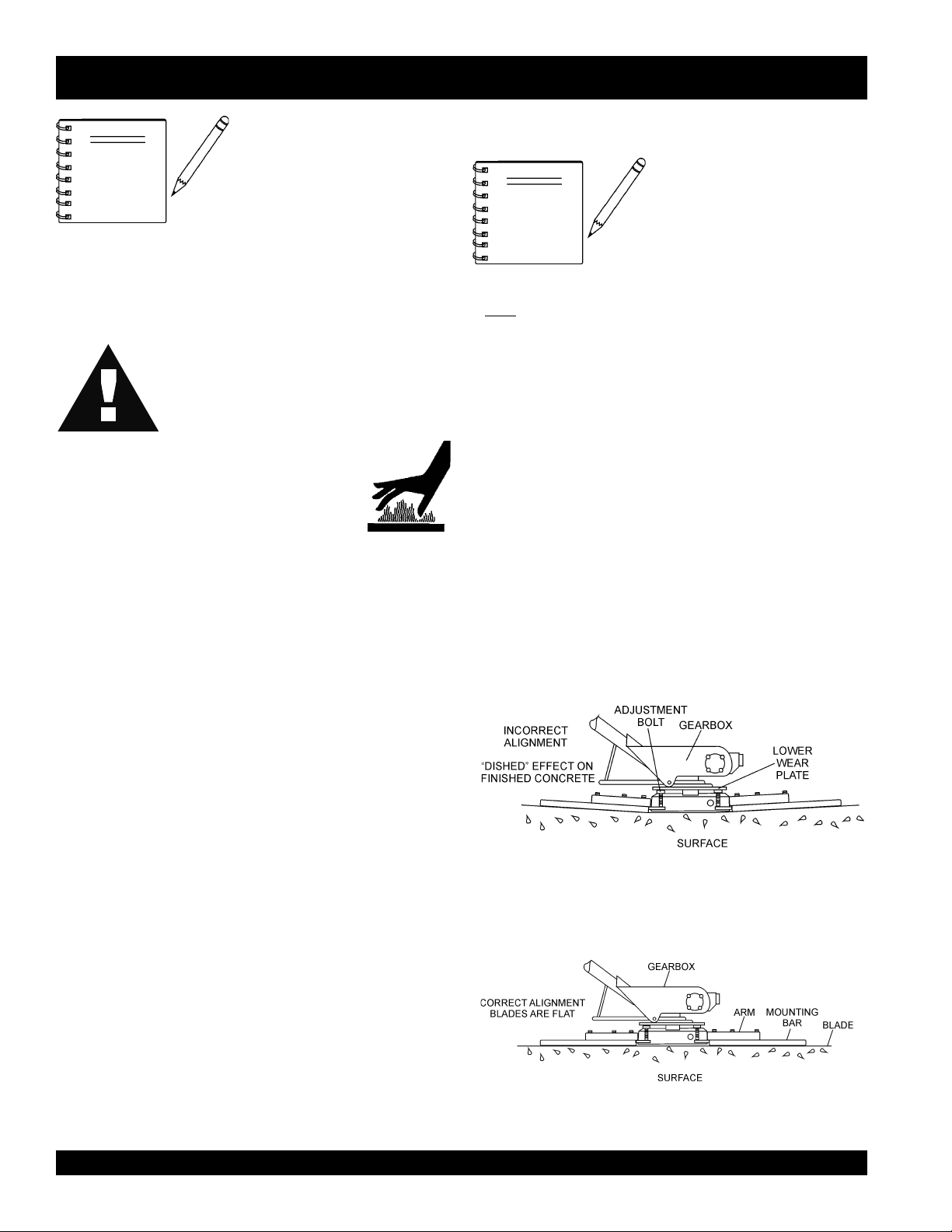

1. To determine which blades need adjustment, place the

trowel in the test area (three-quarter inch thick plate) and look

for the following conditions:

■

■

Figure 23 below illustrates a "

trowel arms

touching (0.10" max. clearance) lower wear plate. All alignment

bolts should be spaced the same distance from the lower wear

plate.

The following procedure should

be followed to adjust trowel arms

when it becomes apparent that

the trowel is finishing poorly or in

need of routine maintenance.

spots

in the floor or debris under the trowel blades

flat

steel plate should be used for testing.

Pitch the blades as flat as possible and look at the

adjustment bolts

with the

that one of them is not making contact, some adjustment

will be necessary.

Is the machine wearing out blades unevenly (i.e. one

blade is completely worn out while the others look new)?

lower wear plate

". Check to see that adjustment bolt is barely

. They should all barely make contact

on the spider. If you can see

worn spider bushings or bent

2. Replace blades if necessary.

3. Check and clean or replace the engine air filter as

necessary.

4. Replace engine oil and filter as necessary, see engine

manual.

Monthly (200-300 Hours)

1. Remove, clean, reinstall and relube the arms and thrust

collar. Adjust the blade arms.

2. Remove, clean, reinstall clutch

Yearly (2000-2500 Hours)

1. Check and replace if necessary the arm bushings, thrust

collar bushings and shaft seals.

2. Check pitch control cables for wear.

3. Adjust blade speed.

PAGE 26 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Figure 24 below illustrates the "

plate (as shipped from the factory).

Figure 24. Correct Spider Plate Alignment

Figure 23 Worn Spider Plate

correct alignment

" for a spider

Page 27

C-4 FINISHER TROWEL — MAINTENANCE

2. Start engine, and bring trowel blades up to full speed and look

for the following conditions:

■

Does the trowel have a perceived rolling or bouncing

motion when in use?

■

Look at the trowel while it is running, does the guard

ring “rock up and down” relative to the ground?

Spider Removal

1. Once it is determined that an adjustment is required, remove

the spider assembly from the gearbox shaft as follows:

a. Remove the zerk fitting and allen head screw desig-

nated by the letter "S" (Figure 25). In addition, on the

opposite side of the spider block there is another zerk

fitting and allen head screw, remove both of these

components.

b. Lift the upper trowel assembly off the spider assembly.

Trowel Arm Removal

1. Remove the two remaining zerk fittings and allen head

screws from the spider assembly (Figure 26).

Trowel Blade Removal

A slight tap with a rubber mallet may be necessary to

dislodge the spider from the main shaft of the gearbox.

Figure 26. Trowel Arms Removal

1. Remove the trowel blades from the trowel arm by removing

the two hex head bolts (Figure 27) from the trowel arm. Set

blades aside.

Figure 27. Trowel Blades

Wire brush

2.

trowel arm. Repeat this for the remaining three arms.

any build-up of concrete from all six sides of the

Figure 25. Spider/Gearbox Removal

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 27

Page 28

C-4 FINISHER TROWEL — MAINTENANCE

Trowel Arm Flatness Test

1. Using a piece of 3/4 inch thick steel plate or any surface which

true

and

flat

is

flatness.

2. Check each of the six sides of the trowel arm (hex section

only) using a ten thousands of an inch (max.) feeler gauge

(Figure 28) between the flat of the trowel arm and an

tremely flat

, check all

test surface.

six sides

of each trowel arm for

Re-Assembly

1. Clean and examine the

thrust collar bushing

Wire brush any concrete or rust build-up. If any of the spider

components are found to be damaged or out of round,

replace them.

2. Insert all trowel arms (4) into spider plate.

ex

-

3. Lock trowel arms in place by tightening the hex head zerk

grease fittings (4) and allen head screws (2).

4. Re-install the blades back onto the trowel arms.

5. Reinstall lower wear plate,

bearing

onto the spider shaft. Make sure that there is little or no lateral

movement between the thrust collar and the spider shaft.

6. Carefully lift

way on gear box main shaft and insert into spider assembly.

7. Lubricate all grease points (zerk fittings) with premium

Lithum 12"

"

consistency.

lower wear plate, thrust collar

. Examine the entire spider assembly.

thrust collar

in the

reverse order

the upper trowel assembly

based grease, conforming to NLG1 Grade #2

that they were dis-assembled

and

thrust collar

, line up the key-

and

Figure 28. Trowel Arm Flatness Test

3. If the trowel arm is found to be

trowel arm. A bent trowel will not allow the trowel to operate

in a smooth fluid rotation.

4. Next, check each of the six sides of the round machined shaft

section of the trowel arm. Each section should have the

clearance

test surface.

between the round of the trowel arm shaft and the

uneven

or

bent

, replace the

same

Trowel arms can be

damaged by rough

handling or by striking

NOTE

exposed plumbing or

forms while in operation.

ALWAYS

look-out for

objects which might

cause damage to the

trowel arms.

PAGE 28 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 29

Changing a Blade

C-4 FINISHER TROWEL — MAINTENANCE

Whiteman recommends that

same time

the blades are changed at one time.

1. Place the machine on a flat, level surface. Adjust the blade

. The machine may wobble or bounce if only some of

pitch control to make the blades as flat as possible. Note the

blade orientation on the trowel arm.

all the blades be changed at the

Before removing the blades,

please note the orientation

NOTE

1. Remove the two bolts and lock washers that secure the blade

to the trowel arm. Remove the blade.

2. Using a wire brush, scrape all concrete particles and foreign

debris from the trowel arm.

3. Install the new trowel blade onto the trowel arm. Make sure

blade is installed correctly, maintaining the proper orientation for direction of rotation

4. Reinstall

blade to the trowel arm. Tighten both bolts securely.

5. Repeat steps 1-4 for all remaining blades.

Hand Clutch Adjustment

This trowel is equipped with a hand-operated clutch that is a belttightener type clutch. It operates by removing

which then transmits power from the engine to the gearbox.

There are two reasons to adjust the hand clutch: 1) operator

comfort; 2) initial belt stretch and break-in.

The easiest and most simple adjustment is to adjust the clutch

cable housing using the adjustment nut (Figure 29) located on the

clutch lever. Rotating the nut provides either more or less

(depending upon the direction of rotation) clutch engagement.

the two bolts and lock washers that secure the

of the blade on the trowel

arm.

.

slack

in the V-belt

Hand Clutch Disengagement

1. Start the trowel as outlined in the "

in this manual. Move the throttle lever so that the engine is

running about 1/4 to 1/3 of full speed.

2. Grip the trowel handle firmly and carefully engage the clutch

by squeezing the clutch lever toward the handle with your left

hand. After the trowel is stabilized and you feel comfortable

with its operation, use your right hand to adjust the housing

adjustment nut.

3.

Rotating the nut so that it backs out of the lever housing

increases the engagement and also the squeezing force

required to keep it engaged.

Too much squeezing force may cause premature hand

fatigue. Too little squeezing force may cause belt slippage

and premature belt wear. Each operator should experiment

with the adjustment to get the optimum combination of

squeeze force and belt grip.

4. After initial break-in (approximately 8 hours) the above

procedure should be repeated to attain optimum operator

comfort and belt wear.

After considerable belt wear, the adjustments mentioned

5.

above may have a little or no effect on clutch engagement. If

this is the case, the belt should be replaced.

Figure 29. Trowel Arm Adjustment Tool

Initial Start-up

" section"

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 29

Page 30

C-4 FINISHER TROWEL — TROUBLESHOOTING (TROWEL)

GNITOOHSELBUORT.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?noitcnuflamhctiwslliK .yrassecenfihctiwsecalperroNOsihctiwsllikehttahterusekaM

.lla

tatonrohguorgninnurenignE

.gninoitcnuftonhctiwsllikytefaS

nislriwsnevenusekamro

.”etercnoc

?leuF

?noitingI

?smelborprehtO .launams’rerutcafunamenignetlusnoC

?snoitcennoceriwesooL .yrassecensaecalpeR.gniriwkcehC

?stcatnocdaB .hctiwsecalpeR

?sedalB

?redipS

?smraleworttneB

,etercnocsllor,secnuob“lewortfI

?sgnihsubmraleworT

.yltcerrocgninoitcnuf

.rabedalbehtotlellarap

.yletaidemmitiecalper,tnebylthgilsnevesi

otdeilppusgniebleufsierehterusekaM.metsysleufehttakooL

.deggolctonsiretlifleufehttahterusneotkcehC.enigneeht

sidnarewopsahhctiwsnoitingiehttahterusneotkcehC

.nrowylevissecxeton,noitidnocdoognierasedalbniatrecekaM

ehtmorf)mm05("2nahtsselonerusaemdluohssedalbhsiniF

onerusaemdluohssedalbobmoc,egdegniliartehtotrabedalb

dnathgiartsebdluohsedalbfoegdegniliarT.)mm98("5.3tahtssel

derusaemsaelgnahctipemasehttateserasedalbllatahtkcehC

thgiehrofelbaliavasiloottnemtsujdadleifA.redipsehtta

.)tnempiuqElanoitpOees(smralewortehtfotnemtsujda

smraehtfoenofI.smraleworttnebrofylbmessaredipsehtkcehC

ybenodebnacsihT.ssenthgitrofsgnihsubmralewortehtkcehC

2.3("8/1nahteromsierehtfI.nwoddnapusmralewortehtgnivom

ebdluohssgnihsubeht,mraehtfopitehttalevartfo)mm

.emitemasehttadecalperebdluohssgnihsubllA.decalper

?ralloctsurhT

?gnihsubralloctsurhT

?nrowgniraebtsurhT

?tfahsniaM

.tniop

.gninnurelihwnoitom

gnillorelbitpecrepasahenihcaM

?ekoY

?hctiPedalB

.ralloctsurhtehtnignihsubeht

.yrassecenfiecalper,pac

.yrassecensaekoyecalpeR.pacraeweht

.ralloctsurhtehtecalper)mm5.0("20.0nahteromybseiravti

ebtonnacdnathgiartsnurtsumtfahsniamehT.ssenthgiartsrof

.launamninoitcesecnanetniamreptsujdA.sedalbrehtollasa

PAGE 30 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

fI.redipsehtnotignitatorybralloctsurhtehtfossentalfehtkcehC

eromtlitnactifI.redipsehtnotignikcorybralloctsurhtehtkcehC

ecalper,].D.Oralloctsurhtehttaderusaemsa[)mm4.2("23/3naht

tsurhT:etoN.eerfgninnipssititahteesotgniraebtsurhtehtkcehC

dekcehcebdluohsylbmessaxobraegehtfotfahstuptuoniamehT

tnemhcattaredipsehttadnuorfotuo)mm80.0("300.0nahterom

noylnevesserpekoyehtfosregnifhtobtahterusekamotkcehC

hctipemasehtevahotdetsujdasiedalbhcaetahterusneotkcehC

Page 31

C-4 FINISHER TROWEL — TROUBLESHOOTING (TROWEL)

)DEUNITNOC(GNITOOHSELBUORT.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?stleb-VnroW tleb-VecalpeR

?hctulclagufirtnecytriD .hctulcnaelcdnaelbmessasiD

lagufirtnectuonrowroevitcefeD

?hctulc

hsiggulsrognippilshctulC

deepsenigneotesnopser

.egnahc

?strap

?xobraeg

?tnemtsujdafotuohctulcdnaH .launamsihtfonoitcesecnanetniamnisnoitcurtsnireptsujdA

hctulcdnahevitcefefronroW

?xobraegnisgniraebnroW

nisraegnekorbronroW

.hctulceritneecalpeR

.yrassecensastrapecalpeR

ehtkcehc,ytluciffidhtiwsetatortfahsfI.dnahybtfahstupnietatoR

.yrassecensaecalpeR.sgniraebtfahstuptuodnatupni

.detatorsitfahstupniehtnehwsetatortfahsxobraegehttahtyfireV

.tesasaraegmrowdnamrowehthtobecalpeR

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 31

Page 32

C-4 FINISHER TROWEL — TROUBLESHOOTING (ENGINE)

)ENIGNE(GNITOOHSELBUORT.5ELBAT

MOTPMYSESUACELBISSOPNOITULOS

?gnigdirbgulpkrapS

ontub,elbaliavasileuf",tratsottluciffiD

."gulpkrapstaKRAPS

?noitalusni

?evitcefedliocnoitingI.liocnoitingiecalpeR

dna,elbaliavasileuf",tratsottluciffiD

."gulpkrapsehttatneserpsiKRAPS

?gnitiucric

?epytleufgnorW

?gulpkrapsnotisopednobraC .gulpkrapsecalperronaelC

gulpkrapstneicifedoteudtiucrictrohS

?paggulpkrapsreporpmI.pagreporpotteS

?detrohssihctiwsFFO/NO

?yrtridstniop,pagkrapsreporpmI

trohsronrownoitalusniresnednoC

?gnitiucrictrohsronekorberiwgulpkrapS

.gulpkraps

.nrowfiecalper

.hctiws

.stniop

.resnednocecalpeR

.gniriw

ecalperronoitalusni,pagkcehC

,noitalusnigulpkrapskcehC

ecalper,gniriwhctiwskcehC

naelcdnapagkrapstcerrocteS

gulpkrapsevitcefedecalpeR

ecalperdna,metsysleufhsulF

.leuffoepyttcerrochtiw

kraps,elbaliavasileuf",tratsottluciffiD

"lamronsinoisserpmocdnatneserpsi

?ytridrenaelcriA .renaelcriaecalperronaelC

?nepOekohC.ekohCesolC

kraps,elbaliavasileuf",tratsottluciffiD

"wolsinoisserpmocdnatneserpsi

?ylreporpdenethgit

?degamad

?deggolcretlifleuF.retlifleufecalpeR

.blubgnimirpedisnitneserpleufoN

?enilleufniriA.enilleufdeelB

?metsysleufnitsudroretaW.metsysleufhsulF

?dedurtorprokcutsevlavtsuahxe/noitcuS.sevlavtaes-eR

?nrowrednilycro/dnagnirnotsiP

tongulpkrapsro/dnadaehrednilyC

teksaggulpkrapsro/dnateksagdaeH

?knatleufnielbaliavatonleuF.leuffoepyttcerrochtiwlliF

?deggolcelohrehtaerbpacknatleuF .packnatleufecalperronaelC

rodnasgnirnotsipecalpeR

.notsip

dnastlobdaehrednilyceuqroT

.gulpkraps

gulpkrapsdnadaehecalpeR

.steksag

PAGE 32 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 33

NOTE PAGE

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 33

Page 34

C-4 FINISHER TROWEL — EXPLANATION OF CODES IN REMARKS

How to read the marks and remarks used in this parts book.

Section 1: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial number

range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model number

or model number variant.

Section 3: Items Found In the “Items Number” Column

All parts with same symbol in the number column,

■

, belong to the same assembly or kit.

, #, +, %, or

*

COLUMN

Note: If more than one of the same reference number is listed,

the last one listed indicates newest (or latest) part available.

NOTE

The contents of this parts

catalog are subject to

change without notice.

PAGE 34 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 35

C-4 FINISHER TROWEL — SUGGESTED SPARE PARTS

C-4 FINISHER TROWEL 1 TO 3 UNITS WITH

HONDA G100K2QA2 ENGINE.

1 to 3 Units

Qty......... P/N .............................. Description

3 ............ 0189 ...................... GRIP

4 ............ 1162 A .................. LUBE CAP

4 ............ 1167 A .................. SCREW

4 ............ 1456 ...................... NUT

4 ............ 1875 ...................... WASHER

4 ............ 1322 ...................... SCREW

1 ............ 2614 ...................... GASKET KIT

1 ............ 2616 ...................... BEARING KIT

2 ............ 9807354776 .......... SPARK PLUG HONDA

2 ............ 17631ZH7003 ....... TANK CAP (HONDA)

3 ............ 17211896000 ........ AIR CLEANER ELEMENT (HONDA)

2 ............ 17218ZE2505 ....... FILTER OUTER (HONDA)

2 ............ 10652 .................... PITCH CABLE

1 ............ 10607 .................... THRUST BEARING

1 ............ 10567 .................... THRUST COLLAR

1 ............ 10639 .................... WEAR PLATE

4 ............ 10611 .................... V-BELT (A-21)

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 35

Page 36

NAMEPLATE AND DECALS

C-4 FINISHER TROWEL — NAMEPLATE AND DECALS

PAGE 36 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 37

C-4 FINISHER TROWEL — NAMEPLATE AND DECALS

NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 10732 DECAL: CAUTION PITCH HANDLE 1

2 11246 DECAL: BELT DRIVE ........................................... 1 ....... PART OF DECAL KIT 12620

3 11246 DECAL: GEAR DRIVE .......................................... 1 ....... PART OF DECAL KIT 12620

4 11246 DECAL: COUNTER CLOCKWISE......................... 1 ....... PART OF DECAL KIT 12620

5 1848 DECAL: MQ/WHITEMAN LOGO 1

6 11246 DECAL: CHECK OIL ............................................. 1 ....... PART OF DECAL KIT 12620

7 DECAL: NAME PLATE .......................................... 1 ....... CONTACT MULTIQUIP

.......................................................................................... PARTS DEPARTMENT

8 11247 DECAL: HELMET, FOOT AND GLOVE ................. 1 ....... PART OF DECAL KIT P/N 12620

9 11246 DECAL: HEAT ....................................................... 1 ....... PART OF DECAL KIT P/N 12620

SEE DECAL ILLUSTRATIONS ON PAGE 12

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 37

Page 38

C-4 FINISHER TROWEL — QUICK PITCH™ HANDLE ASSY.

QUICK PITCH ™ HANDLE ASSY.

PAGE 38 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 39

C-4 FINISHER TROWEL — QUICK PITCH™ HANDLE ASSY.

QUICK PITCH ™ HANDLE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 10657 PITCH CONTROL HANDLE 1

2 10881 LATCHING BAR 1

3 3910382 SHOULDER BOLT 3/8 X 3/8 1

4 10655 LATCH RETURN SPRING COVER 1

5 10654 LATCH RETURN SPRING 1

6 10659 QP LATCHING BOLT 1

6 10878 QP LATCHING BOLT 1

7 0161C LOCK WASHER 5/16” 1

8 10024 LOCK NUT 1/4- 20 1

9 10652 PITCH CONTROL CABLE 1

10 10658 CONTROL HANDLE SUPPORT TUBE 1

11 0189 HANDLE GRIP 1

12 0304 RHMS 10- 24 X 1/4” 2

13 0302 THROTTLE ASSEMBLY CABLE 1

14 5283 LOCK NUT 5/16- 18 1

15 10651 STAR WHEEL 1

16 1456 HEX FINISH NUT 3/8- 16 1

17 3216 COTTER PIN 3

18 0948 FLAT WASHER 1/4” 2

19 10629 HANDLE HINGE PIN 1

20 10133 LOCK NUT 3/8- 16 2

21 10136 FLAT WASHER 3/8” 3

22 1117 SUPPORT BLOCK 1

23 1121 HHCS 3/8- 16 X 2.3/4” 2

24 10701 SWING BOLT 1

25 5291 CLEVIS PIN 1

26 0300B FLAT WASHER 5/16” 2

27 0669A HHCS 5/16- 18 X 2.1/4” 1

28 1512 CLUTCH HAND LEVER 1

29 10843 PAD 1

30 10036 CLUTCH ASSIST HANDLE ASSY.. 1

31 10660 SHIM 1

32 3164 FHSCS 1/4- 20 X 1” 1

33 10634 LOWER HANDLE 1

34 10635 UPPER HANDLE 1

35 10653 CLUTCH CABLE ASSY.. 1

36 10676 ACORN NUT 5/16- 18 1

37 8128 CLAMP 2

39 11015 HANDLE SLIDER 1

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 39

Page 40

SPIDER ASSY.

C-4 FINISHER TROWEL — SPIDER ASSY.

PAGE 40 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 41

C-4 FINISHER TROWEL — SPIDER ASSY.

SPIDER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 10640 YOKE 1

2 10662 YOKE PIN 1

3 5117 COTTER PIN 2

4 0948 FLAT WASHER 1/4” 2

5 10607 THRUST BEARING 1

6 10567 THRUST COLLAR 1

7 10639 WEAR PLATE 1

8 10563 SPIDER 1

9 0164B HHCS 3/8- 16 X 1.1/4” F.T. 4

10 1876 JAM NUT 3/8- 16 4

11 0166A LOCK WASHER 3/8” 4

12 0181B LOCK WASHER 1/4” 8

13 10585 TROWEL ARM.................................................. 4.................TO ME34571

13 10768 TROWEL ARM.................................................. 4.................FROM ME34572

14 10790 HHCSM6- 1 X 30MM 8

15 0685 SHSS 5/16- 18 X 5/16” 2

16 1162A GREASE ZERK CAP 4

17 10587 ARM RETAINING SCREW 4

18 1875 INT. SHKP. WASHER 3/8” 4

19 0244 COMBO BLADE ASM. 4

20 10698 ADJUSTING NUT 5/16- 18 1

23 10687 BLADE ASM. (WITH SCREWS & NUTS) 4

24 1116 BRASS JAM NUT 5/16- 18 1

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 41

Page 42

GEARBOX ASSY.

C-4 FINISHER TROWEL — GEARBOX ASSY.

PAGE 42 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 43

C-4 FINISHER TROWEL — GEARBOX ASSY.

GEARBOX ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1

*

2

*

3

*

4

*

5

*

6

*

7

*

8

*

9

*

10 0627 SQUARE KEY 3/16 X 3/16 X 1.1/4” 1

11

12

13

14

15

16

17

18

19

20 10686 GEARBOX ASSY. .................................... 1 ................ INCLUDES ITEMS W/

21

22

23

24

25

26 2616 BEARING REPLACEMENT KIT ..............1 ................ INCLUDES ITEMS W/%

10583 GEAR CASE 1

0131A HHCS 1/4- 20 X 3/4 8

1136 END CAP 1

2614 GASKET KIT

% 0735A BEARING CUP 2

1132 AIR VENT 1

% 0735 BEARING CONE 2

1828 WORM & COUNTER SHAFT 1

2308 O- RING 2

0753 OIL SEAL 1

*

1133 FLANGE 1

*

1139 WOODRUFF KEY #21 2

*

0121A SQUARE HEAD PIPE PLUG 3/8” 1

*

% 0232A BEARING CUP 2

*

% 0232 BEARING CONE 2

*

1138 RETAINING RING 1

*

1202 BRONZE GEAR 1

*

10580 MAIN SHAFT 1

*

1145 COVER PLATE 1

*

0254 OIL SEAL 1

*

1146 FHSCS 5/16- 18 X 1” 4

*

10235 EXT. SHKP. LOCK WASHER 5/16” 4

*

1143 SEAL RING 1

*

*

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 43

Page 44

C-4 FINISHER TROWEL — ENGINE, 2.5 HP HONDA ASSY.

ENGINE, 2.5 HP HONDA ASSY.

PAGE 44 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 45

C-4 FINISHER TROWEL — ENGINE, 2.5 HP HONDA ASSY.

ENGINE, 2.5 HP HONDA ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 10649 ENGINE, 2.8 HP. HONDA G100 1

2 0202 HHCS 5/16- 18 X 1” 1

3 0161C LOCK WASHER 5/16” 5

4 0300B FLAT WASHER 5/16” 5

5 0205 HHCS 3/8- 16 X 1” 1

6 0166A LOCK WASHER 3/8” 1

7 10136 FLAT WASHER 3/8” 1

8 0655 HHCS 5/16- 18 X 3/4” 2

9 10644 CLUTCH BRACKET 1

10 5277 HHCS 1/4- 20 X 1.1/2” 1

11 2866 HHCS M8- 1.25 X 20MM 2

12 10282 SHOULDER BOLT 3/8 X 1” 1

13 10608 IDLER PULLEY 1

14 10370 HEX NUT M8- 1.25 1

15 10611 BELT (A21) 1

16 0730 HHCS 1/4- 20 X 1” 3

17 0181B LOCK WASHER 1/4” 5

18 10661 BELT GUARD 1

19 10609 PULLEY 1

20 2126 SQUARE KEY 3/16 X 3/16 X 13/16” 1

21 1605 HHCSM8- 1.25 X 25MM 1

22 10641 CLUTCH LEVER 1

23 10610 PULLEY 1

24 0948 FLAT WASHER 1/4” 5

25 1579 HHCS 1/4- 20 X 1/2” 2

26 10740 BELT TENSIONING SHOE 1

27 10450 SHSS 10- 32 X 1/4” 1

28 0949 HEX NUT 1/4- 20 1

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 45

Page 46

GUARD RING ASSY.

C-4 FINISHER TROWEL — GUARD RING ASSY.

PAGE 46 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 47

C-4 FINISHER TROWEL — GUARD RING ASSY.

GUARD RING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

11 0166A LOCK WASHER 3/8" 4

21 0205 HHCS 3/8-16x1: 4

22 10602 GUARD RING 1

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 47

Page 48

C-4 FINISHER TROWEL — BLADES & ADJUSTMENT FIXTURE ASSY.

BLADES & ADJUSTMENT FIXTURE ASSY.

(OPTIONS)

PAGE 48 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 49

C-4 FINISHER TROWEL — BLADES & ADJUSTMENT FIXTURE ASSY.

BLADES & ADJUSTMENT FIXTURE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

20 COMBO FLOAT & FINISH BLADE .......................... 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

20 ENDURO COMBO FLOAT &FINISH BLADE .......... 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

21 FLOAT BLADE ........................................................ 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

22 FINISH BLADE ....................................................... 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

22 ENDURO FINISH BLADE W/ROTATING ................ 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

23 0202 HHCS 5/16-18X1" RING 4

24 0201 GUARD RING LUG RING 4

26 1434 TROWEL LUG (FINISH BLADE ONLY) 4

39 UNIVERSAL COMBO BLADE ................................. 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

39 ENDURO UNIVERSAL COMBO BLADE ................ 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

40 UNIVERSAL FINISH BLADE .................................. 4 ........ CONTACT UNIT SALES DEPT./ACCESSORY ITEM

40 ENDURO UNIVERSAL FINISH BLADE .................. 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

41 UNIVERSAL MOUNTING BAR ............................... 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

42 SNAP PIN 1/4"X1.3/4" ............................................ 8 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

47 REVERSIBLE COMBO BLADE ............................... 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

49 FLOAT DISC ........................................................... 1 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

50 FLOAT DISC LATCH PIN ....................................... 4 ......... CONTACT UNIT SALES DEPT./ACCESSORY ITEM

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 49

Page 50

AIR CLEANER ASSY.

HONDA G100K2QA2 ENGINE — AIR CLEANER ASSY.

PAGE 50 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 51

HONDA G100K2QA2 ENGINE — AIR CLEANER ASSY.

AIR CLEANER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 15721896010 TUBE, BREATHER 1

2 17211896000 ELEMENT, AIR CLEANER 1

3 17212896000 GRID, AIR CLEANER 1

4 17220ZG0000 HOUSING, AIR CLEANER 1

5 17231ZG0000 COVER, AIR CLEANER 1

6 90325044000 WING NUT, TOOL BOX SETTING 1

7 9405005000 NUT, FLANGE 5MM 2

8 9410106800 WASHER, PLAIN 6MM 1

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 51

Page 52

CAMSHAFT ASSY.

HONDA G100K2QA2 ENGINE — CAMSHAFT ASSY.

PAGE 52 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 53

HONDA G100K2QA2 ENGINE — CAMSHAFT ASSY.

CAMSHAFT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 12209ZG1H11 SEAL, VALVE STEM 1

2 14111ZC0000 CAMSHAFT 1

3 14711ZG1H10 VALVE, IN. 1

4 14721ZG1H10 VALVE, EX. 1

5 14732ZC0000 LIFTER, VALVE 2

6 14751896000 SPRING, VALVE 2

7 14771ZG0000 RETAINER, VALVE SPRING 2

8 14801892000 ADJUSTER, TAPPET CLEARANCE 3.15 2

8 14803892000 ADJUSTER, TAPPET CLEARANCE 3.25 2

8 14806892000 ADJUSTER, TAPPET CLEARANCE 3.34 2

8 14809892000 ADJUSTER, TAPPET CLEARANCE 3.43 2

8 14812892000 ADJUSTER, TAPPET CLEARANCE 3.52 2

8 14815892000 ADJUSTER, TAPPET CLEARANCE 3.61 2

8 14818892000 ADJUSTER, TAPPET CLEARANCE 3.72 2

8 14820892000 ADJUSTER, TAPPET CLEARANCE 3.82 2

9 90452ZG0000 WASHER 12MM 1

10 90452ZG0000 WASHER 12MM 1

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 53

Page 54

CARBURETOR ASSY.

HONDA G100K2QA2 ENGINE — CARBURETOR ASSY.

PAGE 54 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 55

HONDA G100K2QA2 ENGINE — CARBURETOR ASSY.

CARBURETOR ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1

2

3

4

6

7

8

9

10 16100ZG0W02 CARBURETOR ASSEMBLY BF11B B ............. 1............. INCLUDES ITEMS W/

11

12

13

14 16211ZG0020 INSULATOR, CARBURETOR 1

15 16212ZG0800 GASKET, INSULATOR 1

16 16221ZG0801 GASKET, CARBURETOR 1

17 16269ZG0800 GASKET, AIR CLEANER 1

18

19

20

21

22

23

24 99101ZG00500 JET, MAIN #50 (OPTIONAL) 1

24 99101ZG00520 JET, MAIN #52 (OPTIONAL) 1

24

25

16010ZG0812 GASKET SET 1

*

16011ZE0005 VALVE SET, FLOAT 1

*

16013ZG0811 FLOAT SET 1

*

16015ZG0811 CHAMBER SET, FLOAT 1

*

16016ZG0W00 SCREW SET 1

*

16024ZE1811 SCREW SET, DRAIN 1

*

16028ZG0811 SCREW SET 1

*

16044ZG0W00 CHOKE SET 1

*

16124ZE0005 SCREW, THROTTLE STOP 1

*

16166ZG0W01 NOZZLE, MAIN 1

*

16173ZG0811 O-RING 1

*

16953ZG0812 LEVER, VALVE 1

*

16954ZE1812 PLATE, LEVER SETTING 1

*

16956ZE1811 SPRING, VALVE LEVER 1

*

16957ZE1812 GASKET, VALVE 1

*

16967ZG0811 CUP, FUEL STRAINER 1

*

93500030060H SCREW, PAN 3X6 2

*

99101ZG00550 JET, MAIN #55 1

*

99204ZE00350 JET SET, PILOT #35 1

*

*

C-4 FINISHER WALK-BEHIND TROWEL — PARTS & OPERATION MANUAL — REV. #1 (07/24/02) — PAGE 55

Page 56

CONTROL ASSY.

HONDA G100K2QA2 ENGINE — CONTROL ASSY.

PAGE 56 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

Page 57

HONDA G100K2QA2 ENGINE — CONTROL ASSY.

CONTROL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 16551ZG0000 ARM, GOVERNOR 1

2 16555ZG0000 ROD, GOVERNOR 1

3 16561ZG0000 SPRING, GOVERNOR 1

4 16562ZG0000 SPRING, THROTTLE RETURN 1

5 16570ZG0W00 CONTROL ASSEMBLY, STANDARD ................ 1.............INCLUDES ITEMS W/

6

7

8

9

10

11

12

13 16594883010 HOLDER, WIRE (OPTIONAL) 1

15 90015ZE5010 BOLT, GOVERNOR ARM 1