Page 1

OPERATION AND PARTS MANUAL

MODELS

C10SH8 (STEEL)

C10PH8 (PLASTIC)

CONCRETE MIXER

(HONDA GX240U1QA2 GASOLINE ENGINE

Revision #0 (03/06/09)

To fi nd the latest revision of this

publication, visit our website at:

www.stowmfg.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandother construction activities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of thesechemicals are:

Leadfromlead-basedpaints.

Crystallinesilica frombricks.

Cementandother masonry products.

Arsenicandchromiumfromchemically

treatedlumber.

Your risk from these exposures varies,

dependingon how often you dothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 3

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 3

Page 4

TABLE OF CONTENTS

C10SH8-PH8

Concrete Mixer

Proposition 65 Warning ........................................... 2

Silicosis/Respiratory Warnings ................................ 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Information .............................................. 6-10

Specifi cations ........................................................ 12

Dimensions ............................................................ 13

General Information ............................................... 14

Components .......................................................... 15

Basic Engine .......................................................... 16

Towing Guidelines .................................................. 17

Safety Chain Connection ....................................... 18

Inspection .............................................................. 19

Operation .......................................................... 20-21

Maintenance (Engine) ......................................22-23

Maintenance (Mixer) ......................................... 24-26

Troubleshooting (Engine) ....................................... 28

Troubleshooting (Mixer) ......................................... 29

Explanation Of Code In Remarks Column ............ 30

Suggested Spare Parts ......................................... 31

Component Drawings

Nameplates And Decals ................................... 32-33

Plastic Drum Assembly ..................................... 34-35

Steel Drum Assembly ....................................... 36-37

Yoke Assembly .................................................. 38-39

Frame Assembly ............................................... 40-41

Hub/Tire Assembly ........................................... 42-43

Cabinet Assembly ............................................. 44-45

Engine Assembly .............................................. 46-47

Terms And Conditions Of Sale — Parts ................ 48

NOTICE

Specifi cations and part numbers are subject to change

without notice.

PAGE 4 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 5

PARTS ORDERING PROCEDURES

www.multiquip.com

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

to log in and save!

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 5

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

Page 6

SAFETY INFORMATION

Do not operate or service the equipment before reading

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

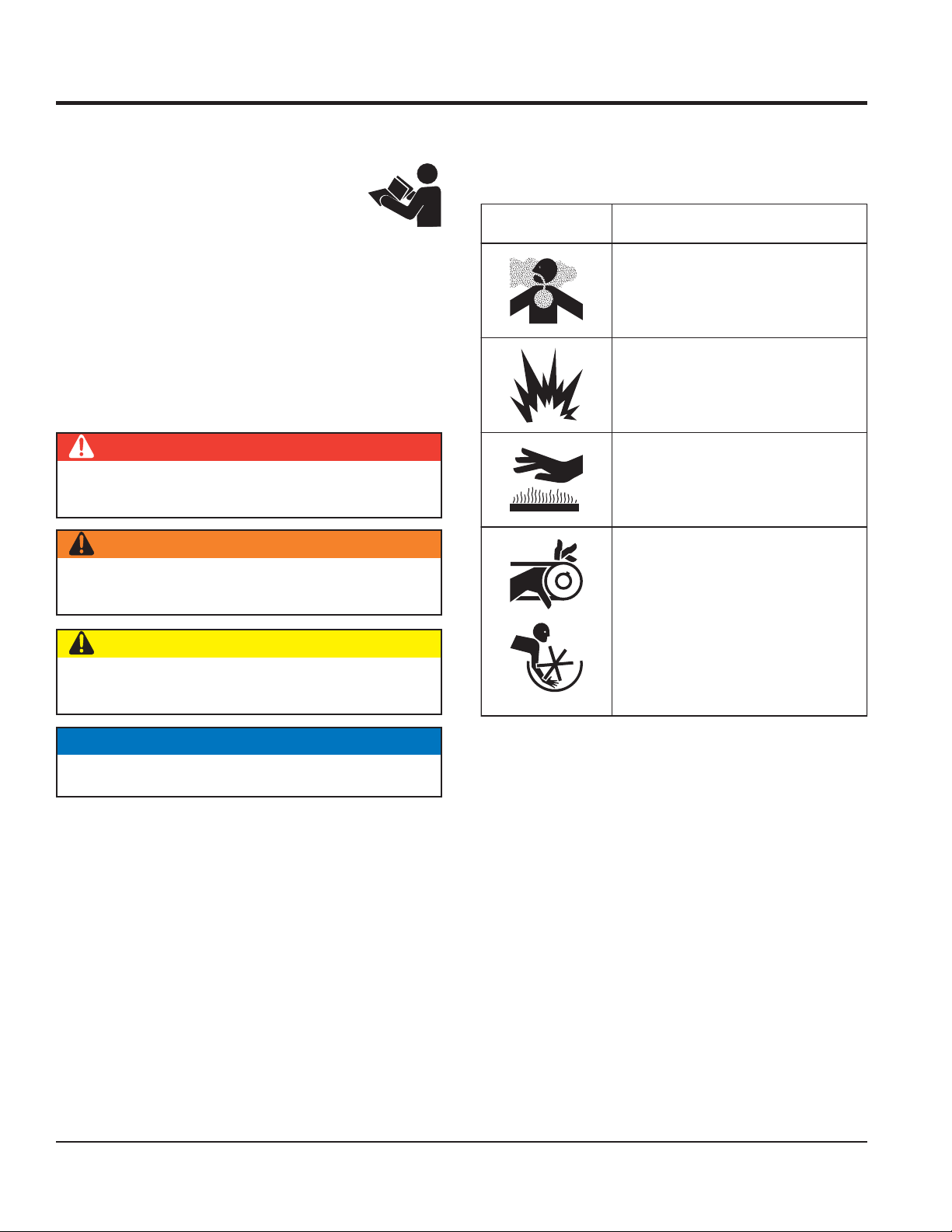

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Potential hazards associated with the operation of this

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

Symbol Safety Hazard

Lethal exhaust gas hazards

Explosive fuel hazards

Burn hazards

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

Rotating parts hazards

PAGE 6 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 7

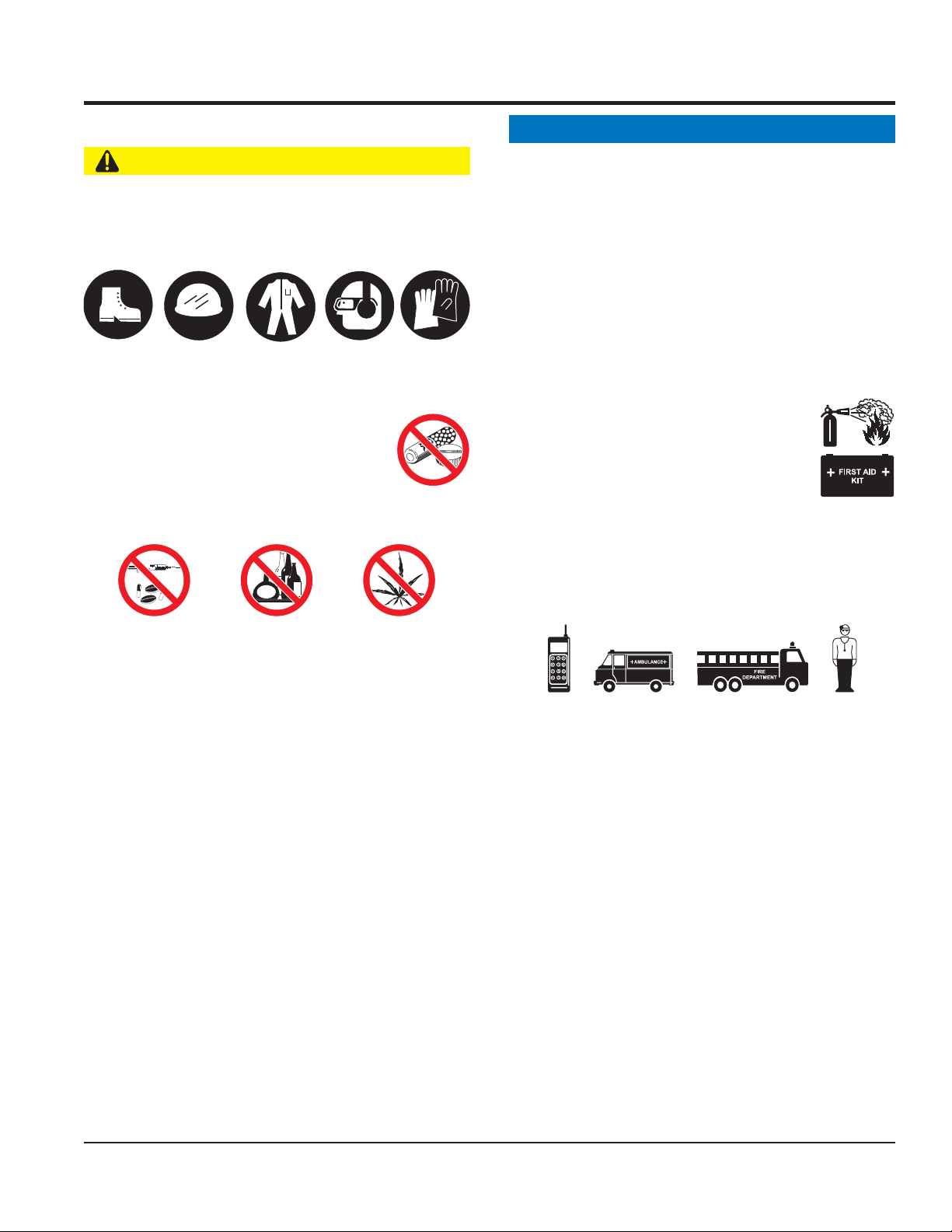

SAFETY INFORMATION

GENERAL SAFETY

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

Avoid wearing jewelry or loose fi tting clothes that may

snag on the controls or moving parts as this can cause

serious injury.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the

infl uence of drugs or alcohol.

NOTICE

This equipment should only be operated by trained and

qualifi ed personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

equipment modifi cation will void all warranties.

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest phone or keep

a phone on the job site. Also, know the phone numbers

of the nearest ambulance, doctor and fi re department.

This information will be invaluable in the case of an

emergency.

ALWAYS clear the work area of any debris, tools, etc.

that would constitute a hazard while the equipment is

in operation.

ALWAYS check the equipment for loosened threads or

bolts before starting.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 7

Page 8

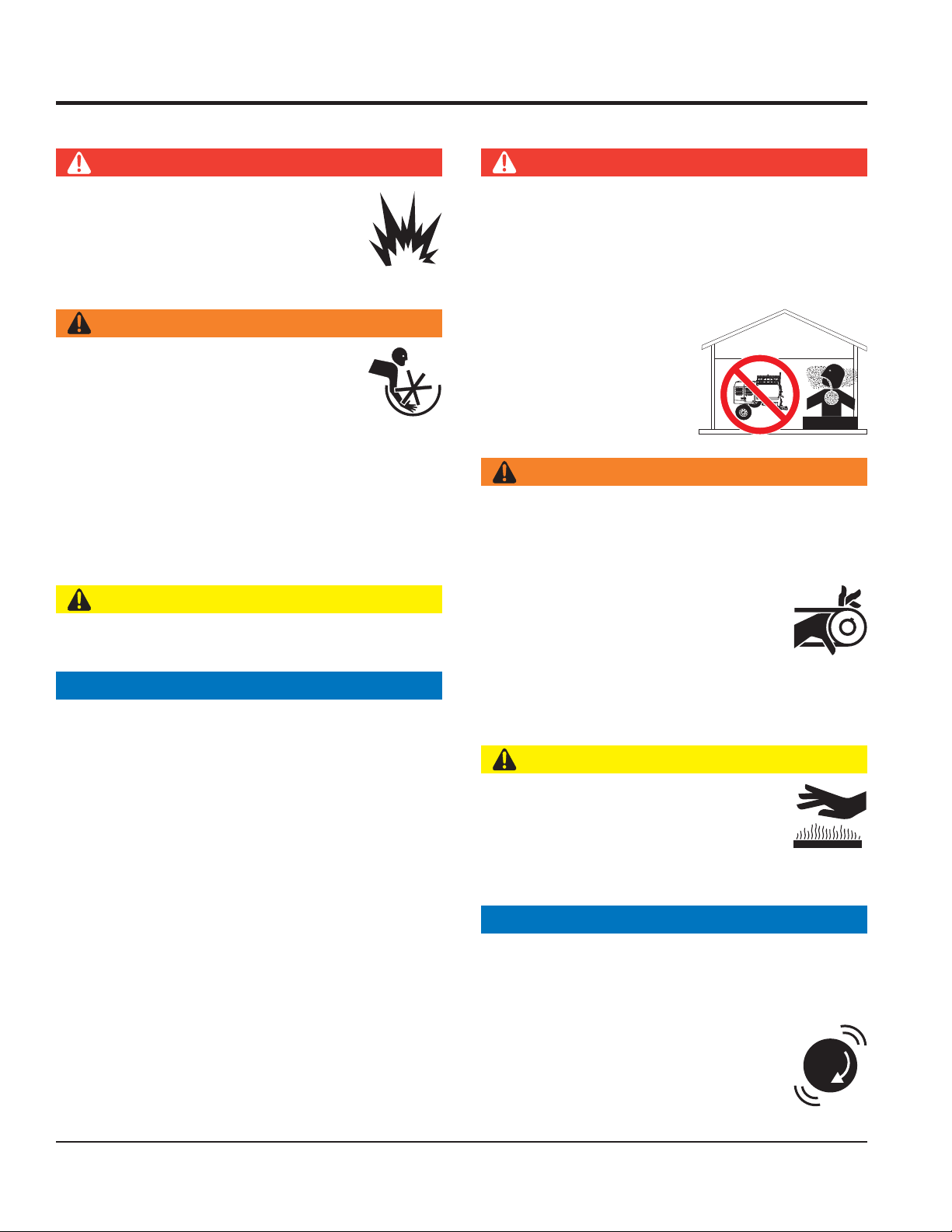

SAFETY INFORMATION

MIXER SAFETY

DANGER

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

DO NOT mix fl ammable or explosive substances.

WARNING

NEVER place your hands inside the drum

while starting or operating this equipment.

NEVER disconnect any emergency

or safety devices. These devices are

intended for operator safety. Disconnection of these

devices can cause severe injury, bodily harm or even

death. Disconnection of any of these devices will void

all warranties.

Before operating mixer, ensure that safety grate is in

position and correctly fi tted.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

NOTICE

ALWAYS keep the machine in proper running condition.

ALWAYS ensure mixer is on level ground before mixing.

Fix damage to machine and replace any broken parts

immediately.

DO NOT tip mixer onto drum mouth when the drum is

rotating.

Ensure the drum is rotating while fi lling and emptying

the drum.

ALWAYS store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

ENGINE SAFETY (GASOLINE MODELS ONLY)

DANGER

Engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment requires an adequate

free fl ow of cooling air. NEVER operate this equipment

in any enclosed or narrow

area where free fl ow of the

air is restricted. If the air

fl ow is restricted it will cause

injury to people and property

and serious damage to the

equipment or engine.

WARNING

DO NOT place hands or fingers inside engine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

DO NOT remove the engine oil drain plug

while the engine is hot. Hot oil will gush out of the oil

tank and severely scald any persons in the general area

of the mixer.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

Make certain the operator knows how to and is capable

of turning the engine OFF in case of an emergency.

NOTICE

NEVER run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

frequently to prevent engine malfunction.

DANGEROUS

GAS FUMES

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

PAGE 8 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 9

SAFETY INFORMATION

FUEL SAFETY (GASOLINE MODELS ONLY)

DANGER

DO NOT start the engine near spilled fuel or combustible

fl uids. Fuel is extremely fl ammable and its vapors can

cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

Power Cord/Cable Safety

DANGER

NEVER let power cords or cables lay in water.

NEVER use damaged or worn cables or cords when

connecting equipment to generator. Inspect for cuts in

the insulation.

NEVER grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

Make sure power cables are securely connected.

Incorrect connections may cause electrical shock and

damage to the mixer.

CAUTION

Ensure that cables and cords will not be tripped over or

trapped underneath the mixer.

NOTICE

DO NOT smoke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

GENERATOR SAFETY

If using a generator to power mixer, refer to

applicable generator manual safety information

section.

ELECTRIC MOTOR SAFETY

(ELECTRIC MODELS ONLY)

NOTICE

Operate electric motor only at the specifi ed voltage

indicated on the nameplate.

DO NOT spray water onto electric motor.

ALWAYS disconnect AC power plug from power source

before moving mixer.

ALWAYS make sure the ON/OFF switch

on the electric motor is in the OFF position

when not in use and before inserting the

mixer’s power plug into an AC receptacle.

ALWAYS make certain that proper power or extension

cord has been selected for the job.

TRANSPORTING SAFETY

CAUTION

NEVER allow any person or animal to stand underneath

the equipment while lifting.

NOTICE

ALWAYS make sure forklift forks are inserted into pockets

(if applicable) as far as possible when lifting the mixer.

ALWAYS shutdown engine before transporting.

NEVER lift the equipment while the engine is running.

Tighten fuel tank cap securely and close fuel cock to

prevent fuel from spilling.

DO NOT lift machine to unnecessary heights.

ALWAYS tie down equipment during transport by

securing the equipment with rope.

NEVER tip the engine to extreme angles during lifting as

it may cause oil to gravitate into the cylinder head, making

the engine start diffi cult.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 9

Page 10

SAFETY INFORMATION

TOWING SAFETY

CAUTION

Check with your local county or state safety towing

regulations, in addition to meeting Department of

Transportation (DOT) Safety Towing Regulations,

before towing your mixer.

In order to reduce the possibility of an accident while

transporting the mixer on public roads, ALWAYS make

sure the towing vehicle is mechanically sound and in

good operating condition.

ALWAYS shutdown engine before transporting.

ALWAYS inspect the hitch and coupling for wear. NEVER

tow a mixer with defective hitches, couplings, chains, etc.

Check the tire air pressure on both towing vehicle and

mixer Mixer tires should be infl ated to 50 psi cold. Also

check the tire tread wear on the vehicle and mixer.

ALWAYS make sure the mixer is equipped with a safety

chain.

ENVIRONMENTAL SAFETY

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

ALWAYS properly attach mixer’s safety chains to towing

vehicle.

The maximum speed for highway towing is 55 MPH unless

posted otherwise. Recommended off-road towing is not to

exceed 15 MPH or less depending on type of terrain.

Avoid sudden stops and starts. This can cause skidding,

or jack-knifi ng. Smooth, gradual starts and stops will

improve towing.

Avoid sharp turns to prevent rolling.

Mixer should be adjusted to a level position at all times

when towing.

Raise and lock mixer wheel stand in up position when

towing.

Place chock blocks underneath wheel to prevent rolling

while parked.

PAGE 10 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 11

NOTES

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 11

Page 12

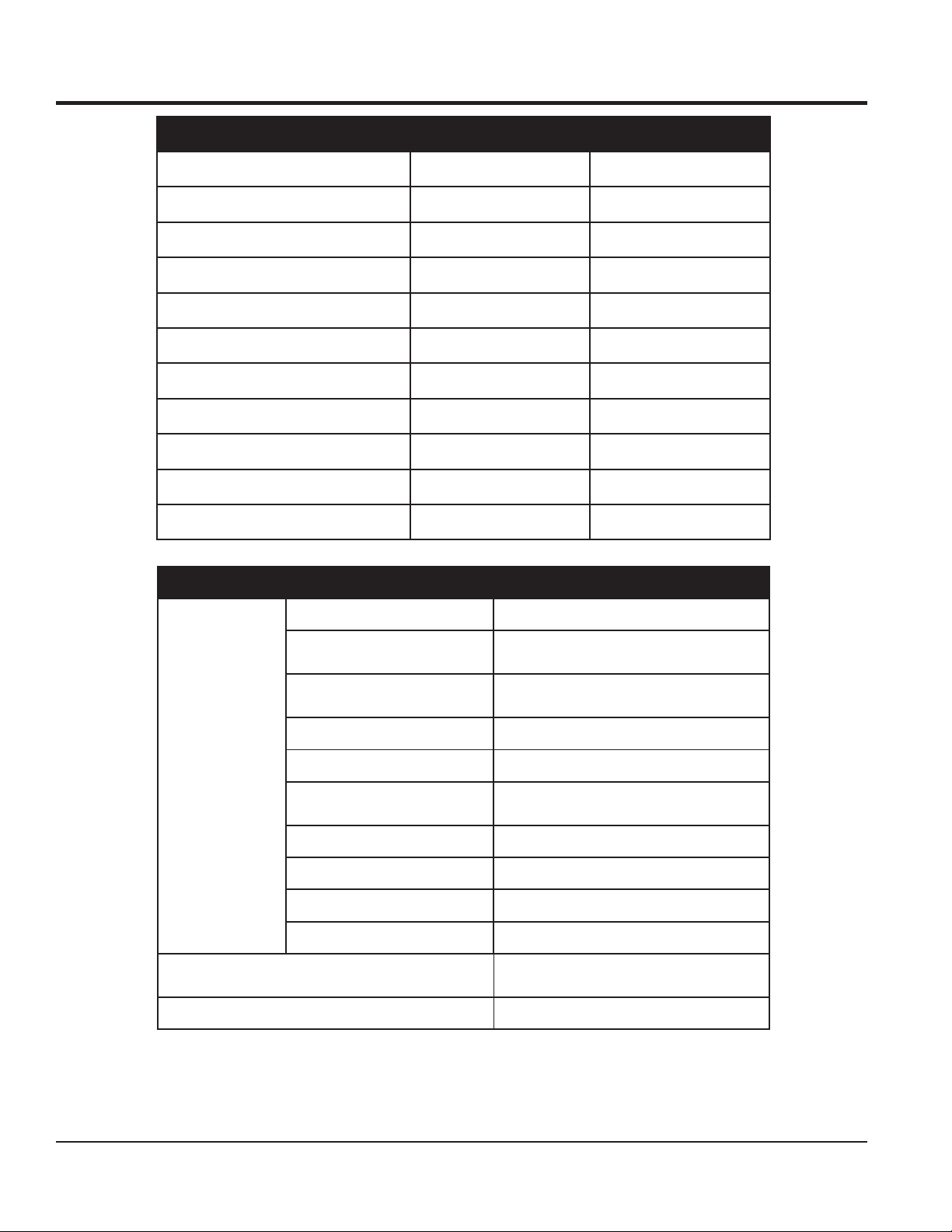

SPECIFICATIONS

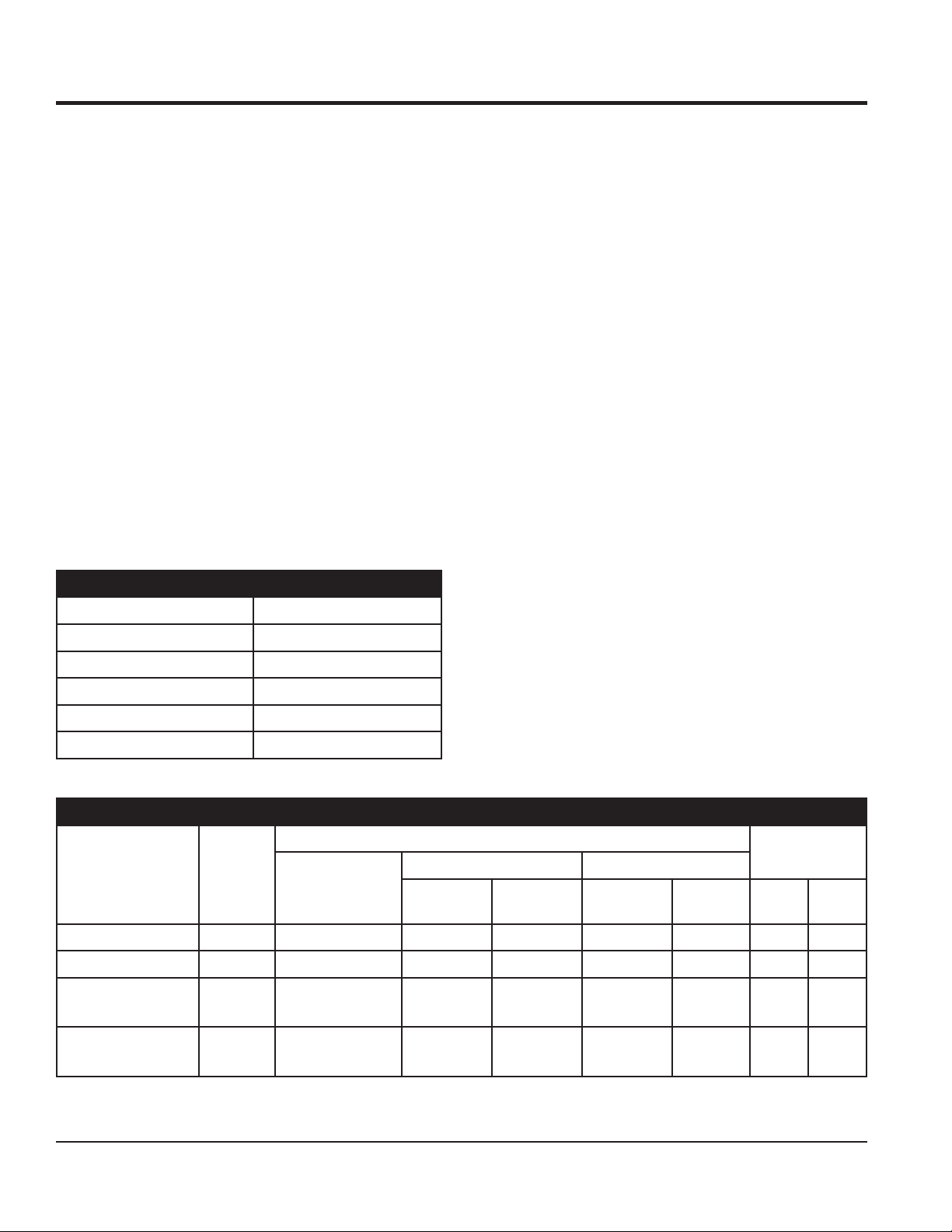

Mixer Specifi cationsTable 1.

Model C10SH8 C10PH8

Drum Material Steel Polyethylene

Bag Capacity 1 1

Drum Capacity — cu.ft. (liters) 9.0 (255) 9.0 (255)

Discharge Height — in. cm. 21.5 (55) 21.5 (55)

Drum Opening — in. cm. 20.0 (51) 19.2 (49)

Drum Depth — in. cm 29 (74) 28 (71)

Tires B78 x 13 B78 x 13

Drive V-Belt V-Belt

Dump Action Manual Manual

Weight - With Engine 600 lbs. (272 Kg.) 620 lbs. (281 Kg.)

Engine Specifi cationsTable 2.

Model HONDA GX240U1QA2

Type

Bore X Stroke

Displacement 14.81 cc

Engine

Dimension

(L x W x H)

Dry Net Weight 55.1 lbs (25 Kg.)

Max Output 8.0 H.P./3600 R.P.M.

Fuel Tank Capacity

Fuel Unleaded Gasoline

Lube Oil Capacity 2-1/3 pints

Speed Control Method Centrifugal Fly-weight Type

Starting Method Recoil Start

Air-cooled 4 stroke, Single Cylinder, OHV,

Horizontal Shaft Gasoline Engine

2.90 in. X 2.30 in.

(73 mm x 58 mm)

Approx. 1.59 U.S. Gallons

(6 Liters)

14.0 x 16.9 X 16.1 in.

(355 X 430 X 410 mm)

PAGE 12 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 13

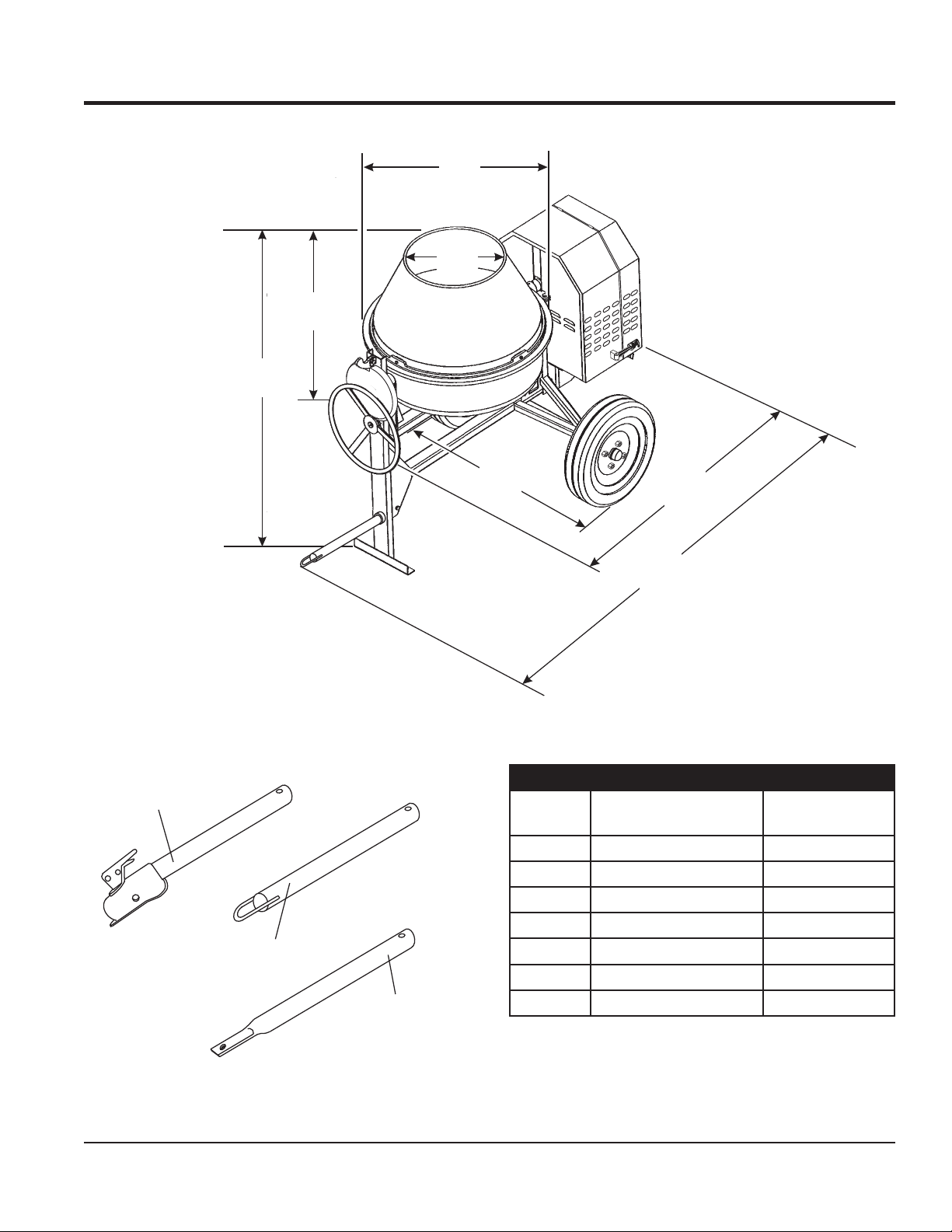

A

DIMENSIONS

C

D

B

OPTIONAL TOW BARS

HBC-1

2-INCH

BALL COUPLER

HLC-1

LOOP COUPLER

HPC-1

1-INCH

PIN COUPLER

E

Reference

F

G

DimensionsTable 3.

Letter

A Height 61 in. (1545 mm)

B Drum height 30 in. (765 mm)

C Drum width 38.6 in. (980 mm)

D Drum neck diameter 21.1 in. (535 mm)

E Width 45.7 in. (1160 mm)

F Length, no tow bar 74.5 in. (1892 mm)

G Length with tow bar 92.7 in. (2355 mm)

Description Dimension

DimensionsFigure 1.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 13

Page 14

GENERAL INFORMATION

APPLICATION

This mixer is only intended for the production of concrete.

The mixer must be used for its intended purpose and

is not suitable for the mixing of fl ammable or explosive

substances. The mixer must not be used in an explosive

atmosphere. Use Table 5 (Mixing Hints) as a guide when

mixing concrete for various applications.

POWER PLANTS

The Stow C10SH8 and C10PH8 mixers are powered by an

air-cooled, 4-stroke Honda GX240U1QA2 gasoline engine.

Refer to Table 2 for engine specifi cations.

HARDWARE

Check all hardware on the mixer before starting Periodically

inspect all hardware. Loose hardware can contribute to

early component failure and poor performance. Use Table

4 as general guideline when the torqueing of mixer

hardware is required. Remember to keep all mixer hardware

components tight.

ENGINE MAINTENANCE

For basic engine maintenance, refer to the engine

maintenance section in this manual. For more detailed

engine maintenance information, refer to the Honda engine

owner’s manual supplied with the engine.

Hardware Torque RecommendationsTable 4.

Hardware Diameter Torque (ft-lbs)

5/16-inch x 18 14

3/8-inch x 16 24

3/8-inch x 24 37

1/2-inch x 13 39

1/2-inch x 13 (Grade 8) 90

Applications

Most Ordinary

Foundations

Rough Mass

Concrete

Mix

Ratios

1:2:4 1/2 Bag 1-1/4 35 2-1/2 71 3 85

1:3:6 1/3 Bag 1-1/4 35 2-1/2 71 2-3/4 78

1:4:8 1/4 Bag 1-1/4 35 2-1/2 71 2-3/4 78

Cement 112

lbs. (50 Kgs.)

Bag

Mixing HintsTable 5.

Batch Quantities

Sand Stone

Cu. Ft. Ltr Cu. Ft. Ltr Cu.Ft. Ltr

Approx. Batch

Output

Watertight Floors,

Tanks, Pits, Etc.

PAGE 14 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

1:1-1/2:3 2/3 Bag 1-1/4 35 3 71 3 85

Page 15

COMPONENTS

11

6

5

4

3

2

6

6

12

Major ComponentsFigure 2.

1

13

7

8

9

10

Figures 2 shows the location of the controls and components

for the C10SH8-PH8 mixer. The function of each control is

described below.

Handwheel 1. — Turn this wheel clockwise or counter-

clockwise to rotate the mixing drum. Remember the

dump latch must be in the up position in order for the

mixing drum to be rotated.

Dump Gear Guard 2. — NEVER operate the mixer with

this guard removed. Its purpose is to prevent dirt and

debris from entering the dump gear. In addition operator

clothing could become entangled in the dump gear,

causing severe injury and bodily harm.

Dump Latch 3. — To rotate the mixing drum, this latch

must be in the up position. To lock the drum, place the

latch in the down position.

Mixing Drum 5. — The C10SH8 uses a 6 cu. ft steel

mixing drum and the C10PH8 uses a 6 cu. ft. plastic

mixing drum. This drum is to be used for mixing of

concrete. Always clean the drum after each use. DO

NOT use this mixing drum for the mixing of volatile

liquids.

Zerk Fittings 6. — There are three zerk fi ttings on the

mixer that lubricate the handwheel, gear and yoke.

Lubricate fi ttings as referenced in the maintenance

section of this manual.

Engine Cabinet 7. — Encloses engine. NEVER run mixer

with cabinet removed.

ON/OFF Switch 8. — This switch is located on the side

of the mixer frame. When activated it will shut down the

engine. Pull out when starting the engine.

Cabinet Latch 9. — Use latches to secure engine

cabinet.

Tire Ply 10. — The tire ply (layers) number is rated in

letters; This mixer uses 13-inch 2-ply tires. Replace

with only recommended type tires.

Chock Blocks 11. — Place these blocks (not included as

part of the mixer package) under each mixer wheel

to prevent rolling when mixer is not connected to the

towing vehicle.

Safety Chain 12. — This mixer uses a 3/16-inch thick,

72-inches long zinc-plated saftey chain. ALWAYS

connect the safety chain when towing.

Tow Bar 13. — This mixer uses various towing bars. Please

reference the frame assembly drawing and parts list

in this manual to determine which tow bar meets your

requirements

Mixing Blades (Steel or Plastic) 4. — Used for the

mixing of concrete. Replace plastic blades when they

show signs of wear. When steel blades show signs

of wear, entire steel mixing drum assembly must be

replaced. See steel and plastic mixing drum assemblies

in the parts section of this manual.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 15

Page 16

Engine Components (Honda GX Figure 3.

Series Engine Shown)

The engine (Figure 3) must be checked for proper

lubrication and fi lled with fuel prior to operation. Refer to the

manufacturer’s engine manual for instructions and details

of operation and servicing.

Fuel Filler Cap 1. — Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fi ll.

BASIC ENGINE

Fuel Valve Lever 5. — OPEN to let fuel fl ow, CLOSE to

stop the fl ow of fuel.

Choke Lever 6. — Used in the starting of a cold engine,

or in cold weather conditions. The choke enriches the

fuel mixture.

Air Cleaner 7. — Prevents dirt and other debris from

entering the fuel system. Remove wing-nut on top of

air fi lter cannister to gain access to fi lter element.

NOTICE

Operating the engine without an air fi lter, with a damaged

air fi lter, or a fi lter in need of replacement will allow dirt to

enter the engine, causing rapid engine wear.

Spark Plug 8. — Provides spark to the ignition system.

Set spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch).

Clean spark plug once a week.

Muffl er 9. — Used to reduce noise and emissions.

WARNING

Engine components can generate extreme

heat. To prevent burns, DO NOT touch

these areas while the engine is running or

immediately after operating. NEVER operate

the engine with the muffl er removed.

DANGER

Adding fuel to the tank should be

accomplished only when the engine is

stopped and has had an opportunity to

cool down. In the event of a fuel spill, DO

NOT attempt to start the engine until the

fuel residue has been completely wiped up, and the

area surrounding the engine is dry.

Throttle Lever 2. — Used to adjust engine RPM speed

(lever advanced forward SLOW, lever back toward

operator FAST).

Engine ON/OFF Switch 3. — ON position permits engine

starting. OFF position stops engine operations.

Recoil Starter (pull rope) 4. — Manual-starting method.

Pull the starter grip until resistance is felt, then pull

briskly and smoothly.

PAGE 16 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Fuel Tank 10. — Holds unleaded gasoline. For additional

information refer to engine owner’s manual.

Page 17

TOWING GUIDELINES

TOWING SAFETY PRECAUTIONS

CAUTION

Check with your county or state safety towing regulations

department before towing your mixer.

To reduce the possibility of an accident while transporting

the mixer on public roads, always make sure that the

mixer towing components and the towing vehicle are in

good operating condition and both units are mechanically

sound.

The following list of suggestions should be used when

towing the mixer:

Make sure that the hitch and coupling of the towing

vehicle are rated equal to, or greater than the trailer

"gross vehicle weight rating" (GVWR).

ALWAYS inspect the hitch and coupling for wear. NEVER

tow the mixer with defective hitches, couplings, chains

etc.

CHECK the tire air pressure on both the towing vehicle

and the trailer. Also check the tire tread wear on both

vehicles.

ALWAYS make sure the mixer is equipped with a "Safety

Chain".

ALWAYS attach trailer's safety chain to the frame of

towing vehicle.

ALWAYS make sure that the towing vehicle's directional,

backup, and brake lights are working properly.

Remember in most cases the maximum speed unless

otherwise posted for highway towing is 45 MPH, however

before towing your mixer, check your local state, and

county vehicle towing requirements. Recommended offroad towing is not to exceed 10 MPH or less depending

on type of terrain.

Place chocked blocks underneath wheels to prevent

rolling, while parked, if disconnected from towing

vehicle.

Inflate tires to correct pressure, inspect tires for

cuts, and excessive wear. See Table 16 (Tire Wear

Troubleshooting).

When towing of the mixer is required, place the drum in

the up position (mouth facing upwards).

ALWAYS make sure that the fuel valve lever is in the OFF

position (gasoline models only).

Check wheel mounting lug nuts with a torque wrench.

Torque wheel lug nuts as described in the maintenance

section of this manual.

Check tightness of U-clamp nuts, torque suspension

hardware as referenced in the maintenance section of

this manual.

Avoid sudden stops and starts. This can cause skidding,

or jackknifi ng. Smooth, gradual starts and stops will

improve gas milage.

Avoid sharp turns to prevent rolling.

CAUTION

If the mixer tow bar is deformed or damaged replace

entire tow bar. NEVER tow the mixer with a defective tow

bar. There exist the possibility of the trailer separating

from the towing vehicle.

Tow Bar to Vehicle Connection (Coupler Only)

Check the vehicle hitch ball, and mixer's coupler for 1.

signs of wear or damage. Replace any parts that are

worn or damaged before towing.

Use only a 2-inch ball diameter (towing vehicle), this will 2.

match the mixer's 2-inch coupler. Use of any other ball

diameter will create an extremely dangerous condition

which can result in separation of the coupler and ball

or ball failure.

After tow bar has been connected to mixer (see next 3.

page), attach mixer's coupler to the hitch ball on the

towing vehicle securely and make sure the lock lever

is in the down position (locked).

Mixer Tow Bar Vehicle Connection (Pintle and Loop)

Make sure the bumper on the towing vehicle is 1.

equipped to handle either a pintle or loop type tow bar

confi guration.

After tow bar has been connected to mixer (see next 2.

page), secure either type of tow bar to the towing vehicle,

following state and county towing regulations.

As a minimum, use a 1/2-inch bolt and nylock nut grade 3.

5 when securing either tow bar to the towing vehicle.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 17

Page 18

SAFETY CHAIN CONNECTION

CAUTION

NEVER tow the mixer with the safety chain removed.

The safety chain is intended to prevent complete

separation of the mixer from the towing vehicle in the

event of a tow bar failure.

Reference Figure 4 for the installation of the Safety

Chain.

Tow Bar to Mixer Connection

Insert the tow bar through the round opening at the 1.

bottom of the mixer stand.

Align the hole on the tow bar with the hole on the mixer

frame, and insert 1/2-inch bolt through tow bar and

frame. Secure tow bar to frame with 1/2-inch nylock

nut. Tighten to 40 ft.-lbs.

Route the safety chain through the holes just above the 2.

tow bar, located on each side of the mixer stand.

Loop the chain together and place under the tow bar.

Secure the loop with the connector link.

Extend the safety chain along the length of the tow bar, 3.

looping it through the tow bar's connector link. Remove

any excess chain slack.

Connect the free end of (clevis safety hook) the safety 4.

chain to the towing vehicle. Remember, it is critical

that the length of the chain be properly adjusted, to

prevent the draw bar and the front of the mixer stand

from dropping to the the ground (contact) in the event

the draw bar becomes disconnected from the towing

vehicle.

MIXER

STAND

STEP 1

CONNECTOR LINK

SAFETY CHAIN

CLEVIS SAFETY HOOK

(TOWING VEHICLE)

STEP 4

SAFETY CHAIN

STEP 2

TOW BAR

STEP 3

Tow Bar and Safety Chain InstallationFigure 4.

1/2-INCH BOLT,

GRADE 5

1/2-INCH NYLOCK

NUT, GRADE 5

SAFETY CHAIN

CONNECTOR LINK

PAGE 18 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 19

INSPECTION

BEFORE STARTING

Read safety instructions at the beginning of manual.1.

Clean the mixer, removing dirt and dust, particularly the 2.

engine cooling air inlet, carburetor and air cleaner.

Check the air fi lter for dirt and dust. If air fi lter is dirty, 3.

replace air fi lter with a new one as required.

Check carburetor for external dirt and dust. Clean with 4.

dry compressed air.

Check fastening nuts and bolts for tightness. 5.

ENGINE OIL CHECK

To check the engine oil level, place the mixer on secure 1.

level ground with the engine stopped.

Remove the fi ller dipstick from the engine oil fi ller hole 2.

(Figure 5) and wipe it clean.

Oil TypeTable 6.

Season Temperature Oil Type

Summer 25°C or Higher SAE 10W-30

Spring/Fall 25°C~10°C SAE 10W-30/20

Winter 0°C or Lower SAE 10W-10

FUEL CHECK

DANGER

Motor fuels are highly fl ammable and can

be dangerous if mishandled. DO NOT

smoke while refueling. DO NOT attempt

to refuel the mixer if the engine is hot or

running.

If fuel is low, remove the fuel fi ller cap and fi ll with unleaded

gasoline.

Remove the gasoline cap located on top of fuel tank.1.

Visually inspect to see if fuel level is low. If fuel is low, 2.

replenish with unleaded fuel.

Engine Oil Dipstick (Removal)Figure 5.

Insert and remove the dipstick without screwing it 3.

into the fi ller neck. Check the oil level shown on the

dipstick.

If the engine oil level is low (Figure 6), fi ll to the edge 4.

of the oil fi ller hole with the recommended oil type (Table

6). See Table 2 for the oil capacity of your type engine.

When refueling, be sure to use a strainer for fi ltration. 3.

DO NOT top-off fuel. Wipe up any spilled fuel.

V-BELT CHECK

A worn or damaged V-belt can adversely affect the

performance of the mixer. If a V-belt is defective or worn,

simply replace the V-belt as outlined in the maintenance

section of this manual.

BLADE CHECK

Check for worn blades. If using a steel tub and the blades

are worn, replace the entire tub assembly. Remember the

blades are welded to tub.

If using a plastic tub, replace the blades using the part

numbers referenced in the parts section of this manual.

START/STOP SWITCHES

This mixer has been equipped with a start/stop switches

for both the gasoline and electric motor mixers. These

switches should be tested every time the engine or motor

is started.

GREASE FITTINGS (ZERK)

Check the zerk fittings (Figure 20) as shown in the

Engine Oil Dipstick (Oil Level)Figure 6.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 19

maintenance section of this manual. These grease fi ttings

lubricate the handwheel,gear and yoke.

Page 20

OPERATION

STARTING THE ENGINE

The following steps outline the procedure for starting the

engine. Depending on the type of engine employed in the

mixer, the steps may vary slightly.

Move the fuel shut-off lever (Figure 7) to the ON 1.

position.

Fuel Shut-Off LeverFigure 7.

To start a cold engine, move the choke lever (Figure 2.

8) to the CLOSED position.

Turn the engine switch (Figure 10) to the ON position.4.

Engine ON/OFF SwitchFigure 10.

Located at the rear of the mixer frame is the main start/5.

stop button (Figure 11). Pull this button outward to start

the engine.

Choke LeverFigure 8.

Move the throttle lever (Figure 9) away from the slow 3.

position, about 1/3 of the way toward the fast position.

Engine Start/Stop ButtonFigure 11.

Pull the starter grip (Figure 12) lightly until you feel 6.

resistance, then pull briskly. The drum should be

rotating at this time.

Starter GripFigure 12.

Throttle LeverFigure 9.

PAGE 20 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 21

OPERATION

OPERATION

To position the tub, make sure the mixer is placed on 1.

fi rm level ground, then pull up on the dump latch

(Figure 13) and turn the hand wheel until the tub is at

the desired position. Once the tub is at the desired

position, pull down on the dump latch to lock the tub

in position.

PULL UP TO RELEASE

PULL DOWN TO LOCK

HAND

WHEEL

ROTATE TO

POSITION TUB

CAUTION

Placing the shovel all the way inside the drum will cause

the shovel to strike the blades. This condition will make

the shovel rotate, and cound cause injury to personnel.

NEVER place hands inside the mixing drum while it is

rotating (Figure 15).

Filling Mixing Drum IncorrectlyFigure 15.

Mixing Drum PositionFigure 13.

As the drum rotates, use a shovel (Figure 14) to place 2.

the cement mix inside the drum, add water as required.

Be careful to only place the tip of the shovel inside the

drum.

STOPPING THE MIXER

Push the main start/stop switch (Figure 16) inward to 1.

stop the engine.

Start/Stop Button (Stop Position)Figure 16.

Place fuel shut-off lever in the OFF position.2.

Clean drum of all debris and foreign matter.3.

Filling Mixing DrumFigure 14.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 21

Page 22

MAINTENANCE (ENGINE)

Use Table 7 as a general maintenance guideline

when servicing your engine. For more detailed engine

maintenance information, refer to the engine owner’s

manual supplied with your engine.

Engine Maintenance Schedule Table 7.

Description (3) Operation Before

Engine Oil

Air Cleaner

All Nuts and

Bolts

Spark Plug

Cooling Fins Check X

Spark Arrester Clean X

Fuel Tank Clean X

Fuel Filter Check X

Idle Speed Check/Adjust X (2)

Valve Clearance Check/Adjust X (2)

Fuel Lines Check Every 2 years (replace if necessary) (2)

Check X

Change X

Check X

Change X (1)

Re-tighten if

Necessary

Check/Clean X

Replace X

X

First Month

or 10 Hrs.

Every 3

Months or 25

Hrs.

Every 6

Months or 50

Hrs.

Every Year or

100 Hrs.

Every 2 Years

or 200 hrs.

(1) Service more frequently when used in DUSTY areas.

(2) These items should be serviced by your service dealer, unless you have the proper tools and are mechanically

profi cient. Refer to the Honda shop manual for service procedures.

(3) For commercial use, log hours of operation to determine proper maintenance intervals.

PAGE 22 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 23

MAINTENANCE (ENGINE)

MAINTENANCE

Perform the scheduled maintenance procedures as defi ned

by Table 7 and below:

DAILY

Thoroughly remove dirt and oil from the engine and

control area. Clean or replace the air cleaner elements

as necessary. Check and retighten all fasteners as

necessary. Check the gearbox for oil leaks. Repair or

replace as needed.

WEEKLY

Remove the fuel fi lter cap and clean the inside of the

fuel tank.

Remove or clean the fi lter at the bottom of the tank.

Remove and clean the spark plug (Figure 17), then adjust

the spark gap to 0.024 ~0.028 inch (0.6~0.7 mm). This unit

has electronic ignition, which requires no adjustment

DANGER

DO NOT use gasoline as a cleaning solvent because

that would create a risk of fi re or explosion.

ENGINE AIR CLEANER

Remove the air cleaner cover and foam fi lter element 1.

as shown in Figure 19.

Tap the paper fi lter element (Figure 19) several times 2.

on a hard surface to remove dirt, or blow compressed

air [not exceeding 30 psi (207 kPa, 2.1 kgf/cm2)]

through the fi lter element from the air cleaner case

side. NEVER brush off dirt. Brushing will force dirt

into the fi bers. Replace the paper fi lter element if it is

excessively dirty.

Clean foam element in warm, soapy water or 3.

nonfl ammable solvent. Rinse and dry thoroughly. Dip

the element in clean engine oil and completely squeeze

out the excess oil from the element before installing.

Spark GapFigure 17.

ENGINE OIL

Drain the engine oil when the oil is 1. warm as shown

in Figure 18.

Remove the oil drain bolt and sealing washer and allow 2.

the oil to drain into a suitable container.

Replace engine oil with recommended type oil as listed 3.

in Table 6. For engine oil capacity, see Table 2 (engine

specifi cations). DO NOT overfi ll.

Install drain bolt with sealing washer and tighten 4.

securely.

Engine Air CleanerFigure 19.

Engine Oil (Draining)Figure 18.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 23

Page 24

MAINTENANCE (MIXER)

BALL SOCKET AND CLAMP FACE

If the towing vechicle is equipped with a ball socket, 1.

smear socket periodically with multi-purpose grease.

This will keep the ball socket well lubricated.

Periodically oil 2. pivot points and clamp face surfaces

of coupler with SAE 30 WT. motor oil.

When parking or storing your mixer. Keep the coupler 3.

off the ground so dirt will not build up in the ball

socket.

GREASE FITTINGS (ZERK)

There are three grease fi ttings (Figure 20) that will require

lubrication. Lubricate these fi ttings once a week. Use

lithium base grease, grade NO. 1.

WHEEL BEARINGS

After every 3 months of operation, remove the hub dust 1.

cap and inspect the wheel bearings (Figure 21). Once

a year, or when required, disassemble the wheel hubs

remove the old grease and repack the bearings forcing

grease between rollers, cone and cage with a good

grade of high speed wheel bearing grease (NEVER

use grease heavier than 265 A.S.T.M. penetration (“No.

2.”)

GREASE

FITTING

AND CAP

Wheel Hub and BearingsFigure 21.

Fill the wheel hub (Figure 21) with grease to the inside 2.

diameter of the outer races and also fi ll the hub grease

cap. Reassemble the hub and mount the wheel. Then

tighten the adjusting nut, at the same time turn the

wheel in both directions, until there is a slight bind to

be sure all the bearing surfaces are in contact.

Then back-off the adjusting nut 1/6 to 1/4 turn or to the

nearest locking hole or suffi ciently to allow the wheel

to rotate freely within limits of .001" to .010" end play.

Lock the nut at this position. Install the cotter pin and

dust cap, and tighten all hardware.

Grease FittingsFigure 20.

MIXER CLEANING

For thorough mix and longer drum life, always wash 1.

drum out after each use.

NEVER2. pour or spray water over the engine.

PAGE 24 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 25

MAINTENANCE (MIXER)

TIRES/WHEELS/LUG NUTS

Tires and wheels are a very important and critical

components of the trailer. When specifying or replacing the

trailer wheels it is important the wheels, tires, and axle are

properly matched.

CAUTION

DO NOT attempt to repair or modify a wheel.

DO NOT install an inter-tube to correct a

leak through the rim. If the rim is cracked,

the air pressure in the inter-tube may cause

pieces of the rim to explode (break-off) with great force

and can cause serious eye or bodily injury.

TIRES WEAR/INFLATION

Tire infl ation pressure is the most important factor in tire

life. Pressure should be checked cold before operation. DO

NOT bleed air from tires when they are hot. Check infl ation

pressure weekly during use to insure the maximum tire life

and tread wear.

Table 8 (Tire Wear Troubleshooting) will help pinpoint the

causes and solutions of tire wear problems.

Tire Wear TroubleshootingTable 8.

Wear Pattern Cause Solution

Center

Wear

Edge

Wear

Side

Wear

Toe

Wear

Cupping

Flat

Spots

Over Infl ation

Under

Infl ation

Loss of

chamber or

overloading

Incorrect

toe-in

Out of

balance

Wheel lockup

and tire

skidding

Adjust pressure to

particular load per

tire manufacturer

Adjust pressure to

particular load per

tire manufacturer.

Make sure load does

not exceed axle

rating. Align wheels.

Align wheels.

Check bearing

adjustment and

balance tires.

Avoid sudden stops

when possible and

adjust brakes.

CAUTION

ALWAYS wear safety glasses when removing

or installing force fitted parts. Failure to

comply may result in serious injury.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 25

Page 26

MAINTENANCE (MIXER)

Lug Nut Torque Requirements

It is extremely important to apply and maintain proper wheel

mounting torque on the trailer. Be sure to use only the

fasteners matched to the cone angle of the wheel. Proper

procedure for attachment of the wheels is as follows:

Start all wheel lug nuts by hand.1.

Torque all lug nuts in sequence. See Figure 22. 2. DO

NOT torque the wheel lug nuts all the way down.

Tighten each lug nut in 3 separate passes as defi ned

by Table 9.

After fi rst road use, retorque all lug nuts in sequence. 3.

Check all wheel lug nuts periodically.

Tire Torque RequirementsTable 9.

Wheel Size

12" 20-25 35-40 50-65

13" 20-25 35-40 50-65

14" 20-25 50-60 90-120

15" 20-25 50-60 90-120

16" 20-25 50-60 90-120

First Pass

FT-LBS

Second Pass

FT-LBS

Third Pass

FT-LBS

Wheel Lug Nuts Tightening Figure 22.

Sequence

MIXER STORAGE

For storage of the mixer for over 30 days, the following is

recommended:

Drain the fuel tank completely, or add STA-BIL to the

fuel.

Run the engine until the fuel is completely consumed.

Completely drain used oil from the engine crankcase

and fi ll with fresh clean oil, then follow the procedures

described in the engine manual for engine storage.

Clean the entire mixer and engine compartment.

Place the mixing drum in the down position (mouth facing

downward).

Cover the mixer and place it a clean dry area, that is

protected from harsh elements.

PAGE 26 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 27

NOTES

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 27

Page 28

TROUBLESHOOTING (ENGINE)

Practically all breakdowns can be prevented by proper

handling and maintenance inspections, but in the event of

a breakdown, please take a remedial action following the

diagnosis based on the Troubleshooting (Tables 10 and 11)

Engine TroubleshootingTable 10.

Symptom Possible Problem Solution

Diffi cult to start

Ignition plug being bridge? Check ignition system.

Fuel is available but spark plug will not

ignite (power available at high tension

cable).

Fuel is available but spark plug will not

ignite (power NOT available at high

tension cable).

Fuel is available and spark plug ignites

(compression normal).

Fuel is available and spark plug ignites

(compression low).

Operation not satisfactory

Not enough power available

(compression normal, no miss-fi ring).

Not enough power available

(compression normal, miss-fi ring).

Rotational speed fl uctuates.

Recoil starter not working properly.

Carbon deposit at ignition? Clean or replace ignition.

Short circuit due to defective insulators? Replace insulators.

Improper spark gap? Set spark plug gap to the correct gap.

Short circuit at stop switch?

Ignition coil defective? Replace ignition coil.

Muffl er clogged with carbon deposits? Clean or replace muffl er.

Fuel in use inadequate (water, dust)?

Air cleaner clogged? Clean or replace air cleaner.

Defective cylinder head gasket?

Cylinder worn? Replace cylinder.

Spark plug loose? Tighten spark plug.

Air cleaner clogged?

Air in fuel line? Bleed (remove air) from fuel line.

Fuel level in carburetor fl oat chamber

improper?

Carbon deposits in cylinder? Clean or replace cylinder.

Ignition coil defective?

Ignition plug often shorts? Replace ignition wires, clean ignition.

Fuel in use inadequate (water, dust)?

Governor adjustment improper? Adjust governor to correct level.

Governor spring defective? Clean or replace ignition.

Fuel fl ow erratic? Check fuel line.

Air taken in through suction line? Check suction line.

Dust in rotating part? Clean recoil starter assembly.

Spring failure? Replace spiral spring.

information shown below and on the next page. If the problem

cannot be remedied, please leave the unit just as it is and

consult our company’s business offi ce or service plant.

Check stop switch circuit. Replace stop

switch if defective.

Flush fuel system and replace with fresh

fuel.

Tighten cylinder head bolts or replace

head gasket.

Adjust carburetor fl oat.

Flush fuel system and replace with fresh

fuel.

Flush fuel system and replace with fresh

fuel.

PAGE 28 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 29

Symptom Possible Problem Solution

Drum rotates rough.

Drum does not rotate at all.

TROUBLESHOOTING (MIXER)

Mixer TroubleshootingTable 11.

Defective ring gear?

Defective pinion gear?

Worn V-belt? Replace V-belt.

Loose pulley? Tighten or replace pulley.

Fuel?

Broken V-belt? Replace V-belt.

Defective ring or pinion gears?

Check that the ring gear and bearings

are not worn. Replace as necessary.

Check that the pinion gear and bearings

are not worn. Replace as necessary.

Check level of fuel in fuel tank. Add fuel

if necessary. Make sure fuel is being

supplied to engine. Check to ensure that

the fuel fi lter is not clogged.

Check that the gears and bearings are

not broken. Replace as necessary.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 29

Page 30

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

QTY. Column

Numbers Used — Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other

parts that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarifi ed in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

same unique symbol will be included when this item is

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarifi ed in the “Remarks” Column.

Serial Number Break — Used to list an effective serial

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specifi c Model Number Use — Indicates that the part

is used only with the specifi c model number or model

number variant listed. It can also be used to show a

part is NOT used on a specifi c model or model number

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

and certain washers and nuts.

“Not Sold Separately” — Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

for sale through Multiquip.

PAGE 30 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 31

SUGGESTED SPARE PARTS

C10SH8-PH8 CONCRETE MIXER WITH HONDA GX240U1QA2 ENGINE

1 to 3 units

Qty. P/N Description

2............EM493399 ............ V-BELT

2............29173-001 ............SWITCH, STOP

4............491010 .................. RUBBER LATCH ASSY.

1............EM903026 ............ BEARING CUP

1............EM903063 ............ BEARING CONE

2............492178 ..................BEARING, SHAFT

2............EM914288 ............ OIL SEAL

1............516592 ..................OIL SEAL

4............EM903113 ............ BEARING CONE

4............EM903012 ............ BEARING CUP

2............3469 ......................DUST CAP

3............9807956846 ..........SPARK PLUG

3............17210ZE2505 ....... AIR FILTER 8.0 HP

1............17620ZH7023 ....... CAP, FUEL

1............28462ZEW211 ...... ROPE, 8.0 HP

NOTICE

Part numbers on this Suggested Spare Parts list may

supersede/replace the part numbers shown in the

following parts lists.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 31

Page 32

NAMEPLATES AND DECALS

WARNING

CRUSH HAZARD

Keep guards and

doors in place.

Shut-off engine

before inspection

or maintenance

CRUSH AND CUT

HAZARD

Moving parts can cut

2

and crush.

SHUT OFF engine

before putting hands

in mixing drum

DCL160

1

1

3

4

WARNING

SAFETYINSTRUCTIONS

1.Read owner’s manual

before operating.

2.Keep unauthorized and

untrained people away from

machine during operation.

3.Make sure all safety devices

are in place before this

machine is started.

4.Make sure engine is turned

off and spark plug wire is

disconnected before cleaning

the machine.

5.Keep hands and fingers

away from moving objects.

6.Do not operate machine in

an enclosed area,proper

ventilation is required.

7.Never leave machine

unattended when operating.

8.Always stop engine and

allow engine to cool before

adding fuel or oil.

WARNING

Toavoid injury,

you MUST read

and understand

operator’s manual

before using this

machine.

This machine to

be operated by

qualified

personnel only.

Ask for training

as needed.

P/N35137

5

REAR VIEW

WARNING

DCL160

PUSH

TO STOP

CRUSH AND CUT

HAZARD

Moving parts can cut

and crush.

SHUT OFF engine

before putting hands

in mixing drum

ENGINE COVER

CRUSH HAZARD

Keep guards and

2

doors in place.

Shut-off engine

before inspection

or maintenance

6

1

3

7

MODEL

SERIAL NO.

PAGE 32 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 33

NAMEPLATES AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 510164 DECAL, STOW A DIVISION OF MULTIQUIP 3

2 DCL160A DECAL, CRUSH WARNING 2

3 DCL151 DECAL, WARNING TOWING 2

4 504713 DECAL, WARNING SAFETY INSTRUCTIONS 1

5 35137 DECAL, READ MANUAL 1

6 EM948630 DECAL, PUSH TO STOP 1

7 NAMEPLATE ............................................................1................CONTACT MQ PARTS DEPT.

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 33

Page 34

PLASTIC DRUM ASSY

8

5

4

11

10

1

12

4

5

13

14

18

20

25

19

21

24

22

17

8

6

9

4

23

4

3

2

5

7

7

24

26

25

27

YOKE

28

29

PAGE 34 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 35

PLASTIC DRUM ASSY

NO. PART NO. PART NAME QTY. REMARKS

1 516658 GEAR RING 1

2 412379 SCREW, CAP 3/8" 4

3 511729 SHIM 8

4 EM969013 NUT, NYLOC 30

5 510909 WASHER 19

6 510916 DRUM, PLASTIC 1

7 511089 SUPPORT BRACKET 4

8 EM963057 SCREW, CAP 3/8" X 1-1/2" 5

9 3019092 WASHER, 3/8" FLAT 2

10 510884 BLADE, PLASTIC DRUM 3

11 515453 SCREW 3

12 515304 PLATE PROTECTION 2

13 515305 PLATE PROTECTION 4

14 507538C BUSHING 8

17 516424 CAP, PLASTIC DRUM 1

18 516618 O-RING 1

19 516678C NUT, KING PIN 1

20 EM924006 PIN, COTTER 1/8 X 3/4 1

21 517134 WASHER 1

22 516504 PIN, KING 1

23 516706 SUPPORT SPIDER 1

24 EM903026 BEARING CUP 2

25 EM903063 BEARING CONE 2

26 503116 BOLT 3/8" NC X 3-3/8" 1

27 516592 OIL SEAL 1

28 492491 SCREW, SET 1

29 516614 NUT 1

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 35

Page 36

STEEL DRUM ASSY

7

8

9

10

13

11

14

12

13

14

1

3

2

6

4

5

1

15

YOKE

17

16

NOTES

MIXING BLADES ARE PART OF

DRUM ASSEMBLY. TO RE-ORDER

1

NEW BLADES A COMPLETE MIXING

DRUM MUST BE PURCHASED.

PAGE 36 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 37

STEEL DRUM ASSY

NO. PART NO. PART NAME QTY. REMARKS

1 516658 GEAR RING 1

2 EM963057 SCREW, CAP 3/8" X 1-1/2" 4

3 511730 SHIM 8

4 492542 NUT 4

5 0166 A WASHER, LOCK 3/8" 4

6 516575 DRUM, STEEL 1

7 516511 CAP, DRUM 1

8 516618 O-RING 1

9 516678 NUT, KING PIN 1

10 EM924006 PIN, COTTER 1/8" X 3/4" 1

11 504447 WASHER 1

12 516495 PIN, KING 1

13 EM903063 BEARING CONE 2

14 EM903026 BEARING CUP 2

15 516592 OIL SEAL 1

16 492491 SCREW, SET 1

17 516614 NUT 1

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 37

Page 38

YOKE ASSY.

1

1

10

9

11

2

3

8

8

4

PART OF

1

5

PART OF

YOKE

1

6

7

FRAME

1

12

NOTES

SEE PLASTIC OR STEEL

DRUM ASSY.

PAGE 38 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 39

YOKE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 491008 FITTING PROTECTOR 1

2 EM916001 GREASE FITTING 1

3 500214 KEY SQUARE 1/4" X 1/4" X 1-1/2" 1

4 503915 PINION GEAR 1

5 492468 SCREW, SET 5/16" 1

6 516654 SUPPORT YOKE 1

7 513991 PINION, JACKSHAFT 1

8 492178 BEARING, SHAFT 2

9 EM963692 SCREW, CAP HHCS, 1/2-13 X 1 2

10 490970 SNAP RING 1

11 514036 HOUSING, JACKSHAFT 1

12 492584 NUT, LOCK 1/2" 2

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 39

Page 40

FRAME ASSY.

7

6

8

5

4

3

2

14

1

7

26

5

9

10

12

11

13

19

17

15

8

24

25

16

A

18

OPTIONAL TOW BARS

A

22

21

CHAIN

20

&

LINK

KIT

23

PAGE 40 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 41

FRAME ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 514245 GUARD, GEAR WHEEL 1

2 3103160 WASHER 4

3 492278 BOLT HEAD ROUND 1/4 X 3/8 4

4 516668 GEAR, DUMP 1

5 492584 NUT, LOCK 1/2" 3

6 490895 DUMP LATCH 1

7 491008 FITTING PROTECTOR 2

8 EM916001 GREASE FITTING 2

9 492329 BOLT, 1/2" NC X 1-3/4" G2 1

10 492259 BOLT, 5/16" NC X 3/4" 3

11 EM923343 WASHER, LOCK 5/16" 3

12 EM963102 BOLT, HHCS 1/2" NC X 1-1/4" 2

13 516534 HANDWHEEL SHAFT 1

14 501808 HANDWHEEL 1

15 490961 RETAINING RING 1

16 10176 NUT, NYLOC 1/2-13 1

17 EM124 BOLT, HHCS 1/2 X 4 G5 1

18% 516581 CLEVIS SAFETY HOOK 1

19 516560 FRAME 1

20 13363KIT CHAIN AND LINK KIT ........................................1................INCLUDES ITEMS W/%

21 HBC-1 BALL HITCH 1

22 HLC-1 LOOP HITCH 1

23 HPC-1 PIN HITCH 1

24% SAFETY CHAIN 2

25% 01004 CONNECTOR LINK 1

26 504447 WASHER 1

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 41

Page 42

FRAME

HUB/TIRE ASSY.

4

5

6

7

1

6

5

11

10

9

12

13

8

NOTES:

COMPLETE HUB ASSEMBLY INCLUDES

1

ITEMS WITHIN DASHED LINES AND

ITEMS 13 AND 14.

PAGE 42 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

14

Page 43

HUB/TIRE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

4% EM914288 OIL SEAL 2

5% EM903113 BEARING CONE 4

6% EM903012 BEARING CUP 4

7 EM941306 HUB ASSY, 4-BOLT 2 INCLUDES ITEMS W/%

8% EM511159 WASHER, FLAT, .087" THICKNESS 2

9% EM501299 WASHER, FLAT, .135" THICKNESS A/R

10 491688 COTTER PIN, 1/8" X 1-1/2" 2

11 8164 NUT, SLOTTED HEX JAM 1"-20 2

12 516476 TIRE AND RIM 2

13 8115 LUG NUT 8

14 3469 DUST CAP 2

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 43

Page 44

CABINET ASSY.

1

4

FRAME

10

11

5

8

9

3

6

2

7

ENGINE

BASE

PLATE

PAGE 44 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 45

CABINET ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 514052 CABINET 1

2 491010 RUBBER LATCH ASSY. 2

3 1307 SCREW, PHP 8-32 X 1/2 PLATED 6

4 492312 BOLT, 3/8" NC X 1-1/4" G2 2

5 3019092 WASHER, FLAT 3/8" 2

6 501028 SPACER 2

7 EM969013 NUT, NYLOC 3/8" 2

8 492357 BOLT, 1/4" NC X 1" G5 4

9 EM923057 WASHER, 1/4" 4

10 2101402 WASHER, LOCK 1/4" 4

11 2101428 NUT, 1/4-20 4

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 45

Page 46

ENGINE ASSY.

15

PART OF

CABINET

16

17

10

1

14

2

7

8

3

4

5

14

10

11

6

13

DRIVE

PINION

SHAFT

12

9

FRAME

PAGE 46 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 47

ENGINE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 GX240U1QA2 ENGINE, HONDA 8.0 HP 1

2 492378 BOLT, 3/8" NC X 1-3/4" G5 4

3 3019092 WASHER, FLAT 3/8" 4

4 0166 A WASHER, LOCK 3/8" 4

5 1456 NUT, HEX 3/8 - 16 4

6 516648 ENGINE BASE PLATE 1

7 EM963692 BOLT, HHCS 1/2 - 13 X 1-1/2 4

8 EM621 WASHER, 1/2" 4

9 492584 NUT, LOCK 1/2" 4

10 492468 SCREW, SET 5/16" 2

11 504075 PULLEY, SMALL 1

12 EM493399 V-BELT 1

13 514060 PULLEY, LARGE 1

14 500214 KEY, SQUARE 1/4 X 1/4 X 1-1/2 2

15 29174-001 BUTTON, STOP 1

16 29173-001 SWITCH, STOP 1

17 510573C HARNESS, STOP SWITCH 1

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 47

Page 48

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for unit sales are 2% 15

days net 30 days from date of invoice unless

otherwise specifi cally stated on our invoice.

Parts invoices have terms of net 10 days.

Minimum parts billing is $15.00 net.

Applicable discounts will be computed on

merchandise value only. Late charges will be

assessed at prevailing rates. Cash discounts

cannot be taken on current billings if any

previously billed amounts are past due.

FREIGHT POLICY

Freight policy is established to offer customers

every advantage possible. Due to bulk freight

ratings on some equipment and other shipping

considerations, freight policies differ by

equipment type. Actual back freight may be

charged for shipments originating from other

than specifi ed FOB warehouses. See Freight

Policy for details.

All STOW domestic sales are FOB nearest

available designated MQ/STOW warehouse.

Export orders are ex-works factory located in

Carson, CA or Boise, ID.

Additions to orders already shipped cannot be

accepted for freight minimums.

Should STOW elect to make partial shipments

of an order originally complying with the

“freight allowed” requirements, transportation

charges will be absorbed by STOW on any

subsequent shipment applying to that order.

All other orders will be shipped collect or

prepaid with charges added to the invoice.

STOW’s responsibility ceases when a signed

manifest has been obtained from the carrier,

and any claim for shortage or damage must

be settled between the consignee and the

carrier.

Parts: FOB Carson, California or Boise, Idaho.

See Freight Policy for details and additional

discounts.

DROP SHIPMENTS

STOW reserves the right to refuse Drop

Shipments outside the normal service area

of the purchasing dealer.

FIELD WAREHOUSES

Field Warehouses are currently located in

California, Georgia, Idaho, Iowa, and New

Jersey

SPECIAL EXPEDITING SERVICE

The higher of a $35.00 surcharge or actual

costs will be added to the invoice for special

handling, including bus shipments, or in cases

where STOW personnel must personally

deliver the equipment or parts to the carrier.

RETURNED GOODS POLICY

Return shipments may be accepted and credit

allowed, subject to the following provisions.

A Returned Material Authorization (RMA) 1.

must be approved by STOW prior to

shipment. Approvals for returned goods

must be with just cause and are at the

sole discretion of STOW. A copy of the

Authorization must accompany the

shipment to the designated Warehouse.

Parts being returned must be listed as 2.

currently supplied on the current parts

list.

Parts must be in new and resalable 3.

condition in the original package, with

part numbers clearly marked.

Units and accessories must be current 4.

models in the latest price list and in new

and resalable condition.

Special order items are not returnable 5.

for credit.

Credit on returned parts and units will be

6.

issued at actual dealer net price at time of

purchase less 15% restocking charge.

All returned shipments are to be made 7.

to the STOW designated receiving point,

freight prepaid at the sender’s expense.

The sender will be notifi ed of any material

received that does not meet the above

provisions. Such material will be held for 30

days from notifi cation pending instructions.

If a reply is not received within 30 days, the

material will be returned to the sender at his

expense with no credit issued.

PRICING, REBATES AND SPECIFICATIONS

Every effort will be made to provide adequate

notice of changes; however, prices and

equipment specifications are subject to

change without notice.

Price changes are effective on a specifi c date

and all orders received on or after that date

will be billed at the revised price.

Rebates for price reductions and added

charges for price increases will not be made

for stock in dealer inventory at the time of a

price change.

STOW reserves the right to quote and sell

direct to Government agencies and to Original

Equipment Manufacturer accounts who use

our products as integral parts of their own

products.

LIMITATION OF SELLER’S LIABILITY

STOW shall not be liable hereunder for

damages in excess of the purchase price

of the item with respect to which damages

are claimed and in no event shall STOW be

liable for loss of profi t or good will or for any

other special, consequential or incidental

damages.

LIMITATION OF WARRANTIES

There are no warranties, express or implied,

made by STOW. hereunder on Products

manufactured or distributed by it except the

warranty against defects in material and

workmanship on new Products to the original

purchaser, as set forth in the STOW New

Product Limited Warranty.

Effective: July 15, 2003

Terms And Conditions Of Sale

STOW Construction Equipment

STOW CONSTRUCTION EQUIPMENT

POST OFFICE BOX 6254

CARSON, CALIFORNIA 90749

310-661-4242 • 877-BUY-STOW

FAX: 310-604-9237

E-MAIL: stow@stowmfg.com

www.stowmfg.com

Atlanta • Boise • Newark • Quebec, Canada

Manchester, UK • Rio de Janeiro, BR • Puebla, MX

PAGE 48 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

Page 49

NOTES

C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09) — PAGE 49

Page 50

OPERATION AND PARTS MANUAL

©

HERE’S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 FAX: 800-672-7877

310-537-3700 FAX: 310-637-3284

SERVICE DEPARTMENT

800-478-1244 FAX: 310-537-4259

310-537-3700

TECHNICAL ASSISTANCE

800-478-1244 FAX: 310-631-5032

WARRANTY DEPARTMENT

800-421-1244, EXT. 279 FAX: 310-537-1173

310-537-3700, EXT. 279

SALES DEPARTMENT

310-661-4242 FAX: 310-604-9237

877-289-7869 (877-BUY-STOW)

COPYRIGHT 2009, MULTIQUIP INC.

Multiquip Inc, and the STOW logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the

property of their respective owners and used with permission.

This manual must accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

The information and specifi cations included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifi cations, design or the information published

in this publication at any time without notice and without incurring any obligations.

Your Local Dealer is:

Atlanta • Boise • Newark • Quebec, Canada

Manchester, UK • Rio de Janeiro, BR • Puebla, MX

MQ STOW CONSTRUCTION EQUIPMENT

A DIVISION OF MULTIQUIP INC.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 888-252-MQ STOW [888-2527869]

FAX: 310-537-1986 • FAX: 800-556-1986

E-MAIL: MQ STOW@multiquip.com • WWW:

stowmfg.com

Loading...

Loading...