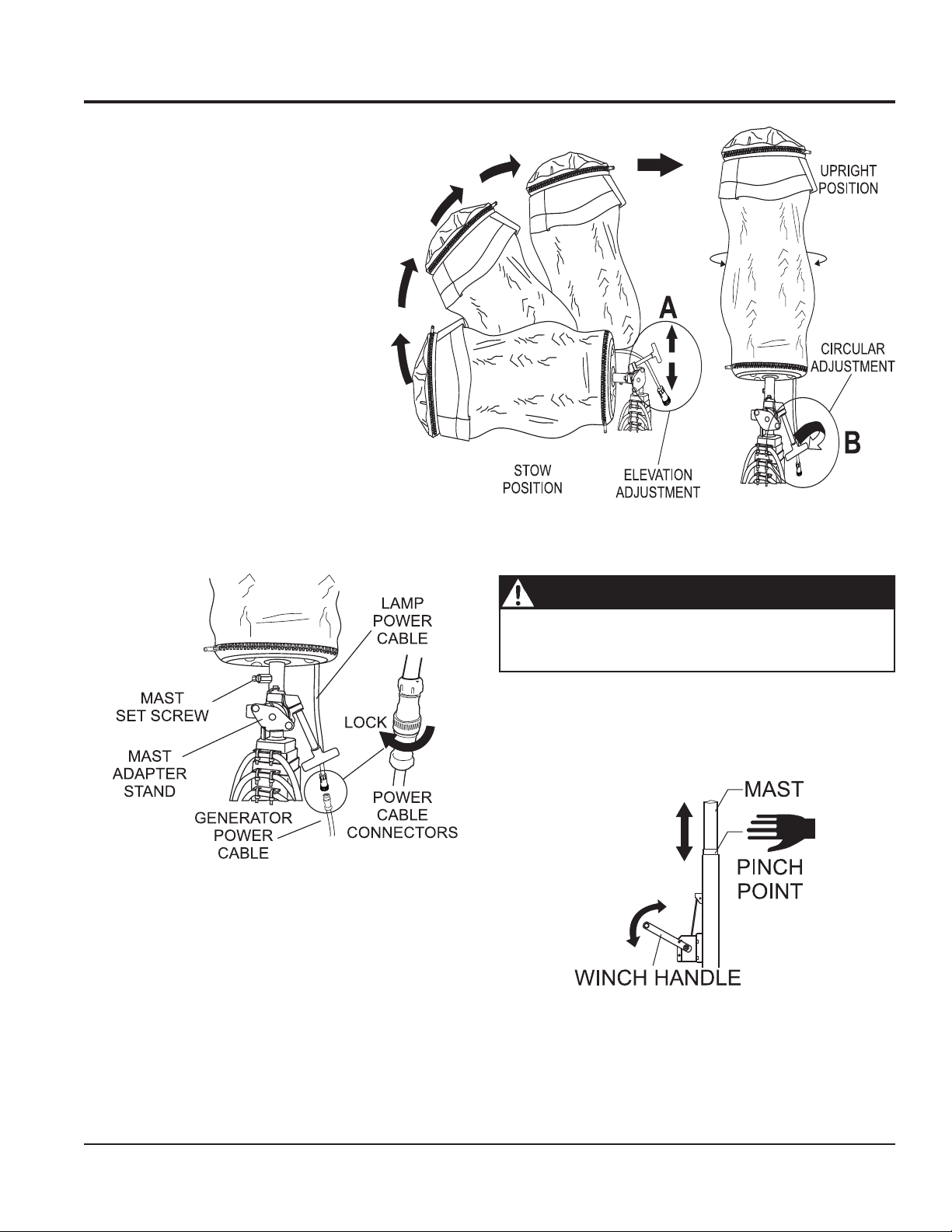

Page 1

OPERATION AND PARTS MANUAL

GloBug

MODEL GB113BC

LIGHTING SYSTEM

(FOR USE WITH MQ SERIES GENERATORS)

Revision #4 (01/06/09)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

Page 2

PROPOSITION 65 WARNING

PAGE 2 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 3

NOTES

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 3

Page 4

TABLE OF CONTENTS

MQ GLOBUG LIGHTING

SYSTEM

Proposition 65 Warning ............................................. 2

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

Safety Information .................................................. 6-9

Specifications .......................................................... 10

Dimensions ............................................................. 11

Floodlight Footcandle Plots (BAL-120 Oval) .......... 12

Floodlight Footcandle Plots (BAL-120R Ref.) ......... 13

Floodlight Footcandle Plots (BAL-115D Drum) ...... 14

General Information ................................................ 15

Components....................................................... 16-17

Setup .................................................................. 18-19

Setup/Operation ...................................................... 20

Shutdown ................................................................ 22

Maintenance ...................................................... 22-31

Troubleshooting (Lamps) ........................................ 32

Troubleshooting (Mast) ........................................... 33

Explanation Of Codes In Remarks Column ............ 34

Suggested Spare Parts ........................................... 35

COMPONENT DRAWINGS

Nameplate and Decals Assembly .....................36-37

T-Handle Assembly ............................................ 38-39

Steering Assembly ............................................. 40-41

Outrigger Assembly ........................................... 42-43

Mast Adapter Assembly .....................................44-45

Main Mast Assembly .......................................... 46-47

Winch Assembly ................................................. 48-49

Mast Section Assembly ...................................... 50-51

Baseplate Cover Assembly ................................ 52-53

Ballast Box Assembly ......................................... 54-55

Fan Blower/Lamp Base Assembly ..................... 56-57

Balloon/Lamp Guard Assembly ......................... 58-59

Terms and Conditions Of Sale — Parts .................. 60

NOTICE

Specification and part number are subject to

change without notice.

PAGE 4 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 5

r

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

Order via Fax

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

(Dealers Only)

to log in and save!

(Dealers Only)

:

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact you

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

:

Domestic (US) Dealers Call:

1-800-427-1244

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Tr uck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 5

Page 6

SAFETY INFORMATION

Do not operate or service the equipment before reading

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifically address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

GENERAL SAFETY

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the influence of

drugs or alcohol.

NOTICE

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

Potential hazards associated with the operation of this

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

This equipment should only be operated by trained and

qualified personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifications. Unauthorized

equipment modification will void all warranties.

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fire extinguisher.

ALWAYS know the location of the nearest

first aid kit.

ALWAYS know the location of the nearest phone or keep

a phone on the job site. Also, know the phone numbers

of the nearest ambulance, doctor and fire department.

This information will be invaluable in the case of an

emergency.

PAGE 6 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 7

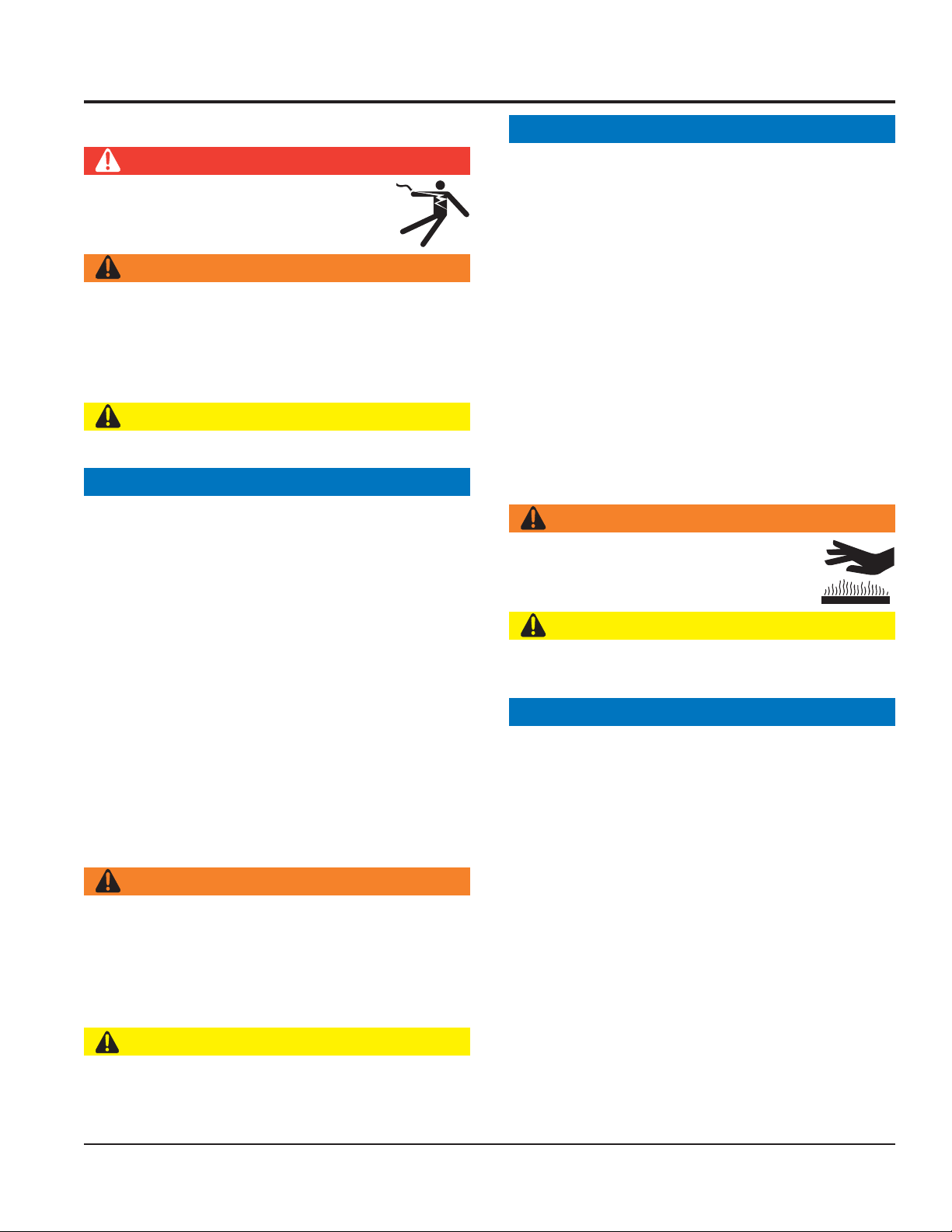

SAFETY INFORMATION

LIGHTING SYSTEM SAFETY

DANGER

NEVER use lighting system in rain, snow or

areas of high humidity that could generate

electrical storms.

WARNING

NEVER disconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of

these devices will void all warranties.

CAUTION

NEVER attempt service on a running machine.

NOTICE

To prevent the lighting system from overturning, NEVER

use in winds that exceed 22mph (10 m/s).

The lighting system should only be used in temperatures

between 23° to 104°F (-5° to 40° C). Failure to comply

with these operating parameters could cause the lamp

to malfunction and shorten the ballast life.

NOTICE

NEVER leave any grease or oil residue on lamp surface

when replacing or removing lamp. This can create hot

spots, reducing the service life of the lamp.

ALWAYS make sure lamp surface is clean and dry.

ALWAYS replace with MQ recommended type lamp. See

parts section of this manual.

If applicable, ALWAYS make sure the lamp guard is

installed correctly. NEVER deform the lamp guard.

NEVER unplug the lamp’s AC power cable during

operation.

ALWAYS have a trained technician to install and

remove lamp or replace any damaged fixture wiring.

BALLOON SAFETY

WARNING

To prevent serious burns, NEVER touch

or unzip the balloon envelope when the

lamp is on.

CAUTION

ALWAYS keep the lighting system in proper running

condition.

Fix damage to lighting system and replace any broken

parts immediately.

ALWAYS store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

LAMP SAFETY

WARNING

NEVER attempt to replace lamp with the power on.

Always unplug the power cord from the generator or

power source when changing the lamp.

ALWAYS allow a sufficient amount of time for the lamp to cool

before changing. The possibility exists of severe burns.

CAUTION

NEVER use force when installing the lamp. Excessive force

could cause the lamp to break, causing bodily harm.

ALWAYS keep the balloon away from sharp objects and

excessive amounts of heat.

NOTICE

To prevent balloon deformation, NEVER use lighting

system in strong winds.

DO NOT place the balloon inside its protective cover

until the lamp has had a sufficient amount of time to cool

down. This will prevent the balloon’s nylon cover from

being burned (touching the lamp surface).

ALWAYS place the balloon inside its protective cover

after each use. This will prolong the life of the balloon

material, keeping it protected from harsh environmental

elements.

Replace balloon immediately if damaged. A damaged

balloon will not inflate properly, and may become more

damaged by touching the hot lamp surface.

DO NOT use excessive force when zipping and unzipping

the balloon. Be gentle with the zipper mechanism. If the

zipper is broken, the balloon will become unusable.

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 7

Page 8

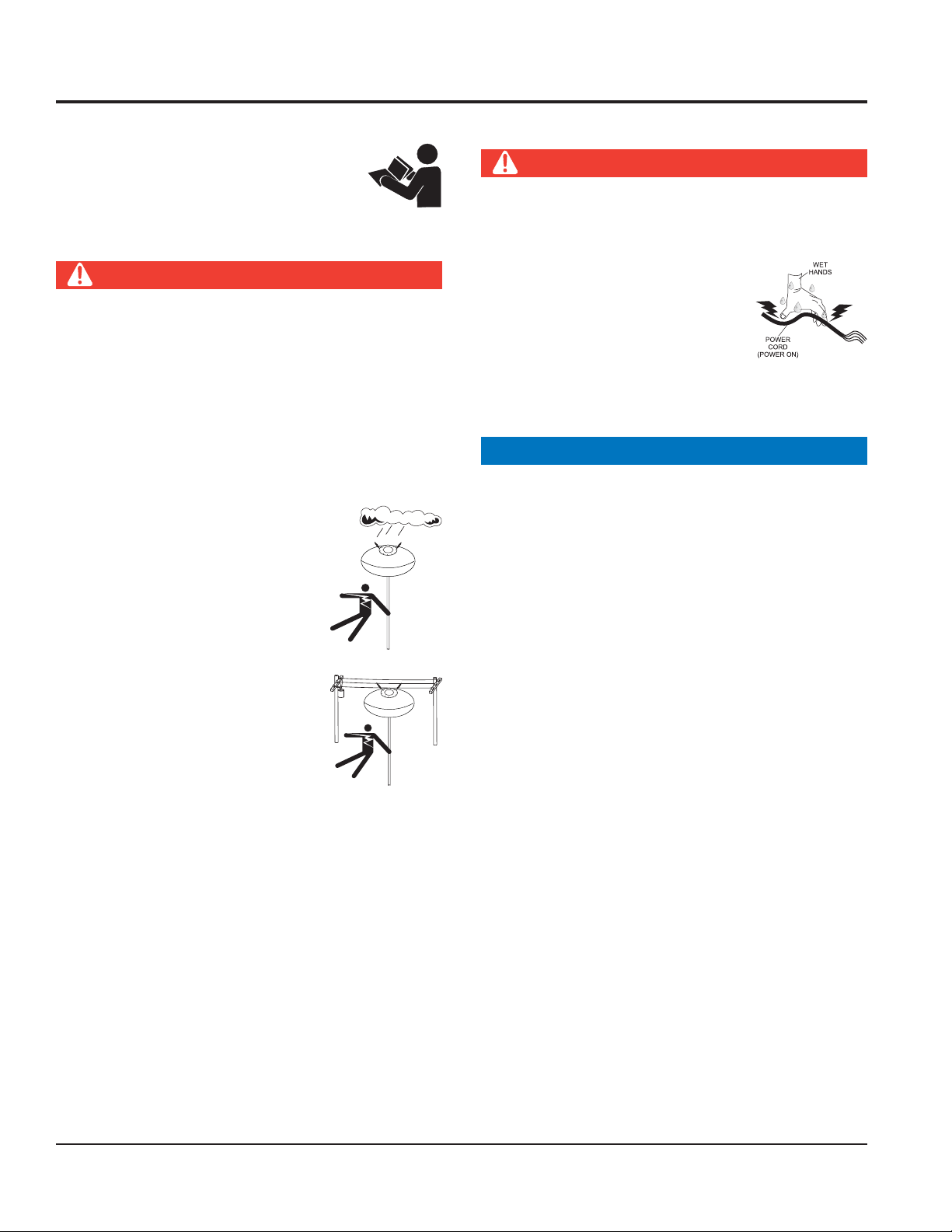

SAFETY INFORMATION

GENERATOR SAFETY

If using a generator to power lighting system,

refer to applicable generator manual safety

information section.

ELECTRICAL SAFETY

DANGER

Lighting system is equipped with a ground pin on the

power plug. For your protection, ALWAYS complete the

grounding path. NEVER insert the AC power plug into a

2-prong receptacle to operate lighting system.

When applying power to the lighting system, ALWAYS

connect the AC power plug to a 3-prong receptacle that

is grounded. The possibility exists of electrical shock,

electrocution and even death if the lighting system is

not grounded.

NEVER operate lighting system or

handle any electrical equipment while

standing in water, while barefoot,

while hands are wet or in the rain. A

dangerous electrical shock could

occur, causing severe bodily harm

or even death.

Power Cord/Cable Safety

DANGER

NEVER let power cords or cables lay in water.

NEVER use damaged or worn cables or cords. Inspect

for cuts in the insulation

NEVER grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

Make sure power cables are securely connected.

Incorrect connections may cause electrical shock and

damage to the lighting system.

NOTICE

ALWAYS make certain that proper power or extension

cord has been selected for the job. See Cable Selection

Chart in this manual.

ALWAYS make sure the area above

the lighting system is open and clear

of overhead power lines and other

obstructions. Contact with overhead

power lines or other obstructions

could result in equipment damage,

electrical shock, electrocution and

even death.

PAGE 8 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 9

SAFETY INFORMATION

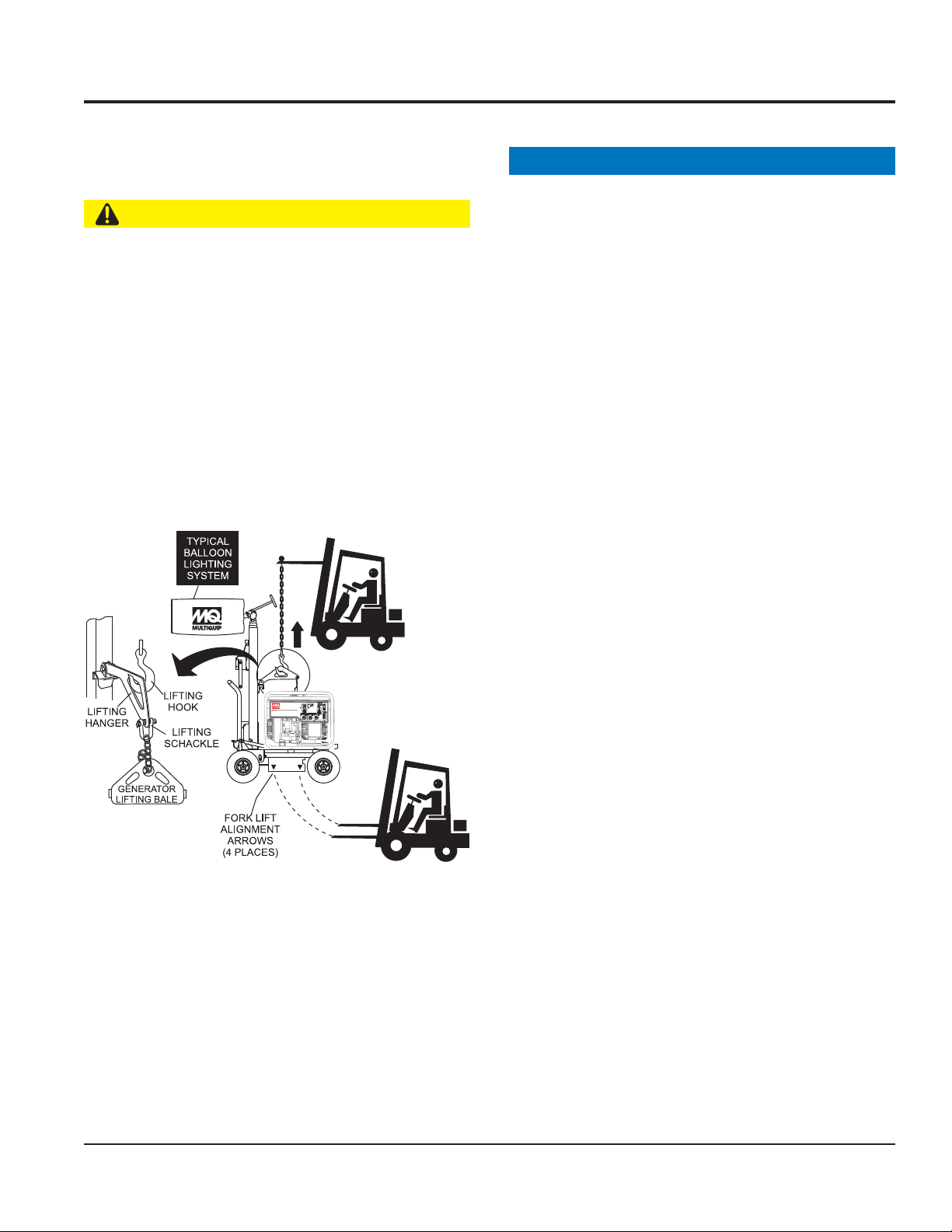

LOADING AND UNLOADING

If lighting system is equipped with a transport lifting hook,

refer to the following safety information.

CAUTION

Before lifting, make sure that lighting system parts are

not damaged and screws are not loosened or lost.

ALWAYS make sure crane or lifting device has been

properly secured to lifting hook of the equipment.

NEVER lift the equipment while lighting system is

running.

Make sure the mast is completely lowered before lifting

the lighting system.

Use adequate lifting cable (wire or rope) of sufficient

strength.

Use one point suspension hook and lift straight upwards.

TRANSPORTING SAFETY

NOTICE

When transporting the lighting system, if applicable,

always place in stow position and place mast in its

carrying case.

ALWAYS remove balloon/lamp assembly from the mast

when transporting lighting system. This will prevent

damage to the bulb due to vibration.

NEVER leave the balloon/lamp exposed during transport.

Exposure to excess wind or rain could damage the

balloon’s nylon cover.

ALWAYS place balloon inside its protective cover during

transport. Be sure the cover is secured tightly around the

balloon/lamp assembly.

Never allow any person or animal to stand underneath the

equipment while lifting.

DO NOT lift machine to unnecessary heights.

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 9

Page 10

guBolG

ledoMCB311BG

egatloVtupnICAV021

ycneuqerFesahP-elgniSzH06

tnerruC.xaMspmA6.9

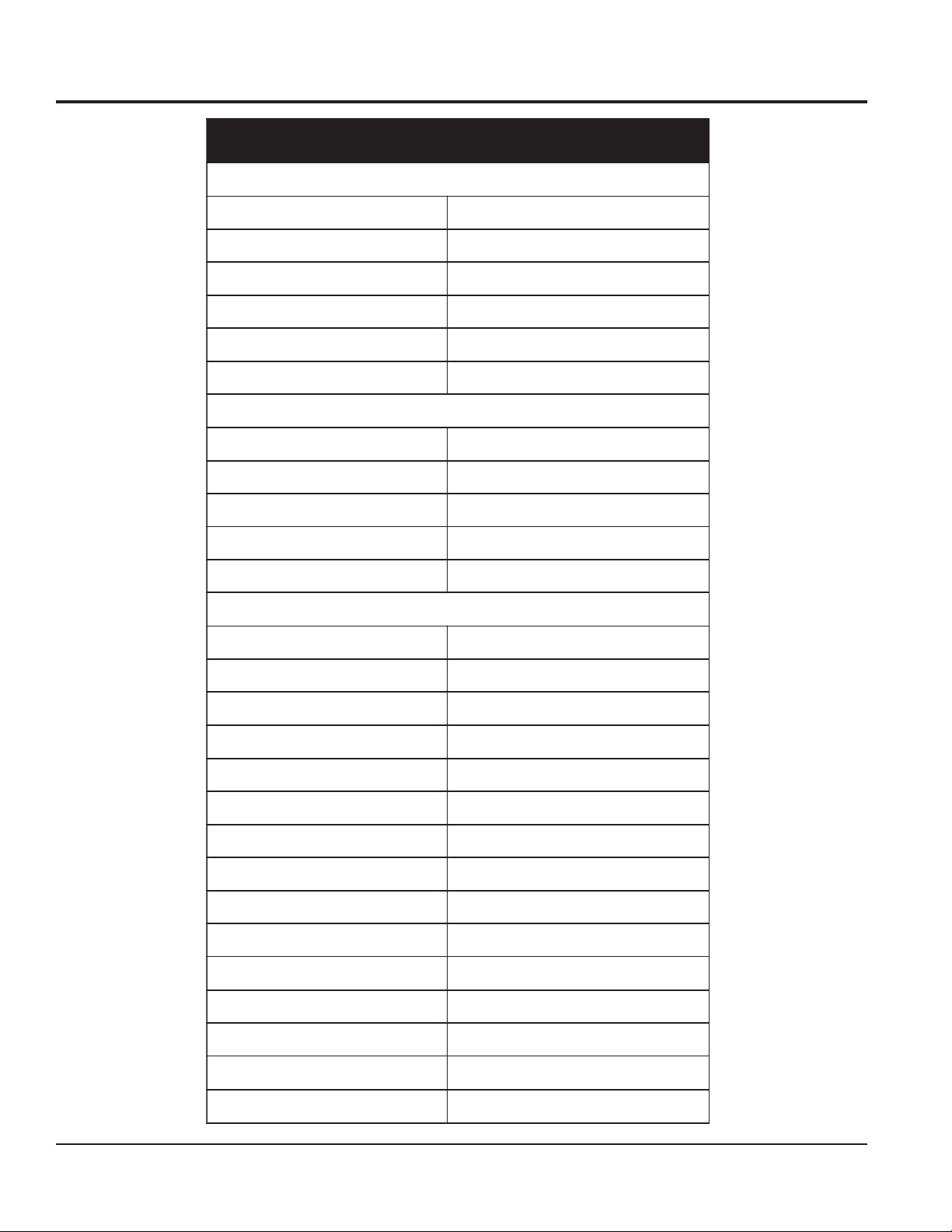

SPECIFICATIONS

snoitacificepS.1elbaT

rotareneGhtiwytilibatSdniW)

)rotarenegssel(thgieW)gk521(.sbl672

pmaL

epyTpmaLedadilaHlateMttaW0001)1(

snemuL000,211

egarevoCthgiL)sretem27.54(.tf051

meTecafruS.xaM)C°412(F°2.714

rotoMnaF

tnerruC.xaMspmA063.

erusserP)APk6.512(ISP62.

noollaB

retemaiD)sretem2.1(.TF9.3

)°063(

)lanidutignoL(erutarepmeTecafruS.xaM)C°742(F°6.674

)lasrevsnarT(erutarep

rotoMnaFnoollaBzH06,CAV511

13

hpk64.08(hpm56

lairetaMnolyNtnatsiseRtaeH

erutarepmeTgnitsiseRtaeH)C°081~061(F°653~023

erutarepmeTgnitleM)C°062(F°005

noollaBfoerutarepmeTlanretnIegarevA)C°25(F°621

ecnatsiseRretaWHmm005,1

tsaM

segatSforebmuN))3(CB311BG

thgieHmumixaM)sretem44.4(.TF85.41

snoisnemiD

rotareneG

0

2

2elbaT,1erugiFeeS

laun

aMrotareneGdeificepSeeS

PAGE 10 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 11

DIMENSIONS

D

A

B

F

SIDE VIEW

TOP VIEW

C

STOW POSITION

REAR VIEW

E

I

G

H

J

Figure 1. Dimensions

SNOISNEMID.2ELBAT

ecnerefeR

retteL

AesaBleehW).mm008(.

B)noitisoPdewotStsaM(thgieH).mm047,1(.tf7.5G )leehWr

CthgieHeldnaH).mm878(.tf88.2H )reggirtuOotleehWtnorF(htgneL).mm055,1(.tf80

DhtgneLgaBnoollaB).mm686(.tf52.2I retemaiDnoollaB).mm341,1(.tf57.3

EmroftalPotkooHtfiL).mm955(.tf38.1J )deyolpe

noitpircseD).mm(.tfnoisnemiD

tf26.2F )noitisoPdeyolpeDtsaM(thgieH.xaM).mm544,4(.tf85.41

ecnerefeR

retteL

noitpircseD).mm(.tfnoisnemiD

aeRottnorF(htgneL).mm040,1(.tf14.3

.5

DsreggirtuO(htdiW).mm006,1(.tf42.5

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 11

Page 12

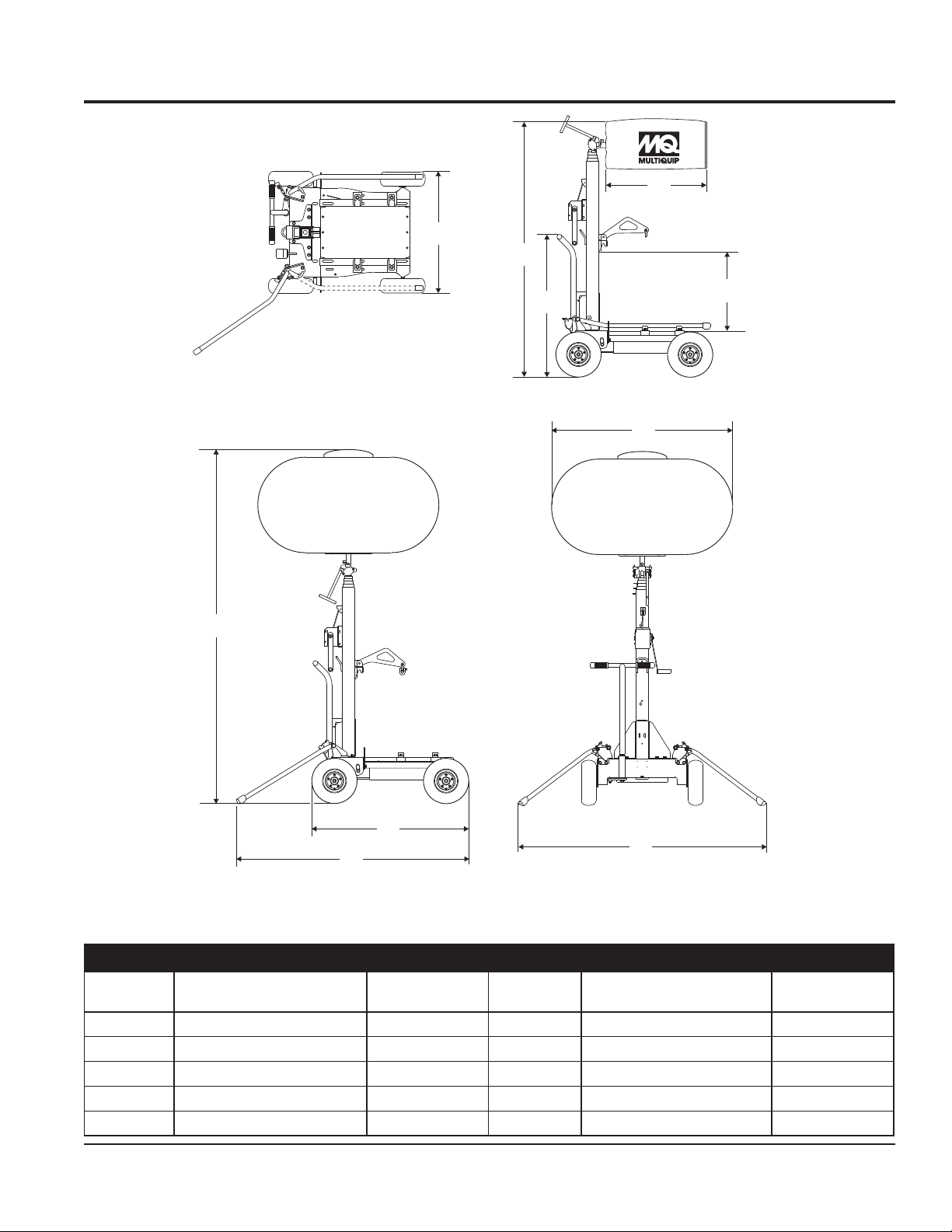

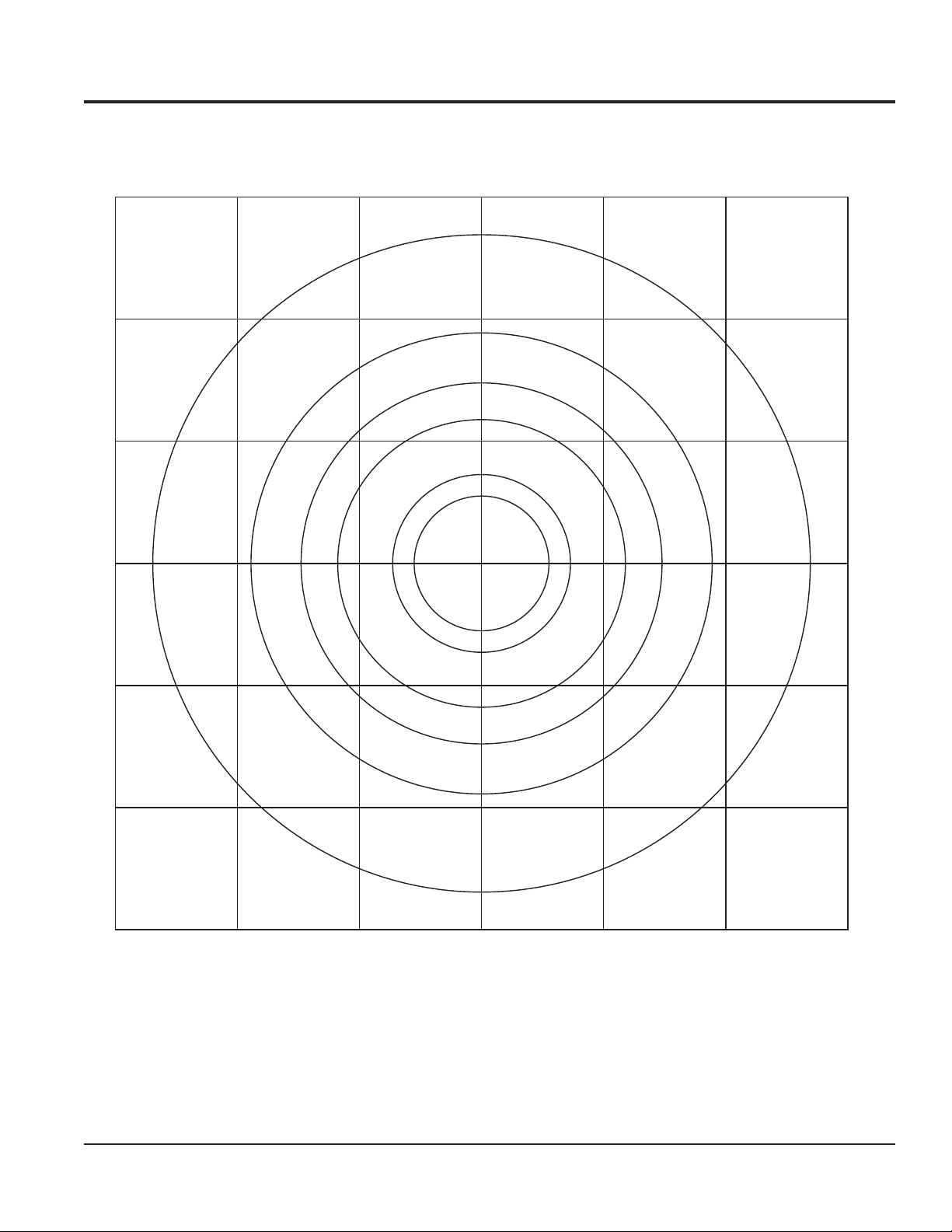

Based on 360°glare-free coverage.

.25

.5

FLOODLIGHT FOOTCANDLE PLOT

1

2

5

10

VALUES LISTED AS FOOTCANDLES

Figure 2. Floodlight Footcandle Plot (Bal120- Oval Shaped)

PAGE 12 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

SCALE: 1 GRID = 50 FT. (15.24 METERS)

Page 13

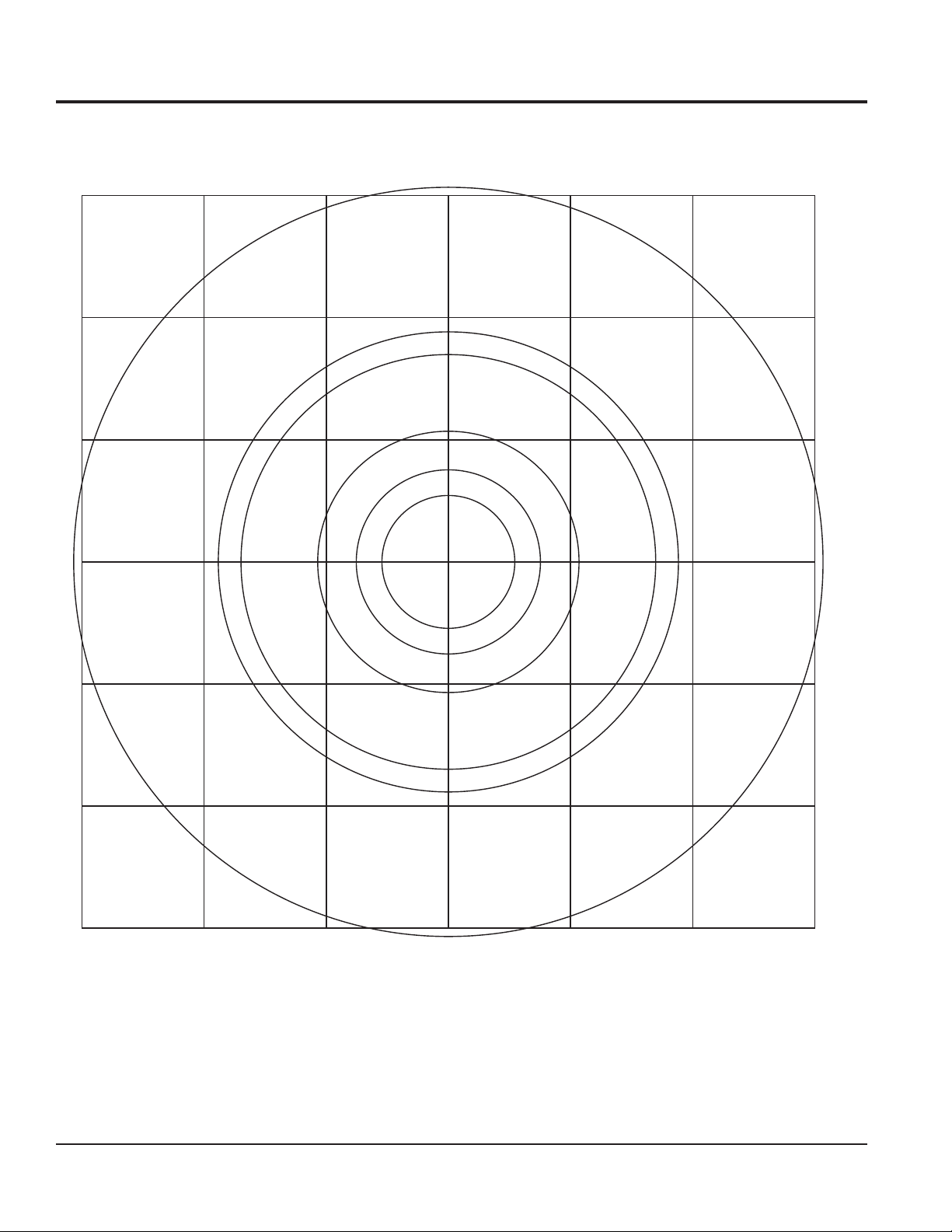

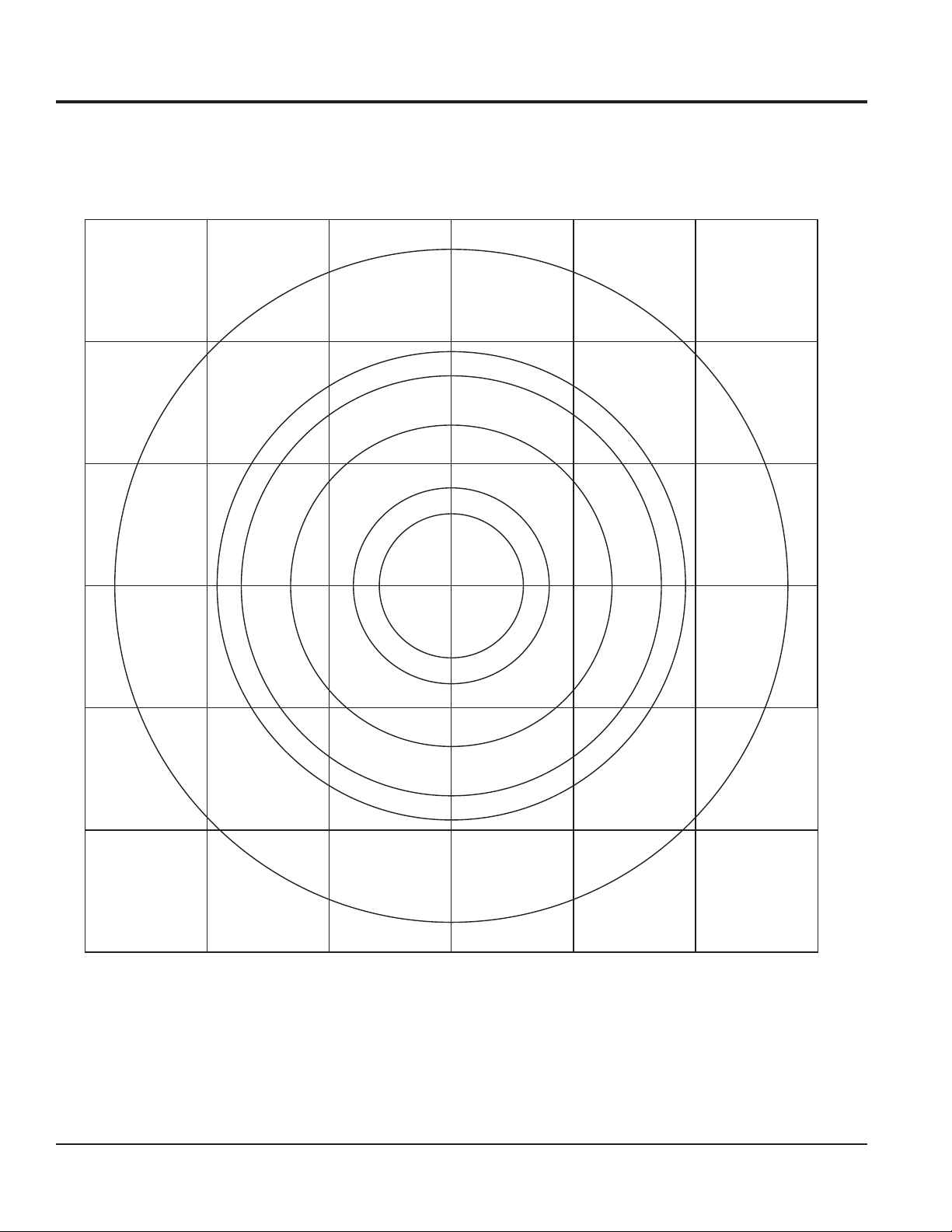

Based on 360°glare-free coverage.

.25

.5

FLOODLIGHT FOOTCANDLE PLOT

1

2

5

10

VALUES LISTED AS FOOTCANDLES

Figure 3. Floodlight Footcandle Plot (BAL120R-Reflector-Shaped Balloon)

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 13

SCALE: 1 GRID = 50 FT. (15.24 METERS)

Page 14

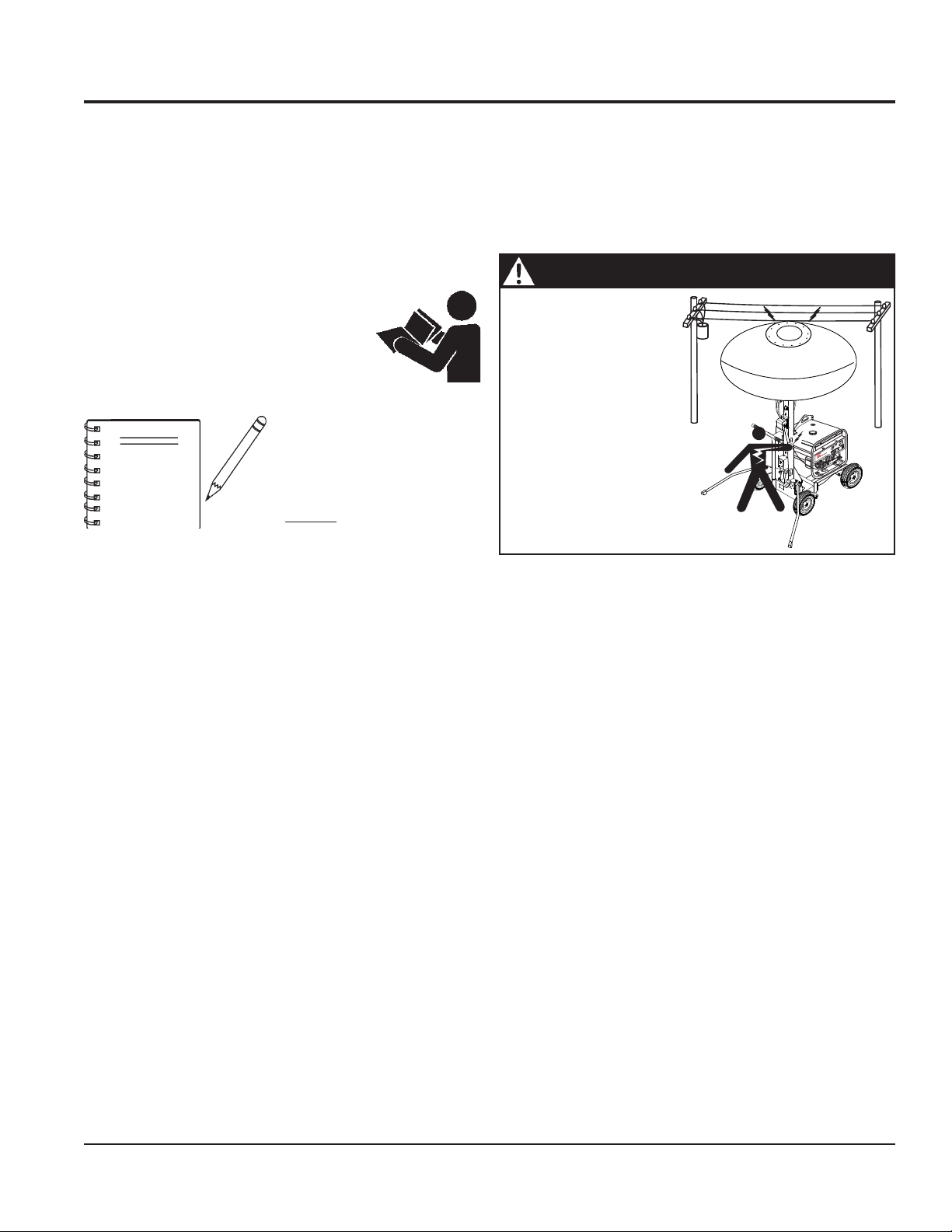

Based on 360°glare-free coverage.

.25

.5

FLOODLIGHT FOOTCANDLE PLOT

1

2

5

10

VALUES LISTED AS FOOTCANDLES

Figure 4. Floodlight Footcandle Plot (BAL-115D-Drum Shaped Balloon)

PAGE 14 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

SCALE: 1 GRID = 50 FT. (15.24 METERS)

Page 15

A

C

C

IR

CUIT

BREAKER

120

/240

V

30A

V

OFF

21

A

GENERAL INFORMATION

The Multiquip GloBug Lighting System is a general purpose

floodlight tower intended for emergency and remote lighting

conditions. The GloBug can be powered by a variety of

Multiquip's series generators. Power requirements for running

the GloBug are 120 VAC, 60 Hz @ 9.6 amps. The GloBug

The lighting system can be raised vertically in excess of 14.58

feet (4.44 meters) by means of a manual winch. The tower

tensioning system is designed to provide the necessary tension

to safely control the pivot of the tower. Outriggers must always be

deployed prior to raising the mast.

can be powered by any MQ portable generator with an output

of 2.9 kW or greater.

DANGER - GloBug Overhead Obstructions

Please read carefully the specified

generator manual that will accompany your

GloBug lighting system. This manual will

explain how to operate and maintain the

generator.

All information related to the

generator will be referenced in a

NOTE

separate (supplied) "Operation

and Parts Manual". Operation

and maintenance of the generator

will not

be referenced in this

manual.

ALWAYS make sure the

area above GloBug is

open and clear of

overhead power lines

and other obstructions.

The tower extends in

excess of 14.58 ft. (4.44

meters). Contact with

overhead powerlines or

other obstructions could

result in equipment

damage,

The lighting system of Multiquip's GloBug Lighting System

is comprised of one "Metal Halide" 1000 watt lamp. This

lamp has an output of 112,000 lumens. Typical lighting

coverage is in excess 150 ft. (45.72 meters) in a 360 degree

pattern.

Located underneath the generator support platform is a

weather resistant ballast box that contains the ballast for

starting the floodlight. The floodlight is activated by an

ON/OFF switch located at the base of the mast.

For ease of service or transport, the floodlight is equipped

with a quick-disconnect connector that allows the lamp fixture

Alarm Buzzer

The GloBug is equipped with a "Balloon Alarm" feature. This

alarm will sound if the lamp is on and the balloon attempts to

make contact with the

is intended to inform the operator that a potential burn hazard

exits between the lamp surface and the balloon material.

Always allow the lamp to cool down before removing the AC

power from the GloBug. In the event the balloon begins to

deflate during normal operation, immediately place the

GloBug's ON/OFF switch in the OFF position.

to be removed quickly. This feature is extremely useful during

transport of the lighting system over rough terrain. It is always

best to remove the floodlight and pack it safely so it will not

be damaged.

Balloon Envelopes

The GloBug can be configured with a variety of balloon

envelopes (canopy). Please contact the MQ sales department

Machine Safety Decals

The GloBug is equipped with a number of safety decals.

These decals are provided for operator safety and

maintenance information. The decal illustrations shown in

the parts section of this manual show the decals as they

appear on the machine. Should any of these decals become

unreadable, replacements can be obtained from your dealer.

for the balloon of your choice. The GloBug, Model GB113BC

is shipped from the factory with the drum type balloon.

Serious Injury or Death

hot!

!

surface of the lamp . This alarm

N

O

N

0

F

F

O

F

F

O

E

L

L

N

D

O

O

I

I

T

R

A

T

H

R

N

C

E

T

P

I

O

O

W

C

S

V

0

A

12

0

0

2

2

1

V

0

24

/

R

V

E

0

W

2

O

P

1

H

L

C

L

T

I

F

U

W

F

F

S

O

0A

2

20V

1

1A

2

T

I

A

U

0

C

3

R

I

R

E

C

K

C

A

A

E

R

B

40V

2

/

A

0

3

120

0

0

0

6

H

6

A

G

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 15

Page 16

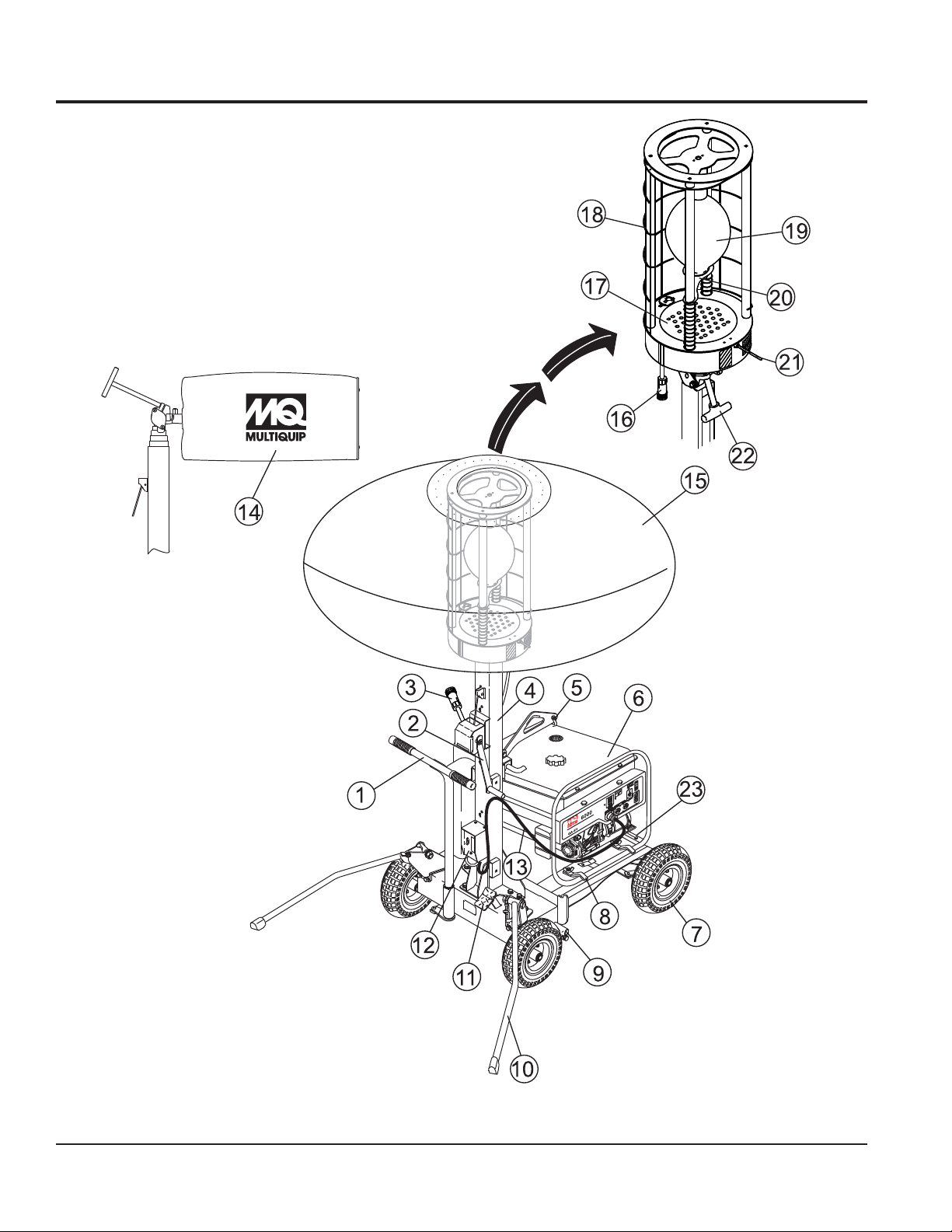

COMPONENTS

Figure 5. Major Components

PAGE 16 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 17

COMPONENTS

Figure 5 shows the location of the controls and components

for the GloBug Lighting System. The functions of each control

is described below:

1. Steering Handle – The GloBug can be moved in either

a forward or reverse direction by pulling back or pushing

forward on the T-handle. In addition the front wheels are

designed to turn in the opposite direction of the T-handle

placement thus allowing the GloBug to turn either left or

right.

2. Mast Winch – Use this mechanical winch to raise and

lower the mast. Always be on the lookout for overhead

obstructions. Keep immediate area free of bystanders

and debris when raising the mast.

3. Lamp Power Cable (Generator) – Connect this quick-

disconnect cable plug (generator-side) to the lamp power

cable plug.

4. Mast – This mast is comprised of three separate stages.

The mast can be raised in excess of 14.58 ft. (4.44

meters). Again when raising the mast, always be on the

lookout for overhead obstructions.

5. Lift Hanger – When lifting of the GloBug is required

always use a suitable lifting device of adequate lifting

capability. NEVER stand underneath the GloBug while it

is being lifted.

6. Generator – MQ GA-Series type generator. This generator will supply the necessary power to run the GloBug. For

operation of generator read generator Operation Manual

supplied with GloBug.

7. Tires – The GloBug uses 4 pneumatic type tires. Replace

with only recommended type tire . NEVER allow the rear

tires to go flat. This could adversely affect the braking

system. Inflate tires to 35.5 psi (245kPa).

8. Locking Clamps – To secure the generator to the

GloBug cart platform, place clamps (4) around the pipe

frame of the generator. Tighten securely to prevent

movement.

9. Brake Pad – When the brake pedal is pressed, this pad

will strike and hold the rear tires in place. Make sure rear

tires are inflated to the correct air pressure.

10. Outriggers – ALWAYS deploy the outriggers when

raising the mast.

11. Brake Pedal – Step on this pedal to apply the brakes. To

release the brakes, press down on brake pedal again.

12. ON/OFF Switch – Place this switch in the ON position

to turn on the lamp. To turn off the lamp place in the down

position (OFF). Please wait for approximately 10 minutes

before attempting to turn the lamp back on.

13. Power Cable – Connect this cable to a 120 VAC, 60 Hz

power source.

14. Balloon Storage Bag – Store the balloon in this storage

bag when the GloBug is not in use. Allow a sufficient

amount of time for the lamp to cool down before placing

balloon inside storage bag. Possibility exists of balloon

getting burned.

15. Balloon – This balloon is made of heat resistant nylon,

with a diameter of 3.9 ft. (1,150 mm). The balloon shall be

inflated to a pressure of 31.26 psi (215.6 kPA).

16. Lamp Power Cable (Balloon) – Connect this quickdisconnect cable plug (balloon-side) to the generator

power cable plug.

17. Fan Motor (Blower) – This electric motor is responsible

for inflating the balloon. It will supply a pressure of 31.26

psi (215.6 kPA). Please note that the balloon will begin to

inflate as soon as power is applied to the GloBug. The

OFF/ON switch

18. Lamp Guard – This guard (cage) protects the lamp from

being hit by objects.

19. Lamp – 1000 watt metal-halide type lamp. Replace with

only MQ recommended type lamp. Always allow a

sufficient amount of time for the lamp to

before changing.

20. Lamp Holder – Screw lamp into this holder. If lamp

becomes difficult to screw into holder or holder is

damaged, replace holder.

21. Balloon Alarm Buzzer – Will sound during normal

operation if the balloon attempts to make contact with the

lamp's

place the GloBug's ON/OFF switch in the OFF position.

22. Adjust Lever – This lever allows the lamp to be positioned up or down. Turn counterclockwise to release lamp

and position. Turn clockwise to tighten.

23. Ballast Compartment – Provides the necessary electronics to light the lamp. To gain access to the ballast

compartment the generator must be removed from the

cart platform.

does not

control the electric fan motor.

cool down

hot!

surface. If this condition occurs, immediately

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 17

Page 18

AC

CIR

CUIT

B

RE

AK

E

R

120

/240V

30A

V

OFF

21A

SETUP

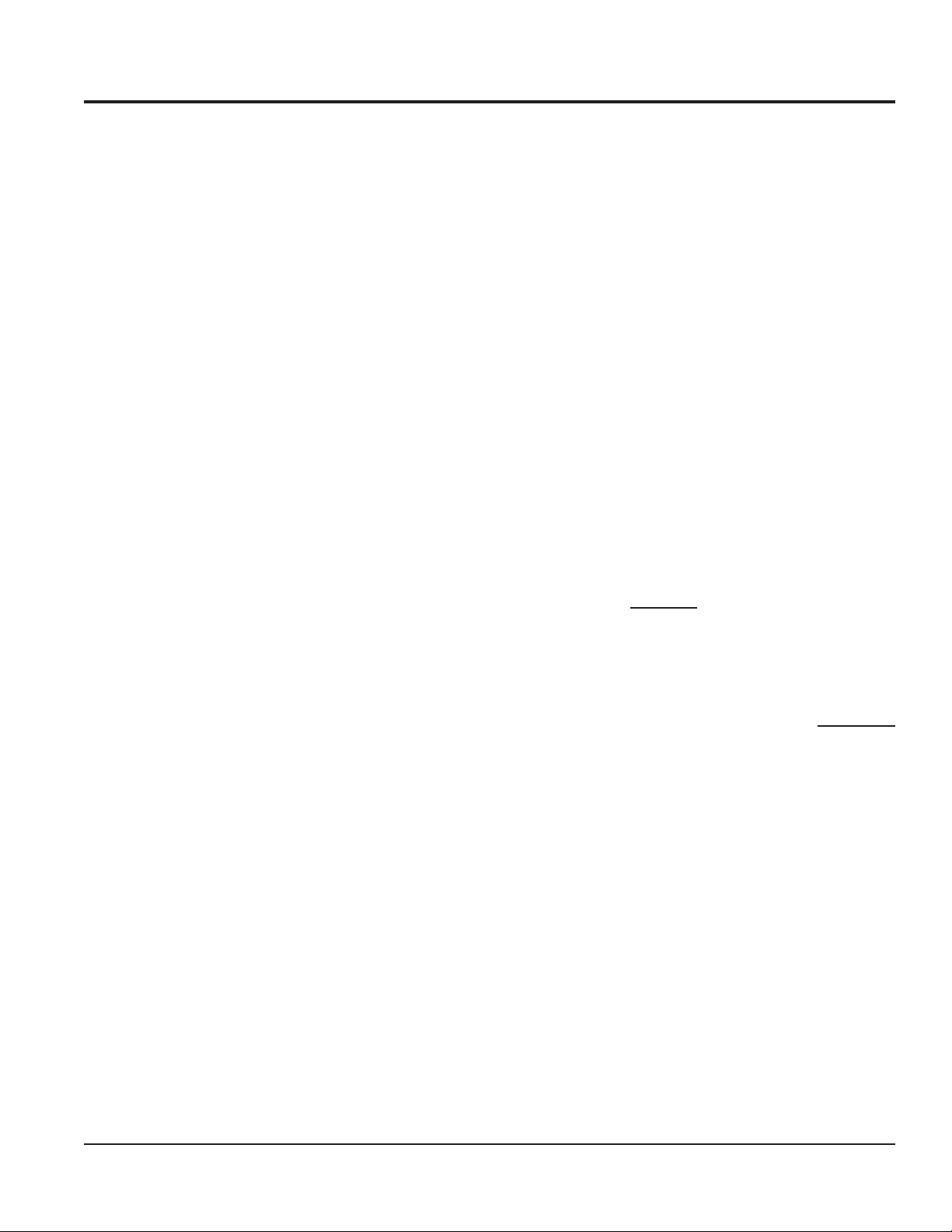

CAUTION - Read Manual

backwards and place it in the deployed position, as shown

in Figure 8. The outriggers will automatically lock in place

3. Lift up on each outrigger (2) from its stow position, rotate

Please read this entire manual carefully

once they touch the ground,

before attempting to operate the GloBug.

Failure to read this manual could cause

damage to the GloBug and serious injury

to the operator.

GloBug Setup

1. Using the T-handle (Figure 6) place the GloBug on a

firm level surface

so that it will not slide or turn over.

STOW

POSITION

N

O

N

0

F

F

O

F

F

O

E

L

L

N

D

O

O

I

I

R

T

A

T

H

R

N

C

E

T

P

I

O

O

W

C

S

V

0

2

A

1

0

0

2

2

1

V

0

4

2

/

R

V

E

0

W

2

O

P

1

H

L

C

L

T

I

F

U

W

F

F

S

O

A

0

2

V

0

A

2

1

1

2

T

I

A

U

0

C

3

R

I

R

E

C

K

C

A

A

E

R

B

V

0

4

2

/

A

0

0

2

3

1

6000

H

6

-

A

G

OUTRIGGERS

DEPLOYED

Figure 8. Outriggers (Deployed Position)

Figure 6. T-Handle (Directional Control)

2. To apply the parking brake (Figure 7), step on the brake

pedal and pull back on the T-handle. This will lock the

rear wheels. For additional safety use chock blocks to

prevent rolling.

STEP DOWN

ON BRAKE PEDAL

4. Expose the balloon by pulling down on the velcro tabs

and unzip the protective cover as shown in Figure 10.

Next, fold the protective cover into itself and zip.

Figure 9. Exposing the Balloon.

PARKING

BRAKE SET

Figure 7. Parking Brake (Set Position)

PAGE 18 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 19

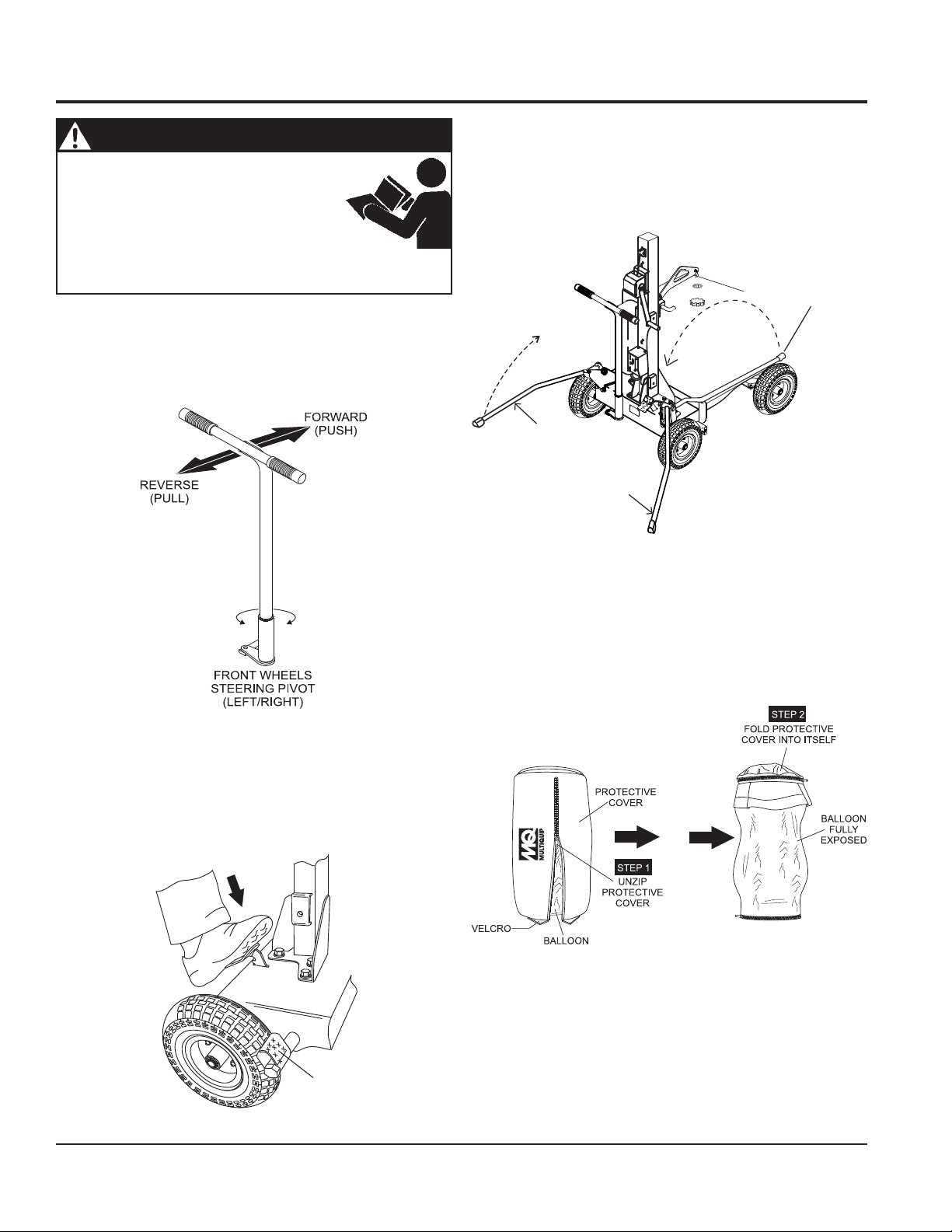

5. To position the balloon, simply loosen

the adjustment lever by turning it counterclockwise and either push down or up

down

on the lever. Pushing

will cause the balloon to rise. Pushing

up

on the lever will allow the balloon to

be lowered. See insert A in Figure 10.

For circular positioning, swing the lever

to the desired position. See insert B in

Figure 11.

6. Before raising the mast, make sure the mast set screw

(Figure 11) is securely tightened (use an 5mm-allen

wrench to tighten). This will prevent the balloon/lamp

assembly from falling off. In addition make sure the power

cable from the generator is connected to the lamp power

cable.

on the lever

CAUTION - MAST PINCH POINT

SETUP

Figure 10. Positioning the Balloon

When raising or lowering the mast, keep hands and fingers

clear of the various mast sections, this will prevent hands

and fingers from getting pinched.

7. Using the mechanical winch (Figure 12),

Figure 11. Mast Set Screw/Power Connections

raise

the mast

to the desired height. Turn winch handle clockwise to

raise mast.

Figure 12. Mechanical Winch Handle

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 19

Page 20

ON

OFF

SETUP/OPERATION

DANGER - HIGH VOLTAGE POWER LINES

When raising mast, ALWAYS be on

the lookout for overhead obstructions

such as high voltage power lines. The

possibility exists of electrocution,

even death! if the GloBug comes in

contact with

high voltage power lines

.

4. Notice that the balloon envelope will begin to deploy as

soon as power is applied by an active generator. This

function

5. Wait until the balloon is fully deployed before attempting

to turn on the lamp. The possibility exists of the balloon

getting burned (touching the lamp).

6. If the balloon is fully deployed, place the GloBug's ON/

OFF switch (15) in the ON position.

Applying Power

1. Make sure the power ON/OFF switch (Figure 13) located

near the bottom of the mast is in the OFF position.

ON

OFF

Figure 15. Power OFF/ON Switch (ON Position)

7. The lamp should now be on. If the lamp is not on, check

all connections and repeat steps 1 through 6. If the lamp

Figure 13. Power OFF/ON Switch (OFF Position)

still does not come on contact the MQ service

department.

is not

controlled by the power ON/OFF switch.

CAUTION - READ GENERATOR MANUAL

Before attempting to operate the

generator, READ the entire operation

section of the manual. Failure to read

manual could cause severe damage to

the equipment and bodily harm to the

operator.

2. The GloBug has a power requirement of 120 VAC, 60 Hz

@ 9.6 amps. Connect the GloBug's AC power cord to

the 120 VAC twist-lock receptacle (Figure 14) on the the

supplied generator.

Figure 14. 120 VAC Receptacle

3. Start the generator as referenced in the "Start-up

Section" of the supplied generator manual.

Shutdown

1. Place the power ON/OFF switch (Figure 16) in the OFF

position.

ON

OFF

Figure 16. Power OFF/ON Switch (OFF Position)

CAUTION - LAMP COOL DOWN

Allow a sufficient amount of time (15-20 minutes) for the

lamp (Figure 17) to

cool down

before turning off

generator. The possibility exists of the balloon getting

burned (touching the lamp).

2. Disconnect the GloBug's AC power cable from the

generator. The balloon should begin to deflate.

3. Shutdown generator as referenced in the "Shutdown

Section" of the supplied generator manual.

PAGE 20 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 21

Figure 17. Hot Lamp Surface

SHUTDOWN

4. Using the mechanical winch (Figure 5, item 2),

lower

the mast. Turn winch handle counter-clockwise to

lower mast.

5. Using the adjustment lever (Figure 5, item 22) place the

balloon/lamp assembly in the stow position.

6. Unzip the protective cover as shown in Figure 18, and

place cover over balloon/lamp assembly.

Figure 18. Covering the Lamp/Balloon Assembly

7. To unlock outriggers, push downward on the counterweight lever indicated by arrow (Figure 19). Grab hold of

outrigger, pull upward, push down and place in stow

position (Figure 20)..

fully

8. Press down on the top of the brake pedal (Figure 21)

and hold, then release. This action will dis-engage the

brake mechanism and allow the GloBug to be moved.

Figure 21. Parking Brake (Release Position)

Storage

1. Wipe and dirt or foreign matter that may have

accumulated on the GloBug during operation. Use a mild

detergent to clean the unit. DO NOT spray the engine

with water.

Figure 20. Outriggers (Stow Position)

2. Avoid storing the GloBug in areas that can be exposed

to rain, harsh elements, and high humidity.

3. Place the GloBug in a clean dry location away from dirt

and debris.

Figure 19. Outriggers (Released)

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 21

Page 22

MAINTENANCE

CAUTION - READ SAFETY GUIDELINES

Before performing any maintenance

procedures, be sure to READ the lamp,

balloon, and general safety guidelines in

this manual. Failure to

understand

these safety guidelines

read

and

could cause severe equipment damage

and bodily harm.

Removing the Lamp/Balloon Assembly

1. Place the lamp/ballon assembly in the STOW position.

2. With a 5 mm allen wrench, loosen the set screw (Figure 22) that

secures the lamp to the mast adapter stand.

CAUTION - BALLOON ZIPPER SAFETY

DO NOT use excessive force when zipping or

unzipping the balloon. The possibility exists

of the zipper tearing, which would make the

balloon unusable.

2. Unzip the zipper (Figure 23) at the bottom of the balloon

and roll the balloon envelope upwards to expose the lamp

(Figure 24). Remove the lamp guard to gain access to the

lamp.. DO NOT use excessive force when un-zipping

the balloon.

Figure 22. Removing the Balloon/Lamp

3. Disconnect the lamp power cable as shown in Figure 22,

and slide the balloon/lamp forward from the mast adapter

stand. Place lamp/balloon assembly on a suitable work

bench that is free of dirt, and sharp objects that could

damage the balloon.

Removing the Lamp

3. Push down and hold the lamp holder (spring loaded) away

from the lamp (Figure 25). Unscrew the lamp (turn counterclockwise) from the lamp socket.

1. Expose the balloon (Figure 23) by pulling down on the

velcro tabs and unzip the protective cover as shown in

Figure 18. Next, fold the protective cover into itself and

zip.

Figure 24. Removing the Lamp Guard

Figure 24. Exposing the Balloon

Figure 25. Removing the Lamp

PAGE 22 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 23

MAINTENANCE

Installing a New Lamp

1. When installing a new lamp (Figure 26) use only MQ

recommended type lamp. See parts section of this

manual. Failure to use correct type lamp could adversely

affect lighting capability and may cause damage to the

equipment.

2. Push down and hold the lamp holder (spring loaded) away

from the lamp. Screw the lamp (turn clockwise) into the

lamp socket. Gently place the lamp holder firmly over

the top of the lamp. This will prevent the lamp from

touching the lamp guard or pipe frame.

2. Zip up the zipper at the bottom (Figure 23) of the balloon

and pull down the balloon envelope to cover the lamp

3. Place the lamp/balloon assembly back onto the mast

adapter stand (Figure 22).

4. With a 5 mm allen wrench, tighten the set screw to 28 ~ 38

ft. lbs (38 ~ 51 N-m) to secure the lamp to the mast adapter

stand

5. Reinstall the protective cover over the balloon/lamp assembly. Be sure to fold the velcro tabs.

6. Reconnect the power cables.

Replacing the Balloon

1. Follow the procedures as outlined in the "Removing the

Balloon Lamp" assembly section.

2. Unzip the zipper at the bottom and top of the balloon.

Slide the balloon over the top of the lamp guard as shown

in Figure 28.

Figure 26. Installing the Lamp

Re-Installing the Lamp/Balloon Assembly

1. Reinstall the lamp guard (Figure 27). Be careful not to install

the lamp guard in the wrong direction.

Figure 27. Installing the Lamp Guard

3. Slide the new balloon over the top of the lamp guard as

shown in Figure 29. Zip up the zipper at the bottom and

top of the balloon.

Figure 28. Removing the Ballon

Figure 29. Removing the Ballon

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 23

Page 24

MAINTENANCE

Check Cable Wear

The wire rope (cable) that raises and extends the mast is a very

important part of the GloBug lighting system. Following the procedure below when replacing wire rope (cable).

Removing the Hanger

1. Remove the M12 x 40 bolt (Figure 31) from the hanger

support assembly, then remove the hanger. Set hanger

aside in a safe place where it will not get damaged.

DANGER - Lighting System Cable System

Safety

Wire rope (cable) will fail if it is worn, frayed, misused, crushed,

kinked or damaged in any way. ALWAYS check the cable and

pulley for any abnormalities before use.

MAIN

MAST

SECTION

DO NOT use it if there is even the slightest cause for

concern and replace any damaged cable or pulley

immediately.

Removing the Lamp/Balloon Assembly

1. Place the lamp/ballon assembly in the STOW position.

2. With a 5 mm allen wrench, loosen the set screw (Figure 22) that

secures the lamp to the mast adapter stand.

3. Remove the lamp/balloon assembly from the mast adapter

Figure 31. Removing the Hanger

stand and set aside in a safe place where it will not get

damaged.

Removal of Winch

1. Fully lower the mast to its vertical resting position.

2. Remove the four retaining screws and washers (Figure 30)

that secure the winch cover. Remove the winch cover.

3. Loosen the winch cable retaining screw. Pull and remove

the winch cable from the locking pin.

4. Remove the three retaining screws and washers that secure

Removing the Lamp Cable

1. Cut all the cable zip ties (Figure 32) that secure the lamp

cable to the various mast sections.

2. Remove the lamp cable from the various mast sections

and set cable aside in a safe place where it will not get

damaged. Mark the order of the cable sections so that

they can be placed back in the same order. Make sure

cable is laid flat and out of the way so that personnel will

not trip over it.

the winch to the mast. Remove the winch.

HANGER

SUPPORT

HANGER

STEP 2

REMOVE

HANGER

STEP 1

REMOVE

M12X40

BOLT

STEP 1

CUT

LAMP CABLE

ZIP TIES

STEP 2

REMOVE

LAMP CABLE

MARK ORDER

MAST

SECTIONS

Figure 32. Cutting the Lamp Cable Zip Ties

Figure 30. Winch/Cable Removal

PAGE 24 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 25

Pulling-Out the Mast Sections

1. Grab hold of the main mast (Figure 33) and begin pulling

the mast sections upwards. Start with second mast, and

then the third mast.

2. From the main mast, pull the winch cable wire to release

the safety stopper pulley at the second mast.

RD

3

MAST

1FT.

(305 MM.)

CABLE RELEASE

ACCESS POINT

MAINTENANCE

CABLE RELEASE

ACCESS POINT

PULLEY

ND

2

MAST

WINCH

CABLE

MAIN

MAST

1FT.

(305 MM.)

ND

2

MAST

SAFETY

STOPPER

MAIN MAST

Figure 34. Cable Release Access Point

5. To release the safety stopper without pulling the cable

wire when removing the second mast from the first (main

mast), insert a screwdriver (Figure 35) nearest the hole

where the latch is caught. Press down on the screwdriver

to lift the pulley inside the second mast upward. Remove the screwdriver lifting the second mast upwards

as the latch is being pulled back. The second mast should

now be able to be pulled out from the first mast.

Figure 33. Mast Sections

MAIN MAST

3. Each mast section should be equally spaced about 12inches from the preceding mast section. See Figure 33.

Figure 35. Releasing the Safety Stop Latches

If the winch cable wire cannot

WARNING - Mast Service Safety

The mast sections are heavy and awkward to handle. Use

proper lifting devices and procedures when servicing the mast

and its components.

NOTE

be pulled because of breakage

of the wire itself, the

stoppers

installed in the sec-

safety

ond mast will lock automatically

at the places indicated by the

arrows in Figure 34.

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 25

Page 26

MAINTENANCE

Installation of Winch Cable

1. Route (pass) a new winch cable through the main mast

A (Figure 36).

pulley

2. Route the winch cable around the

upper pulley

D

the third mast section from back to front.

3. Route the winch cable around the

upper pulley

C

of

second mast section from back to front.

5. Route the winch cable around the

second mast from front to back.

6. Continue pulling the cable and slide down the mast, be-

of

ing careful not to activate the cable stop latches.

8. Route the cable around the pulley of the first mast A .

the

9. Place the second mast into the main (first) mast. Next,

place the third mast into the second mast.

CAUTION - Winch Cable Safety Stopper

When placing the second mast into the main mast (first), pinch

THIRD

MAST

(squeeze) the pulley and pin with pliers (Figure 37) to hold the

stopper (cable latch). This will keep the cable stop latch from

being activated.

D

UPPER

PULLEY

lower pulley

B

of

the

UPPER

PULLEY

WINCH

CABLE

LOWER

PULLEY

C

SECOND

MAST

B

B

MAIN MAST

FRONT-VIEW

BA

A

TO

WINCH

Figure 37. Bypassing Cable Stop Latch

10.Route the tip of the winch cable (Figure 38) through the

eyelet retaining stud. Insert cable retaining screw at top

of stud and tighten.

A

Figure 38. Connecting the Winch Cable to the Winch

Figure 36. Attaching the Winch Cable

PAGE 26 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 27

BALLAST

GUARD BOX

BALLAST

COVER

TRANSFORMER

CAPACITOR

CART

M10X25 BOLT AND

WASHER

4 PLACES

AC POWER

CABLE

MAINTENANCE

Installation of Winch

Ballast Box Removal

1. Reinstall the three retaining screws (Figure 30) and washers

that secure the winch to the mast. Tighten screws between

24~ 33 ft-lbs. (33 ~ 45 N-m).

2. Install the four retaining screws and washers (Figure 30) that

secure the winch cover. Tighten securely.

3. Turning the winch handle clockwise, wind the cable tightly

around the winch shaft.

4. Raise, extend, retract and lower the mast several times to

verify correct operation.

WARNING - HOT SURFACE (BALLAST)

Dangerous conditions exists inside the ballast

compartment. Please use extreme caution when

performing maintenance on the ballast box.

NEVER touch the ballast or ballast cover while

the lamp is on. These components generate an

extreme amount of heat, which makes their surfaces very

ALWAYS allow the ballast box and cover surface to cool down

before servicing.

5. If the winch malfunctions, such as defective brake mechanism, replace entire winch assembly immediately.

DANGER - HIGH VOLTAGE (BALLAST)

Installing the Hanger

The electronic components of the ballast

1. Reinstall the M12 x 40 bolt (Figure 31) that supports the

hanger onto the main mast. Tighten bolt between 28~ 38

ft-lbs. (38 ~ 51 N-m).

generate high voltage conditions. These

conditions can be

harm, even death.

maintenance or troubleshooting, have only

Installing the Lamp Power Cable

experienced personnel work on the ballast.

hot!.

lethal and cause bodily

When performing

1. Check the entire lamp cable for any signs of wear, such

as cuts or frays. If the cable is damaged in any way,

replace entire cable. DO NOT use a worn or damaged

cable to operate the GloBug. The possibility exists of

shock or electrocution.

The ballast electronics are located within the cart frame of the

GloBug. To gain access to the ballast (Figure 39), remove the 4

retaining bolts and washers (M10 X 25) that secure the ballast

cover to the cart.

2. Using zip ties connect the lamp power cable to the various mast sections as shown in Figure 33. Remember to

connect the lamp cables to the mast in the same order

that they were removed.

3. Cutoff any excess zip tie material.

Figure 39. Removing the Ballast

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 27

Page 28

MAINTENANCE

Filter Replacement

WARNING - HOT SURFACE (LAMP FRAME)

DO NOT replace filter immediately, allow a

sufficient amount of time for the lamp assembly

to cool down before changing filter.

1. Remove the balloon as described in the "Removing the

Lamp/Balloon" section.

2. Disconnect the lamp power cable as shown in Figure 22.

3. Rotate the balloon/lamp base assembly so that the filter

is facing upwards. See Figure 40.

5. Install a new filter over the brace as shown in Figure 42.

Be sure to align the

CAUTION - FILTER ALIGNMENT

When placing the filter element, always align the cut of

the filter on top of the brace. This will keep the filter from

being dislodged and getting damaged.

cut of the filter

Figure 42. Filter Placement

over the brace.

Figure 40. Balloon/Lamp Placement

4. Turn the three locking tabs (Figure 41) inward to release

the plate. Remove plate and filter.

6. Turn the three retaining tabs (Figure 43) outward so that

they touch the lamp base.

Figure 43. Filter/Plate Install

Figure 41. Filter Removal

PAGE 28 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 29

MAINTENANCE (WIRING DIAGRAM)

Figure 44. Wiring Diagram

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 29

Page 30

B2

MAINTENANCE

L3

L1

L4

B3

L2

L5

B1

C2

C1

M3

M4

M5

M2

C3

C4

C5

M1

C6

GA-6H

C10

E1

E2

N

O

0N

OFF

F

F

O

E

L

N

D

L

I

O

I

O

T

A

R

R

H

T

E

C

N

P

T

I

O

O

W

S

C

V

0

2

1

20A

V

0

4

2

/

R

V

E

0

W

2

O

P

1

H

L

C

L

T

F

I

U

F

W

F

S

O

20A

A

120V

1

2

CUIT

30A

IR

C

AC

REAKER

B

30A

120/240V

6000

C9

Figure 45. Maintenance Locations

C7

C8

PAGE 30 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 31

For a prolonged life cycle an extended quality follow the

recommended GloBug service guidelines as referenced in

Table 4.

ERUGIFTRAPMETIKCEHCNOITULOS

MAINTENANCE

ECNANETNIAMDNAKCEHCCIDOIREP.4ELBAT

1LepiPemarF?deweksepipemarF.ecalpeR

2LredloHpmaL?esoolredlohpmaL.ecalperronethgiT

pmaL

noollaB

tsaM

3L)esaB(pmaL?esoolesabpmaL.ylerucesniwercS

4LpmaL?pmalevitcefeD.ecalpeR

5LrotcennoC/elbaC?esoolrodetcennocsidelbaC.ylerucestcennoC

1B)epolevnE(noollaB?ytridroevitcefeD.ecalpeR

2BreppiZ?nekorB.ecalpeR

3B)rewolB(rotoMnaF?ylreporpgnikroW.ecalperroriapeR

1MecafruSgnidilStsaM?ylhtoomssedilS.esaergylppA

2MepoReriW?degamaD.ecalperroesaergylppA

3MdnEepoReriW?)gnikluac(degamaddneeriwsI.ecalpeR

4MhcniW?ekarbhcniwevitcefeD.ecalperroriapeR

5MpotSytefaS?evitcefedhctalytefaS.ecalperroriapeR

1CthgieW-retnuoC?ylhtoomsslevarT.esaergyarpS

❖

❖

❖

❖

■

❖

❖

❖

●

❖

❖

❖

▲

●

2CsreggirtuO?ylhtoomsslevarT.esaergyarpS

3CsleehWdnaeldnah-T.tnemevomreporP.ylerucesnethgiT

4CeldnaHroftloB.esooltonsitlobfikcehC.ylerucesnethgiT

5CladePekarB.yltcerrocgnikrowegakniLesaergyarps,kcehC

traC

cirtcelE

5CladePekarB?tuo-nrowhctoN.ecalpeR

6CregnaH.esooltonsinoitallatsniehtfikcehC.ylerucesnetsaF

7CtoviPleehWtnorF?ylhtoomssnruT.esaergylppa,kcehC

8CseriT?)aPk492(isp5.53erusserperiT.tsujdA

9CtfahStnorFrofkniL?ylhtoomssevomegakniL.esaergyarpS

01CekarB?ylreporpgnikroW.tsujdA

1EelbaCrewoP?elbacnrowroevitcefeD.ecalpeR

2EegatloVdaol-noN?CAV521tuptuorotarenegsI.rotarenegecalperrotsujdA

kcehCyliaD-

❖

■

sruoH02yrevE-

●

sruoh001yrevE-

▲

sruoh005yrevE-

●

■

■

❖

❖

■

●

❖

●

❖

❖

●

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 31

Page 32

TROUBLESHOOTING (LAMPS)

Practically all breakdowns can be prevented by proper

handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the

diagnosis based on the Lamp Troubleshooting (Table 5)

information shown below.

MOTPMYSMELBORPELBISSOPNOITULOS

?detcennocylerucesgulpsI.yltcer

?esoolpmalsI .tekcosotniylerucespmalwercS

cennocylreporprotcatnocsI .rotcatnocdetcennocsidtcennoC

gulp)rewotthgilnaht

.thgiltonseodpmaL

?ecruos

If the problem cannot be remedied, please leave the unit

just as it is and consult or company's service department.

?nodehctiwsrewotthgildnarotarenegerA.hctiwsnonruT

?det

rehto(secnailppacirtcelerehtoynaerA

rewopotnideg

GNITOOHSELBUORTPMAL.5ELBAT

rocnigulP

.secnailpparehtollagulpnU

daol-non(lamronegatlovrotarenegsI

?)CAV021-egatlov

?elbitapmocpmalfoledomsI.pmalQMeniunegesU

?niagathgilothguoneloocpmalsI

sisetunim03ot02folavretnI(

)niagapmalnogninruterofeb

arofsthgilylnopmaL

.emittrohs

tonseodnoollaB

.etalfni

eibmasI

?)V021-egatlov

?)C°04(F°401

b(rotomnafsI .)rewolb(rotomnafriaperrokcehC

?evitcefedepolevnenoollabsI .epolevnenoollabecalperroriapeR

deriuqer

daol-non(lamronegatlovrotarenegsI

nahterom(hgihooterutarepmettn

.noitalitnev

?ylreporpgnikrow)rewol

rotarenegecalperroriapeR

.

.nwodloocotpmalroftiaW

.rotarenegecalperroriapeR

reporpsierehterehwpmalevoM

PAGE 32 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 33

TROUBLESHOOTING (MAST)

Practically all breakdowns can be prevented by proper

handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the

diagnosis based on the Mast Troubleshooting (Table 6)

information shown below.

MOTPMYSMELBORPELBISSOPNOITULOS

?tsamnithguacelbacsI.eerfelba

ebtonnactsaM

.desiar

gnimocspeektsaM

.nwod

?hcniw

?esooltfahsmardsI .noitarepostikcehcdnatfahsmardnethgiT

edilstsamfoecafrusseoD .tsamfoecafrusgnidilsotesaergylppA

If the problem cannot be remedied, please leave the unit

just as it is and consult or company's service department.

morfdetcennocsideporeriwfodnesI

?ylhtoomsedilstsamfoecafrusseoD .tsamf

?ylreporpgninoitcnufhctalhcniwsI .ylreporpgninoitcnuft

?ylhtooms

GNITOOHSELBUORTTSAM.6ELBAT

cteS

.hcniwoteporeriwtcennoC

oecafrusgnidilsotesaergylppA

onfitrapecalpeR

ebtonnactsamehT

.derewol

?thgitdlehhcniwfoksidekarbsI

?yltcerrockrowreppotsytefasseoD

seldnahhcniwgnidloH

latsampuhcniW

.)riapeR(tinodaolagnittup

ehtevomer,yleruce

.)riapeR(ylwolstsamrewoldnahctal

ybtsamrewoldnaeltti

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 33

Page 34

EXPLANATION OF CODES IN THE REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

QTY. Column

Numbers Used — Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other

parts that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

same unique symbol will be included when this item is

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

Serial Number Break — Used to list an effective serial

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use — Indicates that the part

is used only with the specific model number or model

number variant listed. It can also be used to show a

part is NOT used on a specific model or model number

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

and certain washers and nuts.

“Not Sold Separately” — Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

for sale through Multiquip.

PAGE 34 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 35

GloBug LIGHTING SYSTEM

1 TO 3 UNITS

Qty. P/N Description

2 ......... E000009800 .... BULB

2 ......... A300033800 .... BALLAST/TRANSFORMER

2 ......... A300038400 .... CAPACITOR, 24

2 ......... A100031301 .... BALLOON CLOTH

3 ......... A400038300 .... FILTER 200 (AIR)

μ

F @480 VDC

SUGGESTED SPARE PARTS

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 35

Page 36

A

C

C

I

R

C

U

IT

BR

E

A

K

E

R

1

2

0

/

2

4

0

V

3

0

A

V

OF

F

2

1

A

ON

OFF

DCL408

23

NAMEPLATE AND DECALS

21

BURN HAZARD

To prevent burns,

touch

lamp is on. These surfaces are

extremely hot! allow

sufficient time for both surfaces

to before touching.

cool down

CART

23

1

CAUTION

COVER

INFORMATION

Before operating GloBug

unzip cover,fold into

ALWAYS

bag on top of balloon and zip.

Bag

Zipper

Cover

NEVER apply power to the

GloBug until the cover has

been inserted inside the bag

and the balloon is fully exposed.

Before storing GloBug,

fully cover balloon to

ALWAYS

prevent damage from dust, dirt

and adverse weather conditions.

DANGER

ELECTRICAL

SHOCK HAZARD

NEVER touch a live power cord

or active electrical components

with wet hands or while standing

in water.The possibility of electrical

shock or even death! exists.

DCL410

20

WARNING

NEVER

ballast or cover while

ALWAYS

DCL415

DANGER

Make sure that generator is loaded when

conveying Lighting Towerby forklift.

Be sure to insert forks at marked position

exactly under pipe frame or base plate

DANGER

Make sure that generator is loaded when

conveying Lighting Towerby forklift.

Be sure to insert forks at marked position

exactly under pipe frame or base plate

DCL413

BALLAST

BOX

19

10

A400116400

A400116400

6

DANGER

ELECTRICAL

SHOCK HAZARD

NEVERplace the GloBug

wheelsin standing water. The

possibilityof electrical shock,

evendeath! Exists.

MODEL

SERIAL NO.

When the GloBug is used for

non-lighting applications,

un-plug GloBug AC power cord

from the generator.

7

8

22

DCL400

18

CAUTION

ALWAYS

DCL402

DCL401

WARNING

Toavoid injury,

you MUST read

and understand

operator’s manual

before using this

machine.

This machine to

be operated by

qualified

personnel only.

Ask for training

as needed.

HIGH VOLTAGE

P/N35137

17

2

CAUTION

LAMP COVER BUZZER

Before operating GloBug

unzip cover,fold into

ALWAYS

bag on top of balloon and zip.

I

f the cover has not been removed

n audible alarm will soundwhen

a

power is applied to the GloBug.

WARNING

When lifting of the GloBug is

required, attach a rope

ALWAYS

or chain to the lift hanger.

use any other lifting points to

lift the GloBug.

LIFT

HANGER

3

When replacing lamp and to prevent electrical

shock, shutdown the generator before

replacing lamp. Remember to let lamp cool before

removing. Use only recommended type lamp as

listed in parts manual.

G

CAUTION

TIRE PRESSURE

ALWAYS keep tires inflated

to correct pressure. Low or

incorrect tire pressure could

result in brake malfunction.

Recommendedtire pressure:

35.5 PSI

(225 kPa)

DANGER

DCL404

DO NOT

DCL412

DCL412

DANGER

ELECTRICAL

SHOCK HAZARD

ALWAYS

CAUTION

LAMP INFORMATION

ALWAYS OFFturn lamp

first, before shutting down

generator.

Once lamp is turned

Allow lamp to cool down

before turning back on.

t will take about 20 minutes

I

before lamp can be turned

back on.

6000

H

-6

A

DCL407

9

DCL418

0

O

E

L

D

I

OL

R

T

N

O

C

V

0

2

1

V

0

4

2

/

V

0

2

1

POWER

F

FULL

F

SWITCH

O

A

0

2

V

0

2

1

21A

T

I

A

U

0

C

3

R

R

I

E

C

K

A

C

E

A

R

B

V

0

4

2

/

A

0

0

2

3

1

DCL416

11

OFF,

DCL409

N

O

N

F

F

F

F

O

N

O

I

T

A

R

H

E

C

P

T

I

O

W

S

A

0

2

DANGER

ELECTRICAL

SHOCK HAZARD

GROUND

Toprevent electrical shock or

electrocution, the generator

be connected to an

MUST

(SeeNEC Article 250)

earth ground.

SETTING:

Pull outrigger upward at the tip end

and rotate backwards until it locks in

place.

RELEASE:

To unlock outrigger, push downward

on the counter-weight lever indicated

by arrow. Grab hold of outrigger, pull

upward, push down and place in stow

position.

4

DCL405

WARNING

OUTRIGGER

DEPLOYMENT

O

U

T

R

D

IG

E

PL

G

O

YED

ADJUSTMENT

LEVER HAZARD

BE CAREFUL NOT TO

STRIKE HEAD AGAINST

TOWER ADJUSTMENT

LEVER. POSSIBLE HEAD

INJURYCAN OCCUR.

15

F

F

O

A

1

2

T

I

U

C

R

I

R

E

C

K

C

A

A

E

R

B

V

0

4

2

/

A

0

0

2

3

1

0

0

0

6

H

6

-

A

G

ER

S

Toprevent burns,

touch lamp while lamp is on.

Lamp surface gets extremely

hot! allow sufficient

time for lamp to

before touching.

WARNING

DCL406

ALWAYSMAKE SURE AREA ABOVE

TOWERMAST IS OPEN AND

OF OVERHEAD .

THE TOWER MAST EXTENDS IN

EXCESSOF 16.5 FT. (5 METERS).

DANGER

GloBug

INFORMATION

Toprevent tipping, use

inwinds that exceed 22 mph

(10m/sec).

NEVERuse on an incline of 5

degreesor more. The possibility

oftipping exists.

NEVERuse in rain or wet

conditions.The possibility of

electrocutionexists.

ALWAYSapply parking brake

toprevent moving.

Whenmoving is required, lower

mastfully.

W

deployoutriggers to prevent

tipping.

ALWAYS OFFturn generator

beforeperforming maintenance.

STOW

POSITION

N

O

N

0

F

F

O

F

F

O

E

L

L

N

D

O

O

I

I

T

R

A

T

H

R

N

C

E

T

P

I

O

O

W

C

S

V

0

2

1

A

0

0

2

2

1

V

0

4

2

/

R

V

E

0

W

2

O

P

1

H

L

C

L

T

I

U

W

F

S

A

0

2

V

0

2

1

A

0

3

DCL414

WARNING

BURN HAZARD

NEVER

ALWAYS

cool down

5

12

DANGER

ELECTRICAL

SHOCKHAZARD

CLEAR

POWER LINES

N

O

N

0

F

F

O

F

F

O

E

L

N

L

D

I

O

I

O

T

A

R

H

R

T

E

C

N

T

P

I

O

O

W

S

C

V

0

2

A

1

0

2

V

0

4

2

/

R

V

E

0

W

2

O

P

1

H

L

C

L

T

F

I

U

F

W

F

S

O

A

0

2

V

0

2

A

1

1

2

T

A

I

0

U

C

3

R

R

I

E

C

K

A

C

E

A

R

B

V

0

4

2

/

A

0

0

2

3

1

0

0

0

6

H

6

A

G

DCL403

NEVER

14

ALWAYShen raising mast,

DCL411

16

DCL417

13

PAGE 36 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 37

NAMEPLATE AND DECALS

NAMEPLATE AND DECALS.

NO. PART NO. PART NAME QTY. REMARKS

1 DCL413 DECAL; CAUTION COVER INFORMATION 1

2 DCL404 DECAL; CAUTION LAMP COVER BUZZER 1

3 DCL412 DECAL; WARNING, LIFT HANGER 1

4 DCL416 DECAL; DANGER, ELECTRICAL SHOCK HAZ. 1

5 DCL417 DECAL; WARNING, BURN HAZARD (LAMP) 1

6 DCL402 DECAL; CAUTION, REMOVE POWER CORD 1

7 DCL428 DECAL; MQ LOGO 1

8 DCL401 DECAL; WINCH UP/DOWN 1

9 DCL407 DECAL; CAUTION, TIRE PRESSURE 1

10 DCL400 DECAL; DANGER, ELECTRICAL SHOCK (TIRES) 1

11 DCL409 DECAL; CAUTION, LAMP INFORMATION 1

12 DCL406 DECAL; WARNING, ADJ. LEVER HAZARD 1

13 DCL403 DECAL; DANGER ELECTRIC SHOCK (GLOBUG) 1

14 DCL411 DECAL; DANGER, GLOBUG INFORMATION 1

15 DCL405 DECAL; DANGER, ELECTRICAL SHOCK (GND.) 1

16 DCL414 DECAL; WARNING, OUTRIGGER DEPLOYMENT 1

17 DCL418 DECAL; DANGER, HIGH VOLTAGE 1

18 35137 DECAL; WARNING, READ MANUAL 1

19 NAMEPLATE .................................................................. 1........... CONTACT MQ PARTS DEPT.

20 DCL415 DECAL; BURN HAZARD (BALLAST) 1

21 DCL410 DECAL; DANGER, ELECTRICAL SHOCK (CORDS) 1

22 DCL408 DECAL; ON/OFF 1

23 A400116400 DECAL; FORKLIFT ALIGNMENT 4

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 37

Page 38

T-HANDLE ASSY.

T-HANDLE ASSY.

2

1

1

3

4

4

5

PAGE 38 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 39

T-HANDLE ASSY.

T-HANDLE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1

*

2 A200023001 HANDLE .........................................................2 ........... INCLUDES ITEM W/

3 0040730000 SNAP RING (30) 1

4 1503300130 SLEEVE BEARING (30DX34DX20) 2

5 A100018905 BASE PLATE 1

1102700130 HANDLE GRIP 2

*

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 39

Page 40

STEERING ASSY.

STEERING ASSY.

15

15

28

15

15

20

22

21

22

10

23

12

22

15

28

5

13

9

4

8

26

25

10

21

22

2

27

7

15

47

24

10

10

13

46

24

47

22

14

21

3

28

22

5

11

15

28

15

PAGE 40 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 41

STEERING ASSY.

STEERING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

2 A200022903 FRONT SHAFT (L) 1

3 A200022803 FRONT SHAFT (R) 1

4 2001200313 BRAKE PEDAL 1

5 2071214010 BRAKE 2

6 2071213211 BRAKE SHAFT 1

7 1041000131 SPRING (BRAKE) 1

8 0010308030 BOLT (M8x30) SUS 1

9 0033108000 NUT (M8) 2

10 0043108000 WASHER (M8) 5

11 0013212075 BOLT (M12x75) 1

12 1521120131 BOLT (M12x75) LEFT SCREW 1

13 1503180130 SLEEVE BEARING (18Dx20Dx20) 2

14 A400055501 LINK (FRONT SHAFT) 1

15 0040720000 SNAP RING (20) 8

20 A300090600 LINK, HANDLE 1

21 0043112000 WASHER (M12) 1

22 1504120130 WASHER (12.2Dx18Dx0.5T) 6

23 0033208000 SELF LOCK NUT (M8) 1

24 0030808000 PUSH NUT (8) 3

25 0013512025 BOLT & WASHER (M12x25) 1

26 0043112041 WASHER (12Dx40Dx3.2T) 1

27 A400055401 LINK (STEERING) 1

28 E000014500 TIRE ASSY (4.10/3.50-5) 4

46 A400055101 SPACER 1

47 E000031200 WASHER, (20Dx36Dx1.5) 2

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 41

Page 42

OUTRIGGER ASSY.

OUTRIGGER ASSY.

PAGE 42 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 43

OUTRIGGER ASSY.

OUTRIGGER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0013116090 BOLT (M16x90) 2

2 A100011601 BRACKET (OUT,R) R 1

3 0013510025 BOLT & WASHER (M10x25) 10

4 1501160111 SPACER (OUT,R) 2

5 A200015303 OUTRIGGER R ............................................ 1............. INCLUDES ITEM W/

6 A200015203 OUTRIGGER L .............................................1 ............. INCLUDES ITEM W/

7

*

8 0043110000 WASHER (M10) 4

9 1501100430 SPACER (10.2dx13.8Dx6.5L) 2

10 0033210000 SELF LOCK NUT (M10) 2

11 0043116000 WASHER (M16) 2

12 0043216000 WASHER, SPRING (M16) 2

13 0033116000 NUT (M16) 2

14 2031321113 WEIGHT (OUT,R) R 1

15 A100011501 BRACKET (OUT,R) L 1

16 2031320213 WEIGHT (OUT,R) L 1

17 A400033402 CATCHER (OUTRIGGER) 2

1641000330 RUBBER FOOT 2

*

*

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 43

Page 44

MAST ADAPTER ASSY.

MAST ADAPTER ASSY.

PAGE 44 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 45

MAST ADAPTER ASSY.

MAST ADAPTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 2202390100 STAND ASSY. ................................................1 ........... INCLUDES ITEMS W/

2

*

3

*

4 2202500230 SPACER (STAND) 1

5 1502280130 WASHER 1

6

*

7

*

8

*

9 A400038801 GRIP SHAFT 1

10

11 0014708010 BUTTON BOLT (M8 X10) 1

2202390112 STAND 1

2202500130 SHAFT (STAND) 1

2202520110 COVER (SPRING) 2

1043002030 SPRING (STAND) L 1

1043002130 SPRING (STAND) R 1

0014808025 BUTTON BOLT & WASHER (M8 X 15) 4

*

*

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 45

Page 46

MAIN MAST ASSY.

MAIN MAST ASSY.

8

5

9

6

1

13

14

7

15

3

11

12

4

2

10

13

13

16

PAGE 46 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 47

MAIN MAST ASSY.

MAIN MAST ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0020105008 SCREW & WASHER, M5X8 4

2 0013510025 BOLT & WASHER (M10x25) 3

3 1011000701 WINCH HM-G103 1

4 A100028105 FIRST MAST 1

5 0033112000 NUT (M12) 1

6 0043212000 WASHER, LOCK (M12) 1

7 0043112000 WASHER (M12) 1

8 1642001430 GROMMET 1

9 1052001710 HANGER 1

10 1711080130 SHACKLE, W/BOLT 2

11 0043112041 WASHER (12dx40Dx3.2t) 1

12 0013112040 BOLT (M12x40) 1

13 0023305015 SCREW & WASHER (M5x15) 5

14 A200039400 SWITCH COVER ...........................................1 ............. FOR FIRST MAST

15 A300117800 SWITCH ASSY. 1

16 0013512025 BOLT & WASHER (M12x25) 6

GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12) — PAGE 47

Page 48

WINCH ASSY.

13

14

12

11

WINCH ASSY.

A

10

9

1

15

16

17

18

19

20

21

28 24

29

22

23

25

26

2

3

4

5

6

7

8

27

PAGE 48 — GB113BC GLOBUG LIGHTING SYSTEM — OPERATION AND PARTS MANUAL — REV. #5 (01/16/12)

Page 49