Page 1

OPERATION MANUAL

MODEL AR14H

RIDE-ON TANDEM DRUM ROLLER

(HONDA GX630RHKAF GASOLINE ENGINE)

Revision #3 (09/06/19)

To find the latest revision of this publication or

associated parts manual, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

PAGE 2 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 3

AR14H Ride-On Tandem

Drum Roller

Proposition 65 Warning ........................................... 2

Safety Information ................................................ 4-8

Specifications .......................................................... 9

Dimensions ............................................................ 10

General Information .......................................... 12-13

Components ..................................................... 14-19

Basic Engine .......................................................... 20

Inspection ......................................................... 21-23

Operation .......................................................... 24-26

Maintenance ..................................................... 27-37

Preparation For Long-Term Storage ...................... 38

Manifold Test Ports ................................................ 39

Hydraulic System Diagram .................................... 40

Wiring Diagram ...................................................... 41

Troubleshooting ................................................ 42-43

TABLE OF CONTENTS

NOTICE

Specifications are subject to change without notice.

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 3

Page 4

SAFETY INFORMATION

Do not operate or service the equipment before reading

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION

SAFETY SYMBOLS

The following table shows the potential hazards associated

with the operation of this equipment.

Symbol Safety Hazard

or NOTICE.

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

Lethal exhaust gas hazards

Explosive fuel hazards

Burn hazards

Respiratory hazards

Rotating parts hazards

NOTICE

Addresses practices not related to personal injury.

PAGE 4 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Pressurized fluid hazards

Electric shock hazards

Runover hazards

Page 5

GENERAL SAFETY

NOTICE

This equipment should only be operated by trained and

Whenever necessary, replace nameplate, operation and

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

keep

Also, know the phone numbers

fi re department.

This information will be invaluable in the case of an

SAFETY INFORMATION

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

ALWAYS check the equipment for loosened threads or

bolts before starting.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

ALWAYS clear the work area of any debris, tools, etc.

that would constitute a hazard while the equipment is

in operation.

qualifi ed personnel 18 years of age and older.

safety decals when they become diffi cult read.

equipment modifi cation will void all warranties.

NEVER

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest phone or

a phone on the job site.

of the nearest ambulance, doctor and

emergency.

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 5

Page 6

SAFETY INFORMATION

ROLLER SAFETY

DO NOT use worn-out hoses or fi ttings. Inspect daily.

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

The engine of this equipment requires an adequate

operate this equipment

place hands or fingers inside engine

operate the engine with heat shields or

while the engine is hot. Hot oil will gush out of the oil

tank and severely scald any persons in the general area

Always turn the engine off before performing maintenance.

DANGER

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

NEVER disconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

devices will void all warranties.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

Never leave the roller unattended with the engine

running. Turn off engine.

Use chock blocks when parking roller on a grade.

Use extreme care when operating near obstructions, on

slippery surfaces, grades, and slide slopes.

ALWAYS

ENGINE SAFETY

DANGER

cause death if inhaled.

free fl ow of cooling air. NEVER

in any enclosed or narrow

area where free fl ow of the

air is restricted. If the air

fl ow is restricted it will cause

injury to people and property

and serious damage to the

equipment or engine.

WARNING

DO NOT

compartment when engine is running.

DANGEROUS

GAS FUMES

When reversing, particularly on the edges and banks

of ditches, as well as in front of obstaces, the operator

must stay in a standing position at a safe distance from

the machine.

When operating near any house/building or pipelines,

always check the effect of machine vibration. Stop work

if necessary.

DO NOT operate the roller with the covers open.

ALWAYS keep the machine away from other personnel

and obstacles. Always keep immediate are free of

bystanders.

NOTICE

ALWAYS keep the machine in proper running condition.

Fix damage to machine and replace any broken parts

immediately.

NEVER

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

DO NOT remove the engine oil drain plug

of the roller.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

PAGE 6 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 7

SAFETY INFORMATION

NOTICE

BATTERY SAFETY (ELECTRIC START ONLY)

drop the battery. There is a possibility that the

keep the battery charged. If the battery is not

charge battery if frozen. Battery can explode.

When frozen, warm the battery to at least 61°F (16°C).

recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

If the battery liquid (dilute sulfuric acid) comes into

, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

NEGATIVE battery terminal

keep battery cables in good working condition.

NEVER run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

NEVER tip the engine to extreme angles during lifting as

it may cause oil to gravitate into the cylinder head, making

the engine start diffi cult.

FUEL SAFETY

DANGER

DO NOT start the engine near spilled fuel or combustible

fl uids. Gasoline is extremely fl ammable and its vapors

can cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

DANGER

DO NOT

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

ALWAYS wear safety glasses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

Use well-insulated gloves when picking up

the battery.

ALWAYS

charged, combustible gas will build up.

DO NOT

ALWAYS

of combustible gases.

If the battery liquid (dilute sulfuric acid)

comes into contact with clothing or skin,

rinse skin or clothing immediately with

plenty of water.

contact with eyes

seek medical attention.

CAUTION

ALWAYS disconnect the

before performing service on the equipment.

ALWAYS

Repair or replace all worn cables.

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 7

Page 8

SAFETY INFORMATION

TRANSPORTING SAFETY

ENVIRONMENTAL SAFETY

EMISSIONS INFORMATION

This equipment conforms with applicable Environmental

Protection Agency (EPA) and California Air Resources

The gasoline engine used in this equipment has been

designed to reduce harmful levels of carbon monoxide

(CO), hydrocarbons (HC) and nitrogen oxides (NOx)

Fuel and vapor recovery hoses, EPA certifi ed SAE J30R7

Tampering with or altering the emission control system may

increase emissions beyond the legal limit. Do not remove

Additionally, modifying the fuel system may adversely affect

evaporative emissions, resulting in fi nes or other penalties.

The Emission control system is valid only for the United

States, its territories and commonwealths to include

The emission control label is an integral part of the emission

If a replacement emission label is needed, please contact

CAUTION

NEVER allow any person or animal to stand underneath

the equipment while lifting.

NOTICE

Before lifting, make sure that the equipment parts are not

damaged and screws are not loose or missing.

Always secure the articulation locking latch prior to lifting

the machine.

Use lifting equipment capable of lifting the weight of

the roller.

Always make sure crane or lifting device has been

properly secured to the lifting bail (hook) of the

equipment.

ALWAYS shutdown engine before transporting.

NEVER lift the equipment while the engine is running.

Tighten fuel tank cap until audible click and securely

close fuel cock to prevent fuel from spilling.

Use adequate lifting cable (wire or nylon rope) of

suffi cient strength.

Use one point suspension hook and lift straight upwards

with suffi cient bearing capacity to prevent machine from

tilting or slipping.

DO NOT lift machine to unnecessary heights.

NOTICE

Board (CARB) emission regulations.

contained in gasoline exhaust emissions.

Mandated Emission Components:

Honda GX630 engine, EPA certifi ed

Fuel cap, EPA certifi ed

or SAE J30R14T2

Charcoal canister, EPA certifi ed

Miscellaneous Parts Associated with Emission System:

Hose clamps and retainer brackets

Roll over valve vapor recovery valve

Steel fuel tank

or alter any part of the system.

ALWAYS make sure that roller is secured correctly when

transporting on a trailer. Make sure all supports attaching

the roller to the trailer are tight.

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

PAGE 8 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Canada.

Emission Control Label

system and is strictly controlled by regulation(s).

The label must remain with the engine for its entire life.

your authorized Honda Engine Distributor.

Page 9

SPECIFICATIONS

Table 1. Specifications (Roller)

Shipping Weight 2,840 lbs. (1,288.20 Kg.)

Operating Weight w/ Water 2,980 lbs. (1,351.70 Kg.)

Operating Weight w/out Water 2,688 lbs. (1,219 Kg.)

Centrifugal Force (Front Drum) 3,400 lbf. (15.1 kN)

Frequency 4,200 VPM (70 Hz)

Dynamic Linear Force Per Drum

2,400 - 2,700 rpm

Oscillating Angle 11 degrees

Travel Speed (Forward/Reverse) 4.8 mph (7.7 kph)

Gradeability (Maximum) 25 %

Outside Turning Radius 223 in. (5,664.2 mm)

Inside Turning Radius 149.5 in. (3,797.3 mm)

Water Tank Capacity 34 Gallons (130 Liters)

Water Delivery Pressurized

Water Tank Construction Plastic

Battery 12V System

Hood Construction Fiberglass

Drum Water Ballast Rear Drum

Table 2. Specifications (Engine)

Model Honda GX630RHKAF Engine

Type

Air-Cooled 4 Stroke, Overhead Valve, 2 cylinders

95.5 lbs./in (17.05 Kg/cm)

(90 degree V-Twin), Gasoline Engine.

Piston Displacement 41.98 cu. in. (688 cc)

Bore x Stroke 3.07 in. x 2.83 in. (78 mm x 72 mm)

Max. Torque 35.62 lbf ft (48.3 Nm) at 2,500 rpm

Starting System Electric Start

Engine Oil Capacity 2.0 qts. (1.90 liters)

Horsepower Rating 20.8 hp (15.5 kW)

Fuel Unleaded gasoline

Fuel Tank Capacity 9.5 gal (15.5 liters)

Operating Speed 3,250 ±50 rpm

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 9

Page 10

DIMENSIONS

E

H

D

I

G

B

A C

Figure 1. Roller Dimensions

Table 3. Dimensions (Roller)

Drum Diameter A 22.0 in. (559 mm.)

Curb Clearance (R and L) B 16.5 in. (419 mm.)

Drum Width C 35.6 in. (904 mm.)

Overall Height (with ROPS) D 95 in. (2,413 mm.)

Overall Length E 73.5 in. (1,867 mm.)

Wall Clearance (R and L) F 1.375 in. (35 mm.)

Drum Thickness G .38 in. (10 mm.)

Overall Width H 37 in. (940 mm.)

Steering Wheel I 58 in. (1,473.2 mm.)

PAGE 10 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 11

NOTES

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 11

Page 12

GENERAL INFORMATION

The AR14H roller has been designed for asphalt application

and compaction of granular soils used in site preparation.

Machine should only be used for the purpose intended and

by experienced personnel who understand this operation

manual and all safety decals. Typical applications for this

roller are compaction of base material, asphalt patching

and roadway construction.

Standard features included with this roller are compact

design, recessed drive motors,maintenance-free articulation

joint and vibrator assembly, easy-to-use controls, 34-gallon

(130 liters) water tank, and hour/tachometer.

POWER PLANT

The AR14H roller is powered by a Honda GX630, aircooled, gasoline engine rated at 20.8 hp @3,600 rpm.

The engine features a side-mounted muffler designed to

direct engine exhaust away from the operator. In the event

of low oil, this engine has a built in "oil alert system" that

will shut down if the engine oil level reaches an unsafe

operating level.

Connected to the axial hydraulic pump is a gear pump

that provides power for the drum vibratory system and the

articulating steering system. Oil from this pump flows to the

manifold control valve block and then to a hydraulic motor

which rotates the eccentric weights inside a sealed housing

containing grease to lubricate the bearings.

A toggle switch located on the side of the travel lever,

activates a valve that engages or disengages the vibratory

action. The drum's vibratory action generates 3,400 lbf

(15.1 kN) of centrifugal force at a frequency of 4,200 vpm

(vibrations per minute). If the vibration appears to be weak

or slow, allow the machine to warm up thoroughly, and

check the hydraulic oil level. Add hydraulic oil if necessary.

The vibrator housing and drum are shock mounted to

isolate the engine compartment and operator from vibration.

The roller nominally has an operating weight of 2,688 lb.

(1,219 Kg) but can be increased to 2,980 lb. (1,352 Kg) by

adding a water ballast to the rear drum.

HYDRAULIC OIL FILTER SYSTEM

HYDRAULIC SYSTEM

The Honda GX630 engine drives an axial hydraulics,

variable displacement pump which is manually controlled

via a cable control system. Pump flow is directed through

an aluminum block manifold which provides the control for

the 3 hydraulic motors.

The hydraulic drum drive system incorporates a series

closed loop configuration operating at a maximum pressure

of 2,900 psi. In addition this hydraulic system offers a "free

wheel valve" which allows the roller to be towed in the event

of an emergency.

The forward-reverse control lever operates the hydrostatic

pump which governs the roller speed and direction of

travel. The speed in which movement of this lever is made

is directly related to the amount of pressure that is applied

to the travel lever in each direction. Travel speed is infinitely

variable from 0 to 4.8 mph. The neutral position of this lever

will cause the roller to stop.

COMPACTION SYSTEM

The hydraulic system oil is filtered by a screen type filter

located in the reservoir filler neck, then doubled filtered

within the system first by a 40 micron mesh-type suction

filter located in the tank and the by a Zinga 10-micron,

cartridge style, spin-on return line filter.

ARTICULATED STEERING SYSTEM

Power for the articulated steering system, which uses a

single hydraulic cylinder, is provided by the gear pump.

This steering system can produce an inside turning radius

of 150 inches (3.81 meters).

SPRINKLER SYSTEM

A 34-gallon (130 liters) water tank, with a pressurized

feed spray bar, is provided for wetting the roller for asphalt

pavement rolling.

The water system is fully adjustable from the operator’s

position with a single volume control.

LIFTING THE ROLLER

The compaction force is delivered by a 35.6-inch wide steel

drum with beveled edges to help prevent asphalt marring.

A fully enclosed hydraulic drive system offers a variable

speed control as well as smooth acceleration and braking.

PAGE 12 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

When lifting of the roller is required, attach a

suitable hook or shackle to the lifting eyes of the

roller. These four lifting points are marked by a

lifting hook decal. Make sure the lifting device

is capable of lifting 4,000 lb. (1,814 Kg).

Page 13

GENERAL INFORMATION

DANGER

DO NOT allow personnel to stand under or near any

suspended machine. Before operating the roller, make

sure that personnel and obstacles are free from the

roller’s path. Serious injury or death may result.

CAUTION

ONLY use approved certified lifting devices capable of

lifting at least 4,000 lb. (1,814 Kg.).

CAUTION

When lifting of the roller is required, only use the

provided lifting eyes to lift the roller. Using other sections

of the roller for lifting purposes may cause severe

damage to the roller.

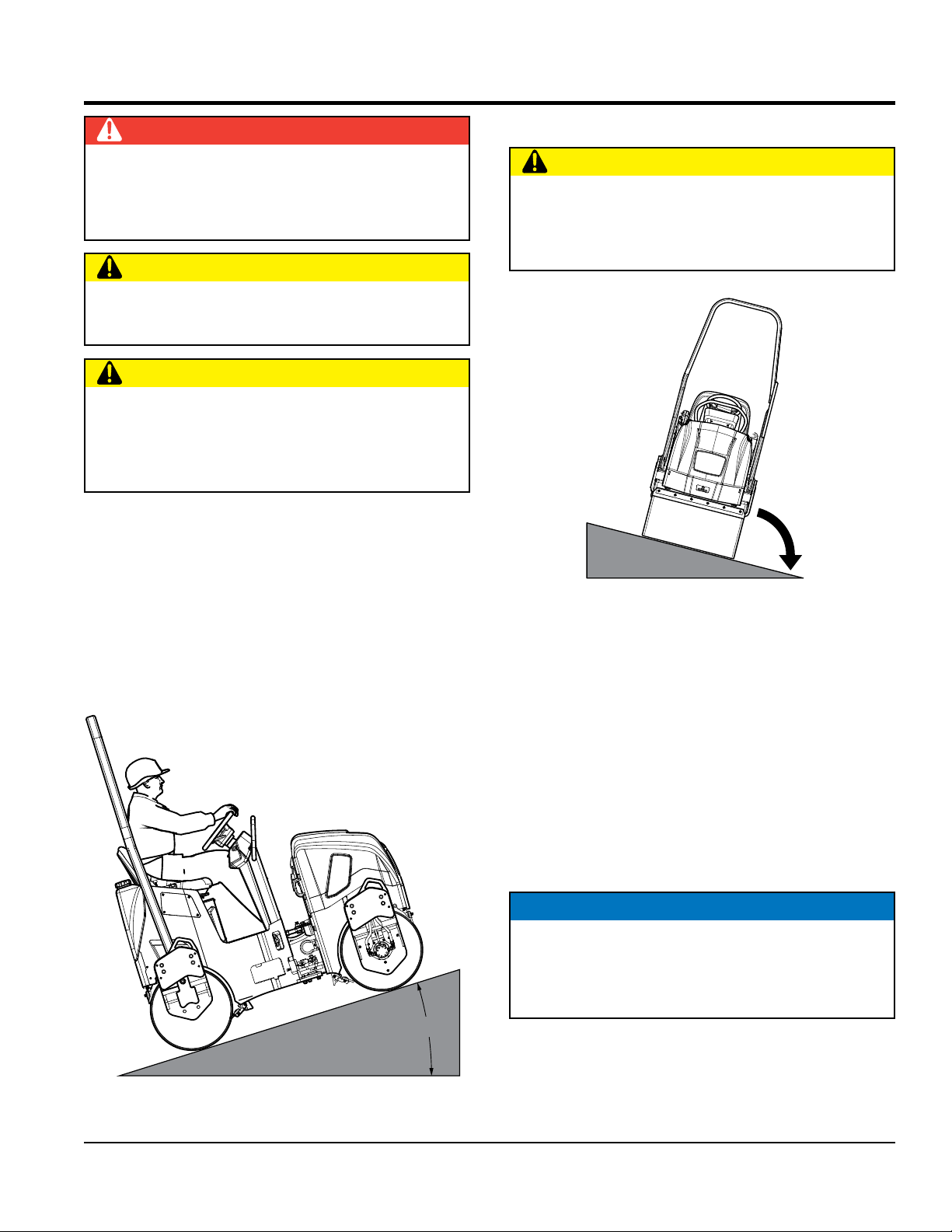

OPERATING ON SLOPES

Special care must be taken when operating the roller on

hills or slopes. There exists the possibility of serious injury

to the operator and severe damage to the roller in the event

of a roll over. ALWAYS operate the roller up and down hills

rather than from side to side. For safe operation, hillside

slopes should not exceed 14 degree (25 % grade). See

Figure 2. Always wear seat belt when operating the roller.

IMPROPER OPERATION ON SLOPES

CAUTION

NEVER operate the roller on side slopes (Figure 3). The

possibility exists that the roller could tip over (roll over),

thus causing bodily harm, even death, and serious

damage to the equipment.

SIDE TO SIDE

OPERATION

NOT

RECOMMENDED

ROLL OVER

Figure 3. Improper Operation on Slope

In the event the roller does tip over, if at all possible, try to

shut down the engine by turning the ignition key to the OFF

position. Extreme care must be taken to prevent damage

to the engine. When the roller has been tipped over, oil

from the engine crankcase can flow into the combustion

chamber, which can severely damage the engine the next

time it is started.

IMMEDIATELY after a unit has tipped over, upright the

unit as soon as possible to prevent oil from leaking into

the combustion chamber.

NOTICE

To prevent damage to the engine after a rollover, the

roller must not be started. NEVER start a roller after

a rollover. Contact your nearest authorized Multiquip

dealer for instructions or servicing.

25%

Figure 2. Recommended Slope

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 13

Page 14

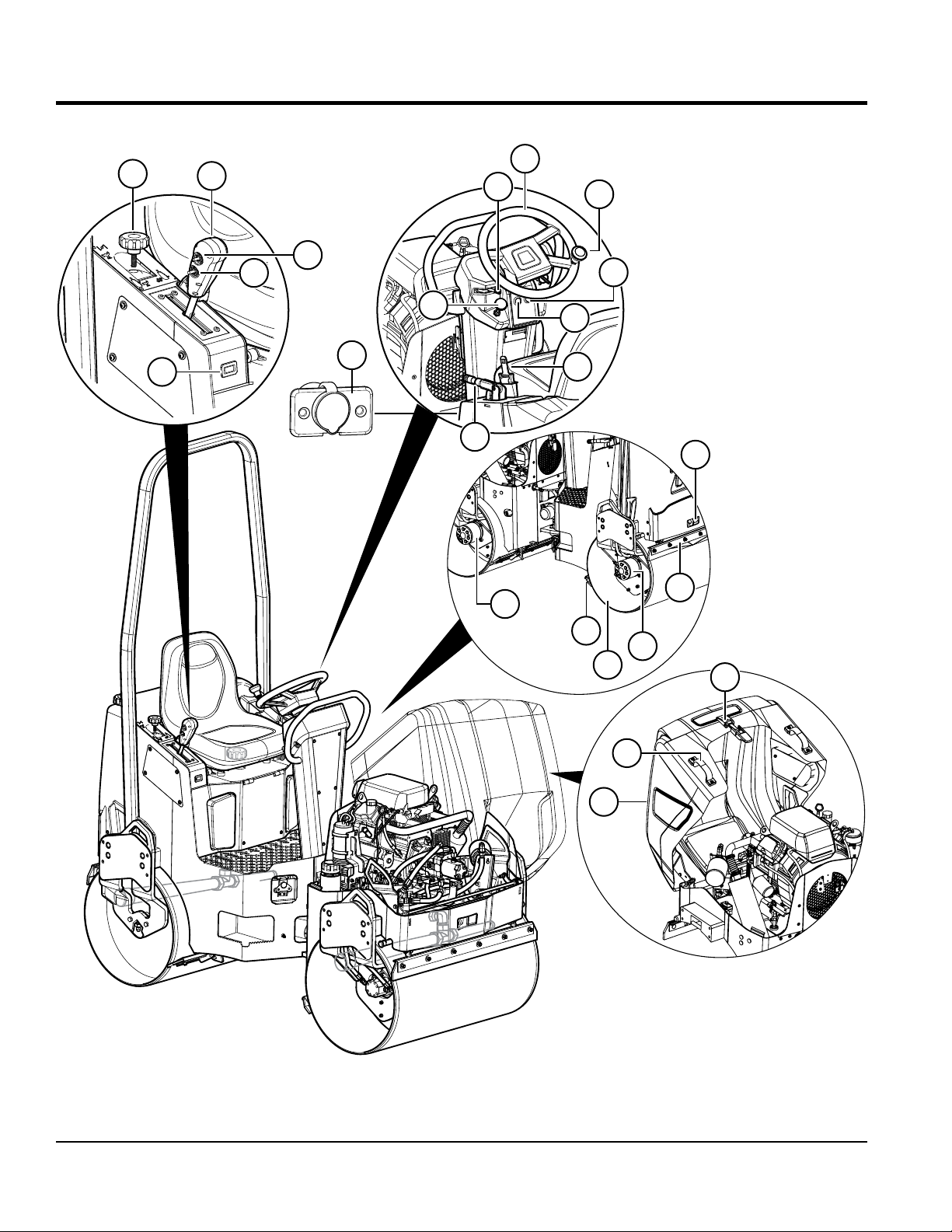

COMPONENTS

1

5

2

3

4

6

14

13

7

15

8

9

10

11

12

16

17

RIGHT SIDE

17

LEFT SIDE

15

18

21

20

19

Figure 4. Roller Components ( 1 of 3)

PAGE 14 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 15

COMPONENTS

Figure 4 shows the location of the components and controls

(1 of 3) for the AR14H compaction roller. The function of

each component or control is described below:

1. Water Volume Control Valve — This valve controls

the volume flow of water to the front and rear spray

bars. Turn the valve to the counterclockwise to increase

water flow and clockwise to decrease water flow.

2. Travel Lever — Push the lever forward to make

the roller travel in a forward direction. Pull the lever

backward to make the roller travel in a reverse direction.

Maximum travel speed is 4.8 MPH (7.7 KPH). Center

position is neutral; no travel.

3. Vibration Control Switch — Toggle switch to activate

the eccentric that will produce a vibration frequency of

4,200 vpm (vibrations per minute). Toggle switch again

to stop vibration.

4. Water Pump Switch — Activates the water pump. The

water pump indicator turns on.

5. Hour/Tachometer — Indicates the number hours the

unit has been in use when engine is off and RPM when

engine is running.

6. Choke Knob — Used in the starting of a cold engine,

or in cold weather conditions. The choke enriches the

fuel mixture.

7. Throttle Control — Slide control to the left to increase

engine rpm. Slide to the right to decrease engine rpm.

Slide all the way to the left to achieve maximum engine

rpm.

8. Steering Wheel — Use this wheel to steer the roller.

9. Steering Wheel Knob — Use this knob to move the

steering wheel with one hand.

10. Engine Oil Indicator — Lights to indicate low engine

oil level. The engine will automatically turn off. Add oil

as necessary.

11. Water Pump Indicator — Lights when the water

pump is on.

12. Seat Belt — When operating the roller, always have

the operator wear the seat belt. NEVER use the roller

without wearing a seat belt. If the seat belt becomes

worn or damaged, replace it immediately.

engage the parking brake. To release the parking brake,

push lever downward.

14. 12V Power Outlet — Charges small portable electronic

devices.

15. Hydraulic Motors — These hydraulic motors provide

forward/reverse drive for drums.

16. Tie-Down Transport Points (Front and Rear) —

Attach a chain or suitable tie-down device to these

when transporting of the roller is required.

TRANSPORT

TIE-DOWN POINT

17. Rear Drum Roller Scraper Bars (2) — Helps prevent

the buildup of material between the drum and frame.

The scraper bar is spring-loaded for easy change and

clean up. No tools are required.

18. Rear Drum — This is a 35.6-inch wide steel drum

with a diameter of 22 inches. It has beveled edges to

help prevent asphalt marring. The rear drum has a

water ballast allowing 34 gallons of water to add 292

of static force.

19. Compartment Hood — Houses the engine, hydraulic

manifold, accessory relay, hydraulic oil filter, hoses,

and hydraulic pump. To lift the compartment hood,

release the rubber bungee latch located on the front

of the hood.

20. Compartment Hood Lift Point — Place hand here

on either side of the roller then lift compartment hood.

21. Bungee Latch — Pull this rubber latch upward and

back to gain access to the engine/pump compartment.

13. Parking Brake Lever — Pull the lever upward to

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 15

Page 16

23

COMPONENTS

25

24

26

22

29

35

RIGHT SIDE

32

27

28

290

33

34

32

30

Figure 5. Roller Components (2 of 3)

30

31

16

PAGE 16 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 17

COMPONENTS

Figure 5 shows the location of components and controls

(2 of 3) for the AR14H compaction roller. The function of

each component or control is described below:

22. Water Tank — Unscrew tethered cap and fill tank with

water. Water tank capacity is 34 gallons (130 liters).

23. Operator's Seat — A contoured seat that provides

visibility of both front and rear drum edges during

operation. NEVER start the roller unless seated in the

operator's seat. The seat has a detent that holds it in

place when lifted for refueling.

24. Cup Holder — Holds standard travel mugs.

25. Roll-Over Bar — This unit is equipped with a Roll

Over Protection System (ROPS) to protect the operator

when the roller is used on slopes.

26. Hand Rail — Grab hold of this hand rail when lifting

yourself onto the operator's platform.

27. Fuel Tank/Fuel Gauge — The fuel capacity of the fuel

tank is 9.5 gallons (36 liters). Fill with unleaded-type

gasoline. There is a gauge on top of the fuel cap to

indicate if fuel level is low. To gain access to the fuel

tank, tilt the front seat forward. Fuel tank has a spill

containment feature.

29. Lifting Points (4) — Attach a crane or suitable lifting

device to these points when lifting of the roller is

required.

30. Front Drum Roller Scraper Bars (2) — Helps prevent

the buildup of material between the drum and frame.

The scraper bar is spring-loaded for easy change and

clean up. No tools are required.

31. Front Drum — This is a 35.6-inch wide steel drum

with a diameter of 22 inches. It has beveled edges to

help prevent asphalt marring. The vibratory assembly

is built into the front drum.

32. Front and Rear Sprinkler System — Pressurized

spray bars are provided for wetting the roll for asphalt

pavement.

33. Platform Latch — Used to release platform to gain

access to the battery, water pump, water filter, and fuel

shut-off valve.

34. Foot Step — To lift yourself onto the roller's platform,

place foot into foot step, then grab hold of hand rail.

35. Rear Drum Grease Zerk Fitting — Grease this fitting

biweekly. See maintenance section of this manual.

28. Seat Adjustment Knob — Allows operator's seat to

be adjusted (slide seat forward or backward).

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 17

Page 18

38

COMPONENTS

39

37

44

36

45

46

47

48

40

41

43

42

49

50

51

59

55

58

57

Figure 6. Roller Components (3 of 3)

57

56

52

54

53

PAGE 18 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 19

COMPONENTS

Figure 6 shows the location of components and controls

(3 of 3) for the AR14H compaction roller. The function of

each component or control is described below:

36. Battery — Provides +12VDC to the electrical system,

and is located underneath foot plate. Replace only with

recommended type battery.

37. Water Filter — Filters the water in the water pump.

38. Water Pump — Provides pressure to the water

sprinklers to allow even distribution of water on the

drums.

39. Fuel Shut-Off Valve — Stops the flow of fuel.

40. Accessory Relay — Provides the +12VDC necessary

to run the electrical accessories.

41. Fuse (10 Amp) — Povides overcurrent protection for

the water pump.

42. Fuse (30 Amp) — Provides overcurrent protection for

the starter.

43. Fuse (20 Amp) — Provides overcurrent protection for

the 12V outlet.

44. Articulating Locking Latch — Secures the front and

rear sections of the roller when lifted during transport

and maintenance.

45. Ignition Switch — With key inserted, turn clockwise

to start the engine.

46. Engine Oil Drain — Used to drain oil from the engine.

47. Engine — This unit incorporates a HONDA

GX630RHKAF, air-cooled engine rated at 20 hp at

3,200 rpm.

48. Charcoal Canister — Keeps gasoline from evaporating

into the atmosphere. The carbon in the canister absorbs

the fuel vapor.

49. Hydraulic Oil Filter — Filters return oil from the front

and rear hydraulic motors.

50. Hydraulic Pump — This unit incorporates an axial

variable displacement hydraulic piston pump.

51. Gear Pump — Controls vibration and steering.

52. Hydraulic Manifold — Aluminum block that controls

the flow of hydraulic pressure to the various hydraulic

motors and other components required to control the

roller.

53. Hydraulic Motor — This hydraulic motor controls the

rotation of the vibratory system.

54. Hydraulic Fluid Filler Port — Remove this cap to

add hydraulic fluid. Fill with type ISO 46 anti-wear

hydraulic fluid.

55. Hydraulic Oil Level Indicator — Indicates the amount

of hydraulic oil present.

56. Hydraulic Oil Drain — Used to drain used hydraulic

oil when oil replacement is necessary.

57. Steering Cylinder Grease Zerk Fitting — Grease

this fitting biweekly. See maintenance section of this

manual.

58. Steering Cylinder — Controls direction of roller.

59. Documentation Canister — Store and maintain

Operation, Parts, and Engine manuals in this container

at all times.

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 19

Page 20

BASIC ENGINE

6

4

3

2

5

1

Figure 7. Engine Components

The engine (Figure 7) must be checked for proper

lubrication and filled with fuel prior to operation. Refer to the

manufacturer's engine manual for operation and servicing

information.

1. Oil Drain Plug — Remove to drain crankcase oil. Fill

with recommended type oil as listed in Table 4.

2. Oil Filter — Spin-on type, filters oil for contaminants.

3. Spark Plug — Provides spark to the ignition system.

Set spark plug gap to 0.6 - 0.7 mm (0.028 - 0.031 inch)

Clean spark plug once a week.

4. Lifting Hook Eye — Attach a lifting device of adequate

lifting capacity at this lifting point whenever lifting of the

engine is required.

7

4

9

8

10

5

1

5. Fuel Filter — Prevents dirt and other debris from

entering the fuel system.

6. Air Filter — Prevents dirt and other debris from

entering the fuel system. Unsnap air filter cover to gain

access to filter element.

7. Oil Filler Cap — Remove to add engine oil.

8. Oil Dipstick — Remove to check amount and condition

of oil in crankcase. Refill or replace with recommended

type oil as listed in Table 4.

9. Starter/Solenoid — Starts engine when ignition key

is rotated to the ON position.

10. Oil Cooler — Helps keep engine oil cooler for longer

engine life.

PAGE 20 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 21

INSPECTION

BEFORE STARTING

1. Read safety instructions at beginning of manual.

2. Clean the roller, removing dirt and dust, particularly

the engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty,

replace air filter with a new one.

4. Check carburetor for external dirt and dust. Clean with

dry compressed air.

5. Check fastening nuts and bolts for tightness.

ENGINE OIL CHECK

1. To check the engine oil level, place the roller on secure

level ground with the engine stopped.

2. Remove the dipstick from its holder (Figure 8) and

wipe it clean.

DIPSTICK

3. Check the oil level shown on the dipstick (Figure 9).

Figure 9. Engine Oil Dipstick Level

4. If the oil level is low, remove the oil filler cap (Figure 10)

and fill to the safe operating level (max) as indicated by

the dipstick. Fill with recommended type oil as listed in

Table 4. Maximum oil capacity is 1.9 quarts (1.8 liters).

Figure 8. Engine Oil Dipstick (Removal)

Table 4. Oil Type

Season Temperature Oil Type

Summer 25°C or Higher SAE 10W-30

Spring/Fall 25°C~10°C SAE 10W-30/20

Winter 0°C or Lower SAE 10W-10

OIL FILLER CAP

Figure 10. Engine Oil Filler Port

NOTICE

The HONDA GX630 engine used on this roller has an

"Oil Alert System". This system will automatically stop

the engine in the event of low oil level. ALWAYS check

the engine oil level prior to starting the engine.

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 21

Page 22

INSPECTION

FUEL CHECK

DANGER

Motor fuels are highly flammable and can

be dangerous if mishandled. DO NOT

smoke while refueling. DO NOT attempt

to refuel the machine if the engine is hot

or running.

1. To check the engine fuel level, place the roller on secure

level ground with the engine stopped.

2. Tilt the operator's seat (Figure 11) forward to gain

access to the fuel tank. The seat is equipped with a

latch that keeps the seat locked in place when tilted

forward.

TILT DRIVER’S SEAT

FORWARD

SEAT

3. Read the fuel gauge (Figure 12) located on top of the

filler cap to determine if fuel level is low.

Figure 12. Fuel Gauge

4. If the fuel level is low, remove the fuel filler cap and

fill with unleaded gasoline. Wipe up any spilled fuel

immediately.

5. Pay attention to the fuel tank capacity when replenishing

fuel. Refer to the fuel tank capacity listed on the

specifications table.

6. After replenishing fuel, make sure filler cap is securely

tightened to fuel tank. Return operator's seat to normal

operating position.

HYDRAULIC OIL CHECK

SEAT

LATCH

ENGAGED

Figure 11. Fuel Tank Access

FUEL FILLER

NECK

1. To check the hydraulic oil level, place the roller on

secure level ground with the engine stopped.

2. Visually inspect the hydraulic oil sight glass (Figure 13)

located on the right rear of the front drum. For normal

operation the hydraulic oil level must be below the

top and above the bottom of the sight glass. DO NOT

OVERFILL!

NORMAL

LEVEL

HYDRAULIC

OIL LEVEL

SIGHT GLASS

LOW LEVEL

ADD

HYDRAULIC

OIL

Figure 13. Hydraulic Oil Sightglass

PAGE 22 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 23

INSPECTION

3. If the hydraulic oil level is low, remove the hydraulic

oil cap (Figure 14) and fill with type ISO 46 anti-wear

type hydraulic oil to the recommended operating level.

HYDRAULIC

OIL CAP

HYDRAULIC

OIL

HYDRAULIC OIL

FILLER NECK

Figure 14. Hydraulic Oil Reservoir Filler Port

BATTERY CHECK

ALWAYS be sure that the battery cables are properly

connected to the battery terminals as shown in Figure 16.

Generally the RED cable will be connected to the positive

terminal of the battery, and the BLACK cable will be

connected to the negative terminal of the battery.

POSITIVE

RED

NEGATIVE

BLACK

WATER TANK CHECK

1. Visually inspect the water level in the water tank. When

the water level is low, water needs to be added to the

water tank (Figure 15). Total tank capacity is 34 gallons

(130 liters.)

NOTICE

During freezing weather conditions, drain water from

system to prevent component damage.

WATER TANK

CAP

WATER TANK

Figure 16. Battery

NOTICE

If the battery cables are connected incorrectly, electrical

damage will occur causing damage to the roller's

electrical circuits. Pay close attention to the polarity of

the battery when connecting the battery.

Figure 15. Water Tank

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 23

Page 24

OPERATION

STARTUP

NOTICE

DO NOT attempt to operate the roller until the Safety,

General Information and Inspection sections have been

read and understood.

1. Place your foot into the roller's foot step, grab hold of

the hand rail located on the steering console, and lift

yourself onto the platform.

2. Sit down in the operator's seat and adjust the seat

for a comfortable position, then fasten the seat belt

(Figure 17) around your waist. NEVER operate the

roller without the seat belt being fastened. Serious

injury could occur if the seat belt is not used.

FASTEN

SEAT BELT

5. In cold weather, start the roller with the choke fully

closed. In warm weather or when the engine is

warm, the roller can be started with choke halfway or

completely open.

PULL UP

TO CLOSE

PUSH DOWN

TO OPEN

Figure 17. Securing Seat Belt

3. Before starting engine, make sure the immediate area

is free of obstructions and debris that may lay in the

roller's path.

4. Make sure that the roller's travel lever (Figure 18) is

placed in the neutral position.

NEUTRAL

Figure 19. Choke Knob

6. Slide the throttle control (Figure 20) all the way to the

left for maximum rpm.

THROTTLE

CONTROL LEVER

FAST

SLOW

Figure 18. Travel Lever (Neutral)

Figure 20. Throttle Control

PAGE 24 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 25

OPERATION

7. Insert the ignition key into the ignition (Figure 21), then

turn and hold the key in the clockwise position until the

engine starts, release key.

OFF

ON

START

IGNITION

KEY

Figure 21. Ignition Switch

8. If the engine does not start, repeat steps 1 through 7

or consult the troubleshooting guide contained in this

manual.

9. Depending on weather conditions, let the engine warm

for 3 to 5 minutes before using roller. Check for fuel

and oil leaks, and noises that would associate with a

loose guard and/or covers.

10. If necessary, return the choke knob to the full OPEN

position.

NOTICE

The CLOSED position of the choke knob enriches the

fuel mixture for starting a COLD engine. The OPEN

position provides the correct fuel mixture for normal

operation after starting, and for restarting a warm

engine.

PARKING BRAKE

1. To release the parking brake, push the parking brake

lever all the way down (Figure 22).

LOCK POSITION

PULL UPWARD

TRAVEL LEVER

1. To make the roller move in a forward direction, move

the travel lever forward as shown in Figure 23.

FORWARD

POSITION

NEUTRAL

POSITION

REVERSE

POSITION

Figure 23. Travel Lever (Moving)

2. Remember the speed of the roller is directly proportional

to the amount of pressure being applied to the lever

in each direction. Travel speed is between 0 and 4.8

mph (7.2 kph).

NOTICE

ALWAYS allow the roller to come to a complete stop

before changing the direction of travel. Changing

directions before the roller comes to a complete stop

will result in excessive force being applied to the

transmission and drive system, which will reduce the

service life of the system.

3. Try maneuvering the roller a few times to get familiar

with the handling. Also place the travel lever in the

opposite direction to get acquainted with driving in

reverse.

4. Make sure that the roller comes to a complete stop

(neutral) before placing the travel lever in either a

forward or reverse position.

RELEASE POSITION

PUSH DOWN

Figure 22. Parking Brake

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 25

Page 26

OPERATION

VIBRATION BUTTON

1. To begin the vibratory action, toggle the vibratory switch

located on the right side of the travel lever as shown

in Figure 24. This will generate 3,400 lbf. (15.1 kN) of

centrifugal force at a frequency of 4200 vpm (vibrations

per minute) to the front drum.

VIBRATION

SWITCH

Figure 24. Vibration Toggle Switch

2. A water volume control valve for the sprinklers is

provided. This control valve (Figure 26) is located

right below the travel lever. The valve controls the

water supply simultaneously to the front and rear drum

spray bars.

a. To increase water volume, turn the control valve

counterclockwise.

b. To decrease water volume, turn the control valve

clockwise.

2. To stop the vibratory action, toggle the vibratory switch

again.

WATER PUMP AND VOLUME CONTROL VALVE

When wetting of a surface is required, perform the following

procedure.

1. Turn on the water pump switch (Figure 25) to activate

the water pump. The water pump indicator will light.

WATER

PUMP

SWITCH

WATER VOLUME

CONTROL VALVE

Figure 26. Water Volume Control Valve

Figure 25. Water Pump Switch

PAGE 26 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 27

Perform roller maintenance as indicated by Figure 27 and Table 5.

Yearly

6 Months

3 Months

Bi-Weekly

Weekly

Daily

3

2

MAINTENANCE

1

2

3

4

5

6

7

8

9

10

11

12

13

5

6

7

6

10

12

11

10

5

6

7

6

1

4

9

8

13

Figure 27. Roller Maintenance Schedule

Table 5. Roller Maintenance Schedule

Daily Notes

Engine Oil Level See Table 4

Water Tank Level

Fuel Level

Hydraulic Oil Level Use ISO 46 Type Hydraulic Oil

Sprinkler System

Scraper Replace when badly worn

Drums (Front/Rear)

Weekly

Air Filter Replace paper element once a year.

Battery Electrolyte Level

Bi Weekly

Grease Zerk Fittings Use Type Alvania #2 or equivalent -3 shots max. DO NOT overgrease

3 Months

Hydraulic Oil Filter (Return) Replace with same type filter.

6 Months

Engine Oil Filter After first 20 hrs, change oil filter every 6 months or 100 hrs.

Yearly

Hydraulic Oil Use ISO 46 Type Hydraulic Oil

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 27

Page 28

MAINTENANCE

HYDRAULIC OIL SYSTEM

The hydraulic system consists of a two-pump stack directly

coupled to the engine. A hydraulic valve block (manifold)

is provided for quick and easy testing and troubleshooting.

Hydraulic oil is filtered by a screen filter located in the tank

filler neck, a 40 micron suction filter located in the tank, and

a 10 micron return filter, with cold oil bypass valve located

in the return circuit.

It is recommended that ISO 46 type hydraulic oil or

equivalent be used when adding or replacing the hydraulic

oil is required.

DO NOT USE MULTI-VISCOSITY OIL. Clean oil is a

very important part of proper hydraulic system operation.

Hydraulic oil is not only used to transfer power; it also

lubricates and cools the system components. Keeping

the hydraulic system clean can help reduce costly repairs.

The hydraulic oil level sight glass is located on the right

rear of the front drum, below the engine compartment. This

level should be checked daily. Oil must be below the top and

above the bottom of the sight glass. DO NOT OVERFILL!

Care should be taken to clean the filler cap before adding oil

to the system. If hydraulic oil has to be added, the machine

should be inspected for leaks.

2. Remove the hydraulic oil drain plug (Figure 28) and

drain the hydraulic oil. Dispose of the used oil in an

environmentally friendly manner. Replace the drain

plug and tighten.

HYDRAULIC OIL

RETURN FILTER

HYDRAULIC OIL

CAP/FILLER PORT

HYDRAULIC OIL

DRAIN PLUG

Figure 28. Hydraulic Filter Locations

The suction filter (Figure 28) is located inside the hydraulic

tank. This filter is attached to the fitting connected to the

hydraulic pump suction hose.

The return filter (Figure 28) is located at the front of the

engine compartment. Replace both filters according to the

Table 5.

CAUTION

DO NOT open hydraulic lines or loosen hydraulic fittings

while engine is running! Hydraulic fluid under pressure

can penetrate the skin, blind, cause burns or create

other potentially dangerous hazards follow all safety

instructions as described throughout this manual.

CHANGING HYDRAULIC OIL AND FILTERS

1. Park the roller on a clean flat work area and set the

parking brake.

3. Remove the return filter and install a new filter. Dispose

of the used filter in an environmentally friendly manner.

4. Disconnect the suction hose and remove the fitting from

the tank. Replace the suction filter. Dispose of the used

filter in an environmentally friendly manner. Replace

the fitting and reconnect the suction hose.

FREEWHEEL ENGAGEMENT VALVE

NOTICE

The freewheel engagement valve (towing) is only for

emergency use. DO NOT move roller over 2 MPH or

long distances as hydraulic system component failure

could result.

This hydraulic system has a freewheel engagement valve

allowing hydraulic oil to be bypassed. Open (turn allen

wrench counterclockwise) this valve (Figure 29) to engage

the freewheel capability of the roller. When the valve is fully

opened, ports A and B are allowed to connect, bypassing

the oil to and from the drum drive motors.

PAGE 28 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 29

MAINTENANCE

ALLEN

WRENCH

OPEN

CLOSED

FREEWHEEL

ENGAGEMENT

VA LV E

Figure 29. Freewheel Engagement Valve

Remember the freewheel engagement valve should only

be used in emergencies when the roller cannot be driven

due to engine or hydraulic system problems.

When towing of the roller has been completed, this

valve must be closed (turn allen wrench fully clockwise)

completely and the lock nut set. Failure to close this valve

completely will result in low power, improper speed, and

excessive hydraulic oil temperature.

DRUM DRIVE

VIBRATION AND STEERING

The vibration and steering system is an open loop circuit

operated by a gear type pump. Separate relief valves control

each circuit. This system consist of the gear pump, relief

valves, electric vibration control valve, vibration drive motor,

steering valve, and steering cylinder.

The vibration circuit is controlled by an electric control

valve located on the valve block (manifold). This valve is

controlled by the toggle switch mounted on the travel lever.

High-pressure oil is supplied by the pump to the valve

block (port P) and is directed to the electric control valve.

When the switch is in the “OFF” position, this valve is open

allowing oil to go to the steering valve, without driving the

vibration motor.

When the switch is in the “ON” position, the electric control

valve closes and oil is directed out of port 1 to the vibration

motor. Return oil from the motor returns to the valve block

via port 2 and is directed to the steering valve.

Steering is controlled by a steering valve and cylinder.

The steering wheel is direct coupled to the steering valve

controlling the oil flow to the cylinder. Oil supplied from the

vibration circuit is directed to port 3 which connects to port

P of the steering valve. When steering is not being used,

oil passes out of port T of the valve block and returns to

the hydraulic tank. When the steering wheel is operated,

the steering valve closes and oil is directed to ports L or R

to extend or retract the steering cylinder.

The drum drive circuit is a series, closed loop system

consisting of a hydrostatic pump, two relief valves, a

freewheel engagement valve, and front and rear drum

drive motors.

The hydrostatic pump is manually controlled by a cable

connected to the forward/reverse travel lever located on

the right side of the operator seat. When the travel lever

is placed in forward, high-pressure oil is supplied by the

hydrostatic pump to the valve block (port A). The valve

block (manifold) directs this high-pressure oil to the front

and rear drum drive motors. Return oil from the motors is

returned to the valve block (port B) and is returned to the

suction side of the hydrostatic pump.

With the travel lever in reverse position, oil will flow in the

opposite direction (port B becomes high-pressure and port

A becomes suction).

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 29

Page 30

MAINTENANCE

RUBBER SCRAPER MAT

Rubber scraper mats have been provided for the cleaning of

the front and rear drums. Adjust the scraper mats as close

as possible to the drums, using the slotted holes (Figure 30)

provided. Replace these rubber mats when they become

badly worn. The scraper bars are spring-loaded for easy

change-out of rubber mats.

NOTICE

In order for the front scraper bar to lock in place, for

easy scraper change, the springs on the inside of the

engine cover must be removed.

SPRING (4)

2. Check hydraulic oil level by viewing the hydraulic oil

sight glass. The hydraulic oil level must be below the

top and above the bottom of the sight glass. DO NOT

OVERFILL!

3. Adjust engine RPM (3,250 ± 50 RPM).

4. Let engine run for 5 to 10 minutes, this will bring the

hydraulic oil operating temperature to a minimum of

135° F.

5. Check and repair all hydraulic leaks.

6. On the manifold block, install a 5,000 psi pressure

gauge (Figure 31) to the forward pressure quick

disconnect test port 2.

7. Run engine at full throttle.

8. Move the travel lever to the forward position. MAKE

SURE FRONT AND REAR DRUMS DO NOT SPIN.

9. Read the pressure gauge. The relief pressure (roller

drums blocked) will read 2,900 ± 145 psi. Under normal

operating conditions this pressure will read 400-600 psi.

ROLLER

RUBBER

SCRAPPER

RUBBER

SCRAPPER

Figure 30. Scraper Bar Adjustment

FORWARD/REVERSE HYDRAULIC PRESSURE

TEST

1. Park the machine on a solid flat surface and stop the

engine. Set the parking brake and block the front drum

securely.

10. Return the travel lever to the neutral position and stop

the engine.

11. Install the pressure gauge into the reverse quick

disconnect port 3 and repeat the above procedures.

The relief pressure reading for the reverse test port 3

will be the same (2,900 psi). Again normal operation

pressure for the reverse port will be 400-600 psi.

12. Normal operating pressures are based on the machine

traveling on level, firm surface. The operating pressures

will increase significantly when traveling uphill.

VIBRATION CIRCUIT PRESSURE TEST

1. Place the front drum on soil, gravel, or a heavy rubber

mat. DO NOT ACTIVATE VIBRATION FEATURE ON

CONCRETE OR HARD SURFACE!

2. On the manifold block install a 5,000 psi pressure

gauge to quick disconnect test port 1.

3. Start the engine and run at full throttle.

4. To start the vibration, toggle the vibration switch on

the travel lever. Under normal operating conditions this

pressure will range between 900-1,500 psi.

PAGE 30 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 31

MAINTENANCE

NOTICE

Vibration relief pressure is hard to read accurately using

this test. It may be necessary to disconnect the pressure

line to the vibration drive motor. Plug this line and retest,

pressure will be exact relief pressure. DO NOT perform

this test for a long period of time — damage could occur.

STEERING PRESSURE TEST

1. On the manifold block, install a 5,000 psi pressure

gauge into quick disconnect test port 1 (Figure 31).

2. Start the engine and run at full throttle.

3. Turn the steering wheel to the left or right (maximum)

and hold. Read the steering relief pressure. The relief

pressure reading for the steering test port 1 will be 700

psi. Again, under normal operating conditions, pressure

for the steering port will be between 200-400 psi.

4. If maximum pressure cannot be reached, plug the

steering cylinder pressure hoses and retest. If pressure

is correct, the steering cylinder is leaking. DO NOT

ACTIVATE THE VIBRATION FUNCTION WHILE

PERFORMING THIS TEST!

STEERING RELIEF VALVE PRESSURE ADJUSTMENT

To adjust the relief valve steering pressure perform the

following:

1. Insert an 8 mm allen wrench into steering relief port 4

(Figure 36) on the manifold block.

8 MM ALLEN

WRENCH

STEERING

RELIEF

VALVE

(PORT 4)

MANIFOLD

BOLD

8 MM ALLEN

WRENCH

ADJUSTMENT

SCREW

VIBRATORY

RELIEF

VALVE

(PORT 5)

MANIFOLD

BLOCK

Figure 31. Manifold Test Ports

TEST

PORT 2

TEST

PORT 1

TEST

PORT 3

5000 PSI

PRESSURE

GAUGE

2000

3000

1000

200

150

4000

100

250

50

300

bar

5000

psi

WIKA

Figure 32. Steering and Vibration Relief Valves

2. On the manifold, connect at 5,000 psi pressure gauge

into quick disconnect test port 1.

3. Start the engine and run at full throttle.

4. Turn the steering wheel to the left or right (maximum)

and hold. Read the steering relief pressure. The relief

pressure reading for the steering test port 1 will should

be 700 psi.

5. If the steering relief pressure is not 700 psi, using the

allen wrench adjust the pressure at port 4 until the

pressure gauge reads 500 psi.

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 31

Page 32

MAINTENANCE

VIBRATION RELIEF VALVE PRESSURE

ADJUSTMENT

1. Insert an 8 mm allen wrench into steering relief port 5

(Figure 32) on the manifold block.

2. On the manifold block, insert a 5,000 psi pressure

gauge into quick disconnect test port 1.

3. Start the engine and run at full throttle.

4. To start the vibration, toggle the vibration switch located

on the travel lever. The relief pressure should read

900 - 1,500 psi.

5. If the vibration relief pressure is not 900 - 1,500 psi,

using the allen wrench, adjust the pressure at port 5

until the pressure gauge reads correctly.

REMOVING AND REPLACING HYDROSTATIC PUMP

1. Set the parking brake.

2. Disconnect the battery.

3. Clean the pump and all connections.

4. Mark and disconnect all hoses and lines from the pump.

5. Disconnect the forward / reverse control cable.

6. Disconnect the pump support bracket.

7. Remove the engine mounting bolts.

REMOVING AND REPLACING VIBRATION/

STEERING PUMP

1. Remove the hydrostatic pump as per preceding

instructions.

2. Remove all hoses and lines.

3. Disconnect the vibration / steering pump and remove.

4. Repair or replace pump as required.

5. Install the pump in the reverse order of removal, using

Locktite 271 on all mounting bolts and nuts.

6. Test operation. Test and adjust the forward and reverse

pressure relief valves as required. Adjust the forward/

reverse control cable. Test and adjust the vibration and

steering pressure relief valves as required.

DRUMS AND MAIN FRAME

1. The front drum is designed to apply vibration and

compaction force to the operating surface for

compaction. This vibration and compaction force is

produced when the vibrator shaft is rotated. Maximum

efficiency is achieved only when the engine is operated

at full throttle.

2. A single drive motor is mounted on the left side of the

drum and is shock mounted. This type of drive motor

is designed for maximum torque and power.

8. Elevate the pump and engine assembly using a proper

lifting device.

9. Disconnect and remove the hydrostatic pump assembly.

10. Repair or replace the hydrostatic pump as required.

11. Install the hydrostatic pump in the reverse order of

removal, using Locktite 271 on all mounting bolts and

nuts.

12. Test operation. Test and adjust the forward and reverse

relief pressures as required. Adjust the forward/reverse

control cable.

PAGE 32 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

3. The vibrator is driven by a gear motor coupled to the

vibrator shaft. The vibrator assembly rotates inside of a

sealed housing containing oil to lubricate the bearings.

This side of the drum is also shock mounted.

FRONT AND REAR DRUM DISASSEMBLY

Refer to Figure 33, Figure 34, Figure 35, and Figure 36

for the disassembly of the front and rear drums to access

different components that may need to be replaced.

Page 33

Figure 33 shows the removal of the exciter assembly from

the right side of the front drum.

STEP 1

MAINTENANCE

STEP 4

COVER

STEP 2

1. JACK FRAME UP SLIGHTLY AT ARTICULATION

JOINT.

2. REMOVE 4 ALLEN HEAD SCREWS HOLDING THE

COVER OF THE DRUM SUPPORT PLATE AND

REMOVE COVER.

5. REMOVE 6 NUTS SECURING THE 3

SHOCK MOUNTS TO THE SUPPORT

PLATE. REMOVE THE SUPPORT

PLATE.

NOTE: MOTOR OR SHOCK MOUNTS

CAN BE REMOVED AND REPLACED

AT THIS POINT.

6. REMOVE THE 6 BOLTS SECURING

THE EXCITER PLATE TO THE

DRUM WALL.

7. PULL EXCITER ASSEMBLY TO

REMOVE FROM DRUM INTERIOR.

STEP 3

DRUM

SUPPORT

PLATE

3. MARK AND DISCONNECT HOSES FROM MOTOR

AND MANIFOLD.

4. REMOVE FOUR BOLTS FROM DRUM SUPPORT

PLATE. (BOLTS MAY NEED TO BE HEATED TO

REMOVE).

FRONT DRUM

STEP 7

STEP 6

EXCITER

ASSEMBLY

EXCITER PLATE

MOTOR

8. REVERSE PROCEDURE TO

INSTALL EXCITER ASSEMBLY

AND REASSEMBLE DRUM. USE

LOCKTITE 271 ON ALL BOLT

THREADS.

Figure 33. Exciter Assembly Removal/Installation (Front Drum - Right Side)

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 33

STEP 5

DRUM

WALL

SHOCK MOUNTS

Page 34

STEP 6

STEP 4

SHOCK

MOUNT

MOTOR

DRUM

SUPPORT

PLATE

FRONT DRUM

Figure 34 shows the removal of the motor and shock

mounts from the left side of the front drum.

STEP 1

STEP 2

COVER

MAINTENANCE

STEP 3

STEP 5

DRUM

SUPPORT

PLATE

1. JACK FRAME UP SLIGHTLY AT ARTICULATION

JOINT.

2. REMOVE 4 ALLEN HEAD SCREWS HOLDING THE

COVER OF THE DRUM SUPPORT PLATE AND

REMOVE COVER.

3. REMOVE FOUR BOLTS FROM DRUM SUPPORT

PLATE. (BOLTS MAY NEED TO BE HEATED TO

REMOVE).

4. REMOVE 4 BOLTS SECURING MOTOR TO THE

SUPPORT PLATE.

5. MARK AND DISCONNECT HOSES

FROM MOTOR AND MANIFOLD.

REMOVE MOTOR AS NECESSARY.

6. REMOVE AND REPLACE SHOCK

MOUNTS AS NECESSARY.

7. REVERSE PROCEDURE TO INSTALL

MOTOR OR SHOCK MOUNTS.

REASSEMBLE DRUM. USE LOCKTITE

271 ON ALL BOLT THREADS.

Figure 34. Motor and Shock Mounts Removal/Installation (Front Drum - Left Side)

PAGE 34 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 35

Figure 35 shows the removal of the bearing from the right

side of the rear drum.

STEP 2

MAINTENANCE

COVER

DRUM

SUPPORT

STEP 3

4. REMOVE THE BEARING.

5. REVERSE PROCEDURE TO INSTALL BEARING AND

REASSEMBLE DRUM. USE LOCKTITE 271 ON ALL

BOLT THREADS.

PLATE

STEP 1

1. JACK FRAME UP SLIGHTLY AT ARTICULATION

JOINT.

2. REMOVE 4 ALLEN HEAD SCREWS HOLDING THE

COVER OF THE DRUM SUPPORT PLATE AND

REMOVE COVER.

3. REMOVE FOUR BOLTS FROM DRUM SUPPORT

PLATE. (BOLTS MAY NEED TO BE HEATED TO

REMOVE).

REAR DRUM

STEP 4

BEARING

DRUM

SUPPORT

PLATE

Figure 35. Bearing Removal/Installation (Rear Drum - Right Side)

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 35

Page 36

STEP 3

Figure 36 shows the removal of the motor from the left side

of the rear drum.

DRUM

SUPPORT

PLATE

STEP 6

MAINTENANCE

COVER

STEP 2

STEP 7

MOTOR

STEP 5

STEP 1

1. JACK FRAME UP SLIGHTLY AT ARTICULATION

JOINT.

2. REMOVE 4 ALLEN HEAD SCREWS HOLDING THE

COVER OF THE DRUM SUPPORT PLATE AND

REMOVE COVER.

3. REMOVE FOUR BOLTS FROM DRUM SUPPORT

PLATE. (BOLTS MAY NEED TO BE HEATED TO

REMOVE).

4. REMOVE 2 SMALL NUTS FROM THE LOWER PART

OF THE DRUM SUPPORT PLATE.

5. REMOVE LARGE NUT FROM THE LOWER PART OF

THE DRUM SUPPORT PLATE.

Figure 36. Motor Removal/Installation (Rear Drum - Left Side)

STEP 4

STEP 8

6. REMOVE 2 BOLTS FROM THE LOWER PART OF

THE DRUM SUPPORT PLATE. REMOVE DRUM

SUPPORT PLATE.

7. MARK AND DISCONNECT HOSES FROM MOTOR

AND MANIFOLD.

8. REMOVE FOUR BOLTS SECURING MOTOR TO THE

DRUM SUPPORT PLATEPLATE. REMOVE MOTOR.

9. REVERSE PROCEDURE TO INSTALL MOTOR AND

REASSEMBLE DRUM. USE LOCKTITE 271 ON ALL

BOLT THREADS.

PAGE 36 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 37

MAINTENANCE

ALTERNATOR/REGULATOR

This roller is equipped with a 20-amp charging system. This

system uses three charge coils connected in parallel. The

windings of each coil are wound with heavy-duty insulated

wire and are further protected by insulating material for long

life. A voltage regulator is provided to control the amount

of charge voltage being delivered to the 12 volt electrical

system. For servicing this charging system, contact your

Honda dealer.

NEUTRAL SAFETY SWITCH

The travel lever is provided with a neutral safety switch

(Figure 37) that prevents the engine from starting when

the lever is in the forward or reverse drive position. Lever

must be placed in the neutral position in order for the starter

to function.

TRAVEL LEVER

To test the vibration solenoid, turn the ignition switch on.

Check for proper supply voltage and ground. If proper

voltage and ground are present, check the solenoid for

continuity. If no continuity, replace the solenoid coil. If

continuity is present, place your hand on the solenoid and

turn the switch to the ON position; movement should be felt.

DO NOT START THE ENGINE FOR THIS TEST.

Figure 38. Vibration Solenoid

BATTERY

Mishandling of the battery shortens the service life of the

battery and adds to maintenance cost. When handling the

battery do the following:

NEUTRAL SAFETY

SWITCH

WHITE

GREEN

Figure 37. Safety Switch

To check this switch, remove the panel located below and

to the rear of the floor. This switch is mounted to the lower

forward/ reverse lever mechanism. Disconnect the white

and green wires. Place the lever in neutral and test for

continuity. Place the lever in forward or reverse; no continuity

should be present. Repair or replace as required.

VIBRATOR SOLENOID

The vibrator solenoid (Figure 38) is located in the manifold

valve block and is controlled by the vibration switch located

on top of the travel lever. This solenoid controls the vibration

control valve which supplies hydraulic oil to the vibration

drive motor.

Be careful not to let the battery electrolyte come in

contact with your body or clothing.

Always wear eye protection and rubber gloves, since

the battery contains sulfuric acid which burns skin and

eats through clothing.

Check the battery regularly and make sure that each

electrolyte level is to the bottom of the vent well

(Figure 42). If necessary, add only distilled water in a

well-ventilated area.

Figure 39. Battery Fluid Levels

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 37

Page 38

PREPARATION FOR LONG-TERM STORAGE

ROLLER STORAGE

For storage of the roller for over 30 days, the following is

recommended:

1. Drain the fuel tank completely, or add STA-BIL to the

fuel.

2. Run the engine until the fuel in the injection system is

completely consumed.

3. Completely drain used oil from the engine crankcase

and fill with fresh clean oil, then follow the procedures

described in the engine manual for engine storage.

4. Drain water tank.

5. Clean the entire roller and engine compartment.

6. Remove battery and store it in cool dry place.

7. Cover the roller and place it a clean dry area, that is

protected from harsh elements.

8. Remove ignition key, and store in a safe place.

PAGE 38 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 39

MANIFOLD TEST PORTS

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 39

Page 40

MAIN

AXIAL PUMP

T1 T2

HYDRAULIC SYSTEM DIAGRAM

EXCITER

RELIEF VALVE

2000 PSI

MANIFOLD

P

STEERING

RELIEF VALVE

TEST

G1

M

W

EXCITER

VALVE

700 PSI

INTERNAL DRIVE PUMP

RELIEF VALVES

2900 ± 145 PSI

P1

S1

TEST

G2

TEST

G3

G

W

X

A

W

W

B

M

TOW

VALV E

T

1

2

P

3

4

T

STEERING VALV E

GEAR PUMP

STEERING & VIBRATION

A

FRONT

DRIVE

MOTOR

W

W

VIBRATION

EXCITER

MOTOR

SERIES

DRIVE

L

R

DRIVE

MOTOR

STEERING

CYLINDER

B

REAR

10 MICRON

SUCTION

FILTER

100 PSI

M

RETURN LINE FILTER

ASSEMBLY

W

FILTER BYPASS

25 PSI

PAGE 40 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 41

BATTERY

30 AMP

F2

RED 14 AWG

+12 VDC

GND

WATER

PUMP ON

LAMP

RED

14 AWG

BLK

14 AWG

WHT

OIL ALARM

LAMP

OIL

SENSOR

RED14

AWG

BLK

BLK14

AWG

WHT

BLK

1

2

BLK/WHT

WHT

3

BLK

4

5

6

GRN

BLK/YEL

1

2

3

4

5

6

RED 14 AWG

BRN

GND

SPLICE

FUEL CUT-OFF

SOLENOID

BLK/YEL

YEL

GRN

GRN

GND

IGNITION

COIL (RIGHT)

CHASSIS

GND.

OIL LEVEL

SWITCH

BLK

IGNITION

COIL (LEFT)

CHASSIS

GND.

YEL

YEL

BLK

+12VDC OUT IG.

GND

BLK

14 AWG

+12VDC

OUTLET

+12VDC INPUT IG.

RED

RED

14 AWG

HOUR METER

BLK

14 AWG

WHT10AWG

26 AMP

CHARGE COIL

WHT

BLUE

GRAY

SPLICE

CONNECTOR

GR

CHASSIS

GND

BLK

SPLICE

WHT/BLU

VOLTAGE

REGULATOR

RED 14 AWG

NC

BLK

14 AWG

+12VDC

YEL

BRN 14 AWG

+12VDC

TRAVEL LEVER

NEUTRAL SAFETY

SWITCH

WHITE

GREEN

VIBRATION

SWITCH

WATER PUMP

SWITCH

IGNITION

SWITCH

5

POSITION

1. OFF

2. RUN

3. START

WHT + BLK/YEL (+12VDC)

CIRCUIT“MAKE”

WHT + BLK/WHT (+12VDC)

IGNITION SWITCH COMBINATION

BLK + GRN (GND.)

PIN NO.

2 + 6

3 + 5

1 + 2

P1 P2

REAR

VIEW

1

2

3

4

5

6

P2

REAR

VIEW

1

4

4

5

6

CHASSIS

GND

YEL 18 AWG

1

FUSE AND RELAY

LOCATOR

5

P1

4

5

6

1

2

3

F1

F2

F3

K1

SAFETY SWITCH

NEUTRAL POSITION

GRN

VIBRATION

SWITCH

5

WHT

WATER PUMP

SWITCH

5

RED

REVERSE

ALARM

SWITCH

RED

BACK-UP

ALARM

2

(OPTION)

WHT

6

6

GRN

BLK

CHASSIS

GND.

YEL

YEL

BLK

BLU 14 AWG

RED

SPLICE

F1

20 AMP

YEL

B (BATT. )

85

10 AMP

K1

86

BLK

GND

F3

WATER

PUMP

30

YEL

BLUE 14 AWG

BLK 14 AWG

K1-NO

WIRING DIAGRAM

GND

87

VIBRATION

SOLENOID

WHT18AWG

HYDRAULIC

VALVE BLOCK

CHASSIS

GND.

NOTES:

1

2

3

4

5

6

AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19) — PAGE 41

GROUND TO STOP ENGINE, (OIL SWITCH).

AUDIBLE ALARM ORDER AS OPTION.

LOCATED INSIDE STEERING COLUMN.

LOCATED UNDERNEATH FOOT PLATFORM.

LOCATED IN ENGINE COMPARTMENT.

GROUND TO START ENGINE, (IGNITION SWITCH).

Page 42

TROUBLESHOOTING

Troubleshooting (Roller)

SYMPTOM POSSIBLE PROBLEM SOLUTION

Low Vibration

No Vibration

Slow Steering

Steers Slow in One Direction Defective steering cylinder?

Slow Forward/Reverse

Speed

Low engine RPM? Check and adjust engine speed.

Low hydraulic pressure? Check and adjust hydraulic pressure.

No voltage to 12 volt solenoid?

No oil pressure?

Broken motor coupler? Replace coupler.

Low hydraulic pressure?

Steering column connector? Inspect bearings and grease if necessary.

Defective steering cylinder? Check seals, replace if necessary.

Low hydraulic pressure?

Rubber scrapper adjustment incorrect?

Rubber shock mount loose?

Check vibration switch, check coil for

continuity.

Check for proper oil pressure or defective

relief valve.

Check pressure for possible

contaminated or defective relief cartridge.

Inspect cylinder for contamination or cut

seals. Replace if necessary.

Check pressure, low oil, or contaminated/

defective relief valve cartridge.

Check for proper adjustment against

drum.

Inspect for broken mount, replace if

necessary.

Main Hydraulic Pressure

Low

Free wheel valve "open"? Close valve.

Speed control cable out of adjustment? Inspect cable and adjust if necessary.

Incorrect engine speed? Adjust engine speed to correct speed.

Rubber shock mounts defective? Inspect for sheared rubber mounts.

PAGE 42 — AR14H RIDE-ON ROLLER • OPERATION MANUAL — REV. #3 (09/06/19)

Page 43

Symptom Possible Problem Solution

Diffi cult to start, fuel is available, but no spark at

spark plug.

Diffi cult to start, fuel is available, and spark is

present at the spark plug.

Diffi cult to start, fuel is available, spark is

present and compression is normal.

Diffi cult to start, fuel is available, spark is

present and compression is low.

No fuel present at carburetor.

TROUBLESHOOTING

Troubleshooting (Engine)

Spark plug bridging? Check gap, insulation or replace spark plug.

Carbon deposit on spark plug? Clean or replace spark plug.

Short circuit due to defi cient spark plug

insulation?