Multiplex ROYALevo9 User Manual

1. Contents

1. Contents 1

2. Introduction 3

3. Safety notes 3

3.1. General safety notes 4

3.2. Range checking 5

4. Liability exclusion / Compensation 6

5. Guarantee 6

6. Specification 6

7. The transmitter 7

7.1. Front face of transmitter 7

7.2. Rear face of transmitter 7

7.3. Inside the transmitter 8

7.4. Mechanical details 8

7.4.1. Opening and closing the transmitter case 8

7.4.2. Adjusting the transmitter aerial,

fitting a new aerial 9

7.4.3. Installing and removing the RF module 9

7.4.4. Changing the transmitter crystal

(HFM-4 module only) 10

7.4.5. Changing the transmitter battery 10

7.4.6. Disabling the stick neutralisation system,

activating the spring for ratchet or friction

operation 10

7.4.7. Adjust the neutralising force 10

7.4.8. Swivelling the stick units 10

7.4.9. Adjusting and replacing the stick tops 11

7.4.10. Stick top with buttons

- how to fit them, how they work 11

7.4.11. Installing the optional switches “P” and “K” 12

8. The transmitter battery 13

8.1. Battery management in the ROYALevo 13

8.1.1. This is what we have already 13

8.1.2. This is NEW 13

8.1.3. This is what you must attend 13

8.2. The battery essentials in brief 13

8.3. Safety notes 13

8.4. Charging the transmitter battery 14

8.5. Maintaining and storing

the transmitter battery 14

8.6. Recycling 15

9. Using the transmitter for the first time 15

9.1. Initial power-ON 15

9.2. Switching on 15

9.2.1. Switching ON

with the HFM-4 RF module for crystals 15

9.2.2. Switching ON

with the HFM-S synthesizer RF module 15

9.2.3. Switching ON

without transmitting an RF signal 15

9.3. Security queries when switching ON 16

9.3.1. Throttle check 16

9.3.2. RF Check with the synthesizer module 16

9.4. Selecting the channel

with an HFM-S synthesizer RF module 16

9.5. The RF status display (red LED) 16

9.6. The status displays 17

Instructions

10. The basic operating philosophy 18

10.1. The keypad 18

10.1.1. Direct menu access buttons (row 1) 18

10.1.2. Task buttons (row 2) 18

10.1.3. Text input 18

10.2. The 3-D digi-adjustors 19

10.2.1. Programming using the 3-D digi-adjustors 19

10.2.2. Making adjustments

10.3. Working with the keypad and 3-D digi-

10.3.1. Calling up main menus 20

10.3.2. Opening sub-menus 20

10.3.3. Changing values 21

10.3.4. Returning from whence you came 21

11. Digital trims 22

11.1. Introduction 22

11.2. Advantages of digital trims 22

11.3. The cruciform digital trim assembly 22

11.4. On-screen trim display 22

12. Creating a new model 23

12.1. Basic information 23

12.2.

12.3.

12.4. Model templates in detail 28

12.5. Template: BASIC 28

12.5.1. Assigned transmitter controls and switches 28

12.5.2. Assigned servos / receiver outputs 28

12.5.3. Fine-tuning 28

12.6. Template: ACRO 29

12.6.1. Assigned transmitter controls and switches 29

12.6.2. Assigned servos / receiver outputs 29

12.6.3. Fine-tuning 29

12.7. Template: HOTLINER 29

12.7.1. Assigned transmitter controls and switches 29

12.7.2. Assigned servos / receiver outputs 29

12.7.3. Fine-tuning 29

12.8. Template: DELTA 30

12.8.1. Assigned transmitter controls and switches 30

12.8.2. Assigned servos / receiver outputs 30

12.8.3. Fine-tuning 30

12.9. Template: GLIDER 30

12.9.1. Assigned transmitter controls / switches 30

12.9.2. Assigned servos / receiver outputs 30

12.9.3. Fine-tuning 30

12.10. Template: 4-Flaps 31

12.10.1. Assigned transmitter controls and switches 31

12.10.2. Assigned servos / receiver outputs 31

12.10.3. Fine-tuning 31

12.11. Template: HELImech 31

12.11.1. Assigned transmitter controls and switches 31

12.11.2. Assigned servos / receiver outputs 31

12.11.3. Fine Tuning 31

12.12. Template: HELIccpm 32

12.12.1. Assigned transmitter controls / switches 32

12.12.2. Assigned servos / receiver outputs 32

12.12.3. Fine tuning 32

12.13. Helicopter with HEIM mechanics 32

using the 3-D digi-adjustors 19

adjustor -the fundamental operating

philosophy 20

A new fixed-wing model 23

A new helicopter 24

ENGLISH

Seite 1

ROYAL evo

13. Main menu „Setup“ L 32

13.1. Sub-menu „Transmitter“ 32

13.1.1. Parameter „Trim graphics“ 32

13.1.2. Parameter „Sounds“ 32

13.1.3. Parameter „Battery alarm“ 32

13.1.4. Parameter „Battery charge“ 33

13.1.5. Parameter „Contrast“ 33

13.1.6. Parameter „ Check throttle “ 33

13.1.7. Parameter “Check RF” 33

13.2. Sub-menu “Define mixer” 33

13.2.1. How the freely definable mixers work 33

13.2.2. Defining mixers 34

13.2.3. The mixer options 34

13.3. Sub-menu “Assignment” 35

13.3.1. Parameter „Mode“ 36

13.3.2. Parameter „Assignment“ 36

13.3.3. Parameter „Assignment - Name“ 36

13.3.4. Parameter „Assignment - Controls“ 36

13.3.5. Parameter „Assignment - Switches“ 37

13.4. Sub-menu “Training” 37

13.4.1. Teacher/Pupil operation 37

13.4.2. The ROYALevo as Teacher transmitter 37

13.4.3. The

ROYALevo

as pupils transmitter 38

13.5. Sub-menu “User” 38

13.5.1. Parameter „PIN“ 38

13.5.2. Parameter „Language“ 38

13.5.3. Parameter „Name“ 38

14. Main menu „Controls“ H 38

14.1. Sub-menu „Control switch“ 38

14.2. Sub-menus for individual controls 39

14.2.1. Control settings for the primary axes 39

14.2.2. Parameter „Trim“ 39

14.2.3. Parameter „Step“ (trim increment) 39

14.2.4. Parameter „D/R“ (Dual-Rates) 40

14.2.5. Parameter „Trvl“ 40

14.2.6. Parameter „Expo“ 40

14.2.7. Parameter „Fixed value“ 40

14.2.8. Parameter „Run time“ (Slow) 40

14.2.9. Parameter „Idle“ (idle trim) 40

14.2.10. Parameter „Collective pitch“ (Coll. pitch curve)40

14.2.11. Parameter "Throttle" (Throttle curve) 41

14.2.12. Parameter „RPM“ for speed regulators 42

15. Main menu „Mixers“ G 42

15.1. Sub-menu „Combi-Switch“ 42

15.2. Sub-menu „A-Diff“ (aileron differential) 42

15.2.1. Parameter „Mode“ 42

15.2.2. Parameter „Diff.“ 42

15.3. Submenu „Gyro“ 42

15.3.1. Parameter „Mode“ 43

15.3.2. Parameter „Heading / Damping“ (Gyro gain) 44

15.3.3. Parameter „Suppression“ 44

15.4. Sub-menu „Tail rotor“ (static tail rotor

compensation/Revo-Mix) 44

15.4.1. Parameter „Collective Pitch+ and -“ 45

15.4.2. Parameter „Yaw diff.“ 45

15.4.3. Parameter „Offset“ 45

15.4.4. Parameter „Zero point“ and Coll.Pitch display 45

15.5. Sub-menu „Rotor head“ (electronic

swashplate mixer/CCPM) 45

15.5.1. Parameter „Geometry“ 46

15.5.2. Parameter „Rotation“ 46

15.5.3. Parameter „Lever +/-“ 46

15.5.4. Helicopter with HEIM mechanics 46

15.6. Sub-menu „Throttle compensation“ 47

15.6.1. Parameter „Rudder“ (Yaw) 47

15.6.2. Parameter „Aileron“ (Roll) 47

15.6.3. Parameter „Elevator“ (Pitch axis) 47

15.7. Setting up “free mixers” 47

16. Main menu „Servo“ K 48

16.1. Sub-menu „Calibrate“ 48

16.1.1. Parameter „REV/TRM“ 48

16.1.2. Parameter „P1 … P5“ 48

16.2. Sub-Menu „Assignment“ 49

16.2.1. Special: MULTInaut IV 50

16.2.2. Assigning servos for fixed wing models 50

16.2.3. Assigning servos for helicopters 50

16.2.4. Notes on assigning 51

16.3. Sub-menu „Monitor“ 51

16.4. Sub-menu „Test run“ 51

17. Main menu „Timer“ A 51

17.1. Sub-menu „Model“ 51

17.2. Sub-menu „Slot“ 51

17.3. Timer „´ Sum“ 52

17.4. Sub-menu „¶¶ Interval“ 52

18. Main menu „Memory“ I 52

18.1. Sub-menu „Select model“ (change memory)

52

18.2. Sub-menu „Copy“ 52

18.3. Sub-menu „Erase“ 53

18.4. Sub-menu „Flight phases“ 53

18.4.1. Selecting flight phase names 53

18.4.2. Block / release flight phase 53

18.4.3. Copying the active flight phase 53

18.5. Sub-menu „Properties“ 53

18.6. Sub-menu „New model“ 54

19. Accessories 54

19.1. Scanner (with HFM-S RF module) 54

19.1.1. Scan the all frequencies/channels in the band54

19.1.2. Channel-Check at power-ON 54

19.1.3. Installation of the scanner module 54

19.2. Channel-Check (with the RF module HFM-4)

54

19.2.1. Installation of the Channel-Check module 54

19.2.2. Operating Channel-Check 54

19.3. Other accessories/spar parts 55

19.3.1. Overview 55

19.4. Using MULTInaut IV 55

19.5. Diagnosis lead 55

19.6. PC interface 56

19.6.1. Accessing transmitter data 56

19.6.2. Flight simulator operation 56

20. Care and maintenance 56

21. Service and support 56

Appendix 1: Factory Settings

1. Assignment of controls and switches 57

2. Mixer definition 58

Seite 2

Instructions

2. Introduction

We are delighted that you have decided to purchase the

MULTIPLEX ROYALevo radio control system. The

ROYALevo was introduced early in 2002, and consti-

tutes a modern digital radio control system, which

represents a further milestone in the development of

radio control systems by MULTIPLEX. In the overall design, development and production of this system we

have invested all our experience of several generations

of radio control equipment. The result is a universal,

ergonomically efficient radio control system of modern

design which is simple to operate, and which is suitable

for use both hand-held and in a transmitter tray. And not least – the

ROYALevo is MADE IN GERMANY.

We placed particular emphasis on convenience of operation during the development of the system software.

The ROYALevo offers you a wide range of functions

selected by experienced users, and these cope effortlessly with any model from simple two-axis gliders to

complex large-scale models and helicopters. Despite its

comprehensive features, the transmitter is simple to

operate and easy to understand.

The essential features of the ROYALevo are as follows:

Ergonomically efficient case, suitable for hand-held

x

or tray use, with precision stick units which swivel

to suit your personal preference

Graphical folding screen (132 x 64 pixels) with variable

x

contrast

Easily accessible digital trims in a cruciform arrange-

x

ment, giving an entirely new feeling to the trims

Low-cost standard RF module* with plug-in crystals,

x

or synthesizer RF module* wit

software channel selection

9 or 12 channels

x

20 or 36 model memories

x

6 buttons for fast, direct access to the main menus

x

5 function buttons and two 3-D digi-adjustors for

x

user-friendly programming

Detailed menu texts, selectable language, various

x

languages available

Comprehensive set-up and mixer facilities for fixed-

x

wing models and helicopters

Sample models (templates) minimise programming

x

effort required

Unrestricted assignment of transmitter controls,

x

switches and servos

4 flight phases per model memory

x

5 timers

x

(3 alarm timers + transmitter and model times)

Facilities for selective Teacher/Pupil (Trainer) opera-

x

tions as standard

We are confident that you will quickly learn to appreciate the ROYALevo, and enjoy using it to control your

models over a period of many years. Please take a little

while to familiarise yourself with the system, referring

constantly to these instructions which are intended to

help you.

Yours – the MULTIPLEX team

Options:

* MULTIPLEX Channel-Check power-on guard system

** Scanner with power-on guard function

See the main MULTIPLEX catalogue for frequency ranges available.

3. Safety notes

!

These operating instructions are an integral

part of the product, and contain important information and safety notes. They should therefore be stored in a safe place where you can refer to them at any time. If you ever dispose of

the equipment be sure to pass on the instructions to the new owner.

!

Read these safety notes!

Read the instructions carefully! Please do not

attempt to use the equipment until you have

read these operating instructions thoroughly,

together with the following safety notes (included in these instructions or supplied separately).

!

It is not permissible under any circumstances to

make technical modifications to the radio control system itself or its components. Use genuine MULTIPLEX accessories and replacement

parts exclusively (especially transmitter battery, crystals, aerial, ...).

!

If you wish to use the system in conjunction

with products made by other manufacturers, it

is up to you to carry out checks to ensure their

quality and compatibility. Every time you make

any change to the system, carry out a careful

check of the functions, and check the effective

range. Don’t operate the system or the model if

you are not sure everything is working correctly; first locate the fault and eliminate it.

!

Warning!

Radio-controlled models are not playthings in

the usual sense. Building these models, installing the RC system, and operating them all demand technical knowledge, due caution and a

responsible, safety-conscious approach. If you

are negligent or make mistakes, the result may

be serious damage and injury. As manufacturers, we have no control over your methods of

building and operating any model, so all we can

do is point out these hazards expressly. We

deny all liability.

!

A model, which is out of control, for whatever

reason, is capable of causing serious personal

injury and damage to property. It is essential

that you should take out suitable third-party

insurance, so that you are covered if, in spite of

all your care, an accident should occur.

!

Always keep to the following sequence when

switching the equipment on and off, as this avoids the danger of an electric power system

bursting into life unexpectedly:

1. When switching on:

Transmitter ON first,

then receiver ON.

Connect flight battery and switch power system

ON

2. When switching off:

First disconnect flight battery and switch power

system OFF

Receiver OFF

Transmitter OFF

ENGLISH

Seite 3

ROYAL evo

!

We recommend that you have your radio con-

trol system transmitters and receivers checked

at regular intervals (every 2 to 3 years) by an

authorised MULTIPLEX Service Centre.

!

If any electrical device gets damp or wet, cease

operations immediately and disconnect the

power supply from it. Open the case if possible

and allow the unit to dry out thoroughly - preferably for several days. After this carry out a

very careful check of all the functions. If you are

not certain that all is well, send the unit to an

authorised MULTIPLEX Service Centre for

checking

!

The operation of this radio control system is

approved for use on particular channels /

transmitter frequencies which vary from country to country. In some cases there are formalities such as registration to be completed before

you may use the system. Please read the notes

which are supplied with this set on a separate

sheet.

3.1. General safety notes

Build the model carefully

x All control surfaces and linkages must be installed

and set up in such a way that the control surfaces

move with complete freedom, and do not tend to

bind or move stiffly at the extremes of travel. Do

not limit the servo travel from the transmitter; it is

always better to adjust the servo output arms,

horns and pushrods instead. Always aim at minimum possible lost motion (slop) in any linkage. All

these points help to minimise the load on the servos, ensuring that their maximum performance is

available to you, and that they will last as long as

possible. This also means maximum reliability and

safety for you and your models.

x Receiver, battery, servos and other RC components

and electronic units should be effectively protected

from vibration to avoid the danger of failure of any

electronic component. All the individual items are

supplied with operating instructions, and these

should be read thoroughly. Standard methods of

avoiding vibration include balancing propellers and

rotor blades before use, replacing damaged blades,

installing glowplug and petrol engines with effective vibration damping, replacing or repairing damaged motors and engines if they do not run

smoothly, and so on.

x Don’t place cables under tension, and don’t bend

them tightly; protect all leads from rotating parts.

x Keep servo leads as short as possible, and don’t use

them unless absolutely necessary. If you must use

extension leads which are 30 - 50 cm or more in

length, fit a separation filter (ferrite ring) in each

lead, and ensure that the conductors are of adequate cross-section to avoid voltage drop. We recommend at least 0.3 mm².

x Don’t coil up the receiver aerial, and do not shorten

it. Never deploy the aerial parallel to conductive

components such as metal pushrods, or inside a fuselage which has a shielding effect, i.e. made of or

reinforced with carbon fibre, or finished in metallic

paint. Don’t deploy the aerial on top of electrically

conducting model components. For large-scale

models we recommend the use of a whip aerial.

Seite 4

x Ensure that the receiver power supply is of ade-

quate capacity. If you are using servos rated at up to

about 40 Ncm you can calculate the required battery capacity using the following rule of thumb:

mAhservosofNomAhCapacity 200.][ ut

If you have no problems with weight or space, it is

always better to select the next larger size of battery.

x Avoid any situation in which parts made of conduc-

tive material (e.g. metal linkage components or

pushrods) are in contact with each other, and move

against each other. This causes what is known as

electrical “noise”, which can interfere with the receiving system.

x Avoid interference pulses due to static charges or

powerful electric or electro-magnetic fields by taking appropriate suppression measures. These include suppressing electric motors with suitable capacitors, using shielded plug caps, ignition leads

and ignition units with spark-ignition petrol engines; keeping the RC system components, including aerial, wiring and batteries, well away from the

ignition circuit.

x Keep the receiving system a safe distance from

high-current leads (e.g. electric power system wiring). High-current cables, especially those between

brushless electric motors and their controllers,

should be as short as possible (guide: max. 10 - 15

cm).

x When you have completed a new model, carry out

the programming of your transmitter in the peace

and quiet of your home. Check all the functions carefully before flying the model. Take the time to

familiarise yourself with the programming procedure and method of operating the transmitter before you use it for the first time to control a model.

Check the model regularly

x Ensure that all control surfaces and mechanical

linkages work smoothly, freely, and without slop.

x Check that pushrods, linkages, hinges etc. are stiff

enough for their purpose and in good condition.

x Carry out a visual check for fractures, cracks, signs of

stress in the model itself and on the components of

the RC system and power system.

x Check that all cables and connectors are in good

condition and are making sound contact.

x Check the state of the power system and its wiring,

including the switch harness, and check the external condition of the cells. Regular care of the battery is important: monitor its voltage and capacity

using a charger and charging process designed for

the battery type you are using.

Pre-flight checks:

x Charge the transmitter, receiver and flight batteries

carefully, and check their state of charge before and

during the session. This means using the correct

type of charger, and a charge process which is suitable for the battery type in use. It also involves

regular care and maintenance of the packs (balancing by a slow charge), and testing the voltage curve

and capacity.

x At the flying site the first step should always be to

check with the other modellers present whether

your own channel (transmitter frequency) is vacant.

If there is a site manager or flight director present,

register with him and check that you understand

the method of frequency control in use. Do not

switch ON until you have done this, otherwise there

is a danger of channel clashes and wrecked models.

x Check the range with the transmitter aerial col-

lapsed.

x Ensure that you have selected the right model

memory.

x Check that all primary and secondary control sys-

tems are working perfectly, and that the control

surfaces are deflecting in the right “sense” (direction).

!

If you detect any irregularity or problem, abort

the flight. Seek out the cause of the error, eliminate it, and then check everything again.

When operating your model:

x If you have little or no experience flying radio-

controlled models, it makes sense to ask an experienced model pilot to help you initially. The use of a

Teacher/Pupil (Trainer) system is strongly recommended, especially for the initial phase of learning

to fly.

x Operate the model only at suitable approved sites.

x Never fly or run your model directly towards or over

spectators.

x Don’t carry out risky manoeuvres when flying or

operating your model.

x Have a clear idea of your abilities and skill; don’t

over-estimate what you can do!

x If you detect any sign of problems or interference,

land the model immediately and carry out a thorough check.

x Caution: static charges!

When the air is extremely dry (in mountainous terrain, in mountain bowls, close to weather fronts)

static charges tend to build up in the transmitter

and/or the pilot. The charge eventually dissipates

through a static spark, which can endanger the pilot or cause interference to the transmitter.

Counter-measures:

When you feel “static”, cease operations as soon as

you possibly can, and walk a little way down the

mountain to reach a less exposed position.

x Minimum distance to mobile phones: 2 m !

When operating the transmitter maintain a minimum distance to mobile phones of 2 meters.

Information on ESD

Electronic devices are sensitive to electrostatic discharges. This module is equipped

with electro-statically sensitive components. They can be destroyed as the result

of an electro-static discharge (potential

discharge) when the module is touched, or their service

life can be affected. At delivery, a conductive ESD protection bag protects the module.

Please make sure the following protective measures for

electro-statically sensitive modules are observed:

x Before inserting or removing the module from the

base unit, equalise the potential between yourself

and your surroundings (e.g. touch a radiator).

If necessary, open the base unit and touch a large

Instructions

part of it in order to provide potential compensation with the base unit.

x Only then remove the module from the conductive

ESD protection bag. Avoid direct contact with the

electronic components or with the soldering points.

Only touch the module at the edge of the board.

x Outside the base unit, store the module inside the

conductive ESD protection bag only. Never allow

direct contact with any conventional non-ESD

compliant plastic foam, Styrofoam or other plastic

container.

3.2. Range checking

Range checking gives reliable information about the

working condition of your radio control system.

Based on our experience and measurements we have

designed a test formula which will always keep you on

the safe side.

1. Set the transmitter aerial in an upright, slightly angled position and

then collapse all the sections together.

2. Set up the model so that the tip of

the receiver aerial is about 1 m

above the ground.

3. Ensure that there are no large metallic objects (e.g. cars, wire fences etc.)

in the vicinity of the model.

4. Carry out the test only if there are no other transmitters switched on - even if they are on different

channels.

5. Switch on the transmitter and receiving system. At

a range of about 80 m between transmitter and

model check that the control surfaces still respond

immediately and definitely to stick deflections,

without carrying out any unwanted movements.

When close to the range limit the servo output

arms will start to jitter; they should not move by

more than the width of the output arm.

6. Secure the model and repeat the test with the

power system running (alternating the throttle setting between idle and full-throttle).

The stated range of 80 m is only an approximate guideline, as the actual range will vary very greatly according

to ambient conditions. For example, effective range

may only be half the stated value at a mountain bowl

site, or close to a public radio transmitter, radar station

or similar.

What can you do to establish the cause of insufficient range?

1. Change the position of the receiver aerial. If it is

close to metal parts or model components reinforced with carbon fibre, the receiver may suffer

adverse effects.

The influence of electric power systems and ignition systems also varies if you alter the position of

the aerial.

2. Disconnect the servos from the receiver one by one,

and repeat the check. Connecting leads of excessive length without suppressor filters have an adverse effect on reception conditions. Remember

that servos deteriorate with age, and then generate

more interference than when new (brush sparking,

suppressor capacitors adrift from motor terminals

etc.).

ENGLISH

Seite 5

ROYAL evo

If you are unable to effect an improvement, try removing the complete system from the model and checking

the equipment on its own. This enables you to determine whether the fault is in the system, or in the installation conditions in the model.

4. Liability exclusion /

Compensation

As manufacturers, we at MULTIPLEX Modellsport GmbH

& Co. KG are not able to ensure that you observe these

instructions when assembling and installing this equipment. Neither are we in a position to influence the

way you install, operate and maintain the radio control

system components. For this reason MULTIPLEX Modellsport GmbH & Co. KG is obliged to deny all liability for

loss, damage or costs which are incurred due to the

incorrect use and operation of our products, or which

are connected with such operation in any way.

Unless otherwise prescribed by law, the obligation of

MULTIPLEX Modellsport GmbH & Co. KG to pay compensation, regardless of the legal argument employed,

is limited to the invoice value of that quantity of

MULTIPLEX products which was immediately and directly involved in the event which caused the damage.

This does not apply if MULTIPLEX Modellsport GmbH &

Co. KG is found to be subject to unlimited liability according to binding legal regulation on account of deliberate or gross negligence.

5. Guarantee

Für unsere Produkte leisten wir entsprechenden den

derzeit geltenden gesetzlichen Bestimmungen Gewähr.

Wenden Sie sich mit Gewährleistungsfällen an den

Fachhändler, bei dem Sie das Produkt erworben haben.

Von der Gewährleistung ausgeschlossen sind Fehlfunktionen, die verursacht wurden durch:

- unsachgemäßen Betrieb,

- falsche, nicht oder verspätet oder nicht von einer

autorisierten Stellen durchgeführte Wartung,

- falsche Anschlüsse,

- Verwendung von nicht originalem MULTIPLEX-

Zubehör,

- Veränderungen/Reparaturen, die nicht von MUL-

TIPLEX oder einer MUTIPLEX-Service-Stelle ausgeführt wurden,

- im Zusammenhang mit Komponenten anderer

Hersteller,

- versehentliche oder absichtliche Beschädigungen,

- Defekte, die sich aus der normalen Abnutzung

ergeben.

- Betrieb außerhalb der technischen Spezifikationen

6. Specification

No. of channels:

ROYALevo 9 9

ROYALevo 12 12

Transmission system: automatic adoption

to servo cpount

Servo 7 – 12 unused FM PPM 6

Servo 8 - 12 unused FM-PPM 7

Servo 9 - 12 unused FM-PPM 8

Servo 10 - 12 unused FM-PPM 9

ROYALevo 12 only!

at least one of the

servos 10 - 12 is used FM-PPM 12

Channel spacing: 10 kHz

Servo signal format: UNI 1,5 r 0,5 ms

MPX 1,6 r 0,55 ms

variable for each channel

Model memories:

ROYALevo 9 20

ROYALevo 12 36

Power supply: 7,2 V, 6 cells, AA size

NiMH-battery

Current drain: ~ 20 mA excl. RF module

~ 180 mA with HFM-4

~ 200 mA with HFM-S

Permissible operating

temperature range: 15 qC bis + 55 qC

Dimensions:

Length approx. 220 mm

approx. 250 mm with

aerial collapsed

Width capprox. 200 mm

Height approx. 60 mm

excl. sticks and carry handle

Weight: approx. 750 g excl. battery

approx. 900 g incl. Battery

Seite 6

7. The transmitter

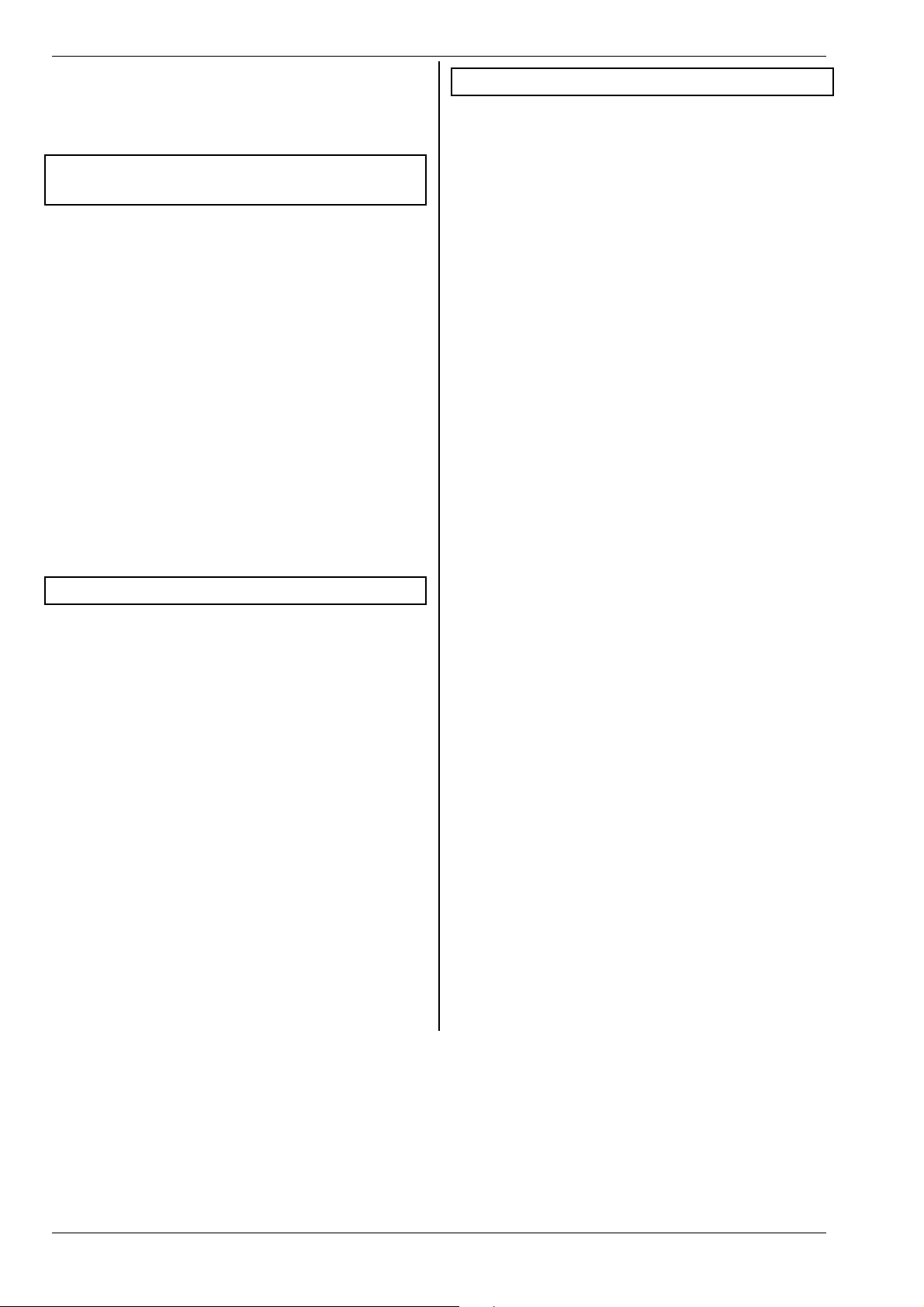

7.1. Front face of transmitter

l

k

k

j

c

c

d

i

e

f

h

Two precision stick units for controlling the 4 pri-

c

mary control axes. Stick ratchet for throttle/spoilers, can

be activated on right or left stick unit (Î 7.4.6.). Both

units can be swivelled to suit the pilot’s personal prefer-

ence (Î7.4.7.). The stick tops can be rotated and are

infinitely variable in length. Various optional versions

are available.

g

Instructions

All switches and buttons (apart from installation wells

“K” and “P”Î 7.4.11arranged as standard in easily accessible positions. They cannot be re-positioned or

swapped over. The designations of the switches and

buttons are neutral (“G”, “H”, “I”, ... “O”, “P”). They can be

defined in any way to provide channel functions and/or

switched functions (transmitter controls or switches Î

13.3.4. and 13.3.5.), i.e. the designations serve only to

identify them.

The transmitter features two 3-D digi-adjustors

k

which are used for programming and adjusting the

system. They are a permanent feature and are fitted as

standard. During the programming process both digiadjustors can be pressed and/or rotated, and work in

parallel with the “ENTER” or „V“(UP) / „W“(DOWN) but-

tons. For operating a model it is possible to assign many

different parameters to the 3-D digi-adjustors, which

can then be used to adjust those settings conveniently

e.g. while the model is flying (Î 10.2.2.).

Mounting lug for attaching a neckstrap

l

(e.g. # 8 5161 or # 8 5646)

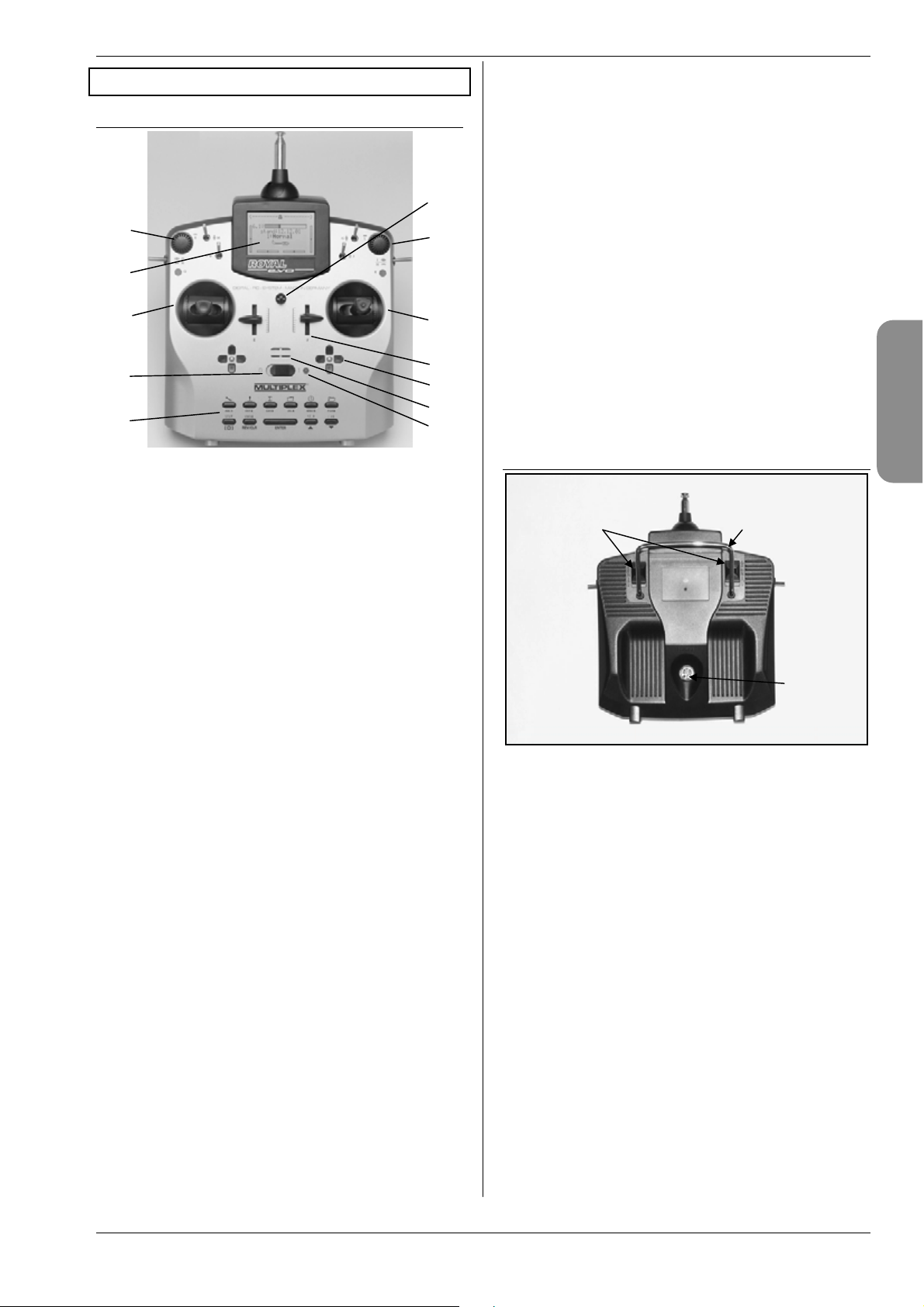

7.2. Rear face of transmitter

c

d

ENGLISH

Two sliders “E” and “F” are fitted as standard, and

d

can be assigned to any channel. They also operate as

switched functions with centre detent.

Two cruciform trim assemblies located below the

e

stick units provide digital trimming facilities on the

primary control axes. Each set consists of a pair of buttons for left/right and up/down.

Audible sounder (piezo beeper)

f

When the transmitter is switched on, the RF status

g

display LED (red LED) indicates whether an RF (Radio

Frequency) signal is being transmitted:

LED glowing constantly o no RF transmission

LED flashing (2 sec.) o RF transmission

The LED is controlled by the current drain of the RF

module. For example, if the transmitter crystal is not

present, or is defective, no RF signal can be generated,

and the constantly glowing LED alerts you to the fact

that an RF signal is not being transmitted.

Keypad consisting of 11 buttons in 2 rows. The 6

h

buttons in the first row provide fast, direct access to the

6 main menus (direct menu access buttons). The 5 buttons in the second row are used for programming procedures. With the exception of the “ENTER” button, all

the buttons have a double function for entering text.

The method of entering text is similar to that used with

mobile telephones.

ON/OFF-switch („O“ / „1“)

i

The screen is a modern, UV-stable, graphical LCD

j

screen (132 x 64 dots) with an anti-reflective coating.

The contrast is variable (Î 13.1.5.). The screen can be

moved through about 40º in order to optimise the viewing angle.

e

Two sliding latches c (OPEN) provide a fast, easy

method of opening and closing the transmitter, e.g. for

changing the crystal or RF module (Î 7.4.3.).

The stout carry handle d enables you to carry the

transmitter safely, and also protects the back of the case

when you put the transmitter down.

As usual with MPX, the ROYALevo features a MULTI-

PLEX multi-function socket e (marked “CHARGE” on

the case) as standard. Its purposes are as follows:

x Charging the transmitter battery (Î 8.4..)

x Connecting the transmitter to another for

Teacher/Pupil operations (Î 13.4..)

x PC interface for backing up model data (Î 19.6.)

x PC interface for updating the transmitter (Î 19.6.)

x PC interface for flight simulators

x Interface for diagnosis lead, i.e. controlling a re-

ceiver for programming and adjustment without

transmitting an RF signal (Î 19.4.)

Seite 7

ROYAL evo

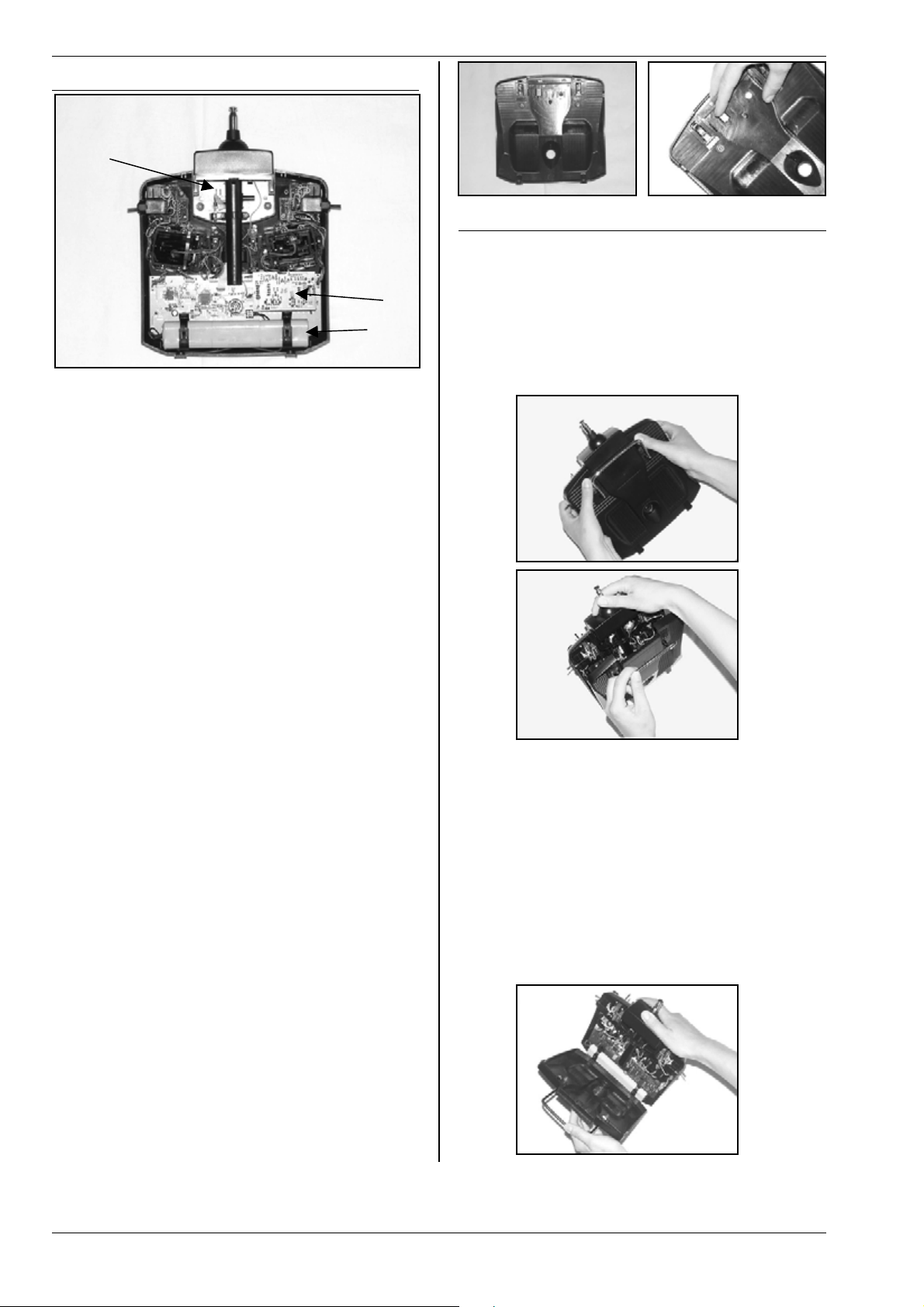

7.3. Inside the transmitter

e

d

c

The rechargeable transmitter battery c is installed as

standard. It consists of 6 environmentally friendly highcapacity AA-size NiMH cells (Nickel-Metal-Hydride). For

safety reasons the individual cells are spot-welded to

ensure constant contact, and the pack is protected by a

heat-shrink sleeve.

!

Use genuine MULTIPLEX batteries only!

Observe charging hints!

(Î 8.4.)

The transmitter battery is fitted with a special

thermo-fuse which protects the battery and above all - the transmitter from short-circuit, reverse polarity and excessive currents. The transmitter itself does not feature a separate fuse, and for

this reason the battery may only be replaced by a

genuine MPX transmitter battery pack designed

exclusively for this transmitter

RF module d (Radio Frequency module). The RF mod-

ule is simply plugged into the main circuit board, and

can easily be changed if you wish to switch to a differ-

ent frequency band (Î 7.4.3.). Two different RF mod-

ules can be used in the ROYALevo:

HFM-4:

! A simple, low-cost RF module with plug-in crystals for

selecting the channel (transmission frequency).

!Use only genuine MULTIPLEX transmitter crystals!

! The optional “Channel-Check” power-on guard mod-

ule can be fitted at any time.

HFM-S:

! A modern synthesizer RF module which allows you to

select the channel (i.e. transmission frequency) by software.

! An optional scanner with power-on guard can be fitted

at any time.

The TORX ® screwdriver e (size T6), which you will find

in a clip below the aerial well, close to the screen, is

used for tasks such as swivelling the stick units, and for

installing the auxiliary switches in wells “K” and “P”.

On the inside of the transmitter back panel there are

crystal holders for 3 spare crystals.

7.4. Mechanical details

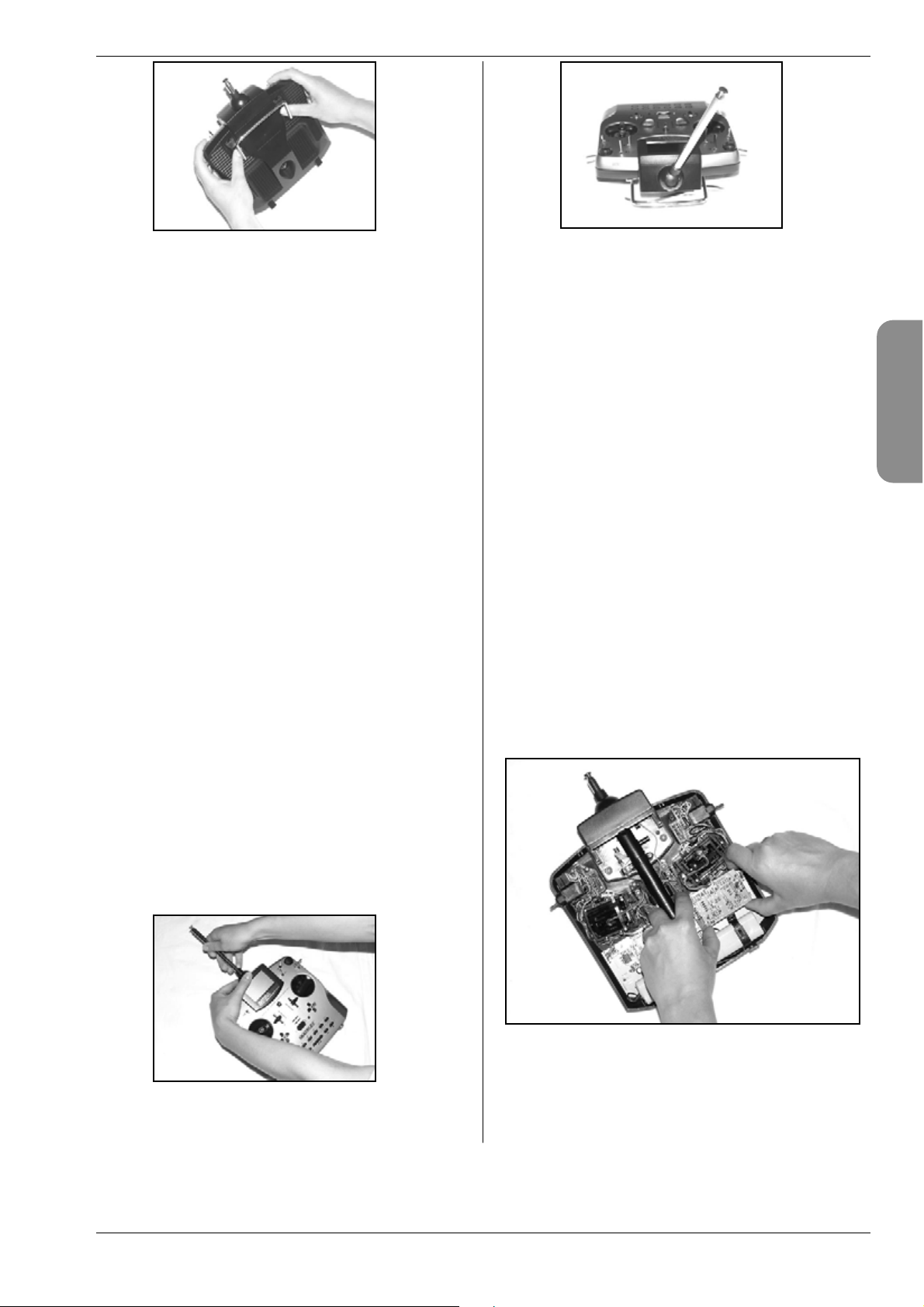

7.4.1. Opening and closing the transmitter case

!

Be sure to switch the transmitter OFF before

opening it (short-circuit hazard)!

Opening the transmitter case:

1. Hold the transmitter in both hands and push the

sliding latches on the back panel downwards with

your thumbs (towards “OPEN”) (Fig. 1).

Carefully lift off the back panel of the case (Fig. 2).

Fig 1:

Fig. 2:

Closing the case:

1. Carefully position the back panel on the rear edge

of the case, holding it at an angle as shown, and

check that both retainer lugs are correctly engaged

(arrow) (Fig. 3).

2. Carefully close the case back (Fig. 4).

! Check that no cables are snagged, and that the

transmitter aerial has not slipped out of its guide

sleeve. It should be possible to fit the case back easily and without forcing.

3. Push the sliding latches up as far as they will go, in

the opposite direction to “OPEN”.

!

Don’t lever the crystals out! Slide them out!

Fig. 3

Seite 8

Instructions

Fig. 4

7.4.2. Adjusting the transmitter aerial,

fitting a new aerial

The transmitter aerial is a permanent fitting in the case.

For transport it can be collapsed completely and recessed into the case. For adjustments and programming

the aerial can be left in this position without damaging

the RF section.

!

When operating a model always extend the

aerial to its full length. Only in this configuration can you be sure of safe operation with

maximum radiated power and range.

The aerial can also be moved to a second position (angled up and to the left), and locked in that position:

1. Pull out the aerial until you feel a distinct resistance

(Fig. 1).

2. Pull the aerial another 3 to 5 mm to overcome the

resistance, pulling fairly hard, and swivel the aerial

up and to the left (Fig. 2). You will again feel resistance at this point, but this time do not push past it.

3. Tilt the aerial as far as it will go, and it will latch in

the correct position..

To swivel it back, the aerial must first be unlocked again

as described under point 2.

!

Check regularly that the aerial is still making

good contact. Contact problems with telescopic

aerials cause adverse effects on radiated power,

and thereby reduce effective range. In such

situations reliable operation can no longer be

guaranteed. Intermittent contact or bent aerials should be replaced at the earliest opportunity, as should an aerial that has become loose

and sloppy through hard use.

If the aerial should be damaged, it can be replaced easily as follows: Remove the case back, and simply push it

back and out of the aerial guide sleeve (replacement

ROYALevo aerial: # 89 3002).

Fig. 2:

7.4.3. Installing and removing the RF module

The two RF modules (HFM-4 and HFM-S) for the ROYALevo are not fitted in protective cases. To avoid damaging them:

x Don’t touch the circuit board and its components.

x Don’t exert any force on the circuit board.

x Protect RF modules from mechanical strain.

Don’t touch components on the circuit board.

!

Don’t change the settings of adjustable components.

If settings have been changed mistakenly or components are damaged, have the module checked

an realigned by the MULTIPLEX service.

Removing the RF module:

1. Switch off the transmitter!

2. Open the transmitter (Î 7.4.1.)

3. Lay the front face of the transmitter on a soft surface, taking care to avoid damage to the sticks and

switches!

4. Grasp the RF module by all four corners using both

thumbs and index fingers, and carefully pull it up

and out (see picture below).

Replacing the RF module:

Grasp the RF module as before. Ensure that the module

is fitted onto the contact pins correctly, i.e. that it is not

offset in any direction.

ENGLISH

!

Fig.1:

Seite 9

When changing the RF module avoid touching

the electrical components at all costs. If the

module is to be stored outside the transmitter,

it is essential to protect it from dirt and damp,

and also from shock and vibration.

ROYAL evo

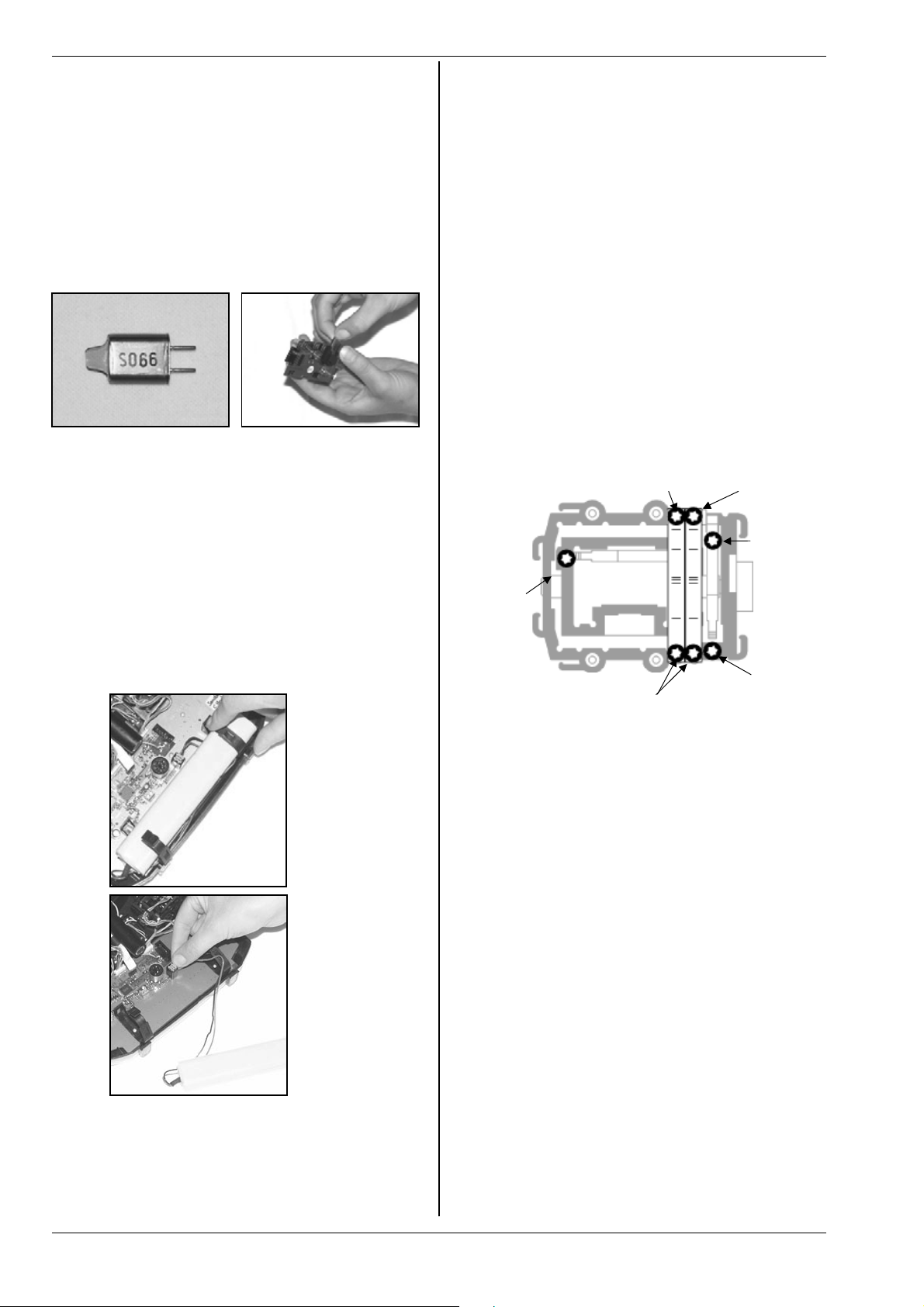

7.4.4. Changing the transmitter crystal

(HFM-4 module only)

First switch the transmitter OFF and remove the RF

module. The crystal should be pulled out of the RF

module by its plastic tag. When fitting a crystal ensure

that it is not mechanically stressed, and that the crystal

pins are not bent.

Use only MULTIPLEX transmitter crystals, designed for

the same frequency band as your RF module. We cannot guarantee reliable operation otherwise. MULTIPLEX

transmitter crystals are enclosed in a translucent blue

plastic sleeve and are printed with the code letters “S”

or “Tx”.

!

Crystals are extremely delicate components,

vulnerable to shock and vibration. They are one

of the crucial parts of your RC system, without

which reliable operation is not possible. For this

reason never drop them, subject them to mechanical load (by pushing them forcibly into the

crystal socket), and always store them carefully.

7.4.5. Changing the transmitter battery

1. Switch the transmitter OFF!

2. Pull the snap-latches of the two plastic battery

holders back towards the battery, and fold them up

(Fig. 1).

3. Remove the battery and disconnect the battery

connector from the main circuit board (Fig. 2).

Fig.1:

7.4.6. Disabling the stick neutralisation system,

activating the spring for

ratchet or friction operation

The ROYALevo transmitter is supplied as standard with

two self-neutralising stick units. The stick neutralising

systems can be disabled, and a stick ratchet spring or

friction mechanism can be activated quickly and easily

as follows:

Switch off the transmitter!

1. Locate the TORX screwdriver (in a clip below the

aerial guide sleeve, close to the screen) and use it to

rotate the TORX screw (1) of the stick neutralising

arm clockwise until the neutralisation is completely

disabled. Don’t unscrew it too far! The neutralis-

ing arm must not be removed!

2. The screws (2) hold the ratchet and friction springs.

Adjust the strength of friction or ratchet with screw

(3). The further the screw is tightened, the greater

the holding force of the spring.

It is also possible to activate both springs if you wish.

This produces a hybrid ratchet / friction movement of

the stick which some pilots find they prefer.

(2) Spring for

friction or ratchet

(1) disable

Neutralisin

force

for

right/left

stick moves

(3) strength for

ratchet/friction

neutralising

neutralising force

for forw./backw

stick moves

7.4.7. Adjust the neutralising force

The neutralising force is adjustable for each of the four

stick axis separately. The illustration down left shows,

where the screws are located. Turning clockwise increases the neutralising force.

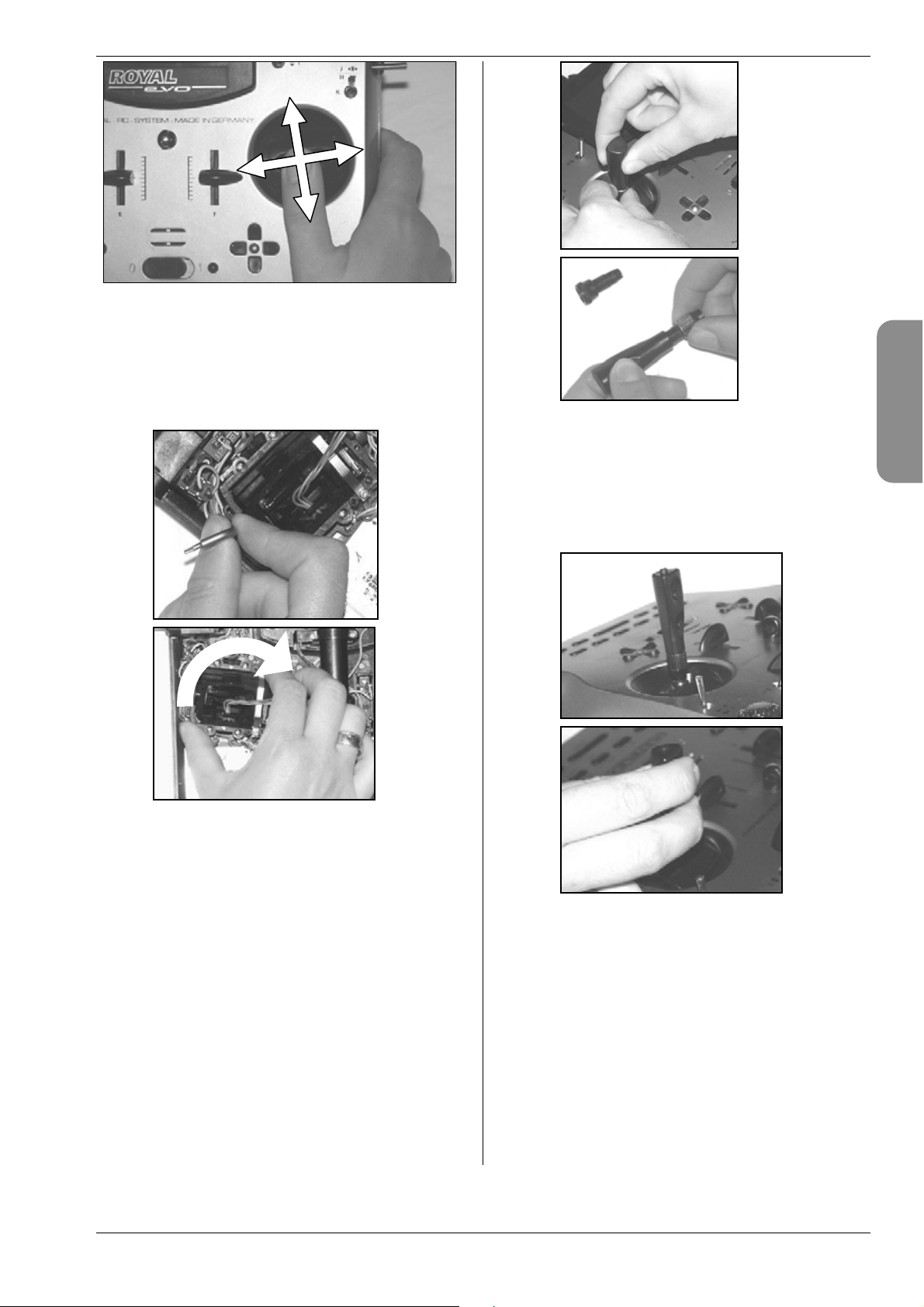

7.4.8. Swivelling the stick units

The stick units of the ROYALevo can be swivelled in

their mountings in order to align them perfectly with

your natural hand movements. This is a unique feature,

and can offer a real advantage when the transmitter is

used hand-held, with the thumbs operating the sticks,

resting on short stick-tops. In this hand position the

“natural” working action of the thumbs is at a slight

angle to the transmitter case, i.e. it does not coincide

exactly with the horizontal and vertical axes of the

transmitter. Both stick units of the ROYALevo are infinitely variable through an angle of about 15°..

Fig. 2:

When installing the battery ensure that the battery lead

is correctly positioned, and cannot become jammed or

snagged when you close the case.

Note:

Model data is not lost when you change the battery.

Seite 10

Instructions

1. Loosen the 3 TORX screws of the stick unit you wish

to swivel, using the TORX screwdriver (in a clip below the aerial guide sleeve, close to the screen) until the unit can be rotated (Fig. 1).

2. Swivel the stick unit to your choice of angle, then

tighten the screws again. Take care not to overtighten them, or you may strip the threads (Fig. 2).

Fig. 1:

Fig. 1

Fig. 2:

7.4.10. Stick top with buttons -

how to fit them, how they work

ENGLISH

If you use the transmitter with the long stick tops, you

will find that the long stick top with buttons (# 7 5303) is

very helpful, as it can be used for many important switched functions. This helps to ensure that auxiliary functions can be operated simply, quickly and safely,

without having to let go of the associated stick.

Fig. 2:

7.4.9. Adjusting and replacing the stick tops

As standard the ROYALevo is supplied with three pairs

of stick tops of different lengths. They are easy to

change, adjust in height, or rotate:

1. Place the transmitter on a flat surface.

2. Hold the stick top firmly in one hand (Fig. 1).

3. With the other hand undo the locking nut by rotating it clockwise (Fig. 1).

The stick shaft is smooth, and the stick top can now be

rotated or adjusted in length (position on the shaft). If

you are changing the stick tops, unscrew the locking

nuts from the old ones, and use them to secure the new

stick tops (Fig. 2).

Before installing the stick tops ensure that the stick

shaft is clean and free of grease and oil. If you don’t do

this you may find that the stick top does not stay in

position reliably.

Fig. 1:

Fig. 2:

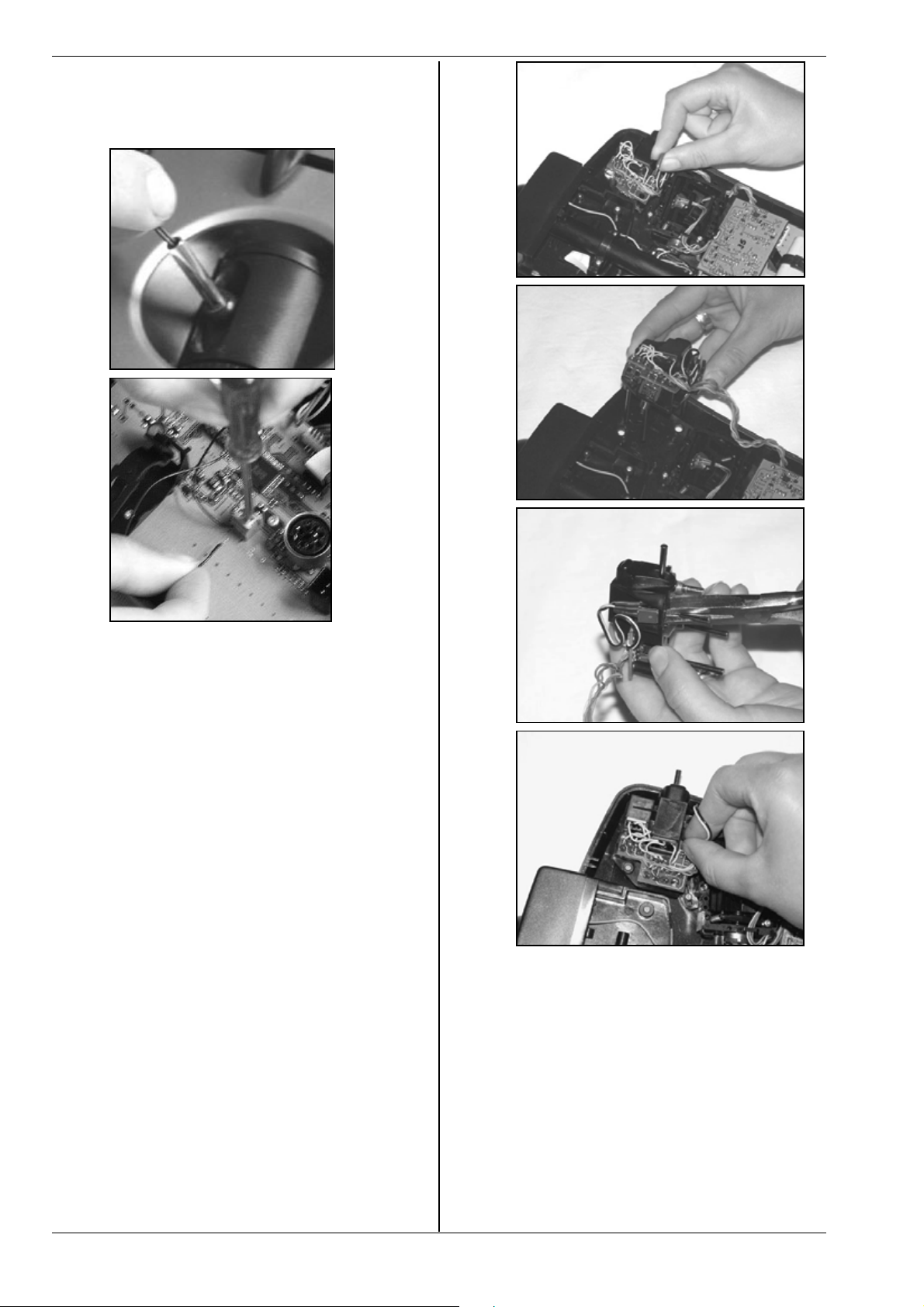

The top button has a non-latching or momentary func-

tion (e.g. pressed = ON, released = OFF), whereas the

two lateral buttons form one complete switch together

(e.g. button 1 = ON, button 2 = OFF). Fitting the stick

tops is a quick, simple procedure, and requires no soldering:

1. Switch off the transmitter and remove the stick top.

2. Thread the two wires attached to the new stick top

through the stick shaft (Fig. 1) and fit the stick top

again, as already described in Section 7.4.9.

3. Clip the wires in the holders designed for them on

the stick unit. Check that the wires have sufficient

freedom when the stick is deflected; they must not

be under tension at any point, and should not snag

anywhere.

Seite 11

ROYAL evo

4. Connect the bare wire ends to the appropriate

screw-terminals on the main circuit board; you will

need a small slot-head screwdriver for this. It does

not matter which way round the wires are connected.

Fig. 1:

Fig. 2:

Fig. 1:

Fig. 2:

Advice for stick button/switch alignment

If a stick handle with button/switch is installed fort the

first time in the transmitter the alignment is done

automatically. Re-alignment is necessary, if the stick

handle is exchanged. To initiate re-alignment check in

Fig. 3:

the data manager the option box for “Reset stick but-

ton/switch alignment” (Î 19.6.). For more information

see the DataManager instructions.

7.4.11. Installing the optional switches “P” and “K”

If you need extra functions 2-position switches can be

installed in the installation wells “P” and “K”. To fit them

the corresponding corner unit must be removed from

the transmitter:

1. Locate the TORX screwdriver (in a clip below the

aerial guide sleeve, close to the screen) and undo

the four TORX screws holding the appropriate stick

unit (Fig. 1).

Fig. 4:

2. Check that the switches are at the centre position,

then carefully withdraw the corner unit from the

transmitter. Remove the rotary knob (push-fit) from

the 3-D digi-adjustor when you withdraw the unit

(Fig. 2).

3. Use a small screwdriver to push out the blind cover

from the inside.

4. Fit the switch and secure it with the retaining nut

supplied (Fig. 3). Note the correct orientation: the

red wire should face the battery.

5. Re-install the corner unit, fit the retaining screws

and push the rotary knob back onto the 3-D digiadjustor (note correct position: internal index

shoulder). Connect the plug attached to the new

switch directly to the micro-connector on the corner unit (Fig. 4).

Seite 12

8. The transmitter battery

The ROYALevo is powered by a high-quality readymade battery pack consisting of 6 NiMH cells (NickelMetal-Hydride) of the AA size. NiMH cells offer a much

higher energy density (capacity : weight) than NiCd

(Nickel-Cadmium) cells, and therefore provide longer

operating times for the same weight. They do require

slightly different handling and greater care, especially

when charging.

8.1. Battery management in the ROYALevo

8.1.1. This is what we have already

Battery voltage display

Most transmitters show the battery voltage in graphic

or numeric form.

Battery alarm

An audible alarm indicates the voltage falling below the

minimum level. In many transmitters the minimum level

can be set by the user.

Both features are available in the ROYALevo of course.

(Battery alarm Î 13.1.3.)

NEW

8.1.2. This is

The battery management in the ROYALevo monitors

the charge status of the transmiiter battery during all

operating conditions, even when the transmitter is

switched off.

In detail the following happens:

a. during charging

If the thransmitter battery is charged with more

than 50 mA via the charging socket, the charging

current is measured regularly and the charge is calculated. The result is stored in the transmitters

memory..

b. during operation

Also during operation the current is measured and

the drawn charge is calculated and subtracted

from the available charge. In the status display 4

(ÎFehler! Verweisquelle konnte nicht gefun-

den werden..) the remaining battery charge is

shown.

Whenever the RF module is active (red LED flashing), the residual operating time is calculated and

displayed. This figure is shown to give a rough idea

of how long the transmitter can be operated.

c. when the transmitter is switched off

Also if your transmitter „sleeps“ on the shelf, the

battery loses charge by the effect of self-discharge

(approx. 1.5% per day). The battery management

automatically reduces the available charge accordingly.

Battery charge an residual values are only intended

!

as a guide. Tolerances and variations between individual examples, and the effects of battery maintenance schedules, can produce considerable discrepancies.

Instructions

8.1.3. This is what you must attend

To get battery management display as reliable as possible, please take care of the following:

a. Correction of th indicated battery charge

The battery management assumes a nominal capacity of 1500 mAh. After the battery has reached

ist full capacity (more than 5 charge/discharge cycles) the true capacity can be set in the menu:

L , Transmitter parameter: Batt. charge

In steps of 50 mAh you can set the capacity measured by your charger.

If battery voltage of 6.5 V or below is de-

!

tected, the available charge is set to 0 mAh.

b. Use a suitable charger (Î 8.4.) and charge via

the socket

Only if the battery is charged via the socket the

battery management can work correctly.

c. chargin with constant current (1/10 C)

If the battery will be charged longer than calculated with the formula in chapter 8.4. the battery

management will limit the available charge at

1500 mAh.

8.2. The battery essentials in brief

x 6 cells, 1500 mAh, NiMH (Nickel-Metal-Hydride)

x Integral thermo-fuse (automatic reset)

x Standard charge (0,1 C = 150 mA) 12 hours

x Fast charge (1 C =1,5 A) = maximum charge current

with automatic cut-off

x Avoid deep-discharging (< 1V/Zelle)

x during longer storage (more than 4 weeks) avoid

temperatures above 30°C

8.3. Safety notes

!

The transmitter battery is responsible for

supplying power to the transmitter, and

therefore makes a vital contribution to the

unit’s operational security. For this reason it is

very important that you observe the following

instructions on charging and maintaining the

battery.

!

The transmitter battery is fitted with a thermo-fuse

with automatic reset which protects the battery

and transmitter from short-circuit, reverse polarity

and excessive current. The transmitter electronics

have no additional fuse! For this reason it is only

permissible to replace the battery with another

genuine MULTIPLEX transmitter pack!

!

Additional safety notes

x Batteries are potentially hazardous, and must be

stored out of the reach of children.

x Before each session check that the battery is in

perfect order. Damaged or defective batteries must

not be re-used.

x Never heat, burn, open or short out batteries. Do

not charge or discharge them at excessive currents,

overcharge or deep-discharge them, nor charge

them with reversed polarity.

x Place batteries on a heat-resistant, non-flammable

and non-conductive surface for charging, and do

not leave them on charge unsupervised.

x Do not make any modifications to the rechargeable

batteries. Never solder or weld direct to the cells.

ENGLISH

Seite 13

ROYAL evo

x If these batteries are mistreated, there is a danger of

fire, explosion, burns and chemical burns. Suitable

extinguishing agents: water, CO2, sand.

x Escaped electrolyte is corrosive!

Do not allow it to contact your skin or eyes. In an

emergency wash the affected area with copious

amounts of water and seek the help of a doctor

immediately.

8.4. Charging the transmitter battery

Never connect the TX without battery to a

!

charger!

Chargers can supply high output voltages if no

battery is connected. This voltages can cause damages in the transmitter.

Rapid charging with 1.5 A max.!

!

Charging with mains chargers or

!

12V-chargers for max. 8 cells

The battery can remain installed in the TX for

charging. Connection to the charger is made via

the charging socket on the back of the transmitter

(Î 7.2.). Use only genuine MULTIPLEX charge

leads (e.g. transmitter charge lead with banana

plugs # 8 6020). For details of other charge leads

and battery chargers please refer to the current

MULTIPLEX main catalogue.

Charging with 12V-chargers

!

for more than 8 cells

Never charge via the charging socket! Unplug

the battery from the electronics board and use the

TX battery direct charge lead # 8 6021.

The battery management can only work correctly

with a permanent connection (even if the transmitter is switched off) between battery and

electronics board to measure into (charging) or out

of (operation) the battery. Chargers for more than

8 cells need voltage converters producing high

voltages, which can damage the transmitter electronics.

Full capacity and performance

NiMH batteries only produce maximum performance

after a series of charge/discharge cycles (~5 cycles). The

first charge/discharge cycles should be carried out at

0.1CA (150 mA). Don’t fast-charge the pack until you

have done this.

What means C in charging advices?

C is the charging current, which supplies 100% of its

nominal capacity to a battery within 1 hour. This is a

current of 1500 mA for the 1500 mAh battey of the

ROYALevo. Charging with this current is named 1-C-

charging. This current can be derived from the nominal

capacity in mAh (or Ah) by just removing the letter “h”.

Standard charging

This means that the pack is charged at a current within

the range 0.05 to 0.2 C (75 mA to 300 mA).

The charge time is then calculated from the following

formula:

][

][

heCharge tim

mAhCapacity

][

mArentCharge cur

Fast charging

This means that the pack is charged at a current within

the range 0.5 to 1 C (750 mA to 1.5 A). The charging is

finished by the automatic cut-off.

Timer-controlled charging is not permissible!

!

Important with fast charging:

!

The charger must be designed to cope with NiMH

batteries, i.e. Delta Peak termination sensitivity < 5

mV/cell, or temperature-controlled termination at

> 0.8°C/min.

Trickle charging

This means that the pack is charged at a current within

the range 0.03 CA to 0.05 CA (45 to 75 mA). Automatic

chargers generally switch over to this mode of charging

when the fast charge phase is concluded. After max. 20

hours trickle charging must be stopped.

This is the correct method of charging:

1. Switch off the transmitter

2. Switch on the battery charger designed for NiMH

batteries (see left column 8.4.) and connect the

charge leads.

3. Check polarity:

Red plug = positive terminal (+)

Blue/black plug = negative terminal (-)

Connecting the charger with reversed polarity

may ruin the battery!

(excessive heat, escape of corrosive electrolyte,

bursting of cells)

4. Connect the charge lead to the transmitter

5. Select the charge current (max. 1.5 A); alternatively

set the current after starting the charge process

Automatic fast chargers:

Use manual current selection! If the fast charger

should interrupt the charge process prematurely,

reduce the charge current and start again.

6. Check the battery temperature regularly during the

charge process

7. Disconnect the transmitter from the charger at the

end of the process.

8. When you have charged the battery enter the

charged-in energy in the menu L Transmitter,

Batt. charge (8.1.3. a.).

Note:

The development of rechargeable batteries continues

apace, just like other technical components. We therefore reserve the right to supply different battery packs

as standard in our transmitters, in order to keep the

equipment abreast of current standards.

8.5. Maintaining and storing

the transmitter battery

Always store NiMH batteries in the fully charged state.

This avoids the danger of deep-discharge.

Store NiMH batteries at a temperature between 0°C and

30°C, in dry conditions, and out of direct sunshine.

Charge unused NiMH batteries every 3 months. This

compensates for the natural self-discharge rate, and

again prevents deep-discharge.

If you have to store a battery for a long period, we recommend that you balance the cells by giving the pack

several charge/discharge cycles. Protracted storage may

reduce the pack’s usable capacity.

Seite 14

8.6. Recycling

Unlike NiCd cells, NiMH cells contain no cadmium,

which is a toxic heavy metal. Nevertheless, exhausted

cells should not just be thrown in the domestic rubbish.

Take the cells to your local specialist recycling centre.

The cells must first be discharged completely and made

safe against short-circuit (wrap in plastic film).

9. Using the transmitter for the

first time

9.1. Initial power-ON

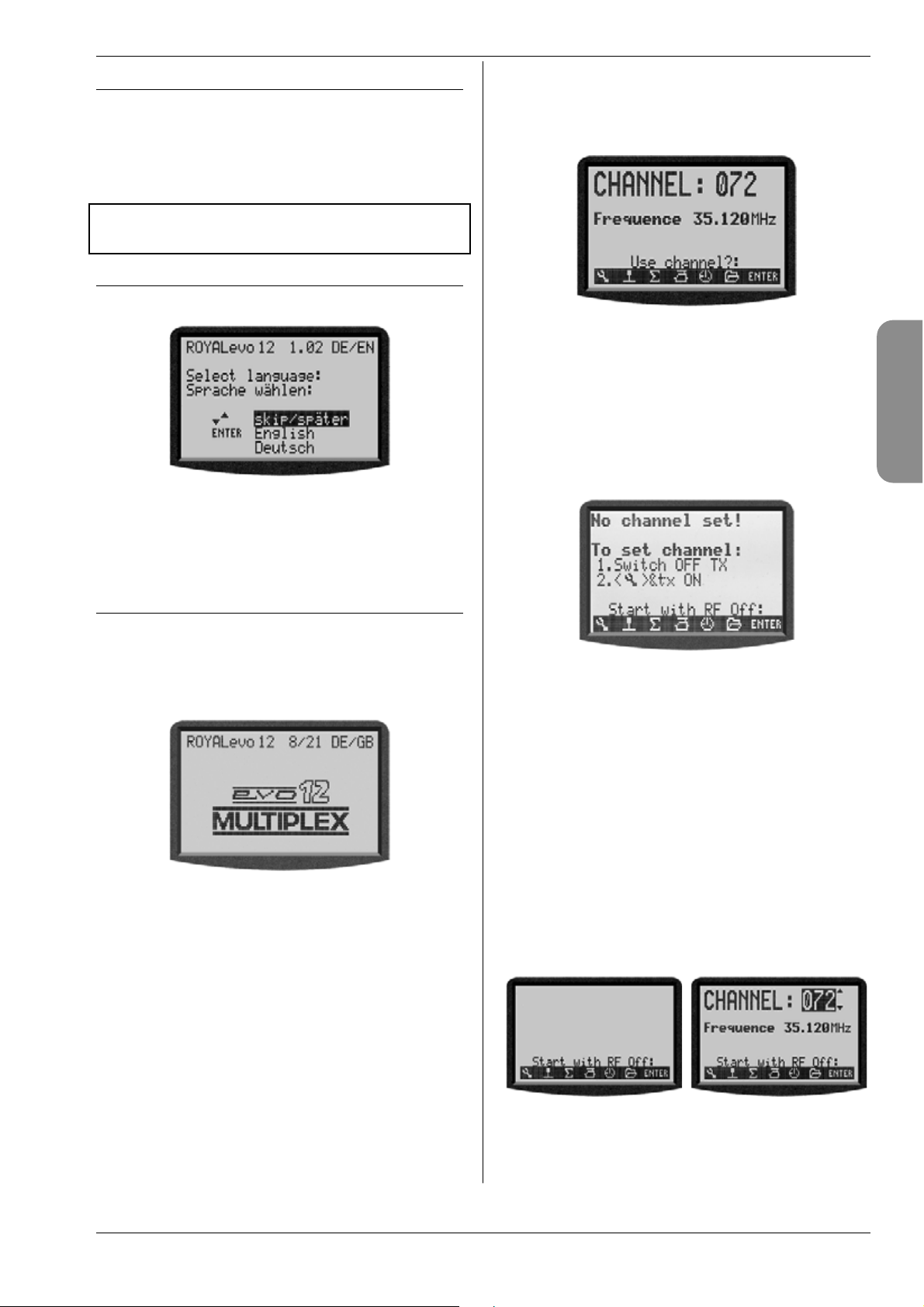

When the transmitter is switched ON for the very first

time the following screen appears:

Use the up and down arrow keys to select the desired

language and confirm by pressing ENTER. This selection

can be changed at any time (Î 13.5.2.). All user-

definable text (e.g. names for mixers, models, assignment lists) will not be changed, if the language selection is changed afterwards in the SETUP menu.

Instructions

9.2.2. Switching ON with the

HFM-S synthesizer RF module

After the power-on info screen (Î 9.1.), the currently

set channel and transmission frequency appears briefly

for your information:

After this the last used status display appears. If everything is in order, the software activates the synthesizer

RF module, and an RF (Radio Frequency) signal is immediately transmitted. The LED starts to flash, the

screen switches to the last active status display, and the

transmitter is ready to use.

The first time you switch the transmitter ON with a synthesizer RF module fitted, or after installing a different

synthesizer RF module, an information screen appears,

replacing the power-on info screen. This tells you how

to set the channel when using a synthesizer RF module:

ENGLISH

9.2. Switching on

When the you switch the transmitter ON, the following

power-on info screen will always appear briefly, regardless of whether an RF module is installed or not. This

gives information on the transmitter type, the current

software version and the languages available for the

screen texts:

If no RF module is fitted, the following message appears

briefly: „Note: No RF!“

9.2.1. Switching ON with the

HFM-4 RF module for crystals

After the power-on info screen (Î 9.1.), the last used

status display appears (Î Fehler! Verweisquelle

konnte nicht gefunden werden..). If everything is in

order, the software immediately activates the RF module for crystals, and an RF (Radio Frequency) signal is

immediately transmitted. The LED starts to flash, the

screen switches to the last active status display, and the

transmitter is ready to use.

The method of selecting a channel when using an HFMS synthesizer RF module is described in Section 9.4.

9.2.3. Switching on without transmitting an RF signal

Whether you are using an HFM-4 RF module for crystals

or an HFM-S synthesizer RF module it is possible to

switch the transmitter ON without transmitting an RF

signal, even when an RF module is installed. The transmitter can then be operated in that mode. This can be

useful for programming when no RF signal is required,

e.g. to minimise current drain, or when your channel is

already in use.

Hold the tool button L pressed in when you switch the

transmitter on you are now at the power-on menu.

RF is OFF ( LED glows constantly)

The following display appears:

With HFM-4 RF module

for crystals

Pressing any direct menu access button, or the ENTER

button, takes you to the last active status display.

With HFM-S4

synthesizer RF module

!

RF stays OFF until the transmitter is switched ON again.

Seite 15

Note:

ROYAL evo

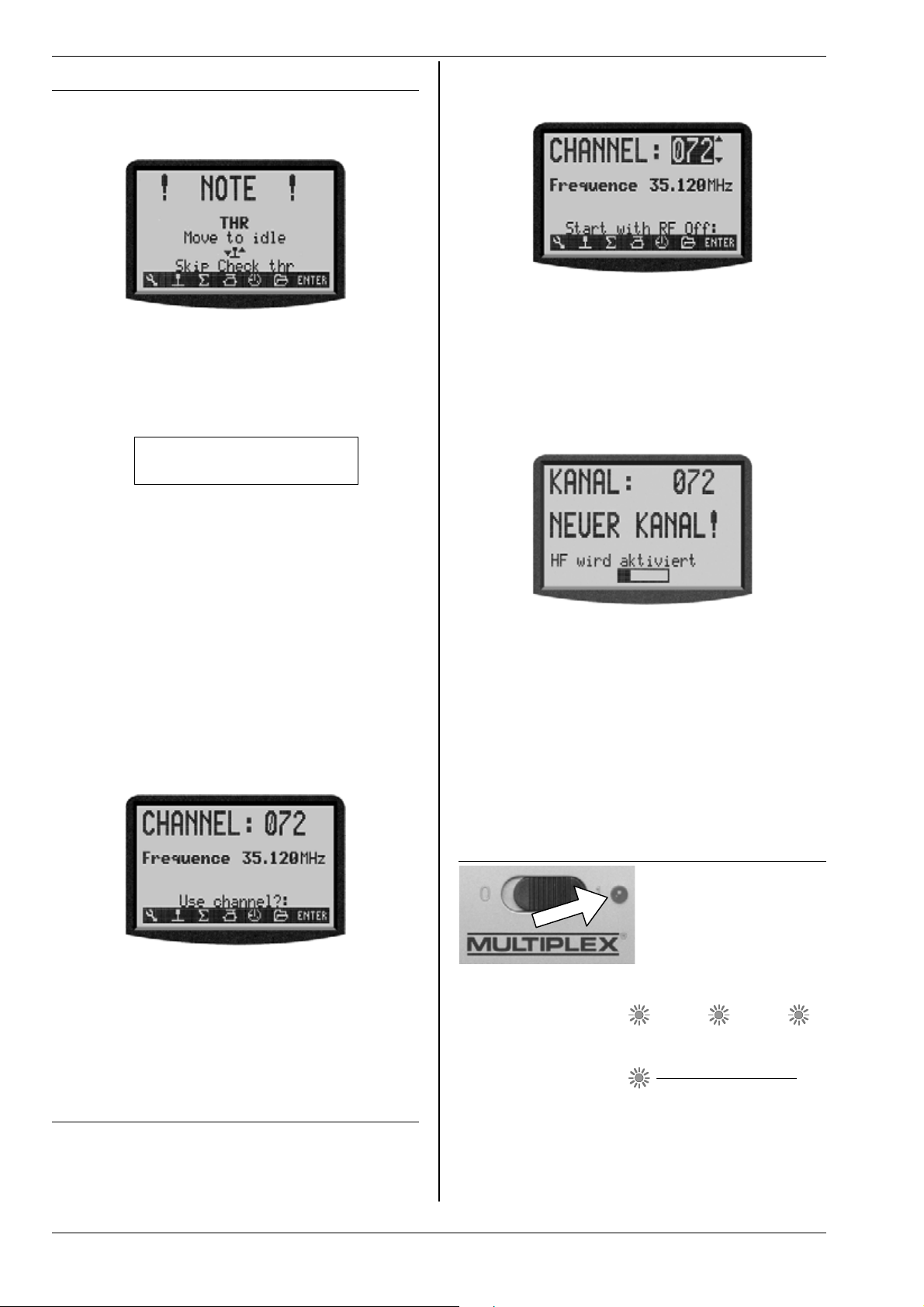

9.3. Security queries when switching ON

9.3.1. Throttle check

If in the menu L Transmitter the parameter Check

thr. is ON ( Î 13.1.6.), the following can appear:

The transmitter does not start until the throttle control

is in idle position. The symbol below the text reminds

you of the control, used for throttle. The figure above

shows the stick symbol.

If Throttle-Cut is active the transmitter immediately

starts operation and the following message appears for

4 sec.:

Throttle-Cut active

H>

You are now at the channel setting menu,

RF is OFF (LED glows constantly).

The following display appears:

Set the channel you wish to use by pressing the „V“(UP)

/ „W“(DOWN) buttons, or one of the two 3-D digi-

adjustors. The channel is displayed as a channel number

and also the associated transmission frequency. To

activate the transmitter on the channel you have just

selected, the transmitter must now be switched OFF,

and then switched on again -.

Switch the transmitter OFF and then ON again

(this time WITHOUT the tool button pressed in)

You will see the following display::

Also in this case the corresponding switch is indicated.

The “Throttle Check” safety query can be switched ON

or OFF as required (Î 13.1.6.).

TIP !

If the safety query does not disappear when you correct

the Throttle and Throttle Cut settings, switch the trans-

mitter ON without RF (Î 9.1.3.) and switch “Throttle

Check” OFF (Î 13.1.6.). When you switch on the next

time the query is by-passed and the transmitter will

start up.

9.3.2. RF Check with the synthesizer module

If a synthesizer RF module is fitted in your ROYALevo, an

additional safety query can be activated (Check RF).

When you switch ON with an HFM-S synthesizer RF

module fitted, the following screen may appear after

the power-on info screen:

For safety reasons RF transmission remains OFF until

you confirm the displayed channel or transmission frequency by pressing any direct menu access button or

the ENTER button. Only then will you see the last active

status screen; RF transmission is then activated.

The “RF Check” safety query can be switched ON or OFF

as required (Î 13.1.7.).

9.4. Selecting the channel with an HFM-S

synthesizer RF module

Channel selection with an HFM-S synthesizer RF module

is very simple, convenient and safe:

Switch on the transmitter with the tool button L

pressed in

C H A N NE L 0 72

NEW CHANNEL!

Activating RF!

For your information the screen displays the previously

set channel. RF transmission remains OFF (=> LED glows

constantly) until the waiting period (horizontal bar on

screen) to activate the new channel has elapsed. During

this waiting period you have the chance to switch off

the transmitter before the RF module is activated, if, for

example, you have inadvertently set the wrong channel.

When the waiting period has elapsed, the last used

status display appears

The LED starts flashing, the transmitter is ready for use.

9.5. The RF status display (red LED)

The red LED (light emitting diode) constantly

indicates the current

status of the RF module

when the transmitter is

switched on, i.e. whether

an RF (Radio Frequency) signal is being transmitted or

not.

RF transmission ON:

The LED flashes at intervals of about 2 seconds and the

transmitter is ready for use.

RF transmission OFF:

The LED glows constantly.

2 sec 2 sec ...

Seite 16

The system monitors the current drain of the RF module

to check whether an RF signal is being transmitted or

not, rather than by checking the status of the RF module. If the current drain is below a typical value, either

no RF signal is being transmitted, or the RF signal is

being transmitted at less than full power (in which case

safe operation cannot be guaranteed!) This method of

monitoring is much safer, as it is also capable of detecting faults and errors::

x Is an RF module installed?

x Is the connection between RF module and trans-

mitter in order (contact fault)?

x Is the RF module working correctly?

x Is a crystal fitted, and is it in order?

(only with HFM-4 RF module for crystals)?

x Is the transmitter aerial installed, and is it making

proper contact?

If the ROYALevo is in use as a Pupil transmitter, or in

diagnosis mode, no RF signal will be transmitted => LED

glows constantly.

9.6. The status displays

There are four different status displays available in total.

You can switch between the individual status displays at

any time (provided that you are at one of the other

status displays, i.e. not in a menu) using the „V“ or „W“

buttons, depending on the information you wish to see.

When you switch the transmitter on, the last used status

display will always appear.

Status display

1

1

2

3

4

5

6

Bars

Line 1 Status of the 3-D digi-adjustors.

Numerous set-up parameters can be assigned

to the 3-D digi-adjustors, which can then be

varied directly (Î 10.2.2.)

Line 2 Current model memory with

No. of the memory (1): model name(BASIC)

Line 3 Current operating voltage of the transmitter

battery in numeric form, and also graphically

in horizontal bar form

Line 4

Line 5

Line 6 Operating time of the

Bars The 4 bars at the sides and bottom of the

Version: ROYALevo 9 or ROYALevo 12

User name (Î 13.5.3.)

current model memory(Î 17.1.)

screen show the current trim positions of the

4 primary control functions/sticks (Î 11.4.).)

Instructions

(flight phases)

Status display

Line 1 Status of the 3-D digi-adjustors, see above

Line 2 Current model memory, see above

Line 3 Current operating voltage, see above

Line 4 Code letter of the switch used to change

Line 5 Current flight mode with

Bars Current trim positions, see above

Status display

Only timers with assigned switches are displayed. Behind the time the switch code letter is shown (P in the

example).

Line 1 Status of the 3-D digi-adjustors, see above

Line 2

Line 3

Line 4

Bars Current trim positions, see above

Status display

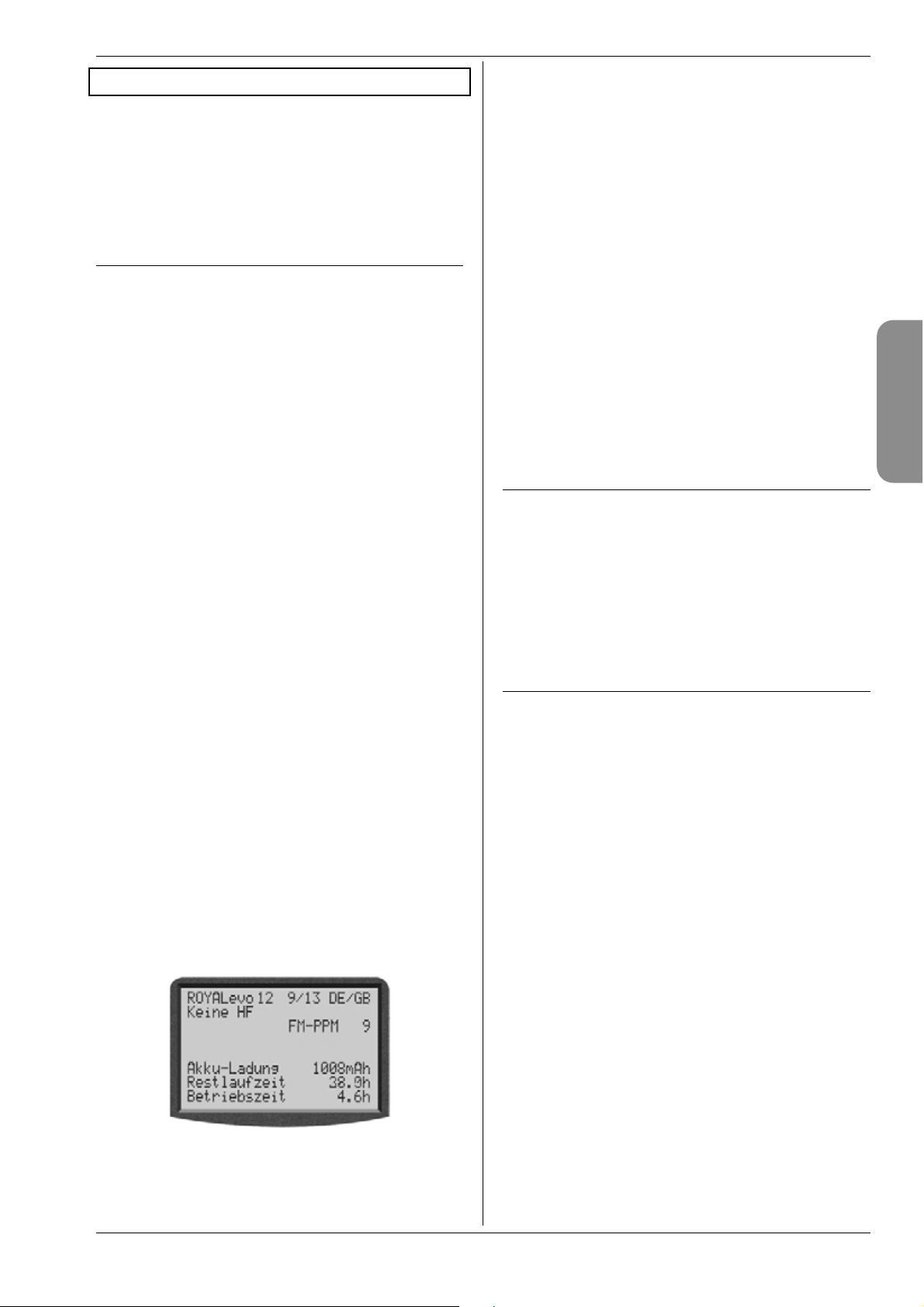

Line 1 Variant (ROYALevo 9 or 12),

Line 2 with synthesizer module: channel no. freq.

Line 3 Transmission system (e.g. FM-PPM 9)

Line 4

Line 5 residual operating time with the residual

Line 6 Overall operating time of the transmitter

2

1

2

3

4

5

flight modes (Î 18.4)

No. (1): name (NORMAL)

(Timers)

3

1

2

3

4

Slot-Timer (Î 17.2.)

Sum Timer (Î 17.3.)

Interval Timer (Î17.4.)

(system)

4

1

2

3

4

5

6

software-version (e.g. 1.09),

language set currently loaded DE/GB

(Î 13.5.2.)

else type of RF module (HFM-4) or "No RF"

depending on servo assignment (Î 16.2.)

available battery charge (Î 8.1.2 and 8.1.3.)

charge at the current power consumption

(Î 8.1.2 and 8.1.3.)

(Î 17.)

ENGLISH

Seite 17

ROYAL evo

10.

The ROYALevo features a new, very simple operating

philosophy which is easy and fast to learn. Proven elements of the operating systems used in our other renowned radio control systems are combined here. The

system is operated by means of a keypad, although one

or both 3-D digi-adjustors can be used optionally for

making adjustments and for navigating within the menus.

The basic operating philosophy

10.1. The keypad

10.1.1. Direct menu access buttons (row 1)

The keypad consisting of these buttons is used for programming or - more accurately - setting up the transmitter.

The 6 buttons in the top row are known as the direct

menu access buttons. When you press one of the buttons you move directly to the corresponding one of the

six main menus, all of which contain appropriate submenus. All these buttons are marked by a relevant symbol:

L

SETUP (configuration)

Button Function in the

status display

REV/CLR Reverse/clear button

ENTER Confirm button

No function

V W

10.1.3. Text input

For some programming procedures it is necessary to

input text. For example, this is required when entering a

model name (model memory), the user’s name, or the

name of a freely definable mixer. The text is entered

using the keypad (using the method commonly adopted with mobile telephones) and a 3-D digi-adjustor.

The keypad is used to select the letters and other symbols. The symbols which can be called up by pressing a

button rapidly and repeatedly are printed in small letters below each of the direct menu access buttons (row

1) and above the task buttons (row 2):

Manual reset or erase

timer times.

UP/DOWN button

Switch between status

displays

Function in

a menu

Cancel or reverse and

erase values and settings.

Select menus and

parameters/settings,

confirm and quit.

Select menus and

prameters/settings,

change values.

TRANSMITTER CONTROLS

H

MIXER

G

K

I

10.1.2. Task buttons (row 2)

What we call the task buttons are required for a wide

variety of operations. The way they work varies according to what you are doing. The table below shows the

function.

Button Function in the

Opens or blocks the

SERVO

TIMER

A

MEMORY

status display

facility to change a

value assigned to one

of the two 3-D digiadjustors.

Function in

a menu

Digi-assignment button

Selects a value which

can be varied using

one of the two 3-D

digi-adjustors.

If you enter a letter at the start of a text input process, or

after a space symbol, the software automatically renders it as a capital letter, and subsequent letters automatically as lower-case letters. If you wish to enter a

series of capitals, “leaf” through the lower-case letters,

and you will find the capital letters thereafter. When you

make a selection, the cursor moves automatically to the

next position. One of the two 3-D digi-adjustors can be

rotated to move the input cursor manually to any position, forward or back.

Press the “ENTER” button to end the text entry process.

You now see the following query:

“Clear rest of line? Yes -> (REV/CLR), No -> ENTER”

x Pressing the (REV/CLR) button erases all characters

following the last position of the cursor

x Pressing the “ENTER” button leaves the content

unchanged.

Enter special characters

Some of the keys have hidden characters, not printed

on the transmitter case.

Button Character Button Character

ABC1

DEF2

GHI3

JKL4

MNO5

Space

ABC1abc

DEF2def

GHI3ghi

JKL4jkl

MNO5mno

PQR6

STU7

VWX8

YZ_9

/-#0

PQR6pqr

STU7stu

VWX8vwx

YZ 9yz_

0/?!-+%#&<>*

Seite 18

Loading...

Loading...