Multiplex MS-8-1H Service Manual

Blended Ice Machine

Multiplex Models MS-8-1H, MS-8-EH

Service Manual

Manufactured exclusively for

McDonald’s® By:

Manitowoc Foodservice

Tel. (888) 436-5442

Tel. (989) 773-7981

Fax (888) 779-2040

Blended Ice Machine

Multiplex MS-8-1H, MS-8-EH

Printed in May 2010 |

Printed in |

|

The United States of America |

Important Warning And Safety Information

WARNING READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING, OR PERFORMING MAINTENANCE ON THE EQUIPMENT.

WARNING FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

WARNING DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING UNLESS ALL COVER AND ACCESS PANELS ARE IN PLACE AND PROPERLY SECURED, DO NOT OPERATE THIS EQUIPMENT.

WARNING THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS WHO LACK EXPERIENCE OR KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN  SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE

SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE  BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

WARNING THIS APPLIANCE IS NOT TO BE PLAYED WITH.

WARNING DO NOT CLEAN WITH WATER JET.

WARNING DO NOT USE ELECTRICAL APPLIANCES INSIDE THE FOOD STORAGE COMPARTMENT OF THIS APPLIANCE.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Retain this manual for future reference.

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

General Information |

|

|

Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

5 |

Serial Number Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

||

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

||

Component Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6 |

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7 |

Clearance Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8 |

Heat of Rejection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8 |

General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8 |

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 |

||

General Maintenance Instructions. . . . . . . . . . . . . . . . . . . . . . . |

. |

9 |

Daily Preventive Maintenance Card . . . . . . . . . . . . . . . . . . . . . . |

. |

10 |

Weekly Preventive Maintenance Card . . . . . . . . . . . . . . . . . . . . . |

. |

12 |

Operation |

|

|

How to Make a Drink. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

17 |

How to Replace a Product Bag. . . . . . . . . . . . . . . . . . . . . . . . |

. |

18 |

Shaver Blade Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . |

|

19 |

Energize Sequence Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . |

|

20 |

Make a Drink Energized Component Flowchart. . . . . . . . . . . . . . . . . . |

|

21 |

Rinsing Energized Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . 24 |

||

Manager’s Menu Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

26 |

Centering the Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

26 |

Troubleshooting |

|

|

Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

27 |

Blender And Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

28 |

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 |

||

Cabinet/Product Thermistors. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

29 |

Ice Shaver/Ice Bin Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

30 |

Product Dispensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

31 |

Rinsing And Water Dispensing . . . . . . . . . . . . . . . . . . . . . . . . |

. |

32 |

Refrigeration Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

33 |

Will Not Run Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 |

||

Weight Beam Diagnostic Flowchart. . . . . . . . . . . . . . . . . . . . . . . |

|

36 |

Ice Shaver Will Not Run Flowchart. . . . . . . . . . . . . . . . . . . . . . . |

|

37 |

Component Check Procedures

ON/OFF Rocker Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

38 |

Control Board Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

39 |

IO (Input/Output) Board. . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

39 |

LCD Touchscreen & Microprocessor Control Board. . . . . . . . . . . . . . . . |

. |

40 |

Cabinet Temperature Thermistor. . . . . . . . . . . . . . . . . . . . . . . . |

|

40 |

|

|

|

05/10 |

|

3 |

Table of Contents (continued)

Component Check Procedures, continued |

|

|

Product Chase Temperature Thermistor. . . . . . . . . . . . . . . . . . . . . |

|

41 |

Chase Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 |

||

Evaporator Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 |

||

Condenser Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

42 |

Ice Bin Lid Microswitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 |

||

Product Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

43 |

Solenoid Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

43 |

Shaver Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

43 |

Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

44 |

Blender Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

44 |

Manual Rinse Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

44 |

Compressor Electrical Diagnostics. . . . . . . . . . . . . . . . . . . . . . . |

|

45 |

Discharge Pressure High Checklist. . . . . . . . . . . . . . . . . . . . . . . |

|

46 |

Discharge Pressure Low Checklist. . . . . . . . . . . . . . . . . . . . . . . |

|

46 |

Suction Pressure High Checklist. . . . . . . . . . . . . . . . . . . . . . . . |

|

46 |

Suction Pressure Low Checklist. . . . . . . . . . . . . . . . . . . . . . . . |

|

46 |

Recovery/Evacuation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 |

||

Assembly & Replacement Parts List |

|

|

Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

48 |

Top. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 |

||

Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

49 |

Duct Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

50 |

Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

50 |

Top Valve & Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

51 |

Lower Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

51 |

VitaMix Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 |

||

Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

52 |

Evaporator Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

52 |

Refrigerant Recovery/Evacuation & Charging Procedures

Charging Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

System Contamination Cleanup . . . . . . . . . . . . . . . . . . . . . . . . |

|

53 |

Mild System Contamination Cleanup Procedure. . . . . . . . . . . . . . . . . . |

|

54 |

Severe System Contamination Cleanup Procedure . . . . . . . . . . . . . . . . |

. 55 |

|

Filter-Driers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

55 |

Total System Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . |

. |

55 |

Operating Pressures Chart. . . . . . . . . . . . . . . . . . . . . . . . . . |

|

55 |

Specifications/Wiring Diagrams/Schematics |

|

|

MS-8-1H Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

56 |

MS-8-EH Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 |

||

Blender Scale & Shaver Schematics. . . . . . . . . . . . . . . . . . . . . . |

. |

58 |

Electronic Control Board. . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

59 |

05/10

General Information

Model Numbers

This manual covers the Blended Ice Machine, model numbers MS-8-1H and MS-8-EH.

Serial Number Location

This number is required when requesting information from your local distributor. The serial number is listed on the SERIAL NUMBER DECAL affixed to the middle of the lower back panel on the Blended Ice Machine. A second decal is located on the front right side of cup dispenser.

General Warranty Information

Your Blended Ice Machine comes with a three-year warranty on parts and labor and a five-year warranty on compressor. Consult your local Multiplex Distributor for terms and conditions of your warranty. Your warranty specifically excludes all general adjustments, cleaning, accessories and related servicing.

The warranty card must be returned to activate the warranty on this equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves the Multiplex factory.

No equipment may be returned to without a written

Return Materials Authorization (RMA). Equipment returned without an RMA will be refused at dock and returned to the sender at the sender’s expense.

Please contact your local distributor for return procedures.

The following Warranty outline is provided for your convenience. For a detailed explanation, read the warranty bond shipped with each product.

Contact your local Multiplex representative or Multiplex if you need further warranty information.

Parts

Multiplex warrants the Blended Ice Machine against defects in materials and workmanship, under normal use and service for three (3) years from the date of original installation.

The evaporator and compressor are covered by an additional two (2) year (five years total) warranty beginning on the date of the original installation.

Labor

Labor required to repair or replace defective components is covered for three (3) years from the date of original installation.

Exclusions

The following items are not included in the Blended Ice Machine warranty coverage:

Normal maintenance, adjustments and cleaning as outlined in this manual.

Repairs due to unauthorized modifications to the

Blended Ice Machine or use of non-standard parts without prior written approval from Multiplex.

Damage caused by improper installation of the Blended Ice Machine, electrical supply, water supply or drainage, or damage caused by floods, storms, or other acts of

God.

Premium labor rates due to holidays, overtime, etc.; travel time; flat rate service call charges; mileage and miscellaneous tools and material charges not listed on the payment schedule. Additional labor charges resulting from the inaccessibility of equipment are also excluded.

Parts or assemblies subjected to misuse, abuse, neglect or accidents.

Damage or problems caused by installation, cleaning and/or maintenance procedures inconsistent with the technical instructions provided in this manual.

Authorized Warranty Service

To comply with the provisions of the warranty, a refrigeration service company qualified and authorized by your Multiplex Distributor, or a Contracted Service

Representative must perform the warranty repair.

Service Calls

Normal maintenance, adjustments and cleaning as outlined in this manual are not covered by the

warranty. If you have followed the procedures listed in this manual, and the Blended Ice Machine still does not perform properly, call your Local Distributor or the

Multiplex Service Department.

05/10 |

5 |

Component Identification

|

Cup |

|

|

Dispenser |

|

Ice Hopper Lid |

(1706175) |

|

|

|

|

(VMP00133) |

|

|

|

Touch |

|

|

Screen |

|

Lid |

Manual Rinse |

|

Dispenser |

Button |

|

(1706142) |

|

|

|

Blender Rinse |

|

|

Location |

Whipped |

Blender Fill |

|

|

|

Cream Door |

|

Pitcher |

|

(000-187-0016) |

(3239630) |

|

|

|

|

|

|

Product |

Syrup Rail |

|

|

|

|

Bins |

(1706194) |

|

(1706267) |

Syrup Rail Divider |

|

|

(1706195) |

|

Pull Out Tray |

|

|

(076-CDZ-0000) |

|

General System Overview

The Blended Ice Machine is a self-contained dispensing unit that allows the operator to make flavor combinations of blended ice drinks. It contains product flavoring in a reach-in enclosure, a refrigeration system and an ice shaving machine.

The operator controls and accesses the unit using a lighted touch screen. Icons on the Drink Selection screen represent the primary flavor combinations for the blended ice drinks. A second screen provides drink size options (S, M, L) and ingredient options, such as

“no yogurt.” Menu changes and additions are uploaded using a USB mass storage device.

On-screen instructions also include operator procedures for cleaning/sanitizing, checking inventory, replacing product bags, selecting drink sizes and manually preparing drinks. Managers and technicians have access to menu/software updates, diagnostics and other service screens.

Part Description |

Number |

Blender Fill Pitcher |

3239630 |

Cleaning Kit |

000-BIC-0008 |

Cleaning Pitcher |

3239631 |

Cup Dispenser |

1706175 |

Gasket, Door |

1706208 |

Gasket, Whipped Cream Door |

1706209 |

Hinge Kit |

RF000066 |

Ice Hopper Lid |

VMP00133 |

Lid Dispenser |

1706142 |

Product Bin |

1706267 |

Pull Out Tray |

076-CDZ-0000 |

Syrup Rail |

1706194 |

Syrup Rail Divider |

1706195 |

Whipped Cream Door |

000-187-0016 |

05/10

Electrical

General

! Warning

All wiring must conform to local, state and national codes.

Minimum Circuit Ampacity

The minimum circuit ampacity is used to help select the wire size of the electrical supply. (Minimum circuit ampacity is not the Blended Ice Machine’s running amp load.) The wire size (or gauge) is also dependent upon location, materials used, length of run, etc., so it must be determined by a qualified electrician.

Electrical Requirements

Refer to Blended Ice Machine Model/Serial Plate for voltage/amperage specifications.

Voltage

The standard voltage is 120VAC-60Hz. A power cord is provided with a NEMA 5-20P electrical plug. A dedicated electrical circuit is required.

NEMA 5-20P Plug Configuration

Minimum Circuit Amperage Chart

Important

Due to continuous improvements, this information is for reference only. Please refer to the serial number tag to verify electrical data. Serial tag information overrides information listed on this page.

Model |

Voltage/Cycle |

Total |

Breaker |

|

Numbers |

Amps |

Size |

||

|

||||

|

|

|

|

|

MS-8-1H |

115/60/1 |

16.0 |

20A |

|

8 flavor |

||||

|

|

|

||

|

|

|

|

|

MS-8-EH |

230-240/50/1 |

9.8 |

16A |

|

8 flavor |

||||

|

|

|

||

|

|

|

|

Grounding Instructions

! Warning

The machine must be grounded in accordance with national and local electrical codes.

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This appliance is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

EXPORT NOTE: For export models replace the supply cord with a 1.5mm2 minimum, 3 conductor H05VV-F harmonized cord.

05/10 |

7 |

Clearance Requirements

Model |

Air Cooled |

|

|

Top |

8" (20 cm) |

|

|

Sides |

6" (15 cm) |

|

|

Back |

6" (15 cm) |

|

|

Front |

30" (76 cm) |

|

|

Heat of Rejection

Model |

Heat of Rejection |

||

|

|

||

Air Conditioning |

Peak |

||

|

|||

|

|

|

|

MS-8-1H |

2100 |

2600 |

|

|

|

|

|

MS-8-EH |

2100 |

2600 |

|

|

|

|

|

General Specifications

Temperature Control Setting |

36°F setpoint 4°F differential |

|

2°C setpoint 2°C differential |

|

controlled by software |

|

|

Ice Capacity |

23 lbs (10 kg) |

|

|

Shipping Weight |

430 lbs (195 kg) |

|

|

Product Bin Capacity |

19.8lbs (9kg) per bim |

|

|

CO2 Regulator Setting |

40lbs |

Water Regulator Setting |

30lbs |

|

|

Location

The location selected for the Blended Ice Machine must meet the following criteria.

•The air temperature must be at least 40°F (4°C), but must not exceed 90°F (32°C), climate class 4.

•The location must not be near heat-generating equipment or in direct sunlight and must be protected from weather.

•Water temperature min/max = 40°F/110°F (4°C/43°C).

•Water pressure min/max = 20 psi/40 psi (138kPa/ 276kPa)

•Always use the water supply line supplied when installing this appliance. Never reuse an old supply line.

•Main supply CO2 pressure to Blended Ice Machine regulator min/max = 100 psi/150 psi (689kPa/ 1034kPa)

! Warning

Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas causes tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO2 gas leak is suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO2 lines and pumps must not be installed in an enclosed space. An enclosed space can be a cooler or small room or closet. This may include convenience stores with glass door self serve coolers. If you suspect CO2 may build up in an area, venting of the B-I-B pumps and / or CO2 monitors must be utilized.

05/10

Maintenance

Door Gasket Maintenance

Door gaskets require regular cleaning to prevent mold and mildew build up and also to retain the elasticity of the gasket. Gasket cleaning can be done with the use of warm soapy water.

Avoid full strength cleaning products on gaskets as this can cause them to become brittle and crack. Never use sharp tools or knives to scrape or clean the gasket. Gaskets can be easily replaced and do not require the use of tools or an authorized service person. The gaskets are “Dart” style and can be pulled out of the groove in the door and new gaskets can be “pressed” back into place.

Drain Maintenance - Base

Each unit has a drain located inside the unit that removes the condensation from the evaporator coil and routes it to an external condensate evaporator pan. Each drain can become loose or disconnected during normal use. If you notice water accumulation on the inside of the unit be sure the drain tube is connected to the evaporator drain pan. If water is collecting underneath the unit make sure the end of the drain tube is in the condensate evaporator in the machine compartment. The leveling of the unit is important as the units are designed to drain properly when level. Be sure all drain lines are free of obstructions.

Caster Maintenance

Wipe casters with a damp cloth monthly to prevent corrosion.

The power switch must be turned to OFF and the unit disconnected from the power source whenever performing service, maintenance functions or

cleaning the refrigerated area. Refrigerators

cleaning the refrigerated area. Refrigerators

The interior and exterior can be cleaned using soap and warm water. If this isn’t sufficient, try ammonia and water or a nonabrasive liquid cleaner. When cleaning the exterior, always rub with the “grain” of the stainless steel to avoid marring the finish. Do not use an abrasive cleaner because it will scratch the stainless steel and can damage the breaker strips and gaskets.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several important steps need to be taken. First, we need to understand the properties of stainless steel. Stainless steel contains 7080% iron, which will rust. It also contains 12-30% chromium, which forms an invisible passive film over the steel’s surface, which acts as a shield against corrosion. As long as the protective layer is intact, the metal is still stainless. If the film is broken or contaminated, outside elements can begin to breakdown the steel and begin to form discoloration or rust. Proper cleaning of stainless steel requires soft cloths or plastic scouring pads.

NEVER USE STEEL PADS, WIRE BRUSHES OR SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride cleaners. Any cleaner containing chlorides will damage the protective film of the stainless steel. Chlorides are also commonly found in hard water, salts, and household and industrial cleaners. If cleaners containing chlorides are used be sure to rinse repeatedly and dry thoroughly. Routine cleaning of stainless steel can be done with soap and water. Extreme stains or grease should be cleaned with a non-abrasive cleaner

and plastic scrub pad. Always rub with the grain of the steel. There are stainless steel cleaners available which can restore and preserve the finish of the steels protective layer. Early signs of stainless steel breakdown are small pits and cracks. If this has begun, clean thoroughly and start to apply stainless steel cleaners in attempt to restore the passivity of the steel.

Never use an acid based cleaning solution! Many food products have an acidic content, which can

deteriorate the finish. Be sure to clean the stainless

steel surfaces of ALL food products. Common items include, tomatoes, peppers and other vegetables.

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the condenser fins must be cleaned of dust, dirt and grease regularly. It is recommended that this be done at least every three months. If conditions are such that the condenser is totally blocked in three months, the frequency of cleaning should be increased. Clean the condenser with a vacuum cleaner or stiff brush. If extremely dirty, a commercially available condenser cleaner may be required.

Failure to maintain a clean condenser coil can initially cause high temperatures and excessive run times. Continuous operation with a dirty or clogged condenser coil can result in compressor failure. Neglecting the condenser coil cleaning procedures will void any warranties associated with the compressor and cost to replace the compressor.

Never use a high-pressure water wash for this cleaning procedure as water can damage the electrical components located near or at the

condenser coil. Doors/Hinges

Over time and with heavy use doors the hinges may become loose. If this happens tighten the screws that mount the hinge brackets to the frame of the unit. Loose or sagging doors can cause the hinges to pull out of the frame, which may damage both the doors and the hinges. In some cases this may require qualified service agents or maintenance personnel to perform repairs.

Do not place hot pans on/against the blue ABS liner. Do not throw items into the storage area. Failure to follow these recommendations could result in damage to the interior of the cabinet or to the blower coil. Overloading the storage area, restricting the airflow, and continuous opening and closing of the doors and drawers will hamper the

units ability to maintain operational temperature. Preventing blower coil corrosion

To help prevent corrosion of the blower coil, store all acidic items, such as pickles and tomatoes, in sealable containers. Immediately wipe up all spills.

Continuous opening and closing of the doors will hamper the unit’s ability to maintain optimum refrigeration temperature. Top section is not intended for overnight storage. Product should be removed from pans. Pans can remain in unit while empty.

05/10 |

9 |

|

Clean Blended Ice Machine (BIM-8) |

|

|

|

Daily |

|

|

|

BE 23 D1 |

|

|||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

To break the bacteria cycle |

|

|

|

|

|

|

|

|

|

|||

Time required |

5 minutes to prepare |

15 minutes to complete |

|

|

|

|

|||||||

Time of day |

At close |

For 24-hour restaurants: During low-volume periods |

|||||||||||

Hazard icons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chemicals |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Precaution: Hazard Communication Standard (HCS) – The procedures on this card include the use of chemical products. These chemical products will be highlighted with bold face letters followed by the abbreviation (HCS) in the tools portion of the procedure. See the Hazard Communication Standard (HCS) manual for the appropriate Material Safety Data Sheet(s) (MSDS).

Tools and supplies

Bucket, clean and Scoop |

Bucket, soiled towels KAY 5 Sanitizer |

KAY Beverage |

No-Scratch Pad |

sanitized towels |

solution (HCS) |

Equipment Cleaner |

|

Procedure

1Empty ice hopper.

Remove ice hopper lid. Use an ice scoop and an empty bucket to remove as much ice as possible from above the ice shelf.

2Replace ice hopper lid.

3Manually dispense remaining ice.

Place a blend pitcher on the pitcher pad. Press Menu then Manual Ice Dispense.

Continue to press the Manual Ice Dispense button until ice hopper is empty.

5Cycle touch pad to cleaning.

On the Menu Screen press Cleaning, then Daily Cleaning. Follow the instructions to gather items shown.

4 |

Remove blender pitcher of ice |

continued |

|

and discard in back sink. |

|

|

|

©McDonald’s Corporation · Planned Maintenance Manual · March 2010 |

Page 1 of 2 |

EH-8-MS 1H,-8-MS Models Machine Ice Blended

Daily

D1 23 BE

10 |

05/10 |

Clean Blended Ice Machine (BIM-8) (continued)

6Remove parts for cleaning and sanitizing.

Remove the following items and take them back to the three compartment sink to wash, rinse and sanitize.

Do not place parts in “Power Soaker” or dishwasher.

Blender pitchers Ice hopper lid Syrup rail

Drip pan (located inside the machine at the bottom)

Splash guard

Splash guard

7With the blender pitchers at the 3-compartment sink, clean pitchers.

Place one KAY Beverage Equipment Cleaner packet into the first pitcher and fill with hot water from the back sink. Allow the product to soak in the pitcher for 5 minutes. Use a no-scratch pad to remove any film build-up. Then pour the solution into the second pitcher and soak for 5 minutes. Once this is completed discard solution, rinse and sanitize both pitchers in the 3-compartment sink. Allow to air dry.

KAY Beverage Equipment Cleaner

8Sanitize ice chute

Use a spray bottle with Sanitizer solution and a sanitize towel:

Above and around the ice chute

Above and around the ice chute

Inside the ice chute

Inside the ice chute

KAY 5 Sanitizer

9Clean pitcher pad and drain area.

Use coffee pot of hot water from the back sink to rinse drain area and drain.

Spray with Sanitizer solution and wipe with a clean sanitize towel.

Clean top and sides of the pad.

KAY 5 Sanitizer

10Re-install all components to air dry.

11Clean the exterior and interior of blended ice machine with a clean, sanitized towel dampened with KAY 5 Sanitizer solution.

Clean inside the machine

Clean inside the machine

Whipped cream holder and gasket (inside) Door gaskets

Whipped cream holder and gasket (inside) Door gaskets

Lid holders

Cup holder tubes and cabinet

Front of the door

Front of the door

Top of the work surface

Top of the work surface

Touch screen

Touch screen  Outside of Ice Hopper

Outside of Ice Hopper

KAY 5 Sanitizer

©McDonald’s Corporation · Planned Maintenance Manual · March 2010 |

Page 2 of 2 |

EH-8-MS 1H,-8-MS Models Machine Ice Blended

Daily

D1 23 BE

05/10 |

11 |

|

Clean Blended Ice Machine (BIM-8) |

|

|

|

|

Weekly |

|

|

|

BE 23 W1 |

|

||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

To break the bacteria cycle |

|

|

|

|

|

|

|

|

|

|

||||

Time required |

10 minutes to prepare |

|

50 minutes to complete |

|

|

|

|

||||||||

Time of day |

At close |

|

|

|

For 24-hour restaurants: During low-volume periods |

||||||||||

Hazard icons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electricity |

|

Chemicals |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Sharp Objects/Surfaces |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Precaution: Hazard Communication Standard (HCS) – The procedures on this card include the use of chemical products. These chemical products will be highlighted with bold face letters followed by the abbreviation (HCS) in the tools portion of the procedure. See the Hazard Communication Standard (HCS) manual for the appropriate Material Safety Data Sheet(s) (MSDS).

Tools and supplies

Cleaning Pitcher |

Cleaning Tubes |

Bucket with SolidSense All |

Bucket with 2 KAY 5 |

Bucket with rinse water Bio-Shield Dispenser |

Bio-Shield Tower Drain |

|

|

Purpose Super Concentrate |

Sanitizer (HCS) packet |

|

Cleaner |

|

|

(APSC) |

|

|

|

Clean, sanitizer-soakedBucket, soiled towels |

KAY 5 Sanitizer Solution |

Scoop |

Empty bucket |

KAY Beverage Equipment |

towels |

|

|

|

Cleaner |

Procedure

1Empty ice hopper.

Remove ice hopper lid. Use an ice scoop and an empty bucket to remove as much ice as possible from above the ice shelf.

2Replace ice hopper lid.

3Manually dispense remaining ice.

Place a blend pitcher on the pitcher pad. Press Menu then Manual Ice Dispense.

Continue to press the Manual Ice Dispense button until ice hopper is empty.

5Cycle touch pad to cleaning.

On the Menu screen press Cleaning, then Weekly Cleaning. Follow the instructions to gather items shown.

4 |

Remove blender pitcher of ice |

continued |

|

||

|

and discard in back sink. |

|

|

|

©McDonald’s Corporation · Planned Maintenance Manual · March 2010 Page 1 of 5 |

EH-8-MS 1H,-8-MS Models Machine Ice Blended

Weekly

W1 23 BE

12 |

05/10 |

Clean Blended Ice Machine (BIM-8) (continued)

6Fill each labeled bucket to the fill line with the appropriate solution and bring to machine.

Fill APSC bucket with hot SolidSense APSC from dispenser at 3-compartment sink.

Fill RINSE bucket with warm, clean water.

Fill SANITIZE bucket with 5 gallons of lukewarm water and 2 packets of KAY 5 Sanitizer and mix thoroughly.

7Remove product bins and bags.

Remove each product bag from the product bin and place in walk-in cooler. Take product bins to 3- compartment sink and wash, rinse and sanitize. Allow to air dry.

8Connect cleaning tubes.

Connect one tube from the cleaning tubes to each inlet line.

9Place tubes in SolidSense

APSC bucket.

Insert the free end of the tubes into the bucket of clean SolidSense APSC solution.

Chemicals

SolidSense APSC solution

10Position black cleaning pitcher.

Place black cleaning pitcher on pitcher pad.

11Press Next.

The message window will display: “APSC cleaning of

Strawberry Banana Line”, then change to the next flavor until all lines have been cleaned. If cleaner solution runs low, press Pause, refill the bucket with cleaner solution and press Resume. After the last line is cleaned, the next cleaning screen will appear.

12Place tubes in RINSE bucket.

Remove tubes from the APSC bucket and place into the warm water RINSE bucket.

13Press Next.

The message window will display: “Rinse of Strawberry Banana Line”, then change to the next flavor until all lines have been rinsed. If water runs low, press Pause, refill the bucket with warm water and press Resume. After the last line is cleaned, the next cleaning screen will appear.

14Place tubes in SANITIZE bucket.

Remove tubes from warm water RINSE bucket and place into the SANITIZE bucket.

Chemicals

KAY 5 Sanitizer

15Press Next.

The message window will display: “Sanitizer fill of

Strawberry Banana Line”, then change to the next flavor until all lines have been sanitized. If sanitizer solution runs low, press Pause, refill the bucket with sanitizer solution and press Resume.

continued

©McDonald’s Corporation · Planned Maintenance Manual · March 2010 |

Page 2 of 5 |

EH-8-MS 1H,-8-MS Models Machine Ice Blended

Weekly

W1 23 BE

05/10 |

13 |

Clean Blended Ice Machine (BIM-8) (continued) |

|

|

|

|

|

|

|

Blended |

|||

|

|

|

|

|

|

|

|||||

16 |

60 Second Sanitizer Hold |

|

23 |

Press Next. |

|

|

|||||

|

|

|

|||||||||

|

“60 Second Sanitizer Hold” |

|

|

display: “Auto prime of |

|

|

|||||

|

After the last line is sanitized, |

|

|

The message window will |

|

|

|

||||

|

will appear for 60 seconds, |

|

|

product lines”. |

|

|

Ice |

||||

|

and then the next cleaning |

|

|

|

|

|

|

|

|

|

|

|

|

24 |

Place discharged product in |

|

|

Machine |

|||||

|

screen will appear. |

|

|

|

|||||||

17 |

Remove tubes from SANITIZE |

|

|

trash or back sink. |

|

|

|

||||

|

25 |

Remove Ice hopper lid. |

|

|

Models |

||||||

|

bucket. |

|

|

|

|||||||

|

Remove tubes from Sanitize |

|

|

|

|

|

|

|

|

|

|

|

solution and lay across the top |

|

|

|

|

|

|

|

|

|

MS |

|

rim of the bucket. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8- |

18 |

Press Next. |

|

26 |

Place black cleaning pitcher |

|

|

1H,- |

||||

|

The message window will |

|

|

|

MS |

||||||

|

display: “Auto purge of |

|

|

on the pitcher pad. |

|

|

|||||

|

Strawberry Banana Line”, |

|

|

|

|

|

|

|

|

|

8- |

|

|

|

|

|

|

|

|

|

|

EH- |

|

|

then change to the next flavor |

|

27 |

Fill pitcher with SolidSense |

|

|

|||||

|

until all lines have been |

|

|

|

|

||||||

|

|

|

APSC. |

|

|

|

|||||

|

purged. The next cleaning |

|

|

Fill a blend pitcher with |

|

|

|

||||

|

screen will appear. |

|

|

SolidSense APSC. |

|

|

|

||||

19 |

|

|

|

|

|

|

|

|

|

|

|

Disconnect cleaning tubes. |

|

|

|

Chemicals |

|

|

|

||||

|

|

SolidSense APSC |

|

|

|

||||||

|

Disconnect the cleaning tubes |

|

|

|

|

|

|||||

|

from each product line. |

|

28 |

Pour in SolidSense APSC. |

|

|

|

||||

|

|

|

|

|

|

||||||

|

|

|

|

Slowly pour the SolidSense |

|

|

|

||||

|

|

|

|

APSC into the ice hopper in a |

|

|

|

||||

20 |

Clean drain pan. |

|

|

circular motion, as close to |

|

|

|

||||

|

|

and as high up the inside |

|

|

|

||||||

|

Pull the bottom drain pan |

|

|

|

|

|

|||||

|

|

|

walls as possible, without |

|

|

|

|||||

|

from inside the machine. |

|

|

|

|

|

|||||

|

|

|

splashing solution outside the |

|

|

|

|||||

|

|

|

|

|

|

|

|||||

|

|

|

|

unit. |

|

|

|

||||

|

|

|

|

Tip |

|

|

|

||||

21 |

Reconnect product bins and |

|

|

Some of the cleaning solution |

|

|

|

||||

|

bags. |

|

|

will dispense out of the area |

|

|

|

||||

|

|

|

above and behind the pitcher |

|

|

|

|||||

|

Retrieve product bags from |

|

|

|

|

|

|||||

|

|

|

pad. This is normal. |

|

|

|

|||||

|

walk-in cooler and install |

|

|

|

|

|

|||||

|

them into the product bins. |

|

29 |

Use clean sanitizer-soaked |

|

|

|

||||

|

Remember: Position the rear |

|

|

|

|

||||||

|

groove of the spout on the |

|

|

towel to clean inside of |

|

|

|

||||

|

product bag into the front slot |

|

|

hopper. |

|

|

|

||||

|

of the product bin. Make sure |

|

|

Use caution when wiping near |

|

|

|

||||

|

it’s properly snapped into |

|

|

the shaver blade. |

|

|

|

||||

|

place. Then install each |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sharp Objects/Surfaces |

|

|

|

|

||

|

product bin into its proper |

|

|

|

|

|

|

|

Weekly |

||

|

|

|

|

|

|

|

|

|

|

||

|

location. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

Replace black cleaning pitcher |

|

|

|

|

|

|

continued |

|

|

|

|

with blending pitcher. |

|

|

|

|

|

|

|

|

|

|

|

|

|

©McDonald’s Corporation · Planned Maintenance Manual · March 2010 |

Page 3 of 5 |

|

W1 23 BE |

|||||

|

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

05/10 |

||

Clean Blended Ice Machine (BIM-8) (continued)

30Rinse ice hopper with clean water.

Fill a blend pitcher with clean water. Slowly pour the water into the ice hopper in a circular motion, as close to and as high up the inside walls as possible, without splashing outside the unit. Repeat if needed for a thorough rinse.

31Remove black cleaning pitcher from the pitcher pad, be careful not to splash any remaining solution from the pitcher.

32Spray interior of ice hopper with Sanitizer Solution.

Allow to air dry.

Sharp Objects/Surfaces

Use caution when near the shaver blade.

KAY 5 Sanitizer

33Remove parts for cleaning and sanitizing.

Remove the following items and take them back to the three compartment sink to wash, rinse and sanitize.

Do not place parts in “Power Soaker” or dishwasher.

Blender pitchers Ice hopper lid Syrup rail

Drip pan (located inside the machine at the bottom)

Splash guard

Splash guard

34With the blender pitchers at the 3-compartment sink, clean pitchers.

Place one KAY Beverage Equipment Cleaner packet into the first pitcher and fill with hot water from the back sink. Allow the product to soak in the pitcher for 5 minutes. Use a no-scratch pad to remove any film build-up. Then pour the solution into the second pitcher and soak for 5 minutes. Once this is completed discard solution, rinse and sanitize both pitchers in the 3-compartment sink. Allow to air dry.

KAY Beverage Equipment Cleaner

35Sanitize ice chute

Use a spray bottle with Sanitizer solution and a sanitize towel:

Above and around the ice chute

Above and around the ice chute

Inside the ice chute

Inside the ice chute

KAY 5 Sanitizer

36Clean pitcher pad and drain area.

Use coffee pot of hot water from the back sink to rinse drain area and drain. Spray the drain area with Sanitizer solution and wipe with a clean sanitize towel.

Clean top and sides of the pad.

KAY 5 Sanitizer

37 Re-install all components.

continued |

Page 4 of 5 |

©McDonald’s Corporation · Planned Maintenance Manual · March 2010 |

EH-8-MS 1H,-8-MS Models Machine Ice Blended

Weekly

W1 23 BE

05/10 |

15 |

Clean Blended Ice Machine (BIM-8) (continued)

38Clean the exterior and interior of blended ice machine with a

clean, sanitized towel dampened with KAY 5 Sanitizer solution.

Clean inside the machine.

Clean inside the machine.

Whipped cream holder and gasket (inside)

Whipped cream holder and gasket (inside)

Door gaskets Lid holders

Cup holder tubes and cabinet

Front of the door

Top of the work surface Touch screen

Outside of ice hopper

KAY 5 Sanitizer

39Slowly pour two full pitchers of hot water from the back sink into the rinser sink area.

40On top of the BIO-SHIELD® dispenser open the pressure relief knob by turning the knob counter clockwise.

41Remove the cap from the BIO-

SHIELD® dispenser.

42Pour two full pitchers of hot water from the back sink into the dispenser.

43Quickly pour one packet of

BIO-SHIELD Beverage Tower Drain Cleaner into the dispenser.

Immediately replace and tighten the cap. Then on top of the BIO-SHIELD® dispenser close the pressure relief knob by turning the knob clockwise. Shake the dispenser to dissolve the cleaner.

Drain Cleaner.

44Carefully purge a small amount of solution from the dispenser into the back sink or utility sink.

This helps prevent

“sputtering” of solution and possible splashing back onto clothing or eyes.

45Carefully spray the solution into the rinser sink drain hole.

46Open the pressure relief knob again by turning the knob counter clockwise on top of the BIO-SHIELD® dispenser.

47Remove the cap from the BIO-

SHIELD® dispenser.

48Rinse the BIO-SHIELD® dispenser.

Rinse the BIO-SHIELD® dispenser with warm water and return the dispenser to the proper storage area.

IMPORTANT! Do not use the drain for at least four hours after cleaning. But the machine can still be used.

©McDonald’s Corporation · Planned Maintenance Manual · March 2010 |

Page 5 of 5 |

EH-8-MS 1H,-8-MS Models Machine Ice Blended

Weekly

W1 23 BE

16 |

05/10 |

Operation

Procedure to Make a Drink

NOTE: Ice must be present in the ice bin and product must be connected and primed to produce a drink.

Drink Selection Touch Screen

1.Place a clean blend container on the container pad.

2.Press the touch screen to select the type of drink desired from list of main menu items. The screen will advance and list the selection. (If the selection is incorrect, press return and reselect).

Size and Option Touch Screen

3.Select drink options:

-Select Return to view the previous screen.

-The yogurt button toggles between including and leaving out the yogurt.

-Select the Multiple button if you want to make multiple drinks of the same flavor.

-Select drink size(s).

NOTE: A green box will highlight the selections.

4.The machine will add the proper amount of ingredients, blend and stop automatically.

5.Pour the drink into a properly sized cup for the drink selection.

6.Place container in rinse position – container is automatically rinsed.

05/10 |

17 |

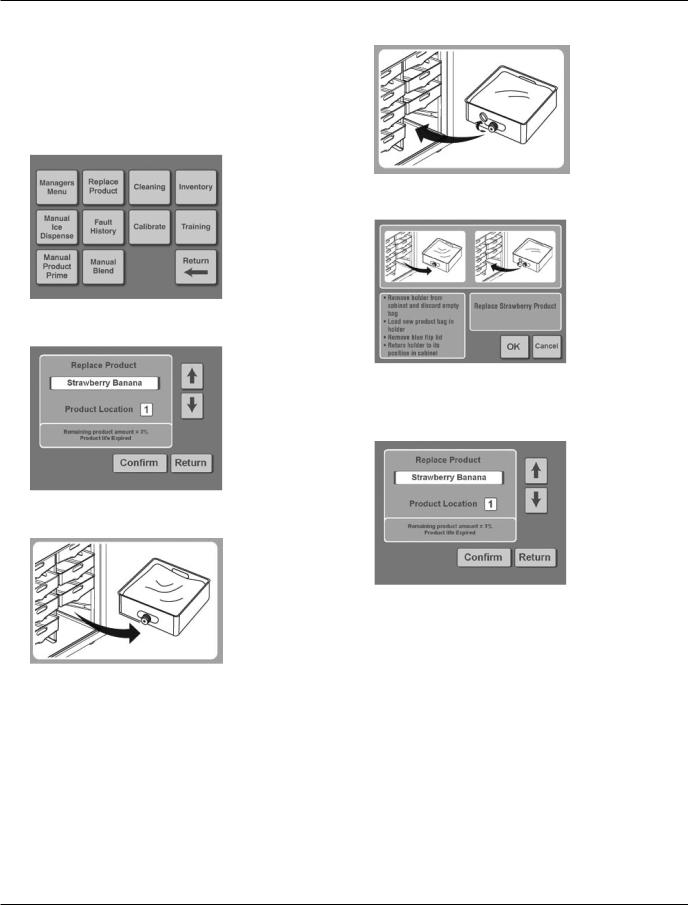

Procedure to Replace a Product Bag

These instructions can be found on the Touch Screen in the Help Menu under “Replace Product”.

1.Touchscreen will indicate the bag is empty “Drink making paused, check product supply”.

2.Press “Replace product”.

3.Use the arrows and the Confirm button to select the product to be replaced.

4.Remove product bin from cabinet and discard empty bag.

5.Wipe the inside of the product bin with a clean sanitize towel.

6.Place bag in product bin with spout down. Position product bag with the spout facing down. Position the rear groove of the spout on the product bag into the front slot of the product bin. Make sure it’s properly snapped into place.

7.Open the cap on the product bag and tear it off.

8. Return product bin to its position in cabinet.

9.Press OK on touchscreen panel. This will reset inventory.

10.Procedure complete. Use the arrows and the Confirm button to select another product to be replaced. Press Return to display the previously active screen.

18 |

05/10 |

Loading...

Loading...