Page 1

MULTIPLEX Modellsport GmbH & Co.KG • Westliche Gewerbestraße 1 • Bretten • Germany

©MULTIPLEX 2014 • Printed in Germany

www.multiplex-rc.de

Operating Instructions

Version 2.11

Page 2

Page 3

MULTIPLEX Modellsport GmbH & Co.KG • Westliche Gewerbestraße 1 • Bretten • Germany

©MULTIPLEX 2014 • Printed in Germany

www.multiplex-rc.de

Contents

Contents 0

1 Introduction 7

1.1 Concept of the PROFI TX ...................................................... 7

1.2 V2 software ....................................................................... 9

1.2.1 Update from V1 to V2 ..................................................... 9

1.2.2 New features in V2 ........................................................ 9

1.2.2.1 Speech output .......................................................... 9

1.2.2.2 Volume ................................................................ 10

1.2.2.3 MagicSwitch .......................................................... 10

1.2.2.4 Switching thresholds ................................................ 10

1.2.2.5 Timer ................................................................... 10

1.3 Contact .......................................................................... 10

1.4 About these operating instructions .......................................... 11

1.5 Basic safety instructions ...................................................... 13

1.6 Safety instructions for the transmitter battery ............................. 15

1.7 ESD notes for electronic sub-assemblies .................................. 16

1.8 Intended use .................................................................... 17

1.9 Liability and indemnification .................................................. 20

1.10 Warranty ......................................................................... 21

1.11 EC declaration of conformity ................................................. 21

1.12 Disposal ......................................................................... 22

2 Transmitter 23

2.1 Transmitter overview .......................................................... 23

2.1.1 Top view ................................................................. 23

2.1.2 Underside view .......................................................... 26

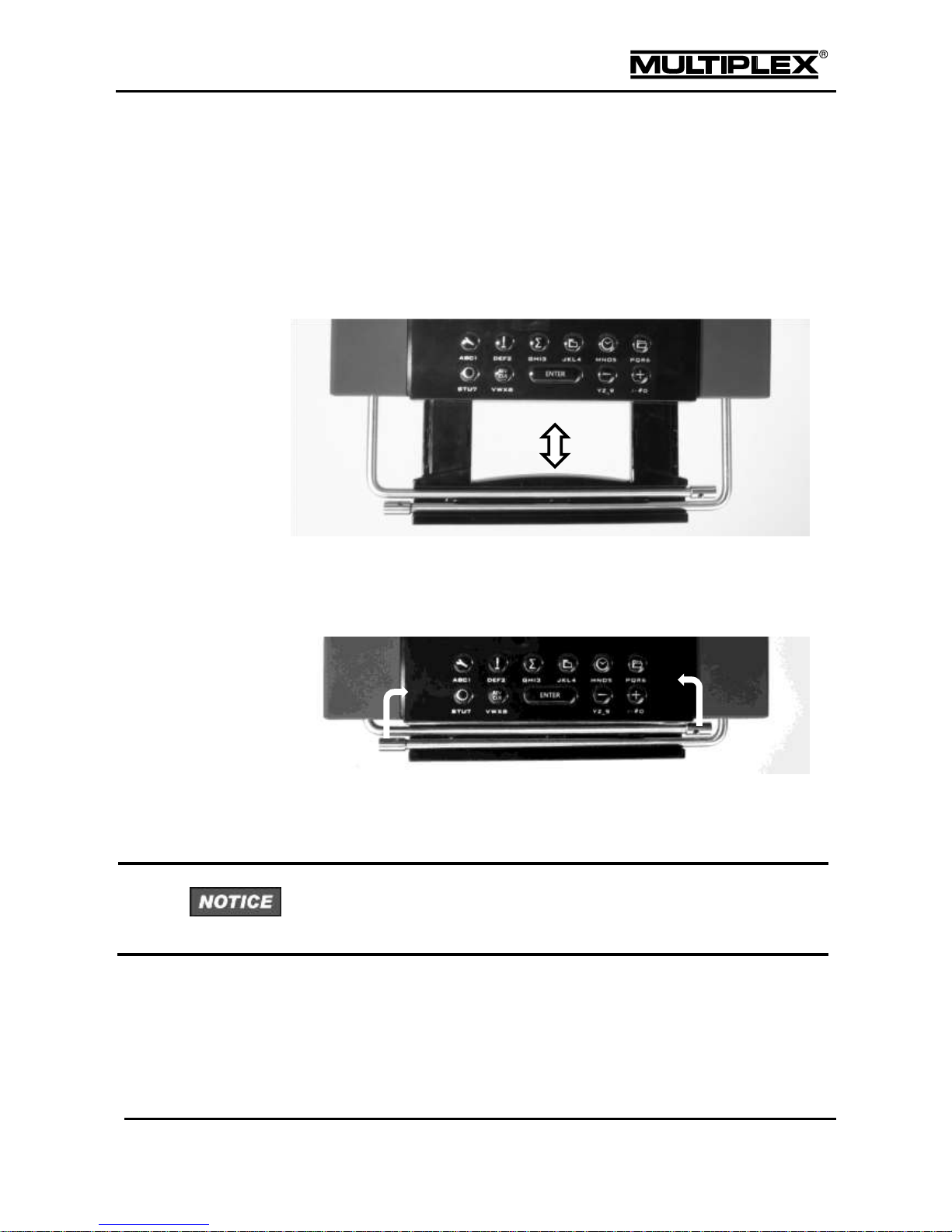

2.1.3 Carry handle / bars ...................................................... 27

2.1.3.1 Carry handle .......................................................... 27

2.1.3.2 Carry bars ............................................................. 27

2.1.4 The interior ............................................................... 28

2.1.5 Connectors ............................................................... 29

2.2 Initial setup ...................................................................... 30

2.3 Mechanical operations on the transmitter .................................. 31

Page 4

Contents

PROFI TX

Page 1

2.3.1 Opening and closing the case ......................................... 31

2.3.2 Adjusting stick units ..................................................... 33

2.3.2.1 Swivelling stick units ................................................. 33

2.3.2.2 Adjusting ratchet, friction and centring force .................... 34

2.3.3 Installing stick tops with a switch or button .......................... 35

2.3.4 Installing additional controls ........................................... 36

2.3.5 Installing additional modules .......................................... 39

2.4 Transmitter battery ............................................................. 40

2.4.1 Charging the battery .................................................... 40

2.4.1.1 Charging via the PC ................................................. 41

2.4.1.2 Charging the battery using the plug-in charger ................. 42

2.4.2 Removing the battery ................................................... 42

2.4.3 Inserting the battery ..................................................... 42

2.4.4 Battery management ................................................... 43

2.5 Switching the transmitter on / off ............................................ 44

2.5.1 Switching on ............................................................. 44

2.5.2 Switching off.............................................................. 45

2.6 Range check .................................................................... 46

2.7 Trainer mode ................................................................... 49

2.8 Digital trim ....................................................................... 50

2.8.1 Overview .................................................................. 50

2.8.2 Trim buttons .............................................................. 51

2.8.3 On-screen trim display ................................................. 51

2.9 microSD card ................................................................... 53

2.9.1 Replacing the microSD card ........................................... 53

2.9.2 microSD card from a different transmitter ........................... 53

2.9.3 New microSD card ...................................................... 53

2.9.3.1 Directory structure on the microSD card ......................... 54

3 Model templates 55

3.1 Templates for fixed-wing models ............................................ 56

3.1.1 BASIC model template ................................................. 58

3.1.2 ACRO model template ................................................. 61

3.1.3 GLIDER+ model template.............................................. 64

3.1.4 DELTA WING model template ........................................ 67

Page 5

Contents

Page 2

PROFI TX

3.1.5 FLYING WING model template ....................................... 69

3.1.6 BIG SCALE model template ........................................... 71

3.2 Templates for helicopter models ............................................ 73

3.2.1 FUNCOPTER model template ........................................ 75

3.2.2 eHeli FBL model template ............................................. 76

3.2.3 eHeliccpm model template............................................. 77

3.2.4 HELIccpm model template ............................................. 78

3.2.5 HELImech. model template ............................................ 79

3.3 Templates for land- or water-based models and tracked vehicles ..... 80

3.3.1 CAR / TRUCK model template ........................................ 80

3.3.2 SHIP / BOAT model template ......................................... 82

3.3.3 TRACKED V. model template ......................................... 84

4 The menus 87

4.1 Status displays ................................................................. 87

4.1.1 Status display #1 ........................................................ 87

4.1.2 Status display #2 ........................................................ 88

4.1.2.1 Battery status ......................................................... 88

4.1.3 Status display #3 ........................................................ 91

4.1.4 Status displays #4 to #8 ................................................ 92

4.2 Menu structure ................................................................. 93

4.3 Setup main menu .............................................................. 94

4.3.1 Volume .................................................................... 95

4.3.2 M-LINK .................................................................... 96

4.3.3 Flight phases ............................................................. 97

4.3.4 Training (principle) ...................................................... 99

4.3.4.1 Student mode ......................................................... 99

4.3.4.2 Teacher mode ....................................................... 100

4.3.5 Sensors .................................................................. 102

4.3.5.1 Vario. & Altitude ..................................................... 102

4.3.5.2 Announce & Alert ................................................... 103

4.3.5.3 Edit name ............................................................ 104

4.3.6 Assign.Controls ......................................................... 104

4.3.7 Assign.Switches ........................................................ 106

4.3.7.1 TriggerPoint .......................................................... 107

Page 6

Contents

PROFI TX

Page 3

4.3.7.2 MagicSwitch ......................................................... 108

4.3.7.3 Switch ................................................................. 109

4.3.8 Define mixer ............................................................. 110

4.3.8.1 Name.................................................................. 110

4.3.8.2 Mixer inputs .......................................................... 110

4.3.9 Transmitter .............................................................. 114

4.3.9.1 Sounds ............................................................... 114

4.3.9.2 Battery alarm ........................................................ 114

4.3.9.3 Contrast .............................................................. 115

4.3.9.4 Trim graph ........................................................... 115

4.3.9.5 Menu direction ....................................................... 115

4.3.10 User data ................................................................ 116

4.3.10.1 PIN .................................................................... 116

4.3.10.2 Language ............................................................. 116

4.3.10.3 Name.................................................................. 117

4.4 ControlFunctions main menu ............................................... 118

4.4.1 Aileron, Elevator, Rudder ............................................. 121

4.4.2 Throttle (fixed-wing models, vehicles, boats, and funcopters) .. 123

4.4.3 Throttle (helicopter) .................................................... 124

4.4.3.1 Throttle curves (Governor OFF) .................................. 125

4.4.4 Spoiler, Flap, Retract.Gear, Speed, Aux-1 to Aux-4 .............. 127

4.4.5 Gyro ...................................................................... 128

4.4.6 Collective (only helicopters) .......................................... 131

4.4.7 Thr.Limiter (only helicopters) ......................................... 131

4.5 Mixer main menu .............................................................. 132

4.5.1 Fixed-wing models ..................................................... 132

4.5.1.1 Combi-Switch ........................................................ 132

4.5.1.2 Differnt.Ail ............................................................ 133

4.5.1.3 Control mixers (Ctrl.Mix) ........................................... 134

4.5.1.4 Mixers on the servo side ........................................... 136

4.5.2 Helicopter models ...................................................... 138

4.5.2.1 TAIL ROTOR ........................................................ 138

4.5.2.2 MAINROTOR ........................................................ 139

4.5.2.3 Control mixers (Ctrl.Mix) ........................................... 144

Page 7

Contents

Page 4

PROFI TX

4.5.2.4 Mixers on the servo side ........................................... 144

4.6 Servo main menu ............................................................. 145

4.6.1 Calibrate ................................................................. 146

4.6.2 Assign .................................................................... 149

4.6.3 Monitor ................................................................... 150

4.6.4 Test run .................................................................. 151

4.7 Timer main menu ............................................................. 152

4.7.1 Model uptime count .................................................... 153

4.7.2 Timer 1 to timer 3 ...................................................... 153

4.7.3 Set Alarm Clock ........................................................ 155

4.7.4 Date & Time ............................................................. 156

4.8 Memory main menu .......................................................... 157

4.8.1 Select..................................................................... 158

4.8.2 Copy ...................................................................... 158

4.8.3 New model .............................................................. 159

4.8.4 Edit name ................................................................ 161

4.8.5 Erase ..................................................................... 162

4.8.6 Safety check ............................................................ 162

4.9 Error messages ............................................................... 163

5 Operating the transmitter 164

5.1 Operation using the keypad ................................................. 164

5.1.1 Menu buttons ........................................................... 164

5.1.2 Buttons for special functions ......................................... 165

5.1.3 Text input ................................................................ 166

5.2 Operation using the wheel ................................................... 167

5.3 Digi-adjuster ................................................................... 168

5.3.1 Allocating a set value .................................................. 168

5.3.2 Setting a value .......................................................... 169

5.3.3 Erasing the allocation .................................................. 169

5.4 Assigning controls to control functions .................................... 170

5.4.1 Assign.Controls ......................................................... 170

5.4.2 Assign.Switches ........................................................ 173

6 Operating the transmitter using the PC 176

6.1 Connecting the transmitter .................................................. 176

Page 8

Contents

PROFI TX

Page 5

6.2 Editing model memories ..................................................... 177

6.3 Software update ............................................................... 178

6.4 Switching to normal mode ................................................... 178

6.5 Model flying simulator ........................................................ 179

6.5.1 Via USB cable .......................................................... 180

6.5.2 Using the MULTIFlight stick .......................................... 181

6.5.3 MULTIFlight simulator ................................................. 181

7 Creating and customising models 182

7.1 Fixed-wing models ............................................................ 182

7.1.1 The procedure in principle ............................................ 182

7.1.2 Creating a new model in the transmitter ............................ 182

7.1.3 Adjusting rotation direction and maximum travels for the servos /

control surfaces ......................................................... 184

7.1.3.1 Configuring aileron differential .................................... 184

7.1.3.2 Adjusting control surface travel and maximum servo travel .. 184

7.1.3.3 Adjusting elevators ................................................. 186

7.1.3.4 Adjusting rudders ................................................... 187

7.1.3.5 Adjusting flaps ....................................................... 187

7.1.3.6 Adjusting the power system ....................................... 187

7.1.4 Using ailerons as spoilers ............................................. 187

7.1.5 Using camber-changing flaps as spoilers .......................... 188

7.1.6 Optimisation ............................................................. 188

7.2 Helicopter models ............................................................. 190

7.2.1 The procedure in principle ............................................ 190

7.2.2 Creating a new model in the transmitter ............................ 190

7.2.3 Preparing controls and switches ..................................... 193

7.2.4 Checking and changing servo assignment ......................... 194

7.2.5 Checking and adjusting the main rotor ............................. 195

7.2.5.1 Checking / changing direction of servo rotation on the main rotor

......................................................................... 195

7.2.5.2 Calibrating servos: setting centre and maximum travel ....... 196

7.2.6 Checking and adjusting the tail rotor ................................ 199

7.2.6.1 Checking / changing the direction of servo rotation for the tail

rotor ................................................................... 199

7.2.6.2 TAIL ROTOR mixer ................................................. 199

Page 9

Contents

Page 6

PROFI TX

7.2.7 Gyro ...................................................................... 201

7.2.7.1 Setting gyro suppression .......................................... 202

7.2.8 Throttle ................................................................... 203

7.2.9 Setting the collective pitch curve ..................................... 204

7.2.10 Working with flight phases ............................................ 205

7.2.10.1 Defaults in the Flight phases menu .............................. 205

7.2.10.2 Assigning switches for flight phases ............................. 206

7.2.10.3 Disabling / enabling flight phases ................................ 206

7.2.10.4 Copying flight phases .............................................. 207

7.2.10.5 Changing flight phase names ..................................... 207

7.2.10.6 Setting the transition time .......................................... 208

8 Speech output & sounds 209

8.1 Volume ......................................................................... 209

8.2 During startup ................................................................. 209

8.3 Battery monitor ................................................................ 209

8.4 Announcing trim ............................................................... 209

8.5 Announcing flight phases .................................................... 209

8.6 Announcing sensor values .................................................. 209

8.7 Announcing altitude........................................................... 210

8.8 Other announcements ....................................................... 211

8.8.1 Teacher / student ....................................................... 211

8.8.2 Safety check ............................................................ 211

9 Maintenance and care 211

10 Appendix 212

10.1 Specifications .................................................................. 212

10.2 Accessories .................................................................... 213

Glossary of technical terms 215

Index 221

Page 10

MULTIPLEX Modellsport GmbH & Co.KG • Westliche Gewerbestraße 1 • Bretten • Germany

©MULTIPLEX 2014 • Printed in Germany

www.multiplex-rc.de

1 Introduction

We are pleased that you have decided to purchase the PROFI TX radio control

system.

The new PROFI TX tray-type transmitter offers numerous innovative and

pioneering features:

Integrated aerial technology (IOAT)

Secure, ultra-fast signal transmission

Clean, clearly arranged menu structure

Operationally secure LiFePo4 battery with battery management

30h operating time with one battery charge

Prior to initial setup, please read these operating instructions and observe all safety

instructions.

1.1 Concept of the PROFI TX

When we initially mapped out the basic philosophy of the PROFI TX, we placed

particular emphasis on providing a high level of user-friendliness, flexibility and the

greatest possible standardization.

User-friendliness is achieved thanks to the clean overall menu structure,

informative and clearly arranged menus and many other useful features which

facilitate programming and operating the transmitter.

Flexibility is guaranteed because you can implement almost any customisations

to the configuration for controlling a model. Controls, mixers and servos can be

assigned freely. Pre-defined mixers can also be customised as required.

Thanks to model templates, you need to press only a few buttons to store your

model in the memory and start operating it.

Special features

Speech output in multiple languages

Digital trim system

o Clear visualisation of the trim positions that are specific to each

flight phase on the screen

o Audible support

o Variable trim increments

Battery monitor with announcement of remaining operating time

(time to empty)

Page 11

Introduction

Page 8

PROFI TX

Battery management system

o Transmitter battery monitor with display of residual charge

o Calculated display of remaining operating time (time to empty)

in hours

Servo monitor with graphical or numerical display for checking settings

without the model

Code lock with PIN (4-digit) for protecting the transmitter against

unauthorised data access

Modern, ergonomically efficient case design with ultra-precise, customisable,

swivelling ball-raced stick units

Graphics screen with high contrast

Modern FLASH processor technology (software updates can be downloaded

from the Internet)

Wireless, selective trainer mode

Clearly designed, efficiently structured menus for simple programming

Quick operation thanks to menu buttons and central wheel

Unique Quick-Select assignment of control functions to teacher and student

Clear text menu system, screen texts can be displayed in various languages

Announcement of altitude and other sensor values

Variometer tone, sink rate configurable

4 flight phases with configurable transition time Additional flight phases

via mixers.

4 mixers on the control side (usage varies between model templates)

7 mixers on the servo side with 8 inputs each and 12 mix options per input

Servo calibration using 2 to 5 points for compensation of mechanical

discrepancies

3 universal timers: Selectable basic function: frame, sum, or interval.

Configurable alarm time, 10 time markers for audible alarms, counter

or count down mode

2 timers for model and transmitter operating time.

Convenient model memory management

o Free-text model names, up to 18 characters

o Copy and erase functions

o Model templates for creating new models.

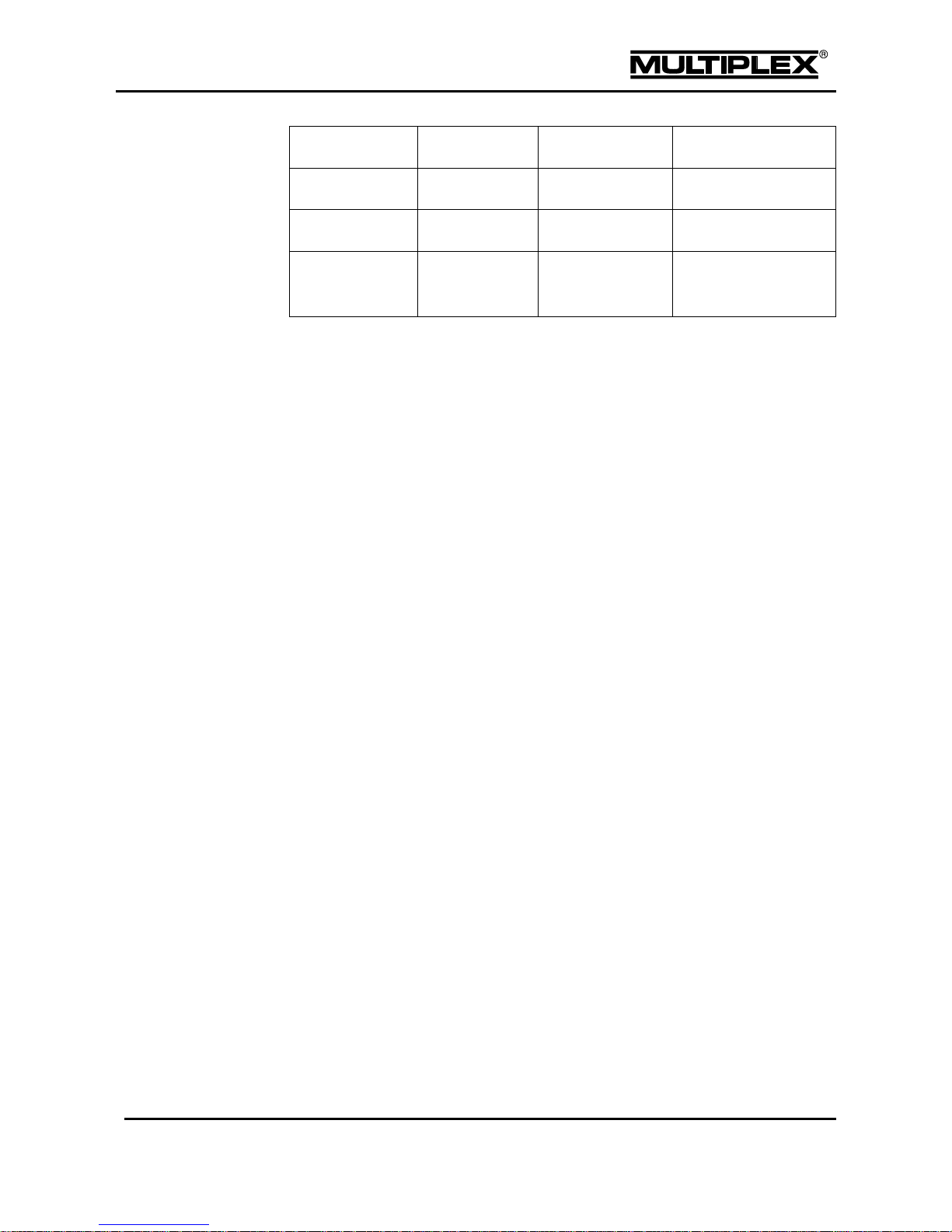

Differences between transmitter versions

Page 12

Introduction

PROFI TX

Page 9

PROFI TX 9

PROFI TX 12

PROFI TX 16

Channels 9 12

16

Model memories

50

100

200

Other

Volume control using

mixers

1.2 V2 software

1.2.1 Update from V1 to V2

Additional files must be installed when updating from software version 1 to

version 2. Refer to section 6.3 "Software update" on page 178 for details.

In version 2.xx, the volume settings are stored in the model memory. The volume is

set to 16 by default for newly created model memories. This setting is not available

in older model memories: The volume is initially set to OFF. You can configure the

desired volume level in the Setup > Volume menu.

1.2.2 New features in V2

1.2.2.1 Speech output

The following information can be output as speech:

remaining operating time (time to empty; in minutes) for the transmitter

flight phase

status of the teacher / student connection

trim position

time markers of the timers

announcement of the altitude

announcement of selected sensor channels

sensor value when a sensor alarm is issued

announcement of the time of day by the alarm clock

Sound and speech output can be customised. Details will be made available in the

Downloads section of our home page by the 3rd quarter 2014.

Page 13

Introduction

Page 10

PROFI TX

1.2.2.2 Volume

The volume can be set by either choosing a fixed value or by configuring

freely assignable controls. We recommend using rotary potentiometers that

are installed on the front (Item No.: 75756).

The variometer volume is configured separately.

With the PROFI TX 16, the volume can also be controlled via mixers.

The volume control data is stored in the model memory.

1.2.2.3 MagicSwitch

The number of MagicSwitches was doubled from 2 to 4.

Each MagicSwitch now has an additional OR input.

1.2.2.4 Switching thresholds

The switching thresholds of controls that are installed on the front were changed

from 50% to 95% (rotary potentiometers are used as switches).

1.2.2.5 Timer

The specialised timers were replaced by universal timers.

Three operating modes are available for each timer: frame, sum, and

interval

The counting mode can be selected: Up or Count down

You can select to have the time announced within 5 minutes before an

alarm occurs or the zero point is passed.

The timers can be renamed as desired.

1.3 Contact

Should you still have any questions regarding your PROFI TX, please feel free to

contact your specialist dealer who will be happy to assist you.

Service partners

The addresses of our service partners are available on our website:

www.multiplex-rc.de

Page 14

Introduction

PROFI TX

Page 11

1.4 About these operating instructions

These operating instructions describe the PROFI TX tray-type transmitter and

contain the following sections:

Section 1 "Introduction" provides an overview of the PROFI TX concept

and information regarding the current firmware version.

Section "Safety instructions" contains important information concerning

safety, intended use and warranty.

Section 2 "Transmitter" describes:

o The PROFI TX hardware.

o How to setup the transmitter for operation.

o Mechanical operations that may have to be carried out on the

transmitter, e.g. installing additional controls.

o How to charge the transmitter battery including battery

management.

o How to switch the transmitter on and off.

o How to perform a range check and the binding procedure.

o How to operate in trainer mode.

o How to trim your model aircraft.

Section 3 "Model templates" describes the model templates available in

the PROFI TX.

Section 4 "The menus" describes the PROFI TX software:

o Navigation within the software.

o The status displays.

o All menus and their parameters.

Section 5 "Operating the transmitter" describes:

o How to operate the transmitter by means of the keypad, the central

wheel and, if necessary, the optional digi-adjusters.

o How to assign controls and switches. This defines which controls

are used to operate the various functions in the transmitter or

model.

Section 6 "Operating the transmitter using the PC" describes how

to connect the transmitter to the PC and the options provided by this

connection.

Section 7 "Creating and customising models" describes step by step

using two examples how to create and configure your own fixed-wing and

helicopter models.

Page 15

Introduction

Page 12

PROFI TX

Section 8 "Speech output & sounds" contains detailed information on

speech output and sound files.

Section 9 "Safety instructions"

Make sure to read and observe the following operating and safety

instructions!

Knowledge of these operating instructions and their observance are a prerequisite

for safe use as well as safe operation and maintenance.

The following basic safety instructions and warnings are an essential component of

these operating instructions and are fundamentally important for product handling.

Keep the operating instructions at hand and pass them on to the new owner on

resale of the product.

Failure to observe the safety instructions can result in property damage, injuries or

even death.

Signal words and their meaning

DANGER identifies an immediate possible dangerous situation with a high risk that

will result in death or severe personal injury if not avoided.

WARNING identifies a possible dangerous situation with a medium risk that may

result in death or (severe) personal injury if not avoided.

CAUTION identifies a possible dangerous situation with a low risk that might result

in minor or moderate personal injury if not avoided.

NOTICE indicates the possibility of misuse which could cause damage to the

product.

INFORMATION that is important for the PROFI TX operator.

Page 16

Introduction

PROFI TX

Page 13

1.5 Basic safety instructions

The following basic safety instructions and warnings are an essential

component of these operating instructions and are fundamentally

important for device handling.

Read the instructions carefully!

Make sure that you have carefully read these operating instructions and the

following safety instructions before setting up the device for operation.

Radio-controlled models are not toys in the usual sense. Assembly, installation, and

operation of the RC system require technical knowledge, care, safety-awareness

and responsibility. Errors or negligence can lead to considerable damage. Since the

manufacturer or the seller does not have any influence and control over the proper

setting up and operation of a model, such risks are expressly pointed out here and

any liability whatsoever is excluded.

A model that goes out of control for whatever reasons can cause significant damage

to property or personal injury. Be aware of safety at all times. Make sure to take out

general liability insurance.

Do not modify the radio control system. Use only original accessories and spare

parts.

If the device is operated in combination with third-party products, ascertain their

quality and functional reliability. Each new or changed combination must undergo

careful functional testing, including a range check. Do not operate the device or

model if there appear to be any problems. First identify the error and troubleshoot it.

In particular, have the radio control transmitter and the receiver inspected at an

authorised MULTIPLEX Service Centre (see section 10.1 "Specifications" on

page 212) at regular intervals (every 2 to 3 years).

Operate the transmitter only in the permissible temperature range (see section 10.1

"Specifications" on page 212). Bear in mind that condensation may form in the

transmitter due to sudden temperature changes (e.g. warm car, cold environment).

Page 17

Introduction

Page 14

PROFI TX

Moisture may impair the function of the transmitter and other components of the

radio control system.

If moisture accumulates in electrical devices, immediately stop using the device,

disconnect it from the power supply and allow it to dry in the open state as far as

possible (up to a few days). Thereafter, perform a careful functional test. In case of

major condensation, have the device inspected at an authorised MULTIPLEX

Service Centre (see section "1.2" on page 9).

Operation of the radio control system is allowed without restrictions within EU

territory and Switzerland.

Program a new model at home in peace. Make sure that the power system of the

model cannot start up unexpectedly. Check all functions carefully. Completely

familiarize yourself with the operation of the transmitter before putting the model

in operation.

Page 18

Introduction

PROFI TX

Page 15

1.6 Safety instructions for the transmitter battery

The transmitter battery powers the device and plays an important role in operational

safety. The charging circuit integrated in the transmitter matches the battery. Do not

charge the battery outside the device.

Batteries are not toys: They must be stored out of the reach of children.

Damaged or defective batteries must not be used and should be disposed of

properly (see section 1.12 "Disposal" on page 22).

Do not heat, incinerate, open or short-circuit rechargeable batteries, do not charge

or discharge them at excessive currents, do not overcharge them, avoid deep

discharge, and do not charge with reversed polarity. Observe of the permissible

temperature range for the battery.

Mishandling the battery incurs the risk of combustion, explosion, chemical burns and

fire.

Page 19

Introduction

Page 16

PROFI TX

1.7 ESD notes for electronic sub-assemblies

The sub-assemblies of radio control transmitters (main circuit board, modules) are

fitted with electrostatically sensitive components. These parts can be destroyed,

suffer imperceptible damage or have their useful life shortened if static discharges

take place (potential equalisation through electro-static discharge) when the subassembly is touched.

The following protective measures are essential if you have to handle

electrostatically sensitive sub-assemblies:

Before fitting or removing such sub-assemblies, equalise the electrical

potential difference between yourself and your environment (e.g. by

touching a heating radiator).

Open the basic device and touch it over a large area in order to equalise

the potential relative to the base unit.

Do not remove any sub-assemblies from their conductive anti-static bags

until you have equalised the potential. Avoid touching electronic components

or solder pads directly. Hold the sub-assembly by the edges of the circuit

board only.

Once removed from the basic device, the sub-assembly should only be

stored in the conductive anti-static bag in which it was delivered. Never allow

the sub-assembly to make direct contact with a conventional, non-ESD

compatible container made of foam, Styrofoam or other plastic.

Page 20

Introduction

PROFI TX

Page 17

1.8 Intended use

The PROFI TX transmitter is intended exclusively for operation of models by

radio control.

Always follow the switching on/off sequence in order to avoid any uncontrolled,

dangerous startup of the power system:

Switching on sequence using the BEC:

1. Disconnect the BEC connector from the receiver.

2. Set the throttle on the transmitter to OFF, then switch on the

transmitter.

3. Connect the power system battery.

4. Connect the BEC connector to the receiver.

Switching off sequence using the BEC:

1. Disconnect the power system battery.

Switching on sequence using the receiver battery:

1. Disconnect the power system battery.

2. Set the throttle on the transmitter to OFF, then switch on the

transmitter.

3. Connect the receiver battery.

4. Connect the power system battery.

Switching off sequence using the receiver battery:

1. Disconnect the power system battery.

2. Disconnect the receiver battery.

Page 21

Introduction

Page 18

PROFI TX

Assemble the model carefully

Install and adjust all control surface linkages in such a way that the surfaces

move smoothly and freely, and are not stalled even at maximum travel. Do

not use the radio control to regularly limit servo travels. Preferable: Adjust

control surface levers and pushrods mechanically and as thoroughly as

possible. Avoid lost motion (sloppy linkages). Use configuration options on

the servo side of the RC transmitter only for fine-tuning.

Observe the above-mentioned guidelines to make full use of the resolution

(positioning accuracy) of your radio control system.

Provide effective protection from vibration to the receiver, battery, servos

and other RC and electronic components. Observe the advice included in

the relevant operating instructions. Balance propellers and rotor blades

before use and replace them at any sign of damage. Install I.C. engines on

vibration-absorbing mounts and replace motors or motor parts which are

damaged or do not run true.

Do not strain or bend cables; protect them against rotating parts.

Keep servo cables as short as possible.

Use cables with sufficient cross-section.

Do not coil up or shorten the receiver aerial. Do not lay the aerial on or close

to electrically conductive components. Deploy aerials outside of fuselages

with a shielding effect (carbon fibre, metallic painted finish).

Ensure that the receiver power supply is of adequate capacity. For servos up

to about 40Ncm torque you can estimate the required battery capacity using

the following formula:

Capacity [mAh] ≥ number of servos x 200 mAh.

Use the next larger size of battery!

Take care to maintain sufficient distance between cables carrying heavy

currents (e.g. electric power system) and the RC system. Especially the

cables between brushless electric motors and their actuators must be kept

as short as possible (guide value: max. 10 to 15 cm).

Page 22

Introduction

PROFI TX

Page 19

Check the model regularly

Free movement and zero backlash of control surfaces and linkages.

Stability and flawless condition of pushrods, linkages, hinge joints, etc.

Carry out a visual check for fractures, cracks, possible shear points etc. on

the model itself, and in its components such as the RC and power systems.

Flawless condition and contact stability of cables and plug connections.

Absolutely essential: Examine the power supply and its wiring, including the

switch harness, and the external condition of the battery.

This entails regular maintenance of the batteries and periodic checks of the

voltage curve and capacity, employing a charge process and battery charger

suitable for the type of battery in use.

Pre-flight checks

Charge the transmitter, receiver and power system batteries carefully to full

capacity, and verify their state of charge at regular intervals.

Ensure that the correct model memory is active on the transmitter.

Carry out a range check (see section 2.6 "Range check" on page 46).

Check the function and effect of all primary and secondary control systems.

If you discover any irregularities, do not fly. Locate the problem, eliminate it, and

then check again.

When operating the model:

If you have never flown a radio-controlled model before, it is highly

recommended you consult an experienced model pilot when getting started.

A trainer (buddy-box) system is ideal for taking the first steps in learning to

fly.

Models should only be operated at suitable sites.

Never fly or drive over or towards spectators.

Do not carry out any high-risk flying or driving manoeuvres.

Know your limits: do not over-estimate your abilities and skills.

If you detect any sign of a problem or interference, land or cease operations

immediately.

Page 23

Introduction

Page 20

PROFI TX

1.9 Liability and indemnification

The model sport with radio-controlled models is a fascinating hobby. However,

model aeroplanes, vehicles and ships are not toys. Their assembly and operation

require a high level of technical knowledge, careful craftsmanship, safetyawareness and responsibility. Errors, inattentiveness or even negligence can

lead to considerable damage to property or severe personal injury. Generally, you

as operator are responsible for any threat arising from your model. This absolute

liability will not be assumed by the manufacturer. This is also applicable in the

event of uncontrollable external influences and interferences. You are expected

to exercise extreme care as operator of a model.

Since manufacturers or dealers cannot have any influence on proper setting up,

maintenance and operation of the model and the radio control system, such risks

are expressly pointed out here.

MULTIPLEX Modellsport GmbH & Co.KG does not assume any liability for loss,

damage or costs which arise through the improper use and operation of our

products, or which are connected with such operation in any way.

As far as is legally permissible, the obligation to provide compensation for

damages, on whatever legal basis, is limited to the invoice amount of the quantity

of MULTIPLEX goods that were directly affected by whatever incident gave rise

to the damage. This does not apply if MULTIPLEX is obliged to accept unlimited

liability in accordance with mandatory law for deliberate or gross negligence.

Furthermore, MULTIPLEX Modellsport GmbH & Co.KG does not extend any

warranty for the completeness and correctness of the documents enclosed with

the radio control components.

Observe also the advice included in the relevant transmitter documentation!

Page 24

Introduction

PROFI TX

Page 21

1.10 Warranty

Our products are covered by the statutory warranty regulations. If you wish to make

a claim under warranty, please contact the model shop where you purchased the

product.

The warranty does not cover defects and malfunctions caused by the following:

improper operation, wrong connections, terminal reversal

use of third-party components; modifications and repairs that were not

carried out at an authorised MULTIPLEX Service Centre

damages caused by the use of force

defects due to improper use and / or normal wear and tear

operation of the equipment outside the technical specifications

Observe the information leaflets included in the relevant transmitter documentation!

1.11 EC declaration of conformity

The PROFI TX devices were assessed in accordance with the relevant harmonised

European directives.

You are therefore the owner of a product whose design fulfils the protective aims of

the European Community relating to the safe operation of equipment.

The detailed declaration of conformity can be downloaded from our website:

www.multiplex-rc.de

under

DOWNLOADS / Product Information

If required, you may also send us your request for the declaration of conformity by

post:

MULTIPLEX Modellsport GmbH & Co.KG

Customer Service

Westliche Gewerbestraße 1

D-75015 Bretten-Gölshausen, Germany

Page 25

Introduction

Page 22

PROFI TX

1.12 Disposal

In the countries of the EU (European Union), electrical equipment must not be

disposed of via the household or residual waste system. Waste equipment must be

taken to your nearest local authority waste collection point or recycling centre.

There, equipment will be disposed of properly and free of charge.

Remove the batteries before disposing of the equipment. (Rechargeable) batteries

are recycled separately.

By returning your waste equipment you can make an important contribution to

protecting the environment.

Recycling of rechargeable batteries

Do not dispose of depleted rechargeable batteries in household waste.

Take them to a suitable recycling system. Rechargeable batteries must be

discharged and short-circuit safe. Tape over the terminals with non-conducting

adhesive tape.

Page 26

Transmitter

PROFI TX

Page 23

2 Transmitter

2.1 Transmitter overview

2.1.1 Top view

Figure 1: Top view of the transmitter

1

Power button with annular light (see "Switching the transmitter on / off" on

page 43).

The annular light indicates the status of the RF module during operation (see

"Annular light" on page 24).

2

UV-stable, anti-glare graphic LCD unit (256 x 64 dots) featuring high contrast.

The screen contrast can be optimised (see section 4.3.9 "Transmitter" on

page 114), and the screen can be raised as required.

3

Warning lights for the sensors used on the model. The warning lights indicate

whether the alarm values for certain sensor groups have been exceeded (see

section "Warning lights" on page 25).

Page 27

Transmitter

Page 24

PROFI TX

4

Two ultra-low friction, ball-raced stick units for controlling the 4 primary

control axes.

The stick ratchet for throttle / spoiler can be activated to the right or

left (see section 2.3.2 "Adjusting stick units" on page 33).

Both stick units can be swivelled to suit the pilot’s ergonomic

preferences (see section 2.3.2.1 "Swivelling stick units" on page 33).

The stick tops can be rotated and freely adjusted in length, and are available in

different variants.

5

Two slide potentiometers (controls <E and F>) with position markers for freely

assignable channel and / or switched functions.

6

Buttons for digital trim of the 4 stick units (see section 2.8 "Digital trim" on

page 50).

7

Central wheel for navigating through the menus and editing set values. The

wheel can be turned in increments to the left or right and can be pressed (see

section 5.2 "Operation using the wheel" on page 167).

8

Keypad, consisting of 11 buttons in 2 rows

The 6 buttons in the upper row are used for quick and direct access to

the 6 main menus (see section 5.1.1 "Menu buttons" on page 164).

The 5 buttons in the second row are used for programming (see section

5.1.2 "Buttons for special functions" on page 165).

With the exception of the ENTER button, all the buttons have a dual

function for text input. Text is entered in a similar way to mobile phones

(see section 5.1.3 "Text input" on page 166).

9

Installation slots for additional controls and digi-adjusters (see section 2.3.4

"Installing additional controls" on page 36).

10

Lug for attaching a support strap (# 8 5161 or # 8 5646).

11

Two sliders (controls <G and H>) for channel and / or switched functions.

Annular light

The annular light indicates the status of the RF module during operation:

Yellow flash: Normal mode, full transmitting power.

Red flash: Range check; reduced transmitting power (see page 46).

Flashing orange light: A binding procedure is in progress (see page 47).

Solid light: A PC is or was connected. No RF is generated.

o Yellow: Battery charging is in progress.

o Red: The battery is not charged.

Page 28

Transmitter

PROFI TX

Page 25

Warning lights

Press the ENTER button to clear the warning bar if status display #2 is shown.

The warning lights serve as markers for the sensor alarms.

The following warning lights are assigned to the sensors:

Battery icon: voltage sensors

Thermometer: temperature sensors

Petrol pump: level and battery charge sensors

IC icon: ECU (Engine Control Unit)

Warning sign: speed and current sensors

Page 29

Transmitter

Page 26

PROFI TX

2.1.2 Underside view

Figure 2: Underside view of the transmitter

1

Recessed control for the sliding latch for USB sockets (see section 2.1.5

"Connectors" on page 29)

2

Fasteners for opening the case (see section 2.3.1 "Opening and closing the

case" on page 31)

3

Carry bars

Page 30

Transmitter

PROFI TX

Page 27

2.1.3 Carry handle / bars

The carry bars are located inside a drawer which also serves as a handle to carry

the transmitter.

2.1.3.1 Carry handle

If you want to use the drawer as a carry handle, pull it out completely (figure). The

carry bars are locked in this position.

2.1.3.2 Carry bars

Pull out the drawer only up to the point where the inside bar is fully exposed. This

is the only position where the bars are unlocked and can be swivelled out (figure).

Carefully swivel out the bars until they snap into place. The drawer can be pulled

out completely to serve as a carry handle or pushed into the back case cover to be

stored away.

Only in this position of the drawer (figure) are the carry bars unlocked. In all other

positions, the carry bars cannot and must not be swivelled out.

Using force will damage the swivel mechanism!

Page 31

Transmitter

Page 28

PROFI TX

2.1.4 The interior

Figure 3: The interior of the transmitter

1

RF module with IOAT aerial

2

Transmitter battery (see section 2.4 "

Transmitter battery" on page 40)

3

Control units

4

microSD card

5

Covers for the slots for controls installable on the front

6

4 slots for additional modules (see section "Installing additional modules" on

page 39)

7

2 clamp terminals for connecting the controls installable on the stick tops

(see section "Installing stick tops with a switch or button" on page 35)

8

TORX screwdriver

Page 32

Transmitter

PROFI TX

Page 29

2.1.5 Connectors

Figure 4: Connectors on the transmitter

1

Headset connector (stereo jack); when a headset is connected, the

loudspeaker of the PROFI TX is switched off

2

Mini USB socket for connecting the PROFI TX to a PC and for charging the

battery via the charging socket (see section 2.4.1 "Charging the battery" on

page 40)

3

USB-A socket for future expansions

Page 33

Transmitter

Page 30

PROFI TX

2.2 Initial setup

The following steps should be performed during initial setup of your PROFI TX.

Refer to the relevant sections listed below for a detailed description.

Briefly charge the battery. It is sufficient to charge the battery for one hour on the

PC (500mA) or for 20 minutes via the plug-in charger (1.5A): Refer to section 2.4

"

Transmitter battery" on page 40 for details.

1. Switch on the transmitter: Press and hold the Power button until the annular

light is fully lit. The device is switched on when you release the button.

Refer to section 2.5.1 "Switching on" on page 44.

2. Select the language to be used in the menus and the texts in the model

templates:

Refer to section "Switching on for the first time" on page 45.

3. Switch off the transmitter: Press the Power button until the annular light turns

off. The device is switched off when you release the button. Refer to section

2.5.2 "Switching off" on page 45.

4. Open the case of the transmitter:

Refer to section 2.3.1 "Opening and closing the case" on page 31.

5. Adjust the stick units to suit your ergonomic preferences.

o If necessary, swivel the stick units:

Refer to section 2.3.2.1 "Swivelling stick units" on page 33.

o Activate the stick ratchet:

Refer to section 2.3.2.2 "Adjusting ratchet, friction and centring

force" on page 34.

6. If necessary, install additional switches:

Refer to section 2.3.4 "Installing additional controls" on page 36.

7. Install the receive system and connect the servos.

Perform the binding procedure to bind the receiver with the transmitter:

Refer to section "Binding" on page 47.

Page 34

Transmitter

PROFI TX

Page 31

2.3 Mechanical operations on the transmitter

2.3.1 Opening and closing the case

Danger of short-circuit!

Switch off the transmitter before opening the case.

Opening the case

1. Switch off the transmitter.

2. Remove the USB and headset cables.

3. Place the transmitter upside down on a soft surface.

4. Press and hold the two fasteners on the side of the screen and gently lift

the back case cover.

5. Release the fasteners, flip up the back case cover and remove it.

Page 35

Transmitter

Page 32

PROFI TX

Closing the case

6. Remove the USB and headset cables.

7. Place the transmitter upside down on a soft surface.

8. Move the controls on the side to the centre position.

9. Place the lower edge of the back case cover vertically onto the case.

10. Swivel the back case cover to the front, push down and press gently to snap it

into place.

Page 36

Transmitter

PROFI TX

Page 33

2.3.2 Adjusting stick units

2.3.2.1 Swivelling stick units

The "natural working axis" of your hands is at a more or less pronounced angle.

The stick units of the PROFI TX can be swivelled to perfectly suit your ergonomic

preferences. The swivelling range is approx. 15°.

Figure 5: Swivelling stick units

Proceed as follows:

1. Using the TORX screwdriver, loosen the three TORX screws retaining the

appropriate stick unit until the unit can be swivelled.

2. Swivel the stick unit to the most comfortable angle for use.

3. Tighten the screws again.

Take care not to over-tighten them or you might strip the threads.

Page 37

Transmitter

Page 34

PROFI TX

2.3.2.2 Adjusting ratchet, friction and centring force

Figure 6: Adjuster screws on the stick

Ratchet and friction

The PROFI TX is supplied as standard with self-centring sticks. The springs for use

with a ratchet or friction system are already fitted to both stick units, and can be

activated quickly and easily.

The screws (2) hold the springs. The screws (3) are used to adjust the level of

ratchet / friction action. The more the screw is tightened, the harder the ratchet or

friction.

If required, you can set a superimposed ratchet / friction action by activating both

springs on one stick. This will help you achieve perfect control as needed.

1. Switch off the transmitter and open it.

2. Using the TORX screwdriver, tighten the TORX screw (turn clockwise) on the

appropriate centring lever (1) to the point where the stick centring action is

completely disabled.

Do not over-tighten the screws. Do not disassemble the centring lever and/or the

centring spring.

(2) Springs for adjusting ratchet or friction

(4) Centring

force

right / left

(1) Deactivate

centring

action

(4) Centring

force forward /

backward

(3) Level of ratchet or friction

Page 38

Transmitter

PROFI TX

Page 35

2.3.3 Installing stick tops with a switch or button

MULTIPLEX® offers three different stick tops with switch or button for the PROFI

TX (see section 10.2 "Accessories" on page 213).

To install a new stick top proceed as follows:

1. Switch off the transmitter and

open it.

2. Remove the battery1.

3. Loosen the grub screw at the

bottom of the stick top (1.5mm

slot-head screwdriver).

Pull off the top from the stick

shaft.

4. Wrap the flexible wires of the

new stick top with a thin

enamelled copper wire. Tightly bend back the section without insulation.

Thread the enamelled copper wire

through the borehole on the stick shaft

until it is visible at the bottom of the stick

unit. Use a pair of pliers to pull the wire

out until you can grab it with your

fingers.

5. Gently pull on the wire until you can

grab the flexible wire with your fingers.

This will be easier if you turn the stick

shaft on the side opposite the point

where the wire exits.

6. Slide the stick top onto the stick shaft, simultaneously pulling the flexible wire

completely through.

7. Tighten the grub screw on the stick top.

8. You can see one three-pin

terminal clamp next to every

1

After re-inserting the battery, date and time need to be set again.

Page 39

Transmitter

Page 36

PROFI TX

stick unit on the main circuit board of the device. Remove the wire.

Clamp the blue flexible wire to the centre terminal and the red wire(s) to the

output terminal(s).

9. Insert the battery and close the transmitter.

10. Switch on the transmitter.

11. Verify that the switch operates correctly.

To test this, assign the new stick switch to any switched function in the

Setup > Assign.Switches menu.

Stick tops

The standard tops can be replaced with the following stick tops (see also

section 10.2 "Accessories" on page 213):

Aluminium stick top, long, with 2-position switch

Item No. 85940

Aluminium stick top, long, with 3-position switch

Item No. 85941

Aluminium stick top, long, with push-button

Item No. 85942

2.3.4 Installing additional controls

You can install 8 controls on each side of the PROFI TX (see section 2.1

"Transmitter overview" on page 23).

The 7 controls can be buttons, 2- or 3-position dip-switches, or rotary

potentiometers in any arrangement.

In addition, a digi-adjuster can be installed on each side. You can assign a

parameter for direct configuration to each digi-adjuster (see section 5.3

"Digi-adjuster" on page 168).

To install a control proceed as follows:

1

Switch off the transmitter.

2

Disconnect the headset and USB cables.

3

Unscrew the knobs from all the digi-adjusters and potentiometers.

Page 40

Transmitter

PROFI TX

Page 37

4

Open the transmitter.

5

Remove the battery.

6

Open the cable cover on the side where you

wish to install the additional control.

When the control is installed on the right

side, the cover of the headset socket must

also be removed. To this end, use a

screwdriver to pry away the clip on the right

side and swivel the cover out to the front.

7

Loosen the 2 screws on the circuit boards

on top of the switch tray using the TORX

screwdriver.

8

Lift off the circuit boards and place them

nearby. Remove the two screws on the

switch tray.

9

Lift out the switch tray and remove the blind

plugs from the required installation slots.

10

Install the controls. Observe the installation

direction for dip-switches: The red cable

must face the transmitter front.

11

Replace the switch tray and secure it using the screws.

12

Replace the circuit boards and secure them using the screws. Replace

the cover over the headset socket and make sure that the clips snap into

place.

13

Refit the connectors of the controls.

14

Close the cap on the slots.

15

Insert the battery and close the transmitter.

Page 41

Transmitter

Page 38

PROFI TX

16

Switch on the transmitter.

17

Verify that the controls operate correctly.

To test this, assign the new controls to any switched function in the

Setup > Assign.Switches menu.

18

Screw the tops of the digi-adjusters and potentiometers back on.

19

Date and time have to be set again in the Timer menu, as the battery

was removed.

Additional controls

The following additional controls can be installed in the PROFI TX (see also

section 10.2 "Accessories" on page 213):

2-position switch (micro), short

Item No. 75750

2-position switch (micro), long

Item No. 75751

3-position switch (micro), short

Item No. 75752

3-position switch (micro), long

Item No. 75753

Digi-adjuster

Item No. 75755

Rotary knob (micro)

Item No. 75756

Push-button (micro)

Item No. 75754

Page 42

Transmitter

PROFI TX

Page 39

2.3.5 Installing additional modules

You can add four modules to the PROFI TX.

Never install two identical modules!

When these operating instructions were released for print, only the COPILOT

module (item no. 45184) was available (see section 10.2 "Accessories" on

page 213).

To install a module proceed as follows:

1

Switch off the transmitter.

2

Disconnect the headset and USB cables.

3

Open the transmitter.

4

Insert the module in one of the 4 slots

and make sure that the respective fixing

clip faces the transmitter centre and is

aligned with a fixing bore on the central

plastic part.

5

Tighten the screw supplied.

Take care not to over-tighten the screw.

6

Close the transmitter.

7

Switch on the transmitter.

8

Verify that the module operates correctly. Refer to the section "Trainer mode"

on page 49 for more details.

Page 43

Transmitter

Page 40

PROFI TX

2.4 Transmitter battery

The PROFI TX is powered by a robust and durable LiFePO4 battery. The battery is

installed with the electronic system for battery management in a welded case. If the

battery is new, the battery capacity of 4000mAh provides an operating time of more

than 30 hours. Additionally installed components increase power consumption and

shorten the operating time. If the device is exposed to temperatures below -10°C,

the operating time is significantly reduced.

2.4.1 Charging the battery

The PROFI TX features two USB sockets at the front on the right-hand side of the

case, which are protected by a sliding latch. The mini USB socket is used for

charging (see section 2.1.5 "Connectors" on page 29).

The following options are available for charging the PROFI TX:

Via your PC or laptop

Via the MULTIPLEX USB car plug-in charger 12V DC

(item no. 145533)

Via the MULTIPLEX USB plug-in charger 100-240V AC

(item no. 145534, see section 10.2, "Accessories" on page 213)

The transmitter must not be connected to a charger when no battery is installed!

Without a consumer, the charger can provide unacceptably high output voltages.

These voltages can damage the transmitter.

Page 44

Transmitter

PROFI TX

Page 41

2.4.1.1 Charging via the PC

Proceed as follows:

1. Switch off the PROFI TX.

2. Lift the device. The recessed control for the sliding latch is located on the

underside of the case.

3. Slide the sliding latch towards the device centre.

4. Switch on the PC. Connect the supplied USB cable to a USB socket on the

PC and to the mini USB socket on the PROFI TX.

o The PROFI TX starts automatically in charging mode.

o The figure below is shown on the screen.

Maximum current: 500mA.

The PROFI TX logs into the PC as mass storage with the name

"PROFI TX".

Upon first time use, the PC automatically installs device drivers. Do not switch

off the PC and/or the transmitter and do not disconnect the USB cable while the

installation is in progress. This may take several minutes. Some operating systems

require an active Internet connection for this process.

If you press and hold the Power button until the annular light is fully lit, the

transmitter switches from charging mode to normal mode. The PROFI TX logs

off from the PC as USB mass storage and logs in again as a game controller

(see section 6 "Operating the transmitter " on page 176).

The RF module is disabled while a USB connection is established. It also remains

switched off after disconnection. Otherwise, the RF module would be re-enabled

when the host (PC, laptop, etc.) is switched off.

Page 45

Transmitter

Page 42

PROFI TX

2.4.1.2 Charging the battery using the plug-in charger

Proceed as follows:

1. Lift the device (the recessed control for the sliding latch is located on the

underside of the case).

2. Slide the sliding latch towards the device centre.

3. Connect the supplied USB cable to the plug-in charger and to the mini

USB socket on the PROFI TX.

4. Connect the plug-in charger to a mains outlet.

The plug-in charger icon is shown on the right side of the screen and the state

of charge and the charging current are displayed on the left. Maximum current

(depending on charger and state of charge): 1500mA.

2.4.2 Removing the battery

1

Open the transmitter.

2

Slide the battery to the left towards the

empty area in the battery dock.

3

Remove the battery.

4

Place the battery on a non-conducting, dry surface.

2.4.3 Inserting the battery

1

Insert the battery on the left side of the

battery dock, with the rounded side facing

to the left.

2

Slide the battery to the right until the stop

is reached.

Page 46

Transmitter

PROFI TX

Page 43

2.4.4 Battery management

The PROFI TX records the current during transmitter operation and while charging

the transmitter battery. The available battery charge is calculated on the basis of

the power meter reading, the temperature and the voltage. The remaining

operating time (time to empty) is calculated from charge and current and is shown

on status display #2 (see page 88). The calculation takes into account that current

consumption slightly decreases with decreasing battery voltage.

Battery alarm

If the remaining operating time falls below a configurable threshold, the remaining

operating time is announced with increasing frequency. The "TX-BATT." section on

the left side of status display #2 flashes.

The factory setting for the alarm threshold is 60 minutes. This value can be

changed in the Setup > Transmitter > Battery alarm menu (see

section 4.3.9 "Transmitter" on page 114).

Self-discharge

If the transmitter is stored for a prolonged period, the available battery charge is

estimated based on the idle voltage when the transmitter is switched on. For this

reason, the displayed charge and time to empty are not initially very accurate.

After one to two charge / discharge cycles the original accuracy is restored.

Under-voltage cut-off

If the operating voltage falls below 2.8V, the device is automatically switched off

without further warning. If the voltage is below 2.9V, it cannot be switched on: The

following message is briefly displayed on the screen: BATTERY DOWN!

Charge the transmitter battery!

If voltage is low, recharge the battery as soon as possible (within 1-2 days) to avoid

damage due to deep discharge. Observe the notes on charging (see section 2.4 "

Transmitter battery" on page 40).

Page 47

Transmitter

Page 44

PROFI TX

2.5 Switching the transmitter on / off

Charge the transmitter battery!

The PROFI TX is supplied with a partially charged transmitter battery. You should

charge the battery prior to setup. Please observe the notes on charging (see

section 2.4 "

Transmitter battery" on page 40).

2.5.1 Switching on

To switch on the device proceed as follows:

1. Press and hold the Power button until the annular light is fully lit. The device is

switched on when you release the button.

If you press and hold the Power button for a prolonged period, the annular light turns

off again and the device is not switched on when you release the button (power-on

protection).

2. At this point, either the safety check prompt is displayed on the screen:

Or the language selection screen is shown, if the menu language has not yet

been selected (see section "Switching on for the first time" on page 45).

The RF module is switched off until the safety check is completed to prevent the

servo from moving to an undesired position.

3. Check if safety-related controls such as landing gear switches, flight phase

switches, and throttle sticks are in the proper position.

4. Press a button on the keypad: The safety check is completed, the RF module

is switched on, and status display #2 is shown.

Page 48

Transmitter

PROFI TX

Page 45

You can switch the safety check on and off in the Memory > Safety check

menu. The safety check is activated by default when you create new model

templates (see page 162).

Switching on in Binding mode

Press and hold the ¡ button during startup until the status display is shown.

Switching on for range check

Press and hold the § button during startup until "Safety check" or the status

display is shown: The device starts up with reduced transmitting power when the

range check is performed (see section 2.6 "Range check" on page 46).

Switching on for the first time

The very first time you switch on the PROFI TX is a special case. A language

selection menu is shown on the screen after startup. Here, you select the

language for:

1. Menus

2. Names of mixers, timers and control functions in the model templates

3. Speech output

The language is selected using the keypad (up/down/ENTER). If you select

"skip/später", transmitter functionality is restricted: Only one model memory is

available and its contents are not stored on the SD card when the device is

switched off. The menu is shown in English.

2.5.2 Switching off

Press and hold the Power button until the red annular light turns off completely to

switch off the device. The device is switched off when the annular ring turns off and

the button is released. If you press and hold the button for a prolonged period, the

annular ring returns to ready status. Now, you can release the button without the

device switching off (power-off protection).

Page 49

Transmitter

Page 46

PROFI TX

2.6 Range check

Regular range checks are necessary for ensuring the reliable functioning of the

radio control system and for timely detection of changes in transmission properties.

Always perform a range check after:

installing, modifying or rearranging components in the model,

reusing components in the model that were involved in a crash,

observing irregularities when operating the model.

The transmitting power can be significantly reduced for the range check, enabling

short distances between transmitter and model.

While the range check is active the status displays #2 to #8 show the flashing

message: RANGE! with the annular ring flashing red. A warning is announced every

minute to alert the operator. The warning is only announced when your are not

navigating in menus so as not to disturb you when performing configurations.

Recommended minimum distance: 40m to 100m, depending on receiver type.

Refer to the receiver operating instructions for detailed information.

Always perform a range check before starting up the model.

A second person must always be present for the range check to secure and

observe the model.

Large metal objects within or in close proximity to the checking range (wire fences,

cars) affect the result of the range check.

Page 50

Transmitter

PROFI TX

Page 47

Procedure

1. If the model is fitted with a power system, switch it off!

2. Press and hold the §button on the transmitter as you switch the transmitter

on.

3. Switch on the receiver.

4. In the Servo > Test run menu, activate the test run for a control function,

e.g. Elevator. This allows you to check that the receive system responds to

control commands with distinct, regular movements of the control surfaces.

5. Increase the distance between transmitter and model. You have reached the

range limit when the servos start to jitter.

6. Repeat the check with the power system running. Secure the model. Perform

the check using throttle positions that vary between idle and full throttle. In

case of electric power systems, the most significant interferences occur at

half throttle.

The range should not diminish significantly.

7. Otherwise, eliminate the cause of the interference (power system, installed

position of the receive system with power supply).

Factors influencing the radio range

The following factors have significant influence on the radio range:

Environmental conditions

Hilltops, ground characteristics, type of terrain, and the atmospheric

conditions affect radio range.

Receiver technology and sophistication

Technically sophisticated receivers have a greater range than simple,

cheap receivers.

Installation situation in the model

Installation position / arrangement of the aerials and the distance to

batteries, power systems, servos, ignition systems, metal / carbon fibre

parts influence the radio range.

Binding

The binding procedure binds the receiver with the transmitter.

M-LINK uses "frequency hopping" and "spread spectrum".

No fixed transmission channel is used for "frequency hopping", but all 39 channels

are used in a sequence that is defined by the transmitter.

Page 51

Transmitter

Page 48

PROFI TX

For "spread spectrum", every data bit is coded in 64 bits (spread). This procedure

provides a high level of immunity to interference. During binding, the transmitter

passes "hopping sequence“, "spreading code", and "response time" to the receiver.

Procedure

The binding procedure can be started in 2 ways: via the keypad during startup or

via the menu.

Starting the binding procedure when the device is switched on:

1. Press and hold the ¡ button for the full duration of the transmitter startup

procedure.

o The annular ring of the Power button is flashing in orange and the flashing

message "BINDING" is shown in the status displays #2 to #8.

2. Now, switch on the receiver while pressing and holding the Set button (connect

the power supply).

o The receiver LED is flashing rapidly.

3. The binding procedure is completed within a few seconds:

o The annular light returns to flashing yellow.

o The receiver LED is flashing slowly.

o The servos that are connected to the receiver can now be controlled.

Starting the binding procedure via the menu

1. Switch off the receiver and switch on the transmitter.

o Press the ¡ button to open the "Setup" menu.

o Use the wheel to select the "M-LINK" menu item. Press the wheel.

o Open the "Binding" menu item. Press the wheel . The input field OFF is

now highlighted.

o Turn the wheel to the right: The text "seeking.." is now displayed in the

input field and the annular light of the Power button is flashing in orange.

The transmitter is searching for a receiver in binding mode.

o You can cancel the binding procedure at any time: Turn the wheel to the

left. The previous condition is restored.

2. Now, switch on the receiver while pressing and holding the Set button (connect

the power supply).

o The receiver LED is flashing rapidly.

3. The binding procedure is completed within a few seconds:

Page 52

Transmitter

PROFI TX

Page 49

o The input field briefly shows the text "OFF" and then indicates the

detected type: "RX", "RX-ID", "MultiFlight", "Teacher" or "Student".

o The annular light returns to flashing yellow.

o The receiver LED is flashing slowly.

o The servos that are connected to the receiver can now be controlled.

If the binding procedure does not complete automatically within a few seconds,

move the transmitter front closer to the receiver aerial(s).

The Setup > M-LINK > Binding menu item indicates if and what type of receiver

is currently connected to the PROFI TX.

The ID is displayed for ID receivers.

2.7 Trainer mode