Page 1

PROFI CAR 403 and 707

Operating instructions

Before operating the transmitter, please select the language (see 9.4, page 42)!

Page 2

Dear customer,

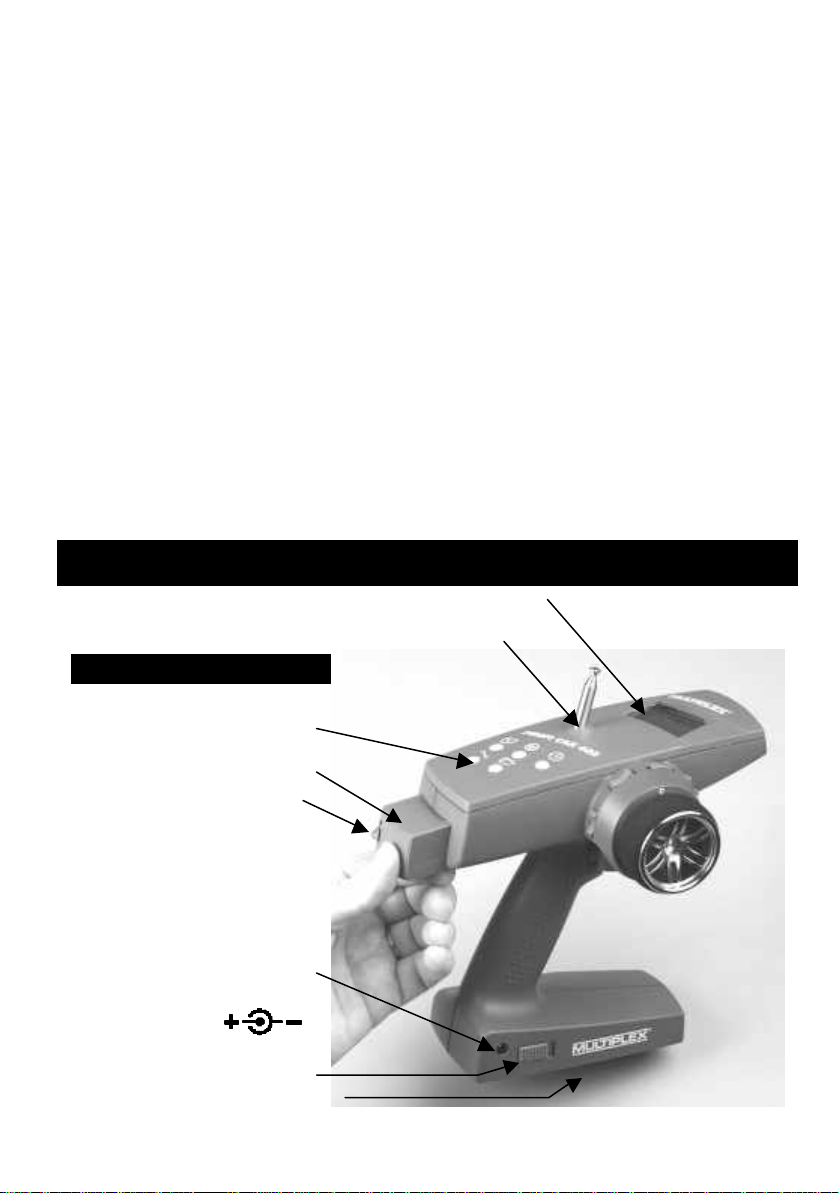

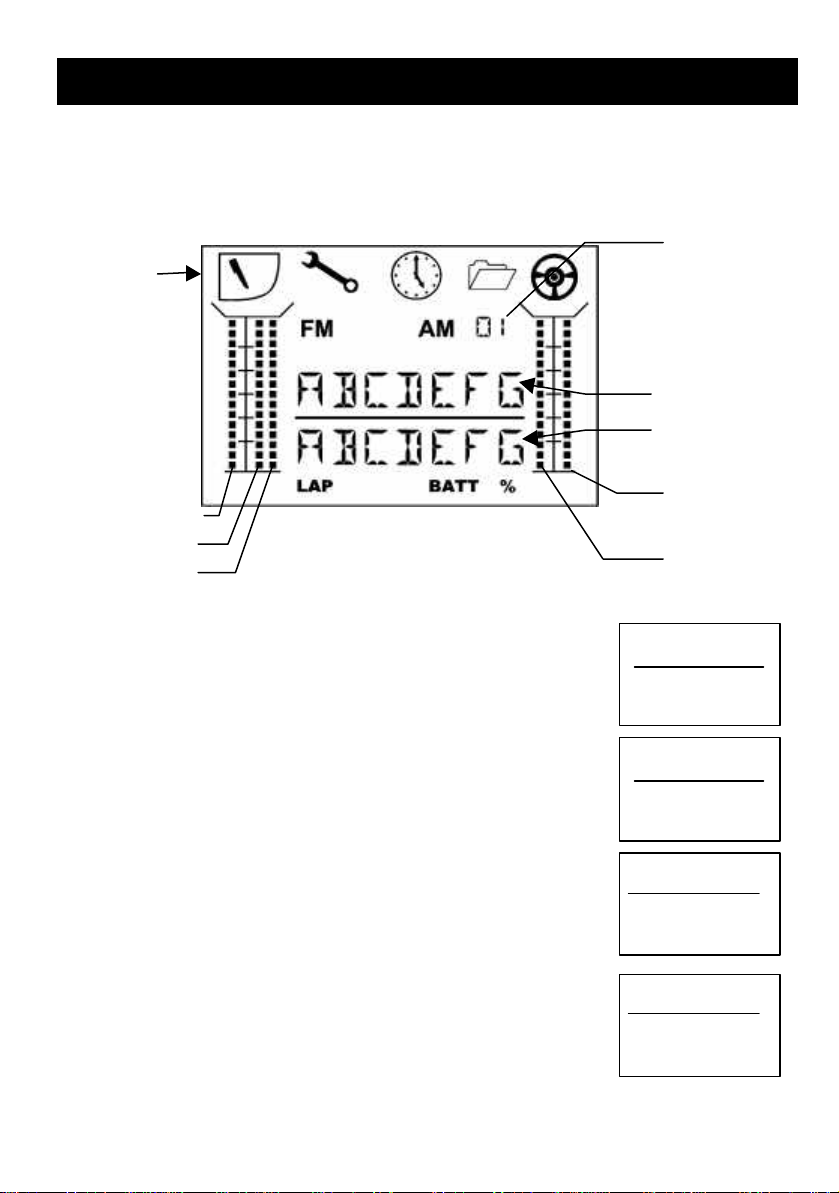

Use only

genuine

crystals

RF module

Charge socket

ON/OFF switch

Aerial (screw fitting)

Menu buttons

Screen

With thermal fuse!

dear fellow modeller,

we are delighted that you have decided to purchase a MULTIPLEX radio control system.

The „PROFI CAR“ is the first „pistol-grip“ transmitter designed and developed by MULTIPLEX.

Ergonomic efficiency and user-friendliness were our top priority during the development

process.

That’s not to say that we have neglected performance: the new system includes many

innovative and practical features, offering you facilities which until now have not been

available in systems of this class. They include:

v Interchangeable RF module, switchable to suit AM and FM receivers

v Up to 7 channels (steering, throttle/brake + 5 auxiliary channels)

v 2 steering servos and 2 brake servos (PROFI CAR 707 only)

v Separate throttle servo (PROFI CAR 707 only)

Of course, you don’t need to use these features; you can still operate the PROFI CAR as a

„completely normal“ set, i.e. with one steering servo and a second servo for throttle/brake.

We are confident that you will have many hours of pleasure with your PROFI CAR.

Yours the MULTIPLEX team

A quick look at the transmitter

Transmitter crystal

MULTIPLEX

maximum 600 mA

Transmitter battery in base

CAUTION:

2

Page 3

Contents

A quick look at the transmitter 2

Contents 3

Safety 5

System facilities 6

The transmitter controls in detail 7

The „instrument panel“ (screen) 8

The principle 9

Switching on for the first time 11

1.1. Charging the transmitter battery (maximum charge current 1 A) 11

1.2. Charging the receiver battery 11

1.3. Fitting the transmitter crystal 11

1.4. Adjusting the trigger loop 11

1.5. Testing the transmitter 12

2. Short and to the point 12

2.1. Selecting the vehicle TYPE 13

2.2. Setting the servo norm, direction of rotation, travels and centre 14

2.3. Adjusting STEERING L 15

2.4. Adjusting THROTTLE A 15

2.5. Adjusting BRAKE A 16

3. More about steering LL 17

3.1. Adjusting the steering servo („T“ menu) 17

3.2. Adjusting the steering trim („T“ menu) 19

3.3. Adjusting the steering CENTRE, accepting the trim setting 19

3.4. Setting the minimum steering TRAVEL 20

3.5. SLOW 21

3.6. EXPO 21

3.7. Auto Dual Rates for steering 21

3.7.1. Reduced Travel RT at full throttle 22

3.7.2. Auto Dual Rate delay 22

3.8. The second steering servo (PROFI CAR 707 only) 22

4. More about THROTTLE AA 23

4.1. 2-point throttle curve with EXPO 23

4.2. 5-point throttle curve 24

4.3. Automatic Start 25

4.3.1. Setting the „addition“ for Initial Throttle „IT+“ 25

4.3.2. Initiating the automatic start function using the trigger 26

4.3.3. Initiating the start function with the handle button or trigger 26

4.3.4. Terminating the automatic start phase 26

4.4. TC = traction control (nur PROFI CAR 707) 27

5. More about BRAKE 28

5.1. Two-point brake curve with EXPO 28

5.2. Trimming the Lock Point LP using rocker D 29

5.3. ABS = Advanced Braking System (PROFI CAR 707 only) 30

5.4. Braking with more than one servo (PROFI CAR 707 only) 31

3

Page 4

6. Timers and lap counters ºº 0000 33

6.1. Timer mode 33

6.2. Lap time memory 34

6.3. Setting the nominal time T-NOM 35

6.4. Setting the race duration (timer mode 3 only 35

6.4.1. Race duration by laps 35

6.4.2. Race duration by time 35

6.5. Checking the transmitter’s operating time 36

6.6. Erasing the timer ERASE 36

7. Model memories 11 37

7.1. Switching to a different model memory 37

7.2. Copying 37

7.3. Entering the model name 38

7.4. Erasing 38

7.5. Reverting to the PREVious state 38

8. Driving trucks 39

8.1. Selecting the model type 2+5 CH (truck) 40

8.2. Setting the control mode for the auxiliary channels 40

8.3. Adjusting travel and centre of the auxiliary channels 41

8.4. Truck steering and throttle/brake 41

9. The “toolbox” TT 41

9.1. Adjusting the trigger deadband („T “ menu, DEADB) 41

9.2. Switching between AM and FM („T “ menu, AM-FM) 42

9.3. Entering the owner’s name („T “ menu, NAME) 42

9.4. Selecting the display language („T “ menu, TEXT) 42

9.5. Setting the battery alarm threshold („T “ menu, ALARM) 42

10. Tips on installing the receiving system in the model 43

11. The system in use 44

11.1. Post Office Regulations for the U.K. 44

11.2. Range testing 44

11.3. Care of the transmitter 45

11.4. Maintenance 45

Specification, system characteristics 46

Menu summary for the PROFI CAR 403 and 707 47

4

Page 5

Safety

Radio-controlled models are not toys!

You can make a major contribution to safety when operating your models by acting

responsibly and handling your radio control system and model with due care.

v Check the electrical and mechanical connections in the model at regular

intervals.

v Check all moving parts regularly: they must be free to move, and must not

exhibit undue lost motion.

v Carry out regular range checks (see „Range testing“).

v When other drivers are present at the track, find out which channels are

already in use before you switch on.

v Before every run: extend the transmitter aerial to full length, and check that

it is in good condition and firmly seated.

v Check that you have selected the model memory corresponding to the

model you are running.

v Check all the working systems in your model before you start:

Do the servos rotate in the correct direction?

Are the travels correct?

v Are the transmitter and receiver battery adequately charged, and in well

maintained and roadworthy condition?

v Use only genuine MULTIPLEX crystals, batteries and accessories.

v If your receiving system includes components which are not covered by

these operating instructions, be sure to read the instructions supplied with

those items.

If you are in doubt on any point - don’t operate your model! Take your time, carefully

check the system again, and eliminate the fault. If you cannot solve the problem,

your local model shop or the MULTIPLEX customer service department will be

pleased to help you with advice and practical help.

Read and observe the notes in Chapter 11 on using the system!

!!

5

Page 6

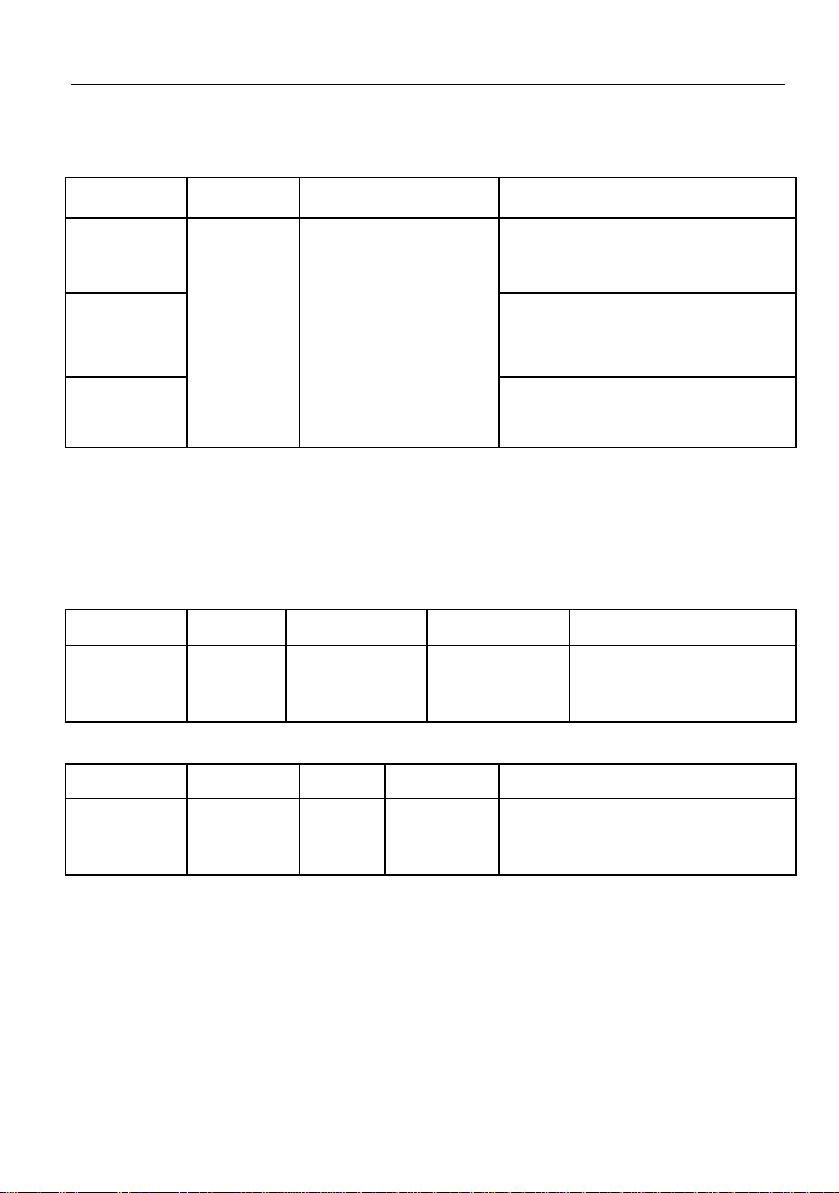

System facilities

403 707

Model memories 6 12

Copy, reset, erase, enter model name

Steering

SLOW, separate for entering and exiting turns ü ü

EXPOnential steering curve (progressive / degressive) ü ü

Variable CENTRE and TRAVEL ü ü

Variable steering trim increment ü ü

Second steering servo - ü

Throttle

Automatic start system ü ü

EXPOnential throttle curve (progressive / degressive) ü ü

Separate THROTTLE / BRAKE servos - ü

5-point throttle curve ü ü

Traction-Control TC - ü

Brake

Variable engage point and lock point ü ü

EXPOnential brake curve (progressive / degressive ) ü ü

ABS (Advanced Braking System) - ü

Second brake servo (front / rear) - ü

Timer and lap counter

Operating time ü ü

Race duration by time / lap ü ü

Lap counter ü ü

Lap time memory 5 50

Mechanical features

Programmable trigger deadband

High-grip steering wheel lining

Ergonomic controls mounted on the handle

Angled screen for optimum legibility

Light weight

Signal transmission

FM or AM transmission, selectable for each model memory

Plug-in RF module (40/41 MHz and 72 MHz)

Externally accessible plug-in transmitter crystal

Power supply

600 mAh / 6-cell battery, approx. 3 hours operating time

Charge socket in transmitter base

6

Page 7

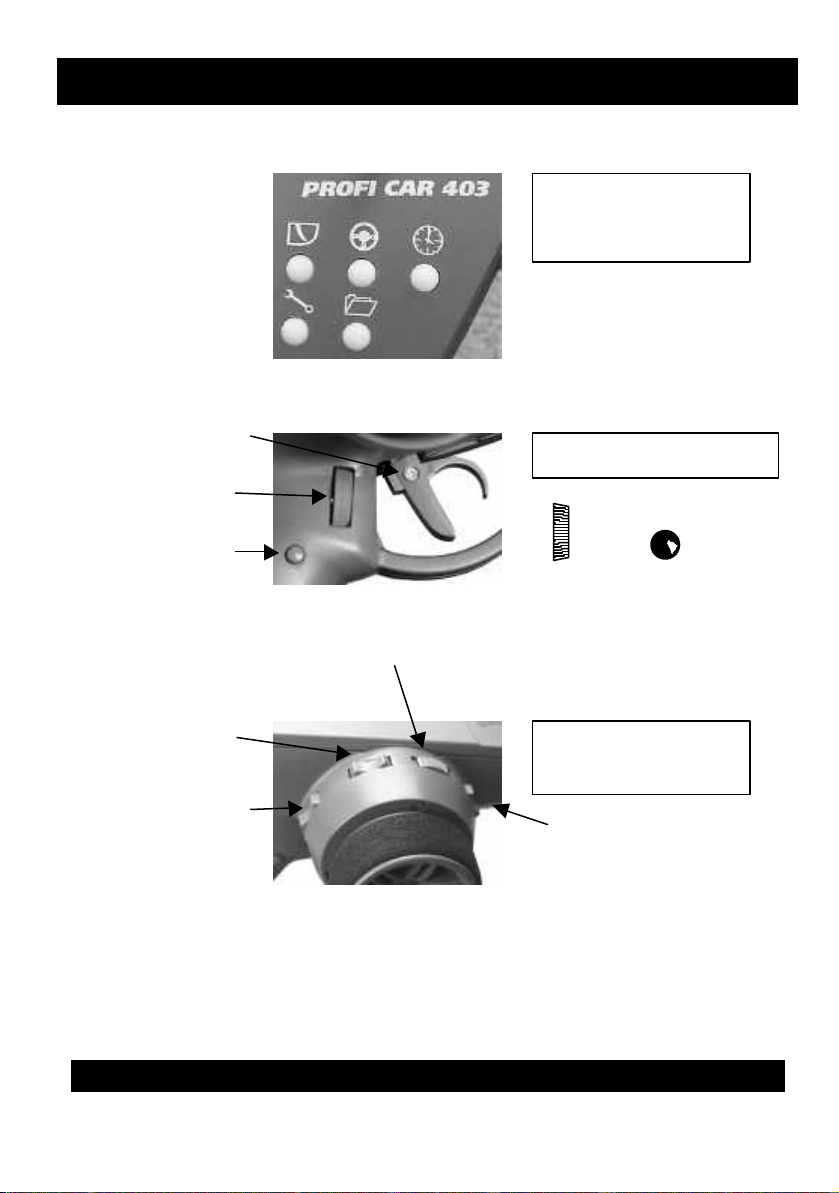

The transmitter controls in detail

HB

Handle Button

Digi Adjustor

Steering

Lock point

(throttle/brake servo)

„tuning centre“

Everything to hand

to the menus

adjustment screw

The three pictures below illustrate the essential controls.

The menu buttons

The trigger duster

Trigger loop

DA

The trim rockers

The „key“

DA HB

Initial throttle

rear brake

Repeat function

All trim rockers have an automatic repeat function when held pressed for longer than

about 1 second.

Special case – TRUCK:

If you wish to control a truck with your Profi Car, you have 5 auxiliary channels

available (see 8: Driving trucks). In this mode only the steering trim (rocker A) is

active; all the other rockers are used to control the auxiliary channels.

7

The

Switched channel or

lock point front brake

nd

(2

brake servo)

Page 8

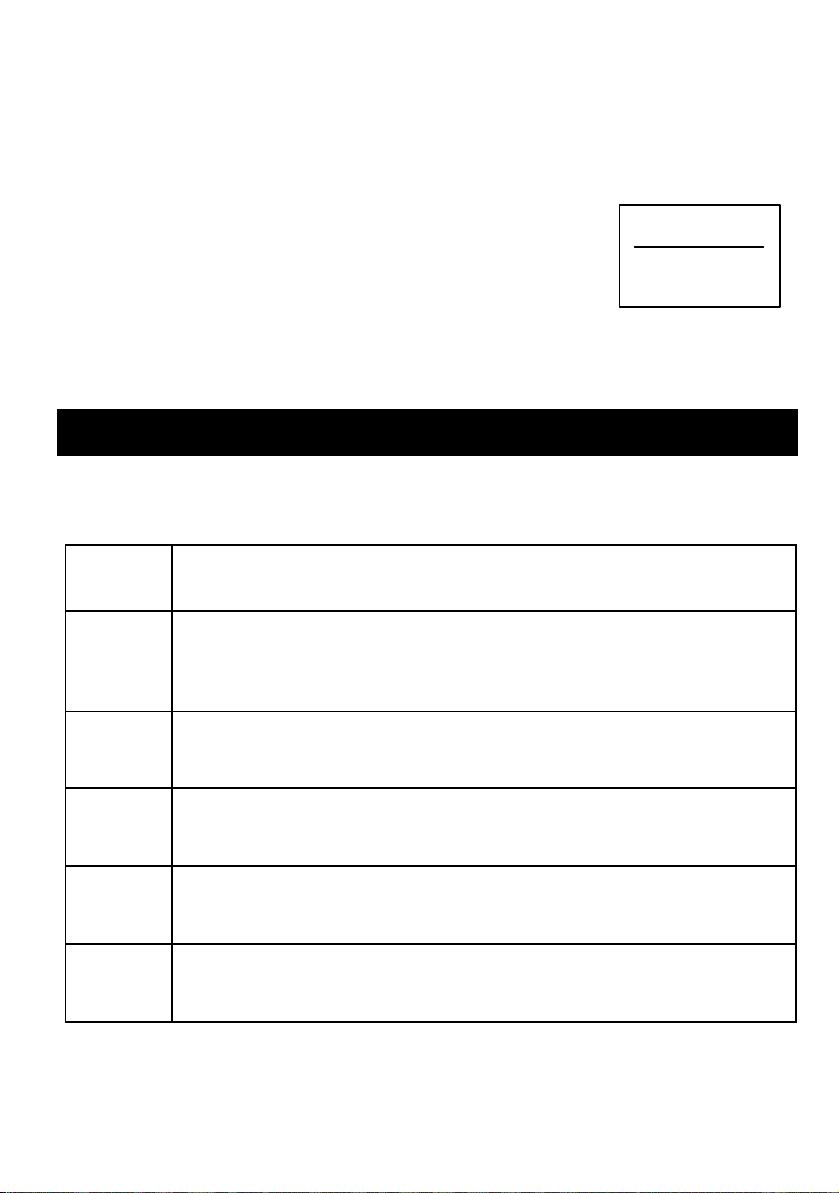

The „instrument panel“ (screen)

Steering travel

IT = Initial Throttle

Steering TRim

Brake 1

Brake 2

Text line 1

model memory

Text line 2

Menu

The picture below shows everything which the screen can display. What you actually

see at any one time depends on what you are doing: whether timers are active,

whether you are currently programming the transmitter, which type of vehicle you

have selected, etc.

A few examples are shown on this page.

Number of

Active

symbols

STV =

Operating display

Timer mode: OFF

If no timer function is active, the first text line displays the

model name you have entered. Text line 2 shows the

transmitter battery voltage.

STR =

BUGGY

7.4V

BATT

Timer Mode: LAP

The second text line shows the number of the lap on the lefthand side. To record the start and end of each lap you press the

handle button G.

Timer-Mode: L+T (Laps + Time memory)

In this mode the second text line shows the number of the lap

on the left (in our example 03) and the time for the current lap

on the right (in our example 28.3 sec).

Timer-Mode: L+T+E (Laps + Time memory + Race duration)

The first text line displays the total duration of the race (in our

example 2 min. 36.5 sec). The second text line shows the

number of laps and the time of the current lap, as in the

previous example.

BUGGY

03 7.4V

LAP BATT

BUGGY

03 28:3

LAP

2:36:5

03 28:3

LAP

8

Page 9

Special case: battery alarm with timer active

If one of the timer modes is active and the battery voltage falls to the alarm

threshold, the screen displays the current lap time and the battery voltage and BATT

warning, alternating at 2-second intervals.

When you are changing settings

When you are changing the transmitter settings, the first text

line shows the selected menu point (in our example: the

throttle curve). On the left of the second text line you see the

parameter which you have selected with the help of the handle

button (in our example full throttle). At bottom right the screen shows the current

value (in our example 87%) above the % symbol

G-CURV

FT 87

%

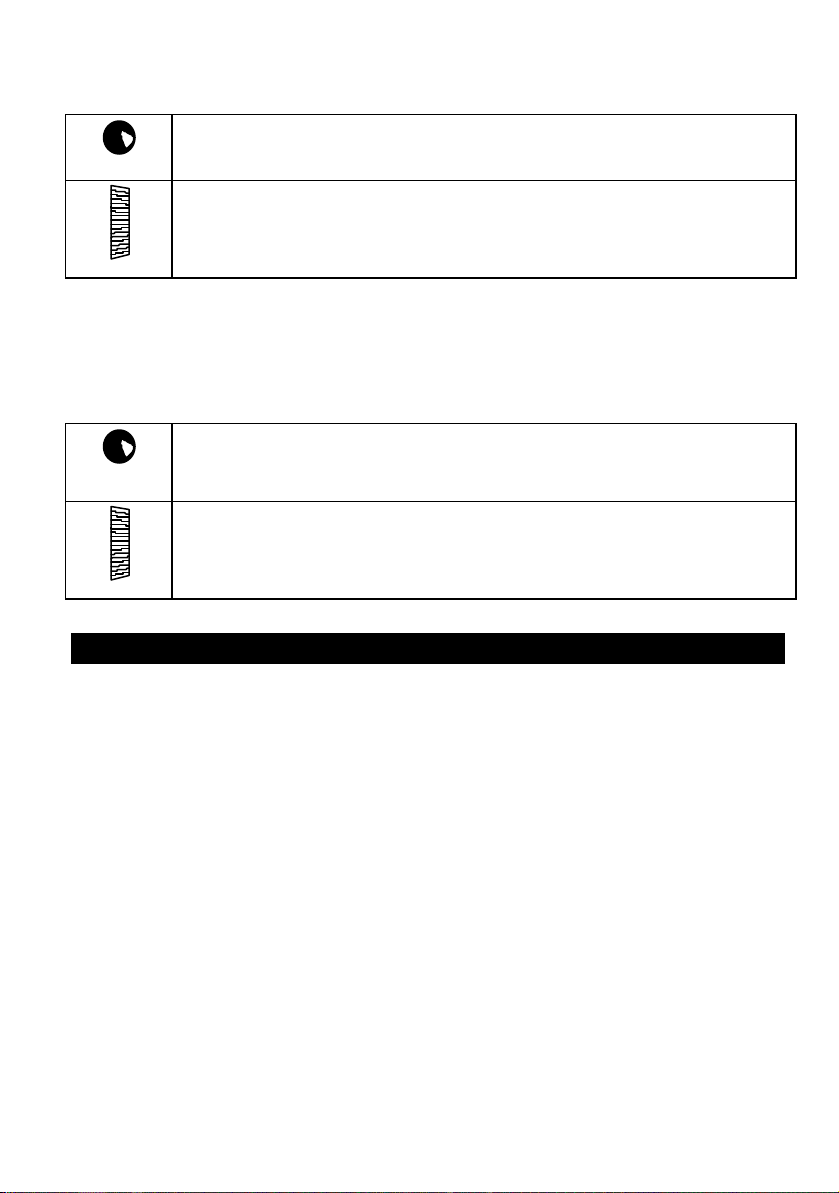

The principle

The five menu buttons on the PROFI CAR transmitter are the key to all set-up

processes. The button symbols tell you which menu points you can access with each

button.

Menu

button

A

L

U

T

F

Menu function

TRIGGER

Adjust everything which is concerned with the throttle, brake and

automatic start function;

on the PROFI CAR 707 it also includes TC (Traction Control) and ABS

STEERING

Adjust the steering to suit the track / vehicle / driver

Centre, travel, Dual Rates, Slow

TIMER

Select the timer mode (T-mode), set nominal time / lap data

Check and erase times

TOOLS

Select the vehicle type

Basic settings for servos, transmitter

MEMORY

Switch, copy, assign name, erase

9

Page 10

When you have found the menu point you want, you can continue by using the digiadjustor and the handle button.

HANDLE BUTTON (HB)

Select curve points

Confirm erasure, ...

DIGI-ADJUSTOR (DA)

Set values (travels, times, ...)

Select sub-menu points (if there is nothing to adjust)

Press any menu button (except the one you last used) to return to the operating

display.

When the operating display is on the screen (i.e. you have finished making

adjustments), the functions of the handle button and digit-adjustor are as follows:

HANDLE BUTTON (HB)

Operate timer functions

Lock brake (PROFI CAR 707 only)

DIGI-ADJUSTOR

Adjust steering travel

10

Page 11

Switching on for the first time

1.1. Charging the transmitter battery (maximum charge current 1 A)

First connect the charge lead (Order No. 12 5023) to the battery charger, then

connect the charge lead to the transmitter.

Charging the battery – important:

•• Automatic battery fuse

The battery of your PROFI CAR features an integral thermal fuse which protects the

battery from excessive currents if a short-circuit should occur.

This transmitter must be used with a genuine MULTIPLEX battery

fitted with this type of fuse!

If a short-circuit occurs and the fuse trips, the fuse element will reset itself about

!!

1 minute after the fault is corrected, and the unit will then work again normally.

•• Charging the battery - note:

If you charge at the standard (slow) rate, no restrictions apply.

If you fast-charge the battery using a charger with automatic termination, the charge

current must not exceed 600 mA. Exceeding this rate may cause the thermal fuse to

trip, and the charge process will be interrupted prematurely.

1.2. Charging the receiver battery

Observe the manufacturer’s notes on charging, as printed on the battery.

Do not exceed the stated charge currents!

1.3. Fitting the transmitter crystal

Transmitter crystals have a blue sleeve and bear the code letter „S“ before the

channel number. Ensure that the transmitter and receiver crystals are on the same

channel.

Plug the transmitter crystal into the RF module (see picture on page 2).

Please be very careful when handling crystals:

v Don’t drop them

v Don’t force a crystal into its socket

v Protect them from vibration in use and in storage

1.4. Adjusting the trigger loop

You can adjust the trigger loop to suit your finger size by loosening the screw in the

trigger.

CAUTION: don’t over-tighten the screw after making the adjustment, as this could

loosen the nut pressed into the other side!

11

Page 12

1.5. Testing the transmitter

Now you can switch on the transmitter and a receiving system and generally try

things out. All you need is a receiver, two servos connected to channels 1 and 2, and

a battery. If you prefer to use an existing model car, make sure that the steering servo

is connected to channel 1 and the throttle/brake servo to channel 2.

Now you can continue with Section 2.

2. Short and to the point

In this section you will discover the five simple steps required to get your first model

car „up to speed“. This is the procedure in brief:

2.1 Select the vehicle type

Adjust the transmitter to suit the model (number of channels, ...)

2.2 Set the servo norm, centre and travels

Adjust the servos to suit the mechanical system in your model

(the „S-NORM“ menu point includes direction of rotation)

2.3 Adjust the steering set up to suit your

2.4 Adjust the throttle personal preferences

2.5 Adjust the brake and the track characteristics

12

Page 13

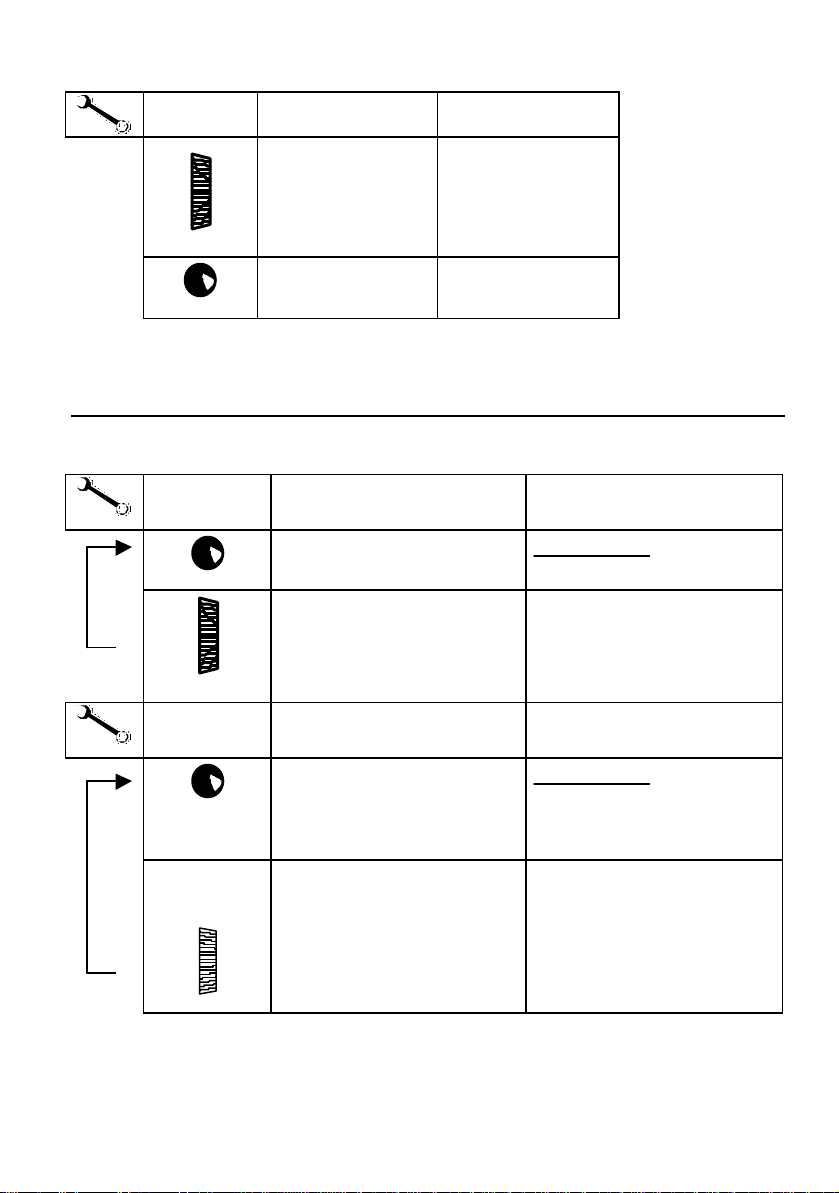

2.1. Selecting the vehicle TYPE

Selecting the vehicle TYPE determines the channels which are to be used to control

your model.

The PROFI CAR 403 offers the following options.

TYPE Steering Throttle + Brake Special features

STANDSTAND

e.g.

electric car

2+1 CH2+1 CH

Servo

1

Servo

2

GP car

2+5 CH2+5 CH

Truck

The PROFI CAR 707 also includes:

v ABS Advanced Braking System

v TC Traction Control

v and two new vehicle types:

TYPE Steering Throttle/brake 2nd brake Special features

4 CH4 CH

TYPE Steering Throttle Brake Special features

5 CH5 CH

Profi

Servo

1 + 4

Servo

1 + 5

Servo

2

Servo 2 Servo

3 + 4

EXPO on THROTTLE

Switched channel for servo 3

5-point curve for THROTTLE

Switched channel for servo 3

Switched channels for servo 3 to 7

EXPO on THROTTLE

Servo

3

2 steering and 2 brake servos

5-point curve on THROTTLE

no auxiliary channel

2nd brake servo on channel 3

5-point curve on THROTTLE

no auxiliary channel

For your first attempts we recommend that you select the vehicle type STAND

(standard) or 2+1 CH.

13

Page 14

This is the procedure:

TYPETYPE

Search for menu

point

Select type

Confirm and

terminate

STAND

2+1CH

4CH

5CH

2+5CH

X Confirm. Beep

2.2. Setting the servo norm,

direction of rotation, travels and centre

If you select STAND or 2+1 CH as the vehicle type, all you need to do is set up the

servos: servo 1 „STEERING“ and servo 2 „THROTTLE/BRAKE“.

SS --NORMNORM

Search for menu point

Select servo

Select norm / direction,

check by moving trigger or

steering wheel

S-NORM

2: MR

UN UNI normal

UR UNI reverse

MN MPX normal

MR MPX reverse

SS --TRAVTRAV

L A

Search for menu point

Select servo

Example:

Servo 2, centre –12%

Right, centre, left

select by turning steering

wheel

(for servo 2 use trigger)

then set using digi-adjustor

S-TRAV

2: • -12

%

ŒŒ right 0 – 100 %

•• centre +/- 25 %

LL left 0 – 100 %

§ Press any button (except T ) to return to the operating display.

14

Page 15

2.3. Adjusting STEERING LL

Steering settings:

CECENTRNTR

TRAVTRAV

DUALDUAL

SLOWSLOW

EXPOEXPO

§ Use the L button to search for the menu point SLOW, EXPO, CENTR or

§ Set the value you want using the digi-adjustor

§ Press any button (except L ) to return to the operating display.

Servo centre (straight ahead) - 50% to + 50%

Minimum steering travel,

if set using digi-adjustor

Auto Dual Rates

DE = delay 0 to 5

RT = reduced travel

Retards steering movements

Enter/exit turn separately

Exponential steering curve

TRAV

30% to 100%

Switch off with „DE = 0“

50% to 100%

0.0 sec to 1.0 sec

+100% = soft

-100% = hard

2.4. Adjusting THROTTLE AA

You must set either a 2-point or 5-point throttle curve, depending on the vehicle

type you have selected.

For the STANDard and TRUCK vehicle types:

2 point throttle curve

LL

IT

FT

EXP

Idle 0% to 100%

Initial throttle =

initial throttle value when trigger

leaves deadband

Full Throttle 0% to 100%

Exponential throttle curve

with EXPO

0% to 100%

+100% = soft start

-100% = hard start

For the vehicle types „2+1 CH“, „4 CH“ and „5 CH“

5-point throttle curve

ID

IT

2T

3T

4T

FT

Idle 0% to 50 % 15%

Initial throttle = initial throttle value

when trigger leaves deadband

Points on the throttle curve 0% to 100%

Full throttle 0% to 100% 100%

15

Range Default setting

0% to 100% 30%

45%

60%

75%

Page 16

This is the procedure for setting the separate points on the throttle curve:

§ Search for the menu point T-CURV (throttle curve) using the A button

§ Search for the point to be adjusted using the handle button G

§ Set the value using the digi-adjustor

§ Press any button (except A ) to return to the operating display

2.5. Adjusting BRAKE A A

The settings for the brake are the same for all vehicle types. EXPO is also available in

all vehicle types.

Point to be adjusted Range

EPEP

LPLP

EXPEXP

IF you set EXPO to +100% the brake is applied „gently“; at -100% the brake is applied

hard. Setting EXPO to 0% switches exponential off.

Engage Point =

Brake setting when trigger leaves deadband

Lock point 0% to 100%

Exponential brake curve ±100%

§ Search for the menu point BREMS1 (brake curve for the throttle/brake

servo) using the AA button.

§ Search for the point to be adjusted (EP/LP/EXP)

using the handle button G.

§ Set the value you want using the digi-adjustor

§ Press any button (except A ) to return to the operating display

0% to 100%

üü That’s all you need to do. It should now be possible to run your car

and control it properly.

16

Page 17

3. More about steering LL

The PROFI CAR provides the following facilities for adjusting the steering:

• Servo centre and servo travel {3.1} (T menu, menu point „S-TRAV“, servo 1)

These facilities allow you to adjust the servo to suit the mechanical set-up in your

model, and at the same time set the maximum steering travel and centre setting

for accurate straight running.

• Steering CENTRE {3.3} (L menu, menu point „CENTRE“)

In this part of the menu you can correct the car’s straight running. The steering

trim also affects this value, and you can „automatically“ accept the trim value as

the centre in this menu point.

• Steering TRAVEL {3.4} (L menu, menu point „TRAVEL“)

At this point you can enter a value for the minimum steering travel which you

can set using the digi-adjustor when the car is running. This avoids the danger of

inadvertently setting such a low value that you suddenly run out of steering

travel when you most need it. 30% is the minimum value.

• SLOW {3.5} (L menu, menu point „SLOW“)

You can adjust the transit speed of the steering servo separately for entering

turns „••“ and for exiting turns „••“.

• EXPO {3.6} (L menu, menu point „EXPO“)

You may like to adjust the steering so that response to the wheel is more or less

sensitive than normal around the centre setting. This is achieved by setting a

value for EXPOnential.

• Auto Dual Rates (L menu, menu point „DUAL“)

Dual Rates means reduced servo travel, and Auto Dual Rates means that the

travel of the steering servo is reduced automatically when the throttle setting is

increased. At full throttle steering travel is small, at idle steering travel is large.

At the DUAL menu point you can

1. set the value at which reduced steering travel (RT) takes effect

2. set the delay (DE) which applies to the automatic travel reduction

• Increment size for steering travel and trim setting {3.2}

(T menu, menu point „STEP“)

Each movement of trim rocker A (steering centre) and of the digi-adjustor

(steering travel) produces one increment of change; the step size can be set to

any value between fine (1% increments) and coarse (10% increments).

3.1. Adjusting the steering servo („TT“ menu)

You must adjust the servo to suit the mechanical set-up in your model before you

alter the steering settings in the L menu. In more detail this means: setting the

direction of rotation / and pulse width (norm) of the servo, and setting appropriate

values for left ( ), straight ( ) and right.

17

Page 18

The diagram on the right

shows an example of the

settings you can change in

the „S-TRAV“ menu. The

stated angles (0° / 45°) show

the servo’s maximum physical travel. The adjustment

points „LL “ and „ŒŒ “ indicate

the maximum travel of the

steering servo which the

user has set. To adjust either

of these points you have to

turn the steering wheel in

the corresponding direction.

When the servo is at the „•• “ point you can adjust the servo setting for „straight“.

In the „S-NORM“ menu point

you can also set the direction of rotation for the servo, and choose between the

MULTIPLEX and UNIVERSAL signal formats. MULTIPLEX norm means that the signal

length (pulse width) for the centre setting is 1.6 ms, and the signal range is

+/- 0.55 ms. The UNIVERSAL norm means that the servos operate on 1.5 ms +/-0.5 ms.

This is the procedure:

SS --NORMNORM

Search for menu

point

SS --TRAVTRAV

L

Select servo 1

Select norm and

direction of

rotation

Search for menu

Point

Select servo 1

Select right, centre,

left by rotating

steering wheel,

then set using digiadjustor

S-NORM

1: MR

UN UNI normal

UR UNI reverse

MN MPX normal

MR MPX reverse

S-TRAV

1: •- 3

%

ŒŒ right 0 – 100 %

• • centre +/- 25 %

L L left 0 – 100 %

18

Page 19

3.2. Adjusting the steering trim („TT“ menu)

The steering is trimmed using the trim rocker A. You

can easily find this rocker „blind“ because its shape

and fluted surface differentiate it from the other

rockers

You can use the steering trim to adjust the centre of

the steering servo by 7 increments in each direction.

Each step offsets the centre by at least 1% (fine) and

at most 10% (coarse). You can select the size of the

trim increments in the menu point STEP of the „*“

menu. The default setting is 2%.

The screen shows the current trim settings in the form of a vertical bar.

STEP

STR 2

%

1 – 10%

T

STEPSTEP

Serrate for menu

point

Search for

parameter

STR =Steering TRim

Set size of

trim increment

3.3. Adjusting the steering CENTRE, accepting the trim setting

In this menu point you can do two things:

v Set the steering servo centre within the range -50% and +50%, and

v accept the trim setting

CENTRE

- 8

%

The current trim value is added to

the centre, and then reset to zero.

L

CENTRECENTRE

> 3 sec

Search for menu

point

Set the centre

(e.g.: -8%)

Accept the trim

setting as centre

19

Page 20

Accepting the trim is a practical and useful facility. For example, if

you suffer a „slight crash“ which knocks the basic setting out, you

can quickly and simply regain the full trim range.

The diagram on the right shows the screen display before and after

accepting the trim setting. On the left the centre is offset by 3 steps,

while on the right the setting has been accepted, and the trim

display is back to centre. If you have selected, say, 3% as the trim

increment when trimming the steering centre SC, this means that

„CENTRE“ is offset by 9% (3 increments of 3%).

3.4. Setting the minimum steering TRAVEL

During a race you can alter the steering travel with the digi-adjustor, so that it is

always accurately matched to the track you are using.

Please note: this only works if the screen shows the operating display!

The actual steering travel you have set is shown by the bar on the far right of

the screen. In our example 2/3 of the maximum possible range is available

between minimum and maximum.

To avoid the possibility of reducing steering travel to zero, you can at this

point set a value for the extent to which steering travel can be reduced using

the digi-adjustor, i.e. you can fix the minimum steering travel. The

adjustment range is 30% to 100%.

L

TRAVELTRAVEL

Search for

menu point

Set travel

(e.g.: 72%)

TRAVEL

72

%

Range: 30% to 100%

Increment: 1% to 10%%

Default setting: 44% travel

2% increment

' TIP !

Set the maximum steering travel by adjusting the basic mechanical set-up of the

steering servo (see 3.1).

Make adjustments in the „T“ menu, menu point „S-TRAVEL“, servo 1.

' TIP !

The rate at which the digi-adjustor affects the steering travel

increment size.

Make adjustments in the „T“ menu, menu point „STEP“, „STV“

20

is determined by the

Page 21

3.5. SLOW

SLOW retards the movement of the steering servo, and reduces the tendency for the

steering system to oscillate when the load on the wheels is light, and the steering

movements are rapid. The delay time is variable separately for „entering the turn“

and „exiting the turn“ (returning to straight running), in both cases within the range

0.1 to 1.0 sec.

If you select the vehicle TYPE „5 CH“, with two steering servos, SLOW affects both

servos simultaneously, as you would expect.

L

SLOWSLOW

Search for menu

point

e.g.: 0,7 sec for

“exit curve”

Search for

parameter

Set time Range: 0,0 to 1,0 sec

SLOW

•• 0.7

•••• enter curve

•••• exit curve

Increment: 0,1 sec

Default setting: 0,0 sec

3.6. EXPO

EXPO affects the steering response of your model car. If you set a positive value (e.g.

+50%), the steering travel around the centre is reduced, making it easier to steer the

model on straight stretches at high speeds.

A negative EXPO value produces the opposite effect, making the steering response

more direct around centre.

L

EXPOEXPO

Search for menu

point

e.g.: +70%

Adjust EXPO Range: -100% to 100%

EXPO

70

%

Increment: 5%

Default setting: 0%

3.7. Auto Dual Rates for steering

The effect of Auto Dual Rates is to produce an automatic reduction in steering travel

when you open the throttle (see 2.7.1.).

It is also possible to program a delay in the speed with which the automatic travel

reduction is applied, to ensure that short bursts of throttle don’t produce an

unwanted reduction in steering response (see 2.7.2.).

This function can be disabled by setting the delay value DE to „0“.

21

Page 22

3.7.1. Reduced Travel RT at full throttle

§ Search for the menu point „DUAL“ using the L

button

§ Search for RT with the handle button G

§ Use the digi-adjustor to set the value you want within the range 50% to

100% (example: 57%).

Finally you must set the delay DE (see next section) to a value within the range 1 to 5.

3.7.2. Auto Dual Rate delay

The delay can be set to any of 5 values. Set DE = 0 to switch the

function off.

§ Search for the menu point „DUAL“ with the L button

§ Search for DE using the handle button G

§ The value can now be set within the range 0 and 5 using the digi-adjustor

(example: 2).

DUAL

RT 57

%

DUAL

DE 2

' TIP !

Before you go onto the track, check the effect of your Auto Dual Rates settings with

the model in the pits (set the steering to full travel, then open the throttle).

3.8. The second steering servo (PROFI CAR 707 only)

At present two steering servos are generally used in models where one servo alone

cannot produce the power required. The two servos are mechanically connected,

and must be synchronised perfectly to avoid them counteracting each other.

You can use two steering servos (on channels 1 and 5) if you select the vehicle type

„5 CH“ on the PROFI CAR 707 transmitter.

IMPORTANT: all settings in the „LL“ menu apply to both servos !

!!

The two servos should be adjusted to suit the model’s mechanical set-up; this is done

in the menu points „S-NORM“ and „S-TRAV“ of the „T“ menu. You can compensate

for any differences between the two servos by making adjustments in the menu

point „S-TRAV“.

' TIP !

If you wish to alter the servo norm or travel, disconnect the mechanical link between

the two servos first to avoid the danger of placing an unnecessary strain on the

servos.

22

Page 23

4. More about THROTTLE AA

The PROFI CAR also has plenty of interesting facilities to offer for throttle:

v 2-point throttle curve with EXPO, or 5-point throttle curve

v Automatic Start

v TC (traction control) PROFI CAR 707 only!

v Separate throttle servo PROFI CAR 707 only!

To help you understand:

The diagram on the right shows

which servo settings are assigned

to the individual points on the

throttle-brake curve.

Between the points Initial Throttle

IT and Full Throttle FT the setting of

the throttle servo is proportional to

the position of the trigger.

At the idle setting (ID) the servo

does not move, provided that the

trigger stays within the deadband {variable: see 9.1}. As soon as the throttle trigger

moves into the working range, the throttle servo jumps to the Initial Throttle position

IT.

4.1. 2-point throttle curve with EXPO

The two-point throttle curve is generally adequate for electric-powered model cars.

With the help of the EXPO facility you can easily set up a throttle response curve

which gives you just the feeling of control you prefer.

Use the menu button A to locate the throttle curve, and the handle button

select the individual points on the curve. The advantage of this system is that you

don’t actually have to apply full throttle in order to adjust the full throttle point.

G

to

The diagram on the right shows the

correlation between the trigger move-met

and the servo travel in graphic form.

The area with the grey background is the

deadband. As long as the trigger stays within

this range, the throttle/brake servo stays at

the idle setting IDL.

Between the two points Initial Throttle IT and

Full Throttle FT the throttle curve is linear assuming that you have set EXPO to 0%. The

dotted lines show how EXPO affects the throttle curve

23

with EXPO

Page 24

This is the procedure:

A

GG --CURVCURV

Search for menu

point

Search for point on

throttle curve

e.g.: Initial Throttle

35%

Set the value

4.2. 5-point throttle curve

The main advantage of the 5-point

throttle curve is to set up a

response curve which compensates

for the characteristics of the

carburettor of an internal combustion engine. Between the two

points Initial Throttle IT and Full

Throttle FT there are three further

points which you can set to the

values you find best.

The settings are adjusted using the

same procedure as described for

the 2-point throttle curve in the

preceding section 4.1.

G-CURV

IT 35

%

ID Idle

IT Initial Throttle

FT Full Throttle

EXP EXPO

The brake curve is the same for all

vehicle types.

24

Page 25

4.3. Automatic Start

The automatic start facility triggers a series of special functions once only at the start

of the race. The automatic start function must first be activated in the * menu. It can

be initiated (triggered) in two ways, depending on the vehicle TYPE you have

selected: either by the action of opening the throttle for the first time, or by pressing

the handle button at the same time.

When you activate the automatic start function, the following happens:

• All vehicle types: the timer and lap counter are set to starting values.

• Vehicle type STAND (standard) and 2+5 CH:

The throttle curve is altered for the start

phase. You will find the start value as „IT+“ in

the menu point „T-CURV“. The value which

you set here increases (or decreases if you

prefer) the „normal“ initial throttle setting.

However, this change only applies until the

initial start phase is finished (see below).

When the automatic start function is

triggered, the throttle response follows curve

Œ. If you stay within the working range of the automatic start function, with your

finger on the trigger, the throttle moves to a fixed setting. This setting can be

fine-tuned to suit your vehicle exactly. When you move the trigger into the

deadband, or above the Initial Throttle setting as increased using the „IT+“ value,

the throttle response reverts to curve •.

• Vehicle type 2+1 CH, 4 CH and 5 CH:

In the vehicle types which feature a 5-point

throttle curve the „addition to Initial

Throttle“ is effective over the first four

points of the throttle curve, as shown in

curve ΠOn this curve the automatic start

function continues in effect until the

throttle trigger exceeds point 4 on the

throttle curve (i.e. in the direction of full

throttle), or if the trigger is moved into the

deadband. From this moment the throttle

response reverts to curve •.

4.3.1. Setting the „addition“ for Initial Throttle „IT+“

' TIP ! The setting for „IT+“ can only be changed when the

automatic start function is active.

§ Search for the menu point „START“ using the A button.

§ Switch the function „ON“ using the digi-adjustor.

You will now see the TRIGGER symbol flashing at the top

left of the screen.

25

START

ON

Page 26

§ Proceed to „T-CURV“ using the A button.

%

§ Search for the „IT+“ value using the handle button G.

§ Set the value you want using the digi-adjustor.

In the example shown on the right the set value is 16%.

If you move back to the operating display by pressing any menu button (except A ),

the top line of the screen will alternate between the model name and „START“.

G-CURV

IT+ 16

' TIP !

The automatic start function can only be triggered when the operating display is on

the screen

4.3.2. Initiating the automatic start function using the trigger

This works with all vehicle types. When the trigger is moved from the deadband in

the direction of full throttle for the first time, the following things happen:

§ The timer and lap counter start running, and are shown on the screen (varies

according to the selected timer mode).

§ The set „addition“ for initial throttle comes into force (see 4.3.1.).

Once the automatic start is initiated, only the model name appears on the screen.

4.3.3. Initiating the automatic start function with the handle button or trigger

If your model is equipped with separate servos for throttle and brake (vehicle types

„3+1 CH“ and „5 CH“), there are two methods of starting:

§ Lock the brake by pressing the handle button G. Now you can blip the

throttle, and the car will not roll away.

§ When you release the handle button G the car will start - provided that the

trigger is not in the deadband.

§ If the trigger is in the deadband (idle) you can release the brake (handle

button). You can then start the car by squeezing the trigger, as described

below.

4.3.4. Terminating the automatic start phase

When the start phase ends, the program switches off the addition to the initial

throttle setting „IT+“, and the throttle response reverse to the „normal“ curve (2 or 5

points)..

The correlation between these values is illustrated in the diagrams in Section 4.3,

termed the „automatic start function working range“.

§ If a 2-point throttle curve is in use, the start phase ends when you move the

trigger to the deadband (idle), or when the throttle trigger exceeds the value

determined by Initial Throttle and IT+.

§ If you have set a 5-point throttle curve, the start phase ends when you move

the trigger into the deadband, or when the throttle trigger exceeds the

fourth point on the throttle curve „4T“.

26

Page 27

4.4. TC = traction control (PROFI CAR 707 only)

Traction Control is a variant of the SLOW function applied to THROTTLE, in this case

only working when you open the throttle. When you close the throttle, the servo (or

speed controller) responds normally, i.e. without any delay.

Traction Control prevents the wheels spinning during acceleration on a smooth

track. In the case of electric cars TC reduces current drain, because the motor is

controlled more „gently“.

There are two parameters to be set for Traction Control:

1. T = Time, between 0 and 2.0 sec

Time factor for retarding the throttle servo

2. ACC = Acceleration, between 0 and 10

works in a similar way to EXPO

The diagram on the right shows

how you can imagine the effect of

the TC function.

We will assume that you want the

throttle to move from the ACTUAL

position to the NOMINAL position

(see labels on graph), because you

have moved the trigger slightly in

the direction of full throttle.

Without TC this change takes place

at a rate determined by the servo’s

transit speed (see curve 1).

If you set the parameter T (= time) for Traction Control to the maximum value 2.0, the

movement of the servo is retarded, but the line of the graph remains linear (curve 2).

If we now add a little ACC to the mix, we obtain the desired line as shown by curve 3.

Initially the throttle opens slowly (thereby preventing the wheels spinning), but the

rate of opening then increases steadily. This set-up shortens the total duration of the

servo’s movement, but without losing the advantage of the „gentle“ start-up.

This is the procedure:

§ Search for the menu point TC using the A button.

§ Select T or ACC using the handle button G.

§ Set the value you want using the digi-adjustor.

Press any menu button (except A ) to return to the operating display.

27

Page 28

5. More about BRAKE

The PROFI CAR offers the following brake functions:

v 2-point brake curve with EXPO {see 5.1}

v ABS Advanced Braking System (PROFI CAR 707 only)

v Second brake servo (PROFI CAR 707 only)

To help you understand:

The diagram on the right shows the

servo positions which correspond

to the individual points on the

throttle-brake curve.

Between the engage point EP and

the locking point LP the servo

responds proportionally to the

movement of the trigger.

At the idle position IDL the servo

does not move, as long as the

trigger stays within the deadband {variable: see 9.1}. As soon as the trigger is moved

into the „brake“ working range, the servo jumps to the Engage Point EP.

5.1. Two-point brake curve with EXPO

Use the menu button A to locate the brake curve. The individual points on the

curve are selected using the handle button

The diagram on the right illustrates the

correlation between the trigger movement

and the servo travel in graphic form.

The area with the grey background is the

deadband. If the trigger stays within this

range, the throttle/brake servo stays at the

idle position IDL.

Between the engage point EP and the

locking point LP the brake curve is linear assuming that you have set EXPO to 0%. The dotted lines show how EXPO alters the

brake curve.

28

Page 29

This is the procedure:

BRAKE1

EP 27

%

IDL Idle -50% to +50%

A

BRABRAKE1KE1

Search for menu

point

Search for point on

brake curve

Example:

Engage point 27%

Set value

EP Engage point OFF or

1 – 100%

LP Lock Pint 0 – 100%

EXP EXPO ± 100%

If you are using a combined throttle/brake servo (all vehicle types except „5 CH“),

!!

the idle point „IDL“ exists on the throttle curve as well as the brake curve

5.2. Trimming the Lock Point LP using rocker D

The lock point of the brake normally changes

during a race, so it is helpful to be able to

compensate for that change. This is done by means

of trim rocker D. Rocker D affects the lock point of

the THROTTLE/BRAKE servo (servo 2) or servo 3 (first

brake servo) of the vehicle types 3+1 CH and 5 CH.

The brake trim allows you to adjust the lock point by

7 increments in each direction. Each increment

offsets the lock point by at least 1% (fine) and at

most 10% (coarse). You can select the size of the

trim increments in the menu point „STEP“ of the „T“ menu.

The default setting is 2%.

29

Page 30

The current trim setting is indicated on the screen by a vertical bar. In the example on

the right the lock point of the first brake servo has been offset in the direction of

„stronger braking effect“ by 3 trim increments.

STEP

LP 78

%

1 – 10%

T

STEPSTEP

Search for menu

point

Select parameter

LP = Lock Point

Set size of

trim increment

' TIP !

If you have a second brake servo (vehicle type „5 CH“), the increment size you select

applies to both trim rockers (B and D).

5.3. ABS = Advanced Braking System (PROFI CAR 707 only)

In the model car racing field ABS corresponds to an intermittent brake: instead of

being applied constantly, the brake is applied then released again continually at

short intervals. This method of braking keeps the vehicle on line better, making it

easier to steer under heavy braking.

In the PROFI CAR the ABS function is activated automatically when the steering

deflection exceeds a variable threshold (TH = threshold point).

' TIP !

If you set the threshold point to 0%, ABS is effective all the time.

This allows you to try out its effect on a straight stretch of track.

A A

ABSABS

Search for menu

point

Select parameter

Set value Effect

ABS

AB 3

%

TH threshold point 0 – 50%

EF Effect 0 – 4

0 OFF

1 soft

...

4 hard

30

Page 31

5.4. Braking with more than one servo (PROFI CAR 707 only)

If you have chosen the „4 CH“ or „5 CH“ vehicle type, you can use two brake servos;

this allows you to control the brakes for the front and rear axles separately.

In vehicle type „4 CH“ you have:

v servo 2 for throttle/brake (rear wheels)

v servo 3 for the second brake (front wheels)

In vehicle type „5 CH“ you have:

v servo 2 for throttle alone

v servo 3 for the first brake (rear wheels)

v servo 4 for the second brake (front wheels)

When you select one of these vehicle types, you can adjust the brakes using the „A “

menu, where you will find the menu points „BRAKE1“ and „BRAKE2“, both of which

feature the same parameters (idle ID, engage point EP, lock point LP and EXPO).

Setting of the brake servos when you open the throttle:

!!

If a combined throttle/brake servo is connected to channel 2, the servo responds to

the throttle and brake commands, but if there is a separate brake servo (servo 3 or 4),

it only moves when the trigger is moved into the brake range. As soon as you open

the throttle, these servos jump to a fixed position which we can term „brake fully off“.

The servo position for „brake fully off“ can be set for servos 3 and 4 in the menu point

„S-TRAV“ within the „T“ menu. To be able to change this value you must hold the

trigger in the throttle range. You will see the symbol „L“ on the screen.

' TIP !

Brake engaged when the trigger is in the deadband (finger relaxed):

If you want the brakes in

your model car to

operate in this way, you

must set the engage

point to 0. Instead of the

0 you will then see „OFF“

on the screen. If the

brake servo is programmed in this way it will

behave as shown in the

diagram at far right. The

servo no longer jumps to

the engage point when

the trigger is moved out of the deadband.

31

Page 32

The lock points for the two brake servos can be

B

D

trimmed using the rockers B and D (see picture). We

have selected these particular rockers so that you

can easily remember the assignment:

front rocker è front brake

rear rocker è rear brake

This is the procedure:

BRAKE2

LP 82

%

IDL Idle -50% to +50%

A

BRAKE1BRAKE1

BRAKE2BRAKE2

Search for menu

point

Select the brake

curve

Example:

Lock point 82%

Set value

EP Engage Point

0 (OFF) to 100%

LP Lock Point 0 to 100%

EXP EXPO ± 100%

Press any menu button (except A ) to return to the operating display.

32

Page 33

6. Timers and lap counters ºº 0000

The PROFI CAR (403 and 707) offers the following facilities for timing and lap

counting:

v Operating time

This timer can be reset to zero in the „T “ menu. It is used to record the

operating time of the transmitter battery or the transmitter itself. This timer

always runs when the transmitter is switched on.

v Nominal lap time

For practising you can set a „nominal time“ (target time) for a single lap. The

transmitter gives an audible signal to let you know whether you were faster

or slower than the set time.

v Race duration

You can enter the race duration in the form of a number of laps or a set time.

The transmitter alerts you to the start of the last lap with an audible signal.

v Memory for 50 lap times

Once you have selected the appropriate operating mode (timer mode), you

can „stop“ lap times with the handle button G . The transmitter’s memory

can store up to 50 lap times, and the times are retained even when you

switch off the transmitter or replace the battery.

v Total race time

A special memory (on-screen symbol „–“) is available as a stopwatch for the

entire race.

You can select the following menu points using the U button:

TT --MODEMODE

OPTIMEOPTIME

ERASEERASE

TIMESTIMES

TT --NOMNOM

DURADURA

Timer mode 6.1

Check transmitter operating time 6.5

Erase lap counter, time memory, nominal time,

race duration (time and lap count) and operating time

Check lap time memory 6.2

Enter the nominal time for a lap 6.3

Enter the race duration as a time or No. of laps 6.4

6.6

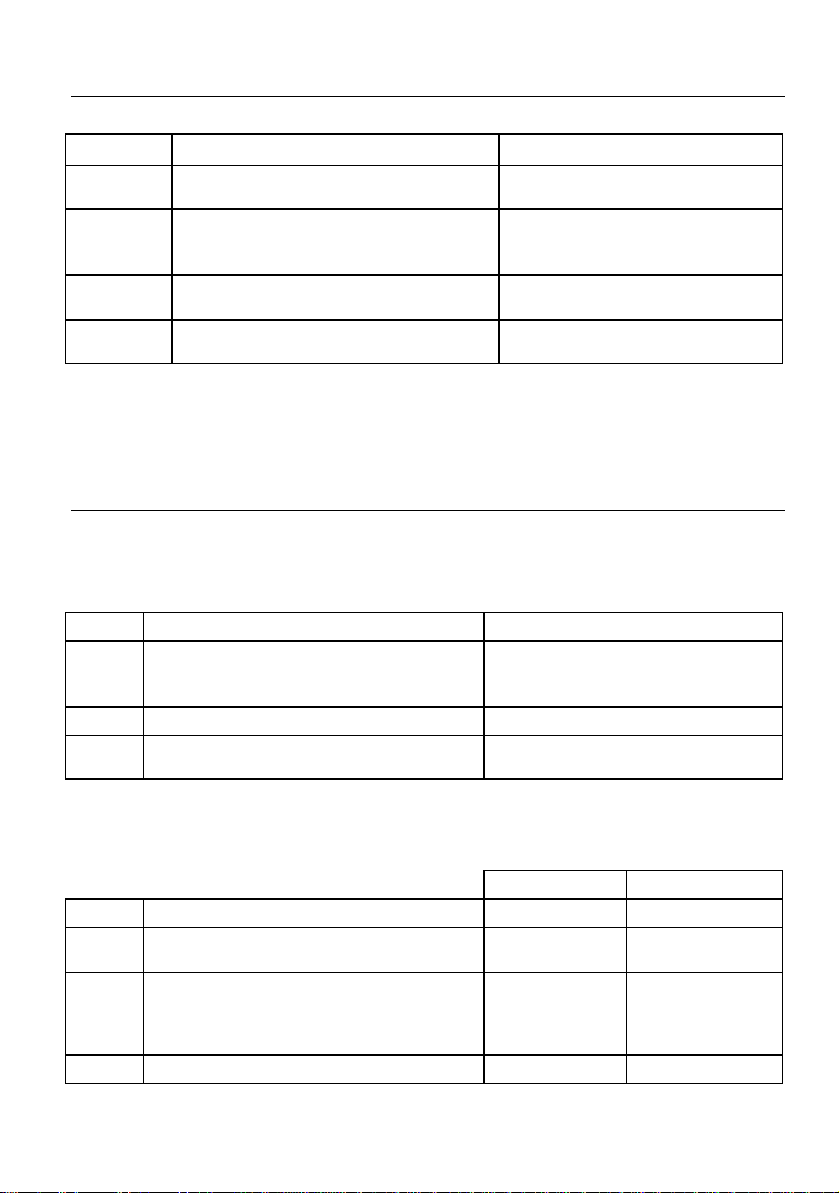

6.1. Timer mode

There are three different modes of operation for the timer. The fourth possible mode

is to switch off the timer functions entirely (T-MODE: OFF).

Mode Effect

OFFOFF

LAPSLAPS

L+TL+T

L+T+DL+T+D

All timer functions switched off

Lap counter active

Lap counter + lap time memory active

Lap counter + lap times + race duration

33

Page 34

The timer mode can be set differently for each model memory.

This is the procedure:

§ Search for the menu point T-MODE using º

§ Select the mode using the digi-adjustor

Press any menu button (except º ) to return to the operating display.

6.2. Lap time memory

The transmitter can store up to 50 lap times and call them up again. When a new lap

is completed, all the lap times already recorded are shifted back by one place. When

the lap memory is full, the oldest value is always erased to make room for the new

one.

§ The time memory „–“ contains the overall time of the last race.

§ The time memory 01 contains the last recorded lap time.

This memory stores all lap times, regardless of the model you are using for that race.

This could mean that you lose track of different races when leafing through the

times, so the screen always shows the number of the model memory associated with

the recorded time.

ºº

02

TIMES

Time memory No. 7 Lap time in sec.

End of lap = start of new lap:

A short press on the handle button triggers four functions:

§ the lap counter LAP is increased by 1,

§ the timing of the current lap halts,

§ the measured lap time is stored in the transmitter’s memory, and

§ the timing of the next lap starts.

End of race:

If you hold the handle button G pressed in for longer than 2 seconds, a long beep

sounds to signal that the transmitter has stopped timing and counting laps.

Calling up recorded lap times:

§ Search for the menu point TIMES using the º button.

§ Leaf through the timer memory 01 to 50 using the digi-adjustor.

„-“is the fifty-first memory containing the total race time.

Press any menu button (except º ) to return to the operating display.

07 17:9

LAP

Model used for the lap

time displayed

34

Page 35

6.3. Setting the nominal time T-NOM

You can enter a nominal time T-NOM for a lap, so that you can check your practice

times against the set value. The maximum variable time is 1 min. 59.9 sec.

When you finish a lap (short press on the handle button G), an audible signal

informs you of the result:

X 1 short beep = lap time equal to or lower than nominal lap

X X X 3 short beeps = lap time longer than nominal lap

This is the procedure for setting the nominal time:

§ Search for the menu point T-NOM using the º button

§ Alter the flashing number with the digi-adjustor

§ Press the handle button G to move to the next digit

Press any menu button (except º ) to return to the operating display.

6.4. Setting the race duration (timer mode 3 only

For practice purposes you can set a race duration, determined either by a particular

number of laps or by a particular time.

6.4.1. Race duration by laps

You can enter the number of laps to be run (max. 99) in the

menu point DURA, LAP. In the example on the right the set

number of laps is 17.

The start of the race is initiated by the automatic start function, or by pressing the

handle button. At the end of each lap you have to press the handle button, to signal

to the transmitter that a lap is finished, that lap timing should begin again, and that

the lap time should be stored.

The transmitter produces the following audible signals:

X X X 3 short beeps at the start of the last lap

DURA

LAP 17

XX 1 longer beep at the end of the race

6.4.2. Race duration by time

You can enter the race duration (max. 1 hour 59 min.) in the

menu point DURA, T. In the example on the right the set time is

12 minutes.

The start of the race is initiated by the automatic start function or by pressing the

handle button. At the end of each lap you have to press the handle button to signal

to the transmitter that a lap is finished, that lap timing should begin again, and that

the lap time should be stored.

The transmitter produces the following audible signals:

X X X 3 short beeps at the start of the last round

DURA

T 0:12

35

Page 36

The transmitter can only produce this signal if your car has completed at least six

laps. The transmitter computes the average time for the last six laps, then calculates

whether a further full lap can be completed in the time remaining to the end of the

race. If not, the 3-beep signal is given. When you next press the handle button the

transmitter stops the timing process.

This is the procedure:

§ Search for the menu point DURA using the º button

§ Select T (time) or LAP (laps) with the handle button G

§ Alter the value using the digi-adjustor

Press any menu button (except º ) to return to the operating display.

6.5. Checking the transmitter’s operating time

This menu point can only be used to check the operating time.

To erase the data you must proceed to the ERASE menu point.

§ Select the menu point OPER using the º button

The time is displayed in hours and minutes.

Press any menu button (except º ) to return to the operating display.

OPTIME

6:17

6.6. Erasing the timer ERASE

This menu point can be used to erase the following times (or settings):

Item this value is erased (reset to 0):

L+TL+T

NOMNOM

DURADURA

OPTIMEOPTIME

The lap counter and all time memories

Set nominal lap time

Time and lap count for the race duration

Operating time

This is the procedure:

§ Search for the menu point ERASE using the º button

§ M Use the digi-adjustor to select the item you wish to erase

§ Hold the handle button G pressed in for longer than 3 sec to erase the data

Press any menu button (except º ) to return to the operating display.

36

Page 37

7. Model memories 11

The model memories are used to store all the settings which you have entered for a

particular vehicle. These settings include:

v Modulation (FM/AM)

v Servo direction, signal format, centre, travels

v Settings for throttle, brake and steering

v Timer settings

v Trim settings

The information in the active model memory is updated when you switch off the

transmitter or switch to a different memory.

v PROFI CAR 403 6 model memories

v PROFI CAR 707 12 model memories

The memory space available is generous, and the spare memories can be exploited

to experiment with copying model data, or trying out different settings for a

particular race track.

7.1. Switching to a different model memory

§ Search for the menu point GO TO using the 1 button

§ Select the target memory with the digi-adjustor

The screen shows the name, memory number and trim

settings.

§ Hold the handle button G pressed in for longer than

3 sec to effect the switch.

A long beep confirms the switch, and the screen reverts to the operating display.

03

GO TO

STAMP

7.2. Copying

§ Search for the menu point COPY using the 1 button

§ Select the target memory with the digi-adjustor

Number

Name

§ Hold the handle button G pressed in for longer than

3 sec to confirm the copy.

The copy process is carried out, and the operating display re-appears. At the same

time the transmitter switches to the memory which you selected as destination for

the copy. The copy process copies the name as well as all the settings (but not the

trims). The previous contents of the target memory are overwritten by the new data.

37

05

KOPIE

BUGGY2

Page 38

7.3. Entering the model name

Six letters, numbers or symbols, are available for the model name. The following

characters can be used:

ABCDEFGHIJKLMNOPQRSTUVWXYZ-0123456789

§ Search for the menu point NAME using the 1 button

§ The first character flashes, and can be changed using

the digi-adjustor.

§ Press the handle button G to move on to the next

character, and from the last back to the first again.

Press any menu button (except 1) to return to the operating display.

NAME

MIRAGE

7.4. Erasing

There are two methods of erasing the contents of a model memory.

1. VALUES (just erases the variable values)

In this case erasing means: the values are reset to the

default settings corresponding to the selected vehicle

type.

The vehicle type, model name, servo norm, direction,

travels, and AM/FM selection are not erased

2. ALL (erases all data)

This option resets the model memory completely to the

default settings. These include:

The vehicle type STAND (standard) Servo travels 100%

§ Search for the menu point ERASE using the 1 button

§ Select the VALUE or ALL option using the digi-adjustor

§ Hold the handle button G pressed in for longer than 3 seconds to confirm.

Press any menu button (except 1 ) to return to the operating display.

ERASE

VALUES

ERASE

ALL

7.5. Reverting to the PREVious state

Any changes which you make to the settings for a particular model are not stored

permanently until you switch off the transmitter or switch to a different model. As a

result it is possible to switch back to the previous settings, and this is the menu point

you use. You can reverse any changes which you have carried out

v since you last switched memory, and/or

v since you last switched on the transmitter

This is a very useful option, as it makes it safe and easy to „try something out“.

§ Search for the menu point „PREV“ using the 1 button

§ Hold the handle button G pressed in for longer than

3 seconds to confirm the function.

Press any menu button (except 1 ) to return to the operating

display.

38

PREV

3

Page 39

8. Driving trucks

An outstanding feature of the PROFI CAR is that you can use it to control complex

trucks which feature auxiliary functions. The vehicle type „2+5 CH“ makes available a

further 5 auxiliary channels in addition to the two primary channels of steering and

throttle/brake. The additional channels are controlled by means of the trim rockers

(except for A - steering trim), the digi-adjustor and the

handle button.

The picture on the right shows the assignment of the

rockers to the auxiliary channels 3, 4 and 5. The

steering trim rocker retains its function.

The digi-adjustor controls channel 6.

Each of the auxiliary channels 3 to 6 can be operated in three different ways or

control modes.

v PR proportional (25 steps)

v FL Flashing

v 3ST 3 stages (left, centre, right)

The screen shot here shows the settings for the

auxiliary channels. Servo 3 is at centre, servos 4 and 5

are at their end-points. Servo 6 is proportionally

controlled and is about 8 steps away from centre.

The trim setting for the steering remains in the same

position on the screen.

When you first select the vehicle type „2+5 CH“ for a

model memory, all the auxiliary channels default to

the control mode „3ST“.

4

3

5

You can adjust the travel and centre for these functions in the menu point „S-TRAV“

of the T menu (see 8.3).

These are the options for controlling the auxiliary channels 3 to 6:

§ Control mode „PR“ (proportional)

Every time you press the associated rocker, the servo position alters by one

increment or step, and the maximum number of steps is 25. The digi-

adjustor controls servo 6 in a similar way.

§ Control mode „FL“ (flashing)

The term „flashing“ means that the servo switches from centre to one end-

point every 0.5 sec. You can switch the flashing on and off by pressing the

associated rocker briefly. The digi-adjustor controls servo 6 in a similar way.

39

Page 40

§ Control mode „3ST“ (3 stages)

In this mode the servo switches between centre and one end-point when

you briefly press the same side of the associated rocker. If you press the

other side of the rocker briefly, the servo switches immediately to the

opposite end-point. The digi-adjustor controls servo 6 in a similar way.

We recommend that you simply try out the different control modes with a servo.

Special case: channel 7 is controlled by the handle button G.

Channel 7 can only be used in the control mode „2ST“ (2 stages). When you press the

handle button, servo 7 runs to its second position, and stays there until you release

the button. The position of servo 7 is not shown on the screen.

You can adjust both servo positions in the menu point „S-TRAV“

of the menu T (see 8.3).

8.1. Selecting the model type 2+5 CH (truck)

If you just want to experiment with this option for a while, switch to a vacant model

memory (menu point „GO TO“).

§ Search for the menu point „TYPE“ using the T button.

§ Select „2+5 CH“ using the digi-adjustor.

• Hold the handle button

selection.

Press any menu button (except T ) to return to the operating display.

If you use the vehicle type „2+5 CH“ (TRUCK), no timer functions are available,

!!

although you can still check the transmitter’s operating time.

pressed in for longer than 3 seconds to confirm your

G

8.2. Setting the control mode for the auxiliary channels

(menu point „S-NORM“)

The control modes for the auxiliary channels are located in the same part of the

menu where you set the signal format and direction of servo rotation.

§ Search for the menu point „S-NORM“ using the T button.

§ Search for the servo you wish to adjust using the handle button G .

§ Use the digi-adjustor to select one of the control modes PRoportional,

FLashing or 3STages.

Press any menu button (except T ) to return to the operating display.

40

Page 41

8.3. Adjusting travel and centre of the auxiliary channels

(menu point „S-TRAV“)

The steering wheel is used to select the servo position to be adjusted for the auxiliary

channels.

§ Search for the menu point „S-TRAV“ using the „T “ button.

§ Search for the servo you wish to adjust using the handle button G.

§ Use the steering wheel to select left (L), centre (•) or right (Œ)

§ Change the setting using the digi-adjustor.

Press any menu button (except T ) to return to the operating display.

8.4. Truck steering and throttle/brake

The method of setting up these functions is exactly the same as with all other vehicle

types (see 1.3 to 1.5).

9. The “toolbox” TT

The „toolbox“ is opened with the T button, and in it you will find:

v All the settings which apply to the transmitter generally

When you select one of these settings, the screen displays the symbol „*“ instead of

the memory number. This is intended to remind you that the setting you have

chosen applies to the transmitter as a whole, and not to a specific model memory.

These settings are: user’s name, trigger deadband, display language, battery alarm

threshold, and confirmation beep ON/OFF.

The following parameters can be set for each model memory individually:

v Vehicle type

v Modulation (AM or FM)

v Base settings for the servos („S-NORM“ and „S-TRAV“)

v Increment (step) size for the trims and the digi-adjustor

Section 9 describes all the adjustment facilities which have not yet been covered.

9.1. Adjusting the trigger deadband („T “ menu, DEADB)

The deadband for the trigger functions prevents the throttle or brake responding

when you simply touch the trigger (or even just shake or disturb the transmitter). The

throttle would then jump from Idle ID to Initial Throttle IT, and the brake from „off“

(corresponding to the servo’s idle position) to the Engage Point EP.

The default setting for the deadband is 5%, but you can set it to any value within the

range 2% to 20%, depending on how „nervous“ your trigger finger is.

41

Page 42

This is the procedure:

§ Search for the menu point „DEADB“ using the „T “ button.

§ Adjust the deadband with the digi-adjustor.

Press any menu button (except T ) to return to the operating display.

9.2. Switching between AM and FM („TT “ menu, AM-FM)

One absolute innovation on the PROFI CAR system is the ability to use the transmitter

with AM (amplitude modulation) receivers as well as FM receivers (frequency

modulation) without changing the RF module. You can decide which modulation is

to be used for each model memory in the menu point AM-FM.

§ Search for the menu point „AM-FM“ using the „T “ button.

§ Select the modulation which matches the receiver in your model using the

digi-adjustor.

Press any menu button (except T ) to return to the operating display.

9.3. Entering the owner’s name („TT “ menu, NAME)

You can customise your transmitter by entering a name consisting of 6 characters,

and this will appear briefly on the screen when you switch on the transmitter. The

following characters are available:

ABCDEFGHIJKLMNOPQRSTUVWXYZ-0123456789

§ Search for the menu point „NAME“ using the „T “ button.

§ The first character flashes, and you can change it using the digi-adjustor.

§ Press the handle button G to move on to the next character, and also from

the last character back to the first.

Press any menu button (except T ) to return to the operating display.

9.4. Selecting the display language („T “ menu, TEXT)

The five optional languages for the screen display are:

GER=German, ENGL=English, FRANCE=French, ITAL=Italian, ESPAN=Spanish

§ Search for the menu point „TEXT“ using the „T “ button.

§ Use the digi-adjustor to select ENGL (English)

Press any menu button (except T ) to return to the operating display.

9.5. Setting the battery alarm threshold („T “ menu, ALARM)

The threshold for the battery alarm can be set to any value within the range 6.80 V to

7.20 V in increments of 0.05 V. The default alarm threshold is 6.80 V.

The higher you set the threshold, the more reserve time you have between the alarm

sounding and the transmitter giving up the ghost

42

Page 43

This is the procedure:

ALARM

§ Search for the menu point „ALARM“

using the „T “ button.

§ Set the alarm threshold to any value in the range 6.80 V

to 7.20 V in increments of 0.05 V.

Press any menu button (except T ) to return to the operating display.

6.80V

BATT

10. Tips on installing the receiving system in the model

There is usually very little scope for altering the arrangement of the receiving system

in a model car, but please take particular care over positioning and deploying the

receiver aerial.

The following points are particularly important:

• Keep the receiver as far as possible away from

- electric motors

- electrical ignition systems

- servos

- batteries

- cables (especially high-current leads)

• Deploy the aerial in as straight a line as possible, and run it out of the model by

the shortest possible route, arranging it vertically upwards.

• If you are obliged to shorten the aerial, note that the minimum length is 40 cm!

• Never wind up the aerial or leave it coiled inside the model.

• Do not deploy the aerial inside carbon fibre model components, and don’t stick or

tape it on top of any component which is reinforced with carbon fibre (shielding

effect).

• Protect the receiver from vibration

(wrap it in foam and stow it loosely in the model)

' TIP ! If your model is powered by an electric motor:

Separate the receiving system from the power system by as large a distance as

possible, as the high currents in the power circuit can produce interference. Ensure

that all electric motors are effectively suppressed.

With electric models it is wise to carry out a particularly thorough range check

before you run the model for the first time (see 11.2.).

43

Page 44

11. The system in use

11.1. Post Office Regulations for the U.K.

Radio controlled models are of two types - those which operate on the ground or on

water, known as „surface“ models, and those which operate in the air. The first group

includes model cars, trucks and buggies, and also model boats of all types. The

second encompasses fixed-wing model aircraft and rotary-wing machines (mainly

helicopters).

The frequency bands available for radio controlled models are 26.960 to 27.280 MHz

General use, 40.665 to 40.955 MHz (Channels 50 - 79 incl.) Surface only, and

458.500 to 459.500 MHz General. Since the 26/27 MHz band is also allocated for

Citizens Band radio and other users, and the 458/459 MHz band is also available for

use by telemetry and other equipment, radio controlled vehicles are generally

operated on the the 40 MHz band.

As of 1 January 1981 model control equipment was exempted from the licensing

requirements of the Wireless Telegraphy Act 1949. This simply means that no licence

is required to operate RC equipment in the U.K. If you need further information

please contact:

The Low Power Radio Section, Radio communications Agency

Room 712, Waterloo Bridge House, Waterloo Road, London SE1 8UA

11.2. Range testing

The range check is one those procedures which make an important contribution to

the operational security and safety of your model. We have many years of experience

in this matter, and have carried out many measurements; the result is an effective

recipe for a range check which will always keep you on the safe side:

§ Collapse the transmitter aerial completely and switch the transmitter on.

§ The test should be carried out with the model’s motor running.

Ask your assistant to hold the model, or pack it up in such a way that the

steering system and driven wheels can move freely.

§ Check that there are no large metal objects (cars, wire fence etc.) in the

vicinity.

§ Ensure that no other transmitters are switched on - even on other channels -

otherwise the test cannot be expected to give meaningful results.

§ Switch on the transmitter, then the receiver. Walk away from the model

holding the transmitter, and check the controls constantly. You should

obtain a safe range of about 30 m between transmitter and car, with the

model still responding immediately and correctly to control commands,

without making any unwanted movements.

' TIP !

If the effective radio range is inadequate, check the following points:

v Electric motors and electrical ignition systems may not be adequately

suppressed.

44

Page 45

v The receiver aerial may be damaged, too short (less than 40 cm) or badly

positioned.

v Ambient conditions may be poor (damp track surface, metal fences

shielding the signal, etc.).

If the range is not sufficient with the aerial collapsed, and you cannot locate the

source of the problem as described above, try the following alternative test: extend

the transmitter aerial fully, then repeat the check as described above. If the effective

range is 1.5 times longer than the farthest reach of the track, you should be safe to

operate the system.

If you are still in any doubt - don’t risk it and run the model! Take your time to

!!

check everything in peace and quiet, so that you can locate and solve the

problem before you place your valuable model at risk!

11.3. Care of the transmitter

Protect your transmitter from mechanical damage, temperatures above 60°C (direct

sun inside a car), damp, solvents, model fuel, combustion residues and dust. Kindly

bear in mind that a rapid change in temperature (e.g. moving the model from a

warm workshop to a cold car) can cause condensation on and in the transmitter, and

condensation may prevent the unit functioning correctly. If this should happen, it

makes sense to carry out a particularly thorough range check, and allow your

transmitter plenty of time to adapt to the ambient temperature. Check that the

transmitter is completely dry both inside (battery compartment) and out before

using it.

Cleaning the transmitter

The best tool for removing dust is a soft paintbrush. The transmitter case can be

cleaned with a slightly moist soft cloth and a mild household cleaner.

Check that no fluid gets inside the transmitter.

!!

11.4. Maintenance

Your transmitter contains no parts which require maintenance.

Nevertheless, we strongly recommend that you carry out a range check and

!!

examine all the working systems at regular intervals.

What should you do if problems arise or you have queries?

The first stop should be your local model shop, where advice is gladly given.

The addresses of our Service Centres are printed on the last page of these