Page 1

Blend In Pitcher

Blended Ice Machine

Features

High Performance

Shaver/Blender System

• Superior performance across today’s recipes/products and excellent

future product expansion capability.

• Powerful drive system blends, not stirs, to completely emulsify frozen or

fresh fruit.

• Patented XP Blade assembly made of hardened stainless steel for long life.

• No sharp or serrated edges ensure crew safety

Spouted Pitcher

• Optimized blender container design creates a large blending vortex for

more efficient, complete blends.

• Fast, accurate pour.

• Constructed of Triton® Material that is BPA-free and chemically resistant

for enhanced cleanability for extended container life.

• Replaceable pitcher blades for extended life and lower cost of ownership.

Intuitive Touch Screen Control

Visual, icon based selection screen:

• Speeds drink and option selection.

• Mitigates entry errors and lowers potential food waste.

• Provides inventory and service feedback and data.

• Reduces user learning curve

.

MS-8: Blend in Pitcher

The Multiplex Blend in Pitcher (BiP) is a complete

Blended Ice preparation system. All aspects of

the BiP are designed for ease of use, long-term

reliability, product consistency, optimum yield and

adaptability across today’s and tomorrow’s menu

items.

The feature-rich, high-performance Multiplex BiP

is the clear choice to support and deliver your

Blended Ice menu o erings.

Product Dispense & Storage

Refrigerated Product Storage

• Strict adherence to food safety standards.

• Ease of product loading and replacement.

• Easily accessible for cleaning and maintenance.

Reliable

Industry and Time-Proven Technology and Innovation

Provides reliable performance, as well as assurance for long life and

durability.

Service Support

Certified Service and Parts Network

An established network of reliable, trained service providers offering strong

commitments to local equipment and customer support.

Included Accessories

Install Kit: Includes required water, CO2 and drain hose/lines and

connectors.

Clean/Sanitize Kit: (1) Cleaning container, (3) 5-gallon (19L) pails, hose

lengths and bracket

2100 Future Dr.

Sellersburg, IN 47150

Tel: 812.246.7000

Fax: 812.246.7024

www.manitowocbeverage.com/us

Page 2

MS-8: Blend in Pitcher

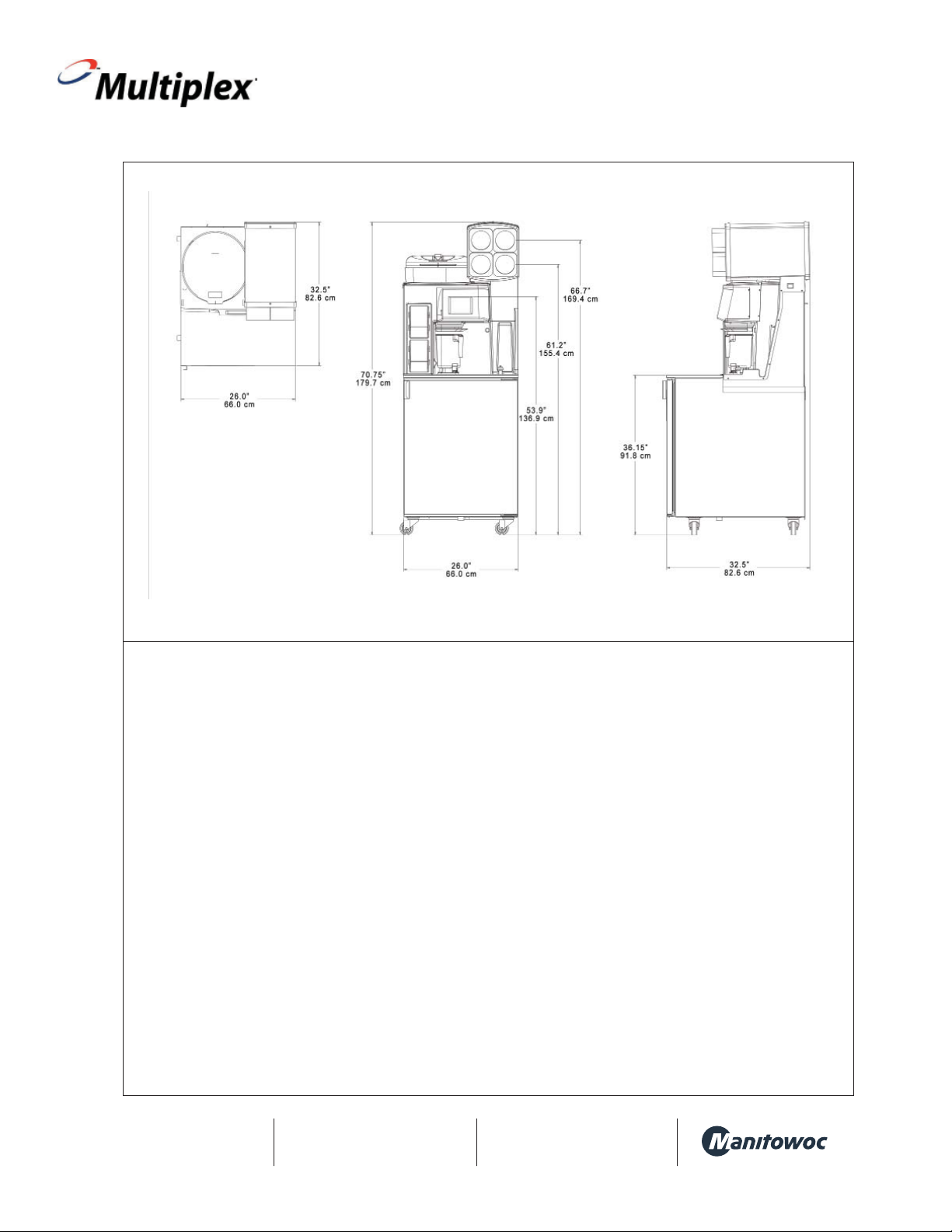

Dimensions

Dimensions

Dimensions

Width 26.00“ (66.0 cm)

Depth 32.52” (82.6 cm)

Height 70.74” (179.7 cm)

Clearances (Air Cooled)

Top 8” (20.3 cm)

Sides 6” (15.2 cm)

Back 6” (15.2 cm)

Front 30” (76.2 cm)

Shipping Weight

430 lbs. (195.5 kg)

Specifications

Storage Capacities

Ice 23 lbs (10.5 kg)

Product 8 x two gal. (7.6L) product packages

Drain

Connection 8' x 1" ID (2.43m 2.5cm ID) hose supplied for

Drop

Requirement

Electrical

Voltage/Cycle 115 VAC-60Hz/1ph

Power Cord 115 VAC units are provided with a NEMA 5-20p

Other A dedicated electrical circuit is required.

Refrigeration

Compressor 1/5 hp

Refrigerant R404a (12 oz. (340G))

Temp. Control 36°F ±2°F (2.2°C ±1.1°C) - controlled by software

Heat of Rej. 2100 A/C (0.61 kW) / 2600 Peak

connection to barb tting connection on machine.

Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter)

electrical plug and 8’ (2.43 m) power cord length

exiting the back of the unit.

CO2 / Air*

Connection

Assembly

Pressure

Supply

Pressure

*Air requires dryer

Water

Water Inlet

Lines

Water Temp.

(min/max)

Pressure

Supply Pressure

(min/max)

Additional

Requirements

Supplied 3/8" panel mounted Colder tting.

40 psi (2.8 BAR)

50 psi/90 psi (3.5BAR/ 6.2BAR)

(min/max) - External regulator required if supply

pressure is greater than 150 psi (10.3 BAR)

Supplied 3/8" panel-mounted Colder tting for

connection of unit into water supply.

40°F/110°F (4°C/43°C)

30 psi (2.1 BAR)

30 Psi/90psi (2.1 BAR/6.2BAR) (water pressure

regulator supplied with unit)

Install water shut-o valve in water line at the rear

of the machine.

Insulate water inlet lines to prevent condensation.

5103 ©2012 Multiplex 10/12 Continuing product improvement may necessitate change of speci cations without notice.

2100 Future Dr.

Sellersburg, IN 47150

Tel: 812.246.7000

Fax: 812.246.7024

www.manitowocbeverage.com/us

Loading...

Loading...