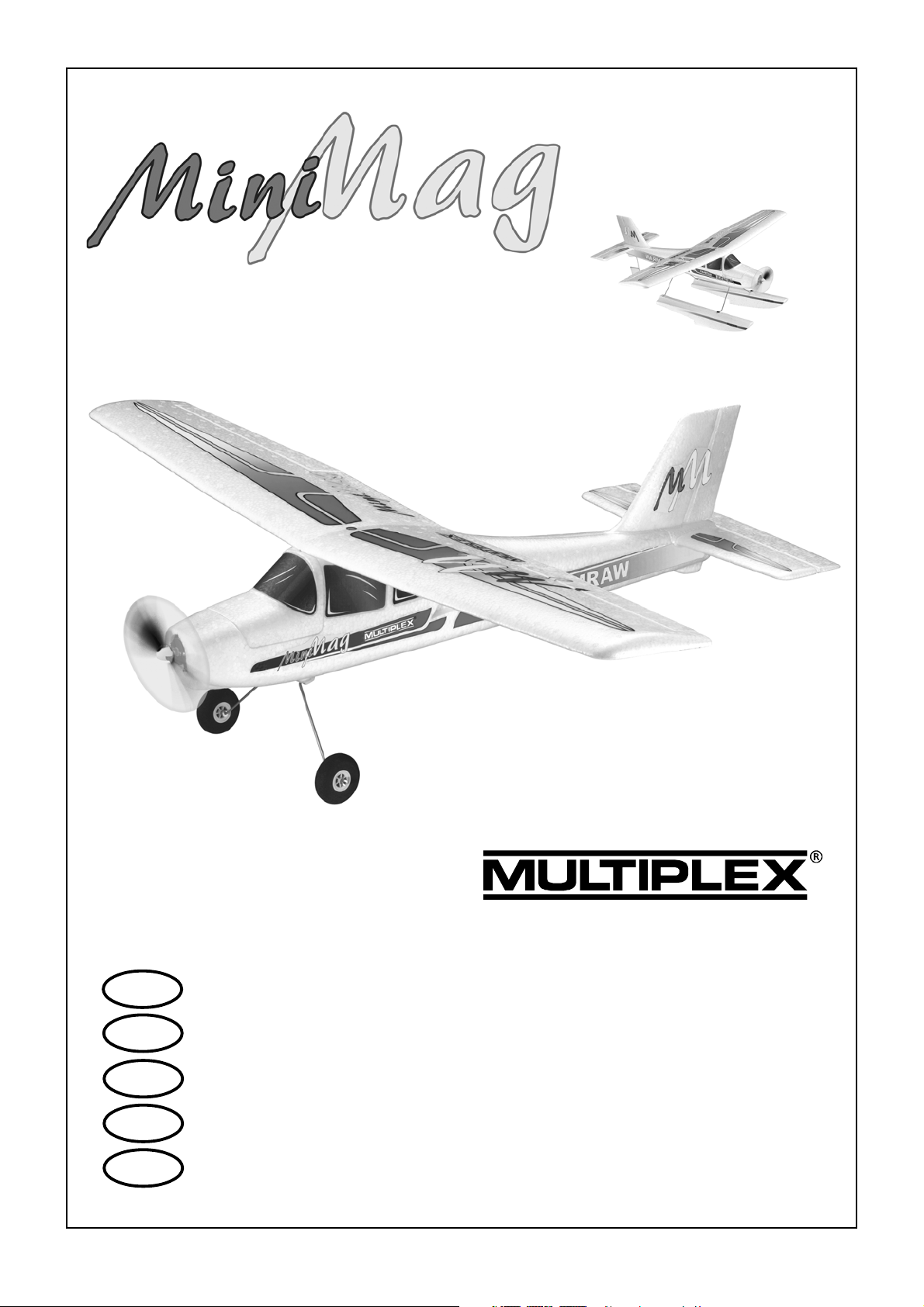

Page 1

Kit MiniMag # 21 4211

D

F

GB

I

E

© Copyright by MULTIPLEX 2006 Version 02

Bauanleitung 3-11

Notice de construction 12-20

Building instructions 21-37

Instruzioni di montaggio 38-46

Instrucciones de montaje 47-55

1

Page 2

# 21 4211

GB

Examine your kit carefully!

MULTIPLEX model kits are subject to constant quality checks throughout the production process, and we sincerely hope

that you are happy with the contents of your kit. However, we would ask you to check all the parts before you start

construction, as we cannot exchange components which you have already worked on. If you find any part is not

acceptable for any reason, we will readily correct or exchange it. Just send the component to our Model Department.

Please be sure to include a brief description of the fault.

We are constantly working on improving our models, and for this reason we must reserve the right to change the kit

contents in terms of shape or dimensions of parts, technology, materials and fittings, without prior notification. Please

understand that we cannot entertain claims against us if the kit contents do not agree in every respect with the instructions

and the illustrations.

Caution!

Radio-controlled models, and especially model aircraft, are by no means playthings. Building and operating

them safely requires a certain level of technical competence and manual skill, together with discipline and a

responsible attitude at the flying field. Errors and carelessness in building and flying the model can result in

serious personal injury and damage to property. Since we, as manufacturers, have no control over the

construction, maintenance and operation of our products, we are obliged to take this opportunity to point out

these hazards, and to emphasise your personal responsibility.

Additional items required for the Mini Mag:

Adhesive and activator Use medium-viscosity cyano-acrylate adhesive (“medium cyano”) in conjunction with activator

(“kicker”). Do not use styrofoam cyano. Epoxy glues appear to produce strong joints, but the strength is only superficial

and the hard adhesive tends to break away from the components under stress. Hot-melt glue can also be used.

MULTIPLEX radio control equipment for the Mini Mag:

PiCO 5/6 UNI receiver 35 MHz A Order No. 5 5920

alternatively: 40 MHz Order No. 5 5921

or: Micro IPD UNI receiver 35 MHz A Order No. 5 5971

alternatively: 40 MHz Order No. 5 5972

Nano S UNI or HS 55 servo (2 x required) Elevator / rudder Order No. 6 5120

and (optional):

Nano S UNI or HS 55 servo (2 x required) Ailerons Order No. 6 5120

300 mm UNI extension lead Aileron servos, 2 x Order No. 8 5031

if necessary: 200 mm UNI separation filter cable Aileron servos, 2 x Order No. 8 5035

MagicMixer #1 for 3-channel transmitter without mixers Order No. 7 3000

Y-lead (UNI) for 4-channel transmitter with separate rudder control Order No. 8 5030

MULTIcont X-16 UNI Speed controller Order No. 7 2271

MULTIPLEX Permabatt NiMH flight battery (AA cells) 7 / 1500 mAh Order No. 15 6030

or MULTIPLEX Permabatt NiMH flight battery (AA cells) 8 / 1500 mAh Order No. 15 6037

or MULTIPLEX Li-Batt (Li-Po) flight battery P-CS 2 / 1-2000 mAh Order No. 15 7016

or MULTIPLEX Li-Batt (Li-Po) flight battery SH BX 2 / 1-2100 mAh Order No. 15 7130

Battery charger:

MULTIcharger LN-5014 DC (charge current 100 mA … 5 A) 1 - 14 NiCd/ NiMH Order No. 9 2531

and 1 - 5 Li-Po cells

Optional:

Float set Order No. 73 3069

Tuning 1: Easy Glider power set (3:1 gearbox and Permax 400) Order No. 33 2688

plus 3.5 mm Ø propeller driver Order No. 33 2310

and 8 x 3.8” propeller Order No. 73 3139

Tuning 2: Powerset „sport“ BL 22/18

Contents: motor, propeller driver, speed controller, propeller Order No. 33 2627

Tools:

Scissors, balsa knife, combination pliers, cross-point / slot-head screwdrivers for servo output arm screws and motor

screws, soldering iron.

Note: please separate the illustrated pages from the centre of this booklet.

21

Page 3

Specification:

Wingspan 1010 mm

Fuselage length overall 820 mm

All-up weight min. 580 g

Wing loading (FAI) min. 26 g/dm²

Power system min. Permax 400 6V

RC functions Elevator, rudder

and throttle; optional ailerons

Important note

This model is not made of styrofoam™! It is not

possible to glue the material using white glue or

epoxy. Please be sure to use cyano-acrylate glue

exclusively, preferably in conjunction with cyano

activator (“kicker”). For all joints use medium-viscosity

cyano-acrylate (“cyano”). When gluing Elapor®

always use this procedure: spray one surface with

activator, allow it to air-dry, then apply cyano to the

other side. Join the parts and position them accurately

immediately.

Please take care when working with cyano adhesives.

These materials harden in seconds, so do not allow

them to get onto your fingers or other parts of your

body. It is important to wear goggles to protect your

eyes. Keep the adhesive out of the reach of children.

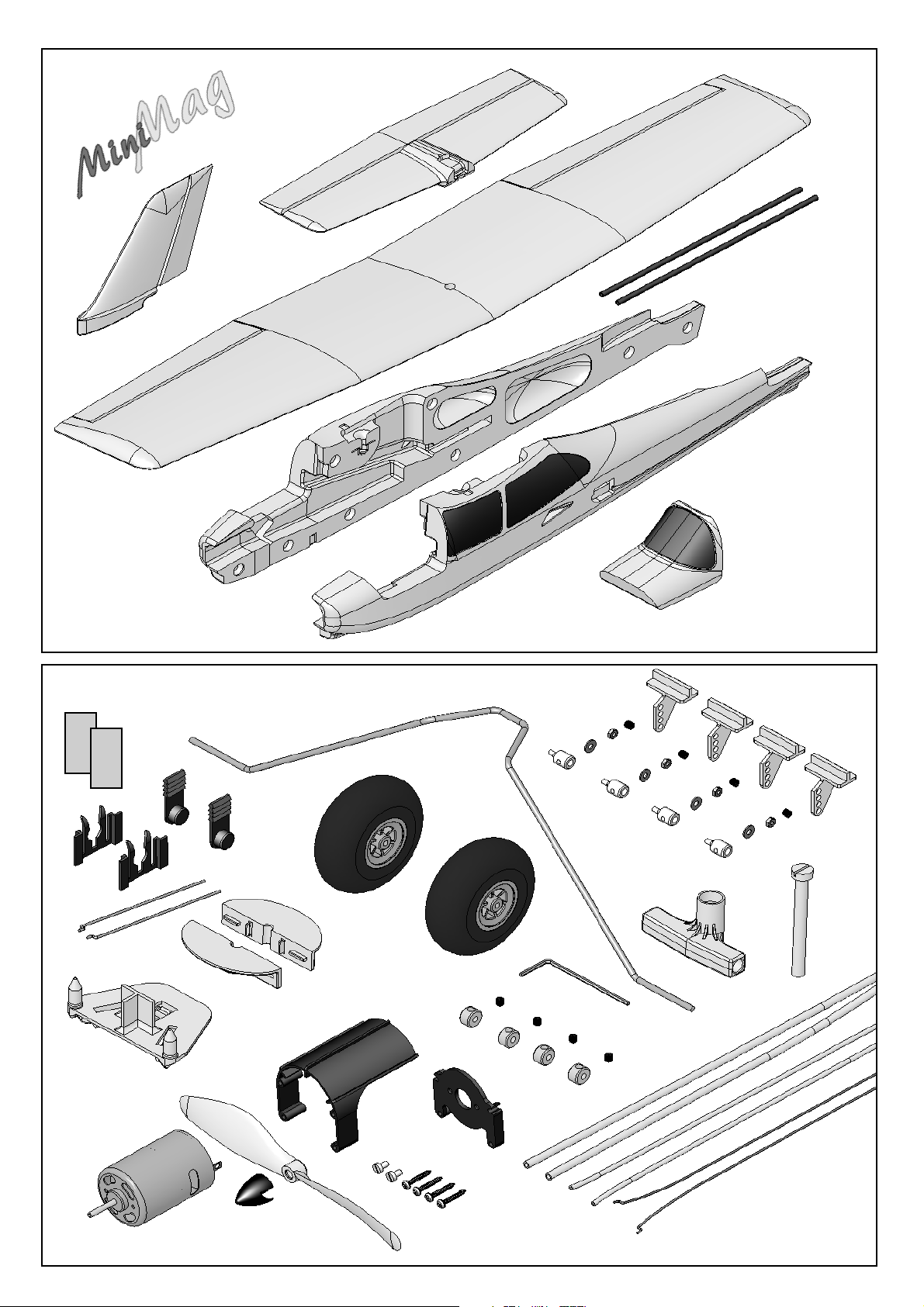

1. Before starting construction

Please check that the contents of your kit are complete.

You will find Figs. 01 + 02 and the Parts List helpful for

this.

2. Preparing the control snakes

Check the length of the elevator snake tubes 43 and 45

and shorten them if necessary.

43 3 / 2 Ø x 275 mm

45 2 / 1 Ø x 300 mm

Steel 41 0.8 Ø x 355 mm

Repeat the procedure with the rudder snake tubes 44 and

46.

44 3 / 2 Ø x 225 mm

46 2 / 1 Ø x 275 mm

Steel 42 0.8 Ø x 325 mmplease insert!

3. Installing the snakes in the fuselage shells

Caution: it is important to glue the snake outer sleeves 43

and 44 to the fuselage shells over their full length, as this

increases the strength of the tail boom considerably.

Check that the control snakes work smoothly, and be careful

not to allow any glue to run inside the outer sleeves.

4. Left-hand fuselage shell:

Trim the shell using a balsa knife, as shown in Fig. 03.

Position the snake outer sleeve 43 in the front of the fuselage

shell, as shown in Fig. 05. Lay the shell down flat, and

glue the outer sleeve 43 to the external channel over its full

length, using cyano.

Installing the servo

Set the servo to neutral (centre) from the transmitter, and

fit the output arm on the output shaft at 90° to the servo

case. Connect the pre-formed end of the steel elevator

pushrod to the second hole from the inside of the servo

output lever. Slip the inner tube 45 over the steel pushrod,

and slide both into the outer sleeve 43 from the servo end.

Fig. 05

Fit the servo in the left-hand fuselage shell from the side as

shown. If you wish to use different servos, it may be

necessary to make minor adjustments here. Tape the servo

lead in the fuselage, so that it does not get in the way

when gluing the fuselage shells together. Glue the servo to

the fuselage with a drop of hot-melt glue at each mounting

lug. Fig. 05

Glue together the wing bolt support components 33 / 34. If

finger power is not sufficient, press them together using

combination pliers, then glue the assembly in the fuselage

shell.

Place the latch clip 22 for the Canopy-Lock canopy retainer

in the fuselage in such a way that the latch lug 23 fits

between the clip 22 and the fuselage side: spray activator

in the recess in the fuselage and allow it to air-dry. Now

apply cyano to the joint surfaces of the latch clip and position

it immediately. Apply more glue to reinforce the joint if

necessary. Fig. 07

5. Option

If you wish, you can fit a tailwheel to your model. This is

actually necessary if you intend to fit floats at a later date,

as a water rudder is absolutely essential for this version,

and this uses the installed tailwheel wire. Figs. 09 - 13

show the procedure.

You will find a bending template in Figs. 12 + 12a. The

steel wire should be 1.3 mm Ø. The tube required is the

remainder of part 44. Cut the water rudder to shape from 3

mm Depron, and fix it inside the steel wire frame using

adhesive tape. Cut a V-notch in both fuselage shells to

accept the wire, as shown in Fig. 10, and pierce a hole in

the tailplane for it; Fig. 11. If you fit the tailwheel, the integral

foam tailskid on the fuselage should be cut off. Cut a slot

in the rudder for the driver wire; Fig. 10.

6. Right-hand fuselage shell:

Trim the shell using a balsa knife, as shown in Fig. 04.

Position the snake outer sleeve 44 in the front of the fuselage

shell, as shown in Fig. 06. Lay the shell down flat, and

glue the outer sleeve 44 to the outer channel over its full

length, using cyano.

Installing the servo

Set the servo to neutral (centre) from the transmitter, and

fit the output arm on the output shaft at 90° to the servo

case. Connect the pre-formed end of the steel rudder

pushrod to the innermost hole of the servo output lever.

Slip the inner tube 46 over the steel pushrod, and slide

both into the outer sleeve 44 from the servo end. Fig. 06

Glue the canopy latch clip in place; Fig. 08

7. Joining the fuselage shells

Start with the right-hand fuselage shell 4. We recommend

medium or thick cyano for this stage.

The fuselage shells 3 and 4 can now be glued together.

22

Page 4

Check that the parts fit together snugly, and carry out any

minor trimming required before reaching for the glue bottle.

Glue the wing bolt support assembly 33 / 34 in one fuselage

shell. Apply a thin coating of activator to the fuselage shell

4 and allow it to air-dry, then apply thick cyano to the mating

surfaces of the fuselage shell 3. Now join parts 3 and 4

carefully and align them quickly. The fuselage joint line must

be straight, i.e. it must not be curved!

Figs. 14 - 15

8. Installing the undercarriage support

Fit the undercarriage support 74 on the underside of the

fuselage “dry” (no glue), and press the spikes into the

fuselage material. Remove the support, then carefully apply

cyano to the joint surface on the fuselage, not forgetting

the pierced holes. Apply activator thinly to the undercarriage

support, and press it firmly into place. Fig. 16

Fit the canopy on the fuselage again, and check that it fits

neatly. Fig. 23

13. Attaching the horn to the elevator

Fit the pushrod connector 25 in the outermost hole of the

elevator horn 24, and secure it with the washer 26 and nut

27. Fig. 24

Caution: note the side on which the connector is fitted!

Tighten the nut gently until the connector swivels smoothly,

but without slop, then apply a tiny drop of cyano to the

outside of the nut on the point of a pin. Fit the socket-head

grubscrew 28 in the pushrod connector 25 using the allen

key 29; do not tighten it at this point.

Apply activator to the recess in the elevator, and glue the

prepared horn 24 in it, with the row of holes facing the hinge

line. Fig. 26

9. Preparing the motor installation

You now have to decide which power system you want to

install:

1. Standard - Permax 400, direct drive

5 x 4” Guenter or MPX propeller

Included in the kit Fig. 17

2. Standard G Permax 400 with 3:1 gearbox

Fig. 20

Easy Glider E power set

(Permax 400 with 3:1 gearbox) # 33 2688

plus 3.5 mm Ø propeller driver # 33 2310

and 8 x 3.8” propeller # 73 3139

3. “Sport” power set: BL-X 22-18 # 33 2627

The set includes the propeller driver and propeller

Attach the motor 50 to the motor mount 60 + 61. If you are

using the geared motor, cut down the motor mount 61 to a

length of 25 mm. Fig. 20

10. Connecting the motor

Carry out a test-run! The propeller must always rotate anticlockwise when viewed from the front. Reverse the motor

terminal connections if the motor spins in the wrong

direction.

11. Installing the motor

Dry-fit the motor assembly (no glue): Figs. 19 and 21;

carry out any minor adjustments required. Apply CA to the

whole surface of the motor mount and carefully fit the

assembly in the fuselage. Fig. 18

12. Installing the canopy latch lugs in the canopy

The canopy latch lugs 23 are fitted in the canopy 5 as a

mirror-image pair, i.e. with the lugs facing inward. Apply CA

to the ridged areas - in this case activator should not be

used - then push the lugs into the slots in the canopy. Fit

the canopy on the model, and allow the latch lugs to engage

in the latch clips 22. Immediately position the canopy

accurately. Allow the glue to harden for about one minute,

then carefully open the canopy again. Apply activator to

the joint areas between the latch lugs and the canopy.

Fig. 22

14. Attaching the horn to the rudder

Fit the pushrod connector 25 in the outermost hole of the

rudder horn 24, and secure it with the washer 26 and nut

27. Fig. 26

Caution: note the side on which the connector is fitted!

Tighten the nut gently until the connector swivels smoothly,

but without slop, then apply a tiny drop of cyano to the

outside of the nut on the point of a pin. Fit the socket-head

grubscrew 28 in the pushrod connector 25 using the allen

key 29; do not tighten it at this point.

Apply activator to the recess in the rudder, and glue the

prepared horn 24 in it, with the row of holes facing the hinge

line. Fig. 26

15. Freeing the elevator and rudder

Work the rudder and elevator to and fro repeatedly to free

up the hinges; they will eventually move relatively easily.

Take care not to separate the control surfaces! Figs. 25 +

27

16. Gluing the tail surfaces to the fuselage

Position the tailplane 7 on the fuselage “dry” (no glue) and

check that it fits correctly. Ensure in particular that it is

parallel to the wing saddle, and that there is no gap between

the tailplane and its mount. You can check this by laying

one of the spar tubes 40 on the wing saddle (e.g. secure it

with masking tape). Now sight over the spar from the

fuselage nose and check that the tailplane is parallel to it.

When you are confident that the tailplane can be aligned

correctly, glue it to the fuselage. Check that alignment is

correct and there are no gaps, then leave the glue to cure.

Place the fin 8 on the fuselage and tailplane “dry”, and

check it for fit. It is important here that the fin is a snug fit,

and is at 90° to the wing saddle and the tailplane; use a

setsquare or similar tool to check this.

Fig. 30

17. Retaining the elevator and rudder pushrods

Fit the front end of the steel pushrods 41 and 42 through

the pushrod connectors 25, set the servos and control

surfaces to neutral (centre) and tighten the socket-head

grubscrews 28. You may find it necessary to bend the

pushrods slightly to obtain correct alignment.

Figs. 31 - 32

23

Page 5

18. Installing the undercarriage

Fit the wheels 71 on the main undercarriage unit 70, using

two collets 72 to retain each one. Fig. 33. Squeeze the

undercarriage together gently, push it into the support 74

and allow it to snap into place. Fig. 34

Completing the wings

19. Installing the spar

Fit the spar tubes 40 in the spar joiner 31, secure them

with glue and trial-fit them in the wing. Apply cyano to the

spar channel in the wing, then push the spars and the spar

joiner quickly into place. Set the wing straight before the

adhesive has a chance to cure. Sight along the wings from

each tip to check for unwanted warps.

Fig. 35

smoothly, but without slop, then apply a tiny drop of cyano

to the outside of the nuts on the point of a pin. Fit the

socket-head grubscrews 28 in the pushrod connectors 25

using the allen key 29; do not tighten them at this point.

Apply activator to the recesses in the ailerons and glue the

horns 24 in them with the row of holes facing the hinge line.

Fig. 38

24. Installing the aileron pushrods

Connect the pre-formed end of the steel pushrods 30 to the

innermost hole of the servo output arm, and fit the plain

end through the pushrod connector 25 on the aileron horn.

Set the aileron and servo to neutral (centre), and tighten

the grubscrew 28 to secure the pushrod.

Fig. 39

Optional ailerons

If you wish to fly the model in rudder / elevator form, simply

skip points 19 - 22. The servo wells can be sealed (later)

using the decals provided.

With the standard dihedral the model flies very well with

rudder or ailerons as the primary turning control. It is also

possible to fit ailerons to the wing at any time.

If you wish to fly the model with ailerons (“full-house” control),

resume construction at this point:

20. Freeing the ailerons, installing the aileron servos

Cut a slot at both ends of the ailerons, which are attached

to the wing 6. Work the ailerons to and fro repeatedly to

free up the hinges; they will eventually move relatively easily.

Take care not to separate the control surfaces!

Fig. 36

21. Installing the aileron servos

Set the servos to neutral from the transmitter. Fit the output

arms on the servos so that the arms are at 90° to the servo

case - 1 x left, 1 x right.

Check that the servos fit snugly in the recesses in the

wings 6. You may need to make minor adjustments to suit

the servo type you are using. Apply a drop of hot-melt glue

to the slots in the wing for the servo mountings lugs, and

press the servos into the recess immediately. Apply another

drop of glue if necessary.

Fig. 37

22. Deploying the aileron servo leads

Deploy the servo leads along the wing towards the centre

section. The lead must fit in the front edge of the spar

channel and run perfectly straight, standing “on edge”. The

leads should project by about 120 mm at the wing root, so

that you can comfortably connect the plugs to the receiver

when the model is assembled. You may need to extend

the standard servo leads. Secure the leads at the centre of

the wings with a drop of hot-melt glue.

23. Attaching the aileron horns

Fit the pushrod connectors 25 in the outermost hole of the

aileron horns 24. Secure the connectors using the washers

26 and nuts 27. Caution: make a handed pair: 1 x left, 1 x

right. Tighten the nuts gently until the connectors swivel

25. Attach the wing to the fuselage using the screw 32.

Fig. 40

26. Installing the radio control system components

The next step is to install the remaining radio components

and the flight battery in the cabin area. Keep one eye on

the recommended Centre of Gravity position when

positioning these items; see Fig. 43.

You can correct the CG position by adjusting the location

of the flight battery.

Pieces of Velcro tape 20 + 21 are supplied in the kit for

securing these components. Please note that the adhesive

on the tape is not very strong, and we recommend that you

stick the tape in the fuselage with cyano for additional

security.

Fit the receiver behind the wing screw, standing upright.

Run the aerial wire out of the fuselage and tape it in place.

The speed controller should be positioned immediately aft

of the motor.

The motor supplied in the kit features internal suppressors,

and these are adequate if you are using a MULTIcont X-16

speed controller, # 7 2271.

If you prefer to use a different controller, it is in your own

interests to fit additional suppression measures to the

electric motor. A suitable suppressor set is available under

# 8 5020. Solder one 47 nF capacitor between one motor

terminal and the motor can, and a second one between the

other terminal and the can. The third 47 nF capacitor should

be soldered across the terminals to form a bridge.

Installing the propeller

The next step is the initial test-run of the motor, but first the

propeller must be fitted. The procedure for this varies

according to the power system you have installed. However,

please be sure it is firmly located in every case. In the

standard version the spinner and propeller should be

secured with a drop of adhesive and glued to the motor

shaft. Use 5-minute epoxy with a Guenter propeller, and

cyano with an MPX prop.

Once the wiring is complete, you are ready to carry out the

first test-run.

24

Page 6

7

# 21 4211

8

6.

2 x 40

4

3

5

2 x 20

2 x 22

2 x 21

74

2 x 23

2 x 30

33

70

34

61

Abb. 01

4 x 24

4 x

25 26 27 28

2 x 71

32

29

31

4 x 73

50

52

2 x 62

4 x 63

60

4 x 72

43 44 45 46 41 42

Abb. 02

25

Page 7

3

4

41

45

22

43

20 mm

Hot

glue

CA

Abb03

CA

Abb. 05

Hot

glue

42

46

44

20 mm

22

Abb. 04

CA

Abb. 06

CA

Ø 26

# 73 3199

Heckrad=Option. Die Teile

liegen dem BK nicht bei!

Tailwheel = option. Parts not

included in the kit

26

Abb. 07

Depron

Abb.09

30

Abb. 08

8

CA

Abb.10

Page 8

Stahl/Steel

Ø 1,3 mm

Rest von Teil 44

7

4

PVC Rohr 2/3 mm

Remainder of part

44; 2/3 mm Ø

PVC tube

Stahl/Steel

Ø 1,3 mm

Abb. 11

M 1:1

Stahl/Steel

Ø 1,3 mm

Depron

3 mm

Abb. 12

Das Teil liegt dem BK nicht bei!

This part not included in the kit

Abb. 12 a

Abb. 13

33 - 34

M 1:1

Die Teile liegen dem BK nicht bei!

These parts not included in the kit

Abb. 13 a

74

CA

4

Abb. 14

27

Page 9

CA

CA

MPX-Prop.

Abb. 15

52 60 50 61

2 x 62

4 x 63

Abb. 17

Abb.16

CA

Abb. 18

Mitnehmer

für Ø 3,5 mm /

3.5 mm Ø driver

# 33 2310

passende Luftschraube / propeller

8 x 3,8“

# 73 3139

28

Abb. 19

Abb.21

# 33 2688

(Antrieb / motor Easy Glider E)

30

23

Abb. 20

CA

5

Abb.22

Page 10

28 25 24 26 27

5

7

Abb. 23

7

27 26 24 25 28

CA

CA

Abb.24

gängig machen!

Move to and fro to ease hinge

8

gängig machen!

Move to and fro to ease hinge

Abb. 25

Abb. 27

8

Abb. 26

CA

Abb. 28

30

CA

!

Abb.29

Abb.30

29

Page 11

Abb. 31

Abb. 32

70

72

40

73

71

31

72

73

Abb. 33

CA

40

74

Abb. 34

Abb. 36

Abb. 35

30

Hot

glue

Abb.37

30

6.

28 25 24 26 27

CA

Abb. 38

Page 12

Abb. 39

32

Abb.40

Abb. 41

# 73 3069

Schwimmerbausatz/Float kit

Abb. 42

Abb.43

31

Page 13

Ersatzteile (bitte bei Ihrem Fachhändler bestellen)

Replacement parts (please order from your model shop)

Pièces de rechanges (S.V.P. à ne commander que chez votre revendeur)

Parti di ricambio (da ordinare presso il rivenditore)

Repuestos (por favor, diríjase a su distribuidor)

# 22 4176

Kabinenhaube

Canopy

Verrière

Capottina

Cabina

# 22 4179

Kleinteilesatz

Small items set

Petit nécessaire

Minuteria

Piezas pequeñas

# 22 4175

Rumpfhälften + Bowdenzüge

Fuselage shells + snakes

Moitié de fuselage + tringlerie

Semigusci fusoliera + bowden

Fuselaje + trans. bowden

# 22 4178

Leitwerkssatz

Tail set

Kit de gouvernes

Piani di coda

Timones

# 22 4177

Tragfläche

panel

Aile

Ali

Alas

# 72 4388

Dekorbogen

Decal sheet

Planche de décoration

Decals

Lámina decorativa

# 22 4180

Fahrwerkssatz

Undercarriage compon.

Train d’atterrissage

Parti per carrello

Kit del tren de aterrizaje

# 70 3455

Gestängeanschluss (2x)

Pushrod connector (2x)

Element de fixitation (2x)

Raccordo rinvii (2x)

Conexión del verillaje(2x)

# 33 2545

Motor

Motor

Moteur

Motore

Motor

# 33 2699

Motorträger

Motor mount

Support moteur

Supporto motore

Soporte del motor

# 72 5136

Canopy-Lock

Kabinenhaubenverschluss

Fermeture de verrière

Chiusura capottina

Cierre de cabina

Permax 400 6V

# 72 4279 / # 72 4293

Luftschraube

Propeller

Hélice

Elica

Hélice

32

# 71 3340

Schraube M5x50mm (10x)

Screw M5x50mm (10x)

Vis M5x50mm (10x)

Vite M5x50mm (10x)

Tornillo M5x50mm (10x)

5,0x4,0" / 12,7x10,2cm

Page 14

Do not connect the flight battery to the speed controller

until you have switched on the transmitter and move

the throttle stick or switch to the “Motor Stopped”

position.

Switch on the transmitter, connect the flight battery to the

speed controller, and the controller to the receiver. With

this model you must use a controller with what is known

as a BEC circuit (receiver power supply from the flight

battery).

Now switch the motor on briefly, and check once more the

direction of rotation of the propeller. Hold the model firmly

when you run the motor, and remove any loose lightweight

objects from the area behind the model before the propeller

does the job for you.

Caution: even small motors and propellers represent

a distinct injury hazard!

27. Setting the control surface travels

It is important to set the control surface travels correctly,

as these settings have a crucial influence on the model’s

overall control response. In all cases the travels are

measured at the point of maximum chord (width of control

surface.

Elevator

up - stick back - approx. + 11 mm

down - stick forward - approx. - 11 mm

Rudder

left and right - approx. 6-10 mm

each way

Ailerons

up - approx. + 7 mm

down - approx. - 3 mm

MagicMixer #1 (optional) # 7 3000

The MagicMixer #1 permits the use of a simple radio control

transmitter without mixer functions. It is adequate for:

MINI MAG 3-channel RC transmitter

Without the MagicMixer #1 you will need at least a fourchannel computer transmitter with mixer functions.

Using this module the Mini Mag can be flown even with a

transmitter such as the Ranger III, as supplied with the

EasyStar and SpaceScooter RTF models.

It provides a means of controlling two aileron servos and

the rudder from a single channel (right / left output) at the

receiver.

The servos, and therefore the control surface travels, are

automatically actuated with the correct deflections. Using

the MagicMixer #1 the degree to which the rudder follows

the ailerons (“combi-switch” / CAR function) and the aileron

differential are fixed, i.e. they cannot be altered.

Aileron differential means that the up-aileron travel is greater

than the down-aileron travel. This helps to prevent the model

swinging away from the turn (adverse yaw) when ailerons

are applied.

If you are using the MagicMixer #1 your transmitter must

offer at least the following channels:

Channel 1: Ailerons, coupled rudder (3 servos)

Channel 2: Elevator (1 servo)

Channel 3: Throttle (1 servo)

Connect the aileron servo leads as described in the

“MagicMixer #1” instructions. Take care to maintain

correct polarity when making these connections: the signal

pin is indicated on the label of the MagicMixer with the

square signal symbol. The signal wire in the servo lead is

generally yellow or orange.

Connections at the MagicMixer #1:

r/l = to receiver, right / left output

AR = to right aileron servo

AL = to left aileron servo

R = to rudder servo

If necessary, set the correct direction of servo travel using

the servo reverse facility on your transmitter.

Y-lead for the aileron servos (optional) # 8 5030

The Y-lead permits the use of a simple four-channel radio

control transmitter, i.e. without mixer functions. The two

aileron servos are actuated simultaneously by a single

receiver servo output.

Please note: in this case the differential aileron movement

must be obtained by mechanical means. This is achieved

by offsetting the servo output arms forward by two splines.

This must be done before you install the servos. The rudder

is controlled via a separate channel with this arrangement.

Computer radio control transmitter

If you have this type of transmitter you need neither a

MagicMixer #1 nor a Y-lead.

The transmitter must feature the following adjustment

facilities:

- Aileron differential mixer

- Servo reverse

- Servo travel adjustment

- Optional combi-switch (coupled rudder / ailerons)

Note: when you apply a right-aileron command at the

transmitter, the right-hand aileron (as seen from the

tail) must deflect up.

If you find that you cannot set the correct control

surface travels with your radio control system, you

will need to change the linkage hole to which the

pushrod is connected.

28. Gilding the lily

The kit includes a multi-colour decal sheet. Cut out the

individual name placards and emblems and apply them to

the model, either following our scheme (kit box illustration)

or using your own arrangement. If you have built the rudder

/ elevator version of the model, you will find decals on the

sheet designed for covering the servo recesses in the wing.

33

Page 15

29. Balancing

If your Mini Mag is to fly safely and stably it must balance

at the correct point - just like every other aircraft. Assemble

your model completely, ready to fly, and install the flight

battery.

Don’t attempt tightly banked turns close to the ground at

first, and especially not on the landing approach.

It is always better to land safely some distance away, and

have to walk to collect the model, than to risk damaging it

by dragging it close to your feet.

The Centre of Gravity should be at a point 67 mm aft of

the leading edge of the wing, measured where the wing

meets the fuselage. You will find markings moulded into

the underside of the wing at this point.

Support the model on your fingertips at the marked point,

and it should balance level. If necessary, adjust the position

of the flight battery until this is the case. Once the correct

position is found, mark it inside the battery box to ensure

that the battery is always replaced in exactly the same

location. Fig. 43

30. Preparing for the first flight

Wait for a day with as little breeze as possible for the first

flight. The evening hours often provide the best conditions.

Be sure to carry out a range check before the first

flight!

The transmitter battery and flight pack must be fully charged

according to the instructions. Ensure that the channel you

are using is not already in use before you switch on the

transmitter.

Collapse the transmitter aerial, and ask a friend to walk

away from you holding the transmitter.

As he walks away your friend should constantly operate

one control function while you watch the model’s servos.

The servo not being operated should stay motionless up to

a range of around 60 m, and the other servo should follow

the transmitter stick movements smoothly and immediately.

This test only provides meaningful results if the radio band

is “clean” (not suffering interference), and if no other radio

control transmitters are switched on, even if they are on

different channels. If successful, repeat the check with

the motor running. The effective range should not be

significantly reduced when the motor is running.

If you are not sure about anything, do not fly the model! If

you cannot eliminate the problem send the whole radio

control system (including battery, switch harness, servos)

to the manufacturer’s service department for checking.

31. Safety

Safety is the First Commandment when flying any model

aircraft. Third party insurance should be considered a basic

essential. If you join a model club suitable cover will usually

be available through the organisation. It is your personal

responsibility to ensure that your insurance is adequate

(i.e. that its cover includes powered model aircraft).

Make it your job to keep your models and your radio control

system in perfect order at all times. Check the correct

charging procedure for the rechargeable batteries used in

your RC set. Make use of all sensible safety systems and

precautions which are advised for your system. An excellent

source of practical accessories is the MULTIPLEX main

catalogue, as our products are designed and manufactured

exclusively by practising modellers for other practising

modellers.

Always fly with a responsible attitude. You may think that

flying low over other people’s heads is proof of your piloting

skill; others know better. The real expert does not need to

prove himself in such childish ways. It is in all our interests

that you let other pilots know that this is also what you

think. Always fly in such a way that you do not endanger

yourself or others. Bear in mind that even the best RC

system in the world is subject to outside interference. No

matter how many years of accident-free flying you have

under your belt, you have no idea what will happen in the

next minute.

We - the MULTIPLEX team - hope you have many hours of

pleasure building and flying your new model.

Klaus Michler

Product development

MULTIPLEX Modellsport GmbH & Co. KG

The first flight ....

Do not test-glide this model!

The model is designed for hand-launching - always exactly

into wind.

We recommend that you ask an experienced

modeller to help you during the first flight.

Allow the model to climb to a safe altitude, then adjust the

trims on the transmitter so that the model flies straight

ahead without any help from you.

At a safe height switch off the motor and make yourself

familiar with the model’s control response on the glide. Carry

out a dummy landing approach at a good height, so that

you will feel confident about the real landing when the flight

pack is flat.

34

Page 16

Parts List Mini Mag kit # 21 4211

Part No. off Description Material Dimensions

1 1 Building instructions Paper A4

2 1 Decal sheet Printed adhesive film 400 x 700 mm

3 1 Left-hand fuselage shell Moulded Elapor foam Ready made

4 1 Right-hand fuselage shell Moulded Elapor foam Ready made

5 1 Canopy Moulded Elapor foam Ready made

6 1 Wing Moulded Elapor foam Ready made

7 1 Tailplane Moulded Elapor foam Ready made

8 1 Fin Moulded Elapor foam Ready made

Small parts set

20 2 Velcro tape, hook Plastic 25 x 60 mm

21 2 Velcro tape, loop Plastic 25 x 60 mm

22 2 Canopy latch clip Inj. moulded plastic Ready made

23 2 Canopy latch lug Inj. moulded plastic Ready made

24 4 Glue-fitting horn Inj. moulded plastic Ready made

25 4 Pushrod connector Metal Ready made, 6 mm Ø

26 4 Washer Metal M2

27 4 Nut Metal M2

28 4 Socket-head grubscrew Metal M3 x 3 mm

29 2 Allen key Metal 1.5 mm A/F

30 2 Aileron pushrod, one Z-bend Metal 1 Ø x 70

31 1 Spar joiner Inj. moulded plastic Ready made

32 1 Screw Plastic M5 x 50 mm

33 1 Wing bolt support A Inj. moulded plastic Ready made, M5

34 1 Wing bolt support B Inj. moulded plastic Ready made, M5

Wire set

40 2 Spar tube GRP tube 6 / 4 Ø x 300 mm

41 1 Steel elevator pushrod, one Z-bend Metal 0.8 Ø x 355 mm

42 2 Steel rudder pushrod, one Z-bend Metal 0.8 Ø x 325 mm

43 1 Elevator snake outer sleeve Plastic 3 / 2 Ø x 275 mm

44 1 Rudder snake outer sleeve Plastic 3 / 2 Ø x 225 mm (275 mm*)

45 1 Elevator snake inner tube Plastic 2 / 1 Ø x 300 mm

46 1 Rudder snake inner tube Plastic 2 / 1 Ø x 275 mm (300 mm*)

*supplied length -> cut to correct length

Power set

60-63 1 Motor mount, Permax 400 (1 off) See below

50 1 Motor Permax 400 6 V Ready made

52 1 Propeller Plastic 125 x 110 mm

Permax 400 motor mount (1 x), two-part incl. screws

60 1 Motor bulkhead Inj. moulded plastic Ready made

61 1 Motor bulkhead holder Inj. moulded plastic Ready made

62 2 Screw Metal M2.5 x 4 mm

63 4 Screw Metal 2.2 x 13 mm

Undercarriage set

70 1 Main undercarriage unit Metal 2.5 Ø, ready made

71 2 Lightweight wheel Plastic 53 Ø, 2.5 mm bore

72 4 Collet Metal 2.7 / 7 Ø x 5 mm

73 4 Socket-head grubscrew Metal M3 x 3 mm

74 1 Undercarriage support Plastic Ready made

CD instructions / movie

80 1 CD instructions / movie Ready made

35

Page 17

Basic information relating to model aircraft

Any aircraft, whether full-size or model, can be controlled around the three primary axes: vertical (yaw), lateral (pitch) and

longitudinal (roll).

When you operate the elevator, the model’s attitude alters around the lateral axis. If you apply a rudder command, the model

swings around the vertical axis. If you move the aileron stick, the model rolls around its longitudinal axis. As our EasyStar has

considerable wing dihedral, ailerons are not required for roll control. In this case the rudder is used both to turn the model

around the vertical axis, and also to roll it (longitudinal axis). External influences such as air turbulence may cause the model to

deviate from its intended flight path, and when this happens the pilot must control the model in such a way that it returns to the

required direction. The basic method of controlling the model’s height (altitude) is to vary motor speed (motor and propeller). The

rotational speed of the motor is usually altered by means of a speed controller. Applying up-elevator also causes the model to

gain height, but at the same time it loses speed, and this can only be continued until the model reaches its minimum airspeed

and stalls. The maximum climb angle varies according to the power available from the motor.

R.H. wing

panel

normal axis

Canopy

Longitudinal axis

Wing section

The wing features a cambered airfoil section over which the

air flows when the model is flying. In a given period of time the

air flowing over the top surface of the wing has to cover a

greater distance than the air flowing under it. This causes a

reduction in pressure on the top surface, which in turn creates

a lifting force which keeps the aircraft in the air. Fig. A

Centre of Gravity (CG)

To achieve stable flying characteristics your model aircraft must

balance at a particular point, just like any other aircraft. It is

absolutely essential to check and set the correct CG position

before flying the model for the first time.

The CG position is stated as a distance which is measured aft

from the wing root leading edge, i.e. close to the fuselage.

Support the model at this point on two fingertips (or - better use the MPX CG gauge, # 69 3054); the model should now

hang level. Fig. B

If the model does not balance level, the installed components

(e.g. flight battery) can be re-positioned inside the fuselage. If

this is still not sufficient, attach the appropriate quantity of trim

ballast (lead or plasticene) to the fuselage nose or tail and

secure it carefully. If the model is tail-heavy, fix the ballast at the

fuselage nose; if the model is tail-heavy, attach the ballast at

the tail end of the fuselage.

The longitudinal dihedral is the difference in degrees between

the angle of incidence of the wing and of the tail. Provided that

you work carefully and attach the wing and tailplane to the

fuselage without gaps, the longitudinal dihedral will be correct

automatically.

Fin

Tailplane

Rudder

Elevator

lateral axis

L.H. wing

Fuselage

panel

GB

If you are sure that both these settings (CG and longitudinal

dihedral) are correct, you can be confident that there will be no

major problems when you test-fly the model. Fig. C

Control surfaces, control surface travels

The model will only fly safely, reliably and accurately if the control

surfaces move freely and smoothly, follow the stick movements

in the correct “sense”, and move to the stated maximum travels.

The travels stated in these instructions have been established

during the test-flying programme, and we strongly recommend

that you keep to them initially. You can always adjust them to

meet your personal preferences later on.

Transmitter controls

The transmitter features two main sticks which the pilot moves

to control the servos in the model, which in turn operate the

control surfaces.

The functions are assigned according to Mode A, although

other stick modes are possible.

The transmitter controls the control surfaces as follows:

Rudder (left / right) Fig. D

Elevator (up / down) Fig. E

Throttle (motor off / on) Fig. F

Unlike the other controls, the throttle stick must not return to

the neutral position automatically. Instead it features a ratchet

so that it stays wherever you put it. Please read the instructions

supplied with your radio control system for the method of setting

up and adjusting the transmitter and receiving system.

36

Page 18

MULTIPLEX Modellsport GmbH & Co.KG Neuer Weg 2 D-75223 Niefern-Öschelbronn www.multiplex-rc.de

56

Loading...

Loading...