Page 1

Beverage Conduit

Beer & Soda

Installation, Use & Care Manual

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocfsg.com

America’s Quality Choice in Refrigeration

Part Number EI211017 10/11

Page 2

Safety Notices

!

Warning

!

Caution

Important

!

Caution

Important

!

Warning

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this manual.

Disregarding the notices may lead to serious injury and/

or damage to the equipment.

Throughout this manual, you will see the following types

of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equip ment. Be sure to

read the Caution statement before proceeding, and

work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this manual. These notices

supply helpful information which may assist you as you

work.

Throughout this manual, you will see the following types

of procedural notices:

Read These Before Proceeding:

Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your Manitowoc equipment. Read and

understand this manual. It contains valuable care

and maintenance information. If you encounter

problems not covered by this manual, do not

proceed, contact Manitowoc. We will be happy to

provide assistance.

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

NOTE: SAVE THESE INSTRUCTIONS.

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will not

cause damage or injury, but it may slow you down as

you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about th e pr oce dur e yo u

are performing.

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Page 3

Section 1

General Information

Section 2

Installation

Table of Contents

Read This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Flame & Smoke Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Specification Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Shipping, Storage, & Relocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Pre-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

REQUIRED TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

UNPACKING & INSPECTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Kitchen Equipment Installer Representative Responsibilities . . . . . . . . . . . 2-1

Other Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installer Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Routing Multiplex Conduit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

FLOOR CHASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Sealing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

OVERHEAD INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

How To Connect The Multiplex Conduit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Conduit Identification Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

COLOR AND NUMBER CODING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

TEEING INTO MULTIPLEX CONDUIT SODA SYSTEMS . . . . . . . . . . . . . 2-7

Soda Conduit Kit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Beermaster Beer Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

FLOOR CHASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

OVERHEAD INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

BASEMENT CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Connecting Beer Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Part Number EI211017 10/11 i

Page 4

Section 3

Operation

Section 4

Maintenance

Table of Contents (continued)

Beermaster Conduit Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Beermaster Conduit Kit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

INSTALLING THE CONDUIT KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

BEER RESTRICTOR LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Periodic Maintenance Listed By Major Components . . . . . . . . . . . . . . . . . . 4-1

Periodic Maintenance Listed By Scheduled Frequency . . . . . . . . . . . . . . . 4-2

Cleaning & Sanitizing The Dispensing Valves & Product Lines . . . . . . . . . 4-3

Cleaning Equipment and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Beverage System Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Bag-In-Box System Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figal Beverage System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Shipping, Storage and Relocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Section 5

Before Calling for Service

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Soda Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

No syrup or insufficient syrup in finished drink . . . . . . . . . . . . . . . . . . . . . . 5-1

No carbonated water or insufficient carbonated water in finished drink . . . 5-2

No water or insufficient water in finished drinks . . . . . . . . . . . . . . . . . . . . . 5-2

Beermaster Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

ii Part Number EI211017 10/11

Page 5

Section 1

!

Warning

!

Caution

General Information

Read This Manual

Manitowoc Beverage Systems developed this manual as

a reference guide for the owner/operator and installer of

this equipment. Please read this manual before

installation or operation of the machine. A qualified

service technician must perform installation and start-up

of this equipment.

If you cannot correct the service problem, call your

Manitowoc Beverage Systems (MBS) Service Agent or

Distributor. Always have your model and serial number

available when you call.

Your Service Agent ____________________________

Service Agent Telephone Number_________________

Your Local MBE Distributor ______________________

Distributor Telephone Number____________________

Model Number _______________________________

Serial Number ________________________________

Installation Date ______________________________

Unit Inspection

Thoroughly inspect the unit upon delivery. Immediately

report any damage that occurred during tr ansportation to

the delivery carrier. Request a written inspection report

from a claims inspector to document any necessary

claim.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Model Numbers

This manual covers the following models:

Beverage Conduit Models

MC095301, MC105301, MC105511, MC105521, MC105581,

MC125311, MC125511, MC125581, MC133301, MC135321,

MC145511, MC145351, MC145521, MC145551, MC165322,

MC175201, MC205501, MC205301, MC205311, MC245301,

MC245501, MC023341, MC043341, MC063341, MC073341,

MC083341, MC103341, MC123341, MC143341, MC163341,

MC193341, MC203341, MC043342, MC053342, MC063342,

MC073342, MC083342, MC103342, MC123342, MC143342,

MC163342, MC193342, MC203342

To Avoid Serious Injury: Read the following

warnings before beginning an installation. Failure to

do so may result in possible death or serious injury.

DO Adhere to all National and Local Plumbing and

Electrical Safety Codes.

DO Turn “off” incoming electrical service switches

when servicing, installing, or repairing

equipment.

DO Check that all flare fittings are tight. This check

should be performed with a wrench to ensure a

quality seal.

DO Inspect pressure on Regulators before starting

up equipment.

DO Protect eyes when working around

refrigerants.

DO Use caution when handling metal surface

edges of all equipment.

DO Handle CO

2 cylinders and gauges with care.

Secure cylinders properly against abrasion .

DO Store CO

DO NOT Exhaust CO

2 cylinder(s) in well ventilated areas.

2 gas (example: beer pump)

into an enclosed area, including all types of

walk in coolers, cellars, and closets.

DO NOT Throw or drop a CO

2 cylinder. Secure the

cylinder(s) in an upright position with a chain.

DO NOT Connect the CO

2 cylinder(s) directly to the

product container. Doing so will result in an

explosion causing possible death or injury.

Best to connect the CO

2 cylinder(s) to a

regulator(s).

DO NOT Sto re C O

2 cylinders in temperature above

125°F (51.7°C) near furnaces, radiator or

sources of heat.

DO NOT Release CO

2 gas from old cylinder.

DO NOT Touch Refrigeration lines inside units, some

may exceed temperatures of 200°F (93.3°C).

NOTE: All utility connections and fixtures shall be sized,

installed and maintained in accordance with Federal,

State, an d Local codes.

Part Number EI211017 10/11 1-1

Page 6

General Information Section 1

Flame & Smoke Rating

INSUL-TUBE® Pipe Insulation in wall thickness of 1" (25

mm) and below has a flame spread rating of 25 or less

and a smoke development rating of 50 or less as tested

by ASTM E 84 Method of Testing entitled: Surface

Burning Characteristics of Building Materials. Duct/

Plenum Applications INSUL-TUBE® is acceptable for

duct/plenum applications, meeting requirements of

NFPA 90A.

Numerical flammability ratings alone may not define the

performance of products under actual fire conditions.

They are provided only for use in the selection of

products to meet limits specified, when compared to a

known standard.

Specification Compliance

• ASTM C 534 Type 1 (Tubing)

• ASTM D 1056-00-2C1

• ASTM C 1534-02

• New York City MEA 186-86-M Vol. IV

• USDA Requirements

• UL 94-5V Flammability Classification (Recognition

No. E147665)

• ASTM E 84 1" 25/50-tested according to UL 723 and

NFPA 255

• Complies with requirements of CAN/ULC S102-M88

Warranty Information

Consult your local MBS Distributor for terms and

conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general

adjustments, cleaning, accessories and related

servicing.

Your warranty card must be returned to MBS to activate

the warranty on this equipment. If a warranty card is not

returned, the warranty period can begin when the

equipment leaves the MBE factory.

No equipment may be returned to MBS without a written

Return Materials Authorization (RMA). Equipment

returned without an RMA will be refused at the MBS

dock and returned to the sender at the sender’s

expense.

Please contact your local MBS distributor for return

procedures.

Shipping, Storage, & Relocation

Store conduit in 60°F (15.5°C) to 80°F (16.6°C)

environment.

- Keep in a cool, dry location.

- Do not expose to direct sunlight.

- Do not store conduit outside the original carton.

- Do not store conduit for more than one year.

- Do not store anything directly on top of conduit.

• NFPA No. 101 Class A Rating

• Meets requirements of NFPA 90A Sect. 2.3.3 for

Supplementary Materials for Air Distribution

Systems.

• Meets requirements of ASTM C 411 (Tested Method

of Hot Surface Performance of High Temperature

Thermal Insulation).

• Meets requirements of UL 181 sections 11.0 and

16.0 (Mold Growth/Air Erosion)

• MIL-P-15280, For T (Tubing)

- Do not store in an enclosed location with high

aromatic compounds.

- Conduit warranty is 2 years from date of

manufacture as printed on the conduit.

If you have any questions or concerns, please contact

the MBE Service Department at 800-367-4233.

1-2

Part Number EI211017 10/11

Page 7

Section 2

!

Warning

Important

Installation

Pre-installation

REQUIRED TOOLS

• Steel Fish Tape

• Length of Rope

•Duct Tape

UNP ACKING & INSPECTING

Carefully inspect the conduit immediately upon unpacking.

Inspect conduit for any damages that may have occurred

during shipping.

LOCATION REQUIREMENTS

Equipment

1. Determine the location where the Tower/Dispenser

will be installed.

2. Locate the mounting template provided with the

installation kit.

3. Using the mounting temp late as a gu ide , pu nc h ou t

the required holes in the counter top.

• Approved Tubing Cutters

• Razor Blade Knife

• Tab Clamp Pliers

Before installing conduit, be sure conduit is proper length for

installation, contains the correct number of lines for

connection, and all lines are proper diameter .

Carbon Dioxide (CO2) displaces oxygen. Exposure to a high

concentration of CO2 gas causes tremors, which are followed

rapidly by loss of consciousness and suffo cation. If a C O2 gas

leak is suspected, particularly in a small area, immediately

ventilate the area before repairing the leak. CO

pumps must not be installed in an enclosed space. An

enclosed space can be a cooler or small room or closet. This

may include convenience stores with glass door self serve

coolers. If you suspect CO

the BIB pumps and/or CO

may build up in an area, venting of

2

monitors must be utilized.

2

lines and

2

KITCHEN EQUIPMENT INSTALLER REPRESENTATIVE RESPONSIBILITIES

Prior to scheduling Multiplex Equipment installer, the following steps listed below must be completed:

1. Usable floor sewer drain.

2. Refer to electrical requirement chart for your model.

3. Usable potable water.

4. CO

Gas (bulk or bottled supply); minimum 3/8" line.

2

5. One 5 gallon (19 L) container or Bag-In-Box

container of each post mix syrup flavor.

NOTE: Do not schedule the authorized Multiplex Equipment Installer until all of the above have been completed. It will

only result in charge-backs to you for the unnecessary trips.

OTHER REQUIREMENTS

• Conduit can be run through floor or ceiling chase.

• 60°F (15.6°C) minimum and 105°F (40.5°C)

maximum operating ambient conditions.

• For indoor installation only.

• Syrup supply can be located on stand or adjacent to

refrigeration unit.

Installer Instructions

These equipment instructions are intended to assist

qualified personnel in the unpacking, locating and the

initial operation of the Multiplex Beverage Equipment

and/or Post Mix Refrigeration Unit.

Recommend conduit to min 75°F ambient temperature

before installing for ease of installation.

Part Number EI211017 10/11 2-1

Page 8

Installation Section 2

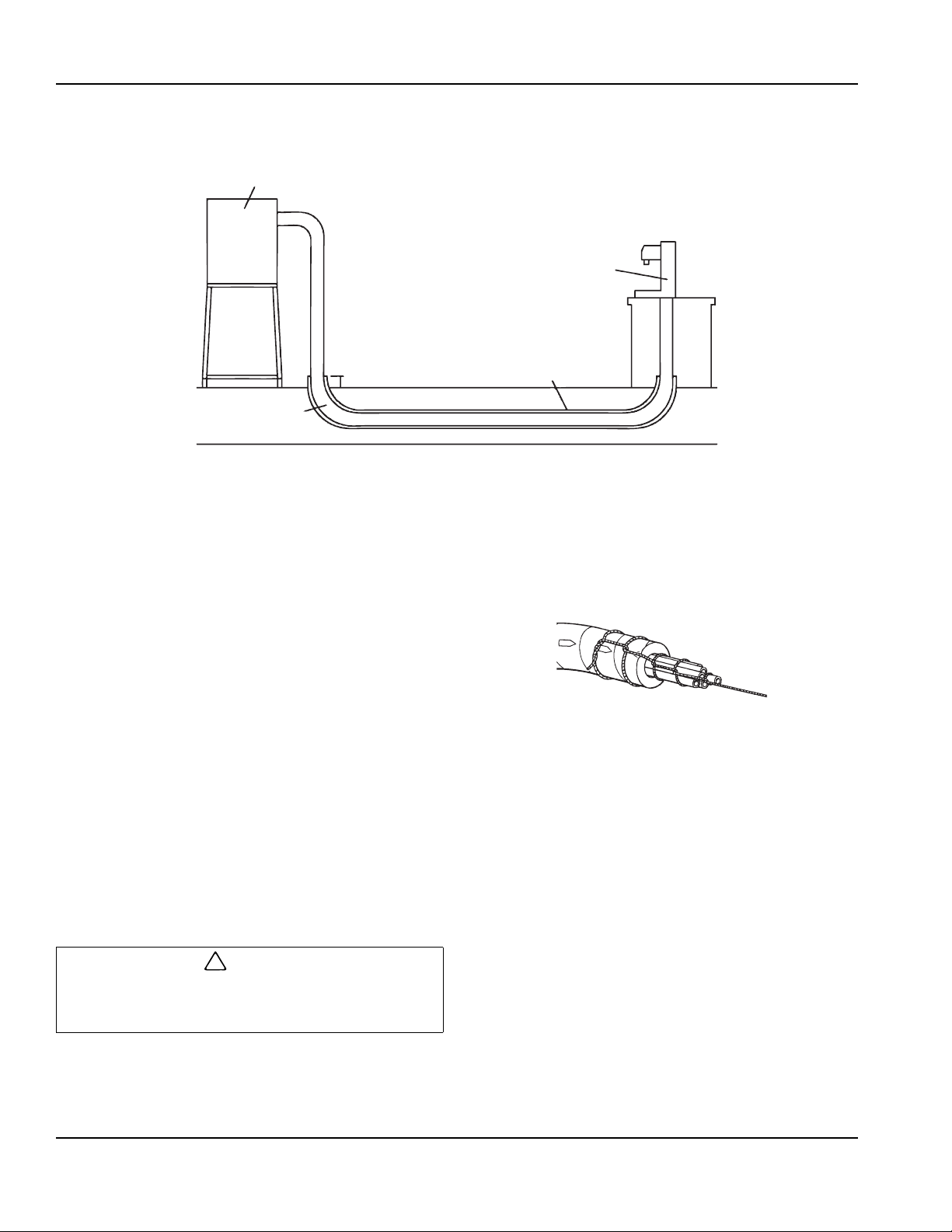

Refrigeration Unit

Dispensing Tower

8” (20.5 cm)

PVC Conduit

6” (15.2 cm)

Wide Sweep Elbows

2 ft (61cm) Radius

Figure 1

!

Caution

Figure 2

Routing Multiplex Conduit

FLOOR CHASES

Before pulling Multiplex conduit through a floor chase,

ensure the floor chase contains the following:

• 8" Minimum PVC Conduit

• Wide Sweep Elbows with a minimum 2 ft (61 cm) radius

• Chase openings should extend 6" (15.2 cm) above floor

• Chase must be clean and dry, no foreign materials

Pulling Conduit Through Floor Chase

1. Determine the most convenient way of routing conduit,

2. Locate steel fish tape and route through chase opening.

3. Locate an appropriate length of rope and tie to end of fish

4. Pull end of fish tape from starting point through chase with

All objects and moisture must be removed from floor

chase before conduit can be routed. It may be necessary

to repeat this process to ensure floor chase is clean.

starting at the end which offers adequate room for

installation. The conduit installation process requires the

assistance of two (2) qualified personnel.

Route fish tape through entire chase until it appears at

opposite end.

tape (end that was routed through chase in step 2).

Approximately 2 ft (61 cm) from steel fish tape/rope

connection, secure a swab to rope (use mop heads or

bundle of rags for swab).

rope and swab. The swab will sweep clean any

construction materials, moisture, or debris that may exist

in floor chase.

Multiplex conduit and uncoil conduit to allow

unrestricted feed during installation process.

6. Locate rope through chase opening and connect to

proper end of Multiplex conduit.

NOTE: Multiplex conduit is designed to be pulled

through a chase in the direction of arrows printed on

conduit (refer to figure 2).

7. After rope has been connected, tape end of co nduit,

including rope, and form conduit end to a point.

Tape will ensure that no contaminants enter conduit

tubes during installation.

8. Place pointed end of Multiplex conduit through

chase opening. While one person pushes the

conduit through chase, another person should be

pulling conduit through chase with rope on opposite

end.

9. Once conduit has been routed through chase, pull

enough conduit through openings to ensure an

adequate supply at each end of chase for

connections.

5. After floor chase has been cleaned, remove steel

fish tape and swab from rope. Locate bundle of

SEALING INSTRUCTIONS

2-2

Part Number EI211017 10/11

Page 9

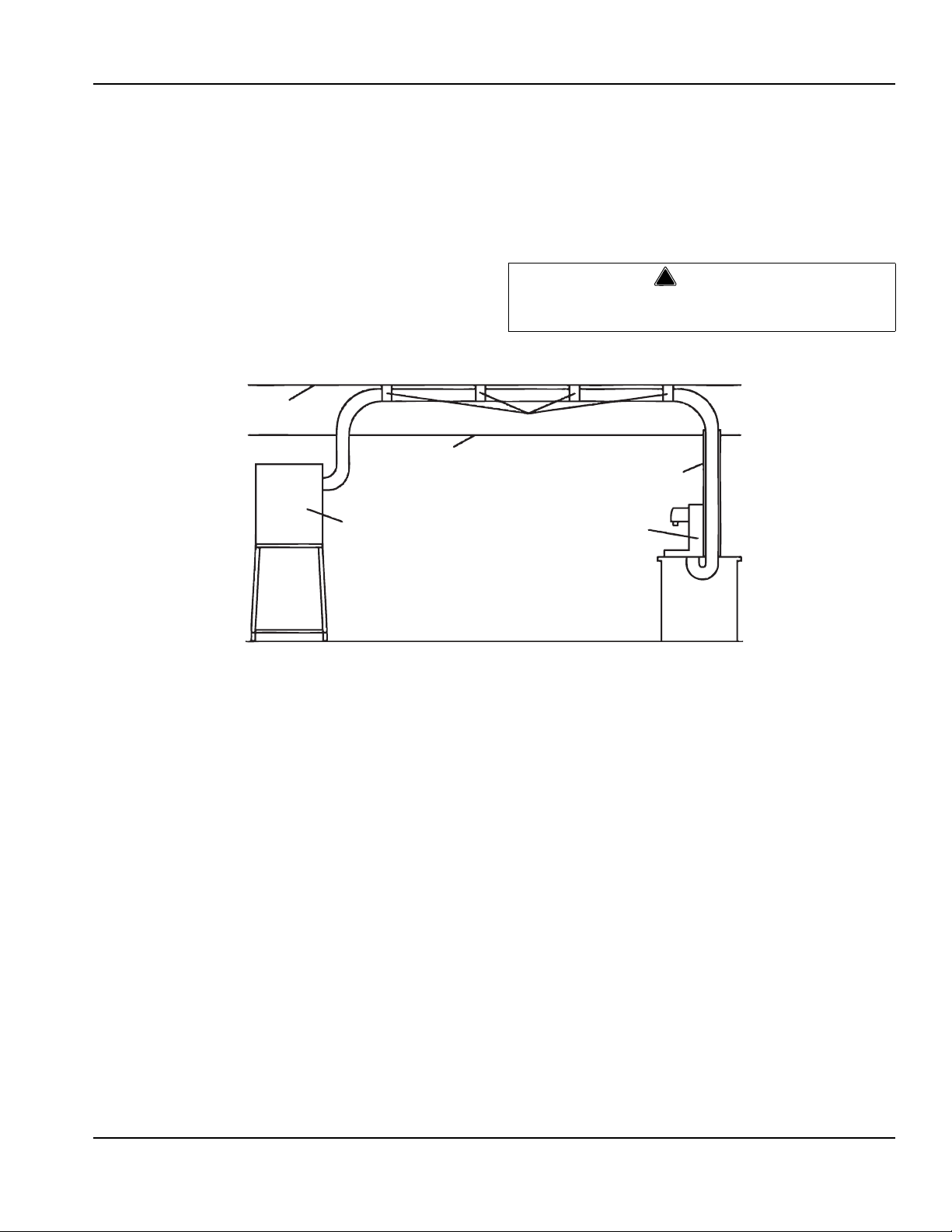

Section 2 Installation

!

Warning

Refrigeration Unit

Dispensing Tower

Ceiling Tiles

Conduit Hangers

Roof

Conduit Shroud

6” (15.2 cm)x 6” (15.2 cm)

Minimum

Figure 3

Aerosol foam is to be used to fill the openings between the

conduit insulation and the inside diameter of the floor

chases. The purpose is to provide an air tight seal at the floor

level to prevent foreign matter from entering the chases.

Please read the manufacturer’s instructions carefully.

1. If the opening is too deep, insert a section of the excess

conduit insulation in the opening prior to using the foam

insulation.

2. Make sure all exposed carbonated water and syrup

lines are well insulated: towers to conduit; conduit

junctions, remote unit to conduit; drive thru junction.

OVERHEAD INSTALLATION

3. Use aluminum foil (if used), and tape, packed in the

inner pack carton to insulate these connections.

4. Cut the conduit sections to fit like a glove over the

exposed lines and fittings.

NOTE: A little extra time spent doing a professional job

initially will eliminate a call back in several days to make

corrections.

Do not inject foam material directly on the connections where

the tubing connects to the barb fittings.

1. Determine the correct location for routing Multiplex

conduit. Be sure to avoid heat ducts, hoods, grills, or any

sharp objects that may exist above drop ceiling tile.

(refer to figure 3)

2. Unspool Multiplex conduit to allow unrestricted feed.

3. Conduit hangers should be spaced no more than 6 ft

centers.

4. Route conduit above ceiling tiles and connect to ceiling

and/or pipes using the appropriate conduit hangers. Be

sure conduit is suspended above ceiling tiles. Concern

should be given when determining appropriate method

of hanging conduit securely. Hangers must not crush or

pinch insulation. This will reduce cooling efficiency.

Once conduit has been routed, ensure an adequate supply

of conduit is provided at each end to make all connections.

Part Number EI211017 10/11 2-3

Page 10

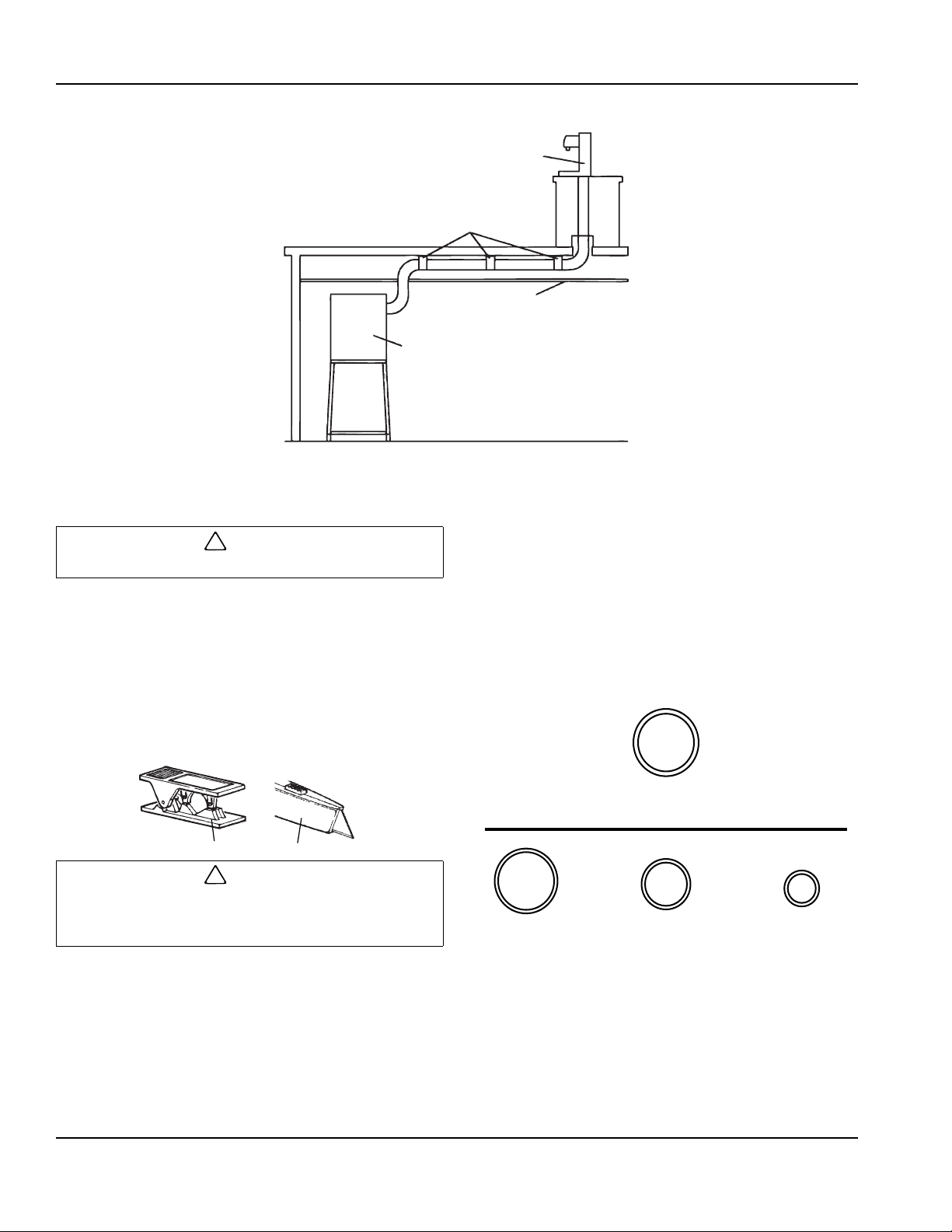

Installation Section 2

Dispensing Tower

Conduit Hangers

Basement Ceiling

Refrigeration Unit

Figure 4

!

Caution

!

Caution

Razor KnifeButterfly Cutter

Figure 5

Thick Wall Tubing

1/2" x 0.083 W

3/8" x 0.062 W 1/4" x 0.062 W1/2" x 0.062 W

NOTE: Shown actuall size.

Figure 6

BASEMENT CONSTRUCTION

1. Uncoil Multiplex conduit to allow unrestricted feed

during installation process.

2. Route the conduit up basement wall and secure with

appropriate conduit hangers.

Don't crush or pinch conduit insulation with hangers.

3. Conduit hangers should be spaced no more than 6 ft centers

How To Connect The Multiplex Conduit

NOTE: Conduit lines should be long enough to allow

adequate work space when servicing equipment.

All Multiplex conduit syrup lines, carbonated water lines,

and the plain water line are coded for quick identification

and easy installation.

Only an approved cutting tool should be used to cut

polyethylene tubing. Use a new blade so that the tubing will

not be crushed when cutting.

1. Locate the lines of Multiplex conduit routed at

refrigeration unit and dispensing tower.

2. Using an approved razor knife, cut Multiplex conduit

insulation by slicing along top side while peeling

insulation back at the same time.

3. For soda systems, connect each syrup line, carbonated

water line, and plain water line to the appropriate stainless

4. Route conduit above ceiling tiles and connect to

ceiling and/or pipes using the appropriate conduit

hangers. Be sure conduit is suspended above

ceiling tiles. Concern should be given when

determining appropriate method of hanging conduit

securely. Hangers must not crush or pinch

insulation. This will reduce cooling efficiency.

Once conduit has been routed, ensure an adequate

supply of conduit is on hand to make all connections.

steel coil in refrigeration unit. For Glycol systems,

connect to bulkhead fittings.

NOTE: Stainless steel cooling coils in our refrigeration units

may contain either barb fittings or John Guest fittings,

depending on model. Before connecting conduit, identify

whether the conduit is thick wall or thin wall tubing (see

illustration). Thick wall tubing should only be used with barb

stem fittings. John Guest fittings can only be used with thin

wall tubing

2-4

Part Number EI211017 10/11

Page 11

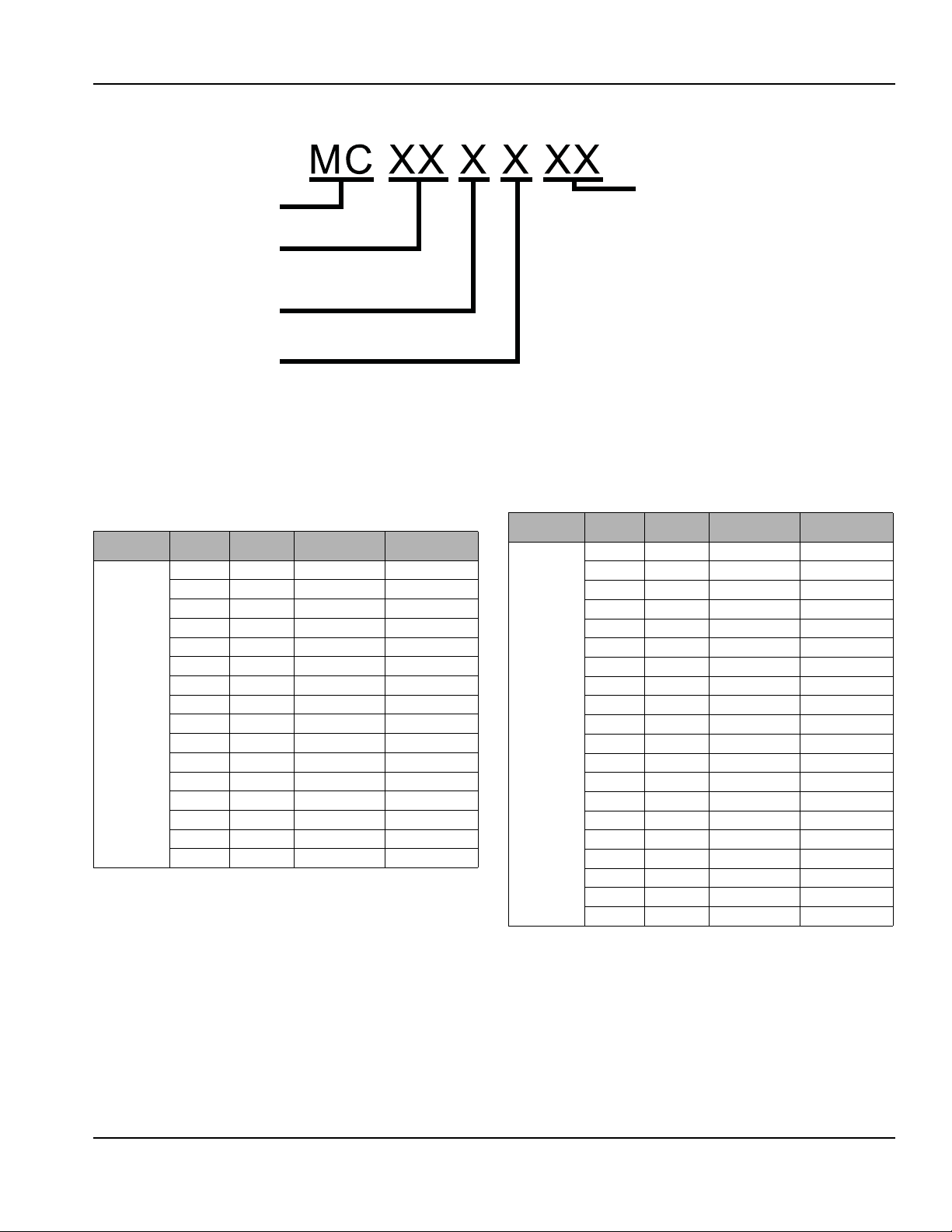

Section 2 Installation

Insulation

X6 = Barrier/Flushable

OX = 3/4" Insulation

1X = 1" Insulation

2X = Special 1" Insulation

3X = w/C02 Wire

4X = Beer Conduit w/Foil Wrap 1" Insulation

5X = Dual Recirculating Circuits

or Special - 2" Insulation

6X = Cabled Chasis

8X = Double Insulation

9X = Uninsulated

Multiplex Conduit

Line Quantity

05 = 5 lines

16 = 16 lines

Water/Glycol 1.0. Line Size

3 = 3/8"

5 = 1/2"

Syrup/Beer 1.0. Line Size

2 = 1/4"

3 = 3/8"

5 = 1/2"

Figure 7

CONDUIT IDENTIFICATION CHART

When suspending Multiplex conduit with conduit hangers, the maximum allowable distance b etween hangers is 6 ft (1.82 m) .

If ambient temperature of the conduit location is 90ºF (32.2ºC) or above, double insulated conduit must be utilized.

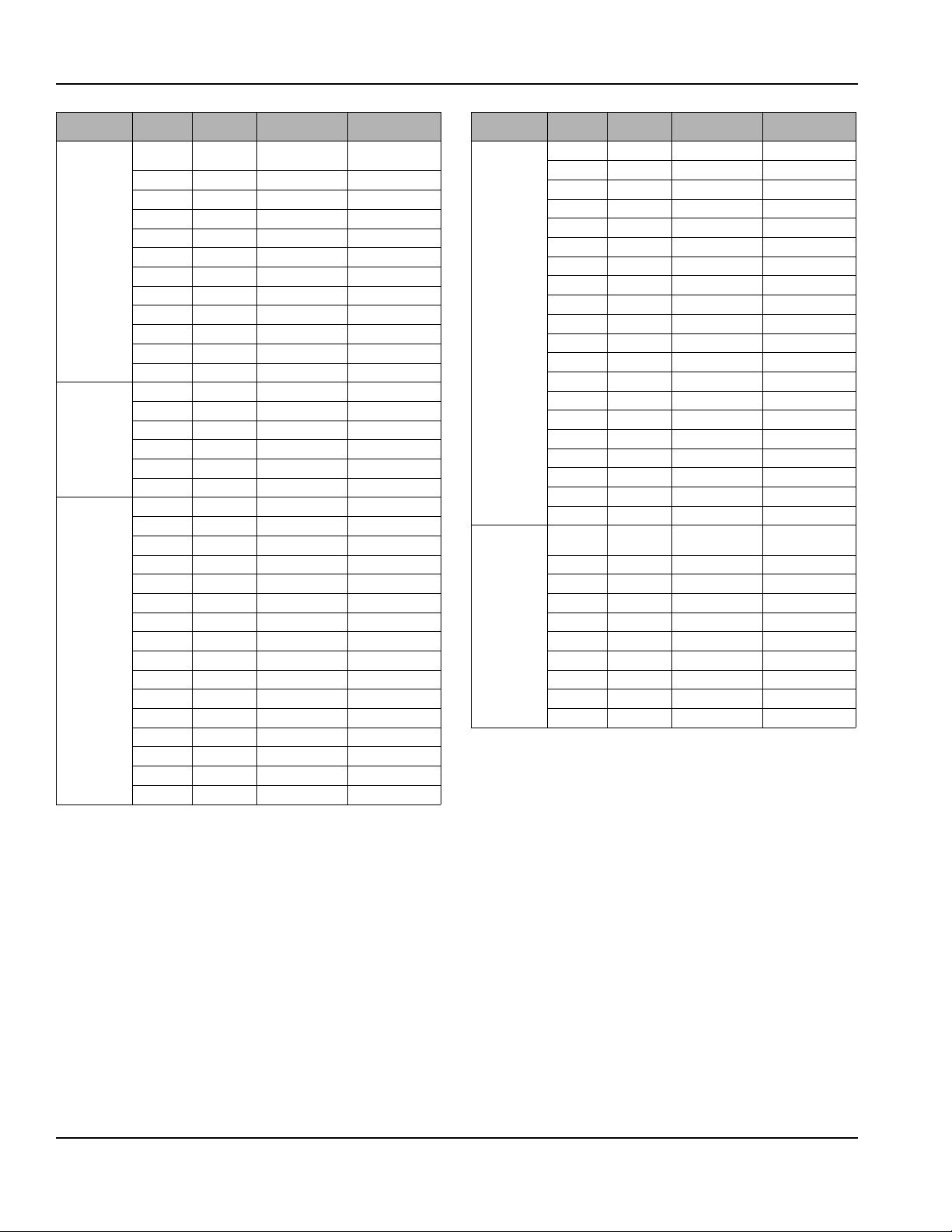

COLOR AND NUMBER CODING

I.D. Size of

Tube / Hose

1/4” Tube

Number Color Suggested Use Tab Clamp Size

S1 White Syrup 10.5

S2 Black

S3 Orange

S4 Red

S5 Blue

S6 Green

S7 Purple

S8 Brown

S9 Pink

S10 Yellow

S11 White

S12 Black

S13 Orange

S14 Red

S15 Blue

S16 Green

I.D. Size of

Tube / Hose

3/8” Tube

Number Color Suggested Use Tab Clamp Size

AF Red Water / Glycol 13.8

AR Red

BF Blue

BR Blue

S1 White Syrup / Beer 13.8

S2 Black

S3 Orange

S4 Red

S5 Blue

S6 Green

S7 Purple

S8 Brown

S9 Pink

S10 Yellow

S11 White

S12 Black

S13 Orange

S14 Red

S15 Blue

S16 Green

Part Number EI211017 10/11 2-5

Page 12

Installation Section 2

I.D. Size of

Tube / Hose

1/2” Tube

1/2” Hose

1/4” Tube

Number Color Suggested Use Tab Clamp Size

VS1 Orange

VS2 Natural

VS3 Green

VS4 White

VS5 Black

VS6 Red

VS7 Blue

VS8 Purple

VS9 Brown

VS10 Pink

VS11 Yellow

VS12 Purple

AF Blue Water / Glycol 18.5

AR Blue

BF Yellow

BR Yellow

WF Black

WR Black

S1 White Syrup 10.5

S2 Black

S3 Orange

S4 Red

S5 Blue

S6 Green

S7 Purple

S8 Brown

S9 Pink

S10 Yellow

S11 White

S12 Black

S13 Orange

S14 Red

S15 Blue

S16 Green

High Viscous

Syrup

17

I.D. Size of

Tube / Hose

3/8” Tube

1/2” Tube

Number Color Suggested Use Tab Clamp Size

AF Red Water / Glycol 13.8

AR Red

BF Blue

BR Blue

S1 White Syrup / Beer 13.8

S2 Black

S3 Orange

S4 Red

S5 Blue

S6 Green

S7 Purple

S8 Brown

S9 Pink

S10 Yellow

S11 White

S12 Black

S13 Orange

S14 Red

S15 Blue

S16 Green

VS1 Orange

VS2 Natural

VS3 Green

VS4 White

VS5 Black

VS6 Red

VS7 Blue

VS8 Purple

VS9 Brown

VS10 Pink

High Viscous

Syrup

17

Product suggestions for conduit tubing

Current conduit tubing is PTE lined. Therefore it is no

longer necessary to make sure pungent flavors are used

with specific tubing. Keeping with that process, when

connecting conduit to syrup boxes and valves, the best

flavor/tubing selection would be to utilize line number S1

for valve number 1, S2 for valve number 2, etc.

2-6

Part Number EI211017 10/11

Page 13

Section 2 Installation

Figure 7

Figure 8

1. Before inserting appropriate conduit lines to John

Guest fittings, ensure that the end of each line is

cut square at a 90° angle.

Figure 10

Figure 11

Figure 12

FITTINGS

Barb Stem Fittings

1. Moisten barbed fittings with warm water .

2. Connect appropriate lines to barbed fittings and secure

with two (2) tab clamps. Tab clamps should be

staggered when connecting (refer to figure 7).

3. Once the end of each line has been cut, lubricate with

water and insert line into John Guest Fitting. Be sure the

tubing is inserted firmly through O-ring in John Guest

fitting.

4. Connect each syrup line, carbonated water line, and

plain water line to the appropriate connection in

dispensing tower. Secure with two (2) tab clamps. If

tower has barbs, a John Guest adapter stem should be

used when connecting to a conduit with John

TEEING INTO MUL TIPLEX CONDUIT SODA SYSTEMS

John Guest Fittings

NOTE: Connections in dispensing towers may contain

either barb stem fittings or John Guest fittings. See

previous section for proper instruction.

1. Locate the section in main conduit where tee

connections are to be made. Measure a 12" (30.5

cm) area in the designated section.

2. Using a razor knife, cut a “X” pattern in designated

section as shown in figure 8. Peel back the ends of foam

insulation and identify each syrup line and water line

located in conduit. Be careful not to cut lines inside

conduit. Even a small “nick” will result in leaks.

3. Using a tubing cutter, cut each syrup line (one [1]

line at a time) in main conduit. Locate barbed tees in

conduit tee kit, connect to each syrup and water line.

Secure with two tab clamps (refer to figure 11).

4. Locate the section of tee conduit. Using a razor

knife, slice foam insulation in a straight line on top

side of conduit. Pull back foam insulation and locate

each syrup line (refer to figure 12).

5. Connect each syrup line in a tee conduit to the

appropriate barbed tee connected to the syrup lines

in the main conduit. Secure with two (2) tab clamps

(refer to figure 11). Be sure to tee line markings

corresponding to the main conduit markings.

Part Number EI211017 10/11 2-7

Page 14

Installation Section 2

Figure 13

Figure 14

6. Locate carbonated water lines in main conduit and

cut using tubing cutter. Locate barbed “Ell” fitting

provided in kit and connect to carbonated water

lines (refer to figure 13).

7. Connect the carbonated water lines in tee conduit to

the appropriate barbed ells connected to carb onated

water lines in main conduit. Secure with two tab

clamps (refer to figure 14).

NOTE: The number of carbonated water lines will vary

depending on the model of the refrigeration unit.

8. Pull the sliced sections of foam insulation back over

openings where connections were made. Using

cloth tape, tape over openings and seal air tight.

9. After ensuring there are no leaks at co nduit

connections, wrap foam insulation tape around the

sliced sections and insulate the Multiplex conduit

completely. This is very important to prevent

condensation and loss efficiency.

10. Seal each chase opening by spraying foam

insulation into each end of chase opening. This will

reduce risk of contamination of conduit in chase.

2-8

Part Number EI211017 10/11

Page 15

Section 2 Installation

Single Circulation Pump - One Circuit

REFRIGERATION UNIT

CIRC.

PUMP

HEAT EXCHANGER

BLUE

TOWER 1

TOWER 2

BLUE

CONDUIT CONDUIT TEE

CARB

TANK

Figure 15

Two Circulation Pump - Two Circuit

REFRIGERATION UNIT

CIRC.

PUMP

HEAT EXCHANGER

CARB

TANK

CIRC.

PUMP

HEAT EXCHANGER

CARB

TANK

CONDUIT CONDUIT TEE

TOWER 1

TOWER 2

BLUE

BLUE

YELLOW

YELLOW

SODA CONDUIT KIT DIAGRAMS

Single Circulation Pump - Two Circuit

REFRIGERATION UNIT

CIRC.

PUMP

CARB

TANK

HEAT EXCHANGER

TOWER 1

BLUE

YELLOW

YELLOW

BLUE

CONDUIT CONDUIT TEE

TOWER 2

Part Number EI211017 10/11 2-9

Page 16

Installation Section 2

Beermaster

Refrigeration Unit

Dispensing

Station

Beer Conduit

6” PVC

Conduit Chase

Wide Sweep Elbows

2 ft Radius

Walk-In Cooler

Figure 1

Figure 2

Beermaster Beer Conduit

INTRODUCTION

The following instructions will provide information for installing Multiplex/Multiplex Beer Conduit with your Beermaster System.

Areas which will be covered include routing the conduit for different bar set-ups, connecting the conduit at the Beermaster

Glycol Chiller, connecting the conduit at the beer cooler , and connecting the conduit at the dispensing stations.

FLOOR CHASES

Before pulling beer conduit through a floor chase, ensure the floor chase contains the following (see Figure 1)

• 6" (minimum) PVC conduit chase

• Wide sweep elbows (2 ft radius)

• Chase openings should extend 6" above floor

• Chase must be clean and dry–no foreign materials

Pulling conduit through floor chase

1. Determine the most convenient way of routing conduit,

starting at the end which offers ade quate room for

installation. The conduit installation process requires the

assistance of at least two (2) qualified personnel.

2. Route the steel fish tape through chase opening. Push

fish tape through entire chase until it appears at

opposite end.

3. Locate an appropriate length of rope and tie to end of

fish tape (end which was routed through chase in step

2). Approximately 2 ft from steel fish tape/rope

connection, secure a swab to rope (use mop heads or a

bundle of rags for swab).

4. Pull end of fish tape from starting point through chase

with rope and swab. The swab will clean any

construction materials, moisture, or debris that may exist

in floor chase. Continue to swab the chase until the

5. After floor chase has been cleaned, remove steel fish

swab exits the chase clean and dry.

tape and swab from rope. Locate bundle of beer conduit

and unspool conduit to allow unrestricted feed during

installation process.

6. Locate rope through floor chase opening and connect to

proper end of beer conduit.

NOTE: The beer conduit is designed to be pulled through

floor chase in the direction of arrows printed on conduit.

7. After rope has been connected, tape end of conduit,

including rope, and form conduit end to a point (see

Figure 2). Tape will ensure that no contaminants enter

conduit tubes during installation.

8. Place pointed end of the conduit through chase

opening. While one person pushes the conduit through

chase, another person should be pulling the conduit

through the chase with rope at the opposite end.

9. Once the conduit has been routed through the chase,

pull enough conduit through the openings to ensure an

adequate supply at each end of the chas e for

connections.

2-10

Part Number EI211017 10/11

Page 17

Section 2 Installation

Figure 3

Beermaster

Refrigeration Unit

Dispensing

Station

Beer Conduit

Conduit Hanger

Walk-In Cooler

Figure 4

OVERHEAD INSTALLATION

Conduit Hanger

Beer Conduit

Beermaster

Refrigeration Unit

Walk-In Cooler

Dispensing

Station

Ceiling Tiles

Refer to Figure 3 for the following:

1. Determine the correct location for routing the beer

conduit. Be sure to avoid heat ducts, hoods, grills, or

any sharp objects that may exist above drop ceiling

tile.

2. Unspool the beer conduit to allow unrestricted feed.

3. Route the conduit above ceiling tiles and connect to

ceiling and/or pipes using the appropriate conduit

BASEMENT CONSTRUCTION

hangers. Be sure the conduit is suspended above

ceiling tiles, not lying on the tiles. Care should be

taken when determining appropriate method of

handing conduit securely. Hangers must not crush

or pinch insulation. This will reduce cooling

efficiency.

4. Once the conduit has been routed, ensure an

adequate supply of conduit is provided at each end

to make all connections.

Refer to Figure 4 for the following:

1. Unspool the beer conduit to allow unrestricted feed

during installation process.

2. Route the conduit up basement wall and secure with

appropriate conduit hangers.

3. After routing the conduit up the basement wall, route

conduit overhead on the basement ceiling. Connect

to the basement ceiling using appropriate conduit

hangers.

4. Once the conduit has been routed, ensure an

adequate supply of conduit is on hand to make all

connections.

Part Number EI211017 10/11 2-11

Page 18

Installation Section 2

Beermaster

Refrigeration Unit

Dispensing

Station

Beer Conduit to

Walk-in Cooler

Main Beer Conduit

Walk-In Cooler

Figure 5

!

Caution

Razor KnifeButterfly Cutter

Figure 6

Connecting Beer Conduit

Before connecting the beer conduit at the walk-in beer

cooler and beer towers, ensure an adequate length of

conduit is being supplied to make proper connections.

Only an approved cutting tool should be used to cut

polyethylene tubing. The cutting tool should contain a

razor sharp cutting blade so that the tubing will not be

crushed when cutting. A razor blade knife or butterfly

tubing cutter is sufficient (see Figure 6). Multiplex packs a

butterfly cutter with each Beermaster Glycol Chiller.

1. Locate the lines of the beer conduit routed to the

Beermaster Glycol Chiller.

2. Using an approved cutting tool, cut the beer conduit

insulation along the top side while peeling i nsulation

back at the same time.

NOTE: Glycol circuit is a pair of lines; one blue and one

red. The blue line is the discharge or su pply line. The red

line is the return line.

3. Locate the return glycol supply lines of the beer conduit

and connect to the corresponding John Guest fitting on

the Beermaster Glycol Chiller.

4. Locate the discharge glycol supply lines of the beer

conduit and connect to the corresponding John Guest

fitting on the Beermaster Glycol Chiller.

5. Locate the glycol lines in the main conduit. Connect the

glycol lines of the beer unit to walk-in cooler conduit to

the glycol lines of the main beer conduit.

6. Locate the beer and glycol supply lines at the

dispensing station. Connect each beer line, incoming

glycol line, and outgoing glycol line to the appropriate

John Guest fitting at the dispensing station.

2-12

Part Number EI211017 10/11

Page 19

Section 2 Installation

Beermaster Conduit Kit

GENERAL

The following instructions will cover installation procedures required for properly connecting each component of the Beermaster

system. These instructions also contain the necessary information required for; calculating restrictor line length, required regulator

operating pressures and start up procedures. It is recommended that before proceeding with these instructions you ensure that

each of the following items have been properly installed. Items listed in suggested order of installation:

1. Glycol Chiller Unit

2. Dispensing Towers

3. Secondary Regulator Kits

4. Beer Conduit

Once the above items have been installed the following instructions can be completed.

NOTE: Your system may not include each item.

Kit contents

Four (4) and Seven (7) line conduit kits

5. High Pressure CO

2 Regulator Kit

6. Blender Kit or Beer Pumps

7. Air Compressor Kit, (optional)

8. Low CO

2 Alarm Kit.

10 and 14 line conduit kits

• Three (3) Return bends

• Eight (8) Elbows

•29 Unions

• Five (5) Tail pieces

• Five (5) Beer nuts

• One (1) 60 ft of PVC tape

• One (1) 60 ft of foil

• One (1) Spanner wrench

• Four (4) Return bends

• 15 Elbows

• 42 Unions

• Eight (8) Tail pieces

• Eight (8) Beer nuts

• One (1) 60 ft of PVC tape

• One (1) 60 ft of foil

• One (1) Spanner wrench

Part Number EI211017 10/11 2-13

Page 20

Installation Section 2

Figure 7

Figure 8

Figure 9

BEERMASTER CONDUIT KIT DIAGRAMS

Single Conduit, Two Beer System

Model 150 Refrigeration Unit

To Beer Keg

Walk-in Cooler

Single Conduit, Eight Beer System

Four Faucet Beer Tower

MC103310 (4 beer & glycol lines)

Model 300 Refrigeration Unit

Single Faucet

Beer Tower

MC043341

(4 line beer conduit [2 beer, 2 glycol lines])

To Beer Keg

Walk-in Cooler

(Shown with optional pump)

Dual Conduit, Eight Beer System

Model 300 Refrigeration Unit

To Beer Keg

Walk-in Cooler

(Shown with optional pump)

To Beer Keg

Walk-in Cooler

MC073341 (2 beer, 2 glycol lines)

MC073341 (2 beer, 2 glycol lines)

MC103310

(8 beer & 6 glycol lines)

Two Faucet

Beer Tower

Two Faucet

Beer Tower

2-14

Part Number EI211017 10/11

Page 21

Section 2 Installation

John Guest

Bulkhead Fitting

Glycol Lines

Figure 10

Figure 11

INSTALLING THE CONDUIT KIT

Connections preview

Review Figures 6, 7 and 8 to determine which best illustrates your particular inst allation. Co nsider the following while

examining the drawings;

Beer conduits have been designed to achieve the proper cooling of each encased beer line. In order to function

properly, you must follow these guidelines:

Up to eight (8) line conduit:

Ten (10) and over line conduit:

• Six (6) beer maximum, One (1) glycol circuit (Two [2]

• Two (2) glycol circuits (Four [4] lines)

lines)

To insure colder dispensing temperatures, glycol should flow directly to the dispensing towers before returning to the

remote Glycol Chiller Unit. After examining the drawings determine the desired glycol circuit to be achieved and

illustrate on paper for referral. Do the same for the assignment of the beer supply lines.

CONNECTIONS

Connecting the glycol chiller to the walk-in cooler or

main beer conduit

1. Route the glycol conduit(s) from the Beermaster

Glycol Chiller to the point of connection on the main

beverage conduit(s). This connection could be done

in the walk-in cooler or at any desired location along

the length of the main beer conduits.

2. Identify the proper glycol lines within the glycol

conduit(s) at the Beermaster Glycol Chiller, cut to

length and insert into the appropriate John Guest

bulkhead fitting(s) found on the side panel of the

Beermaster Glycol Chiller (see Figure 10).

Connecting main beer conduit at walk-in cooler

1. At the top of each beer wall bracket fitting, found on

the dual secondary regulator, secure a Beer Nut,

John Guest adapting tail piece, washer, and 1/2"

John Guest union (see Figure 11).

2. Identify the appropriate beer lines to be connected

to each of the wall bracket fittings, cut to length and

insert into the proper John Guest 1/2" connector

(see Figure 11).

John Guest

Adaptor Tail

Piece

Washer

Wall

Bracket

Fitting

Beer Line to

Tower

1

/2" John

Guest Union

Beer Nut

To Beer Keg

Connecting beer conduit to the tower

3. At the walk-in end of the conduit(s), peel back the

insulation from the beer conduit and identify the

appropriate glycol circuit and lines to be connected

(blue and red). Cut glycol lines and secure to the

appropriate elbow or union connections that are best

suited for connection with the beer conduit.

Glycol lines in

1. Peel the insulation back from the end of the beer

conduit to expose all lines. Locate the appropriate

glycol circuit lines, cut to length and attach a 1/2"

John Guest union to each line (see Figure 12).

2. Attach the opposite end of each 1/2" John Guest

unions to the 1/2" adaptors located at the base of

Part Number EI211017 10/11 2-15

the dispensing tower (see Figure 12).

Page 22

Installation Section 2

Glycol

Manifold

Adjustable

Clamp

Adaptor

1

/2" John

Guest Union

1

/2" John

Guest Union

Glycol

Line

Beer

Line

Beer Conduit

See

"Calculating

Restriction"

for Length

Restrictor

Lines

3

/16" Barb

x 1/2"

John

Guest

Adaptor

Dispensing Tower Dispensing Tower

Dispensing Tower

!

Caution

1/2” John

Guest Union

Branch Beer

Conduit

1/2” John

Guest Elbow

Main Beer Conduit

Figure 13

Figure 12

NOTE: If conduit contains more than one glycol circuit it will be necessary to attach U-bends for each of the additional circuits.

Use a 1/2" U-bend quick connect fitting or the U-bend can be built b y attaching two (2) 1/2" John Guest elbows to one anothe r

by means of a 2" length of 1/2" tubing.

BEER RESTRICTOR LINES

1. Cut each restrictor line to the calculated length and

carefully insert the 3/16" Barb x 1/2" John Guest adaptor

and clamp securely with the adjustable cla mps provided

(see Figure 12).

2. Identify the beer line to be connected to each of the

appropriate restrictor line, cut the beer lines to length

Connecting main beer conduit to branch beer conduit

1. .At the required point of connection carefully split open

and fold back the insulation on the main beer conduit

and identify the correct set of glycol lines (circuit) to

connect to the branch beer conduit. Cut the glycol line(s)

and attach the appropriate 1/2" elbow or union

connections that are best suited to connecting with the

main beer conduit (see Figure 13).

2. Peel the insulation back from the end of the branch beer

conduit to expose all lines. Locate the glycol circuit lines,

cut to length and insert each line into the open end of

the previously attached 1/2" connectors at the m ain beer

conduit (see Figure 13).

3. Locate the appropriate beer line(s) in the main beer

conduit to be connected to the branch conduit. Cut

desired beer line(s) long so that they can be pulled back

and then routed in a smooth curve into the branch

conduit. Attach appropriate beer line(s) from main beer

conduit to beer line(s) in branch beer conduit with 1/2"

John Guest Union(s).

2-16

and attach a 1/2" John Guest Union to each. Neatly

wrap the excess restrictor line securely around the

glycol supply lines to ensure good heat exchange.

Connect the adaptor from each restrictor to the 1/2 "

connector of each of the appropriate beer lines.

To avoid agitation use only straight unio ns when splicing

beer lines.

Part Number EI211017 10/11

Page 23

Section 3

Operation

Once installation is complete, the beverage conduit is ready for op era ti on. Plea se consu lt yo ur eq uipm ent in stallation

guide for instructions on running product. See the maintenan ce section in this manual for information on cleaning and

sanitation.

Part Number EI211017 10/11 3-1

Page 24

Operation Section 3

THIS PA GE INTENTIO NALLY LEFT BLANK

3-2

Part Number EI211017 10/11

Page 25

Section 4

Maintenance

Maintenance Schedule

This section provides a list of periodic maintenance t asks and the scheduled frequency re quired to ensure the proper

operation of your Multiplex dispensing equipment. To ensure quality beverages, prevent down time, and reduce cost s, these

tasks must be performed as indicated.

PERIODIC MAINTENANCE LISTED BY MAJOR COMPONENTS

Dispensing stations

Daily (365 times per year)

• T ake temperature of finished drinks. Pour off the first and

take the temperature of the second drink. The prope r

temperature of drinks must be 40°F (4°C) or less.

Beverage conduits

Every 4 months (3 times per year)

• Inspect beverage conduits for damage. Re-insulate an d

seal any un-insulated areas.

• Remove nozzles and diffusers from each dispensing

valve. Clean with soap and warm water (not hot). Rinse

with carbonated water and reinstall.

• Flush all dispenser drains. Pour hot water down drains at

closing.

• Inspect floor chases and seal any open chase ends.

Air compressor

Monthly (12 times per year)

• Drain condensate water from air compressor tank.

Every 4 months (3 times per year)

• Inspect air compressor filter and replace if clogged. Air

filter must be replaced every 6 months.

Refrigeration unit

Every 4 months (3 times per year)

• • Clean the refrigeration unit air-cooled condenser using

a vacuum cleaner. If equipped with water-cooled

condenser, verify the water discharge temperature is at

105°F (41°C). Adjust water modulating valve if

necessary .

• Inspect water bath to verify water level is at the top of

stand pipe. If below , add water and repair water makeup

device. If excessive amount of water is flowing over

stand pipe, locate leak within bath and repair.

Water filters

• Inspect air compressor to verify cut-in at 70 psi (4.8 bar)

and cut-out at 90 psi (6.3 bar). Adjust pressure switch if

necessary.

• Inspect system for air leaks and repair as required.

• Inspect ice bank within the water bath to verify proper

size ice bank and clarity. Look for uniform, 2" to 4" thick

ice bank.

• Drain, clean, and refill water bath.

• Inspect agitator motor and ensure proper opera tion.

• Inspect the circulating motor/pump assembly. Clean

strainer and oil motor .

• Inspect the carbonating motor/pump assembly. Clean

strainer and oil motor .

• Inspect entire system for leaks and repair as required.

Every 4 months (3 times per year)

• Verify that incoming water pressure is not less than 40

psi (2.8 bar) or greater than 60 psi (4.1 bar) . If equipped

with a water regulator , verify proper setting of 55 ps i (3.8

bar). Adjust if necessary.

Part Number EI211017 10/11 4-1

• If pressure is low, inspect water filter cartridges to ensure

they are able to supply adequate water pressure under

normal system flow . Replace if unable to pro vide

minimum 20 psi (1.4 bar) under load.

Page 26

Maintenance Section 4

Syrup supply

Daily (365 times per year)

Every 4 months (3 times per year)

• Clean general area of syrup hookup with soap and warm

water. Rinse of f all soap.

CO

2 gas supply

Every 4 months (3 times per year)

• Inspect pressure setting at CO

2 high pressure regulator.

Verify proper 90 p si (6.3 bar) pressure setting. Adjust if

necessary .

PERIODIC MAINTENANCE LISTED BY SCHEDULED FREQUENCY

Daily (365 times per year)

• T ake temperature of finished drinks. Pou r off the first and

take the temperature of the second drink. The proper

temperature of drinks must be 40°F (4°C) or less.

• Remove nozzles and diffusers from each dispensing

valve. Clean with soap and warm water (not hot). Rinse

with carbonated water and reinstall.

Every 4 months (3 times per year)

• Using Brix cup and syrup separator, check for proper

carbonated water flows (standard flow: 5 oz. in 4 seconds,

fast flow: 10 oz. in 4 seconds) and syrup to water ratios at

each dispensing station. Adjust as required.

• Inspect beverage conduits for damage. Re-insulate and

seal any un-insulated areas.

• Inspect floor chases and seal any open chase ends.

• Inspect air compressor filter and replace if clogged. Air

filter must be replaced every 6 months.

• Inspect air compressor to verify cut-in at 70 psi (4.8 bar)

and cut-out at 90 psi (6.3 bar). Adjust pressure switch if

necessary .

• Inspect system for air leaks and repair as required.

• Clean the refrigeration unit air-cooled condenser using a

vacuum cleaner. If equipped with water-cooled condenser ,

verify the water discharge temperature is at 105°F (41°C).

Adjust water modulating valve if necessary .

• Inspect water bath to verify water level is at the top of

stand pipe. If below , add water and repair water makeup

device. If excessive amount of water is flowing over stand

pipe, locate leak within bath and repair.

• Inspect ice bank within the water bath to verify proper size

ice bank and clarity . Look for uniform, 2" to 4" thick ice

bank.

• Drain, clean, and refill water bath.

• Inspect syrup lines for proper flavor identification labels.

Replace labels if necessary .

• Disconnect syrup containers. Clean connector with soap

and warm water . Rinse with plain water and reconnect to

syrup containers.

• Inspect pressure setting at syrup pressure regulators.

Verify prop ter pressure setting. Adjust if necessary.

• Inspect system for CO

2 leaks, repair as required.

• Flush all dispenser drains. Pour hot water down drains at

closing.

• Clean general area of syrup hookup with soap and warm

water. Rinse of f all soap.

• Inspect agitator motor and ensure proper operation.

• Inspect the circulating motor/pump assembly. Clean

strainer and oil motor.

• Inspect the carbonating motor/pump assembly. Clean

strainer and oil motor.

• Inspect entire system for leaks and repair as required.

• Verify that incoming water pressure is not less than 40 psi

(2.8 bar) or greater than 60 psi (4.1 bar). If equipped with a

water regulator, verify pr oper setting of 55 psi (3.8 bar).

Adjust if necessary . If pressure is low , inspect water filter

cartridges to ensure they are able to supply adequate

water pressure under normal system flow . Replace if

unable to provide minimum 20 psi (1.4 bar) under load.

• Inspect syrup lines for proper flavor identification labels.

Replace labels if necessary .

• Disconnect syrup containers. Clean connector with soap

and warm water. Rinse with plain water and reconnect to

syrup containers.

• Inspect pressure setting at CO

2 high pressure regulator .

Verify proper 90 psi (6.3 bar) pressure setting. Adjust if

necessary .

• Inspect pressure setting at syrup pressure regulators.

Verify propter pressure setting. Adjust if necessary.

• Inspect system for CO

2 leaks. Repair as required.

4-2

Part Number EI211017 10/11

Page 27

Section 4 Maintenance

!

Warning

!

Warning

CLEANING & SANITIZING THE DISPENSING VALVES & PRODUCT LINES

Maintenance Schedule

Every day

Dispensing valves Remove nozzles and diffusers and soak in mild detergent cleaning solution. Scrub parts

with small bristle brush taking care to clean small crevices and O-ring grooves. Turn OFF

power to dispensing valves. Scrub exterior surfaces, including bottom splash area and

actuator lever, with cleaning solution. Reassemble diffusers and nozzles. Wipe dry exterior

surfaces before turning ON power.

Drip pan and drain hose Wash with mild detergent. Rinse with clean water.

Quick disconnects Wash with mild detergent. Rinse with potable water.

Weekly

Outside, dispenser cabinet Wash with clean water and mild detergent. Wipe dry.

Every 3 months

Syrup circuits Sanitize each syrup circuit. See “Maintenance”.

Water bath Drain, melt ice and clean using detergent and brush; rinse with potable water. Do not use

water over 140°F (60°C).

Every 6 months

Condenser Vacuum fins or use soft bristle brush (scrub brush).

Air purifier filter (if equipped) Replace.

Cleaning Equipment and Supplies

• Recommended cleaner: Any caustic-base (low sudsing,

non-perfumed, easily rinsed) detergent solution which

provides a minimum 2% sodium hydroxide. The solution

must be prepared in accordance wi t h th e ma nu fa cturer’s

instructions. Solution temperature must be between 90°F

(32°C) and 110°F (43°C). Temperatures in excess of this

can cause internal damage to the dispensing valve

components.

• Recommended sanitizer: Any sanitizer which provides a

minimum of 120 parts per million (120 milligrams per liter)

of available chlorine. Solution temperature must be

between 90°F (32°C) and 110°F (43°C). Temperatures in

Sanitizing

BEVERAGE SYSTEM CLEANING

Flush sanitizing solution from syrup system. Residual

sanitizing solution left in system could create a health hazard.

When using cleaning fluids or chemicals, rubber gloves and

eye protection must be worn.

excess of this can cause internal damage to the dispensing

valve components.

• Two five gallon (figals) syrup tanks and fittings, cleaned

and sanitized (one for cleaner; one for sanitizer)

• Containers for cleaner and sanitizer solutions

• Clean, non-abrasive cloths

• Buckets

• Small Brush

• Extra Nozzles

• Extra Jumpers

Sanitize the beverage system at initial start-up as well as

regularly scheduled cleaning. The drain pan must be in

place under soda valves, to carry away detergent and

sanitizing agents that will be flushed through valves.

Part Number EI211017 10/11 4-3

Page 28

Maintenance Section 4

Bag

side

connector

BAG-IN-BOX SYSTEM SANITATION

The procedure below is for the sanitation of one syrup circuit at a time. Repeat to sanitize additional circuits.

Y ou will need the following items to clean and sanitize the

Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 — warm to hot tap water for rinsing.

• Bucket 2 — mild detergent and warm to hot water .

• Bucket 3 — mix a solution of unscented bleach (5%

Na CL O) or commercial sanitizer and warm to hot

water. Mixture sho uld supply 100 PPM available

chlorine (1/4 oz. bleach to 1 gallon water).

2. Disconnect the “syrup-line side” of the BIB connector.

4. Connect syrup connector to BIB connector and immerse

both into Bucket 1. A “bag-side” connector can be

created by cutting the connector from an empty

disposable syrup bag.

5. Draw rinse water through system until clean water is

dispensed. Most beverage valves allow the syrup side to

be manually activated by depressing the syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until solution

is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain

detergent solution.

9. Allow detergent solution to remain in the system for

5 minutes.

10. Connect Bucket 3 to system.

1 1. Draw sanitizing solution through system until solution is

dispensed.

12. Repeat step 11 until all syrup circuit s contain sanitizer

solution.

13. Allow sanitizer solution to remain in system for 15

minutes.

14. Remove nozzles and diffusers from beverage valves.

15. Scrub nozzles, diffusers and all removable valve parts

(except electrical parts) with a plastic brush or a soft cloth

and the detergent solution.

16. Soak nozzles, diffusers and removable valve parts

(except electrical parts) in sanitizer for 15 minutes.

17. Replace nozzles, diffusers and valve parts.

3. Rinse connector with warm tap water .

4-4

18. Connect Bucket 1 to system Draw rinse water through

system until no presence of sanitizer is detected.

19. Attach syrup connectors to BIBs.

20. Draw syrup through system until only syrup is dispensed.

21. Discard first 2 drinks.

Part Number EI211017 10/11

Page 29

Section 4 Maintenance

!

Caution

FIGAL BEVERAGE SYSTEM

1. Prepare the following in three clean Figal tanks:

• Rinse tank - fill with room temperature tap water.

• Detergent tank - mix approved beverage system

cleaner with warm water as directed.

• Sanitizing tank - mix a solution of unscented

bleach (5% Na CL O) or commercial sanitizer and

warm to hot water. Mixture should supply 100 PPM

available chlorine (1/4 oz. bleach to 1 gallon water).

2. Disconnect all product and water lines from product

tanks and remove carbonator.

3. Locate the Figal syrup tank for the circuit to be

sanitized. Remove both quick disconnects from the

Figal syrup tank. Rinse quick disconnects in tap water.

4. Connect rinse tank to the syrup line. Draw clean rinse

water through the valve until syrup is flushed from the

system.

5. Connect detergent tank to the syrup line and draw

detergent through the valve for two minutes. Then,

allow remaining detergent to stay in the system for

five minutes.

6. Connect rinse tank to the syrup line. Draw clean rinse

water through the valve until detergent is flushed from

the system.

7. Remove valve nozzle and diffuser as shown in Daily

Cleaning instructions. Using a plastic brush or a soft

cloth and warm water, scru b the nozzle, diffuser, bottom

of the dispensing valve and cup lever, if applicable.

8. Place removable valve parts (EXCEPT solenoids) in

sanitizing solution for 15 minutes.

Shipping, Storage and Relocation

Before shipping, storing, or relocating this unit,

syrup systems must be sanitized. After sanitizing,

all liquids (sanitizing solution and water) must be

purged from the unit. A freezing environment

causes residual sanitizing solution or water

remaining inside the unit to freeze, resulting in

damage to internal components.

9. Replace valve diffuser and nozzle on the beverage valve.

10. Connect sanitizer tank to the syrup line and draw sanitizer

through the valve for two minutes. Allow sanitizer to

remain in the system for a minimum of 15 minutes.

1 1. Reconnect syrup and carbonated water lines.

12. Draw syrup through the lines to rinse the system.

Discard drinks until at least two cups of satisfactory

tasting beverage are dispensed through the valve.

Part Number EI211017 10/11 4-5

Page 30

Maintenance Section 4

THIS PA GE INTENTIO NALLY LEFT BLANK

4-6

Part Number EI211017 10/11

Page 31

Checklist

!

Warning

Section 5

Before Calling for Service

If a problem arises during operation of your post mix

soda refrigeration unit, follow the checklist below before

calling service. Routine adjustments and maintenance

procedures are not covered by the warranty.

Only trained and certified electrical and plumbing

technicians must service this unit. All wiring and

plumbing must conform to national and local codes.

SODA SYSTEMS

Problem Possible Cause To Correct

All corresponding valves dispensing no

syrup.

No syrup at only one dispensing valve. Syrup Shut-off V alve closed or partially

Malfunction of syrup system. Refer to Troubleshooting “Section 8: Syrup

System” under No syrup or insufficient syrup

in finished drink.

Remove top cover from Dispensing valve or

closed.

Mounting Block restricted. Remove Dispensing valve from Mounting

T ower. Locate Syrup Shut-off Valve on right

hand side of Dispensing valve. Verify shut-off

is turned fully open.

Block. Place cup over Syrup outlet on

Mounting Block and carefully open Syrup

Shut-off V alve. If little or no syrup is present,

Mounting Block is restricted. Remove and

clean mounting block. Replace if necessary.

NO SYRUP OR INSUFFICIENT SYRUP IN FINISHED DRINK

No carbonated water at half or all dispensing

valves.

Flow Control our of adjustment or inoperative. Readjust Flow Control to proper Brix. If no

response, clean Syrup Flow Control. Replace

if necessary.

Valve Port restricted. Clean Syrup valve Port Assembly.

Seat swollen. Replace Syrup Seat.

Solenoid Coil defective. Replace Syrup Solenoid Coil.

Malfunction of Carbonated Water System. Refer to Troubleshooting “Section 2:

Carbonated Water System” under No

carbonated water at any of the dispensing

valves.

Part Number EI211017 10/11 5-1

Page 32

Before Calling for Service Section 5

Problem Possible Cause To Correct

NO CARBONATED WATER OR INSUFFICIENT CARBONATED WATER IN FINISHED DRINK

No Carbonated Water only at one dispensing

valve.

NO WATER OR INSUFFICIENT WATER IN FINISHED DRINKS

All valves dispensing noncarbonated

drinks no water.

Problem occurs at only one dispensing

valve.

Too much Syrup, Carbonated Water or

Water in finished drink. Problem occurs

at only one dispensing valve.

Too much syrup in finished drink. All

valves dispensing same flavor-too much

syrup.

Too much water in finished drink. All

valves dispensing noncarbonated drink

too much water.

Syrup or Carbonated Water or Water

dripping from Nozzle.

Carbonated water Shut-off Valve closed or

partially closed.

Mounting Block restricted. Place cup over Carbonated Water outlet on

Flow Control our of adjustment or inoperative. Readjust Flow Control to proper Brix (5 oz in

Valve Port restricted. Clean Carbonated Water valve Port

Seat swollen. Replace Carbonated Water Seat.

Solenoid Coil defective. Replace Carbonated Water Solenoid Coil.

Carbonated Water Switch defective (black). Replaced Carbonated Water Switch.

Water Shut-off Valve closed or partially

closed.

Syrup, carbonated water, or noncarbonated

water flow control out of adjustment or

inoperative.

Malfunction of syrup system. Refer to Troubleshooting “Section 8: Syrup

Malfunction of water Booster system. Refer to Troubleshooting “Section 9: W ater

Valve port scarred. Disassemble appropriate Syrup or Water

Armature Spring or Retaining Ring

broken.

Seat scarred or obstructed. Disassemble appropriate Syrup or Water

Remove top cover from Dispensing valve or

T ower. Locate Carbonated Water Shut-off

Valve on left hand side of Dispensing valve.

Verify Shut-off Valve is turned fully open.

Remove Dispensing valve from Mounting

Block.

Mounting Block and carefully open

Carbonated Water Shut-off V alve. If little or no

Carbonated Water is present, Mounting

Block is restricted. Remove and clean

mounting block. Replace if necessary.

4 seconds Standard valve, 10 oz in 4

seconds Fast Flow valve). If no response,

clean Carbonated Water Flow Control.

Replace if necessary.

Assembly.

Refer to Troubleshooting “Section 9: Water

Booster System” under Low or No Water

Pressure at Noncarbonated Beverages.

Refer to this section on No carbonated water

at only one dispensing valve in the

dispensing valve.

Readjust appropriate Flow Control. If Flow

Control does not respond to adjustment,

clean Flow Control. Replace if necessary.

Carbonated Water Flow rates: (5 oz in 4

seconds Standard valve, 10 oz in 4 seconds

Fast Flow valve).

System” under Drinks too sweet.

Booster System” under Qualifier: Pump and

motor cycles “on” and “off” excessively .

Assembly. Examine valve Port for scars or

nicks. Replace if necessary.

Disassemble appropriate Syrup or Water

Assembly. Examine Armature, Spring and

Retainer Ring. If damaged, replace.

Assembly. Examine Seat, if scarred, replace.

If foreign material is found in Assembly,

remove, reassemble.

5-2

Part Number EI211017 10/11

Page 33

Section 5 Before Calling for Service

Problem Possible Cause To Correct

Valves will not activate when Selection

Panel pressed. Problem occurs at two (2)

or three (3) consecutive Valves on one

(1) tower.

Problem occurs at all valves on one (1)

dispensing tower.

Problem occurs at only one (1)

dispensing valve.

Valve will not shut “off”. Mo is t u re o n Po r ti o n Co n t ro l T i m e r o r C on t a c t

Transformer inoperative. Verify wire leads from Transformer have solid

connections. Switch low voltage lead from

Transformer supplying power to left and right

hand side of T ower . If V alves operate and the

other three do not, Transformer is defective.

Replace.

Dispensing tower’s “on” and “off” T oggle

defective.

No power to transformer or transformer

defective.

Dispensing tower’s “on” and “off” is Switch

defective.

Poor connection on valve Wire Harness. Trace wiring on defective valve and

Portion Control Timer inoperative. Replace the problem valve Portion Control

Selection Switch inoperative. Replace defective Portion Control Timer with

Poor connection at Contact Clips on

Selection Panel (with Portion Control Timer).

Clips.

Portion Control Timer Adjustment Screw

turned beyond control limit.

If after switching Leads, the three valves still

do not operate, the “on” and “off” Toggle

Switch is defective.

Verify power with a voltmeter at wall outlet.

Verify power across low voltage leads on

transformer. If 24 volts are present “on” and

“off” Toggle Switch is defective. Replace.

Verify Main Power Supply and power at

Transformer Leads replace “on” and “off”

Switch if operative.

reconnect any loose wires. Clean and

reconnect any corroded connections.

Timer with a known Operative Timer. If valve

then operates, Portion Control Timer was

defective. Replace.

operative Timer . If V alves still will not activate,

Selection Panel is defective. Replace

Selection Switch.

Examine Contact Clips on Selection Panel

and insure proper contact between Portion

Control Timer and Contact Clips.

Remove top cover from Dispensing Tower .

Remove all moisture from Portion Control

Timer and Contacts.

Turn Portion Control Adjustment Screws on

defective valve counterclockwise 10

complete turns. If valve shuts off when

selection is pressed, readjust for proper

portions.

Note: Several revolutions may be necessary

to bring control back into range.

Portion Control Timer defective. Verify above probables are not the problem.

Push “on/off” Switch for Dispensing Tower to

the “off” position. If valve ceases to dispense

when pushed to “on” position, Portion Control

Timer is defective. Replace.

Selection Panel defective. Push “on/off” Switch for dispensing tower to

the “off” position. If valve ceases and then

continues to dispense when switch is pushed

in “on” position, Selection Panel is defective.

Replace.

Part Number EI211017 10/11 5-3

Page 34

Before Calling for Service Section 5

Problem Possible Cause To Correct

Foaming of finished products. Nozzles, Syrup Tube Diffusers dirty. Remove and clean Nozzle Assemblies and

reassemble.

Warm drinks. Refer to Troubleshooting “Section 7:

Refrigeration System” under Warm drinks.

Incorrect pressure on syrup. Verify pressure supplied to sugar base

products is at 60 psi (4.2 kg/cm2). Adjust

Medium Pressure Regulator if necessary.

Verify pressure supplied to diet product is at

15 psi (1.1 kg/cm2). Adjust Low Pressure

Regulator if necessary.

Note: Insure the Low Pressure Supply Line

has not mistakenly been switched for a

Medium Pressure Supply Line on the diet

tank.

Unit totally inoperative; all electrical

switches in the “on” position.

Change-over Valve Medium or Low Pressure

is in the wrong position.

Air or CO

Flake ice. Only cube ice should be used for carbonated

Improper adjustment of valve. Insure carbonated water flow is properly set

Power failure, all power to system is “off”, or

Fuse/Circuit Breaker is “open”.

2 gas in syrup line. Replace empty Syrup Tank. Dispense Syrup

Verify valve Medium to Low Pressure is in the

Low Pressure position for diet products.

from valve until consistent flow is achieved

and product stabilizes. If evidence of air is still

entering line, replace Liquid Disconnect

which is allowing air to be drawn into syrup

supply.

beverages.

(5 oz. in 4 seconds standard valve, 10 oz in

4 seconds Fast Flow valve). Insure Brix is

properly set. Adjust as necessary.

Check Circuit Breaker. Reset. Examine T ime

Delay, replace if necessary.

5-4

Part Number EI211017 10/11

Page 35

Section 5 Before Calling for Service

BEERMASTER SYSTEMS

Problem Possible Cause To Correct

Section 1: Restriction

Too little restriction

Too much or too little restriction in a draught beer system will cause drawing problems. If draught beer system does not have

enough restriction it may cause the following problems:

A recovery problem simply means that

the beer is leaving the beer line faster

When drawing one beer, the beer

flows very fast.

than the keg can fill the line. When this

occurs it creates a vacuum in the keg

which acts as if there was a low pressure

on the beer in the keg. This causes the

to come out of the beer line causing

CO

2

If a pitcher is drawn, the beer starts

clear then starts to show intermittent

streaks of foam followed by all foam.

foaming problems. (The following

symptoms occur most frequently during

the high volume time of day.)

Beer draws too fast. If the beer draws

clear but too fast and the pressure is

properly set, there may not be enough

restriction in the system.

Beer draws clear but foams in the

glass.

The beer draws too fast to satisfy the