Page 1

Multiplex

Blended

Beverage System

Technician’s

Handbook

This manual is updated as new information and models are released. Visit

our website for the latest manual. www.manitowocfsg.com

Leader in Ice & Beverage Dispensers

Part Number STH034 3/13

Page 2

Safety Notices

!

Warning

!

Caution

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Page 3

Procedural Notices

Important

As you work on Manitowoc equipment, be sure to read

the procedural notices in this handbook. These notices

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a

procedure more efficiently. Disregarding this

information will not cause damage or injury, but it

may slow you down as you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about the procedure you

are performing.

Page 4

READ THESE BEFORE PROCEEDING:

!

Caution

Important

!

Warning

!

Warning

! Warning

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your equipment. Visit our

website www.manitowocfsg.com for manual

updates, translations, or contact information for

service agents in your area.

Routine adjustments and maintenance

procedures outlined in this handbook are not

covered by the warranty.

Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this

manual can cause property damage, injury or

death.

Do not use electrical appliances or accessories

other than those supplied by Manitowoc for your ice

machine model.

Two or more people or a lifting device are

required to lift this appliance.

Page 5

! Warning

This equipment contains high voltage electricity

! Warning

!

Warning

!

Warning

and refrigerant charge. Installation and repairs are

to be performed by properly trained technicians

aware of the dangers of dealing with high voltage

electricity and refrigerant under pressure.The

technician must also be certified in proper

refrigerant handling and servicing procedures. All

lockout and tag out procedures must be followed

when working on this equipment.

Do not damage the refrigeration circuit when

installing, maintaining or servicing the unit.

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision concerning use of the appliance by a

person responsible for their safety. Do not allow

children to play with this appliance.

All covers and access panels must be in place

and properly secured, before operating this

equipment.

Page 6

!

Warning

Do not obstruct machine vents or openings.

! Warning

! Warning

! Warning

Do not store gasoline or other flammable vapors

or liquids in the vicinity of this or any other

appliance.

Do not clean with water jet.

It is the responsibility of the equipment owner to

perform a Personal Protective Equipment Hazard

Assessment to ensure adequate protection

during maintenance procedures.

Page 7

! Warning

When using electric appliances, basic

precautions must always be followed, including

the following:

a. Read all the instructions before using

the appliance.

b. To reduce the risk of injury, close

supervision is necessary when an

appliance is used near children.

c. Do not contact moving parts.

d. Only use attachments recommended or

sold by the manufacturer.

e. Do not use outdoors.

f. For a cord-connected appliance, the

following must be included:

• Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use

and before servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the

appliance malfunctions or is dropped

or damaged in any manner. Contact

the nearest authorized service facility

for examination, repair, or electrical

or mechanical adjustment.

g. Follow applicable lock out tag out

procedures before working on

equipment.

h. Connect to a properly grounded outlet

only.

Page 8

This Page Intentionally Left Blan k

Page 9

Table of Contents

Safety Notices . . . . . . . . . . . . . . . . . . . . . . 2

Procedural Notices . . . . . . . . . . . . . . . . . . 3

Read These Before Proceeding: . . . . . . . . .4

General Information

About Blend-In-Cup . . . . . . . . . . . . . . . . . 15

Serial Number Location . . . . . . . . . . . . . . 15

Specifications . . . . . . . . . . . . . . . . . . . . . . 16

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 16

Product Delivery Location . . . . . . . . . . . . . .20

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Air / CO2, Plain & Chilled Water Inlets . . . . 25

System Pressures . . . . . . . . . . . . . . . . . . . .26

Drain Connections . . . . . . . . . . . . . . . . . . . .27

Installation

Step-by-Step Installation . . . . . . . . . . . . . 29

Pre-installation Checklist . . . . . . . . . . . . . . . 29

Connections . . . . . . . . . . . . . . . . . . . . . . . .31

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Cleaning & Start-up . . . . . . . . . . . . . . . . . . .34

Demonstrate . . . . . . . . . . . . . . . . . . . . . . . .36

Post Installation Checklist . . . . . . . . . . . . . .37

Component Identification

External . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Left Side & Front . . . . . . . . . . . . . . . . . . . . .39

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Top Rear . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Top Left . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Top Right . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Bottom Cabinet . . . . . . . . . . . . . . . . . . . . . . 45

Maintenance

General Maintenance . . . . . . . . . . . . . . . . 47

Daily, Weekly Monthly . . . . . . . . . . . . . . . . . 47

Door Gasket Maintenance . . . . . . . . . . . . . . 49

Drain Maintenance - Inside Lower Cabinet .50

Refrigerators . . . . . . . . . . . . . . . . . . . . . . . . 50

Part Number STH034 3/13 9

Page 10

Stainless Steel Care & Cleaning . . . . . . . . .51

Doors/Hinges . . . . . . . . . . . . . . . . . . . . . . . . 52

Preventing Blower Coil Corrosion . . . . . . . .53

Cleaning Kits . . . . . . . . . . . . . . . . . . . . . . . .53

Daily Cleaning - Zone 1 . . . . . . . . . . . . . . 54

Gather the following supplies . . . . . . . . . . .55

Blenders / Dispense Area Cleaning & Sanitizing

56

Weekly Cleaning - Zone 2 . . . . . . . . . . . . 67

Gather the following supplies . . . . . . . . . . .68

Product Line Cleaning & Sanitizing . . . . . . .69

Sanitizing Ice Bin & Water Nozzles (Optional) 77

Blenders / Dispense Area Cleaning & Sanitizing

83

Drain Cleaning (Optional) . . . . . . . . . . . . . .94

Monthly Cleaning - Zone 3 . . . . . . . . . . . 100

Gather the following supplies . . . . . . . . . . .100

Ice Maker / Bin Descaling, Cleaning & Sanitizing

102

Other Monthly Tasks . . . . . . . . . . . . . . . . . .113

Biannual Descaling- Zone 3 . . . . . . . . . . 115

Turn ON Descaling . . . . . . . . . . . . . . . . . . .116

Gather the following supplies . . . . . . . . . . .121

Ice Maker / Bin Descaling, Cleaning & Sanitizing

122

Turn OFF Descaling . . . . . . . . . . . . . . . . . .133

Product Line Flush . . . . . . . . . . . . . . . . . 137

Gather The Following Supplies . . . . . . . . . .138

Manual Ice Machine Cleaning . . . . . . . . . 150

For MB-8-1PP . . . . . . . . . . . . . . . . . . . . . . .150

Bin / Dispenser Descale, Clean, & Sanitize .154

Bin / Dispenser Disassembly Descale, Clean, &

Sanitize . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Annual Planned Maintenance . . . . . . . . . 159

Operation

Touch Screens . . . . . . . . . . . . . . . . . . . . . 161

Drink Selection Screen . . . . . . . . . . . . . . . .162

Flavor Selection Screen . . . . . . . . . . . . . . .163

Size Screen . . . . . . . . . . . . . . . . . . . . . . . . .164

Main Menu Screen . . . . . . . . . . . . . . . . . . .168

Manager’s Menu Screen . . . . . . . . . . . . . . .169

Product Inventory Screen . . . . . . . . . . . . . .200

Cleaning Screen . . . . . . . . . . . . . . . . . . . . .204

10 Part Number STH034 3/13

Page 11

Ice Making Sequence of Operation . . . . . 206

Ice Machines R290 Refrigerant . . . . . . . . . .206

Product Dispense Operation . . . . . . . . . . 207

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Refrigerated Cabinet Operation . . . . . . . 208

Normal Operation . . . . . . . . . . . . . . . . . . . .208

Evaporator & Condenser Fan Motor Operation

209

Operation in the Clean/Sanitize cycle . . . . .210

Adaptive Defrost . . . . . . . . . . . . . . . . . . . . .210

High Temp Alarm . . . . . . . . . . . . . . . . . . . .210

Thermistor Failure . . . . . . . . . . . . . . . . . . . .210

Other Operations . . . . . . . . . . . . . . . . . . . 211

Recommended Cups . . . . . . . . . . . . . . . . . . 211

Display Errors . . . . . . . . . . . . . . . . . . . . . . 213

Troubleshooting

Control System . . . . . . . . . . . . . . . . . . . . . 219

Will Not Run Diagnostics . . . . . . . . . . . . . . .219

Beverage System . . . . . . . . . . . . . . . . . . . 221

Beverage System Diagnostics . . . . . . . . . .221

Procedure to Clear Blocked Line . . . . . . . . . 222

Ice System . . . . . . . . . . . . . . . . . . . . . . . . . 224

Water System Checklist . . . . . . . . . . . . . . .225

ICE PRODUCTION & QUALITY CHECK . .226

MB-8-1PP Ice Machine Electrical Troubleshoot-

ing Flowchart . . . . . . . . . . . . . . . . . . . . . . . .228

Refrigerated Cabinet . . . . . . . . . . . . . . . . 235

Reach-in temperature Out of Range . . . . . .239

High Product Temperature . . . . . . . . . . . . . 243

Refrigeration System Diagnostics . . . . . 244

Analyzing Discharge Pressure or Temperature

244

Analyzing Suction Pressure or Temperature 246

Analyzing Discharge Pressure or Temperature

248

Analyzing Suction Pressure or Temperature 250

Procedure to Clear Blocked Line . . . . . . 252

How to Check Air/CO2 Pressure . . . . . . . 255

How to Adjust Air/CO2 Pressure . . . . . . . . . 259

How to Check Plain Water Pressure . . . . 263

Component Check Procedures

Control System . . . . . . . . . . . . . . . . . . . . . 265

Part Number STH034 3/13 11

Page 12

ON/OFF Rocker Switch . . . . . . . . . . . . . . . . 265

Power Relay . . . . . . . . . . . . . . . . . . . . . . . .267

Power Supply . . . . . . . . . . . . . . . . . . . . . . .269

UI (User Interface - Touchscreen) . . . . . . . . 271

SRB Board . . . . . . . . . . . . . . . . . . . . . . . . . .275

Blender Control Board . . . . . . . . . . . . . . . . .279

CIP (Clean In Place) Relay Board . . . . . . . .282

Beverage Components . . . . . . . . . . . . . . 284

Pressure Regulator - Water or CO2 . . . . . .284

Water Dispense Solenoid Valve . . . . . . . . .285

Syrup Solenoid Valve . . . . . . . . . . . . . . . . .286

Non Drip Valve . . . . . . . . . . . . . . . . . . . . . .287

Product Pump . . . . . . . . . . . . . . . . . . . . . . . 288

Step Motor . . . . . . . . . . . . . . . . . . . . . . . . . .289

Blender Motor . . . . . . . . . . . . . . . . . . . . . . .290

Home Position Switch . . . . . . . . . . . . . . . . .291

Door Switches . . . . . . . . . . . . . . . . . . . . . . .292

Water Rinse Solenoid Valve . . . . . . . . . . . . 293

Ice Machine Components . . . . . . . . . . . . 294

High Pressure Cutout (HPCO) Control . . . .294

Ice Maker Bin Level Relay . . . . . . . . . . . . . . 295

ICE CONDENSER COIL FAN . . . . . . . . . . .295

Infrared Ice Bin Control . . . . . . . . . . . . . . . .296

Refrigerated Cabinet . . . . . . . . . . . . . . . . 297

Temperature Thermistor - Nozzle, Cabinet or De-

frost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .297

Evaporator Fan Motor . . . . . . . . . . . . . . . . .299

Duct Fan Motor . . . . . . . . . . . . . . . . . . . . . .300

Condenser Fan Motor . . . . . . . . . . . . . . . . .300

Compressor Electrical Diagnostics . . . . . . . 301

Compressor Drawing Locked Rotor . . . . . .302

Diagnosing Capacitors . . . . . . . . . . . . . . . .302

Filter-Driers . . . . . . . . . . . . . . . . . . . . . . . 303

Charts

Total System Refrigerant Charge . . . . . . 305

Operational Charts . . . . . . . . . . . . . . . . . 306

R290 Refrigerant - Ice Machine . . . . . . . . . .306

Diagrams

Wiring Diagrams . . . . . . . . . . . . . . . . . . . 307

R290 Ice Machine Refrigerant - Control System

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . 308

R290 Ice Machine Refrigerant - Refrigeration

Cabinet Wiring Diagram . . . . . . . . . . . . . . .309

12 Part Number STH034 3/13

Page 13

Models: MB-8-1PP . . . . . . . . . . . . . . . . . . .309

R290 Ice Machine Refrigerant - Ice Maker & Ice

Dispenser Wiring Diagram . . . . . . . . . . . . .310

Models: MB-8-1PP . . . . . . . . . . . . . . . . . . .310

R290 Ice Machine Refrigerant - Ice Maker Wiring

Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .311

Models: MB-8-1PP . . . . . . . . . . . . . . . . . . .311

R290 Ice Machine Refrigerant - CIP BOard Wiring

Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .312

Models: MB-8-1PP . . . . . . . . . . . . . . . . . . .312

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .313

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .314

Ice Machine Cleaning & Sanitizing Diagram 315

Models: MB-8-1PP . . . . . . . . . . . . . . . . . . .315

Ice Machine Cleaning & Sanitizing Diagram 316

Models: MB-8-1PP . . . . . . . . . . . . . . . . . . .316

Dispense System Diagram . . . . . . . . . . . . . 317

Part Number STH034 3/13 13

Page 14

14 Part Number STH034 3/13

Page 15

General Information

About Blend-In-Cup

The Blend-In-Cup beverage system is a self-contained

dispensing unit that allows the operator to make flavor

combinations of blended and non-blended drinks. It

holds product flavoring in a refrigerated reach-in base

enclosure, has a refrigerated ice making machine and

includes one or two mixing modules.

The operator controls and accesses the unit using a

lighted touch screen. Icons on the drink selection

screens represent the primary flavor combinations for

the drinks. There are multiple drink size options. Menu

changes and additions are uploaded using a USB

mass storage device and the Menu Connect Software

platform.

On-screen instructions also include operator

procedures for cleaning/sanitizing, checking inventory,

replacing product bags, selecting drink sizes and

manually preparing drinks. Managers and technicians

have access to menu/software updates, diagnostics

and other service screens.

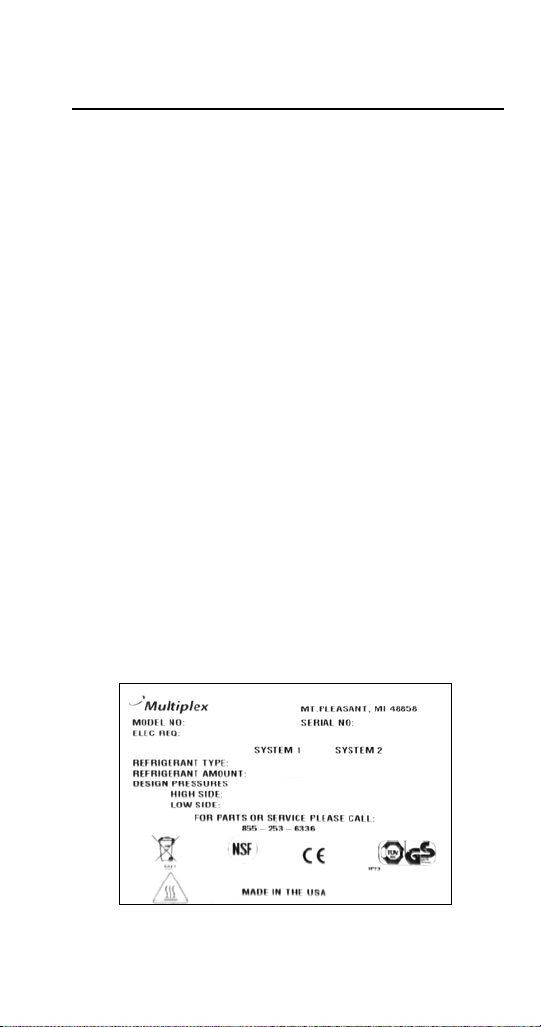

Serial Number Location

The Blend-In-Cup beverage system serial number is

listed on the serial number decal affixed to the middle

of the lower back panel. Another serial number decal

is located on the right side of the machine.

Sample Serial Tag

Part Number STH034 3/13 15

Page 16

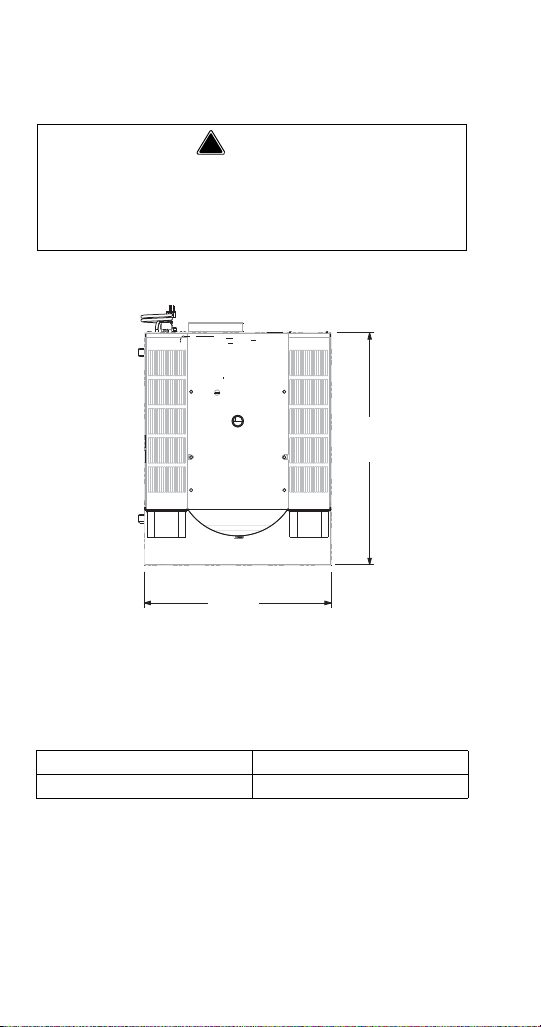

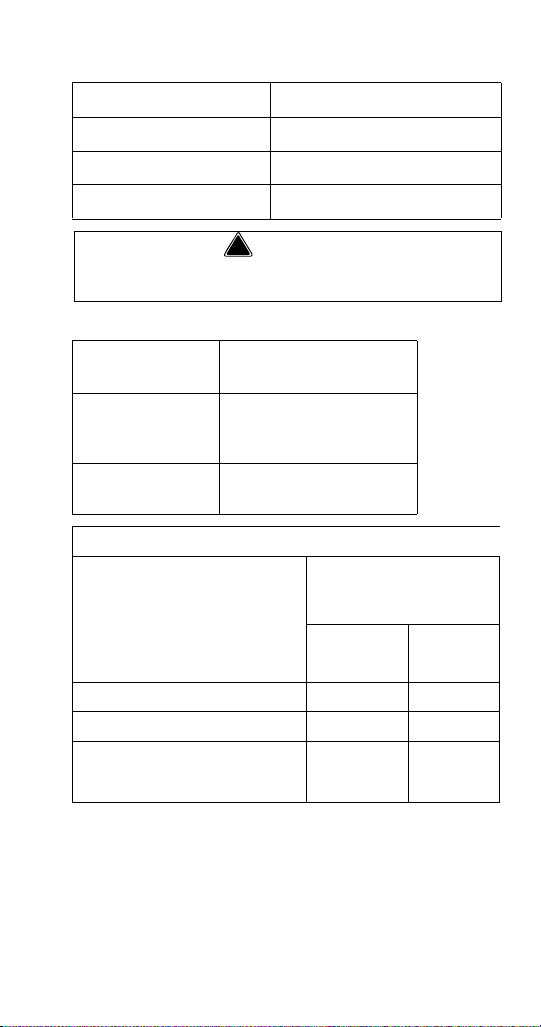

Specifications

! Warning

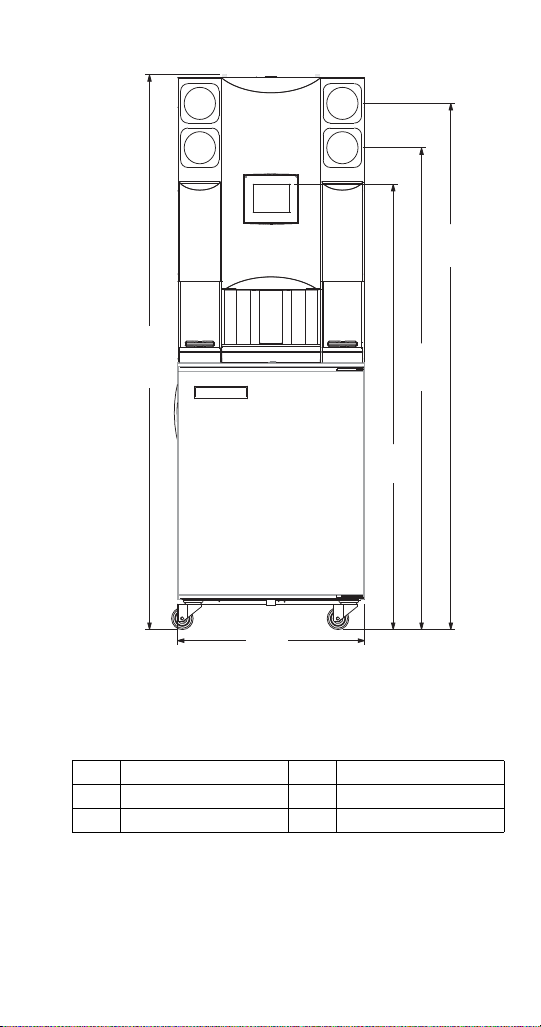

A

B

Elevation View

DIMENSIONS

To avoid instability the installation area must be

capable of supporting the weight of the equipment

and a full bin of ice. Additionally the equipment must

be level side to side and front to back.

A 26.00" (66 cm)

B 32.82" (83 cm)

16 Part Number STH034 3/13

Page 17

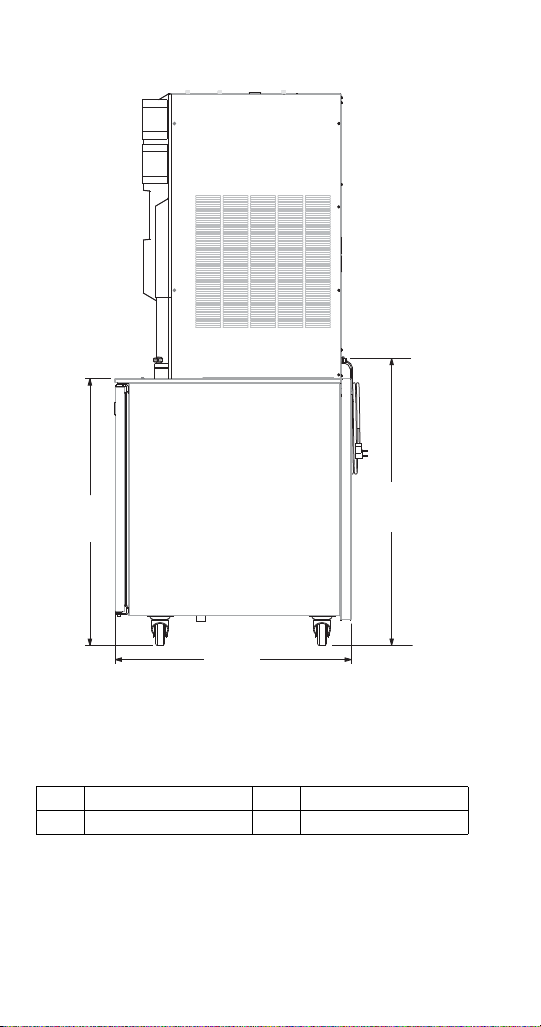

F

H

E

D

C

Elevation View

C 71.19" (181 cm) F 26.00" (66 cm)

D 65.19" (166 cm) H 75.07" (191 cm)

E 60.25" (153 cm)

Part Number STH034 3/13 17

Page 18

G 32.82" (83 cm) J 39.09" (99 cm)

G

I

J

Side View

I 36.15" (92 cm)

18 Part Number STH034 3/13

Page 19

CAPACITY & WEIGHT

MB-8-1PP Ice Capacity H.P.

Refrigerant

Charge

Max

Product

Bin Load

Shipping

Weight

Empty

Weight

Full

Weight

Lower

Cabinet

–1/5

R-290

4.75 oz.

(134.7 g)

19.8 lbs.

(9 kg)

606 lbs

(275 kg)

Crated

492 lbs (

223 kg)

Unpacked

No Ice/

Product

656 lbs

(298 kg)

With Ice/

Product

Ice Maker

310 lbs.

(141 kg)/24 hr.

Bin Storage

30 lbs (14 kg)

1/2

R-290

3.17 oz

(90 g)

–

Part Number STH034 3/13 19

Page 20

PRODUCT DELIVERY LOCATION

!

Warning

The location selected for the Blend-In-Cup Beverage

System must meet the following criteria.

• The air temperature must be at least 40°F (4°C),

but must not exceed 90°F (32°C), climate class 4.

• The location must not be near heat-generating

equipment or in direct sunlight and must be

protected from weather.

• Plain or Chilled Inlet Water Temperature

min/max = 40°F / 90°F (4°C / 32°C).

• Always use the water supply line supplied when

installing this appliance. Never reuse an old supply

line.

• Verify floor of install location is within 1/2” of level

front to back, side to side.

• Keep equipment area clear of combustible

material.

Carbon Dioxide (CO2) displaces oxygen.

Exposure to a high concentration of CO

causes tremors, which are followed rapidly by

loss of consciousness and suffocation. If a CO

gas leak is suspected, particularly in a small

gas

2

2

area, immediately ventilate the area before

repairing the leak. CO2 lines and pumps must not

be installed in an enclosed space. An enclosed

space can be a cooler or small room or closet.

This may include convenience stores with glass

door self serve coolers. If you suspect CO

build up in an area, venting of the B-I-B pumps

and / or CO

monitors must be utilized.

2

may

2

20 Part Number STH034 3/13

Page 21

Clearances

! Warning

To p 18" (46 cm)

Sides 6" (15 cm)

Back 6" (15 cm)

Front 30" (76 cm)

Do not obstruct machine vents or openings.

Heat of Rejection

Model

All Single & Dual

Spindle Base

(Cabinet 1)

Ice Maker

(Cabinet 2)

Heat of Rejection

BTU/h

2100

5150

Operating Pressures PSIG

Air Temperature Entering

Condenser Coil

Freeze

Cycle

Discharge

Pressure

Suction

Pressure

70°F 150-170 17-23

90°F 180-200 18-24

110 °F 225-245 21-27

Part Number STH034 3/13 21

Page 22

ELECTRICAL

! Warning

!

Caution

All wiring must conform to local, state and national

codes.

Minimum Circuit Ampacity

The minimum circuit ampacity is used to help select

the wire size of the electrical supply. (Minimum circuit

ampacity is not the Blend-In-Cup Beverage System’s

running amp load.) The wire size (or gauge) is also

dependent upon location, materials used, length of

run, etc., so it must be determined by a qualified

electrician.

Electrical Requirements

Refer to Blend-In-Cup Beverage System Model/Serial

Plate for voltage/amperage specifications.

Operate equipment only on the type of electricity

indicated on the specification plate.

Voltage

The standard voltage is 230VAC-50Hz. A dedicated

electrical circuit is required, a power cord is provided

with all units.

Some models are available in different voltages and may

be equipped with a different plug, for details on each

model always refer to the serial number tag to verify

electrical data.

22 Part Number STH034 3/13

Page 23

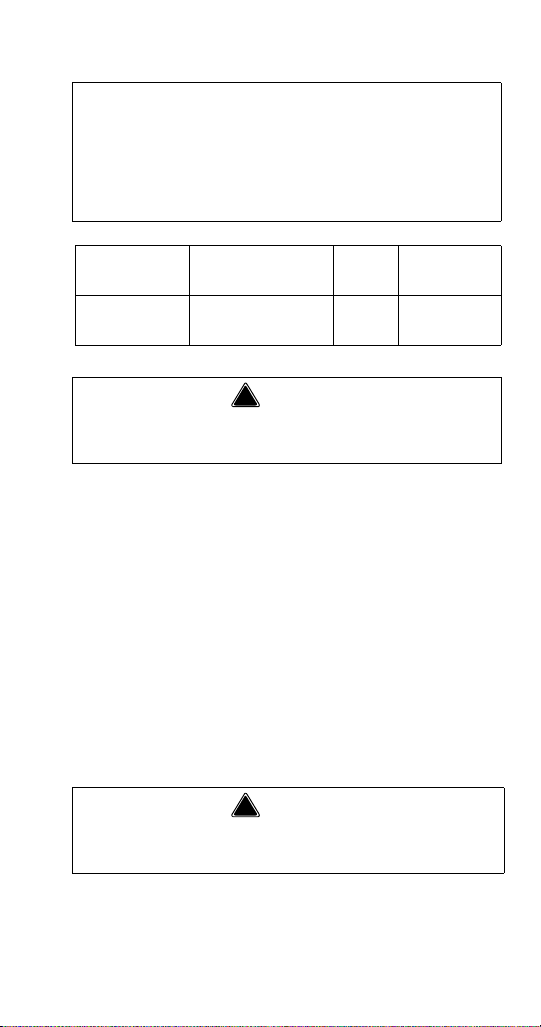

Minimum Circuit Amperage Chart

Important

! Warning

! Warning

Due to continuous improvements, this

information is for reference only. Please refer to

the serial number tag to verify electrical data.

Serial tag information overrides information listed

on this page.

Model

Numbers

MB-8-1PP

Dual Spindle

Voltage/Cycle/

Refrigerant

230-240/50/1

R290

Total

Breaker Size

Amps

6.4 20A

(Max)

Grounding Instructions

The machine must be grounded in accordance

with national and local electrical codes.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the risk

of electric shock. This appliance is equipped with a

cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Bonding Instructions (230-240V 50 Hz Models Only)

This appliance must be connected to the potential

equalization system in accordance with EN60335-1

and EN60335-2-75. A bonding lug is provided on the

lower right front corner of the appliance.

This machine must be connected to the potential

equalization system.

Part Number STH034 3/13 23

Page 24

!

Warning

When using electric appliances, basic

precautions must always be followed, including

the following:

a. Read all the instructions before using

the appliance.

b. To reduce the risk of injury, close

supervision is necessary when an

appliance is used near children.

c. Do not contact moving parts.

d. Only use attachments recommended or

sold by the manufacturer.

e. Do not use outdoors.

f. For a cord-connected appliance, the

following must be included:

• Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use

and before servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the

appliance malfunctions or is dropped

or damaged in any manner. Contact

the nearest authorized service facility

for examination, repair, or electrical

or mechanical adjustment.

g. Follow applicable lock out tag out

procedures before working on

equipment.

h. Always unplug before replacing the lamp.

Replace the bulb with the same type.

i. Connect to a properly grounded outlet

only. See Grounding Instructions.

24 Part Number STH034 3/13

Page 25

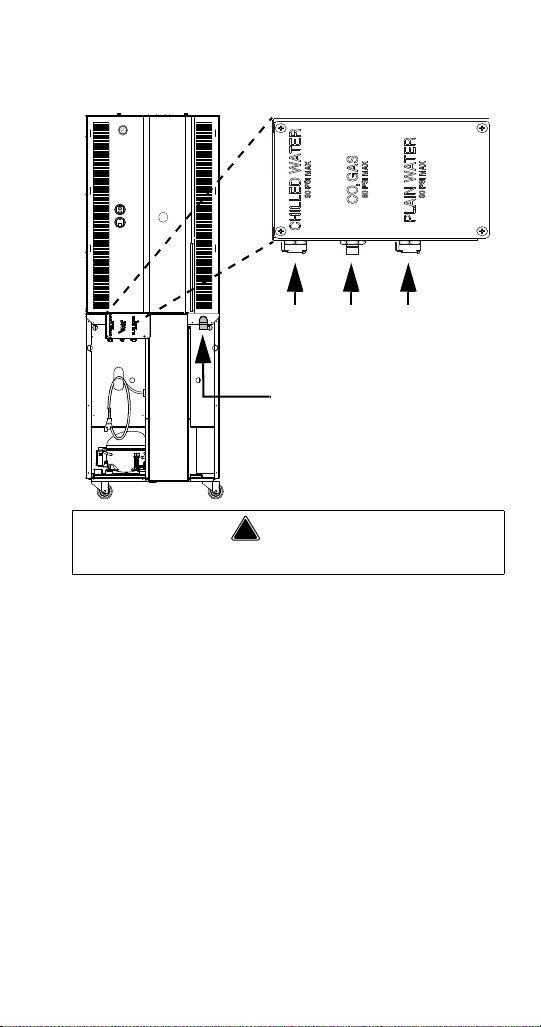

AIR / CO2, PLAIN & CHILLED WATER INLETS

!

Warning

Chilled

Wate r

IN

Air/

CO

2

IN

Plain

Water

IN

Drain

OUT

Connections in the Rear of the Unit

Connect to a potable water supply only.

• Use supplied 3/8” (.95 cm) panel-mounted hose

barb and 6' (1.8 m) of beverage tubing to connect

labeled coupling body fitting(s) on back of unit for

each supply connection.

• Do not connect either water connection to a hot

water supply. Be sure all hot water restrictors

installed for other equipment are working. (Check

valves on sink faucets, dishwashers, etc.)

• Install a water shut-off valve in the water line at the

rear of the machine.

• Insulate water inlet lines to prevent condensation.

Hard Water

In areas where the water is highly concentrated with

minerals the water should be tested by a water treatment

specialist, and the recommendations of the specialist

regarding filtration and/or treatment should be followed.

Part Number STH034 3/13 25

Page 26

SYSTEM PRESSURES

Important

Important

Important

Plain & Chilled Water

Requires the pressure measurement to be taken

only when rinse water is spraying (flowing

conditions) in a blender chamber.

• Plain Water Supply Pressure must be capable of

continuously suppling a minimum of 35 psi (241

kPa, 2.41 bar) during flowing conditions.

• If a separate chilled water source is used the

chilled supply pressure needs to be a minimum of

35 psi (241 kPa, 2.41 bar) at no flow conditions.

Water pressure affects the blender area cleaning,

a water booster may be required if pressure is

too low.

Air / CO

• Supply must be capable of 35 psi (241 kPa, 2.41

• Supply to the unit not to exceed 80 psi (345 / 552

26 Part Number STH034 3/13

2

Requires the pressure measurement to be taken

only when a product pump is being activated

(product pump during flow conditions).

bar) minimum during flowing conditions, measured

at the unit Air/CO

Air/CO2 Pressure on page 255.

kPa, 3.45 / 5.52 bar) maximum during no flow

conditions.

regulator. See How to Check

2

Page 27

DRAIN CONNECTIONS

• Connect supplied 1" ID hose to hose-barb

connection on machine.

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• An air gap is included in the design of the machine

for backflow prevention, plumb to local code.

Part Number STH034 3/13 27

Page 28

28 Part Number STH034 3/13

This Page Intentionally Left Blan k

Page 29

Installation

Important

Step-by-Step Installation

These instructions are provided to assist the qualified

installer. Contact your Manitowoc Foodservice Service

Agent or call Manitowoc Foodservice for information

regarding start-up services.

Failure to follow these installation guidelines may

affect warranty coverage.

PRE-INSTALLATION CHECKLIST

Keep product bags in a cooler at least 24

hours prior to installation.

Any damage should be noted and reported

to the delivering carrier immediately.

Check the lower portion of the unit to be

sure casters are not bent.

Visually inspect the refrigeration package,

compressor compartment housing. Be sure

lines are secure and base is still intact.

Inspect installation location behind the BIC

for electrical outlet location, CO

hose fittings, and shutoff.

Check voltage at outlet dedicated for BIC.

Verify floor of install location is within 1/2” of

level front to back, side to side and all

casters are touching the floor.

Part Number STH034 3/13 29

, water

2

Page 30

! Warning

The mass of this appliance will allow it to move

uncontrolled on an inclined surface. Adequate

means must be provided to prevent uncontrolled

movement at all times.

Remove the side panels from the unit to

make the board connections, Air/CO

Water Regulator gauges accessible.

and

2

Check that board connections are secure

and did not vibrate loose during shipment.

Remove steel top panel. Check that the

black chute cover is sitting securely on the

chute. The ice maker will not operate

properly if it is out of place.

Check that both micro switches are in line

with the motor above the blenders.

30 Part Number STH034 3/13

Page 31

CONNECTIONS

Important

Chilled

Wate r

IN

Air/

CO

2

IN

Plain

Water

IN

Drain

OUT

Connections in the Rear of the Unit

Leave enough slack in the water/CO2/drain lines to

allow access to the rear of the machine without

disconnecting the lines.

Water

1. Connect the Plain and Chilled (if used) water lines

quick disconnect fittings and verify the water

regu lators are se t to 35 psi (241 kPa, 2.41 bar). The

Plain Water regulator is located on the left side of

the unit and the Chilled Water regulator is located

at the rear top. Final, during flow, settings will be

made once the unit is in operation.

See Cleaning

& Start-up on page 34 and/or “How to Check Air/

CO2 Pressure” on page 255.

Part Number STH034 3/13 31

Page 32

Air/CO2

Important

Important

2. Connect Air/CO2 line quick disconnect fitting.

Verify the Air/CO

unit is set to 35 PSI (241 kPa, 2.41 bar). Final

during flow settings will be made once the unit is

in operation.

Regulators are factory set but will need to be

checked and possibly adjusted under flowing

conditions once the unit is operational.

3. Confirm correct orientation of Water and Air/CO2

fittings.

4. Coil excess tubing and secure with tie straps.

Drain

5. Route drain line (minimum 1" ID) to drain,

maintain a 2" (51 mm) air gap. Cut to proper

length if needed (do not leave loops in drain). See

Drain Connections on page 27

Electrical

6. If all electrical and grounding requirements have

been followed (

page 22 & See Grounding Instructions on page

23) proceed to insert electrical plug from BIC into

wall receptacle.

7. Turn power and compressor switches, on the left

hand side of the unit and the rear, to the ON position.

8. The touch screen should energize and inform the

user to perform Zone 2 & 3 cleaning before the

unit can be put into operation.

2 regulator on the left side of the

See Electrical Requirements on

Do not add product to the machine until

cleaning and sanitizing are complete.

32 Part Number STH034 3/13

Page 33

CHECKLIST

Review before proceeding to Cleaning & Start-up.

Has all of the internal packing been

removed?

Have all of the electrical, water and CO2

connections been made?

Is there proper clearance around the

machine for air circulation?

Is the machine grounded / polarity correct?

Has the machine been installed where the

incoming water temperature will remain in

the range of 40°F / 90°F (4°C / 32°C)?

Have the regulators been set to 35 PSI (241

kPa, 2.41 bar)?

Have the blender door sensor position(s)

been checked?

Have the Compressor and Power switches

been turned to the ON position?

Part Number STH034 3/13 33

Page 34

CLEANING & START-UP

9. Clean and sanitize the Blend-In-Cup machine by

following the on screen instructions,

See Weekly

Cleaning - Zone 2 on page 67, “Monthly Cleaning Zone 3” on page 100, By doing so the following

will have been completed;

A. All beverage lines, ice maker, dispense area,

and blender chambers, cleaned and

sanitized.

B. Water run through the drain to verify it is

draining properly.

C. Product bags retrieved from walk-in cooler,

installed into the product bins and placed into

their proper location in the cabinet. See

Assigning Flavors on page 179 & “Procedure to

Install a Product Bag” on page 202.

D. All product lines primed and ready for use.

NOTE: During the cleaning process is an ideal time to

verify pressure regulator settings during flowing conditions.

E. Verify the Plain Water regulator is set correctly

during blend chamber cleaning, the regulator

should maintain 35 psi (241 kPa, 2.41 bar) under

flowing conditions.

F. Verify the Air/CO2 regulator is set correctly

during product line cleaning, the regulator should

maintain 35 psi (241 kPa, 2.41 bar) under flowing

conditions.

NOTE: The Chilled Water Regulator needs to be a

minimum of 35 psi (241 kPa, 2.41 bar) at no flow

conditions.

34 Part Number STH034 3/13

Page 35

Label

Important

10. Add labels to product bins, put labels in correct place.

11. Add labels anywhere else on the unit required.

Software

12. Verify correct firmware is loaded. See Firmware

Update Procedure on page 187.

13. Load recipes. See Recipe Loading Procedure on

page 190.

14. Verify correct drinks and flavors are available.

Calibrate

Allow cabinet to reach operating temperature

36°F/2°C – 38°F/3°C before calibrating.

Calibration will be inaccurate if performed

above operating temperatures.

15. Product calibration can be performed once

operating temperature has been reached.

Calibration Procedure on page 181 for step by

step calibration instructions. Once completed the

Blend-In-Cup machine is ready for use.

16. Reinstall top and side panels.

17. Push BIC into place.

18. Verify the unit is level and shim if necessary.

Part Number STH034 3/13 35

See

Page 36

DEMONSTRATE

19. Using the Interface. See Touch Screens on page 161

20. How to make drink. See Procedure to Make a

Drink on page 165.

21. Manager Menu options, using the default

password “A”. (The password can be changed.)

See Manager’s Menu Screen on page 169.

22. Set date and time to activate warranty. See Date

& Time Setting on page 173

23. Complete start-up form, sign, and have store

manager sign form. (Fax to number on form.)

36 Part Number STH034 3/13

Page 37

POST INSTALLATION CHECKLIST

Has the machine been properly sanitized?

Has each flavor been installed and primed?

Have the Air/CO2 and Plain water regulators

been correctly set during flowing conditions?

Is the machine cycling ON/OFF on the

temperature control?

Has the owner/operator been instructed

regarding maintenance procedures?

Has the owner/operator completed the

warranty registration card?

Part Number STH034 3/13 37

Page 38

38 Part Number STH034 3/13

This Page Intentionally Left Blan k

Page 39

Component Identification

Cup

Dispensers

Touch

Screen

Blending

Station

Doors

Product

Bins

Pull Out Tray

Plain Water

& CO2

Regulator

Gauges

USB Port

Power

Switch

Whip Cream

Door (Optional)

Cabinet Door

Product

Dispense

Area

Syrup Rail &

Dividers

(Optional)

Blending

Station

Doors

External

LEFT SIDE & FRONT

FRONT

Part Number STH034 3/13 39

Page 40

REAR

Compressor

Switch

Power

Switch

Chilled Water

Gauge

Water & Air/

CO2 Inlets

Drain

Power Cord

40 Part Number STH034 3/13

Page 41

Internal

1

2

8

3

4

7

5

6

TOP REAR

1. Chilled Water Regulator

2. Chilled Water Solenoid

3. Ice Maker Gear Box

4. Ice Maker Control

5. CIP Ice Maker Relay

6. Ice Maker Evaporator Fan

7. Ice Maker Compressor

8. Ice Maker Evaporator

Part Number STH034 3/13 41

Page 42

Ice Machine Control Box

SOFTWARE

LABEL

COMP.

DRIVE

L2

FAN

L2

EARTH

L2

L2

L1

L1

L2

60M

2ND

B-T

WTR

B-E

SWITCH

COMP.

COMM.

VAC

24

LINE

VAC

I.D.

DR

20M

C

POWER

RESET

I.D.

PROBE

WATER

Start Cap Start Relay Circuit

Control Board

Switch, on/off,

compressor

Board, stand off

control (4 required)

Gear Motor

Ice Making Unit

Compressor

Control Box

Condenser

Reservoir

Inlet Water Valve

Control Switch

Power Switch

Ice Machine Components

42 Part Number STH034 3/13

Page 43

TOP LEFT

1

3

2

4

5

7

9

6

8

10

11

13

12

18

19

16

14

15

17

1. CIP Board

2. SRB

3. 24 V Power Supply

4. 4 Amp Fuse Power Supply

5. 4 Amp Fuse CIP System

6. Blender Home Position Micro Switch

7. Blender Board

8. Blender Motor

9. Linear Slide Motor

10. ON/OFF Switch

11. USB Port

12. Power Relay

13. Blender Door Relay

14. Blender 1 Rinse Nozzle Solenoid

15. Water Dispense Solenoid

16. Double Water inlet solenoid

17. EMC Filter

18. Air/C02 Regulator

19. Water Regulator

Part Number STH034 3/13 43

Page 44

T OP RIGHT

1

3

9

11

10

12

5

8

4

2

7

6

1. CIP Pump

2. Dump valve

3. Blender Motor

4. Blender Home Position Micro Switch

5. Mixer Board

6. CIP Ice bin solenoid

7. CIP C02/Air solenoid

8. Ice Maker Bin Relay

9. CIP Ice maker solenoid

10. Linear Slide Motor

11. Blender Door Relay

12. Blender 2 rinse nozzle solenoid

44 Part Number STH034 3/13

Page 45

BOTTOM CABINET

4

4

2

2

2

1

3

Pumps & Solenoids

1. None Drip Valves (x8)

2. Product Pumps (x8)

3. Product Bag Nozzles (x8)

4. Solenoid Valves (x2)

Part Number STH034 3/13 45

Page 46

Pump & Solenoid Numbering

1 2 3 4 5 6 7 8

Product

Pumps

Product

Pumps

Expansion Valves

Air/CO2 Solenoids

These numbers correspond to the product bins and inventory

numbers in the User Interface.

4

3

3

2

1

1

1

256

Refrigeration

1. Duct Fan

2. Evaporator Coil

3. Evaporator Fans (2)

4. Cabinet Sensor

3

1256

4

3478

7

8

46 Part Number STH034 3/13

Page 47

Maintenance

General Maintenance

This section covers common unit components and

their care. The chart below is an overview of the

maintenance that the end user and service technician

should perform, and the frequency. These figures are

the minimum required. If the Ice Machine is supplied

with hard water, more frequent cleaning should be

performed. If the condenser air filter is totally blocked,

after one week, more frequent cleaning is

recommended. (X = End User, S = Service Company

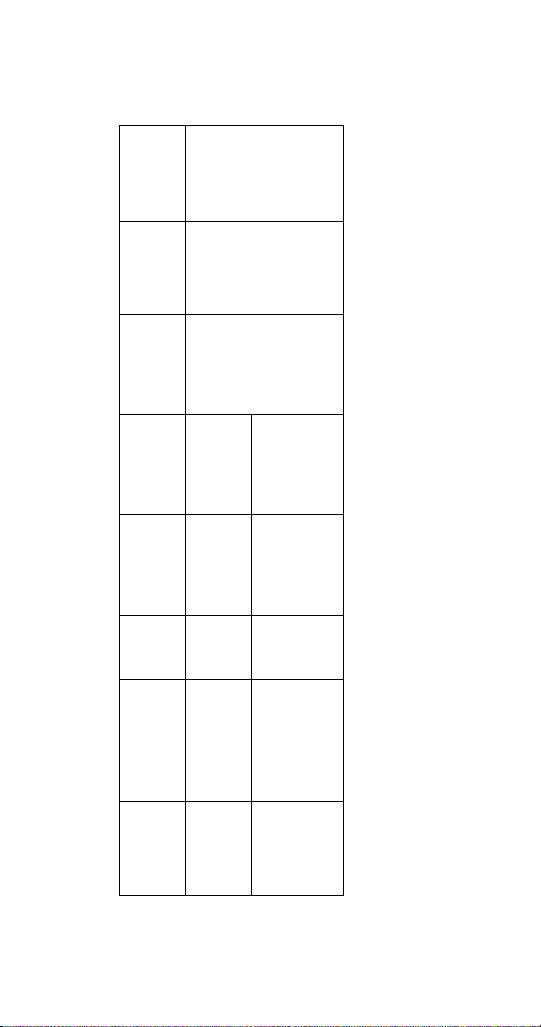

DAILY, WEEKLY MONTHLY

Maintenance Daily Weekly Monthly

Blender / Dispense Area

Cleaning/ Sanitizing

(Zone 1 Cleaning)

Product Line Cleaning &

Sanitizing

(Zone 2 Cleaning)

Drain Cleaning X

Clean Air Filters X

Clean/Sanitize

Ice Maker/Bin

(Zone 3 Cleaning)

Descale

Ice Maker/Bin

(Zone 3 Cleaning)

Clean Condenser Coil

Inspect Ice Maker /

Dispenser Parts

Check Ice Quality X X

X

X

X

Part Number STH034 3/13 47

Page 48

QUARTERLY & BIANNUAL

Maintenance 3 Months 6 Months

Blender / Dispense Area

Cleaning/ Sanitizing

(Zone 1 Cleaning)

Product Line Cleaning &

Sanitizing

(Zone 2 Cleaning)

Drain Cleaning

Clean Air Filters

Clean/Sanitize

Ice Maker/Bin

(Zone 3 Cleaning)

Descale

Ice Maker/Bin

(Zone 3 Cleaning)

Clean Condenser Coil X

Inspect Ice Maker /

Dispenser Parts

Check Ice Quality

ANNUAL, SHUTDOWN & START-UP

After

Maintenance Annual

Blender / Dispense Area

Cleaning/ Sanitizing

(Zone 1 Cleaning)

Product Line Cleaning &

Sanitizing

(Zone 2 Cleaning)

Drain Cleaning X

Clean Air Filters X

Clean/Sanitize

Ice Maker/Bin

(Zone 3 Cleaning)

Descale

Ice Maker/Bin

(Zone 3 Cleaning)

Clean Condenser Coil X

Inspect Ice Maker /

Dispenser Parts

Check Ice Quality S S S

S S S

Prolonged

Shutdown

X S

X S

S

S

At Start-

up

48 Part Number STH034 3/13

Page 49

!

Warning

Disconnect power to the unit before performing

Important

any service or maintenance functions.

If the machine going to be shutdown for any

length of time it is recommended to go through

the Zone 2 - Weekly Cleaning both prior to

turning off the unit and when returned to use.

If the unit is turned off the product will no longer

be kept cool in the refrigeration cabinet, remove

all product bags and keep refrigerated to prevent

spoilage.

DOOR GASKET MAINTENANCE

Door gaskets require regular cleaning to prevent mold and

mildew buildup and also to retain the elasticity of the

gasket. Gasket cleaning can be done with the use of warm

soapy water. Avoid full strength cleaning products on

gaskets as this can cause them to become brittle and

crack. Never use sharp tools or knives to scrape or clean

the gasket. Gaskets can be easily replaced and do not

require the use of tools or an authorized service person.

The gaskets are “Dart” style and can be pulled out of the

groove in the door and new gaskets can be “pressed”

back into place.

Part Number STH034 3/13 49

Page 50

DRAIN MAINTENANCE - INSIDE LOWER CABINET

!

Warning

Each unit has a drain located inside the unit that removes

the condensation from the evaporator coil and routes it to

an external condensate evaporator pan. Each drain can

become loose or disconnected during normal use. If you

notice water accumulation on the inside of the unit, be sure

the drain tube is connected to the evaporator drain pan. If

water is collecting underneath the unit, make sure the end

of the drain tube is in the condensate evaporator in the

machine compartment. The leveling of the unit is important

as the units are designed to drain properly when level. Be

sure all drain lines are free of obstructions.

REFRIGERATORS

Do not damage the refrigeration circuit when

installing, maintaining or servicing the unit.

The interior and exterior can be cleaned using soap

and warm water. If this isn’t sufficient, try ammonia and

water or a nonabrasive liquid cleaner. When cleaning

the exterior, always rub with the “grain” of the stainless

steel to avoid marring the finish. Do not use an

abrasive cleaner because it will scratch the stainless

steel and can damage the breaker strips and gaskets.

50 Part Number STH034 3/13

Page 51

STAINLESS STEEL CARE & CLEANING

Important

To prevent discoloration or rust on stainless steel,

several important steps need to be taken. First, we

need to understand the properties of stainless steel.

Stainless steel contains 70-80% iron, which will rust. It

also contains 12-30% chromium, which forms an

invisible passive film over the steel’s surface, which

acts as a shield against corrosion. As long as the

protective layer is intact, the metal is still stainless. If

the film is broken or contaminated, outside elements

can begin to break down the steel and begin to form

discoloration or rust. Proper cleaning of stainless steel

requires soft cloths or plastic scouring pads.

Never Use Steel Pads, W ire Brushes or Scrapers!

Cleaning solutions need to be alkaline based or nonchloride cleaners. Any cleaner containing chlorides will

damage the protective film of the stainless steel.

Chlorides are also commonly found in hard water,

salts, and household and industrial cleaners. If

cleaners containing chlorides are used, be sure to

rinse repeatedly and dry thoroughly. Routine cleaning

of stainless steel can be done with soap and water.

Extreme stains or grease should be cleaned with a

non-abrasive cleaner and plastic scrub pad. Always

rub with the grain of the steel. There are stainless steel

cleaners available which can restore and preserve the

finish of the steel’s protective layer. Early signs of

stainless steel breakdown are small pits and cracks. If

this has begun, clean thoroughly and start to apply

Part Number STH034 3/13 51

Page 52

stainless steel cleaners in attempt to restore the

!

Caution

!

Caution

passivity of the steel.

Never use an acid based cleaning solution! Many

food products have an acidic content, which can

deteriorate the finish. Be sure to clean the

stainless steel surfaces of ALL food products.

Common items include: tomatoes, peppers and

other vegetables.

Never use a high-pressure water wash for this

cleaning procedure as water can damage the

electrical components located near or at the

condenser coil.

DOORS/HINGES

Over time and with heavy use doors and hinges may

become loose. If this happens tighten the screws that

mount the hinge brackets to the frame of the unit. Loose or

sagging doors can cause the hinges to pull out of the

frame, which may damage both the doors and the hinges.

In some cases this may require trained & qualified service

agents or maintenance personnel to perform repairs.

NOTE: Do not place hot pans on/against the blue ABS

liner. Do not throw items into the storage area. Failure to

follow these recommendations could result in damage to

the interior of the cabinet or to the blower coil. Overloading

the storage area, restricting the airflow, and continuous

opening and closing of the doors and drawers will hamper

the unit’s ability to maintain operational temperature.

52 Part Number STH034 3/13

Page 53

PREVENTING BLOWER COIL CORROSION

Immediately wipe up all spills.

CLEANING KITS

Complete cleaning kits are available for single spindle (part

number 000-BIC-001R) and dual spindle (part number 000BIC-001Q) units. These kits include the following;

• (3) three 5 gallon buckets

• Bucket labels for Wash, Rinse, & Sanitizing

• Red & Blue cups for blender cleaning

• Squeeze Bottle

• Dispense Area Shield

• Tubing Manifold for product line cleaning

Part Number STH034 3/13 53

Page 54

Daily Cleaning - Zone 1

Main Menu Touch Screen

Cleaning Touch Screen

NOTE: The following procedures are the basic daily

cleaning instructions, on screen instructions can vary

depending on the recipe that was created with the

MenuConnect program. * These items are optional

and may not be displayed on all EasyTouch screens

during ZONE 1 Cleaning.

• Time to complete - 15 minutes

1. Cycle touch screen to the Main Menu and select

the Cleaning Icon.

2. In the cleaning screen select the Zone 1 Icon.

54 Part Number STH034 3/13

Page 55

GATHER THE FOLLOWING SUPPLIES

Follow the on screen instructions and gather the

following supplies;

Clean towels (* Cloths)

Spray Cleaner & Detergent

Solution

(Approved dish detergent solution)

Spray Sanitizer & Solution

(Approved sanitizer solution that

provides 100 ppm available chlorine.)

Red & Blue Cleaning Cups

(1 of each per blender station)

RB

* Scoop, Cleaning Brush, Gloves

& Safety Glasses

* These items are optional and may not be displayed on all

EasyTouch screens.

NOTE: If other cleaners are used, it is possible they will

not clean or sanitize your machine to NSF standards.

• Press the down arrow to continue

Part Number STH034 3/13 55

Page 56

BLENDERS / DISPENSE AREA CLEANING & SANITIZING

Blend Chamber Grate Removal

Grate Removal / Blender Station Wash

1. Follow the on screen instructions;

• * Put on gloves & safety glasses.

2. Remove grate from the mixer station(s)

• Press the down arrow to continue

3. Spray all surfaces inside blender station with

cleaning solution.

• * Then scrub thoroughly with approved

cleaning brush.

4. Thoroughly wipe down all surfaces of mixer

station & repeat for the other side if applicable.

• Press the down arrow to continue.

56 Part Number STH034 3/13

Page 57

Dispensing Area Cleaning

Dispense Area Screen

1. Remove center grate from dispensing area.

2. Spray all dispensing area surfaces with cleaning solution.

• * Then use approved cleaning brush to

thoroughly scrub area.

• Press the down arrow to continue.

3. Thoroughly spray each individual dispense nozzle

with cleaning solution and apply cleaner to each

individual dispensing valve.

• * Then use approved cleaning brush to

carefully scrub area.

4. Thoroughly wipe all dispense valves and

dispense area with a clean towel.

• Press the down arrow to continue.

Part Number STH034 3/13 57

Page 58

Mixer Door Removal

Mixer Door Removal Screen

1. Slightly open mixer door.

2. Squeeze at bottom of door.

3. Tilt out and pull the door down and out.

4. Repeat for other door if applicable.

• Press the down arrow to continue.

58 Part Number STH034 3/13

Page 59

Blender Station Wash

Blender Station Wash Screen

1. Completely spray blender station with cleaning solution.

• * Use cleaning brush to thoroughly scrub

down the entire area.

• * Using the approved cleaning brush,

thoroughly scrub down top of blender cap and

blender arm

2. Lift blender cap and thoroughly wipe down top of

blade housing and bottom of blender cap.

• * Scrub (with the approved cleaning brush) top of

blade housing and bottom of blender cap.

• Press the down arrow to continue.

3. Thoroughly spray with sanitizer solution.

• * Using the approved cleaning brush to scrub

entire blender assembly.

4. Repeat for other side if applicable.

• Press the down arrow to continue.

Part Number STH034 3/13 59

Page 60

Reinstall Grate(s)/Door(s)

Important

Grates & Doors Screen

1. Take all grate(s) and door(s) to sink to wash and

sanitize.

Never Use Steel Pads, Wire Brushes, Scrapers,

or any Abrasive Cleaners / Scouring Pads!

2. Do not put in dishwasher or power soaker.

3. Reinstall mixer grate(s).

4. Reinstall dispensing area grate.

5. Reinstall mixer door(s)

• Press the down arrow to continue.

60 Part Number STH034 3/13

Page 61

Blender Wash

Blender Wash Screen

Washing Screen

1. Place blue cleaning cup(s) with wash solution in

blender station(s) and close the blender doors.

• Use approved dish detergent solution)

2. Press the green check to begin.

The blenders will lower into the wash solution and spin

to clean. WASHING will display on the screen.

Part Number STH034 3/13 61

Page 62

Follow the on screen instruction, when prompted remove

Remove Cup Screen

Rinse Cup Screen

the blue cup(s) and pour wash solution down the drain.

Close the blender door(s) and RINSING will display on

the screen while the machine rinses the blenders.

Finished will display on the screen then progress to

the Blender Sanitizing screen.

62 Part Number STH034 3/13

Page 63

Blender Sanitizing

Blender Sanitizing Screen

Washing Screen

1. Place red sanitizing cup(s) with sanitizing solution

in blender station(s) and close the blender doors.

• Use approved sanitizer solution that provides

100 ppm available chlorine.

2. Press the green check to begin.

The blenders will lower into the wash solution and spin

to sanitize. SANITIZE will display on the screen.

Part Number STH034 3/13 63

Page 64

Follow the on screen instruction, when prompted

Remove Cup Screen

Rinse Cup Screen

remove the red cup(s) and pour sanitizing solution

down the drain.

Close the blender door(s) and RINSING will display on

the screen while the machine rinses the blenders.

Finished will display on the screen then progress to

the Blender Station Sanitizing screen.

64 Part Number STH034 3/13

Page 65

Blender Station Sanitizing

Blender Station Sanitizing Screen

1. Completely spray blender station with cleaning

solution.

• * Use cleaning brush to thoroughly scrub

down the entire area.

2. Allow to air dry, Do not wipe off sanitizer!

3. Repeat for other side if applicable.

• Press the down arrow to continue.

Part Number STH034 3/13 65

Page 66

Dispensing Area Sanitizing

Dispense Area Sanitizing Screen

1. Thoroughly spray each individual dispense nozzle

with sanitizer solution.

2. Thoroughly spray dispense area with sanitizer solution.

3. Allow to air dry, Do not wipe off sanitizer!

• * Remove gloves & safety glasses

• Press the green check to signify you have

completed the Zone 1 Daily Cleaning.

66 Part Number STH034 3/13

Page 67

Weekly Cleaning - Zone 2

Main Menu Touch Screen

Cleaning Touch Screen

NOTE: The following procedures are the basic weekly

cleaning instructions, on screen instructions can vary

depending on the recipe that was created with the

MenuConnect program or options chosen in the

Managers Menu. * These items are optional and may

not be displayed on all EasyTouch screens during

ZONE 2 Cleaning.

• Time to complete - 1 hour

1. Cycle touch screen to the Main Menu and select

the Cleaning Icon.

2. In the cleaning screen select the Zone 2 Icon.

Part Number STH034 3/13 67

Page 68

NOTE: Failure to complete the weekly cleaning

RB

123

sequence entirely will not reset the weekly cleaning

timer and will require the process to be repeated.

GATHER THE FOLLOWING SUPPLIES

Follow the on screen instructions and gather the

following supplies;

Clean towels (* Cloths)

Spray Cleaner & Detergent

Solution

(Approved dish detergent solution)

Spray Sanitizer & Solution

(Approved sanitizer solution that

provides 100 ppm available

chlorine.)

Red & Blue Cleaning Cups

(1 of each per blender station)

Set of Three (3) Cleaning Buckets

(Wash, Rinse & Sanitize Solutions)

Splash Shield

Cleaning Manifold

* Drain cleaner & Dispenser

* Scoop, Cleaning Brush,

Gloves & Safety Glasses

* These items are optional and may not be displayed on all

EasyTouch screens.

68 Part Number STH034 3/13

Page 69

NOTE: If other cleaners are used, it is possible they will

Prepare Solutions Screen

not clean or sanitize your machine to NSF standards.

• Press the down arrow to continue

PRODUCT LINE CLEANING & SANITIZING

Prepare Cleaning Solutions

1. Follow the on screen instructions;

• * Put on gloves & safety glasses.

2. Fill wash bucket with water and add detergent.

(Approved dish detergent solution.)

3. Fill rinse bucket with water.

4. Fill sanitizer bucket with water and add approved sanitizer.

(Approved sanitizer solution that provides 100 ppm

available chlorine.)

5. Fill blue cleaning cup(s) with wash solution and set aside.

(Approved dish detergent solution.)

• Press the down arrow to continue.

6. Fill red sanitizing cup(s) with sanitizing solution and

set aside. (Approved sanitizer solution that provides

100 ppm available chlorine.)

• Press the down arrow to continue.

Part Number STH034 3/13 69

Page 70

Washing Instructions

Washing Instructions Screen

1. Remove grate from center dispensing area.

2. Install splash guard in dispense area.

3. Remove product holders from cabinet.

4. Take product holders to refrigerated storage.

• Press the down arrow to continue

5. Spray and wipe each bib connector and area with

cleaner.

6. Spray each bib connector and area with sanitizer.

7. Connect a cleaning hose to each product nozzle.

• Press the down arrow to continue

8. Place cleaning manifold in wash bucket.

9. Press the green check to begin cleaning the lines.

70 Part Number STH034 3/13

Page 71

This will automatically send the wash solution through

Product Line Washing Screen

each line (slot), displaying the progress on the screen,

30 seconds per slot.

When washing has completed the Rinsing Instructions

Screen will appear automatically.

Part Number STH034 3/13 71

Page 72

Rinsing Instructions

Rinsing Instructions Screen

Product Line Rinsing Screen

1. Remove cleaning manifold from wash bucket.

2. Place cleaning manifold in rinse bucket.

3. Press the green check begin rinsing the lines.

This will automatically send the rinse solution through

each line (slot), displaying the progress on the screen,

30 seconds per slot.

When rinsing has completed the Sanitization

Instructions Screen will appear automatically.

72 Part Number STH034 3/13

Page 73

Sanitization Instructions

Sanitizing Instructions Screen

Product Line Sanitizing Screen

1. Remove cleaning manifold from rinse bucket.

2. Place cleaning manifold in sanitize bucket begin

sanitizing the lines.

3. Press the green check begin sanitizing the lines.

This will automatically send the sanitizing solution

through each line (slot), displaying the progress on the

screen, 30 seconds per slot.

When sanitizing has completed the Purging

Instructions Screen will appear automatically.

Part Number STH034 3/13 73

Page 74

Purging Instructions

Sanitizing Instructions Screen

Product Line Purging Screen

1. Disconnect the cleaning hoses from the product nozzles.

2. Press the green check begin purging the lines.

Air is pushed through each line (slot) blowing out any

remaining liquid, displaying the progress on the

screen, 30 seconds per slot.

When purging has completed the Reinstall Inventory

Screen will appear automatically.

74 Part Number STH034 3/13

Page 75

Reinstall Inventory

Reinstall Inventory Screen

Product Line Purging Screen

1. Retrieve product holders from refrigerated storage.

2. Reinstall each product holder into correct slot.

3. Remove splash guard from dispense area.

4. Reinstall center grate under dispensing area.

• Press the down arrow to continue.

5. Place a large cup under dispensing nozzles

6. Press the green check to prime each line.

This will automatically prime each line with product.

The screen will read Priming Slot X. Each slot will

change from Purged to Clean.

When priming has completed the Prime Completion

Screen will appear automatically.

Part Number STH034 3/13 75

Page 76

Auto Prime Complete

Prime Completed Screen

1. Remove and dispose of large cup with primed product.

2. Press the green check to continue to the

Sanitizing Ice Bin & Water Nozzles screen, if this

feature is not turned on in the Managers Menu

proceed to

“Blenders / Dispense Area Cleaning &

Sanitizing” on page 83.

76 Part Number STH034 3/13

Page 77

SANITIZING ICE BIN & WATER NOZZLES (OPTIONAL)

123

* These steps will only display during the ZONE 2

Cleaning on units with this feature turned on in the

Managers Menu. If this feature is not active the

interface will automatically proceed to

“Blenders /

Dispense Area Cleaning & Sanitizing” on page 83.

Gather the Following Supplies

Cleaning Buckets - Set of

Three (3)

Cleaning Hose *

(Located below product bins)

Ice Removal Chute

Splash Guard

Sanitizing Solution

(Approved sanitizer solution that

provides 100 ppm available

chlorine.)

* Scoop, Cleaning Brush,

Gloves & Safety Glasses

* These items are optional and may not be displayed on

all EasyTouch screens.

NOTE: If other cleaners are used, it is possible they

will not clean or sanitize your machine to NSF

standards.

• Press the down arrow to continue

Part Number STH034 3/13 77

Page 78

Removal of Ice

Ice Removal Screen

Ice Dispense Timer Screen

Follow the on screen instructions;

1. Install ice removal chute in dispenser area.

2. Place empty bucket on floor under ice chute.

3. Press the green check to begin dispensing ice.

• The Ice Dispensing Timer Screen will display,

the machine will empty of ice.

78 Part Number STH034 3/13

Page 79

Ice Disposal

Ice Disposal Screen

1. Dispose of ice in the bucket and set aside.

2. Remove ice removal chute from the dispenser

area and set aside.

3. Press the green check.

Part Number STH034 3/13 79

Page 80

Sanitizing Ice Bin & Water Nozzles Prep

Bin & Nozzles Prep Screen

Sanitizing Timer Screen

1. Install splash guard in dispense area.

• * Put on gloves and safety glasses.

2. Fill sanitizer bucket with water and add sanitizer.

(Use approved sanitizer solution that provides

100 ppm available chlorine.)

3. Place cleaning hose into the sanitizer bucket.

4. Press the green check to begin sanitizing the ice

bin and water nozzles.

• The Sanitizing Timer Screen will display, and

count down during the sanitizing process.

80 Part Number STH034 3/13

Page 81

Discard Sanitizer

Discard Sanitizer Screen

1. Install cleaning hose into the bottom of the

refrigerated cabinet.

2. Discard remaining sanitizer from the bucket.

3. Press green check to continue.

Part Number STH034 3/13 81

Page 82

Rinsing Sanitizer Prep

Plain Water Rinse

Rinse Timer Screen

1. Install splash guard in the dispense area.

2. Press the green check to begin the plain water

rinse cycle.

• The Rinse Timer Screen will display, and

count down during the rinsing process then

automatically proceed to the Grate Removal/

Blender Station Wash Screen.

82 Part Number STH034 3/13

Page 83

BLENDERS / DISPENSE AREA CLEANING & SANITIZING

Blend Chamber Grate Removal

Grate Removal / Blender Station Wash

1. Remove grate from the mixer station(s)

2. Spray all surfaces inside blender station with

cleaning solution.

• * Then scrub thoroughly with approved

cleaning brush.

• Press the down arrow to continue.

3. Thoroughly wipe down all surfaces of mixer

station & repeat for the other side if applicable.

• Press the down arrow to continue.

Part Number STH034 3/13 83

Page 84

Dispensing Area Cleaning

Dispense Area Screen

1. Remove center grate from dispensing area.

2. Spray all dispensing area surfaces with cleaning

solution.

• * Then use approved cleaning brush to

thoroughly scrub area.

• Press the down arrow to continue.

3. Thoroughly spray each individual dispense nozzle

with cleaning solution and apply cleaner to each

individual dispensing valve.

• * Then use approved cleaning brush to

carefully scrub area.

4. Thoroughly wipe all dispense valves and

dispense area with a clean towel.

• Press the down arrow to continue.

84 Part Number STH034 3/13

Page 85

Mixer Door Removal

Mixer Door Removal Screen

1. Slightly open mixer door.

2. Squeeze at bottom of door.

3. Tilt out and pull the door down and out.

4. Repeat for other door if applicable.

• Press the down arrow to continue.

Part Number STH034 3/13 85

Page 86

Blender Station Wash

Blender Station Wash Screen

1. Completely spray blender station with cleaning solution.

• * Use cleaning brush to thoroughly scrub

down the entire area.

• * Using the approved cleaning brush,

thoroughly scrub down top of blender cap and

blender arm.

2. Lift blender cap and thoroughly wipe down top of

blade housing and bottom of blender cap.

• * Scrub (with the approved cleaning brush) top of

blade housing and bottom of blender cap.

• Press the down arrow to continue.

3. Thoroughly spray with sanitizer solution.

• * Using the approved cleaning brush to scrub

entire blender assembly.

4. Repeat for other side if applicable.

• Press the down arrow to continue.

86 Part Number STH034 3/13

Page 87

Reinstall Grate(s)/Door(s)

Important

Grates & Doors Screen

1. Take all grate(s) and door(s) to sink to wash and

sanitize.

Never Use Steel Pads, Wire Brushes, Scrapers,

or any Abrasive Cleaners / Scouring Pads!

2. Do not put in dishwasher or power soaker.

3. Reinstall mixer grate(s).

4. Reinstall dispensing area grate.

5. Reinstall mixer door(s).

• Press the down arrow to continue.

Part Number STH034 3/13 87

Page 88

Blender Wash

Blender Wash Screen

Washing Screen

1. Place blue cleaning cup(s) with wash solution in

blender station(s) and close the blender doors.

• 0.425 oz/5 gal or Approved dish detergent

solution)

2. Press the green check to begin.

The blenders will lower into the wash solution and spin

to clean. WASHING will display on the screen.

88 Part Number STH034 3/13

Page 89

Follow the on screen instruction, when prompted

Remove Cup Screen

Rinse Screen

remove the blue cup(s) and pour wash solution down

the drain.

Close the blender door(s) and RINSING will display on

the screen while the machine rinses the blenders.

Finished will display on the screen then progress to

the Blender Sanitizing screen.

Part Number STH034 3/13 89

Page 90

Blender Sanitizing

Blender Sanitizing Screen

Sanitizing Screen

1. Place red sanitizing cup(s) with sanitizing solution

in blender station(s) and close the blender doors.

• Use approved sanitizer solution that provides

100 ppm available chlorine.

2. Press the green check to begin.

The blenders will lower into the wash solution and spin

to sanitize. SANITIZE will display on the screen.

90 Part Number STH034 3/13

Page 91

Follow the on screen instruction, when prompted

Remove Cup Screen

Rinse Screen

remove the red cup(s) and pour sanitizing solution

down the drain.

Close the blender door(s) and RINSING will display on

the screen while the machine rinses the blenders.

Finished will display on the screen then progress to

the Blender Station Sanitizing screen.

Part Number STH034 3/13 91

Page 92

Blender Station Sanitizing

Blender Station Sanitizing Screen

1. Completely spray blender station with cleaning solution.

• * Use cleaning brush to thoroughly scrub

down the entire area.

2. Allow to air dry, Do not wipe off sanitizer!

3. Repeat for other side if applicable.

• Press the down arrow to continue.

92 Part Number STH034 3/13

Page 93

Dispensing Area Sanitizing

Dispense Area Sanitizing Screen

1. Thoroughly spray each individual dispense nozzle

with sanitizer solution.

2. Thoroughly spray dispense area with sanitizer

solution.

3. Allow to air dry, Do not wipe off sanitizer!

• Press the green check to signify you have

completed the Zone 2 Weekly Cleaning or continue

on to Drain Cleaning if equipped with this option.

Part Number STH034 3/13 93

Page 94

DRAIN CLEANING (OPTIONAL)

Drain Cleaning Screen 1

* Only for units with this feature. These steps will only

display during the ZONE 2 Cleaning on units with this

feature turned on in the loaded recipe file. If this

feature is not active the interface will automatically

proceed to

“Weekly Cleaning Completed” on page 99

Prepare Unit for Drain Cleaning

1. Remove doors from blender station(s).

2. Remove grate from center dispensing area.

3. Remove grate from blender station(s).

• Press the down arrow to continue.

4. Slowly pour 1 gal / 3.8 L of hot (120-130°F / 49-54°C)

water into each drain.

• Press the down arrow to continue.

94 Part Number STH034 3/13

Page 95

Prepare Drain Cleaning Solution

Prepare Cleaning Solution

Mix Cleaning Solution

1. On the top of the dispenser, open pressure relief

knob by turning counter-clockwise.

2. Remove the cap rom the dispenser.

• Press the down arrow to continue.

3. Pour 1 gal / 3.8 L of hot (120-130°F / 49-54°C)

water into the dispenser.

• Press the down arrow to continue.

4. Quickly pour one packet of drain cleaner into dispenser.

5. Immediately replace and tighten cap.

6. On the top of the dispenser, close pressure relief

knob by turning clockwise.

• Press the down arrow to continue.

Part Number STH034 3/13 95

Page 96

7. Shake dispenser to dissolve cleaner.

Purge Drain Cleaning Dispenser

• Press the down arrow to continue.

Drain Cleaning

1. Carefully purge a small amount of solution from

the dispenser into the sink.

2. This helps prevent “sputtering” of solution and

possible splash onto clothing or eyes.

• Press the down arrow to continue.

3. Carefully spray an equal amount of the solution

into each drain.

• Press the down arrow to continue.

96 Part Number STH034 3/13

Page 97

Post Drain Cleaning

Post Drain Cleaning Screen

1. Open the pressure relief knob again by turning

counter-clockwise.

2. Remove cap from the dispenser.

3. Rinse the dispenser with warm (75-90°F/23-32°C)

water and return to the proper storage area.

• Press the down arrow to continue.

Part Number STH034 3/13 97

Page 98

Reinstall Grate(s) / Door(s)

Important

Grates & Doors Install Screen

1. Wipe drain areas and work surface with sanitized

towel to remove drain cleaner.

2. Reinstall mixer grate(s).

3. Reinstall dispensing area grate.

4. Reinstall mixer door(s).

• Press the down arrow to continue.

Drain cleaner is most effective when left for four (4)

hours, but the machine can be used as needed.

• Press the green check to continue.

98 Part Number STH034 3/13

Page 99

Weekly Cleaning Completed

Completed Screen

1. * Remove gloves & safety glasses.

2. Weekly cleaning has been completed.

3. Unit will need to be cleaned again in 7 days.

4. Return supplies to cleaning kit.

5. Press the green check to signify you have

completed the Zone 2 Weekly Cleaning. The

screen will return to the Main Menu Screen.

Part Number STH034 3/13 99

Page 100

Monthly Cleaning - Zone 3

Main Menu Touch Screen

Cleaning Touch Screen

NOTE: All steps will be displayed on screen.

* These items are optional and may not be displayed

on all EasyTouch screens during ZONE 3 Cleaning.

• Time to complete - 1 hour 45 minutes

1. Cycle touch screen to the Main Menu and select

the Cleaning Icon.

2. In the cleaning screen select the Zone 3 Icon.

NOTE: Failure to complete the Zone 3 cleaning

sequence in it’s entirety could affect drink quality and

will not reset the monthly cleaning timer which will

require the process to be repeated.

GATHER THE FOLLOWING SUPPLIES

100 Part Number STH034 3/13

Loading...

Loading...