Page 1

Multiplex

Blended

Beverage System

Technician’s

Handbook

This manual is updated as new information and models are released. Visit

our website for the latest manual. www.manitowocfsg.com

Leader in Ice & Beverage Dispensers

Part Number STH034 3/12

Page 2

Safety Notices

!

Warning

!

Caution

Important

As you work on Multiplex equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Procedural Notices

As you work on Multiplex equipment, be sure to read

the procedural notices in this handbook. These notices

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a

procedure more efficiently. Disregarding this

information will not cause damage or injury, but it

may slow you down as you work.

Page 3

NOTE: Text set off as a Note provides you with simple,

!

Caution

Important

! Warning

! Warning

We reserve the right to make product

improvements at any time. Specifications and

design are subject to change without notice.

but useful, extra information about the procedure you

are performing.

Read These Before Proceeding:

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Multiplex equipment. If you

encounter problems not covered by this

handbook, do not proceed, contact Manitowoc

Foodservice. We will be happy to provide

assistance.

Routine adjustments and maintenance

procedures outlined in this handbook are not

covered by the warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been

misused, abused, neglected, damaged, or

altered/modified from that of original

manufactured specifications.

PERSONAL INJURY POTENTIAL

Failure to follow instructions in this manual can

cause property damage, injury or death.

Page 4

! Warning

Do not store gasoline or other flammable vapors

!

Warning

! Warning

! Warning

or liquids in the vicinity of this or any other

appliance.

This appliance is not to be played with. Unless all

cover and access panels are in place and

properly secured, do not operate the equipment.

Do not clean with water jet.

Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment.

Page 5

Table of Contents

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . . 11

Model/Serial Number Location . . . . . . . . 11

Warranty Information . . . . . . . . . . . . . . . . 13

Owner Warranty Registration Card . . . 13

Commercial Warranty Coverage . . . . . . . 13

Limited Warranty For Multiplex Blended

Ice Machine . . . . . . . . . . . . . . . . . . . . .13

Installation

General . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dimensions . . . . . . . . . . . . . . . . . . . . . . . .24

Location . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Clearances . . . . . . . . . . . . . . . . . . . . . 28

Heat of Rejection . . . . . . . . . . . . . . . . . 28

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General . . . . . . . . . . . . . . . . . . . . . . . . 29

Minimum Circuit Ampacity . . . . . . . . . . 29

Electrical Requirements . . . . . . . . . . . 29

Minimum Circuit Amperage Chart . . . . 30

Grounding Instructions . . . . . . . . . . . . 32

Bonding Instructions 230-240V 50 Hz

Models only . . . . . . . . . . . . . . . . . . . . .32

Part Number STH034 3/12 5

Page 6

Water Supply and Drain Requirements . 34

Water Supply . . . . . . . . . . . . . . . . . . . 34

Water Inlet lines . . . . . . . . . . . . . . . . . 34

Drain Connections . . . . . . . . . . . . . . . 35

CO2 Requirements . . . . . . . . . . . . . . . . . 35

Step-by-Step Installation . . . . . . . . . . . . . 36

Installation Checklist . . . . . . . . . . . . . . . . 39

MenuConnect . . . . . . . . . . . . . . . . . . . . . . 40

Start-Up Procedures . . . . . . . . . . . . . . . . 40

Loading Recipes . . . . . . . . . . . . . . . . . 40

Assigning Flavors . . . . . . . . . . . . . . . . 40

Loading Bags . . . . . . . . . . . . . . . . . . . 41

Calibration Procedure . . . . . . . . . . . . . . . 41

Maintenance

General Maintenance . . . . . . . . . . . . . . . . 45

Door Gasket Maintenance . . . . . . . . . 45

Drain Maintenance - Base . . . . . . . . . 45

Caster Maintenance . . . . . . . . . . . . . . 46

Refrigerators . . . . . . . . . . . . . . . . . . . . 46

Stainless Steel Care and Cleaning . . . 46

Cleaning the Condenser Coil . . . . . . . 48

Doors/Hinges . . . . . . . . . . . . . . . . . . . 49

Preventing Blower Coil Corrosion . . . . 49

Annual Planned Maintenance . . . . . . 49

Cleaning Kits . . . . . . . . . . . . . . . . . . . 50

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . 51

Weekly Cleaning . . . . . . . . . . . . . . . . . . . 56

Ice Machine Cleaning . . . . . . . . . . . . . . . 67

Version 1 Ice Machine R404A Refrigerant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Version 2 Ice Machines R404a or R290

Refrigerant . . . . . . . . . . . . . . . . . . . . . 72

6 Part Number STH034 3/12

Page 7

Operation

Touch Screens . . . . . . . . . . . . . . . . . . . . . 77

Manager Screens . . . . . . . . . . . . . . . . . . . 78

Recommended Cups . . . . . . . . . . . . . . . .81

Procedure to Make a Drink . . . . . . . . . . . 82

Procedure to Replace a Product Bag . . . 85

Firmware Update Procedure . . . . . . . . . . 88

Ice Making Sequence of Operation . . . . . 90

Version 1 Ice Machine R404A Refrigerant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Version 2 Ice Machines R404A or R290

Refrigerant . . . . . . . . . . . . . . . . . . . . . 92

Product Dispense Operation . . . . . . . . . .93

Operation . . . . . . . . . . . . . . . . . . . . . . 93

Refrigerated Cabinet Operation . . . . . . . 94

Normal Operation . . . . . . . . . . . . . . . . 94

Evaporator and Condenser Fan Motor

Operation . . . . . . . . . . . . . . . . . . . . . . 94

Operation in the Clean/Sanitize cycle . 95

Adaptive Defrost . . . . . . . . . . . . . . . . . 95

High Temp Alarm . . . . . . . . . . . . . . . . 95

Thermistor Failure . . . . . . . . . . . . . . . . 95

Part Number STH034 3/12 7

Page 8

Troubleshooting

Control System . . . . . . . . . . . . . . . . . . . . 97

Will Not Run Diagnostics . . . . . . . . . . 97

Beverage System . . . . . . . . . . . . . . . . . . . 99

Procedure to Clear Blocked Line . . . . 99

Beverage System Diagnostics . . . . . . 102

Ice System . . . . . . . . . . . . . . . . . . . . . . . . 103

Before Beginning Service . . . . . . . . . . 103

Installation/Visual Inspection Checklist 103

Water System Checklist . . . . . . . . . . . 104

Ice Production/Quality Check . . . . . . . 105

Version 1 Ice Machine R404A Refrigerant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Version 2 Ice Machine R290 Refrigerant

Electrical Troubleshooting Flowchart . 111

Refrigerated Cabinet . . . . . . . . . . . . . . . . 116

Reach-in temperature Out of Range - Check

Refrigeration System and Door Seal. . 120

High Product Temperature - Check Duct

Cooling Fan . . . . . . . . . . . . . . . . . . . . 120

Refrigeration System Diagnostics . . . . . 121

Analyzing Discharge Pressure or

Temperature . . . . . . . . . . . . . . . . . . . . 121

Analyzing Suction Pressure or Temperature

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Analyzing Discharge Pressure or

Temperature . . . . . . . . . . . . . . . . . . . . 125

Analyzing Suction Pressure or Temperature

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8 Part Number STH034 3/12

Page 9

Component Check Procedures

Control System . . . . . . . . . . . . . . . . . . . . . 129

ON/Off Rocker Switch . . . . . . . . . . . . . 129

Power Relay . . . . . . . . . . . . . . . . . . . . 130

Transformer . . . . . . . . . . . . . . . . . . . . .131

LCD Touchscreen & Control Board . . . 132

Beverage Components . . . . . . . . . . . . . . 133

Pressure Regulator - Water or CO2 . . 133

Water Dispense Solenoid Valve . . . . . 134

Syrup Solenoid Valve . . . . . . . . . . . . . 135

Product Pump . . . . . . . . . . . . . . . . . . . 136

Step Motor . . . . . . . . . . . . . . . . . . . . . .137

Blender Motor . . . . . . . . . . . . . . . . . . . 138

Home Position Switch . . . . . . . . . . . . . 139

Door Switch . . . . . . . . . . . . . . . . . . . . . 140

Water Rinse Solenoid Valve . . . . . . . . 141

Ice Machine Components . . . . . . . . . . . . 142

Version 1 Ice Machine R404A Refrigerant -

Solid State Timer . . . . . . . . . . . . . . . . . 142

Version 1 Ice Machine R404A Refrigerant -

Solid State Time Delay Relay . . . . . . . 146

Version 1 Ice Machine R404A Refrigerant -

Float Switch/Water Control Relay . . . . 147

High Pressure Cutout (HPCO) Control 148

Infrared Ice Bin Control - All Models . . 149

Refrigerated Cabinet . . . . . . . . . . . . . . . . 150

Temperature Thermistor - Nozzle, Cabinet

or Defrost . . . . . . . . . . . . . . . . . . . . . . 150

Evaporator Fan Motor . . . . . . . . . . . . . 152

Chase Fan Motor . . . . . . . . . . . . . . . . 153

Condenser Fan Motor . . . . . . . . . . . . .154

Compressor Electrical Diagnostics . . . . 155

The compressor does not start or will trip re-

peatedly on overload . . . . . . . . . . . . . . 155

Compressor Drawing Locked Rotor . . 156

Diagnosing Capacitors . . . . . . . . . . . .156

Filter-Driers . . . . . . . . . . . . . . . . . . . . . . . . 157

Part Number STH034 3/12 9

Page 10

Charts

Total System Refrigerant Charge . . . . . . 159

Operational Charts . . . . . . . . . . . . . . . . . 160

R404A Refrigerant - Refrigerated Cabinet

Operating Pressures . . . . . . . . . . . . . . 160

Version 1 Ice Machine R404A Refrigerant -

Ice Machine Performance Chart . . . . . 161

Version 2 Ice Machine - R290 Refrigerant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Diagrams

Wiring Diagrams . . . . . . . . . . . . . . . . . . . 163

Version 1 Ice Machine R404A Refrigerant -

Control System Wiring Diagram . . . . 165

Version 1 Ice Machine R404A Refrigerant Ice Maker & Ice Dispenser Wiring Diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Version 1 Ice Machine R404A Refrigerant -

Ice Maker Wiring Diagram . . . . . . . . . 168

Version 1 Ice Machine R404A Refrigerant -

Ice Machine Wiring Diagram . . . . . . . 169

Version 1 Ice Machine R404A Refrigerant -

Ice Machine Logic Diagram . . . . . . . . 170

Version 2 Ice Machine R290 Refrigerant -

Control System Wiring Diagram . . . . . 172

Version 2 Ice Machine R290 Refrigerant Refrigeration Cabinet Wiring Diagram 173

Version 2 Ice Machine R290 Refrigerant Ice Maker & Ice Dispenser Wiring Diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Version 2 Ice Machine R290 Refrigerant -

Ice Maker Wiring Diagram . . . . . . . . . 175

Water and Refrigeration Circuit Version 1 Ice

Machine R404A Refrigerant . . . . . . . . . . 176

10 Part Number STH034 3/12

Page 11

General Information

! Warning

Model Numbers

This manual covers the following models:

Blend-In-Cup Beverage Systems

MB-8-1, MB-8-2, MB-8-1E,

MB-8-2E, MB-8-1A, MB-8-2A, MB-8-1D,

MB-8-2D, MB-8-1U, MB-8-2U, MB-8-1P,

MB-8-2P, MB000A01, MB000A02

MB000A03, MB000A04, MB000A05

Model/Serial Number Location

These numbers are required when requesting

information from your local Multiplex Distributor,

service representative, or Manitowoc Foodservice.

The model and serial number are listed on the

OWNER WARRANTY REGISTRATION CARD. They

are also listed on the MODEL/SERIAL NUMBER

DECAL affixed to the machine.

Some 50 hz models may contain up to 15 grams of

R290 (propane) refrigerant. R290 (propane) is

flammable in concentrations of air between

approximately 2.1% and 9.5% by volume (LEL lower

explosion limit and UEL upper explosion limit). An

ignition source at a temperature higher than 470°C

is needed for a combustion to occur. Refer to

nameplate to identify the type of refrigerant in your

equipment. Only trained and qualified personnel

aware of the dangers are allowed to work on the

equipment.

Part Number STH034 3/12 11

Page 12

.

! Warning

!

Warning

!

Warning

! Warning

! Warning

Personal Injury Potential - Do not operate equipment

that has been misused, abused, neglected,

damaged, or altered/modified from that of original

manufactured specifications. This appliance is not

intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have

been given supervision concerning use of the

appliance by a person responsible for their safety.

Do not allow young children to play with the

appliance.

Do not use electrical appliances or accessories

other than those supplied by Multiplex for your

model.

Do not damage the refrigeration circuit when

installing, maintaining or servicing the unit.

Only trained and qualified personnel aware of the

dangers of refrigerant and carbon dioxide under

pressure, electrical shock, and incorrect lifting/

moving hazards, should install, maintain or

service this equipment.

Two or more people or a lifting device are

required to lift this appliance.

12 Part Number STH034 3/12

Page 13

Warranty Information

Important

OWNER WARRANTY REGISTRATION CARD

Warranty coverage begins the day the Blend-In-Cup

Beverage System is installed.

Complete and mail the OWNER WARRANTY

REGISTRATION CARD as soon as possible to

validate the installation date.

If the OWNER WARRANTY REGISTRATION CARD is

not returned, Manitowoc Foodservice will use the date

of sale to the Multiplex Distributor as the first day of

warranty coverage for your new Blend-In-Cup

Beverage System.

Commercial Warranty Coverage

LIMITED WARRANTY FOR MULTIPLEX BLENDED ICE MACHINE

Manitowoc Beverage Systems, a division of

Manitowoc FSG Operations, LLC, (“Company”)

warrants to the original end-user (“Owner”) for a period

of one (1) year from the installation date (except as

limited below) that this new Multiplex Blended Ice

machine manufactured by the Company (the

“Machine”) shall be free of defects in material or

workmanship under normal and proper use and

maintenance as specified by the Company and upon

proper installation and start-up in accordance with the

instruction/use and care manual supplied with the

machine.

Continued on next page …

Part Number STH034 3/12 13

Page 14

The Company's warranty hereunder with respect to

compressors shall apply for an additional forty-eight

months, excluding all labor charges.

The Company's warranty hereunder with respect to

any blender assembly shall apply for one year or

13,000 blender cycles, whichever occurs first,

including labor. At 13,000 blender cycles a blender

assembly preventative maintenance (PM) service is

required. It is the responsibility of the Owner to

complete and pay for this PM. If the blender assembly

has accrued 13,000 cycles prior to expiration of the

initial one year warranty period, then once the PM is

completed in compliance with the instruction manual,

the warranty will continue to be valid for the remainder

of the one year warranty period or accumulation of

another 13,000 cycles, whichever occurs first.

During the warranty period, the Company shall, at

Company's option, repair or replace parts,

components or assemblies determined by the

Company to be defective in material or workmanship.

This warranty is further limited to the cost of parts,

components or assemblies and standard straight time

labor charges at the servicing location.

14 Part Number STH034 3/12

Page 15

Time and hourly rate schedules, as published from

time to time by the Company, apply to all service

procedures. Additional expenses including without

limitation, travel time, overtime premium, material cost,

accessing or removal of the machine, or shipping are

the responsibility of the Owner, along with all

maintenance, adjustments, cleaning, and ice or other

purchases. Labor covered under this warranty must be

performed by a Company Contracted Service

Representative or a service agency as qualified and

authorized by the Company's local distributor. The

Company's liability under this warranty shall in no

event be greater than the actual purchase price paid

by Owner for the Machine.

The foregoing shall be the sole obligation of the

Company under this Limited Warranty with respect to

the Machine and any related products and services.

With respect to equipment, materials, parts and

accessories manufactured by others, Company's sole

obligation shall be to use reasonable efforts to obtain

the full benefit of the manufacturer's warranties.

Company shall have no liability, whether in contract,

tort, negligence, or otherwise, with respect to nonCompany manufactured products.

Continued on next page …

Part Number STH034 3/12 15

Page 16

Who Is Covered

This Limited Warranty is available only to the original

end user of the product and is not transferable.

Exclusions From Coverage

This warranty shall not apply to:

• Any part or assembly that has been altered,

modified, or changed.

• Repair or replacement of parts or assemblies

required because of misuse, abuse, improper care

or storage, negligence, alteration, accident, use of

incompatible supplies or lack of specified

maintenance.

• Normal maintenance items, including but not

limited to, light bulbs, fuses, containers, gaskets,

LMS Valves or product stickers used in the unit, Orings, interior and exterior finishes, lubrication, deliming, broken glass, etc.

• Improper or unauthorized repair.

• Failures caused by improper or erratic voltages.

• Any parts subject to damage beyond the control of

Company, or to equipment which has been subject

to alteration, misuse or improper installation,

accidents, damage in shipment, fire, floods, power

changes, other hazards or acts of God that are

beyond the control of Company.

16 Part Number STH034 3/12

Page 17

• Any machine that has been installed and/or

maintained inconsistent with the technical

instructions provided by the Company.

• Any machine initially installed more than five years

from the serial number production date.

• Any products or equipment manufactured or sold

by Company when such products or commercial

equipment is installed or used in a residential or

non-commercial application. Installations not

within the applicable building or fire codes render

this Limited Warranty and any responsibility or

obligations associated therein null and void. This

includes any damage, costs or legal actions

resulting from the installation of any Company

equipment in a non-commercial application or

installation, where the equipment is being used for

applications other than those approved for by

Company.

• Any product cleaned without using an approved

Company cleaning solution shall void this Limited

Warranty.

• This warranty shall not apply if the Machine's

refrigeration system is modified with a condenser,

heat reclaim device, or parts and assemblies other

than those manufactured by the Company, unless

the Company approves these modifications for

specific locations in writing.

Continued on next page …

Part Number STH034 3/12 17

Page 18

Limitations Of Liability

The preceding paragraphs set forth the exclusive

remedy for all claims based on failure of, or defect in,

products or services sold hereunder, whether the

failure or defect arises before or during the warranty

period, and whether a claim, however instituted, is

based on contract, indemnity, warranty, tort (including

negligence), strict liability, implied by statute, commonlaw or otherwise, and Company its servants and

agents shall not be liable for any claims for personal

injuries or consequential damages or loss, howsoever

caused. Upon the expiration of the warranty period, all

such liability shall terminate. THE FOREGOING

WARRANTIES ARE EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES, WHETHER WRITTEN,

ORAL, IMPLIED OR STATUTORY. NO IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS

FOR PARTICULAR PURPOSE SHALL APPLY.

COMPANY DOES NOT WARRANT ANY PRODUCTS

OR SERVICES OF OTHERS.

18 Part Number STH034 3/12

Page 19

Remedies

The liability of Company for breach of any warranty

obligation hereunder is limited to: (i) the repair or

replacement of the Machine on which the liability is

based, or with respect to services, re-performance of

the services; or (ii) at Company's option, the refund of

the amount paid for said Machine or services. Any

breach by Company with respect to any item or unit of

equipment or services shall be deemed a breach with

respect to that item or unit or service only.

Warranty Claim Procedure

Customer shall be responsible to:

• Immediately advise the Company's Authorized

Service Agent of the equipment serial number and

the nature of the problem.

• Verify the problem is a factory responsibility.

• Cooperate with the Service Agency so that

warranty service may be completed during normal

working hours.

To secure prompt and continuing warranty service, the

warranty registration card must be completed and sent

to the COMPANY within five (5) days from the

installation date.

Continued on next page …

Part Number STH034 3/12 19

Page 20

Governing Law

For equipment, products and services sold in the

United States this Limited Warranty shall be governed

by the laws of the state of Delaware, USA, excluding

their conflicts of law principles. The United Nations

Convention on Contracts for the International Sale of

Goods is hereby excluded in its entirety from

application to this Limited Warranty.

Manitowoc Beverage Systems,

Complete the following and retain for your record:

Distributor/Dealer___________________________

Model Number_____________________________

Serial Number______________________________

Installation Date____________________________

General Conditions

Multiplex shall not be liable in any manner for any

default or delay in performance hereunder caused by

or resulting from any contingency beyond Multiplex’s

control, including, but not limited to, war, governmental

restrictions or restraints, strike, lockouts, injunctions,

fire, flood, acts of nature, short or reduced supply of

raw materials, or discontinuance of any part or the

Motor-Compressor by the unit manufacturer.

Replacement of a defective Motor-Compressor is

limited to one (1) Motor-Compressor by us during the

four (4) year period. Multiplex shall replace the MotorCompressor at no charge.

20 Part Number STH034 3/12

Page 21

This warranty does not give the Original Purchaser of

the Motor-Compressor the right to purchase a

complete replacement Motor-Compressor of the same

make or of another make. It further does not permit the

replacement to be made with a Motor-Compressor of

another kind unless authorized by Multiplex. In the

event Multiplex authorizes the Original Purchaser to

purchase a replacement Motor-Compressor locally,

only the wholesale cost of the Motor-Compressor is

refundable.

Expressly excluded from this warranty are damages

resulting from spoilage of goods.

Except as provided in any Additional Four Year

Protection Plan, if applicable or Optional One or Two

Year Service Agreement, if applicable, the foregoing is

exclusive and in lieu of all other warranties, whether

written or oral, express or implied. This warranty

supersedes and excludes any prior oral or written

representations or warranties. Multiplex expressly

disclaims any implied warranties of merchantability,

fitness for a particular purpose, or compliance with any

law, treaty, rule or regulation relating to the discharge

of substances into the environment. The sole and

exclusive remedies of any person relating to the Unit,

and the full liability of Multiplex for any breach of this

warranty, will be as provided in this warranty.

Other than the Multiplex Standard One Year Limited

Warranty, any applicable Multiplex Additional Four

Year Protection Plan, Optional One or Two Year

Service Agreement, the Original Purchaser agrees

and acknowledges that no other warranties are offered

or provided in connection with or for the Unit or any

other part thereof.

In no event will Multiplex be liable for special,

incidental or consequential damages, or for damages

in the nature of penalties.

Part Number STH034 3/12 21

Page 22

22 Part Number STH034 3/12

This Page Intentionally Left Blan k

Page 23

Installation

Important

General

These instructions are provided to assist the trained &

qualified installer. Contact your Manitowoc

FoodService Service Agent or call Manitowoc

FoodService for information regarding start-up

services.

Failure to follow these installation guidelines may

affect warranty coverage.

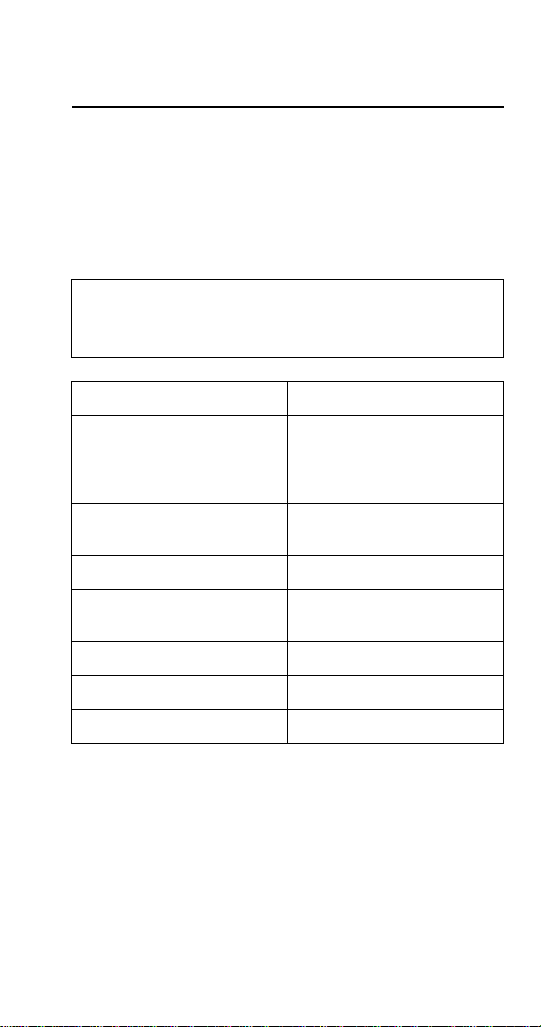

Manager Default Password A

Temperature Control Setting 36°F setpoint 4°F

2°C setpoint 2°C differential

CO

Supply Pressure

2

min / max

CO

Regulator Setting 35 lbs

2

Water supply pressure

min / max

Water Regulator Setting 30 lbs

Ice Capacity 30 lbs (14 kg)

Shipping Weight 430 lbs (195 kg)

Part Number STH034 3/12 23

differential

controlled by software

50 psi / 80 psi

3.5 BAR / 6.2 BAR

30 psi / 90 psi

1.4 BAR / 6.2 BAR

Page 24

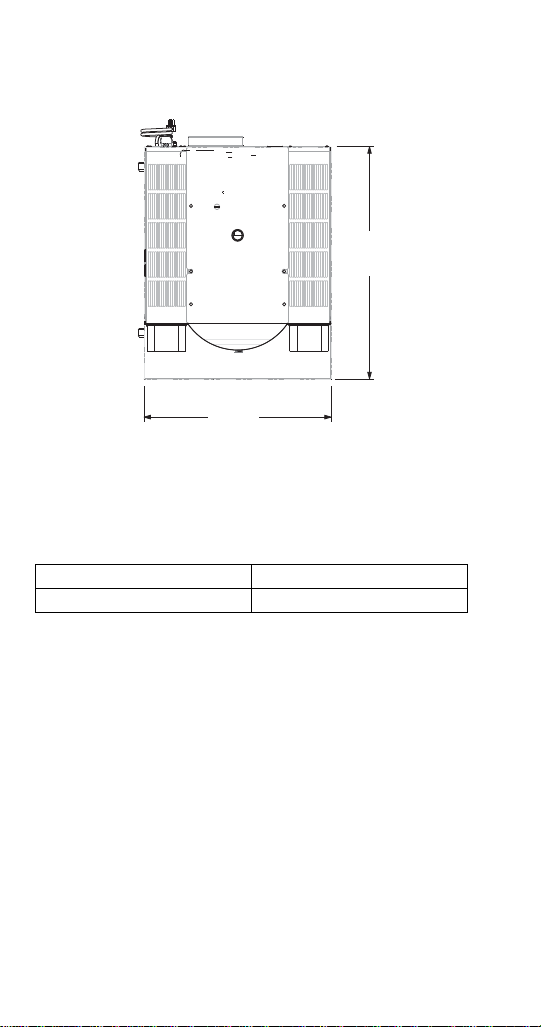

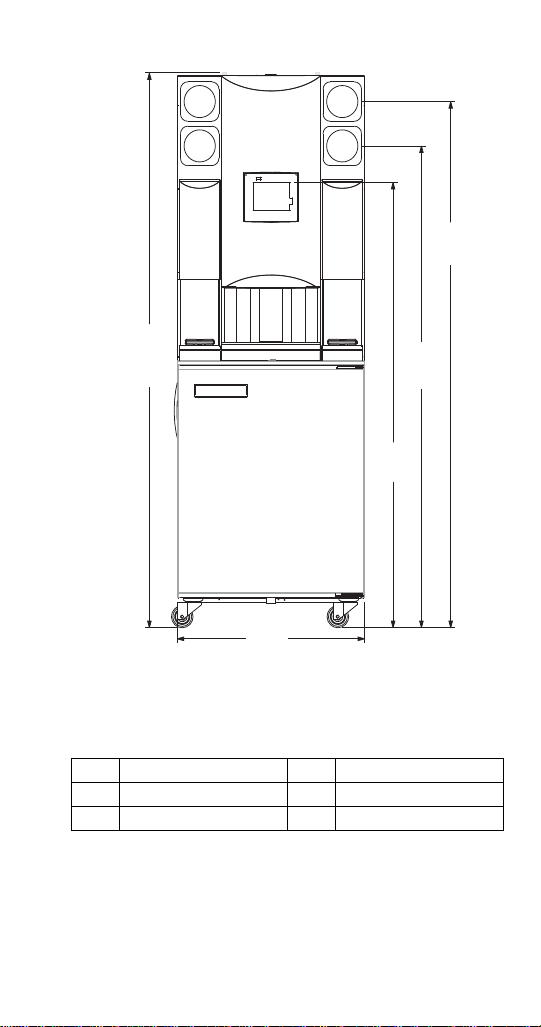

Dimensions

A

B

Elevation View

A 26.00" (66 cm)

B 32.82" (83 cm)

24 Part Number STH034 3/12

Page 25

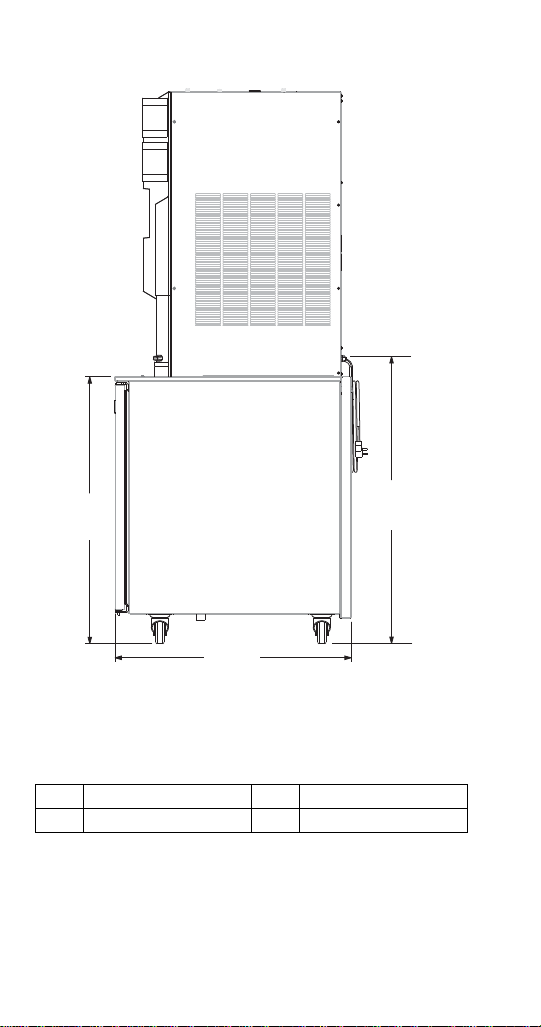

F

H

E

D

C

Elevation View

C 71.19" (181 cm) F 26.00" (66 cm)

D 65.19" (166 cm) H 75.07" (191 cm)

E 60.25" (153 cm)

Part Number STH034 3/12 25

Page 26

G 32.82" (83 cm) J 39.09" (99 cm)

G

I

J

Side View

I 36.15" (92 cm)

26 Part Number STH034 3/12

Page 27

Location

! Warning

The location selected must meet the following criteria:

• The air temperature must be at least 40°F (4°C),

but must not exceed 90°F (32°C), climate class 4.

• The location must not be near heat-generating

equipment or in direct sunlight and must be

protected from weather.

• Water temperature min/max = 40°F/110°F

(4°C/43°C).

• Water supply pressure min/max = 30 psi/90 psi

(1.4 BAR/6.2 BAR).

• Always use the water supply line supplied when

installing this appliance. Never reuse an old supply

line.

• Main supply CO

Beverage System regulator min/max =

50 psi/80 psi (3.5 BAR/6.2 BAR).

• Minimum clearances must be maintained from all

walls and combustible materials.

• Keep equipment area clear of combustible

material.

Carbon Dioxide (CO2) displaces oxygen.

Exposure to a high concentration of CO

causes tremors, which are followed rapidly by

loss of consciousness and suffocation. If a CO

gas leak is suspected, particularly in a small area,

immediately ventilate the area before repairing

the leak. CO2 lines and pumps must not be

installed in an enclosed space. An enclosed

space can be a cooler or small room or closet.

This may include convenience stores with glass

door self serve coolers. If you suspect CO

build up in an area, venting of the B-I-B pumps

and / or CO2 monitors must be utilized.

pressure to Blend-In-Cup

2

gas

2

may

2

2

Part Number STH034 3/12 27

Page 28

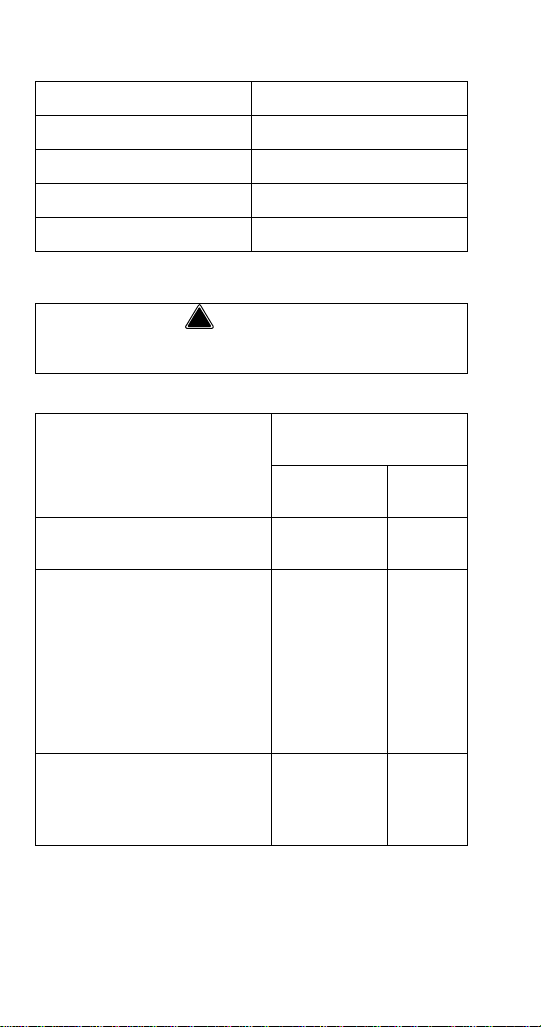

CLEARANCES

!

Warning

Model Air Cooled

Top 18" (46 cm)

Sides 6" (15 cm)

Back 6" (15 cm)

Front 30" (76 cm)

Do not obstruct machine vents or openings.

HEAT OF REJECTION

Heat of Rejection

Model

Air

Conditioning

BTU/h

Peak

Cabinet

All Single & Dual Spindle

Ice Machine

MB-8-1, MB-8-2

MB-8-1E, MB-8-2E

MB-8-1A, MB-8-2A

MB-8-1D, MB-8-2D

MB-8-1U, MB-8-2U

MB-8-1P, MB-8-2P

MB000A01

MB000A02

Ice Machine

MB000A03

MB000A04

MB000A05

28 Part Number STH034 3/12

2100 2600

N/A 5150

N/A 5000

Page 29

Electrical

!

Warning

!

Caution

GENERAL

All wiring must conform to local, state and

national codes.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select

the wire size of the electrical supply. The wire size (or

gauge) is also dependent upon location, materials

used, length of run, etc., so it must be determined by a

trained & qualified electrician.

ELECTRICAL REQUIREMENTS

Refer to Model/Serial Plate for voltage/amperage

specifications.

Operate equipment only on the type of electricity

indicated on the specification plate.

Part Number STH034 3/12 29

Page 30

MINIMUM CIRCUIT AMPERAGE CHART

Important

Due to continuous improvements, this information

is for reference only. Please refer to the serial

number tag to verify electrical data. Serial tag

information overrides information listed on this

page.

Model

Numbers

MB-8-1

Dual

Spindle

MB-8-2

Single

Spindle

MB-8-1E

Dual

Spindle

MB-8-2E

Single

Spindle

MB-8-1A

Dual

Spindle

MB-8-2A

Single

Spindle

MB-8-1D

Dual

Spindle

Voltage/Cycle/

Refrigerant

120/60/1

R404A

120/60/1

R404A

230-240/50/1

R404A

230-240/50/1

R404A

230-240/50/1

R404A

230-240/50/1

R404A

230-240/50/1

R404A

Total Amps

16.0 20A

16.0 20A

8.7

8.7

8.7

8.7

8.7

Breaker

Size

20A

20A

20A

20A

20A

30 Part Number STH034 3/12

Page 31

Model

Numbers

Voltage/Cycle/

Refrigerant

Total Amps

Breaker

Size

MB-8-2D

Single

Spindle

MB-8-1U

Dual

Spindle

MB-8-2U

Single

Spindle

MB-8-1P

Dual

Spindle

MB-8-2P

Single

Spindle

MB000A01

Dual

Spindle

MB000A02

Single

Spindle

230-240/50/1

R404A

230-240/50/1

R404A

230-240/50/1

R404A

230-240/50/1

R404A

230-240/50/1

R404A

120V/60/1 16.0

230-240/50/1

R404A

8.7

20A

8.7

20A

8.7

20A

8.7

20A

8.7

20A

20A

8.7

20A

MB000A03

MB000A04

MB000A05

Part Number STH034 3/12 31

120/60/1

R404A

120/60/1

R404A

120/60/1

R404A

16.0 20A

16.0 20A

16.0 20A

Page 32

GROUNDING INSTRUCTIONS

!

Warning

! Warning

This machine must be grounded in accordance

with national and local electrical codes.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the risk

of electric shock. This appliance is equipped with a

cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

BONDING INSTRUCTIONS 230-240V 50 HZ MODELS ONLY

This appliance must be connected to the potential

equalization system in accordance with EN60335-1

and EN60335-2-75. A bonding lug is provided on the

lower right front corner of the appliance.

This machine must be connected to the potential

equalization system.

32 Part Number STH034 3/12

Page 33

!

Warning

When using electric appliances, basic

precautions must always be followed, including

the following:

a. Read all the instructions before using

the appliance.

b. To reduce the risk of injury, close

supervision is necessary when an

appliance is used near children.

c. Do not contact moving parts.

d. Only use attachments recommended or

sold by the manufacturer.

e. Do not use outdoors.

f. For a cord-connected appliance, the

following must be included:

• Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use

and before servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the

appliance malfunctions or is dropped

or damaged in any manner. Contact

the nearest authorized service facility

for examination, repair, or electrical

or mechanical adjustment.

g. Follow applicable lock out tag out

procedures before working on

equipment.

h. Always unplug before replacing the

lamp. Replace the bulb with the same

type.

i. Connect to a properly grounded outlet

only. See Grounding Instructions.

Part Number STH034 3/12 33

Page 34

Water Supply and Drain Requirements

! Warning

WATER SUPPLY

In most areas, a water filter of some type will be

useful. In areas where the water is highly concentrated

with minerals the water should be tested by a water

treatment specialist, and the recommendations of the

specialist regarding filtration and/or treatment should

be followed.

Connect to a potable water supply only.

WATER INLET LINES

Follow these guidelines to install water inlet lines:

• Use supplied 3/8" panel-mounted hose barb and 6'

(1.8 m) of beverage tubing to connect coupling

body fitting on back of unit into water supply.

• Do not connect to a hot water supply. Be sure all

hot water restrictors installed for other equipment

are working. (Check valves on sink faucets,

dishwashers, etc.)

• Install a water shut-off valve in the water line at the

rear of the machine.

• Insulate water inlet lines to prevent condensation.

• An air gap is included in the design of the machine

for backflow prevention. Local code may require

an additional backflow prevention device.

34 Part Number STH034 3/12

Page 35

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines.

• Connect supplied 1" ID hose to hose-barb

connection on machine.

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

CO2 Requirements

1. Connection Assembly — Use supplied 3/8"

panel-mounted hose barb and 6' (1.8 m) of

beverage tubing to connect coupling insert on

back of unit into CO

2. Supply pressure — 50 PSI (min.) and 80 PSI

(max.).

3. Product pressure — min. 35 PSI. Lowers the

gas pressure before the CO2 gas flows to the

CO

2

product pump. CO

product pump.

4. Beverage pump — Draws product out of the

product package. Product flows through the lines

to the dispenser for blending and dispensing.

There is a beverage pump for each product.

5. Product cassette — Contains a foil bag filled

with product.

supply.

2

pressure activates the

2

Part Number STH034 3/12 35

Page 36

Step-by-Step Installation

! Warning

1. Visually inspect the exterior of the package and

skid or container. Any damage should be noted

and reported to the delivering carrier immediately.

2. If damaged, open and inspect the contents with

the carrier.

3. In the event that the exterior is not damaged, yet

upon opening there is concealed damage to the

equipment, notify the carrier. Notification should

be made verbally as well as in written form.

4. Request an inspection by the shipping company

of the damaged equipment. This should be done

within 10 days from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs

or casters are not bent.

6. Also open the compressor compartment housing

and visually inspect the refrigeration package. Be

sure lines are secure and base is still intact.

7. Freight carriers can supply the necessary damage

forms upon request.

8. Retain all crating material until an inspection has

been made or waived.

The mass of this appliance will allow it to move

uncontrolled on an inclined surface. Adequate

means must be provided to prevent uncontrolled

movement at all times.

9. Inspect behind the BIC for electrical outlet

location, CO

10. Check voltage at outlet dedicated for BIC.

11. Connect 230-240V 50 hz models to the potential

equalization system.

12. Plug unit in and allow base to start cooling, up to a

five minute delay in start-up is normal.

36 Part Number STH034 3/12

, and water hose fittings and shutoff.

2

Page 37

13. Remove steel top panel. Check that the black

chute cover is sitting securely on the chute. The

ice Machine will not operate properly if it is out of

place.

14. The CO2 and Water Regulator gauges can be

viewed through the panel windows, but the side

panel will require removal if the regulators need

adjustment.

15. Remove other side panel to access board

connections.

16. Install quick disconnect fittings from box of parts

supplied with BIC, on existing supply CO2 and

water hose.

17. Confirm correct orientation of fittings.

18. Install drain hose on BIC and cut to proper length

(do not leave loops in drain).

19. Connect water and CO2 hoses to BIC (quick

disconnect fittings).

20. Coil excess tubing and secure with tie straps.

21. Check water and CO

using).

pressures (check while

2

22. Check that board connections are secure, and did

not vibrate loose during shipment.

23. Check that both micro switches are in line with the

motor above the blenders.

24. Check the blender door sensor positions.

25. Reinstall side panels.

26. Push BIC into place.

Continued on next page …

Part Number STH034 3/12 37

Page 38

27. Check BIC for level and shim if necessary.

28. Install clean, sanitized parts on BIC.

29. Fill all three cleaning pails with warm water, add

soap to wash pail, sanitizer to sanitize pail.

30. Demonstrate to store manager BIC cleaning

procedure.

31. Offer to store manager to add labels to product

bins, put labels in correct place.

32. Demonstrate to store manager how to install cold

product bags into product bins and install into

BIC.

33. Demonstrate to store manager how to load

recipes.

34. Demonstrate to store manager how to calibrate.

35. Demonstrate to store manager how to make

drink.

36. Demonstrate to manager options on control,

manager password is A. The password can be

changed.

37. Set date and time to activate warranty.

38. Complete start-up form, sign, and have store

manager sign form. (Fax to number on form.)

38 Part Number STH034 3/12

Page 39

Installation Checklist

Is the machine level?

Has all of the internal packing been

removed?

Have all of the electrical, water and CO2

connections been made?

Has the supply voltage been tested and

checked against the rating on the

nameplate?

Is there proper clearance around the

machine for air circulation?

Is the machine grounded and polarity

correct?

Has the machine been installed where

ambient temperatures will remain in the

range of 40° – 90°F (4°– 32°C)?

Has the machine been installed where the

incoming water temperature will remain in

the range of 40° – 110°F (4° – 43°C)?

Is the machine cycling on/off on the

temperature control?

Are the regulators set properly?

Has the owner/operator been instructed

regarding maintenance procedures?

230-240V 50hz - Has the potential

equalization system been connected?

Part Number STH034 3/12 39

Page 40

MenuConnect

MenuConnect is used to create recipes for your BlendIn-Cup (BIC) machine. The software is easy to use,

versatile and limited only by your imagination. You will

quickly master the basics and be making all types of

drinks quickly and efficiently. After the recipes are

created, they are copied to a usb drive and transferred

to the Blend-In-Cup machine.

Start-Up Procedures

LOADING RECIPES

Plug in the Flash drive (above upper left corner of

screen). From the Main Menu select Manager. Type in

the password and select the green check. Select the

down arrow to navigate to the next screen. Select

Updates. Select Recipes. Select the UPDATE

RECIPES FROM USB icon. Verify the version to be

loaded is correct, and select the green check. Screen

will display status and then UPDATE COMPLETE.

ASSIGNING FLAVORS

From the Main Menu select Manager. Type in the

password and select the green check. Select

Configure Slots. Select Slot Flavor. Select a slot you

want to assign a flavor to. Select Assign Flavor.

Choose from the list of flavors. Continue to select slots

and flavors until you’re finished. Select the Red X.

Select the return arrow twice to return to the Main

Menu.

40 Part Number STH034 3/12

Page 41

LOADING BAGS

From the Main Menu select Inventory. One at a time

select the slots with assigned flavors.

1. Position rear groove of the spout on product bag

into slot of the product bin.

2. The spout must snap into slot of product bin.

3. Open the cap on the product bag and tear it off.

4. Return product bin to its position in cabinet.

Select the green check. Select Full Bag. Place cup

under dispenser. Select the pump icon. Dispensing will

display on the screen. If a small amount of product has

been pumped into the cup, select the green check. If

no product was pumped through to the cup, select the

pump icon again, confirm product has been pumped

through and then select the green check. Continue

through all the slots that have been assigned flavors.

Select the return arrow when complete.

Calibration Procedure

• From the main menu select the manager icon.

• Enter the manager’s password.

• Select Configure Slots.

Part Number STH034 3/12 41

Page 42

• Select Calibrate Flavor.

• Select the flavor, water or ice to calibrate.

1. Get Scale

2. Tare Empty Cup Weight

3. Position Cup For Dispense

Flavor and water target is 4 oz. Ice target is 6 oz.

1. Wait until dispensing is done

2. Weigh cup

42 Part Number STH034 3/12

Page 43

3. Tap button to enter weight.

• Enter the cup weight.

• Select the green arrow.

• The calibration screen will return, select the green

arrow.

Part Number STH034 3/12 43

Page 44

• Flavor, 4 oz. Calibration Complete

• The calibration screen returns. Chose another

flavor, water or ice to calibrate or return to the

Configure Slots screen.

44 Part Number STH034 3/12

Page 45

Maintenance

! Warning

General Maintenance

Disconnect power to the unit before performing

any service or maintenance functions.

DOOR GASKET MAINTENANCE

Door gaskets require regular cleaning to prevent mold

and mildew buildup and also to retain the elasticity of

the gasket. Gasket cleaning can be done with the use

of warm soapy water. Avoid full strength cleaning

products on gaskets as this can cause them to

become brittle and crack. Never use sharp tools or

knives to scrape or clean the gasket. Gaskets can be

easily replaced and do not require the use of tools or

an authorized service person. The gaskets are “Dart”

style and can be pulled out of the groove in the door

and new gaskets can be “pressed” back into place.

DRAIN MAINTENANCE - BASE

Each unit has a drain located inside the unit that

removes the condensation from the evaporator coil

and routes it to an external condensate evaporator

pan. Each drain can become loose or disconnected

during normal use. If you notice water accumulation on

the inside of the unit, be sure the drain tube is

connected to the evaporator drain pan. If water is

collecting underneath the unit, make sure the end of

the drain tube is in the condensate evaporator in the

machine compartment. The leveling of the unit is

important as the units are designed to drain properly

when level. Be sure all drain lines are free of

obstructions.

Part Number STH034 3/12 45

Page 46

CASTER MAINTENANCE

Important

Wipe casters with a damp cloth monthly to prevent

corrosion.

NOTE: The power switch must be turned to OFF and

the unit disconnected from the power source

whenever performing service, maintenance functions

or cleaning the refrigerated area.

REFRIGERATORS

The interior and exterior can be cleaned using soap

and warm water. If this isn’t sufficient, try ammonia and

water or a nonabrasive liquid cleaner. When cleaning

the exterior, always rub with the “grain” of the stainless

steel to avoid marring the finish. Do not use an

abrasive cleaner because it will scratch the stainless

steel and can damage the breaker strips and gaskets.

STAINLESS STEEL CARE AND CLEANING

To prevent discoloration or rust on stainless steel,

several important steps need to be taken. First, we

need to understand the properties of stainless steel.

Stainless steel contains 70-80% iron, which will rust. It

also contains 12-30% chromium, which forms an

invisible passive film over the steel’s surface, which

acts as a shield against corrosion. As long as the

protective layer is intact, the metal is still stainless. If

the film is broken or contaminated, outside elements

can begin to break down the steel and begin to form

discoloration or rust. Proper cleaning of stainless steel

requires soft cloths or plastic scouring pads.

Never Use Steel Pads, Wire Brushes or

Scrapers!

46 Part Number STH034 3/12

Page 47

Cleaning solutions need to be alkaline based or non-

!

Caution

chloride cleaners. Any cleaner containing chlorides will

damage the protective film of the stainless steel.

Chlorides are also commonly found in hard water,

salts, and household and industrial cleaners. If

cleaners containing chlorides are used, be sure to

rinse repeatedly and dry thoroughly. Routine cleaning

of stainless steel can be done with soap and water.

Extreme stains or grease should be cleaned with a

non-abrasive cleaner and plastic scrub pad. Always

rub with the grain of the steel. There are stainless steel

cleaners available which can restore and preserve the

finish of the steel’s protective layer. Early signs of

stainless steel breakdown are small pits and cracks. If

this has begun, clean thoroughly and start to apply

stainless steel cleaners in attempt to restore the

passivity of the steel.

Never use an acid based cleaning solution! Many

food products have an acidic content, which can

deteriorate the finish. Be sure to clean the

stainless steel surfaces of ALL food products.

Common items include: tomatoes, peppers and

other vegetables.

Part Number STH034 3/12 47

Page 48

CLEANING THE CONDENSER COIL

!

Caution

In order to maintain proper refrigeration performance,

the condenser fins must be cleaned of dust, dirt and

grease regularly. It is recommended that this be done

at least every three months. If conditions are such that

the condenser is totally blocked in three months, the

frequency of cleaning should be increased. Clean the

condenser with a vacuum cleaner or stiff brush. If

extremely dirty, a commercially available condenser

cleaner may be required.

Failure to maintain a clean condenser coil can initially

cause high temperatures and excessive run times.

Continuous operation with a dirty or clogged

condenser coil can result in compressor failure.

Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor

and cost to replace the compressor.

Never use a high-pressure water wash for this

cleaning procedure as water can damage the

electrical components located near or at the

condenser coil.

48 Part Number STH034 3/12

Page 49

DOORS/HINGES

Over time and with heavy use doors and hinges may

become loose. If this happens tighten the screws that

mount the hinge brackets to the frame of the unit.

Loose or sagging doors can cause the hinges to pull

out of the frame, which may damage both the doors

and the hinges. In some cases this may require

trained & qualified service agents or maintenance

personnel to perform repairs.

NOTE: Do not place hot pans on/against the blue ABS

liner. Do not throw items into the storage area. Failure

to follow these recommendations could result in

damage to the interior of the cabinet or to the blower

coil. Overloading the storage area, restricting the

airflow, and continuous opening and closing of the

doors and drawers will hamper the unit’s ability to

maintain operational temperature.

PREVENTING BLOWER COIL CORROSION

Immediately wipe up all spills.

ANNUAL PLANNED MAINTENANCE

The following parts are recommended for annual

planned maintenance replacement to ensure optimum

unit performance and minimize downtime:

• Refrigerator door gasket (cleaning may be

sufficient)

• (2) #6 O rings for the water and CO

connect lines

/air quick

2

• (9) LMS valves

• (1 Or 2) Mixer assemblies

Part Number STH034 3/12 49

Page 50

CLEANING KITS

Complete cleaning kits are available for single

and dual spindle units.

These kits include the following;

• (3) three 5 gallon buckets

• Bucket labels for Wash, Rinse, & Sanitizing

• Red & Blue cups for blender cleaning

• Dispense Area Shield

• Tubing Manifold for product line cleaning

50 Part Number STH034 3/12

Page 51

Daily Cleaning

On the Menu screen, press the

washing hand (cleaning icon).

Press Daily.

Gather the following supplies:

Clean towels

Spray cleaner (KAY®

SolidSense All Purpose

Super Concentrate, min.

0.085 oz/gal. or 0.425 oz/5

gal*)

Spray sanitizer (KAY-5®

Sanitizer/Cleaner, min.

0.40 oz/gal or 2.0 oz/5

gal*)

Medium cups with wash

and sanitize solution

Press the down arrow to

continue.

*If other cleaners are used, it is

possible they will not clean or

sanitize your machine to NSF

standards.

Grate removal/mixer station wash:

1 Remove grate from left

and right mixer stations

2 Spray all mixer station

inside surfaces with

cleaning solution

Part Number STH034 3/12 51

Page 52

3 Thoroughly wipe down all

surfaces of mixer station

4 Repeat for the other side

Press the down arrow to

continue.

Dispensing area cleaning:

1 Remove center grate from

dispensing area

2 Spray all dispensing area

surfaces with cleaning

solution

3 Thoroughly wipe down all

surfaces of dispensing

area and verify dispense

area drains completely

Press the down arrow to

continue.

4 Thoroughly spray each

individual dispense nozzle

with cleaning solution

5 Thoroughly wipe with a

clean towel

Press the down arrow to

continue.

52 Part Number STH034 3/12

Page 53

Mixer door removal:

1 Slightly open mixer door

2 Squeeze at bottom of door

3 Tilt out and pull the door

down and out

4 Repeat for other door

Press the down arrow to

continue.

Blender assembly wash:

1 Completely spray blender

assembly with cleaning

solution

2 Thoroughly wipe down top

of blender cap and blender

arm

3 Lift blender cap and

thoroughly wipe down top

of blade housing and

bottom of blender cap

4 Thoroughly spray blender

assembly with sanitizer

solution

5 Repeat for other side

Press the down arrow to

continue.

Part Number STH034 3/12 53

Page 54

Reinstall grates/doors:

1 Take all grates and doors

to sink to wash and

sanitize

2 Do not put in dishwasher

or power soaker

3 Reinstall left and right

mixer grates

4 Reinstall dispensing area

grate

5 Reinstall left and right

mixer doors

Press the down arrow to

continue.

Blender wash:

1 Place cup with wash

solution in both blender

stations

Close the blender doors

2 Press the green check

The blenders will lower into the

wash solution and spin to clean.

Washing will display on the

screen

Follow the on screen

instruction, Remove Cup.

Follow the on screen

instruction, Close Door.

54 Part Number STH034 3/12

Page 55

Rinsing will display on the

screen while the machine rinses

the blenders

Finished will display on the

screen

Blender sanitizing:

1 Pour wash solution down

the drain

2 Place cup with sanitizer

solution in both blender

stations

3 Press the green check

Sanitizing will display on the

screen

Mixer station sanitize:

1 Remove cup from each

blender station and pour

sanitizing solution down

the drain and verify

dispense area drains

completely

2 Spray all mixer station

inside surfaces with

sanitizer solution

3 Allow to air dry

4 Do not wipe off sanitizer!

5 Repeat for other side

Press the down arrow to

continue.

Part Number STH034 3/12 55

Page 56

Dispensing area sanitizing:

1 Thoroughly spray each

individual dispense nozzle

with sanitizer solution

2 Thoroughly spray

dispense area with

sanitizer solution

3 Allow to air dry

4 Do not wipe off sanitizer!

Cleanup any spills on or around

he unit, then press the green

check to signify you have

completed the daily cleaning.

Weekly Cleaning

On the Menu screen, press the

washing hand (cleaning icon).

Press Weekly.

Gather the following supplies:

1 Clean towels

2 Spray cleaner (KAY®

56 Part Number STH034 3/12

SolidSense All Purpose

Super Concentrate, min.

0.085 oz/gal. or 0.425

oz/5 gal*)

Page 57

3 Spray sanitizer (KAY-

5® Sanitizer/Cleaner,

min. 0.40 oz/gal or 2.0

oz/5 gal*)

4 Medium cups with wash

and sanitize solution

Press the down arrow to

continue.

5 Buckets with wash,

rinse and sanitize

solution

6 Splash shield

7 Cleaning manifold

Press the down arrow to

continue.

*If other cleaners are used, it is

possible they will not clean or

sanitize your machine to NSF

standards.

Washing instructions:

1 Remove grate from

2 Install splash guard in

3 Remove product

4 Take product holders to

Press the down arrow to

continue.

center dispensing area

dispense area

holders from cabinet

walk-in refrigerator

Part Number STH034 3/12 57

Page 58

5 Spray and wipe each bib

connector and area with

cleaner

6 Spray each bib

connector and area with

sanitizer

7 Connect a cleaning

hose to each product

nozzle

8 Place cleaning manifold

in wash bucket

9 Press the green check

Select Manual Clean or Auto

Clean

Auto clean will send the wash

solution through each line (slot),

displaying the progress on the

screen.

Manual Clean forces you to

select each slot separately to

send the wash solution through

that line. Each slot will display

Washed as you progress.

Press the green check

58 Part Number STH034 3/12

Page 59

Rinsing instructions:

1 Remove cleaning

manifold from wash

bucket

2 Place cleaning manifold

in rinse bucket

3 Press the green check

Rinse solution runs through

each line (slot). The screen will

read Rinsing Slot X. Each slot

will change from Washed to

Rinsed.

Sanitization instructions:

1 Remove cleaning

manifold from rinse

bucket

2 Place cleaning manifold

in sanitize bucket

3 Press the green check

Sanitizing solution runs through

each line (slot). The screen will

read Sanitizing Slot X. Each slot

will change from Rinsed to

Sanitizing.

Part Number STH034 3/12 59

Page 60

Pause for the Sanitation Hold

Time.

Purging instructions:

1 Disconnect the cleaning

hoses from the product

nozzles

2 Press the green check

Air is pushed through each line

(slot) blowing out any remaining

liquid. The screen will read

Purging Slot X. Each slot will

change from Sanitized to

Purged.

Reinstall inventory:

1 Retrieve product

holders from walk in

2 Reinstall each product

holder into correct slot

3 Remove splash guard

4 Reinstall center grate

Press the down arrow to

continue.

5 Place a large cup under

60 Part Number STH034 3/12

from dispense area

under dispensing area

dispensing nozzles

Page 61

6 Press the green check

Each line will fill with product.

The screen will read Priming

Slot X. Each slot will change

from Purged to Clean.

Grate removal/mixer station wash:

1 Remove grate from left

and right mixer stations

2 Spray all mixer station

inside surfaces with

cleaning solution

3 Thoroughly wipe down

4 Repeat for other side

Press the down arrow to

continue.

all surfaces of mixer

station

Dispensing area cleaning:

1 Remove center grate

2 Spray all dispensing

3 Thoroughly wipe down

Part Number STH034 3/12 61

from dispensing area

area surfaces with

cleaning solution

all surfaces of

dispensing area and

verify dispense area

drains completely

Page 62

Press the down arrow to

continue.

4 Thoroughly spray each

individual dispense

nozzle with cleaning

solution

5 Thoroughly wipe with a

clean towel

Press the down arrow to

continue.

Mixer door removal:

1 Slightly open mixer door

2 Squeeze at bottom of

door

3 Tilt out and pull the door

down and out

4 Repeat for other door

Press the down arrow to

continue.

62 Part Number STH034 3/12

Page 63

Blender assembly wash:

1 Completely spray

blender assembly with

cleaning solution

2 Thoroughly wipe down

top of blender cap and

blender arm

3 Lift blender cap and

thoroughly wipe down

top of blade housing

and bottom of blender

cap

4 Thoroughly spray

blender assembly with

sanitizer solution

5 Repeat for other side

Press the down arrow to

continue.

Reinstall grates/doors:

1 Take all grates and

doors to sink to wash

and sanitize

2 Do not put in

dishwasher or power

soaker

3 Reinstall left and right

mixer grates

4 Reinstall dispensing

5 Reinstall left and right

Part Number STH034 3/12 63

area grate

mixer doors

Page 64

Press the down arrow to

continue.

Blender wash:

1 Place cup with wash

solution in both blender

stations

Close the blender doors

2 Press the green check

The blenders will lower into the

wash solution and spin to clean.

Washing will display on the

screen

Follow the on screen instruction,

Remove Cup.

Follow the on screen instruction,

Close Door.

Rinsing will display on the

screen while the machine rinses

the blenders

Finished will display on the

screen

64 Part Number STH034 3/12

Page 65

Blender sanitizing:

1 Remove cup from each

blender station and pour

wash solution down the

drain and verify

dispense area drains

completely

2 Place cup with sanitizer

solution in both blender

stations

3 Press the green check

Sanitizing will display on the

screen

Mixer station sanitize:

1 Remove cup from each

blender station and pour

sanitizing solution down

the drain

2 Spray all mixer station

inside surfaces with

sanitizer solution

3 Allow to air dry

4 Do not wipe off

5 Repeat for other side

Press the down arrow to

continue.

Part Number STH034 3/12 65

sanitizer!

Page 66

Dispensing area sanitizing:

1 Thoroughly spray each

individual dispense

nozzle with sanitizer

solution

2 Thoroughly spray

dispense area with

sanitizer solution

3 Allow to air dry

4 Do not wipe off

sanitizer!

Cleanup any spills on or around

he unit, then press the green

check to signify you have

completed the daily cleaning.

Weekly cleaning completed:

1 Weekly cleaning has

been completed

2 Unit will need to be

cleaned again in 7 days

3 Press the green check

The Weekly cleaning has been

completed. The screen will

return to the Menu Screen.

66 Part Number STH034 3/12

Page 67

Ice Machine Cleaning

VERSION 1 ICE MACHINE R404A REFRIGERANT

The ice machine must be cleaned and sanitized at

least twice a year. More frequent cleaning may be

required in some existing water conditions.

The parts listed below should be inspected at least

once a year or every 10,000 hours of operation. Their

service life, however, depends on water quality and

environment. More frequent inspection and

maintenance are recommended. To have the optimum

performance of this ice Machine, the following

consumable parts need periodic inspection,

maintenance and replacement:

• Extruding Head

• Housing

• Lower Bearing

• Gear Motor

• Auger

• Mechanical Seal

To prevent injury to individuals and damage to the ice

Machine, do not use ammonia type cleaners.

Follow carefully any instructions provided with the

bottles of Ice Machine cleaner or sanitizing solution.

Always wear liquid-proof gloves to prevent the

cleaning and sanitizing solutions from coming into

contact with skin.

1. Flip the rocker switch to “Drain” position. This

switch is the lower switch on the back of the unit.

2. Remove the unit top by removing four

thumbscrews.

3. Remove ice chute cover.

Part Number STH034 3/12 67

Page 68

4. Remove ice dispense motor assembly by

removing four thumbscrews. Place motor

assembly in a location that it will not fall.

5. Remove ice chute by removing two thumbscrews.

There is a gasket between the ice chute and ice

extruding head, remove it.

6. Remove ice bin cover and place cover in a

location that it will not fall.

7. Remove all ice manually and discard. Be cautious

of the washer in between the ice agitator and the

bottom of the ice bin.

8. Use an approved cleaning solution as noted

below.

NOTE: For safety and maximum effectiveness, use

the solution immediately after dilution.

Mix 10 fl. oz. (296 ml) “LIME-A-WAY” (Economics

Laboratory, Inc.) with 2 gallon (6 l) of warm water

or follow the dilution instructions and warnings on

descaler bottle.

9. Use an approved sanitizing solution or mix 1

ounce of household bleach to 2 gallons of warm

(95°F-115°F) water.

10. Remove ice agitator. clean, rinse and sanitize the

ice agitator.

11. Remove the dispense wheel assembly.

12. Locate small washer, it will be stuck to the

bushing or inside the agitator shaft.

68 Part Number STH034 3/12

Page 69

13. Soak the following parts for 20 minutes in

cleaning solution. Rinse the parts thoroughly.

Soak the removed parts in sanitizing solution for

10 minutes and wipe them down.

If solution is left on these parts, they will rust.

• 2 chute parts

• gasket

• dispense wheel and housing

• small washer

14. Wipe the inner ice bin wall with cleaning solution.

Rinse with a clean towel soaked in clean water

and wipe dry. Repeat with sanitizer solution.

Rinse with a clean towel soaked in clean water

and wipe dry.

15. With a bottle brush, brush the ice nozzle at bottom

of ice bin with cleaning solution. Rinse with a

clean towel soaked in clean water and wipe dry.

Repeat with sanitizer solution. Rinse with a clean

towel soaked in clean water and wipe dry.

16. Use an approved Ice Machine cleaning solution

as noted below.

NOTE: For safety and maximum effectiveness, use

the solution immediately after dilution.

Mix 5 fl. oz. (142 ml) “LIME-A-WAY” (Economics

Laboratory, Inc.) with 1 gallon (3 l) of warm water

or follow the dilution instructions and warnings on

an ice machine descaler bottle.

Part Number STH034 3/12 69

Page 70

17. Turn OFF the ice Machine power switch located

on the back.

18. Slowly pour 1 gallon of cleaning solution into the

top of the freeze barrel where the ice normally

exits.

19. Allow the ice Machine to sit for about 20 minutes.

20. After 20 minutes, turn ON the ice Machine power

switch.

21. After the cleaning solution is drained, roughly two

minutes, move the rocker switch to the “ICE”

position.

22. Allow the reservoir to fill with fresh water. Move

the rocker switch to the “Drain” position for 2

minutes.

23. Repeat fill and drain process again by moving the

rocker switch to the “ICE” position. Allow the

reservoir to fill with fresh water. Move the rocker

switch to the “Drain” position for 2 minutes.

24. Turn OFF the ice Machine power switch.

25. Use an approved sanitizing solution or mix 1

ounce of household bleach to 2 gallons of warm

(95°F-115°F) water.

70 Part Number STH034 3/12

Page 71

26. Fill the freeze barrel with sanitizing solution where

the ice normally exits.

27. Allow the ice Machine to sit for about 10 minutes.

28. Replace ice chute, gasket and (2) black

thumbscrews.

29. Lay the unit top over the bin overflow switch. The

bin overflow switch must be depressed for the ice

machine to work properly.

30. Turn ON the ice Machine power switch.

31. Move the rocker switch to the “ICE” position.

32. Run the ice Machine for 20 minutes.

33. Turn OFF the ice Machine power switch.

34. Remove ice chute in order to replace parts.

NOTE: Discard the ice. Do not use ice made from the

sanitizing solution. Be careful not to leave any ice or

solution in the storage bin.

35. Rinse bin with water.

36. Replace all cleaned parts in their correct

positions:

• small washer

• assembled dispense wheel/plates

• auger

• bin cover

• motor

• gasket

• ice chute

• ice chute cover.

37. Replace the unit top cover with four thumbscrews.

38. Cleanup any spills on or around the unit.

39. Turn ON the ice Machine power switch.

Part Number STH034 3/12 71

Page 72

VERSION 2 ICE MACHINES R404A OR R290 REFRIGERANT

The ice machine must be cleaned and sanitized a

minimum of once every six months. More frequent

cleaning may be required in some existing water

conditions. Always wear liquid-proof gloves and safety

glasses to prevent the cleaning and sanitizing

solutions from coming into contact with skin or eyes.

Use Manitowoc Ice Machine Cleaner part number

000000084.

Use Manitowoc Ice Machine Sanitizer part number

94-0565-3.

1. Turn off the ice making water supply and

disconnect power.

2. Remove the following parts:

• Top by removing four thumbscrews.

• Ice chute cover.

• Ice dispense motor assembly by removing

four thumbscrews -Place motor assembly in a

location that it will not fall.

• Ice chute by removing two thumbscrews.

There is a gasket between the ice chute and

ice extruding head that also needs to be

removed.

• Remove ice bin cover and place cover in a

location that it will not fall

• Remove all ice manually. Be cautious of the

washer in between the ice agitator and the

bottom of the ice bin.

3. Remove the following parts for cleaning and

sanitizing:

• Ice agitator

• Dispense wheel assembly

• Small washer - It will be stuck to the bushing

or inside the agitator shaft.

72 Part Number STH034 3/12

Page 73

4. Soak the parts in cleaning solution, then rinse the

parts thoroughly.

5. Soak the parts in sanitizing solution and allow to

air dry.

6. Wipe the inner ice bin wall with cleaning solution,

rinse and wipe dry. Repeat with sanitizer solution

and allow to air dry.

7. Use a bottle brush and cleaning solution to clean

the ice nozzle at bottom of ice bin. Rinse, wipe

dry, repeat with sanitizer solution and allow to air

dry.

8. Drain water from evaporator and reservoir

through the evaporator/reservoir drain line and

reinsert hose into hose clip.

9. Follow the chart and premix cleaner and water.

Amount of Luke Warm

Water

Amount of Cleaner

Part Number 000000084

1 gallon (4 Liters) 4 ounces (120 ml)

10. Remove top cover from the water reservoir, block

up reservoir float and fill the evaporator and

reservoir with cleaning solution. Remainder of

solution will be used for hand cleaning.

Part Number STH034 3/12 73

Page 74

11. Verify the compressor rocker switch is in the OFF

position, then reconnect power and run the

gearmotor for 15 minutes. Perform the following

procedures during the 15 minute period:

• Remove ice compression nozzle from

evaporator and soak in cleaning solution.

• Descale drain pan by gently flexing, then

remove any scale residue.

• Inspect water feed and drain lines and clean

as needed.

• Connect ice transport tube direct to

evaporator and secure with hose clamp.

12. Disconnect power, then drain the water from the

evaporator and reservoir through the evaporator/

reservoir drain line - Using a pitcher, fill and drain

the evaporator/reservoir 4 times and reinsert the

hose into the hose clip.

13. Refer to chart and premix water and sanitizer.

Amount of

Luke Warm Water

Amount of Sanitizer

1 Gallon (4 L) Water 1/2 ounce (15 ml)

14. Fill reservoir and evaporator with sanitizer/water

solution.

15. Verify the compressor rocker switch is in the OFF

position, then reconnect power and run the

gearmotor for 10 minutes.

74 Part Number STH034 3/12

Page 75

16. During the 10 minute period rinse cleaner from

compression nozzle with potable water and then

soak in sanitizer/water solution.

17. Move the compressor rocker switch to the ON

position. The ice machine will make ice with the

sanitizer/water solution and deposit the ice in the

bin/dispenser. Make ice for 5 minutes - add

sanitizer/water solution as the water level in the

reservoir drops.

NOTE: Do not allow the sanitizer/water level to drop

below the sensing probes. The ice machine will start a

20 minute delay period if the sensing probes lose

contact with the water for more than 10 seconds.

18. Move the compressor rocker switch to the OFF

position and disconnect power.

19. Drain the evaporator/reservoir and reinsert the

drain hose into the hose clip.

20. Reinstall the ice compression nozzle and

reservoir cover.

21. Remove blocking from under reservoir float and

reinstall reservoir cover.

Part Number STH034 3/12 75

Page 76

22. Turn on the ice making water supply, reconnect

power and move the compressor rocker switch to

ON.

23. Allow the ice machine to run for 10 minutes, then

place the compressor rocker switch in the OFF

position, disconnect power and discard all ice

produced.

24. Turn ON the ice Machine power switch.