Page 1

Blend-In-Cup® (BIC)

Manual Fill BeverageSystem

Installation, Operation and Maintenance Manual

Original Instructions — This manual is updated as new information and models are released.

Visit our website for the latestmanual. www.manitowocbeverage.com/us

Part Number 9294699 12/16/15

Page 2

Safety Notices

As you work on Multiplex equipment, be sure to pay close

attention to the safety notices in this manual. Disregarding

the notices may lead to serious injury and/or damage to the

equipment.

Throughout this manual, you will see the following types of

safety notices:

Warning

n

Text in a Warning box alerts you to a potential personal

injury situation. Be sure to read the Warning statement

before proceeding, and work carefully.

Caution

,

Text in a Caution box alerts you to a situation in which

you could damage the equipment. Be sure to read

the Caution statement before proceeding, and work

carefully.

Procedural Notices

As you work on Multiplex equipment, be sure to read the

procedural notices in this manual. These notices supply

helpful information which may assist you as you work.

Throughout this manual, you will see the following types of

procedural notices:

Important

Text in an Important box provides you with information

that may help you perform a procedure more efficiently.

Disregarding this information will not cause damage or

injury, but it may slow you down as you work.

Read These Before Proceeding:

Caution

,

Proper installation, care and maintenance are essential

for maximum performance and trouble-free operation

of your Multiplex equipment. Read and understand

this manual. It contains valuable care and maintenance

information. If you encounter problems not covered

by this manual, do not proceed, contact Manitowoc

Foodservice. We will be happy to provide assistance.

Important

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the warranty.

Warning

n

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

• All models intended for sale and use in Australia and

New Zealand use only R-404A as a refrigerant. No

flammable refrigerants are used.

• All models intended for sale and use in Australia and

New Zealand are of climatic class 4.

• All models intended for sale and use in Australia and

New Zealand use ecomate® as the insulation blowing

gas which is nonflammable.

NOTE: Text set off as a Note provides you with simple, but

useful, extra information about the procedure you are

performing.

NOTE: SAVE THESE INSTRUCTIONS.

We reserve the right to make product improvements at

any time. Specifications and design are subject to change

without notice.

Page 3

Section 1

General Information

Section 2

Installation

Table of Contents

Read This Manual ............................................................................................................... 5

About Blend-In-Cup ...........................................................................................................5

Unit Inspection ................................................................................................................... 5

Model Numbers .................................................................................................................. 5

Serial Number Location ..................................................................................................... 5

Warranty Information ........................................................................................................ 6

Specifications .....................................................................................................................7

Dimensions ...............................................................................................................................................7

Capacity & Weight ..................................................................................................................................7

Product Delivery Location ...................................................................................................................8

Refrigerant Charge .................................................................................................................................8

Electrical ....................................................................................................................................................9

Air / CO2, Plain & Chilled Water ...................................................................................................... 10

System Pressures ................................................................................................................................. 10

Regulator Settings & Location ........................................................................................................ 11

Drain Connections .............................................................................................................................. 11

Section 3

Operation

Step-by-Step Installation .................................................................................................13

Pre-installation Checklist .................................................................................................................. 13

Connections .......................................................................................................................................... 14

Checklist ................................................................................................................................................. 15

Start-up & Cleaning ............................................................................................................................ 15

Post Installation Checklist ................................................................................................................ 17

Sequence of Operation ....................................................................................................19

Normal Operation ............................................................................................................................... 19

Component Identification ...............................................................................................20

Touch Screens ................................................................................................................... 21

Drink Selection Screen ...................................................................................................................... 21

Flavor Selection Screen ..................................................................................................................... 22

Size Screen ............................................................................................................................................. 23

Main Menu Screen .............................................................................................................................. 26

Manager’s Menu Screen....................................................................................................................27

Calibration Procedure ........................................................................................................................ 29

Product Inventory Screen .................................................................................................................31

Cleaning Screen ................................................................................................................................... 33

Other Operations .............................................................................................................34

Loading Recipes ................................................................................................................................... 34

Manual Fill Ice ....................................................................................................................................... 34

Recommended Cups ..........................................................................................................................34

Part Number 9294699 12/16/15 3

Page 4

Section 4

Maintenance

Section 5

Troubleshooting

Table of Contents (continued)

General Maintenance .......................................................................................................35

Door Gasket Maintenance ............................................................................................................... 35

Drain Maintenance - Inside Lower Cabinet ................................................................................35

Refrigerator ............................................................................................................................................ 36

Stainless Steel Care & Cleaning ...................................................................................................... 36

Doors/Hinges ........................................................................................................................................ 36

Preventing Blower Coil Corrosion ................................................................................................. 36

Daily Cleaning - Zone 1 ....................................................................................................37

Gather the Following Supplies ....................................................................................................... 37

Ice Bin Wash ........................................................................................................................................... 38

Blenders / Dispense Area Cleaning & Sanitizing ...................................................................... 39

Weekly Cleaning - Zone 2 ................................................................................................43

Gather the Following Supplies ....................................................................................................... 43

Product Line Cleaning & Sanitizing .............................................................................................. 44

Blenders / Dispense Area Cleaning & Sanitizing ...................................................................... 48

Drain Cleaning - BIO-SHIELD® (Optional) .................................................................................... 52

Other Monthly Tasks ........................................................................................................................... 54

Product Line Flush ............................................................................................................55

Gather the Following Supplies ....................................................................................................... 55

Annual Planned Maintenance .........................................................................................61

Before Calling For Service Checklist ...............................................................................63

Procedure to Clear Blocked Line .....................................................................................65

How to Check Product Pumps Air/CO2 Pressure ............................................................66

How to Check Plain Water Pressure ................................................................................67

Section 6

Tools & Cleaning Supplies

Cleaning Kits ..................................................................................................................... 69

4 Part Number 9294699 12/16/15

Page 5

Section 1

General Information

Read This Manual

Manitowoc Beverage Systems developed this manual as a

reference guide for the owner/operator and installer of this

equipment. Please read this manual before installation or

operation of the machine. A qualified service technician must

perform installation and start-up of this equipment. Consult

Section 5 within this manual for service assistance.

If you cannot correct the service problem, call your Service

Agent or Distributor. Always have your model and serial number

available when you call.

Your Service Agent ____________________________________

Service Agent Telephone Number ________________________

Your Local Distributor __________________________________

Distributor Telephone Number __________________________

Model Number ______________________________________

Serial Number _______________________________________

Installation Date ______________________________________

About Blend-In-Cup

Class A: EMC Registration is done on this equipment for

business use only (Class A). Product seller and user should

notice that this equipment is not for household use.

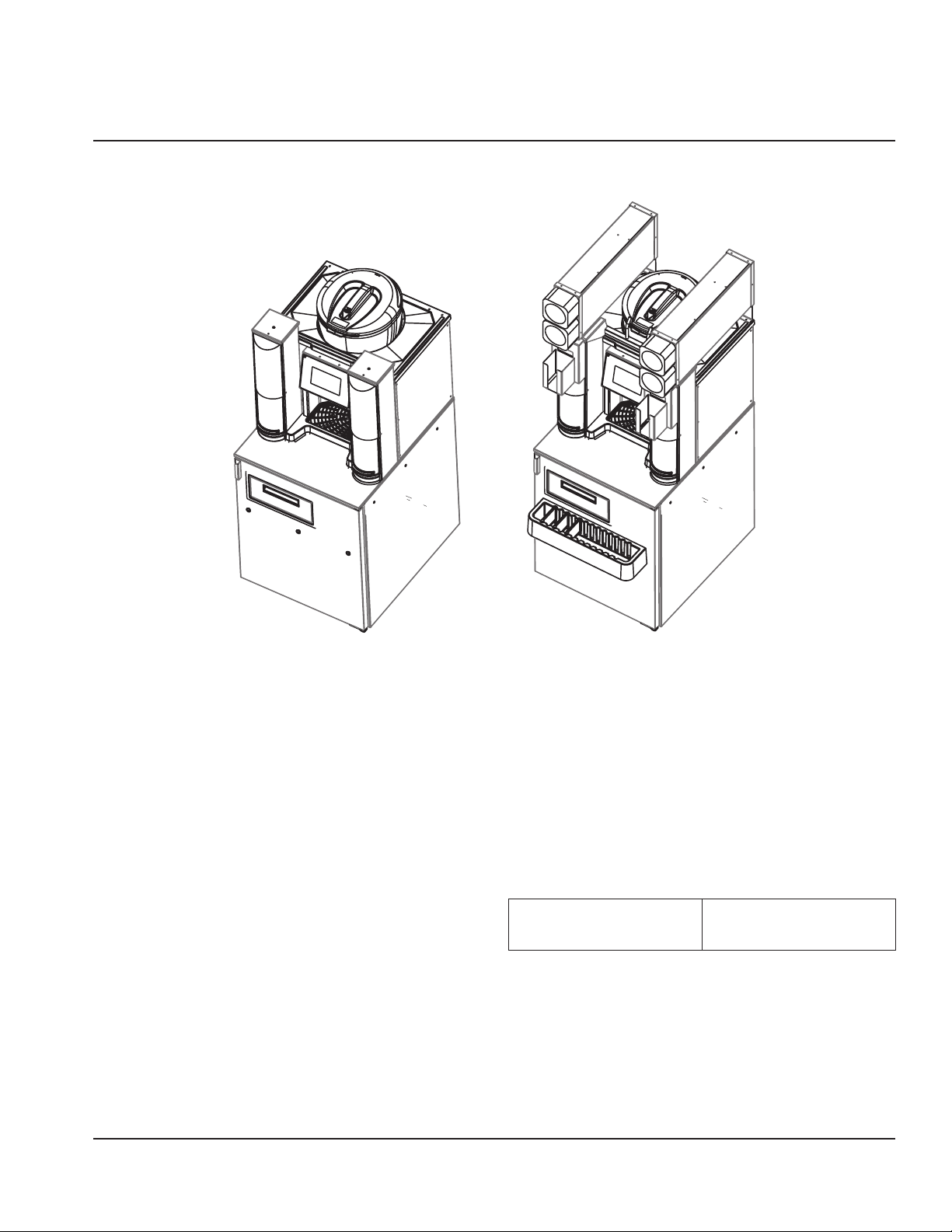

The Blend-In-Cup beverage system is a self-contained dispensing

unit that allows the operator to make flavor combinations of

blended and non-blended drinks. It holds product flavoring in a

refrigerated reach-in base enclosure, has a manual fill ice bin and

includes one or two mixing modules.

The operator controls and accesses the unit using a lighted touch

screen. Icons on the drink selection screens represent the primary

flavor combinations for the drinks. There are multiple drink size

options. Menu changes and additions are uploaded using a USB

mass storage device and the Menu Connect Software platform.

On-screen instructions also include operator procedures for

cleaning/sanitizing, checking inventory, replacing product bags,

selecting drink sizes and manually preparing drinks. Managers

and technicians have access to menu/software updates,

diagnostics and other service screens.

Warning

n

Do not damage the refrigeration circuit when installing,

maintaining or servicing the unit.

Warning

n

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible

for their safety.

Model Numbers

This manual covers the following models:

Blend-In-Cup Beverage Systems

MA-8-2, MA-8-2BF, MA-8-2AF

Serial Number Location

The Blend-In-Cup beverage system serial number is listed on the

serial number decal affixed to the middle of the lower back panel.

Another serial number decal is located on the right side of the

machine.

Unit Inspection

Thoroughly inspect the unit upon delivery. Immediately report

any damage that occurred during transportation to the delivery

carrier. Request a written inspection report from a claims

inspector to document any necessary claim. See “Pre-installation

Checklist” on page 13.

Part Number 9294699 12/16/15 5

Sample Serial Tag

Page 6

General Information Section 1

Warranty Information

Consult your local Service Agent or Representative for terms

and conditions of your warranty. Your warranty specifically

excludes all general adjustments, cleaning, accessories and

related servicing.

Your warranty card must be returned to activate the

warranty on this equipment. If a warranty card is not

returned, the warranty period can begin when the

equipment leaves the Manitowoc Beverage Systems factory.

No equipment may be returned to Manitowoc Beverage

Systems without a written Return Materials Authorization

(RMA). Equipment returned without an RMA will be refused

at Manitowoc Beverage System’s dock and returned to the

sender at the sender’s expense.

Please contact your local distributor for return procedures.

Full explanation of the Limited Warranty for Multiplex

Blended Ice Machines can be found in the warranty

statement shipped with the unit.

See “Limited Warranty” on page 71.

6 Part Number 9294699 12/16/15

Page 7

Section 1 General Information

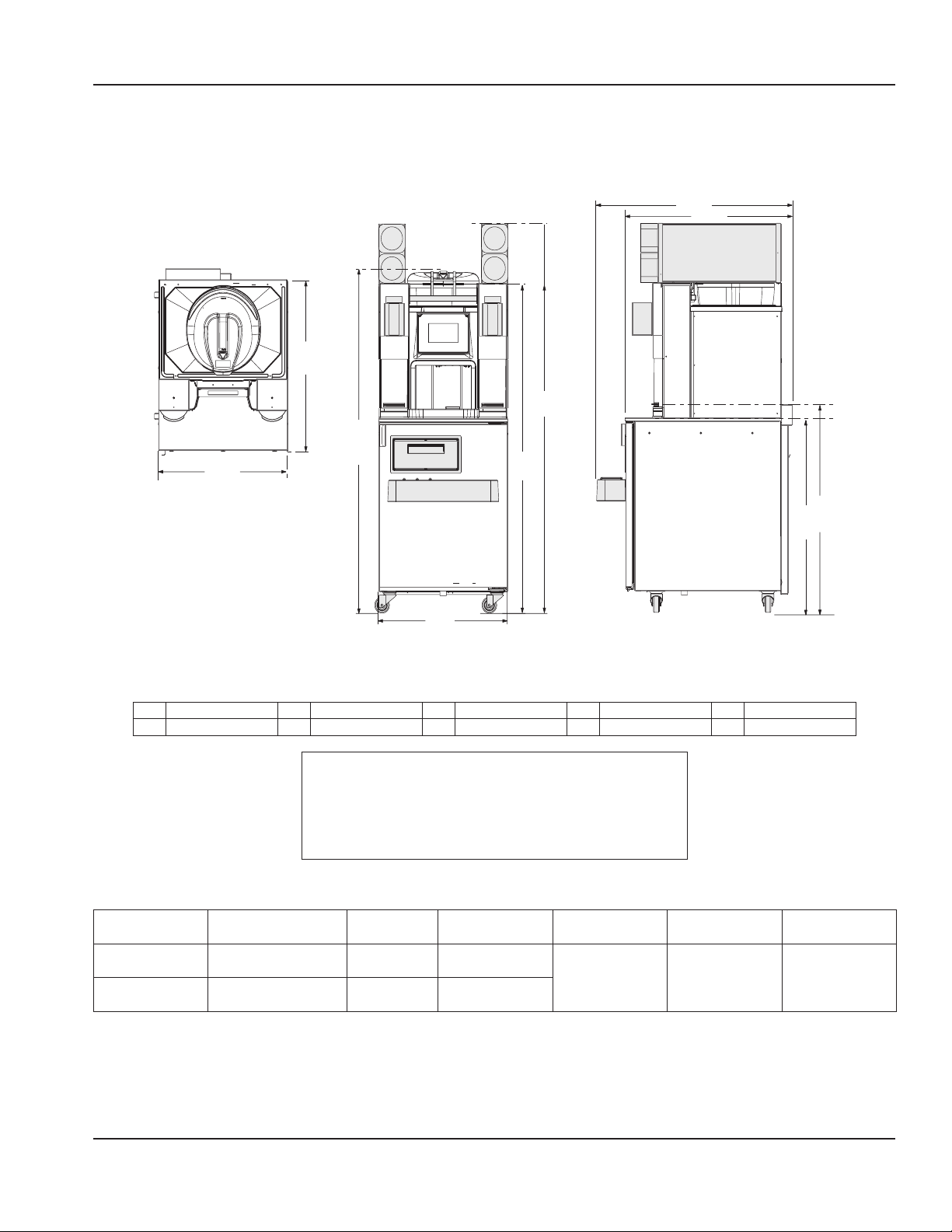

D

G

I

F

* H

E

A

C

B

J

Specifications

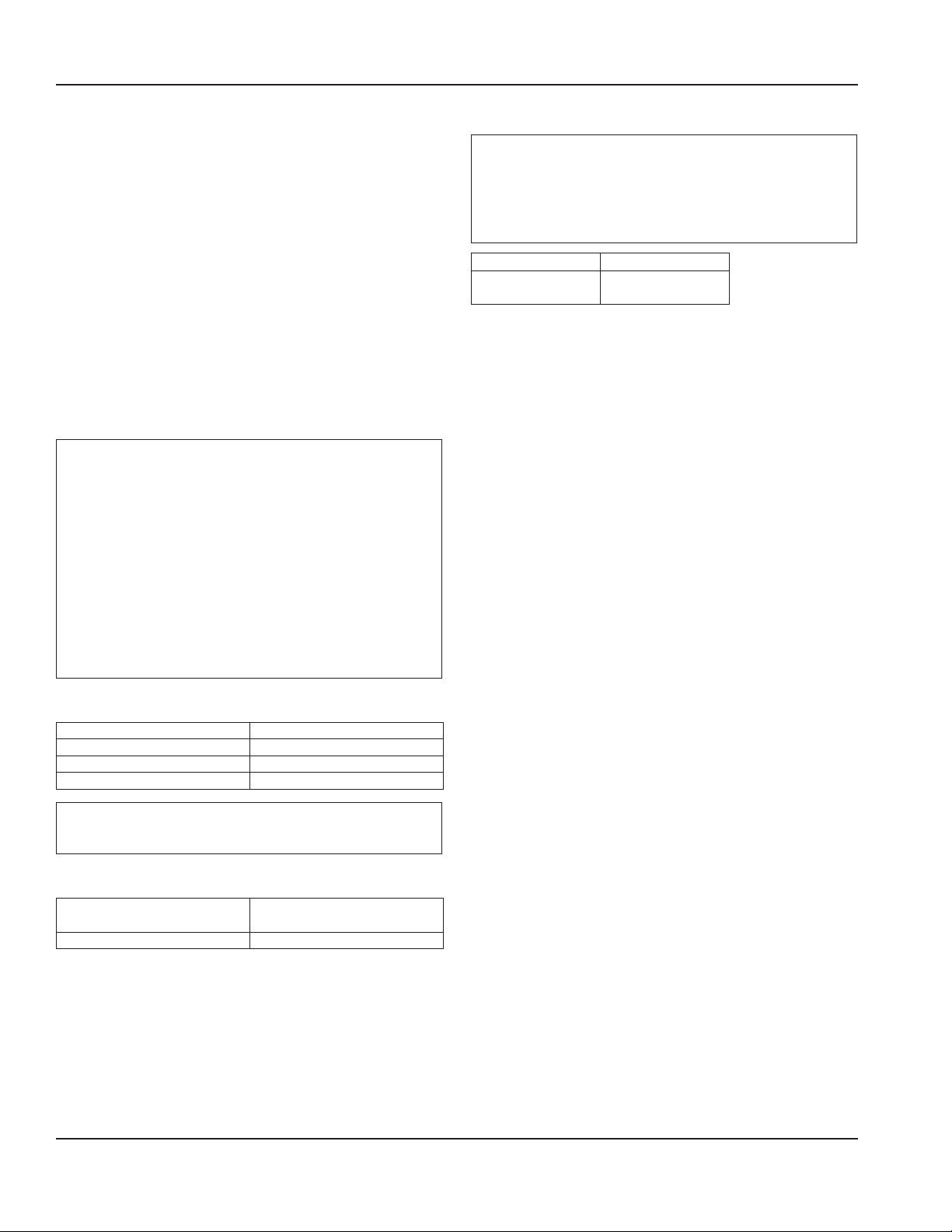

DIMENSIONS

Elevation View Side View

Plan View

NOTE: This illustration covers all

models, grayed out areas are options

that may be on the unit. Dimension

C is the same on all models.

* Low profile casters reduce height by 1.5” (4 cm)

A 71.25" (181 cm) C 26.00" (66 cm) E 60.25" (153 cm) G 33.74" (86 cm) I 36.15" (92 cm)

B 32.82" (83 cm) D 40.10" (102 cm) F 26.00" (66 cm) *H 63.48" (161 cm) J 39.09" (99 cm)

Warning

n

To avoid instability the installation area must be capable

of supporting the weight of the equipment and a full

bin of ice. Additionally the equipment must be level side

to side and front to back.

CAPACITY & WEIGHT

Lower Cabinet – 1/5 19.8 lbs

Ice Bin 23 lbs (10 kg) – –

Ice Capacity HP Max Product

BinLoad

(9 kg)

Shipping

Weight

461 lbs

(209 kg)

Crated

Empty Weight Full Weight

347 lbs

(157 kg)

Unpacked No

Ice/Product

500 lbs

(227 kg)

With Ice/

Product

Part Number 9294699 12/16/15 7

Page 8

General Information Section 1

PRODUCT DELIVERY LOCATION

The location selected for the Blend-In-Cup Beverage System

must meet the following criteria.

• The air temperature must be at least 40°F (4°C), but

must not exceed 90°F (32°C), climate class 4.

• The location must not be near heat-generating

equipment or in direct sunlight and must be protected

from weather.

• Plain or Chilled Inlet Water Temperature:

min/max = 40°F / 90°F (4°C / 32°C).

• Always use the water supply line supplied when

installing this appliance. Never reuse an old supply line.

• Verify floor of install location is level front to back, side

to side.

• Keep equipment area clear of combustible material.

Warning

n

Carbon Dioxide (CO2) displaces oxygen. Exposure to a

high concentration of CO2 gas causes tremors, which

are followed rapidly by loss of consciousness and

suffocation. If a CO2 gas leak is suspected, particularly

in a small area, immediately ventilate the area before

repairing the leak. CO2 lines and pumps must not be

installed in an enclosed space. An enclosed space can

be a cooler or small room or closet. This may include

convenience stores with glass door self serve coolers. If

you suspect CO2 may build up in an area, venting of the

B-I-B pumps and / or CO2 monitors must be utilized.

REFRIGERANT CHARGE

Important

Due to continuous improvements, this information is

for reference only. Please refer to the serial number tag

to verify electrical data. Serial tag information overrides

information listed on this page.

R-404a

Lower Cabinet

(Cabinet 1)

12 oz.

(339 g)

Clearances

Top 18" (46 cm)

Sides 0" (0 cm)

Back 6” (15 cm)

Front 30" (76 cm)

Warning

n

Do not obstruct machine vents or openings.

Heat of Rejection

Models Heat of Rejection

BTU/h

R404a Base Cabinet (Cabinet 1) 2100

8 Part Number 9294699 12/16/15

Page 9

Section 1 General Information

ELECTRICAL

Warning

n

All wiring must conform to local, state and national codes.

Minimum Circuit Ampacity

The minimum circuit ampacity is used to help select the

wire size of the electrical supply. (Minimum circuit ampacity

is not the Blend-In-Cup Beverage System’s running amp

load.) The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., it must be

determined by a qualified electrician.

Voltage

A dedicated electrical circuit is required, a power cord

is provided with all units. Some models are available in

different voltages and may be equipped with a different

plug. Refer to Blend-In-Cup Beverage System Model/Serial

Plate for voltage/amperage specifications.

Minimum Circuit Amperage Chart

Important

Due to continuous improvements, this information is

for reference only. Please refer to the serial number tag

to verify electrical data. Serial tag information overrides

information listed on this page.

Model Voltage/Cycle/

Phase

MA-8-2 120/60/1 8.6

MA-8-2AF 230-240/50/1

Grounding Instructions

n

The machine must be grounded in accordance with

national and local electrical codes.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the

risk of electric shock. This appliance is equipped with a

cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

Total Amps Breaker Size

5.0

Warning

(Max)

20AMA-8-2BF 220/60/1

Bonding Instructions (230-240V 50 Hz Models Only)

This appliance must be connected to the potential

equalization system in accordance with EN60335-1 and

EN60335-2-75. A bonding lug is provided on the lower right

front corner of the appliance.

Warning

n

This machine must be connected to the potential

equalization system.

Warning

n

When using electric appliances, basic precautions must

always be followed, including the following:

A. Read all the instructions before using the

appliance.

B. To reduce the risk of injury, close supervision

is necessary when an appliance is used near

children.

C. Do not contact moving parts.

D. Only use attachments recommended or sold by

the manufacturer.

E. Do not use outdoors.

F. For a cord-connected appliance, the following

must be included:

• Do not unplug by pulling on cord. To unplug,

grasp the plug, not the cord.

• Unplug from outlet when not in use and

before servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in

any manner. Contact the nearest authorized

service facility for examination, repair, or

electrical or mechanical adjustment.

G. Follow applicable lock out tag out procedures

before working on equipment.

H. Connect to a properly grounded outlet only. See

Grounding Instructions.

Part Number 9294699 12/16/15 9

Page 10

General Information Section 1

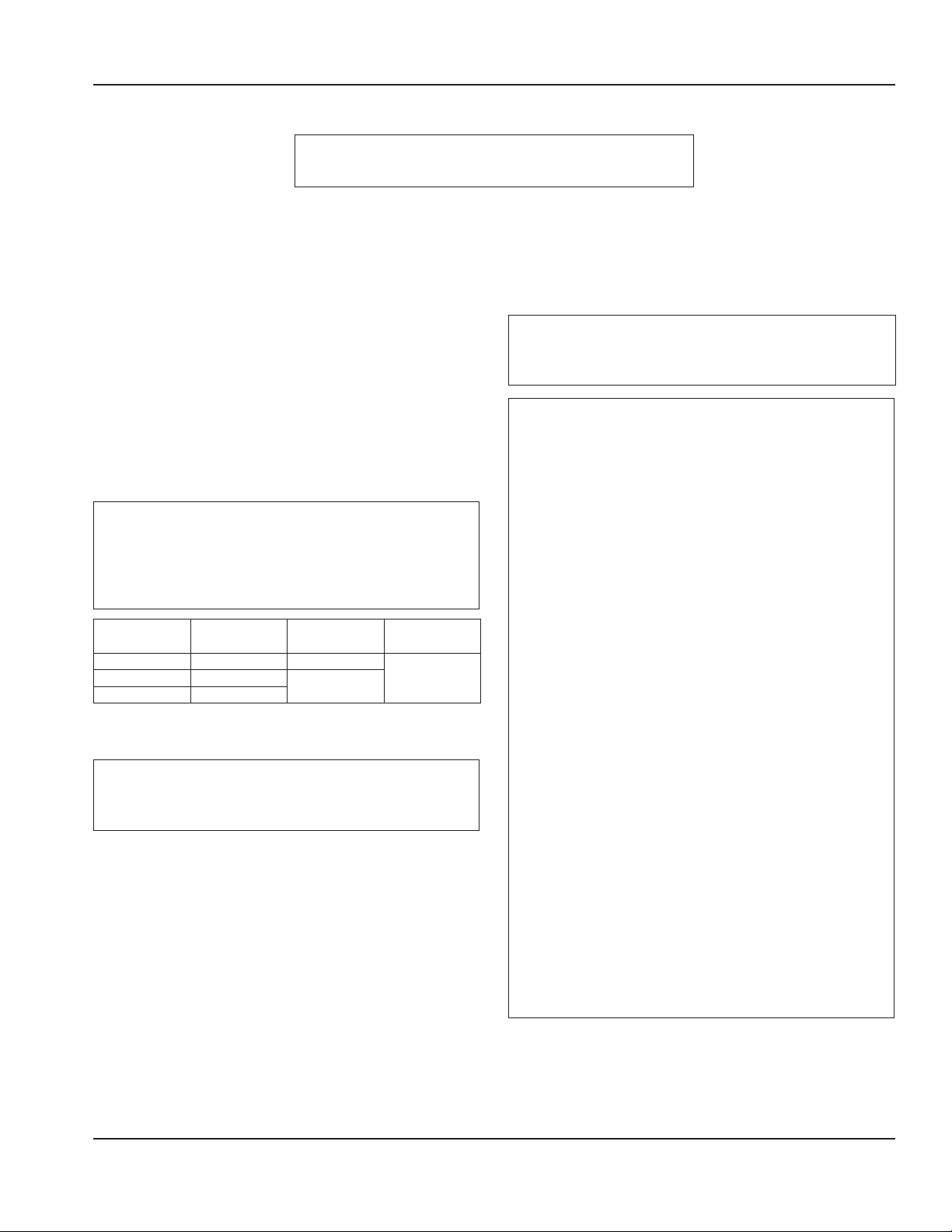

AIR / CO2, PLAIN & CHILLED WATER

Warning

n

Connect to a potable water supply only.

• Use supplied 3/8" (.95 cm) panel-mounted hose barb

and 6' (1.8 m) of beverage tubing to connect labeled

coupling body fitting(s) on back of unit for each supply

connection.

• Do not connect either water connection to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on sink

faucets, dishwashers, etc.)

• Install a water shut-off valve in the water line at the rear

of the machine.

• Insulate water inlet lines to prevent condensation.

Drain

OUT

Plain

Water

IN

Air/CO2

IN

Hard Water

In areas where the water is highly concentrated with

minerals the water should be tested by a water treatment

specialist, and the recommendations of the specialist

regarding filtration and/or treatment should be followed.

SYSTEM PRESSURES

Supply to the Unit

Warning

n

Do not supply more than 80 psi (0.551 MPa , 551 kPa,

5.51 bar) Air/CO2 to the unit, excessive pressure to

product pumps may cause failure.

This table shows the Minimum / Maximum supply of Water and

Air/CO2 required at the rear of the machine at no flow conditions.

MINIMUM MAXIMUM

Air / CO

2

Supply

Plain Water

Supply

(..345 MPa , 345 kPa, 3.45 bar)

(0.448 MPa , 448 kPa, 4.48 bar)

50 psi

65 psi

80 psi

(0.551 MPa , 551 kPa, 5.51 bar)

90 psi

(0.620 MPa, 620 kPa, 6.20 bar)

10 Part Number 9294699 12/16/15

Page 11

Section 1 General Information

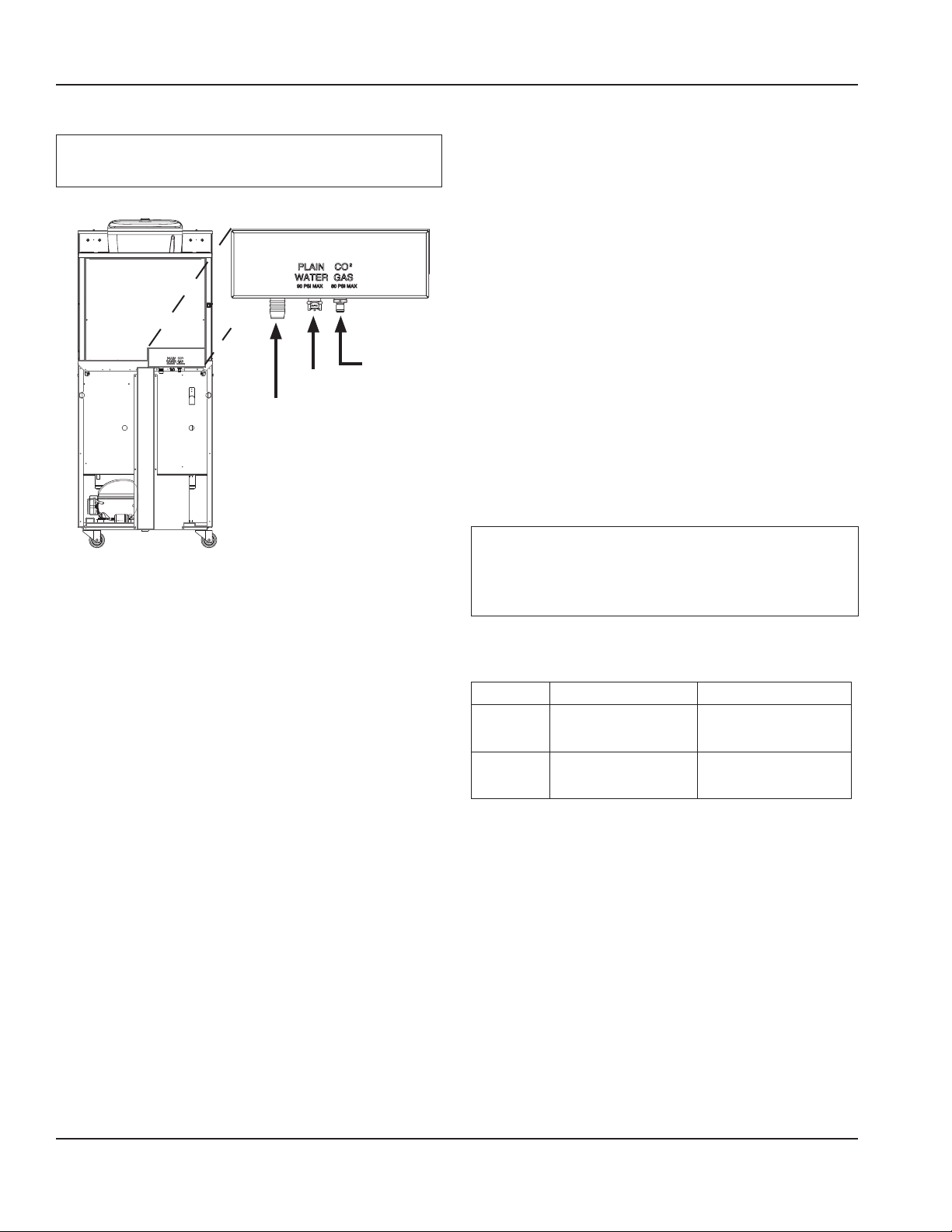

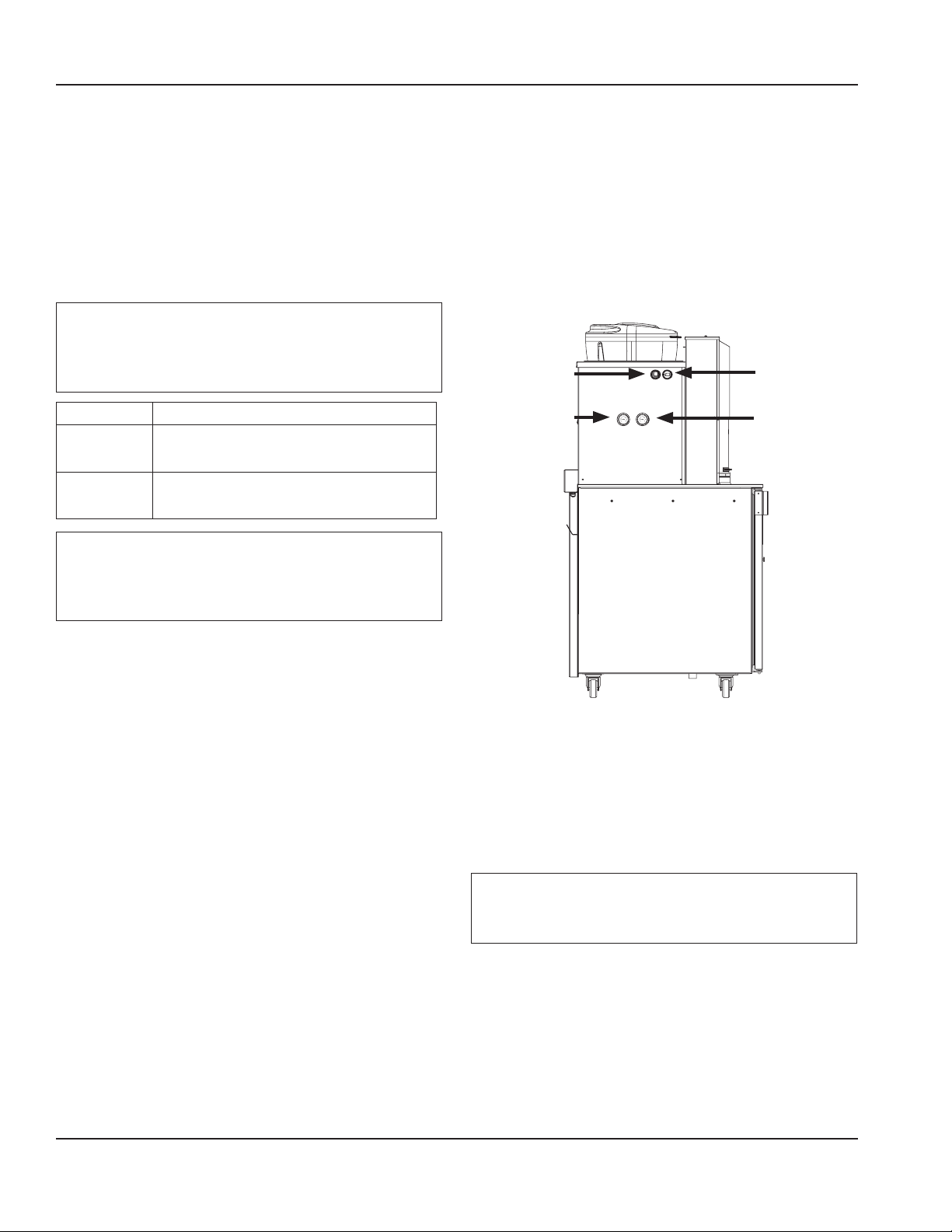

REGULATOR SETTINGS & LOCATION

Regulator Settings

Important

Air/CO2 Requires the pressure measurement to be taken

ON/OFF

Switch

Air/CO2 (Pumps)

Regulator

35 psi (0.24 MPa,

241 kPa, 2.41 bar)

USB Port

Plain Water

Regulator

35 psi (0.24 MPa,

241 kPa, 2.41 bar)

only when a product pump is being activated (product

pump during flow conditions).

Important

Water requires the pressure measurement to be taken

only when rinse water is spraying (flowing conditions)

in a blender chamber.

Important

Water pressure affects the blender area cleaning, a

water booster may be required if pressure is too low.

REGULATOR SETTINGS (During Flowing Conditions)

Pumps

Air / CO

2

Plain Water

(0.24 MPa, 241 kPa, 2.41 bar)

(0.24 MPa, 241 kPa, 2.41 bar)

35 psi

35 psi

DRAIN CONNECTIONS

• Connect supplied 1” ID hose to hose-barb connection

on machine.

• Drain lines must have a 1.5 inch drop per 5 feet of run

(2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to accommodate

drainage from all drains.

• An air gap is included in the design of the machine for

back flow prevention. Plumb to local code.

Part Number 9294699 12/16/15 11

Page 12

General Information Section 1

THIS PAGE INTENTIONALLY LEFT BLANK

12 Part Number 9294699 12/16/15

Page 13

Section 2

Installation

Step-by-Step Installation

These instructions are provided to assist the qualified

installer. Contact your Manitowoc Foodservice Service

Agent or call Manitowoc Foodservice for information

regarding start-up services.

Important

Failure to follow these installation guidelines may affect

warranty coverage.

PREINSTALLATION CHECKLIST

Keep product bags in a cooler at least 24 hours

prior to installation.

Any damage should be noted and reported to the

delivering carrier immediately.

Check the lower portion of the unit to be sure

casters are not bent.

Visually inspect the refrigeration package,

compressor compartment housing. Be sure lines

are secure and base is still intact.

Inspect installation location behind the BIC for

electrical outlet location, CO2, water hose fittings,

and shutoff.

Check voltage at outlet dedicated for BIC.

Verify floor of install location is level front to back,

side to side and all casters are touching the floor.

Warning

n

The mass of this appliance will allow it to move

uncontrolled on an inclined surface. Adequate means

must be provided to prevent uncontrolled movement

at all times.

Remove the side panels from the unit to make the

board connections, Air/CO2 and Water Regulator

gauges accessible.

Check that board connections are secure and did

not vibrate loose during shipment.

Check that both micro switches are in line with the

motor above the blenders.

Part Number 9294699 12/16/15 13

Page 14

Installation Section 2

CONNECTIONS

See “System Pressures” on page 10 and “Regulator Settings &

Location” on page 11

1. Confirm correct orientation of Water and Air/CO2

fittings.

2. The line set included with the unit should be equipped

with male quick connect fitting(s) for the water supply

line(s) and female quick connect fitting(s) for the Air/

Electrical

See “Electrical” on page 12

5. If all electrical and grounding requirements have been

followed proceed to insert electrical plug from BIC into

wall receptacle.

6. Turn power switch on the left hand side of the unit to

the ON position.

CO2 supply line

Important

Leave enough slack in the water/CO2/drain lines to allow

access to the rear of the machine without disconnecting

the lines.

ON/OFF

Switch

USB Port

REGULATOR SETTINGS (During Flowing Conditions)

Pumps

Air / CO

2

Plain Water

(0.24 MPa, , 241 kPa, 2.41 bar)

(0.24 MPa, 241 kPa, 2.41 bar)

35 psi

35 psi

Important

Regulators are factory set but will need to be checked

and possibly adjusted under flowing conditions once

the unit is operational.

See “How to Check Product Pumps Air/CO2 Pressure” on page

66 and “How to Check Plain Water Pressure” on page 67

3. Coil excess tubing and secure with tie straps.

Drain

See “Drain Connections” on page 11

4. Route drain line (minimum 1” ID) to drain, maintaining

a 2” (51 mm) air gap. Cut to proper length if needed (do

not leave loops in drain).

Air/CO2 (Pumps)

Regulator

35 psi (0.24 MPa,

241 kPa, 2.41 bar)

Plain Water

Regulator

35 psi (0.24 MPa,

241 kPa, 2.41 bar)

7. The touch screen should energize and inform the user to

perform Zone 2 & 3 cleaning before the unit can be put

into operation. See “Start-up & Cleaning” on page 15

Important

Do not add product to the machine until cleaning and

sanitizing are complete.

14 Part Number 9294699 12/16/15

Page 15

Section 2 Installation

CHECKLIST

Review before proceeding with Start-Up & Cleaning.

All internal packing has been removed?

Have all of the electrical, water and CO2

connections been made?

Is there proper clearance around the machine for

air circulation?

Is the machine grounded / polarity correct?

Has the machine been installed where the

incoming water temperature will remain in the

range of 40°F / 90°F (4°C / 32°C)?

Have the regulators been properly set?

Have the blender door(s) sensor position(s) been

checked?

Has the Power switch been turned to the ON

position?

STARTUP & CLEANING

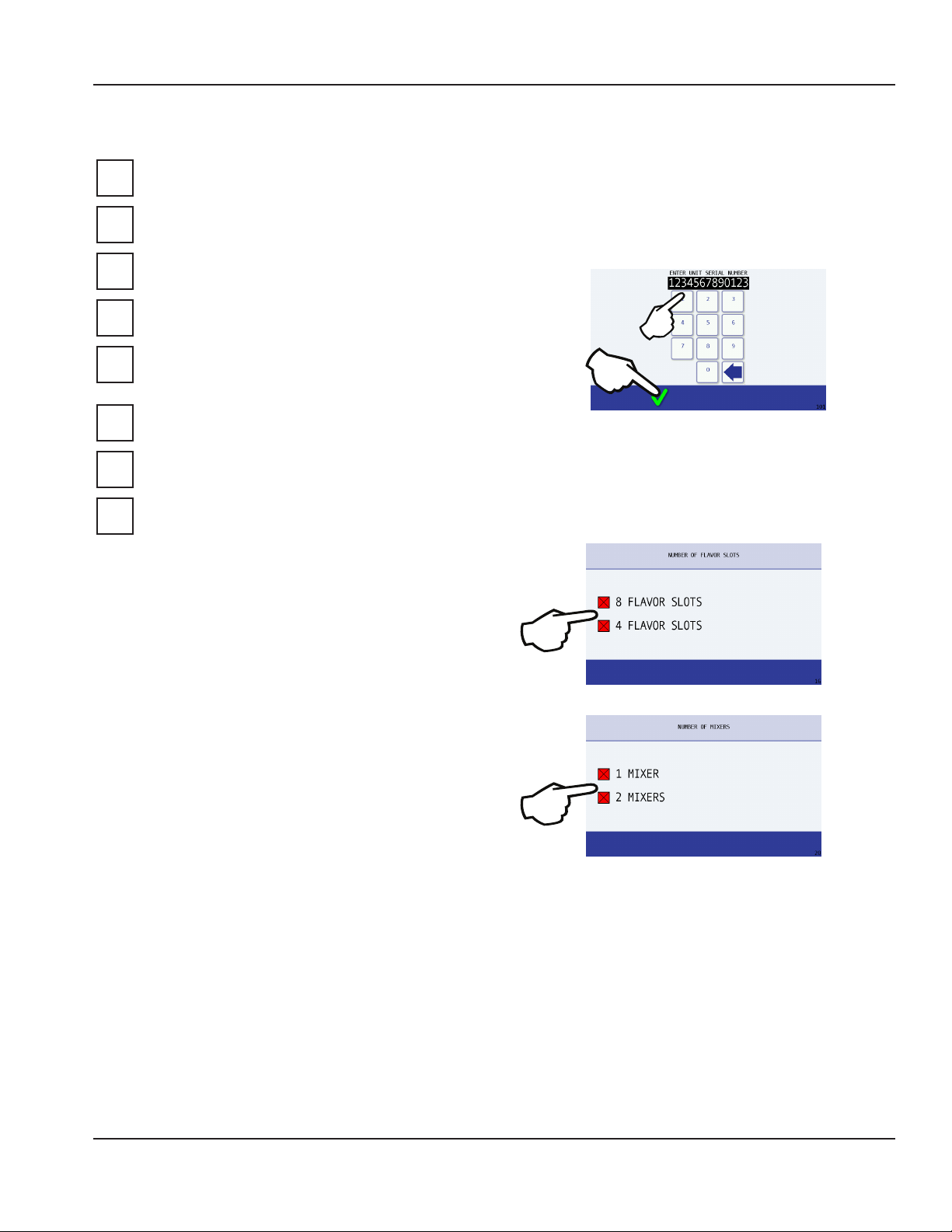

Serial Number

8. During the first start-up of the machine the installer will

be asked to input the unit’s 13 digit serial number.

A. Enter the serial number.

B. Press the green check to continue.

A

B

Set Flavors & Mixers

9. Installer must also choose the number of flavors and

mixers to be configured before being granted access to

the user interface.

NOTE: These can be changed later through the Manager’s

Menu if needed.

Part Number 9294699 12/16/15 15

Page 16

Installation Section 2

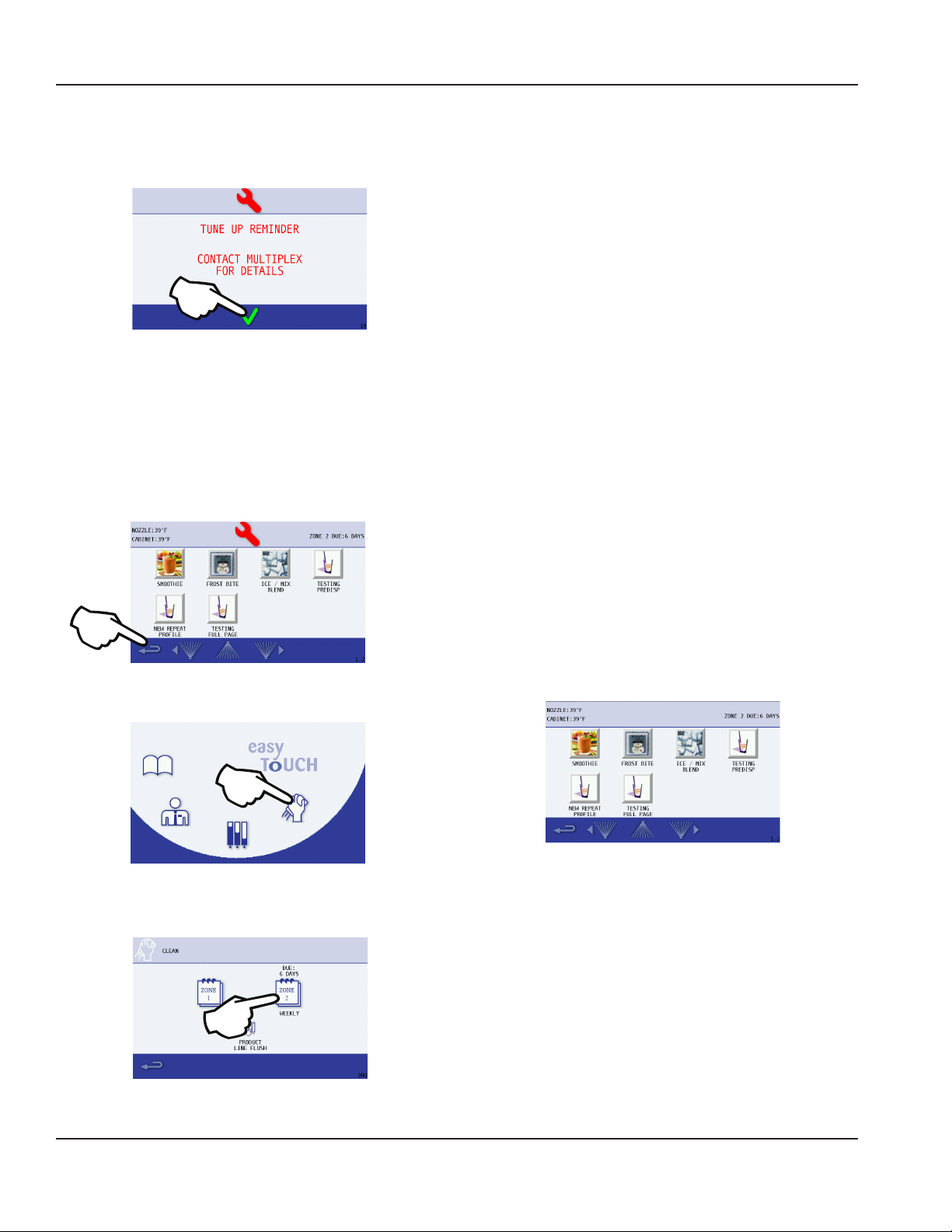

Tune-Up Reminder

10. The Tune-Up reminder screen will appear during initial

installation, press the green check to continue.

NOTE: See “Weekly Cleaning - Zone 2” on page 43. By

doing so, the following will have been completed:

A. All beverage lines, ice bin, dispense area, and blender

chambers, cleaned and sanitized.

B. Water run through the drain to verify it is draining properly.

C. Verify all regulators are set correctly during

cleaning.

NOTE: During the cleaning process is an ideal time to verify

pressure regulator settings during flowing conditions. See

11. The red wrench at the top of the screen and reminder

will periodically popup until the installation date is set

in the Managers Menu.

NOTE: This will be done once Start-Up and Cleaning have

been completed.

12. Press the Back Arrow in the lower left corner to access

the Main Menu.

“Regulator Settings & Location” on page 14

D. Ice bin manually filled with ice. See “Manual Fill Ice” on

page 34 .

E. Product bags retrieved from walk-in cooler, installed into

the product bins and placed into their proper location in

the cabinet. See “Procedure to Install a Product Bag” on

page 32 & “Assigning Flavors” on page 28.

13. Select the Cleaning Icon.

14. Select Zone 2, Clean and sanitize the Blend-In-Cup

machine by following the on screen instructions.

F. All product lines primed and ready for use.

Label

15. Add labels to product bins, put labels in correct place.

16. Add labels anywhere else on the unit required.

Software

17. Load recipes. See “Loading Recipes” on page 34.

18. Verify correct drinks and flavors are available.

Drink Selection Screen

(Drink choices will vary depending on loaded recipe file)

16 Part Number 9294699 12/16/15

Page 17

Section 2 Installation

Calibrate

See “Calibration Procedure” on page 29

19. Product calibration can be performed once operating

temperature has been reached. Once completed, the

Blend-In-Cup machine is ready for use.

20. Reinstall all side panels.

21. Push the BIC unit into place.

22. Verify the unit is level and shim if necessary.

Demonstrate

23. Demonstrate using the Interface. See “Touch Screens”

on page 21.

24. Demonstrate how to make drink. See “Procedure to

Make a Drink” on page 24.

25. Demonstrate Manager Menu options, using the

default password. (The password can be changed.) See

“Manager’s Menu Screen” on page 27.

26. Set date and time to activate warranty.

27. Complete start-up form, sign, and have store manager

sign form. (Fax to number on form.)

POST INSTALLATION CHECKLIST

Has the machine been properly sanitized?

Has each flavor been installed and primed?

Has ice been added to the bin?

Have the all regulators been correctly set during

flowing conditions?

Is the machine cycling ON/OFF on the temperature

control?

Has the owner/operator been instructed regarding

maintenance procedures?

Has the owner/operator completed the warranty

registration card?

Part Number 9294699 12/16/15 17

Page 18

Installation Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

18 Part Number 9294699 12/16/15

Page 19

Sequence of Operation

Section 3

Operation

Dual Blend Chamber without

Cup Dispenser

NORMAL OPERATION

Drink Selection screen appears after power-up of the unit.

Operator presses one of the drink type buttons on the Drink

Selection screen, and the Flavor Options screen appears.

Once a flavor is selected, the Size screen appears. See

“Procedure to Make a Drink” on page 24.

Next the drink preparation sequence commences. If add-ins

are required for the drink, the user will be prompted. Here,

according to the drink size selected and when initiated

through the touch screen, the machine dispenses product

and ice into the cup in the dispense area. The cup is then

placed into an available blend chamber.

Dual Blend Chamber with Top Mount

Cup Dispenser

With the blend chamber door closed and after “Start Mixer”

is selected on the touch screen, the machine blends the

drink for the correct time at the proper blender speed. If

add-ins are required for the drink after blending, the user

will be prompted.

After the drink is removed and the operator closes the

blend chamber door, the automatic rinse of the blender

initiates. The Drink Selection screen re-appears.

Default Temperature

ControlSetting

36°F/2°C set point

2°F/1°C differential

controlled by software

Part Number 9294699 12/16/15 19

Page 20

Operation Section 3

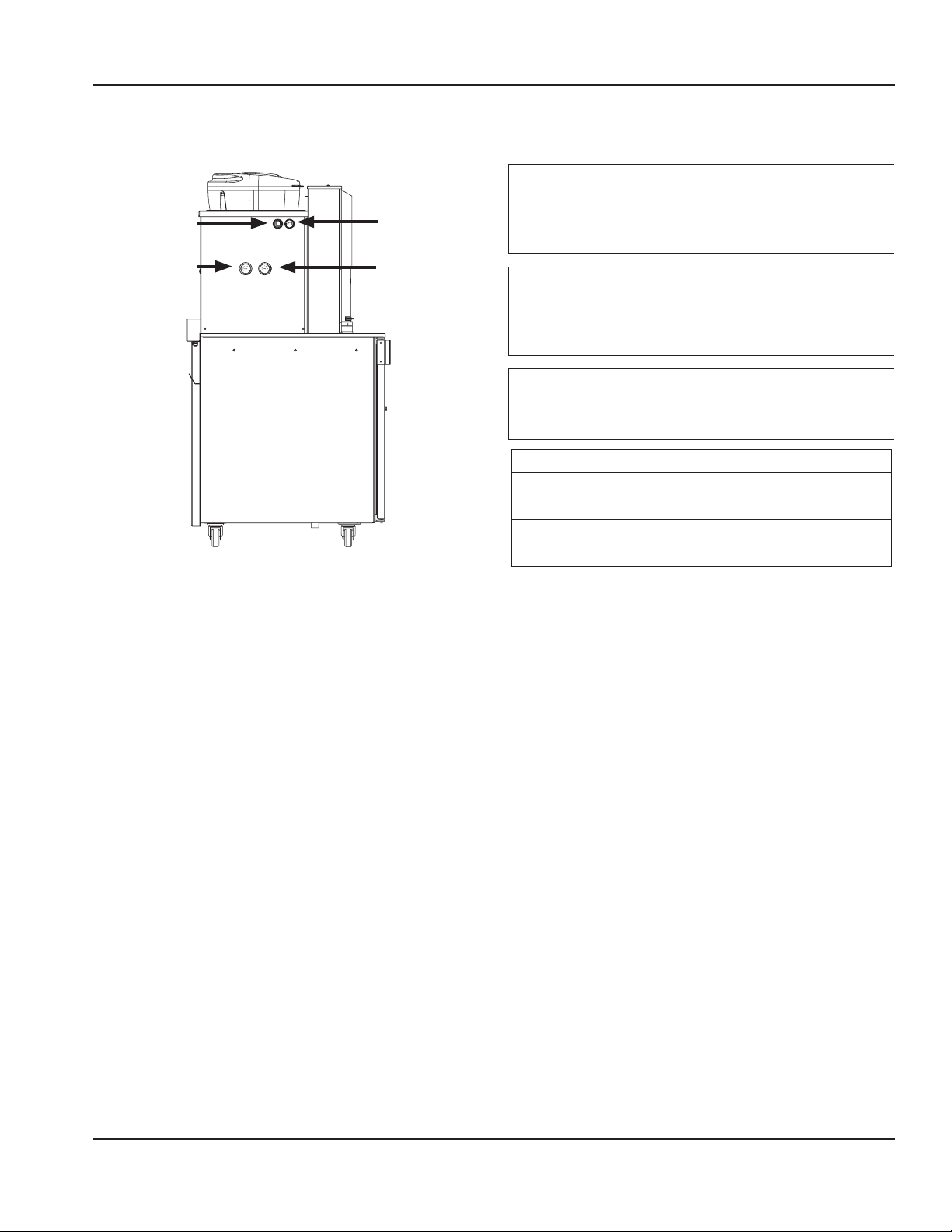

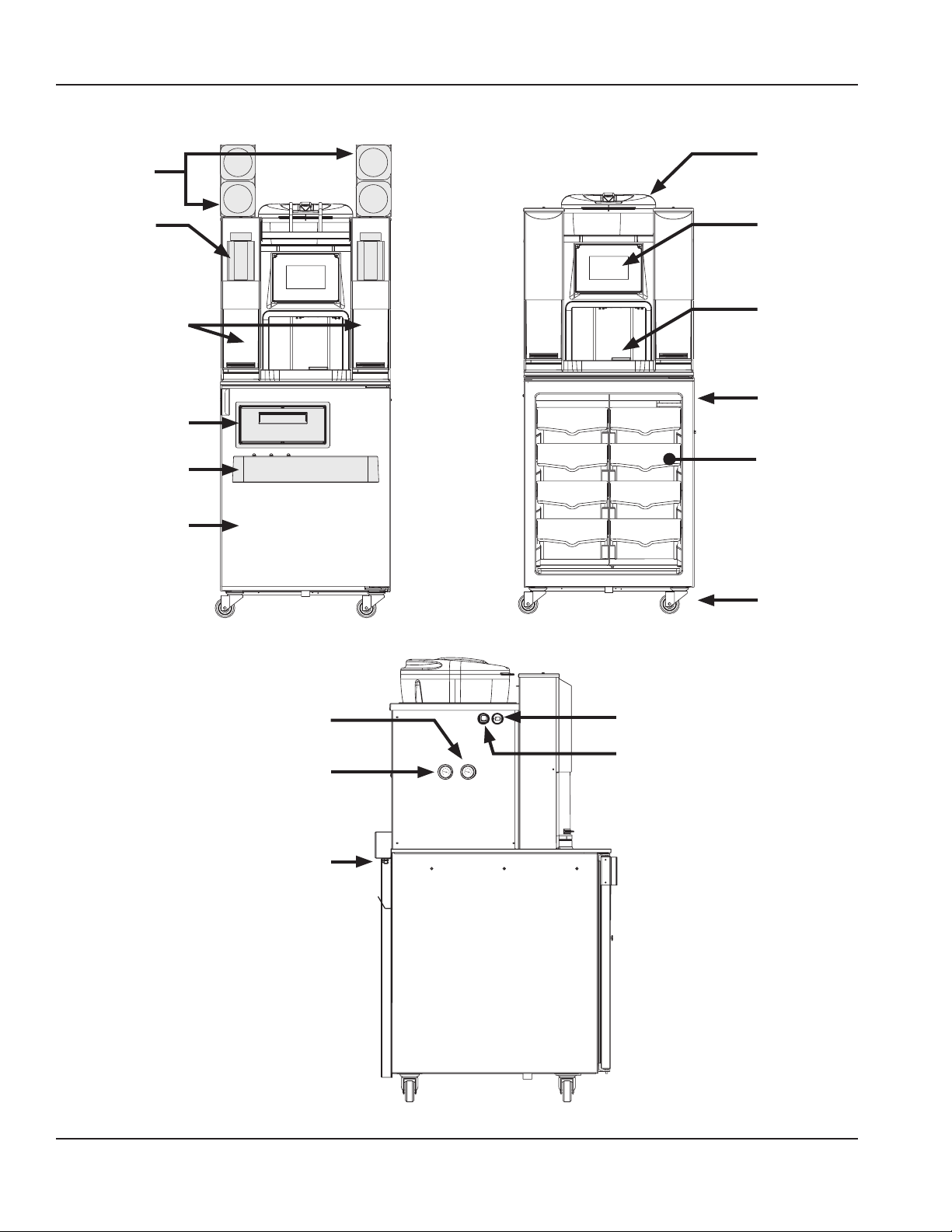

Component Identification

Ice Bin

Cup Dispensers

(Optional)

Lid Dispenser

(Optional)

Blending Station

Door(s)

Whipped Cream Door

(Optional)

Syrup Rail

(Optional)

Cabinet Door

(Optional)

Touch Screen

Product

Dispense Area

Product Cabinet

Product Bins

Casters

Water Regulator

Air/CO2 Regulator

Drain, Water &

Air/CO2 Inlets

USB Ports

Power Switch

20 Part Number 9294699 12/16/15

Page 21

Section 3 Operation

Touch Screens

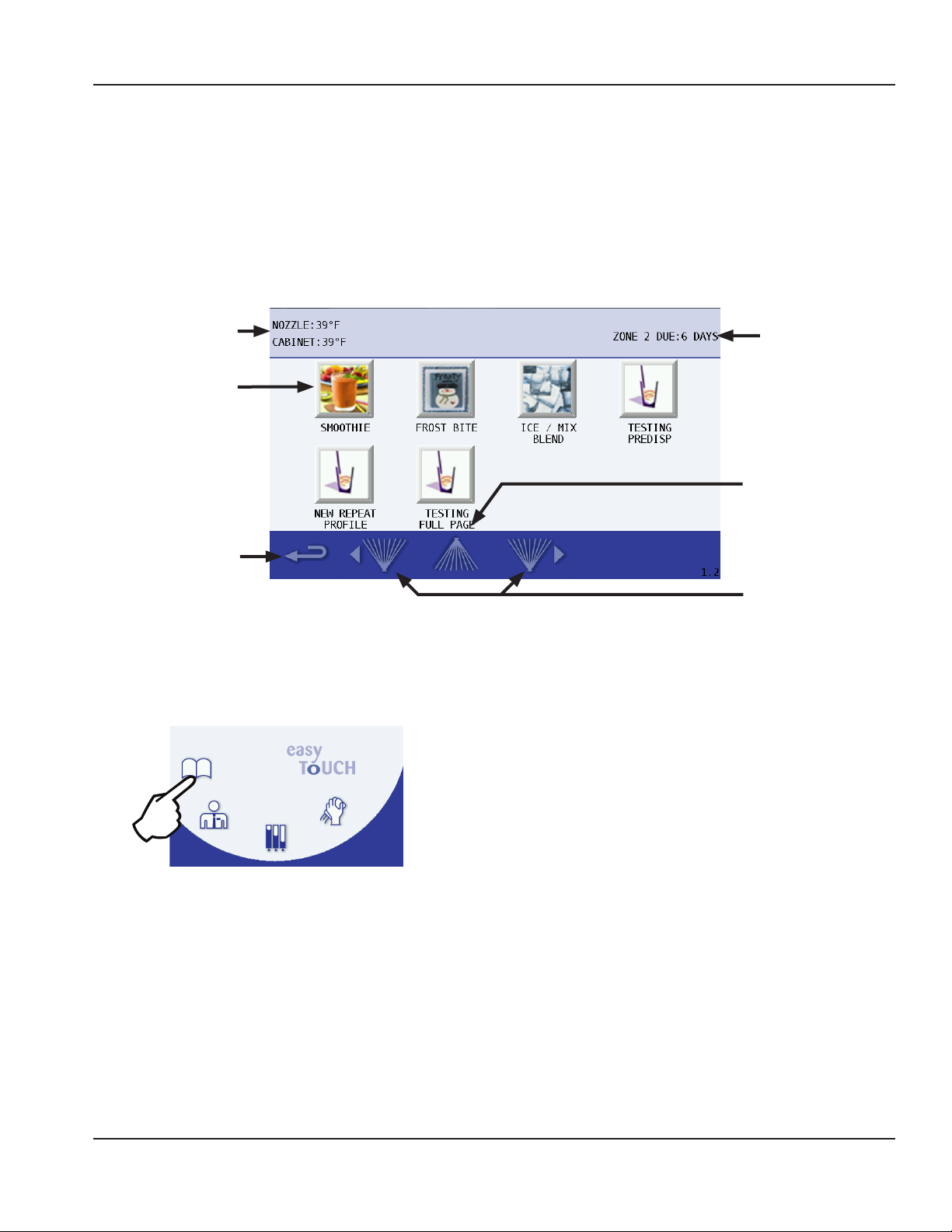

The “easy ToUCH” screen has four selections. One is for the drink making procedure: Drink Selection displays by default at

start-up. The Manager’s Menu is for accessing the machine’s settings. Inventory is for product information and Cleaning is for

routine maintenance of the machine.

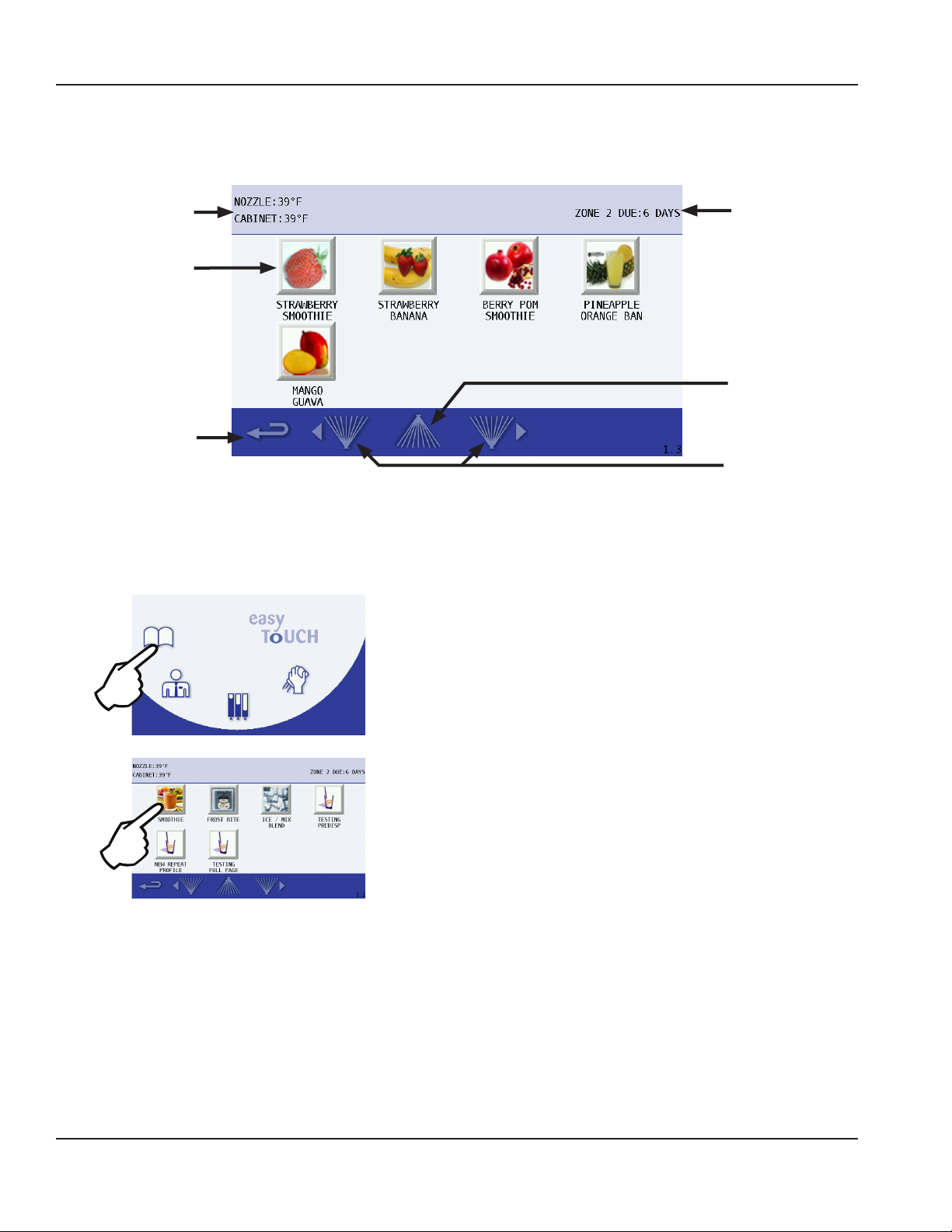

DRINK SELECTION SCREEN

The Drink Selection screen appears on power-up (except where clean/sanitize limitations have been exceeded, in which case

the Cleaning screen appears). See “General Maintenance” on page 35 for Daily, Weekly and Monthly cleaning/sanitization.

The Drink Selection screen’s primary function is to select a drink to make or to access the Main Menu.

Nozzle & Cabinet

Temperatures

Drink Categories

Go to Main

MenuScreen

How to Access

The Drink Selection screen displays by default unless

cleaning is required. This screen can also be accessed

through the main menu Book Icon.

NOTE: Available drink selections may vary depending on

the recipe file installed.

Icon Button Descriptions

• NOZZLE & CABINET Temperatures

Displays the current temperature for dispense point

nozzle and the refrigeration cabinet. Unit of measure can

be changed in the Manager’s Menu.

• Drink Categories

The main product categories are displayed left to right

on the Drink Selection screen. Touching a category will

display the drink flavor options available for the category.

Cleaning

Reminders

Ice Chute

Rinse Button

Rinse Button(s)

• Main Menu Arrow

Navigates to the Main Menu screen.

(See “” on page 25)

• Cleaning Reminders

Displays the time remaining in days until ZONE 2

(Weekly) and ZONE 3* (Monthly) cleaning is required.

* If equipped with this feature.

• Rinse Button(s)

Press to rinse the left or right blender chambers. Blend

chamber door(s) must be closed.

• Ice Chute Rinse Button

Press this button to rinse the ice chute if it becomes

clogged. Repeat if necessary.

Part Number 9294699 12/16/15 21

Page 22

Operation Section 3

FLAVOR SELECTION SCREEN

The Flavor Selection screen appears after a Drink Selection has been made. Flavor options will vary depending on what

recipes are configured on the unit. This screen’s primary function is to select a drink flavor.

Nozzle & Cabinet

Temperatures

Drink Flavor

Buttons

Go Back One

Screen

How to Access

The Flavor Selection screen displays after a drink selection

has been made from the Drink Selection screen.

Cleaning

Reminders

Ice Chute

Rinse Button

Rinse Button(s)

• Drink Flavor Buttons

Flavor choices for the drink type that was selected.

• Yellow Border

If any of the drink ingredients will expire soon, the

yogurt has expired, or there is less than 10% left in

the product bag. Check the Product Inventory Screen

for exact amount of product remaining.

(See “Product Inventory Screen” on page 31)

• Red Border

Product expired, flavor selection unavailable. Will

need to replace product bag. (See “Procedure to Install

a Product Bag” on page 32)

NOTE: Available flavor selections may vary depending

on the recipe file installed.

• Back Arrow

Navigates to previous Drink Selection screen.

(See “Drink Selection Screen” on page 21)

• Cleaning Reminders

Displays the time remaining in days until ZONE 2

(Weekly) and ZONE 3* (Monthly) cleaning is required.

Icon Button Descriptions

• NOZZLE & CABINET Temperatures

Displays the current temperature for dispense point

nozzle and the refrigeration cabinet. Unit of measure

can be changed in the Manager’s Menu.

* If equipped with this feature.

• Rinse Button

Press to rinse the left or right blender chambers. Blend

chamber door(s) must be closed.

• Ice Chute Rinse Button

Press this button to rinse the ice chute if it becomes

clogged. Repeat if necessary.

22 Part Number 9294699 12/16/15

Page 23

Section 3 Operation

SIZE SCREEN

The Size screen appears after a drink flavor has been chosen from the Flavor Selection screen. This screen’s primary function

is to select size and make a drink. Optional Add-Ins are also performed through this screen if the drink requires them.

Nozzle & Cabinet

Temperatures

Add-in Topping

(If Required)

Drink Size

Selection Buttons

Go Back One

Screen

Icon Button Descriptions

• NOZZLE & CABINET Temperatures

Displays the current temperature for dispense point

nozzle and the refrigeration cabinet. Unit of measure

can be changed in the Manager’s Menu.

• Add-Ins

These are not functioning buttons, only a graphic

representation of the add-in used when making the

selected drink. The screen will prompt the user when

the add-in is to be added to the drink.

NOTE: Not all drinks have an add-in. Drink add-ins may

vary depending on the recipe file installed.

• Drink Size Buttons

Press a drink size (SMALL, MEDIUM, or LARGE) to start

the drink making process.

Cleaning

Reminders

The screen will prompt to place cup in mixer when

dispensing is complete and return to the Drink Selection

screen while blending the drink. (See “Procedure to Make a

Drink” on page 24)

• Back Arrow

Navigates to previous Flavor Selection screen.

(See “Flavor Selection Screen” on page 22)

• Cleaning Reminders

Displays the time remaining in days until ZONE 2

(Weekly) and ZONE 3* (Monthly) cleaning is required.

* If equipped with this feature.

NOTE: Make sure the correct cup is in place before pressing

the drink size button, once one is selected the unit will

start dispensing product and the screen will display

“DISPENSING“.

Part Number 9294699 12/16/15 23

Page 24

Operation Section 3

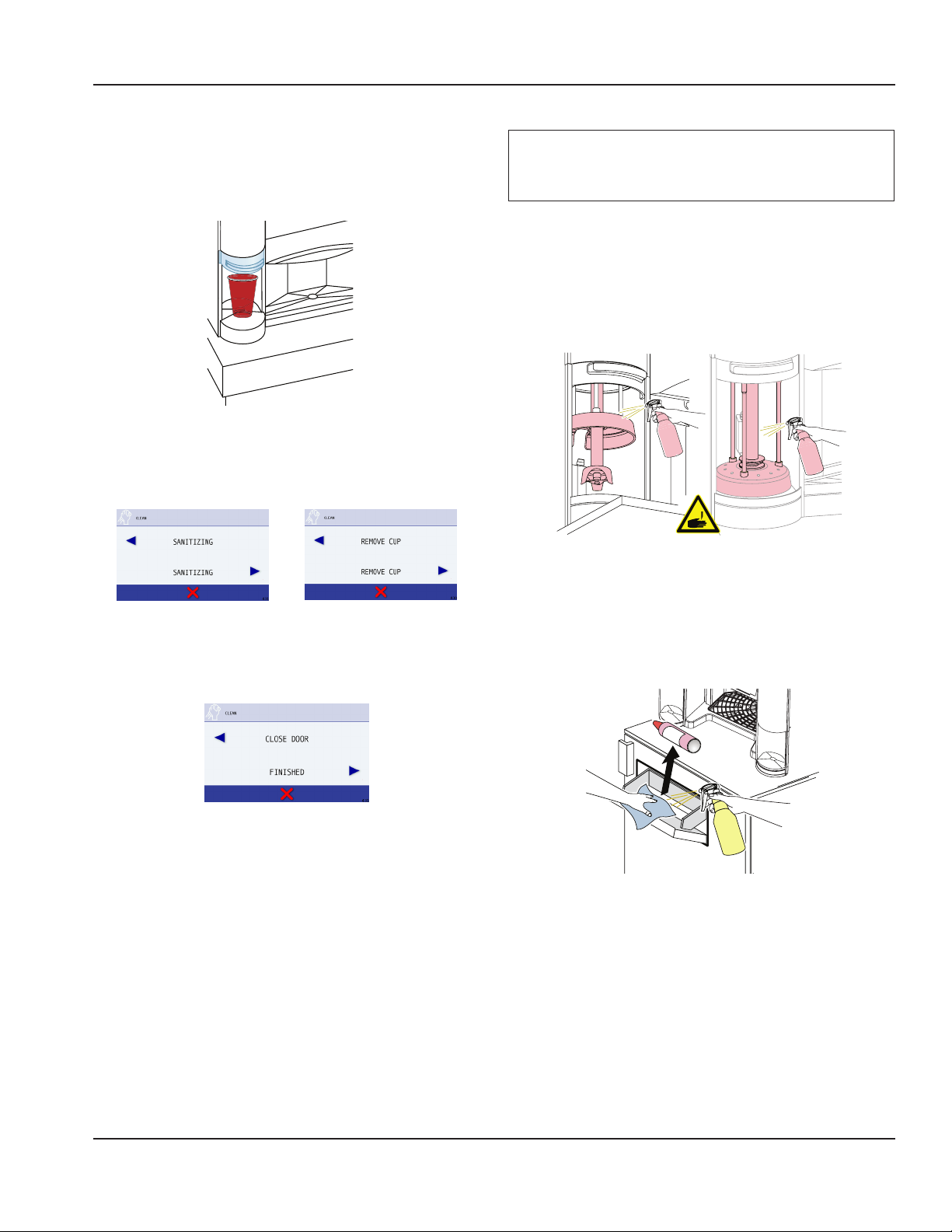

Procedure to Make a Drink

NOTE: Ice must be present in the ice bin, product must be connected and primed to produce a drink.

1. Press the Open Book icon.

2. Select a category of drink recipes.

3. Specific drink combinations are displayed on the next

screen. If a drink is not available, it will be highlighted

with a red square around it. Unavailable flavors have

expired and will need to be replaced. (See “Procedure to

Install a Product Bag” on page 32)

4. Drink size is the next selection.

5. Place cup under center dispenser and press the

corresponding drink size (SMALL, MEDIUM, or LARGE)

to start the drink making process.

6. As the flavor dispenses into the cup, the screen will

display DISPENSING.

7. If Add-in ingredients need to be manually added, the

screen will give specific directions. More ingredients

may be required later, follow the screen directions.

8. The screen will prompt you to use an available mixer,

place the cup into the blender chamber, and shut the

door. Press the corresponding right or left flashing

green/blue arrow to mix the drink.

NOTE: Single mixer unit will only display a right arrow. Press

the red X to cancel.

24 Part Number 9294699 12/16/15

Page 25

Section 3 Operation

9. While the drink is mixing, the top of the screen will read

BLENDING

Drink Status

.

NOTE: On dual mixer units, a second drink can be selected

and blended simultaneously.

10. Follow all drink specific screen directions for add-ins if

necessary and press the flashing arrow if prompted.

Add-In

Notification

11. When the blender is done mixing, open the door and

remove the drink. The blending station will go through

a rinse cycle after the door is closed again.

NOTE: The blend station will not be available again until the

door is closed and the rinse cycle is completed.

Part Number 9294699 12/16/15 25

Page 26

Operation Section 3

MAIN MENU SCREEN

Accessed primarily though the Drink Selection screen, this screen’s primary function is to provide access to all other

procedures and adjustments that can be performed on the unit.

Drink Recipes

Menu

Inventory

Managers Menu

Cleaning

Category Icon Descriptions

• Drink Recipes Menu

Displays the Drink Selection screen.

(See “Drink Selection Screen” on page 21)

• Managers Menu

Displays a Password Keypad screen. When password is

correctly entered, a menu of protected information for a

manager will display.

(See “” on page 26)

• Inventory

Displays the remaining percentage of product in each

bag, and NOZZLE and CABINET temperature readings.

(See “Product Inventory Screen” on page 31)

• Cleaning

Displays the Cleaning screen and gives the options

for ZONE 1 (Daily), ZONE 2 (Weekly) cleaning, and

PRODUCT LINE FLUSH.

(See “General Maintenance” on page 35)

26 Part Number 9294699 12/16/15

Page 27

Section 3 Operation

MANAGER’S MENU SCREEN

Accessed though the Main Menu screen, this screen’s primary function is to provide on-screen access to Manager-only

functions.

Password

Display Area

Password

Input Keypad

Accept

Password

How to Access

Clear Password

Display

Cancel

Manager Menu Features

After selecting Manager’s Menu icon from the Main Menu,

the Password Keypad screen appears. The manager screens

Manager Menu Screens

are password protected. Enter the Manager’s pass code using

the QWERTY keypad, then press the green check to accept.

After typing in the correct password, Language, Date/Time,

Temperatures, Edit Password, Configure Slots, Updates,

Auto Wash Timer and Service screens are accessible. When

the manager screens are inactive for a time period, the

screen will return to the drink menu.

Important

• Manager Screen 1

• LANGUAGE

• DATE & TIME Settings

• TEMPERATURES

• EDIT PASSWORD

• CONFIGURE SLOTS

• Manager Screen 2

Do not change the language, edit the password or

configure the slots unless instructed to do so by the

factory. The service screen is password protected,

contact the factory for access.

• UPDATES

• AUTO WASH TIMER

• SERVICE (Password Protected Sub Screens)

• Manager Screen 3

This screen displays all current software versions on the unit.

• Manager Screen 4

This screen displays the drink counter.

Part Number 9294699 12/16/15 27

Page 28

Operation Section 3

Assigning Flavors

1. From the Main Menu select the Manager icon.

6. Select a slot you want to assign a flavor to.

2. Type in the password.

2

3

3. Select the green check.

4. Select CONFIGURE SLOTS.

7. Select from available flavors.

NOTE: Available flavors will vary depending on the recipe

file that is loaded on the machine. Select ASSIGN FLAVOR.

• Screen will return to the Select Slot screen.

• The flavor name will now display and the slot will be

highlighted green.

8. Continue to select slots and flavors until all required

slots are assigned.

5. Press the SLOT FLAVOR icon.

9. Select the Back Arrow when finished to return to the

Configure Slots screen. Select the return arrow two (2)

more times to return to the Main Menu.

NOTE: In order to dispense product a product bag must be

loaded (See “Procedure to Install a Product Bag” on page 32)

and calibrated (See “Calibration Procedure” on page 29).

28 Part Number 9294699 12/16/15

Page 29

Section 3 Operation

CALIBRATION PROCEDURE

Important : Pre-calibration Checklist

1. From the Main Menu, select the Manager icon.

If calibrating ice, go to the Drink Menu and

dispense 4 large cups of ice prior to calibrating.

Check for empty product bags in the cabinet and

replace if necessary.

Ensure that each flavor has a bag more than 1/3 full.

Check bag to ensure the spout is securely locked in

position and the spout side of bag is facing down.

Ensure product flavors to be calibrated have been

refrigerated for 24 hours in a 34°F/1°C – 40°F/4°C

2. Enter the manager’s password.

3. Select CONFIGURE SLOTS.

environment and the product cabinet is at

operating temperature 32°F/0°C – 34°F/1°C.

Check Zone 2 cleaning was completed over 1 hour ago.

Check CO2/air pressure. If CO2/Air pressure has

changed, reset pressure to required level.

Check that Machine has been turned on for at least

1 hour – Do not proceed with this check during

peak time - Dispense 2 large cups of ice.

Gather the following supplies

Digital Scale

Empty & Clean Cups

NOTE: Except for Water and Ice, a flavor must first be assigned

and product bag loaded before a slot can be calibrated.

4. Select CALIBRATE FLAVOR.

5. Select a flavor, water or ice to calibrate.

Selectable Flavors will have a drop shadow

NOTE: If a flavor cannot be selected the bag loading

procedure must first be performed (See “Procedure to Install

a Product Bag” on page 32).

Part Number 9294699 12/16/15 29

Page 30

Operation Section 3

6. Follow the on-screen instructions and do the following:

• Get a digital scale.

• Tare empty cup weight.

• Position an empty cup for dispense.

• Press Green Check when ready.

A. Wait until dispensing is done.

B. Weigh cup.

C. Flavor and water target is 4 oz. (113 grams) +/-

10%. Ice target is 6 oz. (170 grams) +/- 10%.

D. If weight is not within range, tap button to enter

weight and continue to step 7.

E. If weight is within range press the red X to exit and

choose another flavor, water or ice to calibrate if needed.

8. The calibration screen will display again with the

weight entered on the previous screen.

A. If the weight displayed is incorrect, press the

button again and re-enter weight.

B

A

B. Press Green Check when done to save and

complete calibration for the slot.

9. The CALIBRATION COMPLETE screen will display.

7. The Enter Weight screen will appear.

A. Enter the cup weight using the number pad.

A

B

B. Select the Green Check when done to continue.

NOTE: If the weight entered was not 4 oz. (113 grams)

for a flavor/water or 6 oz. (170 grams) for ice, the unit will

electronically adjust the dispense calibration based on the

weight entered to obtain the correct target dispense weight.

No mechanical adjustments are required.

• Press Green Check to return to the Calibration Slot

Choice screen.

10. The newly calibrated slot will be highlighted in green.

A

B

11. Repeat steps 5 - 6 to verify weight is within range.

12. Once weight is within range;

A. Choose another flavor, water or ice to calibrate.

B. Or press the Back Arrow to return to the

CONFIGURE SLOTS Screen. From there press the

back arrow twice to reach the Main Menu and

place the unit into operation.

30 Part Number 9294699 12/16/15

Page 31

Section 3 Operation

PRODUCT INVENTORY SCREEN

This screen’s primary function is to provide visual product inventory information for the user. The Product Inventory screen is

normally accessed through the Main Menu.

Product Bin Number

Product Inventory

Bar Graph

Days Until

Expiration

Nozzle

Temperature

Back to Main

Menu

Unassigned

Product Bin

Cabinet Temperature

Bag Loading

Instructions ON/OFF

The inventory screen visually displays levels for all flavors. Underneath each flavor is the time remaining until the flavor

expires in days. NOZZLE and CABINET temperatures are also on the inventory screen. When a flavor is touched on the screen,

the instructions to replace a product bag will begin. (See “Procedure to Install a Product Bag” on page 32)

How to Access

• NOZZLE Temperature

Displays the current temperature near the dispense point.

Can be set to Celsius or Fahrenheit in the Manager’s

Menu. (See “” on page 26)

• Back Arrow

Navigates to previous Main Menu screen.

Icon Button Descriptions

• Product Bin Number

Displays the product bin number the Product Inventory

Bar Graph represents.

• Product Inventory Bar Graph

• Days Until Expiration

Displays the number of days remaining until the

product bag expires. Pressing the corresponding

product bar graph will access the Replace Product

screen, displaying the steps to follow for replacement.

(See “Procedure to Install a Product Bag” on page 32)

Product inventory tracking estimates the remaining

flavoring in each product’s bag in the reach-in

compartment in 5% increments.

• Green Bar

Product inventory is above 10% and not near expiration.

• Yellow Bar

Product inventory has fallen below 10% or less than

24 hours until expiration, a message appears on the

Drink Selection screen for the affected drink(s).

• Red Bar

If the bar representing a product’s inventory level is

red, the bag is empty or expired. Replace product. (See

“Procedure to Install a Product Bag” on page 32)

• UNASSIGNED

• CABINET Temperature

Displays the current temperature in the refrigeration

cabinet. Can be set to Celsius or Fahrenheit in the Manager’s

Menu. (See “” on page 26)

• Show Instructions

= Show bag loading instructions on screen

= No instructions on screen.

If UNASSIGNED is displayed below the product bin

number, no product is currently assigned to the bin.

Part Number 9294699 12/16/15 31

Page 32

Operation Section 3

Procedure to Install a Product Bag

1. From the Main Menu touch the Inventory icon.

7. Press the Green Check to continue.

8. Select inventory level from FULL BAG or NO BAG.

2. On the Inventory screen, select the product to be

installed.

NOTE: To see the on screen instructions during bag load

the “Show Instructions“ will need to be ON and displaying a

green box with a check mark.

9. Select FULL BAG when installing a new product bag

and the Prime screen will display.

10. Place cup under dispenser and press the Prime icon to

prime the line with the new product bag, DISPENSING

will display on the screen. Repeat until product

consistently flows into the cup.

11. Press the green check to continue.

• Products with less than 10% inventory or less than 2

hours until product expires will be displayed with a

yellow bar.

• Products that are expired will be displayed with a red bar.

3. Prepare unit for new product bag.

• Remove product bin from cabinet and discard empty

bag if there is one.

• Wipe the inside of the product bin with a clean towel.

• Place new product bag with the spout facing down

into product bin.

• Follow the on screen instructions.

4. Position rear groove of the spout on product bag into

slot of the product bin.

Important

The spout must snap into the slot of the product bin!

5. Open the cap on the product bag and tear it off.

6. Return product bin to its position in cabinet.

12. Installation is now complete. The inventory bar will now

display full, green, and days until expiration will reset.

13. Select another product to be installed or return to the

previously active screen by pressing the back arrow.

Important

Resetting a product’s inventory without replacing the

product bag will cause the Product Inventory screen,

percentages, and expiration to be inaccurate.

32 Part Number 9294699 12/16/15

Page 33

Section 3 Operation

CLEANING SCREEN

The Cleaning screen appears after selected from the Main Menu or when prompted to perform routine cleaning. This

screen’s primary function is to perform routine cleaning and sanitation of the machine.

Cleaning

Countdown

ZONE 1

Daily Cleaning

Main Menu

How to Access

Icon Button Descriptions

• ZONE 1 - Daily Cleaning

Displays the Daily Cleaning screen and guides the user

through all daily cleaning requirements.

See “Daily Cleaning - Zone 1” on page 37.

• ZONE 2 - Weekly Cleaning

Displays the Weekly Cleaning screen and guides the

user through all weekly cleaning requirements. See

“Weekly Cleaning - Zone 2” on page 43.

• Back Arrow

Returns to the previous screen or Main Menu.

ZONE 2

Weekly Cleaning

PRODUCT LINE

FLUSH

• Cleaning Count Down

Days left until Cleaning is required. Shown in DAY

increments, changes to HOURS when there is less than a

day (24 hours) until cleaning of the machine is required.

Resets once cleaning has been completely performed.

Important

Once the time limit has been exceeded the machine

will no longer make a drink until cleaning has been

completed.

• PRODUCT LINE FLUSH

Displays the Product Line Flush screen and guides the

user on how to flush all product lines. See “Calibration

Procedure” on page 29.

Part Number 9294699 12/16/15 33

Page 34

Operation Section 3

Other Operations

LOADING RECIPES

Plug in the Flash drive (above upper left corner of screen).

From the Main Menu select the Manager icon. Type in the

password and select the green check. Select the down

arrow to navigate to the next screen. Select UPDATES.

Select “RECIPES”. Select the “UPDATE RECIPES FROM USB”

icon. Verify the version to be loaded is correct, and select

the green check. Screen will display status and then

“UPDATE COMPLETE”.

MANUAL FILL ICE

Procedure to add ice to the Ice bin.

1. Remove lid from ice bin and set aside.

2. Using a clean/sanitized container transfer ice from the

back room ice machine to the ice bin.

3. Pour the ice from the transfer container into the ice bin

until it is full; do not overfill.

4. Replace ice bin lid and verify lid seats in place.

5. The lid must fit in place to activate the ice bin lid switch.

RECOMMENDED CUPS

Although a variety of cups may work in the BIC machine,

the most success (without cup cracking) has come from

polyethylene (PETE) cups. Other varieties such as glass,

polypropylene, and thick walled styrofoam have also

proven workable. Cup thickness, material composition,

diameter and cup height play an important role in the

workability of the cup within the machine.

The following are cup general guidelines. Cups outside

these parameters may work but are not recommended.

Testing in the machine with the product will be necessary.

Contact the Multiplex team for a detailed cup evaluation.

• Cup heights between 4.25" and 7.00".

• Cup opening diameter greater than 3.50" and less than 4.18".

• Cup base diameter greater than 2.38" and less than 2.62".

• Approved Materials - PET, PET-R, Glass & Metal

Changing the Cup Dispenser Size

Turn the inner dial so that the notch sets at 1, 2, 3 or 4.

Setting 1 will hold the smallest cup and 4 the largest cup.

When the dial moves from 1 to 2, the dispenser fingers

retract and allow for a larger cup to be inserted.

Position 1 Position 2

Position 3 Position 4

34 Part Number 9294699 12/16/15

Page 35

General Maintenance

Section 4

Maintenance

This section covers common unit components and their care.

The chart below is an overview of the maintenance that

the end user and service technician should perform, and

the frequency. These figures are the minimum required. If

Maintenance Daily Weekly Monthly 3 Months 6 Months Annual After Prolonged

Blender / Dispense Area

Cleaning/ Sanitizing

(Zone 1 Cleaning)

Product Line Cleaning &

Sanitizing

(Zone 2 Cleaning)

Drain Cleaning X X

Clean Air Filters X X

Clean Condenser Coil X X

Ice Bin Wash X

Clean/Sanitize

Inspect Ice Bin /

Dispenser Parts*

Check Ice Quality X X S X S

Warning

n

X

X X S

The power switch must be turned to OFF and the

unit disconnected from the power source whenever

performing service, maintenance functions or cleaning

the refrigerated area

the Ice Machine is supplied with hard water, more frequent

cleaning should be performed. If the condenser air filter is

totally blocked after one week, more frequent cleaning is

recommended. (X = End User, S = Service Company)

Shutdown

S X S

DOOR GASKET MAINTENANCE

Door gaskets require regular cleaning to prevent mold and

mildew buildup and also to retain the elasticity of the gasket.

Gasket cleaning can be done with the use of warm soapy water.

Avoid full strength cleaning products on gaskets as this can cause

them to become brittle and crack. Never use sharp tools or knives

to scrape or clean the gasket. Gaskets can be easily replaced and

Important

If the machine going to be shut down for any length

of time, it is recommended to go through the Zone 2 Weekly Cleaning both prior to turning off the unit and

when returned to use.

If the unit is turned off, the product will no longer

be kept cool in the refrigeration cabinet. Remove all

product bags and keep refrigerated to prevent spoilage.

do not require the use of tools or an authorized service person.

The gaskets are “Dart” style and can be pulled out of the groove in

the door and new gaskets can be “pressed” back into place.

DRAIN MAINTENANCE INSIDE LOWER CABINET

Each unit has a drain located inside the unit that removes the

condensation from the evaporator coil and routes it to an

external condensate evaporator pan. Each drain can become

loose or disconnected during normal use. If you notice water

accumulation on the inside of the unit, be sure the drain tube

is connected to the evaporator drain pan. If water is collecting

underneath the unit, make sure the end of the drain tube is in

the condensate evaporator in the machine compartment. The

leveling of the unit is important, as the units are designed to drain

properly when level. Be sure all drain lines are free of obstructions.

At Start-Up

Part Number 9294699 12/16/15 35

Page 36

Maintenance Section 4

REFRIGERATOR

Warning

n

Do not damage the refrigeration circuit when installing,

maintaining or servicing the unit.

The interior and exterior can be cleaned using soap and

warm water. If this isn’t sufficient, try ammonia and water

or a nonabrasive liquid cleaner. When cleaning the exterior,

always rub with the “grain” of the stainless steel to avoid

marring the finish. Do not use an abrasive cleaner because

it will scratch the stainless steel and can damage the

breaker strips and gaskets.

STAINLESS STEEL CARE & CLEANING

To prevent discoloration or rust on stainless steel, several

important steps need to be taken. First, we need to

understand the properties of stainless steel. Stainless steel

contains 70-80% iron, which will rust. It also contains 1230% chromium, which forms an invisible passive film over

the steel’s surface, which acts as a shield against corrosion.

As long as the protective layer is intact, the metal is still

stainless. If the film is broken or contaminated, outside

elements can begin to break down the steel and begin to

form discoloration or rust. Proper cleaning of stainless steel

requires soft cloths or plastic scouring pads!

DOORS/HINGES

Over time and with heavy use, doors and hinges may

become loose. If this happens, tighten the screws that

mount the hinge brackets to the frame of the unit. Loose

or sagging doors can cause the hinges to pull out of the

frame, which may damage both the doors and the hinges.

In some cases this may require qualified service agents or

maintenance personnel to perform repairs.

NOTE: Do not place hot pans on/against the blue ABS liner.

Do not throw items into the storage area. Failure to follow

these recommendations could result in damage to the

interior of the cabinet or to the blower coil. Overloading

the storage area, restricting the airflow, and continuous

opening and closing of the doors and drawers will hamper

the unit’s ability to maintain operational temperature.

PREVENTING BLOWER COIL CORROSION

Immediately wipe up all spills.

Warning

n

Never Use Steel Pads, Wire Brushes or Scrapers!

Cleaning solutions need to be alkaline-based or nonchloride cleaners. Any cleaner containing chlorides will

damage the protective film of the stainless steel. Chlorides

are also commonly found in hard water, salts, and

household and industrial cleaners. If cleaners containing

chlorides are used, be sure to rinse repeatedly and dry

thoroughly. Routine cleaning of stainless steel can be done

with soap and water. Extreme stains or grease should be

cleaned with a non-abrasive cleaner and plastic scrub pad.

Always rub with the grain of the steel. There are stainless

steel cleaners available which can restore and preserve the

finish of the steel’s protective layer. Early signs of stainless

steel breakdown are small pits and cracks. If this has begun,

clean thoroughly and start to apply stainless steel cleaners

in attempt to restore the passivity of the steel.

Caution

,

Never use an acid-based cleaning solution! Many food

products have an acidic content, which can deteriorate

the finish. Be sure to clean the stainless steel surfaces of

ALL food products. Common items include: tomatoes,

peppers and other vegetables.

36 Part Number 9294699 12/16/15

Page 37

Section 4 Maintenance

Daily Cleaning - Zone 1

NOTE: The following procedures are the basic daily cleaning

instructions, on-screen instructions can vary depending

on the recipe that was created with the MenuConnect

program. * These items are optional and may not be displayed

on all easyToUCH screens during ZONE 1 Cleaning.

Warning

n

Sharp Objects/Surfaces - Beware of the shaver blade

located in the bottom of the ice bin.

Warning

n

When in contact with cleaning and sanitizing solution

chemicals gloves and safety glasses are recommended.

• Time to complete - 15 minutes

1. Cycle touch screen to the Main Menu and select the

Cleaning icon.

GATHER THE FOLLOWING SUPPLIES

Follow the on-screen instructions and gather the following

supplies:

Clean towels (Cloths*)

Spray Cleaner & Detergent Solution

(Approved mild dish detergent solution)

Spray Sanitizer & Solution

Approved sanitizers:

Solution that provides 100 ppm available

chlorine minimum.

Or solution providing 300 ppm Quaternary

Ammonium minimum.

Or Manitowoc sanitizer part number

9405653, use 3.25 oz/5 gal (96 ml/19L).

Red & Blue Cleaning Cups

(1 of each per blender station)

2. In the Cleaning screen select the ZONE 1 icon.

Ice Scoop

Cleaning Brush, Gloves & Safety Glasses*

* These items are optional and may not be displayed on all easyToUCH

screens.

NOTE: If other cleaners are used, it is possible they will not

clean or sanitize your machine to NSF standards.

• Press the Down Arrow to continue.

UI Version 02.00.05

Part Number 9294699 12/16/15 37

Page 38

Maintenance Section 4

ICE BIN WASH

Empty Ice Bin

1. Remove ice bin lid.

Warning

n

Sharp Objects/Surfaces - Beware of the shaver blade

located in the bottom of the ice bin.

2. Use an ice scoop and an empty bucket to remove as

much ice as possible from above the ice shelf.

Wash Lid & Ice Bin Ring

1. Remove the ice bin lid and ice bin ring for cleaning and

sanitizing. Take them back to a 3 compartment sink to

wash, rinse and sanitize.

2. Do not put in dishwasher or power soaker.

Warning

n

When in contact with cleaning and sanitizing solution

chemicals gloves and safety glasses are recommended.

3. Reinstall all components.

3. Replace ice bin lid.

• Press the Down Arrow to continue.

Dispense Remaining Ice

1. Place a large cup on the center grate.

2. Press manual ice dispense button until ice bin is empty,

discarding ice in sink as necessary.

NOTE: Ice will not dispense if ice bin lid is not in place.

2

3. Remove cup once bin is empty.

• Press the Down Arrow to continue.

3

• Press the Down Arrow to continue.

38 Part Number 9294699 12/16/15

Page 39

Section 4 Maintenance

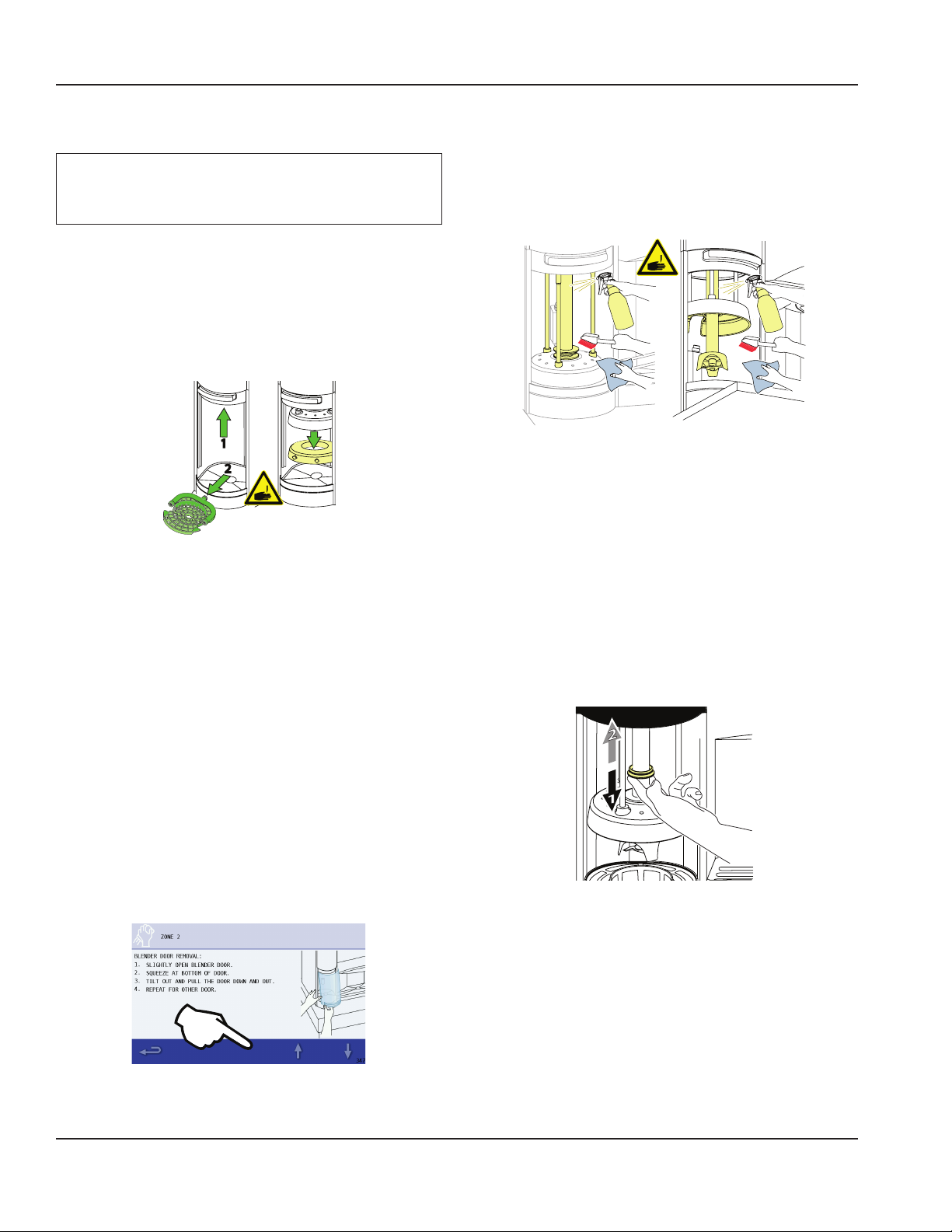

BLENDERS / DISPENSE AREA CLEANING & SANITIZING

Grate Removal / Blender Station Wash

Warning

n

The blender station contains sharp moving parts. Wear

gloves to protect hands.

Follow the on screen instructions:

• Put on gloves and safety glasses.*

1. Remove grate from blender station(s) by pulling up and out.

2. Remove the cup cover seal from the cup cover by

pushing on the front and pulling down.

3. Spray all surfaces inside of the blender station(s)

with cleaning solution, then scrub thoroughly with

approved cleaning brush.

4. Thoroughly wipe down all surfaces of blender station

with a clean towel.

• Press the Down Arrow.

5. Repeat for other side if applicable.

• Press the Down Arrow. The Slide Progress screen

will display while the blender(s) move into cleaning

position.

Blender Door Removal

1. Slightly open blender door.

2. Squeeze at bottom of door.

3. Tilt out and pull the door down and out.

4. Repeat for other door if applicable.

• Press the Down Arrow to continue.

Blender Station Wash

1. Completely spray blender station with cleaning

solution use approved cleaning brush to thoroughly

scrub the entire area.

2. Using the approved cleaning brush, thoroughly scrub

down top of blender cap and blender arm.

3. Lift blender cap and thoroughly scrub ()with approved

cleaning brush) top of blade housing and bottom of

blender cap.

4. Thoroughly spray with sanitizer solution and use

approved cleaning brush scrub entire blender assembly.

5. Repeat for other side if applicable.

• Press the Down Arrow to continue.

Part Number 9294699 12/16/15 39

Page 40

Maintenance Section 4

Wash Blender Grate(s) / Door(s)

1. Take all grates, cup cover seals, and doors to sink to wash

and sanitize.

2. Do not put in dishwasher or power soaker.

Warning

n

When in contact with cleaning and sanitizing solution

chemicals gloves and safety glasses are recommended.

• Press the Down Arrow to continue.

Reinstall Blender Door(s)

1. Reinstall blender door(s).

Blender Wash

1. Place blue cleaning cup with wash solution in blend

chamber(s) and close the blender door(s).

• Use approved mild dish detergent solution.

2. Press the Green Check to begin.

The blenders will lower into the wash solution and spin to

clean. WASHING will display on the screen.

• Press the Down Arrow. The Slide Progress screen will display

and the blender(s) will move into operating position.

Reinstall Blender Grate(s)

1. Reinstall blender grate(s) and cup cover(s).

• Press the Down Arrow.

Follow the on screen instruction, when prompted remove

the blue cup(s) and pour wash solution down the drain.

Close the blender door(s) and RINSING will display on the

screen while the machine rinses the blenders.

FINISHED will display on the screen then progress to the

Blender Sanitizing screen.

40 Part Number 9294699 12/16/15

Page 41

Section 4 Maintenance

Blender Sanitizing

1. Place red sanitizing cup(s) with sanitizing solution in

blender station(s) and close the blender door(s).

• Use approved sanitizer solution.

2. Press the Green Check to begin.

The blenders will lower into the wash solution and spin to

sanitize. SANITIZE will display on the screen.

Follow the on screen instruction, when prompted remove

the red cup(s) and pour sanitizing solution down the drain.

Close the blender door(s).

Blender Station Sanitizing

Warning

n

The blender station contains sharp moving parts. Wear

gloves to protect hands.

1. Completely spray blender station with sanitizer

solution and use approved cleaning brush to

thoroughly scrub area.

2. Allow to air dry, Do not wipe off sanitizer!

3. Repeat for other side if applicable.

• Press the Down Arrow to continue.

Whipped Cream Door Cleaning *

1. Remove contents from the whipped cream door and

place in refrigerator.

• For units equipped with this option.

FINISHED will display on the screen then progress to the

Blender Station Sanitizing screen.

2. Completely spray interior and exterior of whipped

cream door with cleaning solution, wipe thoroughly.

3. Thoroughly wipe down interior and exterior of

whipped cream dispense station, let dry completely.

4. Return contents to the whipped cream door.

• Press the Down Arrow.

Part Number 9294699 12/16/15 41

Page 42

Maintenance Section 4

Dispense Area Cleaning

Caution

,

Do Not Insert a brush or sharp object into the red

dispense nozzles.

1. Spray all dispensing area surfaces with cleaning

solution, then use cloth and/or use approved cleaning

brush to thoroughly scrub area.

2. Thoroughly spray each individual dispense nozzle with

cleaning solution and apply cleaner to each individual

dispensing valve, then use approved towel to wipe the area.

• Press the Down Arrow to continue.

Dispensing Area Sanitizing

1. Thoroughly spray each individual dispense nozzle with

sanitizing solution.

2. Thoroughly spray dispense area with sanitizing

solution.

3. Do Not wipe off sanitizer! Allow to air dry.

4. Press the Green Check to signify you have completed

the Zone 1 Daily Cleaning.

• Clean, Rinse, Sanitize, and Dry any equipment before

storing in a safe, protected location.

NOTE: The touch screen will return to the Main Cleaning

screen.

42 Part Number 9294699 12/16/15

Page 43

Section 4 Maintenance

Weekly Cleaning - Zone 2

NOTE: The following procedures are the basic weekly

cleaning instructions, on-screen instructions can vary

depending on the recipe that was created with the

MenuConnect program or options chosen in the Managers