Page 1

Multiplex

NEW!

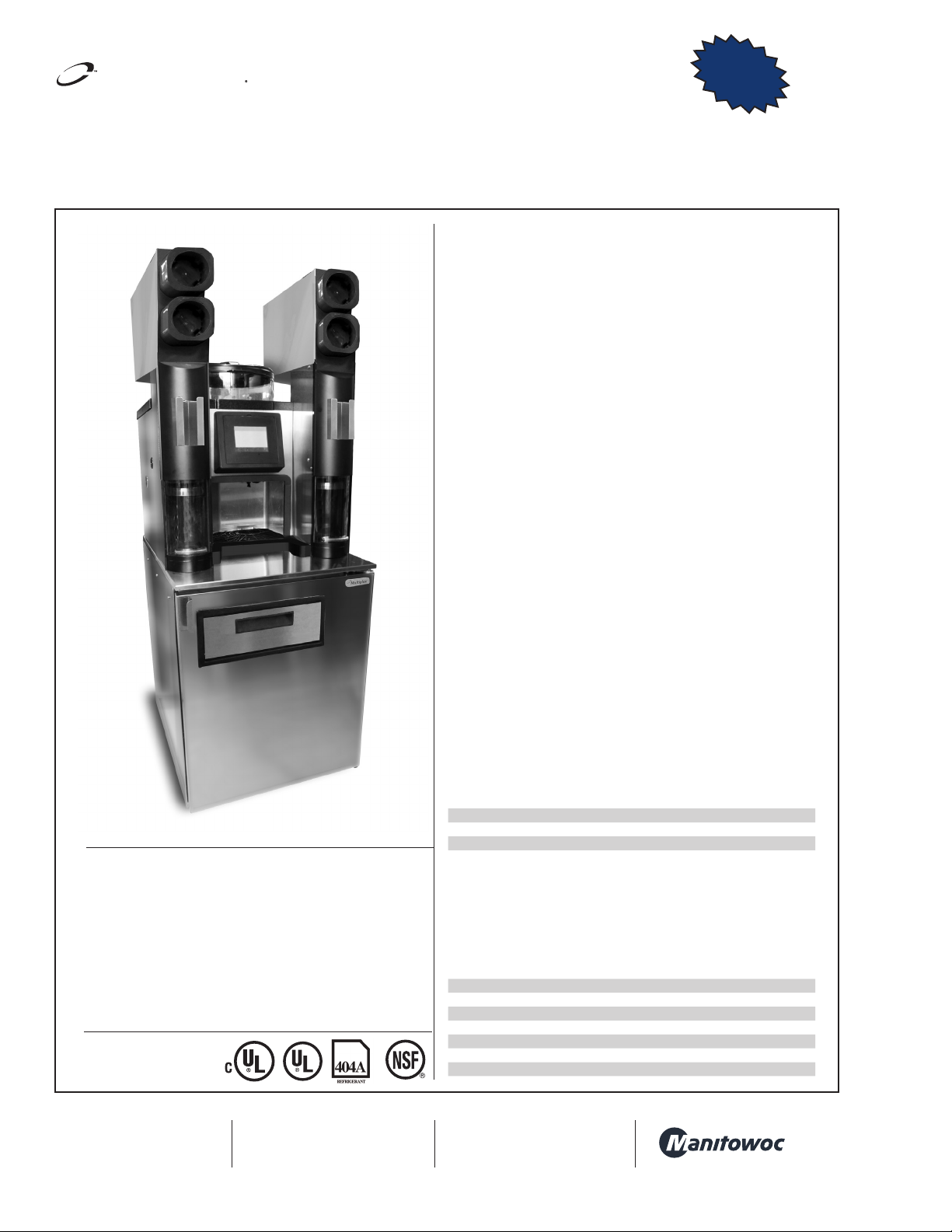

MAM9904 Blend-In-Cup® - Manual Fill

Blended Ice Machine

Features

Next generation Blended Ice System

Designed for restaurant and retail applications

• Blends and dispenses up to 3 different drinks at once

• Enhanced speed of service with sumultaneous dispense and blending capability

• Ease of product loading and replacement

• Base unit accomodates 8 flavor bins, each holding (1) 2 gal. (7.6 L) bag

• Automatic blending chamber rinse

Intuitive controls and prompts

Visual, icon based selection screen

• Speeds drink and option selection

• Mitigates entry errors and reduces learning curve

• Provides inventory and service feedback and data collection

• Step by step cleaning instructions

High Performance Yield

Automated portioning and dispense

• Recipe accuracy (ice, mix, syrups, add-ins), yield and product consistency

• Minimizes food waste and costs, maximizes yield (up to 12% more yield)

• Patented anti-drip technology

Blend-in-Cup Technology

Software driven, variable blend/mix profiles facilitates unique drink

characteristics

• Product and ice dispensed and blended directly in the cup to reduce labor and

product waste

• Guarantees consistent cup fill level

• Allows for excellent adaptability and capability for future product expansion

Focus on operator priorities

Provides equipment performance that results in:

• Strict adherence to food safety standards

• Reduced serve time with automated dispense and three drink capability

• No side clearance required

Service Support

Certified service and parts network

• An established network of reliable, trained service providers offering strong

commitments to local equipment and customer support

Warranty

• 1 year parts & labor limited warranty, compressor additional 4 years parts only

• Extended warranty program available for purchase within 60 days of machine

install date

Base Models

MAM9904R01 with cup and lid holders - RHD

MAM9904L01 with cup and lid holders - LHD

MAM9904R without cup and lid holders - RHD

- Save over $3,500 per year in syrup cost

- Quiet...50% less noise

- Fast...make 3 drinks at once and up to 120 drinks

per hour

- Happy customers and crew...faster service with

no pouring or pitchers to manage

MAM9904L without cup and lid holders - LHD

Included Accessories

Install Kit: Includes required water, CO2 and drain hose/lines and connectors.

Clean/Sanitize Kit: (1) Cleaning container, (3) 5-gallon (19L) pails, hose lengths,

bracket and brushes.

Digital scale

Optional Accessories

BEV00009 Ice assist bar

1708665 Bag lifters (8)

BEV00003 Syrup rail

BEV00004 Syrup rail & bag lifter

BEV00005 Syrup rail & ice assist bar

BEV00006 Syrup rail & bag lifters & ice assist bar

BEV00007 Ice assist bar & bag lifters

BEV00008 Single cup holder

MAM9904 Blend-In-Cup® - Manual Fill

2100 Future Dr.

Sellersburg, IN 47150

Tel: 812.246.7000

Fax: 812.246.7024

www.manitowocbeverage.com/us

Page 2

cm

Multiplex

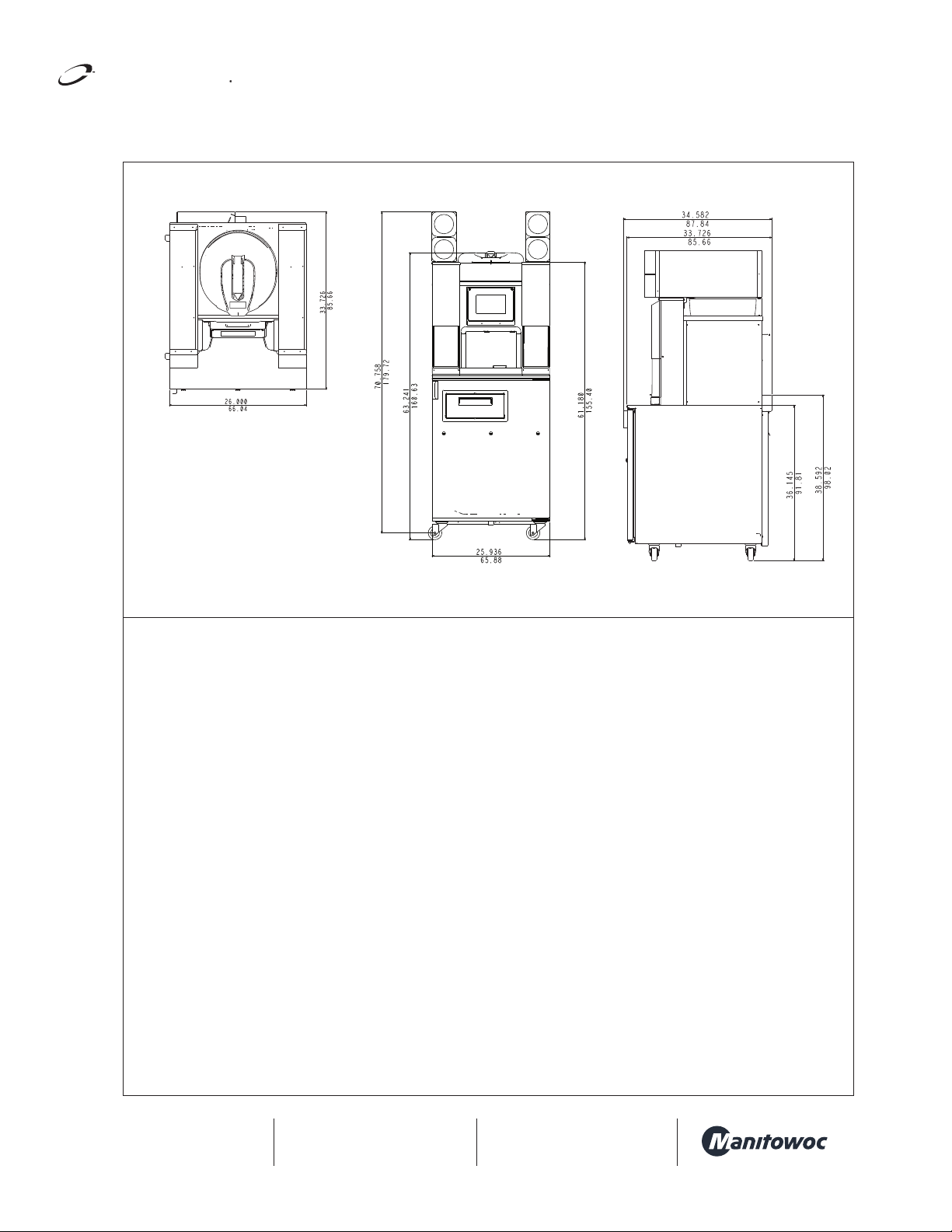

Dimensions

Dimensions

cm

cm

Dimensions

Width 26.00“ (66.0 cm)

Depth 33.73” (85.7 cm)

Height 63.52” (161.3 cm)

Clearances (Air Cooled)

Top 18” (46 cm)

Sides 0” (0 cm)

Back 6” (15 cm)

Front 30” (76 cm)

Shipping Weight

461 lbs. (209 kg)

Specifications

Storage Capacities

Ice 25 lbs (11 kg)

Product 8 x 2 gal. (7.6L) product packages

Drain

Connection 8' x 1" ID (2.43m 2.5ID) hose supplied for

Drop

Requirement

Electrical

Voltage/Cycle 115 VAC-60Hz/1ph

Power Cord Provided with NEMA 5-20P United States

Other A dedicated electrical circuit is required.

connection to barb tting connection on machine.

Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter)

The functional power cord length exiting the back

of unit is 8’ (2.43 M).

Cabinet Refrigeration

Compressor 1/5 hp

Refrigerant R404a (12 oz. (339G))

Temp. Control 36°F ±2°F (2.2°C ±1.1°C) - controlled by software

Heat of Rej. Base - 2100 BTU/h (0.62 kW)

CO2 / Air

Connection

Assembly

Pressure

Supply Pressure

*Speak to your Multiplex representative for information on the recommended air ltration system.

Supplied 3/8" panel mounted tting.

35 psi (2.4 BAR) Dynamic

50 psi/80 psi (3.5BAR/ 5.5BAR) (min/max)

MAM9904 Blend-In-Cup® - Manual Fill

2100 Future Dr.

Sellersburg, IN 47150

Tel: 812.246.7000

Fax: 812.246.7024

cm

cm

cm

cm

cm

cm

cm

Water

Water Inlet Lines Supplied 3/8" panel-mounted tting for

Water Temp.

(min/max)

Water Temp.

(optimum)

Pressure

Supply Pressure

(min/max)

Filtration

Requirements

Additional

Requirements

connection of unit into water supply.

40°F/90°F (4°C/32°C)

Target 50

°F (10°C) results based on ARI capacity

testing at 70°F (21°C) air temperature

35 psi (2.4 BAR)

35 Psi/90psi (2.4 BAR/6.2BAR) Dynamic (water

pressure regulator supplied with unit)

Filtered water with low mineral content required

for ice system.

Install water shut-o valve in water line at the rear

of the machine.

Insulate water inlet lines to prevent condensation.

Cups*

Specifications The BiC provides value by increasing the operator

Cup Height 4” (101mm) - 7” (177mm)

Cup Top Dia. 3.5” (89mm) - 4.18” (106mm)

Cup Bottom Dia. 2.38” (61mm) - 2.62” (67mm)

Approved Mat. PET, PET-R, Glass & Metal

*For any cups outside of specications, contact Multiplex for detailed evaluation.

www.manitowocbeverage.com/us

5897 6/15

eciencies and dramatically reducing the waste

associated with a Blend-in-Pitcher system through

the process of blending the drink ingredients

directly in the cup. The cup must be capable of

withstanding the forces generated through the

blending process. The minimum cup specications

are listed below.

©2015 Multiplex Continuing product improvement may necessitate change of specications without notice.

Loading...

Loading...