Multiaqua MAC120-02-N-R407, MHCCW04-00-03, MHCCW04-02-03, MHCCW04-00, MHCCW04-03 Operating Manual

...

Table of Contents (Hydronic)

About Us

System Modeling Software

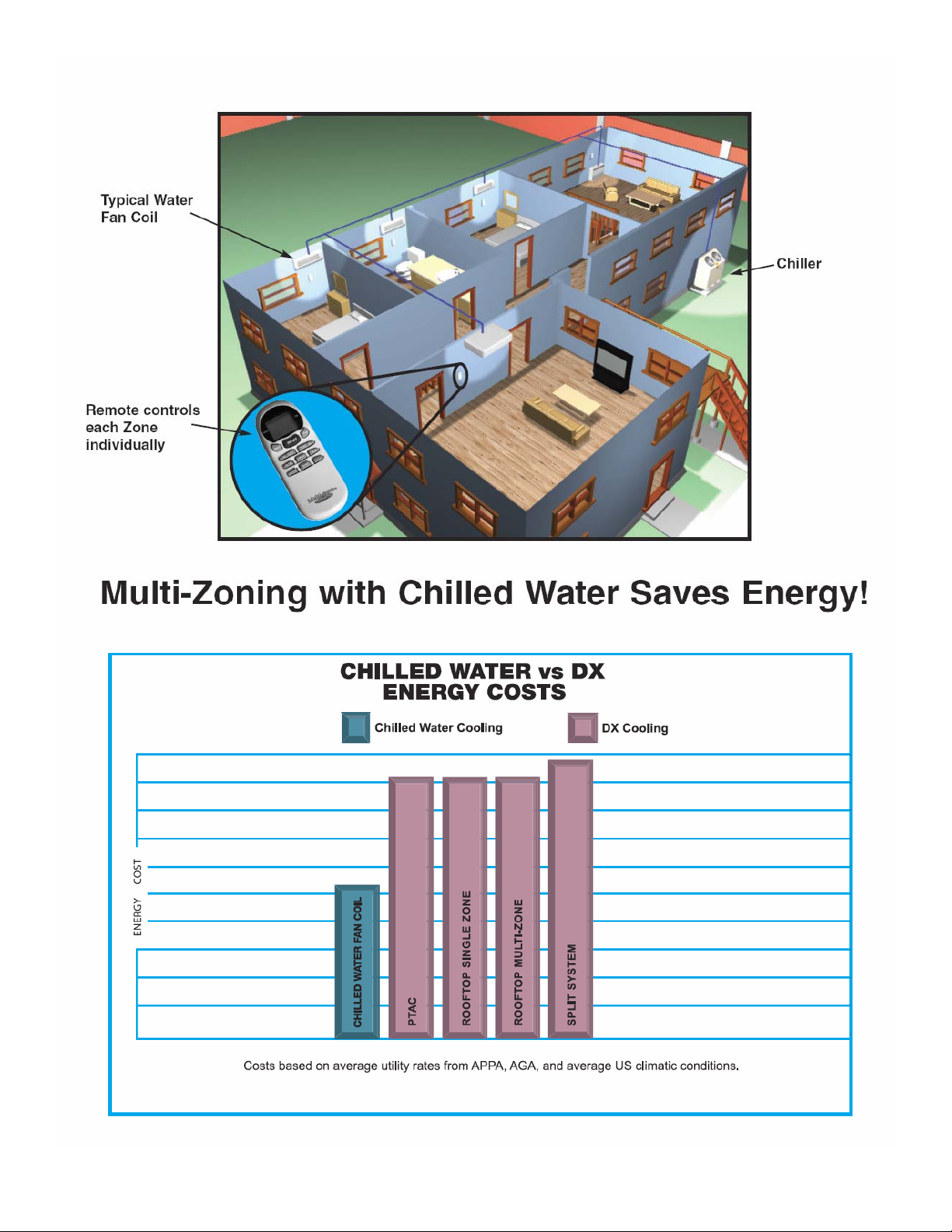

Multi-Zoning and Energy Cost

Features and Benefits

Water Products Overview

DX Products Overview

Accessory Products Overview

Equipment Sound Data

Page

1

2

3

4

5

6

7

8

MAC120 Air-Cooled Chiller

Nomenclature Breakdown

Guide Specifications

Product Specifications

Capacities

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

MAC036,048 and 060 Air Cooled Chiller

Nomenclature Breakdown

Guide Specifications

Product Specifications

Capacities

Circulating Pump Curve

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

MHCCW (Ceiling Concealed) 2-pipe Chilled Water with Electric Heat. 1 to 3 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Chilled Water Capacities

Hot Water Capacities

Electric Heat Capacities

CFM and Glycol Adjustments

Capacity Adjustment Factors

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

9

10

11

13

15

17

34

43

44

45

46

48

50

56

57

74

83

84

85

86

88

89

94

99

100

101

102

113

116

MHNCCW (Ceiling Concealed) 4-Pipe Chilled and Hot Water. 1 to 3 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Chilled Water Capacities

Hot Water Capacities

CFM and Glycol Adjustments

Capacity Adjustment Factors

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

117

118

119

121

122

127

132

133

134

145

147

Table of Contents (Hydronic Continued)

MCCW (Ceiling Concealed) 2-Pipe Chilled and Hot Water. 4 to 5 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Chilled Water Capacities

Hot Water Capacities

CFM and Glycol Adjustments

Capacity Adjustment Factors

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

Page

148

149

150

152

153

155

157

157

158

169

170

MHWW (Hi-Wall) 2-Pipe Chilled and Hot Water. 1 to 3 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Chilled Water Capacities

Hot Water Capacities

Capacity and Glycol Adjustment Factors

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

CFFWA (Universal Mount) 2-Pipe Chilled and Hot Water. 1 to 5 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Chilled Water Capacities

Hot Water Capacities

Capacity and Glycol Adjustment Factors

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

CWA2 (Air Handler) 2-pipe Chilled Water with Electric Heat. 1.5 to 5 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Chilled Water Capacities

Hot Water Capacities

CFM and Glycol Adjustments

Capacity Adjustment Factors

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

171

172

173

175

176

181

186

187

202

206

207

208

209

211

212

218

224

225

231

232

233

234

235

237

238

243

246

247

249

257

258

CWA4 (Air Handler) 4-pipe Chilled and Hot Water 2 to 5 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Chilled Water Capacities

Hot Water Capacities

CFM and Glycol Adjustments

Capacity Adjustment Factors

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

259

260

261

263

264

268

269

270

271

279

280

Table of Contents (Direct Expansion)

MHCCX (Ceiling Concealed) DX with Electric Heat. 1 to 3 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Capacities

CFM Adjustments

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

Page

281

282

283

285

287

288

289

300

304

MCCX (Ceiling Concealed) DX Only. 4 to 5 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Capacities

CFM Adjustments

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

MHNCCX (Ceiling Concealed) DX with Hot Water. 1 to 3 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

DX Capacities

CFM Adjustments

Glycol Adjustments

Capacity Adjustment Factors

Hot Water Capacities

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

MHWX (Hi-Wall) DX Only. 1 to 3 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Capacities

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

305

306

307

309

309

309

310

316

317

318

319

320

322

323

323

323

324

325

330

341

343

344

345

346

348

348

349

363

371

FSFCA (Universal Mount) DX Only. 1 to 5 Tons

Nomenclature Breakdown

Guide Specifications

Product Specifications

Capacities

Installation and Operating Manual

Wiring Diagrams

Certified Drawing

372

373

374

376

376

377

383

384

Table of Contents (Accessories)

Accessories

Storage Tanks

Expansion Tank and Air Scoop

Liquid Solution Bypass Valve

Liquid Solution Control Valves

Condensate Pump

Control Thermostats

Wye Strainer

Circulating Pumps (1,1.5 & 2 HP)

Circulating Pump Curve (1,1.5 & 2 HP)

Circulating Pumps (.5 HP)

Circulating Pump Curve (.5 HP)

Ceiling Concealed Enclosures

Sample Piping

Banked Chiller Configuration

Page

385

387

388

389

391

392

395

396

397

398

399

400

407

408

409Warranty Information

About Us

Setting new industry standards is what we do best.

At Multiaqua, our commitment to creating innovative air conditioning products has made us one

of the most respected organizations in the industry. From concept to market, Multiaqua takes a

hands-on approach to ensure that each and every step meets our stringent standards of quality,

durability and dependability.

All Multiaqua products are designed with the future in mind. That’s why all air conditioning

products are flexible, which makes it easy to adapt to virtually all kinds of building applications.

Whether it’s residential or commercial air conditioning needs, Multiaqua has the products to

meet or exceed all expectations.

Manufacturing Excellence

Our beliefs in quality is more than just a practice, it is something we take great pride in. Our

quality management system is integrated with international quality requirements of ISO 9002.

That is why some of the biggest OEM names in the air conditioning industry use Multiaqua

products in their units. In fact, Multiaqua chillers were part of air conditioning system that won

first place awards in the Quality Home Comfort Awards Competition, which was created to

honor the best in residential comfort system design and application.

Our products are tested and certified to the UL, CE, ETL, UL1995 and ARI standards; the most

respected and stringent in the world.

Experience The Future

At Multiaqua, we invite you to come experience the future of air conditioning and see why more

and more companies are discovering the new standard of air conditioning excellence. And by

combining cost effectiveness, innovation and quality, Multiaqua will continue to provide air

conditioning products that will be the most sought after in the world.

1

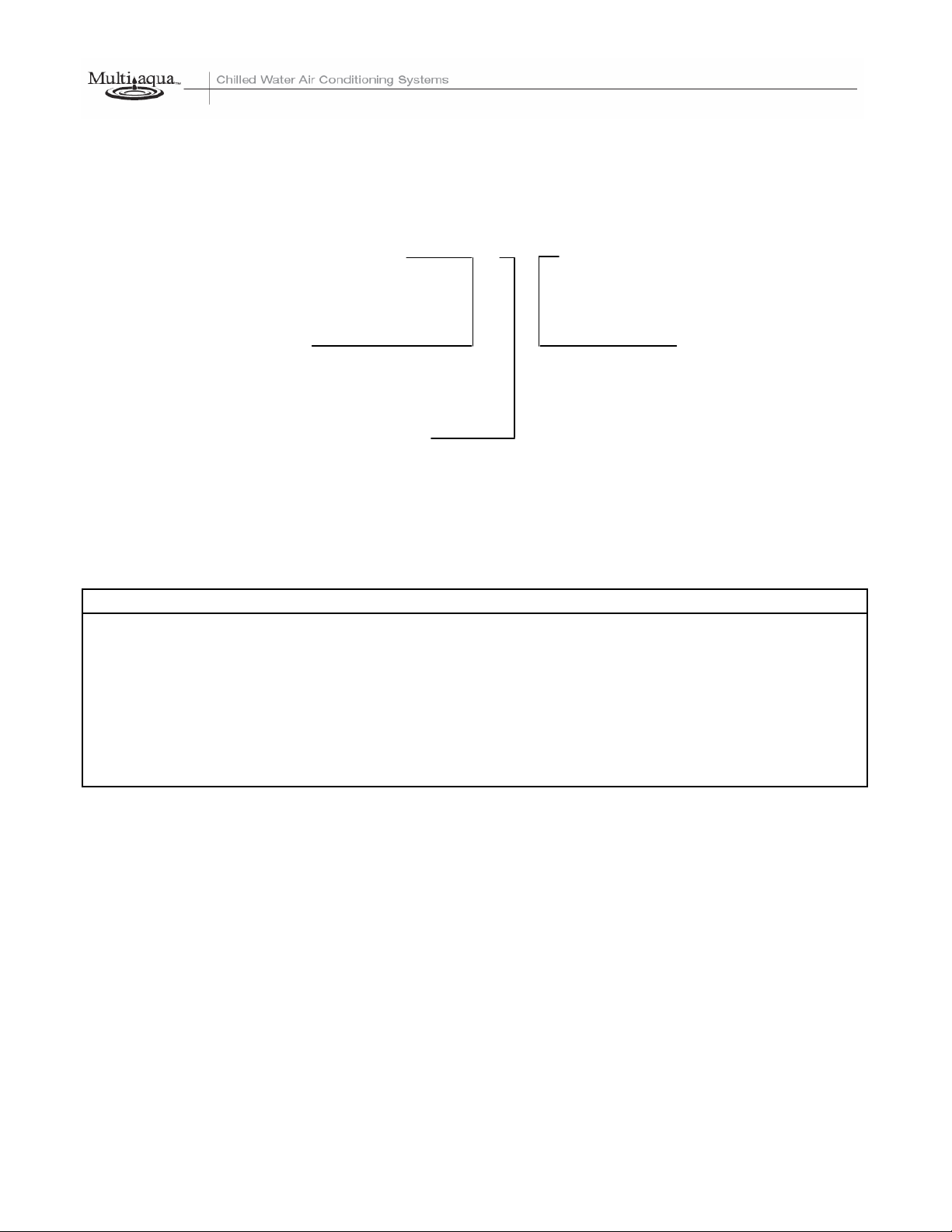

Multiaqua Makes Hydronic System Design Easy

(

)

F

F

2

F

H

F

F

F

5

H

M

F

H

F

F

F

L

F

F

H

(

)

"

"

"

"

"

"

"

"

"

A

NAME: MULTIAQU

LOCATION: SOUTH CAROLINA

60000 BTU/H

12.6 GPM

ICL-1

55°

45°

100'

1.25 "

36000 BTU/H

ICL-

45°

1.25"

100'

7.6 GPM

145'

1.25

24000 BTU/

ICL-3

55°F

45°

1

145'

1.25"

5 GPM

1.25"145'

ICL-4

55°

45°F

1"

145'

1.25

24000 BTU/H

5 GPM

1"

5'

1"

1.5"

1.5

55°

1"

1.5

145'

2"

49 GPM

66.7 FT

145'

0'

BYPASS VALVE

2.5"

1'

2.5"

1.5

1"10'

73.1 GA

STOR-1

24000 BTU/

4.9 GP

ICL-

45°

11.5 GAL

ET-1

0'

1'

2

ICL-7

45°

55°

1.25"5'

1.25"5'

117000 BTU/

55°

45°

117 000 BTU/H

55°F

45°F

3600 0 BTU/H

7.6 GPM

9.8 TONS

24.5 GPM

50%

CH- 2

9.8 TONS

24.5 GPM

50%

CH-1

55°F

30000 BTU/

6.3 GPM

ICL-6

45°

55.4°F

1

1"5'

1"5'

1.5 "

5'

2

2.5"

5'

2.5"5'

1.25"5'

1'

1.5"1' 1.25"5'

5'

2"

P-1

Sample Design Shown

Introducing System Modeling Software

Multiaqua has teamed up with HVAC Solutions and would like to introduce the newest version of the HSS

Software. This software will contain a selection model that includes Mutiaqua’s Air Cooled Chillers, Fan Coils

and Air Handling Units.

HSS software will allow you to drag and drop components to design hydronic systems. It includes the necessary

piping, piping components and equipment. It is capable of exporting calculation reports, equipment schedules

and a bill of material. Visit www.multiaqua.com for software down load.

2

3

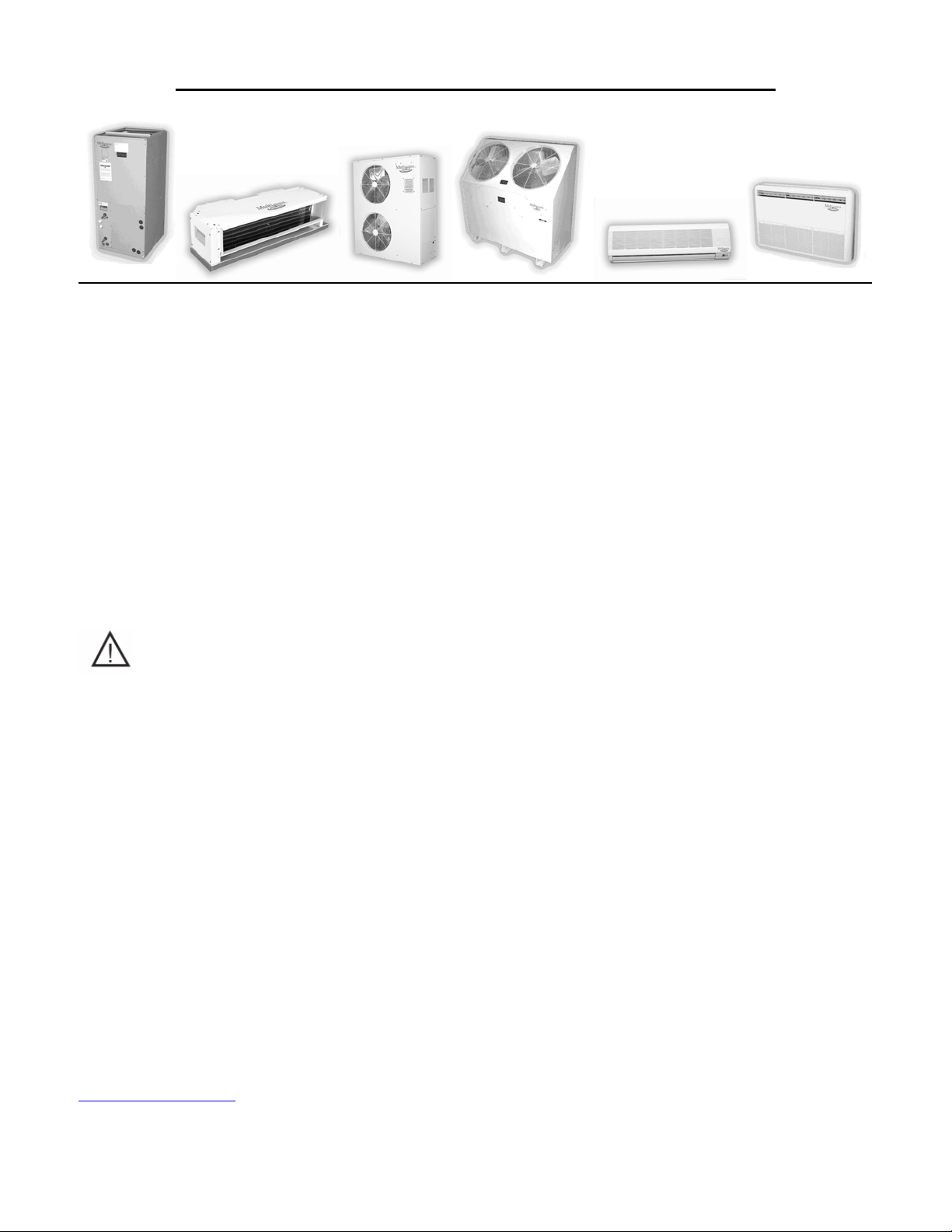

Ductless and Ducted Hydronic Air Conditioning & Heating Systems.

FOR MULTIZONING FACILITIES

• Zoning saves energy

• Better Control of Humidity

• Separate Climate in each Room

1. More Energy Efficient Thru Zoned Comfort Cooling.

2. Zoning Allows For Diversity.

3. Diversity and Load Calculations Allows For Reducing The Size of The Outdoor

Power Plant.

4. Banking Chillers Allows For Huge Efficiencies Thru Staging.

5. Helps Control The Growth Of Mold, Mildew and Fungus.

6. Low Installation Costs.

7. No Refrigerant Handling.

8. No Ductwork No Line Sets.

9. Heat & Cool with the Same Units.

10. No Line Length Limitations.

11. Unlimited Tonnage with Single Phase Power.

12. Easy To Expand System.

Think Water !!!

4

p

p

,

,

n

g

Water Product Overview

Page 44 Page 9

MAC036, 048 & 060 Air Cooled Chiller MAC120 Air Cooled Chiller

• 3, 4 & 5 Ton Air Cooled Chiller

• R 407c Refrigerant

• Horizontal Air Discharge

• Stainless Steel Pump Included

Page 84 Page 117

• 10 Ton Air Cooled Chiller

• Copeland Scroll Compressor Technology • Copeland Scroll Compressor Technology

• R 407c Refrigerant

• Vertical Air Discharge

• Two Stages of Coolin

MHCCW (Ceiling Concealed) Chilled Water 2-Pipe

With or Without Electric Heat

• 12,000- 36,000 BTUH

• Available with or without Electric Heat

• Ceiling Concealed Design for Clean Installation

• Removes Equipment from Conditioned Space

• Heavy Gauge Metal Cabinet

• Powder Painted Galvanized Steel

• Field Reversible Hand of Connection Coil

• Manual Air Vents

• Discharge May be Ducted for Small Spaces

Page 171 Page 148

MHWW (Hi-Wall) Chilled/Hot Water 2-Pipe

• 9,000- 36,000 BTUH

• High Wall Mounting

• Attractive Seamless Appliance Design

• Cleanable Air Filter Provided

• Wireless Infrared Remote Included

• Wired Controller Option

MHNCCW (Ceiling Concealed) Chilled/Hot Water 4-Pipe

• 12,000-36,000 BTUH

• Ceiling Concealed Design for Clean Installation

• Removes Equipment from Conditioned Space

• Heavy Gauge Metal Cabinet

• Powder Painted Galvanized Steel

• Double Field Reversible Hand of Connection Coil

• Manual Air Vents

• Discharge May be Ducted for Small Spaces

MCCW (Ceiling Concealed) Chilled/Hot Water 2-Pipe

• 48,000 – 60,000 BTUH

• Ceiling Concealed Design for Clean Installation

• Removes Equipment from Conditioned Space

• Heavy Gauge Metal Cabinet

• Powder Painted Galvanized Steel

• Manual Air Vents

• Discharge May be Ducted for Small Spaces

Page 233

Page 207

Page 259

CWA2 With or Without Electric Heat 2-Pipe

CFFWA Universal Mount Fan Coil 2-Pipe

• 12,000- 60,000 BTUH

• Floor

Low Wall or Horizontal Ceiling Mounting • Up Flow, Left or Right Hand Horizontal Installatio

• Attractive Modular Design

• Cleanable Air Filter Included

• Optional Wireless Remote

CWA4 Chilled & Hot Water 4-Pi

• Available in 2 or 4-Pi

• 18

000- 60,000 BTUH

• Equipped with R4.2 Insulation

• CWA2 in 208/240-1-60 & CWA4 in 120-1-60

• Electric or Hot Water Heat

5

e Configuration

e

i

DX Product Overview

DX Fan Coils are Compatible with R410a Refrigerant and are 13 SEER Compatible

All DX Coils come Shipped From the Factory with a TXV Installed.

MHCCX (Ceiling Concealed) DX 2-Pipe

With or Without Electric Heat

• 12,000-36,000 BTUH

• Available with or without Electric Heat

• Ceiling Concealed Design for Clean Installation

• Removes Equipment from Conditioned Space

• Heavy Gauge Metal Cabinet

• Powder Painted Galvanized Steel

• Field Reversible Hand of Connection Coil

• TXV Provided

• Discharge May be Ducted for Small Places

•13 SEER Compatible

MCCX (Ceiling Concealed) DX

• 48,000-60,000 BTUH

• Ceiling Concealed Design for Clean Installation

• Removes Equipment from Conditioned Space

• Heavy Gauge Metal Cabinet

• Powder Painted Galvanized Steel

• TXV Provided

• Discharge May be Ducted for Small Spaces

MHNCCX (Ceiling Concealed) DX 4-Pipe

with Hot Water

• 12,000-36,000 BTUH

• Ceiling Concealed Design for Clean Installation

• Removes Equipment from Conditioned Space

• Heavy Gauge Metal Cabinet

• Powder Painted Galvanized Steel

• Double Field Reversible Hand of Connection Coil

• TXV Provided

• Discharge May Be Ducted for Small Places

• Hot Water Heating Coil

•13 SEER Compatible

FSFCA (Universal Mount) DX or Heat Pump

• 12,000- 60,000 BTUH

• Floor, Low Wall or Horizontal Ceiling Mounting

• Attractive Modular Design

• Cleanable Air Filter Included

• Optional Wireless Remote

• TXV Provided

•13 SEER Compatible

MHWX (Hi-Wall) DX or Heat Pump

• 9,000- 36,000 BTUH

• High Wall Mounting

• Attractive Seamless Appliance Des

• Cleanable Air Filter Provided

• Wireless Infrared Remote Included

• Wired Control Option

6

Accessories Overview

Page 385 Page 387 Page 388

Storage Tanks

20 & 42 Gallon

Page 389 Page 395 Page 391

Motorized Valves

2 & 3-Way

Page 392 Page 396 Page 398

Expansion Tank & Air Scoop Liquid Solution Bypass Valve

Condensate PumpWye Strainer

Thermostats

EnclosuresCirculating Pumps

7

January 2008

Multiaqua Equipment Sound Levels

The following will detail the “Sound Levels” of the Multiaqua equipment line.

Air Cooled Chillers

MAC 036, 048, 060 Chillers: 69 dbs (A)

MAC120 Chillers: 75 dbs (A)

Hi-Wall Fan Coils

MHWX-09 / MHWW-09: DX and chilled water Hi-Wall fan coils: 42 dbs (A).

MHWX-12 / MHWW-12: DX and chilled water Hi-Wall fan coils: 43 dbs (A).

MHWX-18 / MHWW-18: DX and chilled water Hi-Wall fan coils: 45 dbs (A).

MHWX-24 / MHWW-24: DX and chilled water Hi-Wall fan coils: 46 dbs (A).

MHWX-36 / MHWW-36: DX and chilled water Hi-Wall fan coils: 48 dbs (A).

Universal Mount Fan Coils

FSFCA-04 / CFFWA-04: DX and chilled water Universal Mount fan coils: 42 dbs (A).

FSFCA-06, 08 / CFFWA-06, 08: DX and chilled water Universal Mount fan coils: 44 dbs (A).

FSFCA-10 / CFFWA-10: DX and chilled water Universal Mount fan coils: 46 dbs (A).

FSFCA-10, 12 / CFFWA-10, 12: DX and chilled water Universal Mount fan coils: 48 dbs (A).

FSFCA-16, 20 / CFFWA-16, 20: DX and chilled water Universal Mount fan coils: 50 dbs (A).

Hideaway Fan Coils

MHCCX-04 / MHCCW-04: DX / chilled water with electric heat Hideaway fan coils: 42 dbs (A)

MHCCX-06 / MHCCW-06: DX / chilled water with electric heat Hideaway fan coils: 44 dbs (A)

MHCCX-08 / MHCCW-08: DX / chilled water with electric heat Hideaway fan coils: 46 dbs (A)

MHCCX-10 / MHCCW-10: DX / chilled water with electric heat Hideaway fan coils: 48 dbs (A)

MHCCX-12 / MHCCW-12: DX / chilled water with electric heat Hideaway fan coils: 49 dbs (A)

MHNCCX-04 / MHNCCW-04: DX / chilled water with hot water heat Hideaway fan coil: 40 dbs (A)

MHNCCX-06 / MHNCCW-06: DX / chilled water with hot water heat Hideaway fan coil: 42 dbs (A)

MHNCCX-08 / MHNCCW-08: DX / chilled water with hot water heat Hideaway fan coil: 44 dbs (A)

MHNCCX-10 / MHNCCW-10: DX / chilled water with hot water heat Hideaway fan coil: 46 dbs (A)

MHNCCX-12 / MHNCCW-12: DX / chilled water with hot water heat Hideaway fan coil: 48 dbs (A)

MCCX-16 / MCCW-16: DX and chilled water Hideaway fan coil. 46 dbs (A)

MCCX-20 / MCCW-20: DX and chilled water Hideaway fan coil. 46 dbs (A)

Disclaimer: Specifications are subject to change without notice. All tests conducted in nonechoic chambers. Sound levels were measured at five feet from the unit. Levels were measured

using free air delivery.

8

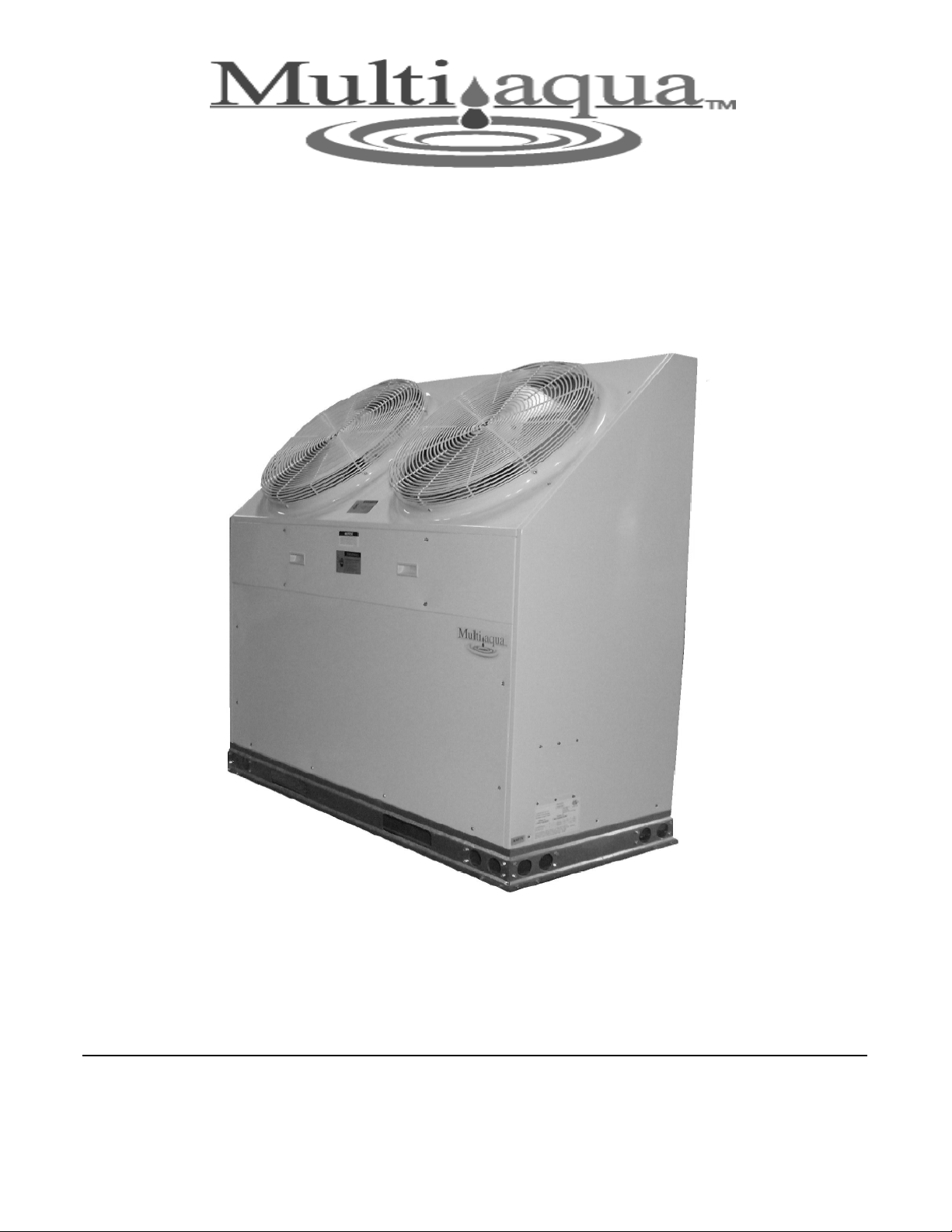

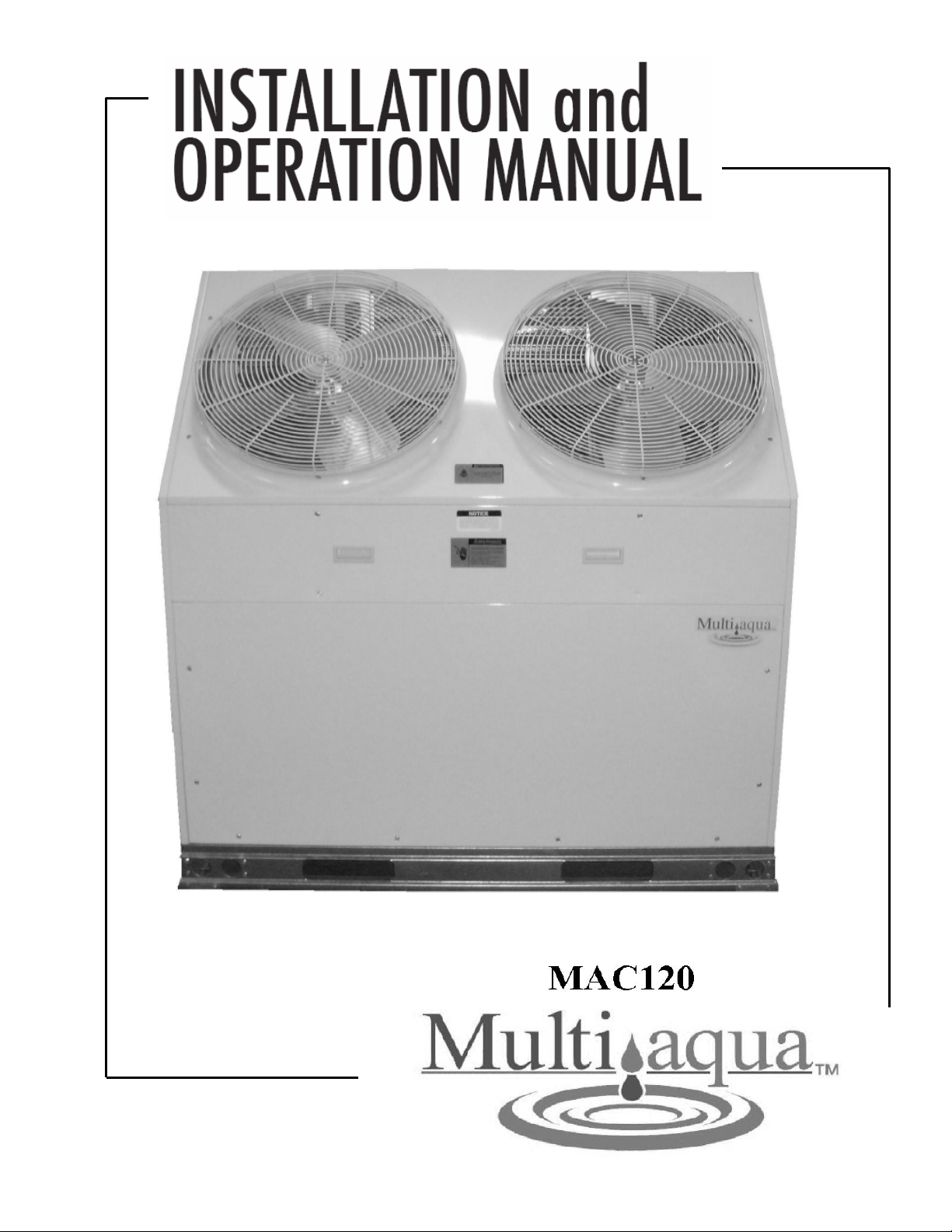

MAC120 Air-Cooled Chiller

Air-Cooled Chillers for Global Residential

and Light Commercial MicroClimates

9

MAC120 NOMENCLATURE BREAKDOWN

MAC120 - XX - X - R407

10-Ton

Air-Cooled Chiller

Voltage

01 = 208/230-1-50/60

02 = 208/230-3-50/60

03 = 380/460-3-50/60

Available Model Numbers

MAC120-01-N-R407

MAC120-01-L-R407

MAC120-02-N-R407

MAC120-02-L-R407

MAC120-03-N-R407

MAC120-03-L-R407

Accessory

Options

N= No Options

L= Low Ambient Kit

10

HVAC Guide Specifications

Air-Cooled Liquid Chiller

Nominal Size:

10 Tons

Multiaqua Model Number:

MAC120-01-N-407, MAC120-01-L-407

MAC120-02-N-407, MAC120-02-L-407

MAC120-03-N-407, MAC120-03-L-407

Part 1-General

1.01 System Description

Multiaqua air-cooled liquid chillers are designed using scroll compressors and low sound condenser fans.

1.02 Quality Assurance

A. Certified in accordance with U.L. Standard 95, latest version (U.S.A.)

B. Construction shall comply with ASHRAE 15 Safety Code, NEC and ASME applicable codes. (U.S.A.

Codes)

C. Manufactured in a facility registered to ISO 9002, Manufacturing Quality Standard.

D. ETL certified.

E. Fully load tested at the factory.

F. Damage resistant packaging.

1.03 Delivery, Storage and Handling

A. Packaged and readied for shipment from the factory.

B. Controls shall be capable of withstanding 150°F storage temperatures in the control compartment.

C. Stored and handled per manufacturer’s rec o mmendations.

Part 2-Product

2.01 Equipment

A. General:

1. Unit shall be a factory assembled and tested air-cooled liquid chiller.

2. Shall be assembled on heavy gauge steel mounting/lifting rails.

3. Contained within the unit cabinet shall be all factory wiring, piping, controls, refrigerant charge

(R407c), POE oil and special accessories required prior to start up.

4. Brass body strainer with 20 mesh screen and blow down shall be supplied in cabinet as a

field installable accessory.

B. Unit Cabinet:

1. Composed of heavy gauge galvanized steel casing with a baked polyester powder.

2. Capable of withstanding 500-hour salt spray test in accordance with the ASTM (U.S.A.) standard.

C. Condenser Fans:

1. 4-blade, aluminum construction and shall be dynamically balanced and corrosion resistant.

2. Discharge air at a 45° vertical angle.

3. Motors and blades shall be protected by coated steel wire safety guards.

D. Fan Motors:

1. Condenser fan motors shall be single speed, direct drive.

2. Totally enclosed.

3. Permanently lubricated sleeve bearings and Class F insulation.

4. Internal overload protection.

E. Compressors:

1. Unit shall contain two fully hermetic scroll compressors.

2. Direct-drive, 3500 rpm (60Hz)

3. Compressor motor shall be suction gas cooled.

4. Internal motor protection.

5. Externally protected by low and high pressure cutout devices.

6. Individual vibration isolators .

11

F. Pump:

1. Unit shall be capable of incorporating a field installed chilled liquid solution pu mp.

(Space restricted)

2. Unit shall have provisions to allow for chilled liquid solution piping to the exterior of the cabinet.

G. Evaporator:

1. Evaporator shall have two independent r ef rigerant circuits.

2. Rated for a refrigerant side working pressure of 450 psig and a maximum water side working

pressure of 60 psig.

3. Single pass, ANSI type 316 stainless steel, brazed plate construction.

4. Externally insulated with closed cell, elastomeric foam. (ASTM518)

H. Condenser:

1. Condenser coil shall be air-cooled with integral subcooler.

2. Two independent refrigerant circuits.

3. Constructed of rifled copper tubing mechanically bonded to aluminum fins.

4. Cleaned and dehydrated.

5. Factory leak tested to 450 psig.

I. Refrigerant Circuits:

1. Each circuit shall contain a sight glass, liquid line filter, thermal expansion valve,

refrigerant charge of R407c and POE compressor oil.

Part 3-Controls and Safeties

3.01 Controls

A. Chiller shall be completely factory wired and tested.

B. Capacity control shall be based on leaving chilled liquid solution temperature.

1. Temperature accuracy shall be + - 1.0°F.

2. Controls shall be capable of staging the two compressors.

C. Controls shall include the following components.

1. 24vac transformer to serve all controllers relays and control components.

2. Microprocessor based liquid solution temperature controller.

3. Leaving water temperature thermistor.

4. Pump bypass timer.

5. Compressor recycle timer.

6. Optional fan cycling control for low ambient operation.

7. Chilled liquid solution flow switch.

3.02 Safeties

A. Unit shall be equipped with thermistors and all necessary components in conjunction with the

control system to provide the following protectants.

1. Low refrigerant pressure.

2. High refrigerant pressure.

3. Low chilled liquid solution temperature.

4. Low chilled liquid solution flow.

5. Thermal overload.

6. Short cycling.

Part 4-Operating Characteristics:

4.01 Temperatures

A. Unit shall be capable of starting and running at outdoor temperatures from 55°F to 120°F.

B. Optional Low Ambient Kit shall allow starting and running at outdoor temperatures to -20

field supplied and installed crank case heater must be used when operating at these temperatures.

C. Unit shall be capable of starting up with a maximum 80°F and a sustained 70°F entering fluid

solution temperature to the evaporator.

D. Minimum 10% Glycol solution is required. For outdoor temperatures below 32°F, reference

MAC Glycol Solution Data table.

4.02 Electrical Requirements

A. Primary electrical power supply shall enter the unit at a single location.

B. Electrical power supply shall be rated to withstand 120°F operating ambient temperature.

C. Units shall be available in 1 or 3-phase power at the voltages shown in the equipment electrical data.

D. Control points shall be accessed through terminal block.

12

°F. A

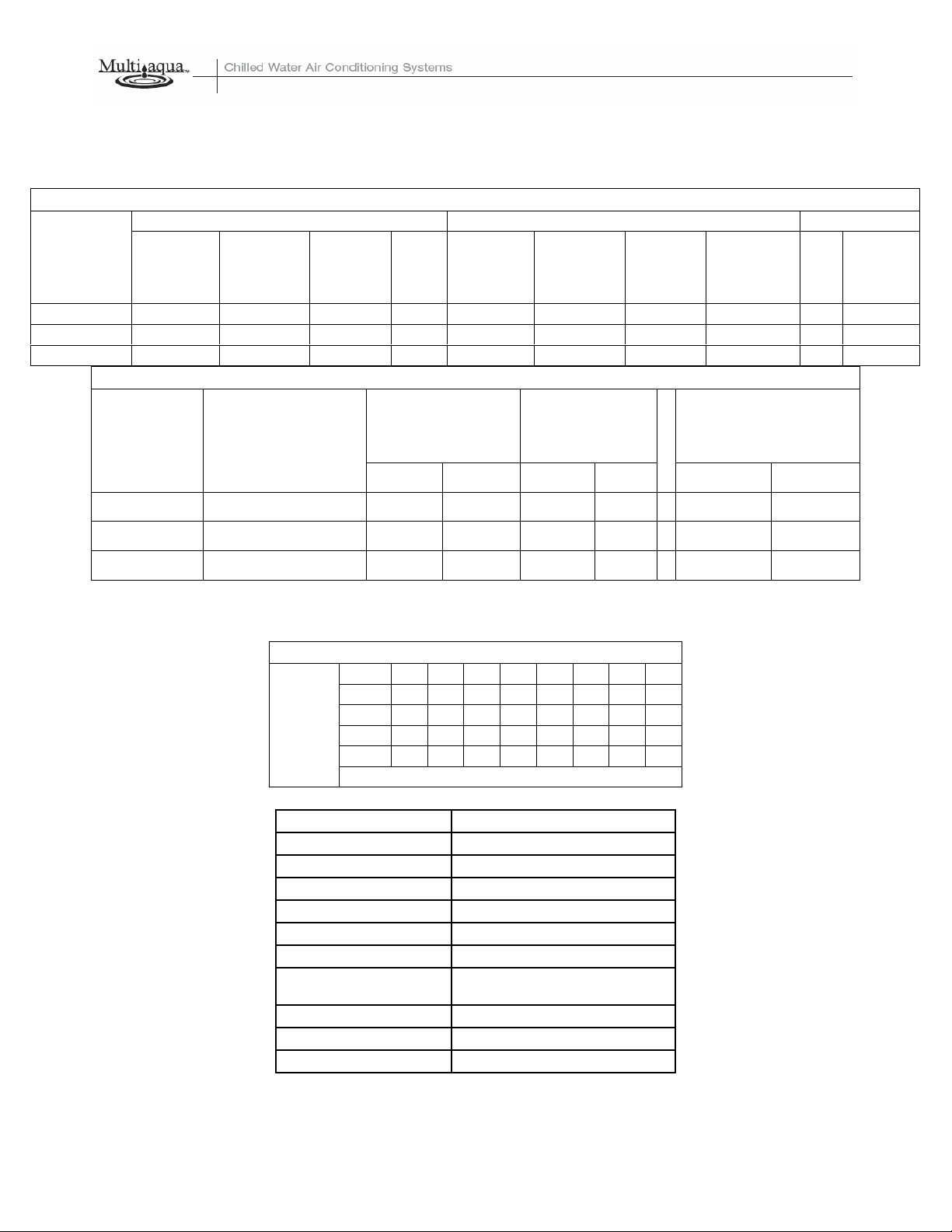

MAC120 Product Specifications

Physical Data

Condenser Coil Chiller Weight (lbs)

Model

Number

Height

(in)

Length

(in)

MAC120-01 52.5 48 3/8 3 60 58.25 25.25 104 oz x 2 650 700

MAC120-02 52.5 48 3/8 3 60 58.25 25.25 104 oz x 2 650 700

MAC120-03 52.5 48 3/8 3 60 58.25 25.25 104 oz x 2 650 700

Copper

Tubing

Diameter

(in)

Coil

Rows

Height

(in)

Electrical Data

Length

(in)

Width

(in)

Refrigerant

R407c

Net Shipping

Compressor

Model

Number

Volts/ Phase/ Hertz

(Qty 2)

(RLA) (LRA) (RLA) (RPM)

MAC120-01 208/230-1-50/60 32.1 x 2 169 x 2 2.3 x 2 900

MAC120-02 208/230-3-50/60 19.3 x 2 137 x 2 2.3 x 2 900

MAC120-03 380/415/460-3-50/60 10 x 2 75 x 2 1.6 x 2 900

Condenser Fan

Motor

(Qty 2)

Fuse or HACR Circuit

44.73 x 2

Breaker

Minimum

Amps

“See note 1”

48.03

“See note 2”

25.70

“See note 2”

Maximum

Amps

75 x 2

“See note 1”

65

“See note 2”

35

“See note 2”

Note:

1. MAC120-01 has two independent line voltage terminations.

2. MAC120-02 & MAC120-03 has one independent line voltage termination.

Copper Wire Size (1% Voltage Drop)

200 6 4 4 4 3 3 2 2

150 8 6 6 4 4 4 3 3

100 10 8 8 6 6 6 4 4

50 14 12 10 10 8 8 6 6

Supply Wire

15 20 25 30 35 40 45 50

Length in Feet

Supply Circuit Ampacity

Compressor Copeland Scroll

Refrigerant R407c

Heat Exchanger Brazed Plate

Max Flow Rate 28.8 gpm

Min Flow Rate 18 gpm

Supply Water Temp 44°

Return Water Temp 54°

Minimum System

Solution Content

50 Gallons

Expansion Tank Size 3% of Total System

Water Connections 1 3/8" OD Supply & Return

Internal Pressure Drop 18 ft of head

Multiaqua chillers are designed to operate exclusively with R407c refrigerant in a self-contain ed, pre-charged refrigerant system. Do

not access the closed refrigerant circuit for any reason other than after-sale, after installation component replacement. Routine

maintenance and service is to be performed by qualified personnel only.

These specifications are subject to change without notice.

13

MAC120 Product Specifications

MAC120 Capacity / Watts / EER*

TONS 9.4 9.0 8.8 8.7 8.7

KILOWATTS 10.9 11.5 11.5 12.1 12.4

EER 10.35 9.39 9.18 8.63 8.42

* Refrigerant system performance only, pump data not included.

82 95 100 105 110

MAC120 Glycol Solution Data

Propylene Glycol %

10% x 1.020 x 0.99 26°F x 1.01

20% x 1.028 x 0.98 18°F x 1.03

30% x 1.036 x 0.98 8°F x 1.07

40% x 1.048 x 0.97 -7°F x 1.11

50% x 1.057 x 0.96 -29°F x 1.16

Example: 30% glycol solution.

Maximum Flow Rate = 12gpm x 1.036

System capacity x .98

*Use Propylene Glycol Only

Water

Flow

Capacity Min. Ambient Temp GPM Adjustment= 100% Capacity

Important

If the outside temperature is expected to fall below freezing (32°F) in the area the Multiaqua chiller is to be

installed; the installer must take the following precautions. Failure to do so will void the warranty.

To not engage in cold ambient mitigation will result in the failure of components such as the heat

exchanger, piping, circulating pump, etc… and or property damage.

• Keep the liquid solution at a minimum of 10% percent Propylene Glycol even in areas where there is no

danger of freezing.

• The percentage amount of glycol recommended is dependent on the expected ambient temperatures and the

solution makeup recommendation of the glycol manufacturer. Refer to the MAC120 Glycol Solution Data table

above.

• Ensure the system circulating pump is in a constant energized mode to keep a continuous circulation of liquid

solution.

The Multiaqua chiller is a self-contained air-cooled condenser, coupled with an insulated brazed plate heat

exchanger (evaporator). The system utilizes a scroll compressor to circulate refrigerant between the condenser

and heat exchanger. The refrigerant is metered into the heat exchanger with a thermal expansion valve.

Protecting the system are high and low pressure switches as well as a pump flow switch.

Liquid solution (water and Propylene Glycol; minimum 10 % is required) is circulated through the heat

exchanger by an externally mounted pump. The liquid solution flows through the heat exchanger to the system

supply piping and on to the air handlers.

Low ambient kits are available for operating ambient temperatures down to -20 degrees Fahrenheit. A field

supplied and installed crankcase heater must be installed when operating at these temperatures. The low

ambient kits consist of an ICM 325 (+) ICM (175) for single and three phase 208/230 vac chillers. For the three

phase 380/460 vac chillers a pressure activated fan control is used.

These specifications are subject to change without notice.

Outdoor Air °F

14

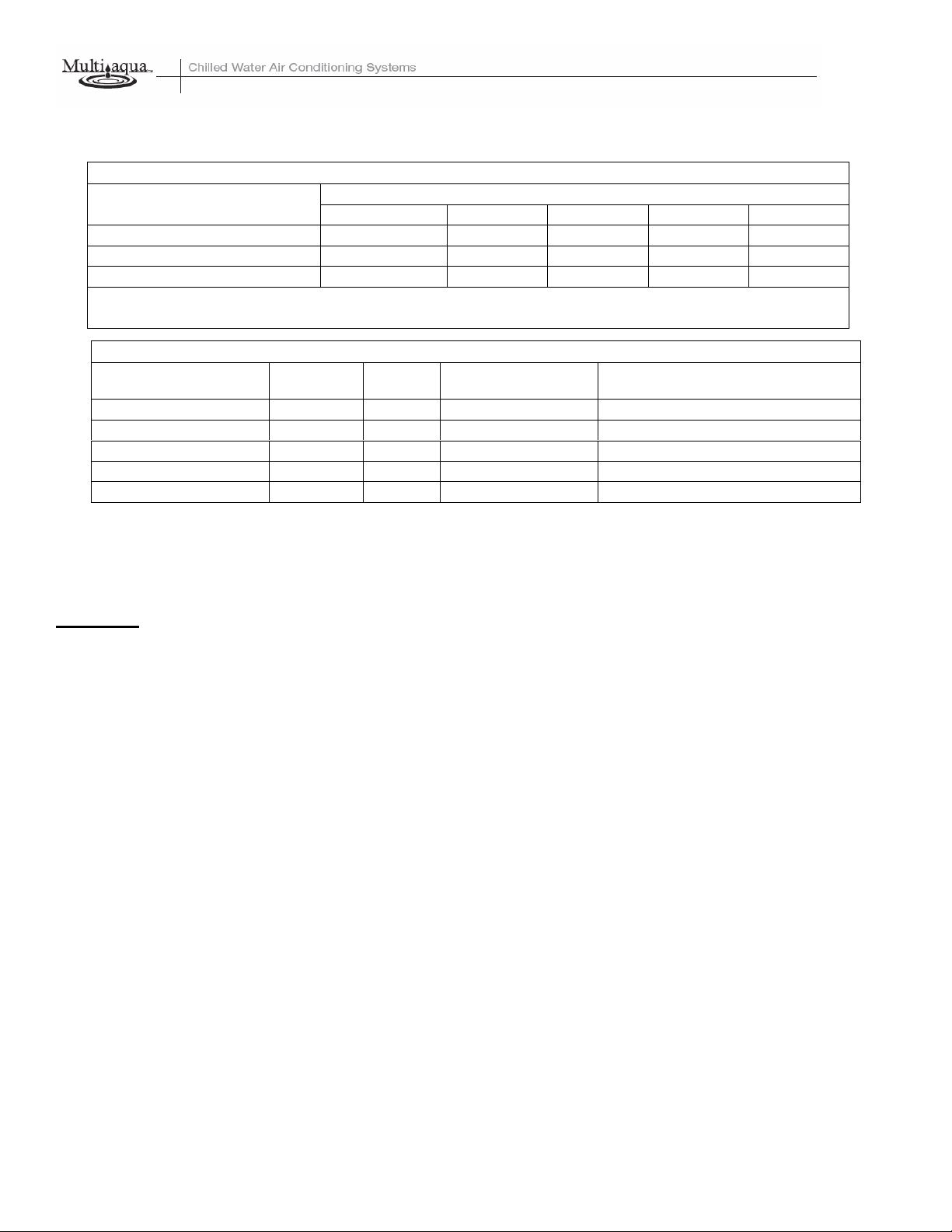

MAC120 Cooling Performance Data

MAC120 CAPACITIES with 0% Glycol

LWT (°F)

35 7.9 7.6 7.4 7.3 7.1

40 8.8 8.4 8.2 8.1 8.1

42 9.1 8.7 8.5 8.4 8.4

44 9.4 9.0 8.8 8.7 8.7

45 9.6 9.2 9.0 8.8 8.8

46 9.7 9.3 9.1 9.0 9.0

48 10.1 9.7 9.4 9.3 9.3

50 10.4 10.0 9.7 9.6 9.6

55 11.3 10.9 10.5 10.4 10.3

60 12.3 11.8 11.4 11.2 11.1

82 95 100 105 110

TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM

28.8 28.8 28.8

MAC120 CAPACITIES with 10% Glycol

LWT (°F)

35 7.8 7.5 7.3 7.2 7.0

40 8.7 8.3 8.1 8.0 8.0

42 9.0 8.6 8.4 8.3 8.3

44 9.3 8.9 8.7 8.6 8.6

45 8.5 9.1 8.9 8.7 8.7

46 9.6 9.2 9.0 8.9 8.9

48 10.0 9.6 9.3 9.2 9.2

50 10.3 9.9 9.6 9.5 9.5

55 11.2 10.7 10.4 10.3 10.2

60 12.1 11.6 11.2 11.0 10.9

82 95

TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM

28.8 28.8

ENTERING AIR TEMPERATURE (°F)

28.8

ENTERING AIR TEMPERATURE (°F)

100 105

28.8 28.8 28.8

28.8

110

MAC120 CAPACITIES with 20% Glycol

LWT (°F)

35 7.7 7.4 7.2 7.1 6.9

40 8.6 8.2 8.0 7.9 7.9

42 8.9 8.5 8.3 8.2 8.2

44 9.2 8.8 8.6 8.5 8.5

45 9.4 9.0 8.8 8.6 8.6

46 9.5 9.1 8.9 8.8 8.8

48 9.9 9.5 9.2 9.1 9.1

50 10.1 9.8 9.5 9.4 9.4

55 11.1 10.6 10.2 10.1 10.0

60 12.0 11.5 11.1 10.9 10.8

82 95 100 105 110

TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM

28.8 28.8 28.828.8

ENTERING AIR TEMPERATURE (°F)

These specifications are subject to change without notice.

15

28.8

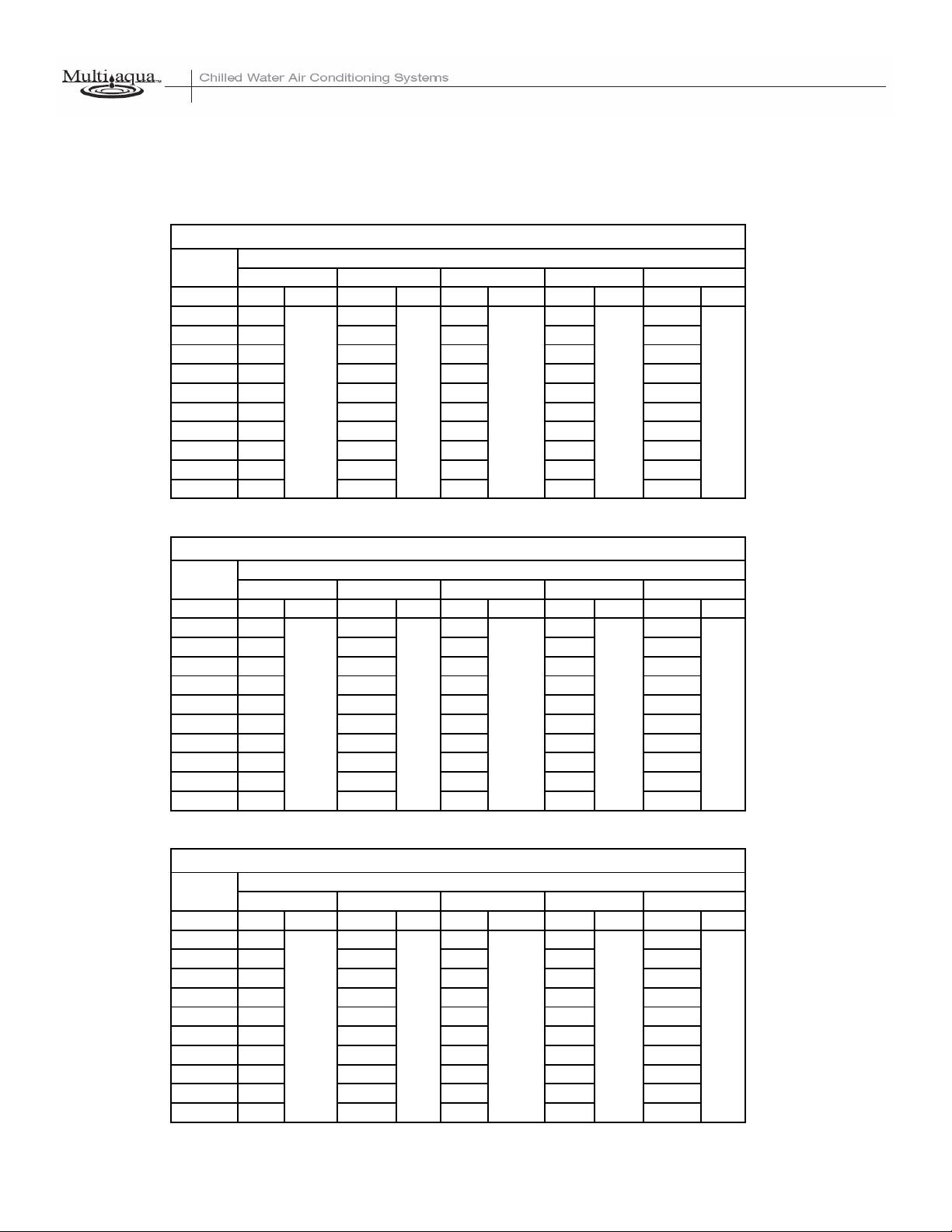

MAC120 Cooling Performance Data

MAC120 CAPACITIES with 30% Glycol

LWT (°F)

35 7.7 7.4 7.2 7.1 6.9

40 8.5 8.1 8.0 7.9 7.9

42 8.8 8.4 8.2 8.1 8.1

44 9.1 8.7 8.5 8.4 8.4

45 9.3 8.9 8.7 8.5 8.5

46 9.4 9.0 8.8 8.7 8.7

48 9.8 9.4 9.1 9.0 9.0

50 10.1 9.7 9.4 9.3 9.3

55 11.0 10.6 10.2 10.1 10.0

60 11.9 11.5 11.1 10.9 10.8

82

TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM

MAC120 CAPACITIES with 40% Glycol

LWT (°F)

35 7.6 7.3 7.1 7.0 6.8

40 8.5 8.1 7.9 7.8 7.8

42 8.8 8.4 8.2 8.1 8.1

44 9.1 8.7 8.5 8.4 8.4

45 9.3 8.9 8.7 8.5 8.5

46 9.4 9.0 8.8 8.7 8.7

48 9.8 9.4 9.1 9.0 9.0

50 10.0 9.7 9.4 9.3 9.3

55 10.9 10.5 10.1 10.0 9.9

60 11.9 11.4 11.0 10.8 10.7

82 95 100 105 110

TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM

28.8 28.8 28.8

ENTERING AIR TEMPERATURE (°F)

95 100 105 110

28.8 28.828.8 28.8 28.8

ENTERING AIR TEMPERATURE (°F)

28.8 28.8

MAC120 CAPACITIES with 50% Glycol

LWT (°F)

35 7.5 7.3 7.1 7.0 6.8

40 8.4 8.0 7.8 7.7 7.7

42 8.7 8.3 8.1 8.0 8.0

44 9.0 8.6 8.4 8.3 8.3

45 9.2 8.8 8.6 8.4 8.4

46 9.3 8.9 8.7 8.6 8.6

48 9.7 9.3 9.0 8.9 8.9

50 9.9 9.6 9.3 9.2 9.2

55 10.8 10.4 10.0 9.9 9.8

60 11.8 11.3 10.9 10.7 10.6

82 95 100 105 110

TONS GPM TONS GPM TONS GPM TONS GPM TONS GPM

These specifications are subject to change without notice.

ENTERING AIR TEMPERATURE (°F)

28.8 28.828.8 28.8 28.8

16

17

Table of Contents

Page

Introduction 19

System Description & Sequence of Operation 20

Electrical & Physical Data 21

Description of Electrical Controls 23

Chiller Controls Sequence of Operation 25

Refrigeration System Operation 26

Description of Refrigeration Components 26

Piping System Components 28

Layout & Design 29

Banked Chiller Configuration 30

Installation Notes 31

Propylene Glycol Content 32

Expansion Tank 32

Filling the System with Propylene Glycol 33

Air Elimination 33

18

Multiaqua Chiller Manual

The Multiaqua Chiller System is the only air conditioning/refrigeration system of its kind in the world

today offering the degree application flexibility described in the following manual.

The Multiaqua Chiller System is not only unique in its application flexibility; it is unique in superior

quality, rated capacities and rugged durability. When installed in accordance with these instructions the

system will deliver years of trouble free service.

Proper equipment sizing, piping design and installation are critical to the performance of the chiller. This

manual is meant to be a “how to” introduction to piping and installing the Multiaqua Chiller System.

MAC120 Chiller Features

• Copeland Scroll Compressors

• Advanced Motor Protection

• Loss of Flow Protection

• Control Power Transformer

• Low Ambient Option

• Integrated Chilled Solution Pump Control

• Flow Switch

• Strainer Connection Kit

• Painted Metal Condenser Protector Grille

• Dual Refrigeration Circuits and Single Liquid Solution Circuit

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY OR

INSTRUCTION RELATED INFORMATION.

Web site information addresses are supplied throughout this manual for piping and accessory information.

The plumbing industry also has pressure drop information on ferrous and copper piping systems.

The following sections will describe each component and how it functions within the system. Installation

information is supplied where appropriate. The piping design section will explain the design and layout

the piping system from a “how to” perspective. Following the examples provided will enable the installer

to determine the correct pipe and accessory sizing, as well as equipment location. It is important to know

before installation if the proposed system will operate correctly and by doing a formal layout of a new

application or review of an existing piping system will make that determination.

Throughout this manual the term “liquid solution” is used in place of water. The chiller circulates a

solution of water and Propylene Glycol.

It is essential to operate the system with a minimum of 10% glycol. DO NOT OPERATE THIS

SYSTEM USING WATER ALONE.

For proper liquid solutions mix ratios, refer to page 14 or the glycol manufacture’s recommended mix

ratios.

19

System Description & Sequence of Operation

The Multiaqua Chiller is a self-contained, air-cooled condenser, coupled with an insulated brazed plate

heat exchanger (evaporator). The system utilizes scroll comp ressors to circulate refrigerant between the

condenser and heat exchanger. The refrigerant is metered into the heat exchanger with a thermostatic

expansion valve. Protecting the system are high and low pressure switches as well as a pump flow switch.

Liquid solution (water and Propylene Glycol is circulated through the heat exchanger by a field supplied

pump. The liquid solution flows through the heat exchanger to the system supply piping and on to the air

handlers.

A solenoid-operated, motorized valve or circulator controls the flow of the chilled liquid solution through

the air handlers. The valves or circulators can be actuated by a variety of different control schemes.

Liquid solution temperature is controlled by a chiller mounted digital electronic controls. A system

sequence of operation, individual control description, troubleshooting information and a schematic are

included in the controls section.

It must be recognized that ferrous pipe may cause acceleration deterioration of the brazed

plate heat exchanger and could void the heat exchanger warranty.

Cooling load Diversity

Equipment sizing for a chilled liquid solution system can utilize Cooling Load Diversity. Diversity is

described as the actual amount of cooling needed (heat load) by various sections of a structure at a given

time. Conventional air conditioning systems are designed for the highest structure heat load. The

conventional system determines and selects equipment based on the peak heat load demanded by the

structure. A system sized to take advantage of diversity would determine the heat load by the time of day,

building exposure and usage. As an example the sections of a structure facing west, demand more cooling

in the afternoon, than sections facing east. The opposite of this is true in the morning, where the east

section is exposed to a higher heat load requiring more cooling. Utilizing diversity the chiller system

would adapt to the needs of each side of the structure during peak demand by delivering more cooling to

that area and less to the areas that do not need it. A structure utilizing a conventional DX system, requires

8 tons of cooling at peak load, could utilize a much smaller capacity system (potentially 4 or 5 tons) if the

system installed could take advantage of load diversity, which would supply the necessary amount of

cooling to the space, as and when needed instead of keeping a larger capacity available at all times.

Cooling load diversity can best be determined by referring to ACCA. (Air Conditioning Contractors of

America) Manual “J”, Refer to the appendix A-2, Multi-Zone Systems. ACCA’s Internet address is

http://www.acca.org/

Because of diversity a Multiaqua Chiller can serve more total air handler tonnage than chiller capacity. A

10-ton chiller may be delivering chilled liquid solution to 15 or more tons of air handler capacity. Because

of cooling load diversity, the building does not need equal amounts of cooling in each area at the same

time.

20

ELECTRICAL AND PHYSICAL DATA

The information contained in this manual has been prepared to assist in the proper installation, operation

and maintenance of the chiller. Improper installation, or installation not made in accordance with these

instructions can result in unsatisfactory operation and/or dangerous conditions and can cause the related

warranty not to apply.

Read this manual and any instructions packaged with separate equipment required to make up the system

prior to installation. Retain this manual for future reference.

Separate and independent power supplies and disconnects must be provided. These chillers have

separate and discreet power requirements within one cabinet.

All power to the chiller must be turned off prior to opening cabinet and or servicing.

Failure to properly ground chiller can result in death.

Disconnect all power wiring to chiller before maintenance or service work. Failure to do so can

cause electrical shock resulting in personal injury or death.

All wiring must be done in accordance with the NEC (National Electric Code) as well as state and

local codes, by qualified electricians.

Product warranty does not cover any damages or defect to the chiller caused by the attachment or

use of any components, accessories or devices (other than those authorized by the manufacturer) into,

onto or in conjunction with the chiller. You should be aware that the use of unauthorized components,

accessories or devices may adversely affect the operation of the chiller and may also endanger life and

property. The manufacturer disclaims any responsibility for such loss or injury resulting from the use of

such unauthorized components, accessories or devices.

Upon receiving the chiller and components, inspect for any shipping damage. Claims for damage,

either apparent or concealed should be filed immediately with the shipping company.

No liquid other than the solution of water and Propylene Glycol (mixed in accordance with table

6 page 32) shall be used in the piping system.

Corrosive environments may subject metal parts of the chiller to rust and deteriorate. The

oxidation could shorten the chiller’s useful life. Corrosive elements include salt spray, fog or mist in sea

coastal areas, sulfur or chlorine from lawn watering systems and various chemical contaminants from

industries such as paper mills and petroleum refineries.

If the unit is to be installed in an area where contaminates are likely to be a problem, special attention

should be given to the equipment location and exposure.

• Avoid having lawn sprinklers spray directly on the chiller cabinet.

• In coastal areas, locate the chiller on the side of the building away from the water front.

• Elevating the chiller off of its slab or base enough to allow air circulation will help avoid holding water

in contact with the cabinet base.

• Regular maintenance will reduce the build-up of contaminants and help protect the cabinet finish.

• In severe locations having the chiller coated with an “epoxy” or other coating formulated for air

conditioning systems located in coastal areas may be necessary.

21

Consult local building codes or ordinances for special installation requirements. When

selecting a site to locate the chiller, consider the following:

• A minimum clearance of 60” on the service access front, 12” on the rear air inlet and a 60” fan discharge

clearance.

• The chiller can be located out or indoors. If installed indoors there must be 9000 cfm of outdoor air

changes circulated through the mechanical room to sufficiently operate the chiller. No ductwork can be

connected to the chiller’s condenser or condenser fans.

• If a concrete slab is used, do not connect the slab directly to any building’s foundation or structure to

prevent sound transmission.

• Locate the slab on a level surface that is above grade to prevent ground water from entering the chiller

cabinet.

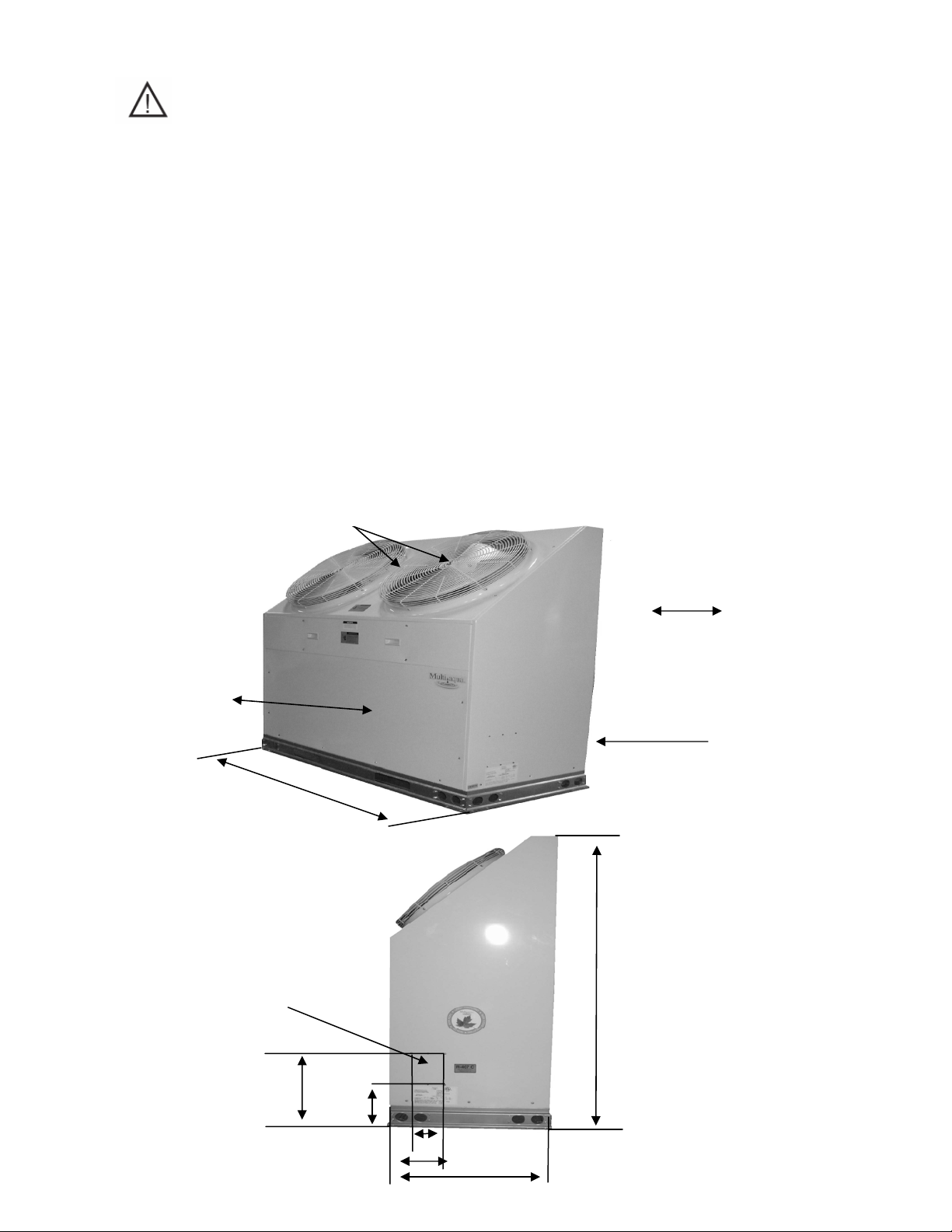

Stated Service Clearances

60” Fan Discharge Clearance

60” Front Service

Clearance

Chiller Supply and Return

Piping Access

58.25

58.25”

60.00”

60.00”

12” Rear Clearance

0” Side Clearance

60.00”

15”

10”

13”

”

25.25”

22

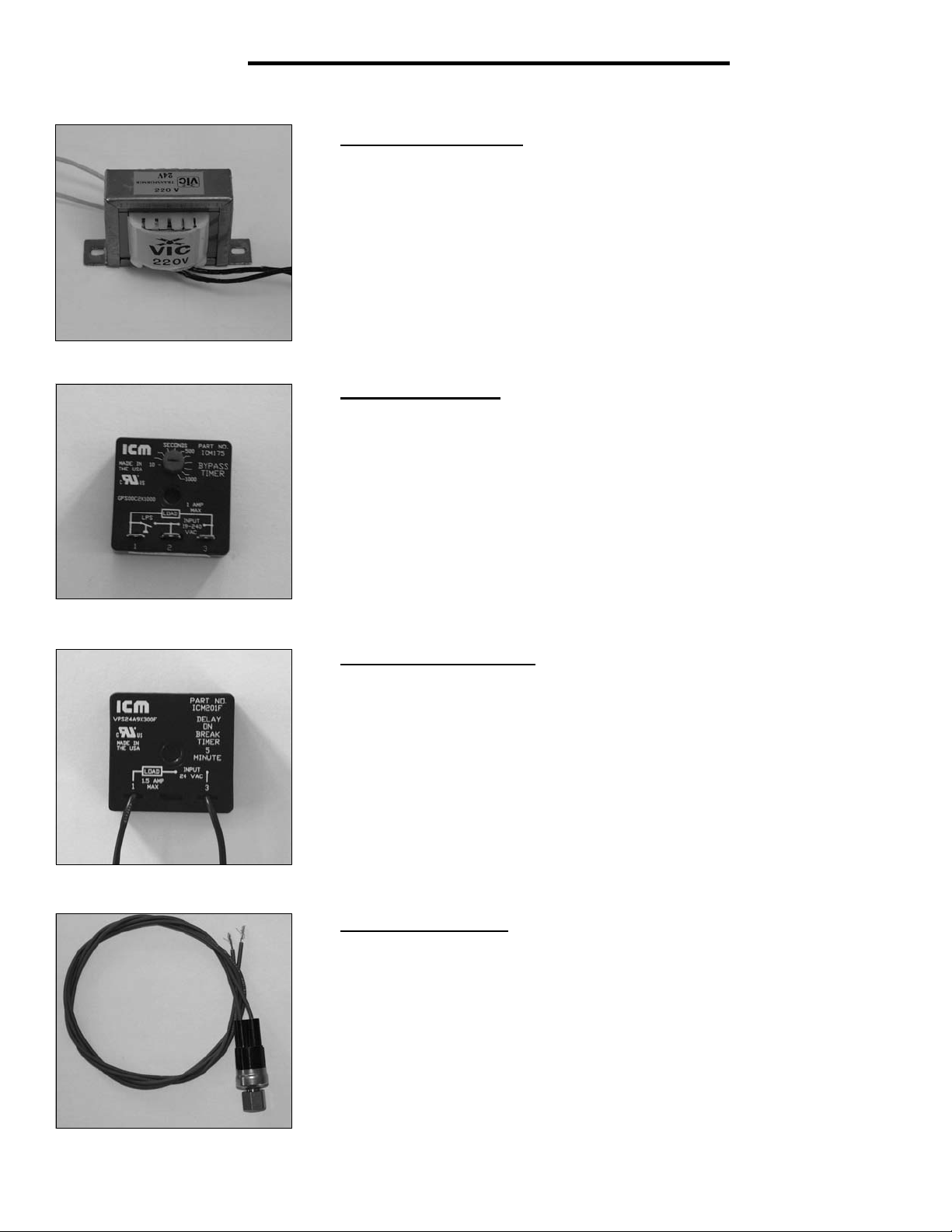

Description of Electrical Controls

Control Transformer: The control transformer is rated at 24 vac, 40 va

(1.6 amps @ 24vac)

Pump Bypass Timer: The pump bypass timer is a 24 vac, 3-wire control.

When energized the timer will bypass the flow switch for 10 seconds (by

creating a circuit to the pump relay), energizing the pump relay, allowing the

pump to operate long enough to close the flow switch. In a normally operating

system the flow switch will stay closed powering the pump relay in series with

the low and high- pressure switches. Should the flow switch open, the timer

can only be reset by opening and closing the chiller's line voltage disconnect.

Refrigerant System Timer:

on break, 20wire timer. The normally closed contacts of the timer energize

the compressor contactor through the chilled solution control. When the chilled

solution control contacts open, the timer delays by opening its contact for 5minutes before resetting to the closed position.

High Pressure Switch: The high-pressure switch is an automatic reset control

that senses compressor discharge line pressure. It opens at 400 PSIG and

closes at 300 PSIG.

The refrigerant timer is a 24 vac, 5-minute delay

23

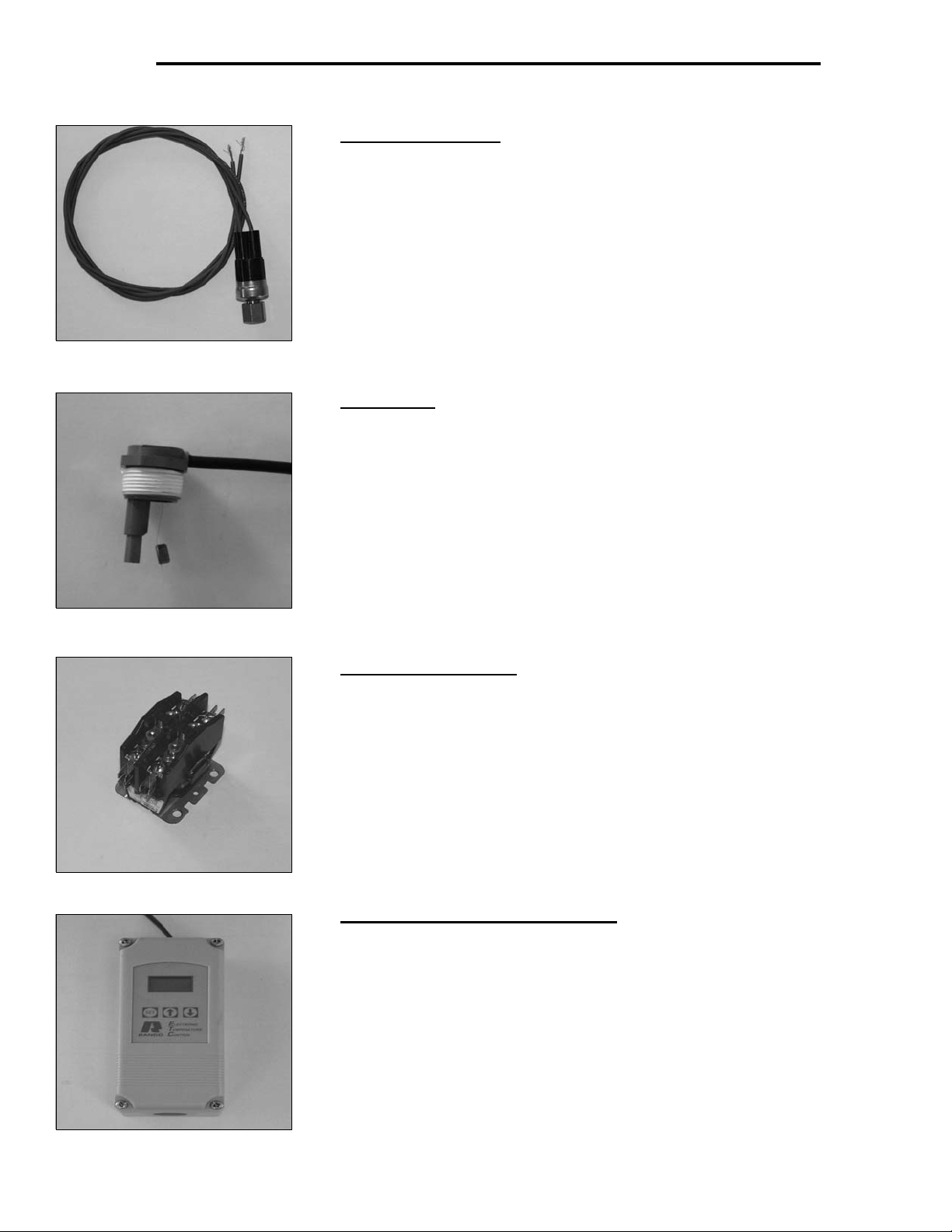

Description of Electrical Controls (continued)

Low Pressure Switch:

that senses compressor suction line pressure. It opens at 40 PSIG and

closes at 80 PSIG.

Flow Switch:

switch is inserted through a fitting into the pump discharge line. Liquid solution

flow deflects the paddle closing the switch. The flow switch is position sensitive.

The arrow ↑ on the switch must point in the direction of liquid solution flow.

The flow switch senses liquid solution flow. The paddle of the

The low-pressure switch is an automatic reset control

Compressor Contactor:

through the two or three normally open contacts. The contactor coil operates

(closes the contacts) when energized by 24 vac.

Liquid Solution Temperature Control:

is an adjustable microprocessor based temperature control. This control receives

temperature information from a thermistor located on the liquid solution supply

line. A liquid crystal display continually indicates liquid solution temperature. The

control is mounted inside the chiller cabinet.

The compressor contactor energizes the compressor

The liquid solution temperature control

24

Chiller Controls Sequence of Operation

When powered up, the Multiaqua chiller system energizes the control transformer creating 24 vac control voltage.

First the pump bypass timer is energized and temporarily bypasses the flow switch, energizing the pump relay. The

pump then starts to move liquid solution through the piping system (in a properly filled and air purged system). The

movement of liquid solution from the pump discharge keeps the flow switch closed. After a 10 second delay the pump

contact opens, connecting the flow switch in series with the high and low pressure switches. The pump will now run

continually unless the power supply is interrupted, or the flow switch opens.

If the liquid solution temperature controller is calling for cooling the control circuit is routed through the short cycle

timer and the three safety switches (the flow, high and low pressure switches) to the compressor contactor. This will

energize the compressor(s) and condenser fan motors. The liquid solution controller will open at the user programmed

set point, causing the refrigerant short cycle timer to open it's contact for 5 minutes as it delays before resetting to the

closed position. This will de-energize the compressor. Power fluctuations will also initiate a 5 minute time delay. The

5 minute delay allows the refrigerant system a period for pressure equalization, protecting the compressor(s) from

short cycling.

The chiller temperature controller utilizes a thermistor to monitor the liquid solution temperature change. The

temperature is then compared to the set point and differential temperatures programmed into the control by the user.

The set point is the liquid solution temperature which will cause the control switch to open. For example: The control

set point is programmed at 44°F LWT with a 10°F differential, which opens the controller at 44°F LWT and closes at

54°F. The differential temperature is the number of degrees above set point temperature programmed into the

controller. If liquid solution temperature falls to the set point, the controller cycles the compressors off.

Chillers are shipped with the control set point adjusted to 44°F LWT and a 10°F differential. Liquid solution

temperature set point should not be set below 35°F.

25

SYSTEM FAULTS:

Flow Switch Opening:

interrupted for any reason, the control will open shutting down and locking out the chiller operation. The only exception

to this is when power is first applied to the chiller and the pump bypass timer bypasses the flow switch for 10 seconds.

When the system is first filled with liquid solution and the pump is started, expect the system to cycle off

on the flow switch until all of the air is removed from the piping system. The system will have to be

reset by opening and then closing the disconnect switch or circuit breaker powering the chiller.

Low Pressure Switch Opening: Should the compressor suction pressure go low enough (40 PSI) to open the low-

pressure switch, the compressor and condenser fan motors will shut down. Check for a refrigerant leak, inoperative

thermal expansion valve, low liquid solution control setting, low ambient operation, low liquid solution flow, etc.

High Pressure Switch Opening: Should the compressor discharge pressure go high enough to open the high- pressure

switch the compressor and condenser fan motors will shut down. Check for a dirty condenser coil, inoperable fan motor(s)

or the recirculation of condenser air.

The flow switch is normally closed during pump operation. Should liquid solution flow be

Refrigeration System Operation

The refrigeration system is a closed loop consisting of 2 compressors, dual circuit heat exchanger (evaporator), metering

devices (TXVs) and condenser coil. The refrigerant circulated is R407c. Hot gas is pumped from the compressors to the

to the condenser coil where the two condenser fans pull cooler air across the coil condensing and sub cooling the refrigerant.

The now liquid refrigerant flows through the liquid line to the thermal expansion valves, where the refrigerant pressure

drops causing the refrigerant to boil at a much lower temperature (34-40°F). The refrigerant leaves the expansion valves and

swirls through the plates of the heat exchanger absorbing heat from the circulating liquid solution.

The evaporator or heat exchanger is designed to operate with an 8-10 °F superheat. The condenser is designed to

condense the refrigerant and sub cool it to 10 °F below condensing temperature.

Description Of Refrigerant Components

Scroll Compressor: All Multiaqua chillers feature Scroll compressors. Scroll

technology ensures reliable high performance at a low sound level over a wide range

of operating conditions.

Caution the top half of the scroll compressor operates at a temperature high

enough to cause serious injury.

26

Description Of Refrigerant Components (continued)

Brazed Plate Heat Exchanger: The "Heat Exchanger" or evaporator is of a

brazed copper and stainless steel design. Refrigerant and liquid solution is channeled

through narrow openings between plates and flows in opposite directions. The counter

flow design and fluid turbulence ensures maximum heat exchange at minimal pressure

drop.

Thermal Expansion Valve: Multiaqua chillers are equipped with Thermal Expansion

valves. The valves feature a liquid charged sensing bulb for consistent superheat at

various load conditions.

Condenser Coil: The air-cooled condenser coil is of copper tube with aluminum fin

construction. The coil is protected by a painted metal condenser grille.

27

Piping System Components

Supply Storage Tank: The supply storage tank must be used in the system with less

than 25 gallons of liquid solution. The tank prevents rapid cycling of the compressors

and acts as a reserve for chilled liquid solution.

Supply storage tank must be insulated in the field.

Part Number: WX202H (20 Gallon)

WX202H (42 Gallon)

Expansion Tank and Air Scoop: The Expansion Tank and Air Scoop assembly is

used to compensate for the expansion and contraction of liquid in the system. The

air scoop eliminates air entrance in the liquid solution.

Part Number: 1500/1"

Liquid Solution Bypass Valve: The liquid solution bypass valve relieves system

pressure from the liquid solution supply to the return as system air handler control

are cycled off.

Part Number: D146M1032- 3/4"

D146M1040- 1 1/4"

Motorized Valve: The air handler motorized valve controls the flow of liquid solution

to the systems air handlers. Each air handler in the system should have a motorized

or solenoid valve.

Part Number: MZV524E-T 1/2" 2-Way Zone Valve

MZV525E-T 3/4" 2-Way Zone Valve

MZV526E-T 1" 2-Way Zone Valve

VT3212G13A020 1/2" 3-Way Zone Valve

VT3212G13A020 3/4" 3-Way Zone Valve

28

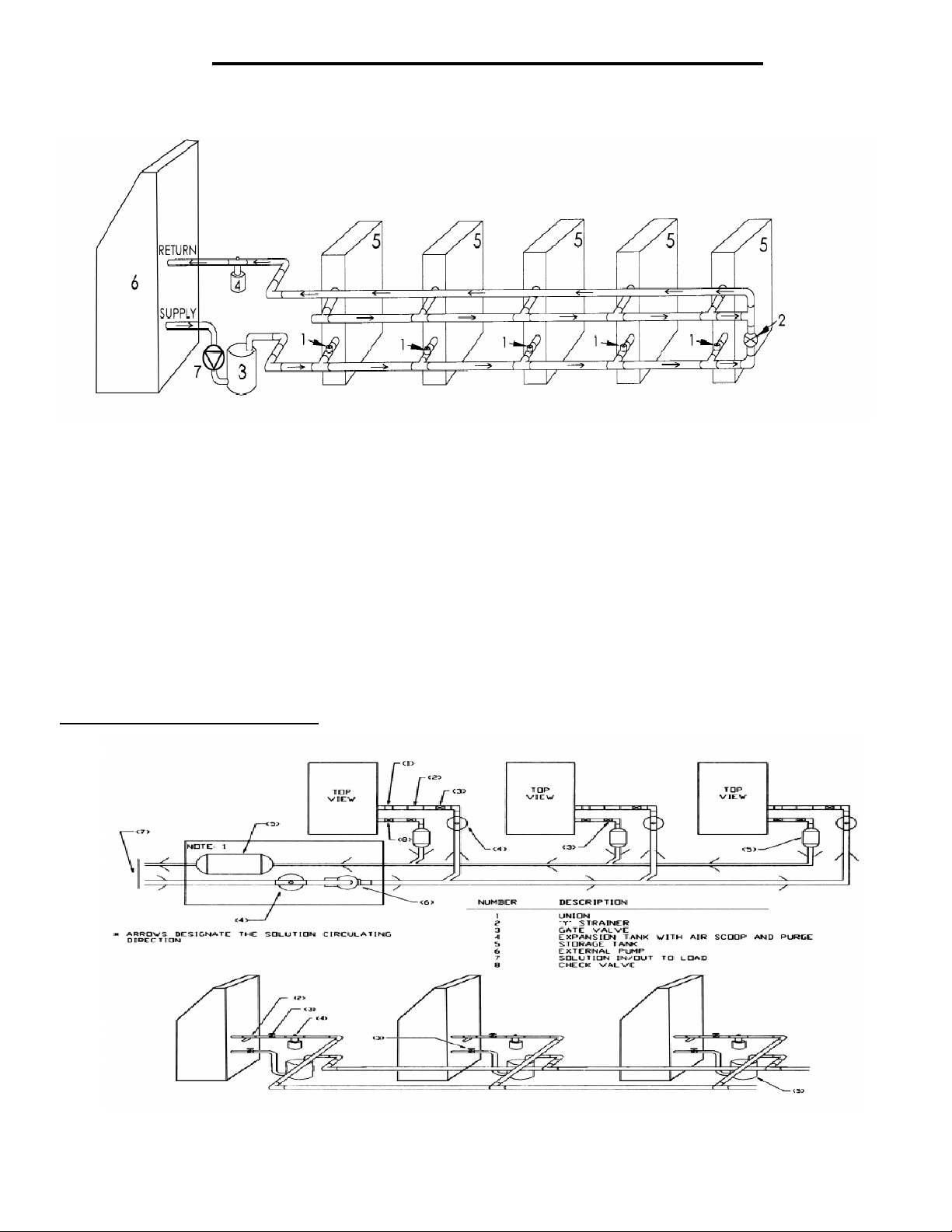

Composite Piping Layout and Design

Understanding the function and friction loss of each part of the piping system is important to the layout and successful

installation of a chilled liquid solution system.

2-Way Liquid Solution Control Valves

1-

Bypass Valve

2-

Storage Tank

3-

Expansion Tank

4-

Coil

5-

Chiller

6-

Pump

7-

The circulation pump is the key performer in the piping system. The pump must circulate the liquid solution through the

heat exchanger and piping system to the air handlers. Pumps are designed to deliver a flow rate measured in gallons

per minute(GPM). The pump must be able to overcome the resistance to flow (pressure drop) imposed by the chiller

components, piping system and air handlers while maintain the necessary flow rates in gallons per minute. Pump

capacities in gallons per minute and pressure drop (feet of head) are listed in table 1.

An adjustable valve must be used to throttle the discharge liquid solution flow rate to appropriate levels based

on capacity and glycol mix percentages.

Chiller System Data

Table 1

GPM

GPM

MAC-120

18

28.8

50

3% of Total

1.85

1.5

MAC Series

Min. Liquid Solution Flow Rate

Max.Liquid Flow Rate

Min. Liquid Solution Content in System

Expansion Tank Size

Internal Chiller Pressure Loss

Chiller Liquid Solution Content

Piping resistance or pressure drop is measured in feet of head. A foot of head is the amount of pressure drop imposed

in lifting liquid solution one foot. Pumps in the Multiaqua system are designed to move rated liquid solution flow (see

table 1) in GPMs.

Gallons

Gallons

Ft.of Head

Gallons

29

Banked Chiller Configuration

Notes:

Installing Multiaqua chillers in parallel is recommended.

30

n

Installation Notes:

Piping such as PEX,steel, copper or PVC can be used with the Multiaqua system. Check local building codes for

material conformation. Care must be taken when using PVC as the presence of propylene glycol may destroy

plastics. Pressure drop data for the selected piping material is readily available and should be used. Should the

Multiaqua chiller be installed using existing steel (ferrous metal) piping system, dielectric fittings must be used

at the chiller and air handler. The factory supplied wye strainer will capture particles of rust and sediment

inherent with steel piping and should be checked and cleaned after initial start up and open a regular maintenance

during the life of the system.

Any piping used to conduct liquid solution must be insulated in accordance with local and national mechanical

codes. Information on insulation installation and application can be obtained from Armaflex web site at

www.armaflex.com

of the chiller and air handlers, it is suggested that shutoff valves be installed at the chiller and air handler(s). If

ball valves are used, they can double as balancing valve(s) in the supply piping at each air handler. Chiller

shutoff valves should be attached at the chiller connections with unions.

The air handlers are to be controlled with electrically operated "slow-opening" solenoid valves, circulators or

motorized zone valves as manufactured by Erie controls (www.eriecontrols.com/products/index.htm

thermostat or air handler installed digital control operate the valves.

and Owens-Corning site at www.owenscorning.com/mechanical/pipe/. For future servicing

) A remote

Bypass valves as shown in drawing 1, should be installed between the supply and the return chilled liquid

solution supply pipes at a convenient location to the installation. The bypass valve operates to bypass liquid solutio

between the supply and return chilled liquid solution lines. In the event air handlers valves should shut down, the

bypass valve is set to open up and bypass liquid solution between the supply and return lines, relieving pressure

and eliminating the possibility of pump cavitations. To adjust the valve, run the system with one air handler

solenoid actuated. De-energize the solenoid valve, (at this point no liquid solution will be flowing through the air

handlers.) and adjust the bypass valve to relieve pressure between the supply and return piping.

Bleed ports will be factory installed on all Multiaqua air handlers. Bleed ports are opened to eliminate air trapped

in the air handlers after filling the system with liquid solution and Propylene Glycol and before operating the

refrigerant compressor in the chiller.

The minimum liquid solution content in the chiller system,(piping, chiller, and air handlers), is 50 U.S. gallons.

Estimate the system liquid solution content. Should the system have less than 50 gallons of liquid solution

content, a chilled liquid solution storage tank must be installed. The tank stores enough chilled liquid solution

to prevent frequent chiller compressor cycles at light load and prevents chilled liquid temperature swings at

higher load conditions when the chiller compressor is waiting to cycle on the time delay control.

Propylene Glycol must be added to the water used in the system

low ambient temperature conditions and low chilled liquid solution temperatures. In comparison to water,

Propylene Glycol slightly lessons the temperature exchange in the chiller heat exchanger. However, that is

offset by the increased flow of liquid solution through the piping system enabled by the Propylene Glycol. To

determine the Propylene Glycol content for various ambient temperatures refer to table 6 page 32.

. Propylene helps prevent freeze-ups due to

In no instance should a Multiaqua chiller be installed with less than 10% Propylene Glycol content in the piping

system. Using less than the recommended Propylene Glycol percentage content voids equipment warranty.

31

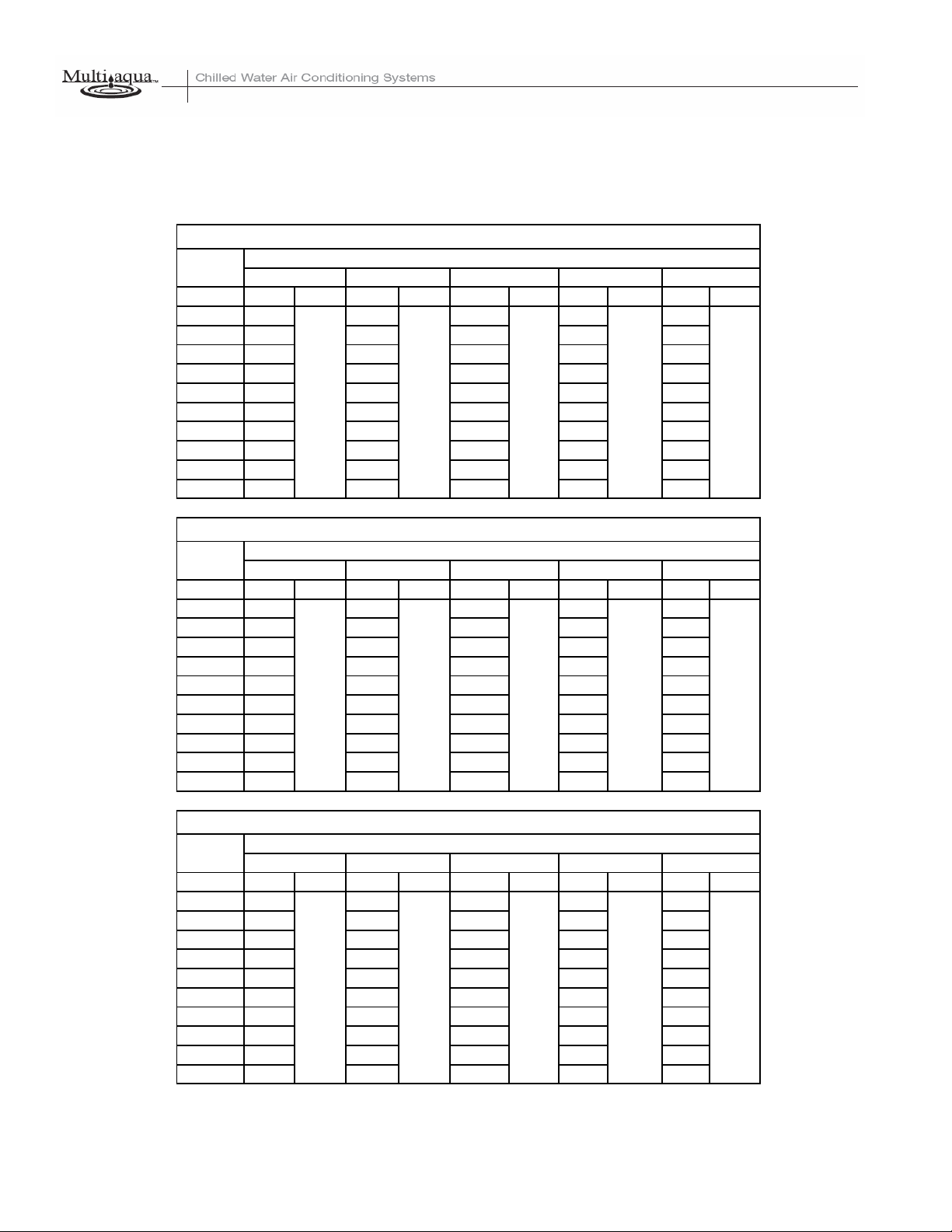

Polypropylene Glycol System Content vs.

Minimum Ambient Temperature

To not engage in cold ambient mitigation will result in the failure of components, property damage and

void warranty.

Table 6

Percent of Propylene Glycol to Water Content

Propylene Water

Glycol % Flow

10% x 1.020

20% x 1.028

30% x 1.036

40% x 1.048

50% x 1.057

Ethylene Glycol is environmentally hazardous and not recommended. Inhibited Propylene Glycol ( typical

automotive coolant) is not to be used in a Multiaqua Chiller under any circumstances.

family of Glycol-based coolants of food grade Propylene Glycol is suggested. Information on Ambitrol is available

from Dow at www.dow.com,

Capacity

x .99

x .98

x .98

x .97

x .96

search word "Ambitrol".

Min. Ambient

Temperature

26°F

18°F

8°F

-7°F

-29°F

GPM Adjustment

= 100 % Capacity

x 1.01

x 1.03

x 1.07

x 1.11

x 1.16

Dow Chemical's "Ambitrol"

Expansion Tanks:

Liquid solution expansion and contraction within the closed system must be compensated for with an expansion

tank. The expansion tank used with the Multiaqua system, is a steel tank with a rubber bladder attached to it

internally. There is air pressure on one side of the rubber bladder that keeps the bladder pushed against the

sides of the tank before the system is filled with liquid solution (illustration above). As the liquid solution heats

up the bladder will be pushed further away from the tank walls, allowing for expansion and contracting as the

liquid solution temperature changes. By flexing, the bladder controls the system pressure adjusting to

temperature variations of the chilled liquid solution system.

It is critical that the expansion tank's air bladders pressure be less than the system solution pressure. Air

pressure can be measured with an automotive tire gauge at the bicycle valve port on the expansion tank. Bleeding

air out of the bladder or increasing the pressure with a bicycle pump will adjust pressure.

System must use a liquid solution storage tank if system volume is less than 50 U.S. gallons.

32

Filling System with Liquid Solution and Coolant

(Propylene Glycol)

Before filling system with Propylene Glycol and water, pressure test the piping system with compressed air.

Testing should be done at a maximum of 50 psi.The system should hold air pressure for a minimum of

one hour with no leakage.

Concentrations of Propylene Glycol in excess of 50% will destroy o-rings in fittings and pump. Water should

be added to the system first or a liquid solution diluted Propylene Glycol mix.

System that contains 50 or more U.S. gallons should have a tee fitting with a stopcock installed in the return

line close to the chiller. The stopcock can be opened and attached to a hose with a female X female hose

fitting. In the open end of the hose section (1 -1.5 feet long) insert a funnel and pour into the system the

diluted Propylene Glycol/liquid solution mixture or add water first and then the quantity of Propylene Glycol

needed for minimum ambient protection (refer to Table 6). After adding the Propylene Glycol/water mixture, or

liquid solution and then coolant proceed to add enough water to the system to achieve a 15 psi gauge pressure.

To measure system pressure shut off the stopcock, remove hose and attach a water pressure gauge. Open

the stopcock to read system pressure.

Systems that use the Chilled Liquid Solution Storage Tank should be filled at the tee/stopcock fitting in the

outlet fitting of the storage tank. Fill the tanks with 10 gallons of water and with a funnel pour the calculated

(refer to Table 6) amount of Propylene Glycol into the tank. The amount of Propylene Glycol added should be

calculated to achieve minimum ambient protection. After adding Propylene Glycol, fill the system with enough

liquid solution to bring system pressure to approximately 15 psi gauge pressure. To measure system pressure

shut off the stopcock and attach a water pressure gauge. Open the stopcock to read system pressure.

Air Elimination

Since we have the system filled we must eliminate the air left in the system. Briefly open each bleed valve at

the air handlers and allow trapped air to escape. This will eliminate much of the air left in the system.

Next we will start the pump and continue bleeding air from the system. Be sure the chiller has line voltage

available to it and set the chilled liquid solution control up to 100 °F, which will ensure that only the pump runs

at this point. The pump should now start and remain running. Should the pump stop at any time during this

process it is an indication that the flow switch had air move across it allowing the circuit to be interrupted.

Continue to bleed some air out of the system at the highest locations before resetting the pump bypass timer

to get the pump running again. Open and close the power supply switch to the chiller to restart the pump.

Continue bleeding air with the pump operating. You may have to start and re-start the pump a few times to

complete air removal.

If you continue having air entrapment issues, it will be necessary to install a micro bubble remover device.

All piping systems should have a minimum of 10% Propylene Glycol in the system even in climates with nonfreezing ambient temperatures.

Using less than the recommended Propylene Glycol percentage content voids equipment warranty.

Liquid solution control valves (solenoid or motorized valves) should be selected for low pressure drop. If a selected

valve contributes to pushing your total head calculation to more than 50 feet of head, a larger valve may be

needed to bring your total head below the maximum of 50 feet.

Liquid Solution Balancing:

Liquid solution balancing will require an accurate digital thermometer to measure return line liquid solution

temperature at each air handler. Set the chilled liquid solution temperature control in the chiller at a normal

operational temperature (44°F) and measure pump discharge temperature with the digital thermometer to check

system solution temperature. After the chilled liquid solution temperature has lowered to the set point begin the

balancing process. The system must be free of air and each air handler set at a temperature low enough to

continue cooling operation (and liquid solution flow) during the balancing process. Begin by measuring the return

line chilled liquid solution temperature of each air handler. Begin incrementally closing the supply line balance

valve at the air handlers with the lowest return line chilled liquid solution temperature. Continue this process

until each air handler has close to the same return line chilled liquid solution temperature.

33

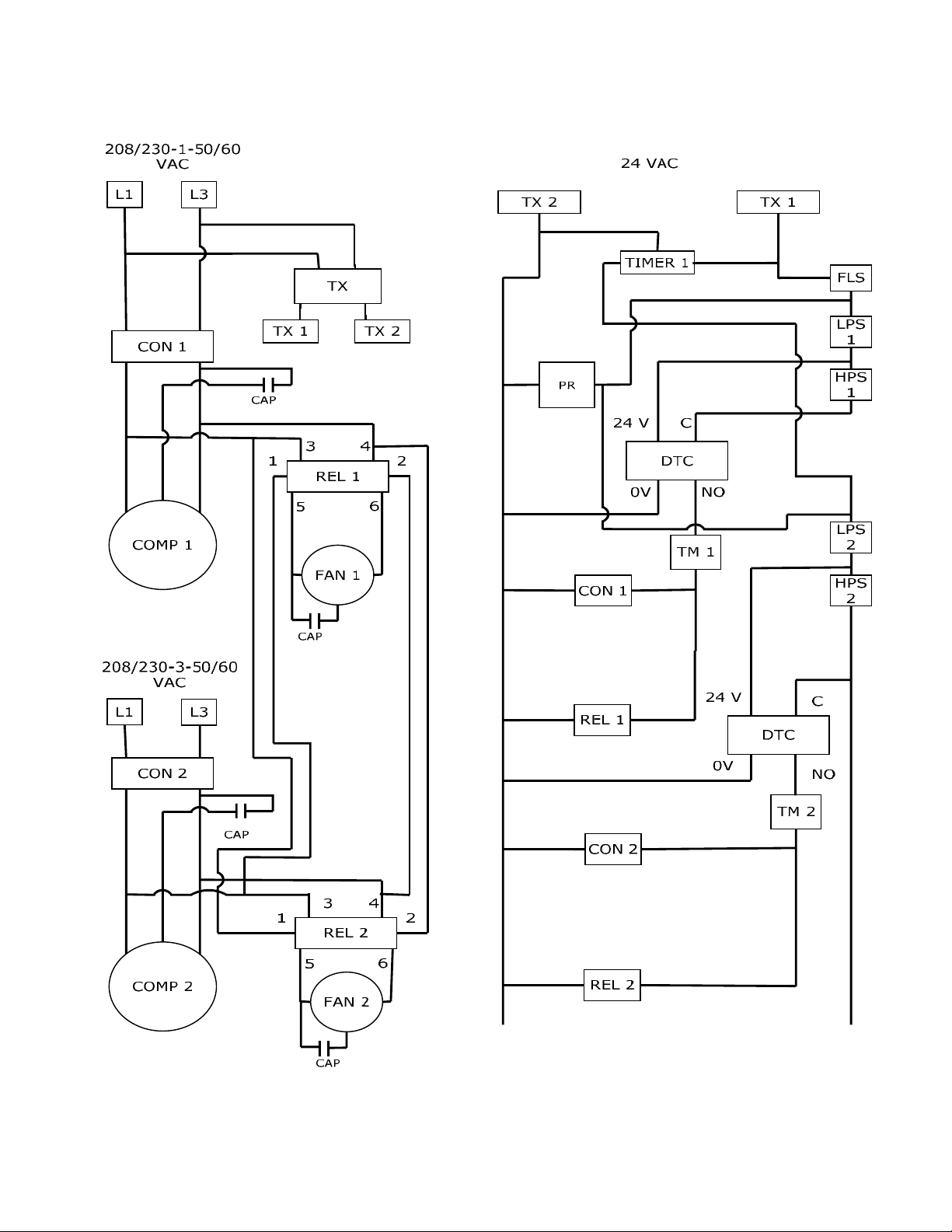

MAC120-3 Ladder Wiring Diagram

380/460-3-50/60

34

MULTIAQUA

380/460-3-50/60

BK

L1

RD

L2

WH

L3

GND

BK

WH

NOTE 1

DTC 1 DTC 2

BL

WH BK

MAC120-3 Wiring Diagram

380/460-3-50/60

BL

BK

BK

T1

RD

CON1`

BKBK

CON2

REL 2REL 1

BL

NONO C C

COM24 vac COM 24 vac

WH

COMP

T2

WH

T3

BK

T1

RD

COMP

T2

WH

T3

BK

BLBL

BK

BK

1

2

FC1

BK

RD

WH

FAN

TRANSFORMER

380/460-3

24 vac

BKBLBK

1

YL

YL

BL

FC2

FAN

RD

FS

BK

BL

BL

1

2

3

BK

4

BK

BK

1

2

3

4

2

LPS1

HPS1

TIMER1

BK

BK

2

TM2

BK

1

BL

LPS2

BK BK

HPS2

BK

2

TM2

BK

1

BKBK

BL

TITLE

AUTHOR

DATE

REVISION

MAC120-03 380/460-3-50/60

kjg

09/22/08

0807300029 REV 1

LEGEND:

FACTORY WIRING

FIELD WIRIN G

DIGITAL T EMPERA TURE CONT ROLLER

DTC

FC

CONDENSER FAN CONTACTOR

REL

CONDENSER FAN RELAY

35

COMPRESSOR CONTACTOR

CON

FLOW SWITCH

FS

LOW PRESSURE SWITCH

LPS

HIGH PRESSURE SWITCH

HPS

TIMER

PUMP BYPASS TIMER

TM2

REFRIG ERANT SYS TEM TIME R

NOTES:

1.PUMP STARTER RELAY

MAC120-3-L with Low Ambient Kit Wiring Diagram

MULTIAQUA

380/460-3-50/60

BK

L1

RD

L2

WH

L3

GND

BK

NOTE 1

FAN CYCLE

PRESSURE

SWITCH

FAN CYCLE

PRESSURE

SWITCH

DTC 1 DTC 2

REL 1

CON1`

CON2

BKBK

REL 2

NONO C C

COM24 vac CO M 24 vac

380/460/-3-50/60

BL

BK

T1

RD

COMP

T2

WH

BK

RD

WH

BK

1

T3

T1

COMP

T2

2

T3

BLBL

BK

BK

FC1

NOTE 2

FAN

TRANSFORMER

380/460-3

24 vac

BKBL

1

31

FC2

YL

YL

BL

1

2

3

4

BK

FAN

2

1 3

4

64 6

NOTE 3

RD

BK

BK

BK

BK

BK

1

2

3

4

BK

BK

FS

BK

BL

BL

LPS1

HPS1

TIMER1

BKBK

2

TM2

1

BL

LPS2

BK BK

HPS2

2

TM2

1

BL

TITLE

AUTHOR

DATE

REVISION

MAC120-03 WITH LOW AMBIENT KIT

kjg

09/22/08

0608400097 REV 1

LEGEND:

FACTORY W IR IN G

FIELD WIRING

DIGITAL TEMPE R ATU R E C ON TR O LLER

DTC

FC

CONDENSER FAN CONTACTOR

REL

CONDENSER FAN RELAY

36

COMPRESSOR CONTACTOR

CON

FLOW S WITCH

FS

LOW PRESSURE SWITCH

LPS

HIGH P R E SSURE SWITCH

HPS

TIMER

PUMP BYPASS TIMER

TM2

REFRIGERANT SYSTEM TIMER

NOTES:

1. PUMP ST A R TE R RELAY

2. LOW AMB IE NT R E LAY #1

3. LOW AMBIE NT RE LAY #2

MAC120-2 Ladder Wiring Diagram

208/230-3-50/60

37

MAC120-2 Wiring Diagram

208/230-3-50/60

38

MAC120-2-L with Low Ambient Kit Wiring Diagram

208/230-3-50/60

39

MAC120-1 Ladder Wiring Diagram

208/230-1-50/60

40

MAC120-1 Wiring Diagram

208/230-1-50/60

41

MAC120-1-L with Low Ambient Kit Wiring Diagram

208/230-1-50/60

42

MAC120 CERTIFIED DRAWING

43

MAC036,048 & 060 Air-Cooled Chiller

Air-Cooled Chillers for Global Residential

and Light Commercial MicroClimates

44

MAC036,048 & 060 NOMENCLATURE BREAKDOWN

MACXXX - XX - X

Accessory

Air-Cooled Chiller

036= 36,0000 BTUH

048= 48,0000 BTUH

060= 60,0000 BTUH

Voltage

01 = 208/230-1-50/60

02 = 208/230-3-50/60

03 = 380/460-3-50/60

Options

N= No Options

L= Low Ambient Kit

Available Model Numbers

MAC036-01-N MAC048-01-N

MAC036-01-L

MAC036-02-N

MAC036-02-L

MAC048-01-L

MAC048-02-N

MAC048-02-L

MAC060-01-N

MAC060-01-L

MAC060-02-N

MAC060-02-L

MAC060-03-N

MAC060-03-L

45

HVAC Guide Specifications

Air-Cooled Liquid Chiller

Nominal Size:

3, 4 & 5 Tons

Multiaqua Model Number:

MAC036-01-N-407, MAC036-01-L-407: MAC036-02-N-407, MAC036-02-L-407,

MAC048-01-N-407, MAC048-01-L-407: MAC048-02-N-407, MAC048-02-L-407,

MAC060-01-N-407, MAC060-01-L-407, MAC060-02-N-407, MAC060-02-L-407,

Part 1-General

1.01 System Description

Multiaqua air-cooled liquid chillers are designed using scroll compressors, low sound condenser fans and high

efficiency pumps.

1.02 Quality Assurance

A. Certified in accordance with U.L. Standard 95, latest version (U.S.A.)

B. Construction shall comply with ASHRAE 15 Safety Code, NEC and ASME applicable codes. (U.S.A.

Codes)

C. Manufactured in a facility registered to ISO 9002, Manufacturing Quality Standard.

D. ETL Certified

E. Fully load tested at the factory.

F. Damage resistant packaging.

1.03 Delivery, Storage and Handling

A. Packaged and readied for shipment from the factory.

B. Controls shall be capable of withstanding 150°F storage temperatures in the control compartment.

C. Stored and handled per manufacturer’s rec o mmendations.

Part 2-Product

2.01 Equipment

A. General:

1. Unit shall be a factory assembled and tested air-cooled liquid chiller.

2. Shall be assembled on heavy gauge steel mounting/lifting rails.

3. Contained within the unit cabinet shall be all factory wiring, piping, controls, refrigerant charge

(R407c), POE oil and special accessories required prior to start up.

4. Brass body strainer with 20 mesh screen and blow down shall be supplied in cabinet as a

field installable accessory.

B. Unit Cabinet:

1. Composed of heavy gauge galvanized steel casing with a baked polyester powder.

2. Capable of withstanding 500-hour salt spray test in accordance with the ASTM (USA) standard.

C. Condenser Fans:

1. 4-blade, aluminum construction and shall be dynamically balanced and corrosion resistant.

2. Horizontal discharged air.

3. Motors and blades shall be protected by coated steel wire safety guards.

D. Fan Motors:

1. Condenser fan motors shall be single speed, direct drive.

2. Totally enclosed.

3. Permanently lubricated sleeve bearings and Class F insulation.

4.

Internal overload protection.

E. Compressors:

1. Unit shall contain one fully hermetic scroll compressors.

2. Direct-drive, 3500 rpm (60Hz)

3. Compressor motor shall be suction gas cooled.

4. Internal motor protection.

5. Externally protected by low and high pressure cutout devices.

6. Individual vibration isolators .

46

F. Pump:

1. Circulating pump shall be stainless steel with high efficiency enclosed motor.

2. Unit shall have chilled liquid solution piping to the exterior of the cabinet.

G. Evaporator:

1. Evaporator shall have one independent refrigerant circuit and one liquid solution circuit.

2. Rated for a refrigerant side working pressure of 450 psig and a maximum water side working

pressure of 150 psig.

3. Single pass, ANSI type 316 stainless steel, brazed plate construction.

4. Externally insulated with closed cell, elastomeric foam. (ASTM518)

H. Condenser:

1. Condenser coil shall be air-cooled with integral subcooler.

2. One independent refrigerant circuit.

3. Constructed of rifled copper tubing mechanically bonded to aluminum fins.

4. Cleaned and dehydrated.

5. Factory leak tested to 450 psig.

I. Refrigerant Circuits:

1. Each circuit shall contain a sight glass, liquid line filter, thermal expansion valve,

refrigerant charge of R407c and POE compressor oil.

Part 3-Controls and Safeties

3.01 Controls

A. Chiller shall be completely factory wired and tested.

B. Capacity control shall be based on leaving chilled liquid solution temperature.

1. Temperature accuracy shall be + - 1.0°F.

2. Controls shall be capable of staging the two compressors.

C. Controls shall include the following components.

1. 24vac transformer to serve all controllers relays and control components.

2. Microprocessor based liquid solution temperature controller.

3. Leaving water temperature thermistor.

4. Pump bypass timer.

5. Compressor recycle timer.

6. Optional low pressure bypass timer for low ambient operation.

7. Optional fan cycling control for low ambient operation.

8. Chilled liquid solution flow switch.

3

.02 Safeties

A. Unit shall be equipped with thermistors and all necessary components in conjunction with the

control system to provide the following protectants.

1. Low refrigerant pressure.

2. High refrigerant pressure.

3. Low chilled liquid solution temperature.

4. Low chilled liquid solution flow.

5. Thermal overload.

6. Short cycling.

Part 4-Operating Characteristics:

4.01 Temperatures

A. Unit shall be capable of starting and running at outdoor temperatures from 55°F to 120°F.

B. Optional Low Ambient Kit shall allow starting and running at outdoor temperatures to -20°F. A