Page 1

Rev. 1.2

Page 2

INSTALLATION & OPERATING

MANUAL

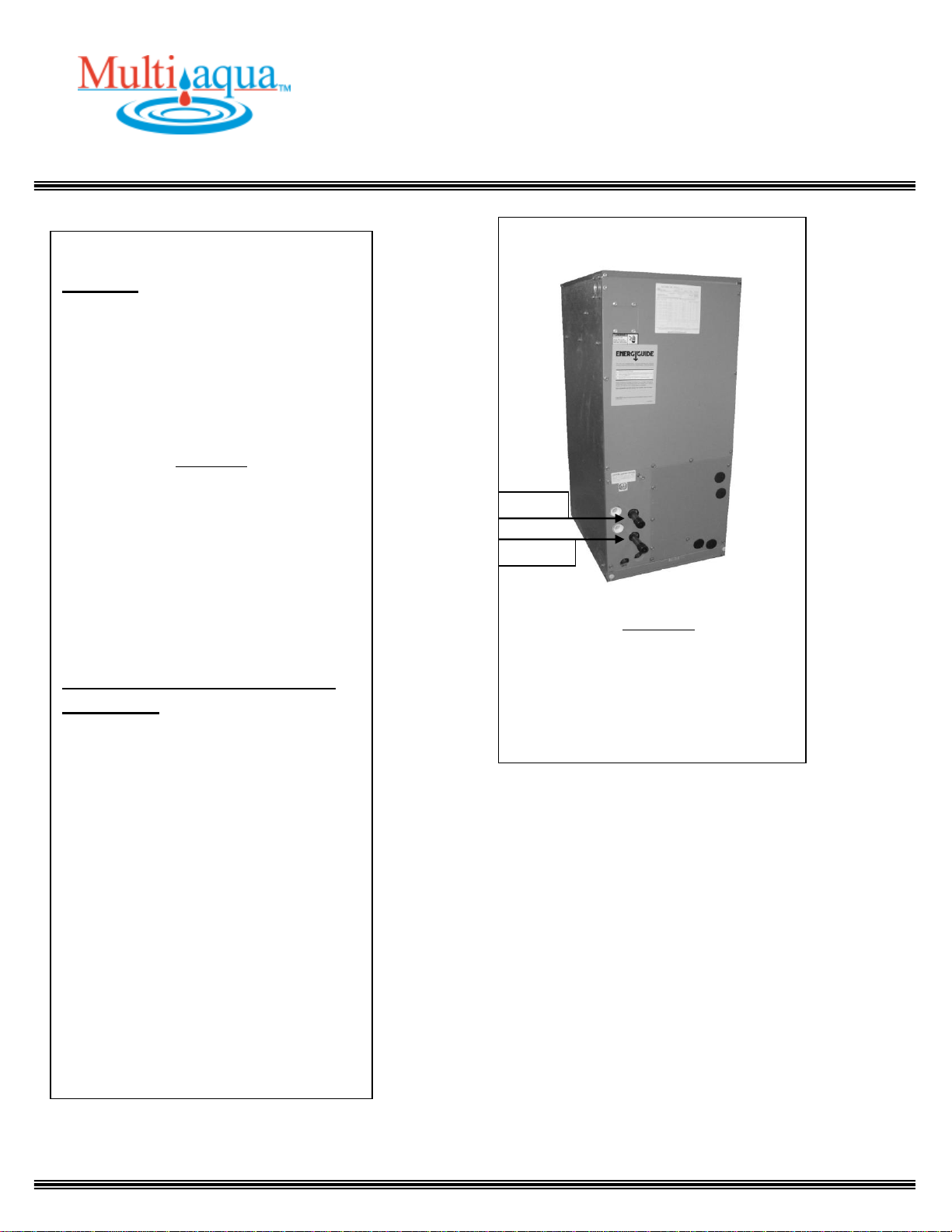

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

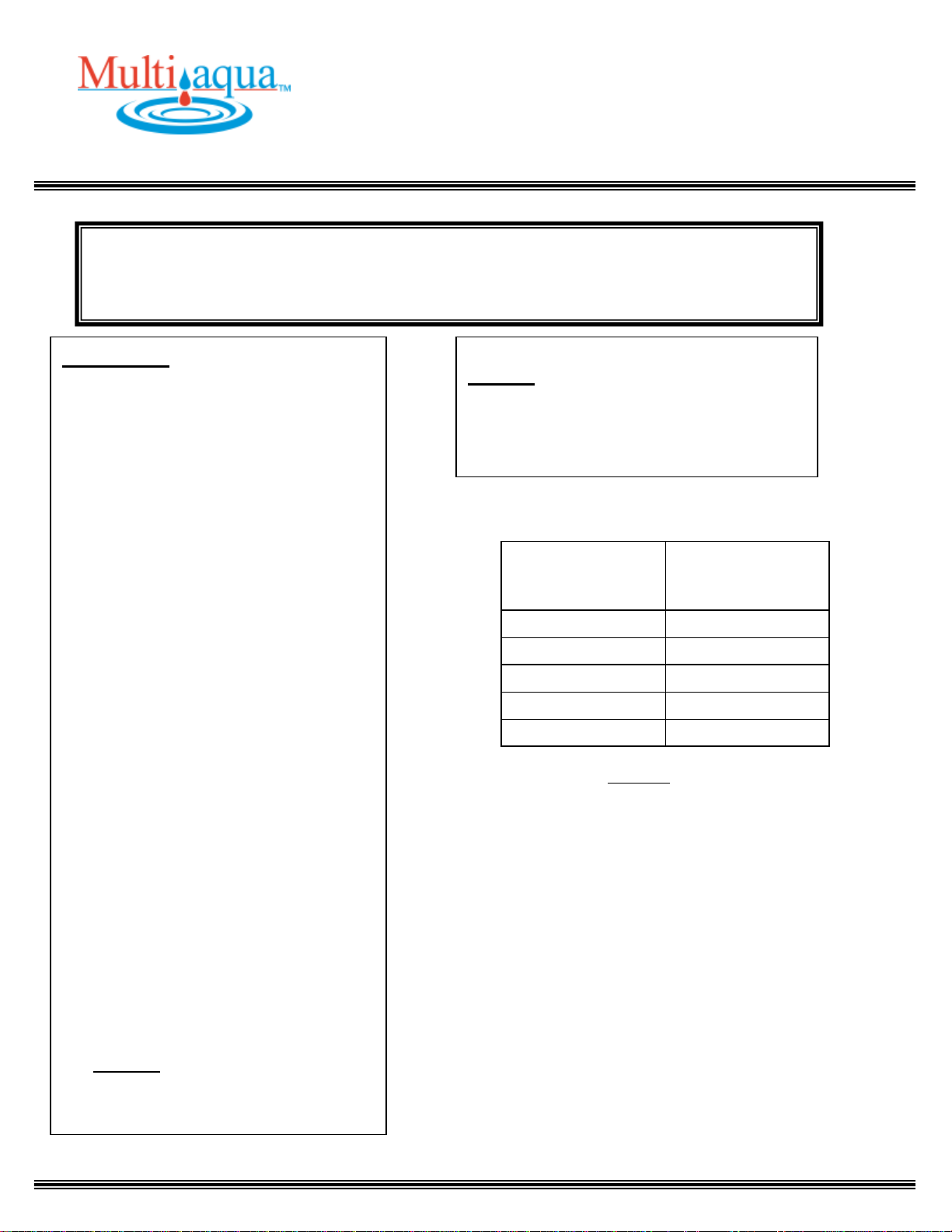

FAN COIL

APPROXIMATED

WEIGHTS (lbs.)

MODEL

NUMBER

18CWA2-00

118

24CWA2-00

118

36CWA2-00

145

48CWA2-00

170

60CWA2-00

180

GENERAL

Read the entire contents of this manual

before beginning installation. Multiaqua

assumes no responsibility for equipment

installed contradictory to any code

requirement or installation instructions.

The components of this fan coil have

been inspected at the factory and readied

for shipment. Upon receiving the

shipment a visual inspection of the

packaging must be performed.

If any damage to the packaging is

discovered, an inspection of the

components must be performed and

noted on the delivery documents. If

component damage is found a damage

claim must be filed by the receiving party

against the delivery party immediately.

This product is designed and

manufactured to permit installation in

accordance with national codes. It is the

installer’s responsibility to install the

product in accordance with national

codes and/or prevailing local codes and

regulations.

Care must be taken to ensure the

structural integrity of the supporting

members, clearances and provisions for

servicing, power supply, coil connections

and/or condensate removal. Before the

installation ensure the structural strength

of the supporting members is sufficient.

See Figure 1 for hanging weights of the

fan coils.

This unit is designed to be installed in a

-------------------------------------- CAUTION --------------------------------------

Care must be taken when handling sheet metal. Sheet metal parts have sharp edges and could

cause injury.

vertical or horizontal configuration. See

Figure 2 for fan coil only dimensions.

The coil hand of connection is field

reversible.

Figure 1

2

Page 3

INSTALLATION & OPERATING

MANUAL

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

Physical Dimensions (inches)

Model Number

A B C D E

18CWA2-00

17.50

21.00

39.75

12.50

16.00

24CWA2-00

17.50

21.00

39.75

12.50

16.00

36CWA2-00

17.50

21.00

39.75

12.50

16.00

48CWA2-00

21.50

25.00

49.75

17.25

19.50

60CWA2-00

21.50

25.00

49.75

17.25

19.50

A B C E D

Figure 2

3

Page 4

INSTALLATION & OPERATING

MANUAL

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

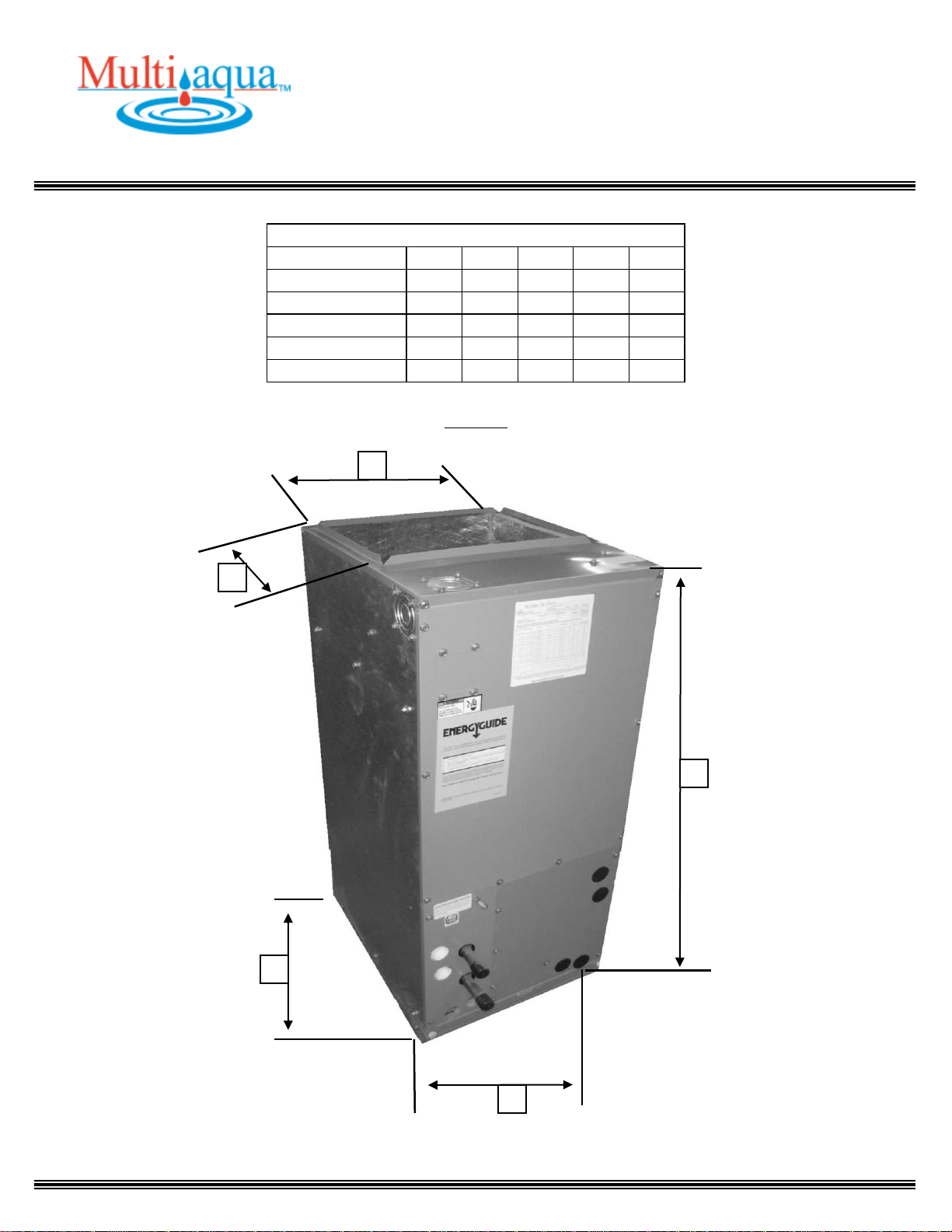

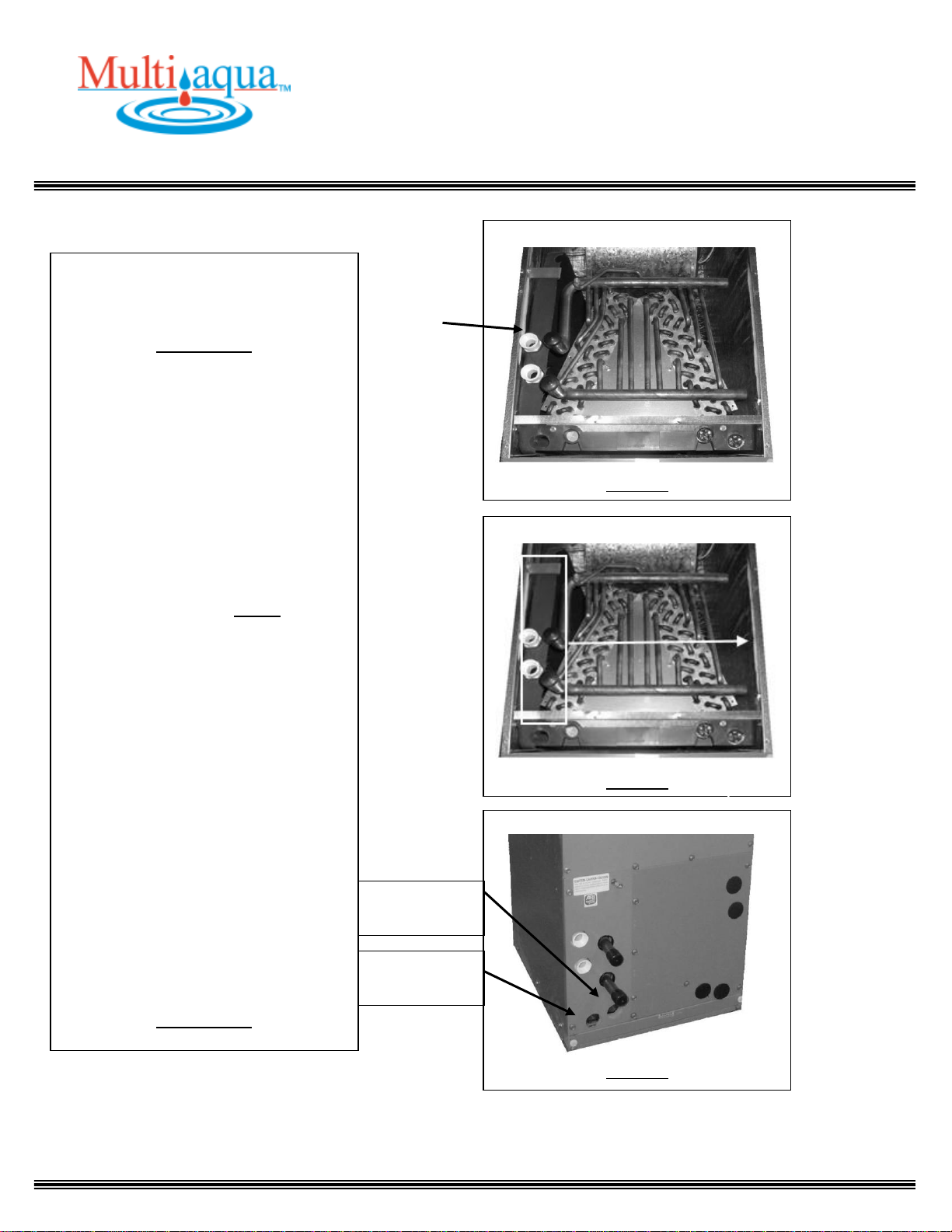

Figure 3

Figure 4

-------- CAUTION -------

Care must be taken when

handling sheet metal. Sheet

metal parts have sharp edges

and could cause injury.

INSTRUCTIONS FOR

INSTALLING FAN COIL

The CWA2 is a chilled water fan

coil with optional electric heat is

designed for multi-position

applications in closets, attics or

basements or crawl spaces. They

are field convertible to horizontal

applications without the need for

additional parts. Unit is not suitable

for down flow applications.

Figure 3 & 4

CONVERTING FAN COIL

TO RIGHT HAND

DISCHARGE

The CWA2 fan coil comes shipped

from the factory assembled with a

left hand air discharge

configuration.

Figure 4

1. To convert the fan coil to right

hand discharge remove the three

front panels.

2. Remove the three screws from

the coil mounting brackets and pull

entire A-coil assembly out of the

fan coil.

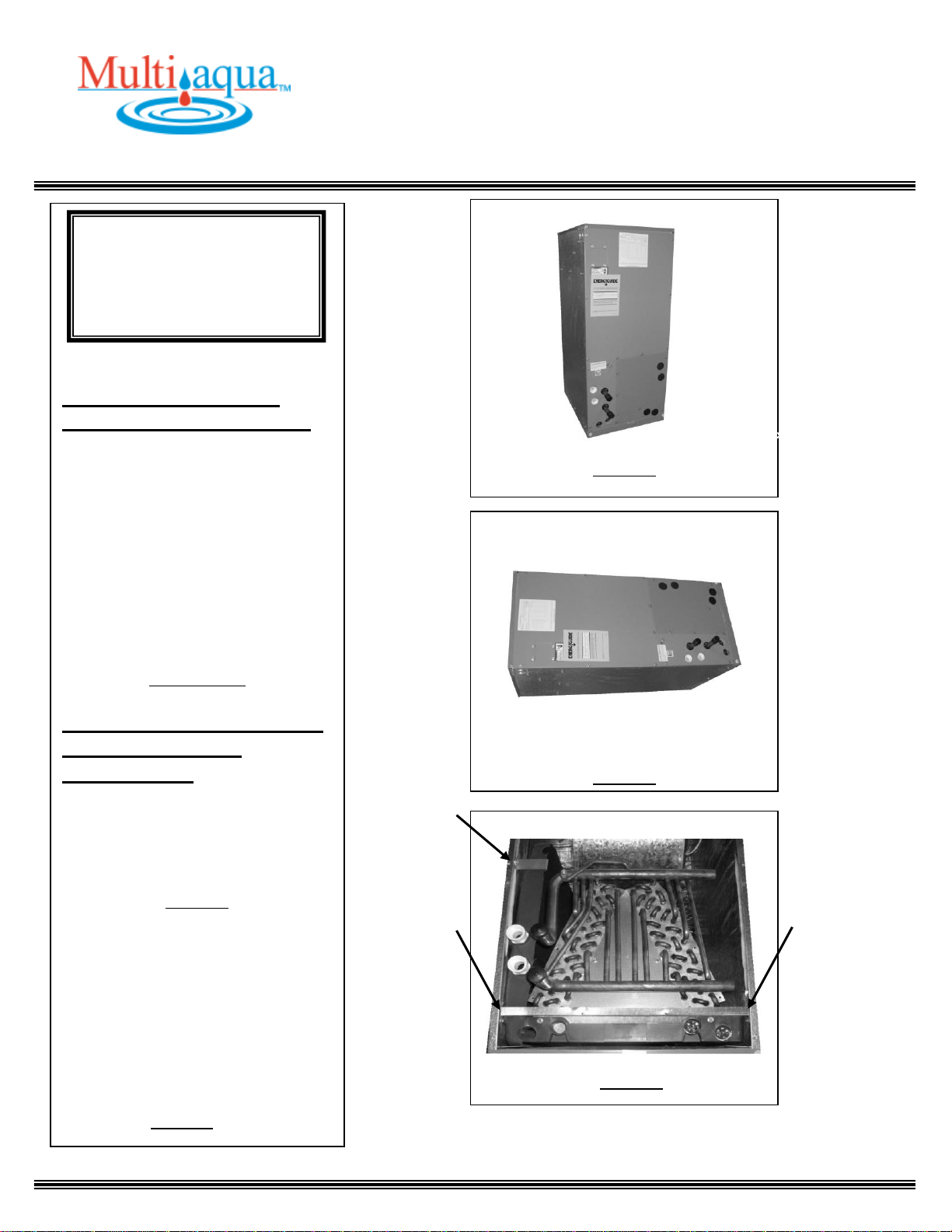

Figure 5

Figure 5

4

Page 5

INSTALLATION & OPERATING

MANUAL

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

Figure 6

UP FLOW DISCHARGE

Figure 8

Figure 7

3. Remove the horizontal drain pan

from the coil and re-install it on the

other side.

Figure 6 & 7

4. Ensure the coil mounting brackets

are secure in order to avoid coil

misplacement inside the cabinet.

Check coil slope to make sure that

the drain pan slopes toward the drain

outlet. An incorrectly installed coil

could result in damages to the fan

coil and property.

5. Re-install the three front panels

previously removed in step 1.

6. The unit shall be suitable for 0”

clearance to combustible materials.

Sufficient clearance must be provided

at the front of the fan coil to allow

access for maintenance and servicing.

7. The fan coil comes with one

primary and one secondary

condensate drain connection per

configuration. Ensure when

connecting the field installed

condensate drain lines, the lower of

the two fan coil drain connections is

piped into the buildings condensate

removal method.

Figure 8 & 9

PRIMARY

DRAIN

SECONDARY

DRAIN

5

Page 6

INSTALLATION & OPERATING

MANUAL

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

Figure 10

Figure 11

HORIZONTAL DISCHARGE

Figure 9

8. The “A” coil includes an L-shaped

piece of sheet metal with one leg of

the L covering the top length of one

coil slab; the other leg is

between/inside the two slabs.

Figure 10

When converting the unit to righthand horizontal discharge, the Lshaped piece of sheet metal should be

removed, re-positioned and installed

so that it covers the length of the top

coil slab. This will force any

condensate on the end of the top coil

slab to run down the inside leg before

dripping onto the lower slab. This

will also help to prevent any possible

condensate water blow off.

Figure 11

SECONDARY

DRAIN

PRIMARY

DRAIN

6

Page 7

INSTALLATION & OPERATING

MANUAL

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

Figure 12

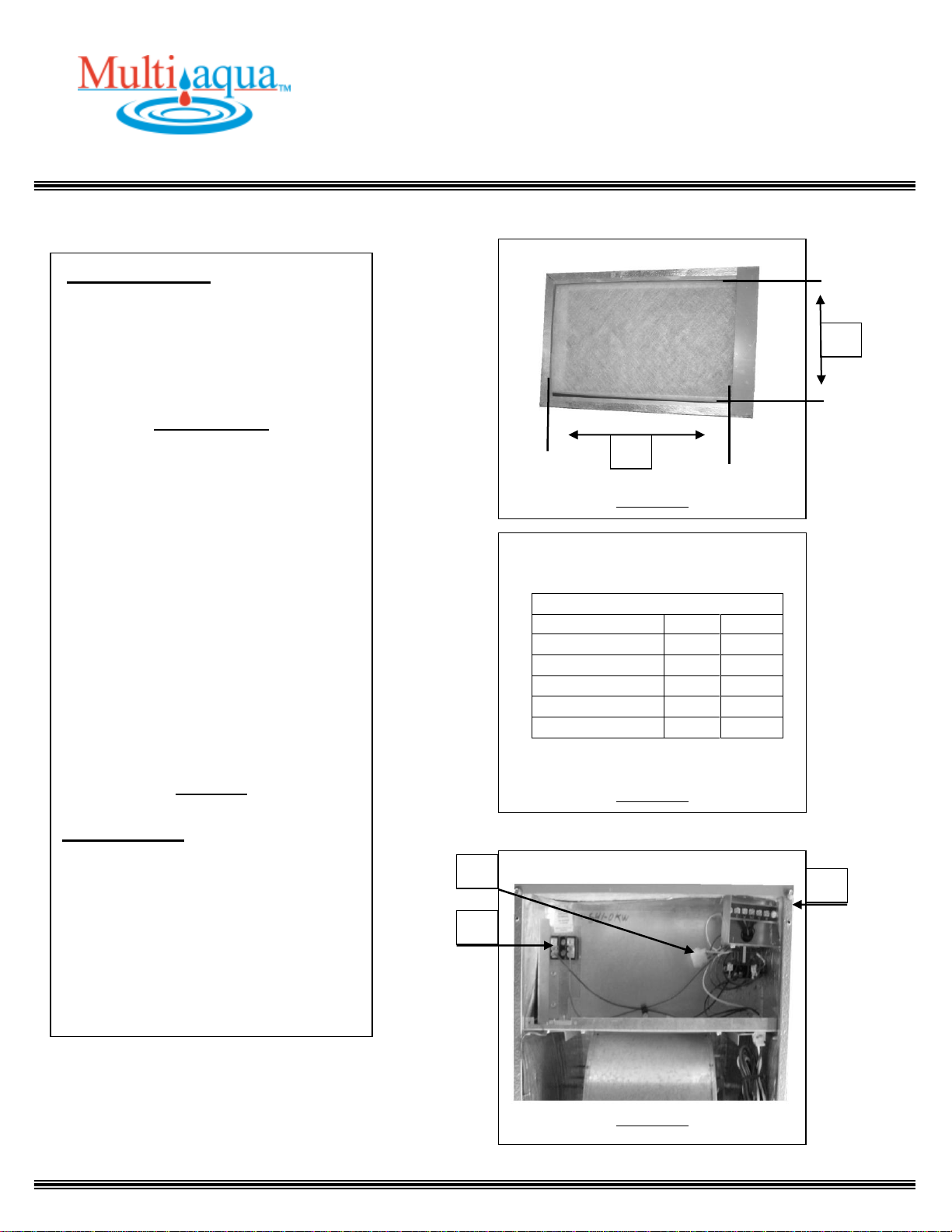

CWA2 Inlet Air Dimensions

A

B

18CWA2-00

15

17.5

24CWA2-00

15

17.5

36CWA2-00

15

17.5

48CWA2-00

19.25

22.25

60CWA2-00

19.25

22.25

Dimensions are in inches

Figure 13

Figure 14

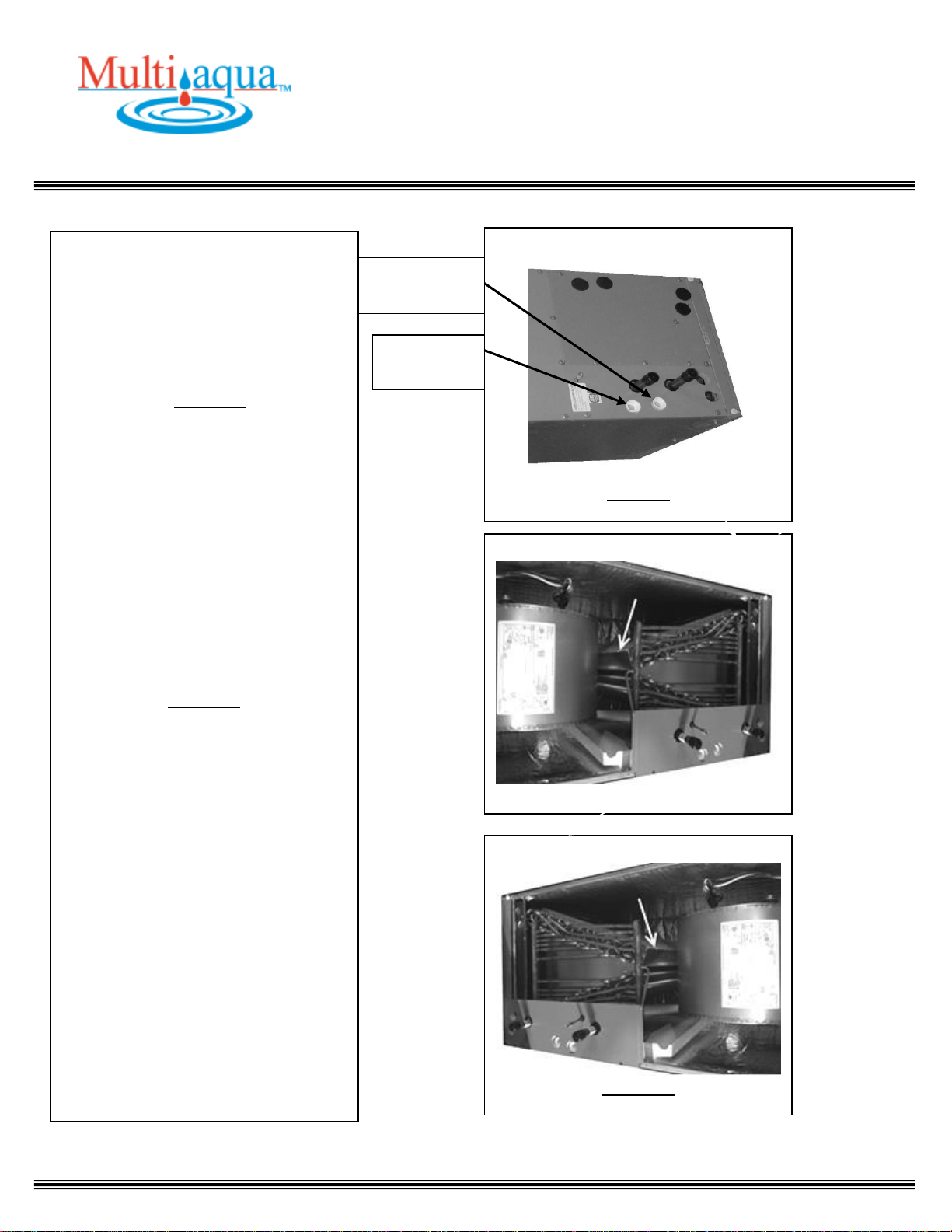

ELECTRICAL

9. All duct work must be installed per

local and national codes. The return air

duct and the return air opening

provided in the fan coil must have the

same area.

Figure 12 & 13

All wiring must comply with local and

national codes. High and low voltage

terminal blocks are provided. An

electrical plug is provided for the field

installation of electric heat packages.

Knockouts are provided in the cabinet

for field wiring of the electrical. See

page 8 for electric heat package

installation instructions.

A = High Voltage terminal block.

B = Electric Heat Package Connection

Plug.

C = Low Voltage Terminal Block.

Figure 14

CONTROLS

A 24 VAC transformer, fan relay and

electric heat sequencer are provided

inside cabinet. All supplied controls are

wired onto the low voltage terminal

block.

B

A

A C B

7

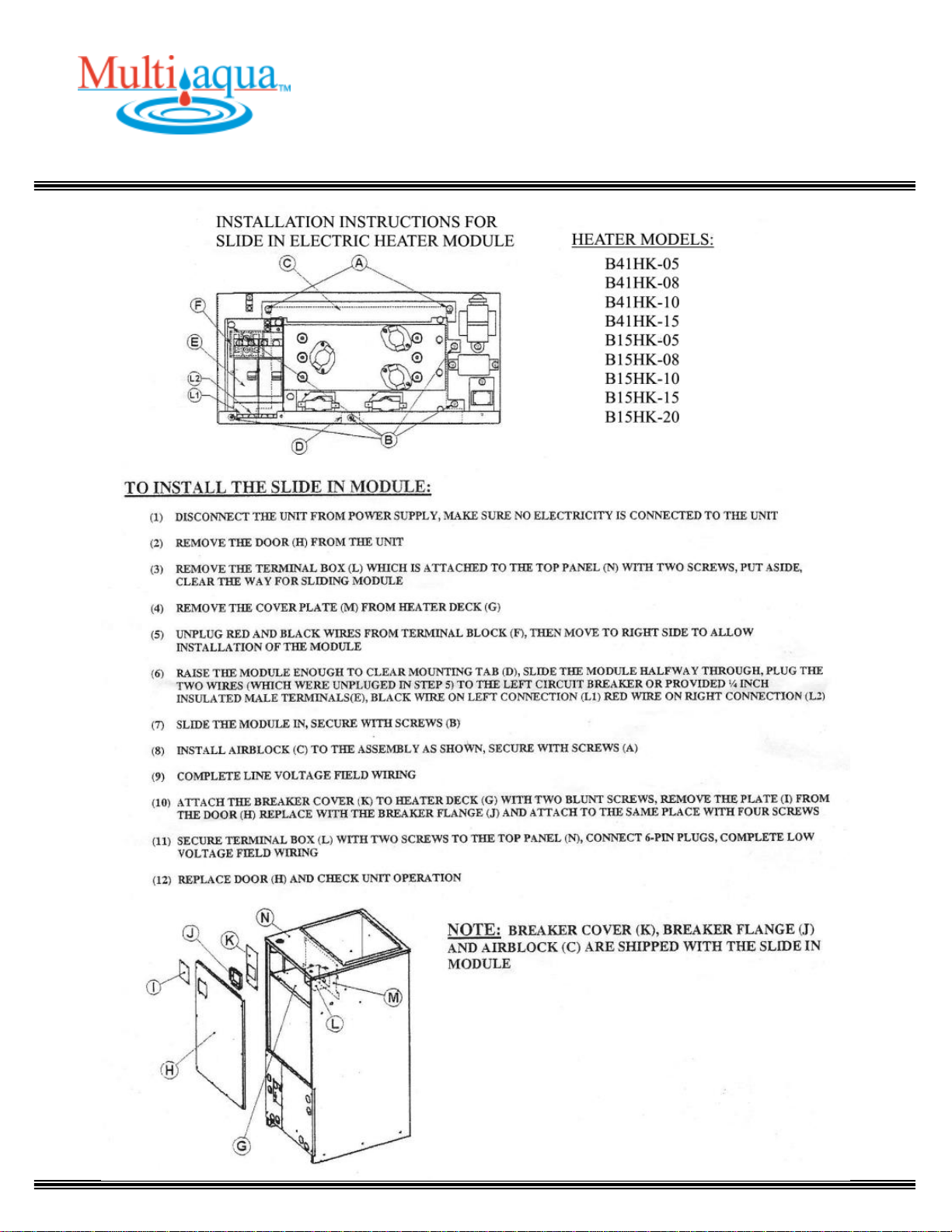

Page 8

INSTALLATION & OPERATING

MANUAL

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

8

Page 9

INSTALLATION & OPERATING

MANUAL

CWA2 Chilled Water Air Handler with Electric Heat

18,000 – 60,000 BTUH

Figure 15

PIPING

10. This fan coil is supplied with one

water coil that can be used for chilled

and/or hot water. The coil has one

dedicated water inlet and outlet. Ensure

that both lines are insulated according

to local and national building codes.

Figure 15

11. Condensate drains must be installed

with at least .25” of slope per foot away

from the fan coil. Since the drain pan is

located on the suction side of the

blower, a minimum trap of 1.5” must

be installed in the drain line for proper

drainage.

ROUTINE CHECK UP AND

SERVICE

This product is designed to provide

many years of dependable, trouble free

comfort when properly maintained.

Proper maintenance will consist of

routine filter cleanings/changes, biannual check-ups that include but not

limited to filter inspections, electric

heater inspections /cleaning of the

internal electrical and heat transfer

components by a qualified service

technician. Failure to provide periodic

check-ups and cleaning can result in

excessive operating cost and/or

equipment failure.

INLET

OUTLET

9

Loading...

Loading...