MTW Create Assembly Manual

MTW Create

Assembly Guide

1 — Last update: 2016/09/20

Maker's Tool Works

Table of Contents

3D PDF And how to view it......................................................................................................................... 2

Install the Z Rails........................................................................................................................................ 3

Assembling the Base ................................................................................................................................. 7

Assembling the Y Axis ............................................................................................................................. 12

Assembling the X Axis ............................................................................................................................. 18

Assembling the OctoPi LCD .................................................................................................................... 24

Assemble the Top Deck plates ................................................................................................................ 26

Install the Y Axis & Top Deck Plates ....................................................................................................... 31

Assembling the Y Carriage ...................................................................................................................... 36

Installing the X Axis ................................................................................................................................. 40

Installing the Lead Screws....................................................................................................................... 44

Installing the X Carriage .......................................................................................................................... 49

Extruder Assembly and Installation ........................................................................................................ 52

Hotend Assembly and Installation........................................................................................................... 57

Installing the ABL Sensor ........................................................................................................................ 65

Installing the Fans and Endstops ............................................................................................................ 68

Tightening the belts ................................................................................................................................. 73

Installing the Glass and Bed Heater ........................................................................................................ 75

Wiring........................................................................................................................................................ 77

External Wire Management ................................................................................................................... 78

IEC, PSU and LED................................................................................................................................ 81

RAMBo – Connecting steppers ............................................................................................................. 88

RAMBo – Connecting Endstops, ABL and Thermistors.......................................................................... 91

RAMBo – Connecting Heaters............................................................................................................... 94

RAMBo – Connecting Fans ................................................................................................................... 96

USB and testing .................................................................................................................................... 98

Spool Holder........................................................................................................................................... 100

Downloads .............................................................................................................................................. 101

Drivers and Firmware.......................................................................................................................... 102

Software ............................................................................................................................................. 109

STL Files ............................................................................................................................................ 110

Configuring WiFi on your MTW Create.................................................................................................. 111

Bringing your MTW Create online ......................................................................................................... 115

Powering Up and Testing .................................................................................................................... 116

Applying 3D Eeez ............................................................................................................................... 121

Calibrating your Auto Bed Leveling Sensor ......................................................................................... 123

Starting your first Print ........................................................................................................................ 130

Bringing Online without OctoPi............................................................................................................ 134

Dual Extruder Supplement..................................................................................................................... 143

Step 1 – Hardware Changes ............................................................................................................... 144

Step 3 – Software Setup ..................................................................................................................... 145

Step 3 – Offset Fine Tuning ................................................................................................................ 147

Troubleshooting ..................................................................................................................................... 149

Maker's Tool Works MTW Create Assembly Guide - 1

3D PDF And how to view it.

We make extensive use of 3D PDF files to help you visualize how the printer is suppose to go together. 3D

PDFs let you pan, zoom and rotate the model, as well as hide and show individual parts or assemblies in

the model to easier understand what is going on.

3d PDF is an Open file format, but unfortunately it is not as well supported as the standard PDF file format.

In particular, most PDF Browser plugins will not properly display them.

The Genuine Adobe Acrobat Reader is one excellent choice, but there are a variety of viewers available for

all platforms. If you Google for “3d PDF Viewer” you should be able to find an option that you like.

>>>>>>MTW Create 3D PDF Link<<<<<<

Page 2 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Install the Z Rails

Install the Top Caps

Parts required.

• 2 – 450mm Extrusions

• 2 – Top Cap Plate

• 4 – M5 × 8 SHCS

• 4 – M5 Washer

1. One end of each 450 mm extrusion is tapped. Install each Top Cap Plate using 2 each M5 × 8 SHCS

and M5 Washer onto the tapped end of the extrusion..

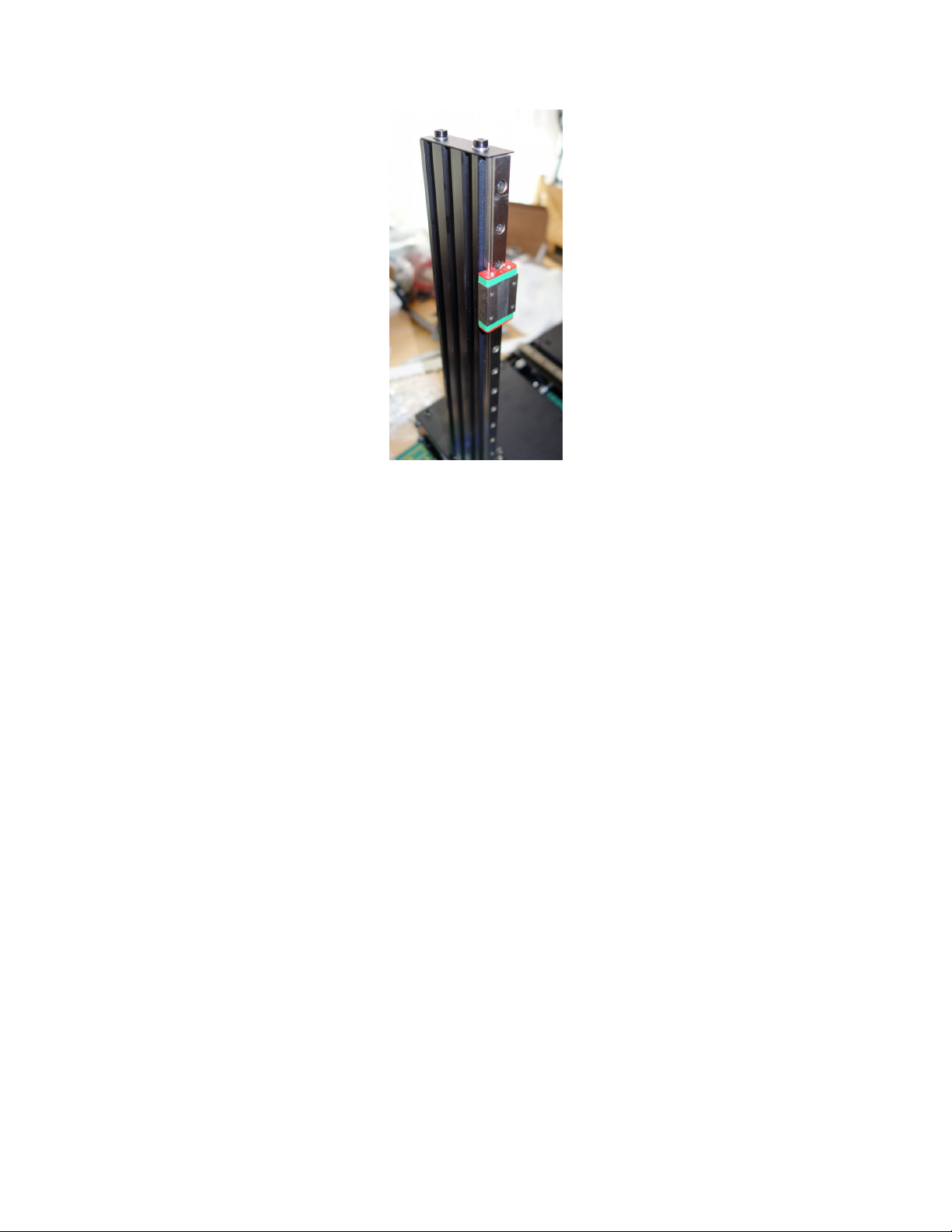

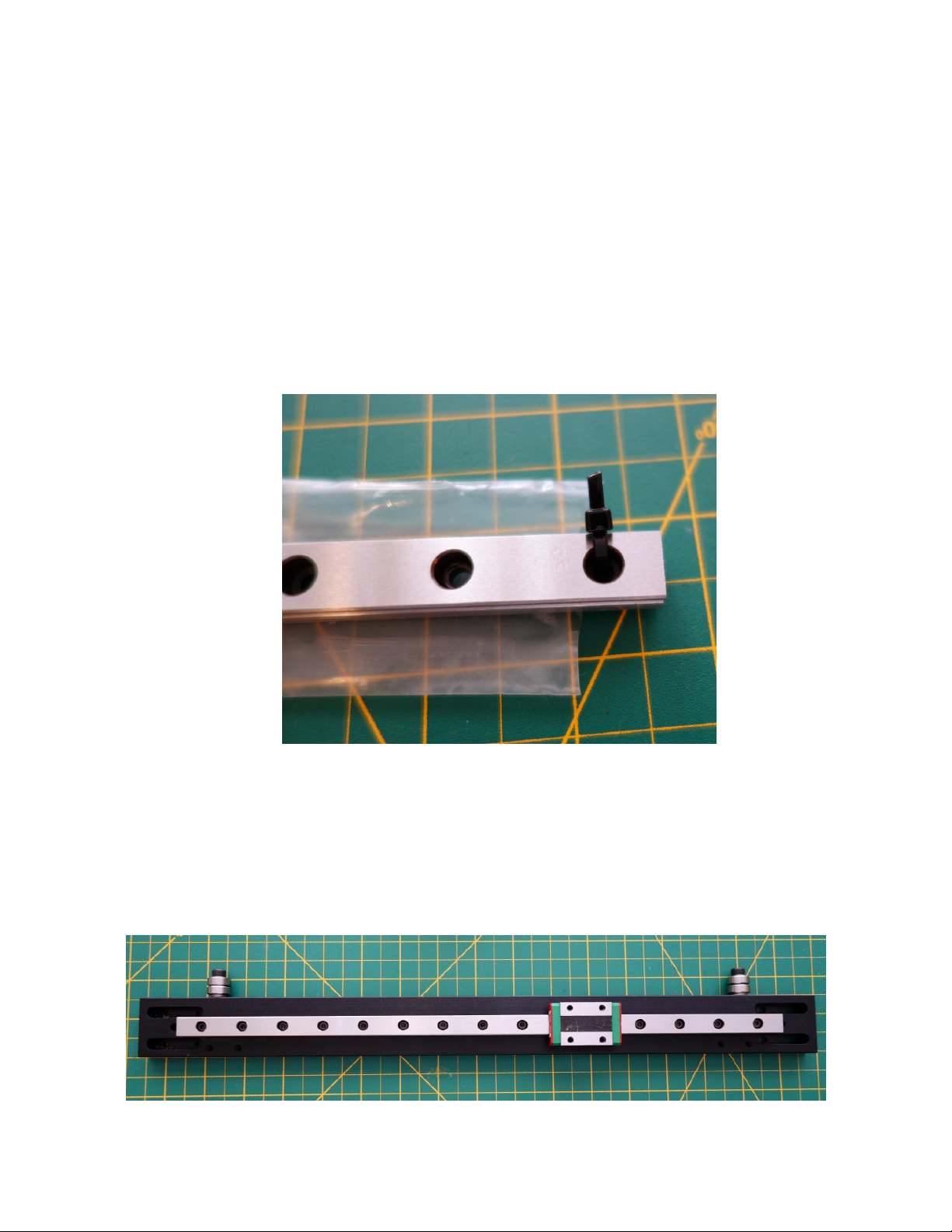

Installing the Z Linear Rails

Parts Required

• 2 – 380mm Linear Rails

• 2 – Rail Spacer Plates

• 30 – M3 × 10 SHCS

• 30 – M3 Post Install Nut

• 3 – Nut Alignment Jigs

2. Install 15 M3 Post Install Nuts in each vertical extrusion and use the Nut Alignment Jig (the jigs are

12mm wide, and the color may differ from the pictured below) to properly set their spacing. As you

add additional nuts, remove the first jig and place it after the last nut until you have added 15 screws

per side. Be sure to install the nuts on the same side of the extrusion as the longer end of the

top cap.

Page 3 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

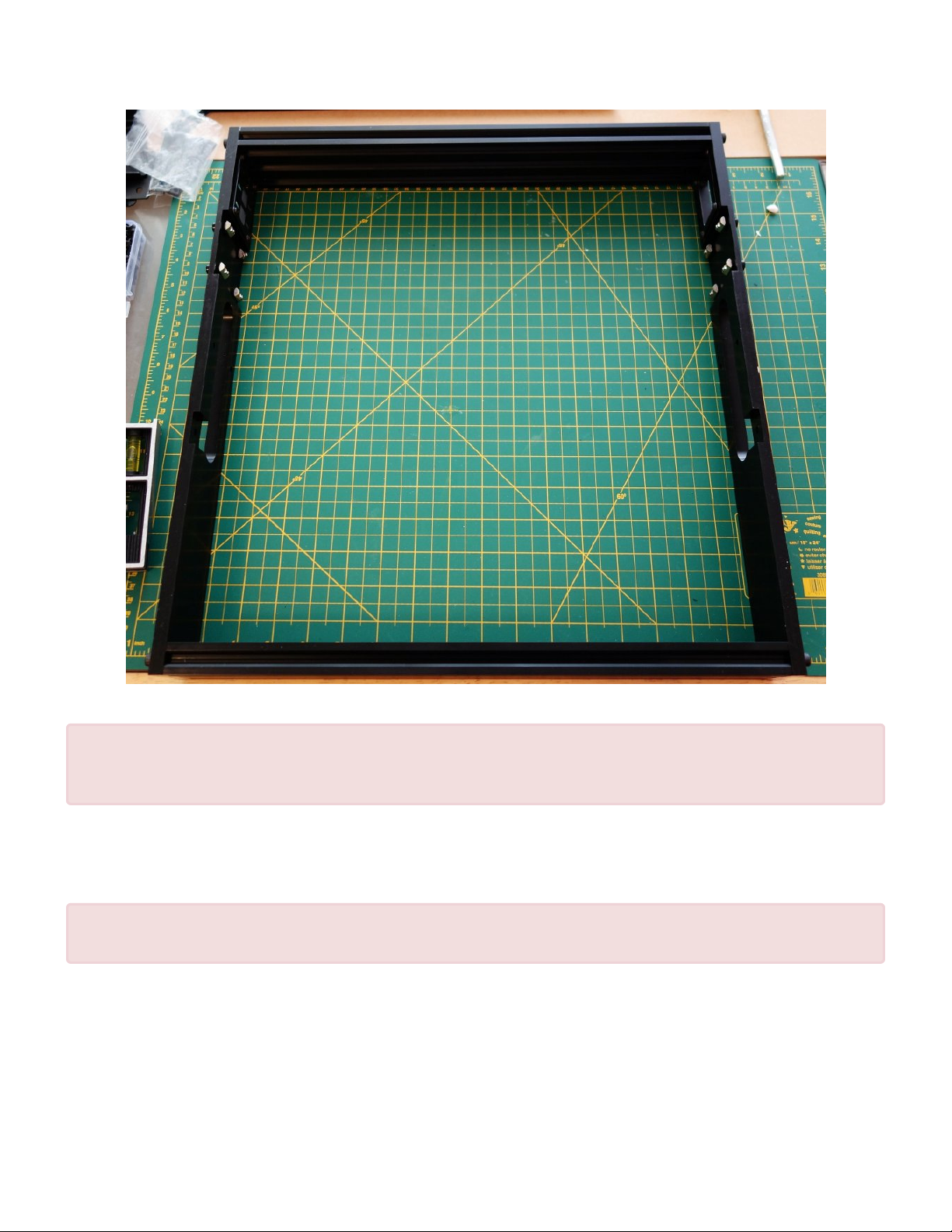

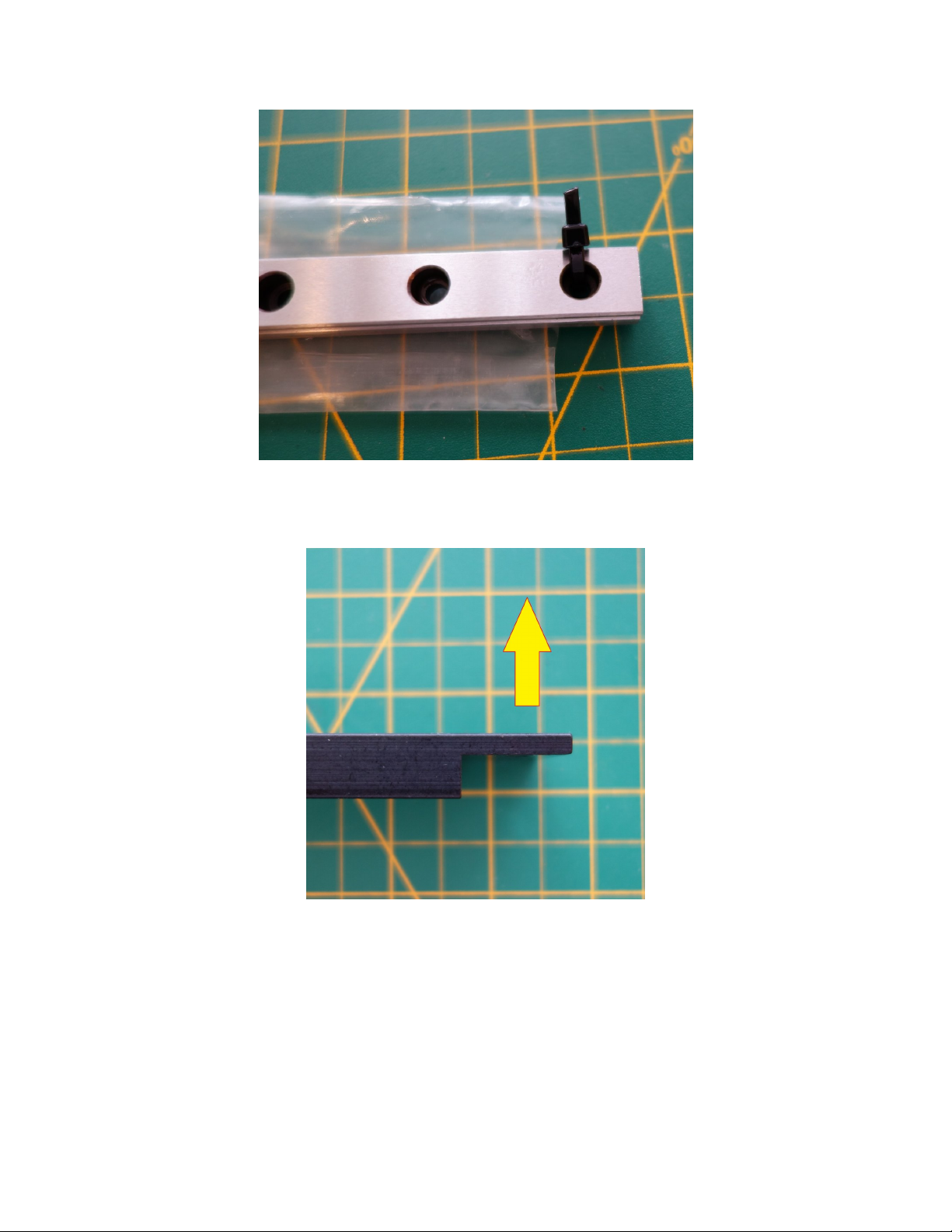

Be sure all the nuts are inserted in the same orientation or the spacing will be incorrect. For

easiest insertion, insert the end with the spring ball into the slot first as shown below

*

Use caution removing the rail from the bag. Do not allow the block to come off the rail.

!

A couple small strong magnets placed on each end of the rail can keep the blocks from

sliding off.

1. DO NOT REMOVE THE BLOCKS. They are not designed to be removed from the rail.

We highly recommend using Blue Loctite on the screws in the following steps

*

2. Install each of the 380mm Linear Rails, with the Rail Spacer Plate sandwiched between the

extrusions and the Rails. Leave the screws slightly loose.

Page 4 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Note that the rail spacer plate (Shown below) is important. It is easy to miss in the photo

!

above. Note, the plate may have 3 slots or 5, but either function identically.

3. Slide the rails up so that the top edge of the rail is flush with the bottom of the Top Cap Plate.

Page 5 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

4. Tighten the screws holding the rails.

Page 6 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

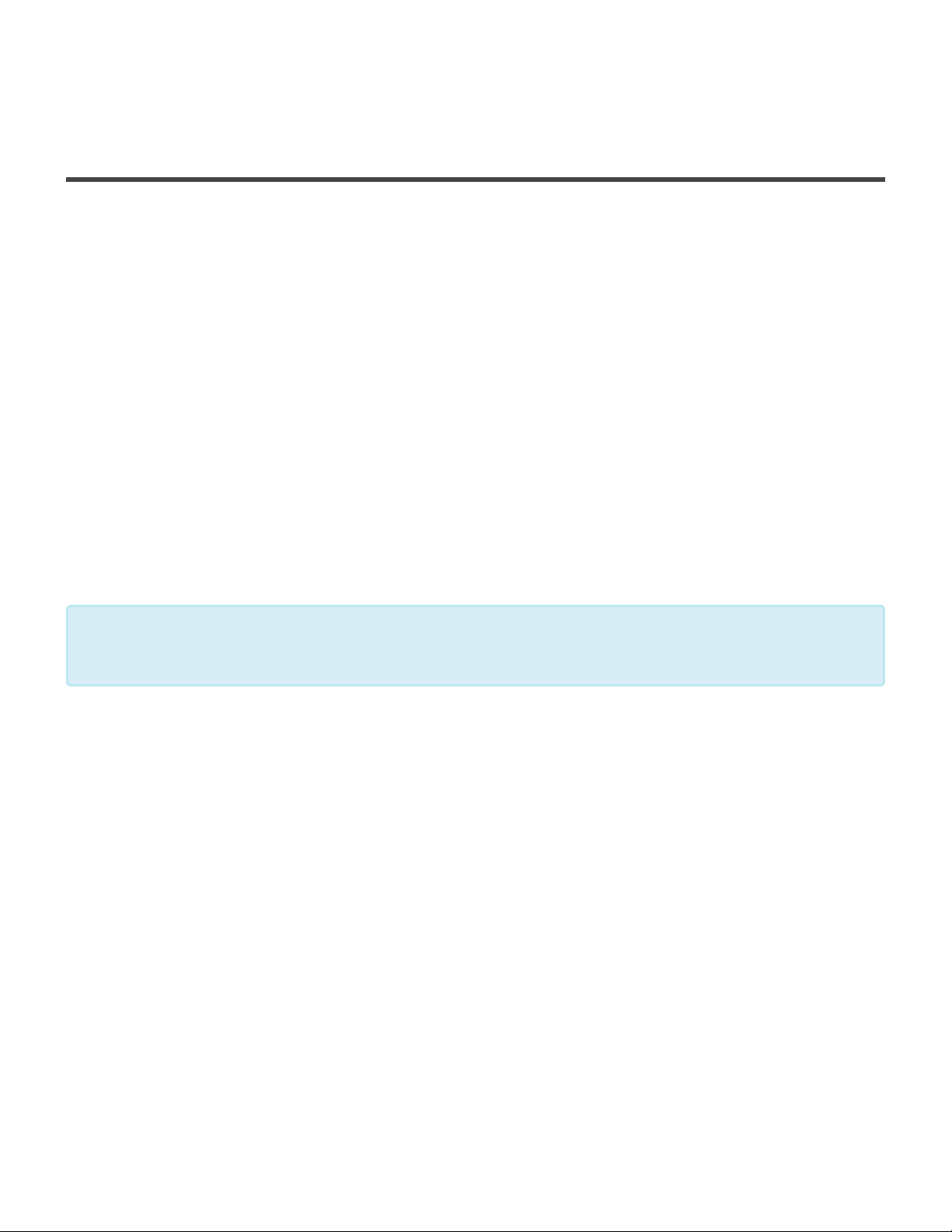

Assembling the Base

Parts Required:

• 2 – 400mm Extrusions

• 2 – 450mm Extrusions with Z Rails pre-installed

• 2 – Machined Side Plates

• 1 – USB Adapter Plate

• 1 – IEC Adapter Plate

• 8 – M3 × 6 BHCS

• 8+ – M3 Washers

• 8 – M5 × 10 SHCS

• 8 – M5 × 16 SHCS

• 8 – M5 Washers

• 4 – M3 Post Install Nuts

• 4 – M3 × 10 SHCS

• 4 – Rubber Feet

The Machined Side Plates have a notch on one edge near the handle, that notch designates

the top of the base.

*

1. Install the USB Adapter Plate onto the Left Machined Side Plate using 4 M3 × 6 BHCS with one or

more M3 Washers as needed.

2. Repeat the last step with the IEC Adapter Plate on the Right Machined Side Plate.

Page 7 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

3. Loosely assemble the side plates to the 400mm extrusions using 8 M5 × 16 SHCSs and 8 M5

Washers. Do not tighten the screws yet.

Page 8 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

The following step needs to be completed on a known flat surface. A granite or formica

!

countertop is ideal, or flat, non-carpeted floor will work in a pinch.

4. Sit the assembled base upside down (Machined Side Plate notch down) on a known flat surface and

tighten the screws holding the assembly, then flip the assembled base back up.

Only one end of the 450mm extrusions is tapped. Be sure to orient that end to the top.

!

5. Install the two uprights using 4 M5 × 10 SHCS, 4 M5 Washer and 4 M5 Post Install Nut each. Align

each extrusion so it is flush with the bottom of the Machined Side Plate and is pressed against the

forward edge of the cutout in the MSP to maintain proper vertical alignment.. Be sure the tapped end

of the 450mm extrusion is up!

Page 9 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Note that the Z rails are not shown installed in the photos on this page. We revised the

assembly order to make things easier. We will update these photos soon.

*

6. On the bottom of the Machined Side Plate install one rubber foot on each end of the two extrusions

using an M3 × 10 SHCS and an M3 Post Install Nut. They should be approximately 20mm from the

end of each extrusion.

Page 10 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

7. Sit the assembled base aside for now.

Page 11 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Assembling the Y Axis

A 3D PDF Showing just this section available to aid your assembly. For help viewing this

file, see our note here

*

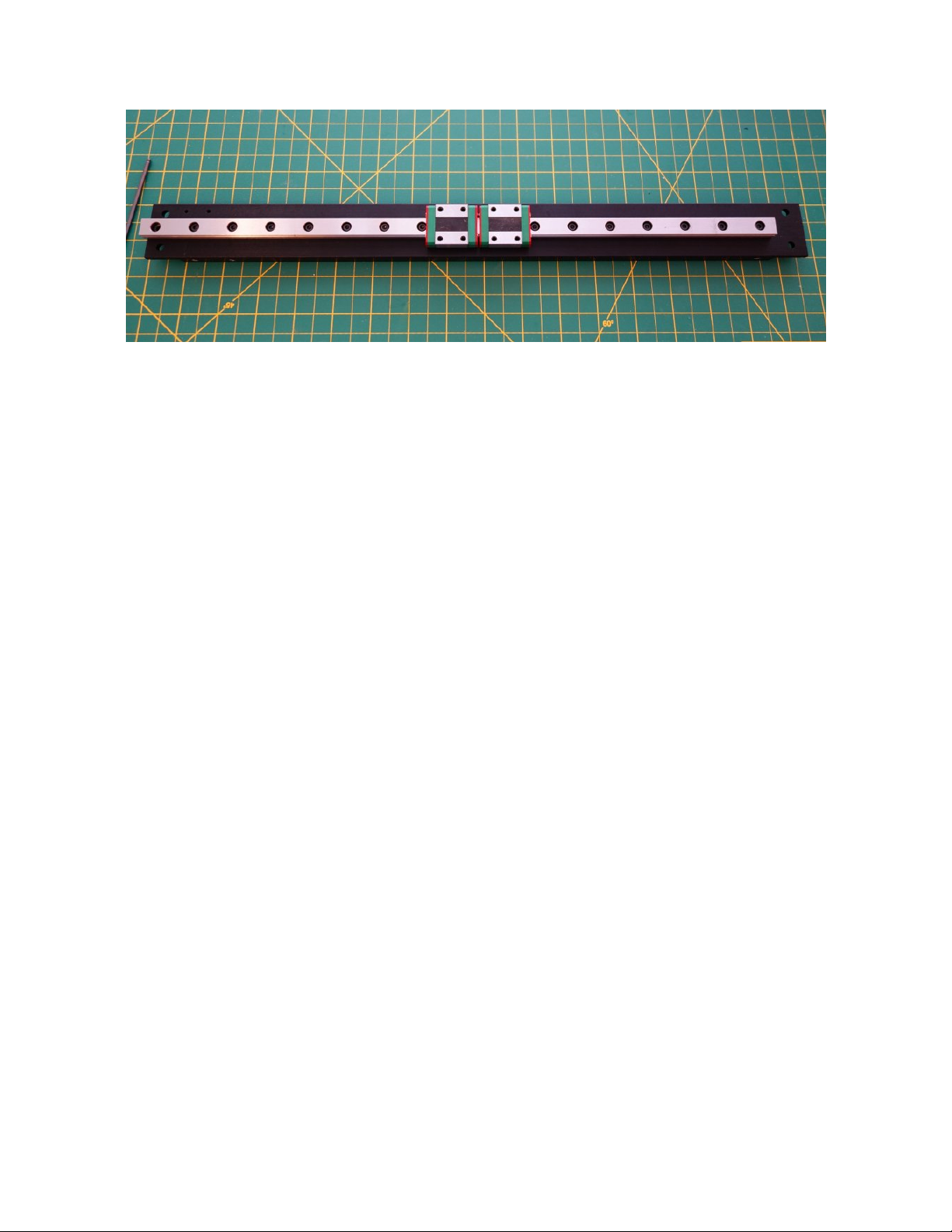

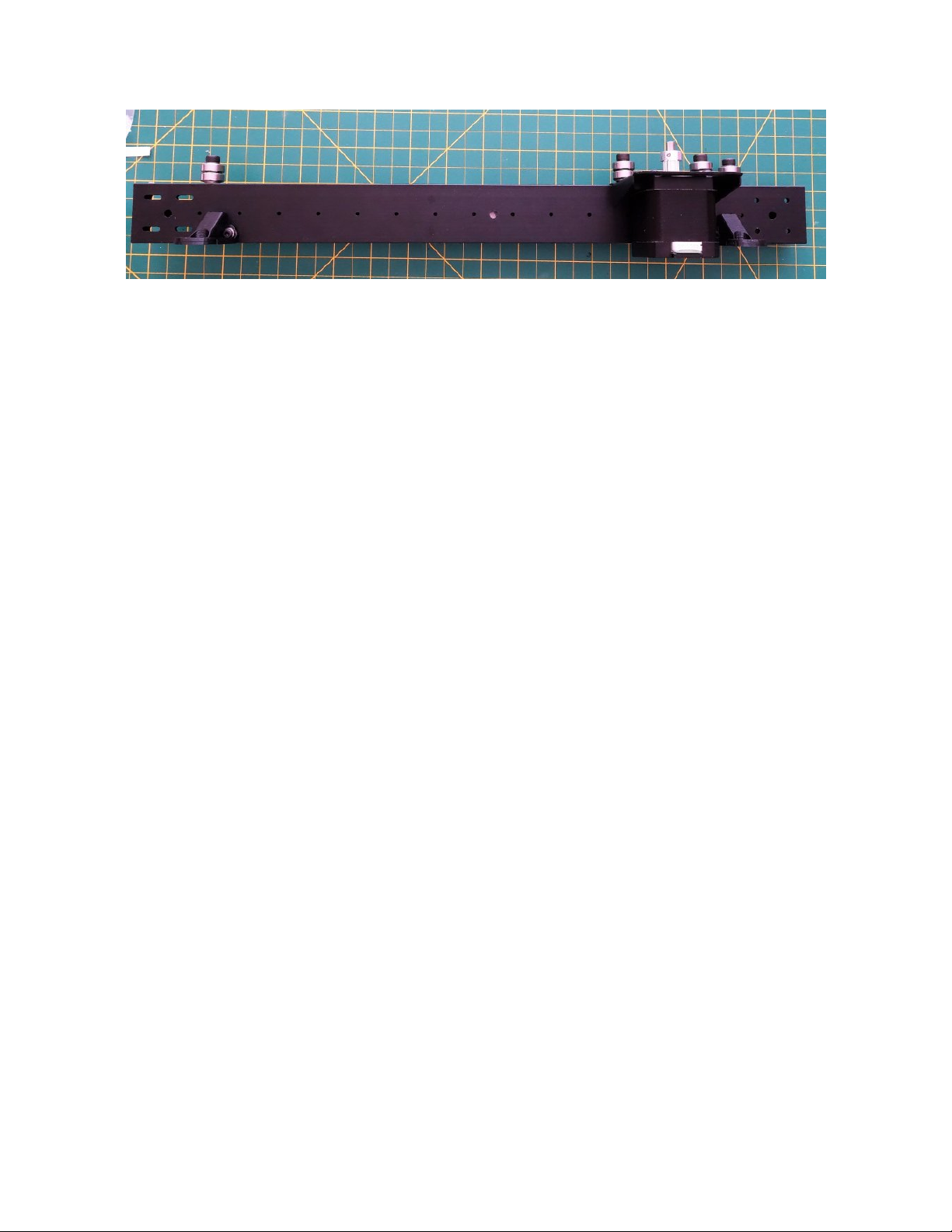

Installing the Linear Rail

Parts Required

• 400mm Linear Rail

• Machined Y Plate

• 16 – M3 × 10 SHCS

• 2 – M5 × 10 SHCS

• 2 – M5 Washer

• 2 – M5 Nut

1. Carefully remove the linear rail from the bag. Remove the Zip ties on the ends.

2. DO NOT REMOVE THE BLOCKS. They are not designed to be removed from the rail. If the block

sliding feels a bit rough, it is normal, it will not affect the operation, and in time will break in.

Page 12 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

3. Be sure to orient the Machined Y Plate with the “wings” up.

4. Install the Y axis rail using 16 M3 × 10 SHCS. The screws should be tightened until they are snug

only. Try to make sure you tighten them to a consistent level. Do not over-tighten the screws.

Page 13 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

5. We recommend adding one each M5 × 10 SHCS, M5 Washer and M5 Nut temporarily to each end to

each end of the assembly to prevent the cars from being able to come off.

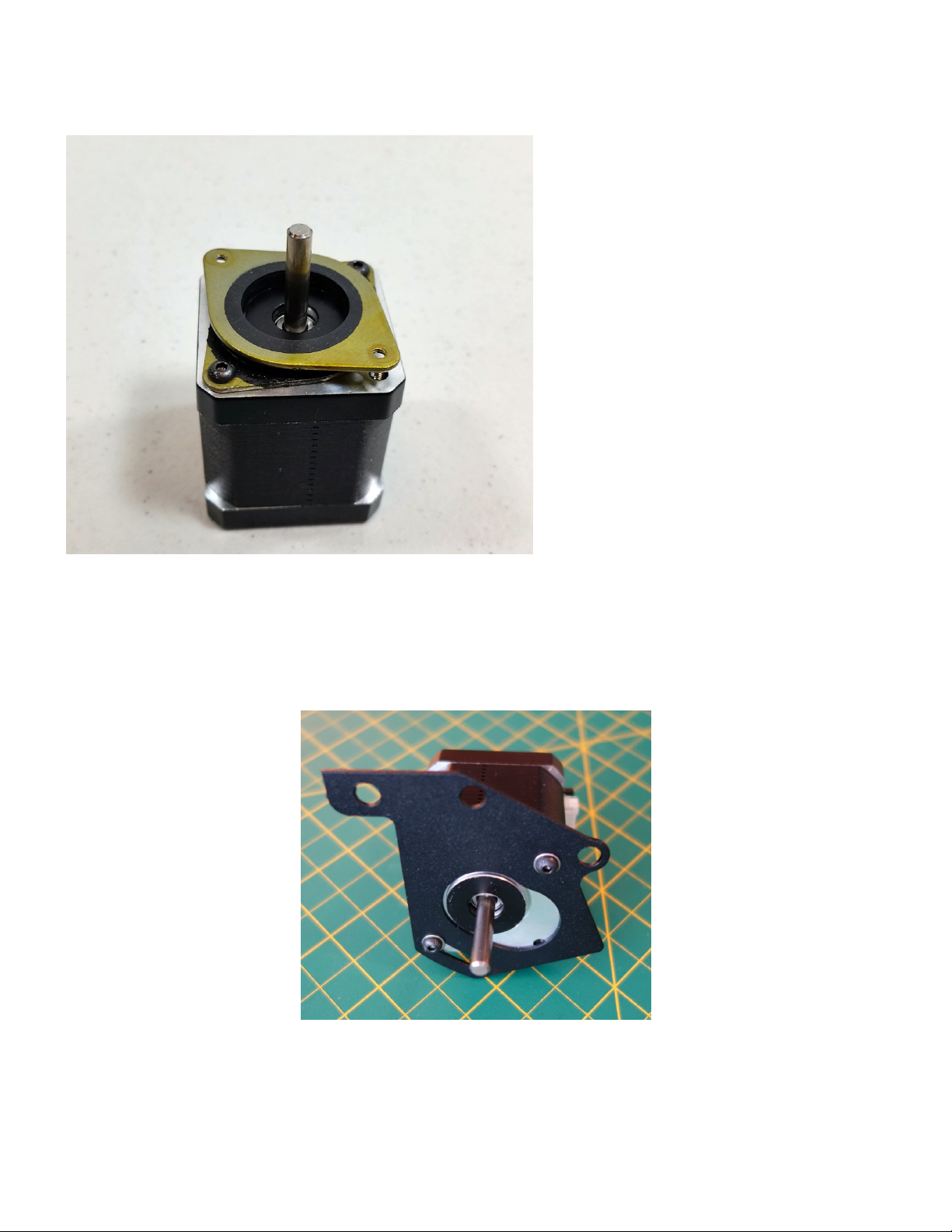

Assembling the Y Motor Mount & Belt Idlers

Parts Required

• 1- Y Motor Mount

• 2 – M3 × 6 BHCS

• 2 – M3 Washer

• 1 – M5 × 8 SHCS

• 2 – M5 × 20 SHCS

• 4+ – M5 Washer

• 1 – M5 Nut

• 4 – 605zz Bearing

• 1 – Stepper Motor

• 1- Pulley

Newer Create kits are supplied with noise vibration dampening mounts. Attach the motor to the mount using

two button head M3-6 screws. two of the holes on the mount are tapped and two are not tapped. To mount

Page 14 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

the motor to the mount use the two holes that are not tapped.

1. Install the Y Motor assembly with 2 M3 × 6 BHCS and 2 M3 Washer. These screws will insert into the

tapped holes of the vibration dampening mount. See the pictures below for the proper orientation

relative to the rest of the assembly. Be sure that the motor is in the uppermost position so when we

later install the belt you have plenty of room to adjust it.

Page 15 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

2. Install the pulley, leaving about 1-2mm between the bottom of the pulley and the top of the motor.

Install it with the set screw end of the pulley away from the motor. Be sure one of the pulley set

screws is aligned with the flat of the motor shaft.

3. All three Idlers will Install in the following order: M5 × 20 SHCS > Zero or more M5 Washer as needed

> 605zz Bearing > M5 Washer > 605zz Bearing > M5 Washer > Y Motor Mount or Machined Y

Plate. The two upper idlers will screw directly into the tapped holes on the Machined Y Plate. The

lower idle will screw into an M5 Nut Use as many washers below the screw head as needed to keep

the bearings snugly in place (probably 2-3).

4. Locate the two 5mm tapped holes on the side of the Machined Y Plate and attach the Y motor plate

using an Idler Bearing assembly and an M5 × 10 SHCS with a M5 Washer. See the images below for

clarification.

Page 16 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Sit the assembled Y Axis aside for the time being.

Page 17 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Assembling the X Axis

Assembling the X Motor Mount

Parts Required

• 1 – X Motor Mount

• 1 – Stepper Motor

• 1 – Pulley

• 4 – M3 × 6 BHCS

• 4 – M3 Washer

• 2 – M5 × 20 SHCS

• 8+ – M5 Washer

• 2 – M5 Nut

• 4 – 605zz Bearing

1. Install the idlers in two 5mm holes, using the following order: M5 × 20 SHCS > 605zz Bearing > M5

Washer > 605zz Bearing > M5 Washer > X Motor Mount > M5 Nut.

Page 18 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

New Create kits are provided with a vibration dampening mount for this axis. Two of the holes on the mount

are not tapped. Use these holes and two m3-6 button head screws to attach the mount to the stepper motor.

2. Install the Stepper Motor Assembly using 2 M3 × 6 BHCS and 2 M3 Washer. Two of the slots of the

motor mount plate will not be used. Mount it in the position closest to the idlers. Make sure the port on

the motor where the cable connects faces the rear of the printer.

Page 19 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

3. Install the pulley, leaving about 1-2mm between the bottom of the pulley and the top of the motor

mount plaTE. Install it with the set screw end of the pulley toward the motor (The opposite of how it

pictured). Be sure one of the pulley set screws is aligned with the flat of the motor shaft.

Installing the Idlers

Parts Required

• 2 – M5 × 20 SHCS

• 8+ – M5 Washer

• 4 – 605zz Bearing

1. Install the idlers in two 5mm tapped holes, using the following order: M5 × 20 SHCS > zero or more

M5 Washer as needed > 605zz Bearing > M5 Washer > 605zz Bearing > M5 Washer > Machined X

Plate. Use 2-3 washers below the bearings as pictured.

Page 20 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

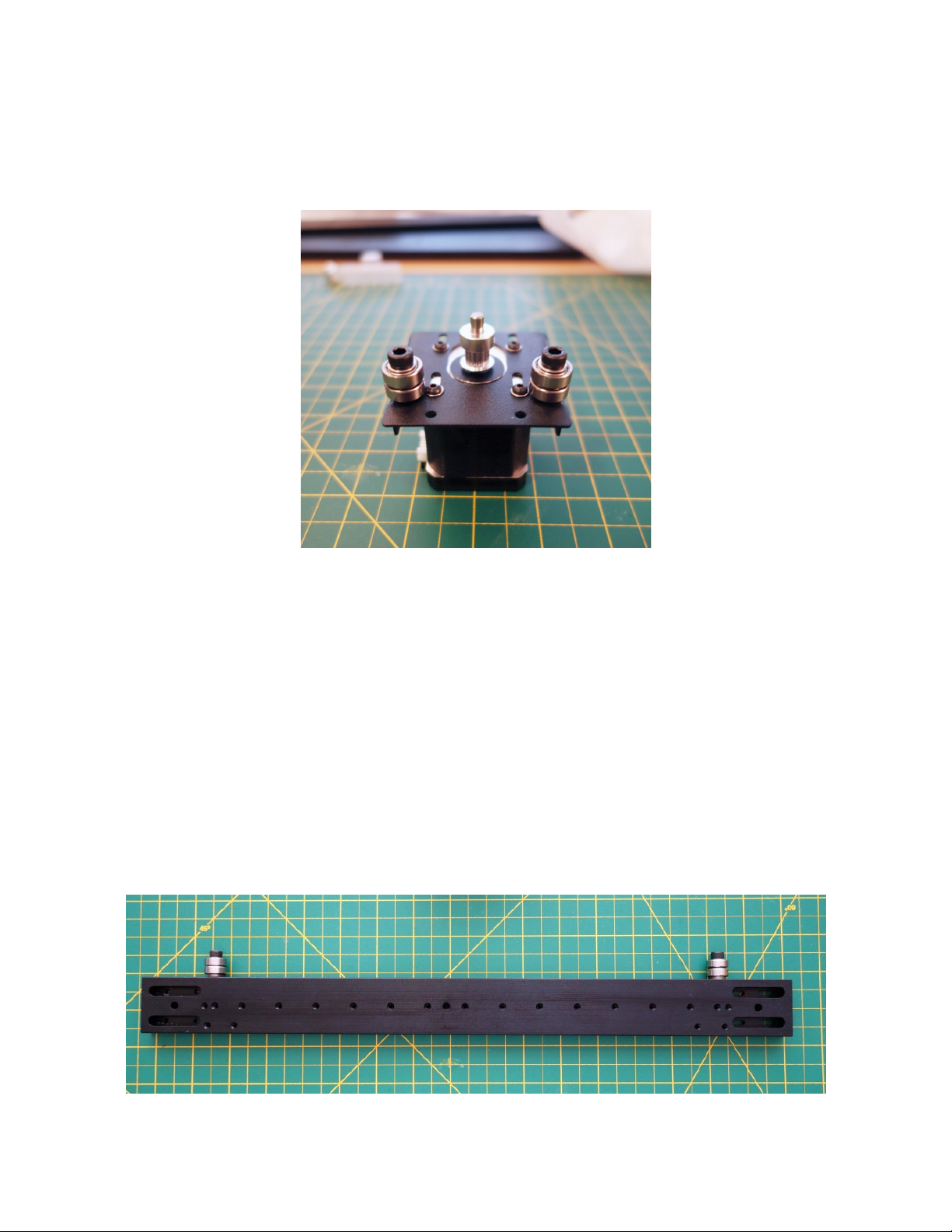

Mounting the Linear Rail

Parts Required

• 1 – Machined X Plate Assembly

• 1 – 380mm Rail Assembly

• 15 – M3 × 10 SHCS

1. Carefully remove the 380mm Rail Assembly from the bag. Watch closely for any loose balls in the

bag. If you find any contact our support for instructions on how to re-insert them. Cut off the zip ties

on the ends.

2. DO NOT REMOVE THE BLOCK. They are not designed to be removed from the rail.

3. Install the 380mm Rail Assembly on the side of the Machined X Plate with the machined slots using

15 M3 × 10 SHCS. The screws should be tightened until they are snug only. Try to make sure you

tighten them to a consistent level. Do not over-tighten the screws.

Page 21 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Handle the assembly carefully after this point. Until it is fully installed, the cars can come off

!

the end of the rail. A couple small strong magnets placed on each end of the rail can keep

the blocks from sliding off.

Installing the X Motor Mount

Parts Required

• Machined X Plate Assembly

• X Motor Mount assembly

• 2 – M3 × 6 BHCS

• 2 – M3 Washer

1. Mount the X Motor Mount Assembly to the X Axis Assembly using 2 M3 × 6 BHCS and 2 M3

Washer.

Installing the Lead Nut Adapters

Parts Required

• 2 – Printed Lead Nut Adapters

• 4 – M3 × 10 SHCS

• 4 – M3 Washer

• Install the two Lead Nut Adapters using two M3 × 10 SHCS with M3 Washers

Page 22 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Page 23 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Assembling the OctoPi LCD

Assembling the X Motor Mount

Parts Required

- RPi3

- LCD

- HDMI coupler

- LCD hardware

1. Attach the LCD to the Pi. Line up the pins on the PI with the sockets in the back of the LCD.

Use the hardware supplied with the LCD to ensure solid connection.

Make sure the hdmi ports on the LCD and the Pi line up

2. Connect the LCD hdmi to the Pi hdmi using the supplied HDMI coupler

Page 24 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

Page 25 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

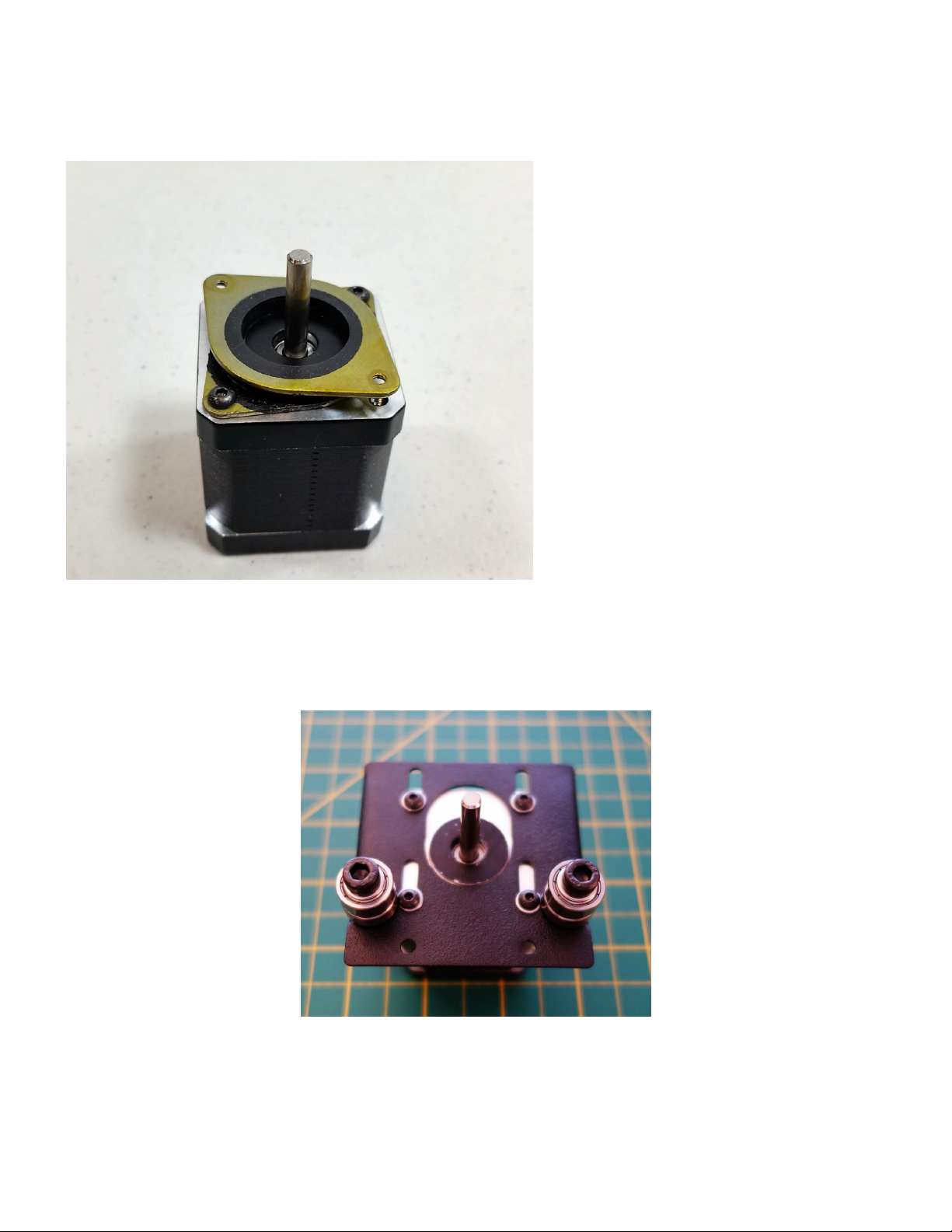

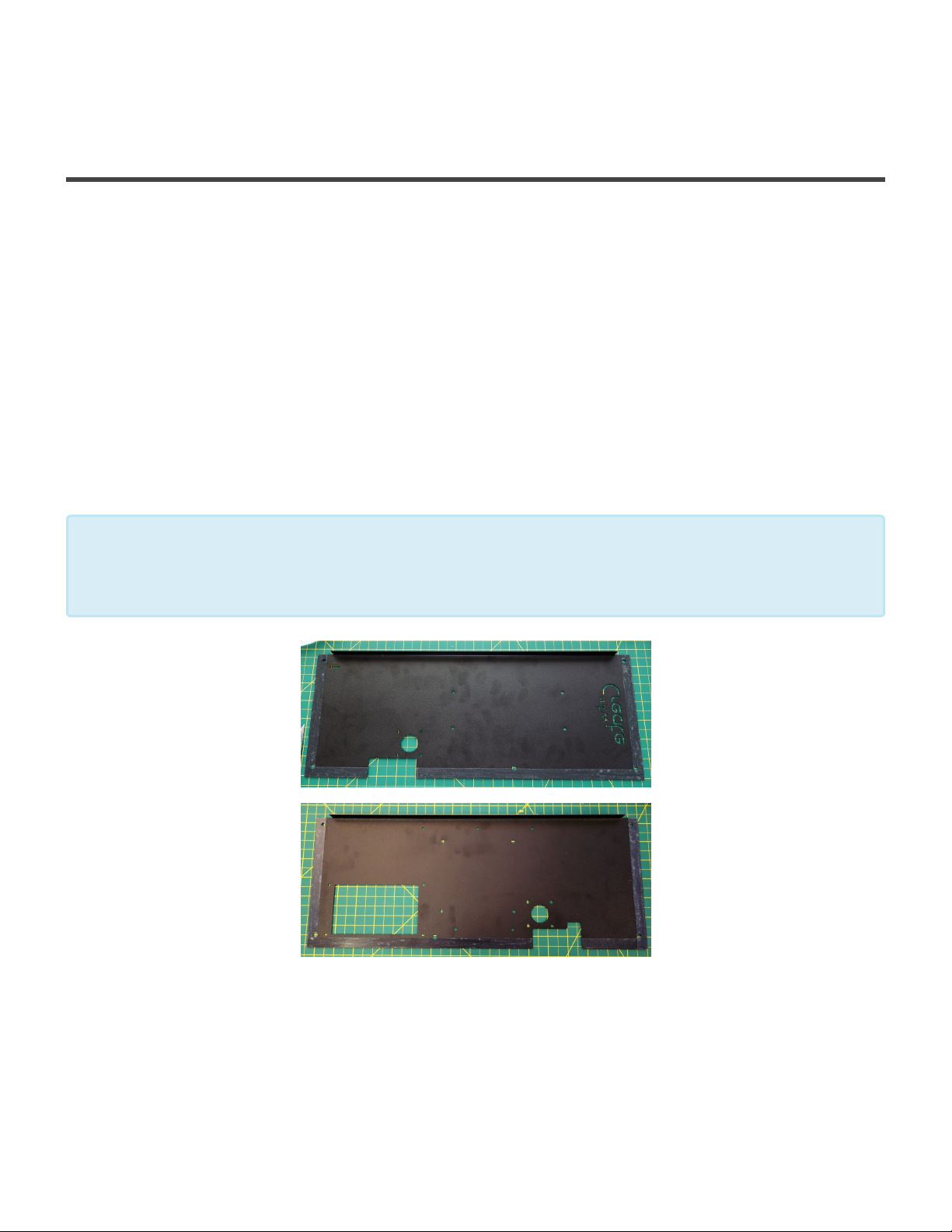

Assemble the Top Deck plates

Assemble the Top Deck – Right Side

Parts Required

• Top Deck Right (includes the MTW Create Logo)

• Power Supply

• 1 – Stepper Motor

• 4 – M3 × 6 BHCS

• 4 – M3 Washers

• 4 – M4 × 5 SHCS

• 4 – M5 Washers

You may optionally apply a couple layers of rubber cement to the outside edges of the top

deck plates, to assist with noise reduction. Place the the cement where the tape is on the

*

picture below.

1. Mount the Stepper Motor using 4 M3 × 6 BHCS and 4 M3 Washers, leave the motor slightly loose

until the deck plate is installed.

2. Mount the Power Supply using 4 M4 × 5 SHCS and 4 M5 Washers.

Page 26 of 151

Maker's Tool Works MTW Create Assembly Guide - 1

!

Make sure to set the PSU to the appropriate voltage!

3. Set the assembly aside.

Assemble the Top Deck – Left Side

Parts Required

• Top Deck Left (includes the cutout for the LCD)

• RAMBo Controller

• 1 – Stepper Motor

• 4 – M3 × 6 BHCS

• 17 – M3 Washers

• 9 – M3 × 10 SHCS

• 4 – M3 × 16 SHCS

• 17 – M3 Nuts

• 4 – Nylon Spacers

• 2 – Printed LCD Mounts

• LCD

Page 27 of 151

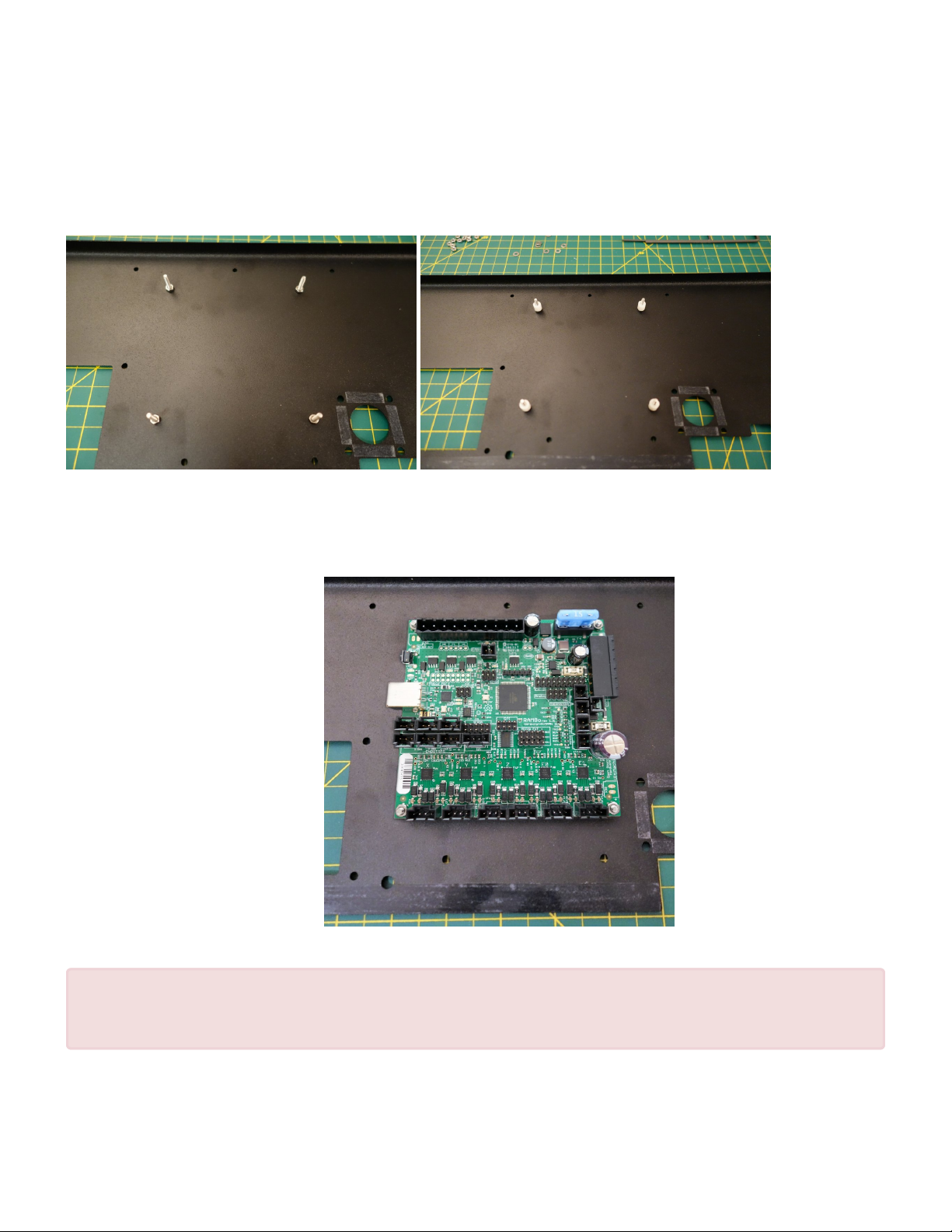

Maker's Tool Works MTW Create Assembly Guide - 1

1. Install the screws to mount the RAMBo Controller using 4 M3 × 16 SHCS and 4 M3 Nuts. Installing

the screws like this makes the following steps much easier and simplifies any future maintenance.

Leave these nust just slightly loose to allow you to reposition the screws if needed when installing the

RAMBo Controller, and put the 4 Nylon Spacers on the screws.

2. Install the RAMBo Controller onto the pre-installed studs using 4 Nylon Spacers to offset it from the

metal. Use 4 M3 Nuts to hold it in place. Orient it with the USB toward toward the front of the printer

for easier connection to the RPi.

Tighten the nuts holding the RAMBo Controller, carefully so not to damage any of the board

!

components.

Page 28 of 151

Loading...

Loading...