MTP 2200 User manual

USER MANUAL

61301603708 Rev. A

®

SERIES 2200

TUNNEL, CAGE, AND UTENSIL WASHERS

USER MANUAL

®

SERIES 2200

TUNNEL, CAGE, AND

UTENSIL WASHER

Getinge/Castle, Inc.

1777 East Henrietta Road

Rochester, New York 14623-3133

Phone: (800) 950-9912 USA

Facsimile: (800) 950-2570

WARNING |

CAUTION |

NOTE

NOTE

USER MANUAL 61301603708

Rev. A New Release(08/31/2000)

Related Publications:

Service Data Manual 61301603707

Customer Manual—keyed to the customer’s specific serial number

DESCRIPTION OF SYMBOLS & NOTES IN MANUAL

The following symbols with related notes appear in this manual.

“Warning” notes alert the user to the possibility of personal injury.

“Caution” notes alert the user to the possibility of damage to the equipment.

“Notes” alert the user to pertinent facts and conditions.

This manual contains proprietary information of Getinge/Castle, Inc. It shall not be reproduced in whole or in part without the written permission of Getinge/Castle, Inc.

Castle® and |

® |

are registered trademarks of Getinge/Castle, Inc. |

Copyright ©2000 by Getinge/Castle, Inc.

Table of Contents

SPECIAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . vii

Section 1 General Description

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

EXTERNAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . 1–4

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Emergency Stop Cable . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Alarm (not shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Wash Chamber Access Doors. . . . . . . . . . . . . . . . . . . 1–5

Rinse Chamber Access Door. . . . . . . . . . . . . . . . . . . . 1–5

Final Rinse Heat Exchanger . . . . . . . . . . . . . . . . . . . . 1–5

Drawer and Basket-Type Debris Filters . . . . . . . . . . . . 1–5

Agent Injection Ports (not shown) . . . . . . . . . . . . . . . . 1–5

Exhaust Plenum (not shown) . . . . . . . . . . . . . . . . . . . . 1–5

Six-Foot Recirculated Air Dryer (not shown) . . . . . . . . 1–5

Seven-Foot 99% Plastic Cage Dryer . . . . . . . . . . . . . . 1–5

Ten-Foot Recirculated Air Dryer (not shown) . . . . . . . 1–5

Unload Roller Conveyor. . . . . . . . . . . . . . . . . . . . . . . . 1–6

Control Box Access Panel . . . . . . . . . . . . . . . . . . . . . . 1–6

Electrical Disconnect Switch . . . . . . . . . . . . . . . . . . . . 1–6

INTERNAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Upper Spray Manifold . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Lower Spray Manifold . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Hydraulic Hold Down (not shown) . . . . . . . . . . . . . . . . 1–8

Wash, Rinse, and Final Rinse Treatment Temperature

Guarantees (not shown) . . . . . . . . . . . . . . . . . . . . 1–8

Water Conservation (not shown) . . . . . . . . . . . . . . . . . 1–8

MOST COMMON OPTIONS . . . . . . . . . . . . . . . . . . . . . . . 1–9

Stainless Steel Treatment Components . . . . . . . . . . . 1–9

House Tap Water Temperature Booster . . . . . . . . . . . 1–9

Steam and Water Pressure Gauges . . . . . . . . . . . . . . 1–9

Automatic Self Cleaning Debris Filter . . . . . . . . . . . . . 1–9

Automatic Drain System . . . . . . . . . . . . . . . . . . . . . . . 1–9

Drain Discharge Cool Down Injection System . . . . . . . 1–9

Washer Interior Cleaning and Descaling System . . . . 1–9

Automatic Conveyor Stop . . . . . . . . . . . . . . . . . . . . . . 1–9

Recorder/Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

61301603708 |

iii |

GENERAL MACHINE DESCRIPTION. . . . . . . . . . . . . . . 1–10

Automatic Treatment Cycle . . . . . . . . . . . . . . . . . . . . 1–10

Treatment Schedule . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Temperature Guarantee System . . . . . . . . . . . . . . . . 1–11

Section 2 The Control Panel

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

TOUCH CONTROL PANEL (TCP) . . . . . . . . . . . . . . . . . . 2–2

Control Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Cycle Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Example: Programming a Sample Cycle. . . . . . . . . . . 2–8

LED CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Key Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Data Entry Keys (keypad) . . . . . . . . . . . . . . . . . . . . . 2–15

Control Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . 2–16

Processing Cycle Screen Description . . . . . . . . . . . . 2–18

Standby Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–18

SELECT CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–18

REVIEW CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–19

MANUAL MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

Cycle Programming . . . . . . . . . . . . . . . . . . . . . . . . . . 2–21

Cycle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–22

Programming a Cycle . . . . . . . . . . . . . . . . . . . . . . . . 2–22

Example: Programming a Sample Cycle. . . . . . . . . . 2–24

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

Starting Wash Cycle . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

ELECTRO-MECHANICAL CONTROLS . . . . . . . . . . . . . 2–27

Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–27

Cycle Programming . . . . . . . . . . . . . . . . . . . . . . . . . . 2–30

Final Rinse Temperature Settings . . . . . . . . . . . . . . . 2–30

Internal Timers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

Section 3 Operating Instructions

GENERAL MACHINE OPERATION . . . . . . . . . . . . . . . . . 3–1

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Treatment Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

DAILY CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Operational Readiness . . . . . . . . . . . . . . . . . . . . . . . . 3–3

iv

EMERGENCY STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Using the Emergency Cable . . . . . . . . . . . . . . . . . . . . 3–4

EMERGENCY SHUT-DOWN . . . . . . . . . . . . . . . . . . . . . . . 3–4

Shutting Down the Washer . . . . . . . . . . . . . . . . . . . . . 3–4

Section 4 Maintenance

GENERAL MAINTENANCE SCHEDULE. . . . . . . . . . . . . . 4–1

ROUTINE MAINTENANCE SCHEDULE—STANDARD . . 4–2

When required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Six Months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

RECOMMENDED SPARE PARTS LIST . . . . . . . . . . . . . . 4–6

Consumable Stock. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

Section 5 Troubleshooting

CYLE INTERRUPT CONDITIONS . . . . . . . . . . . . . . . . . . . 5–3

Resettable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Non-Resettable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Section 6 Installation Instructions

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

UNCRATING & EQUIPMENT INSPECTION . . . . . . . . . . . 6–1

INSTALLATION /ASSEMBLY CHECKLIST . . . . . . . . . . . . 6–2

Equipment Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

STARTUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Touch Control Panel (TCP) . . . . . . . . . . . . . . . . . . . . . 6–3

LED Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Electro-Mechanical Controls . . . . . . . . . . . . . . . . . . . . 6–5

CHECK-OUT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 6–6

TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

Section 7 Options

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

MOST COMMON OPTIONS . . . . . . . . . . . . . . . . . . . . . . . 7–1

Right or Left Handed Service. . . . . . . . . . . . . . . . . . . . 7–1

Wash and Rinse Treatment Temperature Guarantee . 7–1

61301603708 |

v |

Final Rinse Temperature Guarantee . . . . . . . . . . . . . . 7–1

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

RS232 Data Computer Port. . . . . . . . . . . . . . . . . . . . . 7–3

RS485 Data Computer Port. . . . . . . . . . . . . . . . . . . . . 7–3

Bedding Dispenser Controls . . . . . . . . . . . . . . . . . . . . 7–3

Bedding Dump Station Controls . . . . . . . . . . . . . . . . . 7–3

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Stainless Steel Treatment Components . . . . . . . . . . . 7–7

Automatic Self Cleaning Debris Filter . . . . . . . . . . . . . 7–8

Automatic Drain System . . . . . . . . . . . . . . . . . . . . . . . 7–8

Wash Interior Cleaning and Descaling System . . . . . . 7–9

Acid Treatment System . . . . . . . . . . . . . . . . . . . . . . . . 7–9

Non-Recirculated Final Pure Water Rinse. . . . . . . . . 7–10

Water Pressure Reducing Station . . . . . . . . . . . . . . . 7–10

House Tap Water Temperature Booster . . . . . . . . . . 7–10

Automatic Agent Injection System (Optional) . . . . . . 7–10

Automatic Agent Injection System – Time Based . . . 7–12

Agent Neutralization System Non-Monitored . . . . . . 7–12

pH Monitored . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

Mechanical Hold Down System. . . . . . . . . . . . . . . . . 7–13

Six Foot Recirculated Air Dryer Section . . . . . . . . . . 7–14

Seven Foot 99% Plastic Cage Dryer . . . . . . . . . . . . . 7–14

Ten Foot Recirculated Air Dryer Section . . . . . . . . . . 7–15

Load/Unload Conveyor . . . . . . . . . . . . . . . . . . . . . . . 7–15

Power Discharge Unload Conveyor . . . . . . . . . . . . . 7–15

Automatic Conveyor Stop . . . . . . . . . . . . . . . . . . . . . 7–15

Exhaust Plenum System . . . . . . . . . . . . . . . . . . . . . . 7–16

Power Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–16

Drain Discharge Cool-Down Injection System –

Non-Monitored . . . . . . . . . . . . . . . . . . . . . . . . . . 7–17

Steam and Water Pressure Gauges . . . . . . . . . . . . . 7–17

Chilled Water Vapor Removal Condenser. . . . . . . . . 7–17

Barrier Trim Flange System. . . . . . . . . . . . . . . . . . . . 7–17

M.O.D.E.M. (MTP Online Diagnostics, Evaluation,

and Monitoring) System . . . . . . . . . . . . . . . . . . . 7–18

Seismic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–18

Appendix A Manual Screens

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

PROGRAMMING A CYCLE USING MANUAL MODE. . . . A–1

Index

vi

SPECIAL SAFETY INSTRUCTIONS

THE FOLLOWING SAFETY INSTRUCTIONS APPEAR WITHIN THIS

MANUAL. READ THEM CAREFULLY BEFORE OPERATING THE UNIT.

WARNING |

“Warning” notes alert the user to the possibility of personal injury.

Warnings Summary |

p. xi |

BURN HAZARD:This washer operates at extremely high temperatures. Prior to any machine maintenance or service, the washer should be allowed sufficient time to cool. Caution should be used in and around the washer chamber and external piping. Water flow and discharge piping can cause personal injury such as burns. Operators should partially open the chamber door to allow hot air to exhaust and to allow all loads adequate time to cool. Opening the chamber door fully may cause large amounts of steam to escape.

SHOCK HAZARD: Prior to any service or maintenance on the washer, all utilities should be disconnected and the lockout/tagout procedures should be followed to insure safety and prevent accidental shock.

PERSONAL HAZARD AND EQUIPMENT DAMAGE: Safe and efficient operation of this equipment requires scheduled preventative maintenance. Routine adjustments and replacement of parts by other than qualified maintenance personnel may cause personal injury or the equipment to perform less than its capabilities.

General Machine Operation |

p. 3-1 |

BURN HAZARD: Do not open station access doors during a cycle. This could release hot water through the door opening, resulting in burns to personnel.

Daily Checklist |

p. 3-3 |

HOT SURFACES: The area surrounding the load and unload end of the washer could be hot. Use caution when loading or unloading ware.

Routine Operation: Detail |

p. 3-6 |

BURN HAZARD: Do not open a Washer door during a cycle. This could release hot water through the door opening, resulting in burns to personnel.

Routine Maintenance Schedule - Standard, Every Six Months |

p 4-4 |

ELECTRIC SHOCK HAZARD: Only an electrician should perform this test!

61301603708 |

vii |

viii

Section 1 General Description

INTRODUCTION

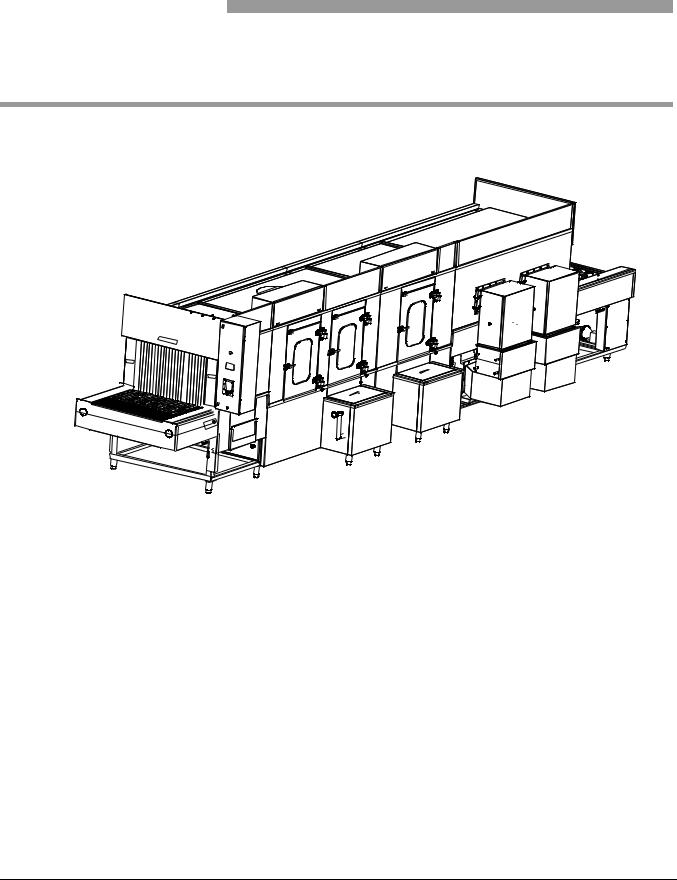

Figure 1–1. MTP 2200 SERIES WASHERS

MTP 2200 series units are automatic, heavy duty, tunnel-type hydrospray washers with conveyors. They are designed for continuous high volume processing. These units are designed to clean, sanitize, and dry— efficiently and thoroughly —metal or plastic cages, racked watering bottles, and utensils used in research animal care facilities.

Units may be recessed through one or two walls or installed free standing. Left side service access and control terminal location is standard with right side service access and control terminal location optional.

61301603708 |

1–1 |

General Description

Models and dimensions are listed in Table 1–1.

Table 1–1. MTP 2200 series washers

Standard Features

MODEL |

CHAMBER (in. [cm]) |

OVERALL (in. [cm]) |

|

|

|

2224 |

25x25 |

65½x85 |

|

[64x64] |

[145x213] |

|

|

|

2230 |

31x25 |

71½x85 |

|

[79x64] |

[160x213] |

|

|

|

2236 |

37x25 |

77½x85 |

|

[94x64] |

[175x213] |

|

|

|

2242 |

43x25 |

83½x85 |

|

[107x64] |

[212x213] |

|

|

|

2248 |

48x25 |

89½x85 |

|

[122x64] |

[227x213] |

|

|

|

Routine operation consists of manually placing the items to be cleaned upside down on the conveyor belt at the load end of the unit. The items are conveyed automatically through the process treatments and discharged at the unload end for removal.

Treatment solutions are delivered by means of stationary manifolds equipped with jet spray nozzles. These manifolds are located above and below the conveyor at each station (except dry).

Processing cycles are controlled by means of a Programmable Logic Controller (PLC) equipped with a touch screen interface or LED Control Panel. Twelve cycle selections are possible. The user selects and starts an appropriate cycle.

A standard cycle has these phases: Prewash, Agent Wash, Recirculated Rinse, Final Rinse, and Recirculated Air Dry. The cycle, once activated, is completely automatic.

•Microcomputer Color Touch Screen Control

•Twelve User-Programmable Cycles

•Personnel Safety System

•Wash and Rinse Temperature Assurance

•180°F Non-recirculated Final Rinse

•Water Conservation System

•Removable Spray Headers

•Hydraulic Hold Down System

•7.5 HP Wash Pump (10HP on Models 2230 & 2236)

•3 HP Recirculated Rinse Pump

•Basket and Drawer Type Debris Screens

•Agent Injection Ports and Contacts

•Stainless Steel Steam Coil Heating

•Stainless Steel Flat Wire Conveyor Belt

•All Stainless Steel Construction

1–2

Series 2200 Washers

Optional Features

•Side Hinged Chamber Access Doors

•Exhaust Plenum with Single Point Connection

•Insulated Chamber Construction

•Left Service Side Installation

•Program Access Code Security

•Strip Chart Printer

•RS232 or RS485 Port for Data Download

•Right Service Side Installation

•Stainless Steel Treatment Components

•Automatic Self-Cleaning Debris Filter

•Automatic Fill and Drain with Interior Tank Cleaning

•Non-Recirculated Final Pure Water Rinse

•Water Supply Temperature Booster

•Automatic Agent Injection Systems

•Acid Wash Tunnel Section

•Six, Seven, or Ten Foot Recirculated Dryer Section

•Four, Six, or Eight Foot Unload Conveyor

•Automatic Conveyor Stop

•Power Exhaust Fan

•Vapor Removal Condenser

•Drain Discharge Cool Down System

•Treatment Solution pH Neutralization

•High Altitude Inducers

•Barrier Wall Recessing System

•Remote Control Terminal Location

•Seismic Design

•Knocked Down Shipment

61301603708 |

1–3 |

General Description

EXTERNAL COMPONENTS

Figure 1–2. EXTERNAL COMPONENTS

SEVEN FOOT

RECIRCULATED

AIR DRYER

ELECRICAL

DISCONECT

SWITCH

RINSE CHAMBER

ACCESS DOOR

WASHER CHAMBER

ACCESS DOORS

UNLOAD END

CONTROL BOX

ACCESS PANEL

CONVEYOR

CONTROL

PANEL

RECORDER/ PRINTER (Option)

CONVEYOR

GREASE FITTINGS

LOAD END

BASKET TYPE

DEBRIS SCREEN

DRAWER TYPE

DEBRIS SCREEN

EMERGENCY

EMERGENCY STOP RESET

STOP CABLE

GREASE FITTINGS

Control Panel

Emergency Stop Cable

Alarm (not shown)

Provides a touch screen interface with the Programmable Logic Controller (PLC) located in the control box. Enables the user to select, program, and monitor processing cycles.

An emergency stop cable is provided at both the load and unload ends of the unit to terminate all process and conveyance functions. Processing is resumed by resetting the emergency stop cable and pressing the cycle start button.

Each chamber access door is equipped with a disconnect switch to terminate all processing and conveyance functions upon opening of any door. Processing cannot be resumed unless all doors are fully closed.

Sounds an audible alert:

•when the emergency stop cable is pulled

•when a chamber access door is opened.

1–4

|

Series 2200 Washers |

Conveyor |

A stainless steel, flat wire conveyor runs the full length of the processing |

|

chamber carrying soiled ware through the unit’s treatment stations. |

|

Sprockets at both the load and unload ends provide positive belt tracking. |

|

Belt tension and speed are adjustable. |

Wash Chamber Access

Doors

Rinse Chamber Access Door

Final Rinse Heat Exchanger

Drawer and Basket-Type

Debris Filters

Agent Injection Ports (not shown)

Exhaust Plenum (not shown)

Removable, side hinged splash proof doors provide easy access to unit Wash Chamber

Removable, side hinged splash proof door provides easy access to unit Rinse and Final Rinse Chambers.

Ensures that a minimum 180oF final rinse temperature is attained and maintained. Should the final rinse temperature assurance set point not be attained or maintained the variances are annunciated to the user.

The pre-wash, agent wash, and recirculated rinse treatments are filtered through drawer or basket-type stainless steel screens to prevent plugged spray jets. The screens are easily accessible for cleaning.

Three agent injection ports and dry electrical contacts are provided for installation of automatic agent injection systems.

A stainless steel exhaust plenum is provided for exhausting the washer and dryer through a single point connection. Each machine vent is provided with its own individual manual damper.

Six-Foot Recirculated Air Dryer (not shown)

Seven-Foot 99% Plastic Cage

Dryer

Ten-Foot Recirculated Air Dryer (not shown)

An insulated stainless steel six-foot long dryer section to recirculate hot air to dry the load is provided. The system consists of a steam to air heat exchanger, a single 5 HP blower capable of providing a 1600 CFM air flow and a stainless steel plenum system. Moisture is eliminated by exhausting a portion of the recirculated air to the facility exhaust system. Plastic cages are delivered at the unload end 95% dry. All air ducting is stainless steel and includes required manual dampers.

An insulated stainless steel seven-foot long dryer section to recirculate hot air to dry the load is provided. The system consists of a steam-to-air heat exchanger, a dual 5 HP blower capable of providing a 3200 CFM air flow and a stainless steel plenum system. Moisture is eliminated by exhausting a portion of the recirculated air to the facility exhaust system. The conveyor belt is separated from the wash compartment to remove the excess water remaining on the plastic cages exiting the recirculated air dyer. This system delivers the plastic cages 99% dry at the discharge of the dryer, permitting filling of the cage immediately.

An insulated stainless steel ten-foot long dryer section to recirculate hot air to dry the load is provided. The system consists of a steam to air heat exchanger, a dual 5 HP blower capable of providing a 3200 CFM air flow and a stainless steel plenum system. Moisture is eliminated by exhausting a portion of the recirculated air to the facility exhaust system. Plastic cages are delivered at the unload end 95% dry. All air ducting is stainless steel and includes required manual dampers.

61301603708 |

1–5 |

General Description

Unload Roller Conveyor

Control Box Access Panel

Electrical Disconnect Switch

A stainless steel, roller type, gravity conveyor is at the output end of the unit to facilitate unloading.

Permits access to the unit’s control box located above Washer Chamber door. Box contains the programmable controller, fuses, contactors, relays, etc., and other essential components of the unit’s electrical system. (Access restricted to qualified personnel only).

An UL/CSA approved, non-fusible 3 pole, electrical disconnect switch is provided in the primary control box to provide additional protection to the facilities personnel. The disconnect switch incorporates a handle mechanism mounted through the control box front access panel and is sealed to a NEMA 4X water tight rating. The handle must be turned to the “OFF” position, disconnecting the incoming electrical service prior to accessing the internal control box components.

1–6

Series 2200 Washers

INTERNAL COMPONENTS

Figure 1–3. INTERNAL COMPONENTS

|

|

UPPER |

|

UPPER |

SPRAY MANIFOLD |

|

FINAL RINSE STATION |

|

|

SPRAY MANIFOLD |

|

UPPER |

RINSE STATION |

|

SPRAY MANIFOLD |

|

|

WASH STATION |

|

|

UPPER

SPRAY MANIFOLD

PREWASH STATION

|

LOWER |

LOWER |

|

SPRAY MANIFOLD |

|

|

SPRAY MANIFOLD |

|

|

FINAL RINSE STATION |

|

|

RINSE STATION |

|

LOWER |

LOWER |

|

SPRAY MANIFOLD |

|

|

SPRAY MANIFOLD |

|

|

WASH STATION |

|

|

PREWASH STATION |

|

|

|

|

Upper Spray Manifold

Lower Spray Manifold

A stationary, single manifold that delivers the jet spray and treatment agent down on to soiled ware as it is conveyed through each station. These manifolds are located in the following stations:

•Prewash

•Wash

•Rinse

•Final Rise

A stationary, single manifold that delivers the jet spray and treatment agent up into soiled ware that is conveyed through each station. These manifolds are located in the following stations:

•Prewash

•Wash

•Rinse

•Final Rise

61301603708 |

1–7 |

General Description

Hydraulic Hold Down (not shown)

Wash, Rinse, and Final Rinse Treatment Temperature Guarantees (not shown)

Water Conservation (not shown)

Jet spray header throttle valves are properly sized and positioned to hydraulically hold down light plastic cage and steel pans to the conveyor. By setting the throttle valve to restrict flow to the lower header, the pressure differential will allow a higher volume of water to push down on caging.

An agent wash, recirculated rinse, or final rinse temperature guarantee may be programmed to ensure that minimum treatment temperatures are attained and maintained. Should the temperature guarantee set points not be attained or maintained, the conveyer belt will temporarily stop until the treatment solution reaches the set point temperature. The controls signal the user if there are any variances.

The hot tap final rinse water is sprayed through the jet system and collected in the recirculated rinse tank. The water is used for the recirculated wash, rinse and pre-wash for water and energy conservation.

1–8

Series 2200 Washers

MOST COMMON OPTIONS

Stainless Steel Treatment

Components

House Tap Water

Temperature Booster

Steam and Water Pressure

Gauges

Automatic Self Cleaning

Debris Filter

Automatic Drain System

Drain Discharge Cool Down

Injection System

Washer Interior Cleaning

and Descaling System

Automatic Conveyor Stop

Recorder/Printer

All components including valves, pump, and piping that come in contact with the recirculating treatment solution are 304 stainless steel to provide system life and durability

An instantaneous steam to water heat exchanger is provided to raise the house tap water supply temperature.

Pressure gauges are provided on the incoming steam and water lines to monitor the facility utilities.

The output of the wash pump is provided with a self cleaning debris screen having perforations smaller than the spray jets’ orifices to prevent plugged jets. The debris filter is automatically controlled to filter the recirculated was solution and to periodically back flush debris to the drain. The screen element may be accessed without the use of tools.

Provides the capability to automatically drain the agent wash and recirculated rinse tanks at the end of the processing period.

Cold tap water is automatically injected into the drain discharge to lower the discharge temperature before entering into the building’s drain system.

Provided in the interior of each tank are jets to wash the walls of the tank to remove debris build up. When activated the control system automatically drains the wash tank, refills the tank with fresh water and a descaling agent, and activates the belt and pumps for a user programmable period of time, automatically draining and flushing each tank. This system reduces or eliminates the need to clean the tanks manually.

A photoelectric switch is located at the end of the discharge conveyor to automatically stop the conveyor drive when an item reaches the end of the conveyor. A second photo eye may be located at the end of a bedding dispenser, if equipped, user may program cycle to stop at end of washer or dispenser. A stopped conveyor condition is visually annunciated to the user on the control screen.

Issues a printed record of all pertinent cycle data, including treatment functions, temperature, time and date. A Take-Up Reel is provided to retrieve and rewind the print-out onto a spool. See also: Appendix A: Recorder/Printer.

61301603708 |

1–9 |

General Description

GENERAL MACHINE DESCRIPTION

Automatic Treatment Cycle

Treatment Schedule

At the start of the processing period, the user activates the unit for automatic operation by turning on the main disconnect switch. The unit automatically goes through a self diagnostic test then fills with fresh water and heats to programmed temperature.

The user at this time can press the start prompt and place the load to be cleaned on the stainless steel flat wire. The unit will automatically proceed through the treatment process and deliver the items at the unload end of the machine.

The standard treatment cycle consists of a pre-wash, an agent wash, a recirculated rinse, final rinse, and recirculated air dry. All wash and rinse treatments are recirculated under pump pressure. The cycle, once activated, is completely automatic. Additional cycle treatment phases are available.

PRE-WASH

Hot water from the recirculated rinse tank is directed through the upper and lower jet spray headers under pump pressure to remove gross debris. This solution is not recirculated and is sent to drain.

AGENT WASH

Hot chemical solution, from the wash tank, is recirculated through the wash jet spray headers under pump pressure and retained in the wash tank. Wash temperature is progammable up to 190oF.

RECIRCULATED RINSE

Hot water from the rinse tank, is recirculated through the rinse jet spray headers (top to bottom) under pump pressure and retained in the rinse tank. Rinse temperature is programmable up to 190oF.

NON-RECIRCULATED FINAL RINSE

Hot tap water from house supply is heated by a steam heat exchanger and directed through separate final rinse jet spray headers under house supply pressure and retained in the rinse tank for the recirculated rinse and prewash. Final rinse temperature is manually adjustable to 195oF.

RECIRCULATED AIR DRY (Optional)

Hot air is recirculated through a finned steam coil and directed through flat air knives. The dryer temperature is manually adjustable. Moisture is eliminated by exhausting a portion of the recirculated air to the facility exhaust system.

1–10

Temperature Guarantee

System

NOTE

Series 2200 Washers

When selected, this will cause the unit to fill and spray water normally for that phase. If at any time the tank temperature should fall below setpoint, the conveyor belt will stop until the temperature exceeds setpoint. Failure to do so in a set period of time will generate a “too long to heat” alarm.

•Operation (conveyor/recirculation) pauses if:

1)the wash or rinse water temperature setpoints not be met, or

2)the contents of a wash or rinse tank drop below its low level limit. Otherwise, the unit runs until stopped by operating personnel.

•Water supplies held in Wash and Rinse Tanks are re-used until drained at the end of the day (or as required—a determination made by operating personnel).

61301603708 |

1–11 |

General Description

1–12

Section 2 The Control Panel

INTRODUCTION

Your unit has one of the following control panels:

•TOUCH CONTROL PANEL (TCP), see page 2–2

•LED CONTROLLER, see page 2–12

•ELECTRO-MECHANICAL CONTROLS, see page 2–27

The control panel provides an interface linked to the Programmable Logic

Controller (PLC) in the control box.

Using the control panel, the user can:

•Program treatment temperatures.

•Select treatments.

•Start the unit.

•Monitor the status of unit operation.

•Drain the unit’s wash and rinse water tanks.

•Control conveyor operation.

In addition, supervisory personnel can:

•Access load counters and time display

•Protect cycle programming

61301603708 |

2–1 |

The Control Panel

TOUCH CONTROL PANEL (TCP)

Control Screens |

|

MAIN CONTROL SCREEN |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CYCLE SELECTION SCREEN

SELECT CYCLE FOR OPERATION

|

Cycle |

|

Cycle |

|

Cycle |

|

Cycle |

|

|

|

|||||

|

1 |

|

2 |

|

3 |

|

|

4 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cycle |

|

Cycle |

|

Cycle |

|

Cycle |

|

|

|

|||||

|

5 |

|

6 |

|

7 |

|

|

8 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cycle |

|

Cycle |

|

Cycle |

|

Cycle |

|

|

|

|||||

|

9 |

|

10 |

|

11 |

|

12 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

PUSH ANY BUTTON TO CONTINUE |

|

|

|

|

|

||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MANUAL |

|

EVENT |

|

|

REVIEW |

|

|

|

||||||

|

MODE |

|

PRINT OFF |

|

CYCLE |

|

CYCLE |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press the desired cycle of operation

Press to start the automatic drain and shut down operation. You will be directed to the Automatic Shut down Cycle screen to begin this process

After a cycle is selected, press to review the cycle and show the CYCLE START prompt

Press to print cycle parameters

When selected, prints live readings during the cycle

Press to enter manual mode, to test functions

2–2

Series 2200 Washers

REVIEW PROGRAMMED PHASES SCREEN

|

|

|

|

|

|

|

|

|

|

|

|

Shows the selected cycle |

|

|

|

|

|

|

|

|

|

|

|

|

Shows the current TCP Screen |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CYCLE 1 |

|

REVIEW PROGRAMMED |

|

||||||||

|

|

|

|

|||||||||

|

|

PHASES |

|

|

||||||||

|

|

|

|

|

|

|

|

Shows the final rinse status |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RECIRCUL'D |

|

RECIRCUL'D |

|

FINAL |

|

|

|

||||

|

|

|

|

|

|

|

||||||

|

WASH |

|

RINSE |

|

RINSE |

|

AIR DRYER |

|

|

|||

|

SYSTEM OFF |

|

SYSTEM OFF |

|

SYSTEM OFF |

|

SYSTEM OFF |

|

Shows the dryer status |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shows the rinse status |

|

|

|

|

|

|

|

|

|

|

|

|

Shows the wash status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REVIEW, START OR PROGRAM |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Press to enter the access screen |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAIN |

|

|

START |

|

PROGRAM |

|

|

|

|

and program the selected cycle |

|

|

MENU |

|

|

MODE |

|

|

CYCLE |

|

|

|

Press to print cycle parameters |

|

|

|

|

|

|

|

|

|

|

|

CYCLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press to start the selected cycle |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press to return to the main menu |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shows the cycle selected |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Any errors or alarms during |

|

|

CYCLE 1 |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

AUTOMATIC CYCLE |

|

|

|||||||||||||

|

|

|

|

|

|

operation display here |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO ACTIVE ALARMS EXIST |

|

|

|

Displays the current temperature of the Wash |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Displays the current temperature of the Rinse |

|||

|

|

WASH |

|

|

RINSE |

|

|

|

FR |

|

|

|

|

||||||

|

|

TEMP |

|

|

TEMP |

|

|

|

TEMP |

|

|

|

|

Displays the current temperature of the Final Rinse |

|||||

|

|

185 |

|

|

|

185 |

|

|

|

|

185 |

|

|

|

|

|

|

|

Displays the status of the Wash |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Displays the status of the Rinse |

|

|

WASH |

|

|

RINSE |

|

|

|

FINAL |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

RINSE |

|

|

|

|

|

|

Displays the status of the Final Rinse |

|||||

|

SYSTEM |

|

SYSTEM |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

SYSTEM |

|

|

|

|

|

|

|||||||||

|

|

ON |

|

|

ON |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

ON |

|

|

|

CYCLE |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press to stop all functions and sound alarm |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

MAIN |

|

|

START |

|

|

ANSWER |

|

|

ABORT |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

MENU |

|

CYCLE |

|

|

ALARM |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press to acknowledge all alarms

Press to start the cycle

Press to return to the Main Control Screen

61301603708 |

2–3 |

The Control Panel

AUTOMATIC SHUT DOWN CYCLE SCREEN

AUTOMATIC SHUT DOWN CYCLE |

|

|

|

Shows the current TCP screen |

|

|

|

||

|

|

|

|

Describes the actions available |

|

|

|

|

|

Depress START or ABORT OPERATION |

|

|

||

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press to start automatic shut down |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

START |

|

|

|

|

ABORT |

|

|

|

|

|

|

|

Press to stop automatic shut down |

||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

Automatic shut down |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROGRAM RECIRCULATED WASH SCREEN |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shows the current cycle |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

CYCLE 1 |

|

|

|

|

|

|

|

|

|

|

|

Shows the screen function |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program Recirculated Wash Menu |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turns on or off wash treatment chamber |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Recirculated agent Wash |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

On |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tank Temp |

|

|

Temp |

|

|

|

|

|

|

|

|

|

|

|

Turns on or off the temperature guarantee |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

165 |

|

|

|

|

Guarantee |

|

|

|

|

|

|

|

|

|

|

Changes the temperature in the wash tank |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AGENT SELECTION |

|

|

|

|

|

|

|

|

|

|

|

Select an alkaline wash, |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AKALINE AGENT |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

acid wash, or no agent |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

ACID AGENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

NO AGENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: SOME FEATURES SHOWN ON THE TOUCH PANEL MAY NOT BE AVAILABLE IF OPTIONS WERE NOT SELECTED.

2–4

Series 2200 Washers

PROGRAM RINSE, FINAL RINSE AND DRYER SCREEN

CYCLE 1

PROGRAM RINSE & DRYER

|

RECIRCULATED |

|

|

|

|

FINAL RINSE |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||

|

RINSE ON |

|

|

GUARANTEE ON |

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tank Temp |

|

No Temp |

|

FR Temp |

|

|

Clean |

|

|

|

|

|

|||||||||||

|

185 |

|

|

|

Guarantee |

|

|

|

|

|

|

|

300 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

185 |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAIN

DRYER MENU

ON

|

|

|

|

|

|

|

|

ACCESS SCREEN |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CYCLE PASSWORD |

|

|

|

|

|

|

|

|

|||

|

SERVICE PASSWORD |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter |

|

Change |

|

|

|

|

|

|

Service |

|

|

|

Password |

|

Password |

|

|

|

|

|

|

Password |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unlocked |

|

Press to |

|

|

|

|

|

LOCKED |

|

||

|

|

change |

|

|

|

|

|

|

||||

|

|

|

P/W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Event Print |

|

Adjust |

|

||||

|

Program |

|

MAIN |

|

Frequency |

|

|

|||||

|

|

|

|

Calendar |

|

|||||||

|

|

|

|

|

|

|

|

|

||||

|

Cycle |

|

MENU |

|

|

|

|

|

|

|

||

|

|

|

|

|

300 |

|

|

Clock |

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shows the current cycle

Shows the screen function

Shows status of Recirculated Rinse

Press to change status

Shows status of Final Rinse

Press to change status

Sets time to descale the chamber interior

Sets the final rinse temperature

Shows status of the recirculated rinse guarantee

Press to change status

Sets the rinse tank temperature

Returns to the main menu

Shows status of the Dryer

Press to change status

Press and enter the password to unlock the operator's program

Only for Factory authorized personnel

Changes the operator's password

This program is read only, showing the status of program access (LOCKED )

Changes the password to unlock the operator's program

This program is read only, showing the status of program access (UNLOCKED )

Sets the time and date

Sets the frequency (in seconds) of the printing of live readings of the chamber temperature

Returns to MAIN MENU

Allows access to the programming screens

(after unlocking with ENTER PASSWORD)

CALENDAR CLOCK

61301603708 |

2–5 |

The Control Panel

CALENDAR CLOCK-ENTER NEW VALUES THEN PRESS “SAVE CHANGES” PROMPT

PLC Month |

|

|

PLC Day |

|

|

PLC Year |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

10 |

|

|

|

00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

New Month |

|

|

New Day |

|

New Year |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

10 |

|

|

|

1 |

|

|

|

01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

PLC Hour |

|

PLC Minute |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

56 |

|

|

|

|

|

|

BACK TO |

|

|

|

|

|

|

|

|

|

SAVE |

|

||

|

|

|

|

|

|

|

|

|

|

ACCESS |

||

New Hour |

|

New Minute |

|

CHANGES |

|

|||||||

|

|

|

SCREEN |

|||||||||

|

9 |

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Displays the current screen description

Displays current Year (read-only)

Displays current Day (read-only)

Displays current Month (read-only)

Press to change the Year

Press to change the Day

Press to change the Month

Displays current Hour (read-only)

Displays current Minute (read-only)

Press to return to the Main Access Screen Press to save all changes made in this screen Press to change the Minute

Press to change the Hour

2–6

Series 2200 Washers

MANUAL MODE SCREEN

|

|

|

|

|

|

|

|

|

|

MANUAL MODE |

|

Select Desired |

|

||||

|

|

Function/Abort to Quit |

|

|||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wash |

|

Rinse |

|

Drive |

|

Alkaline |

|

|

|

|

|

Agent |

|

|||

|

Pump |

|

Pump |

|

System |

|

|

|

|

|

|

|

Pump |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wash Tank |

|

Rinse Tank |

|

Dryer |

|

Acid Agent |

|

|

Fill |

|

Fill |

|

System |

|

Pump |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wash Tank |

|

Rinse Tank |

|

Back Flush |

|

Neut. |

|

|

Steam |

|

Steam |

|

Valves |

|

Pump |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wash |

|

Rinse |

|

|

|

|

|

|

Drain |

|

Drain |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wash Tank |

|

Rinse Tank |

|

MAIN |

|

ABORT |

|

|

Flush |

|

Flush |

|

MENU |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•Press any prompt to activate a selected component.

•Press the prompt again to stop the selected component, or press ABORT to stop all activated components.

•All safety interlocks are intact in the manual mode. The wash or rinse pumps do not operate if there is not enough water in the tank.

•Tank fill does not activate if the tank is full.

•Tank fill stops when the tank is full.

•Drains remain open until a prompt is pressed again or until the screen is changed.

•Wash and rinse tank steam shut off when the programmed temperature is reached.

•When the rinse pump is activated, the final rinse is activated.

•For more on manual screens, see on page -1.

61301603708 |

2–7 |

The Control Panel

Cycle Programming

Example: Programming a

Sample Cycle

The following is a SAMPLE cycle along with detailed instructions on how to program the cycle for your reference.

PHASE |

On/Off |

|

TEMPERATURE (°F) |

TEMPERATURE |

AGENT |

(NS) |

(NS) |

|

GUARANTEE |

||

|

|

|

|||

|

|

|

|

|

|

Sample Cycle 1—Touch Control Panel |

|

|

|

||

|

|

|

|

|

|

Pre-wash |

|

|

|

|

|

|

|

|

|

|

|

Wash |

On |

|

140 |

Guaranteed |

Alkaline |

|

|

|

|

|

|

Recirculated Rinse |

On |

|

180 |

Off |

|

|

|

|

|

|

|

Final Rinse |

On |

|

180 |

|

|

|

|

|

|

|

|

Recirculated Air Dryer |

On |

|

|

|

|

|

|

|

|

|

|

WHEN THIS SCREEN APPEARS

CYCLE SELECTION SCREEN

SELECT CYCLE FOR OPERATION

Cycle |

1 |

Cycle

5

Cycle

9

Cycle |

|

Cycle |

|

Cycle |

2 |

|

3 |

|

4 |

|

|

|

|

|

|

|

|

|

|

Cycle |

|

Cycle |

|

Cycle |

6 |

|

7 |

|

8 |

|

|

|

|

|

|

|

|

|

|

Cycle |

|

Cycle |

|

Cycle |

10 |

|

11 |

|

12 |

|

|

|

|

|

PUSH ANY BUTTON TO CONTINUE |

|||

MANUAL |

EVENT |

REVIEW |

|

MODE |

PRINT OFF |

CYCLE |

CYCLE |

FOLLOW THESE STEPS

1.Press CYCLE 1

2.Select REVIEW CYCLE

2–8

Loading...

Loading...