Page 1

USER MANUAL

61301603708 Rev. A

®

SERIES 2200

TUNNEL, CAGE, AND

UTENSIL WASHERS

Page 2

Page 3

USER MANUAL

®

SERIES 2200

TUNNEL, CAGE, AND

UTENSIL WASHER

Getinge/Castle, Inc.

1777 East Henrietta Road

Rochester, New York 14623-3133

Phone: (800) 950-9912 USA

Facsimile: (800) 950-2570

Page 4

WARNING

CAUTION

USER MANUAL 61301603708

Rev. A New Release(08/31/2000)

Related Publications:

Service Data Manual 61301603707

Customer Manual—keyed to the customer’s specific serial number

DESCRIPTION OF SYMBOLS & NOTES IN MANUAL

The following symbols with related notes appear in this manual.

“Warning” notes alert the user to the possibility of personal injury.

“Caution” notes alert the user to the possibility of damage to the equipment.

NOTE

NOTE

“Notes” alert the user to pertinent facts and conditions.

This manual contains proprietary information of Getinge/Castle, Inc. It shall

not be reproduced in whole or in part without the written permission of

Getinge/Castle, Inc.

Castle

®

and are registered trademarks of Getinge/Castle, Inc.

®

Copyright ©2000 by Getinge/Castle, Inc.

Page 5

SPECIAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . vii

Section 1 General Description

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

EXTERNAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . 1–4

INTERNAL COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . 1–7

MOST COMMON OPTIONS . . . . . . . . . . . . . . . . . . . . . . . 1–9

Table of Contents

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Emergency Stop Cable . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Alarm (not shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Wash Chamber Access Doors. . . . . . . . . . . . . . . . . . . 1–5

Rinse Chamber Access Door. . . . . . . . . . . . . . . . . . . . 1–5

Final Rinse Heat Exchanger . . . . . . . . . . . . . . . . . . . . 1–5

Drawer and Basket-Type Debris Filters. . . . . . . . . . . . 1–5

Agent Injection Ports (not shown) . . . . . . . . . . . . . . . . 1–5

Exhaust Plenum (not shown). . . . . . . . . . . . . . . . . . . . 1–5

Six-Foot Recirculated Air Dryer (not shown) . . . . . . . . 1–5

Seven-Foot 99% Plastic Cage Dryer . . . . . . . . . . . . . . 1–5

Ten-Foot Recirculated Air Dryer (not shown) . . . . . . . 1–5

Unload Roller Conveyor. . . . . . . . . . . . . . . . . . . . . . . . 1–6

Control Box Access Panel . . . . . . . . . . . . . . . . . . . . . . 1–6

Electrical Disconnect Switch . . . . . . . . . . . . . . . . . . . . 1–6

Upper Spray Manifold . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Lower Spray Manifold . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Hydraulic Hold Down (not shown) . . . . . . . . . . . . . . . . 1–8

Wash, Rinse, and Final Rinse Treatment Temperature

Guarantees (not shown) . . . . . . . . . . . . . . . . . . . . 1–8

Water Conservation (not shown) . . . . . . . . . . . . . . . . . 1–8

Stainless Steel Treatment Components . . . . . . . . . . . 1–9

House Tap Water Temperature Booster . . . . . . . . . . . 1–9

Steam and Water Pressure Gauges . . . . . . . . . . . . . . 1–9

Automatic Self Cleaning Debris Filter . . . . . . . . . . . . . 1–9

Automatic Drain System . . . . . . . . . . . . . . . . . . . . . . . 1–9

Drain Discharge Cool Down Injection System . . . . . . . 1–9

Washer Interior Cleaning and Descaling System . . . . 1–9

Automatic Conveyor Stop . . . . . . . . . . . . . . . . . . . . . . 1–9

Recorder/Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

61301603708 iii

Page 6

Section 2 The Control Panel

GENERAL MACHINE DESCRIPTION. . . . . . . . . . . . . . . 1–10

Automatic Treatment Cycle . . . . . . . . . . . . . . . . . . . . 1–10

Treatment Schedule . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Temperature Guarantee System. . . . . . . . . . . . . . . . 1–11

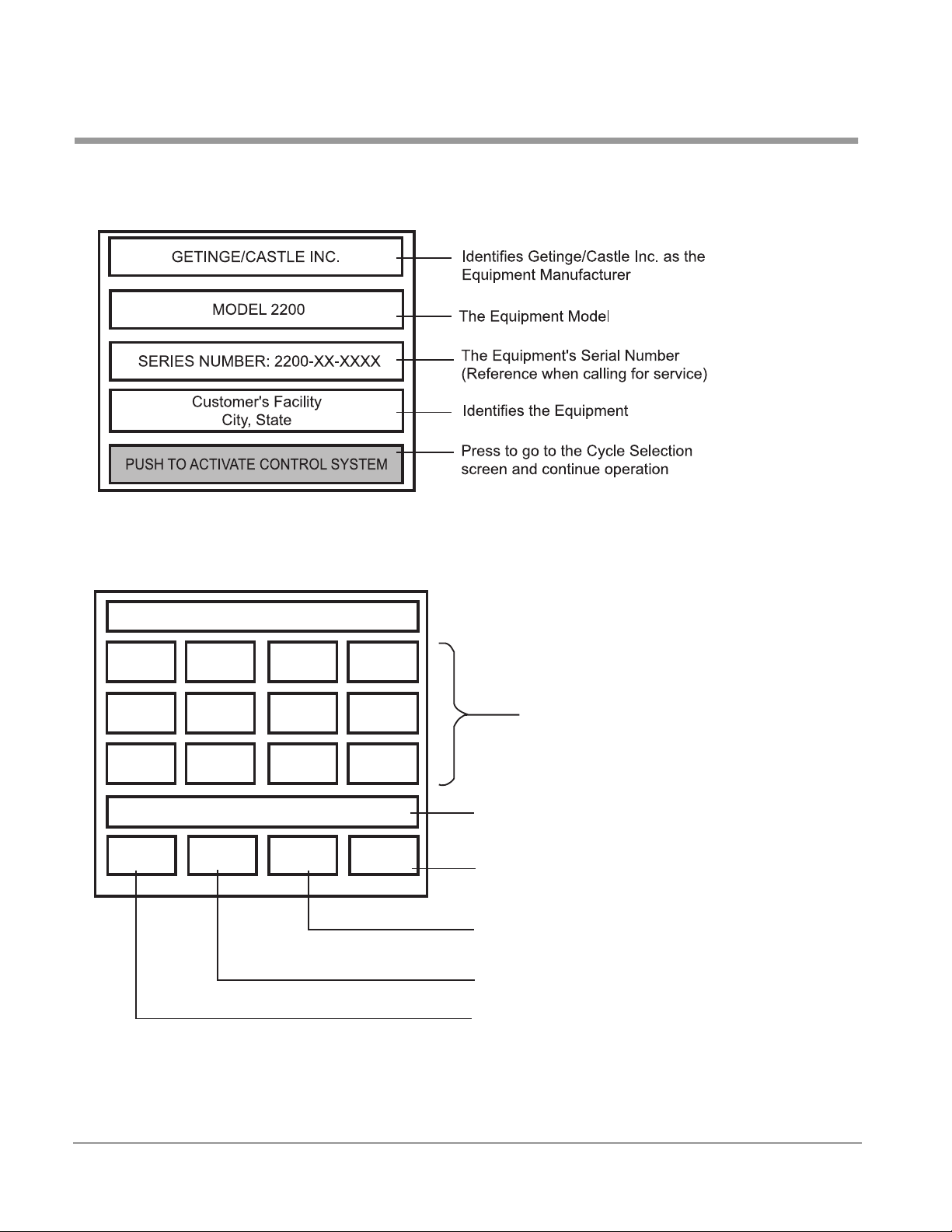

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

TOUCH CONTROL PANEL (TCP) . . . . . . . . . . . . . . . . . . 2–2

Control Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Cycle Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Example: Programming a Sample Cycle. . . . . . . . . . . 2–8

LED CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Key Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Data Entry Keys (keypad) . . . . . . . . . . . . . . . . . . . . . 2–15

Control Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . 2–16

Processing Cycle Screen Description . . . . . . . . . . . . 2–18

Standby Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–18

SELECT CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–18

REVIEW CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–19

MANUAL MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

Cycle Programming. . . . . . . . . . . . . . . . . . . . . . . . . . 2–21

Cycle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–22

Programming a Cycle . . . . . . . . . . . . . . . . . . . . . . . . 2–22

Example: Programming a Sample Cycle. . . . . . . . . . 2–24

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

Starting Wash Cycle . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

ELECTRO-MECHANICAL CONTROLS . . . . . . . . . . . . . 2–27

Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–27

Cycle Programming. . . . . . . . . . . . . . . . . . . . . . . . . . 2–30

Final Rinse Temperature Settings. . . . . . . . . . . . . . . 2–30

Internal Timers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

Section 3 Operating Instructions

GENERAL MACHINE OPERATION . . . . . . . . . . . . . . . . . 3–1

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Treatment Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

DAILY CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Operational Readiness . . . . . . . . . . . . . . . . . . . . . . . . 3–3

iv

Page 7

Section 4 Maintenance

Section 5 Troubleshooting

EMERGENCY STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Using the Emergency Cable . . . . . . . . . . . . . . . . . . . . 3–4

EMERGENCY SHUT-DOWN. . . . . . . . . . . . . . . . . . . . . . . 3–4

Shutting Down the Washer . . . . . . . . . . . . . . . . . . . . . 3–4

GENERAL MAINTENANCE SCHEDULE. . . . . . . . . . . . . . 4–1

ROUTINE MAINTENANCE SCHEDULE—STANDARD . . 4–2

When required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Six Months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

RECOMMENDED SPARE PARTS LIST . . . . . . . . . . . . . . 4–6

Consumable Stock. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

CYLE INTERRUPT CONDITIONS. . . . . . . . . . . . . . . . . . . 5–3

Resettable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Non-Resettable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Section 6 Installation Instructions

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

UNCRATING & EQUIPMENT INSPECTION . . . . . . . . . . . 6–1

INSTALLATION /ASSEMBLY CHECKLIST . . . . . . . . . . . . 6–2

Equipment Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

STARTUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Touch Control Panel (TCP) . . . . . . . . . . . . . . . . . . . . . 6–3

LED Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Electro-Mechanical Controls . . . . . . . . . . . . . . . . . . . . 6–5

CHECK-OUT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 6–6

TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

Section 7 Options

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

MOST COMMON OPTIONS . . . . . . . . . . . . . . . . . . . . . . . 7–1

Right or Left Handed Service. . . . . . . . . . . . . . . . . . . . 7–1

Wash and Rinse Treatment Temperature Guarantee . 7–1

61301603708 v

Page 8

Final Rinse Temperature Guarantee. . . . . . . . . . . . . . 7–1

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

RS232 Data Computer Port. . . . . . . . . . . . . . . . . . . . . 7–3

RS485 Data Computer Port. . . . . . . . . . . . . . . . . . . . . 7–3

Bedding Dispenser Controls . . . . . . . . . . . . . . . . . . . . 7–3

Bedding Dump Station Controls . . . . . . . . . . . . . . . . . 7–3

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Stainless Steel Treatment Components . . . . . . . . . . . 7–7

Automatic Self Cleaning Debris Filter . . . . . . . . . . . . . 7–8

Automatic Drain System . . . . . . . . . . . . . . . . . . . . . . . 7–8

Wash Interior Cleaning and Descaling System . . . . . . 7–9

Acid Treatment System . . . . . . . . . . . . . . . . . . . . . . . . 7–9

Non-Recirculated Final Pure Water Rinse. . . . . . . . . 7–10

Water Pressure Reducing Station . . . . . . . . . . . . . . . 7–10

House Tap Water Temperature Booster . . . . . . . . . . 7–10

Automatic Agent Injection System (Optional) . . . . . . 7–10

Automatic Agent Injection System – Time Based . . . 7–12

Agent Neutralization System Non-Monitored . . . . . . 7–12

pH Monitored. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

Mechanical Hold Down System. . . . . . . . . . . . . . . . . 7–13

Six Foot Recirculated Air Dryer Section . . . . . . . . . . 7–14

Seven Foot 99% Plastic Cage Dryer . . . . . . . . . . . . . 7–14

Ten Foot Recirculated Air Dryer Section. . . . . . . . . . 7–15

Load/Unload Conveyor . . . . . . . . . . . . . . . . . . . . . . . 7–15

Power Discharge Unload Conveyor . . . . . . . . . . . . . 7–15

Automatic Conveyor Stop . . . . . . . . . . . . . . . . . . . . . 7–15

Exhaust Plenum System . . . . . . . . . . . . . . . . . . . . . . 7–16

Power Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–16

Drain Discharge Cool-Down Injection System –

Non-Monitored . . . . . . . . . . . . . . . . . . . . . . . . . . 7–17

Steam and Water Pressure Gauges . . . . . . . . . . . . . 7–17

Chilled Water Vapor Removal Condenser. . . . . . . . . 7–17

Barrier Trim Flange System. . . . . . . . . . . . . . . . . . . . 7–17

M.O.D.E.M. (MTP Online Diagnostics, Evaluation,

and Monitoring) System . . . . . . . . . . . . . . . . . . . 7–18

Seismic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–18

Appendix A Manual Screens

Index

vi

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

PROGRAMMING A CYCLE USING MANUAL MODE. . . . A–1

Page 9

SPECIAL SAFETY INSTRUCTIONS

THE FOLLOWING SAFETY INSTRUCTIONS APPEAR WITHIN THIS

MANUAL. READ THEM CAREFULLY BEFORE OPERATING THE UNIT.

WARNING

“Warning” notes alert the user to the possibility of personal

injury.

Warnings Summary p. xi

BURN HAZARD:This washer operates at extremely high temperatures.

Prior to any machine maintenance or service, the washer should be allowed

sufficient time to cool. Caution should be used in and around the washer

chamber and external piping. Water flow and discharge piping can cause

personal injury such as burns. Operators should partially open the chamber

door to allow hot air to exhaust and to allow all loads adequate time to cool.

Opening the chamber door fully may cause large amounts of steam to

escape.

SHOCK HAZARD: Prior to any service or maintenance on the washer, all

utilities should be disconnected and the lockout/tagout procedures should

be followed to insure safety and prevent accidental shock.

PERSONAL HAZARD AND EQUIPMENT DAMAGE: Safe and efficient

operation of this equipment requires scheduled preventative maintenance.

Routine adjustments and replacement of parts by other than qualified

maintenance personnel may cause personal injury or the equipment to

perform less than its capabilities.

General Machine Operation p. 3-1

BURN HAZARD: Do not open station access doors during a cycle.

This could release hot water through the door opening, resulting in

burns to personnel.

Daily Checklist p. 3-3

HOT SURFACES: The area surrounding the load and unload end of the

washer could be hot. Use caution when loading or unloading ware.

Routine Operation: Detail p. 3-6

BURN HAZARD: Do not open a Washer door during a cycle. This could

release hot water through the door opening, resulting in burns to personnel.

Routine Maintenance Schedule - Standard, Every Six Months p 4-4

ELECTRIC SHOCK HAZARD: Only an electrician should perform this test!

61301603708 vii

Page 10

viii

Page 11

INTRODUCTION

Section 1 General Description

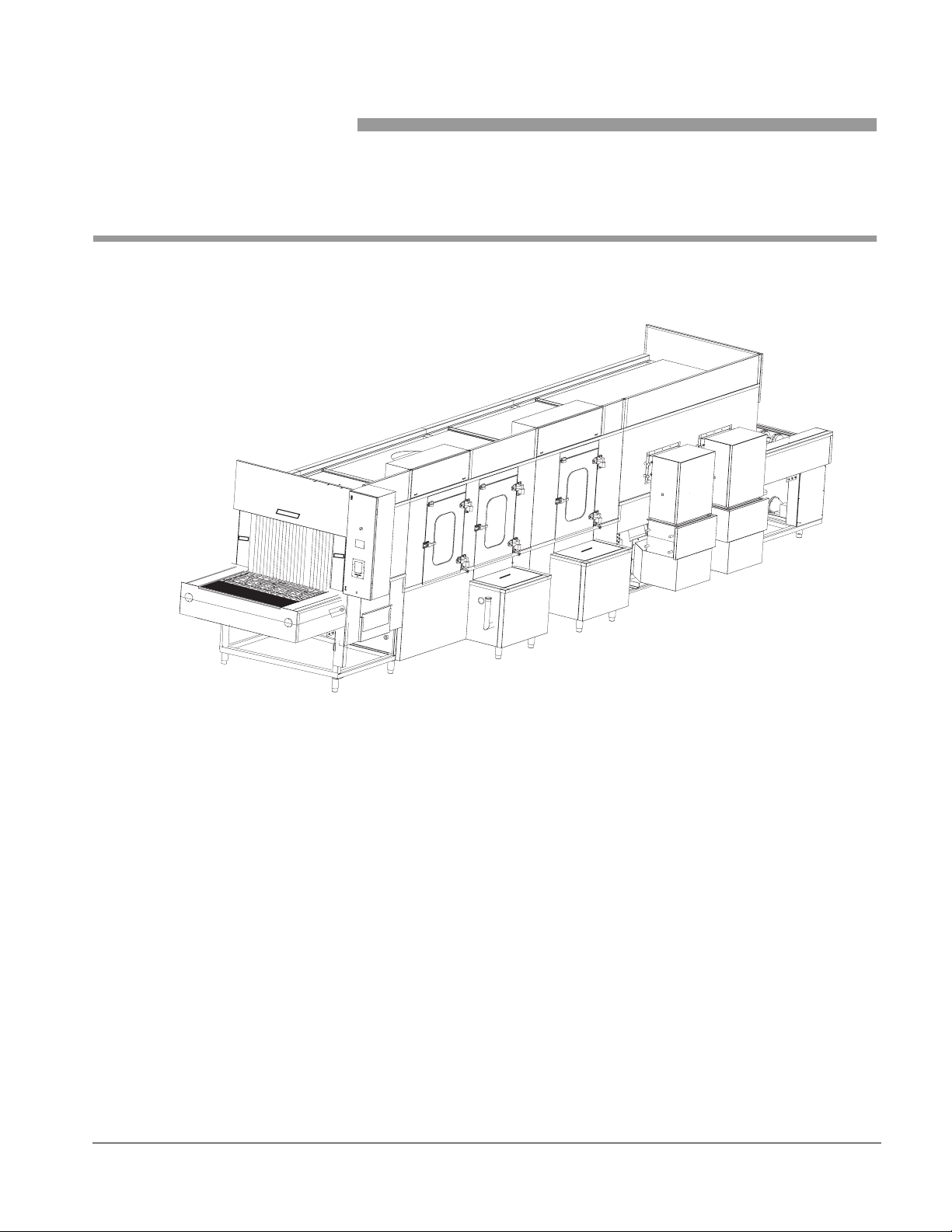

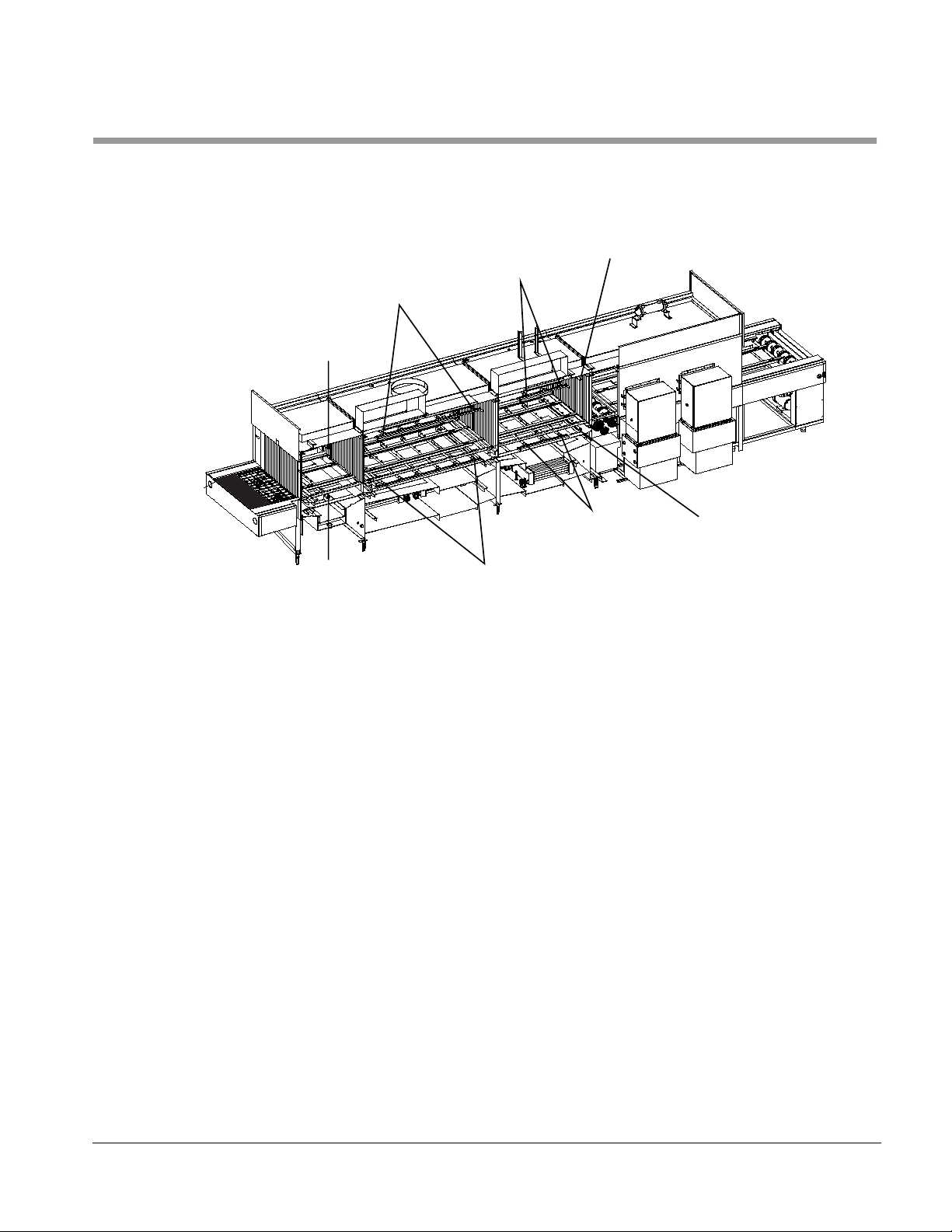

Figure 1–1. MTP 2200 SERIES WASHERS

MTP

2200 series units are automatic, heavy duty, tunnel-type hydrospray

washers with conveyors. They are designed for continuous high volume

processing. These units are designed to clean, sanitize, and dry— efficiently

and thoroughly —metal or plastic cages, racked watering bottles, and

utensils used in research animal care facilities.

Units may be recessed through one or two walls or installed free standing.

Left side service access and control terminal location is standard with right

side service access and control terminal location optional.

61301603708 1–1

Page 12

General Description

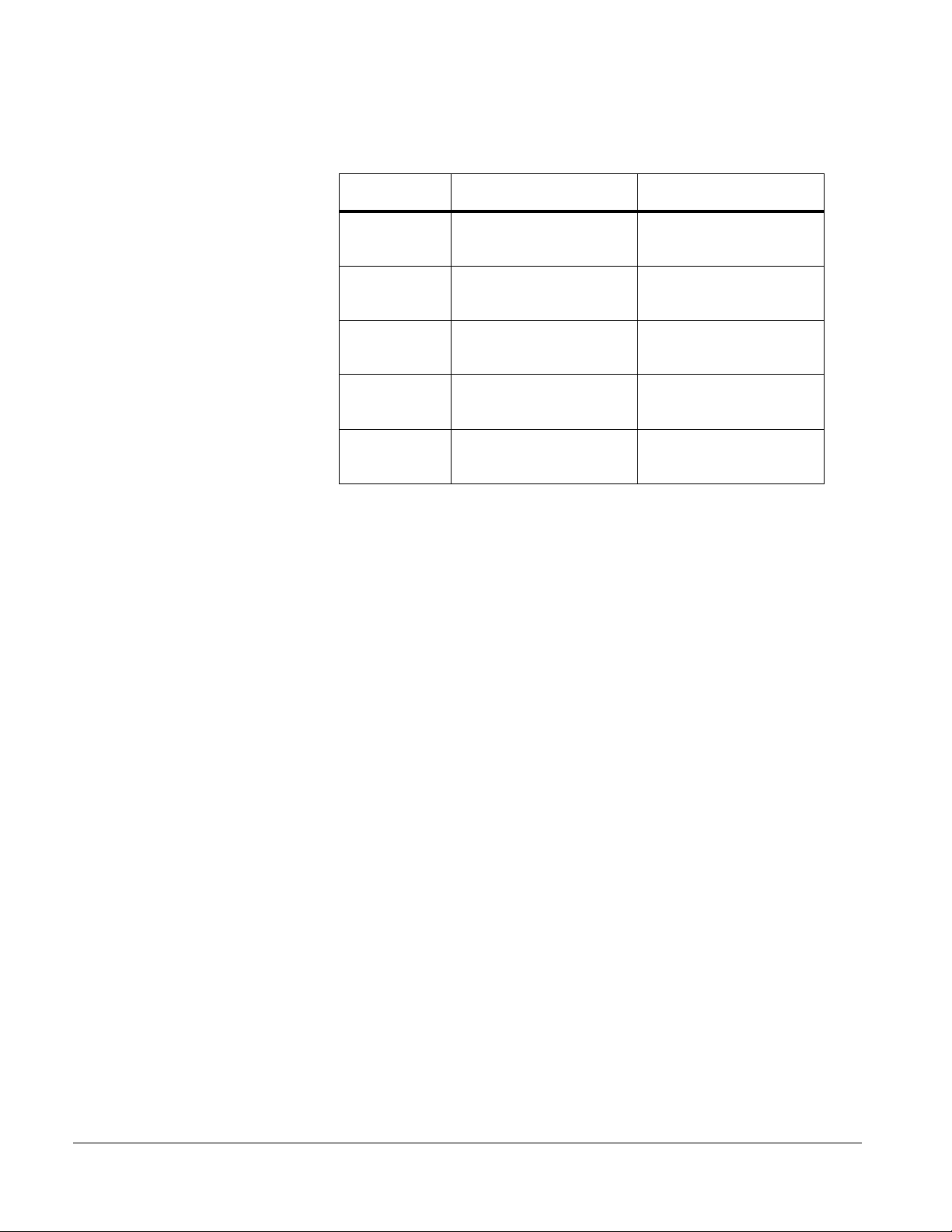

Models and dimensions are listed in Table 1–1.

Table 1–1. MTP 2200 series washers

MODEL CHAMBER

2224 25x25

[64x64]

2230 31x25

[79x64]

2236 37x25

[94x64]

2242 43x25

[107x64]

2248 48x25

[122x64]

(in. [cm])

OVERALL

(in. [cm])

65½x85

[145x213]

71½x85

[160x213]

77½x85

[175x213]

83½x85

[212x213]

89½x85

[227x213]

Routine operation consists of manually placing the items to be cleaned

upside down on the conveyor belt at the load end of the unit. The items are

conveyed automatically through the process treatments and discharged at

the unload end for removal.

Treatment solutions are delivered by means of stationary manifolds

equipped with jet spray nozzles. These manifolds are located above and

below the conveyor at each station (except dry).

Standard Features

Processing cycles are controlled by means of a Programmable Logic

Controller (PLC) equipped with a touch screen interface or LED Control

Panel. Twelve cycle selections are possible. The user selects and starts an

appropriate cycle.

A standard cycle has these phases: Prewash, Agent Wash, Recirculated

Rinse, Final Rinse, and Recirculated Air Dry. The cycle, once activated, is

completely automatic.

• Microcomputer Color Touch Screen Control

• Twelve User-Programmable Cycles

• Personnel Safety System

• Wash and Rinse Temperature Assurance

• 180°F Non-recirculated Final Rinse

• Water Conservation System

• Removable Spray Headers

• Hydraulic Hold Down System

• 7.5 HP Wash Pump (10HP on Models 2230 & 2236)

• 3 HP Recirculated Rinse Pump

• Basket and Drawer Type Debris Screens

• Agent Injection Ports and Contacts

• Stainless Steel Steam Coil Heating

• Stainless Steel Flat Wire Conveyor Belt

• All Stainless Steel Construction

1–2

Page 13

• Side Hinged Chamber Access Doors

• Exhaust Plenum with Single Point Connection

• Insulated Chamber Construction

• Left Service Side Installation

• Program Access Code Security

Series 2200 Washers

Optional Features

• Strip Chart Printer

• RS232 or RS485 Port for Data Download

• Right Service Side Installation

• Stainless Steel Treatment Components

• Automatic Self-Cleaning Debris Filter

• Automatic Fill and Drain with Interior Tank Cleaning

• Non-Recirculated Final Pure Water Rinse

• Water Supply Temperature Booster

• Automatic Agent Injection Systems

• Acid Wash Tunnel Section

• Six, Seven, or Ten Foot Recirculated Dryer Section

• Four, Six, or Eight Foot Unload Conveyor

• Automatic Conveyor Stop

• Power Exhaust Fan

• Vapor Removal Condenser

• Drain Discharge Cool Down System

• Treatment Solution pH Neutralization

• High Altitude Inducers

• Barrier Wall Recessing System

• Remote Control Terminal Location

• Seismic Design

• Knocked Down Shipment

61301603708 1–3

Page 14

General Description

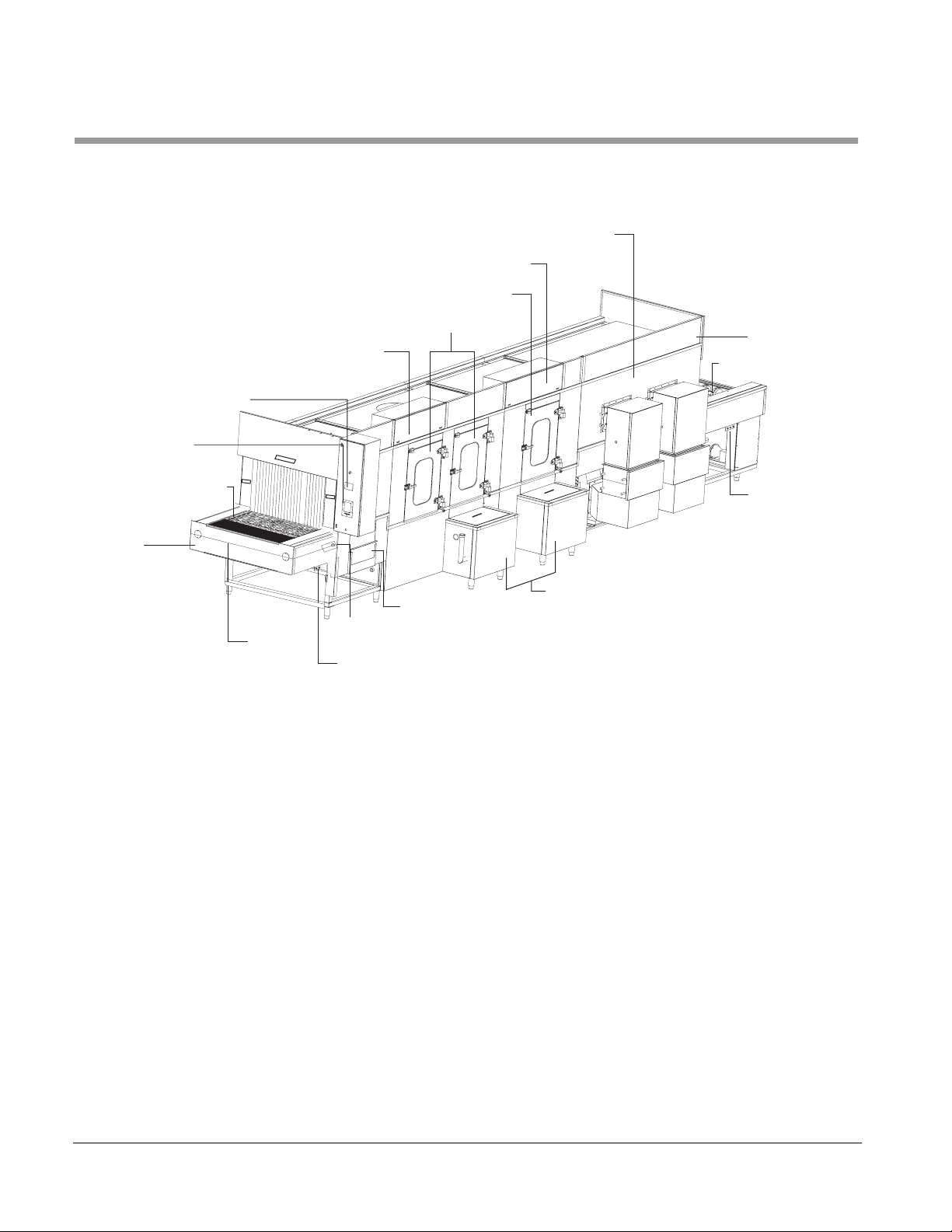

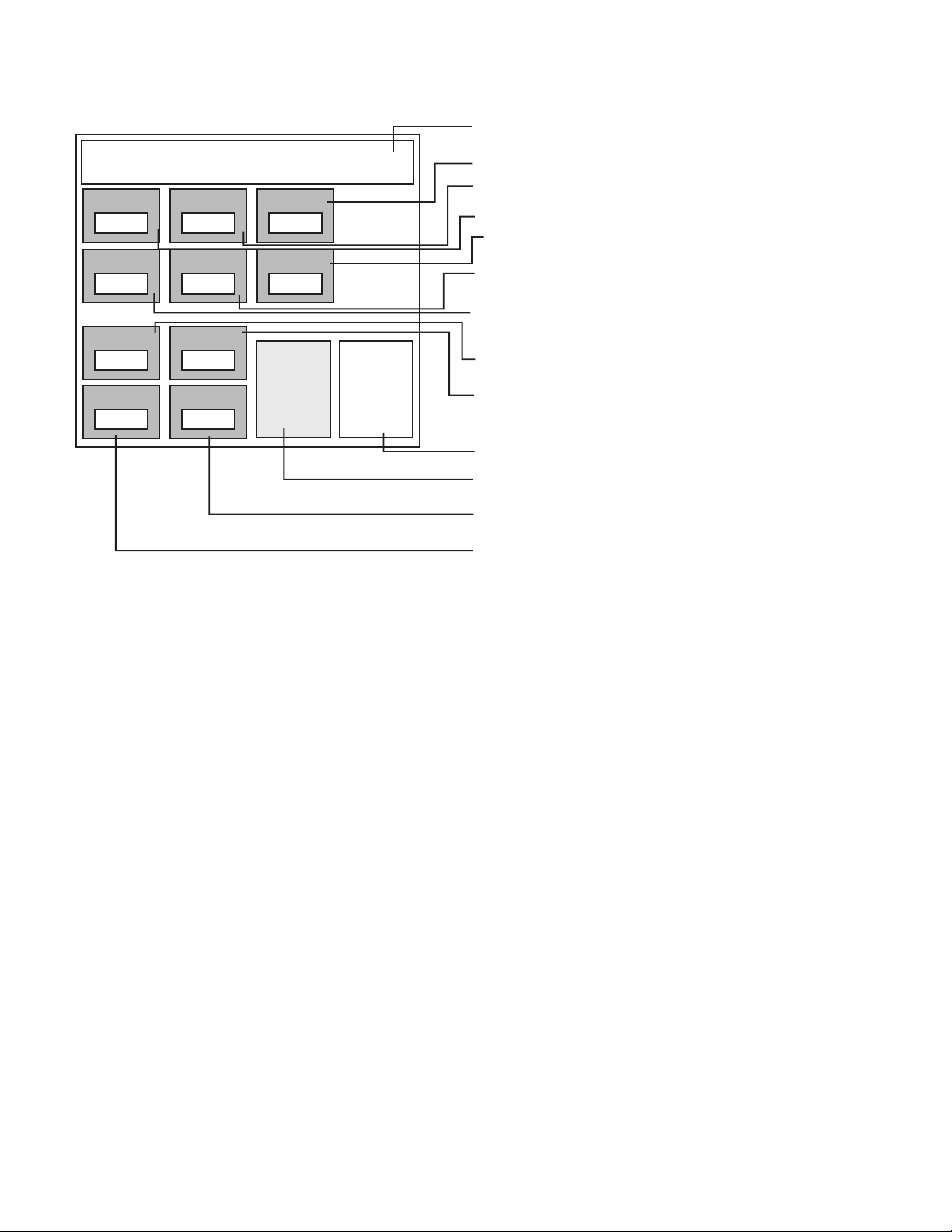

EXTERNAL COMPONENTS

CONTROL BOX

ACCESS PANEL

CONTROL PA NE L

RECORDER/

PRINTER

(Option)

Figure 1–2. EXTERNAL COMPONENTS

SEVEN FOOT

RECIRCULATED

ELECRICAL

DISCONECT

SWITCH

RINSE CHAMBER

ACCESS DOOR

WASHER CHAMBER

ACCESS DOORS

AIR DRYER

UNLOAD END

CONVEYOR

CONVEYOR

LOAD END

Control Panel

Emergency Stop Cable

EMERGENCY

STOP CABLE

GREASE FITTINGS

BASKET TYPE

DRAWER TYPE

EMERGENCY

STOP RESET

GREASE FITTINGS

DEBRIS SCREEN

DEBRIS SCREEN

Provides a touch screen interface with the Programmable Logic Controller

(PLC) located in the control box. Enables the user to select, program, and

monitor processing cycles.

An emergency stop cable is provided at both the load and unload ends of

the unit to terminate all process and conveyance functions. Processing is

resumed by resetting the emergency stop cable and pressing the cycle start

button.

Each chamber access door is equipped with a disconnect switch to

terminate all processing and conveyance functions upon opening of any

door. Processing cannot be resumed unless all doors are fully closed.

Alarm (not shown)

1–4

Sounds an audible alert:

• when the emergency stop cable is pulled

• when a chamber access door is opened.

Page 15

Series 2200 Washers

Conveyor

Wash Chamber Access Doors

Rinse Chamber Access Door

Final Rinse Heat Exchanger

Drawer and Basket-Type Debris Filters

Agent Injection Ports (not shown)

Exhaust Plenum (not shown)

A stainless steel, flat wire conveyor runs the full length of the processing

chamber carrying soiled ware through the unit’s treatment stations.

Sprockets at both the load and unload ends provide positive belt tracking.

Belt tension and speed are adjustable.

Removable, side hinged splash proof doors provide easy access to unit

Wash Chamber

Removable, side hinged splash proof door provides easy access to unit

Rinse and Final Rinse Chambers.

Ensures that a minimum 180oF final rinse temperature is attained and

maintained. Should the final rinse temperature assurance set point not be

attained or maintained the variances are annunciated to the user.

The pre-wash, agent wash, and recirculated rinse treatments are filtered

through drawer or basket-type stainless steel screens to prevent plugged

spray jets. The screens are easily accessible for cleaning.

Three agent injection ports and dry electrical contacts are provided for

installation of automatic agent injection systems.

A stainless steel exhaust plenum is provided for exhausting the washer and

dryer through a single point connection. Each machine vent is provided with

its own individual manual damper.

Six-Foot Recirculated Air Dryer (not shown)

Seven-Foot 99% Plastic Cage Dryer

Ten-Foot Recirculated Air Dryer (not shown)

An insulated stainless steel six-foot long dryer section to recirculate hot air

to dry the load is provided. The system consists of a steam to air heat

exchanger, a single 5 HP blower capable of providing a 1600 CFM air flow

and a stainless steel plenum system. Moisture is eliminated by exhausting a

portion of the recirculated air to the facility exhaust system. Plastic cages

are delivered at the unload end 95% dry. All air ducting is stainless steel and

includes required manual dampers.

An insulated stainless steel seven-foot long dryer section to recirculate hot

air to dry the load is provided. The system consists of a steam-to-air heat

exchanger, a dual 5 HP blower capable of providing a 3200 CFM air flow

and a stainless steel plenum system. Moisture is eliminated by exhausting a

portion of the recirculated air to the facility exhaust system. The conveyor

belt is separated from the wash compartment to remove the excess water

remaining on the plastic cages exiting the recirculated air dyer. This system

delivers the plastic cages 99% dry at the discharge of the dryer, permitting

filling of the cage immediately.

An insulated stainless steel ten-foot long dryer section to recirculate hot air

to dry the load is provided. The system consists of a steam to air heat

exchanger, a dual 5 HP blower capable of providing a 3200 CFM air flow

and a stainless steel plenum system. Moisture is eliminated by exhausting a

portion of the recirculated air to the facility exhaust system. Plastic cages

are delivered at the unload end 95% dry. All air ducting is stainless steel and

includes required manual dampers.

61301603708 1–5

Page 16

General Description

Unload Roller Conveyor

Control Box Access Panel

Electrical Disconnect Switch

A stainless steel, roller type, gravity conveyor is at the output end of the unit

to facilitate unloading.

Permits access to the unit’s control box located above Washer Chamber

door. Box contains the programmable controller, fuses, contactors, relays,

etc., and other essential components of the unit’s electrical system. (Access

restricted to qualified personnel only).

An UL/CSA approved, non-fusible 3 pole, electrical disconnect switch is

provided in the primary control box to provide additional protection to the

facilities personnel. The disconnect switch incorporates a handle

mechanism mounted through the control box front access panel and is

sealed to a NEMA 4X water tight rating. The handle must be turned to the

“OFF” position, disconnecting the incoming electrical service prior to

accessing the internal control box components.

1–6

Page 17

INTERNAL COMPONENTS

UPPER

SPRAY MANIFOLD

PREWASH STATION

Figure 1–3. INTERNAL COMPONENTS

UPPER

SPRAY MANIFOLD

WASH STATION

UPPER

SPRAY MANIFOLD

RINSE STATION

FINAL RINSE STATION

UPPER

SPRAY MANIFOLD

Series 2200 Washers

Upper Spray Manifold

Lower Spray Manifold

LOWER

SPRAY MANIFOLD

PREWASH STATION

A stationary, single manifold that delivers the jet spray and treatment agent

down on to soiled ware as it is conveyed through each station. These

manifolds are located in the following stations:

• Prewash

• Wash

• Rinse

• Final Rise

A stationary, single manifold that delivers the jet spray and treatment agent

up into soiled ware that is conveyed through each station. These manifolds

are located in the following stations:

• Prewash

• Wash

• Rinse

• Final Rise

SPRAY MANIFOLD

LOWER

SPRAY MANIFOLD

WASH STATION

LOWER

RINSE STATION

LOWER

SPRAY MANIFOLD

FINAL RINSE STATION

61301603708 1–7

Page 18

General Description

Hydraulic Hold Down (not shown)

Wash, Rinse, and Final Rinse Treatment Temperature Guarantees (not shown)

Water Conservation (not shown)

Jet spray header throttle valves are properly sized and positioned to

hydraulically hold down light plastic cage and steel pans to the conveyor. By

setting the throttle valve to restrict flow to the lower header, the pressure

differential will allow a higher volume of water to push down on caging.

An agent wash, recirculated rinse, or final rinse temperature guarantee may

be programmed to ensure that minimum treatment temperatures are

attained and maintained. Should the temperature guarantee set points not

be attained or maintained, the conveyer belt will temporarily stop until the

treatment solution reaches the set point temperature. The controls signal

the user if there are any variances.

The hot tap final rinse water is sprayed through the jet system and collected

in the recirculated rinse tank. The water is used for the recirculated wash,

rinse and pre-wash for water and energy conservation.

1–8

Page 19

MOST COMMON OPTIONS

Series 2200 Washers

Stainless Steel Treatment Components

House Tap Water Temperature Booster

Steam and Water Pressure Gauges

Automatic Self Cleaning Debris Filter

Automatic Drain System

Drain Discharge Cool Down Injection System

Washer Interior Cleaning and Descaling System

All components including valves, pump, and piping that come in contact with

the recirculating treatment solution are 304 stainless steel to provide system

life and durability

An instantaneous steam to water heat exchanger is provided to raise the

house tap water supply temperature.

Pressure gauges are provided on the incoming steam and water lines to

monitor the facility utilities.

The output of the wash pump is provided with a self cleaning debris screen

having perforations smaller than the spray jets’ orifices to prevent plugged

jets. The debris filter is automatically controlled to filter the recirculated was

solution and to periodically back flush debris to the drain. The screen

element may be accessed without the use of tools.

Provides the capability to automatically drain the agent wash and

recirculated rinse tanks at the end of the processing period.

Cold tap water is automatically injected into the drain discharge to lower the

discharge temperature before entering into the building’s drain system.

Provided in the interior of each tank are jets to wash the walls of the tank to

remove debris build up. When activated the control system automatically

drains the wash tank, refills the tank with fresh water and a descaling agent,

and activates the belt and pumps for a user programmable period of time,

automatically draining and flushing each tank. This system reduces or

eliminates the need to clean the tanks manually.

Automatic Conveyor Stop

Recorder/Printer

A photoelectric switch is located at the end of the discharge conveyor to

automatically stop the conveyor drive when an item reaches the end of the

conveyor. A second photo eye may be located at the end of a bedding

dispenser, if equipped, user may program cycle to stop at end of washer or

dispenser. A stopped conveyor condition is visually annunciated to the user

on the control screen.

Issues a printed record of all pertinent cycle data, including treatment

functions, temperature, time and date. A Take-Up Reel is provided to

retrieve and rewind the print-out onto a spool. See also: Appendix A:

Recorder/Printer.

61301603708 1–9

Page 20

General Description

GENERAL MACHINE DESCRIPTION

At the start of the processing period, the user activates the unit for

automatic operation by turning on the main disconnect switch. The unit

automatically goes through a self diagnostic test then fills with fresh water

and heats to programmed temperature.

The user at this time can press the start prompt and place the load to be

cleaned on the stainless steel flat wire. The unit will automatically proceed

through the treatment process and deliver the items at the unload end of the

machine.

Automatic Treatment Cycle

Treatment Schedule

The standard treatment cycle consists of a pre-wash, an agent wash, a

recirculated rinse, final rinse, and recirculated air dry. All wash and rinse

treatments are recirculated under pump pressure. The cycle, once

activated, is completely automatic. Additional cycle treatment phases are

available.

PRE-WASH

Hot water from the recirculated rinse tank is directed through the upper and

lower jet spray headers under pump pressure to remove gross debris. This

solution is not recirculated and is sent to drain.

AGENT WASH

Hot chemical solution, from the wash tank, is recirculated through the wash

jet spray headers under pump pressure and retained in the wash tank.

Wash temperature is progammable up to 190

RECIRCULATED RINSE

Hot water from the rinse tank, is recirculated through the rinse jet spray

headers (top to bottom) under pump pressure and retained in the rinse tank.

Rinse temperature is programmable up to 190

NON-RECIRCULATED FINAL RINSE

Hot tap water from house supply is heated by a steam heat exchanger and

directed through separate final rinse jet spray headers under house supply

pressure and retained in the rinse tank for the recirculated rinse and pre-

wash. Final rinse temperature is manually adjustable to 195

o

F.

o

F.

o

F.

1–10

RECIRCULATED AIR DRY (Optional)

Hot air is recirculated through a finned steam coil and directed through flat

air knives. The dryer temperature is manually adjustable. Moisture is

eliminated by exhausting a portion of the recirculated air to the facility

exhaust system.

Page 21

Series 2200 Washers

Temperature Guarantee System

NOTE

When selected, this will cause the unit to fill and spray water normally for

that phase. If at any time the tank temperature should fall below setpoint, the

conveyor belt will stop until the temperature exceeds setpoint. Failure to do

so in a set period of time will generate a “too long to heat” alarm.

• Operation (conveyor/recirculation) pauses if:

1) the wash or rinse water temperature setpoints not be met, or

2) the contents of a wash or rinse tank drop below its low level limit.

Otherwise, the unit runs until stopped by operating personnel.

• Water supplies held in Wash and Rinse Tanks are re-used until drained at

the end of the day (or as required—a determination made by operating

personnel).

61301603708 1–11

Page 22

General Description

1–12

Page 23

INTRODUCTION

Section 2 The Control Panel

Your unit has one of the following control panels:

• TOUCH CONTROL PANEL (TCP), see page 2–2

• LED CONTROLLER, see page 2–12

• ELECTRO-MECHANICAL CONTROLS, see page 2–27

The control panel provides an interface linked to the Programmable Logic

Controller (PLC) in the control box.

Using the control panel, the user can:

• Program treatment temperatures.

• Select treatments.

• Start the unit.

• Monitor the status of unit operation.

• Drain the unit’s wash and rinse water tanks.

• Control conveyor operation.

In addition, supervisory personnel can:

• Access load counters and time display

• Protect cycle programming

61301603708 2–1

Page 24

The Control Panel

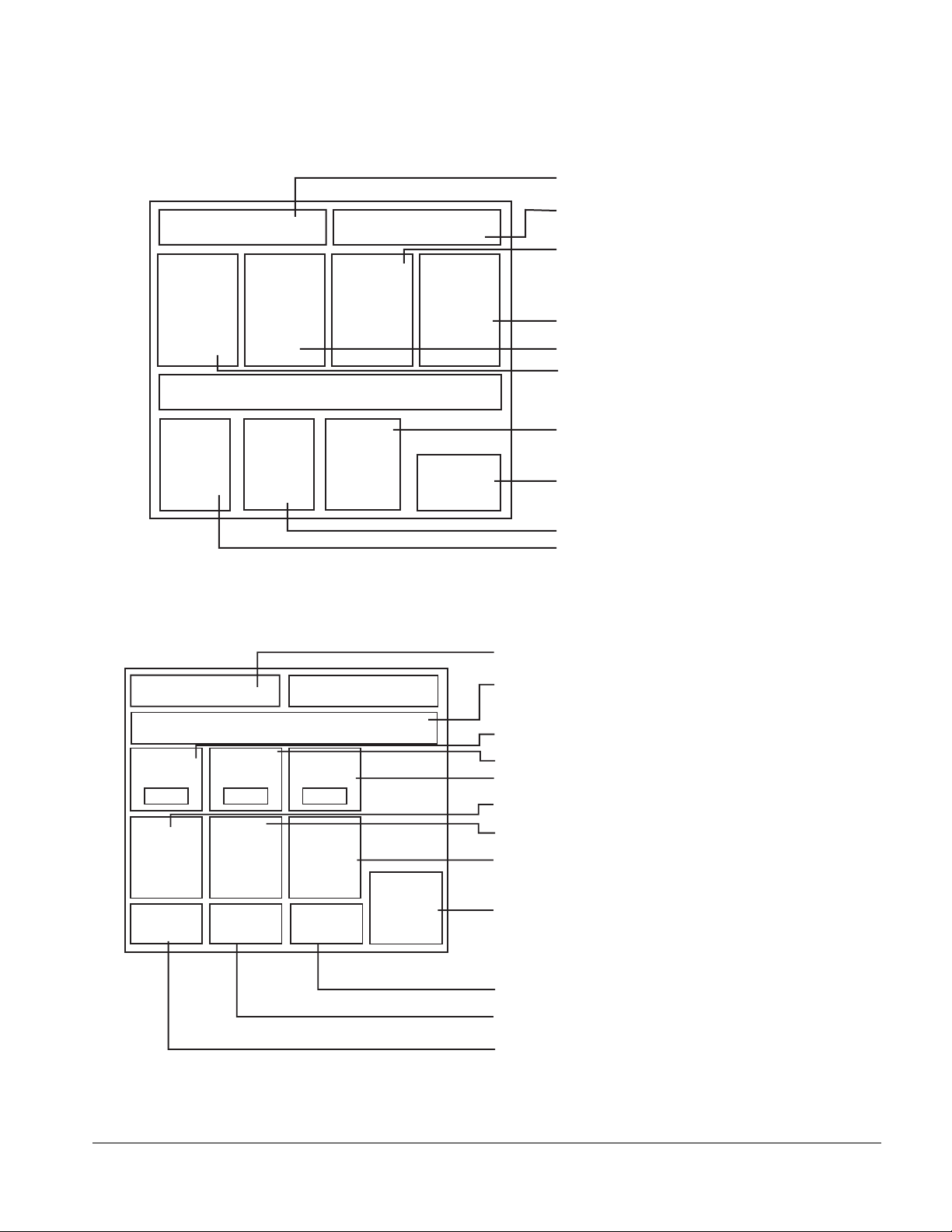

TOUCH CONTROL PANEL (TCP)

Control Screens

SELECT CYCLE FOR OPERATION

MAIN CONTROL SCREEN

CYCLE SELECTION SCREEN

Cycle

1

Cycle

5

Cycle

9

PUSH ANY BUTTON TO CONTINUE

MANUAL

MODE

Cycle

2

Cycle

6

Cycle

10

EVENT

PRINT OFF

Cycle

3

Cycle

7

Cycle

11

PRINT

CYCLE

Cycle

4

Cycle

8

Cycle

12

REVIEW

CYCLE

Press the desired cycle of operation

Press to start the automatic drain and shut down

operation. You will be directed to the Automatic

Shut down Cycle screen to begin this process

After a cycle is selected, press to review the

cycle and show the CYCLE START prompt

Press to print cycle parameters

When selected, prints live readings

during the cycle

Press to enter manual mode, to test

functions

2–2

Page 25

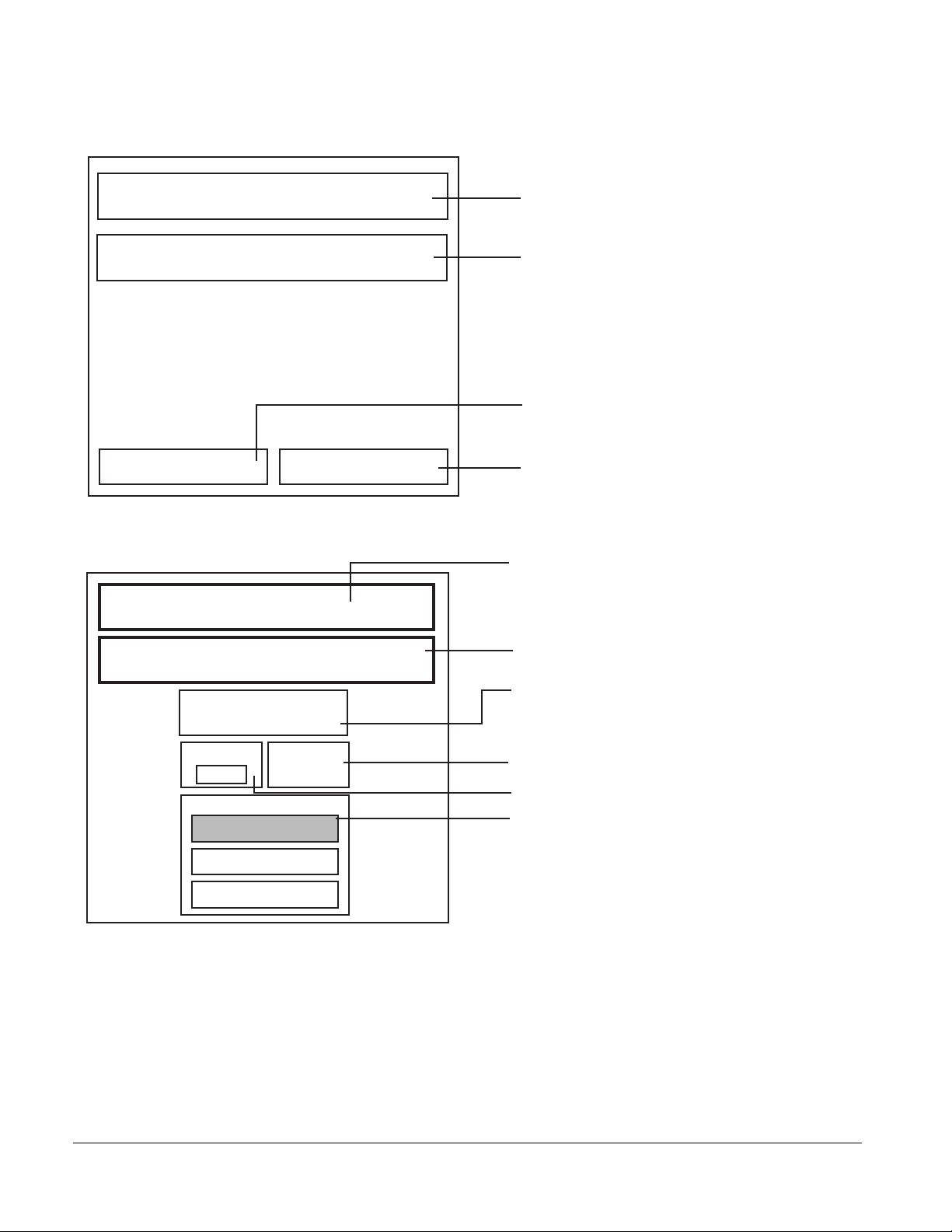

REVIEW PROGRAMMED PHASES SCREEN

Shows the selected cycle

Series 2200 Washers

CYCLE 1

RECIRCUL'D

WASH

SYSTEM OFF

REVIEW, START OR PROGRAM

MAIN

MENU

RECIRCUL'D

RINSE

SYSTEM OFF

START

MODE

REVIEW PROGRAMMED

PHASES

FINAL

RINSE

SYSTEM OFF

PROGRAM

CYCLE

AIR DRYER

SYSTEM OFF

PRINT

CYCLE

Shows the current TCP Screen

Shows the final rinse status

Shows the dryer status

Shows the rinse status

Shows the wash status

Press to enter the access screen

and program the selected cycle

Press to print cycle parameters

Press to start the selected cycle

Press to return to the main menu

Shows the cycle selected

CYCLE 1

WASH

TEMP

185

WASH

SYSTEM

ON

MAIN

MENU

AUTOMATIC CYCLE

NO ACTIVE ALARMS EXIST

RINSE

TEMP

185

RINSE

SYSTEM

ON

START

CYCLE

FR

TEMP

185

FINAL

RINSE

SYSTEM

ON

ANSWER

ALARM

CYCLE

ABORT

Any errors or alarms during

operation display here

Displays the current temperature of the Wash

Displays the current temperature of the Rinse

Displays the current temperature of the Final Rinse

Displays the status of the Wash

Displays the status of the Rinse

Displays the status of the Final Rinse

Press to stop all functions and sound alarm

Press to acknowledge all alarms

Press to start the cycle

Press to return to the Main Control Screen

61301603708 2–3

Page 26

The Control Panel

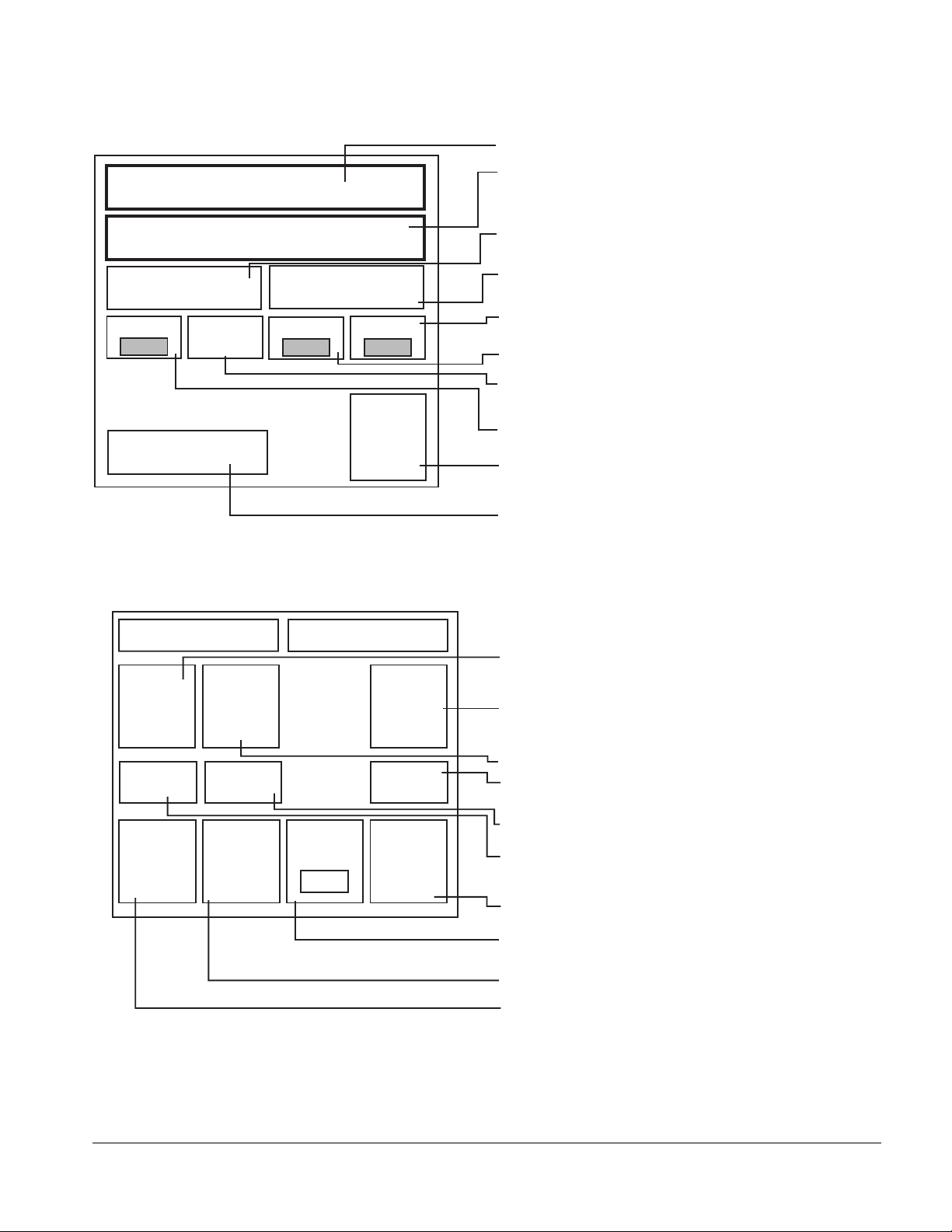

AUTOMATIC SHUT DOWN CYCLE SCREEN

AUTOMATIC SHUT DOWN CYCLE

Depress START or ABORT OPERATION

START

Automatic shut down

ABORT

PROGRAM RECIRCULATED WASH SCREEN

CYCLE 1

Shows the current TCP screen

Describes the actions available

Press to start automatic shut down

Press to stop automatic shut down

Shows the current cycle

Program Recirculated Wash Menu

Shows the screen function

Turns on or off wash treatment chamber

Recirculated agent Wash

On

Tank Temp Te mp

165

AGENT SELECTION

AKALINE AGENT

ACID AGENT

Guarantee

NO AGENT

NOTE: SOME FEATURES SHOWN ON THE TOUCH PANEL MAY NOT BE AVAILABLE IF

OPTIONS WERE NOT SELECTED.

Turns on or off the temperature guarantee

Changes the temperature in the wash tank

Select an alkaline wash,

acid wash, or no agent

2–4

Page 27

CYCLE 1

Series 2200 Washers

PROGRAM RINSE, FINAL RINSE AND DRYER SCREEN

Shows the current cycle

Shows the screen function

PROGRAM RINSE & DRYER

RECIRCULATED

RINSE ON

Ta n k Te mp

185

Guarantee

No Temp

GUARANTEE ON

FR Temp

DRYER

ON

CYCLE PASSWORD

Enter

Password

Change

Password

FINAL RINSE

Clean

185

300

MAIN

MENU

ACCESS SCREEN

SERVICE PASSWORD

Service

Password

Shows status of Recirculated Rinse

Press to change status

Shows status of Final Rinse

Press to change status

Sets time to descale the chamber interior

Sets the final rinse temperature

Shows status of the recirculated rinse guarantee

Press to change status

Sets the rinse tank temperature

Returns to the main menu

Shows status of the Dryer

Press to change status

Press and enter the password to unlock the

operator's program

Only for Factory authorized personnel

Changes the operator's password

This program is read only, showing the status of

program access (LOCKED )

Unlocked

Press to

change

P/W

LOCKED

Changes the password to unlock the

Program

Cycle

MAIN

MENU

Event Print

Frequency

300

Adjust

Calendar

Clock

operator's program

This program is read only, showing the status of

program access (UNLOCKED )

Sets the time and date

Sets the frequency (in seconds) of the printing

of live readings of the chamber temperature

Returns to MAIN MENU

Allows access to the programming screens

(after unlocking with ENTER PASSWORD)

CALENDAR CLOCK

61301603708 2–5

Page 28

The Control Panel

g

Displays the current screen description

CALENDAR CLOCK-ENTER NEW VALUES

THEN PRESS “SAVE CHANGES” PROMPT

PLC Month12PLC Day

10

New Month

10

PLC Hour10PLC Minute

New Hour9New Minute

New Day

1

56

14

PLC Year

00

New Year

01

SAVE

CHANGES

BACK TO

ACCESS

SCREEN

Displays current Year

Displays current Day

Displays current Month

(read-only)

(read-only)

(read-only)

Press to change the Year

Press to change the Day

Press to change the Month

Displays current Hour

Displays current Minute

(read-only)

(read-only)

Press to return to the Main Access Screen

Press to save all changes made in this screen

Press to change the Minute

Press to chan

e the Hour

2–6

Page 29

MANUAL MODE SCREEN

Series 2200 Washers

MANUAL MODE

Wash

Pump

Wash Tank

Fill

Wash Tank

Steam

Wash

Drain

Wash Tank

Flush

• Press any prompt to activate a selected component.

• Press the prompt again to stop the selected component,

or press ABORT to stop all activated components.

Rinse

Pump

Rinse Tank

Fill

Rinse Tank

Steam

Rinse

Drain

Rinse Tank

Flush

Select Desired

Function/Abort to Quit

Drive

System

Dryer

System

Back Flush

Valves

MAIN

MENU

Alkaline

Agent

Pump

Acid Agent

Pump

Neut.

Pump

ABORT

• All safety interlocks are intact in the manual mode. The wash or rinse

pumps do not operate if there is not enough water in the tank.

• Tank fill does not activate if the tank is full.

• Tank fill stops when the tank is full.

• Drains remain open until a prompt is pressed again

or until the screen is changed.

• Wash and rinse tank steam shut off when the programmed temperature

is reached.

• When the rinse pump is activated, the final rinse is activated.

• For more on manual screens, see on page -1.

61301603708 2–7

Page 30

The Control Panel

Cycle Programming

Example: Programming a Sample Cycle

PHASE

(NS)

The following is a SAMPLE cycle along with detailed instructions on how to

program the cycle for your reference.

On/Off

(NS)

TEMPERATURE (°F)

TEMPERATURE

GUARANTEE

AGENT

Sample Cycle 1—Touch Control Panel

Pre-wash

Wash On 140 Guaranteed Alkaline

Recirculated Rinse On 180 Off

Final Rinse On

Recirculated Air Dryer On

180

WHEN THIS SCREEN APPEARS

CYCLE SELECTION SCREEN

SELECT CYCLE FOR OPERATION

Cycle

1

Cycle

5

Cycle

9

PUSH ANY BUTTON TO CONTINUE

MANUAL

MODE

Cycle

2

Cycle

6

Cycle

10

EVENT

PRINT OFF

Cycle

3

Cycle

7

Cycle

11

PRINT

CYCLE

Cycle

4

Cycle

8

Cycle

12

REVIEW

CYCLE

FOLLOW THESE STEPS

1. Press CYCLE 1

2. Select REVIEW CYCLE

2–8

Page 31

Series 2200 Washers

WHEN THIS SCREEN APPEARS

CYCLE REVIEW SCREEN

CYCLE 1

RECIRCUL'D

WASH

SYSTEM OFF

RECIRCUL'D

RINSE

SYSTEM OFF

REVIEW, START OR PROGRAM

MAIN

MENU

START

MODE

REVIEW PROGRAMMED

PHASES

FINAL

RINSE

SYSTEM OFF

PROGRAM

CYCLE

AIR DRYER

SYSTEM OFF

PRINT

CYCLE

FOLLOW THESE STEPS

➢ Select PROGRAM CYCLE to enter the

CYCLE ACCESS SCREEN

CYCLE ACCESS SCREEN

CYCLE PASSWORD

Enter

Password

UNLOCKED

Program

Cycle

Change

Password

Press to

change

P/W

MAIN

MENU

SERVICE PASSWORD

Service

Password

LOCKED

Event Print

Frequency

Adjust

Calendar

300

Clock

1. Press ENTER PASSWORD

2. Unlock the system.

a. Type in correct password “12345”.

b. Press ENTER.

c. Press DONE.

3. Select PROGRAM CYCLE

61301603708 2–9

Page 32

The Control Panel

WHEN THIS SCREEN APPEARS

PROGRAM WASH PHASE SCREEN

CYCLE 1

Program Recirculated Wash Menu

Recirculated Agent

Wash On

Tank Temp Temp

140

AGENT SELECTION

AKALINE AGENT

Guarantee

FOLLOW THESE STEPS

1. Press RECIRCULATED AGENT WASH to ON.

2. Press TANK TEMP, set desired temperature.

3. Press TEMP GUARANTEE to ON if desired.

4. Toggle agent to desired agent.

5. Press NEXT PHASE button when all parameters

are set.

NEXT

PHASE

PROGRAM RINSE PHASE SCREEN

CYCLE 1

PROGRAM RINSE & DRYER

RECIRCULATED

RINSE ON

Ta n k Te mp

180

Guarantee

DRYER

ON

No Temp

FINAL RINSE

GUARANTEE ON

1. Press RECIRCULATED RINSE to ON.

2. Press TANK TEMP. Set desired temperature.

3. Press FINAL RINSE GUARANTEE to ON.

4. Press FR TEMP. Set desired temperature.

5. Press DRYER ON. Set desired temperature.

6. Press MAIN MENU to return to ACCESS MENU.

FR Temp

180

MAIN

MENU

2–10

Page 33

Series 2200 Washers

WHEN THIS SCREEN APPEARS

CYCLE ACCESS SCREEN

CYCLE PASSWORD

Enter

Password

Unlocked

Program

Cycle

Change

Password

Press to

change

P/W

MAIN

MENU

SERVICE PASSWORD

Service

Password

LOCKED

Event Print

Frequency

Adjust

Calendar

300

Clock

FOLLOW THESE STEPS

➢ Press MAIN MENU to return

to CYCLE SELECTION SCREEN.

61301603708 2–11

Page 34

The Control Panel

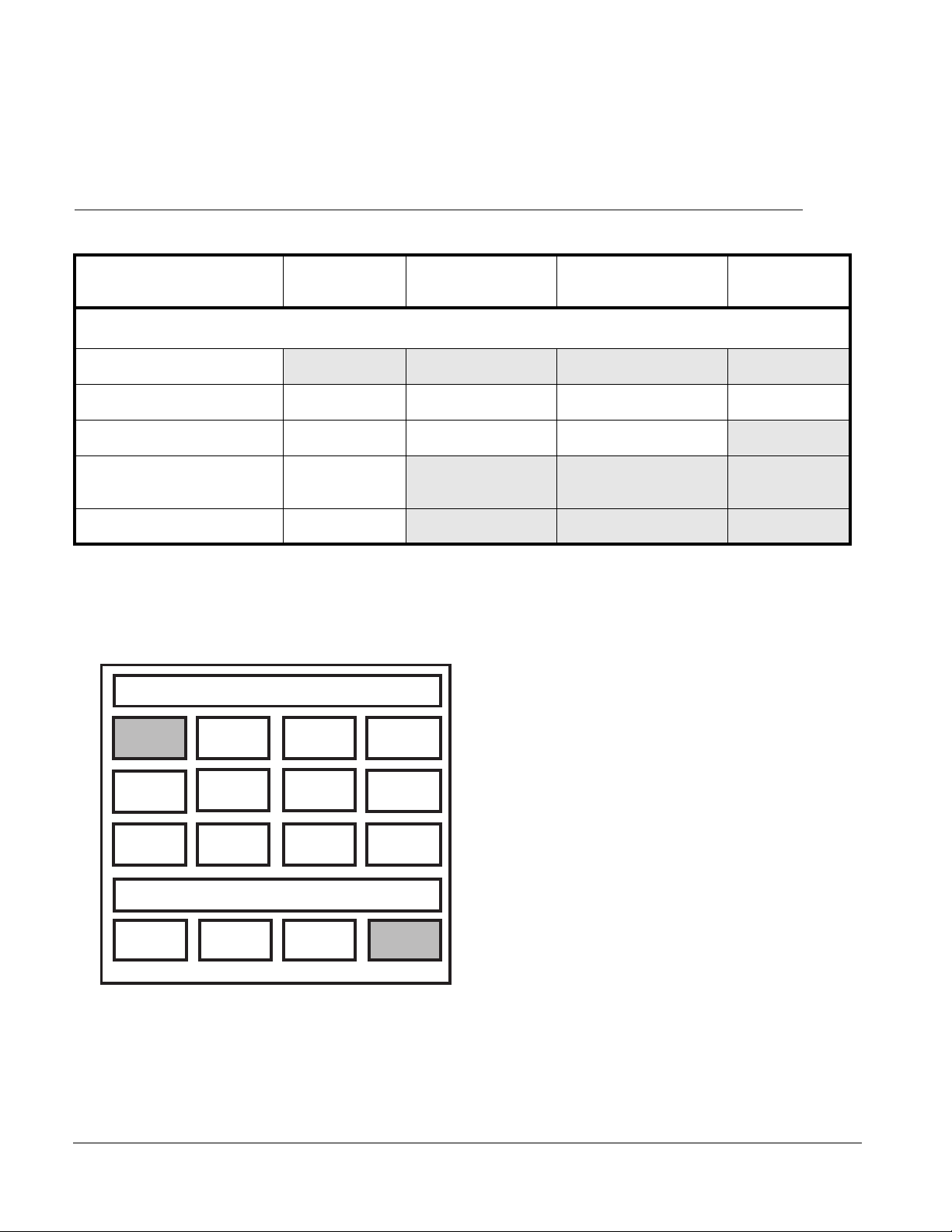

LED CONTROLLER

Key Locations

DISPLAY

STATUS LIGHTS

START

ABORT

MANUAL

MODE

Wash

Fill

Wash

Heat

Rinse

Rinse

Heat

Fill

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

FUNCTIONS

MESSAGE

ALARM

GETINGE CASTLE, INC. MTP MODEL 22XX

TUNNEL, CAGE, AND UTENSIL WASHERS

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

PROGRAM

CYCLE

AUTO

DRAIN

PRINT

CYCLE

LAST

MESSAGE

NEXT

MESSAGE

PAG E

UP

PAG E

DOWN

PRINT

SCREEN

SETUP

HELP

➧

12

ALARM

➧

ACK

4

56

➧

7

±

DATA ENTRY

8

0

PRINTRUN

+

➧

-

TOGGLE

CLEAR

3

DELETE

E

9

N

T

E

R

.

2–12

The above screen has been separated into 3 sections:

• Status Lights, see page 2–13

• Function keys, see page 2–14

• Data Entry keys, see page 2–15

Information on each section follows.

Page 35

Status Lights

Series 2200 Washers

Wash

Fill

Wash

Heat

Rinse

Fill

Rinse

Heat

FUNCTION KEY FUNCTION

Wash Fill Status light indicates when tank is filling

Wash Heat Status light indicates when tank is heating

Rinse Fill Status light indicates when tank is filling

Rinse Heat Status light indicates when tank is heating

Status Light Not used

Status Light Not used

Status Light Not used

Status Light Not used

61301603708 2–13

Page 36

The Control Panel

Function Keys

START

ABORT

MANUAL

MODE

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

PROGRAM

CYCLE

AUTO

DRAIN

PRINT

CYCLE

FUNCTION KEY FUNCTION

START Start the selected cycle.

ABORT Stop all functions of washer.

MANUAL MODE Enter the manual mode.

SELECT CYCLE Access cycle selection screen.

ENTER SERVICE

MODE

For authorized service technician only.

SILENCE ALARM Silence audible alarm.

REVIEW CYCLE Review selected cycle.

EXIT SERVICE

MODE

EVENT PRINT

ON/OFF

Exit service mode and return to stand-by

screen.

Record live readings of selected cycle as

load is being processed.

PROGRAM CYCLE Access selected cycle program for

parameter changes.

AUTO DRAIN Activate automatic drain system.

PRINT CYCLE Print parameters of selected cycle.

2–14

Page 37

Data Entry Keys (keypad)

Series 2200 Washers

LAST

MESSAGE

NEXT

MESSAGE

LAST

MESSAGE

NEXT

MESSAGE

PAG E

PAG E

DOWN

Used to review last screen

Used to review next

available screen

UP

PRINT

SCREEN

12

ALARM

➧

SETUP

HELP

ACK

4

7

±

Key/Function

HELP

Used to receive help

information

±

Used for the #2 or

to move cursor up

2

➧

56

➧

8

0

+

➧

-

TOGGLE

3

9

.

CLEAR

DELETE

E

N

T

E

R

-

TOGGLE

Used for the #9

9

Used to activate components or deactivate compo-

.

nents in Manual Mode.

PAG E

UP

PAG E

DOWN

SETUP

Used to scroll to

previous page

Used to scroll to next page

Used for the #1

Used for the #4 or

to move cursor left

Used for the #7 or

place TCP into direct

7

MODEM contact

ALARM

ACK

+

Used for the #5

5

Used for the #8 or

to move cursor down

8

Used for the #0

0

Used for the #3

3

Used for the #6 or

to move cursor right

6

CLEAR

DELETE

E

N

T

E

R

Used to clear old

parameters

Not used

Used to enter new

parameter

61301603708 2–15

Page 38

The Control Panel

Control Sequences

START UP

Turn the power ON to the unit. The unit runs a diagnostic test.

Once the controller runs the test, the display screen shows

“Getinge/Castle

Model 22XX Tunnel and Cage Washer.

MTP

The unit is now in the standby mode and ready to be used or

programmed.

PROGRAMMING

1. The user can program up to 12 different cycles. To begin,

press SELECT CYCLE. Press CLEAR on the key pad, and

input a cycle between 1 through 12 to be programmed,

then press ENTER. This brings up the Review Cycle

screen. The user can review the phases of the cycle by

pressing the PAGE UP and PAGE DOWN buttons on the

key pad.

2. The Prewash phase has fixed settings and cannot be

altered. The prewash water is generated from the

Recirculated Rinse phase. If the Recirculated Rinse phase

is turned OFF, the Prewash phase will also be turned OFF.

3. The Wash phase can be turned ON/OFF using the

TOGGLE button on the key pad. Toggle the wash phase to

ON. Use the arrow keys, on the keypad, to move the cursor

to each item of the phase. Enter the desired water

temperature and turn temperature guarantee ON/OFF (as

needed). Select detergent type and press ENTER. Press

the PAGE DOWN button to go on to the Recirculated Rinse

phase.

2–16

4. The Recirculated Rinse phase can be turned ON by using

the TOGGLE button on the key pad. Enter the desired

water temperature and turn temperature guarantee ON/

OFF (as needed). Press ENTER. Press the PAGE DOWN

button to go to the Final Rinse phase.

5. The Final Rinse phase is always ON. Enter the desired

water temperature and turn temperature guarantee ON/

OFF (as needed). Press ENTER. Press the PAGE DOWN

button to go on to the Recirculated Air Dry phase.

6. The Recirculated Air Dry phase can be turned ON by using

the TOGGLE button on the key pad. Press ENTER. Press

the PAGE DOWN button to go on to the clock set and

password screen, or if programming is complete, press

ABORT to exit the program mode.

7. The clock set settings are entered in the same way as the

time and temperature are done. Press CLEAR, key in new

Page 39

Series 2200 Washers

settings, and press ENTER. Use arrow keys to move

between settings which need to be changed. Press SAVE

SETTINGS to save new clock settings. Press the PAGE

DOWN button to go on to the password screen, or if

programming is complete, press ABORT to exit the

program mode.

8. The user can input up to a five-digit password (between

0-32000). Press CLEAR, enter the new password, and

press ENTER. Press ABORT to exit program mode.

STARTING WASH CYCLE

To start the unit, the user chooses a preprogrammed cycle by

pressing SELECT CYCLE. Press CLEAR on the key pad, and

input a cycle between 1 and 12, and press ENTER. Press the

START button on the key pad to run the cycle.

ALARM

If an alarm should sound at any time, press SILENCE ALARM

to turn the sound off, then follow the prompt on the display

screen to solve the problem. Press ALARM ACK on the keypad

to return to the program.

HELP

A help screen is provided to assist the user. Press the HELP

button on the keypad for more information on a particular

function.

61301603708 2–17

Page 40

The Control Panel

Processing Cycle Screen Description

Standby Screen

Wash

Fill

MESSAGE

ALARM

PRINTRUN

Rinse

Wash

Rinse

Heat

Heat

Fill

GETINGE CASTLE, INC. MTP MODEL 22XX

TUNNEL, CAGE, AND UTENSIL WASHERS

SELECT CYCLE

START

ABORT

MANUAL

MODE

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

PROGRAM

CYCLE

AUTO

DRAIN

PRINT

CYCLE

LAST

MESSAGE

NEXT

MESSAGE

PAG E

UP

PAG E

DOWN

PRINT

SCREEN

12

ALARM

➧

ACK

4

SETUP

7

HELP

±

➧

➧

From the Standby Screen, choose:

1) SELECT CYCLE to select the desired cycle

2) REVIEW CYCLE to review parameters of selected cycle.

3) MANUAL MODE to test functions of individual components.

+

CLEAR

3

DELETE

➧

56

-

9

8

TOGGLE

.

0

E

N

T

E

R

2–18

From Standby Screen (shown above)

Press SELECT CYCLE button (screen shown below).

1. Press CLEAR.

2. Enter the number of the desired cycle (1 through 12)

3. Press ENTER.

Page 41

Series 2200 Washers

REVIEW CYCLE

REVIEW SCREEN #1.

Press PAGE DOWN to view all parameters of the selected cycle

REVIEW SCREEN #2

Press PAGE DOWN to view all parameters of the selected cycle

REVIEW SCREEN #3

Press PAGE DOWN to view all parameters of the selected cycle

REVIEW SCREEN #4

Press PAGE DOWN to view all parameters of the selected cycle

REVIEW SCREEN #5

Press PAGE DOWN to view all parameters of the selected cycle

REVIEW SCREEN #6

Press PAGE DOWN to view all parameters of the selected cycle

61301603708 2–19

Page 42

The Control Panel

MANUAL MODE

Manual mode allows the user or maintenance technician to test the

functions of individual components

When MANUAL MODE is selected, the screen shows individual

components that may be activated or deactivated. More than one

component may be activated or deactivated at the same time. Press PAGE

DOWN or PAGE UP to view more components.

To activate or deactivate a component in Manual Mode:

1. Press PAGE DOWN or PAGE UP until the desired component shows.

2. Use the arrow keys to move the cursor to the desired component.

3. To activate the component, press TOGGLE when the cursor is under

the deactivated component.

4. To deactivate a component, press TOGGLE when the cursor is under

the activated component.

5. To deactivate all components and return them to standby, press

ABORT.

MANUAL SCREEN #1

MANUAL SCREEN #2

MANUAL SCREEN #3

MANUAL SCREEN #4

2–20

Page 43

Cycle Programming

Wash

Series 2200 Washers

Rinse

Wash

Rinse

Heat

Heat

Fill

Fill

GETINGE CASTLE, INC. MTP MODEL 22XX

TUNNEL, CAGE, AND UTENSIL WASHERS

MESSAGE

ALARM

PRINTRUN

START

ABORT

MANUAL

MODE

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

PROGRAM

CYCLE

AUTO

DRAIN

PRINT

CYCLE

LAST

MESSAGE

NEXT

MESSAGE

PAG E

UP

PAG E

DOWN

PRINT

SCREEN

12

ALARM

➧

4

SETUP

7

HELP

±

➧

➧

ACK

56

➧

8

TOGGLE

0

+

CLEAR

3

DELETE

-

E

9

N

T

E

R

.

From the Standby Screen the user may change the parameters of the cycle

by following these steps:

1. Press SELECT CYCLE.

2. Press CLEAR.

3. Key in the cycle number.

4. Press ENTER.

5. Press the PAGE DOWN or PAGE UP buttons until the screen shows

the phase were the change needs to be made.

6. Use the arrow keys to move the cursor to the parameter that needs to

be changed

7. Press CLEAR.

8. Enter new time or temperature.

9. Press TOGGLE to turn ON/OFF status of phase.

10. Press ENTER to enter all changes.

When all desired changes have been made:

11. Press REVIEW CYCLE to review changes or “PROGRAM CYCLE” to

return to the standby screen

12. If equipped with a printer, press PRINT CYCLE to record new

parameters on paper printout.

61301603708 2–21

Page 44

The Control Panel

Cycle Selection

From Standby Screen (shown above)

Press SELECT CYCLE button (screen shown below).

1. Press CLEAR.

2. Enter the number of the desired cycle (1 through 12)

3. Press ENTER.

4. Press PROGRAM CYCLE.

Programming a Cycle

5. Press PAGE UP or PAGE DOWN until the desired screen appears.

PROGRAM SCREEN #1.

1. Use the arrow keys to move the cursor to the parameter to be changed.

Press TOGGLE to turn selection ON/OFF.

2. Press CLEAR, key in new setting, then press ENTER to change

parameters.

PROGRAM SCREEN #2.

1. Press PAGE DOWN to view the parameters of selected cycle.

2. Use the arrow keys to move the cursor to the parameter to be changed.

Press TOGGLE to turn selection ON/OFF.

2–22

3. Press CLEAR, key in new setting, then press ENTER to change

parameters.

Page 45

Series 2200 Washers

PROGRAM SCREEN #3.

1. Press PAGE DOWN to view the parameters of selected cycle.

2. Use the arrow keys to move the cursor to the parameter to be changed.

Press TOGGLE to turn selection ON/OFF.

3. Press CLEAR, key in new setting, then press ENTER to change

parameters.

PROGRAM SCREEN #4.

1. Press PAGE DOWN to view the parameters of selected cycle.

2. Use the arrow keys to move the cursor to the parameter to be changed.

Press TOGGLE to turn selection ON/OFF.

3. Press CLEAR, key in new setting, then press ENTER to change

parameters.

PROGRAM SCREEN #5.

When setting new parameters for DATE AND TIME, enter desired changes,

toggle SAVE SET to ON, and press ENTER.

PROGRAM SCREEN #6.

To protect the program from unauthorized changes, enter a password here

to lock out access to the PROGRAMING CYCLE phase of the program.

61301603708 2–23

Page 46

The Control Panel

Example: Programming a Sample Cycle

PHASE On/Off TEMPERATURE (°F)

The following is a SAMPLE cycle along with detailed instructions on how to

program the cycle for your reference.

TEMPERATURE

GUARANTEE

AGENT

Sample Cycle 1—LED Controller

Pre-wash

Wash On 165 Guaranteed Alkaline

Recirculated Rinse On 180 Off

Final Rinse On 180 Guaranteed

Recirculated Air Dryer On

Rinse

Wash

Rinse

Wash

Fill

Heat

Heat

Fill

MESSAGE

ALARM

PRINTRUN

GETINGE CASTLE, INC. MTP MODEL 22XX

TUNNEL, CAGE, AND UTENSIL WASHERS

START

ABORT

MANUAL

MODE

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

PROGRAM

CYCLE

AUTO

DRAIN

PRINT

CYCLE

LAST

MESSAGE

NEXT

MESSAGE

PAG E

UP

PAG E

DOWN

PRINT

SCREEN

12

ALARM

➧

ACK

4

SETUP

7

HELP

±

+

➧

➧

56

➧

-

8

TOGGLE

0

CLEAR

3

DELETE

E

9

N

T

E

R

.

Start Up Turn the power ON to the unit. At this time, the unit will go

through a diagnostic test. Once the controller runs the test, the

display screen will show, “Getinge Castle, Inc. MTP Model 22XX

Tunnel and Cage Washer.” The unit is now in the standby mode

and ready to be used or programmed.

Programming 1. The user can program up to 12 different cycles. To begin,

press SELECT CYCLE. Press CLEAR on the key pad,

input a cycle between 1 through 12 to be programmed,

then press ENTER. This will bring up the Review Cycle

2–24

Page 47

Series 2200 Washers

screen. Using PAGE UP and PAGE DOWN on the key pad,

the user can review each phase of that cycle. If the cycle

needs to be programmed or changed, press PROGRAM

CYCLE. You are now ready to program each phase of the

sample cycle noted on the previous page.

2. The Prewash phase has fixed settings and cannot be

altered. The prewash water is generated from the

Recirculated Rinse phase. If the Recirculated Rinse phase

is turned OFF, the Prewash phase will also be turned OFF.

3. The Wash phase can be turned ON/OFF by using the

TOGGLE button on the key pad. Toggle the wash phase to

ON. Use the arrow keys, on the keypad, to move the cursor

to each item of the phase. Move the cursor to

TEMPERATURE, press CLEAR, input 165, and press

ENTER. Move the cursor to GUARANTEE and toggle ON.

Move the cursor to AGENT and toggle to ALKALINE. Once

you have completed the wash phase, press PAGE DOWN

to go on to the Recirculated Rinse phase.

4. The Recirculated Rinse phase can be turned ON/OFF by

using the TOGGLE button on the key pad. Move the cursor

to TEMPERATURE, press CLEAR, input 180, and press

ENTER. Move the cursor to GUARANTEE and toggle OFF.

Once you have completed the Recirculated Rinse phase,

press PAGE DOWN to go on to the Final Rinse phase.

5. The Final Rinse phase is always ON. Move the cursor to

TEMPERATURE, press CLEAR, input 185, and press

ENTER. Move the cursor to GUARANTEE and toggle ON.

Once you have completed the Final Rinse phase, press

PAGE DOWN to go on to the Recirculated Air Dryer phase.

6. The Recirculated Air Dry phase can be turned ON/OFF by

using the TOGGLE button on the key pad. Once you have

completed the Recirculated Air Dryer phase, press PAGE

DOWN button to go on to the Clock Set and Password

screen. If programming is complete, press ABORT to exit

program mode.

7. The Clock Set settings are entered in the same way as the

time and temperature are done. Press CLEAR, key in new

setting, and press ENTER. Use arrow keys to move

between settings which need to be changed. Press SAVE

SETTINGS to save new clock settings. Press PAGE DOWN

to go on to the Password screens. If programming is

complete, press ABORT to exit program mode.

61301603708 2–25

Page 48

The Control Panel

8. You can input up to a five digit password (between

0-32000). Press CLEAR, input the new password, and

press ENTER. Press ABORT to exit program mode.

Starting Wash Cycle To start the unit, choose a preprogrammed cycle by pressing

SELECT CYCLE. Press CLEAR on the key pad, input a cycle

between 1 through 12, and press ENTER. Press START button

on the key pad to run cycle.

Alarm If an alarm should sound at any time, press ALARM SILENCE

to turn the sound off, then follow the prompt on the display

screen to solve the problem. Press ALARM ACK on the keypad

to return to the program.

Help A help screen is provided to assist the user. Press the HELP

button on the keypad for more information on a particular

function.

2–26

Page 49

ELECTRO-MECHANICAL CONTROLS

Control Panel

Series 2200 Washers

61301603708 2–27

Page 50

The Control Panel

Item # Component

1. POWER Switch Turns power ON/OFF to the control

circuit. (Must be ON for the machine to

operate.)

2. START Starts an automatic cycle (after the

machine is ready and the start light is

ON).

3. STOP Stops all function of the unit without

sounding the alarm.

4. Low Water Level

Wash Tank

5. Low Water Level

Rinse Tank

6. Low Wash Temperature An indicator light only. Lights when the

7. Low Rinse Temperature An indicator light only. Lights when the

8. Low Final Rinse

Temperature

9. Emergency System

Activated

An indicator light only. Lights when the

wash fill timer times out. When indicator

is on, all functions stop except for the fill

operation.

An indicator light only. Lights when the

rinse fill timer times out. When this

indicator is on, all functions stop except

for the fill operation.

wash steam timer times out. When

indicator is ON, all functions stop except

for the heating operation.

rinse steam timer times out. When

indicator is ON, all functions stop except

for the heating operation.

An indicator light only. Lights when the

final rinse steam timer times out. When

indicator is ON, all functions stop except

for the heating operation.

An indicator light only. Lights when the

Emergency Cable at the load or unload

end of the machine has been pulled.

2–28

10. Door Open An indicator light only. Lights when one

or more of the chamber access doors

are opened. All doors must be closed

and safety reset switch activated before

unit will allow a restart.

Page 51

Series 2200 Washers

Item # Component

11. Conveyor Full An indicator light only. Lights when the

photo eye at the unload end is blocked.

When the indicator is ON, all functions of

the machine are active except for the

conveyor belt. When the obstruction is

removed, the conveyor belt resumes

operation.

12. Power An indicator light only. Lights when the

power switch is ON.

13. Machine Ready for

Operation

14. Wash Temperature This controls and monitors the heat in

15. Rinse Temperature This controls and monitors the heat in

16. Final Rinse Temperature This monitors the heat in the final rinse

An indicator light only. Lights when all

conditions are satisfied–wash and rinse

tanks are full and at set point

temperature. Only at this point should

the START button be pressed

the wash tank.The controller displays

the temperature as the machine is

running. Temperature settings may be

changed by pressing the up arrow or

down arrow key to the desired settings.

the rinse tank. The controller displays

the temperature as the machine is

running. Temperature settings may be

changed by pressing the up arrow or

down arrow key to the desired settings.

water. The controller displays the

temperature as the machine is running.

Temperature settings may be changed

by pressing the up arrow or down arrow

key to the desired settings. When the

temperature falls below the set point, the

final rinse steam timer starts to time. If

the set point is not achieved before the

timer times out, the conveyor belt stops

and LOW FINAL RINSE

TEMPERATURE lights.

61301603708 2–29

Page 52

The Control Panel

Cycle Programming

1. PreWash The prewash is powered by the rinse pump and only controlled by the hand valve located on the utility side load end.

2. Wash Section The wash is recirculated by the wash pump. The wash

pump will activate when in automatic cycle if water level is up to proper

level. The tank refills during processing from the wash tank fill valve.

3. Wash Temperature Controller Temperature controller is

programmable from 160° to 190°F. To change temperature, press the

arrow in the direction of desired change (up arrow to increase

temperature and down arrow to decrease temperature).

Figure 2–1. WASH TEMPERATURE CONTROLLER

4. Rinse Treatment pump The rinse is controlled by the rinse pump. The

rinse pump activates when in automatic cycle if water level is up to

proper level. The tank refills during processing from the rinse tank fill

valve. The rinse tank will normally not need to refill during the normal

processing period due to the constant flow of final rinse water flowing

into the rinse tank.

Final Rinse Temperature Settings

5. Rinse Temperature Controller Temperature controller is

programmable from 160° to 190°F. To change temperature, press the

arrow in the direction of desired change (up arrow to increase

temperature and down arrow to decrease temperature).

6. Final Rinse Temperature Controller Temperature controller is

programmable from 160° to 195°F.

1. Turn water to full open setting.

2. Turn steam to full open setting (temperature not to exceed 195°F).

3. If water at full open and steam at full open does not create an output

temperature of 195°F, turn water flow down until 195°F is achieved.

4. If water at full open and steam at full open exceeds 195°F, turn steam

throttle valve down until in 195°F range.

5. If temperature becomes unstable, turn the water pressure regulator

down to 5 psi lower than dynamic house pressure and repeat steps 1

to 4.

2–30

Page 53

Figure 2–2. WATER AND STEAM FLOW DIAGRAM

TEMPERATURE

GUAGE

STEAM

SOLENOID

WATER

THROTTLE

VALV E

STEAM FLOW

STEAM THROTTLE VALVE

Series 2200 Washers

VACUUM

BREAKER

WATER

SOLENOID

Internal Timers

WATER

PRESSURE

REDUCER

STEAM TRAP

DIRECTION OF

WATER FLOW

1. Wash Fill Timer times how long wash tank should require to fill. If

wash tank does not fill before timer times out unit will shut down.

2. Rinse Fill Timer times how long rinse tank should require to fill. If rinse

tank does not fill before timer times out unit will shut down.

3. Safety System Reset allows user to reset safety system after alarm

has been satisfied (closed door or by placing machine in stand by to

refill or heat) switch will return to normal position when released.

4. Wash Steam Timer times how long wash tank should need to reach

programmed temperature. If temperature is not achieved before timer

times out unit will shut down.

5. Rinse Steam Timer times how long rinse tank should need to reach

programmed temperature. If temperature is not achieved before times

out unit will shut down.

6. Final Rinse Timer times how long the final rinse needs to heat up to

the programmed temperature. If temperature is not achieved before

timer times out unit will shut down.

7. Variable Speed Controller controls the speed of the conveyor belt.

Turn knob located on the back side of the control panel clock wise to

minimum speed 2 feet per minute, maximum speed 10 feet per minute.

Figure 2–3. VARIABLE SPEED CONTROLLER

61301603708 2–31

Page 54

The Control Panel

2–32

Page 55

GENERAL MACHINE OPERATION

Instructions here apply to the daily operation of this unit. They assume that

the unit has been properly installed and pre-tested: that the compartment is

clean, cycle selections have been programmed, the liquid supplies are set

up, and any optional equipment is ready.

Section 3 Operating Instructions

WARNING

HS

• BURN HAZARD: Do not open chamber access doors during

a cycle. This could release hot water through the door

opening, resulting in burns to personnel.

• HOT SURFACES: The metal surface that surrounds the

opening at the load and unload end of unit becomes hot

during normal operation. Use caution when loading and

unloading the washer.

Start-up At the start of the processing period, activate the unit for auto-

matic operation:

Turn on the main disconnect switch.

• The unit automatically goes to a self diagnostic test

then fill with fresh water and start heating up to programmed temperature. When filling and heating are

complete the display shows “Ready for Operation”.

• Units with Touch Control Panel (TCP) only: The

Touch Control Panel (TCP) immediately lights and performs a self-diagnostic test. Once complete the system

Standby Screen displays and the machine is ready for

operation.

Operating Instructions 1. Place the load to be cleaned on the stainless steel flat wire

conveyor.

2. Select the desired cycle

(see “Treatment Schedule” on page 3–2).

3. Press the START button.

• The unit automatically proceeds through the treatment

process and delivers the items at the unload end of the

machine.

• A photoelectric switch at the end of the discharge con-

veyor automatically stops the conveyor drive when an

61301603708 3–1

Page 56

Operating Instructions

item reaches the end of the conveyor. A stopped conveyor condition is indicated on the control screen.

Shutdown At the end of the processing period, place the unit in the

standby mode:

Press the STOP button.

• All processing functions immediately stop and the

wash and rinse tanks automatically refill and maintain

heat.

Treatment Schedule

The treatment schedule is listed below. For additional information, refer to

“Treatment Schedule” on page 1–10. The process for the wash cycle is as

follows:

• Prewash

• Agent Wash

• Recirculated Rinse

• Non-Recirculated Final Rinse

• Recirculated Air Dry

3–2

Page 57

DAILY CHECKLIST

Series 2200 Washers

WARNING

HS

HOT SURFACES: The metal surface that surrounds the

opening at the load and unload end of unit is hot during normal

operation. To avoid burns, use caution when loading and

unloading the washer.

Before operating the unit each day:

1. Check the printer paper roll and replace it if necessary. See

page 7–4.

2. Clean the debris basket and drawers in the chamber drain.

See page 4–3

3. Check chemical supplies.

4. Clean drawer-type and basket-type debris filters.

5. Check the chemical dispenser (if the unit has the optional

Automatic Agent Injection System, see “Automatic Agent

Injection System” on page 7–10).

Operational Readiness To ensure that the washer is ready for processing without

requiring a warm-up period, leave the washer ON during

regular periods of inactivity.

61301603708 3–3

Page 58

Operating Instructions

EMERGENCY STOP

Burn hazard. Do not open a station access door for at least five

WARNING

HS

seconds after stopping a processing cycle that was running a

hot wash or rinse water phase. This allows time for the spray

manifolds to stop functioning; otherwise hot water could spray

out of the door opening, resulting in burns to personnel.

Using the Emergency Cable 1. Pull the EMERGENCY CABLE either at the load end or the

unload end.

• The unit ceases operation.

2. To resume operation, press EMERGENCY CABLE RESET

either at the load end or the unload end.

EMERGENCY SHUT-DOWN

Shutting Down the Washer

WARNING

In an emergency, it may be necessary to remove electrical power supplied

to the washer or to turn off the steam and water supplies. All users should