Page 1

USER MANUAL

61301603579 Rev. A

SERIES 2100

CAGE, RACK, AND

UTENSIL WASHERS

Page 2

Page 3

USER MANUAL

SERIES 2100

CAGE, RACK, AND

UTENSIL WASHERS

Getinge/Castle, Inc.

1777 East Henrietta Road

Rochester, New York 14623-3133

Phone: (800) 950-9912 USA

Facsimile: (800) 950-2570

Page 4

WARNING

USER MANUAL 61301603579

Rev. A First Release (07/31/2000)

Related Publications:

Service Data Manual 61301603580

Customer Manual—keyed to the customer’s specific serial number

DESCRIPTION OF SYMBOLS & NOTES IN MANUAL

The following symbols with related notes appear in this manual.

“Warning” notes alert the user to the possibility of personal injury.

CAUTION

NOTE

NOTE

“Caution” notes alert the user to the possibility of damage to the equipment.

“Notes” alert the user to pertinent facts and conditions.

This manual contains proprietary information of Getinge/Castle, Inc. It shall

not be reproduced in whole or in part without the written permission of Getinge/Castle, Inc.

Castle

Copyright ©2000 by Getinge/Castle, Inc.

®

and are registered trademarks of Getinge/Castle, Inc.

Page 5

Table of Contents

SPECIAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . ix

DESCRIPTION OF SYMBOLS ON THE EQUIPMENT . . . . . xi

WARNINGS SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

PERSONNEL SAFETY SYSTEM. . . . . . . . . . . . . . . . . . . . . xiv

Section 1 General Description

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

EXTERIOR COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . 1–4

INTERIOR COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Table of Contents

Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

To Activate the Personnel Safety System . . . . . . . . . . . xiv

To Reset the Personnel Safety System. . . . . . . . . . . . . xv

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

EMERGENCY STOP Switch . . . . . . . . . . . . . . . . . . . . 1–4

Electrical Disconnect Switch . . . . . . . . . . . . . . . . . . . . 1–4

Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Door Closed Switches . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Alarm (Not Shown). . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Service Area (Not Shown) . . . . . . . . . . . . . . . . . . . . . . 1–5

Dispenser (Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Pit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Automatic Self-Cleaning Debris Filter (Not Shown). . . 1–5

EMERGENCY CABLE RESET SYSTEM . . . . . . . . . . 1–6

IN PROGRESS Indicator . . . . . . . . . . . . . . . . . . . . . . . 1–6

COMPLETE CYCLE Indicator . . . . . . . . . . . . . . . . . . . 1–6

OPEN DOOR Switch (Option) . . . . . . . . . . . . . . . . . . . 1–6

EMERGENCY STOP Switches

(Load and Unload End) . . . . . . . . . . . . . . . . . . . . . 1–6

Spray Manifold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Spray Manifold Drive Assembly. . . . . . . . . . . . . . . . . . 1–7

Hand Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Floor Grates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

Sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

61301603579 iii

Page 6

Section 2 The Control Panel

Exhaust Damper (Not Shown). . . . . . . . . . . . . . . . . . . 1–8

OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

Floor Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

Recorder/Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Floor Loading Ramp . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Hydraulic Low Entry Loading Platform . . . . . . . . . . . 1–10

Cart Tilt Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Universal Cage and Pan Processing Rack . . . . . . . . 1–10

Cage Processing Rack . . . . . . . . . . . . . . . . . . . . . . . 1–10

Pan Processing Rack . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Manifold Feeder Bottle Rack . . . . . . . . . . . . . . . . . . . 1–10

Cage Processing Rack For Central Header System . 1–10

Feeder Bottle Baskets . . . . . . . . . . . . . . . . . . . . . . . . 1–11

Stainless Steel Pit Plates. . . . . . . . . . . . . . . . . . . . . . 1–11

PROCESSING CYCLE DESCRIPTION. . . . . . . . . . . . . . 1–12

Automatic Seven Phase Treatment Cycle. . . . . . . . . 1–12

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

Treatment Schedule . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

TOUCH CONTROL PANEL (TCP) . . . . . . . . . . . . . . . . . . 2–2

Control Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Manual Mode #1 Cycle Screen Description . . . . . . . 2–11

Cycle Programming. . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Example: Programming a Sample Cycle. . . . . . . . . . 2–12

LED CONTROL PANEL. . . . . . . . . . . . . . . . . . . . . . . . . . 2–17

Key Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–17

Control Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . 2–21

Processing Cycle Screen Description . . . . . . . . . . . . 2–22

Stand-by Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–22

Cycle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–22

Review Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–23

Manual Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

Cycle Programming. . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

Cycle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–27

Programming a Cycle . . . . . . . . . . . . . . . . . . . . . . . . 2–27

Example: Programming a Sample Cycle. . . . . . . . . . 2–29

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

Starting Wash Cycle . . . . . . . . . . . . . . . . . . . . . . . . . 2–32

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–32

ELECTRO-MECHANICAL CONTROL PANEL . . . . . . . . 2–33

iv

Page 7

Section 3 Operating Instructions

GENERAL MACHINE OPERATION. . . . . . . . . . . . . . . . . . 3–1

Start-up Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Shut-down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

General Operating Instructions . . . . . . . . . . . . . . . . . . 3–2

Treatment Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

DAILY CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Operational Readiness . . . . . . . . . . . . . . . . . . . . . . . . 3–3

AUTOMATIC AGENT INJECTION SYSTEM . . . . . . . . . . . 3–4

Pump ON/OFF Indicator (Not Shown) . . . . . . . . . . . . . 3–4

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Inlet Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Outlet Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Checks Prior To Routine Operation. . . . . . . . . . . . . . . 3–4

END OF DAILY OPERATION . . . . . . . . . . . . . . . . . . . . . . 3–5

TO HALT THE PHASE TIMING DURING A CYCLE . . . . . 3–6

EMERGENCY STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Using the EMERGENCY STOP Switch . . . . . . . . . . . . 3–7

Pulling The Safety Cables to Stop the Wash Cycle. . . 3–7

Pressing ABORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Open any Manual Door to Stop the Wash Cycle . . . . . 3–7

CYCLE INTERRUPT CONDITIONS . . . . . . . . . . . . . . . . . 3–8

Resettable Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Non-Resettable Conditions . . . . . . . . . . . . . . . . . . . . . 3–8

Shutting Down the Washer . . . . . . . . . . . . . . . . . . . . . 3–9

Section 4 Maintenance

Section 5 Troubleshooting

GENERAL MAINTENANCE SCHEDULE. . . . . . . . . . . . . . 4–1

ROUTINE MAINTENANCE SCHEDULE—STANDARD . . 4–2

When required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Every Three Months. . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

Every Six Months. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

RECOMMENDED SPARE PARTS LIST . . . . . . . . . . . . . . 4–7

Consumable Stock. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–7

Recommended Spare Parts. . . . . . . . . . . . . . . . . . . . . 4–7

TROUBLE ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

SCREENS ACTIVATED BY ALARMS . . . . . . . . . . . . . . . . 5–4

61301603579 v

Page 8

Section 6 Installation Instructions

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

UNCRATING & EQUIPMENT INSPECTION. . . . . . . . . . . 6–2

INSTALLATION/ASSEMBLY CHECKLIST . . . . . . . . . . . . 6–3

Equipment Location. . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

LED Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

TCP Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Electro-Mechanical Unit. . . . . . . . . . . . . . . . . . . . . . . . 6–4

CHECK-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

Section 7 Options

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

MOST COMMON OPTIONS . . . . . . . . . . . . . . . . . . . . . . . 7–2

Right or Left Handed (Sump). . . . . . . . . . . . . . . . . . . . 7–2

Manual Door or Powered Door . . . . . . . . . . . . . . . . . . 7–2

Single Door or Double Door (Pass-Through) . . . . . . . 7–2

Door Interlock (Only Available on Double Door

Automatic Floor Tilting System . . . . . . . . . . . . . . . . . . 7–2

Pan Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

Alkaline Wash Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . 7–7

Acid Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Heat Exchanger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Floor Spray Headers . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Automatic Damper. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–9

Exhaust Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–10

Drain Discharge Cool-Down System. . . . . . . . . . . . . 7–10

Bottle Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–12

Rack Flush. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–12

Treatment Solution pH Neutralization System. . . . . . 7–12

Service Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

Seismic Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

Final Rinse Water Saver System. . . . . . . . . . . . . . . . 7–13

Automatic Alkaline Agent Injection System -

Automatic Alkaline Agent Injection System -

[Pass-Through]) . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Monitored (RF001) . . . . . . . . . . . . . . . . . . . . . . . 7–14

Time Based (RF003). . . . . . . . . . . . . . . . . . . . . . 7–15

vi

Page 9

Automatic Acid Agent Injection System -

Automatic Acid Agent Injection System -

Alkaline Agent Wash Saver System . . . . . . . . . . . . . 7–17

ADDITIONAL OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . 7–19

Appendix A Miscellaneous Screens

MANUAL MODE #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

PROCESS SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Index

Monitored (RF007) . . . . . . . . . . . . . . . . . . . . . . . 7–16

Time Based (RF004). . . . . . . . . . . . . . . . . . . . . . 7–16

61301603579 vii

Page 10

viii

Page 11

SPECIAL SAFETY INSTRUCTIONS

THE FOLLOWING SAFETY INSTRUCTIONS APPEAR WITHIN THIS

MANUAL. READ THEM CAREFULLY BEFORE OPERATING THE UNIT.

Series 2100 Washers

WARNING

“Warning” notes alert the user to the possibility of personal

injury.

Warnings Summary p. xv

FALL HAZARD: Areas located immediately around the washer may become

a fall hazard due to water dripping from the plumbing components. For a

safe environment, insure floor is kept clean and dry.

BURN HAZARD: This washer operates at extremely high temperatures.

Prior to any machine maintenance or service, the washer should be allowed

sufficient time to cool. Caution should be used in and around the washer

chamber and external piping. Water flow and discharge piping can cause

personal injury such as burns. The user should partially open the chamber

door to allow hot air to exhaust and to allow all loads adequate time to cool.

Opening the chamber door fully may cause large amounts of steam to

escape.

SHOCK HAZARD: Prior to any service or maintenance on the washer, all

utilities should be disconnected and the lockout/tagout procedures should

be followed to insure safety and prevent accidental shock.

PERSONAL HAZARD AND EQUIPMENT DAMAGE: Safe and efficient

operation of this equipment requires scheduled preventative maintenance.

Routine adjustments and replacement of parts by other than Authorized

Service Technicians may cause personal injury or the equipment to perform

less than its capabilities.

General Machine Operation p. 3-1

BURN HAZARD: Do not open a Washer door during a cycle. This could

release hot water through the door opening, resulting in burns to personnel.

RISK OF FALLING: The chamber floor may be slippery when wet. When

inside the chamber, walk carefully to maintain balance and avoid injurious

falls.

Daily Checklist p. 3-4

HOT SURFACES: The Chamber could be HOT. Turn OFF the Electrical Disconnect Switch and make sure the Washer is cool before removing the SelfCleaning Debris Filter Screen for cleaning.

Emergency Stop p. 3-7

BURN HAZARD: Do not open a Washer door for at least five seconds after

stopping a processing cycle that was running a hot wash or rinse water

61301603579 ix

Page 12

phase. This allows time for the spray manifolds to stop functioning; otherwise hot water could spray out of the door opening, resulting in burns to personnel.

RISK OF FALLING: Do not enter a Washer chamber immediately after stopping a processing cycle that had been running a Dry phase. Allow sufficient

time for all metal surfaces within the chamber to cool. Otherwise hot surfaces may contact and cause burns to personnel.

Cycle Abort Condition p 3-9

The Electrical Disconnect Switch de-energizes the washer. The switch disconnects the 3 phase power to the controls of the washer but does not

remove all electrical power from the control box.

Routine Maintenance Schedule - Standard, Every Six Months p 4-4

ELECTRIC SHOCK HAZARD: Only an electrician should perform this test!

x

Page 13

DESCRIPTION OF SYMBOLS ON THE EQUIPMENT

Series 2100 Washers

Switches

ELECTRICAL DISCONNECT SWITCH

Rotate the switch from the OFF to the ON position to supply electrical power

and operate the washer.

EMERGENCY STOP

Locate the EMERGENCY STOP Switch on the Load and Unload end of the

washer.

Press to:

1. Terminate all functions, and

2. Sound the alarm.

To reset:

1. Pull the button, and

2. Turn the power off/on to reset the washer.

EMERGENCY CABLE RESET SYSTEM

Indicators

Pulling the safety cables in the wash chamber sounds the alarm and lights

the emergency button. Press the EMERGENCY CABLE RESET SYSTEM

button to enable the washer to operate.

OPEN DOOR (Power Door, Double Door Model Only)

Pressing the OPEN DOOR switch opens the door.

IN PROGRESS (Pass-Through models Only)

Indicates that the washer in IN PROGRESS or a wash cycle has started.

COMPLETE CYCLE (Pass-Through Models Only)

Indicates that the wash cycle has finished and the user can unload the

washer.

61301603579 xi

Page 14

Labels

The following labels on the Control Box alert service personnel to possible

hazards.

HIGH VOLTAGE

Prior to any service or maintenance on the washer, all utilities should be disconnected and the lockout/tagout procedures should be followed to insure

safety and prevent accidental shock.

CAUTION

CAUTION

To reduce the risk of electrical shock, do not remove cover. Refer servicing

to Authorized Service Technicians.

xii

Page 15

WARNINGS SUMMARY

W

S

ARNING

Series 2100 Washers

SPECIAL SAFETY INSTRUCTIONS THAT FOLLOW APPEAR WITHIN

THE MANUAL.

READ THEM CAREFULLY BEFORE OPERATING THE UNIT, AND FOLLOW THE INSTRUCTIONS.

FALL HAZARD:

•

Areas located immediately around the washer

may become a fall hazard due to water dripping from the

plumbing components. For a safe environment, insure floor

is kept clean and dry.

BURN HAZARD:

•

This washer operates at extremely high

temperatures. Prior to any machine maintenance or service,

the washer should be allowed sufficient time to cool. Caution

should be used in and around the washer chamber and

external piping. Water flow and discharge piping can cause

personal injury such as burns. The user should be cautious

when opening the door before the chamber cools. Partially

open the chamber door to allow hot air to exhaust and to

allow all loads adequate time to cool. Opening the chamber

door during a cycle may cause large amounts of steam to

escape.

SHOCK HAZARD

•

: Prior to any service or maintenance on the

washer, all utilities should be disconnected and the lockout/

tagout procedures should be followed to insure safety and

prevent accidental shock.

PERSONAL HAZARD AND EQUIPMENT DAMAGE

•

: Safe and efficient

operation of this equipment requires scheduled preventative

maintenance. Routine adjustments and replacement of parts

by other than Authorized Service Technicians may cause

personal injury or the equipment to perform less than its

capabilities.

61301603579 xiii

Page 16

PERSONNEL SAFETY SYSTEM

To Activate the Personnel Safety System

NOTE

This washer is equipped with a personnel safety system. The system

includes six major components. The Washer will not start the wash cycle

when the:

1. Load Door is open.

2. Unload Door is open.

3. Safety Cables are too loose or the cable tension is not adjusted correctly. The Safety Cables need to be within specification to reset the

Plunger on the Safety Switch.

4. Safety Cables are pulled.

The Alarm sounds and the Emergency Buttons lights.

Location

from the Load End to the Unload End. Red in color for easy recognition.

Purpose

Cable.

When the automatic treatment cycle begins, the audible alarm sounds.

: Inside the cabinet, on both sides of the Chamber, running

: To shut down all functions of the Washer by pulling the Safety

When to Use

sounds, pull the Safety Cable to immediately abort the start of a wash

cycle and open the doors. This will terminate all washer functions.

This feature can be used by anyone inside the Chamber when the

doors are closed.

5. Load End EMERGENCY STOP Switch is pushed.

The Emergency Button lights and the Alarm sounds.

6. Unload End EMERGENCY STOP Switch is pushed.

The Emergency Button lights and the Alarm sounds.

On washers with Power Telescoping Doors, when either the Safety Cables

are pulled or the EMERGENCY STOP Switch is pushed, the doors open

automatically.

On washers with a printer, when the alarm occurs, a time stamp is printed.

: When the wash cycle starts and the audible alarm

xiv

Page 17

Series 2100 Washers

To Reset the Personnel Safety System

When the personnel safety system is used, all washer functions

stop. To reset the system, do one of the following:

If the: Do one of the following:

Load Door or the Unload Door is

open.

Safety cable was pulled. Press the EMERGENCY CABLE

EMERGENCY STOP Switch was

pushed.

Close the door. Press START.

RESET SYSTEM switch. Turn the

power off/on to reset the washer.

Pull the EMERGENCY STOP

Switch. Turn the power off/on to

reset the washer.

61301603579 xv

Page 18

xvi

Page 19

INTRODUCTION

Section 1 General Description

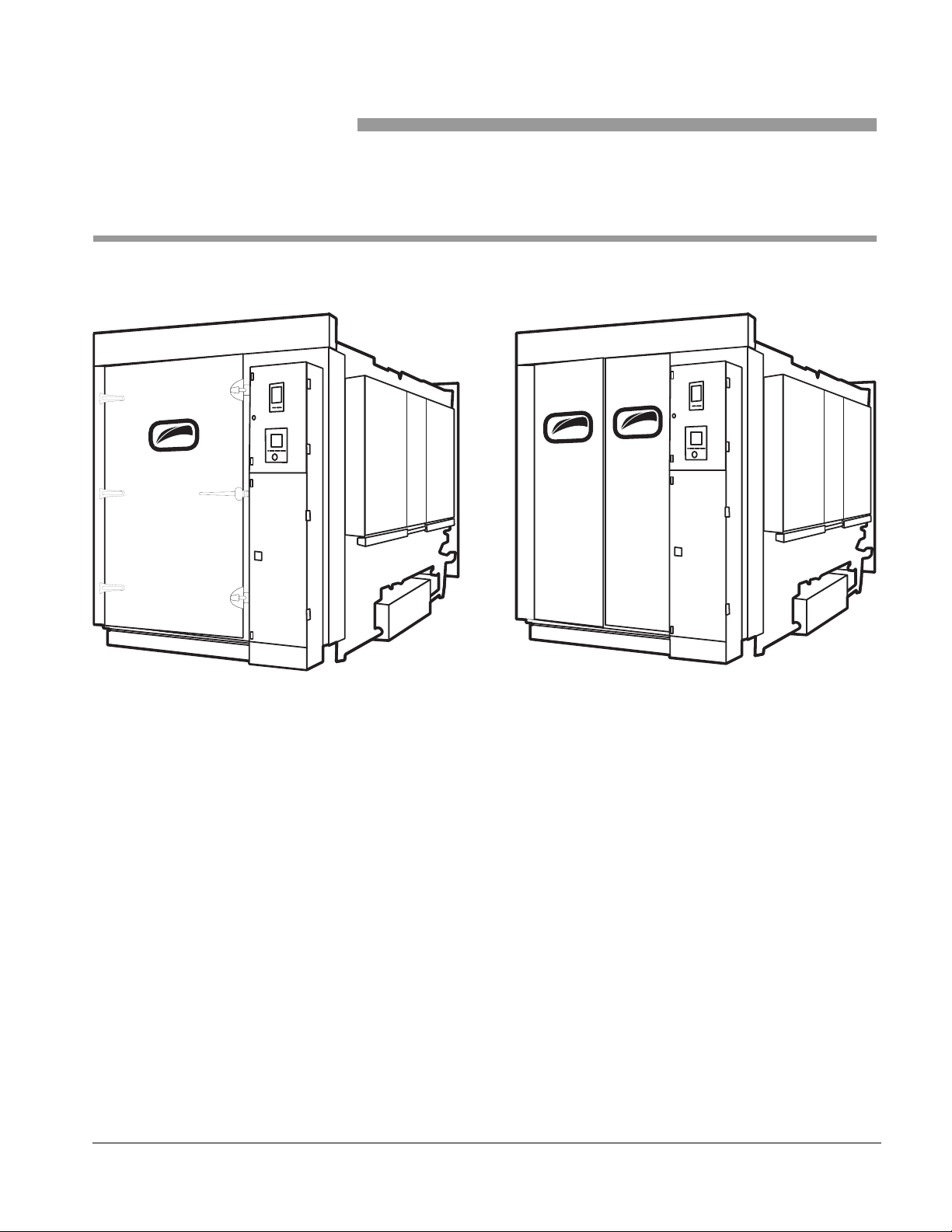

Figure 1–1. 2100 SERIES WASHERS

A03579-F

MANUAL DOOR POWERED DOOR

2100 series units are automatic, heavy duty, multi-cycle, single chamber,

floor loading, hydro-spray washers. These units are designed to efficiently

and thoroughly clean, sanitize and dry cages, racks, racked utensils, and

bottles used in research animal care facilities.

Both powered single or double door pass-through units are available. Units

may be floor or pit mounted through one or two walls or installed free

standing. Left or right side service access and control panel locations are

available

A03579-A

61301603579 1–1

Page 20

General Description

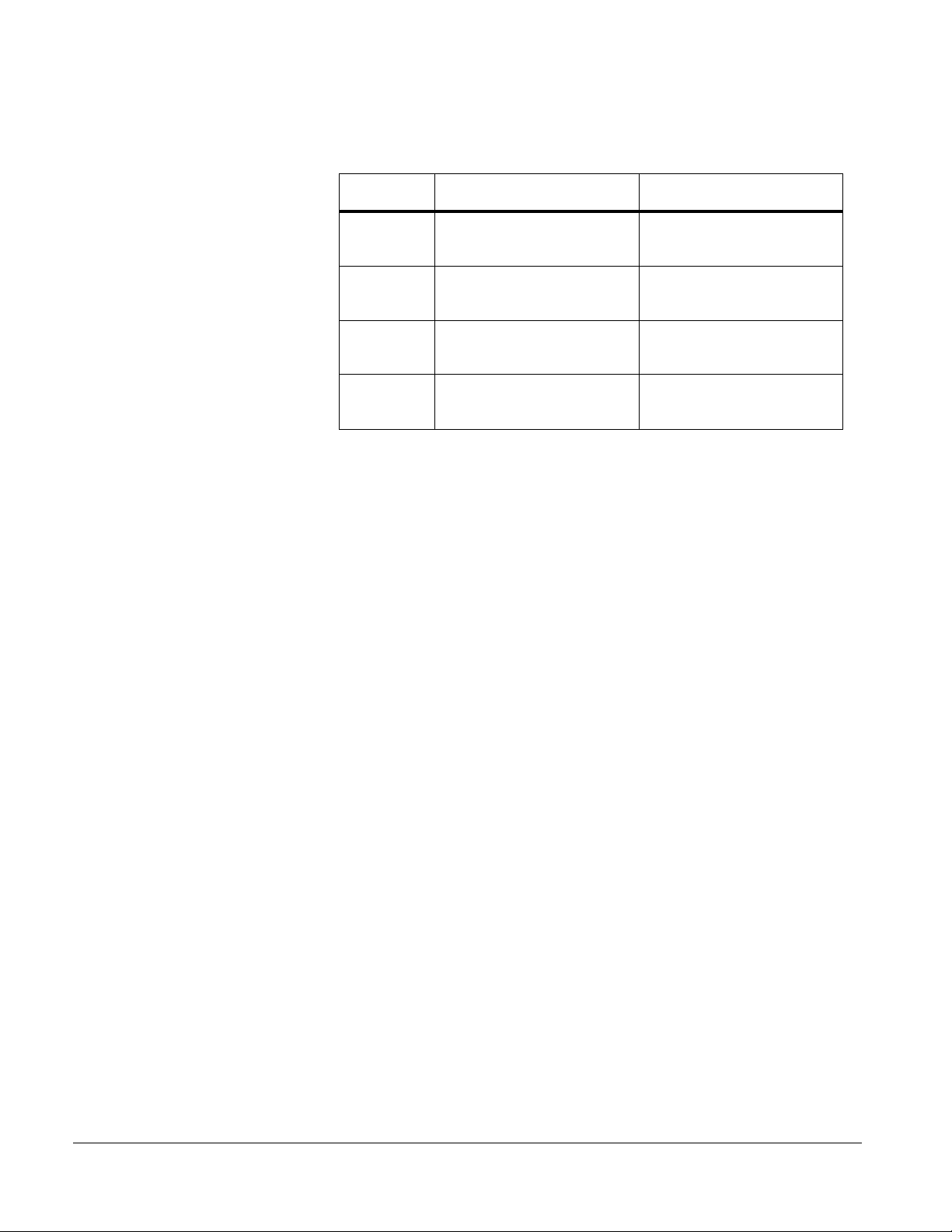

Models and typical dimensions are listed in Table 1–1.

Table 1–1. 2100 SERIES WASHERS

MODEL CHAMBER

(in. [cm])

2110 46 W x 85 H x 93 L

[117 x 216 x 236]

2120 46 W x 85 H x 141 L

[117 x 216 x 358]

2130 46 W x 85 H x 189 L

[117 x 216 x 480]

2150 72 W x 85 H x 141 L

[183 x 216 x 358]

OVERALL

84 W x 105 H x 105 L

[213 x 267 x 267]

84 W x 105 H x 153 L

[213 x 267 x 389]

84 W x 105 H x 201 L

[213 x 267 x 511]

123 W x 105 H x 153 L

[312 x 267 x 389]

(in. [cm])

Routine operation consists of loading the chamber, closing the door, and

pressing START. The Washer then performs the processing cycle and

automatically shuts off when the cycle is complete. Following completion,

either the Unload End door (Double Door Pass-Through model only) or the

Load Door is opened and the load is removed.

Treatment solutions are delivered by means of an oscillating (back and forth

motion) manifold equipped with spray nozzles. Automatic dispensing of

detergent during the Wash phase is a standard feature.

Processing cycles are controlled by means of a Programmable Logic

Controller (PLC) equipped with a Touch Control Panel (TCP) or a LED

screen. Twelve cycle selections are possible. The user needs to select and

start an appropriate cycle.

Standard Features

1–2

A standard cycle consists of the following sequential phases: Prewash,

Wash 1, Wash 2, Rinse 1, Rinse 2, Rinse 3, and Exhaust. Any adjustments

to a cycle's phase timing are made at the control panel.

The washer may be installed in a pit (Pit-Mounted) or installed at floor level

(Floor Mounted Option). When installed in a pit, the floor of the wash

chamber is the same level as the room floor allowing direct loading and

unloading of carts. When installed at floor level, the floor of the chamber is

higher than the room floor; ramps are provided as standard equipment to

facilitate loading and unloading.

• Microcomputer Control System

• Twelve User Programmable Cycles

• Automatic Seven Phase Treatment Cycles

• Program Access Code Security

• Wash and Rinse Temperature Assurance

• Built-in Service Diagnostics

• Personnel Safety System

• Oscillating Jet Spray System

• Fully Draining Treatment Pump and Sump

• No Treatment Solution Carry Over

Page 21

• Automatic Sump Water Level Control

• Automatic Self-Cleaning Debris Filter

• Stainless Steel Steam Coil Heating

• Power Slide Telescoping Door(s)

• All Stainless Steel Construction

• Smooth Chamber Interior Construction

• Full Chamber Stainless Steel Floor Grating

• Insulated Chamber Construction

• Illuminated Chamber Interior

• Left or Right Service Side Installation

• Pit or Floor Mounting

Series 2100 Washers

Optional Features

• Printer

• LED Controls

• Electro-Mechanical Controls

• RS232 or RS485 Port for Data Download

• Air Dry System

• Double Door Pass-Through

• Double Door Interlocks for Manual Doors

• Manual Swing-Out, Side Hinged Doors

• Stainless Steel Treatment Components

• Alkaline or Acid Wash Agent Saver System

• Cold Water Prewash Treatment

• Non-Recirculated Rinse Systems

• Water Supply Temperature Booster

• Automatic Agent Injection Systems

• Floor Jet Spray Header

• Automatic Manifold Bottle/Utensil Rack Coupling

• Center Header System

• Pan Washing

• Automatic Water Rack Flushing System

• Automatic Damper

• Exhaust Fan

• Vapor Removal Condenser

• Drain Discharge Cool-Down System

• Treatment Solution pH Neutralization

• Free-Standing Cabinet System

• Seismic Design

• Knocked Down Shipment

• Modem

• Modem Troubleshooting

• Pit Flush

Accessories

• Floor Loading

• Hydraulic Low Entry Loading Platform

• Cart Tilt Ramps

• Universal Cage and Pan Processing Rack

• Cage Processing Rack

• Pan Processing Racks

• Manifold Feeder Bottle Rack

• Cage Processing Rack for Central Header System

• Feeder Bottle Baskets

• Stainless Steel Pit Plates

61301603579 1–3

Page 22

General Description

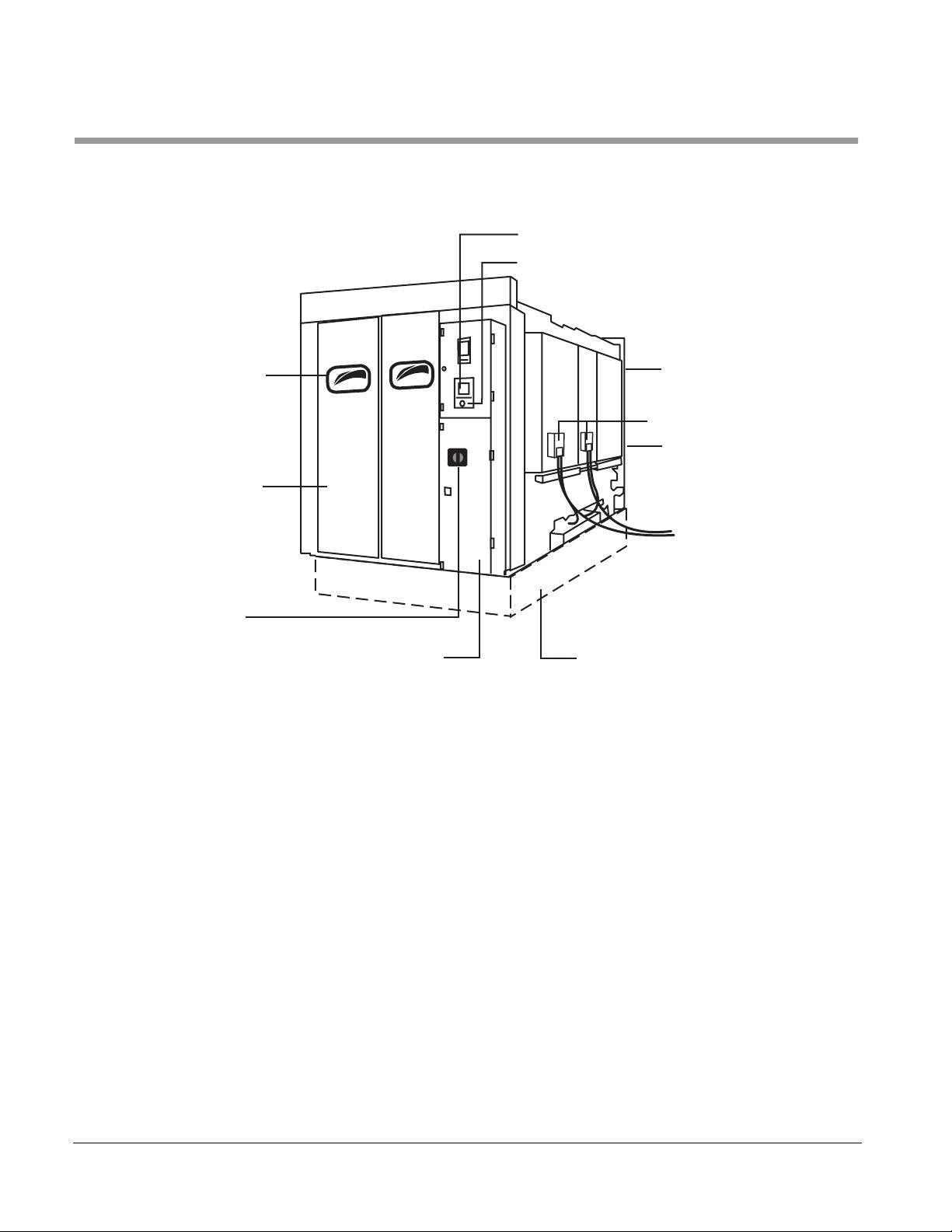

EXTERIOR COMPONENTS

Figure 1–2. EXTERNAL COMPONENTS

CONTROL PANEL

EMERGENCY STOP SWITCH

OBSERVATION

WINDOW

ELECTRICAL DISCONNECT SWITCH

Control Panel

LOAD END

DOOR

UNLOAD END

CONTROL PANEL

DISPENSERS

CONTROL

I ON

0 OFF

PIT

UNLOAD END

DOOR

BOX

Standard unit shown: pit mounted

Provides a pressure sensitive touch screen for the user that is connected to

a Programmable Logic Controller (PLC) located in the Control Box. Enables

the user to select, program, and monitor processing cycles.

EMERGENCY STOP Switch

Electrical Disconnect Switch

Doors

1–4

The EMERGENCY STOP Switch should be used to terminate all treatment

functions and activate the audible alarms.

Rotate the Electrical Disconnect Switch to the:

• ON position to energize the washer.

• OFF position to de-energize the washer.

Provide access to the Washer chamber. Each door is equipped with an

Observation Window. Safety Latches are included on all Swing-out Door

models. Safety Latches are designed to release a closed door when a

moderate amount of physical force is applied against the surface of the door

from the inside.

Page 23

Series 2100 Washers

Door Closed Switches

Alarm (Not Shown)

Service Area (Not Shown)

Dispenser (Option)

Pit

Automatic Self-Cleaning Debris Filter (Not Shown)

Stops Washer operation if a Load or Unload End Door is opened during a

cycle. Prevents the start of washer operation if a door is not closed. Located

on the Load and Unload End Control Panels.

Sounds an audible alert when:

• A cycle is completed (Pulsing/Audible alarm).

• A cycle is aborted.

• A Safety Cable is pulled.

• The Programmable Logic Controller (PLC) detects processing

problems.

Contains piping, valves, pumps, control box, manifold drive motor, etc.

An optional Chemical Dispenser automatically pumps the required chemical

into the water solution held in the sump. The Dispenser is activated during

the wash phases of a processing cycle.

Supports the bottom structure of the washer within a drained enclosure,

thus enabling the Washer chamber to be situated at floor level for ease of

loading and unloading.

The output of the wash pump is provided with a self-cleaning debris filter

screen having perforations smaller than the spray jet orifices to prevent

plugged jets. The filter is attached to the Treatment Pump and is back

flushed by a ball valve operated by the control system. The filter screen can

be accessed without the use of tools.

A screen is provided at the input to the pump to prevent large debris from

entering the pumping system.

The automatic self-cleaning debris filter screen should be rinsed clean

weekly, removing any debris. See Table 4–1, “Maintenance Schedule—

Standard,” on page 1.

61301603579 1–5

Page 24

General Description

Figure 1–3. UNLOAD END CONTROL PANEL

EMERGENCY CABLE

RESET SYSTEM

IN PROGRESS

COMPLETE

CYCLE

OPEN DOOR

EMERGENCY CABLE RESET SYSTEM

IN PROGRESS Indicator

COMPLETE CYCLE Indicator

OPEN DOOR Switch (Option)

EMERGENCY

STOP

After the Personnel Safety System has been used, press the EMERGENCY

CABLE RESET SYSTEM shaft to reset the switch. Turn the power off/on to

reset the washer. For more information, see “PERSONNEL SAFETY

SYSTEM” on page -xiv. The EMERGENCY CABLE RESET SYSTEM

Switch is located on the Unload End Control Panel.

Displays a red light for the duration of an ongoing processing cycle. The IN

PROGRESS Indicator is located at the Unload End of the Washer. Displays

the operational status of the unit at the Unload End.

Displays a green light whenever the Electrical Disconnect Switch is turned

ON, as long as a cycle is not operating. The light turns off at the start of a

processing cycle. When the cycle ends, the light comes back on. The

CYCLE COMPLETE Indicator is located at the Unload End of the Washer.

Displays the operational status of the unit at the Unload End.

Press and release the OPEN DOOR Switch to open the power door when

the washer is not in a cycle. Located on the Unload End. This option is

available on power door models only.

EMERGENCY STOP Switches (Load and Unload End)

1–6

Pressing the EMERGENCY STOP switch terminates all functions of the

washer and sounds the alarm.

Page 25

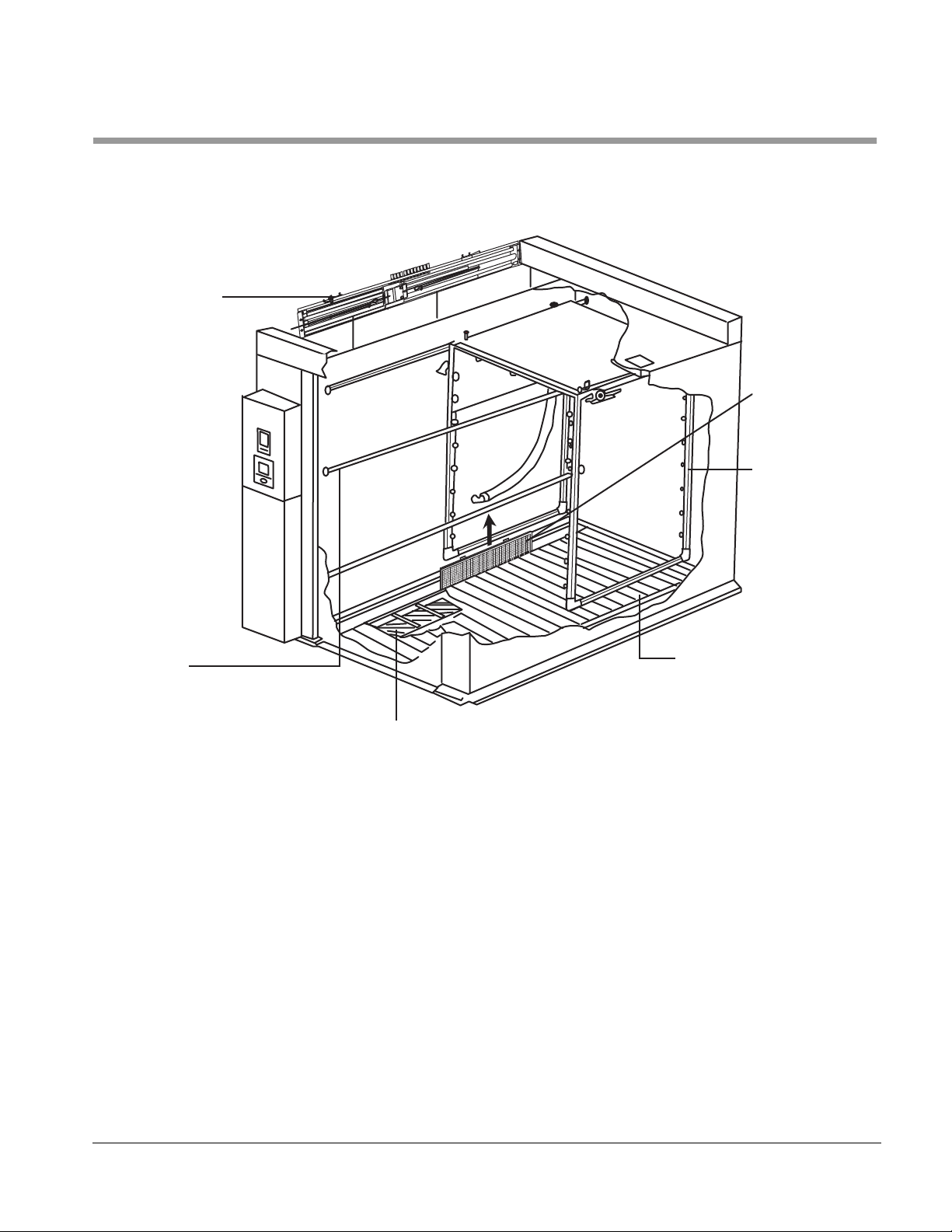

INTERIOR COMPONENTS

SPRAY MANIFOLD

DRIVE ASSEMBLY

Series 2100 Washers

Figure 1–4. CHAMBER COMPONENTS

PRIMARY

DEBRIS FILTER

SPRAY MANIFOLD

HAND

RAIL

Spray Manifold

Spray Manifold Drive Assembly

Hand Rail

FLOOR GRATES

SUMP

a03579C

Delivers the various wash and rinse spray treatments to the load during a

processing cycle. Vertical and horizontal sections, fitted with spray nozzles,

make up the complete assembly.

Moves the Spray Manifold back and forth along the length of the chamber

during a processing cycle.

Functions as a restraint to keep items, such as utensil carts, from being

improperly positioned. Four rails are provided, two on each side of the

chamber.

61301603579 1–7

Page 26

General Description

Floor Grates

Sump

Exhaust Damper (Not Shown)

The grates are removable in sections; the number of sections depending on

the length of the chamber. In the Inclined Floor Grating option, the floor

grates are slightly pitched to assist in the draining of pans and racks.

Holds the supply of solution (wash and rinse) that is pumped to the Spray

Manifold during a processing cycle. During processing, it collects all

drainage for recirculation. A steam heating coil installed in the sump

maintains the temperature of the wash solution and other treatment

solutions - if specified. Drain screens cover the inlet to the extended sump to

prevent large particles of foreign matter from entering.

Opens during the Exhaust phase of a wash cycle to permit residual vapors

to escape from the chamber. Partially closed during the wash and rinse

phases of the wash cycle.

1–8

Page 27

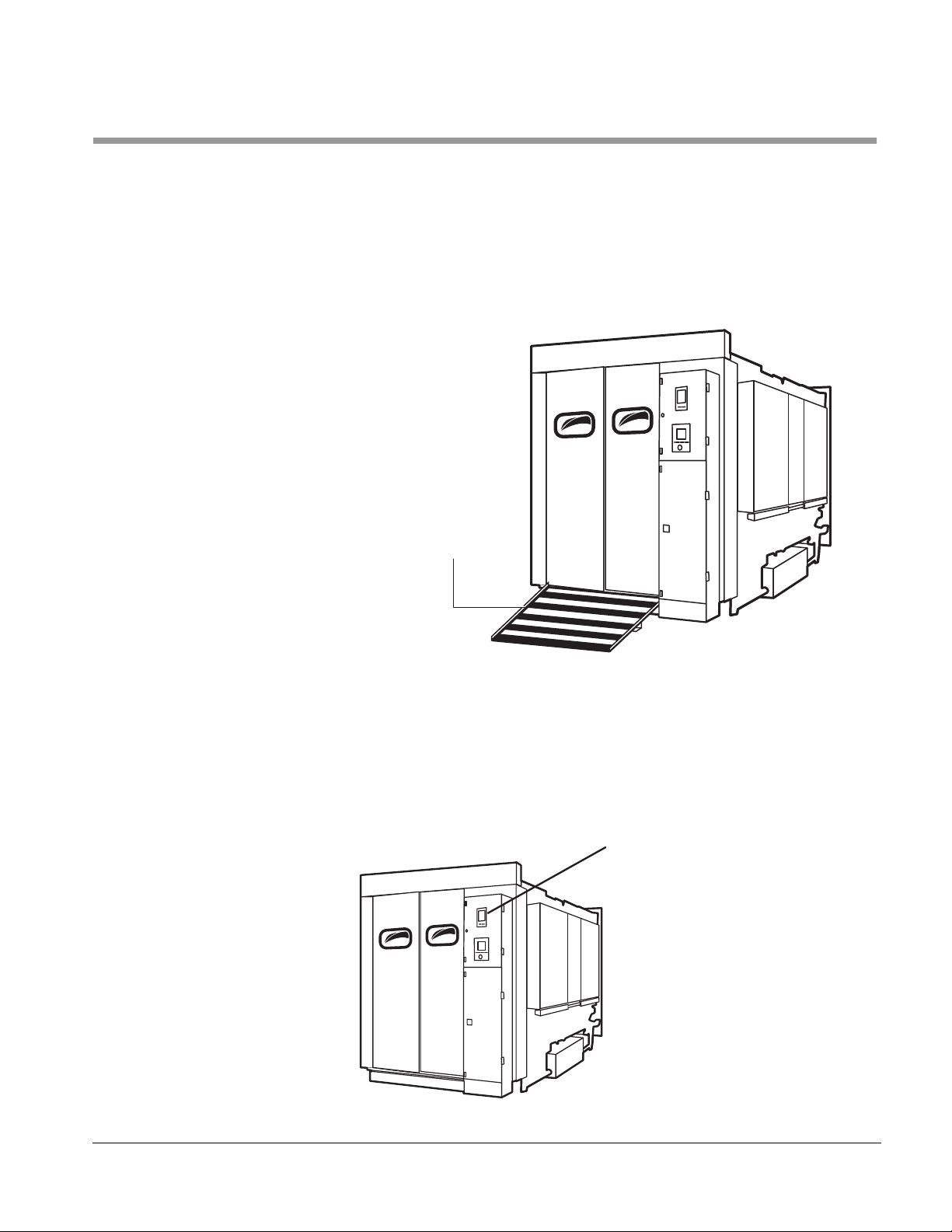

OPTIONS

Series 2100 Washers

The 2100 Washer may be equipped with the following options:

Floor Mounting

Washer may be installed at floor level if a shallow pit is undesirable or

impractical. The result is a chamber floor that is higher than the surrounding

room floor. Door Ramps are provided with Floor Mounted units to facilitate

loading and unloading.

Figure 1–5. FLOOR MOUNTING (Option)

Floor Loading Ramp

A03579-D

Recorder/Printer

Issues a printed record of all pertinent cycle data, including treatment

functions, temperature, time, and date. A Take-Up Reel is provided to

retrieve and wind the print-out onto a spool. See “Printer” on page 7-4 for

additional information.

Figure 1–6. RECORDER/PRINTER (Option)

RECORDER/PRINTER

A03579-E

61301603579 1–9

Page 28

General Description

ACCESSORIES

The following is a list of Accessories. Below the list is a description of each.

• Floor Loading Ramp

• Hydraulic Low Entry Loading Platform

• Cart Tilt Ramp

• Universal Cage and Pan Processing Rack

• Cage Processing Rack

• Pan Processing Rack

• Manifold Feeder Bottle Rack

• Cage Processing Rack For Central Header System

• Feeder Bottle Baskets

• Stainless Steel Pit Plates

Floor Loading Ramp

Hydraulic Low Entry Loading Platform

Cart Tilt Ramp

Universal Cage and Pan Processing Rack

Cage Processing Rack

Pan Processing Rack

A stainless steel ramp(s), with a non-skid surface, is provided to permit

loading and unloading of floor mounted units.

A stainless steel hydraulic powered lifting platform with a non-skid loading

surface is provided to aid in the loading and/or unloading of the washer

chamber. The cart or rack is rolled onto the platform. The user operates the

platform raising the cart/rack to the level of the chamber floor. The user rolls

the rack into the wash chamber for processing. This lifting system eliminates

the hazard of pushing or pulling heavy racks up a fixed loading ramp. A

separate 30 AMP electrical connection is required.

A stainless steel ramp is installed inside the chamber to incline the carts to

permit the most effective draining and drying.

A stainless steel rack with an automatic pivoting counterweight is provided

to accommodate cages from 5'' to 8'' in height and pans with a maximum

depth of 3''. The rack is transported by casters and roller bearings. Rack

capacity varies, depending on the model.

A stainless steel rack is provided to process cages from 5'' to 8'' in height.

The rack is transported by casters and roller bearings. Rack capacity varies,

depending on the model.

A stainless steel rack to process pans with a maximum depth of 3''. The rack

is 32'' wide, 70'' high, and 72'' long and is transported by casters and roller

bearings. Rack capacity: Rabbit Pans - 30.

Manifold Feeder Bottle Rack

Cage Processing Rack For Central Header System

1–10

A stainless steel manifold, multi-jet type rack is provided for processing

feeder bottles. The 8, 16, and 32 oz. bottles can be processed along with

the stainless steel baskets used to transport the bottles. The rack is

supported by casters and roller bearings and couples to the manifold rack

coupling system. The racks can be configured for two, four, or six basket

capacity.

A stainless steel cage rack is provided for processing large volumes of

standard mouse cage or rat cages. (Note: Rack to be set up for either

mouse or rat cages). The rack is supported by casters and roller bearings

Page 29

Series 2100 Washers

and couples to the manifold rack coupling system. Rack capacity: Mouse

Cages - 200, or Rat Cages - 96 or Rabbit Pans - 80.

Feeder Bottle Baskets

Stainless Steel Pit Plates

Stainless steel bottle baskets are provided for processing 8, 16, or 32 oz.

bottles. The baskets are configured either to a 4x6 or a 5x5 bottle pattern.

Provided are stainless steel pit plates to be installed in the pit (by others) in

lieu of cold rolled steel. Reference pit drawing.

61301603579 1–11

Page 30

General Description

PROCESSING CYCLE DESCRIPTION

A 2100 washer runs the following processing cycle.

Automatic Seven Phase Treatment Cycle

Operation

Treatment Schedule

The standard treatment cycle consists of a Prewash, Wash 1, Wash 2,

Rinse 1, Rinse 2, Rinse 3, and an Exhaust. All cycle phases are adjustable

from 0 - 60 minutes. All wash and rinse treatments are recirculated under

pump pressure. The cycle, once activated, is completely automatic.

Additional cycle treatment phases are available.

At the start of the processing period, the user places the load to be cleaned

in the chamber, closes the door, selects the desired cycle and presses the

cycle start switch. The washer automatically proceeds through the

treatment process and alerts the user when the process is complete. The

user then opens the chamber door and removes the cleaned load.

PREWASH

Hot water, from house supply, fills the sump, or water remaining in the sump

from Rinse 3 of the previous cycle, is recirculated through the jet spray

system under pump pressure and pumped to drain upon completion. Phase

time and temperature is user programmable, from 0-60 minutes and 120°-

190°F respectively.

WASH 1

Hot water, from house supply, fills the sump and wash agent is automatically

added. The treatment solution is recirculated through the jet spray system,

under pump pressure, and is pumped to drain upon completion. Phase time

and temperature is user programmable, from 0-60 minutes and 120°-190°F

respectively.

NOTE

Agent Saver Option: If the agent saver option is selected, the hot agent

solution from the agent solution reservoir fills the sump and is recirculated through the jet spray system. At the end of the treatment, the

agent solution is returned to the agent solution reservoir.

Soak Option: A subsequent soak period may be programmed from 060 minutes, to permit the acid solution to work on the load before proceeding to the second wash and/or rinse treatments. A soak option can

only be activated after an acid wash.

When selected, the soak always follows the “Acid” agent wash.

WASH 2

Hot water, from house supply, fills the sump and wash agent is automatically

added. The treatment solution is recirculated through the jet spray system,

under pump pressure, and is pumped to drain upon completion. Phase time

and temperature is user programmable, from 0-60 minutes and 120°-190°F

respectively.

Agent Saver Option: If the agent saver option is selected, the hot agent

solution from the agent solution reservoir fills the sump and is recircu-

1–12

Page 31

Series 2100 Washers

lated through the jet spray system. At the end of the treatment, the

agent solution is returned to the agent solution reservoir.

Soak Option: A subsequent soak period may be programmed from 060 minutes, to permit the acid solution to work on the load before proceeding to the rinse treatments. A soak option can only be activated

after an acid wash.

NOTE

When selected, the soak always follows the “Acid” agent wash.

RINSE 1

Hot water, from house supply, fills the sump and is recirculated through the

jet spray system under pump pressure and pumped to drain upon

completion. Phase time and temperature is user programmable, from 0-60

minutes and 120°-190°F respectively.

RINSE 2

Hot water, from house supply, fills the sump and is recirculated through the

jet spray system under pump pressure and pumped to drain upon

completion. Phase time and temperature is user programmable, from 0-60

minutes and 120°-190°F respectively.

RINSE 3

Hot water, from house supply, fills the sump and is recirculated through the

jet spray system under pump pressure and pumped to drain upon

completion or saved in the sump to be used for the prewash phase of the

next cycle. Phase time and temperature is user programmable, from 0-60

minutes and 120°-190°F respectively.

Non-Recirculated Option: Hot water, from house supply, under house

pressure is sprayed directly through a separate jet system. Phase time

is user programmable from 0-60 minutes.

EXHAUST or VAPOR REMOVAL

Unit stands idle for a sufficient period of time for the facility vent system to

remove vapor from within the chamber. Phase time is user programmable

from 0-60 minutes.

Air Dry System Option: During the vapor removal phase, the air dry

system consists of a forced ambient or heated air manifold to blow residue water off the cages, pans, and racks. Phase time is user programmable from 0-60 minutes.

TEMPERATURE GUARANTEE SYSTEM:

All phases of the wash cycle except Soak and Exhaust have the option to

select a Temperature Guarantee Mode. When selected, this causes the unit

to fill and spray water normally for that phase, without allowing the main

timer to start counting down until the setpoint temperature has been

attained. If at any time the sump temperature should fall below the setpoint,

the main timer stops until the temperature exceeds the setpoint. Failure to

do so in a set period of time generates a “too long to heat” alarm.

61301603579 1–13

Page 32

General Description

1–14

Page 33

INTRODUCTION

Section 2 The Control Panel

The Control Panel on this Washer provides the user with an interface linked

to the Programmable Logic Controller (PLC) located in the Control Box.

Using the Control Panel, the user is able to do:

• Select a processing cycle.

• Program the cycle phase timing.

• Program the cycle phase temperature.

• Start a processing cycle.

• Monitor the status of an ongoing cycle.

• Manually drain the washer's sump.

In addition to the above, supervisory personnel are able to:

• Access load counters and time display

• Protect cycle programming

Your washer has one of the following control panels:

• TOUCH CONTROL PANEL (TCP),

• LED CONTROL PANEL, or

• ELECTRO-MECHANICAL CONTROL PANEL

Information on each control panel follows.

61301603579 2–1

Page 34

The Control Panel

TOUCH CONTROL PANEL (TCP)

Control Screens

SERIAL NUMBER: 2100-XX-XXXX

CUSTOMER'S FACILITY,

PUSH TO ACTIVATE CONTROL SYSTEM

GETINGE CASTLE

MODEL 2100

CITY, STATE

The following pages illustrate the available Control Screens. To advance

from screen to screen, note that each illustrated screen below contains a

gray area. Press the prompt on the screen, as it is highlighted on the

illustration, and the next screen will display. Programming a cycle should not

be accomplished from this section of the user manual. See “Cycle

Programming” on page 2-12.

Figure 2–1. MACHINE/CUSTOMER IDENTIFICATION SCREEN

Identifies Getinge/Castle Inc. as the

Equipment Manufacturer.

The Equipment Model Number.

The Equipment's Serial Number

(reference when calling for service).

Identifies the Equipment Owner.

Press this prompt to access the "SELECT CYCLE"

screen and continue operation.

2–2

Page 35

LOAD UNIT – SELECT CYCLE – REVIEW

CYCLE

2

CYCLE

CYCLE

3

7

CYCLE

CYCLE

1

5

CYCLE

6

Figure 2–2. CYCLE SELECTION SCREEN

CYCLE

4

CYCLE

8

Press the prompt of the desired cycle of operation.

Series 2100 Washers

CYCLE

9

LOAD DOOR

MANUAL

MODE

CYCLE

10

EVENT

PRINT OFF

CYCLE

11

UNLOAD DOOR

PRINT

CYCLE

CYCLE

12

REVIEW

CYCLE

Manual Doors: Prompts are "read only" and not used as touch

cells. When the Load Door is open, "LOAD DOOR" will be back-lit

red in color. When the Load Door is closed, "LOAD DOOR" will be

back-lit blue in color. Note that "UNLOAD DOOR" will be available

only on washers equipped with this option.

Power Door(s): When the washer is equipped with the power

door(s) option the "LOAD DOOR" and "UNLOAD DOOR" area on

the control panel is a pressure sensitive touch cell.

After the user has selected a cycle, this prompt must be pressed

to review the cycle and display the next screen.

Pressing this prompt will allow the printer to print the cycle

parameters.

When this prompt displays "EVENT PRINT ON", the operating

cycle will be printed.

Pressing this prompt places controls in "MANUAL MODE" to

test individual components.

61301603579 2–3

Page 36

The Control Panel

Figure 2–3. REVIEW PROGRAMMED PHASES SCREEN

Describes the current cycle selected.

CYCLE 1

PREWASH

RINSE

1

REVIEW AND START OR PROGRAM CYCLE

MAIN

MENU

WASH

1

RINSE

2

START

CYCLE

REVIEW PHASES

WASH

2

RINSE

3

PROGRAM

CYCLE

Describes the current control screen display.

SOAK

EXHAUST

PRINT

CYCLE

Illuminated prompts indicate phases

programmed to operate in this cycle.

Displays available options for this control

screen.

Pressing this prompt will allow user to change

cycle parameters if password is keyed in to unlock.

Pressing this prompt will print selected cycle

parameters.

Depress to start selected cycle.

Depress prompt to return to main menu.

Figure 2–4. PASSWORD SCREEN

Press prompt to enter password.

Unlocks user program.

2–4

CYCLE PROGRAM MODE

ENTER

PASSWORD

UNLOCKED

PROGRAM

CYCLE

CHANGE

PASSWORD

PRESS TO

CHANGE P/W

MAIN

MENU

SERVICE

PASSWORD

LOCKED

ADJUST

CALENDAR

CLOCK

Prompt is used for changing the user's password.

Prompt is for the Authorized Sevice Technician.

Press prompt to change password for the user program.

Prompts are "read only", showing the status of

program access ("LOCKED" or "UNLOCKED").

Prompt is used in setting the time and date.

Press prompt to go to "MAIN MENU."

When program is unlocked, prompt will allow

access to the programming screens.

Page 37

Figure 2–5. PASSWORD SCREEN

Series 2100 Washers

CURRENT VALUE

1

4

7

+

/–

PASSWORD

2

5

8

0

UNLOCKING PASSWORD

1. Enter Password.

MAXIMUM >>>32000

MINIMUM >>> 1

3

6

9

–

B/S

E

N

T

E

R

D

O

N

E

90

2. Press "ENTER".

3. Press "DONE".

90

New value must be above minimum and below maximum.

4. Screen will revert back to "PROGRAM CYCLE" screen.

Screen "UNLOCKED" displays.

5. Press "PROGRAM CYCLE".

6. Program is now accessible to change parameters.

Figure 2–6. PROGRAM CYCLE

CYCLE PROGRAM MODE

ENTER

PASSWORD

UNLOCKED

PROGRAM

CYCLE

CHANGE

PASSWORD

PRESS TO

CHANGE P/W

MAIN

MENU

SERVICE

PASSWORD

LOCKED

ADJUST

CALENDAR

CLOCK

Press prompt to enter password.

Unlocks user program.

Prompt is used for changing the user's password.

Prompt is for the Authorized Sevice Technician.

Press prompt to change password for the user program.

Prompts are "read only", showing the status of

program access ("LOCKED" or "UNLOCKED").

Prompt is used in setting the time and date.

Press prompt to go to "MAIN MENU."

When program is unlocked, prompt will allow

access to the programming screens.

61301603579 2–5

Page 38

The Control Panel

Figure 2–7. PROGRAM PREWASH SCREEN

CYCLE 1

PROGRAM PREWASH MENU

PREWASH ON

TIMER

60

TEMP

120

GUARANTEE

OFF

NEXT

PHASE

Displays the current cycle number.

Displays the phase of cycle to be programmed.

Displays status of phase. Press prompt to toggle "OFF".

Displays length of time the phase will be activated in seconds.

Displays the status of temperature guarantee.

Press prompt to change status to "TEMP. GUARANTEE".

Displays the programmed temperature of the sump.

Press prompt and enter new parameters.

Pressing this prompt will advance the menu to the next

phase screen.

2–6

Page 39

Figure 2–8. PROGRAM WASH #1 SCREEN

Series 2100 Washers

PROGRAM WASH 1 MENU

TIMER

300

SUMP TEMP

165

CYCLE

AGENT WASH #1 OFF

AGENT SELECTION

ALKALINE AGENT – DRAIN

1

Figure 2–9. PROGRAM WASH #2 SCREEN

GUARANTEE

OFF

NEXT

PHASE

Displays the current cycle.

Displays the phase of cycle to be programmed.

Displays status of phase. Press prompt to toggle "ON".

Displays length of time phase will be activated.

Displays status of temperature guarantee.

Press the prompt to change the status.

"AGENT SELECTION" prompt allows the programming of

agent washes, alkaline or acid, to be saved or drained

at the end of the phase, if Agent Saver Option is purchased.

Press the prompt to advance menu to the next phase screen.

Displays the current temperature parameter of the

sump solution. Press the prompt to allow a new parameter

to be entered.

PROGRAM WASH 2 MENU

TIMER

300

SUMP TEMP

165

CYCLE 1

AGENT WASH #2 ON

AGENT SELECTION

ACID AGENT DRAIN

GUARANTEE

OFF

NEXT

PHASE

Displays the current cycle.

Displays the phase of cycle to be programmed.

Displays status of phase. Press prompt to toggle "ON".

Displays length of time phase will be activated.

Displays the status of temperature guarantee.

Press the prompt to change the status.

"AGENT SELECTION" prompt allows the programming of

agent washes, alkaline or acid, to be saved or drained

at the end of the phase, if Agent Saver Option is purchased.

Press the prompt to advance the menu to the next

phase screen.

Displays the current temperature parameter of the

sump solution. Press the prompt to allow a new parameter

to be entered.

61301603579 2–7

Page 40

The Control Panel

Figure 2–10. PROGRAM SOAK SCREEN

CYCLE 1

PROGRAM SOAK MENU

SOAK ON

TIMER

120

NEXT

PHASE

Figure 2–11. PROGRAM RINSE #1 SCREEN

CYCLE 1

Displays the current cycle.

Displays the phase of the cycle to be programmed.

Displays the status of the phase. Press prompt to toggle "ON".

Displays the length of time the phase will be activated.

Press this prompt to advance the menu to the next

phase screen.

Displays the current cycle.

PROGRAM RINSE 1 MENU

RINSE #1 ON

TIMER

120

SUMP TEMP

185

TEMP.

GUARANTEED

PHASE

Displays the phase of the cycle to be programmed.

Displays status of the phase. Press prompt to toggle "ON".

Displays length of time the phase will be activated.

Displays status of temperature guarantee.

Press prompt to change status to "GUARANTEE OFF".

Displays the programmed parameter of the sump solution.

Press the prompt to allow a new parameter to be entered.

NEXT

Press this prompt to advance the menu to the next

phase screen.

2–8

Page 41

Figure 2–12. PROGRAM RINSE #2 SCREEN

Series 2100 Washers

CYCLE

1

PROGRAM RINSE 2 MENU

RINSE #2 OFF

TIMER

0

SUMP TEMP

0

GUARANTEE

OFF

PHASE

Figure 2–13. PROGRAM RINSE #3 SCREEN

Displays the current cycle.

Displays the phase of cycle to be programmed.

Displays status of the phase. Press prompt to toggle "ON".

Displays the length of time the phase will be activated.

Displays status of the temperature guarantee.

Press prompt to change status to "TEMP. GUARANTEE".

Displays the programmed parameter of the sump solution.

Press the prompt to allow a new parameter to be entered.

NEXT

Press the prompt to advance the menu to the next

phase screen.

CYCLE

PROGRAM RINSE 3 MENU

RINSE #3 OFF

TIMER TEMP

60

MAIN

MENU

SUMP TEMP

120

1

GUARANTEE

Displays the current cycle.

Displays the phase of cycle to be programmed.

Displays status of the phase. Press prompt to toggle "ON".

Displays length of time the phase will be activated.

Displays status of the temperature guarantee.

Press prompt to change status to "TEMP. GUARANTEE".

Displays the programmed parameter of the sump solution.

Press the prompt to allow new a parameter to be entered.

Press this prompt to return to the "MAIN MENU".

61301603579 2–9

Page 42

The Control Panel

Figure 2–14. CALENDAR CLOCK

This prompt is "read only" and displays current month.

CALENDAR CLOCK - ENTER NEW VALUES

THEN PRESS CHANGE PB TO CHANGE VALUES

PLC MONTH

NEW MONTH

PLC HOUR

NEW HOUR NEW MINUTE

PLC DAY

NEW DAY NEW YEAR

PLC MINUTE

PLC YEAR

SAVE

CHANGES

BACK TO

ACCESS

SCREEN

Displays the current screen description.

This prompt is "read only" and displays the current Day.

This prompt is "read only" and displays the current Year.

This prompt is used for changing the Day. Press the prompt

and enter the desired Day.

This prompt is used for changing the Year. Press the prompt

and enter the desired Year.

This prompt is used for changing the Month. Press the

prompt and enter the desired Month.

Press this prompt to take user back to the access screen.

Press this prompt to save all of the settings in the

"CALENDAR CLOCK" screen.

This prompt is "read only" and displays the current minute.

This prompt is "read only" and displays the current hour.

This prompt is used for changing the Minute.

Press the prompt and enter the desired Minute.

This prompt is used for changing the Hour.

Press the prompt and enter the desired Hour.

2–10

ACCESSING THE CALENDAR CLOCK SCREEN

1. From the CYCLE SELECTION screen, press “REVIEW

CYCLE”.

2. From the REVIEWED PROGRAMMED PHASES screen,

press, “PROGRAM CYCLE”.

3. On the Password screen, press “ADJUST CALENDAR

CLOCK”.

Page 43

Series 2100 Washers

Manual Mode #1 Cycle Screen Description

MANUAL MENU #1

TREATMENT

PUMP OFF

ALKALINE

DETERGENT

SUMP HEAT DAMPER

JET VALVE

OPEN

ACID

DETERGENT

MAIN

MENU

Figure 2–15. MANUAL MODE EXAMPLE

SELECT DESIRED

FUNCTION/ABORT TO QUIT

DRAIN

VALV E

ACID

NEUTRALIZE

DRAIN

COOLING

ANSWER

ALARM

HEADER

DRIVE

SUMP FILL

ABORT

Press any prompt to activate the selected components.

Press the prompt again to stop selected component or

"ABORT" to stop all of the components activated.

All safeties are intact in the manual mode. The wash or

rinse pumps will not operate if there is not enough

water in the sump. The Wash pump will operate for 60

seconds without water.

Sump fill will not activate if sump is full.

Sump fill will stop when sump is full.

ACCESSING THE MANUAL MODE SCREEN

1. From the CUSTOMER IDENTIFICATION screen, press

“PUSH TO ACTIVATE CONTROL SYSTEM”.

2. From the CYCLE SELECTION screen, press “MANUAL

MODE”.

61301603579 2–11

Page 44

The Control Panel

Cycle Programming

Example: Programming a Sample Cycle

PHASE

TIME

(seconds)

The following is a SAMPLE cycle along with detailed instructions on how to

program the cycle for your reference.

TEMPERATURE

(°F)

TEMPERATURE

GUARANTEE

Sample Cycle 1—Touch Control Panel

Prewash 60 120 Off

Wash 1 300 165 Off

Soak none

Wash 2 300 165 Off

Soak none

Rinse 1 120 185 On

Rinse 2 None Off Off

SAVE/DUMP TO

DRAIN

AGENT

Alkaline Save

Acid Drain

TANK

TEMP (°F)

Rinse 3 60 180 Off

LOAD UNIT – SELECT CYCLE – REVIEW

CYCLE 1

CYCLE 5

CYCLE 9 CYCLE 10 CYCLE 11 CYCLE 12

LOAD DOOR

MANUAL

MODE

CYCLE 2 CYCLE 3 CYCLE 4

CYCLE 6

EVENT

PRINT OFF

CYCLE 7

UNLOAD DOOR

PRINT

CYCLE

CYCLE 8

REVIEW

CYCLE

CYCLE SELECTION SCREEN:

Programmer should-

Ø Press the “CYCLE 1" prompt.

Ø Press the “REVIEW CYCLE” prompt.

2–12

Page 45

CYCLE SELECTION SCREEN:

Programmer should-

Series 2100 Washers

CYCLE 1

PREWASH

RINSE

1

WASH

1

RINSE

2

REVIEW PHASES

WASH

2

RINSE

3

SOAK

EXHAUST

REVIEW AND START OR PROGRAM CYCLE

MAIN

MENU

START

CYCLE

PROGRAM

CYCLE

PRINT

CYCLE

CYCLE PROGRAM MODE

ENTER

PASSWORD

CHANGE

PASSWORD

SERVICE

PASSWORD

Ø Press the “PROGRAM CYCLE” prompt.

CYCLE SELECTION SCREEN:

Programmer should-

Ø Press the “ENTER PASSWORD” prompt.

Ø Enter the correct password “12345”.

Ø Press the “ENTER” prompt.

Ø Press the “DONE” prompt. This unlocks the system.

Ø Press the “PROGRAM CYCLE” prompt.

UNLOCKED

PROGRAM

CYCLE

PRESS TO

CHANGE P/W

MAIN

MENU

LOCKED

ADJUST

CALENDAR

CLOCK

61301603579 2–13

Page 46

The Control Panel

CYCLE SELECTION SCREEN:

Programmer should-

CYCLE 1

PROGRAM PREWASH MENU

PREWASH ON

TIMER TEMP

60

120

GUARANTEE

OFF

Ø If “PREWASH OFF” is displayed, press “PREWASH

OFF” prompt to change the phase to “PREWASH ON”.

Ø Press the “TIMER” prompt and set the phase time to 60

seconds.

Ø Press the “TEMP” prompt and set the temperature to

120°F.

Ø If “TEMP. GUARANTEE” is displayed, press “TEMP.

GUARANTEE” to change the status to “GUARANTEE

OFF”.

Ø Press the “NEXT PHASE” prompt.

NEXT

PHASE

CYCLE SELECTION SCREEN:

Programmer should-

CYCLE

PROGRAM WASH 1 MENU

AGENT WASH #1 ON

TIMER

300

SUMP TEMP

165

AGENT SELECTION

ALKALINE AGENT – SAVE

1

GUARANTEE

OFF

NEXT

PHASE

Ø If “AGENT WASH #1 OFF” is displayed, press “AGENT

WASH #1 OFF” prompt to change the phase to “AGENT

WASH #1 ON”.

Ø Press the “TIMER” prompt and set phase time to 300

seconds.

Ø Press the “SUMP TEMP” prompt and set the phase temp

to 165°F.

Ø If “TEMP. GUARANTEE” is displayed, press “TEMP.

GUARANTEE” prompt and change the phase to “GUAR-

ANTEE OFF”.

Ø Press the “AGENT SELECTION” prompt to select

“ALKALINE AGENT – SAVE”.

Ø Press the “NEXT PHASE” prompt to continue.

2–14

Page 47

CYCLE SELECTION SCREEN:

Programmer should-

Series 2100 Washers

PROGRAM WASH 2 MENU

TIMER

300

SUMP TEMP

165

CYCLE

AGENT WASH #2 ON

AGENT SELECTION

ACID AGENT – DRAIN

1

GUARANTEE

OFF

NEXT

PHASE

Ø If “AGENT WASH #2 OFF” is displayed, press the

“AGENT WASH #2 OFF” prompt to change the phase to

“AGENT WASH #2 ON”.

Ø Press the “TIMER” prompt and set the phase time to 300

seconds.

Ø Press “SUMP TEMP” and set the phase temperature to

165°F.

Ø If “TEMP. GUARANTEE” is displayed, press “TEMP.

GUARANTEE” prompt to change the phase to “GUARAN-

TEE OFF”.

Ø Press the “AGENT SELECTION” prompt to select “ACID

AGENT – DRAIN”.

Ø Press the “NEXT PHASE” prompt to continue.

CYCLE SELECTION SCREEN:

Programmer should-

CYCLE

1

PROGRAM RINSE 1 MENU

RINSE #1 ON

TIMER

120

SUMP TEMP

185

TEMP.

GUARANTEED

PHASE

Ø If “RINSE #1 OFF” is displayed, press the “RINSE #1

OFF” prompt to change the phase to “RINSE #1 ON”.

Ø Press the “TIMER” prompt and set the phase time to 120

seconds.

Ø Press the “SUMP TEMP.” prompt and set the phase

temp to 185°F.

Ø If “GUARANTEE OFF” is displayed, press “GUARAN-

TEE OFF” prompt to change the phase to “TEMP. GUARANTEE”.

Ø Press the “NEXT PHASE” prompt to continue.

NEXT

61301603579 2–15

Page 48

The Control Panel

CYCLE

PROGRAM RINSE 2 MENU

RINSE #2 OFF

1

CYCLE SELECTION SCREEN:

Programmer should-

Ø If “RINSE #2 ON” is displayed, press the “RINSE #2 ON”

prompt the phase to “RINSE #2 OFF”.

Ø Press the “Next Phase” prompt to continue.

TIMER

0

SUMP TEMP

0

GUARANTEE

OFF

NEXT

PHASE

CYCLE 1

PROGRAM RINSE 3 MENU

RINSE #3 ON

TIMER GUARANTEE

60

SUMP TEMP

180

OFF

CYCLE SELECTION SCREEN:

Programmer should-

Ø If “RINSE #3 OFF” is displayed, press the “RINSE #3

OFF” prompt to change the phase to “RINSE #3 ON”.

Ø Press the “TIMER” prompt and set the phase time to 60

seconds.

Ø Press the “SUMP TEMP” prompt and set the phase temp

to 180°F.

Ø If “TEMP GUARANTEE” is displayed, press the “TEMP

GUARANTEE” prompt to change the phase to “GUARAN-

TEE OFF”.

Ø Press the “MAIN MENU” prompt to continue.

MENU

2–16

MAIN

Page 49

LED CONTROL PANEL

Key Locations

SECTION 1

STATUS LIGHTS

Series 2100 Washers

SECTION 2

FUNCTION KEYS

SECTION 3

DATA ENTRY KEYS

The above screen has been separated into 3 sections

• Section 1 Status Lights

• Section 2 Function Keys

• Section 3 Data Entry Keys

Information on each section follows.

61301603579 2–17

Page 50

The Control Panel

#1 status light will be on when left and right cables have not been pulled

#2 status light will be on when left and right cables are within adjustment

Section 1— Status lights

#3 status light will be on when load door is in the closed position

#4 status light will be on when unload door is in the closed position

#5 status light will be on when alkaline tank is full

Cable

OK

Cable

OK

Load

Door

Unload

Door

Tank

Full

Tank at

set point

Sump

Full

#8 status light NOT USED

#7 status light will be on when sump is full of water

#6 status light will be on when alkaline tank is at programmed temperature

2–18

Page 51

Section 2— Function keys

Series 2100 Washers

START

ABORT

MANUAL

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

LOAD

DOOR

FUNCTION KEY FUNCTION

START Start the selected cycle.

ABORT Stop all functions of washer.

MANUAL Enter the manual mode.

LOAD DOOR Open or close load door.

PROGRAM

CYCLE

CYCLE

HOLD

PRINT

CYCLE

SELECT CYCLE Access cycle selection screen.

ENTER SERVICE

MODE

SILENCE ALARM Silence audible alarm.

REVIEW CYCLE Review selected cycle.

EXIT SERVICE MODE Exit service mode and return to stand-by

EVENT PRINT

ON/OFF

PROGRAM CYCLE Access selected cycles program for

CYCLE HOLD Stop cycle timer in current phase of

PRINT CYCLE Print parameters of selected cycle.

For authorized service technician only.

screen.

Record live readings of selected cycle as

load is being processed.

parameter changes.

operation.

61301603579 2–19

Page 52

The Control Panel

Section 3— Data Entry keys

LAST

MESSAGE

NEXT

MESSAGE

Used to review last screen

Used to review next

available screen

LAST

MESSAGE

NEXT

MESSAGE

PAG E

UP

PAG E

DOWN

PRINT

SCREEN

12

ALARM

4

SETUP

7

HELP

±

Key/Function

HELP

Not used

±

Used for the #2 or

to move cursor up

2

ACK

56

8

0

+

-

TOGGLE

3

9

.

CLEAR

DELETE

E

N

T

E

R

-

TOGGLE

Used for the #9

9

Used to activate components or deactivate compo-

.

nents in Manual Mode.

PAG E

UP

PAG E

DOWN

SETUP

Used to scroll to

previous page

Used to scroll to next page

Used for the #1

Used for the #4 or

to move cursor left

4

Used for the #7 or

place PLC into direct

7

MODEM contact

ALARM

ACK

+

Used for the #5

5

Used for the #8 or

to move cursor down

8

Used for the #0

0

Used for the #3

3

Used for the #6 or

to move cursor right

6

CLEAR

DELETE

E

N

T

E

R

Used to clear old

parameters

Not used

Used to enter new

parameter

2–20

Page 53

Series 2100 Washers

Control Sequences

START-UP

Energize the unit. The unit operates a diagnostic test. Once the

controller operates the test, the screen displays “Getinge Castle, Inc.”. The programmed unit is now ready to be used or programmed.

OPERATION

At the beginning of the processing period, the user activates

the unit for automatic operation. The unit automatically

advances to the “READY” state when the required operational

conditions are attained.

The operator places the load to be cleaned into the chamber,

closes the chamber door, selects the desired cycle, reviews the

cycle, and presses the “START” function key on the control

panel. The washer automatically proceeds through the treatment process and alerts the user when the process is complete. The user then opens the chamber door and removes the

cleaned load.

ALARM

If an alarm should sound at any time, follow the prompt on the

display screen and then press “Alarm Ack” on the keypad to

turn the sound off, and to return to the program.

HELP

A help screen is provided to assist the user.

61301603579 2–21

Page 54

The Control Panel

Processing Cycle Screen Description

Stand-by Screen

Cable

Message

Unload

Door

Tank

Tank at

Sump

Full

set point

Full

Load

Cable

Door

OK

OK

Alarm

Print

Run

Cycle Selection

START

ABORT

MANUAL

LOAD

DOOR

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

PROGRAM

CYCLE

CYCLE

HOLD

PRINT

CYCLE

LAST

MESSAGE

NEXT

MESSAGE

PAG E

UP

PAG E

DOWN

PRINT

SCREEN

12

4

SETUP

7

HELP

±

ALARM

ACK

56

8

0

TOGGLE

+

CLEAR

3

DELETE

-

E

9

N

T

E

R

.

From the STAND-BY SCREEN the user can press the following

function keys:

1. “SELECT CYCLE” to select the desired cycle

2. “REVIEW CYCLE” to review parameters of selected cycle.

3. “MANUAL” to test functions of individual components.

4. “PROGRAM CYCLE” to modify the parameters of the

selected treatment cycle.

MTP MODEL 2110

CAGE, RACK & UTENSIL WASHER

2–22

From the STAND-BY SCREEN (shown above):

1. Press the “SELECT CYCLE” function key (screen shown

below).

MTP MODEL 2110

CAGE, RACK & UTENSIL WASHER

2. Press “Clear” on the keypad.

3. Enter the cycle number, ranging from “1”-”12”.

Page 55

4. Press “ENTER” on the keypad.

Series 2100 Washers

Review Cycle

REVIEW SCREEN #1.

PREWASH = ON

TEMP = 120 F

TIME = 60 SEC

GUAR = OFF

*

Pressing “Page Down”, user can view all parameters of the

selected cycle.

REVIEW SCREEN #2

WASH 1 = ON

TEMPERATURE = 165 F

TIME = 300 SEC

ACID

GUARANTEE = OFF

DRAINED

*

Pressing “Page Down”, user can view all parameters of the

selected cycle.

REVIEW SCREEN #3

WASH 2 = ON

TEMPERATURE = 165 F

TIME = 300 SEC

ACID

GUARANTEE = OFF

SAVED

*

Pressing “Page Down”, user can view all parameters of the

selected cycle.

REVIEW SCREEN #4

RINSE 1 = ON

TEMPERATURE = 185 F

TIME = 0 SEC

GUARANTEE = ON

*

Pressing “Page Down”, user can view all parameters of the

selected cycle.

REVIEW SCREEN #5

RINSE 2 = OFF

TEMPERATURE = 0 F

TIME = 0 SEC

GUARANTEE = OFF

*

Pressing “Page Down”, user can view all parameters of the

selected cycle.

REVIEW SCREEN #6

RINSE 3 = ON

TEMPERATURE = 120 F

TIME = 60 SEC

GUARANTEE = OFF

*

Pressing “Page Down”, user can view all parameters of the

selected cycle.

61301603579 2–23

Page 56

The Control Panel

REVIEW SCREEN #7

SOAK = OFF

TIME = 0 SEC

*

Pressing “Page Down”, the user can view all parameters of the

selected cycle.

Manual Mode

Pressing the “MANUAL” function key allows the user or maintenance

technician to test the functions of individual components

When “MANUAL” is selected, the screen displays individual components

that may be activated or deactivated. More than one component may be

activated or deactivated at the same time. Press “Page Down” or “Page Up”

to view more components.

To activate or deactivate a component in the “MANUAL” Mode:

1. Pressing “Page Down” or “Page Up” until the desired component is displayed.

2. Using the arrow keys, move the cursor to the desired

component.

3. To activate the component, press “Toggle” on the keypad (if

conditions are correct).

4. To deactivate a component, press “Tog gl e ” on the keypad

when the cursor is under the activated component.

5. To deactivate all components and return them to stand-by,

press the “ABORT” function key.

MANUAL SCREEN #1

2–24

WASH PUMP 1 = OFF

POWER DRAIN VALVE = CLOSED

MANUAL SCREEN #2

ALK. PUMP = OFF

SUMP HEAT = OFF

MANUAL SCREEN #3

JET VALVE = OPEN

GRAVITY DRAIN VALVE = CLOSED

SUMP FILL = OFF

HEADER = OFF

ACID PUMP = OFF

NEUT PUMP = OFF

*

*

*

Page 57

MANUAL SCREEN #4

Series 2100 Washers

TANK 1 FILL = OFF

HEAT = OFF

DUMP = OFF

TEMPERATURE SET = 165 F

MANUAL SCREEN #5

TANK 2 FILL = OFF

HEAT = OFF

DUMP = OFF

MANUAL SCREEN #6

# OF REUSES BEFORE ALK DUMP = 5

# OF REUSES BEFORE ACID DUMP = 5

MANUAL SCREEN #7

TANK DESCALE = OFF

DESCALE TIME = 200 SEC

RETURN = OFF

RETURN = OFF

TEMPERATURE SET = 165 F

*

*

*

*

61301603579 2–25

Page 58

The Control Panel

Cycle Programming

Cable

OK

START

ABORT

MANUAL

LOAD

DOOR

Cable

OK

Load

Door

Unload

Door

SELECT

CYCLE

ENTER

SERVICE

MODE

SILENCE

ALARM

Message

PRINT

SCREEN

SETUP

HELP

Alarm

1

ALARM

ACK

4

7

±

Tank

Tank at

Sump

Full

set point

Full

REVIEW

CYCLE

EXIT

SERVICE

MODE

EVENT

PRINT

ON/OFF

PROGRAM

CYCLE

CYCLE

HOLD

PRINT

CYCLE

LAST

MESSAGE

NEXT

MESSAGE

PAG E

UP

PAG E

DOWN

Print

Run

+

TOGGLE

CLEAR

3

DELETE

6

-

E

9

N

T

E

R

.

2

5

8

0

From the STAND-BY SCREEN the user can change the parameters of the cycle by doing the following:

1. Press the “SELECT CYCLE” function key.

2. Press “Clear” on the keypad.

3. Enter the cycle number, ranging from “1”-”12”.

4. Press “ENTER” on the keypad.

5. Press “Page Down” or “Page Up” on the keypad until the

screen displays the phase were the change needs to be

made.

6. Use the arrow keys to move the cursor to the parameter

that needs to be changed.

7. Press “Clear” to enter the new time or temperature or

“To gg l e” to change the status on or off of any phase.

8. When all desired changes have been made, press:

a. “REVIEW CYCLE” to review the changes, or

b. “PROGRAM CYCLE” to return to the stand-by screen.

9. If equipped with a printer, press the “PRINT CYCLE” function key to print the new parameters on the printer paper.

2–26

Page 59

Cycle Selection

Series 2100 Washers

MTP MODEL 2110

CAGE, RACK & UTENSIL WASHER

From the STAND-BY SCREEN (shown above):