INFRARED RAY HEAT GENERATOR

GÉNÉRATEUR DE CHALEUR À RAYONS INFRAROUGES

L-L 113.00-BM

FIRE

INSTRUCTIONS MANUAL

LIVRET D´ENTRETIEN

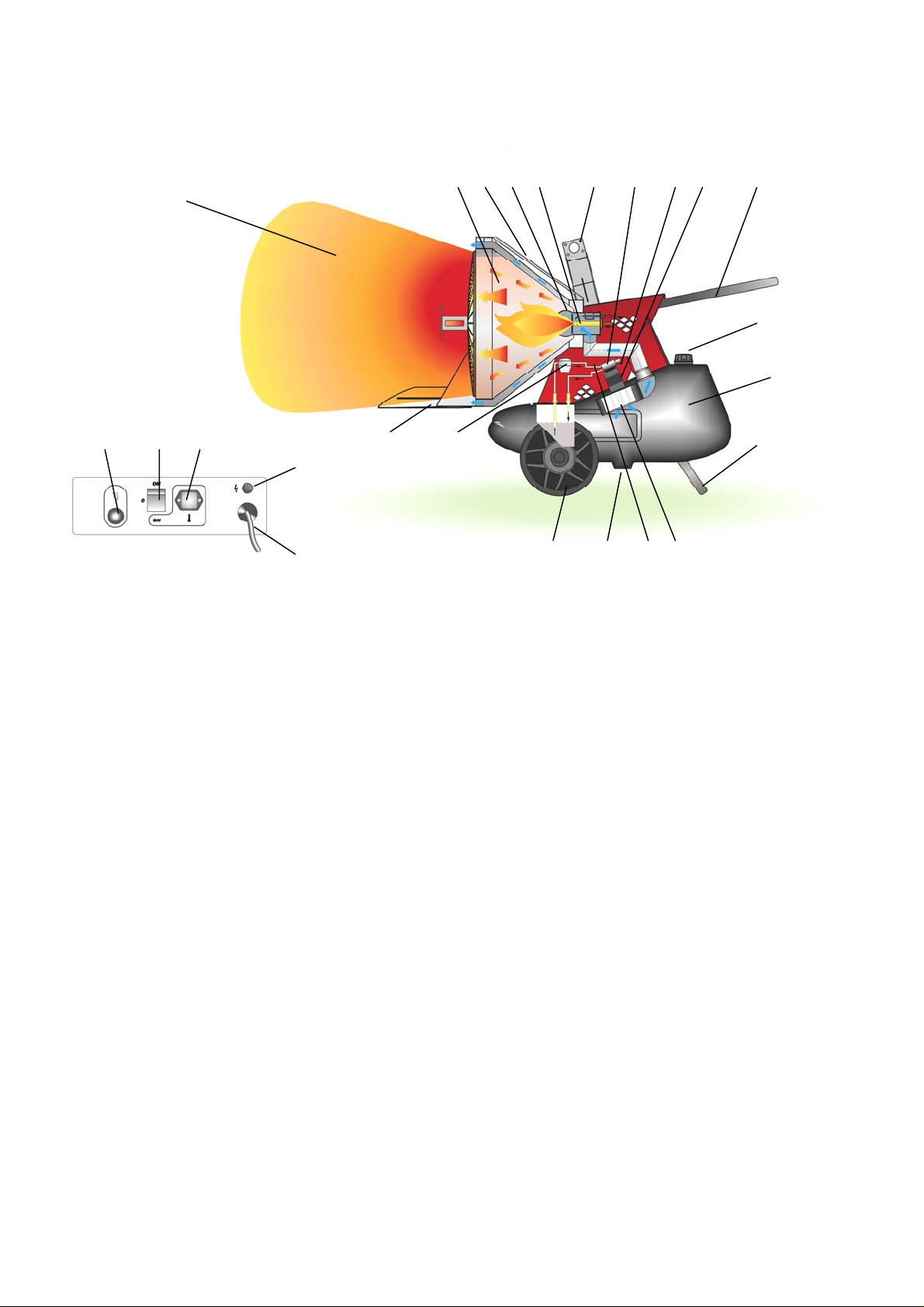

OPERATING DIAGRAM - SCHEMA DE FONCTIONNEMENT

1 3 2 19 5 4 6 10

22

18

14

13 15

16

17

1 COMBUSTION CHAMBER

CHAMBRE DE COMBUSTION

2 BURNER

BRULEUR

3 NOZZLE

GICLEUR

4 SOLENOID VALVE

ELECTROVANNE

5 DIESEL PUMP

POMPE FIOUL

6 MOTOR

MOTEUr

7 FAN

VENTILATEUR

8 FUEL FILTER

FILTRE COMBUSTIBLE

9 FUEL CIRCUIT

CIRCUIT COMBUSTIBLE

10 SUPPORT/HANDLE

SUPPORT/POIGNEE

11 WHEEL

ROUE

12 FUEL TANK

RESERVOIR COMBUSTIBLE

13 RESET BUTTON WITH CONTROL LAMP

BOUTON REARMEMENT AVEC LAMPE TEMOIN

23

8

11

7 9 7

14 MAIN SWITCH

INTERRUPTEUR MARCHE-ARRET

15 ROOM THERMOSTAT PLUG

PRISE THERMOSTAT D’AMBIANCE

16 CONTROL LAMP

LAMPE TEMOIN D’ALIMENTATION

17 POWER CORD

CABLE ELECTRIQUE

18 HEAT FLOW

FLUX DE CHALEUR

19 LIFTING HOOK

CROCHET DE LEVAGE

20

TAPPO DI CARICO

BOUCHON DE REMPLISSAGE DU RÉSERVOIR

21 DRAIN PLUG

BOUCHON DE VIDANGE DU RÉSERVOIR

22 UPPER GUARD

CARTER DE PROTECTION SUPERIEUR

23 BOTTOM GUARD

CARTER DE PROTECTION INFERIEURE

20

12

10

EN

IMPORTANT

Before using the heater, read and understand all

instructions and follow them carefully. The manufacturer

is not responsible for damages to goods or person s due

to improper use of units.

GENERAL RECOMMENDATIONS

The heater described in this manual is a portable oil-fuelled

infrared heat generator running on heating oil No. 2 max.

Its easy handling and large fuel tank allow it to be used locally and

temporarily with complete stand-alone operation. The area to be

heated is therefore hit by an even and uniform flow of heat, as can be

seen by the shape of the irradiation cone (18), without air movement.

The unit is a direct combustion hot generator that works by

sending both hot air and combustion products in the room you wish

to heat: all the necessary precautions must therefore be taken to

guarantee a sufficient exchange of air.

Always follow local ordinances and codes when using this heater:

• Read and follow this owner’s manual before using the heater;

• THE INSTALLATION OF THE UNIT SHALL BE IN

ACCORDANCE WITH THE REGULATIONS OF THE

AUTHORITIES HAVING JURISDICTION. Also, as a

recommended installation practice reference should be made to

the current issue of CSA B139, Installation Code for Oil Burning

Equipment in Canada and NFPA 31 Standard for the Installation

of Oil-Burning Equipment In the USA;

• Use only in places free of flammable vapours or high dust

content;

• Never use heater in immediate proximity of flammable materials

(the minimum distance must be 10 feet);

• Make sure fire fighting equipment is readily available;

• Make sure sufficient fresh outside air is provided according to

the heater requirements. Direct combustion heaters should only

be used in well vented areas in order to avoid carbon monoxide

poisoning;

• A rough estimate of opening required for each gallon (US) of

capacity is three square foot at heater level, for direct-fired

heaters;

• The heater is installed and connected to an electrical

switchboard;

• Ensure that the machine resting surface or ground is not made

of flammable material;

• Minimum clearances from combustible material must be:

30” from side and rear (air inlet) of heater

80” from ceiling

40” on air outlet of heater.

• Never block air inlet (rear) or air outlet (front);

• In case of very low temperatures add kerosene to the heating

oil;

• Connect the power cord to the mains and wait 15 mi n at least

be fore starting heater, to allow pre-heated filter warming

heating oil inside the filter;

• Make sure heater is always under surveillance and keep

children and animals away from it;

• Before starting the heater always check free rotation of

ventilator;

• Heater is not ductable.

• Unplug heater when not in use.

SAFETY DEVICES

The unit is fitted with an electronic flame control box. In case of

malfunction this box will cut in and stop the heater, at the same time

the pilot lamp in the control box reset button (13) will light up.

Warning

The reset push-button emits a different colour light,

depending on the state of the machine:

• green, when the machine is running regularly;

• red, when the machine is in safety lock-out mode: to

restart it , the reset button (13) must be pressed.

Heaters are also equipped with an overheat thermostat safety cut

out which will stop the heater in case of overheating. This thermostat

will reset automatically but you will have to depress button (13) on

control box before being able to restart the heater.

OPERATION

Before any attempt of starting the heater is made, check that your

electrical supply conforms to the data on the model plate.

Warning

Heater requires to be plugged to receptacle fused by

15 Amp. breaker.

The hot generator must be placed on a flat, stable and level

surface to avoid machine tipping and/or gas oil leakage from the tank

fuel cap.

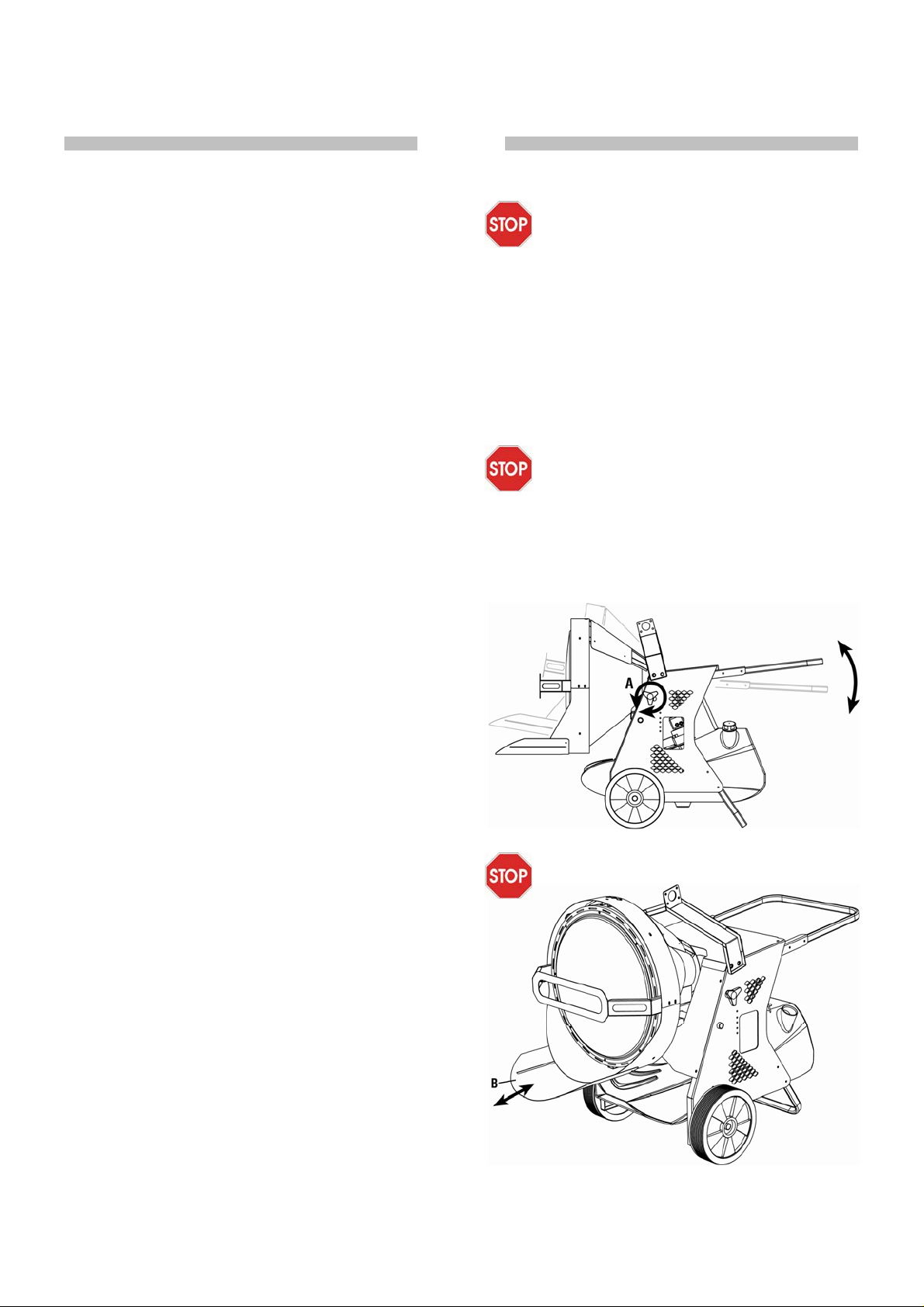

The flow of heat can be directed upward with an approximately 10°

angle: loosen the two locking knobs (A) and tilt the combustion unit

by pressing on the handle until the desired angle is reached, then

lock the knobs (A) by screwing them.

Warning

Before start-up, always ensure the guard (B) has been

completely pulled out, so as to guarantee maximum

protection of the machine resting surface.

EN

You can run the generator in manual by setting switch (14) to ON.

The heater can only work automatically when a control device,

such as for example a thermostat or a timer, is connected to the

generator.

Connection to the heater is made by removing the socket cover (4)

and inserting the thermostat plug.

To start the machine you must:

• if connected to the thermostat, turn the switch to (ON +

• if not connected to the thermostat, turn the switch to (ON).

When unit is started for the first time or is started after the oil tank

has been totally emptied, the flow of oil to the burner may be

impaired by air in the circuit. In this case the control box will cut out

the heater and it might be necessary to renew the starting procedure

once or twice by depressing the reset button (13).

Should the heater not start, check that oil tank is full and depress

reset button (1).

Should the heater still not work, please refer to chapter

“OBSERVED FAULTS, CAUSES AND REMEDIES”.

);

STOPPING THE HEATER

Set main switch (14) on “0” position or turn thermostat or other

control device on lowest setting.

The flame goes out and the fan continues to work for approx. 90

sec. cooling the combustion chamber.

TRANSPORT

Before heater is moved, it must be stopped and unplugged. Before

moving the heater wait till it has totally cooled off and make sure oil

tank cap is securely fixed.

Warning

generator by the handle and roll it on its wheels. In case of need, the

generator can be lifted using ropes or chains secured to the hook

(19) provided on the machine. In this case it is always best to ensure

During handling and transport gasoil may leak: the

tank fuel cap cannot guarantee sealing to allow the

introduction of air and tank emptying during machine

operation.

For handling in short to medium distances, it is enough to grab the

that the ropes and/or chains are securely hooked and that they are

intact and stably in place before handling.

MAINTENANCE

Preventive and regular maintenance will ensure a long trouble free

life to your heater.

Warning

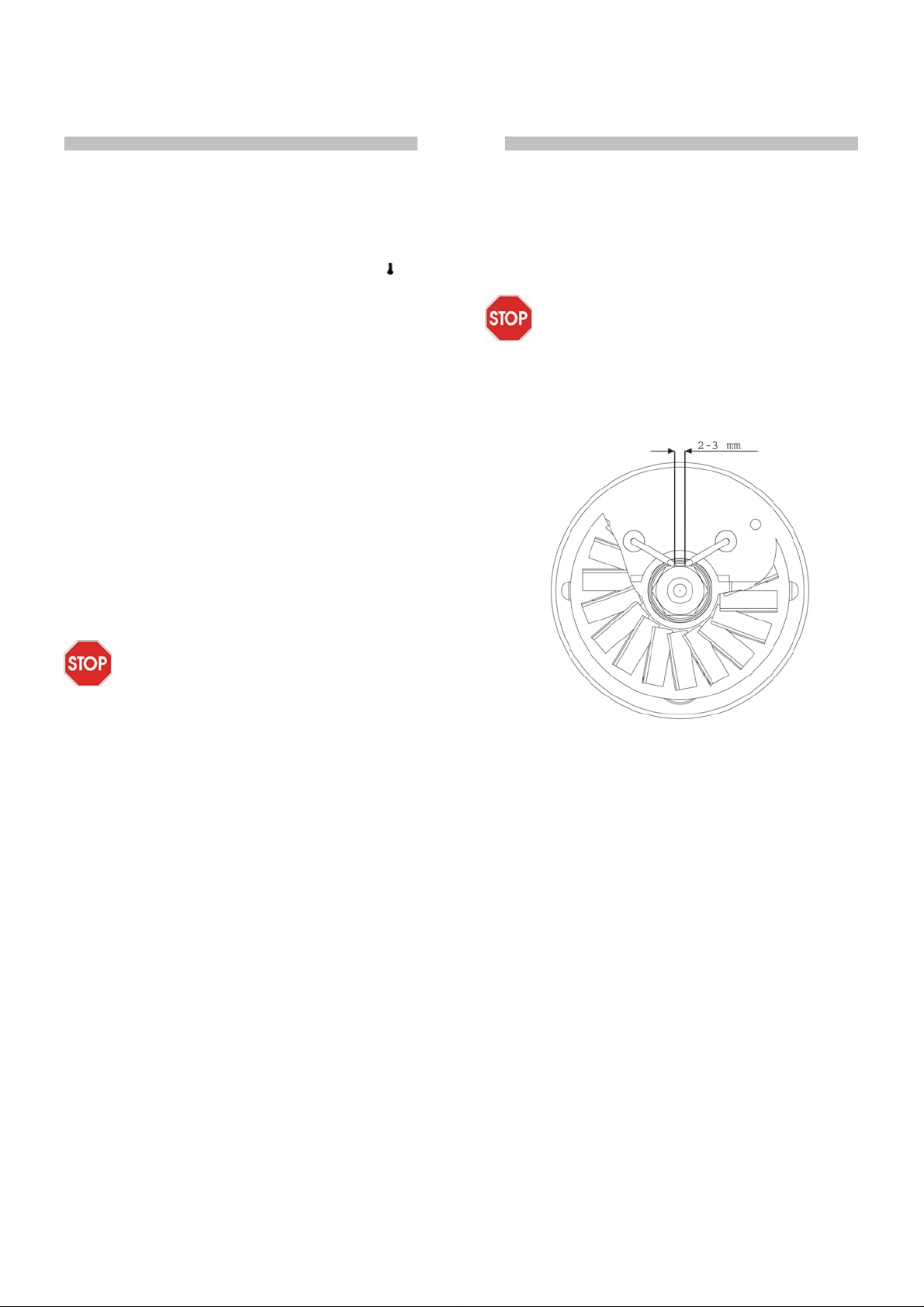

Every 50 hours of operation: disassemble filter and wash with clean

oil, remove upper body parts and clean inside and ventilator with

compressed air, check correct attachment of H.T. connectors to the

electrodes and check H.T. cables, remove burner assembly, clean

and check electrode settings, adjust according to the following

scheme.

Never service heater while it is plugged in, operating

or hot.

Severe burns or electrical shock can occur.

EN

OBSERVED FAULTS, CAUSES AND REMEDIES

OBSERVED FAULT CAUSE REMEDY

• Check mains

• No electrical current

• Motor does not start, no

ignition

• Motor starts, no ignition or

cuts out

• Motor starts, heater emits

smoke

• Heater does not stop • Solenoid defective • Replace solenoid coil or complete solenoid

If heater is still not working properly, please revert to nearest authorized dealer.

• Wrong setting of room thermostat or other control

(thermostat and clock)

• Thermostat or other control defective • Replace control device

• Electrical motor defective • Replace electrical motor

• Electrical motor bearings defective • Replace electrical motor

• Burned out condenser • Replace condenser

• Electric ignitor defective

• Flame control box defective • Replace control box

• Photocell defective • Clean or replace photocell

• Not enough or no fuel at all at burner

• Solenoid defective

• Not enough combustion air

• Too much combustion air • Check setting of combustion air flap

• Fuel contaminated or contains water

• Air leaks in fuel circuit • Check fuel line and filter for possible leaks

• Not enough fuel at burner

• Too much fuel at burner

• Check proper positioning and functioning of

switch

• Check fuse

• Check correct setting of heater control. If

thermostat, make sure selected temperature is

higher than room temperature

• Check connection of H.T. Ieads to electrodes and

transformer

• Check electrodes setting (see scheme Fig. 2)

• Check electrodes for cleanliness

• Replace H.T. transformer

• Check state of motor-pump plastic coupling

• Check fuel line system including fuel filter for

possible leaks

• Clean or replace oil nozzle

• Check electrical connection

• Clean or replace solenoid

• Make sure air inlet and outlet are free

• Check setting of combustion air flap

• Clean burner disc

• Drain fuel in tank with clean fuel

• Clean or replace oil filter

• Check pump pressure

• Clean or replace fuel nozzle

• Check pump pressure

• Replace nozzle

FR

IMPORTANT

Avant d’utiliser le générateur, nous vous prions de lire

attentivement toutes les instructions pour l’emploi,

mentionnées ci-après, et d’en suivre scrupuleusement

les indications. Le constructeur n’est pas responsable

pour les dommages aux choses et/ou personnes dus à

une utilisation impropre de l’appareil.

RECOMMANDATIONS GENERALES

Le générateur décrit dans ce manuel est un générateur de chaleur

à infrarouges mobile, fonctionnant au fuel No. 2 max.

Sa maniabilité et le grand volume de son réservoir permettent un

emploi localisé et temporaire en autonomie totale. La forme du cône

d'irradiation (18) permet, sans déplacement d'air, de chauffer la zone

souhaitée avec un flux de chaleur homogène et uniforme.

Il s'agit d'un générateur à combustion directe qui fonctionne en

émettant dans le local à réchauffer, aussi bien l'air chaud que les

produits de la combustion: il est donc impératif de garantir un

renouvellement d'air suffisant.

Les conditions d’installation et d’utilisation doivent respecter les

normes et les lois en vigueur relatives à l’utilisation de l’appareil.

Il convient de s’assurer que:

• les instructions contenues dans ce livret soient suivies

scrupuleusement;

• L'INSTALLATION DE LA MACHINE DOIT ETRE FAITE

CONFORMEMENT AUX LOIS EN VIGUEUR. L'installation doit

tenir compte des règles CSA B139, Installation Code for Oil

Burning Equipment et NFPA 31 Standard for the Installation of

Oil-Burning Equipment in the USA;

• le générateur ne soit pas installé dans des locaux où il y aurait

des risques d’explosion ou d’incendie;

• des matériaux inflammables ne soient pas déposés à côté de

l’appareil (la distance minimum doit être de 9 piéd);

• de mesures suffisantes de prévention anti-incendie aient été

prévues;

• l’aération du local dans lequel se trouve le générateur soit

garantie et suffisante pour les nécessités du générateur, et en

particulier, pour le générateurs à combustion directe le

renouvellement d’air doit être évalué enconsidérant que ce

générateur envoie dans la pièce aussi bien de l’air chaud que

les produits de combustion;

• Une évaluation du rechange d'air pour chaque gallon (US) de

capacité est 3 pieds carrés pour les générateurs à combustion

directe;

• le générateur soit installé et relié à un coffret électrique;

• contrôler que le sol destiné à recevoir la machine ne soit pas en

matériau inflammable.

• Les distances minimales de tout matériau combustible doivent

être:

30” des parties latérales et de l'aspiration d'air;

80” de le plafond;

40” de la sortie d'air

• il n’y ait pas d’obstacles ou d’obstructions à l’aspiration et à la

sortie de l’air, tels que des toiles ou des couvertures étendues

sur l’appareil ou sur les parois, ou des objets encombrants à

côté du générateur;

• du kérosène soit ra jouté dans le réservoir si la température de

la pièce est très basse;

• Brancher le cordon d'alimentation au réseau et attendre 15

minutes au moins avant d'allumer l'appareil de chauffage afin

de permettre le préchauffage du fuel dans le filtre.

• le générateur soit contrôlé avant sa mise en marche et

régulièrement surveillé durant son utilisation; il faut éviter que

des enfants ou des animaux non surveillés s’en approchent;

• au début de chaque période d’utilisation, avant de brancher la

fiche dans la prise électrique, contrôler que le ventilateur tourne

librement;

• Générateur pas canalisable ;

• à la fin de chaque période d’utilisation enlever la fiche de la

prise de courant.

DISPOSITIFS DE SECURITE

Le générateur est muni d’un coffret électronique pour le contrôle

de la flamme. En cas de mauvais fonctionnement ce coffret provoque

l’arrêt du générateur et l’allumage de la lampe témoin du bouton de

réarmement (13).

Attention

La couleur du bouton de réarmement peut changer :

• vert: la machine est en condition de fonctionnement

correct.

• rouge: la machine est en condition d'arrêt de

sécurité.

Pour relancer le fonctionnement il est nécessaire

d'enfoncer le bouton de réarmement (13).

Un thermostat de surchauffe intervient et provoque l’interruption

de l’alimentation du fuel si le générateur surchauffe: le thermostat se

réarme automatiquement quand la température de la chambre de

combustion diminue jusqu’à rejoindre la valeur maximale admise.

Avant de remettre en marche le générateur il faut trouver et éliminer

la cause qui a produit la surchauffe (par ex. obstruction de l’entrée ou

de la sortie de l’air, arrêt du ventilateur). Pour faire redémarrer le

générateur il faut pousser le bouton de réarmement (13) et répéter

les instructions spécifiques du paragraphe “MISE EN MARCHE”.

MISE EN MARCHE

Avant de mettre en marche le générateur et donc, avant de le

brancher au réseau électrique d’alimentation, il faut contrôler que les

caractéristiques du réseau électrique correspondent à celles écrites

sur la plaque de fabrication.

Attention

Le générateur doit être branché à une prise munie d’un

fusible 15 ampères

Le générateur doit être placé sur une surface plane, stable et

nivelée, de façon à éviter qu'il se renverse ou que du fuel puisse

sortir par le bouchon de remplissage du réservoir.

Le flux de chaleur peut être orienté vers le haut, avec un angle

d'environ 10°: desserrer les deux poignées de blocage (A), incliner le

groupe de combustion en appuyant sur la poignée jusqu'à atteindre

la position la plus inclinée puis bloquer les deux poignées (A) en les

revissant

FR

Attention

l'interrupteur (14) sur la position ON.

lorsqu'un dispositif de contrôle est connecté (par ex. un thermostat

ou une montre). La connexion au générateur doit être faite en retirant

le couvercle de la prise (4) et en branchant la fiche du thermostat.

position (ON +

la position (ON).

du fuel, le flux du fuel au gicleur peut être insuffisant et causer

l’intervention du coffret de contrôle de la flamme; le générateur alors

s’arrête.

réarmement et faire redémarrer l’appareil.

operations à faire sont les suivantes:

Avant de démarrer la machine, contrôler toujours que

lecarter de protection (B) est complètement sorti, de

façonà garantir la protection maximum de la surface

d'appuide la machine.

Le générateur peut fonctionner en mode manuel en plaçant

Le générateur peut fonctionner en mode automatique uniquement

Pour démarrer la machine:

• si elle est pilotée par le thermostat, placer l’interrupteur sur la

);

• si elle n'est pas pilotée par le thermostat, placer l’interrupteur sur

A la première mise en service ou après la vidange totale du circuit

Dans ce cas après avoir attendu une minute, pousser le bouton de

Au cas où la machine ne fonctionnerait pas, les premières

1. Contrôler que le réservoir contienne encore du fuel;

2. Pousser le bouton de réarmement (13);

3. Si après ces opérations le générateur ne fonctionne pas, il faut

consulter le paragraphe “ANOMALIES DE FONCTIONNEMENT,

CAUSES ET SOLUTIONS” et découvrir la cause qui empêche le

fonctionnement.

ARRET

Pour arrêter le fonctionnement du générateur il faut mettre

l’interrupteur (14) sur la position “0” et agir sur le dispositif de

contrôle, (par ex., en réglant le thermostat sur une température plus

basse). La flamme s'éteint mais le ventilateur continue de fonctionner

pendant environ 90 secondes pour refroidir la chambre de

combustion

TRANSPORT ET DEPLACEMENT

Attention

Avant de déplacer l’appareil il faut:

• Arrêter le générateur en suivant les indications du

paragraphe “ARRET”;

• Débrancher l’alimentation en enlevant la fiche de la

prise de courant;

• Attendre que le générateur soit froid.

Avant de soulever ou de déplacer le générateur il faut s’assurer

que le bouchon du réservoir soit bien fixé.

Attention

Pour les déplacements courts et moyens, il suffit de saisir le

générateur par la poignée et de le déplacer sur ses roues. Il est

également possible de soulever le générateur à l'aide de sangles ou

de chaînes à accrocher aux crochets (19) prévus sur la machine.

Dans ce cas, contrôler le bon accrochage des sangles et/ou chaînes,

leur intégrité et leur solidité avant de procéder au levage.

En cours de déplacement et de transport du fuel peut

s'échapper: en effet, le bouchon de remplissage du

réservoir n'est pas étanche afin de permettre

l'introduction d'air dans le réservoir et l'aspiration du

fuel pendant le fonctionnement de la machine.

ENTRETIEN

Pour que l’appareil fonctionne régulièrement, il est nécessaire de

nettoyer périodiquement la chambre de combustion, le brûleur et le

ventilateur.

Attention

fuel propre;

interne et les pales du ventilateur;

les électrodes;

nettoyer les électrodes et régler leur distance

Avant de commencer une quelconque opération

d’entretien il faut:

• Arrêter le générateur selon les indications du

paragraphe “ARRET”;

• Débrancher l’alimentation électrique en enlevant la

fiche de la prise de courant;

• Attendre que le générateur soit froid.

Toutes les 50 heures de fonctionnement il est nécessaire de:

• Démonter la cartouche du filtre, l’extraire et la nettoyer avec du

• Démonter la carrosserie externe cylindrique et nettoyer la partie

• Contrôler l’état des câbles et des connexions haute tension sur

• Démonter le brûleur et en nettoyer les différentes parties,

.

ANOMALIES DE FONCTIONNEMENT, CAUSES ET SOLUTIONS

ANOMALIE DE

FONCTIONNEMENT

• Le courant électrique n’arrive pas

• Le ventilateur ne démarre

pas et la flamme

nes’allume pas

• Le ventilateur démarre et

la flamme ne s’allumeas

ou ne reste pas allumée

• Le ventilateur démarre et

la flamme s’allume

enroduisant de la fumée

• Le générateur ne s’arrête

pas

Si ces contrôles et ces solutions ne sont pas la cause du mauvais fonctionnement du générateur,

veuillez contacter notre plus proche centre de vente - assistance autorisé.

• Mauvais réglage d’un éventuel dispositif

deontrôle (de l’horloge et thermostat)

• Dispositif de contrôle défectueux • Remplacer le dispositif de contrôle

• Bobinage du moteur brûlé ou interrompu • Remplacer le moteur

• Roulements du moteur bloqués • Remplacer le moteur

• Condensateur du moteur brûlé • Remplacer le condensateur

• L’allumage ne fonctionne pas

• Le coffret de contrôle de la flamme défectueux • Remplacer le coffret

• La cellule photo ne fonctionne pas • Nettoyer la cellule photo ou la remplacer

• Le fuel n’arrive pas au brûleur ou arrive enantité

insuffisante

• L’électro-vanne ne fonctionne pas

• L’air de combustion est insuffisant

• L’air de combustion est excessif • Vérifier la position du volet de réglage de l'air

• Le fuel utilisé est sale ou contient de l’eau

• Infiltrations d’air dans le circuit du fuel

• Quantité insuffisante de fuel au brûleur

• Quantité excessive de fuel au brûleur

• L’électrovanne ne ferme pas • Remplacer le corps de l’électrovanne

CAUSE SOLUTION

• Vérifier les caractéristiques de

l’installationélectrique

• Vérifier le fonctionnement et la position

del’interrupteur

• Vérifier l’efficacité du fusible

• Vérifier que le réglage du dispositif de

contrôlesoit correct (par ex. la température

choisie surle thermostat doit être supérieure à

latempérature du local)

• Vérifier les branchements des câblesd’allumage

aux électrodes et au transformateur

• Vérifier la position des électrodes et leurdistance

selon le schéma FIG. 2

• Vérifier que les électrodes soient propres

• Remplacer le transformateur d’allumage

• Contrôler l’efficacité du raccord moto-pompe

• Contrôler qu’il n’y ait pas d’infiltrations d’airans le

circuit du fuel en vérifiant l’étanchéitées tuyaux

• Nettoyer ou s’il le faut changer le gicleur

• Contrôler le branchement électrique

• Nettoyer et éventuellement remplacer l’électrovanne

• Enlever tous les obstacles ou obstructions à

l'aspiration ou à la sortie de l'air

• Vérifier la position du volet de réglage de l'air

• Nettoyer le disque du brûleur

• Vidanger et remplacer par du fuel propre

• Nettoyer le filtre du fuel ou le remplacer

• Vérifier l'étanchéité des tuyaux et du joint du filtre

du fuel

• Vérifier la valeur de la pression de la pompe

• Nettoyer et remplacer le gicleur

• Vérifier la valeur de la pression de la pompe

• Subtituer le gicleur

WIRING DIAGRAM – SCHEMA ELECTRIQUE

AP CONTROL BOX

COFFRET DE SECURITE

TA ROOM THERMOSTAT PLUG

PRISE THERMOSTAT D’AMBIACE

ST PILOT LAMP

LAMPE TEMOIN D’ALIMENTATION

LI1 OVERHEA T THERMO STAT

THERMOSTAT DE SURCHAUFFE

EV1 SOLENOID VAL VE

ELECTROVANNE

FO PHOTOCELL

PHOTORESISTANCE

CO CAPACITOR

CONDENSATEUR

MV FAN MOTOR

MOTEUR DU VENTILATOR

FUA FUSE

FUSIBLE

LF ANTI-JAMMING FILTER

FILTRE ANTIPARASITES

RV MAIN SWITCH

COMMUTATEUR

RF HEATED FILTER

FILTRE GASOIL RECHAUFFE

>>>OPTIONAL

TECHNICAL SPECIFICATIONS

CARACTERISTIQUES TECHNIQUES

Max heating output

Puissance thermique max

Fuel consumption

Consommation

Phase

Phase

Power supply

Alimentatione électrique

Power consumption

Puissance électrique

Nozzle

Gicleur

Pump pressure

Pression pompe

Voltage

Tension

Frequency

Fréquence

FIRE 155

[BTU/h] 154.237

[gal/h] 1,10

1

[V] 120

[Hz] 60

[W] 440

[USgal/h] Delavan 0,85 - 80° W

174

Adjustment of combustion air flap

Réglage du volet d'air comburant

Tank capacity

Capacité rése rv o i r

Noise level at 1 m

Niveau sonore à 1 m

Dimensions, L x W x H

Dimensions, L x P x H

Weight

Poids

[N°] 2

[USgal] 17.17

[dBA] 72

[in] 55.5 x 28.03 x 41.5

[lb] 161

Biemmedue S.p.A.

Via Industria 12

12062 Cherasco (CN) – ITALIA

www.biemmedue.com – e-mail: info@biemmedue.com

Loading...

Loading...