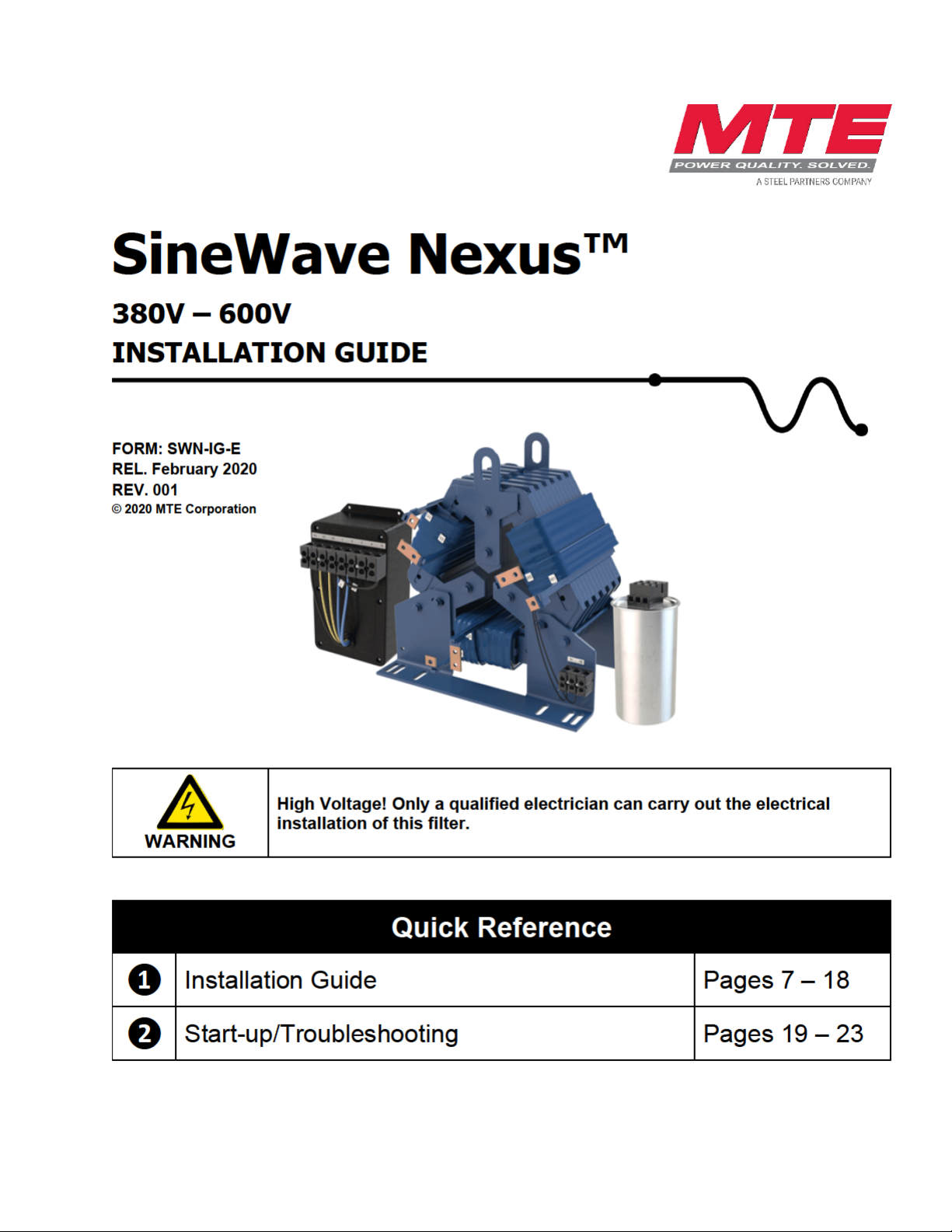

MTE SineWave Nexus Installation Guide

This page intentionally left blank

TABLE OF CONTENTS

1. SAFETY .................................................................................................................................................... 4

W

ARNINGS AND CAUTIONS .......................................................................................................... 4

ENERAL SAFETY INSTRUCTIONS ................................................................................................ 5

G

2. GENERAL INFORMATION ...................................................................................................................... 6

R

ECEIPT & REPAIR STATEMENT .................................................................................................. 6

W

ARRANTY ................................................................................................................................. 6

3. HOW TO INSTALL ................................................................................................................................... 7

I

NSTALLATION CHECKLIST ........................................................................................................... 7

P

OWER WIRING CONNECTION ..................................................................................................... 9

C

OMMON MODE ASSEMBLY CONNECTION ................................................................................. 10

M

ODULAR UNIT INTERCONNECTION DIAGRAM ............................................................................ 12

NCLOSED UNIT INTERCONNECTION DIAGRAM ........................................................................... 13

E

B

ASIC SCHEMATIC DIAGRAM ..................................................................................................... 14

T

RANSFORMER DIAGRAM .......................................................................................................... 15

C

OMMON MODE ASSEMBLY CONNECTION DIAGRAM .................................................................. 16

T

ORQUE RATINGS 380-480V .................................................................................................... 17

ORQUE RATINGS 600V ........................................................................................................... 18

T

4. START-UP .............................................................................................................................................. 19

S

AFETY PRECAUTIONS .............................................................................................................. 19

5. TROUBLESHOOTING ............................................................................................................................ 21

List of Figures

Figure 3-1: Modular Interconnection ........................................................................................... 12

Figure 3-2: Enclosed Interconnection ......................................................................................... 13

Figure 3-3: Basic Schematic Diagram ........................................................................................ 14

Figure 3-4: Transformer Diagram ............................................................................................... 15

Figure 3-5: DC Bus Connected Configuration ............................................................................ 16

Figure 3-6: Ground Connected Configuration ............................................................................. 16

List of Tables

Table 3-1: Overtemperature Switch .............................................................................................. 8

Table 3-2: Torque Ratings 380-480V .......................................................................................... 17

Table 3-3: Torque Ratings 600V ................................................................................................. 18

Table 5-1: Performance Specifications ....................................................................................... 22

Table 5-2: Troubleshooting Guide .............................................................................................. 23

WARNING

WARNING

1. SAFETY

Warnings and Cautions

The following symbols are used in this manual:

High Voltage Warning: warns of situations that dangerously

Caution

high voltage is involved. Failure to use proper precautions may

lead to serious injury or death.

General Warning: warns of situations that can result in serious

injury or death if proper precautions are not used.

General Caution: identifies situations that could lead to

malfunction or possible equipment damage.

SineWave Nexus™ Installation Guide 380V – 600V

4 Form: SWN-IG-E February 2020 REV. 001

SineWave Nexus™ Installation Guide 380V - 600V

High Voltage! Only a qualified electrician can carry out the electrical

installation of this filter.

High voltage is used in the operation of this filter. Use extreme caution to

observed.

General Safety Instructions

WARNING

WARNING

avoid contact with high voltage when operating, installing or repairing this

Injury or death may result if safety precautions are not

filter.

The opening of the branch circuit protective device may be an indication

that a fault current has been interrupted. To reduce the risk of fire or

electrical shock, current-carrying parts and other components of the filter

should be examined and replaced if damaged.

An upstream disconnect/protection device must be used as required by

the National Electrical Code (NEC) or governing authority.

Even if the upstream disconnect/protection device is open, the drive

downstream of the filter may feed back high voltage to the filter. The drive

safety instructions must be followed. Injury or death may result if safety

precautions are not observed.

The filter must be grounded with a grounding conductor connected to all

grounding terminals. Modular filters must have reactor grounded through

a 2”x2” area cleaned of paint and varnish on lower mounting bracket.

Only spare parts obtained from MTE Corporation or an authorized MTE

distributor can be used.

Caution

After removing power, allow at least five minutes to elapse and verify that

the capacitors have discharged to a safe level before contacting internal

components. Connect a DC voltmeter across the capacitor terminals and

ensure that the voltage is at a safe level.

Review the schematic prior to connecting unit in DC Bus Configuration.

Connecting the unit incorrectly could result in failure of drive and filter

components.

Loose or improperly secured connections may damage or degrade filter

performance. Visually inspect and secure all electrical connections before

power is applied to the filter.

Prior to start-up; confirm the drive operation mode is property set (Volts

per Hertz). Please consult drive manual/manufacturer to configure proper

parameters. Failure to do so may result in failure of drive or filter

components.

Form: SWN-IG-E February 2020 REV. 001 5

SineWave Nexus™ Installation Guide 380V – 600V

2. GENERAL INFORMATION

The purpose of the manual is to aid in the proper installation of the SineWave Nexus.

For most current information, please refer to website:

http://www.mtecorp.com/nexus-sinewave-filter/

SineWave Nexus filters transform the output of Variable Frequency Drives (VFDs) to a near

perfect sinusoidal waveform for the best level of motor protection. MTE's unique design offers

high performance in both differential and common mode with smaller size and better efficiency

than traditional industry solutions.

Receipt & Repair Statement

Upon Receipt of this Filter:

The SineWave Nexus motor protection filter has been subjected to demanding factory tests

before shipment. Carefully inspect the shipping container for damage that may have occurred in

transit. Then unpack the filter and carefully inspect for any signs of damage. Save the shipping

container for future transport of the filter.

In the event of damage, please contact and file a claim with the freight carrier involved

immediately.

If the equipment is not going to be put into service upon receipt, cover and store the filter in a

clean, dry location. After storage, ensure that the equipment is dry and that no condensation or

dirt has accumulated on the internal components of the filter before applying power.

Warranty

Three years from the date of shipment. See http://www.mtecorp.com/industry-leading-warranty/

for details.

6 mtecorp.com Form: SWN-IG-E February 2020 REV. 001

SineWave Nexus™ Installation Guide 380V - 600V

WARNING

3. HOW TO INSTALL

Installation Checklist

Prior to installation, please review the safety instructions on page 4 & 5.

Failure to practice this can result in body injury!

WARNING

SineWave Nexus filters are supplied in the following mechanical configurations:

• Modular: Modular units consist of a reactor, a common mode assembly and one or more

capacitor or capacitor panel assemblies (referred to as cap-panels on drawings and

diagrams). Additional wiring between the reactor, common mode assembly and

capacitor/capacitor panel assembly is required by customer.

• Floor mounted general purpose NEMA 1/2 and NEMA 3R cabinets: Reactor, common mode

assembly and capacitor/capacitor panel assemblies are supplied in a cabinet with all items

pre-wired together.

Minimum Required Space:

Open panel SineWave Nexus filters are designed for mounting within the customer’s enclosure.

When determining the internal temperature rise and cooling requirements of the enclosure,

include the power dissipation of the filter along with all the other components located in the panel.

A general guideline is to allow a side clearance of four (4) inches and a vertical clearance of six

(6) inches for proper heat dissipation and access within the enclosure. Clearances may be less if

proper ventilation exists. Filter components must operate within temperatures specified in this

manual or filter operating life will be compromised. Also, be aware of minimum electrical

clearances as defined by the appropriate system safety standard(s). Modular SineWave Nexus

filters generate heat and should be positioned away from heat sensitive components. Avoid

locations where the filter would be subjected to excessive vibrations. Locate the filter as close to

the inverter as possible.

NOTE: Locate the capacitor(s) and common mode assembly in the lowest temperature

regions of the enclosure – generally toward the bottom and away from high temperature

components.

General purpose NEMA 1/2 and NEMA 3R enclosed filters are designed for floor mounting in an

environment suitable for the enclosure type. Do not install in or near a corrosive environment.

Avoid locations where the filter would be subjected to excessive vibrations. Allow a minimum side

and back clearance of eight (8) inches and front clearance of thirty-six (36) inches for proper heat

dissipation and access.

Input and output wiring to the filter should be performed by authorized

personnel in accordance with NEC and all local electrical codes and

regulations.

The filter is designed for use with copper conductors with a minimum

temperature rating of 75 degrees C.

Form: SWN-IG-E February 2020 REV. 001 7

SineWave Nexus™ Installation Guide 380V – 600V

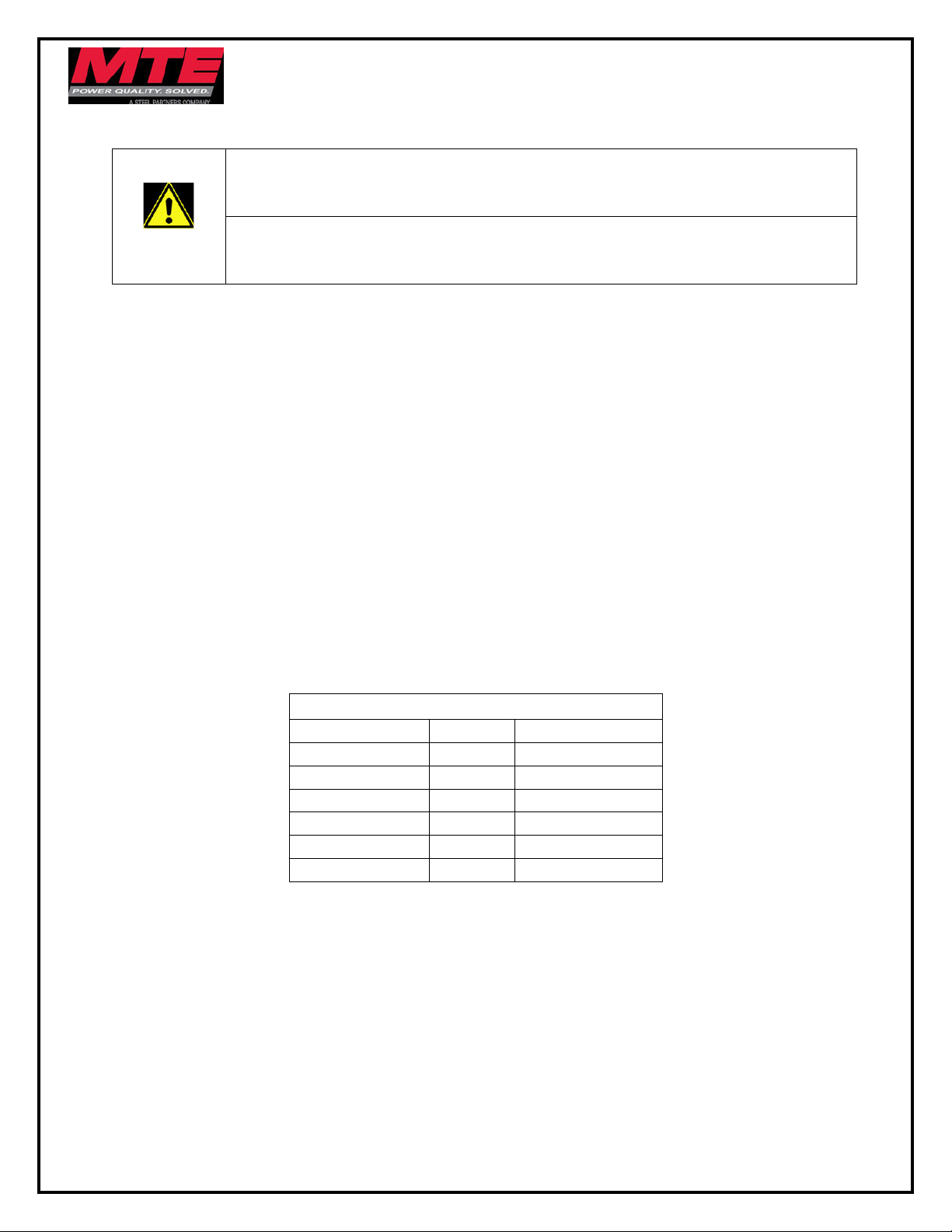

NC Switch opens at 180 Deg. +/- 5 Deg. C

Current Amps

Voltage

Contact Load

6

120 AC

Resistive Loads

3

120 AC

Inductive Loads

3

240 AC

Resistive Loads

2.5

240 AC

Inductive Loads

8

12 VDC

Resistive Loads

4

24 VDC

Resistive Loads

Grounding

The filter must always be grounded with a grounding conductor connected to ground

terminals.

WARNING

NOTE: For cable shield grounding follow the drive manufacturer’s recommendations.

Grounding and Ground Fault Protection

Due to high leakage currents associated with variable frequency drives, ground fault protective

devices do not necessarily operate correctly. When using this type of device, its function should

be tested in the actual installation.

Overtemperature Interlock

An overtemperature interlock circuit should be used in conjunction with thermal switch to turn off

the drive to prevent filter damage due to abnormal operating conditions. The temperature switch

is normally closed and will open when an internal reactor temperature of 180°C is reached. See

Table 3-1: Overtemperature Switch, below for contact rating information and the drive user

manual for interconnection information.

For modular units, ensure a 2” X 2” area is cleaned of paint and varnish on lower

mounting bracket for ground connection.

Table 3-1: Overtemperature Switch

MTE highly recommends the use of the overtemperature switch to prevent damage to the filter

in rare instances of overheating from abnormal operating conditions.

8 Form: SWN-IG-E February 2020 REV. 001

Loading...

Loading...