Page 1

owner’s guide and parts list

MODEL NO. ZYJ-192A

MASTER COPY

00 NOT

REIL LAWN MOW®

^ S'

MONTGOMERY ¥MRD

Oôn-345

Page 2

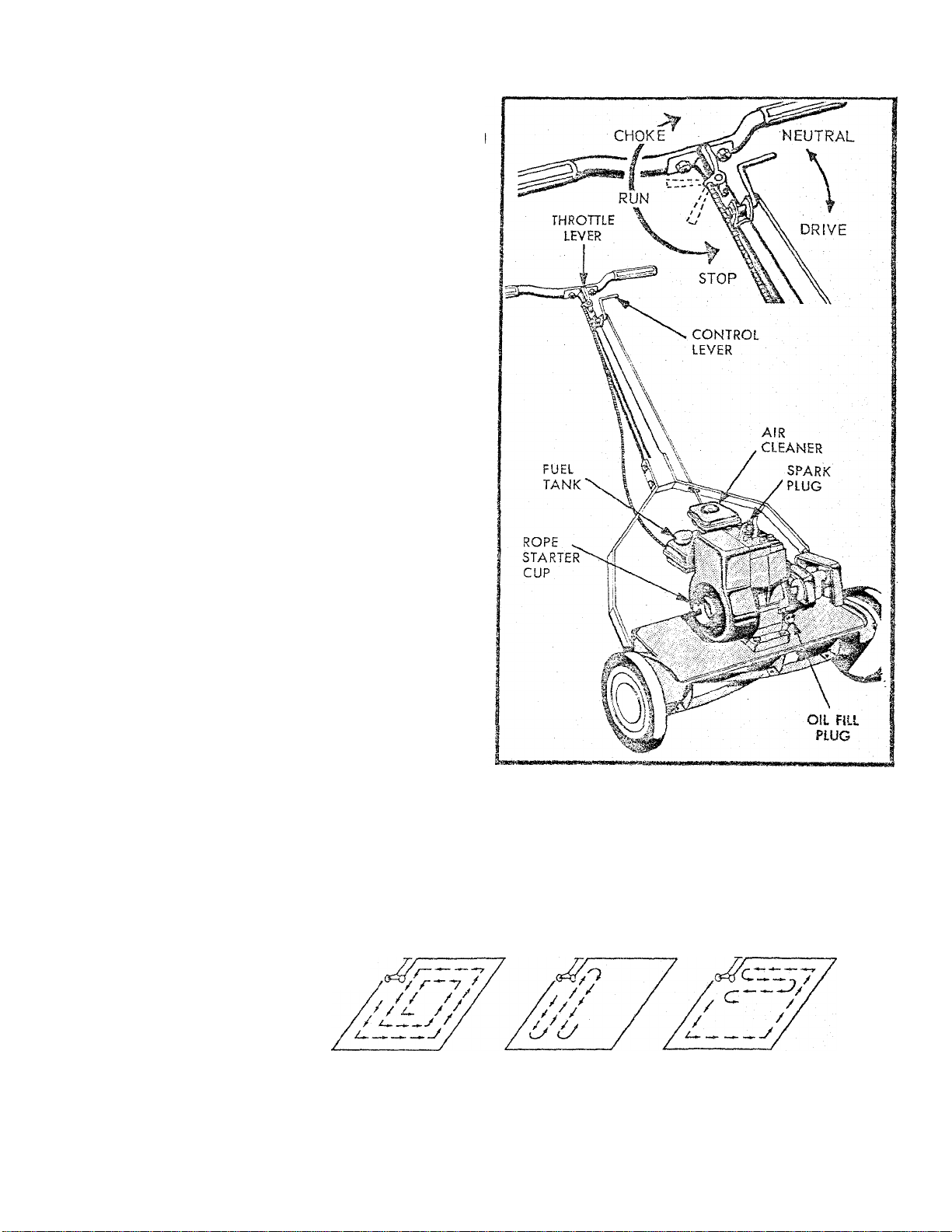

BEFORE STARTING ENGINE

]. (Fig. 1) Remove oil fill plug. Place mower leve

and fill engine crankcase to top of oil fill plug

with S.A.E. No. 30 oil. Tilt mower to make sure

oil flows completely into crankcase. Replace fill

plug and tighten.

2. The air cleaner protects the engine agoinst grit

and dirt. CAUTION, an extremely dirty air cleaner

element may cause engine to stall. SEE ENGINE

INSTRUCTION MANUAL FOR PROPER AIR CLEANER

MAINTENANCE.

3. Fill tank with good grade regular, clean fresh

gasoline. DO NOT MIX OIL with gasoline.

FOR COMPLETE ENGINE INFORMATION READ ENGINE

INSTRUCTION BOOKLET FURNISHED WITH YOUR

MOWER BEFORE STARTING OR OPERATING-

TO START ENGINE

1. Move control lever to NEUTRAL position

2. Set throttle lever in choke position.

3. Pull starter rope with quick full stroke once. Move

throttle lever to "FAST" position. Pull starter rope

again.

4. When engine starts move throttle lever to "IDLE"

position until engine warms up- Regulate engine

speed with hand lever from "IDLE" to "FAST."

OPERATING CONTROLS

1. Set operating control lever to "DRIVE" position

for rnovving

2. Throttle lever regulates choke, run, idle and stop.

OPERATING AND LAWN MOWING HINTS

1. Don't cut your grass to short. The best height is 1 l-i

to 2 inches. See instructions for cutting height ad

justment.

USE A SYSTEM

WHEN YOU MOW

3*3ts ths edges

fosf and it's

2. Your Power Reel mower is easy to transport. Push

down on handle, tilt mower on rollers and push

your mower. The blades will be raised for passing

over rocks, curbs, etc.

A pause at eoch end is

more restfu! but it misses

the edges.

COMBINE FOR

BEST RESULTS

Page 3

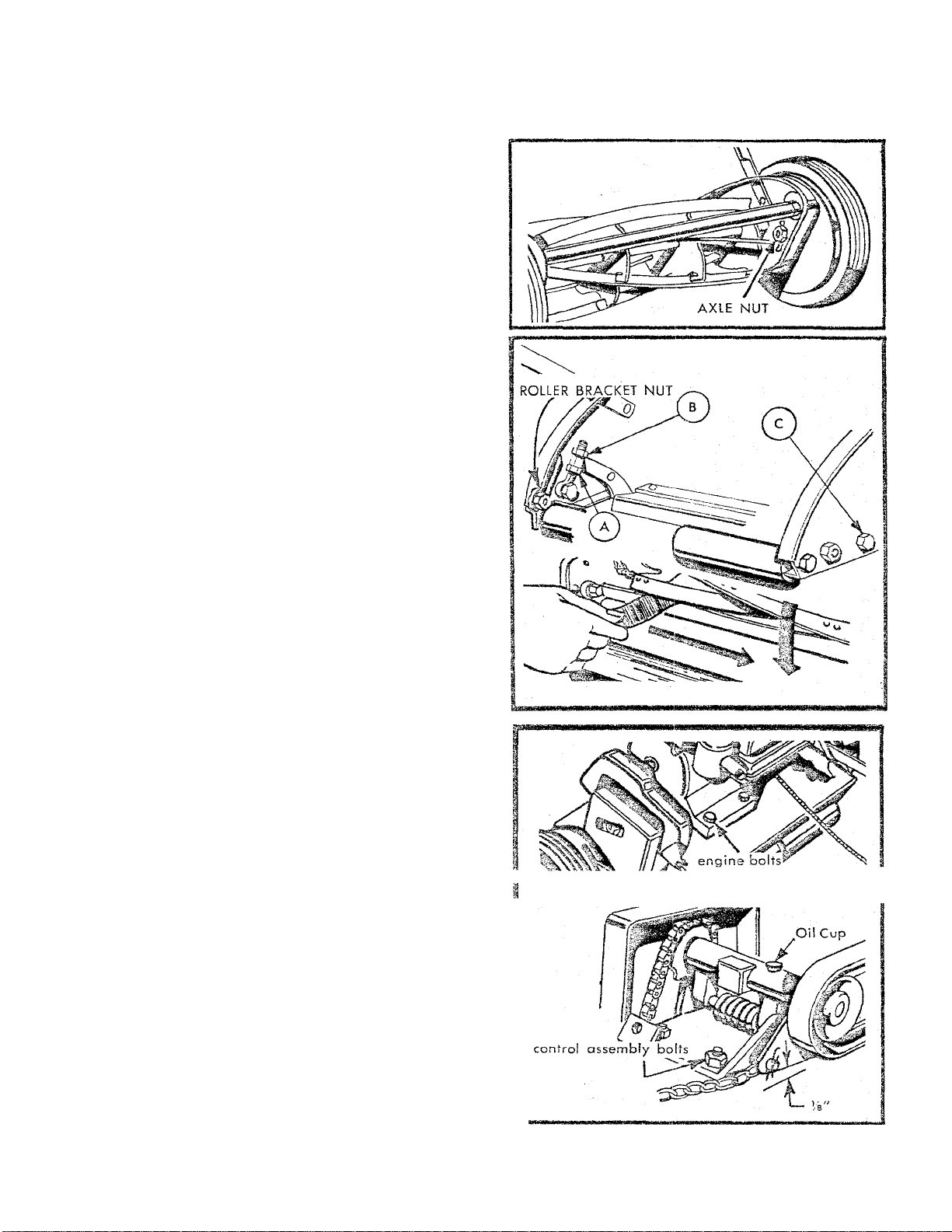

IMPORTANT

DISCONNECT SPARK PLUG WIRE BEFORE MAKING MOWER ADJUSTMENTS.

ADJUSTMENTS

TO CHANGE WHEELS FROM

HIGH TO LOW CUT

1. Loosen axle nuts on inside of end plates and move

axle up to desired position (Fig. 2). Be sure both

wheels are located in same relative position and

tighten axle nuts securely. IMPORTANT axle nut

shoulders must be properly seated in notches.

TO ADJUST ROLLER

Loosen roller bracket nuts and move roller up or down

to attain desired height of cut and level chassis.

TO TIGHTEN CUTTER BAR

ADJUSTMENT

1. Loosen lower adjusting nut (A) and tighten upper

adjusting nut (B) until reel contacts cutter bar

lightly (Fig. 3). Adjustment may also be determined

by inserting strip of newspaper between reel and

cutting bar. Reel should cut the paper when turned

backwards slowly. Tighten nuts (A) and (B) securely.

2. IMPORTANT Cutter bar pivot bolts (C) must be

tight offer adjustment. Right hand pivot bolt on

right hand side of mower must be turned counter ■

clockwise, left hand pivot bolt must be turned

clockwise to tighten.

TO ADJUST CHAIN DRIVE

1. Set hand control lever in "DRIVE" position.

2. Loosen 4 engine mount bolts and puli engine back.

3. Loosen 4 control assembly bolts,

4. Pull the control assembly back to tighten chain.

Allow Is inch slack in chain. Tighten 4 control

bolts. Leave spacer plate nut loose.

TO TIGHTEN DRIVE BELT

1. Loosen engine mounting bolts, place control lever

in drive position, and move engine forward

until approximately Vs" clearance Is attained be

tween belt guard bracket and mower deck as

shov/n, RetIghten engine bolts securely.

LyBRICATiON

1. Seals on all bearings hold dirt out and grease in.

Your mower left the factory properly lubricated at

these points and no further offenfion is required

until mower is sharpened.

2. Lubricc te roller and Jackshaft periodically os reqcl.

belt guard bracket

Page 4

Page 5

WARRANTY

This lawn mower was inspected before shipment from our factory. We warrant

it to be free from defects in material and workmanship and to operate satis

factorily when used for the purpose designed, provided it is properly assembled

and operated according to the Owner's Guide.

WARRANTY—For a period of one year from date of purchase. Wards will furnish

without charge, when brought to a Ward Branch, any labor necessary to repair,

replace or examine any part or assembly of this mower that is defective in

materia! or workmanship subject to our examination.

This Warranty is in lieu of ail other warranties, expressed or implied.

PARTS LIST

MODEL - ZYJ ~ 192A

r left hand (L.H.) as

PART NO.

REF.

LTR.

2132-42-48

A

3603-53-41

B

1538-8

C

1529-15

D

E 70

769

F

2117-21-41

G

H 67

1509-31

1

2664-5-41

J

1710-7

K

1 112-22-48

L

1530-19

M

1 129-193L-4

N

313529-48

O

1129-194R--

P

1652-51

Q

1540-22

R

1650-24

S

323

T

1635-29

u

V 1531-11

2604-24

W

3134-19-48

X

Y 451

52

z

1635-30

AA

BB 1658-15

1540-59

cc

1624-73

DD

2632-90

EE

2609-194-41

FF

877

GG

1118-17-48

HH

3636-15

il

NAME OF PART

Engine Bracket

Handle Brace.

Nut (M-20 Lock)

*Bolt (34-20 X %. Carr.)

*Nut (3<6-18 hex)---------

*Bo!t (Fi's-IS X 2 hex hd)

Handle Shaft....

*Nut (34-20 hex)

-----------------------

------

-------------------

_____________

-------------

-----

-------

----------

.................

.........

_____________

*Boit (34-20 X hex. hd.).....

Cross Handle

Handle Grip

Spacer Tube

* Rivet

_______________________

__________-

________ ___

_________

....

_____

_______

48 End Plate—L.H-------------------------

Reel Assy

48 End Plate—R.H

Bearing

Washer

__________________

______________

------

-----------------------------

_____________________

Retaining Ring______________

Pawl

____

____------

Pinion—R.H

*Rivet________________

Blade

____________

Cutter Bar with blade

Bolt

________________________

------------

------

_____________—

___

___

_______

------------

_

*Nut (/i-24 hex)_______________

Pinion—L.H

Roller.....:

*Washer

Spacer

Roller Shaft

8 Bracket—L.H

-------------

-------- ------

__________

----

----------------

__________

_________________

________

____

__________ ______

-----------

____

___

*Nut %-24 Hex. Lock "Gripco"

Gear Housing

Wheel

__________

____________

________

___

REF. PART NO.

LTR.

1137-3

JJ

1513-42

KK

1631-27

LL

1540-31

MM

1650-22

NN

2619-31

CO

2674-23-41

pp

1507-3

QQ

116

.

RR

SS

TT

UU

117

1552-7

109

W 455

1694-12

WW

XX

1511-12

1509-86

YY

1509-37

BA

BC 1539-33

BD 2609-195-48

2121-12

BE

BF 1548-5

1609-199

BG

1545-7

BH

1654-9

B1

BJ 1683-16

1509-2

BK

153S-8

8L

1132-26

BM

1547-4

BN

1509-3

BO

2142-48

BP

1534-8

BQ

NAME OF PART

Nut—Special

Screw—Special..

Axle

_______

Washer

^Retaining Ring

Tire...____

Hub Cap

‘Screw (10-32)

*Nuf (10-32 square)

‘Screw (10-32 x 34)

Wave Washer

Felt Wosher

Screw—Special

Clamp

________________

______

___

______

_______

_____________________

_______

____

___

___

___ ____

_____

_____

______

_______

________

___________

___________

_____

__________

__________

__________

_____

______

___

_______

Screw (10-32 X % Thd. Cut.'

Screw (/s-24—L.H. thd.)...

Bolt (3(6-18 X A)

Nut (3(6-18 Special)

Bracket—R.H

Sprocket

Roilpin____

____________

_________

________

_____

___________________

___

______________

Bracket________________

Clevis Pin

Chain

Clutch Red

Bolt (34-20 X VA)

Nut (34-20 Lock)

Lever & Brkt Assy

Hairpin Cotter

Bolt (10-32 X 134)

Throttle Control

Nut (10-32 Hex Lock).

___________

_____

___________________

___________

________

____________

__________

......

......

..............

___________

____________

_______

______

___

___

___

___

___

.......

___

____

_

_

_

_

.

_

For illustration See Page 4

'^Standard Hardware Item—May Be Purchosed Locally

Page 6

Page 7

J

HOW TO OBTAIN REPLACEMENT PARTS

Repair parts may be obtained from your Wards Retail

Store, Catalog Store, or Mail Order House and will be made

available at current prices, if requested, prices will be

quoted in advance. NOTE: Many of the nuts, bolts, etc.,

listed in the parts list of this m.anual ore standard hard

ware parts and are indicated with on asterickf*). These

parts may be purchased locally for your convenience and

for faster service. Check the Hardware Department of your

local store.

When requesting repair parts, be sure to give the model and serial number

which is shown on the model plate. Also give the part number and the name

of the part as shown in the repair parts listing. In addition, when ordering parts

for your gasoline engine, also furnish the information which appears on the

engine model plate. If you order by mail, you will pay the transportation

charges from the shipping point.

PARTS LIST

MODEL - ZYJ - 192A

PART NO.

REF.

NO.

ABriqqs & Stratton Engine Mode! 60101 Type 940239 Y

В 70

1025

C

1529-1 1

D

E

1724-7

1509-69

F

1651-20

G

1508-13

H

1

1548-1 1

J

2120-34-41

К

1540-17

L

1511-9

M

1540-55

N

1151-2-41

О

2102-20-48

P

3601-64-48

Q

1652-1

R

1691-2

S

1632-26

T

1546-2

u

1Ó54-2

V

1638-16

W

1036

X

NAAiE OF PART

*Nut {Xe Hex)----------------------------------------*Locl<washer (Xd)

*Bo!f (hd-IS X iVs Carriage)

Keeper-Belt Upper---------

*Screw (¡4-20 X 1% Fillister Hd.) —

"V" Belt...

Set Screw (/fs-24 x % Self Lock)

Rolipin

_____

Pulley Assembly.....................—-----------

*Washar {Vs x ’hid)....

*Screw (10-32 X 'A Sems. Ph.

Hd. Thd.) (Cutting)....

Washer

V/asher

____________________________

Beit Guard... ... ----------

Jackshaft Housing, Bearings &

Oiler Assembly....

Jackshaft Housing

Bearing

Oiler

Jackshaft..

Pin.......___

Chain

Sorocket.

___________________________

.....- --------------

.............

---------------

--------------------------------

------------------

---------------------

____

___________________

________

------

----------

_______________________

...........................

_____

—I-- -

------------

----

----

-------------

..............

------

-------------

-----------

------------------

-----

________________

-------------------

--------------

-------------------------

------------

------------

............

-------------

......

.. JJ

...........

---

---------

...

___

REF. PART NO.

NO.

Z

AA

BB

CC

DD 1642-30-48

EE

FF 1018

.

GG

HH

II

KK

LL 1605-256

MM

NN 1529-15

GO

PP

QQ

RR

SS

TT

Name of p.art

1538-16

1113-13

1650-10

1547-3

1534-8

67

3609-82-48

3639-42-48 Guard________________________•_...

1513-8

1501-20

1020

3153-22-48

1624-69

1724-9

1606-48

1624-117

1 522-3

1539-7

Nut (>is-20 Hex Jam Lock Gripco)..

Connector Link

Retainina Ring.

Pin ...

____________

Nut (10-32 Gripco)

Spring..

Nut (’4-20 Hex).........................................

Lockwasner

Bracket..

Bolt {-'{5-24 X Уг Sems)____________

Screw (10-32 X ltd Sems)

Screw (6 X Seif tap)

Name Plate..

Deck__________________

Bolt (Li--?0 X %)......

Spacer _____

Lower Beit Keeper

Belt Keeper Bracket

Spacer...

*Boit (A 10 sht. mtl.)

Nut '’U'" Type ,.

_______

____

-------

---------------

............

...............

_________

___________

.....................................

_______

___________.,

_

____ ______

__________

----

.....;___

................

________________

_____________

................

________________

........... .....

______

__________

____

_____

-------------------

____ _____

....... . ... _ ..

.....

...........

_____

____

.........

______

. ...

..............

...............

___ ______

________

__

.

_

.

.

.....

_

HOW TO OBTAIN SERVICE

The merchandise you have purchased from us has been

carefully engineered and manufactured under Wards rigid

quality standards and should give you satisfactory and

dependable operation. Hov/ever, like oil mechanical mer

chandise, it may occasionally require adjustment or main

tenance. Should you ever need technical assistance, please

contact or write your nearest Wards retail store, catalog

store, or mail order house. Provide the following;

1. Modal, serial number and all data shown on the model plate.

2. The date and the Words branch from whicii you purchased your lawn mower.

3. State briefiy the trouble you are having.

mmmmanmm

Page 8

Do not attempt to clean, adjust or repair machine while engine is

running.

2.

Disconnect the v/ire from the spark plug before working on machine

to prevent accidental starting.

3. Keep hands, feet and loose clothing clear of ail moving parts. Do

not attempt to remove wire, branches or objects lodged in the blade

v/hile engine is running or while wire is attached to spark plug.

4.

Remove loose objects from area before each mowing. Avoid striking

rocks, or roots, or other objects. Loose objects or chips from objects,

if struck by the mower blade, may be thrown, causing injury to oper

ator, bystander, property, or to the mower itself.

Never leave machine running unattended. Do not permit machine

5.

to be operated by persons not acquainted with its use, and the rules

for safe operation.

6. Do not run engine indoors, exhaust gases contain carbon monoxide

which is odorless and is a deadly poison. If for some reason the

engine is run indoors, open all doors and windows to provide suffi

cient ventilation..

When mowing a terrace, slope or incline, mow lengthwise. Do not

7.

mow up and down.

V

Disengage self propelling unit or drive clutch on units so equipped

8.

before starting.

Do not Pill gasoline tank when engine is running or while engine is

hot. V'/ipe off any spilled gasoline before starting engine. Gasoline

is highly flammable, always handle with care.

If your mower is equipped with a ratchet type self starter, be sure

10.

and read the handling and safety precautions in the engine manual

furnished with this mower.

@ ©

©

89L-28Î B'-

Loading...

Loading...