Page 1

YM2BP

2-Cycle Backpack Blower

Operator’s Manual

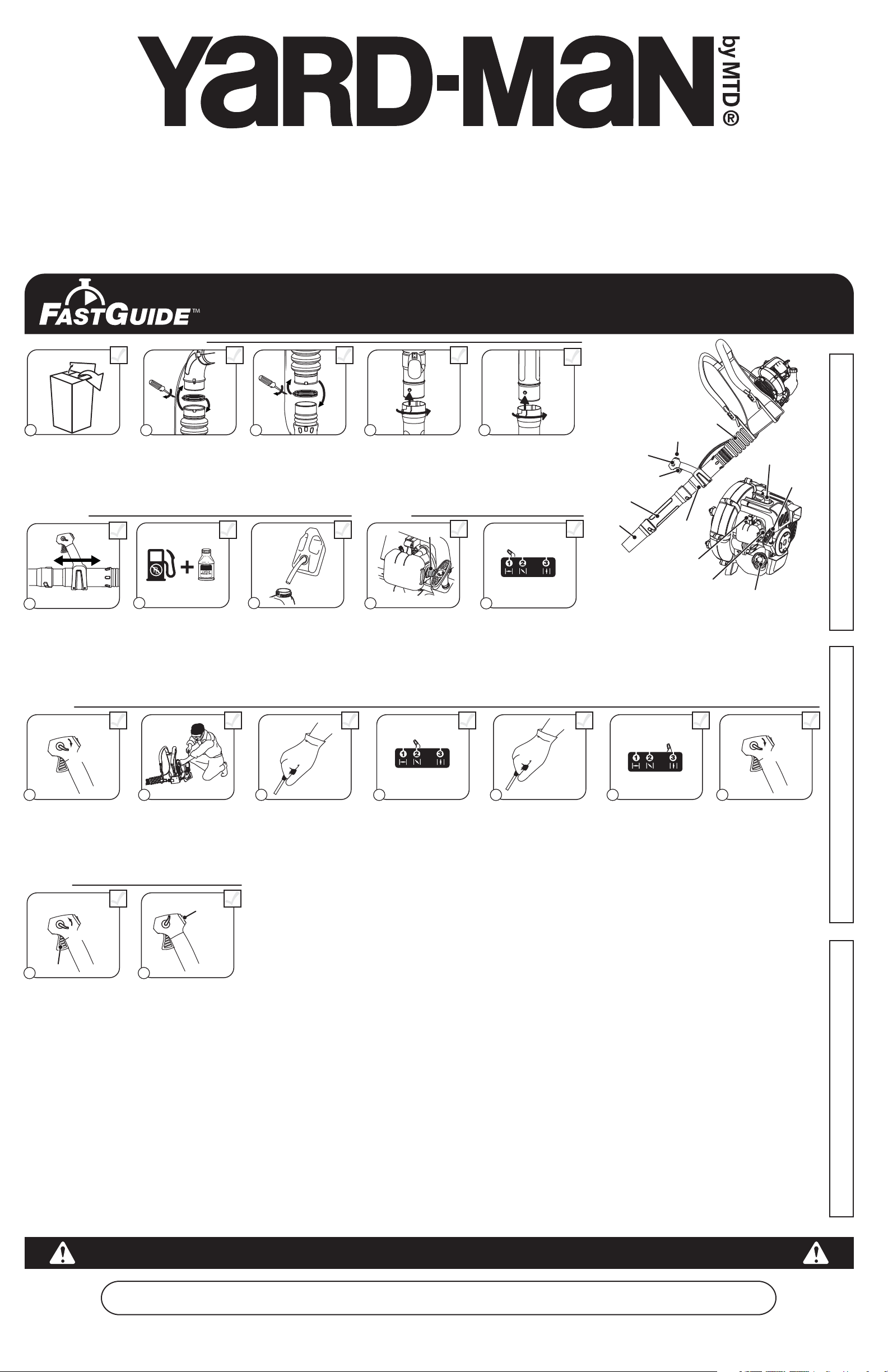

Remove Unit From Carton

11 2

Remove all contents from

the carton.

Assemble The Unit

6

Loosen the 2 screws on

the throttle control. Move

the throttle control to the

position that provides the

best grip and tighten.

Assemble The Unit

Place a hose clamp over

the end of the Flex Tube

and slide the end of the

with the clamp on it over

the elbow tube. Tighten

the clamp screw.

40:1

1 Gallon 3.2 oz

7

Mix thoroughly in separate

fuel can:

– 3.2 fl. oz. of 2-cycle

engine oil

– 1 gallon of unleaded

gasoline

NOTE: Do not mix directly

in fuel tank.

3

Place a hose clamp over

the other end of Flex Tube

and slide the end over the

top end of the upper

blower tube. Tighten the

clamp screw.

8

Place unit on a level

surface and fill fuel tank.

DO NOT overfill.

4

Insert the upper blower

tube into the lower blower

tube and twist the lower

tube clockwise unit it locks

into place.

Start The Unit

Primer

Bulb

10 X

9 10

Press primer bulb 10

times, or until fuel is

visible

5

Insert the lower blower

tube into the nozzle and

twist the nozzle clockwise

until it locks into place.

Zip tie the throttle cable to

the elbow tube.

Move choke lever to

Position 1.

Tools Required-

Phillips Screwdriver

T-20 Torx

Lower Blower Tube

®

Screwdriver

On/Off Switch

Cruise Control

Trigger

Nozzle

Upper Blower

Choke Lever

IF the engine hesitates, return the choke lever to

Position 2 and continue the warm-up.

IF the engine does not start, go back to step 9.

IF the unit fails to start after 2 attempts, move choke

lever to Position 3 and pull rope until unit starts

Flex Tube

Spark Plug

Tube

Primer Bulb

Fuel Cap

DIDN’T START?

Repeat these instructions.

Starter Rope

ENGLISH — PAGE 1

Start The Unit

SLOW

FAST

11

Press down cruise control

to FAST position.

Stop The Unit

SLOW

FAST

Trigger

18

Release your hand from

the trigger or raise the

cruise control. Allow the

engine to cool down by

idling.

12

Crouch in starting

position.

On/Off

Switch

19

Press the On/Off Switch

in the OFF (O) position

and hold until the engine

comes to a complete

stop.

5 X

13

Pull rope 5 times. Move choke lever to

14

Position 2 .

15

Pull rope 3-5 times to

start engine. Keep the

cruise control in FAST

position and allow unit to

warm up for 30 to 60

seconds.

16

Move choke lever to

Position 3.

SLOW

FAST

17

Continue to keep the

cruise control in FAST

position and warm unit for

an additional 60 seconds

to complete warm-up. Unit

may be used during this

time.

FRANÇAIS — PAGE 5

ESPAÑOL — PAGE 9

IMPORTANT: READ OPERATOR’S MANUAL THOROUGHLY AND FOLLOW THE SAFE OPERATION PRACTICES WHILE OPERATING THE UNIT.

NEED HELP? Call 1-800-800-7310 in U.S. or 1–800–668–1238 in Canada

769-06206 P00 10/10

Page 2

TABLE OF CONTENTS

Safety Rules ........................................................................................................................................... 2

Oil and Fuel Information ......................................................................................................................... 3

Operating Instructions ...........................................................................................................................3

Maintenance and Repair Instructions .................................................................................................... 3

Cleaning and Storage ............................................................................................................................4

Troubleshooting Chart ............................................................................................................................ 4

Specifi cations ........................................................................................................................................ 4

For service call 1-800-800-7310 in the United States, or 1-800-668-1238 in Canada to obtain a

list of authorized service dealers near you. For more details about your unit, visit our website at

www.yardman.com or www.yardman.ca.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED FOR

WARRANTY SERVICE.

Service on this unit both within and after the warranty period should be performed only by an authorized

and approved service dealer.

All information, illustrations, and specifi cations in this manual are based on the latest product information

available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2010 MTD SOUTHWEST INC, All Rights Reserved.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and

Washington require, by law that certain internal combustion engines operated on forest brush and/or grasscovered areas be equipped with a spark arrestor, maintained in effective working order, or the engine be

constructed, equipped and maintained for the prevention of fi re. Check with your state or local authorities

for regulations pertaining to these requirements. Failure to follow these requirements could subject you to

liability or a fi ne. This unit is factory equipped with a spark arrestor. If it requires replacement, ask your

LOCAL SERVICE DEALER to install the Accessory Part #753-06418 Muffl er Assembly

RULES FOR SAFE OPERATION

CALIFORNIA PROPOSITION 65 WARNING

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE

OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper

accident prevention measures.

SYMBOL MEANING

SAFETY ALERT: Indicates danger, warning or caution. Attention is required in

order to avoid serious personal injury. May be used in conjunction with other symbols or

pictographs.

NOTE: Advises of information or instructions vital to the operation or maintenance of the

equipment.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to

others. Always follow the safety precautions to reduce the risk of fi re, electric shock and

personal injury.

WARNING: Failure to obey a safety warning can result in injury to yourself and others.

Always follow the safety precautions to reduce the risk of fi re, electric shock and personal

injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal

READ ALL INSTRUCTIONS BEFORE OPERATING

GENERAL SAFETY

injury to yourself or to others. Always follow the safety precautions to reduce the risk of

fi re, electric shock and personal injury.

• IMPORTANT SAFETY INSTRUCTIONS •

WARNING: When using the unit, all safety rules must be followed. Please read these

instructions before operating the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

• Read the instructions carefully. Be familiar with the controls and proper use of the unit.

• Do not operate this unit when tired, ill, or under the infl uence of alcohol, drugs, or medication.

• Children and teens under the age of 15 must not use the unit, except for teens guided by an adult.

• All guards and safety attachments must be installed properly before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for fuel leaks. Make sure all fasteners

are in place and secure. Replace parts that are cracked, chipped, or damaged in any way. Do not

operate the unit with loose or damaged parts.

• Carefully inspect the area before starting the unit. Remove all debris and hard or sharp objects such

as glass, wire, etc.

• Clear the area of children, bystanders, and pets. At a minimum, keep all children, bystanders, and

pets outside a 50 feet (15 m.) radius; there still may be a risk to bystanders from thrown objects.

Bystanders should be encouraged to wear eye protection. If you are approached, stop the unit

immediately.

• Squeeze the throttle control and check that it returns automatically to the idle position. Make all

adjustments or repairs before using unit.

• Never store the unit, with fuel in the tank, inside a building where fumes may reach an open fl ame

(pilot lights, etc.) or sparks (switches, electrical motors, etc.).

• Allow the engine to cool before storing or transporting. Be sure to secure the unit while transporting.

• Store the unit in a dry place, either locked up or up high to prevent unauthorized use or damage.

Keep out of the reach of children.

• Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean, and free from

debris. Clean after each use, see Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them to instruct other users. If you loan this

unit to others, also loan these instructions to them.

• Wear safety glasses or goggles that are marked as meeting ANSI Z87.1–1989 standards and are

marked as such. Wear ear/hearing protection when operating this unit.

• Never run the unit without the proper equipment attached.

• To reduce the risk of hearing loss associated with sound level(s), always wear ear/hearing protection

when operating this unit.

• Wear heavy long pants, boots, gloves, and a long sleeve shirt. Do not wear loose clothing, jewelry,

short pants, sandals or go barefoot. Secure hair above shoulder level.

• Use the unit only in daylight or good artifi cial light.

• Keep outside surfaces free from oil and fuel.

• Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator

and unit must be in a stable position while starting. Refer to Starting/Stopping Instructions.

• Do not set unit on any surface except a clean, hard area while engine is running. Debris such as

gravel, sand, dust, grass, etc. could be picked up by the air intake and thrown out by the discharge

opening, damaging unit, property, or causing serious injury to bystanders or operator.

• Use the right tool. Only use this tool for its intended purpose.

• Do not force unit. It will do the job better and with less likelihood of injury at a rate for which it was

designed.

• Do not overreach or use from unstable surfaces such as ladders, trees, steep slopes, rooftops, etc.

Always keep proper footing and balance.

• Always hold the unit with a fi rm grip when operating.

•

Keep hands, face, and feet away from all moving parts. Do not touch or try to stop the impeller when it

is rotating. Do not operate without guards in place.

RULES FOR SAFE OPERATION

• Do not put any object into openings. Do not use with any opening blocked; keep free of dirt, debris,

and anything that may reduce the air fl ow.

• Do not touch the engine or muffl er. These parts get extremely hot from operation, even after the unit

is turned off.

• Do not operate the engine faster than the speed needed to do the job. Do not run the engine at high

speed when not in use.

• Always stop the engine when operation is delayed or when walking from one location to another.

• Use only genuine factory replacement parts and accessories for this unit. These are available from

your authorized service dealer. Use of any unauthorized parts or accessories could lead to serious

injury to the user or damage to the unit, and void your warranty.

• If you strike or come into contact with a foreign object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do not operate the unit with loose or damaged

parts.

• To reduce fi re hazard, replace faulty muffl er and spark arrestor. Keep the engine and muffl er free from

grass, leaves, excessive grease or carbon build up.

OIL AND FUEL SAFETY

WARNING: Gasoline is highly fl ammable and its vapors can explode if ignited. Take

the following precautions:

• Store fuel only in containers specifi cally designed and approved for the storage of such materials.

• Always stop the engine and allow it to cool before fi lling the fuel tank. Never remove the fuel tank

cap or add fuel when the engine is hot. Never operate the unit without the fuel cap securely in

place.

• Always mix or add fuel in a clean, well-ventilated outdoor area where there are no sparks or

fl ames. Do not smoke.

• Never Operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any spilled fuel from the unit

immediately before starting the unit. Move the unit at least 30 feet (9.1 m) from the fueling source

and site before starting the unit. Do not smoke.

• Never start or run the unit inside a closed room or building. Breathing exhaust fumes can be fatal.

Operate this unit only in a well-ventilated outdoor area.

• Check the unit for fuel leaks.

• Loosen the fuel tank cap slowly to relieve any pressure in the tank.

• Never store the unit with fuel in the tank, inside a building where fumes may reach an open fl ame

(pilot lights, etc.) or sparks (switches, electrical motors, etc.).

• To reduce fi re hazard, replace a faulty muffl er and spark arrestor. Keep the engine and muffl er free

from grass, leaves, excessive grease or carbon build up.

• Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator

and unit must be in a stable position while starting. Refer to Starting/Stopping Instructions.

• Do not touch the engine, gear housing or muffl er. These parts get extremely hot from operation, even

after the unit is turned off.

• Turn the engine to off and disconnect the spark plug for maintenance or repair.

BLOWER SAFETY

• Stop the engine for maintenance, repair, to install or remove the blower tubes. The unit must be

stopped and the impeller no longer turning to avoid contact with the rotating blades.

• Never point the blower in the direction of bystanders, animals, windows or automobiles.

SAVE THESE INSTRUCTIONS

• SAFETY & INTERNATIONAL SYMBOLS •

This operator’s manual describes safety and international symbols and pictographs that may

appear on this product. Read the operator’s manual for complete safety, assembly, operating and

maintenance and repair information.

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other

symbols or pictographs.

• READ OPERATOR’S MANUAL

WARNING: Read the operator’s manual(s) and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the operator and/or

bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING:

Thrown objects and loud noise can cause severe eye injury and hearing

loss. Wear eye protection meeting ANSI Z87.1-1989 standards and ear protection when

operating this unit. Use a full face shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING: It has been proven that fuel containing greater than 10% ethanol

will likely damage this engine and void the warranty.

• ON/OFF CONTROL

ON / START / RUN

• ON/OFF CONTROL

OFF or STOP

• OIL

Refer to operator’s manual for the proper type of oil.

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

• THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY

WARNING: Small objects can be propelled at high speed, causing injury. Keep

away from the rotating rotor.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children and pets, at least 50 feet

(15 m.) from the operating area.

• HOT SURFACE

WARNING: Do not touch any metal engine components. The engine gets

extremely hot from operation and may cause severe burns. Allow the unit to

completely cool prior to any maintenance or servicing.

• BLOWERS – ROTATING IMPELLER BLADES CAN CAUSE SEVERE INJURY

WARNING: Stop the engine and allow the impeller to stop before opening the

vacuum door, installing or changing tubes or bag, or before cleaning or performing

any maintenance.

2

Page 3

OIL AND FUEL

OIL AND FUEL MIXING INSTRUCTIONS

WARNING: Gasoline is extremely fl ammable. Ignited vapors may explode. Always stop

the engine and allow it to cool before fi lling the fuel tank. Do not smoke while fi lling the

tank. Keep sparks and open fl ames at a distance from the area.

WARNING: Add fuel in a clean, level and well ventilated outdoor area. Wipe up any

spilled fuel immediately. Avoid creating a source of ignition for spilled fuel. Do not start the

engine until fuel vapors dissipate.

WARNING:

Remove fuel cap slowly to avoid injury from fuel spray. Never operate the unit

without the fuel cap securely in place.

Be sure to use fresh, clean unleaded fuel and follow instructions carefully for proper fuel/oil mixture.

Defi nition of Blended Fuels

WARNING: Fuel containing greater than 10% ethanol will likely damage the engine and

void the warranty.

Today’s fuels are often a blend of gasoline and oxygenates such as ethanol, methanol, or MTBE (ether)

which absorb water. Use fuel within 30 days of purchase. Blended fuels older than 30 days will affect

the performance and life of the engine.

Using Blended Fuels

If the use of blended fuel is unavoidable, follow recommended precautions:

• Always use the fresh fuel mix explained in the operator’s manual

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

It is recommended to use the manufacturers 2-cycle oil with this unit. If unavailable, use a good

2-cycle oil designed for air-cooled engines along with a fuel additive, such as STA-BIL® Gas Stabilizer

or an equivalent.

Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel according to the instructions on the container.

NEVER add fuel additives directly to the unit’s fuel tank.

Mixing The Fuel

Thoroughly mix the proper ratio of 2-cycle engine oil with unleaded fuel in a separate fuel can. Use a

40:1 fuel/oil ratio. Do not mix them directly in the engine fuel tank.

IF... the unit came with a bottle of 2-cycle oil; pour the entire bottle into 1 gallon of gas and mix

thoroughly.

NOTE: One gallon (3.8 liters) of unleaded fuel mixed with one 3.2 oz. (95 ml.) bottle of 2-cycle oil

makes a 40:1 fuel/oil ratio.

NOTE: Dispose of the old fuel/oil mix in accordance to Federal, State and Local regulations.

OPERATION

USING THE CRUISE CONTROL

1. Once the engine has been started and warmed up, squeeze

the trigger to accelerate the unit as needed (Fig. 1).

2. For longer periods of operation and to eliminate possible

fi nger fatigue, move the cruise control toward the

FAST position to incrementally increase or maintain the unit’s

engine speed (Fig. 1). When the cruise control is pressed, the

trigger will recede into the handle.

3. To decrease engine speed, move the cruise control to the

SLOW position and the trigger will return to the idle position

(Fig. 1).

PUTTING ON THE UNIT

1. Place the shoulder supports over the shoulders so that the

engine rests on the operator’s back.

2. Pull the shoulder support straps down to tighten the shoulder

supports (Fig. 2).

NOTE: The unit must be started prior to putting it on. See

Starting/Stopping Instructions.

TAKING OFF THE UNIT

1. Pull up on the bottom tabs of the shoulder support buckles to

loosen the shoulder supports (Fig. 3).

2. Remove the unit.

HOLDING THE BLOWER

Before operating the unit, stand in the operating position and

check for the following (Fig. 4):

• The operator is wearing eye protection and proper clothing.

• If the conditions are dusty, the operator is wearing a dust

mask.

• The unit is secure and comfortable on the operator’s back.

• The right arm is slightly bent and the right hand is gripping the

throttle control.

OPERATING TIPS

• Never direct the unit at anyone while the unit is in operation.

• Always hold the unit securely when operating.

• To reduce the risk of hearing loss associated with sound

level(s), hearing protection is required.

• Operate power equipment only at reasonable hours. Comply

with times listed in local ordinances. Usual recommendations

are 9:00 am to 5:00 pm, Monday through Saturday.

• To reduce noise levels, operate power blowers at the lowest possible speed to do the job and limit

the total number of pieces of power equipment used at any one time.

• Check unit before operating, especially muffl er, air intakes and air fi lters, for debri and possible

blockages.

• Use rakes and brooms to loosen debris before blowing.

• In dusty conditions, slightly dampen surfaces.

• Conserve water by using power blowers instead of hoses for many lawn and garden applications,

including cleaning debri from areas such as screens, patios, grills, porches, and gardens.

• Watch out for children, pets, open windows or freshly washed cars, and blow debris safely away.

• Use the full blower nozzle extension so the air stream can work closer to the ground.

• Clean up after using blowers and other equipment. Dispose of debris appropriately.

• Use the cruise control to make continuous operation easier.

APPLICATIONS

• Use the blower for trees, shrubs, fl ower beds and hard-to-clean areas.

• Use the unit around buildings and for other normal cleaning procedures.

• Use the blower around walls, overhangs, fences and screens.

Cruise

Control

Trigger

Shoulder

Support

Straps

SLOW

FAST

Fig. 1

Fig. 2

Shoulder

Buckles

Fig. 3

Fig. 4

Shoulder

Supports

MAINTENANCE

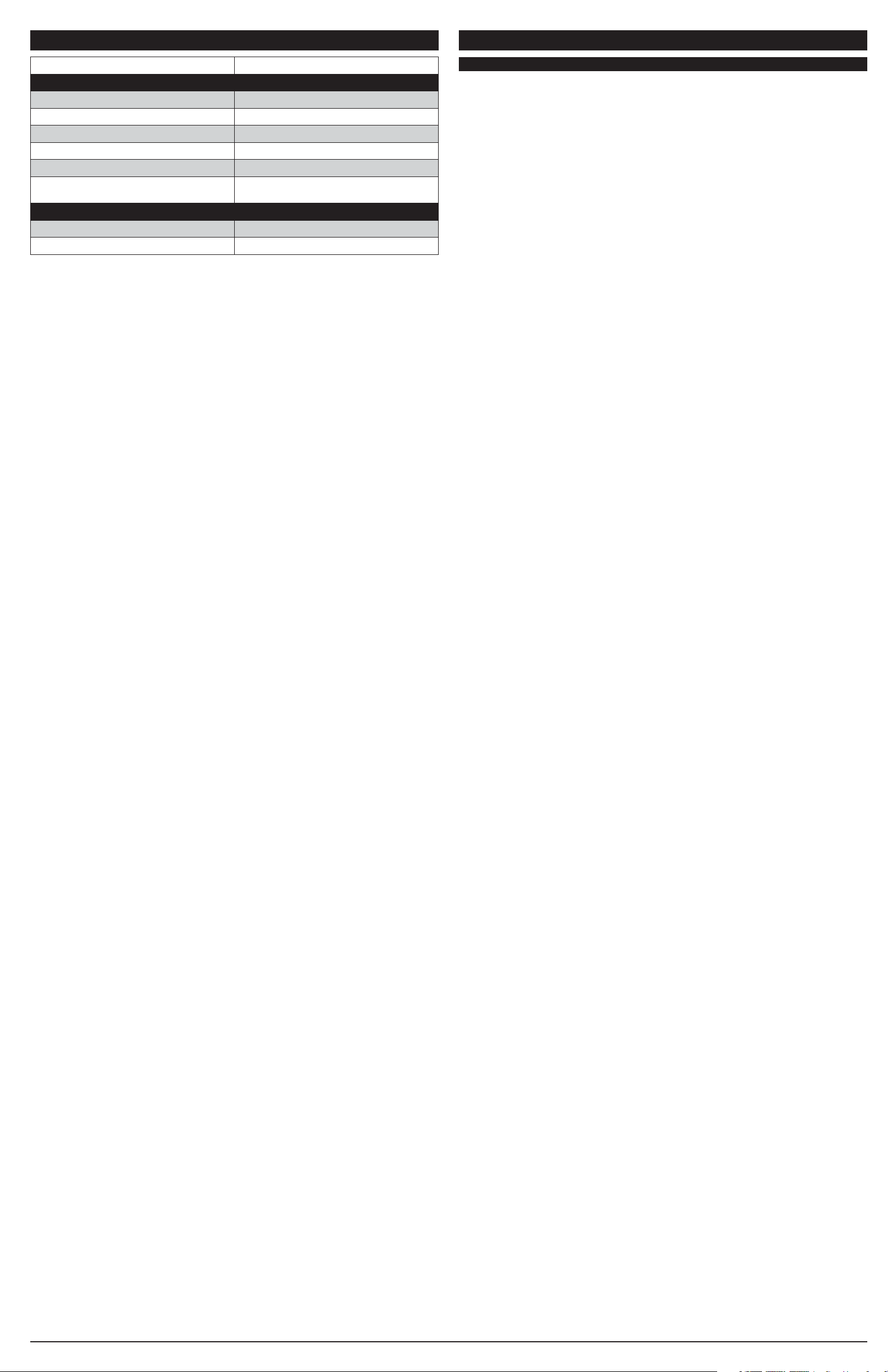

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These

procedures should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. For these types of repairs

call 1-800-800-7310 for more information.

NOTE: Please read the California/ EPA statement that came with the unit for a complete listing of

terms and coverage for the emissions control devices, such as the spark arrestor, muffl er,

carburetor, etc

FREQUENCY MAINTENANCE REQUIRED SEE

Every 10 hours Clean air fi lter p. 3

Every 25 hours Check the spark plug condition and gap p. 3

AIR FILTER MAINTENANCE

WARNING: To avoid serious personal injury, always turn the unit off and allow it to cool

before cleaning or maintaining it.

Failure to maintain the air fi lter properly can result in poor

Air Filter

Cover

Tab

performance or cause permanent damage to the engine.

1. Open the air fi lter cover and remove the air fi lter (Fig. 5).

2. Wash the fi lter in detergent and water. Rinse thoroughly and

allow to dry.

3. Apply clean SAE 30 motor oil to fi lter.

4. Squeeze fi lter to spread and remove excess oil.

5. Replace air fi lter (Fig. 6).

NOTE: Operating unit without air fi lter WILL VOID warranty.

6. Reinstall the air fi lter cover and press down until it snaps into

place (Fig. 5).

Lock Tabs

Fig. 5

Air Filter

ADJUST IDLE SPEED SCREW

The idle speed of the engine is adjustable. An idle adjustment

screw is between the air fi lter cover and the engine cover (Fig. 7).

NOTE: Careless adjustments can seriously damage your unit.

An authorized service dealer should make carburetor

adjustments.

If, after checking the fuel and cleaning the air fi lter, the engine still

will not idle, adjust the idle speed screw as follows:

1. Start the engine and let it run at a high idle for a minute to

warm up. Refer to Starting/Stopping Instructions.

Fig. 6

Idle Adjustment

Screw

2. Move the cruise control to the SLOW position and let

the engine idle. If the engine stops, insert a small Phillips

screwdriver in between the air fi lter cover and the engine

cover (Fig. 7). Turn the idle speed screw in, clockwise, 1/8 of a

turn at a time (as needed) until the engine idles smoothly.

Checking the fuel mixture, cleaning the air fi lter, and adjusting the

idle speed should solve most engine problems. If not and all of the

following are true:

• engine will not idle

• engine hesitates or stalls on acceleration

• there is a loss of engine power

Fig. 7

take the unit to a qualifi ed service dealer.

REPLACING THE SPARK PLUG

Use a replacement part number 753-06193 or Champion spark plug #RDJ7J. The correct spark gap

is 0.025 in. (0.635 mm).

1. Stop the engine and allow it to cool.

2. Grasp plug wire fi rmly and pull.

WARNING: Do not sand blast, scrape or clean spark plug electrodes. Grit in the engine

could damage the cylinder.

3. Clean around spark plug and remove using a 5/8-inch socket

counterclockwise.

4. Set the air gap, according to specifi cations, using a feeler

gauge (Fig. 8).

5. Install spark plug turning clockwise and torquing as stated:

• Torque to: 110-120 in.•lb. (12.3-13.5 N•m) Do not over

tighten.

Do not over tighten.

6. Reconnect the spark plug wire.

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household

cleaners that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can

damage plastic housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes may reach an open fl ame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

LONG TERM STORAGE

If you plan on storing the unit for an extended time, use the following storage procedure:

1. Remove all fuel from the fuel tank and dispose in accordance with federal, state and local

regulations

2. Start the engine and allow it to run until it stalls. This ensures that all fuel has been drained from

the carburetor.

3. Allow the engine to cool.

4. Remove the spark plug and put 3 - 5 drops of any high quality motor oil or 2-cycle oil into the

cylinder. Pull the starter rope slowly to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the cylinder before attempting to start

the blower after storage.

5. Thoroughly clean the unit and inspect it for any loose or damaged parts. Repair or replace

damaged parts and tighten loose screws, nuts or bolts. The unit is ready for storage.

TRANSPORTING

• Allow the engine to cool before transporting

• Drain fuel from unit before transporting

• Tighten fuel cap before transporting

• Secure the unit while transporting

0.025 in.

(0.635 mm)

Fig. 8

3

Page 4

TROUBLESHOOTING

SPECIFICATIONS

PROBLEM SOLUTION

ENGINE WILL NOT START, IDLE OR ACCELERATE

Empty fuel tank Fill fuel tank with fuel

Primer bulb wasn't pr

Old fuel Drain fuel tank and add fresh fuel mix

Fouled spark plug Replace or clean the spark plug

Air fi lter is plugged Replace or clean the air fi lter

Improper idle speed

ENGINE LACKS POWER OR STALLS

Old fuel Drain fuel tank and add fr

Fouled spark plug Replace or clean the spark plug

essed enough Slowly press primer bulb 10 times

Adjust according to the Idle Speed

Adjustments section.

esh fuel mix

UNIT*

Engine Type ............................................................................................................. Air-Cooled, 2-Cycle

Displacement ................................................................................................................................. 27 cc

Idle Speed RPM ........................................................................................................... 3,200–4,400 rpm

Operating RPM ............................................................................................................ 6,900-7,200 rpm

Spark Plug Gap .................................................................................................... 0.025 inch (0.635 mm)

Lubrication ..................................................................................................................... Fuel/Oil Mixture

Fuel/Oil Ratio ................................................................................................................................... 40:1

Fuel Tank Capacity ............................................................................................................20 oz. (591 ml)

Approximate Unit Weight (No fuel) ............................................................................. 17.8 lbs. (8.07 kg)

* All specifi

reserve the right to make changes at any time without notice.

cations are based on the latest product information available at the time of printing. We

4

Page 5

YM2BP

Souffl eur à dos 2 temps

Manuel de l’utilisateur

Retirer l’appareil du carton

11 2

Retirez tous les éléments

du carton.

Assembler l’appareil

6

Desserrez les 2 vis sur la

manette des gaz. Placez

la manette des gaz dans

la position offrant la

meilleure prise et

resserrez.

Démarrer l’appareil

Assembler l’appareil

Placez un collier de

serrage sur l’extrémité du

tube flexible et faites

glisser l’extrémité du tube

flexible muni du collier sur

le tube coudé. Serrez la

vis de la bride.

40:1

1 Gallon 3.2 oz

7

Mélangez soigneusement

dans un bidon d’essence :

– 0,09 litre (3,2 oz.) d’huile

pour moteur 2 temps

– 3,8 litres (1 gallon)

d'essence sans plomb

REMARQUE : ne faites pas le

mélange directement

dans le réservoir de

carburant.

3

Placez un collier de serrage

à l’autre extrémité du tube

flexible et faites glisser

l’extrémité sur l’extrémité

supérieure du tube de

soufflage supérieur. Serrez

la vis de la bride.

8

Placez l’appareil sur une

surface plane et

remplissez le réservoir de

carburant. VEILLEZ À NE

PAS trop le remplir.

4

Insérez le tube de soufflage

supérieur dans le tube de

soufflage inférieur et

pivotez le tube inférieur

vers la droite jusqu’à ce

qu’il soit parfaitement en

place.

Démarrer l’appareil

9 10

Pressez la poire

d’amorçage 10 fois ou

jusqu’à ce que le

carburant soit visible.

10 X

Poire

d’amorçage

5

Insérez le tube de soufflage

inférieur dans la buse et

pivotez la buse vers la droite

jusqu’à ce qu’elle soit

parfaitement en place. Fixez

le câble de la manette des

gaz sur le tube coudé à l’aide

de l’attache autobloquante.

Mettez le levier

d’étranglement en

position 1.

Outils requis :

• Tournevis cruciforme

• Tournevis Torx

Régulateur

de vitesse

Tube de soufflage

inférieur

Buse

®

T-20

Bouton marche/

arrêt (On/Off)

Gâchette

Tube de

soufflage

supérieur

Levier d’étranglement

Tube flexible

Bougie

Poire d’amorçage

Bouchon du réservoir de carburant

Cordon de

démarrage

L’APPAREIL NE DÉMARRE PAS ?

SI le moteur fait des accrocs, remettez le levier d’étranglement

en position 2 et continuez de chauffer le moteur.

SI le moteur ne démarre pas, retournez à l’étape 9.

SI le moteur ne démarre pas après 2 tentatives, placez le levier

d’étranglement en position 3 et tirez le cordon de démarrage

jusqu’à ce que le moteur démarre.

ENGLISH — PAGE 1

LENT

RAPIDE

11

Appuyez sur le régulateur

de vitesse pour le placer

en position RAPIDE.

Arreter l’appareil

LENT

RAPIDE

Gâchette

18

Relâcher la gâchette ou

régulateur de vitesse et

laisser le moteur refroidir

en le faisant tourner au

ralenti.

12

Placez-vous en position

de démarrage.

Bouton

marche/arrêt

(On/Off)

19

Appuyer et maintenir la

commande Marche/Arrêt

enfoncée en position

ARRET (O) jusqu’à ce que

le moteur soit complètement arrêté.

5 X

13

Tirez 5 fois sur le cordon. Mettez le levier

14

d’étranglement en

position 2.

15

Tirez sur le cordon 3 à 5

fois de suite pour

démarrer le moteur.

Maintenez le régulateur

de vitesse en position

RAPIDE et laissez le

moteur chauffer pendant

30 à 60 secondes.

16

Mettez le levier

d’étranglement en

position 3.

LENT

RAPIDE

17

Continuez de maintenir le

régulateur de vitesse en

position RAPIDE et laissez

le moteur chauffer

pendant encore 60

secondes pour terminer le

réchauffage. L’appareil

peut être utilisé pendant ce

temps.

FRANÇAIS — PAGE 5

ESPAÑOL — PAGE 9

IMPORTANT : LISEZ ATTENTIVEMENT LE MANUEL DE L’UTILISATEUR ET CONFORMEZ-VOUS AUX INSTRUCTIONS POUR UNE UTILISATION DE L’APPAREIL EN TOUTE SÉCURITÉ.

BESOIN D’AIDE ? Appelez le 1-800-800-7310 aux États-Unis ou le 1–800–668–1238 au Canada

769-06206 P00 10/10

Page 6

TABLE DES MATIÈRES

Règles pour une utilisation en toute sécurité ......................................................................................... 6

Informations sur l’huile et le carburant...................................................................................................7

Instructions d’utilisation ......................................................................................................................... 7

Instructions d’entretien et réparations ................................................................................................... 7

Nettoyage et entreposage .....................................................................................................................7

Résolutions de problèmes .....................................................................................................................8

Spécifi cations ........................................................................................................................................ 8

Pour obtenir la liste des concessionnaires agréés, appelez le 1-800-800-7310 aux États-Unis ou le

1-800-668-1238 au Canada. Pour de plus amples informations à propos de votre appareil, visitez

www.yardman.com o www.yardman.ca

NE RETOURNEZ PAS L’APPAREIL AU DÉTAILLANT CHEZ QUI VOUS L’AVEZ ACHETÉ. TOUT

SERVICE SOUS GARANTIE NÉCESSITE UNE PREUVE D’ACHAT.

Avant d’assembler votre nouvel équipement, repérez la plaque signalétique de l’appareil et copiez ses

informations dans l’espace ci-dessous. Ces informations sont essentielles si vous désirez obtenir de l’aide

auprès de notre service technique ou d’un distributeur agréé. Un exemple de plaque signalétique est

présenté ci-dessous.

Toutes les informations, illustrations et spécifi cations contenues dans ce manuel tiennent compte des

dernières informations techniques disponibles au moment de mettre sous presse. Nous nous réservons

le droit d’y apporter des modifi cations à tout moment, sans préavis.

Copyright© 2010 MTD SOUTHWEST INC., Tous droits réservés.

REMARQUE CONCERNANT LE PARE-ÉTINCELLE

REMARQUE : À l’intention des utilisateurs utilisant l’appareil dans les terres forestières des États-Unis

et dans les états de Californie, du Maine, de l’Oregon et de Washington. Toutes les terres forestières

des États-Unis et de l’état de Californie (Codes sur les ressources publiques 4442 et 4443), de l’Oregon

et de Washington exigent de par la loi que certains moteurs à combustion interne utilisés dans des zones

couvertes de taillis et/ou d’herbes soient équipés d’un pare-étincelles en parfait état de fonctionnement, ou

qu’ils soient conçus, équipés et entretenus pour la prévention des incendies. Renseignez-vous auprès des

autorités locales ou régionales concernant la réglementation en vigueur. Vous pourriez être passible d’une

amende ou être tenu responsable si vous ne respectez pas cette réglementation. Cet appareil est équipé

d’un pare-étincelle en usine. Si l’écran du pare-étincelle, réf. 753-05900, doit être remplacé, contactez

votre RÉPARATEUR LOCAL AGRÉE.

RÈGLES POUR UNE UTILISATION EN TOUTE SÉCURITÉ

PROPOSITION 65 DE L’ÉTAT DE CALIFORNIE

AVERTISSEMENT

LES GAZ D’ÉCHAPPEMENT DU MOTEUR DE CET APPAREIL CONTIENNENT DES

PRODUITS CHIMIQUES CONSIDÉRÉS PAR L’ÉTAT DE CALIFORNIE COMME POUVANT

PROVOQUER DES CANCERS, DES MALFORMATIONS CONGÉNITALES OU D’AUTRES

EFFETS NOCIFS SUR LA REPRODUCTION.

L’objectif de ces symboles de sécurité est d’attirer votre attention sur des dangers potentiels. Ces

symboles de sécurité et leurs explications méritent que vous les lisiez et compreniez bien. Les seuls

avertissements de sécurité n’éliminent pas le danger. Les consignes ou avertissements de sécurité ne

remplacent pas les mesures appropriées de prévention des accidents.

SYMBOLE SIGNIFICATION

ALERTE DE SÉCURITÉ : Indique un danger, un avertissement ou une mise en

garde. Soyez vigilant afi n d’éviter toute blessure grave. Ce symbole peut être combiné à

d’autres symboles ou pictogrammes.

REMARQUE : Vous donne des informations ou des instructions essentielles pour l’utilisation ou

l’entretien de l’equipement.

DANGER : Le non-respect d’une consigne de sécurité entraînera des blessures graves

pour vous-même ou pour les autres. Respectez toujours les consignes de sécurité pour

réduire les risques d’incendie, de décharge électrique et de blessures corporelles.

AVERTISSEMENT :

Le non-respect d’une consigne de sécurité peut entraîner des

blessures pour vous-même ou pour les autres. Respectez toujours les consignes de sécurité

pour réduire les risques d’incendie, de décharge électrique et de blessures corporelles.

ATTENTION : Le non-respect d’une consigne de sécurité peut entraîner des dégâts

LISEZ CETTE NOTICE INTÉGRALEMENT AVANT D’UTILISER L’APPAREIL

CONSIGNES DE SÉCURITÉ D’ORDRE GÉNÉRAL

• Lisez soigneusement cette notice. Familiarisez-vous avec les commandes et la marche à suivre

• N’utilisez pas cet appareil lorsque vous êtes fatigué, malade ou sous l’infl uence de l’alcool, de

• L’appareil ne doit pas être utilisé par un enfant ou adolescent de moins de 15 ans, à moins que

• Tous les dispositifs de protection et de sécurité doivent être correctement installés avant d’utiliser

• Inspectez l’appareil avant utilisation. Remplacez les pièces endommagées. Assurez-vous qu’il n’y

• Inspectez la zone avec attention avant de démarrer cet appareil. Retirez tous les débris et objets

• Éloignez les enfants, les animaux domestiques et les personnes à proximité de la zone

• Appuyez sur la manette des gaz et vérifi ez que le régime du moteur revient automatiquement au

• N’entreposez jamais l’appareil avec de l’essence dans le réservoir à l’intérieur d’un bâtiment où

• Laissez refroidir le moteur avant de ranger ou de déplacer l’appareil. Attachez bien l’appareil

• Entreposez l’appareil dans un endroit sec éventuellement sous clef ou en hauteur pour éviter tout

• Ne mouillez et n’humidifi ez jamais l’appareil avec de l’eau ou un liquide quelconque. Conservez

• Conservez ces instructions. Consultez-les régulièrement et utilisez-les pour donner des consignes

• L’appareil ne doit pas être démarré ou utilisé à l’intérieur d’une pièce ou d’un bâtiment fermé.

• Portez des lunettes de sécurité conformes aux normes ANSI Z87.11989, lesquelles doivent être

• N’utilisez jamais l’appareil sans l’accessoire adéquat.

• Pour diminuer le risque de perte d’audition due au niveau sonore, portez toujours une protection

• Portez un pantalon long et épais, des bottes, des gants et une chemise à manches longues. Ne

• Utilisez l’appareil uniquement à la lumière du jour ou sous un éclairage artifi ciel satisfaisant.

• Gardez toutes les surfaces extérieures exemptes d’huile et d’essence.

matériels ou des blessures graves pour vous-même ou pour les autres. Respectez toujours

les consignes de sécurité pour réduire les risques d’incendie, de décharge électrique et de

blessures corporelles.

• CONSIGNES DE SÉCURITÉ IMPORTANTES •

AVERTISSEMENT :

sécurité. Veuillez lire ces consignes avant d’utiliser l’appareil afi n de garantir votre sécurité et

celle des personnes à proximité. Conservez-les pour vous y référer ultérieurement.

pour une bonne utilisation de l’appareil.

drogues ou de médicaments.

l’adolescent soit sous la supervision d’un adulte.

l’appareil.

a pas de fuites de carburant. Assurez-vous que toutes les attaches sont en place et solidement

fi xées. Remplacez les pièces fi ssurées, ébréchées ou endommagées. N’utilisez pas l’appareil avec

des pièces endommagées ou ayant du jeu.

durs ou tranchants tels que du verre, des câbles, etc.

d’utilisation. Au minimum, faites reculer les enfants, les personnes à proximité et les animaux

domestiques de 15 m (50 pieds) ; il existe néanmoins un risque de projectile pour les personnes

à proximité. Encouragez-les à porter des lunettes de sécurité. Si quelqu’un s’approche de vous,

arrêtez l’appareil immédiatement.

ralenti. Effectuez tous les réglages et toutes les réparations avant d’utiliser l’appareil.

les vapeurs peuvent entrer en contact avec toute source de fl ammes (lampes témoin, etc.) ou

d’étincelles (interrupteurs, moteurs électriques, etc.).

pendant le transport.

usage non autorisé et pour éviter qu’il soit endommagé. Gardez toujours l’appareil hors de la

portée des enfants.

les poignées sèches et propres. Nettoyez l’appareil après chaque utilisation ; consultez les

Instructions de nettoyage et rangement.

aux autres utilisateurs. Si vous prêtez cet appareil à quelqu’un, transmettez également ces

instructions.

Inhaler les fumées du pot d’échappement peut provoquer la mort. Utilisez cet appareil uniquement

en extérieur, dans une zone bien aérée.

indiquées sur les lunettes mêmes. Portez une protection auditive lorsque vous utilisez cet appareil.

auditive lorsque vous utilisez cet appareil.

marchez pas pieds nus et évitez de porter des vêtements amples, des bijoux, des pantalons

courts et des sandales. Relevez les cheveux au-dessus des épaules.

Lors de l’utilisation de l’appareil, respectez toutes les consignes de

RÈGLES POUR UNE UTILISATION EN TOUTE SÉCURITÉ

• Évitez les démarrages accidentels. Soyez en position de démarrage lorsque vous tirez sur le

cordon de démarrage. L’utilisateur et l’appareil doivent se trouver dans une position stable lors du

démarrage. Consultez les Instructions de démarrage et d’arrêt.

• Ne posez l’appareil que sur une surface propre et stable lorsque le moteur tourne. Les débris tels

que le gravier, le sable, la poussière, l’herbe, etc. pourraient être entraînés par une prise d’air et

éjectés par l’ouverture d’expulsion, et endommager l’appareil, les objets environnants, ou causer

des blessures graves aux personnes avoisinantes ou à l’utilisateur.

• Utilisez les outils appropriés. N’employez cet outil que pour son usage prévu.

• Ne forcez pas l’appareil. Il sera plus effi cace et vous courrez moins de risques de blessures en

l’utilisant de façon adéquate.

• N’essayez pas d’atteindre des branches trop éloignées et évitez de vous tenir sur des surfaces

trop instables comme une échelle, un arbre, une pente raide, un toit, etc. Gardez toujours une

position stable et un bon équilibre.

• Gardez toujours une prise ferme sur l’appareil lorsque vous l’utilisez.

• Gardez les mains, le visage et les pieds éloignés des parties en mouvement. N’essayez pas de

toucher ou d’arrêter l’hélice lorsqu’elle tourne. N’utilisez pas l’appareil si les protections ne sont

pas en place.

• N’insérez pas d’objets dans les ouvertures. N’utilisez pas l’appareil si une ouverture est obstruée ;

enlevez la poussière et les débris et tout ce qui pourrait réduire le passage de l’air.

• Ne touchez pas au moteur ou au pot d’échappement. Ces pièces deviennent extrêmement

chaudes lors du fonctionnement, même après l’arrêt de l’appareil.

• Ne faites pas tourner le moteur à une vitesse supérieure à celle qui est nécessaire pour effectuer le

travail. Ne faites pas tourner le moteur à haut régime lorsque vous n’utilisez pas l’appareil.

• Arrêtez toujours le moteur lorsque l’utilisation est interrompue ou lorsque vous vous déplacez d’un

endroit à l’autre.

• Si l’appareil heurte ou se prend dans un objet, arrêtez le moteur immédiatement et vérifi ez que

l’appareil n’a pas été endommagé. N’utilisez pas l’appareil avant d’avoir réparé les dommages.

N’utilisez pas l’appareil avec des pièces endommagées ou ayant du jeu.

• Pour cet appareil, utilisez uniquement les pièces et accessoires de rechange du fabricant. Vous

pouvez vous les procurer auprès de votre distributeur agréé. L’utilisation de pièces ou accessoires

non agréés pourrait entraîner de graves blessures pour l’utilisateur, ou endommager l’appareil, et

annuler votre garantie.

• Afi n de réduire les risques d’incendie, remplacez le pare-étincelle et le pot d’échappement s’ils

sont défectueux. Nettoyez l’herbe, les feuilles, les couches de graisse excessives et les dépôts de

carbone du moteur et du pot d’échappement.

CONSIGNES DE SÉCURITÉ POUR L’HUILE ET LE CARBURANT

AVERTISSEMENT : L’essence est extrêmement infl ammable. Les vapeurs qui s’en

dégagent peuvent exploser si on y met le feu. Prenez les précautions suivantes.

• Stockez uniquement le carburant dans des conteneurs prévus spécifi quement à cet effet et approuvés

pour le stockage de telles substances.

• Coupez toujours le moteur et laissez-le refroidir avant de remplir le réservoir d’essence. Ne retirez jamais

le bouchon du réservoir de carburant et ne remplissez jamais ce dernier lorsque le moteur est chaud. Ne

démarrez jamais l’appareil avant d’avoir bien revissé le bouchon du réservoir de carburant.

• Mélangez et ajoutez toujours le carburant en extérieur, dans une zone propre, bien aérée, à l’abri des

étincelles ou des fl ammes. Ne fumez pas.

• Ne démarrez jamais l’appareil avant d’avoir bien revissé le bouchon du réservoir de carburant.

• Évitez tout ce qui pourrait enfl ammer le carburant renversé. L’essence s’étant échappée de l’appareil doit

être essuyée immédiatement avant de démarrer l’appareil. Éloignez l’appareil d’au moins 9,1 m (30 pieds)

du site et de la source du carburant avant de démarrer le moteur. Ne fumez pas.

• L’appareil ne doit pas être démarré ou utilisé à l’intérieur d’une pièce ou d’un bâtiment fermé. L’inhalation

des fumées d’échappement peut être mortelle. Utilisez cet appareil uniquement en extérieur, dans une

zone bien aérée.

• Assurez-vous que l’appareil ne présente pas de fuites de carburant.

• Dévissez lentement le bouchon du réservoir d’essence afi n de réduire la pression.

• N’entreposez jamais l’appareil avec de l’essence dans le réservoir à l’intérieur d’un bâtiment où les

vapeurs peuvent entrer en contact avec toute source de fl ammes (lampes témoin, etc.) ou d’étincelles

(interrupteurs, moteurs électriques, etc.).

• Afi n de réduire les risques d’incendie, remplacez les pare-étincelles et les pots d’échappement

défectueux. Nettoyez l’herbe, les feuilles, les couches de graisse excessives et les dépôts de carbone du

moteur et du pot d’échappement.

• Évitez les démarrages accidentels. Tenez-vous en position de démarrage lorsque vous tirez sur le cordon

de démarrage. L’utilisateur et l’appareil doivent se trouver dans une position stable lors du démarrage.

• Ne touchez pas au moteur, à la transmission ou au pot d’échappement. Ces pièces deviennent

extrêmement chaudes lors du fonctionnement, même après l’arrêt de l’appareil.

• Éteignez le moteur et débranchez la bougie pour effectuer son entretien ou sa réparation.

CONSIGNES DE SÉCURITÉ POUR SOUFFLEUR

• Arrêtez le moteur pour effectuer l’entretien, la réparation, pour installer ou enlever les tubes de

souffl age. L’appareil doit être arrêté et l’hélice ne doit plus tourner pour éviter tout contact avec les

lames en rotation.

• Ne jamais orienter le souffl eur en direction de personnes ou d’animaux domestiques, ni en

direction de fenêtres. Ne jamais diriger les débris souffl és en direction de personnes, d’animaux et

de fenêtres. Faire particulièrement attention en souffl ant les débris à proximité d’objets solides tels

que des arbres, voitures, murs, etc.

CONSERVEZ CES INSTRUCTIONS

• SYMBOLES INTERNATIONAUX ET DE SÉCURITÉ •

Ce manuel de l’utilisateur décrit les symboles et pictogrammes de sécurité internationaux qui peuvent

apparaître sur ce produit. Lisez ce manuel de l’utilisateur pour obtenir des informations complètes sur

la sécurité, l’assemblage, l’utilisation, l’entretien et les réparations.

SYMBOLE SIGNIFICATION

• SYMBOLE D’ALERTE DE SÉCURITÉ

Indique un danger, un avertissement ou une mise en garde. Ce symbole peut être

combiné à d’autres symboles ou pictogrammes.

• LISEZ LE MANUEL DE L’UTILISATEUR

AVERTISSEMENT : Lisez le(s) manuel(s) de l’utilisateur et suivez toutes

les consignes de sécurité et de prévention. Tout manquement peut entraîner des

blessures graves pour les utilisateurs et/ou pour les personnes à proximité.

• PORTEZ DES LUNETTES DE SÉCURITÉ ET DES PROTECTIONS AUDITIVES

AVERTISSEMENT :

Les objets projetés et le bruit peuvent entraîner des lésions

oculaires et des pertes auditives. Portez toujours des protections oculaires conformes

aux normes ANSI Z87.1-1989 et des protections auditives lorsque vous utilisez cet outil.

Protégez-vous le visage avec un masque intégral au besoin.

• ESSENCE SANS PLOMB

Utilisez toujours de l’essence sans plomb fraîche et propre.

• N’UTILISEZ PAS D’ESSENCE E85 DANS CET APPAREIL

AVERTISSEMENT : Il a été prouvé que l’utilisation de carburant contenant

plus de 10 % d’éthanol endommagera très certainement ce moteur et annulera la

garantie.

• COMMANDE MARCHE/ARRÊT

MARCHE / DÉMARRAGE / FONCTIONNEMENT

• COMMANDE MARCHE/ARRÊT

ARRÊT ou STOP

• LES OBJETS PROJETÉS ET LA TÊTE DE COUPE PEUVENT CAUSER DES

BLESSURES GRAVES

AVERTISSEMENT : De petits objets peuvent être projetés à grande vitesse

et entraîner des blessures. Tenez-vous à l’écart du rotor tournant.

• ÉLOIGNEZ LES PERSONNES SE TROUVANT À PROXIMITÉ

AVERTISSEMENT :

particulier les enfants et les animaux, d’au moins 15 m (50 pieds) de la zone de travail.

Faites reculer les personnes se trouvant à proximité, en

Page 7

RÈGLES POUR UNE UTILISATION EN TOUTE SÉCURITÉ INSTRUCTIONS D’UTILISATION

SYMBOLE SIGNIFICATION

• SURFACE CHAUDE

AVERTISSEMENT : Ne touchez aucun des composants métalliques du

moteur. Le moteur devient très chaud lors de l’utilisation et peut entraîner de

graves brûlures. Laissez refroidir complètement le moteur avant d’entreprendre

toute tâche d’entretien ou de réparation.

• HUILE

Consultez le manuel de l’utilisateur pour connaître le type d’huile à utiliser.

• POIRE D’AMORÇAGE

Appuyez sur la poire d’amorçage lentement et complètement, dix (10) fois.

• SOUFFLEURS – LES LAMES ROTATIVES PEUVENT INFLIGER DES

BLESSURES GRAVES

AVERTISSEMENT : Arrêter le moteur et laisser l’hélice parvenir à l’arrêt

complet avant d’installer ou de changer les tubes ou le sac et avant toute

opération de nettoyage, d’entretien ou de réparation.

INFORMATIONS SUR L’HUILE ET LE CARBURANT

INSTRUCTIONS DE MÉLANGE HUILE/ESSENCE

AVERTISSEMENT : L’essence est extrêmement infl ammable. Les vapeurs qui

s’en dégagent peuvent exploser si on y met le feu. Coupez toujours le moteur et laissezle refroidir avant de remplir le réservoir de carburant. Ne fumez pas en remplissant le

réservoir. Éloignez toute source d’étincelles ou de fl ammes vives de la zone.

AVERTISSEMENT : Ajoutez du carburant en extérieur, dans un lieu propre, plan

et bien aéré. Si de l’essence est renversée, essuyez-la immédiatement. Évitez tout ce

qui pourrait enfl ammer le carburant renversé. Ne démarrez pas le moteur avant que les

vapeurs de carburant ne se soient dissipées.

AVERTISSEMENT : Enlevez le bouchon du réservoir lentement pour ne pas être

blessé par les jets d’essence. Ne démarrez jamais l’appareil avant d’avoir bien revissé le

bouchon du réservoir de carburant.

Prenez soin d’utiliser de l’essence sans plomb fraîche et propre et suivez à la lettre les instructions de

mélange d’huile et d’essence.

Défi nition des carburants mélangés

AVERTISSEMENT : L’utilisation de carburant contenant plus de 10 % d’éthanol

endommagera très certainement ce moteur et annulera la garantie.

Les carburants d’aujourd’hui sont souvent un mélange d’essence et d’oxygénés comme l’éthanol, le

méthanol ou l’éther MTBE qui absorbent l’eau. Utilisez le carburant dans un délai de 30 jours après

l’achat. L’utilisation de carburants mélangés vieux de plus de 30 jours aura des conséquences sur les

performances de l’appareil et la durée de vie du moteur.

Utilisation de carburants mélangés

Si vous ne pouvez éviter d’utiliser un carburant mélangé, suivez les conseils ci-dessous :

• Utilisez toujours un mélange de carburant frais, tel qu’expliqué dans le manuel de l’utilisateur.

• Agitez toujours le mélange de carburant avant d’alimenter l’appareil.

• Videz le réservoir et faites tourner le moteur jusqu’à l’assécher avant d’entreposer l’appareil.

Utilisation d’additifs pour carburant

Nous vous recommandons d’utiliser de l’huile pour moteur 2 temps de la marque du fabricant. Si elle

n’est pas disponible, utilisez une huile de qualité pour moteur 2 temps à refroidissement par air en y

ajoutant un additif, tel que le stabilisant de gaz STA-BIL® ou un produit équivalent.

Ajoutez 23 ml (0,8 oz) d’additif par gallon (3,8 litres) de carburant selon les instructions indiquées sur

le bidon. N’ajoutez JAMAIS d’additifs directement dans le réservoir d’essence de l’appareil.

Mélange du carburant

Mélangez soigneusement l’huile pour moteur 2 temps avec de l’essence sans plomb dans un bidon

séparé. Utilisez un rapport essence/huile de 40:1. Ne les mélangez pas directement dans le réservoir

de carburant.

SI... l’appareil est livré avec bidon d’huile pour moteur 2 temps ; versez la totalité du bidon

d’huile dans un gallon (3,8 litres) de carburant et mélangez soigneusement.

REMARQUE : 3,8 litres (1 gallon) d’essence sans plomb mélangés avec un fl acon de 95 ml (3,2 oz)

d’huile 2 temps donnent un rapport d’essence/ huile de 40:1.

REMARQUE : Éliminez le mélange de carburant usagé conformément aux réglementations locales,

régionales et nationales en vigueur.

INSTRUCTIONS D’UTILISATION

UTILISATION DU RÉGULATEUR DE VITESSE

1. Dès que le moteur a démarré et qu’il est chaud, actionnez la

gâchette pour accélérer l’appareil (Fig. 1).

2. Pour des périodes d’utilisation plus longues et pour éviter

l’engourdissement des doigts, placez le régulateur de vitesse

en position RAPIDE pour augmenter progressivement ou

maintenir la vitesse du moteur de l’appareil (Fig. 1). Lorsque

vous appuyez sur le régulateur de vitesse, la gâchette

s’enfonce dans la poignée.

3. Pour diminuer la vitesse du moteur, déplacez le régulateur de

vitesse vers la position LENTE : la gâchette revient alors en

position de ralenti (Fig. 1).

PRISE DE L’APPAREIL

1. Placez les sangles sur les épaules pour que le moteur repose

sur le dos de l’utilisateur.

2. Tirez sur les brides des sangles pour serrer ces dernières (Fig. 2).

REMARQUE : L’appareil doit être mis en marche avant toute

prise en mains. Consultez les Instructions de démarrage

et d’arrêt.

DÉPOSE DE L’APPAREIL

1. Tirez sur les languettes inférieures des boucles des sangles

d’épaule pour les desserrer (Fig. 3).

2. Retirez l’appareil.

POSITION ADÉQUATE POUR TENIR LE SOUFFLEUR

Avant de démarrer l’appareil, placez-vous en position de démarrage

et assurez-vous de respecter les points suivants (Fig. 4) :

• L’utilisateur porte des lunettes de sécurité et une tenue

appropriée.

• Si les conditions sont poussiéreuses, l’utilisateur porte un

masque antipoussière.

• L’appareil est sécurisé et confortablement installé sur le dos

de l’utilisateur.

• Le bras droit est légèrement plié et la main droite tient la

manette des gaz.

CONSEILS D’UTILISATION

• Ne jamais diriger l’appareil vers quiconque lorsqu’il

fonctionne.

• Tenez toujours l’appareil bien en main lorsque vous l’utilisez.

• Pour réduire le risque d’une perte auditive à cause du niveau

sonore de l’appareil, portez systématiquement une protection

auditive.

• Utilisez les outils à moteur uniquement à des heures raisonnables. Conformez-vous aux horaires

indiqués par les autorités locales (généralement de 9h00 à 17h00, du lundi au samedi).

• Pour réduire le niveau sonore, utilisez le souffl eur à sa plus basse vitesse possible pour effectuer le

travail et limitez le nombre total d’équipements électriques utilisés en même temps.

• Contrôlez l’appareil avant toute utilisation, en particulier le pot d’échappement, les entrées d’air et

les fi ltres à air afi n de déceler la présence d’éventuels débris ou obstructions.

• Désagrégez grossièrement les débris à l’aide de râteaux et de balais avant d’utiliser le souffl eur.

• En cas de poussière, humidifi ez légèrement les surfaces.

• Économisez l’eau en utilisant des souffl eurs plutôt que des tuyaux d’arrosage pour différents

travaux de jardin et de pelouse, tels que le nettoyage des grillages, des terrasses, des grilles, des

auvents et des jardins.

Régulateur

de vitesse

Gâchette

Brides

des

sangles

LENT

RAPIDE

Fig. 1

Fig. 2

Boucles

d’épaule

Fig. 3

Fig. 4

Sangles

d’épaule

• Faites attention aux enfants, animaux domestiques, fenêtres ouvertes, voitures qui viennent d’être

lavées et souffl ez les débris en toute sécurité dans la direction opposée.

• Utilisez l’accessoire de buse de souffl age au complet de façon à diriger le fl ux d’air plus près du

sol.

• Nettoyez après avoir utilisé le souffl eur ou d’autres appareils. Éliminez les débris de façon

appropriée.

• Utilisez le régulateur de vitesse pour faciliter l’utilisation en continu.

APPLICATIONS

• Utilisez le souffl eur autour des arbres, des arbustes, des parterres de fl eurs et des zones diffi ciles

à nettoyer.

• Utilisez le souffl eur autour des bâtiments et pour d’autres tâches habituelles de nettoyage.

• Utilisez le souffl eur pour nettoyer autour des murs, des parties en surplomb, des clôtures et des

grillages.

CONSIGNES D’ENTRETIEN

PROGRAMME D’ENTRETIEN

Effectuez ces procédures d’entretien obligatoires aux fréquences indiquées dans le tableau

d’entretien. Ces procédures devraient également avoir lieu lors de toute révision de début de saison.

REMARQUE : Certaines procédures d’entretien peuvent nécessiter des outils ou compétences

spécifi ques. Pour ces types de réparations, appelez le 1-800-800-7310 pour plus

d’informations.

REMARQUE : Veuillez lire la déclaration EPA/Californie fournie avec l’appareil pour obtenir une liste

complète des conditions et de la couverture s’appliquant aux dispositifs de contrôle

des émissions, tels que le pare-étincelles, le pot d’échappement, le carburateur, etc.

FRÉQUENCE ENTRETIEN REQUIS VOIR

Toutes les 10

heures

Toutes les 25

heures

Nettoyez et appliquez de l’huile sur le fi ltre à air p. 7

Vérifi er l’état de la bougie ainsi que son écartement p. 8

ENTRETIEN DU FILTRE A AIR

AVERTISSEMENT : La tête de coupe continue de tourner durant l’ajustement du

ralenti. Portez des vêtements de sécurité et respectez toutes les consignes pour éviter des

blessures graves.

Couvercle du

Tout défaut d’entretien du fi ltre à air peut entraîner une baisse des

performances ou des dégâts permanents au moteur.

fi ltre à air

Languette

1. Ouvrez le couvercle du fi ltre à air et retirez le fi ltre à air (Fig. 5).

2. Lavez le fi ltre avec du détergent et de l’eau. Rincez

soigneusement et laissez-le sécher.

3. Appliquez de l’huile pour moteur SAE 30 propre sur le fi ltre.

4. Pressez le fi ltre pour répartir et enlever l’excédent d’huile.

5. Remettez le fi ltre à air (Fig. 6).

REMARQUE : L’utilisation de l’appareil sans le fi ltre à air

ANNULERA la garantie.

6. Réinstallez le couvercle du fi ltre à air et appuyez jusqu’à ce

Languettes de

verrouillage

Fig. 5

Filtre à air

qu’il soit parfaitement en place. (Fig. 5).

AJUSTEMENT DU RALENTI

Il est possible de régler la vitesse de ralenti du moteur. Une vis de

réglage du ralenti se trouve entre le couvercle du fi ltre à air et le

couvercle du moteur (Fig. 19).

REMARQUE : Un mauvais réglage peut sérieusement

endommager votre appareil. Le réglage du carburateur

doit être confi é à magasin Sears ou un autre

Fig. 6

concessionnaire agréé.

Ajustez la vis de réglage du ralenti

Si, après avoir vérifi é le niveau de carburant et nettoyé le fi ltre à

air, le moteur ne tourne toujours pas au ralenti, ajustez la vis de

réglage du ralenti comme suit :

Vis de réglage du

ralenti

1. Démarrez le moteur et laissez-le chauffer conformément aux

Instructions de démarrage et d’arrêt.

2. Relâchez la gâchette et laissez tourner le moteur au ralenti. Si

le moteur s’arrête, insérez un petit tournevis cruciforme entre

le couvercle du fi ltre à air et le couvercle du moteur (Fig. 19).

Tournez la vis de réglage du ralenti vers la droite, 1/8 de tour

à la fois, jusqu’à ce que le moteur tourne au ralenti de façon

régulière.

Fig. 7

La vérifi cation du niveau de carburant, le nettoyage du fi ltre à air et le réglage de la vitesse de ralenti

devraient résoudre la plupart des problèmes du moteur. Dans le cas contraire et en présence des

symptômes suivants :

• le moteur ne tourne pas au ralenti

• le moteur hésite et cale lors de l’accélération

• vous constatez une perte de puissance moteur : emmenez l’appareil dans un magasin Sears ou

chez un concessionnaire agréé.

Apportez l’appareil chez un concessionnaire agréé.

REMPLACEMENT DE LA BOUGIE D’ALLUMAGE

Utilisez une bougie de rechange de référence 753-06193 ou une bougie Champion de référence

RDJ7J. L’écartement de la bougie doit être de 0,635 mm (0,025 po).

AVERTISSEMENT : Ne jamais gratter, sabler ou nettoyer les électrodes de la bougie

d’allumage. Des saletés dans le moteur pourraient endommager le cylindre.

REMPLACEMENT DE LA BOUGIE D’ALLUMAGE

Utilisez une bougie de rechange de référence 753-06193 ou

Champion RDJ7J. L’espace doit être de 0,635 mm (0,025 pouce).

1. Arrêtez le moteur et laissez-le refroidir.

2. Saisissez fermement le fi l de la bougie et tirez.

3. Nettoyez bien l’espace autour de la bougie et retirez-la en

tournant une douille de 5/8 pouce vers la gauche.

4. Réglez l’écartement conformément aux indications, à l’aide

d’une jauge d’épaisseur (Fig. 8).

5. Installez la bougie en tournant vers la droite en respectant le

couple indiqué :

• Serrez à : 110-120 in.•lb. (12.3-13.5 N•m) Ne serrez pas trop fort.

Ne serrez pas trop fort.

NETTOYAGE

N’utilisez pas de détergents agressifs ou de produits d’entretien ménagers contenant des huiles

aromatiques, telles que le pin ou le citron, et des solvants tels que le kérosène, qui peuvent

endommager le boîtier en plastique ou la poignée. Utilisez une petite brosse pour nettoyer l’appareil et

essuyez toute trace d’humidité avec un chiffon doux.

RANGEMENT

• N’entreposez jamais un appareil moteur à essence où les vapeurs peuvent entrer en contact avec

d’éventuelles étincelles ou fl ammes nues.

• Laissez le moteur refroidir avant d’entreposer l’appareil.

• Gardez l’appareil sous clef pour éviter tout usage non autorisé et pour éviter qu’il soit

endommagé.

• Entreposez l’appareil dans un endroit sec et bien aéré.

• Entreposez l’appareil hors de la portée des enfants.

ENTREPOSAGE À LONG TERME

Si vous comptez entreposer l’appareil pendant 30 jours ou plus, suivez la procédure ci-dessous :

1. Videz tout le carburant du réservoir dans un récipient et éliminez-le conformément aux

réglementations locales, régionales et nationales en vigueur.

2. Démarrez le moteur et laissez-le tourner jusqu’à ce qu’il s’arrête par faute d’essence pour vous

assurer que le moteur est bien vide, puis laissez-le refroidir.

0,635 mm

( 0,025 po)

Fig. 14

7

Page 8

CONSIGNES D’ENTRETIEN

3. Retirez la bougie et versez 3 à 5 gouttes d’huile moteur dans le cylindre. Tirez lentement sur le

cordon de démarrage pour bien répartir l’huile et remettez la bougie en place.

REMARQUE : Retirez la bougie et videz toute l’huile se trouvant dans le cylindre avant d’essayer de

4. Nettoyez soigneusement l’appareil et inspectez-le méticuleusement pour vérifi er s’il n’y a pas de

pièces détachées ou endommagées. Réparez ou remplacez les pièces endommagées et serrez

tous les boulons et vis desserrés.

démarrer l’appareil après l’entreposage.

RÉSOLUTION DES PROBLÈMES

PROBLÈME SOLUTION

LE MOTEUR NE DÉMARRE PAS, NE TOURNE PAS AU RALENTI OU N’ACCÉLÈRE PAS

Réservoir de carburant vide Remplissez le réservoir avec du carburant

Poir

e d’amorçage pas assez enfoncée

Carburant trop vieux

Bougie encrassée Nettoyez ou remplacez la bougie

Filtre à air bouché Nettoyez ou remplacez le fi ltre à air

Vitesse de ralenti mal réglée

LE MOTEUR MANQUE DE PUISSANCE OU CALE

Carburant trop vieux

Bougie encrassée Nettoyez ou remplacez la bougie

Pressez lentement la poire d’amorçage à dix

reprises

Videz le réservoir de carburant et remplissez-le

avec du carburant frais

Ajustez la vitesse conformément aux

indications de la section Ajustement du ralenti

idez le réservoir de carburant et remplissez-le

V

avec du carburant frais

SPÉCIFICATIONS

APPAREIL*

Type de moteur .................................................................................. 2 temps, à refroidissement par air

Cylindrée ......................................................................................................................................... 25 cc

Régime au ralenti .................................................................................................... 3 200 – 4 400 t/min

Régime de fonctionnement ....................................................................................... 6 900 – 7 200 t/min

Écartement de bougie ........................................................................................... 0,635 mm (0,025 po)

Rapport essence/huile ...................................................................................................................... 40:1

Capacité du réservoir d’essence .......................................................................................591 ml (20 oz)

Poids approximatif de l’appareil (réservoir vide) ........................................................... 8,07 kg (17,8 lb)

’ensemble des caractéristiques sont basées sur les toutes dernières informations disponibles sur

* L

le produit à l’impression de ce guide. Nous nous réservons le droit d’effectuer des modifi cations à

tout moment sans notifi cation préalable.

8

Page 9

YM2BP

Sopladora de Mochila de 2 Tiempos

Manual del Operador

Sacar la unidad de su caja

11 2

Saque todo el contenido

de la caja.

Ensamblar la unidad

6

Afloje los 2 tornillos del

control del regulador.

Mueva el control del

regulador a la posición

que dé el mejor agarre y

asegúrelo.

Arrancar la unidad

Ensamblar la unidad

Ponga una abrazadera

encima del extremo del

tubo flexible y pase este

extremo con la abrazadera

por encima del tubo

acodado. Apriete el tornillo

de la abrazadera.

40:1

1 Gallon 3.2 oz

7

Mezcle bien en un recipiente

aparte para combustible:

– 3.2 onzas líquidas

de aceite para motor

de 2 tiempos

– 1 galón de gasolina

sin plomo

NOTA: No los mezcle

directamente en el

tanque de combustible.

3

Ponga otra abrazadera en

el otro extremo del tubo

flexible y pase ambos por

encima del extremo de

arriba del tubo superior de

la sopladora. Apriete el

tornillo de la abrazadera.

8

Coloque la unidad sobre

una superficie llana y llene

el tanque del combustible

NO rebose el tanque.

4

Inserte el tubo superior de

la sopladora en el inferior y

dele vuelta a este último en

el sentido de las manecillas

del reloj hasta que encaje

en su lugar.

Arrancar la unidad

Pera del

cebador

10 X

9 10

Presione la pera del

cebador 10 veces o

hasta que se vea el

combustible.

5

Inserte el tubo inferior de la

sopladora en la boquilla y dele

vuelta a esta última en el

sentido de las manecillas del

reloj hasta que encaje en su

lugar. Amarre con la cincha

plástica el cable del regulador

al tubo acodado.

Mueva la palanca del

obturador a la Posición 1.

Herramientas

necesarias:

• Destornillador Phillips

• Destornillador Torx® T-2 0

Interruptor de

Encendido/Apagado

Control de crucero

Gatillo

Tubo inferior

de la sopladora

Boquilla

Palanca del obturador

Tubo flexible

Tubo

superior

de la

sopladora

Pera del cebador

Bujía

Tapa del tanque

de combustible

Cuerda de

arranque

¿NO ARRANCÓ?

SI el motor falla, vuelva a colocar la palanca del obturador en

SI después de 2 intentos de arranque el motor no reacciona,

mueva la palanca del obturador a la posición 3 y tire de la

la posición 2 y continúe calentándolo.

SI el motor no arranca, regrese al paso 6.

cuerda de arranque hasta que el motor eche a andar.

ENGLISH — PAGE 1

LENTO

RÁPIDO

11

Mueva hacia abajo la

perilla del control de

crucero para ponerla en la

posición RÁPIDO (FAST).

Parada la unidad

LENTO

RÁPIDO

Gatillo

18

Libere el gatillo o el

control de crucero. Deje

que el motor se enfríe

dejándolo funcionar en

mínima.

12

Agáchese en la posición

de arranque.

Interruptor de

Encendido/Apagado

19

Oprima y mantenga

oprimido el Control de

encendido y apagado en

la posición APAGADO (O)

hasta que el motor se

detenga por completo.

5 X

13

Tire de la cuerda de

arranque 5 veces.

14

Mueva la palanca del

obturador a la Posición 2.

15

Tire la cuerda de 3 a 5

veces para arrancar el

motor. Mantenga el

control de crucero en la

posición RÁPIDO y deje

que la unidad se caliente

de 30 a 60 segundos.

16

Mueva la palanca del

obturador a la Posición 3.

LENTO

RÁPIDO

17

Aún con el control de

crucero en la posición

RÁPIDO, caliente la

unidad otros 60 segundos.

La unidad se puede usar en

este momento.

FRANÇAIS — PAGE 5

ESPAÑOL — PAGE 9

IMPORTANTE: LEA BIEN EL MANUAL DEL OPERADOR Y, AL OPERAR LA UNIDAD, SIGA LAS INSTRUCCIONES PARA EL FUNCIONAMIENTO SEGURO.

¿NECESITA AYUDA? Llame al 1-800-800-7310 en EE.UU. o al 1–800–668–1238 en Canadá

769-06206 P00 10/10

Page 10

TABLA DE CONTENIDO

Normas para operarlo de manera segura ............................................................................................ 12

Información sobre el aceite y el combustible ......................................................................................13

Instrucciones de operación..................................................................................................................14

Instrucciones de mantenimiento .......................................................................................................... 14

Limpieza y almacenamiento ................................................................................................................15

Localizacíon y solución de problemas .................................................................................................15

Especifi caciones ..................................................................................................................................15

Garantía ...............................................................................................................................................16

Llame 1-800-800-7310 en EE.UU. o al 1-800-668-1238 en Canada para obtener una lista de distribuidores

de servicio localizados cerca de usted. Para obtener más detalles sobre su unidad, visite nuestro sitio en

www.yardman.com o www.yardman.ca.

NO REGRESE SU UNIDAD AL VENDEDOR. PARA SOLICITAR SERVICIO POR LA GARANTIA,

DEBERA PRESENTAR PRUEBA DE SU COMPRA.

El servicio de esta unidad, ya sea durante o después del período cubierto por la garantía, debe ser

realizado solamente por un proveedor de servicios autorizado y aprobado.

Antes de que empiece a ensamblar su nuevo equipo, por favor ubique la placa que contiene el modelo

de la unidad y escriba esa información en el espacio en blanco aquí debajo. Aquí debajo se explica la

muestra de una placa del modelo.

Toda la información, las ilustraciones y las especifi caciones contenidas en este manual se basan en