Page 1

Operators Manual

Model Series

370 thru 389

Rotary Mowers

IMPORTANT:READSAFETYRULESANDINSTRUCTIONSCAREFULLY

Warning: This unit is equipped with an internal combustion engine and _hou[d not be used on or near ally unimproved foresl-

CoMered, _3FUSII_Covor ed Or g_a_s-_v_rgd IB+ndfJrl(ess IE1__noit3_'s exhaust Sy_tsyt_ is {_qul{3p_ WItll _ _p_ fl/_Ir_t_r m¢3OliD_

addllo_dle Iooal or Glat_ raw8 Ill any). if a spark arrestor is used, II sl_ouid be malnlait_ hi eflectIve working order by the operator,

In the SLat_ Of Oalifornl_.Ih_ abavo is required DV law ISeclion 4442 of the CEtlilorr_ia Public Resources Code) Other s t_te,_ rosy hays

similar laws. Federal laws apply on federal land_. A spa_ arrestor for tile muffler is awii_ble Ihro_lgh your nearest _nglne =lktlhorlz ed

service de_ler or conlact the service dep_rtmer_t, PO. 19o_ 368022 _levoland. Ohio 44136-g722

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED rN U.S.A.

FORM NO. 770-10114

(10/98)

Page 2

SECTION 1: FINDING YOUR MODEL NUMBER

This Operator's ManL_al is an important pert of your new walk behhld. It will help you assemble, prepare alqd

maintain your walk behind. Please read and understand what it says,

Before you start to prepare your walk behind for ds first use, please locate the model plate and copy the

ihformaiien from It in this Operator's Manual. The Information on the model pla[e is very important if you need

help from your dealer or the MTD CLlstomer support department.

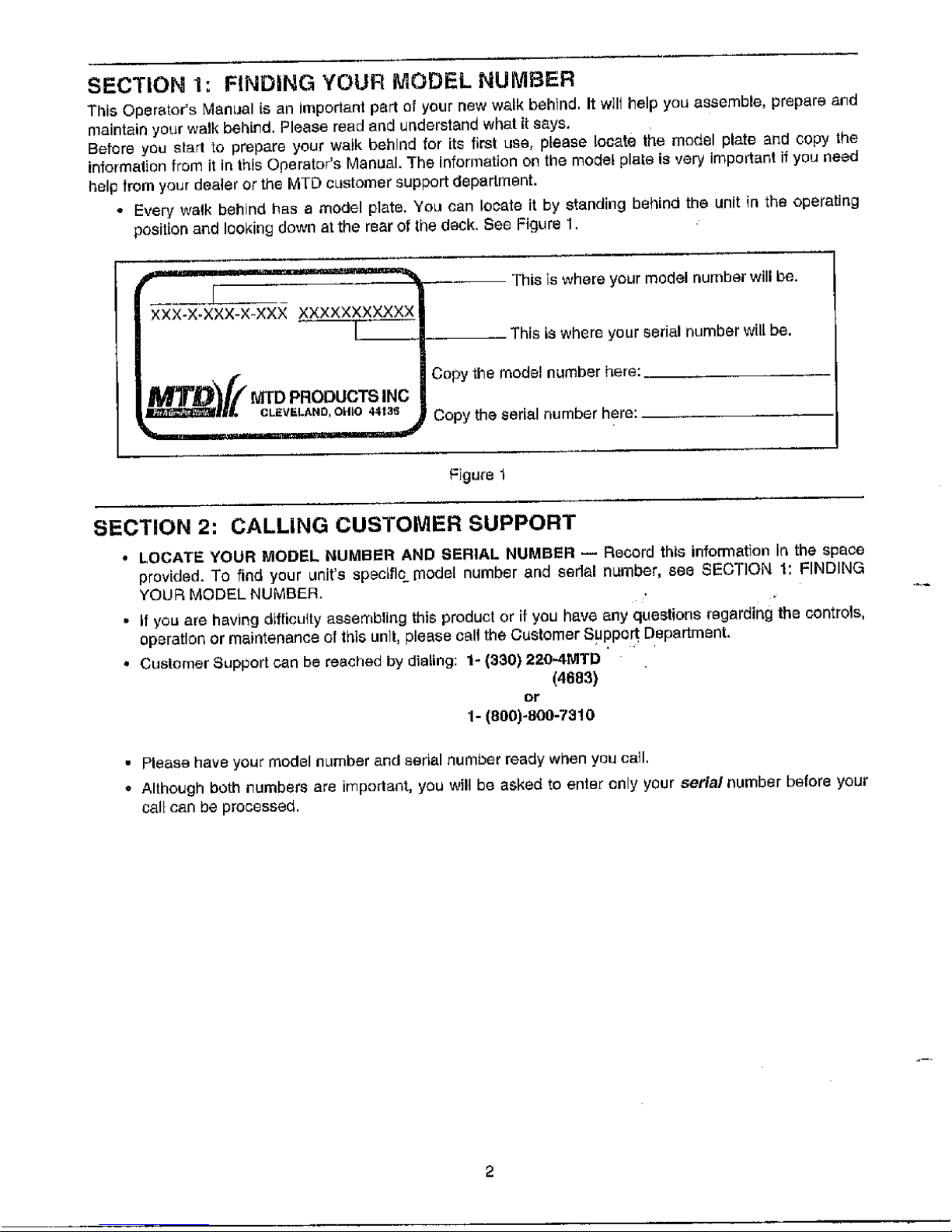

Every' walk behind has a model plate, You can Io_afe it by standing behirM the unit in the operating

position and looking down at the rear of the deck. See Figure 1.

×XX-X-XXX-X-XXX XXXXXXXXXXX

This is where your model number will be.

- This is where your serial number will be.

Copy the model nLImber here:

Copy the serial number here:

Figure 1

SECTION 2: CALLING CUSTOMER SUPPORT

• LOCATE YOUR MODEL NUMBER AND SERIAL NUMBER -- Record this information fn the space

provided. To find your unit's specific model number and eedal n_mber, see SECTION 1: FINDING

YOUR MODEL NUMBER.

• If you are having dLfficulty assembling this product or if you have any questions regarding t_e controls,

operation or maintenance Of this unit, please call the Customer Support Department,

• Customer Support can be reached by dialing: 1- 1330) 2204MTD

(4683)

or

1- (800)-800-7310

• Please have your model number and serial number ready when you call.

• Although both numbers are irnport_nt, you Wffl be asked to enter only your sofia/number before your

ee.II can be processed.

Page 3

SECTION 3: IMPORTANT SAFE OPERATION PRACTICES

,ik

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR LAWN MOWER. FAILURE TO COMPLY W[TH

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL,

HEED ITS WARNING,

WARNING: The Engine Exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

DANGER= Your lawn mower was built to be operated according to the rulas for safe operation in

this manual. As with any type of power equipment, carelessness or error on the part of the operator

can result in serious injury. TMs lawn mower is capable of amputating hands and feet and throwing

objects. Failure to observe the following safety i£struotlons could result in serious injury or deatl)

1. GENERAL OPERATION

• Read this operator's manual carefully in its entirety

before attempting to a68emble this machine. Read,

understand, and follow all instructions on the

machine and in the manual(s) before operation. Be

completely familiar with the controls and the proper

use of this machine before operating It Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts,

• Your rotary mower is a preelston piece of power

equipment, not a plaything. Therefore, exorcise

extreme cautton aL all limes. Your unit has been

designed to perform one job: to mow gross• DO not

use if for any other purpose,

• Never allow children under 14 yea_s old to operate

a power mower. Children 14 years old and over

should only operate mower under close parental

supervision. Only responsible {ndividuals who are

familiar with these rules of safe operation should be

allowed to use your mower,

, Keep the area of operation clear of all persons,

particularly small children and pets. Stop engine

when they are ]n the vicinity of your mower to help

prevent blade contact or th_wn object inJury,

Although the area of operation should he

compLetely cleared of foreign objects, an object

may have been ovedeoked and could he

accldenlally thrown by the mower in any direc_ton

and cause serious personal injury to the operator or

any others allowed in the area.

• Wear sturdy, rough-soled work shoes and close-

fitting slacks and shirts. Shirts and pants that cover

the arms and legs and steel-teed shoes are

recommended. Do noL wear loose fitting clelhes or

Jewelry They can be caught In moving parts, Never

operate a unit in bare feet, sandals, slippery or light

weighL(eg cenvas) shoes

• Always wear eatery glasses or safely goggles

during operation or while pertorrning an adjustment

or repair, to prefect eyes from foreign objects that

may be thrown from the machine in any direction.

• Thoroughly inspect the area where the equipment

i_ to he used¸ Remove all stones, sticks, wire,

I_o_nes, toys and other foreign ebject_ which could

be picked up and thrown by the mowe_ in any

direction and cause serfou8 personal injury to the

operator or any Others allowed in the areEt, Plan

your mowing pattern to avoid dl_charg_ of material

toward roads, sidewalks, bystanders and the like,

TO help avoid a thrown objects Injury. keep

children, by6thnd_rs anrf helpers at least 75 feet

Sore the mower while g i6 i_ opertalon.

° DO riot put band8 or leer near or under rotating

ports¸ Keep clear of discharge opening at al! times

e_ the rotating blade can cause injury.

• Many injuries occur as a result of the mower being

pulled over the foot dudng a fall. Do not hang on to

the mower if you are falling; release the h_ndIe

iinmediately

• Never pull the mower toward you while you are

walking If you must back the mower away from a

walt or obstruction first took down and behind, and

then fellow these 8tops:

. Step back from the mower to, frilly extend your

arm_.

• Be SLate you are well balanced with sure

fooling.

• Puff the mower back slow_y, no moRe than haq

way toward yOL_.

• Repeat these siege a9 needed¸

• Do n_l e_eralo the mower while under Ihe

Influence o_ alcohol or drugs.

Page 4

• DO not engage the self-prabelled mechanism cn

units so equipped while sthrLing engine,

• The blade control handle is a safety device Never

attempt to bypass its operagon. Doing so makes

the safety device inoperative and may result in

personal in{ury through contact with the rotating

blade. The blade control handle must operate

easily in both direntions and autornatically return te

the disengaged poaltfon when released,

• Never operate the mower in wet grass. Always be

sure of your footing. A slip and far can cause

sedous personal thjur), Keep a firm hold on the

handle and walk, never run. If you feel you are

losing your footing, RELEASE THE BLADE

CONTROL HANDLE IMMEDIATELY and the blade

will stop rofahng within three seconds.

• Mow only in daylight or good artificial light.

• Stop the blade when croe81ng gravel drives, walks

or roads,

• If the equipment shoald start to vibrate abnormally,

stop the engine and check immediately for the

cause, Vibration is generally a warning at trouble,

• Shut the engine off and wait until the blade comes

to a complete stop before removing the grass

eel=her er unclogging the chute, The cut_ng blade

continues to rotate for a few seconds after the

engine is shut off. Never place any part of the body

in the blade area until you are sure the blade has

stopped rotabng,

• Never operate mower without proper guards, grass

catcher, plates or other safety protective devices in

place.

• Muffler and engine become hot and can cause a

burn, DO not touch.

• Only use accessories approved for this machine by

the manufaablrer. Read, understand, and Iollow all

]nstruc_ens provided wgh the abprovab accessory.

• If siluations occur which are not covered Jn this

manual, use care and good judgment. Contact your

dealer for assistance Telephone 1-800-800-7310

for the name of your nearest dealer,

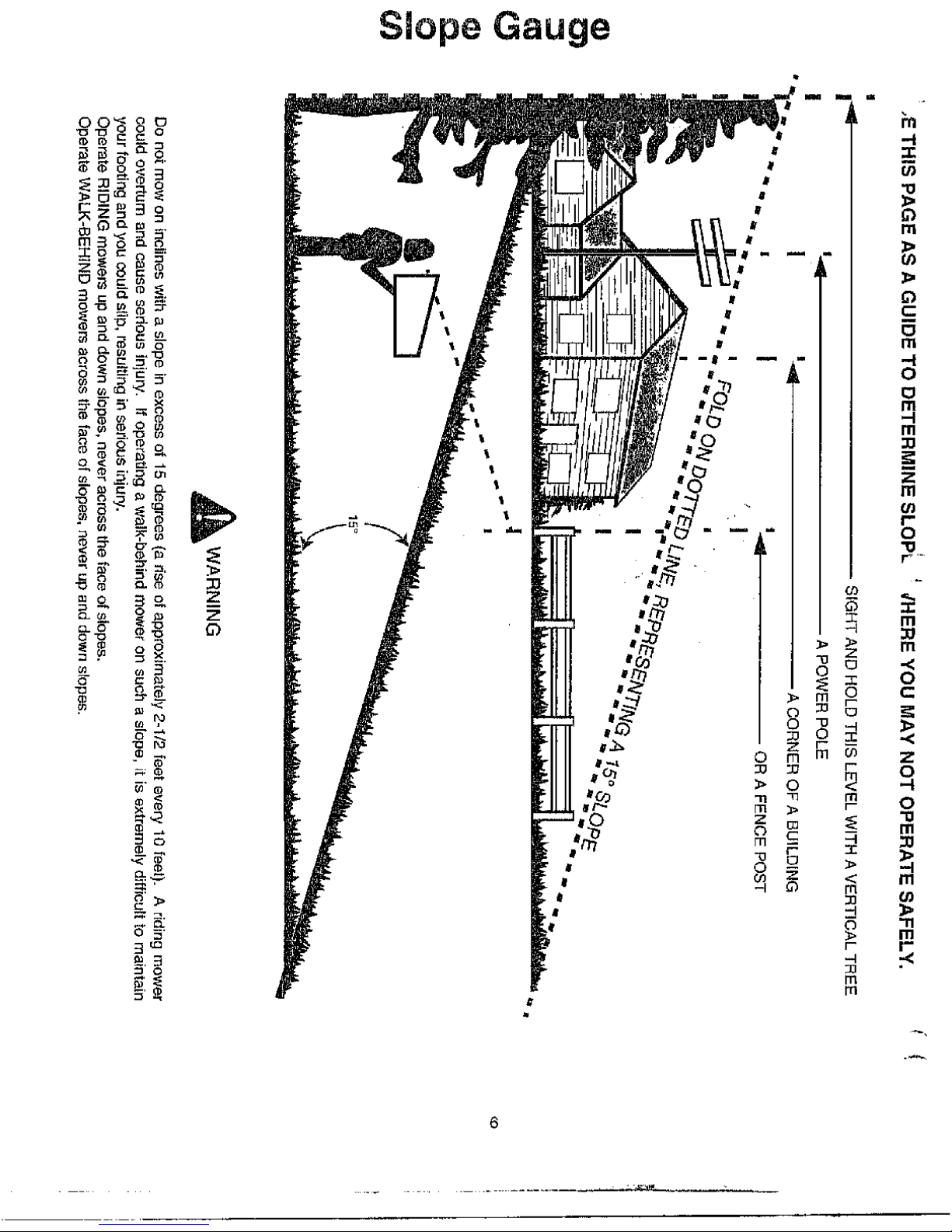

2, SLOPE OPERATION

For your safety, use the slope gauge included as pad of

this manual _e measure sJopes before oper_ing fhfs unit

on a eloped or hilly area. If the _lope is greater than 15

degrees as shown on the slabe gauge, do not operate this

ung on that area or serious inlury could result.

DO:

• Mew across the face of slopes; never uo and down.

E_ercise extreme osugen when changing direction

on slopes.

• Watch for holes, ruts, hidden objects, or bumps.

Tall grass can hide obstacles.

• A_ways be sur_ of your footing. A alip and fall can

cause serious personal injury¸ if you feel you are

losing your balance release the blade control

handle immediately and the blade will stop in less

than 3 seconds.

DO NOT:

• Do not mow near drop-offs, ditches or

embankments, The operator could [ose foogng or

balance.

• De net mow slopes greater than 15 degrees as

shown on the slope gauge.

• DO not mow on wet grass. Reduced footing could

cause slipping.

3. CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children, Children are eden aLtracted to the

mower and the mowing activity. Never assume thai

children will remain where you last _aw them,

• Keep children out of the mowmg ares and under

the watabthl care of a responsible adult other than

the operator.

• Be alert and turn mower off if a chad enters the

area,

• Before and while moving backwards, look behind

and down for small children or othe_" object _.

• Never atlow children under age14 to operate the

mower. Children 14 years of age and above

should read and understand the operation

instrucgons and safety rules in this rns.nuaL

• Use extreme care when approaching blind comets.

shrLths_ trees, or other objeOt_ that may obscure

your vision of a child or hazard,

4. SERVICE

• Use extreme care in handling gasolthe and other

feels. They are extremely flammable and the

vapors are explosive.

• Use only an 8pthoved gasoline co[ltathe_

• Never remove gas cap or add fuel while the engine

is running, Allow engine to cool at least two

minutes before refueling.

• Replace gasoline cap securely and wipe off any

spbled gasoline before starting the engine as [t may

cause a fire or explosion,

• Ext]nguiab all cigarettes, cigars, pipe8 and other

sources of ignition

• Never retoel machine indoors because flammable

vapors will ,_ccumala[e in the area,

• Never store the machine or fuel ¢o_iner inside

where there is an open flame or spark such as a.

gas water heater, space heater or furnace.

• Never run _.n engine inside & calsed ares.,

Page 5

• TO reduce life hazard, _eep mower free of grass,

leaves, or other deeds build-up. Clean up oil or fuer

spillage. Allow m_Jwer to cool at least 5 minutes

LgefQre storing.

• Before cleanirlg, repairitTg, or inspecting, make

c_rtain the blade _rld eli moving parts have

stopped. Disconnect the 3park plug wire, and keep

the wire away from the 8park plug to prevent

accidental _tartfog.

• Chock the blade and engine mounting bolt_ at

Irequent intervals for proper tlghtne._s. Also,

alsually inspect blade for damage (e.g,, bent,

cracked or worn). Replace with btade which meets

original equipment spec_ficeffons listed in this

marlua].

• Keep all nuts, bolts, and screws tight to be sure the

equipment Is In safe working condition.

• Never tamper with safety devices. Check their

proper operation regularly.

• After striking a foreign object, stop the etlglne,

remove the wire from the spark p_u_, and

thoroughly inspect _he mower for any damage.

Repair the damage before stantng and eperefing

the mow0r.

• Never attempt to make a wheel or cutting height

adiustment while the engine is runr_ing

• Grass catcher components are subject to wear,

damage arid dcterioreffon, which could expose

movirlg patts or alfow objects to be thrown. For

safety protection, frequently check components and

replace with manuf&ct[Jrer's recommended parts,

whgn necessary.

• Mower btedes are sharp and can cut. Wrap the

blade(s) or wear gfov_'s, and t_e extra cautfo_

when servicing them.

• Do not change th_ engine gawmor setting or

overs_oeq the engine. Excessive engine speeds

are dartgereus.

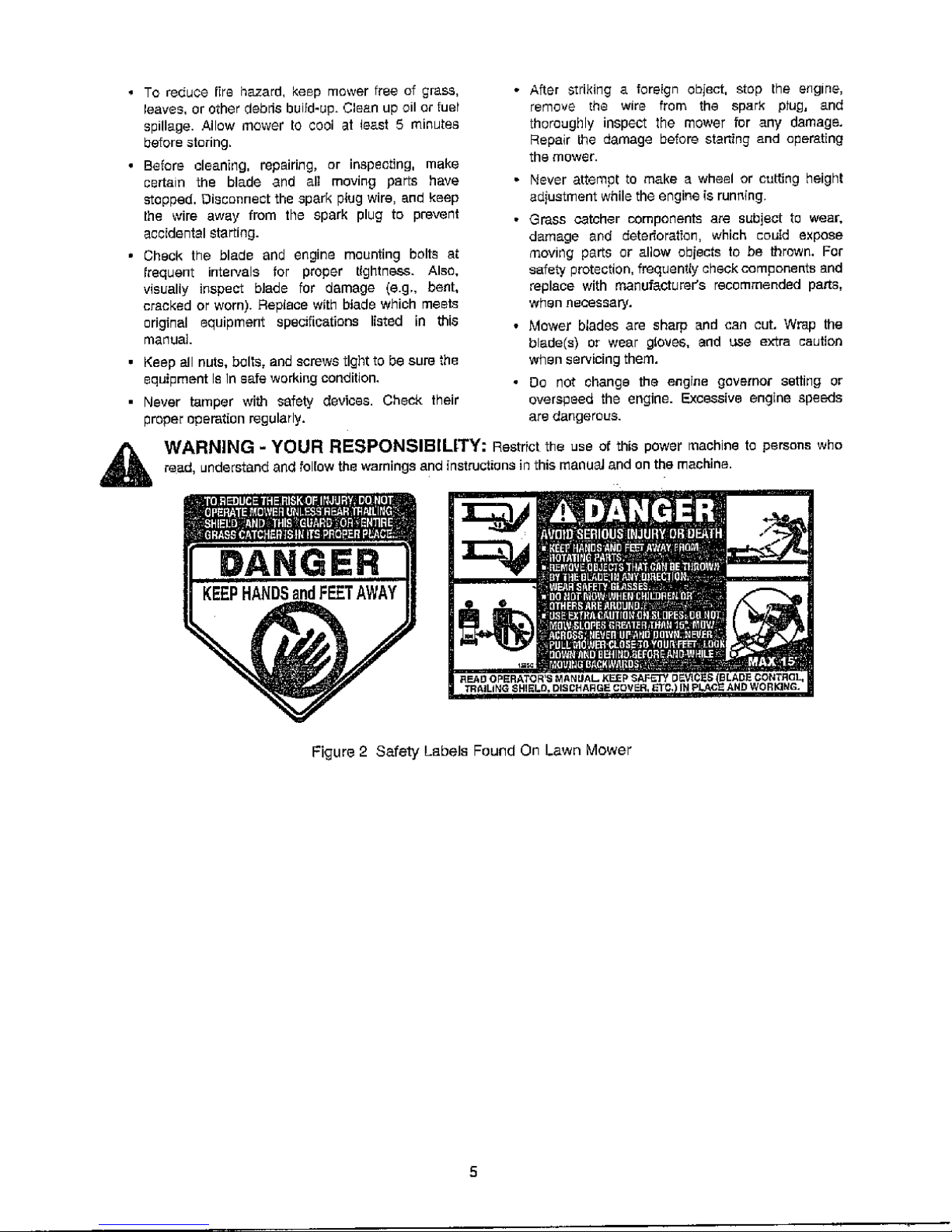

WARNING - YOUR RESPONSIBILITY: RestrFct the use of this power machine to persons who

re_d, undersandaag o owthewarnmgsaed nsructons n h'smaRu_aRdonthemachne.

DANGER

Figure 2 Safety Labels Found On Lawn Mower

Page 6

SaopeGauge

6

Page 7

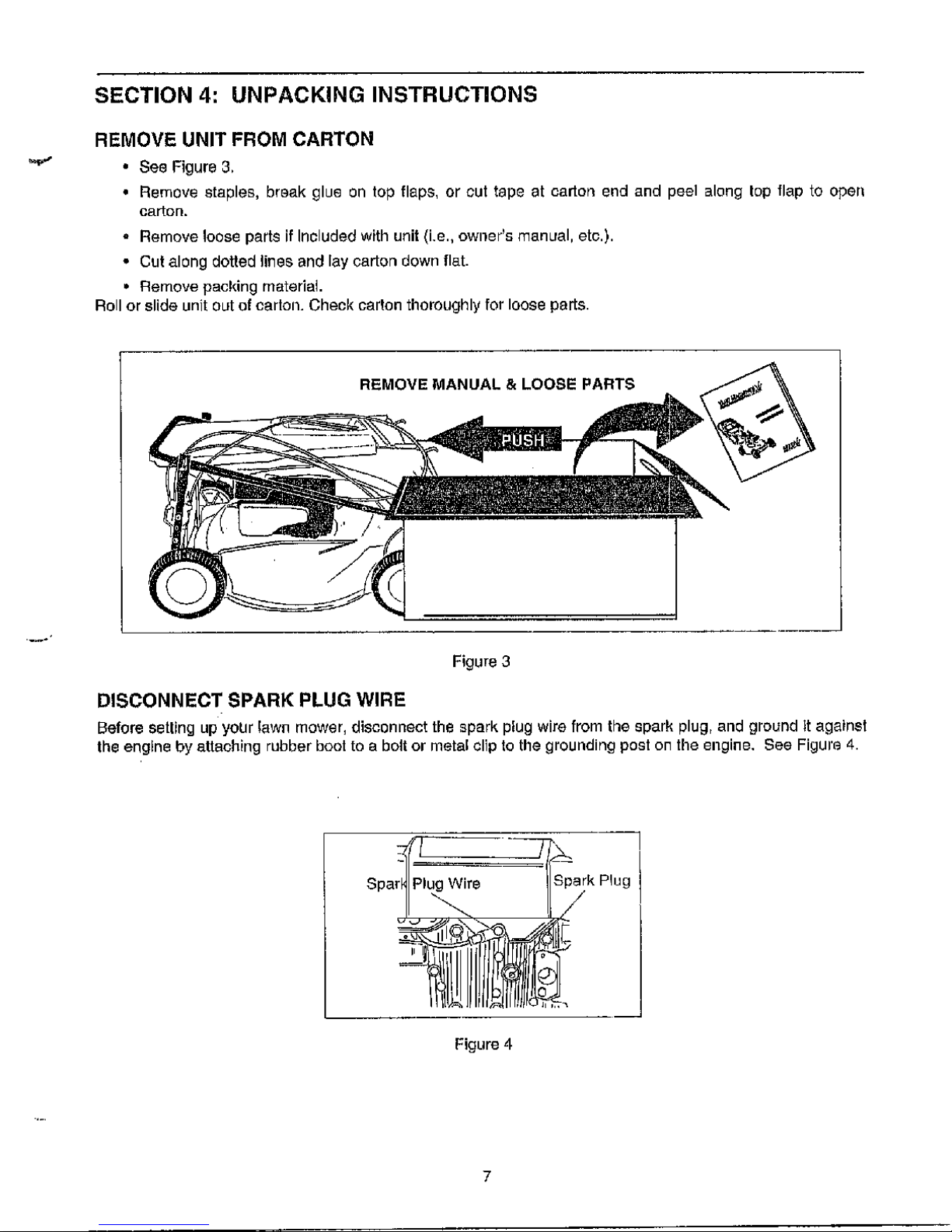

SECTION 4: UNPACKING INSTRUCTIONS

REMOVE UNIT FROM CARTON

• See Figure 3,

• Remove staples, break glue on top flaps, or cut tape at oarto_ end and peel along top flap to open

carton.

• Remove loose parts if Included with unit (i.e., owner's manual, etc.).

• Cut along dotted lines and lay carton down flat.

• Remove packing material

Roll or slide unit out of carlon. Check carton thoroughly for loose parts.

REMOVE MANUAL & LOOSE PARTS

Figure 3

DISCONNECT SPARK PLUG WIRE

Before setting up your lawn mower, disconnect the spark plug wire from the spark plug, and ground it against

the engine by attaching rubber boot to a bolt or metal clip to the grounding post on the engine, See Figure 4.

Spark Plug

Figure 4

Page 8

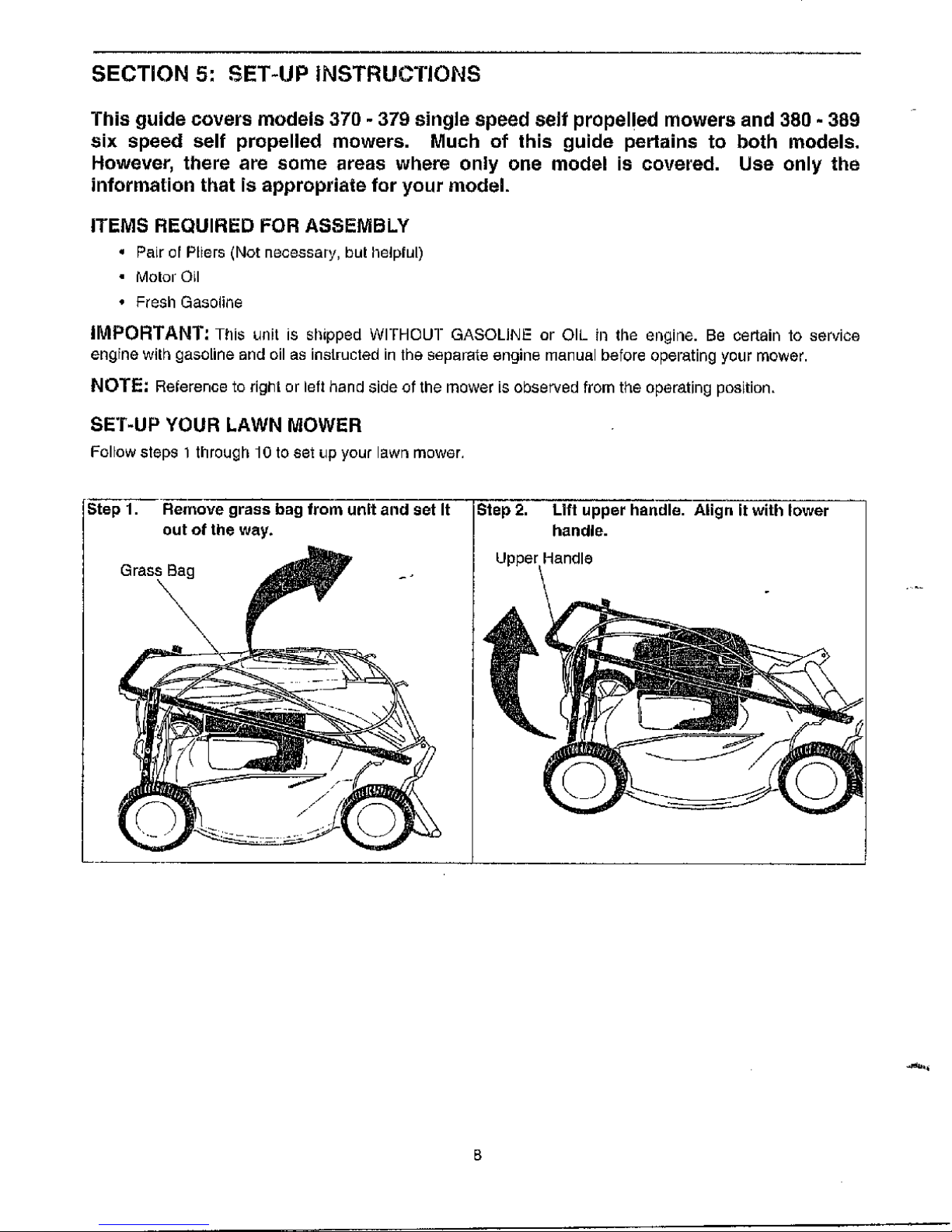

SECTION 5: SET-UP INSTRUCTIONS

This guide covers models 370 - 379 single speed self propelled mowers and 380 - 389

six speed self propelled mowers. Much of this guide pertains to both models.

However, there are some areas where only one model is covered. Use only the

information that is appropriate for your model.

ITEMS REQUIRED FOR ASSEMBLY

• PairefPliers(Notnocessary, butheipful)

• Motel Oil

• Fresh Gasoline

IMPORTANT: This unit is shipped WITHOUI GASOLINE or OIL {ll the e!_gine. Be certain to service

engine with gasoline and oil as instructed in the separate engine manual before operating your mower.

NOTE; Relerence to right or loft hand side of the mower is observed from the operating position,

SET-UP YOUR LAWN MOWER

Follow steps 1 through10 toset up your lawn mower.

S_ep_'_ Re;er_ve grass bag from unit and set It

out of the way.

Grass Bag -.

\

IStep 2, Lift upper handle. Align it with lower

I UpperC,':

Page 9

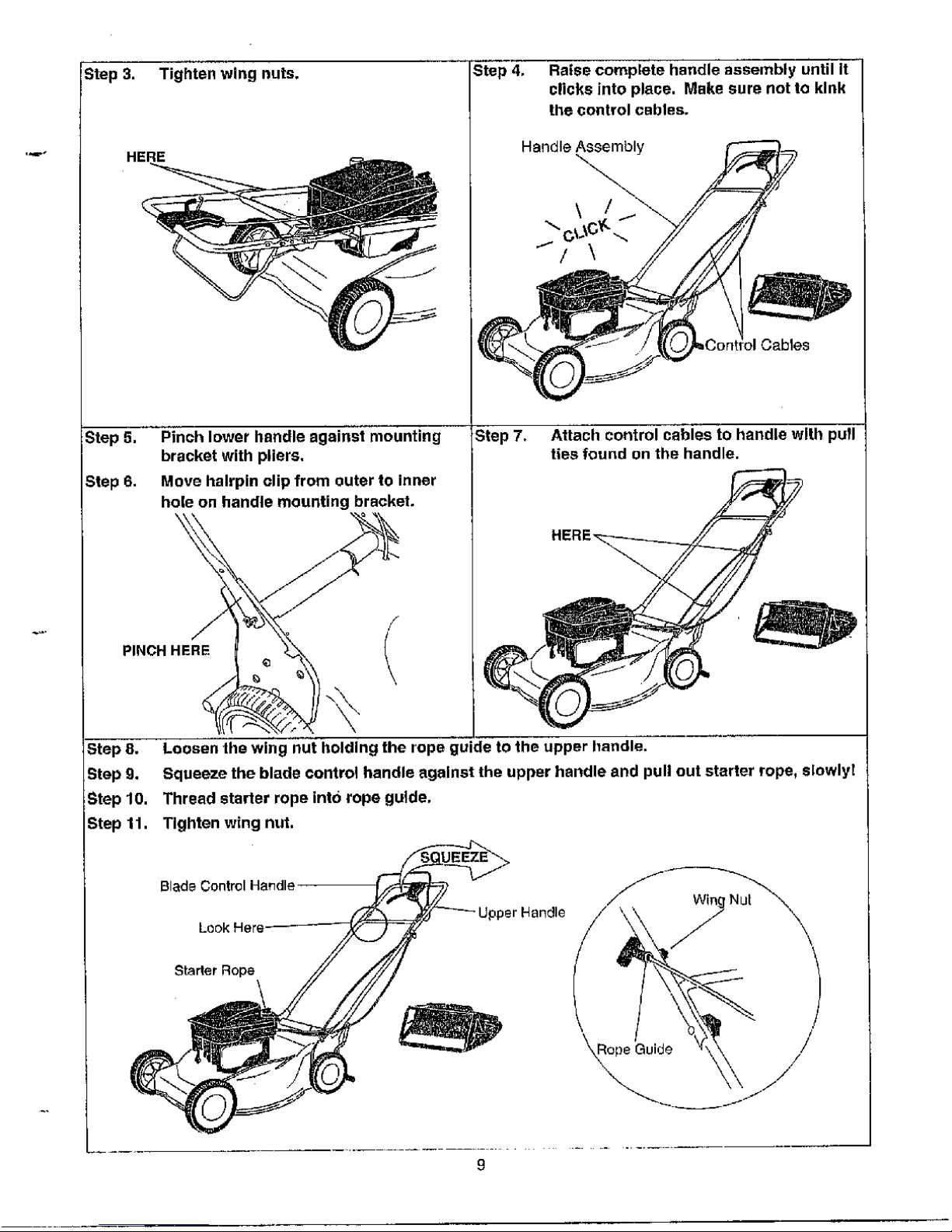

Step 3. Tighten wing nuts.

Step 5.

Step 6.

Step 4, Raise complete handle assembly until It

clicks into place. Make sure not to kink

the control cables.

Handle Assembly

Pinch lower handle against mounting

bracket with pliers,

Move hairpin clip from outer to inner

hole on handle mounting bracket.

G

PINCH ERE

Step 7, Attach control cables to handle with pull

ties found on the handle.

NE== 7

Step 8. Loosen the wing nut holding the rope guide to the upper handle.

Step g. Squeeze the blade control handle against the upper handle and pull out starter rope, slowly!

Step 10. Thread starter rope into rope guide.

Step 11. Tighten wing nut.

Blade Control Hat, die

Upper Nandle

Starter Rope

_Rope Guide /

9

Page 10

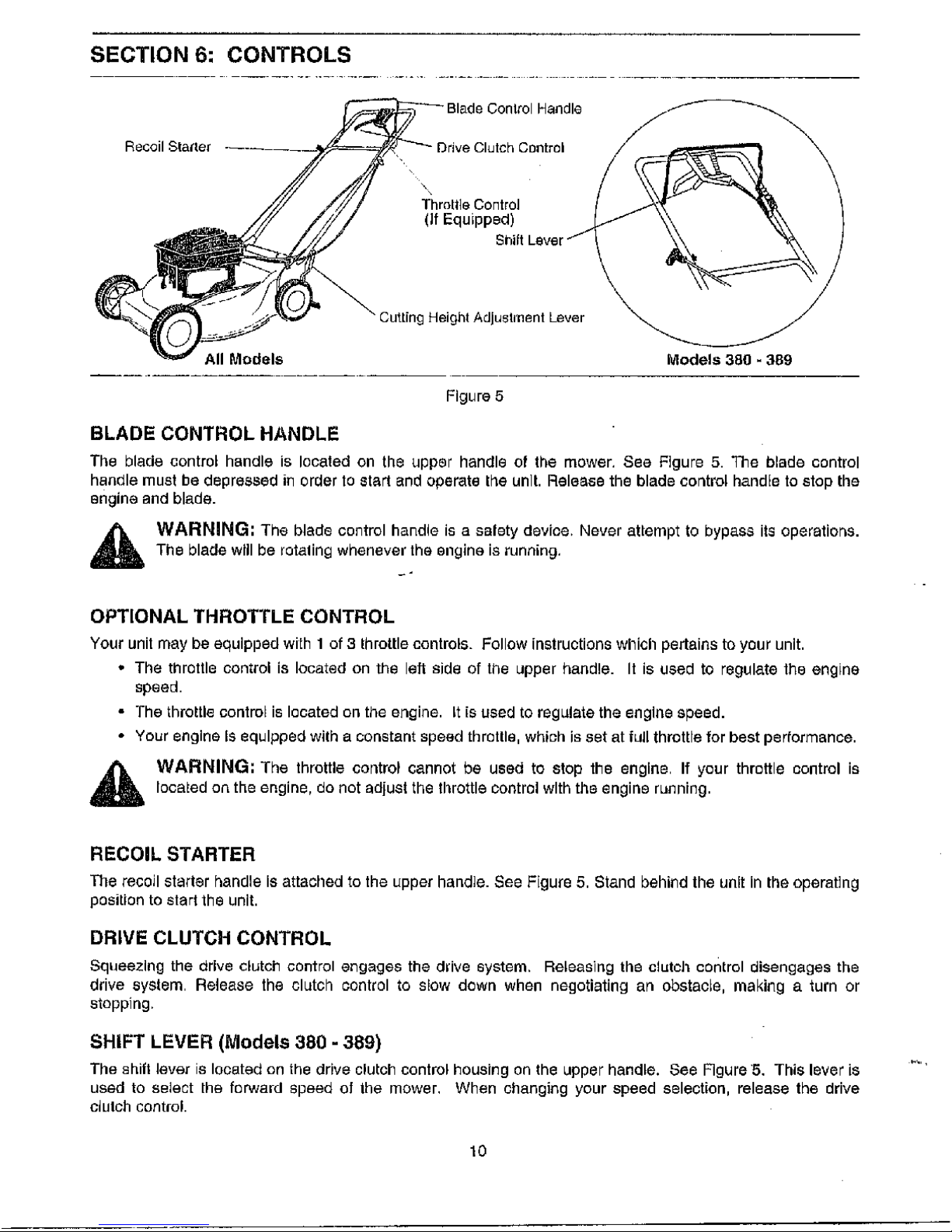

SECTION 6: CONTROLS

Blade Conlrol HaNdl+__

Recoil Starter , , _ five Clutch Control

(If Equipped) "'

Throttle Control

All Models Models 380 - 389

Figure 5

BLADECONTROLHANDLE

The blade control handle is located on the upper handle of the mower, See Figure 5. The blade control

handle must he depressed in order to 8tart _nd operate the unit. Release the blade control handle to stop the

engine and blade.

WARNING; The blade control handle is a salety device. Never attempt to byp_.ss its operations.

The blade will he rotaling whenever the engine is running,

OPTIONAL THROTTLE CONTROL

Your unit may be equipped with 1 of 3 throttle controls. Follow instructions which pertains to your unit.

• The throttle control is located on the left side of tile upper handle. It is used to regul&te the engine

speed.

• The throttle control is located on the engine, it [s used to regulate the engine speed.

• Your engine Is equipped wgh a constant speed thretlle, which is set at full throttle for best performance.

WARNING; The throttle control cannot be used to stop the engine If your throttle control is

located on the engine, do not adjust the throftle control with the engine running.

RECOIL STARTER

The recoil starter handle Is attached to the upper handle. See Figure 5. Stand behind the unit In the operating

position to start the unit.

DRIVE CLUTCH CONTROL

Squeezing the drive clutch control engages the ddve eystem. Releasing the clutch control disengages the

drive system Release the clutch control to slow down when negotiating an obstacle, making a turn or

stopping.

SHIFT LEVER (Models 380 - 389)

The shift lever is located on the drive clutch control housing an the upper handle. See Figure 5. This lever is

used to select the ferwald speed of the mower, When changing your speed selection, release the drive

clulch control.

10

Page 11

NOTE: Only move the shift lever when the engine is running. Changing the shift lever setting with the

engine off can cause damage to the mower.

CUTTING HEIGHT ADJUSTMENT LEVER

The cutting height adiustment lever is located above the left rear wheel. To adjust the culting height, pull the

lever out and away from lhe mower and then move it forward or back for a new cutting height. See Figure 6.

g Height Adjustment Lever

Figure 6

NOTE: For rough or uneven lawns, move the height adjustment lever to a higher position. This will help

stop scalping.

ENGINE CONTROLS

See the engine manual for the Iooationand funclionof the controls located on the engine.

SECTION 7: OPERATION

_lb WARNING: Keep bands and feet away from the chule area on cutting deck. The operation of

any lawn mower can result in foreign objects being thrown into the eyes, which can result in severe

eye damage. Always wear safety glasses or eye shields.

NOTE: For best results raise the cutting position until it is determined whlch height is best for your lawn. See

CUqI'FING HEIGHT ADJUSTMENT LEVER in the CONTROLS section.

GAS AND OIL FILL;UP

Service the engine with gasofine and oil as Instructed tn the separate engine manual. Read all instructions

carefully.

WARNING: Never fill fuel tank indoors, with engine running or until the engine has been allowed

to cool for at least two minutes after running.

Page 12

EACH TIME BEFORE YOU START YOUR MOWER

• Altach spad_ plug w_re [o spark plug. Make cerLein the metal cap on the end of the spark plug wire is

fastened securely over the metal tip on the spark plug.

, Check for proper drive clutch operation usin9 the NEUTRAL ADJUSTMENT TEST.

NEUTRAL ADJUSTMENT TEST

To pedorm the NEUTRAL ADJUSTMENT TEST answer the following questions.

• With the drive clutch control released, push mower iorward and pull it baekwerd. Does it move freely?

• Squeeze Ihe drive clutch control an_ pull the mower backward, Do the rear wheels lock (not turn)?

• Is the drive clutch control cable free of kinks or sharp bends?

If you answered "yes" to all three questions, your mower passed the test and you can start your mower. If

you answered "no" to any of the three questions, you need to go through the DRIVE CLUTCH CONTROL

ADJUSTMENT found in the ADJUSTMENTS section

TO START ENGINE AND ENGAGE BLADE

• Move the throttle control lever, if equipped, air the way to the last position,

* Prime engine as instructed in the separate engine manual,

• BtandbehlndtheuniL squeezeandholdthebladecontrolhandleagainsttheupperhandle,

• Grasp starter handle and pull rope out slowly unk] engine reaches start of compression cycle (rope will

pull slightly harde¢ at this point). Let the rope rewind slowly.

• Pull rope with a rapid, cominuous, {ull arm stroke, Keep a firm grip on starter handle. Return it slowly to

the rope guide.

• After engine starts, move throttle control to desired engine speed. (The mower Is designed to be

operated at full throttle)

NOTE: If any problems are encountered, refer to the TROUBLE SHOOTING 8ection of this manuel,

TO STOP ENGINE AND BLADE

• Release the blade control dandle to stop the engine and blade.

WARNING: The blade continues to rotate for a few seconds after the engine is shut off.

USING YOUR ROTARY MOWER

Be sure lhaL lawn is clear of stones, sticks, wire, or olher obiects which could damage the lawn mower er

e_gine. Su6h objects could he eccide_ltly thrown by the mower in any direction and gauss serious personal

injury to the operator and others.

For the best resugs, do not out wet grass beoause it tends to stick to the underside of the mower, preventing

proper discharge of grass clippings, and could cause you to slip and fall New grass, thiok grass or wet g_ss

may require a n_rrower cut,

For a healthier lawn, never cut og more than one-third of the total length of the graee. YoLir lawn should be cut

in the lall as long as there is growth.

This mower is designed to be operated at full Ihrotge [o give you the beet cut and do the most effective job of

mowing or mulching,

WARNING: If you stbke a foreign object, stop the engine. Remove wire from spark pIug,

thoroughly inspect the mower for any damage, end repair the damage before restarting and

operating lhe mower. Extensive vibration of the mower during operation is an indication of damage.

The unit should be promptly inspected and repaired.

12

Page 13

BAGGING GRASS CLIPPINGS

This mower can bag grass clippings. Follow steps 1 and 2 to ready the mower for bagging.

Step 1. Remove mulching plug, if installed.

Step 2, Hang grass bag on mower.

HERE

EMPTYING A FULL BAG OF GRASS

Once he grass bag is full it w II need tobe empt'ed, follow steps 3 and 4 to empty the grass bag.

Step 4.

Lift bag up and away from mower. Dump

the grass clippings.

MULCHING GRASS CLIPPINGS

This mower can also mulch grass clippings. Follow step to ready his mower fo mulch rig.

lu ching plug top and bottom v=ew.

This side up

This side down

Step 1.

Lift rear flap, remove grass bag, if

installed, and nsert mulch'ng plug,

\

/

_3

Page 14

SIDE DISCHARGING GRASS CLIPPINGS (Optional)

F -- --_ ............ _:i'_p-l__" Lift r_aarflap, remove grass bag, or

iSide Discharge Top and Left V=ew.

This side up

mulch plug if installed,. Hang side

discharge chute.

Hang

SECTION 8: ADJUSTMENTS

WARNING; Do not at any time make any adjustment to lawn mower without first stopping engine

and disconnecting spark plug wire,

HANDLE HEIGHT ADJUSTMENT

r

Lower Handle _ Notch

FIgiJre 7

Your mower is shipped with the handle in the higher height position. TO lower the har_dle height, proceed as

follows.

, Remove the starter rope from the rop_ guide.

= Remove the upper handle by removing Ihe hand knobs end carriage bolts. Lay the upper handle out of

tile way, being careful not to bend or kink the cables.

• Remove Ihe hairpin clips from the weld pins on the handle brackets. Press out on thB legs of the lower

handle Remove lower handle from the mower.

• Turn the lower handle aroL_ad so the notch on the bottom of the lower handle is facing forward as

shown in Figure 7. Reassemble, placing [he bottom holes in the handle over the weld pins in the

handle mouniing bracket,

• Reassemble the upper handle to the lower handle.

• Place the hairpin clips in the inner holes in the weld pins and attach the starter rope as instructed in the

Set Up Instructions.

14

Page 15

THROTTLE CONTROL ADJUSTMENT

(If Equipped)

On Engine

Figure 8

If the throttle control located on the left side of the upper handle requires adiLIstment or if It has been

replaced, adjust the throtge control as follows.

• Remove the screw shown in Figure 8. Remove the cable clamp from the cable.

• Push the throttle contrM lever on the handle all the way forward as far as it will go, then back it off one

"click". Make cerlain the thml_le control Iever remains in this position.

• Push the conti'ol lever on the engine as far toward the rear el the engine as it will go. Secure the cable

in this position with the oable clamp and screw.

NOTE: If the throttle control is located on the engine or if it is a constanl speed throttle, the throttle will not

need adjustment,

DRIVE CLUTCH CONTROL ADJUSTMENT

The drive clutch control adjustment wheel is located in the drive clutch control handle housing and is used to

tighten or loosen the drive belt. You will have to adjust the drive clutch contlol if any of the following happens:

• The mower does not propel itself with the drive clutch engaged

• The mower's drive wheels hesitate with Ihe drive clutch engsged.

To resolve the above problems, rotate the adjustment wheel with your fingers. Clockwise to tighten the cable

and eounler-clockwise to loosen the cable. See Figure £.

Models 370 - 379

Models 380 * 38g

® ®

Figure 9

Note: For some people the drive clLJtch handle may not be in a comfortable position. You can adjust the

handle out by tightening the adjustment wheel,

15

Page 16

SECTION 9: LUBRICATION

WARNING: Always stop engine and disconnect spark plug wire before cleaning, lubbcatlng or

doing any kind of work on the lawn mower.

Blade Control Handle

LUBI

Wheels

Engine

BEE ENGINE MANUAL

Figure 10

Blade Control: Lubricate the pivot points on the blade control handle and the brake cable at beast once a

season with light oil. See Figure 10 The blade control must operate freely In both directions.

Wheels: Lubdcate the wheel at least once a season with light oil (or engine oil), Also, if the wheels are

removed for any reason, lubricate the surface of the axle bolt and the inner surface of the wheel with Ught oil.

See Figure 10. -_

Engine: Follow engine rna_ual for lubricalion instructions,

SECTION 10: MAINTENANCE

WARNING; Be sure to disconnect and ground the spark plug wire before performing any repairs

o[ maintenance.

NOTE: When tipping the unit, empty Ihe fue! tank and keep engine, spark plug side up. Never tip the

mower more than 90 degrees and do not leave the mower tipped for any length of time. Oil can drain into the

upper pad of the engine causing a starting problem

ENGINE

Refer to the separate engine manual for all engine maintenance instructions.

• Maintain engine oil as iJqstructed in the separate engine manual packed with your unit. Read and follow

instructions carefully,

• Service air cleaner every 25 hours ullder norl'nal (3ondltlon$. Clean every few hours u_bel" extremely

dusty conditions. Poor engine performance and flooding usually indicates that the air cleaner should be

serviced. "To service the air cleaner, refer to the separate engine raanual p_cked with your unit.

• Ihe spark plug should be cleaned and the gap reset once a season. Spark plug replacement is

recommerldsd at the start of each mowlng season; check etlgine manual for correct plug type and gap

specifications.

• Clean the engine regularly with a cloth or brush. Keep the cooling system (blower housing area) clean

to permit proper air droulatlon which is essential to engine pertormanee and life. Be certain to remove

_11grass, did and combustible debds from muffler area.

16

Page 17

DECK

The underside of the mower deck should be cleaned after each use to prevent a buildup of grass clippings,

leaves, dirt or other matter. If this debds Is allowed to accumulate, it will invite rust and corrosion, and may

prevent proper mulching, dlecharge or bagging.

The deck may be cleaned by tilting the mower and scraping clear_ with a suitable tool (make certain the spark

plug wire Is drsconnected).

CUTTING BLADE REMOVAL, REPLACEMENT AND SHARPENING

Blade Adapter

Blade Bell Support

× Bolt

Figure 11

• When removing the cutting blade for sharpening or replacement, protect hands by using heavy gloves

or a rag before grabbing the blade.

• Remove the bolt and blade bell support which hold the blade and adapter to the engine crankshaft,

See Figure lt.

• Remove the blade and adapter from the crankshaft.

WARNING; Periodically inspect the blade adapter for cracks, especially if you strike a foreign

object. Replace when necessary.

When sharpening the blade, follow the original angle of gdnd as a guide, g is extremely important that each

curling edge receives an equal amoul}t of gdnding to prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration when rotating at high speeds. It may cause damage to the mower, and It could

break causing personal injury,

The blade can be tested by balancing it on e round shaft screwdriver. Remove metal from the heavy side until

it balances evenly, It is recommended that the blade always be removed from the adapter for the when

testing for balance.

Before reinstalling the blade and the blade adapter to the unit, lubricate the engine crankshaft and the inner

sudace of the blade adapter with light oil.

• Be sure to install the blade with the side of the blade marked "Bottom" (or with part number) facing the

ground when the mower is in the operating position.

• Slide blade adapter onto engine crankshaft

• Place blade on adapter. Becertalnthebladeisalignedwithandseatedonththebladeadapterflanges.

• Place blade bell support or_blade. Make sure the notches on the blade bell support are aligned with the

small here in the blade,

• Replace hex bolt.

• Tighten hex bolt to thrque: 450 in. Ibs. rain., 600 in. Ibs. max.

NOTE: To ensure safe operation of your unit, the blade bolt must be checked pedodical]y for correct torque.

TROUBLE SHOOTING

Refer to the trouble shooting section of this manual for helpful inlormagon.

17

Page 18

SHIFT LEVER CABLE ADJUSTMENT (Models 380 - 389 Only)

Periodic adjustment of the six speod shilt cable may be required due to normal wear on the cable.

Adjustment is needed il all six speeds do not work

The adjustable cable bracket is located on the left side of the mower, beside the engine. Follow steps 1

through 7 to adjust the shift lever.

Step 1, Start engine.

Step 2. Place speed control in the sixth speed position.

Step 3. Stop engine.

Step 4, Disconnect the spark plug wire and ground it.

_Speed Control Lever

Step 5, Loosen hex nut (A) which secures the adjustable cable bracket,

Step 6, Push back on the adjustable cable bracket.

Step 7. Tighten hex nut (A),

Adjustable Cable Bracket

Hex Nut (A)_

18

Page 19

DRIVE BELT REMOVAL AND REPLACEMENT (Model 370 Series)

If you need to replace a worn or broken drive belt, follow steps1 through22.

Step 1,

Step 2,

Step 3.

Step 4.

Disconnect the spark plug and ground it.

Drain the fuel tank. '

Remove rear hub caps and wheels.

Remove eight phillips head screws,

(Behind Wheel

/7

_tep 5,

gtep 6.

Step 7.

Step 8.

Step g.

Blade _"

Tip mower back on its handle and block

securely.

Remove blade and blade adapter.

Remove three hex head screws holding

smag baffle.

Remove small baffle,

Remove large baffle,

Small

Large Baffle

Hex Head Screw

Step 10. Loosen hex lock nut holding Fdler bearing.

Step 11. Push back and rotate belt keeper.

Step 12, Remove and replace belt.

Step 13. Replace belt Imeper to Its original

position. Tighten the hex lock nut.

Belt Keeper

Hex Lock Nut

Mower shown !ipped on engine for clari!y,

Remember, only bp mower back on ds handle wdh

the spark plug facing up. Othet_vlse, oil will spill il

turned upside down.

19

Page 20

Step 14. Replace large baffle.

Step 15. Replace small baffle and three hex head

screws holding It in place.

Step 16. Replace blade adapter and blade. See the

Blade Removal, Sharpening and

Replacement Section for proper

assembly.

Small

Bla_e AdapLe_

Large Safge

Step 17. Replace the eight phillips head screws

that hold the large baffle in place,

Step iS, Replace the rear wheels, rear wheel gears

and hub caps. The gears need to be put

on In the right way for the self propelled

mechanism to work. Check the

Installation of the gear by spinning the

wheel, It should spin freely in one

direction but not the other. If the wheel

spins freely in both directions, flip the

gear over.

Step 19. Tip mower back onto its wheels

Step 20. Go through the neutral adjustment test in

Section 7 - Operation,

2O

Page 21

DRIVE BELT REMOVAL AND REPLACEMENT (Model 380 Series)

you r_aedOreplacea worn orbrokendrive belt,followsteps 1though30.

Step 1. Disconnect the spark plug and ground it.

Step g, Drain the fuel tank,

Step 3, Remove rear hub caps and wheels.

Step 4. Remove eight phillips head screws.

Step 5. Tip mower back on its handle end block

securely.

Step 6. Remove blade and blade adapter.

Step 7. Remove three hex head screws holding

small baffle.

Step g, Remove small baffle.

Step g. Remove large baffle.

Small

Large Baffle

(Behind W _ " _"

8

_p 10. Loosen hex lock nut holding idler bearin

Step 11. Using a pair of pliers, pull back and

belt keeper bracket from the slot on idler

pulley.

Step 12, Slide the belt out from between the Belt

Keeper Bracket and the idler pulley.

Transmissiofl

Pulley

Belt_

Bracket

Idler Pulle_

Bracket

Idler Pulley

Bolt and /

Locknut

21

Page 22

Step 13. squeeze the 5elt togeiliei a_d-push belt ..... St_,p 1g--Pivot tb_control arm down away from the

fon_vard Press the control arm inward towards

the deck and remove the six speed cable from

the slot

Six-Speed

Cable Slot Belt

COlltroJ

Step 14, Place the new belt over the Iransmission

pullBy. Start the belt in pulley groove and rotate

pulley until belt is seated in transmission puiley.

Step 15. Place beg between Idler pulley and the belt

keeper bracket.

Step 16, Using pliers, rotate the belt keeper bracket

so that it snaps into slut eL7the idler bracket.

Step 17. Tighten the Idler pulley bolt and Ioeknut

using two 7/16" wrenches.

Transmlss{on

Pulley

Belt_

Beg Keeper

Bracket

Idler Pulle_,

Bracket

Transmission

Bert =

Locknut

pulley and belt,

Control

Arm

Step 19. Lift off the lower pulley assembly and

remove the old belt from around the crankshaft.

Lower Pultey

e o

• Crankshaft

Step 20, Place belt between the two pulley halves on

the crankshaft, Make sure to route the belt

inside the belt guard pin.

O o

Upper

Pulley_

Hatf

Tab_.._

Belt

Belt

Pulley

Pin Half

IMPORTANT: When changing the belt, do not disassemble

the lower pulley assembly.

22

Page 23

Step 21. Pinch belt together so that it is not in the

pulley groove, and the lower pulley can be

pushed towards the engine.

Lower Pulley

Ha]f 0 0

_ _ _ Guard

_'_" Pin

Step 24. Replace[arge baffle.

Step 25. Replace small baffle and three hex head

screws holding d in place.

Step 26. Replace blade adapter and blade. See

the Blade Removal, Sharpening and

Replacement Section for proper

assembly.

Small affle

S.

Hex H

Step 22. Pivol the control arm back to its original

position and reilqstal! the six-speed cable into the

slot.

Step 23. Check and make sure the bal_ is routed

inside the pulley halves alld the belt guard pin.

Step 27.

Step 28.

Step 2g.

Step 30.

Replace the eight phillips head screws

that hold the large baffle in place.

Replace the rear wheels, rear wheel

gears and hub caps. The gears need to

be put on in the right way for the self

propelled mechanism to work. Check

the Installation of the gear by spinning

the wheel. It should spin freely in one

direction but not the other. If the wheel

spins freely In both directions, flip the

gear over.

Tip mower back onto its wheels

Go through the neutral adjustment test

in Section 7 - OPERATION.

23

Page 24

SECTION 11: OFF-SEASON STORAGE

The following steps should be taken to prepare lawn mower ='orstorage.

• Clean and lubricate mower thoroughly as described in the lubrlcagon ir_structlons.

• Refel to engine manual lot correct engifl@ storage instructions.

* Coat mower's cutting blade with chassis grease to prevent rusting.

• Store mower in a dl_/, clean area Do nol store next to corrosive materials, such as fertilizer,

NOTE; When storing any type of power equipment in 811 poorly ventltated or metal storage shed, care

should be taken to rust-proof the equipment. Using a light oil or silicone, eo_,t the equipment, especially

cables and all moving pat_s.

SECTION 12: TROUBLE SHOOTING GUIDE

Trouble

Engine fails to stag

Engine runs er_sfls

Possible Cause(s}

Blade control handle disengaged.

Spark plug wire disconnectod.

I'brottle control level not in correct

_aritng position

:uel tanl_ empty, or stale fuel.

Blocked fuel line.

=_ulty spark plug.

=ngine itooded

Jnit running in START position.

_park plug wire loOSe.

Sleeked fuel line or stale fuel

_'entin gas cap plugged¸

Nater or dirLin fuel system.

Sir_ air cleaner,

_rburetor out of adju_lmenb

:ngine oil level low.

kit itow rectrlcted.

=_,arburefor no1 adjusted properly¸

¸Spark plug gap too close.

Spark plug fouled, taugy or gap too

wide.

Carburetor improperly adjusted¸

Dirty air cleane_.

Cutting blade loose or unbalanced.

Bent cutting blade.

Engine speed toe low

Wet grass.

Excessively high grass.

Engine overheats

Occasional skip (hesitates) at

high speed

Idles poorly

Excessive vibration

Mower will not mulch grass

Unevenest

Dull blade

Wheels i oi positioned correctly.

Du!l blade.

Corrective Action

Engage blade control handle.

Connect wire to spark plug,

Move lhrotUe lever to FAST or START posi-

lion

Fill tank with clean, fresh gasoline.

Clean fuel line.

Clean, adjust gap er replace.

Crank engine with throttle in FAST position.

Move throttle lever fo FAST positron.

Connect and tighten spark plug wire.

Clean fuel line; fill tank with clean, fresh

gasoline.

Clear vent.

Drain fuel tank Refill with fresh fuel

Ctean air cleaner.

Adjust cerburetoc

Fill crankcase wilh proper oil.

Remove blower heusLng and dean.

Adjust oarburetoc

Adjust gap _o .O3O".

Reset gap to .o3g" or replace spark plug.

Adjust carburetor.

Clean air cleaner.

Tighton blade and adapter. Balance blade.

Replace blade.

Set throttle between 3/4 and full throttle.

De not mow when grass is wet; wait until

later to cut

Mow once at a high cutting height, then

mow again at desired height or make a nat-

rower cutting swa_h (1/2 width).

Shaq_en or replace blade.

P_ace all four wheels in same beight posi-

tion.

Sbarpen or replace blade.

Refer to separale ellgi_e manual packed with your mower for more ergkle related information,

NOTE: For repairs beyond the minor adjustments listed above, contact your nearest authorized service

dealer or call 1-800-800-7310 for the Customer Suppor_ Center.

24

Page 25

Models 370 thru 389

Front Axle Assembly & Height Adjuster

REF,

NO. PART NO,

1 611-0060

2 710-1348

3 714-0104

4 732-0820

5 747-0920A

6 736-0!00

7 738-0102

6 __jr=

0 t

DESCRIPTION

Axle Ass'y, Prt.

ASPan Sc_ 1/4-14x 50 Lg,

Cotter Pin ,072 x 1,12 L0,

Ext. Spdn 0

Adj. Rod ___

Bpr, Washer

ShL Bolt .498 × 1.445 3/8-16

WheelAss" - Complete

g_-Y ..........

See Wheel and Hub Cap Chart on Page 26

10

_5

15

18

27

RE_

NO. PARTNO,

! 712_3626

2 7S0_0420

6 756 0656

4 736_36B4

S 712_0sg0

0 762-7066

7 741_0666

S 706-1656

9 6S2_0027A

16 716_626g

11 732_0B4gA

12 _41-6662A

13 235_652B

14 721_B32g

tS 018_BSS3

16 763_6_16

1_ 717_1_

16 _6-6_14

1_ _S-0_66

2g 616_6_62

_1 _10_6g4_

_ 76_-_661_

_ _41_6_

2_ 611_6_1

65 _1-6_6

_5 _17_400

g_ _tl-llg_

_6 _367_

_g _S_0_60

_ _60 _5g5

61 _4_2_

3_ _36_36_

_S _5_g3

DESCRIPTION

Hx. Jam Nut 5/16-24

Bell Wash, .325 x .030 x 045

Pulley

FI. Wash..510x 1.120 x 060

H×. Jam Nut 114-28

Belt Keeper

Bearing

Flange Spacer

Idler Bracket Ass'y

H×. Cap Scr. 1/4-28 x 1.00 Gr. 5

Torsion Spring

Bearing Sleeve

FI. Wash..885 x 1,145 _.030

Oil Seal

Upper Housing Ass'y.

Pl. Wash..604 × .700 × .030

Pinion Shaft 10 T.

Thr. Wash, 3/8 x ,7g x 030

Thr. Wash. 388 x ,625 × .062

Lower Housing Ass'y.

H×, Scr. 1/2 20 x 75

Cable Bracket

Beadn 0

Shah Ass'y.

Plug

Gear 34 T.

Output Shaft 6 T.

Flange Bearing

Oi! Seal

PivotBracket

Flange Bearing

Wash. FI..508 LD x 1,OOO,D. × .020

Thrust Bearing

61@ 0263A, . T[an_{llj_ssi2r!Cemp[gle ..........

29

Page 26

Models 370 thru 379

121

\

\

/

126

114

Size

t OPTIONAL HUB CAPS

Description Part No.

Black (4-1/4" Dia.) 731-0354

Gray 14-1/4" Dia.} 731-0355A

Gray (5-1/2" Dia,) 731-0961A

Yellow (5-1/2" Dia.) 731_1426

26

Page 27

Models 370 thru 379

REF. REF.

NO. PART NO, DESCRIPTION NO. PART NO, DESCRIPTION

647=0804 Control Handle Ass'y IDelLIxe)

2 731=1630 Bagle

3 710-0600 Oval C-Sunk Math - Screw'

4 796-0501 spring Washer .66" ID

5 720-0279 Handle Knob 1/4-28 Thd,

6 646-0675 Throttle Body*

7 712-0324 Hex L-Nul !/4-20

6 746-04390 Upper Handle

9 746-0876 Throttle Lever*

12 746-0843 Throttle Control Wire - 06"*

746-0846 Thr uttle Control Wire * 47"*

746-0641 Throttle Control Wire * 60"*

13 710-1205 Rope Guide

14 732-0700 Wire-4T' L9.

15 720-0276 Hand Knob

16 746-(3555 Control Cable-65"

746-(3551 Control Cable°43"

17 726-0240 Cable _e

18 718-1174 Cr.HB Bolt0/16*18x2_Lg.

19 746-6907A Lower Handle

20 611-00165 Thretfe Ams'y Comp IIn¢l 3,4,6,7,9) +

21 710-1237 He× Self-Tap Scr. 810-38 X .69"*

710-0871 Hex SBms S_r. 810-92 x ,3" Lg. *

22 735-0639 Spark Plug Beet

83 7516213146 Cable Clamp CB&S)*

7510007776 Cable Clamp (TSCI*

24 710-1220 Screw H.L. 12-24

26 710-0351 Screw Mech. B Tapp.

27 Engine

28 731-1714A Be!t Cover

35 714-0104 Int, Golfer Pitt 5/15': DIe.

37 747-0922 Pivot Rod

38 750-1065 6pacBr .365 I.D.

39 732-06(39 Torsion Spring LH,

44 782-3839 Handle Srkt. A_s'y - LI4

45 710-0653 Screw, Tap 1/4-20

47 712-0400 U-Nut

46 702-9030 Handle Brkt. Ass'y - R.H

49 710-1348 Screw AB 1/4-20

52 718-0664A Hex L-Wash. Hd. Scr. 8/8-16 x 1"

53 682-0037 21" Oeck ASB'y W/O MTS Icon

602-0075 21" Deck Ass'y W! MTG Icon

66 731-1236 Rear Flap 17.77 Lg.

67 782-7599S Rear Chute Door

68 762-9050 Srkt, I_11g, Grassbag - Slack

89 731-0068 Hdlop Bag Cover

781-6066 Hdlop Bag Cover w/Icon

691-0077 Hdlop Bag Cover w/F!e Pnd

631-0076 Hdlop Bag Cover w/Flo Ind / Icon

61 747-0919 Catcher Frame

60 664-0080 Grass Bag - Black

664-0079 Grassbag- SoIt top w/MTO Logo

72 786-0624A Brade Sell Support

73 742-0741 21" Muichfng Blade w/Star

742-0641 21" Std Blade W/Star

74 753-0608 Blade Adaptor Kll w/Star

79 710-1287 Nex Bolt 8/8.24 x 2 5 Lg

76 748-0358 Spacer

77 736-0514 FL Wash. 986 x 189 x 06

70 736-05! 3 Spr. Wash¸ 890 x :7x 04

" Optional

88

61

62

63

84

65

86

87

86

89

gO

91

02

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

10B

108

110

111

112

116

114

115

116

!17

118

119

120

121

122

123

124

125

186

128

129

130

131

132

136

134

135

+36

_37

lgB

750-0979

tt

638-0005

682-7518

682-7524

710 0604

710-0663

710-0751

710-1652

710-1315

711 0835

713 0421

714-0474

720-0230

732 0803A

732-0818

736-0270

736 0369

788 0529

741-0624

741-0522

74%0978

748-0318

17_0-0807

] 750-1056

i 750-1075

782-0566A

i 762-0568

746 0713

731 1059

731-1057

731-1058

721-0620

710 1667

718 0414

16865

749-01866

748-0391

738-0137A

10622B

t

731-168_

731-1461

747-0968

7f2-0324

710-0624

720-0294

754-0271

782-7018

710-1026

738 0329

736-3020

712 0287

631-0060

731 1644

731-1798

710-1270

748-0883

7i0-1663

Pulley Half - Lower

Wheel Assembly

Axle Assy: RR

Axle Assy: Trans,

Cover Ass'y - Chain

Scr, FT 5118-16

Scr, TT 1/4-20

Hx Cap Screw 114-20

Nex Washer Screw 1/4 20 x ,625

Scrg/B-18x125

Pin - Cir. ,500 Dia,x.4 62 Lg

Chain:Endless 48:.500P x 22 Lg.

Pin-Cotter ,125 0.[3. x .76

Grip-Foam

Spring Lever

Torsfon Spring

Bell W_sher ,285 x 75 x .062

Wash.Flat .5081.13. x 1.00 D.: 020

Nut- Shoulder ,825 x ,165 Lg.

Bear[ng-FI 9 Flex

Searing FPg, Hex

Be_dng Sleeve

Ratchet Wheel

Spaoer - .385 × ,685 x .700

Spacer Shld..385 ID,x ,715 Lg,

Speeer 8Iv..520 LD, x 368 Lg.

Pivot Arm

Spdng Bracket

SR Cable 525"

Mounling Cap

Centre[ Cover - Upper

COlltro_ Cove[ - Lower

Lever

Screw 8!0-16 x .625

Weld ]bp L. 1/4-20

Pawl Plate

Pawl L H (Not Shown

Pawl R,H,

Shldr. Scr..340x 285

Spring, Ratchel

Hub Cap

Mulch Plug

Chute Deflector

Chute Mour_tlng Rod

Flex-L-Nut 1/4-20 Ihd.

Maeh, Scr. !/4-20

Foam Grip (Optional)

Bett

Pulley Cever

Scr Tll/4-20:1.750 Hx IndWash

Leckwasher 1/4 _ Reg,

Ff. Wash, .271 x .830 x ,065

Nut 1/4 20

FEe Indiealor Ass'y

Fro Indlcalor Bait

Fro Ii]dicator Housing

Sor. 1/4-20:1 31 Lg.

H_using (w/o Throgle)

Hex Washer 6clew 1/4-20 x .625

27

Page 28

Models 380 thru 389

36

/

131

114

B1

28

Page 29

Models 380 thru 389

REF.

NO.

2

3

4

5

6

7

8

9

12

13

f4

15

16

17

16

19

20

21

22

23

24

25

27

28

83

30

31

32

33

35

37

38

39

40

41

42

43

44

45

46

47

48

49

PARTNO.

647-0004

731-1639

710-0805

736-0501

720-0279

648-0875

712-0384

749-0439B

746-0876

746-0876

746-0848

746-0841

710-f208

732-0700

720-0276

746-0554

746-0555

746-0581

726-0240

710-1174

749-0907A

811-00185

710-1237

710-0671

735-0839

7818213146

7810007775

710-_280

710-0351

781-1714A

710-0167

710-0396

712-0287

736-0270

736-0329

714-0104

747-0922

780-1068

732-0809

756-0625

788-7574

782-7575

856-0618

782-9029

710-0683

711 1114

71g-B400

788.3030

710 1348

REF.

DESCRIPTION NO.

Control Handle Ass'y CStdl 50

Contror Handle Ass'y {Deluxe) 81

Saffle 82

Ova! C-Sunk Mach- Screw* 53

Spring Washer •66= ID"

Handle Knob 1/4-20 Thd, 66

Throttle Body* 57

Hex L-Nut 1/4-20 58

Upper HandTe 59

Throttle Lever*

Throttle Control Wire-55""

', Throttle Control Wlre-4T'*

ThreSfe Control Wire-60"* 61

Rope Guide 62

Wlre-47"bg.

Hand Knob 72

Control Cable-40.5" 73

Control Cable-55' 74

Control Cable-43" 75

Cable Tie 76

Curved Hd. Bolt 5/16-18×2" Lg. 77

Lower Handle 78

Throttle Ass'y Coop (Inel 3,4,6,7,9)* 79

Hex Self-Tap Scr. 010 32 x 62" Lg. 81

(B&S)* 82

Hex Seres Scr. 010-32 × ,3" Lg. 83

(Tee.)* 84

Spark P_ug Boot 88

Cable Clamp {B&S)* 86

Cable Clamp (Tee.)* 87

Screw H.L. 12-24 86

Screw Math. B lapp. 89

Engine 98

Belt Cover gl

Son 1/4-20:.50 Lg. 92

8or,;AB 1/4-20:.626 Lg. 93

Hex Nut: 1/4-20 94

Bel! Wash..265 x .75 x .082 95

Lock Wash. 1/4 96

Int Cotter Pin 5/15" Oi_. 87

Pivot Rod 98

Shoulder Spacer 99

Torsion Spring L FI 100

Roller Cable 101

6 Sp, Cable Adj Bracket 102

8 Sp Cable Mtg. Bracket 103

Pulley Assembly 104

Handle Brkb Ass'y - L.H 105

Screw, Tap I/4-20 108

Pivot Shall 107

U-Nut 108

Handle Brkt Ass'y- B.H 109

Screw AS 1/4-20 110

• OplionsI

PART NO.

732-0807

736-0586

710-0654A

682-0037

683-0075

731-1236

782-7599A

782-9050

731-0068

731-0066

731-6077

731-0078

747 0919

664-0080

864-0079

Y36-O524A

742-0741

753-0609

?104257

750 1070

750-1071

782-7596

789-7897

fl

638 0005

682-7618

682-7824

710-0604

710-0653

710-0751

710-0896

7!0_1315

711-0835

719-0421

714-0474

720-0230

732-0803A

732-0818

736-0270

736-0669

738-0528

741-0324

741.0522

741 0978

748-0318

750-0807

780-1066

790-1075

788 0566A

782-0568

731-0904

731-0924

7!3-0397

DESCRIPTION

Tore/on Spring

Wv.Wash.1 38 O.D. x .88 LDT.Ogg

H×LWashHd $er. 3/816,1 Lg.

21" Deck Ass'y w/rcon

21' Deck Ass'y w/o Icon

Rear Brap 1777 Lg.

Sea/Ohule Door

Brkt Mtg, GrassbaB - Black

Hd_op Bag Cover

Hd_op Bag Cover w/F,_TD Logo

Hdtop Bag Cover w/BID Ind.

Hdtop Bag Cover w/FIo Ind. / Logo,

Catcher Frame

Grass Bag- Black

Gra_sbag- 8o0 top w/LOgo

Blade Bell Supper!

21" MuPchlng Blade w/Star

Blade Adaptor Nil w/SLar

Flex Bolt 9/8-24 _ 2 6 [d

Spacer - Sleeve

Spacer - Sleeve

6 Sp Conlrot Arm

6 Sp PivolBracket

Wheel Assembly

Axle Ass'y: RR

A×le Ass'y: Trans,

Cover Ass'y - Chain

Son IT 5/16-18

Scr. TT 1/4-20

Hx Cap Screw 1/4-20

Scr. AB 1/4-20

Scr 3/8-16 x 1.2_

Pin - CIv .500 Oia. x 4.82 L0.

Chain: Endless 4&.SBOP x 22L

Pin-Cotter H25 O.D, x .75

Grip Foam

Spring Lever

Torah Sp#n 6

Bell Washer,265 x 75 x 062

Wash-FI 808 ID. × ! 00D. xO20

Nut - Shoulder 828 x H65Lg,

Bearing-Fig Hex

Beadng-FIg Sex

Bearing-Sleeve

Rather Wheel

Spacer. •385 x ,886 x 760

Spacer-Shoulder 385LD _ 715L6.

Spacer Sleeve •520 I.D x .980 Lg

Pivot Arm

Sprfng Bracket

Upper Control Housing

8 Speed Shift Lever

Gear Inset!

29

Page 30

REF. 1171 REF.

NO. PART NO_ DESCRIPTION NO. PART NO.

111 1g-0841 C-SunkTapScr _!0x.75 Lg, g6 73 0905

112 732-gg27 Shilt Lever Sprirlg 127 731-0906

113 16864

114 712-0414

115 16855

_16 748-0381

748-01888

117 738-0137A

118 106228

119 f

12D 731-1885

121 731-1461

122 74710958

123 712-0324

124 i 7104)924

6 Sp Rack Cable Bracket

WBId Top [. 1/4-20

Pawl Plate

Paw_ R.H,

Pawi L.H. (Not Shown)

Shldt Scr. ,340 x •285

Spgng, Rather

Hub Cap

Mulch Plug

Chute Deflector

Chute Mounting Rod

Hex-L-Nul 1/4-20 thd.

Mach. Scr. 1/4-20

128

129

130

131

132

183

134

135

136

137

138

139

140

I 746-0711A

751-062g

746-0939

754-0271

782-7018

712-0138

738-0924

631-0060

731-1844

73%1738

710-1352

746-0g83

710q270

DESCRIPTION

Cow_ _c,_tToIHousing

Cable Mounting Cap

S.E Cable

Control Lever

6 Speed Cable - 53" Lg.

Bell

PulLey Cover

Nut 1/4-28

Sh, Sot 114-28:,375 Lg.

FIg Indlc_t or Ass'y

Fig Indicator Ball

FEeIndicator Housing

Hex Washe[ Screw 1/4-20 x ,gg5

Housing (w/o Throtlle)

Screw 1/4-20 x 20

1.25 __720-0294 Foam Grip (Optional)

,r@,

30

Page 31

Shroud Chart

Pad NO. Part No. Er_<kC°t°r Part No, i_rP_we Part No. Color

751B281499 Dark Red 731-1395A Red 731-1587A Black 731-1061 SIack

751B28!440 _lack 731 1396A 731-1603A Yellow

751B201443 Bright Red 731-1397A !Gray 701-1610A

____ i 731-1620A =Gray ...............

HardwBre: Hardware: Hardware: Hardware;

710-1256........ Screw , i'!0-1250 (Screw) ,710 1184 (Sere_w)....... 75!0042823...... (Screw)

jJ

731-1492A Yellow H0143208 3lack 731-1585B B]ack 701-1580B 3lack

731-1694 Black ;1-1612A _ed

731-1695 Silver

731 1934 Charcoal

Hardware: ...... Hard.rare: I-iardware: Hardware:

710-1258 Screw 7510942923 (Screw) 710-1274 (Screw) 7510042823 (Screw) ......

751B281ZL51 Gray 751B281470 Black 7511681311 Black

751B281777 IYellow 7511681911 Red

7511682611 Gray

Hardware:710-1206 Hardware:710-1237 Hardware: - - ,Hardware:

31

Page 32

MANUFACTURER'S LIMITED WARRANTY FOR:

ffAR#MACHINES

For TWO YEARS from the date of retail purchase

withil7 the United States of America, its possessions

and territories, MTD PRODUCTS INC will, al its

option, repab or replace, for the original purchaser,

free of charge, any purl er parts found to be

defective in material or workmanship. This wartan[y

covers units which have been operated and

maintained In accordance with the operating

instructions furnished with the unit, and which bare

not bead subject to misuse, abuse, commercial use,

neglect, accident, improper maintenance or

alteration

Normal wear parts or components tlqereof are

subject to separate terms as noted below in the ':No

Fault Ninety Day Consumer Warranty" cJause,

All rlormal wear part failures will be covered on this

product for a period of 90 days regardless of cause

After 90 days, but within tbe two year period, normal

wear parts failures will be covered ONLY IF caused

by defects in material or workmanship of OTHER

component parts. Normal wear parts are defined as

batteries*, belts, blades, blade adapters, grass bags,

rider deck wheels, seats, snow thrower skid shoes,

shave plates and tires

How to obtain service: Warranty service is

available, with proof of purchase, through your local

authorized service deale_. To locate the dealer in

your area, please check the yellow pages or contact

the Customer Service Depadmenl of MTD

PRODUCTS INC, P. O, Box 388022, Cleveland,

Ohio 44136-9722 Phone 1 (800) 800 7310 The

return of a complete unit will not be accepted by the

factory unless pnor written permission has been

extended by the Customer Service Department of

MTD PRODUCTS INC,

Transporter{on char£1es; Transportation charges

for the movemenl of any power equipment unit or

attachment are the responsibility of the purchaser.

Units exported out of the United States; MTD

PRODUCTS INC does not extend any warranty for

products sold or exported outside of the United

States of America, its possessions and territories,

except those sold through MTD PRODUCTS ]NC's

authorized channels of export distribution,

Other Warranties:

1, Tbe engine or component parts thereof carry

8eps.rate warranties from tbeir manLftacturef8

Please refer to the applicable manufacturer's

warranty on these items.

2. *Batteries are covered by a 90-day replacement

ws.rranty,

3. Log splitter pumps, valve£ and cylinders or

component part8 thereof are covered by a one

year warranty.

4. All ether warranties, express or implied,

including any implied warranty of merchantability

or Illness for 8, particular purpose, are hereby

expressly disclaimed in their emirety.

5. The provisions as sel forth in this warranty

provide the sole and exclusive remedy of MTD

PRODUC-FS INC's obligations arising from the

sales of its products. MTD PRODUCTS INC will

not be liable for incidental or consequential loss

or damage.

How state law relates to this warranty; This

limited warranty gives you specific legal rights, and

you may also bare other rights which vary from state

to state. Certain disclaimers are not allowed in some

states and therefore they may not apply to you

under all c#cumstances

NOTE: This warranty does not cover routine

maintenance items such as lubricants, filters, blade

sharpening and tune-ups, or adjustments such as

brake adjustments , clutch adjustments or deck

adjustments. Nor does this warranty cover normal

detedoratien of the exterior finish due to Lisa or

exposure.

Loading...

Loading...