MTD Yard Machines 316E610E000, Yard Machines 316E640F000, Yard Machines 316E660G000 Owner's Manual

Page 1

OWNER'S

AMERICAN _ AMERICAN

M A D E 0 WNED

OUTDOOR POWER EQUIPMENT

24", 26" and 28"

SNOW

THROWERS

Model Numbers

316E610E000

316E640F000

316E660G000

MTD PRODUCTS INC • P.O. BOX 368022 • CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 770-8782L

Page 2

IMPORTANT

SAFEOPERATIONPRACTICES

_:_ HIS SYMBOLPOINTSOUTIMPORTANTSAFETYIIJSTRUCTIONSWHICH, IF NOT FOLLOWED,COULDENDANGERTHE PERSONAL A_

SAFETYAND/OR PROPERTYOF YOURSELFAND )THERS. READAND FOLLOWALL INSTRUCTIONS IN THIS MANUAL BEFORE

ATTEMPTINGTOOPERATEYOUR SNOWTHROWEF.FAILURETO COMPLYWITH THESEINSTRUCTIONSMAYRESULTIN PERSON-

AL INJURY. WHENYOU SEETHIS SYMBOL-- _'_ -IEEDITSWARNING.

I _ Yoursnowthrower was Luilt to be operatedaccordingto the rules lor safe operationin this manual. As

DANGER: with anytype of poweret uipment, carelessnessorerror on the part of the operator can result in serious

injury. If youviolate any (f theserules, you may causeserious injuryto yourselfor others.

TRAINING

1. Readthis owner's guide carefully in its entirety befo

ing to assemble or operate this machine. Becompl,

iar with the controls and the proper use of this mac!

operating it. Keep this manual in a safe place for

regular referenceandfor ordering replacement parts

2.. Never allow children under 14 years old to oper_

thrower. Children 14 years old and over should o_

snow thrower under close parental supervision. Or

well acquainted with these rules of safe operation

allowed to useyour snow thrower.

3. Noone should operate this unit while intoxicated o_

ing medication that impairs the senses or reactions.

4. Keepthearea of operation clear of all persons, espe

children and pets.

5. Exercisecaution to avoid slipping or falling, espec

operating in reverse.

,_ PREPARATION

1. Thoroughly inspect the areawhere the equipment is

and remove all door mats, sleds, boards, wires an(

eign objects.

2. Disengage all clutches and shift into neutral befo

engine.

3. Do not operate equipment without wearing adeqt

outer garments. Do not wear jewelry, long scar1

loose clothing which could become entangled in mc

Wear footwear which will improvefooting on slipper

4. Before working with gasoline, extinguish all cigz

other sources of ignition. Check the fuel before s

engine. Gasolineis an extremely flammable fuel. Do

gasoline tank indoors, while the engine is runnir

engine has been allowed to cool at least two minut_

gasoline cap securely and wipe off any spilled gasc

starting the engine as it may causeafire or explosio

5. Use a grounded three wire plug-in for all units w

drive motors or electric starting motors.

6. Adjust collector housing height to clear gravel or cr

surface.

7. Neverattempt to makeany adjustments while engin_

(exceptwhere specifically recommendedby manufacl

8. Let engine and machine adjust to outdoor tempera

starting to clear snow.

9. Always wear safety glasses or eye shields during o

while performing an adjustment or repair, to protec!

foreign objects that may be thrown from the macl

direction.

_bb OPERATION

1. Do not put hands or feet near or under rotating r

clearof discharge opening and auger atall times.

2. Exercise extreme caution when operating on or cros

drives, walks, or roads. Stay alert for hidden hazard

Do not carry passengers.

3. After striking a foreign object, stop the engine, rc

from spark plug, and thoroughly inspect the snow

any damage. Repair the damage before restarting

ing the snow thrower.

4. Ifthe snow thrower should start to vibrateabnormal

engine and check immediately for the cause. Vibral

erally a warning of trouble.

e attempt-

_telyfamil-

_inebefore

future and

te a snow

_lyoperate

ly persons

should be

while tak-

_iallysmall

ially when

to beused

otherfor-

"e starting

ate winter

s or other

ring parts.

/ surfaces.

rettes and

tarting the

not fill the

g, or until

s. Replace

line before

1.

th electric

Jshedrock

is running

_rer).

:urebefore

)eration or

eyesfrom

_inein any

arts. Keep

singgravel

; or traffic.

move wire

hrowerfor

nd operat-

y, stop the

ion is gen-

5. Stop enginewhenever you leavethe operating position, before

unclogging the collector/impeller housing or discharge guide,

and making any repairs, adjustments, or inspections. Never

place your hand in the discharge or collector openings. Use a

stick or wooden broom handle to unclog the discharge open-

ing.

6. Take all possible precautions when leavingthe unit unattended.

Disengage the collector/impeller, shift into neutral, stop the

engine, and removethe key.

7. When cleaning, repairing, or inspecting, make certain collec-

tor/impeller and all moving parts have stopped. Disconnect

spark plugwire and keepaway from plug to prevent accidental

starting.

8. Do not run engine indoors, except when starting engine and

transporting snow thrower in or out of building. Open doors.

Exhaustfumes are dangerous.

9. Do not clear snow across the face of slopes. Exerciseextreme

caution when changing direction on slopes. Do not attempt to

clear steepslopes.

10. Never operate snow thrower without guards, plates, or other

safety protection devices in place.

11. Never operate snow thrower near glass enclosure, automo-

biles, window wells, drop off, etc., without proper adjustments

of snow thrower discharge angle. Keepchildren and petsaway.

12. Do not overload machine capacity by attempting to clear snow

at too fast a rate.

13. Never operate the machine at high transport speeds on slip-

perysurfaces. Look behind and usecarewhen backing.

14. Never direct discharge at bystanders or allow anyone in front

of unit.

15. Disengage power to collector/impeller when transporting or

not in use.

16. Use only attachments and accessoriesapproved bythe manu-

facturer of snow thrower (such as wheel weights, counter

weights, cabs, etc.).

17. Never operatethe snow thrower without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles. Walk, never run.

18. Muffler and engine become hot and can cause a burn. Do not

touch.

MAINTENANCEANDSTORAGE

1. Check shear bolts, engine mounting bolts, etc., at frequent

intervalsfor propertightnessto be sure equipment is in safe

working condition.

2. Never store the machine with fuel in the fuel tank inside a

building where ignition sources are present,such as hot water

andspaceheaters, clothes dryers, and the like.Allow engine to

coolbefore storing inany enclosure.

3. Always refer to owner's guide instructionsfor importantdetails

if snow throweristo bestored foran extendedperiod.

4. Run machine a few minutes after throwing snow to prevent

freeze up of collector/impeller.

5. Check clutch controls periodicallyto verify they engage and

disengage properlyand readjust if necessary.Referto owner's

guide for adjustment instructions.

Page 3

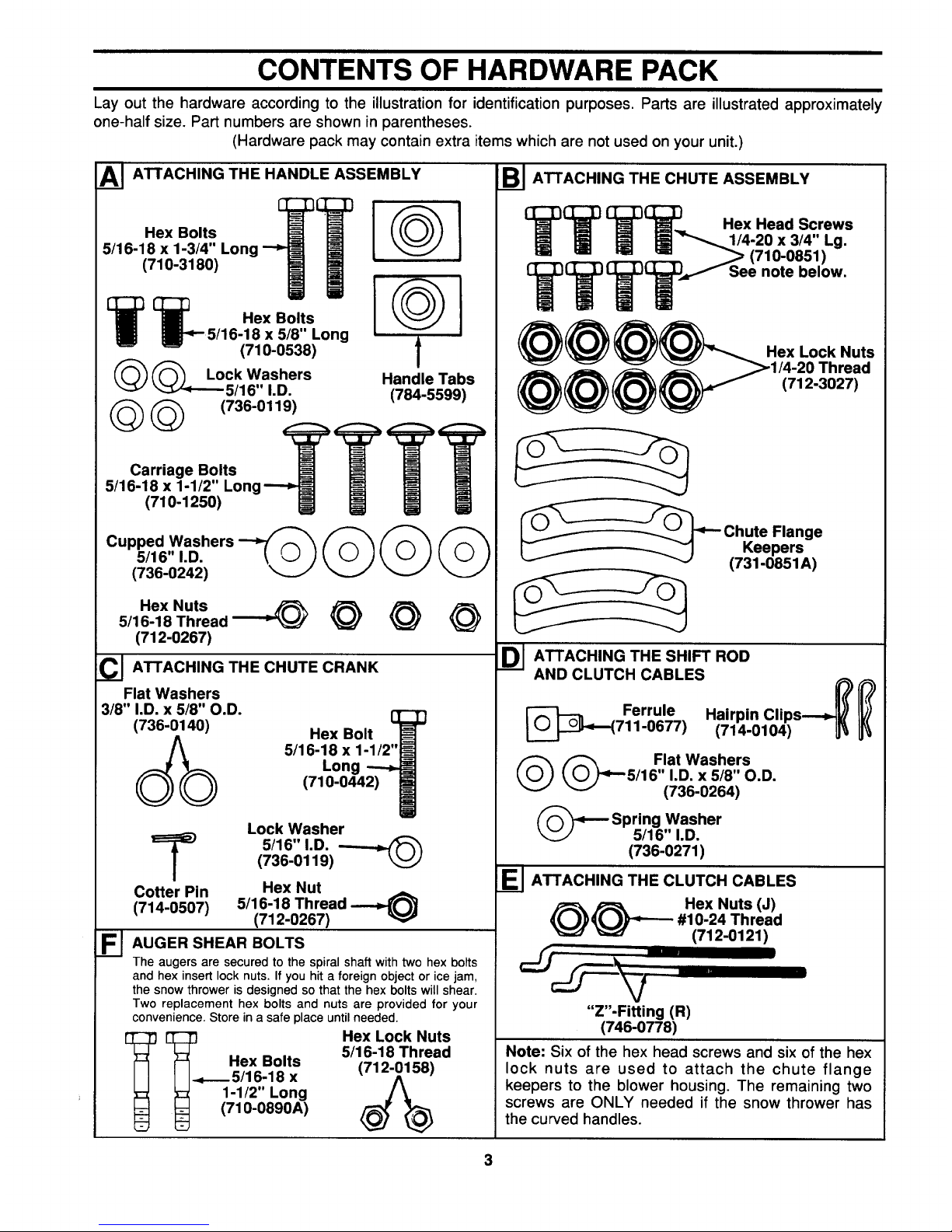

CONTENTS OF HARDWARE PACK

Lay out the hardware according to the illustration for identification purposes. Parts are illustrated approximately

one-half size. Part numbers are shown in parentheses.

(Hardware pack may contain extra items which are not used on your unit.)

AI ATTACHING THE HANDLE ASSEMBLY

Hex Bolts

5/16-18 x 1-3/4" Long

(710-3180)

@

1_{_ Hex Bolts

5/16-18 x 5/8" Long

(710-0538) t

(_(_ Lock Washers Handle Tabs

"--_!,J"_'-- 5/16" 1.D. (784-5599)

(_(_ (736-0119)

Carriage Bolts _TTT

5/16-18 x 1-1/2" Long

(710-1250)

Cupped Washers

5/16" I.D.

(736-0242)

©©

Hex Nuts

5/16-18 Thread _"_ _

(712-0267)

CI ATTACHING THE CHUTE CRANK

Flat Washers

3/8" I.D. x 5/8" O.D.

(736-0140)

&

Hex Bolt

5/16-18 x 1-1/2"

Long

(710-0442)

Lock Washer

T 5/16",.o.

(736-0119)

Cotter Pin Hex Nut

5/16-18 Thread

(714-0507)

(712-0267)

FI AUGER SHEAR BOLTS

The augers are secured to the spiral shaft with two hex bolts

and hex insert lock nuts. If you hit a foreign object or ice jam,

the snow thrower is designed so that the hex bolts will shear.

Two replacement hex bolts and nuts are provided for your

convenience. Store in a safe place until needed.

Hex Lock N(_ts

[3_ 5/16-18 Thread

Hex Bolts

I I-._.--5/16-18 x

1-1/2" Long

_ (710-0890A)

Sl ATTACHING THE CHUTE ASSEMBLY

(_ _C]_[} Hex Head Screws

[_] I_"_"-..,,, 1/4-20 x 3/4" Lg.

_,.,.__,.,_ _ (710-0851)

TT,_,/'f See note below.

@@ Hex Lock Nuts

(712-3027)

Chute Flange

Keepers

(731-0851 A)

DI ATTACHING THE SHIFT ROD

AND CLUTCH CABLES

[_}_i_( Ferrule Hairpin Clips-_) __)

711-0677) (714-0104) IJ_

_(_ Flat Washers

5/16" I.D. x 5/8" O.D.

(736-0264)

Spring Washer

5/16" I.D.

(736-0271)

_ ATTACHING THE CLUTCH CABLES

_)_ Hex Nuts (J)

#10-24 Thread

(712-0121)

"Z"-FitUng (R)

(746-0778)

Note: Six of the hex head screws and six of the hex

lock nuts are used to attach the chute flange

keepers to the blower housing. The remaining two

screws are ONLY needed if the snow thrower has

the curved handles.

3

Page 4

I I

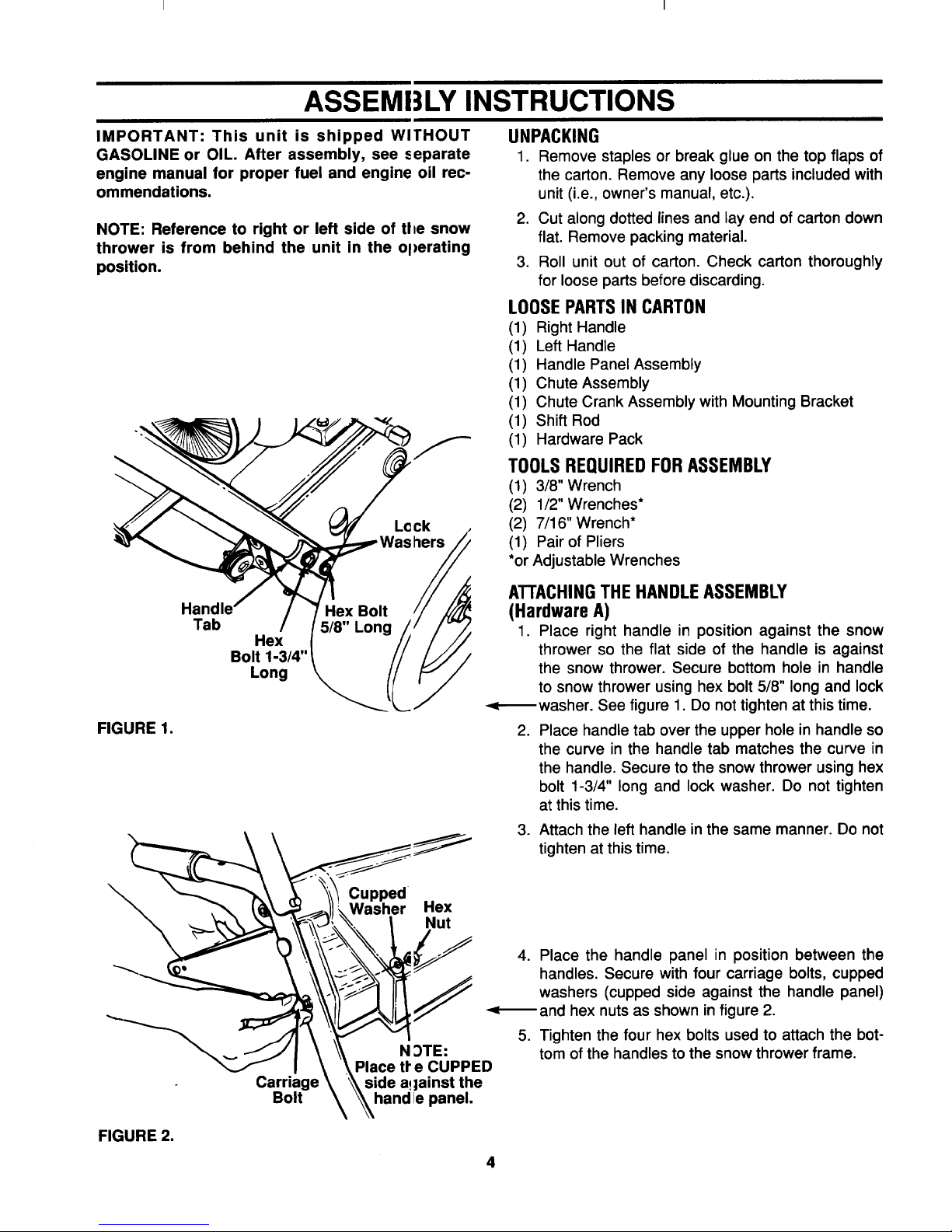

ASSEMi3LY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, see separate

engine manual for proper fuel and engine oil rec-

ommendations.

NOTE: Reference to right or left side of tl_e snow

thrower is from behind the unit in the ol)erating

position.

Hex Bolt

Tab 5/8" Long

Hex

Bolt 1-3/4"

Long

L©ck

/

FIGURE 1.

UNPACKING

1. Remove staples or break glue on the top flaps of

the carton. Remove any loose parts included with

unit (i.e., owner's manual, etc.).

2. Cut along dotted lines and lay end of carton down

flat. Remove packing material.

3. Roll unit out of carton. Check carton thoroughly

for loose parts before discarding.

LOOSEPARTSIN CARTON

(1) Right Handle

(1) Left Handle

(1) Handle Panel Assembly

(1) Chute Assembly

(1) Chute Crank Assembly with Mounting Bracket

(1) Shift Rod

(1) Hardware Pack

TOOLS REQUIRED FOR ASSEMBLY

(1) 3/8" Wrench

(2) 1/2" Wrenches*

(2) 7/16" Wrench*

(1) Pair of Pliers

*or Adjustable Wrenches

ATTACHINGTHE HANDLEASSEMBLY

(HardwareA)

1. Place right handle in position against the snow

thrower so the flat side of the handle is against

the snow thrower. Secure bottom hole in handle

to snow thrower using hex bolt 5/8" long and lock

-<--_washer. See figure 1. Do not tighten at this time.

2. Place handle tab over the upper hole in handle so

the curve in the handle tab matches the curve in

the handle. Secure to the snow thrower using hex

bolt 1-3/4" long and lock washer. Do not tighten

at this time.

.

Attach the left handle in the same manner. Do not

tighten at this time.

FIGURE 2.

Carriage

Bolt

Cupped

Washer Hex

Nut

N _TE:

Place tPe CUPPED

side a!|ainst the

hand lepanel.

4. Place the handle panel in position between the

handles. Secure with four carriage bolts, cupped

washers (cupped side against the handle panel)

-<_and hex nuts as shown in figure 2.

5. Tighten the four hex bolts used to attach the bot-

tom of the handles to the snow thrower frame.

4

Page 5

FIGURE3.

ChuteAssembly

HexHead

Screw

FlatWasher

HexLockNut

Chute

Flange

Keeper

Lock Washer

Hex Nut

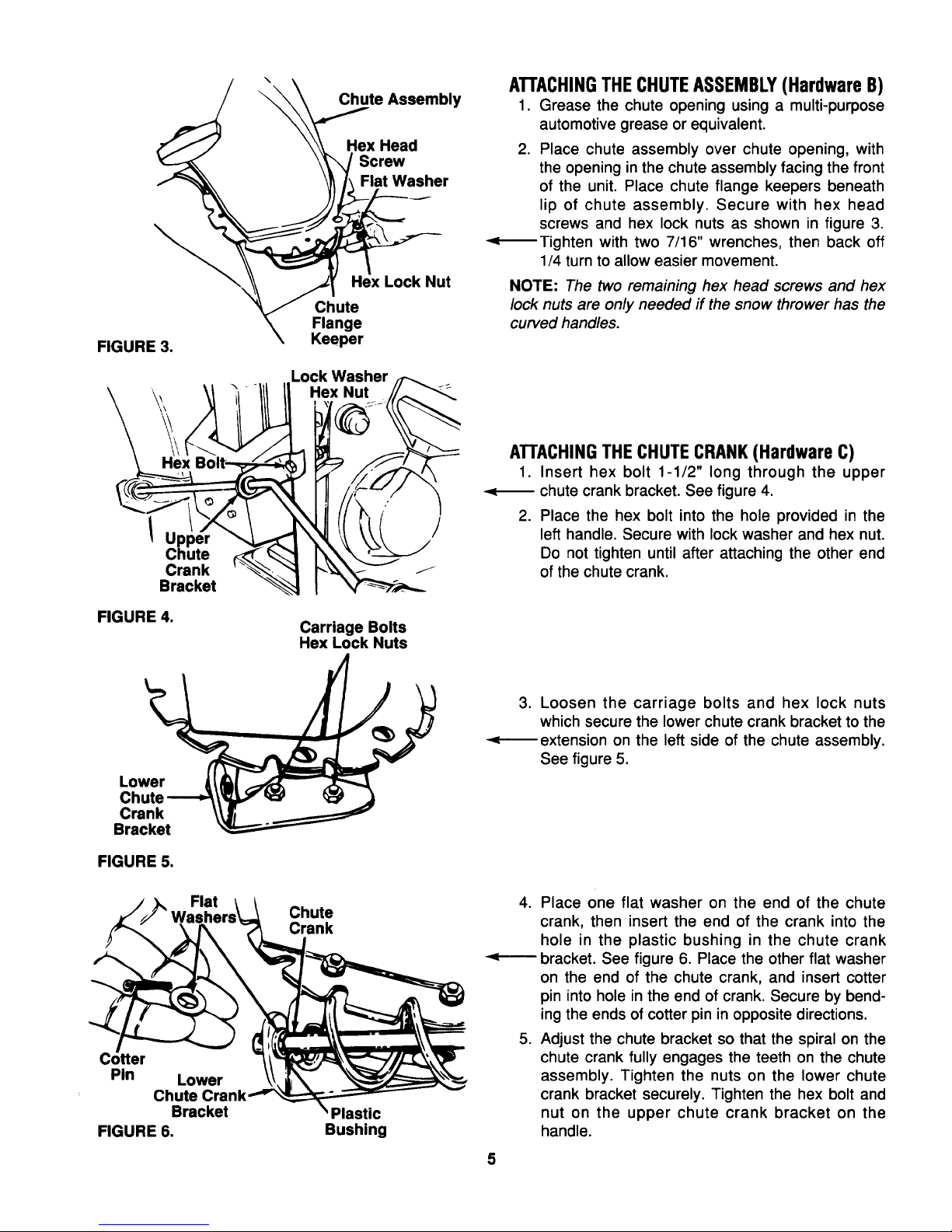

ATTACHINGTHECHUTEASSEMBLY(HardwareB)

1. Grease the chute opening using a multi-purpose

automotive grease or equivalent.

2. Place chute assembly over chute opening, with

the opening in the chute assembly facing the front

of the unit. Place chute flange keepers beneath

lip of chute assembly. Secure with hex head

screws and hex lock nuts as shown in figure 3.

-<_Tighten with two 7/16" wrenches, then back off

1/4 turn to allow easier movement.

NOTE: The two remaining hex head screws and hex

lock nuts are only needed if the snow thrower has the

curved handles.

Hex

Upl

Chute

Crank

Bracket

FIGURE 4.

Carriage Bolts

Hex Lock Nuts

ATTACHINGTHECHUTECRANK(HardwareC)

1. Insert hex bolt 1-1/2" long through the upper

-<_ chute crank bracket. See figure 4.

2. Place the hex bolt into the hole provided in the

left handle. Secure with lock washer and hex nut.

Do not tighten until after attaching the other end

of the chute crank.

Lower

Crank

Bracket

FIGURE 5.

3. Loosen the carriage bolts and hex lock nuts

which secure the lower chute crank bracket to the

extension on the left side of the chute assembly.

See figure 5.

Flat

Cotter

Pin Lower

Chute Cra

Bracket

FIGURE 6.

Chute

Crank

'Plastic

Bushing

4. Place one flat washer on the end of the chute

crank, then insert the end of the crank into the

hole in the plastic bushing in the chute crank

-<----- bracket. See figure 6. Place the other flat washer

on the end of the chute crank, and insert cotter

pin into hole in the end of crank. Secure by bend-

ing the ends of cotter pin in opposite directions.

5. Adjust the chute bracket so that the spiral on the

chute crank fully engages the teeth on the chute

assembly. Tighten the nuts on the lower chute

crank bracket securely. Tighten the hex bolt and

nut on the upper chute crank bracket on the

handle.

5

Page 6

E I

IMPORTANT: Attach the shift rod and chltch cables as follows. THEN CHECK THE ADJUSTMENTS AS

INSTRUCTED, AND MAKE ANY FINAL ADJUSTMENTS NECESSARY BEFORE OPERATING YOUR

SNOW THROWER. Failure to follow the ivtstructions may cause damage to the snow thrower.

Hairp,n

Clip !

FIGURE 7.

Traction

Shift

Lever

Spring

Washer

it Washer

om

Hole

ATTACHINGTHE SHIFT ROD (Hardware D)

1. Insert the ferrule through the lower hole in the

shift lever (beneath the handle panel) from the left

side. Secure with flat washer and hairpin clip. See

figure 7.

Place the shift lever in the sixth (6) speed position

(all the way forward).

3. Start threading the shift rod into the ferrule. Push

down on the shift arm assembly as far as it will

go. Thread shift rod into the ferrule until the end

of the shift rod lines up with the hole in the shift

arm assembly. Secure with spring washer, flat

washer and hairpin clip.

Make certain to check for correct adjustment of the

shift rod as instructed in the Final Adjustment section

before operating the snow thrower.

ATTACHINGTHE CLUTCH CABLES

The "Z" end of the clutch cables are hooked into the

clutch grips on each handle. Attach cables as follows.

1. Thread the hex lock nuts (in hardware pack) all

the way up the threaded portion of the "Z" ends

of the clutch cables.

2. Make certain each cable is in groove of cable

roller guides. Place the clutch grip in the raised

(up) position.

3. Thread the cable onto the threaded portion of the

"Z" end until there is no slack in the cable, but the

cable is NOT tight. Do not overtighten cable.

See figure 8.

&

WARNING: If cable is tightened so there

is tension on the cable with the clutch

grip released, the safety features of the

snow thrower may be overridden.

4. When correct adjustment is reached, tighten the

hex nut against the bottom portion of the cable to

lock it in position.

FIGURE 8.

is Straight

/

6

FINAL ADJUSTMENTS

Auger Drive Clutch

To check the adjustment of the auger drive clutch,

push forward on the left hand clutch grip (depress the

rubber bumper). There should be slack in the cable.

Release the clutch grip. The cable should be straight.

Make certain you can depress the auger drive clutch

grip against the left handle completely.

Page 7

Ifnecessary,loosenthehexlocknutandthreadthe

cablein(forlessslack)orout(formoreslack)asnec-

essary.Referto figure8. Rechecktheadjustment.

Tightenthe locknut againstthe cablewhencorrect

adjustmentisreached.

Traction Drive Clutch and Shift Lever Adjustment

To check the adjustment of the traction drive clutch

and shift lever, tip the snow thrower forward so that it

rests on the auger housing. First move the shift lever

all the way forward to sixth (6) position. With the trac-

tion drive lever released, spin the snow thrower

wheels by hand. They should turn freely. Then

engage the traction drive clutch grip. The wheels

should stop turning.

Now release the traction drive clutch grip, and spin

the wheels again. Move the shift lever back to the fast

reverse position, then all the way forward again.

There should be no resistance in the shift lever, and

the wheels should keep turning.

If you have resistance when moving the shift lever or

the wheels stop when they should not, loosen the lock

nut on the traction drive cable and unthread the cable

one turn. If the wheels do not stop when you engage

the traction drive clutch grip, loosen the lock nut on

the traction drive cable and thread the cable in one

turn. Recheck the adjustment and repeat adjustment

as necessary. Tighten the lock nut to secure the cable

when correct adjustment is reached.

NOTE: If you are uncertain that you have reached the

correct adjustment, refer to the Adjustment section on

page 10.

ADJUSTING THE SKID SHOES

The space between the shave plate and the ground

can be adjusted. For close snow removal, place skid

shoes in the low position. Use middle or high position

when area to be cleared is uneven. See figure 9.

Adjust skid shoes by loosening the four hex nuts and

carriage bolts and moving skid shoes to desired posi-

tion. Make certain the entire bottom surface of skid

shoe is against the ground to avoid uneven wear on

the skid shoes. Retighten nuts and bolts securely.

It is not recommended that you operate this snow

thrower on gravel as loose gravel can be easily

picked up and thrown by the auger causing an injury

or damage to the snow thrower.

Skid

Shoe

FIGURE 9.

Hex Nuts

Carriage Bolts

OPTIONAL ELECTRICSTARTER

If your unit is equipped with an optional electric starter

which has not been installed at the factory, install at

this time. Follow the instructions packed with the elec-

tric starter for installation.

TIRE PRESSURE (Pneumatic Tires)

The tires are over-inflated for shipping purposes.

Check tire pressure and reduce to 15 to 20 psi.

NOTE: If the tire pressure is not equal in both tires,

the unit may pull to one side or the other.

Auger

Drive

Clutch

CONTROLS

Traction

Drive/

Auger

Clutch

Lock

SHIFT LEVER

(See figures 10 and 11)

The shift lever is located in the center

of the handle panel. The shift lever may

be moved into one of eight positions.

Run engine with throttle in the fast posi-

tion. Use the shift lever to determine

ground speed.

Forwardmone of six speeds. Position

number one (1) is the slowest. Position

number six (6) is the fastest.

FIGURE 10.

7

Reverse--two reverse (R) speeds. "R"

closest to the operator (all the way

back) is the faster of the two.

FIGURE 11.

Page 8

I I

AUGER DRIVE (See figure 10)

The auger drive clutch is located on the lef handle.

Squeeze the clutch grip to engage the augers.

Release to stop the snow throwing action. Traction

drive clutch must also be released.)

TRACTION DRIVE/AUGER CLUTCH LOCK

(See figure 10)

The traction drive clutch is located on the righc handle.

Squeeze the traction drive clutch to engage tile wheel

drive. Release to stop.

This same lever also locks the auger clutct_ so you

can turn the chute crank without interrupting 1he snow

throwing process. If the auger drive clutch is .=ngaged

with the traction drive clutch engaged, the _perator

can release the auger drive clutch (on the lef handle)

and the augers will remain engaged. Release the

traction drive clutch to stop both the augers atld wheel

drive (auger drive clutch must also be release J).

CHUTECRANK (See figure 10)

The chute crank is located on left hand sic e of the

snow thrower.

To change the direction in which snow is thrc,wn, turn

chute crank as follows:

1. Crank clockwise to discharge to the left.

2. Crank counterclockwise to discharge to ttne right.

THROTTLE CONTROL(See figure 12)

The throttle control is located on the engine. It regu-

lates the speed of the engine.

SAFETYIGNITION SWITCH (See figure 12)

The ignition key must be inserted in the switch before

the unit will start. Remove the ignition key when snow

thrower is not in use.

Choke

Primer

Rope

Ignit Starter

Key Throttle Handle

Control

FIGURE 12.--Model 610E Shown

13PERATION

GASAND OIL FILL-UP

Service the engine with gasoline anq! oil as

instructed in the separate engine manual packed with

your snow thrower. Read instructions carefi dly.

NOTE: Your snow thrower is shipped without oil;how-

ever, a small amount of oil may be present from the

factory. Do not overfill.

,_ WARNING: Never fill fuel tank indoors,

with engine running or while eulgine is

hot. Do not smoke when filling fu=:ltank.

ELECTRICSTARTER

WARNING: The optional electric starter is €_quipped

with a three-wire power cord and plug and is

designed to operate on 120 volt AC housel_old cur-

rent. It must be properly grounded at all times to avoid

the possibilityof electric shock which may be injurious

to the operator. Follow all instructions carefully.

Determine that your house wiring is a th'ee-wire

grounded system. Ask a licensed electrician i: you are

not certain. Ifyour house wiring system is no1 a three-

wire grounded system, do not use this electr c starter

under any conditions. If your system is grour ded and

a three-hole receptacle is not available at 1he point

your starter will normally be used, one should be

installed by a licensed electrician.

When connecting the power cord, always connect

cord to starter on engine first, then plug the other end

into a three-hole grounded receptacle.

When disconnecting the power cord, always unplug

the end from the three-hole grounded receptacle first.

TO START ENGINE

IMPORTANT: If unit shows any sign of motion (drive

or augers) with the clutch grips disengaged, shut

engine off immediately. Readjust as instructed in the

"Final Adjustments" section of the Assembly

Instructions.

1. Attach spark plug wire to spark plug.

2. Make certain the auger drive and traction

drive clutch grips are in the disengaged

(released) position.

3. Move throttle control up to FAST position. Insert

ignition key into slot. See figure 12. Be certain it

snaps into place. Do not turn key.

4. Rotate choke knob to FULL choke position (cold

engine start).

If engine is warm, place choke in OFF position

instead of FULL.

8

Page 9

5. Electric Start Only (Optional): Connect power

cord to switch box on engine. Plug the other end

of power cord into a three-hole, grounded 120

volt AC receptacle.

6. Push primer button t_vo or three times. See figure

12.

If engine is warm, push primer button once only.

NOTE: Always cover vent hole in primer button when

pushing. Additional priming may be necessary for first

start if temperature is below 15°F.

7. Recoil Start: Grasp starter handle (see figure 12)

and pull rope out slowly, until it pulls slightly hard-

er. Let rope rewind slowly. Pull starter handle

rapidly. Do not allow handle to snap back. Allow it

to rewind slowly while keeping a firm hold on the

starter handle.

.

9.

Electric Start (Optional): Push starter button on

top of the engine to crank the engine. When

engine starts, release starter button.

Repeat step 7 until engine starts. If engine fails to

start, repeat steps 6 and 7 until engine starts.

As engine warms up and begins to operate even-

ly, rotate choke knob slowly to OFF position. If

engine falters, return to FULL choke, then slowly

move to OFF position.

Recoil Starter: With engine running, pull starter rope

with a rapid, continuous full arm stroke three or four

times. Pulling the starter rope will produce a loud clat-

tering sound, which is not harmful to the engine or

starter.

3. To stop engine, remove the ignition key. Do not

turn key. Disconnect the spark plug wire from the

spark plug to prevent accidental starting while

equipment is unattended.

NOTE: Do not lose ignition key. Keep it in a safe

place. Engine will not start without the ignition key.

4. Wipe all snow and moisture from the carburetor

cover in the area of the control levers. Also, move

control levers back and forth several times. Leave

throttle control lever in the STOP or OFF position.

Leave choke control in the FULL choke position.

AVOIDINJURYFROM ROTATING

AUGERm KEEPHANDS,FEET

ANDCLOTHINGAWAY. ,_,

TO STOP ENGINE

1. Run engine for a few minutes before stopping to

help dry off any moisture on the engine.

2. To help prevent possible freeze-up of starter, pro-

ceed as follows.

Optional Electric Starter: Connect power cord to

switch box on engine, then to 120 volt AC receptacle.

With the engine running, push starter button and spin

the starter for several seconds. The unusual sound

made by spinning the starter will not harm engine or

starter. Disconnect the power cord from receptacle

first, and then from switch box.

TO ENGAGEDRIVE

1. With the engine running near top speed, move

shift lever into one of the six FORWARD positions

or two REVERSE positions. Select a speed

appropriate for the snow conditions that exist.

Use the slower speeds until you are familiar with

the operation of the snow thrower.

2. Squeeze the traction drive clutch grip against the

right handle and the snow thrower will move.

Release it and the drive motion will stop.

NOTE: NEVER move shift lever without first releasing

the drive clutch.

TIRE CHAINS (Optional Equipment)

Tire chains should be used whenever extra traction is

needed.

OPERATINGTIPS

NOTE: Allow the engine to warm up for a few minutes

as the engine will not develop full power until it reach-

es operating temperature.

&

WARNING: Temperature of muffler and

surrounding areas may exceed 150°F.

Avoid these areas.

Page 10

t I

1. For most efficient snow removal, remo_e snow

immediately after it falls.

2. Discharge snow downwind whenever Ic,ossible.

Slightly overlap each previous swath.

3. Set the skid shoes 1/4" below the scrap_ r bar for

normal usage. The skid shoes may be _djusted

upward for hard-packed snow. Adjust d(_wnward

when using on gravel or crushed rock.

4. Be certain to follow the precautions list_ d under

"To Stop Engine" on page 9 to prevent possible

freeze-up.

5. Clean the snow thrower thoroughly after each

use.

ADJUSTMENTS

WARNING: NEVER attempt t(, clean

chute or make any adjustments while

engine is running.

CHUTEASSEMBLYADJUSTMENT

The distance snow is thrown can be adjL,sted by

adjusting the angle of the chute assembly. Th_ sharp-

er the angle, the shorter the distance snow is thrown.

See figure 13.

To adjust chute assembly, loosen the hard knob.

Pivot the top of the chute assembly to )osition

desired. Retighten the hand knob.

TRACTIONDRIVECLUTCHADJUSTMENT

Refer to the Final Adjustment section of the Assembly

Instructions to adjust the traction drive clutch. If you

are uncertain that you have reached the correct

adjustment, the adjustment can be physically checked

as follows.

With the snow thrower tipped forward (be certain to

drain the gasoline or place plastic film under the gas

cap if the snow thrower has already been operated),

remove the frame cover underneath the snow thrower

by removing six self-tapping screws.

With the traction drive clutch released, there must be

clearance between the friction wheel and the drive

plate in all positions of the shift lever. With the traction

drive clutched engaged, the friction wheel must con-

tact the drive plate. See figure 14.

If adjustment is necessary, loosen the lock nut on the

traction drive cable and thread the cable in or out as

necessary. Tighten the lock nut to secure the cable

when correct adjustment is reached. Reassemble the

frame cover.

NOTE: If you placed plastic under the gas cap, be

certain to remove it.

Friction

Wheel

Gear Shaft

!

Drive

Pl_

FIGURE 14.

FIGURE 13.

SKID SHOE ADJUSTMENT

The space between the shave plate and th_ ground

can be adjusted. Refer to page 7 of the A ;sembly

Instructions.

AUGERCLUTCH ADJUSTMENT

To adjust the auger clutch, refer to Final Adjustment

section of Assembly Instructions.

10

SHIFT ROD ADJUSTMENT

To adjust the shift rod, remove the hairpin clip and flat

washer which secure the shift rod to the shift arm

assembly. Refer to figure 7. Adjust as specified in

Assembly Instructions.

Page 11

CARBURETORADJUSTMENT

&

WARNING: If any adjustments are made

to the engine while the engine is running

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor carburetor adjustment may be required to com-

pensate for differences in fuel, temperature, altitude

and load.

Refer to the separate engine manual packed with

your unit for carburetor adjustment information.

DRIVE WHEELS

The wheels may be adjusted for two different meth-

ods of operation. The adjustment is made by placing

the klick pins in one of two different holes on the right

side of the unit. See figure 15.

1. One Wheel DrivingmPlace klick pin in the out-

side axle hole on the right side. This position

gives power drive to the left wheel only, making

the unit easier to maneuver.

,

Both Wheels Driving--Place klick pin in the hole

in the hub next to the rim on the right side. This

position is good for heavy snow as there is power

drive in both wheels.

IMPORTANT: Keep all grease and oil off of the

friction wheel and drive plate.

Shifting Mechanism

Lubricate the shifting mechanism and pivot points on

the shift rod with engine oil at least once a season or

after every 25 hours of operation,

Traction Drive/Auger Clutch Lock

The cams on the ends of the control rods which inter-

lock the traction drive and auger drive clutches must

be lubricated at least once a season or every twenty-

five hours of operation. The cams can be accessed

beneath the handle panel. Refer to page 16, refer-

ence 39. Use a multi-purpose automotive grease.

Gear Case

The gear case is lubricated with grease at the factory

and does not require checking. If disassembled for

any reason, lubricate with 2 ounces of Shell Alvania

grease, part number 737-0168.

Bearings

Lubricate the auger and wheel bearings once a sea-

son with lightoil.

AUGERS

The augers are secured to the spiral shaft with two

hex bolts and hex lock nuts. See figure 16. If you hit a

foreign object or ice jam, the snow thrower is

designed so that the hex bolts will shear.

If the augers will not turn, check to see if the hex bolts

have sheared. Two replacement hex bolts and hex

lock nuts have been provided with the snow thrower.

For future use, order part number 710-0890 (hex bolt

5/16-18 x 1.5" long) and 712-0429 (hex insert lock nut

5/16-18 thread).

Outside Hole

in Axle

FIGURE 15.

MAINTENANCE

WARNING: Disconnect the spark plug

wire and ground against the engine

before performing any repairs or mainte-

nance.

LUBRICATION

Gear Shaft

Lubricate the gear shaft with "Slick 50 Grease" at

least once a season or after every 25 hours of opera-

tion (available at automotive stores, or order part

number 737-0290). Refer to figure 14.

Au Bolts

FIGURE 16.

11

SHAVE PLATEAND SKID SHOES

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. They should be

checked periodically and replaced when necessary.

Page 12

[ I

To remove skid shoes, remove the four carri_ ge bolts,

belleville washers and hex nuts which attacl" them to

the snow thrower. Reassemble new skid sl'oes with

the four carriage bolts, belleville washers (cupped

side goes against skid shoes) and hex nu s. Make

certain the skid shoes are adjusted to be leveI.

To remove shave plate, remove the carria;le bolts,

belleville washers and hex nuts which attact" it to the

snow thrower housing. Reassemble new sh_ve plate,

making sure heads of the carriage bolts a'e to the

inside of the housing. Tighten securely.

ENGINE

Refer to separate engine manual for al engine

maintenance procedures.

BELTREMOVALAND REPLACEMENT

WARNING: Disconnect the sp_rk plug

wire from the spark plug and grm,nd.

AUGER BELTS

NOTE: It is necessary to remove both belts h_order to

change either one. If changing just one beh, be cer-

tain to check the condition of the other be 't (model

610E has only one auger belt).

1. Remove the plastic belt cover on the fr(nt of the

engine by removing the two self-tappin( screws.

See figure 17.

5. Roll the front and rear auger belts off the engine

pulley. See figure 18.

Drive

Belt

Rear

Auger Engine

Front

er

Belt

Engine

Pulley

Idler Idler

Pulley Pulley

FIGURE 18.

6. Unhook the idler spring from the hex bolt on the

auger housing. See figure 19.

7. Unhook the support bracket spring from the

frame.

8.

.

Lift the front auger belt from the auger pulley, and

slip belt between the support bracket and the

auger pulley. See figure 19. Repeat this step for

rear auger belt (except model 610E).

Replace both auger drive belts by following

instructions in reverse order.

Belt Lpping

Cover €;crews

FIGURE 17.

2. Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cal).

3. Tip the snow thrower up and forward _;o that it

rests on the housing.

4. Remove six self-tapping screws from tile frame

cover underneath the snow thrower.

12

DRIVE BELT

1. Follow steps 1 through 4 of previous instructions.

2. Pull idler pulley up, and lift belt off engine pulley

and friction wheel disc. See figure 18.

3. Using a 7/16" wrench, loosen the nut on the stop

bolt until the support bracket rests on the auger

pulley. See figure 20.

4. Slip belt between friction wheel and friction wheel

disc. See figure 20. Remove and replace belt.

Reassemble following the instructions in reverse

order.

NOTE: The support bracket must rest on the stop bolt

after the new belt has been assembled. See figure 20.

Page 13

Friction

Wheel

Auger

Pulley Auger

Pulley

Idler Auger Support

Spring Housing Bracket

SpringFIGURE 19.

Bolt

Drive

Belt

,

Remove the klick pins which secure the wheels,

and remove the wheels from the axle,

5. Remove the gear shaft from the unit by removing

the bolts, lock washers and flat washers from

each side of the frame. See figure 21. Hold the

friction wheel assembly, and slide the gear shaft

out of the unit toward the right hand side. Refer to

figure 14.

6. Remove the six screws from the friction wheel

assembly (three from each side). Remove the

friction wheel rubber from between the friction

wheel plate.

7. Reassemble new friction wheel rubber to the fric-

tion wheel assembly, tightening the six screws in

rotation and with equal force.

8. Slide the friction wheel assembly up onto the shift

mechanism as shown in figure 14, and slide the

gear shaft back into the unit. Reassemble in

reverse order.

FIGURE 21.

Auger

FIGURE 20. Pulley

CHANGING THEFRICTION WHEEL RUBBER

The rubber on the friction wheel is subject to wear

and should be checked after 25 hours of operation,

and periodically thereafter. Replace the friction wheel

rubber if any signs of wear or cracking are found.

1. Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

2. Tip the snow thrower up and forward, so that it

rests on the housing.

3. Remove six self-tapping screws from the frame

cover underneath the snow thrower.

OFF-SEASON STORAGE

13

WARNING: Never store engine with fuel

in tank indoors or in poorly ventilated

areas, where fuel fumes may reach an

open flame, spark or pilot light as on a

furnace, water heater, clothes dryer or

other gas appliance.

If unit is to be stored over 30 days, prepare for stor-

age as follows:

1. Remove all gasoline from carburetor and fuel

tank to prevent gum deposits from forming on

these parts and causing possible malfunction of

engine.

Page 14

I I

a. Run engine until fuel tank is empty anq| engine

stops due to lack of fuel.

b. Drain carburetor by pressing upward on bowl

drain, located below the carburetor cov,=r.

,_ WARNING: Drain fuel into approved con-

tainer outdoors, away from opelJ flame.

Be certain engine is cool. Do not .,;moke.

Fuel left in engine during warm Neather

deteriorates and will cause serioL_s start-

ing problems.

NOTE: Fuel stabilizer (such as STA-BIL) is ar accept-

able alternative in minimizing the formatioJ1 of fuel

gum deposits during storage. Add stabilizer to gaso-

line in fuel tank or storage container. Alwaj's follow

mix ratio found on stabilizer container. Run _ngine at

least 10 minutes after adding stabilizer to a,!ow it to

reach carburetor. Do not drain carburetor if u ring fuel

stabilizer.

2. Remove spark plug and pour one (1) ounce of

engine oil through spark plug hole into cylinder.

Crank engine several times to distribute oil.

Replace spark plug.

3. Remove all dirt from exterior of engine and equip-

ment.

4. Follow lubrication recommendations on page 11.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rust proof the equipment. Using a light oil or

silicone, coat the equipment, especially any chains,

springs, bearings and cables.

14

Page 15

TROUBLE SHOOTING GUIDE

Possible Cause(s) Corrective Action

Trouble

Engine fails to start

Engine runs erratic

Loss of power

Engine overheats

Excessive vibration

Hard to shift, or will

not shift

Unit fails to propel itself

Unit fails to discharge

snow

1. Fuel tank empty, or stale fuel.

2. Blocked fuel line.

3. Key not in switch on engine.

4. Spark plug wire disconnected.

5. Faulty spark plug.

1. Unit running on CHOKE.

2. Blocked fuel line or stale fuel.

3. Water or dirt in fuel system.

4. Carburetor out of adjustment.

1. Spark plug wire loose.

2. Gas cap vent hole plugged.

1. Engine oil level low.

2. Carburetor not adjusted properly.

Loose parts or damaged impeller.

Shift rod misadjusted.

1. Incorrect adjustment of drive clutch.

2. Drive belt loose or damaged.

1. Auger shear bolt broken.

2. Discharge chute clogged.

3. Foreign object lodged in auger.

4. Incorrect adjustment of auger drive

clutch.

5. Auger drive belt loose or damaged.

1. Fill tank with clean, fresh gasoline.

2. Clean fuel line.

3. Insert key.

4. Connect wire to spark plug.

5. Clean, adjust gap or replace.

1. Turn choke knob to OFF position.

2. Clean fuel line; fill tank with clean

fresh gasoline.

3. Use carburetor bowl drain to drain

fuel tank. Refill with fresh fuel.

4. Adjust carburetor. See separate

engine manual.

1. Connect and tighten spark plug

wire.

2. Remove ice and snow from cap.

Be certain vent hole is clear.

1. Fill crankcase with proper oil.

2. Adjust carburetor. See separate

engine manual.

Stop engine immediately and

disconnect spark plug wire. Tighten

all bolts and nuts. Make all

necessary repairs. If vibration

continues, have unit serviced by

authorized service dealer.

Readjust shift rod. See Adjustment

section of this manual.

1. Adjust drive clutch. Refer to

Adjustment section.

2. Replace drive belt. Refer to

Maintenance section.

1. Replace auger shear bolt. Refer to

Maintenance section.

2. Stop engine immediately and

disconnect spark plug wire. Clean

discharge chute and inside of auger

housing.

3. Stop engine immediately and

disconnect spark plug wire.

Remove object from auger.

4. Adjust auger clutch. Refer to

Adjustment section.

5. Replace auger drive belt. Refer to

Maintenance section.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service dealer.

15

Page 16

E I

Copy lh¢ information from

your model plate here:

NNN NNSN NNN

NNNNNNNN

1-11ZII-Ii-II-II-II-II-II-II-1FI

modelnumber

available

whenyoucall

Model Series

Shave Plate

Skid Shoe

Auger Belts

Drive Belt

Friction Wheel Rubber

Friction Wheel Ass'y. Comp.

SAE 5W30

Electric Start Kit

Tire Chains

ht Kit

Drift Cutter Kit

Snow Cab

Illustrated Parts List*

E610E

, '25-1660

7 34-5581A

84-5580

54-0430

E640F

725-1660

784-5579

784-5580

754-0430(2 _q'd.)

_'54-0343

;'35-0243

634-0042A

J-8C

730226

:;tandard

3c0-139-000

N/A

3_c0-679-000

3cO-674-000

770-96-9B

754-0346

735-0243

684-0042A

J-8C

730226

Standa_

390-991-000

390-255-000

390-679-000

390-674-000

770-96-9B

E660G

725-1660

784-5582A

784-5580

754-0430(2

754-0346

735-0243

684-0042A

J-8C

730226

Standard

390-655-000

390-255-000

390-679-000

390-674-000

770-96-9B

*Either use the order form attached to this manual or telephone 1 (800) 800-7310.

Wait for the message and then press _2) for literature. An operator will take your order.

For Parts, Acces;sorles or Service Information,

CALL NOW!

1f8oo) 8oo-y31o

8:00 AM to 8:00 PM Monday Through Saturday

12 Noo n to 6:00 PM Sunday

Eastern Tim • (winter hours may vary)

The only way to ensure the pe=/ormance of your product

is to use original equipmen: parts and accessories.

MTD designs and engineers quality parts to exacting

specifications. When you sub stitute, you take a chance

on quality, reliability, safety al=d performance. Use MTD

original equipment, the be.,;t buy on the American

Landscape---American Made _nd American Owned!

Loading...

Loading...