Page 1

MTD SERVICE LLC Product Training and Education Department

Page 2

TABLE OF CONTENTS

WORK SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Batteries And Charging Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3

Safety Interlock Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Interlock Systems - Changes for 1991 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Electric Start System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Recoil Start System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

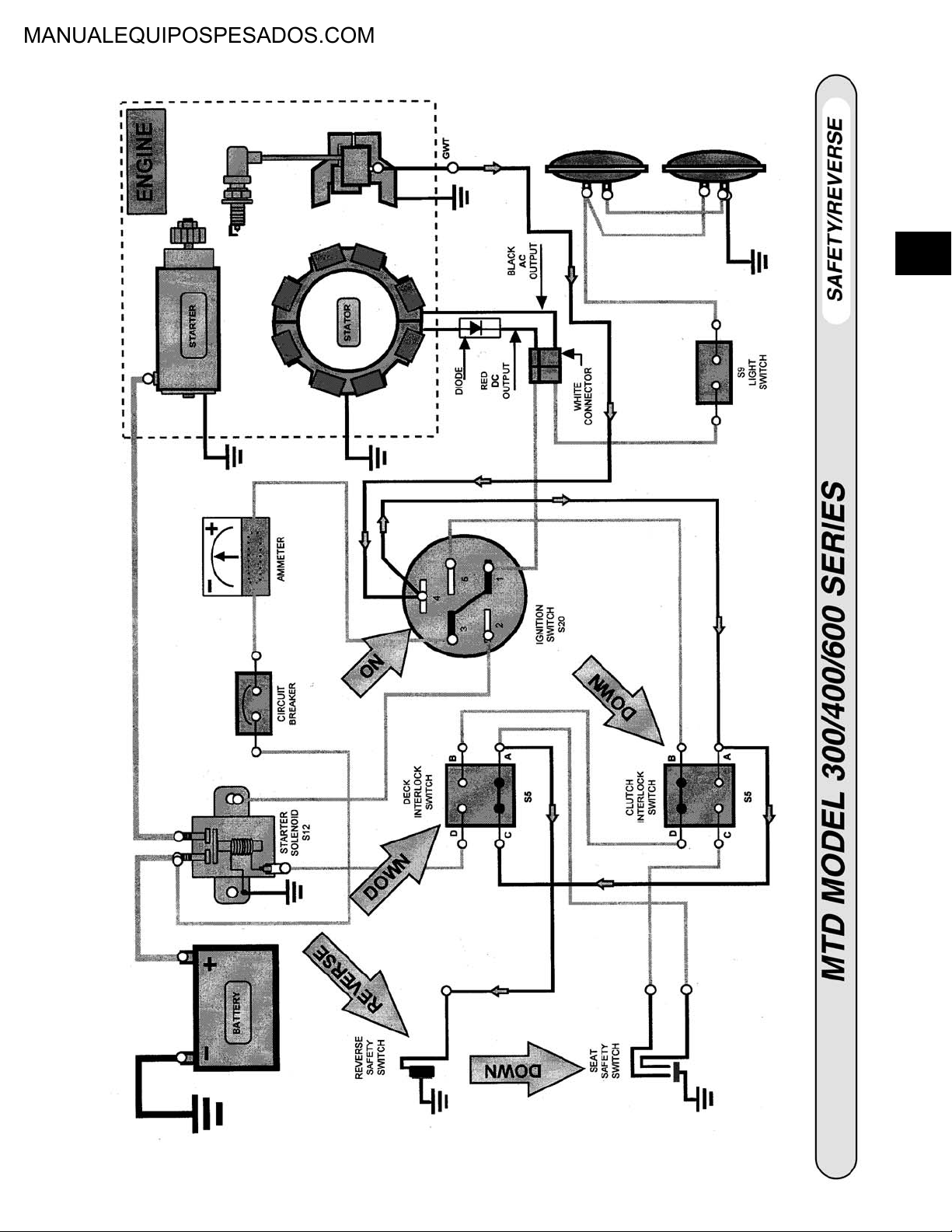

Safety Interlock Systems Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Troubleshooting Safety Interlock Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Evaluating Electric Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

BELTS AND DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Proper Storage of Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Causes of V-Belt Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

V-Belt Problems with Rotary Tillers, Self-Propelled Mowers and Riding Mowers . . . . . . . . . . . . . . . . . . . . 4-4

Belt Wear Due to Normal Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Pulley Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Idlers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Maintenance Of Variable Speed Pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Four Wheel Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Disassembly Of Four Wheel Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Brake Adjustment for 600 and 700 Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

1

1

2

3

4

5

6

7

HYDROSTATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 5

TRANSAXLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Transaxle Changes For 1990, 1991, 1992 and 1997 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Disassembly/Assembly of Transaxle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Hydrostatic Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Integrated Hydrostatic Transaxle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

LAWN TRACTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 7

300 and 400 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Rear Engine Riding Mowers 500 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Transmatic LT 600A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Hydrostatic Drive 700 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

YARD BUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 8

Deck Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Blade Brake/PTO Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Speed Control Pedal Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Steering Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Removal and Installation of Deck Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Removal and Installation of Mowing Deck Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Removal and Replacement of the Drive Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Transmission Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Transmission Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8

Page 3

y

AUTO DRIVE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 9

Leveling the Cutting Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Deck Belt Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Cutting Deck Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Brake Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Autodrive Pedal Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Drive Belt Removal and Reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Transmission Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Transmission Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Deck Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Hydrostatic Transmission Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Steering Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Autodrive/Autocruise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

MTD Z SERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 10

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Neutral/Steering Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Removal of ZTT Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

ZERO TURN TRACTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 11

624 Zero Turn Tractor - The Revolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

46" Cutting Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Cutting Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Lower Deck Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Servicing the IZT Drive Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Servicing the IZT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

Adjustments to the IZT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Under Dash Service Points1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Dash Panel Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

ATTACHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 12

Cutting Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

Grass Collectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-37

Front Bumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-39

Trapac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-39

42" Dozer Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-40

GLOSSARY

9

10

11

12

Glossar

Page 4

WORK SAFELY—FOLLOW THESE RULES

This symbol is used to call your attention to instructions concerning

your personal safety. Be sure to observe and follow these instructions.

1. To prevent accidental starting, always pull the

high tension wire(s) off the spark plug(s) before

servicing and/or adjusting the machine.

2. To prevent injury, do not allow children or

bystanders around the machine while it is

being adjusted and/or serviced.

3. Do not wear rings, wrist watches or loose fitting

clothing when working on machinery; they

could catch on moving parts causing serious

injury. Wear sturdy, rough-soled work shoes.

Never adjust and/or service a machine in bare

feet, sandals or sneakers.

4. Always wear safety glasses when using a

hammer, chisel or other tools that may cause

chips to fly.

1

d. Keep the heater at least four feet from

combustible materials.

e. Never use gasoline as fuel.

8. Handle gasoline with care—it is highly flammable.

a. Use approved gasoline container.

b. Never remove the fuel tank cap or fill the

fuel tank when the engine is running, is hot

or indoors. Also, do not smoke when working

around flammable fuel.

c. Avoid fires—be sure container or funnel

does not touch the battery. Do not overfill

the fuel tank. Wipe up spilled gasoline.

5. Be sure to reinstall safety devices, guards or

shields after adjusting and/or servicing the

machine.

6. When operating a power washer to clean a

machine before servicing, be careful at all

times to avoid injury. Maintain proper footing

and balance at all times. Never direct the spray

at people or animals, as high pressure spray

can cause serious injury.

7. If a portable heater is used to heat the service

area, the following precautions must be

observed

a. Do not use portable heaters in presence of

volatile materials such as gasoline or paint,

as fire or explosion may result.

b. To avoid being burned, do not touch the

heater during operation.

c. Portable heaters consume oxygen and

combustion fumes can be hazardous.

Heater should be used only in a well-ventilated area. Keep a window or door partially

open to provide ventilation.

d. Replace fuel tank cap securely.

9. Never use trouble lights or electric powered

tools that have cut and/or damaged cords or

plugs. Be sure all electric tools are properly

grounded.

10. Never run an engine in a confined area such

as a garage or storage building any longer

than is necessary for immediate moving of the

machine out of or into the area. EXHAUST

GASES ARE TOXIC. OPENING DOORS AND

WINDOWS MAY NOT PROVIDE ADEQUATE

VENTILATION.

11.After servicing, be sure all tools, parts or servicing equipment are removed from the

machine.

12. Electrical storage batteries give off highly

inflammable hydrogen gas when charging and

continue to do so for some time after receiving

a steady charge. Do not under any circumstances allow an electric spark or an open

flame near the battery. Always disconnect a

battery cable before working on the electrical

system.

1-1

Page 5

13. Hydraulic fluid escaping under pressure can

have enough force to penetrate the skin.

Hydraulic fluid may also infect a minor cut or

opening in the skin. If injured by escaping fluid,

see a doctor at once. Serious infection or reaction can result if medical treatment is not given

immediately. Do not attempt to repair or tighten

hoses that are under pressure, when the boom

is raised or with the tractor engine running.

Cycle all hydraulic control valves to relieve all

pressure before disconnecting the lines or performing other work on the hydraulic system.

Make sure all connections are tight and hoses

and lines are in good condition before applying

pressure to the system. To locate a leak under

pressure, use a small piece of cardboard or

wood. Never use hands.

14 When using an acetylene torch, always wear

welding goggles and gloves. Keep a charged

fire extinguisher within reach. Do not weld or

heat areas near fuel tanks or fuel lines and utilize proper shielding around hydraulic lines.

15. Always use safety stands in conjunction with

hydraulic jacks or hoists. Do not rely on the

jack or hoist to carry the load; it could fail.

Always use a safety bar to block hydraulic cylinders.

16. When splitting tractors or disassembling

machines, be sure to use safety stands and

adequate supports to prevent tipping or rollover.

17. Use a safety catch on all hoist hooks. Do not

take a chance, the load could slip off the hook.

18. Use pullers to remove bearings, bushings,

gears, cylinder sleeves, etc. when applicable.

Use hammers, punches and chisels only when

absolutely necessary. Then, be sure to wear

safety glasses.

19. Be careful when using compressed air to dry

parts. Use approved air blow guns, do not

exceed 30 psi, wear safety glasses or goggles

and use proper shielding to protect everyone in

the work area.

20. Petroleum based solvents, often used for

cleaning parts, are flammable. Use care to

avoid fire or explosion when using these solvents.

IMPORTANT: The above is only a partial list of

safe work rules. In addition, always refer to the

Operator’s Manual for the specific machine for

additional safe work rules regarding the

machine operation.

1-2

Page 6

GENERAL INFORMATION AND SAFETY PRECAUTIONS

2-1. SAFETY PRECAUTIONS.

2-1.1 Refer to the Safety Summary on page 1-1, and

observe all WARNINGS and CAUTIONS when

servicing equipment covered in this manual.

2-2. GENERAL.

2-2.1 This service manual covers lawn mowers, rid-

ing equipment, snowthrowers, chore performers, rotary tillers and accessories through

model year 1998.

2-2.2 More detailed instructions can be found in

each of the individual model service manuals.

NOTE

LEFT and RIGHT indicate the left and right

side when facing forward in the driver’s seat or

behind the piece of equipment.

2-4. NUMBERING SYSTEM.

2-4.1 Due to the many different models, types of

equipment and parts, it is very important to

understand the MTD numbering system and

how it is used. The following pages, Figures

and Tables will explain the system and what

each number and digit means.

2

2-3. REFERENCE DATA.

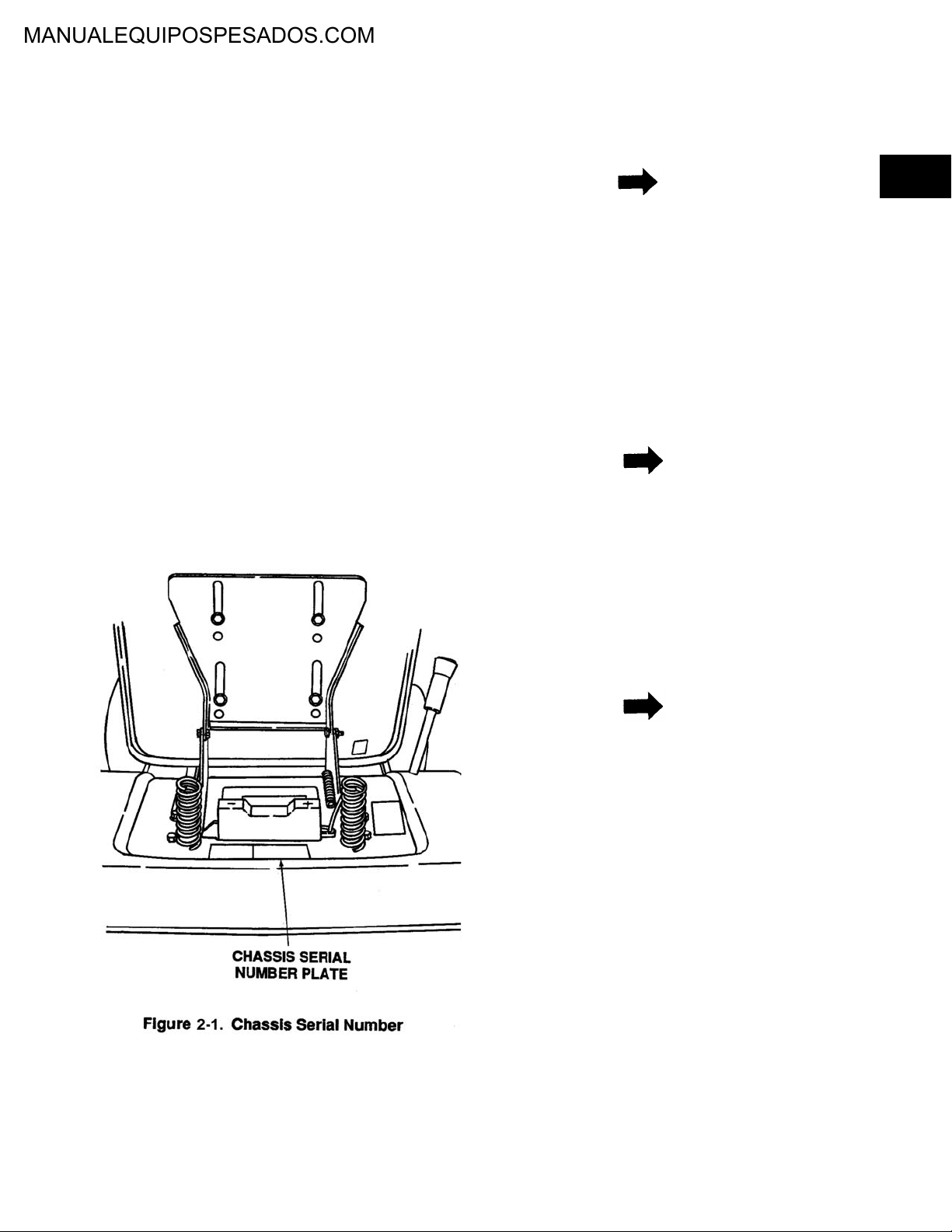

2-3.1 Serial Number Location. Serial number plate is

located behind the seat on the rear fender. See

Figure 2-1.

NOTE

IMPORTANT: When ordering replacement

parts, it is necessary to use both the model

number and the date code.

2-4.2 Due to the many different colors of rims and

different tire tread designs on riding mowers,

orders for replacement tires and wheel assemblies must specify both color and tire brand.

These can be identified by using the appropriate 900 series number after the part number.

NOTE

If you are entering an order electronically, the

tire identification number can be entered where

the paint code number is entered for a painted

part.

2-5. CUSTOMER NUMBERS.

2-5.1 In addition to customers who purchase tractors

and equipment marked with the MTD brand

and name logos, there are customers who

order tractors and equipment marked with their

own brand name and/or logos. Basic units are

the same except for color and decoration.

2-6. GENERAL.

2-6.1 The main storage or electrical power in our

electric start lawn mowers, riders and tractors

is the battery. With proper setup and mainte-

2-1

Page 7

BATTERIES AND CHARGING SYSTEMS

nance the battery will last for years. However,

in some remote cases even with proper maintenance a battery can lose power. This is

unavoidable and should be handled as per

warranty guidelines.

2-6.2 A chemical reaction between the battery’s

electrolyte and plates, or electrodes, will supply electrical energy to an external circuit.

When the battery is being used, or discharging, the positive plate (lead dioxide) and the

negative plate (sponge lead) are both changed

to lead sulphate. At the same time, part of the

electrolyte (diluted sulfuric acid) is changed to

water. This conversion of diluted sulfuric acid

to water reduces the specific gravity of the

electrolyte. By measuring this specific gravity,

a direct measure of how far the discharge process has progressed can be made.

2-7. BATTERIES AND CHARGING RATES.

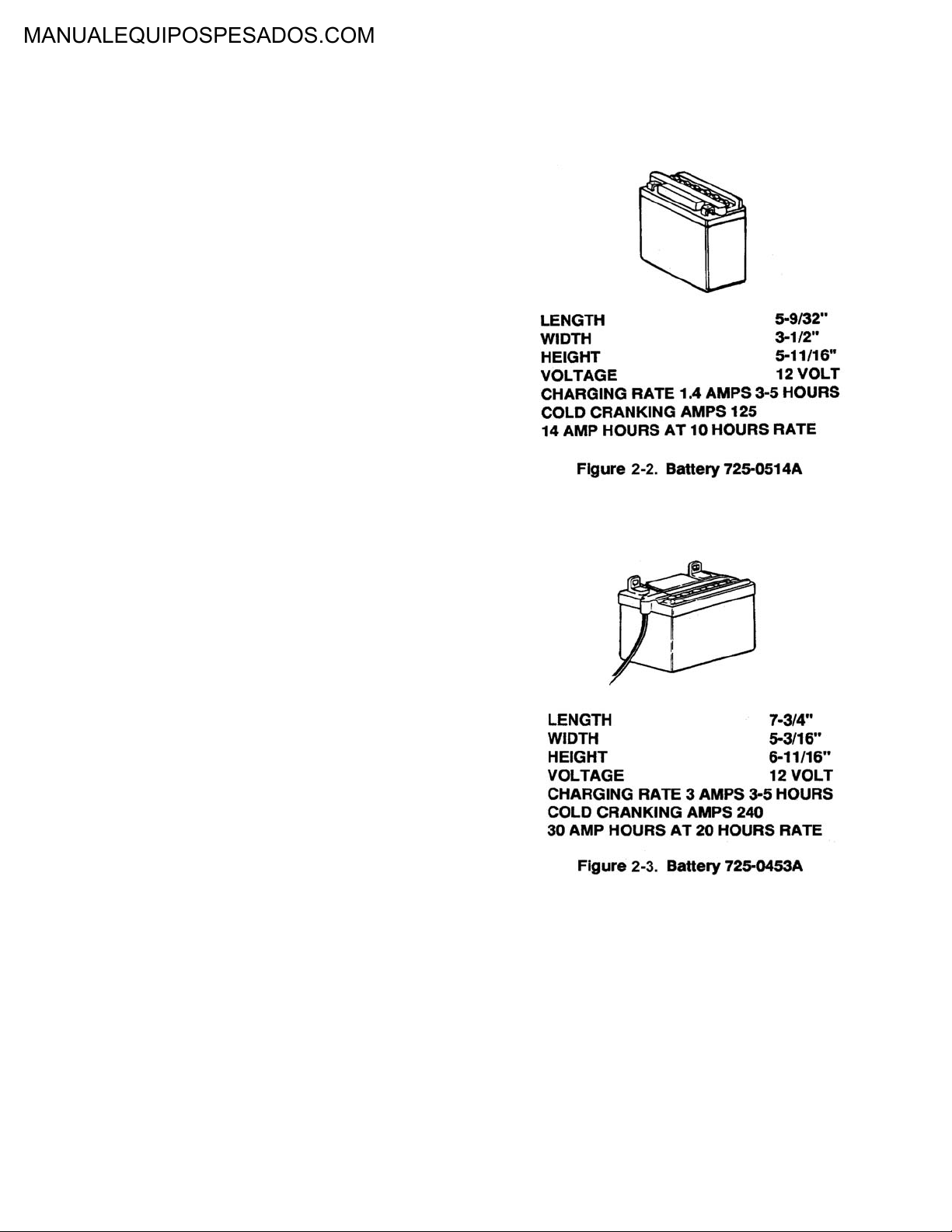

2-7.1 There are basically 5 different batteries used.

In this section we will show the battery number,

the replacement number, cause of replacement, size, cold cranking amps and amp hours

at a given rate.

1. Battery 725-0514A (Figure 2-2) is replaced by

725-1633. These batteries are used on riders

and are the same size with the same cold

cranking amps. The number was changed due

to shipping regulations which would not allow

acid packs to be shipped with batteries. Acid

packs can be obtained by ordering part number 725-1637; however, we suggest dealer

obtain acid locally. Battery caps, part number

725-0691, can also be ordered separately.

2. Battery 725-0453A (Figure 2-3) is shipped with

no acid. Acid can be obtained by ordering part

number 725-1637, but it is suggested acid be

purchased locally. Battery caps can also be

purchased separately by ordering part number

725-0690. Battery 725-0453A was used on

1989 and prior 700 and 800 series tractors.

This battery is currently used in the 900 series

tractor.

3. Battery 725-1105 which was supplied in 1987

is no longer available. Use kit number 7530459 as a replacement. The kit includes a battery, cover and adapting clip. The larger terminal end goes on the negative side of the

battery. The adapting clip also goes on the

negative side. The electric start unit uses a 7

amp fuse system

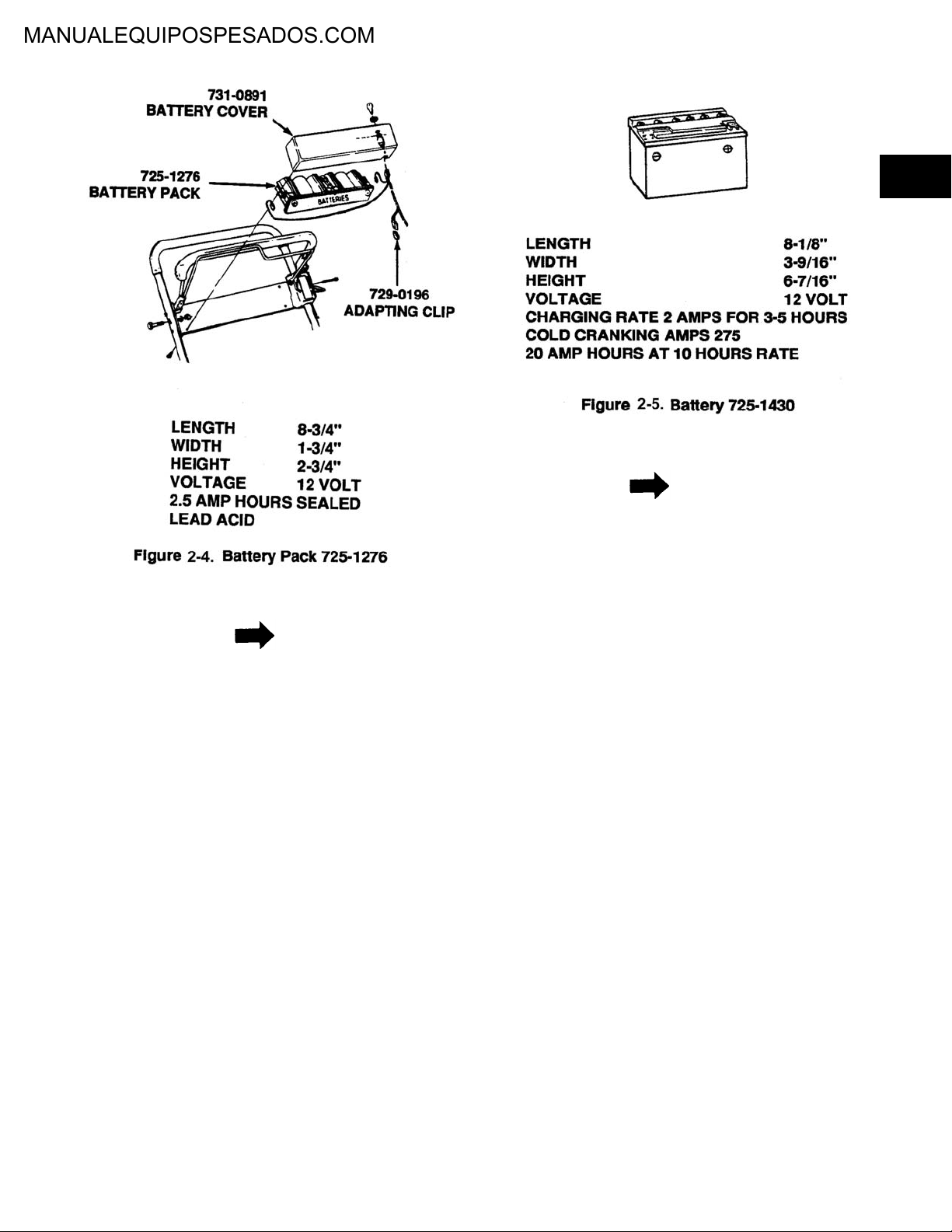

4. Battery pack 725-1276 (Figure 2-4) is installed

in electric lawn mowers.

2-2

Page 8

2

NOTE

NOTE

During shipment, the hot wire can vibrate off

the battery and the unit will not start. Take the

battery cover off, hook up the wire and charge

the battery.

5. Battery 725-1430 (Figure 2-5) is replaced by

725-1635. These batteries are the same size

with the same cold cranking amp. The number

was changed due to shipping regulations

which do not allow acid packs to be shipped

with batteries. Acid packs can be obtained by

ordering part number 725-1637; however, we

suggest dealers obtain acid locally.

Batteries 725-1430 only contain a special

chemical sulfate stop that has been added to

reduce sulfate crystal deposits (which eventually prevent the battery from accepting a

charge). Sulfate stop is a white powder chemical that may be visible before the battery is

activated, but dissolved once electrolyte is

added. After charging the battery (with sulfate

stop added), the specific gravity of electrolyte

rises to 1.280 or above. On a 5 ball hydrometer, it is acceptable to see the fifth ball float. If

the battery contains sulfate stop and has not

been in use for a long period of time, extended

recharging time is required.

2-3

Page 9

2-7.2 BATTERIES SECTION 1996-1998

#725-0453 E

Battery Type U1-11L

Dry 380 CCA Cold Cranking Amps @ Zero Degrees

Group No. U1L

Voltage 12V

Size Top 5.18 x 7.7

Number of plates 66

Height 6.12 to top of post 7.16

Weight wet 20.6 lbs.

Electrolyte capacity 72 oz.

Previously this battery was 240 CCA and it has been

upgraded to 380 CCA which gives added cranking

power in cold weather. It is shipped dry and it is suggested that the acid should be purchased locally. The

acid pack number as shown is #725-1670 but acid is

considered to be hazardous material, therefore when

shipped, charges will be excessive due to special handling.

Battery #725-1704

Note! New Warning symbols

Battery Type U-1

Wet 125 CCA Cold Cranking Amps

All batteries are date coded

Replaced by #725-1707 C DRY 275 CCA Cold

Cranking Amps

Size 5.18 x 7.7

Height 6.12 with Post 7.29

Voltage 12 volts

The #725-1704 is a wet battery meaning that it is

shipped in the rider and it is hooked up with the positive

terminal connected and the negative terminal has a

plastic cover over it to protect from shorting out. The

purpose of this is to assist stores with fast product turnover and in this manner the unit is ready to operate in

the least amount of set-up time.

Battery #725-1705C

WET 150 CCA Cold Cranking Amps.

Battery Type U-1

All batteries are date coded

Replaced by #725-1707C DRY 275 CCA Cold

Cranking Amps.

Voltage 12V

The #725-1705C is a wet battery and it is the same as

stated above. If a failure occurs in warranty the #7251707C will be shipped.

Battery #725-1706

WET 270 CCA Cold Cranking Amps.

Battery Type U-1

Negative terminal covered with a plastic cover and

shipped with the positive cable connected.

Replaced by #725-1707C DRY 275 CCA Cold

Cranking Amp.

All batteries are date coded

Battery is non-serviceable

Voltage 12V

The #725-1706 is a wet battery and is shipped in the

tractor and is ready to go by just removing the plastic

cover on the negative terminal and connecting the negative cable to the negative terminal.

Battery #725-1707C

DRY 275 CCA Cold Cranking Amps.

Battery Type U-1 Flat Top

Size 5.19 x 7.72

Height 6.12 Including Post 7.30

Voltage 12V

Manifold Vented

Specifications for ’97-’98 will be the same except all will

be flat top style. The knobs will be flush with the top of

the battery.

YUASA - EXIDE makes the DRY, add acid type batteries EAST PENN makes the WET non-serviceable type

battery.

WET batteries are anticipated to be used in 50% of

our production for fast moving product customers, all

batteries can not be shipped wet because they would

have a shorter shelf life than a dry battery.

For ’97-’98 little changes are anticipated. Dependability

over all styles will remain the same. Replacement batteries will continue to be shipped without acid, and acid

must be obtained locally due to acid being a hazardous

material, therefore requires special handling when

shipped.

New for ’98 season batteries will be similar in size but

top will be flat with nothing sticking up except the posts.

Fill caps will be flush with the top of the battery.

2-4

Page 10

Batteries must be properly maintained if you

want long-life, this remark is repeated over and

over.

1. Check the electrolyte and add only water.

2. Keep clean, excessive acid build up around

the terminals and top of battery will cause a

discharge and drain the battery.

3. Check cables and clamps and battery case for

obvious reasons of leakage as this could

cause damage to the painted surfaces, the

battery compartments and to the pulleys and

transmission.

4. Make sure of the routing of the vent tubes and

that it is not pinched and left to drip on pulleys,

etc.

5. Replace caps firmly, if one or two gets lost,

replace them as soon as possible, often they

can be obtained from old batteries.

6. Maintain a fully charged battery with a reading

by hydrometer showing 1.265.

2-7.3 Recently, a man well experienced in automo-

biles and lawn and garden equipment was

charging a battery in his automobile in the

garage for a long period of time and decided to

check on how it was progressing. He walked

into a partially dark garage, not thinking, and

leaned over the battery and flipped on this cigarette lighter. Well, you can guess what happened next. The electrolyte gas exploded,

which is hydrogen and oxygen. He was very

lucky to have glasses on as the top of the battery hit him in the face. He quickly remembered

to turn the hose on his face and wash off the

acid which was starting to burn and no damage

was done, but he was left quite shaken and

thankful that things worse didn’t take place.

Think about it. His glasses were broken and

bent tight to his eyes which helped protect his

eyes, which proves it is a good practice to

wear glasses when working with batteries.

•Starter. A series wound, low resistance, high

current draw direct current motor.

NOTE

Sometimes the circuit breaker kicks out and

will not allow the unit to crank. Check the diode

wires to see if they are crossed. Reverse the

diode wires if crossed.

2-9. BATTERY CHARGING SYSTEM.

2-9.1 There are four types of charging systems typi-

cally used on lawn and garden equipment.

•Single circuit—3 amp system with one diode

•Dual circuit—3 amp AC system that runs the

lights and a 3 amp DC circuit to charge battery

•Tri-circuit—5 amp two diode system

•Regulated 16 amp system

MTD mainly uses the dual circuit and regulated

systems.

2-9.2 Regulated systems are installed on units with

electric clutches. These are Briggs and Stratton engines with a voltage regulator. Some of

the early units had an 8 amp circuit breaker in

the unit. This is a 16 amp unit and needs a 20

amp circuit breaker (part number 725-1382).

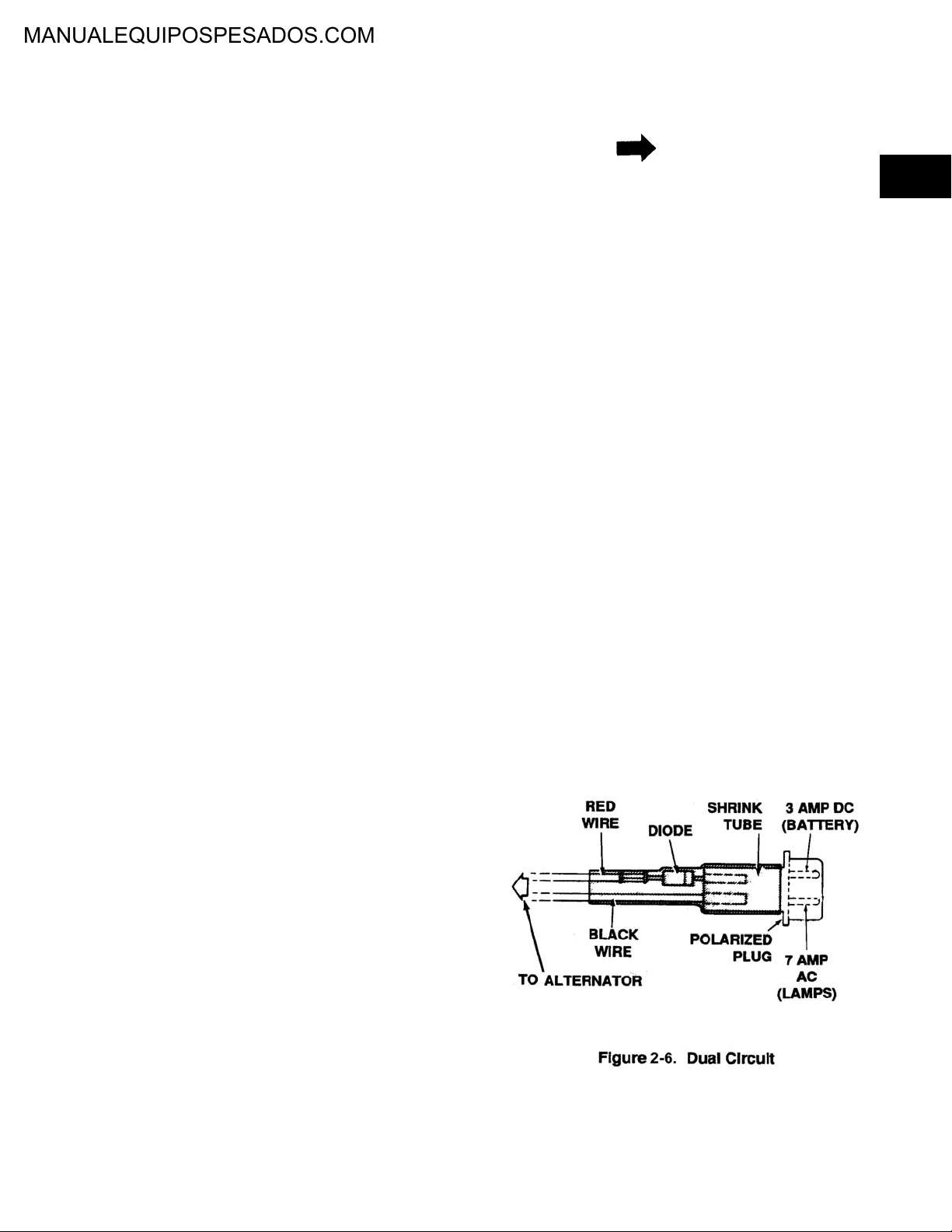

2-9.3 Dual Circuit (Engine Alternator) (Figure 2-6).

1. The charging system is an alternator located

under the flywheel. A half wave rectification

(single diode) is unregulated and rated at 3

amps at 3600 RPM.

2

2-8. BATTERY STARTING CIRCUITS.

2-8.1 Battery starting circuits consists of the following:

•Battery as a source of energy

•Starter solenoid switch to transfer high starting

current from battery to starter (starter relay)

•Key start switch or other switch to energize

the starter solenoid

2-5

Page 11

2. The diode changes AC to DC to charge the

battery. A bad diode can either fail to charge

the battery or discharge the battery if the alternator is shorted as well as the diode.

3. The 7 amp AC terminal operates the head

lamps. The voltage rises from 8 volts at 2400

RPM to 12 volts at 3600 RPM. Therefore, the

brightness of the lights changes with engine

speed. In certain situations it is necessary to

make use of the entire AC signal. To accomplish this we use multiple diodes in a bridge

configuration. This produces full wave rectification (regulator) which is regulated and rated 16

amps at 3600 RPM.

4. The 16 amp DC terminal at 3600 RPM operates the head lamp. The regulated system produces 12 volts DC which goes to the battery.

Engine speed will determine amount of amps

regulated.

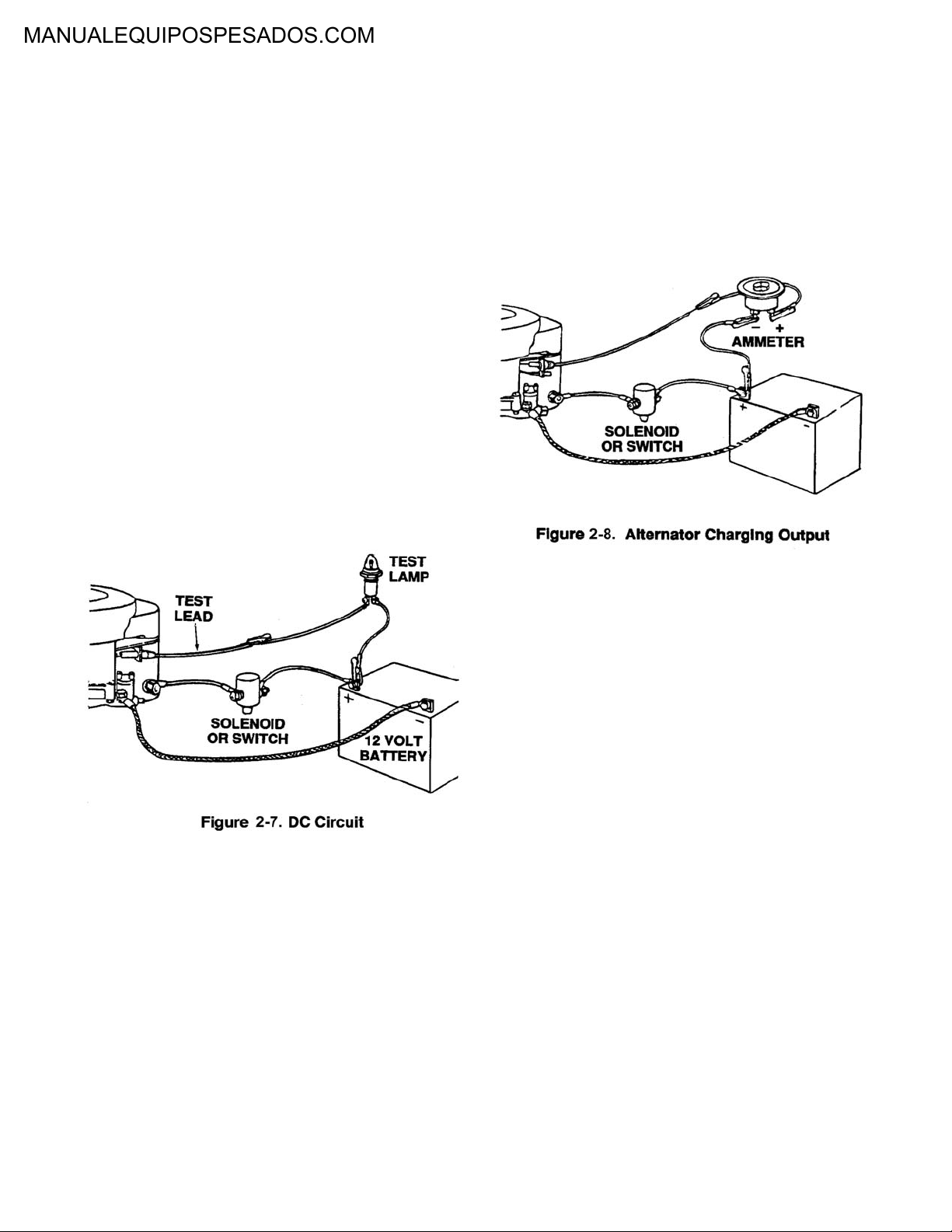

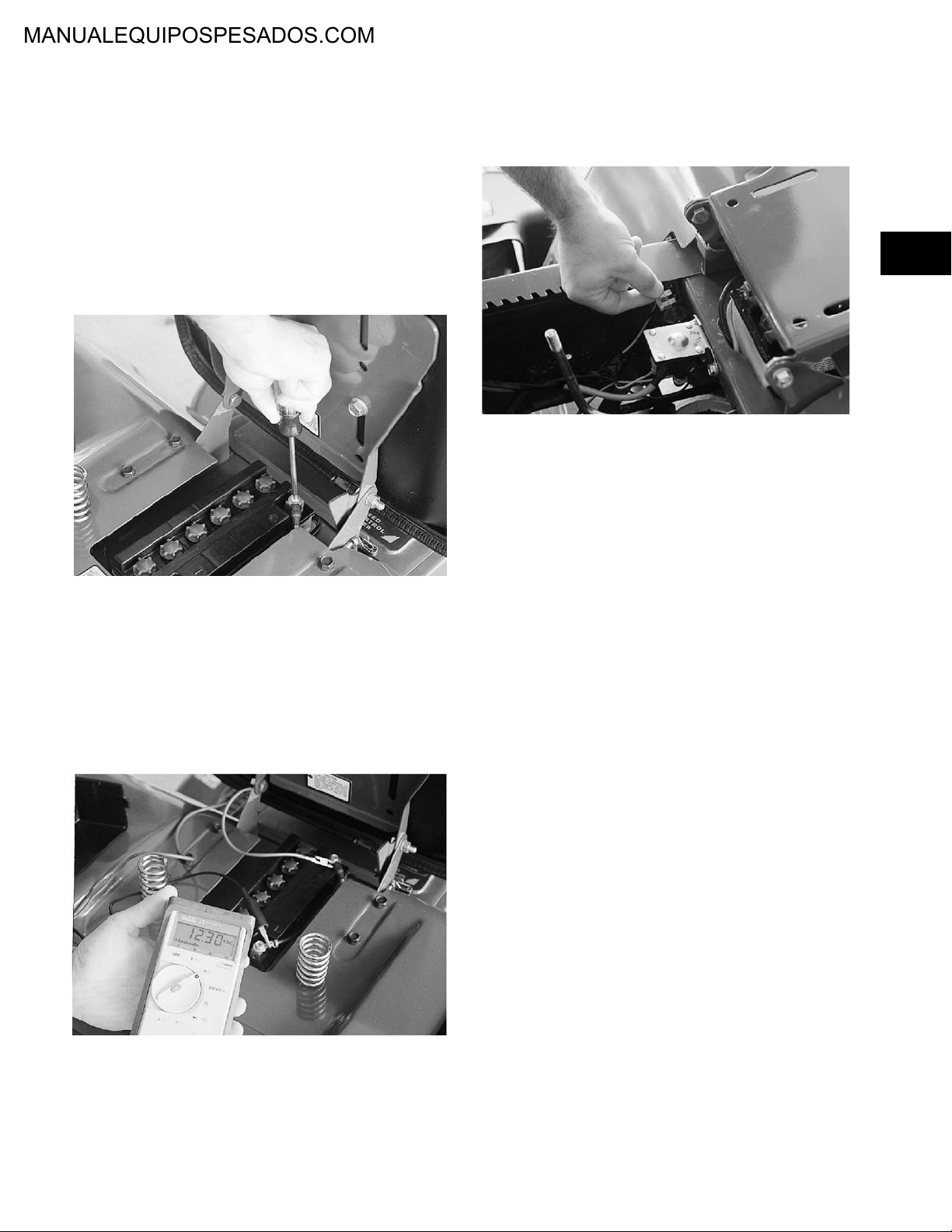

2-9.4 Testing the DC Circuit (Figure 2-7).

2-9.5. Battery Runs Down.

2-9.5.1 Testing Alternator Charging Output.

Install ammeter in series with charging lead.

See Figure 2-8. Start engine. Ammeter should

indicate charge. The charge rate is dependent

upon the condition of the battery. If ammeter

shows no charge, test stator and regulator.

1. Disconnect the charger lead from the battery

(small red wire).

2. Connect a 12 volt test lamp between the DC

charge lead and the positive terminal of the

battery.

3. With the engine off, the lamp should not light. If

it does, the diode and possibly the alternator

may have failed.

2-10. BATTERY SHIPPING AND STORAGE.

2-10.1 Check List For Proper Battery Storage.

1. Electrolyte level correct.

2. Battery fully charged.

3. The exterior of the battery is clean.

4. Store battery in a cool place.

5. Rotate stock. Always use the oldest battery

first.

2.10.2 Dry Charged Battery Storage.

1. A dry charged battery has a shelf life of about

five years.

2. Keep in a cool, dry place with the humidity as

low as possible with a temperature between

60°F and 90°F. The temperature should be uniform and not subject to frequent changes.

4. Start the engine. The lamp should light. If it

does not, the alternator (starter) or lead wire

could be bad.

3. Once a dry charged battery is actuated, it must

be maintained the same as any wet battery.

2-6

Page 12

2-10.3 Wet Battery Storage.

1. Wet batteries will slowly discharge while in

storage.

2. Batteries not used in the winter should be

stored in a fully charged condition.

3. Batteries in storage discharge slower when

kept cold than when too warm.

4. The best place to store the battery is in the

equipment.

2-11. ACTIVATING BATTERY.

2-11.1 The instructions listed below are packed with

every battery shipped with each unit. Following

these steps will prevent premature battery failure.

WARNING

LAWN AND GARDEN EQUIPMENT BATTERY

(DRY AND CHARGED) FILLING AND INSTALLATION INSTRUCTIONS. Do not fill with electrolyte until battery is actually placed in service.

This battery is supplied dry and charged. Do

not fill with electrolyte until battery is to be

used.

WARNING

DANGER—BATTERY CONTAINS SULFURIC ACID MAY CONTAIN EXPLOSIVE

GASES.

•Keep sparks, flame, cigarettes or any flame

away.

•Shield eyes, protect skin and clothing when

handling acid or battery containing acid or

working near such batteries.

•Ventilate when charging or using battery in

enclosed space.

•Make sure venting path of battery is always

open once battery is filled with acid.

NOTE

When the battery is charged, the heat will

expand the electrolyte.

1. Allow the battery to sit 20 to 30 minutes. This

allows the chemical action to take place.

2. The battery must be charged at the maximum

rate until a specific gravity is reached. See

paragraph 2-1.4.

2

WARNING

POISON—CAUSES SEVERE BURNS. Contains sulfuric acid. Avoid contact with skin,

eyes or clothing. To prevent accidents, neutralize excess acid with baking soda and rinse

empty container with water. KEEP OUT OF

THE REACH OF CHILDREN.

ANTIDOTE:

EXTERNAL—Flush with water.

INTERNAL—Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

eggs or vegetable oil. Call physician immediately

EYES—Flush with water for 15 minutes and

get prompt medical attention.

3. Add electrolyte until it reaches the split ring.

CAUTION

DO NOT ADD ACID. Add only distilled water.

4. After charging, replace vent plugs firmly, wash

off acid spillage with water and dry the battery.

5. If time does not permit charging the battery, or

if charging equipment is not available, the battery should be installed and the unit should be

run continuously for 20 to 30 minutes in order

to sufficiently charge the battery.

2-11.2 Preparation for filling the battery is very impor-

tant.

1. Remove vent plugs just before filling with electrolyte.

2-7

Page 13

WARNING

Internal gas pressure can cause battery to

explode if sealing tube is left in place.

2. If your battery has a short sealing tube on the

vent elbow and is supplied with a separate

long tube, pull off short one and replace with

long one.

WARNING

Electrolyte is sulfuric acid solution. Avoid spillage and contact with skin, eyes and clothing.

See WARNING on back panel of battery.

CAUTION

Do not use water or any other liquid to activate. During cold weather, if electrolyte (acid)

is stored in cold area, warm electrolyte to room

temperature before filling.

3. Fill battery with electrolyte (diluted sulfuric

acid) of a specific gravity of 1.265. Fill to upper

level as indicated on battery. Electrolyte should

be at room temperature before filling.

2-12. BATTERY INSTALLATION INSTRUCTIONS.

1. Remove old battery. Mark which cable is connect ed to positive (+) and negative (-) terminals. Positive cable is usually red.

2. Clean cable connectors with wire brush or

sand paper to remove oxidation.

CAUTION

Connecting in reverse, positive to negative and

negative to positive, can cause serious damage to electrical system.

4. Check vent tube to avoid any crimping or

obstruction to the tube.

5. Securely fasten battery to the unit using its battery hold-down arrangement. This will minimize

destructive vibration.

2-13. COMMON CAUSES FOR BATTERY

FAILURE.

2-13.1 Overcharging. Charging a battery greatly in

excess of what is required is harmful in several

ways, as follows:

1. Severely corrodes the positive plate grids with

consequent mechanical weakening and loss of

electrical conduction.

2. Decomposes water of electrolyte into hydrogen and oxygen gas. Gas bubbles tend to

wash active material from the plates and carry

moisture and acid from the cells as a fine mist.

3. Decomposition of water leaves acid more concentrated. Concentrated acid is harmful to cell

components, particularly at high temperatures

over a prolonged period of time.

4. High internal heat is created, which accelerates the above mentioned corrosion of positive

plate grids and damages separators and negatives. Also, containers may be softened and

distorted.

3. After filling with acid and charging (see instructions), install new battery. Connect cables to

the proper terminals. Positive cable to positive

terminal (+) and negative cable to negative terminal (-). CONNECT NEGATIVE CABLE

LAST.

5. Overcharging alone or in combination with a

previous condition of undercharging may

cause severe buckling and warping of positive

plates with accompanying perforation of separators.

6. May cause damage by corrosion to battery

box, cables and other vital electrical and

engine parts by forcing liquid from the cells if

charge rates are excessive.

2-8

Page 14

2-13.2 Undercharging.

1. A battery operated with insufficient charge over

a long period of time may develop a type of

sulfate in the plates which is dense, hard and

coarsely crystalline and which cannot be

readily electrochemically converted to normal

active material again. Such lead sulfate, being

less dense than the active material from which

it was formed, will set up strains in the positive

plates so that distortion or bowing of the plates,

called buckling, may result. Buckling will be

produced, especially if the sulfated battery is

subjected to sudden prolonged overcharging,

as might be experienced by an alternator or

generator-regulator system which has gotten

out of adjustment. Severely buckled plates will

pinch the separators at the plate corners or

chafe the center of the separators. This may

result in perforations of the separators and

develop a short circuit in the cell.

2. A battery operated in an undercharged condition is not only unable to deliver full power, but

is liable to freeze during severe winter weather.

See par graph 2-8.7.

3. Lead sulfate formed on the plates during discharge is relatively insoluble as long as the

specific gravity of the electrolyte indicates a

substantially charged condition. If allowed to

drop much below this state the lead sulfate

becomes increasingly soluble and, aided by

temperature fluctuations of the electrolyte, may

migrate over a considerable period of time into

the pores of the separators and deposit as a

white crystalline mass. Subsequent charging

may convert these crystalline deposits to

metallic lead which may short the positive and

negative plates through the areas of the separators affected. These small shorts may cause

a condition of low cell voltage when the battery

is charged. For this reason battery cells should

not be allowed to stand idle in a discharged

condition.

2-13.3 Lack of Water. Water is one of the essential

chemicals of a lead-acid storage battery and

under normal conditions of operation is the

only component of the battery which is lost as

a result of charging. It should be replaced as

soon as the liquid level falls to the top of the

separators. If water is not replaced, and the

plates are exposed, the acid will reach a dangerously high concentration that may char and

disintegrate the separators and may permanently sulfate and impair the performance of

the plates. Plates can not take full part in the

battery action unless they are completely covered by the electrolyte. Sulfuric acid must

never be added to a cell unless it is known that

acid has been spilled out or otherwise loose

from the cell.

2-13.4 Loose Holddowns. Holddowns, if not properly

adjusted, may allow the battery to bounce

around in the battery box. This may cause the

bridges on which the elements rest to notch

the bottom of the separators and may cause

the plates to notch the bridge tops causing a

severe disarrangement of the elements. The

bouncing of the battery may also crack or wear

the container badly and cause acid to leak.

Leaking acid corrodes terminals and cables

and results in high resistance battery connections, thereby weakening the battery’s power

and shortening its life. If holddowns are too

tight, they can distort or crack the container,

allowing loss of acid from the cells. This will

cause loss of battery capacity.

2-13.5 Battery Electrolyte Substitutes. No satisfac-

tory substitute electrolyte has been found for

the simple mixture of sulfuric acid in water. Use

no substitutes.

2-13.6 Excessive Loads. A battery should never be

used to propel the rider by the use of the starting motor with clutch engaged except in a

great emergency. This may produce extremely

high internal battery temperature and damage

the starting motor.

2-13.7 Freezing of Electrolyte.

1. The electrolyte of a battery in various states of

charge will start to freeze at temperatures indicated below. The given temperatures indicate

the approximate points at which the first ice

crystals begin to appear in the solution. The

solution does not freeze solid until a lower temperature is reached. Solid freezing of the electrolyte may crack the container and damage

the positive plates.

2

2-9

Page 15

2. A 3/4 charged automotive battery is in no danger from freezing. Keep batteries at 3/4 charge

or more, especially during winter weather.

3. Battery power decreases while the need for

engine power increases with falling temperatures.

80°F 100%

32°F 66%

0°F 46%

4. Sub-zero temperatures reduce the capacity of

a fully charged battery to 30% of its normal

power and at the same time increases cranking load beyond the normal warm weather

load.

NOTE

The above failures do not constitute a warranty.

2-14. TESTING THE BATTERY.

2-14.1 A visual inspection of battery should be done

by checking for:

3. A correct specific gravity reading can be measured only when the electrolyte temperature is

80°F. If the electrolyte temperature varies from

this temperature, compensation must be made

in the reading as follows:

a. Add four gravity points (.004) for each 10°

electrolyte temperature is above 80°F.

b. Subtract .004 for each 10° below 80°F.

1. Broken or leaking cover.

2. Broken case.

3. Damaged post.

4. Other.

2-14.2 Batteries should be handled with care. Never

leave battery standing in a discharged position.

WARNING

Never test a battery by striking a cable across

the output terminals. An internally shorted battery could EXPLODE.

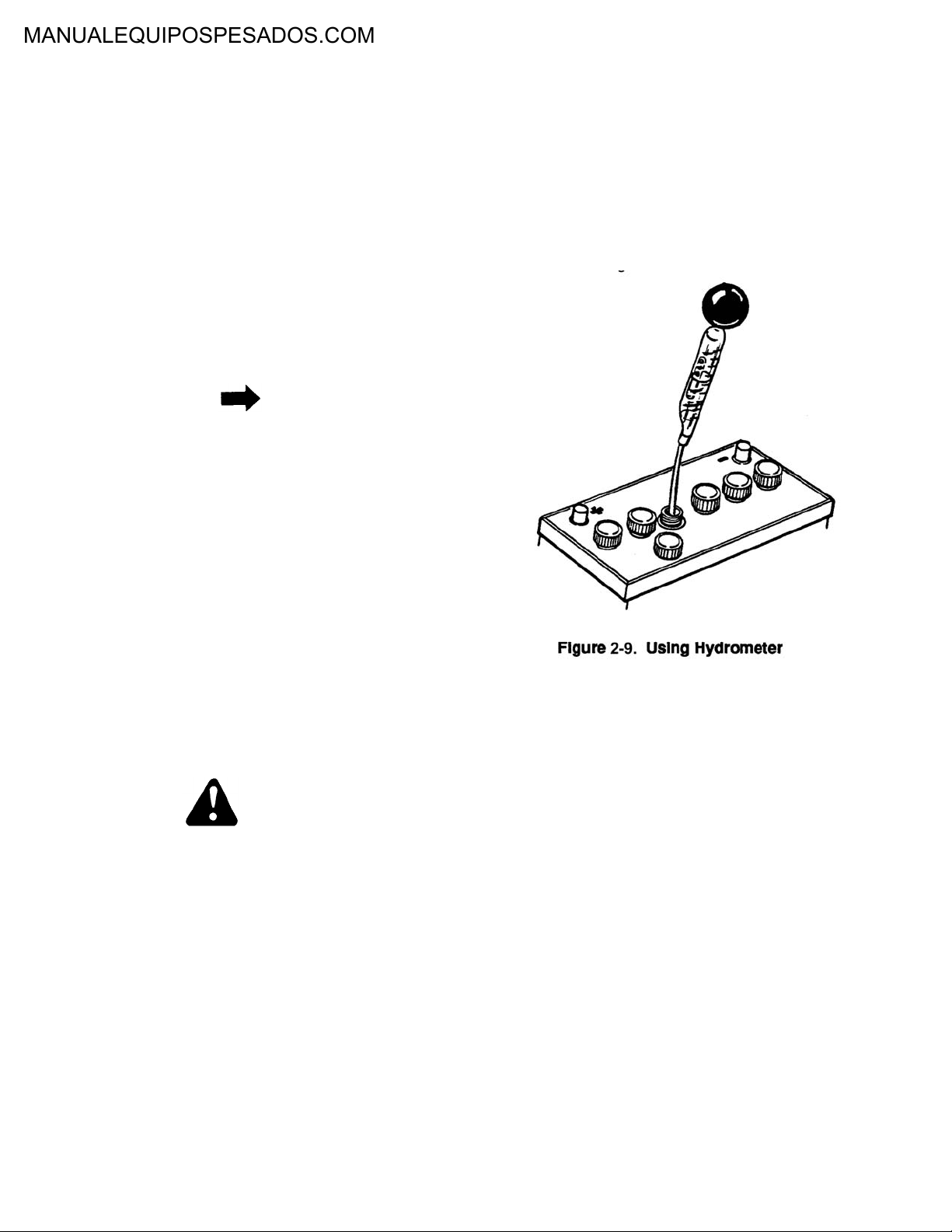

2-14.3 The hydrometer measures the state of charge.

Use of the hydrometer will also pinpoint a

shorted cell which, in some instances, cannot

be charged or will not hold a charge. See Figure 2-9.

1. Specific gravity tests must be performed

before adding water to the battery.

2. In the event the electrolyte level is too low to

test with the hydrometer, add water and charge

before testing.

4. In taking the hydrometer reading, the float

must be floating freely and the eye must be

even with the liquid level to obtain accurate

readings.

5. When all cells are tested, if the specific gravity

between the highest and lowest cell varies 50

points (.050) or more, condemn the battery; it

is no longer serviceable.

6. If there is less than a 50 point variation

between the highest and lowest cell, and the

specific gravity in one or more cells is below

1.235, recharge the battery.

7. The inability to bring the specific gravity of any

one cell up to 1.235 after charging is also an

indication of an unserviceable battery and it

should be condemned.

8. After the recharge, let the battery stand at least

24 hours, and repeat hydrometer test on all

cells. If there is a variation of 50 points or more

between the highest and lowest cell, condemn

the battery.

2-10

Page 16

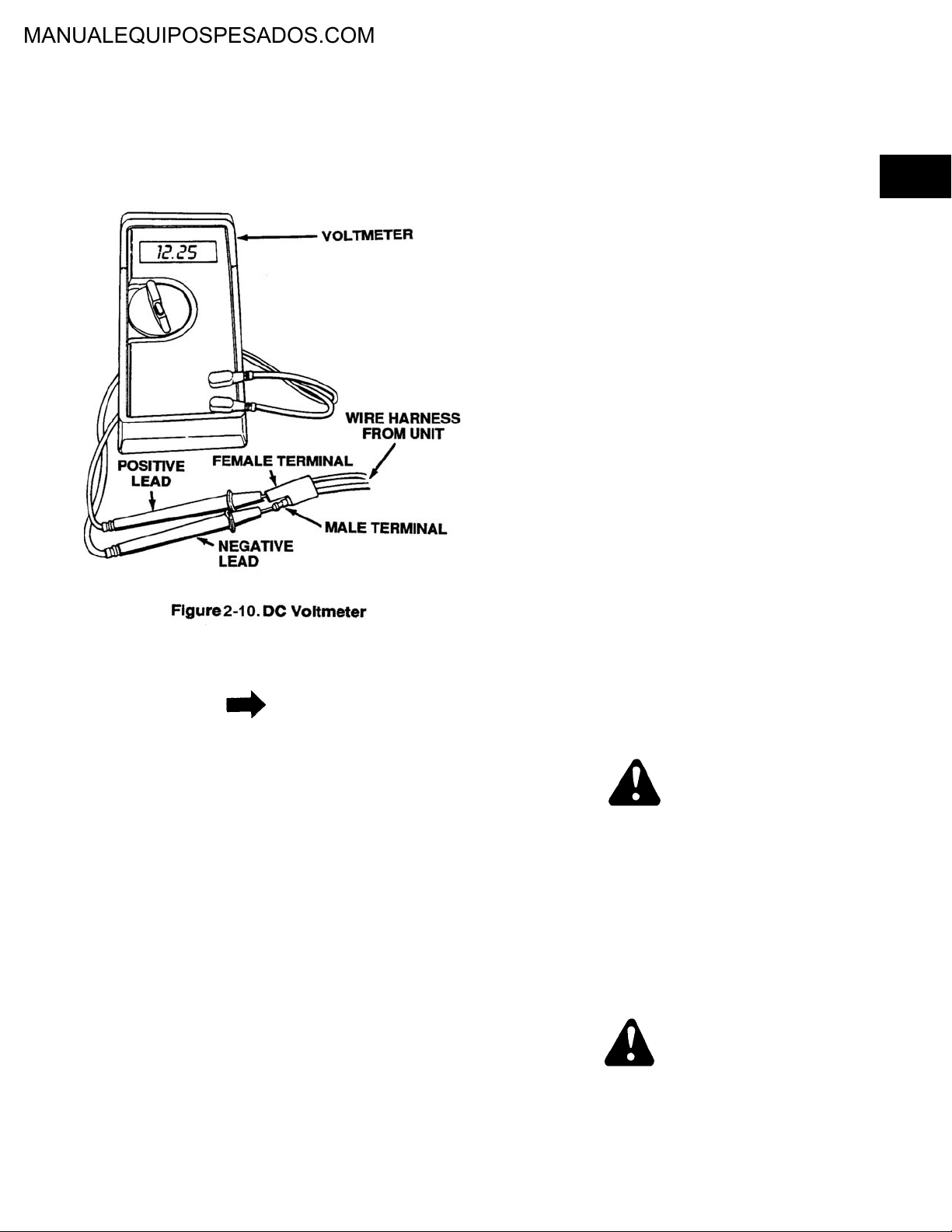

2-14.4 Batteries 725-1105 and 725-1276 are 12 volt

sealed lead-acid batteries. These batteries can

be checked by using a standard DC voltmeter.

When checking the voltage, the male terminal

of the connector plug of the harness is the negative terminal. See Figure 2-10.

2-15.1 Restore charge.

1. An electric current is sent through the cell in

the reverse direction to that in which the current flows when the battery is delivering current. The charging rate must be slightly higher

than the voltage. A single battery cell produces

approximately 2 volts. A 12 volt battery will

consist of six 2 volt cells. To charge a 12 volt

battery requires (.5 volts x 6 cells = 3 volts) (12

volts + 3 volts = 15 volts). When a battery is

discharged, its internal resistance is low. In this

low resistance condition, the battery will draw a

greater charging current. As the battery

becomes charged, the internal resistance

increases and the current draw will diminish.

2. Batteries should only be tested with a hydrometer for specific gravity, or a test device that

applies a current draw to the battery while testing. A voltmeter does not give an accurate indication of battery condition, as even a partially

discharged battery will indicate correct voltage

when not under load. The normal specific gravity of a charged battery should be between

1.285 and 1.300 approximately. A discharged

battery cell has a specific gravity of 1.150

approximately.

2

2-14.5 Check battery charge with voltmeter as fol-

lows:

NOTE

Check to be certain the in-line fuse in the wire

harness is OD.

1. Connect the negative lead of the voltmeter into

the male end of the plug on the wire harness.

2. Connect the positive lead of the voltmeter into

the female pin on the plug on the wire harness.

3. A fully charged battery will register 13.0 volts

on the voltmeter.

4. A battery that needs charging should read

between 11.0 and 13.0 volts.

5. If the reading is below 10.0 volts on the voltmeter, the battery probably will not accept a

charge and should be replaced.

2-15.2 Recharging is necessary when you find lights

get dim, and/or when battery is not used for

longer than one month. Charge the 12 volt battery with a 12 volt 1 amp automotive charger.

Recommended charging for 6 volt or a 12 volt

battery should not exceed 1 amp. Charge until

battery gases freely and specific gravity of

electrolyte rises to 1.265 or above.

WARNING

When charging, care must be taken to ventilate the fumes from the battery as they are

highly EXPLOSIVE. The gases issuing from a

charging battery are a mixture of hydrogen and

oxygen gases and will explode with great violence and spraying of acid if a spark or flame is

brought too near them. A room or compartment

in which charging batteries are confined should

be ventilated. Do not bring flame or sparks

near vent openings.

WARNING

2-15. BATTERY CHARGERS AND CHARGING.

In all automotive battery cells small quantities

of hydrogen gas are given off at the negative

plates when the cells are not being charged. It

2-11

Page 17

must therefore be assumed that explosive mixtures of hydrogen gas are present within the

cells at all times. A torch, match flame, lighted

cigarette or sparks from metal tools accidentally contacting the terminals could cause ignition of the gases.

WARNING

To avoid sparks, do not disturb connections

between batteries while charging: first throw

switch “off” at the charger. The possibility of

ignition of hydrogen gas by static electricity

when working on or near batteries is minimized

by grounding ones self and the vehicle to

remove any static charge.

WARNING

The improper use of a booster battery to start a

rider, when the normal battery is inadequate,

presents a definite explosion hazard. To minimize this hazard the following procedures are

suggested.

CAUTION

negative to negative. Most have a negative

grounded electrical system.

c. Connect the first end of the second jumper

cable to the other terminal of the booster battery. With the other end make final connection

and this is to be the rider frame of the mower

with the discharged battery as far away as possible from the battery.

2-15.3 Charging the Battery.

1. Connect the charger to the lawn mower harness.

2. Plug the charger into a 110 volt AC wall outlet.

3. Check the charger after 15 minutes. The

charger should be warm to the touch (approximately 100°F).

WARNING

Charger could be HOT and cause burns.

4. If the charger is hot, it is drawing too much current and should be disconnected immediately.

One of the following conditions exist:

Exceeding the recommended charging rate

can cause warping of the plates and will affect

the life of the battery.

1. When possible, use equipment with a switch in

the line connecting the booster battery to the

installed battery. Check to see that both batteries have the same voltage type: e.g., 6 volt or

12 volt.

2. If only jumper cables are available and the

booster battery is in a car, set the hand brakes,

turn off accessory switches and ignition keys

and place the gearshift or gear selector in the

neutral or park position for both vehicles. Now

proceed in exact sequence.

3. Always rock the connector clips to insure

secure grip contact.

a. Connect one end of first cable to the terminal

of the discharged battery which is connected to

the starter switch or solenoid (not grounded).

Note if this is the positive or negative battery

terminal.

b. Connect the other end of the first cable to the

terminal post of the booster battery having the

same marking; that is, positive to positive or

a. The battery is defective.

b. The polarity of the battery connectors is

reversed.

c. There is a short in the wire harness.

5. If the charger is cold to the touch, one of the

following conditions exist:

a. The battery is not connected to the wire har-

ness.

b. The charger is bad. Check the output voltage.

It should be above 9 volts DC with the male

terminal of the charger being positive.

c. There is no voltage present at the wall socket.

d. The charger should be checked once more by

touch within an hour. Use caution when touching the charger.

6. Normally, if the unit starts the first time, it is

unlikely that the wire harness is defective.

However, if the wire harness is suspect after

using the above procedures, it should be

replaced.

2-12

Page 18

2-15.4 Plug-in Trickle Chargers. Different trickle

chargers are used for different batteries. The

following is a list of chargers and the rate at

which the batteries are to be charged.

Plug-In Trickle Chargers

725-0727 300 ma. use on 725-1105 and 725-1276

battery

725-0507 1/2 amp charger, used on 725-0415

725-0579 Alligator clips for 725-0507 charger to be

used when charger does not plug into the

wire harness

725-0156 Old red Schauer charger. Not available.

Use 753-0220. This kit consists of:

1 725-0507 charger

1 725-0579

Charging Rates

725-0130 automotive type with tapered terminals 15

amp maximum

1.150 5°F

1.100 18°F

1.050 27°F

2-16 MAINTENANCE AND SERVICE.

2

2-16.1 Proper maintenance and service could extend

the life of a battery. The following procedures

should be taken:

1. Clean battery top with a stiff brush, being careful not to scatter corrosion products. Wipe off

with a cloth wetted with ammonia or baking

soda in water. Fully wipe with a cloth with clean

water.

2. Inspect cables—urge replacement if unserviceable. Inspect the terminals posts to see

that they are not deformed or broken.

3. Clean the battery and cable contact surface to

a bright metal finish whenever they are

removed. Coat the contact surfaces with mineral grease or petroleum jelly before the terminals are reconnected.

725-0453

725-0661 4-5 amp maximum

725-0117

725-0726 300 ma. elec. start self-propelled

725-1104 lawn mowers

725-1276

725-0514 motorcycle type 3 amp maximum

2-15.5 New Information Concerning Battery

Charging. It is important that new batteries are

charged according to the owner’s guide or

Technical Handbooks Volume I, II and III. We

have found that rider and tractor batteries do

not have memories, and the capability of

recharging a low or dead battery is feasible. A

3 to 10 amp taper charger should be used;

charging time varies between 12 to 40 hours.

This charging procedure should be followed

prior to checking the specific gravity or condemning any rider or tractor battery.

Table 2-1. Specific Gravity Freezing Points

Specific Gravity Freezing Point

1.265 -75°F

1.225 -35°F

1.200 -17°F

4. Inspect battery box and adjust holddowns.

Urge replacement if unserviceable.

5. Check electrolyte level once a month. If found

below middle of UPPER and LOWER LEVEL,

add clean drinking water to restore level.

WARNING

NEVER use ACID to refill a battery.

6. Make hydrometer or voltage test.

7. Keep exhaust tube free of kinks and obstructions.

8. Store battery with a full charge. A discharged

battery will freeze.

NOTE

All batteries discharge during storage.

Recharge battery every two months and before

returning to service.

9. Carefully inspect and recharge the battery at

the beginning and end of each mowing season.

2-13

Page 19

2-14

Page 20

SAFETY INTERLOCK SYSTEMS

3-1. GENERAL.

3-1.1 There are two basic electric wiring systems

used: one for battery start models and one for

recoil start models. All safety systems used are

based on the same principle.

3-1.2 Most riders and tractors produced in 1982

were equipped with a reverse safety switch.

This safety system required the cutting deck to

be disengaged before the unit can be shifted

into reverse gear. These systems will be used

on all current production units.

3-1.3 The lift and disengagement lever is used to

raise and lower the cutting deck which determines the cutting height. Pulling it all the way

back and locking it disengages the blades. The

lift and disengagement lever MUST be in the

disengaged position when starting the engine,

when shifting into reverse or if the operator

leaves the seat.

3-1.4 All lawn and garden tractors produced after

July, 1987 were requested by ANSI (American

National Standards Institute) to have an operator present as an added safety feature. If the

operator leaves the seat with the blades or

PTO engaged, the engine will shut off. This

seat switch is a safety device, designed for

your protection. See Figure 3-1.

WARNING

NEVER attempt to bypass this operation.

3-1.8 For further information regarding this section,

refer to the Technical Service Video “Safety

Interlock Systems.”

3

WARNING

NEVER attempt to bypass this operation.

3-1.5 In mid 1986, safety switches were added to

most lawn and garden tractors, internally

mounted in the seat.

3-1.6 On 1988 production, the location and type of

safety switch was changed on most front

engine lawn tractors. It was mounted on the

seat bracket under the seat and it will shut off

the engine with the deck engaged, with less

than 40 lbs. of weight on the safety seat.

3-1.7 The 1990 riders and tractors have incorporated

a new seat safety switch. The operator must

engage the parking brake before leaving seat

or unit will stall out. This new switch will also be

present on riders and tractors with electric

PTO’s.

3.2 SAFETY INTERLOCK SYSTEM – CHANGES

FOR 1991.

NOTE

The safety interlock system for 1991 has some

changes that may or may not retrofit prior production units.

WARNING

At no time should the safety interlock system

be bypassed for consumer’s operation or convenience.

3-1

Page 21

3-2.1 600 Series Rider Only.

1. The PTO safety switch mounting bracket was

changed for added support to 14 gauge steel.

This will retrofit 1990 production units. See Figure 3-2.

2. The standard battery used in the 600 series is

725-0514 (125 cold cranking amps). This battery can now be replaced by part number 7251430 (275 cold cranking amps) by removing

the battery spring retainer to allow clearance

for the larger battery. This will not retrofit prior

production units. See Figure 3-3.

Tighten the cable tie on the insert to securely

hold the wires in position.

5. Snap the steering wheel insert over the four

spokes making sure the indicator lights are

positioned towards the bottom.

6. Tighten the special cable tie in such a manner

so the cable tie can slide up and down the wire

harness which goes through the dash panel.

(Slide the cable tie up until it rests against the

hole on the inside of the dash panel.)

b. Place the five wires through the slotted hole

located towards the center of the steering

wheel hub. With the front wheels positioned

straight forward, place the steering wheel over

the steering shaft. Secure with the cupped

washer and lock nut provided in the screwpack. See Figure 3-4.

3. Attach the steering wheel and indicator light

panel as follows:

a. Place the indicator wires through the steering

bellows and place the bellows over the steering shaft.

4. Place the indicator wires through the cable tie

located on the bottom side of the steering

wheel insert. Connect the wires to the corresponding wires in the steering wheel insert.

NOTE

The indicator wires should be positioned at the

bottom of the steering wheel (6 o’clock position).

CAUTION

Do not cut off excess cable tie. The excess end

will help keep the harness from being drawn up

into the steering wheel and causing serious

damage to the wires.

3-2

Page 22

7. Turn the steering wheel fully in both directions.

Pull the wires down from the dash and slide

the cable tie down an additional 1/4 inch and

tighten the cable tie securely. While doing this

procedure the cable tie will automatically position itself on the harness to prevent damage to

the wires during normal operation.

3-2.2 All Riders and Tractors.

1. The clutch safety switch has a retainer bracket

for added support. This will retrofit 1990 production units. See Figure 3-5.

NOTE

This boss plate goes all the way through the

two spring switches and will reduce the

chances of a short. This also will retrofit prior

production units.

3-2.3 600, 700 and 800 Series Only. The circuit

breaker is being replaced by a standard automotive type fuse. Nonregulated electrical systems will use a 7-1/2 amp fuse. On regulated

electrical systems, a 20 amp fuse will be used.

This will not retrofit prior production units. See

Figure 3-7.

3

NOTE

If the clutch safety switch (part number 7253169A) is ordered, it will NOT come with the

retainer bracket or screws. To retrofit to a pre

1991 production unit, it is necessary to order

the retaining bracket (part number 179162)

and two screws (part number 710-0351).

2. The seat safety switch insulator nut plates

have been redesigned to reduce the chances

of a direct short. This will retrofit 1990 production units. See Figure 3-6.

NOTE

Although this will not retrofit our prior production units, there are, however, two separate

fuses: the 7.5 amp fuse for a standard dual circuit alternating system and the 20 amp fuse for

a regulated system.

3-3. ELECTRIC START SYSTEM.

3-3.1 Before the engine will crank, the key must be

turned on and both of the safety switches must

be activated. One is activated when the clutch

is depressed and one is activated when the

blade is disengaged. When this happens the

circuit will be complete between the battery

and the coil primary of the solenoid. This will

close the solenoid which will allow the starter

motor to crank the engine. The safety switches

are wired in series on the electric start models. See Figure 3-8.

3-3.2 Testing the Interlock System on the Electric

Start System.

3-3

1. Starting instructions:

a. Disengaged the blade or PTO.

b. Depress the clutch pedal.

c. Set the throttle (and choke if separate).

d. Turn the ignition key to the START posi-

tion.

Page 23

NOTE

If the engine does not crank, use the following

procedure to check out the system. If the

engine cranks but does not start, the problem

is not with the interlock system.

2. Check the two safety switches to see that the

disengaging of the blade and the depressing of

the clutch depresses the black plunger a minimum of 1/8 inch.

3. Check the fuse or circuit breaker between the

positive terminal of the battery and the ignition

switch. If the fuse or circuit breaker is blown

the engine will not crank.

4. Check the following terminal to see that the

wires are in place.

a. The positive terminal of the battery. A large

and a small wire should be fastened

securely to this terminal. On some units

both wires are cast into one clamp.

b. The negative terminal on the battery and

the ground to the frame.

c. The ignition switch terminal.

d. The clutch safety switch.

e. The blade safety switch.

f. The solenoid terminals. A small wire is fas-

tened to the coil primary and the two larger

wires are fastened to each side.

5. Check the condition of your battery. Even if the

battery is dead you should be able to hear the

solenoid click. This would verify that the starting system is operating at least to the solenoid.

The specific gravity of the battery should be

1.265.

3-4

Page 24

6. A continuity tester can be used to check the

continuity between each component of the

inter-lock system. Follow the instructions

packed with the continuity tester which can be

purchased at electrical shops.

WARNING

To test the interlock system further, you will be

bypassing the safety switches. Make sure that

the clutch is disengaged and the blade

engagement lever is in the disengaged position. If the clutch cannot be locked in the disengaged position, place the gear shift lever in

the neutral (N) position. When using a jumper

wire in the following tests the engine may

crank over.

NOTE

Disconnect the spark plug lead and ground it

against the engine block

7. Use a jumper wire between the following

points:

crank, however, you can crank the starter

using the jumper wire, the problem is with the

solenoid. Check the base of the solenoid to

see that it has a good ground to the frame of

the unit. If it still fails to operate, replace it.

NOTE

Transmission lever must not be touching the

reverse spring switch and the key must be in

the ON position.

1. Disconnect the yellow wire going to the magneto on the engine.

2. Disconnect the wire attached to the spring

switch.

3. Attach one lead of a continuity tester to the

spring switch and the other lead to ground. If

there is continuity, the fiber washers could be

damaged and should be replaced.

3-3.4 Testing the Solenoid on Electric Start Rid-

ers and Tractors.

3

a. The positive terminal on the battery to the

terminal on the solenoid (coil primary). If

the engine cranks, then test within this circuit to find the exact area of the problem.

See steps b and c below.

b. The positive terminal of the battery and the

S terminal on the ignition switch. If the

engine cranks, the problem is between the

battery and the ignition switch.

c. The S terminal on the ignition switch to the

coil primary terminal on the solenoid. If the

engine cranks, the problem is between the

ignition switch and the solenoid.

d. Jump between the two large terminals on

the solenoid.

3-3.3 Testing the Safety Reverse Switch on the

Electric Start Systems. If the engine can be

started, but stalls when the blade is engaged,

use the following procedure to determine if the

problem is in the reverse safety switch:

NOTE

Only use a wire as heavy as the wire from the

solenoid to the starter with an alligator clip. If

you have current up to the coil primary terminal of the solenoid and the starter will not

NOTE

Through examination of returned warranty

parts, we have found instances of solenoids

being replaced unnecessarily on electric start

riders.

1. The following are real solenoid problems and

require replacement of the solenoid:

a. Solenoid is stuck – Unit will start with igni-

tion key in OFF position.

b. Coil wire (inside solenoid) is bad – Sole-

noid will not function.

c. Bad washer (inside solenoid) – Solenoid

clicks but starter motor does not turn.

2. Other problems which can appear to be a

defective solenoid:

a. Faulty ground.

b. Defective safety switch.

c. Discharged battery.

d. Defective starter motor.

e. Blown circuit breaker.

3-5

Page 25

f. Defective ignition switch.

g. Defective wire harness.

1. Coil Check:

a. Disconnect the spark plug wire from the

spark plug.

b. Disconnect the coil wire from the solenoid.

c. Using a DVOM (in the OHMS setting)

attach the red lead to the coil connection

and the black lead to system ground.

d. The resistance reading should be about 5

ohms.

*Meter readings greater than 10 ohms or

less than 3 ohms indicates solenoid failure.

e. Remove meter leads and reconnect coil

wire.

2. Contact Check:

a. Disconnect the spark plug wire from the

spark plug.

b. Disconnect the wire AT THE STARTER

which runs to the solenoid.

c. Using a DVOM (in the OHMS setting),

attached the red lead to a contact bolt and

the black lead to the other contact bolt.

The meter should read “OPEN” circuit, or

infinity.

*A “closed” circuit indicates solenoid failure.

d. Energize the solenoid using the start

switch. WARNING: DO NOT HOLD “ON”

FOR MORE THAN 5 SECONDS AT A

TIME.

e. The meter should read “CLOSED” circuit,

or less than 10 ohms.

*An “OPEN” circuit indicates solenoid failure.

f. Remove meter leads and reconnect the

starter wire.

3-4. RECOIL START SYSTEM.

3-4.1 The recoil start system is completely different

than the electric start system. If the clutch is not

depressed (disengaged) the blade is not disengaged or the ignition key is not ON, the ignition

will be disabled and the engine cannot be

started. In order for the blades and clutch to be

engaged without killing the engine, you must

insert the recoil starter handle into the dash

panel and turn it a quarter turn. This will disengage the wire that grounds the magneto. The

safety switches are wired in parallel on the recoil

start models. See Figure 3-9.

3-6

Page 26

3

3-4.2 Pushing the plunger in breaks the contact of

the circuit. The red or white plunger identifies

the switch as being the correct one to use on

the recoil start models. See Figure 3-10.

5 -4. If the engine will not start and the gasoline

shut-off valve is open, there is fuel in the gasoline tank and the spark plug wire is attached,

use the following procedure to determine if the

problem is in the engine or the safety interlock

system:

1. Check the two interlock switches to see that

the disengaging of the blade and the depressing of the clutch depresses the red plunger a

minimum of 1/8 inch.

2. Disconnect the yellow wire from the ignition

switch to the engine where it attaches to the

primary wire from the breaker assembly.

3. If the engine starts now, the problem is within

the interlock system.

4. Check the grounding system behind the recoil

starter handle. When the recoil starter handle

is being pulled, the bolt on the spring should be

grounded against the rivet. When the recoil

starter handle is locked in place, the bolt on the

spring should not touch the rivet.

3-4.3 Testing the Interlock System on the Recoil

Start System.

1. Start the engine as follows:

a. Disengage the blade.

b. Depress the clutch pedal and lock it in the

disengaged position.

3-7

Page 27

c. Set the throttle control.

d. Turn the ignition key to the ON position.

e. Grasp the recoil starter handle and unlock

it by twisting it 1/4 turn. Pull out sharply

and hold it in the out position. See Figure

3-11.

WARNING

The engine can no longer be shut off with the

key.

2. Disassembly procedure. Disassemble safety

seat as follows:

a. Remove molding clip on lower front of

seat. Remove molding.

b. Remove seat covering and foam padding.

3-4.5 Testing the Safety Reverse Switch on

Recoil Start Systems. If the engine can be

started, but stalls when the blade is engaged,

use the following procedure to determine if the

problem is in the reverse switch:

1. Disconnect the yellow wire going to the magneto on the engine.

2. Disconnect the wire attached to the spring

switch.

f. Slowly let it rewind and pull it out again if

the engine does not start.

g. After the engine starts, slowly let the recoil

starter handle rewind and lock it into the

dashboard by turning it a quarter turn. See

Figure 3-12.

WARNING

3. Attach one lead of a continuity tester to the

spring switch and the other lead to ground. If

there is continuity, the fiber washers could be

damaged and should be replaced.

3-4.6 Testing Procedure for Operator Present

System (Safety Seat).

1. To check the operation of the safety seat, proceed as follows:

a. Start the unit as instructed in the owner’s

guide.

b. Set the parking brake.

c. Place shift lever in neutral gear.

d. Engage the PTO or blades.

e. Raise up off seat (this will activate the seat

kill mechanism).

WARNING

To determine if the problem is in the engine or

interlock system, it is necessary to make the

mower unsafe by bypassing the safety switches.

Use extreme caution in performing these tests.

The recoil start system is not a fail-safe system. When a wire becomes unplugged from

any component, it does not prevent starting as

the electric start system does. If the engine can

be started with either the clutch or blade

engaged or with the ignition key in the OFF

3-8

Page 28

position, the unit should not be returned to the

customer.

NOTE

The transmission lever must not be touching

the reverse spring switch and the key must be

in the ON position.

At this point the engine should stop running. If

unit continues to run, check wire lead and seat

plug for proper connection. If this connection is

satisfactory, then the seat switch mechanism

and wire lead continuity should be inspected

for shorts in the electrical system. See Table 3-

1.

NOTE

Covering and padding are bonded together.

c. Remove phillips head screws, metal plate,

bushings and foam pad. See Figure 3-13.

3

NOTE

When reassembling, note the position of nylon

bushings. Shoulder of bushing must be placed

upward through plate.

2. Disassembly procedure. Disassemble safety

seat as follows:

d. Check for broken terminal end or frayed

plug wire tape to the bottom of the seat

pan.

3. Assemble seat in reverse order. Once assembled, check by pushing downward on metal

plate. Distance between metal plate and phillips head screws must be maintained for

proper switch operations.

NOTE

For 1988 production, the location and type of

safety switch has been changed on most front

engine lawn tractors. It is now mounted on the

seat bracket under the seat. See Figure 3-14.

a. Remove molding clip on lower front of

seat. Remove molding.

b. Remove seat covering and foam padding.

3-9

Page 29

3-10

Page 30