Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

OperatOr’s Manual

Single-Stage Snow Thrower — Squall 521

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-00309E

(June 21, 2007)

Page 2

To The Owner

Thank You

Thank you for purchasing a Snow Thrower manufactured by

Troy-Bilt LLC. It was carefully engineered to provide excellent

performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the unit, its

features and operation. Please be aware that this Operator’s

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. Troy-Bilt LLC

reserves the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Table of Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 6

Controls & Features................................................8

Operation ................................................................10

1

This product has met the rigid safety standards of the Outdoor

Power Equipment Institute and an independent testing

laboratory. If you have any problems or questions concerning

the unit, phone a authorized Troy-Bilt service dealer or contact

us directly. Troy-Bilt’s Customer Support telephone numbers,

website address and mailing address can be found on this page.

We want to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position

The engine manufacturer is responsible for all engine-related

issues with regards to performance, power-rating, specifications,

warranty and service. Please refer to the engine manufacturer’s

Owner’s/Operator’s Manual, packed separately with your unit, for

more information.

Maintenance & Adjustment .................................11

Service .....................................................................12

Troubleshooting .....................................................14

Replacement Parts .................................................15

Record Product Information

Before setting up and operating your new equipment, please

locate the model plate on the equipment and recod the

information in the provided area to the right. You can locate the

model plate by standing at the operator’s position and looking

down at the rear of the deck. This information will be necessary,

should you seek technical support via our web site, Customer

Support Department, or with a local authorized service dealer.

MOdel nuMber

serial nuMber

Customer Support

Please do NOT return the unit to the retailer or dealer without first contacting our Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit us on the web at www.troybilt.com

◊

Call a Customer Support Representative at (800) 828-5500 or (330) 558-7220

◊

Write us at Troy-Bilt LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

◊

2

Page 3

Important Safe Operation Practices

WARNING: This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

DANGER: This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet and throwing debris. Failure to observe the following safety instructions could

result in serious injury or death.

2

Training

Read, understand, and follow all instructions on the

1.

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

Be familiar with all controls and their proper operation.

2.

Know how to stop the machine and disengage them

quickly.

Never allow children under 16 years of age to operate this

3.

machine. Children 16 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and be trained and supervised by an

adult.

Never allow adults to operate this machine without proper

4.

instruction.

Keep bystanders, helpers, pets, and children at least 75 feet

5.

from the machine while it is in operation. Stop machine if

anyone enters the area.

Never run an engine indoors or in a poorly ventilated area.

6.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

Do not put hands and feet near rotating parts or in the

7.

feeding chambers and discharge opening. Contact with

the rotating impeller can amputate fingers, hands, and

feet.

Never attempt to unclog either the feed intake or

8.

discharge opening, remove or empty bag, or inspect and

repair the machine while the engine is running. Shut the

engine off and wait until all moving parts have come to a

complete stop. Disconnect the spark plug wire and ground

it against the engine.

Preparation

Thoroughly inspect the area where the equipment is to

1.

be used. Remove all rocks, bottles, cans, or other foreign

objects which could be picked up or thrown and cause

personal injury or damage to the machine.

Always wear safety glasses or safety goggles during

2.

operation and while performing an adjustment or repair,

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

Wear sturdy, rough-soled work shoes and close-fitting

3.

slacks and shirts. Loose fitting clothes or jewelry can be

caught in movable parts. Never operate this machine

in bare feet or sandals. Wear leather work gloves when

feeding material in the chipper chute.

Before starting, check all bolts and screws for proper

4.

tightness to be sure the machine is in safe working

condition. Also, visually inspect machine for any damage at

frequent intervals.

Maintain or replace safety and instructions labels, as

5.

necessary.

3

Page 4

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

Use only an approved gasoline container.

a.

Never fill containers inside a vehicle or on a truck

b.

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

When practical, remove gas-powered equipment

c.

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment on

a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel

d.

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

Extinguish all cigarettes, cigars, pipes and other

e.

sources of ignition.

Never fuel machine indoors.

f.

Never remove gas cap or add fuel while the engine

g.

is hot or running. Allow engine to cool at least two

minutes before refueling.

Never over fill fuel tank. Fill tank to no more than ½

h.

inch below bottom of filler neck to allow space for

fuel expansion.

Replace gasoline cap and tighten securely.

i.

If gasoline is spilled, wipe it off the engine and

j.

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

To reduce fire hazards, keep machine free of grass,

k.

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

Never store the machine or fuel container inside

l.

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

Operation

Do not put hands and feet near rotating parts or in the

1.

feeding chambers and discharge opening. Contact with

the rotating impeller can amputate fingers, hands, and

feet.

Before starting the machine, make sure the chipper chute,

2.

feed intake, and cutting chamber are empty and free of all

debris.

Thoroughly inspect all material to be shredded and

3.

remove any metal, rocks, bottles, cans, or other foreign

objects which could cause personal injury or damage to

the machine.

If it becomes necessary to push material through the

4.

shredder hopper, use a small diameter stick. Do not use

your hands or feet.

If the impeller strikes a foreign object or if your machine

5.

should start making an unusual noise or vibration,

immediately shut the engine off. Allow the impeller to

come to a complete stop. Disconnect the spark plug wire,

ground it against the engine and perform the following

steps:

Inspect for damage.

a.

Repair or replace any damaged parts.

b.

Check for any loose parts and tighten to assure

c.

continued safe operation.

Do not allow an accumulation of processed material to

6.

build up in the discharge area. This can prevent proper

discharge and result in kickback of material through the

feed opening.

Do not attempt to shred or chip material larger than

7.

specified on the machine or in this manual. Personal injury

or machine damage could result.

Never attempt to unclog either the feed intake or

8.

discharge opening while the engine is running. Shut

the engine off, wait until all moving parts have stopped,

disconnect the spark plug wire and ground it against the

engine before clearing debris.

Never operate without the shredder hopper, chipper chute,

9.

or chute deflector properly attached to the machine.

Never empty or change discharge bag while the engine is

running.

Keep all guards, deflectors and safety devices in place and

10.

operating properly.

Keep your face and body back and to the side of the

11.

chipper chute while feeding material into the machine to

avoid accidental kickback injuries.

Never operate this machine without good visibility or light.

12.

Do not operate this machine on a paved, gravel or non-

13.

level surface.

Do not operate this machine while under the influence of

14.

alcohol or drugs.

Muffler and engine become hot and can cause a burn. Do

15.

not touch.

Never pick up or carry machine while the engine is running.

16.

If situations occur which are not covered in this manual, use

17.

care and good judgement. Contact Customer Support for

assistance and the name of your nearest servicing dealer.

Maintenance & Storage

Never tamper with safety devices. Check their proper

1.

operation regularly.

Check bolts and screws for proper tightness at frequent

2.

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage and repair,

if needed.

Before cleaning, repairing, or inspecting, stop the engine

3.

4 sectiOn 1 — iMpOrtant safe OperatiOn practices

Page 5

and make certain the impeller and all moving parts have

stopped. Disconnect the spark plug wire and ground it

against the engine to prevent unintended starting.

Do not change the engine governor settings or overspeed

4.

the engine. The governor controls the maximum safe

operating speed of the engine.

Maintain or replace safety and instruction labels, as

5.

necessary.

Follow this manual for safe loading, unloading,

6.

transporting, and storage of this machine.

Never store the machine or fuel container inside where

7.

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer, etc.

Always refer to the operator’s manual for proper

8.

instructions on off-season storage.

If the fuel tank has to be drained, do this outdoors.

9.

Observe proper disposal laws and regulations for gas, oil,

10.

etc. to protect the environment.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM) and Three Way Catalyst (TWC) if so equipped.

Spark Arrestor

WARNING: This machine is equipped with an

internal combustion engine and should not be used

on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the

engine’s exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if

any).

If a spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark arrester for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

Average Useful Life

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years, or 60

hours of operation. At the end of the Average Useful Life, buy

a new machine or have the machine inspected annually by an

authorized service dealer to ensure that all mechanical and

safety systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

5sectiOn 1 — iMpOrtant safe OperatiOn practices

Page 6

Chute Handle

Assembly & Set-Up

Contents of Carton

Two Ignition Keys• One 20 oz. Bottle 5W-30 Oil• One Extension Cord•

One Snow Throwers Operator’s

• One Tecumseh Engine Operator’s

Manual

Assembly

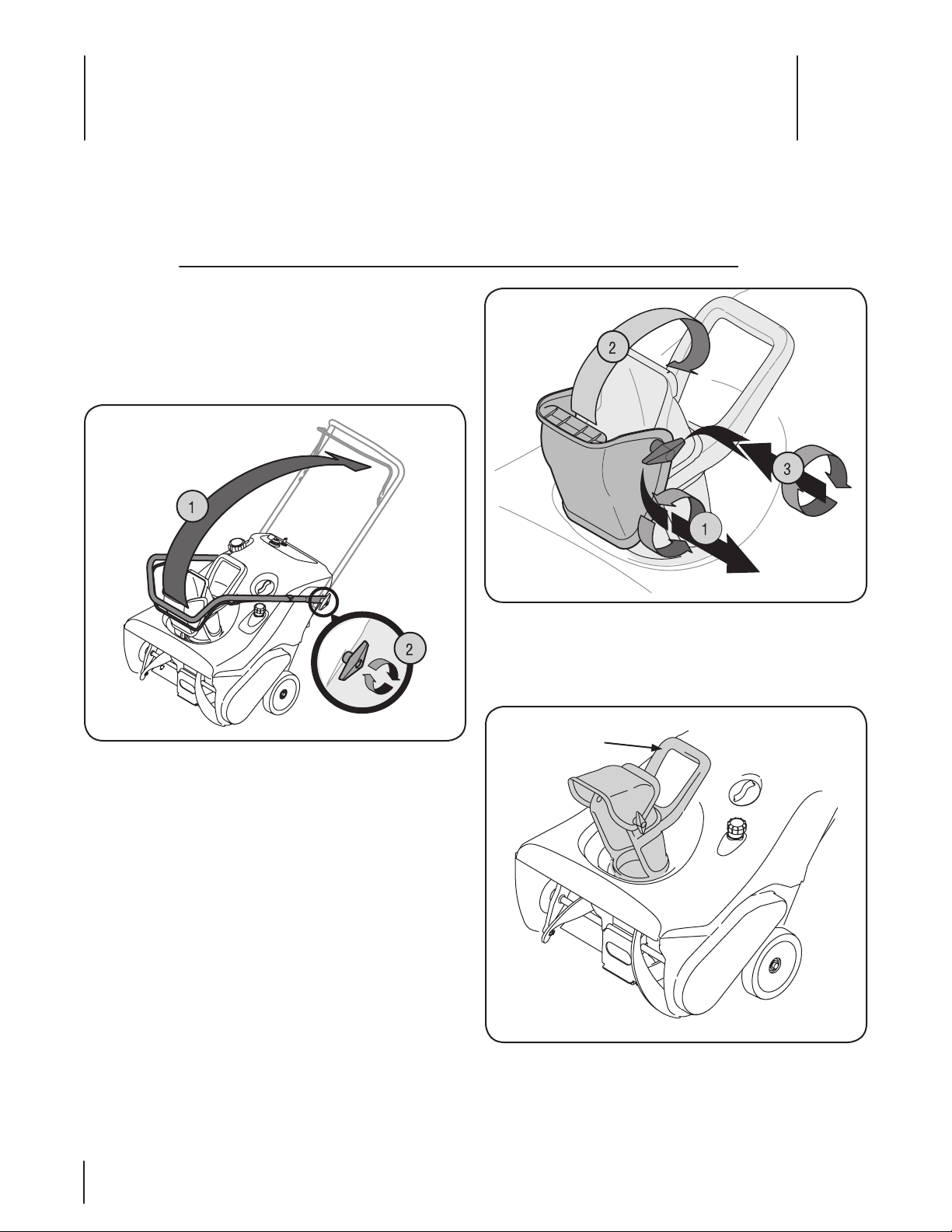

Positioning the Upper Handle

Making sure not to pinch the cable in the process, pivot the

1.

upper handle into the operating position as illustrated in

Figure 3-1 until it clicks into place.

•

Manual

3

2.

Assembling the Discharge Chute

For shipping reasons, the snow thrower has been packaged with

the upper chute pivoted all the way down. To pivot it upward,

proceed as follows:

NOTE: Turn the chute until the chute opening is facing straight

ahead.

1.

Figure 3-1

Tighten the wing knobs to secure the handle in place as in

Figure 3-1.

Remove the wing knob, flat washer and carriage bolt from

the lower chute. See Figure 3-2.

Figure 3-2

Pivot the upper chute upward over the lip on the lower

2.

chute so that there is NO gap between the upper chute

and the lower chute.

Secure with the hardware just removed. Refer to Figure 3-3.

3.

Figure 3-3

6

Page 7

Gas and Oil Fill-Up

WARNING! Use extreme care when handling

gasoline. Gasoline is extremely flammable and the

vapors are explosive. Never fuel the machine

indoors or while the engine is hot or running.

Extinguish cigarettes, cigars, pipes and other

sources of ignition.

Service the engine with gasoline and oil as instructed in the

Tecumseh Engine Operator’s Manual packed seperately with

your snow thrower. Read instructions carefully.

NOTE: Your snow thrower is shipped with oil in the engine.

However, you MUST check the oil level before operating.

Refer to the Tecumseh Engine Operator’s Manual for detailed

instructions.

Adjustments

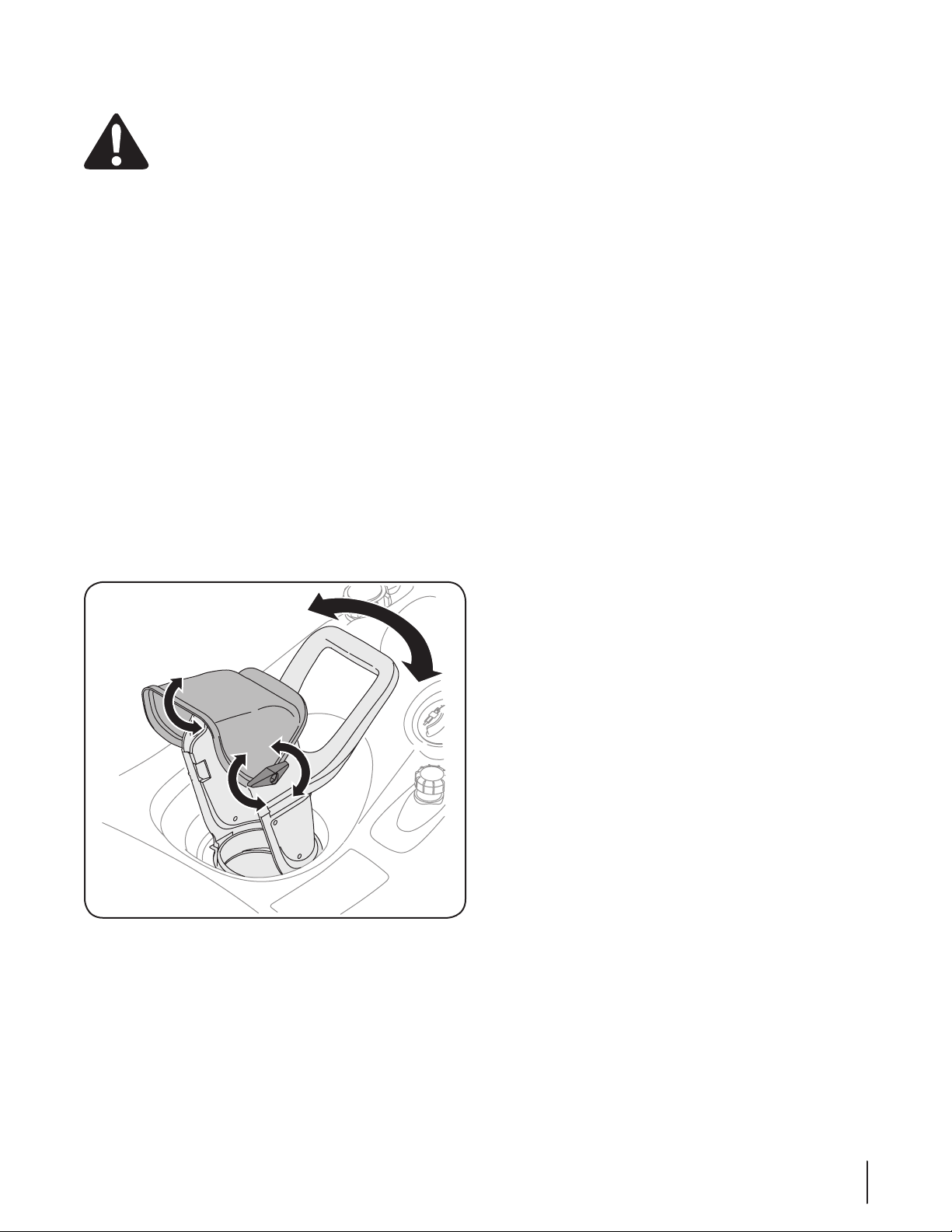

Chute Assembly

The pitch of the chute assembly controls the angle at which the

snow is thrown.

Loosen the wing knob found on the left side of the chute

1.

assembly and pivot the upper chute upward or downward

to the desired pitch. Retighten the wing knob before

operating the snow thrower.

Position the chute assembly opening by using the Chute

2.

Handle to throw the snow in the desired direction. See

Figure 3-4.

Figure 3-4

7sectiOn 2 — asseMbly & set-up

Page 8

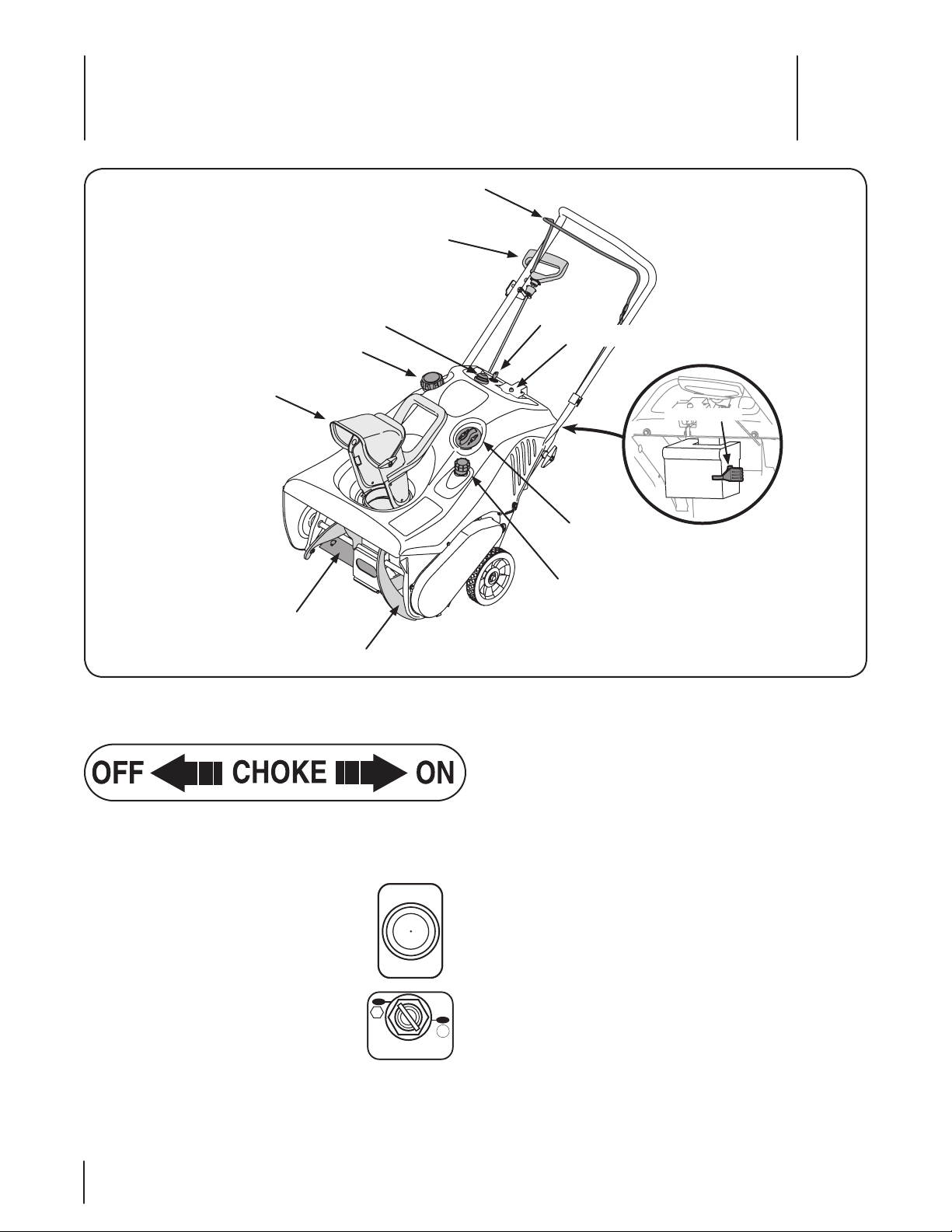

Gasoline Cap

Primer

retratS lioceR

Auger Control Handle

Choke Lever

Chute Assembly

Shave Plate

Auger

Oil Fill

Electric Starter Button

Ignition Key

Spark Plug Cover

P

R

I

M

E

R

P

R

I

M

E

R

PRIMER

PUSH FOR A

COLD ENGINE

P

R

I

M

E

R

P

R

I

M

E

R

PRIMER

PUSH FOR A

COLD ENGINE

OFF

Stop

Run

ON

IGNITION

OFF

Stop

Run

ON

IGNITION

Controls and Features

4

8

Choke Lever

Activating choke control closes the choke plate on carburetor

and aids in starting engine. Refer to the engine manual packed

with unit for more detailed instructions.

Primer

Depressing primer forces fuel directly into

engine’s carburetor to aid in cold-weather

starting. Refer to engine manual packed with

unit for more detailed instructions.

Ignition Key

Ignition key must be present, inserted in key

switch, and in the “ON” position for engine to

start.

Figure 4-1

Recoil Starter

The starter handle is used to manually start the engine.

Electric Starter Button

Pressing the electric starter button engages the engine’s electric

starter when plugged into a 120V power source

Electric Starter Outlet

Requires use of a three-prong outdoor extension cord (packed

with the snow thrower) and a 120V power source/wall outlet.

Spark Plug Cover

Remove spark plug cover to access spark plug.

Auger

When engaged, the augers rotation draws snow into the auger

housing and throws it out the discharge chute. Rubber paddles

on the augers also aid in propelling the unit as they come in

contact with the pavement.

Page 9

Auger Control Handle

Located on the upper handle, the auger control handle is used

to engage and disengage drive to the auger. Squeeze the control

handle against the upper handle to engage auger; release it to

disengage.

Chute Assembly

Rotate the chute ass embly to the lef t or right using chute

handle. Pitch of the chute assembly controls angle at

which the snow is thrown. Lo os en wing knob o n side of the

chute assembly be fore p ivoting chute assem bly upward or

downward. Retighten the knob once desired position has

been achieved.

Shave Plate

The shave plate maintains contact with pavement as the snow

thrower is propelled, allowing snow close to pavement’s surface

to be discharged.

Gasoline Cap

Remove gas cap to add fuel.

Oil Fill

Remove cap to add oil. Refer to engine owner’s manual packed

with this unit for instructions on adding oil.

9sectiOn 4 — cOntrOls and features

Page 10

Operation

5

Before Starting

WARNING! Read, understand, and follow all

instructions and warnings on the machine and in

this manual before operating.

NOTE: For complete and detailed engine starting, stopping and

storing instructions, it is recommended that you read the engine

manual also included with this machine.

1.

The spark plug wire was disconnected for safety. Attach

spark plug wire to spark plug before starting.

Starting the Engine

1.

To avoid carbon monoxide poisoning, make sure engine is

outdoors in a well-ventilated area.

2.

Insert ignition key into slot. Turn key to ON position.

3.

Now follow the instructions below as it pertains to your

machine.

Electric Starter

WARNING! The electric starter must be used with

a properly grounded three-prong receptacle at all

times to avoid the possibility of electric shock.

Follow all instructions carefully prior to operating

the electric starter.

1.

The electric starter is equipped with a grounded three-wire

power cord and plug, and is designed to operate on 120

volt AC household current.

2.

Determine that your house wiring is a three-wire grounded

system. Ask a licensed electrician if you are not certain.

3.

If your home wiring system is not a three-wire grounded

system, do not use this electric starter under any

conditions.

4.

If your home electrical system is grounded, but a threehole receptacle is not available, one should be installed by

a licensed electrician before using the electric starter.

5.

If you have a grounded three-prong receptacle, proceed as

follows.

6.

Move Choke Control to the “Full” position.

7.

Push Primer three (3) times, making sure to cover vent hole

when pushing.

8.

Connect power cord to switch box on dash panel. Plug

the other end of power cord into a three-prong 120-volt,

grounded, AC receptacle.

9.

Push starter button to crank engine.

10.

When engine starts, release starter button, and move

choke gradually to ⁄ Choke until the engine runs smoothly.

Next move Choke to OFF. If engine falters, move choke

immediately to FULL and then gradually to ⁄ then to OFF.

11.

Disconnect the power cord. Always unplug from the outlet

first, and then from the snow thrower.

Recoil Starter

1.

Move choke lever to FULL choke position (cold engine

start).

2.

If engine is warm, place choke in OFF position instead of

FULL.

3.

Push Primer three (3) times, making sure to cover vent hole

when pushing.

4.

If engine is warm, push primer button only once.

NOTE: Always cover vent hole in primer button when

pushing. Additional priming may be necessary for first start

if temperature is below 15 degrees Fahrenheit.

5.

Grasp starter handle and pull rope out slowly, until it pulls

slightly harder. Let rope rewind slowly.

6.

Pull starter handle rapidly. Do not allow handle to snap

back. Allow it to rewind slowly while keeping a firm hold

on the starter handle.

1.

As engine warms up and begins to operate evenly, rotate

choke lever slowly to the ⁄ Choke position. When the

engine begins to run smoothly, move the choke to the OFF

position. If engine falters, return to FULL choke, then slowly

move to ⁄ then OFF position.

Stopping the Engine

1.

Run the engine for a few minutes before stopping to help

dry any moisture on the engine.

2.

To stop the engine turn the ignition key counter-clockwise

to the OFF/STOP position.

3.

Remove the ignition key and store in a safe place.

4.

Wipe all snow and moisture from the area around the

engine.

WARNING! Muffler, engine and surrounding areas

become hot and can cause a burn. Do not touch.

To Engage Augers

1.

To engage the augers and start throwing snow, squeeze

the auger control against the upper handle. Release to stop

the augers.

NOTE: Discharge snow downwind whenever possible.

Slightly overlap each previously cleared path.

To Engage Drive

1.

Lifting up on the handle will allow the rubber on the

augers to propel the snow thrower forward. Pushing

downward on the handle will raise the augers off the

ground and stop forward motion.

NOTE: Excessive upward pressure on the handle will result

in premature wear on the rubber auger.

10

Page 11

Side View

Maintenance & Adjustments

6

Adjustments

Engine

Refer to Tecumseh Engine manual packed with your machine for

all engine maintenance.

WARNING! Before servicing, repairing, or

inspecting the snow thrower, disengage the auger

control. Stop engine and remove the key to prevent

unintended starting.

Shave Plate

To check the adjustment of the shave plate, place the unit

1.

on a level surface. The wheels, shave plate and augers

should all contact level surface. Note that if the shave plate

is adjusted too high, snow may blow under the housing. If

the shave plate wears out excessively, or the unit does not

self-propel, the shave plate may be too low and needs to

be adjusted.

NOTE: On new units or units with a new shave plate

installed, the augers may be slightly off the ground.

To adjust, tip the snow thrower back so that it rests on the

2.

handle. Loosen the four lock nuts and bolts which secure

the shave plate to the housing. See Figure 6-1. Move the

shave plate to desired position and retighten the nuts and

bolts securely.

Control Cable

As a result of both the control cable and the drive belt stretching

due to wear, periodic adjustments may be necessary.

If the auger seems to hesitate when rotating, proceed as follows:

The upper hole in the control handle provides for an adjustment

in cable tension. To adjust, disconnect the end of control cable

from the bottom hole in the control handle and reinsert it in the

upper hole as shown in Figure 6-2. Test the snow thrower to see

if there is a noticeable difference.

Figure 6-1

Figure 6-2

Chute Assembly

Refer to the Assembly and Set-up section for instructions on

adjusting the chute assembly.

Maintenance

Lubrication

Lubricate pivot points on the control handle and the extension

spring at the end of the control cable with light oil once every

season and before storage of the snow thrower at the end of the

season

Off-Season Storage

If the snow thrower will not be used for 30 days or longer, follow

storage instructions below.

Store equipment in a clean, dry area.

1.

If storing the snow thrower in an unventilated area,

2.

rustproof the machine using a light oil or silicone to coat

the snow thrower.

Clean the exterior of the engine and the snow thrower.

3.

11

Page 12

Belt Keeper

Idler pulley

Auger Pulley

Engine Pulley

Service

7

Replacing Belt

1.

Remove the belt cover by removing five hex screws which

secure it. See Figure 7-1.

Remove the belt by grasping it from the bottom of the

2.

auger pulley and pull outward.

NOTE: Push down on the idler pulley to release the belt

from under the belt keeper. See Figure 7-1.

To install the replacement belt, procede as follows. Refer to

Figure 7-2:

Push down on the Idler pulley.

1.

Position the belt on top of the auger pulley, under the belt

2.

keeper.

Route the belt around the engine pulley.

3.

Push the belt over the bottom of the auger pulley.

4.

Reinstall the belt cover removed earlier.

5.

Figure 7-1

Figure 7-2

12

Page 13

Replacing Auger Paddles

The snow thrower auger’s rubber paddles are subject to wear

and should be replaced if any signs of excessive wear is present.

CAUTION: Do NOT allow the auger’s rubber

paddles to wear to the point where portions of the

metal auger itself can come in contact with the

pavement. Doing so can result in serious damage to

your snow thrower.

To change the rubber paddles, proceed as follows:

Remove the existing rubber paddles by unthreading the

1.

self-tapping screws which secure them to the auger. See

Figure 7-3.

Figure 7-3

Secure the replacement rubber paddles to the auger using

2.

the hardware removed earlier.

Replacing Shave Plate

The shave plate is attached to the bottom of the auger housing

and is subject to wear. It should be checked periodically. There

are two wearing edges and the shave plate can be reversed.

Remove the four carriage bolts and hex lock nuts which

1.

attach it to the snow thrower housing.

Install new shave plate, making sure the heads of the

2.

carriage bolts are on the inside of the housing.

Adjust the shave plate as instructed on page 11. Refer to

3.

Figure 6-1.

Tighten securely once adjusted.

4.

13sectiOn 7 — service

Page 14

Troubleshooting

Problem Cause Remedy

8

Engine Fails to start Fuel tank empty, or stale fuel.

Engine runs erratic Unit running on choke.

Engine overheats Carburetor out of adjustment.1. Refer to engine manual for instruction.1.

Loss of power Spark plug wire loose.

Excessive vibration Loose parts or damaged auger.1. Stop engine immediately and disconnect

Unit fails to self-propel Drive cable out of adjustment.

Augers continue to rotate Cable out of adjustment.1. Adjust auger control cable as shown in

Unit fails to discharge snow Chute assembly clogged.

1.

Improper fuel mixture.

2.

Blocked fuel line.

3.

Key not in ON position.

4.

Spark plug wire disconnected.

5.

Faulty spark plug.

6.

Engine not primed.

7.

Engine flooded from excessive priming.

8.

1.

Fuel line blocked, or stale fuel.

2.

Water or dirt in fuel system.

3.

Carburetor out of adjustment.

4.

1.

Vent in gas cap plugged.

2.

1.

Drive belt loose or damaged.

2.

1.

Shear pin sheared.

2.

Foreign object lodged in auger.

3.

Auger control cable out of adjustment.

4.

Auger belt loose or damaged.

5.

Fill tank with clean fresh gasoline.

1.

Mix new fuel at a ratio of 50:1.

2.

Clean fuel line.

3.

Insert key and turn to ON position.

4.

Connect wire to spark plug.

5.

Clean spark plug, readjust gap, or replace.

6.

Prime engine four times.

7.

Wait at least ten minutes before starting.

8.

Move choke lever to OFF position.

1.

Clean fuel line and fill tank with fresh, clean

2.

gasoline.

Refer to engine manual for remedy.

3.

Refer to engine manual for remedy.

4.

Firmly connect spark plug wire.

1.

Clear vent.

2.

1.

spark plug wire. Check for possible damage.

Tighten all bolts and nuts. Repair as needed.

If the problem persists, take unit to an

authorized service dealer.

Adjust auger control cable as shown in

1.

Maintanence and Adjustments section.

Replace drive belt.

2.

1.

Maintenance and Adjustments section.

Stop engine and disconnect spark plug wire.

1.

Clean chute and inside of auger housing with

clean-out tool or stick.

Replace shear pin.

2.

Stop engine immediately and disconnect the

3.

spark plug wire. Remove object from auger.

Adjust auger control cable.

4.

Replace auger belt.

5.

14

Page 15

Replacement Parts

Component Part Number and Description

9

929-0071 Extension Cord

731-1033 Shave Plate

954-0101A Auger Drive Belt

735-04033 Rubber Paddle

735-04032 Rubber Spiral-Crescent

925-0201 Keys (set of 2)

TC-35062 Key Starter

746-04237 Cable Clutch

Phone (800) 828-5500 to order replacement parts or a complete Parts Manual (have your full model number and serial number ready).

Phone (800) 828-00-7310 to order replacement parts or a complete Parts Manual (have your full model number and serial number

Parts Manual downloads are also available free of charge at www.mtdproducts.com.

ready). Parts Manual downloads are also available free of charge at www.mtdproducts.com.

15

Page 16

MANUFACTURER’S LIMITED WARRANTY FOR

The limited warranty set forth below is given by Troy-Bilt LLC with

respect to new merchandise purchased and used in the United States

and/or its territories and possessions, and by MTD Products Limited

with respect to new merchandise purchased and used in Canada

and/or its territories and possessions (either entity respectively,

“Troy-Bilt”).

“Troy-Bilt” warrants this product (excluding its Normal Wear Parts

and Attachm ents as described below) against defects in material and

workmanship for a period of two (2) years commencing on the date

of original purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or workmanship.

This limited warranty shall only apply if this product has been

operated and maintained in accordance with the Operator’s Manual

furnished with the product, and has not been subject to misuse,

abuse, commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water, or damage because of other

peril or natural disaster. Damage resulting from the installation or

use of any part, accessory or attachment not approved by Troy-Bilt

for use with the product(s) covered by this manual will void your

warranty as to any resulting damage.

Normal Wear Parts are warranted to be free from defects in material

and workmanship for a period of thirty (30) days from the date of

purchase. Normal wear parts include, but are not limited to items

such as: batteries, belts, blades, blade adapters, tines, grass bags,

wheels, rider deck wheels, seats, snow thrower skid shoes, friction

wheels, shave plates, auger spiral rubber and tires.

Attachments — Troy-Bilt warrants attachments for this product

against defects in material and workmanship for a period of one (1)

year, commencing on the date of the attachment’s original purchase

or lease. Attachments include, but are not limited to items such as:

grass collectors and mulch kits.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE, through your local authorized service dealer.

To locate the dealer in your area:

In the U.S.A.

Check your Yellow Pages, or contact Troy-Bilt LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-866-840-6483,

1-330-558-7220 or log on to our Web site at www.troybilt.com.

In Canada

Contact MTD Products Limited, Kitchener, ON N2G 4J1, or call 1-800668-1238 or log on to our Web site at www.mtdcanada.com.

This limited warranty does not provide coverage in the following

cases:

a. The engine or component parts thereof. These items may carry a

separate manufacturer’s warranty. Refer to applicable manufacturer’s warranty for terms and conditions.

b. Log splitter pumps, valves, and cylinders have a separate one-

year warranty.

c. Routine maintenance items such as lubricants, filters, blade

sharpening, tune-ups, brake adjustments, clutch adjustments,

deck adjustments, and normal deterioration of the exterior finish

due to use or exposure.

d. Service completed by someone other than an authorized service

dealer.

e. Troy-Bilt does not extend any warranty for products sold or

exported outside of the United States and/or Canada, and their

respective possessions and territories, except those sold through

Troy-Bilt’s authorized channels of export distribution.

f. Replacement parts that are not genuine Troy-Bilt par ts.

g. Transportation charges and service calls.

h. Troy-Bilt does not warrant this product for commercial use.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose, applies after

the applicable period of express written warranty above as to the

parts as identified. No other express warranty, whether written or

oral, except as mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product, shall

bind Troy-Bilt. During the period of the warranty, the exclusive

remedy is repair or replacement of the product as set forth above.

The provisions as set forth in this warranty provide the sole and

exclusive remedy arising from the sale. Troy-Bilt shall not be liable

for incidental or consequential loss or damage including, without

limitation, expenses incurred for substitute or replacement lawn

care services or for rental expenses to temporarily replace a

warranted product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages, or limitations on how long an implied

warranty lasts, so the above exclusions or limitations may not apply

to you.

In no event shall recovery of any kind be greater than the amount of

the purchase price of the product sold. Alteration of safety features of

the product shall void this warranty. You assume the risk and liability

for loss, damage, or injury to you and your property and /or to others

and their property arising out of the misuse or inability to use the

product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased as a

gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This limited

warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

IMPORTANT: Owner must present Original Proof of Purchase to

obtain warranty coverage.

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-866-840-6483, 1-330-558-7220

MTD Canada Limited - KITCHENER, ON N2G 4J1; Phone 1-800-668-1238

GDOC-100020 REV. A

Page 17

Medidas importantes de seguridad • Conguración • Funcionamiento • Mantenimiento • Servicio • Solución de problemas • Garantía

Manual del OperadOr

Máquina quitanieve de etapa única — Squall 521

LEA Y SIGA TODAS LAS INSTRUCCIONES DE ESTE MANUAL

ANTES DE PONER EN FUNCIONAMIENTO ESTA MÁQUINA.

SI NO RESPETA ESTAS INSTRUCCIONES PUEDE PROVOCAR LESIONES PERSONALES.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Impreso en Estados Unidos de América

ADVERTENCIA

Formulario No. 769-00309E

(Junio 21, 2007)

Page 18

Al propietario

Gracias

Gracias por comprar una máquina quitanieve fabricada por

Troy-Bilt LLC. La misma ha sido diseñada cuidadosamente

para brindar excelente rendimiento si se la opera y mantiene

correctamente.

Por favor lea todo este manual antes de operar el equipo.

Le indica cómo configurar, operar y mantener la máquina

con seguridad y fácilmente. Por favor asegúrese de seguir

cuidadosamente y en todo momento las prácticas de seguridad

recomendadas, y hacérselas seguir a cualquier otra persona que

opere la máquina. En caso de no hacerlo podrían producirse

lesiones personales o daños materiales.

Toda la información contenida en este manual hace referencia

a la más reciente información de producto disponible en el

momento de la impresión. Revise el manual frecuentemente

para familiarizarse con la unidad, sus características y

funcionamiento. Por favor tenga en cuenta que este Manual

del Operador puede cubrir una gama de especificaciones de

productos de diferentes modelos. Las características y funciones

incluidas y/o ilustradas en este manual pueden no ser aplicables

a todos los modelos. Troy-Bilt LLC se reserva el derecho de

1

modificar las especificaciones de los productos, los diseños y el

equipo estándar sin previo aviso y sin generar responsabilidad

por obligaciones de ningún tipo.

Este producto cumple con las estrictas normas de seguridad

del Outdoor Power Equipment Institute y de un laboratorio

de pruebas independiente. Si tiene algún problema o duda

respecto a la unidad, llame a un distribuidor de servicio Troy-Bilt

autorizado o póngase en contacto directamente con nosotros.

Los números de teléfono, dirección del sitio web y dirección

postal de la Asistencia al Cliente de Troy-Bilt se encuentran en

esta página. Queremos garantizar su entera satisfacción en todo

momento.

En este manual, las referencias al lado derecho o izquierdo de la

máquina se observan desde la posición del operador.

El fabricante del motor es el responsable de todas las

cuestiones relacionadas con el rendimiento, potencia de salida,

especificaciones, garantía y mantenimiento del motor. Para

obtener mayor información consulte el Manual del Propietario /

Operador entregado por el fabricante del motor, que se envía, en

un paquete por separado, junto con su unidad.

Índice

Importante Medidas importantes de seguridad .. 3

Ensamblado y Conguración ................................. 6

Controles y Características ....................................10

Funcionamiento .....................................................13

Registro de información de producto

Antes de configurar y operar su equipo nuevo, por favor localice

la placa del modelo en el equipo y registre la información en

el área situada a la derecha. Para encontrar la placa de modelo,

colóquese detrás de la unidad en la posición del operador y mire

hacia la parte inferior de la sección trasera del chasis. Si tiene

que solicitar soporte técnico a través de nuestro sitio web, el

Departamento de Asistencia al Cliente, o de un distribuidor de

servicio autorizado local, necesitará esta información.

Mantenimiento y Ajustes .......................................15

Servicio ....................................................................18

Solución de Problemas ......................................... 22

Piezas de Reemplazo ............................................ 23

núMerO de MOdelO

núMerO de serie

Asistencia al Cliente

Por favor, NO devuelva la unidad al minorista o distribuidor sin ponerse en contacto primero con el Departamento de

Asistencia al Cliente.

En caso de tener problemas para montar este producto o de tener dudas con respecto a los controles, funcionamiento o

mantenimiento del mismo, puede solicitar la ayuda de expertos. Elija entre las opciones que se presentan a continuación:

Visite nuestro sitio web en www.troybilt.com

◊

Llame a un representante de Asistencia al Cliente al (800) 828-5500 ó (330) 558-7220

◊

Escríbanos a Troy-Bilt LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

◊

2

Page 19

Medidas importantes de seguridad

ADVERTENCIA: La presencia de este símbolo indica que se trata de instrucciones

importantes de seguridad que se deben respetar para evitar poner en peligro su seguridad

personal y/o material y la de otras personas. Lea y siga todas las instrucciones de este manual

antes de poner en funcionamiento esta máquina. Si no respeta estas instrucciones puede

provocar lesiones personales.

PROPOSICIÓN 65 DE CALIFORNIA

ADVERTENCIA: El escape del motor de este producto, algunos de sus componentes y

algunos componentes del vehículo contienen o liberan sustancias químicas que el estado

de California considera que pueden producir cáncer, defectos de nacimiento u otros

problemas reproductivos.

CUANDO vea este símbolo. TENGA EN CUENTAS LAS ADVERTENCIAS!

PELIGRO: Esta máquina está diseñada para ser utilizada respetando las normas de seguridad

contenidas en este manual. Al igual que con cualquier tipo de equipo motorizado, un

descuido o error por parte del operador puede producir lesiones graves. Esta máquina es

capaz de amputar dedos, manos y pies y de arrojar objetos extraños con gran fuerza. De no

respetar las instrucciones de seguridad siguientes se pueden producir lesiones graves o la

muerte.

2

Capacitación

1.

Lea, entienda y cumpla todas las instrucciones incluidas en

la máquina y en los manuales antes de montarla y utilizarla.

Guarde este manual en un lugar seguro para consultas

futuras y periódicas, así como para solicitar repuestos.

2.

Familiarícese con todos los controles y con el uso adecuado

de los mismos. Sepa cómo detener la máquina y desactivar

los controles rápidamente.

3.

No permita nunca que los niños menores de 14 años

utilicen esta máquina. Los niños de 14 años en adelante

deben leer y entender las instrucciones de operación y

normas de seguridad contenidas en este manual, y en la

máquina ydeben ser entrenados y supervisados por un

adulto.

4.

Nunca permita que los adultos operen esta máquina sin

recibir antes la instrucción apropiada.

5.

Los objetos arrojados por la máquina pueden producir

lesiones graves. Planifique el patrón en el que va a ir

arrojando nieve para evitar que la descarga de material se

realice hacia los caminos, los observadores, etc.

6.

Mantenga a los observadores, ayudantes, mascotas y niños

por lo menos a 75 pies de la máquina mientras la misma

está en funcionamiento. Detenga la máquina si alguien se

acerca.

7.

Sea precavido para evitar patinarse o caerse especialmente

cuando opera la máquina en reversa.

Preparativos

8.

Inspeccione minuciosamente el área donde utilizará el equipo.

Saque todos los felpudos, periódicos, trineos, tablas, cables y

otros objetos extraños con los que podría tropezar o que podrían

ser arrojados por la barrena / impulsor.

Para protegerse los ojos utilice siempre anteojos o

1.

antiparras de seguridad mientras opera la máquina o

mientras la ajusta o repara. Los objetos arrojados que

rebotan pueden producir lesiones oculares graves.

No opere la máquina sin la vestimenta adecuada para

2.

estar al aire libre en invierno. No utilice alhajas, bufandas

largas u otras prendas sueltas que podrían enredarse en las

partes móviles. Utilice un calzado especial para superficies

resbaladizas.

Use un prolongador y un tomacorriente de tres cables con

3.

conexión a tierra para todas las máquinas con motores de

encendido eléctrico.

Ajuste la altura de la caja del tomacorriente para limpiar la

4.

grava o las superficies con piedras trituradas.

Desengrane todas las palancas de control antes de arrancar

5.

el motor.

Nunca intente realizar ajustes mientras el motor está

6.

en marcha excepto en los casos específicamente

recomendados en el manual del operador.

Deje que el motor y la máquina se adapten a la

7.

temperatura exterior antes de comenzar a sacar la nieve.

3

Page 20

Manejo seguro de la gasolina

Para evitar lesiones personales o daños materiales tenga mucho

cuidado cuando trabaje con gasolina. La gasolina es sumamente

inflamable y sus vapores pueden causar explosiones. Si se

derrama gasolina encima o sobre la ropa se puede lesionar

gravemente ya que se puede incendiar. Lávese la piel y cámbiese

de ropa de inmediato.

Utilice sólo los recipientes para gasolina autorizados.

a.

Apague todos los cigarrillos, cigarros, pipas y otras

b.

fuentes de combustión.

Nunca cargue combustible en la máquina en un

c.

espacio cerrado.

Nunca saque la tapa del combustible ni agregue

d.

combustible mientras el motor está caliente o en

marcha.

Deje que el motor se enfríe por lo menos dos

e.

minutos antes de volver a cargar combustible.

Nunca llene en exceso el depósito de combustible.

f.

Llene el tanque a no más de ½ pulgada por debajo

de la base del cuello de llenado dejando espacio

para la dilatación del combustible.

Vuelva a colocar la tapa de la gasolina y ajústela

g.

bien.

Limpie el combustible que se haya derramado sobre

h.

el motor y el equipo. Traslade la máquina a otra

zona. Espere 5 minutos antes de encender el motor.

Nunca almacene la máquina o el recipiente de

i.

combustible en un espacio cerrado donde haya

fuego, chispas o luz piloto (por ejemplo, hornos,

calentadores de agua, calefactores, secadores de

ropa, etc.).

Deje que la máquina se enfríe por lo menos 5

j.

minutos antes de guardarla.

Nunca llene los recipientes en el interior de

k.

un vehículo o camión o caja de remolque con

recubrimientos plásticos. Coloque siempre los

recipientes en el piso y lejos del vehículo antes de

llenarlos.

Si es posible, retire el equipo a gasolina del camión o

l.

remolque y llénelo en el suelo. Si esto no es posible,

llene el equipo en un remolque con contenedor

portátil, en vez de desde una boquilla dispensadora

de gasolina.

Mantenga la boquilla dispensadora en contacto

m.

con el borde del depósito de combustible o con la

abertura del recipiente en todo momento, hasta

terminar la carga. No utilice un dispositivo de

apertura/cierre de boquilla.

Funcionamiento

No ponga las manos o los pies cerca de las piezas

1.

rotatorias, en la caja de la barrena / impulsor o en el

montaje del canal de descarga. Hacer contacto con piezas

giratorias puede resultar en la amputación de manos o

pies.

La palanca de control de la barrena / impulsor es un

2.

dispositivo de seguridad. Nunca evite su funcionamiento.

De hacerlo la operación de la máquina es riesgosa y puede

ocasionar lesiones.

Las palancas de control deben funcionar bien en ambas

3.

direcciones y regresar automáticamente a la posición de

desengrane cuando se las suelta.

4 sectiOn 2 — Medidas iMpOrtantes de seguridad

Nunca opere la máquina si falta un montaje del canal o si

4.

el mismo está dañado. Mantenga todos los dispositivos de

seguridad en su lugar y en funcionamiento.

Nunca encienda el motor en espacios cerrados o en una

5.

zona con poca ventilación. El escape del motor contiene

monóxido de carbono, un gas inodoro y letal.

No utilice la máquina bajo la influencia del alcohol o las

6.

drogas.

El silenciador y el motor se calientan y pueden causar

7.

quemaduras. No los toque. Mantenga a los niños alejados.

Sea sumamente precavido cuando opere la máquina sobre

8.

una superficie con grava o cuando la cruce. Manténgase

alerta por si se presentan peligros ocultos o tránsito.

Tenga cuidado cuando cambie de dirección o cuando

9.

opere la máquina en pendientes.

Planifique el patrón en el que va a ir arrojando nieve para

10.

evitar que la descarga de material se produzca hacia las

ventanas, las paredes, los automóviles, etc. y evitar así

posibles daños materiales o lesiones producidas por los

rebotes.

Nunca dirija la descarga hacia los niños, los observadores

11.

o las mascotas ni deje que nadie se pare delante de la

máquina.

No sobrecargue la capacidad de la máquina tratando de

12.

sacar la nieve muy rápidamente.

Nunca opere esta máquina sin buena visibilidad o

13.

iluminación. Siempre debe estar seguro de que está bien

afirmado y sujetando firmemente las manijas. Camine,

nunca corra.

Corte la corriente a la barrena / impulsor cuando transporte

14.

la máquina o cuando la misma no está en uso.

Nunca opere la máquina a alta velocidad de

15.

desplazamiento sobre superficies resbaladizas. Mire hacia

abajo y hacia atrás y tenga cuidado cuando vaya marcha

atrás.

Si la máquina comenzara a vibrar de manera anormal,

16.

detenga el motor, desconecte el cable de la bujía y póngala

de manera que haga masa contra el motor. Inspeccione la

máquina minuciosamente para ver si está dañada. Repare

todos los daños antes de encender y operar la máquina.

Desengrane todas las palancas de control y detenga el

17.

motor antes de dejar la posición de operación (detrás de

las manijas). Espere a que la barrena / impulsor se detenga

por completo antes de destapar el montaje del canal o

realizar ajustes e inspecciones.

Nunca ponga las manos en las aberturas de descarga o

18.

de recolección. Utilice siempre la herramienta de limpieza

que se adjunta para destapar la abertura de descarga. No

destape el montaje del canal mientras el motor está en

funcionamiento. Antes de destaparlo, apague el motor

y permanezca detrás de las manijas hasta que todas las

partes móviles se hayan detenido.

Use sólo uniones y accesorios aprobados por el fabricante

19.

(por ejemplo, pesas para las ruedas, cadenas para los

neumáticos, cabinas, etc.).

Para encender el motor, jale de la cuerda lentamente hasta

20.

que sienta resistencia, luego jale rápidamente. El repliegue

rápido de la cuerda de arranque (tensión de retroceso) le

jalará la mano y el brazo hacia el motor más rápido de lo

que usted puede soltar. El resultado pueden ser huesos

rotos, fracturas, hematomas o esguinces.

Si se presentan situaciones que no están previstas en este

21.

manual, sea cuidadoso y use el sentido común. Póngase en

contacto con Asistencia al Cliente para solicitar ayuda y el

nombre del distribuidor de servicio más cercano.

Page 21

Mantenimiento y Almacenamiento

Nunca altere los dispositivos de seguridad. Controle

1.

periódicamente que funcionen correctamente. Remítase a

las secciones de mantenimiento y ajuste de este manual.

Antes de realizar la limpieza, reparar o revisar la máquina,

2.

desengrane todas las palancas de control y detenga el

motor. Espere a que la barrena / impulsor se detenga

por completo. Desconecte el cable de la bujía y póngalo

haciendo masa contra el motor para evitar que se encienda

accidentalmente.

Controle frecuentemente que todos los pernos y tornillos

3.

estén bien ajustados para comprobar que la máquina se

encuentra en condiciones seguras de funcionamiento.

Además, haga una inspección visual de la máquina para

verificar si está dañada.

No cambie la configuración del regulador del motor

4.

ni acelere demasiado el mismo. El regulador del motor

controla la velocidad máxima segura de funcionamiento

del motor.

Las placas de raspado y las zapatas antideslizantes que se

5.

usan con la máquina quitanieve se desgastan y se dañan.

Para proteger su seguridad, verifique frecuentemente

todos los componentes y reemplácelos sólo con partes

de los fabricantes de equipos originales (OEM). “¡El uso

de piezas que no cumplen con las especificaciones del

equipo original puede resultar en rendimiento inadecuado

además de poner en riesgo la seguridad!”

Revise las palancas de control periódicamente para

6.

verificar que engranen y desengranen adecuadamente y

ajústelos si es necesario. Consulte la sección de ajustes de

este manual del operador para obtener instrucciones.

Mantenga o reemplace las etiquetas de seguridad e

7.

instrucciones según sea necesario.

Respete las normas referentes a la disposición correcta y las

8.

reglamentaciones sobre gasolina, aceite, etc. para proteger

el medio ambiente.

Antes de almacenar la máquina enciéndala unos minutos

9.

para sacar la nieve que haya quedado en la misma y para

evitar así que se congele la barrena / impulsor.

Nunca almacene la máquina o el recipiente de combustible

10.

en un espacio cerrado donde haya fuego, chispas o luz

piloto como por ejemplo, calentadores de agua, hornos,

secadores de ropa, etc.

Consulte siempre el manual del operador para obtener

11.

instrucciones adecuadas para el almacenamiento fuera de

temporada.

Verifique frecuentemente la línea de combustible, el

12.

tanque, el tapón, y los accesorios buscando rajaduras o

pérdidas. Reemplace de ser necesario.

No dé arranque al motor si no está la bujía de encendido.

13.

No modifique el motor

Para evitar lesiones graves o la muerte, no modifique el motor

bajo ninguna circunstancia. Si cambia la configuración del

regulador el motor puede descontrolarse y operar a velocidades

inseguras. Nunca cambie la configuración de fábrica del

regulador del motor.

Aviso referido a emisiones

Los motores que están certificados y cumplen con las

regulaciones de emisiones federales EPA y de California para

SORE (Equipos pequeños todo terreno) están certificados para

operar con gasolina común sin plomo y pueden incluir los

siguientes sistemas de control de emisiones: Modificación de

motor (EM) y catalizador de tres vías (TWC) si están equipados de

esa manera.

Guardachispas

ADVERTENCIA:ESTA máquina está equipada

con un motor de combustión interna y no debe

ser utilizada en o cerca de un terreno agreste

cubierto por bosque, malezas o hierba excepto si el

sistema de escape del motor está equipado con un

amortiguador de chispas que cumpla con las leyes

locales o estatales correspondientes, en caso de

haberlas.

Si se utiliza un amortiguador de chispas el operador lo debe

mantener en condiciones de uso adecuadas. En el Estado

de California las medidas anteriormente mencionadas son

exigidas por ley (Artículo 4442 del Código de Recursos Públicos

de California). Es posible que existan leyes similares en otros

estados. Las leyes federales se aplican en territorios federales.

Puede conseguir el amortiguador de chispas para el silenciador

a través de su distribuidor autorizado de motores o poniéndose

en contacto con el departamento de servicios, P.O. Box 361131

Cleveland, Ohio 44136-0019.

Vida útil media

Según la Comisión de Seguridad de Productos para el

Consumidor de los Estados Unidos (CPSC) y la Agencia de

Protección Ambiental de los Estados Unidos (EPA), este

producto tiene una vida útil media de siete (7) años, ó 60 horas

de funcionamiento. Al finalizar la vida útil media, adquiera una

máquina nueva o haga inspeccionar anualmente ésta por un

distribuidor de servicio autorizado para cerciorarse de que todos

los sistemas mecánicos y de seguridad funcionan correctamente

y no tienen excesivo desgaste. Si no lo hace, pueden producirse

accidentes, lesiones o muerte.

ADVERTENCIA: Su responsabilidad—Restrinja el uso de esta máquina motorizada a las personas que lean,

comprendan y respeten las advertencias e instrucciones que figuran en este manual y en la máquina.

GUARDE ESTAS INSTRUCCIONES

5sectiOn 2 — Medidas iMpOrtantes de seguridad

Page 22

Montaje y Configuración

Manija del canal

Contenido de la caja

Dos llaves de encendido• Una botella de 20 oz. de aceite 5W-30• Un prolongador•

Un Manual del operador de la

• Un Manual de operación Tecumseh para

máquina quitanieve

Montaje

Colocación de la manija superior

Gire la manija superior hasta la posición de operación,

1.

como se ilustra en la Figura 3-1 hasta que quede en su

lugar, cuidando de no pellizcar el cable en el proceso.

•

motores

3

2.

Montaje del canal de descarga

Por razones de envío, la máquina quitanieve ha sido embalada

con el canal superior girado completamente hacia abajo. Para

girarlo hacia arriba proceda de la siguiente manera:

NOTA: Gire el canal hasta que la abertura del mismo quede

mirando directamente hacia adelante.

1.

Figura 3-1

Apriete las perillas a mariposa para ajustar la manija en su

lugar como en la Figura 3-1.

Saque la perilla a mariposa, la arandela plana y el bulón del

carro del canal inferior. Vea la Figura 3-2.

Figura 3-2

Gire el canal superior hacia arriba sobre el borde del canal

2.

inferior de manera que NO quede ningún espacio entre el

canal superior y el inferior.

Asegúrelo con los herrajes que acaba de quitar.

3.

Vea la Figura 3-3.

Figura 3-3

6

Page 23

Llenado de gasolina y aceite

ADVERTENCIA! Tenga mucho cuidado al trabajar

con gasolina. La gasolina es sumamente inflamable

y sus vapores pueden causar explosiones. Nunca

agregue combustible a la máquina en interiores ni

mientras el motor está caliente o en

funcionamiento. Apague cigarrillos, cigarros, pipas y

otras fuentes de combustión.

Cargue el motor con gasolina y aceite como se indica en el

manual de operación Tecumseh para motores que viene

embalado por separado con su máquina quitanieve. Lea las

instrucciones con atención.

NOTA: Su máquina quitanieve se despacha con aceite en el

motor. Sin embargo, usted DEBE controlar el nivel de aceite antes

de hacerla funcionar. Para obtener instrucciones detalladas,

consulte el manual de operación Tecumseh para motores.

Ajustes

Montaje del canal

La inclinación del montaje del canal controla el ángulo con el

que se arroja la nieve.

Afloje la perilla a mariposa que se encuentra del lado

1.

izquierdo del montaje del canal y gire el canal superior

hacia arriba o hacia abajo hasta alcanzar la inclinación

deseada. Vuelva a ajustar la perilla a mariposa antes de

poner la máquina quitanieve en funcionamiento.

Posicione la abertura del montaje del canal con la manija

2.

del canal para arrojar la nieve en la dirección deseada. Vea

la Figura 3-4.

Fig. 3-4

7sección 2 — MOntaje y cOnfiguración

Page 24

Controles y Características

P

R

I

M

E

R

P

R

I

M

E

R

PRIMER

PUSH FOR A

COLD ENGINE

P

R

I

M

E

R

P

R

I

M

E

R

PRIMER

PUSH FOR A

COLD ENGINE

OFF

Stop

Run

ON

IGNITION

OFF

Stop

Run

ON

IGNITION

Manija de control de la barrena

Arrancador de retroceso

4

Montaje del canal

Placa de raspado

Palanca del cebador

Cebador

Tapa de la gasolina

Barrena

Llave de encendido

Botón de arranque eléctrico

Palanca del cebador

Cubierta de la bujía

Llenado de aceite

Fig. 4-1

Arrancador de retroceso

La manija del arrancador se utiliza para arrancar el motor

manualmente.

Al activar el control del cebador se cierra la placa del cebador

del carburador y se ayuda a encender el motor. Para obtener

instrucciones más detalladas, consulte el manual del motor que

se entregó con la unidad.

Cebador

Al presionar el cebador se envía combustible

directamente al carburador del motor para

facilitar el arranque cuando hace frío. Para

obtener instrucciones más detalladas, consulte

el manual del motor que se entregó con la

unidad.

Llave de encendido

La llave de encendido debe estar presente y en

la posición “ON” (encendido) para que el motor

arranque.

Botón del arrancador eléctrico

Si oprime el botón del arrancador eléctrico se engrana el

arrancador eléctrico del motor cuando se lo enchufa a una

fuente de energía de 120V.

Salida del arrancador eléctrico

Es necesario usar un cable prolongador para exteriores de tres

espigas (embalado junto con la máquina quitanieve) y una

fuente de energía / tomacorriente de pared de 120V.

Cubierta de la bujía

Saque la cubierta de la bujía para acceder a la bujía.

Barrena

Cuando está engranada, la rotación de la barrena dirige la nieve

dentro de la caja de la barrena y la arroja hacia afuera por el canal

de descarga. Las paletas de caucho de las barrenas también

ayudan a impulsar la unidad al ponerse en contacto con el

pavimento.

8

Page 25

Manija de control de la barrena

La manija de control de la barrena está ubicada en la manija

superior y se usa para engranar y desengranar la transmisión de

la barrena. Apriete la manija de control contra la manija superior

para engranar la barrena, aflójela para desengranarla.

Montaje del canal

Haga rotar el m ontaje del canal hacia izquierda o de recha

usado la manija del canal. La inclinación del montaje del

canal controla el ángulo con el que se arroja la nieve. Afloje

la perilla a mariposa que se encuentra en el costado del

montaje del canal antes de girarlo hacia arrib a o hacia

abajo. Vuelva a ajustar la perilla después d e alca nzar la

posición deseada.

Placa de raspado

La placa de raspado hace contacto con el pavimento a medida

que se impulsa la máquina quitanieve, permitiendo que se

descargue la nieve que está cerca de la superficie del pavimento.

Tapa de la gasolina

Saque la tapa de la gasolina para agregar combustible.

Llenado de aceite

Saque el tapón para agregar aceite. Consulte las instrucciones

para agregar aceite en el manual del propietario del motor que

se entregó con la unidad.

9sección 4 — cOntrOles y características

Page 26

Mantenimiento y Ajustes

Vista lateral

6

Ajustes

Motor

Consulte el manual de operación Tecumseh para motores

embalado con la máquina para ver el mantenimiento del motor.

ADVERTENCIA! Antes de realizar tareas de

mantenimiento, reparación o inspección en la

máquina quitanieve, desengrane el control de la

barrena. Apague el motor y retire la llave para evitar

el encendido accidental del motor.

Placa de raspado

Para verificar el ajuste de la placa de raspado, ubique la

1.

unidad sobre una superficie nivelada. Tanto las ruedas

como la placa de raspado y las barrenas deben hacer

contacto con la superficie nivelada. Observe que si la

placa de raspado está demasiado alta la nieve puede

volar debajo de la caja. Si la placa de raspado se desgasta

excesivamente, o la unidad no se autopropulsa, es posible

que la placa de raspado esté demasiado baja y deba ser

ajustada.

NOTA: En las unidades nuevas o en las que tienen una

placa de raspado nueva las barrenas pueden estar un poco

separadas del suelo.

Para ajustarlas, incline la máquina quitanieve hacia atrás

2.

hasta que quede apoyada sobre la manija. Afloje las cuatro

tuercas y pernos de seguridad que fijan la placa de raspado

a la caja. Vea la Figura 6-1. Mueva la placa de raspado hacia

la posición deseada y vuelva a apretar las tuercas y los

pernos bien ajustados.

Cable de control

Es posible que necesite realizar ajustes periódicos debido al

estiramiento del cable de control y de la correa de transmisión

ocasionados por el desgaste.

Si la barrena parece titubear mientras gira, haga lo siguiente:

El agujero superior de la manija de control tiene en cuenta el

ajuste de la tensión del cable. Para realizar el ajuste, desconecte

el extremo del cable de control del agujero inferior de la manija

de control e insértelo en el agujero superior como se muestra en

la Figura 6-2. Pruebe la máquina quitanieve para ver si se logra

una diferencia apreciable.

11

Fig. 6-1

Fig. 6-2

Montaje del canal

Consulte la sección Montaje y Configuración para ver las

instrucciones de ajuste del montaje del canal.

Mantenimiento

Lubricación

Lubrique los puntos de giro de la manija de control y del resorte

de extensión del extremo del cable de control con un aceite

liviano una vez por temporada y antes de almacenar la máquina

quitanieve al final de la temporada.

Almacenamiento fuera de temporada

Si no se va a usar la máquina quitanieve durante 30 días o más,

siga las siguientes instrucciones de almacenamiento.

Almacene el equipo en un área despejada y seca.

1.

Si almacena la máquina en un lugar mál ventilado, debe

2.

realizarle un tratamiento antioxidante cubriéndola con un

aceite ligero o silicona, especialmente cualquier

Limpie el exterior del motor y de la máquina quitanieve.

3.

Page 27

Funcionamiento

Antes de encender

ADVERTENCIA! Lea, comprenda y siga todas las

instrucciones y advertencias que aparecen en la

máquina y en este manual antes de operarla.

NOTA: Para ver instrucciones completas y detalladas sobre el

encendido y apagado del motor y el almacenaje, le sugerimos que

lea el manual del motor que también se incluye con esta máquina

El cable de la bujía fue desconectado por seguridad. Enchufe

1.

el cable de la bujía a la bujía antes de encender la máquina.

Encendido del motor

Para evitar el envenenamiento por monóxido de carbono,

1.

asegúrese de que el motor esté al aire libre en un área bien

ventilada.

Inserte la llave de encendido en la ranura. Gire la llave a la

2.

posición ON (encendido).

Ahora siga las instrucciones que aparecen debajo según

3.

corresponda a su máquina.

Arrancador eléctrico

ADVERTENCIA! El arrancador eléctrico debe ser

utilizado con un receptáculo de tres terminales

correctamente conectado a tierra en todo momento

para evitar la posibilidad de descargas eléctricas.

Siga todas las instrucciones cuidadosamente antes

de operar el arrancador eléctrico.

El arrancador eléctrico está equipado con un cable de

1.

alimentación y un enchufe de tres terminales conectados a

tierra y está diseñado para operar con corriente doméstica

de 120 voltios.

Determine si la instalación eléctrica de su casa es una

2.

instalación de tres cables conectados a tierra. Consulte con

un electricista matriculado si no está seguro.

Si la instalación eléctrica de su casa no es una instalación

3.

de tres cables conectados a tierra, no utilice este

arrancador eléctrico bajo ninguna circunstancia.

Si la instalación eléctrica de su casa tiene conexión a tierra,

4.

pero no cuenta con un receptáculo de tres terminales,

debe hacer instalar uno por un electricista matriculado

antes de utilizar el arrancador eléctrico.

Si tiene un receptáculo de tres terminales con conexión a

5.

tierra, siga los siguientes pasos:

Ponga el control del cebador en la posición “Full”.

6.

Presione tres (3) veces el botón del cebador, asegurándose

7.

de cubrir el orificio de ventilación cuando empuja.

Conecte el cable de alimentación a la caja del interruptor

8.

en el tablero de instrumentos. Enchufe el otro extremo

del cable de alimentación en un receptáculo de CA y 120

voltios con tres terminales conectados a tierra.

Presione el botón del arrancador para arrancar el motor

9.

con la manivela.

Cuando el motor arranca, suelte el botón arrancador y

10.

mueva el cebador gradualmente a la posición ⁄ hasta que

el motor funcione uniformemente. Ponga la palanca del

cebador en la posición OFF (apagado). Si el motor falla,

mueva el cebador inmediatamente a la posición FULL y

luego gradualmente a ⁄ y luego a OFF.

Desconecte el cable de alimentación. Siempre desconecte

11.

primero del enchufe, y luego de la máquina quitanieve.

Arrancador de retroceso

Mueva la palanca del cebador a la posición FULL

1.

(encendido con el motor en frío).

Si el motor está caliente, ubique el cebador en la posición

2.

OFF en lugar de FULL.

Presione tres (3) veces el botón del cebador, asegurándose

3.

de cubrir el orificio de ventilación cuando presiona.

Si el motor está caliente, presione el botón del cebador una

4.

sola vez.

NOTA: Siempre cubra el orificio de ventilación en el botón

cebador cuando lo presiona. Tal vez deba cebar la máquina

más para el arranque inicial si la temperatura es menor a 15

grados Fahrenheit.

Tome la manija del arrancador y tire de la soga lentamente

5.

hasta que quede un poco más tirante. Deje que la soga se

enrolle lentamente.

Tire de la manija del arrancador rápidamente. No permita

6.

que la manija tironee. Permita que se enrolle lentamente

mientras sujeta firmemente la manija del arrancador.

Mientras el motor se calienta y comienza a funcionar

1.

uniformemente, gire la palanca del cebador lentamente

hacia la posición ⁄. Cuando el motor comienza a funcionar

regularmente, mueva el cebador a la posición OFF. Si

el motor falla, vuelva a la posición FULL, luego mueva

lentamente a ⁄ luego a la posición OFF.

Detención del motor

Deje el motor encendido durante algunos minutos antes de

1.

detenerlo para ayudar a secar toda la humedad del motor.

Para detener el motor, gire la llave de encendido en sentido

2.

contrario a las agujas del reloj hasta la posición OFF/STOP.