Page 1

Safety • Set-Up • Operation • Adjustments • Maintenance • Troubleshooting • Parts Lists • Warranty

OPERATOR’S MANUAL

Model 230, S230

Model 240, S240

Model 250, S250

Model 260, S260

Model 261, S261

Single-Stage Snow Thrower

IMPORTANT

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY BEFORE OPERATION

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland,

Ohio 44136-0019.

FORM NO. 769-00805D

07/12/07

PRINTED IN U.S.A.

For US Customers: MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

For Canadian Customers: MTD Products Ltd., P.O. BOX 1386, KITCHENER, ONTARIO N2G 4J1

Page 2

This Operator’s Manual is an important part of your new snow thrower. It will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety

Safe

Set Up & Adjustment ..........................................6

Know Your Snow Thrower ..................................

Operation ............................................................. 8

Labels ......................................................3

Operation Practices ................................... 4

7

Finding and Recording Model Number

BEFORE YOU START ASSEMBLING

YOUR NEW EQUIPMENT,

please locate the model plate on the equipment and copy the

the model number and the serial number to the sample model

plate provided to the right. You can locate the model plate by

standing at the operating position and looking down at the

frame.

Adjustments & Maintenance ...........................10

Off-Season Storage .......................................... 12

Trouble

Illustrated Parts Lists .......................................

Warranty ............................................................

Shooting .............................................. 13

14

18

Customer Support

Please do

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of this unit,

you can seek help from the experts. Choose from the options below:

1. Visit www.mtdcanada.ca for many useful suggestions, click on Customer Support button.

2. Call a Customer Support Representative: For US Customers: 1-330-220-4MTD (4683)or 1-800-800-7310

3. The engine manufacturer is responsible for all enigne-related issues with regards to performance, power-rating, specifica

tions, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual, packed separately with

your unit, for more information.

Please have your unit’s model number and serial number ready when you call. See previous section to locate this information.

You will be asked to enter the serial number in order to process your call.

NOT

return the unit to the retailer from which it was purchased,

without first contacting Customer Support.

For Canadian Customers: 1-800-668-1238

2

-

Page 3

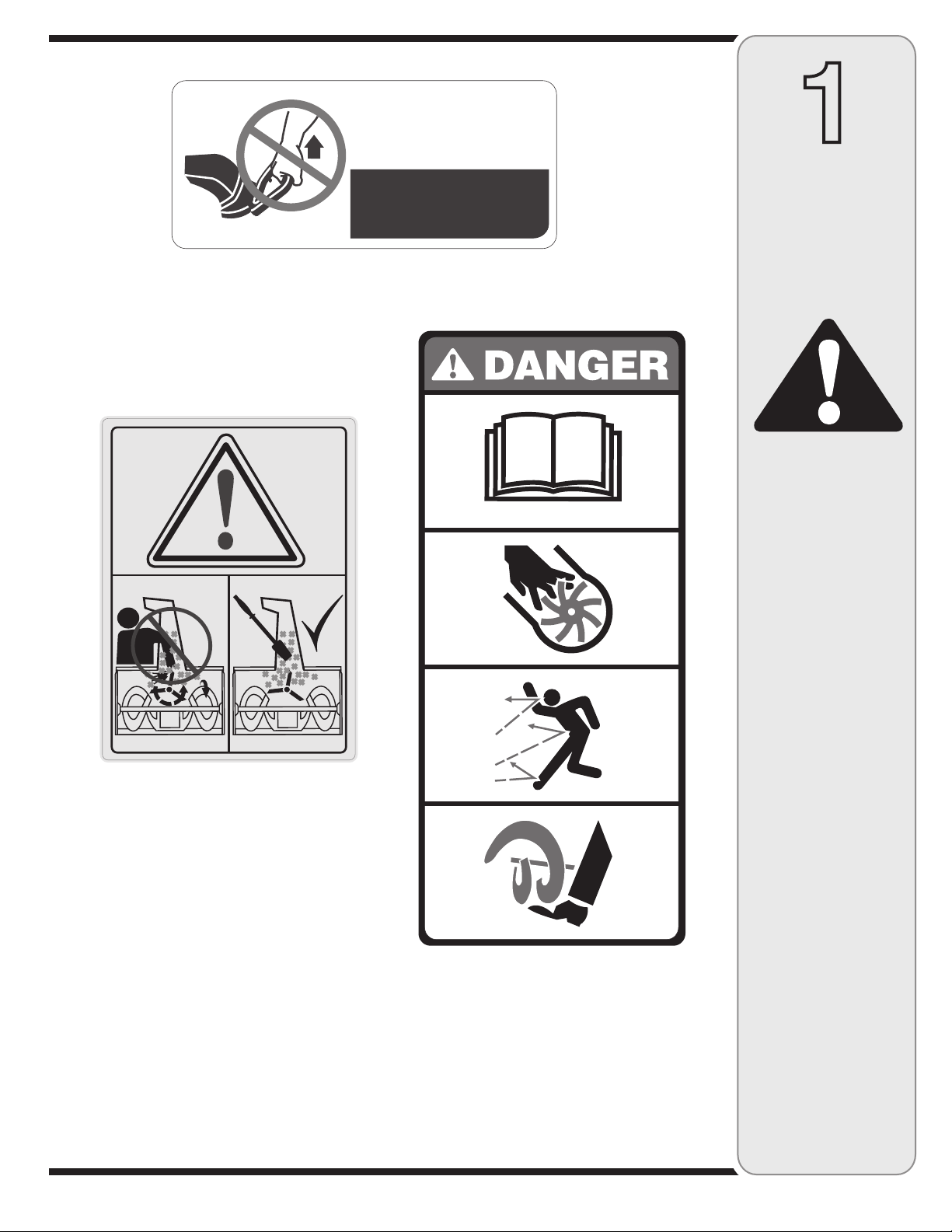

1

FOR TURNING,

NOT LIFTING

POUR TOURNER,

PAS POUR LE LEVAGE

Safety

Labels

WARNING

This symbol points

out important safety

instructions which, if

not followed, could

endanger the personal

safety and/or property

of yourself and others.

Read and follow all

instructions in this

manual before attempting to operate

this machine. Failure

to comply with these

instructions may result

in personal injury. When

you see this symbol.

HEED ITS WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

3

Page 4

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to State of California to cause cancer and

birth defects or other reproductive harm.

2

Safe

Operation

Practices

WARNING

This symbol points

out important safety

instructions which,

if not followed, could

endanger the personal safety and/or

property of yourself

and others. Read and

follow all instructions

in this manual before

attempting to operate

this machine. Failure

to comply with these

instructions may

result in personal

injury. When you see

this symbol, HEED

ITS WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

DANGER: This machine was built to be operated according to the safe operation practices in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the instructions and safe operation practices

in this manual and on the machine and be trained and

supervised by an adult.

4. Never allow adults to operate this machine without proper

instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75 feet

from the machine while it is in operation. Stop machine if

anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be

used. Remove all doormats, newspapers, sleds, boards,

wires and other foreign objects, which could be tripped

over or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or repair

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer gar

ments. Do not wear jewelry, long scarves or other loose

clothing, which could become entangled in moving parts.

Wear footwear which will improve footing on slippery

surfaces.

4. Use a grounded three-wire extension cord and receptacle

for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all control levers before starting the engine.

7. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator’s manual.

8. Let engine and machine adjust to outdoor temperature

before starting to clear snow.

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes, which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is hot

or running.

e. Allow engine to cool at least two minutes before refuel

ing.

f. Never over fill fuel tank. Fill tank to no more than ½ inch

below bottom of filler neck to provide space for fuel

expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and equip

ment. Move machine to another area. Wait 5 minutes

before starting the engine.

i. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light (e.g. furnace,

water heater, space heater, clothes dryer etc.).

j. Allow machine to cool at least 5 minutes before storing.

-

-

-

4

Page 5

Operation

1. Do not put hands or feet near rotating parts, in the

auger/impeller housing or chute assembly. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller control lever is a safety device. Never

bypass its operation. Doing so makes the machine unsafe

and may cause personal injury.

3. The control levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4. Never operate with a missing or damaged chute assembly.

Keep all safety devices in place and working.

5. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless and

deadly gas.

6. Do not operate machine while under the influence of alcohol

or drugs.

7. Muffler and engine become hot and can cause a burn. Do

not touch.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while operat

ing on slopes.

10. Plan your snow-throwing pattern to avoid discharge towards

windows, walls, cars etc. Thus, avoiding possible property

damage or personal injury caused by a ricochet.

11. Never direct discharge at children, bystanders and pets or

allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles. Walk, never run.

14. Disengage power to the auger/impeller when transporting or

not in use.

15. Never operate machine at high transport speeds on slippery

surfaces. Look down and behind and use care when

backing up.

16. If the machine should start to vibrate abnormally, stop the

engine, disconnect the spark plug wire and ground it against

the engine. Inspect thoroughly for damage. Repair any

damage before starting and operating.

17. Disengage all control levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the chute assembly, making any adjustments, or

inspections.

18. Never put your hand in the discharge or collector openings.

Always use the clean-out tool provided to unclog the discharge opening. Do not unclog chute assembly while engine

is running. Shut off engine and remain behind handles until

all moving parts have stopped before unclogging.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. If situations occur which are not covered in this manual, use

care and good judgment. Call customer assistance for the

name of your nearest servicing dealer.

Maintenance & Storage

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and adjustment sections of this manual.

2. Before cleaning, repairing, or inspecting machine disengage

all control levers and stop the engine. Wait until the

auger/impeller come to a complete stop. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original equipment

manufacturer’s (OEM) parts only. “Use of parts which do

not meet the original equipment specifications may lead to

improper performance and compromise safety!”

6. Check controls periodically to verify they engage and

disengage properly and adjust, if necessary. Refer to the

adjustment section in this operator’s manual for instructions.

7. Maintain or replace safety and instruction labels, as neces

sary.

8. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator’s manual for proper instructions

on off-season storage.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and may

include the following emission control systems: Engine Modification (EM) and Three Way Catalyst (TWC) if so equipped.

Average Useful Life

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years, or

60 hours of operation. At the end of the Average Useful Life,

buy a new machine or have the machine inspected annually by

an authorized service dealer to ensure that all mechanical and

safety systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

2

Safe

Operation

Practices

WARNING

-

This symbol points

out important safety

instructions, which

if not followed, could

endanger the personal safety and/or

property of yourself

and others. Read and

follow all instructions

in this manual before

attempting to operate

this machine. Failure

to comply with these

instructions may

result in personal

injury. When you see

this symbol, HEED

IT’S WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

5

Page 6

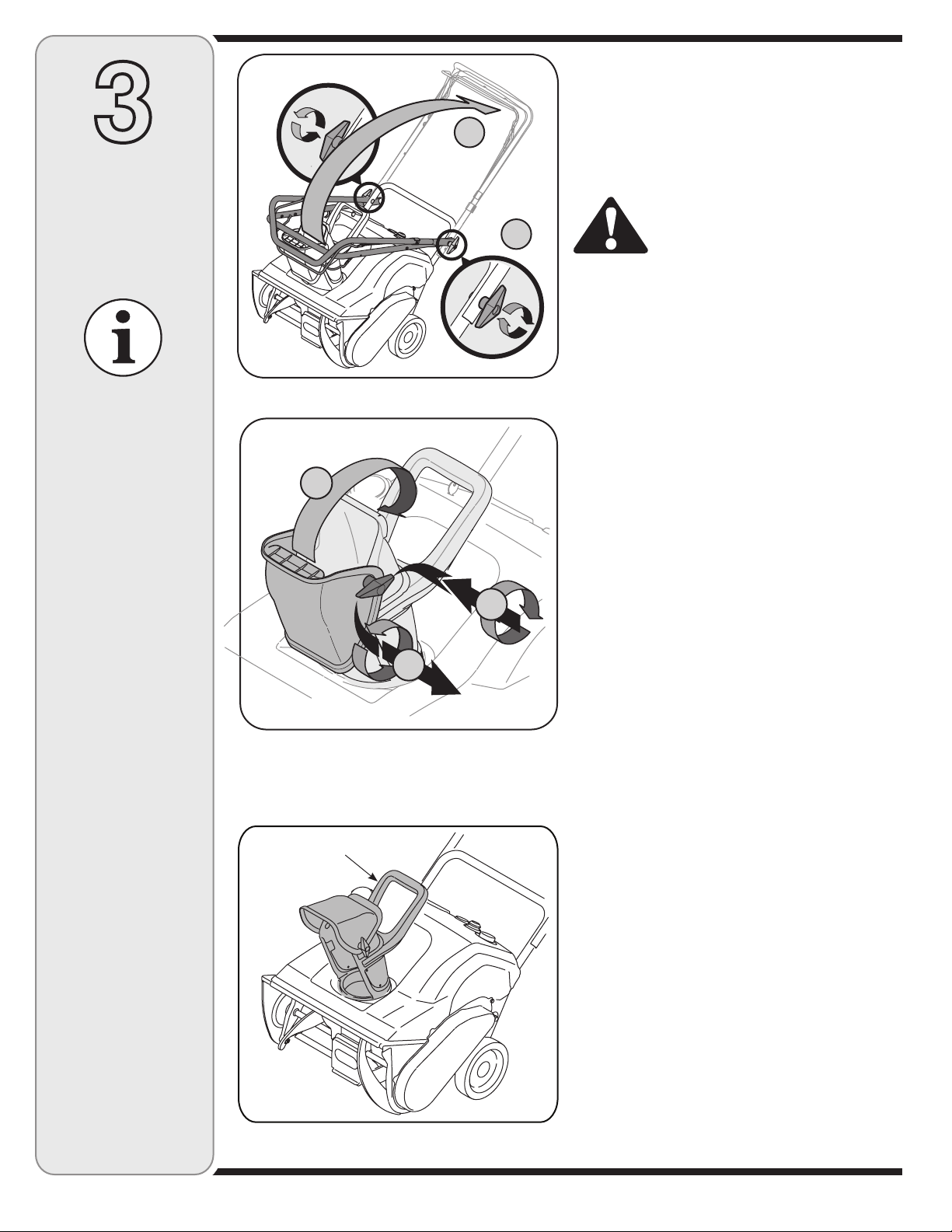

3

Setup And

Adjustment

NOTE: This Operator’s

Manual covers several

models. Snow thrower

features vary by

model. Not all features

discussed in this

manual are applicable

to all snow thrower

models.

NOTE: All references

to left or right side of

the snow thrower is

from the operating

position only.

Contents of Carton

Carton contents are listed below with part numbers in

parentheses.

1

2

1. Two Ignition Keys (725-0201)

2. 2.6 oz Bottle of 2 Cycle Oil (737-04037)

3. Extension Cord (if so equipped) (629-0236)

WARNING: Disconnect the spark plug

wire and ground it against the engine to

prevent unintended starting.

Positioning the Upper Handle

1. Remove packing material, if present.

2. Making sure not to pinch the cable in the process,

pivot the upper handle into the operating position as

illustrated in Figure 1 until it clicks into place.

Figure 1

3. Tighten the wing knobs to secure the handle in place

as in Figure 1.

Assembling the Discharge Chute

For shipping reasons, the snow thrower has been

2

3

1

Figure 2

packaged with the upper chute pivoted all the way down.

To pivot it upward, proceed as follows:

1. Turn the chute until the chute opening is facing

straight ahead. Remove the wing knob and carriage

bolt from the lower chute. See Figure 2.

2. Pivot the upper chute upward over the lip on the lower

chute so that there is NO gap between the upper

chute and the lower chute.

3. Resecure with the hardware just removed. If installed

correctly, your snow thrower should look like Figure 3.

IMPORTANT: Do not use the chute handle to lift the

snow thrower.

IMPORTANT:

Do not use the chute

handle to lift the snow

thrower.

Chute Handle

Figure 3

6

Page 7

Figure 4

Figure 4A

Choke Lever

Fuel Cap

Primer

Chute Assembly

Chute Handle

Electric Starter Button

Key

Auger Control

Starter Handle

Spark Plug Access

Auger

Shave Plate

IMPORTANT: This unit runs on a mixture of gasoline

and oil. Do NOT operate the snow thrower without first

reading the engines operator’s manual for instructions

regarding proper fuel and engine oil.

Choke Lever

Activating choke control closes the choke plate on

carburetor and aids in starting engine. Refer to the engine

manual packed with unit for more detailed instructions.

Primer

Depressing primer forces fuel directly into engine’s

carburetor to aid in cold-weather starting. Refer to engine

manual packed with unit for more detailed instructions.

Ignition Key

Ignition key must be present, inserted in key switch, and

in the “ON” position for engine to start.

Recoil Starter

The starter handle is used to manually start the engine.

Electric Starter Button (If so equipped)

Pressing the electric starter button engages the

engine’s electric starter when plugged into a 120V

power source

Electric Starter Plug (If so equipped)

Requires use of a two-prong outdoor extension cord

(packed with the snow thrower) and a 120V power

source/wall outlet.

Spark Plug Cover

Remove spark plug cover to access spark plug.

Auger

When engaged, the augers rotation draws snow into the

auger housing and throws it out the discharge chute.

Rubber paddles on the augers also aid in propelling the

unit as they come in contact with the pavement.

Auger Control Handle

Located on the upper handle, the auger control handle

is used to engage and disengage drive to the auger.

Squeeze the control handle against the upper handle to

engage auger; release it to disengage.

Discharge Chute / Chute Handle

Rotate the discharge chute to the left or right using chute

handle. Pitch of the discharge chute controls angle at

which the snow is thrown. Loosen wing knob on side

of the discharge chute before pivoting discharge chute

upward or downward. Retighten the knob once desired

position has been achieved.

Shave Plate

The shave plate maintains contact with pavement as

the snow thrower is propelled, allowing snow close to

pavement’s surface to be discharged.

4

Know

Your Snow

Thrower

IMPORTANT:

This unit runs on a

mixture of gasoline

and oil. Do NOT

operate the snow

thrower without first

reading the engines

operator’s manual for

instructions regarding proper fuel and

engine oil.

7

Page 8

5

Operation

WARNING

Read, understand,

and follow all instructions and warnings

on the machine and

in this manual before

operating.

Use extreme care

when handling

gasoline. Gasoline is

extremely flammable

and the vapors are

explosive. Never fuel

the machine indoors

or while the engine

is hot or running.

Extinguish cigarettes,

cigars, pipes and

other sources of

ignition.

The electric starter

must be used with a

properly grounded

three-prong receptacle at all times to

avoid the possibility

of electric shock. Follow all instructions

carefully prior to

operating the electric

starter.

Before Starting

WARNING: Before starting the

engine, read, understand, and follow

all instructions and warnings on the

machine and in this manual.

1. The spark plug wire was disconnected for safety.

Attach spark plug wire to spark plug before starting.

IMPORTANT: For complete and detailed engine

starting, stopping and storing instructions, it is recommended that you read the engine manual also included

with this unit.

Fuel And Oil Mixture

WARNING: Use extreme care when

handling gasoline. Gasoline is

extremely flammable and the vapors

are explosive. Never fuel machine

indoors or while the engine is hot or

running. Extinguish cigarettes, cigars,

pipes and other sources of ignition.

IMPORTANT: This unit runs on a mixture of gasoline

and oil. Do NOT operate the snow thrower without

first reading the engines operator’s manual for detailed

instructions regarding proper fuel and engine oil.

Do NOT operate the snow thrower without the fuel cap

securely in place on the fuel tank.

Positioning the Discharge

Chute

1. Loosen the wing

knob found on

the left side of the

discharge chute

and pivot the upper

chute upward or

downward to the

desired pitch.

Retighten the

star knob before

operating the snow

thrower.

2. Rotate the discharge chute to the left or right using

the chute handle. See Figure 5.

Figure 5

To Start Engine

1. Insert ignition key into slot.

2. Now follow the instructions below as it pertains to

your unit. See Figure 5 for location of controls.

Electric Starter(if equipped)

WARNING: The electric starter must

be used with a properly grounded

three-prong receptacle at all times to

avoid the possibility of electric shock.

Follow all instructions carefully prior to

operating the electric starter.

1. The electric starter is equipped with a grounded threewire power cord and plug, and is designed to operate

on 120 volt AC household current.

2. Determine that your house wiring is a three-wire

grounded system. Ask a licensed electrician if you are

not certain.

3.

If your home wiring system is not a three-wire

grounded system, do not use this electric starter

under any conditions.

4. If your home electrical system is grounded, but

a three-hole receptacle is not available, one should

be installed by a licensed electrician before using the

electric starter.

5. If you have a grounded three-prong receptacle,

proceed as follows.

6. Move Choke Control to the “Full” position.

7. Push Primer three (3) times, making sure to cover

vent hole when pushing.

8. Connect power cord to switch box on dash panel.

Plug the other end of power cord into a three-prong

120-volt, grounded, AC receptacle.

9. Push starter button to crank engine.

10. When engine starts, release starter button, and move

choke gradually to 1/2 Choke until the engine runs

smoothly. Next move Choke to OFF. If engine falters,

move choke immediately to FULL and then gradually

to 1/2 then to OFF.

11. Disconnect the power cord.

outlet first, and then from the snow thrower.

Always unplug from the

Recoil Starter

1. Move choke lever to FULL choke position (cold engine

start).

2. If engine is warm, place choke in OFF position instead

of FULL.

3. Push Primer three (3) times, making sure to cover

vent hole when pushing.

4. If engine is warm, push primer button only once.

NOTE: Always cover vent hole in primer button when

pushing. Additional priming may be necessary for first

start if temperature is below 15 degrees Fahrenheit.

5. Grasp starter handle and pull rope out slowly, until it

pulls slightly harder. Let rope rewind slowly.

6. Pull starter handle rapidly. Do not allow handle to snap

back. Allow it to rewind slowly while keeping a firm

hold on the starter handle.

8

Page 9

7. As engine warms up and begins to operate evenly,

rotate choke lever slowly to the 1/2 Choke position.

When the engine begins to run smoothly, move the

choke to the OFF position. If engine falters, return

to FULL choke, then slowly move to 1/2 then OFF

position.

To Stop Engine

1. To stop engine, turn ignition key counter-clockwise.

Disconnect the spark plug wire from the spark plug

to prevent accidental starting while equipment is

unattended.

To help prevent possible freeze-up of starter,

proceed as follows:

1. Run engine for a few minutes before stopping to help

dry off any moisture on the engine.

2. Electric Starter: Connect power cord to switch box

on engine, then to 120 volt AC receptacle. With the

engine running, push starter button and spin the

starter for several seconds. The unusual sound made

by spinning the starter will not harm engine or starter.

Disconnect the power cord from receptacle first, and

then from switch box.

3. Recoil Starter: With engine running, pull starter rope

with a rapid, continuous full arm stroke three or four

times. Pulling the starter rope will produce a loud

clattering sound, which is not harmful to the engine or

starter.

4. Wipe all snow and moisture from the carburetor cover

in the area of the control levers. Also, move control

levers back and forth several times. Leave choke

control in the FULL choke position.

5. Remove ignition key and disconnect spark plug wire to

prevent accidental starting.

Operating the Snow Thrower

The pitch of the chute assembly controls the angle at

which the snow is thrown.

1. Loosen the star knob found on the left side of the

chute assembly and

pivot the upper chute

upward or downward

to the desired pitch.

Retighten the star

knob before operating

the snow thrower.

2. Position the chute

assembly opening

by using the Chute

Handle to throw the snow in the desired direction.

See inset Figure 6.

Figure 6

Clearing Snow

WARNING: Never operate the snow

thrower with bystanders in front of or

near the discharge chute opening.

1. Engage the auger by squeezing the auger control

handle against the upper handle. See Figure 5.

2. Lift up slightly on the handle to allow the rubber

paddles on the auger to contact the pavement and

propel the snow thrower forward. Pushing downward

on the handle will raise the augers off the ground

and stop forward motion.

3. Discharge snow downwind whenever possible.

Slightly overlap each previously cleared path.

NOTE: Excessive upward pressure on the handle will

result in premature wear on the rubber auger blades

which would not be covered by warranty.

5

Operation

WARNING

Muffler, engine and

surrounding areas

become hot and

can cause a burn.

Do not touch.

Never operate the

snow thrower with

bystanders in front of

or near the discharge

chute opening.

Operating Tips

1. Run the engine for a few minutes before stopping to

help dry any moisture on the engine.

2. Clean the snow thrower thoroughly after each use.

WARNING: Muffler, engine and

surrounding areas become hot and

can cause a burn. Be careful and do

not touch when hot.

NOTE: Excessive

upward pressure on

the handle will result

in premature wear

on the rubber auger

blades which would

not be covered by

warranty.

9

Page 10

6

Adjustments

&

Maintenance

WARNING

Disconnect the

spark plug wire

and ground it against

the engine to prevent

unintended starting.

NEVER attempt to

make any adjustments while

the engine is running, except where

specified in

the operator’s

manual.

Before servicing,

repairing, or inspecting, disengage the

control bail and

stop engine. Wait

until all moving

parts have come to a

complete stop.

Side View

Figure 7

Figure 8

WARNING: Disconnect the spark plug

wire and ground it against the engine

to prevent unintended starting.

WARNING: NEVER attempt to make

any adjustments while the engine is

running, except where specified in the

operator’s manual.

Shave Plate

1. To check the adjustment of the shave plate, place the

unit on a level surface. The wheels, shave plate and

augers should all contact level surface. Note that if the

shave plate is adjusted too high, snow may blow under

the housing. If the shave plate wears out excessively,

or the unit does not self-propel, the shave plate may

be too low and needs to be adjusted.

NOTE: On new units or units with a new shave plate

installed, the augers may be slightly off the ground.

2. To adjust, tip the snow thrower back so that it rests

on the handle. Loosen the lock nuts and bolts which

secure the shave plate to the housing. See Figure 7.

Move the shave plate to desired position and retighten

the nuts and bolts securely.

Replacing Shave Plate

The shave plate is attached to the bottom of the auger

housing and is subject to wear. It should be checked

periodically. There are two wearing edges and the shave

plate can be reversed. Refer to Figure 7.

1. Remove the carriage bolts and hex lock nuts which

attach it to the snow thrower housing.

2. Install new shave plate, making sure the heads of the

carriage bolts are on the inside of the housing.

3. Adjust the shave plate according to instructions

above. Tighten the nuts securely before operating the

snow thrower.

NOTE: For information regarding the price and availability

of Shave Plate Kit refer to customer support on page 2.

Control Cable

As a result of both the control cable and the drive belt

stretching due to wear, periodic adjustments may be

necessary.

If the auger seems to hesitate when rotating while the

engine maintains a constant speed, an adjustment is

necessary. Proceed as follows:

The upper hole in the control handle provides for an

adjustment in cable tension. To adjust, disconnect the

end of control cable from the bottom hole in the control

handle and reinsert it in the upper hole. Insert the cable

from the outside as shown in Figure 8. Test the snow

thrower to see if there is a noticeable difference.

Carburetor

WARNING: If any adjustments need to

be made to the engine while the engine

is running (e.g. carburetor), keep

clear of all moving parts. Be careful of

muffler, engine and other surrounding

heated surfaces.

1. Refer to the separate engine manual, packed with

your unit, for carburetor adjustment information.

10

Page 11

Replacing Belt

WARNING: Before servicing, repairing,

or inspecting, disengage the control

bail and stop engine. Wait until all

moving parts have come to a complete

stop. Disconnect spark plug wire and

ground it against the engine to prevent

unintended starting.

Remove the belt cover by removing five hex screws. See

Figure 9. Then simply pull the belt off by grasping it from the

bottom of the auger pulley and pulling off. Once you remove

the belt from the pulleys, you can push down on the idler

pulley to release the belt from under the belt keeper.

To replace the belt follow these instructions and refer to

Figure 10:

1. Push down on the Idler pulley.

2. Put belt on top of the auger pulley, under belt keeper.

3. Thread belt around engine pulley.

4. Push belt over bottom of auger pulley.

Reinstall the belt cover removed earlier.

Engine

1. Refer to the separate engine manual for all engine

maintenance procedures.

2. Check engine and snow thrower frequently for loose

hardware, and tighten as needed.

Lubrication

Lubricate pivot points on the control handle and the

extension spring at the end of the control cable with a

light oil once every season and before storage of the

snow thrower at the end of the season.

Idler Pulley

6

Adjustments

&

Maintenance

Belt Keeper

To remove, pull belt off here

Figure 9

WARNING

Before servicing,

repairing, or inspecting,

disengage the control

bail and stop engine.

Wait until all moving

parts have come to a

complete stop. Disconnect spark plug wire

and ground it against

the engine to prevent

unintended starting.

Replacing Auger Paddles

The snow thrower auger’s rubber paddles are subject to

wear and should be replaced if any signs of excessive

wear is present.

IMPORTANT: Do NOT allow the auger’s rubber paddles

to wear to the point where portions of the metal auger

itself can come in contact with the pavement. Doing so

can result in serious damage to your snow thrower.

NOTE: For information regarding the price and availability

of Auger Kit refer to customer support on page 2.

To change the rubber paddles, proceed as follows:

1. Remove the existing rubber paddles by unscrewing the

self-tapping screws which secure them to the auger.

See Figure 11.

2. Secure the replacement rubber paddles to the auger

using the hardware removed earlier.

Figure 10

IMPORTANT:

Do NOT allow the

auger’s rubber

paddles to wear

to the point where

portions of the metal

auger itself can come

in contact with the

pavement. Doing so

can result in serious

damage to your snow

thrower.

Figure 11

11

Page 12

7

Off-Season

Storage

WARNING

Never store snow

thrower with fuel

in tank indoors or

in poorly ventilated

areas, where fuel

fumes may reach an

open flame, spark

or pilot light as on a

furnace, water heater,

clothes dryer or gas

appliance.

Observe the following, when preparing your snow

thrower for off-season storage:

• Drain fuel into an approved container outdoors, away

from any open flame. Allow engine to cool. Extinguish cigarettes, cigars, pipes and other sources

of ignition prior to draining fuel. Fuel left in engine

during warm weather deteriorates and will cause

serious starting problems.

•

If unit is to be stored over 30 days, prepare for

storage as instructed in the separate engine manual

packed with your unit.

• Run engine until fuel tank is empty and engine stops

due to lack of fuel.

• Remove gasoline from carburetor and fuel tank to

prevent gum deposits from forming on these parts

and causing possible malfunction of engine.

• Drain carburetor by pressing upward on bowl drain,

located below the carburetor cover.

• Fuel stabilizers, such as STA-BIL®, are an acceptable alternative in minimizing the formation of fuel

gum deposits during storage. Do not drain carburetor

if using a fuel stabilizer.

• Wipe equipment with an oiled rag to prevent rust.

• Remove spark plug and pour one ounce of engine

oil through spark plug hole into cylinder. Cover spark

plug hole with rag. Crank engine several times to

distribute oil. Replace spark plug.

• Follow the lubrication recommendations found in the

Maintenance Section.

• Always store the snow thrower in a clean, dry area.

Drain fuel into an

approved container

outdoors, away from

any open flame. Be

certain engine is

cool. Do not smoke.

Fuel left in engine

during warm weather

deteriorates and

will cause serious

starting problems.

Do not drain

carburetor if using

fuel stabilizer.

Never use engine or

carburetor cleaning

products in the fuel

tank or permanent

damage may occur.

12

Page 13

CauseProblem Remedy

Engine fails to start

Engine runs erratic

Engine overheats

1. Choke not in ON position.

2. Spark plug wire disconnected.

3. Fuel tank empty or stale fuel.

4. Engine not primed.

5. Faulty spark plug.

6. Blocked fuel line.

7. Safety key not in ignition on engine.

8. Fuel shut-off valve closed. (If

1. Unit running on CHOKE.

2. Blocked fuel line or stale fuel.

3. Water or dirt in fuel system.

4. Carburetor out of adjustment.

1. Move choke to ON position.

2. Connect wire to spark plug.

3. Fill tank with clean, fresh gasoline.

4. Prime engine as instructed in

“Operating Your Snow Thrower”.

5. Clean, adjust gap, or replace.

6. Clean fuel line.

7. Insert key fully into the switch.

8. Open fuel shut-off valve.

1. Move choke lever to OFF position.

2. Clean fuel line; fill tank with clean,

fresh gasoline.

3. Drain fuel tank. Refill with

fresh fuel.

4. Contact Service Center.

1. Contact Service Center.1. Carburetor not adjusted properly.

8

Trouble-

Shooting

NOTE: This section

addresses minor

service issues. For

further details, contact

customer assistance.

Excessive

Vibration

Loss of power

Unit fails

to propel itself

Unit fails

to discharge snow

1. Loose parts or damaged auger.

1. Spark plug wire loose.

2. Gas cap vent hole plugged.

3. Exhaust port plugged.

1. Drive control cable in need of adjustment.

2. Drive belt loose or damaged.

1. Chute assembly clogged.

2. Foreign object lodged in auger.

3. Auger belt loose or damaged.

1. Stop engine immediately and

disconnect spark plug wire. Tighten

all bolts and nuts. If vibration

continues, have unit serviced by a

Service Center.

1. Connect and tighten spark plug

wire.

2. Remove ice and snow from gas

cap. Be certain vent hole is clear.

3. Contact Service Center.

1. Adjust drive control cable. Refer to

“Adjustments”.

2. Replace drive belt.

1. Stop engine immediately and

disconnect spark plug wire. Clean

chute assembly and inside of

auger housing with clean-out tool

or a stick.

2. Stop engine immediately and

disconnect spark plug wire.

Remove object from auger.

3. Refer to Maintenance section.

13

Page 14

23

33

31

26

34

42

21

44

25

43

32

25

36

5

7

7

1

6

5

48

19

4

28

47

41

30

37

27

39

3

14

11

15

45

46

12

13

8

22

35

38

51

52

2

10

40

16

18

24

25

20

29

17

50

49

9

Models/Modèles 230-260

14

Page 15

REF PART

NO. NO.

N° DE N° DE

RÉF PIÈCE DE SCRIP TION DE SCRIP TION

1 629-0236 Cord-Extension 110V3M 2 Prong Corde

2 710-0627 Hex L-Bolt 5/16-24 x .75 Gr. 5 Boulon hex 5/16-24 x 0,75 Qual. 5

3 710-1003 Hex Wash B-Tapp Scr #10 x .62" Lg. Vis taraudée no. 10 x 0,62 po de lg.

* 4 710-0805 Screw-Hex Cap 5/16-18 x 1.5 Gr. 5 Vis à tête hex. 5/16-18 x 1,5 Qual. 5

** 710-3025 Screw-Hex Cap 5/16-18 x .625 Gr. 5 Vis à tête hex. 5/16-18 x 0,625 Qual. 5

5 712-04063 Flange Locknut 5/16-18 Gr. F, Ny lon Contre-écrou à embase 5/16-18 Qual. F, ny lon

6 725-0157 Ca ble Tie Attache-câble

7 726-0154 Push Mount Tie Tige de poussoir

8 726-0205 Hose Clamp Col lier

9 736-0119 Lockwasher 5/16 Rondelle frein 5/16

10 736-0242 Cupped Washer .340 ID x .872 OD x .06 Rondelle creuse 0,340 DI x 0,872 DE x 0,06

11 747-04150 Gas Tank Sup port Wire Fil de sup port - réservoir à carburant

12 7511825510 Choke Le ver Knob Manette du volet de départ

13 751-0535 Fuel Line Ligne d’essence

14 751-10023 Fuel Tank 2 Quart Réservoir de car burant de 2 quarts

15 751-10487 Cap-Fuel Capuchon d’essence

* 16 754-0367 V-Belt Courroie trapezoïdale

** 754-0101A V-Belt 1/2 x 35.0" Lg. Courroie trapezoïdale 1/2 x 35,0 po de lg

17 756-0416B Pulley Half .625 ID x 2.25 OD Moitié poulie 0,625 DI x 2,25 DE

* 18 756-04243 Pul ley Poulie

** 756-04232 V-Pulley 1/2 x 6,0" OD Poulie, 1/2 x 6,0" DE

19 790-00225 2-cy cle Mount ing Bracket Support de montage

20 734-04070 Wheel, 7 x 1.50 dia. Lug Roue, 7 x 1,50 diam. Lug

21 684-04253 Au ger As sem bly Ensemble de la tarière

22 710-0106 Hex Screw 1/4-20 x 1.25 Gr. 5 Vis à tête hexagonale 1/4-20 x 1,25 Qual 5

23 710-0642 Thd Form ing Scr. 1/4-20 x .75 Lg. Vis taraudée 1/4-20 x 0,75 lg.

24 710-0653 Hex Wash HD Tapp Scr 1/4-20 x .375 Vis auto-taraudeuse hexagonale 1/4-20 x 0,375

25 710-0896 Hex B-Tap Scr 1/4-28 x .25" Lg Vis taraudée à tête hexagonale 1/4-28 x 0,25

26 710-1005 Hex Tap Scr. 1/4-14 x .5" Lg. Vis taraudée 1/4-14 x 0,50 po de lg.

27 710-3008 Hex Bolt 5/16-18 x .75" Lg. Gr. 5 Boulon hex. 5/16-18 x 0,75 po de lg. Qual. 5

28 712-04064 Flange Locknut 1/4-20 Gr. F, Ny lon Contre-écrou à embase 1/4-20 Qual. F, ny lon

29 726-0299 Push Cap x 1/2" Rod Écrou pour tige de 1/2 po

30 732-0357A Extension Spring .33 OD x 1.12 Lg. Ressort d’extension 0,33 DE x 1,12 po de lg

31 736-0176 Flat Washer .25 ID x .93 OD x .125 Rondelle plate 0,25 DI x 0,93 DE x 0,125

32 790-00249 Bear ing Cup Roulement à cuvette

33 736-0329 L-Wash 1/4 ID Rondelle frein 1/4 DI

34 741-04188A Ball Bear ing .625 x 37 x 12.63 Roulement à billes 0,625 x 37,0 x 12,63

35 684-04168 Idler Pul ley (1/4" hole) Poulie du tendeur (trou 1/4 po)

36 748-0234 Shoulder Spacer .25 Thk. Entretoise épaulée

37 712-0896 Hex Ins Jam L-Nut 1/4-28 Contre-écrou de blocage 1/4-28

38 750-04571 Shoul der Spacer Entretoise

39 790-00238A Idler Bracket Support du tendeur

40 790-00045A Belt Cover Couvercle de courroie

41 756-0625 Cable Guide Roller Guide du câble

42 735-04033 Rub ber Pad dle Pale en caou tchouc

43 735-04032 Rub ber Spi ral-Cres cent Spirale en caoutchouc - crois sant

44 684-04252 Auger Ass’y 21" w/Solid Shaft Ensemble de la tarière de 21 po avec arbre solide

(w/o rub ber paddels) (sans pale en caou tchouc)

45 7510009636 Re coil Han dle, Mit ten Poignée du démarreur

46 7512B1476 Primer Amorçeur

47 738-0924A Hex Shld.Scr.1/4-28 x .375 Vis à épaulement 1/4-28 x 0,375

48 684-04227 Au ger As sem bly Hous ing Logement de la tarière

* 49 750-04757 Auger Spacer LH Entretoise de la tarière - gauche

* 50 750-04758 Auger Spacer RH Entretoise de la tarière - droite

* 51 750-0589 Spacer .325 ID x .625 OD x .88 Entretoise 0,325 DI x 0,625 DE x 0,88

* 52 750-0716A Spacer .630 x .88 x .747 Entretoise 0,630 DI x 0,88 DE x 0,747

* 98 cc Tec. only/98 cc Tec. seulement

** 139 cc Tec. only/139 cc Tec. seulement

31A-2501

6.26.07

Models/Modèles 230-260

NOTE: Snow thrower features/components vary by model. NOT all parts listed above and pictured on the previous

page are standard equipment.

15

9

Illustrated

Parts/

Pièces

détachés

For parts and/or

accessories refer to

customer support on

page 2.

Adressez-vous au

«Service après-vente»

à la page 2 pour ce qui

concerne les pièces

et/ou accessoires.

Page 16

Models/Modèles 230-260

�

16

25

25

27

28

29

27

37

35

3

4

15

6

34

17

7

2

36

14

32

21

20

33

19

31

30

27

29

5

11

18

24

4

13

9

5

16

Page 17

Models/Modèles 230-260

REF PART

NO. NO.

N° DE N° DE

RÉF PIÈCE DE SCRIP TION DE SCRIP TION

1 684-04127 Lower Chute Ass’y (Incl. #5-7 and 10) Ens. de la goulotte inf. comp. les nos. 5-7 et 10

2 710-04071 Carriage Screw 5/16-18 x 1.0 Vis ordinaire 5/16-18 x 1,0

3 710-0451 Carriage Bolt 5/16-18 x .75 Boulon ordinaire 5/16-18 x 0,75

4 712-04063 Flange Locknut 5/16-18 Gr. F, Ny lon Contre-écrou à embase 5/16-18 Qual. F, ny lon

5 720-0284 Han dle Knob As sem bly Bou ton

6 731-04388A Chute Han dle Poignée - goulotte d’éjection

7 731-04354B Up per Chute Goulotte supérieur

8 736-0159 Flat Washer .349 ID x .879 OD x .063 Rondelle plate 0,349 DI x 0,879 DE x 0,063

9 710-04532 Carriage Bolt 5/16-18 x 2.0 Gr. 5 Boulon ordinaire 5/16-18 x 2,0 Qual. 5

11 725-0157 Ca ble Tie Attache-câble

13 747-04165 Gull Wing Bail Étier de sus pension

14 749-1092A Up per Han dle Guidon supérieur

15 684-04144 Shroud Ass’y (98 cc) Capot (98 cc)

684-04042 Shroud Ass’y (139 cc) Capot (139 cc)

16 710-04187 Hi-Lo Screw 1/4-15 x .50 Vis 1/4-15 x 0,50

17 710-04669 Hex Wash B-Tapp Scr #10 x .62" Lg. Vis taraudée no. 10 x 0,62 po de lg.

18 710-1882 Hex Scr. 5/16-18 x 1.50 Gr. 5 Vis hex agonal 5/16-18 x 1,50 Qual. 5

19 712-0252 Hex Nut 5/8-32 x .12 Spe cial Écrou à six pans 5/8-32 x 0,12 speciale

20 725-2018 Key Switch-Electric Start Contacteur d’allumage - démarreur électrique

21 736-0225 L-Washer In ter nal Rondelle frein interne

22 736-0400 Flat Washer .218" ID x .62" OD Rondelle plate 0,218" DI x 0,62" DE

24 736-0362 Flat Washer .22 ID x 1.25 Rondelle plate 0,22 DI x 1,25

25 710-0134 Carriage Bolt 1/4-20 x .62 Boulon ordinaire 1/4-20 x 0,62

27 712-04064 Hex L-Flanged Nut 1/4-20 Gr. F Ny lon Contre-écrou à embase 1/4-20 Qual. F ny lon

28 731-1033 Shave Plate Grat toir

29 736-0176 Flat Washer .25 ID x .93 OD x .125 Rondelle plate 0,25 DI x 0,93 DE x 0,125

30 746-04237 Con trol Ca ble Câble de la commande

31 749-04114 Lower Han dle Guidon inférieur

32 725-0201 Ig ni tion Key Clavette

33 731-1133C Spark Plug Cover Couvercle de la bougie

34 731-04127 Lower Chute 5" Dia Goulotte d’éjection inferieur dia. 5 po

35 731-04353 Ring-Lower Chute Bague - goulotte d’éjection inférieur

36 731-04886 Chute Adapter 5" Dia Adaptateur de la goulotte 5 po de dia.

37 732-04111 Chute Ad just ment Spring Ressort d’ajustement - goulotte d’éjection

31A-2502

6.27.07

9

Illustrated

Parts/

Pièces

détachés

17

For parts and/or

accessories refer to

customer support on

page 2.

Adressez-vous au

«Service après-vente»

à la page 2 pour ce qui

concerne les pièces

et/ou accessoires.

Page 18

10

Warranty

Failure to comply

with suggested

maintenance

and lubrication

specifications will

void warranty.

TWO YEAR LIMITED WARRANTY

The limited warranty set forth below is given by MTD LLC with respect to new merchandise purchased and used in the United

States and/or its territories and possessions, and by MTD Products Limited with respect to new merchandise purchased and

used in Canada and /or its territories and possessions (either entity respectively, “MTD” ).

MTD warrants this product (excluding its normal wear parts as described below) against defects in material and workman

ship for a period of two (2) years commencing on the date of original purchase and will, at its option, repair or replace, free

of charge, any part found to be defective in materials or workmanship. This limited warranty shall only apply if this product

has been operated and maintained in accordance with the Operator’s Manual furnished with the product, and has not been

subject to misuse, abuse, commercial use, neglect, accident, improper maintenance, alteration, vandalism, theft, fire, water,

or damage because of other peril or natural disaster. Damage resulting from the installation or use of any part, accessory

or attachment not approved by MTD for use with the product(s) covered by this manual will void your warranty as to any

resulting damage.

Normal wear parts are warranted to be free from defects in material and workmanship for a period of thirty (30) days from the

date of purchase. Normal wear parts include, but are not limited to items such as: batteries, belts, blades, blade adapters,

grass bags, rider deck wheels, seats, snow thrower skid shoes, friction wheels, shave plates, auger spiral rubber and tires.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate the dealer in your area;

In the U.S.A.: Check your Yellow Pages, or contact MTD LLC at P.O. Box 361131, Cleveland, Ohio 44136-0019, or call

1-800-800-7310 or

1-330-220-4683 or log on to our Web site at www.mtdproducts.com.

In Canada: Contact MTD Products Limited, Kitchener, ON N2G 4J1, or call 1-800-668-1238 or log on to our Web site at

www.mtdcanada.com.

This limited warranty does not provide coverage in the following cases:

a. The engine or component parts thereof. These items may carry a separate manufacturer’s warranty. Refer to applicable

manufacturer’s warranty for terms and conditions.

b. Log splitter pumps, valves, and cylinders have a separate one-year warranty.

c. Routine maintenance items such as lubricants, filters, blade sharpening, tune-ups, brake adjustments, clutch adjust

ments, deck adjustments, and normal deterioration of the exterior finish due to use or exposure.

d. Service completed by someone other than an authorized service dealer.

e. MTD does not extend any warranty for products sold or exported outside of the United States and/or Canada, and their

respective possessions and territories, except those sold through MTD’s authorized channels of export distribution.

f. Replacement parts that are not genuine MTD parts.

g. Transportation charges and service calls.

h. If Products are used commercially. (MTD may separately offer Limited Commercial Warranties on certain select

products. Ask your dealer or retailer for details or contact MTD Service for more information.)

-

-

No implied warranty, including any implied warranty of merchantability of fitness for a particular purpose, ap

plies after the applicable period of express written warranty above as to the parts as identified. No other express

warranty, whether written or oral, except as mentioned above, given by any person or entity, including a dealer or

retailer, with respect to any product, shall bind MTD. During the period of the warranty, the exclusive remedy is

repair or replacement of the product as set forth above.

The provisions as set forth in this warranty provide the sole and exclusive remedy arising from the sale. MTD shall

not be liable for incidental or consequential loss or damage including, without limitation, expenses incurred for

substitute or replacement lawn care services or for rental expenses to temporarily replace a warranted product.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, or limitations on how long

an implied warranty lasts, so the above exclusions or limitations may not apply to you.

In no event shall recovery of any kind be greater than the amount of the purchase price of the product sold. Alteration of

safety features of the product shall void this warranty. You assume the risk and liability for loss, damage, or injury to you

and your property and/or to others and their property arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the original purchaser or to the person for whom it was purchased

as a gift.

HOW LOCAL LAWS RELATE TO THIS WARRANTY: This limited warranty gives you specific legal rights, and you may also

have other rights that vary in different jurisdictions.

IMPORTANT: Owner must present Original Proof of Purchase to obtain warranty coverage.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-800-800-7310, 1-330-220-4683

MTD Products Ltd., P. O. BOX 1386, KITCHENER, ON N2G 4J1; Phone: 1-800-668-1238

-

18

Loading...

Loading...