Page 1

OWNER'S OPERATING MANUAL

Garden Shredder Mulcher

MANUEL D'UTILSATION

Broyeur de Jardin

MANUAL DEL USUARIO

Picador de Desperdicios de Jardin

Model No. 2001

IMPORTANT:

It is vital that you retain and thoroughly read and understand

these safety and operating instructions. Incorrect use will make this machine

in operable.

IMPOR

TANT:

Il est vital pour vous de lire entièrement et de bien comprendre

ces instructions sur la sécurité d'utilisation, et de les retenir. Un maniement

incorrect de cette machine la rendrait inutilisable.

IMPOR

TANTE:

Es esencial que usted conserve y lea y entienda cabalmente estas instrucciones

de seguridad y funcionamiento. El uso incorrecto hará que esta máquina no

funcione.

Page 2

ENGLISH

READ ALL INSTRUCTIONS

WARNING! When using electric gardening tools,

basic safety precautions should always be followed to

reduce the risk of fire, electric shock, and personal

injury, including the following.

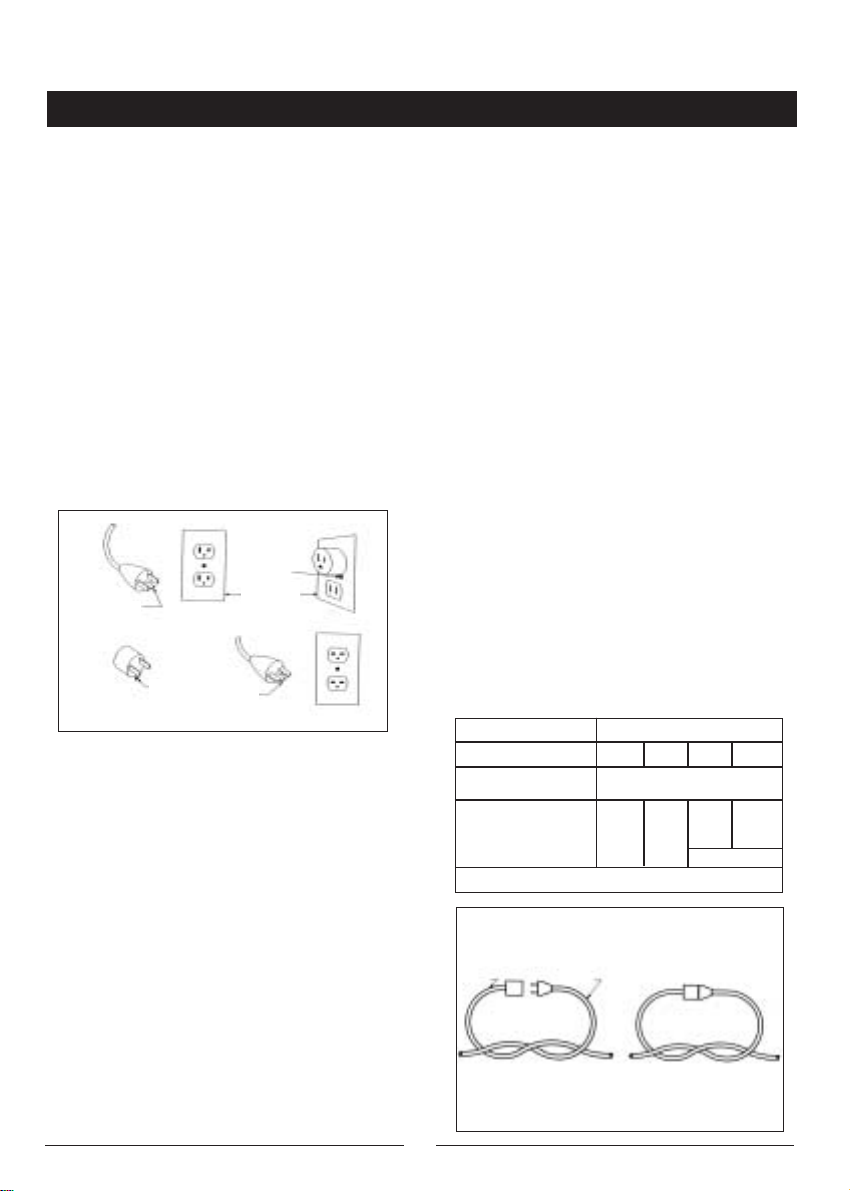

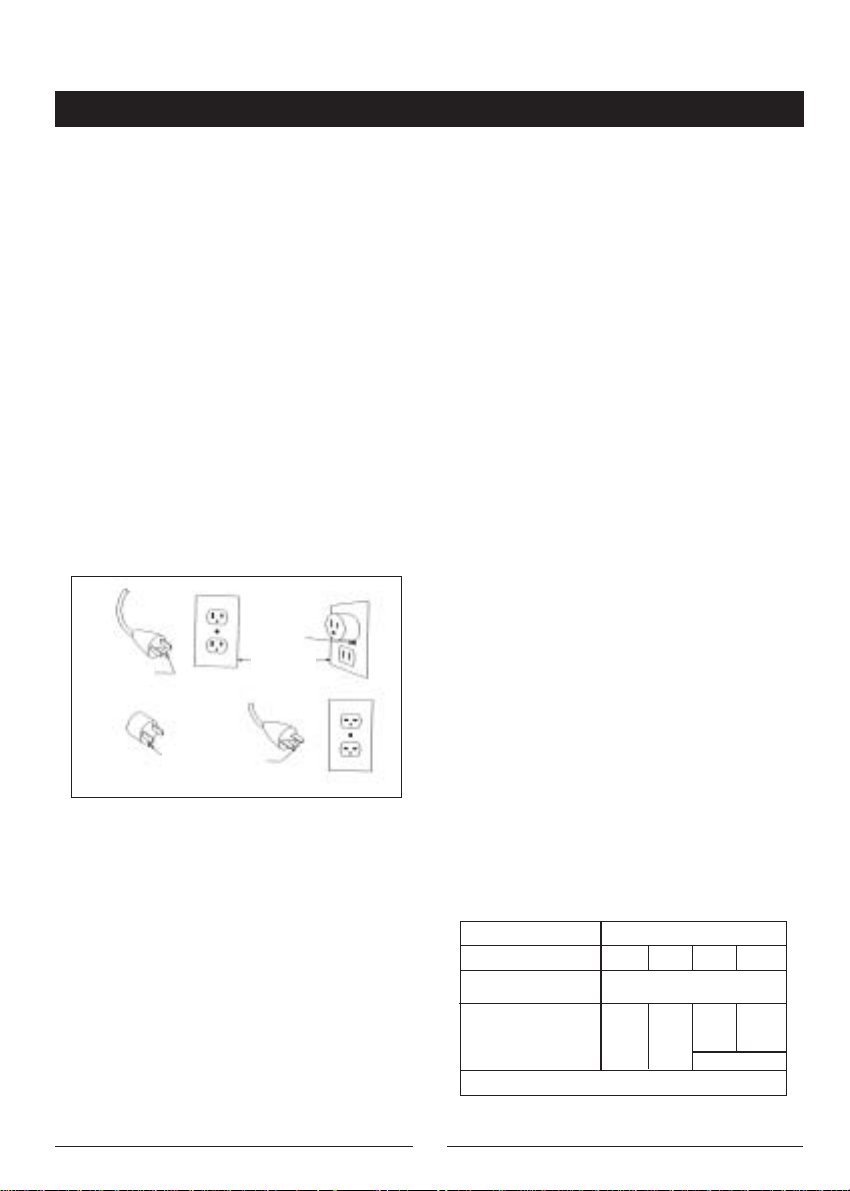

GROUNDING INSTRUCTIONS

This tool should be grounded while in use to reduce

the risk of electric shock to the operator. The tool is

equipped with a 3-conductor cord and 3-prong

grounding plug to fit the proper grounding

receptacle. The green or green and yellow wire to

live terminal. If your unit is for use on less than 150

volts, it has a plug as illustrated in sketch A in Figure

1 on page 2. If it is for use on 150 to 250 volts, it has

a plug as illustrated in sketch D, Fig.1, Page 2.

An adapter, sketches B and C, is available for

connecting plugs as illustrated in sketch A to 2-prong

receptacles. The green-colored rigid ear, lug, or the

like, must be connected to permanent ground, such

as a properly grounded outlet box. No adapter is

available for the plug illustrated in sketch D.

EXTENSION CORDS

Use only three-wire outdoor extension cords that

have three-prong grounding plugs and grounding

receptacles that accept the appliance’s plug.

METAL SCREW

COVER OF

GROUNDING

PIN

ADAPTER

GROUNDING

MEANS

GROUNDED

DUTLET BOX

GROUNDING

PIN

FIG. 1

Avoid dangerous environment. Do not use

appliance in damp or wet locations.

Don’t use in rain. Water entering a power tools will

increase the risk of electric shock.

Do not abuse cord. Never yank it to disconnect

from receptacle. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of

electric shock.

Personal Safety

Keep children away. All visitors should be kept at a

distance from work area.

Dress properly. Do not wear loose clothing or jewelry.

They can be caught in moving parts. Use of rubber

gloves and substantial footwear is recommended

when working outdoors. Wear protective hair

covering to contain long hair.

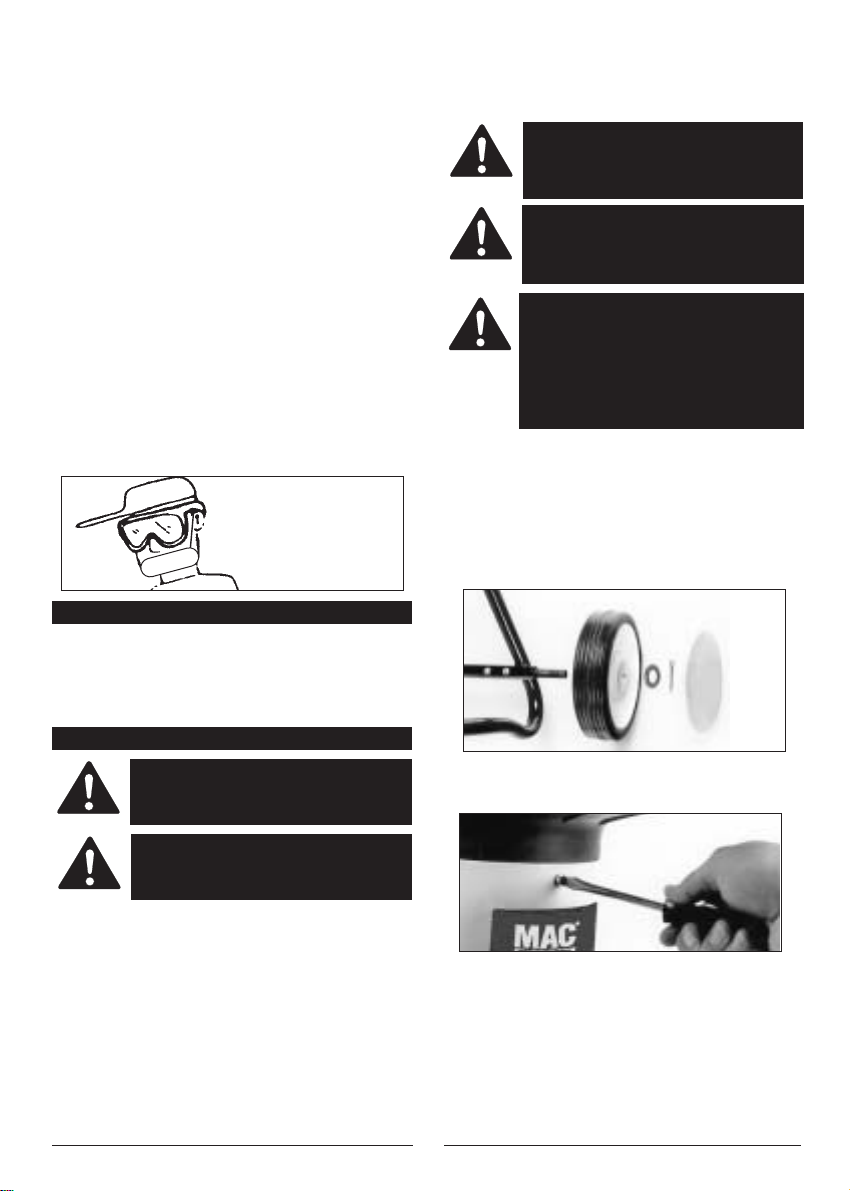

Use safety glasses. Always use face or dust mask if

operation is dusty.

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tools while tired or under the influence of

drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in

serious personal injury.

Avoid unintentional starting. Do not move

plugged-in appliance with finger on switch. Be sure

switch is off when plugging in.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables

better control of the tool in unexpected conditions.

No accessories or attachments are necessary for

the operation of this gardening tool. The use of

any accessories or attachments for this gardening tool

is not recommended. Such use of any attachment or

accessory may increase the risk of injury to the user.

Tool Use and care

Use right appliance. Do not use appliance for any

job except that for which it is intended.

Ground Fault circuit Interrupter (GFCI)

protection should be provided on the circuit(s)

or outlet(s) to be used for the gardening

appliance. Receptacles are available having built-in

GFCI protection and may be used for this measure of

safety.

Warning! To reduce the risk of electric shock, use

only with an extension cord intended for outdoor

use, such as an extension cord of cord type SW-A,

SOW-A, STW-A, STOW-A, SJW-A, SJOW-A, SJTW-A,

SJTOW-A.

Extension cords of the type specified above are

available at local hardware stores.

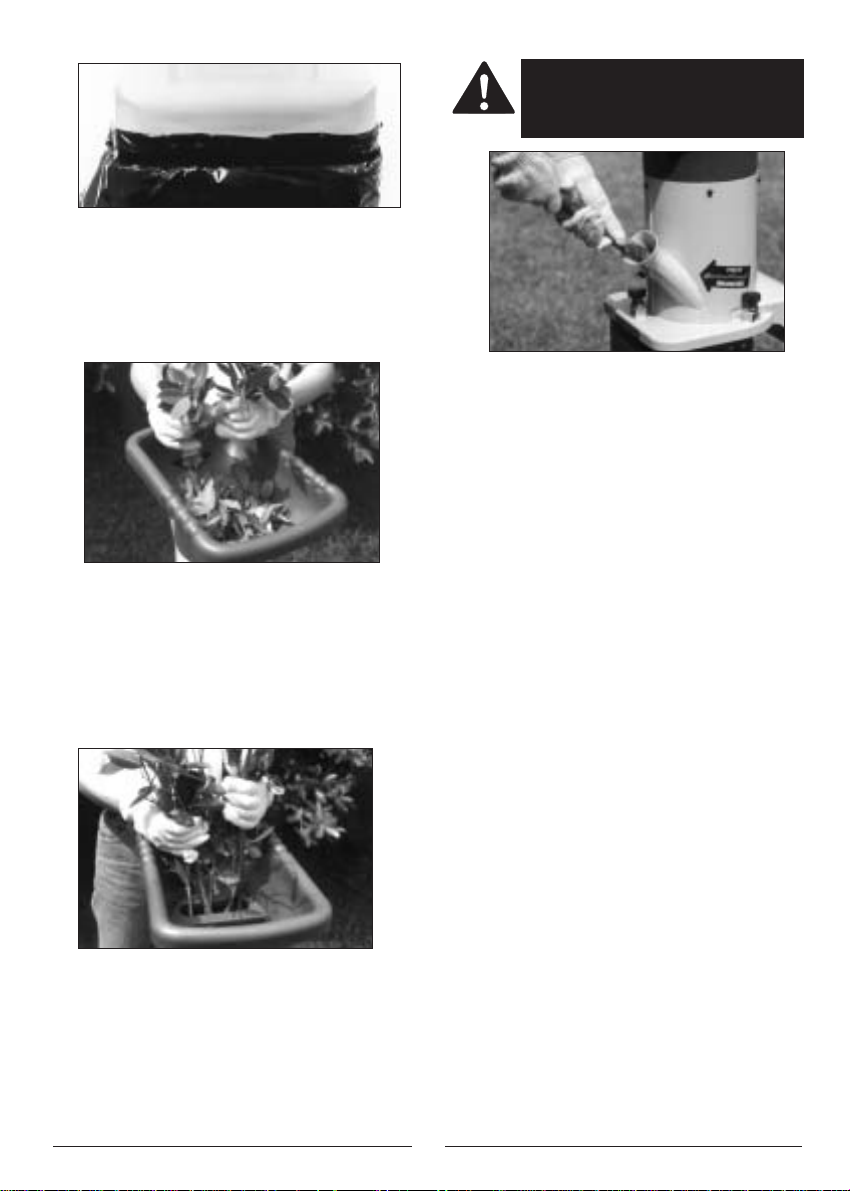

Extension cord-Make sure your extension cord is in

good condition. When using an extension cord, be

sure to use one heavy enough to carry the current

your product will draw. An undersized extension cord

will cause a drop in line voltage resulting in loss of

power and overheating. Table 1 shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage.

Number, the heavier the cord. To reduce the risk of

disconnection of appliance cord from the extension

cord during operating:

Make a knot as shown in Figure 2;

Volts

120V

Ampere Rating

More than Not more than

0-6

6-10

10-12

12-16

Total length of cord in feet

25 50

18

18

16

14

100 150

16

16

14

16

14

16

12

Not recommended

TABLE 1

Method of securing extension cord

CORD

SET

(A) TIE CORD AS SHOWN

FIG. 2

1

APPLIANCE

CORD

(B) CONNECT PLUG AND

RECEPTACLE

16

14

14

Page 3

Do not force tool. The correct tools will do the job

better and safer at the rate for which it is designed.

Disconnect the plug from the power source

before making any adjustment, changing

accessories, or storing the tool. Such preventive

safety measures reduce the risk of starting the tool

accidentally.

Store idle tools indoors. When not in use, tools

should be stored indoors in dry, and high or

locked-up lace, out of reach of children.

Maintain tools with care. Keep cutting tools sharp

and clean for best performance and to reduce the risk

of injury. Follow instructions for lubricating and

changing accessories. Inspect tool cord periodically,

and if damaged, have it repaired by an authorized

service facility. Keep handling surface dry, clean, and

free from oil and grease.

Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other condition that may affect its operation. A guard or other

part that is damaged should be properly repaired or

replaced by an authorized service center unless indicated elsewhere in this manual.

WEAR YOUR

SAFETY GLASSES

AND DUST MASK

SPECIFICATIONS

Motor Input . . . . . . . . . .120V~,60Hz, 14Amp

Hopper Size . . . . . . . . . . . 394x270x200mm

No Load Speed . . . . . . . .2800R.P.M.

Net Weight . . . . . . . . . . .35Kg

. . . . . . . . . .(15-1/2”x10-5/8”x7-7/8”)

PRECAUTIONS FOR USING TRISECTA

WARNING: Extreme caution should be

taken to ensure shreddable material does

not contain metal. Rocks, bottles. Cans or

other foreign objects.

CAUTION! Do not allow hands or any

other part of the body, or clothing to enter

inside the feeding chambers or discharge

chute, while machine is operating.

• Wear gloves while operating the machine.

• Before starting the machine, ensure that all

screws and other fasteners are properly secured.

• Machine should be operated on firm level

surfaces only.

• Before starting the machine, check that the

cutting chamber is empty.

• Motor should be kept clean of debris and other

accumulations.

• Keep all guards and deflections in good working

condition.

• Stand clear of discharge chute at all times.

• Do not over reach and keep face and body back

form the feed opening.

• Never pull the machine by the power cord and

keep cord away form water or sharp edges.

• Disconnect the power cord when the machine is

not in use.

WARNING! If machine should become

clogged, switch off the motor, disconnect

the power cord, make sure all moving

parts are completely stopped before

cleaning clogged debris.

WARNING! Ensure the power cord is

always in good condition. A cord with

broken insulation is extremely dangerous

and can result in fire, electric shock or

serious personal injury.

WARNING! The operation of any tools can

result in foreign objects being thrown into

your eyes, which can result in severe eye

damage Before operating power tool,

always wear safety goggles or safety glasses

with side shields and a full face shield when

needed. We recommend wide Vision Safety

Mask for use over eyeglasses or standard

safety glasses with side shields.

HOW TO ASSEMBLE YOUR TRISECTA

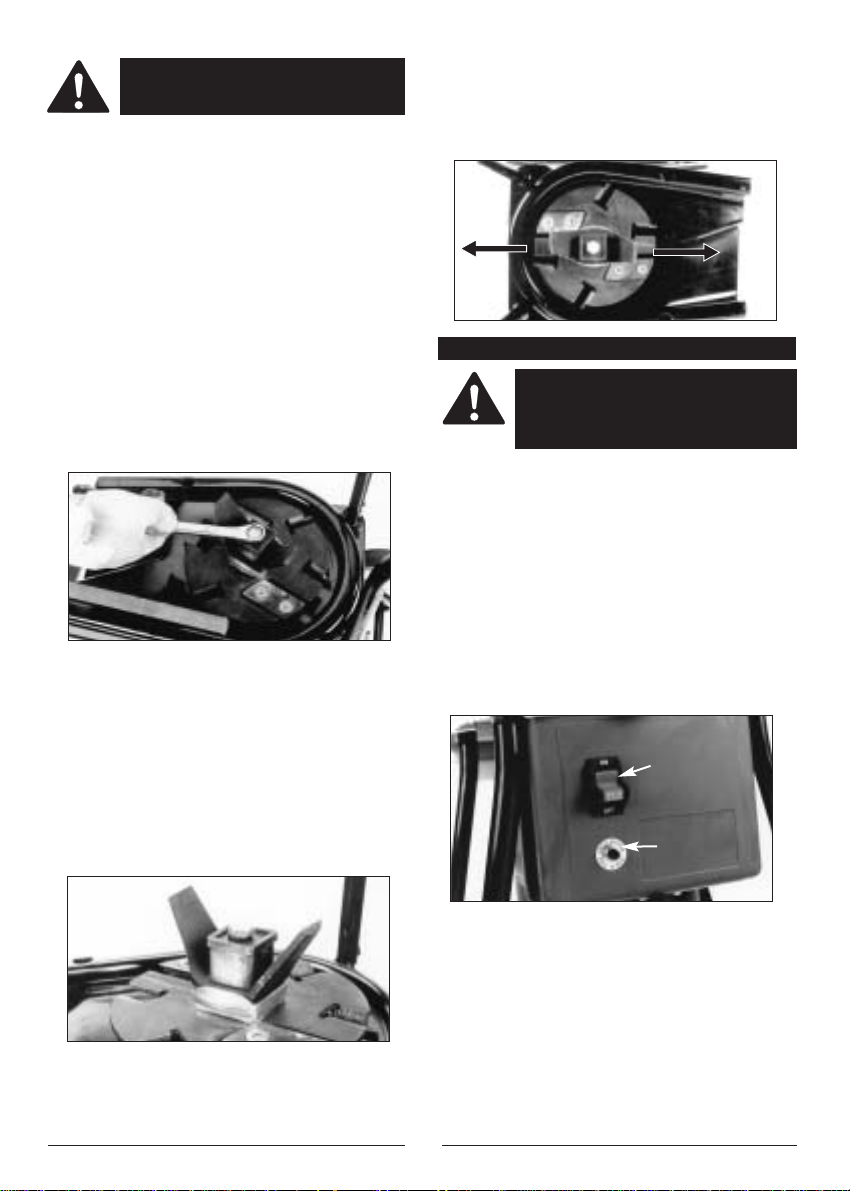

1. Push the large diameter section of the axle into

the axle tube and secure the axle into position

using the M8 x 40 hex screws and star washer.

(2 per side)

2. Push the wheel and then the 12mm flat washer

over the axle.

3. Push the split pin through the hole in the end of

the axle and bend the ends over using pliers.

4. Fix on wheel covers.

Fig. 1

HOPPER (FIG.2) Place the hopper on top of the feed

tube and align the fixing holes. Secure with the

safety set screws.

Fig. 2

MAINTENANCE

Your Trisecta has been designed for a low level of

maintenance, involving routine cleaning and

inspection. The motor of the Trisecta is maintenance

free and requires no attention. For the best results

the blades must be kept sharp at all times. The blades

have dramatically less cutting power when blunt.

The Trisecta will tear rather than cut when the blades

are blunt. When this occurs rotate the double sided

blades or replace the blades immediately.

2

Page 4

WARNING! Before attempting any

maintenance switch the machine off and

disconnect the power cord.

V-CUTTER MAINTENANCE

• Switch the machine off and disconnect the power

cord ensuring all moving parts are completely

stopped.

• Wear gloves when attempting any maintenance

to the cutting blades.

JAMMING if blades become jammed rotate knob

under motor. If blades can not be worked loose refer

to disassembly instructions (Item1) and then remove

obstruction.

DISASSEMBLY

1. Loosen caging knobs and remove the top cover

assembly.

2. Rotate the cutter base anti clockwise and place a

piece of wood between the cutter base and

cutting chamber wall so as to stop the cutting

base retating. (Fig 3)

3. Remove the center hold down bolt by turning it

anti clockwise using a 17mm spanner.

4. Remove the square washer, square bush, V-cutter

to expose cutter base.

Fig. 3

SHREDDING BLADES MAINTENANCE

To inspect or renew the double sided shredding

blades there is no need to remove the cutter base. To

remove simply undo the counter sunk screws with the

6mm hex wrench supplied with the machine and turn

them through 180 These blades are double ground

and can be used on both sides. When blunt on both

sides renew and ensure they are screwed in tightly.

ASSEMBLY This is carried out in the reverse sequence

to that of disassembly but with careful inspection of

all components. Ensure that cutter base is assembled

with the scraping plates facing down towards the

motor and that the spring washer is situated under

the head of the centre hold down bolt. (Fig 4)

Fig. 4

Before replacing the top cover assembly ensure that

the V-cutter is positioned as shown in (Fig.5) Replace

the top cover assembly and secure tightly the caging

knobs. If caging Knobs are not tight the motor will

not start due to the motor lock out switch not being

activated.

CLEANING After use, always wipe clean the outside

of the Trisecta to remove any build up of material

with a damp cloth. Clean the inside of the cutting

chamber and remove any left over material, Do not

hose down with water.

Fig. 5

OPERATION

CAUTION! Read and understand the safety

instructions in this owners manual before

using your Trisecta. Failure to comply can

result in accidents involving fire, electric

shock, or serious personal injury.

• Connect the Trisecta to a suitable power outlet.

• To start and stop the Trisecta, depress the switch

located at the rear of the Motor (Fig 6)

OVERLOAD PROTECTION AND MOTOR

JAMMING If overfeeding clogs the machine the over-

load protection switch may cut out the motor. To

restart, firstly switch the machine off and disconnect

the power cord.

Loosen caging knobs and remove top cover assembly,

then remove any clogged debris from the cutting

chamber. If the top cover assembly becomes jammed

and will not lift off, turn the V-cutter by pushing a

piece of wood through the back chute of the top

hopper to rotate the V-cutter to enable the top cover

assembly to be removed. Reset motor overload protection switch (Fig 6)

Fig. 6

ON-OFF Switch

Overload

protection

switch

IMPORTANT: Before replacing top cover assembly

ensure that the V-cutter is positioned as shown in

(Fig 5).

Replace the top cover assembly together with the top

cover screw knob ensuring this is tight. If the top

cover screw knob is not tight the motor will not start

due to the motor lock out switch not being activated.

ATTACHING MULCH BAG Place a heavy duty trash

bag using the mulch bag strap. (Fig 7)

3

Page 5

Fig. 7

TOP HOPPER-FRONT CHUT The large sloping front

chute of the Top Hopper is designed to accept leaves

and small garden clippings. Shredding and mulching

is achieved by natural suction of the debris through

the blade chamber.

Do not overfeed and do not feed wet, soggy material

into the Trisecta as this may clog the blade chamber

and the discharge chute. (Fig 8)

WARNING!Do not under any circumstances, place hands inside the geeding

chutes while the machine is operation.

Force feeding of debris is not necessary due

to the natural suction action of the trisecta.

Fig. 10

Fig. 8

TOPHOPPER-BLACK CHUTE The smaller back chute

of the top Hopper accepts medium to larger size

garden clippings.

Shredding and mulching is achieved through the

same action as the front chute. If a finer type mulch is

required than is initially achieved, re-feed the mulch

through again until the desired result is obtained.

(Fig 9).

Do not feed solid branches through the two Top

Hopper chutes.

Fig. 9

UNPACKING

1. Carefully remove all parts from the shipping

carton.

2. Do not discard material until you have identified

all the parts using the parts list.

3. If all parts have been included proceed to

assembly.

4. If you are missing a parts, contact the retailer

you purchased it form before attempting to

assemble your Trisecta.

5. Examine all the parts to make sure no break age

has occurred during shipping. Any damaged part

should be replaced before attempting to use the

Trisecta.

LOOSE PARTS LIST

Assemble the following parts in accordance with the

instructions on the following pages.

• Hopper Assembly

• Connecting Tube Assembly

• Hex Wrench

• 5 Safety Set Screws M5 X 15

• 2 Split Pins

• 2 Wheels

• 2 Flat Washers 12mm

• 2 Hex Screws M8 X 40

• 2 Flat Washers 8mm

• 2 Spring Washers 8mm

• 2 Wheel Covers

SIDE CHUTE The elongated chute located at the rear

of the machine is specially designed to accept solid

garden clippings and branches up to 1-1/2" (38mm) in

diameter.

IMPORTANT: When feeding long, large diameter

material, control the rate of feed by pulling back on

the material so as not to stall or overload the motor.

(Fig 10)

4

Page 6

FRANÇAIS

LISEZ TOUTES LES INSTRUCTIONS

Attention! Lorsque vous utilisez des outils

électriques de jardin, vous devesz toujours respecter

les règles de sécurité de base pour diminuer tout

risque d’incendie, d’électrocution et de blessures

corporelles, comprenant ce qui suit.

INSTRUCTIONS DE MISE À LA MASSE

Cet outil doit être mis à la masse lors de son

utilisation afin de réduire tout risque d’électrocution

pour l’utilisateur. L’outil est équipé d’un cordon

électrique à 3 conducteurs et d’une prise à 3 broches

avec masse afin de s’adapter au réceptacle de masse

adéquate. Le fil vert ou vert et jaune est connecté au

terminal. Si votre appareil est destinéà être utilisésous

une tension inférieur à 150 volts, il possède une prise

comme celle illustrée dans le schéma A de la figure 1

à la page 2. S’il est destiné à être utilisé sous 150 ou

250 volts, il possède une prise comme illustré dans le

schéma D Fig. 1, page 2.

Un adaptateur, schéma B et C, est disponible pour

brancher les prises femelles à broches comme illustré

sur le schéma A. Les oreilles rigides, poignées ou

autres de couleur verte, doivent être connectées à

une masse permanente, telle qu’un boîtier de prise

avec une prise de terre correcte. Aucun adaptateur

n’est fourni pour la prise illustrée dans le schéma D.

VIS MÉTALLIQUE

CACHE DU

BROCHE DE

MISE À LA

TERRE

ADAPTATEUR

(C)

PLOT DE

MISE À LA

FIG. 1

RALLONGES

Utilisez seulement des rallonges pour utilisation en

extérieur à trois fils qui possède trois broches avec

prise de terre et une prise femelle qui soit compatible

avec la prise de l’appareil.

Evitez tout environnement dangereux. N’utilisez

pas l’appareil dans des lieux mouillés.

Ne pas utiliser sous la pluie. L’eau pénétrant dans

un outil électrique augmente le risque

d’électrocution.

Nemailtraitez pas le cordon électrique. Ne tirez

jamais sur le cordon pour le débrancher de la prise.

Maintenez le cordon à l’abri de la chaleur, d’huile,

d’angles coupants ou d’objets en mouvement.

Remplacez immédiatement tout cordon endommagé.

Des cordons endommagés augmentent le risque

d’électrocution.

Sécurité Personnelle

Gardez les enfants à l’écart. Tous les visiteurs

doivent rester à distance de la zone de travail.

Habillez vous de façon appropriée. Ne portez pas

de vêtements amples ou de bijoux. Ils pourraient se

perendre dans les pièces en mouvement. Il est

conseillé d’utiliser des gants en caoutchouc et des

chaussures adéquates lorsque vous travaillez en

extérieur. Portez une protection maintien pour les

cheveux longs.

TERRE

(A)

BROCHE DE

BOÎTIER DE

PRISE AVEC

MISE À LA

TERRE

TERRE

(B)

(D)

Utilisez des lunettes de protection. Utilisez

toujours une protection pour le visage ou un masque

à poussière si le travail est poussiéreux.

Restez vigilant, faites attention à ce que vous

faites et utilisez votre bon sens lorsque vous

utilisez un outil électrique. N’utilisez pas d’outils

quqand vous êtes fatigué fatigué ou sous l’influence

de drogues, d’alcool ou de médicaments. Un moment

d’inatention quand vous utilisez des outils électriques

peut entraîner des blessures corporelles graves.

Evitez les démarrages accidentels. Assurez vous

que l’appareil n’est pas allumé avant de le brancher.

N’essayez pas d’en faire trop. Gardez un bon

équilibre et une bonne assise à tout moment. Une

bonne assise et un bon équilibre permettent un

meilleur contrôle de l’outil dans des conditioins

inattendues.

Aucun accessoire ou adjonction n’est nécessaire

pour l’utilisation de cet outil de jardin.

L’utilisation de tout accessoire ou adjonction pour cet

outil de jardin n’est pas recommandée. L’utilisation de

telles adjonctions ou accessoires peuvent augmenter

le risque de blessure pour l’utilisateur.

Utilisation de l’Outil et Précautions

Utilisez le matériel adéquat. N’utilisez pas de

matériel dans des travaux pour lesquels il n’est pas

prévu.

Un Interrupteur avec protection de Défaut de

mise à la masse (GFCI) doit être joint au circuit

(s) ou aux prises devant être utilisés pour les

matériels de jardins. Des réceptacles avec

protection GFCI sont disponibles et doivent être

utilisés pour cette mesure de sécurité.

Attention! Pour diminuer le risque d’électrocution,

utilisez uniquement des rallonges destinées à un

usage en extérieur, telles que des rallonges ayant un

type de cordon SW-A, SOW-A, STW-A, STOW-A,

SJW-A, SJOW-A, SJTW-A, SJTOW-A.

Les rallonges des types spécifiés ci-dessus sont

disponibles dans toutes les quincailleries.

Rallonges-Assurez vous que votre rallonge est en bon

état. Lorsque vous utilisez une rallonge, assurez vous

d’en utiliser une assez puissante pour supporter le

courant consommé par votre matériel. Une rallonge

sous calibrée entraînera une baisse de tension dans la

ligne ce qui créera une perte de puissance et une

surchauffe. Le Tableau 1 montre la taille correcte à

utiliser en fonction de la longueur du cordon et de

l’ampérage stipulé sur la plaque de l’outil. En cas de

doute, utilisez le calibrage immédiatement au-dessus,

pour un cordon plus puissant. Pour diminuer le risque

que le cordon de l’appareil se débranche de la

rallonge en cours d’utilisation:

Faites un nœud ainsi qu’il est montré dans la Figure 2;

Volts

120V

Ampérage Plus de

Pasplus de

0-6

6-10

10-12

12-16

Longueur totale du

cordon en pieds

25 50

18

18

16

14

100 150

16

16

14

16

14

16

12

Pas recommandé

TABLEAU 1

5

16

14

14

Page 7

Méthode pour brancher correctement une rallonge

ROLLONGE

(A) NOUER AINSI QU’IL

EST DÉCRIT

FIG. 2

Ne forcez pas sur l’outil. Un outil adéquat fera un

meilleur travail et d’une façon plus sûre, lorsqu’il est

utilisé à la vitesse pour laquelle il est conçu.

Débranchez la prise mâle de la source

d’alimentation avant de procéder à tout

réglage, de changer des accessoires ou de

ranger l’outil. De telles mesure de prévention

diminuent le risque de mettre un outil en marche

accidentellement.

Rangez les outils que vous n’utilisez pas en

intérieur. Quand ils ne sont pas utilisés, les outils

doivent être rangés à l’intérieur d’un local au sec, en

hauteur ou dans un endroit fermé, hous de la portée

des enfants.

Entretenez les outils avec soin. Maintenez les

outils coupants bien aiguisés et propres pour de

meilleures performances et pour réduire le risque de

blessure. Suivez les instructions pour la lubrification

et le changement d’accessoires. Inspectez les cordons

des outils régulièrement, et s’ils sont endommagés

faitesles réparer par un service compétent. Maintenez

les parties servant à manier l’outil sèches, propres et

sans huile ou graisse.

Vérifiez s’il y a des pièces endommagées. Avant

toute utilisation suplémentaire de l’outil, une

protection ou une autre partie que serait

endommagéedoit être vérifiée soigneusement afin de

déterminer si elle peut fonctionner correctement et

réaliser la fonction pour laquelle elle est conçue.

Vérifiez l’alignemnt des pièces en mouvement, la

fixation des pièces en mouvement, les cassures dans

les pièces, le montage, ou tout ce qui pourrait

affecter son bon fonctionnement. Une protection ou

toute autre pièce qui serait endommagée devra être

correctement réparée ou remplacée par un service

compétent à moins que cela ne soit stipulé

différemment ailleurs dans ce manuel.

CORDON DE

L’APPAREIL

(B) CONNECTER LA PRIS

MÂLE AVEC LA PRISE

FEMELLE

PORTEZ DES

LUNETTES

PROTECTRICES ET

UNE

MASQUE

ANTI- POUSSIÈRE

CARACTERISTIQUES TECHNIQUES

Alimentation du Moteur 120V~,60Hz, 14Amp

Taille du Magasin . . . . . .394x270x200mm

Vitesse à Vide . . . . . . . . .2800/min.

Poids Net . . . . . . . . . . . . .35Kg

. . . . . . . . . .(15-1/2”x10-5/8”x7-7/8”)

PRÉCAUTION CONSERNANT

L'UTILISATION DE TRISECTA

ATTENTION! Veillez particuliérement à ce que

les matiéres devant être broy es ne contiennent

pas de métal, de pierres, de bouteilles, de

canettes ou tout autre objet étranger.

PRÉCAUTION! Ne mettez pas vos mains ou

toute autre partie du corps à l'intérieur de

la chambre de chargement ou de la

descente de déchargement, veillez aussi à

ce que les habits n'entrent pas à l'intérieur

de la chambre ou de la descente lorsque la

machine fonctionne.

• Portez des gants lorsque vous vous servez de la

machine.

• Avant de mettre la machine en route,

assurez-vous que toutes les vis et autres

dispositifs d'assemblage sont correctement fixés.

• La machine doit être utilisée seulement sur un sol

plan et ferme.

• Avant de mettre la machine en route

assurez-vous que la chambre de chargement est

vide.

• Le moteur doit être propre de tout d bris ou de

tout autre dépôt.

• Maintenez toutes les protections et tous les

déflecteurs en bon état de marche.

• A tout moment restez à l'écart de la descente de

déchargement.

• Ne vous approchez pas trop et gardez votre

visage et votre corps à l'écart de l'ouverture de

chargement.

• Ne tirez jamais la machine par son fil

d'alimentation et maintenez le fil à l'écart de

l'eau et de tout objet coupant.

• Débranchez le fil d'alimentation lorsque la

machine n'est pas utilisée.

ATTENTION! Si la machine venait à se bloquer, éteignez le moteur, débranchez le fil

d'alimentation, assurez-vous que toutes les

parties mobiles sont complètement

arrêtées avant de dégager les d bris

responsables du bourrage.

ATTENTION! Assurez-vous que le fil

d'alimentation est toujours en bon état. Un

fil comportant une isolation défectueuse est

extrêmement dangereux et peut

occasionner un incendie, une électrocution

ou de sévères blessures corporelles.

ATTENTION! L'utilisation de tout outil

peut entraîner l'introduction d'un corps

étranger dans vos yeux, ce qui peut

entraîner de sévères blessures aux yeux.

Avant d'utiliser des outils électriques,

portez toujours des lunettes de protection

comportant des protections latérales et un

masque englobant tout le visage lorsque

cela est nécessaire. Nous recommandons

des masques de protection à large vision

pouvant être utilisés par-dessus des

lunettes de vue ou des lunettes de

protection normales avec protections

latérales.

6

Page 8

COMMENT ASSEMBLER VOTRE TRISECTA

1. Poussez la section à large diamètre de l'essieu

dans le tube d'essieu et fixez l'essieu en position

au moyen des vis hexagonales M8 X 40 etédes

rondelles en étoile. (2 par côté )

2. Poussez la roue et la rondelle en étoile de 12 mm

sur l'essieu.

3. Passez la goupille fendue à travers le trou situé à

l'extrémité de l'essieu et rabattez ses extr mit s

au moyen d'une paire de pinces.

Fig. 1

2. Faites tourner la base de coupe dans le sens

inverse des aiguilles d'une montre et placez une

pièce de bois entre la base de coupe et la paroi

de la chambre de coupe afin de coincer la base

de coupe. (Fig. 3)

3. Retirez l'écrou de retenue central en le tournant

dans le sens nverse des aiguilles d'une montre au

moyen d'une clé de 17 mm.

4. Retirez la rondelle carrée, du r ceptacle carré, du

coupeur en V afin de découvrir la base de coupe.

Fig. 3

MAGASIN (Fig. 2) Placez le magasin au sommet du

tube de remplissage et alignez les trous de fixation.

Assurez la fixation au moyen du jeu de vis de

sécurité.

Fig. 2

ENTRETIEN

Votre Trisecta a été con u afin de ne nécessiter que

peu d'entretien, comprenant les nettoyages de

routine et les vérifications. Le moteur du Trisecta ne

réclame aucun entretien et ne nécessite aucune

attention particuliére. Pour obtenir les meilleurs

résultats, les lames devront être maintenues

parfaitement aiguisées. Le pouvoir coupant des lames

diminue grandement lorsqu'elles sont émoussées. Le

Trisecta aura tendance à déchirer plutôt que de

couper lorsque les lames sont émoussées. Lorsque cela

se produit, retournez les lames à double tranchant ou

remplacez les lames immédiatement.

ATTENTION! Avant de commencer tout

entretien éteignez la machine et

débranchez le fil d'alimentation.

ENTRETIEN DU COUPEUR EN V

• Eteignez la machine et débranchez le fil

d'alimentation et assurez vous que toutes les

parties mobiles sont complètement arrêtées.

• Portez des gants lorsque vous entreprenez tout

entretien sur les lames de coupe.

BLOQUAGE Si les lames venaient à se coincer,

tournez le bouton situé sous le moteur. Si vous ne

pouvez pas donner un peu de jeu aux lames

reportez-vous aux instructions de démontage

(élément 1) et dégager ce qui obstrue.

DÉMONTAGE

1. Desserrez les boutons de capot et retirez

l'assemblage du couvercle supérieur.

ENTRETIEN DES LAMES DE COUPE

Pour vérifier ou changer les lames de coupe à double

tranchant il n'est pas nécessaire de retirer la base de

coupe. Pour les retirer dévissez simplement les écrous

prisonniers à l'aide de la clé hexagonale de 6 mm

fournie avec la machine et tournez les à 180. Ces

lames sont à double tranchant et peuvent être utilisées sur chaque face. Lorsqu'elles sont émoussées sur

les deux côtés changez-les et assurez-vous qu'elles

sont fixées fermement.

ASSEMBLAGE Procédez de la façon inverse utilisée

pour le démontage mais en vérifiant soigneusement

chaque élément. Assurez-vous que la base de coupe

est assemblée avec les plateaux

racleurs dirigés vers le moteur et que la rondelle

bloquante est située sous l'écrou central de fixation.

(Fig.4)

Fig. 4

Avant de replacer l'ensemble du couvercle supérieur

assurez-vous que le cooupeur en V est positionné

ainsi qu'il est montré sur la Fig. 5. Replacez

l'ensemble du couvercle supérieur et fixez fermiiment

les boutons de capot. Si le bouton de capot n'est pas

serré fermement, le moteur ne démarrera pas étant

donné que l'interrupteur de fermeture ne sera pas

activé.

Fig. 5

7

Page 9

NETTOYAGE Après utilisation, essuyez toujours

l'extérieur du Trisecta pour retirer tout dépôt de

matiéres à l'aide d'un chiffon humide. Nettoyez

l'intérieur de la chambre de coupe et retirez tout

débris. N'aspergez pas au jet.

UTILISATION

ATTENTION! Lisez et comprenez bien

toutes les instructions de sécurité contenues

dans ce manuel d'utilisateur avant d'utiliser

votre Trisecta. Le non-respect de ces

instructions pourrait entraîner des accidents

tels que l'incendie, l'électrocution ou des

blessures corporelles sérieuses.

• Connectez le Trisecta à une prise de courant

adéquate.

• Pour mettre en route et arrêter le Trisecta,

appuyez suré à l'interrupteur situé à l'arriére du

moteur (Fig. 6)

Fig. 6

Interrupteur

ON-OFF

Interrupteur

de Protection

de Surcharge

PROTECTION DE SURCHARGE ET BLOQUAGE

MOTEUR

En cas de surcharge de la machine l'interrupteur de

protection de surcharge peut arrêter le moteur. Pour

redémarrer commencez tout d'abord par éteindre la

machine et débranchez le fil d'alimentation.

Desserrez le bouton de capot et retirez l'ensemble du

couvercle supérieur, puis retirez tout débris formant

bourrage dans la chambre de coupe. Si l'ensemble du

couvercle supérieur était coincé et ne pouvait pas

être enlevé, faites tourner le coupeur en V en

introduisant une pièce de bois à travers la descente

arrière du magasin supérieur afin de faire tourner le

coupeur en V permettant ainsi de retirer l'ensemble

du couvercle sup rieur. Réamorcer l'interrupteur de

protection de surcharge (Fig. 6).

IMPORTANT: Avant de replacer l'ensemble du

couvercle supérieur assurez-vous que le coupeur en V

est positionné ainsi qu'il est montr sur la (Fig. 5).

Replacez l'ensemble du couvercle supérieur avec le

bouton écrou de couvercle supérieur et assurez-vous

qu'il est bien serré. Si le bouton écrou du couvercle

supérieur n'est pas serré fermement, le moteur ne

démarrera pas étant donné que l'interrupteur de

fermeture ne sera pas activé.

FIXATION DU SAC À COMPOSTE Placez un sac à

ordures à forte résistance en utilisant la sangle de

fixation de sac à composte. (Fig. 7)

Fig. 7

DESCENTE AVANT DU MAGASIN SUPÉRIEUR La

large descente avant de la partie supérieure du

magasin est conçue afin de recevoir des feuilles et des

petits déchets de jardin. Le broyage et la mise en

composte sont réalisés par aspiration naturelle des

débris à travers la chambre de coupe. Ne surchargez

pas et n'introduisez pas de matières détrempées ou

mouillées dans le Trisecta car cela pourrait obstruer la

chambre de coupe et la descente de déchargement.

(Fig. 8).

Fig. 8

DESCENTE ARRIÈRE DU MAGASIN SUPÉRIEUR La

descente arrière plus petite du magasin supérieur

peut recevoir des déchets de jardin de taille moyenne

ou large taille. Le broyage et

déchiquetage sont réalisés de la même façon que par

la descente avant. Si vous désirez un déchiquetage

plus fin que celui réalisé précédemment, rechargez

les copeaux dans la descente jusqu'à ce que le r sultat

voulu soit obtenu. (Fig. 9).

Fig. 9

Ne chargez pas les deux descentes du magasin

supérieur avec des grosses branches.

DESCENTES LATÉRALES Les descentes allongées

situées à l'arrière de la machine sont conçues spécialement pour recevoir des débris de jardin plus

importants et des branches allant jusqu' à 38mm de

diamètre.

IMPORTANT: Lorsque vous chargez de longs et gros

matériaux, contrôlez la vitesse de chargement en

retenant les matériaux afin de ne pas coincer ou de

faire forcer le moteur. (Fig. 10)

8

Page 10

ATTENTION! En aucune circonstance vous

ne devez introduire vos mains dans les

descentes pendant que la machine est en

route. Il n'est pas nécessaire de forcer le

chargement des débris étant donné l'action

de succion naturelle du Trisecta.

Fig. 10

DEBALLAGE

1. Retirez avec précaution toutes les pièces

contenues dans l'emballage.

2. Ne jetez aucun élément tant que vous ne les

avez pas tous identifiés au moyen de la liste de

pièces.

3. Si toutes les pièces sont présentes proc dez à

l'assemblage.

4. S'il vous manque une pièce, contactez le vendeur

chez qui vous avez acheté l'appareil avant de

tenter d'assembler votre Trisecta.

LISTE PARTIELLE DES PIÈCES

Assemblez les pièces suivantes conformément aux

instructions des pages qui suivent.

• Assemblage du magasin

• Connexion du tube d'assemblage

• Clé Hexagonale

• Jeu de 5 Vis de Sécurité M5 X 15

• 2 Goupilles fendues

• 2 Roues

• 2 Rondelles Plates 12mm

• 2 Vis Hexagonales M8 X 40

• 2 rondelles Plates 8mm

• 2 Rondelles bloquante 8mm

• 2 Capots de Roue

9

Page 11

ESPAÑOL

REGLAS GENERALES DE SEGURIDAD

ADVERTENCIA! Cuando use herramientas de

jardineria electricas, se deberia seguir siempre las

precauciones de seguridad basicas para reducir el

riesgo de fuego, electrocutaciones e injuria personal,

incluyendo lo siguiente.

INSTRUCCIONES DEL TERRENO

Esta herramienta debería estar en el suelo mientras

esté en uso para reducir el riesgo de electrocutar al

manipulador. La herramienta está equipada con 3

cables conductores y 3 tomas de tierra para acoplar al

receptáculo de tierra apropiado. El cable verde o

verde y amarillo para el terminal vivo. Si su unidad es

para usar en menos de 150 voltios, tiene una clavija

como está ilustrada en el dibujo A en la Fig. 1 de la

pagína 2. Si su unidad es para usar desde 150 hasta

250 voltios, tiene una clavija como está ilustrada en el

dibujo D, Figura 1 de la pagina 2.

Un adaptador, dibujos B y C está disponible para

conectar clavijas como está ilustrado en el dibujo A

para receptáculos de 2 puntas. La oreja rígida

coloreada en verde, la oreja o similar, deben ser

conectados a la tierra mermanente, como la caja

adecuada de salidas de tierra. No hay disponible

adaptador para la clavija ilustrada en el dibujo D.

CABLES DE EXTENSION

Use solamente cables de extensión trifasicas

exteriores que tengan clavijas de tres puntas de

tomatierra y receptáculos que acepten la clacija del

aparato.

TORNILLO DE

METAL

COVERTURA

PIN DE TIERRA

ADAPTADO

TOMA DE

TIERRA

FIG. 1

Evite entornos peligrosos . No use aparatos en

lugares húmedos o mojados.

No lo use bajo lluvia . Si se filtra agua en una

herramienta eléctrica aumentará el riesgo de

electrocutaciones.

No abuse del cable . Núnca lo estire del receptáculo

para desconectar. Mantenga el cable fuera del

alcance del calor, aceite, filos afilados o partes

moviles. Reemplace los cables dañados

inmediatamente. Los cables dañados pueden

aumentar el riesgo de electrocutaciones.

Seguridad personal

Mantenga apartado de los niños. Todos los

visitantes deben mantenerse fuera de una distancia

del área de trabajo.

Vistase adecuadamente. No lleve ropa

desabrochada o joyas. Esto podría engancharse a las

partes moviles. Use guantes de caucho y se

recomienda calzado sólido cuando se trabaja en el

exterior. Lleve protector para el cabello para guardar

el cabello largo.

DE LA SALIDA

DE TIERRA

PIN DE

TIERRA

Permanezca en alerta , fijese en lo que está

haciendo y use sentido comun cuando

esté operando una herramienta enchufada . No

use herramientas mientras esté cansado o bajo la

influencia de drogas, alcohol o medicación. Un

momento de desatención mientras esté operando

herramientas enchufadas podria resultar injurias

personales serias.

Evite arranques desintencionadas. No mueva

aparatos enchufados con los dedos en el interruptor.

Estese seguro de que el interruptor esta apagado

cuando lo conecte.

NO exceda. Mantenga la relación y equilibrio

apropiados en todo el tiempo. Una relación y

equilibrio adecuados permiten un mejor control de la

herramienta en las condiciones inesperadas.

No se necesitan accesorios ni apliques para la

operación de esta herramienta de jardineria . El

uso de cualquier accesorio o apliques para

estaherramienta de jardineria no está recomendado.

Tales usos de cualquier aplique o accesorio podría

aumentar el riesgo de injuria al accesorio.

El uso y cuidado de la herramienta

Use el aparato adecuado . No use el aparato para

ningún trabajo excepto para lo que está propuesto.

Interruptor de circuito del fallo del suelo (GFCI)

se debería proveer de protección en el(los)

circuito(s) o salida(s) para el aparato de

jardinería que vaya a ser usado. Los receptáculos

están disponibles teniendo la protección de GFCI

incorporada y podría ser usada para esta medida de

segurida.

ADVERTENCIA! Para reducir el riesgo de

electrocutación, use solamente con un cable de

extensión especial para uso de exterior , tales como

cables de extensión del tipo SW-A, SOW-A, STW-A,

STOW-A, SJW-A, SJOW-A, SJTW-A, SJTOW-A.

Cable de extensión - Asegurese de que su cable de

extensión está en buenas conciciónes . Cuando use un

cable de extension, estese seguro de que usa uno

suficientemente pesado para portar la corriente que

su producto vaya a necesitar. Un cable de extensión

de tamaño inferior causará una caida en la línea del

voltage, resultando en pérdida de potencia y

sobrecalentamiento. La tabla 1 muestra el tamaño

correcto para usar dependiendo en la longitud del

cable y de la proporción del amperio de la placa. Si

está en duda, use el equivalente al siguiente numero

más pesado para el cable . Para reducir el riesgo de

desconexión del cable del aparato del cable de la

extensión durante la operación:

Haga un nudo como está mostrado en la Figure 2;

Voltios

120V

Proporción del amperio

Más de No más de

0-6

6-10

10-12

12-16

Longitud total del cable en piés

25 50

18

18

16

14

100 150

16

16

14

16

14

16

12

No recomendado

16

14

14

TABLE 1

10

Page 12

Método de fijar el cable de extensión

SET E

CABLE

(A) ATE EL CABLE TAL

FIG. 2

No fuerce la herramienta. En lo correcto las

herramientas harán el trabajo mejor y más seguro en

la proporción para los que están diseñados.

Desconecte la clavija del suministro de energia

antes de hacer cualquie ajuste, cargando

accesorios o guardando la herramienta. Tales

medidas de prevencion para la seguridad reducen el

riesgo de activar la herramienta accidentalmente.

Guarde las herramientas que no vaya a usar en

el interior. Cuando no lo use , las herramientas

deberían estar guardadas en el interior en lugar seco

y alto o cerrado , fuera del alcance de los niños.

Mentenga las herramientas con cuidado.

Mantenga las herramientas de corte afilados y límpios

para mejor funcionamiento y para reducir el riesgo de

injurias. Siga las instrucciones para la lubricación y el

cambio de accesorios. Inspeccione periodicamente el

cable de la herramienta, y si está dañado, hagalo

reparar por el servicio de un experto autorizado.

Mantenga la superficie de manipulación seca,

límpia y libre de aceite y grasa.

Revise las partes dañadas. Antes incluso del uso de

la herramienta , un protector u otra parte que esté

dañada debería ser cuidadosamente revisada para

determinar que si operará adecuadamente y actue su

función como está intencionado. Revise la

alineacion de las partes móviles, la fijación de las

partes móviles, la rotura de las partes, montaje y

cualquiera otra condición que pueda afectar su

operación. Un protector u otra parte que esté dañada

debería ser reparada adecuadamente por un centro

autorizado de servicio a no ser que lo indique en otra

parte en este manual.

CABLE DEL

APARATO

COMO SE MUESTRA

(B) CONECTE LA CLAVIJA

Y EL RECEPTACULO

USE SUS ANTEOJOS

DE SEGURIDAD Y

MASCARA ANTIPOLVO

ESPECIFICACIONES

Motor Input . . . . . . . . . .120V~, 60Hz, 14Amp

Tamaño de la Tolva . . . . .394x270x200mm

Velocidad en vacó . . . . . .2800/min.

Peso neto . . . . . . . . . . . .35 Kg

. . . . . . . . . .(15-1/2”x10-5/8”x7-7/8”)

PRECAUCIONES PARA EL USO DE LA

TRISECTA

ADVERTENCIA: Se debe usar sumo cuidado

para asegurarse de que los materiales a picar no

contengan metal, piedras, botellas, latas u otros

objetos extraños.

ADVERTENCIA: No permita que las

manos, u otra parte del cuerpo o la ropa,

entren a los conductos de alimentación o

al conducto de descarga mientras la

máquina esté funcionando.

• Use guantes al hacer funcionar la máquina.

• Antes de hacer partir la máquina, asegúrese de

que todos los tornillos y otras sujeciones estén

correctamente ajustados.

• La máquina se debe usar sólo en superficies

firmes a nivel.

• Antes de hacer partir la máquina, asegúrese de

que la caja de corte esté vacía.

• Se debe mantener el motor limpio de desperdicios y otras acumulaciones.

• Mantenga todas las protecciones y deflectores

en buenas condiciones de uso.

•Manténgase alejado en todo momento del conducto de descarga.

• No se estire demasiado y mantenga su cara y

cuerpo alejados de la entrada de alimentación.

• Nunca tire la máquina del cordón electrico y

mantenga el cordón alejado del agua y de los

bordes afilados.

• Desconecte el cordón eléctrico cuando no se

esté usando la máquina.

ADVERTENCIA: Si la máquina se obstruye,

apague el motor, desconecte el cordón

eléctrico y asegúrese de que todas las

partes móviles se hayan detenido antes de

quitar los desperdicios atascados.

ADVERTENCIA: Asegúrese de mantener

siempre el cordón eléctrico en buenas

condiciones. Un cordón con el aislador roto

es sumamente peligroso y puede resultar en

un incendio, golpe eléctrico o serias lesiones

personales.

ADVERTENCIA: Al hacer funcionar

cualquier herramienta pueden saltar cuerpos extraños a los ojos, lo que puede

causar grave daño a los ojos. Antes de

usar una herramienta eléctrica, use siempre gafas de seguridad o anteojos con

protecciones laterales y una máscara facial

completa cuando sea necesaria.

Recomendamos la Máscara de Seguridad

de Visión Panorámica para usar sobre

anteojos o gafas de seguridad corrientes

con protecciones laterales.

11

Page 13

ARMADO DE SU TRISECTA

1. Empuje la sección de diámetro grande del eje en

el tubo de eje y afianza el eje en posición usando

los tornillos hexagonales M8X40 y arandela

estrella. (2 por lado)

2. Empuje la rueda y entonces la arandela llana de

12mm encima del eje.

3. Empuje la clavija partidora por el hoyo en la

punta del eje y curva las untas encima usando

alicateses.

4. Fije las tapas de la rueda.

Fig. 1

Torval (FIG.2) colocar el torval encima del tubo de

alimentacción y alinea los hoyos de fijación. Afiance

con el conjunto de tornillos de seguridad.

Fig. 2

MANTENIMIENTO

El su Trisecta has sido diseñado para un bajo nivel de

mantenimiento, envolviendo limpieza rutinaria e

inspección. El motor del Trisecta es libre de

mantenimiento y no requiere atención. Para obtener

resultados mejores, las hojas deben ser afiladas todas

las veces. Las hojas tienen dramáticamente menos

poder de corte cuando desafiladas.

El Trisecta rasgará en lugar de cortar cuando las hojas

son desafiladas. Cuando ésto ocurre rueda las hojas

de doble lado o reemplaza las hojas inmediatamente.

ADVERTENCIA! Antes de intentar hacer

cualquier mantenimiento, desconecta la

máquina y desconecta el cable de energía.

MANTENIMIENTO DEL CORTADOR-V

• Desconecta la máquina y desconecta el cable de

energía asegurando que todas las partes moviles

están completamente paradas.

• Usar guanted cuando intentar cualquier

mantenimiento a las hojas cortantes.

INTERFERENCIA Si hojas se vuelven bloqueadas, gira

el botón debajo del motor. Si las hojas no pueden

trabajar a suelto, consulta a las instrucciones de

desmontaje (Item1) y entonces quita obstrucción.

DESMONTAJE

1. Suelte los botones cajas y quita la montaje de

tapa superior.

2. Ruede la base del cortador en el sentido

contrario de las agujas del reloj y coloca un

pedazo de madera entre la base del cortador y

pared de la cámara de corte para parar la

rotación de la base cortante. (Fig 3)

3. Quite el tornillo central sujetador lo volvendo en

el sentido contrario a las agujas del reloj usando

una llave inglesa de 17mm.

4. Quite la arandela cuadrada, cojinete cuadrado,

cortador-V para exponer la base cortadora.

Fig. 3

MANTENIMIENTO DE LAS HOJAS TRITURADORAS

Para inspeccionar o renovar las hojas trituradoras de

doble lado no es necessario quitar la base cortadora.

Para qitar simplemente deshace los tornillos

avellanados con una llave hexagonal de 6mm provista

con la máquina y vuelve los 180˚. Esta hojas son

doblemente trituradoras y se pueden usar ambos

lados. Cuando desafiladas en ambos lados renueva y

asegurate de que ellos están atornillados

herméticamente.

MONTAJE Esto es hecho en sucesión inversa al de la

desmontaje pero con inspección cuidadosa de todos

los componentes. Asegurese que la base cortadora es

montada con platos raspadores mirando hacia el

motor y que se la arandela del muelle están situadas

bajo la cabeza del tornillo central sujetador. (Fig 4)

Fig. 4

Antes de reemplazar la montaje de la tapa superior

asegurase que el cortador-V está posicionado como

mostrado en (fig.5) Reemplace la montaje de la tapa

superior y afianza los botones herméticamente. Si los

botones non están apretados, el motor no comenzará

debido al interruptor di cerradura del motor no estar

activado.

Fig. 5

LIMPIEZA Después de usar, siempre frote el exterior

de la Trisecta con un paño húmedo para eliminar

cualquier acumulación de material. Limpie el interior

de la caja de corte y saque cualquier material

sobrante. No la mangueree con agua.

12

Page 14

FUNCIONAMIENTO

PRECAUCION: Lea y entienda las instruc-

ciones de seguridad contenidas en este

manual del dueño antes de usar su Trisecta.

El no hacerlo puede resultar en accidentes

en que se produzcan incendios, golpes eléctricos, o lesiones personales serias.

• Conecte la Trisecta a un enchufe eléctrico

adecuado.

• Para hacer partir y detener la Trisecta, apriete el

interruptor de encendido/apagado ubicado en la

parte posterior del Motor(Fig 6)

Fig. 6

Interruptor

Interruptor de

prot ección

contra carga

excesiva

PROTECCION CONTRA SOBRECARGA Y TRABADO

DEL MOTOR Si la máquina se atasca debido a

alimentación excesiva, el interruptor de protección

contra sobrecarga puede apagar el motor. Para

hacerlo partir de nuevo, primero apague la máquina

y desconecte el cordón eléctrico. Saque la perilla del

interruptor de seguridad de la cubierta superior y la

cubierta superior y quite cualquier desperdicio

atascado en la caja de corte. Si la cubierta superior se

traba y no se desprende, haga rotar el cortador en ‘V’

empujando un pedazo de madera a través del

conducto posterior de la tolva superior para hacer

hacer rotar el cortador en ‘V’ permitiendo así el

desprendimiento de la cubierta superior. Encienda

nuevamente el interruptor de protección contra

sobrecarga. (Fig 6)

IMPORTANTE: Antes de reemplazar la cubierta

superior, asegúrese de que el cortador en ‘V’ esté

ubicado como se muestra en la (Fig 5).

Reemplace la cubierta superior junto con la perilla del

interruptor de seguridad de la cubierta superior

asegurándose de que quede apretada. Si la perilla del

interruptor de seguridad superior no está apretada, el

motor no partirá debido a que no se activará el

interruptor de desconexión del motor.

INSTALACION DE LA BOLSA DE DESPERDICIOS

Instale una bolsa de servicio pesado sobre el labio del

conducto de descarga, asegurándola en posición

correcta usando la correa de la bolsa de

desperdicios. (Fig 7)

Fig. 7

TOLVA SUPERIOR - CONDUCTO FRONTAL

El conducto frontal grande inclinado de la Tolva

Superior está diseñado para aceptar hojas y cortes de

jarín pequeños. El rasgado y picado se logra debido a

la succión natural de los desperdicios a través de la

caja de la cuchilla. No alimente la Trisecta excesivamente y no la alimente con material mojado o saturado porque ésto puede atascar la caja de la cuchilla y

el conducto de descarga. (Fig 8)

Fig. 8

TOLVA SUPERIOR - CONDUCTO POSTERIOR

El conducto posterior menor de la Tolva Superior

acepta recortes de jardín medianos a grandes. El

rasgado y picado se logra debido a la misma acción

que la del conducto frontal. Si se necesita un picado

más fino que el obtenido inicialmente, alimente el

picado nuevamente hasta que se obtenga el

resultado deseado. (Fig 9).

No alimente ramas sólidas a través de los dos

Conductos Superiores de la Tolva.

Fig. 9

CONDUCTO LATERAL El conducto alargado ubicado

en la parte posterior de la máquina está diseñado

especialmente para aceptar recortes de jardín sólidos

y ramas de hasta 38mm de diámetro.

IMPORTANTE: Cuando alimente material largo, de

diámetro mayor, controle la velocidad de

alimentación tirando del material de manera que no

se detenga o sobrecargue el motor. (Fig 10)

PRECAUCION: Bajo ninguna circunstancia

ponga las manos dentro de los conductos

de alimentación mientras la máquina esté

funcionando. No es necesario alimentar los

desperdicios a la fuerza gracias a la acción

de succión natural de la Trisecta.

13

Page 15

Fig. 10

DESEMPAQUE

• Saque cuidadosamente todas las partes de la caja

de transporte.

• No deseche ningún material hasta que haya

identificado todas las partes usando la lista de

partes.

• Si se han incluido todas las partes, proceda con el

armado.

• Si falta una parte, diríjase al distribuidor donde la

compró antes de tratar de armar su Trisecta.

• Examine todas las partes para asegurarse de que

no se haya quebrado nada durante el transporte.

Cualquier parte dañada debe ser reemplazada

antes de tratar de usar su Trisecta.

LISTA DE PARTES SUELTAS

Arme las siguientes partes de acuerdo a las

instrucciones en las páginas siguientes.

•Tolva Superior

•3 tornillos y golillas de sujeción de un sólo sentido

• Conjunto del Mango

•2 Tornillos Posi Drive de Cabeza Redonda M6 x

12mm

•2 Golillas Estrella 6mm

• Llave Hexagonal 6mm (para instalar la cuchilla)

• Correa para el Saco de Desperdicios

•Tubo de Alimentación, Motor y Conjunto de Base

•2 Ruedas

•2 Ejes

•2 Pasadores de Aleta

•2 Golillas Planas 14mm

•4 Tornillos Posi Drive de Cabeza Redonda M8 x

12mm

•4 Golillas Estrella 8mm

•2 Tapas de Rueda

14

Page 16

For problems or questions, DO NOT return

STOP

this product to the store. Contact your

Customer Service Agent at 1-800-521-8559.

ARRÊT

ALTO

au préposé du Service à la clientèle en composant le 1-800-521-8559.

Para problemas o preguntas, NO regrese este producto a la tirnada.

Contacte a su Agente de Servicio al Cliente al teléfono 1-800-521-8559.

En cas de problèmes ou pour des questions,

NE PAS renvoyer ce produit au magasin. S’adresser

6096-200118

1-800-521-8559

McCulloch Marketing

P.O.Box 31567 • Tucson, AZ 85751-1567 • USA

Jenn Feng U.S.A.

P.O.Box 5921 • Orange, CA 92863-5921 • USA

Jenn Feng Industrial Co., Ltd.

No. 19, Lane 118, Min Tsu Road, sec. 2

Ping Chang City, Taoyuan, Taiwan, R.O.C.

Made in Taiwan/Made in Taiwan/Made in Taiwan

Loading...

Loading...