Page 1

v

@WNERDS

MANUAL

O

ASSEMBLY

O

OPERATION

O

MAINTENANCE

O

PARTS

LIST

lmportant:

Read

Safety

Rules

and

Instructions

Caref

ully

Model

No.

218-405-065

5

H.P.

REAR

TINE

CHAIN

DRIVE

TI LLER

FIFTY

CENTS

PRINTED

1N

U.S.A.

FORM

NO. 770-8092

Page 2

LIMITED

WARRANTY

For

one

year

from the

date

of original

retail

purchase,

MTD

PRODUCTS

INC

will either

repair or

replace,

at

its option,

free of charge,

F.O.B.

factory

or authorized

service

firm,

any

part

or

parts

found

to be defective

in

material or

workmanship.

Transportation

charges

for

replacement

under

this

warranty

must be

paid

by

the

purchaser

unless

return

is

requested

by

MTD PRODUCTS

lNC.

This

warranty

will

not apply

to any

part

which

has become

inoperative

due

to

misuse,

excessive

use,

accident,

neglect,

improper

maintenance,

alterations,

or unless

the unit

has

been

operated

and

maintained

in accordance

with

the

instructions

furnished.

This

warranty does

not apply to

the engine,

motor, battery,

battery

charger

or component

parts

thereof

.

Please

refer to

the applicable

manufacturer's

warranty

on

these

items.

This

warranty

will not apply

where

the unit

has been

used

commercially.

Warranty service

is available

through

your

local authorized

service

dealer

or distributor'

lf

you

do

not

know the dealer

or distributor

in

your

area,

please

write

to the

Customer

Service

bepartmei't

of

MTD.

The

return of a

complete

unit

permission

has been

extended

This warranty

gives

you

specif

ic legal

rights.

You

may also

have other

rights

which

vary

from state

to state.

WARNING

TO PURCHASERS

OF INTERNAL

COMBUSTION

ENGINE

EQUIPPED

MACHINERY OR

DEVICES IN

THE STATE

OF CALIFORNIA

The

equipment

which

you

have

just

purchased

does

not

have a spark

arrester.

lf this

equipment

is used

on

any

forest

covered

land,

brush

covered land, or

grass

covered

unimproved

land

in the State

of

California,

before using

on

such

land, the California

law requires that

a spark

arrester

be

provided.

In addition,

spark

arrester

is required

by

law to be

in

effective

working order.

The spark

arrester

must

be attached

to the

exhaust

system and comply

with Section

4442 of the Calif

ornia

Public

Resources

Code.

J

not be accepted

by

the

factory

unless

prior

written

MTD.

J

Page 3

U

't.

Do

not wear loose fitting clothing

get

caught on the

tiller.

Do

not

start the engine

unless the

is in the neutral

(N)

position.

11. Do not fill

gasoline

tank while

engine is

running.

Spilling

gasoline

on

hot

engine may

cause a f ire or

explosion.

Do not run the

engine

while indoors. Exhaust

gases

are deadly

poisonous.

Be

careful

not

to touch

the

muff ler

after

the

engine has

been

running,

it is hot.

Before

any

maintenance

work is

performed

or

adjustments

are made,

remove the spark

plug

wire and

ground

it

on the

engine block

for

added

safety.

Use caution when

tilling near

buildings and

fences, rotating

tines

can cause damage

or

in

jury.

Before attempting to remove rocks,

bricks

and other objects from tines,

stop the engine

and

be sure the tines

have

stopped

completely. Disconnect

the spark

plug

wire

and

ground

to

prevent

accidental starting.

Check

the

tine

and

engine

mounting

bolts

at

f requent

intervals

for

proper

tightness.

Keep all

nuts, bolts and

screws

tight to

be

sure

the equipment

is

in safe

working

condition.

Never store

the equipment

with

gasoline

in

the

tank

inside

of a building

where

fumes

may

reach an

open

flame

or spark.

Allow

the

engine

to

cool before

storing

in any

enclosure.

12.

13.

14.

2.

3.

(+-

15.

16.

5.

6.

that

could

shift

lever

7. Do

not stand

in front of the tiller while

starting

the

engine.

8.

Do

not

place

feet and

hands on or

near the

tines

when starting

the engine

or while the

engine

is

running.

9.

Do

not leave the

tillei unattended

with

the

engine

running.

10. Do not walk

in front

of the tiller

while

the

englne

is running.

17.

18.

+tMPoRrANr

It is suggested

that this

manual

be

read in its

entirety

before attempting to assemble or operate. Keep

this

manual

in

a safe

place

f or f

uture

reference

and for

ordering replacement

parts.

This unit

is shipped

WITHOUT

GASOLINE

or

OlL.

Af

ter assembly, see operating

section

of this manual

f

or

proper

f

uel

and

amount.

your

tiller

is a

precisron

piece

of

power

equipment,

not

a

play

thing.

Therefore, exercise

extreme caution

at all times.

SAFE

OPERATION

PRACTICES

FOR

TILLERS

Read the Operating

and Service Owner's

Manual

carefully.

Be

thoroughly

familiar with

the controls and

the

proper

use

of the

equipment.

Never allow children

to operate a

power

tiller.

Only

persons

well acquainted

with these

rules

of safe operation

should be allowed

to use

your

tiller.

Keep the a(ea

of operation

clear

of all

persons, particularly

small

children

and

pets.

Do not operate

equipment

when barefoot

or

wearing

open sandals.

Always wear substan-

tialfootwear.

19.

Page 4

INDEX

Limited

Warranty

.........2

SafeOperationPractices...

.....3

lntroduction....

.........4

ContentsinHardwarePack

......5

Tillerldentification

.......6

Assembly

Instructions

....

......7

Adjustments....

.........9

Controls

...10

EnginePreparation

......13

Ooeration

........13

Tilling

.....14

Tilling

Hints.

......15

Maintenance....

........15

Off-Season

Storage

......19

Transmission-RepairParts

.......

... 20

Tiller-RepairParts

......22

Partslnformation.

.....

BackCover

J

INTRODUCTION

This

Product

has

been

designed,

engineered

and

manufactured

to

give you

the

and

performance.

Should

you

experience any

problem

you

cannot easily

remedy,

please

contacl

listed

on the back of this

manual.

best

possible

dependability

your

nearest service

dealer

J

PRE-ASSEMBLY

--\"

D

7'

NOTE

The

right

and

left

side

of

your

tiller

is determined from operator's

posi-

tion.

Bef

ore any step is

undertaken,

the instructions

f or

that step should be read through.

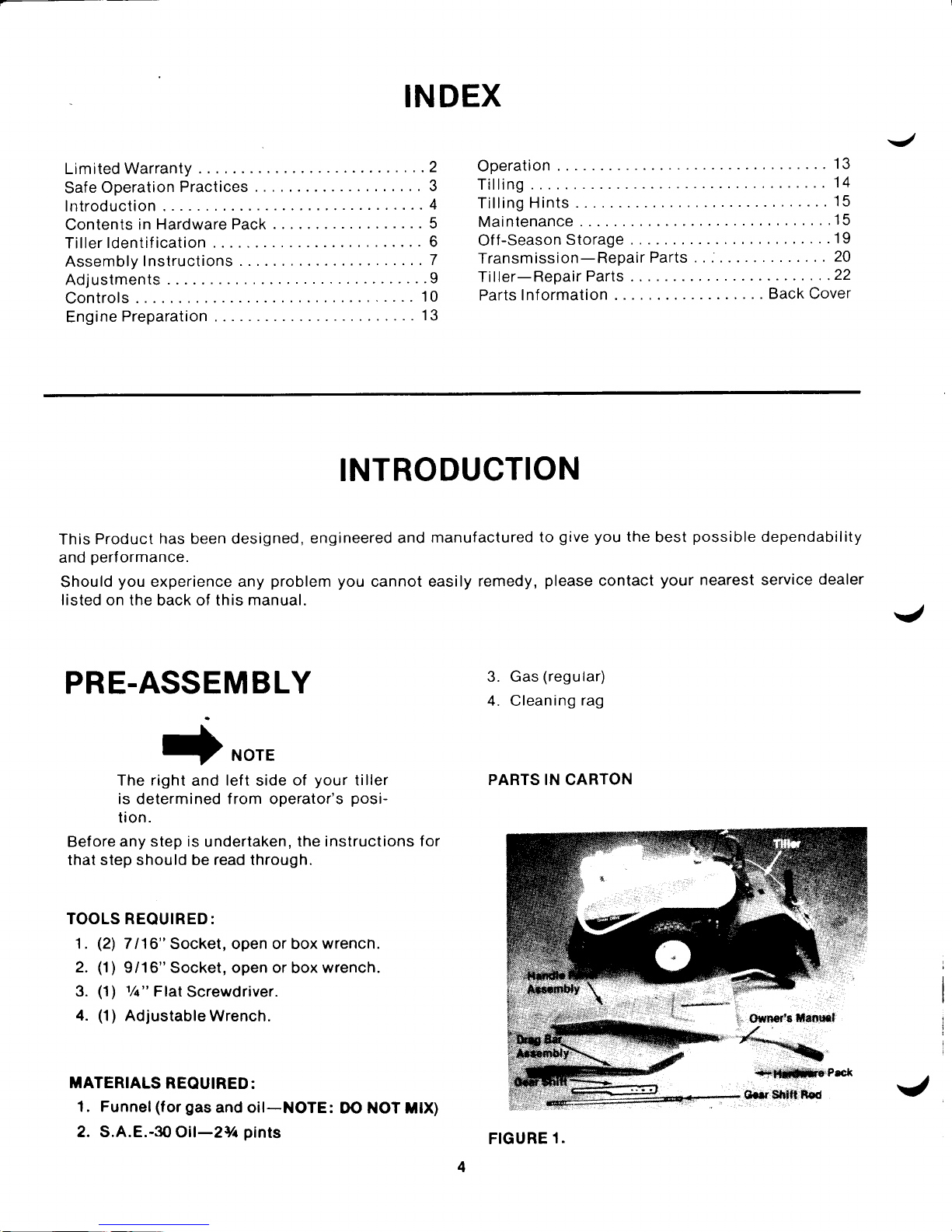

TOOLS REQUIRED:

1.

(21

7116"

Socket, open or box

wrencn.

2.

(1)

9/16"

Socket,

open or

box

wrench.

3.

(1)

1/c"

Flal

Screwdriver.

4.

(1)

AdjustableWrench.

lTATERIALS

REQUIRED:

1. Funnel(for

gas

and oil-NOTE:

DO NOT iltx)

2. S.A.E.-3O

Oil-2Vr

pints

3. Gas

(regular)

4. Cleaning

rag

PARTS IN CARTON

FIGURE

1.

Page 5

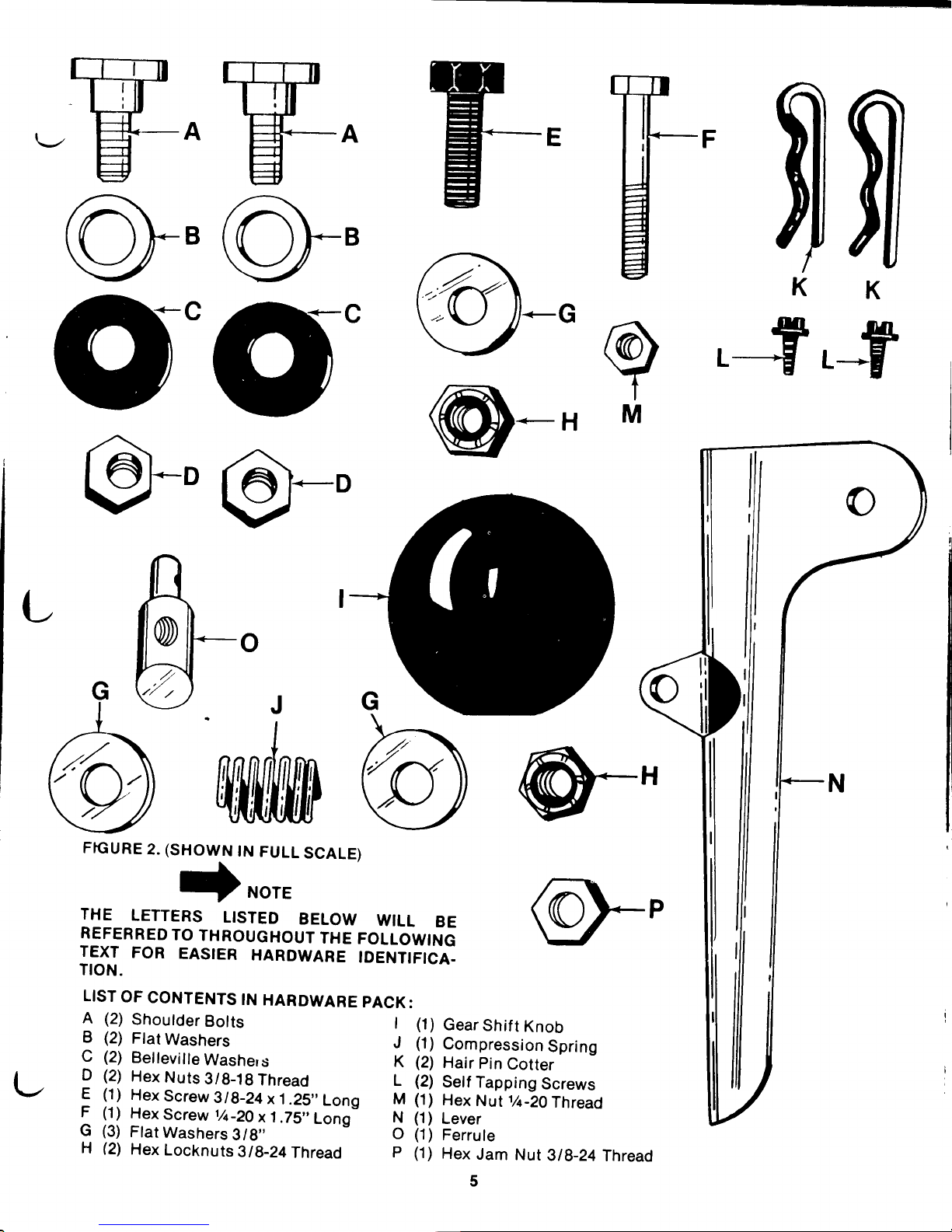

A

c

c

Fflfl

&-o,

FrcuRE

2.

(SHOWN

tN

FULL

SCALE)

NOTE

A

(2)

Shoulder

Botts

I

B

(2)

Flat

Washers

J

C

(2)

Bellevilte

Washers

K

D

(2)

Hex

Nuts

3/8-18

Thread

L

F

(1)

Hex

Screw

3tg-24

x

1.25"

Long

M

|

(1)

Hex

Screw

1/c-2O

x 1

.75"

Long-

N

G

(3)

Flat

Washers

3/8"

O

H

(2)

Hex

Locknuts

3l}-24Thread

p

I

.+.ifl

M

L

THE

LETTERS

LISTED

BELOW

WILL

BE

REFERRED

TO

THROUGHOUT

THE

FOLLOWING

TEXT

FOR

EASIER

HARDWARE

IDENTIFICA.

TION.

LIST

OF

CONTENTS

IN

HARDWARE

PACK:

(1)

Gear

Shif

t

Knob

(1)

Gompression

Spring

(2)

Hair

Pin

Cotter

(2)

Self

Tapping

Screws

(1)

Hex

Nut

%-20

Thread

(1)

Lever

(1)

Ferrule

(1)

Hex

Jam

Nut

318-24

Thread

5

(--

Page 6

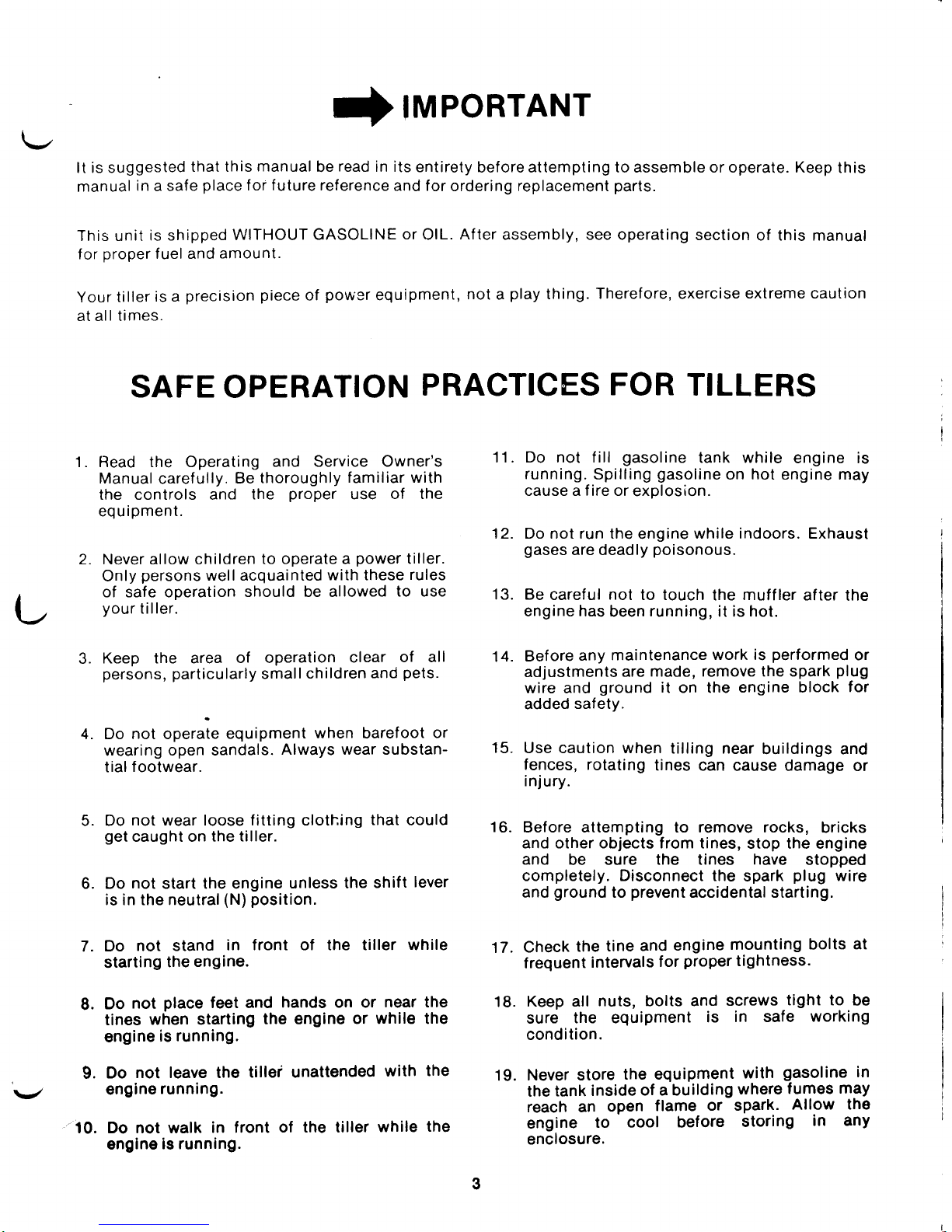

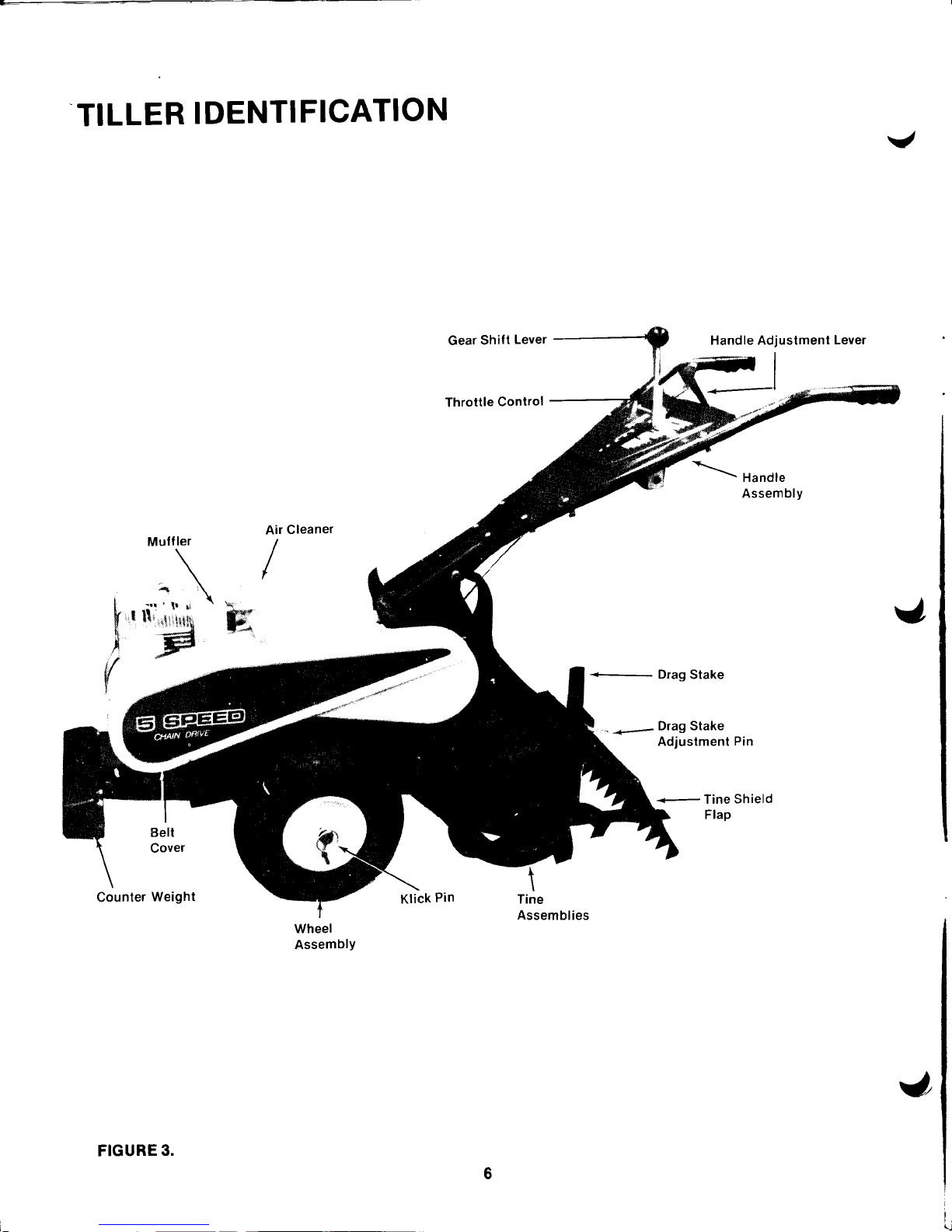

TILLER

IDENTIFICATION

Belt

Cover

Counter

Weight

Wheel

Assembly

J

Handle Adjuslment

Lever

7_-l

I

r

!

,

{

I

-

Drag Stake

-

<-

Drag Stake

Adjustment Pin

+-

Tine

shield

FIGURE

3.

a

Page 7

\-,

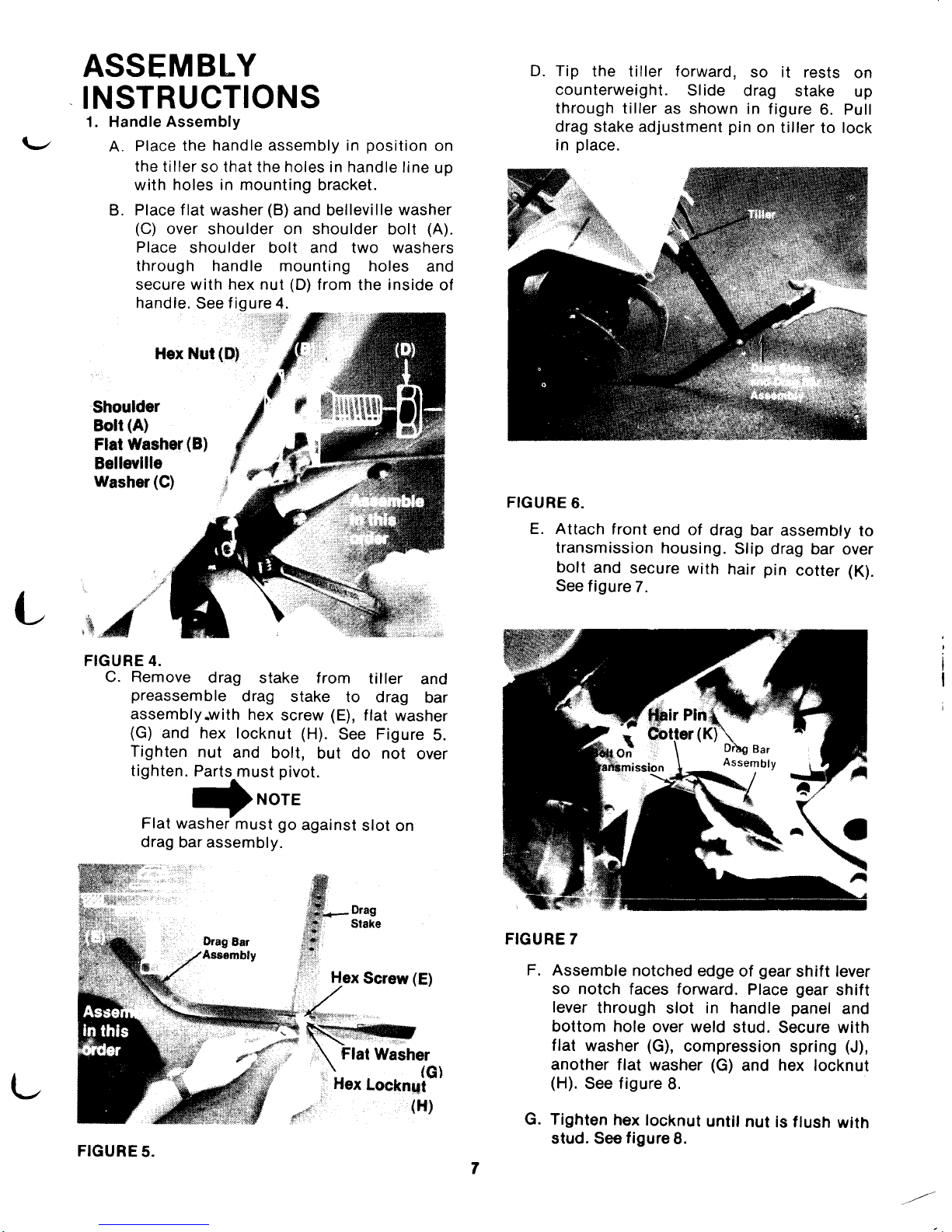

ASSEMBLY

INSTRUCTIONS

1. Handle

Assembly

A.

Place

the

handle assembly in

position

on

the tiller

so that the holes in handle

line

up

with

holes in mounting

bracket.

B.

Place f lat washer

(B)

and belleville

washer

(C)

over shoulder on shoulder

bolt

(A).

Place

shoulder bolt and two washers

through handle mounting holes

and

secure with hex nut

(D)

from

the

inside

of

handle.

See f igure 4.

Hex

Nul

(B)

Shoulder

sotr

(A)

Flat

Washer(B)

Bellevllle

Washer

(G)

t

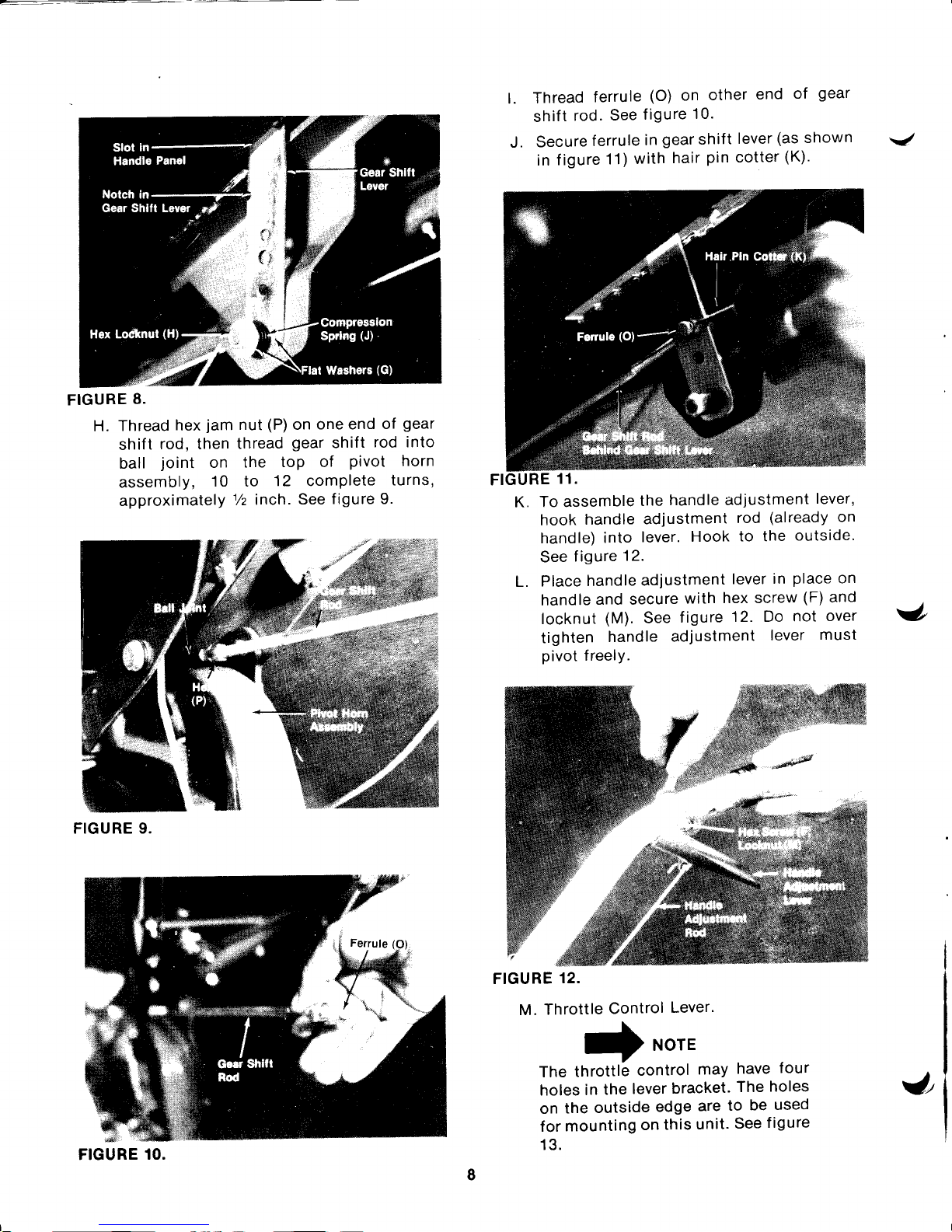

D. Tip

the tiller forward,

so it rests

on

counterweight.

Slide

drag

stake

up

through

tiller

as shown in

figure

6. Pull

drag stake adjustment

pin

on

tiller

to

lock

in

place.

FIGURE

6.

E. Attach

front

end of

drag bar

assembly

to

transmission

housing.

Slip drag

bar over

bolt

and

secure

with

hair

pin

cotter (K).

See

f igure

7.

FIGURE

7

F. Assemble

notched

edge

of

gear

shift

lever

so notch

faces forward.

Place

gear

shift

lever

through

slot

in

handle

panel

and

bottom hole

over weld

stud.

Secure with

flat

washer

(G),

compression

spring

(J),

another

flat washer

(G)

and

hex

locknut

(H).

See figure

8.

G. Tighten

hex tocknut

until nut

is flush

with

stud. See

figure

8.

Hex

Screw

(E)

K

RT'f,r

\

Flat

Washer

)r"r

lo"*nu[G)

o,uf

,'

{H}

L

,,uX"

FIGURE 4.

C. Remove

drag

stake from

tiller

and

preassemble

drag

stake

to drag

bar

assembly-with

hex

screw

(E),

flat

washer

(G)

and

hex locknut

(H).

See Figure

5.

Tighten

nut

and

bolt,

but do not

over

tighten.

Parts-must

pivot.

-J

-NOTE

Flat washer'must go

against

slot

on

drag

bar assembly.

Pln

(.-

FIGURE

5.

Page 8

FIGURE

8.

H.

Thread

hex

jam

nut

(P)

on

one end

of

gear

shift

rod, then

thread

gear

shift

rod into

ball

joint

on

the

toP of

Pivot

horn

assembly,

10 to

12 comPlete

turns,

approximately

1/z

inch.

See

figure 9.

FIGURE 9.

t.

FIGURE

12.

M.

Throttle

Control

Lever'

\

-

NOTE

-

The

throttlb

control

maY

have

four

holes

in

the

lever

bracket.

The

holes

on

the

outside

edge

are

to

be

used

for

mounting

on

this

unit.

See

f igure

13.

Thread

ferrule

(O)

on

other

end

of

gear

shift

rod.

See

f igure

10.

Secure

ferrule

in

gear

shift

lever

(as

shown

in

f igure

11)

with

hair

pin

cotter

(K).

To assemble

the

handle adjustment

lever,

hook

handle

adjustment

rod

(already

on

handle)

into

lever.

Hook

to the

outside.

See

f igure

12.

Place

handle

adjustment

lever

in

place

on

handle

and secure

with

hex screw

(F)

and

locknut

(M).

See

figure

12. Do

not

over

tighten

handle

adjustment

lever

must

pivot

freely.

J.

J

K.

L.

J

FIGURE

10.

J,

Page 9

(*-'

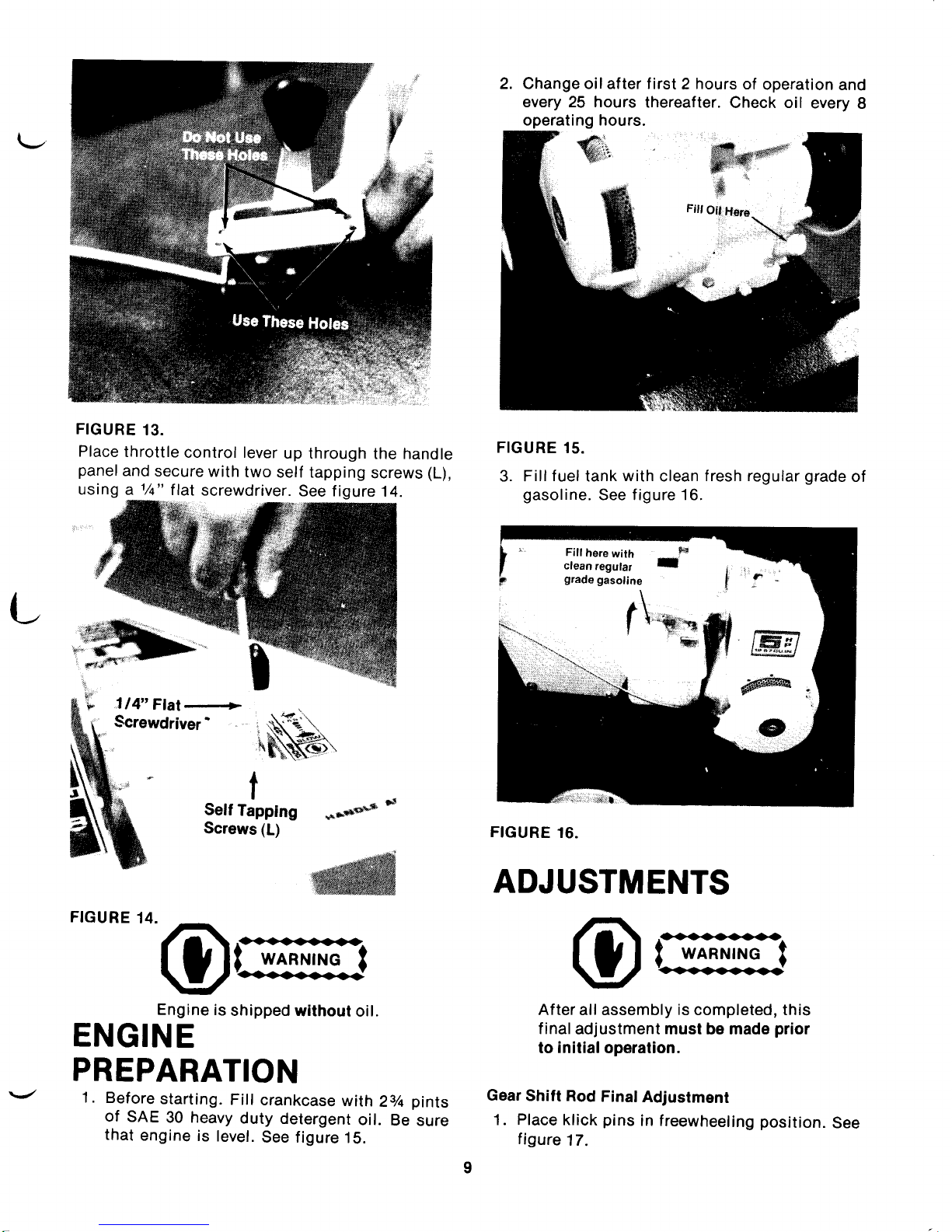

FIGURE

13.

Place

throttle

control lever

up through

the handle

panel

and

secure

with

two

self tapping

screws

(L),

using a

1/q"

tlal

screwdriver.

See f igure

14.

714"

Flal+

Screwdriver

-

2. Change oil af ter f irst 2 hours

of

operation

and

every 25 hours

thereafter.

Check oil

every

8

operating hours.

FIGURE

15.

3. Fillfuel tank

with

clean

fresh regular

grade

of

gasoline.

See f igure 16.

Fill

here

with

F

clean

regular

I

grade

gasoline

\

I

4\

I

l

"m.-

l\-

,

t*s

FIGURE

16.

ffi

{D

a

'k

I

I

Self

Tapping

Screws (L)

**&e

a

ADJUSTMENTS

F,GURE"ot:I^"$E

Engine

is

shipped

without

oil.

ENGINE

PREPARATION

1.

Before

starting.

Fill

crankcase

with

23/e

pints

of

SAE

30 heavy

duty

detergent

oil.

Be

sure

that

engine

is

level.

See figure

15.

.<}e-}(F-Oe-O.

t

wanrurnc

t

<re

After

all assembly

is

completed, this

f inaladjustment

must

be

made

prior

to

initialoperation.

Gear

Shift

Rod

Final

Adjustment

1. Place klick

pins

in freewheeling

position.

See

figure

17.

Page 10

FIGURE

17.

2.

Pull thedrag

baradjustment

pin

and

move

the

drag

stake

all the

way

down,

so

the

tines

DO

NOT

touch

the

ground.

See

f igure 18.

3.

Block

the

front

wheels

as shown

in figure

18.

FIGURE

18.

4.

Place

the

gear

shift

lever

in

Neutral

(N)

position.

5.

Place

the

throttle

in the

Start

position.

6.

Pull choke

lever out

(if

engine

is

cold).

7. Start

the

engine.

8.

Engage

the

gear

shift

lever

through

the

five

gears

with

the

engine

running

and

return to

Neutral(N).

9.

Stop

the

engine.

10. Remove

the

hair

pin

from

ferrule and

pull

out

of

gear

shift

lever.

11.

Place

gear

shift

lever

in first

gear

(and

pull

iever to

rear of slot).

Adjust

the

ferrule to

fit

gear

shift

lever, and

replace

the

hair

pin.

Figurelg

is

viewed

from

the

bottom

of

handle

Panel.

Use

if

not enough

free

PlaY.

Normal

setting.

Use

if

pin

will

not withdraw

completel

bracket

,}

FIGURE

19.

To

make

the

above

adjustment

loosen

hex

locknut

and

reposition

the

rod

in Hole

A, B

or

C.

Additional

adjustment

for the

gear

shift

rod

can

be

made

after

the

tiller

has been

in service

for a

while.

FIGURE

20.

When

the

belt

has

become

worn and/or

stretched

or

the

friction

wheel

has become

worn,

make

the

following

adjustment.

1.

Move

the

control

bracket

to

the

bottom

hole

on

the

pivot

horn

assembly

and

readjust

the

gear

shif

t

rod.

See

f igure

20.

HandleAdjustment

Lever.

(See

figure

19.)

\

A.

B.

c.

+NorE

J

y

from

$

J

H€xLocknut

10

Page 11

\_,

CONTROLS

Location

anct Use.

1.

Gear

Shift

Lever:

The

gear

shift

lever

is

located

in

the center

of handle

panel.

A.

Forward (1

thru

S)-Move

the lever

to

the

left

and forward

for

each

gear.

See figure

21.

4)cAUfloN

Do not

attempt

to

shift

gears

unless

engine

is

running.

FIGURE

21.

B.

Use

(1)

first

and

(2)

second

gears

breaking-the

sod for

the f irst

time.

c.

E. Neutral

(N)-Move

lever

to

center

detent.

See

figure

22.

FIGURE

23.

F.

Reverse

(R)-Pult

the

gear

shift lever

back

(upward)

slowly

to obtain

reverse.

Always

use

caution

when

using

the reverse.

When

using reverse,

if

gear

shif

t lever

is

released

it

will

snap

back into

neutral

(N).

See

figure

23.

2. Throltle

Control:

The

throtile

control

lever

is

located

on

the right

hand

side

of

handle

panel

and

controls

the

engine

speed.

* $

FIGURE

24.

Stop-Pull

lever

back

(upward)

to stop

the

engine. See figure

24.

Start-Push

throttle

control

lever

forward

(down)

to start

position.

See f igure

25.

when

D.

Use

(3)

third

and

(4)

fourth

gears

when

tilling

soil which

has

been

tilled

before.

Use

(5)

f ifth

gear

for

putverizing

soit.

s?.

^

.*"-r S

o.

d

*c.

t

T,,

-J

""s',{J"fl

t

t

*.

&i''

$:r

.x-

A.

FIGURE

22.

11

B.

Page 12

4. Handle

Adjustment:

The

release

is located on

the

bar.

See

tigure

27.

handle adjustmenl

right hand

handle

r4

{'d

$'

FIGURE 25.

3.

Choke:

The choke

is

located

just

below

the air

cleaner.

engine

pull

the choke

lever

out.

on the engine

To choke

the

See

f igure 26.

FIGURE 26.

FIGURE

28.

FIGURE

29.

Nine

(9)

Handle

Positions

FIGURE 27.

12

FIGURE 30.

Page 13

A.

SqueOze

up

on handle

adjustment

lever

and

place

the

handle

in

one

of nine

(9)

positions

See f igures

28,

29,30

and

31 .

r)NorE

Figure

28

is viewed

from

the

front

of

tiller

f or

clarity.

FIGURE

31.

2.

4.

OPERATION

Your

tiller has

freewheeling

and

drive

positions.

A.

Freewheeling position

is when

the

klick

pin

is

placed

in

the

outer

hole

on

wheel

shaft,

as

shown in

32.

Freewheeling

is

used for

transporting

the

tiller

to

and from

the

work

area,

with

the

engine

off

and

the

gear

shift lever

in

Neutral (N)

position.

FIGURE

33.

TO

START ENGINE:

1.

1

l

\

cAUfloN

BE

SURE NO

ONE IS

STANDING

IN

FRONT

OF THE TILLER

WHILE

THE

ENGINE

IS

RUNNING

OR BEING

STARTED.

Place

the

gear

shif t lever

in neutral

(N)

position.

See f igure

22.

Place

the throttle

control

lever

in

FAST

position.

See f

igure

25.

Choke engine.

Pull

choke lever

out.

See f igure

26. Once the

engine

starts,

push

the lever

up.

Stand at side

of tiller,

grasp

the

starter handle

and

pull

out rapidly.

Return

it

slowly

to the

engine. Repeat

as

necessary.

See f igure 34.

B.

Drive

position

is when

the ktick

pin

is

inserted

into

the inside

hole

of wheel

shaft

(hole

in

wheel

hub)

as

shown in

figure

33.

Drive

position

is

used

for tilting.

L

FIGURE

32.

13

FIGURE

34.

Page 14

r

TILLING

TILLING

HINTS

Soil

conditions

are

important

for

proper

tilling'

The tines

will

not

readily

penetrate

dry,

hard soil.

This

may contribute

to

excessive

bounce

and

diff

icult

handling

of

the

tiller.

Hard soil

should

be

moistened

prior

to tilling.

Extremely

wet soil

will cause

soil

to ball

up

or

clumD.

When

tilling

in the

Fall,

all

vines

and

long

grass

should

be

removed.

This

will

prevent

vines

form

wrapping

around

the

tine

shaft

which

slows

tilling

operation.

The best

method

will be

determined

by

the soil

condition.

In

some

soils,

the

desired

depth

is

obtained

the

first time

over

the

garden.

In other

soils,

the

desired

depth

is obtained

by

going

over

the

garden

two

or

three

times.

In the

latter

case,

the

drag

stake

should

be

raised before

each

succeeding

pass

over

the

garden,

and

passes

should

be

made

across

the

length

and

width

of the

garden

alternately.

Rocks

which

are

turned up

should

be

removed

from

the

garden

area.

Handle

Pressure:

Further

control

of

tilling

depth

and

travel

speed

can

be

obtained

by

variation

of

pressure

on

the

handles.

When using

the

drag

stake

a downward

pressure

on

the

handles

will

increase

the

working

depth

and

reduce

the

forward

speed.

An

upward

pressure

on

the

handles

will

reduce

the

working

depth

and

increase

the

f orward

speed'

The type

of

soil

and

working

conditions

will determine

the

actual

setting

of the

drag

staKe'

MAINTENANCE

BELT

REPLACEMENT:

[.or'on

Do

not use an off-the-shelf

belt.

lf belt

replacement

is

required,

order

belt

or oelts

by

part

number

from

your

nearest

authorized

dealer.

.zDrag

t

stake

M

FIGURE 35.

1.

Adjust

the

drag stake

by

pulling

the

drag

stake

adjustment

pin.

Release

the drag

stake'

See

f igure 35.

2.

Lower

the

drag

stake

for

shallow

tilling

and

raise

the drag

stake

for deeper

tilling.

3.

Select

gear

on

handle

panel

and

tiller will

propel

itself

.

_

A.

For tilling

in

sod,

raise the

drag

stake

so

the drag bar

is one

to two

inches

above

the

tines.

This setting

is used

for

breaking

up

the

sod

and

shallow-cultivation.

For

further

depth

raise

the drag

stake

and

make one

or

two

more

passes

over the

area.

B. For

tilling

loose and

sandy

soil,

further

depth

in tilling

can be

achieved

by

raising

the

drag stake

to

its

highest setting.

Orml

When

tilling,

if a hard spot

or

rock

is

encountered,

the tines

may

lift

the

back

of the tiller

out of

the

ground

and start

to

walk across the

ground.

To correct

this

problem

raise

uP

on

the handles.

Part

No.

754-0224

5/8"

x 26"

Short

Belt

Part

No.

754-0221

5/8"

x 52"

Long

Belt

Your tiller

has been

engineered

with the

above

belts

and

should

not be

replaced

with

an

off-the-shelf

belt.

The above

belts

are

made of

special

material

(Kevlar

Tensile)

for longer

life and

better

performance.

14

Page 15

REMOVING

AND

REPLACING

BELTS.

1.

Remove

belt cover,

remove

three

bolts,

two

nuts and

two

f lat washers.

See f igure

36.

A

(gcAUTrON

HOT

muffler in the area

of belt

cover. Only

remove

the

belt

cover

when engine

is

cool.

FIGURE

36.

2.

To

remove the

front belt

(short)

pull gear

shift

lever

back

to

Reverse

(R)

position

and

hold.

With

a 7 t16"

wrench

remove

three

screws

and

lockwashers

holding

the

friction disc.

See

figure 37.

FIGURE

37.

3.

Hold the

gear

shift

lever

in Reverse

(R)

position

and slip

the belt

off engine

pulley,

towards

the engine

as shown in f igure 38.

FIGURE

38.

4. Place

the

gear

shif

t

lever in one

of the

forward

gears (as

far forward

as

possible).

5.

Pull the idler

pulley

down by

hand

and

remove

the belt

from idler

pulley

and

transmission

pulley.

See

figure

39.

FIGURE

39.

Remove

the

forward belt

(short)

from

variable

speed

pulley

and slip

belt

off

engine

pulley.

See

figure

40.

Remove

rear belt

(long)

and

replace with

belts.

the

the

6.

7.

+NorE

Upon

reassembly

short

belt

is inside

See figure

41.

make

sure

the

the

guide

pins.

15

Page 16

FIGURE

40.

FIGURE

41.

B.

Reverse

steps

1 through

7 for

reassembly'

\

DNOTE

7

Upon

reassemblY

of

friction

disc,

tighten

three

screws

equallY.

CARE

AND

MAINTENANCE:

Transmission:

The

transmission

is

pre-lubricated and

sealed

at

the

factory.

lt

requires

no additional

lubrication

unless

the

transmission

is disassembled'

To

f ill

with

grease, lay the

left

half

of

the

transmission

on

its

side,

add

28 ounces

of

Plastilube

#1

grease

and

assemble

the

right

half

to

it.

This

grease

can

be

purchased

f rom

your

nearest

authorized

dealer'

(Order Part

No.

737-0133')

Engine:

1. You

MUST

CHANGE

THE

OIL

in the

crankcase

after

the

first two

hours

of

opera-

tion

of

your new engine

and

after each

25

hours

of use

thereaf

ter

to ensure

proper

lubri-

cation

of

internal

parts

for trouble

free

opera-

tion

and

to

prevent

costly

repair

due

to

excessive

wear.

(Take

care

to

remove

dirt

around

f iller

plug.)

Be sure

oil

level

is

main-

tained

full

to

point

of

overf

lowing.

See

f igure

42.

z--_:{_

FIGURE

42.

To change

oil

remove

drain

plug (f

igure 43)

and

tip

the

tiller

forward

while

engine

is warm.

Replace

drain

plug.

Remove

oil

filler

cap and

refill with

SAE

30

heavy

duty

detergent

oil.

Replace

filler

cap.

Drain

Plug

FIGURE 43.

2.

Use

only

a

good

grade

of

fresh, clean,

regular

gasoline. Do

not use

gasoline

that

has been

sitting

for

a

long

period

of time.

Stale

gasoline

may cause

engine

to run

poorly

or

not at

all.

3.

Keep

your

engine

CLEAN.

Wipe

off all

spilled

f

uel

and

oil.

Keep

the engine

clean

of

foreign

matter and

be sure

the

cooling

f ins

on the

cylinder

are

kept

clean

to

permit

proper

air

cir-

culation.

You

must

REMEMBER

that

this

is

an air

cooled

engine

and

free

flow of

air

is

essential

to

proper

engine

performance

and

lif

e.

4.

You

must SERVICE

YOUR

AIR CLEANER.

The air cleaner

prevents

damaging

dirt,

dust,

etc.

from

entering

the carburetor

and

being

forced

into

the

engine

and

is important

to

engine

life and

Performance.

To remove

air

cleaner:

See

f igures

44 and 45.

A.

Remove

Screw.

B.

Remove

air

cleaner

carefully

to

prevent

dirt

f rom entering

carburetor'

v

I

I

I

I

9t

Oil

Filler

Plug

t6

Page 17

E.

Wrap

foam

in

cloth

and

squeeze

dry.

F.

Coat

element

with

two

tablespoons

of

oil,

squeeze

to

distribute

and

remove

oil. See

f

igure

45.

G.

Wipe

air

cleaner

body

with

same

sotution

to

remove

excess

oil.

H.

Reassemble

(See

figure

44.)

by

inserting

element

into

body

and

snapping

cover

rnto

place,

fasten

to

carburetor

with

screw.

FIGURE

45.

NEVER

RUN

YOUR

ENGINE

WTTHOUT

AIR

CLEANER

COMPLETELY

ASSEMBLED.

Carburetor

Adjustment

:

1.

Never

make

unnecessary

adjustments.

The

factory

settings

are

correct

for

most

applica_

tions.

2.

lf

adjustments

are

needed,

proceed

as

follows:

A.

lNlTlAL

ADJUSTMENT.

See figure

46.

Close

needle

valve (turn

clockwise)

then

open

l1/z

turns (turn

counterclockwise).

This

initial

adjustment

will

permit

the

engine

to

be

started

and

warmed

up

before

making

f inal

adjustment.

B.

FINAL

ADJUSTMENT.

See f

igure

46.

With

engine

running

at

fast

operating

speed

(approximatety

3,000

RpM

without

toad)

close

the

needle

valve (turn

clockwise)

until

engine

starts

to

lose

speed (lean

mixture).

Then

slowly

open

needle

valve

(rurn

counterclockwise)

past

the

point

of

smootirest

operation

until

engine

just

begins

to

run

unevenly.

This

mixture

should

be

rich

enough

for

best

oerform_

ance

under

load.

Hold

throtile

in

idlrng

position.

Tu;-n

idle

speed

adjusting

screw

until

fast

idle

is

obtained

(1,750

RpM).

Test

the

engine

and

if

it

tends

to

stail

or

die

out,

it

usually

indicates

that

the

mixture

is

slighily

lean

and

it

may

be

necessary

to

open

the

needle

valve

slightly

to

provide

a richer

mixture.

This

ricner

mixture

may

cause

a

slight

unevenness

In

idling.

FIGURE

46.

+NorE

ALWAYS

ALLOW

SEVERAL

SEC.

ONDS

BETWEEN

EACH

ADJUST.

MENT

FOR

THE

ENGINE

CARBU.

RETOR

TO

REACT

TO

THE

NEW

SETTING.

3. Never

attempt

to

change

maximum

engine

speed

as

THtS

tS

PRESET

AT

THE

FACTORY.

Excessive

speed,

caused

by

by_passing

the

governor,

can

cause

extensive

damage

to

your

engine.

SPARK

PLUG:

1.

Remove

the

spark

each

time

you

change

the

oil

and

inspect

it.

See

tigure

47.

C.

D.

Take

air

cleaner

aoart.

Wash

element

in

detergent

and

solutron

squeezing

similar

to

a

sponge.

W

*'Lm

by

J

J

eng

I ne

EXCESS

f"-'t

Air

Clehner

Basel

I

./#

!

iff

FIGURE

44.

ldle

Adjusting

Screw

{l

17

Page 18

A.

The electrodes

should be

kept clean

and

free OF

CARBON.

The

presence

of carbon

or excess

oil

will

greatly

deter

proper

engine

performance.

-\

.030"

Feeler

Gauge

_.-'-'----=---

)

FIGURE

47.

B.

lf

possible,

check

the spark

plug gap

(area

between

electrodes)

using

a

wire feeler

gauge.

This

plug

gap

should

be

.030.

2.

lf

you

need a spark

plug

refer to the

parts

list

for the

proper

replacement

spark

plug.

ADJUSTMENT

OF

THROTTLE CONTROL

CABLE

1.

Place the throttle control

lever in stop

position.

2. Loosen the casing

clamp screw

and

move the

throttle control

wire

in

as

far as

possible.

3.

Tighten the casing clamp

screw. See

figure

48.

TIRE

PRESSURE

Tires should

be inf

lated

from 8

to

15

p.s.l.

OFF.SEASON

STORAGE

lf the

tiller

is to be

inoperative

for a

period

longer

than

30 days,

the

follcwing

precautions

are

t,

recommended.

Keep

your

tiller

in a weatherproof

dry

area.

lf stored

for over

30

days the

following

steps

will

protect

the

essential

engine

parts

from

gum

deposits.

1.

Working

outdoors,

drain

all

f uel

from

the f uel

tank. Use

a clean

dry

cloth

to absorb

the small

amount

of f uel

remaining

in

the

tank,

then

run

the

engine

until

all

fuel

in carburetor

is

exhausted.

.€€^

t

wanNrr'rc

I

,_*_€t

DO

NOT

DRAIN

FUEL

WHILE

SMOKING,

OR

IF

NEAR

AN OPEN

FIRE.

2.

Drain

all

the

oil

from

the

crankcase

(this

should

be

done

after

the

engine

has been

operated

and

is siill

warm)

and

ref ill the

crankcase

with

clean

new oil. See

f igure 15.

3.

Disconnect

the

spark

plug

wire

and

remove

the

spark

plug

from

the

cylinder.

Pour

about

six

drops

of engine

oil

into

the

cylinder,

and

then

pull

the

recoil

starter

several

times

to

spread

the

oil

on

the

cylinder

wall.

Replace

the spark

plug,

but

DO

NOT

connect

the

wire.

4.

Clean

the

engine

and

the

entire

tiller

thoroughlY.

5.

Wipe

tines

with

oiled

rag

to

prevent

rust.

TILLER

WINTERIZING

INSTRUCTIONS

FOR USE

WITH

SNOW

BLADE:

For

cold

weather

(below

32'F'),

drain

oil

f rom

tiller engine

crankcase

and

replace

with

SAE

10W

or

10W-20W

detergent

oil.

Replace

any

remaining

f

uel

on

hand

or

in the

engine

fuel tank

with a

fresh supply

of

winter

grade

fuel.

Winter

fuels

contaln

additives

for

faster

starts.

Keep f uel

tank f ull.

J.

-7

NorE

It

may be

necessarY

to enrich

the

carburetor

idle

and

high

speed

jets

1/8

to

1/c

lurn

(counterclockwise) for

good

performance.

ln the

spring

of the

year,

before

the

tilling

season,

be

sure

to

change

engine

oil back

to

SAE

30W

detergent

oil.

^A

^/ I \CAUTTON

Do

not exceed 30

p.s.i.

1.

2.

tURE

48.

18

3.

Page 19

J

NOTES

J

J

19

Page 20

218-405-065

t6^-

.qr':.l

(;

J).)

v

55

7--

\a.

i

5/

51

il

9

tt,t

2t)

)a

7.,:

z

t1

t5

*rA

r.

.l;

'

'c'f

v

NOTE: Use

28 ounces of

Plastilube #1

grease.

Order

part

no. 737-0133.

20

U

Page 21

PARTS

LIST

FOR

TRANSMTSSION

ASSEMBLY

04878

*t.

,or,

aoro,

--l

NO.l

pO.-

cbDl'

DESCRIPTION

---

-r-

1_)

7-4!_0155

--_

jBail

Bearins

|

/z+|-uIc3

tJ4ilueanng

?

0-!822

-606

lCnain

CasjAss'y.-R.H.

3 738-0379

Input

Shaf t

5/8,,

Dia.

4

714-0122

Sq. Key

3/16

x

3/16 x

.75"

Lo.

5

750-0379

Spacer

.637

t.D.

x .281

O.D.

-

6 717-0210

I

.01"3i;,tnni

x .500

pitch

7

750-0378

Spacer

.637

t.D.

x .781

O.D.

8

04862

,,,T"t#i,T;.'"

9 736-0259

Ft-Wash.1.0,'1.D.

x1.62"

O.D. x

.09

10

741-0189

Ftange

Brg.

1.00"

t.D.

x.1.188

O.D.x1.'12

11

i

721-0163

Gasket-Horrsino

11

i

721-0163

Gasket-Housinq

12

|

04821

-606

Chain

Case

Ass'i.

-L.

H.

]9 9?93^4^ -

Bearins

Housins

14

736-0329

i

L-Was6.

t/q',

Scl.*

15

712-0138

i

Hex

Nut

1/t-28fhd.,

31

736-0329

L-Wash.

j/q"

Scr.*

32

750-0388

Hub

Steeve

3/9,' t.D.

x

5/g"

33 748-0184

]

r:;3"

A,.';]%t

bl D

x

z53

N

O.D.

x .75

34

713-0226

Chain

#50-S/8"

pitch

x

52

Links

Endless

35

712-0375

HexCent.L-Nut3/8-16Thd.

1q

721-0102

lSeatr.0', t.D.

x 1.38"

O.D.

17

736-0219

Beil.

Wash.

3/8',

LD.

rvv

varv

ucil.

Vvdbil.

J/O

l,l

18

736-0169

L-Wash.3/8"

Scr..

19

712-0214

Hex

Nut

3/8-24

Thd.

-

20

04872

Side

ptate

21

736-0219

lBeil.

Wash.3/8"

t.D.

22

736-0169

j

L-Wash.

3/8"

Scr.

-

23

710-0411

I Hex Scr 3 tR-16 u t

<: 1991]1i ,

Hex

Scr.

3/B_16

x

4.00,,

19..

24

710-0601

I

Hex

Taptite

5/16_18

x .75;

ln

25

, 736-0242 Rell Waeh ?246 | F\ v

qa

,

736-0242

Beil.

Wash.

.345

LD.

x.gg

o.D.

26ti

721-0162

i

Gasket-Side

ptate

29'

721-0102

Seat1.0',

t.D.

x

1.38"

O.D.

]

to

]

712-0138

,

Hex

Nut

1/q_2}Thd.-

L]

'For

faster

service

obtain

standarrd

nuts,

bolts

ano

wasners

locally.

lf

these items

cannot

be

obtained

localry,

oroer

oy

part

number

and

size

as

shown

on

garls

list.

19 !13-9237

Sprocket

Hub

Ass'y.

N

37

713-0165

*izo

Cnain

,i',

iitl,n

,

st

Li nks

38

713-0154

Master

Link

t/2"

pitch

40

750-0314

Spacer

1 .0"

t.

D.

x 2.0',

O. D.

x .68

41-

713-0222

Sprocket

Ass'y.

42

748-0184

rtlO_e

Brg.

.628

t.D.

x .253

O.D. x.75

43

750-0374

Hub

Steeve

.38

t.D.

x .625

i

i

o.D.

44

741-0189

Ftange

Brg.

1.00,'t.D.

x

1.188

0.D

45

736-0259

I

Ft-Wash.

1 .0"

t.

D.

x 1 .62"

o.D.

N

46

04873

L

Axte

Shaft Ass'

47

713-0225

AXte

Dnar r ASS

y.

N

#420

Chain

1/2"

Pitch

x 42

Links

Endless

48

750-0314

Spacer1.0,,t.D.

x 2.0,'O.D.

!? 119-919q

j

Hex

scr.

i/q-28

x.62"

Ls..LV.

50

736-02'19

Beileviile

Wash,

I 91

710-0629

Hex

Scr.

3tB-24

x2.tS,'Lg..

52

736-0159

i

Ft-Wash.

5/16',

Scr..

53

736-0119

L-Wash.5/16,'Scr..

wu

,uu-vt

t:z

L-VVaSII.

C/ lO

bcf.

i

Uo 710-0627

Hex

L-Scr.

St16-24

x .75',

i

Lg..

55 756-0297

I

Inpu"t

puiley-Chain

Case

21

Page 22

218-405-065

v

v

\r,

i

),)i;.

.

a'',1

69

91

5o

9J

\"

J"

^?

zvf,

sg-

/'-

.t9

.20

\'

-

-'*-

I

-\

'.\..

\

-\,

'1

t

"

l4

'i,,

TB

v

--90

\d-

38

22

Page 23

PARTS

LIST FOR MODEL

218.405.065

REF

NO

PARl

NO.

COLOR

EODF

DESCRIPTION

NEW

PA RI

REF.

NO.

PART

NO.

COLOR

CODE

DESCRIPTION

NEW

PARI

1

2

3

4

5

b

'7

B

I

10

11

12

13

14

16

2A

21

22

23

24

25

26

27

28

29

30

31

32

34

35

36

37

3B

39

40

41

42

46

47

48

49

16

17

18

19

710-0227

746-0304

747-0255

71

0-01

36

749-0268

720-0180

712-0107

04830

04831

-606

749-A269

720-0183

04892

714-0104

736-01 01

732-0193

712-0214

04833

-606

710-0344

714-0115

732-0306

747-0256

747-0252

04804

710-0623

736-01 69

71 0-0623

736-01 69

736-01 01

712-0130

04879

04909

04683

71 1

-0599

742-0175

71

0-01

91

04857

736-01

69

712-0241

71 4-01

45

742-0174

04855

736-01

69

712-O't30

04878

-606

712-0267

Hex

Wash.

Hd. Tap Scr. #B

x.50"

Lg."

Throttle

Control

Ass'y.

Como.

Handle

Lock

Rod

Hex Scr.

1/q-20

x 1 .75" Lg..

Handle-R.

H.

Grip

Hex Cent.

L-Nut

1/a-2OThd

Clutch

Grio

Handle

Panel Ass'y.

Hand

le-L. H.

Ball

Knob

3i B-16

Thd.

Clutch

Handle

Ass'y.

Hair

Pin

Cotter

Fl-Wash.

Compression

Spring

.88

O.D.

x .81 Lg.

Hex Nut 318-24

Thd.

-

Deoth

Bar

50"

Lg.

x

1.00'

Hex

Scr.

3/B-16

x

1

Cotter

Pin 1/8"

Dia

Lg.'

Compression

Spring

Depth

Bar Adjustment

Pin

Hinge

Rod

Tine Shield

Hinge

Flap

Ass'y.

Hex

Wash. Hd. Self

Tap Scr.

3/8-16

x .75" Lg.

L-Wash. 3/8"

Scr..

Hex

Wash.

Hd.

Self

Tap Scr.

3/8-16

x .75"

Lg.

L-Wash. 3/8" Scr..

Fl-Wash.

Hex lns. L-Nut 3/B-16

Thd.

I

Drag

Bar Ass'y.

I

Inner

Tine Adapter Ass'y.

I

Outer

Tine Adapter Ass'y.

I Clevis

Pin 3/8"

Dia. x 1.75"

I

Lg.

I

Tine-L.

H.

I

Hex Scr. 318-24

x 1.25"

Lg..

I

Outer

Tine

Ass'y. Comp.-

I

L.H.

I L-Wash. 3/8" Scr..

lHex

Nut 3lB-24Thd."

lHair Pin Cotter

lTine-R.H.

I

Inner Tine

Ass'y. Comp.-

I

r.n.

I

L-Wash.

3/8" Scr..

I

Hex

Ins. L-Nut 3/8-16

Thd.

I

Transmission Ass'y. Comp.

lHex

Nut5/16-18Thd..

N

N

N

N

50

51

52

53

54

55

56

57

5B

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77)

78

1

I

80

I

81

I

82

1

83

l

84

1

85

I

86

1

8rl

I

88

1

Bel

e0

l

e1

|

s2

l

I

e3

I

94

1

736-01 1 9

04850

-606

736-01 69

712-0116

714-047

4

736-0290

736-01 1 9

738-0258

736-01 05

710-0623

04841

71 0-0601

710-0216

714-01i 5

04796

-606

712-0130

736-01 69

714-047 4

04806

-606

747-0278

723-0156

04812

-606

712-0221

71 1

-0663

732-0132

714-0474

736-0253

747-0254

736-01 92

712-0158

748-051 6

0481

I

736-0289

738-01 43

712-0267

736-01

1 9

71 0-0458

04792

-606

746-0305

710-0152

712-0181

748-01 50

71 1

-01

98

712-0711

L-Wash. 5/16" Scr.'

Handle

Positioner Ass'y.

L-Wash. 3/8" Scr.

*

Hex lns.

L-Nut

3lB-24Thd.

Cotter

Pin 1/8"

Dia. x .75"

Lg.*

Fl-Wash.

.630l.D. x

1.0"

O.D.

x.063

L-Wash.5/16"

Scr..

Shld.

Scr.

.50 x .25

Belleville

Wash.

Hex Wash.

Hd.

Self

Tap Scr.

3/B-16

x .75" Lg.

Control

Brkt.

Hex Wash.

Hd.

Self

Tao

Scr.

Hex

Scr.3/8-16

x.75" Lg..

Cotter

Pin 1/8" Dia.

x 1.00"

Lg.

-

Tine Shield

Ass'y.

Hex

Ins. L-Nut 3/B-16

Thd.

L-Wash. 3/8"

Scr.

-

Cotter

Pin 1

/8"

Dia. x .75"

Lg.

-

Pivot Horn Ass'y.

Gear Shift

Rod

Rod End 3lB-24rhd.

Pivot Brkt.

Ass'y.

Hex lns.

L-Nut

5/B-16

Thd.

Locking

Pin

Compression

Spring

Cotter

Pin 1

/8"

Dia. x .75"

Lg.

-

Bell.

Wash. .505l.D.

x 1.00"

o.D.

Lower

Handle Control

Rod

Fl-Wash.

.50" l.D. x

1.00"

o.D.

Hex Nut5/16-1BThd."

Pivot Handle Brg.

Pivot

Handle Link

Bushing

Wash.

Shld. Scr.

.500" Dia. x .660

Hex Nut

5/16-18

Thd..

L-Wash.5/16" Scr.'

Carr. Bolt 5/16-18

x 1 .75"

Lg.

Handle Mtg. Brkt.

Ass'y.

Conduit and

Wire

Hex Scr. 3lB-24

x 1 .00" Lg..

Hex Top L-Nut 3/8-16

Thd.

Sleeve

Brg. .50l.D.

x.62

O.D.

x 1.12" Lg.

Ferru le

Hex Jam Nut 3/8-24

Thd.

N

N

J

TINE CHART

Not Shown

I

Inner

Tine Ass'y. Comp.-R.

H.

42

llnner

Tine

Ass'y. Comp.-L.H.

Not Shown

lOuter

Tine Ass'y. Comp.-R.H.

37

lOuter

Tine Ass'y.

Comp.-L.H.

J

23

Page 24

218-405-065

\,

\

\,/

_-i\

-/

"t'-

./

-21

----11-*

17

i;-

22

79 ....

78\

\

77\

t-t-t'-t\

69

76.

tut*

63'^

61

t7-

v

r65

B9

.i.

62

u'

t.

11

$1--

f.\

/r-:\

\!X

I

/

B7

t

sg'

.

//--

ou,

'.>Z

,/

-'-,,--

-'-"/"'"

,/

i'----

,,

24

\,

Page 25

PARTS LIST

FOR MODEL

218.405.065

DESCRIPTION

oog6g

736-01

1 4

710-0121

754-0224

717-0343

754-0221

750-0387

756-0297

736-01 59

736-0

1 1

I

710-0627

712-0130

736-01 69

756-0225

04836

736-0329

71 0-0230

736-01

33

71

0-01 51

04790

-312

71 0-0599

05034

741-4155

71 4-0122

738-0372

710-0502

736-0'169

710-0623

04878

-606

712-0138

741-0246

710-0347

716-0102

734-0832

734-0833

734-0338

734-0339

04874

04875

REF.

NO.

9

10

11

12

13

14

15

16

17

1B

19

48

49

50

51

52

EA

55

56

57

5B

59

60

61

62

63

64

1

z

4

q

o

8

N

N

to

77

78

79

BO

B1

82

83

84

86

87

88

89

20

21

22

34

37

3B

39

40

41

42

4J

44

45

40

47

Engine

B.

& S.

Belt

Cover Support

Ass'y.

lnternal L-Wash.

1/2"

Scr."

Hex Scr.

1/z-20

x.75" Lg..

"V"-Belt

5/8"

x 26" Lg.

Variable

Speed

Ass'y.

"V"-Belt

5/8" x 52"

Lg.

Spacer.637l.D.

x.78 O.D. x

1 .44" L9.

I

nput Pul ley-Chaincase

Fl-Wash. 5/16" Scr..

L-Wash.

5/16"

Scr..

Hex L-Scr. 5116-24

x .75"

Lg

Hex Ins. L-Nut

3/8-16

Thd.

L-Wash.

3/8" Scr.

-

Fl-ldler 2.75"

Dia.

Friction Disc

L-Wash.

1/+"

Scr.*

Hex

Scr.

l/q-28

x.50" Lg.

Fl-Wash.

.375 l. D. x 1 .25

O.D.

x .10

Hex

Scr. 3lB-24 x 2.00"

Lg. "

Belt

Cover

Hex Wash. Hd.

Self

Tao

Scr.

Bearing Housing

Ball Bearing

Sq.

Key

3/16 x .75" Lg.

Shoulder Soacer

Hex Self Tap

Scr. 3/B-16 x

1.25" Lg.

L-Wash.

3i 8" Scr..

Hex

SF

Tap

Scr. 3/8-16 x

.75" L9.

Transm ission

Ass'y.

Comp.

Hex Nut

1/q-28Thd.

Bearing 1 .0" l.D. x

1 .12" Lg.

Hex

Scr. 3/8-16 x 1 .75" Lg.

Snap Ring

Wheel

Ass'y.

Comp.-R.H.

Wheel Ass'y.

Comp.-L.H.

(Not

Shown)

Tire Only

Inner Tube Only

Wheel

Hub

Ass'y.-R.H.

Wheel Hub Ass'y.-L.H.

(Not

Shown)

710-0152

71

0-01 1 8

04860

736-01

59

71 4-0151

723-0340

712-0214

712-0267

736-01 1

9

04844

-606

732-0153

04864

712-4138

712-0130

04837

736-0256

714-047

4

738-0380

71

0-01 06

712-0324

04841

710-0623

710-0621

736-01 1

I

05080

756-0301

71 0-0599

04876

-312

736-0173

71 2-0117

736-01

73

71 0-01

95

71

0-0599

71 4-01

05

71 0-0380

750-0382

04863

751-0233

750-0379

Hex

Scr. 318-24 x

1.00"

Lg.

Hex

Scr. 5/1 6-1 B x

3/a

Lg.

Weight Mtg.

Brkt.

Fl-Wash.

5/16l.D.

x7l8

O.D.

x.056

Klick Pin

Weight

Hex

Cent. L-Nut 318-24

Thd..

Hex Nut

5/16-18 Thd..

L-Wash.

5/16" Scr..

Frame

Ass'y.

Extension

Spring

ldler Arm Ass'y.

Hex

Cent.

L-Nut

1/a-28Thd.

Hex Ins. L-Nut

3/8-16 Thd.

Variable

Speed Brkt. Ass'y.

Fl-Wash.

.625

l.D.

x 1.25

o.D.

Cotter

Pin

1

/8"

Dia. x .75"

Lg.*

Shoulder

Scr. .50 x.267

Hex

Scr.

1/q-20

x 1 .25" Lg.

-

Hex lns. L-Nut

1/q-2OThd.

Control Brkt.

Hex

Wash. Hd.

Self Tao

Scr.

Hex

Scr. 5/16-18 x .50"

Lg..

L-Wash.

5/16" Scr..

Friction Wheel

Ass'y.

Engine Pulley

Ass'y.

5/8 V

x .75 l.D.

Hex

Wash. Hd.

Self Tap

Scr.

Belt

Cover Extension

Ass'y.

Fl-Wash.

't/a"

Scr.

Hex

Cent. L-Nut

1/q-28Thd.

Fl-Wash.

1/q"

Scr.

Hex

Scr.

1/q-28

x.62" Lg..

Hex Wash.

Hd.

Self Tap

Scr.

Key

3/16 x 3/16 x

1.00" Lg.

Hex

Scr. 5/16-18 x'1.75

Lg..

Spacer

Rear

Belt Cover

Support

Brkt.

Muff ler Def lector

Spacer .637

l.D.

x .781

O.D

x .85"

Lo.

65

66

67

6B

69

70

71

72

74

75

'For

faster

service

obtain

standard

nuts,

bolts

and washers

locally.

lf

these

itams

cannot

be

obtained

locally, order

by

part

number

and

size

as

shown

on

parts

list.

(606-

Majestic Orange)

When

ordering

parts,

ilcolor

or f inish

is

imDortant

use

the

appropriate.color

cod€

shown

above

{e.g. Majestic

Orange Finish-04831

(606).)

Theengine

is not

under

warranty

by the

tiller

manufacturer.

lf repairs

or service is n€eded

on

16"

fTil'Yrffi

engine'

ploes€

con?ct

your

near€st

authorlzed

ongin€

service

outiet.

Check

the

"yellow

pages"

ot

ll

In Thc

ll

your

t€lephonr

book under "Englnes

-

Gasotine."

llveilow

pegcrll

reP-Jr

v

Page 26

ACCESSORIES

AVAILABLE

FOR

TILLER

MODEL

218-405'065

298-167

298-1 68

298-1

69

298-1

90

298-1

91

298-192

2gB-194

298-1 95

298-1 96

298-197

Hilling

Plow

(Must

be

used

with

298-169

"V"

Bar

Frame

AdaPter)

Six

Tang

Cultivator

(Recommended

use

of

298-191

DePth

Gauge

Wheels)

"V"

Bar Frame

Adapter

(Recom-

mended use

of 298-191

DePth

Gauge

Wheels)

Four Shovel

Cultivator

(Must

be

used

with

298-169

"V"

Bar

Frame

Adapter)

Depth

Gauge

Wheels

Tine Cultivating

Shields

WheelWeights

Tire Chains

(13"

x

5")

32"

Angle

Dozer

Blade

Front

Hitch

Mount

(Required

to

mount

298-196

32"

Angle

Dozer

Blade)

v

v

26

v

Page 27

PARTS

INFORMATION

POWER

EOUIPMENT

PARTS

AND SERVICE

Parts

and

service

for all

Mark

Master

power

equip-

ment are

available

through

the authorized

service

f irms listed

below.

All orders

should specify

the

model

number of

your

unit,

parts

number,

description

of

parts

and

the

quantity

of each

part

req u ired.

+NorE

ORDERING

INSTRUCTIONS

FOR PAINTED PARTS

All

parts

are shipped

in the

color

currently

available

unless

otherwise

specif

ied. When

parts

must be

a specif

ied

color,

use

the color

code

as

a

suf

f ix.

Majestic

Orange

White

Black

Example:

Handle

Panel

Required

in

Majestic

Orange

Order

as:

Handle

Panel

MASSACHUSETTS

SOUTHBORO

Crandell-Hicks

Co

Ft

9

BRIGGS & STRATTON,

TECUMSEH

AND PEE\J,

LESS

PARTS AND SERVICE

-

Briggs

& Stratton,

Tecumseh

and Peerless

parts

and

service should be

handled

by

your

nearest

authorized engine service

f

irm.

Check the

yellow

pages

of

your

telephone directory under

the

listing

Engines-Gasoline,

Briggs

& Stratton or Tecumseh

Lauson.

NEW

YORK

SYRACUSE

GTP Leisure

Products

Inc. .... 420 Marse lus

St 13204

NORTH

CAROLINA

WINSTON-SALEM

606

312

452

MINNESOTA

Power Tools.

Inc

04831

04831-606

ST.

PAUL

. 3771 Sibley

Memorial Hwy

Carswell

Distributing

Co

P

O.

Box4193

.

oHto

Bur'i-,n

SuPi:',

P

O Bcx 929

OKLAHOMA

Forest

Sales,

Inc.

..

PENNSYLVANIA

Stull

Equiprrent

CorP

TEN

N ESSEE

Hasson-Bryon

Hardware

3750

N. Lrberty

Strssl

.

North Station

..

27105

YOUNGSTOWN

1301

Logan

Ave

OKLAHOMA

CITY

1039

N.W.

63rd St

CHESTER

. . . . .742 W. Front

St

MORRISTOWN

114 W. Main

St

44501

01772

55122

v

73116

19013

3781

4

MISSOURI

OSAGE

BEACH

Crowell

Distributing Co .

. P.O. Box

185

ST.

JOSEPH

Ross-Frazier

Supply

Co.

.

. . .

Bth

and Monteral'

65063

64503

WARRANTY

PARTS AND SERVICE

POIICY

The

purpose of worronfy

is to

prolecf lhe

cuslomer from delects

in workmonship

ond moleriols, defects

which ore

NOT delecled of

the time ol

monufocfure.

lt does

noi

provide

lor

the

unlimifed ond unreslricted

replocemenl

of

ports.

Use ond

moinlenonce ore

the responsibilify

of

fhe

cusfomer.

The monufoclurer

connot ossume responsibiliiy

for conditions which

it hos no conlrol. Simply

pui,

if it's

the monu{ocfurer's

foult. it's

fhe

monufocfurer's

responsibilify;

if il's ihe

cuslomer's

foult,

it's lhe

cusiomer's

resPonsibilify.

CLAIMS

AGAINST

THE MANUFACTURER'S

All cloims MUST be

substontioled

with

the f ollowing

informolion:

*ARRANTY lNctuDEs

l '

Model Number

of unit

involved'

l. RepfocementolMirsingPorlsonnewequipmenl.

2,

Dofeunitwospurchosedorfirstpulintoservice.

2.

Replocement

of Delective

Portc wilhin

the worronty

period.

3. Dote of

foilure.

3.

Repolr of

Defec|l within

lhe worronty

period.

4.

Nolure of

foilure.

Manufacfured

for

MARK

MASTER

by MTD

Products Inc..5389

West 130th Streel

.

P.O. Box 2741

Cleueland, Ohio

441 11

v

Loading...

Loading...