Page 1

L04

FORM NO. 769-01545

MTD Products Aktiengesellschaft • Saarbrücken • Germany

Page 2

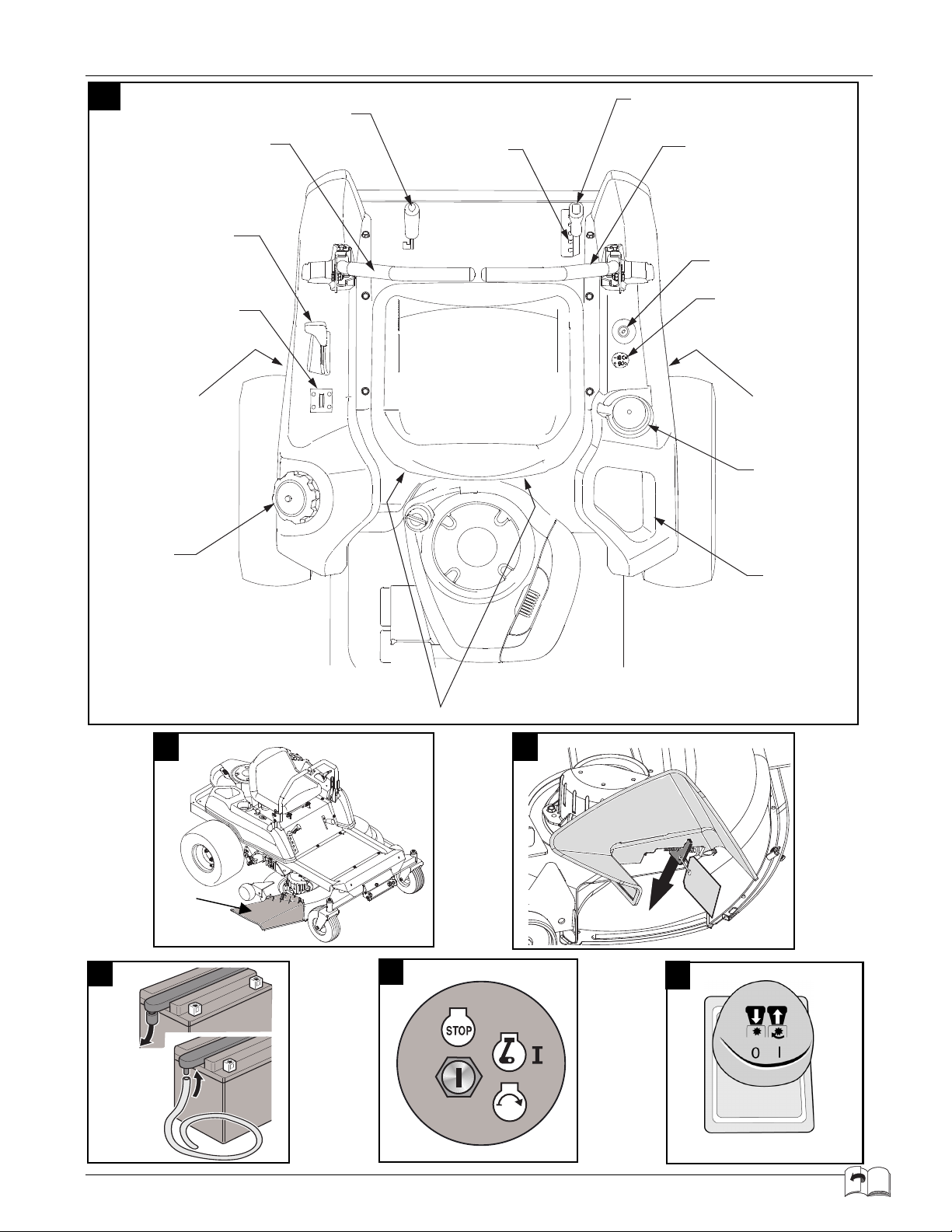

10

N

C

M

L

F

A

B

C

D

E

F

G

4

K

2

5

H

J

3

6

1.

2.

0

Page 3

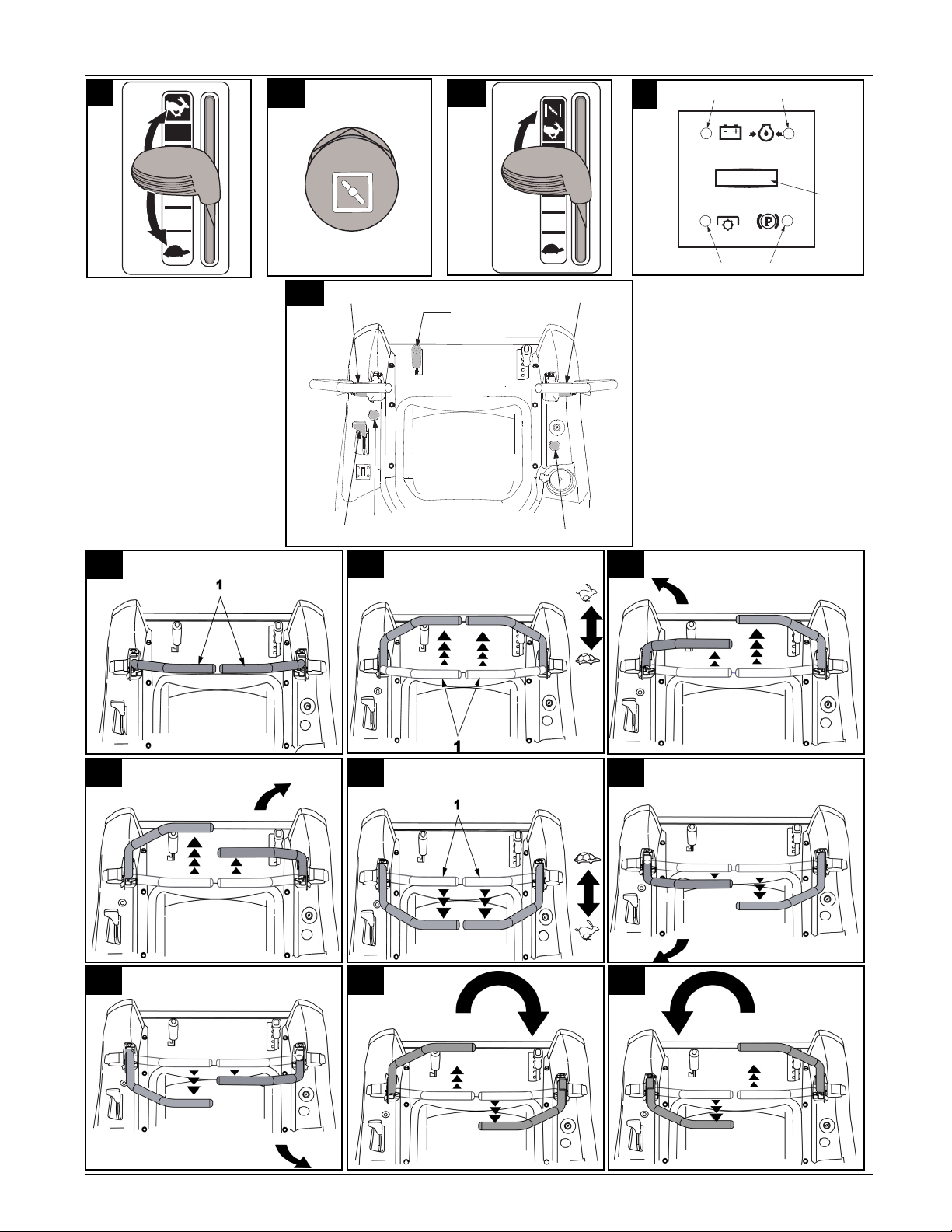

7

8a

10

8b

1

2

5

6

3

4

9

1

5

2

3

4

12

13 11

14 15 16

17 18 19

Page 4

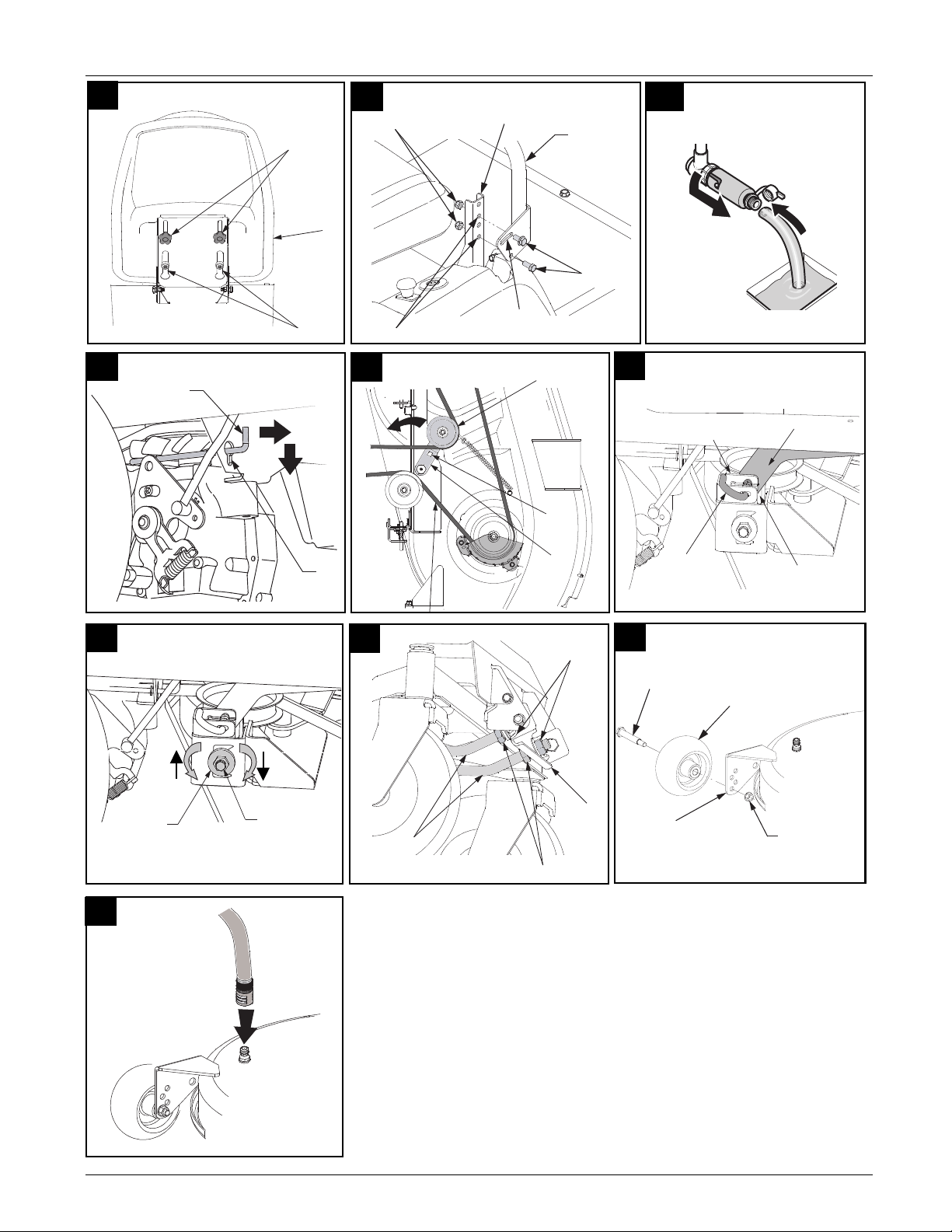

20

23

A

1.

25

22

2.

1

1.

2

21

1

1

2

3

6

4

3

2

5

24

2.

1

26

29

B

27

2

1

4

2

28

1

2

3

4

1

2

4

3

3

Page 5

English Operating instructions

Details on the rating plate

These details are very important for

identifying your appliance when you

order spare parts or contact our

aftersales service. The rating plate

is found under the driver’s seat.

Enter all the details on your

appliance’s rating plate in the

following fields.

For your safety

Use the appliance properly

This appliance has been designed

– as a riding mower to mow the lawns

of domestic and leisure gardens,

– in accordance with the details and

safety information given in these

operating instructions.

The appliance must not be put to any

other use. The user is liable for all

damage caused to third parties and

their property.

The manufacturer is not liable for any

damage incurred as a result of

unauthorised changes to the appliance.

You are not permitted to use this

appliance on public roadways nor

for transporting persons.

General safety information

Before using the appliance for the first

time, read and follow these operating

instructions carefully.

Inform other users how the vehicle

is used properly.

Operate the appliance only when it

is in good technical condition as

stipulated and delivered by the

manufacturer.

Keep these operating instructions in

a safe place and within reach every

time the appliance is used.

Hand over the operating instructions

together with the appliance when there

is a change of ownership.

Replacement parts must comply with

the requirements specified by the

manufacturer. For this reason, use

only original replacement parts or

replacement parts approved by the

manufacturer. All repair work must be

conducted exclusively at a specialised

garage.

Before working with the appliance

Persons using the vehicle must not be

under the influence of intoxicants, e.g.

alcohol, narcotics, medication, etc.

Persons under sixteen years of age

must not operate the vehicle (bylaws

may stipulate a different minimum

age).

Before starting work, familiarise

yourself with all the installations and

controls as well as their functions.

Store fuel in approved receptacles

only, and never near sources of heat,

e.g. ovens, hot water tanks, etc.

Replace damaged exhausts, fuel tanks,

and filler caps.

Observe the regulations before

attaching trailers and add-on

equipment.

Add-on equipment, trailers, ballast,

and filled grass catchers affect the

handling properties, in particular

manoeuvrability, braking behaviour,

and roll-over stability.

When working with the appliance

When working with or on the

appliance, wear suitable working

clothes (e.g. safety shoes, long

trousers, tight-fitting garments,

goggles).

Operate the appliance only when it

is in perfect technical condition.

Do not fuel the appliance when the

engine is running or hot. Fuel the

appliance outdoors only.

Avoid naked flames and sparking,

and do not smoke.

Make sure that there are no persons,

in particular children and animals,

near the running appliance.

Check the terrain the appliance is to

mow, and remove all objects that

could be caught and ejected.

This helps you to prevent risks to

persons and damage to the appliance.

Do not mow on inclines steeper than

15 %. Working on inclines is

dangerous: the appliance can roll over

or lose traction. Whenever possible,

always start and brake the appliance

gently on inclines. Keep the clutch

engaged and drive slowly on downhill

stretches. Never drive directly up or

down inclines, but always across

them.

Always work with the appliance only

during daylight or with adequate

artificial lighting.

You are not permitted to use this

appliance for transporting persons.

Do not take passengers.

Before all work on this appliance

Before all work on this appliance, you

can prevent injury by observing the

following:

– switch OFF the engine,

– take out the ignition key,

– wait until all moving parts have

come to a complete stop and the

engine has cooled down,

– disconnect the spark plug terminal

on the engine so that it cannot start

by accident,

– engage the locking brake.

After working with the appliance

Never leave the appliance until you

have switched OFF the engine,

engaged the locking brake, and

removed the ignition key.

Safety devices

Safety devices serve for your protection

and must be fully functional at all times.

You must not make any changes to the

safety devices or circumvent their

functions.

Never use the appliance when the

safety devices are defect.

1

Page 6

English Operating instructions

k

5

The safety devices are the following.

Deflector

Fig 2

The deflector protects you from

injuries that can be caused by the

cutters or ejected solid objects.

The appliance must be operated only

when the deflector is installed.

Safety lock system

The safety lock system allows you to

start the engine only when

– the driver is sitting on the seat,

– the locking brake is engaged,

i.e. at Park,

– the PTO switch is at OFF,

– both drive control levers are in the

outer Neutral recesses.

The safety lock system switches OFF

the engine as soon as the operator

leaves the seat without engaging the

locking brake and/or turning the PTO

switch to OFF.

Note!

To restart the engine you must

turn the PTO switch back to OFF.

The safety lock system switches OFF

the engine when one or both drive

control levers are not in the outer

Neutral recesses when the locking

brake is engaged.

The safety lock system prevents the

appliance from reversing when the

cutters are activated (PTO).

The cutters are switched OFF

automatically

Note! As soon as both drive control

levers are moved back to Neutral or

Drive, the cutters (PTO) are switched

back ON automatically.

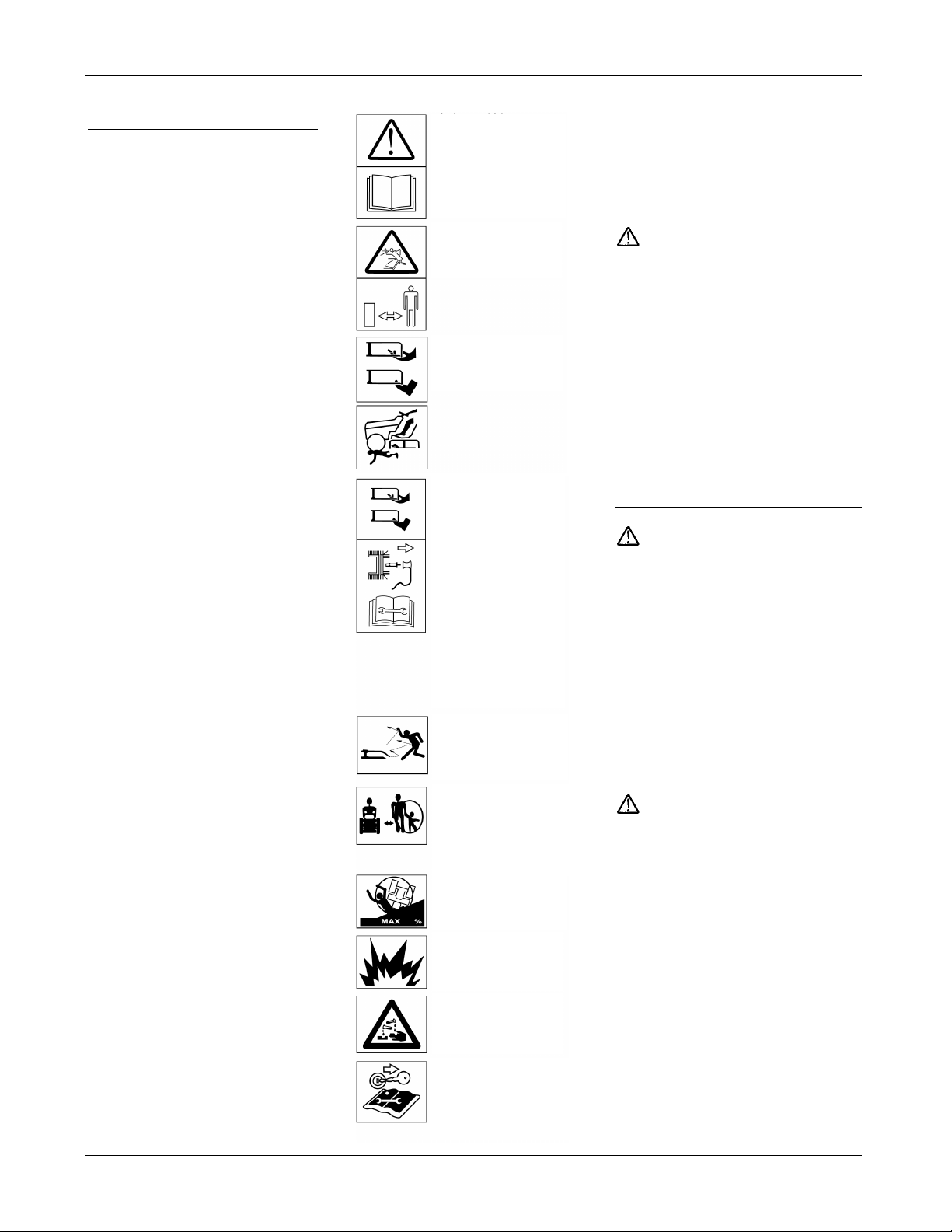

Symbols on the appliance

On the appliance you will find various

symbols on adhesive labels. These

symbols are explained in the

following.

.

Caution!

Read the operating

instructions before

starting the

appliance!

Keep bystanders out

of the danger zone!

Risk of injury from

rotating cutters or

parts!

Disconnect the spar

plug terminal before

all work on the

cutters! Keep fingers

and feet away from

the cutters! Switch

OFF the appliance

and disconnect the

spark plug terminal

before adjusting,

cleaning, or

inspecting the

appliance!

Risk of injury from

ejected grass or solid

objects!

There must be no

persons, and especially no children or

animals, near the

running appliance!

Working on inclines

can be dangerous!

1

Caution!

Risk of explosion!

Danger of injury from

battery acid!

Remove the ignition

key and observe the

information in these

instructions before all

work on the appliance!

Always keep these symbols on the

appliance in a legible state.

Symbols in these instructions

These instructions make use of the

following symbol:

Caution! Danger!

This points out dangers that are

connected with the described activity

and that can cause injury to persons

and damage to property.

Directions

When directions are described for the

appliance (e.g. left, right) the view is

always from the driver’s seat.

Figures

The details in the figures may differ

slightly from the purchased appliance.

Preparing the appliance

Battery

Risk of poisoning and injury from

battery acid.

Wear goggles and protective gloves.

Avoid skin contact with battery acid.

If battery acid should spray in your

face or eyes, immediately rinse with

cold water and consult a doctor. If you

accidentally swallow battery acid,

drink copious amounts of water and

immediately consult a doctor. Keep

batteries out of the reach of children.

Never tip the battery: battery acid may

spill out. Give unwanted battery acid

to your dealer or a disposal company.

Battery acid and vapours from

battery acid can cause fire,

explosions, and corrosion.

Immediately clean appliance parts that

have come into contact with battery

acid. Battery acid is corrosive.

Do not smoke, and keep burning

and hot objects at a distance.

Charge batteries only in wellventilated and dry rooms.

Work on the battery can cause short

circuits.

Do not place any tools or metal

objects on the battery.

Note the order of terminals when

connecting and disconnecting the

battery. Make sure that the ignition

key has been removed.

Danger!

Caution!

2

Page 7

English Operating instructions

Disconnecting

• First disconnect the black cable

(–), and then the red cable (+).

• Remove the battery from the

appliance.

Connecting

• First connect the red cable (+),

and then the black cable (–).

Note!

The battery’s positive terminal is

marked with a plus sign (+).

The battery’s negative terminal is

marked with a minus sign (–).

Always make sure that the battery’s

vent line is correctly installed

(unobstructed downwards flow).

When a “maintenance-free/sealed”

battery (type 1) has been delivered

(battery without vent plug)

The battery is filled with battery acid

and sealed at the manufacturer’s.

The battery may have to be recharged.

To do so, see the section on servicing

the battery.

When an unfilled battery (type 2)

is delivered

(battery with vent plug)

• Remove the vent plug for the

battery cells.

• Slowly fill each cell with battery

acid until the level is 1 cm below

the filling aperture.

• Leave the battery for thirty

minutes so that the lead can

absorb the battery acid.

• Check the acid level,

if necessary top up the acid level.

• Before using the battery for the

first time, charge it with a battery

charger (max charging current 6 A

at 12 V) for 2–6 hours. After

charging, first disconnect the

mains plug to the charger and then

take out the battery (see also the

operating instructions for the

charger).

• Replace the vent plugs for the

battery cells.

• Remove the blank plug for the

battery’s vent. Attach the vent line

so that it runs downwards through

the appliance. Make sure that the

line is unobstructed!

(Fig 4)

• Install the battery in the appliance.

• First connect the red cable (+),

and then the black cable (–).

• Refill the battery afterwards with

distilled water only.

(Check every two months.)

• Keep the battery clean.

Fuelling and checking/topping up

the oil level

Fill the machine with petrol and oil as

described in the provided engine

handbook.

Note! The engine may have been

filled with oil at the manufacturer’s –

please check and if necessary refill.

(The oil level must lie between the

Full/Max and Add/Min marks.) Never

fill the petrol tank to overflowing, but

until the level reaches 1 cm below the

filler’s lower edge.

Seal the petrol tank securely.

Risk of asphyxiation from carbon

monoxide

Run the IC engine outdoors only.

Risk of explosion and fire

Fuel/petrol vapours are explosive,

and fuel is highly flammable. Fill the

engine with fuel before turning the

ignition. Keep the petrol tank closed

when the engine is running or is still

hot. Refill with fuel only when the

engine has been switched OFF and has

cooled down. Avoid naked flames and

sparking, and do not smoke. Fuel the

appliance outdoors only. Do not start

the engine when fuel has overflowed.

Remove the appliance from the fuelcontaminated site and wait until the

fuel has completely evaporated.

To prevent the risk of fire, please keep

the following parts free of grass and

leaking oil: engine, exhaust, battery,

fuel tank.

Removing the transport safety plate

on the cutters

Fig 3

Push the deflector back slightly, and

remove the transport safety plate.

The deflector closes automatically.

Checking the tyre pressure

Pressurise the front tyres to approx.

2.3 bar and the rear tyres to approx.

0.8 bar. See also the manufacturer’s

recommendation on the tyre walls.

Controls and indicators

Fig 1

A. cutting height segment

B. cutting height lever

C. right and left drive control lever

D. ignition lock

E. PTO switch

F. gear release for hydrostatic drive

(not shown)

G. cup holder

H. storage tray

J. seat adjuster (not shown)

K. tank cap

L. composite indicator (optional)

M. accelerator lever

N. control lever for the locking brake

Cutting height segment (A)

Fig 1

Each notch corresponds to approx.

1.25 cm:

lowest position: approx. 4 cm

highest position: approx. 10 cm

Cutting height lever (B)

Fig 1

This lever adjusts the cutting height

and is locked in place by the

respective recesses.

Right and left drive control lever

(C)

Fig 1

These levers change the drive

direction, control the speed, and stop

the appliance (see detailed description

in the section “Operation”).

Note!

Before the engine can be

started, both control levers must be in

the outer Neutral recesses.

Ignition lock (D)

Fig 5

The ignition lock has three settings.

1. O/ = OFF/engine stop.

2. ON/ = electrical system

switched ON or engine run mode.

3. Start/ = starter confirmation:

when the engine is running,

release the key.

3

Page 8

English Operating instructions

PTO switch (E)

Fig 6

The PTO switch actuates an electromagnetic/mechanical clutch to switch

ON and OFF the cutters.

ON = pull the switch

OFF = press the switch

Note!

Before the engine can be started

the PTO switch must be switched

OFF.

Gear release for hydrostatic drive

(F)

Fig 23

To push the appliance with the engine

switched OFF, first pull up the two

levers (near each rear wheel), and then

press them down.

To drive the appliance, pull up and

press in the levers.

Cup holder (G)

Fig 1

This holds a cup.

Storage tray (H)

Fig 1

This holds diverse small items.

Seat adjuster (J)

Fig 20

After loosening the two wing nuts (1)

you can adjust the seat (2) backwards

and forwards along the slide rail (3).

Tank cap (K)

Fig 1

This is removed when the appliance is

fuelled with regular unleaded petrol.

Combined indicator (L) – optional

Fig 9

Depending on the design the

combined indicator can comprise the

following elements:

1. battery indicator

2. oil pressure

3. operating hour meter

4. PTO switch

5. locking brake

Battery indicator

When ON the indicator (1) lights up

briefly and the battery voltage appears

briefly on the display (3).

When indicator (1) lights up and the

engine is running, the battery is not

adequately charged (battery voltage

less than 10.5–12 V).

This then also appears on the display

(3). The battery or charger must be

checked by qualified personnel.

If necessary, consult a garage.

Oil indicator

When ON the indicator lamp (2) lights

up.

When the indicator lamp (2) lights up

and the engine is running,

immediately switch OFF the engine

and check the oil level. If necessary,

consult a garage.

Operating hour meter

This shows the operating hours in

hours and tenths of hours on the

display (3).

Note! When ON the battery voltage

appears briefly before the operating

hours are displayed (these are also

counted at the ON position).

PTO switch

The indicator (5) lights up when the

cutters (PTO) are not switched OFF

when the engine is started (ON or

Start).

Brake indicator

The indicator (4) lights up when the

locking brake is engaged when the

engine is started (ON or Start).

Accelerator lever (M)

Figs 7 and 8b

This lever controls the engine speed:

fast = “ ”

slow = “ ”

Note! When powered fittings such as

cutters or other add-on equipment is

used, always operate the appliance

with the accelerator lever at Fast

(hare symbol).

Choke control

Figs 8a and 8b

To start a cold engine, pull out the gas

accelerator (Fig 8b) to Choke or the

Choke button (Fig 8a) if your model

features this.

Control lever (N) for the locking

brake

Fig 1

Engaging the locking brake

Pull the lever into the top left recess

until it engages.

Disengaging the locking brake

Pull the lever upwards and to the right,

then slowly pull it down.

Note!

Before engaging the locking

brake, make sure that the two drive

control levers are in the outer Neutral

recesses, otherwise the engine is

switched OFF. The locking brake

must be engaged when the engine

is started.

Operation

Observe also the instructions in the

engine handbook!

Danger!

Risk of injury!

All persons, and especially children

and animals, must never be near the

appliance when it is mowing.

They can suffer injury from ejected

stones, etc. Children must never

operate the appliance. Emptying

a grass catcher can cause injury to

yourself and others from ejected

cuttings. Never empty a grass catcher

when the cutters are running.

When mowing on steep inclines the

appliance can roll over causing injury.

Never drive directly up or down an

incline, but always along it.

Never drive on inclines steeper than

15 %. Do not turn on an incline.

If absolutely necessary, then turn the

appliance down the incline slowly and

carefully. When mowing wet grass the

appliance can lose traction on the

ground and you can fall. Mow only

when the grass is dry. Excessive speed

can raise the risk of accident.

When mowing in border areas, keep

at an adequate distance e.g. from steep

inclines, trees, bushes, and hedges.

Be particularly careful when

reversing. Check the terrain the

appliance is to mow and remove all

objects that can be caught and ejected.

When the cutters hit a foreign body

(e.g. a stone), immediately switch

OFF the engine, inspect the device for

damage, and consult a specialised

garage when damage is apparent.

Do not operate the appliance when the

cutters are not installed. The altered

axle load distribution can cause the

appliance to roll over. Never attempt

to stabilise the appliance by dangling

one foot. When the tyres lose traction

on an incline, switch OFF the PTO

switch and slowly drive straight ahead

down the incline.

4

Page 9

English Operating instructions

Risk of asphyxiation from carbon

monoxide

Run the IC engine outdoors only.

Risk of explosion and fire

Fuel/petrol vapours are explosive,

and fuel is highly flammable. Fill the

engine with fuel before turning the

ignition. Keep the petrol tank closed

when the engine is running or is still

hot. Refill with fuel only when the

engine has been switched OFF and has

cooled down. Avoid naked flames and

sparking, and do not smoke. Fuel the

appliance outdoors only. Do not start

the engine when fuel has overflowed.

Remove the appliance from the fuelcontaminated site and wait until the

fuel has completely evaporated.

To prevent the risk of fire, please keep

the following parts free of grass and

leaking oil: engine, exhaust, battery,

fuel tank.

Risk of injury from defect

appliance

Operate the appliance only when it is

in perfect technical condition. Subject

the appliance every time to a visual

check before you operate it. Check for

any damage in particular on the safety

devices, the cutters and their mounts,

the controls, and the screw unions, and

make sure they all sit tightly. Replace

any damaged parts before operating

the appliance.

Operating hours

Observe the national and the

municipal regulations governing the

times the appliance may be used

(if necessary ask your local authority).

Before operating the appliance

Check the following:

• all guards

• the engine’s oil level (see engine

handbook)

• the fuel tank level

• the tyre pressure (see section

“Servicing”)

• side panels.

Also check add-on equipment and

the areas near air filters for soiling

and cuttings.

Adjustments before driving the

appliance

Do not make any adjustments when

the engine is running or the

appliance is moving

• Park the appliance on a firm,

• Perform all work when the engine

When working on moving parts:

• remove in addition the spark plug

Adjusting the driver’s seat

Fig 20

• Loosen the two wing nuts (1).

• Push the seat (2) along the slide

• Retighten the wing nuts (1).

Adjusting the drive control levers

Fig 21

If necessary the drive control levers

can be adjusted higher or lower and

to the side.

Adjusting the height

• Remove the nuts (1).

• Remove the drive control lever

• Use the screws (2) to secure the

• Again fasten (tighten) the nuts

Adjusting the sides

• Loosen (do not remove) the nuts

• Move the drive control lever in

• Retighten the nuts (1).

Adjusting the cutter wheels

Fig 28

The cutter wheels should always be

6–12 mm above the ground at their

lowest cutter position. The cutter

wheels are not designed to bear the

weight of the cutters.

If necessary, arrange the wheels at

equal distances.

Caution!

horizontal surface and engage

the locking brake.

is switched OFF.

terminal from the spark plug.

rail (3) to the desired position.

(3), but without removing the

screws (2).

drive control lever in the other

pair of holes (6) in the mount (4).

(1).

(1).

the adjusting segment (5)

backwards or forwards to the

desired position.

Starting the engine

Fig 10

• Sit on the driver’s seat.

• Place both drive control levers

into the outer Neutral recesses

(1 and 3).

• Turn the PTO switch (4) to OFF.

• Move up the cutters.

• Engage the locking brake.

• Do not

operate the drive control

levers.

• Move the accelerator lever (6)

to “Fast/ ”.

When the engine is cold, move

the accelerator lever to or pull

the choke (5) if your model

features this (a hot engine may

not need the choke).

• Turn the ignition key clockwise

to “Start/ ”. Once the engine

is running, release the key. It will

then return to ON/ .

Note! Do not keep the ignition key at

Start/ for longer than five seconds

per start attempt. Wait about one

minute before the next start attempt.

• Slowly press in the choke button

(if your appliance features this).

• Pull back on the accelerator lever

until the engine runs quietly.

Stopping the engine

• Turn the ignition key

anticlockwise to “O/ ”.

• Before leaving the appliance,

engage the locking brake and

withdraw the ignition key.

Driving the appliance

Caution!

Avoid abrupt engine starts, excessive

speed, and flat-out braking.

Be particularly careful when

reversing. Never change direction

(forwards to reverse and vice versa

or zero or pivot turns) without first

stopping the appliance. This appliance

has no turning circle; instead the rear

tyres serve as a pivot. A conventional

appliance can turn in a circle, but this

circle has a minimum diameter.

Owing to its short length and the

ability to turn about its own axis the

appliance exhibits superior

manoeuvrability.

5

Page 10

English Operating instructions

Instead of a steering wheel this

appliance features two control levers

that serve to steer and drive the

appliance. When the control levers

are moved to the max positions,

the wheels rotate at the speed set at

the accelerator lever. The control lever

positions between Neutral and

Maximum are proportional to the

speed set at the accelerator lever.

In order to familiarise yourself with

how to operate the appliance (approx.

thirty minutes) you should start the

appliance on flat terrain without

spectators.

Note!

Before mowing with the

appliance you should familiarise

yourself with the appliance’s new

controls. Start the appliance, move

the accelerator lever to the middle

position (mid engine speed), and leave

the PTO switch switched OFF.

Moving the control lever then causes

the appliance to move at a slow speed

only, and you can therefore familiarise

yourself with the controls.

• Start the engine as specified.

• Let the engine heat up.

• Move the accelerator lever to the

corresponding position.

• Disengage the locking brake.

• Pull both drive control levers (1)

inwards into Neutral (Fig 11)

Caution!

Always keep both hands on the drive

control levers. Never let go of the

drive control levers when operating

the appliance. Always move the drive

control levers by hand to Neutral

before slowing or stopping the

appliance. Move the drive control

levers slowly at all times. Abrupt or

hasty movements or taking too sharp

corners can lead to uncontrolled

movements and the appliance can

roll over causing serious injury.

Be particularly careful when

reversing.

Just one more tip before you drive

off

To slow or stop the appliance move

the two control levers slowly and

steadily to Neutral (Fig 11).

Drive mode: straight ahead

Fig 12

Press both control levers steadily

forwards. The more they are pressed

forwards, the faster the appliance

moves.

Drive mode: left corner

Fig 13

Push both control levers forwards:

the right control lever must be slightly

ahead of the left control lever.

Drive mode: right corner

Fig 14

Push both control levers forwards:

the left control lever must be slightly

ahead of the right control lever.

Note on cornering

distance between the two control

levers the tighter the corner taken.

Reverse mode: straight ahead

Fig 15

Pull back on both control levers

steadily. The more they are pushed

back, the faster the appliance moves.

Reverse mode: left corner

Fig 16

Pull back on both control levers:

the right control lever must be slightly

further back than the left control lever.

Reverse mode: right corner

Fig 17

Pull back on both control levers:

the left control lever must be slightly

further back than the right control

lever.

Turning clockwise around the axis:

zero turn

Fig 18

1. Always move both control levers

to Neutral to stop the appliance.

2. Press the left control lever

forwards, and at the same time

pull back on the right control

lever.

Turning anticlockwise around the

axis: zero turn

Fig 19

1. Always move both control levers

to Neutral to stop the appliance.

The greater the

2. Press the right control lever

forwards, and at the same time

pull back on the left control lever.

Information on executing zero turns

During a zero turn one wheel turns

forwards and another backwards.

Incorrectly executing a zero turn can

cause damage to your lawn.

Turning right or left: pivot turn

Fig 11

1. Always move both control levers

to Neutral to stop the appliance.

2. Depending on the direction,

push one control lever forwards

or back; the other control lever

remains at Neutral.

Note!

During a pivot turn only one

wheel turns. The stationary wheel then

rubs against the ground and can cause

damage to your lawn.

Slowing or stopping the

appliance

• Slowly and steadily move both

control levers to Neutral.

Mowing

Do not change direction when the

appliance is driving or coasting (see

the section “Driving the appliance”).

• Start the engine as specified.

• Move the accelerator lever to

position .

• Switch ON the cutters (PTO).

• Lower the cutters.

• Disengage the locking brake.

• Pull both drive control levers (1)

inwards into Neutral.

• Steadily press both control levers

forwards. The more they are

pressed forwards the faster the

appliance moves.

The safety lock system prevents

Note!

the appliance from reversing when the

cutters (PTO) are switched ON.

The cutters are switched OFF

automatically when both drive control

levers are moved to Reverse. As soon

as one or both drive control levers are

moved back to Neutral or Drive the

cutters (PTO) are automatically

switched back ON.

6

Page 11

English Operating instructions

Never tow away the appliance.

General

When adjusting the cutting height

and drive speed make sure that the

appliance is not overloaded.

The length, type, and wetness of

cuttings may necessitate adjustments

to the cutting height and drive speed.

Additional safety

information on the drive

• When the appliance is driven

straight ahead but veers to one

side or when the appliance does

not remain stationary but creeps

at Neutral, switch OFF the

appliance (do not use the

appliance any more) and contact

a specialised garage.

For the optimal mowing results

Mow the first two lanes so that the

cuttings fall at the centre of the sides.

• Never let grass grow too long.

• Never mow grass too short.

• Mow over straight stretches.

• Do not mow at high speed,

particularly when a mulching kit

or grass catcher is installed.

This appliance is designed to

Note!

mow lawns. It must not be used to

cut scrub, weeds, or too tall grass.

Parking the appliance

• Stop the appliance.

• Move both drive control levers

to the outer Neutral recesses.

• Switch OFF the cutters (PTO).

• Raise the cutters.

• Turn the ignition key

anticlockwise to “O/ ”.

• Before leaving the appliance

engage the locking brake.

• Remove the ignition key.

Pushing the appliance

Fig 23

Push the appliance only when the

engine is switched OFF.

• Disengage the locking brake.

• Release both gears (left and

right): pull out and up both levers

(A) and then press them

down (B).

Before starting the engine, return both

gear release levers.

Note!

This can cause serious damage to the

gears.

Tips on caring for your lawn

A number of tips for a healthy and

uniform lawn

Mowing

Lawns consist of various grass types.

Frequent mowing promotes the

growth of grass, resulting in strong

roots and a firm sward. Infrequent

mowing promotes the growth of tall

grasses and other wild-growing plants

(e.g. clover, daisies). The normal

height of a lawn is approx. 4–5 cm.

Only one third of this height should be

mown, i.e. 7–8 cm should be mown to

the normal height. Wherever possible,

do not mow the lawn to shorter than

4 cm, otherwise dry spells can damage

the sward. Tall grass (e.g. after

a holiday) should be mown to the

normal height over several stages.

Mulching (with accessories)

Various appliances can be used for

mulching when fitted with the

corresponding accessories. Ask your

specialised dealer for accessories.

When mown, the grass is cut into

small pieces (approx. 1 cm), which

remain lying. The lawn therefore

retains many nutrients. For the optimal

results the lawn must always be kept

short (see also the section “Mowing”).

When mulching, observe the

following instructions:

–

Do not mow wet grass.

–

Never mow more than 2 cm.

–

Mow slowly.

–

Use the max engine speed.

–

Clean the cutters at regular

intervals.

Transporting

Drive the appliance only short

distances when moving between sites.

For larger distances use a transport

vehicle.

Note! Under the German Road Traffic

Act the appliance is not permitted on

public roadways.

Short stretches

Danger!

Objects can be caught and ejected by

the rotating cutters and cause damage.

Switch OFF the cutters before you

drive the appliance.

Long stretches

Transport damage

The use and type of transport media

(e.g. transport vehicle, loading ramp,

etc.) must comply with their

respective design objectives (see the

corresponding operating instructions).

When transported the appliance must

be secured against slipping.

Environmental hazard from leaking

fuel

Do not transport the appliance on its

side.

• Prepare the transport vehicle.

• Attach the loading ramp to the

• Push the appliance by hand on the

• Engage the locking brake.

• Secure the appliance against

Caution!

transport vehicle.

loading ramp (see “Pushing the

appliance”).

slipping.

Cleaning / servicing

Danger!

Accidentally starting the engine can

cause injury.

Protect yourself from injury.

Before all work on the appliance:

• switch off the engine,

• engage the locking brake,

• take out the ignition key,

• wait until all moving parts have

come to a complete stop and the

engine has cooled down,

• disconnect the spark plug

terminals on the engine so that it

cannot start by accident.

Additional precautions before all

work on the cutters

Danger!

Danger of injury from sharp cutters

Wear working gloves.

On appliances with more than one

cutter set, the movement of one cutter

set can lead to the movement of all

others.

7

Page 12

English Operating instructions

Cleaning the appliance

Caution!

Risk of damage to the appliance

Do not use high-pressure media to

clean the appliance.

• Whenever possible, clean the

appliance directly after mowing.

• Park the appliance on a firm and

horizontal surface.

• Engage the locking brake.

Cleaning the cutters

Risk of injury

Clean the cutters with care.

Caution!

Possible engine damage

Do not tip the appliance through more

than 30°: fuel can enter the

combustion chamber and cause

damage to the engine.

• Raise the cutters to the topmost

position.

• Clean the cutter chamber with

a (hand) brush or cloth.

• Remove grass residue from the

deck and around the cutter

spindles.

Cutters with cleaning nozzle

(option)

Fig 29

Park the appliance on a horizontal

surface free of loose stones, etc.,

and engage the locking brake.

1. Use a commercially available

quick-release coupling to attach

a water hose to the cleaning

nozzle.

2. Start the engine.

3. Lower the mower unit and switch

it ON for a few minutes.

4. Switch OFF the mower unit and

the engine.

5. Remove the water hose. Repeat

steps 1–5 on the second cleaning

nozzle (when installed).

After ending the cleaning procedure

(steps 1–5):

• raise the mower unit,

• start the engine, and switch ON

the mower unit for a few minutes

to dry it.

Removing the cutters

Figs 24 and 25

Danger!

Risk of injury from sharp cutters

Wear working gloves.

The cutters can be correctly removed

only when you proceed as follows:

• install the cutter wheels at the

highest possible position,

• lower the cutters by moving the

lever for raising the cutters to the

lowest recess,

• insert a ½” square spanner into

the recess (1) in the tensioning

arm (2) (Fig 24),

• use the square spanner to press

the tensioning arm in the direction

of the arrow: this releases the

tension on the V belt,

• remove the V belt from the PTO

clutch (engine pulley),

• look into the cutters from the

appliance’s right side, and locate

the locking pins (4) on the right

rear side of the cutters (Fig 25),

• pull out the pin to disconnect the

cutters from the suspension (2)

(Fig 25),

• repeat these steps for the

appliance’s left side;

Keep a firm hold on the

Note!

cutters so that they cannot fall

on the ground.

• move the lever for raising the

cutters to the topmost recess,

• let the cutters slide forwards to

the front of the appliance, making

sure that the cutters’ pick-up

hooks are detached from the

appliance’s front rail,

•

carefully draw out the cutters

(from the right side) from

underneath the appliance.

Installing the cutters

Fig 25

Follow the above instructions in

reverse order to install the cutters.

An assistant can accelerate the

procedure. Make sure that each

suspension (2) is engaged in the

recesses (3) on the cutter mount (1).

Basic adjustments to

(aligning) the cutters

Note! Before aligning the cutters,

check the appliance’s tyre pressure.

Aligning the sides

Fig 26

When the cutters seem to mow

irregularly, the sides can be aligned.

Proceed as follows.

• Park the appliance on a firm,

horizontal surface.

• Move the lever for raising the

cutters to the topmost recess.

• Turn the cutters so that they form

a right angle with the appliance.

• Measure the distance between the

outer left cutter edge (cutter left)

and the ground and the distance

between the outer right cutter

edge (cutter right) and the ground.

These two measurements should

be equal. If they are not, continue

with the next step.

• Loosen (do not remove) the

hexagon head bolt (1) from the

right mounting plate on the

cutters.

• Turn the adjusting segment (2)

to align the cutters until the two

measurements described above

are equal.

•

Retighten the hexagon head bolt

(1) when the alignment is

satisfactory.

Aligning front and rear

Fig 27

The front section of the cutters is fitted

with a holding device (2) that can be

adjusted to align the cutters’ front and

rear sections. The cutters’ front

section should be 3–6 mm lower than

their rear section. If necessary, align

the cutters as follows.

• Park the appliance on a firm,

horizontal surface, move the lever

for raising the cutters into the

topmost recess (max position),

and turn the cutters nearest to the

ejector so that they are parallel to

the appliance.

8

Page 13

English Operating instructions

• Measure the distance between the

cutters’ front edge and the ground

and between the cutter’s rear edge

and the ground. The measured

distance from the front edge

should be 3–6 mm lower than the

distance from the rear edge. If this

is not the case, continue with the

next step.

• Loosen the two locknuts (3),

if installed.

Steadily tighten the nuts (1) to

raise the front side of the cutters;

steadily loosen the nuts (1) to

lower the front side of the cutters.

• When the sides are correctly

aligned, retighten the locknuts (3),

if installed.

Note!

You must make sure that the

hanger (4) is fully engaged to the stop

in the cutters’ pick-up hook.

Servicing

Observe the maintenance regulations

in the engine handbook. At the end of

the season a specialised garage must

inspect and service the appliance.

Caution!

Environmental hazard from engine

oil

After changing the oil, give unwanted

oil to an authorised disposal site or

company.

Environmental hazard from batteries

Used batteries do not belong in

household waste. Give unwanted

batteries to your dealer or a disposal

company. Remove the batteries before

the appliance is scrapped.

After 5 operating hours

• First engine oil change: see the

engine handbook for further

intervals.

• Quick oil drain (Fig 22) (option):

this is used for draining off oil.

Every 10 operating hours

• Clean or replace the air filter

(see engine handbook).

• Apply grease type 251H EP

through the nipples to lubricate

all cutter shafts, tension pulleys,

and tension pulley receivers.

This work must be performed at

a specialised garage.

• Apply grease type 251H EP

through the nipples to lubricate

the front wheels’ bearings and

axles.

Every 25 operating hours

• Apply grease type 251H EP

through the nipples to lubricate

the cutters’ front wheels.

Every 50 operating hours

• A specialised garage must remove

soiling and grass residue from the

drive gears.

Every 2 months

• Pressurise the front tyres to

approx. 2.3 bar and the rear tyres

to approx. 0.8 bar. See also the

manufacturer’s recommendation

on the tyre walls.

• For battery type 2 only:

Fill the battery cells with distilled

water until the level reaches 1 cm

below the filling aperture.

When needed

Cleaning the battery

Clean the battery at regular intervals.

Keep the battery terminals and cables

clean. Grease the battery terminals

with a little vaseline.

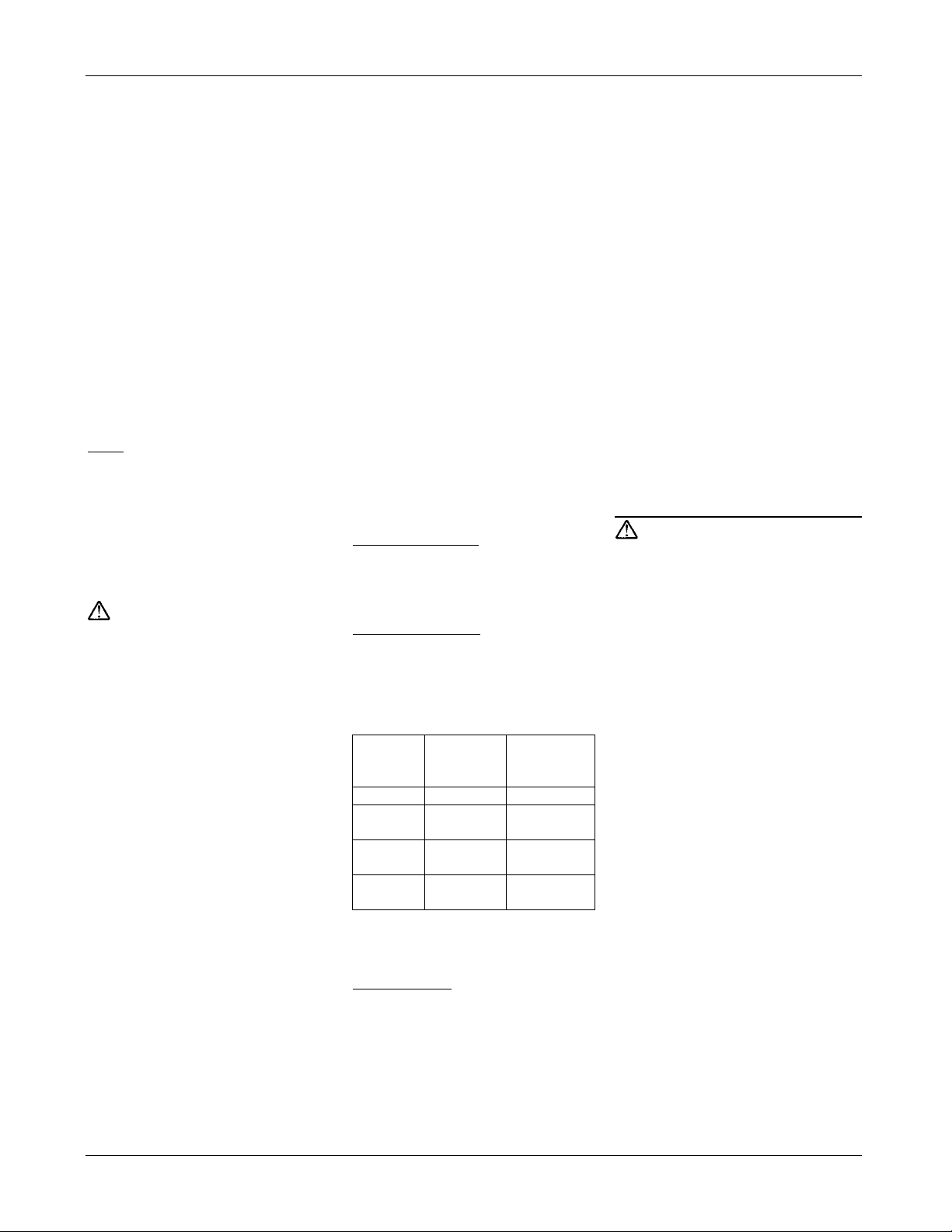

Charging the battery

Use a voltmeter to check the battery

voltage. When the voltage is lower

than 12.6 V (dc), the battery must be

charged in accordance with the table

(max charging current 6 A at 12 V).

Voltmeter

reading

Battery’s

charged

state

Requisite

charging time

12.7 V 100 % -

12.4 V 75 % approx.

90 min

12.2 V 50 % approx.

180 min

12.0 V 25 % approx.

280 min

Note! Observe the information in the

operating instructions for your battery

charger

Replacing fuses

• Replace defect fuses with fuses of

equal ratings only.

Once a season

• Lubricate the steering gear teeth

with a multipurpose grease.

• Lubricate the steering assembly’s

joints with a few drops of light

oil.

• Lubricate all rotating and bearing

sites (control levers, cutter height

adjuster, etc.) with a few drops of

light oil.

• Clean the spark plug and adjust

the electrode gap or replace the

spark plug (see engine handbook).

• The cutters must be sharpened or

replaced at a specialised garage.

Take the appliance to a specialised

garage for inspection and maintenance

once a season. Observe also the

instructions in the engine handbook

for engine maintenance.

Storing

Caution!

Material damage to the appliance

Keep the appliance only in clean and

dry rooms when the engine is cold.

For longer periods of inactivity,

protect the vehicle in all events against

rust, e.g. in winter. At the end of the

season or when the vehicle will not be

used for longer than a month:

• clean the appliance and

accessories,

• to protect metal parts from rust,

wipe them all down with an oiled

cloth or apply an oil spray,

• charge the battery,

• before winterising the appliance,

remove and charge the battery and

store this in a cool, dry place

(protected against frost); recharge

the battery every four to six

weeks and before installing it in

the appliance,

• drain off fuel (outdoors only) and

put the engine out of operation as

described in the engine handbook,

• lubricate the appliance adequately

at all points,

pressurise the tyres to the

•

respective values,

• keep the appliance in a clean, dry

room.

9

Page 14

English Operating instructions

Warranty

The warranty rules issued by our

company or the importer apply to

every country.

As part of the warranty, we remedy

malfunctions on your vehicle free of

charge provided that this malfunction

is caused by a material or

manufacturing defect. In the event of

a warranty claim, please turn to your

dealer or the nearest branch office.

Information on the

engine

The manufacturer of the engine is

liable for all engine-related problems

with respect to output power, power

measurement, specifications,

warranties, and service. More detailed

information can be found in the

owner / operator handbook provided

separately by the engine manufacturer.

Assistance with

malfunctions

Danger!

Accidentally starting the engine can

cause injury.

Protect yourself from injury, above all

when working on the vehicle.

• Switch off the engine.

• Engage the parking / locking

• Take out the ignition key.

• Wait until all moving parts have

• Disconnect the spark plug terminals

Malfunctions when your appliance is

operating often have simple causes

that you should know and be able to

(partially) eliminate yourself. In cases

of doubt your specialised garage will

be pleased to assist you further.

Troubleshooting

Problem Possible cause(s) Remedy

Engine does not start Safety lock system activated

Battery not connected correctly

Depleted or low battery

Fuse has tripped

Starter turns, engine

does not start

Smoke from engine Too much engine oil in the engine or engine

Strong vibrations

Choke and accelerator lever at wrong

positions

No fuel supplied to the carburettor

Defect or soiled spark plug

No spark

defect

Damaged cutter shaft or defect cutters Immediately switch OFF the appliance. Defect parts

To start the engine sit on the driver’s seat, move

both drive control levers into the outer Neutral

recesses, engage the locking brake, and switch OFF

the PTO switch.

Connect the black cable to the (–) terminal and the

red cable to the (+) terminal on the battery.

Charge the battery.

Replace the fuse. If the fuse trips repeatedly look for

the cause (in most cases a short circuit).

See the section “Starting the engine”.

Petrol tank empty. Refill.

Check the spark plug (see engine handbook).

Ignition must be checked at a specialised garage.

Immediately switch OFF the appliance.

Check the engine oil level.

The engine must be checked at a specialised garage.

must be replaced at a specialised garage.

brake.

come to a complete stop and the

engine has cooled down.

on the engine so that it cannot start

by accident.

Cutters do not eject

grass, or cut ragged

Low engine speed or too high drive speed Raise the engine speed or lower the drive speed.

10

Page 15

07'3URGXFWV$NW LHQJHVHOOVFKDI W

,QGXVWULHVWUDH

'6DDUE UFNHQ

*HUPDQ\

(

MTD Handelsgesellschaft mbH

Welser Straße 122

4614 Marchtrenk

( 07 24 26 05 55

07 24 26 05 54

A. Verbeke NV

Industriepark Nord

Tavernierlaan 1

8700 Tielt

( 0 51 40 24 41

0 51 40 37 75

MTD Motorgeräte GmbH

Industriestraße 9–11

73054 Eislingen / Fils

( 0 71 61 85 05 0

0 71 61 85 05 70

MTD Denmark ApS

Messingvej 22C

8900 Randers

( 87 11 91 00

87 11 96 00

MTD International France

B.P. 453 Saint-Etienne du

Rouvray

76806 Cedex

( 02 32 91 94 32

02 32 91 94 36

E.P.Barrus LTD

Launton Road

OX6 0UR Bicester, Oxfordshire

( 0 18 69 36 36 36

0 18 69 36 36 20

MTD Hungária Kft

Dózsa György út 1

8248 Nemesvámos

( 06 88 51 55 00

06 88 50 55 20

MTD Trädgårdsmaskiner

Sätunavägen 3

52141 Falköping

( 0 51 51 71 00

0 51 57 11 41 4

MTD Schweiz AG

Allmendstraße 14

5612 Villmergen

( 05 66 18 46 00

05 66 18 46 09

MTD Poland sp. z o.o.

UL. Ogrodnicza 1

84-252 Orle

( 058 57 20 701

058 57 20 699

© 2005 MTD Products AG

Loading...

Loading...