Page 1

Page 2

SAFETY INSTRUCTIONS

This symbol is used to coil your attention to instructions concerning your personal

safety, Be sure to observe and follow these instructions.

Disengage all clutches and shift into neutralbefore

starting the engine.

Dis engage power to any attachments and

stop engine before leaving operator's seat or

making any repairs or adjustments.

Know the controls and how to stop quicklyREAD

THE OPERATOR'S MANUAL.

Do not allow children or adults to operate

the equipment without proper instructions.

Clear work area of objects which might be

picked up by the mower and thrown.

Disengage power to any attachment when

transporting or not in use.

Do not carry passengers. Keep children

and pets a safe distance away.

power take-off, shifting into neutral, settingthe

parking brake, stopping the engine and

removing ignition key when leaving machine

unattended.

to prevent tipping or los s of control.

Watch out for traffic when crossing or nearroadways.

When u~ing any attachments, never direct

discharge of material toward bystanders nor

allow anyone near the machine while in

operation.

Handle gasoline with care -it is highly

flammable: A. Use approved gasoline container.

B. Never remove the fuel tank cap or fill the

fuel tank when the engine is running, is hot, or

fill the fuel tank indoors. Als 0, do not smoke

when working around inflammable fuel. Wipe

up spilled gasoline. C. Replace gasoline cap

securely... Open doors if engine is in a

garage -exhaust gasses are dangerous.

Use gasoline' only as a fuel, and never asa

cleaner.

Keep machine in good operating condition

and keep safety devices in place. Use guards

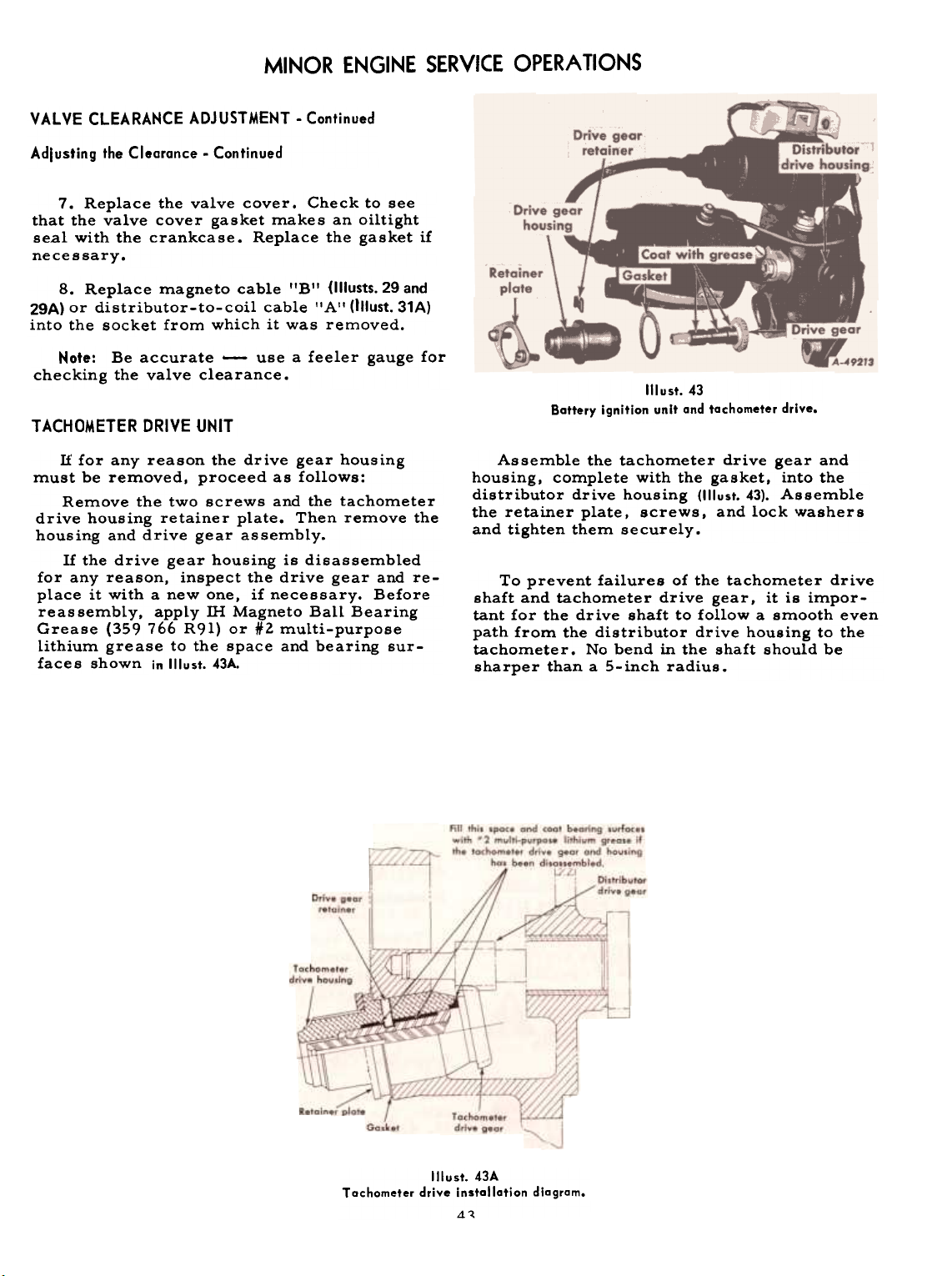

as instructed in Operator1s Manual.Take precautions, such as disengaging

It is recommended that the machine be

stopped and inspected for damage after striking

a foreign object and that any damage be repaired before restarting and operating themachine.Reduce speed on slopes and in sharp turns

Stay alert for holes in terrain and other

hidden hazards. Hydraulic fluid es caping under pres sure

can have enough force to penetrate the skin.

Don't stop or start suddenly when going

uphill or downhill.

Use care when pulling loads or using heavy

equipment: A. Use only approved drawbar

hitch points. B. Limit loads to those you can

safely control. C. Don't turn too sharp, and

use care when backing. D. Use counterweight

or wheel weights when suggested in Operator's

Manual.

Hydraulic fluid may also infect a minor cut or

opening in the skin. If injured by escaping fluid,see

a doctor at once. Serious infection or reaction can result if medical treatment is not

given immediately. Make sure all connections

are tight and that hoses and lines are in good

condition before applying pressure to the

system. Relieve all pressure before disconnecting the lines or performing other work

on the hydraulic system. To find a leak under

pressure use a small piece of cardboard orwood.

Never use hands.

Page 3

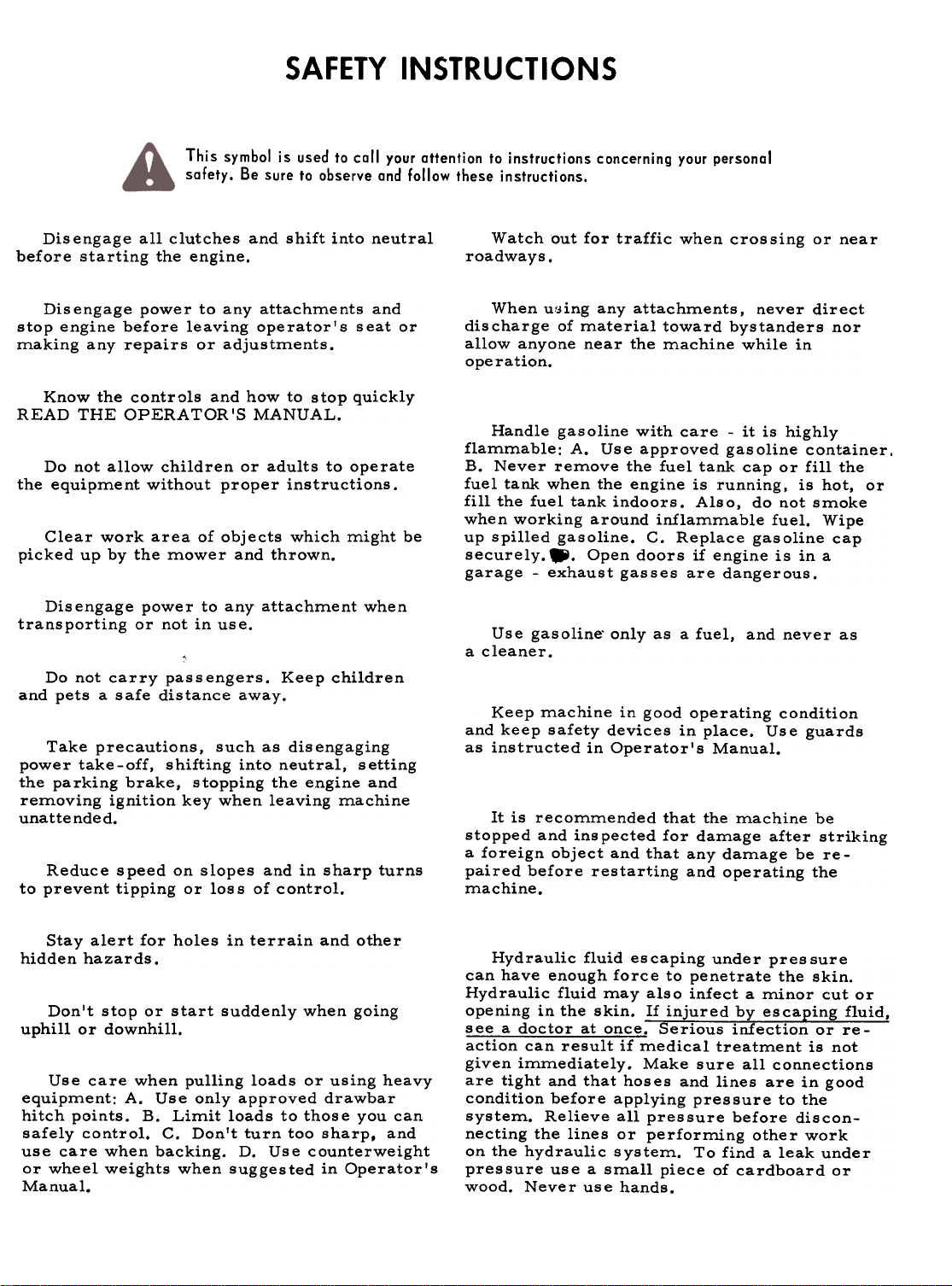

Ilrust.2

International Cub La-Bay Tractor.

Assembled in this manual are operation,

lubrication, and maintenance instructions for

International Cub and Cub Lo-Boy Tractors.

This material has been prepared in detail in

the hope that it will help you to better under-

stand the correct care and efficient operation

of the tractor.

Your International Harvester dealer has

factory-trained servicemen, modern tools,

and IH service parts to assure you of satisfac-

tory tractor operation. To get the most out of

the t.ractor, and to assure economical opera-

tion and top performance, the tractor should

be inspected periodically by your International

Harvester dealer.

Depending upon your use of the tractor,

these inspections should be performed as

needed, or at least once a year, at which time

a tune-up or other necessary service work

should be performed. Proper pre-season

maintenance will assure you of minimum lost

time when your tractor is most needed.

Dealers are kept informed on the latest

methods of servicing tractors. They carry

stocks of IH parts, and are backed in every

case by the full facilitie s of a nearby

International Harve ster district office and

parts depot.

2

Page 4

INTRODUCTION

In order to provide a tractor equipped as

nearly as possible to suit each customer's

needs, a variety of extra equipment and acces-

sories is available. Refer to page 76.

Where operating and maintaining instruction on these items is required, it is included

in the instructions for operating or maintaining the tractor. Disregard the instructions

for equipment not on your tractor.

The illustrations in this manual are numbered to correspond with page s on which they

appear; for example. 'Ilusts. 3, 3A and 38, are an

page 3.

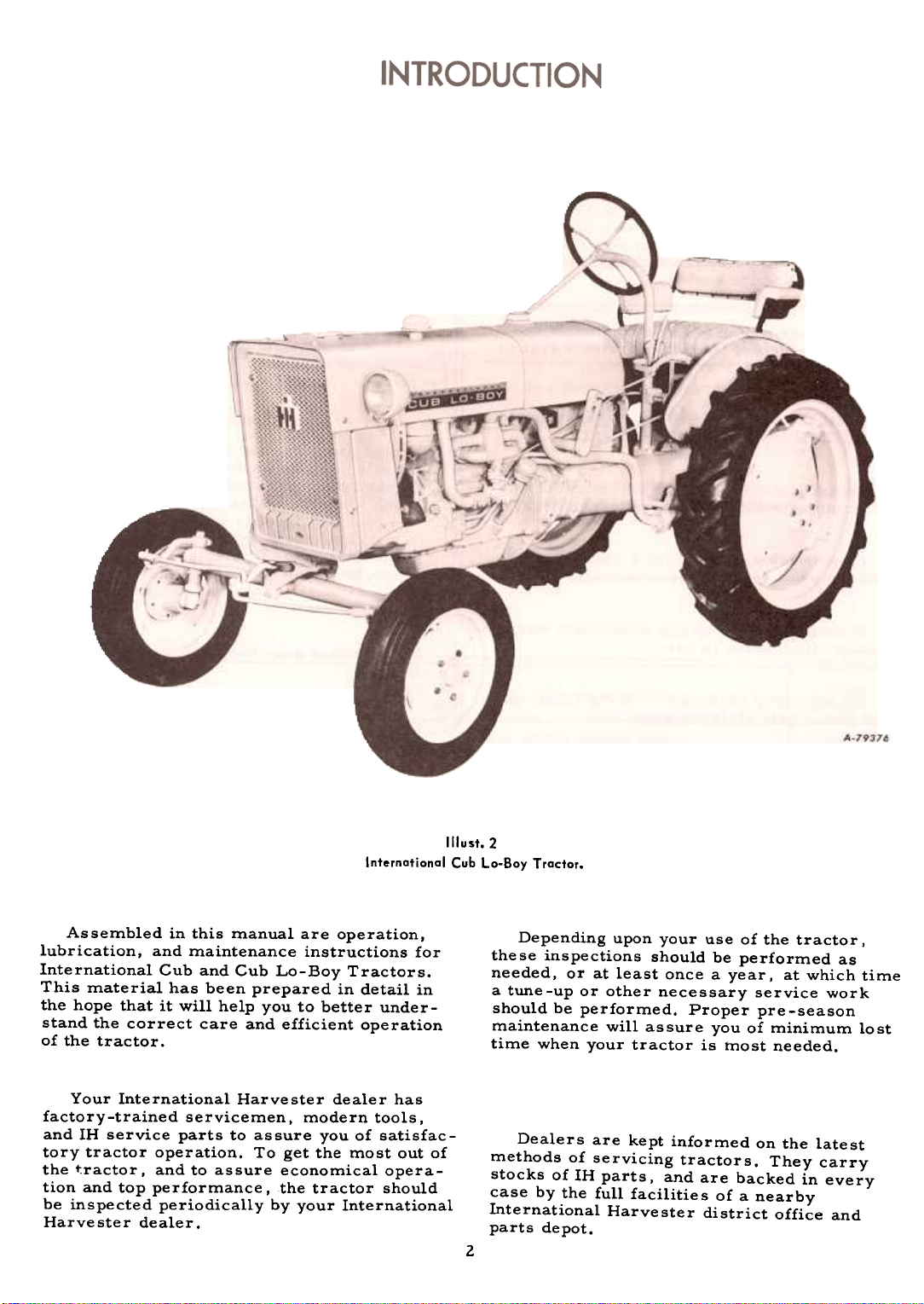

Throughout this manual the use of the terms

LEFT, RIGHT, FRONT, and REAR must be

understood to avoid confusion when following

instructions. LEFT and RIGHT indicate the

left and right sides of the tractor when facing

forward in the driver's seat. Reference to

FRONT indicates the radiator end of the tractor;

to REAR; the hitch end. See Illust. 3.

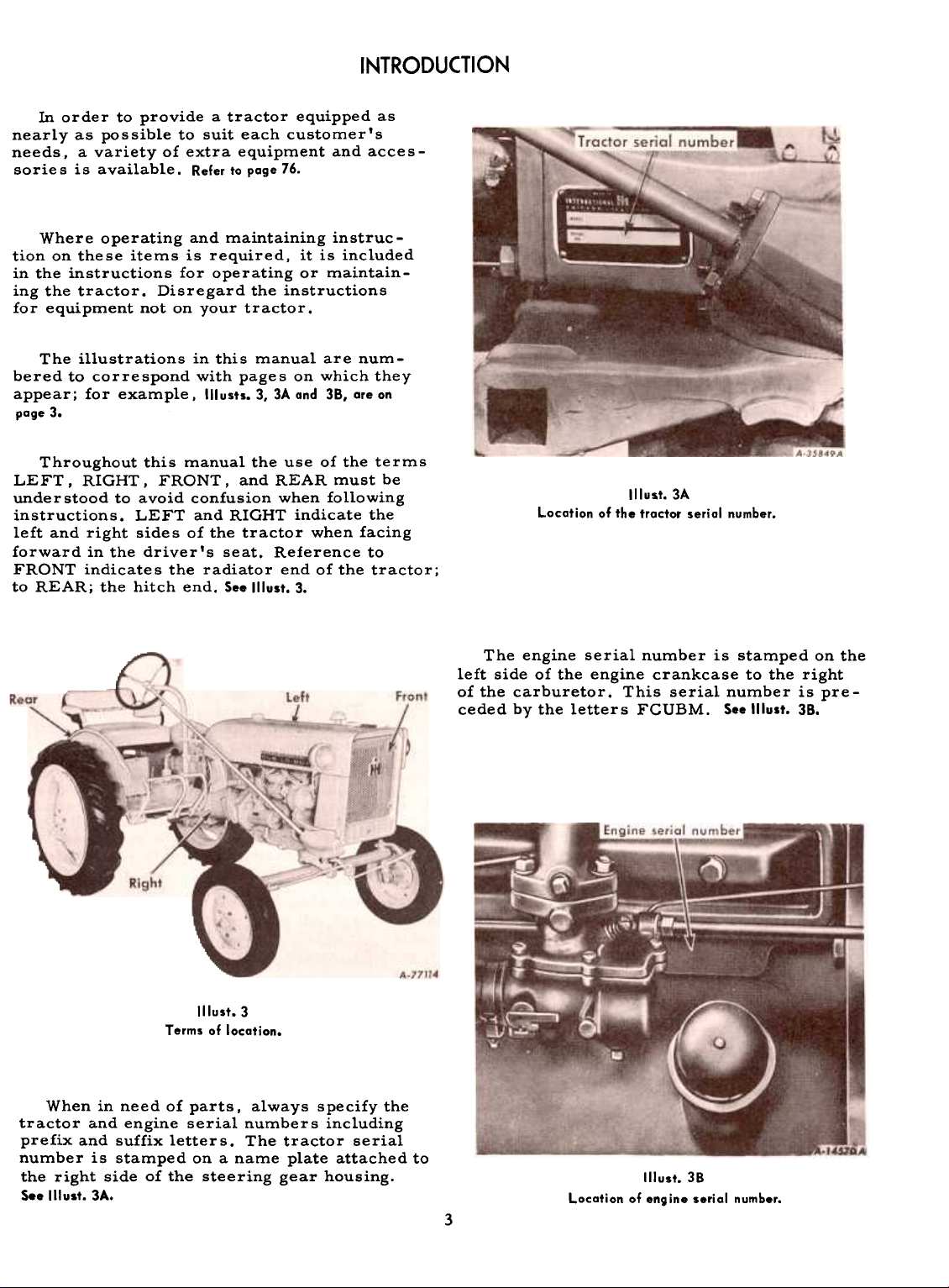

Illust.3A

Location of the troctor seriol number.

Illust.3

Terms of location.

When in need of parts. always specify the

tractor and engine serial numbers including

prefix and suffix letters. The tractor serial

number is stamped on a name plate attached to

the right side of the steering gear housing.

S.. Illust. 3A.

The engine serial number is stamped on the

left side of the engine crankcase to the right

of the carburetor. This serial number is preceded by the letters FGUBM. S..lllust. 38.

Illust. 38

Location of engine serial number.

3

Page 5

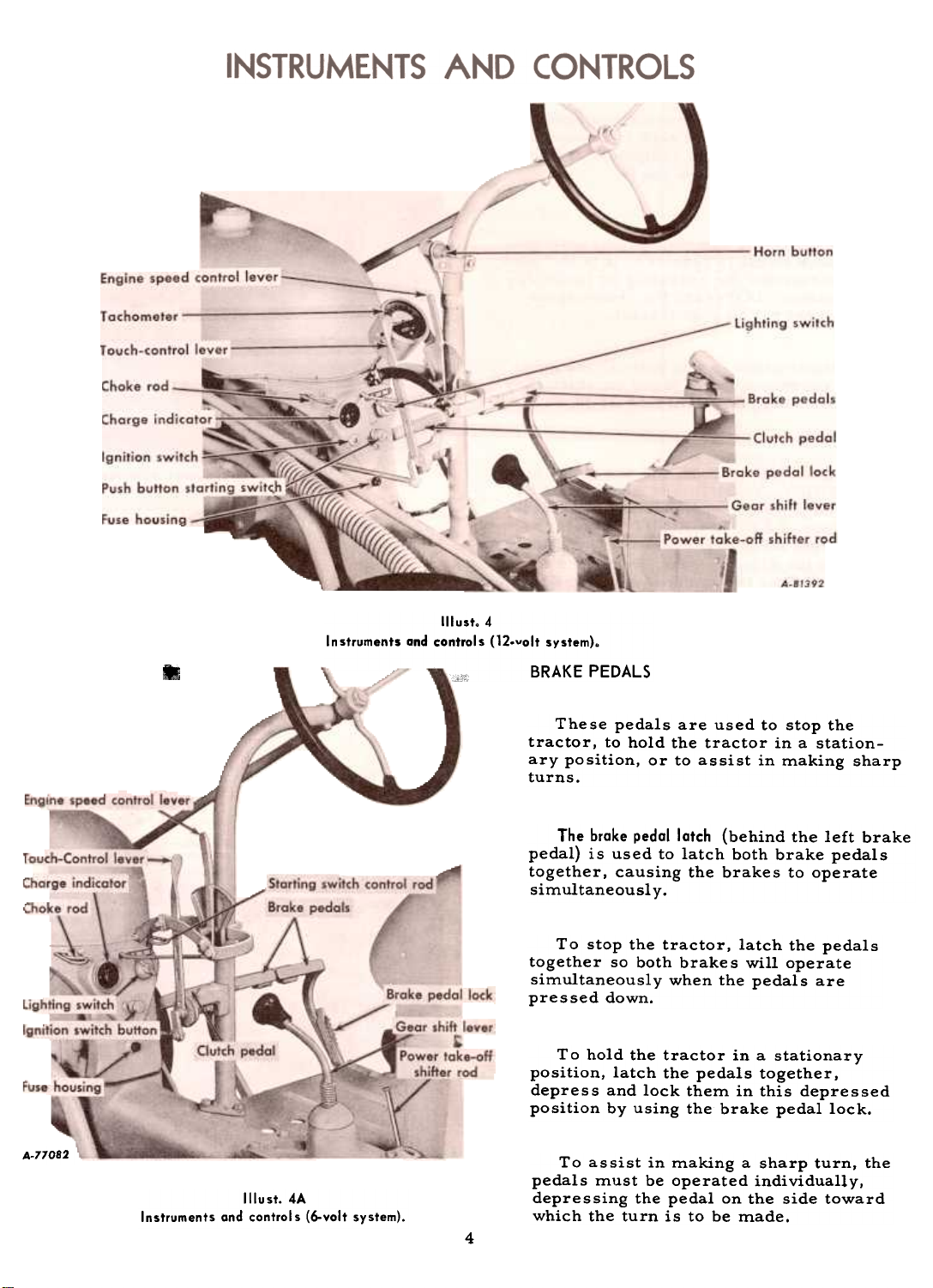

Illust.4

Instruments and controls (12.volt system).

-BRAKE PEDALS

These pedals are used to stop the

tractor, to hold the tractor in a stationary position, or to assist in making sharpturns.

The brake pedal latch (behind the left brake

pedal) is used to latch both brake pedals

together, causing the brakes to operate

simultaneously.

To stop the tractor, latch the pedals

together so both brakes will operate

simultaneously when the pedals are

pressed down.

To hold the tractor in a stationary

position, latch the pedals together,

depress and lock them in this depressed

position by using the brake pedal lock.

81

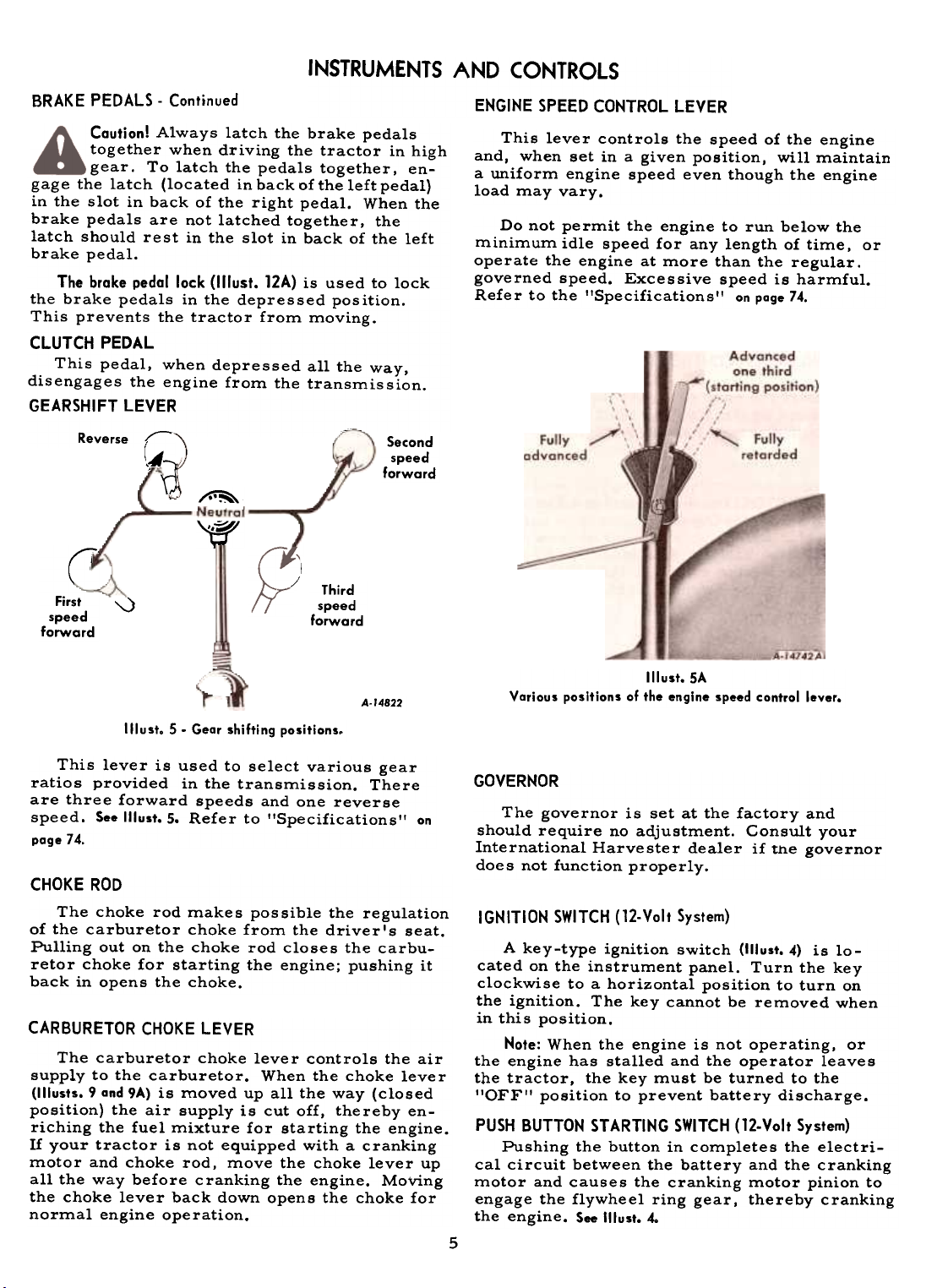

A-77082

Instruments and control s (6-volt system).

Illust.4A

To assist in making a sharp turn, the

pedals must be operated individually,

depressing the pedal on the side toward

which the turn is to be made.

4

Page 6

INSTRUMENTS AND CONTROLS

BRAKE PEDALS -Continued

Caution! Always latch the brake pedals

together when driving the tractor in high

gear. To latch the pedals together. engage the latch (located in back of the left pedal)

in the slot in back of the right pedal. When the

brake pedals are not latched together. the

latch should rest in the slot in back of the left

brake pedal.

The brake pedal lock (1IIust. 12A) is used to lock

the brake pedals in the depressed position.

This prevents the tractor from moving.

CLUTCH PEDAL

This pedal. when depressed all the way.

disengages the engine from the transmission.

GEARSHIFT LEVER

Reverse ~ -c

Second

speed

forward

~~

~

ENGINE SPEED CONTROL LEVER

This lever controls the speed of the engine

and, when set in a given position, will maintain

a uniform engine speed even though the engine

load may vary.

Do not permit the engine to run below the

minimum idle speed for any length of time. or

operate the engine at more than the regular.

governed speed. Excessive speed is harmful.

Refer to the "Specifications'! on poge 74.

r'

First

speed

forward

This lever is used to select various gear

ratios provided in the transmission. There

are three forward speeds and one reverse

speed. See Illust. 5. Refer to "Specifications" on

page 74.

'-..)

5. Gear shifting positions.

Third

speed

forward

A-14822

CHOKE ROD

The choke rod makes possible the regulation

of the carburetor choke from the driver's seat.

Pulling out on the choke rod closes the carbu-

retor choke for starting the engine; pushing it

back in opens the choke.

CARBURETOR CHOKE LEVER

The carburetor choke lever controls the air

supply to the carburetor. When the choke lever

(1IIusts. 9 and 9A) is moved up all the way (closed

position) the air supply is cut off, thereby enriching the fuel mixture for starting the engine.

If your tractor is not equipped with a cranking

motor and choke rod, move the choke lever up

all the way before cranking the engine. Moving

the choke lever back down opens the choke for

normal engine operation.

Illust. SA

Various positions of the engine speed control lever.

GOVERNOR

The governor is set at the factory and

should require no adjustment. Consult your

International Harvester dealer if the governor

does not function properly.

IGNITION SWITCH (12-Volt System)

A key-type ignition switch (1IIust. 4) is located on the instrument panel. Turn the key

clockwise to a horizontal position to turn on

the ignition. The key cannot be removed when

in this position.

Note: When the engine is not operating, or

the engine has stalled and the operator leaves

the tractor, the key must be turned to the

"OFF" position to prevent battery discharge.

PUSH BUTTON STARTING SWITCH (12-Volt System)

Pushing the button in completes the electri-

cal circuit between the battery and the cranking

motor and causes the cranking motor pinion toengage

the flywheel ring gear, thereby cranking

the engine. See Illust. 4.

5

~

'!Iust.

Page 7

INSTRUMENTS AND CONTROLS

IGNITION SWITCH BUTTON (6-Volt System)

This button (1IIust. 4A) closes and opens the

electrical circuit for operating and stopping

the engine. Pull the button out for operatingand

push it in to stop the engine.

Note: On tractors with battery ignition,

when the engine is not operating or the engine

has stalled and the operator leaves the tractor,

the ignition switch button must be pushed all

the way in, so that the switch is in the "OFF'!

position, to prevent battery discharge.

STARTING SWITCH CONTROL ROD (6-Volt System)

To start the engine, adjust the choke rod

and pullout on the starting switch control rod

as explained on poges 9 and 10. See Illust. 4A.

LIGHTING SWITCH (Tractors Equipped with Electric

Starting and Warning Light)

The switch has two positions; "OFF" and

"ON". Placing the switch in the ., ON" posi-

tion activates the warning light.

LIGHTING SWITCH (Tractors Equipped with Electric

Starting and Lightin g)

The switch has four positions: "OFF"

position; "D" position for dim headlights,

bright instrument lights, a red taillight, and

a warning light; "B" position for bright

headlights, instrument lights, a red taillight,

and a warning light; and "R'I position for

bright headlights, instrument lights, and a

white rear light. The red taillight should

always be used when traveling on the highway

at night or during times of poor visibility.

The white rear light is for field use only and

should not be used on the highway.

BELT PULLEY AND POWER TAKE-OFF SHIFTER ROD

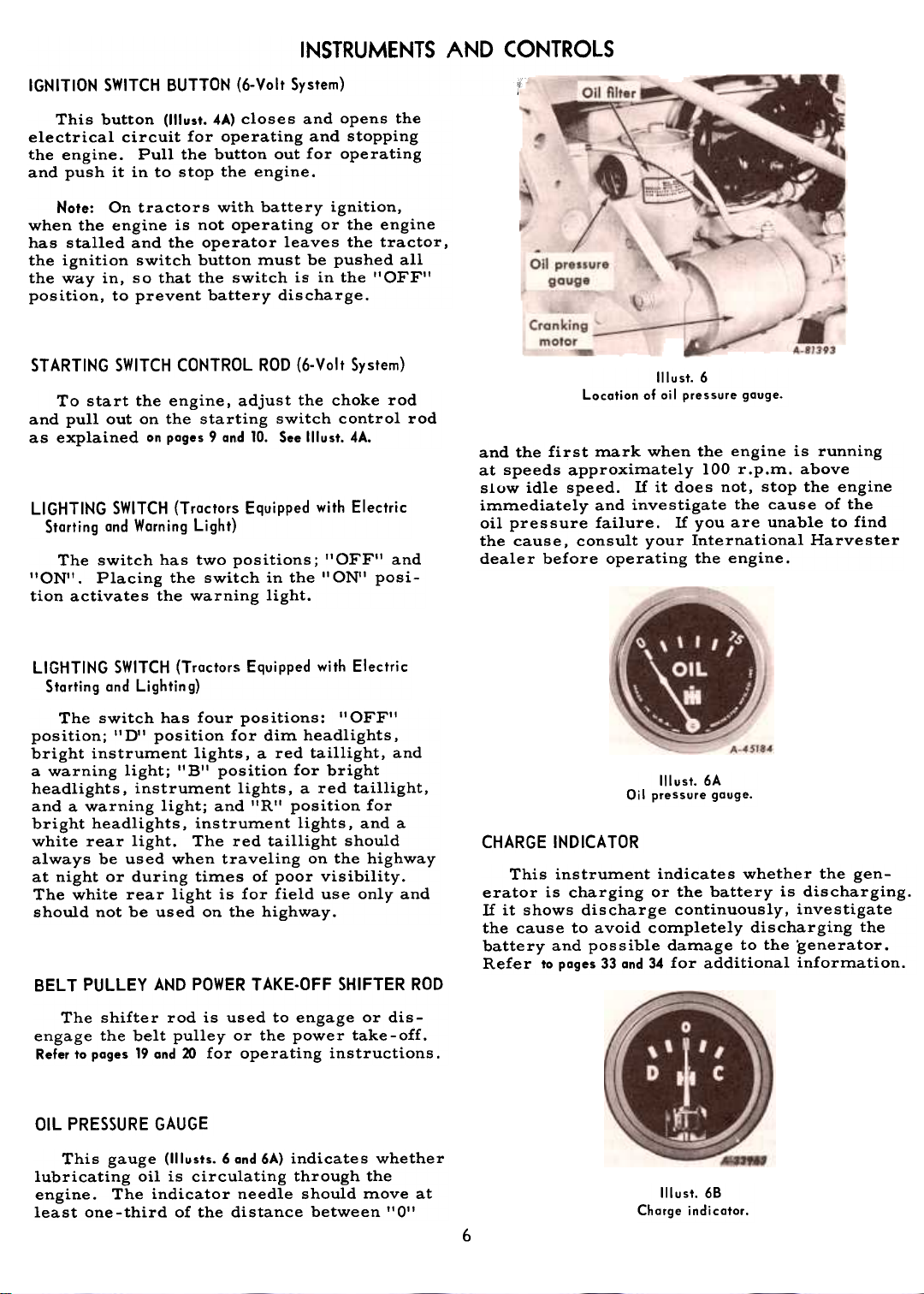

Location of 0; I pressure gauge.

Illust. 6

and the first mark when the engine is running

at speeds approximately 100 r.p.m. above

slow idle speed. If it does not, stop the engine

immediately and investigate the cause of the

oil pressure failure. If you are unable to find

the cause, consult your International Harvester

dealer before operating the engine.

Illust. 6A

Oil pressure gouge.

CHARGE INDICATOR

This instrument indicates whether the gen-

erator is charging or the battery is discharging.

If it shows discharge continuously, investigate

the cause to avoid completely discharging the

battery and possible damage to the .generator.

Refer to pages 33 and 34 for additional information.

The shifter rod is used to engage or dis-

engage the belt pulley or the power take-off.

Refer to pages 19 and 20 for operating instructions.

OIL PRESSURE GAUGE

This gauge (II lusts. 6 and 6A) indicates whether

lubricating oil is circulating through the

engine. The indicator needle should move at

least one-third of the distance between "0"

Illust. 68

Charge indicatar.

6

Page 8

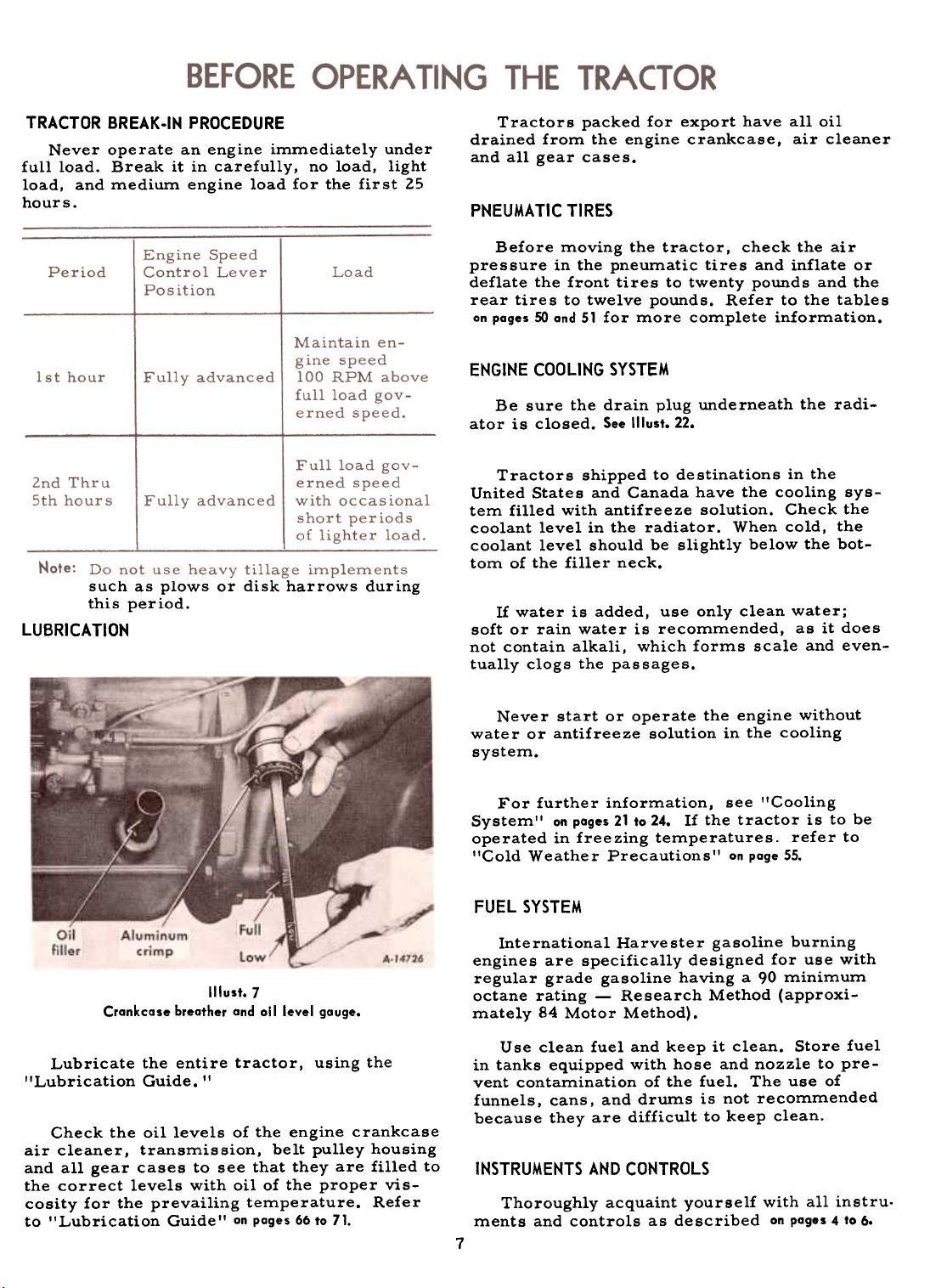

TRACTOR BREAK.IN PROCEDURE

Never operate an engine immediately under

full load. Break it in carefully, no load, light

load, and medium engine load for the first 25hours.

such as plows or disk harrows during

this period.

LUBRICA TICH

Tractors packed for export have all oil

drained from the engine crankcase, air cleaner

and all gear cases.

PNEUMATIC TIRES

Before moving the tractor, check the air

pressure in the pneumatic tires and inflate or

deflate the front tires to twenty pounds and the

rear tires to twelve pounds. Refer to the tables

on poges 50 ond 51 for more complete information.

ENGINE COOLING SYSTEM

Be sure the drain plug underneath the radi-

ator is closed. See Illust. 22.

Tractors shipped to destinations in the

United States and Canada have the cooling system filled with antifreeze solution. Check the

coolant level in the radiator. When cold, the

coolant level should be slightly below the bottom of the filler neck.

If water is added, use only clean water;

soft or rain water is recommended, as it does

not contain alkali, which forms scale and even-

tually clogs the passages.

Illust.7

Crankcase breather and all level gauge.

Lubricate the entire tractor, using the

"Lubrication Guide. II

Check the oil levels of the engine crankcase

air cleaner, transmission, belt pulley housing

and all gear cases to see that they are filled to

the correct levels with oil of the proper vis-

cosity for the prevailing temperature. Refer

to "Lubrication Guide" on poges 66 to 71.

Never start or operate the engine without

water or antifreeze solution in the cooling

system.

For further information, see "Cooling

System" on pages 21 to 24. If the tractor is to be

operated in freezing temperatures. refer to

"Cold Weather Precautions" on page 55.

FUEL SYSTEM

International Harvester gasoline burning

engines are specifically designed for use with

regular grade gasoline having a 90 minimum

octane rating -Research Method (approximately 84 Motor Method).

Use clean fuel and keep it clean. Store fuel

in tanks equipped with hose and nozzle to prevent contamination of the fuel. The use of

funnels, cans, and drums is not recommended

because they are difficult to keep clean.

INSTRUMENTS AND CONTROLS

Thoroughly acquaint yourself with all instru-

ments and controls as described on pages 4to 6.

7

Page 9

Air cleaner cap. Remove any dirt or chaff.

Air cleaner oil cup Remove, clean and refill. See the "Lubrication Guide. II

Lubrication points. See "Lubrication Guide. "

Cooling system. Check the level of the coolant in the radiator.

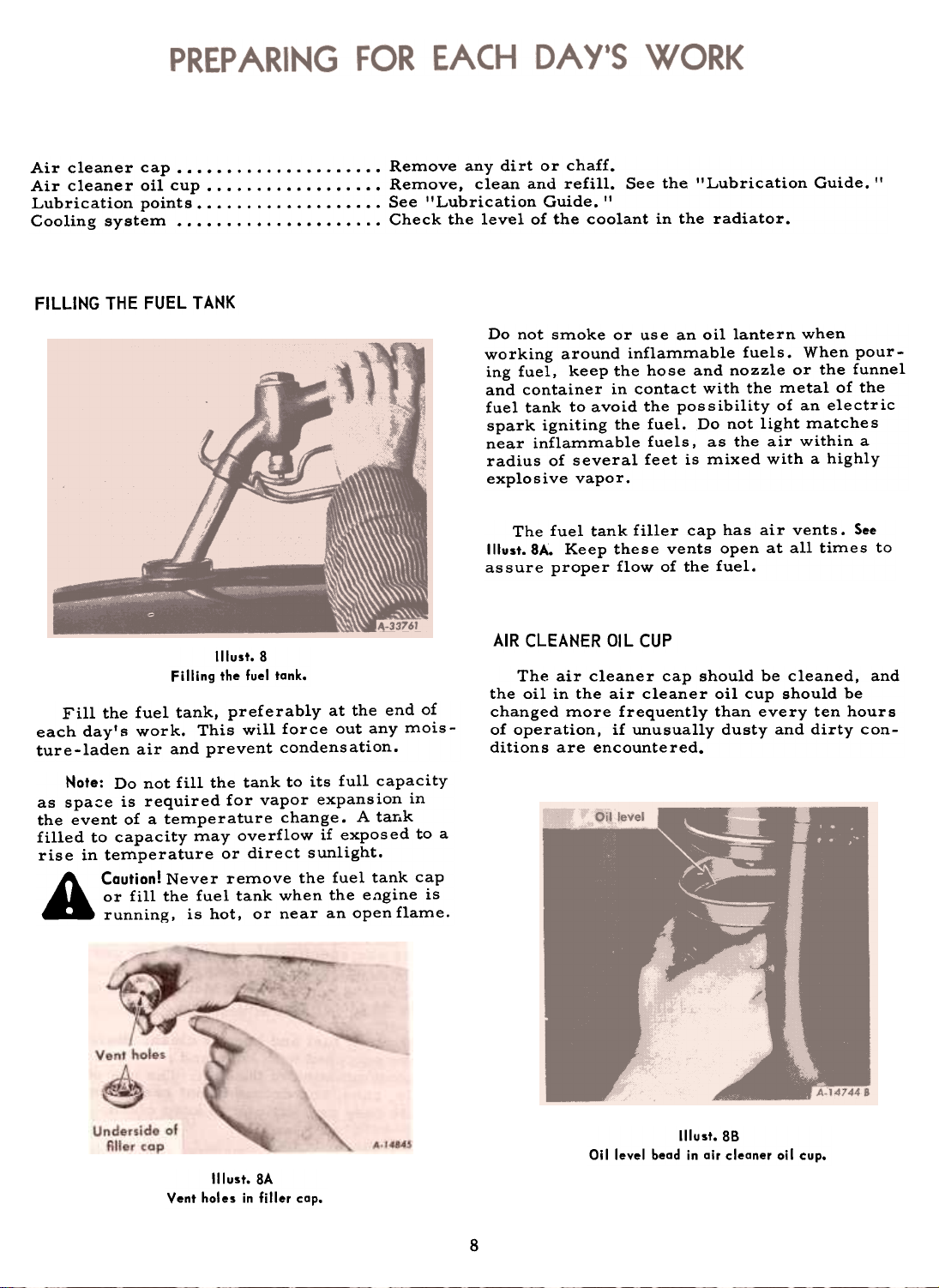

FILLING THE FUEL T AHK

Do not smoke or use an oil lantern when

working around inflammable fuels. When pour-

ing fuel, keep the hose and nozzle or the funnel

and container in contact with the metal of the

fuel tank to avoid the possibility of an electric

spark igniting the fuel. Do not light matches

near inflammable fuels, as the air within a

radius of several feet is mixed with a highly

explosive vapor.

The fuel tank filler cap has air vents. See

Illust. SA. Keep these vents open at all times to

assure proper flow of the fuel.

Illust.8

Filling the fuel tank.

Fill the fuel tank, preferably at the end of

each day's work. This will force out any moisture-laden air and prevent condensation.

Note: Do not fill the tank to its full capacity

as spa~e is required for vapor expansion in

the event of a temperature change. A tar.k

filled to capacity may overflow if exposed to a

rise in temperature or direct sunlight.

A Caution! Never remove the fuel tank cap

or fill the fuel tank when the e.'lgine is

running, is hot, or near an open flame.

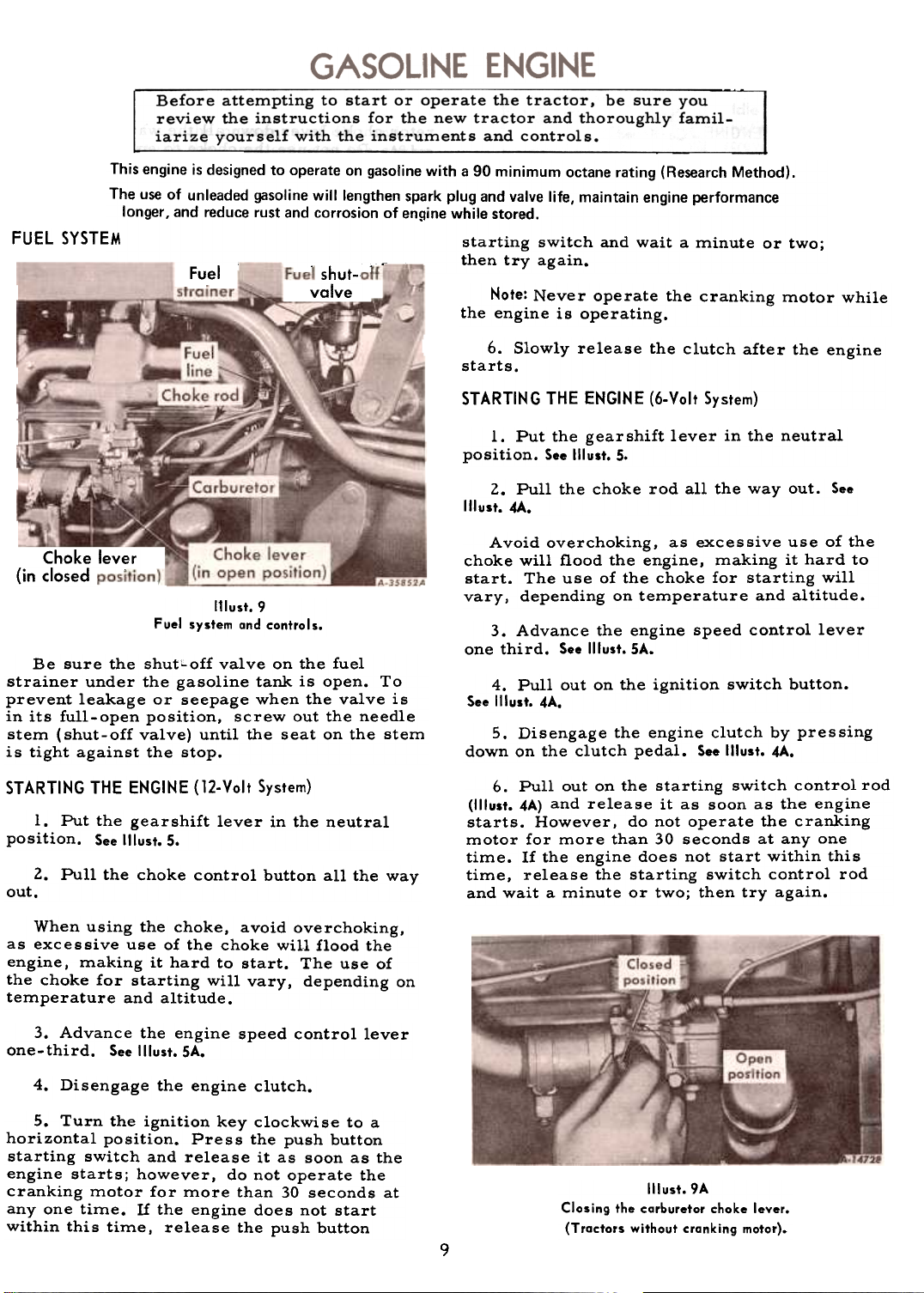

Illust. SA

Vent holes in filler cop.

AIR CLEANER OIL CUP

The air cleaner cap should be cleaned, and

the oil in the air cleaner oil cup should be

changed more frequently than every ten hours

of operation, if unusually dusty and dirty conditions are encountered.

Illust.88

Oil level bead in air cleaner oil cup.

8

~

Page 10

This engine is designed to operate on gasoline with a 90 minimum octane rating (Research Method).

The use of unleaded gasoline will lengthen spark plug and valve life, maintain engine performance

FUEL SYSTEM

Before attempting to start or operate the tractor, be sure you

review the instructions for the new tractor and thoroughly famil-

iarize yourself with the instruments and controls.

longer, and reduce rust and corrosion of engine while stored.

starting switch and wait a minute or two;

then try again.

Fuel

shut-r

valve

Note: Never operate the cranking motor while

the engine is operating.

6. Slowly release the clutch after the enginestarts.

STARTING THE ENGINE (6-Volt System)

1. Put the gear shift lever in the neutral

position. See Illust. 5.

2. Pull the choke rod all the way out. See

Illust. 4A.

Choke lever

(in closed I

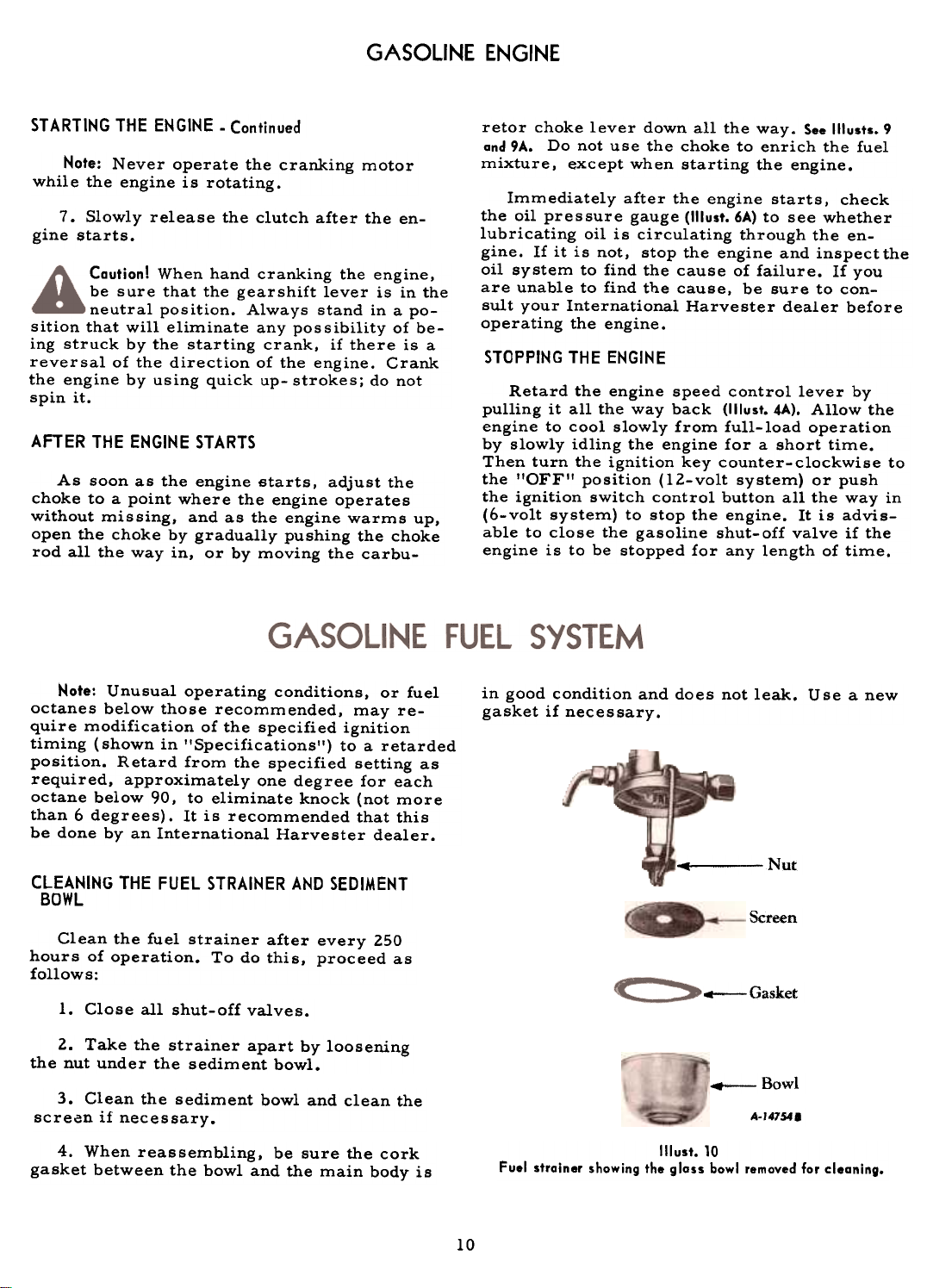

111ust.9

Fuel system and controls.

Be sure the shutLoff valve on the fuel

strainer under the gasoline tank is open. To

prevent leakage or seepage when the valve is

in its full-open position, screw out the needle

stem (shut-off valve) until the seat on the stem

is tight against the stop.

STARTING THE ENGINE (12-Volt System)

1. Put the gearshift lever in the neutral

position. See Illust. 5.

2. Pull the choke control button all the way

out.

When using the choke, avoid overchoking,

as excessive use of the choke will flood the

engine, making it hard to start. The use of

the choke for starting will vary, depending on

temperature and altitude.

3. Advance the engine speed control lever

one-third. See Illust. SA.

Avoid overchoking, as excessive use of the

choke will flood the engine, making it hard to

start. The use of the choke for starting will

vary, depending on temperature and altitude.

3. Advance the engine speed control lever

one third. See Illust. SA.

4. Pullout on the ignition switch button.

See Illust. 4A.

5. Disengage the engine clutch by pressing

down on the clutch pedal. See Illust. 4A.

6. Pullout on the starting switch control rod

(1IIust. 4A) and release it as soon as the engine

starts. However, do not operate the cranking

motor for more than 30 seconds at anyone

time. If the engine does not start within this

time, release the starting switch control rod

and wait a minute or two; then try again.

4. Disengage the engine clutch.

5. Turn the ignition key clockwise to a

horizontal position. Press the push button

starting switch and release it as soon as the

engine starts; however, do not operate the

cranking motor for more than 30 seconds at

anyone time. If the engine does not start

within this time, release the push button

Illust.9A

Closing the carburetor choke lever.

(Tractors without cranking motor).

9

Page 11

GASOLINE ENGINE

STARTING THE ENGINE -Continued

while the engine is rotating.

7. Slowly release the clutch after the en-

gine starts.

Caution! When hand cranking the engine,

be sure that the gearshift lever is in the

neutral position. Always stand in a po-

sition that will eliminate any possibility of being struck by the starting crank, if there is a

reversal of the direction of the engine. Crank

the engine by using quick up- strokes; do not

spin it.

AFTER THE ENGINE STARTS

As soon as the engine starts, adjust the

choke to a point where the engine operates

without missing, and as the engine warms up,

open the choke by gradually pushing the choke

rod all the way in, or by moving the carbu-

retor choke lever down all the way. See !llusts. 9

and 9A. Do not use the choke to enrich the fuel

mixture, except when starting the engine.Note: Never operate the cranking motor

Immediately after the engine starts, check

the oil pressure gauge (1IIust. 6A) to see whether

lubricating oil is circulating through the engine. If it is not, stop the engine and inspect the

oil system to find the cause of failure. If you

are unable to find the cause, be sure to con-

sult your International Harvester dealer before

operating the engine.

STOPPING THE ENGINE

Retard the engine speed control lever by

pulling it all the way back (1IIust.4A). Allow the

engine to cool slowly from full-load operation

by slowly idling the engine for a short time.

Then turn the ignition key counter-clockwise to

the !'OFF'! position (12-volt system) or push

the ignition switch control button all the way in

(6-volt system) to stop the engine. It is advisable to close the gasoline shut-off valve if the

engine is to be stopped for any length of time.

Note: Unusual operating conditions, or fuel

octanes below those recommended, may require modification of the specified ignition

timing (shown in "Specifications") to a retarded

position. Retard from the specified setting as

required, approximately one degree for each

octane below 90, to eliminate knock (not more

than 6 degrees). It is recommended that this

be done by an International Harvester dealer.

CLEANING THE FUEL STRAINER AND SEDIMENT

BOWL

Clean the fuel strainer after every 250

hours of operation. To do this, proceed asfollows:

Close all shut-off valves.

2. Take the strainer apart by loosening

the nut under the sediment bowl.

3. Clean the sediment bowl and clean the

screan if necessary.

4. When reassembling, be sure the cork

gasket between the bowl and the main body is

in good condition and does not leak. Use a new

gasket if necessary.

..Nut.

Screen

-Gasket

Bowl

4-147541

(1Iust.10

Fuel strainer showing the gloss bowl removed for cleaning.

1.

10

Page 12

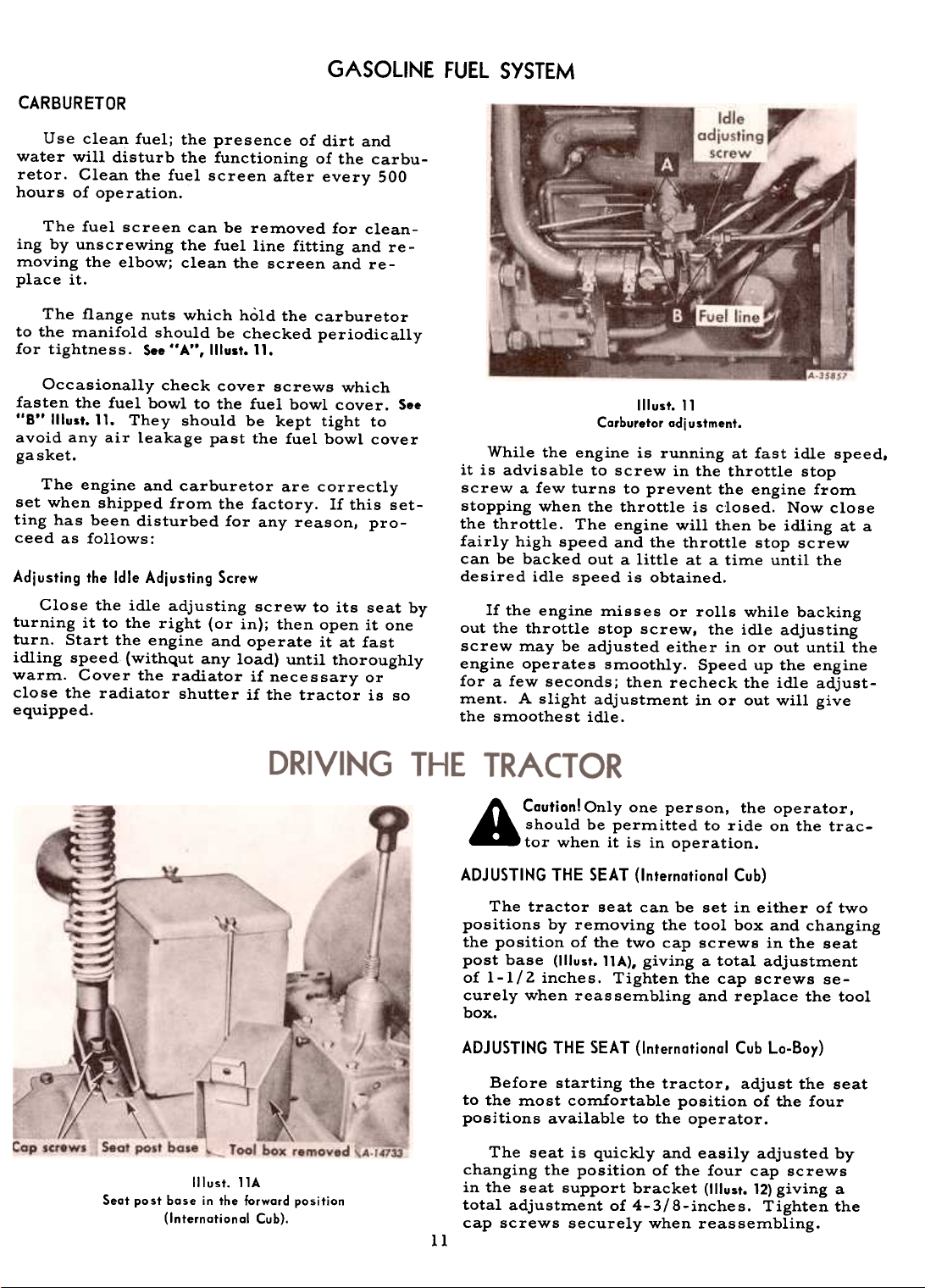

GASOLINE FUEL SYSTEM

CARBURETOR

Use clean fuel; the presence of dirt and

water will disturb the functioning of the carburetor. Clean the fuel screen after every 500

hour s of ope ration.

The fuel screen can be removed for cleaning by unscrewing the fuel line fitting and re-

moving the elbow; clean the screen and re-

place it.

The flange nuts which hold the carburetor

to the manifold should be checked periodically

for tightness. See "A", Illust. 11.

Occasionally check cover screws which

fasten the fuel bowl to the fuel bowl cover. S..

"B" 1!lust. 11. They should be kept tight to

avoid any air leakage past the fuel bowl cover

ga sket.

The engine and carburetor are correctly

set when shipped from the factory. If this set-

ting has been disturbed for any reason, pro-

ceed as follows:

Adjusting the Idle Adjusting Screw

Close the idle adjusting screw to its seat by

turning it to the right (or in); then open it one

turn. Start the engine and operate it at fast

idling speed (withqut any load) until thoroughly

warm. Cover the radiator if necessary or

close the radiator shutter if the tractor is so

equipped.

Illust. 11

Carburetor adjustment.

While the engine is running at fast idle speed.

it is advisable to screw in the throttle stop

screw a few turns to prevent the engine from

stopping when the throttle is closed. Now close

the throttle. The engine will then be idling at a

fairly high speed and the throttle stop screw

can be backed out a little at a time until the

desired idle speed is obtained.

If the engine misses or rolls while backing

out the throttle stop screw, the idle adjusting

screw may be adjusted either in or out until the

engine operates smoothly. Speed up the engine

for a few seconds; then recheck the idle adjustment. A slight adjustment in or out will give

the smoothest idle.

ADJUSTING

11

Illust. llA

Seat post base in the forward position

(Internotional Cub).

A CautionlOnlY one person, the operator,

should be permitted to ride on the tractor when it is in operation.

THE SEAT (International Cub)

The tractor seat can be set in either of two

positions by removing the tool box and changing

the position of the two cap screws in the seat

post base (1IIust. llA). giving a total adjustment

of 1-1/2 inches. Tighten the cap screws se-

curely when reas sembling and replace the tool

box.

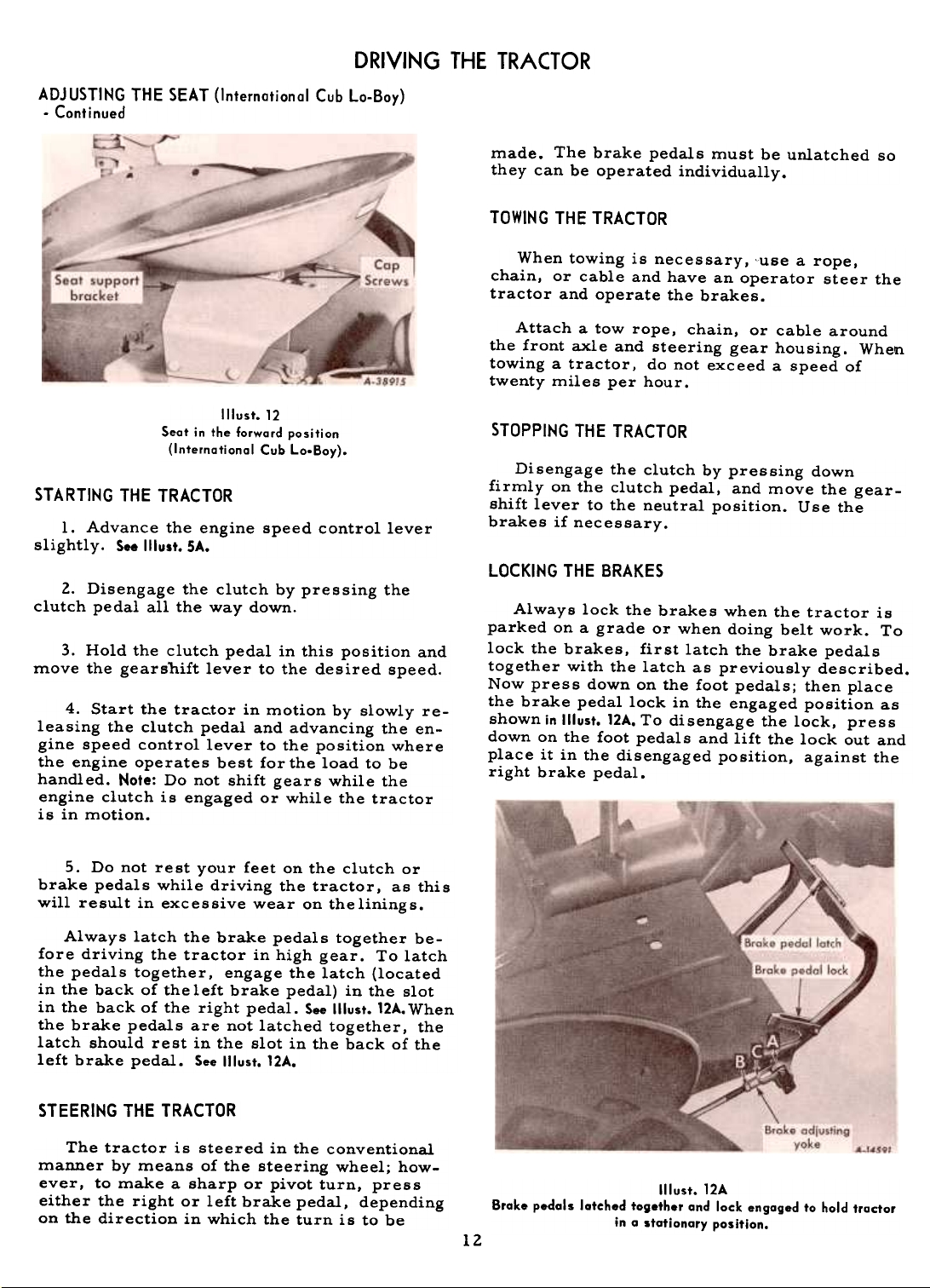

ADJUSTING THE SEAT (International Cub La-Boy)

Before starting the tractor, adjust the seat

to the most comfortable position of the fourpositions

available to the operator.

The seat is quickly and easily adjusted by

changing the position of the four cap screws

in the seat support bracket (1IIust. 12) giving a

total adjustment of 4-3/8-inches. Tighten the

cap screws securely when reassembling.

Page 13

DRIVING THE TRACTOR

ADJUSTING THE SEAT (International Cub Lo-Boy)

-Continued

made. The brake pedals must be unlatched so

they can be operated individually.

TOWING THE TRACTOR

When towing is necessary, cuse a rope,

chain, or cable and have an operator steer the

tractor and operate the brakes.

Attach a tow rope, chain, or cable around

the front axle and steering gear housing. When

towing a tractor, do not exc eed a speed of

twenty miles per hour.

Seat in the forward position

Illust.12

(International Cub Lo-Bay).

STARTING THE TRACTOR

1. Advance the engine speed control lever

slightly. See Illust. SA.

2. Disengage the clutch by pressing the

clutch pedal all the way down.

3. Hold the clutch pedal in this position and

move the gearshift lever to the desired speed.

4. Start the trac.tor in motion by slowly releasing the clutch pedal and advancing the engine speed control lever to the position where

the engine operates best for the load to be

handled. Note: Do not shift gears while the

engine clutch is engaged or while the tractor

is in motion.

50 Do not rest your feet on the clutch or

brake pedals while driving the tractor, as this

will result in excessive wear on theliningso

STOPPING THE TRACTOR

Disengage the clutch by pressing down

firmly on the clutch pedal, and move the gear-

shift lever to the neutral position. Use thebrakes

if necessary.

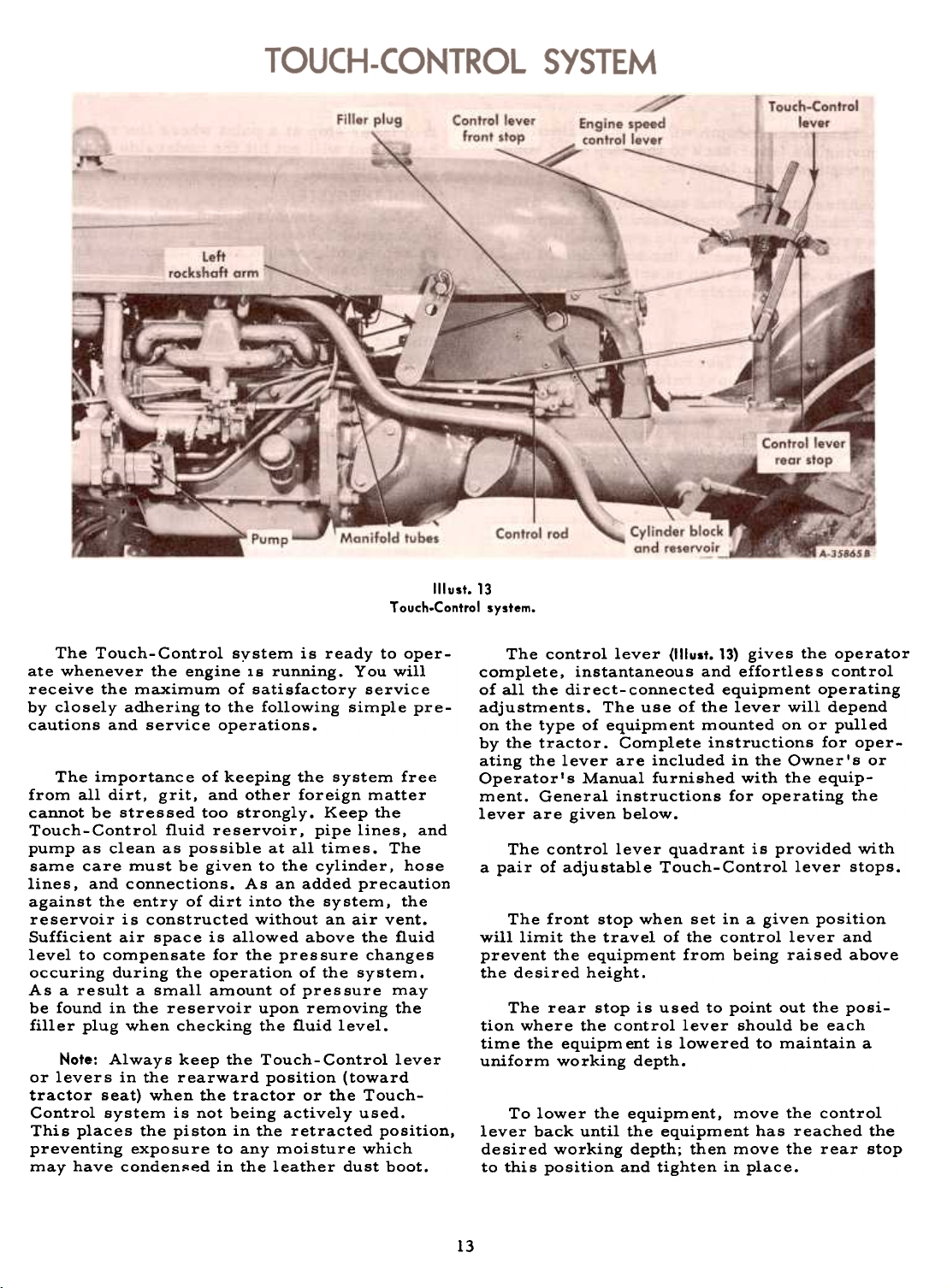

LOCKING THE BRAKES

Always lock the brakes when the tractor is

parked on a grade or when doing belt work. To

lock the brakes, first latch the brake pedals

together with the latch as previously described.

Now press down on the foot pedals; then place

the brake pedal lock in the engaged position as

shown in Illust. 12A. To disengage the lock, press

down on the foot pedals and lift the lock out and

place it in the disengaged position, against the

right brake pedal.

Always latch the brake pedals together be-

fore driving the tractor in high gear. To latch

the pedals together, engage the latch (located

in the back of the left brake pedal) in the slot

in the back of the right pedal. See Illust. 12A. When

the brake pedals are not latched together, the

latch should rest in the slot in the back of the

left brake pedal. See Illust. 12A.

STEERING THE TRACTOR

The tractor is steered in the conventional

manner by means of the steering wheel; how-

ever, to make a sharp or pivot turn, press

either the right or left brake pedal, depending

on the direction in which the turn is to be

Brake pedals latched together and lock engaged to hold tractor

Illust. 12A

in a stationary position.

12

Page 14

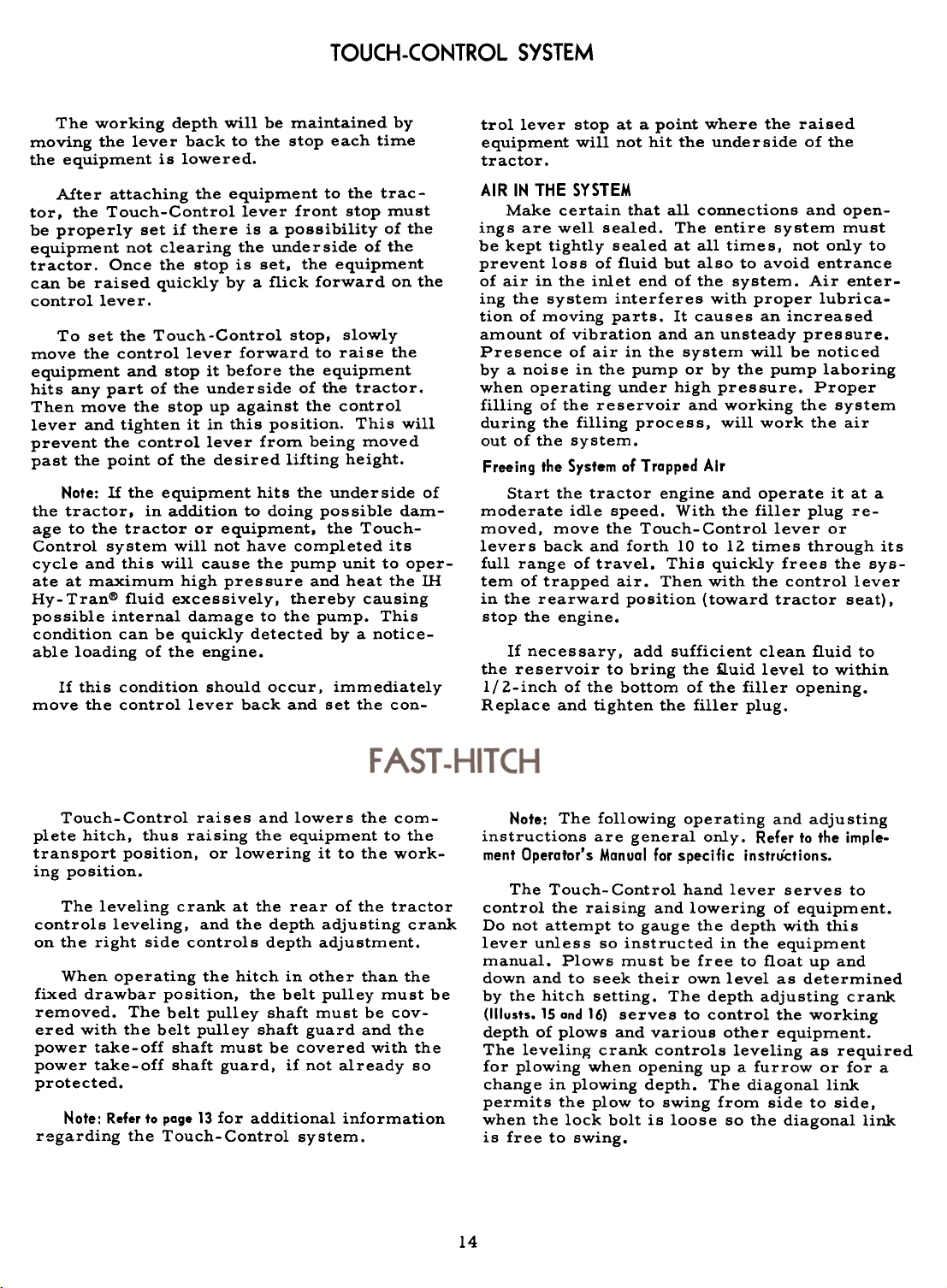

Illust.13

Touch.Control system.

The Touch-Control system is ready to operate whenever the engine is running. You will

receive the maximum of satisfactory service

by closely adhering to the following simple precautions and service operations.

The importance of keeping the system free

from all dirt, grit, and other foreign matter

cannot be stressed too strongly. Keep the

Touch-Control fluid reservoir, pipe lines, and

pump as clean as possible at all times. The

same care must be given to the cylinder, hose

lines, and connections. As an added precaution

against the entry of dirt into the system, the

reservoir is constructed without an air vent.

Sufficient air space is allowed above the fluid

level to compensate for the pressure changes

occuring during the operation of the system.

As a result a small amount of pressure may

be found in the reservoir upon removing the

filler plug when checking the fluid level.

Note: Always keep the Touch-Control lever

or levers in the rearward position (toward

tractor seat) when the tractor or the Touch-

Control system is not being actively used.

This places the piston in the retracted position,

preventing exposure to any moisture which

may have conden~ed in the leather dust boot.

The control lever ('Ilust. 13) gives the operator

complete, instantaneous and effortless control

of all the direct-connected equipment operating

adjustments. The use of the lever will depend

on the type of equipment mounted on or pulled

by the tractor. Complete instructions for operating the lever are included in the Owner's or

Operator's Manual furnished with the equip-

ment. General instructions for operating the

lever are given below.

The control lever quadrant is provided with

a pair of adjustable Touch-Control lever stops.

The front stop when set in a given position

will limit the travel of the control lever and

prevent the equipment from being raised above

the desired height.

The rear stop is used to point out the position where the control lever should be each

time the equipm ent is lowered to maintain a

uniform working depth.

To lower the equipment, move the control

lever back until the equipment has reached the

desired working depth; then move the rear stop

to this position and tighten in place.

13

Page 15

TOUCH-CONTROL SYSTEM

The working depth will be maintained by

moving the lever back to the stop each timethe

equipment is lowered.

After attaching the equipment to the tractor, the Touch-Control lever front stop must

be properly set if there is a possibility of the

equipment not clearing the underside of the

tractor. Once the stop is set, the equipment

can be raised quickly by a flick forward on the

control lever.

To set the Touch-Control stop. slowly

move the control lever forward to raise the

equipment and stop it before the equipment

hits any part of the underside of the tractor.

Then move the stop up against the control

lever and tighten it in this position. This will

prevent the control lever from being moved

past the point of the desired lifting height.

Note: If the equipment hits the underside of

the tractor. in addition to doing possible dam-

age to the tractor or equipment. the Touch-

Control system will not have completed its

cycle and this will cause the pump unit to operate at maximum high pressure and heat the IH

Hy- Tran@ fluid exces si vel y. thereby causing

possible internal damage to the pump. This

condition can be quickly detected by a notice-

able loading of the engine.

If this condition should occur. immediately

move the control lever back and set the con-

trol lever stop at a point where the raised

equipment will not hit the underside of the

tractor.

AIR IN THE SYSTEM

Make certain that all connections and openings are well sealed. The entire system must

be kept tightly sealed at all times, not only to

prevent loss of fluid but also to avoid entrance

of air in the inlet end of the system. Air entering the system interferes with proper lubrica-

tion of moving parts. It causes an increased

amount of vibration and an unsteady pressure.

Presence of air in the system will be noticed

by a noise in the pump or by the pump laboring

when operating under high pressure. Proper

filling of the reservoir and working the system

during the filling process, will work the air

out of the system.

Freeing the System of Trapped Air

Start the tractor engine and operate it at a

moderate idle speed. With the filler plug re-

moved, move the Touch-Control lever or

levers back and forth 10 to 12 times through its

full range of travel. This quickly frees the system of trapped air. Then with the control lever

in the rearward position (toward tractor seat),

stop the engine.

If necessary. add sufficient clean fluid tothe

reservoir to bring the iluid level to within

liZ-inch of the bottom of the filler opening.Replace

and tighten the filler plug.

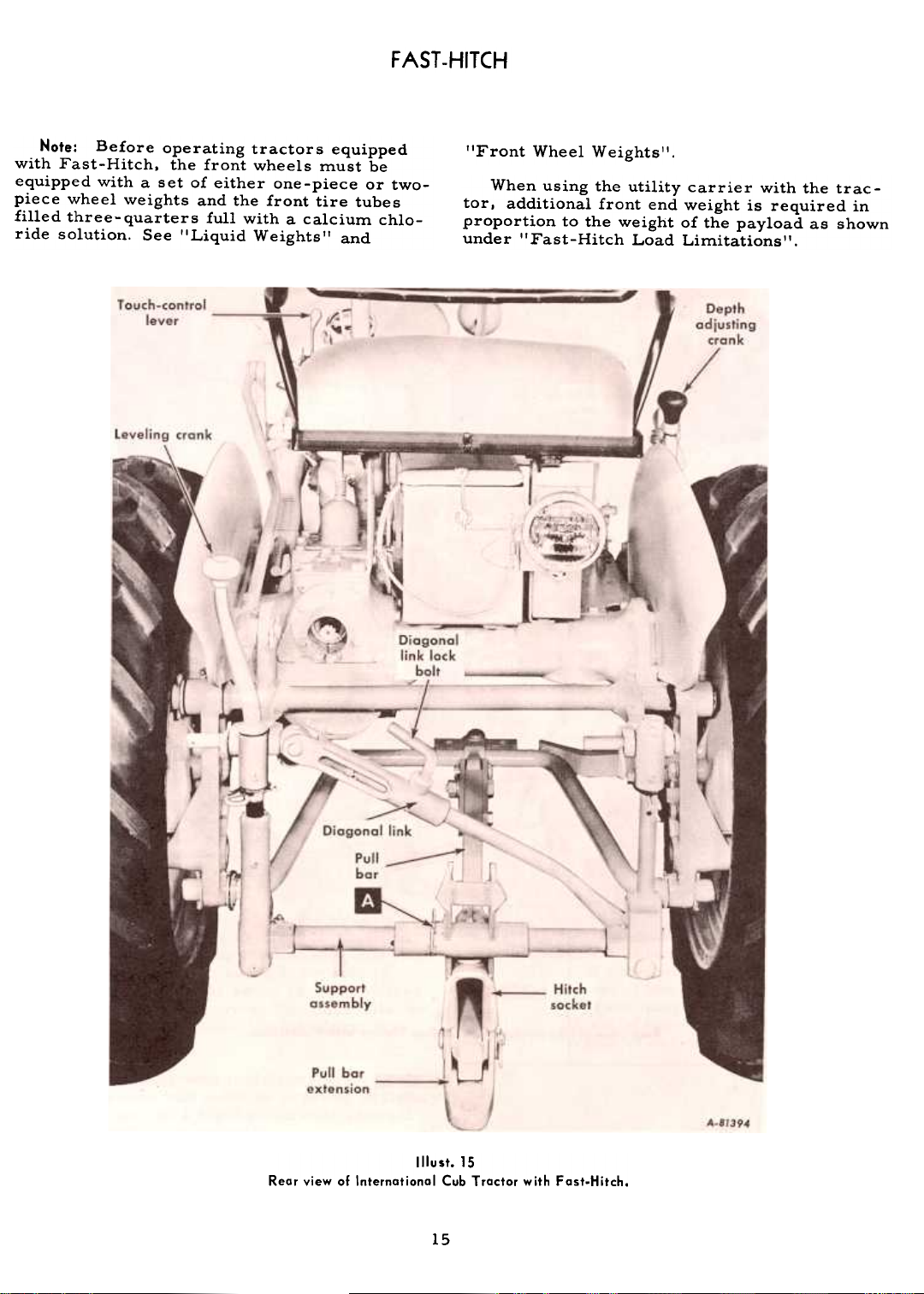

Touch-Control raises and lowers the com-plete

hitch, thus raising the equipment to the

instructions are general only. Refer to the imple-

transport position, or lowering it to the work-

ing position.

The leveling crank at the rear of the tractor

controls leveling. and the depth adjusting crank

on the right side controls depth adjustment.

When operating the hitch in other than thefixed

drawbar position, the belt pulley must be

removed. The belt pulley shaft must be covered with the belt pulley shaft guard and the

power take-off shaft must be covered with the

power take-off shaft guard, if not already soprotected.

Note: Refer to page 13 for additional information

r~garding the Touch-Control system.

Do not attempt to gauge the depth with this

lever unless so instructed in the equipment

manual. Plows must be free to float up and

down and to seek their own level as determined

The leveling crank controls leveling as required

permits the plow to swing from side to side,

is free to swing.

14

Note: The following operating and adjusting

ment Operator's Manual for specific instroctions.

The Touch- Control hand lever serves to

control the raising and lowering of equipment.

by the hitch setting. The depth adjusting crank

(1IIusts. 15 and 16) serves to control the working

depth of plows and various other equipment.

for plowing when opening up a furrow or for a

change in plowing depth. The diagonal link

when the lock bolt is loose so the diagonal link

Page 16

FAST-HITCH

Note: Before operating tractors equipped

with Fast-Hitch. the front wheels must be

equipped with a set of either one-piece or twopiece wheel weights and the front tire tubes

filled three-quarters full with a calcium chlo-

ride solution. See IlLiquid Weights" and

"Front Wheel Weights".

When using the utility carrier with the trac-

tor, additional front end weight is required in

proportion to the weight of the payload as shown

under "Fast-Hitch Load Limitations".

Illust. 15

Rear view af International Cub Troctor with Fost.Hitch.

15

Page 17

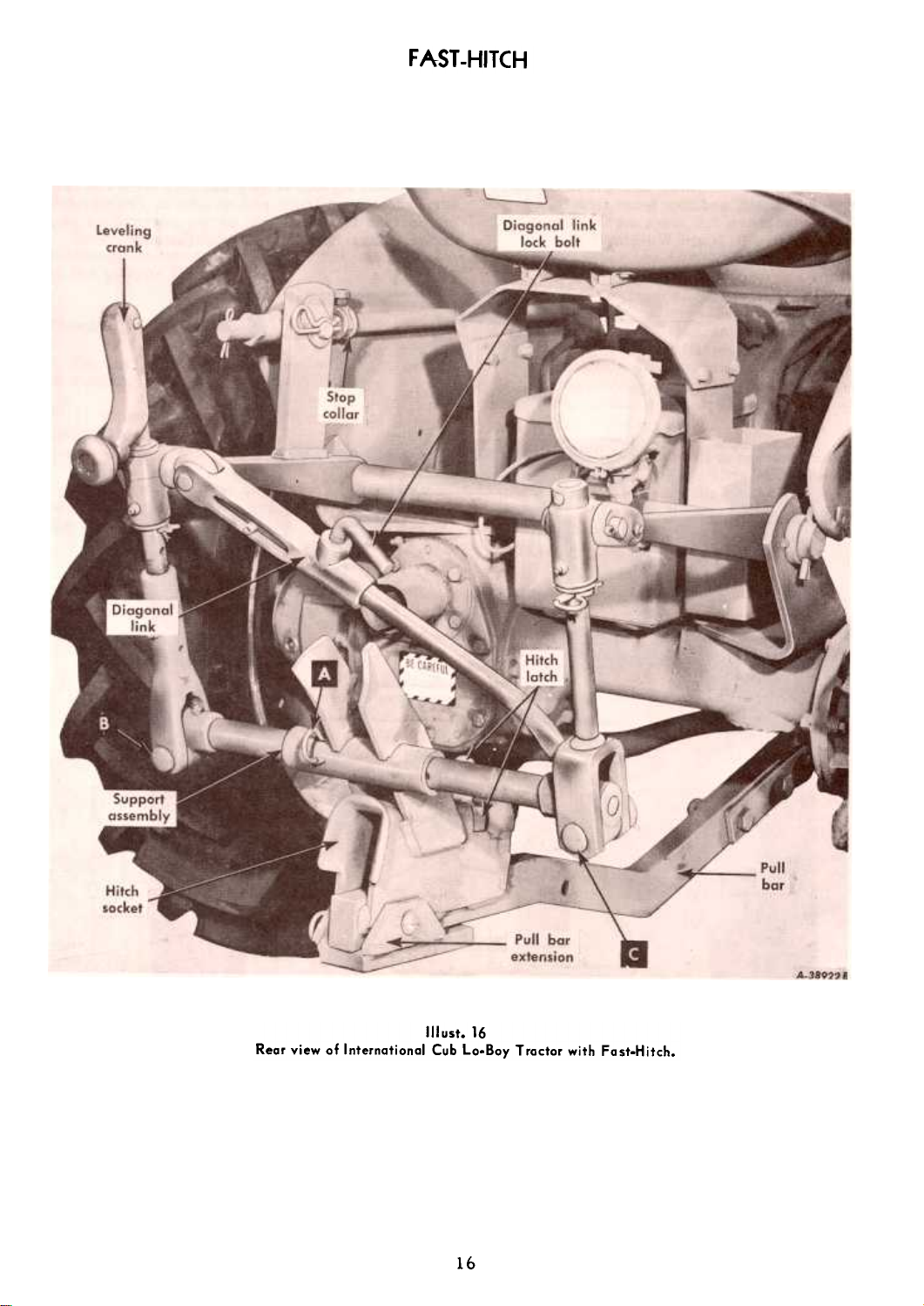

FAST-HITCH

Rear view of International Cub La.Bay Tractor with Fast.Hitch.

Illust. 16

16

Page 18

FAST-HITCH

COUPLING THE EQUIPMENT

Adjust the height of the hitch socket with

the Touch-Control and level the hitch with the

leveling crank so the prong of the equipment

can enter the hitch socket when the tractor is

backed against the equipment (1IIusts. 15 and 16).

The latch snaps shut when the prong reaches

the proper position.

To uncouple the equipment on ground level.

lower the equipment to the ground. reach back

and lift the hitch latch (II lusts. 15 and 16) with the

forefinger. If the latch is difficult to disengage.

back the tractor slightly against the equipment

to relieve the strain on the latch. The latch

will remain open until the equipment prong is

withdrawn.

HITCH ADJUSTMENTS

The height of the hitch determines the

working depth of the equipment. The depth

adjusting crank (1IIusts. 15 and 16) raises and

lowers the front end of the pull bar to reach

the desired working depth called for in the in-

structions in your equipment manual.

Fast-Hitch pull bar and diagonal links may be

removed to provide more clearance under thetractor.

FAST-HITCH LOAD LIMITATIONS

Caution! Do not overload the rear axle or

the Fast-Hitch components with the

equipment or accessories.

The transport loads listed below are considered satisfactory for Fast-Hitch operation.

The equipment weights shown in the following

examples do not include any allowance for ad-

ditional weights on the equipment.

a. Five-foot disk harrow with ten 20-inch

disks-360 pounds-use a rear wheel tread set-

ting up to 56-inches.

b. Rotary hoe-355 pounds-use a re~r

wheel tread setting up to 56-inches.

Utility carrier.

International Cub -with a 400 pound payload in

the center of the platform -use a rear

wheel tread setting up to 56-inches.

PULL BAR EXTENSION

A pull bar extpnsion is available for pulling

trailing-type equIpment. When in use, the

extension is attached to the pull bar with the

hitch hole toward the rear. It is held in place

by a pivot pin and a quick attachable cotter

pin. When not in use, the pull bar extension

should be turned with the hitch hole toward

the front. See Illusts. 15 and 16.

When plowing. the lock bolt (or hand

screw) on the diagonal link must be loose or

unscrewed far enough so that the diagonal link

is free so the plow can swing from side to

side. Additional lateral swing can be obtained

when required. by removing the quick- attachable cotter pin "A" (1IIusts. 15 and 16) from the

pull bar support.

When operating with middlebusters or culti-

vator s, the lock bolt must be screwed in tightly

to keep the unit in a rigid position to prevent

the equipment from swinging.

When cultivating crops with high foliage,

turn the depth adjusting crank so the hitch bail

is set at its highest position. If necessasy the

International Cub Lo-Boy -use a rear wheel

tread setting up to 56-inches with the front

tire tubes filled three-quarters full with a

calcium chloride solution, the pay load must

be proportioned to the amount of front end

weight as follows:

Maximum

Carrier

Payload i

200 Ibs.

250 Ibs.

In general, the loads must decrease as the

tread settings increase, and the loads must

decrease as the distance from the rear axle

to the center of gravity of the load increases.

Minimum Front End Weight

set of one-piece weights (50 1bs.)

i set of two-piece weights or 2 sets

of one-piece weights (100 1bs. )

-set of two-piece weights and 1 set

of one-piece weights (150 1bs.)

set of two-piece weights and 2

sets of one-piece weights (2001bs.)

c.

3151bs.

3751bs.

17

Page 19

The tractor exerts its pulling power on

trailing-type equipment by means of the draw-

bar, which is adjustable up and down to ac-

commodate different hitches. Proper hitching

will save both the tractor and the equipment it

is pulling from undue strains. Hitch so the

center line of pull of the tractor will fall in

line with, or at least near, the center line of

draft of the trailing equipment. Hitching to

one side or the other of the line of draft will

cause stresses and strains on both the tractor

and the equipment being pulled, frequently

great enough to do permanent damage. Incor-

rect hitching will also tend to make the tractor

difficult to steer and will result in unsatis-

factory work by the equipment being pulled.

When using a long chain to hitch the tractor

to the load. drive the tractor forward slowly

until all of the slack is taken out of the chain.

~

/"00('1 .

'" 5~'i't1'i

-,

A-IZ".f

When the tractor is pulling power equipment, be

sure that all power line shielding is in place and in

good order.

REMOVING THE DRAWBAR

The quick-attachable drawbar can be

easily removed. To remove the drawbar,

loosen the bolts "A" (1IIust. 18) and unhook the

complete drawbar.

The drawbar on International Cub tractors

can be reversed and placed in the forward po-

sition when so de sired.

ADJUSTING THE DRAWBAR

The drawbar can be set at three different

heights to obtain the proper hitch position.

To raise or lower the drawbar, remove

bolts "B" (1!lust. 18A), and raise or lower the

drawbar to the upper or lower hole in the drawbar bracket. Replace bolts "B" and tighten se-

curely.

Illust. 18

Removing the drawbor.

Illust. 18A

Orawbar adjustment.

18

Page 20

BELT-PULLEY

pull bar and support assembly must be disconnected and lowered to the ground by removing the pin 'IB'I at the leveling screw housing and the pin lICIt at the lateral link clevises.

Then move the diagonal link to one side. See

Illust. 16.

OPERATING THE BELT PULLEY OR POWER T AKE.OFF

WITH THE TRACTOR STANDING STILL

1. The transmission gearshift lever must be

in the neutral position.

2. Move the engine speed control lever back

to low idle speed.

Don't put on or r~mov~ th~ b~lt from th~ b~lt

pull~y whil~ th~ pull~y is in motion.

If your tractor is equipped with a belt pulley

or power take-off, the following instructions

and precautions should be carefully studied

and followed.

The belt pulley and power take-off are

started and stopped by the sarn.e engine clutch

as the tractor. Be sure to disengage the engine

clutch before rn.oving the belt pulley or power

take-off shifter rod. The belt pulley is driven

by the power take-off shaft; therefore, the sarn.e

shifter rod is used to operate either the belt

pulley or power take-off. The shifter rod

should always be in the disengaged (forward)

position when the belt pulley or power take-off

is not in use.

Note: When the International Cub Lo-Boy

tractor is equipped with the Fast-Hitch, the

3. Depress the clutch pedal to disengage theengine

clutch.

4. Press down on the shifter rod and move it

back to the engaged position; release the shifter

rod and allow it to lock in place.

5. Slowly release the clutch pedal.

6. Observe the following instructions whenusing

the tractor belt pulley:

Secure the equipment to receive power

in the desired location.

Align the tractor belt pulley with the

equipment pulley. Keep the tractor

level if possible.

Observe the direction of belt travel in-

dicated on the belt. and install the belt

accordingly to prevent damaging it.

Tighten the belt enough to prevent the

belt from rubbing against itself during

operation. Do this by driving the tractor into the belt, locking the brakes,

and blocking the tractor rear wheels.

(When using a very long belt or a

crossed belt, it will not be possible to

eliminate all rubbing).

1

2.

3.

4.

Always stop the power take-oIl belore dis-

mounting Irom the tractor.

5. Gradually bring the tractor engine up

to speed, making sure the belt is running trae.

Note: Static electricity, generated by belt

work, can be discharged harmlessly from tractors with pneumatic tire s, by attaching a chain

to the tractor and allowing it to touch the ground

For belt and pulley speeds. refer to poge 75.

l~

Page 21

BELT -PULLEY AND POWER TAKE-OFF

OPERATING THE POWER TAKE-OFF WITH TRACTOR IN

MOTION

Follow the first four steps outlined above;

then release the power take- off shifter rod and

allow it to lock in place. Keep your foot

pressed down on the clutch pedal (in the disengaged position), advance the engine speed con-

trollever and move the transmission gearshift

lever to the speed that is desired to run the

tractor. Slowly release the clutch pedal. This

will start the tractor in motion with the power

take-off in operation.

Caution! When operating power take-off

driven machines not equipped with an

overrunning clutch (such as a rotary

brush cutter), the following precautions shouldbe

taken:

Slowdown when approaching trees, fences,

or ditches. Flywheel effect of the driven ma-

chine will drive the tractor forward after the

engine clutch is disengaged. To stop the for-ward

travel more quickly, retard the engine

speed control lever, disengage the engine

clutch, move the gear shift lever to the neu-

tral position, and apply tractor brakes.

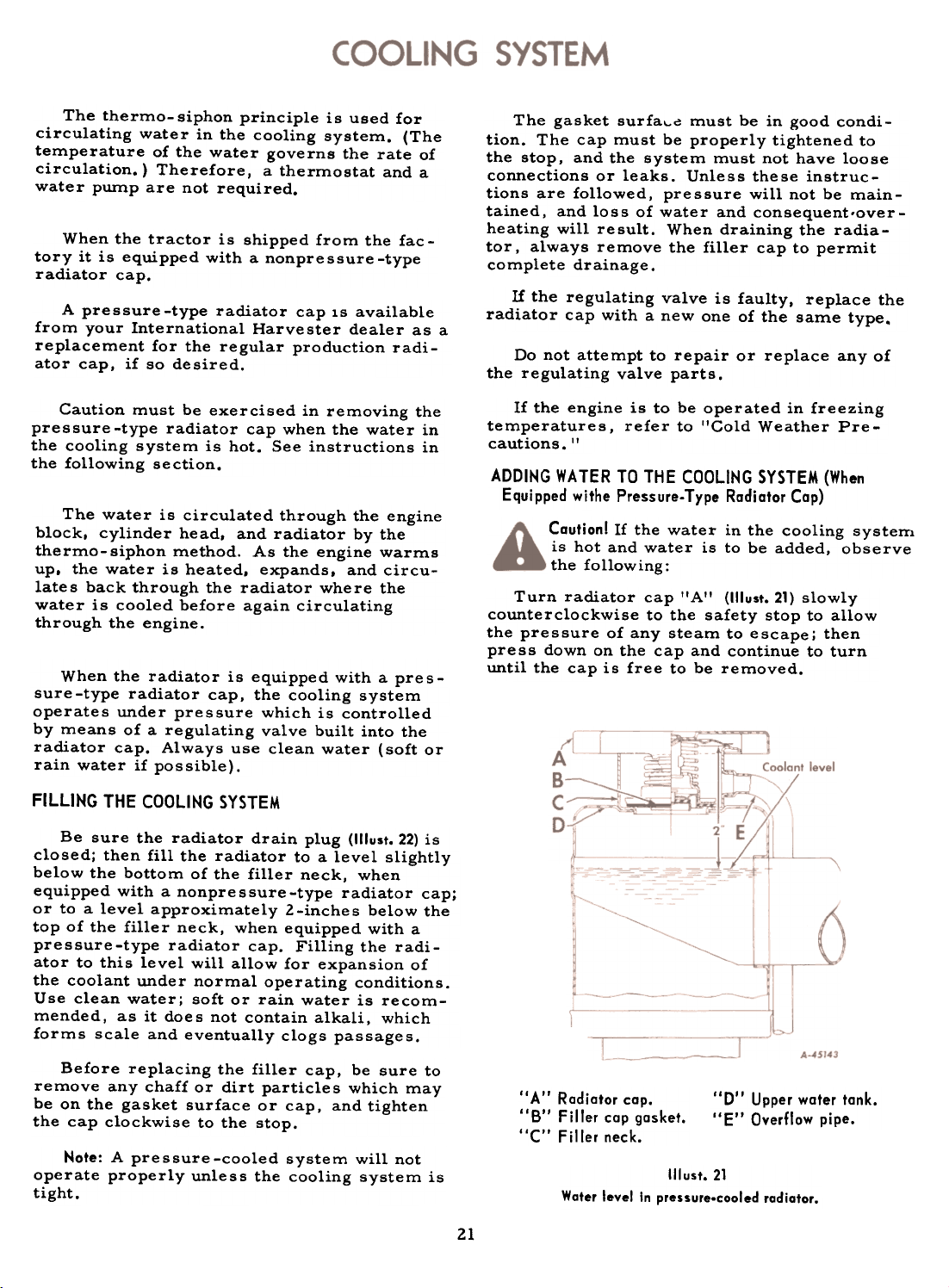

Replace the removed cap screws with the

extra cap screws supplied with the belt pulley

and power take-off. Use two 3/8 N. C. x 1-3/8-

inch cap screws at 'lA" (1IIust. 20A) and the three

3/8 N. C. x 1-1/8-inch cap screws at 'IB'I. Use

flat washers in front of the lock washers and

tighten the cap screws securely.

Caution! Always cover the power take-offexposed

shaft with the guard flC" (1IIust.

20A) when the power take-off is not being

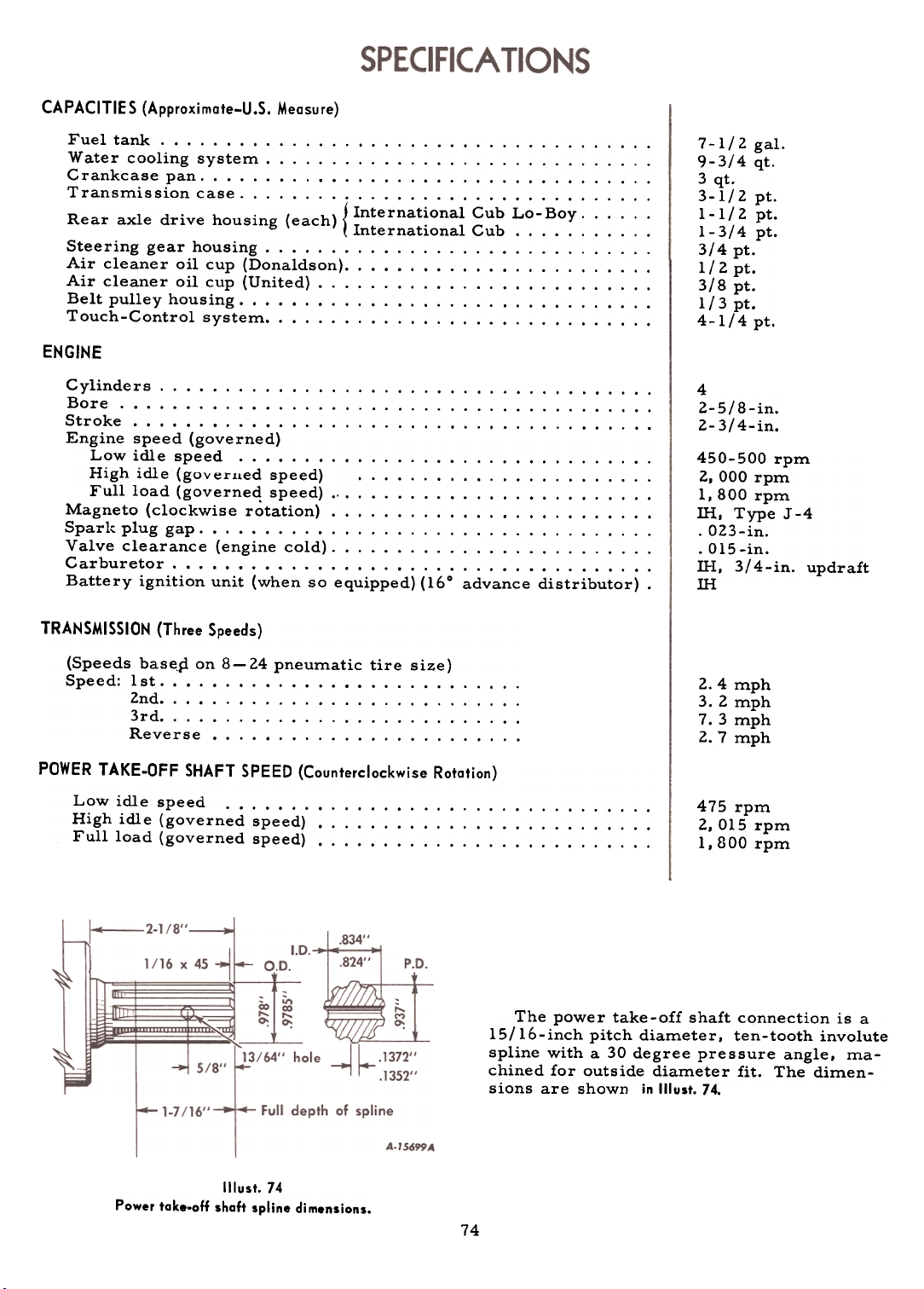

The specifications for the power take-off

will be found on page 74.

CHANGING FROM POWER TAKE-OFF TO BELT PULLEY

Remove two 3/8 N. C. x 1-3/8-inch cap

screws "A" (1IIust.20A) and the three 3/8 N. C.

x 1-1/8-inch cap screws at "B". Apply a light

coating of grease to the power take-off shaft

and female spline in the belt pulley housing.

Then slide the belt pulley and housing complete

on to the power take-off splined shaft.

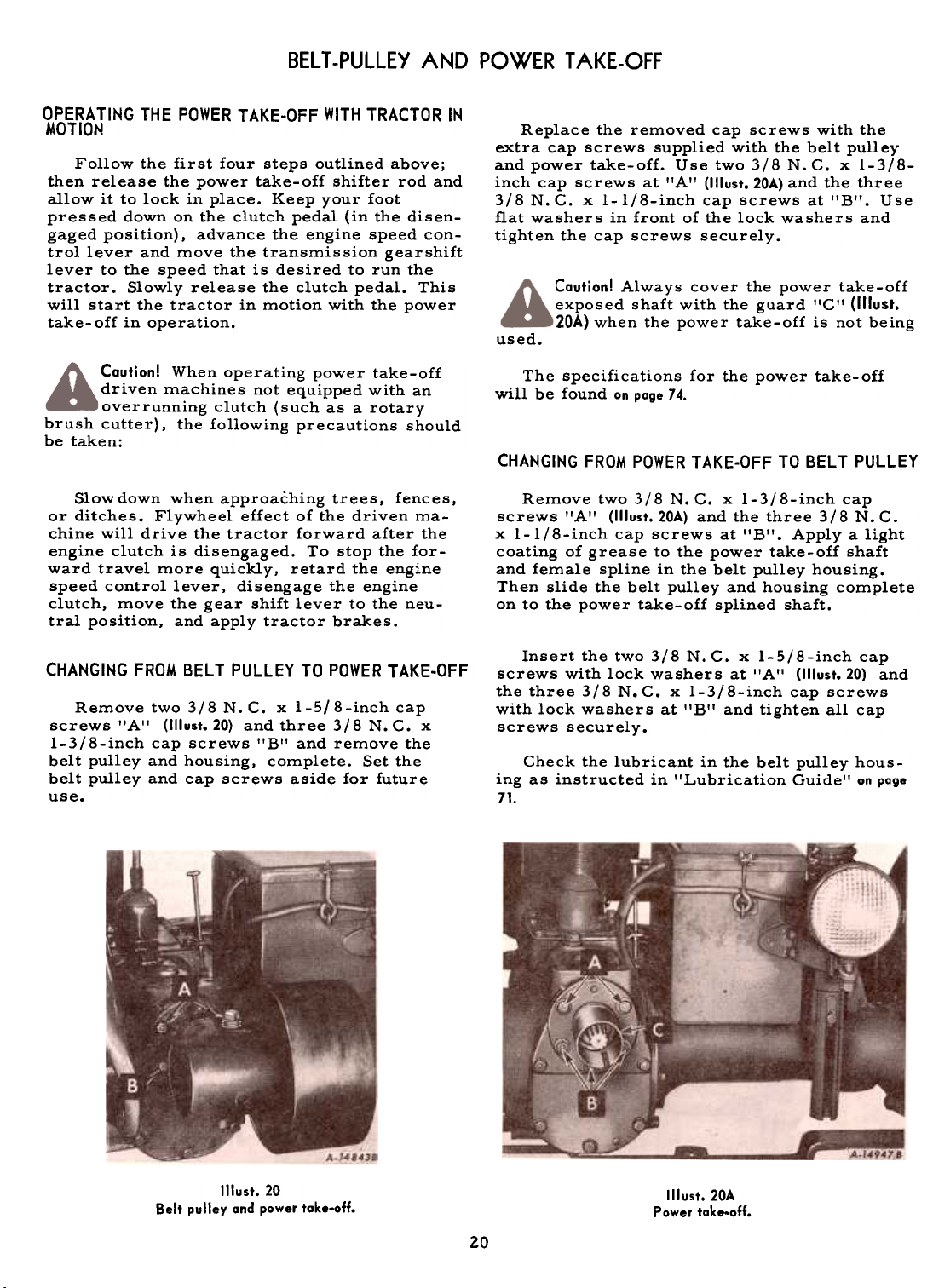

CHANGING FROM BELT PULLEY TO POWER TAKE-OFF

Remove two 3/8 N. C. x I-S/8-inch cap

screws "A" (1IIust.20) and three 3/8 N. C. x

1-3/8-inch cap screws "B" and remove the

belt pulley and housing. complete. Set the

belt pulley and cap screws aside for futureuse.

Insert the two 31B N. C. x 1-5/B-inch cap

screws with lock washers at "A" (1IIust.20) and

the three 31B N. C. x 1-3IB-inch cap screws

with lock washers at I'B'I and tighten all cap

screws securely.

Check the lubricant in the belt pulley hous-

ing as instructed in "Lubrication Guide'! on page

71.

used.

Belt pulley and power take-off.

Illust. 20

II lust. 20A

Power take-off.

20

Page 22

The thermo- siphon principle is used for

circulating water in the cooling system. (The

temperature of the water governs the rate of

circulation.) Therefore, a thermostat and a

water pump are not required.

When the tractor is shipped from the fac-

tory it is equipped with a nonpressure -type

radiator cap.

A pressure-type radiator cap IS available

from your International Harvester dealer as a

replacement for the regular production radiator cap. if so desired.

The gasket surfa...~ must be in good condi-

tion. The cap must be properly tightened to

the stop, and the system must not have loose

connections or leaks. Unless these instruc-

tions are followed, pressure will not be main-

tained, and loss of water and consequent.overheating will result. When draining the radiator, always remove the filler cap to permit

complete drainage.

If the regulating valve is faulty, replace the

radiator cap with a new one of the same type.

Do not attempt to repair or replace any of

the regulating valve parts.

Caution must be exercised in removing the

pressure-type radiator cap when the water in

the cooling system is hot. See instructions in

the following section.

The water is circulated through the engine

block, cylinder head, and radiator by the

thermo- siphon method. As the engine warms

up, the water is heated, expands, and circulates back through the radiator where the

water is cooled before again circulating

through the engine.

When the radiator is equipped with a pres-

sure -type radiator cap, the cooling system

operates under pressure which is controlled

by means of a regulating valve built into the

radiator cap. Always use clean water (soft or

rain water if possible).

FILLING THE COOLING SYSTEM

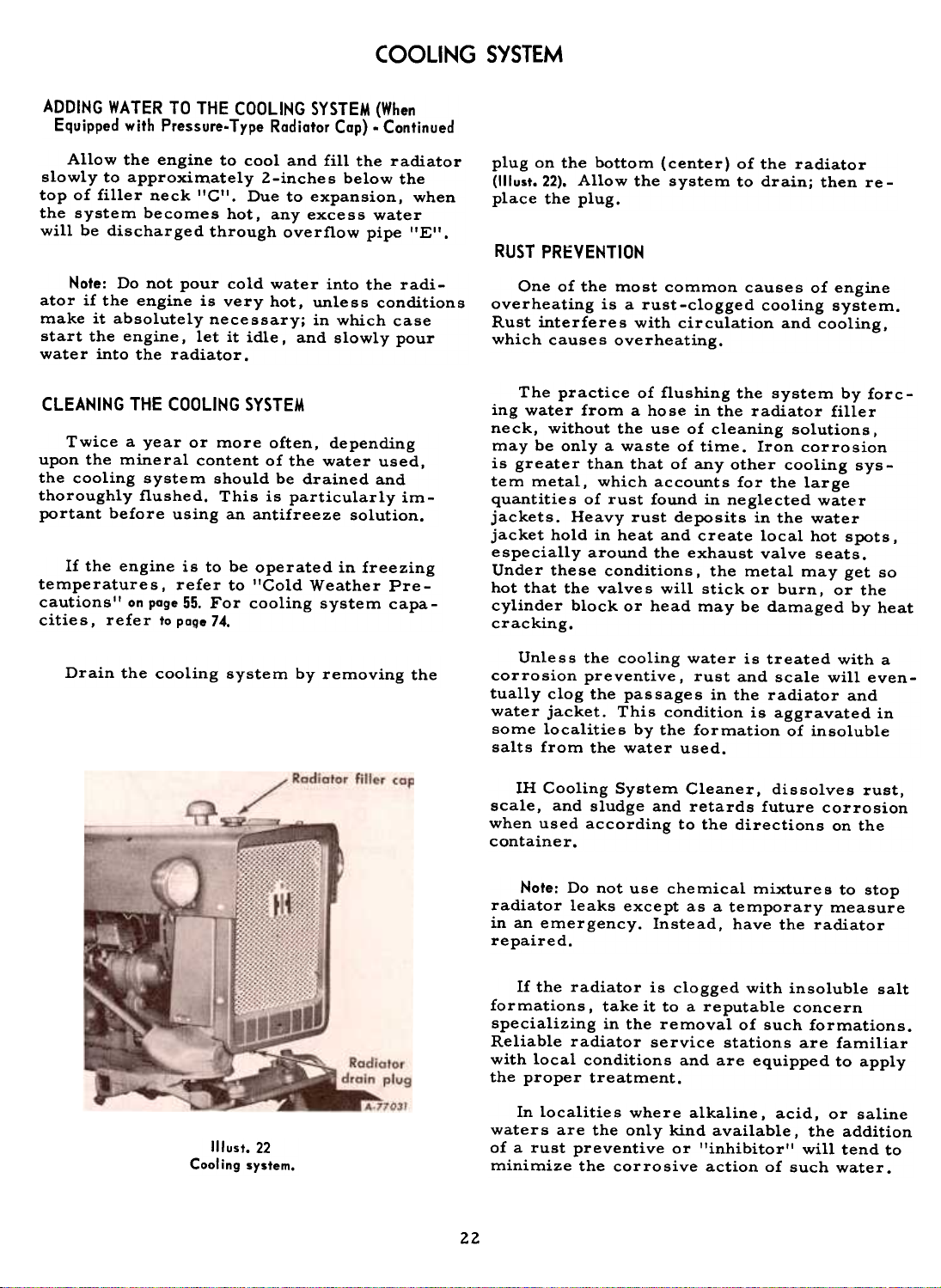

Be sure the radiator drain plug (1IIust. 22) is

closed; then fill the radiator to a level slightly

below the bottom of the filler neck, when

equipped with a nonpressure-type radiator cap;

or to a level approximately 2-inches below the

top of the filler neck, when equipped with a

pressure-type radiator cap. Filling the radi-

ator to this level will allow for expansion of

the coolant under normal operating conditions.

Use clean water; soft or rain water is recommended, as it does not contain alkali, which

forms scale and eventually clogs passages.

If the engine is to be operated in freezing

temperatures, refer to "Cold Weather Precautions. II

ADDING WATER TO THE COOLING SYSTEM (When

Equipped withe Pressure-Type Radiator Cap)

Caution! If the water in the cooling system

is hot and water is to be added, observe

the following:

Turn radiator cap IIAII (1IIust. 21) slowly

counterclockwise to the safety stop to allow

the pressure of any steam to escape; then

press down on the cap and continue to turn

until the cap is free to be removed.

Before replacing the filler cap, be sure to

remove any chaff or dirt particles which may

be on the gasket surface or cap, and tightenthe

cap clockwise to the stop.

Note: A pressure -cooled system will not

operate properly unless the cooling system is

tight.

21

"A" Radiator cap.

"B" Filler cap gasket.

"C" Filler neck.

Illust. 21

Water level In pressure-cooled radiator.

., D" Upper water tank.

"E" Overflow pipe.

Page 23

COOLING SYSTEM

ADDING WATER TO THE COOLING SYSTEM (When

Equipped with Pressure-Type Radiator Cap) -Continued

Allow the engine to cool and fill the radiator

slowly to approximately 2-inches below the

top of filler neck I'C'I, Due to expansion, when

the system becomes hot, any excess water

will be discharged through overflow pipe I'E",

Note: Do not pour cold water into the radiator if the engine is very hot, unless conditions

make it absolutely necessary; in which case

start the engine, let it idle. and slowly pour

water into the radiator.

CLEANING THE COOLING SYSTEM

Twice a year or more often, depending

upon the mineral content of the water used,

the cooling system should be drained and

thoroughly flushed. This is particularly im-

portant before using an antifreeze solution.

If the engine is to be operated in freezing

temperatures. refer to "Cold Weather Pre-

cautions" on page 55. For cooling system capa-

cities, refer to page 74.

Drain the cooling system by removing the

plug on the bottom (center) of the radiator

(1IIust.22). Allow the system to drain; then re-

place the plug.

RUST PRi:VEHTIOH

One of the most common causes of engine

overheating is a rust-clogged cooling system.

Rust interferes with circulation and cooling,

which causes overheating.

The practice of flushing the system by forc-

ing water from a hose in the radiator filler

neck, without the use of cleaning solutions,

may be only a waste of time. Iron corrosion

is greater than that of any other cooling sys-

tem metal, which accounts for the large

quantities of rust found in neglected water

jackets. Heavy rust deposits in the water

jacket hold in heat and create local hot spots,

especially around the exhaust valve seats.

Under these conditions. the metal may get so

hot that the valves will stick or burn, or the

cylinder block or head may be damaged by heat

cracking.

Unless the cooling water is treated with a

corrosion preventive, rust and scale will eventually clog the passages in the radiator and

water jacket. This condition is aggravated in

some localities by the formation of insoluble

salts from the water used.

Illust. 22

Cooling system.

IH Cooling System Cleaner, dissolves rust,

scale, and sludge and retards future corrosion

when used according to the directions on thecontainer.

Note: Do not use chemical mixtures to stop

radiator leaks except as a temporary measure

in an emergency. Instead, have the radiatorrepaired.

If the radiator is clogged with insoluble salt

formations, take it to a reputable concern

specializing in the removal of such formations.

Reliable radiator service stations are familiar

with local conditions and are equipped to apply

the proper treatment.

In localities where alkaline, acid, or saline

waters are the only kind available, the addition

of a rust preventive or "inhibitor" will tend to

minimize the corrosive action of such water.

22

Page 24

COOLING SYSTEM

RUST PREVENTION. Continued

For rust prevention during winter use of

the engine, a fre sh filling of antifreeze containing an effective corrosion preventive

should be used. In the spring, drain and discard the old antifreeze solution, as the rust

preventive or "inhibitor" may be exhausted

from contamination and continued use.

After draining the antifreeze, a rust preventive should be added to the cooling water

to protect the cooling system during warm

weather operation. This inhibitor solution

should be drained and discarded in the fall

when danger of freezing again makes nec-

essary the use of an antifreeze.

RADIATOR CORE

Overheating is often caused by bent or

clogged radiator fins. If the spaces between

the radiator fins become clogged. clean them

with forced air or water. When straightening

bent fins. be careful not to injure the tubes

or break the bond between the fins and tubes.

FAN BELT TENSION

Belts on new tractors (also new replace-

ment belts) lose their tension as they "seat"

themselves in the pulleys. New belts should

be checked after the first 10 hours of engine

operation and eve.ry 50 hours of engine operation thereafter to assure maintenance of the

correct tension. The tension is correct when

the belt can be depressed without effort by the

thumb. approximately 1/ 2-inch to 3/4-inch.

midway between the two pulleys. See Illust. 23.

If the slack is more than I-inch. adjust the

belt as follows:

Illust. 23A

Fan and generatar belts.

before adjusting the fan belt tension. The ten-

sion of the fan belt is adjusted by loosening fan

spindle "G II (1IIust.23A) and moving the fan and

hub assembly up or down until the correct ten-

sion is obtained. After the correct tension is

obtained, tighten fan spindle ffG 'f. To adjust

the generator belt, see "Generator Belt."

After a new belt has been in use approxi-

mately 10 hours, check the tension and adjust

again if necessary.

Illust. 23

Correct belt tension.

Adjusting the Fan Belt

When the tractor is equipped with a gener-

ator, first loosen nuts "A II and "B" (1IIust. 23A)

Removing the Fan Belt

To remove the fan belt. loosen fan spindle

lIC't (1IIust.23A) and slide the fan and hub assembly to the bottom of the groove on the crank-

case front cover. The fan belt can then be

slipped over the bottom drive pulley and

worked up over the fan blades.

Replacing the Fan Belt

Replace the fan belt when it becomes soaked

with grease, or when it is so badly worn that

it does not drive the fan at the proper speed.

When replacing the belt, reverse the procedure outlined uIlder "Removing Fan Belt,"

except that belt can be started on the lower

pulley by hand, and by slowly cranking the

engine. the belt will find the correct position.

23

Page 25

COOLING SYSTEM

GENERA TOR BELT

After the fan belt tension has been adjusted,

move the generator toward or away from the

engine to get the correct generator belt tension;

then tighten nuts I'A'! and "B" (1IIust. 23A). The

generator belt should be tight enough as not to

allow slippage, but not so tight as to cause

side thrust on the generator bearing. Allow

1/4 -inch slack. See Illust. 23.

FAN HUB LUBRICATION

Every six months or after every 500 hours

of operation, whichever occurs first. remove

oil retainer screw !'F'! (II lust. 23A) and turn

the fan assembly so that the oil filler hole is

at the right horizontal posit~on. Add engine oil

until the oil reache s the level of the hole. Now

turn the assembly so that the hole is on the

bottom and allow any excess oil to drain out.

The oil is then up to level of the top of the

stand pipe (approximately 1-1/2 ounces). See

Illust.24. Replace the oil retainer screw and

Fan hub partially disassembled showing oil level.

Illust.24

be sure that the retainer screw gasket is inplace.

Note: The rubber gasket located behind the

hub at I'E'I (1IIust.23A) is used for shipping pur-poses

only. It does not have to be replaced

when worn out.

'f

Clean air for combustion is assured by an

oil-type air cleaner. A heavy screen in t~1e

air intake cap prevents large particles from

entering the air cleaner. The air then passes

to the oil cup where it goe s through a bath of

oil. As the air rises to the intake manifold, it

passes through a series of oil-bathed screens

and the fine dust is removed. As the oil from

the screen works back down, it carries the

dirt with it and settle s in the oil cup. Hever allow

dirt to build up in the cup more than 1/2-inch deep.

OIL CUP SERVICE

Clean and refill the oil cup every day J or

every 10 houirs of operation (more frequently

when operating under dusty conditions). Refill

the oil cup to the oil level bead with the same

grade of oil used in the engine crankcase. For

the oil cup capacity J refer to page 65.

Do not remove the oil cup while the engine

is operating. Before replacing the oil cup,

clean or wipe oil or grit from the top bead of

the oil cup.

Illust.24A

Servic ing the oi I cup.

24

Page 26

AIR CLEANING SYSTEM

AIR INTAKE CAP AND SCREEN

The screen in the air intake cap prevents

chaff and other coarse dirt from getting into

the air cleaner. Keep this screen clean and

free from all chaff, oil, dust, or paint, as

clogged holes in the screen will reduce the

power of the engine by restricting the flow ofair.

WASHING THE CLEANER

After every 150 hours of operation -par-

ticularly if operating the tractor in an atmos-

phere heavily laden with dust, chaff or lint -

remove the entire air cleaner from the trac-

tor, disassemble it (1IIust. 25) and wash the parts

thoroughly in kerosene. Be sure to clean out

the air intake pipe.

After all parts have been thoroughly cleaned,

replace the air cleaner body on the tractor.

Make sure all joints are airtight. Replace the

air intake cap. Fill the oil cup to the proper

level with the specified grade of oil and replace

it on the air cleaner. Be sure it is held securely

in place by the oil cup bailor clamp.

GEN ERAL PRECAUTIONS

As an added precaution against dirt entering

the engine, frequently inspect the flexible rub-

ber hose connections between the carburetor

and the air cleaner. If they show any sign of

deterioration, replace them. To eliminate

strain on the rubber hose connections, be sure

the pipes line up. All joints between the air

cleaner, carburetor, manifold and cylinders

of the engine should be tight. All gaskets must

be in good condition and the bolts should be

drawn up tight.

CRANKCASE BREATHER

The crankcase breather and oil filler cap

(1IIust.7) has an oiled aluminum crimp filler

which acts as a dust filter for crankcase ven-

Exploded view of air cleaner.

Illust. 25

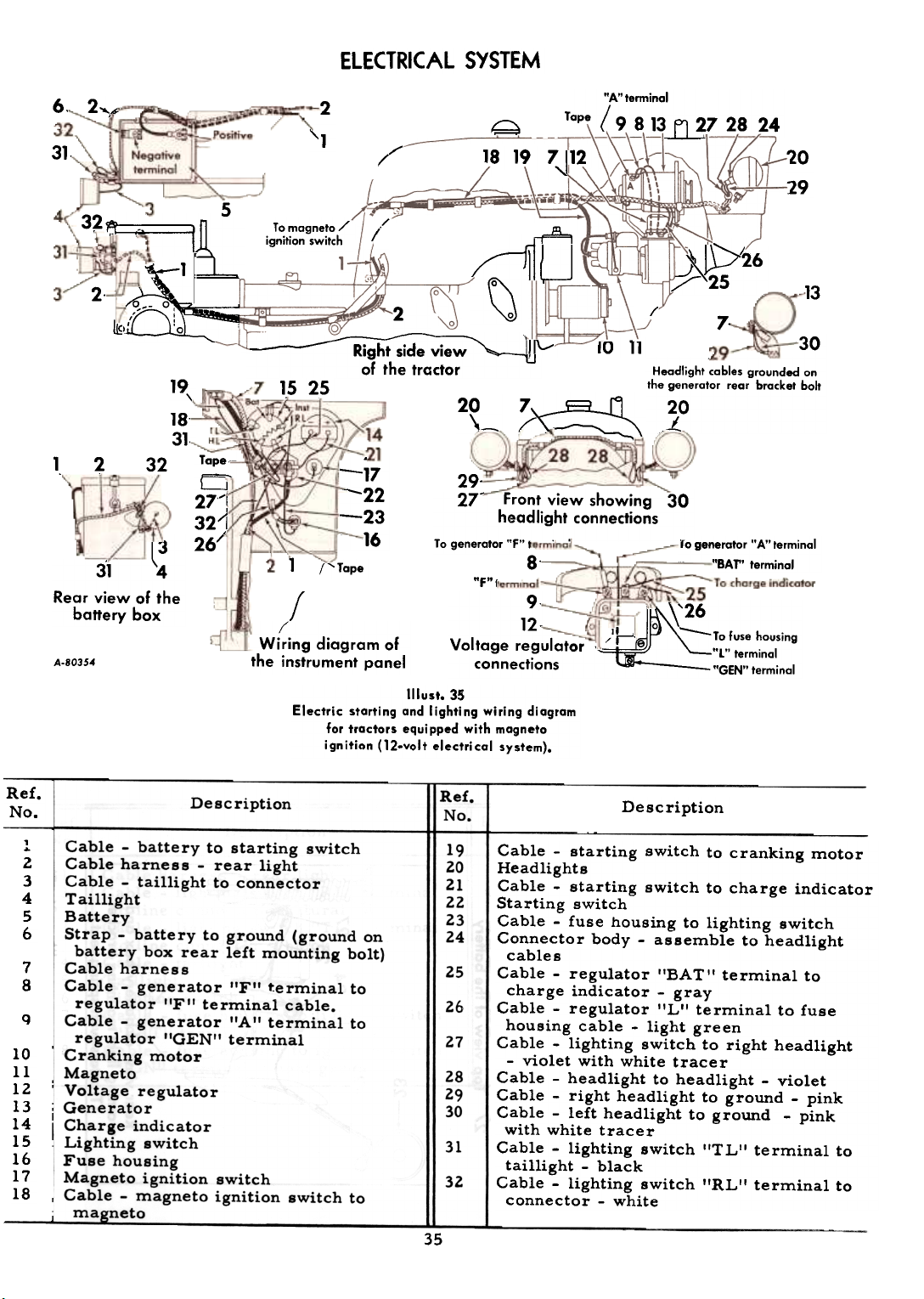

International Cub Tractors with serial num- tions. Be sure all terminals are clean and se-

bers 224401 and up or International Cub Lo- curely fastened.

Boy Tractors with serial numbers 18701 and

up are equipped with a twelve volt electrical I

system. I

International Cub Tractors with serial num- "

bers below 224401 or International Cub Lo-Boy

tilation. Clean and reoil this breather each

time the engine oil is changed.

ITractors with serial numbers below 18701 are

equipped with a six volt electrical system.

The electrical system of the tractor con- I

sists of a generator. voltage regulator. crank-

ing motor. lights. lighting switch. electrical I

instruments. a battery. and either a magneto

or a battery ignition unit. Colored plasticcovered cables are contained in a harness of

nonmetallic. oilproof. and waterproof woven

braid.

,

Use the illustrations on pages 25 and 26, andthe

wiring diagrams on pages 35 to 41 as a guide

for identifying the various electrical units and

for tracing the electrical cables and connec-

Deluxe seat and battery bax covers removed

Illust.25A

for servicing the battery (12-volt system).

25

Page 27

ELECTRICAL SYSTEM

Illust. 26

Electrical units and cables an right side

of engine (12-volt system).

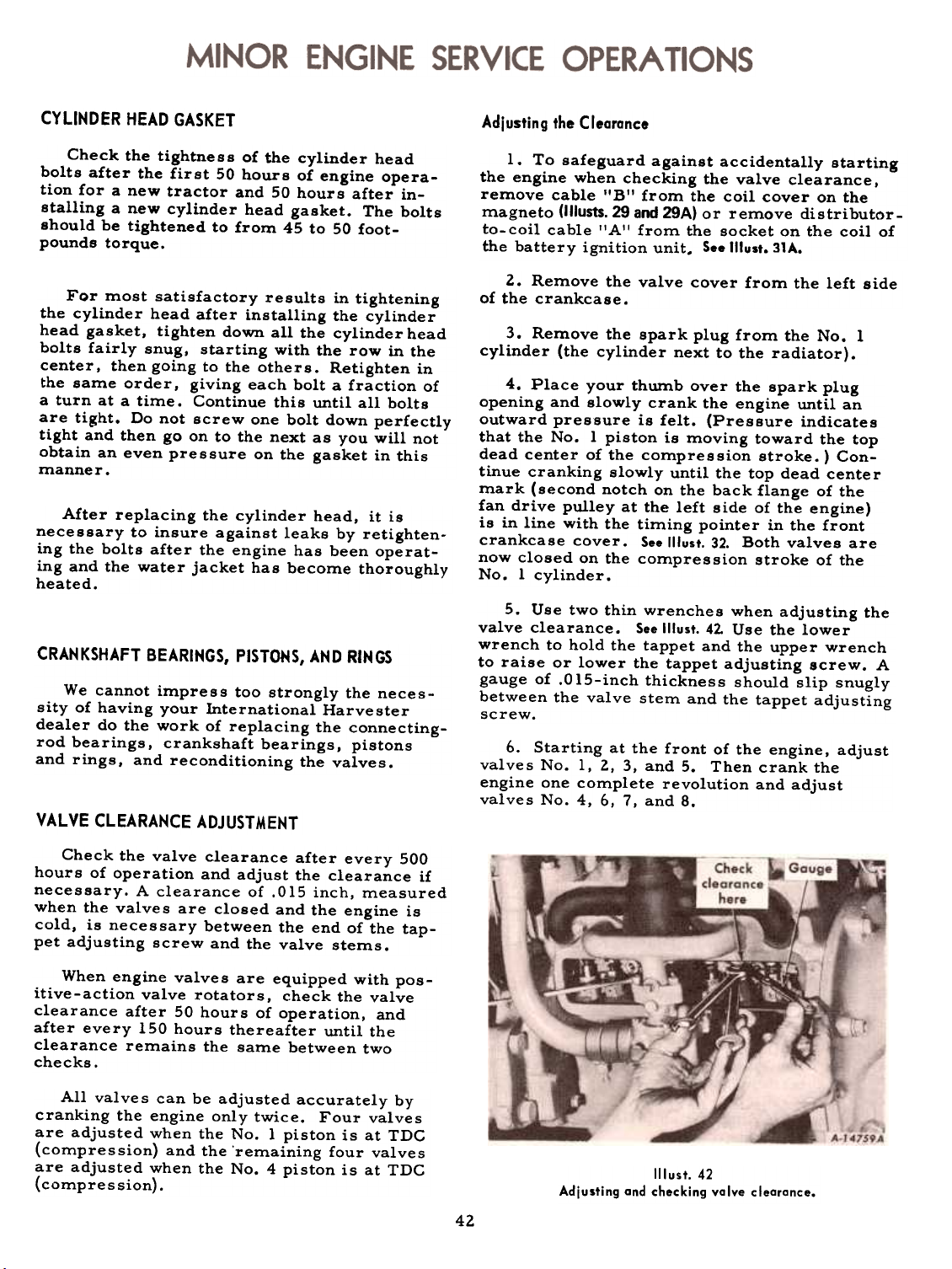

When the electrical equipment was installed Remove the spark plugs after every 200 to

at the factory,~he battery-to-ground cable 300 hours of operation for cleaning and checkwas left disconnected and taped. Before at- ing the gaps between electrodes. A gap of .023

tempting to start the tractor, make certain inch should be maintained.

that the ground cable is connected.

When making this adjustment, always bend

the outer electrode. Never bend the center

electrode, as it will damage the insulator. If

the gap between the electrodes is too great,

due to improper setting or burning off of the

ends, the engine will misfire and be hard to

start.

Illust.26A

Battery and cables (6-valt system shawn

an International Cub LaBoy Tractor).

Note: on the twelve-volt battery the negative

(-) terminal is the ground and on the six-volt

battery the positive (+) terminal is the ground.

SPARK PLUGS AND CABLES

Note: Remove all dirt from the base of the

spark plug before removing the spark plug.

Checking the spark plug gap.

Illust. 268

26

Page 28

ELECTRICAL SYSTEM

SPARK PLUGS AND CABLES. Continued

Illust.27

Spark plug wiring. Engine firing order Is 1. 3, 4. 2.

(Magneto shown on the engine.)

Cleaning the Spark Plugs

Sandblasting is the recommended method

of cleaning spark plugs. Never scrape or

clean the insulator with anything which will

scratch the porcelain. Scratched porcelain

allows carbon and dirt to accumulate muchfaster.

Always use a spark plug wrench when re-

moving or replacing plugs. This helps to

prevent cracking the porcelain.

Screw the spark plugs into the cylinder

head, using a new copper gasket with each one.

Do not tighten more than enough to compressthe

gasket to seal the plug and assure a good

heat ~ransfer between the plug and the cylinder head. Torque the spark plugs to 34 foot-

pounds torque. If a torque wrench is not avail-

able, tighten the plug 1/2 to 3/4 turns past

finger tight. Replace defective plugs with newplugs.

MAGNETO

Greasing the Breaker Mechanism and Checking the Points

(1Iust.27A

Adjusting the breake, points.

It is important that the breaker chamber be

kept clean, as oil on the breaker points willcause

rapid burning. Inspect the breaker

chamber after every 250 hours of operation,to

assure that it is clean. To reach the breaker

mechanism, remove the distributor cap, and

crank the engine slowly until end I'BI' of the

distributor rotor arm point~ toward the No. I

terminal on the distributor cap. and the im-

pulse coupling just trips. Take off the distrib-

utor body by removing three screws I'A'I(1IIust.28).

See that the points are in good condition and have the proper clearance. If the

chamber is clean, no attention is necessary

other than checking the clearance of the points,

but if the chamber is dirty. all parts must bethoroughly

cleaned.

Do not crank the engine while distributor

body is removed or it might be necessary to

retime the magneto to the engine.

Remove the breaker arm from the chamberand

clean all parts. Inspect the breaker points

and, if necessary, dress them with a sharp,fine

file. If the points are worn excessively,replace

both points.

See your International Harvester dealer

for various makes of replacement plugs for

normal or special service. These plugs have

been tested and recommended as best suitedfor

this engine.

If the spark plug cables are removed for

any reason, note the position of each cable

on the distributor cap as shown in Illust. 27.

Fill the recess in the breaker post with IH

High Temperature Grease (21372-D) and pack

a small quantity of the same grease in back ofthe

breaker arm rubbing block (1IIusts. 27A and 28).See

your International Harvester dealer for

the proper grease to use.

Replace the breaker arm and be sure thepoints

line up when the breaker arm is in place.

27

Page 29

MAGNETO. Continued

ELECTRICAL SYSTEM

Illust. 28

Magneto disassembled.

Greasing the Breaker Mechani sm and Checking the

Points. Continued

Check the opening between the breaker points

(1IIust.27A.) with a feeler gauge. The point opening should be .013 inch when the rubbing block

is on the high part of the cam. If the opening is

not correct, adjust it by loosening the screw

holding the adjustable point (1IIust. 27A.) and moving the point up or down until the gauge slips

snugly into the opening. After the proper ad-

justment has been made, tighten the screw.

With the engine on the top dead center of

the No. 1 firing stroke, turn the distributor

rotor until end "B" of the distributor rotor

arm points to the No. 1 terminal on tfie dis-

tributor cap. Place the distributor body on the

magneto and be sure the rotor shaft enters the

"D" shaped hole in the magneto rotor pinion.

Be sure the gasket is in place and tighten three

screws "A" (1IIust. 28). Replace the distributor cap.

Greasing the Distributor Gear

After every 2,000 hours of operation or at

least every year, the distributor gear and

distributor gear chamber should be cleaned and

repacked with 1H Magneto Ball Bearing Grease

(359 766 R91). We recommend this be done by

your International Harvester dealer.

Distributor Cap

Every three or four months, remove the

distributor cap and examine the inside. If any

dust, moisture or oil deposits are present,

thoroughly clean and wipe dry. To assure long

life of the distributor, care must also be taken

to keep the three small ventilator holes in the

bottom of the distributor cap open at all times.

Also see that the distributor rotor is kept

clean.

If the distributor cap terminal nipples are

removed, be sure that the terminals and coil

cover terminals are clean and dry.

The magneto is equipped with these nipples

to prevent any external electrical leakage

when the tractor is operating under adverse

conditions.

Magneto Impulse Coupling and Magneto Drive Chamber

When the engine is hand-cranked, the im-

pluse coupling should trip (click) twice for

each revolution of the engine. Failure to do so

indicates the need of cleaning or service.

Remove the magneto as described below.

Hold the magneto at an angle of approximately

45 degrees, and flush the impulse coupling and

magneto drive chamber with kerosene. During

warm weather, oil the impulse coupling lib-

erally with light oil, such as cream separator

or sewing machine oil. Do not use oil during

cold weather (below +10 degrees F.). Flushing

with kerosene is all that is required.

If it is necessary to remove the impulse

coupling from the magneto for cleaning or

service, we recommend that this be done by

your International Harvester dealer.

28

Page 30

MAGNETO. Continued

Removing the Magneto

ELECTRICAL SYSTEM

!llust. 29

Removing the mogneto.

1. Disconnect switch cable "A" (1IIust.29) by

removing the nut and lock washer attaching the

cable to the magneto terminal.

2. Pullout cable "B" from coil cover "C"

and remove the distributor cap.

3. Loosen the nut holding magneto mounting

clip "D" and remove cap screw "E". The mag-

neto assembly can then be removed. See Illust. 29.

Installing and Timing the Magneto to the Engine

1. Crank the engine until the No.1 piston

(the piston next to the radiator) is on the top

dead center of the compression stroke. The

compression stroke can be determined by removing the No.1 spark plug. placing the thumb

over the opening. and cranking the engine until

an outward pressure is felt. Continue cranking

slowly until the top dead center mark (second

notch on the back flange of the fan drive pulley

at the left side of the engine) is in line with

pointer on crankcase front cover. S- Illust. 298.

Both intake and exhaust valves will now be

closed.

Illust. 29A

Magneto wiring (clockwise rotation).

Firing order 1,3,4,2.

3. Assemble the magneto on the engine,

making sure that the lugs on the impulse coupling engage in the slots on the magneto drive

coupling. (Assemble the magneto so that the

top is as close to the crankcase as possible.)

4. Insert magneto mounting bolt "Ell loosely

in the magneto flange, just enough to hold the

magneto in place. Then crank the engine one

complete revolution to the next top dead center.

Now pull the upper part of the magneto away

from the engine until the impulse coupling justtrips.

2. Turn the magneto impulse coupling (1IIust.

30), in a counterclockwise direction (as viewed

from the coupling end) until end "B'I of the distributor rotor arm points toward the No. 1

terminal on the distributor cap. See Illust. 28.

Then replace the distributor cap.

Notches on the fan drive pulley and the timing pointer.

Illust. 298

2.9

Page 31

ELECTRICAL SYSTEM

DISTRIBUTOR AND COIL UNITMAGNETO. Continued

Installing and Timing the Magneto to the Engine

.Continued

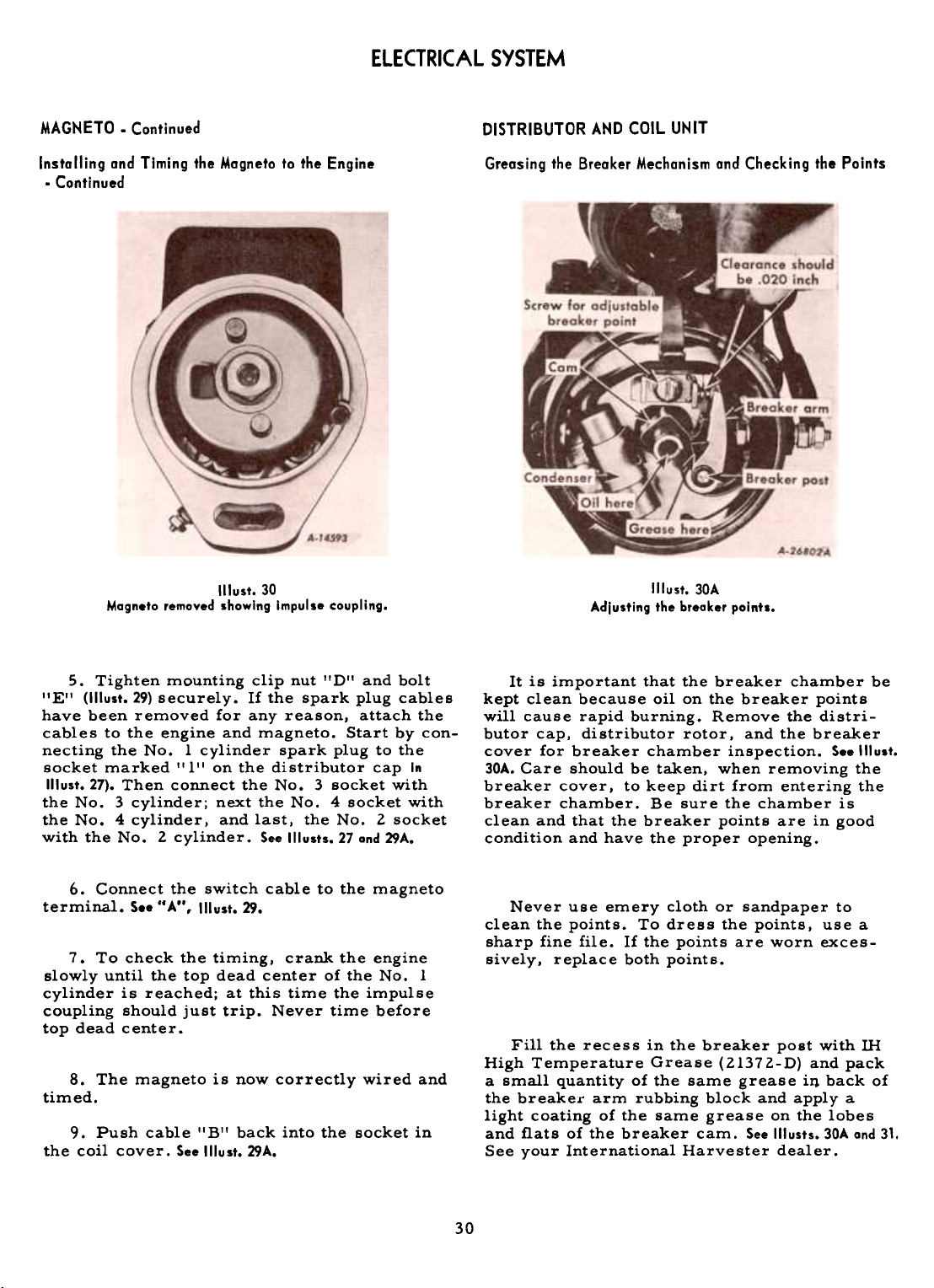

1(lust. 30

Magneto removed showing Impulse coupling.

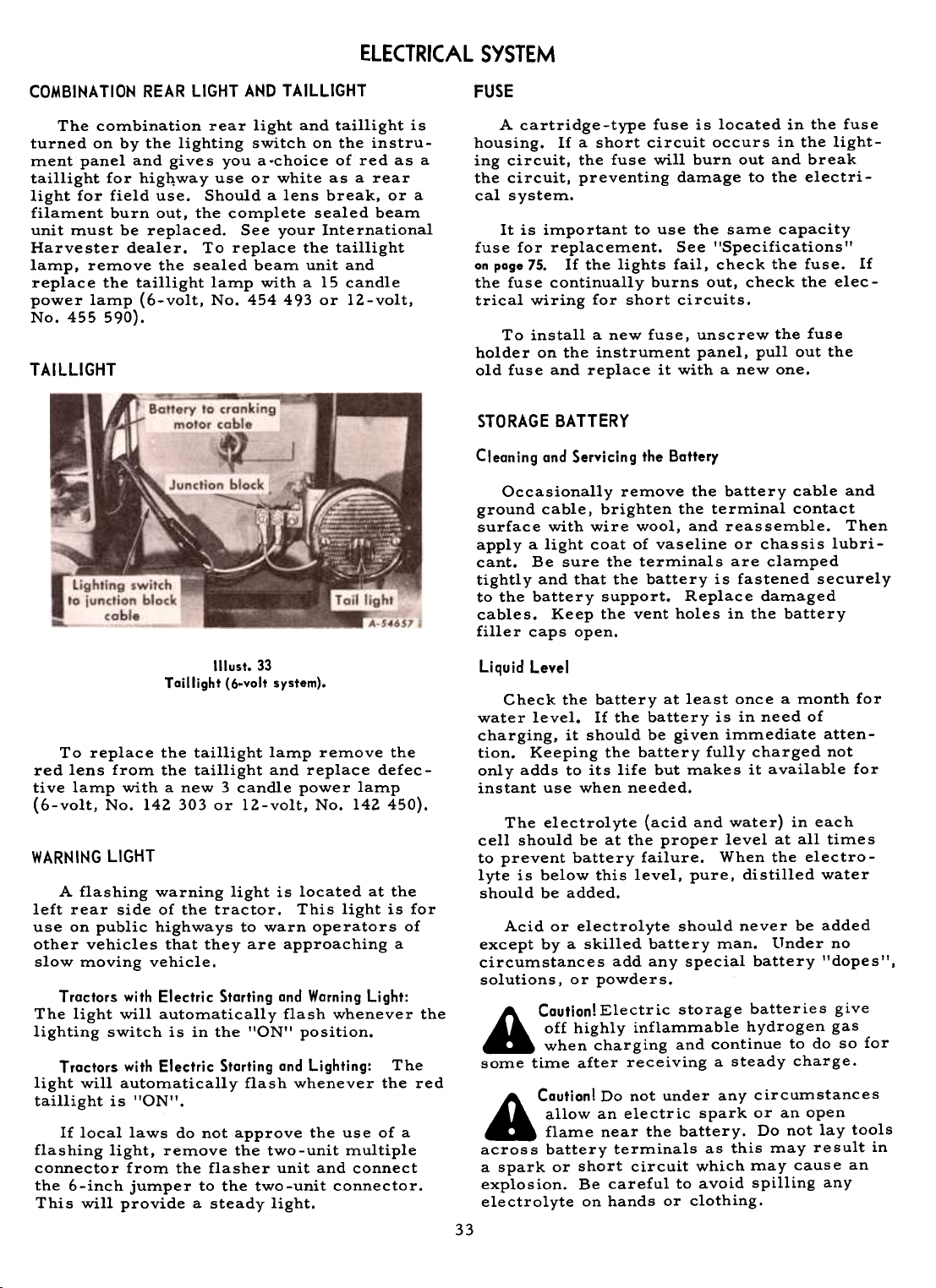

Greasing the Breaker Mechanism and Checking the Paints

Illust. 30A

Adlusting the breaker paints.

5. Tighten mounting clip nut "D" and bolt

"E" (1IIust. 29) securely. If the spark plug cables

have been removed for any reason, attach the

cables to the engine and magneto. Start by connecting the No. I cylinder spark plug to the

socket marked 1'1" on the distributor cap In

Illust.27). Then connect the No.3 socket with

the No.3 cylinder; next the No.4 socket with

the No.4 cylinder, and last, the No.2 socket

with the No.2 cylinder. See Illusts. 27 and 29A.

It is important that the breaker chamber be

kept clean because oil on the breaker points

will cause rapid burning. Remove the distributor cap, distributor rotor, and the breaker

cover for breaker chamber inspection. See Illust.

30A. Care should be taken, when removing the

breaker cover, to keep dirt from entering the

breaker chamber. Be sure the chamber is

clean and that the breaker points are in good

condition and have the proper opening.

6. Connect the switch cable to the magneto

terminal. S.. "A", Illust. 29. Never use emery cloth or sandpaper to

clean the points. To dress the points. use a

sharp fine file. If the points are worn exces-

7. To check the timing, crank the engine

sively. replace both points.

slowly until the top dead center of the No.1

cylinder is reached; at this time the impulse

coupling should just trip. Never time before

top dead center.

Fill the recess in the breaker post with IH

High Temperature Grease (21372-D) and pack

8. The magneto is now correctly wired and

timed.

9. Push cable "B" back into the socket in

the coil cover. See Illust. 29A.

a small quantity of the same grease iIJ back of

the breaker arm rubbing block and apply a

light coating of the same grease on the lobes

and flats of the breaker cam. See Illusts. 30A and 31.

See your International Harvester dealer.

30

Page 32

ELECTRICAL SYSTEM

DISTRIBUTOR AND COIL UNIT. Continued

Greasing the Breaker Mechanism and Checking the P.oints

.Continued

Distributor partially disossembled for servicing.

Check the condition of the breaker points

for build-up or lip formation. If present, the

points must be dressed before the point open-

ing can be checked or set. Check the opening

between the breaker points with a feeler gauge

as shown in Illust. 30A. The point opening should

be .020 inch when the rubbing block is on the

high part of the cam. If the opening is not

correct, adjust it by loosening the screw holding the adjustable point. Then move the point

toward or away from the point on the breaker

arm until the gauge slips snugly into the opening. After the adjustment has been made,

tighten the screw.